Patents

Literature

290results about How to "Non-combustible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

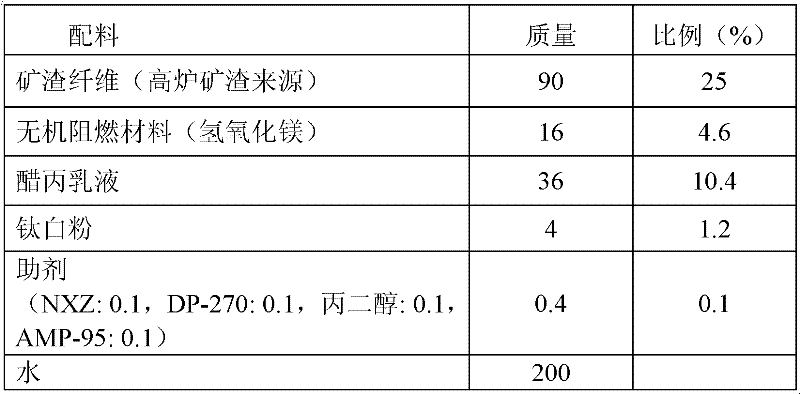

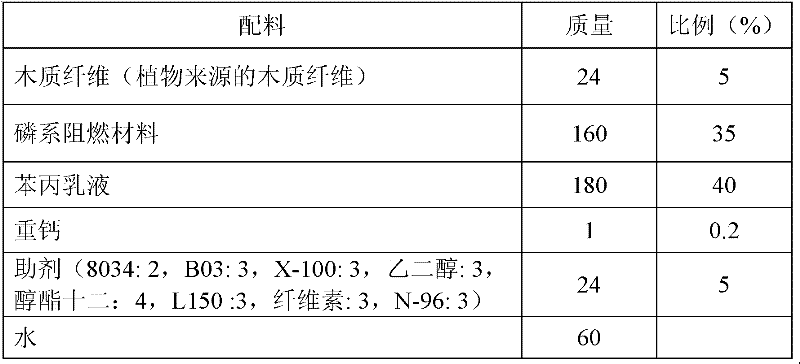

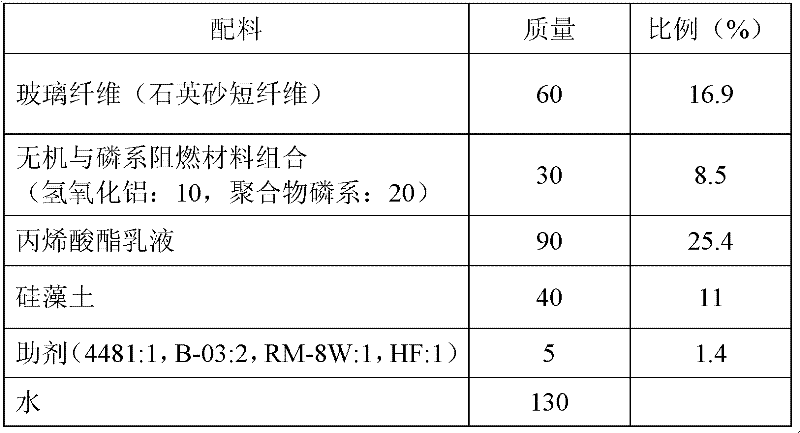

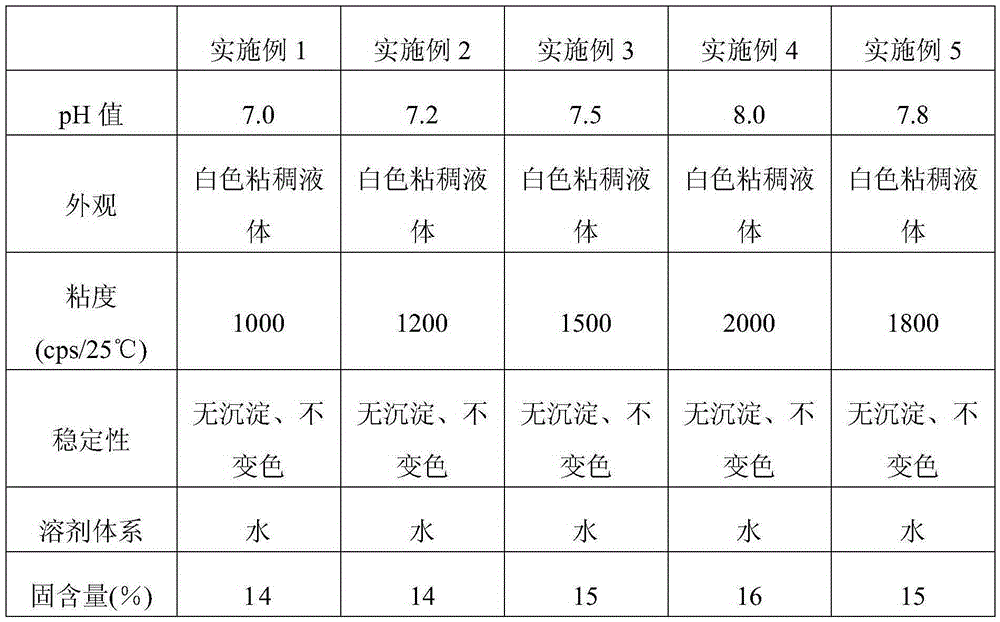

Sound-absorbing coating material and preparation method thereof

ActiveCN102533016AImprove sound absorptionNon-combustibleCoatingsNoise reduction coefficientGlass fiber

The invention discloses a sound-absorbing coating material, wherein every 100 parts by mass of coating contains 5-50 parts by mass of sound-absorbing function materials, 0.1-35 parts by mass of flame retardant materials, 10-40 parts by mass of binding materials, and the balance of an inorganic filling, an assistant and water in a common coating. The sound-absorbing function materials are selected from one or composite of some of materials such as slag fibers, mineral fibers, glass fibers and wood fibers, with fiber structures, and the sound-absorbing function materials are subjected to waterproof modification treatment. According to the invention, NRC (Noise Reduction Coefficient) of the coating material is tested to be more than 0.4 by using a standing wave tube method, and the sound-absorbing coating material has a good sound-absorbing denoising performance, excellent flame resistance and low heat conductivity coefficient, can be used for reducing the energy consumption of a building, is an environmental-friendly functional sound-absorbing coating material integrated with functions of sound absorption, flame resistance and decoration, and can be used on the surface of the building.

Owner:CHINA BUILDING MATERIALS ACAD

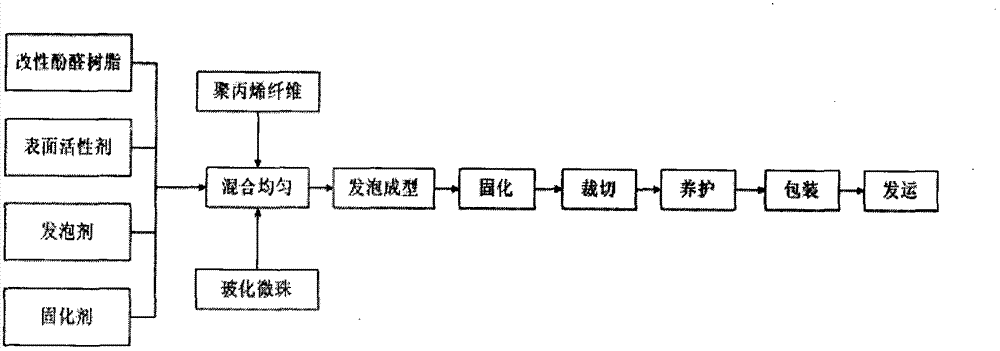

Fire-proof and thermal-insulation board and manufacturing method thereof

InactiveCN102787670AHigh bonding strengthNon-combustibleHeat proofingSound proofingFiberAdhesive cement

The invention relates to a fire-proof and thermal-insulation board and a manufacturing method thereof, and belongs to the technical field of constructional materials. According to the manufacturing method of the fire-proof and thermal-insulation board, modified phenolic resin, reinforcing fibers and inorganic micro bead thermal insulation fillings with the weight ratio of 1:(0-0.05):(0.3-1) are prepared; and after the steps of preparing adhesive, preparing a mixture, foaming, forming and solidifying to form are finished, a foam board is subjected to thermal insulation to be formed, so that the fire-proof and thermal-insulation board in a closed cell foamed structure is obtained. According to manufacturing method, organic materials and inorganic materials are organically combined, so that a novel fire-proof and thermal-insulation material with the fire-proof property of the inorganic thermal insulation materials and the thermal-insulation property of the organic thermal insulation materials is manufactured; and the fire-proof and thermal-insulation board is simple in forming technology, and can practically satisfy the energy saving and safety requirements of wall construction.

Owner:万国骅

Method of producing architectural decorative material and wall bady material using phosphogypsum

InactiveCN1651348AGood weather resistanceImprove corrosion resistanceSolid waste managementFoaming agentPolymer science

A process for preparing wall material or decorative material from ardealite includes washing with water, drying, calcining, grinding, proportionally mixing it with PVC resin and auxiliary, stirring to obtain powdered material, heating to become paste, adding foamer, extruding and vacuum foaming in mould to obtain wall material, or heating while extruding said powdered material to become particles, heating and moulding to become decorative material.

Owner:GUIYANG PENGHONG HIGH NEW TECH DECORATION MATERIAL

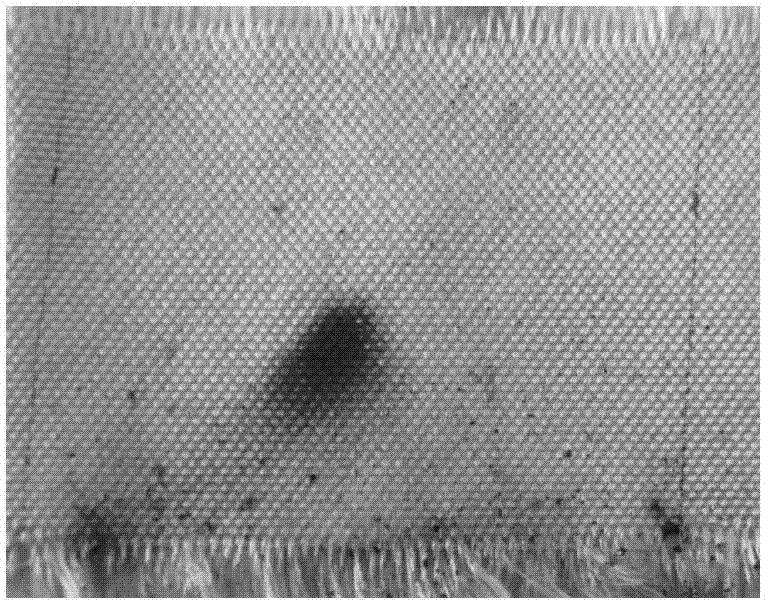

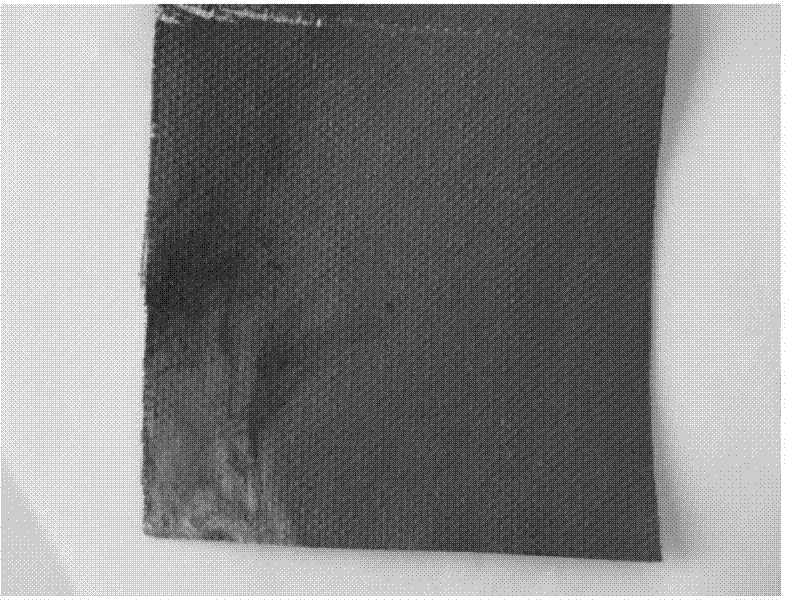

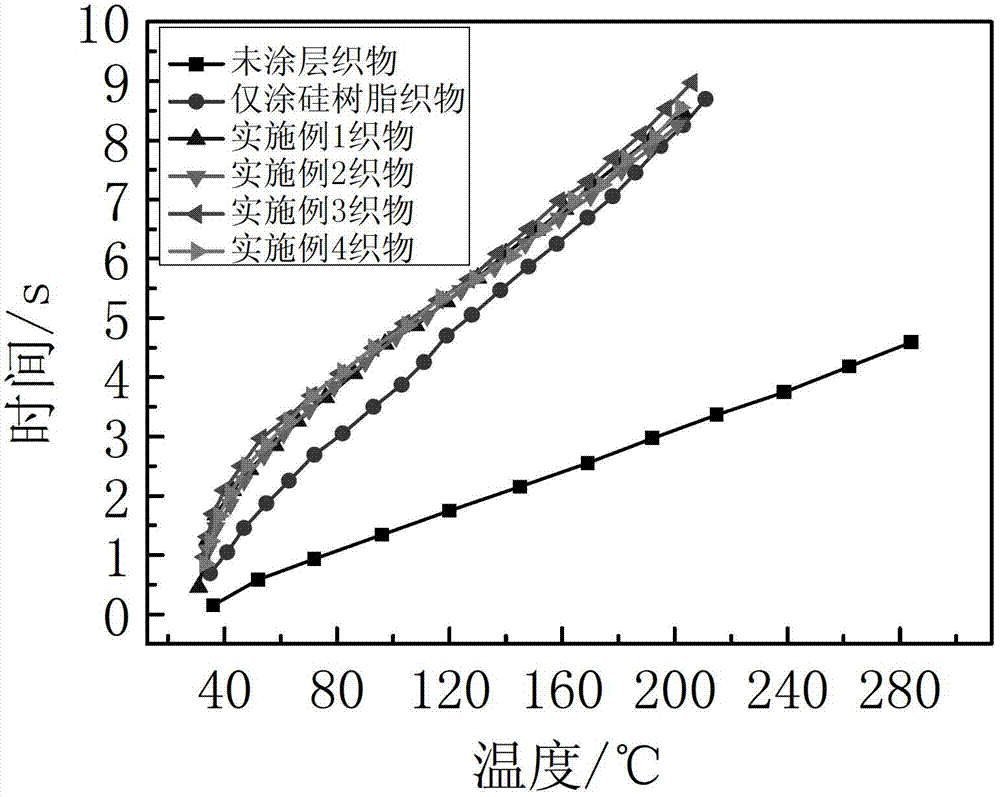

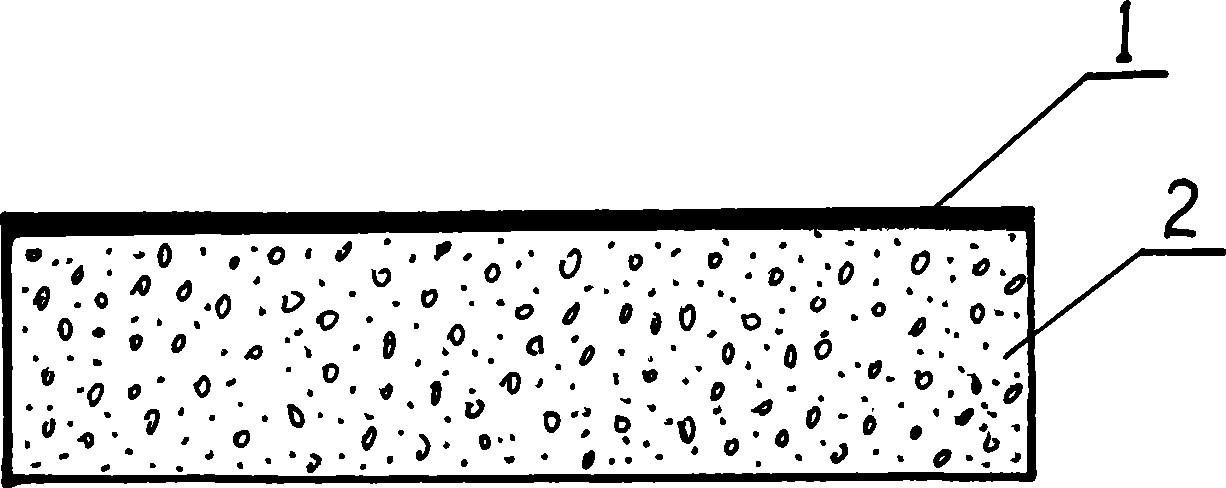

Heat-insulating and ablation-resistant glass fiber fabric and preparation method thereof

ActiveCN103205896AImprove heat resistanceImprove crack resistanceFibre treatmentResin coatingEngineering

The invention provides a heat-insulating and ablation-resistant glass fiber fabric and a preparation method thereof, belonging to the technical field of thermal protection fabrics and preparation thereof. The heat-insulating and ablation-resistant glass fiber fabric product comprises a fabric layer and coating layers on the front and back surfaces of the fabric layer, wherein the thicknesses of the coating layers on the front and back surfaces of the fabric layer are controlled at 30-80 micros; the fabric layer is made from glass fiber fabrics; the coating layers are composite organic silicon resin coating layers which are prepared by mixing an organic silicon resin solution, white carbon black, mica powder and the like in certain percentage by weight; a solute of the organic silicon resin solution is phenyl methyl silicone, a solvent of the organic silicon resin solution is dimethylbenzene, toluene or a mixture of the two, and the mass ratio of the solvent to the solute is 1:1; and a preparation method of a composite organic silicon resin coating layer solution comprises the following steps of: sequentially adding the white carbon black, the mica powder, wollastonite in powder and metallic oxide into the organic silicon resin solution, and stirring to ensure that the substances are uniformly dissolved. The heat-insulating and ablation-resistant glass fiber fabric is simple in process, easy to operate, and excellent in heat resistance, weather resistance, insulating property, reinforcement performance, scrubbing resistance and weathering resistance.

Owner:赵晓明 +1

Adhesive and preparation method thereof as well as application of adhesive in vegetable fiberboard or artificial board

ActiveCN104449411ANo pollution in the processGuaranteed environmental performanceNon-macromolecular adhesive additivesInorganic adhesivesAdhesiveVegetable fibers

The invention discloses an adhesive, which is mainly prepared from the following components in parts by weight: 50-60 parts of a sodium silicate solution, 10-20 parts of brine, 20-30 parts of nanosilicon dioxide, 6-8 parts of packing, 0.4-0.6 part of a modifying agent and 0.1-0.3 part of a stabilizer. The preparation method comprises the following steps: firstly mixing and dissolving magnesium chloride and magnesium sulfate at a certain molar ratio, and stirring to obtain brine; adding the sodium silicate solution to the prepared brine and adding the nanosilicon dioxide to the prepared sodium silicate-brine mixture, so as to obtain a mixture; adding the packing to the mixture, and stirring evenly, so as to obtain a semi-finished product; and adding the modifying agent and the stabilizer to the semi-finished product, so as to obtain an adhesive product. The adhesive disclosed by the invention can be applied to the vegetable fiberboard or the artificial board as an inorganic adhesive, does not release pollutants, and is low in cost; and the strength, the fire resistance and the water tolerance of the product can be significantly improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Light mortar inside and outside combined exterior wall heat-preserving system

InactiveCN101245613AMeet the requirements of building fire protectionEasy to adjustCovering/liningsWallsFire preventionMaterials science

An external wall insulation system of a lightweight screed inside and outside combination is formed by smearing plaster lightweight screed and cement lightweight screed on the external wall of a building; wherein, the inner side of the external wall is coated with the plaster lightweight screed and the outer side of the external wall is coated with the cement lightweight screed, and both the plaster lightweight screed and the cement lightweight screed comprise lightweight aggregate which contains organosilicone modified expanded perlite. The external wall insulation system has the advantages that: aiming at the different requirements of the inner side and the outer side of the external wall of the building, the inner side of the external wall adopts the plaster lightweight screed and the outer side adopts the cement lightweight screed so as to form the novel insulation structure, thus exerting the function of the two insulation sand pulps and being beneficial to humidity control and fire prevention in the building; the external wall insulation system has the advantages of low coefficient of heat conductivity, excellent intensity index of each item, ensuing safe use, effectively reducing the deadweight of the building and the burden of basis load, extremely simple construction technique, stable physical property, existing no hollowing and crazing after construction, extremely low radioactivity, ensuring the inhabited environment to be healthy and safe as well as wide application scope.

Owner:上海中绿建材有限公司

Glass fiber reinforcement cement board and production method thereof

InactiveCN101386509AGuaranteed StrengthGuaranteed lifeSolid waste managementCeramicwareExpanded clay aggregateCement board

The invention relates to a building material and a method for preparing the same, in particular to a glass fiber reinforced cement board and a method for preparing the same. The glass fiber reinforced cement board comprises the following components in weight portion: 100 portions of Portland cement, 13.6 to 15 portions of high alumina cement, 3.1 to 3.4 portions of fly ash, 5.7 to 6.3 percent of plaster stone powder, 120 to 132 portions of ceramsite, 6.5 to 7.1 percent of foaming agent, 74.5 to 81.3 percent of dispersing agent, 53 to 58.7 portions of pure water and 3.6 to 4 portions of plastic-coated glass fiber grid cloth. The preparation method sequentially comprises the following steps: mixing weighed-up solid materials, adding weighed-up liquid materials in the previous step, cavity forming, roll extruding, vibration, cutting and curing. The invention has the advantages that: the glass fiber reinforced cement board has advantages of light volume weight, high strength, low dry shrinkage wet swelling coefficient, no after expansion and shrinkage, corrosion resistance, sound insulation, heat insulation, fire resistance and non-combustion; the preparation method has the characteristics of scientific and reasonable method, continuous production, high efficiency and low cost, flat board surface, convenient in-site mounting and the like; the glass fiber reinforced cement board is good in water resistance, and particularly applied to the finishing of internal and external walls and ceilings of various buildings in wet environments; moreover, the glass fiber reinforced cement board and a method for preparing the same have the advantages of ensuring the strength and service life of cement due to the adoption of the plastic-coated anti-alkali glass fiber grid cloth, along with reasonable blending ratio and reduced alkalinity.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

Ultra-low apparent density and high-performance foam concrete material and its preparation method

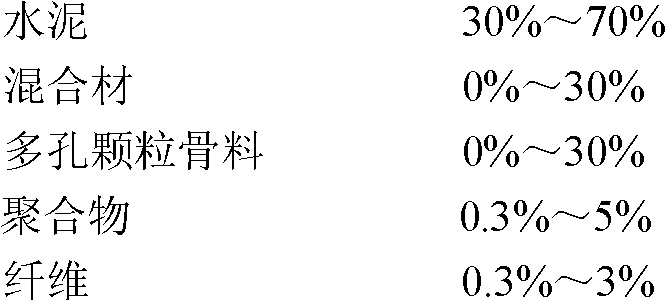

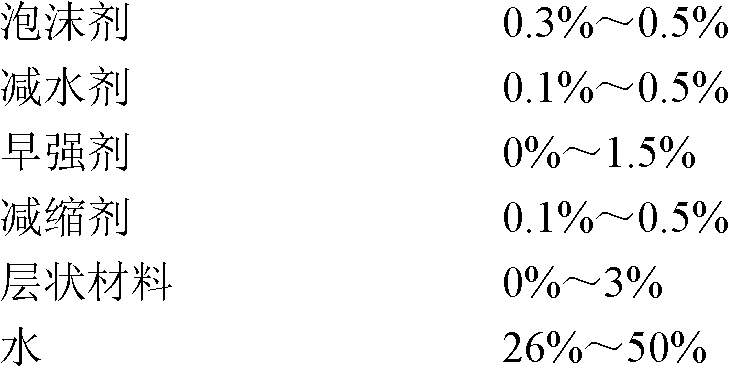

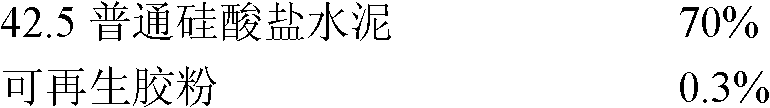

InactiveCN102424556ALow apparent densityLow thermal conductivityCeramicwareFoam concreteShrinkage cracking

The invention relates to an ultra-low apparent density and high-performance foam concrete material and its preparation method. The material comprises the following components by mass: 30%-70% of cement, 0%-30% of an admixture, 0%-30% of a porous particle aggregate, 0.3%-5% of a polymer, 0.3%-3% of a fiber, 0.3%-0.5% of a foaming agent, 0.1%-0.5% of a water reducing agent, 0%-1.5% of an early strength agent, 0.1%-0.5% of a shrinkage reducing agent, 0%-3% of a layered material, and 26%-50% of water. Compared with ordinary foam concrete, the material prepared in the invention has the technical advantages of ultra-low apparent density, small coefficient of heat conductivity, and no dry shrinkage cracking, etc. And compared with current foam polyphenyl boards for exterior wall external thermalinsulation, the material of the invention has the advantage of non-combustion.

Owner:TONGJI UNIV

Waterborne polyurethane material and preparation method thereof

InactiveCN102746818AResistant to yellowingNon-toxicPolyureas/polyurethane adhesivesPolyurethane dispersionNon toxicity

The invention relates to a waterborne polyurethane material and a preparation method of the material, in particular to a waterborne polyurethane material for laminating and compounding of foods or drugs in the packaging process and a preparation method of the material. The waterborne polyurethane material is prepared by compounding the following components by weight: 100 parts of anti-yellowing waterborne polyurethane dispersion, 0.01-0.2 parts of leveling agent and 0.01-0.2 parts of de-foaming agent. The waterborne polyurethane material has the advantages of yellowing resistance, non-toxicity, non-combustibility, safety in use, environmental protection and the like. The requirements of the laminating and compounding process on the waterborne polyurethane material are comprehensively considered, and the bonding strength and appearance in the laminating and compounding process are improved through carrying out chain extension for multiple times and adding the leveling agent and the waterborne de-foaming agent, wherein the T stripping strength and the readily oxidizable substance in the laminating and compounding process meet the industrial requirements for laminating and compounding of the foods or the medicines.

Owner:NANJING TECH UNIV

Waterborne anticorrosive coating and preparation method

InactiveCN105176313AReduce surface tensionIncrease wettabilityAnti-corrosive paintsEpoxy resin coatingsMeth-Sodium phosphates

The invention discloses a waterborne anticorrosive coating. The waterborne anticorrosive coating comprises the following components: waterborne epoxy resin emulsion, a pigment filler, a film forming assistant, a leveling agent, a defoaming agent, a thickening agent, a dispersing agent, water and a curing agent, wherein the pigment filler is mixture of iron oxide red and zinc phosphate which are mixed according to a mass ratio of 1:1; the film forming assistant is glycol; the leveling agent is polyacrylic acid or hydroxymethyl cellulose; the defoaming agent is tributyl phosphate; the thickening agent is hydroxymethyl cellulose; the dispersing agent is sodium hexametaphosphate; the curing agent is one of diethylenetriamine, m-phenylenediamine, modified phenolic amine and diamino diphenyl sulfone (DDS). The invention further discloses a preparation method of the waterborne anticorrosive coating, the coating has good anticorrosive performance, the preparation method is simple and feasible and the cost is low.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Fireproof coating for thick formed steel constructions

The invention provides a fireproof coating for thick formed steel constructions. The coating is prepared from a fireproof filler, a fire retardant, a main binder, an auxiliary binder, a water-proofing agent and mica powder; the binding performance of the fireproof coating for the steel constructions is improved, meanwhile, the dosage of the fire retardant is optimized and the long fire resistance of the fireproof coating for thick formed steel constructions is guaranteed; other auxiliaries as the water-proofing agent are added to improve the water tolerance, anti-penetrability performance and weather fastness of the fireproof coating for the steel constructions are improved. The fireproof coating for the steel constructions has the characteristics of water tolerance, anti-permeability, fire resistance, impact resistance, simple preparation process, convenience for application, non-toxicity and harmlessness, long service life and the like. The fireproof coating for thick formed steel constructions is suitable for fireproof protection of the exposed parts of steel construction buildings high in fire endurance.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

Thermal insulation material

The invention discloses a novel thermal insulation material, and the composition comprises expanded perlite, cement, gypsum powder, fibers, redispersible rubber powder, casein glue, and the like. The thermal insulation material has the advantages of high strength, aging resistance, excellent thermal insulation effect, energy conservation, environmental protection, fire protection, sound insulation, low cost, convenient use, and the like. The novel thermal insulation material can be directly applied on buildings, containers, pipelines, reactors, household appliances and the like through a plurality of construction methods, thereby achieving the effects of thermal insulation and energy conservation.

Owner:ORDOS DONGRONGCI TECH DEV

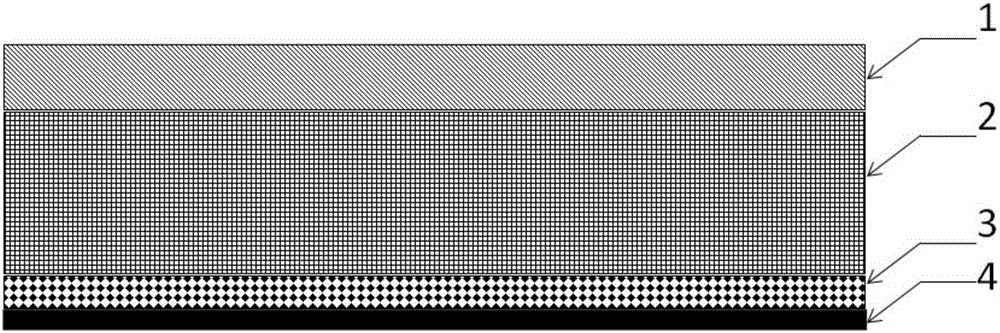

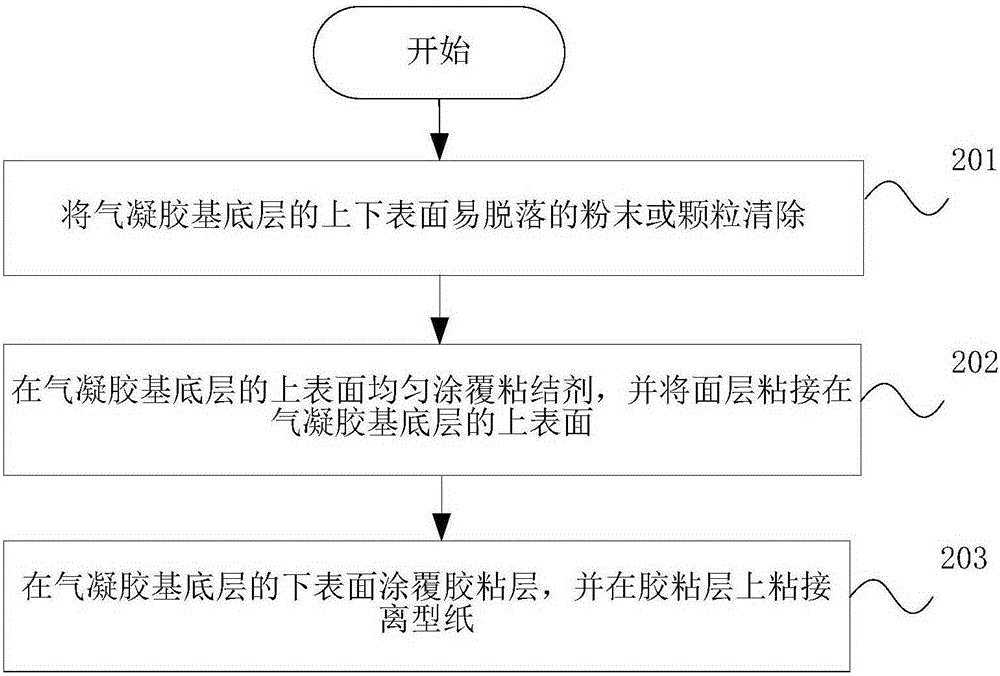

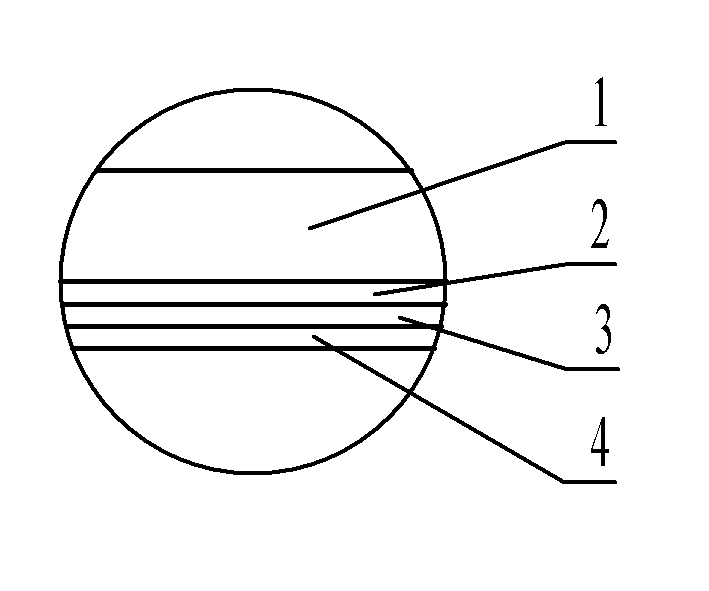

Instant aerogel composite heat isolation adhesive tape and preparing method of instant aerogel composite heat isolation adhesive tape

InactiveCN105256902ANon-combustibleHigh temperature resistantLaminationLamination apparatusIsolation effectAdhesive

The invention discloses an instant aerogel composite heat isolation adhesive tape and a preparing method of the instant aerogel composite heat isolation adhesive tape, wherein the adhesive tape is of a layered structure and comprises a face layer, an aerogel substrate layer, a bonding layer and release paper; the face layer covers the upper surface of the aerogel substrate layer; the bonding layer coats the lower surface of the aerogel substrate layer; and the release paper covers the lower surface of the bonding layer. According to the tnstant aerogel composite heat isolation adhesive tape and the preparing method, the characteristics of inorganic property, nonflammability, high-temperature resistance, waterproof performance and the like are realized; the cost is low; the preparing process is simple; and the use is convenient, so that the instant aerogel composite heat isolation adhesive tape belongs to an instant thermal insulation and heat isolation material. The thermal insulation and heat isolation effect is good, and the heat conducting coefficient is low, so that the instant aerogel composite heat isolation adhesive tape belongs to an inorganic thermal insulation and heat isolation material, and can reach grade-A fireproof standards; and the instant aerogel composite heat isolation adhesive tape can be flexibly applied to construction, and is particularly applied to heat insulation, heat insulation restoration or temporary heat insulation of door and window side frames and at joint seam parts of building house wall bodies, roofs, doors and windows and the like.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Carbon-based composite building wave absorption and heat preservation material and preparation method thereof

The invention discloses a carbon-based composite building wave absorption and heat preservation material and a preparation method thereof. According to the preparation method, carbon-based wave absorbing agent, common silicate cement, expanded and vitrified small balls, re-dispersible latex powder, hydroxypropyl methyl cellulose, wood fiber, polypropylene fiber, surfactant, foam stabilizer, waterreducing agent, coupling agent, water and the like are adopted; and the material is obtained by adopting the steps of stirring, pouring molding, curing and the like. The material has the advantages of good wave absorption performance and heat insulation performance, low apparent density, low cost, high fire resistance, durability and the like, and is easy to construct. The material can be used for pouring roofs and walls of buildings, so that aims of electromagnetic radiation protection and energy conservation of the buildings are fulfilled.

Owner:CHONGQING UNIV

Hollow vitrified micro bubbles heat preservation and insulation composite material

The invention discloses a hollow vitrified micro bubbles heat preservation and insulation composite material which comprises vitrified micro bubbles and a cementing material, the vitrified micro bubbles are taken as a light aggregate of mixed mortar and mixed with the cementing material. The hollow vitrified micro bubbles heat preservation and insulation composite material is characterized in that contents of the vitrified micro bubbles and the cementing material are 20-50 parts of the vitrified micro bubbles and 40-55 parts of the cementing material respectively; the cementing material is a mixture of cement, sand, a foaming agent and a water-proofing agent, and the cementing material consists of the 40-60 parts of the cement, 2.5-3.3 parts of the sand, and a proper amount of the foaming agent and the water-proofing agent. The hollow vitrified micro bubbles heat preservation and insulation composite material has the advantages of good heat preservation, heat insulation, fire prevention and construction properties, is insusceptible to the biting of insects and ants, and is economical and environment-friendly.

Owner:刘春雨

Thermal insulation sheet material and preparation method thereof

The invention, belonging to the field of building materials, particularly relates to a lightweight thermal insulation sheet material for building walls. The thermal insulation sheet material comprises the following ingredients: 8.5-10.5 weight portions of fly ash floating bead, 30-38 weight portions of closed cell perlite, 43-52 weight portions of cement, 7-8.5 weight portions of bentonite, 0.04-0.06 weight portions of cellulose ether, 0.07-0.09 weight portions of short fiber, 0.04-0.06 weight portions of wood fiber, and 0.3-0.4 weight portions of gelatine powder. The thermal insulation sheetmaterial is prepared by using organic materials, and has the characteristics of no toxicity, good thermal insulation property, high temperature resistance, low temperature resistance, non-inflammableproperty, high efficiency, and aging resistance. When the thermal insulation sheet material is used for building walls, the thermal insulation property of the sheet material can not be reduced with time, and the sheet material has the same service life with the building.

Owner:安徽瑞蒙科技有限公司

Novel composite material for blast pipe sheet

The new complex material for blast-pipe plate comprises: high-tension environmental friend slurry (10~20% magnesium chloride, 40~60% magnesium oxide, 20~30% calcium bicarbonate, 0.1~1% ultramarine powder, 0.2~1% inorganic foaming liquid, 0.1~0.5% phosphoric acid, and 10~20% water), four-layer Pt-interlace middle-alkali glass fiber reinforcement cloth, and slow burning polystyrene foam material. This product has well physical and chemical properties, and can also be used to decorate partition plate and ceiling with service time more than twenty years.

Owner:沈金良

Method for extracting lycium barbarum extract by supercritical CO2

InactiveCN102988605APrevent oxidationAvoid decompositionBulk chemical productionPlant ingredientsChinese boxthornExtraction methods

The invention relates to an extraction method for lycium barbarum polysaccharide, and particularly relates to a method for extracting a lycium barbarum extract by supercritical CO2, which is used for achieving the purpose of high-efficiency extraction for lycium barbarum polysaccharide. The method comprises the following steps of: a, drying and crushing lycium barbarum, and then placing the lycium barbarum in an extraction kettle; b, injecting CO2 in a supercritical state in the extraction kettle, and extracting for 3.5-4.5 hours in the conditions of a temperature of 45-55 DEG C, a pressure of 1.2-2.0 Mpa and a CO2 flow velocity of 0.10-0.15 L / min; and c, conveying a CO2 fluid dissolved with the lycium barbarum plant extract in a separation kettle to separate a CO2 gas, compressing the CO2 gas, and then conveying the CO2 gas in the extraction kettle for cycle use. The content of lycium barbarum polysaccharide in the lycium barbarum plant extract obtained by extraction adopting the method for extracting a lycium barbarum extract by supercritical CO2 is up to 17%.

Owner:山西五台山沙棘制品有限公司

Mosquito-expelling paste

The invention discloses a mosquito-expelling paste which comprises a matrix layer with mosquito-expelling plant essential oil. The matrix layer is composited on backing, the backing is connected with an adhering layer, a protecting layer is covered outside the adhering layer, and the mosquito-expelling plant essential oil is one of citronella essential oil and eucalyptus essential oil or a mixture of the citronella essential oil and the eucalyptus essential oil. A pure plant essential oil formula is adopted by the mosquito-expelling paste to expel mosquitoes, and the mosquito-expelling paste has the advantages of being green, non-toxic, safe, efficient, healthy and environment and is convenient to carry, safe to use and lasting in mosquito-expelling effect.

Owner:GUANGXI LIUZHOU HAOBANG DAILY CHEM

Material special for flame-retardant antistatic plastic flange and preparation method thereof

InactiveCN101817979AHigh temperature resistantCorrosion resistanceFlanged jointsFiberPolymer science

The invention relates to the field of organic plastic, in particular to a material special for a flame-retardant antistatic plastic flange and a preparation method thereof. The material consists of the following components in part by weight: 40 to 60 parts of polyphenylene sulfide resin, 10 to 40 parts of carbon fiber, 20 to 40 parts of glass fiber, 0.1 to 1 part of processing thermal stabilizer and 0.1 to 2 parts of processing lubricant. The preparation method thereof comprises the following steps of: uniformly mixing the polyphenylene sulfide resin, the processing thermal stabilizer and the processing lubricant; then adding the carbon fiber and the glass fiber into the mixture and melting and blending the mixture by using an extruder; and finally bracing, water-cooling, pelletizing and drying the obtained material so as to obtain the material special for the flame-retardant antistatic plastic flange. The plastic flange made of the material of the invention overcomes the defect of easy corrosion of a traditional metal flange, has permanent flame resistance, antistatic performance and high mechanical strength, and is suitable for connection of non-metal pipelines underground coal mine and in other combustible and explosive environments.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

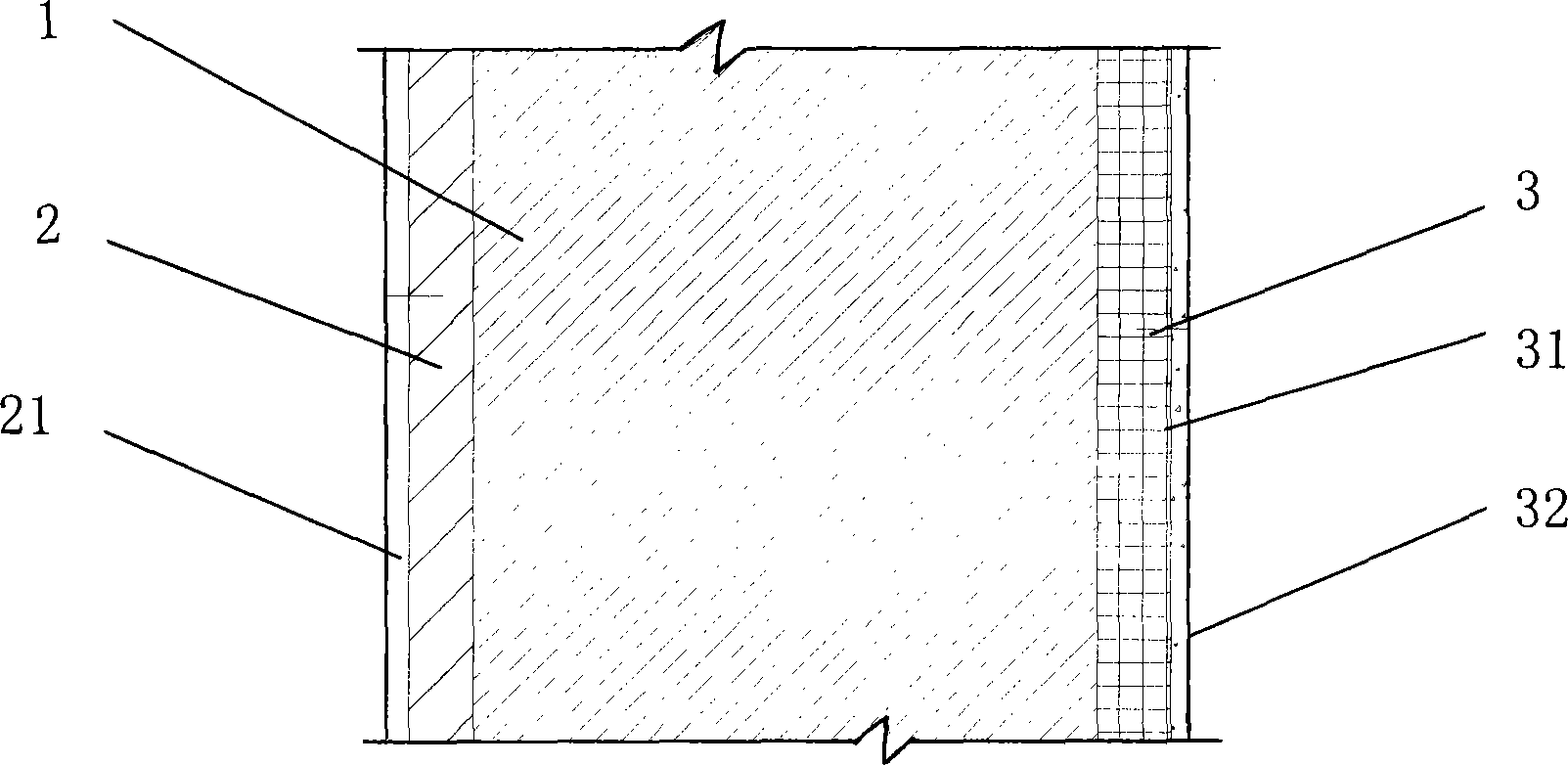

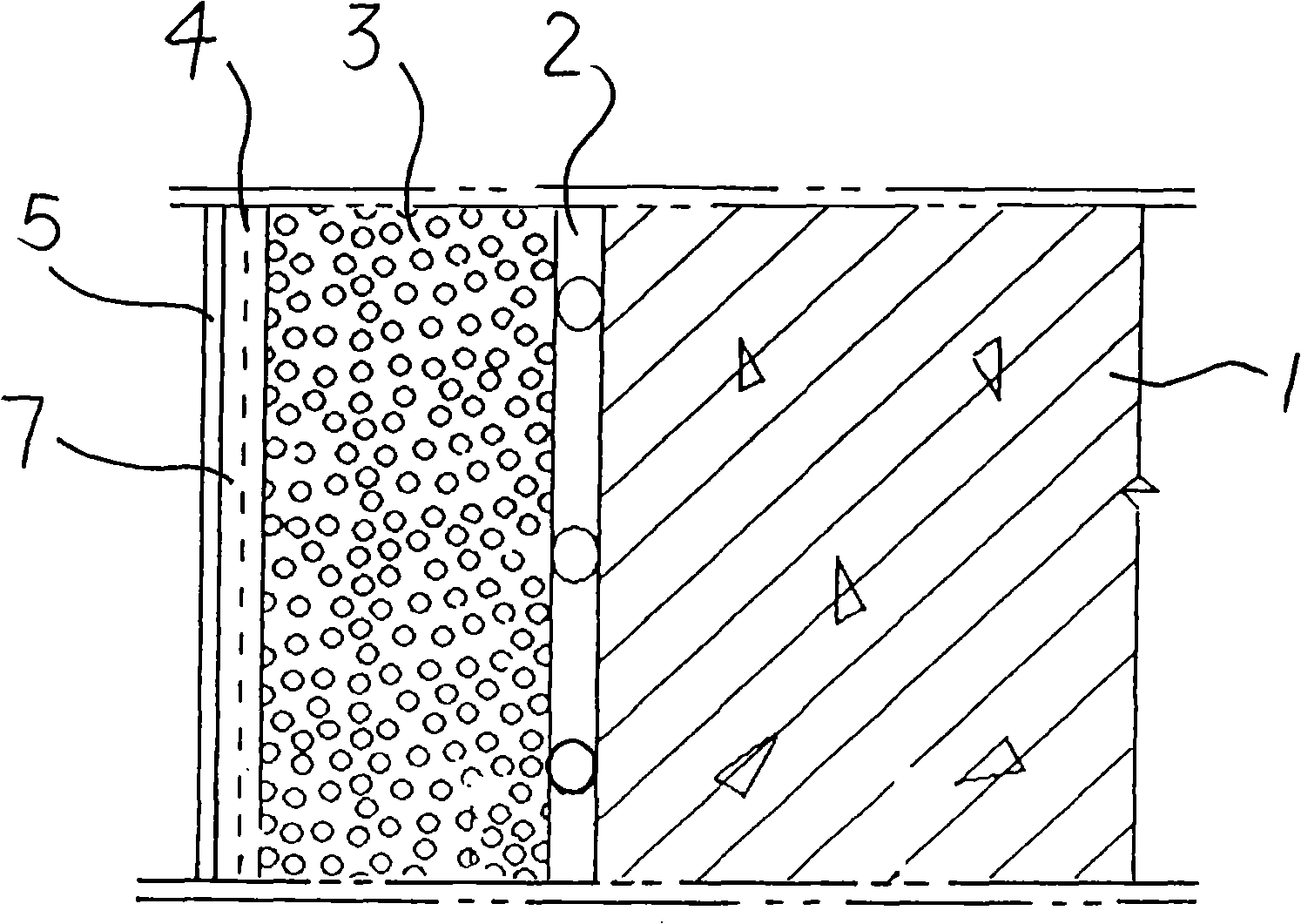

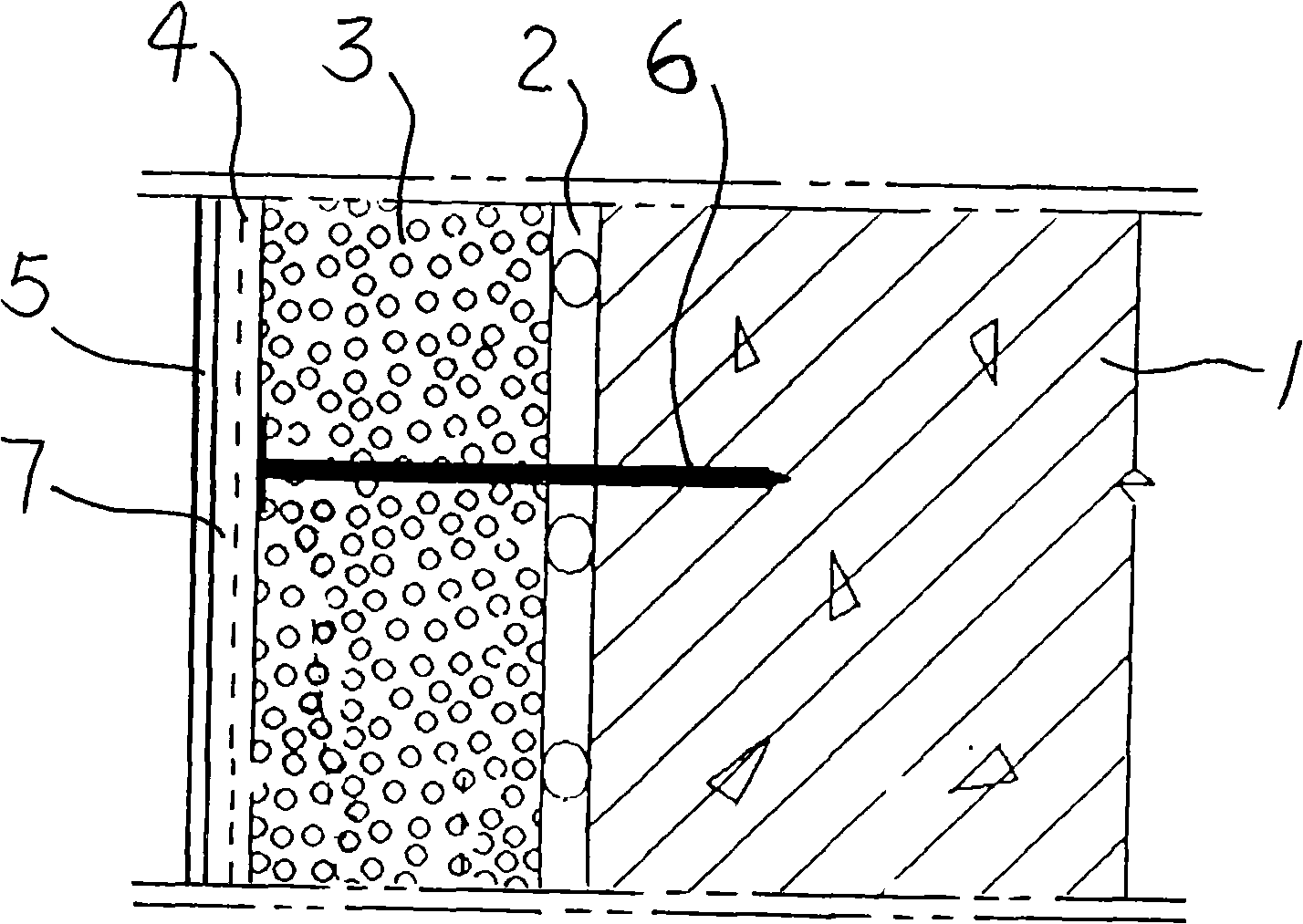

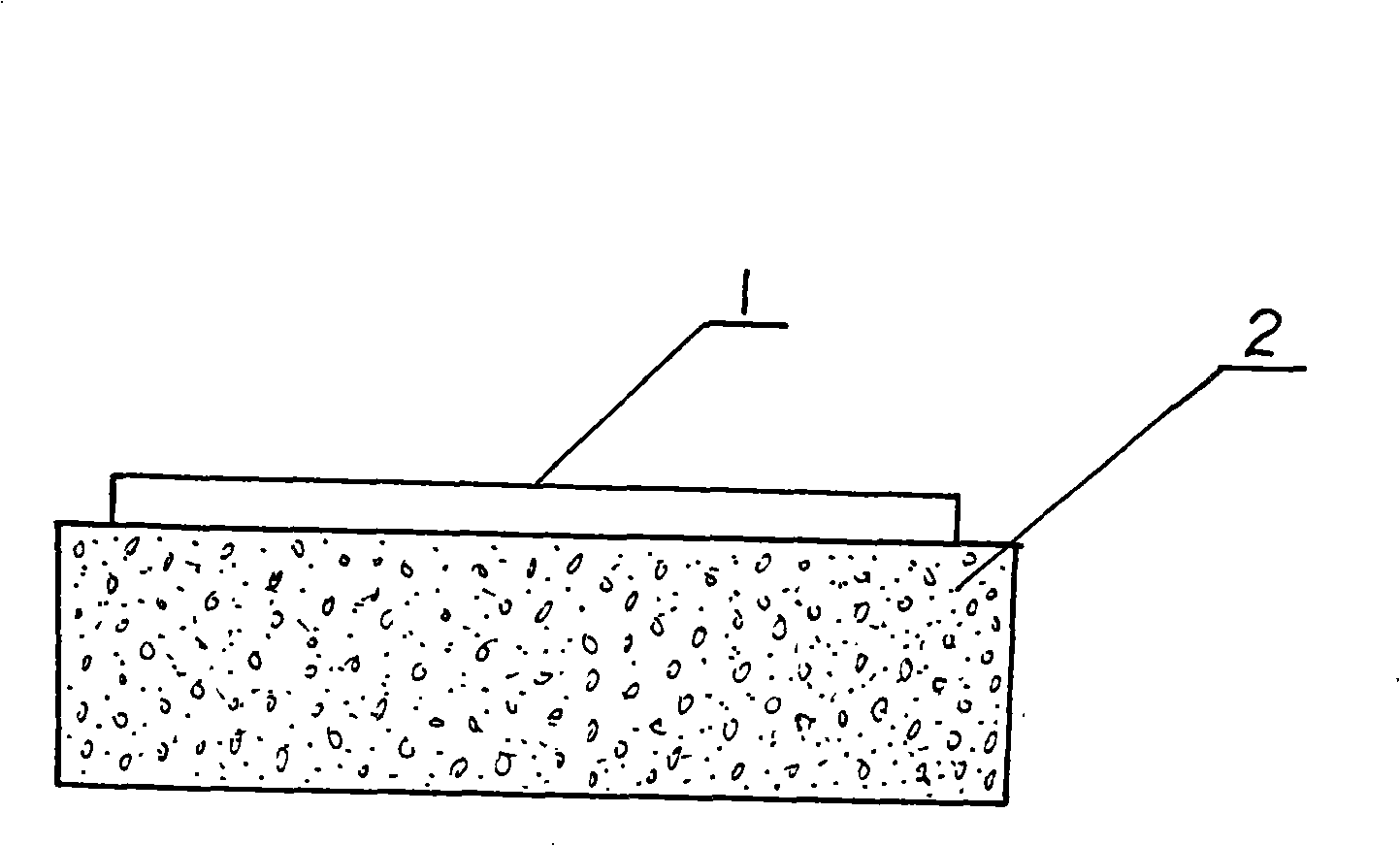

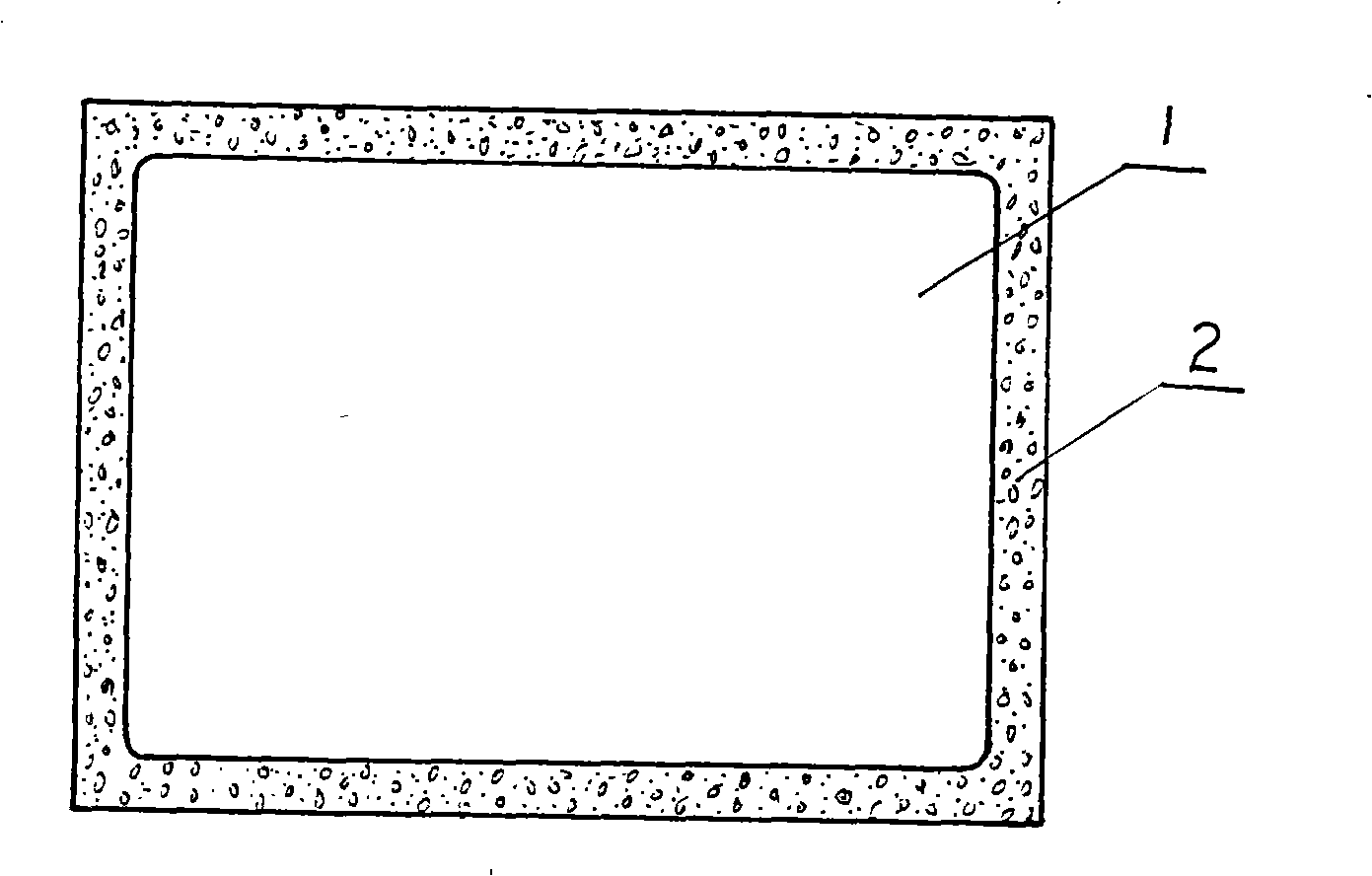

Inorganic heat-preserving metal facing one-piece type fire wall section material and its production method

InactiveCN101503903AExtended service lifeEnvironmentally friendlyCovering/liningsSolid waste managementInorganic ChemicalAdhesive

The invention relates to an integral fireproof wall profile for an inorganic insulating metal facing and a preparation method thereof. The wall profile is provided with an insulating layer and a facing layer, the insulating layer is formed by mixing and pressing inorganic insulating light aggregate and slurry, the facing layer adopts a metal sheet, and the insulating layer and the facing layer are adhered by adopting an adhesive and pressed to form an integral structure. The insulating layer of the wall profile is compounded by a plurality of natural inorganic mineral composite materials, so the wall profile has a plurality of good performances such as innocuity, tastelessness, incorruption, incombustibility, acid resistance, alkali resistance, heat isolation, heat preservation and the like, and is a comparatively ideal environment-friendly building material; and the metal facing is adopted, so the wall profile not only has good anti-flaming, fire-proof, water-proof and crack-resisting functions to protect a wall body and the insulating layer most ideally, but also has the sensorial effects of high-grade luxury and decorative beautified environment.

Owner:信阳天意节能技术股份有限公司

Construction method of building wall

The invention relates to the building construction technical field, in particular to a construction method which is suitable for various industrial and civil building walling having the requirement of energy conservation in a large part of China under different climate conditions. The construction method comprises the following steps that: a bonding agent is used for bonding an insulation board on the walling; mortar is coated on the insulation board and a piece of medium-alkali mesh cloth is wrapped in the mortar; and coating is plastered on the mortar, and the insulation board is a foam glass insulation board. The construction method effectively utilizes waste resources, reduces the environmental pollution, improves the utilization rate of energy, not only solves the problems of cracking and hollowing of the building walling but also improves the heat-insulating property, guarantees the elegant appearance of a veneer of the building walling, prevents the occurrence of a fire disaster, and protects the life and property safety of people.

Owner:上海永丽节能墙体材料有限公司

Water-based super-fogging super-blackening treating agent for synthetic leather and preparation method thereof

The invention relates to a water-based super-fogging super-blackening treating agent for synthetic leather, and the water-based super-fogging super-blackening treating agent is applied to a later period technology of the synthetic leather. The water-based super-fogging super-blackening treating agent is prepared from water-based resin, a water-based dispersing agent, a defoaming agent, silicon dioxide matting powder, a wetting agent, a Deuchem thickening agent and water. The invention further relates to a preparation method of the water-based super-fogging super-blackening treating agent for the synthetic leather. According to the water-based super-fogging super-blackening treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent is natural in gloss, clear in color and luster, better in color developing and excellent in comprehensive effect, meanwhile, a prepared spraying dilute solution has the very good storage stability, and pigments are not prone to sedimentation. The water-based super-fogging super-blackening treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Preparation method for epoxy-organic silicon resin modified polyurethane-acrylate water-dispersion and water-based epoxy zinc-rich primer paint

InactiveCN105218752AGood weather resistanceHigh mechanical strengthAnti-corrosive paintsWater basedEthylenediamine

The invention discloses a preparation method for an epoxy-organic silicon resin modified polyurethane-acrylate water-dispersion. The method comprises the following steps: firstly subjecting a silane coupling agent and epoxy resin to reaction so as to obtain a component A; then adding polycarbonate polyol and isophorone diisocyanate and carrying out reaction, then adding diethylene glycol, trimethylolpropane, dimethylolpropionic acid, acetone and a catalyst, continuing reaction, then dropwise adding methyl methacrylate and hydroxyethyl acrylate, then adding triethylamine and deionized water under stirring, and adding ethylenediamine and carrying out chain extension so as to obtain a prepolymer; and finally, adding the acetone of azodiisobutyronitrile and initiating polymerization reaction of an acrylic monomer so as to obtain the water-dispersion. The water-based epoxy zinc-rich primer paint prepared in the invention has tough paint film, high mechanical strength, good adhesive force to a substrate and excellent anticorrosion performance, facilitates to matching with a finish paint, is free of flash erosion, and has strong market potential.

Owner:JIANGSU LONGSHENG POLYMER MATERIAL TECH CO LTD

Integrated nano inorganic wall light heat insulation facing section bar and preparation thereof

InactiveCN101348355AWith thermal insulationEnvironmentally friendlyCovering/liningsSolid waste managementFiberSilicon oxide

The invention relates to an integrated type nano inorganic wall light weight heat preservation veneer and a method for preparing the same. The veneer consists of a heat preservation substrate which is formed by the one-piece pressure moulding of a plurality of inorganic mineral materials and a veneering layer, wherein the heat preservation substrate is prepared by husk type expanded perlite light-weight aggregate, cement, silicon oxide micropowder, wood fiber micropowder, organosilicon emulsion and cement reinforcing agent according to the blending ratio; the veneering layer is prepared by quartz sand, calcium carbonate, cement, silicon oxide micropowder and wood fiber micropowder according to the blending ratio and is in one-piece pressure moulding. Compaed with prior art, the veneer has the advantages of light weight, high strength, good heat insulation and heat preservation effects, tight bonding, energy conservation and environmental protection, resource conservation, easy construction, short construction period, low cost and long service life, etc.

Owner:信阳天意节能技术股份有限公司

Wall heat insulating material and preparation method therefor

The invention provides a wall heat insulating material and a preparation method therefor and relates to the field of building materials. The wall heat insulating material is prepared from the following raw materials in parts by weight: 16-20 parts of calcium silicate powder, 10-26 parts of granite powder, 15-17 parts of polyurethane, 17-21 parts of aluminum silicate powder, 5-7 parts of magnesia, 7-11 parts of mineral wool, 11-21 parts of furnace slag powder, 15-17 parts of glass fibers, 11-29 parts of vermiculite, 15-21 parts of aerogel, 15-21 parts of polyethylene foam plastics, 22-34 parts of meerschaum, 13-21 parts of polypropylene fibers, 27-31 parts of cement, 0.2-0.6 part of air entraining agent, 0.1-0.5 part of setting retarder, 0.1-0.3 part of thermal stabilizer, 0.5-0.9 part of water reducing agent, 0.2-0.6 part of foamer and 3-9 parts of water. The preparation method comprises the following steps: (1) raw material weighing, (2) roasting, (3) stirring, (4) extrusion forming, and (5) baking. According to the wall heat insulating material and the preparation method therefor, the problem that defects are still present when the existing wall heat insulating materials are applied to buildings with high requirements on compressive strength, tensile strength and heat preservation and insulation is solved.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

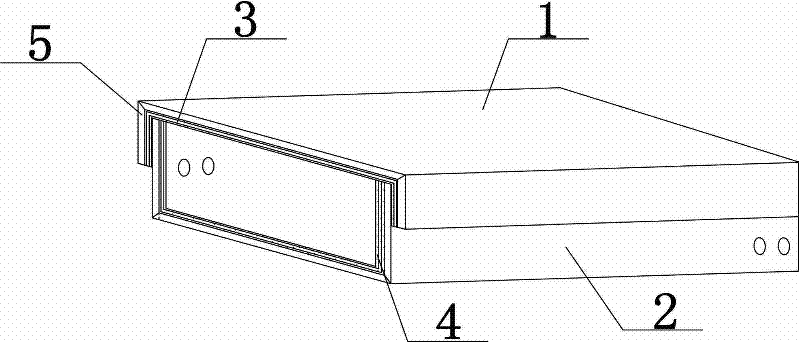

Waterproof non-inflammable cable fireproof groove box and manufacturing method thereof

InactiveCN102361278AControl electromagnetic radiationHigh strengthElectrical apparatusPhosphoric acidEngineering

The invention discloses a waterproof non-inflammable cable fireproof groove box and a manufacturing method thereof. The waterproof non-inflammable cable fireproof groove box comprises a groove box cover plate, a tray and a connecting plate. The waterproof non-inflammable cable fireproof groove box is manufactured by using raw materials including magnesium oxide, magnesium chloride, running water, glass cloth, phosphoric acid, an aqueous solution agent, waterproof powder, a metal net and a modifier through the following steps of: firstly, preparing the concentration of chlorine water according to a certain proportion, adding a certain quantity of chlorine water into an agitator, then adding additives, and preparing and blending the magnesium oxide to form slurry or paste daub; then placing the slurry or paste daub of the magnesium oxide into an equipment hopper on an extrusion production line; adding shielding layers in a way that one layer of the daub and one layer of glass cloth are alternately arranged; starting to extrude a composite molding plate; when the composite molding plate enters into a mould, carrying out two-layer film treatment, demolding after a curing reaction; trimming, punching, finishing the product subjected to the demolding until checking to be qualified. The product provided by the invention is suitable for being used in various places with severe envelopments, such as places with intensive cables, humid environments, cable tunnels and the like and has the advantages of waterproofness, non-inflammability, corrosion resistance, isolation from the outside and control of electromagnetic radiation of the cable.

Owner:QINYANG PENGWEI IND

Water-based PU silky waxy-feeling treatment agent for synthetic leather and its preparation method

The invention relates to a water-based PU silky waxy-feeling treatment agent for synthetic leather and its preparation method. The treatment agent consists of water-based PU resin varnish, water-based amino-modified silicone oil, water, modified wax emulsion, silicon dioxide matting agent, organosilicon leveling agent, organosilicon defoaming agent and water-based PU thickening agent. The treatment agent realizes intercoordination and coaction of components of the treatment agent, has good film forming property and firm adhesive property, and forms coating with solvent resistance, cold resistance, hydrolysis resistance and thermal aging resistance, and synthetic leather treated via the treatment agent achieves perfect cloudy effect, unique silky hand feeling, strong real leather feeling, fine texture, air permeability and hand feeling, smoothness, water-proof property and wax feeling comprehensive effects.

Owner:JIANGSU BAOZE POLYMER MATERIAL

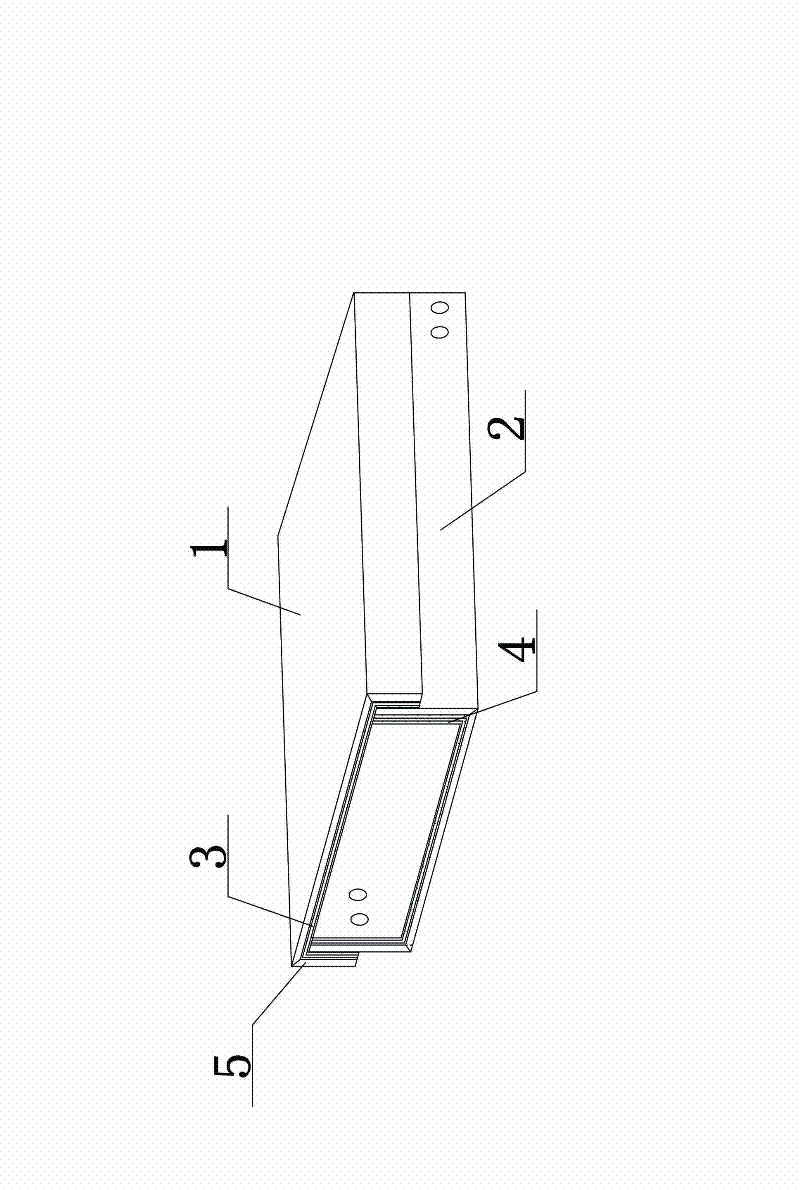

Composite board for fire and smoke exhaust pipe

The invention discloses a novel special composite board for a fire and smoke exhaust pipe, and belongs to the field of fireproof panel. The novel special composite board is made by compounding high-intensity environment-friendly materials, medium-alkali cloth or alkali-free cloth and a supporting material by a hot pressing process, wherein, the high-intensity environment-friendly materials consist of 30-40% of magnesium oxide, 10-20% of magnesium chloride, 20-40% of quartz powder, 0.5-1% of a foaming agent, 0.5-1% of a modifier and 10-20% of water; the supporting material is of a centrifuge glass wool board or made by stirring 40% of magnesium oxychloride cement and 60% of foamed polystyrene materials, and the components are measured by weight percentage. The materials have the advantages of being non-inflammable, environmentally friendly, energy saving, light, highly intensive and the like; the board made from the materials has smooth surface, without rusting, going moldy or bittern accumulation, has low cost and more than 20 years of service life, is a superior material for fire control and smoke exhaust and ventilation, and has excellent popularization and application prospects.

Owner:HANGZHOU KECHUANG AIR HOSE CO LTD

Elastic high-strength antistatic shoe sole material and preparation method thereof

The invention discloses an elastic high-strength antistatic shoe sole material, which comprises the following raw materials in parts by weight: 6-10 parts of organotin stabilizer, 7-9 parts of anti-slip agent, 2-4 parts of conductive filler, and 25-35 parts of hydroxylated polypropylene 50-60 parts of elastic filler, 4-8 parts of calcium carbonate, 5-7 parts of binder, 10-18 parts of reinforced inorganic fiber, 1-2 parts of antistatic agent, 3-5 parts of coupling agent, processing aid Dose 10-12 parts. The sole material of the present invention has good elasticity and mechanical strength, good anti-slip effect, excellent antistatic performance, excellent heat resistance, weather resistance and impact resistance; meanwhile, the raw material components of the present invention are safe and reliable, and have no pollution to the environment, and the raw material It is easy to obtain, low in cost, simple in process, low-carbon, environmentally friendly and pollution-free, and has high practical value and good application prospect.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com