Patents

Literature

323results about How to "Reduce crosslink density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimicrobial radiation curable coating

InactiveUS7098256B2The environment is moreOptimal for incorporationBiocideAntifouling/underwater paintsCross-linkCarbamate

Owner:MICROBAN PROD CO INC

Antimicrobial radiation curable coating

InactiveUS20050080158A1Activity depletedInferior antimicrobial efficacyBiocideAntifouling/underwater paintsCross-linkOligomer

The invention is a radiation curable coating containing an antimicrobial agent, where upon irradiation with UV light, the radiation curable coating rapidly cures to a polymeric coating. The polymeric coating has durable antimicrobial properties, being especially effective at preventing the growth of Staphylococcus aureaus and Kleibsella pneunoniae on wood flooring and furniture. The major components in the radiation curable coating are a urethane acrylic oligomer, a radiation cure package, an antimicrobial agent, a cross-linking agent, and optionally, an additive package. The radiation curable urethane oligomer is a relatively short chain backbone urethane polymer that is end capped with a radiation curable moiety, where the moiety is an acrylic. The cross-linking agent is one or more monomers used to lower the viscosity and promote cross-linking, and include acrylate esters of mono-, di-, tri-, or tetrafunctional alcohols. The radiation cure package contains at least one photoinitiator.

Owner:MICROBAN PROD CO INC

Crosslinker for Superabsorbent Polymers

InactiveUS20080140037A1Reduce crosslink densityPromote absorptionOrganic chemistryBaby linensSuperabsorbent polymerPhotochemistry

Owner:EVONIK DEGUSSA GMBH

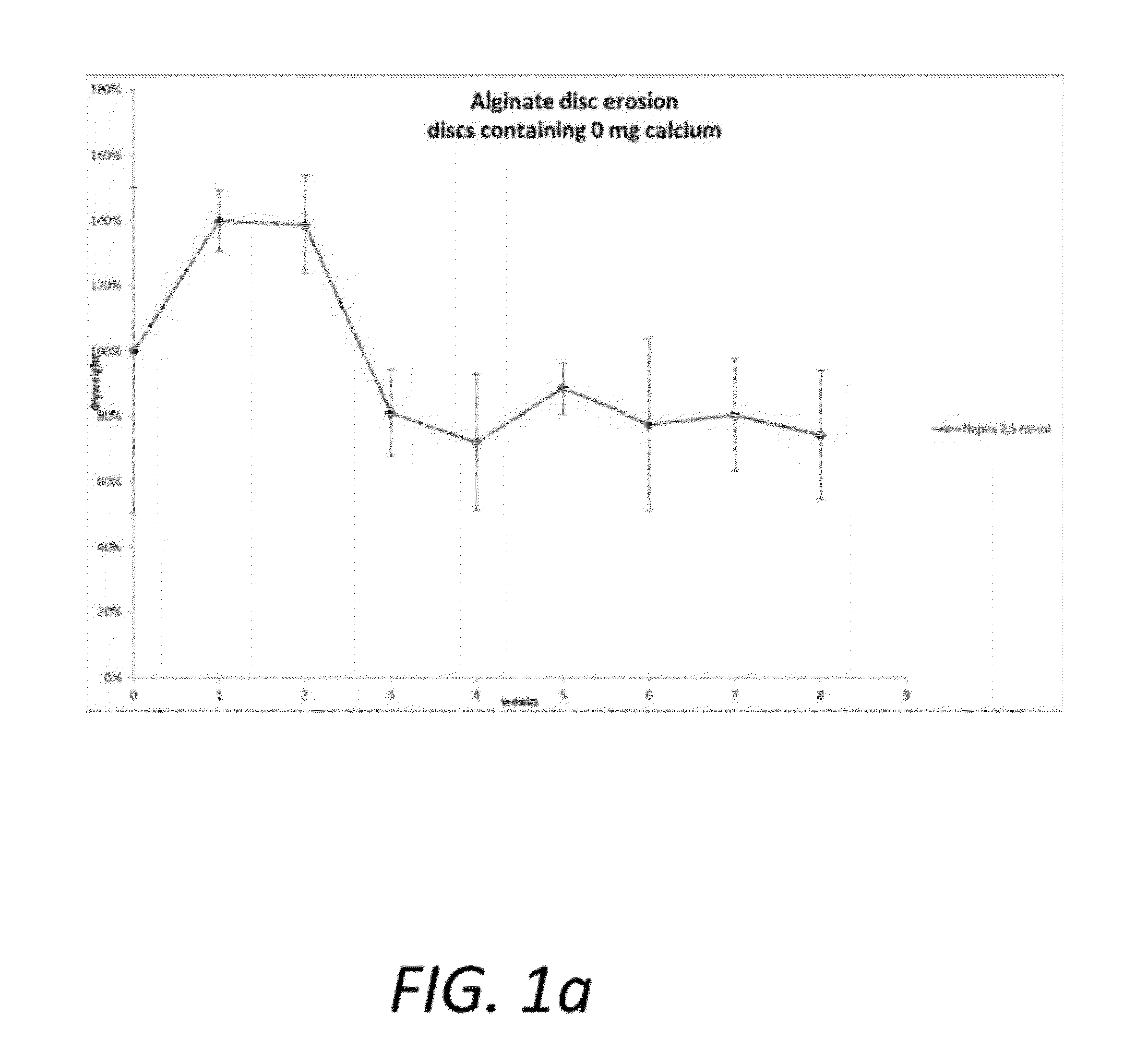

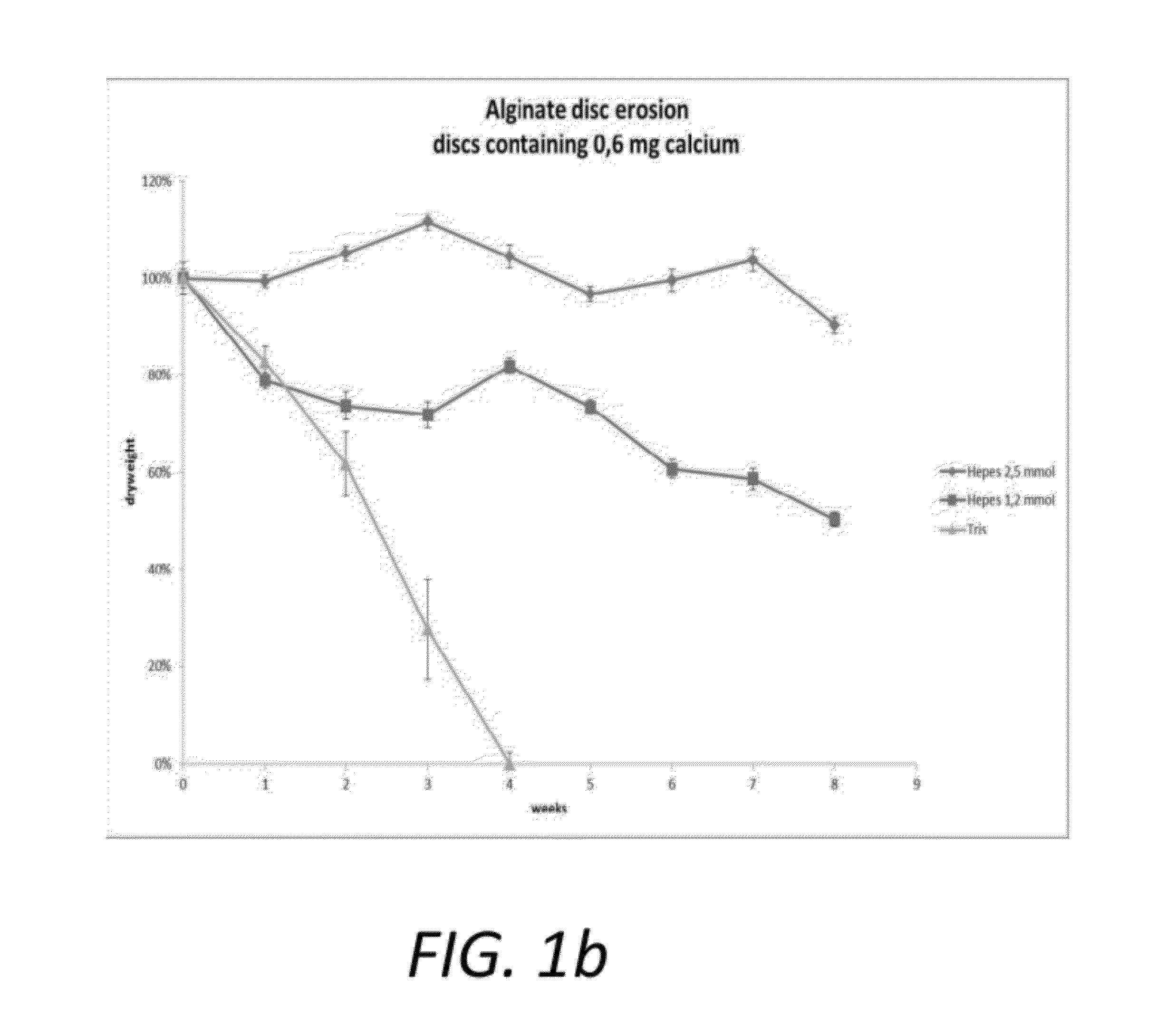

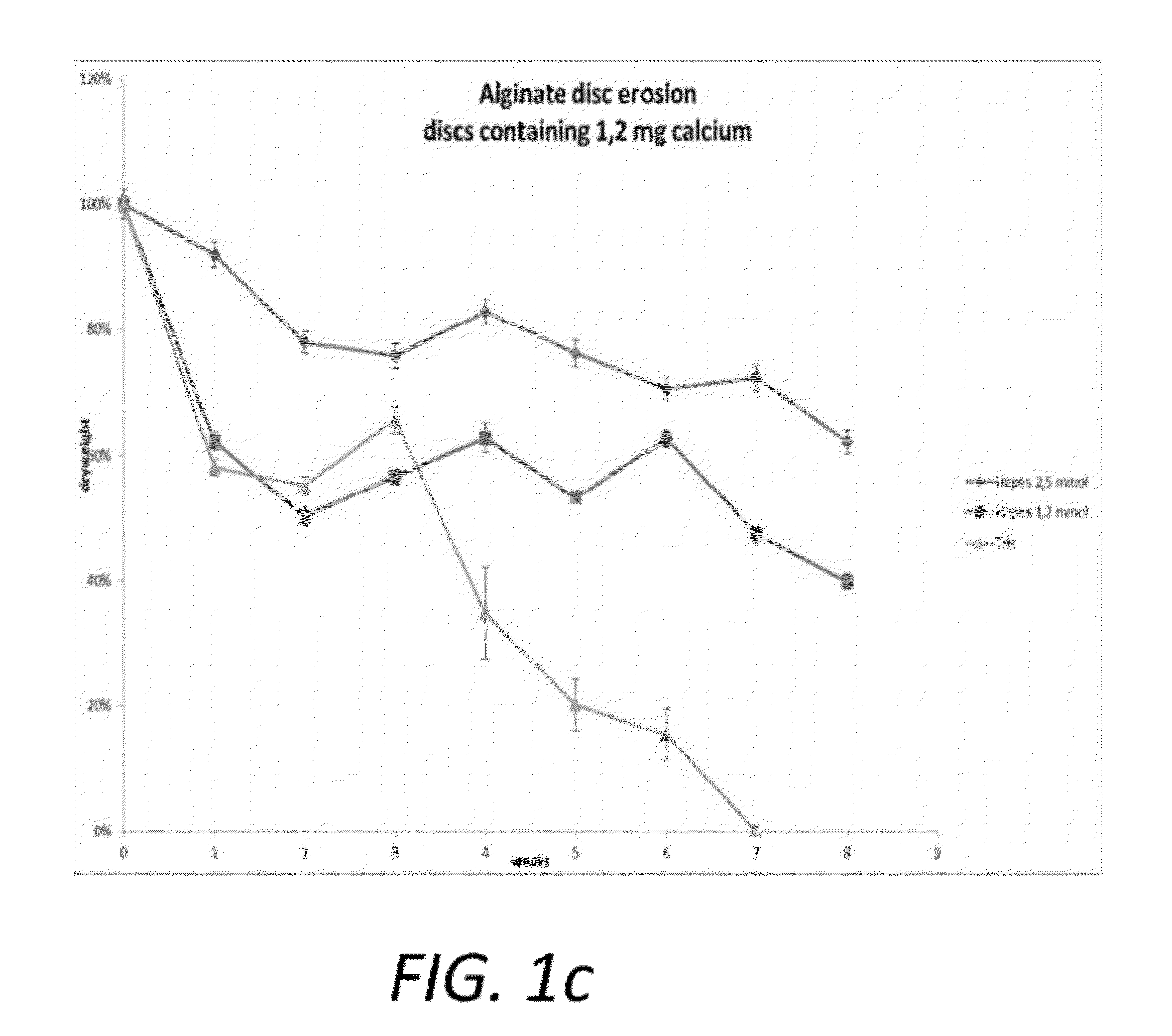

Anti-Adhesion Alginate Barrier of Variable Absorbance

Described are mono- and bi-layer alginate post-surgical anti-adhesion barriers with tailored absorption profiles and non-migrating characteristics. Muco-adhesive properties of alginates in their solid state are used to localize the device, and lubricious properties of alginates in their liquid state are used to mitigate adhesion formation during wound healing. In addition, the design of the implant can be selected such that the crosslinking agent is released from the device under specific conditions and the absorbance profile modified. A medicinal agent may optionally be incorporated.

Owner:MAST BIOSURGERY

Two component coating compositions and coatings produced therefrom

ActiveUS20040010091A1Reduce decreaseUnacceptable functionalityLiquid surface applicatorsLocks for portable objectsMethacrylateEpoxy

The present invention is directed to two component coating compositions that cure under ambient conditions and more particularly to those having low VOC (volatile organic content) that are suitable for use in automotive refinish and Original Equipment Manufacturing (OEM) applications. The coating composition includes crosslinkable and crosslinking components, wherein the crosslinkable component includes a low polydispersity, low molecular weight copolymer having on an average 2 to 25 functional groups, such as hydroxyl, carboxyl, acetoacetoxy, primary and secondary amine, and epoxy. The copolymer is polymerized from a monomer mixture that includes one or more non-functional acrylate monomers and one or more functional methacrylate monomers provided with the functional groups. The crosslinking component includes polyisocyanate, polyamine, ketimine, melamine, epoxy, polyacid or a combination thereof. The invention is also directed to coating produced from the coating composition.

Owner:AXALTA COATING SYST IP CO LLC

Hyaluronic acid-based cross-linked nanoparticles

InactiveUS20070224277A1Reaction is slowReduce crosslink densityBiocideOrganic active ingredientsCross-linkControlled release

Methods are disclosed for preparing novel biodegradable cross-linked nanoparticles based on covalently cross-linking modifications of hyaluronic acid. The final products of the present invention are stable in aqueous media, and may be used as detergents and as additives for pharmaceutical compositions for drug delivery, DNA carrier system and other applications. The nanoparticles made from the biopolymers of the present invention may also be used in controlled release applications, super-absorbent materials as well as biomaterials like enzyme immobilization.

Owner:BORBELY JANOS +3

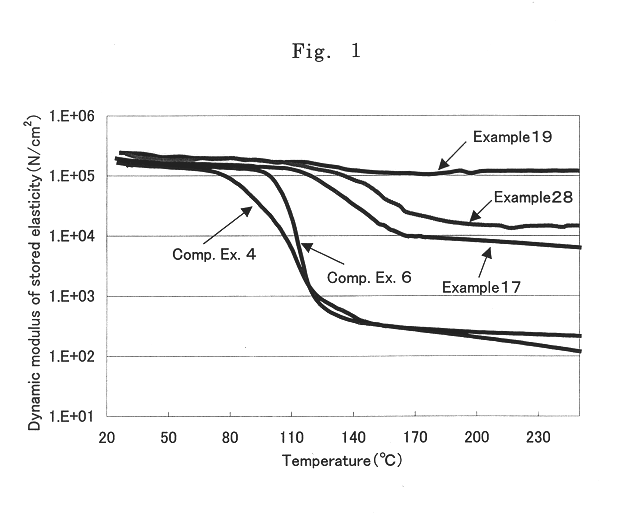

Curing agent for epoxy resin, epoxy resin composition and method for preparing siloxane-modified phenol resin

The present invention provides a curing agent for epoxy resin containing a siloxane-modified phenol resin (3) obtained by dealcoholization condensation reaction between a phenol resin (1) and a hydrolyzable alkoxysilane (2). The present invention further provides an epoxy resin composition comprising an epoxy resin and the above-mentioned curing agent for epoxy resin. The present invention further provides a method for preparing a siloxane-modified phenol resin (3) characterized by subjecting a phenol resin (1) and a hydrolyzable alkoxysilane (2) to dealcoholization condensation reaction.

Owner:ARAKAWA CHEM IND LTD

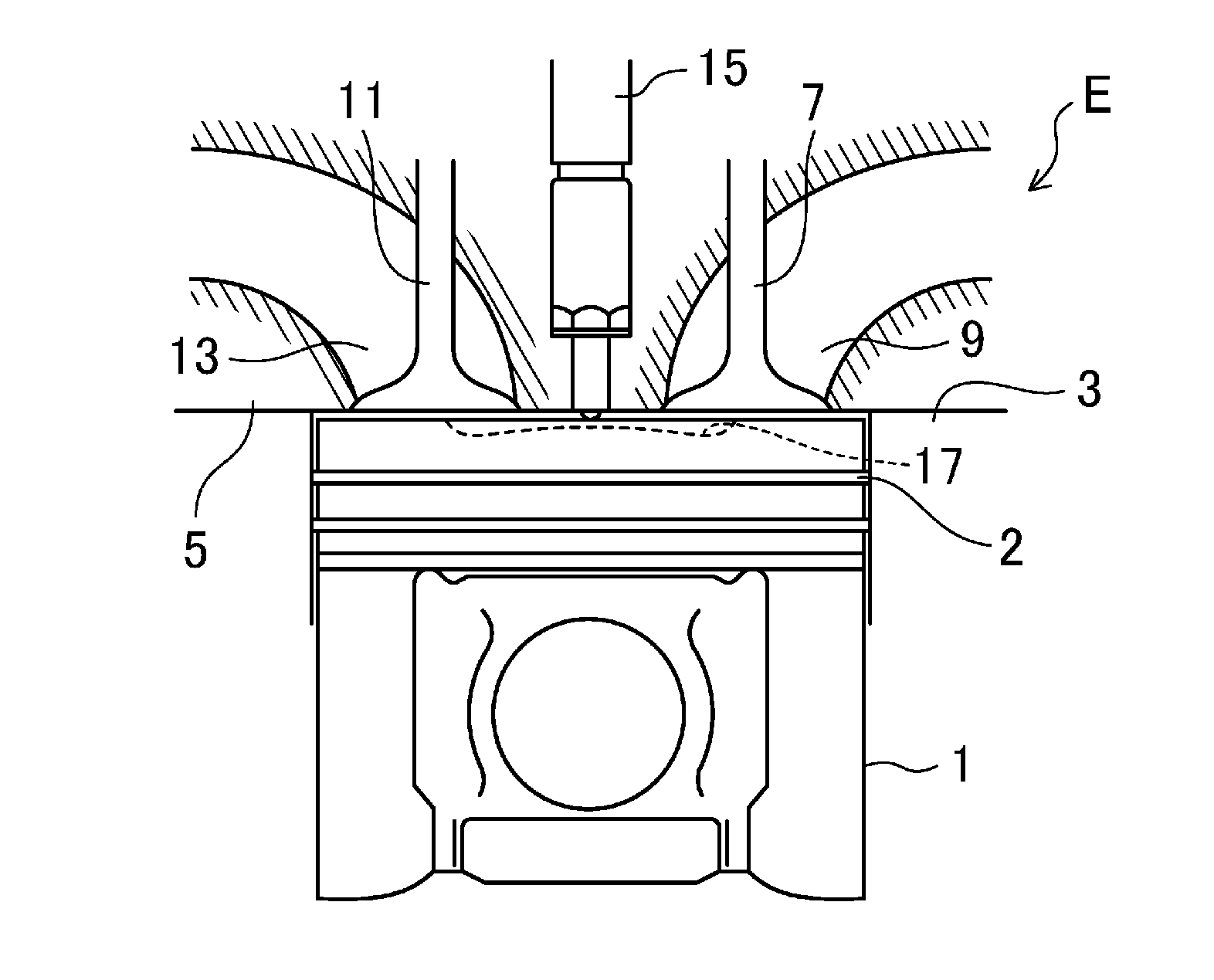

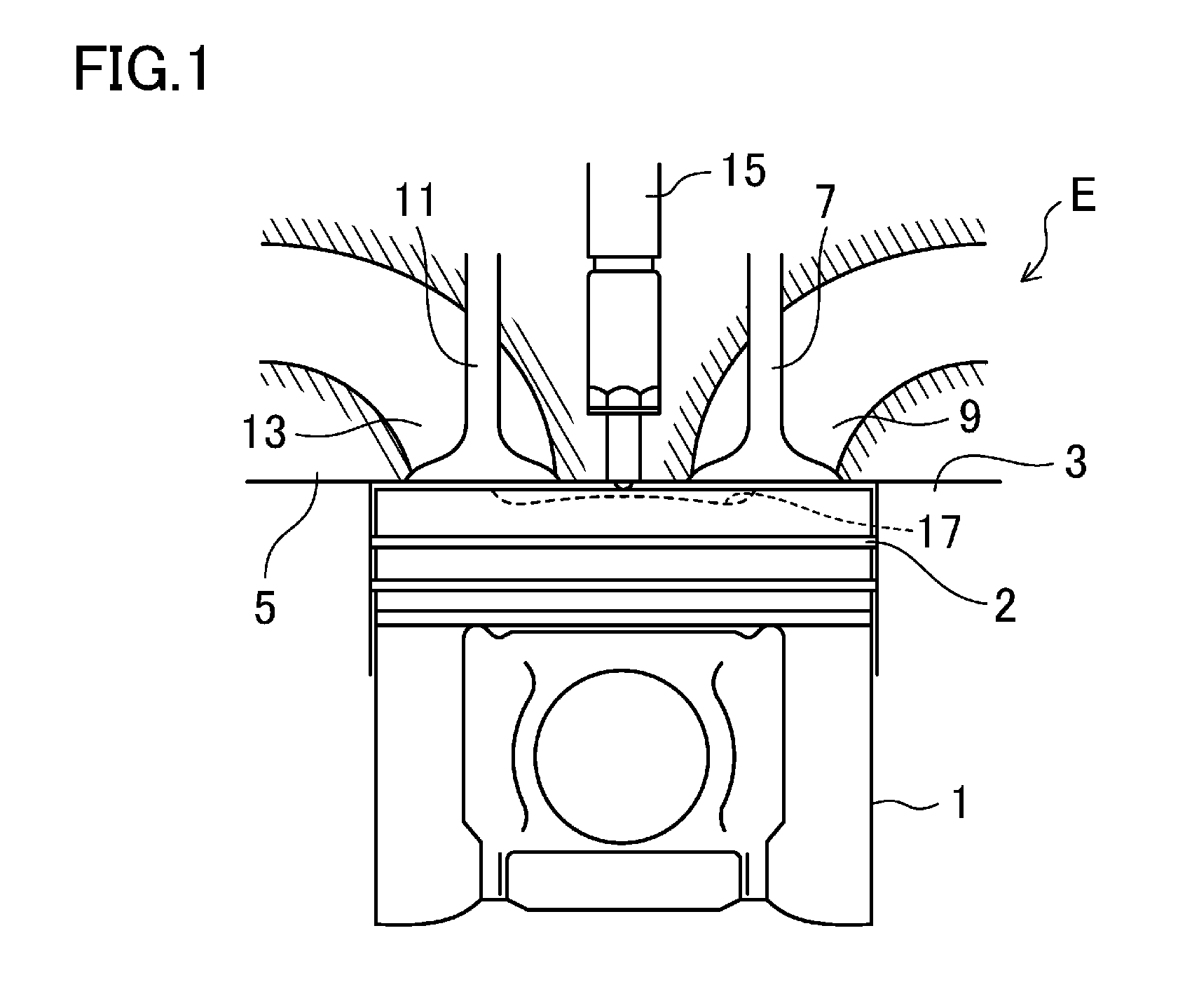

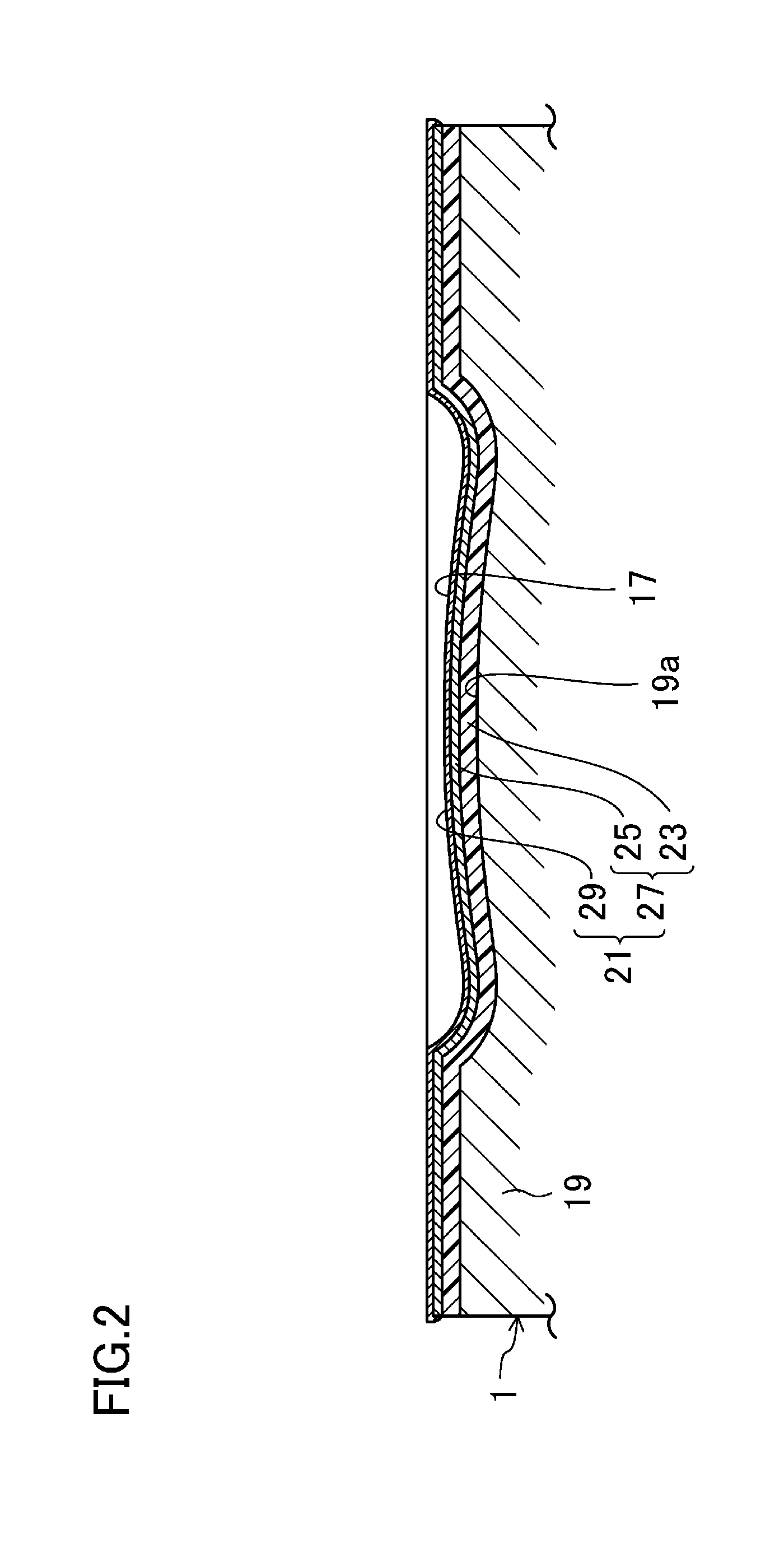

Heat-insulating structure of member facing engine combustion chamber, and process for producing same

InactiveUS20150204233A1Reduce the occurrence of cracksOccurrence of peeling be reducedInternal combustion piston enginesCylinder headsHigh resistanceCombustion chamber

A heat-insulating layer exhibiting high resistance to cracks, peeling, deformation, and gasoline and high heat insulation is obtained on the wall surface of an engine member (19). First, a heat insulator layer including a silicone-based resin and hollow particles containing a Si-based oxide is formed on a wall surface of the engine member (19). Then, Si-based oxide is produced through oxidation of a silicone-based resin in at least part of the surface of the heat insulator layer by heating the surface of the heat insulator layer. Thereafter, a catalytic metal is added to the silicone-based resin in the surface of the heat insulator layer and / or Si-based oxide derived from the hollow particles. Using the catalytic metal as nuclei, electroless plating is performed. In this manner, a heat-insulating layer (21) in which the surface of the heat-insulating film (27) is covered with a plating film (29) is obtained.

Owner:MAZDA MOTOR CORP

Preparation method of flame-retardant melamine hard foam

The invention belongs to the technical field of macromolecular foam materials, and in particular relates to a preparation method of flame-retardant melamine hard foam. The method comprises the steps of performing reaction on melamine and paraformaldehyde according to a mole ratio of 1:(1.5 to 3.5), melamine and a modifier I according to a mass ratio of 1:(0.1 to 0.6) and alcohol serving as a solvent under a water bath of 75 DEG C till the materials are clarified and transparent, adding a modifier II and melamine into resin according to a mass ratio of (0.05 to 0.2):1, continuously performing reaction for 0.5-2 hours, removing the solvent, and adjusting the solid content by water to 85-92 percent to obtain a foam prepolymer. The flame-retardant melamine hard foam prepared by the preparation method disclosed by the invention has the advantages of high compressive strength, high closing rate, excellent flame retardancy and the like, cannot enable powder to fall off and can be applied to the air conditioner air pipe, laminboard and external wall heat preservation material markets.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

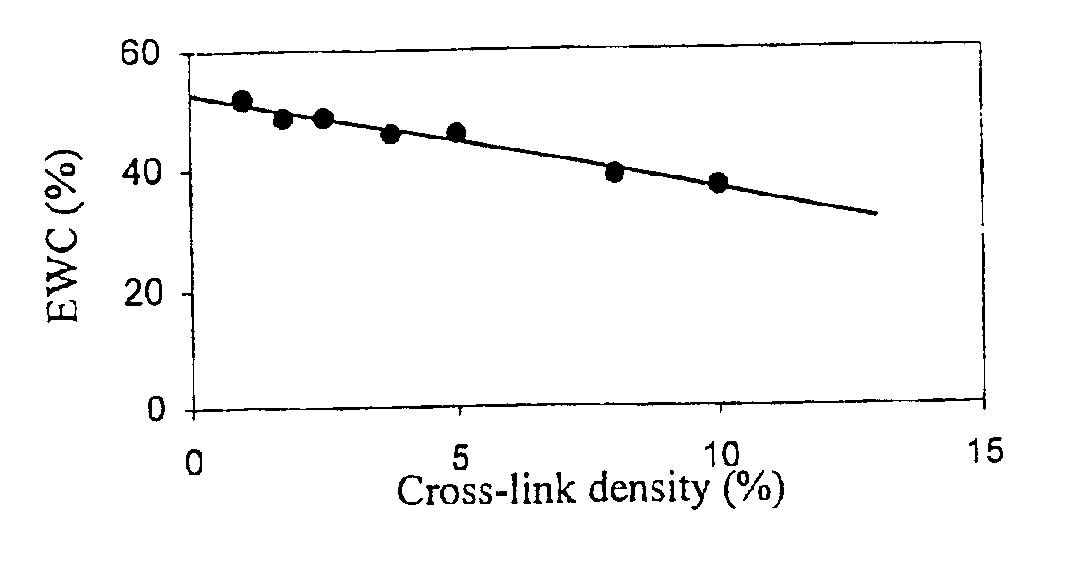

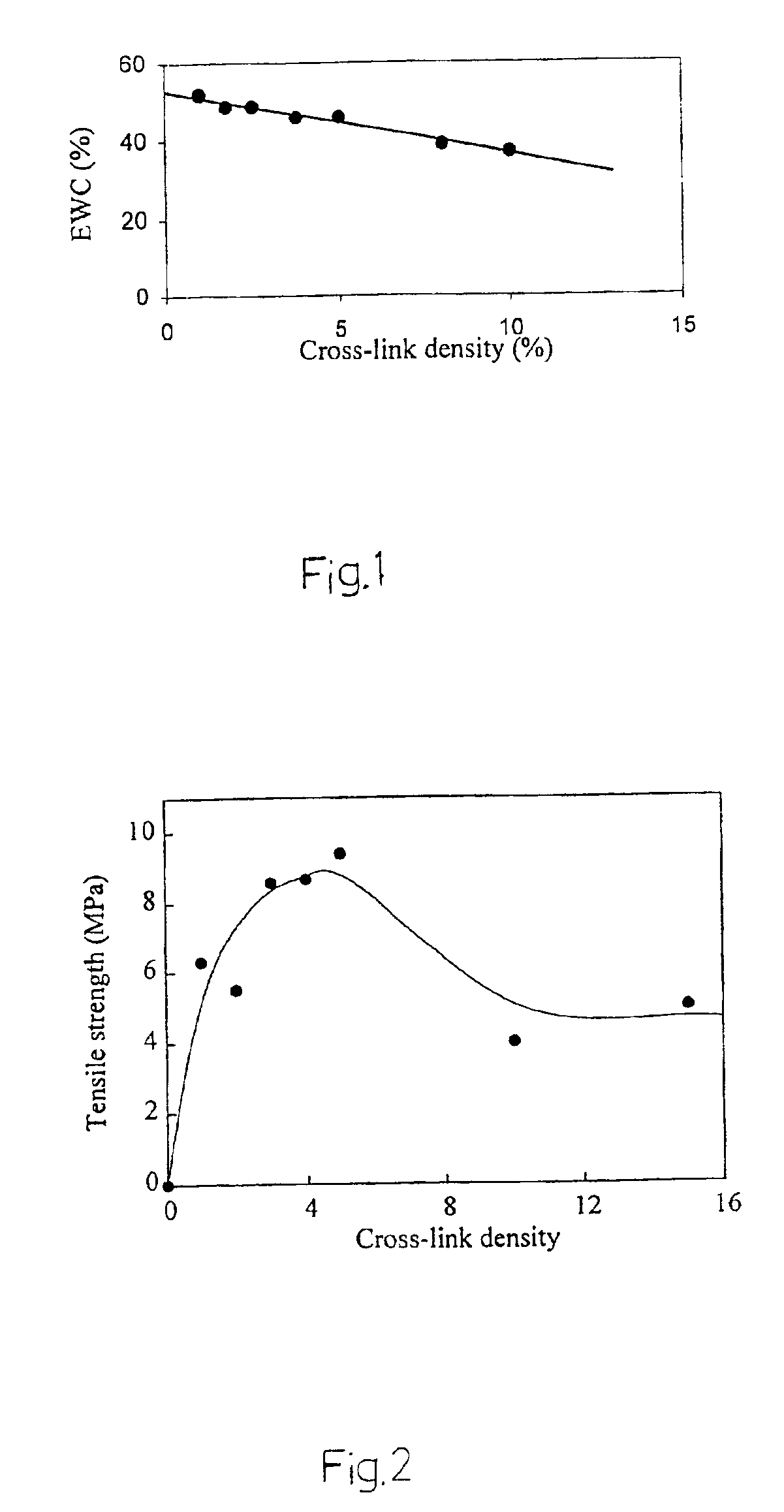

Hydrogels and methods for their production

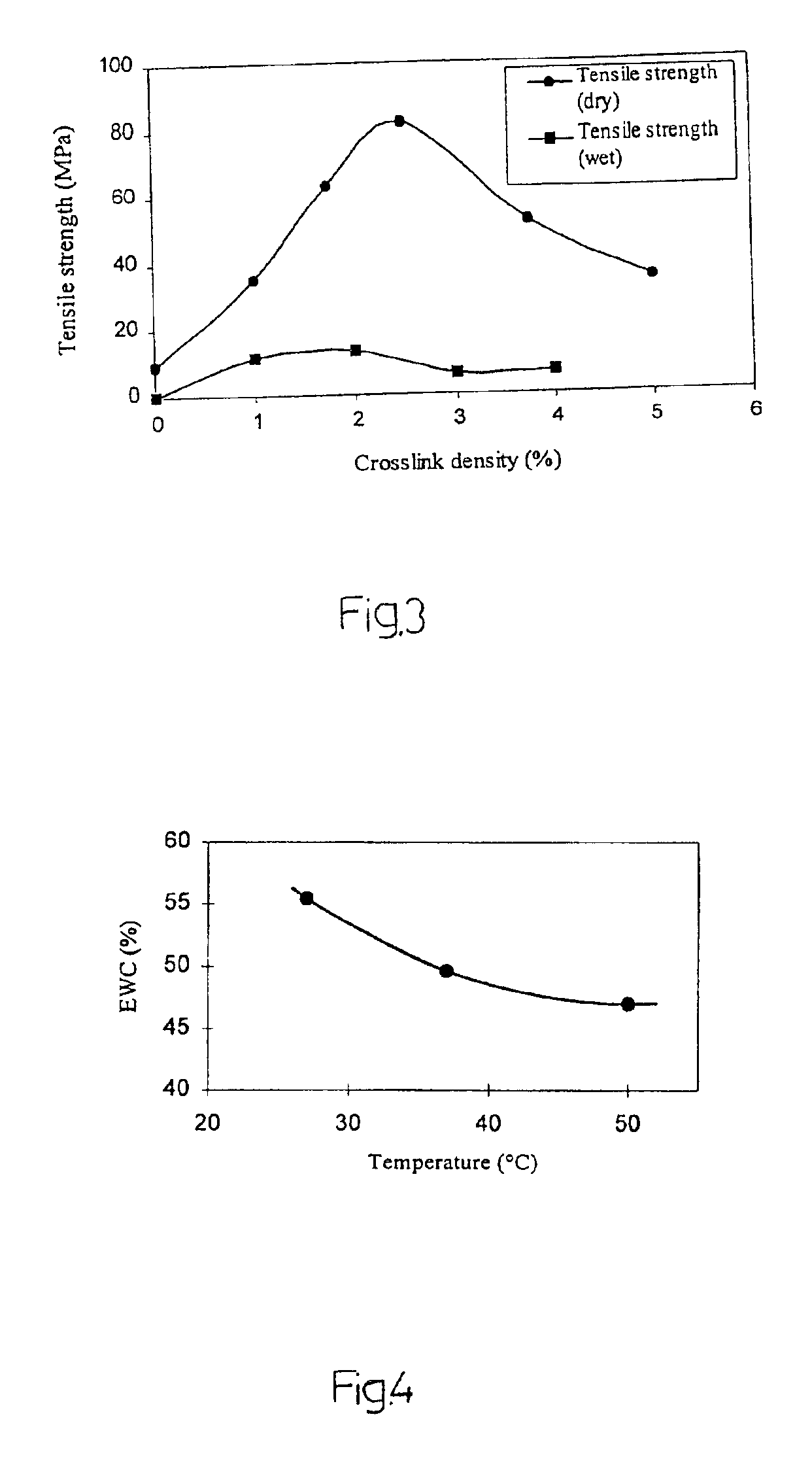

InactiveUS6846875B2Advantageous mechanical characteristicHigh strengthPowder deliveryIntraocular lensHydrophilic polymersSolvent

The present invention relates to new hydrogels with improved mechanical properties and methods of their preparation. The hydrogels are formed from hydrophilic polymers having function hydroxyl groups and have low elasticity modulus typically less than about 10 kPa, a tensile strength above 1 MPa, an elongation above 50% which makes suitable as medical implants, in particular intraocular lenses. The hydrogels are prepared by a crosslinking method with a comparatively low concentration of hydrophilic polymer of a sufficiently high molecular weight dissolved in a good solvent.

Owner:AMO GRONINGEN

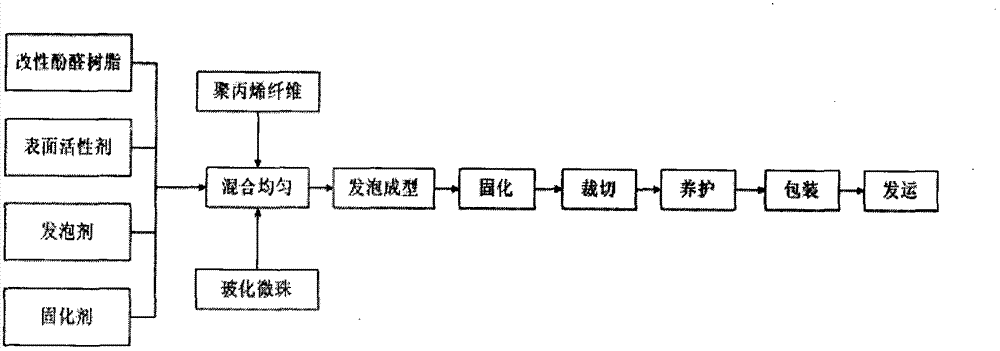

Fire-proof and thermal-insulation board and manufacturing method thereof

InactiveCN102787670AHigh bonding strengthNon-combustibleHeat proofingSound proofingFiberAdhesive cement

The invention relates to a fire-proof and thermal-insulation board and a manufacturing method thereof, and belongs to the technical field of constructional materials. According to the manufacturing method of the fire-proof and thermal-insulation board, modified phenolic resin, reinforcing fibers and inorganic micro bead thermal insulation fillings with the weight ratio of 1:(0-0.05):(0.3-1) are prepared; and after the steps of preparing adhesive, preparing a mixture, foaming, forming and solidifying to form are finished, a foam board is subjected to thermal insulation to be formed, so that the fire-proof and thermal-insulation board in a closed cell foamed structure is obtained. According to manufacturing method, organic materials and inorganic materials are organically combined, so that a novel fire-proof and thermal-insulation material with the fire-proof property of the inorganic thermal insulation materials and the thermal-insulation property of the organic thermal insulation materials is manufactured; and the fire-proof and thermal-insulation board is simple in forming technology, and can practically satisfy the energy saving and safety requirements of wall construction.

Owner:万国骅

Crosslinker for superabsorbent polymers

InactiveCN101094695APromote absorptionEasy to processAbsorbent padsBandagesSuperabsorbent polymerPhotochemistry

Owner:EVONIK DEGUSSA GMBH

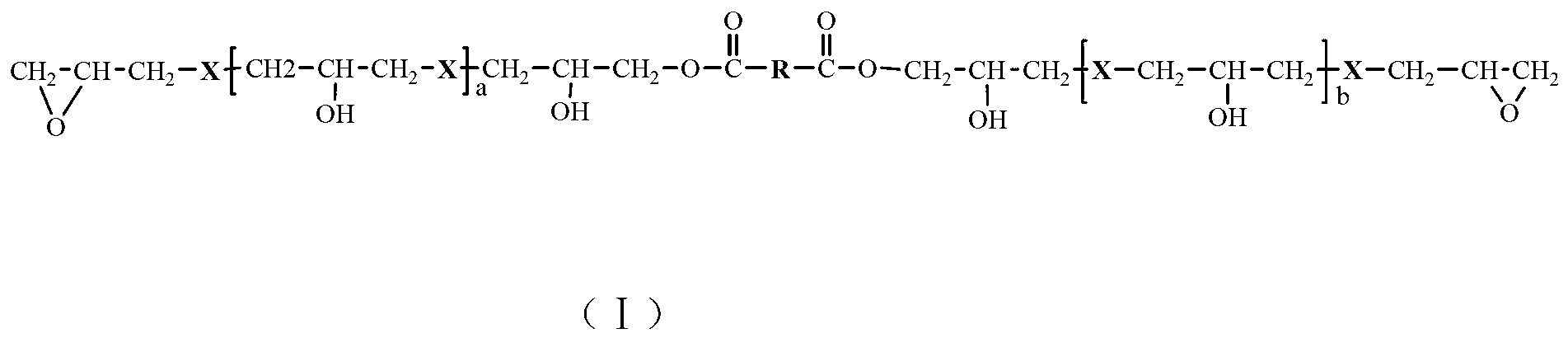

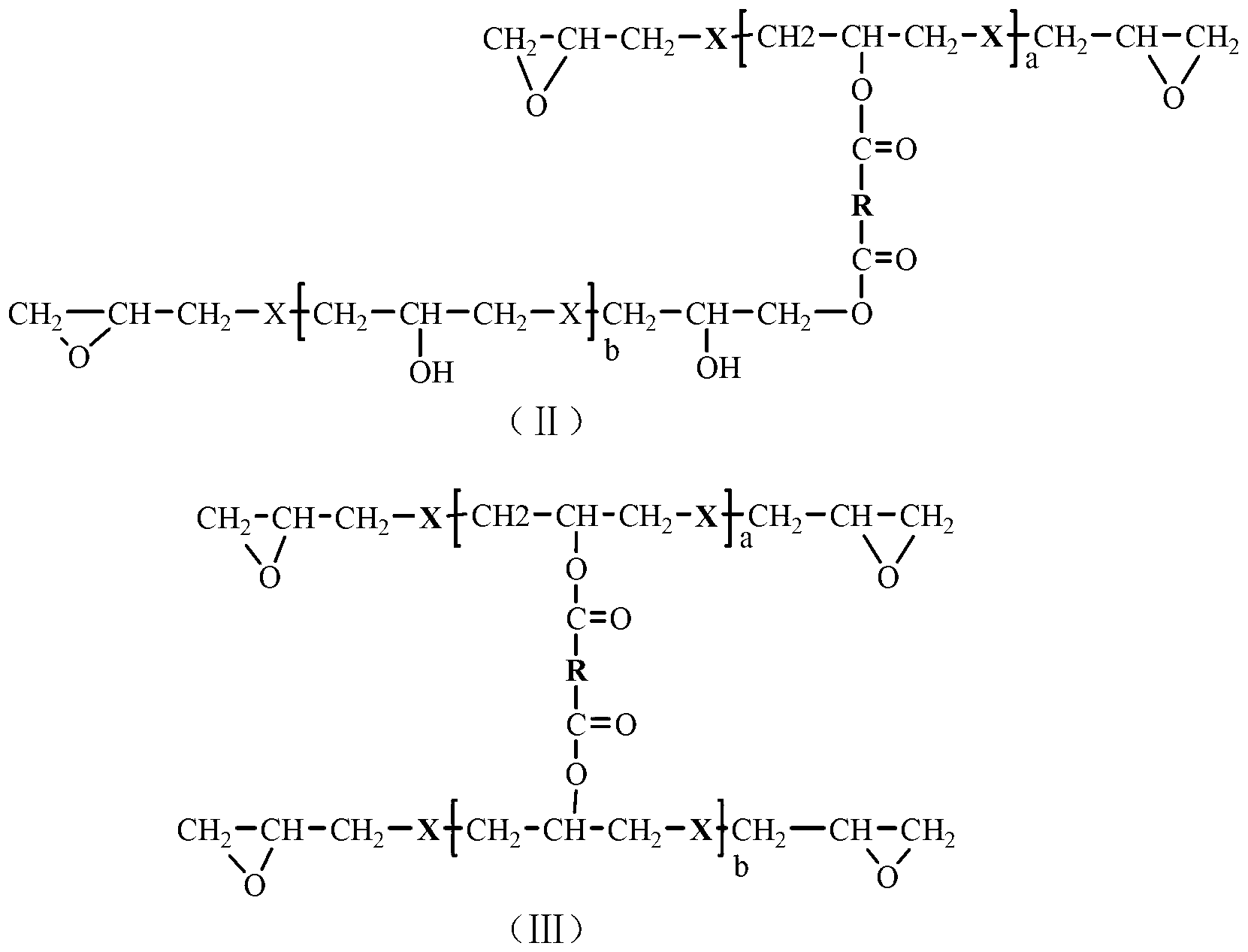

Fatty acid modified epoxy resin and preparation method thereof

ActiveCN103073701AReduce crosslink densityImproved film toughnessAnti-corrosive paintsEpoxy resin coatingsCross-linkEpoxy

The invention discloses a fatty acid modified epoxy resin and a preparation method thereof. Through uniformly mixing a liquid difunctional epoxy resin and fatty acid, reacting the liquid difunctional epoxy resin with the fatty acid under a condition with a catalyst and adding a fatty acid flexible chain segment to a low molecular weight liquid epoxy resin molecule, the cross-linking density of the obtained fatty acid modified epoxy resin after being cured is reduced, so that the toughness of a film is improved, the adhesion force of the film to a metal substrate is increased and the reaction activity of the film is not reduced; the fatty acid modified epoxy resin can be cured at a normal temperature, so that construction requirements of various heavy anti-corrosion coatings are satisfied.

Owner:EPOXY BASE ELECTRONICS MATERIAL

Transparent hardened film for in-mold decoration

ActiveCN102786874AHigh surface hardnessIncrease crosslink densitySynthetic resin layered productsPolyurea/polyurethane coatingsPolyethylene glycolUltraviolet

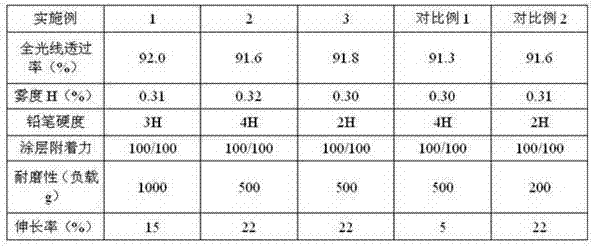

The invention provides a transparent hardened film for in-mold decoration. The transparent hardened film comprises a base film and a hardened coating layer coated thereon. The base film is a PET (polyethylene glycol terephthalate) film, and the thickness of the hardened coating layer ranges from 3 micrometers to 5 micrometers. The hardened coating layer comprises, by weight, 15-30 parts of high-functionality polyurethane acrylate prepolymer, 5-20 parts of low-functionality polyurethane acrylate prepolymer, 5-10 parts of organic-inorganic hybrid materials, 5-10 parts of photoinitiators, 0.01-0.1 part of flattening agents and 30-64 parts of organic solvent which are subjects to ultraviolet curing. The transparent hardened film has the advantages of high hardness, excellent stretch forming performance, good wear resistance, high transparency and low haze.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

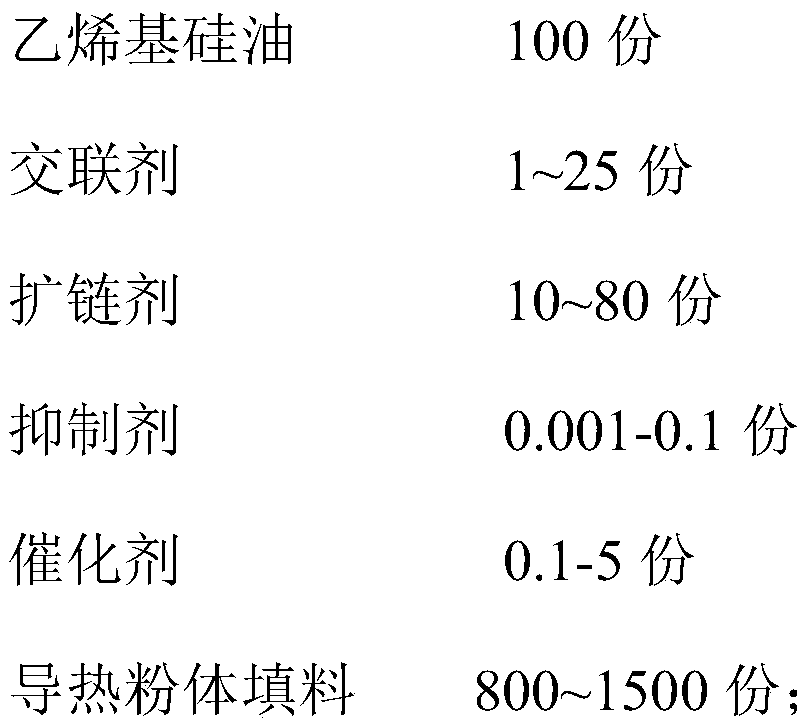

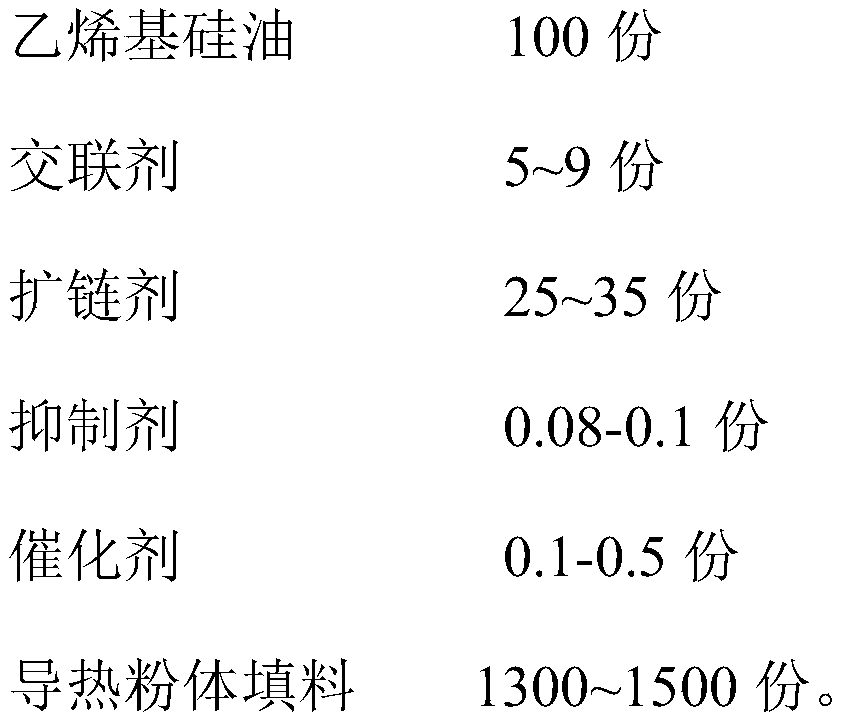

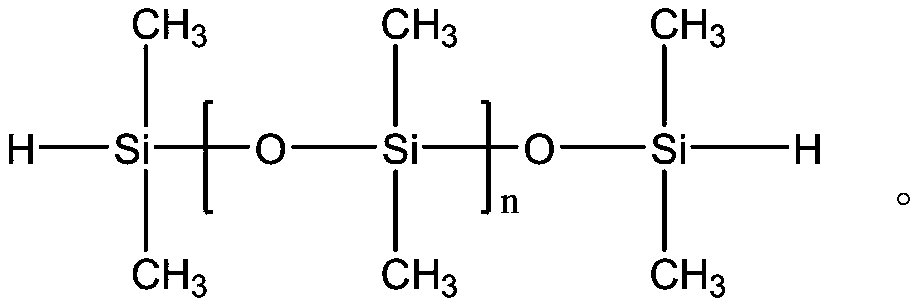

High-performance silicon-based heat conduction mud and preparation method thereof

The invention relates to high-performance silicon-based heat conduction mud and a preparation method thereof. The silicon-based heat conduction mud is prepared from the following raw materials in parts by weight: 100 parts of vinyl silicone oil, 1-25 parts of a cross-linking agent, 10-80 parts of a chain extender, 0.001-0.1 part of an inhibitor, 0.1-5 parts of a catalyst and 800-1500 parts of a heat conduction powder filler, wherein the vinyl silicone oil is composed of single-ended vinyl silicone oil, double-ended vinyl silicone oil and lateral vinyl silicone oil; the cross-linking agent is lateral hydrogen silicone oil; and the chain extender is terminal hydrogen silicone oil. The silicon-based heat conduction mud has the advantages of no oil seepage, no powder falling, no elasticity, moderate viscosity, moderate elongation at break, high heat conduction coefficient and excellent comprehensive performance, and can meet the personalized construction conditions and requirements of different electronic devices.

Owner:GUANGZHOU BAIYUN CHEM IND

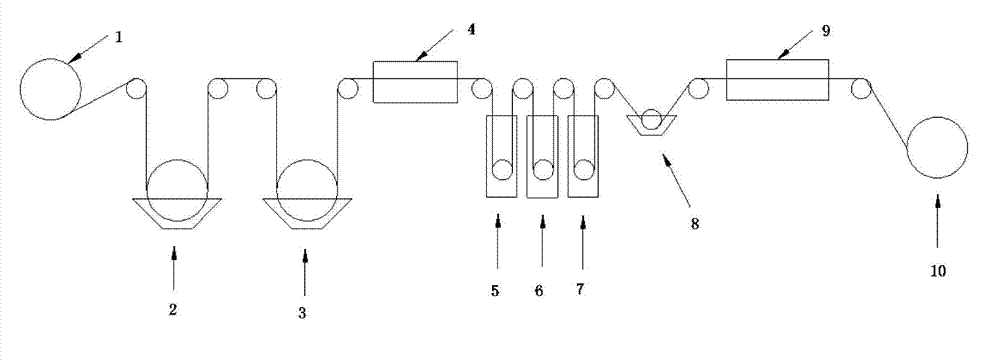

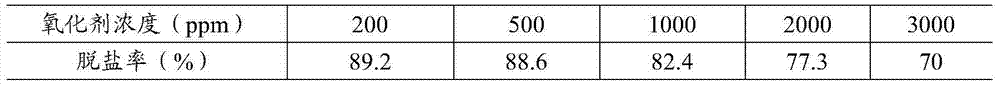

Method for online preparing high-throughput composite reverse osmosis membrane

ActiveCN103657430AReduce crosslink densityIncrease water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationReverse osmosis

The invention discloses a method for online preparing a high-throughput composite reverse osmosis membrane. The method comprises the following steps of using a membrane coating machine to enable an ultrafiltration base membrane to pass through m-phenylenediamine aqueous solution, normal hexane solution of trimesoyl chloride, an oven, a purge tank, an oxidation tank, a reduction cell, a glycerite tank and a protective liquid tank; drying in the oven to obtain the high-throughput composite reverse osmosis membrane. The method has the characteristics that the process is simple, the water flux of the membrane is high, dry films of the high-throughput composite reverse osmosis membrane can be directly produced, membrane components can be wound conveniently, large-scale production can be realized, the process is stable, and the like. The high-throughput composite reverse osmosis membrane can be applied in the field of household water purification, municipal administration tap water is utilized to supply pressure without an additional booster pump, the cost is greatly reduced, and the energy is saved.

Owner:BEIJING ORIGIN WATER FILM TECH

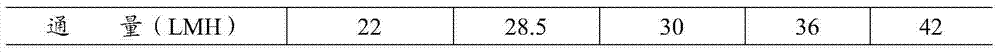

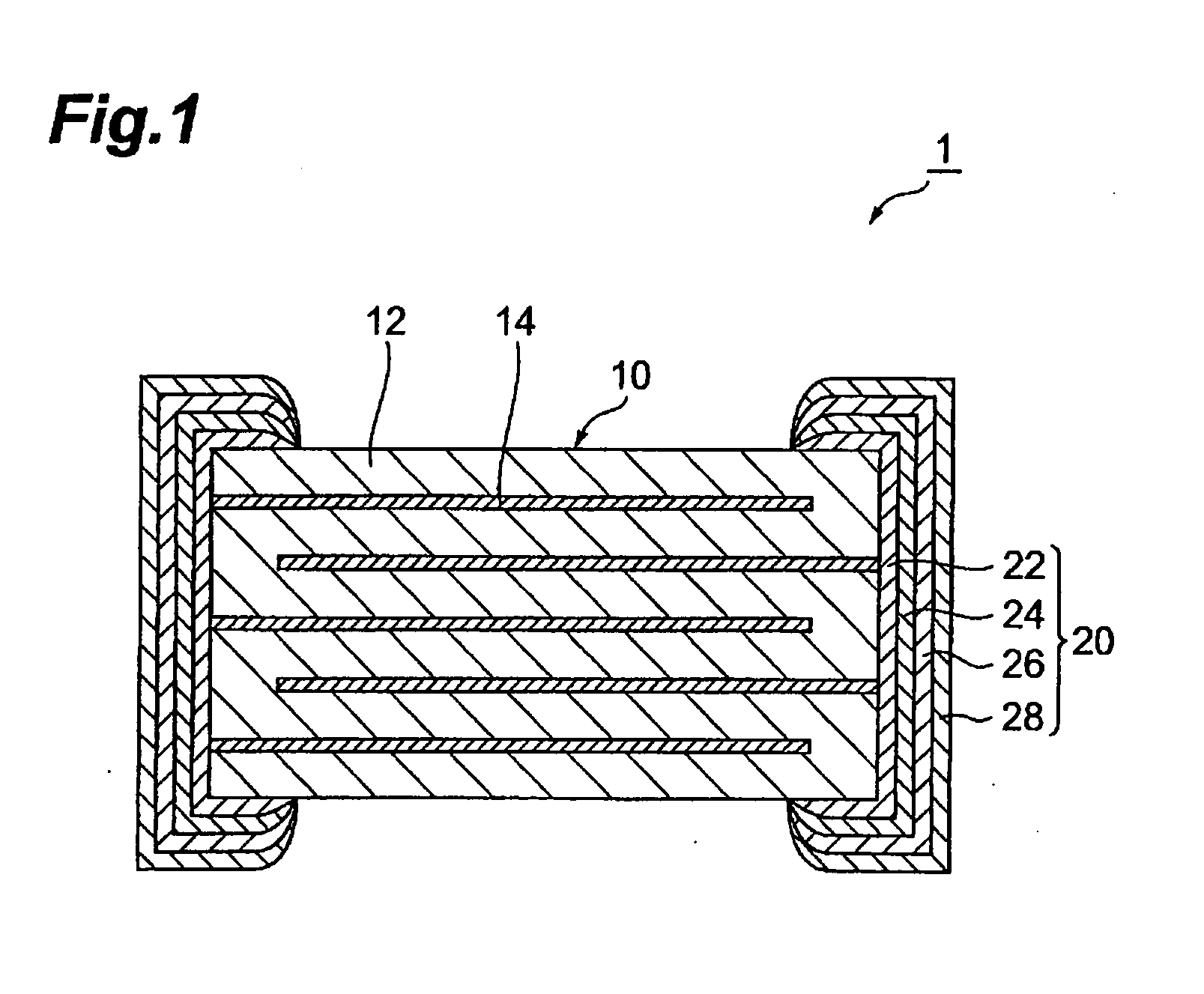

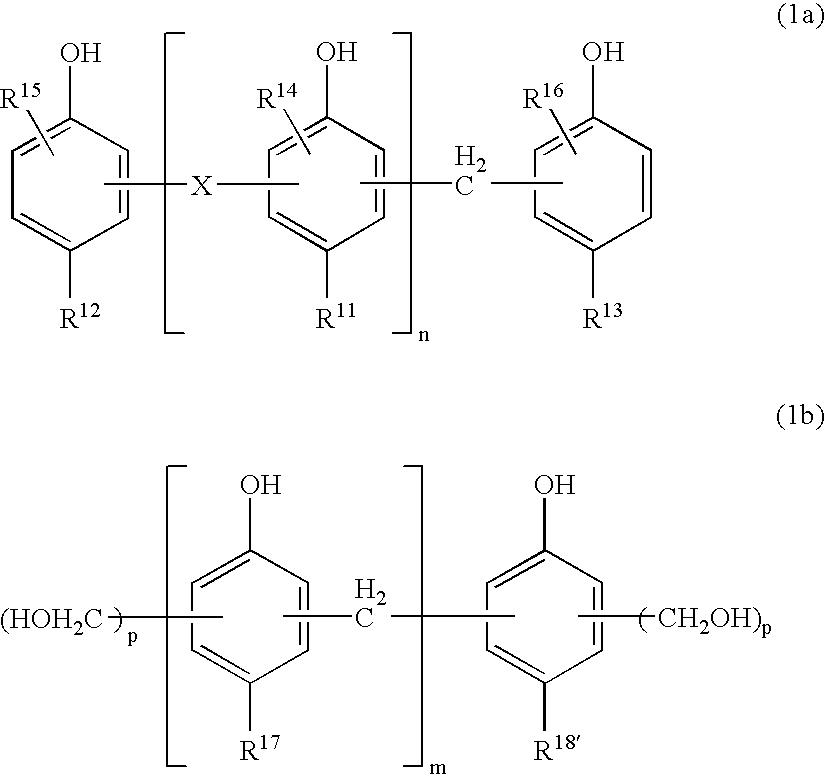

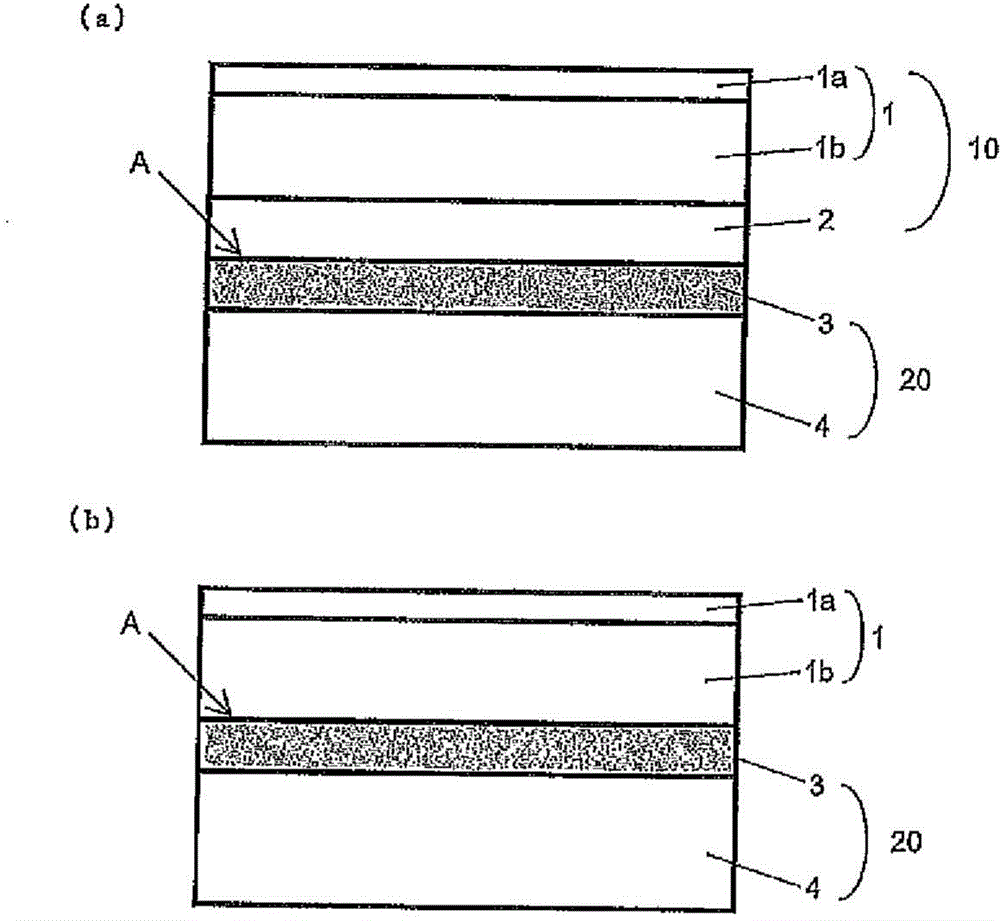

Electronic component

ActiveUS20070201183A1Reduce crosslink densityRelaxation stressPiezoelectric/electrostrictive device manufacture/assemblyFixed capacitor electrodesSide chainCeramic capacitor

The present invention aims to provide an electronic component capable of reducing the occurrence of cracks at the joining portion to a board etc. A capacitor 1 (laminated ceramic capacitor) being one example of the electronic component is provided with an element assembly 10 (ceramic) and a pair of external electrodes 20 formed on both side surfaces of the element assembly 10. In the element assembly 10, a dielectric layer 12 and an internal electrode 14 are laminated alternately. The external electrode 20 has such constitution that a first electrode layer connected with the internal electrode, a second electrode layer (electroconductive resin layer) including a hardened product of thermohardening resin containing a polyphenol compound having a side chain composed of an aliphatic group, a third electrode layer composed of Ni and a fourth electrode layer composed of Sn are formed in this order from the element assembly side.

Owner:TDK CORPARATION

Carrier film for transparent conductive films and laminate

ActiveCN104419342AReduce crosslink densityInhibit the zipper phenomenonConductive layers on insulating-supportsFilm/foil adhesivesTransparent conducting filmGlass transition

Owner:NITTO DENKO CORP

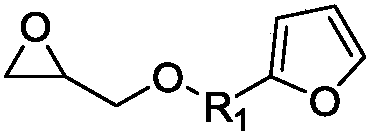

Flip chip bottom filling adhesive with normal temperature rapid capillary fluidity and rapid repairability

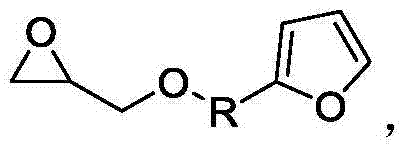

ActiveCN104745133AImprove connection reliabilityHigh TgNon-macromolecular adhesive additivesRubber derivative adhesivesFuranAdhesive

The invention relates to a flip chip bottom filling adhesive with normal temperature rapid capillary flowing property and rapid repairability. The flip chip bottom filling adhesive is prepared from the following raw materials in percentage by weight: 10-60% of epoxy resin, 10-20% of polyether modified epoxy resin, 5-20% of bismaleimide modified toughening resin, 5-20% of furan alkyl glycidyl ether, 5-30% of a curing agent, 5-20% of a curing accelerator, 0.5-3% of a coupling agent, 0-40% of spherical silica powder and 0-6% of pigments. The bottom filling adhesive provided by the invention is mainly applied to bottom filling of flip chips so as to improve the connection reliability and has the characteristics of high Tg, good normal-temperature rapid flowing property, good connection reliability and good rapid curing property.

Owner:王传广 +1

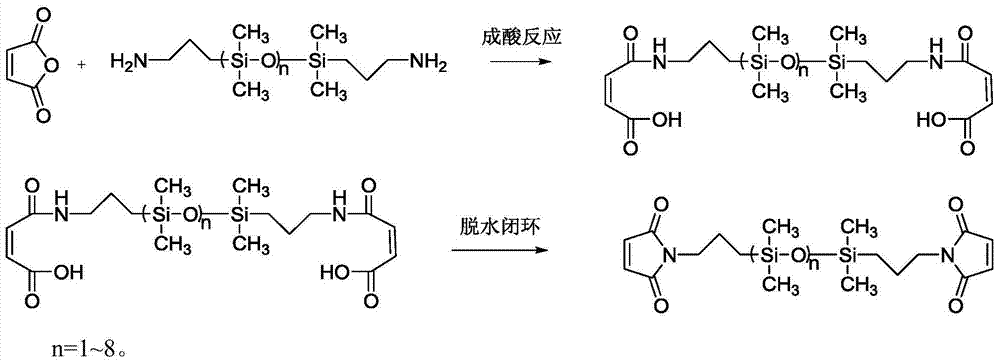

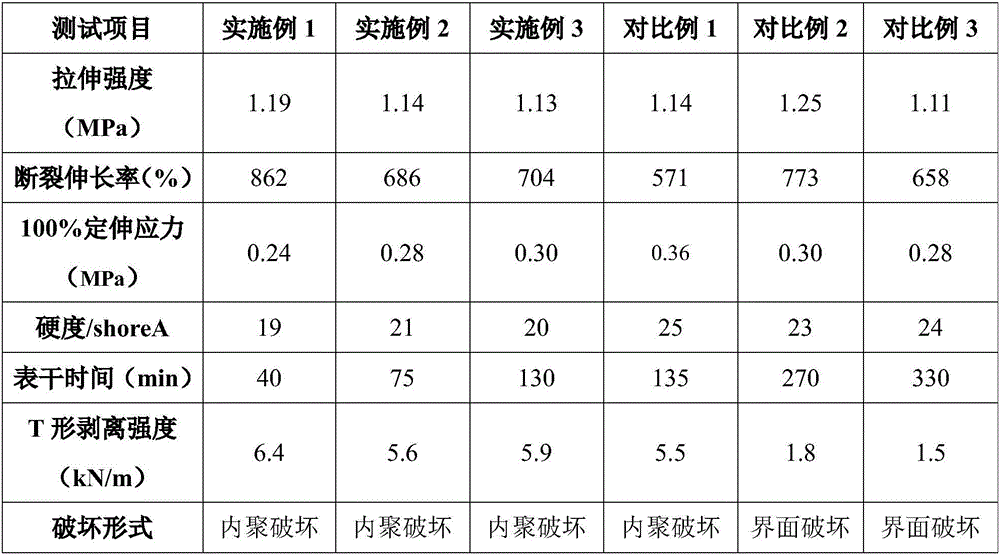

Low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and preparation method thereof

InactiveCN106833503AImprove adhesionImprove mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationALUMINUM STEARATES

The invention discloses a low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and a preparation method thereof. The silicon sealant is prepared from hydroxyl end-blocked dimethylsiloxane, a plasticizer, white mineral oil, gas phase method silica aerogel, a reinforcing filler, aluminum stearate, pigment, a crosslinking agent, a vulcanization accelerator, a silane coupling agent and a catalyst. The preparation method comprises the following steps: 1) uniformly mixing the hydroxyl end-blocked dimethylsiloxane, the plasticizer, the white mineral oil, the gas phase method silica aerogel, the reinforcing filler, the aluminum stearate and the pigment, and drying the mixture fully to obtain a premix compound; 2) performing vacuum full kneading on the premix compound to obtain base; 3) adding the crosslinking agent, the vulcanization accelerator and the silane coupling agent into the base, performing vacuum stirring uniformly;4) adding the catalyst into the base, performing vacuum stirring uniformly, discharging the mixture, and performing filling and sealing. The low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant provided by the invention has the advantages of neutral solidification, strong bonding power, excellent mechanical property, and good heat resistance and oil resistance.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

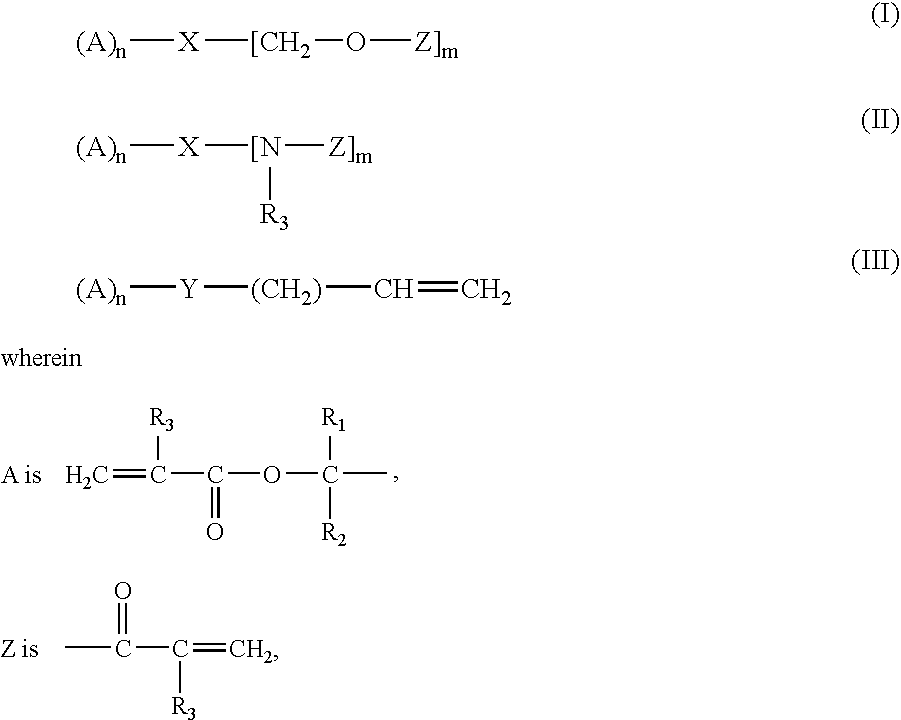

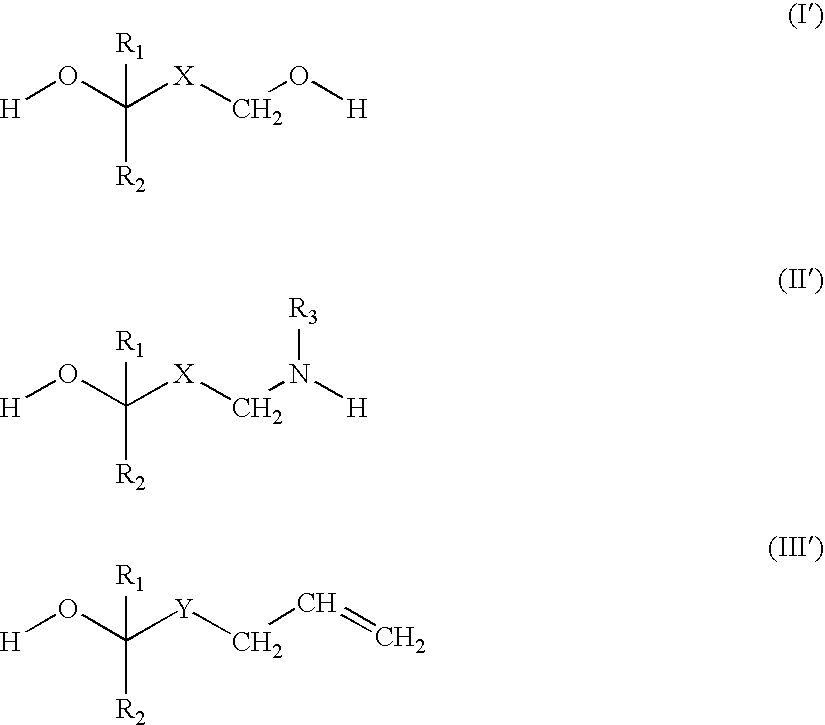

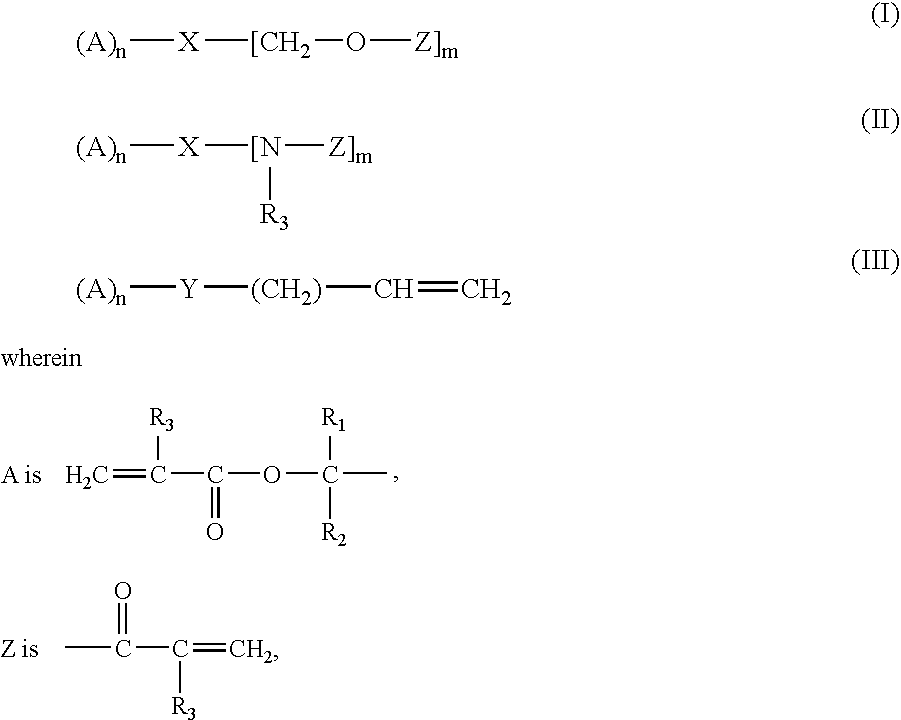

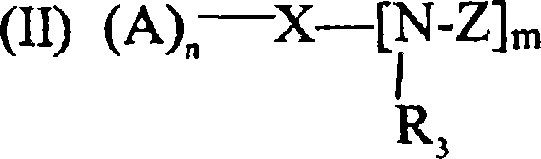

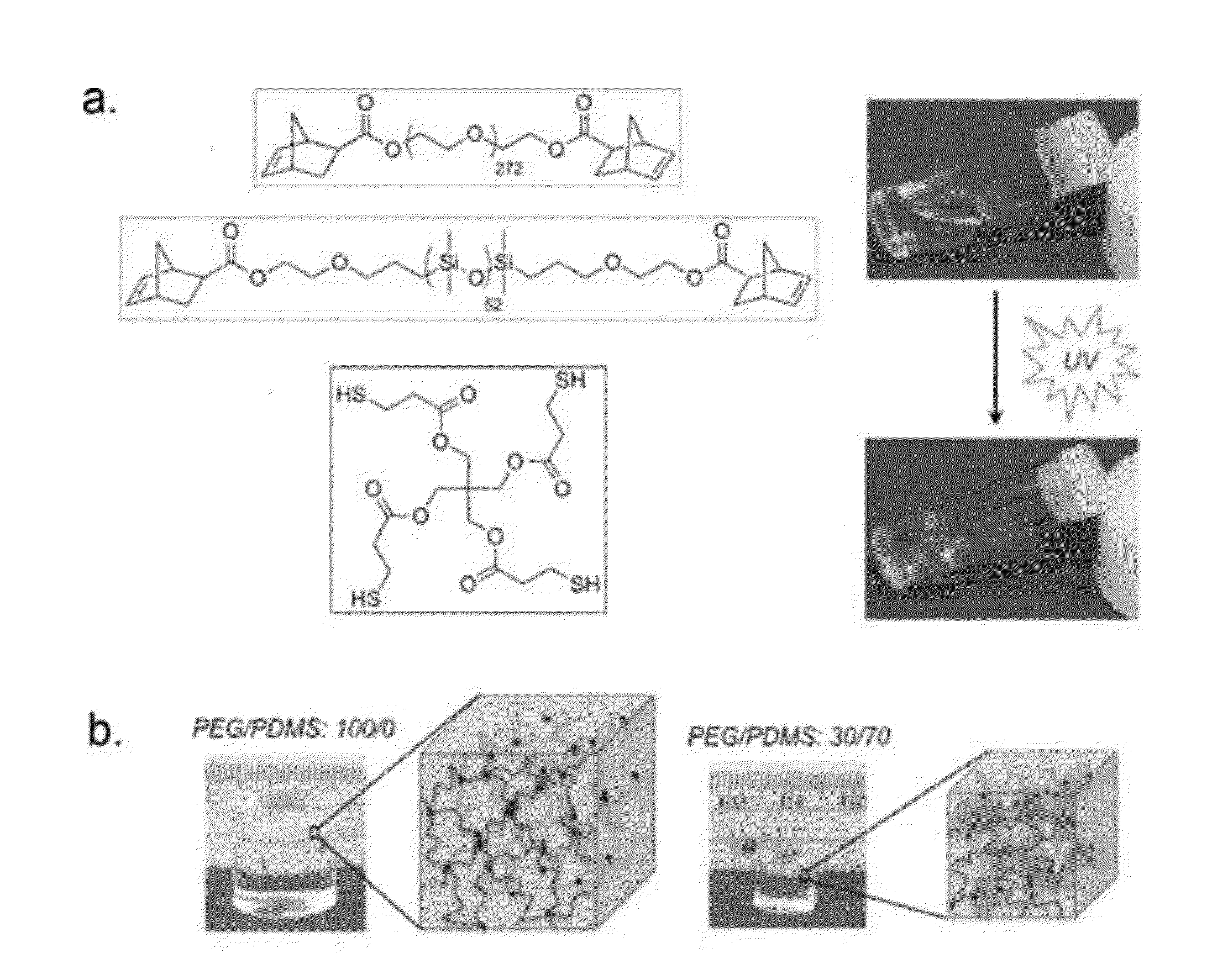

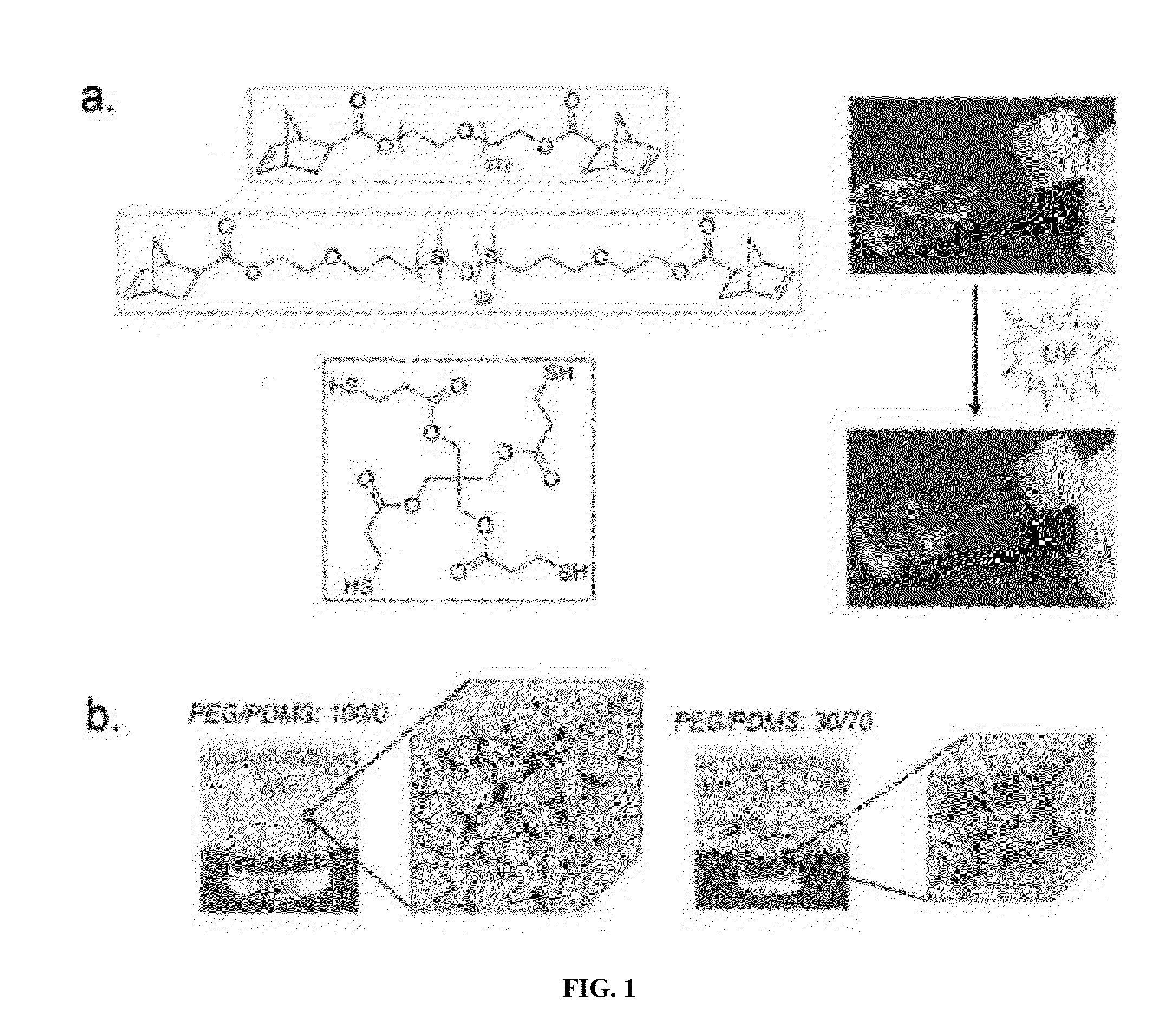

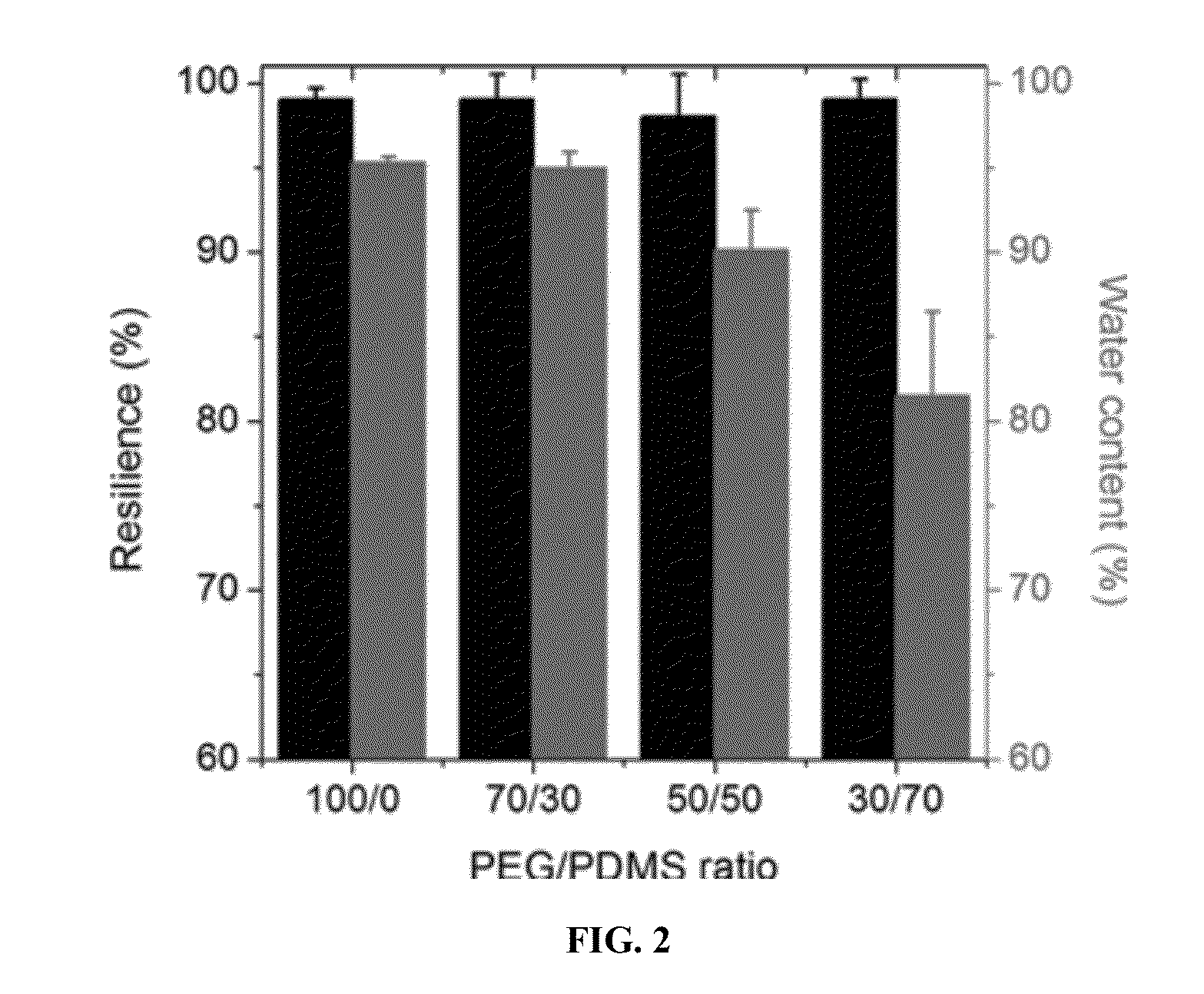

Telechelic based networks from novel macromonomers, compositions, preparation and uses thereof

The invention provides highly resilient synthetic hydrogels, which can be prepared, for example, by using the efficient thiol-norbornene chemistry to cross-link hydrophilic poly(ethylene glycol) (PEG) and hydrophobic polydimethylsiloxane (PDMS) polymer chains. The simple hydrogel system with enhanced mechanical properties is useful in many applications, including in the biomedical field and in the design of protective and corrective wear.

Owner:UNIV OF MASSACHUSETTS

Organic silicone modified high water absorption resin and preparation method thereof

The invention discloses an organic silicane high-adsorbing resin, which is copolymerized by soluble polycondensation product and vinyl monomer free radical with the content of organic silica as 0.1-5wt% as vinyl monomer, wherein the organic silicane is represented through Y (CH2) nSiX3 (Y is vinyl, epoxy radical, mercapto radical and so on; X is methoxyl, ethyoxyl, isopropoxy and so on); the resin adsorbs deionized water and salt water, which displays optical, heat and ultraviolet stability in the agricultural and hygiene domain.

Owner:安徽省农业科学院原子能农业应用研究所 +1

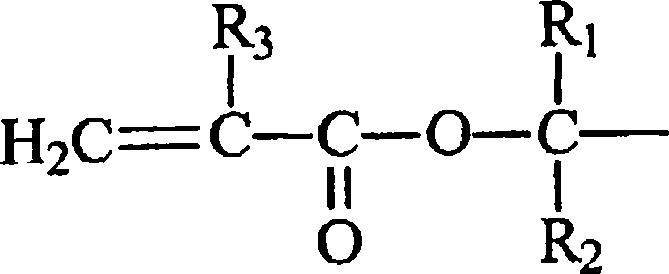

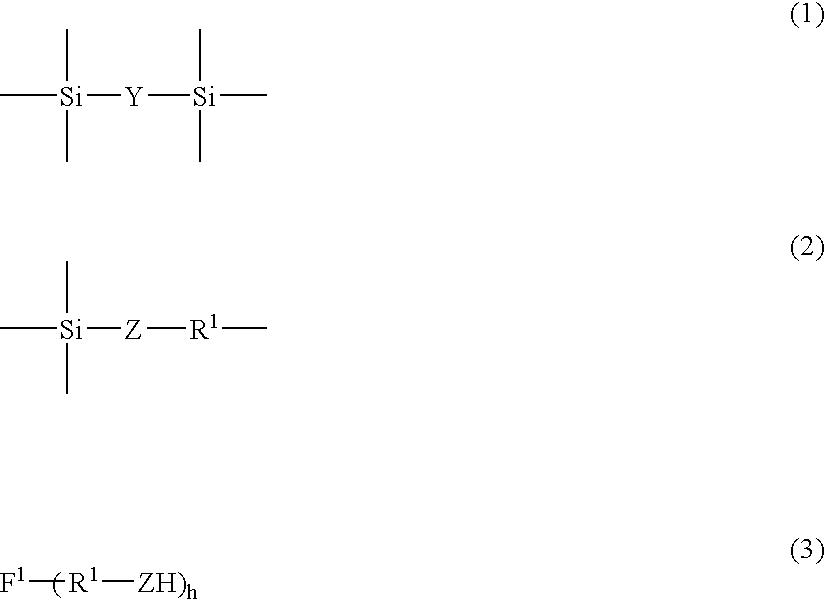

Electrophotographic photoreceptor, method for producing the same, image forming apparatus and process cartridge

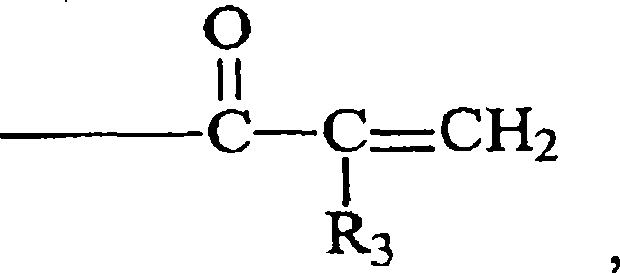

InactiveUS20040197690A1Reduce crosslink densityLack of durabilityElectrographic process apparatusCorona dischargeChemical compoundImage formation

The present invention relates to an electrophotographic photoreceptor comprising a conductive support having formed thereon a specific photosensitive layer. The photosensitive layer comprises a siloxane resin-containing layer containing a siloxane resin having a structural unit represented by general formula (1) shown below, a structural unit represented by general formula (2) shown below, and an organic group derived from a compound having hole transport capability, or comprises a siloxane resin-containing layer containing a siloxane resin obtained by using an organic silicon compound having a structural unit represented by general formula (1) shown below and a hydrolytic group, and a compound represented by general formula (3) shown below: The formulas are defined in the specification.

Owner:FUJIFILM BUSINESS INNOVATION CORP

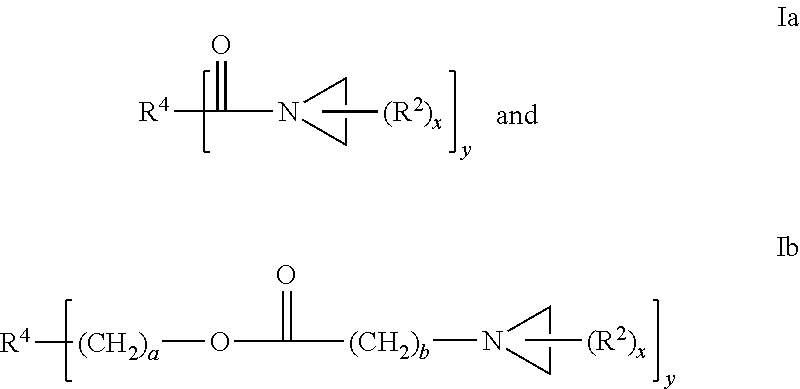

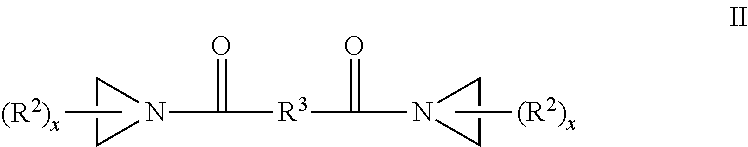

Crosslinkable acrylate adhesive polymer composition

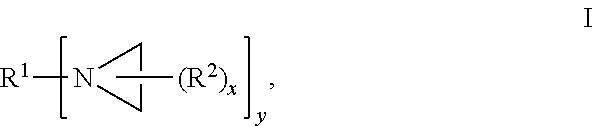

InactiveUS8524836B2Reduce sensitivityIncreased shear strengthSynthetic resin layered productsEster polymer adhesivesSolventPolyaziridine

Owner:3M INNOVATIVE PROPERTIES CO

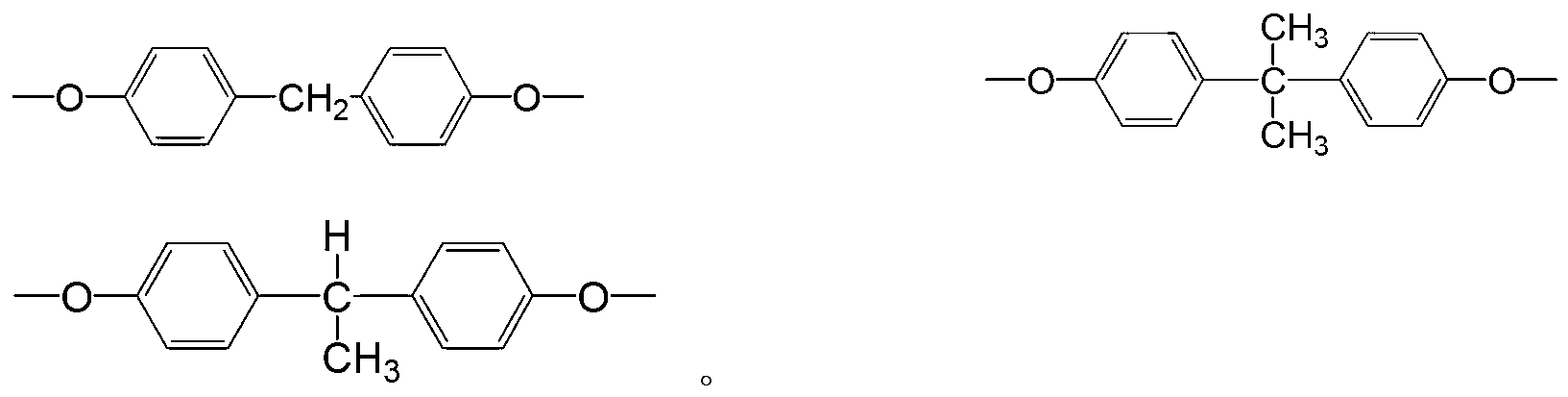

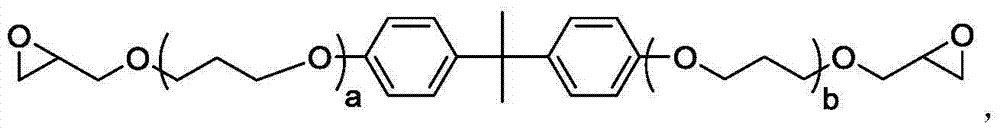

Ultrahigh-toughness epoxy resin material for hot-mixed epoxy asphalt and preparation method thereof

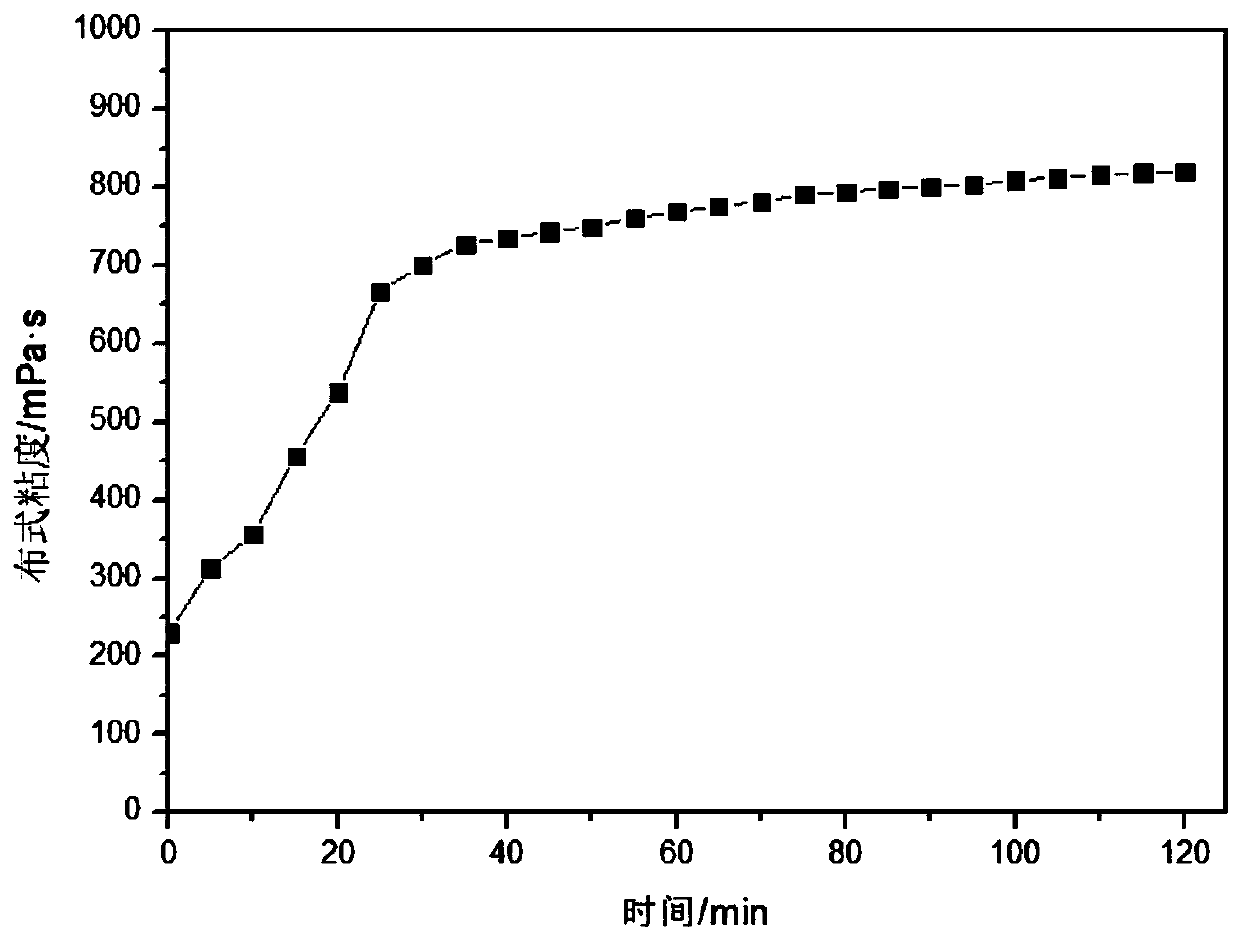

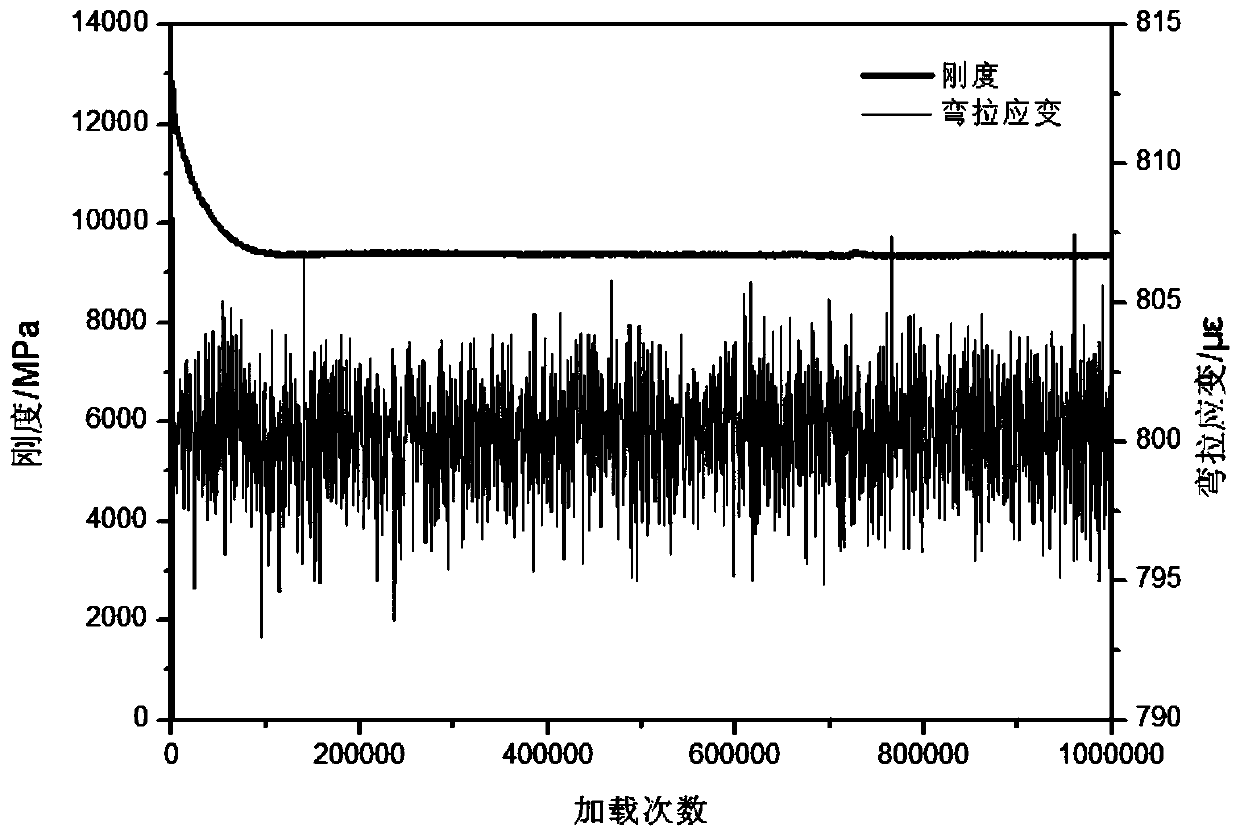

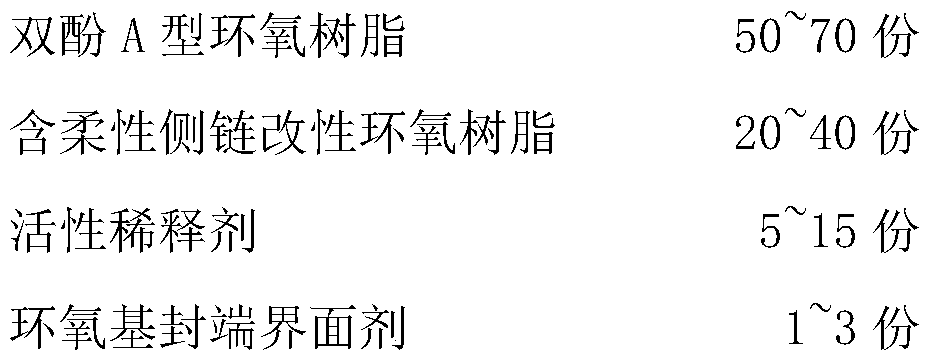

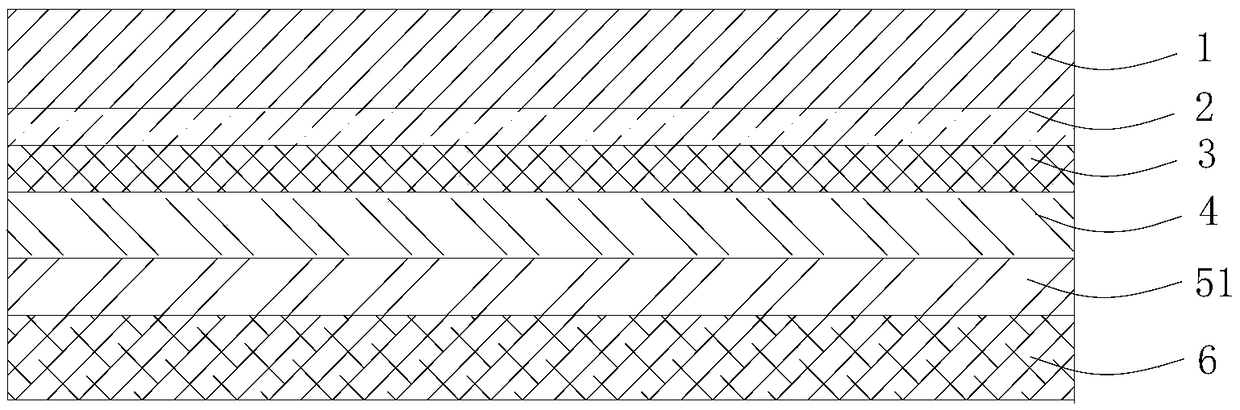

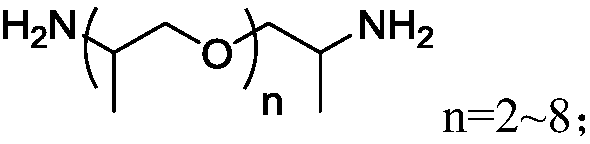

ActiveCN110713695AReduce crosslink densityGuaranteed viscosityBuilding insulationsPolymer scienceSide chain

The invention discloses an ultrahigh-toughness epoxy resin material for hot-mixed epoxy asphalt and a preparation method of the ultrahigh-toughness epoxy resin material. The key points of the technical scheme are as follows: the ultrahigh-toughness epoxy resin material for the hot-mixed epoxy asphalt consists of a main agent A and a curing agent B, wherein the main agent A comprises bisphenol A epoxy resin, modified epoxy resin containing a flexible side chain, a reactive diluent and an epoxy terminated interface agent; the curing agent B comprises following components in parts by weight: long-chain fatty primary amine and an accelerant. The crosslinking density of an epoxy cured product is controlled by synthesizing monofunctional long-chain fatty primary amine, and finally, the operabletime of the hot-mixed epoxy asphalt material is longer than 2 hours; the compatibility problem between an asphalt phase and an epoxy phase is solved on the basis of a 'reaction induced phase splitting' technical principle; by introducing the modified epoxy resin containing the flexible side chain, the fatigue resistance of the hot-mixed epoxy asphalt material is greatly improved.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD +1

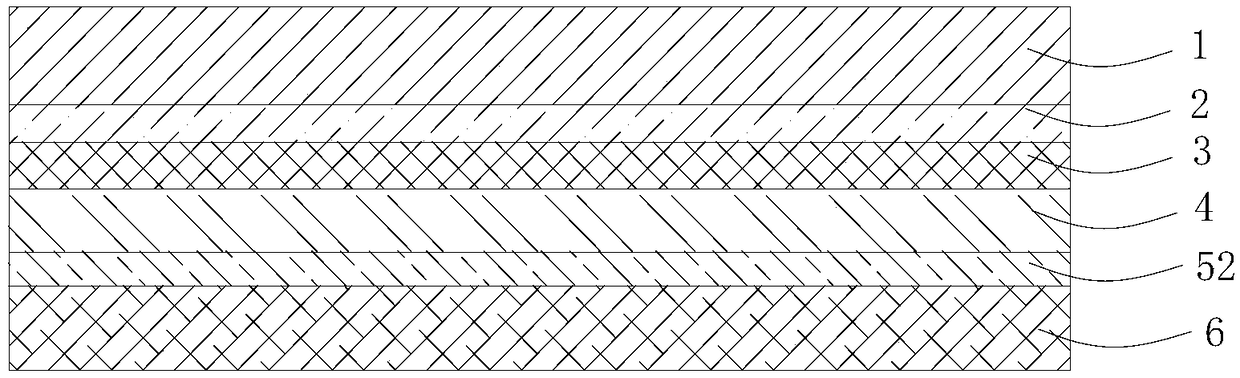

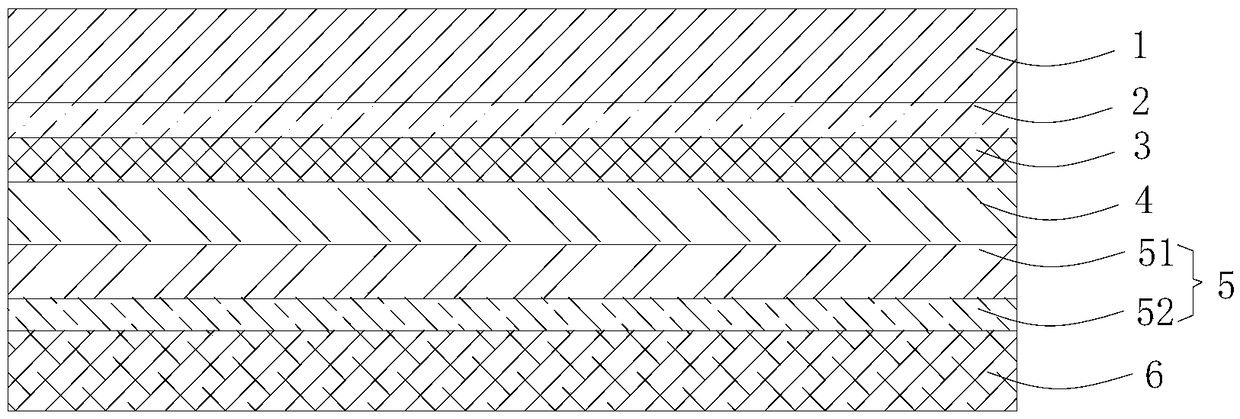

Double-layer electromagnetic shielding film and preparation method thereof

ActiveCN109130383AMalleableImprove shielding effectRadiation-absorbing paintsReflecting/signal paintsPliabilityPolyurethane coating

The invention discloses double-layer electromagnetic shielding film. The shielding film comprises carrier film, a first insulating coating layer coated on the barrier film, a second insulating coatinglayer coated on the first insulating coating layer, a metal layer compounded on the metal layer, an electromagnetic wave shielding coating layer coated on the metal layer and release type protectivefilm arranged on the electromagnetic wave shielding coating layer; the carrier film is matt release film; coating of the first insulating coating layer is wear-resisting acrylate coating or polyurethane coating, the abrasive resistance performance is greater than 1000 times, and the thickness is 1-2 microns; coating of the second insulating coating layer is high-filling high-toughness acrylate coating or polyurethane coating or rubber coating, the number of bending resistance times is greater than 80000, and the thickness is 2-7 microns; the metal layer is thin film prepared from rolled metalfoils, and the thickness of the metal layer is 3-9 microns. The film has better toughness, bending resistance performance and product smoothness and a better shielding effect.

Owner:SHENZHEN HONGHAI ELECTRON MATERIAL TECH CO LTD

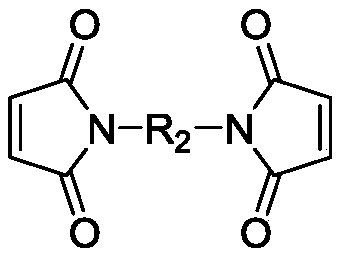

High-reliability fast-curing filling glue

ActiveCN109401706AAchieve reworkabilityIncrease crosslink densityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention relates to filling glue and a preparation method thereof, in particular to high-reliability fast-curing filling glue. The high-reliability fast-curing filling glue is prepared from the following raw materials in percentage by weight: 10-50% of epoxy resin, 5-20% of an epoxy diluent, 5-15% of epoxy resin with capability of free radical reaction, 0-10% of an olefin monomer with capability of free radical reaction, 5-20% of a toughener, 0.5-3% of a coupling agent, 0.1-5% of a cationic initiator, 0.1-5% of a radical initiator, 0-5% of filler and 0-5% of pigment. The bottom filling glue provided by the invention can fast cure, has a high glass-transition temperature (Tg), a low expansion coefficient and good repair property, and can be mainly used for flip chip bottom filling to improve the connection reliability.

Owner:深圳广恒威科技有限公司

Epoxy adhesive toughened by tertiary-amide modified liquid nitrile butadiene rubber

ActiveCN106085325AGuaranteed toughening effectIncreased curing crosslink densityRubber derivative adhesivesEpoxy resin adhesivesCross-linkGlass transition

The invention discloses an epoxy adhesive toughened by tertiary-amide modified liquid nitrile butadiene rubber. The adhesive is prepared from the following components in parts by weight: 100 parts of bisphenol-A or bisphenol-F epoxy resin, 8 to 60 parts of amine curing agent and 10 to 70 parts of tertiary-amide modified liquid nitrile butadiene rubber. The curing condition is that all components are uniformly mixed and are cured at a room temperature for 4 to 7 days or are cured at a temperature of 50 DEG C for 1 day. The adhesive has main properties that the tensile strength is 20 to 40 MPa, the elongation at break is 5 percent to 30 percent, the impact strength is 20 to 150 kJ / m2 and high-temperature glass transition temperature is 90 to 120 DEG C. The toughened epoxy adhesive disclosed by the invention has the advantages that excellent mechanical property and excellent toughness are obtained; the curing cross-linking density of the epoxy resin is improved, the high-temperature glass transition temperature of the epoxy adhesive is not reduced, and the high-temperature usage temperature of the adhesive is not reduced while the adhesive is toughened by utilization of the characteristics of catalyzing and curing epoxy functional groups by a tertiary amine group.

Owner:NANJING UNIV

Polysiloxane modified epoxy resin and preparation method thereof

The invention discloses polysiloxane modified epoxy resin and a preparation method thereof. The preparation method comprises the following steps: firstly mixing and dissolving epoxy resin and polysiloxane in an organic solvent, dropwise adding a catalyst at a temperature of 60-100 DEG C in a nitrogen environment, then carrying out stirring for reacting to obtain polysiloxane modified epoxy resin,removing unreacted polysiloxane after the reaction is finished, and carrying out reduced-pressure distillation to remove the organic solvent to obtain the pure modified resin. The polysiloxane modified epoxy resin prepared by the invention can be cured into a film at room temperature, the obtained coating has good flexibility and impact resistance, the ultraviolet aging resistance is remarkably improved, and the service life is greatly prolonged. In addition, the process is simple, and energy consumption is low.

Owner:FUZHOU UNIV

Hyaluronic acid-based cross-linked nanoparticles

InactiveUS7879818B2Reaction is slowReduce crosslink densityPowder deliveryOrganic active ingredientsCross-linkBiopolymer

Methods are disclosed for preparing novel biodegradable cross-linked nanoparticles based on covalently cross-linking modifications of hyaluronic acid. The final products of the present invention are stable in aqueous media, and may be used as detergents and as additives for pharmaceutical compositions for drug delivery, DNA carrier system and other applications. The nanoparticles made from the biopolymers of the present invention may also be used in controlled release applications, super-absorbent materials as well as biomaterials like enzyme immobilization.

Owner:BORBELY JANOS +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com