Aid-grinding and oil absorption steel slag composite modifier and preparation method thereof

A technology of composite modifier and steel slag, which is applied in the field of steel slag modifier, can solve the problems of poor grindability and poor compatibility of steel slag, and achieve the effects of improving oil absorption value, improving grinding effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

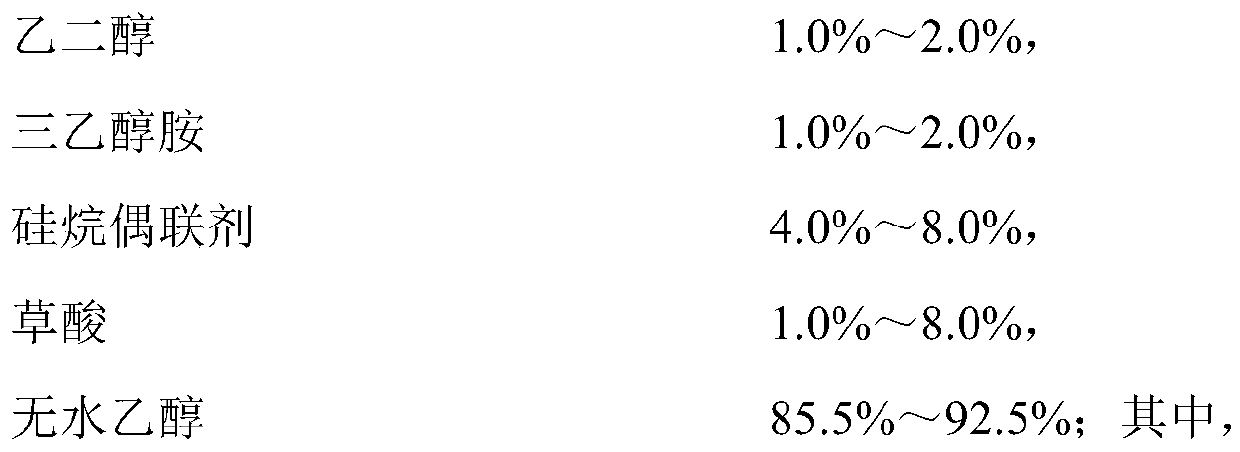

[0023] Taking the preparation of product 100g of the present invention as an example, the components used and the quality thereof are:

[0024]

[0025]

[0026] First, mix ethylene glycol, triethanolamine and 1 / 4 of the amount of absolute ethanol, and then use a constant temperature magnetic stirrer to stir at a temperature of 20°C at a speed of 800r / min for 70min to obtain an ethylene glycol-triethanolamine mixed solution. Secondly, after mixing the silane coupling agent, oxalic acid and 3 / 4 of the amount of absolute ethanol, use a constant temperature magnetic stirrer to stir at a temperature of 30°C at a speed of 1200r / min for 110min to obtain a silane coupling agent-oxalic acid mixture. Finally, after mixing the ethylene glycol-triethanolamine mixed solution with the silane coupling agent-oxalic acid mixed solution, the steel slag composite modifier was obtained by using a constant temperature magnetic stirrer at a temperature of 25° C. at a speed of 500 r / min to sti...

Embodiment 2

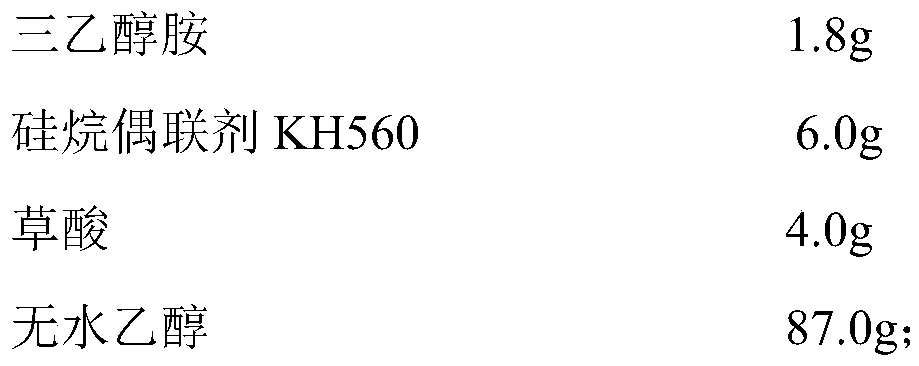

[0028] Taking the preparation of product 100g of the present invention as an example, the components used and the quality thereof are:

[0029]

[0030] First, mix ethylene glycol, triethanolamine and 1 / 4 of the amount of absolute ethanol, and then use a constant temperature magnetic stirrer to stir at a temperature of 35°C at a speed of 600r / min for 90min to obtain an ethylene glycol-triethanolamine mixed solution. Secondly, after mixing the silane coupling agent, oxalic acid and 3 / 4 of the amount of absolute ethanol, use a constant temperature magnetic stirrer to stir at a temperature of 25°C at a speed of 600r / min for 70min to obtain a silane coupling agent-oxalic acid mixture. Finally, the ethylene glycol-triethanolamine mixed solution was mixed with the silane coupling agent-oxalic acid mixed solution, and stirred with a constant temperature magnetic stirrer at a temperature of 30° C. at a speed of 800 r / min for 20 minutes to obtain a steel slag composite modifier.

Embodiment 3

[0032] Taking the preparation of product 100g of the present invention as an example, the components used and the quality thereof are:

[0033]

[0034]

[0035] First, mix ethylene glycol, triethanolamine and 1 / 4 of the amount of absolute ethanol, and then use a constant temperature magnetic stirrer to stir at a temperature of 30°C at a speed of 400r / min for 60min to obtain an ethylene glycol-triethanolamine mixed solution. Next, after mixing the silane coupling agent, oxalic acid and 3 / 4 of the amount of absolute ethanol, use a constant temperature magnetic stirrer to stir at a temperature of 35°C at a speed of 1000r / min for 90min to obtain a silane coupling agent-oxalic acid mixture. Finally, after mixing the ethylene glycol-triethanolamine mixed solution with the silane coupling agent-oxalic acid mixed solution, the steel slag composite modifier was obtained by stirring with a constant temperature magnetic stirrer at a temperature of 20° C. at a speed of 700 r / min for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com