Method for preparing polyamide-imide enamelled wire varnishes

A technology of polyamide-imide and enameled wire varnish, applied in the direction of coating, etc., can solve the problems of cumbersome steps, unstable storage, large solvent consumption, etc., and achieve the effect of simple operation and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

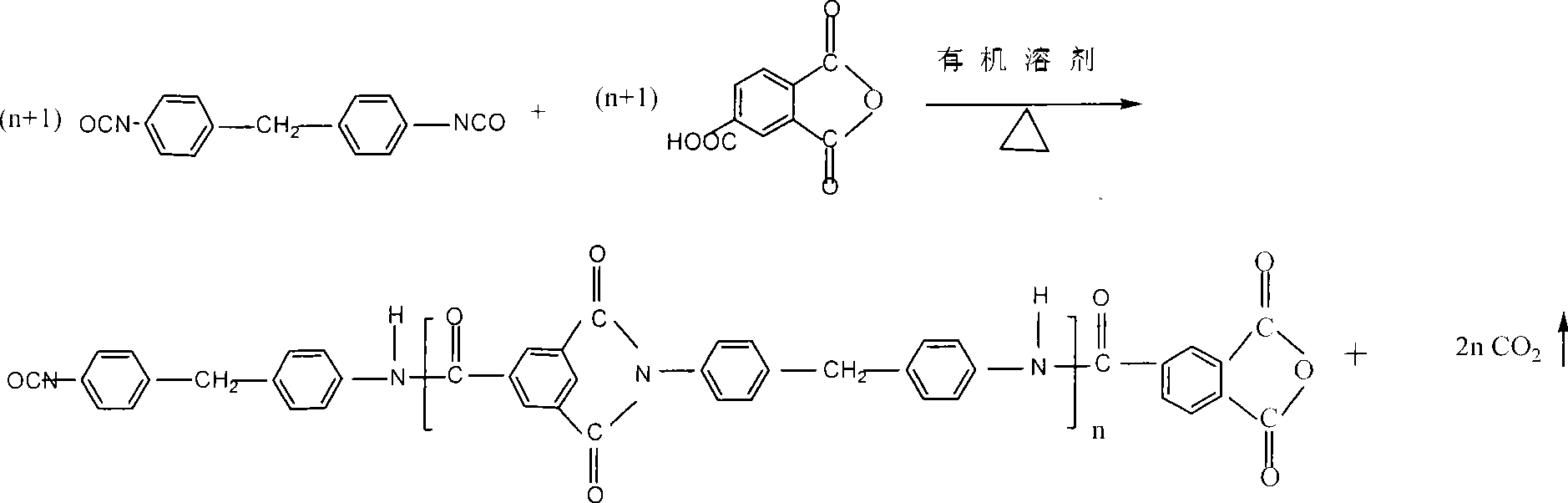

Method used

Image

Examples

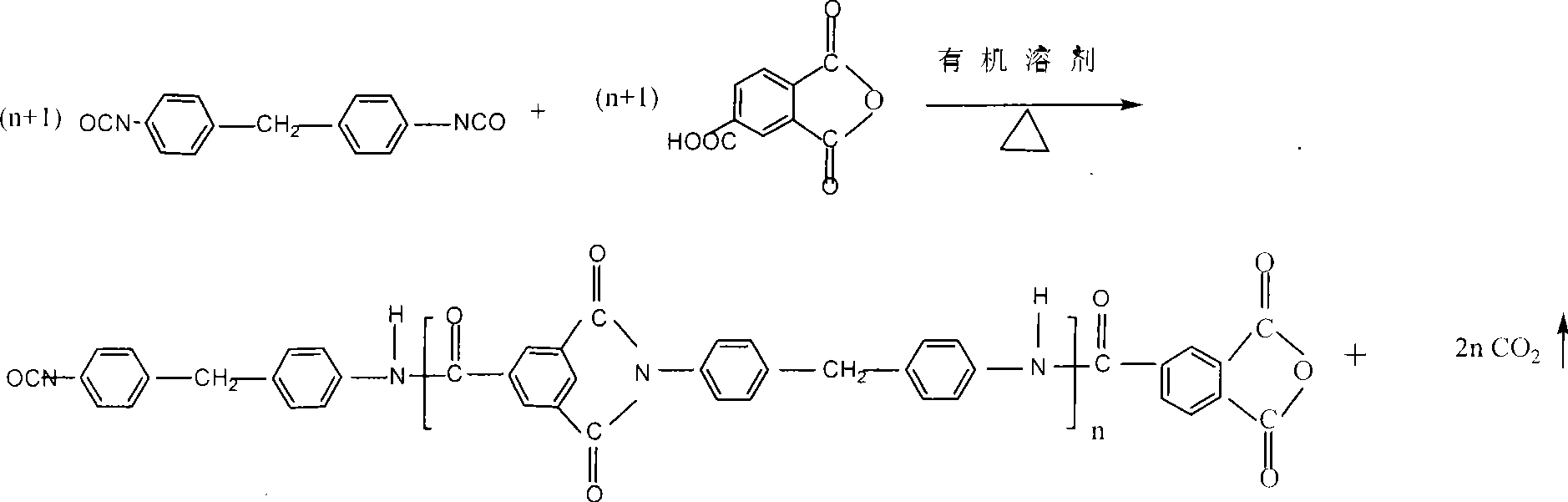

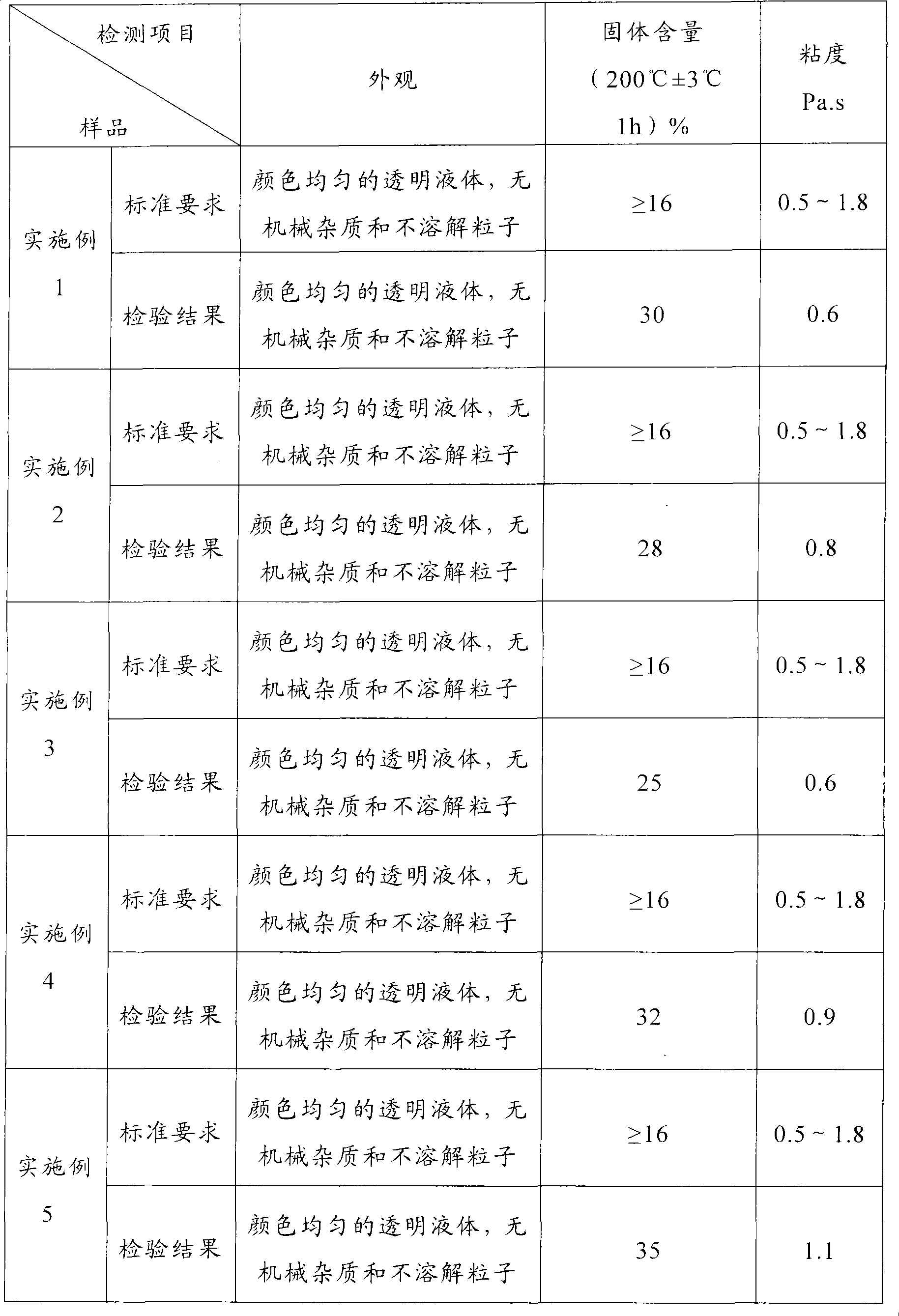

Embodiment 1

[0025] Synthesis of polyamide-imide wire enamel with high temperature resistance

[0026] Add 125 grams (0.50 moles) of solid 4,4-diphenylmethane diisocyanate into a flask with a condenser, stirrer and thermometer, heat to dissolve, and wait until 4,4-diphenylmethane diisocyanate is completely dissolved After adding 371 grams (3.75 moles) of polar solvent N-methyl-2-pyrrolidone and 96 (0.50 moles) of trimellitic anhydride, react at low temperature for a certain period of time and then slowly rise to a specific temperature, until the end of the reaction, cool down Then add 110 g (1.50 moles) of N,N-dimethylformamide for dilution to generate a brown transparent liquid.

Embodiment 2

[0028] Synthesis of polyamide-imide wire enamel with high temperature resistance

[0029] Add 125 grams (0.50 moles) of solid 4,4-diphenylmethane diisocyanate into a flask with a condenser, stirrer and thermometer, add 396 grams (4.00 moles) of N-methyl-2- Add 100 grams (0.52 moles) of pyrrolidone to the trimellitic anhydride for a certain period of time, then slowly heat up to the end of the reaction, add 120 grams (1.64 moles) of N, N-dimethylformamide after cooling to dilute, and generate a brown transparent liquid.

Embodiment 3

[0031] Synthesis of polyamide-imide wire enamel with high temperature resistance

[0032] Add 125 grams (0.50 moles) of solid 4,4-diphenylmethane diisocyanate into a flask with a condenser, stirrer and thermometer, and add 247 grams (2.49 moles) of N-methyl-2-diisocyanate after heating to dissolve. Pyrrolidone, then add 83 grams (0.43 moles) of trimellitic anhydride to react for a certain period of time, slowly heat up to the end of the reaction, add 164 grams (2.25 moles) of N,N-dimethylformamide after cooling to dilute, and generate a brown transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com