Patents

Literature

742 results about "Trimellitic anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mellitic anhydride, the anhydride of mellitic acid, is an organic compound with the formula C₁₂O₉. Containing no other elements (e.g., hydrogen) besides carbon and oxygen, mellitic anhydride is an oxide of carbon (oxocarbon), and, along with CO₂, CO, and C₃O₂, is one of the only four that are reasonably stable under standard conditions. It is a white sublimable solid, apparently obtained by Justus Liebig and Friedrich Wöhler in 1830 in their study of mellite ("honey stone") and has the empirical formula C₄O₃. The substance was properly characterized in 1913 by H. Meyer and K. Steiner. It retains the aromatic character of the benzene ring.

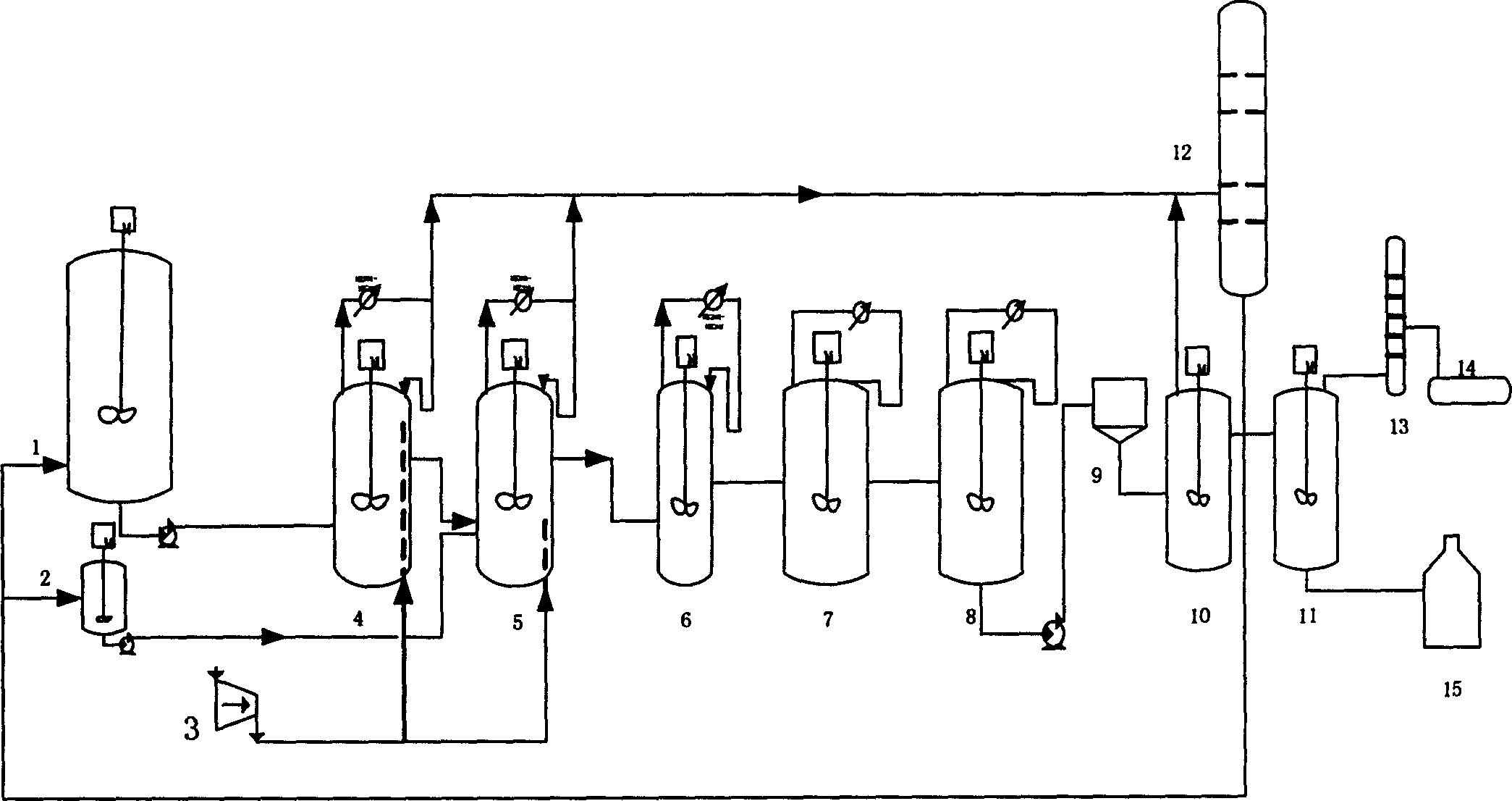

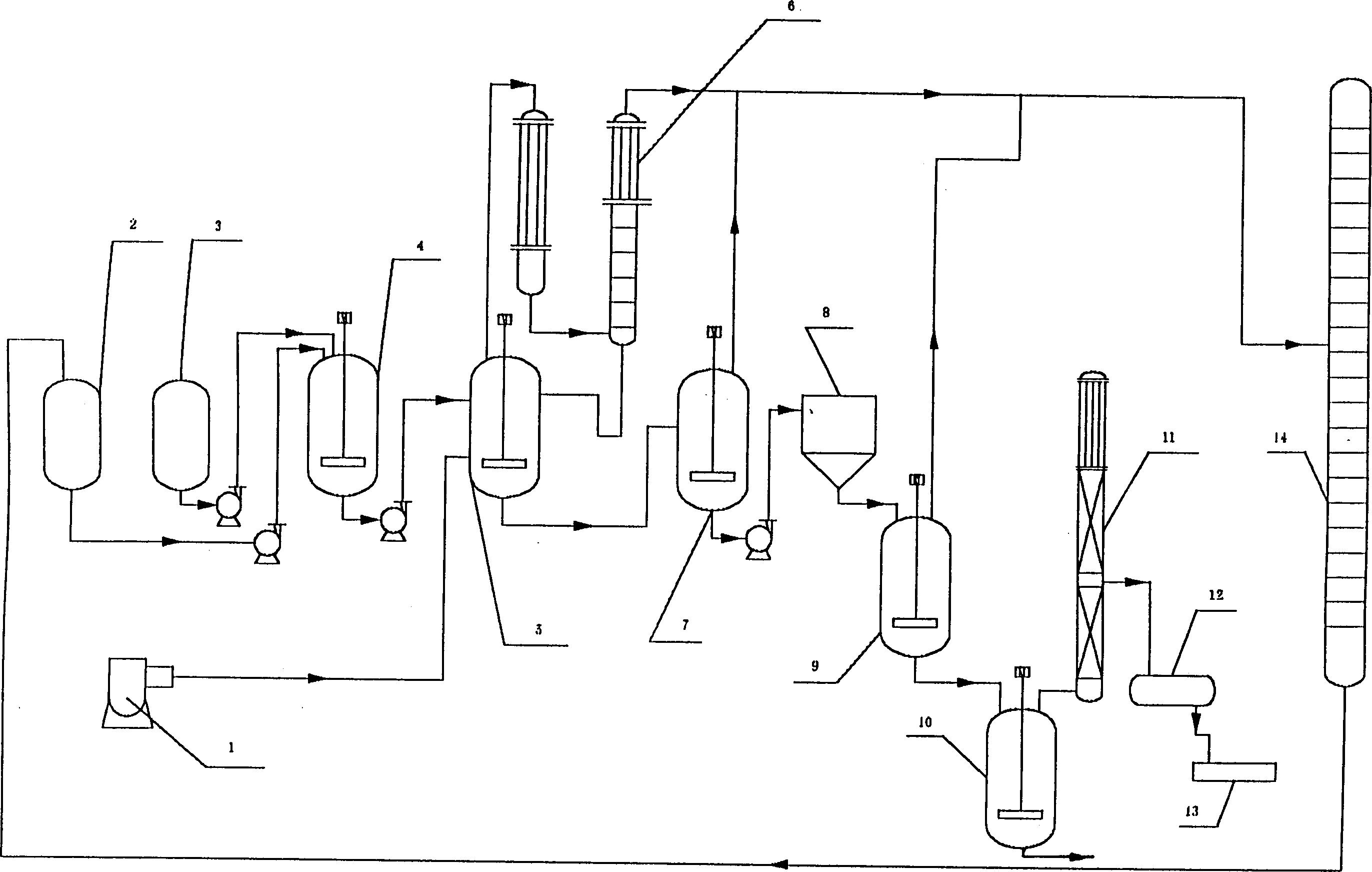

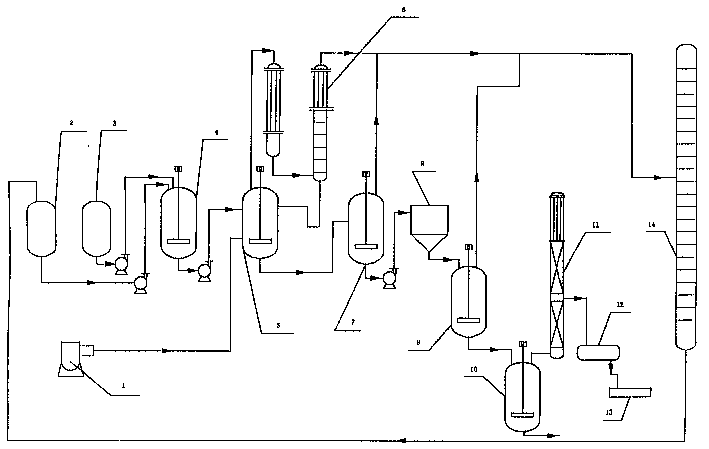

Process for continuous preparation of trimellitic anhydride by step catalytic oxidation process

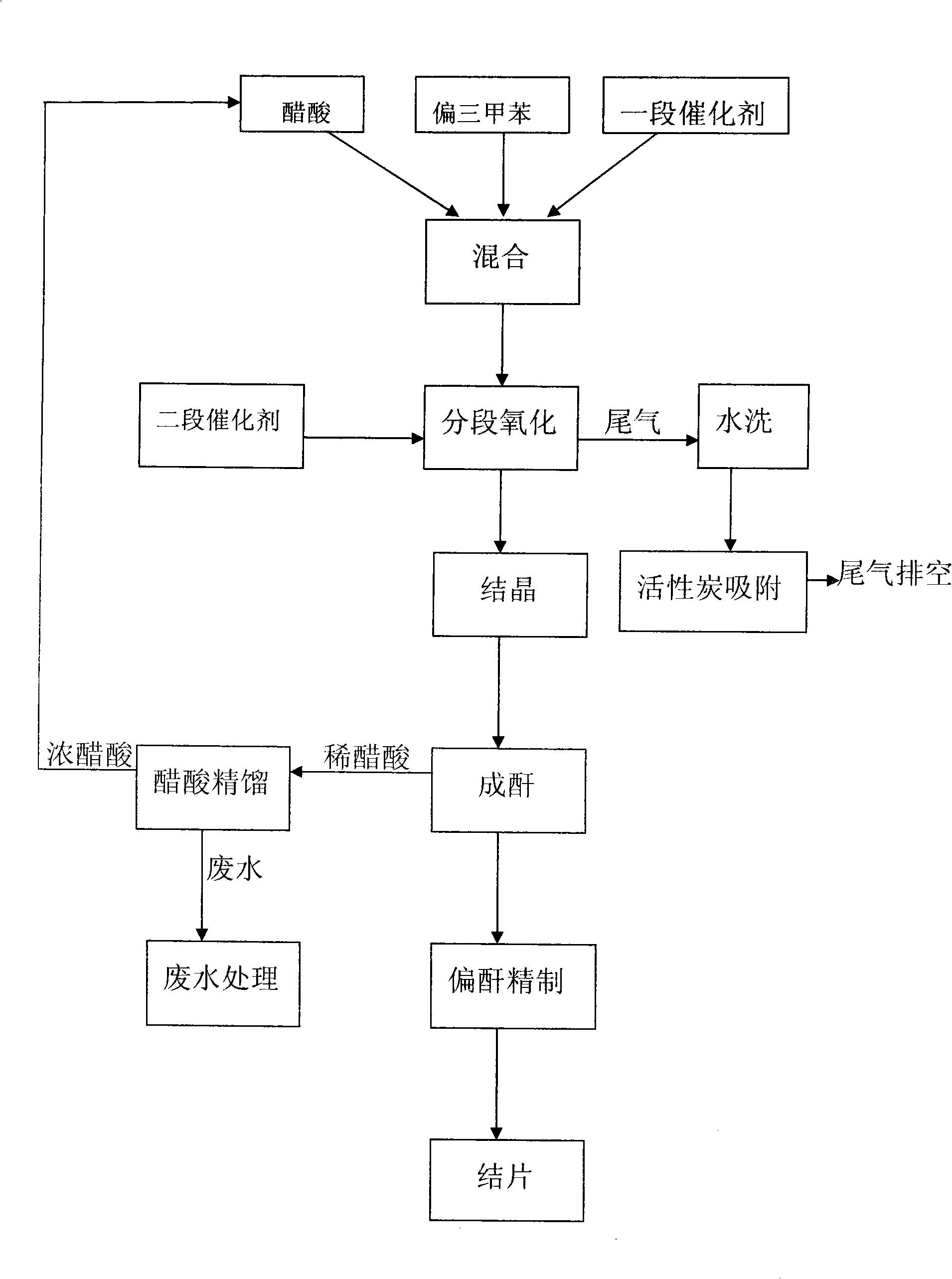

The invention provides a process for continuous preparation of trimellitic anhydride by step catalytic oxidation process by using pseudocumene as raw material, fatty group carboxylic acid as dissolvent, cobalt, manganese and bromine as catalyst, the preparing process comprises the steps of, (1) stepwise continuous catalysis oxidizing process, (2) crystallization and liquid-solid separation, (3) anhydride forming procedure, (4) subtractive process, and (5) solvent reclamation.

Owner:CHINA PETROLEUM & CHEM CORP +2

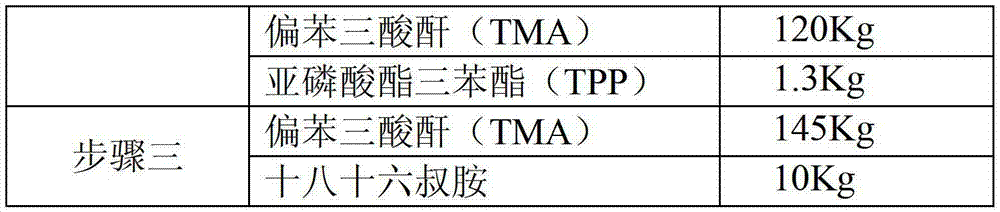

Method for preparing solventless unsaturated polyester-imide wire coating enamel

InactiveCN101514276AHigh temperature resistantEnergy saving and environmental protectionPlastic/resin/waxes insulatorsCoatingsImideAcid value

The invention relates to a method for preparing solventless unsaturated polyester-imide wire coating enamel. The method comprises preparation of unsaturated polyester-imide and processing of paint mixing, wherein the unsaturated polyester-imide is prepared by the following steps: first step, adding polylol, dibasic acid or estolide into a reaction kettle according to a mol ratio of 1.05-1.5:1; stirring and heating the mixture to a temperature of between 160 and 170 DEG C; preserving the heat for 0.5 to 2 hours; and slowly heating the mixture to a temperature of between 200 and 205 DEG C until the acid value is no less than 50 mg KOH / g; and second step, cooling the mixture to a temperature of between 110 and 120 DEG C, adding trimellitic anhydride and diamine with the mol ratio of 2:1, and preserving the heat at a temperature of between 130 and 150 DEG C until the material is transparent; and after 1 hour of heat preservation, slowly heating the material to a temperature of between 200 and 205 DEG C until the acid value is no less than 30 mg KOG / g. Machine winding dipped by the solventless resin has the advantages of small volatilization loss, high filling rate, few times of paint dipping, short baking time, strong binding power, excellent performance of electrical appliance, environmental pollution reduction, and the like.

Owner:上海新天和树脂有限公司 +1

Aqueous dispersion comprising a branched triol having trimellitic anhydride and associated method

An aqueous dispersion comprising a reaction product of trimellitic anhydride and a polyol, wherein the molar ratio of trimellitic anhydride to polyol in the reaction product ranges from 1:2 to 1:4, and wherein the reaction product is further reacted with an anhydride to form another reaction product. A method of making a resin comprising the reaction product described above is also disclosed.

Owner:PPG IND OHIO INC

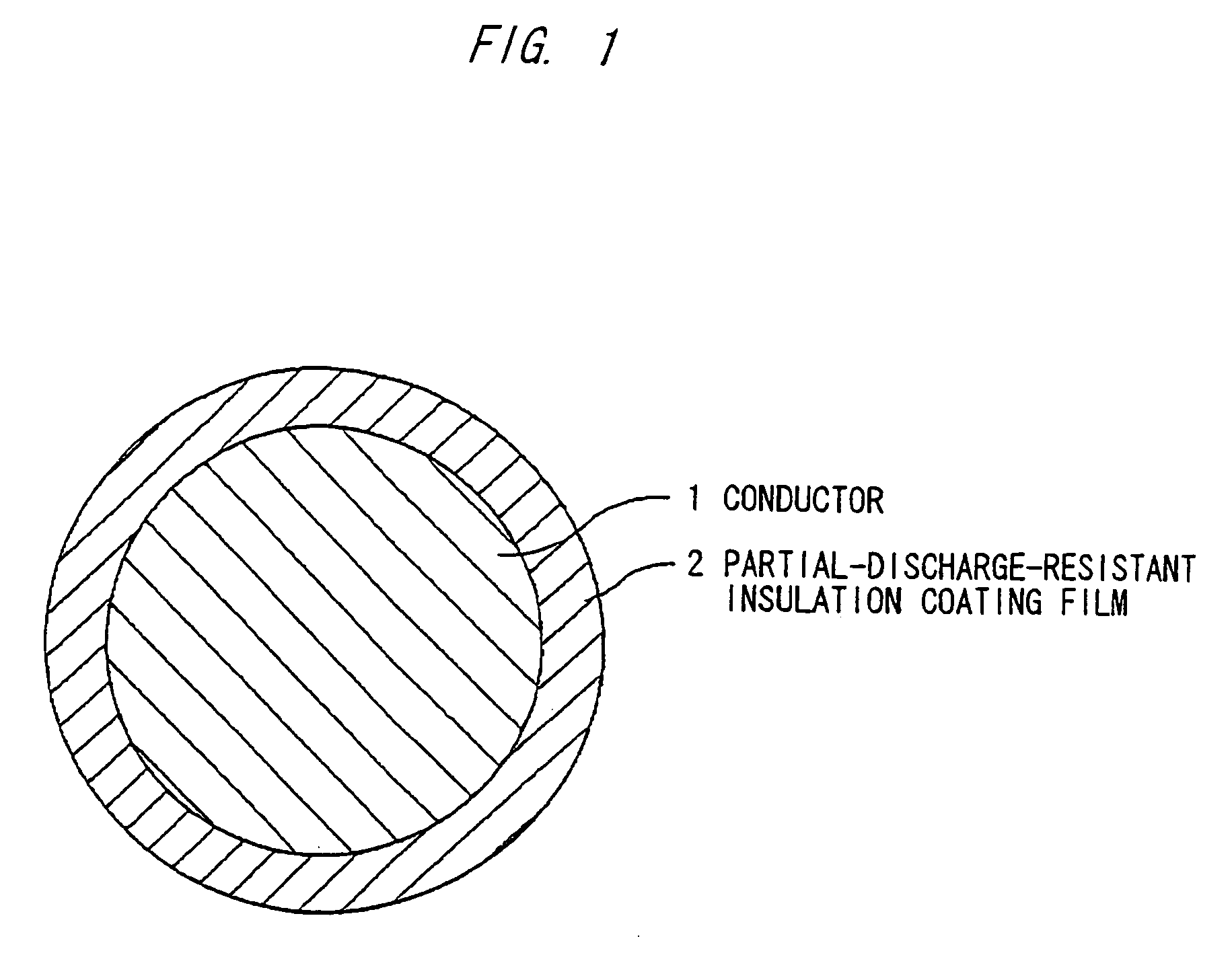

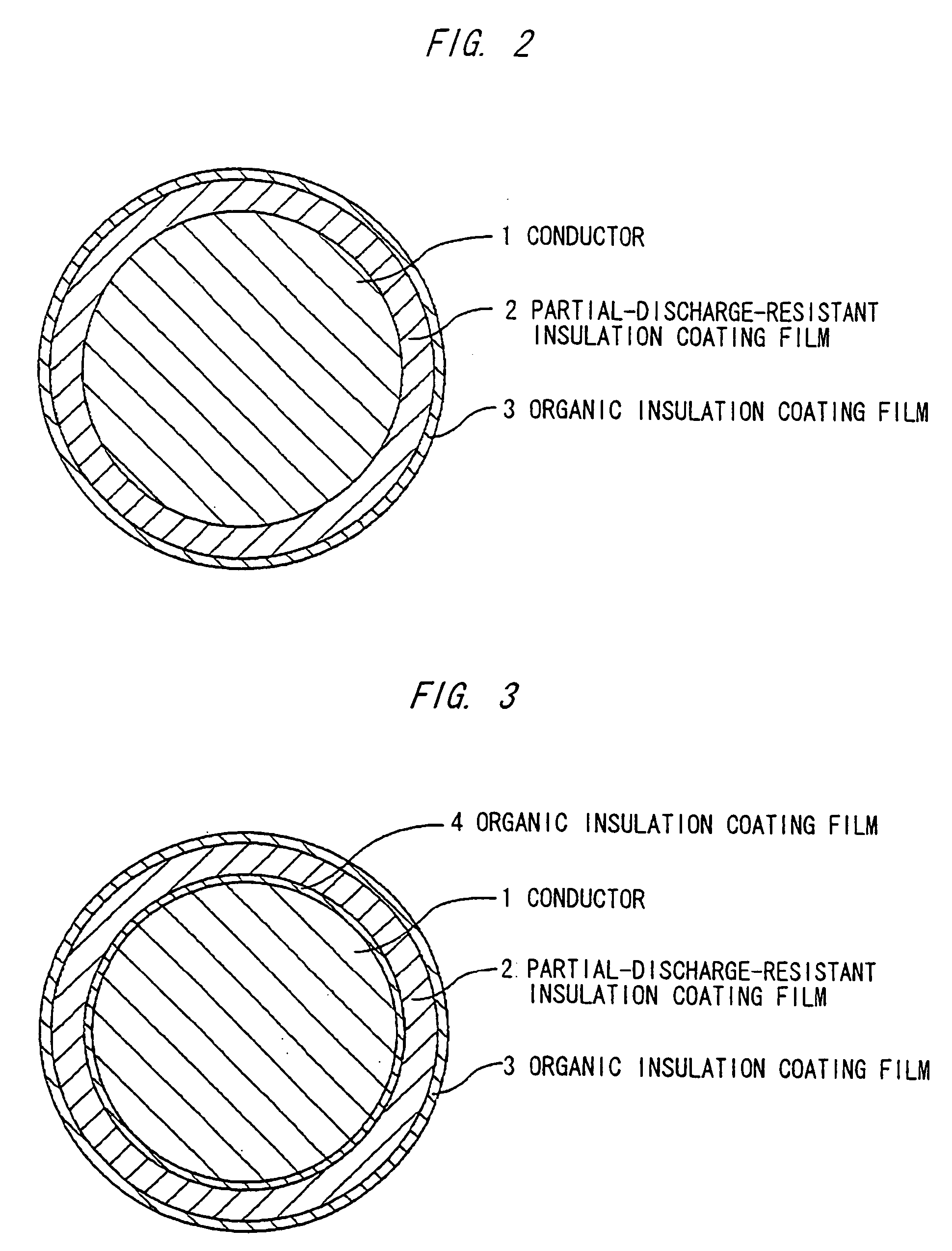

Polyamide-imide resin insulating coating material, insulated wire and method of making the same

ActiveUS20060240255A1Evenly dispersedInhibit aggregationLiquid surface applicatorsInsulatorsPolyamide-imideInsulative paint

A polyamide-imide resin insulating coating material, which is obtained by reacting an isocyanate component with an acid component, has a main solvent component of γ-butyrolactone. In the coating material, a total compounding ratio of 4,4′-diphenylmethane diisocyanate (MDI) and trimellitic anhydride (TMA) is 85 to 98 mol %, where the total compounding ratio is given by averaging a compounding ratio of MDI to the isocyanate component and a compounding ration of TMA to the acid component.

Owner:HITACHI METALS LTD

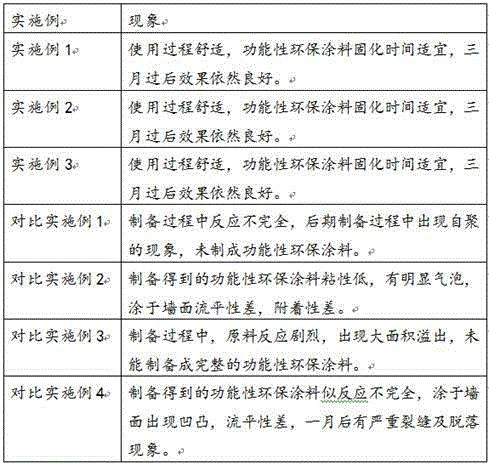

Method for preparing functional environmentally-friendly paint

The invention relates to a method for preparing a functional environmentally-friendly paint. The preparation method comprises: adding 10-100 parts of glycerol, 10-100 parts of pentaerythritol, 5-80 parts of trimethylolpropane, 20-200 parts of phthalate, 3-60 parts of adipic acid, 10-80 parts of trimellitic anhydride, and 15-150 parts of maleic acid into a reactor; heating the reactor to make the substances therein react; after a complete reaction, adding in 0.03-3 parts of a defoamer; cooling the reactants, and gradually adding in 0.05-2 parts of hydrogenated castor oil and 0.05-2 parts of a polymerization inhibitor during the cooling process; adding in 8-95 parts of styrene to modify a product; and adding in 4-60 parts of triethylamine, 3-70 parts of a solvent, 15-230 parts of a pigment and a filler, 0.01-2 parts of a leveling agent, 0.5-6 parts of a catalyst, 3-7 parts of a first solid additive, 1.5-6 parts of a second solid additive, 6-9 parts of a first composite modifier, 7-11 parts of a second composite modifier, and 8-14 parts of a third composite modifier to obtain the functional environmentally-friendly paint. The functional environmentally-friendly paint prepared by the method is stable in performance, little in environmental effect, and suitable for large-scale popularization.

Owner:ANJI QILONG NEW BUILDING MATERIAL

Organic anti-reflective coating compositions for advanced microlithography

InactiveUS6846612B2Radiation applicationsSemiconductor/solid-state device manufacturingEpoxyAnti-reflective coating

New polymers and new anti-reflective compositions containing such polymers are provided. The compositions comprise a polymer (e.g., epoxy cresol novolac resins) bonded with a chromophore (4-hydroxybenzoic acid, trimellitic anhydride). The inventive compositions can be applied to substrates (e.g., silicon wafers) to form anti-reflective coating layers having high etch rates which minimize or prevent reflection during subsequent photoresist exposure and developing.

Owner:BREWER SCI

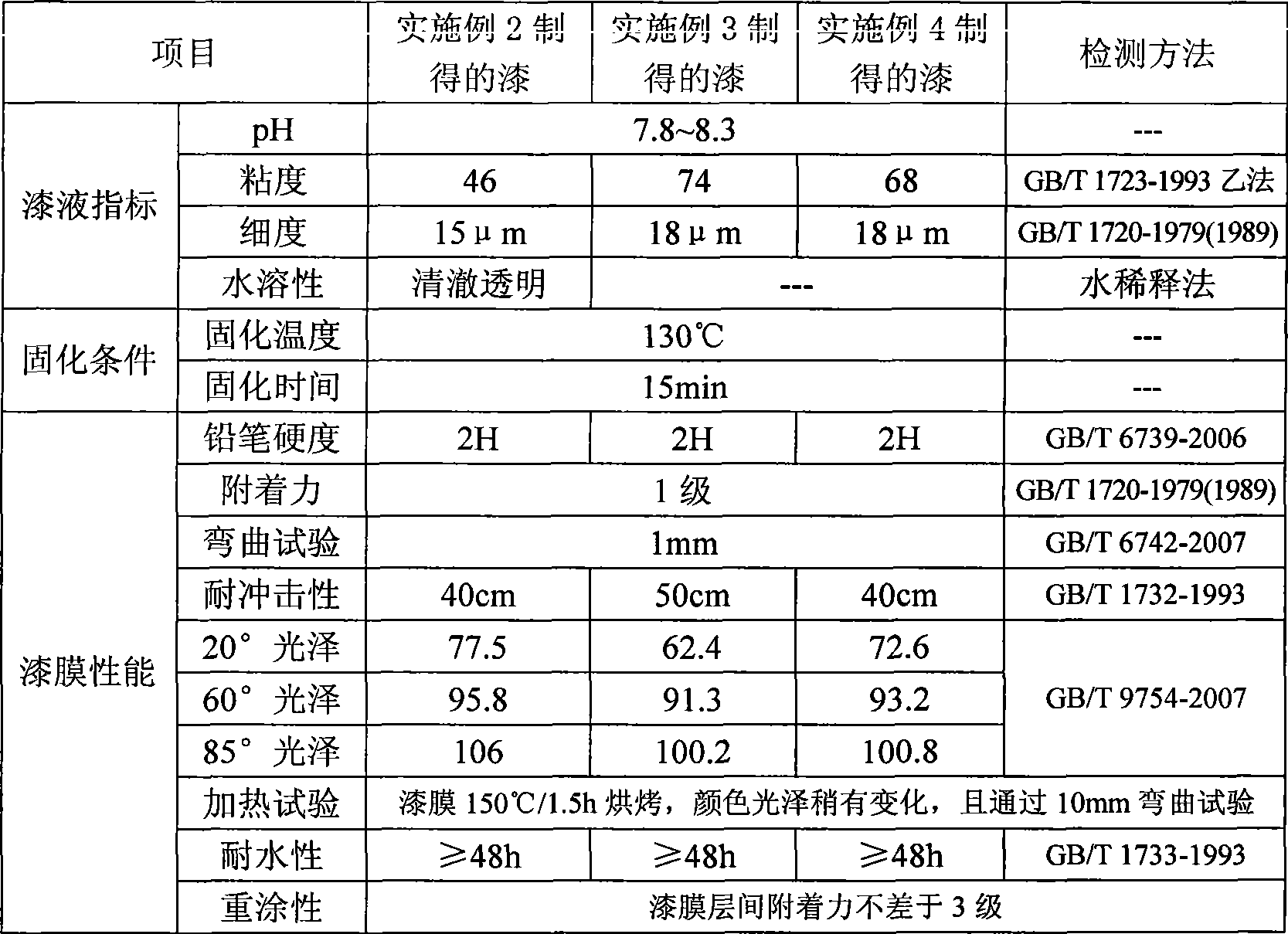

Epoxy-modified water-based alkyd resin and water-based alkyd amino stoving varnish and preparation method of epoxy-modified water-based alkyd resin and water-based alkyd amino stoving varnish.

InactiveCN104072742ASolve the hardnessSolve Adhesion ProblemsPolyester coatingsWater basedVegetable oil

The invention discloses epoxy-modified water-based alkyd resin, water-based alkyd amino stoving varnish and a preparation method of the epoxy-modified water-based alkyd resin and the water-based alkyd amino stoving varnish, belonging to the technical field of high molecular materials. The preparation method comprises the following steps: mixing vegetable oil, bisphenol A glycidyl ether epoxy resin and polyhydric alcohols to synthesize an alcoholysate monoglyceride; then, carrying out esterification reaction with phthalic anhydride, then hydrating by using trimellitic anhydride, and finally neutralizing and dispersing to obtain the epoxy-modified water-based alkyd resin (as a component A); and then, mixing the component A with various types of amino resins (as a component B) and a certain amount of pigments and filler, cosolvent, neutralizer and deionized water to prepare the amino stoving varnish. By using vegetable oil as a main raw material, an extremely small amount of solvent is used, and the method hardly depends on petroleum and is low in cost and the production process is simple and easy to control. The prepared stoving varnish can be widely applied to the fields such as industrial corrosion prevention and belongs to the environment-friendly coating.

Owner:SOUTH CHINA UNIV OF TECH

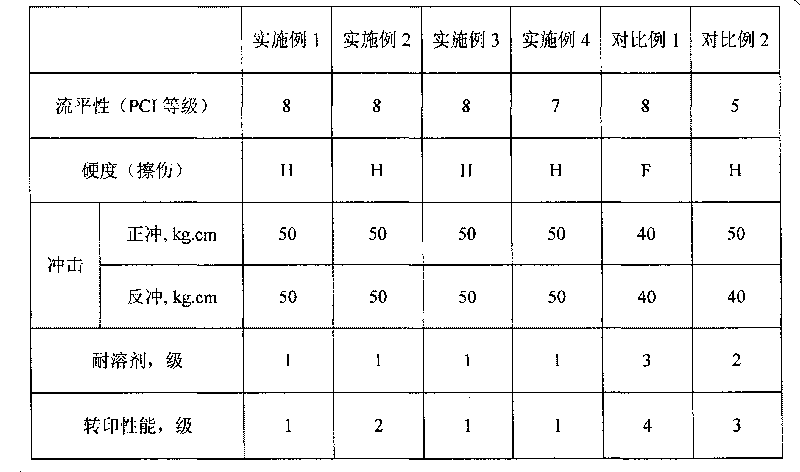

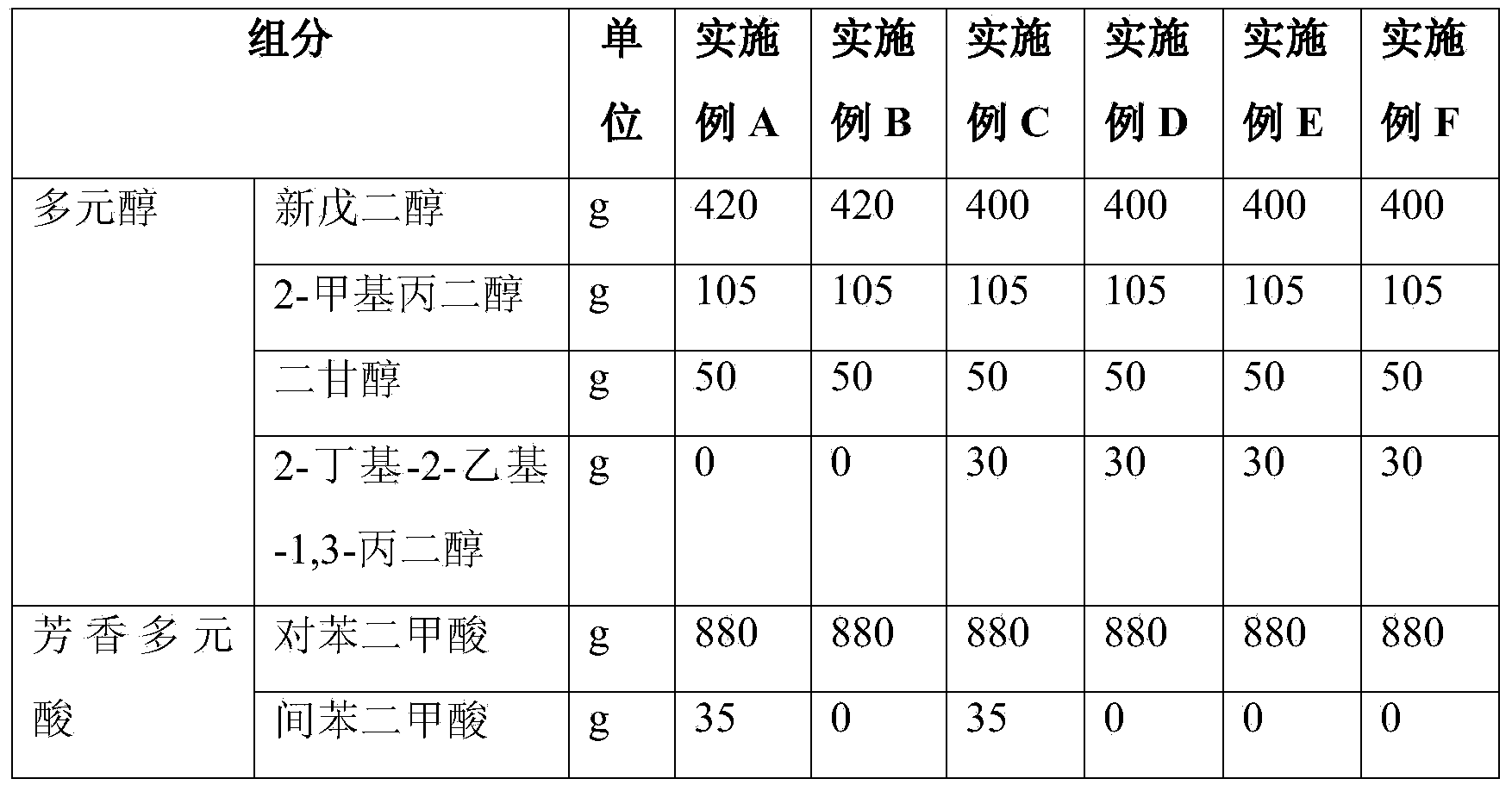

Polyester resin for mixed powder coating and preparation method thereof

ActiveCN101704945AUniform reaction rateGood solvent resistancePowdery paintsPolyester coatingsLow temperature curingAdipic acid

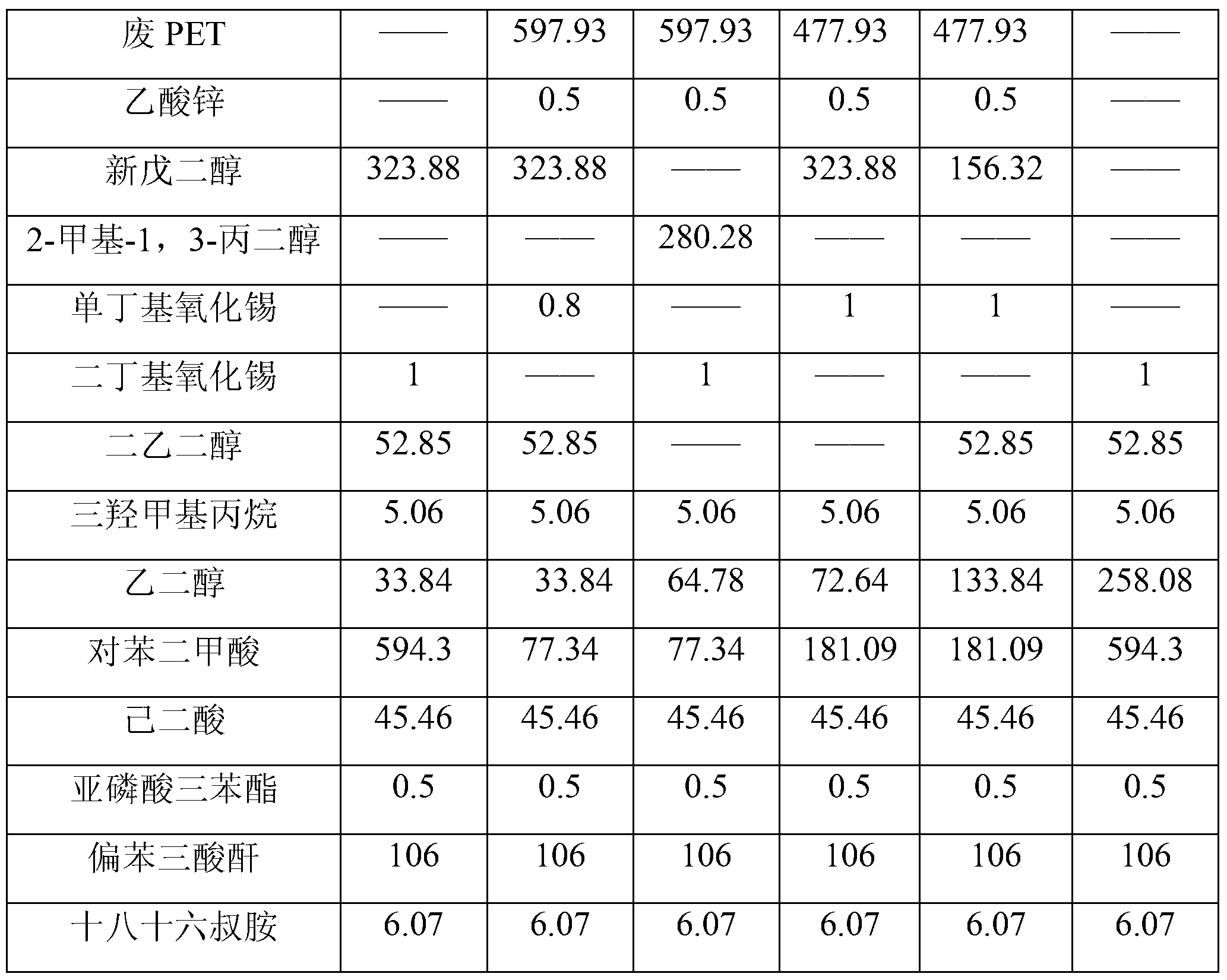

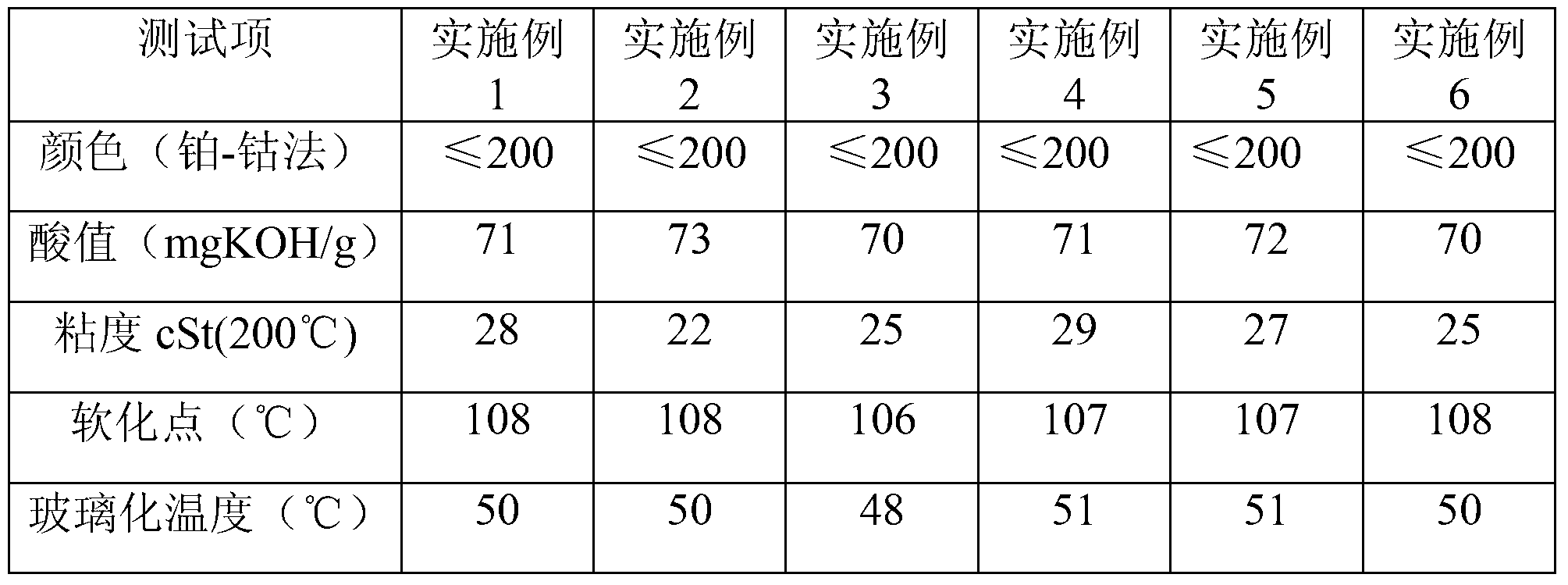

The invention relates to the field of powder coatings, in particular to a polyester resin for a mixed thermal transfer powder coating and a preparation method thereof. The polyester resin for the mixed thermal transfer powder coating comprises the following components and contents: 1 mole percent of acids, 1.05-1.20 mole percent of alcohols, 10-15wt% of trimellitic anhydride and 0.1-1.0wt% of recomposed onium salts, wherein the alcohols accounting for the total alcohol mol percent comprise 10-90 mol% of neopentyl glycol, 0-45 mol% of dimethyl-1,3-propanediol, 0-20 mol% of ethanediol, 10-25 mol% of diethylene glycol; and the acids accounting for the total acid mol percent comprise 80-100 mol% of terephthalic acid, 0-10 mol% of m-phthalic acid and 0-10 mol% of mol% of adipic acid. The functionality of the polyester resin is regulated according to the amount of the branched components of the trimellitic anhydride, thus the obtained cured film has better surface appearance, low temperature (160 DEG C) curing is realized, the curing percent of film coating at low temperature is high, the curing film has fine solvent resistance and the transfer-printed transfer printing film is clear, vivid and easy to tear.

Owner:HUANGSHAN SHENJIAN NEW MATERIAL CO LTD

Water soluble alkyd resin solution and water-soluble alcohol acid amino baking varnish

The invention discloses a water soluble alkyd resin solution and water soluble alkyd amino baking finish. The water soluble alkyd amino baking finish takes the water soluble alkyd resin solution as a base material. The water soluble alkyd resin solution comprises the following components by weight percentage: 14 to 18.8 percent of castor oil, 2.3 to 4.4 percent of benzoic acid, 17.3 to 19.5 percent of benzene anhydride, 0 to 6.5 percent of trimellitic anhydride, 3.7 to 5.8 percent of neopentylene glycol, 3.5 to 10.8 percent of dihydroxymethyl propaneoic acid, 8 to 12 percent of pentaerythrite, 9.0 to 11.5 percent of cosolvent, 4.0 to 6.5 percent of neutralizer and 16.5 to 20.0 percent of water. The water soluble alkyd amino baking finish comprises the following components by weight percentage: 35 to 70 percent of water soluble alkyd resin solution, 0 to 30 percent of pigment, 0.2 to 1.5 percent of additive, 10 to 20 percent of amino resin, 0 to 5 percent of cosolvent and 15 to 25 percent of water.

Owner:广东鲸鲨化工有限公司

High-performance aqueous alkyd resin paint

InactiveCN102604517AGood storage stabilitySave raw materialsPolyester coatingsCooking & bakingCombustion

The invention relates to a high-performance aqueous alkyd resin paint prepared through the steps that: (a) plant oil aliphatic acid is subject to a reaction with polybasic acid and polyol, such that oleiferous alkyd resin is obtained; (b) oleiferous alkyd resin is subject to a reaction with trimellitic anhydride, such that oleiferous alkyd resin with excessive carboxyl is obtained; (c) the oleiferous alkyd resin with excessive carboxyl is neutralized by using a neutralizing agent, such that aqueous alkyd resin is obtained; and (d) the aqueous alkyd resin is mixed with aqueous amino resin and water, and the pH value is regulated, such that the aqueous alkyd resin paint is obtained. The aqueous alkyd resin paint provided by the invention has good storage stability, and a paint film prepared with the paint has good mechanical properties. With the novel preparation method provided by the invention, reaction time is shortened, and production energy consumption is reduced. Water is used as a diluent of the product. The product causes no toxicity, no combustion, and no pollution to the environment. The paint can be used as common industrial baking paint, vehicle top paint, bicycle baking paint, and the like.

Owner:ETERNAL CHEM (CHINA) CO LTD

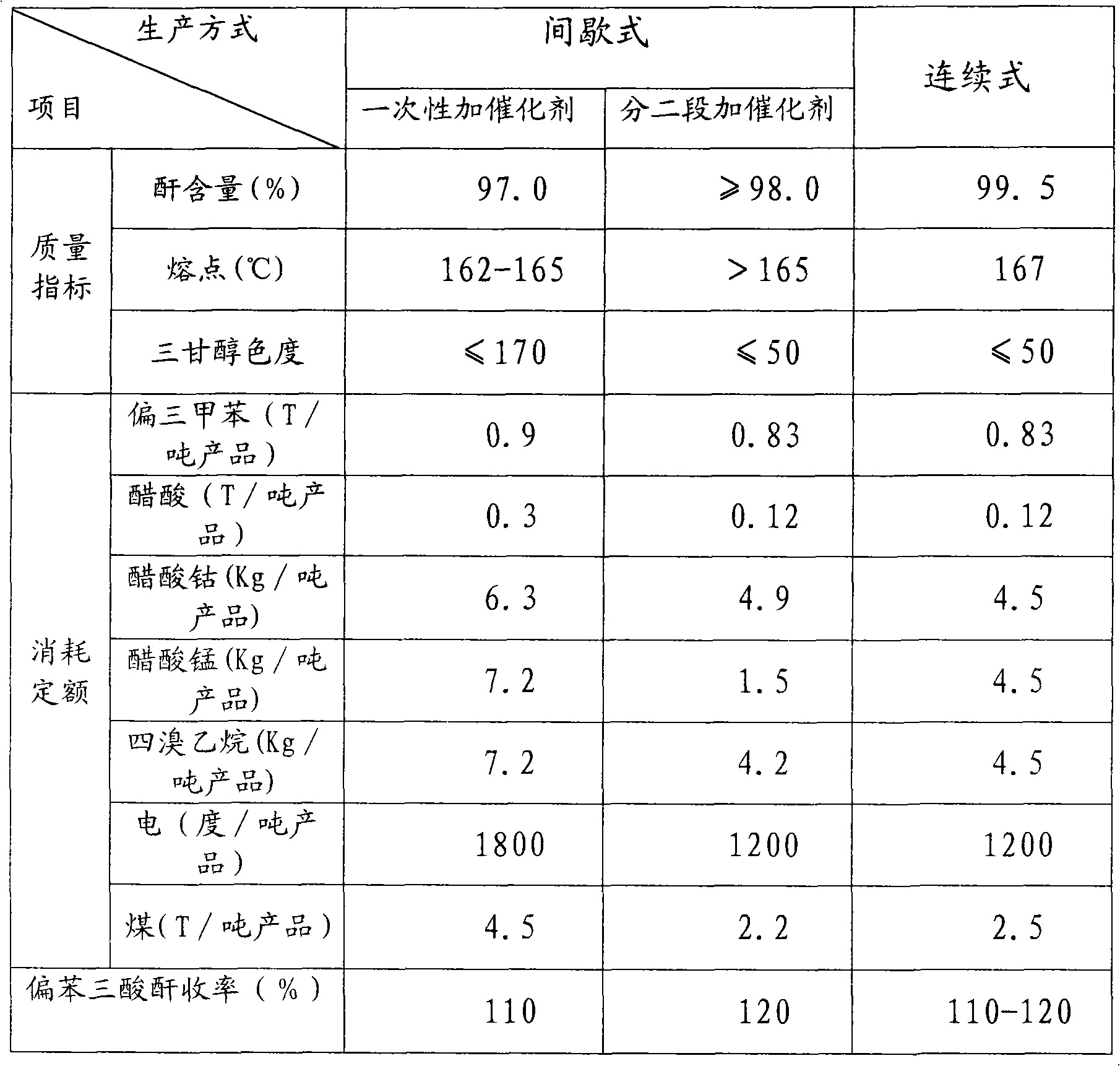

Process for production of trimellitic anhydride by continuous oxidizing process

A process for preparing trimellitic anhydride from metatritoluene, acetic acid as solvent, and catalyst (cobalt acetate, manganess acetate, tetrebromoethane, or hydrogen bromide) by continuous oxidization method includes continuous oxidizing reaction, anhydridization, refining, slicing or granulating and recovering solvent. Its advantages are high yield (up to 120%), high safety, high quality of product, and long service life of equipment.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Powder coating polyester containing organic silicon and preparation method thereof

InactiveCN102838740AGood weather resistanceReduce tensionPowdery paintsPolyester coatingsPolymer sciencePtru catalyst

The invention relates to powder coating polyester containing organic silicon and a preparation method thereof. The preparation method is characterized in that the method comprises the following steps of: adding organic silicon intermediate, neopentyl glycol, ethylene glycol and catalyst A into a reaction kettle with a stirrer, a thermometer and a fractionating column at normal temperature, feeding nitrogen into the reaction kettle, and increasing temperature to 100-190DEG C for reaction for 0.5-1.5 hours to obtain modified hydroxy-terminated intermediate containing the organic silicon; adding terephthalic acid, isophthalic acid, adipic acid and trimethylolpropane into the reaction kettle, and in the nitrogen protection atmosphere, increasing the temperature to 150-250DEG C for esterification till reaction solution is fully clarified; adding antioxidant, conducting vacuum polycondensation till the acid value is acceptably 3-15mg KOH / g to obtain hydroxy-terminated polyester resin; adding 1, 2, 4-trimellitic anhydride; and adding catalyst B and polymerization inhibitor into the reaction kettle, preserving heat at 180-220DEG C, stirring for 0.5-1 hour and discharging the materials to obtain light yellow solid powder coating polyester containing the organic silicon, wherein the acid value of the powder coating polyester is 30-60mg KOH / g, the glass transition temperature is 40-70DEG C and the viscosity is 10-50 poise.

Owner:广东大盈新材料科技有限公司 +1

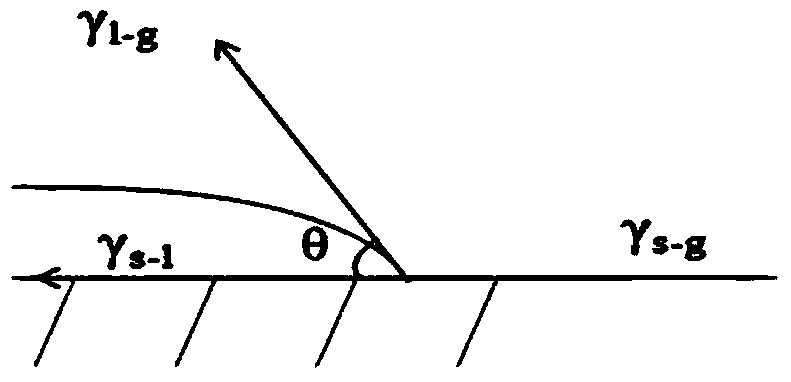

Polyester resin for epoxy-cured powder coating with high glossiness and high leveling property and preparation method thereof

ActiveCN103642014AControl surface tensionControl Melt ViscosityPowdery paintsEpoxy resin coatingsEpoxy1,3-Propanediol

The invention relates to a polyester resin for an epoxy-cured powder coating with high glossiness and high leveling property and a preparation method thereof. The polyester resin has relatively high glass-transition temperature. The technical scheme is as follows: the polyester resin for the epoxy-cured powder coating with high glossiness and high leveling property orderly comprises the following components: neopentyl glycol, 2-methylpropanediol, diglycol, 2-butyl-2-ethyl-1, 3-propylene glycol, terephthalic acid, isophthalic acid, sebacic acid and trimellitic anhydride. The preparation method of the polyester resin for the epoxy-cured powder coating with high glossiness and high leveling property comprises the following steps: 1) adding a proportioning amount of polyhydric alcohol to a reaction kettle, heating at normal temperature, and then feeding a proportioning amount of polyatomic acid and esterification catalyst; 2) carrying out thermal reaction until the water yield of the esterified water can be up to 95% or more of theoretical water yield; 3) adding trimellitic anhydride and isophthalic acid, and carrying out thermal reaction; 4) gradually vacuumizing, and reacting; 5) discharging.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

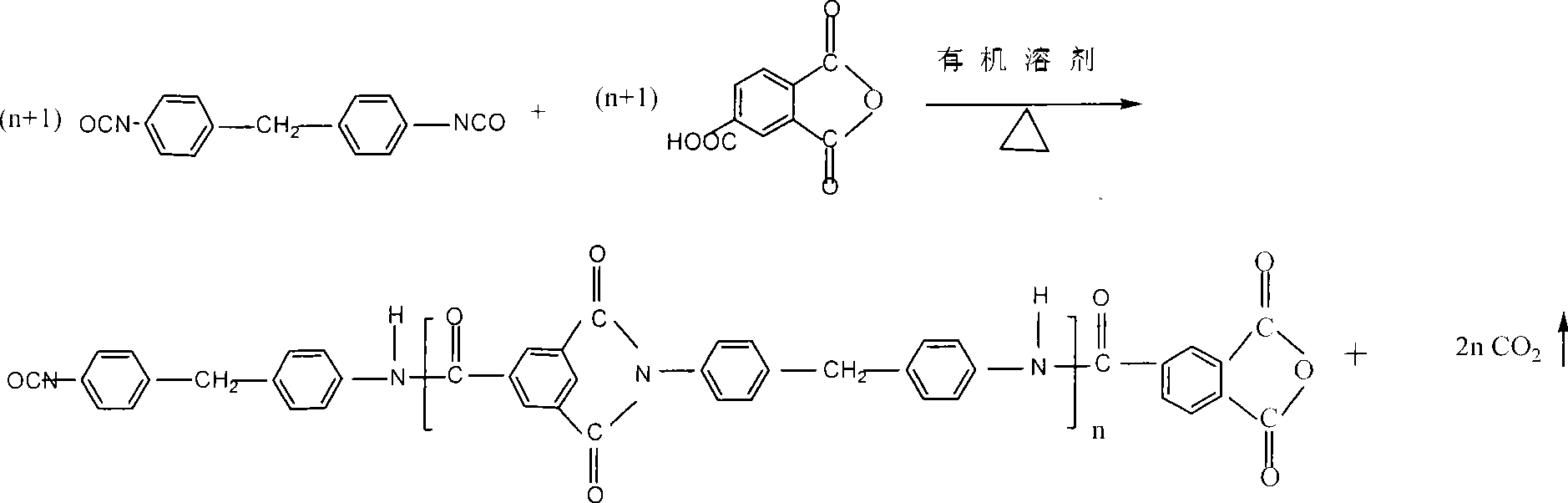

Method for preparing polyamide-imide enamelled wire varnishes

The invention relates to a wire enamel technology, in particular to the wire enamel with high temperature resistance. The invention provides a method for synthesizing polyamide-imide wire enamel by adopting trimellitic anhydride and isocyanate to react in a polar solvent. The mixture ratio of materials MDI and TMA used by the method can be: MDI / TMA equal to 1:0.85 to 1.05, the addition of solvent used by the method is: MDI / solvent equal to 1:5.0 to 10.0, and the mixture ratio of added diluent can be: MDI / diluent equal to 1:1.5-4.5. The reaction process of the invention does not need catalyst, and the cyclization can be completed without curing agents in the muffle furnace process. The technology of the invention has short process flow and simple operation, and the synthetic PAI solution is characterized by low viscosity and stable storage.

Owner:BAOSHAN IRON & STEEL CO LTD

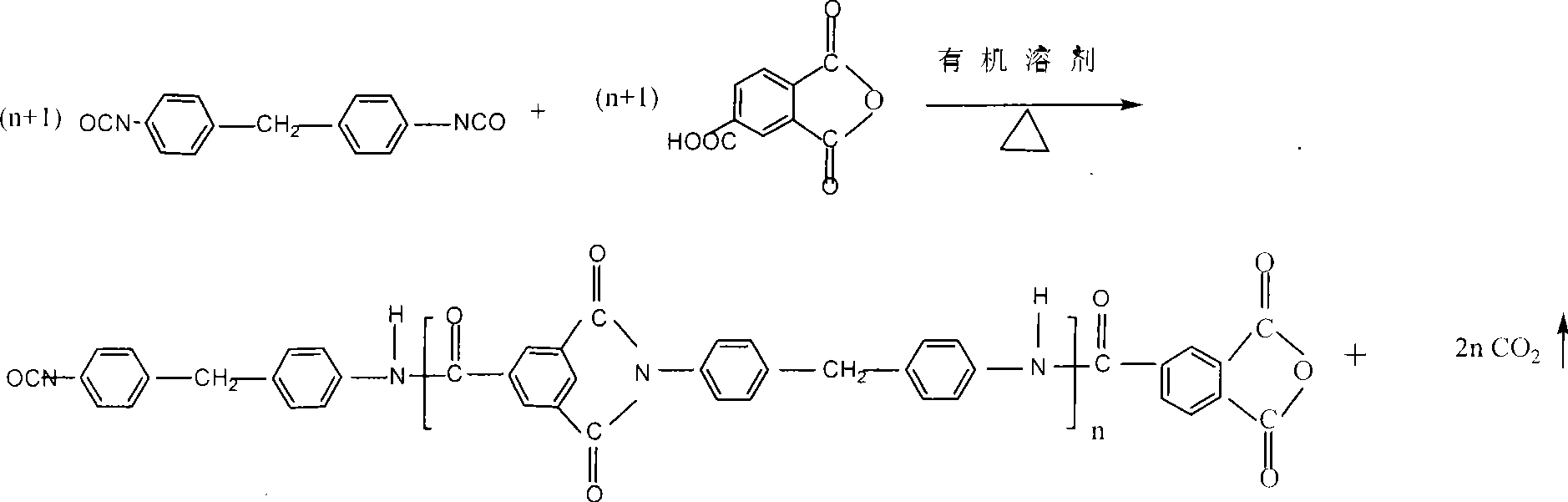

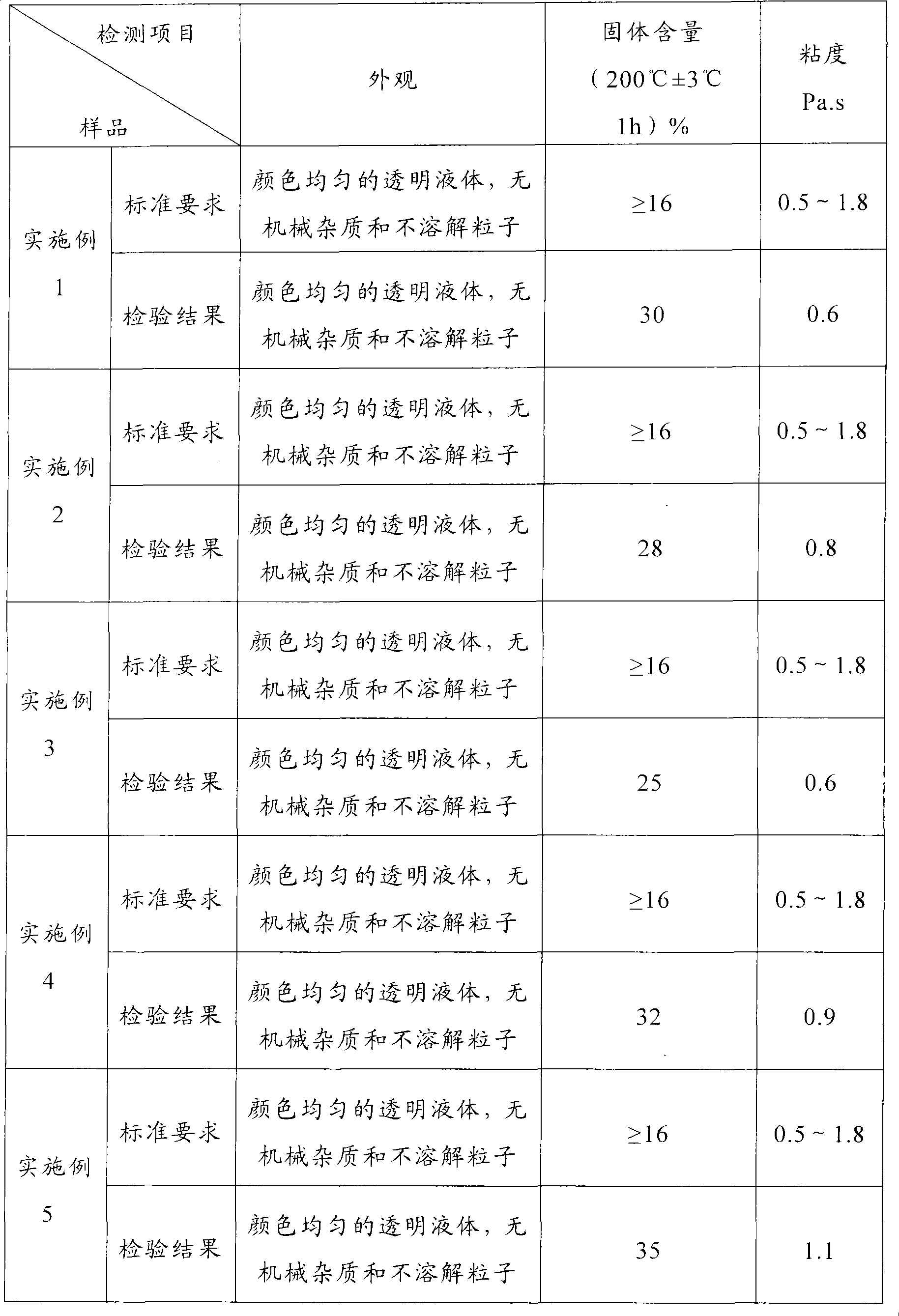

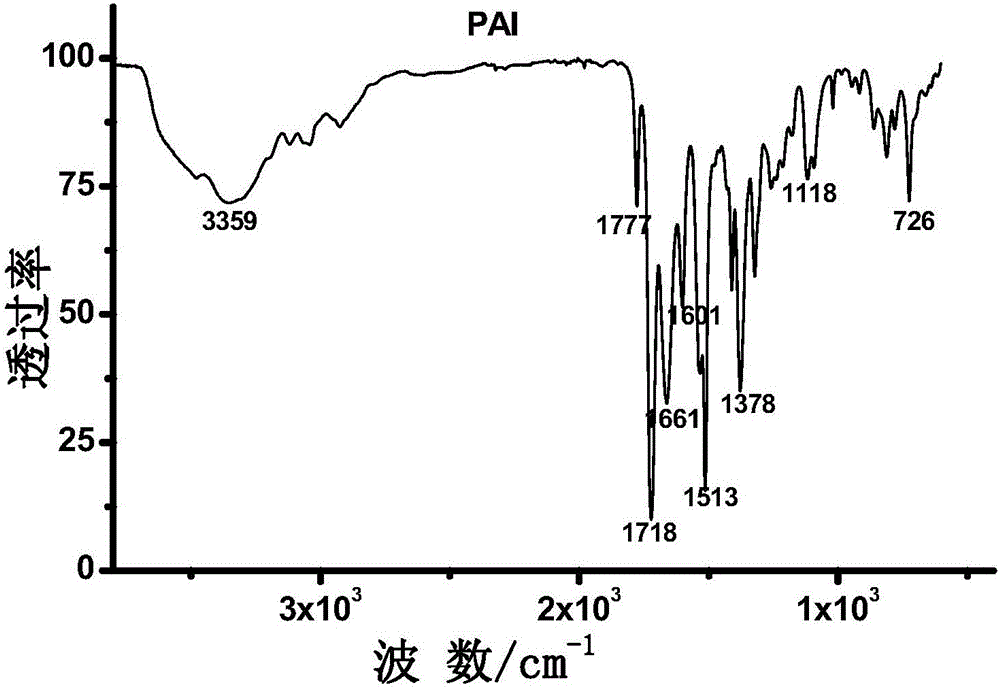

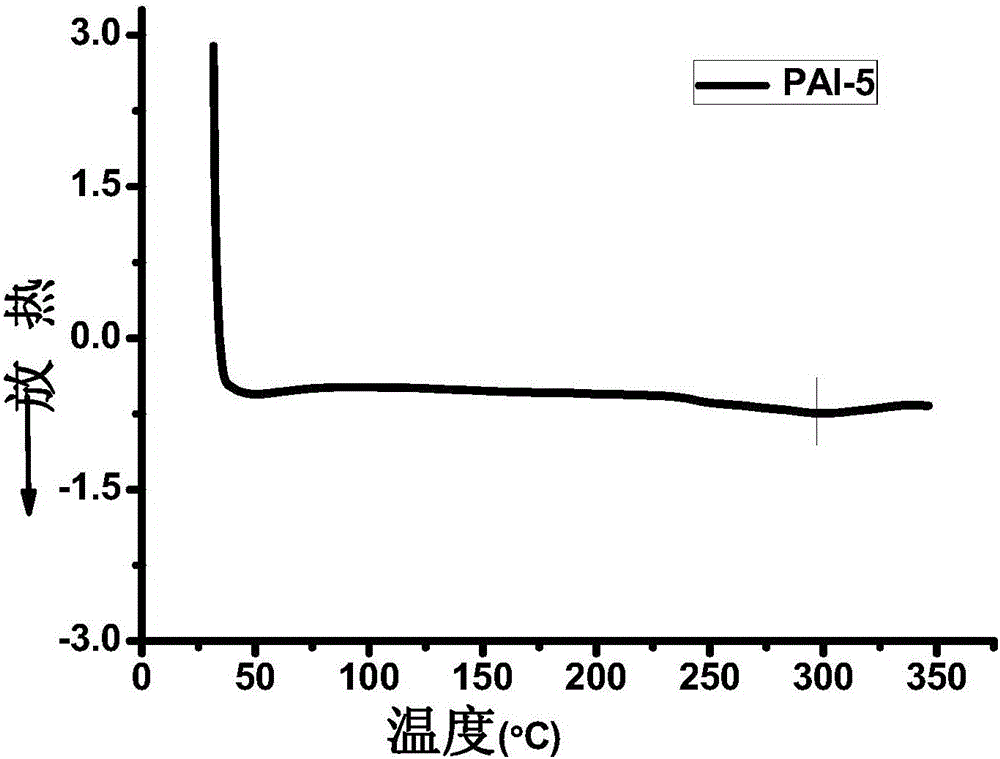

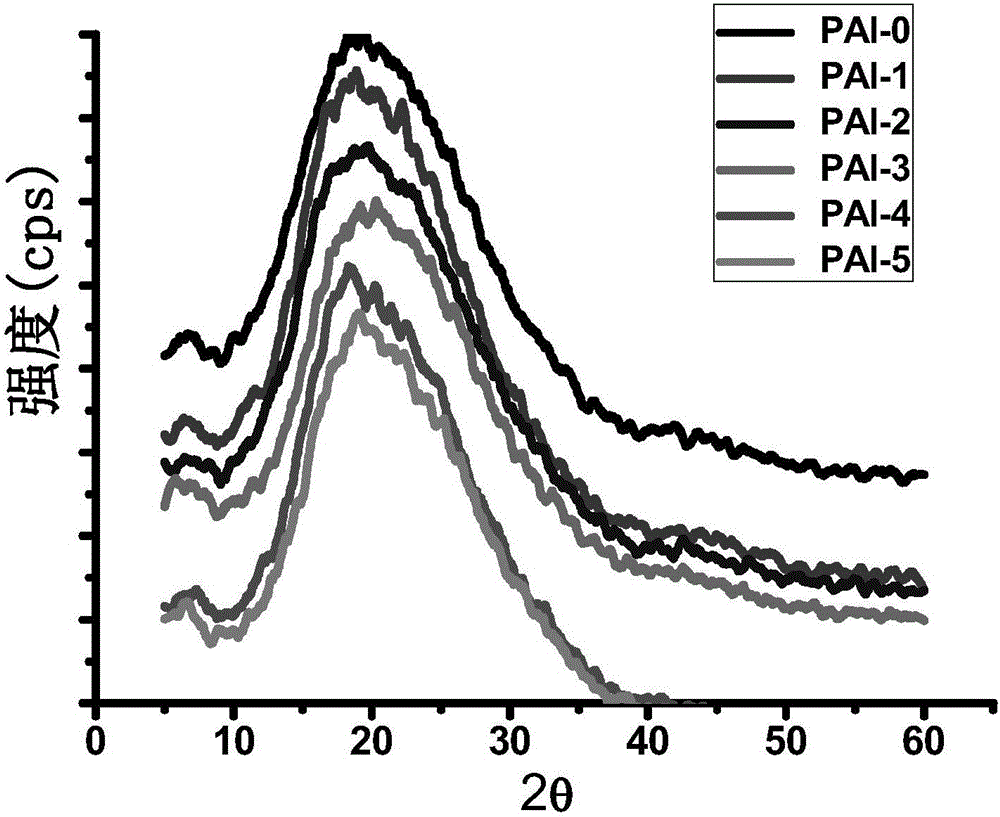

Preparation method of soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film

InactiveCN105017534AReduce the potential energy of the condensation reactionExcellent mechanicsPolymer scienceThermal expansion

The invention discloses a preparation method of a soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film. According to the prepared film, fluorine-containing diamine monomers serve as diamine monomers, trimellitic anhydride acid chloride serves as anhydride monomers, and the polyamide imide film is further prepared through a trimethylchlorosilane activation mechanism under a simple and moderate synthesis condition. The prepared polyamide imide film has high dimensional stability (the CTE is 5-15 ppm / DEG C or so) and good temperature resistance (Tg is 300 DEG C or so), the transmittance of visible light wavebands is 90% or so, the prepared polyamide imide film can be dissolved in an aprotic polar solvent and is convenient to machine and process, and the comprehensive performance of the prepared polyamide imide film meets the material performance requirement of a part of devices in the microelectronics and optoelectronics field.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

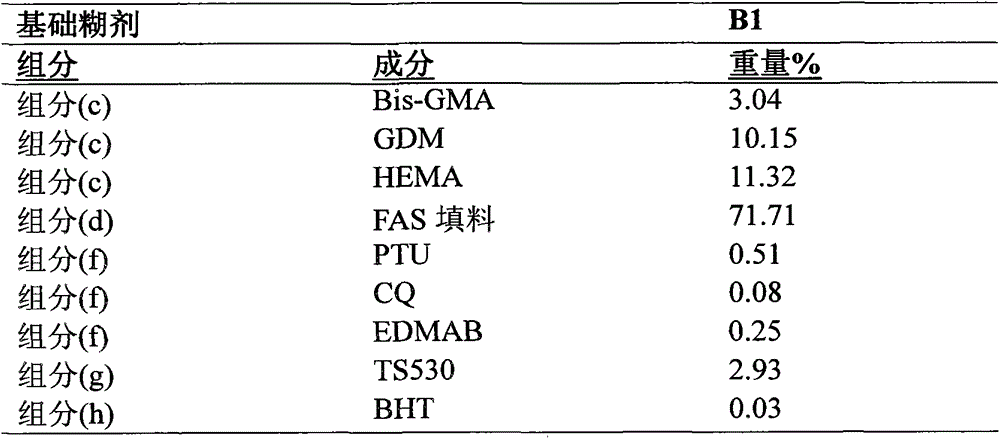

Dental resin modified glass-ionomer composition

The dental resin modified glass-ionomer composition includes an acidic polymer; an acidic polymerizable monomer selected from 4-(meth)acryloxyalkyltrimellitic anhydride, 4-(meth)acryloxyalkyltrimellitic acid, and a combination thereof; a non-acidic polymerizable monomer; a fluoroaluminosilicate glass filler; water; and at least one polymerization initiator system. The dental resin modified glass-ionomer composition is useful for a dental restorative composition, an endodontic composition, and / or an orthodontic composition, and provides significantly enhanced adhesive property toward tooth structure.

Owner:THE KERR

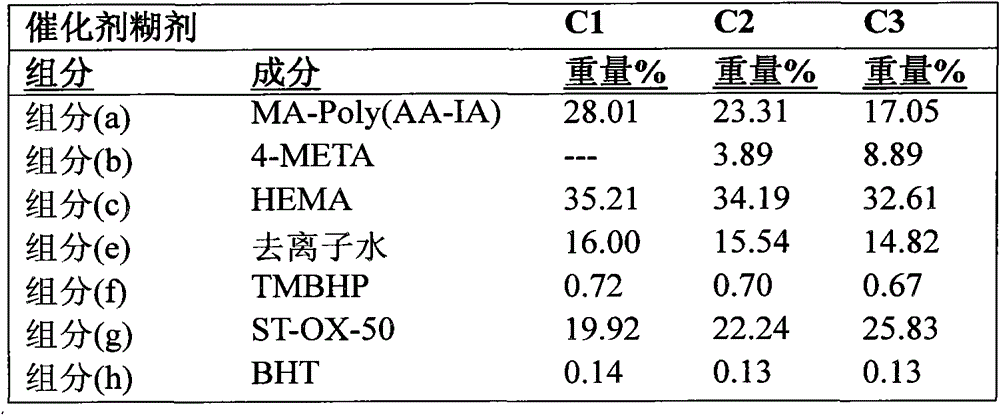

Polyester resin for engineering machinery

InactiveCN110511365AImprove mechanical propertiesGood flexibilityPowdery paintsPolyester coatingsCrack resistanceAntioxidant

The object of the present invention is to provide polyester resin for engineering machinery, the polyester resin comprises polyhydric alcohol, aromatic polybasic acid, a branching agent, an acidolysisagent, an esterification catalyst, an antioxidant and a curing accelerator, the acidolysis agent comprises one or a mixture of at least two of isophthalic acid (IPA), adipic acid (ADA), 1,4-cyclohexanedicarboxylic acid (CHDA), fumaric acid (FCC), trimellitic anhydride (TMA), succinic acid (BA) and dodecanedioic acid (DDDA), more preferably comprises at least the IPA and the ADA; the polyester resin can be combined with curing agents (TGIC, hydroxyalkylamide or blocked isocyanate), curing accelerators, pigments, fillers, leveling agent, degassing agents and the like to prepare powder coatingsfor engineering machinery. Compared with conventional polyester resin, the polyester resin has excellent mechanical properties and flexibility, water boiling resistance, weather resistance, low temperature frost resistance, thick coating resistance and unchanged performance when the curing temperature is changed, and crack resistance under freezing impact and bending of iron plates and electrophoresis plates at-18 DEG C, and the polyester resin is very suitable for coating in the field of engineering machinery.

Owner:ANHUI SHENJIAN NEW MATERIALS

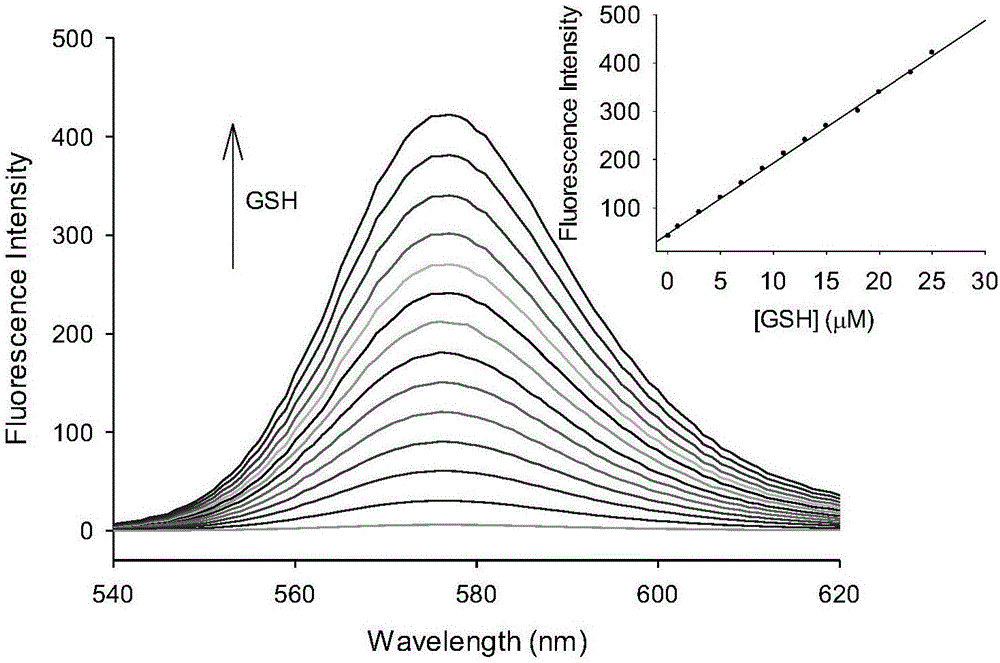

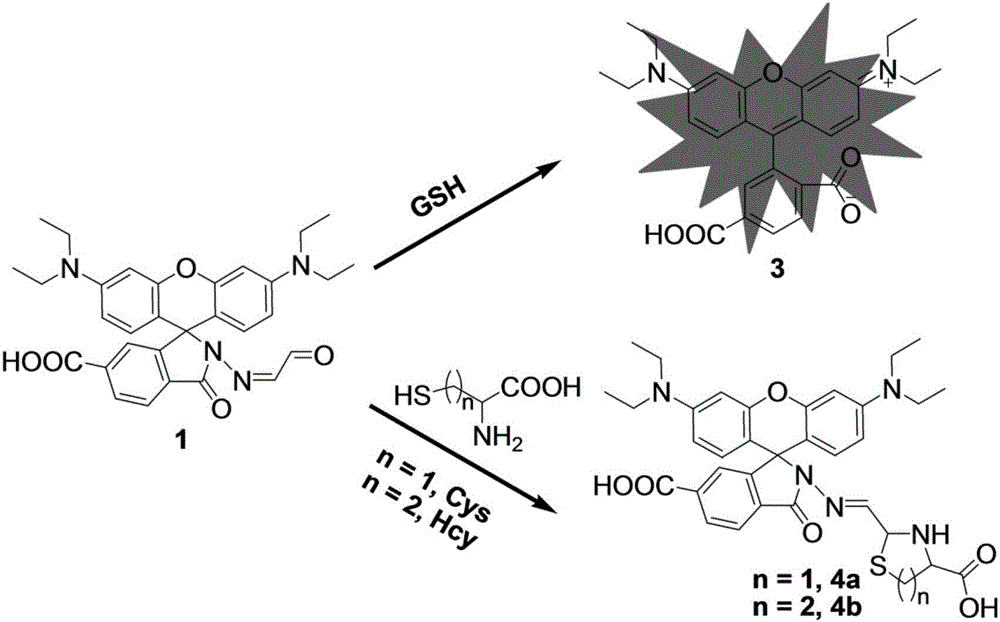

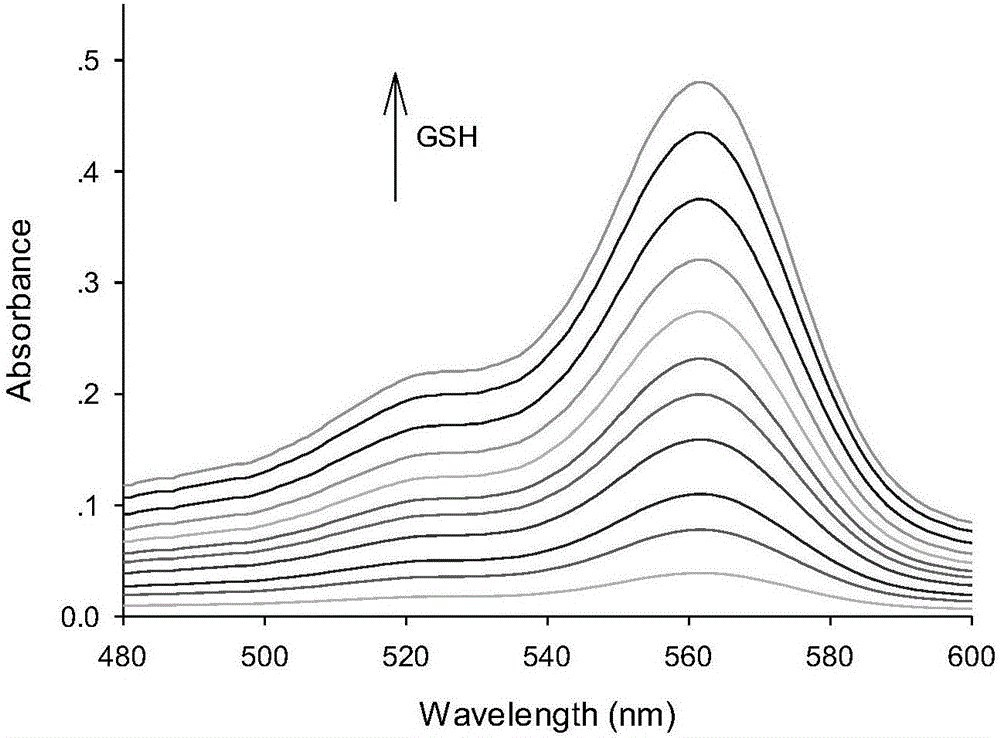

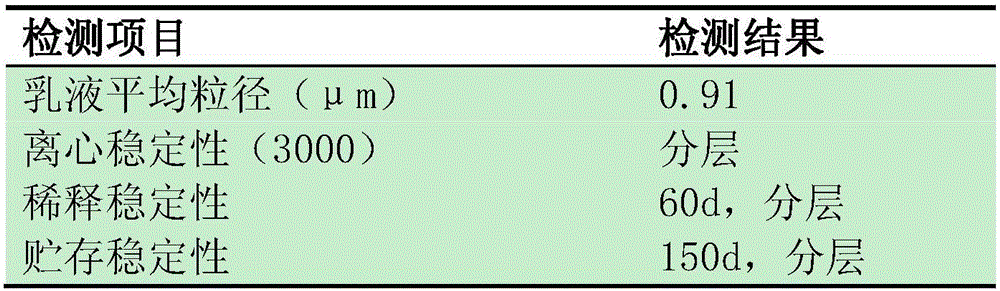

Preparation method and application of GSH (glutathione) water-soluble fluorescent probe based on rhodamine

InactiveCN106432257AGood water solubilityGood choiceOrganic chemistryFluorescence/phosphorescenceSolubilityStructural formula

The invention discloses a preparation method and an application of GSH (glutathione) water-soluble fluorescent probe based on rhodamine. A structural formula of the fluorescent probe is represented in the specification. The invention provides a water-soluble fluorescent probe for detecting GSH with high selectivity on the basis of rhodamine derivatives. 1,2,4-trimellitic anhydride, 3-diethylaminophenol, hydrazine hydrate and glyoxal are taken as raw materials to synthesize the fluorescent probe. On one hand, the rhodamine structure is modified with carboxyl, and water solubility of the probe can be greatly improved; on the other hand, a hydrolysis-addition reaction is performed between SH of an analyte and aldehyde groups of the probe, and GSH, Cys and Hcy are distinguished. The fluorescent probe is the first one capable of efficiently distinguishing GSH, Cys and Hcy in a 100% aqueous solution on the basis of the rhodamine derivatives. The probe shows quite high sensitivity and good selectivity on GSH, and can be applied to cell imaging and detect intracellular GSH.

Owner:XIANGTAN UNIV

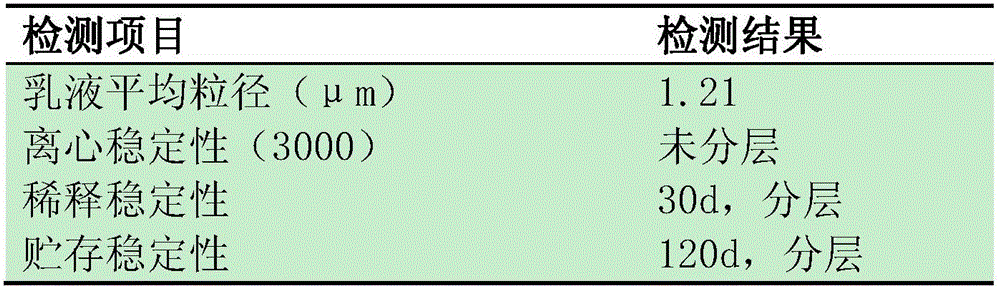

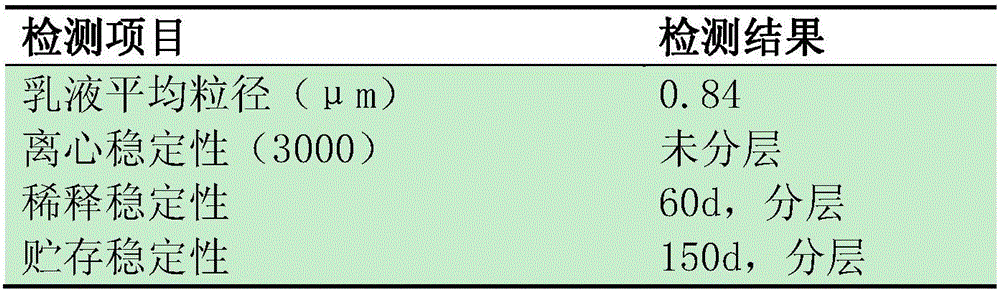

Preparing method of bifunctionality epoxy resin emulsifier and emulsion

The invention relates to a preparing method of bifunctionality epoxy resin emulsifier and emulsion. The preparing method comprises the specific steps that 1, trimellitic anhydride (TMA) and a catalyst (boron trifluoride diethyl etherate) are added into polyethylene glycol (PEG4000), and the temperature is raised for reaction; 2, a proper amount of bisphenol A epoxy resin E-44 is added into the reaction liquid, and the temperature continues to be raised for the reaction, so that multi-block epoxy resin emulsifier (PEGDET for short) is obtained; 3, a proper amount of epoxy resin and the emulsifier are mixed, deionized water is slowly added dropwise at a certain temperature, high-speed stirring is carried out until viscosity of a system is reduced abruptly, at the moment, the system is subjected to phase inversion, and water continues to be added, so that the water-borne epoxy resin emulsion is obtained. The water-borne epoxy resin emulsion prepared through the method has the advantages of being small in average grain diameter, low in dispersion, excellent in centrifuge, dilution and storage stability performance and the like, and a new thought is provided for preparing high-performance water-borne epoxy emulsion.

Owner:CHANGZHOU UNIV +1

Method for producing trioctyl trimellitate with trimellitic acid

ActiveCN101429126ATemperature is not harshLower requirementOrganic compound preparationCarboxylic acid esters preparationTrimellitic acidOctanol

The invention relates to a method for producing trioctyl trimellitate through using trimellitic acid. Intermediate products of trimellitic acid and methanol in the process of producing the trimellitic anhydride are esterified to generate trimethyl trimellitate; the trimethyl trimellitate and 2-ethylhexanol (commonly called asoctanol) are subjected to ester exchange to produce trimellitate (2-ethyl) trihexyl ester (trioctyl trimellitate). The method of methyl esterification and ester exchange can reduce requirement on a technology and equipment so that the intermediate product of the trimellitic acid in the process of producing the trimellitic anhydride is flexibly utilized.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

Modified waterborne alkyd resin of organic acid salt and preparation method thereof

The invention relates to a modified waterborne alkyd resin of organic acid salt and a preparation method thereof. The modified waterborne alkyd resin of organic acid salt is prepared by adopting the following materials: 4 to 9 portions of dihydric alcohol, 10 to 17 portions of polyhydric alcohol, 11 to 23 portions of dibasic acid or anhydride A, 5 to 10 portions of organic acid, 5 to 10 portions of unsaturated acid B, 0.03 to 0.1 portion of esterification catalyst, 3 to 8 portions of trimellitic anhydride, 10 to 20 portions of xylene and 25 to 35 portions of ethylene glycol monobutyl ether; all the portions are weight portions. The modified waterborne alkyd resin of organic acid salt can be dissolved in water directly by neutralization with little alkali; the prepared paint has good storing stability, and is not easy to form flash stain when being used for painting the metal surface; the painted film has fast drying and high hardness; the production technique is simple and the cost is low.

Owner:湘江涂料科技有限公司

Preparation method of hyper-branched bio-based epoxy resin

The invention relates to a preparation method of hyper-branched bio-based epoxy resin. The method comprises the following steps: initiating ring-opening polymerization of lactide by a coinitiator polyol to obtain hydroxyl-terminated polylactic acid with a low molecular weight, synthesizing carboxyl-terminated hyper-branched polyester from trimellitic anhydride and the obtained polylactic acid, and synthesizing the hyper-branched epoxy resin from chloropropylene oxide and the obtained hyper-branched polyester. Lactide is from corn, potato and other crops, has wide sources, and is in favor of reducing the consumption of petroleum resources and the discharge of CO2, and the obtained epoxy resin is a novel functional material with excellent performances, has the advantages of low viscosity, high solid content, easy film formation, and good adhesion and thermal stability, has good toughening and manufacturability improving effects when blended with common epoxy resin, can be used in adhesives, coatings and composite materials as a matrix, and is suitable for molding technologies of various composite materials, so the hyper-branched bio-based epoxy resin has very wide application prospect.

Owner:JIANGSU SUPLA BIOPLASTICS CO LTD

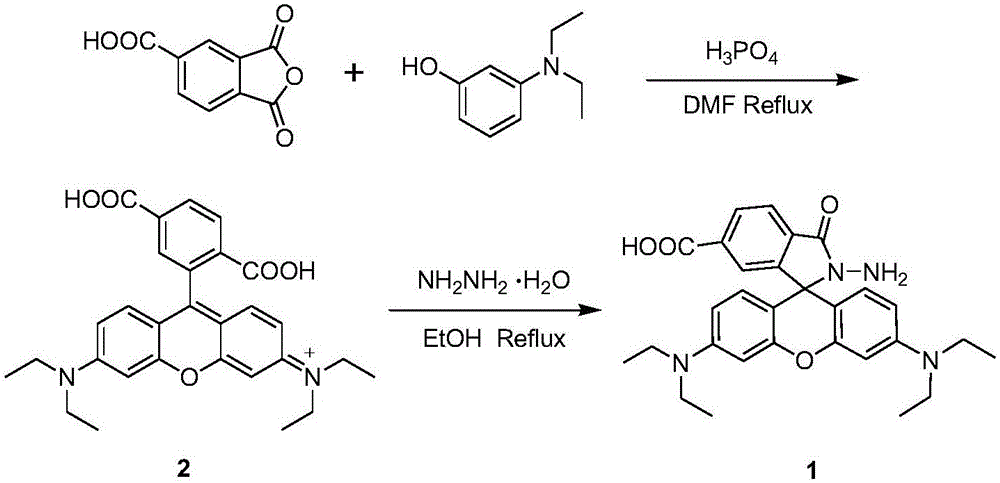

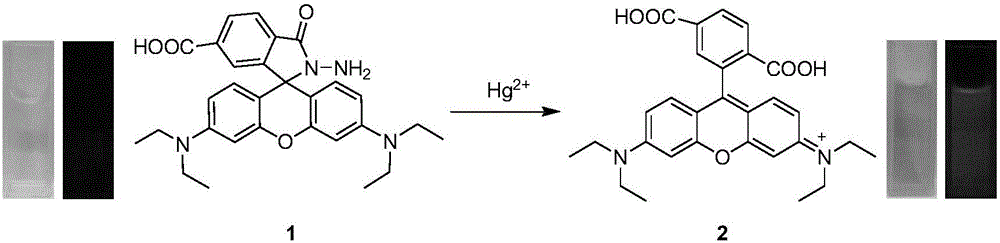

Method for preparing water-soluble mercury ion fluorescence probe on basis of rhodamine and application of water-soluble mercury ion fluorescence probe

InactiveCN105885828AOrganic chemistryFluorescence/phosphorescenceHydrazine compoundStructural formula

The invention discloses a method for preparing a water-soluble mercury ion fluorescence probe on the basis of rhodamine and application of the water-soluble mercury ion fluorescence probe. A structural formula of the Hg<2+> fluorescence probe are shown, and the water-soluble mercury ion fluorescence probe is synthesized from 1, 2, 4-trimellitic anhydride, 3-diethylamino phenol and hydrazine hydrate. The method and the application have the advantages that the water-soluble Hg<2+> fluorescence probe prepared by the aid of the method is simple in structure, is based on rhodamine derivatives and is the first fluorescence probe for detecting Hg<2+> in 100% aqueous solution by the aid of rhodamine lactam derivatives; ring opening of rhodamine lactam structures can be carried out under the induction effects of the Hg<2+> in systems, intense fluorescence can be generated, and the water-soluble mercury ion fluorescence probe is high in Hg<2+> detection sensitivity; the fluorescence probe is excellent in Hg<2+> selectivity and is almost free of interference of other positive ions; the Hg<2+> can be measured by the fluorescence probe without disturbance when pH (potential of hydrogen) values range from 5.0-8.0, the fluorescence probe and the Hg<2+> can act quickly, and the response time is shorter than 3 minutes; the probe further can be applied to measuring Hg<2+> in environmental water samples and carrying out fluorescence imaging on Hg<2+> in biological cells.

Owner:XIANGTAN UNIV

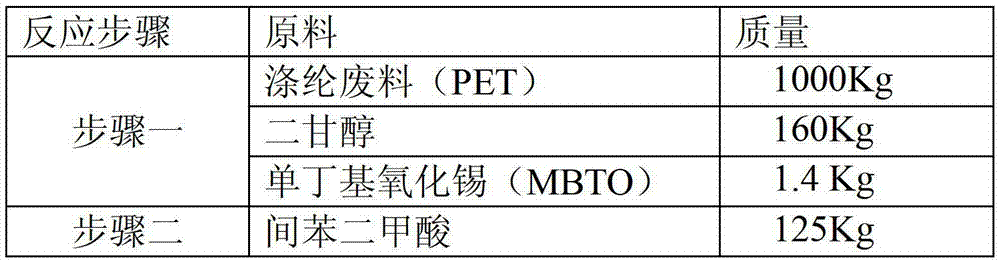

Preparation method of polyester resin

InactiveCN103205093AAchieve recyclingReduce manufacturing costPlastic recyclingPolyester coatingsPolyethylene terephthalate glycolZinc Acetate Dihydrate

The invention discloses a preparation method of polyester resin. The preparation method comprises the following steps of: carrying out alcoholysis on dacron, polybasic alcohol, an alcoholysis catalyst zinc acetate and monobutyl tin oxide; carrying out ester exchange reaction and esterification reaction on the molten mass, which is obtained after the alcoholysis, polyprotic acid and a stabilizer phosphite ester triphenyl ester; after the ester exchange reaction and esterification reaction, carrying out decompression polycondensation reaction; adding trimellitic anhydride and a curing agent octadecyl hexadecyl tertiary amine; and filtering impurities after reaction to obtain the polyester resin. By adopting the technical scheme disclosed by the invention, PET (polyethylene terephthalate) type waste materials with various shapes and performances can be used for producing the polyester resin, the recycling of waste and old PET is realized, an effect of environmental friendliness is achieved, the production cost is reduced, and compared with the prior art, the reduction degree reaches more than 10%. The polyester resin obtained by adopting the technical scheme has good luster, impact resistance and leveling performance, and the waste pollution caused by dacron and PTA (pure terephthalic acid) is reduced.

Owner:江苏宝田新材料股份有限公司

Novel polyester enamelled wire paint and its preparation method

InactiveCN102433067AImprove heat resistanceGood solvent resistanceCoatingsPolyesterDimethyl terephthalate

The invention relates to novel polyester enamelled wire paint and its preparation method. The paint is prepared by mixing the raw materials of rosin, maleic anhydride, dimetyl terephthalate, trimellitic anhydride, diaminodiphenylmethane, methylphenol, xylene, tetrabutyl titanate, diacid, aromatic diamine, dihydric alcohol, and trihydric alcohol in a certain ratio by weight for reaction. The preparation method of the invention is characterized by simplicity and low cost, and the prepared enamelled wire paint has the advantages of good heat resistance, solvent resistance, and freezing resistance.

Owner:安徽省六安市立华电工有限公司

Polyamideimide composition

InactiveUS20040236012A1Stress minimizationReduces large, detrimental craze formationPlastic/resin/waxes insulatorsFibre treatmentPolyamide-imideFluoropolymer

Polyamideimide coating compositions for magnet wire which exhibit solvent or varnish-induced craze resistance. The polyamideimide compositions include a compound selected from the group consisting of diacid compounds, trimellitic anhydrides, benzophenonetetracarcoxylic anhydrides and mixtures thereof, a diisocyanate compound, dihydroxyl compound, a trihydroxyl compound, a fluoropolymer, and a mineral filler.

Owner:GENERAL CABLE TECH CORP

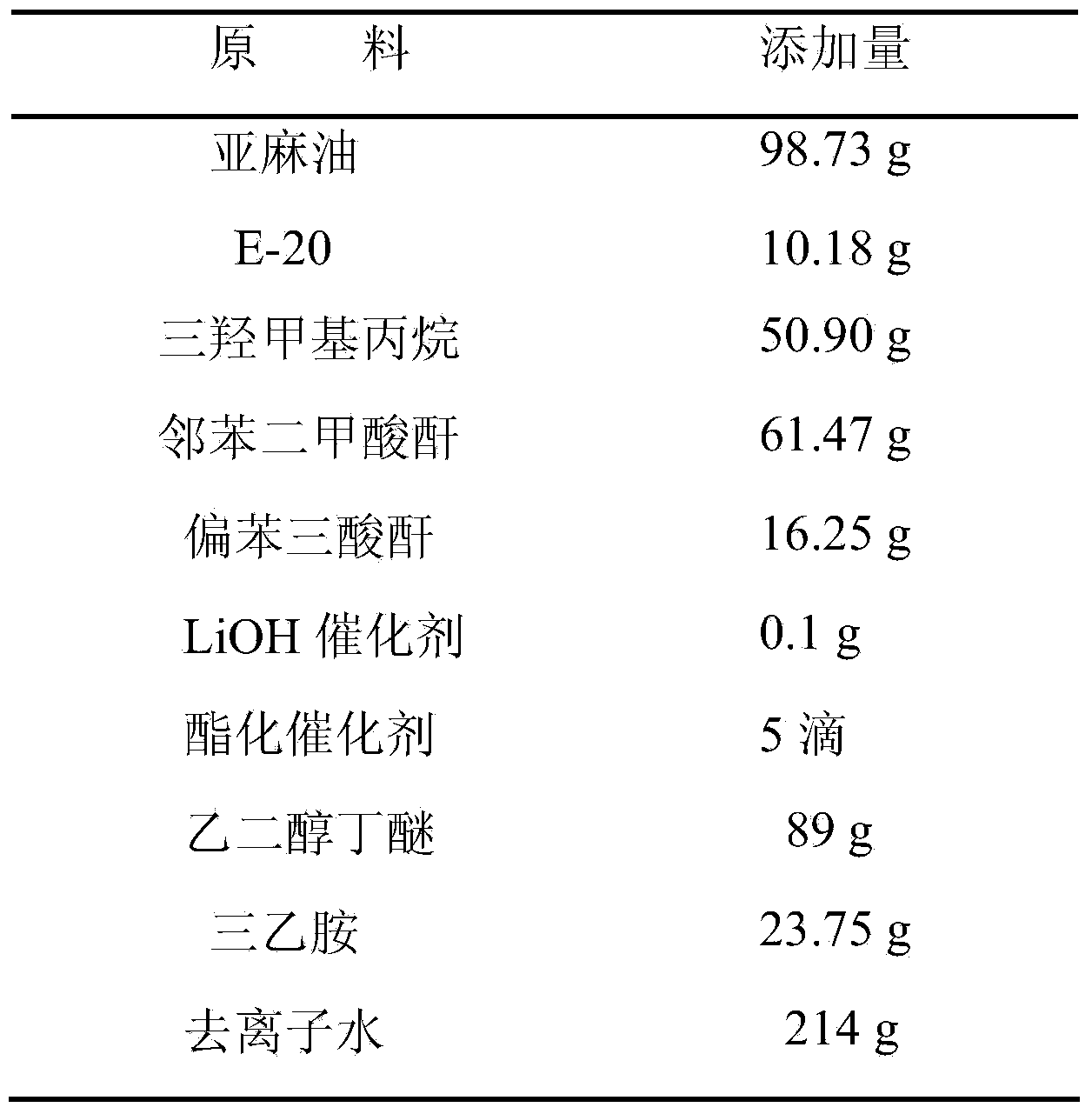

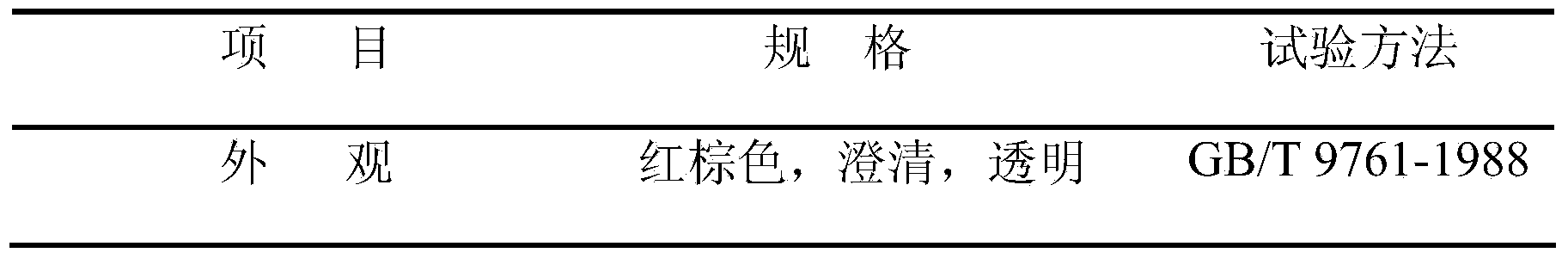

Production of aqueous-dispersing alkyd resin

InactiveCN101029123AImprove performanceExcellent physical and chemical propertiesWater dispersibleLithium hydroxide

Production of hydro-dispersion alkyd resin is carried out by ester-exchange reacting for dewatered castor oil and tri(hydroxymethyl)propane under existence of lithium hydroxide, adding into phthalic anhydride or maleic anhydride, ester reacting at high-temperature, lowering temperature while reaching into a certain of acid value, adding into trimellitic anhydride, reacting, neutralizing by neutralizer, adding into flux, and adding into deionized-water to obtain the final product. It's simple and cheap, has more purity and less impurities, no environmental pollution, excellent stability, hardness, impact and water resistances.

Owner:TONGJI UNIV

Preparation method for polyamide imide coating

The present invention relates to a preparation method for a polyamide imide coating. The preparation method comprises: dissolving pyromellitic dianhydride and trimellitic anhydride in an aprotic polar solvent, after stirring and dissolving the pyromellitic dianhydride and the trimellitic anhydride under protection of nitrogen gas, adding diphenylmethane diisocyanate and stirring the solution to obtain a polyamide imide solution; carrying out solvent exchange to obtain a yellowish-brown solid; and drying the obtained yellowish-brown solid to prepare the polyamide imide coating. The method is simple, short in polymerization process time and easy in treatment, and does not need secondary operation for carrying out imidization; and the obtained polyamide imide coating is strong in adsorption capacity and excellent in thermal oxidation resistance, so that the production cost of the polyamide imide is further lowered and the preparation method has a wide application prospect.

Owner:DONGHUA UNIV

Preparation method of polyester resin for epoxy hybrid powder coating

InactiveCN103304792AAchieve recyclingReduce productionPowdery paintsEpoxy resin coatingsPolymer sciencePolyethylene terephthalate glycol

The invention discloses a preparation method of polyester resin. The preparation method comprises the following steps of: (1) melting and mixing PET (Polyethylene Terephthalate) raw materials and dihydric alcohol to obtain a molten mixture, then adding the molten mixture into the molten dihydric alcohol, and carrying out ester exchange reaction in the existence of an ester exchange catalyst; and (2) adding polyhydric alcohol, polyatomic acid / acid anhydride and a stabilizer, carrying out esterification reaction under the action of an esterification catalyst, and then, adding trimellitic anhydride and octadecyl / hexadecyl tertiary amine to react while stirring to obtain the polyester resin. The polyester resin obtained according to the technical scheme disclosed by the invention not only has the characteristics of specific xanthochroia resistance, roasting resistance, salt mist resistance and the like of a powder coating produced through synthesizing high-quality polyester resin, but also has better luster and impact resistance and favorable leveling property, and can be used for reducing the generation of polyester wastes and environment pollution caused by esterified water generated by synthesizing purified terephthalic acid so as to be an environment-friendly technical scheme.

Owner:江苏宝田新材料股份有限公司

Method for producing trimellitic anhydride with pseudocumene liquid phase air segmenting hydrocarbonylation

The invention relates to a method for producing trimellitic anhydride by using a pseudocumene liquidoid air subsection oxidation method. Pseudocumene is used as a raw material, acetic acid is used as a solvent, and cobalt acetate, manganese acetate, and tetrabromoethane are used as catalysts; the solvent weight ratio of pseudocumene to acetic acid is between 1 to 2.5 and 1 to 10; and the weight ratio of the total catalysts to the pseudocumene is as follows: the ratio of the pseudocumene to the cobalt acetate to the manganese acetate to the tetrabromoethane is 1 to 0.005-0.05 to 0.005-0.05 to 0.005-0.05. The method comprises the following: a step of mixture, in which the pseudocumene and the acetic acid are weighed out according to the proportion, are added with the cobalt acetate and the tetrabromoethane which account for 40 to 60 percent of the total weight at a temperature between 60 and 100 DEG C; a step of subsection oxidation, in which the mixed materials enter the first reaction period which lasts for 30 to 50 minutes from the beginning of the oxidation, at a temperature between 140 and 180 DEG C and at a pressure of between 0.4 and 1.0 Mpa, then enter the second reaction period at a temperature of 180 and 300 DEG C and at a pressure of between 1.0 and 3.0 Mpa, and finally are added with the residual catalysts; a step of anhydride formation; and a step of fine purification. The method effectively solves the problem of self-inhibition in oxidation reaction.

Owner:安徽泰达新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com