Fire-proof and thermal-insulation board and manufacturing method thereof

A fireproof insulation board and a manufacturing method technology, which are applied in the directions of thermal insulation, fire prevention, building thermal insulation materials, etc., can solve the problems of inconvenient transportation, installation, poor thermal insulation performance, etc. impactful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

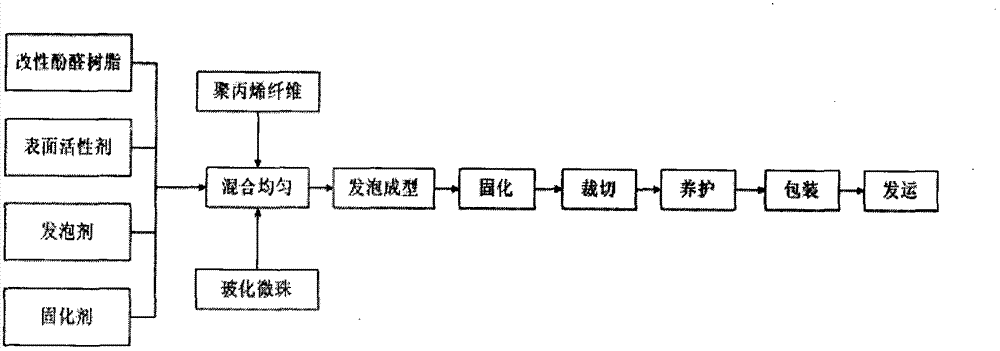

[0021] The specific steps of the fireproof insulation board of the present embodiment and its manufacturing method are as follows (see figure 1 ):

[0022] The first step, material preparation—prepare the modified phenolic resin with a weight ratio of 1:0.01:0.8, polypropylene fiber and vitrified microbeads, the modified phenolic resin is outsourced or produced by itself, the self-made method is detailed in the Chinese patent of 200910226671.9 Application documents, polypropylene fiber was purchased from Wuhan Zhongding Development Co., Ltd., with a length of 6 mm; vitrified microbeads were purchased from Fuxin Environmental Protection Thermal Insulation Material Factory in Pingqiao District, Ziyang City, and the main component is SiO 2 and AI 2 o 3 , Irregular balls with a hollow closed-cell structure with a particle diameter of 0.15-1.5mm.

[0023] Second step, adhesive agent---adding its weight percentage successively in modified phenolic resin is 4% tensio-active agent-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com