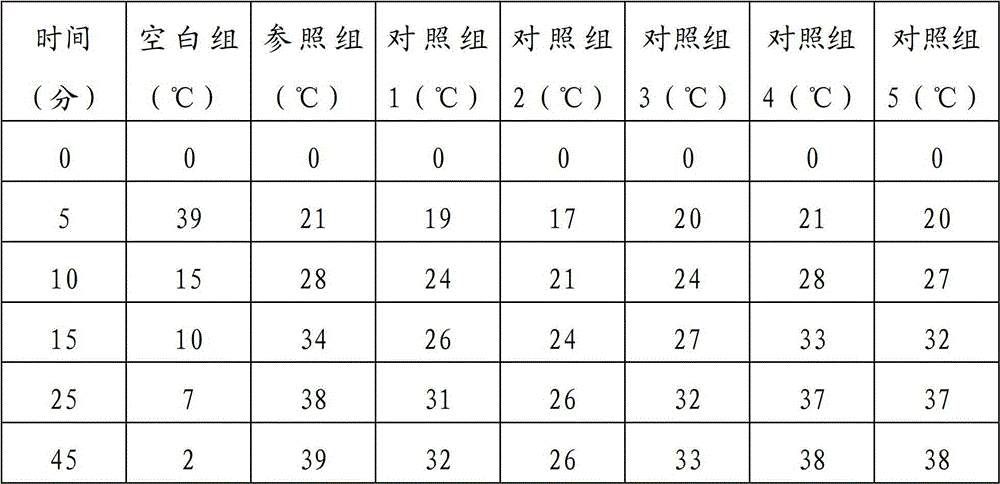

Patents

Literature

79 results about "Insulative paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Insulative paints, or insulating paints, claim to use a technology where a broad spectrum thermally reflective coating is applied to a specific type of micro-spheres to block heat radiation in a much larger or broader range of thermal energy (heat) to dissipate heat rapidly. This type of coated thermally reflective material (coated micro-sphere) reduces heat transfer through the coating with 90% of solar infrared radiation and 85% of ultraviolet radiation being radiated back from the coated surface.

Polyamide-imide resin insulating coating material, insulated wire and method of making the same

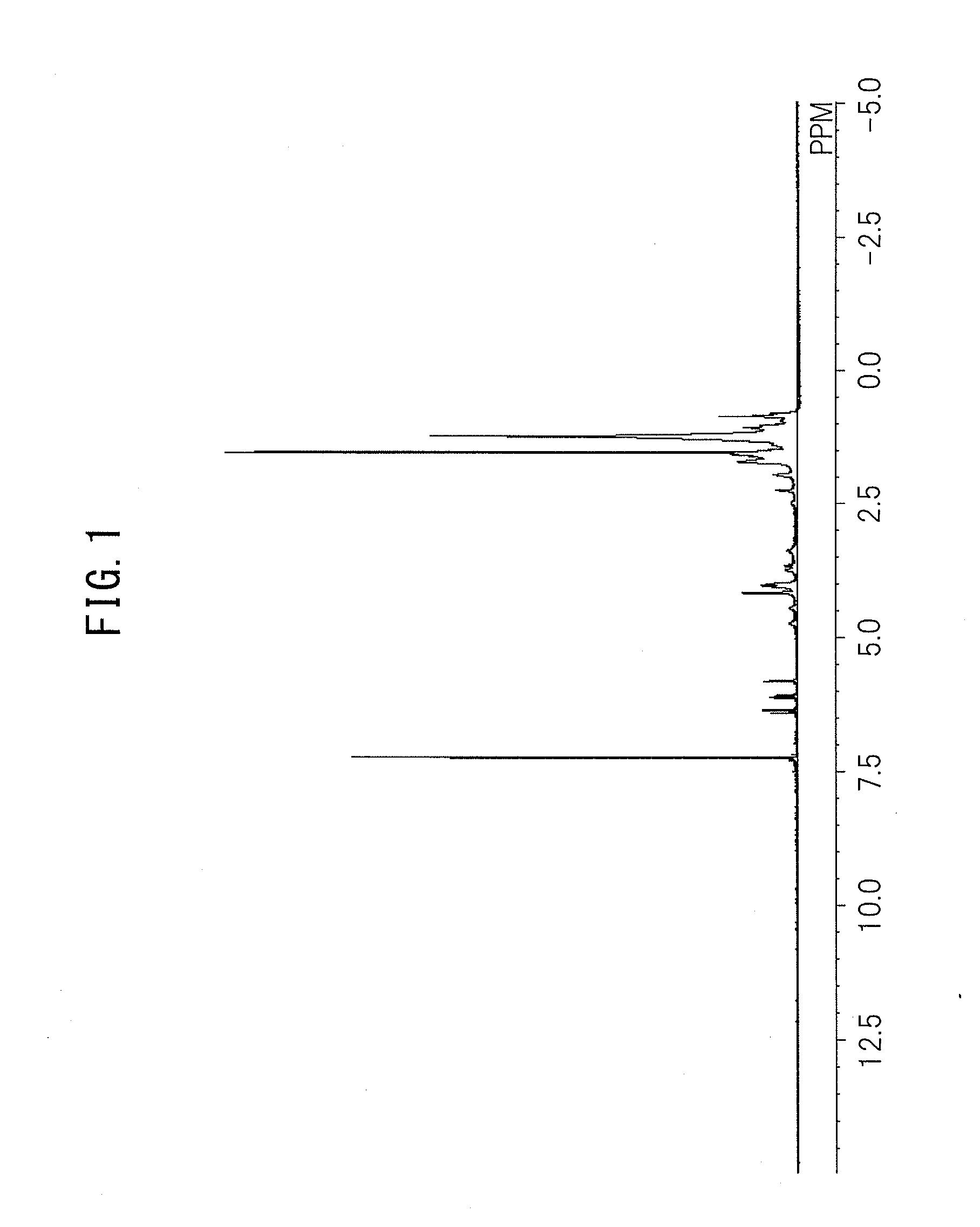

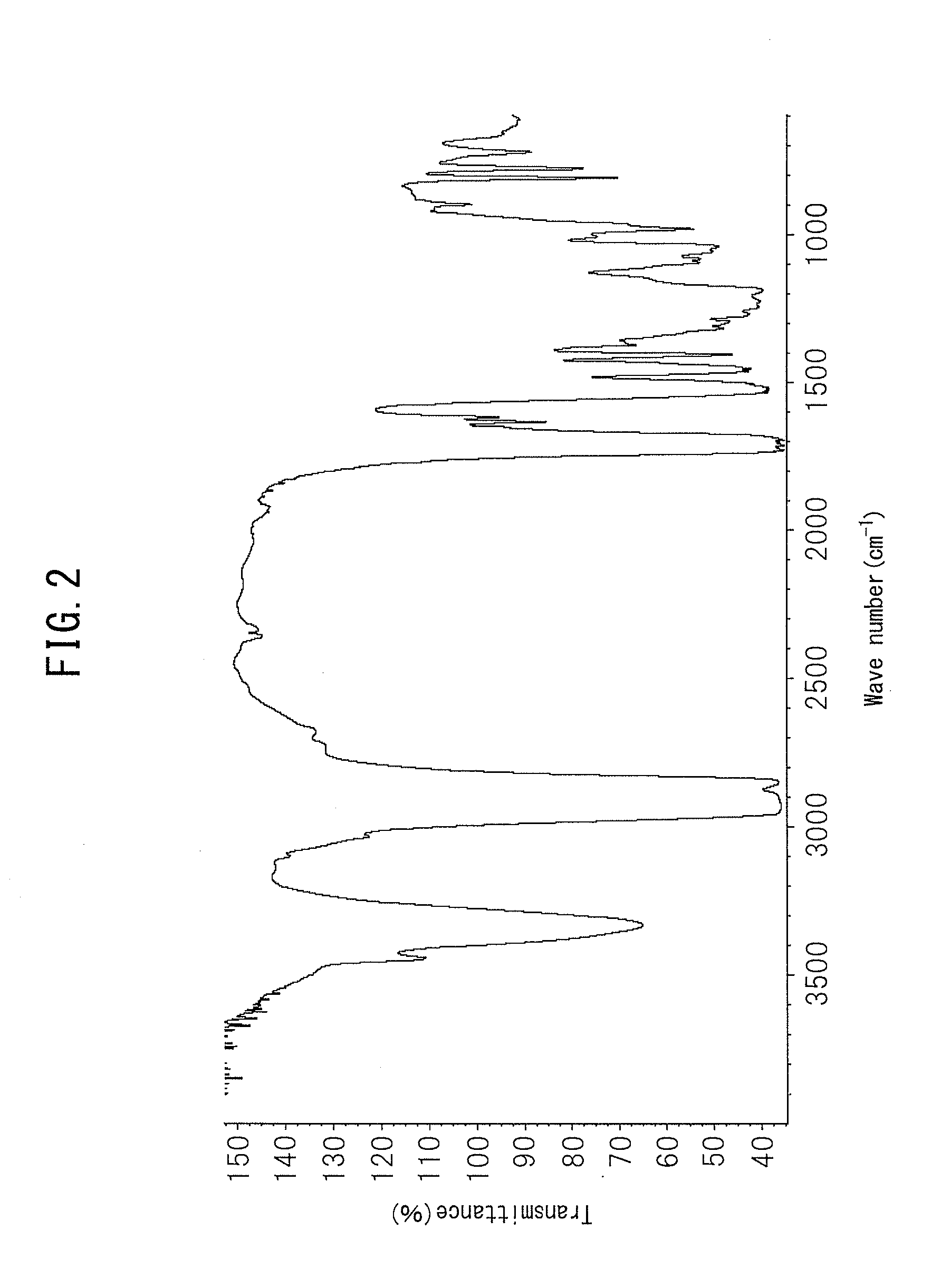

ActiveUS20060240255A1Evenly dispersedInhibit aggregationLiquid surface applicatorsInsulatorsPolyamide-imideInsulative paint

A polyamide-imide resin insulating coating material, which is obtained by reacting an isocyanate component with an acid component, has a main solvent component of γ-butyrolactone. In the coating material, a total compounding ratio of 4,4′-diphenylmethane diisocyanate (MDI) and trimellitic anhydride (TMA) is 85 to 98 mol %, where the total compounding ratio is given by averaging a compounding ratio of MDI to the isocyanate component and a compounding ration of TMA to the acid component.

Owner:HITACHI METALS LTD

Daylight-resisting heat insulation paint

A heat-insulative paint against sunlight. It comprises: 7-15 parts of phenylpropionic acid emulsion, 4-8 parts of an adhesive of trimerized cyanamide modified polyvinyl alcohol, 2-20 parts of polyvinyl acetate, 3-7 parts of silicasol (liquid),0.3-0.8 part of carbamideíó0.8-1.0 part of glycolíó3-7 parts of white titanium pigmentíó12-18 parts of light calcium carbonateíó3-7 parts of calcite powderíó2-4 parts of expanded perliteíó18-22 parts of sepioliteíó1-3 parts talcum powderíó0.8-1.2 parts of gray calcium powder,1-2 parts of powdery silcate fiber ,0.3-0.8 part of alumen, 0.4-0. 6 part of penetrating agent T, 0.1-0.2 part of sodium carbonateíó appropriate amount of thickening agentíó18-26 parts of wateríó0-0.5 of dyes with high optical stability, 0-0.8 g jellebekite powder. The paint could reflect sunlight and insulate heat, has a bright surface.

Owner:黄维环

Semi-inorganic environment-friendly insulating paint for non-oriented silicon steel and coating preparation method thereof

The invention discloses a semi-inorganic environment-friendly insulating paint for non-oriented silicon steel and a coating preparation method thereof, and belongs to the technical field of non-oriented silicon steel paint. The semi-inorganic environment-protecting insulating paint for the non-oriented silicon steel is prepared by the following components by mass percent: 5-40% of aluminum dihydrogen phosphate, 0.5-10% of manganese dihydrogen phosphate, 1-12% of zinc dihydrogen phosphate, 0.5-1.5% of zinc oxide, 0.1-1% of magnesium oxide, 1.0-7% of boric acid, 5.0-27% of resin, 2.0-6.0% of organic solvent, 0.1-0.8% of other auxiliaries, and the balance of water. The paint is an environment-friendly paint free from chromium; at the same time, the coating is uniform in brightness, better in corrosion resistance than the ordinary phosphate coating, and good in insulation, adhesiveness, punching, weldability, heat resistance and corrosion resistance. In addition, the source of the semi-inorganic environment-friendly insulating paint for the non-oriented silicon steel is rich, so that the production cost is low, and the paint can be widely applied.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

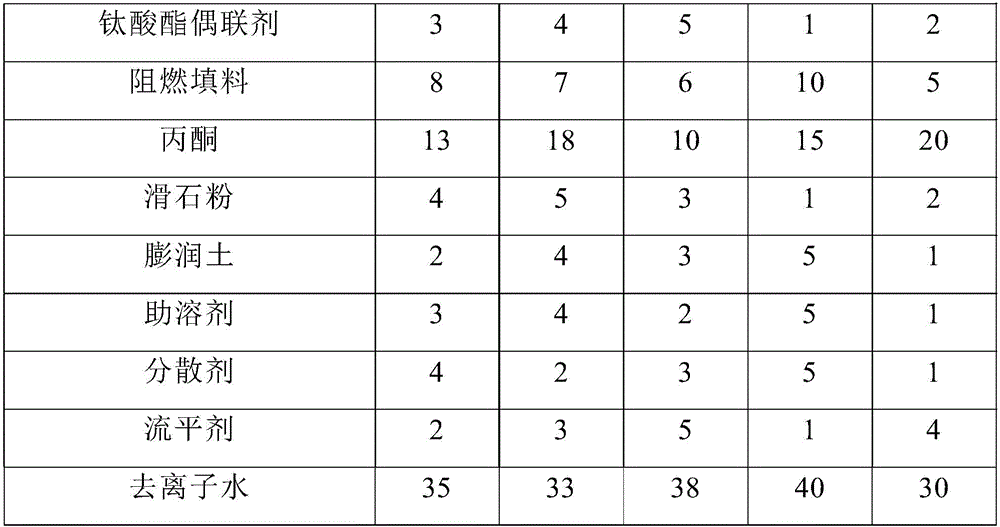

Environment-friendly flame retardant insulating paint and preparation method thereof

InactiveCN106047164AHigh glossImprove antistatic performanceFireproof paintsPolyurea/polyurethane coatingsEpoxySpray coating

The invention provides environment-friendly flame retardant insulating paint and a preparation method thereof. The paint is prepared from the following components: organosilicon modified epoxy resin, acrylic modified polyurethane resin, silicon nitride, calcium carbonate, nano silicon carbide, nano magnesium oxide, magnesium oxide, carboxymethyl cellulose, a titanate coupling agent, flame retardant filling, acetone, talcum powder, bentonite, a cosolvent, a dispersant, a leveling agent and de-ionized water. The paint adopts the organosilicon modified epoxy resin matched with the acrylic modified polyurethane resin, so the paint has good gloss, good antistatic effect and better mechanical properties, ageing resistance and wear resistance; addition of the nano silicon carbide, flame retardant filling and nano magnesium oxide can effectively improve the oxidation resistance and flame retardant ability of the paint; moreover, the paint has the advantages of low price, environment protection, strong adhesion, good ductility, high temperature resistance and long service life; and roller coating is substituted for spray coating during application, so that the production environment is effectively improved and physical health of workers is benefited.

Owner:TAICANG JINXIN PAINT

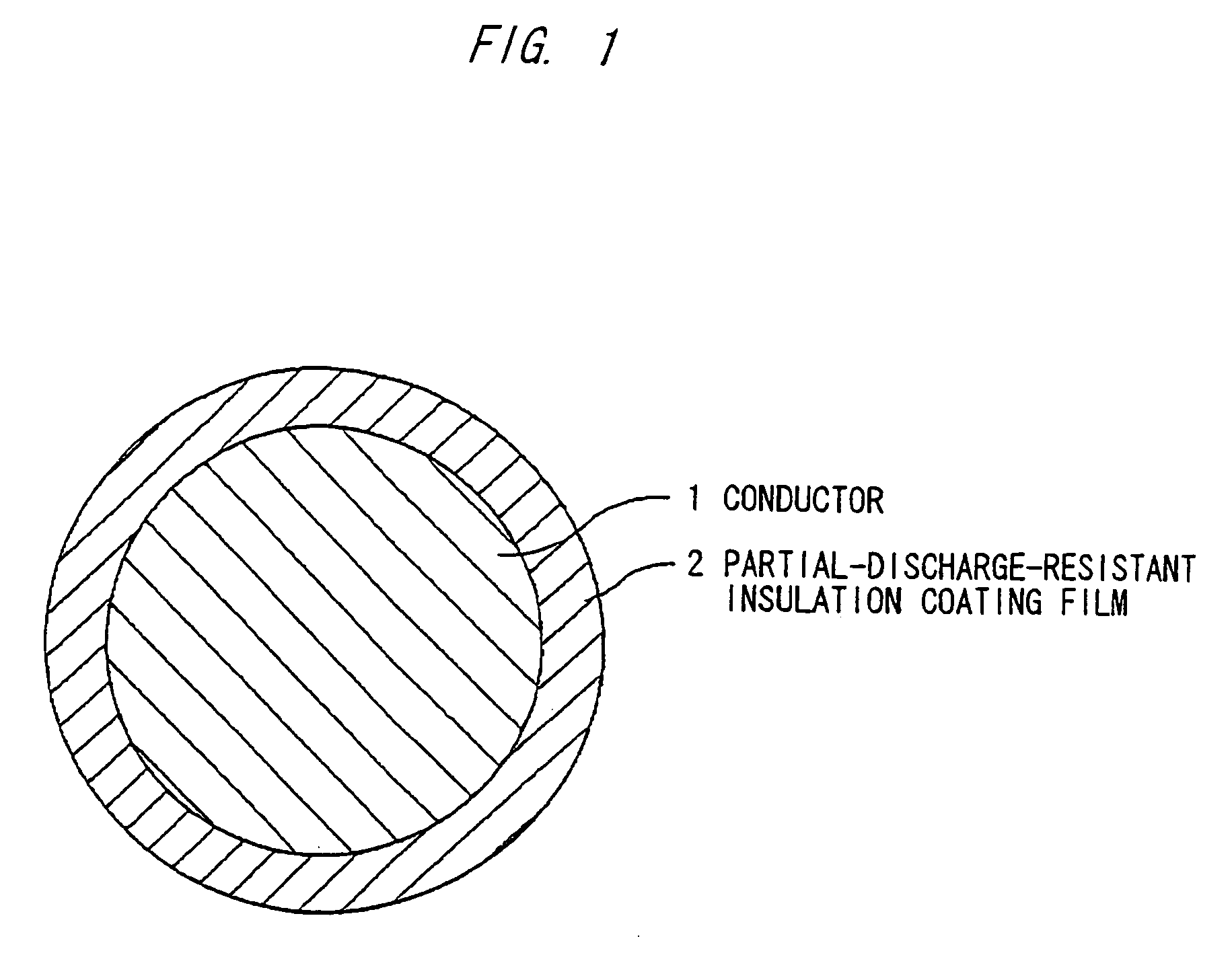

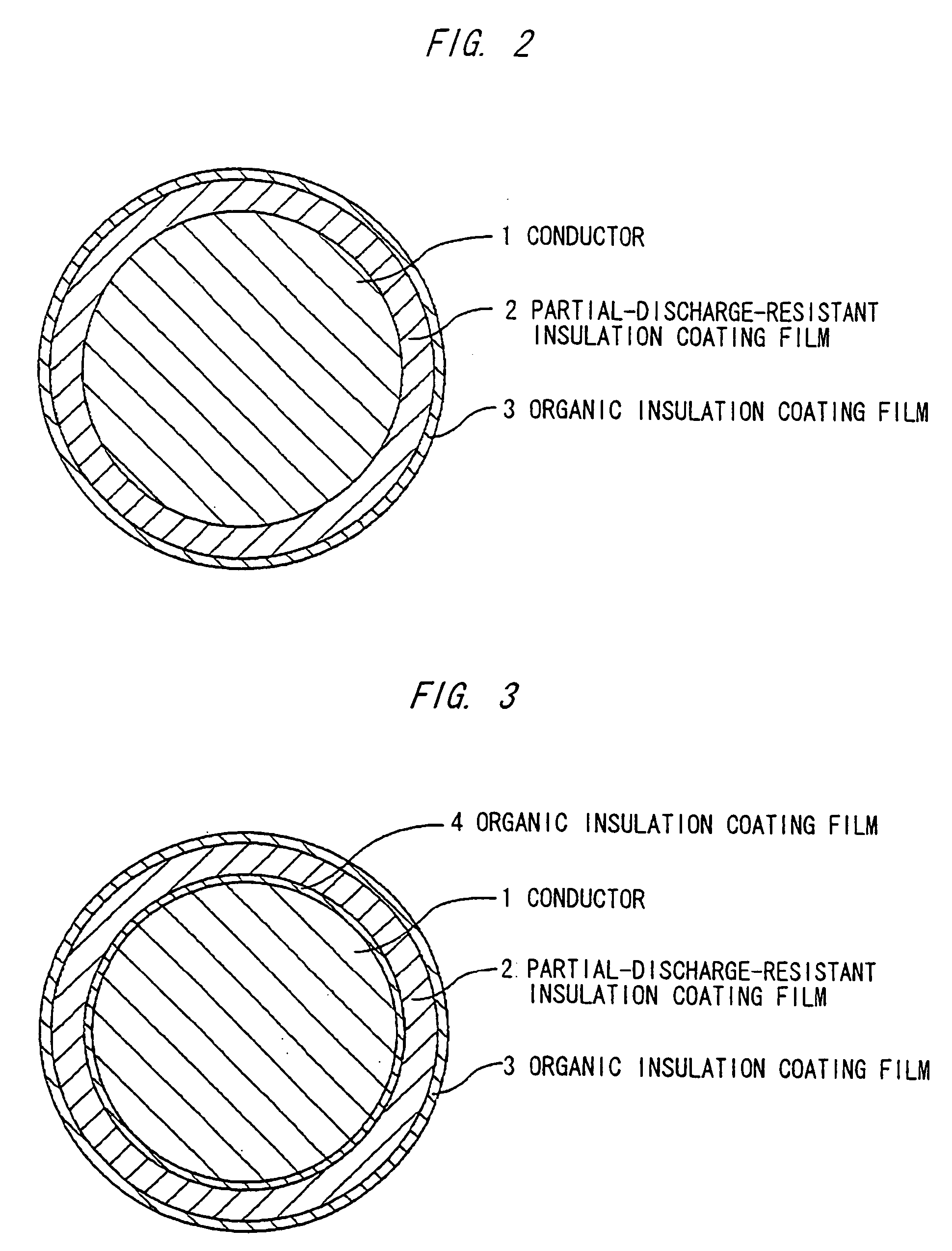

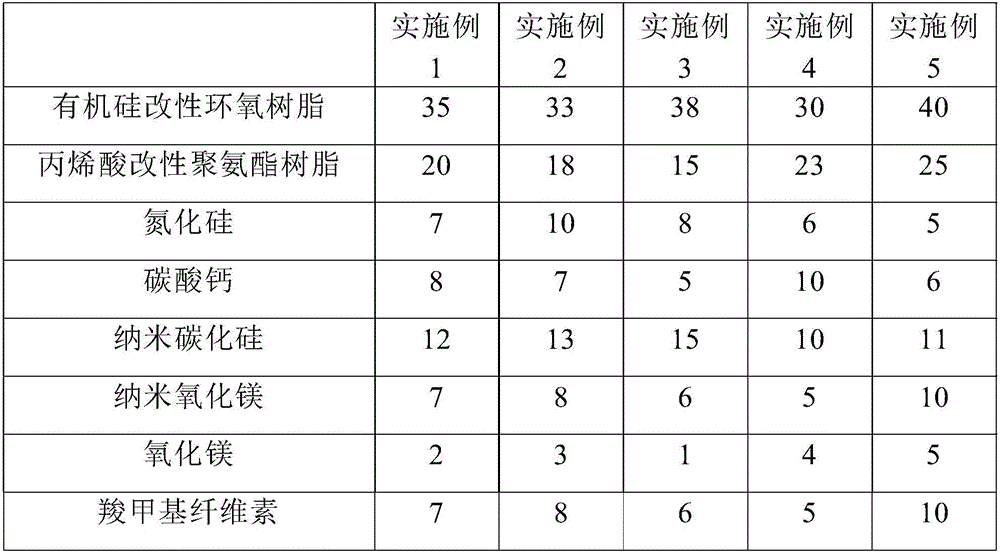

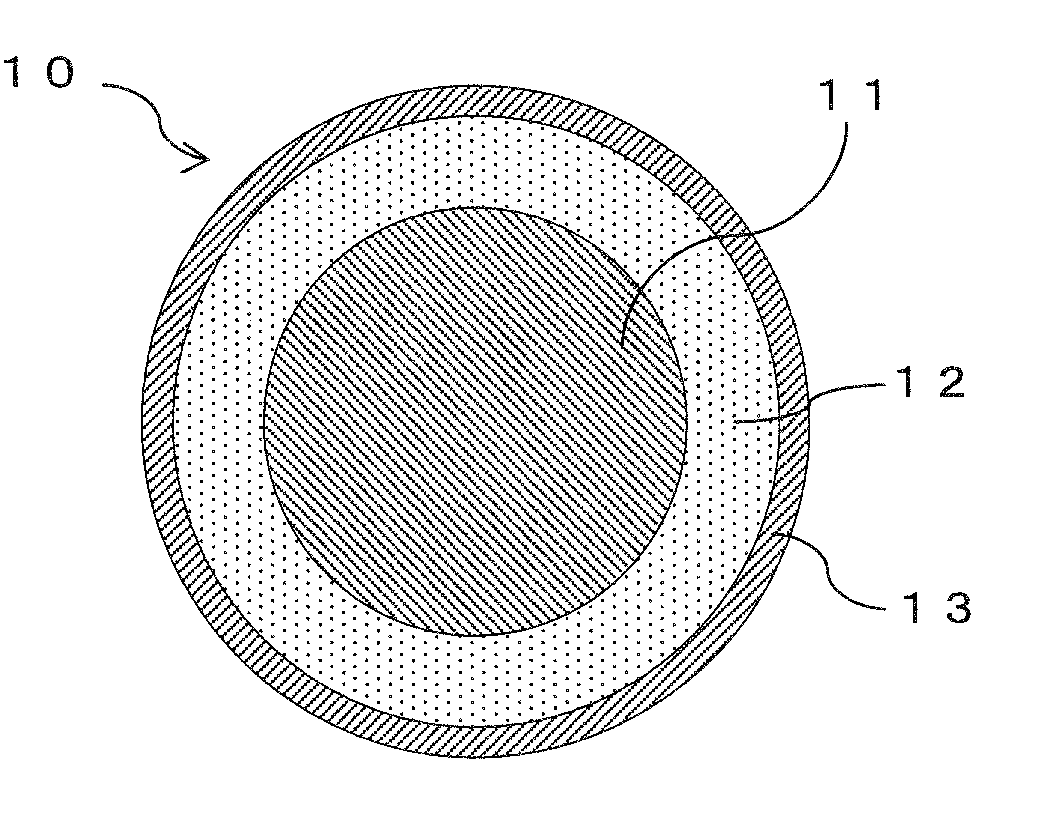

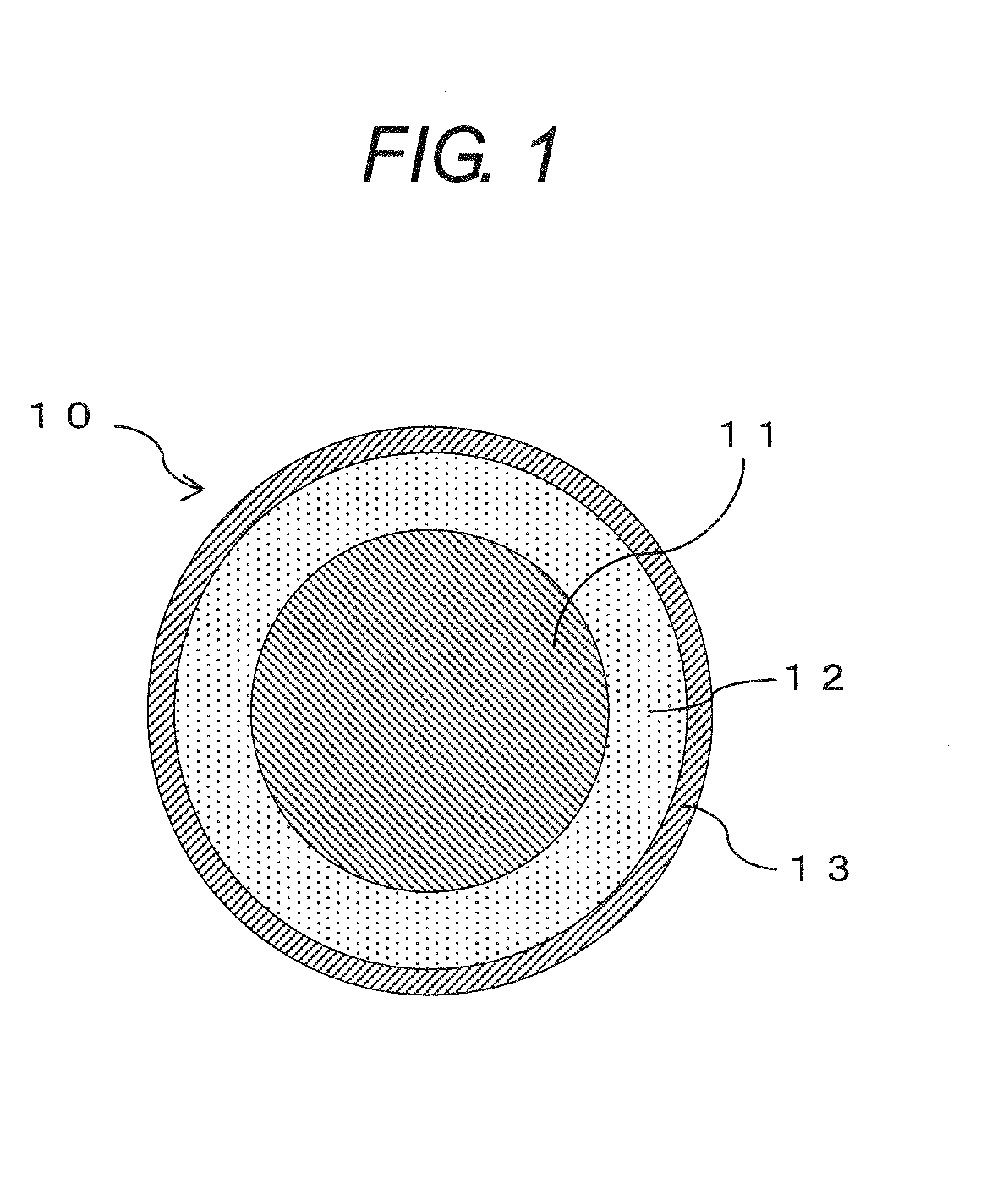

Polyester imide resin insulating coating material, insulated wire using same, and coil

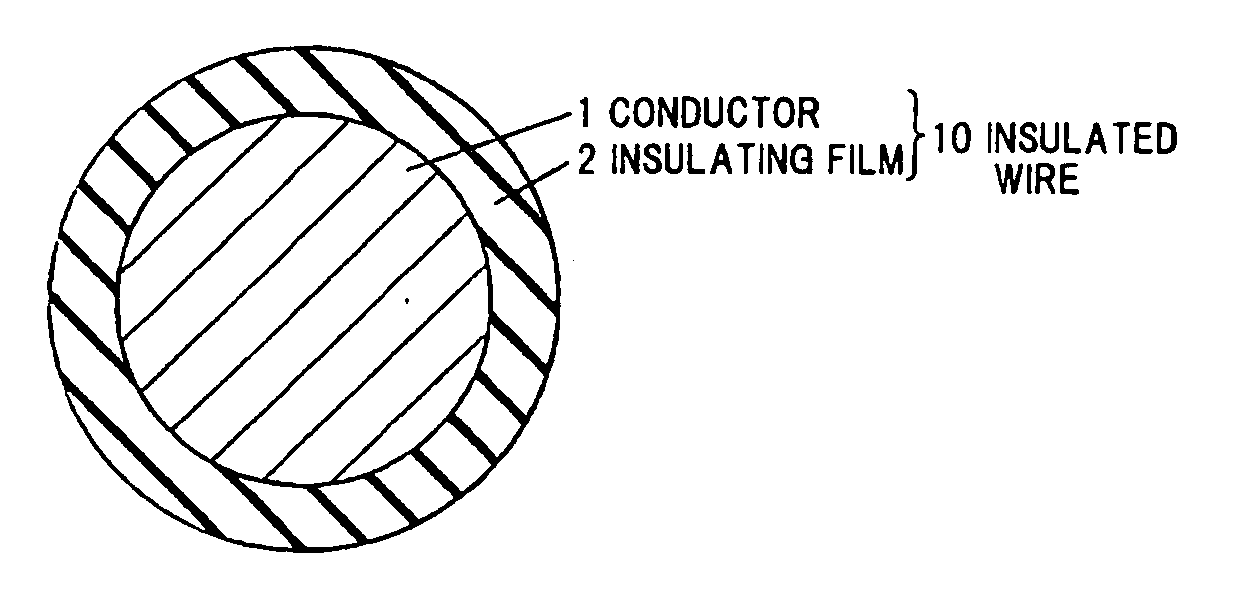

A insulated wire includes a conductor, and an insulating coating on a periphery of the conductor. The insulating coating includes an insulating film formed by applying and baking a polyester imide resin insulating coating material, and the insulating film has a relative permittivity of less than 3.5 both in a dried state and in a moisture-absorbed state. The insulating film is formed by applying and baking a polyester imide resin insulating coating material including an imide dicarboxylic acid and an alcohol component, the imide dicarboxylic acid being obtained by synthesizing a diamine component including aromatic diamine having not less than three aromatic rings and an acid component including aromatic tricarboxylic acid anhydride.

Owner:HITACHI METALS LTD

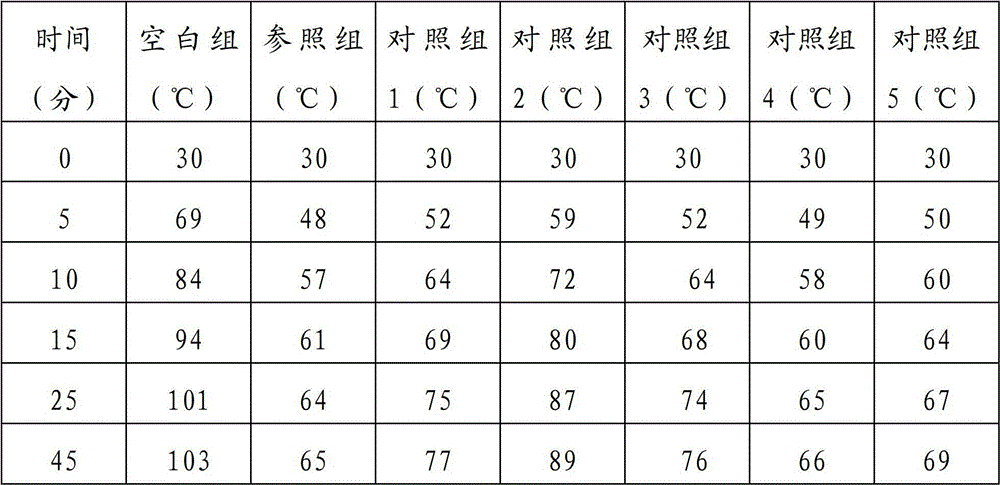

Reflective thermal-insulation paint

ActiveCN104212218AImprove adhesionImprove the decorative effectFireproof paintsAntifouling/underwater paintsThermal insulationAbsorbed energy

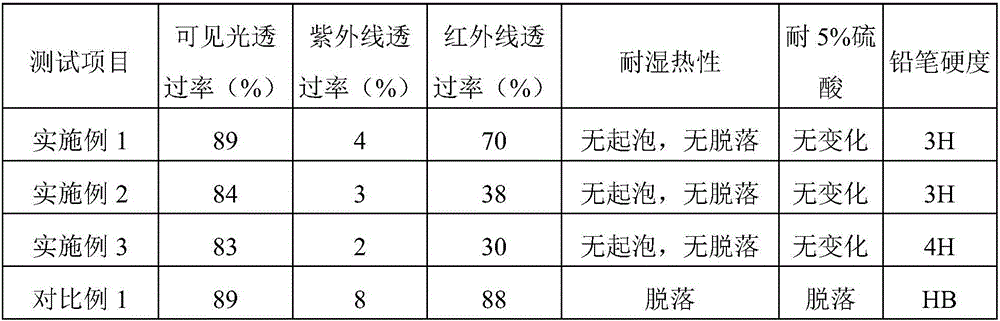

The invention relates to a reflective thermal-insulation paint which successively includes a putty layer, an undercoat layer and a finishing coat layer, wherein the putty layer is 1-3 cm in thickness, the undercoat layer is 20-40 [mu]m in thickness and the finishing coat layer is 90-110 [mu]m in thickness. By means of the reflective insulation paint, a coating layer, which is high in reflective rate, is high in radiation rate and is low in thermal-conductive rate, can be obtained mainly through control of a solar energy reflective rate, an infrared radiation rate and a thermal-conductive rate of a material. Visible lights and infrared light in sunlight are reflected due to the high reflective rate of the material and meanwhile absorbed energy is dissipated in a manner of thermal-radiation by means of the high radiation rate of the material so that a surface-layer temperature of the material is reduced and heat transmitted into an internal environment is reduced. Meanwhile, by means of the low thermal-conductive rate of the coating layer, heat is further insulated from being transmitted into the internal environment so that the temperature of the internal environment is maximumly maintained, thereby achieving an object of insulating heat and maintaining temperature. The reflective insulation paint not only is good in thermal-insulation effect but also is environmental-protective and toxic-free.

Owner:NANJING SHUANGSHAN PAINT

High-solid-content aqueous ultraviolet curing transparent heat-insulation paint and preparation method thereof

InactiveCN106243988AEasy to useResistant to yellowingPolyurea/polyurethane coatingsThermal insulationInsulative paint

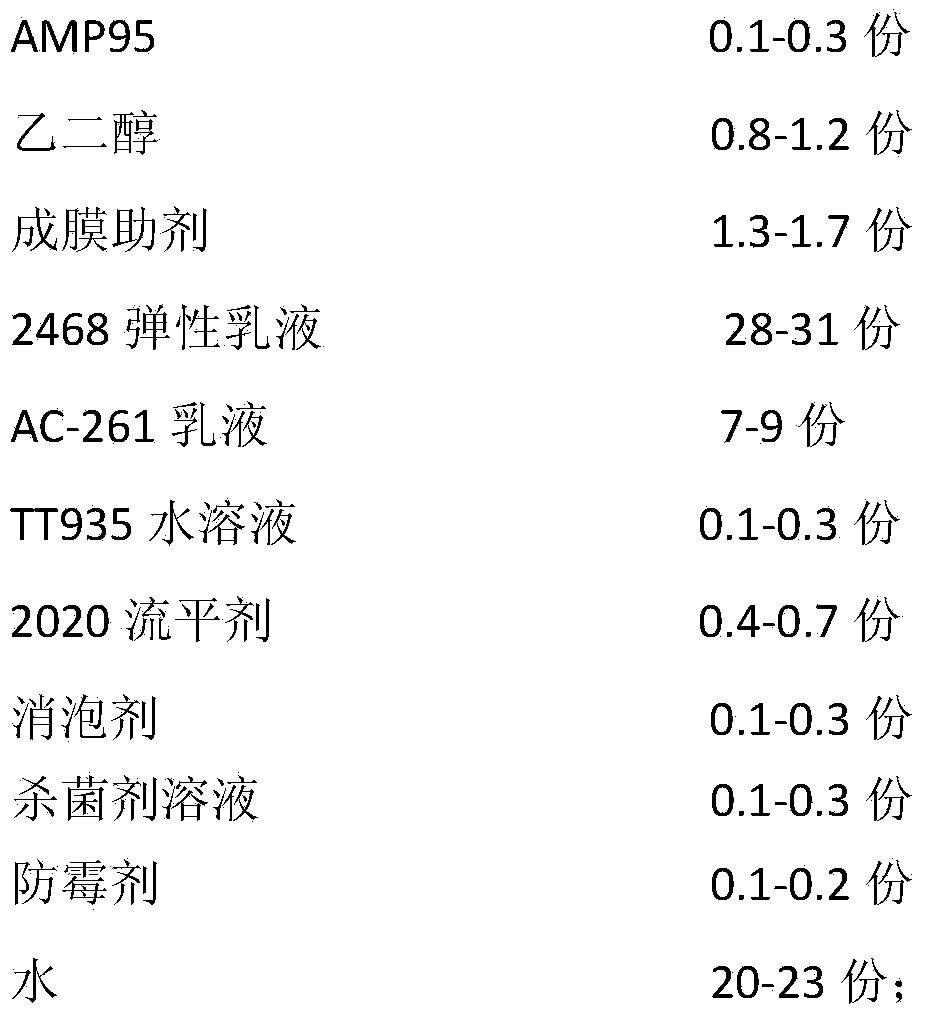

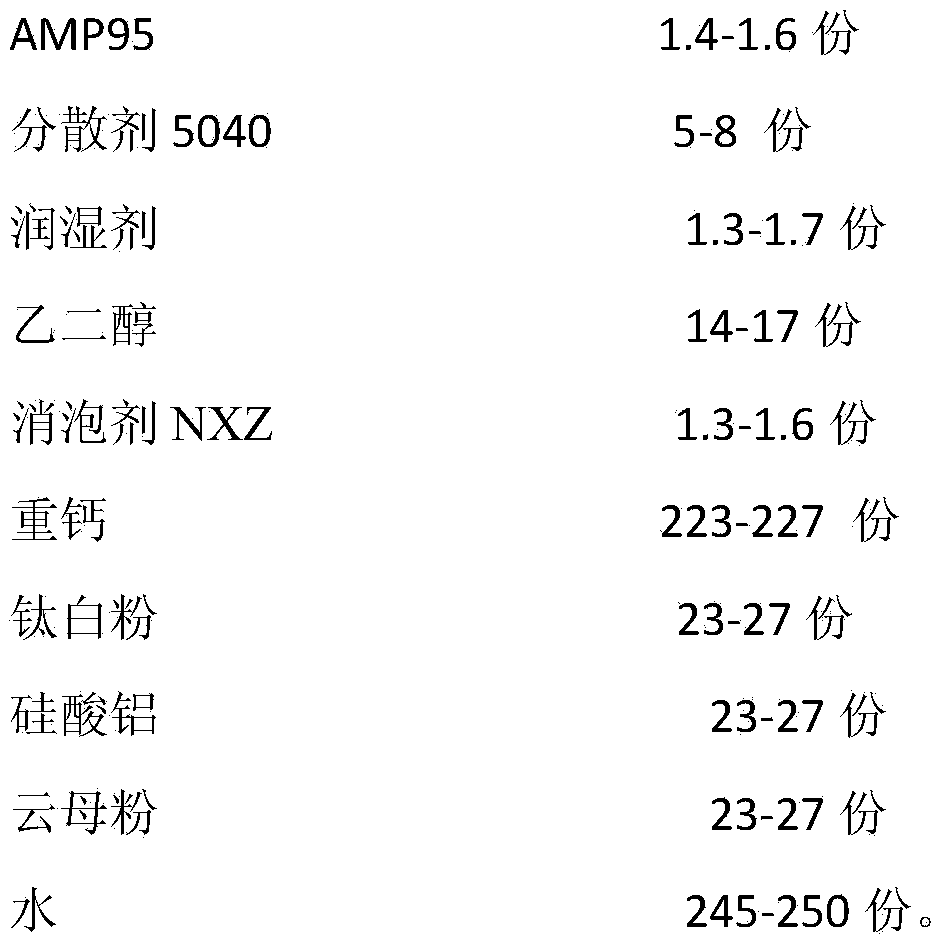

The invention relates to high-solid-content aqueous ultraviolet curing transparent heat-insulation paint and a preparation method thereof. The high-solid-content aqueous ultraviolet curing transparent heat-insulation paint is characterized by being prepared from the following raw material components in parts by mass: 100 parts of high-solid-content aqueous polyurethane dispersoid, 0.2-0.5 part of a water-soluble photoinitiator, 1-5 parts of a nano function element, 0.05-0.2 part of a flatting agent, and 0.1-0.2 part of an antifoaming agent, and the components are uniformly mixed, so that the high-solid-content aqueous ultraviolet curing transparent heat-insulation paint is prepared. The main property indexes of the high-solid-content aqueous ultraviolet curing transparent heat-insulation paint are as follows: the mass solid content is 48-52%, and the stickiness is 20-100mPa.s. The paint has the advantages of being non-toxic, incombustible, safe to use, resistant to yellowing, thermal-insulation, good in light permeability and the like, and can be used in occasions of curtain wall glass for buildings, automotive window glass and the like.

Owner:NANJING UNIV OF TECH

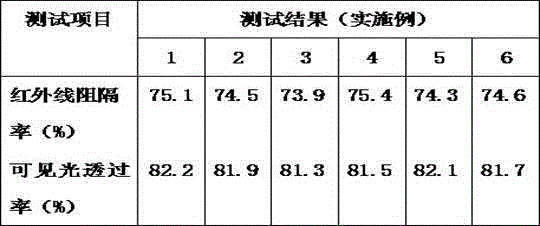

High-hardness one-component transparent heat-insulation paint for glass

InactiveCN102477230ASimplify the construction processReduce use costCoatingsPolymer resinInsulative paint

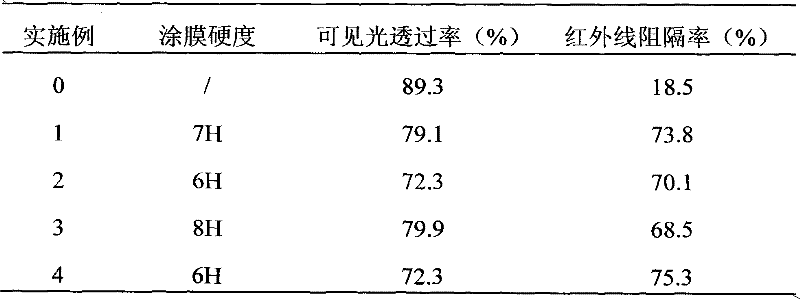

The invention provides high-hardness one-component transparent heat-insulation paint for glass. The paint contains the following ingredients of: by weight, 50-90 parts of high-hardness polymer resin, 10-50 parts of a nanometer heat-insulation slurry, 0-10 parts of a cosolvent, 0-0.5 part of an antifoaming agent, 0-0.5 part of a foam inhibitor, 0-0.5 part of a base-material wetting agent and 0-0.5 part of a leveling agent. The high-hardness one-component transparent heat-insulation paint for glass in the invention has more than 6H of paint film hardness, can effectively avoid the destroy of outside force to the paint film when used on a single piece of glass, has over 50% of infrared ray blocking rate and more than 70% of visible light transmittance, can block most daylight radiant heat, but has little influence on lighting. The paint provided by the invention has advantages of simple construction process and low use cost.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Sun-reflection heat-insulation paint and manufacturing method thereof

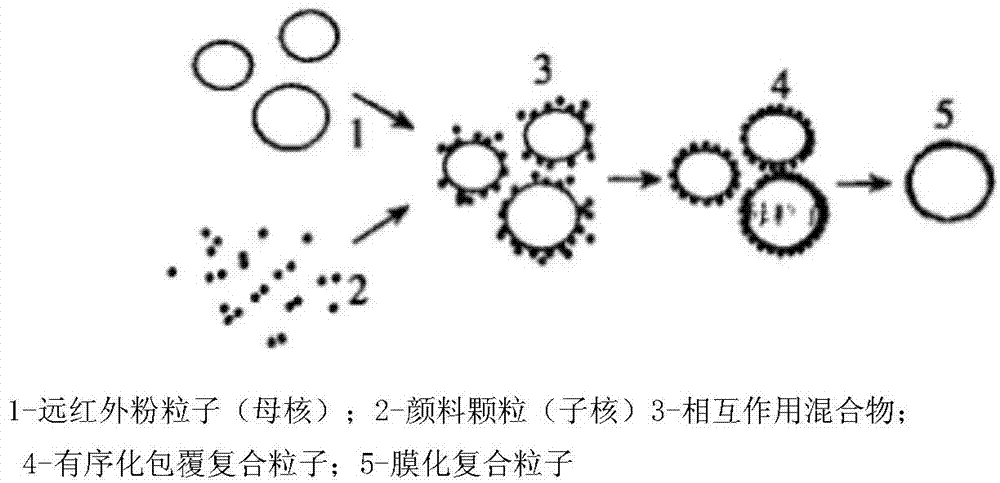

ActiveCN104327654ALow thermal conductivityAdditive effectPaints with biocidesPigment treatment with macromolecular organic compoundsWater basedMineral particles

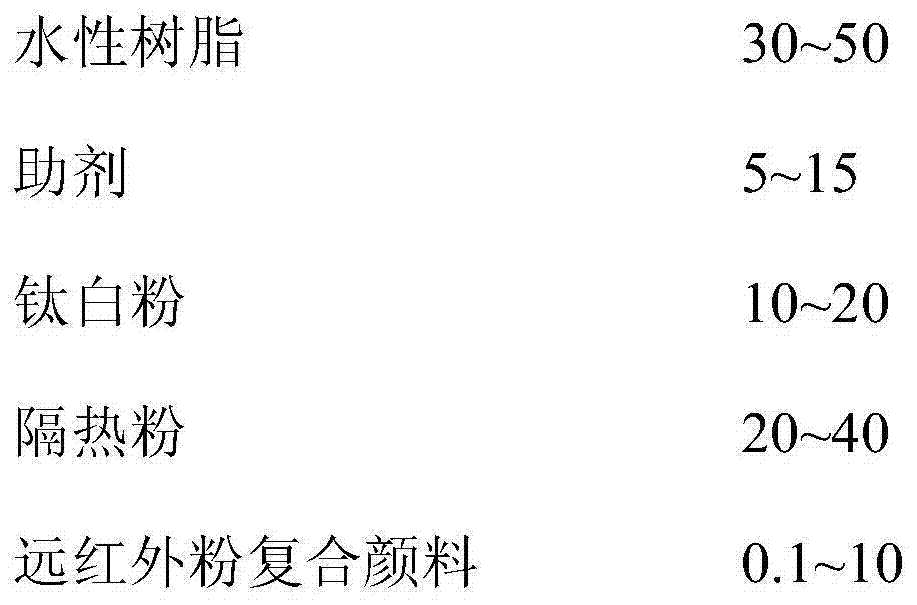

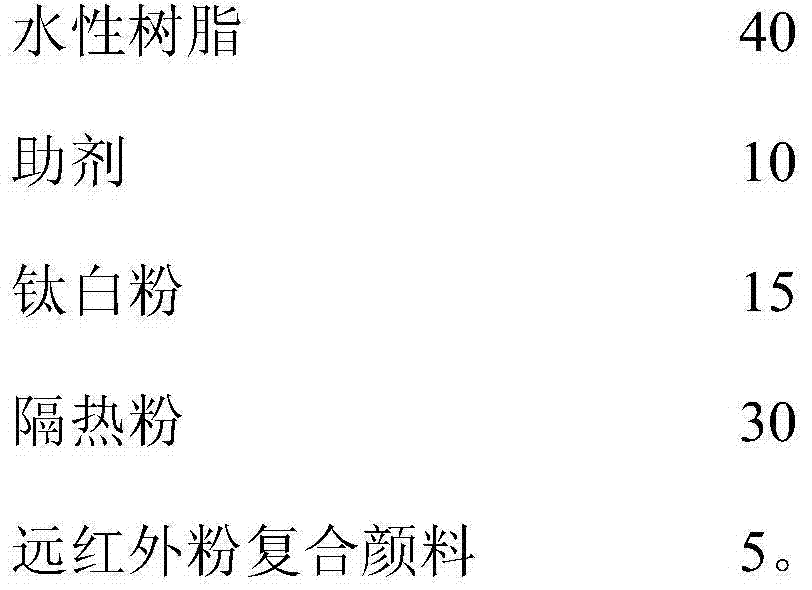

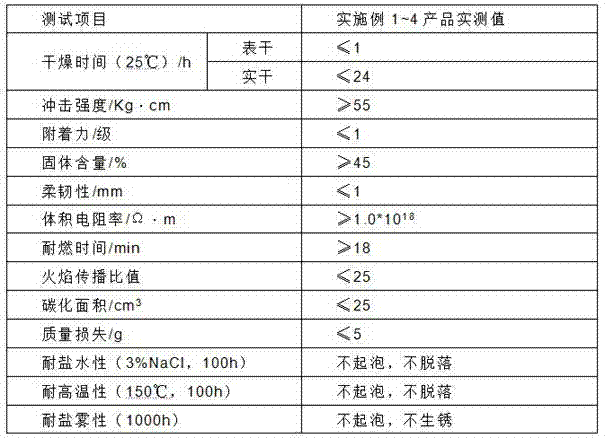

The invention relates to a sun-reflection heat-insulation paint and a manufacturing method thereof. The invention aims to provide a paint with favorable heat-insulation property. The technical scheme is as follows: the sun-reflection heat-insulation paint comprises a water-based resin, assistants, titanium white, heat-insulation powder and a far-infrared powder composite pigment, wherein the water-based resin is a pure acrylic emulsion or fluorocarbon resin emulsion or silicone acrylate resin emulsion; and the assistants comprise a preservative, a bactericide, a dispersing agent, a leveling agent, a defoaming agent, a film formation assistant, a thickener and an antifreezing agent. The manufacturing method comprises the following steps: (a) proportionally and uniformly mixing porous mineral particles, silane coupling agent, dispersing agent, deionized water and anhydrous ethanol; (b) proportionally and uniformly mixing far-infrared powder, anti-phase-separating agent, water and anhydrous ethanol; (c) proportionally and uniformly mixing the liquids formed in the steps (a) and (b), and aging to obtain a gel; and (d) drying and holding the gel to obtain the composite powder.

Owner:ZHEJIANG HUADE NEW MATERIALS CO LTD

Flame-retardant insulating paint

InactiveCN103756506AStrong adhesionHigh mechanical strengthFireproof paintsEpoxy resin coatingsElectrical conductorFirming agent

The invention relates to a flame-retardant insulating paint, belonging to the technical field of paint. The flame-retardant insulating paint comprises the following components in parts by weight: component A: 100-120 parts of epoxy resin, 7-10% of magnesium hydroxide whisker, 6-12 parts of Tetraphenyl resorcinol bis(diphenylphosphate), 10-25% of silica micropowder, 4-8 parts of 2,4-dihydroxybenzophenone, 0-5 parts of pigments, 0.5-2 parts of polycarboxylic acid sodium salt, 0.2-0.5% of defoaming agent, 5-10 parts of acetone, and 8-15 parts of ethyl acetate; component B: 2-10 parts of curing agent. The paint not only has the advantages of being strong in adhesion force, high in mechanical strength, good in high temperature resistance property, excellent in anti-corrosion and humidity resistance properties, fast in low-temperature drying speed, and good in storage stability, but also has excellent flame-retardant property, electric insulating property and anti-ultraviolet property, and can be used for flame-retardant insulating paint for surfaces of conductors in various electrical devices.

Owner:吴江市东泰电力特种开关有限公司

Urethane (METH)acrylate and moisture-proof insulating coating material

InactiveUS20150005406A1Improve insulation performanceSmall environmental loadPlastic/resin/waxes insulatorsPolyurea/polyurethane coatingsPolyesterDimer acid

Provided is a photocurable moisture-proof insulating coating material which places little burden on the environment and has excellent surface curability with low irradiation. In addition, this photocurable moisture-proof insulating coating material is hydrophobic and exhibits high adhesion to a substrate material. Also provided is a novel urethane (meth)acrylate which is used for this moisture-proof insulating coating material. A urethane (meth)acrylate of the present invention is obtained by reacting (a) a polyester polyol that has a structural unit derived from a hydrogenated dimer acid and a structural unit derived from a hydrogenated dimer diol, (b) a polyisocyanate compound and (c) a hydroxyl group-containing (meth)acrylate. A moisture-proof insulating coating material of the present invention contains this urethane (meth)acrylate and a (meth)acryloyl group-containing compound that does not contain a silicon atom.

Owner:SHOWA DENKO KK

Insulating paint containing calcium fluoride, and preparation method, insulating coating, battery pole piece and lithium-ion battery

ActiveCN105244456AReduce hardnessImprove insulation performanceSecondary cellsJackets/cases materialsMass ratioHardness

The invention discloses an insulating paint containing calcium fluoride, and a preparation method, an insulating coating, a battery pole piece and a lithium-ion battery. The insulating paint comprises an insulating material and a binder at the mass ratio of (80-98) to (2-20), wherein the insulating material is the calcium fluoride or a mixture of the calcium fluoride and at least one of aluminum oxide and silicon dioxide; the mass content of the calcium fluoride in the insulating material is 70%-100%; and the insulating paint coats a to-be-insulated region and is dried, so as to obtain the insulating coating. Through reasonable collocation of the binder and the insulating material containing the calcium fluoride, the hardness of the insulating coating is effectively lowered on the basis that a good insulating effect of the insulating coating is kept, so that abrasion of related equipment can be effectively reduced when the pole piece is rolled and cut; and the service lifetime of a pole piece slitting mold is prolonged.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Environment-friendly insulating paint for doors/windows and preparation method thereof

InactiveCN104725989ANo emissionsSimple processFireproof paintsAnti-corrosive paintsPhosphateFirming agent

The invention discloses an environment-friendly insulating paint for doors / windows, which comprises self-made aluminum dihydrogen phosphate, an organic resin, a filler, an assistant and a solvent. The organic resin is a mixture of an epoxy resin and a water-based polyurethane modified epoxy resin in a mass ratio of 1:5-1:2. The filler is one or mixture of more of barium sulfate, talcum powder, zinc phosphate, aluminum phosphate and titanium dioxide. The assistant comprises a chelator, a dispersing agent, a defoaming agent, a curing agent and a silane coupling agent. The solvent is deionized water or n-butanol. The invention also discloses a preparation method of the environment-friendly insulating paint for doors / windows, which is simple and easy to implement and is pollution-free in the preparation process. The environment-friendly insulating paint has the advantages of favorable adhesiveness, favorable corrosion resistance, favorable fire resistance, favorable insulativity, environment friendliness and higher safety, and prolongs the service life of the door / window.

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

One-component curable electrical insulation coating

InactiveUS20080182943A1Extended shelf lifeLow curing temperatureEpoxy resin coatingsPolyester coatingsInsulative paintChemistry

A one-component curable insulating coating composition comprises encapsulated catalysts and encapsulated curing agents mixed with an unsaturated resin. The encapsulated catalyst and / or curing agent is prevented from chemically contacting the resin until a cure temperature is achieved. The one-component coating composition has a shelf life that is equal to or greater than 6 months and a cure temperature and / or cure time that is lower than the cure temperature and / or cure time normally associated with currently available multi-component coating compositions.

Owner:ELANTAS PDG

Glass transparent thermal-insulation paint

InactiveCN104817910ABlock sun radiation heatLittle impact on lightingCoatingsAcrylic resinThermal insulation

The invention discloses a glass transparent thermal-insulation paint which comprises the following components in parts by weight: 20-30 parts of modified acrylic resin, 15-25 parts of nano ATO (antimony tin oxide) slurry, 5-12 parts of nano zinc oxide, 1-5 parts of leveling agent, 2-8 parts of wetting agent, 3-9 parts of dispersing agent, 2-7 parts of defoaming agent and 30-40 parts of solvent. The glass transparent thermal-insulation paint has a barrier action on different radiation wave bands in sunlight, and can barrier most solar radiation heat. The visible light transmissivity is up to 80% above. The glass transparent thermal-insulation paint has the advantages of low influence on lighting, low cost and simple production technique, and is suitable for the field of application and heat insulation of building doors / windows and windshields.

Owner:黎司华

Manufacturing method of vehicle glass thermal-insulation paint

ActiveCN104556727AGood light transmissionGood heat insulationCoatingsToluene diisocyanateHazardous substance

The invention provides a manufacturing method of a vehicle glass thermal-insulation paint, which comprises the following steps: (1) preparing a nano ATO (antimony tin oxide) slurry; (2) preparing a nano thermal-insulation paint; and (3) coating a film on glass. The thermal-insulation material prepared from the ATO nano material is glittering and translucent, and has the advantages of excellent water resistance, higher surface hardness and superhigh adhesion; the stabilizing agent adopted in the technique is a composite lead salt stabilizing agent; the leveling agent adopts acrylic acid; the defoaming agent adopts organosiloxane; the thickener adopts methyl cellulose; and thus, the thermal-insulation paint is free of benzene, ketone, TDI (toluene diisocyanate) and other harmful substances, and is green and environment-friendly. The thermal-insulation paint adopts a rotary coating process, and thus, is uniformly covered on the glass surface; and the rotary coating process has the advantages of favorable transparency and low paint consumption, and can well control the film thickness. The thermal-insulation paint has the advantages of favorable light transmittance, favorable thermal-insulation effect and small sheltering coefficient, and has broad market prospects and higher popularization value.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Sunlight reflective thermal-insulation paint, and preparation method thereof

InactiveCN108753058AGood heat insulationBarrier penetrationReflecting/signal paintsThermal insulationHigh reflectivity

The invention discloses a sunlight reflective thermal-insulation paint, and a preparation method thereof. The sunlight reflective thermal-insulation paint comprises, by weight, 35 to 50 parts of fluorocarbon resin emulsion, 5 to 15 parts of a high reflectivity pigment, 5 to 10 parts of polymer hollow micro-sphere, 5 to 10 parts of a reflective material, 5 to 15 parts of nanometer metal powder, 3 to 8 parts of nanometer silica, 0.2 to 0.5 part of a wetting dispersant, 0.4 to 0.8 part of a thickening agent, 0.2 to 0.4 part of a bactericide, 0.5 to 2.5 parts of a film forming auxiliary agent, 0.6to 1.6 parts of an antifoaming agent, and 15 to 25 parts of deionized water. The sunlight reflective thermal-insulation paint is capable of reflecting thermal energy transmission effectively, blocking heat radiation, blocking infrared heat energy, is excellent in thermal insulation performance, is low in energy consumption, is obvious in thermal insulation effect, and is long in service life; thepreparation method is simple, and is suitable for large scale production and applications.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Reflecting thermal-insulation paint

ActiveCN102898905BGood weather resistanceImprove stain resistanceReflecting/signal paintsSolar lightThermal insulation

The invention relates to the field of paints, in particular to a reflecting thermal-insulation paint, which comprises the following components in percentage by weight: 40 to 60% of fluorocarbon resin, 0.2 to 1.5% of fumed silica, 8 to 16% of aid, 15 to 30% of pigment, 6 to 20% of hollow glass microspheres, and 5 to 15% of solvent. The reflecting thermal-insulation paint disclosed by the invention is easy to prepare and use in construction, high in weather resistance and stain resistance, high in film density, small in dry film thickness and good in thermal-insulation effect, the solar light reflection rate and hemispherical reflection rate of the paint can keep stable for a long time together with reflecting and thermal-insulation performance. The paint can prevent heat from being transmitted to the interior of a vehicle, which not only saves energy, but also reduces the temperature of the interior and increases the comfort of the vehicle.

Owner:烟台佳隆纳米产业有限公司

Insulating paint used for overhead high voltage line and preparation method thereof

InactiveCN101781498BGuaranteed super weather resistanceGuaranteed self-cleaningPlastic/resin/waxes insulatorsCoatingsInsulative paintPhysical chemistry

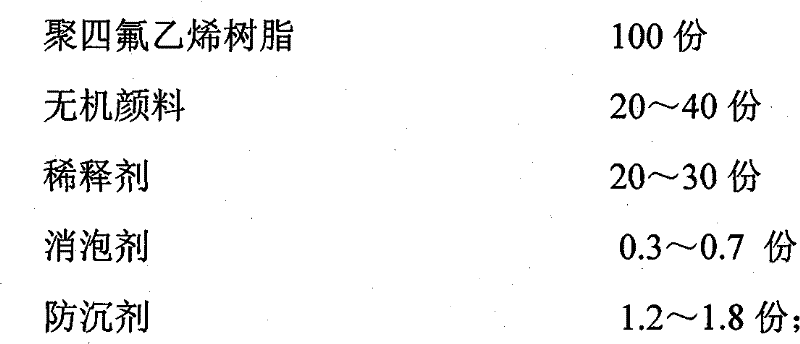

The invention discloses insulating paint used for an overhead high voltage line, which has the excellent properties of self cleaning, snow accumulation prevention and high voltage prevention, and the property thereof can reach the insulating requirement of resisting 35 KV voltage. The insulating paint used for the overhead high voltage line of the invention comprises a component A and a componentB, wherein the component A is formed by mixing the following components in parts by weight: 100 parts of teflon resin, 20-40 parts of inorganic pigment, 20-30 parts of diluent, 0.3-0.7 part of defoamer and 1.2-1.8 parts of anti-settling agent; the component B is a curing agent. When in use, the component A and the component B are evenly mixed to be used, and the amount of the component B is equalto 6-8 parts by taking 100 parts of the teflon resin in the component A as the reference.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

Annealing rustproof water-based insulating paint for electrical sheets and preparation method for annealing rustproof water-based insulating paint

InactiveCN102585694AHigh dielectric constantImprove surface resistivityCoatingsWater basedFilling materials

The invention particularly relates to an annealing rustproof water-based insulating paint for electrical sheets and a preparation method for the annealing rustproof water-based insulating paint. The invention adopts the technical scheme that 10 to 40 percent by weight of water-based organic-inorganic hybrid resin, 30 to 60 percent by weight of filling material, 0 to 10 percent by weight of assistant, 0 to 10 percent by weight of corrosion inhibitor and 1 to 30 percent by weight of deionized water are mixed, then are milled in a sand mill until the fineness is lower than 15 micrometers, and finally are packaged. The components of the annealing rustproof water-based insulating paint do not contain chromate and poisonous and hazardous ingredients, so that the annealing rustproof water-based insulating paint is environmental-friendly; the prepared paint is coated on the surface of an electrical sheet, can withstand high-temperature annealing treatment of 800 DEG C, and forms a protective layer on the surface, wherein the protective layer has strong adhesiveness, very high surface resistivity, excellent corrosion resistance and very strong weldability.

Owner:HUNAN SANLIDA CHEM

Insulating paint

InactiveCN102702817AEasy to prepare ingredientsHas the function of insulationCoatingsPolyesterInsulative paint

The invention discloses an insulating paint. The paint consists of the following raw materials: 1-1.1 parts of cobalt naphthenate, 4-5 parts of butyl alcohol, 33-34 parts of linoleic acid and 23-23.5 parts of ethanedioic acid polyester. The insulating paint can overcome the defects of the normal insulating paint and has the advantages of simple manufacturing raw materials, insulation function and low raw material production cost.

Owner:桑达化工(南通)有限公司

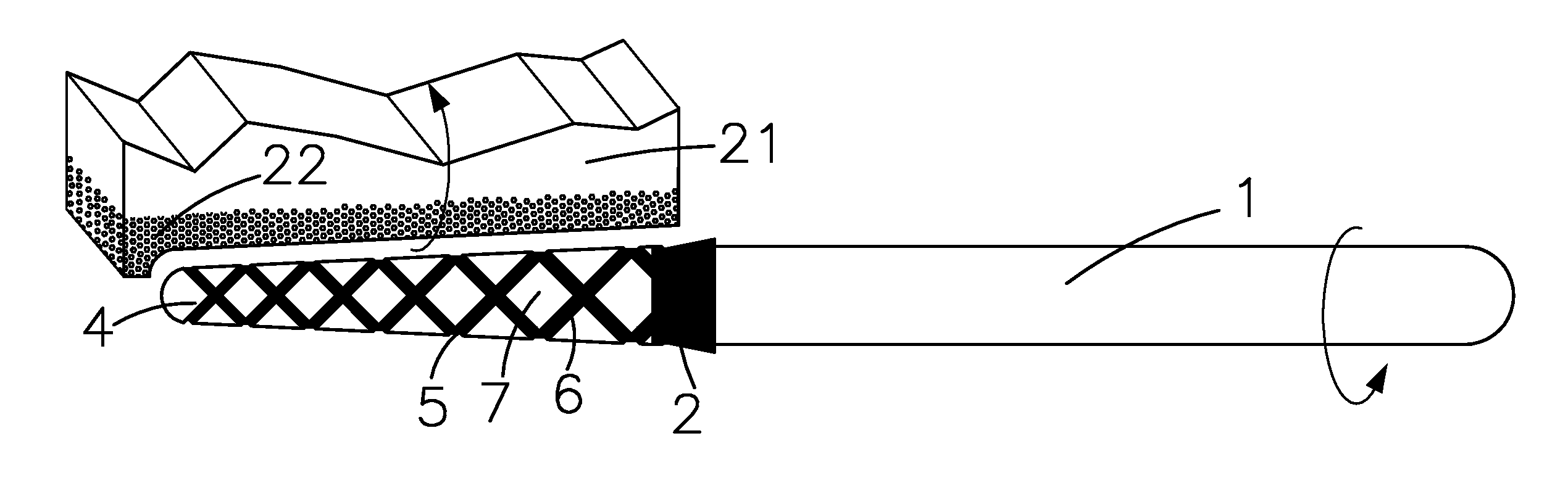

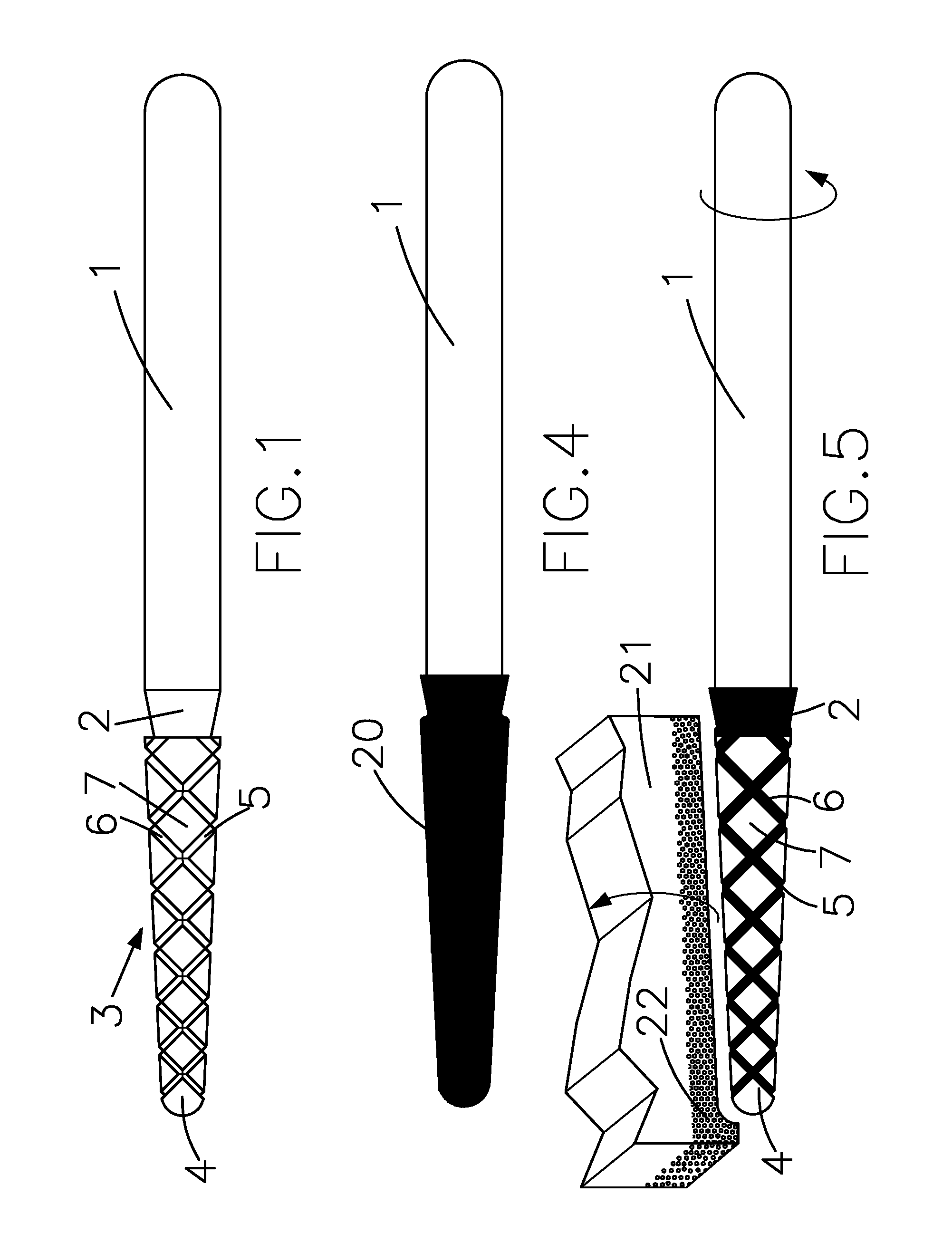

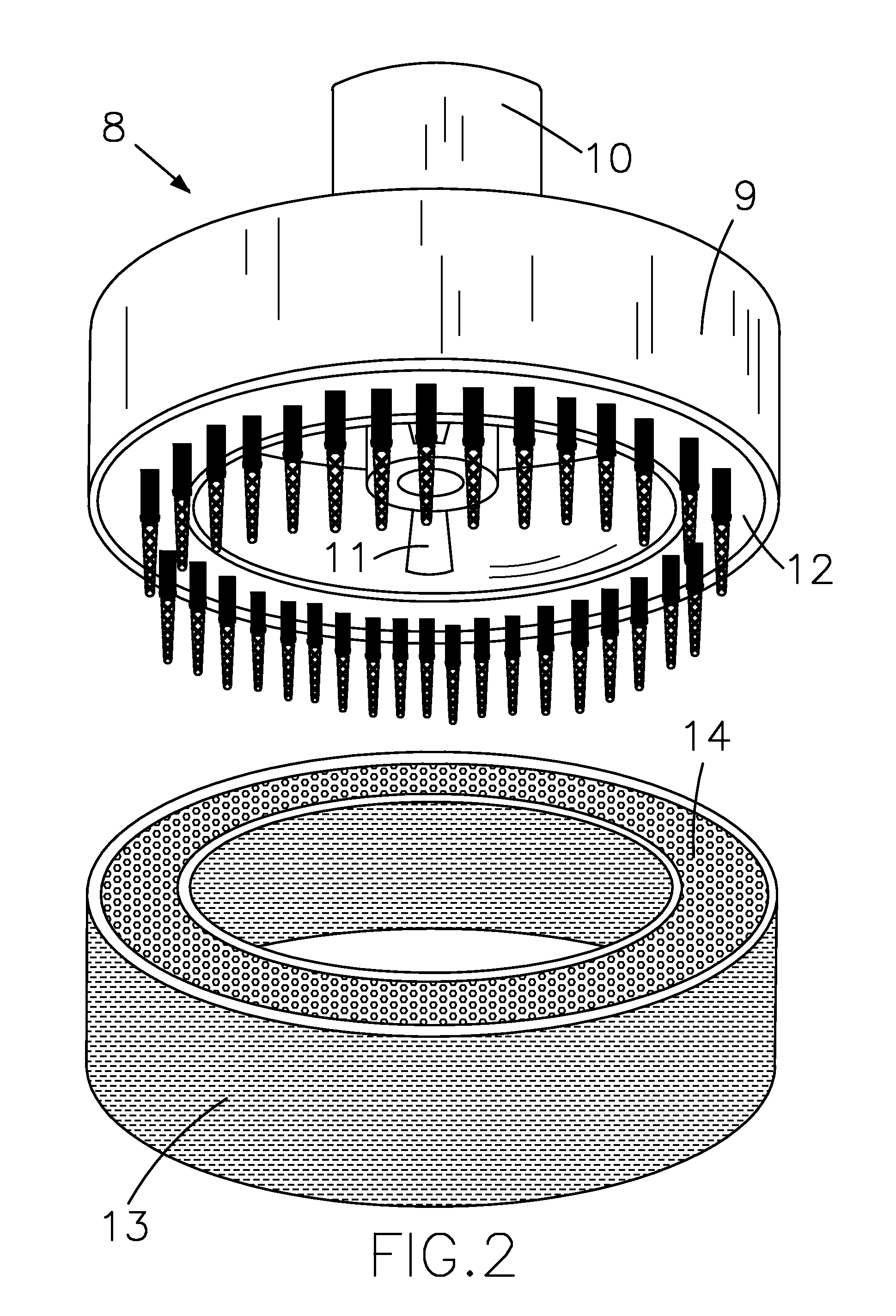

Method for applying a powdered-diamond coating to the surface of cutters for dentistry excluding slot surfaces

ActiveUS20110197517A1Low production costQuality lossPigmenting treatmentElectrolytic coatingsElectrolysisMarking out

The surface of cutters for dentistry is rendered passive to electroplating by immersion in a concentrated aqueous solution of nitric acid for a certain period of time. This is followed by painting a length including the surface marked out by the slots, the surface inside the slots and the surface at the tip, using an electrically insulating paint resistant to acids. Each cutter is then ground using a grinding wheel with rotating disk having an abrasive edge shaped like the continuous profile of the painted surface. Grinding removes the paint together with a micrometric layer of metal from the surface except for that inside the slots. The shank is ground and painted for a length adjacent to the slots. Further processes are then carried out in the following order: activation of the exposed metal surface by electrolysis of reversed polarity in a Wood bath; initial electrolytic nickel-plating in a Wood bath; application of a powdered diamond coating in a Watts bath by a second process of electrolytic nickel-plating containing powdered diamond in contact with the cutters; stabilization of the diamond coating by a third process of electrolytic nickel-plating in a Watts bath containing no powdered diamond; removal of the residual insulating paint by immersing the cutters coated with powdered diamond in a non-halogenous solvent treated with ultrasounds.

Owner:NORTH BEL INT

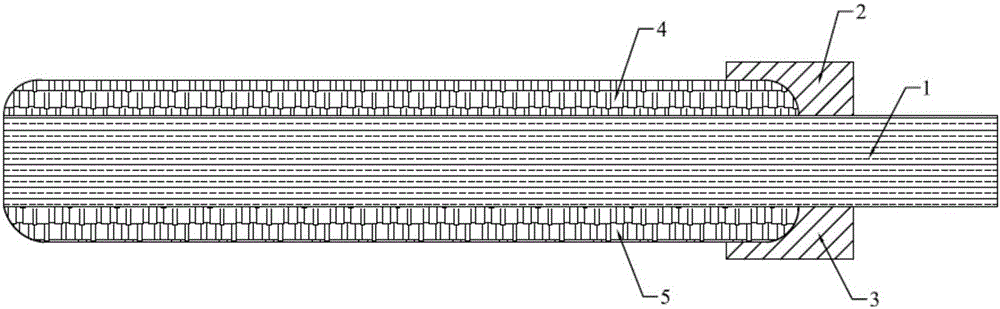

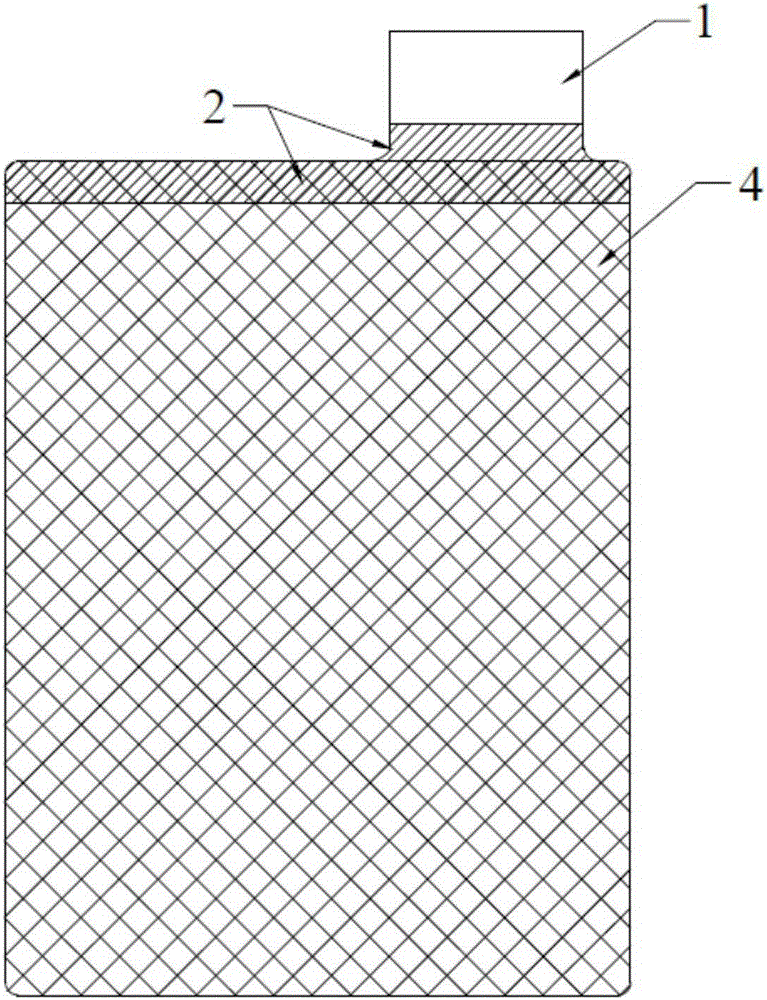

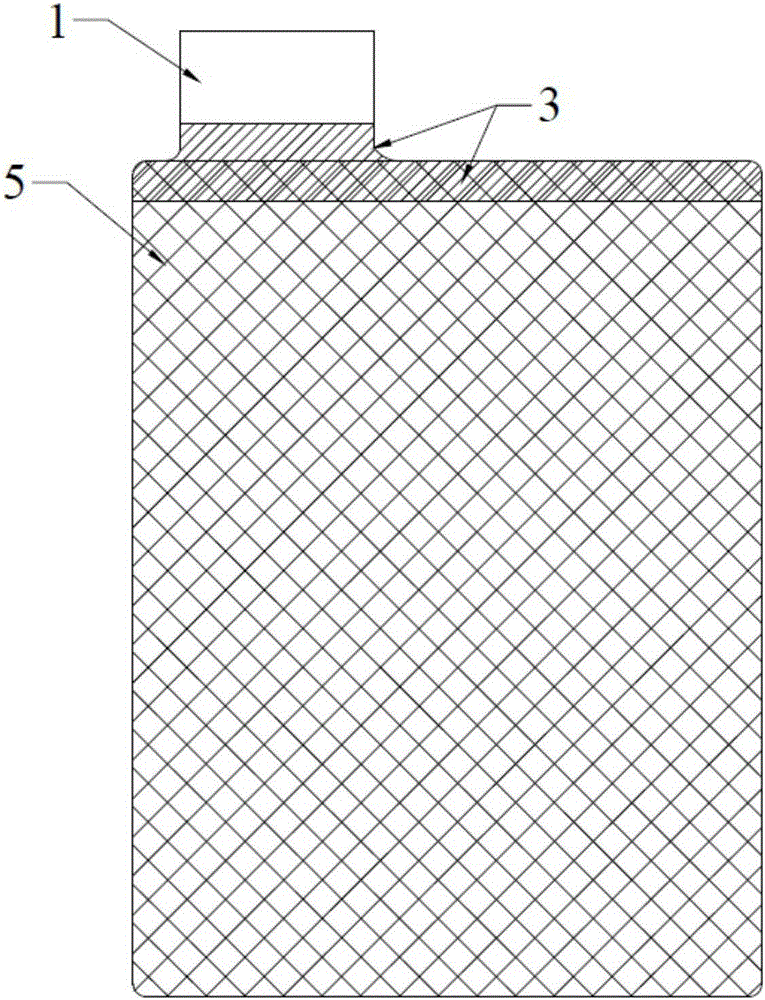

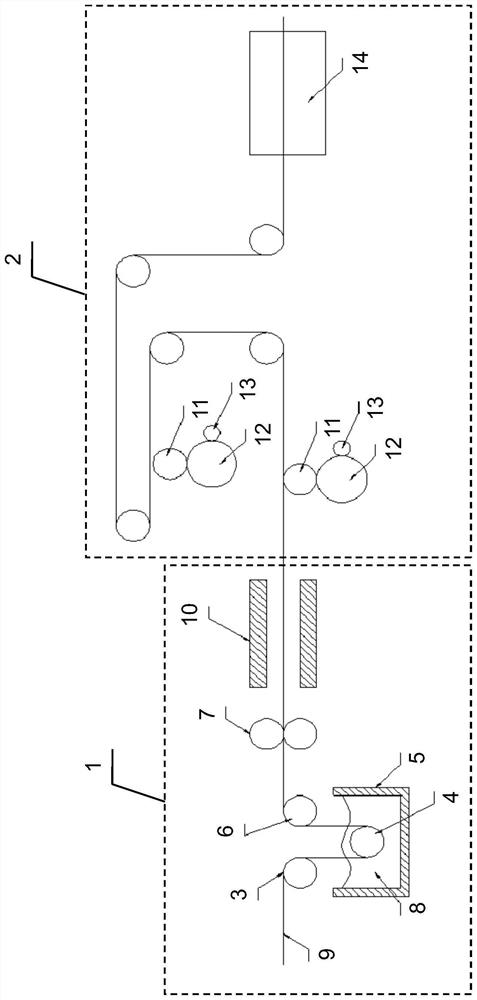

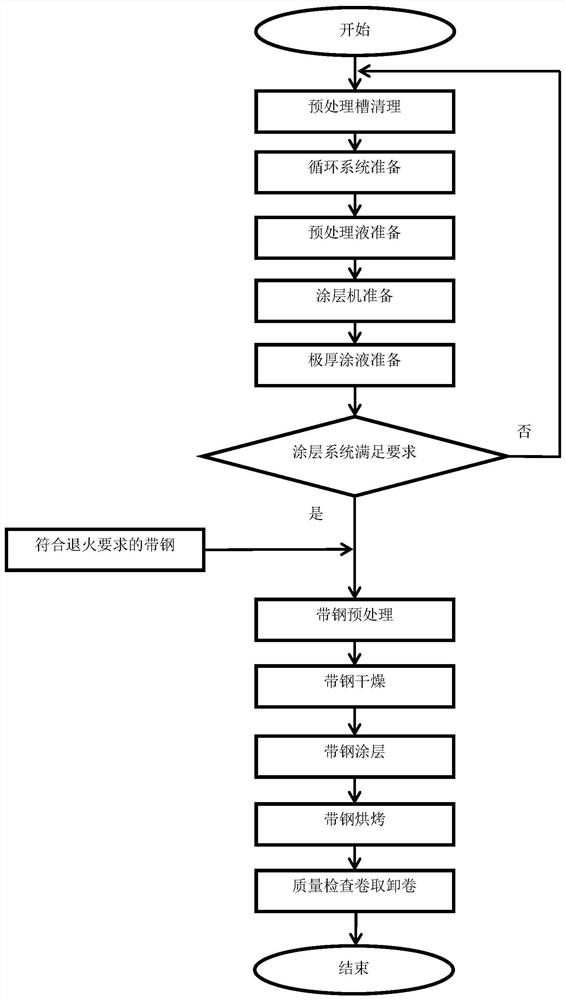

Production method of non-oriented silicon steel for extra-large generator and insulating coating of non-oriented silicon steel for extra-large generator

PendingCN112126937AGood adhesionSolve the phenomenon of shedding "exposing the bottom"Pretreated surfacesFurnace typesCoated surfaceInsulative paint

The invention discloses a production method of non-oriented silicon steel for an extra-large generator. The production method comprises a strip steel cleaning process, and further comprises a strip steel cleaning promoting process and a strip steel coating process which are sequentially arranged behind the strip steel cleaning process, the strip steel cleaning process comprises an uncoiling procedure, a cleaning procedure, a drying procedure and a high-temperature annealing procedure, the strip steel cleaning promoting process comprises a secondary cleaning procedure and a secondary drying procedure, and the strip steel coating process comprises a coating process and a baking and drying process; and the invention further discloses an insulating coating of the non-oriented silicon steel forthe extra-large generator. According to the production method of the non-oriented silicon steel for the extra-large generator and the insulating coating of the non-oriented silicon steel for the extra-large generator, the problems that the secondary paint coating falls off and the bottom is exposed, and bubbles and bright spots are usually easily generated on the surface of the thick coating areeffectively solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Insulating coating composition and an insulated wire, and a coil formed using the same

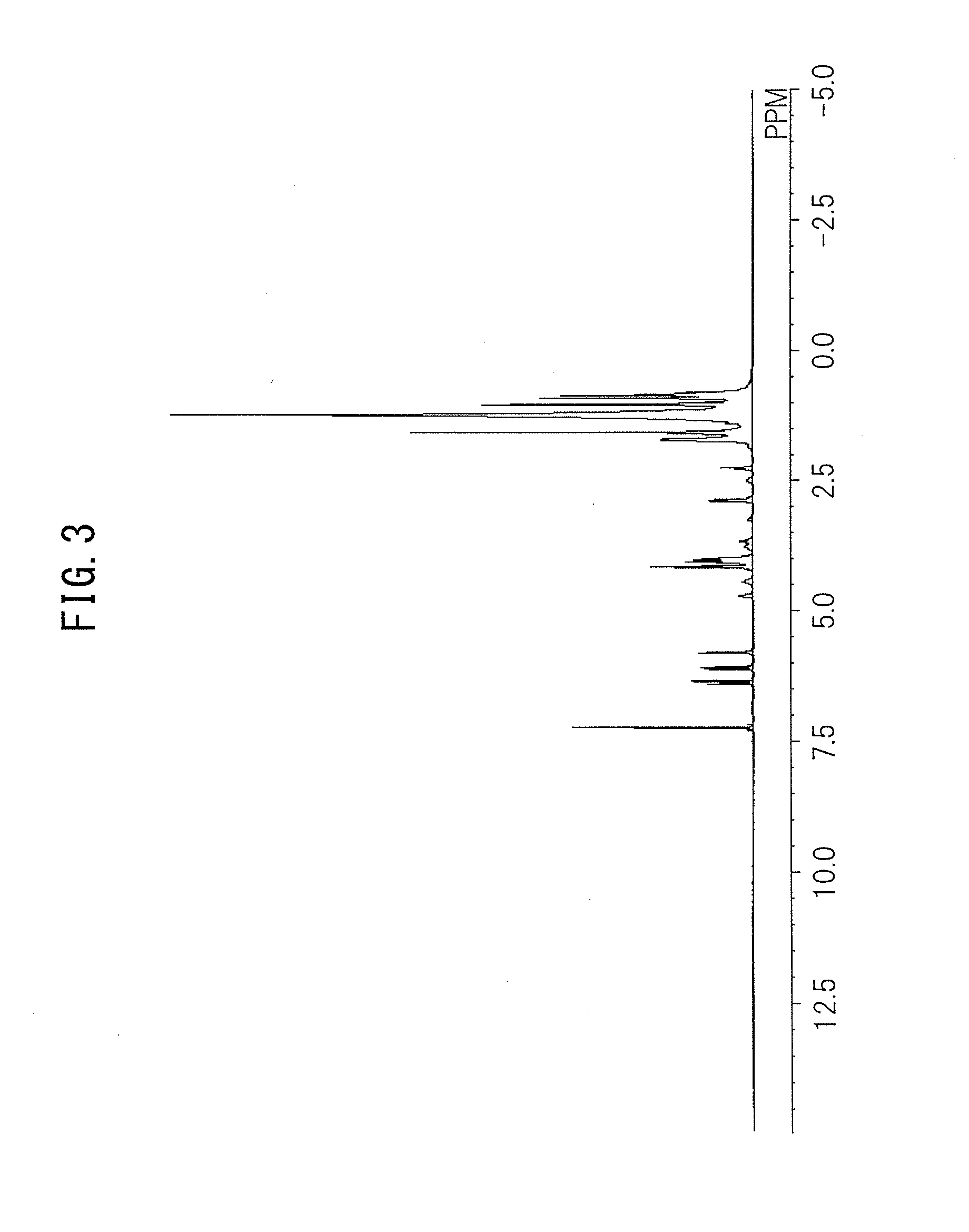

ActiveUS20100231345A1Good insertion effectIncrease surface lubricityPlastic/resin/waxes insulatorsSynthetic resin layered productsCarbon numberPolyamide-imide

An insulating coating composition that improves lubricity without reduction of the varnish adhesion strength and an insulated wire using the insulating coating composition, and a coil using the insulated wire are provided. An insulating coating composition comprises a polyamide-imide resin, which is obtained through a synthetic reaction of isocyanate component with acid component, and a lubricant component, wherein the terminal isocyanate group of the polyamide-imide resin is capped with a blocking agent of higher alcohol having a carbon number of eight or more.

Owner:HITACHI MAGNET WIRE CORP

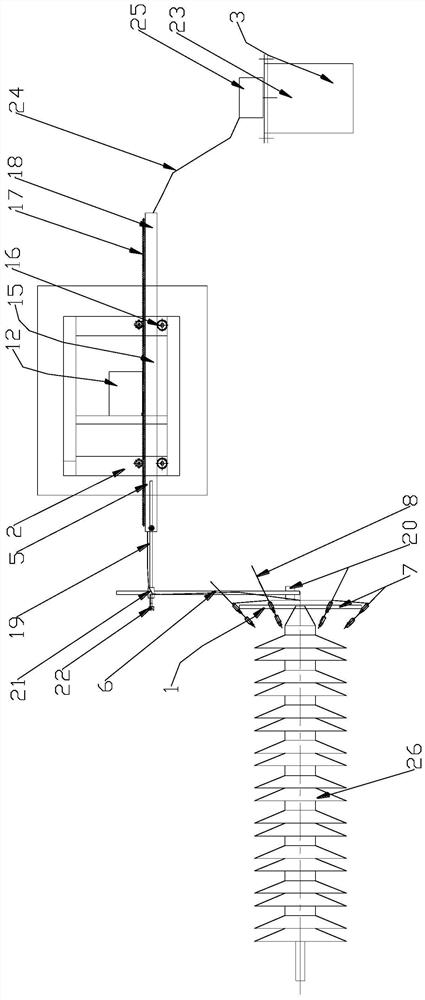

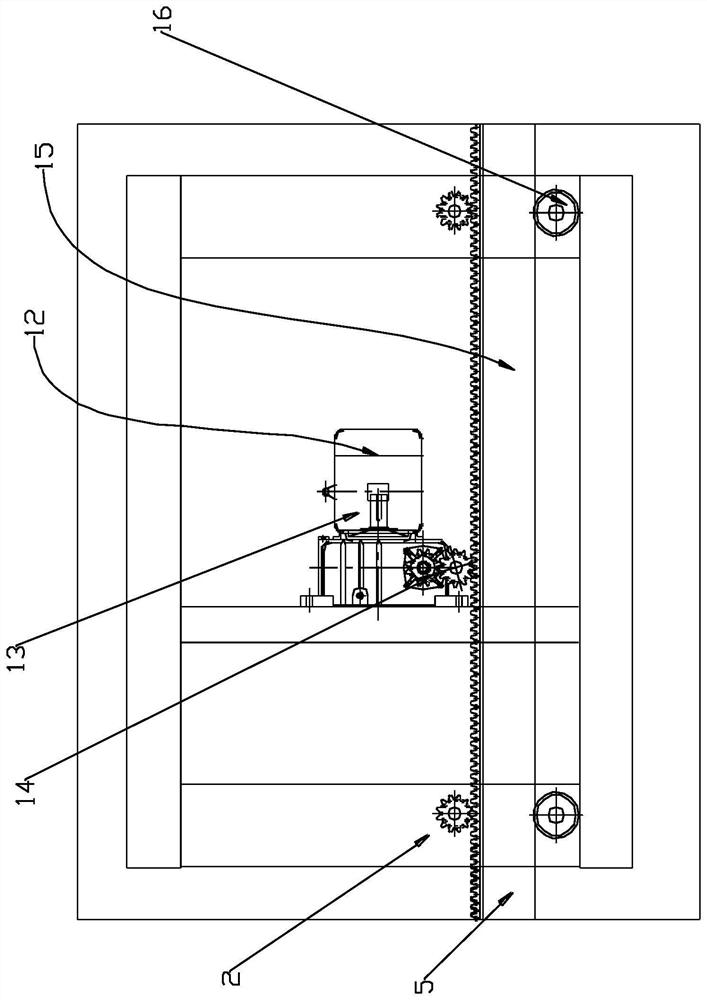

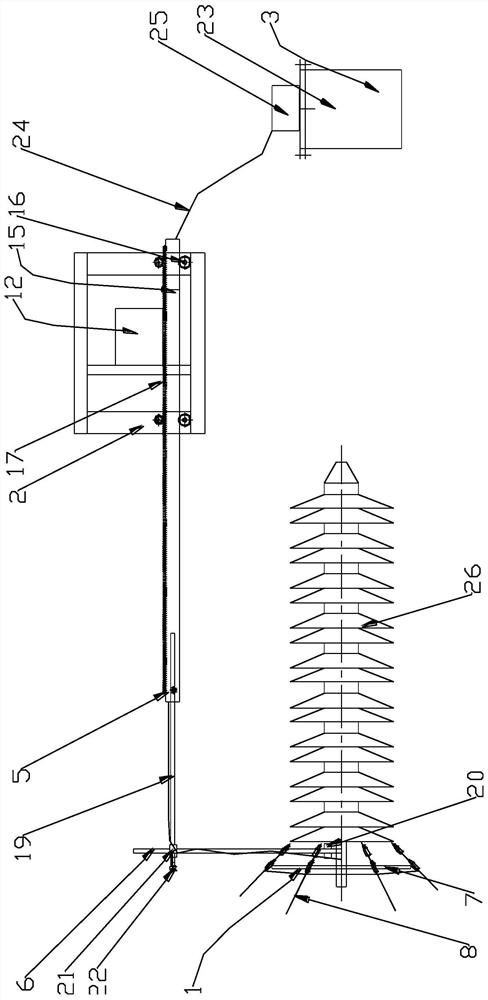

Insulating paint brushing device and using method

ActiveCN111871663AMeet the needs of on-site coatingImplement interactive distributionLiquid spraying apparatusInsulative paintStructural engineering

The invention relates to the technical field of insulator surface spraying, and provides an insulating paint brushing device and a using method. The insulating paint brushing device comprises a spraying mechanism, a material supply mechanism used for supplying paint to the spraying mechanism, and a control mechanism used for controlling the spraying mechanism and the material supply mechanism, thespraying mechanism comprises a workbench, first connecting rods arranged on the workbench, supporting rings arranged on the first connecting rods, first adjusting rods arranged on the supporting rings, first spray heads arranged on the first adjusting rods, second adjusting rods arranged on the first adjusting rods in a sliding manner and second spray heads arranged on the second adjusting rods,and the material supply mechanism is further used for supplying materials to the first spray heads and the second spray heads. The first spray heads and the second spray heads perform profiling motionalong the surface of a sprayed object. The problem that in the prior art, a good micro-nano structure is difficult to form through an insulating coating brushing manner is solved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

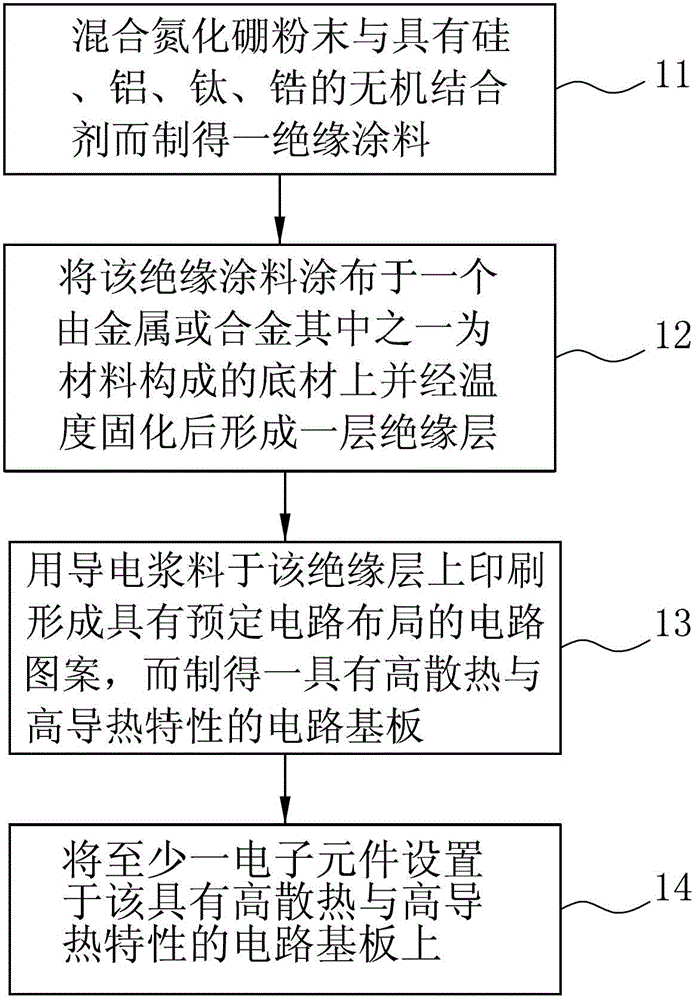

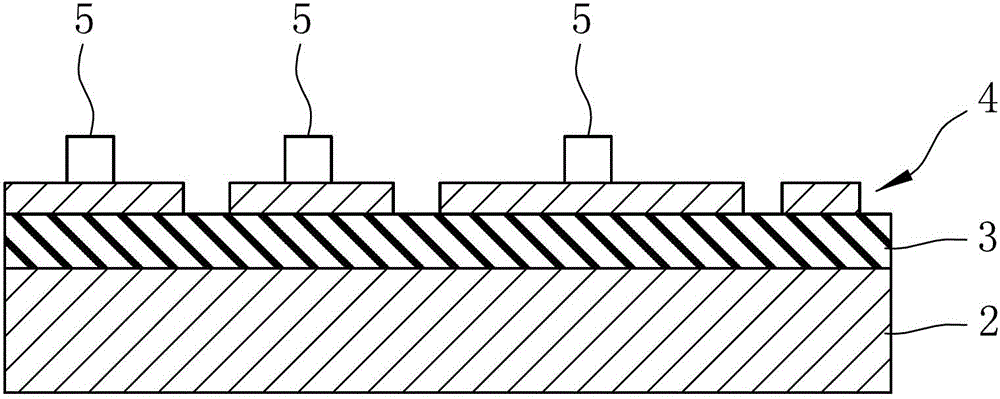

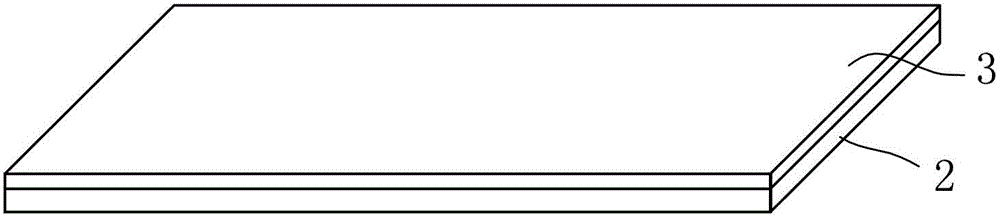

Method for manufacturing circuit substrates and circuit boards with high heat dissipation and high heat conductivity

InactiveCN102724806AImprove thermal conductivityImprove bindingPrinted circuit manufactureCircuit susbtrate materialsElectricityScreen printing

The invention relates to a method for manufacturing circuit substrates and circuit boards with high heat dissipation and high heat conductivity. The method comprises the steps as follows: firstly mixing boron nitride powder with an inorganic bonding agent containing silicon, aluminum and zirconium to prepare insulating paint; applying the insulating paint on a substrate made of metal or alloy, and heating for curing to form an insulating layer with good heat conductivity and in excellent combination with the substrate; and applying conductive material on the insulating layer to form a circuit pattern with a scheduled circuit layout in a screen printing or sputtering mode to prepare a circuit substrate with high heat dissipation and high heat conductivity. Through the insulating layer with good heat conductivity and in excellent combination with the substrate, heat energy generated by actuating electronic components in electric connection to the circuit pattern can be quickly conducted to the substrate, thereby achieving the effects of fast heat conduction and high heat dissipation rate.

Owner:田宝祥

Heat dissipation insulating coating as well as preparation method and application thereof

ActiveCN110982409AImprove aging resistancePrevent leakagePolyurea/polyurethane coatingsEpoxy resin coatingsLightning strokesInsulative paint

The invention relates to the technical field of insulating coatings, in particular to a heat dissipation insulating coating as well as a preparation method and application thereof. Under the radiationcondition of a 300W ultraviolet lamp at 60 DEG C, the heat dissipation insulating coating has the aging-resistant time of 4800h, the aging-resistant performance is excellent, and the maintenance frequency and the maintenance cost can be greatly reduced; the volume resistivity of the cured coating is larger than 1012 ohm.m, the alternating current dielectric strength is larger than 35 kv / mm, bareconductor electric leakage can be effectively prevented, and potential safety hazards caused by bare conductor breakdown are prevented; the comprehensive thermal radiation coefficient of the cured coating is greater than 0.89 epsilon, and the cured coating has good heat dissipation performance and can effectively prevent the ablation phenomenon of bare conductor after lightning stroke.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Nanometer heat-insulation paint

Disclosed nanometer heat-insulation paint comprises the following compositions in parts by weight: 100 parts of UV varnish, 175-200 parts of a nanometer ceramic powder liquid, 5-15 parts of a suspension dispersion liquid, 0-50 parts of a diluent, 5-10 parts of a liquid-crystal mixing agent, and 0-5 parts of an initiator. The paint is low in solidification temperature requirement, rapid in solidification speed, and finishes solidification at 110 DEG C within 1 min. The energy consumption during solidification is low, and the UV solidification energy requirement is 100-110 MJ / m<2> and can be realized by using an ultraviolet lamp with the power of 120 W. By utilizing a cholesterol liquid crystal particle to reflect infrared ray and ultraviolet ray, a conventional technology of utilizing a heat-insulation material to slow a hot fluid is replaced, the coating thickness is relatively thin, the heat insulation effect is relatively obvious, and the heat insulation effect can reach 96% or more. The paint is added with the nanometer ceramic powder liquid prepared by diluting a nanometer ceramic powder, so that the hardness of the coating is substantially improved, the hardness is measured to be 4 H, and the service life is greatly prolonged.

Owner:江苏凯尚碳科技有限公司

Method for preparing winding iron core and iron core therewith

InactiveCN101800127AImprove interlayer insulation performanceReasonable structureInductances/transformers/magnets manufactureMagnetic materialsTemperature resistanceMaterials science

The invention discloses a method for preparing a winding iron core. The iron core comprises a ribbon-shaped non-oriented magnetic material. The method comprises the following steps of: (1) preparing mixed insulating paint; (2) loading the material; (3) feeding the material; (4) setting the parameters; (5) and producing. The method has the advantages of fewer working steps and simple preparation, greatly reduces the production cost, ensures the precision and consistency of the products and greatly enhances the interlaminar insulation property, high temperature resistance, magnetic conducting effect and percent of pass of the iron core. The method adopts a constant pressure gas and high oil pressure mode, combines the non-oriented magnetic material which is uniformly rolled and wound by 360degrees and meanwhile matches to coat the mixed insulating paint on the surface of the non-oriented magnetic material to fully fill the tiny gap generated by material deformation and permeate into the interior of the material, thereby wholly enhancing the performance of the product. The iron core of the invention has the advantages of reasonable structure, high temperature resistance, high interlaminar insulation property and higher magnetic conducting effect.

Owner:广州高炬知识产权代理有限公司

Preparation method of porous coated resin foamed particles, and outer wall heat-reflection thermal-insulation paint and preparation method thereof

ActiveCN104177964AWeak convective conductionGood heat insulationVacuum evaporation coatingSputtering coatingMetal coatingEmissivity

The invention discloses a preparation method of porous coated resin foamed particles, which comprises the following step: sequentially carrying out expansion foaming and magnetron sputtering metal coating on thermoplastic resin particles to obtain the porous coated resin foamed particles. The invention also discloses an outer wall heat-reflection thermal-insulation paint and a preparation method thereof. The paint is prepared by using the porous coated resin foamed particles as a heat-reflection thermal-insulation filler, an organic silicon modified acrylic acid emulsion as a base material, and an inorganic flaky material and water as auxiliary materials. The inside of the porous coated resin foamed particles is a porous structure, the pore diameter is 0.5 mu m or so, and the porous coated resin foamed particles have the free path approximate to air at 40 DEG C, and have weak convection conductivity and favorable thermal-insulation effect. The particle surface is provided with the metal coating, and thus, has favorable heat-reflection effect. The sun reflectivity of the heat-reflection thermal-insulation paint is greater than or equal to 0.80, and the hemispherical emittance is greater than or equal to 0.78; and the heat-reflection thermal-insulation paint has the advantages of high reflectivity, low heat conductivity coefficient and excellent thermal-insulation effect.

Owner:广西防城港美好涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com