Patents

Literature

1207 results about "Polyamide-imide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyamide-imides are either thermosetting or thermoplastic, amorphous polymers that have exceptional mechanical, thermal and chemical resistant properties. Polyamide-imides are used extensively as wire coatings in making magnet wire. They are prepared from isocyanates and TMA (trimellic acid-anhydride) in N-methyl-2-pyrrolidone (NMP). A prominent distributor of polyamide-imides is Solvay Specialty Polymers, which uses the trademark Torlon.

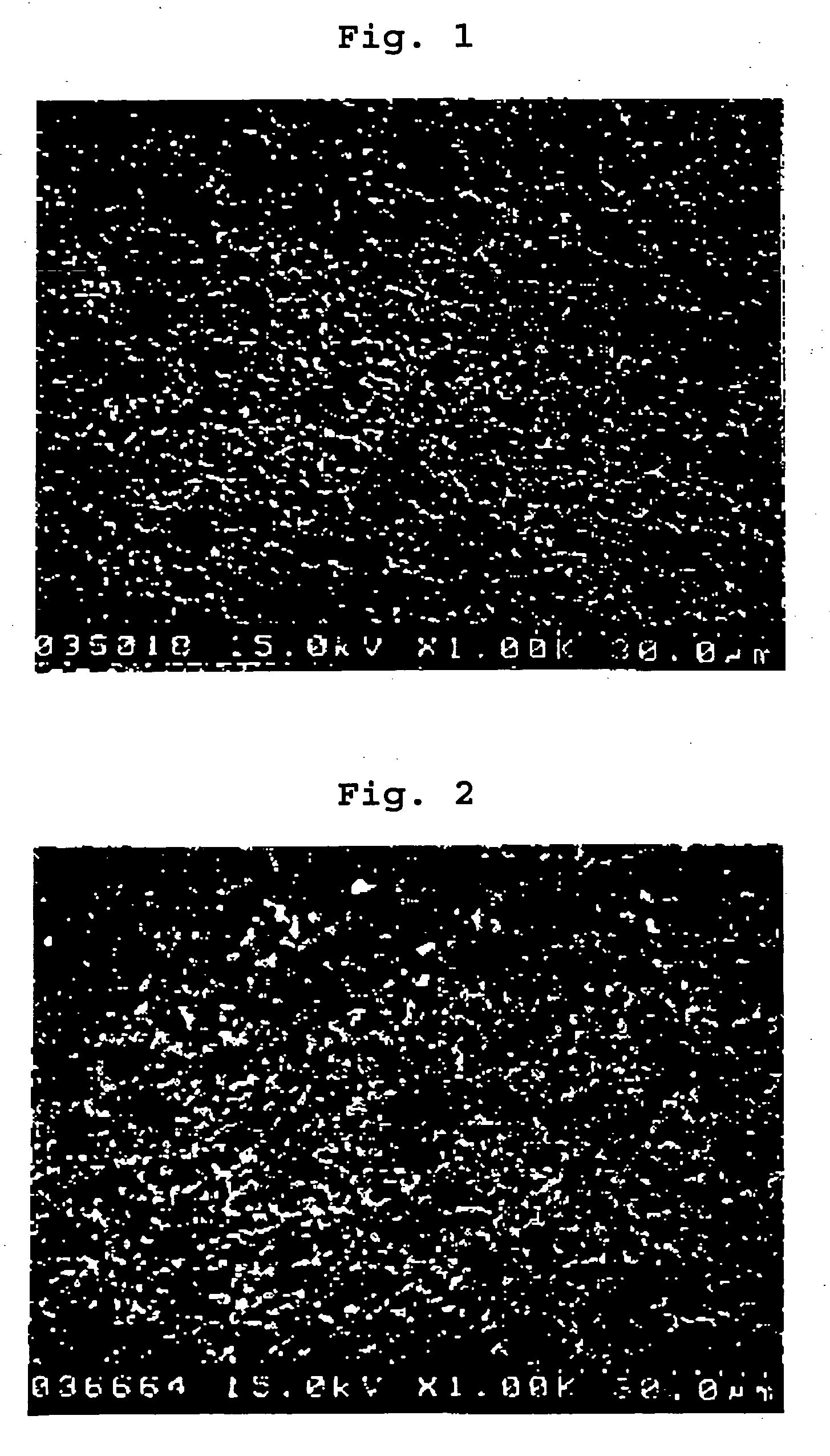

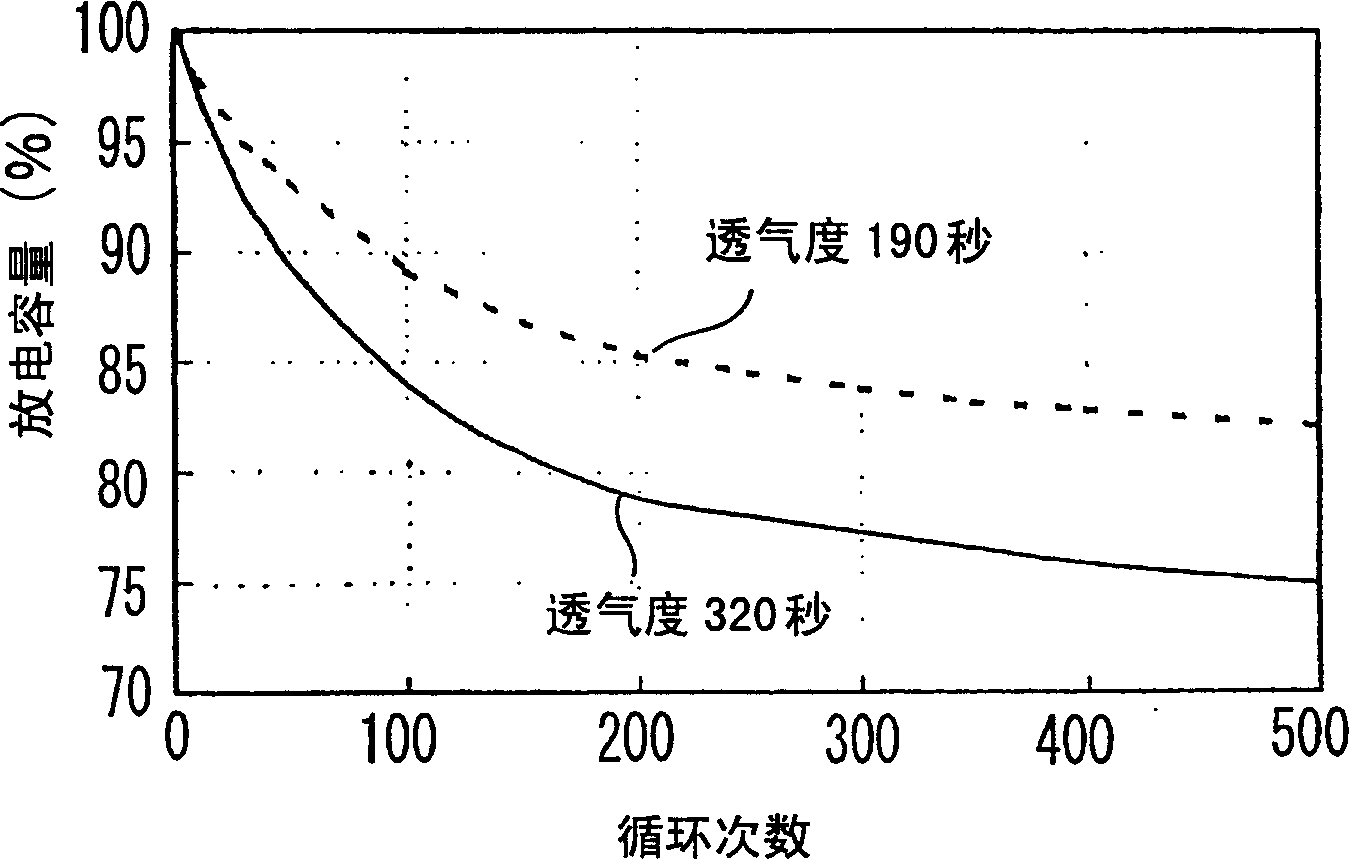

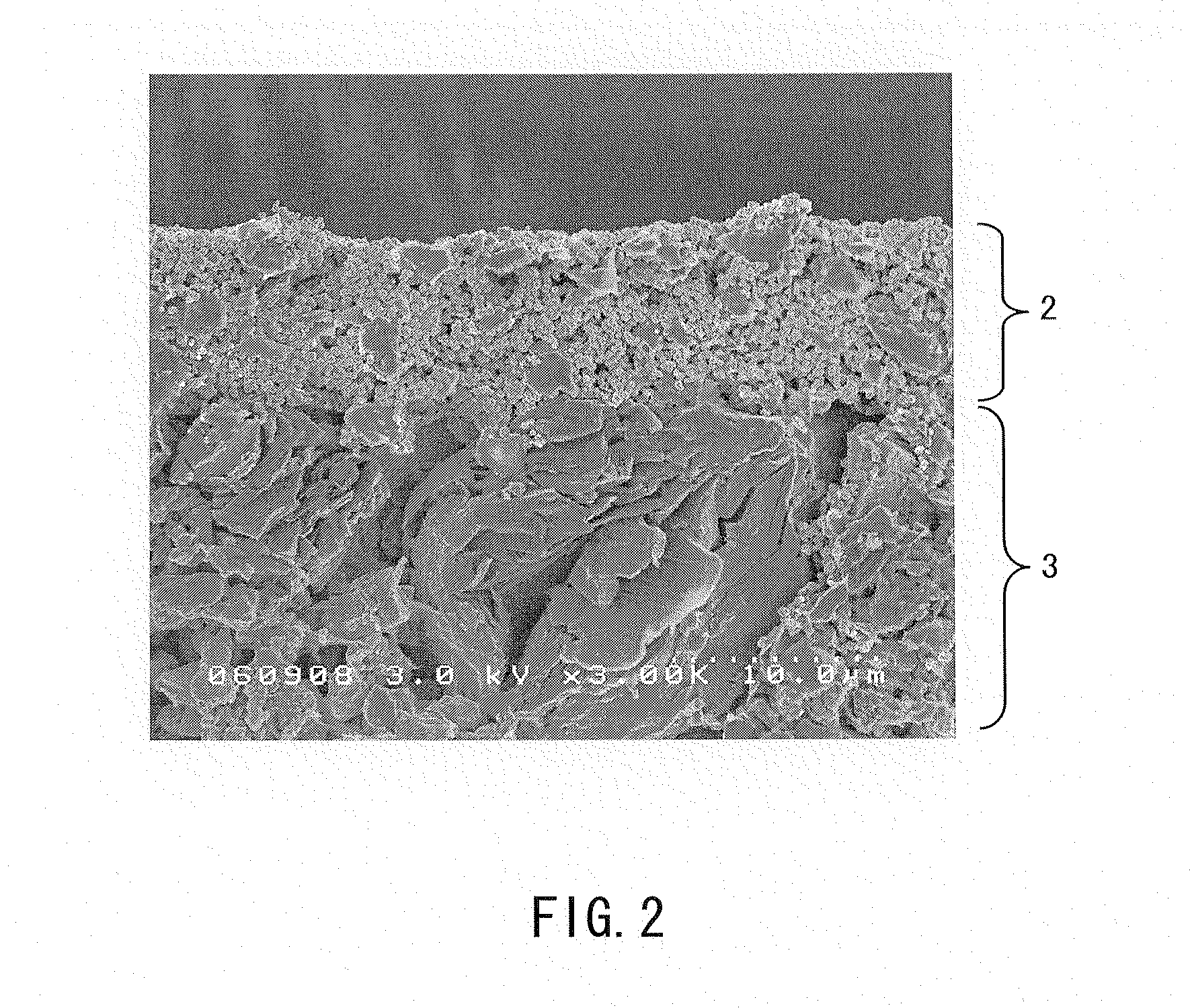

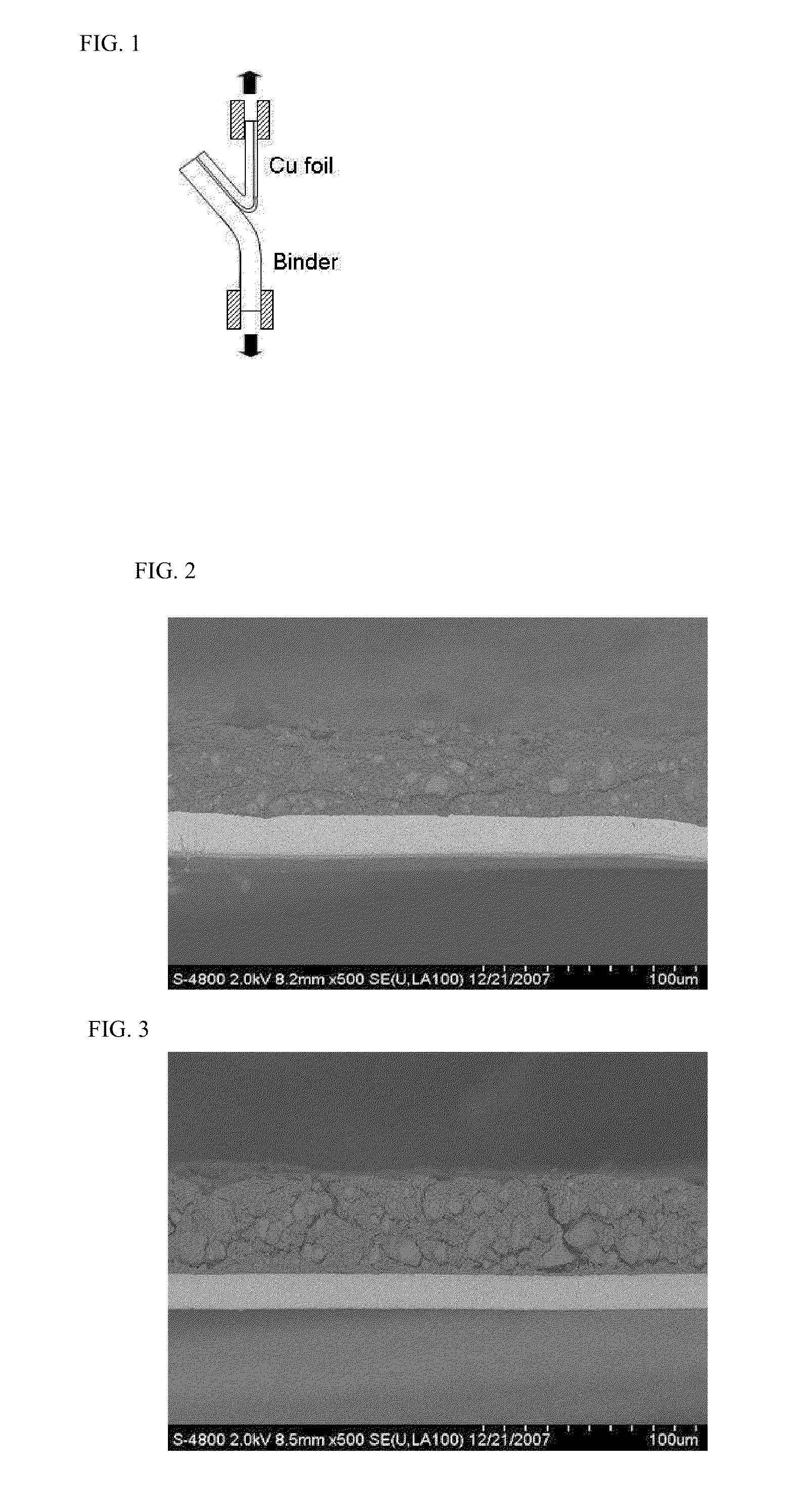

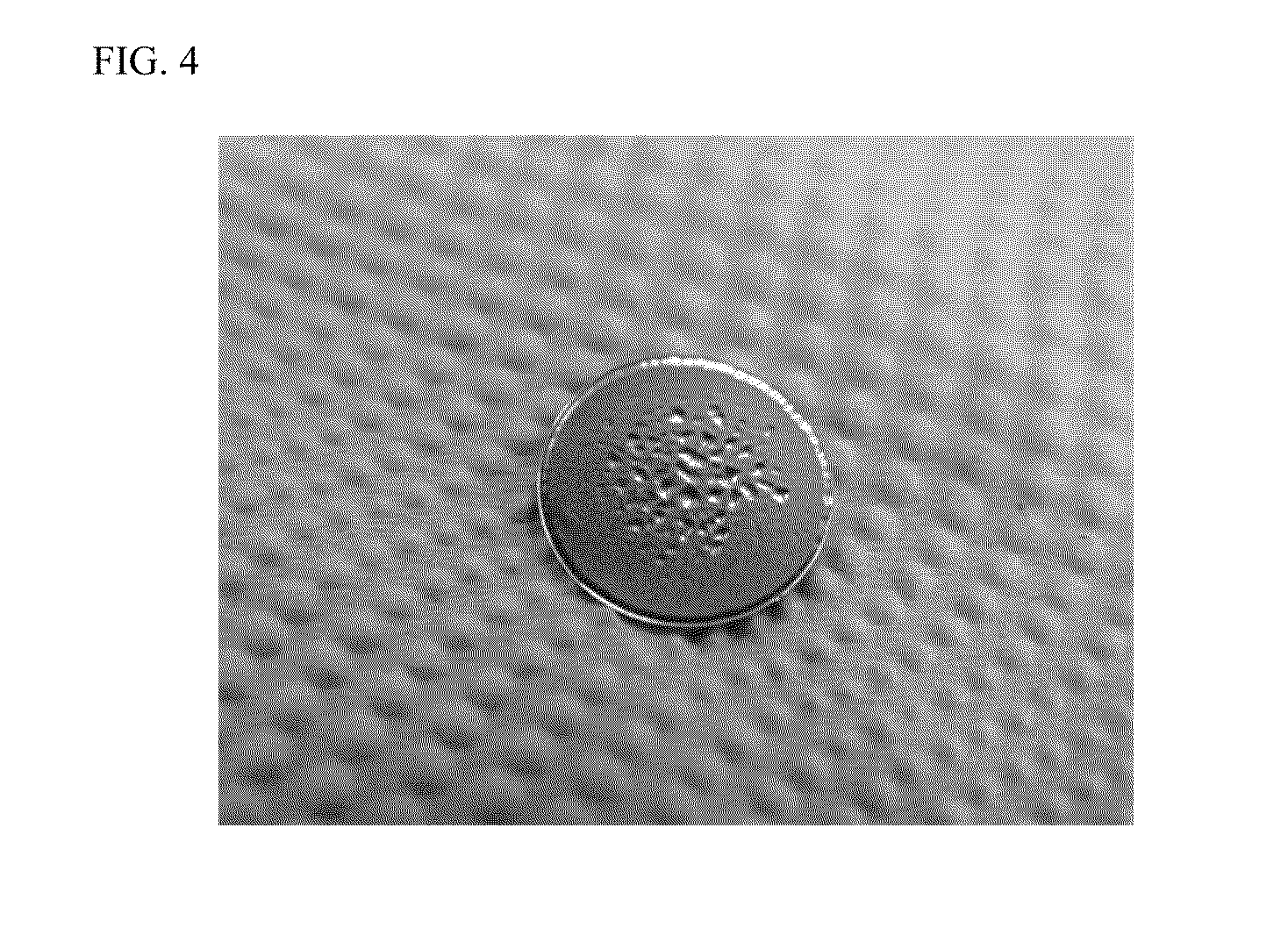

Separator for non-aqueous electrolyte battery and non-aqueous electrolyte battery

InactiveUS20060019154A1Small heat shrinkageImprove cycle performanceCell seperators/membranes/diaphragms/spacersCell electrodesPolyolefinHeat resistance

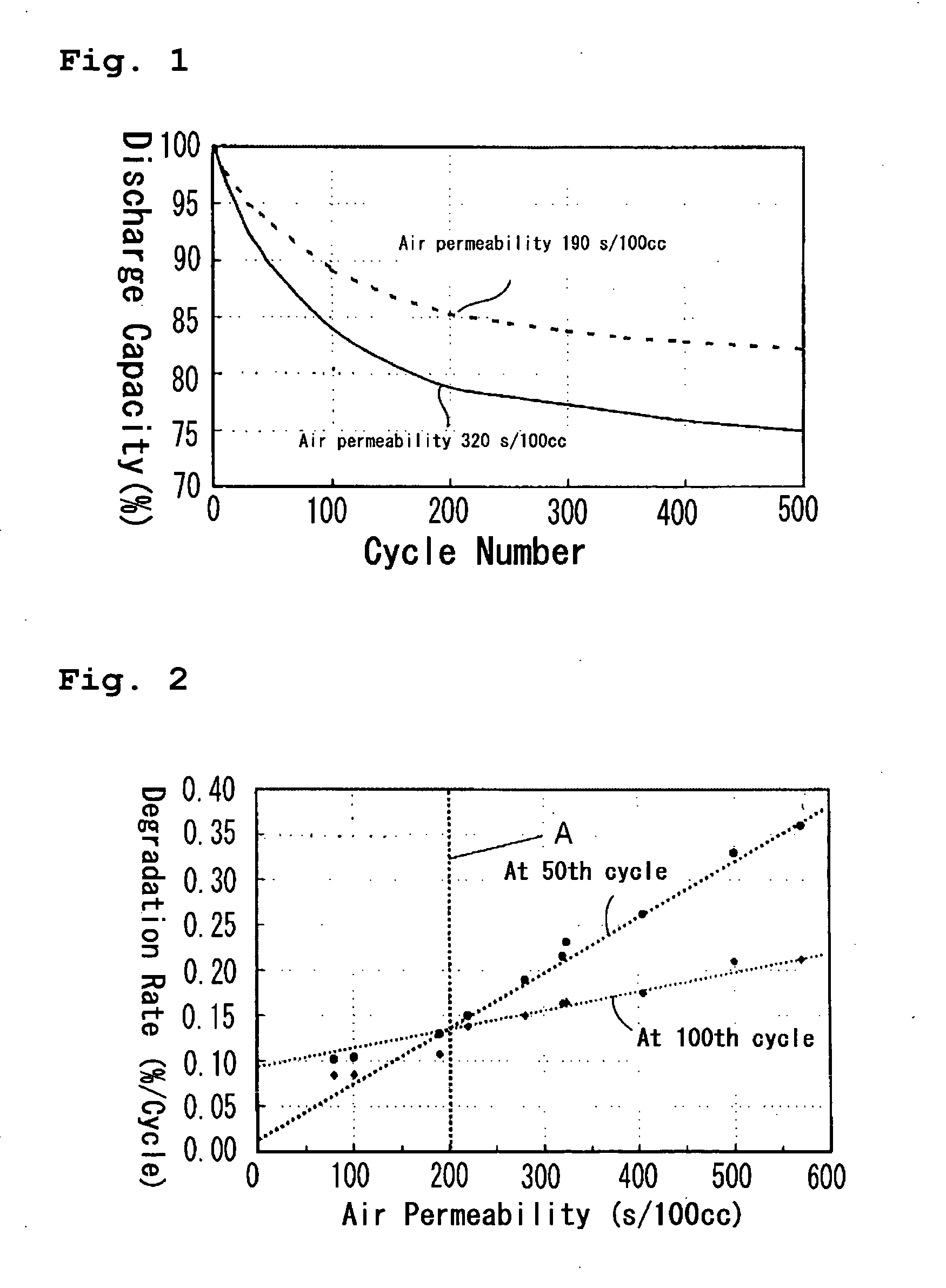

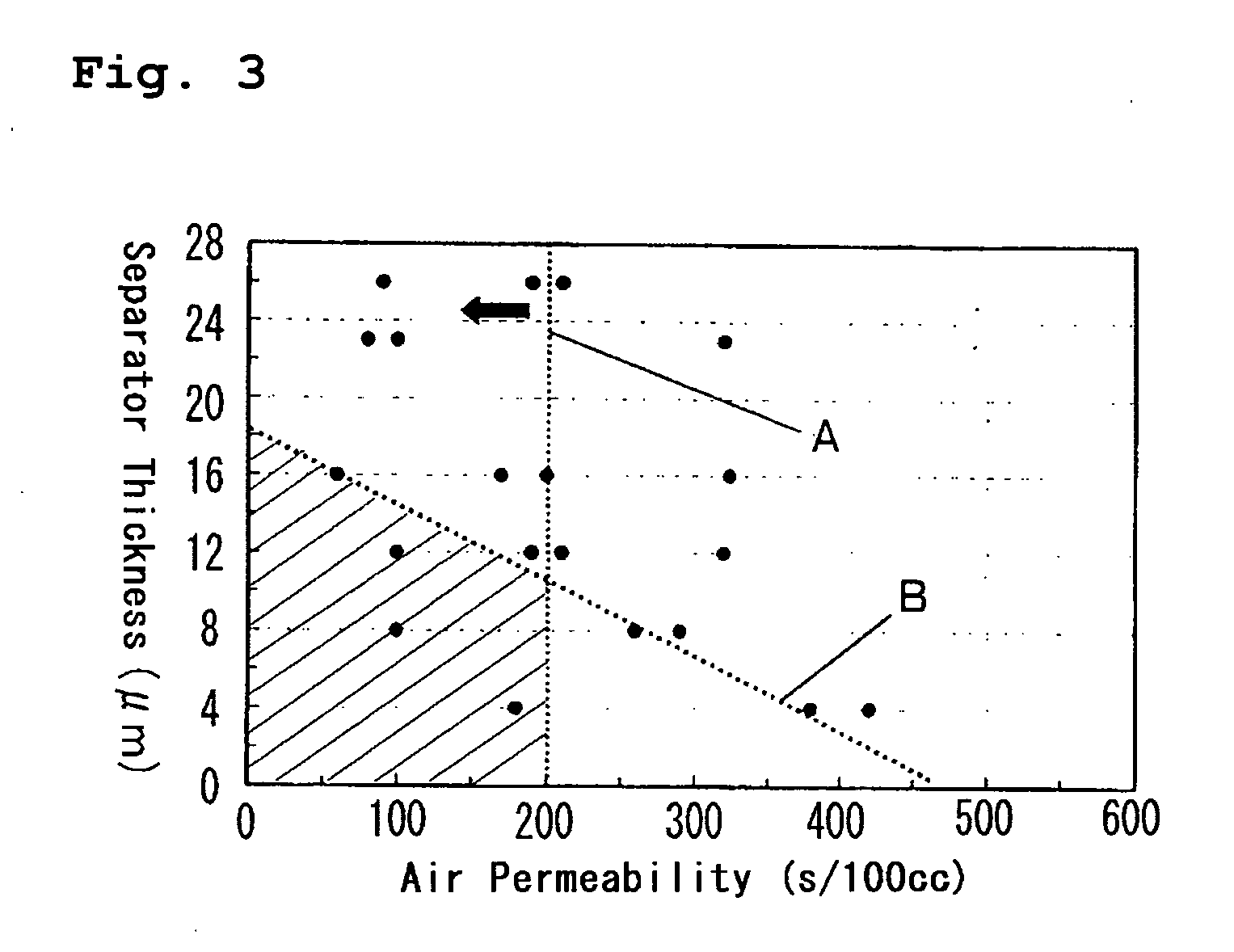

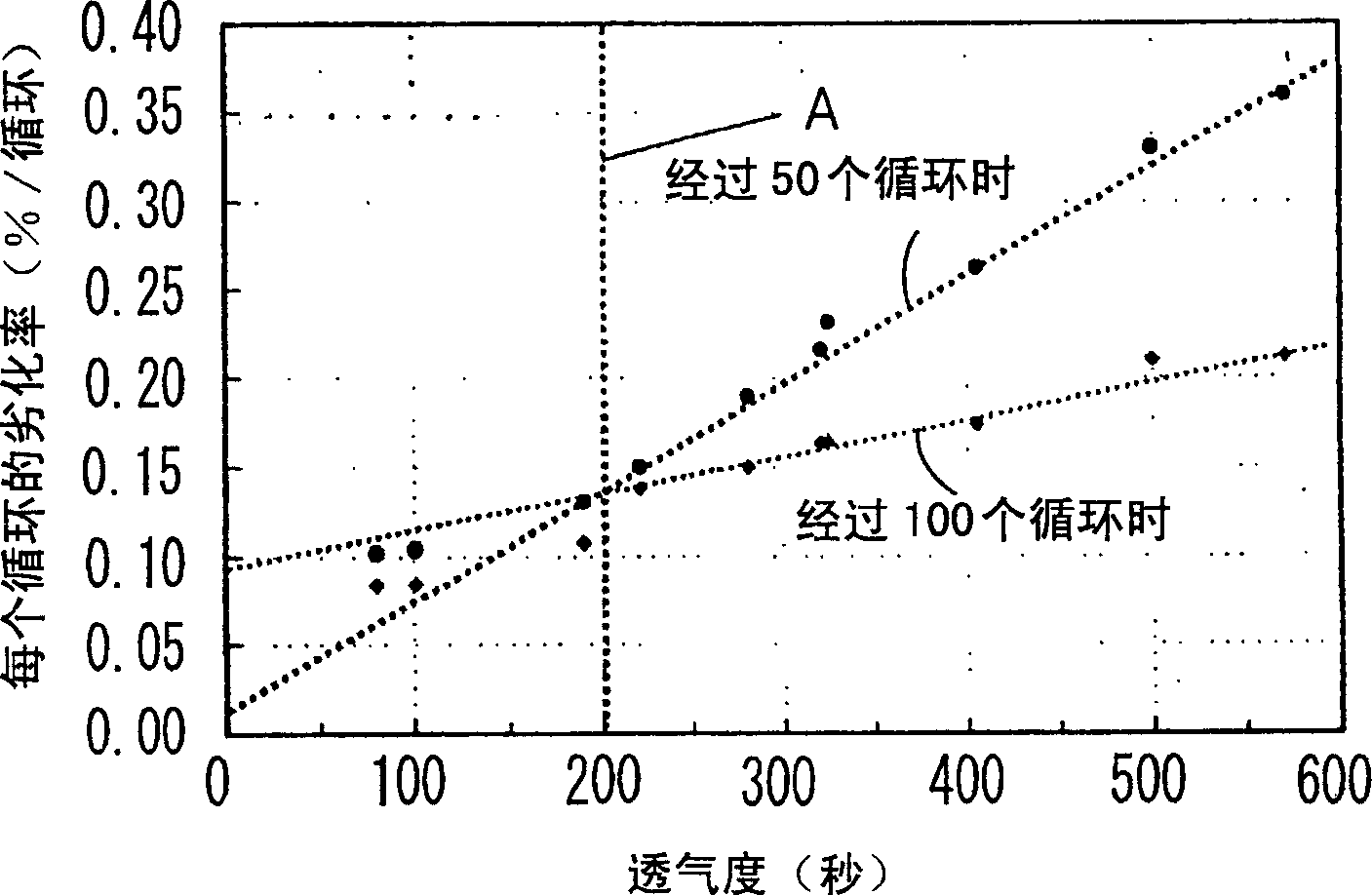

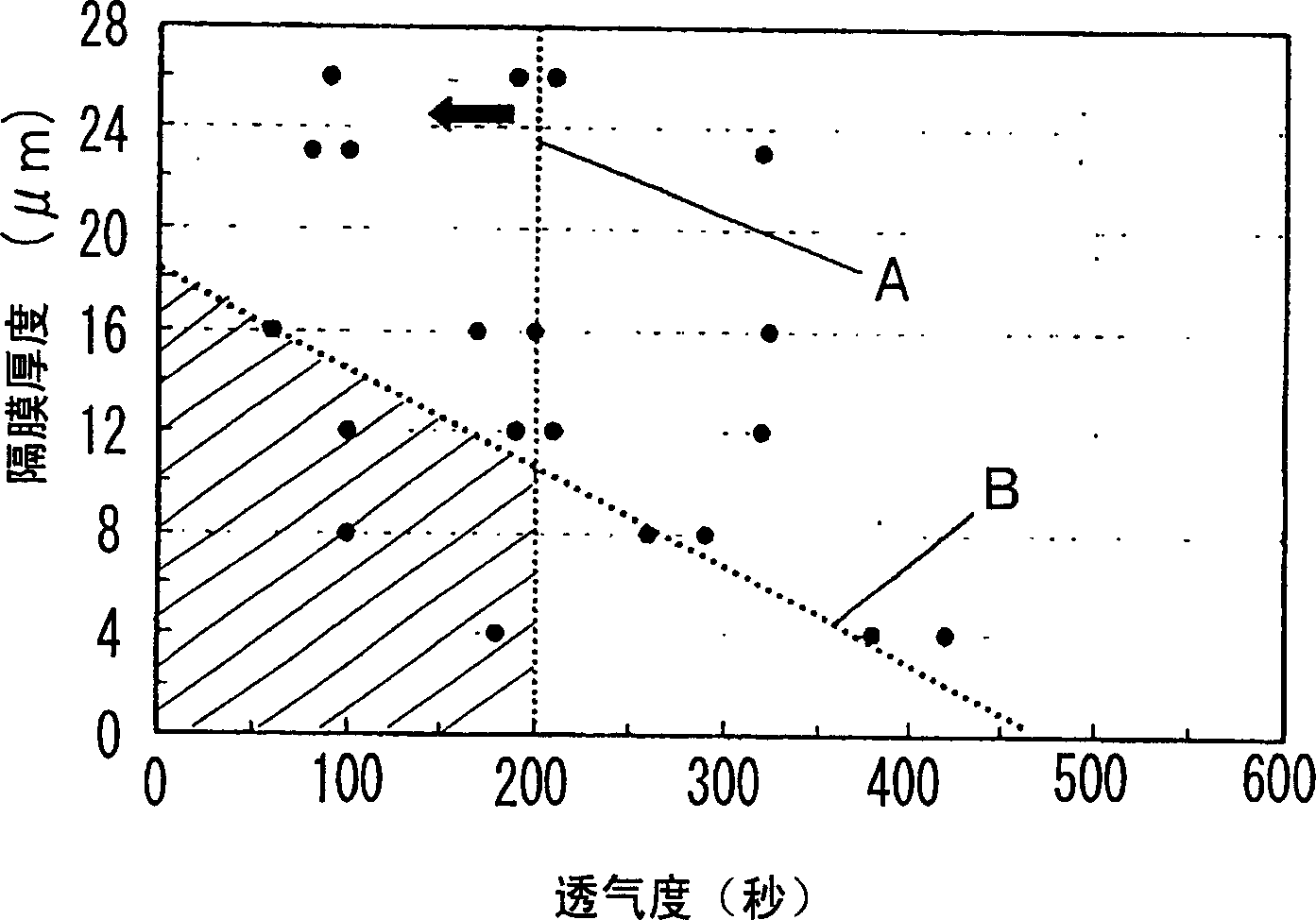

A separator for non-aqueous electrolyte batteries is provided that has small heat shrinkage and achieves good heat resistance and good cycle performance. A non-aqueous electrolyte battery using the separator is also provided. A separator for non-aqueous electrolyte batteries includes a microporous film in which a polyolefin layer and a heat-proof layer are adhered. The heat-proof layer has a thickness of from 1 μm to 4 μm, and is formed of polyamide, polyimide, or polyamideimide having a melting point of 180° C. or higher. The air permeability of the separator is 200 sec / 100 mL or less.

Owner:SANYO ELECTRIC CO LTD

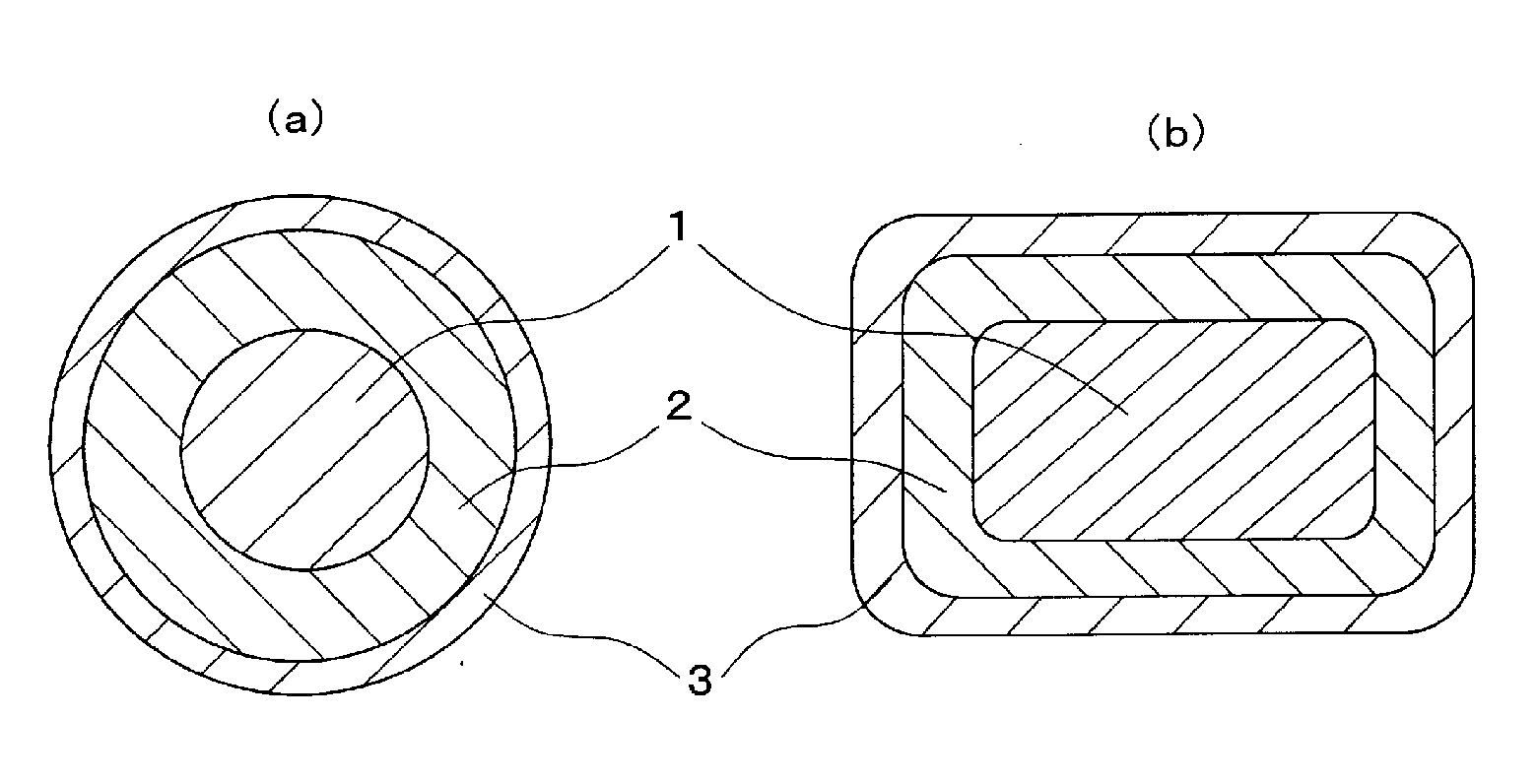

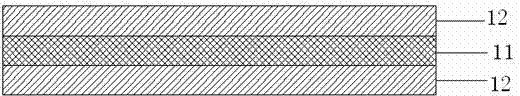

Enameled wire

InactiveUS6906258B2Improve withstand lifetimeLimited amountPlastic/resin/waxes insulatorsInsulated cablesPolyesterImide

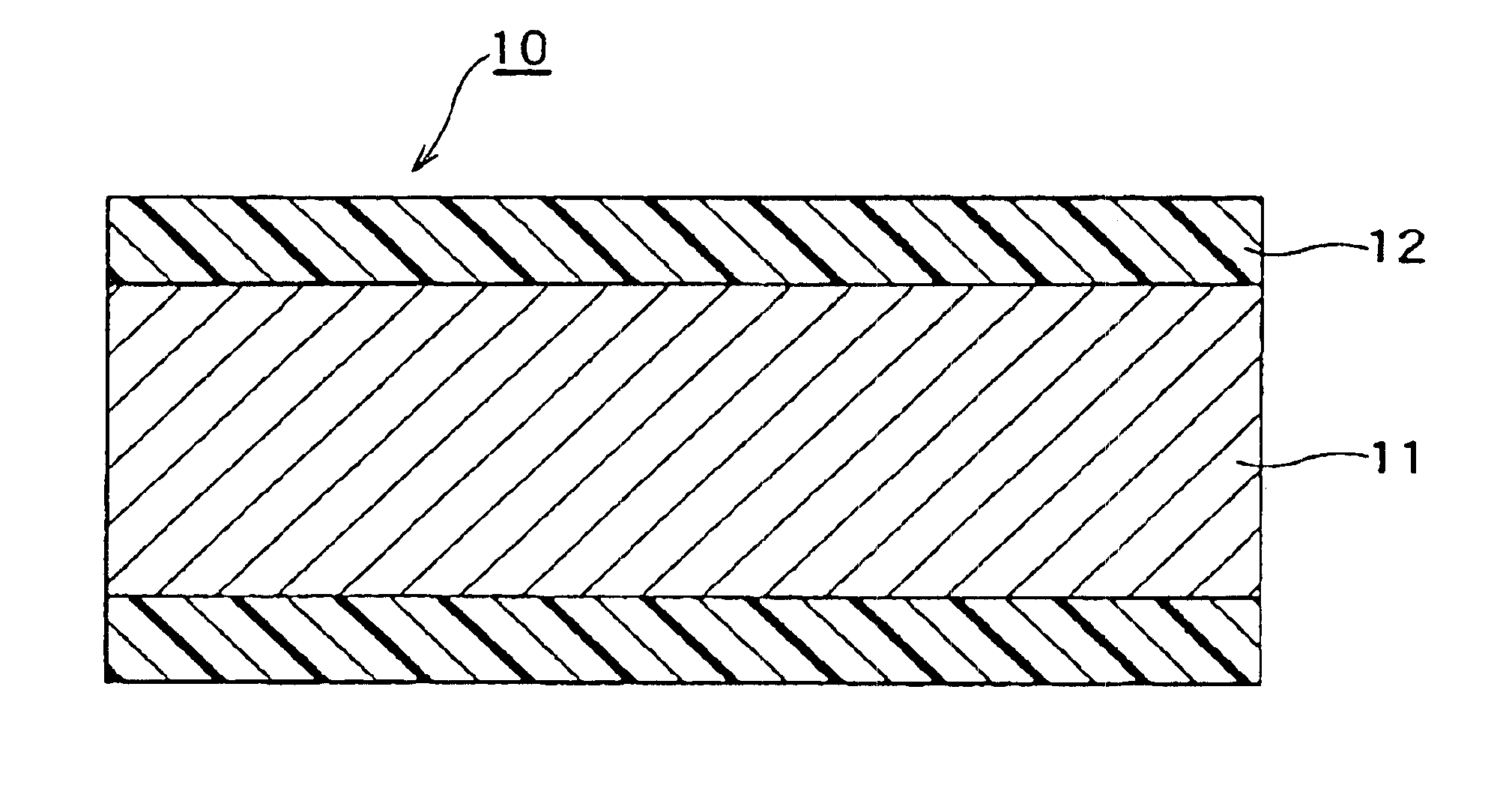

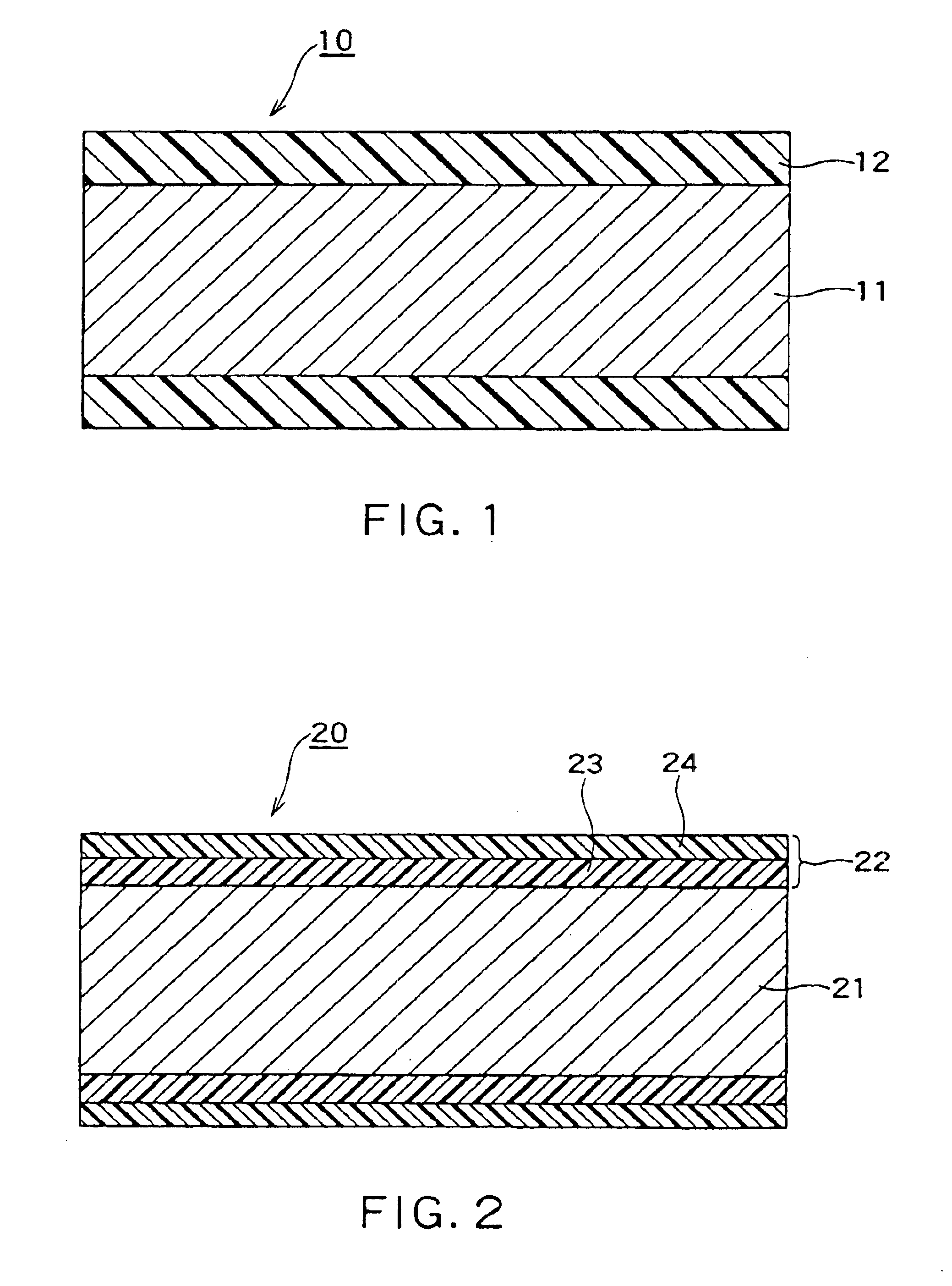

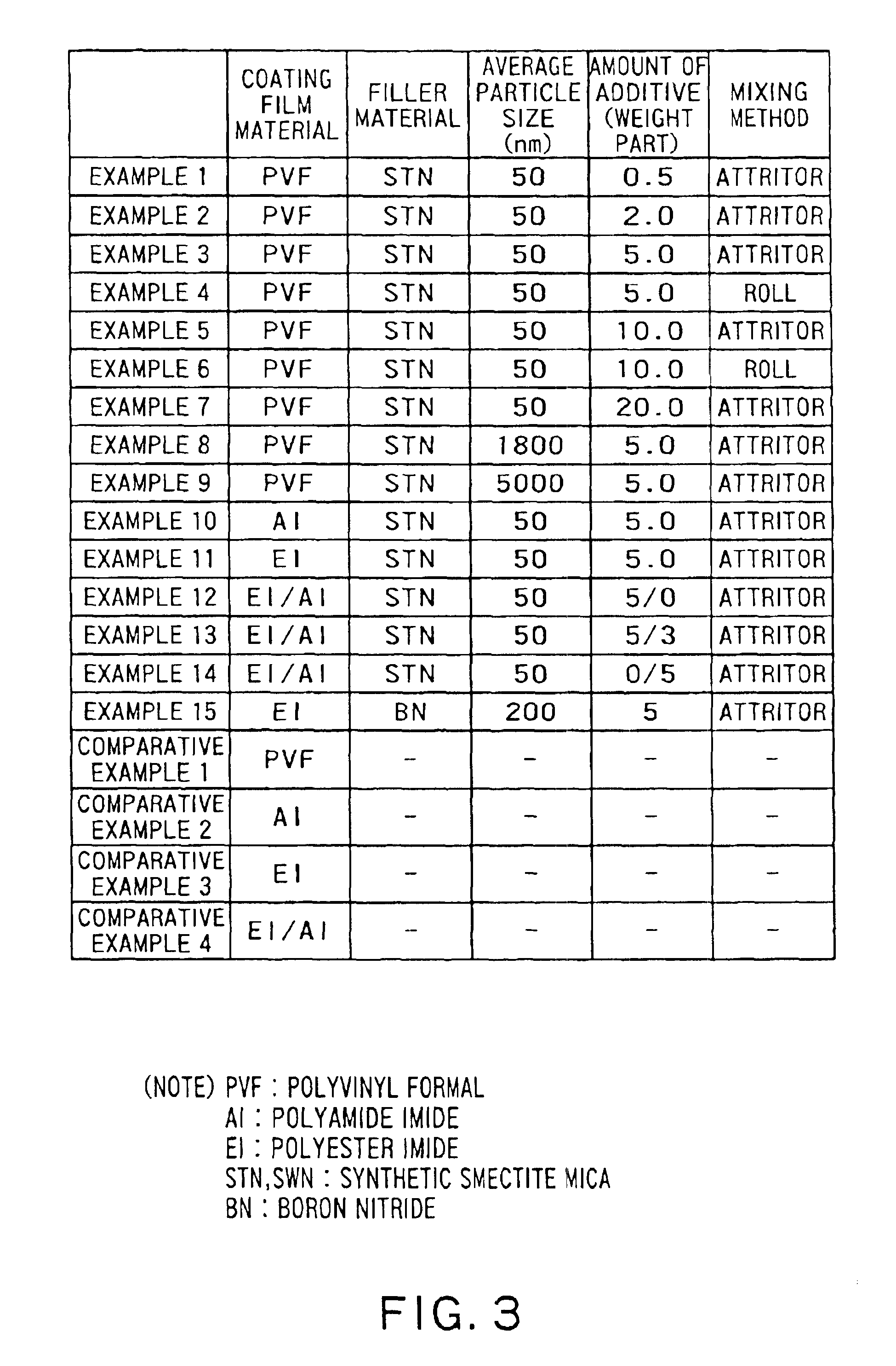

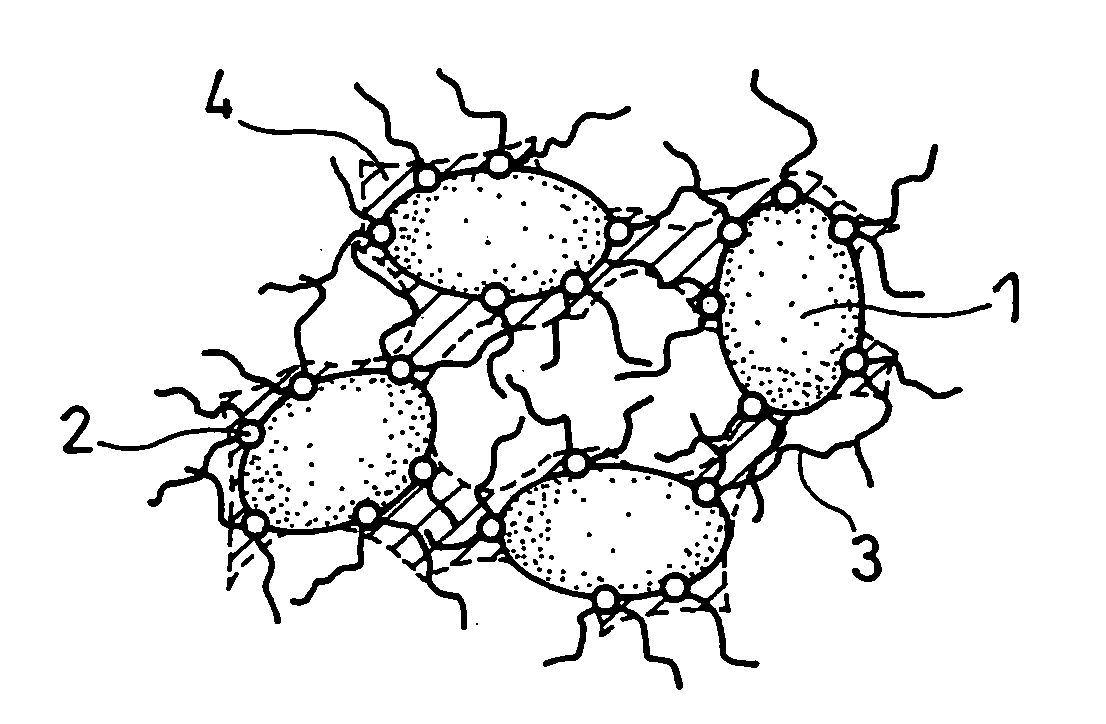

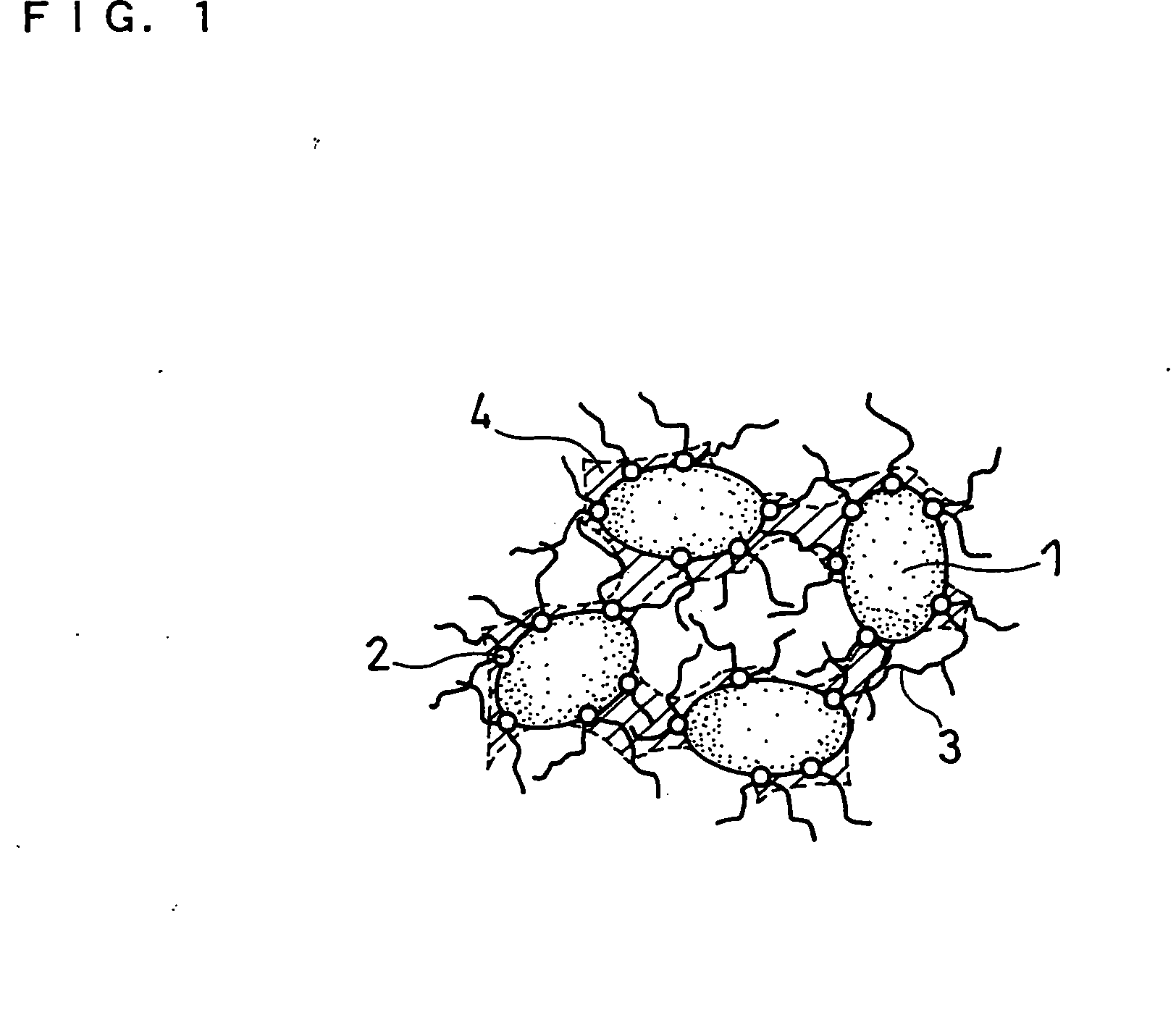

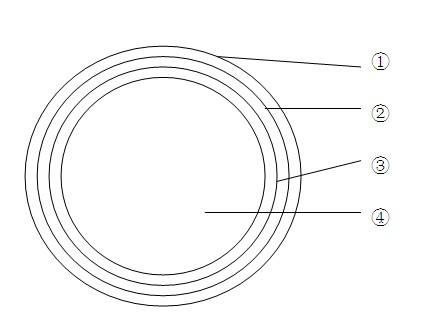

An enameled wire capable of improving withstand lifetime with respect to the application of surge voltage of an inverter and thermal degradation thereof while restricting an amount of an inorganic filler material is provided. The enameled wire includes an electrically conductive wire (11) and a coating (12) formed of a high molecular compound uniformly mixed with an inorganic filler material in the form of fine flat particles provided around the electrically conductive wire (11). The enameled wire may include an electrically conductive wire (21), a coating (23) formed of a polyester imide resin solution mixed with an inorganic filler material in the form of fine flat particles and provided on the conductive wire and a coating (24) formed of polyamide imide and provided on the coating (23).

Owner:KK TOSHIBA

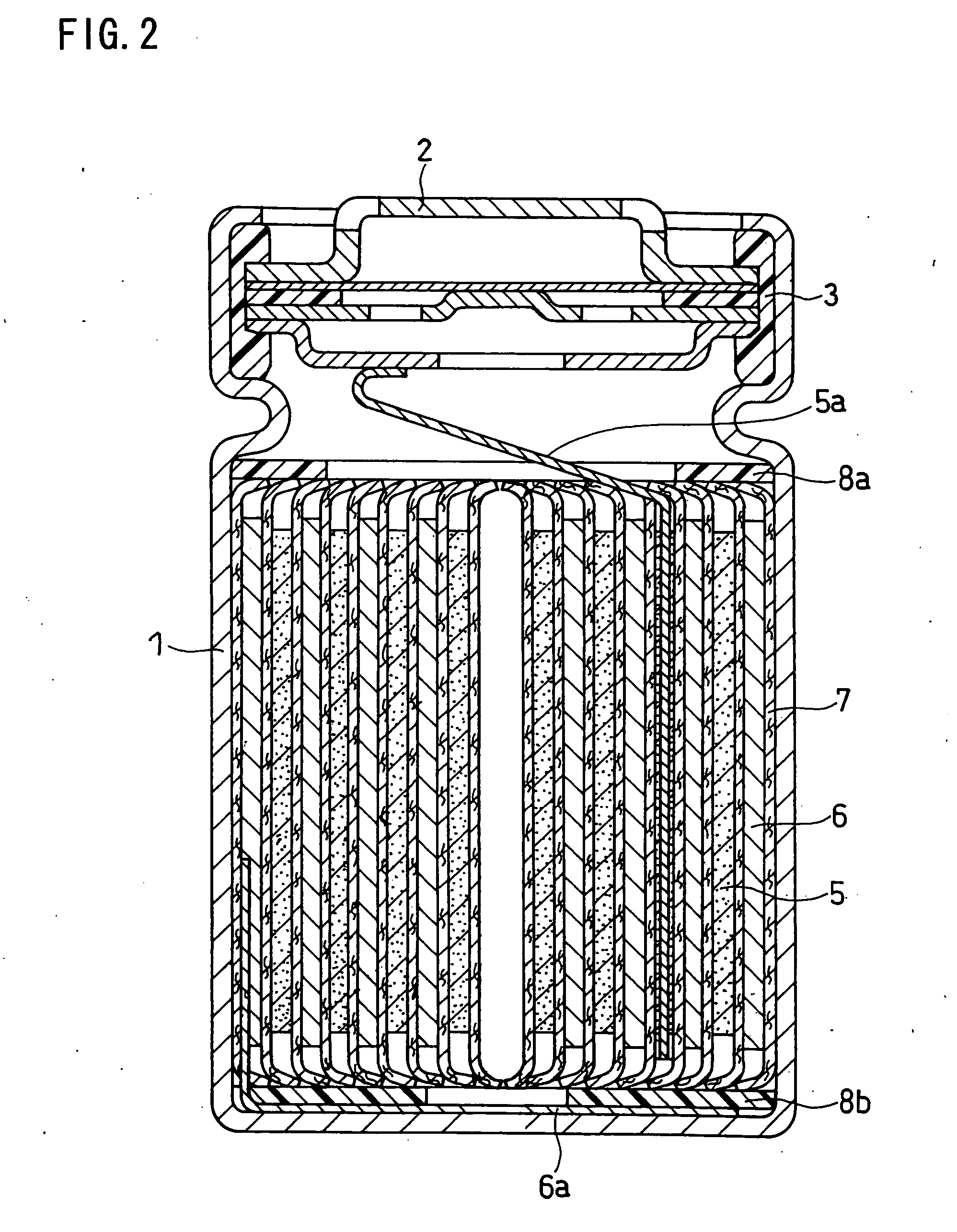

Non-aqueous electrolyte secondary battery

InactiveUS20070099081A1Improve reliabilityHigh charge and discharge capacityMaterial nanotechnologyNon-aqueous electrolyte accumulatorsPolyetherimidePolyamide

A non-aqueous electrolyte secondary battery including a positive electrode, a negative electrode, a separator interposed between the positive and negative electrodes, and a non-aqueous electrolyte. The negative electrode includes composite particles and a binder. Each of the composite particles includes: a negative electrode active material including an element capable of being alloyed with lithium; carbon nanofibers that are grown from a surface of the negative electrode active material; and a catalyst element for promoting the growth of the carbon nanofibers. The binder comprises at least one polymer selected from the group consisting of polyimide, polyamide imide, polyamide, aramid, polyarylate, polyether ether ketone, polyether imide, polyether sulfone, polysulfone, polyphenylene sulfide, and polytetrafluoroethylene.

Owner:PANASONIC CORP

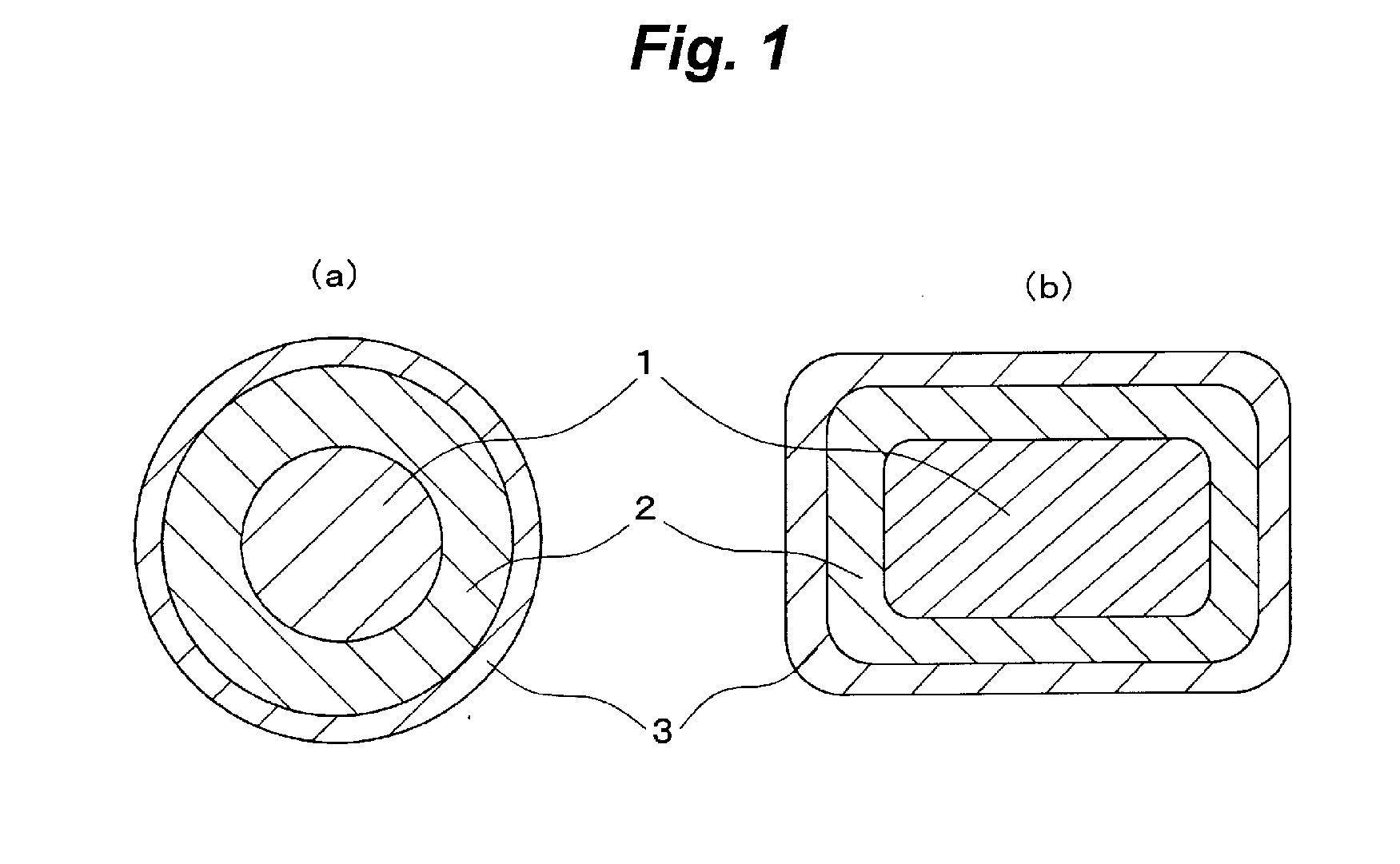

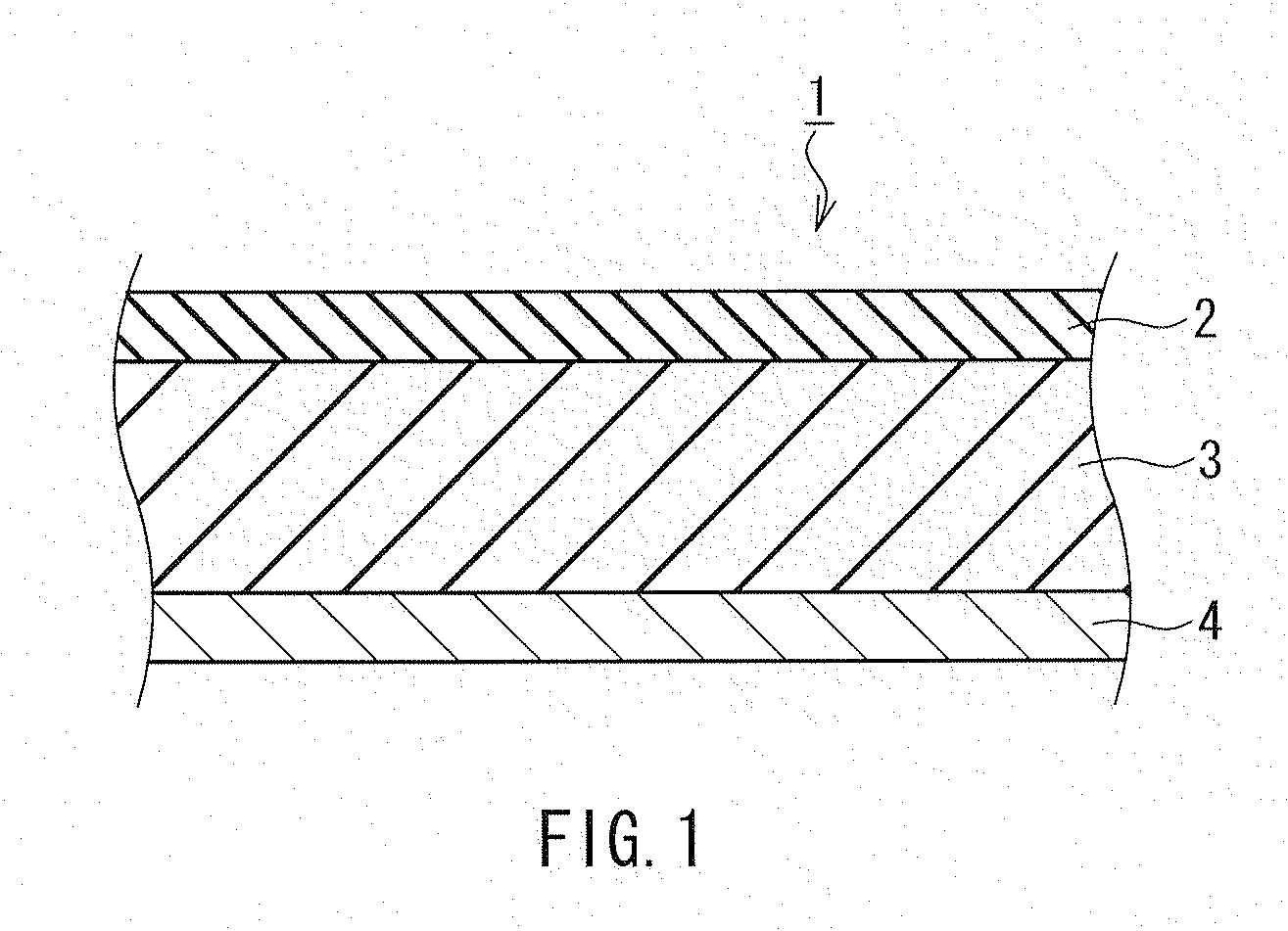

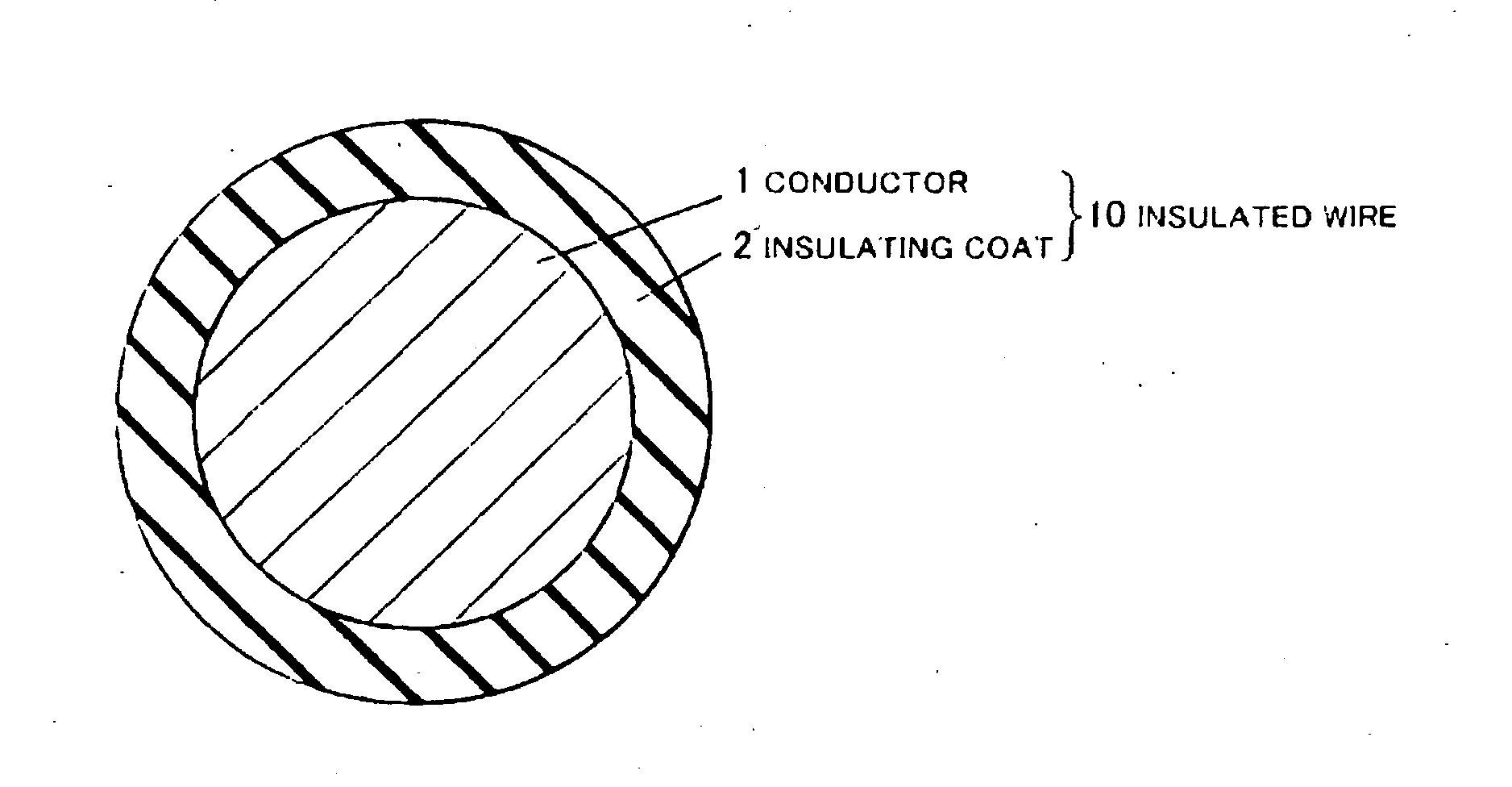

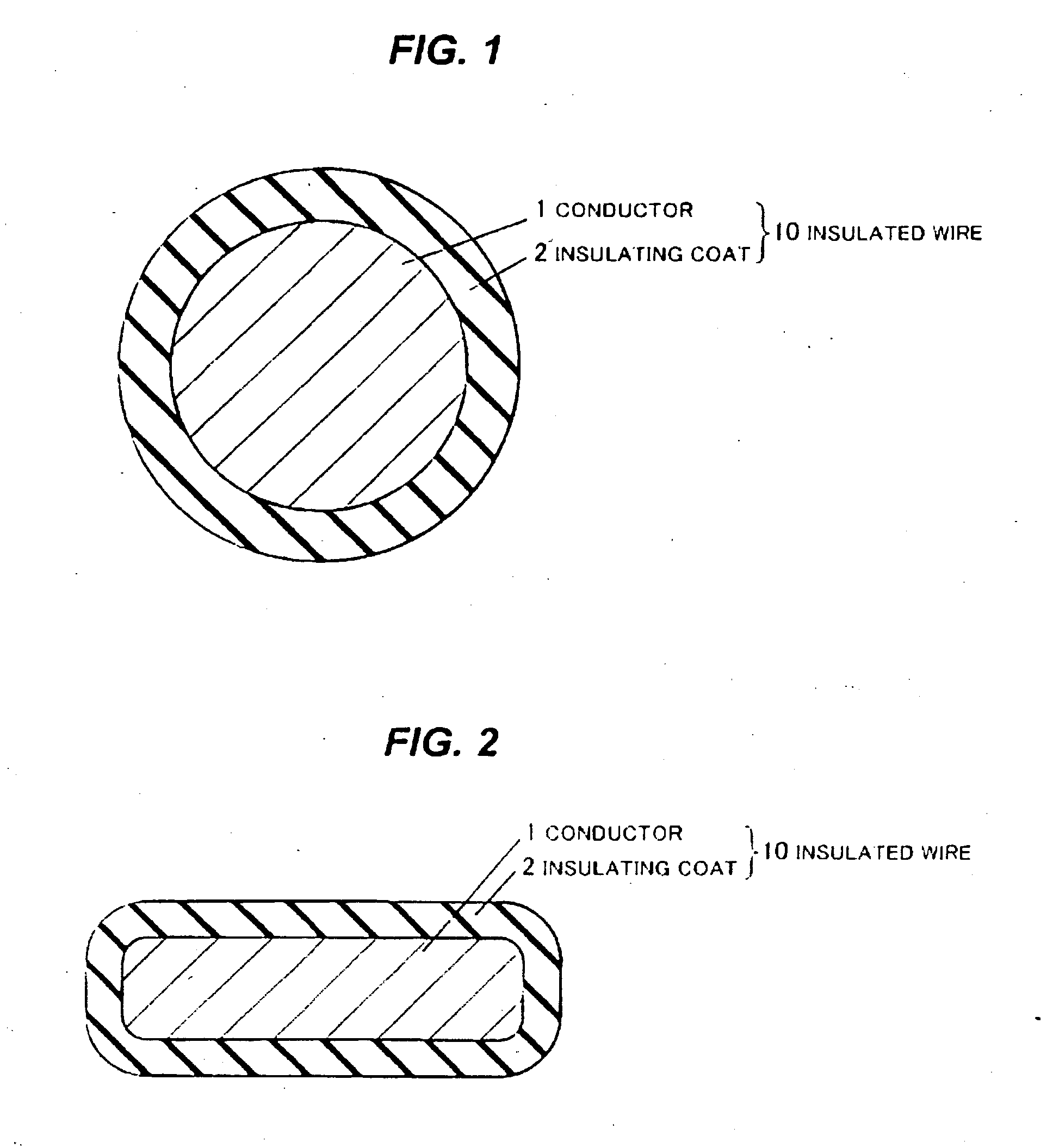

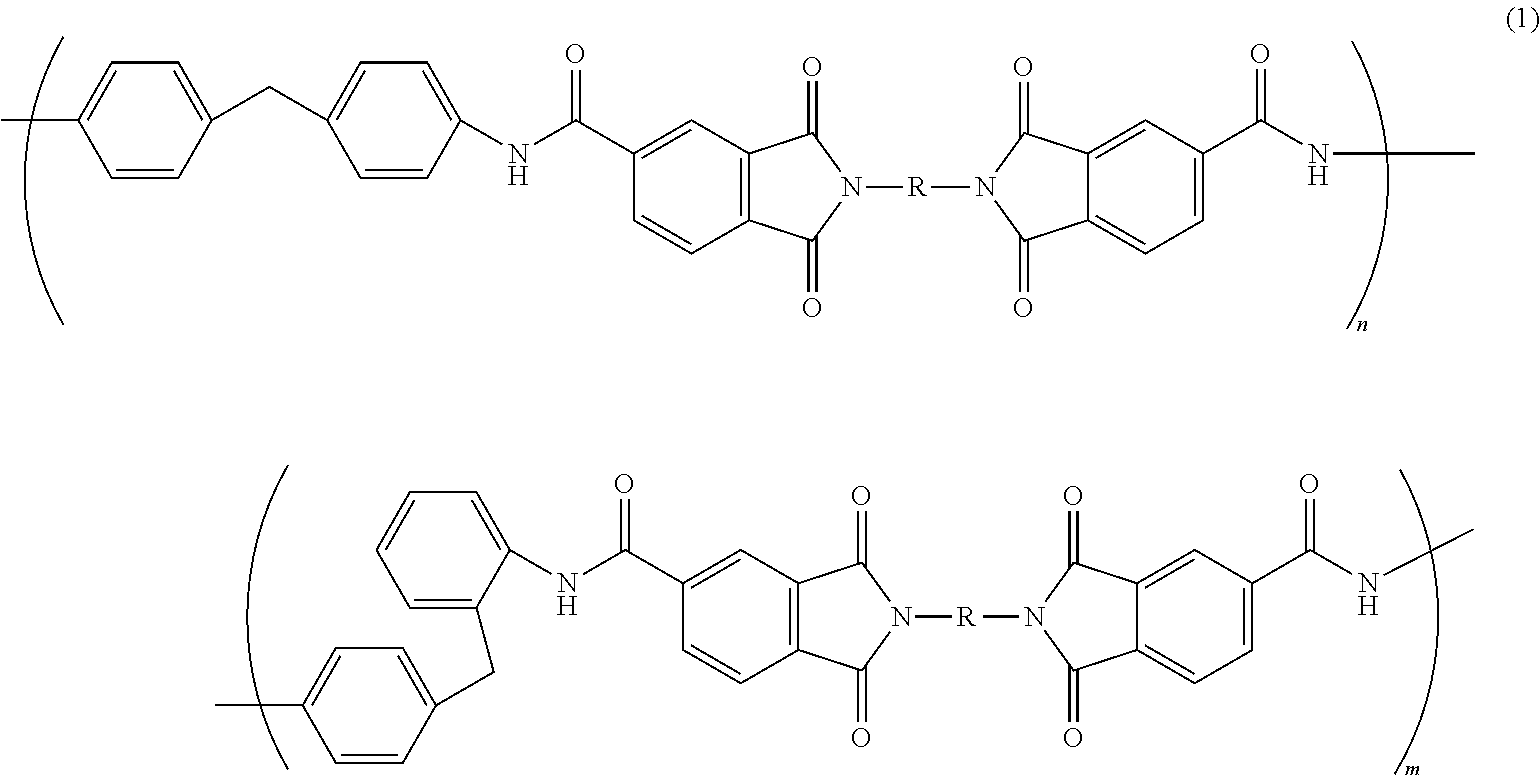

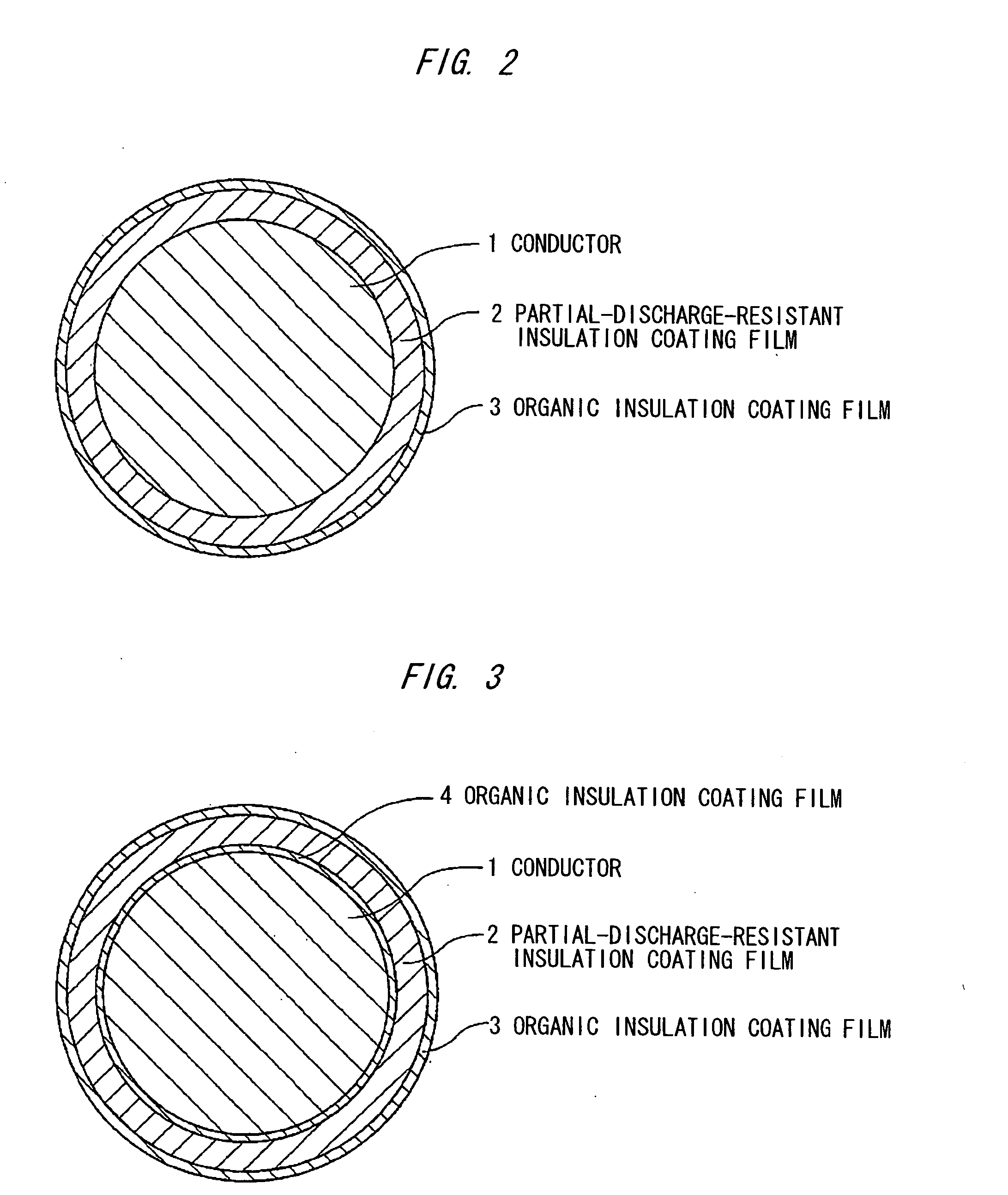

Insulated wire

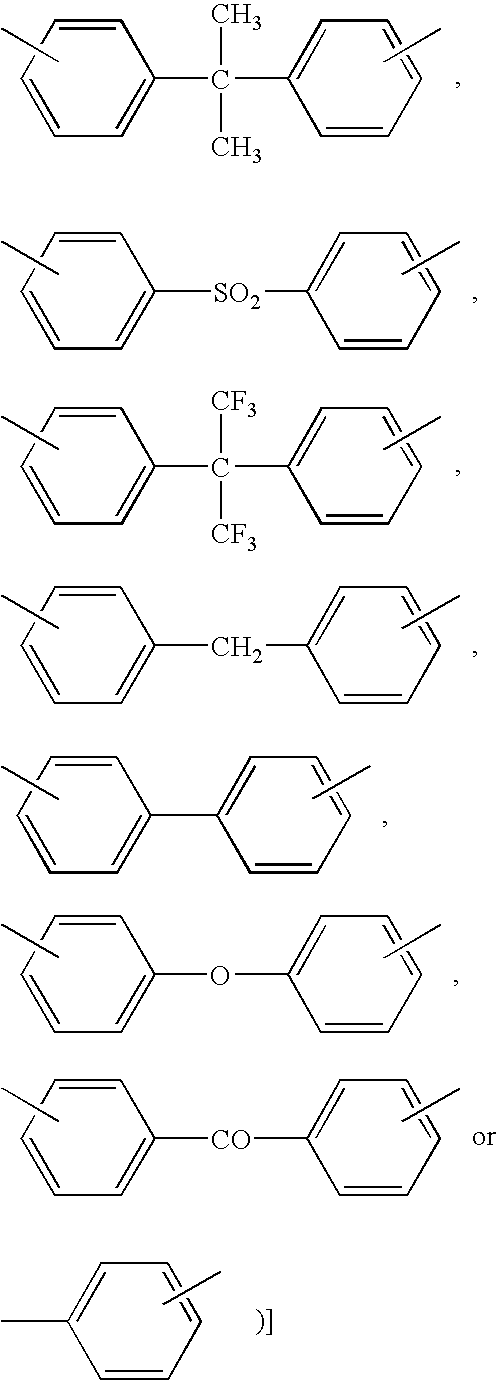

ActiveUS20130037304A1Plastic/resin/waxes insulatorsInsulated cablesElectrical conductorPolyamide-imide

An insulated wire having:a conductor,a baked enamel layer containing at least a polyamide-imide provided on the outer periphery of the conductor directly or through an insulated layer, andat least one extrusion-coated resin layer provided on the outer side of the baked enamel layer,wherein the baked enamel layer has at least one functional group selected from the group consisting of a carboxyl group, an ester group, an ether group and a hydroxyl group on the outer surface thereof, and adheres to the extrusion-coated resin layer.

Owner:ESSEX FURUKAWA MAGNET WIRE JAPAN CO LTD +1

Proppant

InactiveUS20120018162A1Less resourcesImprove performanceLiquid surface applicatorsFluid removalPolyamide-imideChemistry

Owner:BASF AG

Resin composition for interlayer insulation of multilayer printed wiring board, adhesive film and prepreg

ActiveUS20050008868A1Insufficient heat resistanceElectrical controlPrinted circuit aspectsEpoxyElectrical conductor

Resin compositions which comprise the following components (A) to (E) are useful for interlayer insulation of a multilayer printed wiring board: (A) an epoxy resin having 2 or more epoxy group in one molecule and which exists in a liquid state at a temperature of 20° C.; (B) an aromatic epoxy resin having 3 or more epoxy groups in one molecule and an epoxy equivalent of 200 or less; (C) a phenol type curing agent; (D) one or more resins selected from the group consisting of a phenoxy resin, a polyvinyl acetal resin, a polyamide resin, a polyamideimide resin, and mixtures thereof, and having a glass transition temperature of 100° C. or more; and (E) an inorganic filler, wherein: the inorganic filler (E) is present in an amount of 35% by weight or more based on the total weight of the non-volatile components of the resin composition; the epoxy resin (A) and the aromatic epoxy resin (B) are present in a weight ration of from 1:0.3 to 1:2 by weight of epoxy resin (A) to aromatic epoxy resin (B); the epoxy resin (A), the aromatic epoxy resin (B), and the phenol type curing agent (C) are present in relative amounts such that the weight ratio of epoxy groups in the resin composition and phenolic hydroxyl groups in the phenol type curing agent (C) is from 1:0.5 to 1:1.5; and the resin (D) is present in an amount of from 2 to 20% by weight based on the total weight of the non-volatile components of the resin composition. Such resin compositions are useful for interlayer insulation of a multilayer printed wiring board and are capable of forming an insulating layer which has a low thermal expansion coefficient and exhibits excellent peel strength for a conductor layer. Such resin compositions are also useful for preparing adhesive films and prepregs for a multilayer printed wiring boards, as well as multilayer printed wiring boards having an insulating layer formed of a cured product of the resin composition or the prepreg.

Owner:AJINOMOTO CO INC

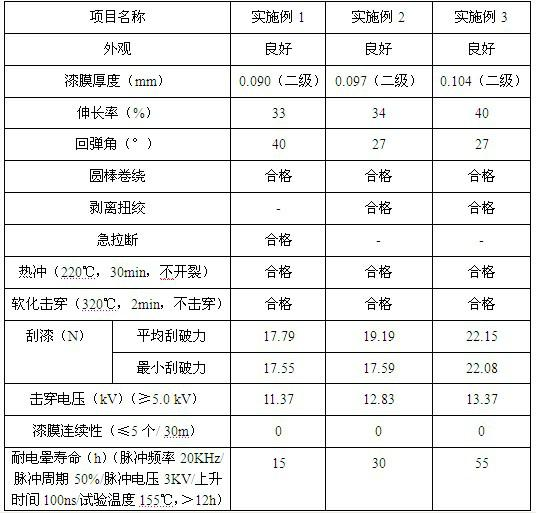

Technique for manufacturing frequency conversion varnished wire

InactiveCN101325102AImprove corona resistanceExtended service lifePlastic/resin/waxes insulatorsInsulating conductors/cablesPolyesterFrequency conversion

The invention discloses a production process of a frequency conversion lacquered wire. The process comprises the following steps: (1) paying off; (2) wire drawing; (3) cleaning; (4) annealing; (5) cooling; (6) varnishing, backing and cooling: firstly the surface of a norm wire is coated with 10 passes of the frequency conversion polyester paint, and then, 3 passes of polyamide-imide paint, after the surface is coated with each pass of paint, backing and cooling are performed, then the surface is coated with the next pass of the paint, the backing is performed from the lower layer to the upper layer during the process of backing, the temperature at the inlet of a baking oven is 220 DEG C, the temperature in the lower layer is 330 DEG C, the temperature is 330 DEG C before the primary catalyzing is performed, and the supplementary heat temperature is 430 DEG C after the catalyzing is performed; (7) lubricating; and (8) wire winding. By adopting the production process, the lacquered wire can be guaranteed to achieve the good corona resistance, thereby the insulation aging phenomena can be slowed down, and the service life of the motor can be prolonged.

Owner:JIANGSU DAZHONG ELECTRIC MOTOR

Separator for non-aqueous electrolyte battery and non-aqueous electrolyte battery

InactiveCN1725524ASmall thermal shrinkageImprove heat resistanceElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersPolyolefinHeat resistance

The present invention provides a membrane that is used in non aqueous electrolyte batteries. And the present invention is characterized in that the membrane is formed by a micro-porous membrane that consists of a polyolefin layer and a heat-resistant layer, which overlap on each other. The heat-resistant layer is 1 Mu m to 4 Mu m thick and is formed by polyamide, polyimide, or polyamide imide, the melting point of which is above 180 DEG C. The air permeability of the membrane is less than 200 seconds. And the present invention can be used for preparing the membrane, which is used in non aqueous electrolyte batteries and has small thermal shrinkage, excellent heat resistance and excellent cycling characteristics, and also the non aqueous electrolyte batteries that adopt the membrane.

Owner:SANYO ELECTRIC CO LTD

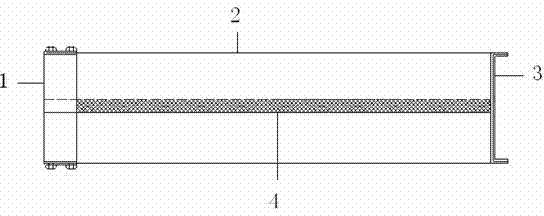

Method for preparing corona-resistant enameled wire and product

ActiveCN101958158AGood adhesionImprove corona resistanceFlexible cablesFlexible conductorsImidePolyester

Owner:株洲兆源机电科技有限公司

Anti-static polytetrafluoroethylene filter bag and preparation method thereof

InactiveCN103191602AHigh temperature resistantCorrosion resistantDispersed particle filtrationSynthetic resin layered productsChemical industryEngineering

The invention discloses an anti-static polytetrafluoroethylene filter bag and a preparation method thereof. The anti-static polytetrafluoroethylene filter bag comprises a bag head, a bag body and a bag bottom, wherein the bag head is made from a polytetrafluoroethylene filter material; the polytetrafluoroethylene filter material comprises a base cloth; the base cloth is weaved through warps and wefts by twisting polytetrafluoroethylene filament fibers and stainless steel fibers; the upper surface and lower surface of the base cloth are symmetrically covered with non-woven layers; the non-woven layers are prepared by blending polytetrafluoroethylene fibers or one or more of the polytetrafluoroethylene fibers, polyphenylene sulfide fibers, polyamide fibers, polyamide-imide fibers and glass fibers; and the overlapped edge of the bag body is provided with a stainless steel wire mesh layer. The filter material prepared through the method disclosed by the invention has the advantages of good high temperature resistance, corrosion resistance and electric conductivity and persistent static elimination, reduces the fire hazard or explosion generated due to electrostatic sparks and can be widely applied to the high-temperature fire prevention, explosion prevention and dust removal in the fields of iron and steel smelting, refuse burning, a coal-fired power plant, cement, chemical industry, and the like.

Owner:南京际华三五二一环保科技有限公司

Heat-resistant film and composite ion-exchange membrane

InactiveUS20060138042A1High ion conductivityHigh mechanical strengthElectrolyte holding meansIon-exchanger regenerationSurface layerHeat resistance

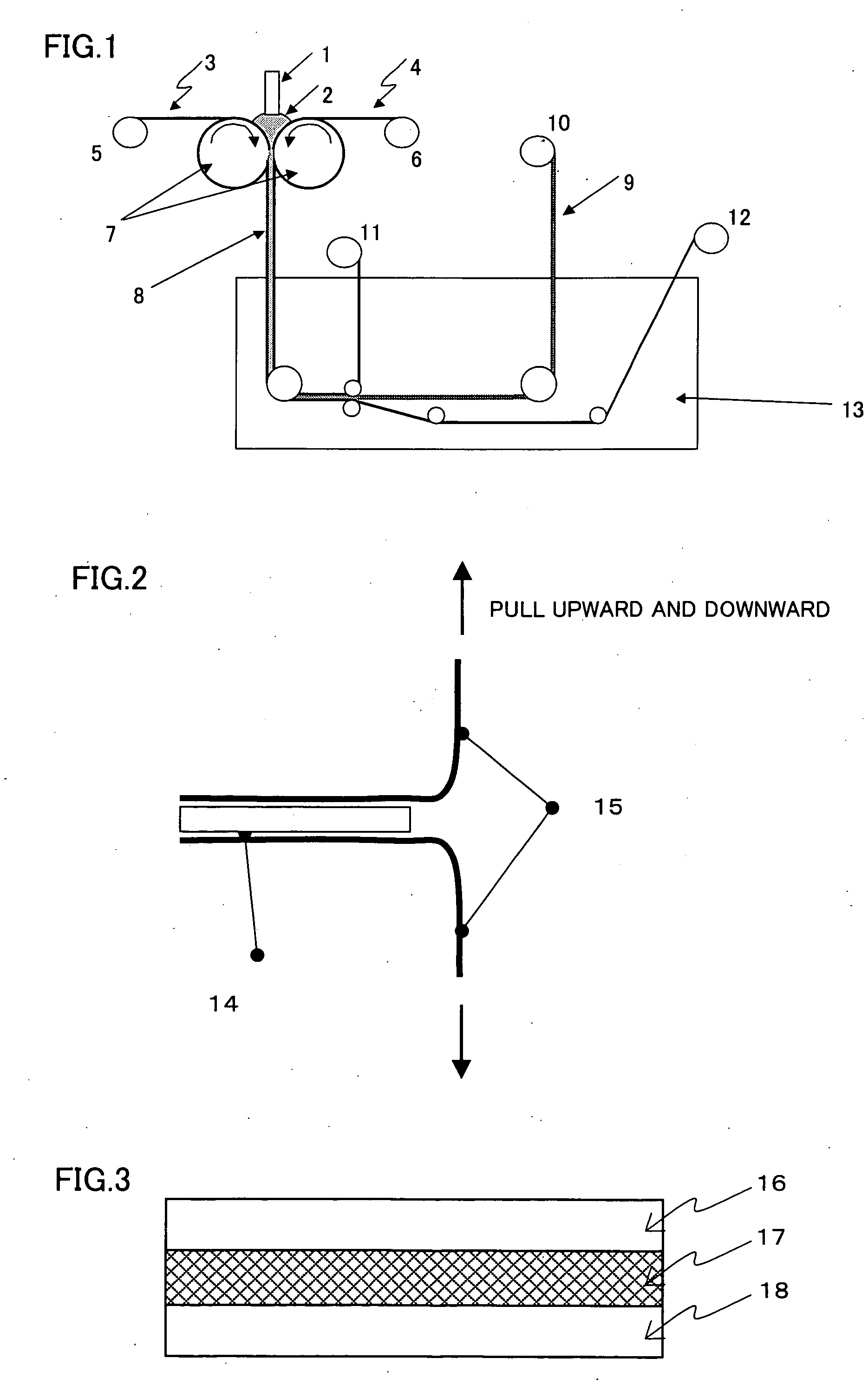

The present invention is a heat-resistant film comprising at least any one of a polybenzazole, aramid and polyamideimide produced by introducing a thin film made by a roll, slit or press from a polymer solution sandwiched between at least two supports into a coagulating bath and peeling the supports off in the coagulating bath to effect the coagulation, and a composite ion-exchange membrane having a surface layer consisting of an ion-exchange resin excluding a porous film on the both side of a composite layer formed by impregnating said film with the ion-exchange resin. A heat-resistant film having a combination of excellent heat resistance, mechanical strength, smoothness and interlaminar peeling resistance, especially a microporous heat-resistant film, and a composite ion-exchange membrane employing the same which has an excellent ion conductivity are provided.

Owner:TOYO TOYOBO CO LTD

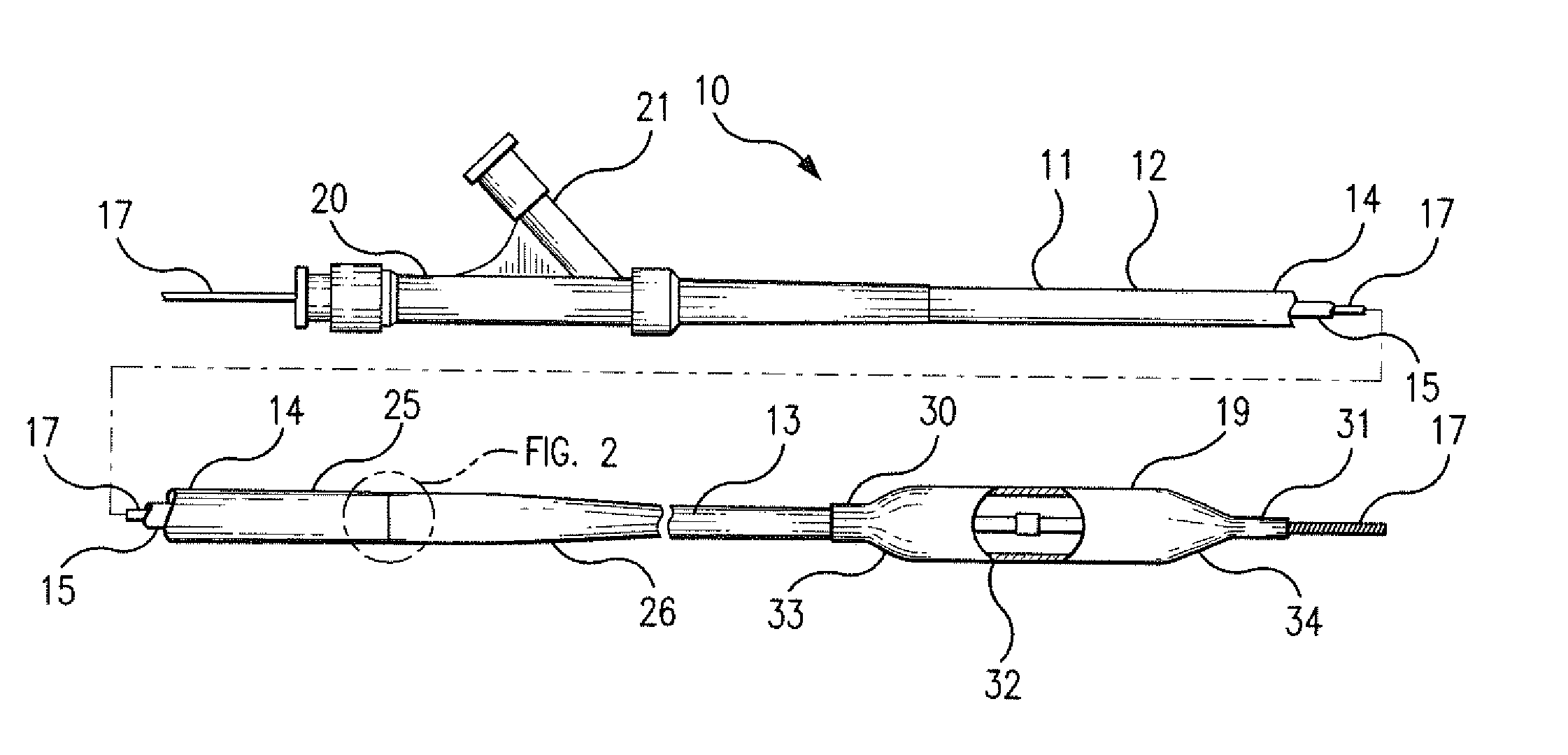

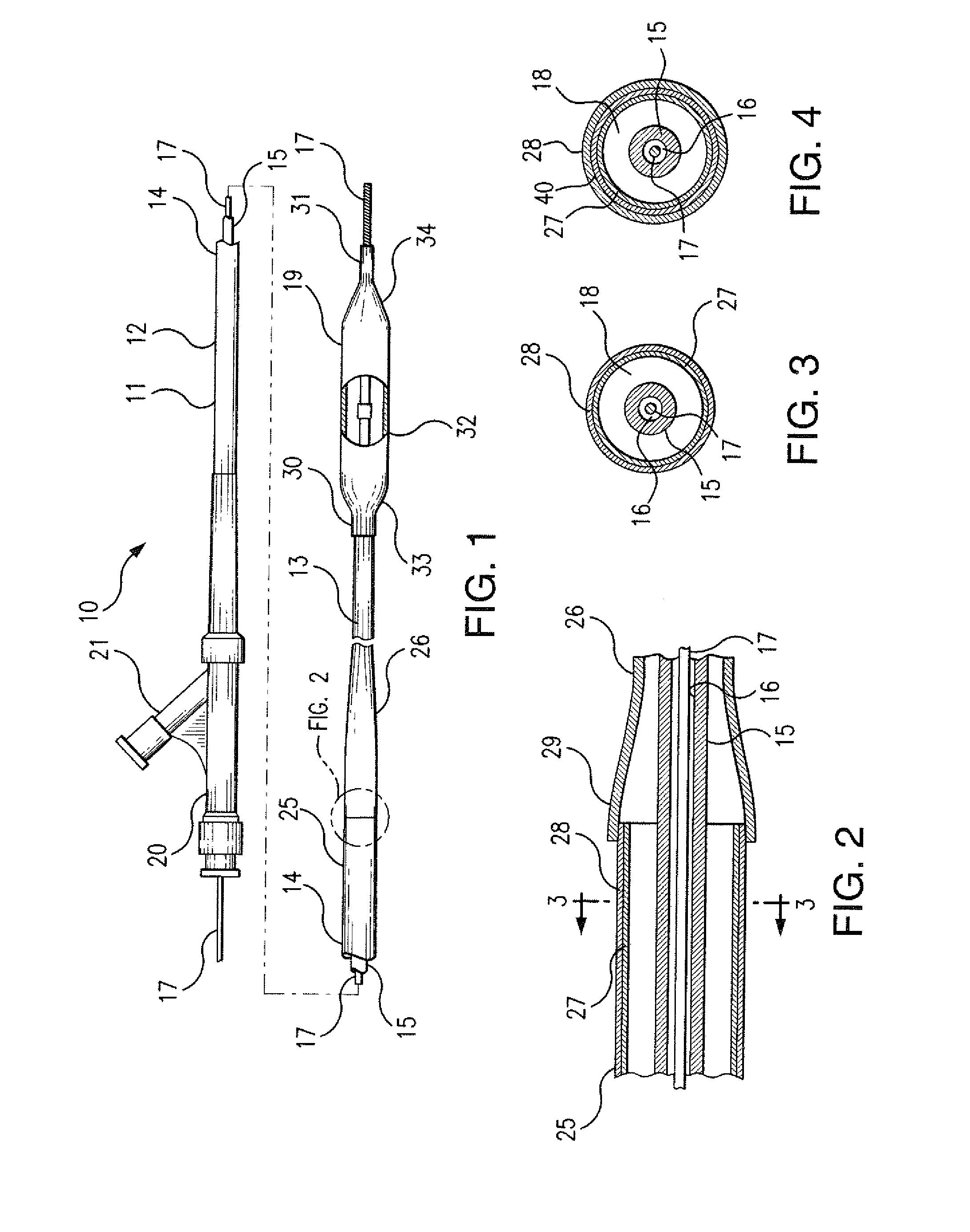

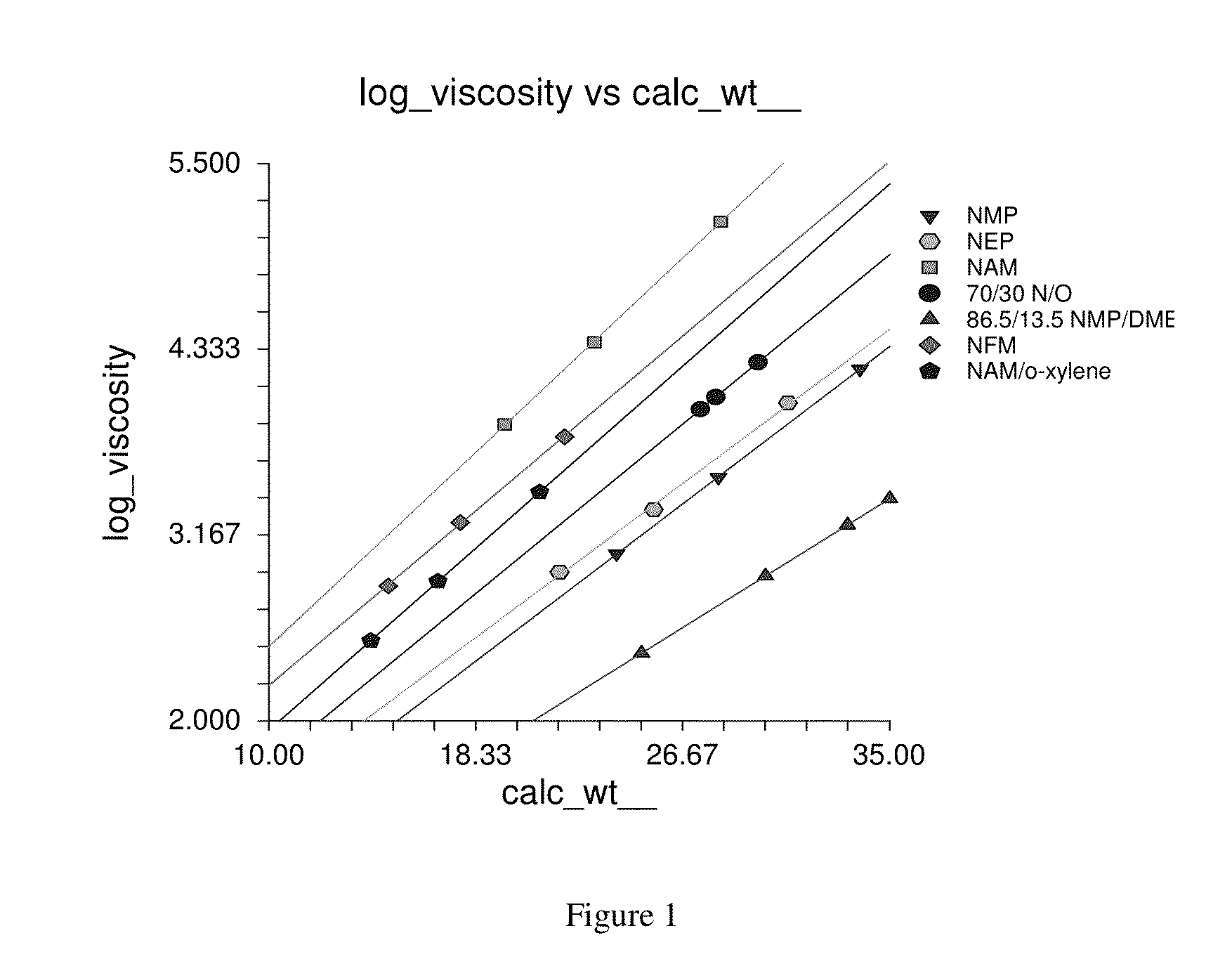

Catheter Shaft and Method of Forming Same

InactiveUS20140276401A1Increase thrustBalloon catheterSurgeryPolytetramethylene terephthalateHeat deflection temperature

Elongate, flexible catheter includes an elongated shaft having a proximal end, a distal end, and a lumen defined therein. The shaft includes a tubular member having an outer layer and an inner layer. The outer layer includes a first polymer selected from the group consisting of nylon 12, polyether block amide, and combinations thereof. The inner layer includes a second polymer having a heat deflection temperature greater than about 53° C. selected from the group consisting of nylon 11, nylon 6, nylon 6,6, nylon 6,12, polyamide-imide, polyetherimide, polypropylene, polyethylene terephthalate, polybutylene terephthalate, polyethereetherketone, and combinations thereof. Method of making an elongate, flexible catheter is also provided.

Owner:ABBOTT CARDIOVASCULAR

Resin composition and adhesive film for multi-layered printed wiring board

ActiveUS20050019554A1High mechanical strengthEasy to manufactureLayered product treatmentAdhesive articlesBenzoxazolePolyetherimide

Resin compositions, which contain: (a) a heat-resistant resin which is soluble in organic solvents wherein the heat-resistant resin is one or more heat-resistant resin(s) selected from the group consisting of a polyimide resin, a polyamide-imide resin, a polyamide resin, a polyether imide resin, a polybenzoxazol resin, a polybenzimidazole resin, copolymers thereof, and mixtures thereof; (b) a thermosetting resin; (c) a filler; and (d) resin having a polybutadiene structure and / or a polysiloxane structure, wherein: the heat-resistant resin (a) and the thermosetting resin (b) are present in a weight ratio of heat-resistant resin (a) to thermosetting resin (b) of from 100:1 to 1:1; the heat-resistant resin (a), thermosetting resin (b), and filler (c) are present in relative amounts such that weight ratio of the total amount of heat-resistant resin (a) and thermosetting resin (b) to filler (c) by weight is from 100:1 to 3:2; the resin having a polybutadiene structure and / or a polysiloxane structure (d) is present in an amount of 0.1 to 15 parts by weight based on 100 parts by weight of the heat-resistant resin (a); and the heat-resistant resin (a), thermosetting resin (b), filler (c), and resin having a polybutadiene structure and / or a polysiloxane structure (d) are present in a total amount of not less than 70% by weight, based on the total weight of the resin composition, are useful for preparing adhesive films, which are, in turn, useful for forming interlayer insulation layers for multi-layered printed wiring boards having an excellent mechanical strength and capable of being roughened by an oxidizing agent.

Owner:AJINOMOTO CO INC

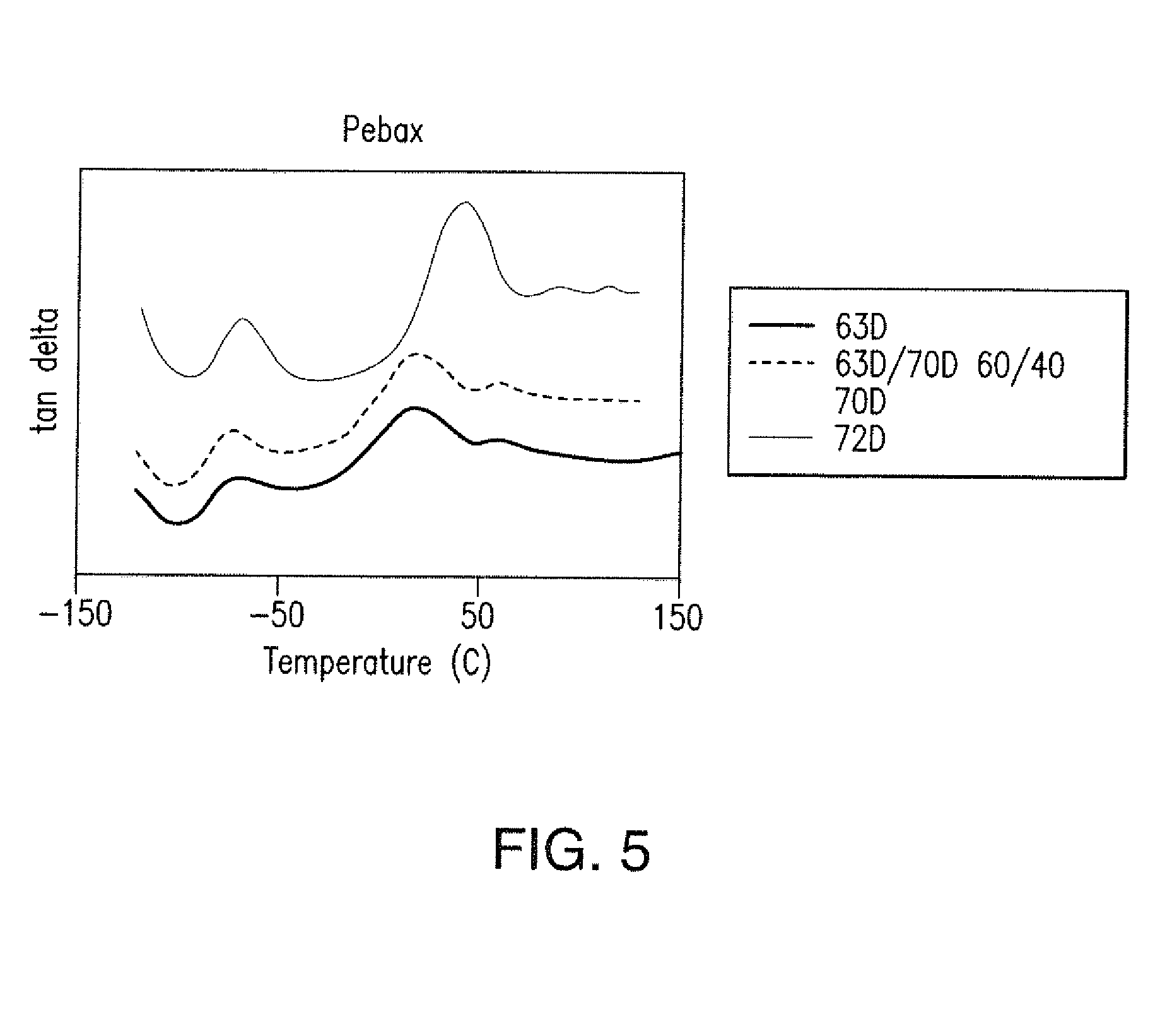

Low Toxicity Solvent System for Polyamideimide and Polyamide Amic Acid Resins and Coating Solutions Thereof

InactiveUS20130217812A1Safer and practical alternativeLow toxicityLiquid carbonaceous fuelsCoatingsPolymer resinPolyamide-imide

Disclosed is a low toxicity aprotic alkyl amide solvent system used for the dissolution and application of polyamideimide and polyamide amic acid polymer resins. The solvent system can be used for the dissolution of polyamideimide and polyamide amic acid resins as an efficient method for incorporating these resins into functional coating compositions with the use of the solvent system.

Owner:CYMER DAYTON LLC

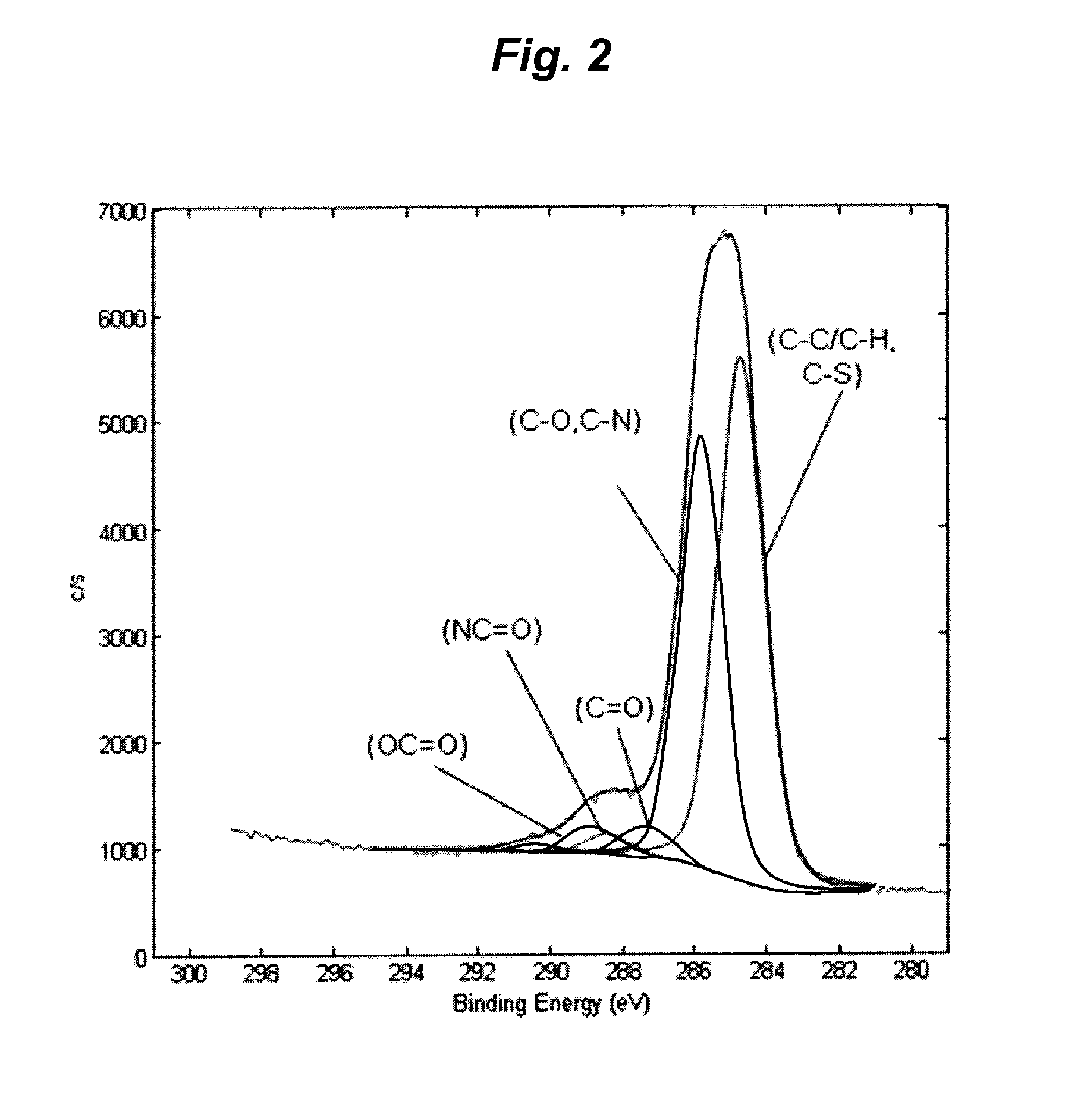

Polyamide-imide resin insulating coating material, insulated wire and method of making the same

ActiveUS20060240255A1Evenly dispersedInhibit aggregationLiquid surface applicatorsInsulatorsPolyamide-imideInsulative paint

A polyamide-imide resin insulating coating material, which is obtained by reacting an isocyanate component with an acid component, has a main solvent component of γ-butyrolactone. In the coating material, a total compounding ratio of 4,4′-diphenylmethane diisocyanate (MDI) and trimellitic anhydride (TMA) is 85 to 98 mol %, where the total compounding ratio is given by averaging a compounding ratio of MDI to the isocyanate component and a compounding ration of TMA to the acid component.

Owner:HITACHI METALS LTD

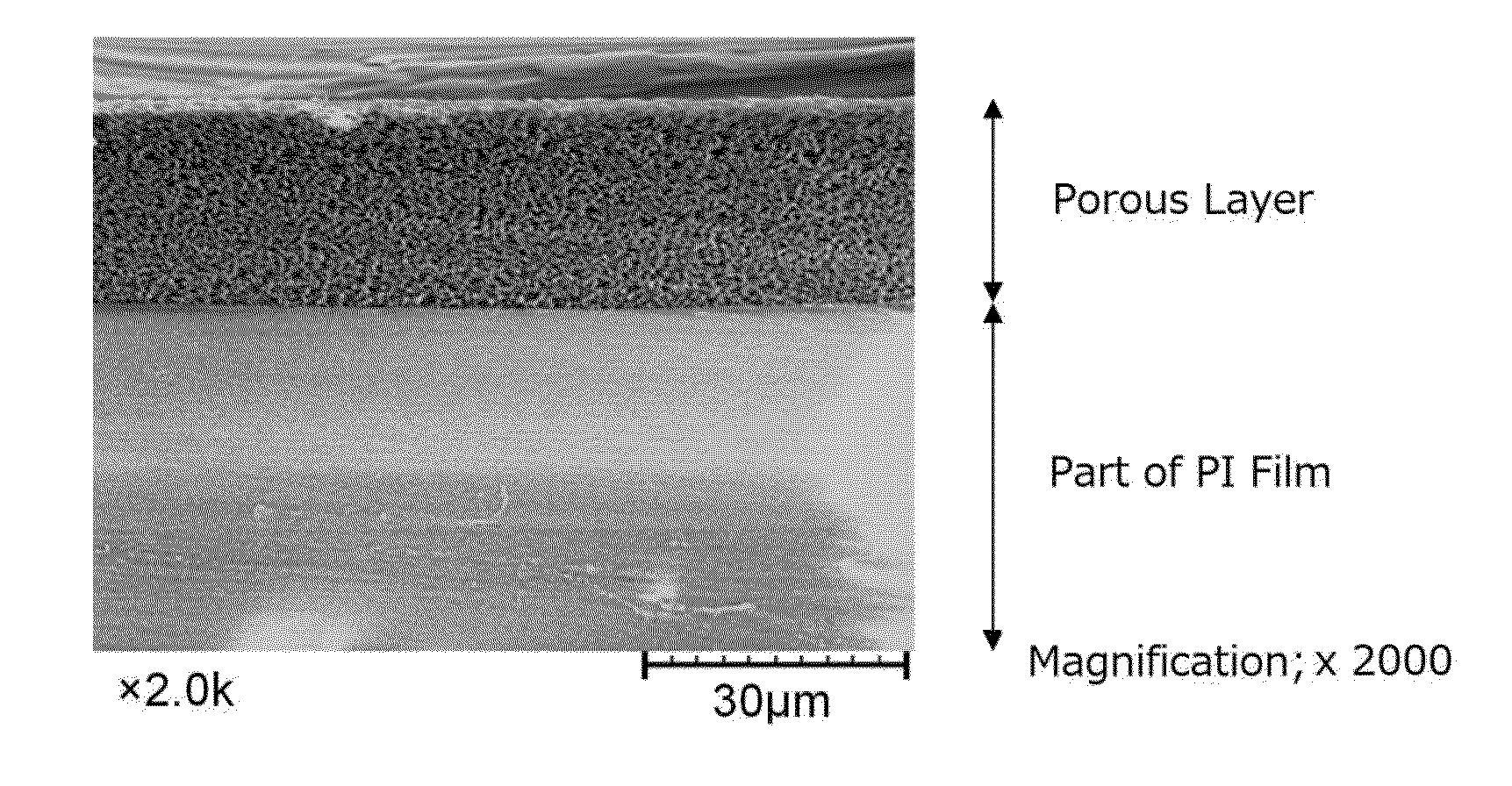

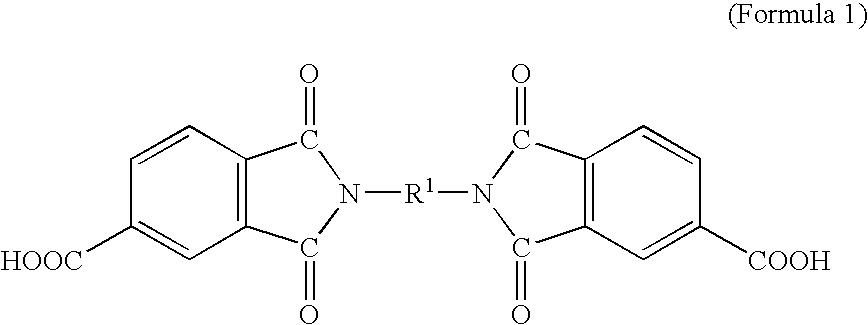

Electrode for nonaqueous secondary battery, nonaqueous secondary battery using the same, and method for producing electrode

InactiveUS20100203392A1Large capacityImprove charge and discharge cycle characteristicsElectrode thermal treatmentNon-aqueous electrolyte accumulator electrodesPorous layerPolyamide-imide

The non aqueous secondary battery electrode of the present invention includes a mixture layer and a porous layer formed on the surface of the mixture layer. The mixture layer includes an electrode material expressed by the composition formula SiOx where x in the composition formula satisfies 0.5≦x≦1.5, a conductive material and at least one binder selected from the group consisting of polyimide, polyamideimide and polyamide. The porous layer includes an insulating material unreactive with Li.

Owner:HITACHI MAXELL ENERGY LTD

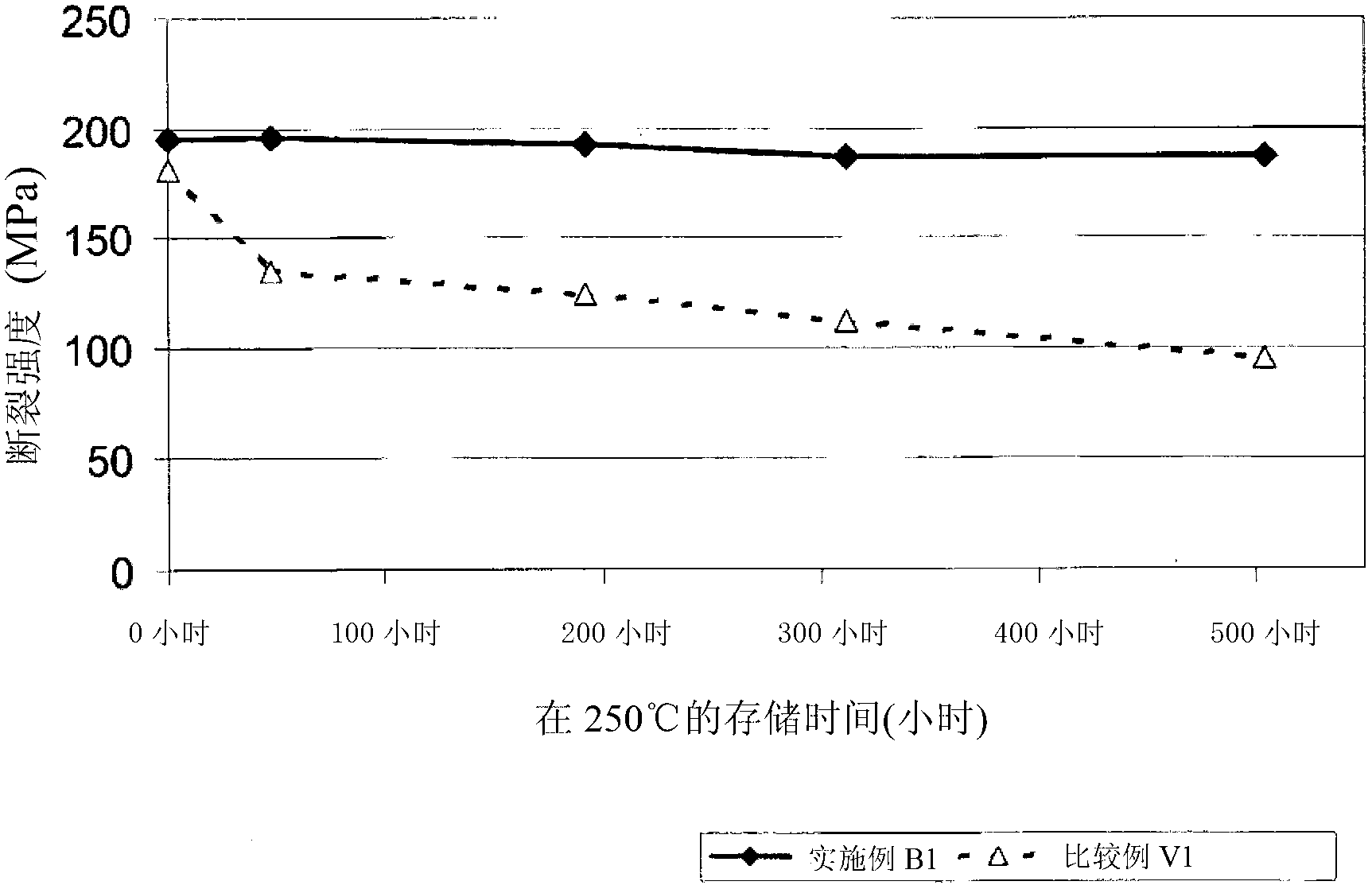

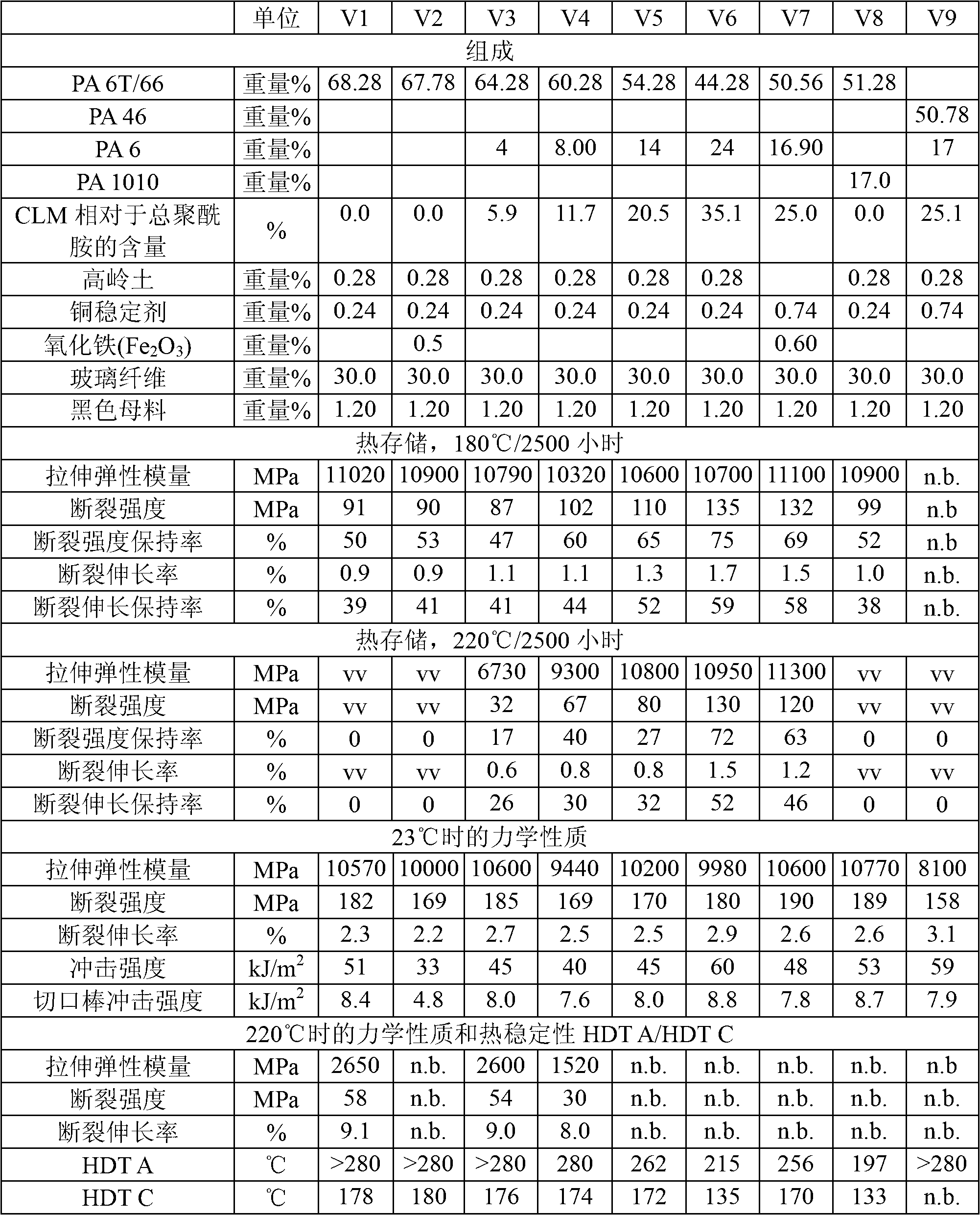

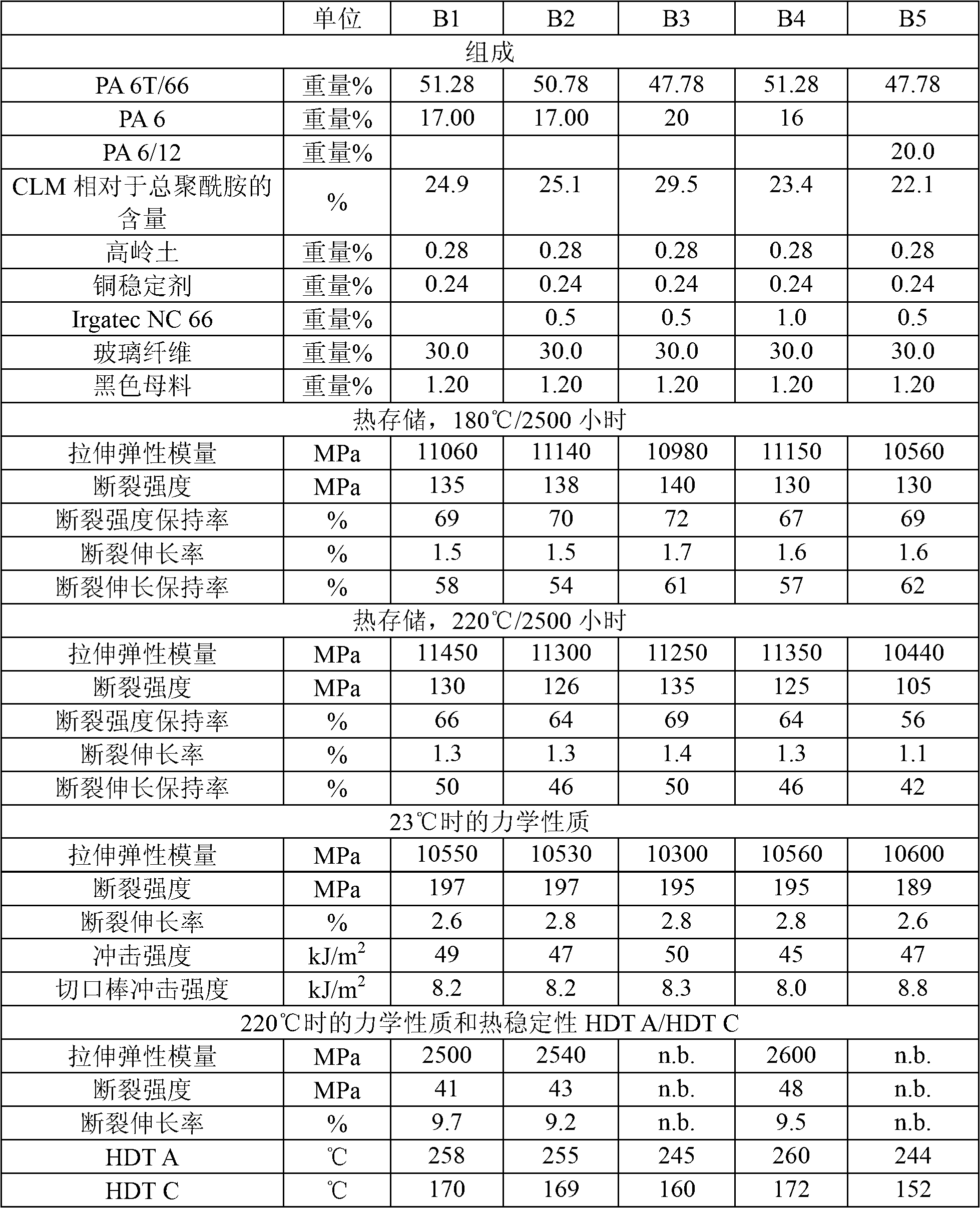

Semiaromatic moulding masses and their applications

The prevent invention provides a polyamide molding plastic and a moulded parts prepared by the polyamide molding plastic. The molding plastic is composed of (A) a polyamide mixture, (B) fillers and reinforcing agents, (C) thermal stabilizers and (D) additives, wherein the sum total of components (A) to (D) is 100 wt %. The polyamide molding plastic is free of transition metal salts and / or metallic oxides of groups VB, VIB, VIIB or VIIIB of the periodic table. The polyamide mixture consists of (A1) a semiaromatic, semicrystalline polyamide having a melting point of 275 DEG C to 330 DEG C, and (A2) a caprolactam-containing polyamide that is different from (A1) and that has a caprolactam content of at least 50 wt %, where the total caprolactam content is 22-30 wt %, with respect to the polyamide mixture.

Owner:EMS PATENT AG

Transparent polyamide-imide resin and film using same

Disclosed are a transparent polyamide-imide resin and a film using the same, which can be colorless and transparent, can show excellent thermal stability and mechanical properties, and can have low birefringence, making it possible to serve in various fields including a semiconductor insulator, a TFT-LCD insulator, a passivation layer, a liquid crystal alignment layer, materials for optical communication, a protective film for a solar cell, a flexible display substrate and the like.

Owner:KOLON IND INC

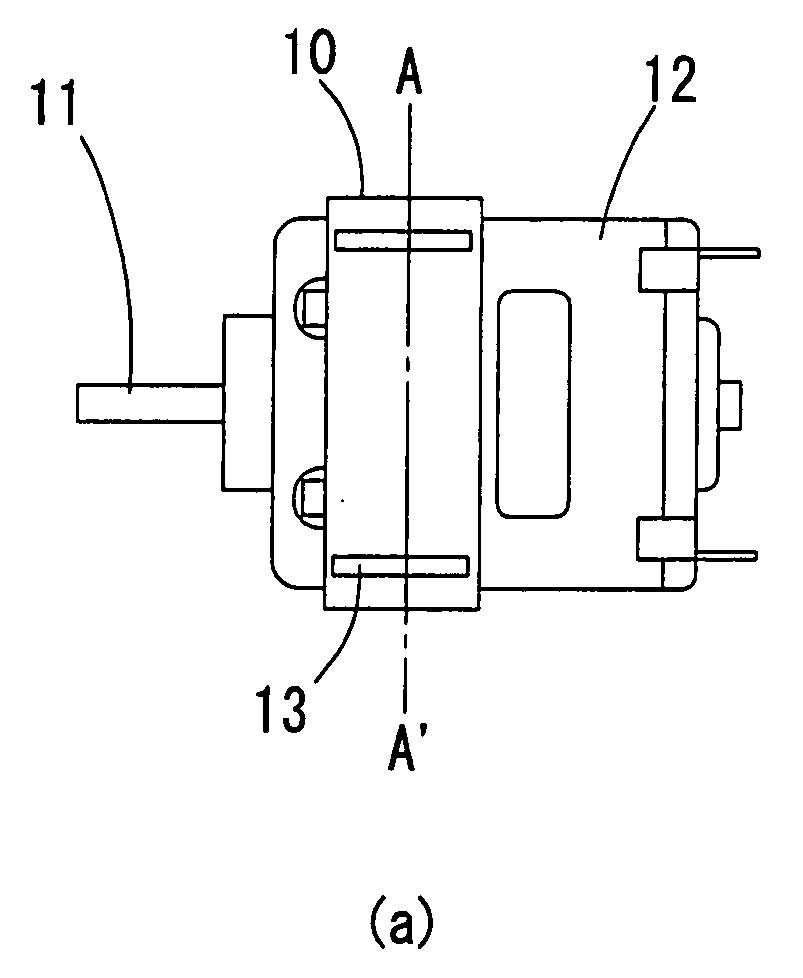

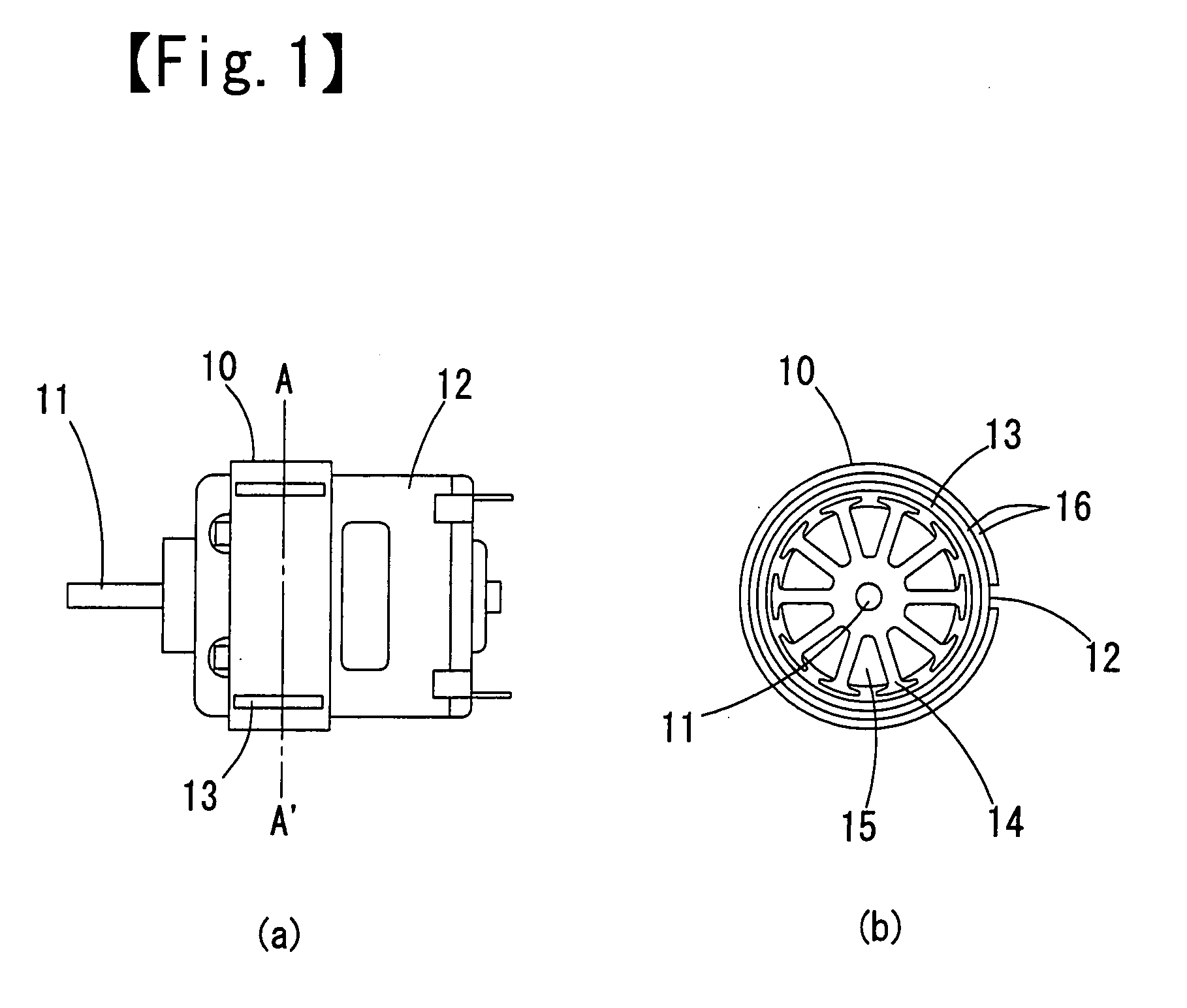

Permanent Magnet For Motor, Motor Housing, and Motor Device

InactiveUS20080124235A1Low densityControl thicknessCircumferential flow pumpsTransverse flow pumpsEpoxyMetallurgy

[Object] To improve resistance of a motor device against an organic solvent and to suppress degradation in performance of the motor device with time.[Solving Means] In a motor device, an excitation magnet is formed using a hollow-cylinder shaped anisotropic bonded magnet 13. This bonded magnet 13 is press-fitted in a housing 12 and is held. The bonded magnet 13 is formed of a hollow-cylinder shaped anisotropic rare earth bonded magnet which is obtained by compounding an anisotropic rare earth magnet powder with a phenol-novolac type epoxy resin, followed by molding. The anisotropic rare earth bonded magnet 13 is press-fitted along an inner peripheral portion of the housing 12, and on an exposed surface layer of the anisotropic rare earth bonded magnet press-fitted in the housing, a coating layer is formed by an infiltration treatment using a polyamide-imide-based resin.

Owner:AICHI STEEL

Anticorrosion coating composition, an anticorrosion film and an anticorrosive article

A coating composition, an anticorrosion film formed by the composition, as well as an anticorrosive article, are disclosed. The coating composition comprises 1-35% by weight of one or more fluoropolymer; 1-70% by weight of one or more epoxy resin; 5-70% by weight of one or more polyamideimide; 0-40% by weight an auxiliary binder consisting of one or more of polyethersulfone, polyphenylene sulfide, polyamide, polyimide, polyether ether ketone, polyetherimide, polyurethane, alkyd resin, polyester, or acrylic polymers; and, based on 100 parts by weight of the above components, 100-400 parts by weight of solvent.

Owner:THE CHEMOURS CO FC LLC

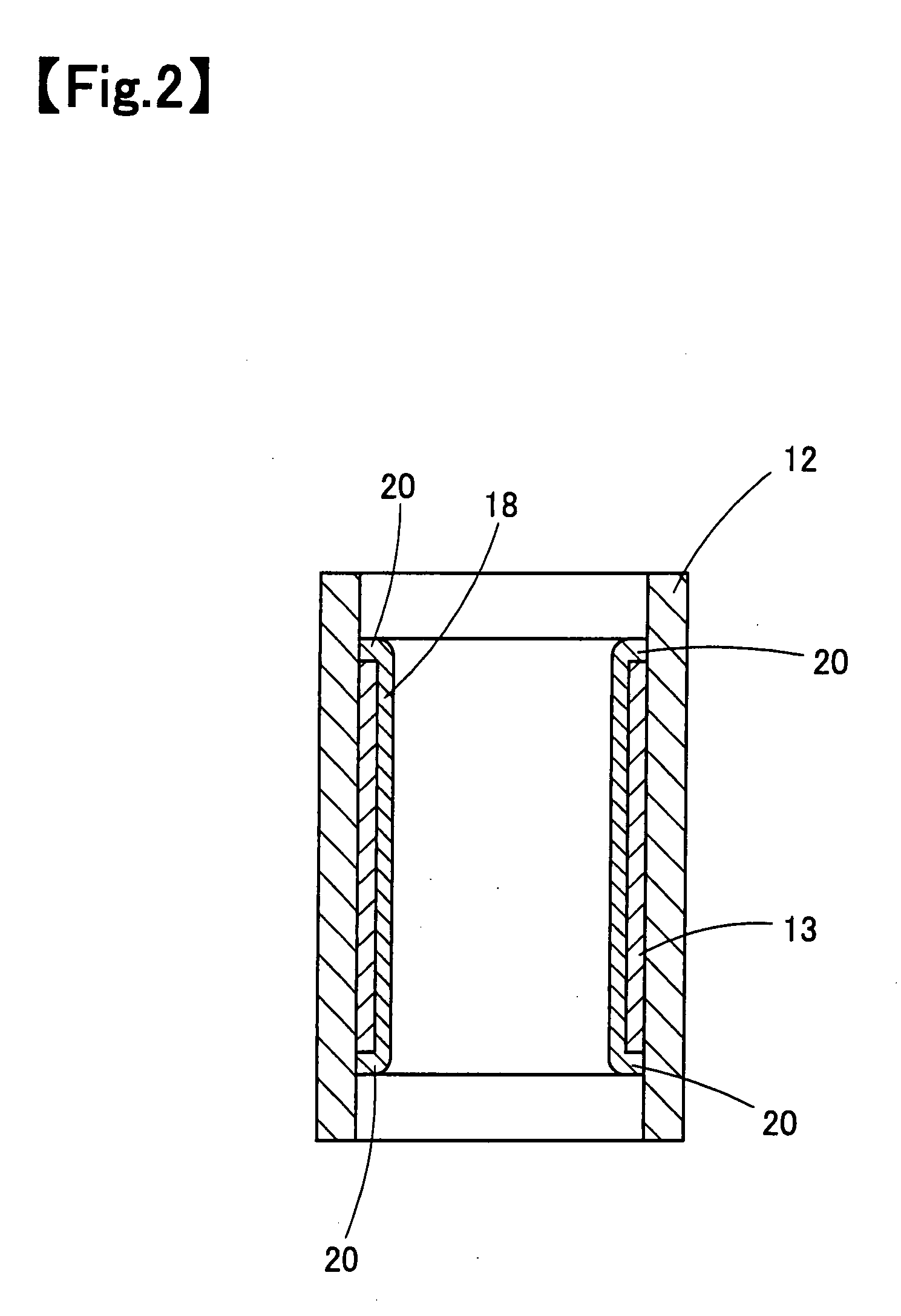

Laminated body comprising porous layer and functional laminate using same

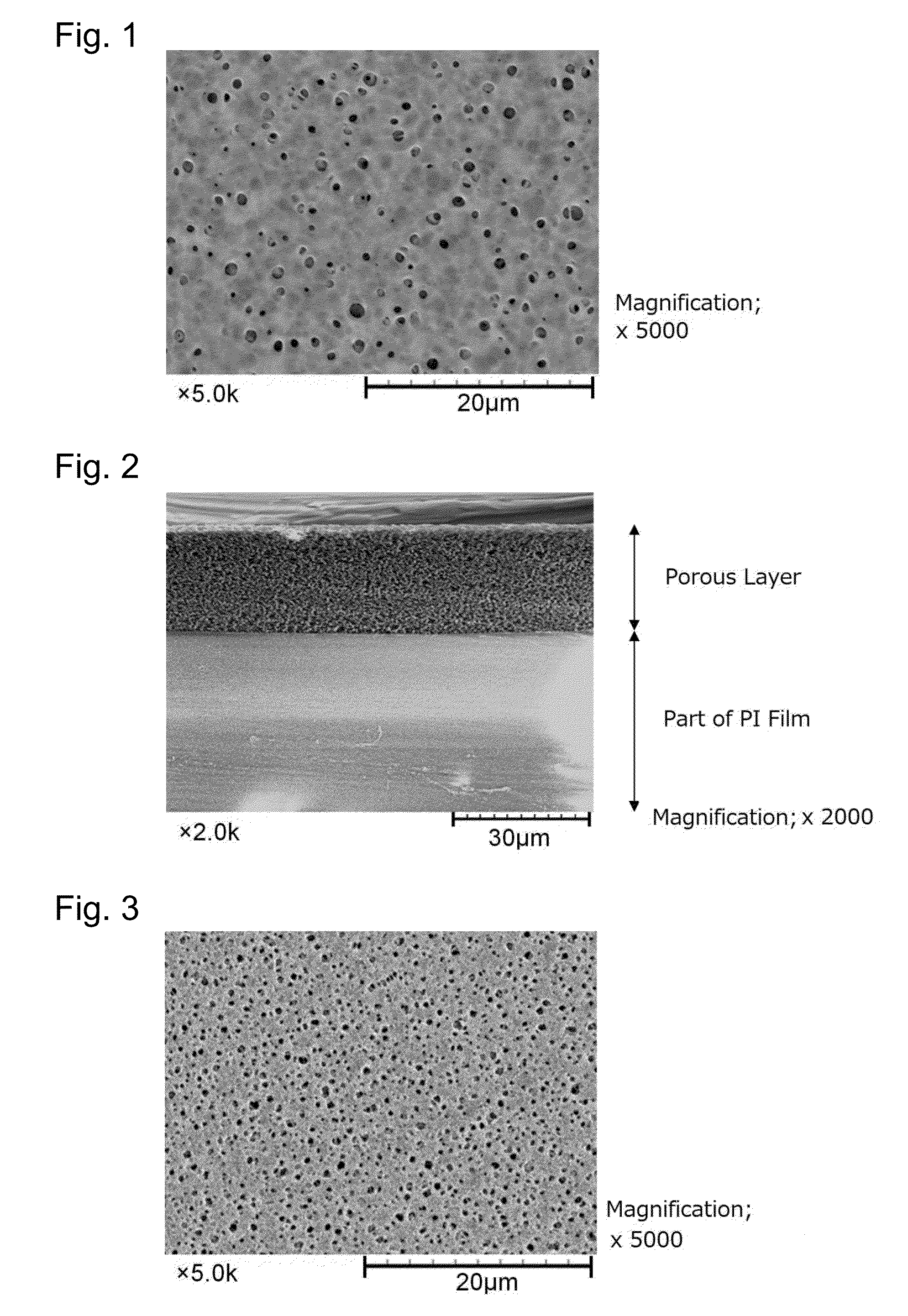

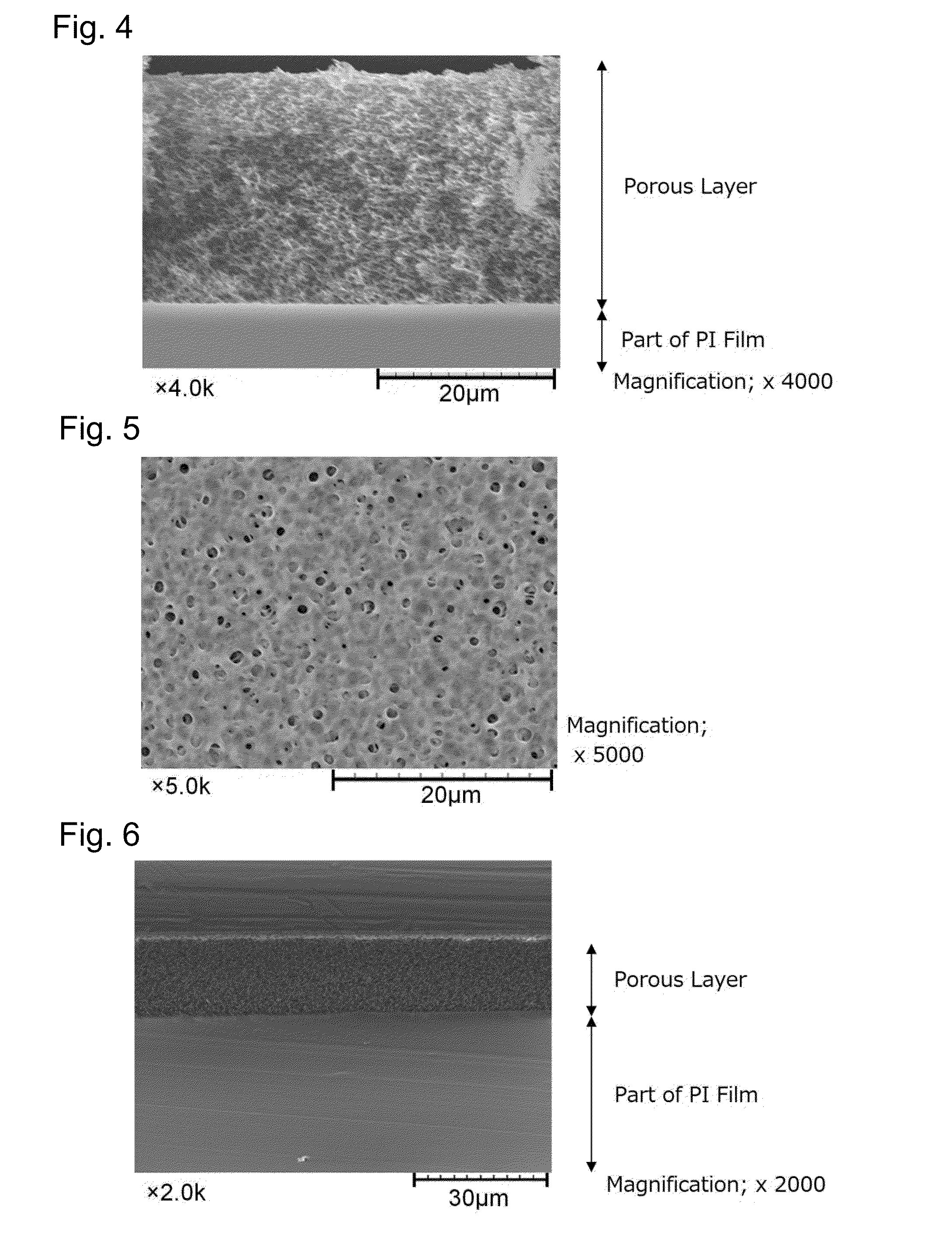

InactiveUS20130020117A1Good flexibilityHigh strengthSynthetic resin layered productsPretreated surfacesPolyetherimideMetal foil

A layered body which includes a porous layer. The layered body having improved properties, such as adhesion between its substrate and its porous layer by the formation of a crosslinked structure; a functional laminate using the porous layer layered body; and a production processes thereof. The layered body includes a base and the porous layer on at least one surface of the base. The base is a resin film made of at least one resin material of polyimide resins, polyamideimide resins, polyamide resins, and polyetherimide resins, or is a metal foil piece, and the porous layer is made of a composition containing at least one polymer of polyimide resins, polyamideimide resins, polyamide resins, and polyetherimide resins as a main component, and a crosslinking agent. Additionally, the porous layer has fine pores having an average pore diameter of 0.01 to 10 μm, and a porosity of 30 to 85%.

Owner:DAICEL CHEM IND LTD

Flame-retardant heat-resistant resin composition and adhesive film comprising the same

InactiveUS20050054776A1Superior thermal-stress-reducing effectEasy to useInsulating substrate metal adhesion improvementFilm/foil adhesives without carriersPhosphorPolyamide-imide

Owner:HITACHI CHEM CO LTD

Water-based solid lubricant

InactiveCN101768500AReduce coefficient of frictionIncrease frictionAdditivesWater basedOrganic solvent

The invention aims to provide a water-based dispersoid solid lubricant material and the preparation method thereof; wherein, the water-based dispersoid solid lubrication material can be used as solid lubrication material, has good filming and adhesive properties, anticorrosion and wear resistance, and adopts polyamide imide and PTFE as main adhesive material; the water-based solid lubricant is environmental protection, anticorrosive and wear resistant, has low friction coefficient and good high and low temperature resistance, overcomes the problems that the organic solvent of solid lubrication material in prior art has greater toxicity, easy volatilization and is not wear resistant so that the water-based solid lubricant has good application prospect.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

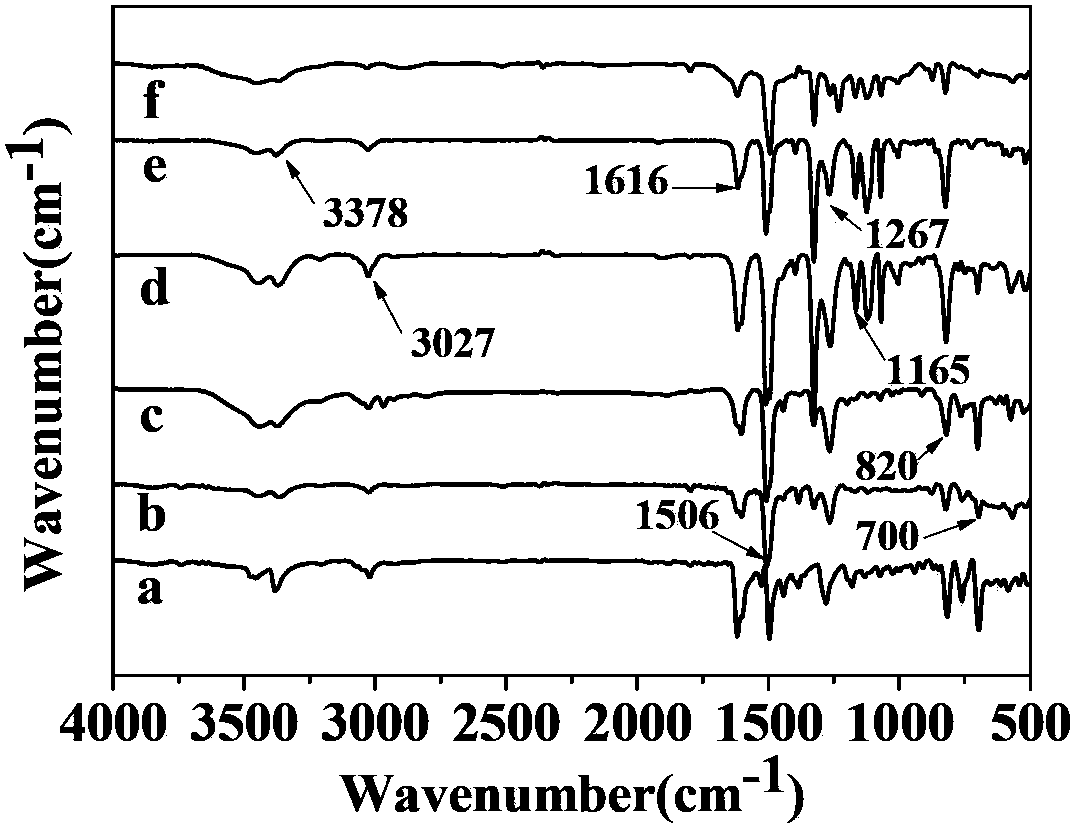

Insulating varnish and insulated wire formed by using the same

InactiveUS20110290528A1Improve compatibilityHigh partial discharge inception voltagePlastic/resin/waxes insulatorsInsulated cablesPolyamide-imideVarnish

An insulating varnish includes a polyamide-imide resin varnish including a solvent and a polyamide-imide resin, and an organosol. The polyamide-imide resin varnish is obtained by a synthesis reaction between a resin component (X) and an isocyanate component (Y). The resin component (X) is obtained by a synthesis reaction between a diamine component and an acid component in presence of an azeotropic medium. The diamine component includes aromatic diamines including a divalent aromatic group having three or more aromatic rings. The isocyanate component (Y) includes a diisocyanate (Y1) a molecule of which includes a bend structure.

Owner:HITACHI CABLE

Electrode binder for secondary battery and secondary battery using the same

InactiveUS20100323242A1Improve cohesionInhibiting separation of electrodeConductive materialElectrode carriers/collectorsElectrical batteryPolyvinyl alcohol

Disclosed is an electrode binder for a secondary battery, an electrode including the electrode binder, and the secondary battery. The disclosed electrode binder for the secondary battery includes a polymer whose cohesion force with a metal (loid) electrode active material is equal to or more than 100 gf / cm, and adhesion force with an electrode current collector ranges from 0.1 gf / mm to 70 gf / mm, the metal (loid) electrode active material being capable of reversibly storing and discharging lithium, wherein the polymer includes at least one kind selected from the group including polyamide imide, polyamide, polyacrylonitrile, polyacrylic acid and polyvinyl alcohol.

Owner:LG CHEM LTD

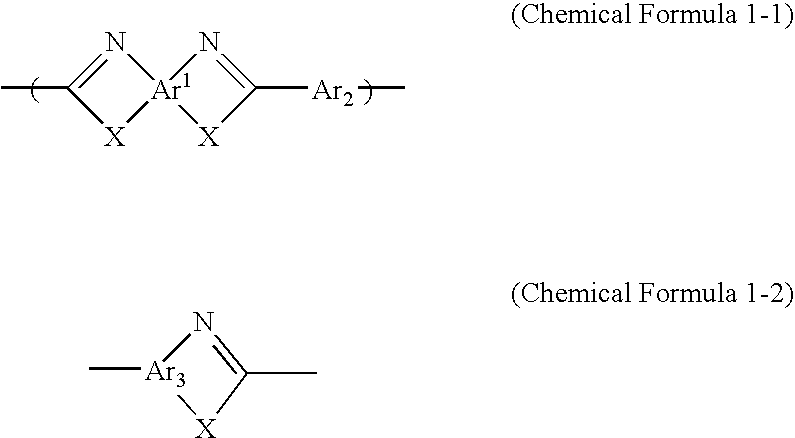

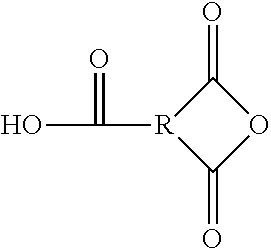

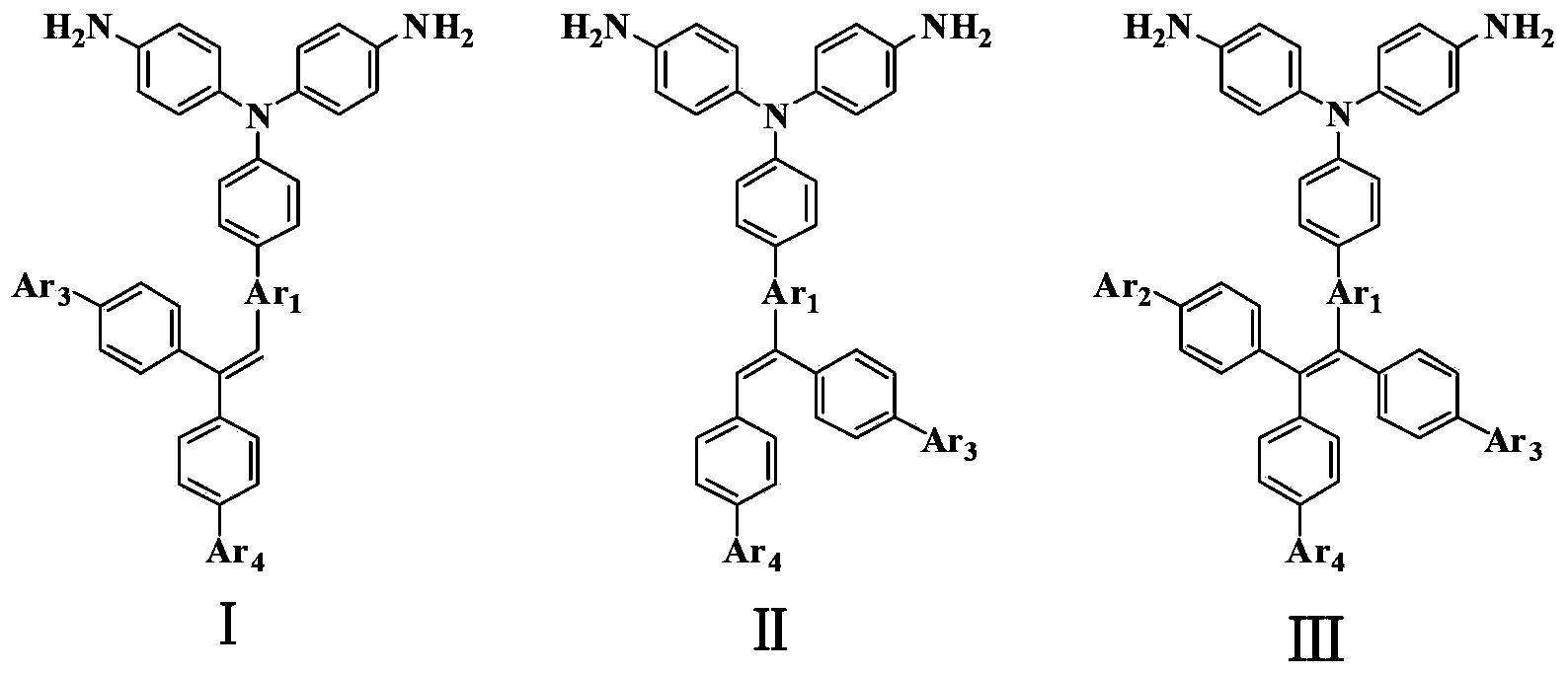

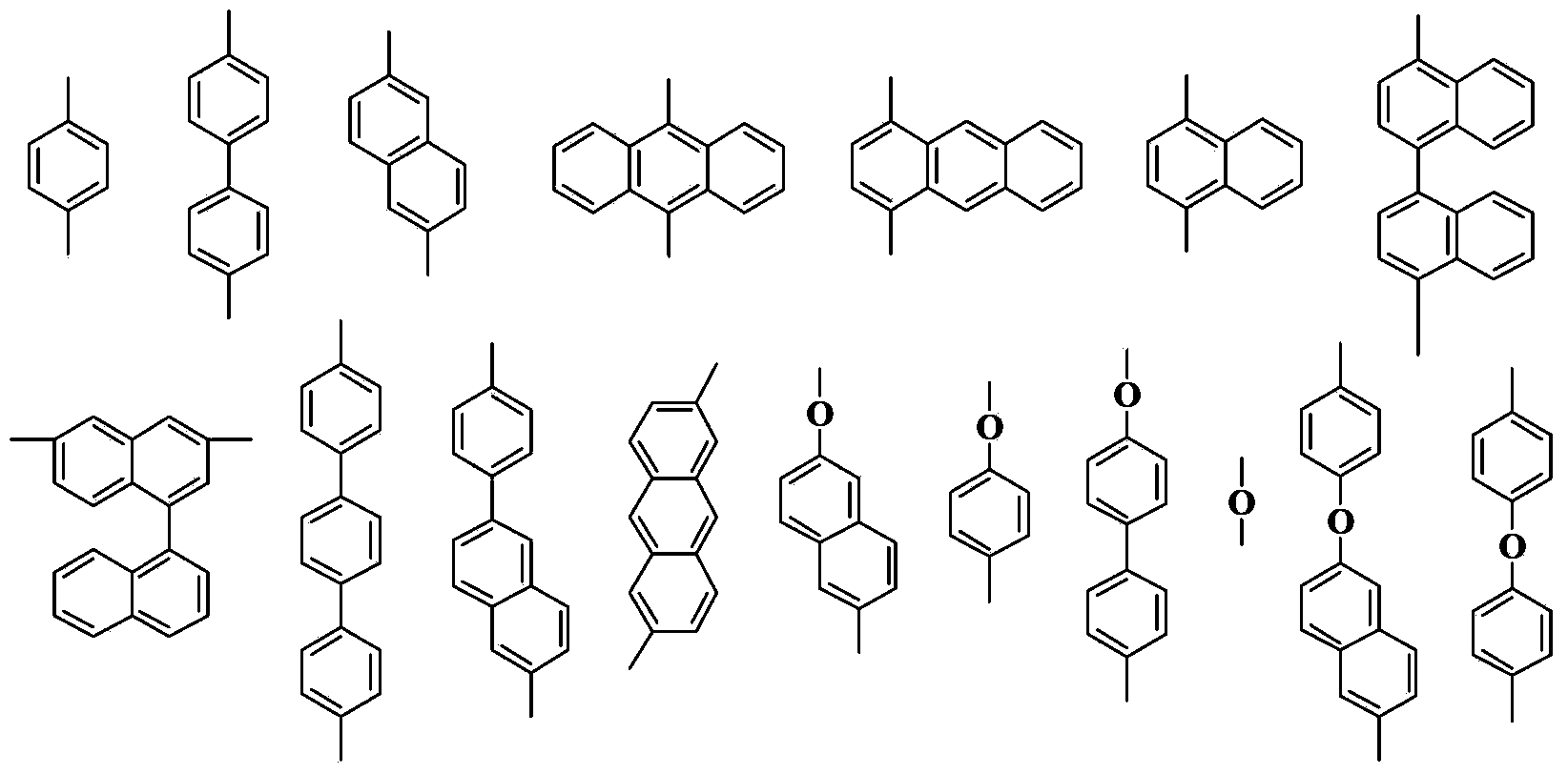

Novel diamine compound, and preparation method and application thereof

ActiveCN104341311AThe synthesis process is simpleEasy to purifyAmino preparation from aminesOrganic compound preparationSynthesis methodsNitrobenzene

The invention discloses a novel diamine compound, and a preparation method and an application thereof. The preparation method of the novel functional diamine compound comprises the following steps: a large conjugate structure comprising benzophenone carbonyl group is obtained; the ketone carbonyl group is subjected to a Wittig or Wittig-Horner reaction, such that a large conjugate system with a triphenylethylene / tetraphenylethylene structure and comprising a halogen atom is obtained; the halogen atom is further subjected to a Suzuki reaction or a plurality steps of reactions, such that a monoamine compound comprising a triphenylethylene / tetraphenylethylene large conjugate system is obtained; the monoamine compound is subjected to a reaction with halogenated nitrobenzene, such that a dinitro monomer comprising triphenylamine and the triphenylethylene / tetraphenylethylene large conjugate system is obtained; and the dinitro monomer is reduced into the novel diamine compound, such that the novel functional diamine compound comprising triphenylamine and a triphenylethylene / tetraphenylethylene structure is obtained. The synthesis method provided by the invention is simple. Purification is easy. The method is suitable for industrial productions. The synthesized diamine compound has a significant aggregation-induced emission property, and can be used for synthesizing high-performance and functional polymers such as polyamide, polyimide, polyamideimide, polyesterimide, and the like.

Owner:SUN YAT SEN UNIV

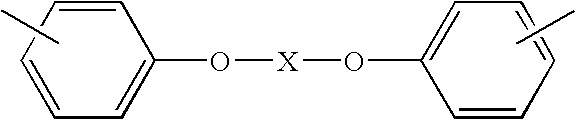

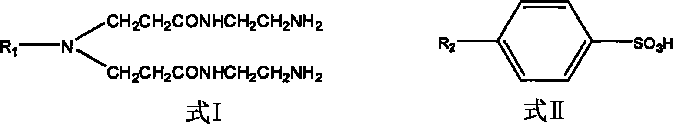

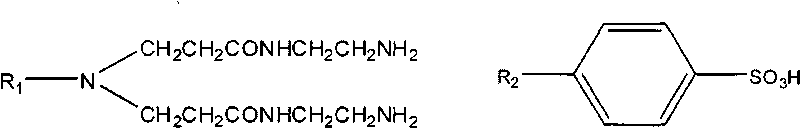

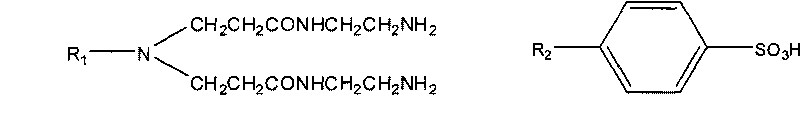

Reversed phase emulsion splitter and preparation method thereof

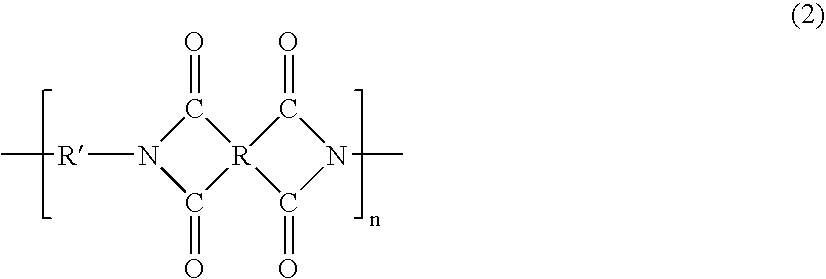

InactiveCN101716475AImprove abilitiesGood viscosity reduction effectTransportation and packagingMixingEmulsionPolyamide-imide

The invention provides a reversed phase emulsion splitter, which is a product of the combination of long-chain alkyl 1.0G polyamide-imide and long-chain alkyl benzenesulfonic acid in a solvent, wherein the long-chain alkyl 1.0G polyamide-imide is a compound of a general structural formula I and the long-chain alkyl benzenesulfonic acid is a compound of a general structural formula II; in the formula I, R1 is an alkyl of which the main chain has 6 to 28 carbon atoms; and in the formula II, R2 is an alkyl of which the main chain has 6 to 24 carbon atoms. The reversed phase emulsion splitter has high emulsion splitting performance for O / W type emulsions and can be used in the field of the low-temperature dehydration of reversed phase emulsions and the treatment of oil-containing waste water.

Owner:INST OF CHEM CHINESE ACAD OF SCI

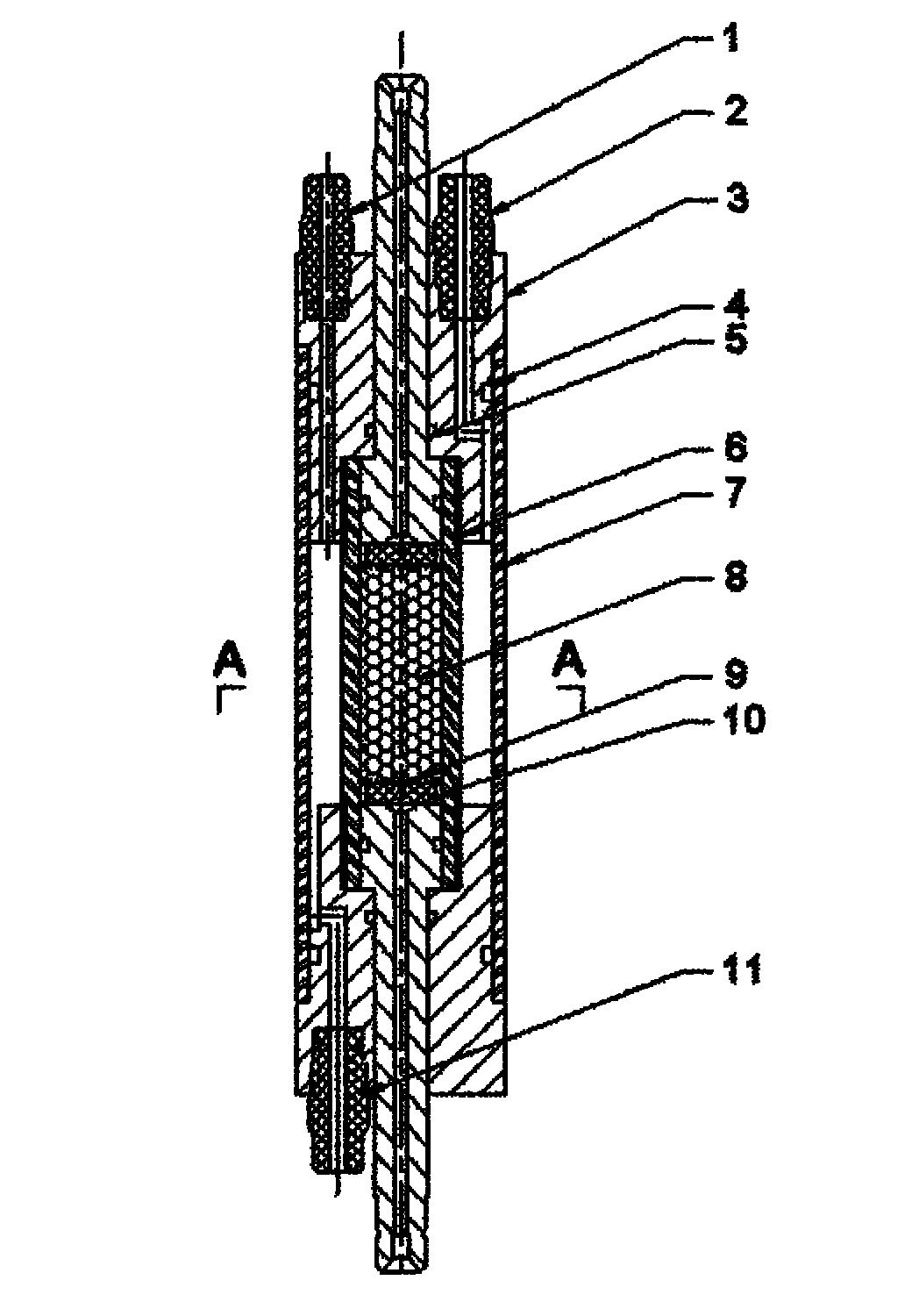

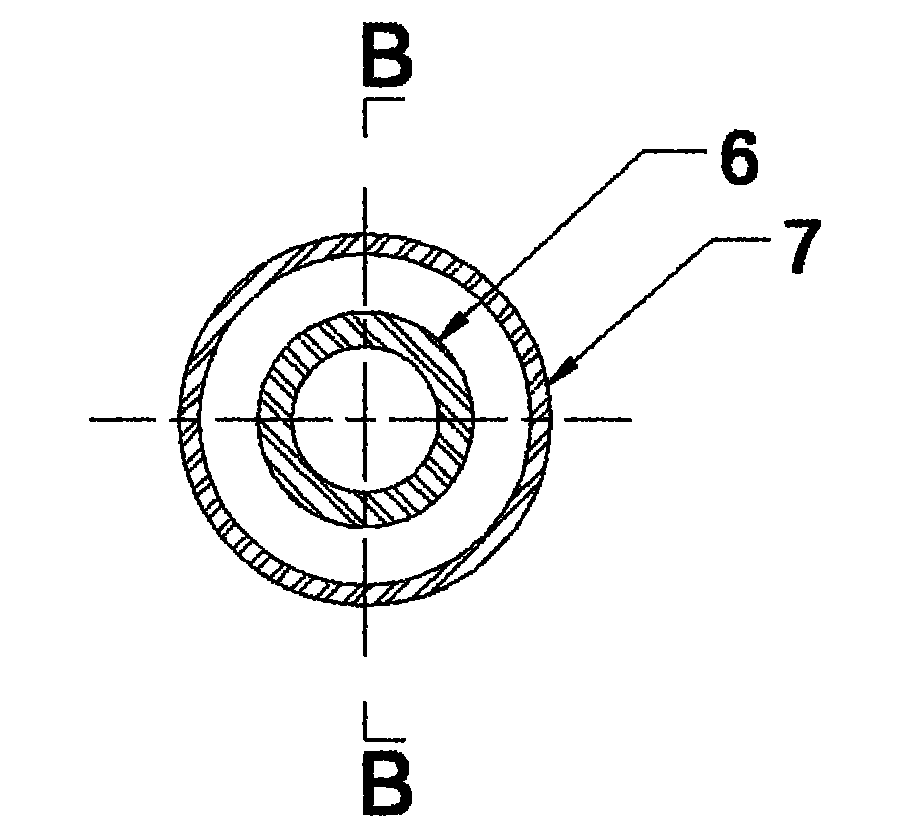

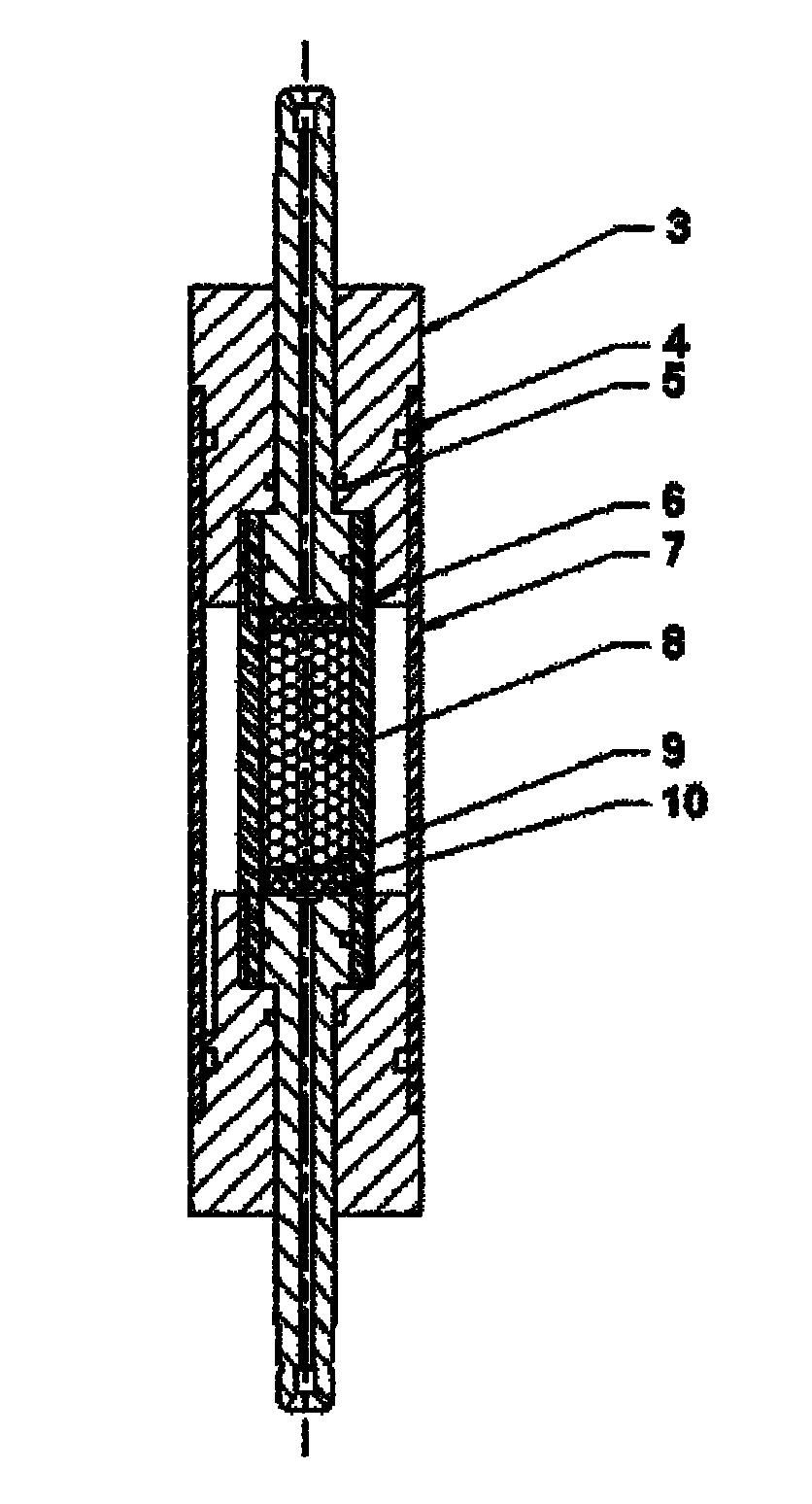

Sand-filling type clamp fastener for nuclear magnetic resonance imaging

InactiveCN102062742AEasy to meet high temperature and high pressure requirementsCompact designAnalysis using nuclear magnetic resonancePermeability/surface area analysisMicro imagingImide

The invention relates to a sand-filling type clamp fastener for nuclear magnetic resonance imaging, which belongs to the technical field of scientific research apparatuses for petroleum. The sand-filling type clamp fastener is vertically inserted into a micro-imaging probe of a nuclear magnetic resonance imager, the design pressure is 0-15MPa, and the design temperature is 0-70 DEG C. The sand-filling type clamp fastener can be used for carrying out indoor experiment research on the seepage and transport properties of a multi-phase multi-component fluid in an analog core. Besides a seal ring, all components of the sand-filling type clamp fastener are made from a polyamide-imide material which does not have magnetism, meets the high-temperature high-pressure requirements and has no effect on nuclear magnetic signals. The sand-filling type clamp fastener has the advantages of compact design structure, multiple times of filling, repeatability of use, convenience of operation in an experiment process, simplicity and applicability.

Owner:DALIAN UNIV OF TECH

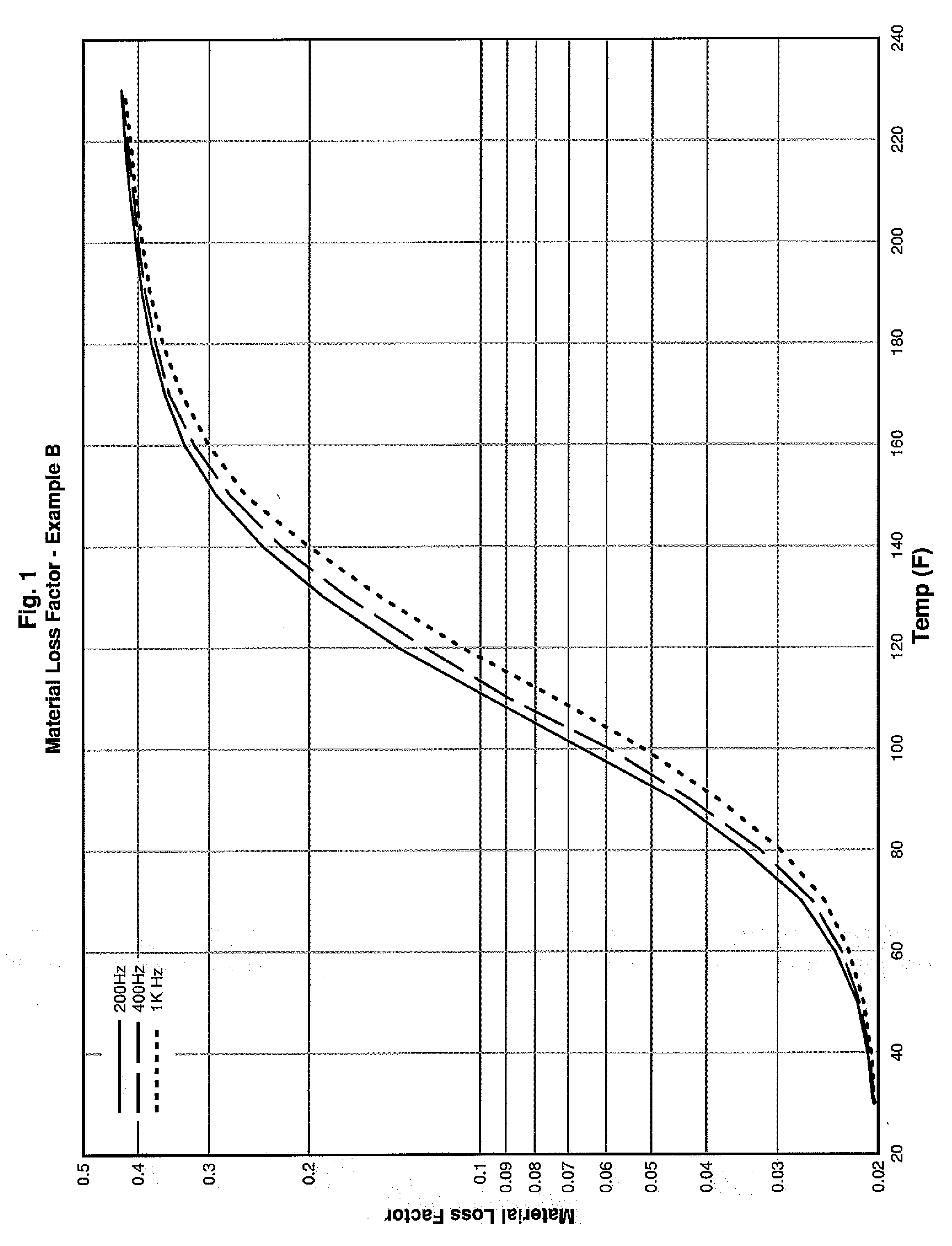

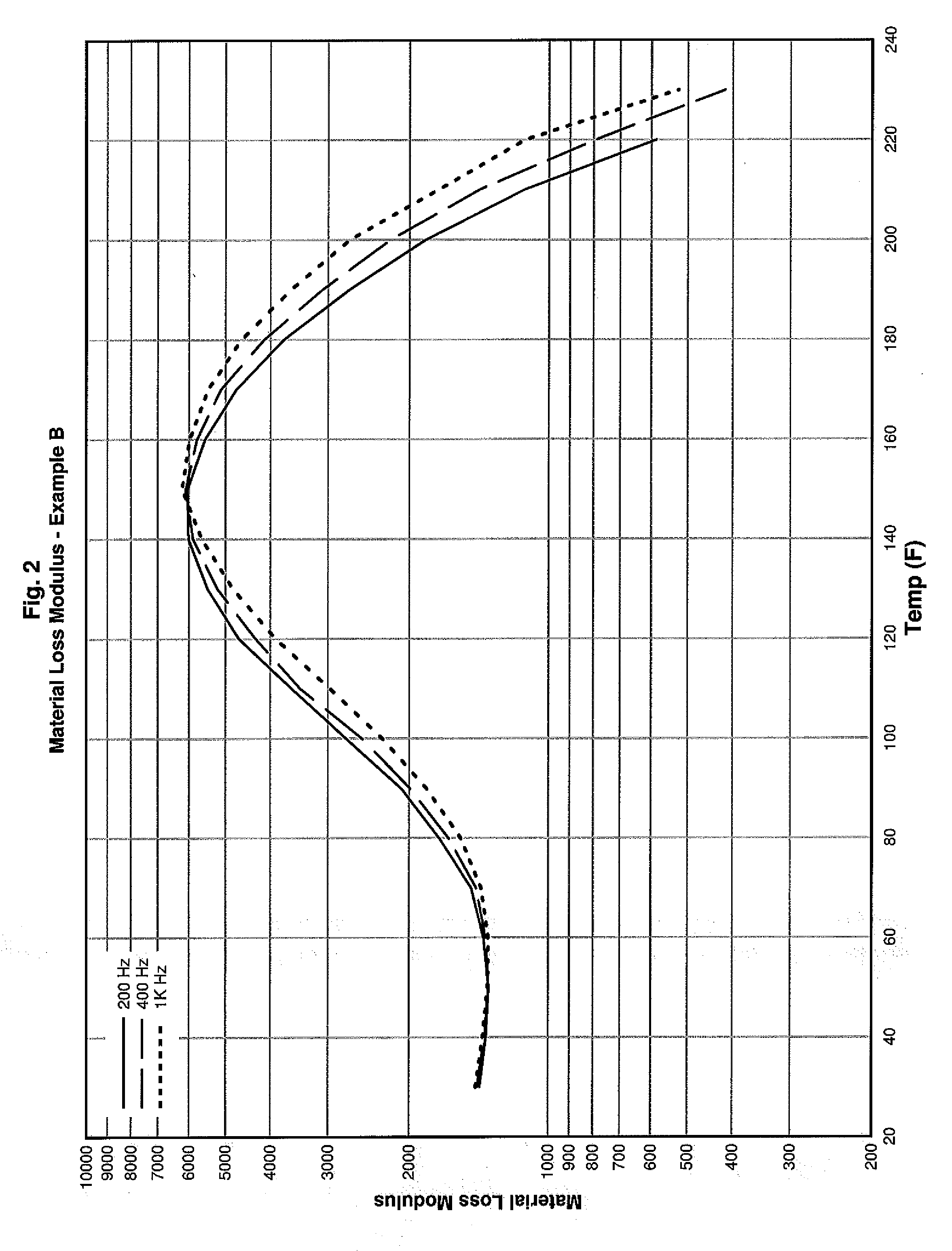

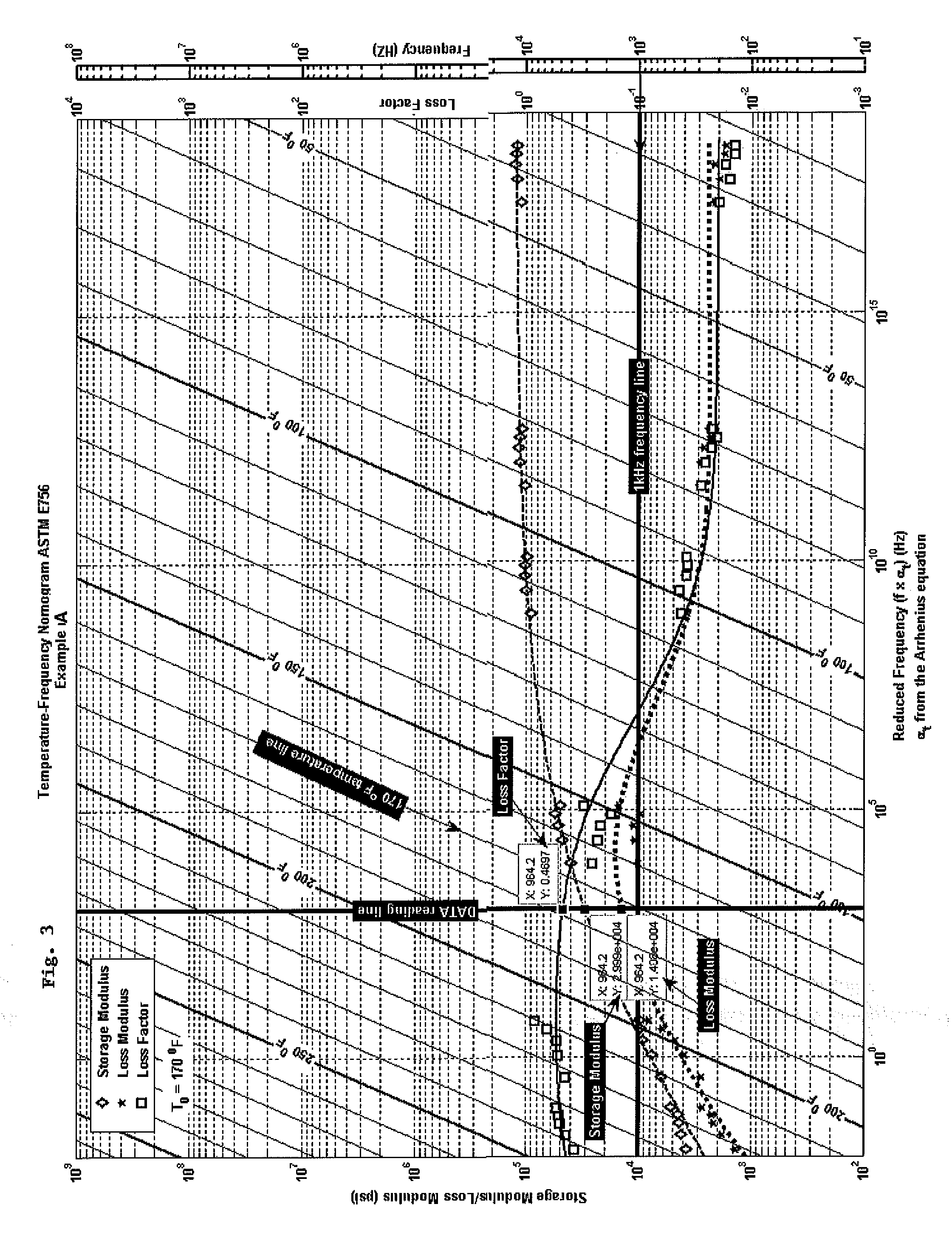

Coated articles demonstrating heat reduction and noise reduction properties

Coated articles are provided comprising:(a) a substrate having two opposing surfaces;(b) a first curable film-forming composition applied to one surface of the substrate, the first curable film-forming composition comprising:(i) a resinous binder comprising a polyepoxide, a polyamideimide, a polyimide, and / or a polysiloxane;(ii) optionally, a curing agent having functional groups reactive with functional groups on the resinous binder in (a); and(iii) a metallic reflective pigment; and(c) a second curable film-forming composition applied to the opposing surface of the substrate, the second curable film-forming composition comprising:(i) a polyepoxide containing at least two epoxide groups per molecule;(ii) a thermoplastic polyester polymer;(iii) a curing agent having functional groups reactive with the epoxide groups in (c)(i);(iv) a mineral filler; and(v) microspheres comprising expandable microspheres and / or hollow microspheres.Coated articles provide heat reflection, heat insulation, vibration damping, and sound absorption.

Owner:PPG IND OHIO INC

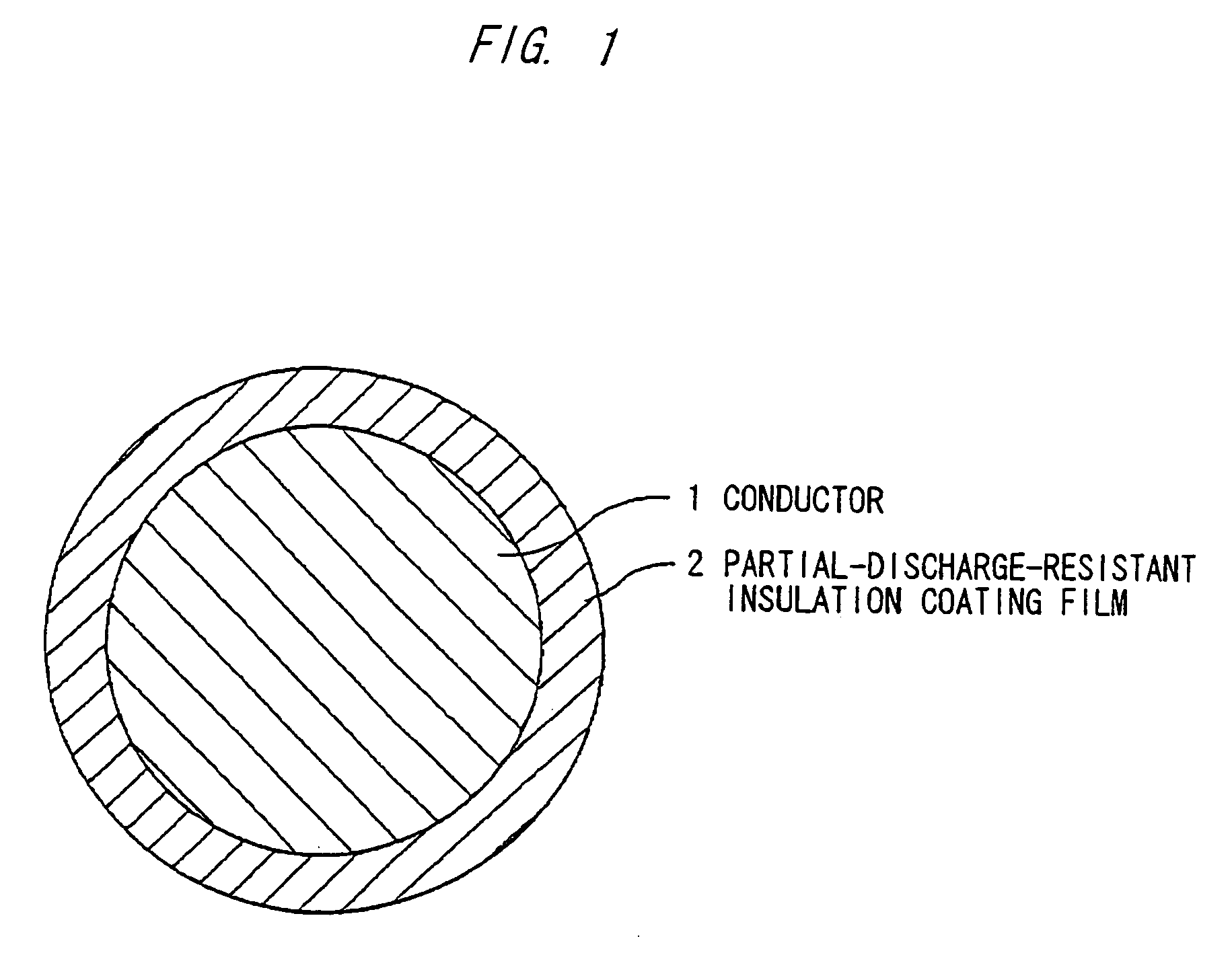

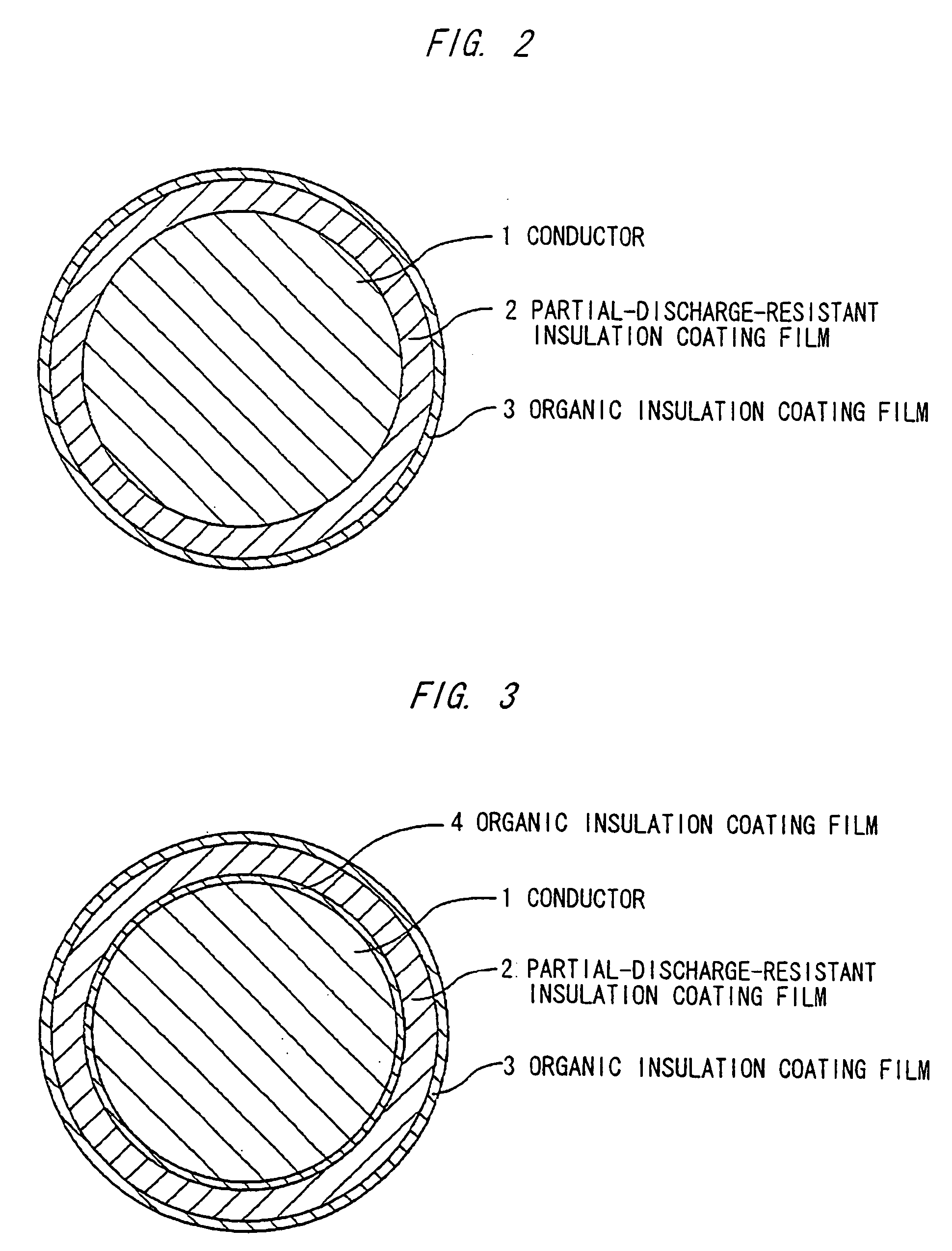

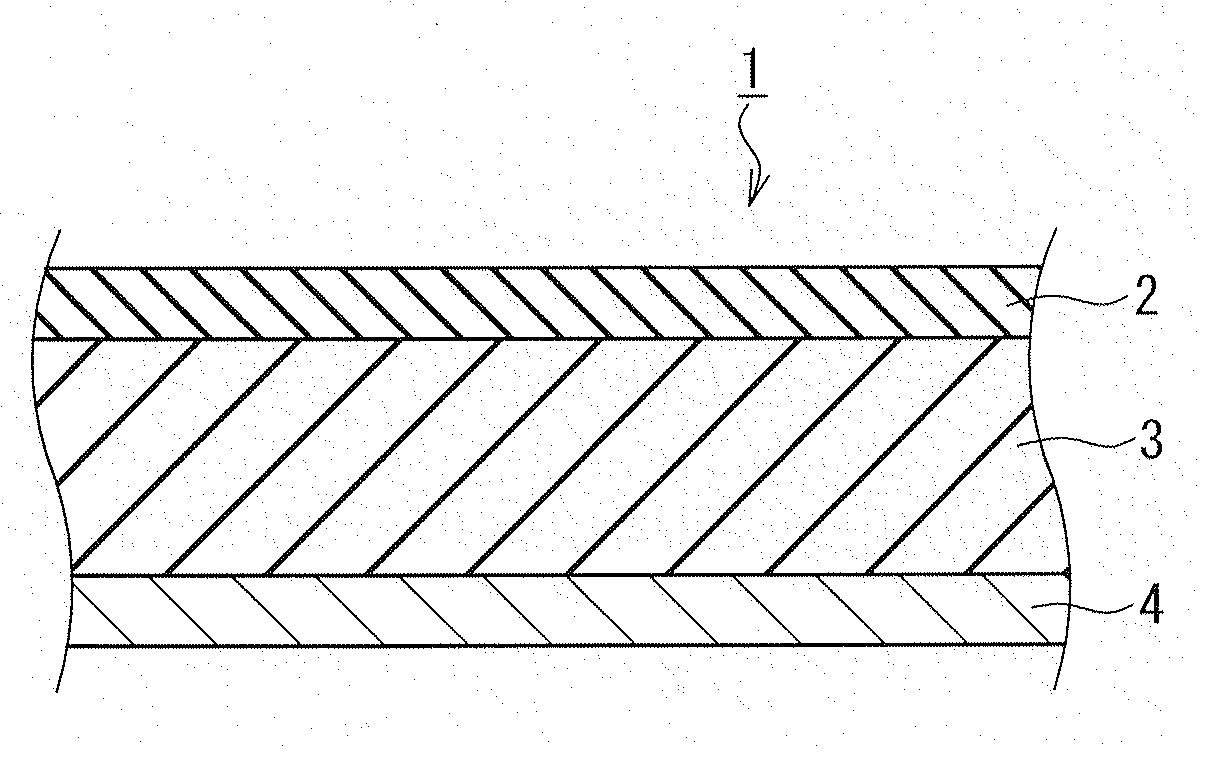

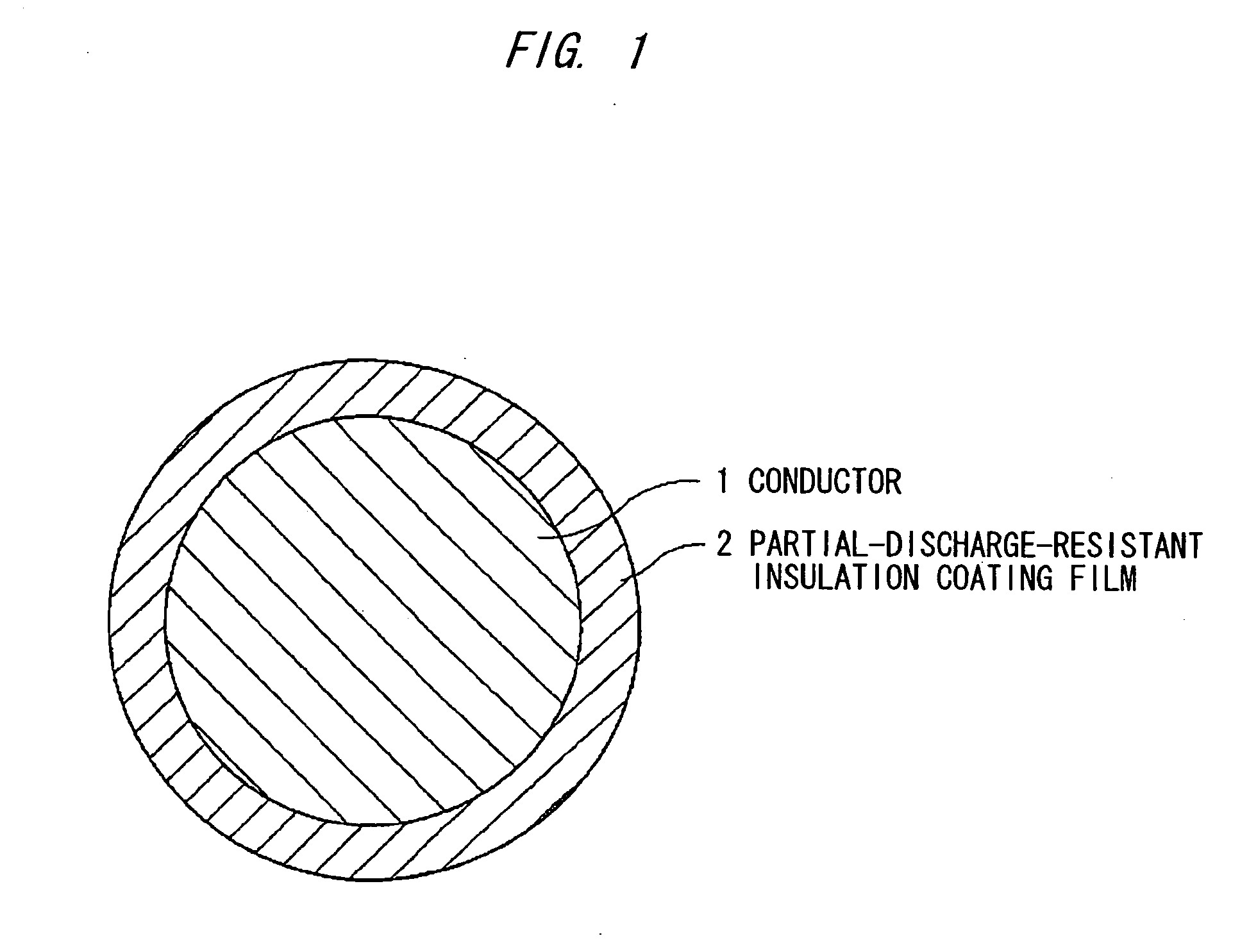

Partial-discharge-resistant insulating varnish, insulated wire and method of making the same

ActiveUS20060240254A1Enhanced partial discharge resistanceInhibit aggregationPlastic/resin/waxes insulatorsSpecific water treatment objectivesImidePolymer science

A partial-discharge-resistant insulating varnish has a polyamide-imide enamel varnish and an organo-silica sol that are dispersed in a solvent. The solvent has 50 to 100% by weight of γ-butyrolactone. An insulated wire has a conductor, and a partial-discharge-resistant insulation coating film formed on the surface of the conductor. The partial-discharge-resistant insulation coating film is made of the partial-discharge-resistant insulating varnish.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com