High-solid-content aqueous ultraviolet curing transparent heat-insulation paint and preparation method thereof

A high-solid content, heat-insulating coating technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor water resistance, poor leveling, poor mechanical properties, etc., to improve dispersion and stability, good water resistance the effect of improving the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

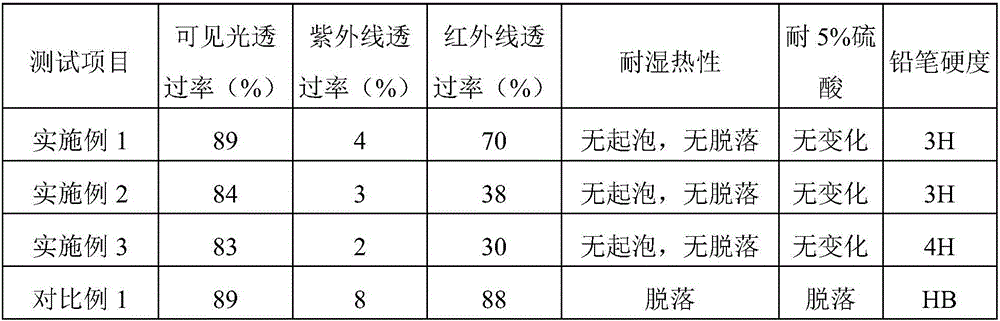

Examples

Embodiment 1

[0026] Add 40 g of polyester polyol (Jiangsu Jintan Lihe Adhesive Factory, 108-I) to a reactor equipped with a stirrer, a thermometer, and a reflux condenser, vacuumize and dehydrate at 100°C for 1 hour, cool down to room temperature, and add isofluorine 10g of ketone diisocyanate, 6.4g of hexamethylene diisocyanate, heated to 70°C, reacted for 1h, added 1.6g of dimethylol butyric acid, 1.3g of ethylene glycol, 0.03g of dibutyltin dilaurate, and stirred Continue to react for 4h, add 18.6g of pentaerythritol triacrylate, continue to react for 1h to obtain a prepolymer, then cool down to room temperature, add 0.75g of triethylamine to neutralize the prepolymer into a salt; Add 86 g of deionized water under shearing, add 0.74 g of ethylenediamine for chain extension reaction for 30 minutes, and discharge to obtain a high-solid content aqueous polyurethane dispersion. The main performance indicators are: solid content of 48%, and viscosity of 21 mPa.s.

[0027] In a disperser equi...

Embodiment 2

[0029] In a reactor equipped with a stirrer, a thermometer, and a reflux condenser, add 40 g of polyester polyol (Shandong Huacheng Hi-Tech Adhesive Co., Ltd., AD-60), vacuumize and dehydrate at 105°C for 1.5 h, cool down to room temperature, and add benzene Dimethylene diisocyanate 14.2g, heat up to 75°C, react for 1.5h, add 2.3g of dimethylolpropionic acid, 0.5g of diethylene glycol, 0.1g of stannous octoate, continue to react for 3h under stirring, add 9.2 pentaerythritol Trimethacrylate, continue to react for 2 hours to obtain a prepolymer, then cool down to room temperature, add 1.7g triethylamine to neutralize the prepolymer into a salt; discharge it into a disperser, add deionized 70g of water was added, and 1.7g of diethylenetriamine was added for chain extension reaction for 20 minutes to obtain a high-solid content aqueous polyurethane dispersion. The main performance indicators were: the solid content was 50%, and the viscosity was 43mPa.s.

[0030] In a disperser e...

Embodiment 3

[0032] In a reactor equipped with a stirrer, a thermometer, and a reflux condenser, 40 g of polyester polyol (Zhejiang Huafon New Material Co., Ltd., PA-1225T) was added, vacuum dehydrated at 110°C for 2 hours, cooled to room temperature, and 4 , 27.4g of 4'-dicyclohexylmethane diisocyanate, heated to 80°C, reacted for 1h, added 3g of dimethylolpropionic acid, 0.9g of 1,4-butanediol, 0.19g of dibutyltin dilaurate, and stirred The reaction was continued for 2 hours, 15.6g of pentaerythritol triacrylate was added, and the reaction was continued for 2 hours to obtain a prepolymer, then cooled to room temperature, and 2.4g of triethylamine was added to neutralize the prepolymer to form a salt; Add 87g of deionized water under high-speed shearing, and add 4.9g of tetraethylenepentamine for chain extension reaction for 10 minutes to obtain a high-solid content aqueous polyurethane dispersion. The main performance indicators are: solid content of 52%, viscosity of 98mPa.s .

[0033]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com