Low-modulus optical adhesive composition

An adhesive, low modulus technology, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve the problems of display module and panel contamination, increased energy required for curing, and reduced touch screen accuracy and accuracy. , to avoid warping and deformation, low viscosity, improve precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

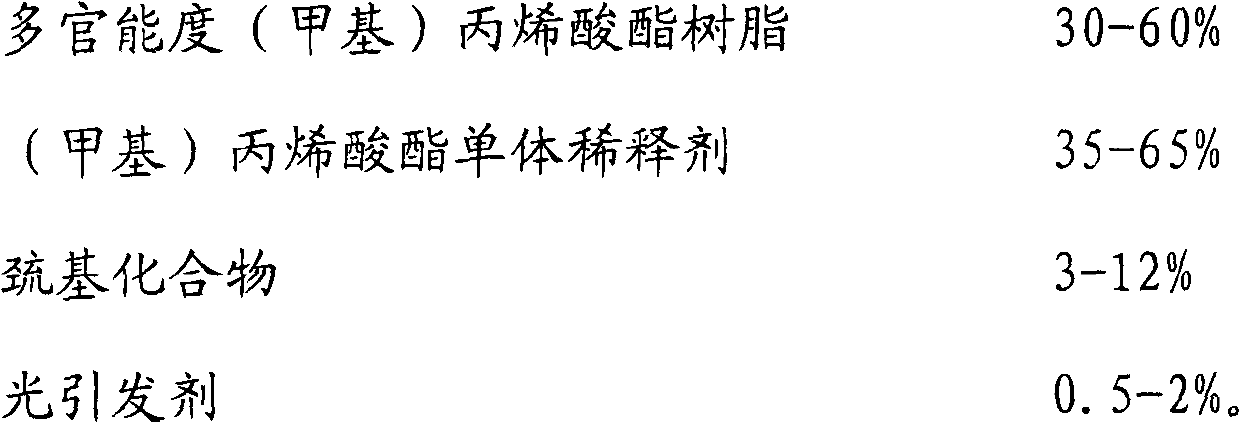

Method used

Image

Examples

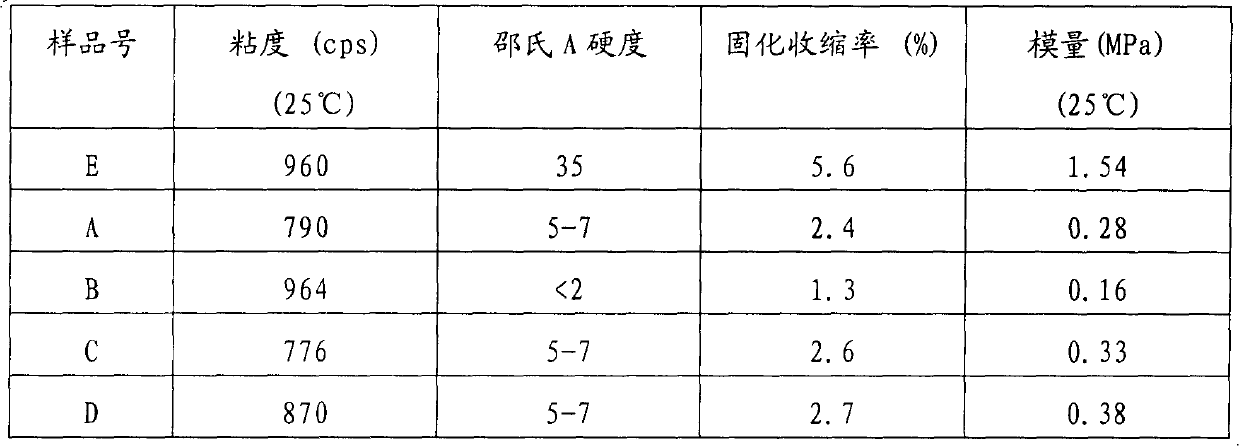

Embodiment 1

[0017] Take 30Kg multi-functional (meth)acrylate resin, 65Kg (meth)acrylate monomer diluent and 3Kg mercapto compound into the stirrer, stir for 30 minutes; then add 2Kg photoinitiator, stir under dark conditions The initiator is completely dissolved in 60-90 minutes to obtain the finished product A.

Embodiment 2

[0019] Take 56Kg multi-functionality (meth)acrylate resin, 40Kg (meth)acrylate monomer diluent and 3Kg mercapto compound into the stirrer, stir for 30 minutes; then add 1Kg photoinitiator, stir under dark conditions The initiator is completely dissolved in 60-90 minutes to obtain the finished product B.

Embodiment 3

[0021] Take 60Kg of multi-functional (meth)acrylate resin, 35Kg of (meth)acrylate monomer diluent and 4Kg of mercapto compound into the stirrer, stir for 30 minutes; then add 0.5Kg of photoinitiator and 0.5Kg of auxiliary agent, Stir for 60-90 minutes under the condition of avoiding light to completely dissolve the initiator, and obtain the finished product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com