Preparation of hyperbranched polymer and hyperbranched epoxy resin

A technology of hyperbranched polymer and epoxy resin, which is applied in the field of preparation of hyperbranched polymer, can solve the problems of heat resistance decline, and achieve the effects of excellent heat resistance, low raw material cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare according to the hyperbranched epoxy resin of the present embodiment through the following steps successively:

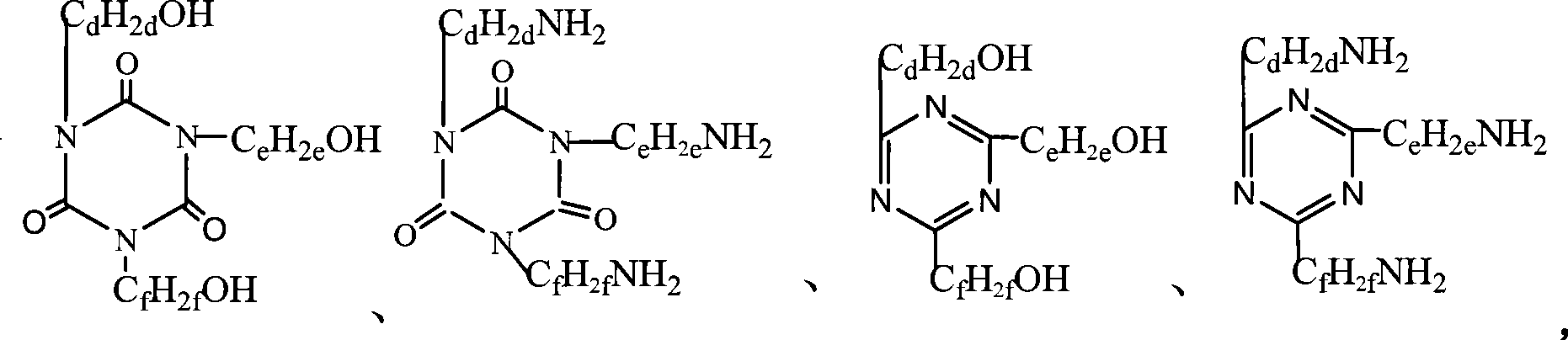

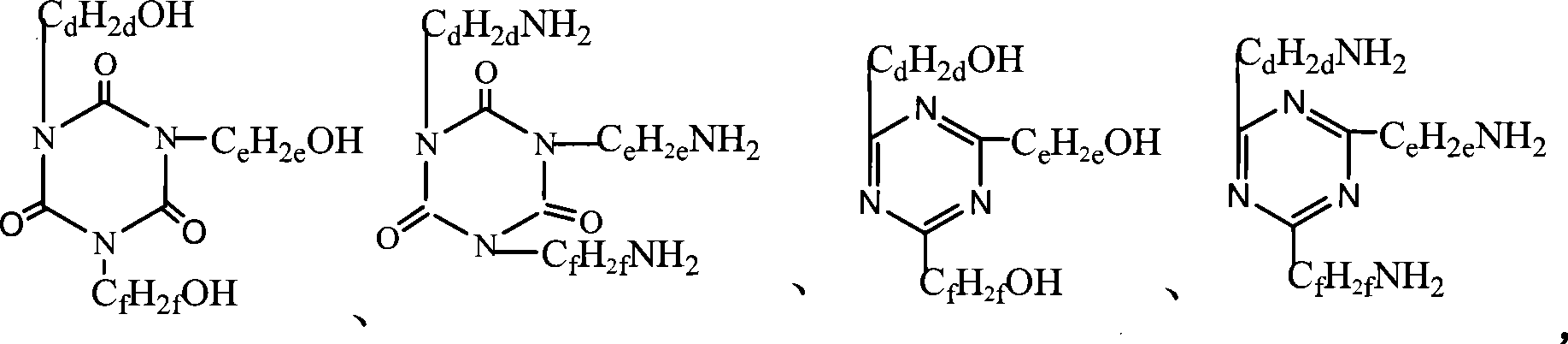

[0031] (1), synthetic hydroxyl end hyperbranched polymer: with 0.9mol phthalic acid, 0.9mol trimethylolpropane, 0.1mol trimethylol cyanurate, 1.5g p-toluenesulfonic acid (consumption is monomer 0.5% of the total mass), 500ml of xylene and 100ml of dimethylacetamide were added to a three-necked flask equipped with a water separator, a condenser, a thermometer and a stirrer, and the temperature was slowly raised to 170-180°C, and kept at this temperature After reacting for 6 hours, a hyperbranched polymer containing 12 mol terminal hydroxyl groups was obtained.

[0032] (2), Synthesis of hyperbranched epoxy resin: 0.1mol of the hyperbranched polymer containing 12mol terminal hydroxyl groups prepared above, 4.8mol of epichlorohydrin and 0.05mol of cetyltrimethylammonium bromide are added to the reactor In the process, keep the reaction at 100°C for 2 ho...

Embodiment 2

[0034] Prepare according to the hyperbranched epoxy resin of the present embodiment through the following steps successively:

[0035] (1), synthetic carboxyl-terminated hyperbranched polymer: the consumption of 0.9mol phthalic anhydride, 0.12mol phthalic acid, 0.9mol diethanolamine, 0.1mol triamine methyl cyanurate, p-toluenesulfonic acid is the amount of monomer Add 0.8%, 800ml of xylene into a three-necked flask equipped with a water separator, a condenser, a thermometer and an agitator, slowly raise the temperature to 160-170°C, and keep the reaction at this temperature for 8 hours to obtain a hyperbranch containing 12mol terminal carboxyl groups. chemical polymer.

[0036] (2), synthetic hyperbranched epoxy resin: 0.1mol hyperbranched polymer prepared in step (1), 12mol epichlorohydrin and 0.12mol cetyltrimethylammonium bromide, under the condition of 110 ℃ After 6 hours of reaction, excess epichlorohydrin was removed in vacuo. Then drop to room temperature, add enough ...

Embodiment 3

[0038] Prepare according to the hyperbranched epoxy resin of the present embodiment through the following steps successively:

[0039] (1), the hyperbranched polymer of synthetic terminal hydroxyl: the consumption of 0.42mol trimellitic anhydride, 0.82mol ethylene glycol, 0.02mol trimethylol cyanurate, sulfuric acid is 0.5% of monomer, xylene 400ml, toluene Add 300ml and 100ml of dimethylformamide into a three-necked flask equipped with a water separator, condenser, thermometer and stirrer, slowly raise the temperature and react at 150-160°C for 10 hours to obtain a hyperbranched polymer.

[0040](2), synthetic hyperbranched epoxy resin: the hyperbranched polymer that 0.05mol step (1) makes, 10mol epichlorohydrin and 0.08mol concentration are 5% sodium hydroxide aqueous solution, under the condition of 60 ℃ After 10 hours of reaction, excess epichlorohydrin was removed in vacuo. Then lower it to room temperature, add enough ethanol to dissolve it fully under stirring conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com