Patents

Literature

237results about "Rubber derivative adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for translating natural-language speech using multiple output phrases

InactiveUS6859778B1Accurate synchronizationQuality improvementNatural language translationAdhesive processes with adhesive heatingLanguage understandingSadness

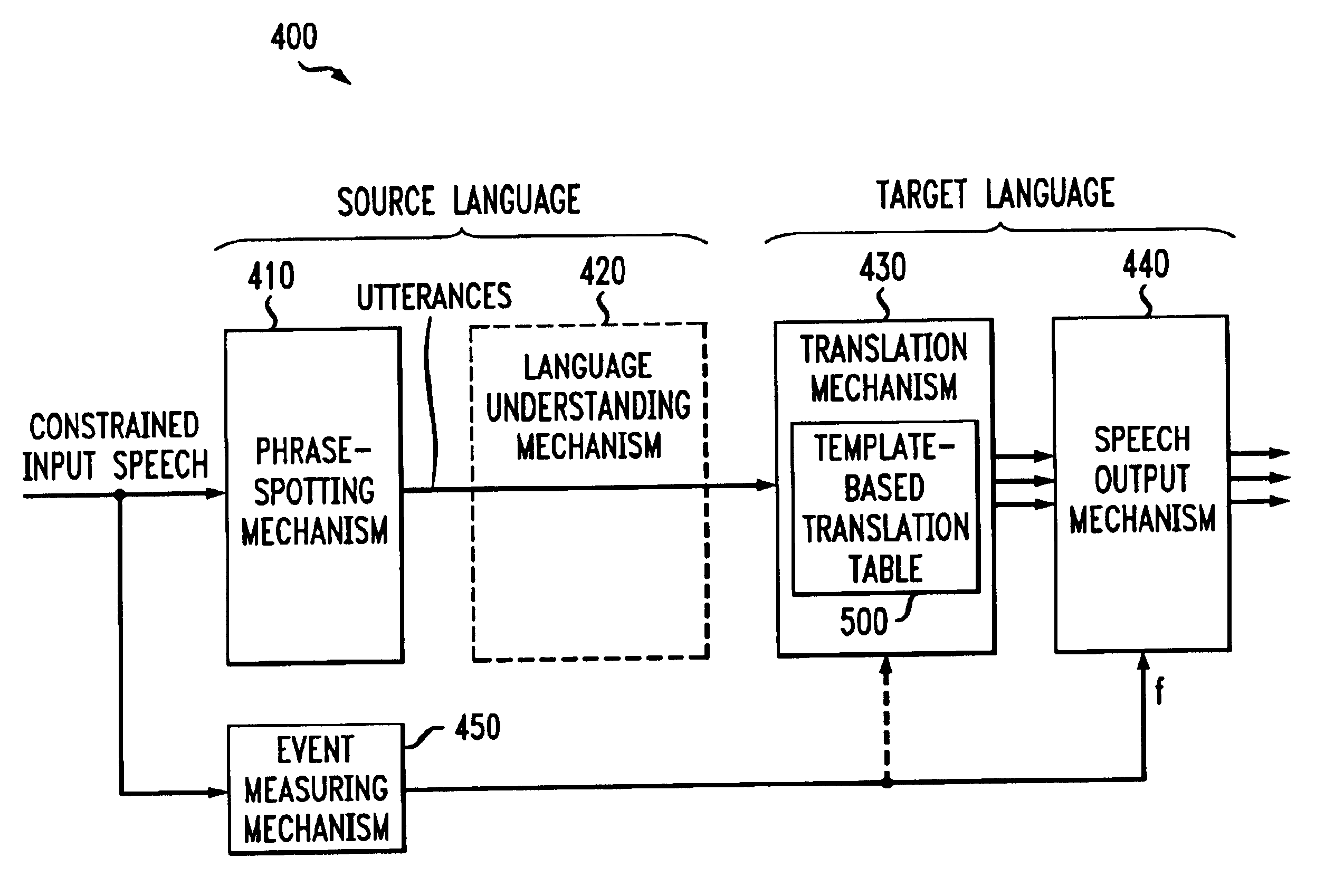

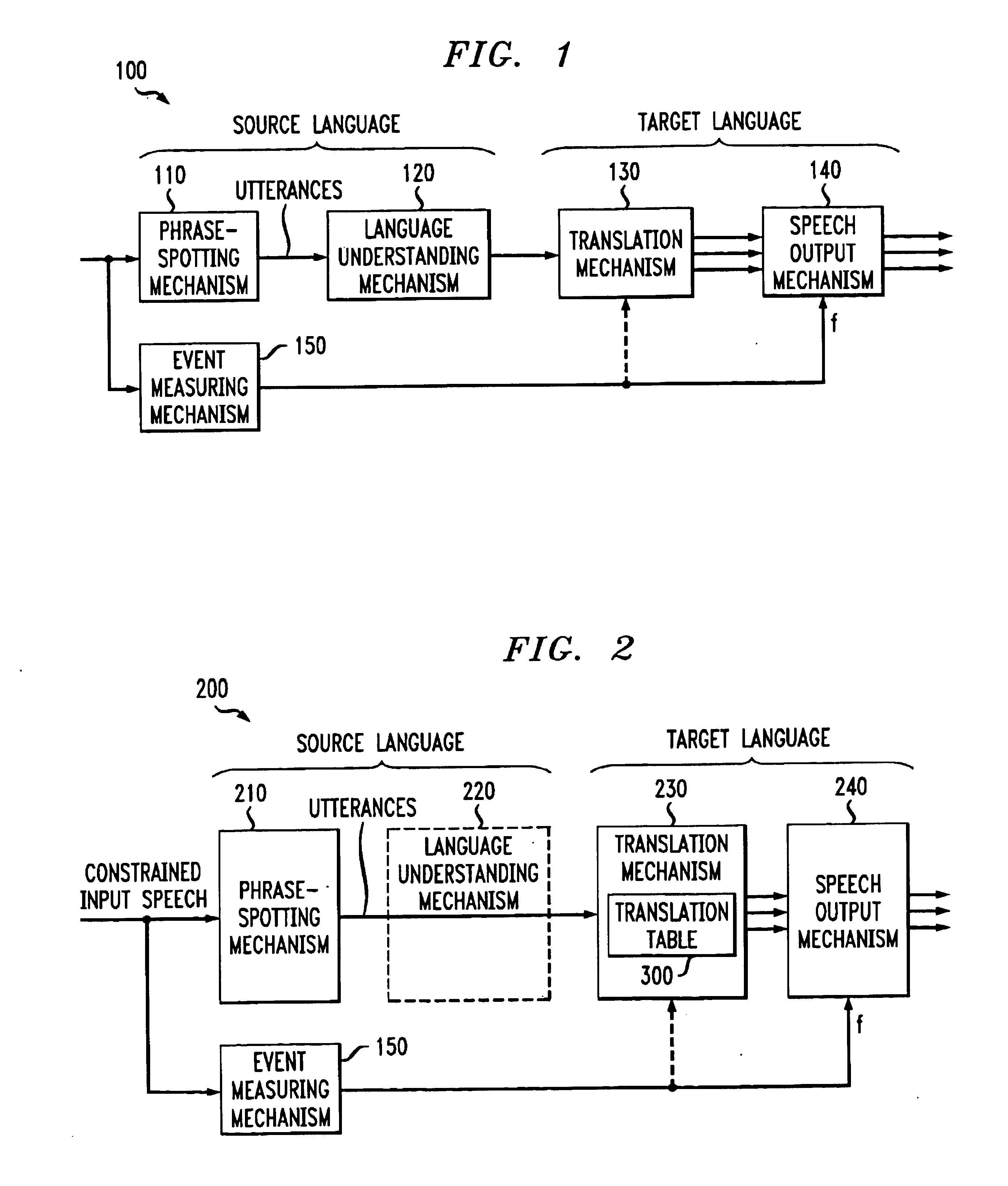

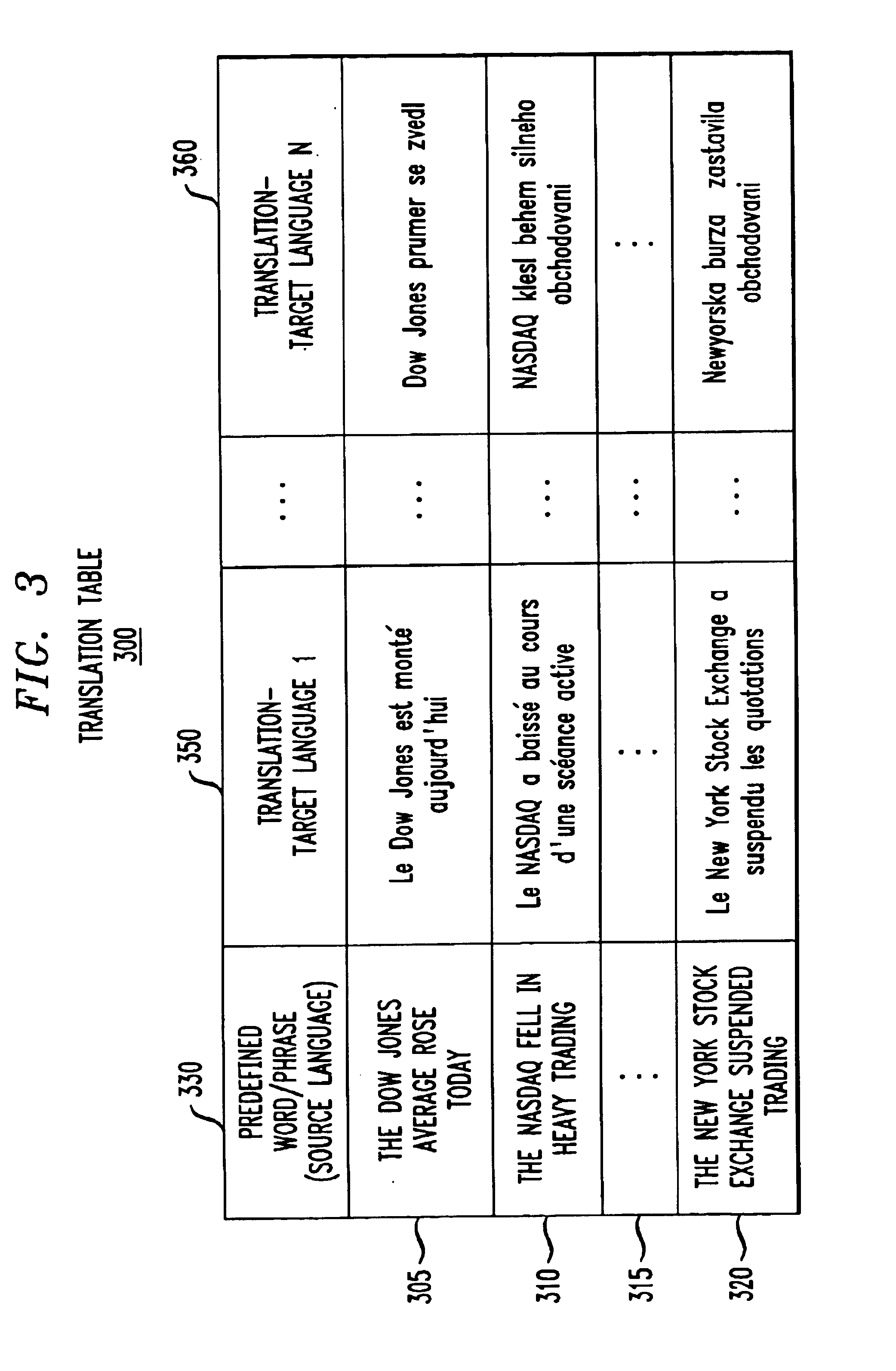

A multi-lingual translation system that provides multiple output sentences for a given word or phrase. Each output sentence for a given word or phrase reflects, for example, a different emotional emphasis, dialect, accents, loudness or rates of speech. A given output sentence could be selected automatically, or manually as desired, to create a desired effect. For example, the same output sentence for a given word or phrase can be recorded three times, to selectively reflect excitement, sadness or fear. The multi-lingual translation system includes a phrase-spotting mechanism, a translation mechanism, a speech output mechanism and optionally, a language understanding mechanism or an event measuring mechanism or both. The phrase-spotting mechanism identifies a spoken phrase from a restricted domain of phrases. The language understanding mechanism, if present, maps the identified phrase onto a small set of formal phrases. The translation mechanism maps the formal phrase onto a well-formed phrase in one or more target languages. The speech output mechanism produces high-quality output speech. The speech output may be time synchronized to the spoken phrase using the output of the event measuring mechanism.

Owner:IBM CORP +1

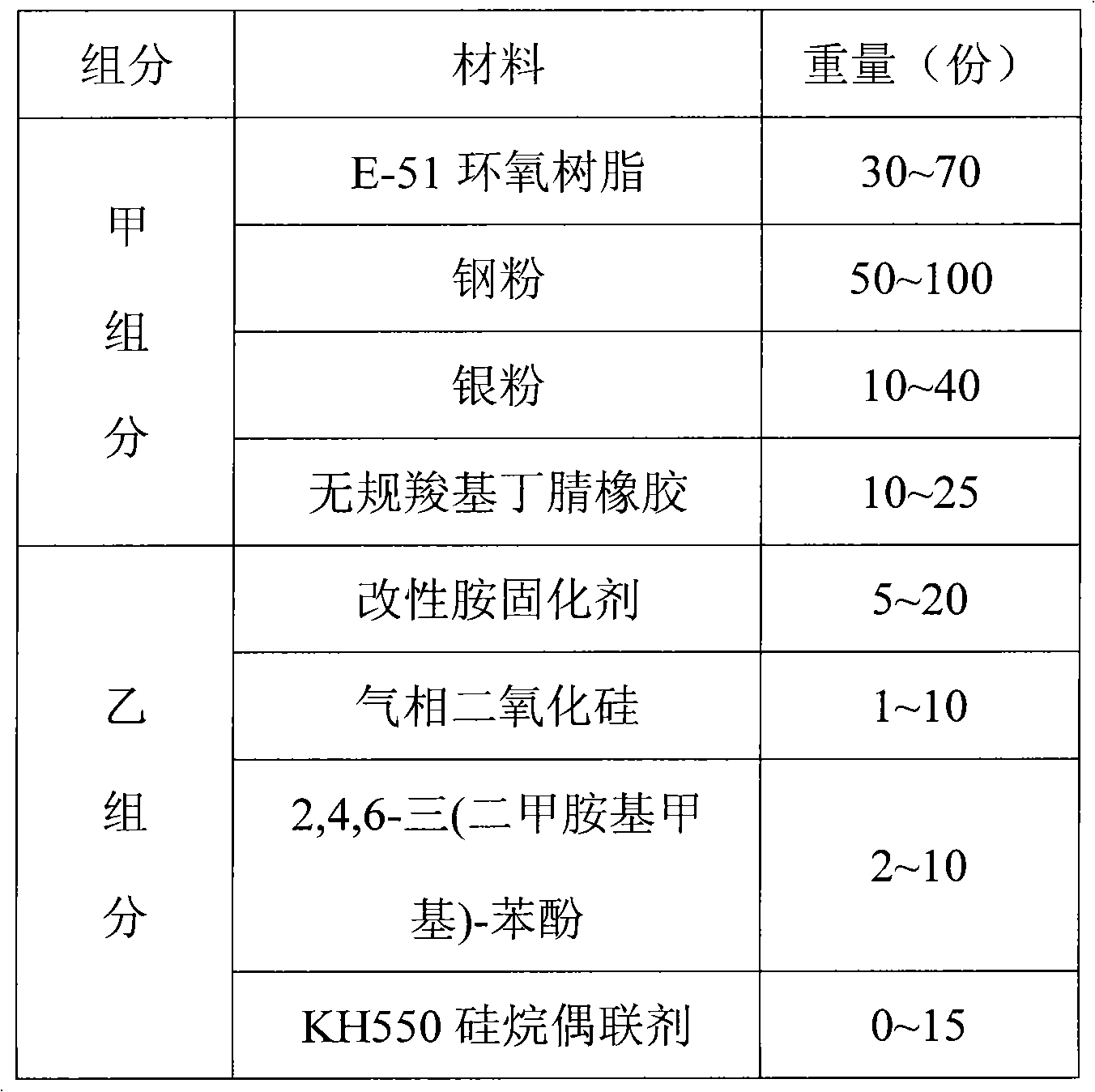

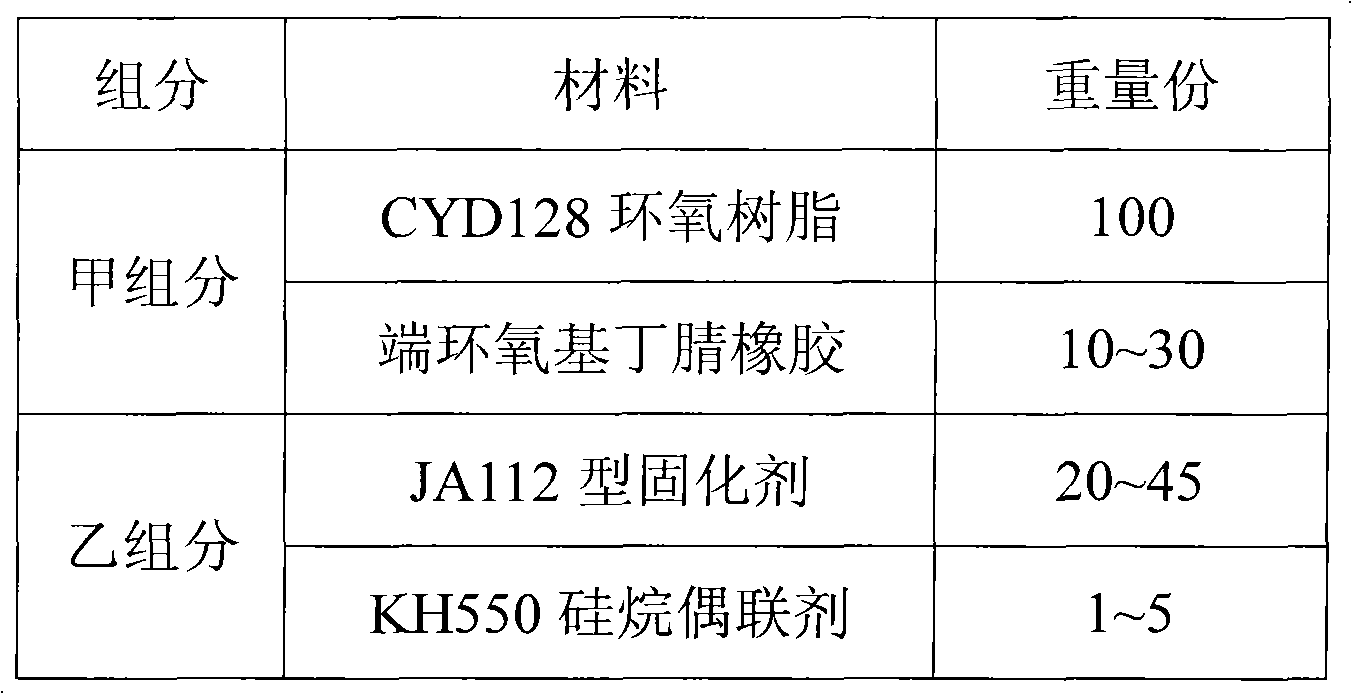

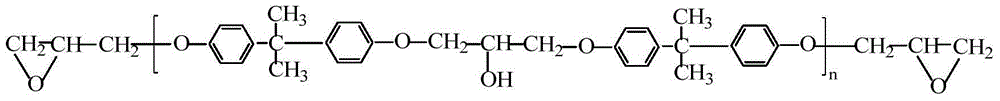

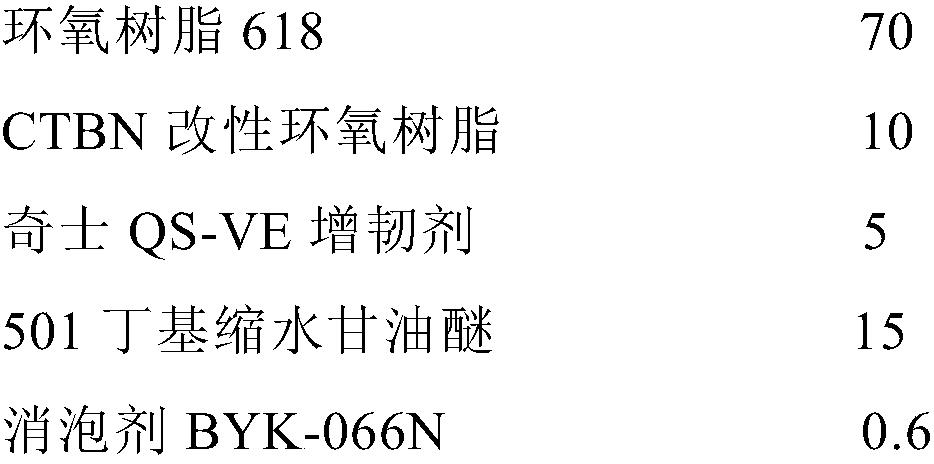

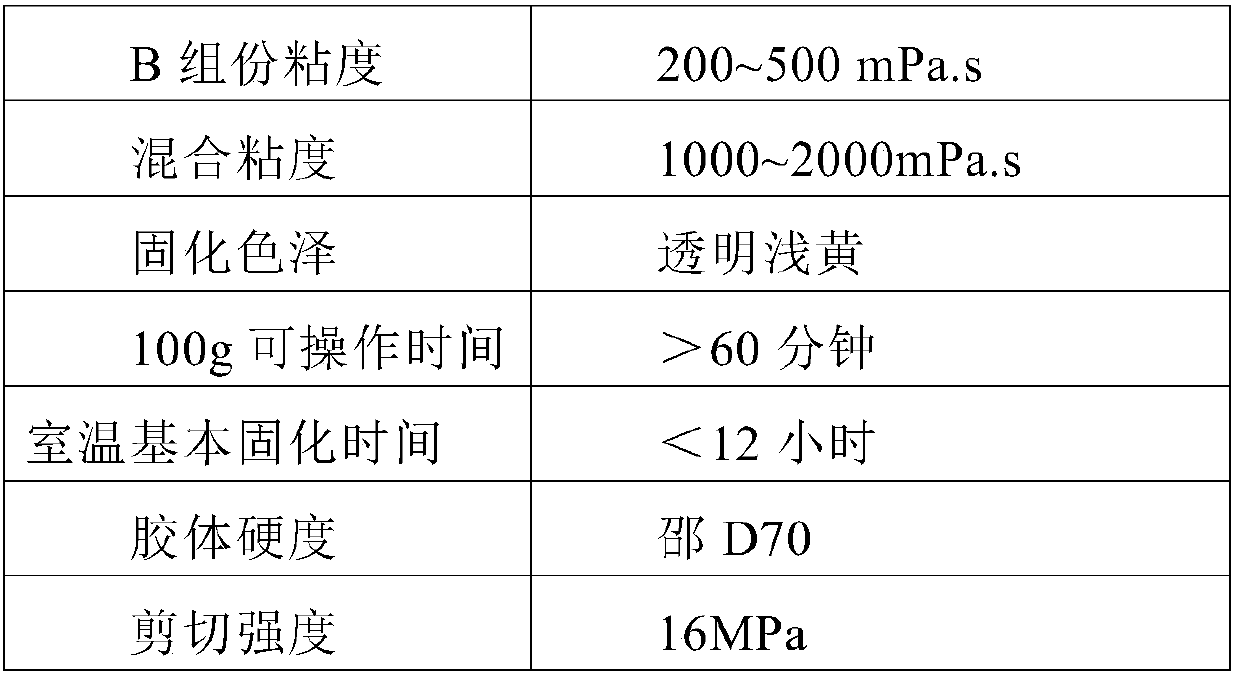

Modified epoxy adhesive and preparing method thereof

ActiveCN106433537AHigh peel strengthImprove performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSheet steelHoneycomb

The invention discloses a modified epoxy adhesive and a preparing method thereof. The adhesive is used for adhesive composite between an aluminum plate and an aluminum / paper honeycomb core or between a steel plate and the aluminum / paper honeycomb core, and the adhesive is composed of bi-component of component A and component B, wherein the ratio of the component A to the component B is 2 : 1 or 1 : 1, the component A is a modified epoxide resin system used as a base stock, and the component B is an amine curing agent system with modified amine and polyamide being principal materials and is used as a curing agent. The adhesive is prepared by preparing the component A and the component B respectively. The modified epoxy adhesive and the preparing method thereof have the advantages of being excellent in performance, simple in technology and low in cost.

Owner:佛山市桐立新材料科技有限公司

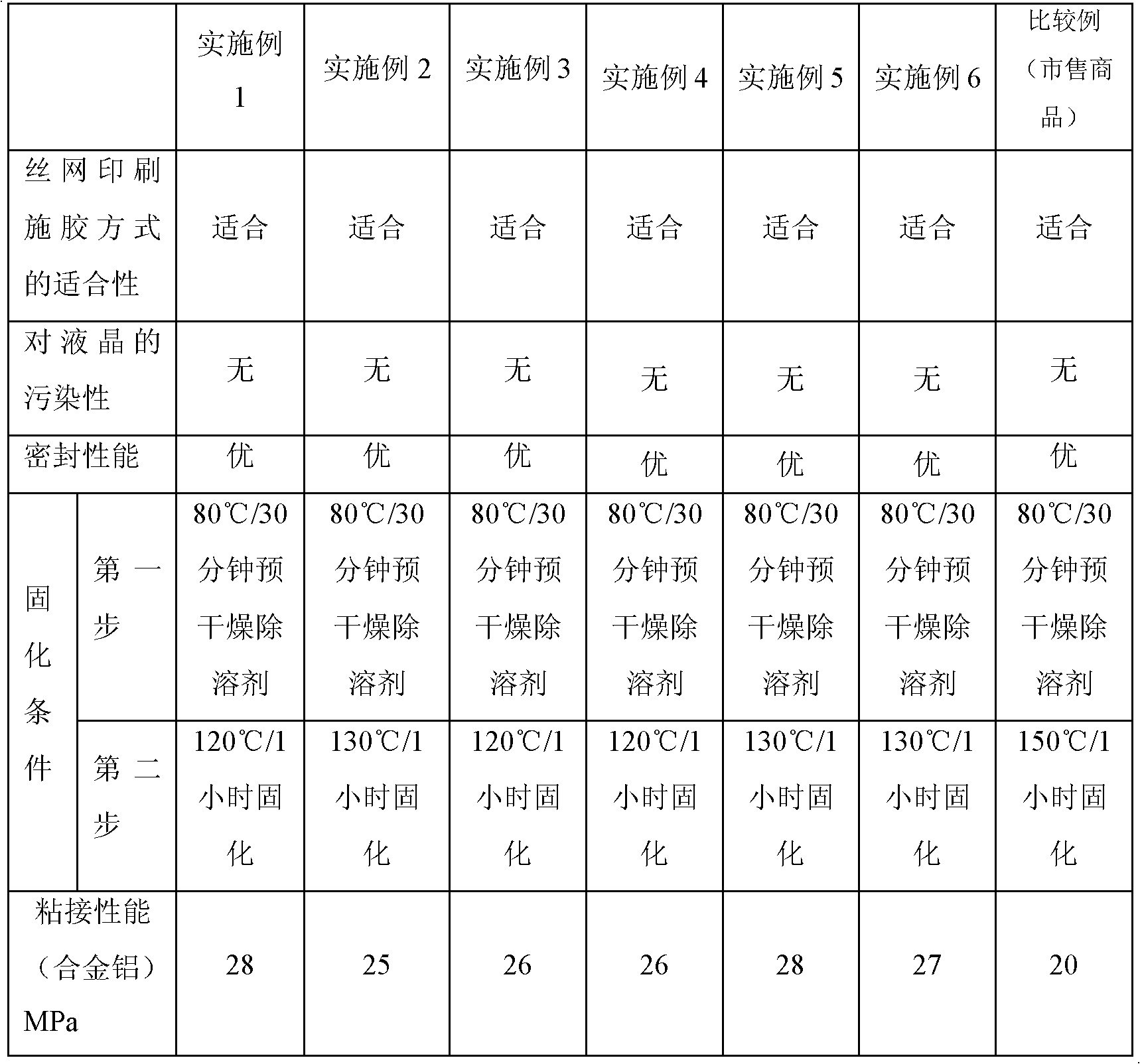

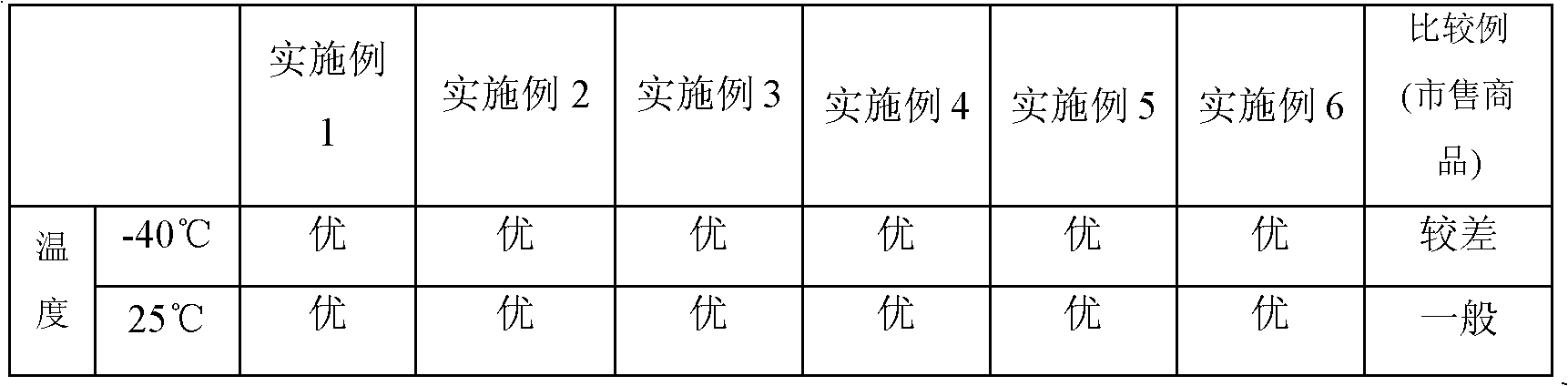

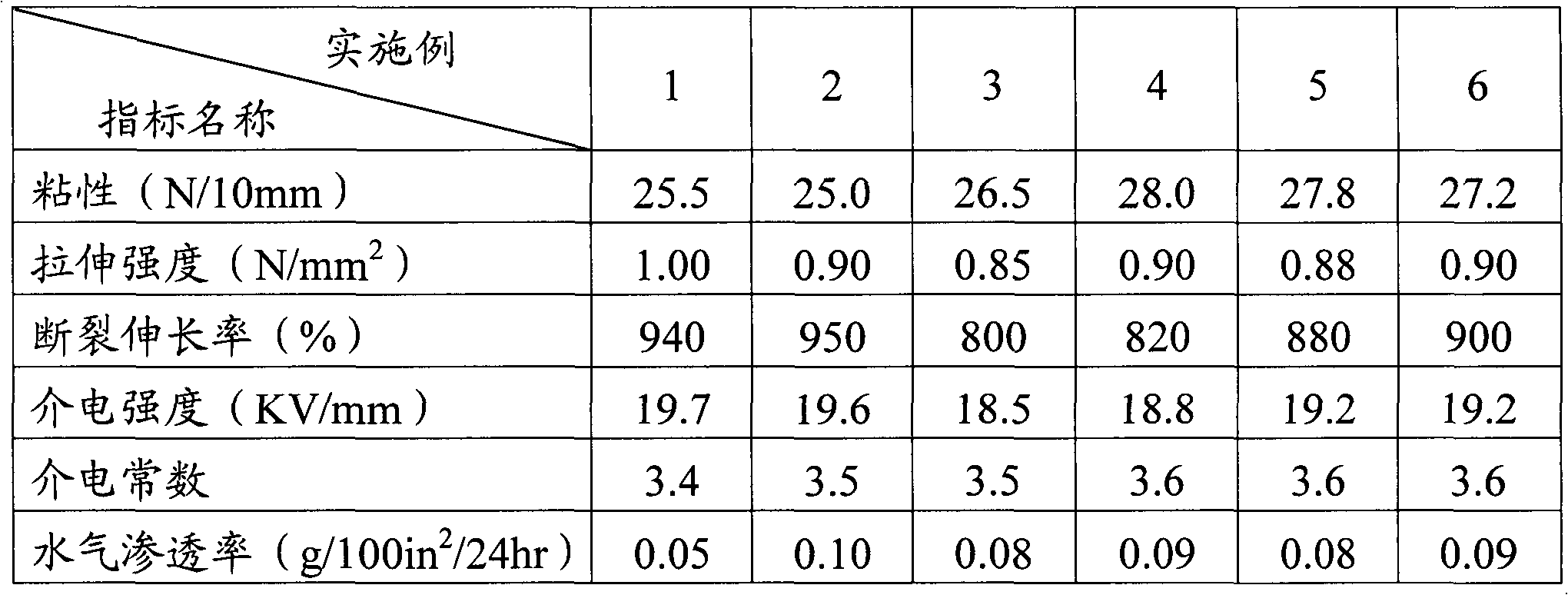

Frame sealing adhesive, and preparation method and application thereof

InactiveCN102585745AEasy to storeSmall water absorptionNon-macromolecular adhesive additivesOther chemical processesScreen printingEpoxy

The invention discloses a frame sealing adhesive and a preparation method and application thereof. The frame sealing adhesive comprises the following component: epoxy resin, a curing agent, a rubber powder, an organic filler, a thixotropic agent, a silane coupling agent and a solvent. The frame sealing adhesive has excellent storage performance and an adhesive applying manner suitable for screen printing and is used for sealing a side frame of a TN (twisted nematic) (STN-super twisted nematic) liquid crystal box; in addition, the solidified frame sealing adhesive has the advantages of low hydroscopic property, long-lasting and excellent sealing performance, excellent heat resistance and electric insulation performance, no pollution to liquid crystal, high rigidity, high toughness and high size stability, and important application value.

Owner:绵阳艾萨斯电子材料有限公司

Paint, adhesive composition, bonding method and laminate

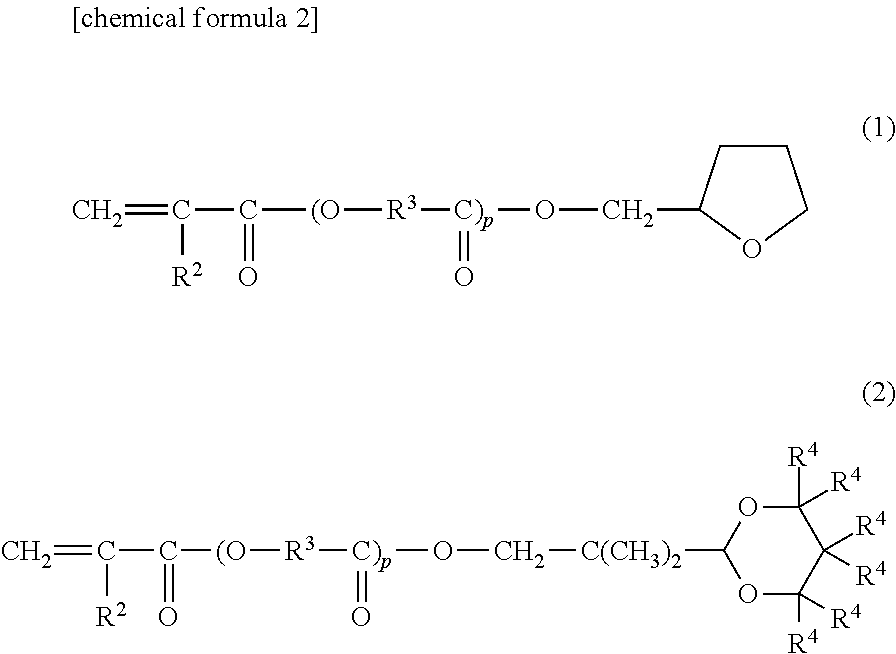

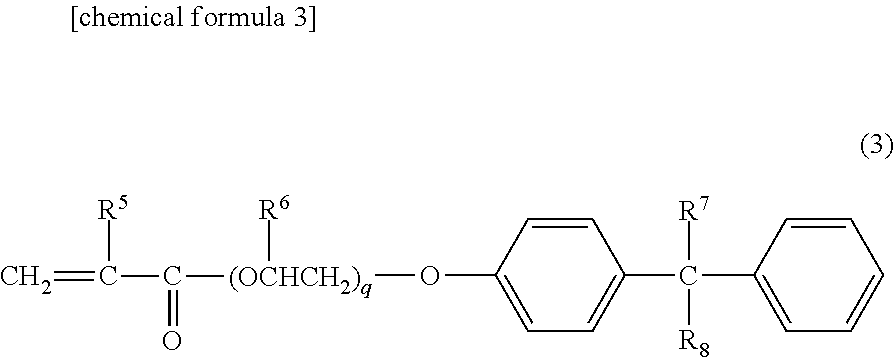

ActiveUS20130078460A1Satisfactory adhesion propertyImprove working environmentAdhesive processesMaterial nanotechnologyVinyl esterUnsaturated polyester

A paint and an adhesive composition of the present invention containing (a) a vinyl ester resin or unsaturated polyester resin by 20 to 40 mass %, (b) a modifying agent by 0.1 to 50 mass %, (c) a vinyl monomer and / or (meth)acrylate monomer by 30 to 70 mass % (provided that the total of the components (a), (b) and (c) is 100 mass %) and (d) an initiator by 0.1 to 15 parts by mass to a total of 100 parts by mass of the components (a), (b) and (c).

Owner:RIKEN TECHNOS CORP +1

Pipeline repairing carbon fiber composite material system and application thereof

ActiveCN102464861ASmall expansion coefficientGood resistance to cathodic disbondmentOther chemical processesSynthetic resin layered productsAdhesiveRoom temperature

The invention relates to a pipeline repairing carbon fiber composite material system and an application thereof. The pipeline repairing carbon fiber composite material system consists of a defect filling material, an anti-cathodic disbonding insulating primer and a carbon fiber composite material, wherein the defect filling material is used for overcoming pipeline defects; a pipeline defect reinforcing area is coated with the anti-cathodic disbonding insulating primer; an interlayer adhesive is used for coating and soaking carbon fiber cloth and paving a reinforced repairing area; a stainless steel tape is used for fastening and curing a composite material repairing layer; the repairing layer fastened by using stainless steel is cured at room temperature or heated and cured through an external heating belt; the repairing layer is subjected to external anti-corrosion treatment after a heating device and the stainless steel tape are removed; and the phenomena of debonding, lamination, hollowing, cracking, bubbling and the like of the repairing material and a pipe body occurring in the serving process of the repaired repair reinforcing layer can be avoided, construction effectiveness in a cold and wet severe environment is effectively increased, the repairing construction quality and reinforcing repair effect of the composite material are ensured, and the reliability of pipeline defect repairing construction is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

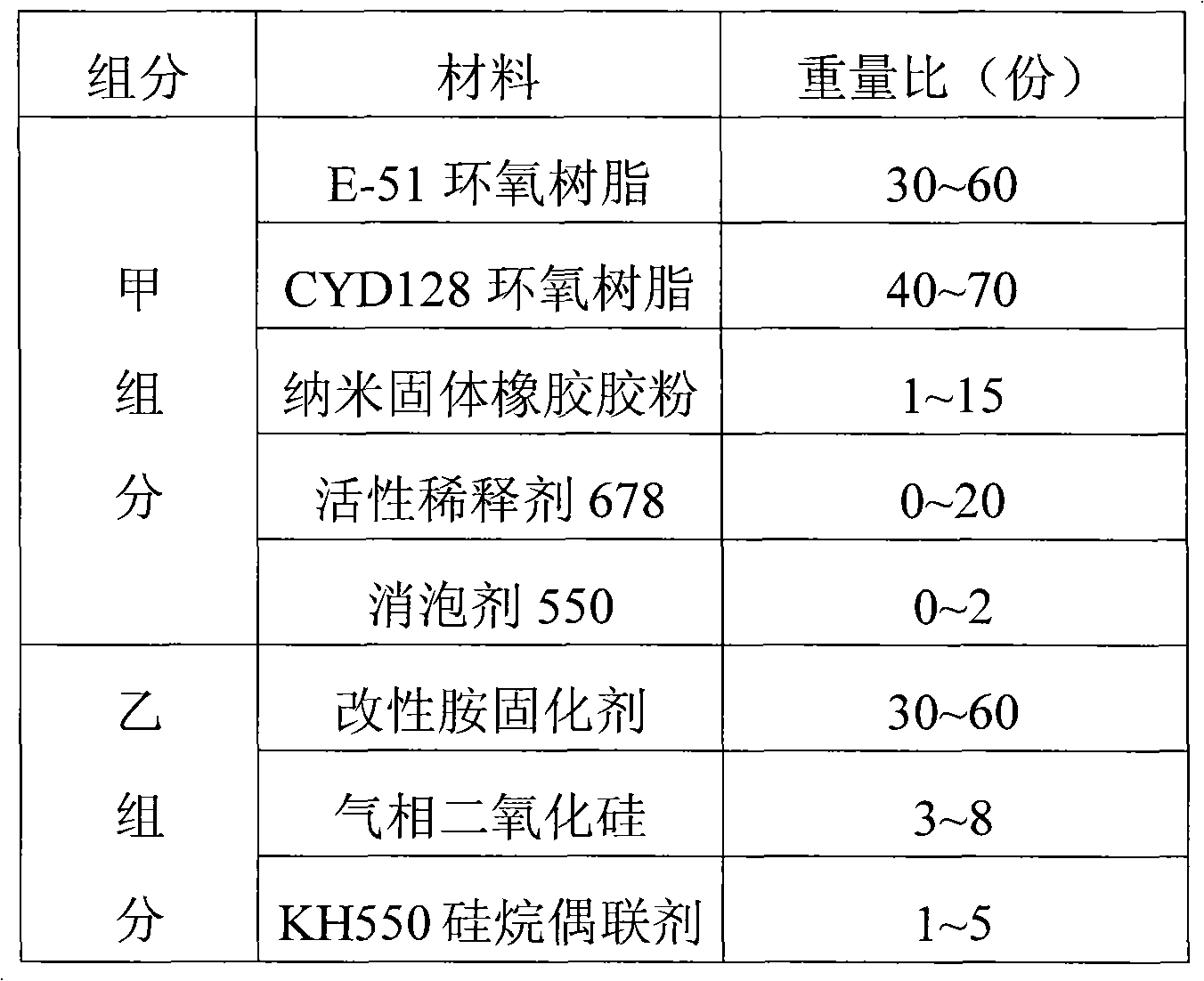

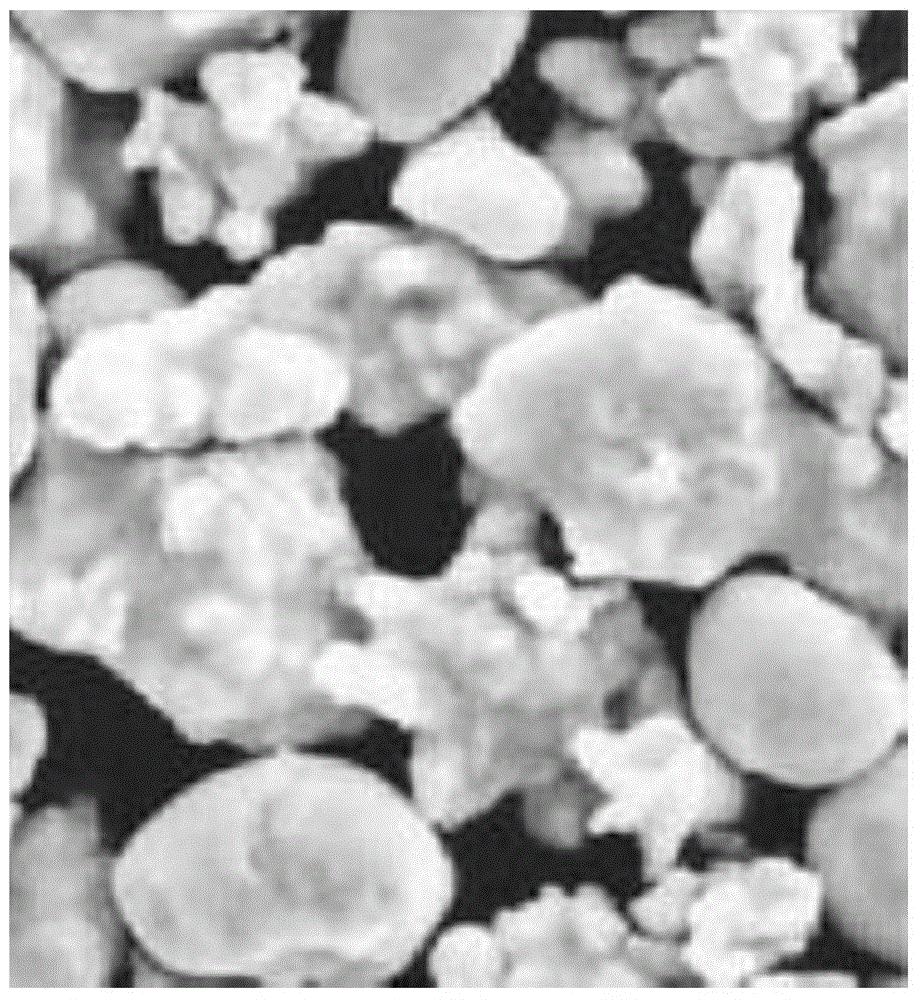

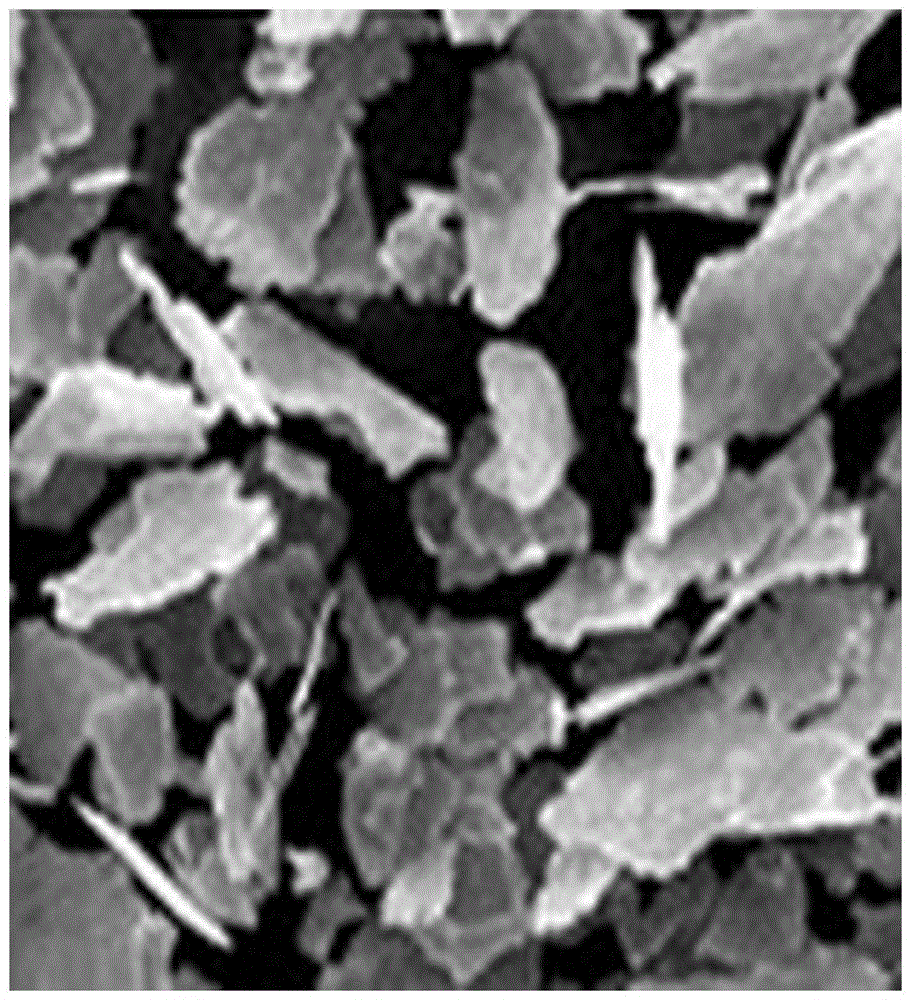

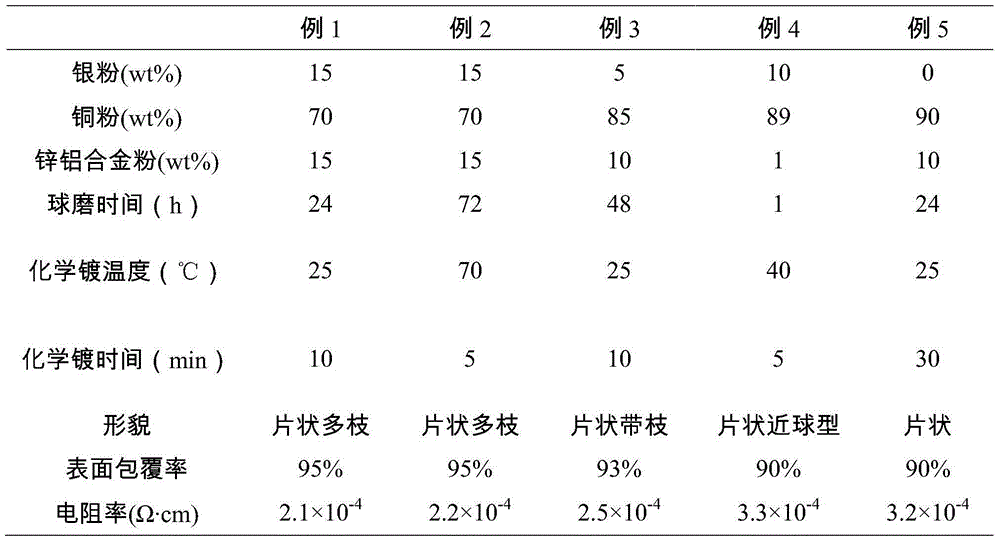

Sheet/branch silver-coated copper powder and green halogen-free low-silver-content economical electrically conductive adhesive capable of replacing traditional electrically conductive adhesives with high silver contents

ActiveCN104830247AIncrease coverageImprove conductivityNon-macromolecular adhesive additivesRubber derivative adhesivesEpoxyIntrinsic conductivity

The invention relates to sheet / branch silver-coated copper powder, a green halogen-free low-silver-content economical electrically conductive adhesive capable of replacing traditional electrically conductive adhesives with high silver contents, and a preparing method of the electrically conductive adhesive. The morphology of the sheet / branch silver-coated copper powder is in a sheet shape and / or a branch shape. The silver coating area rate on the surface of copper powder is 90-95%. The content of a zinc-aluminum alloy in the silver-coated copper powder is lower than 15 wt%. The electrically conductive adhesive comprises following raw materials by weight: 60-90% of the sheet / branch silver-coated copper powder, 0-30% of micron order silver power, 6-12% of epoxy resin, 1-8% of an active diluting agent, 1-6% of toughening resin, 1-3% of a curing agent, 0-1% of a curing promoter and 0.5-2% of a coupling agent. The sheet / branch silver-coated copper powder is high in silver coating rate on the surface of Cu and excellent in electrically conductive performance, so that the electrically conductive adhesive prepared from the sheet / branch silver-coated copper powder is excellent in performance, low in cost and good in intrinsic conductivity.

Owner:重庆邦锐特新材料有限公司

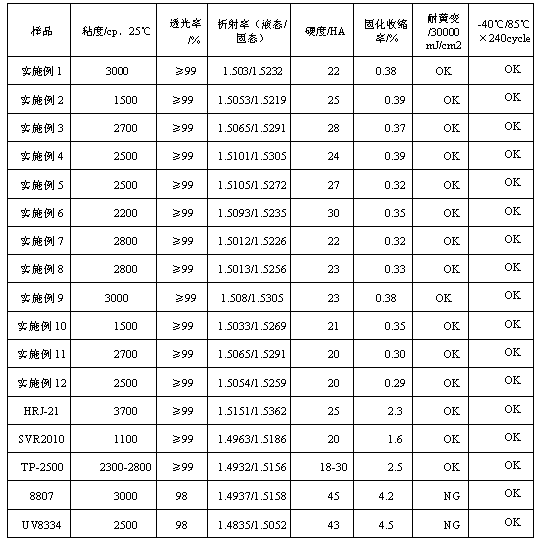

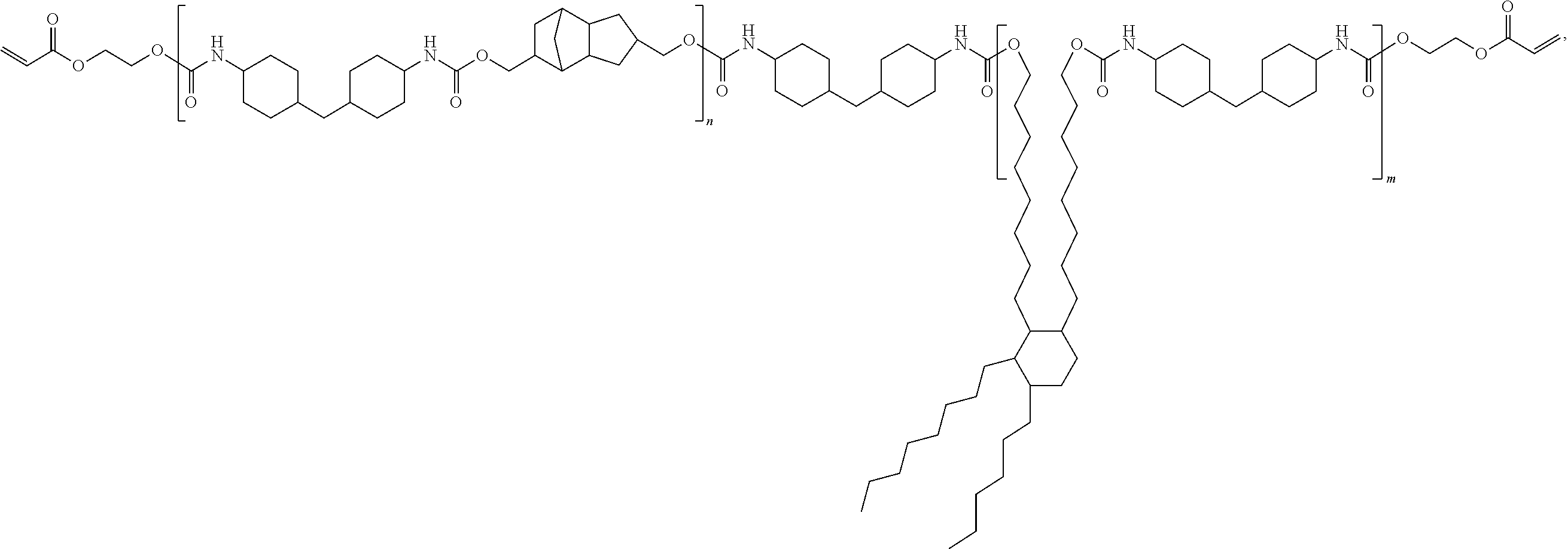

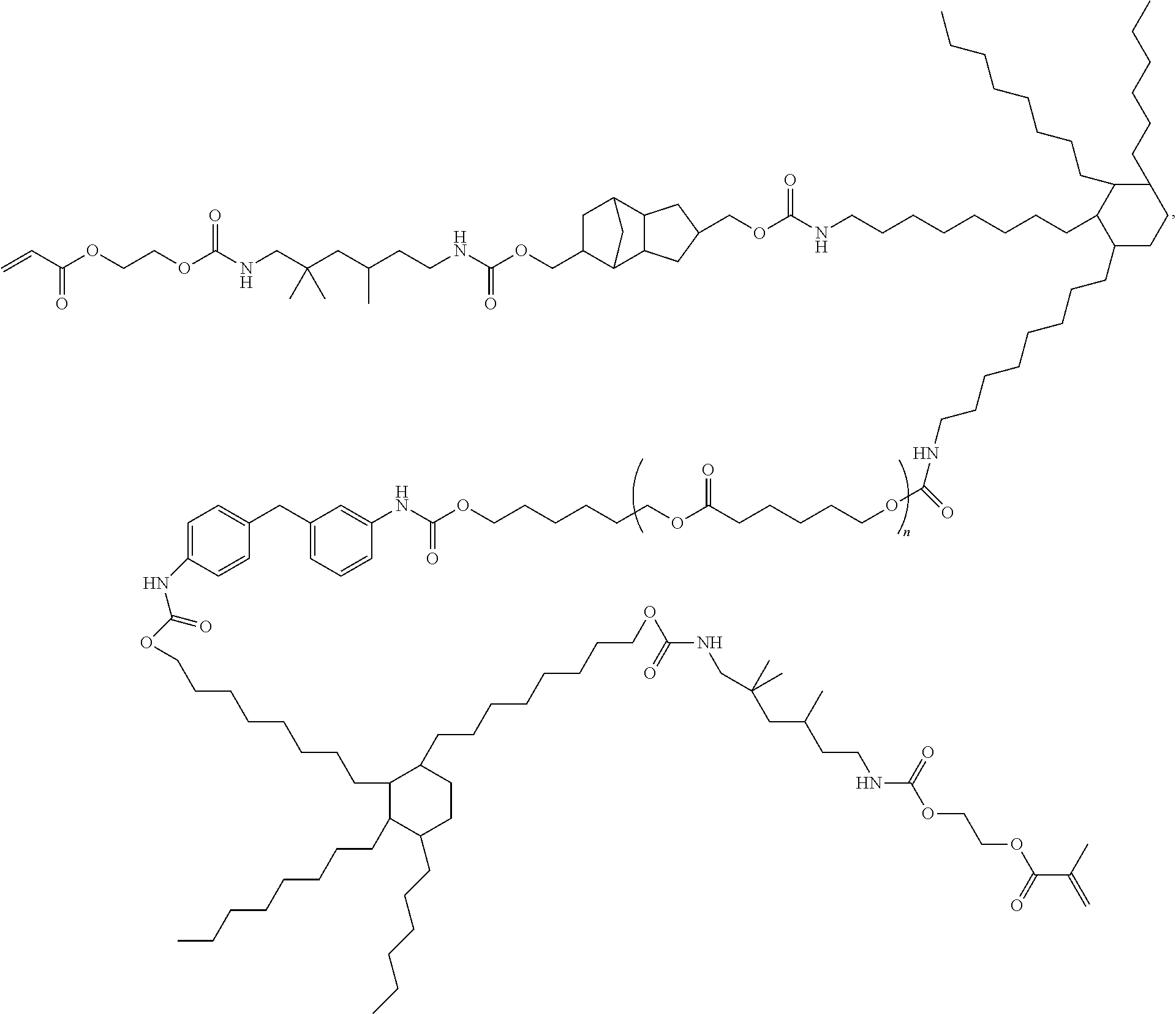

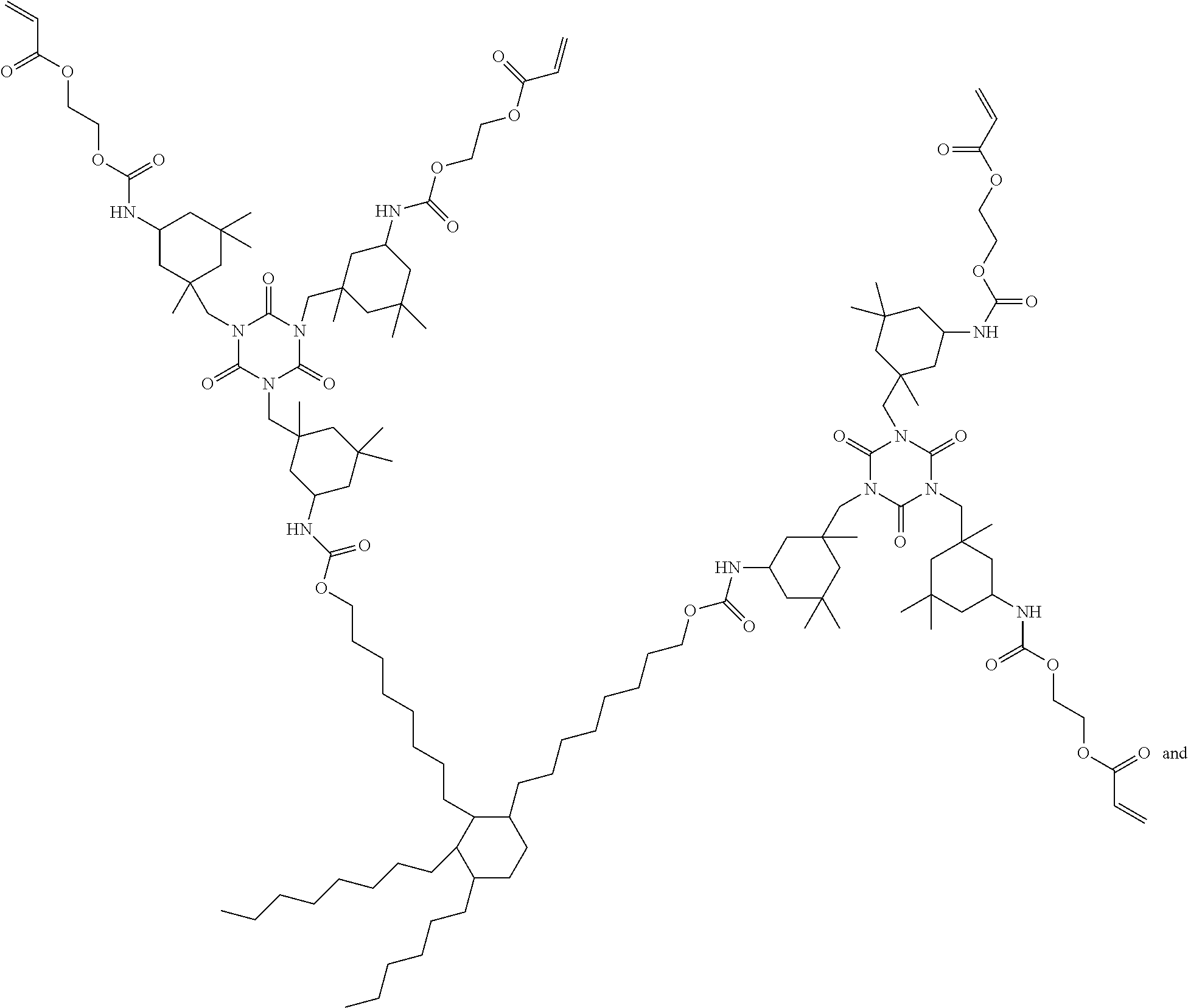

Light curing adhesive for splicing capacitive touch screen and preparation method of light curing adhesive

InactiveCN103184029AHigh refractive indexHigh light transmittancePolyureas/polyurethane adhesivesRubber derivative adhesivesVinyl etherPolymer science

The invention discloses a light curing adhesive for splicing a capacitive touch screen. The light curing adhesive is prepared from the following components by weight percent: 30-50% of main body resin, 20-40% of auxiliary resin, 10-30% of an active monomer, 0.5-5% of a photoinitiator, and 0.1-5% of an auxiliary agent, wherein the main body resin is aliphatic urethane acrylate resin; the auxiliary resin is one substance or a mixture of more substances: cyanuric acid resin modified by acrylic ester, liquid nitrile rubber, liquid polybutadiene rubber and liquid isoprene rubber; the active monomer is one or a mixture of more of a vinyl ether monomer and an acrylate monomer; the photoinitiator is one or a mixture of two of a free radical initiator and a cationic photoinitiator; and the auxiliary agent is one or mixture of two of a silane coupling agent and a flatting agent. The light curing adhesive for splicing the capacitive touch screen has the advantages of high refractive index, high light transmittance, low color brightness, low hardness, low cure shrinkage rate, good reliability, good yellowing resistance and the like.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Curable composition with rubber-like properties

InactiveUS20120065336A1Polyureas/polyurethane adhesivesRubber derivative adhesivesFiberPolymer science

Low viscosity, radiation curable compositions have been developed that produce plastics with silicone rubber-like properties. These compositions have also been shown to give great adhesion to plastics. The combination of an ethylenically unsaturated oligomer with di- or polythiol compound, reactive diluents and a radical initiator will produce these properties. These materials can find use in many areas such as: Electronics packaging, displays, conformal coatings, seals, gaskets, fiber optics coatings, and golf ball coatings.

Owner:DESIGNER MOLECULES

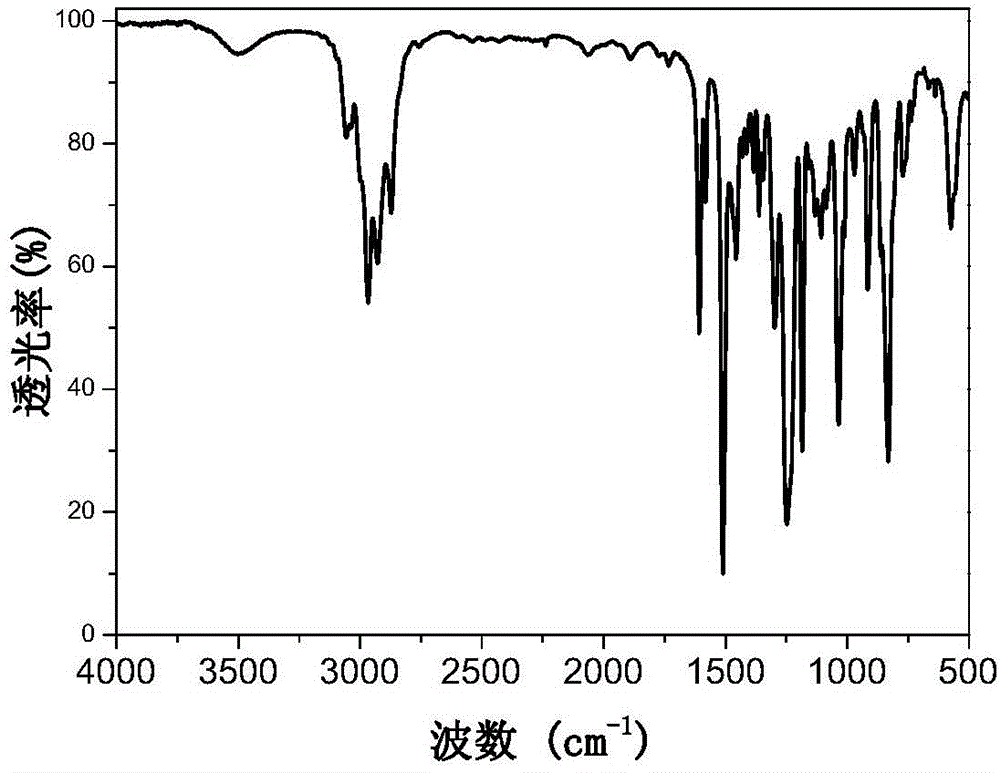

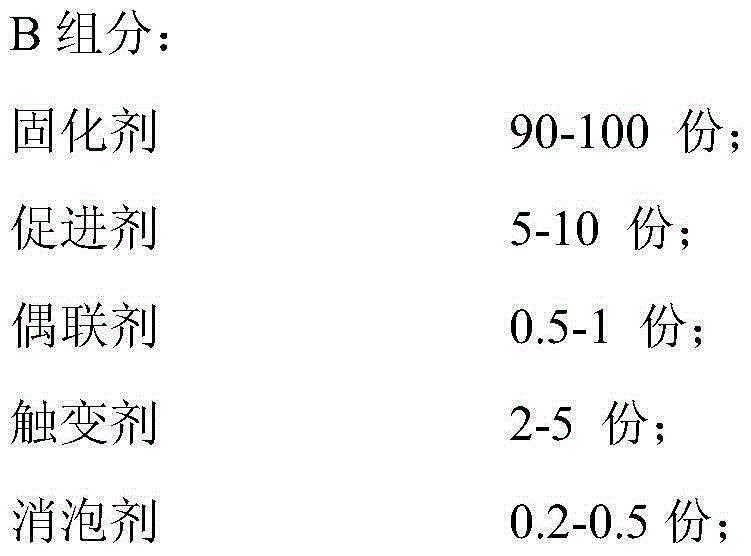

Secondary curing epoxy resin adhesive for roads and bridges and preparation method thereof

InactiveCN104059591AIncreased durabilityImprove flexibilityNon-macromolecular adhesive additivesRubber derivative adhesivesEpoxyRoad surface

The invention discloses a secondary curing epoxy resin adhesive for roads and bridges, which comprises a component A and a component B. The component A comprises the following components in parts by mass: 65-70 parts of low-viscosity epoxy resin and 30-35 parts of modifying toughener. The component B comprises the following components in parts by mass: 90-100 parts of curing agent, 5-10 parts of accelerator, 0.5-1 part of coupling agent, 2-5 parts of thixotropic agent and 0.2-0.5 part of defoaming agent. The ratio of the component A to the component B to the component C is 100:(90-100):110. The epoxy resin adhesive is suitable for binding and waterproofing for pavements of steel decks, municipal viaducts, cement concrete decks, tunnels, highways and the like. The invention also discloses a preparation method of the epoxy resin adhesive.

Owner:南京淳净新材料有限公司

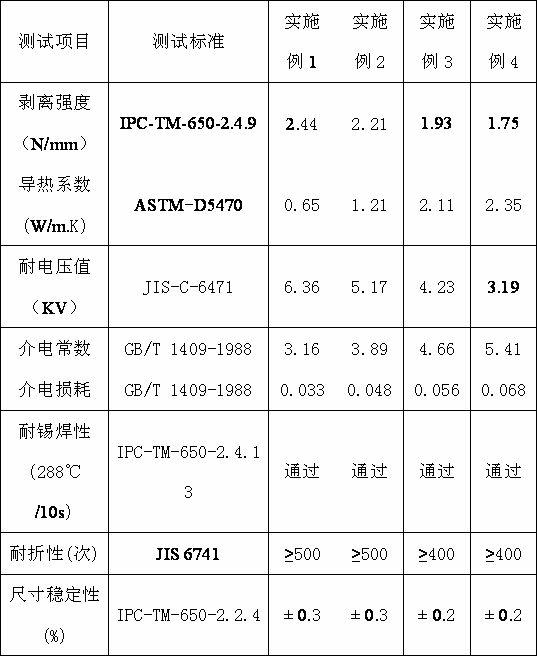

Method for preparing flexible heat conducting insulating adhesive film used in LED heat radiation substrate

InactiveCN102676109AGood flexibilityImprove insulation performanceNon-macromolecular adhesive additivesLaminationAdhesive cementTemperature control

A method for preparing flexible heat conducting insulating adhesive film used in an LED heat radiation substrate comprises the preparation of a flexible heat conducting insulating adhesive and that of the flexible heat conducting insulating adhesive film, wherein the flexible heat conducting insulating adhesive comprises liquid epoxy resin, solid epoxy resin, flexibilizer, curing agent, high-heat conductivity inorganic packing, organic solvent, coupling agent, dispersing agent and flatting agent. The method for preparing the flexible heat conducting insulating adhesive film comprises the following steps: coating the flexible heat conducting insulating adhesive on a release film through a coating machine; baking through a temperature control baking channel to obtain an flexible heat conducting insulating adhesive layer used in the LED heat radiation substrate; coating the release film on the adhesive surface in a compounding manner; and rolling and forming to obtain the flexible heat conducting insulating adhesive film used in the LED heat radiation substrate. The adhesive film used in the LED heat radiation substrate has the characteristics of high heat dissipation, insulation, heat resistance and peel strength, flexibility and the like.

Owner:HAISO TECH

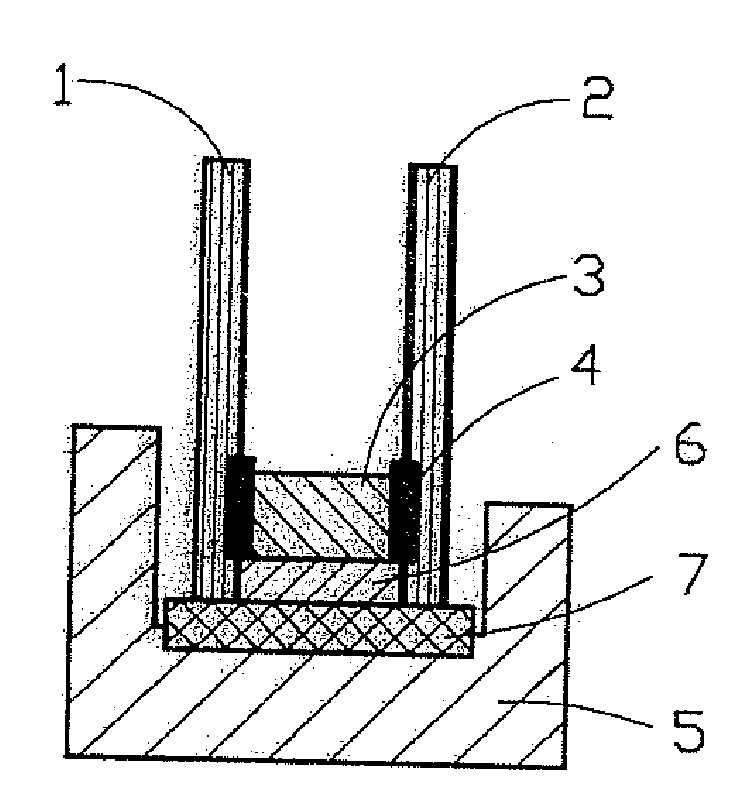

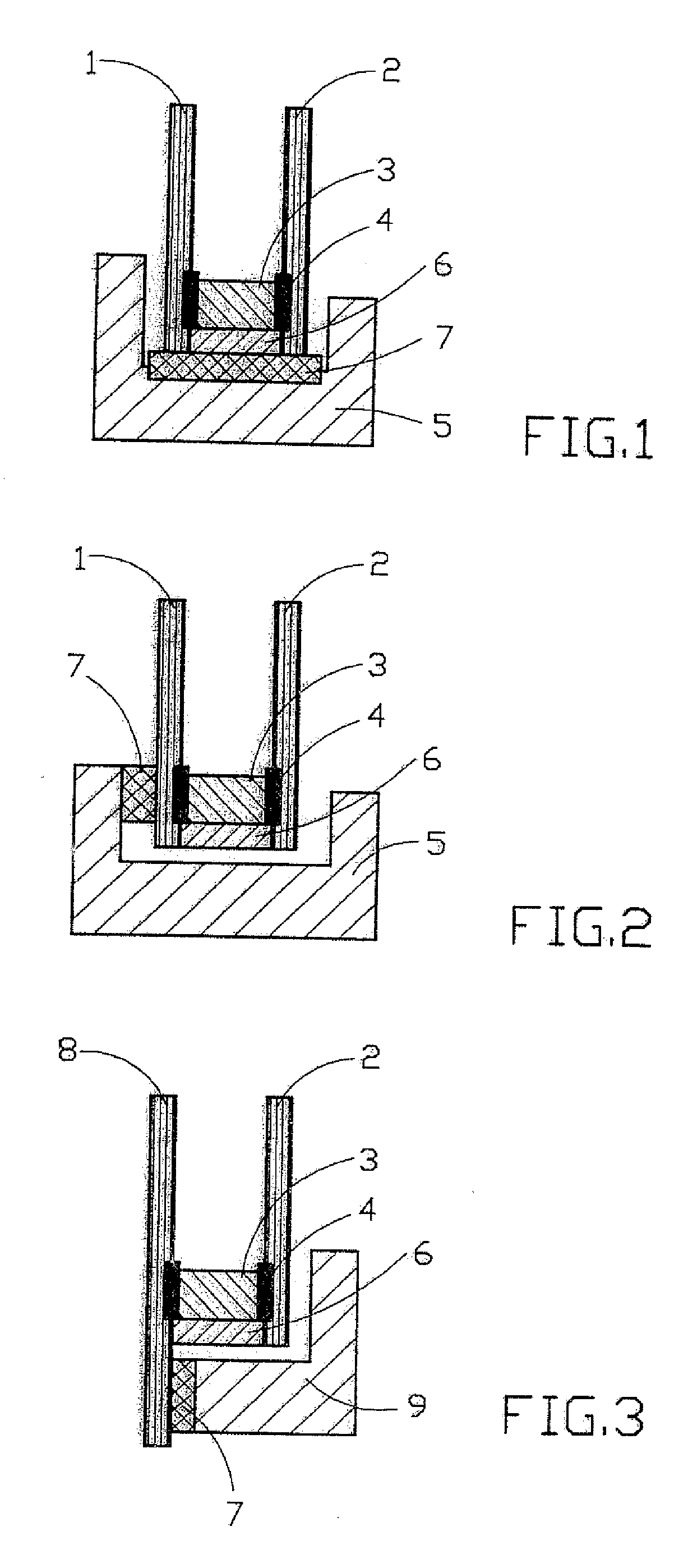

Use of Polysulphide- Containing Two- Component Adhesives for the Production of Windows

A polysulphide-containing two-component adhesive / sealant consists of a binder component and a curing agent component, and is suitable for use as the secondary seal in the edge region of the insulating glass and / or for bonding the insulating glass unit in the frame or window sash of a window unit in a friction locked manner according to the process of rebate base bonding or back bedding.

Owner:HB FULLER CO

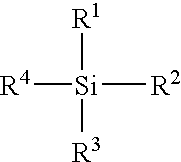

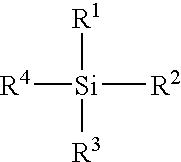

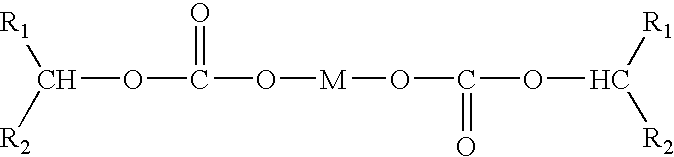

Adhesive composition and method for bonding to rubber

ActiveUS20040149382A1High strengthPromote migrationSurgical adhesivesPneumatic tyre reinforcementsPolymer scienceVulcanization

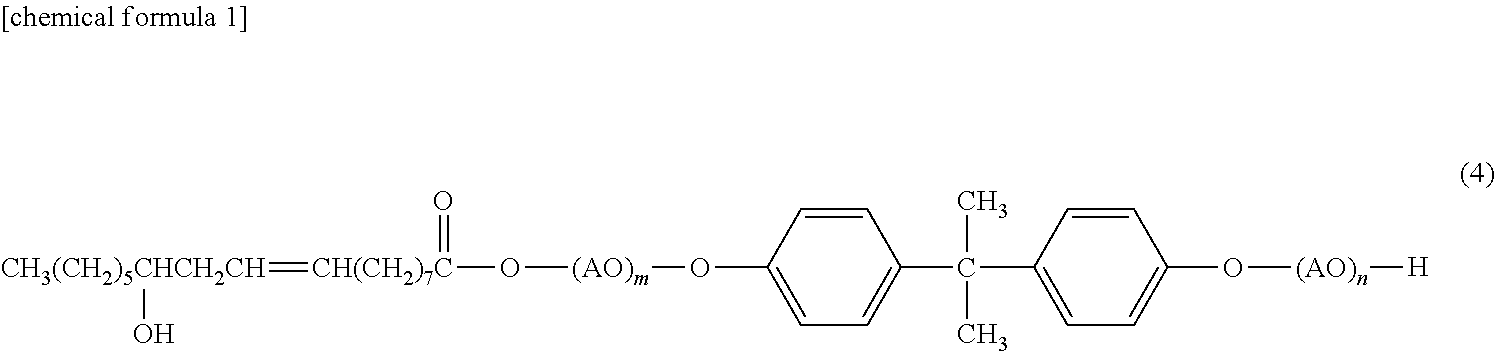

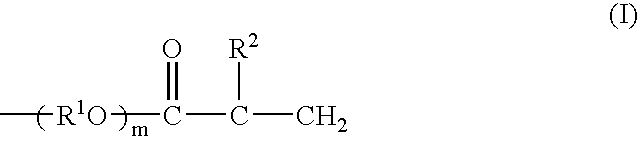

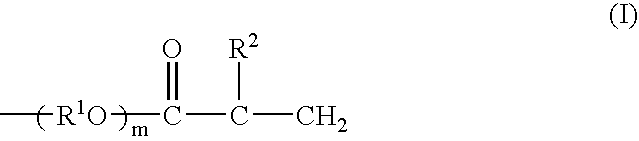

An adhesive composition of the present invention comprises (A) a conjugated diene polymer having a weight-average molecular weight of 500 to 100,000 and (B) an electron pair-donating basic compound; or comprises (A) A conjugated diene polymer having a weight-average molecular weight of 500 to 100,000, (C) a compound having in its molecule three or more functional groups selected from the group consisting of acryloyloxy group, methacryloyloxy group and groups represented by the following formula I: wherein R<1>, R<2 >and m are the same as defined in the specification, and (D) a compound having in its molecule one or two functional groups selected from the group consisting of acryloyloxy group and methacryloyloxy group. At least a part of the surface of an adherend is coated with the adhesive composition to form an adhesive layer. After optionally irradiating the adhesive layer with ultraviolet light or radiation, the vulcanization is preformed while bringing an unvulcanized rubber into press-contact with the adhesive layer, thereby attaining a strong adhesion between the rubber and the adherend. The rubber / adherend composite thus produced is suitably used for the production of rubber-reinforcing materials and rubber articles.

Owner:BRIDGESTONE CORP

Composite molding with adhesive composition layer comprising conjugated diene polymer having cyclic structure, and coating material

InactiveUS7267887B2Rubber derivative coatingsSynthetic resin layered productsPolymer scienceAdditive ingredient

Owner:ZEON CORP

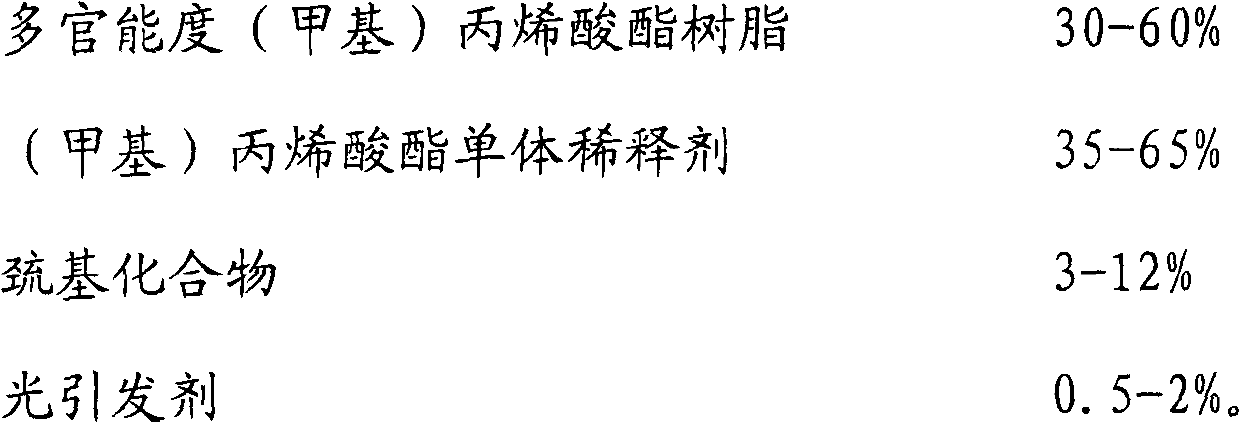

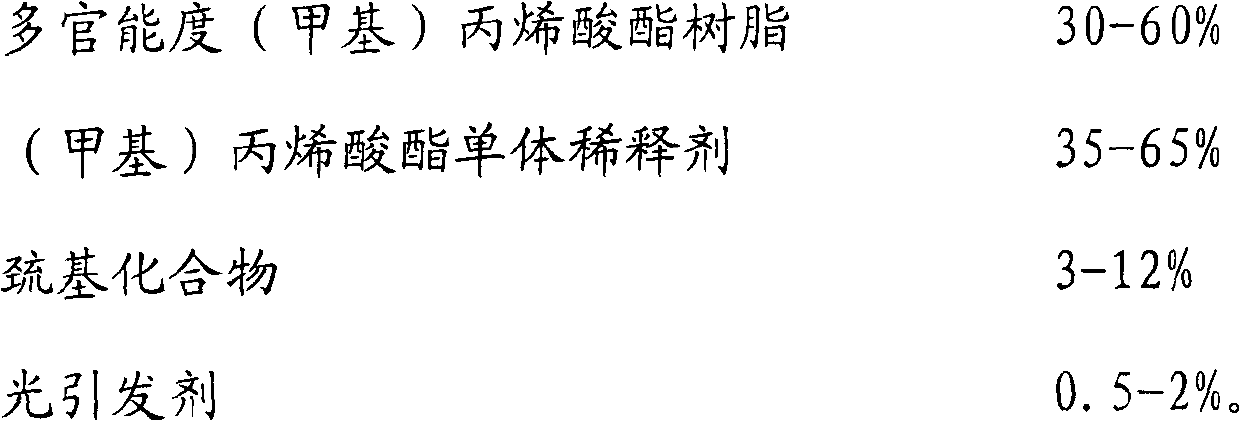

Low-modulus optical adhesive composition

ActiveCN103305178ALow viscosityHigh precisionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPlasticizerDiluent

The invention discloses a low-modulus optical adhesive composition comprising the following components: 30-60 % of polyfunctional (meth) acrylate resin, 35-65 % of a (meth) acrylate monomer diluents, 3-12 % of a mercapto compound and 0.5-2 % of a photoinitiator. The low-modulus optical adhesive composition provided by the invention does not contain a plasticizer, and has characteristic of relatively low viscosity. By using the composition of the invention for bonding, electro-conductive glass membrane, display modules and panels are not polluted due to shift of the plasticizer, thereby improving precision and accuracy of touch screens. Furthermore, the composition of the invention does not rely on increasing a content of an active diluent to achieve the effect of low viscosity, thereby preventing generation of relatively large internal stress to cause warp and deformation at bonding positions.

Owner:塔威新材料科技(上海)有限公司

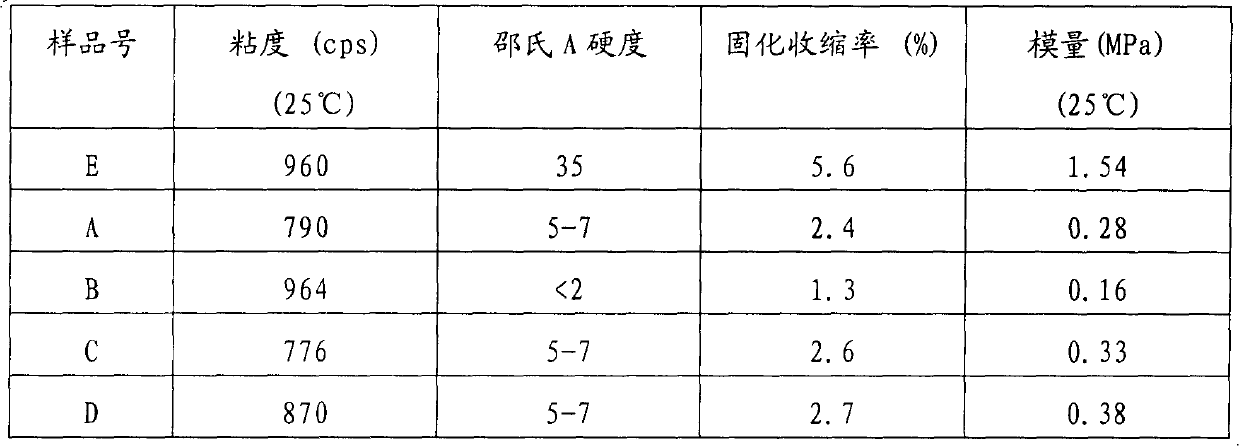

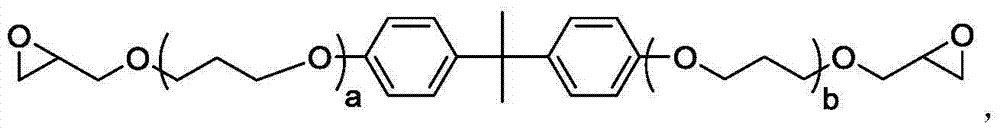

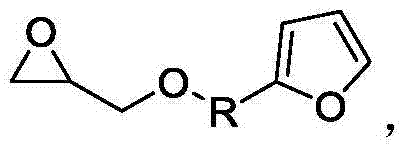

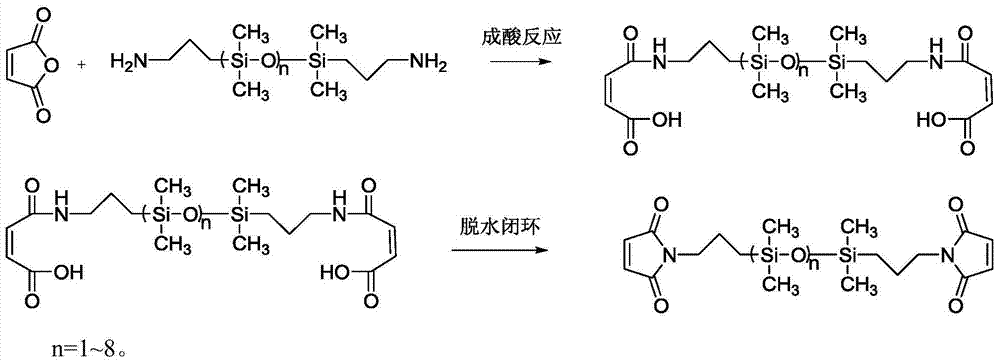

Flip chip bottom filling adhesive with normal temperature rapid capillary fluidity and rapid repairability

ActiveCN104745133AImprove connection reliabilityHigh TgNon-macromolecular adhesive additivesRubber derivative adhesivesFuranAdhesive

The invention relates to a flip chip bottom filling adhesive with normal temperature rapid capillary flowing property and rapid repairability. The flip chip bottom filling adhesive is prepared from the following raw materials in percentage by weight: 10-60% of epoxy resin, 10-20% of polyether modified epoxy resin, 5-20% of bismaleimide modified toughening resin, 5-20% of furan alkyl glycidyl ether, 5-30% of a curing agent, 5-20% of a curing accelerator, 0.5-3% of a coupling agent, 0-40% of spherical silica powder and 0-6% of pigments. The bottom filling adhesive provided by the invention is mainly applied to bottom filling of flip chips so as to improve the connection reliability and has the characteristics of high Tg, good normal-temperature rapid flowing property, good connection reliability and good rapid curing property.

Owner:王传广 +1

High-intensity epoxy shell adhesive and preparation method thereof

InactiveCN107779146AImprove performanceImprove aging resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The invention relates to a high-intensity epoxy shell adhesive and a preparation method thereof. During use of the high-intensity epoxy shell adhesive, a first component and a second component are mixed according to a weight ratio of (2 to 4) to 1; the first component is prepared from the following constituent raw materials in parts by weight: 50 to 80 of epoxy resin, 5 to 25 of an activated toughening agent, 3 to 20 of a diluent and 0.5 to 5 of a deformaing agent; the second component is prepared from the following constituent raw materials in parts by weight: 30 to 80 of a toughening curingagent, 10 to 60 of a hardening curing agent and 0.3 to 1 of a coupling agent. Compared with the prior art, the high-intensity epoxy shell adhesive has the advantages of medium resistance, high-temperature resistance, low-temperature resistance, impact resistance, pressure resistance, aging resistance and the like.

Owner:上海海鹰粘接科技有限公司

Liquid insulating glue for cable joint

InactiveCN101962519AVolatile fastHigh elongationRubber derivative adhesivesConnection insulationEngineeringCopper

The invention belongs to electric wire and cable protection and electric insulating adhesive tapes, and particularly relates to liquid insulating glue for a cable joint. The liquid insulating glue contains modified rubber and non-polar solvent and also can contain oil-soluble resin and / or copper corrosion inhibitor, wherein the consumption of the modified rubber is 10 to 40 percent of the total mass; and a formed insulating protective layer has excellent insulating performance and properties of resisting moisture, water, oxidation and acid and alkali corrosion. The liquid insulating glue can be used for joint coating and insulation of a metal lead, and also can be used for repair of cable outer sheaths and waterproof seal of embedded electric wires and cables.

Owner:海宁市科泰克金属表面技术有限公司

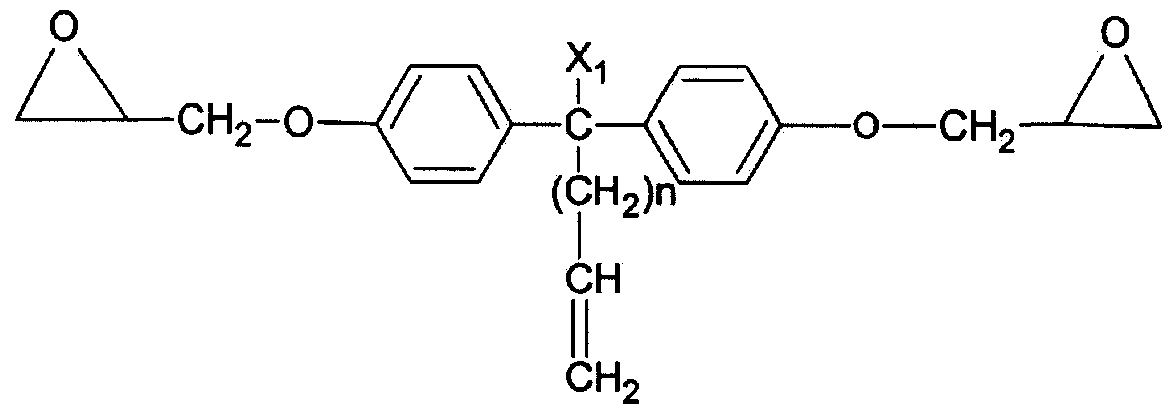

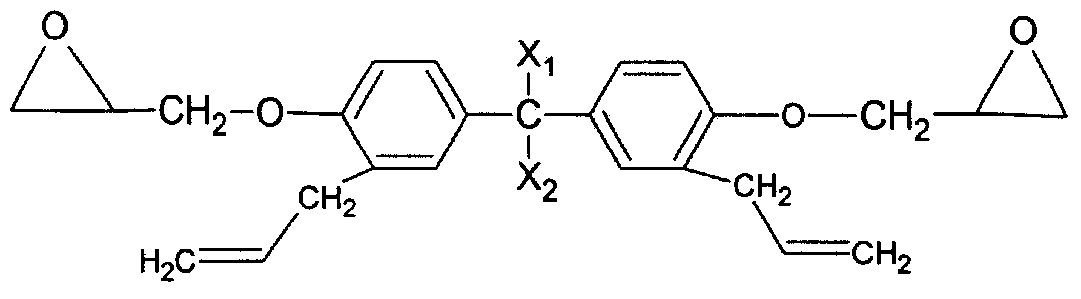

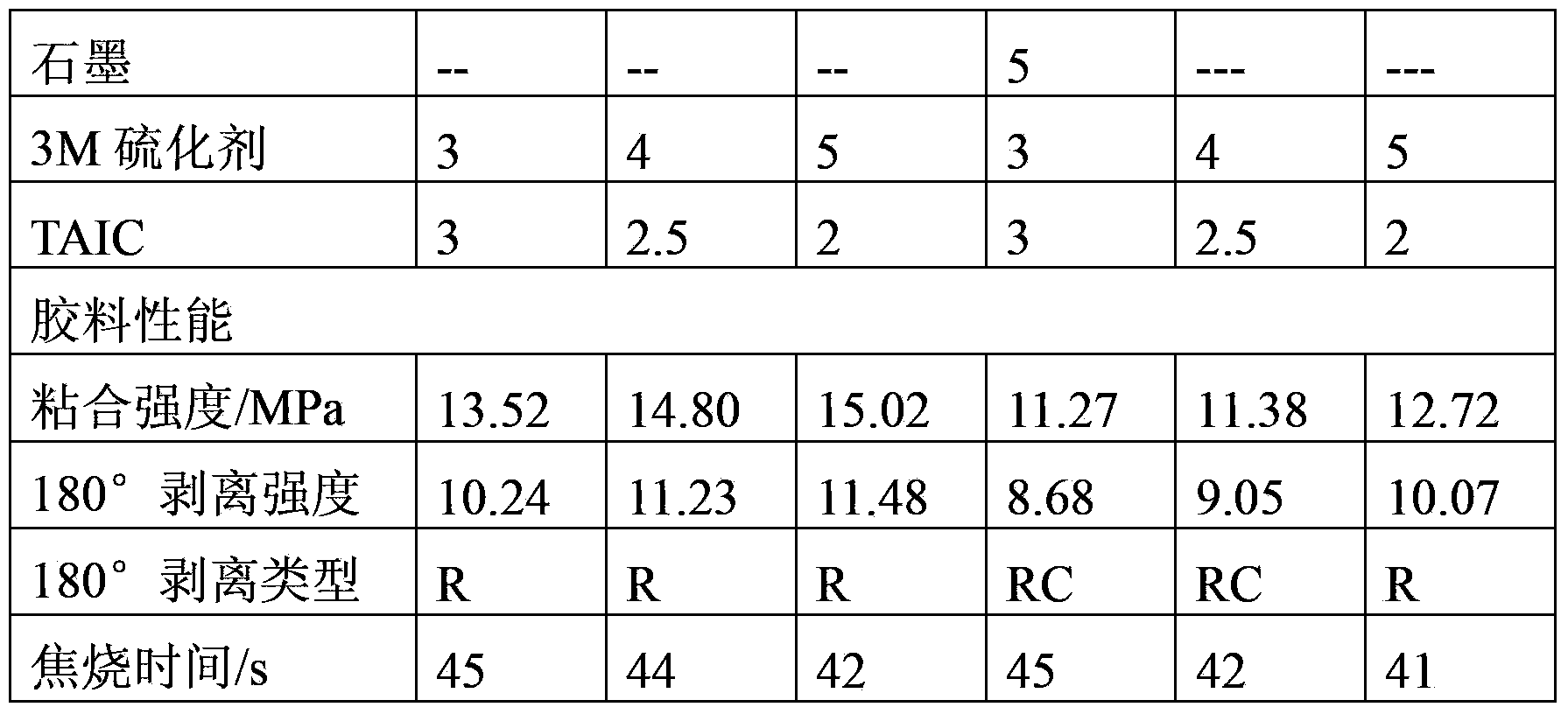

High-performance double-bond-containing epoxy resin/liquid rubber adhesive

PendingCN104694063AHigh bonding strengthNon-macromolecular adhesive additivesRubber derivative adhesivesEpoxyVulcanization

The invention discloses a high-performance double-bond-containing epoxy resin / liquid rubber adhesive, belonging to the technical field of adhesives. The epoxy resin refers to an epoxy resin containing an epoxy ring and unsaturated double bonds; the rubber refers to liquid rubber containing unsaturated bonds; and a curing system comprises a general epoxy resin curing agent, a vulcanizing agent and a vulcanization accelerator. The preparation method comprises the following steps: mixing 100 parts of epoxy resin containing double bonds, 0-100 parts of liquid rubber, 10-60 parts of an epoxy curing agent, 3-20 parts of a vulcanizing agent and 0-8 parts of a vulcanization accelerator according to the ratio, and mechanically and uniformly stirring at normal temperature or in a heating mode, wherein the curing temperature is 140-200 DEG C, and the curing time refers to 2-4 hours. The adhesive disclosed by the invention can serve as a metal and rubber adhesive and has high bonding strength.

Owner:BEIJING UNIV OF CHEM TECH

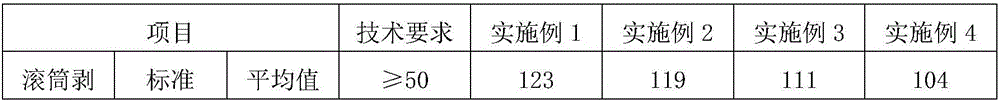

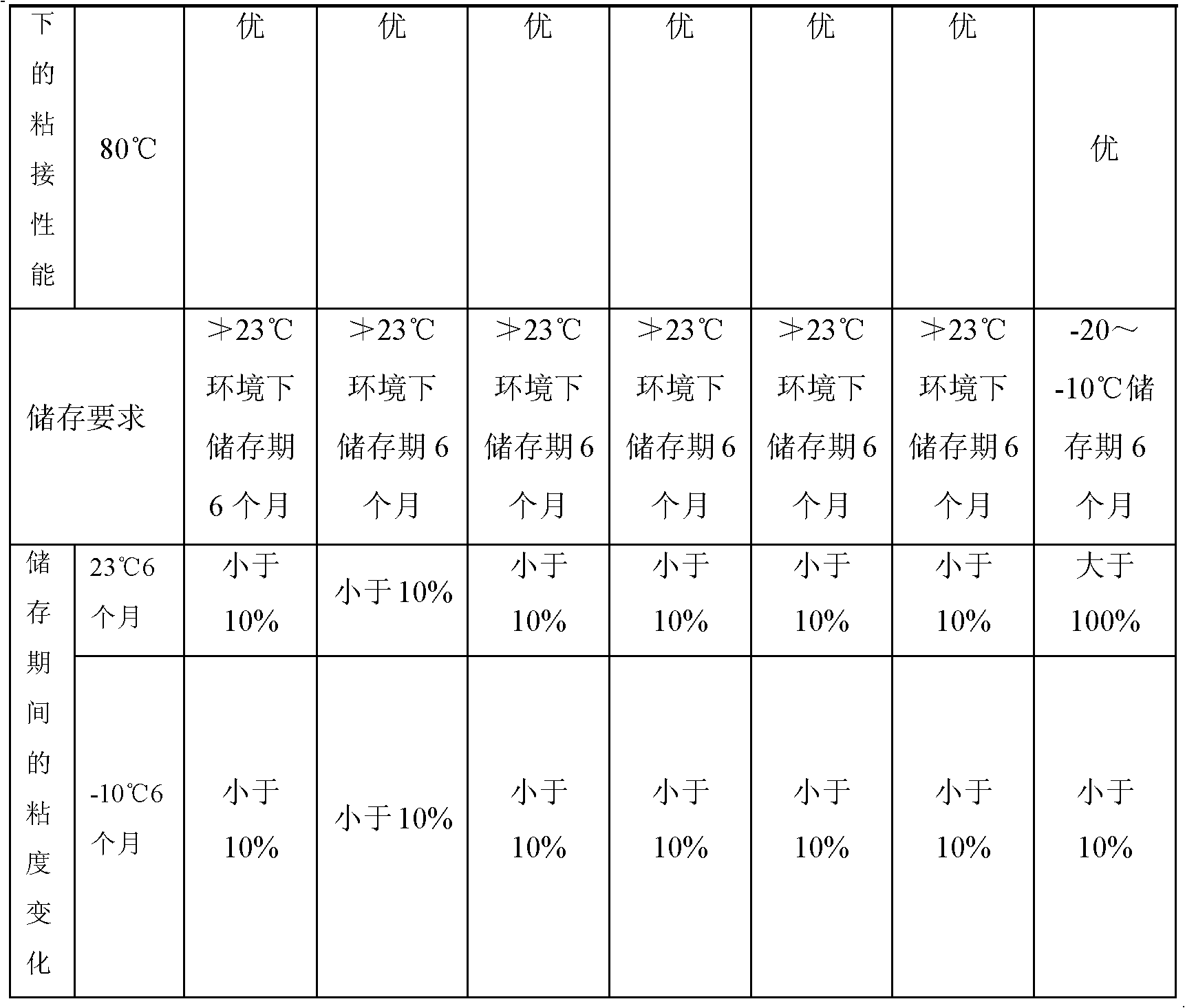

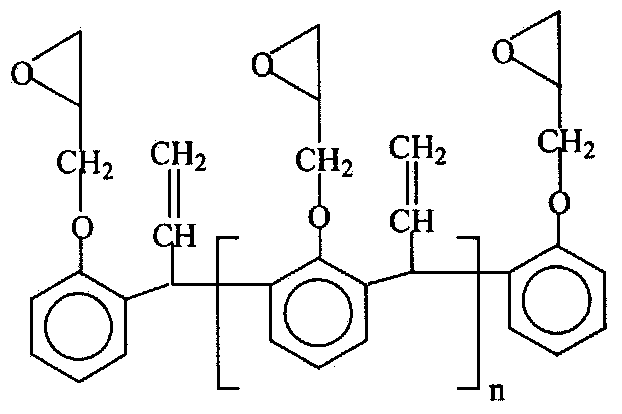

Epoxy adhesive toughened by tertiary-amide modified liquid nitrile butadiene rubber

ActiveCN106085325AGuaranteed toughening effectIncreased curing crosslink densityRubber derivative adhesivesEpoxy resin adhesivesCross-linkGlass transition

The invention discloses an epoxy adhesive toughened by tertiary-amide modified liquid nitrile butadiene rubber. The adhesive is prepared from the following components in parts by weight: 100 parts of bisphenol-A or bisphenol-F epoxy resin, 8 to 60 parts of amine curing agent and 10 to 70 parts of tertiary-amide modified liquid nitrile butadiene rubber. The curing condition is that all components are uniformly mixed and are cured at a room temperature for 4 to 7 days or are cured at a temperature of 50 DEG C for 1 day. The adhesive has main properties that the tensile strength is 20 to 40 MPa, the elongation at break is 5 percent to 30 percent, the impact strength is 20 to 150 kJ / m2 and high-temperature glass transition temperature is 90 to 120 DEG C. The toughened epoxy adhesive disclosed by the invention has the advantages that excellent mechanical property and excellent toughness are obtained; the curing cross-linking density of the epoxy resin is improved, the high-temperature glass transition temperature of the epoxy adhesive is not reduced, and the high-temperature usage temperature of the adhesive is not reduced while the adhesive is toughened by utilization of the characteristics of catalyzing and curing epoxy functional groups by a tertiary amine group.

Owner:NANJING UNIV

Building sealant composition

A curable sealant composition is provided. The composition includes a polymer including at least conjugated dime contributed monomer units in a backbone of the polymer and terminal groups including silicon. The composition also includes additional sealant ingredients selected from the group consisting of plasticizers, filler, reinforcing agents, modifiers, curing catalysts / hardeners, stabilizers, and mixtures thereof.

Owner:BRIDGESTONE CORP

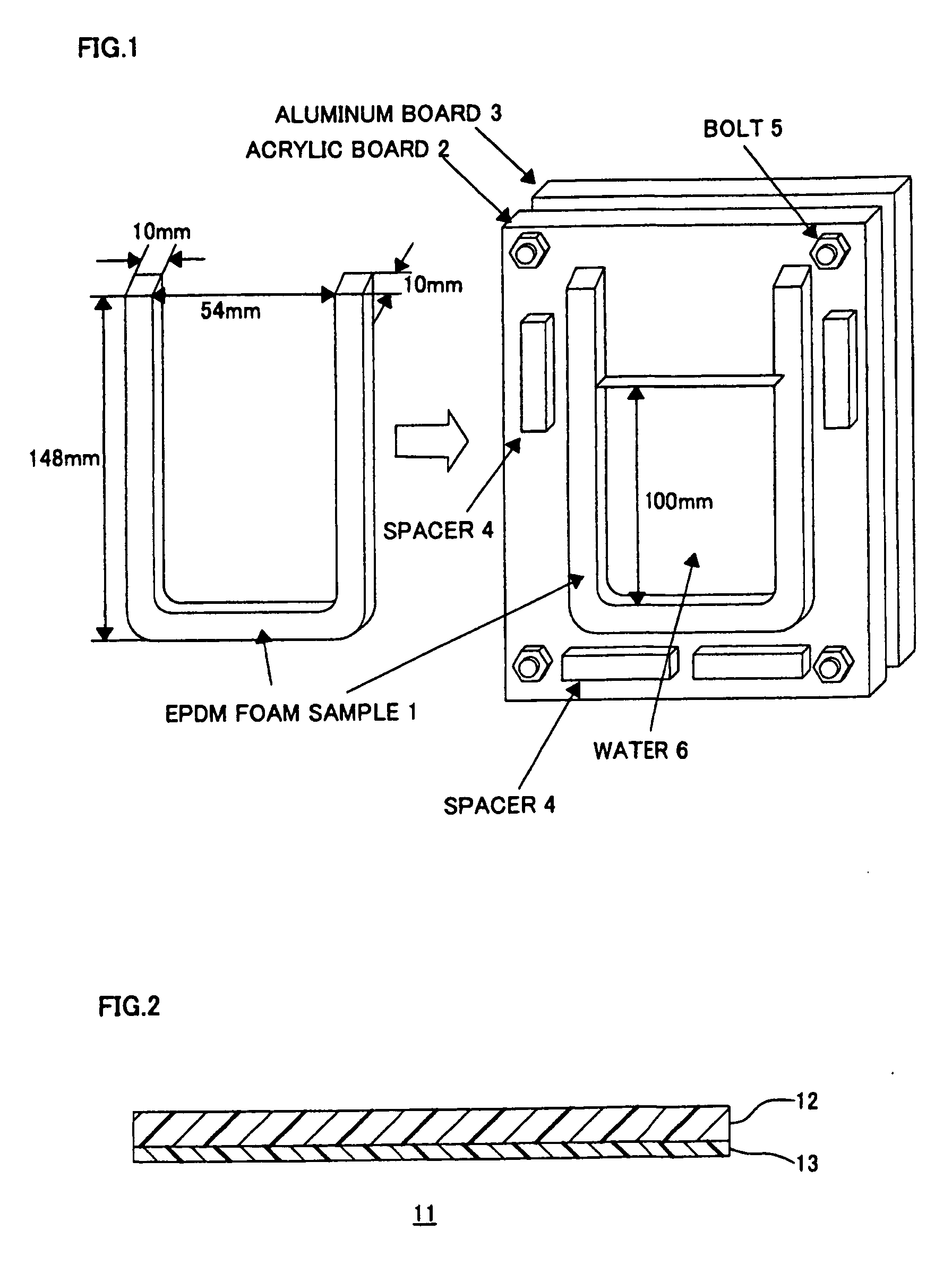

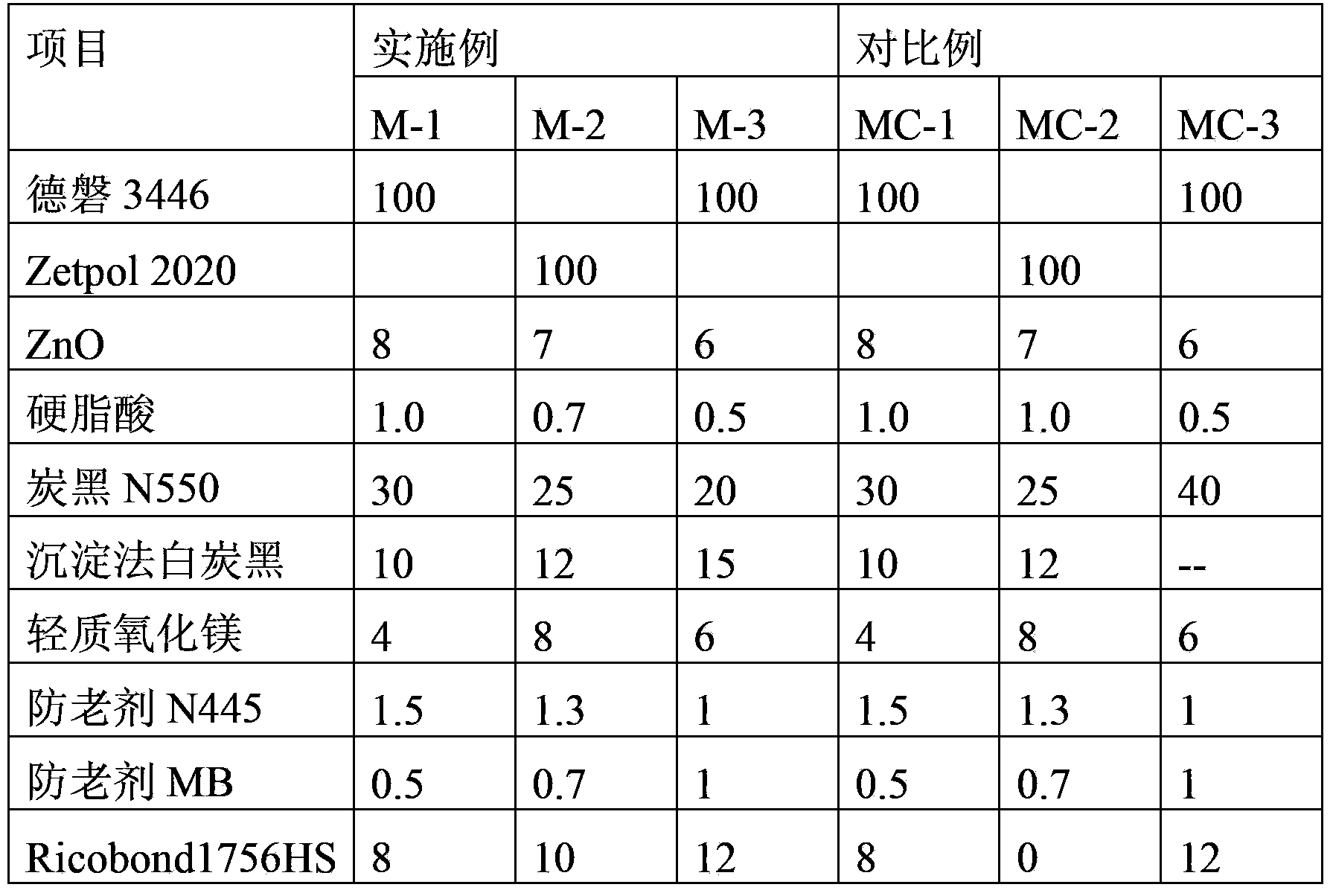

EPDM foam and adhesive sealing material

InactiveUS20120277337A1Improve the water-stop effectSame level of sealingOther chemical processesRubber derivative adhesivesMetalEPDM elastomer

Owner:NITTO DENKO CORP

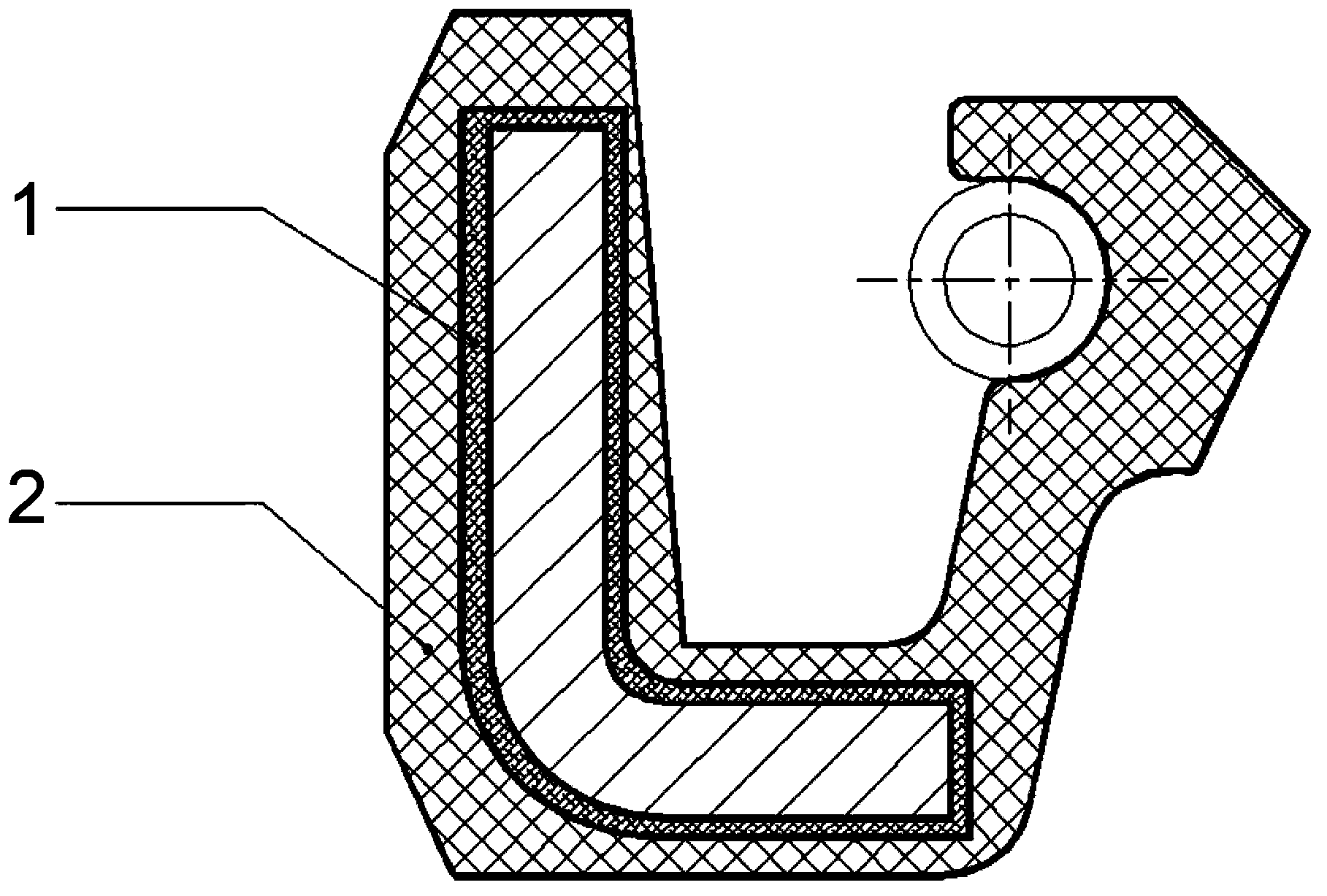

Large-scale hydrogenated nitrile butadiene skeleton oil seal, and preparation method and application thereof

ActiveCN103407010AImprove bond reliabilityImprove wear resistanceNon-macromolecular adhesive additivesRubber derivative adhesivesAdhesive cementCoil spring

The invention discloses a large-scale hydrogenated nitrile butadiene skeleton oil seal, and a preparation method and application thereof. The large-scale hydrogenated nitrile butadiene skeleton oil seal provided by the invention is a skeleton oil seal with an internal diameter greater than 400 mm, and comprises a metal skeleton, an oil seal body and a self-tightening helical spring. The oil seal body comprises a lip glue layer and an adhesive glue layer. The adhesive glue is applied with the metal skeleton through a binding bar wrapping or adhesive cement coating process, and is finally vulcanized with lip gel by mould pressing, so as to obtain the hydrogenated nitrile butadiene skeleton oil seal. The large-scale hydrogenated nitrile butadiene skeleton oil seal involved in the invention has strong reliability, good wear resistance of lip and long service life, and can be applied to the field of sealing of high speed rotary bearing.

Owner:广州国机密封科技有限公司

Butyl adhesive containing maleic anhydride and optional nanoclay

InactiveUS20080081872A1Improve adhesionImproved sail materialMaterial nanotechnologyNanostructure manufacturePolyesterPolymer science

An adhesive polymer comprising a maleic anhydride grafted butyl rubber and a polymer compound made from the adhesive polymer further comprising a functionalized siliceous nanoclay. The adhesive polymer and polymer compound exhibit greatly improved adhesion to certain substrate surfaces. Examples of substrate materials include stainless steel, glass, mylar or Teflon®. The greatest adhesion was observed in polymer compounds comprising maleic anhydride grafted butyl rubber produced according to a solution process and from 5 to 15 phr of a montmorillonite nanoclay. The adhesion is improved with increasing levels of nanoclay content in the compound up to a limit where filler-filler interactions occur.

Owner:LANXESS INC

Improved epoxy resin adhesive

InactiveCN103589380AImprove toughnessImprove flame retardant performanceNon-macromolecular adhesive additivesRubber derivative adhesivesOrganic solventNitrile rubber

The invention discloses an improved epoxy resin adhesive which comprises the following components in parts by weight: 65-85 parts of epoxy resin, 20-30 parts of aromatic amine curing agent, 5-15 parts of imidazole curing accelerator, 25-35 parts of nitrile rubber, 1-2.5 parts of coupling agent, 15-25 parts of diluent, 10-20 parts of phosphorus based flame retardant, 5-10 parts of plasticizer, 10-15 parts of calcium carbonate filler and an appropriate amount of organic solvent. According to the improved epoxy resin adhesive, the tenacity of the epoxy resin adhesive can be improved by means of the addition of the hydroxyl-terminated nitrile rubber. The phosphorus-containing flame retardant can influence the glue overflow amount and the shelf life and improve the flame retardance of the adhesive; the tenacity can be improved by the plasticizer. Therefore, the epoxy resin adhesive has favourable flame retardance and tenacity and relatively high viscosity.

Owner:苏州威仕薄膜科技有限公司

Radiation Cross-Linkable Hot-Melt Contact Adhesives

InactiveUS20080039594A1Low viscosityImprove thermal stabilityLamination ancillary operationsSynthetic resin layered productsOligomerCrosslinked polymers

The invention relates to a radiation crosslinkable hot melt pressure sensitive adhesive comprised of a radiation crosslinkable polymer as component (A) based on epoxidized polyoflefins, wherein the epoxy groups are not consolidated in blocks; a tackifying resin possessing no epoxy groups as component (B); optionally a low molecular weight oligomer as component (C) that possesses reactive groups that can react with the epoxy groups of component (A); and an additive comprising a photo initiator as component (D).

Owner:HENKEL KGAA

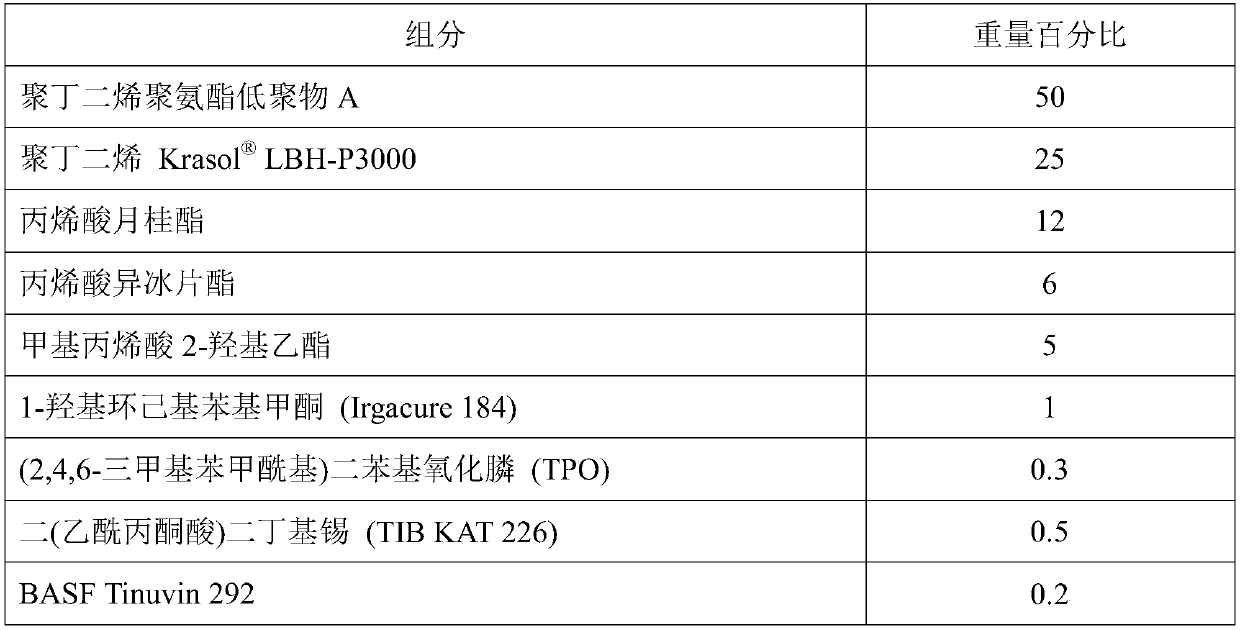

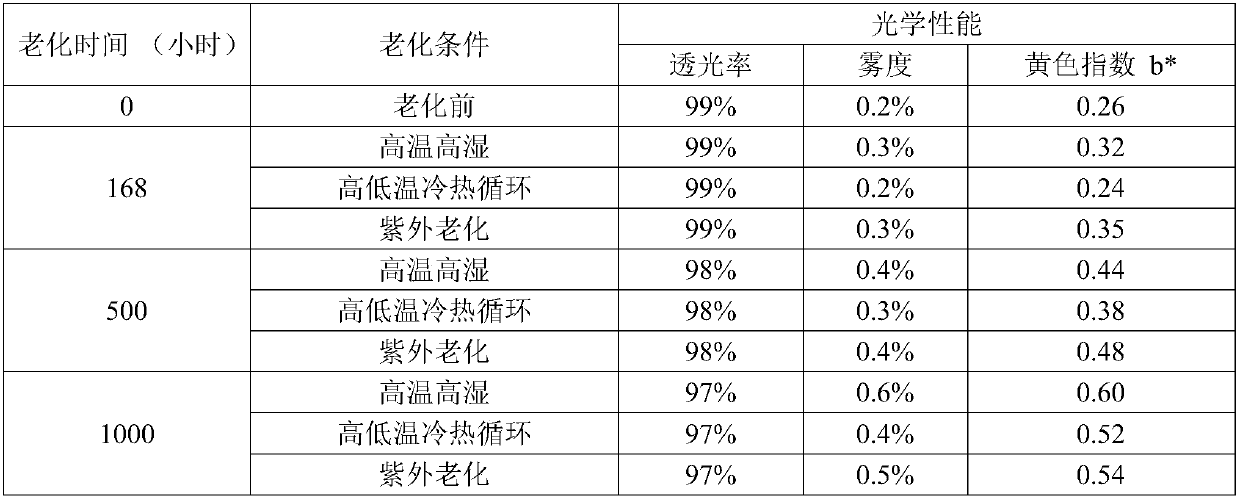

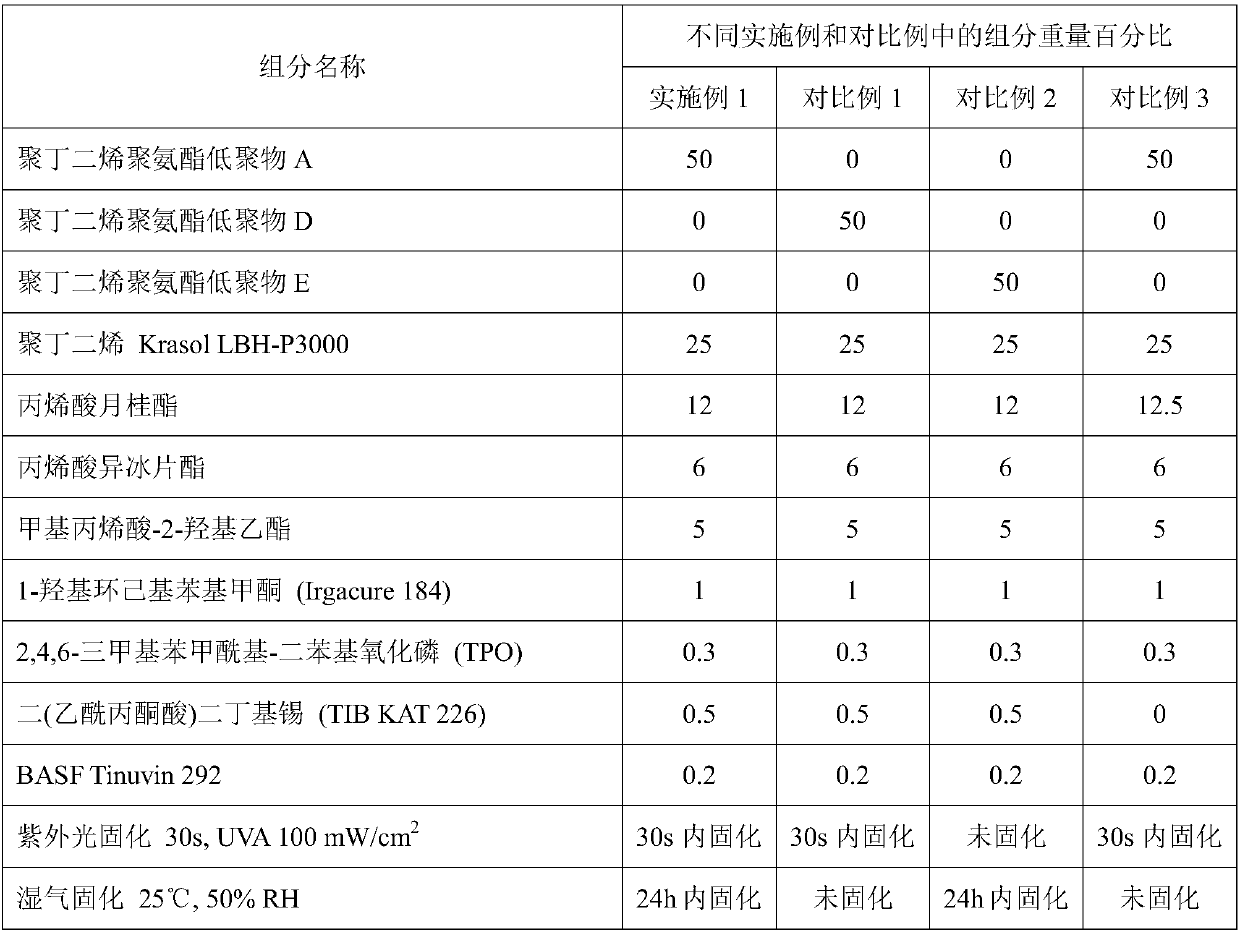

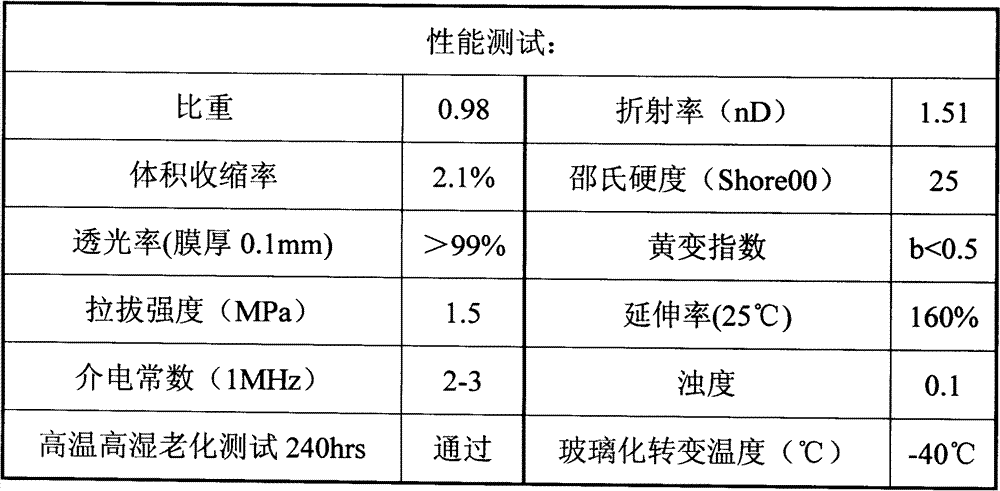

Ultraviolet radiation and moisture dual-curing adhesive composition and application thereof

PendingCN109575871AIncrease crosslink densityImprove curing efficiencyAdhesive processesNon-macromolecular adhesive additivesOptical bondingUltraviolet

The invention provides an ultraviolet radiation and moisture dual-curing adhesive composition. A secondary moisture curing function of the composition is particularly suitable for occasions having shadow area curing requirements in the field of optical bonding and electronic packaging. An adhesive is prepared from the following raw materials: 30 to 50 percent by weight of an aliphatic polyurethaneoligomer having a (methyl)acryloyloxy group and an alkoxysilane functional group, 20 to 40 percent by weight of a (methyl) acrylate reactive diluents, 20 to40 percent by weight of an inert plasticizer not involved in crosslinking curing, 1 to 4 percent by weight of free radical photoinitiator, 0.1 to 1 percent by weight of organometallic compound moisture curing catalyst, and 0.2 to 1 percent byweight of an ultraviolet stabilizer and antioxidant.

Owner:WANHUA CHEM GRP CO LTD

Liquid optical clear adhesive for liquid crystal display touch screen and preparation method thereof

InactiveCN102732183AGood softness and ductilityImprove adhesion strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a liquid optical clear adhesive (LOCA) for a liquid crystal display (LCD) touch screen and a preparation method thereof. The adhesive comprises 0-75 weight parts of liquid synthetic rubber A or B in primary forms, 10-30 weight parts of butadiene polymer, 3-5 weight parts of liquid polybutadiene and its derivative, 1-5 weight parts of terpene resin, 1-5 weight parts of modifier, 0.1-1 weight parts of antioxidant, 0.1-1 weight parts of latent curing agent, and 0.1-3 weight parts of photoinitiator, wherein the A is maleated isoprene telomer with the molecular weight being between 12000-18000, the B is maleated isoprene telomere with the molecular weight being between 32000-38000, and A and B are not 0 weight part simultaneously. The preparation method comprises the steps of mixing and dissolving, filtering, conducting vacuum pumping, etc. The LOCA of the invention has high bonding strength, high light transmittance, good ductility, small cure shrinkage, and yellowing resistance, and the preparation method is simple and green. The invention has a wide scope of application.

Owner:烟台伟昌电子材料有限公司

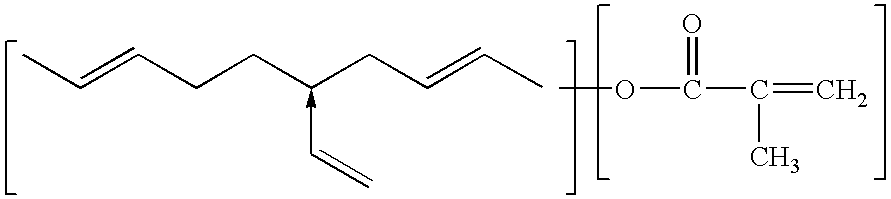

Farnesene-based tackifying resins and adhesive compositions containing the same

ActiveUS20170029668A1Improve efficiencyReduce molecular weightFilm/foil adhesivesMacromolecular adhesive additivesElastomerCelsius Degree

A tackifying resin includes a farnesene-based polymer having monomeric units derived from a farnesene monomer and one or more optional comonomers selected from the group consisting of dienes, branched mono-olefins, and vinyl aromatics and has a softening point greater than or equal to 80 degrees Celsius. A method of making the farnesene-based polymer includes combining a farnesene monomer and a solvent and optionally adding one or more comonomers selected from the group consisting of dienes, branched mono-olefins, and vinyl aromatics, to provide a monomer feed, and polymerizing the monomer feed by combining the monomer feed with a Friedel-Crafts catalyst in a vessel. The tackifying resin may be combined with an elastomer to form a hot melt adhesive composition.

Owner:RESIN SOLUTIONS LLC

Epoxy glue for processing of crystal liable to separate during boiling, and preparation method of epoxy glue

InactiveCN106753121AFast curingGood adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerEpoxy

The invention discloses epoxy glue for processing of a crystal liable to separate during boiling, and a preparation method of the epoxy glue. The modified epoxy glue consists of a component A and a component B, wherein the component A contains epoxy resin, an elastomer, a degumming separating agent, a plasticizer, fillers and a thixotropic agent; the component B contains a polymercaptan curing agent, a tertiary amine accelerant, a silane coupling agent, a degumming separating agent, fillers and a thixotropic agent. The glue has high adhesive strength and high medium resistance when being used for positioning and adhering processing of the crystal material; when the crystal material is completed and heated to be subjected to degumming separation, the temperature is not high, and the residual glue is easy to clean.

Owner:云南光电辅料有限公司

Electrolyte-resistant rubber solution as well as preparation method and electrolyte-resistant rubber tape thereof

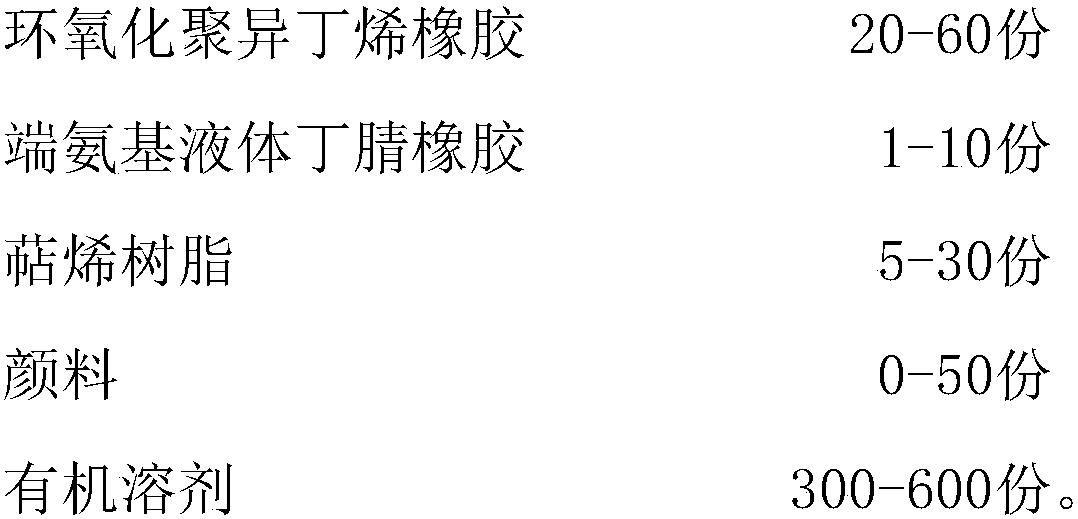

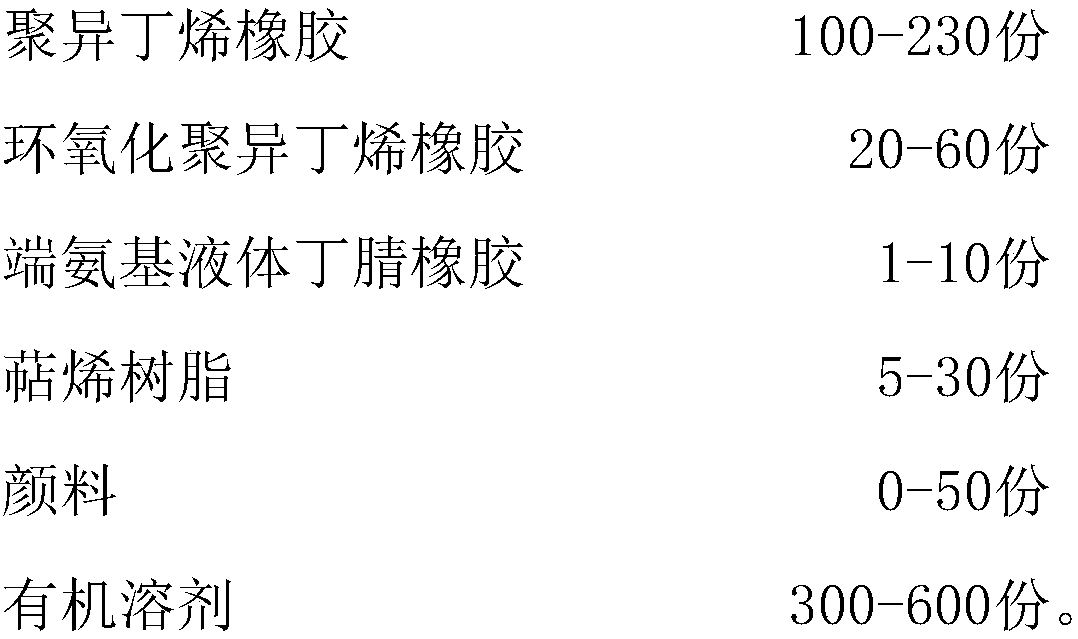

ActiveCN108192532ASimple coating processSuitable for mass productionMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesEpoxyPolymer science

The invention relates to the technical field of rubber, in particular to an electrolyte-resistant rubber solution as well as a preparation method and an electrolyte-resistant rubber tape thereof. Theelectrolyte-resistant rubber solution comprises the following raw materials in parts by weight: 100-230 parts of polyisobutylene rubber, 20-60 parts of epoxy polyisobutylene rubber, 1-10 parts of amino-terminated liquid nitrile rubber, 5-30 parts of a terpene resin, 0-50 parts of a pigment and 300-600 parts of an organic solvent. According to the electrolyte-resistant rubber solution which is provided by the invention, the polyisobutylene rubber which is excellent in chemical resistance is adopted as a main material, the epoxy polyisobutylene rubber and the amino-terminated liquid nitrile rubber are used, and through cross-linking reactions of the epoxy polyisobutylene rubber and the amino-terminated liquid nitrile rubber,not only the bonding property of the electrolyte-resistant rubber solution provided by the invention with aluminum foil in a lithium battery is improved, but also the electrolyte corrosion resistance of the electrolyte-resistant rubber solution is improved.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com