Method for modifying high-temperature steel slag by using compound materials of tailings

A technology of tailings and steel slag, which is applied in the field of high-temperature steel slag modification and high-temperature furnace slag modification, can solve the problems of poor grindability and high energy consumption of grinding, meet environmental protection requirements, low input cost, improve grindability and The effect of gelling activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

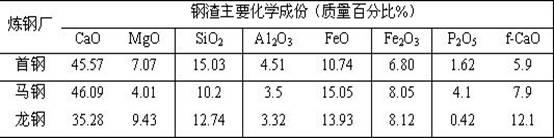

[0031] 1. The compound materials of high-alumina silicate tailings, high-calcium silicate tailings and calcareous carbonate tailings are selected as steel slag upgrading materials, among which bauxite tailings, gold mine tailings and The limestone tailings were mixed according to the parts by weight of 20, 80 and 5 respectively, and the main components of the mining tailings used are shown in Table 2.

[0032] 2. The particle size of the tailing compound material used as a high-temperature steel slag reforming material is less than 3 mm, and it is pelletized into an agglomerated mass, specifically an ellipsoid with a major axis of 5 mm and a minor axis of 3 cm.

[0033]3. The above-mentioned steel slag reforming material is mixed with the high-temperature steel slag discharged from the Shougang steelmaking plant and the high-temperature reforming material in a ratio of 70:30 by mass. The method of adding is: put the tailings compound material with a mass percentage of 60% in t...

Embodiment 2

[0037] 1. The compound materials of high-alumina silicate tailings, high-calcium silicate tailings and calcareous carbonate tailings are selected as steel slag upgrading materials, among which coal gangue, gold mine tailings and limestone gravel are respectively used Mixing according to the parts by weight of 30, 60 and 12 respectively, the main components of the used mining tailings are shown in Table 2.

[0038] 2. The particle size of the tailing compound material used as a high-temperature steel slag reforming material is less than 3 mm, and it is pelletized into an agglomerated mass, specifically an ellipsoid with a major axis of 5 mm and a minor axis of 3 cm.

[0039] 3. The above-mentioned steel slag reforming material is mixed with the high-temperature steel slag discharged from the Shougang steelmaking plant and the high-temperature reforming material at a ratio of 80:20 by mass. The way of adding is: put the 50% mass percentage of tailings compound in the slag tank o...

Embodiment 3

[0043] 1. The composite material of high-alumina silicate tailings, high-calcium silicate tailings and calcareous carbonate tailings is selected as steel slag upgrading material, among which coal gangue, iron tailings and limestone tailings are respectively used according to The parts by weight are respectively 24, 70 and 10 for mixing, and the main components of the used mining tailings are shown in Table 2.

[0044] 2. The particle size of the tailings composite material used as a high-temperature steel slag reforming material is less than 3 mm, and a spherical agglomeration block with a diameter of 4.5 cm is prepared by pelletizing.

[0045] 3. Mix the above-mentioned steel slag reforming material with the high-temperature steel slag discharged from the converter of Masteel and the high-temperature reforming material in a ratio of 75:25 by mass. The way of adding is: put the tailings compound material with a mass percentage of 40% in the slag tank or slag pan in advance, af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com