Foaming ceramic heat-insulating wallboard based on graphene and preparation method thereof

A technology of foamed ceramics and thermal insulation wall panels, applied in the field of new building materials, can solve problems that need to be improved, achieve high hardness, improve fire performance, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

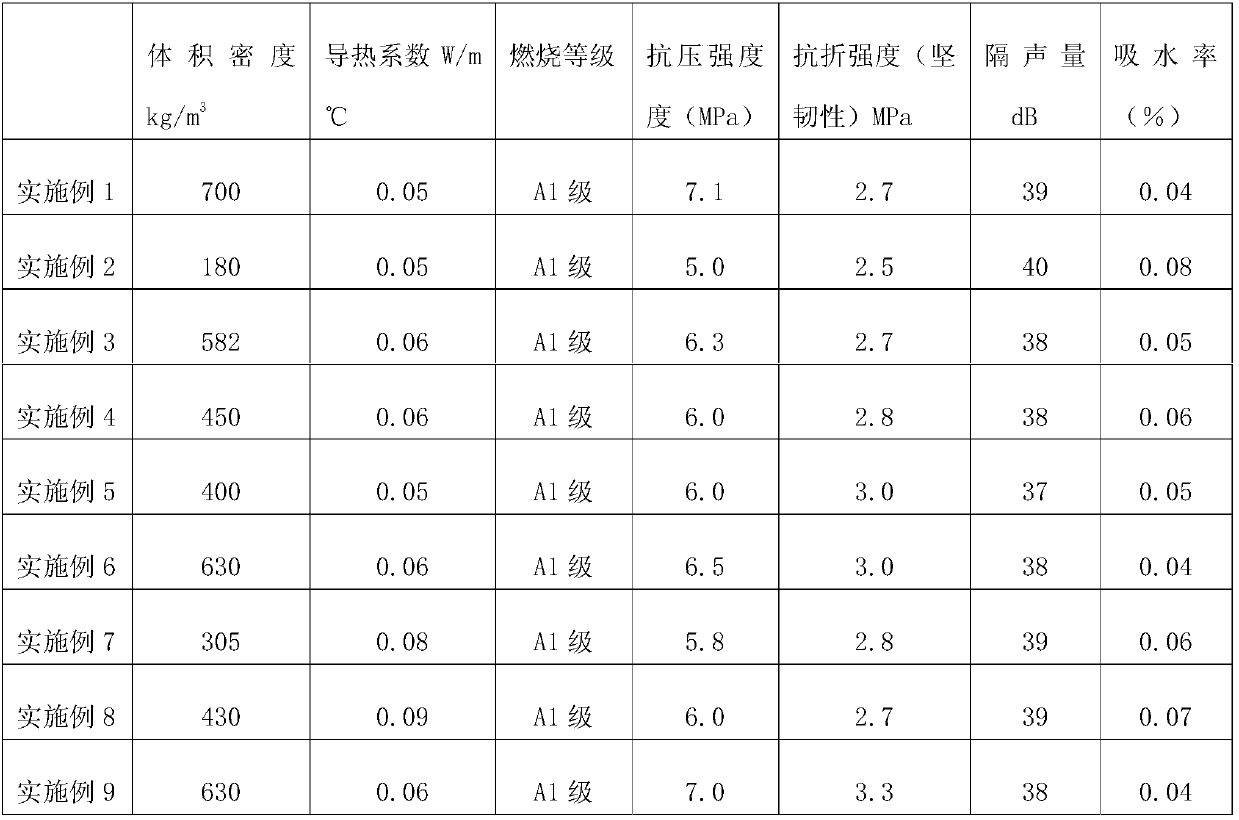

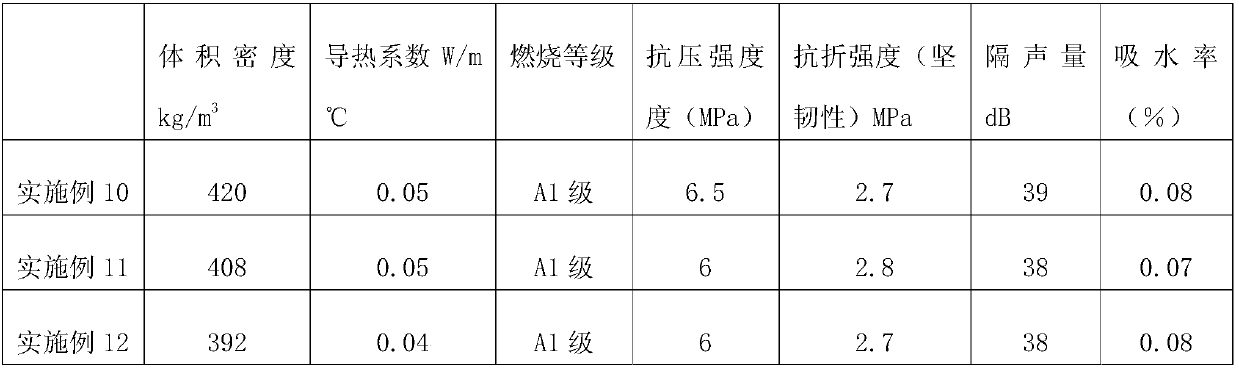

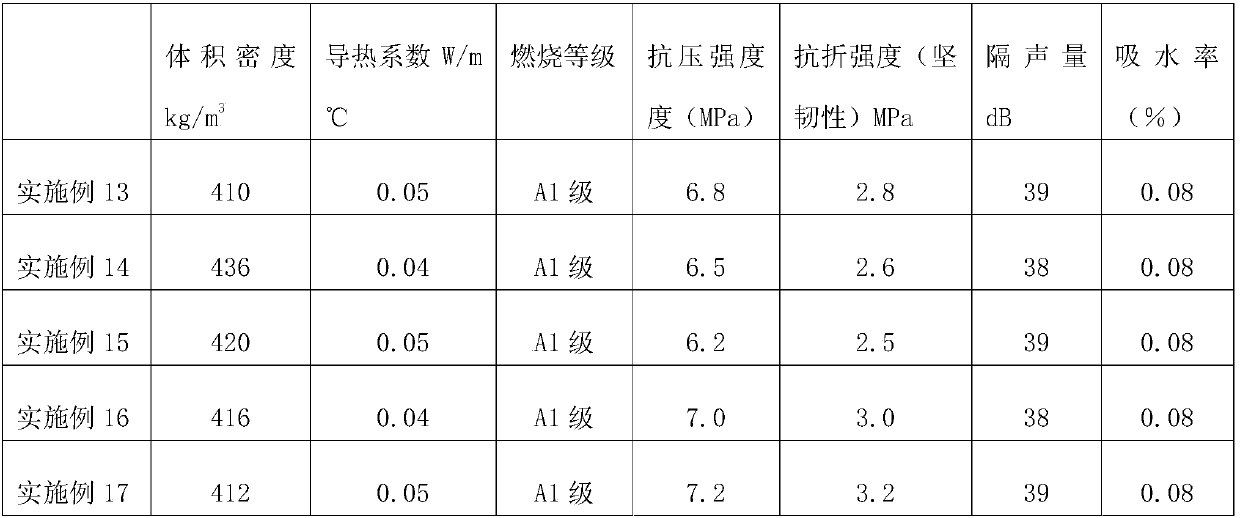

Examples

Embodiment 1

[0042] A graphene-based foamed ceramic insulation wallboard is made of the following components by weight percentage:

[0043] Potassium sodium feldspar 70%, clay 3%, graphene 7%, vermiculite 5%, high temperature flux 6%, expanded graphite 2%, zirconia 1%, stabilizer 3%, debonding agent 3%.

[0044] Among them, the clay is manganese mud and kaolin; the high-temperature flux is calcined talc; the stabilizer is yttrium oxide; the debonding agent is a water-soluble organic polycarboxylic acid, which can improve the fluidity of the lightweight aggregate.

[0045] A preparation method of a graphene-based foamed ceramic insulation wallboard, comprising the following steps:

[0046] S1. Raw material preparation: Weigh the materials according to the mass percentage of each raw material, mix them, and use a ball mill to mix and mill them for 10 hours until the fineness reaches 250 mesh and pass through a sieve, and finally put them into the storage bin for mixing and homogenization.

...

Embodiment 2

[0054] A graphene-based foamed ceramic insulation wallboard is made of the following components by weight percentage:

[0055] Potassium sodium feldspar 48%, ceramic waste residue 18%, clay 2%, graphene 10%, vermiculite 7%, high temperature flux 6%, expanded graphite 2%, zirconia 1%, stabilizer 3%, debonding agent 3%.

[0056] Among them, the clay is yellow mud and fluorite; the high-temperature flux is calcined talc and fluorite; the stabilizer is cerium oxide.

[0057] The rough product is cut into shape, and the specifications are: length: 3000mm, width: 1200mm, thickness: 100mm, and the finished product is based on graphene foamed ceramic insulation wallboard.

[0058] The preparation method is the same as in Example 1.

Embodiment 3

[0060] A graphene-based foamed ceramic insulation wallboard is made of the following components by weight percentage:

[0061] Potassium sodium feldspar 60%, ceramic waste residue 10%, clay 3%, graphene 2%, vermiculite 10%, high temperature flux 6%, expanded graphite 2%, zirconia 1%, stabilizer 3%, debonding agent 3%.

[0062] Among them, the clay is yellow mud; the high-temperature flux is calcined talc; the stabilizer is yttrium oxide.

[0063] The rough product is cut into shape, and the specifications are: length: 3000mm, width: 1200mm, thickness: 100mm, and the finished product is based on graphene foamed ceramic insulation wallboard.

[0064] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com