Patents

Literature

414 results about "Free calcium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Free Calcium. Free calcium is the only active form of calcium in the fluid outside your cells, which makes it the best indicator of calcium status in the body. Around half of total calcium is normally in the form of free calcium. Normal free calcium levels in an adult range from approximately 4.5 to 5.1 mg/dL.

Environmental-friendly dust-free calcium-zinc composite heat stabilizer for PVC processing

ActiveCN101602863AAchieve individual synthesisAvoid it happening againCarboxylic acid salt preparationThermal stabilityZinc

The invention relates to an environmental-friendly dust-free calcium-zinc composite heat stabilizer for PVC processing, which comprises the following components: 20 to 80 percent of metallic soap of main stabilizer, 10 to 60 percent of auxiliary stabilizer and 5 to 30 percent of lubricant. The invention also provides a preparation method of the heat stabilizer. The environmental-friendly dust-free calcium-zinc composite heat stabilizer has the advantages of meeting the requirements for environmental protection, along with excellent thermal stability, low cost of production and use, high efficiency and innocuity.

Owner:九江天盛塑料助剂有限公司

Method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder

InactiveCN101851071AF-CaO content decreasedAchieve stabilizationCalcium/strontium/barium carbonatesGas treatmentSlagResource utilization

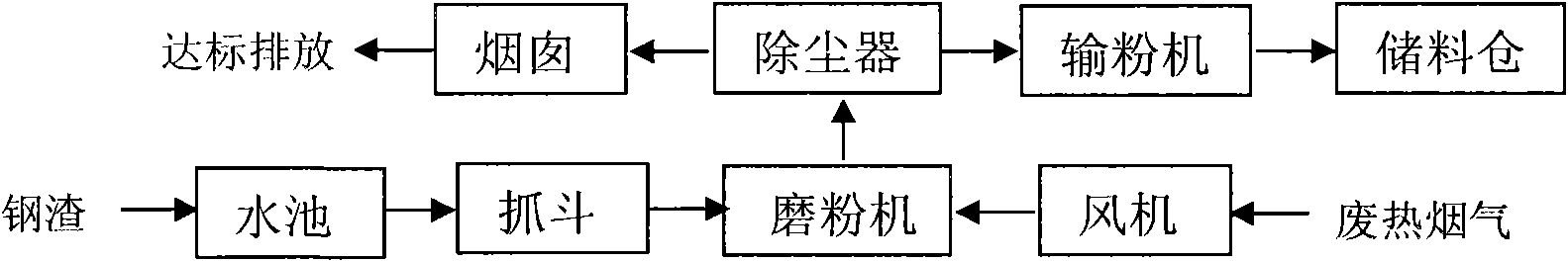

The invention relates to a method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder, which belongs to the technical field of the carbon dioxide reduction and the industrial solid waste resource utilization. Converter steel slag is soaked in water, then the steel slag after being soaked in the water is added into a grinding machine, at the same time, waste heat smoke gas containing carbon dioxide is introduced into the grinding machine with the steel slag to carry out the stabilization reaction, and the steel slag is ground and dried; the waste heat smoke gas brings out the steel slag micro powder after being ground and dried from the tail section of the grinding machine to enter a power collection device, and the steel slag micro powder is discharged from the bottom part of the powder collection device; and the temperature of the waste heat smoke gas is 150 to 180 DEG C. The method has the advantages that: carbon dioxide in the waste smoke gas is used for chemically modifying the steel slag micro powder, so the content of the f-CaO is reduced, the chemical stability of the steel slag micro powder is improved, and technical requirements of the national standard GB / T 20491 - 2006 of steel slag powder for cement and concrete can be reached. The carbon dioxide also can be cured, so the exhaustion of the greenhouse gas can be reduced, and the environment-friendly carbon cycling mode can be realized.

Owner:SHOUGANG CORPORATION

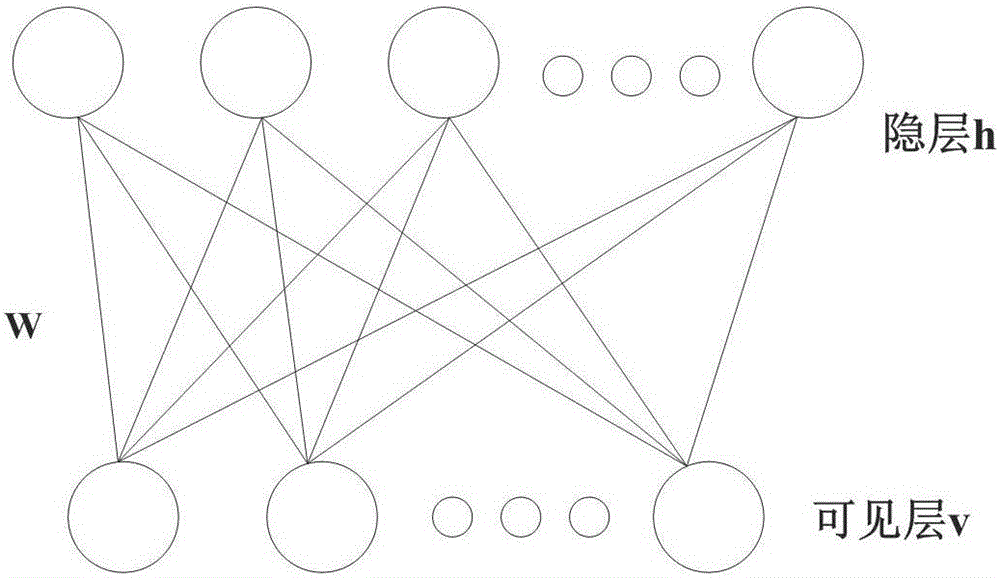

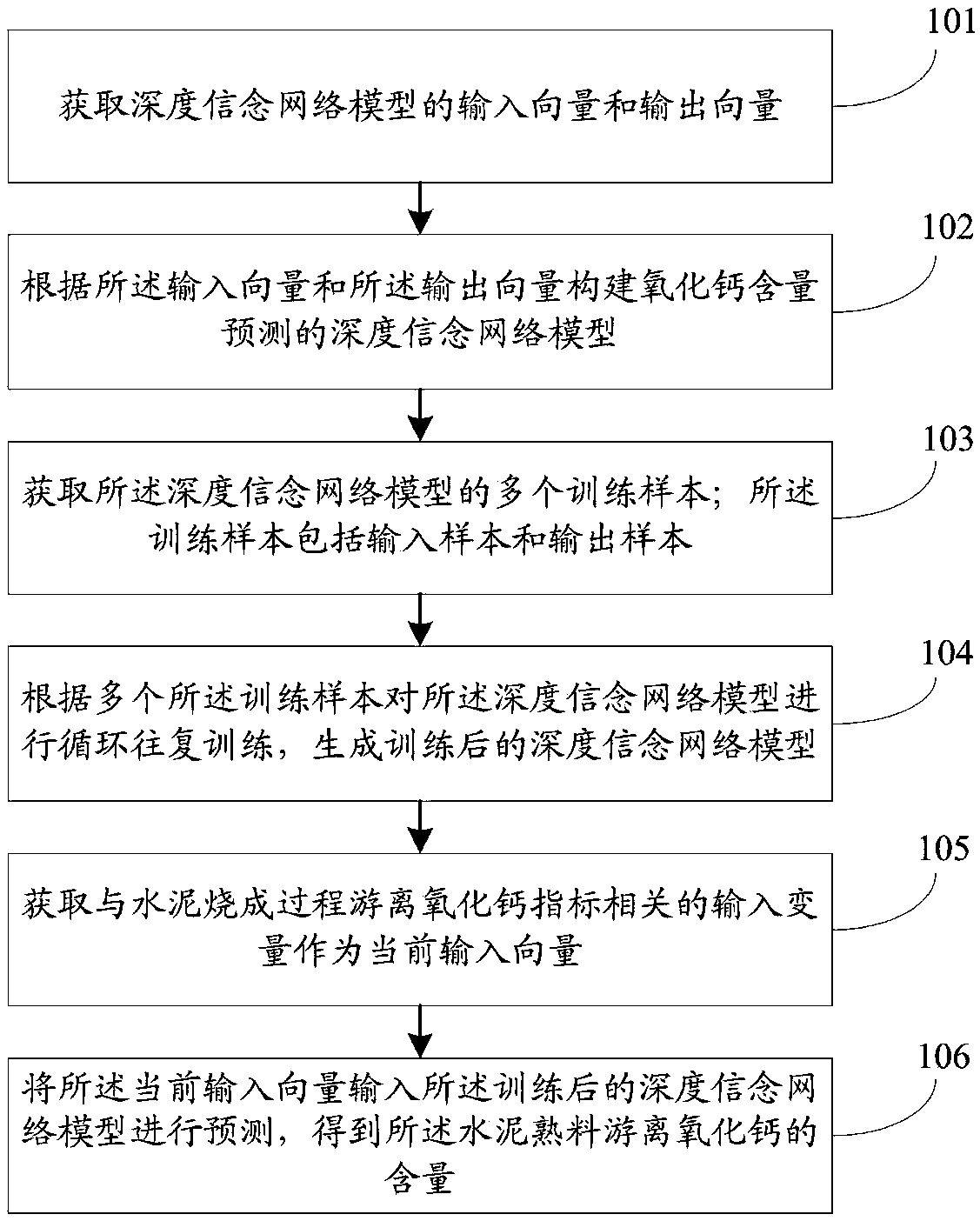

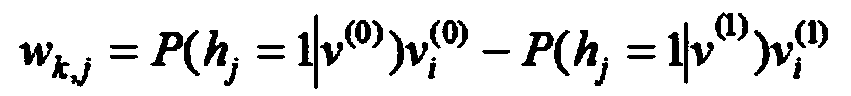

Deep belief network model based cement clinker free calcium content prediction method

InactiveCN106202946AAccurately reflect actual operating conditionsQuality assuranceInformaticsSpecial data processing applicationsDeep belief networkReal-time data

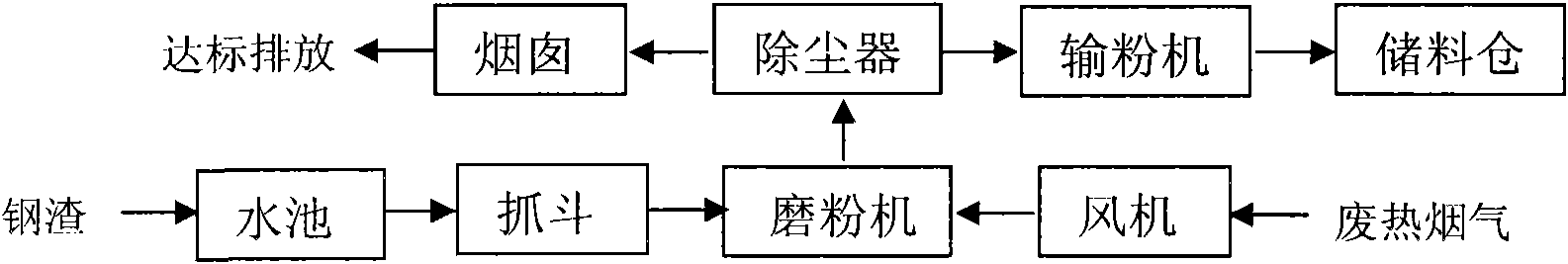

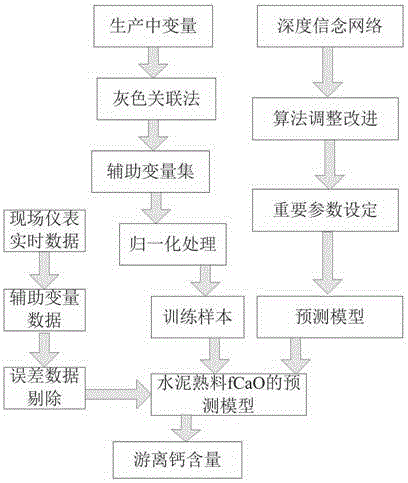

The invention relates to a deep belief network model based cement clinker fCaO prediction method. The method comprises the steps that major variables capable of reflecting the firing situation of a cement clinker are preliminarily selected to form an auxiliary variable set, and a prediction variable is the cement clinker fCaO content; a field instrument and an operator recorder respectively acquires auxiliary variables and field data of the cement clinker fCaO content, a grey relational analysis method is adopted conduct dimensionality reduction on the auxiliary variable set; parameters in a deep belief network structure, namely parameters training the deep belief network are determined according to a deep belief network algorithm and sample data volume, and further optimization of weighting and bias of the whole network is achieved; a counter-propagation algorithm is adopted to conduct error correction on the determined parameters in a deep belief network structure, and further a prediction model of the cement clinker fCaO is determined; real-time data of the auxiliary variable set is acquired, and errors of the obtained real-time data of the auxiliary variable set are eliminated according to 3delta criterions; further, the cement clinker fCaO content is predicted.

Owner:YANSHAN UNIV

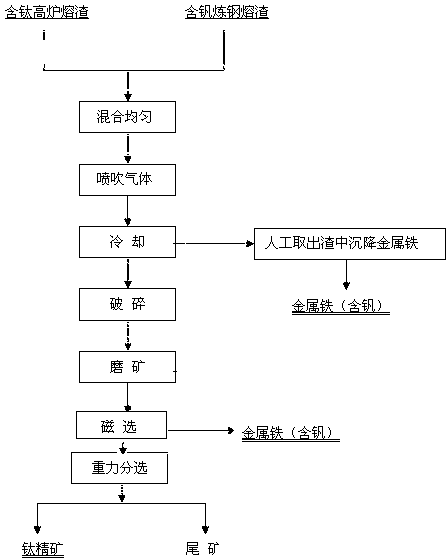

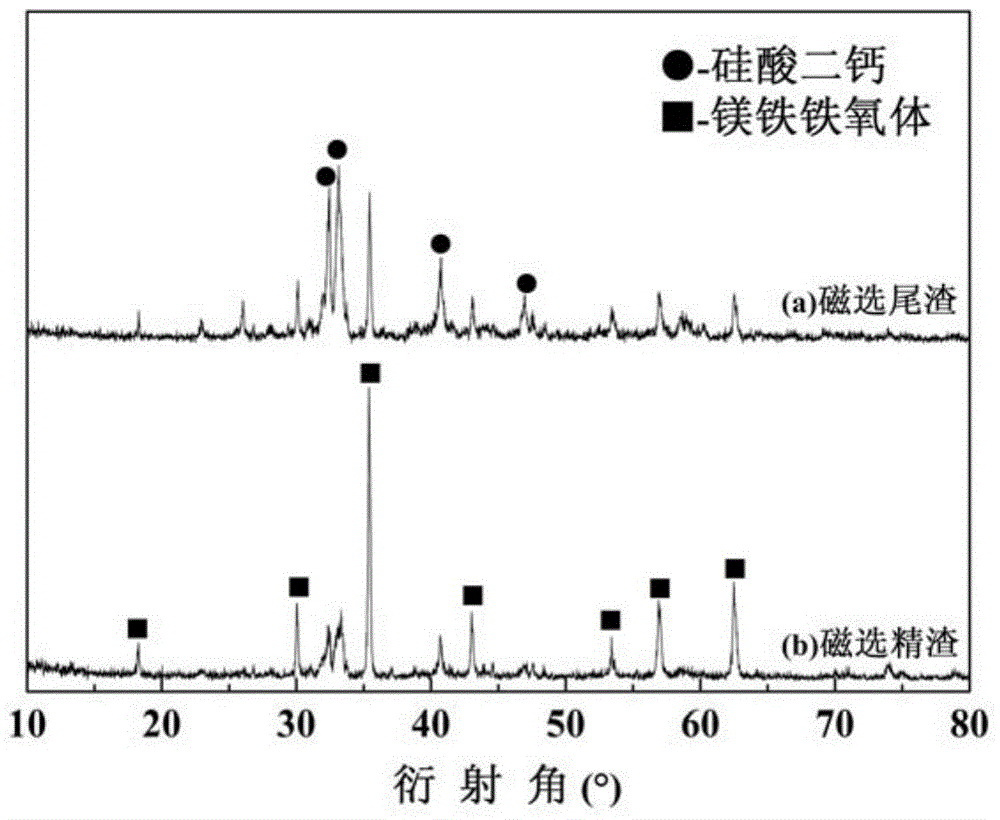

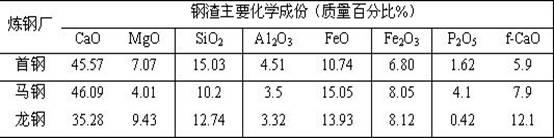

Method for separating titanium, iron, vanadium and calcium from mixed titaniferous slag

ActiveCN103343174ATake advantage ofIncrease temperatureRecycling and recovery technologiesProcess efficiency improvementMolten slagGravity separation

The invention belongs to the field of metallurgy, and in particular relates to a method for separating titanium, iron, vanadium and calcium from mixed titaniferous slag. The method comprises the following steps of: sufficiently mixing blast furnace liquid molten titaniferous blast furnace slag and converter vanadium-containing steel slag flowing out from slag discharge holes, so as to form mixed molten slag, blowing an oxidization gas into a mixed molten body, after the gas blowing is accomplished, naturally cooling down the molten slag, manually taking out the vanadium-containing metal iron which is settled to the bottom of the molten slag, further separating the rest vanadium-containing metal iron in a magnetic separation mode, and finally separating titaniferous ingredients in the molten slag from gangue phase by using a gravity separation method so as to obtain titanium concentrate and tailings the main phases which are perovskite phases, wherein the mass percentage of TiO2 in the titanium concentrate is 35-50%. According to the method, the physical thermal resource of the molten slag is sufficiently utilized, the efficiency is high, the energy is saved, and meanwhile the titanium ingredient, the iron ingredient, the vanadium ingredient and the free calcium oxide ingredient in the mixed molten slag are recycled, so that the purpose of comprehensive high-efficiency recycling on secondary resource is achieved.

Owner:NORTHEASTERN UNIV

Special concrete using waste and old rubber particle and steel slag particle as aggregate

InactiveCN101921087AImprove volume stabilityImprove the natural environmentSolid waste managementSlagRoad surface

The invention provides a special concrete using waste and old rubber particles and steel slag particles as aggregate, which comprises the following components in parts by mass: 100 parts of cement, 0.1-3 parts of water reducing agent, 0-50 parts of mineral admixture, 0-600 parts of sand, 200-400 parts of steel slag particle, 15-50 parts of rubber particle and 20-80 parts of water. The invention has the advantages that the two wastes of the waste and old rubber particles and steel slag are simultaneously added into concrete, the wastes can be greatly utilized, and the natural environment is improved; the expansion stress of free calcium oxide in steel slag is adsorbed by utilizing the elastic characteristic of the waste and old rubber particles, the steel slag can be utilized without special processing, and the integral volume stability of materials is high; by adding the waste and old rubber particles, the elasticity of the special concrete is higher than that of common concrete; and the special concrete can be widely applied to places in which common concrete, such as road surfaces, parking lots, buildings, and the like can be applied.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Steel slag stability modifier and steel slag stability processing method

InactiveCN101328517AStability changeSimple processing methodRecycling and recovery technologiesSteelmakingMaterials science

The invention discloses a steel slag stability modifier and a method for treating the stability of steel slag. The method comprises the following steps that: the steel slag modifier is added into a steelmaking slag tank according to a proportion of between 0.5 and 50 percent of the total steel slag amount for carrying out modification treatment; the steel slag stability modifier comprises the following compositions in percentage by weight that: 30 to 99.88 percent of SiO2, 0.001 to 40 percent of Al2O3, 0.001 to 40 percent of CaO and 0.001 to 20 percent of MgO; and the introduced substances of the compositions can be one of blast furnace slag, quartz sand and riversand or a mixture of a plurality of kinds of the blast furnace slag, quartz sand and riversand. The steel slag stability modifier has wide material source and low cost; the method for treating the stability of steel slag is simple, safe, reliable and easy to operate. The method directly adopts the steel slag stability modifier with low cost after the steel slag is treated in a converter, properly carries out injection treatment in order to change the stability of the steel slag, thereby effectively reducing a content of free calcium oxide in the steel slag and enlarging a safe use range of the steel slag.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Carbonated steel slag aggregate and preparation method thereof

The invention discloses a carbonated steel slag aggregate and a preparation method thereof. The method comprises the following steps: sieving steel slag subjected to iron separation, taking particles with size between 0.5-25 mm particle for high pressure water flushing, and naturally drying the particles; immersing the dried steel slag particles in a mixed solution of 20-300 g / L caustic soda and 60-300 g / L sodium carbonate for 24 h, and maintaining the temperature at 20-60 DEG C; draining the soaked steel slag particles, immediately placing the particles in a sealed carbonation reactor, and introducing CO2 gas with purity over 99.9% for curing at the temperature of 70-90 DEG C for 0.5 h, and with the CO2 gas pressure at 0.2-0.5 MPa; cooling the steel slag particles subjected to carbonation treatment under natural conditions to room temperature, so as to obtain the carbonated steel slag aggregate. The steel slag aggregate treated by the method has compact surface structure to reduce water for concrete mixing; free magnesium oxide and free calcium oxide are conversed into carbonate precipitation to eliminate the hidden trouble of adverse stability; CO2 can be stored stably; the amount of natural aggregate is reduced to save nonrenewable resources; and the method has easily available raw materials and simple process.

Owner:UNIV OF JINAN

Steel slag treating method

ActiveCN102559960AEliminate hazardsSafe useRecycling and recovery technologiesThermal energyCalcium silicate

The invention provides a steel slag treating method comprising the following steps of: directly mixing thermal-state revolving furnace steel slag with blast furnace slag in an arc furnace in proportion, adjusting the molten slag in the furnace into a proper temperature by virtue of the arcing of the arc furnace, and stirring the molten slag by virtue of arc disturbance, so that acidic oxide and basic oxide in the molten slag are sufficiently reacted with each other; reacting free calcium oxide and free magnesium oxide in the raw steel slag with silicon dioxide component and low-calcium calcium silicate in the blast furnace slag to generate safe calcium silicate and magnesium silicate, quenching the molten slag to form glass-state solid slag which is higher in hydration reactivity and free of short-term or long-term inflation harm, and further finely grinding the solid slag into slag powder which can be safely used for related building material as the blast furnace slag. According to the method, the damage caused by the free calcium oxide and free magnesium oxide in the steel slag can be removed, and a basis is provided for the whole use of the steel slag. The heat energy of the thermal-state molten slag can be sufficiently used, so that the energy source can be saved, the energy consumption can be reduced, the cost can be reduced, and the discharge of CO2 can be reduced, and the method is extremely high in social meaning and economic meaning.

Owner:北京联合荣大工程材料股份有限公司

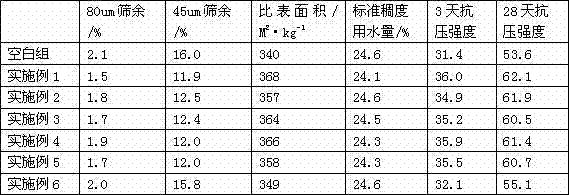

Wet-discharging fly ash composite carbide slag blending slurry and method for preparing the same

InactiveCN101182167APromote secondary hydration reactionStimulate early activitySolid waste managementSlagSlurry

The invention relates to highly active mineral admixture slurry and a preparation method thereof. Wet fly ash composite carbide slag admixture slurry is characterized in that the slurry is made from wet fly ash, carbide slag, a modifier and water after the wet filling. The weight portions of the components are 65-75 portions of the solid content of the wet fly ash, 22-34 portions of the solid content of the carbide slag, 1-3 portions of the modifier and 80-100 portions of the water. The water includes the weight of the water in the wet fly ash and the carbide slag. The moisture content (weight) of the wet fly ash is 25-35 percent, the content of free calcium oxide is less than or equal to 2.5 percent, the content of sulfur trioxide is less than or equal to 3 percent, the carbon content is less than or equal to 12 percent, and the Blaine specific surface area is 350-400m<2> / kg. The modifier consists of a strengthening agent and a surface modifier. The modifier weight percent of the components is 30-40 percent of the strengthening agent and 60-70 percent of the surface modifier. The invention overcomes a problem that the wet fly ash and the carbide slag are hard to be utilized and has the advantages of simple production process, low cost, high waste utilization rate, high activity, high performance of prepared concrete, etc.

Owner:WUHAN UNIV OF TECH

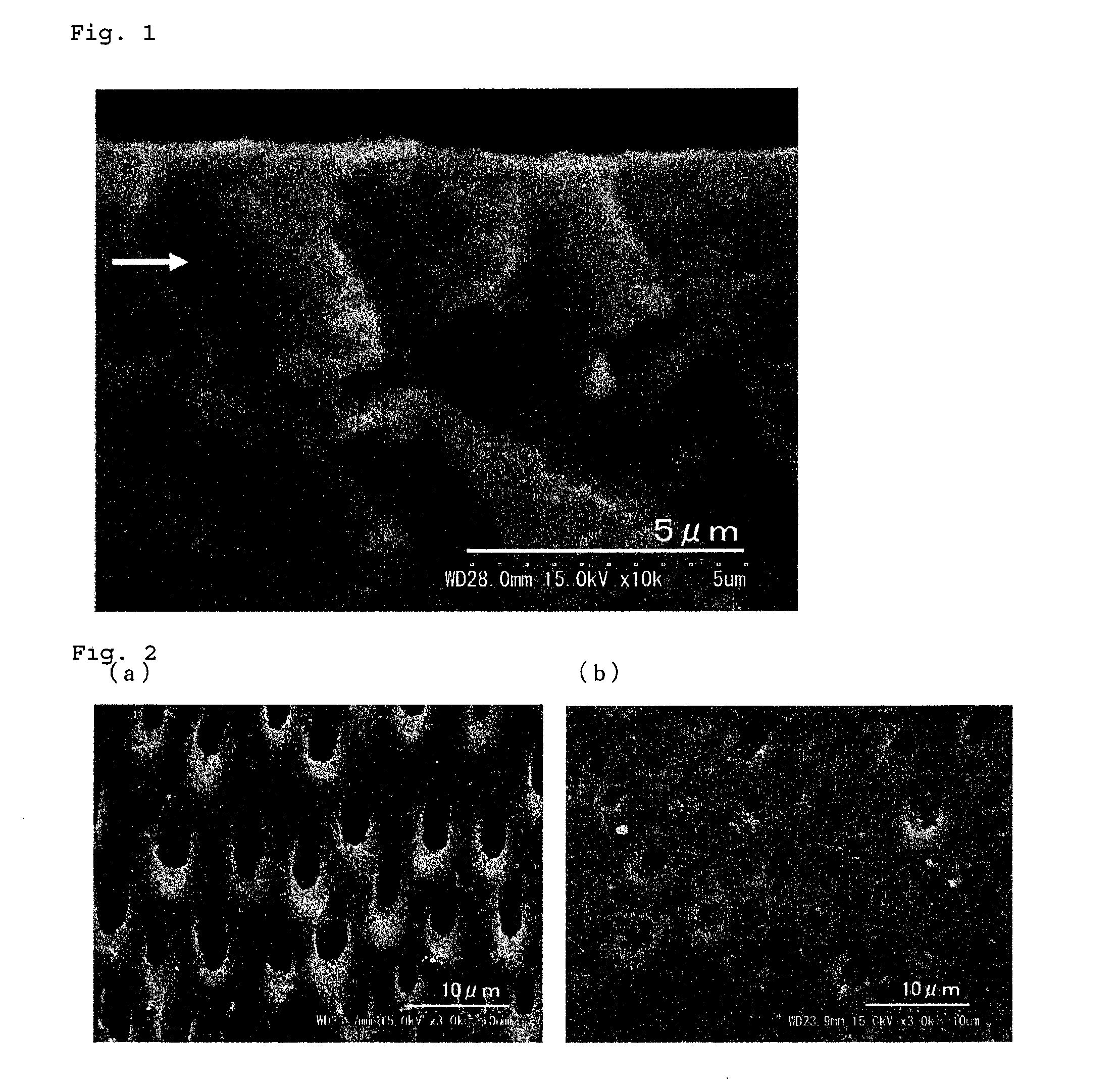

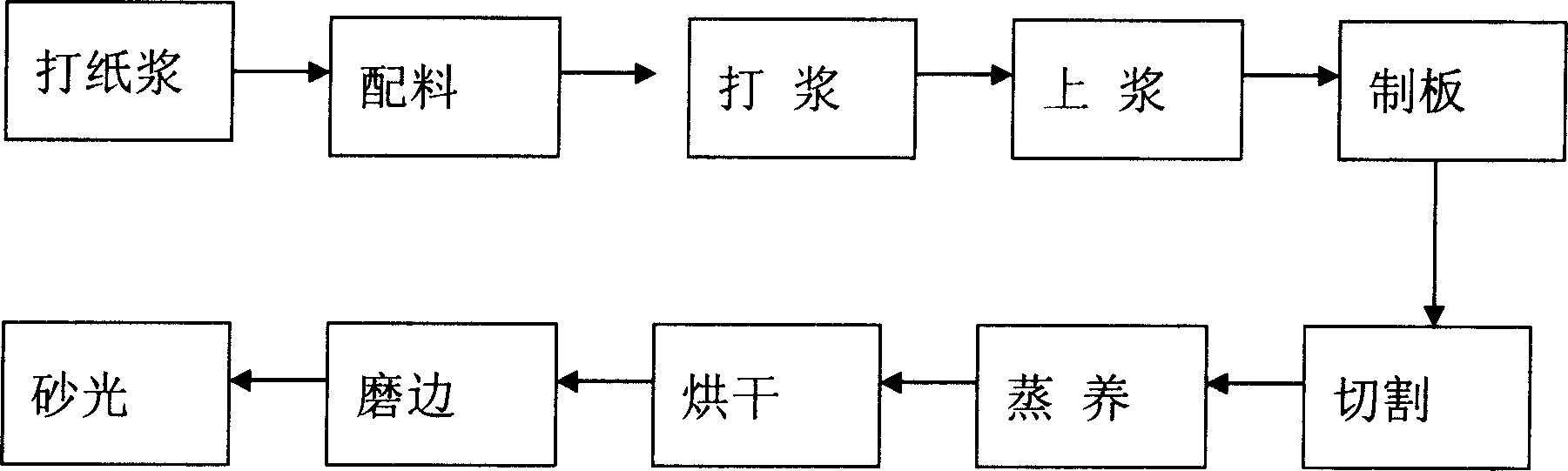

Dentinal tubule sealant and method for producing the same

InactiveUS20130189337A1Impart caries resistanceSubstance may accumulateCosmetic preparationsImpression capsCalcium biphosphateDentinal Tubule

A dentinal tubule sealant comprises poorly-soluble calcium phosphate particles (A), a phosphorus-free calcium compound (B), and water (C), wherein the particles (A) are at least one member selected from the group consisting of dicalcium phosphate anhydrous [CaHPO4] particles, α-tricalcium phosphate [α-Ca3(PO4)2] particles, β-tricalcium phosphate [β-Ca3(PO4)2] particles, amorphous calcium phosphate [Ca3(PO4)2.nH2O] particles, calcium pyrophosphate [Ca2P2O7] particles, calcium pyrophosphate dihydrate [Ca2P2O7.2H2O] particles, octacalcium phosphate pentahydrate [Ca8H2(PO4)6.5H2O] particles, and dicalcium phosphate dihydrate [CaHPO4.2H2O] particles, and the dentinal tubule sealant contains 30 to 76% by weight of the particles (A), 0.001 to 4% by weight of the compound (B), and 23 to 69% by weight of the water (C). Thus, there is provided a dentinal tubule sealant capable of sealing dentinal tubules of an exposed dentin and also remineralizing the surrounding dentin after the sealing.

Owner:KURARAY NORITAKE DENTAL

Cement mortar saltpetering inhibition additive

The invention provides a cement mortar saltpetering inhibition additive capable of obviously inhibiting mortar saltpetering, comprising the following materials in percentage by weight: 75%-90% of high-activity mineral fillers, 3%-5% of complexing resin and 10%-15% of additives. The invention enhances the mortar compactness and consumes the free calcium ions by reacting the high-activity mineral fillers with redundant calcium hydroxide contained in cement hydration products, constraints the early calcium ion migration by adding the complexing resin, reduces the water absorption quantity of mortar by adding a water-repelling agent, a defoaming agent, a superplasticizer, and the like, decreases the carriers for the calcium ion migration and effectively inhibits the saltpetering forming conditions, thereby achieving the effect of inhibiting the cement mortar saltpetering; and in addition, the cement mortar saltpetering inhibition additive has excellent performance, reasonable formula and low cost and can be used for preparing better cement mortar which is difficult to generate the saltpetering and be suitable for the decoration of inner and outer walls of common residences or plants.

Owner:JIANGSU NIGAO SCI & TECH +1

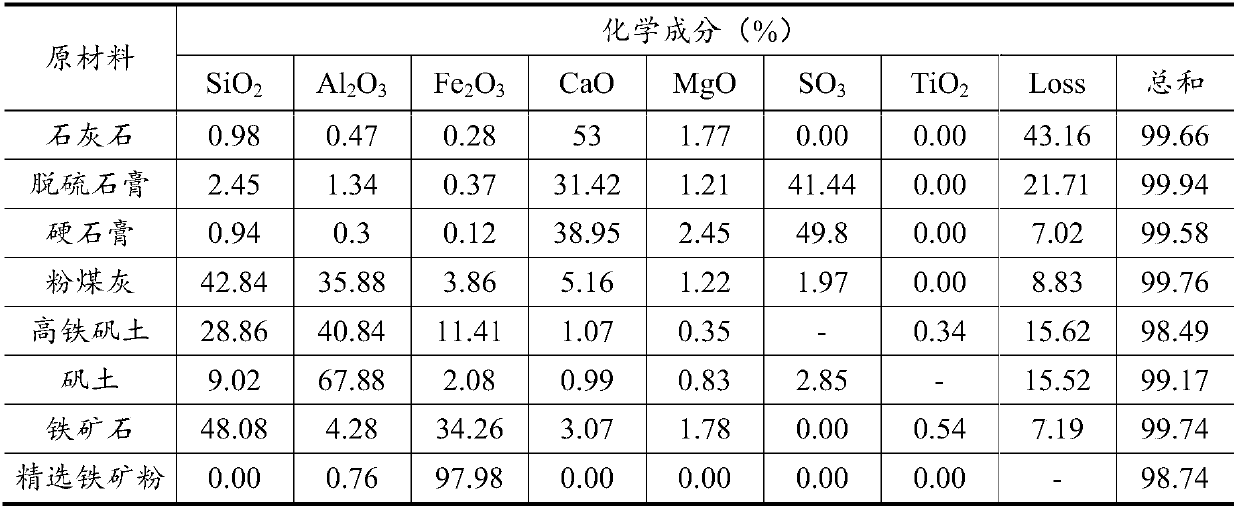

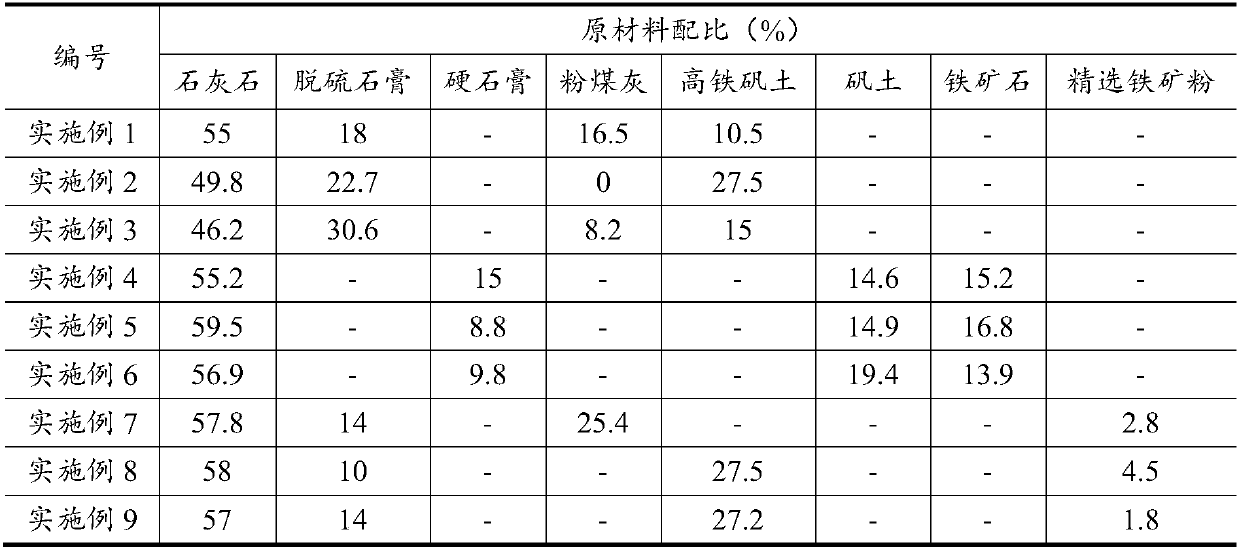

Asbestos-free calcium silicate board and method for making same

InactiveCN1884180AStrong anti-sagImprove fire performanceSolid waste managementCeramic materials productionFiberGreen environment

The invention discloses a non-amianthine calcium silicate board and preparing method in the architectural profession, which comprises the following parts: 38-48 percent quartz sand, 18-24 percent cement, 18-24 percent lime, 3-8 percent wollastonite needle powder, 1-5 percent mica powder, 5.5-8 percent wood fiber, 0.5-1%. polyacetamide, The invention belongs to new green environment-protective building material, which fits for high-grade space with higher cleanness need.

Owner:章燕芳

Environment-friendly, high-efficient and composite liquid cement grinding aid and preparation method thereof

The invention relates to an environment-friendly, high-efficient and composite liquid cement grinding aid and a preparation method thereof. The grinding aid is prepared from following materials: 1-20 parts of triethanolamine, 1-20 parts of triisopropanolamine, 10-20 parts of glycerol, 10-20 parts of molasses, 2-8 parts of propylene glycol, 3-6 parts of sodium tripolyphosphate, 3-8 parts of sodiumhexametaphosphate and 30-50 parts of water. The grinding aid of the invention has low toxicity, does not volatilize and has stable source, sufficient supply, simple processing and preparation and lowcost; the indexes meet standard requirement of JC / T667-2004 Cement Grinding Aid; after the cement is doped, the distribution and shape of the separated particles can be improved and no bad influence for cement quality exists; the yield and quality of the cement are good. The performance is stable, the price is low and the performance cost ratio is high. The adaptability is wide, the doping quantity is low, the grinding effect is improved, the free calcium oxide in the cement is reduced, and the early strength and long-term strength of the cement are improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Concrete seal curing agent

The invention provides a concrete seal curing agent which comprises the following components in percentage by weight: 50%-70% of silicate, 10%-30% of a silane coupling agent, 1%-3% of nano titanium dioxide and the balance of water. After the concrete seal curing agent provided by the invention is applied to the surface of a concrete structure, silicate in the concrete seal curing agent can quickly permeate into concrete and reacts with free calcium to generate insoluble amorphous calcium silicate hydrate so as to block the fine pores of the concrete structure and improve the hardness of the concrete structure; meanwhile, the silane coupling agent and nano titanium dioxide in the curing agent interact to form a hydrophobic membrane layer on the surface of the concrete structure and improve the surface hydrophobicity of the concrete structure; the experimental result shows that the surface Mohs hardness is higher than 7, the water absorption rate is lower than 0.6%, and the liquid drop contact angle is less than 95 degrees after the surface of the concrete structure is coated with the concrete seal curing agent provided by the invention.

Owner:上海牧桔新型材料有限公司

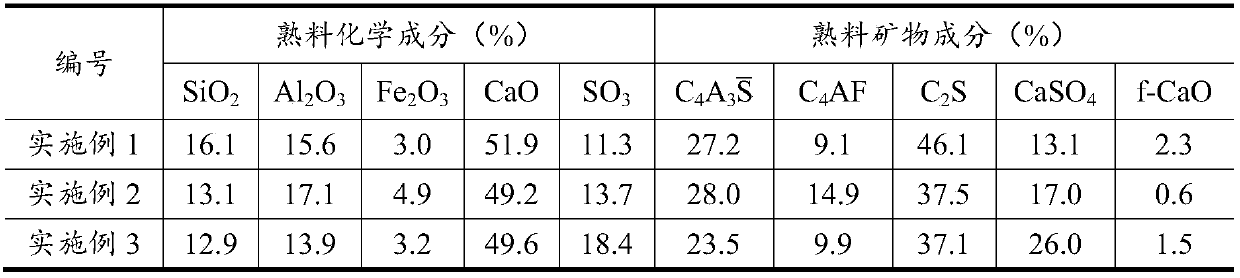

Anticorrosion high-belit sulfoaluminate cement clinker and preparation method thereof, anticorrosion high-belit sulfoaluminate cement and preparation method of cement

ActiveCN107935423AImprove early strengthImprove seawater erosion resistanceCement productionSulfateUltimate tensile strength

The invention provides an anticorrosion high-belit sulfoaluminate cement clinker and a preparation method thereof, anticorrosion high-belit sulfoaluminate cement and a preparation method of the cement, and relates to the field of building material. The anticorrosion high-belit sulfoaluminate cement clinker comprises the following mineral components by the weight percentage: 12%-30% of anhydrous calcium sulfoaluminate, 9.04%-35% of tetracalcium aluminoferrite, 37%-49% of dicalcium silicate, 6%-26% of calcium sulfate and 0.5%-4.1% of free calcium oxide. The anticorrosion high-belit sulfoaluminate cement clinker is used in cement to alleviate the technical problems of poor seawater erosion resistance and poor corrosion resistance of conventional cement used in marine environments, has the advantages of high early strength and easy construction, and can be used for preparing high-corrosion-resistant marine cement concrete for marine environments.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Slagging process for removing free calcium oxide fCao from converter slag

The invention discloses a slagging process for removing free calcium oxide fCao from converter slag, which is characterized in that the smelting process of a common converter is not changed much, thechange of the process is in the latter half period of blowing, and SiO2 material or calcium silicate material is used for replacing a part of lime in the original process for slagging and melting. Theprocess has low cost and no addition of slag amount, decreases the slag basicity, improves the fluidity, greatly enhances the dephosphorization capacity and sufficiently reduces the content of fCao in the slag.

Owner:王虎

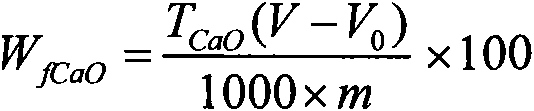

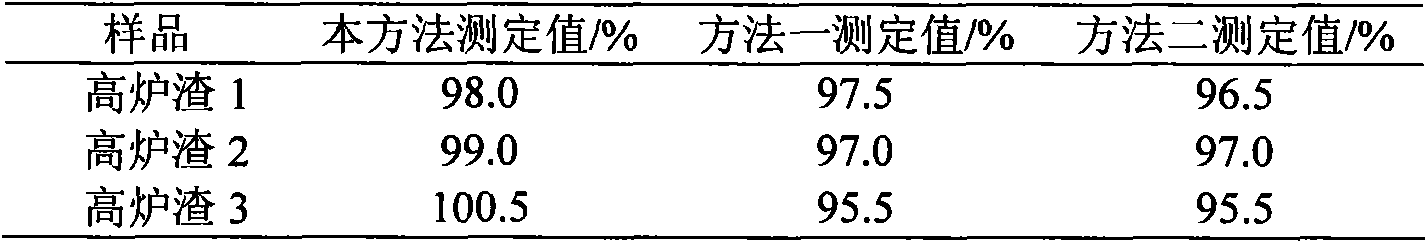

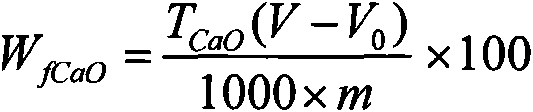

Determination method of free calcium oxide in furnace slag

InactiveCN102401822AAccurate analysisQuick analysisChemical analysis using titrationPreparing sample for investigationWater bathsSlag

The invention discloses a determination method of free calcium oxide in furnace slag, mainly comprising the following technological steps of: (1) dissolving a slag sample by the use of a glycol-anhydrous ethanol mixed solution, and adding a few cane sugar and glycerol to assist the dissolution, so as to make glycol and free calcium oxide to form a water-soluble complex; (2) oscillating for a certain time, and carrying out water-bath heating; (3) cooling, filtering and separating the solution to filter and remove other undissolved impurities; and (4) determining the content of free calcium oxide in the filtrate by an EDTA titration method. According to the invention, the glycol-anhydrous ethanol mixed solution only performs a quantitative reaction with free calcium oxide to form the complex of glycol and calcium oxide without the interference of other calcium phase, thus guaranteeing accuracy and precision of determination results and realizing high-selective, rapid and accurate analysis of free calcium oxide in the furnace slag.

Owner:ANGANG STEEL CO LTD

Cement composite grinding aid

The invention discloses a cement composite grinding aid which is characterized by comprising the following components in parts by weight: 10-30 parts of polyol amine, 10-30 parts of polyol, 5-15 parts of molasses, 5-15 parts of lignosulphonate, 2-6 parts of sodium metasilicate pentahydrate, 3-7 parts of sodium hexametaphosphate and 20-30 parts of water. The cement composite grinding aid disclosed by the invention is stable in raw material source, environmental-friendly, low in toxicity and easy to produce, and ensures that the components achieve preferable synergistic effect by confirming the components and a content range, thus optimizing the efficacy of a powder grinding process and improving the power granule distribution and morphology of cement without adverse effect on cement quality. The cement composite grinding aid disclosed by the invention has the advantages of preferably increasing the yield increase and enhancing the cement quality and has the effects of saving the electricity consumption, improving the powder efficiency and the cement strength, reducing the free calcium oxide contained in the cement and enhancing the early strength and later strength of the cement.

Owner:湖州华仑助剂科技有限公司

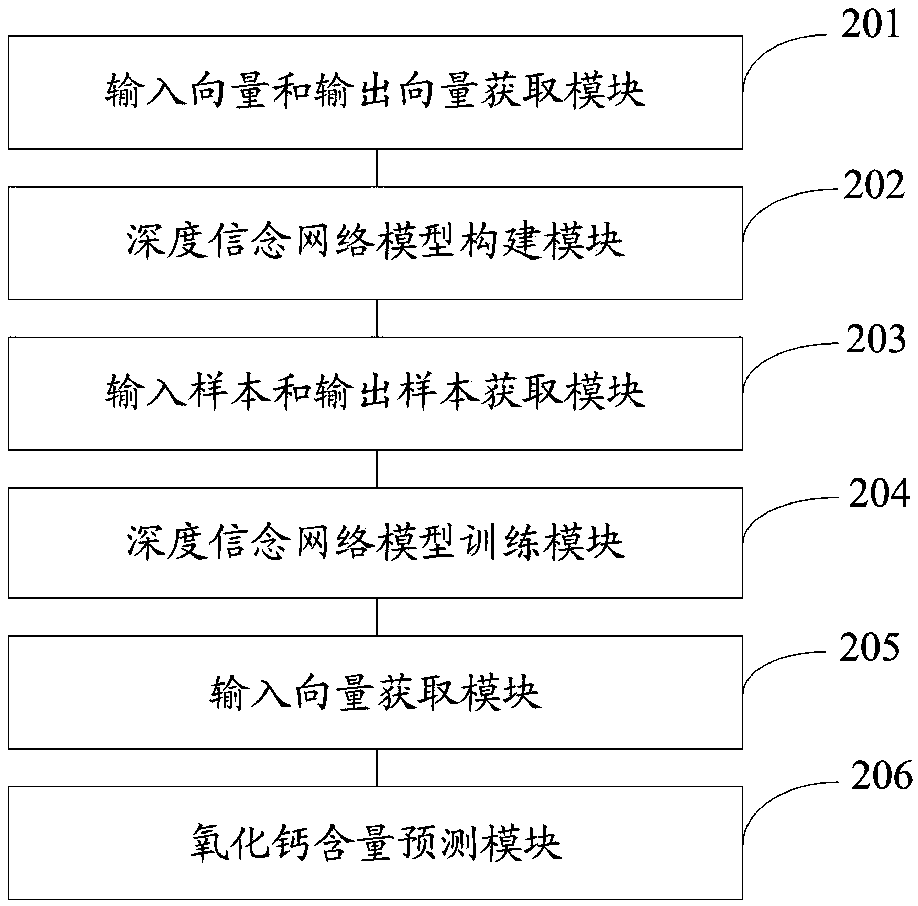

A method and a system for on-line prediction of free calcium oxide content of cement clinker

InactiveCN109165798AImprove product qualityHigh precisionForecastingNeural architecturesDeep belief networkPredictive methods

The invention discloses a method and a system for on-line prediction of free calcium oxide content of cement clinker. The method includes: obtaining the input vector and output vector of the deep belief network model; according to the input vector and output vector, constructing a deep belief network model for calcium oxide content prediction; acquiring a plurality of training samples of a deep belief network model, wherein the training samples include input samples and output samples; according to the training samples, repeatedly training the depth belief network model, and generating the depth belief network model after training; obtaining the input variables related to the free calcium oxide index in the cement firing process as the current input vectors, wherein the input vectors are the input vectors introduced into the time series; obtaining the free calcium oxide content of cement clinker d by predicting the depth of belief network model after the current input vector is input into the training. The invention can solve the problem of time-varying delay between the variable data and the free calcium oxide index in the cement firing process.

Owner:YANSHAN UNIV

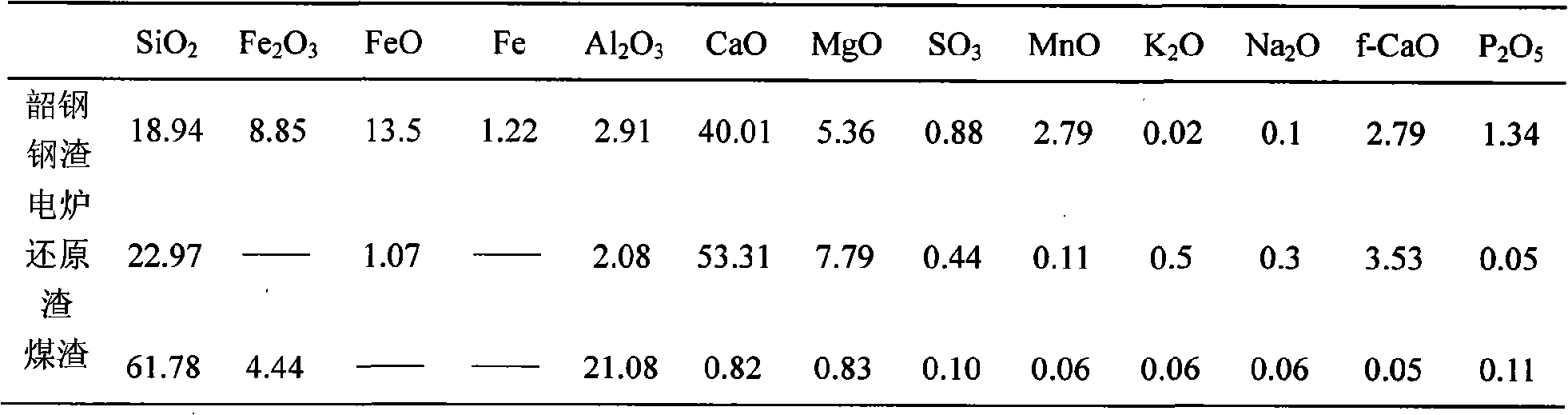

Performance adjustment material for activating steel slag at high temperature and application thereof

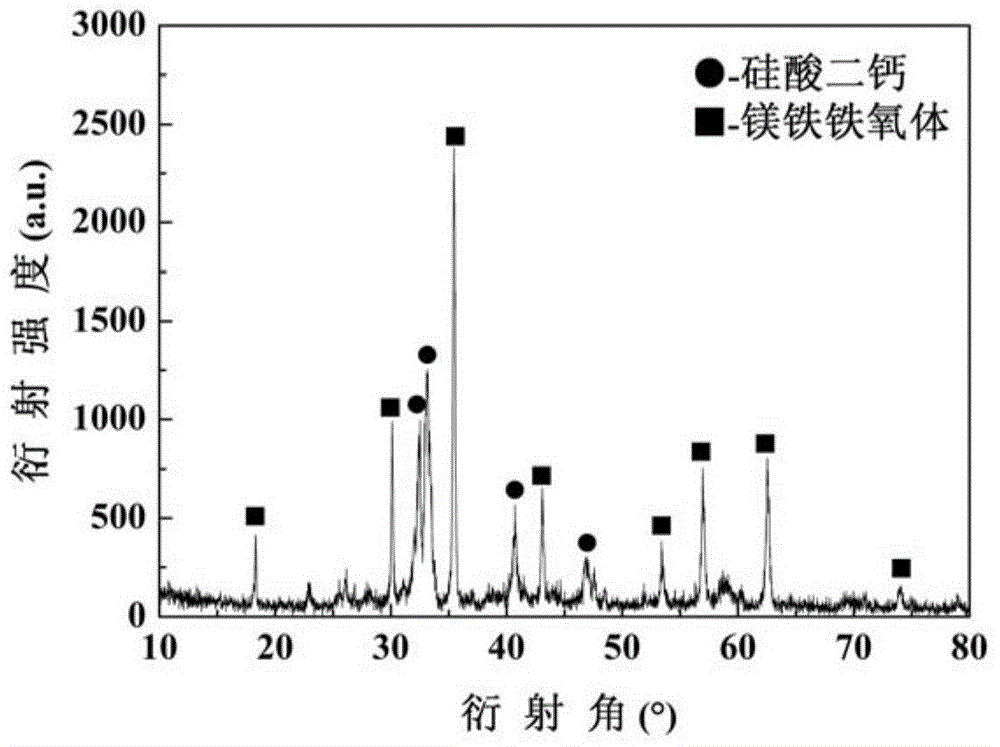

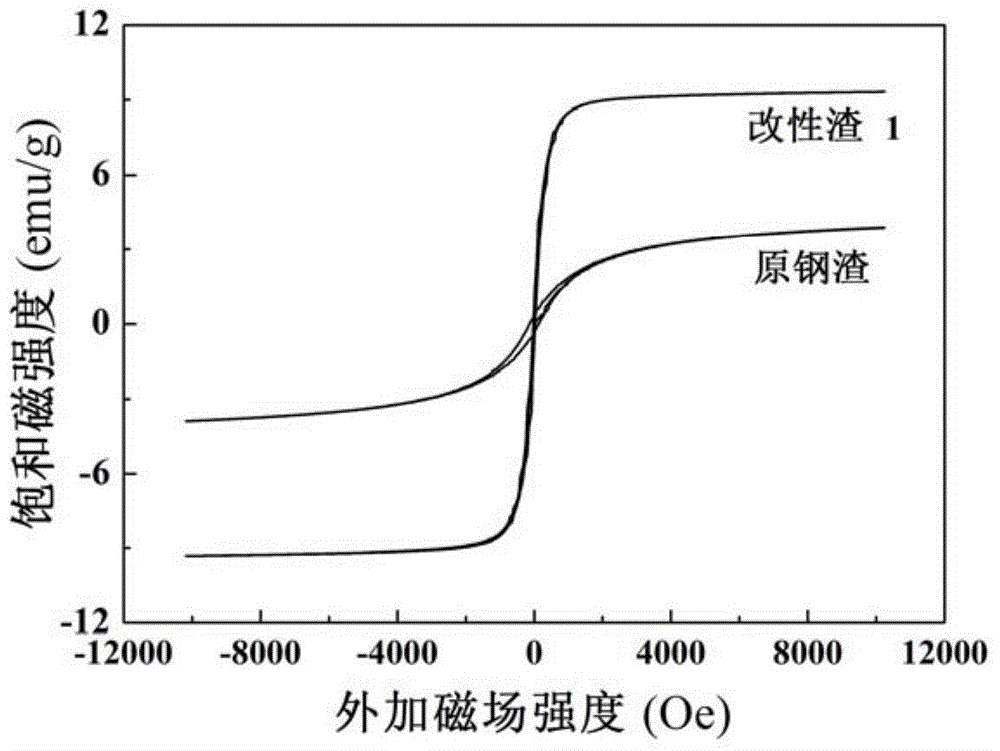

InactiveCN101560578AImprove hydrationHigh activityRecycling and recovery technologiesChemical reactionElectric arc furnace

The invention discloses a performance adjustment material for activating steel slag at high temperature and the application thereof. The performance adjustment material is prepared by mixing electric arc furnace restored slag, coal slag and starch polymer or poval. The application of the material is as follows: after being mixed, the performance adjustment material and the steel slag chemically react under the action of high temperature so as to improve the hydration and the cohesive activity of the steel slag. The invention utilizes the electric arc furnace restored slag, the coal slag and a small quantity of starch polymer or poval to prepare the performance adjustment material; and the performance adjustment material and the steel slag are mixed and chemically react at the certain temperature so as to improve the hydration and the cohesive activity of the converter steel slag. After reaction, the content of free calcium oxide in the steel slag is lower than 2 percent; and when the specific surface area of steel slag powder ranges from 400 to 500m / kg after activation, the 28d activity index is higher than 85 percent. The activated steel slag powder prepared by the invention can be used as cement admixture or concrete admixture, and can be widely applied to the construction projects of industrial and civil architecture, water conservancy, roads, airports, etc.

Owner:SOUTH CHINA UNIV OF TECH

Steel slag high-temperate modification method

The invention discloses a method for performing high-temperature modification on converter steel slag by using a siliceous-rich material, and for performing magnetic separation to remove iron and obtain activated cement clinker, which belongs to the technical field of converter steel slag application and is mainly applied to cement and concrete. The method comprises the following steps: forging steel slag with the siliceous-rich material at 1500 DEG C to perform reconstruction reaction, sampling at the high temperature of 1250 DEG C, quenching, and subsequently performing magnetic separation to remove iron. The free calcium oxide (f-CaO) is eliminated, the volume stability of the steel slag is improved, the dicalcium ferrite (C2F) is decomposed, a part of iron-bearing minerals are separated through magnetic separation, the content of an activated mineral dicalcium silicate (C2S) in the steel slag tailings is increased, and an iron-making material with relatively high content of iron is obtained.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Method for extracting bone calcium by fermentation, and osteocalcin

The invention discloses a method for extracting bone calcium by fermentation, and osteocalcin. The method comprises the steps of crushing the bone, fermenting lactic acid bacteria, heating for sterilization, enzymolizing, adding alkali to neutralize an enzymatic hydrolysate, inactivating and drying to obtain the osteocalcin. Compared with the osteocalcin prepared by a convention technology, the osteocalcin prepared by the enzymolysis technology has greatly increased free calcium content. The final prepared product has better balanced nutrition.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV

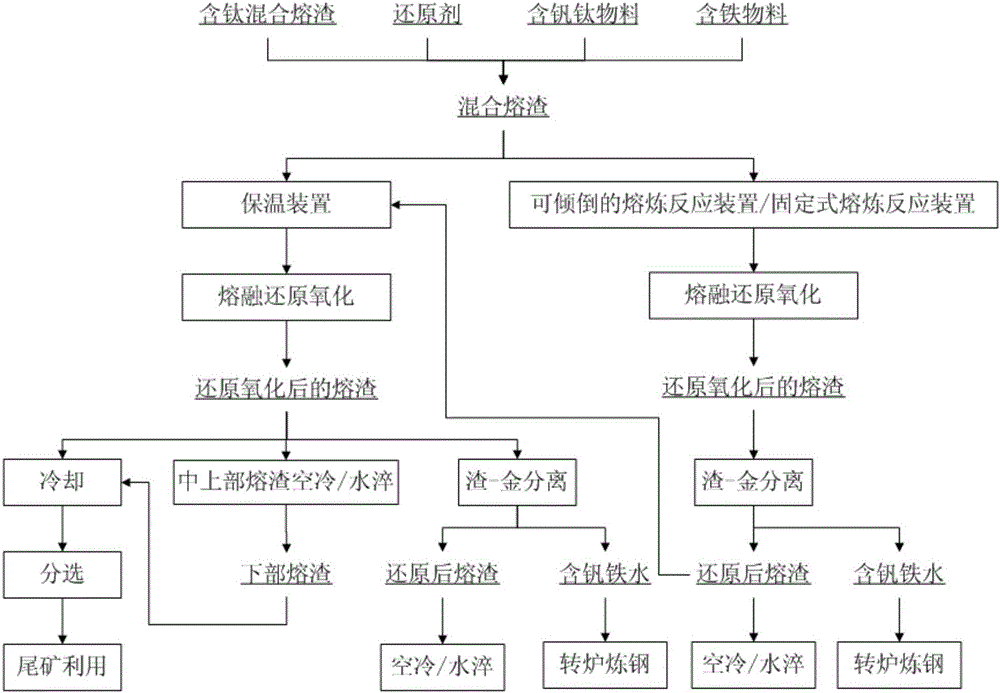

Smelting reduction production and thermal refining method for titanium-containing slag mixture

ActiveCN106048107AAchieve growthAchieve settlementRecycling and recovery technologiesProcess efficiency improvementMolten stateMaterials science

The invention provides a smelting reduction production and thermal refining method for a titanium-containing slag mixture. The smelting reduction production and thermal refining method for the titanium-containing slag mixture comprises the following steps of (1) adding a reduction agent, a vanadium-titanium-containing mineral and / or an iron-containing material into the titanium-containing slag mixture and performing heating to a set temperature to enable the slag mixture to be in a molten condition, and then injecting oxidative gas for smelting reduction and oxidation, and controlling the temperature range of the slag mixture and the alkalinity ratio range of CaO / SiO<2>; and (2) performing separation and recovery according to different reaction devices. According to the method, the titanium component, the iron component, the vanadium component, the phosphorus component and the free calcium oxide component in the slag mixture can be recycled efficiently; solid-state materials containing vanadium, titanium and iron can be processed massively by using a smelting reduction ironmaking technology for the production of high-grade titanium slag and vanadium-enriched slag, and at the same time the method is the novel smelting reduction ironmaking technology which is capable of realizing thermal refining of the slag and efficient and comprehensive utilization of resources. The method is short in reaction time, high in metal recovery rate, low in production cost, strong in raw material adaptability, large in processing capacity and capable of solving the problem of efficient recovery and use of multi-metal complex ore metallurgical resources and heat energy effectively.

Owner:NORTHEASTERN UNIV

Method for modifying high-temperature steel slag by using compound materials of tailings

ActiveCN102605113AChange compositionChange physical stateIncreasing energy efficiencyCalcium in biologySteelmaking

The invention relates to method for modifying steel slag, in particular to a method for modifying high-temperature steel slag discharged in the final steelmaking stage by using a large amount of mining tailings with low cost, comprising the following steps: mixing 15-30 parts by weight of high alumina silicate tailings, 60-80 parts by weight of high calcium silicate tailings and 5-15 parts by weight of calcium carbonate tailings to obtain compound materials of the tailings; granulating to prepare agglomerated blocks of 3-5cm; adding the compound materials of the tailings into steel slag pot or disc by batches according to the proportion of (70-80%):(20-30%) of the discharged steel slag and the compound materials of the tailings; carrying out steel slag splashing for furnace maintenance, wherein the left steel slag is not poured into the steel slag pot or disc for modifying the steel slag; preserving the temperature of the steel slag at 1,200-1,400 DEG C for 30-60min; quenching by using water, applying heat or covering by heat when the temperature is below 1,200-1,400 DEG C; breaking; and carrying out magnetic separation. Due to the adoption of the method, the separation effect of the steel slag can be improved significantly, the grindability of the separated steel slag can be improved, the total recovery rate of the scrap steel can be up to 95-100%, the components of the separated steel slag are controllable and have high activity, and the separated steel slag contain less than 1.5% by weight of the free calcium oxide, has the grinding work index of 14-17kw.h / t and can replace the portland cement clinker.

Owner:迁安金隅首钢环保科技有限公司

Method for melting and digesting free calcium oxide in converter slag

The invention provides a method for melting and digesting free calcium oxide in converter slag. The method comprises the steps that SiO2 and molten blast furnace slag are added into the converter slag by serving as calcium stabilizers at the temperature of 1,450 DEG C or above, and melt blending is conducted according to a certain weight proportion, wherein the adding amount of SiO2 accounts for 8%-50% of the amount of the treated converter slag, the adding amount of the molten blast furnace slag accounts for 30%-100% of the amount of the treated converter slag, SiO2 and the molten blast furnace slag can be added in an echelon mode or added simultaneously, and constant-temperature digesting is conducted for at least 5 minutes in each echelon of the digesting process, so that full and uniform mixing is guaranteed, entire melt blending is completed within 30 minutes, and water cooling or air cooling can be adopted as the cooling mode. According to the method, the content of free calcium oxide in the improved molten mixed slag reaches the national standard, w(CaO) / w(SiO2) is moderate, the size stability is good, comprehensive resource utilization of solid metallurgy waste is achieved, and more ways are developed for energy saving and consumption reducing of a metallurgy enterprise.

Owner:UNIV OF SCI & TECH LIAONING

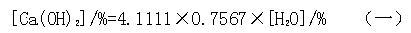

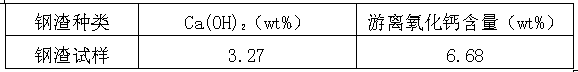

Method for determining content of free calcium oxide in steel slag

InactiveCN103558113AAccurate free calcium oxide valueThe result is accurateWeighing by removing componentCalcium hydroxideSlag

The invention discloses a method for determining the content of free calcium oxide in steel slag. The method comprises the following steps: 1, carrying out heating decomposition of a steel slag sample in inert atmosphere, and using a weight loss caused by the water volatilization during the heating decomposition of the slag sample to calculate the content of Ca(OH)2; 2, determining the content of free total calcium in the steel slag sample subjected to the heating decomposition; and 3, subtracting the Ca(OH)2 content by the amount of the free total calcium to obtain the content of the free calcium oxide. The determination utilizing a principle that calcium oxide can be generated after heating Ca(OH)2 is characterized in that a water evaporation weight loss method is used to calculate the content of calcium hydroxide (Ca(OH)2), a simple easy-implementation determining method is used to determine the amount of free total calcium, and finally an accurate free calcium oxide value is obtained. The determination method disclosed in the invention changes a present situation of the result inaccuracy caused by the interference of Ca(OH)2, and has the characteristics of short use time, accurate result, and maneuverability of all above processes.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Bone calcium extraction method by double fermentation and bone gla protein

The invention discloses a bone calcium extraction method by double fermentation. The bone calcium extraction method by double fermentation includes the steps of fermenting before enzymolysis, enzymolysis and fermenting after enzymolysis. Free calcium content of bone gla protein made by the bone calcium extraction method compared with the prior art is increased greatly. The obtained bone gla protein has fine taste and fragrance, and peculiar odors in extract are removed.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV

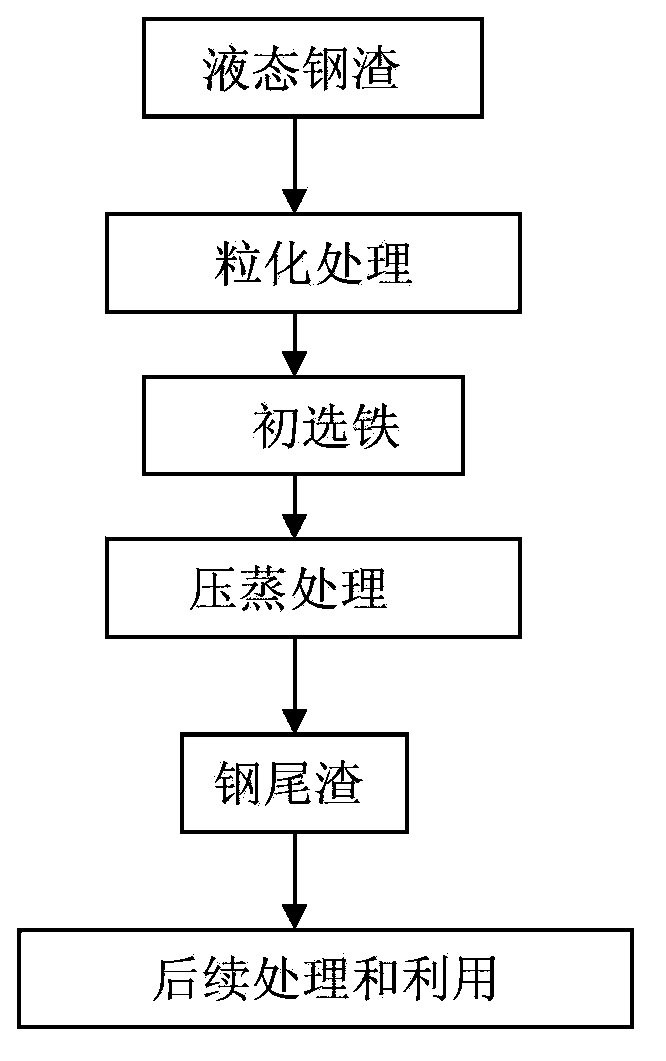

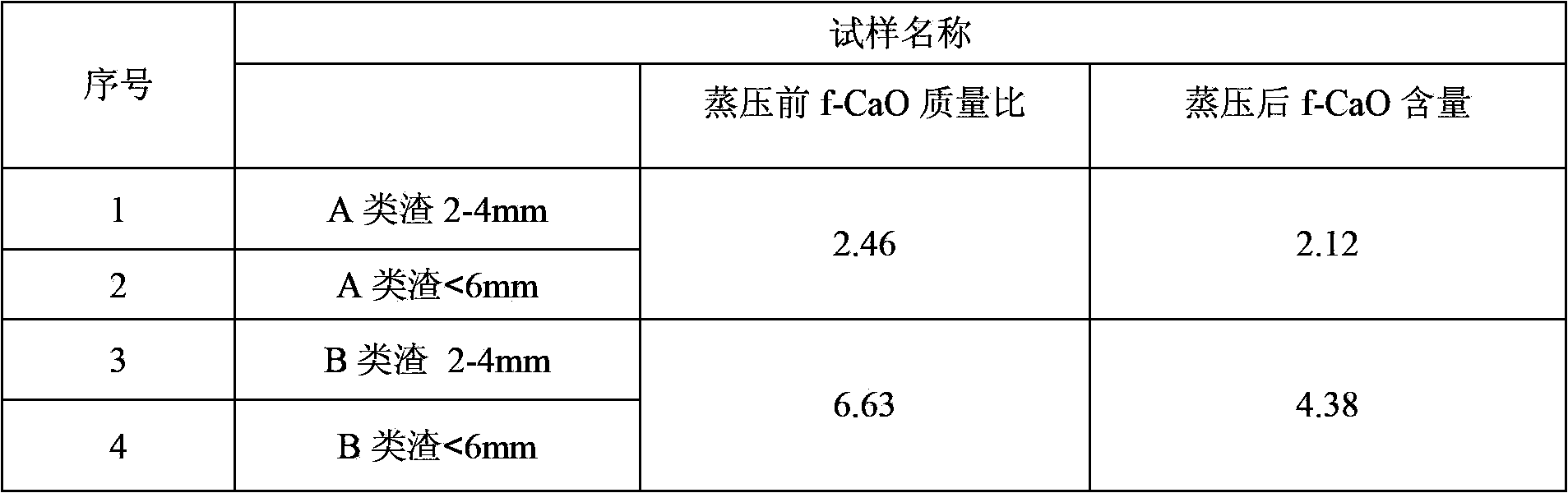

Autoclaving treatment modification technology for converter steel slag and applications thereof

ActiveCN103571983AImprove use valueIncrease added valueRecycling and recovery technologiesSlagAdditional values

The invention relates to the field of steel smelting, and particularly discloses a method of reducing contents of free calcium oxide and magnesium oxide in converter steel slag and improving steel slag stability. The method includes maintaining the temperature of the steel slag by utilization of waste heat after liquid steel slag pelletization treatment, increasing pressure during a temperature maintaining process, and subjecting the pelletized steel slag to autoclaving treatment. By utilization of the technology, the waste heat after steel slag treatment is effectively utilized, and therefore heat lost during treatment processes of the steel slag is utilized reasonably and effectively, thus saving energy, and increasing additional value of steel slag production.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

Method for resource utilization of fluidized bed combustion ash residues

InactiveCN103011367AReduce adverse effectsImprove use valueCement productionWater/sewage treatment by sorptionResource utilizationSorbent

The invention discloses a method for resource utilization of fluidized bed combustion ash residues. The method comprises the following steps of: mixing the fluidized bed combustion ash residues with water to obtain mortar, and crushing the mortar until the particle size is 1 to 20 micrometers; introducing flue gas of a coal-fired boiler until the pH value of the solution is lower than 7, and filtering to remove water to obtain the ash residues; mixing the ash residues with density separation liquid, collecting and separating out dross which floats on the surface layer of the solution; feeding material liquid into a centrifuge for centrifugally separating centrifugal residues of which the density is greater than that of the separation liquid; and filtering centrifugate in a filter to obtain residues, mxing the residues with the dross to obtain a mixture, activating the mixture in the absence of oxygen at a temperature of 300 to 500 DEG C, cooling and then crushing the mixture, cleaning the crushed mixture by using hydrochloric acid and water, and drying the cleaned mixture to obtain an adsorbent product. By adopting the method, adverse effects caused by calcium sulfite, unburned carbon granules and free calcium oxide on the products such as cement, concrete and the like are eliminated, and the calcium sulfite, the unburned carbon granules and other porous materials are separated from the products and used as useful waste water purification adsorbents, so that the utilization value of the fluidized bed combustion ash residues is improved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

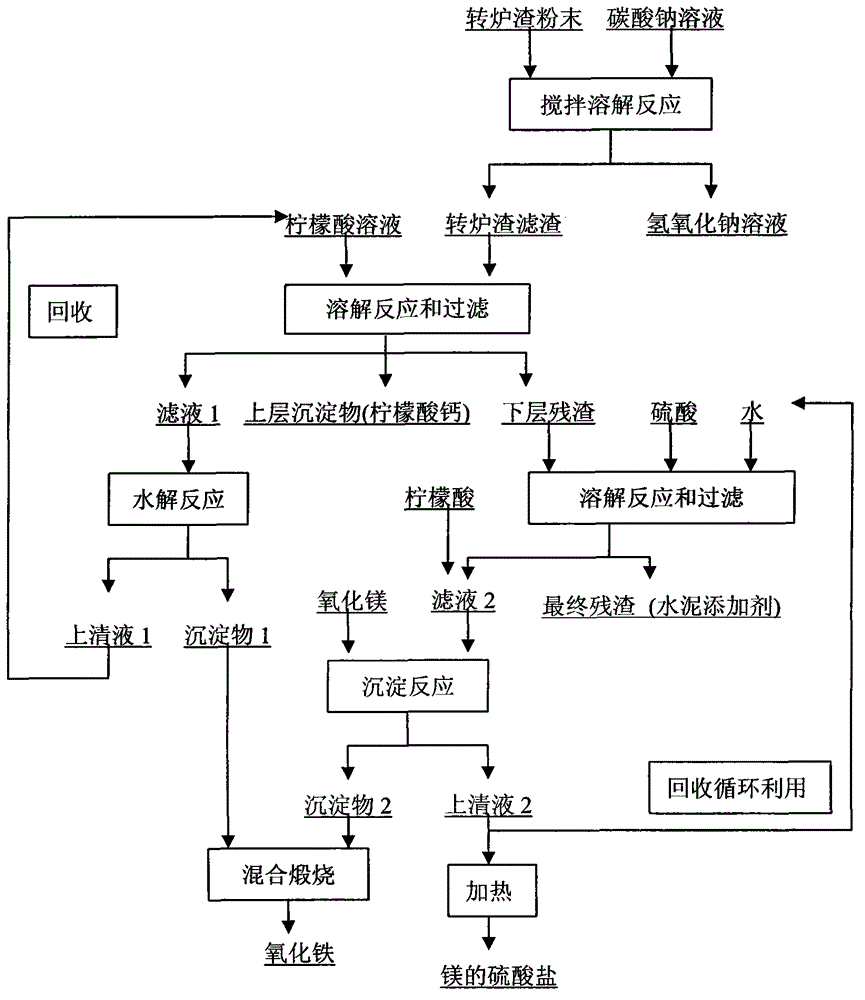

Comprehensive utilization method for converter slag

InactiveCN102912145AWide variety of sourcesLow costRecycling and recovery technologiesProcess efficiency improvementSlagFiltration

The invention provides a comprehensive utilization method for converter slag. The converter slag, which comprises free calcium oxide in weight percent more than 3%, total calcium in weight percent of 23%-38% and total iron in weight percent of 8%-28%, is used in the method as the raw material. According to the method, sodium hydroxide, calcium citrate, iron oxide, magnesium sulfate and cement additive can be obtained through processing steps including pretreatment of the converter slag, citric acid dissolution reaction and filtration, hydrolysis reaction, sulfuric acid dissolution and filtration, iron precipitation reaction, iron oxide preparation and magnesium sulfate preparation. The method aims to utilize the converter slag discharged in large scale, so as to solve the environmental pollution problem and fully utilize iron and calcium resources in the converter slag.

Owner:张悦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com