Preparation method of graphene oxide grafted POSS (polyhedral oligomeric silsesquioxane) modified epoxy resin

An epoxy resin and graphene technology, applied in the field of graphene oxide, can solve the problems of limited application and development, low upper limit temperature, poor fracture toughness and impact resistance, etc., and achieves an increase in the initial temperature of thermal decomposition and improvement in tensile strength. , the effect of increased bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

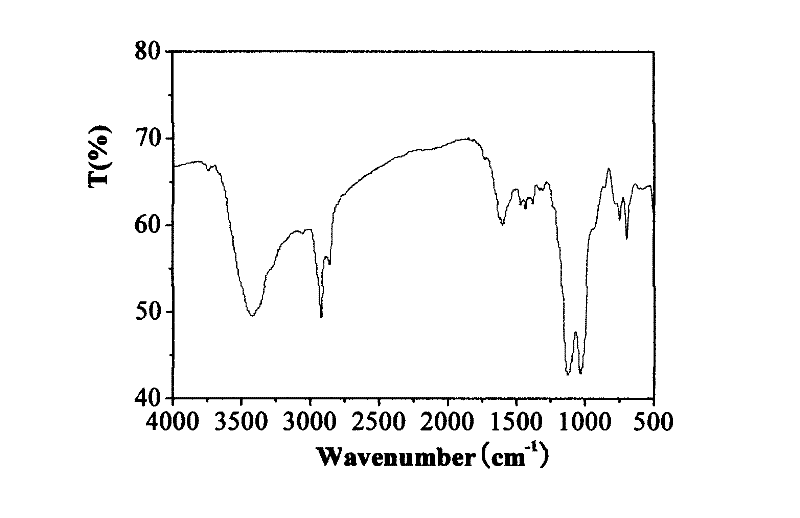

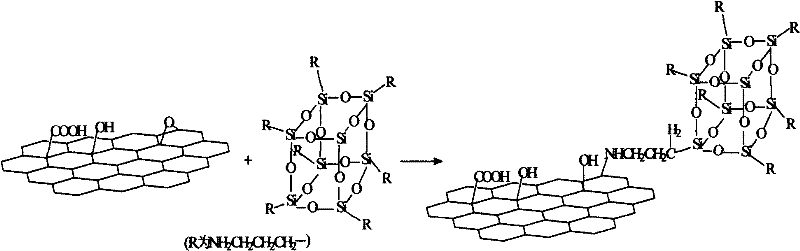

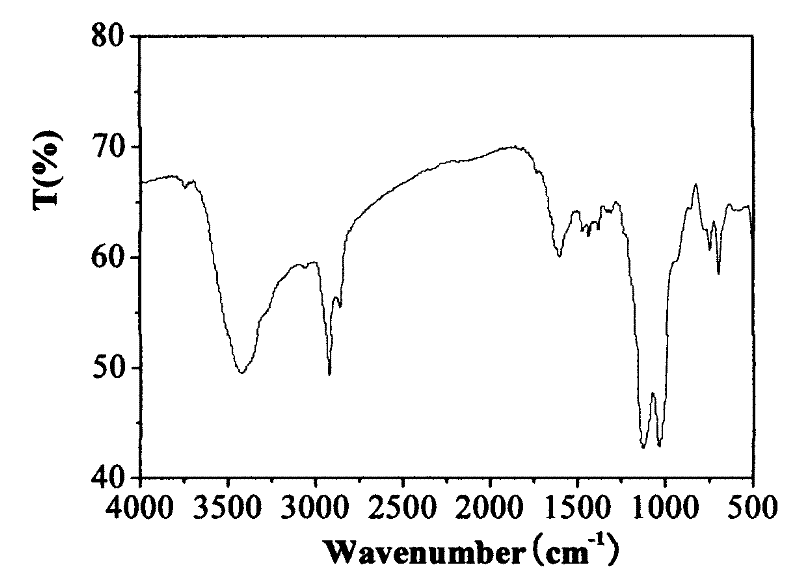

[0018] (1) take flake graphite as raw material, adopt Hummers oxidation method to prepare graphite oxide, add 0.5g graphite oxide in 250ml there-necked flask, add 200ml distilled water, disperse 30min under ultrasonic environment, form the graphene oxide mixed solution of uniform dispersion, then Add 5ml of γ-aminohexahedral silsesquioxane (POSS) and 1.0g of NaOH, and adjust the pH value to 7, continue ultrasonic dispersion at 90°C for 3 hours, cool to room temperature after the reaction, add a large amount of water to precipitate, and depressurize Suction filtration, the product was washed 3 times with absolute ethanol to obtain graphene oxide / POSS black powder;

[0019] (2) Take 0.26g of graphene oxide / POSS prepared in step (1) and add it to 26g of epoxy resin E-51 matrix, depressurize and pump, then add 7.8g of 4,4'-diaminodiphenyl sulfone (DDS) Curing agent, mixed and dissolved, poured into a steel mold coated with silicon ester, and cured at 120°C / 2 hours + 160°C / 2 hours ...

Embodiment 2

[0022] (1) take flake graphite as raw material, adopt Hummers oxidation method to prepare graphite oxide, add 0.5g graphite oxide in 250ml there-necked flask, add 200ml distilled water, disperse 30min under ultrasonic environment, form the graphene oxide mixed solution of uniform dispersion, then Add 5ml of γ-aminohexahedral silsesquioxane (POSS) and 1.0g of NaOH, and adjust the pH value to 7, continue ultrasonic dispersion at 90°C for 3 hours, cool to room temperature after the reaction, add a large amount of water to precipitate, reduce Pressure suction filtration, the product was washed 3 times with absolute ethanol to obtain graphene oxide / POSS black powder;

[0023] (2) Take 0.78g of graphene oxide / POSS prepared in step (1) and add it to 26g of epoxy resin E-51 matrix, depressurize and pump, then add 7.8g of 4,4'-diaminodiphenyl sulfone (DDS) Curing agent, mixed and dissolved, poured into a steel mold coated with silicon ester, and cured at 120°C / 2 hours + 160°C / 2 hours +...

Embodiment 3

[0026] (1) take flake graphite as raw material, adopt Hummers oxidation method to prepare graphite oxide, add 0.5g graphite oxide in 250ml there-necked flask, add 200ml distilled water, disperse 30min under ultrasonic environment, form the graphene oxide mixed solution of uniform dispersion, then Add 5ml of γ-aminohexahedral silsesquioxane (POSS) and 1.0g of NaOH, and adjust the pH value to 7, continue ultrasonic dispersion at 90°C for 3 hours, cool to room temperature after the reaction, add a large amount of water to precipitate, reduce Pressure suction filtration, the product was washed 3 times with absolute ethanol to obtain graphene oxide / POSS black powder;

[0027] (2) Take 1.30g of graphene oxide / POSS prepared in step (1) and add it to 26g of epoxy resin E-51 matrix, vacuum pump, then add 7.8g of 4,4'-diaminodiphenyl sulfone (DDS) Curing agent, mixed and dissolved, poured into a steel mold coated with silicon ester, and cured at 120°C / 2 hours + 160°C / 2 hours + 180°C / 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com