Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

A foamed concrete and functional gradient technology, used in thermal insulation, ceramic products, other household appliances, etc., can solve the problems of large internal stress, obvious interlayer interface, low strength of foamed concrete, etc. The effect of improving surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

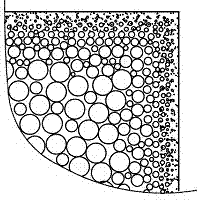

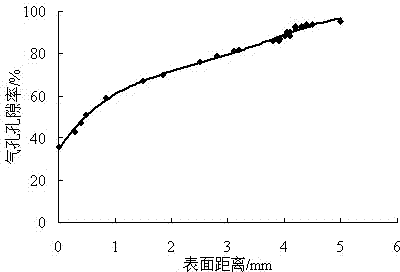

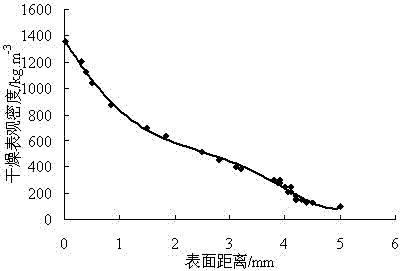

[0035] Example 1 The manufacturing method of the functional gradient foam concrete thermal insulation material is to make the foam concrete thermal insulation inner core by using inorganic gelling material, chemical foaming agent and foam stabilizer as the pore forming components, and then wrap the outer surface of the foam concrete thermal insulation core with fast Hard inorganic gelling materials, chemical foaming agents, and foam stabilizers are made of pore-forming components. The pore diameter increases continuously from 0.1 to 8mm from the surface to the inside, and the porosity increases from 35% to 95% from the surface to the inside. A functionally graded layer with a thickness of 5mm that increases continuously through the gradient.

[0036] Among them, the raw materials of the foam concrete thermal insulation core are: 100 parts of inorganic gelling material, 5 parts of foaming agent, 0.1 part of foam stabilizer, 1 part of fiber reinforcing material, 3 parts of ...

Embodiment 2

[0041] Example 2 The manufacturing method of the functional gradient foam concrete insulation material is to first make the foam concrete insulation inner core by using inorganic gelling material, physical foam agent and foam stabilizer as the pore forming components, and then wrap the outer surface of the foam concrete insulation inner core with rapid hardening Type inorganic gelling material, chemical foaming agent, and foam stabilizer are made of pore-forming components. The pore diameter increases continuously from 0.2 to 6mm from the surface to the inside, and the porosity continues from 5% to 90% from the surface to the inside. A functionally graded layer with a gradient height of 20 mm.

[0042] Among them, the raw materials of the foam concrete insulation core are calculated by mass percentage: 100 parts of inorganic gelling material, 0.5 part of foaming agent, 0.01 part of foam stabilizer, 0.05 part of fiber reinforcement material and 5 parts of industrial waste ...

Embodiment 3

[0046] Example 3 The manufacturing method of the functional gradient foam concrete insulation material is to first make the foam concrete insulation inner core by using inorganic gelling material, chemical foaming agent and foam stabilizer as the pore forming components, and then wrap the outer surface of the foam concrete insulation inner core with fast Hard inorganic gelling materials, physical foaming agents, and foam stabilizers are made of pore-forming components. The pore diameter increases continuously from the surface to the inside from 0.1 to 5 mm, and the porosity continues from 8% to 85% from the surface to the inside. Functionally graded layers with increasing gradient thickness of 3mm.

[0047] Among them, the raw materials of the foam concrete thermal insulation core are: 100 parts of inorganic gelling material, 12 parts of foaming agent, 0.15 parts of foam stabilizer, 2 parts of fiber reinforcing material, 5 parts of waterproofing agent and 50 parts of indu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com