Patents

Literature

3680 results about "UV curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV curing is the process by which ultraviolet light is used to initiate a photochemical reaction that generates a crosslinked network of polymers. UV curing is adaptable to printing, coating, decorating, stereolithography, and in the assembly of a variety of products and materials. In comparison to other technologies, curing with UV energy may be considered a low temperature process, a high speed process, and is a solventless process, as cure occurs via direct polymerization rather than by evaporation. Originally introduced in the 1960s, this technology has streamlined and increased automation in many industries in the manufacturing sector.

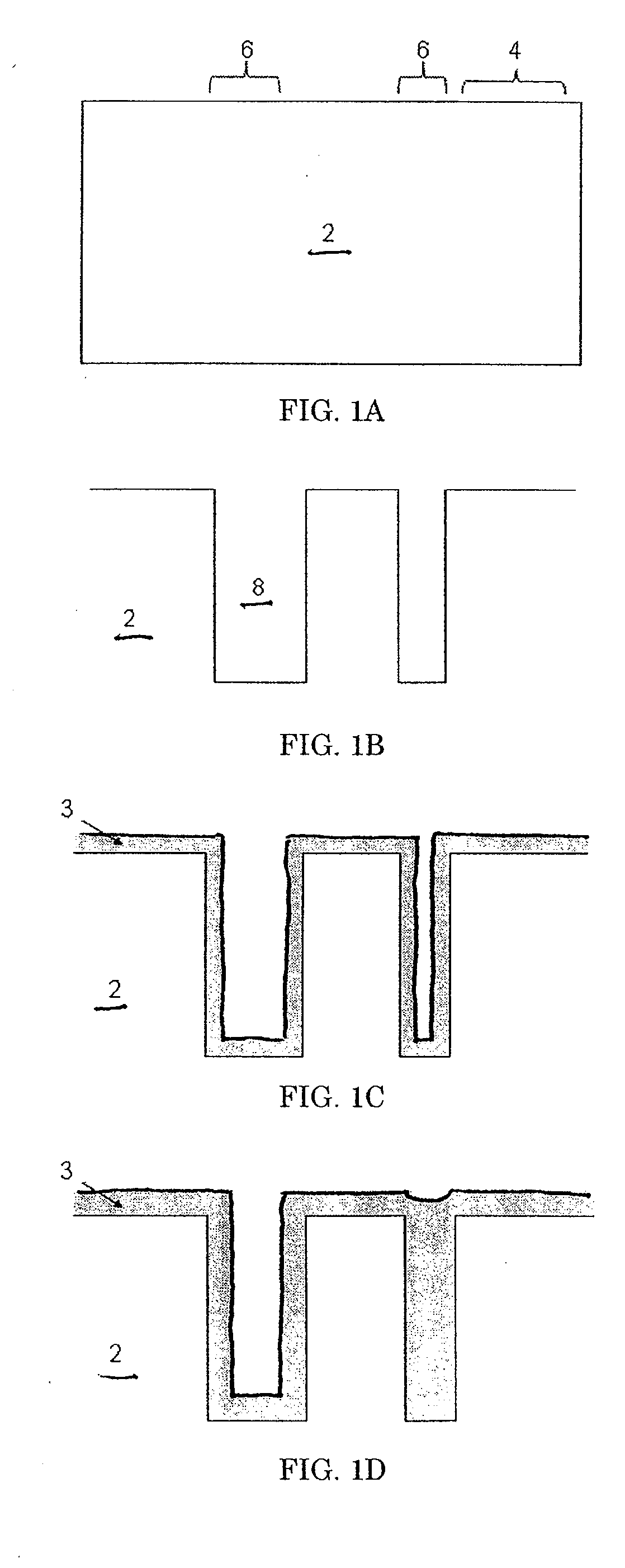

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

ActiveUS20080020591A1Improve performanceFilm stress is increasedTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaUV curing

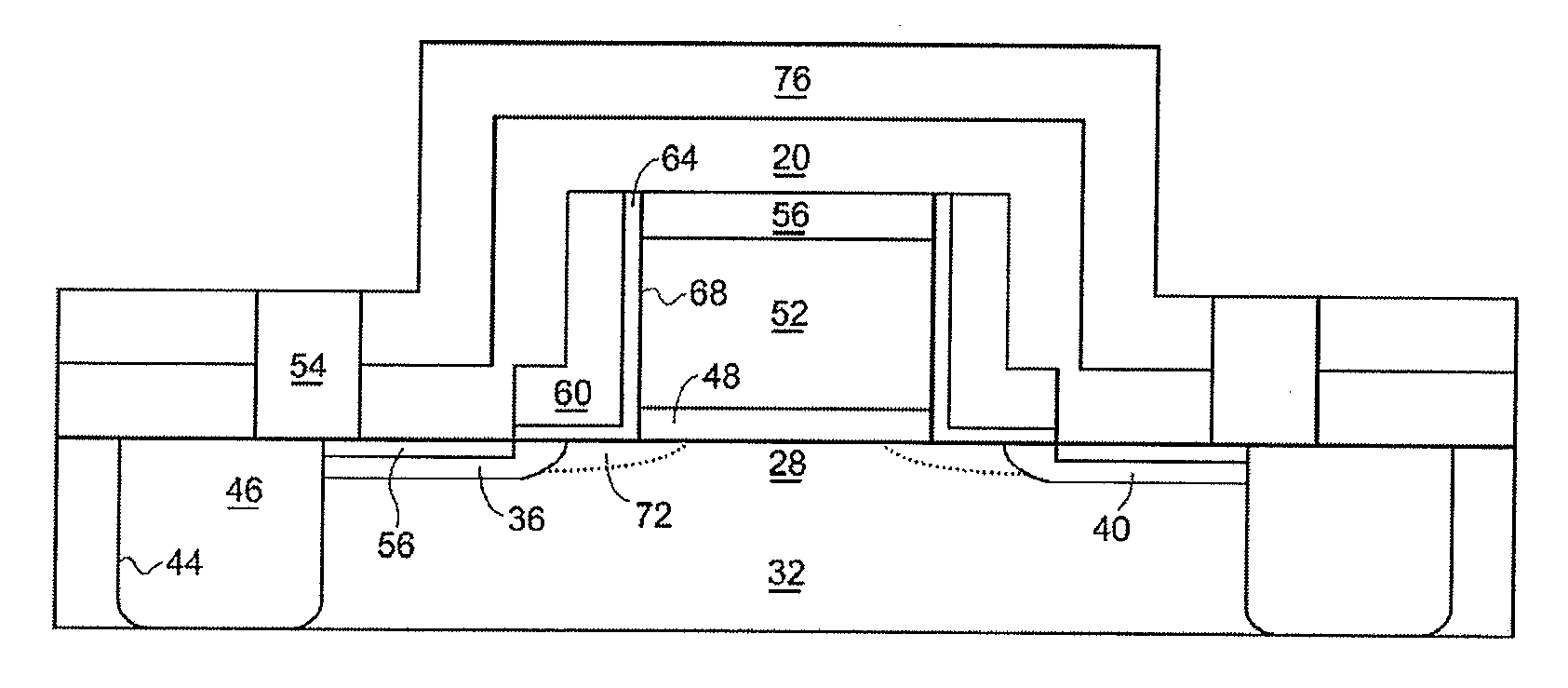

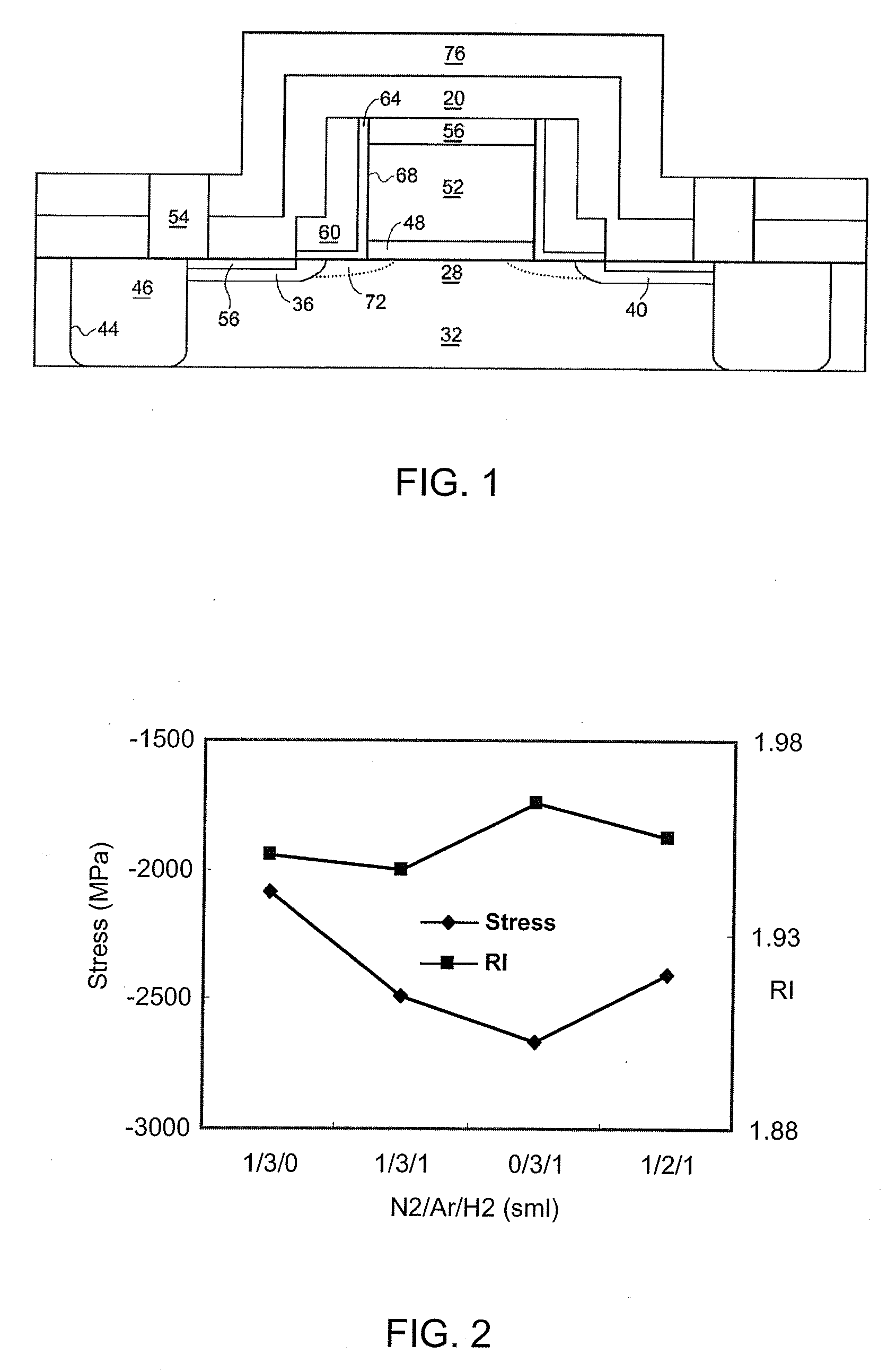

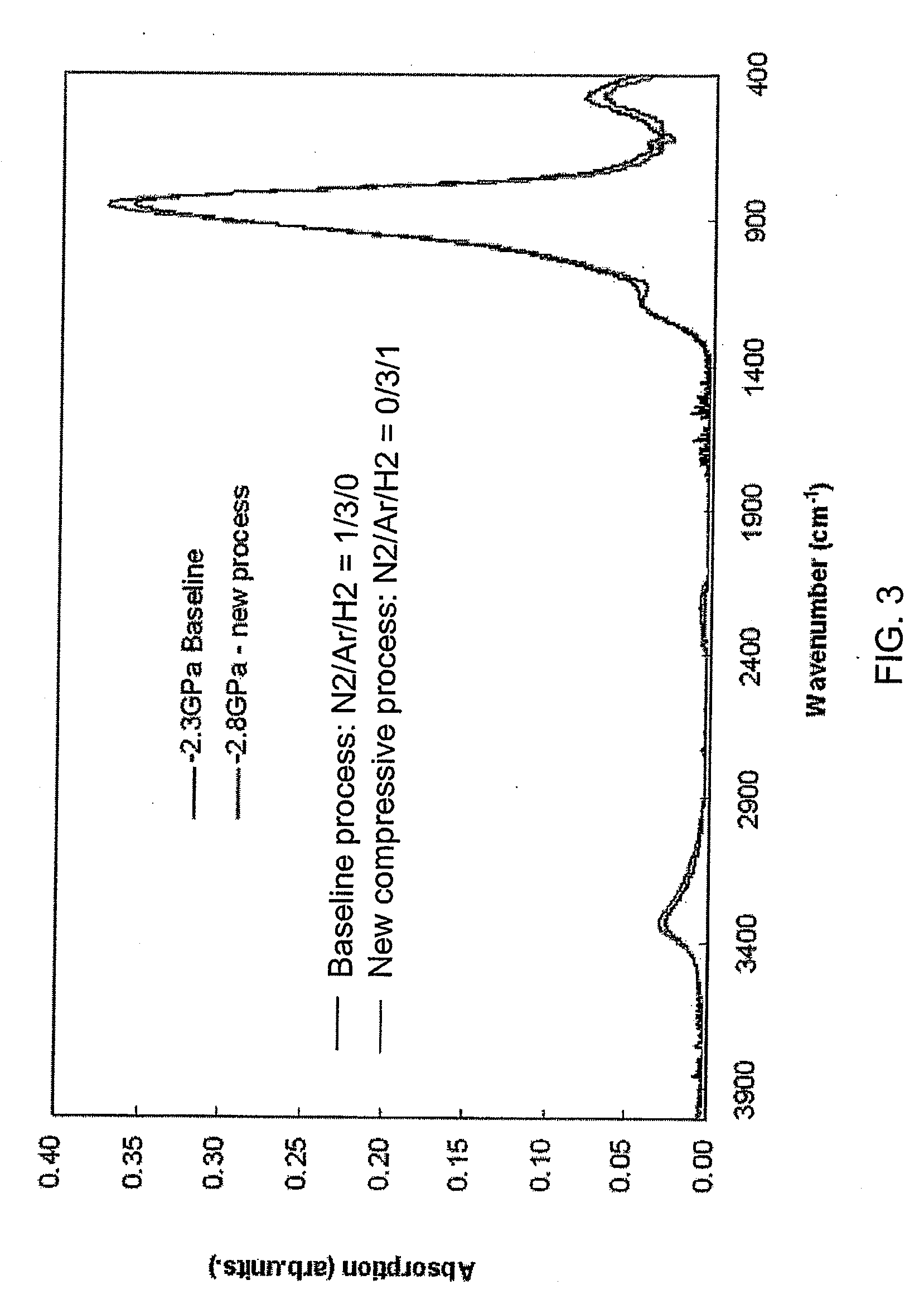

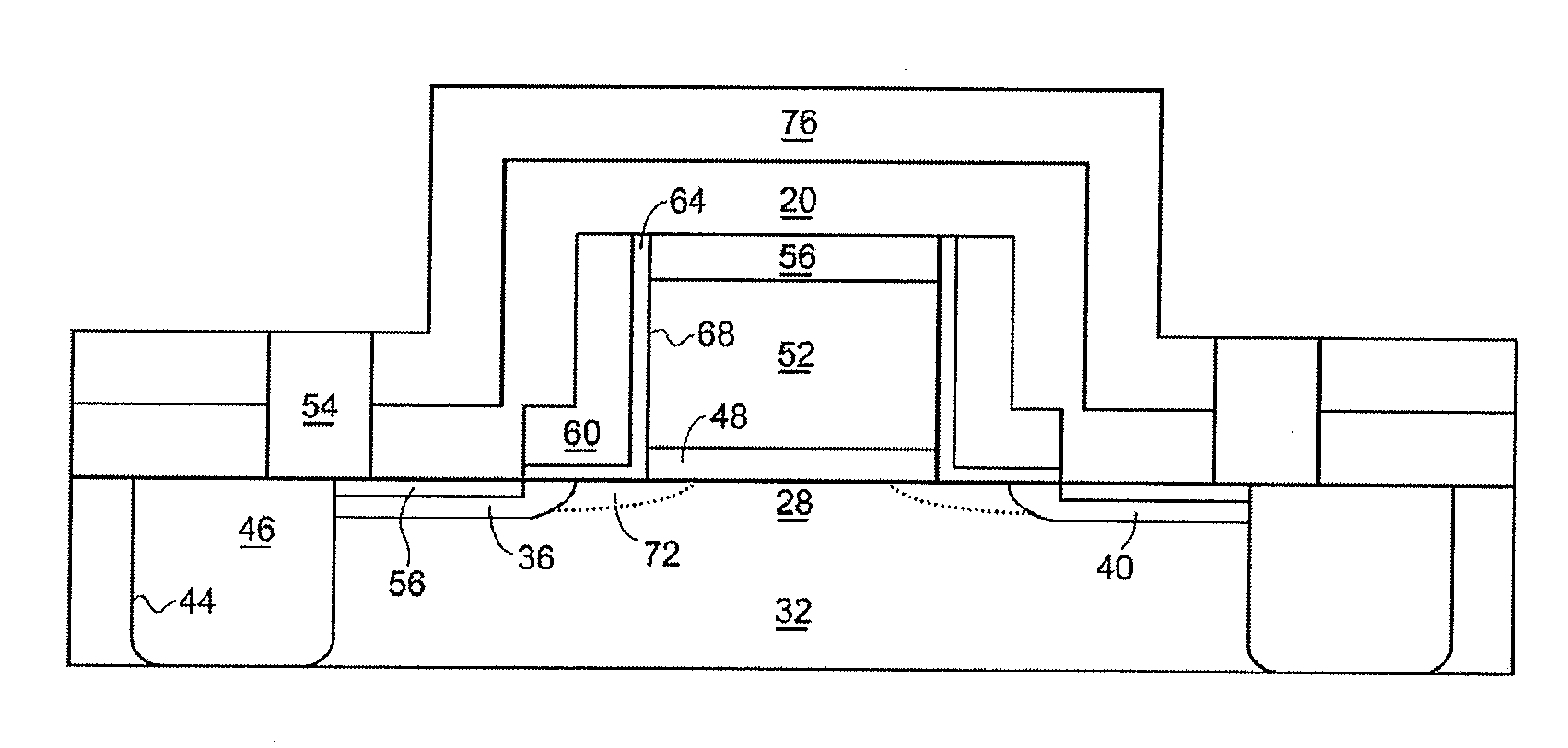

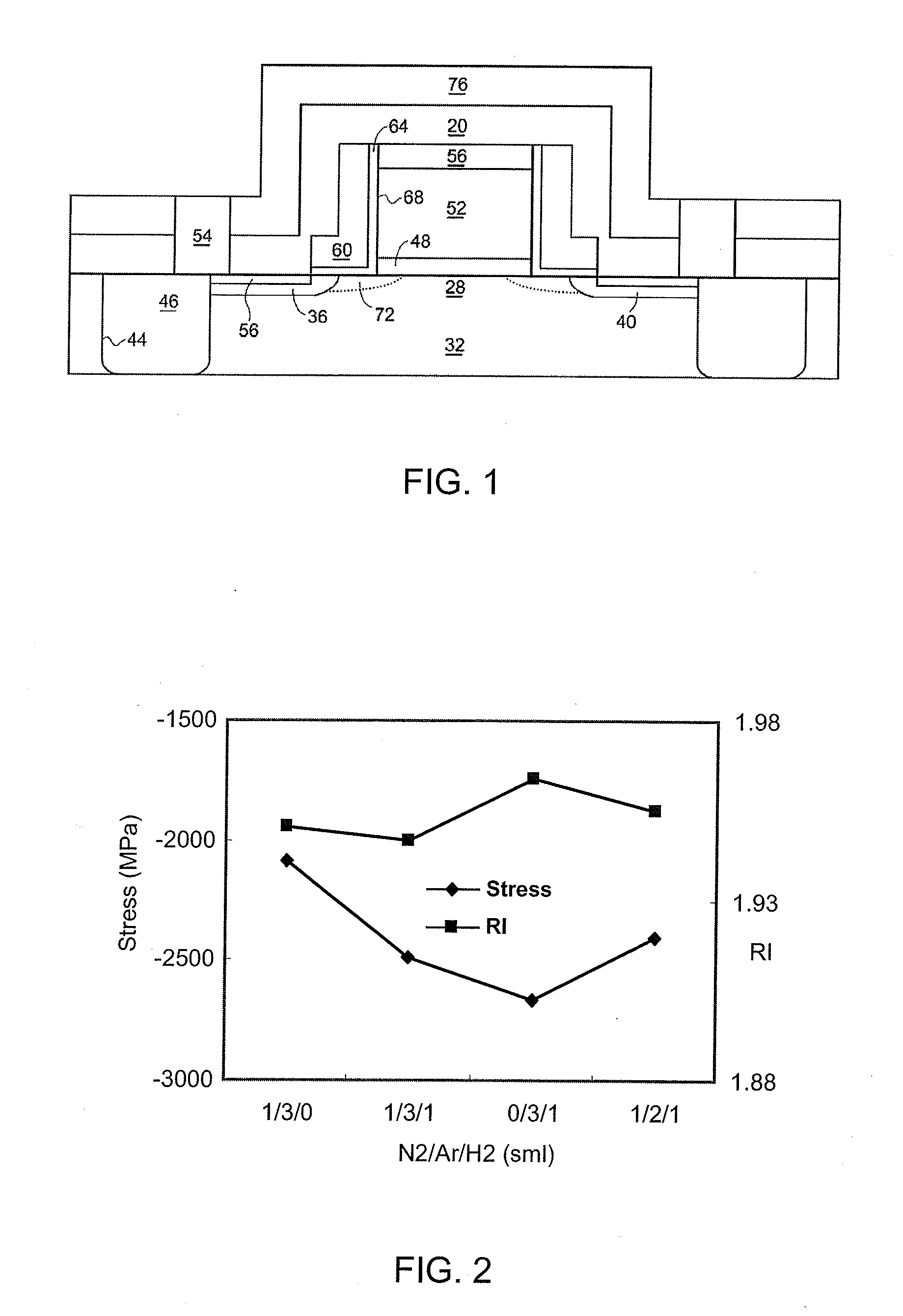

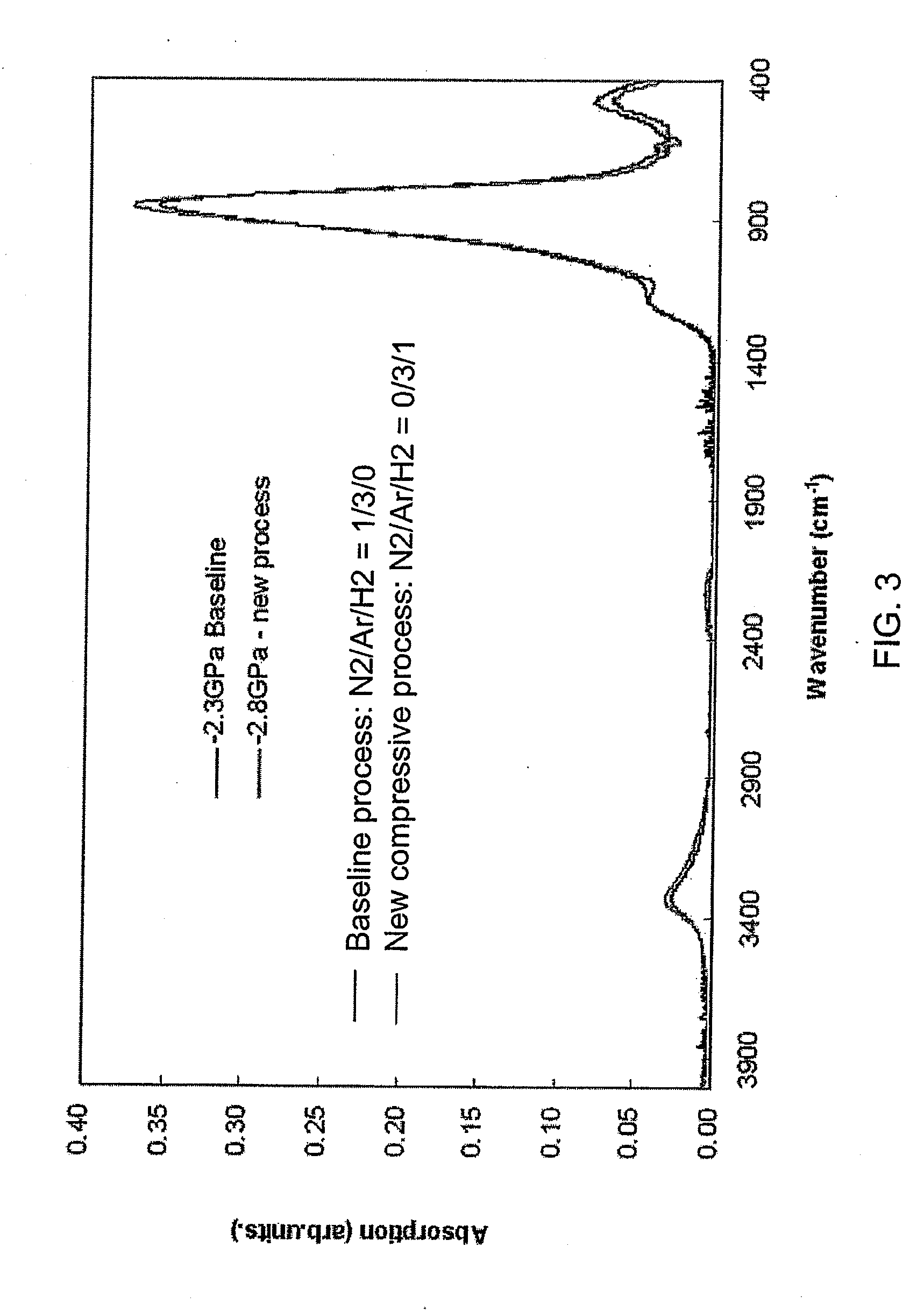

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with alternative embodiments, a deposited silicon nitride film is exposed to curing with ultraviolet (UV) radiation at an elevated temperature, thereby helping remove hydrogen from the film and increasing film stress. In accordance with still other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

InactiveUS20120196450A1Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with some embodiments, a deposited silicon nitride film is exposed to curing with plasma and ultraviolet (UV) radiation, thereby helping remove hydrogen from the film and increasing film stress. In accordance with other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

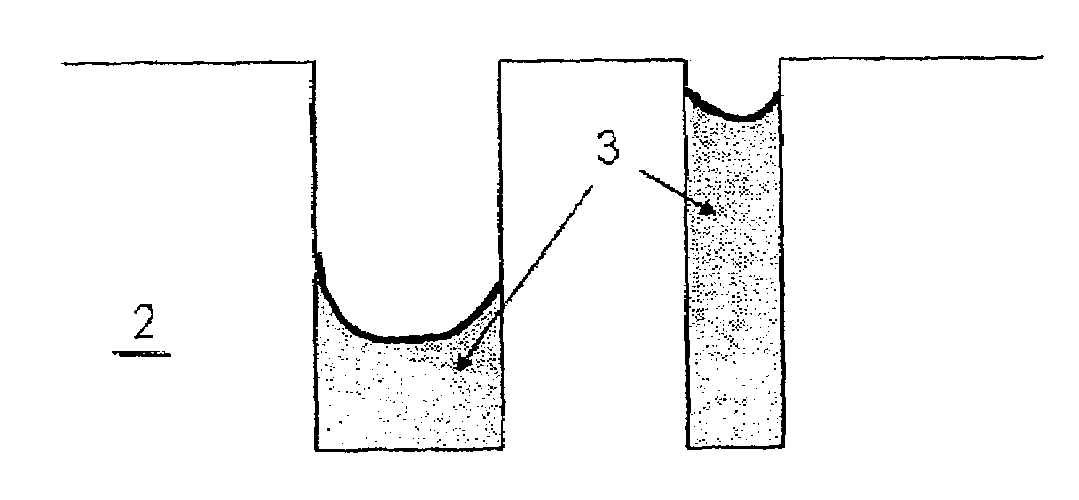

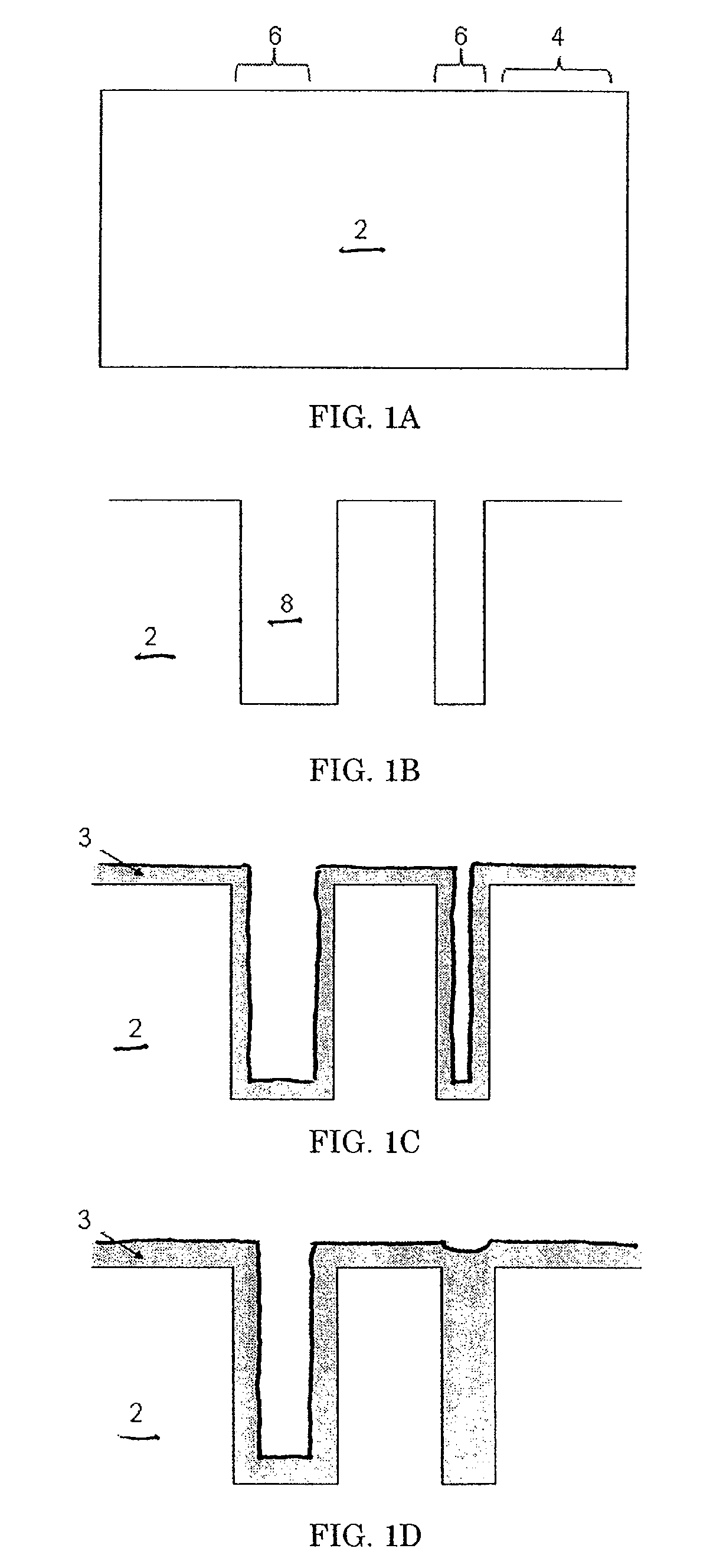

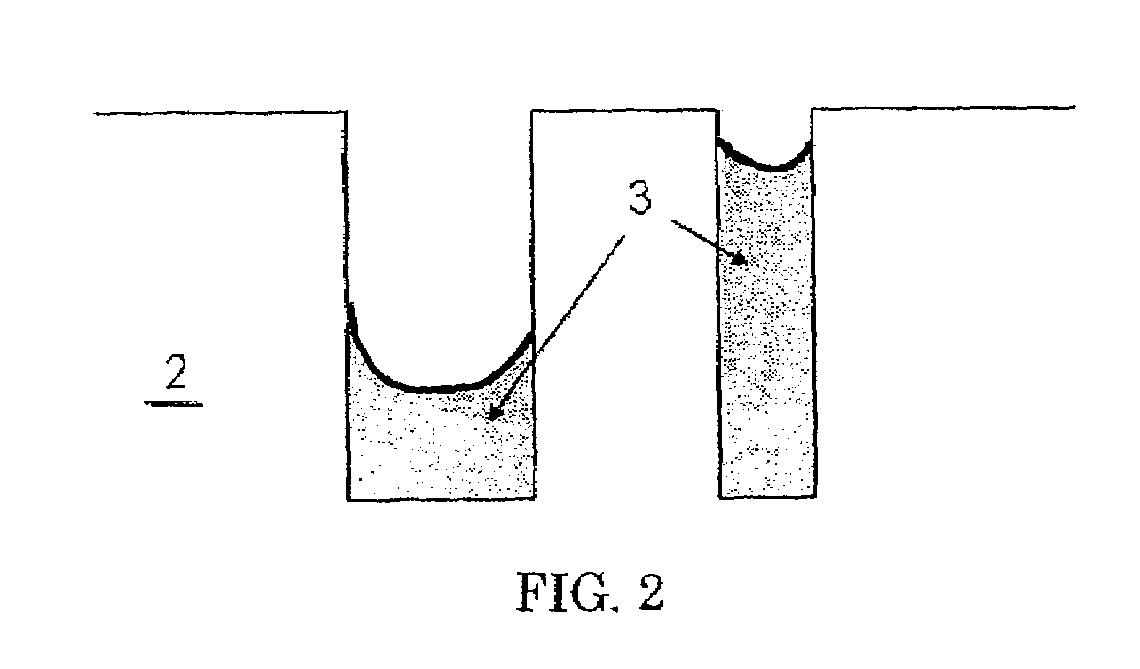

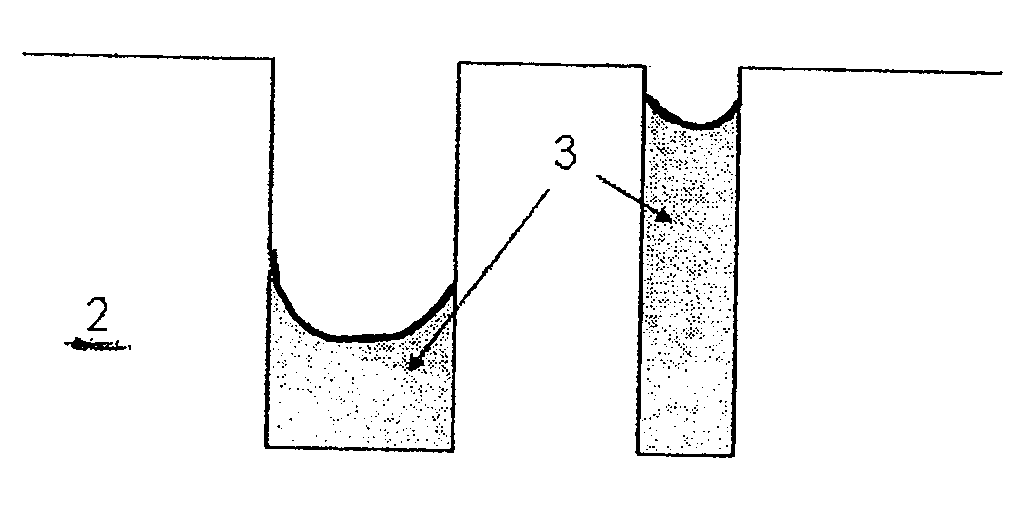

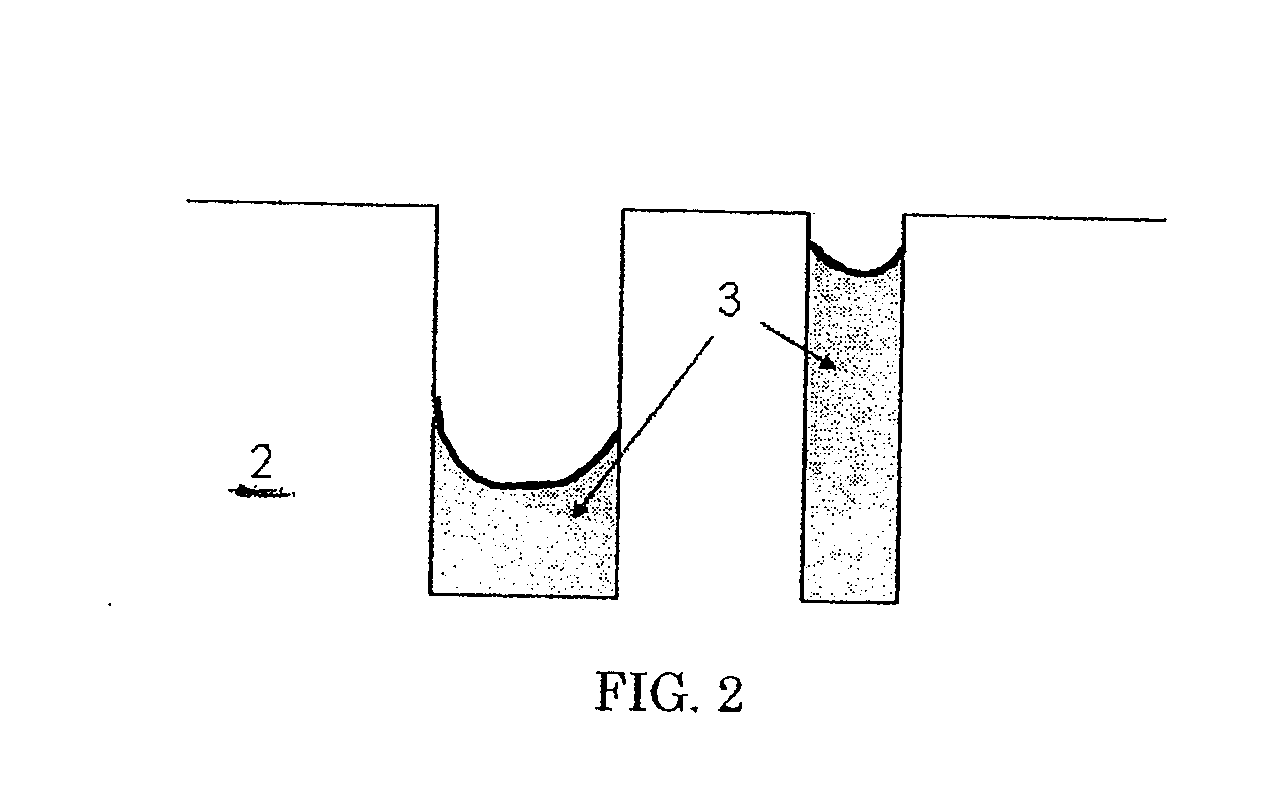

Device isolation technology on semiconductor substrate

A method of forming device isolation regions on a trench-formed silicon substrate and removing residual carbon therefrom includes providing a flowable, insulative material constituted by silicon, carbon, nitrogen, hydrogen, oxygen or any combination of two or more thereof; forming a thin insulative layer, by using the flowable, insulative material, in a trench located on a semiconductor substrate wherein the flowable, insulative material forms a conformal coating in a silicon and nitrogen rich condition whereas in a carbon rich condition, the flowable, insulative material vertically grows from the bottom of the trenches; and removing the residual carbon deposits from the flowable, insulative material by multi-step curing, such as O2 thermal annealing, ozone UV curing followed by N2 thermal annealing.

Owner:ASM JAPAN

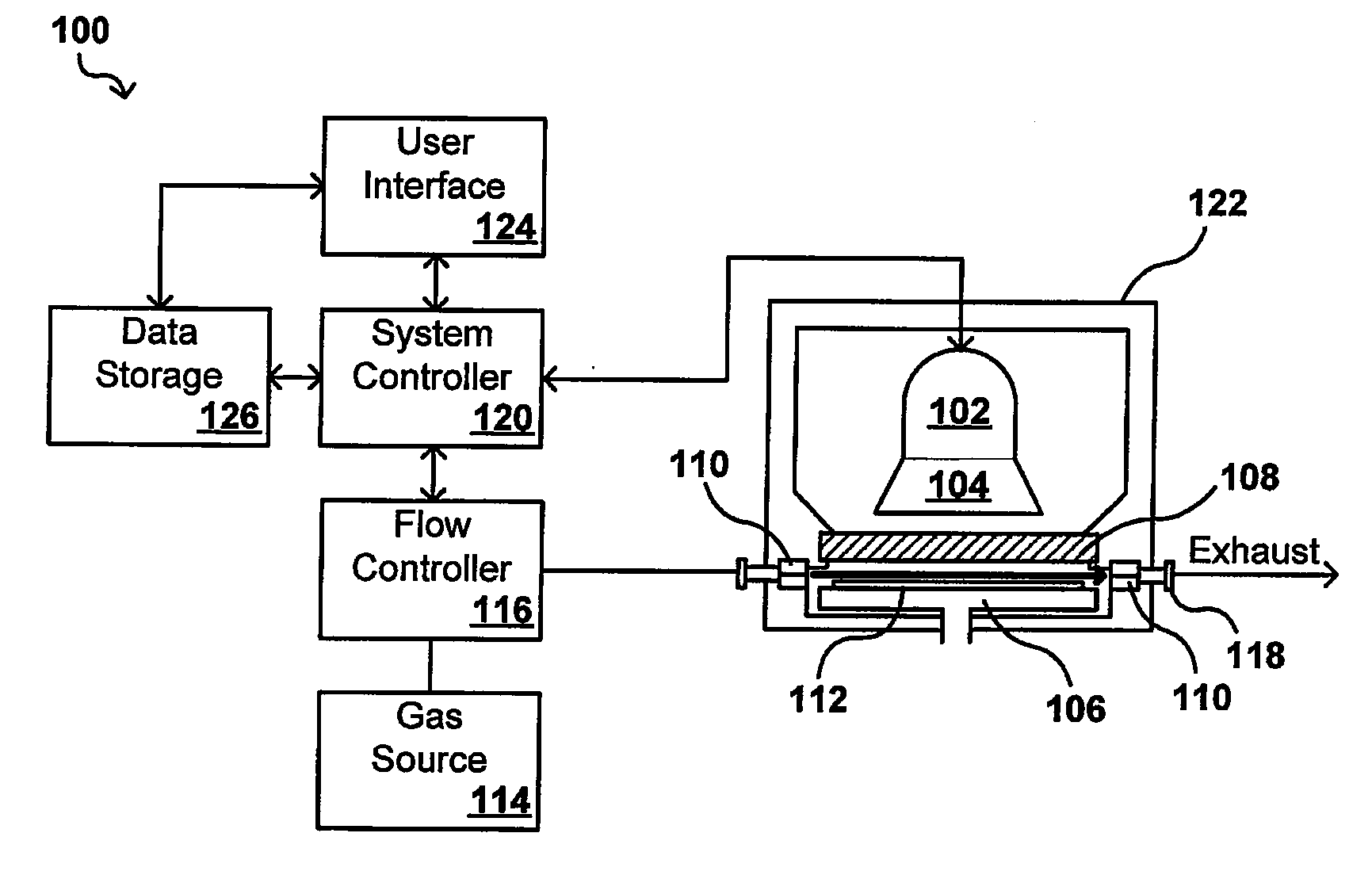

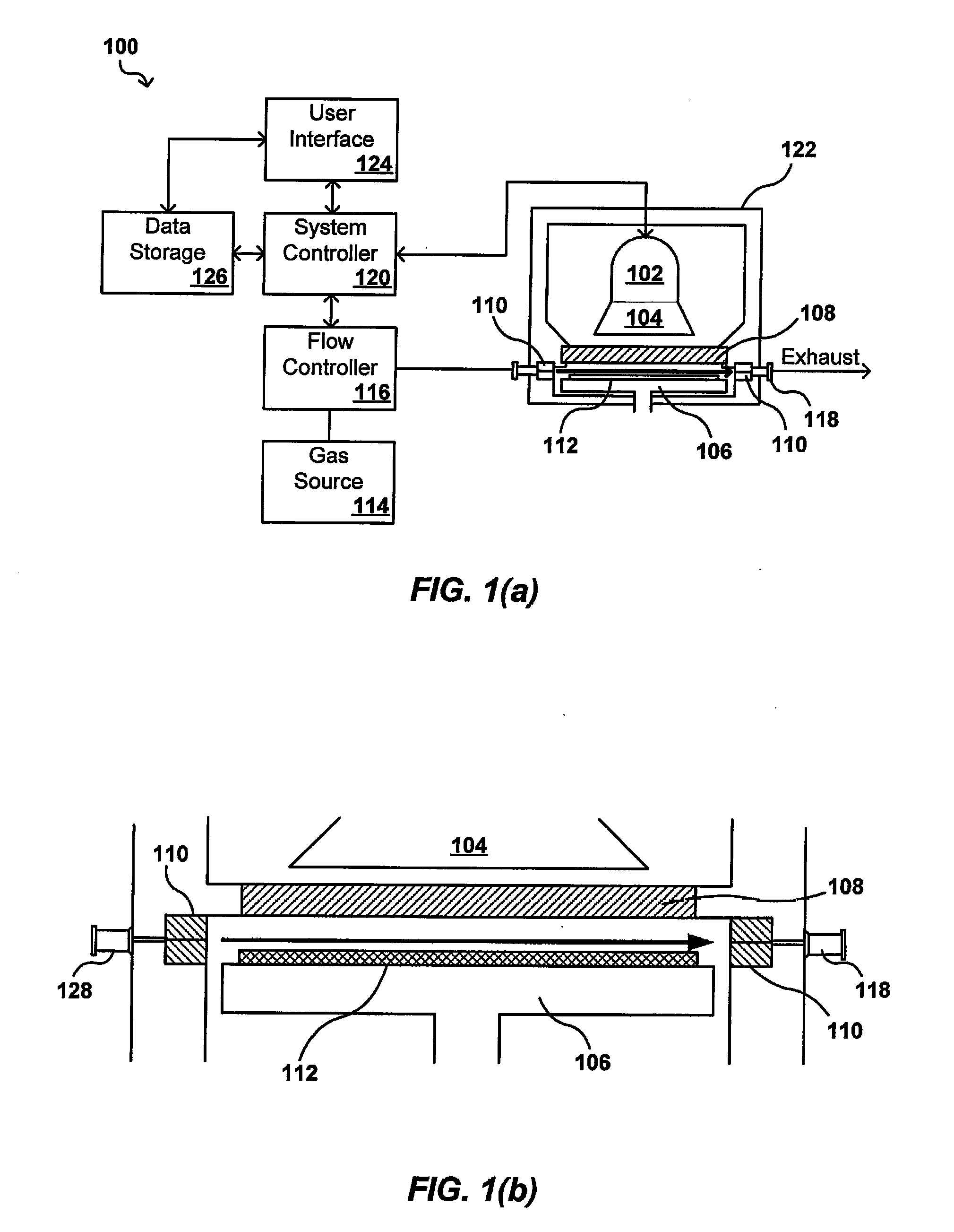

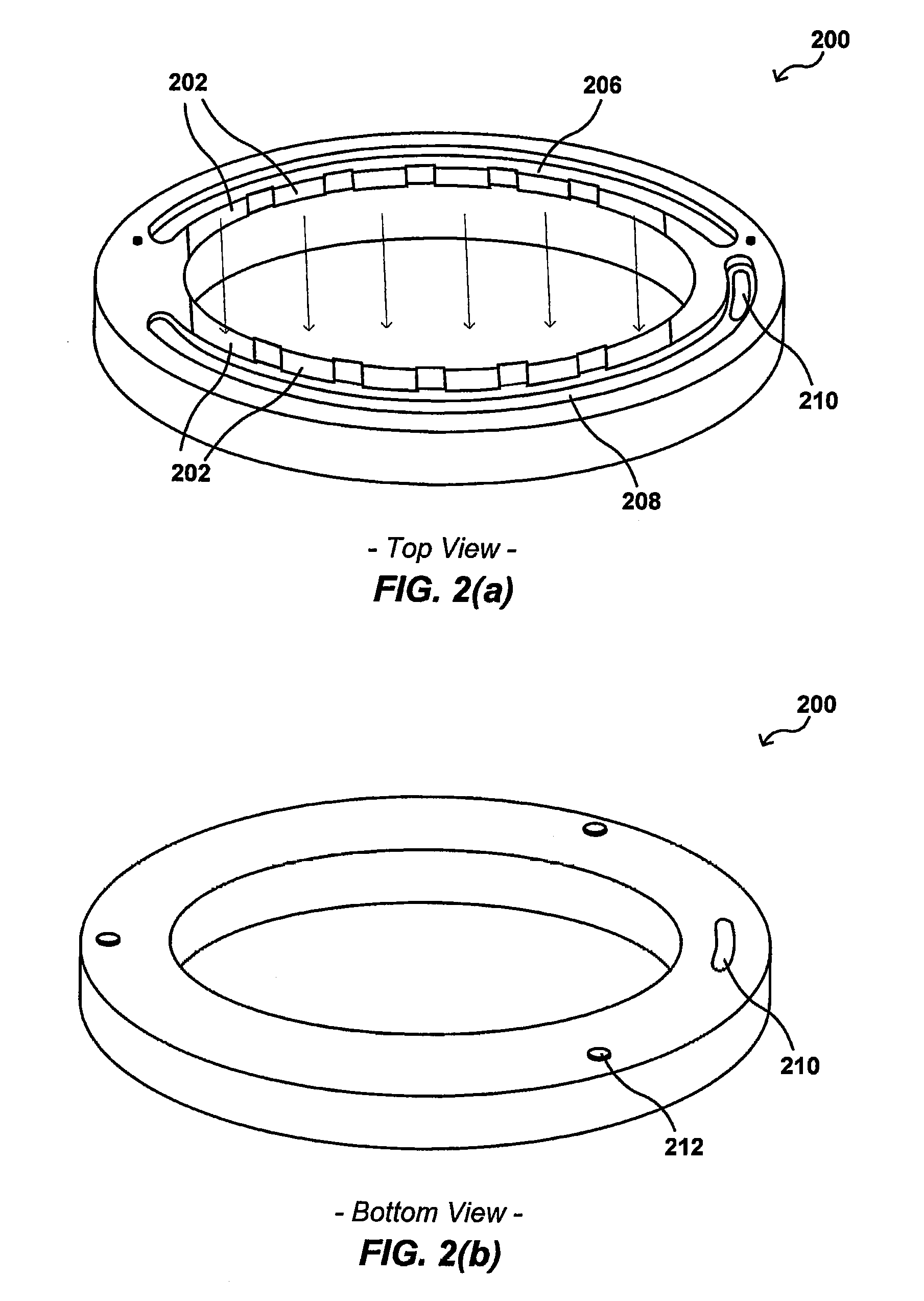

Increased tool utilization/reduction in mwbc for UV curing chamber

ActiveUS20070298362A1Avoid collectingHigh emissivitySemiconductor/solid-state device manufacturingCharge manipulationUV curingInjection port

A pump liner is used to direct a laminar flow of purge gas across a workpiece to remove contaminants or species outgassed or otherwise produced by the workpiece during processing. The pump liner can take the form of a ring having a plurality of injection ports, such as slits of a variety of shapes and / or sizes, opposite a plurality of receiving ports in order to provide the laminar flow. The flow of purge gas is sufficient to carry a contaminant or outgassed species from the processing chamber in order to prevent the collection of the contaminants on components of the chamber. The pump liner can be heated, via conduction and irradiation from a radiation source, for example, in order to prevent the condensation of species on the liner. The pump liner also can be anodized or otherwise processed in order to increase the emissivity of the liner.

Owner:APPLIED MATERIALS INC

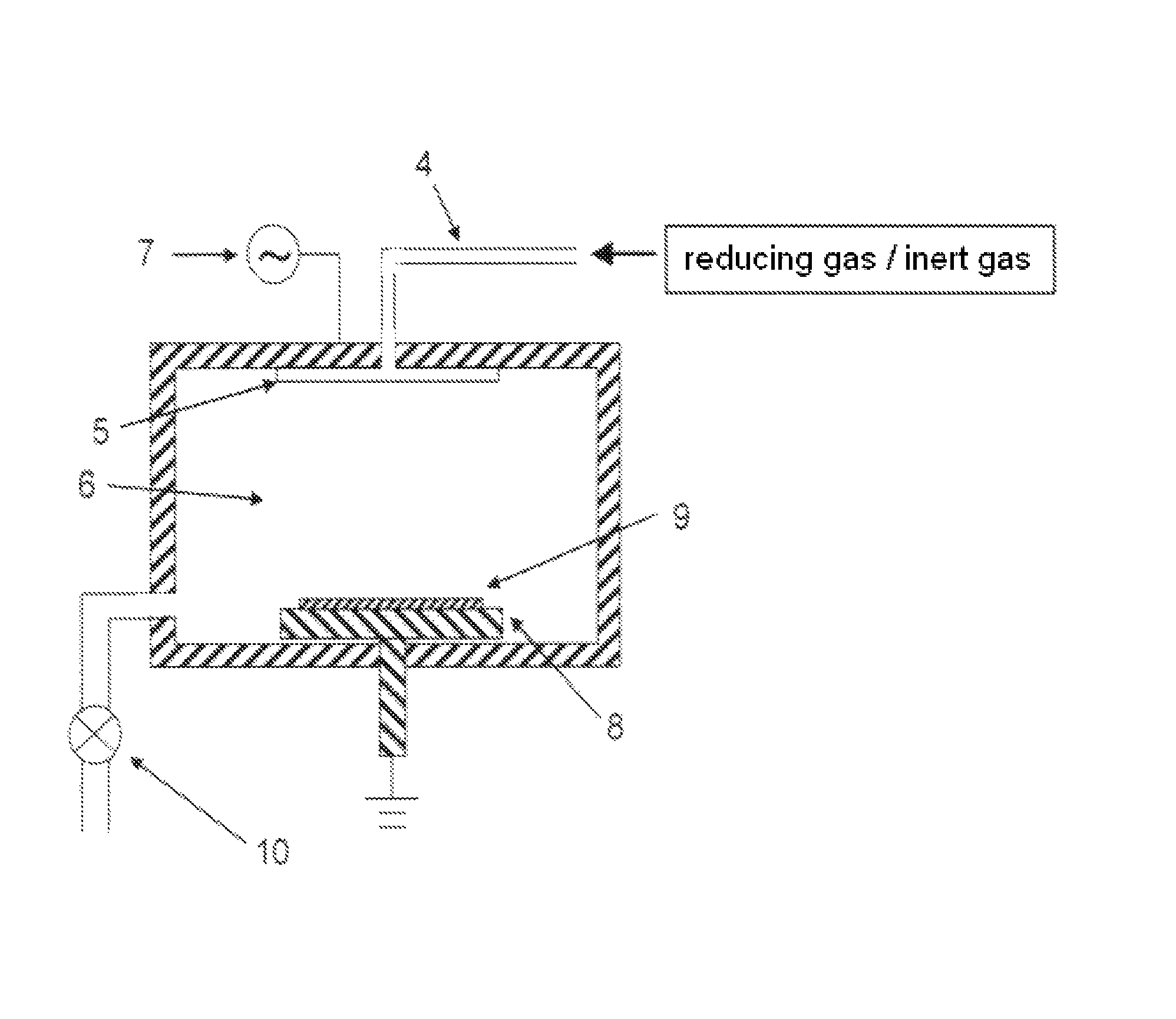

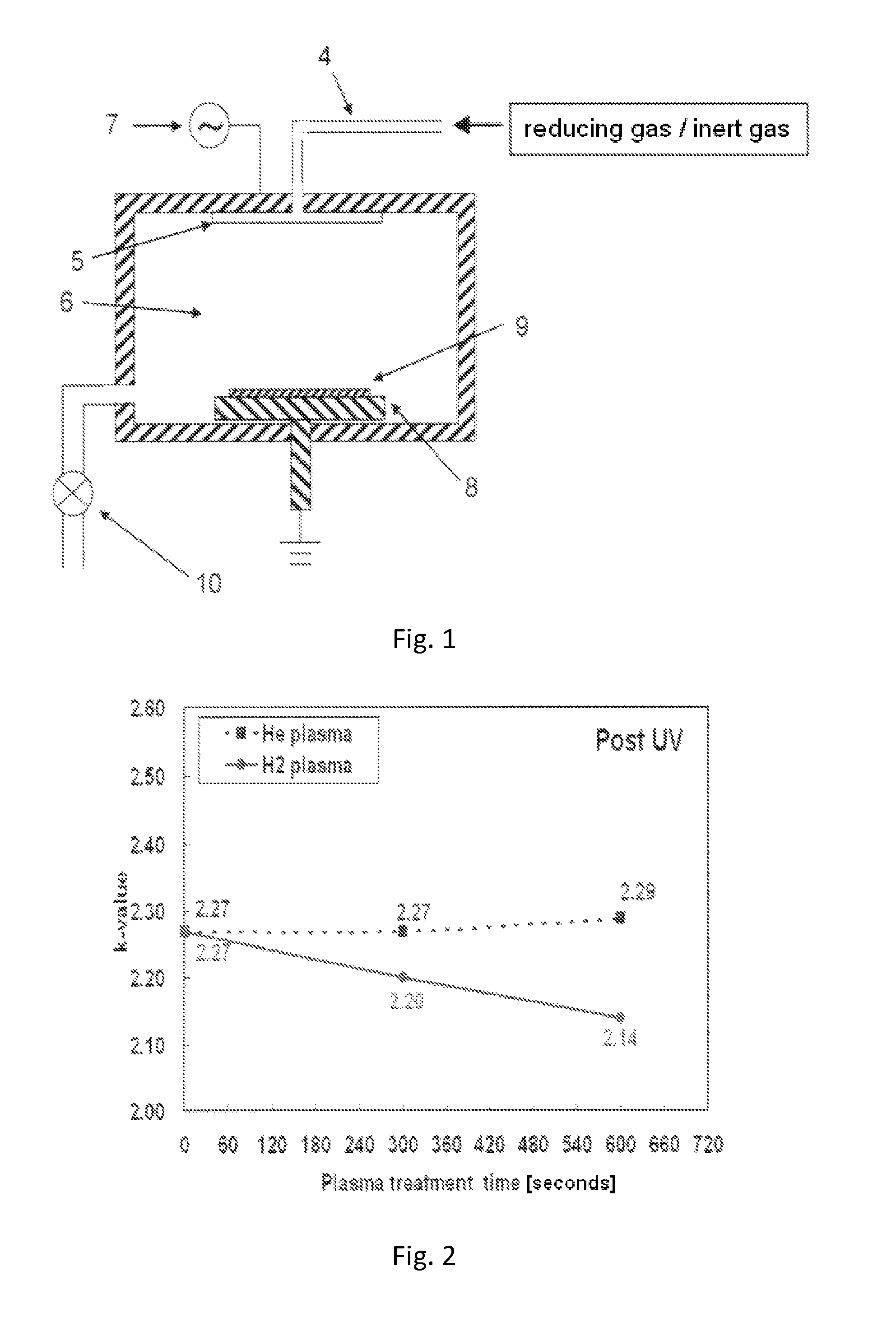

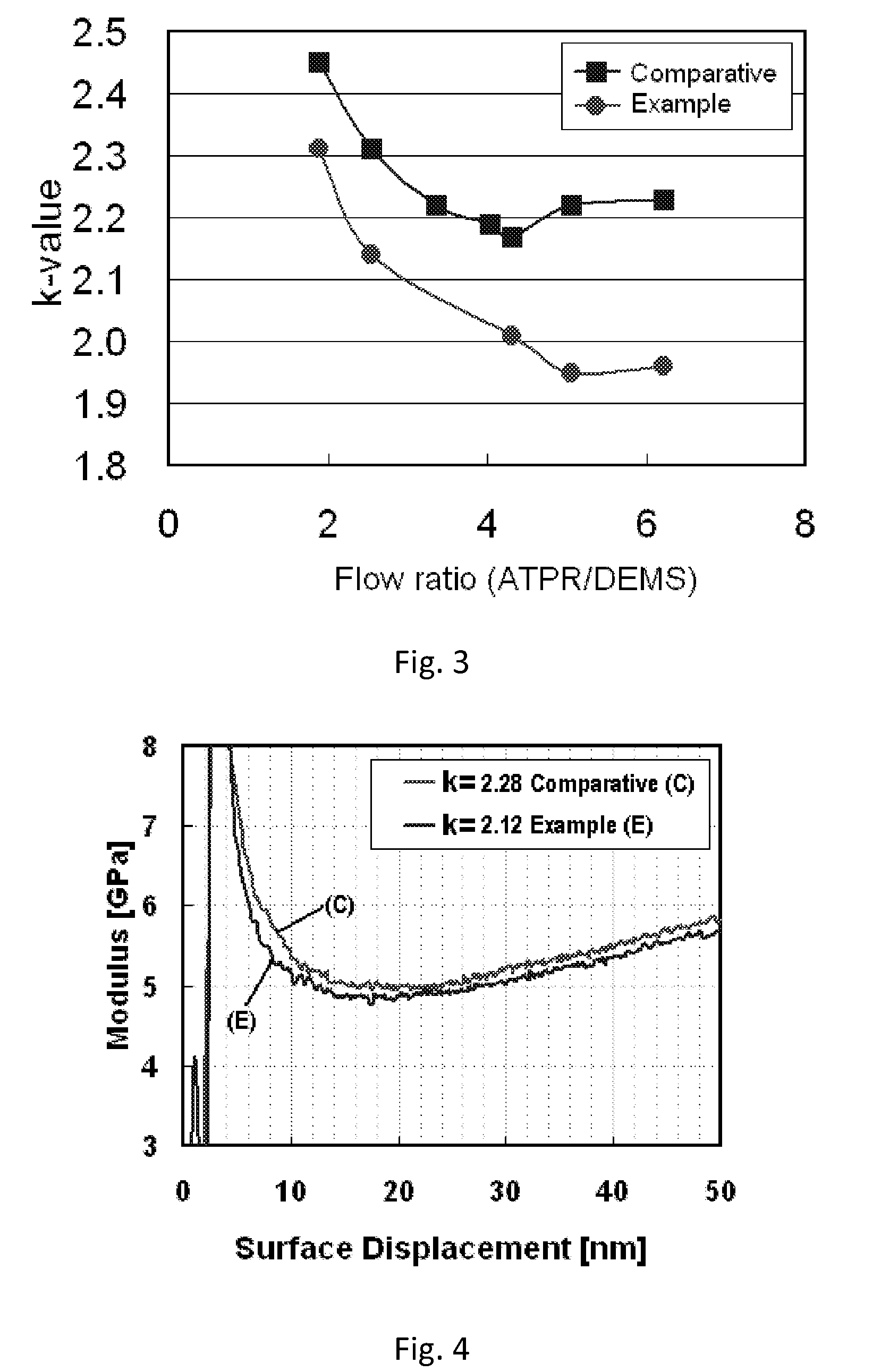

Method for reducing dielectric constant of film using direct plasma of hydrogen

ActiveUS8551892B2Low dielectric constantMaintain mechanical strengthElectric shock equipmentsSemiconductor/solid-state device detailsDielectricCapacitance

A method for reducing a dielectric constant of a film includes (i) forming a dielectric film on a substrate; (ii) treating a surface of the film without film formation, and (III) curing the film. Step (i) includes providing a dielectric film containing a porous matrix and a porogen on a substrate, step (ii) includes, prior to or subsequent to step (iii), treating the dielectric film with charged species of hydrogen generated by capacitively-coupled plasma without film deposition to reduce a dielectric constant of the dielectric film, and step (iii) includes UV-curing the dielectric film to remove at least partially the porogen from the film.

Owner:ASM JAPAN

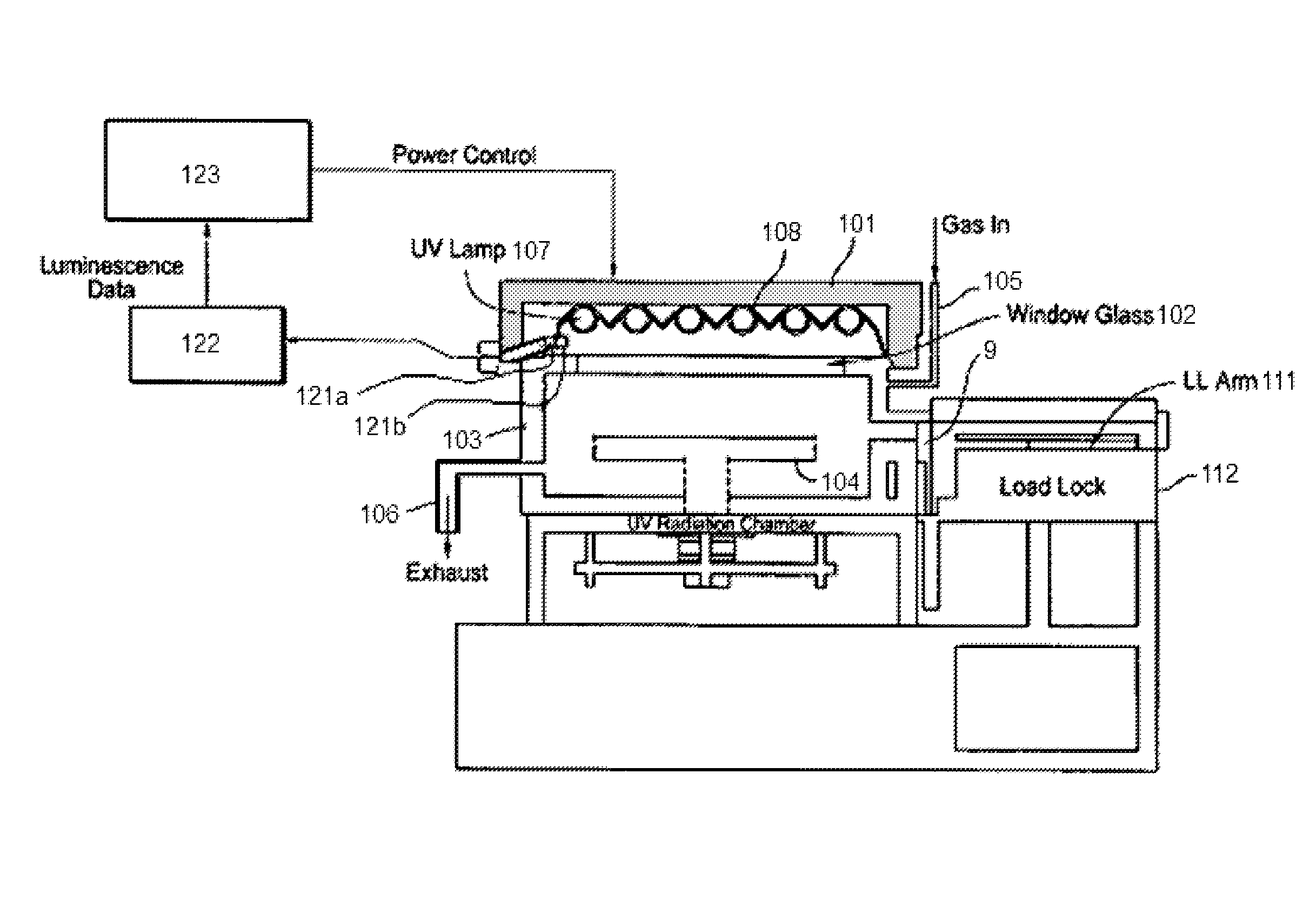

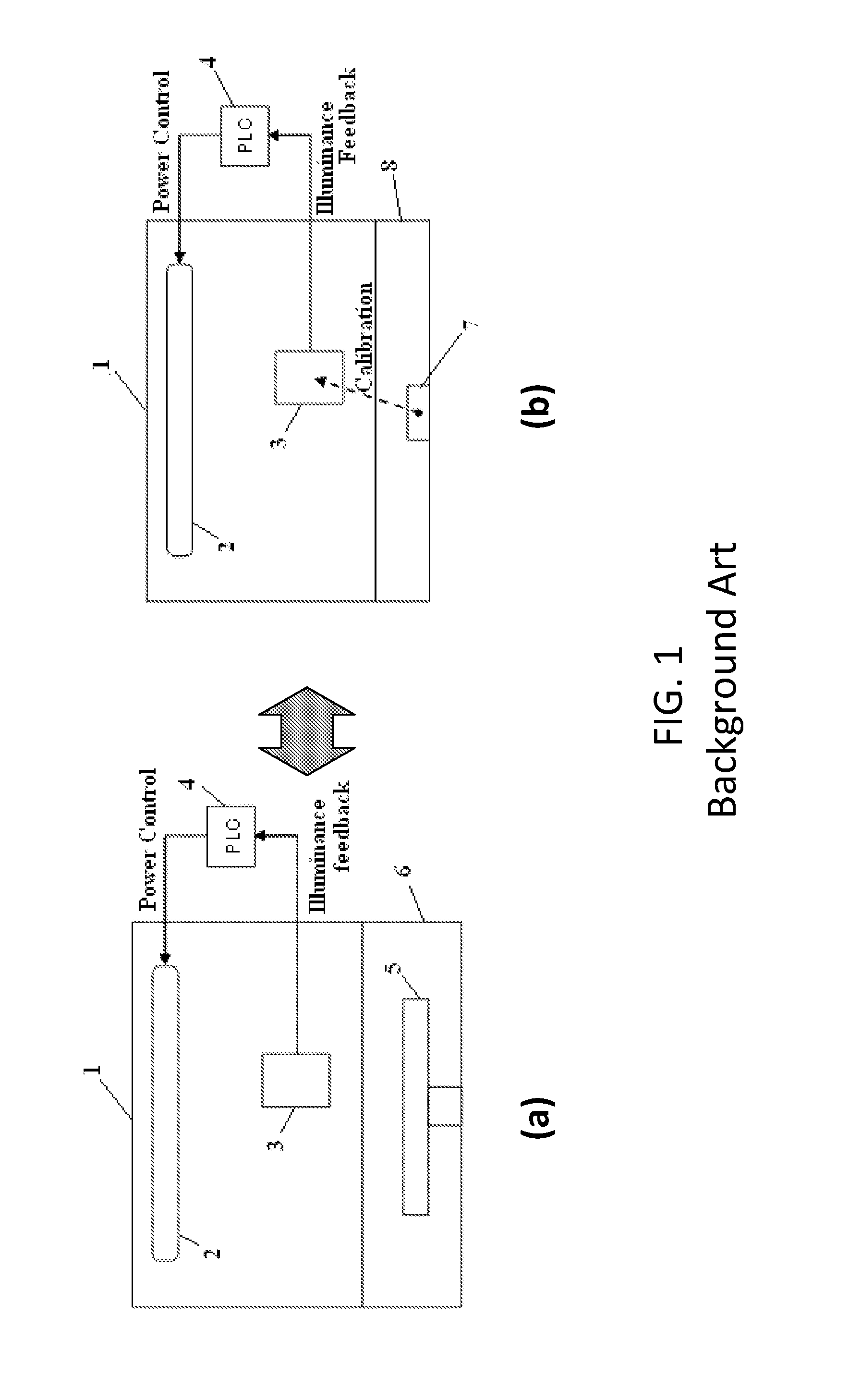

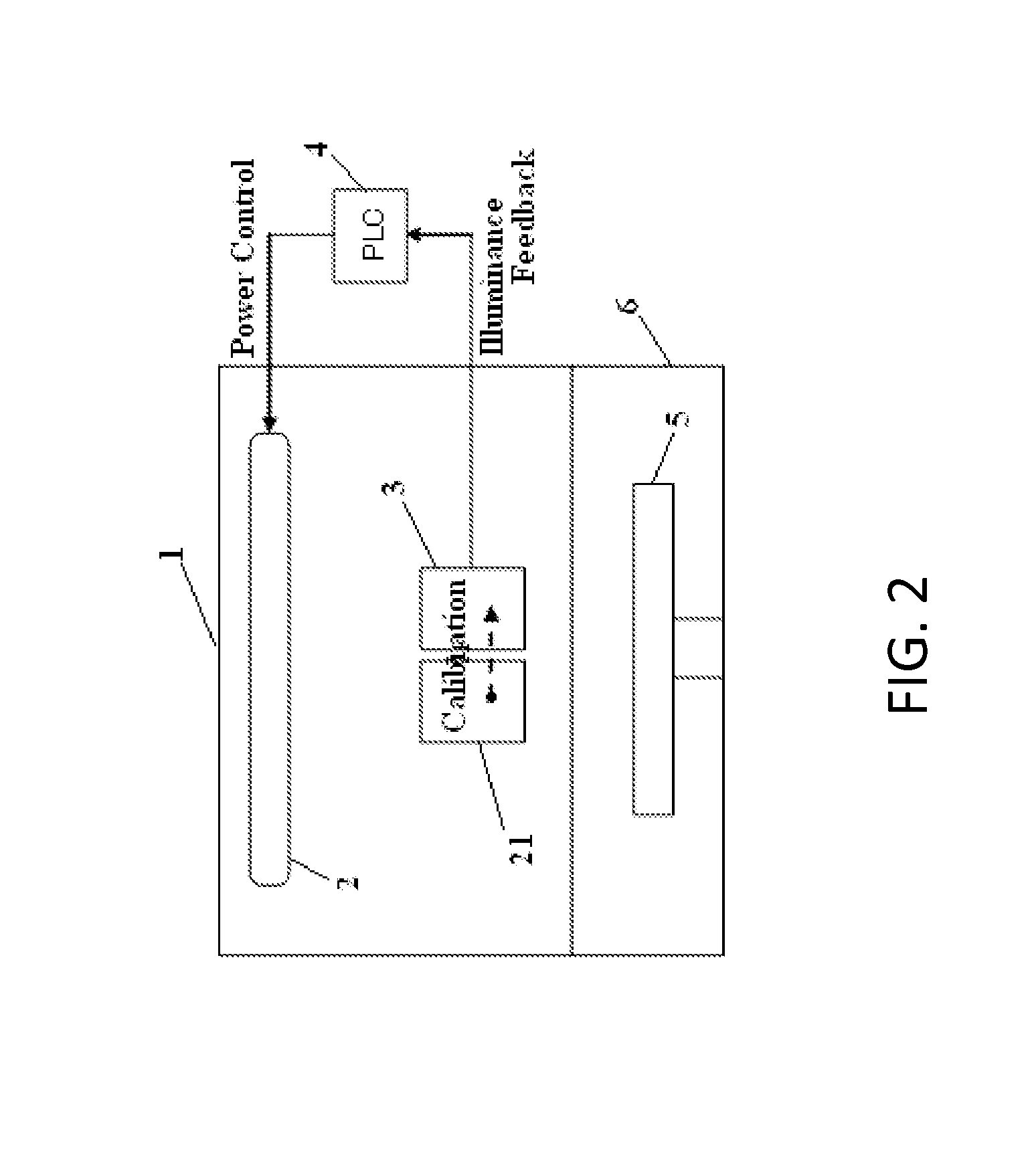

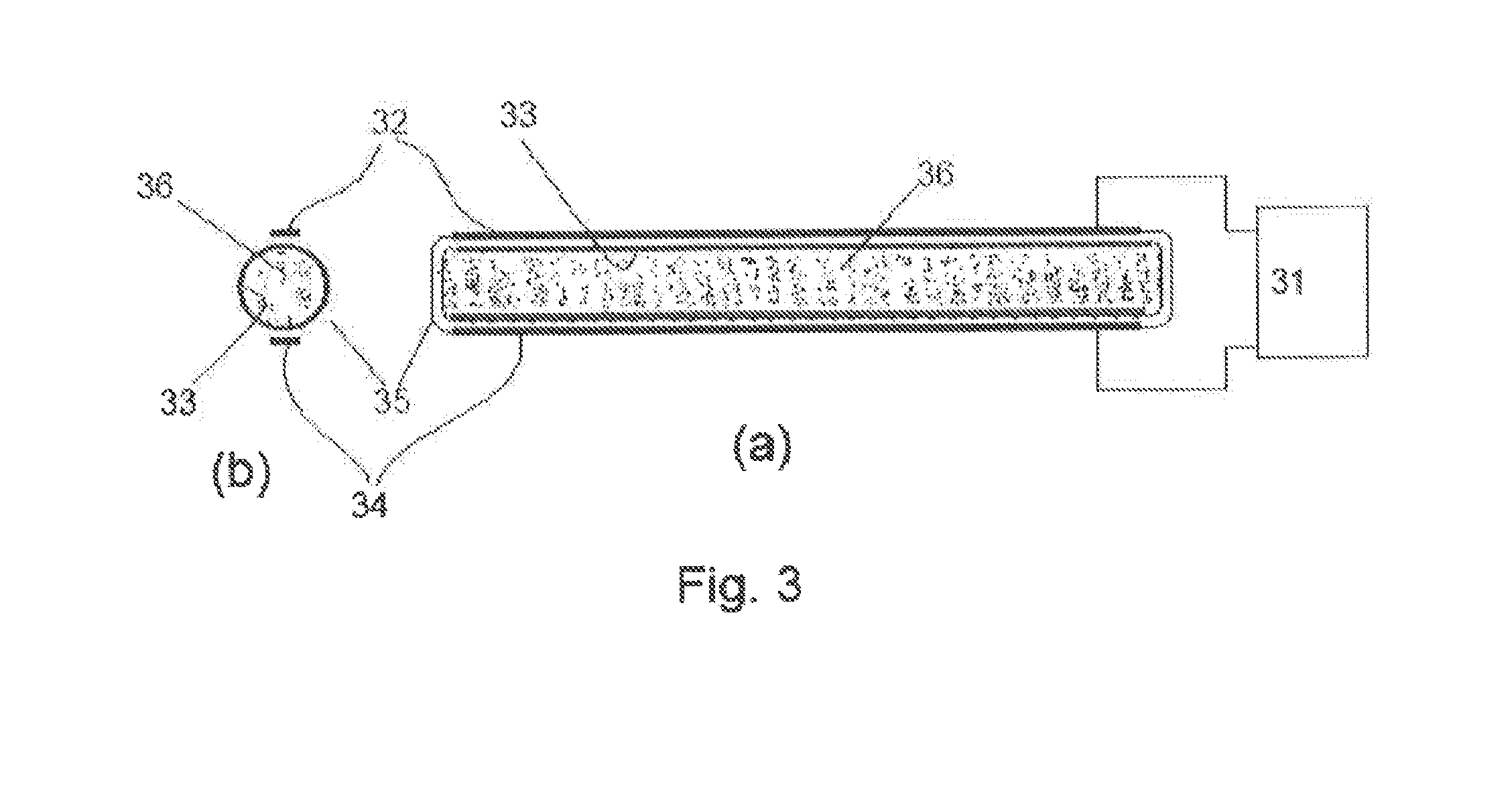

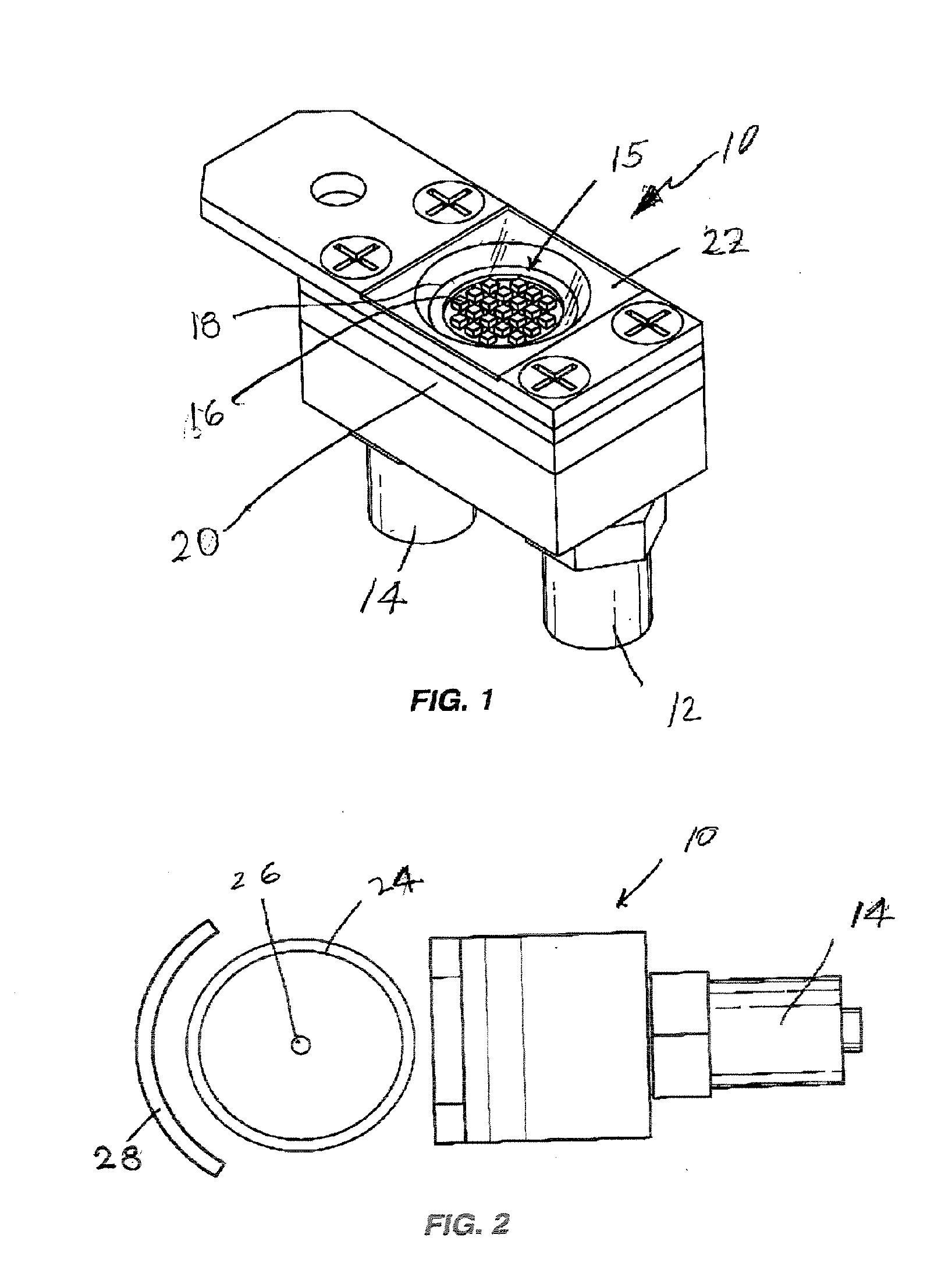

Calibration method of UV sensor for UV curing

ActiveUS8466411B2Reduce exposureEliminate errorsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingUV curingUltraviolet

A method for managing UV irradiation for treating substrates in the course of treating multiple substrates consecutively with UV light, includes: exposing a first UV sensor to the UV light at first intervals to measure illumination intensity of the UV light so as to adjust the illumination intensity to a desired level based on the measured illumination intensity; and exposing a second UV sensor to the UV light at second intervals to measure illumination intensity of the UV light so as to calibrate the first UV sensor by equalizing the illumination intensity measured by the first UV sensor substantially with the illumination intensity measured by the second UV sensor, wherein each second interval is longer than each first interval.

Owner:ASM JAPAN

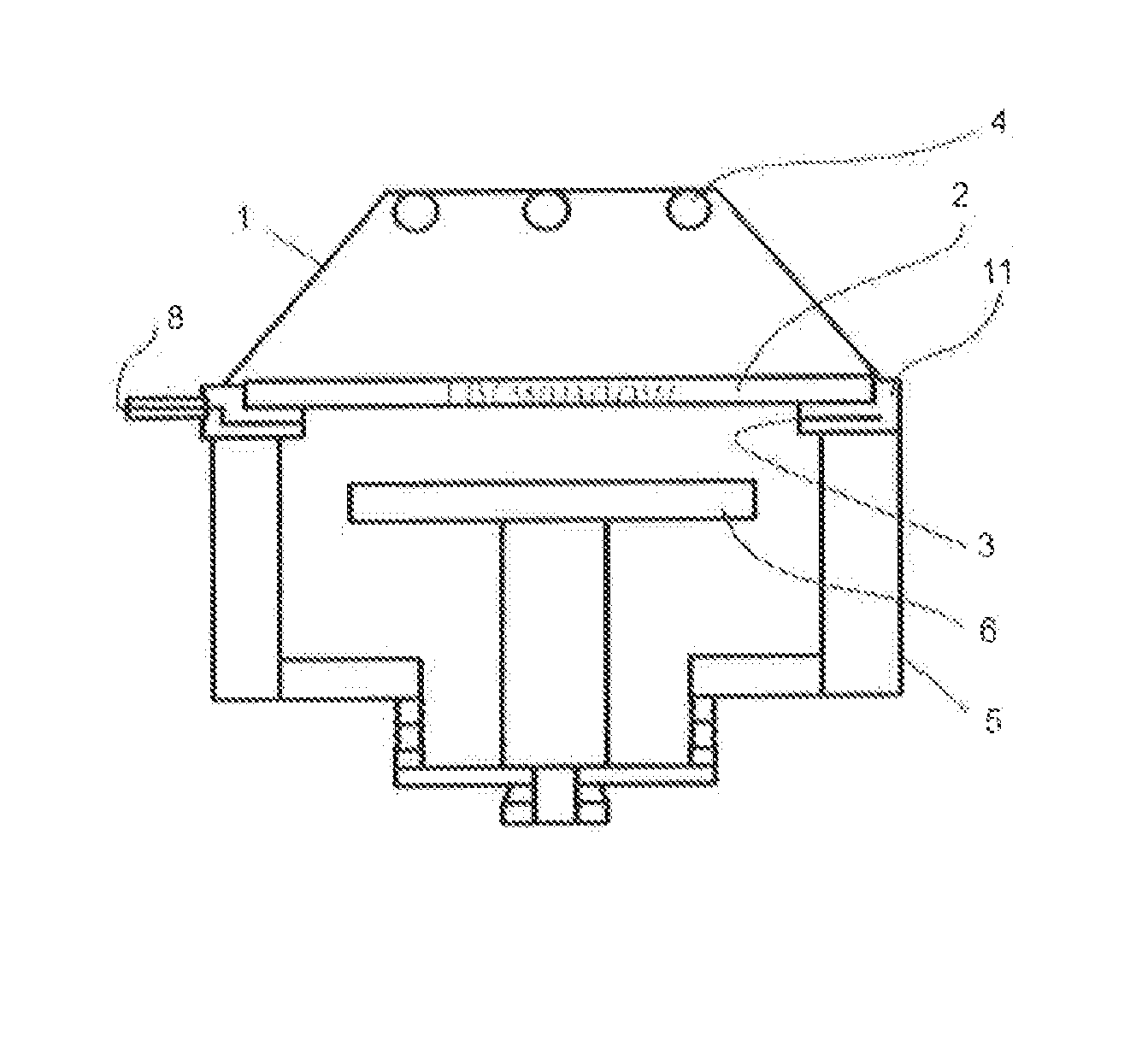

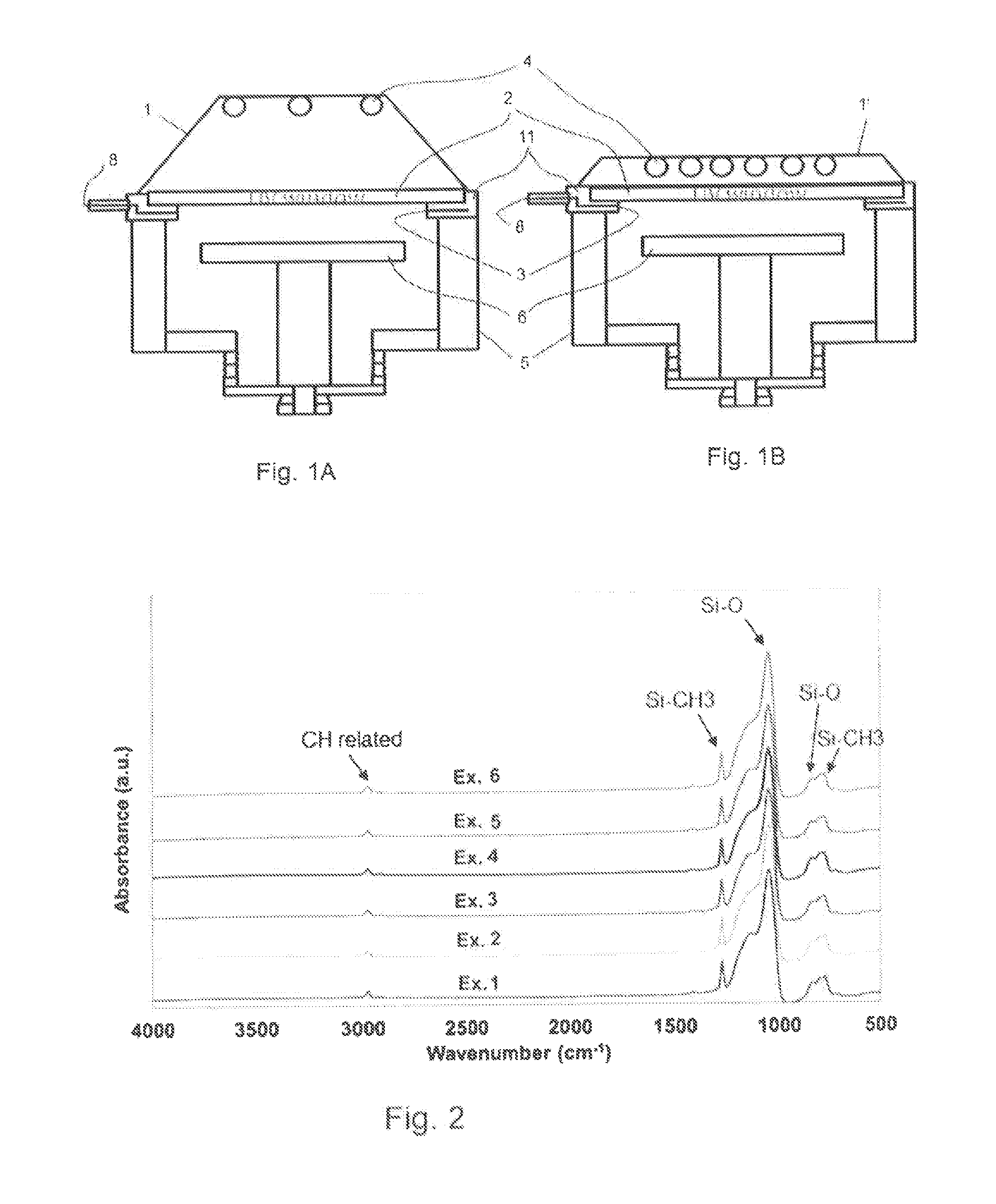

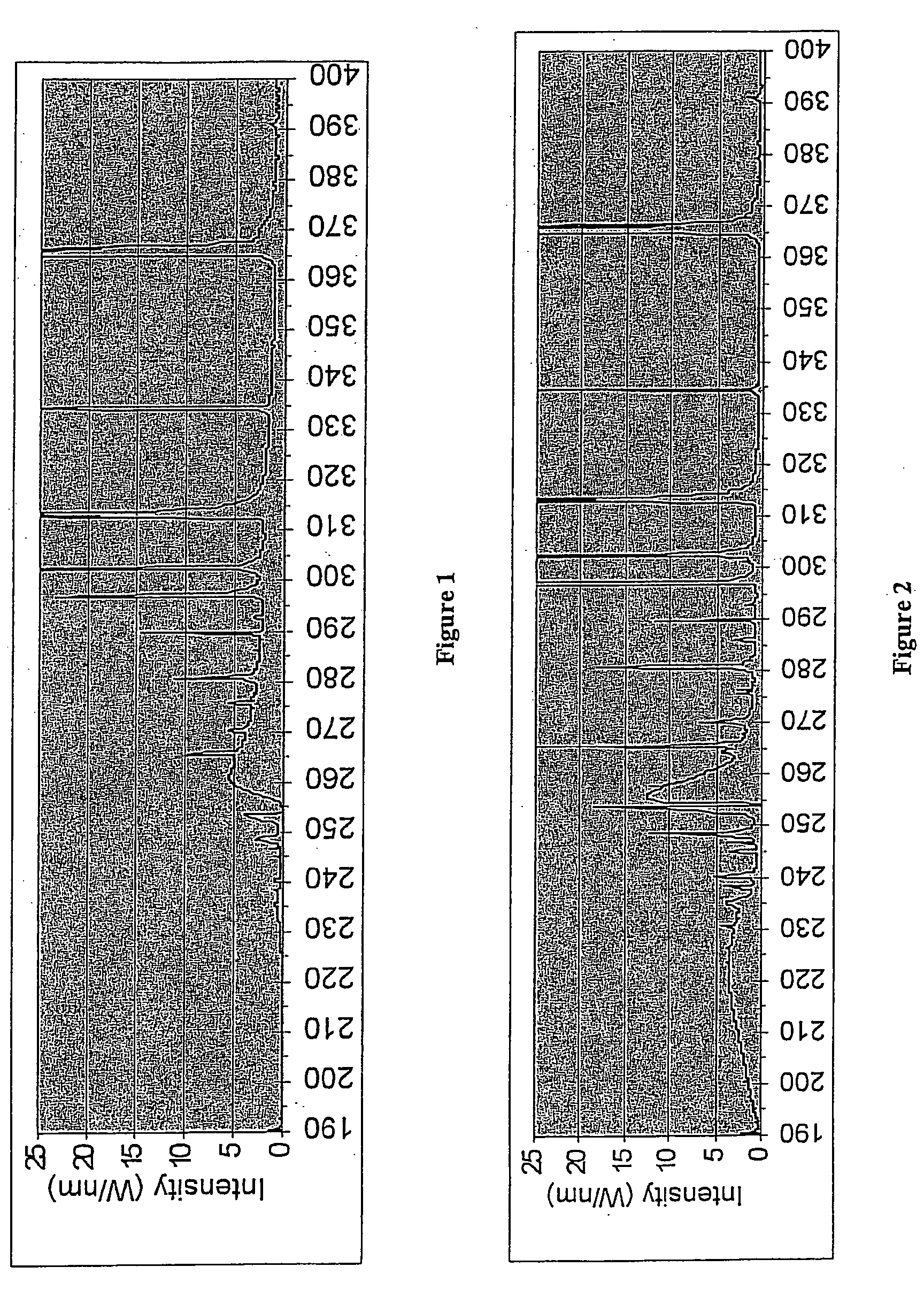

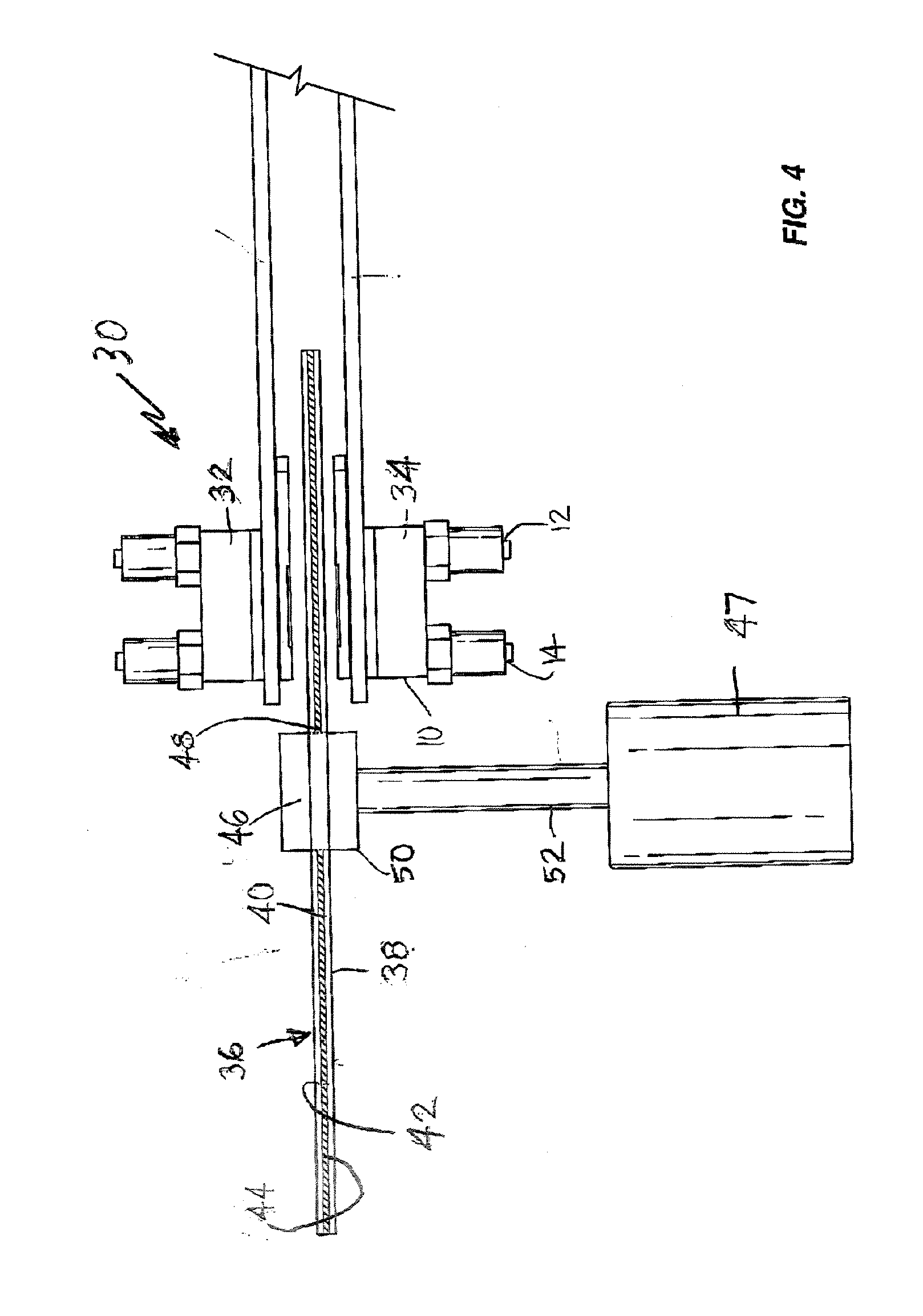

UV-Curing Apparatus Provided With Wavelength-Tuned Excimer Lamp and Method of Processing Semiconductor Substrate Using Same

InactiveUS20140099798A1Prevents unnecessary riseLow costMaterial analysis by optical meansSemiconductor/solid-state device manufacturingFluorescenceUltraviolet

A UV irradiation apparatus for processing a semiconductor substrate includes: a UV lamp unit having at least one dielectric barrier discharge excimer lamp which is constituted by a luminous tube containing a rare gas wherein an inner surface of the luminous tube is coated with a fluorescent substance having a peak emission spectrum in a wavelength range of 190 nm to 350 nm; and a reaction chamber disposed under the UV lamp unit and connected thereto via a transmission window.

Owner:ASM IP HLDG BV

Device isolation technology on semiconductor substrate

A method of forming device isolation regions on a trench-formed silicon substrate and removing residual carbon therefrom includes providing a flowable, insulative material constituted by silicon, carbon, nitrogen, hydrogen, oxygen or any combination of two or more thereof; forming a thin insulative layer, by using the flowable, insulative material, in a trench located on a semiconductor substrate wherein the flowable, insulative material forms a conformal coating in a silicon and nitrogen rich condition whereas in a carbon rich condition, the flowable, insulative material vertically grows from the bottom of the trenches; and removing the residual carbon deposits from the flowable, insulative material by multi-step curing, such as O2 thermal annealing, ozone UV curing followed by N2 thermal annealing.

Owner:ASM JAPAN

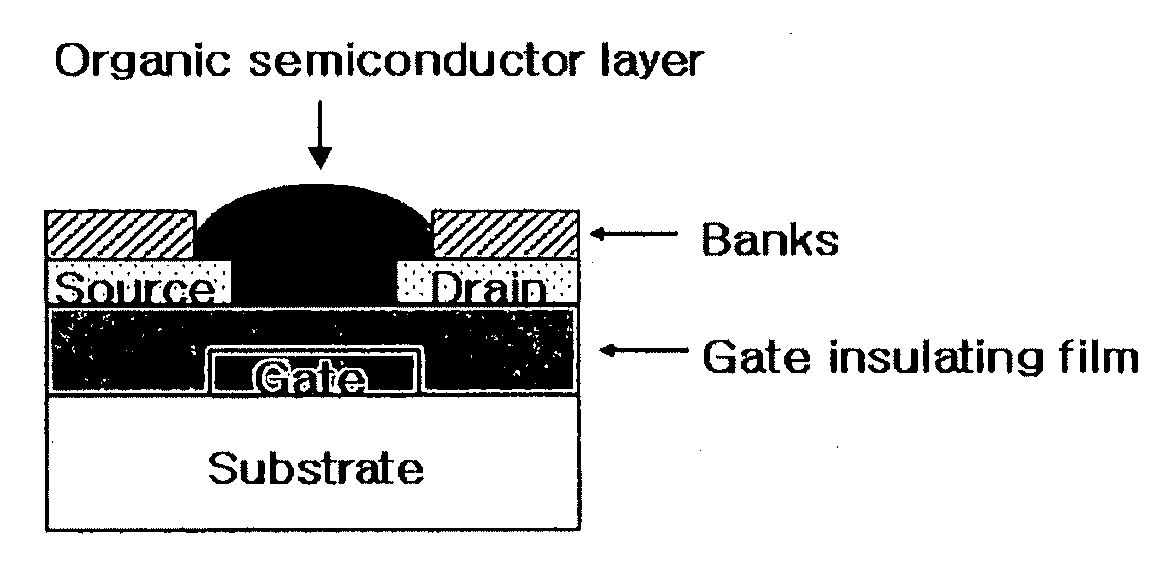

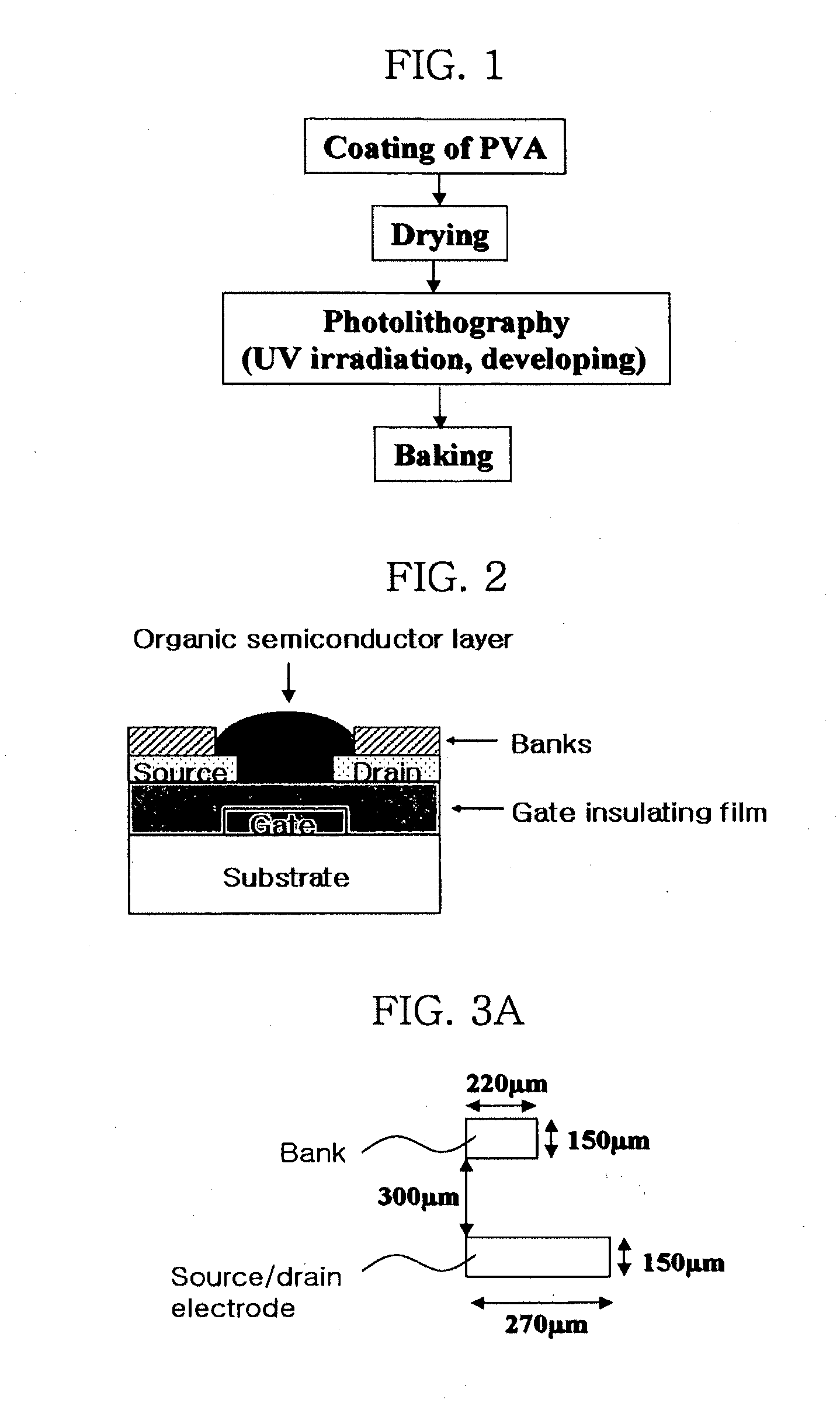

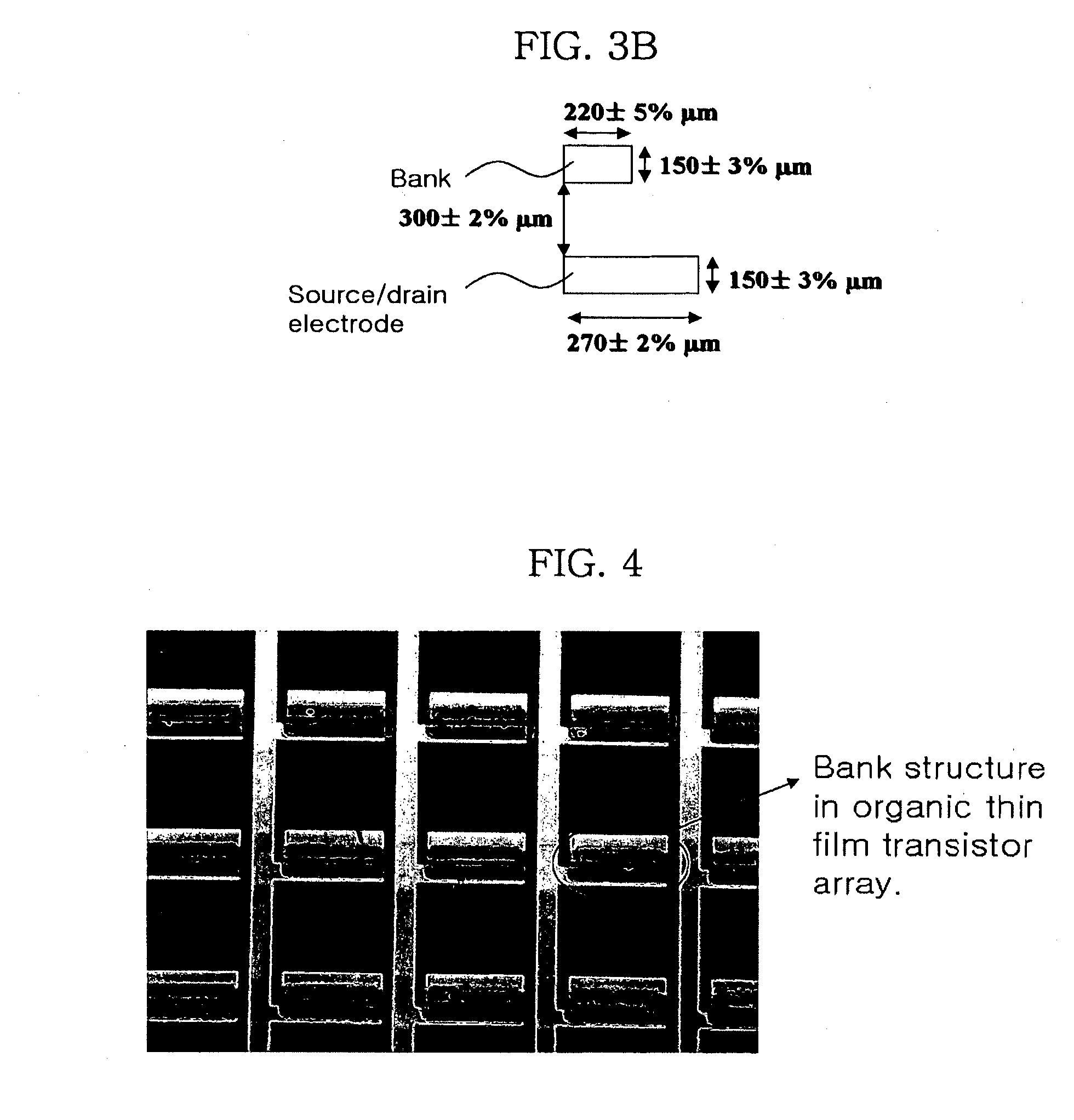

Methods of fabricating organic thin film transistors

InactiveUS20120122275A1Suppresses and eliminates adverse effectSuppress and eliminate degradationSolid-state devicesSemiconductor/solid-state device manufacturingOrganic structureSemiconductor materials

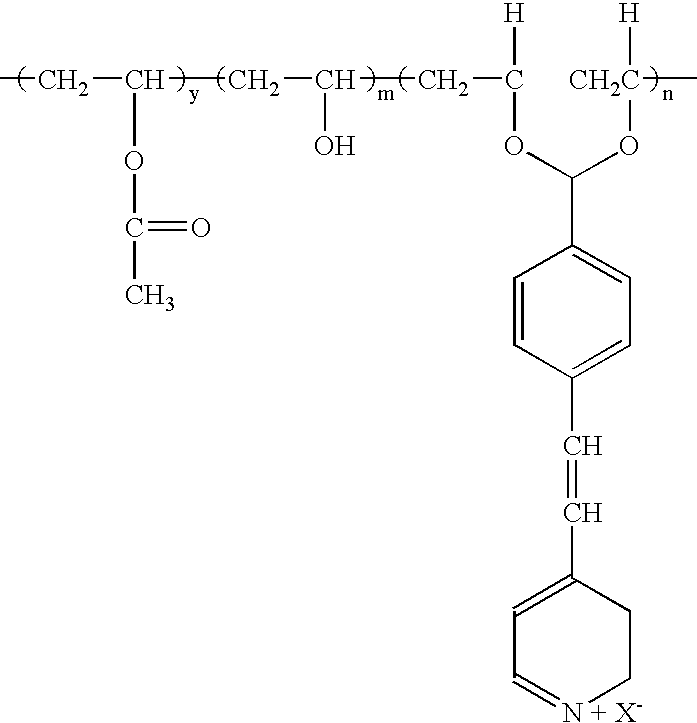

Disclosed is a method for forming banks during the fabrication of electronic devices incorporating an organic semiconductor material that includes preparing an aqueous coating composition having at least a water-soluble polymer, a UV curing agent and a water-soluble fluorine compound. This coating composition is applied to a substrate, exposed using UV radiation and then developed using an aqueous developing composition to form the bank pattern. Because the coating composition can be developed using an aqueous composition rather than an organic solvent or solvent system, the method tends to preserve the integrity of other organic structures present on the substrate. Further, the incorporation of the fluorine compound in the aqueous solution provides a degree of control over the contact angles exhibited on the surface of the bank pattern and thereby can avoid or reduce subsequent surface treatments.

Owner:SAMSUNG ELECTRONICS CO LTD

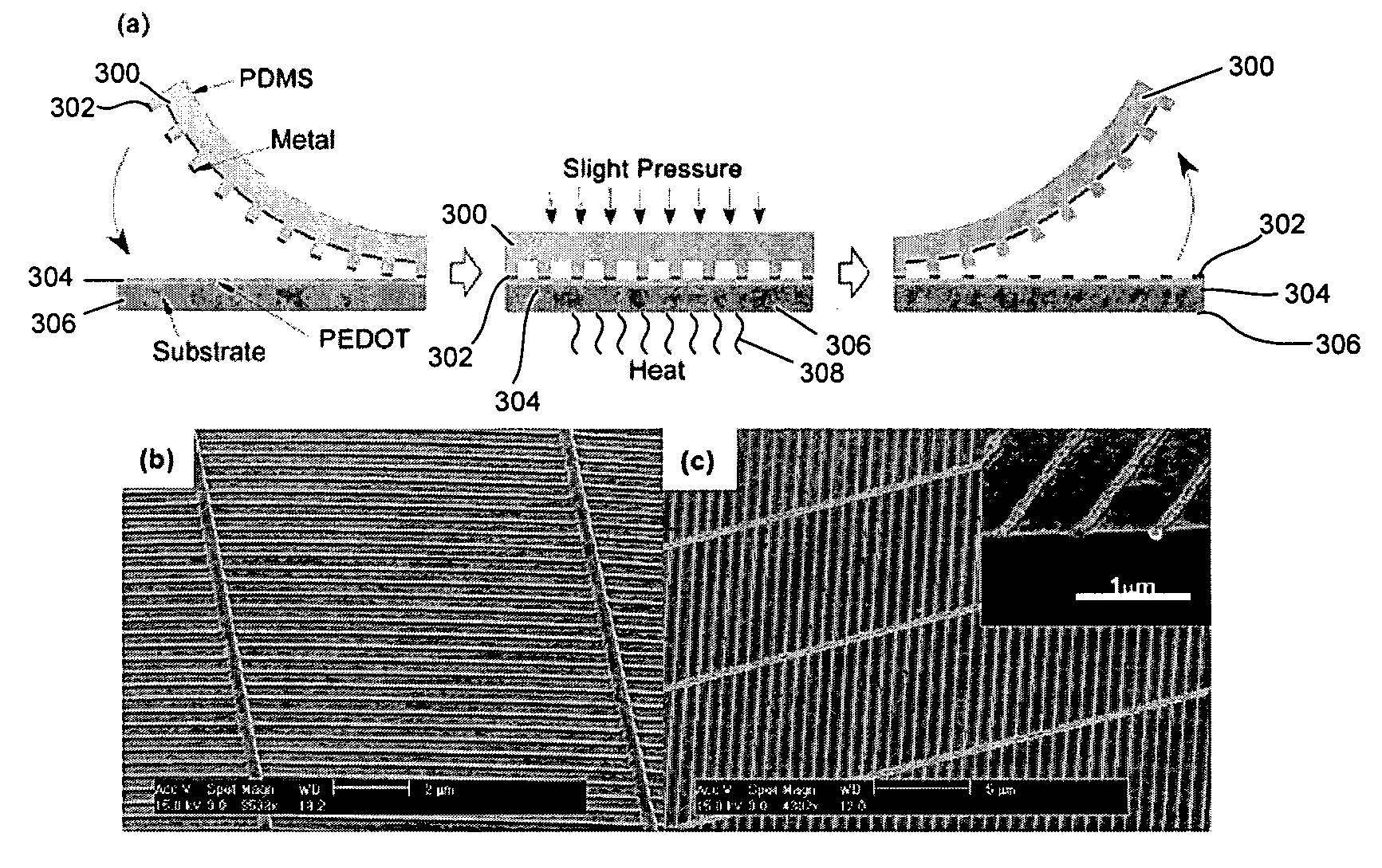

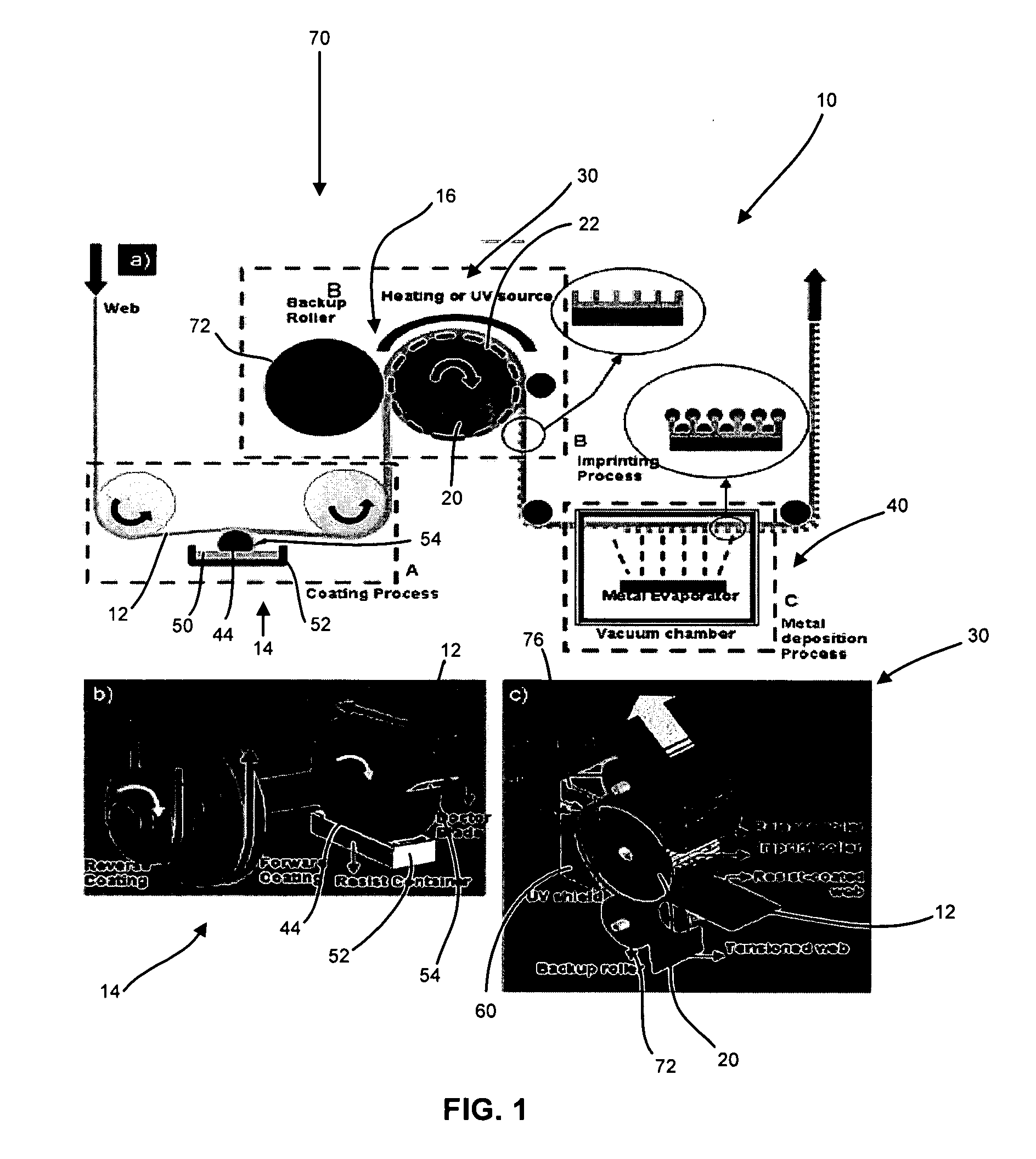

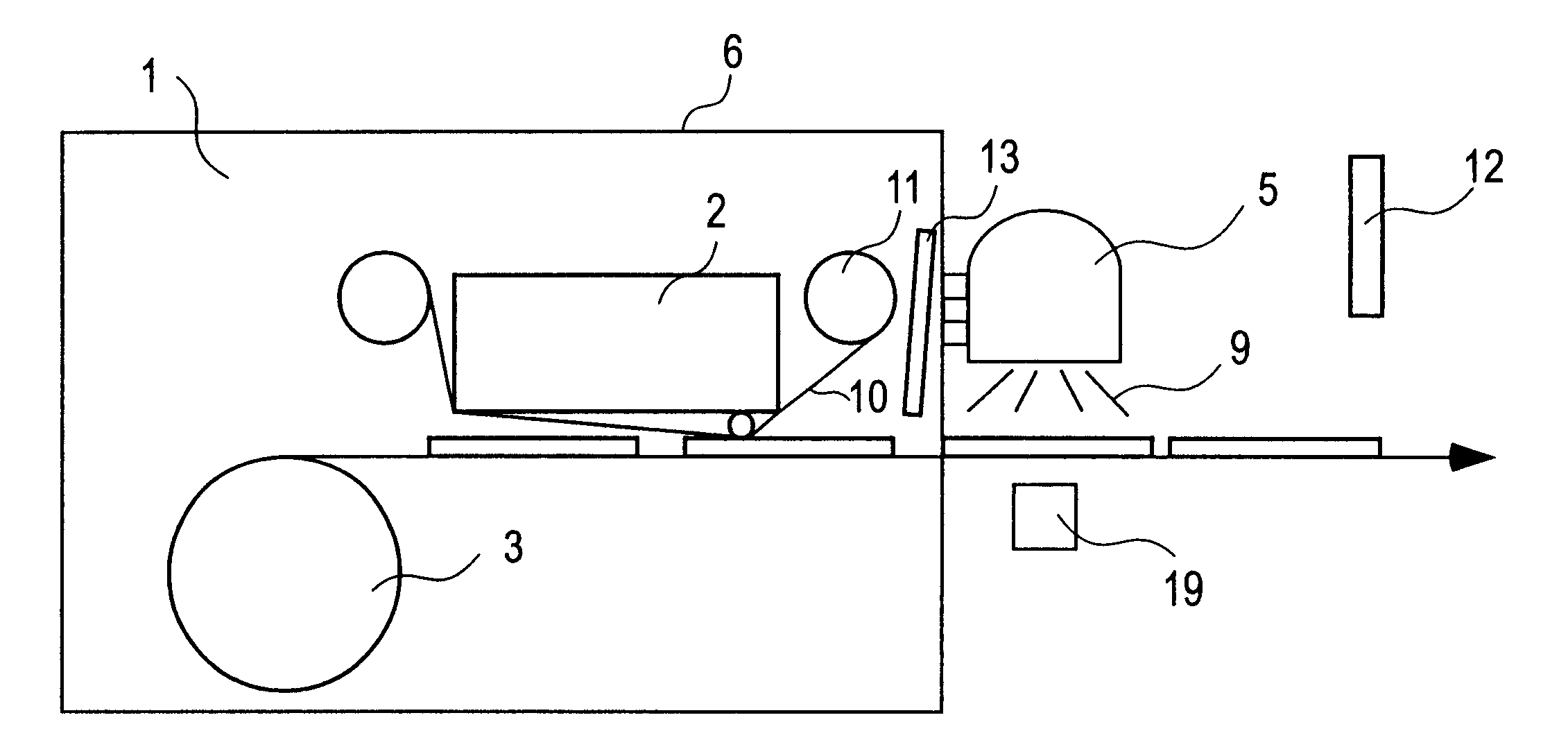

Roll to roll nanoimprint lithography

Apparatus and methods for a nano-patterning process to fabricate nanostructures. A roller type mold is used to continuously imprint nanostructures onto a flexible web or a rigid substrate. The process includes a coating and an imprinting module, which rotate the web synchronously. Liquid resist materials are used for imprinting and the patterns are set by thermal or UV curing. The process is used to produce bilayer metal wire-grid polarizers, organic solar cells, and organic light emitting diodes.

Owner:RGT UNIV OF MICHIGAN

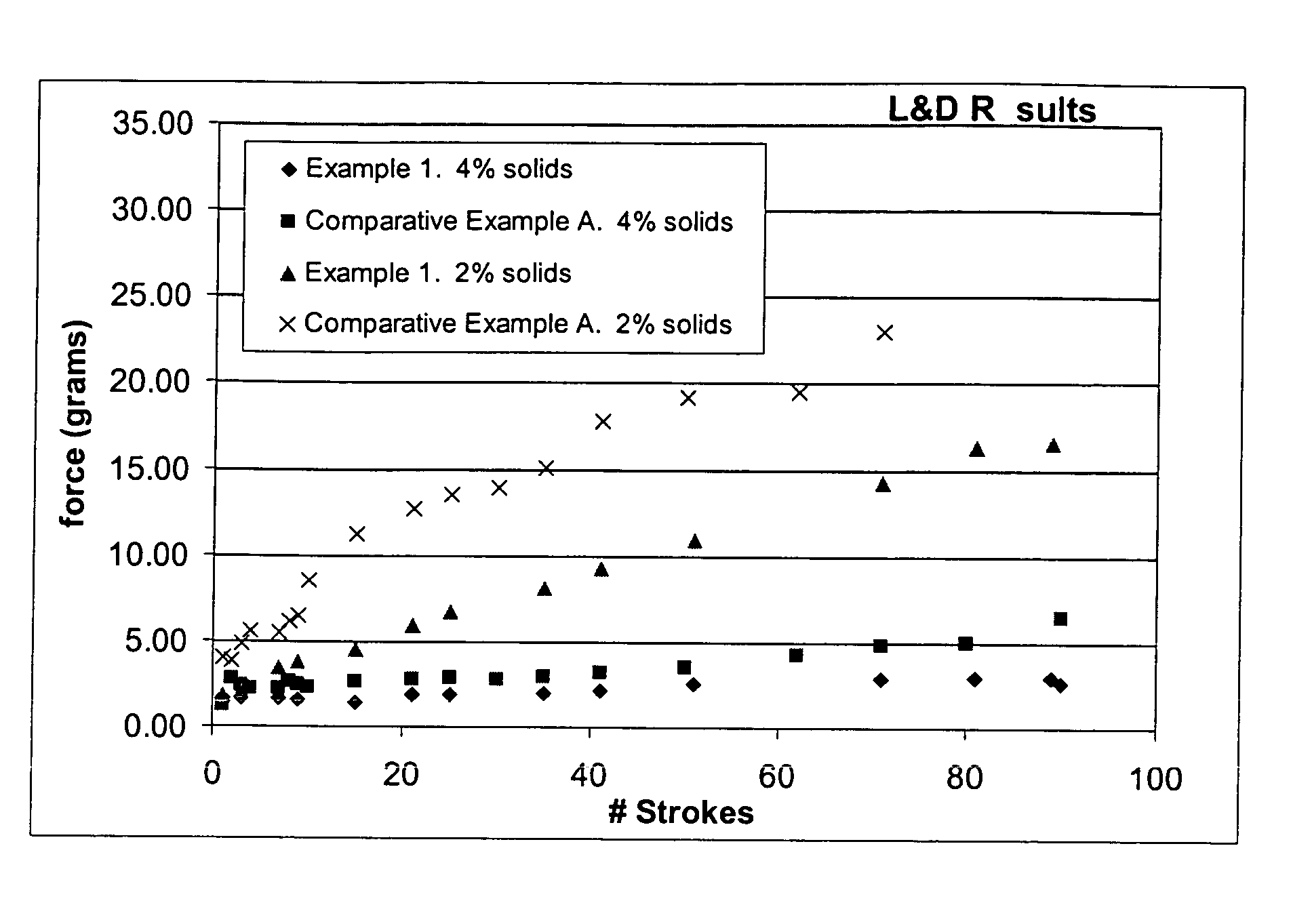

Lubricious coatings for medical device

An ultraviolet curable lubricious coating including at least one lubricious polymer and at least one oxygen-insensitive crosslinkable polymer, methods of making and using the same, and articles coated therewith.

Owner:BOSTON SCI SCIMED INC

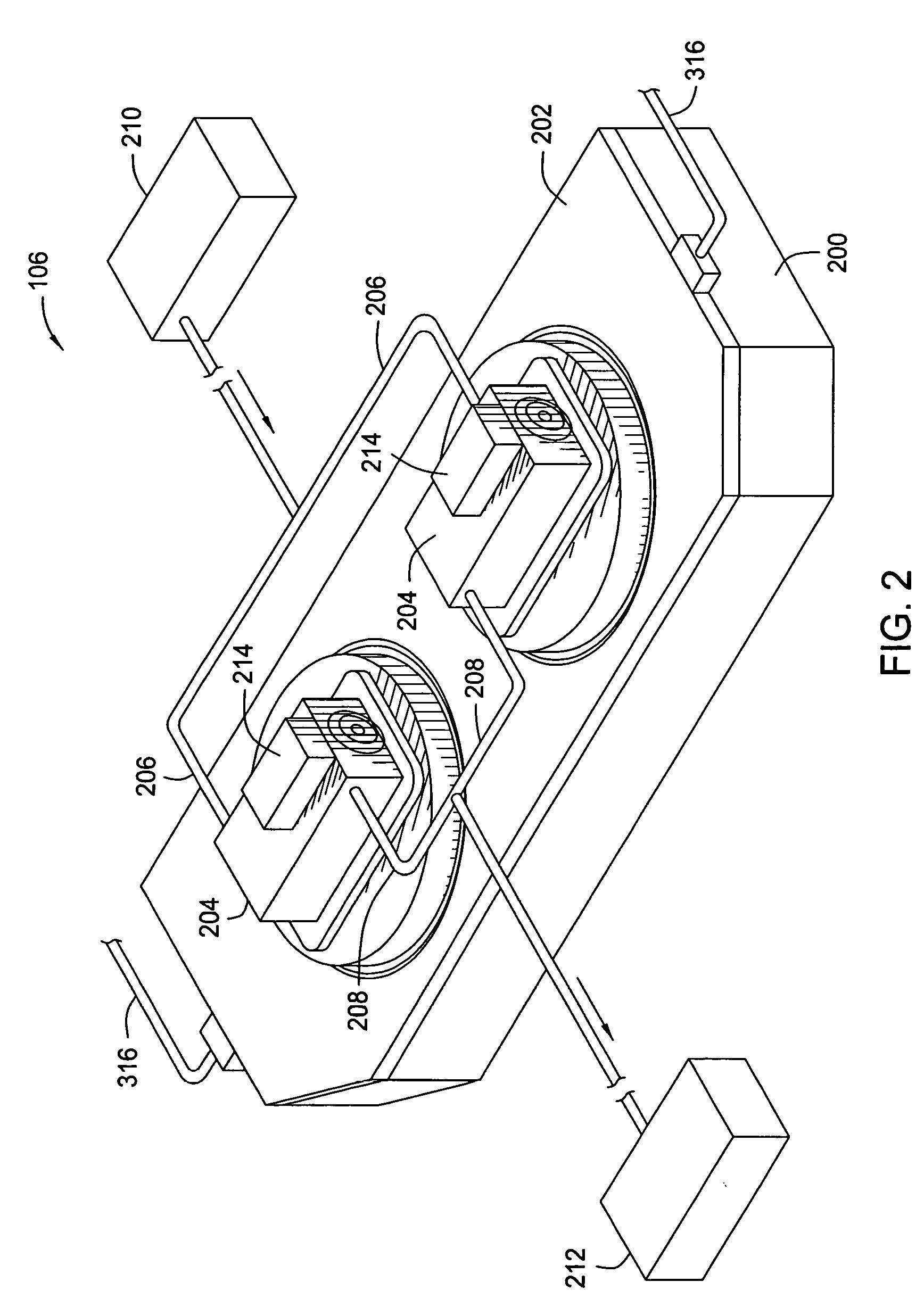

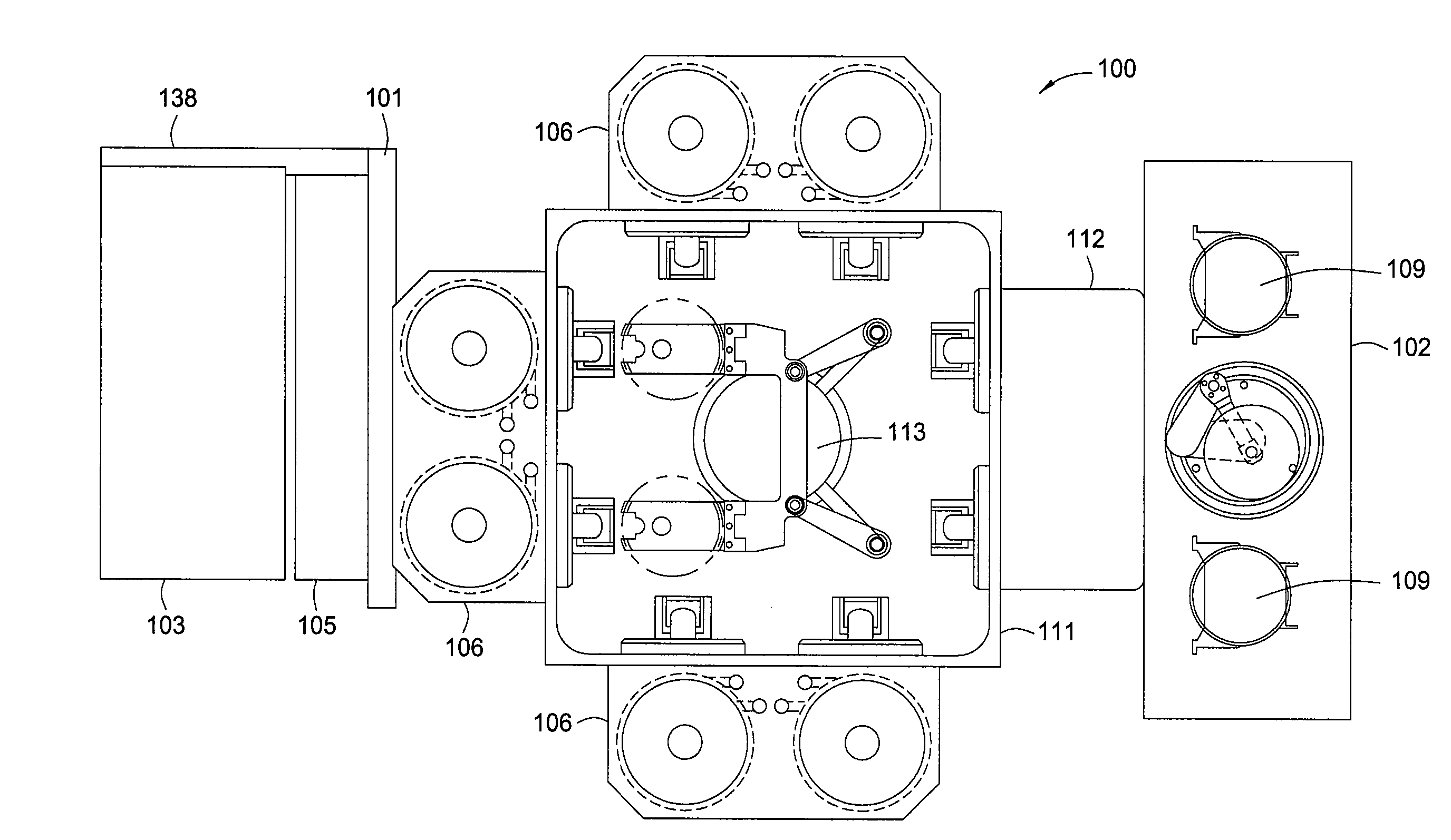

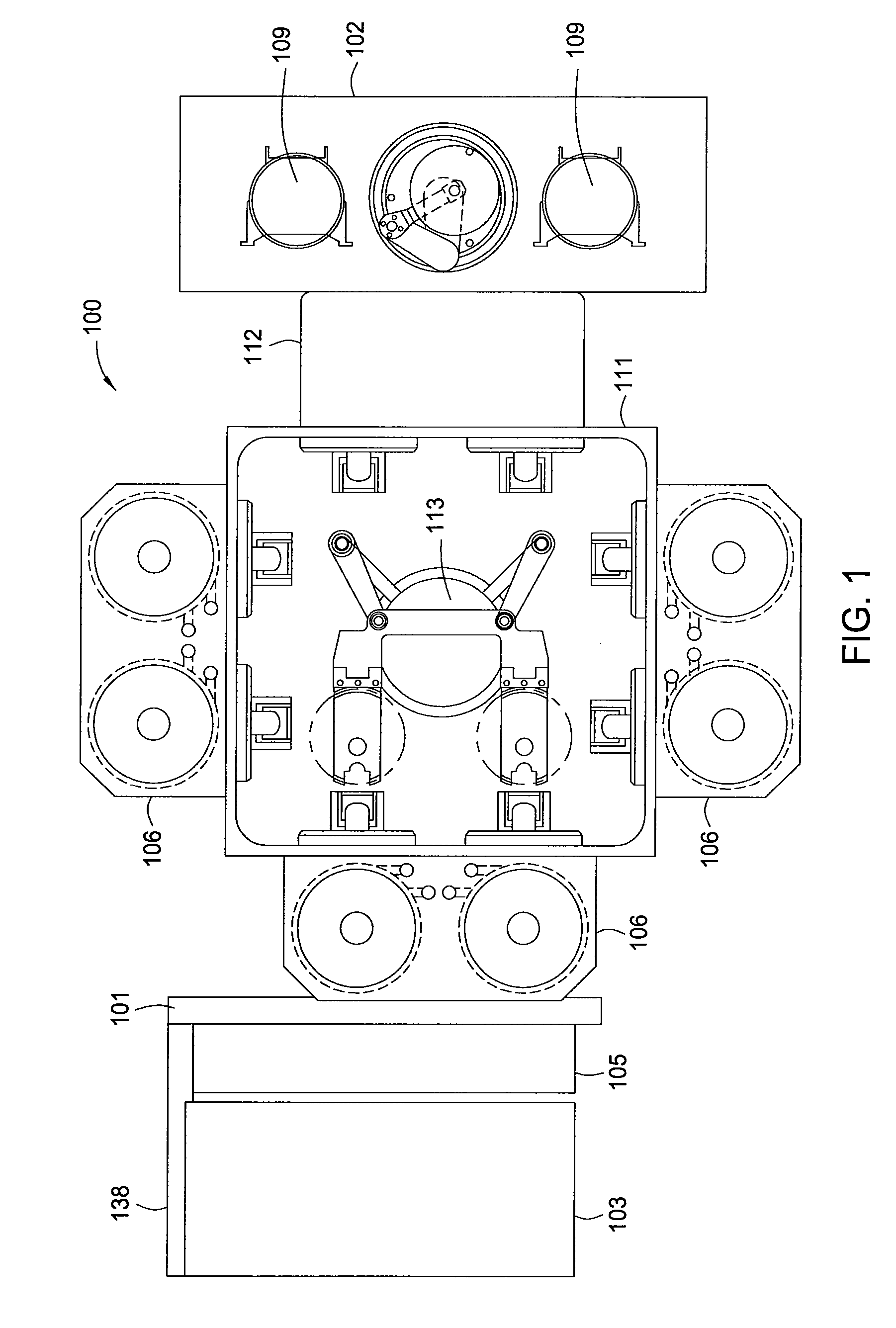

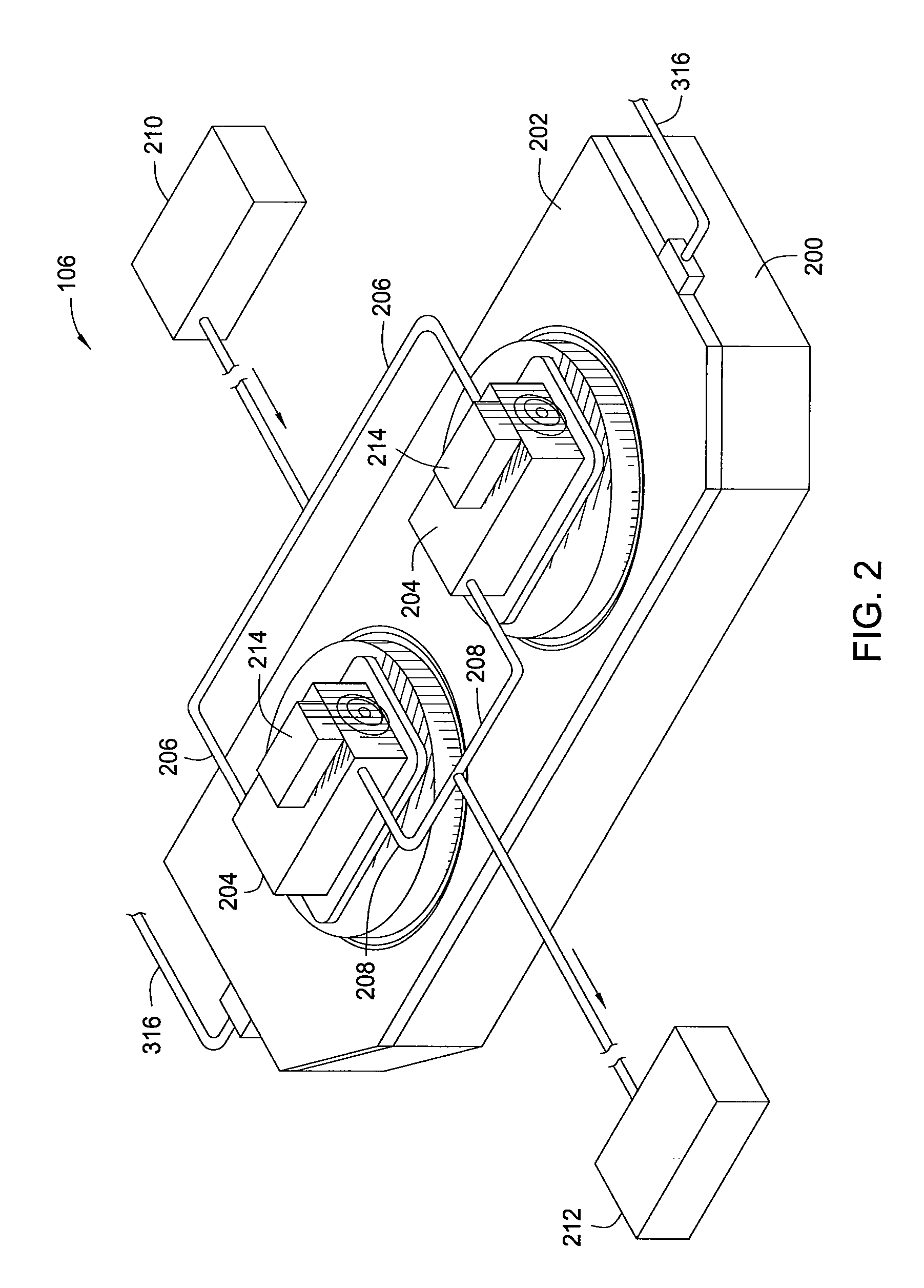

High efficiency UV curing system

InactiveUS20060249175A1Improve uniformityLighting and heating apparatusHollow article cleaningUV curingUltraviolet

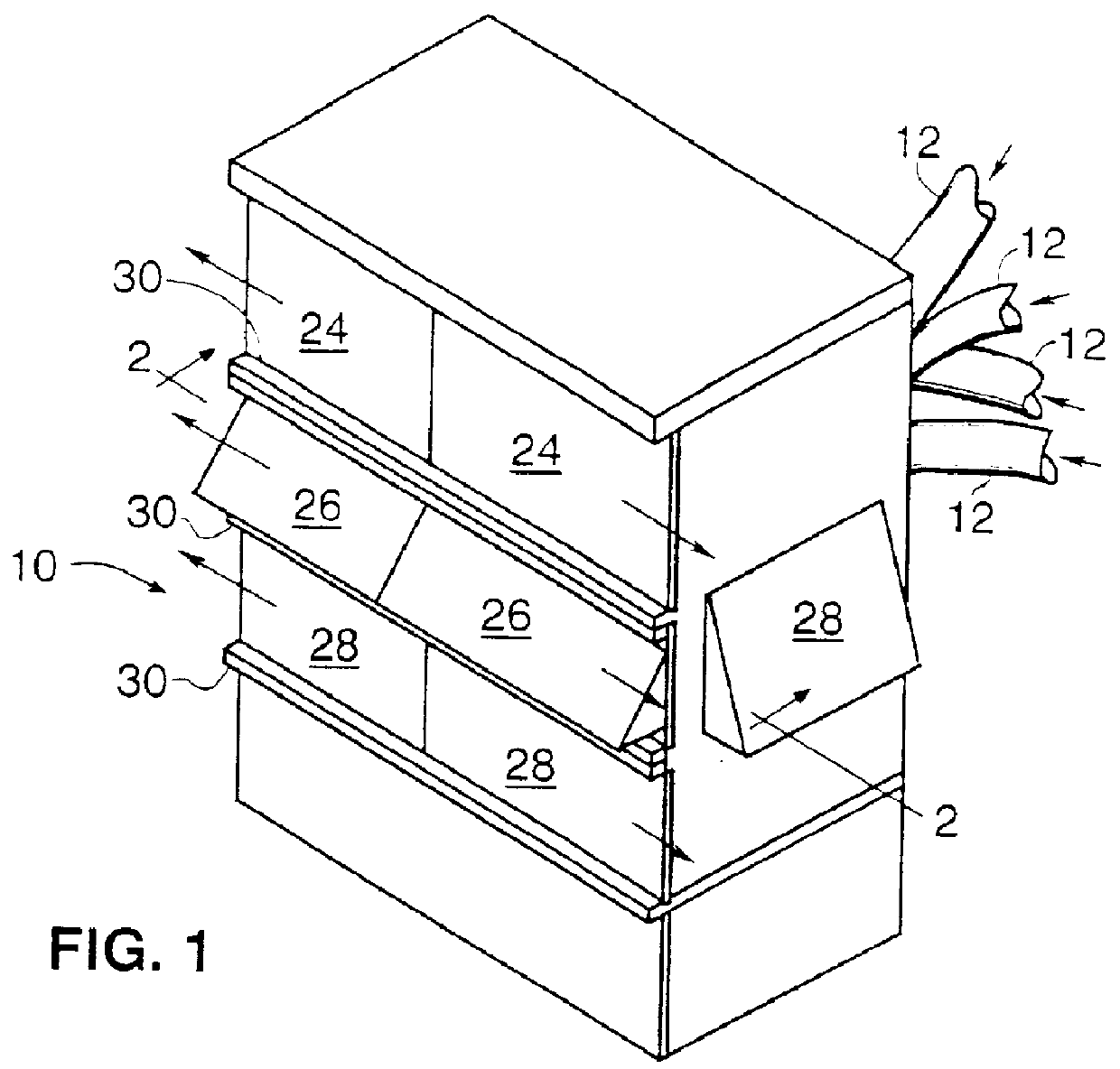

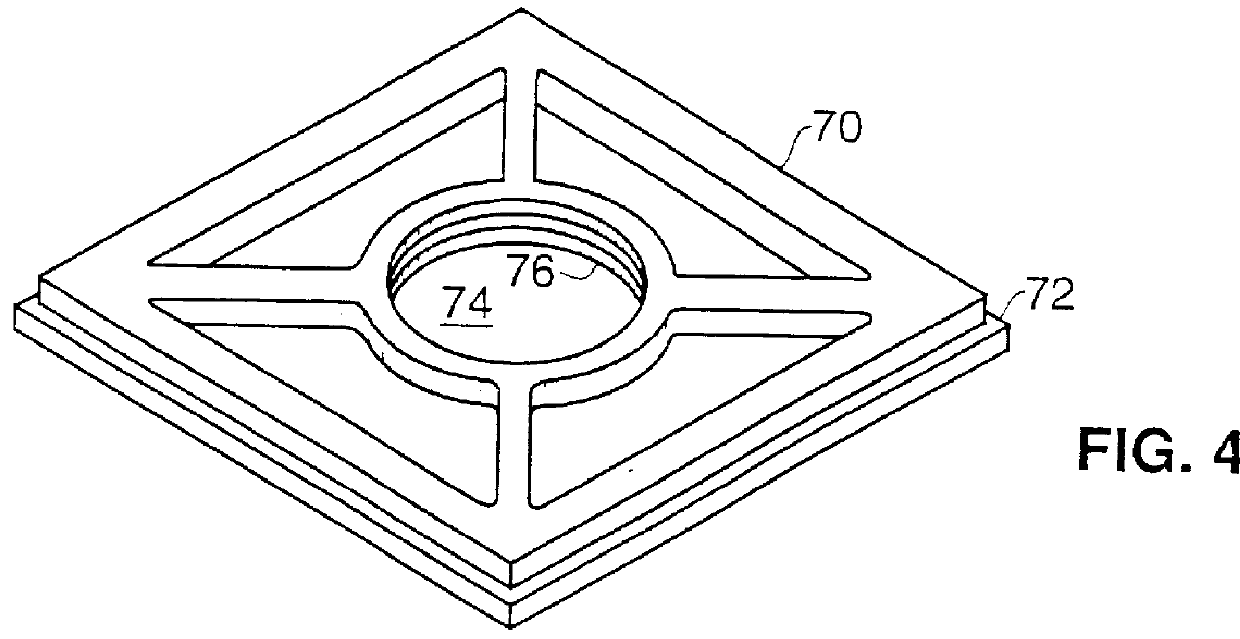

An ultraviolet (UV) cure chamber enables curing a dielectric material disposed on a substrate and in situ cleaning thereof. A tandem process chamber provides two separate and adjacent process regions defined by a body covered with a lid having windows aligned respectively above each process region. One or more UV bulbs per process region that are covered by housings coupled to the lid emit UV light directed through the windows onto substrates located within the process regions. The UV bulbs can be an array of light emitting diodes or bulbs utilizing a source such as microwave or radio frequency. The UV light can be pulsed during a cure process. Using oxygen radical / ozone generated remotely and / or in-situ accomplishes cleaning of the chamber. Use of lamp arrays, relative motion of the substrate and lamp head, and real-time modification of lamp reflector shape and / or position can enhance uniformity of substrate illumination.

Owner:APPLIED MATERIALS INC

Gel pad and UV-curving production method thereof

The invention relates to a gel pad and a uv-curing production method thereof. This invention, including the gel bag, is characterized in that the gel bag is filled with gel which is prepared from gel monomers, a cross-linking agent and a photoinitiatorandwater prepared from the UV curving. The gel consists of monomers, cross-linking agents, cross-linking agents, photo initiators and water. The said monomer are two or more than two of an acrylic acid alkali metal salt, ester generated by methacrylic acid ,acrylamide ,methacrylamide and AMPS(2-acrylamide-2-methyl-propanesulfonic acid ). The said cross-linking agent is a non-conjugated double bond compound which is polyol(glycerol )N,N'-methylene bisacrylamide. The said photoinitiator is a cracking type initiator or a photosensitive initiator or a cationic initiator. The advantages of the method are that the production process is simple, the gel solidification is fast and the gel pad produced is flattened.

Owner:朱雪兵

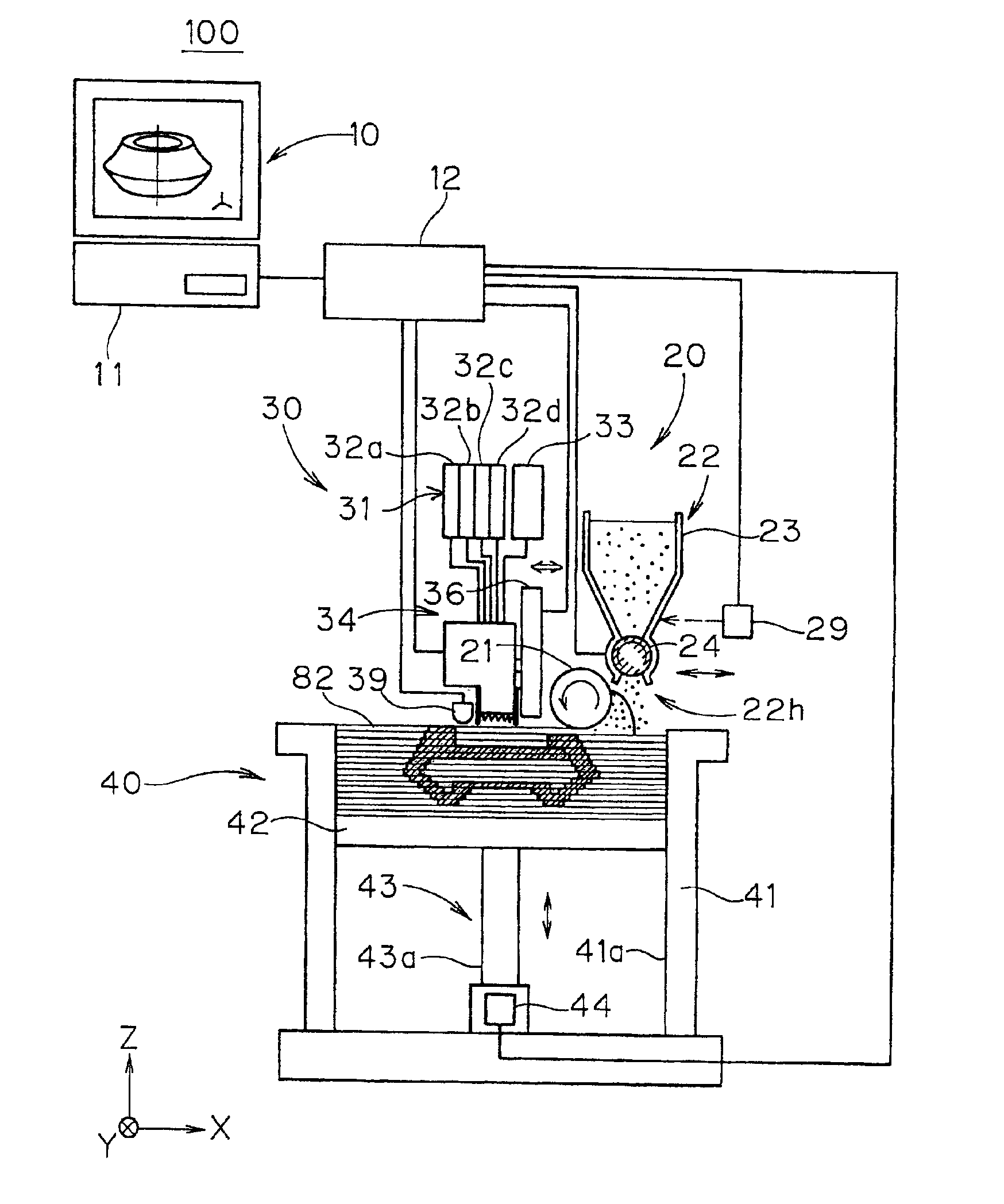

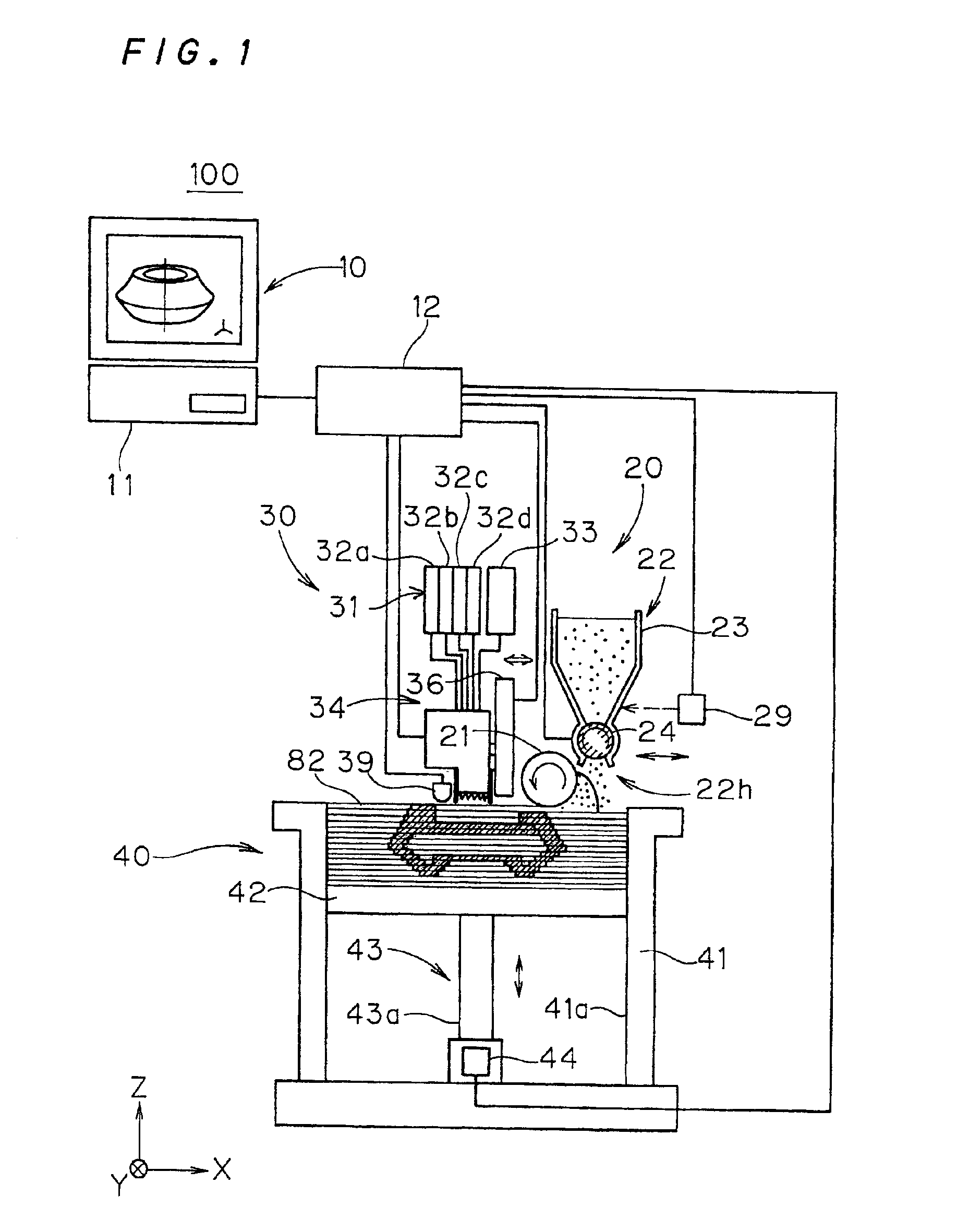

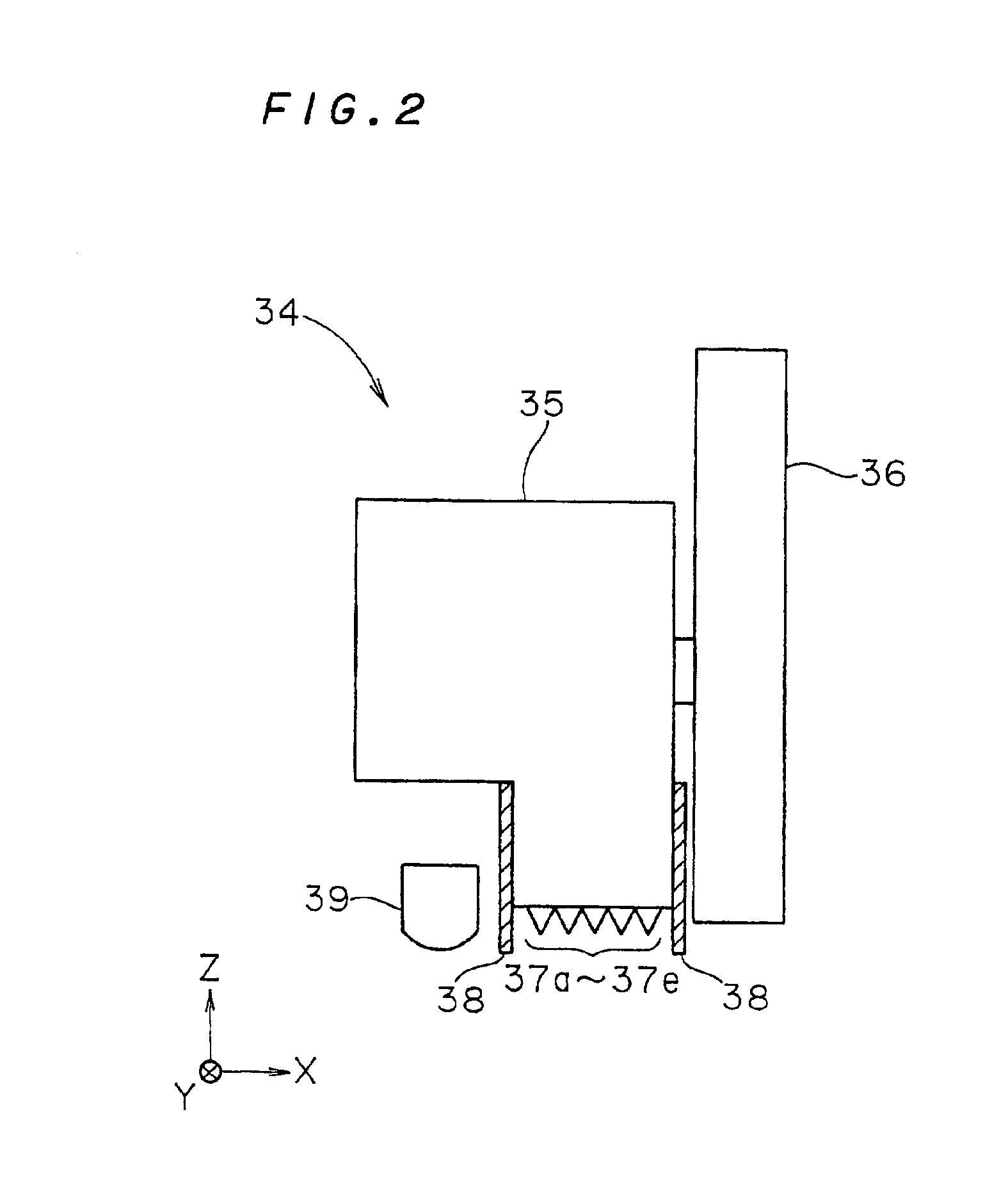

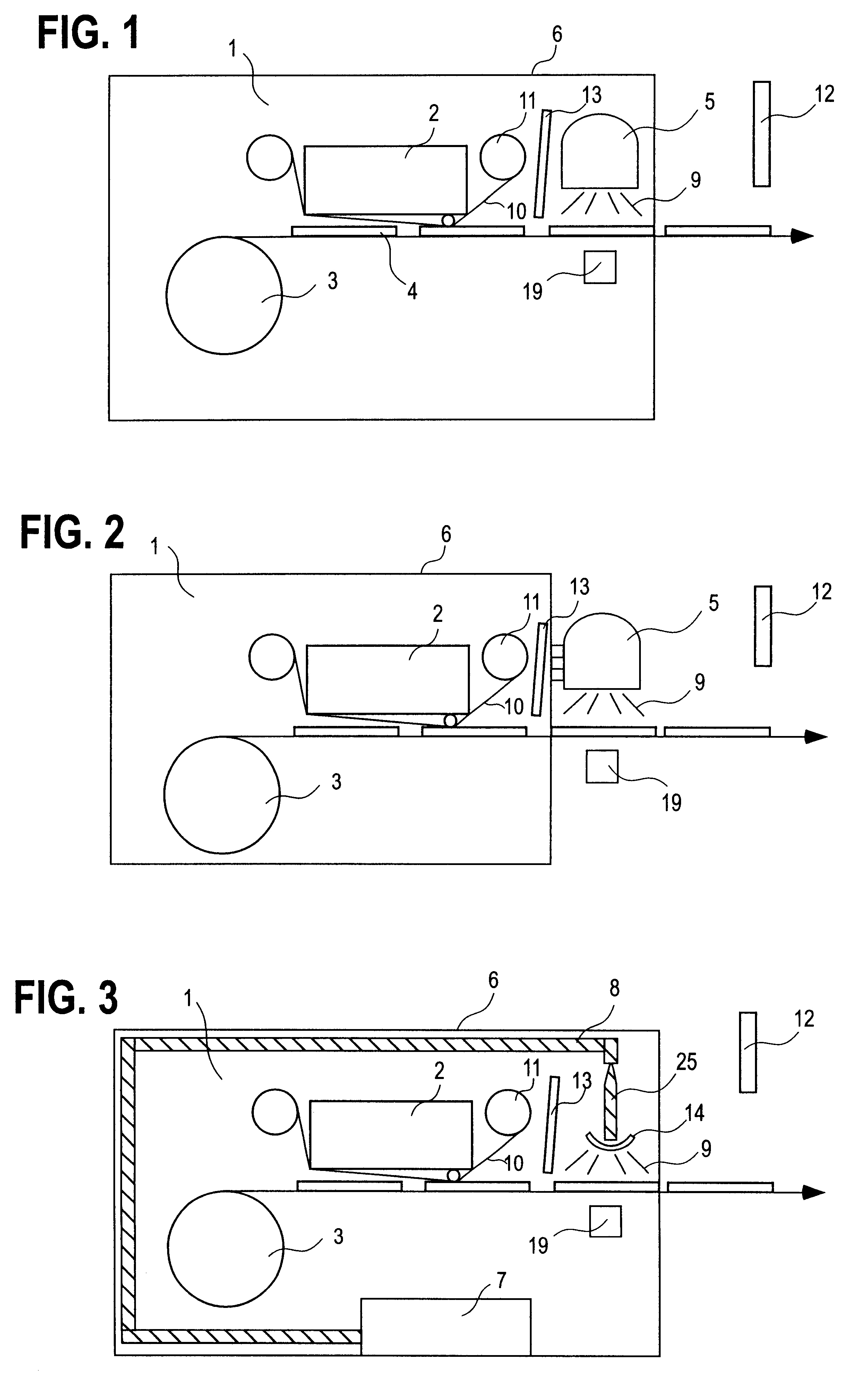

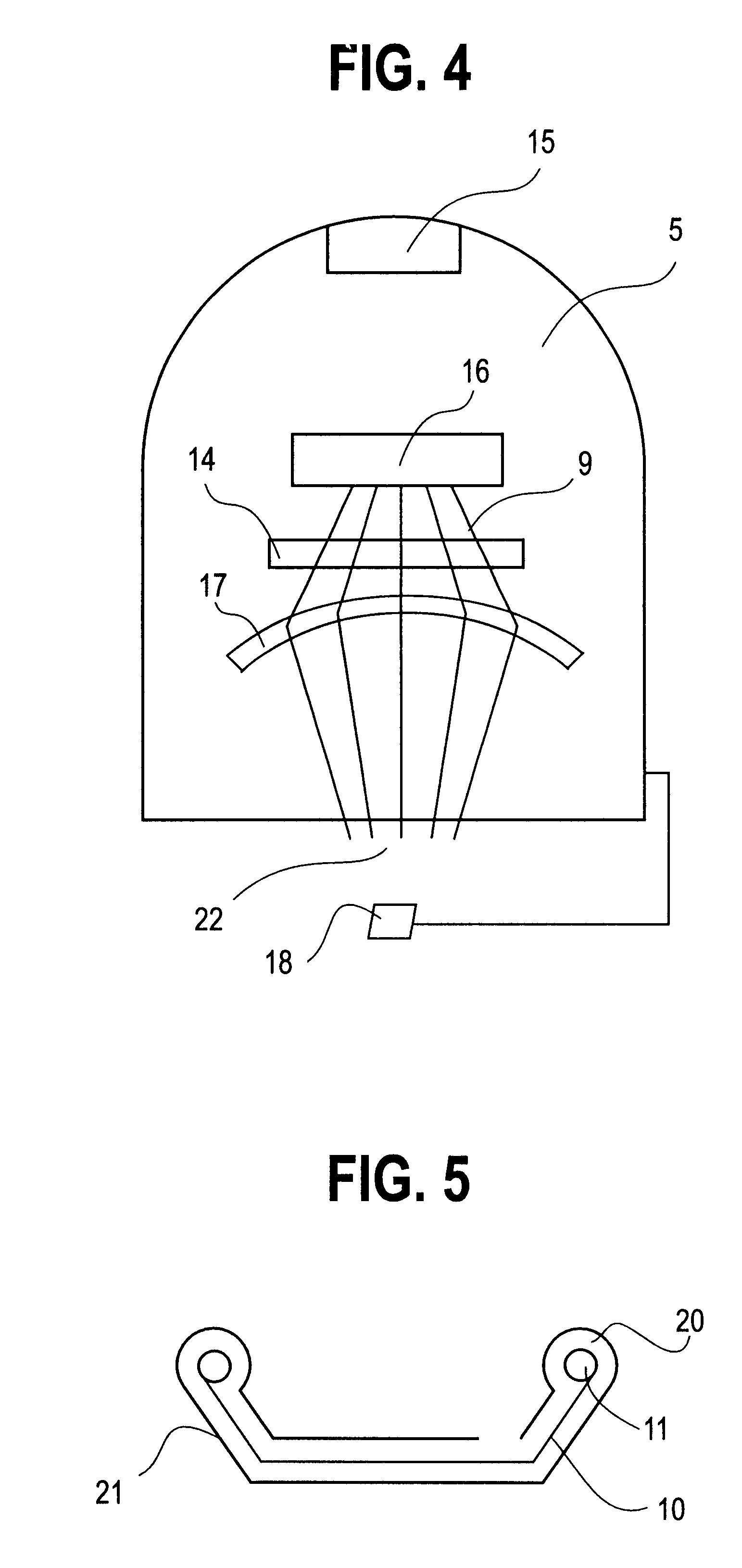

Three-dimensional molding apparatus and three-dimensional molding method

To provide a three-dimensional molding technique capable of generating a three-dimensional molded article in short time.In a three-dimensional molding apparatus, a powder material is allowed to drop via an opening while moving a thin layer formation section in the +X direction, thereby forming a powder layer on a molding stage. With respect to a selected region in the powder layer, a binder of ultraviolet-ray hardening resin is discharged from a head section. Then, the powder layer is irradiated with ultraviolet rays from an ultraviolet irradiation section, making the ultraviolet-ray hardening resin applied on the powder layer harden to thereby bind the powder material. By repeating this operation with respect to the powder layer which is sequentially formed, a three-dimensional molded article is formed. In this way, since an ultraviolet-ray hardening resin is used as a binder and a powder material can be bound rapidly by ultraviolet irradiation, it is possible to generate a three-dimensional molded article in short time.

Owner:MINOLTA CO LTD

Display panel and display device using the same

InactiveUS6218679B1Liquid crystal compositionsBuilt-on/built-in screen projectorsDisplay deviceUltraviolet

Owner:GK BRIDGE 1

Methods for eyeglass lens curing using ultraviolet light

InactiveUS6022498AControl generationControl releaseOther chemical processesOptical articlesUV curingRadiation pulse

Method and apparatus for making [and coating] a plastic lens is provided. [Oxygen barrier containing photoinitiator is used to cure incompletely cured lens portions. Radiation pulses are used to control lens curing rate. Lens is postcured while in a mold cavity using a conductive heat source.] More particularly, the invention relates to applying alternating periods of ultraviolet light to lens forming composition. Such composition is cured while controlling the rate of heat generation and / or dissipation via manipulation of the duration of the radiation or the cooling in the curing chamber. The ultraviolet light is directed toward the lens forming composition which is preferably disposed in a mold cavity formed by two mold members. The ultraviolet light may be directed in pulses or continuously.

Owner:Q2100

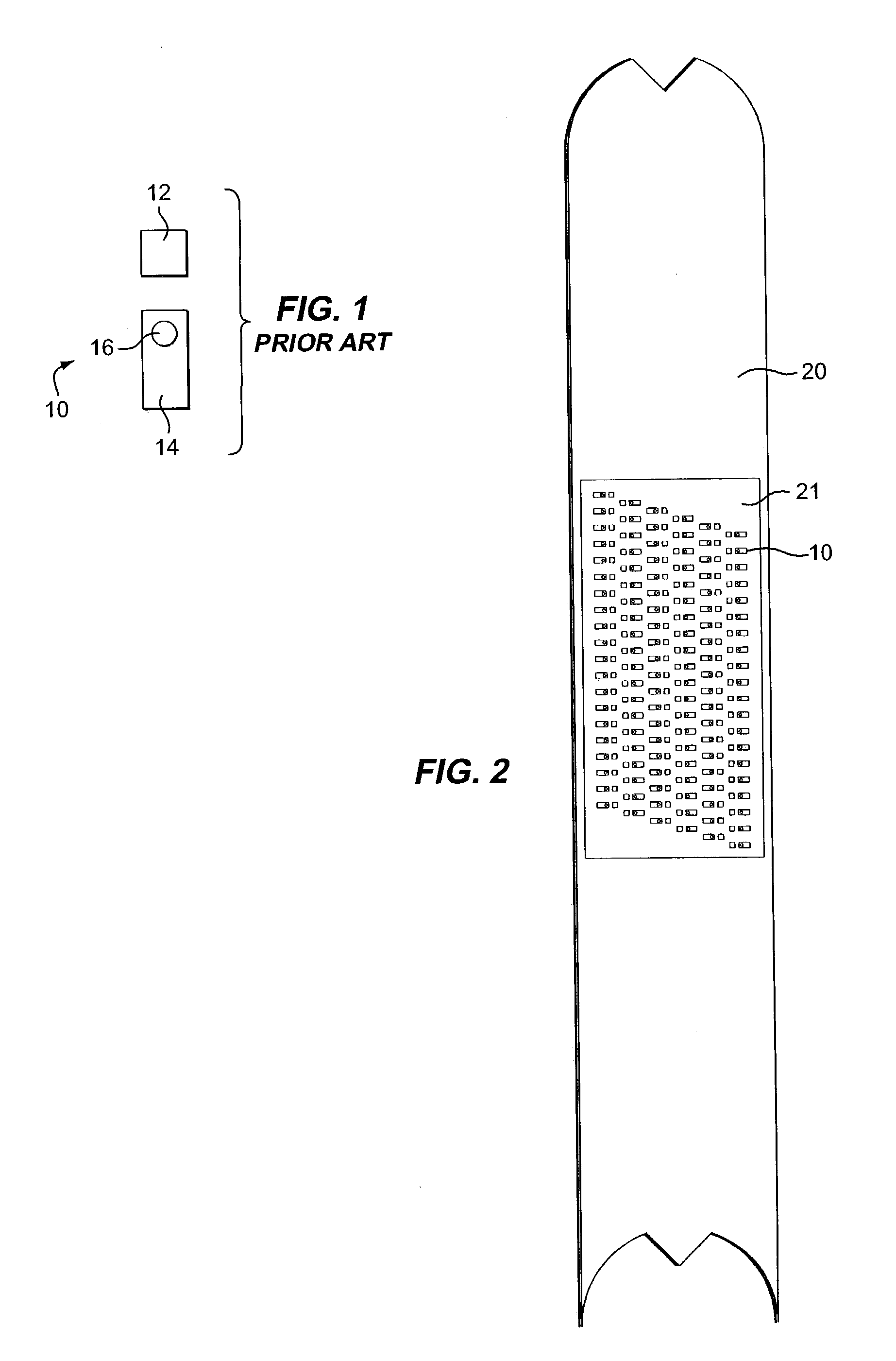

Ink jet UV curing

A method and apparatus for printing a product, article or other object at a printing station and for enhancing the application of UV light to UV photo initiators in a UV curable ink being applied to a product, article or other object at the printing station, comprising the steps for: printing a UV-curable ink with a printing head of a printer on a substrate, product, article or other object at a printing station; providing a primary light source of UV light preferably comprising at least one set of UV-LED arrays of UV-LED chips adjacent the printing head; and partially curing the ink dots by emitting light on the ink dots from the primary light source to set and partially polymerize, coalesce, coagulate and / or gel the ink dots so as to substantially inhibit the growth of the ink dots and prevent, running or smudging of the ink dots. The curing of the ink dots are completed by emitting light on the ink dots from a secondary light source, such as from one or more fluorescent lamps.

Owner:CON TROL CURE

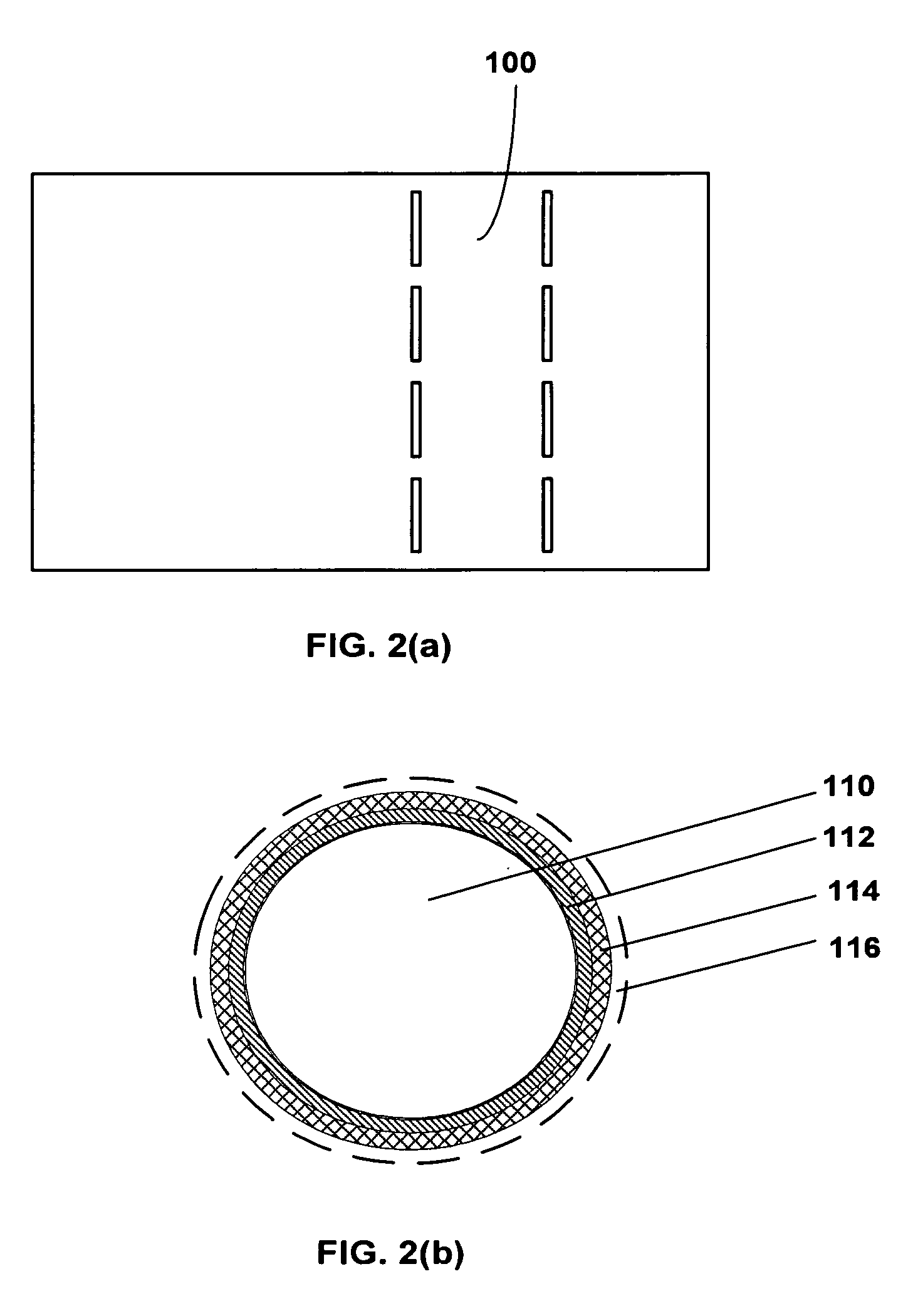

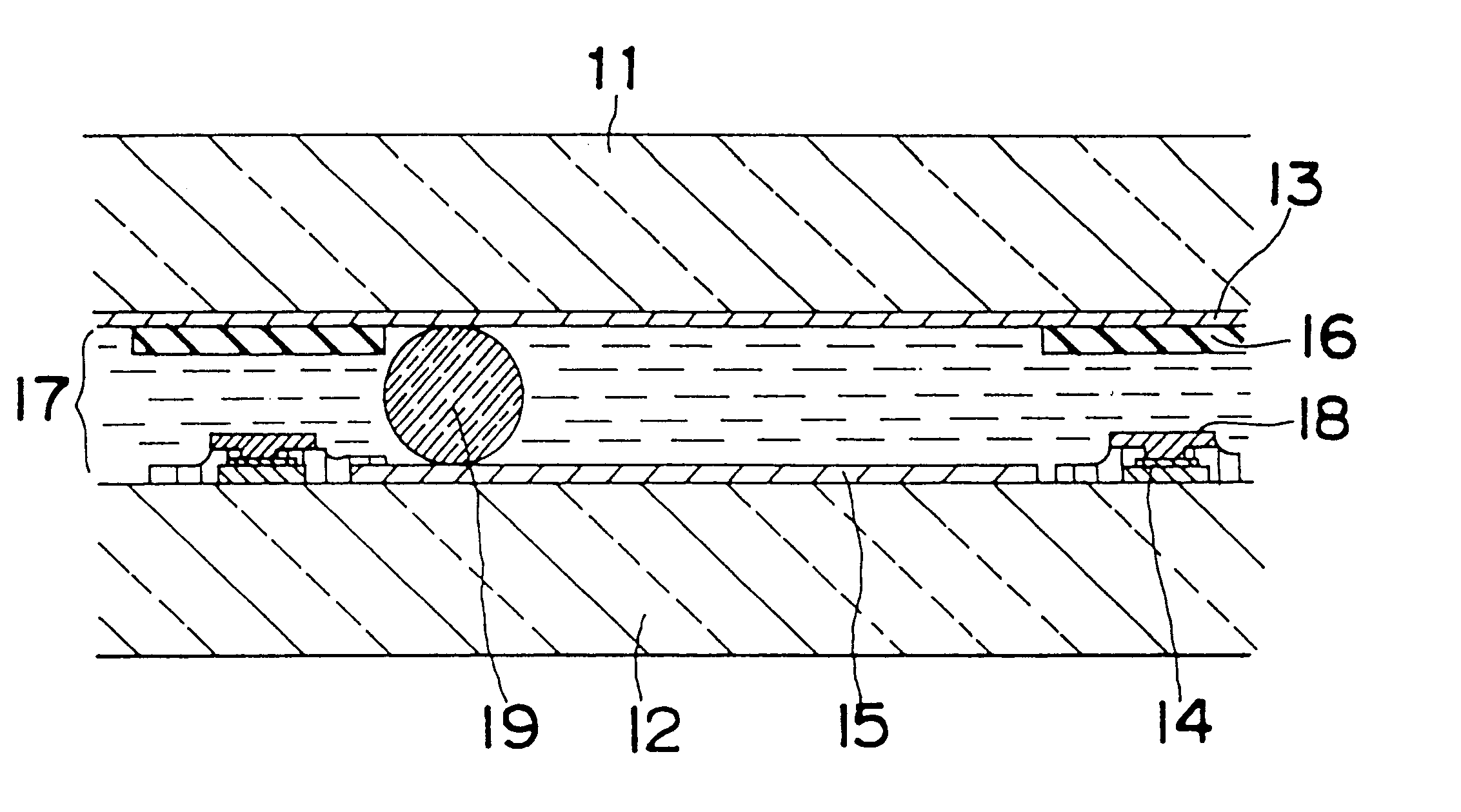

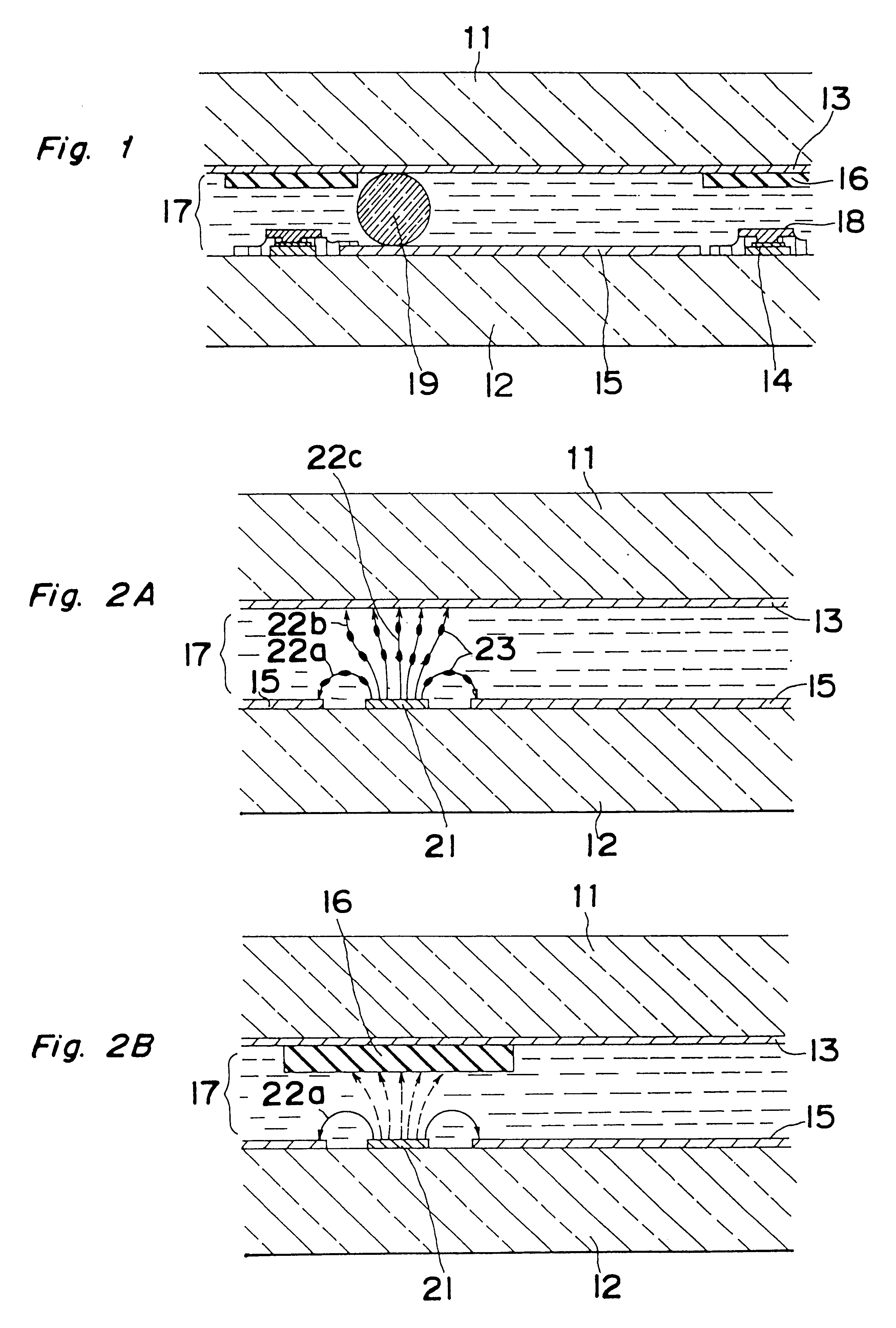

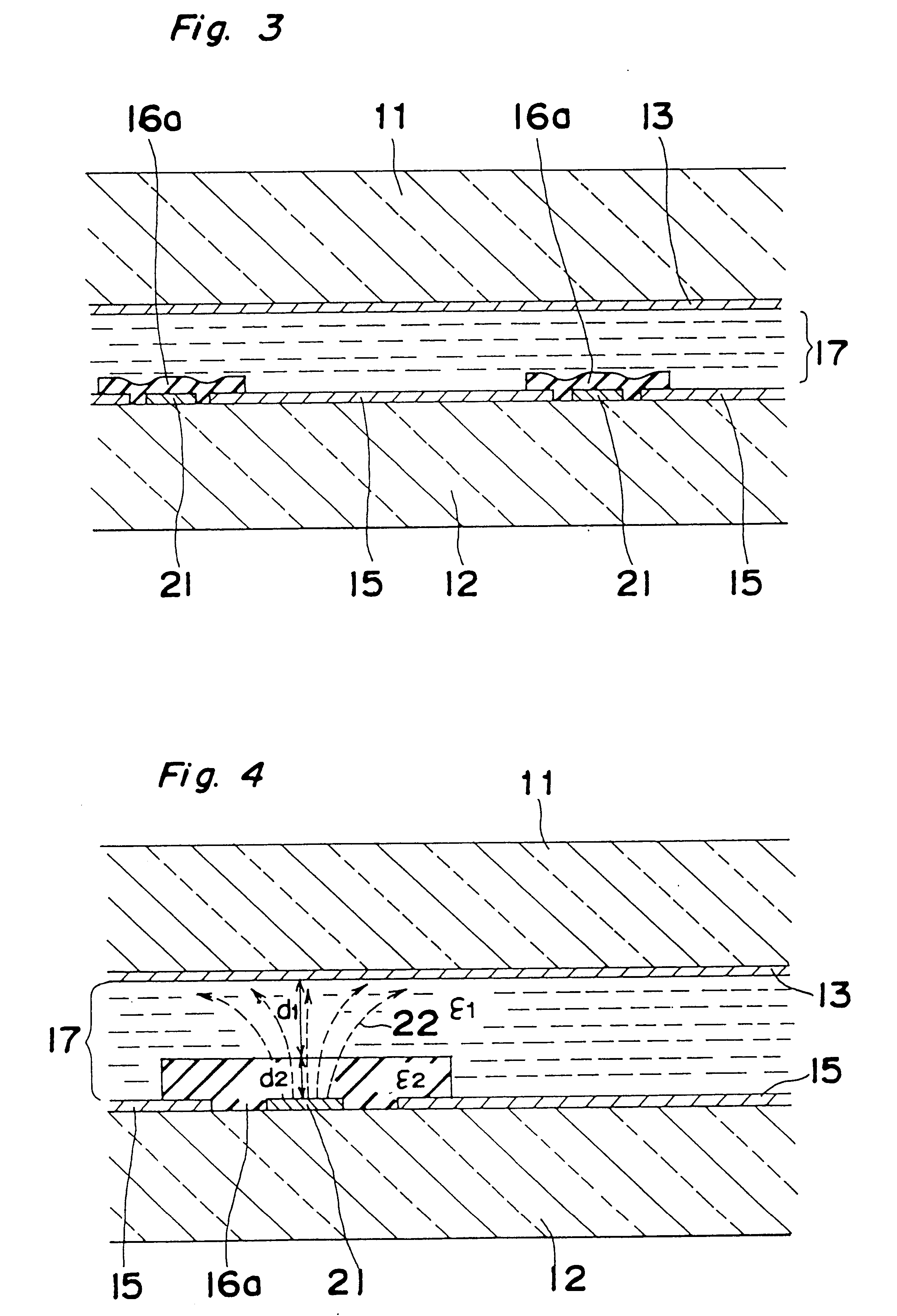

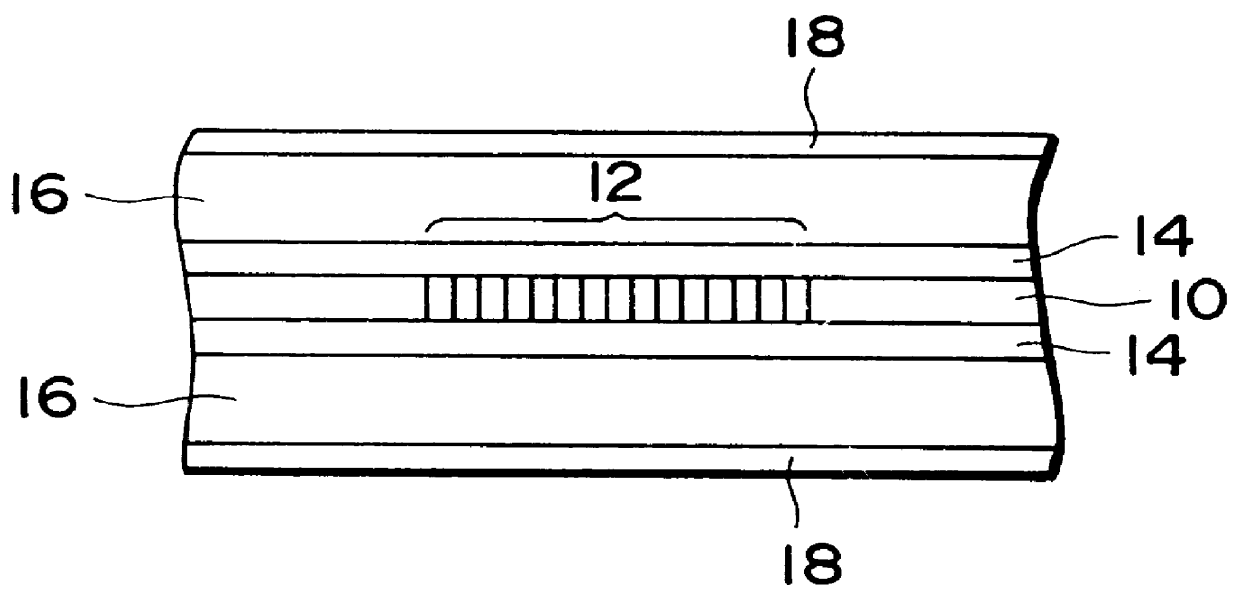

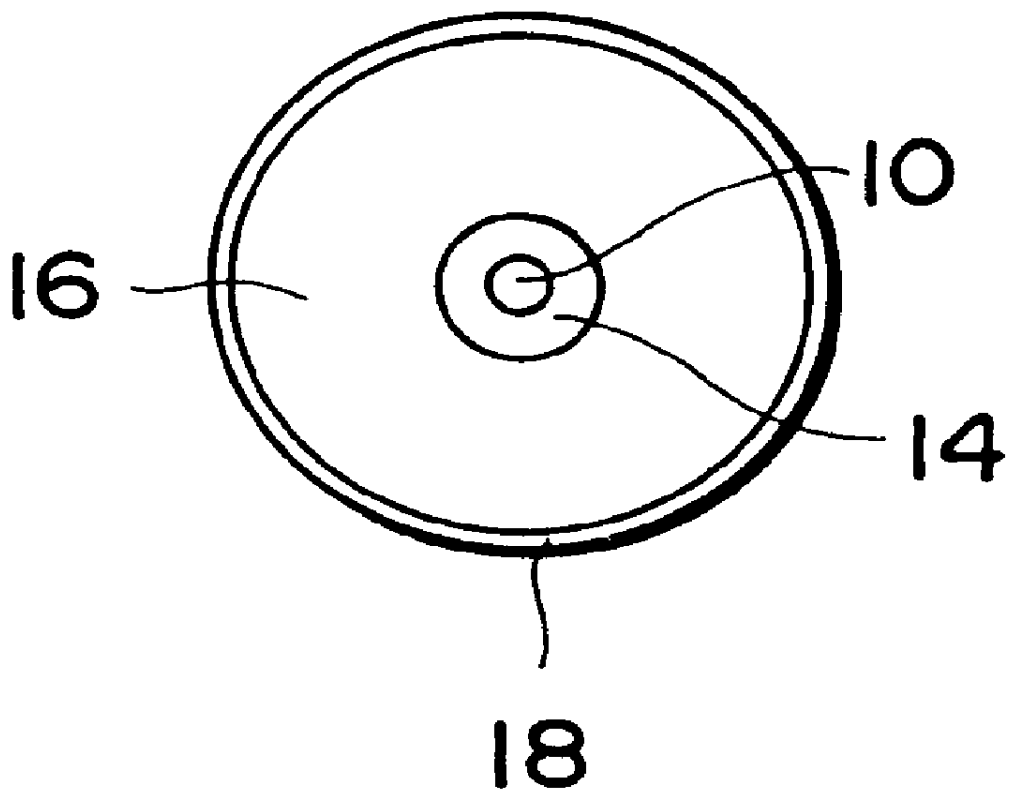

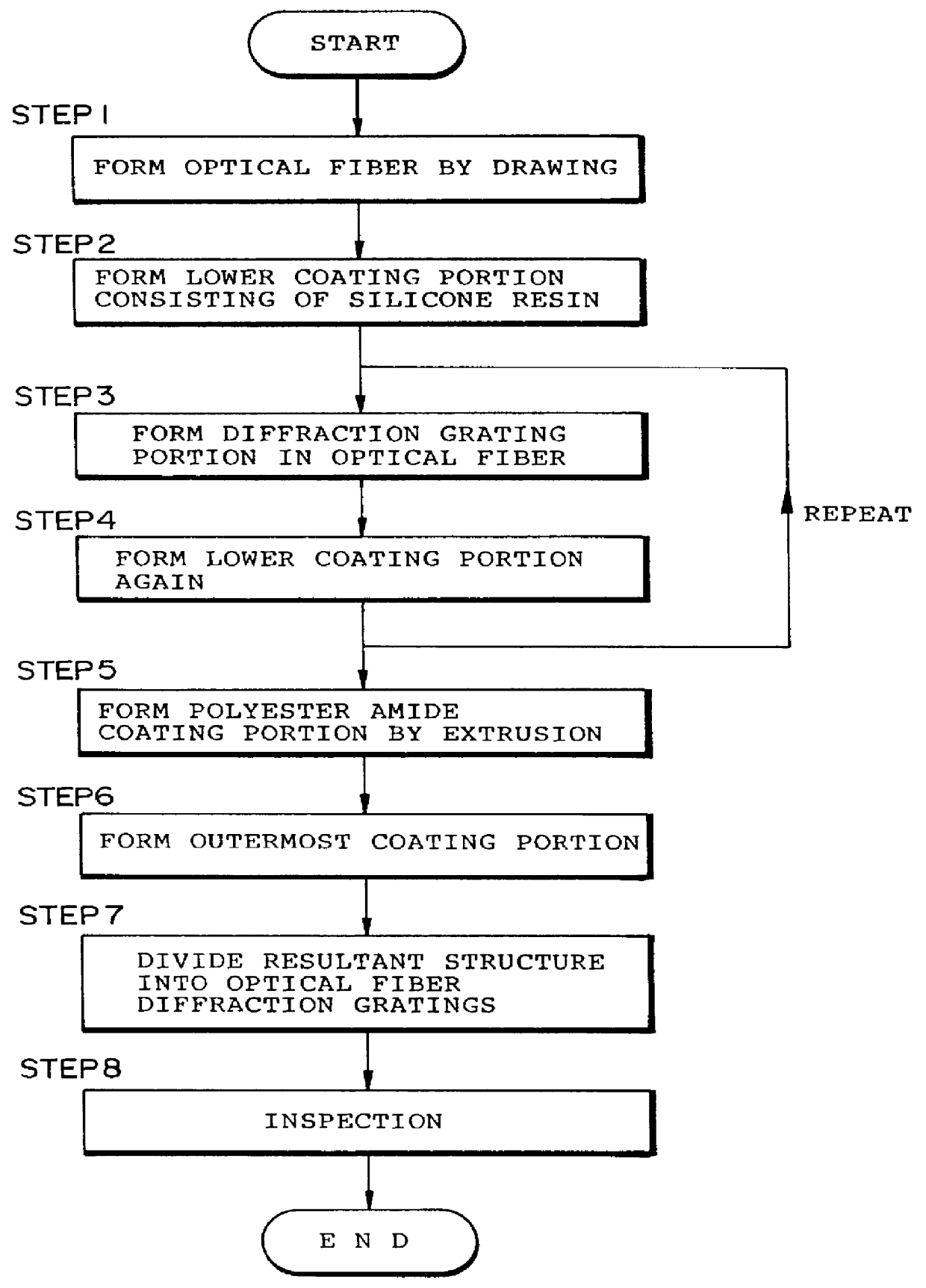

Optical fiber diffraction grating, a method of fabricating thereof and a laser light source

InactiveUS6067392ACanceled outPositive linear thermal expansion coefficientOptical fibre with multilayer core/claddingCoupling light guidesPolyesterLaser light

PCT No. PCT / JP96 / 03000 Sec. 371 Date Jun. 16, 1997 Sec. 102(e) Date Jun. 16, 1997 PCT Filed Oct. 16, 1996 PCT Pub. No. WO97 / 14983 PCT Pub. Date Apr. 24, 1997A diffraction grating portion (12) is formed in an optical fiber (10), having a diameter of 125 mu m and serving to transmit light, along its optical axis. The optical fiber is concentrically surrounded by a lower coating portion (14) having an outer diameter of 300 mu m and consisting of a silicone resin. The lower coating portion is concentrically surrounded by a coating portion (16) having an outer diameter of 900 mu m and consisting of a liquid crystal polymer, e.g., polyester amide. The coating portion is further surrounded by an outermost coating portion (18) having an outer diameter of 1 mm and consisting of a UV curing resin colored for identification. Both the optical fiber (10) and the lower coating portion (14) have positive thermal expansion coefficients. In contrast to this, the coating portion (16) consisting of the liquid crystal polymer has a negative thermal expansion coefficient.

Owner:SUMITOMO ELECTRIC IND LTD

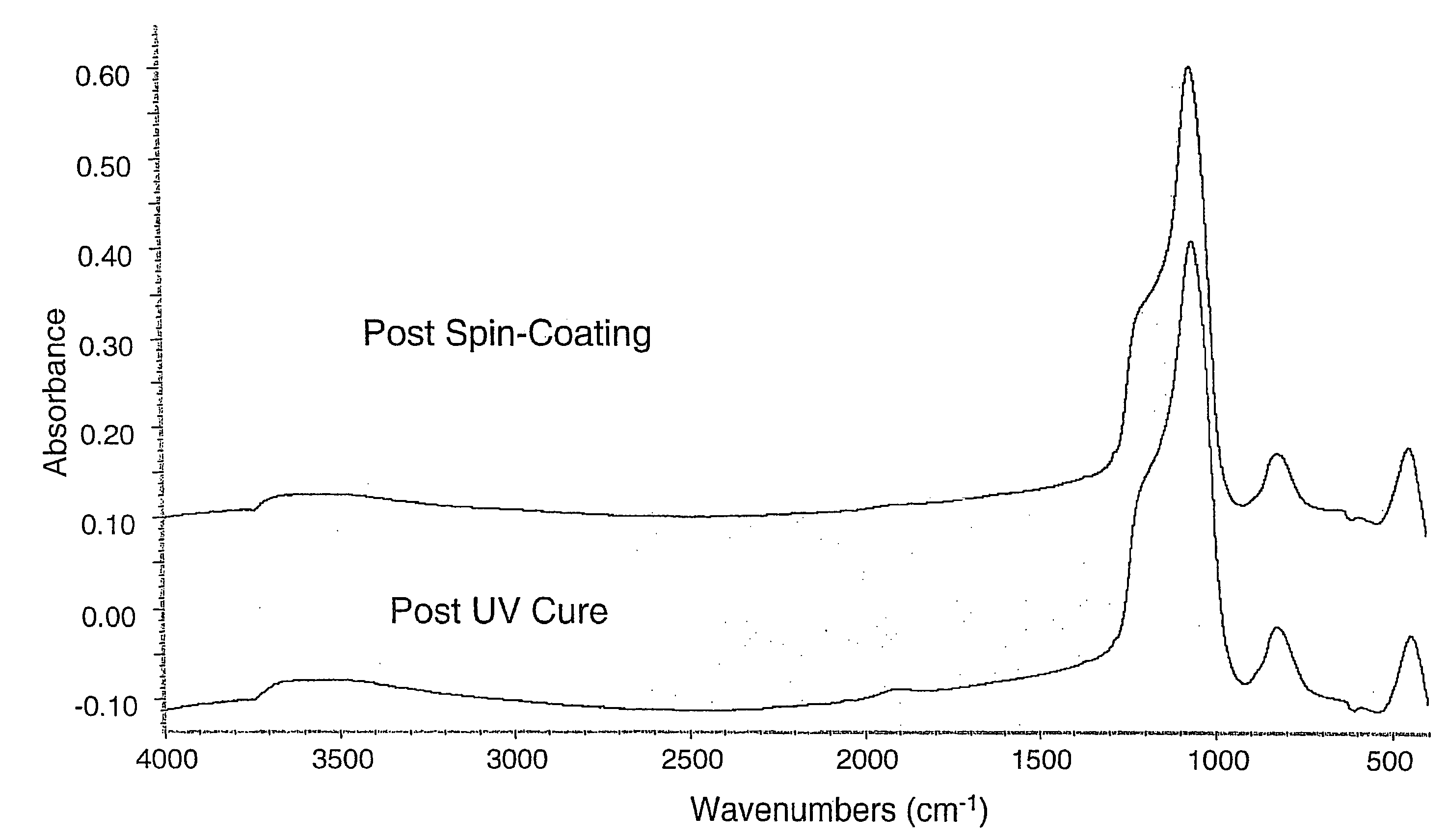

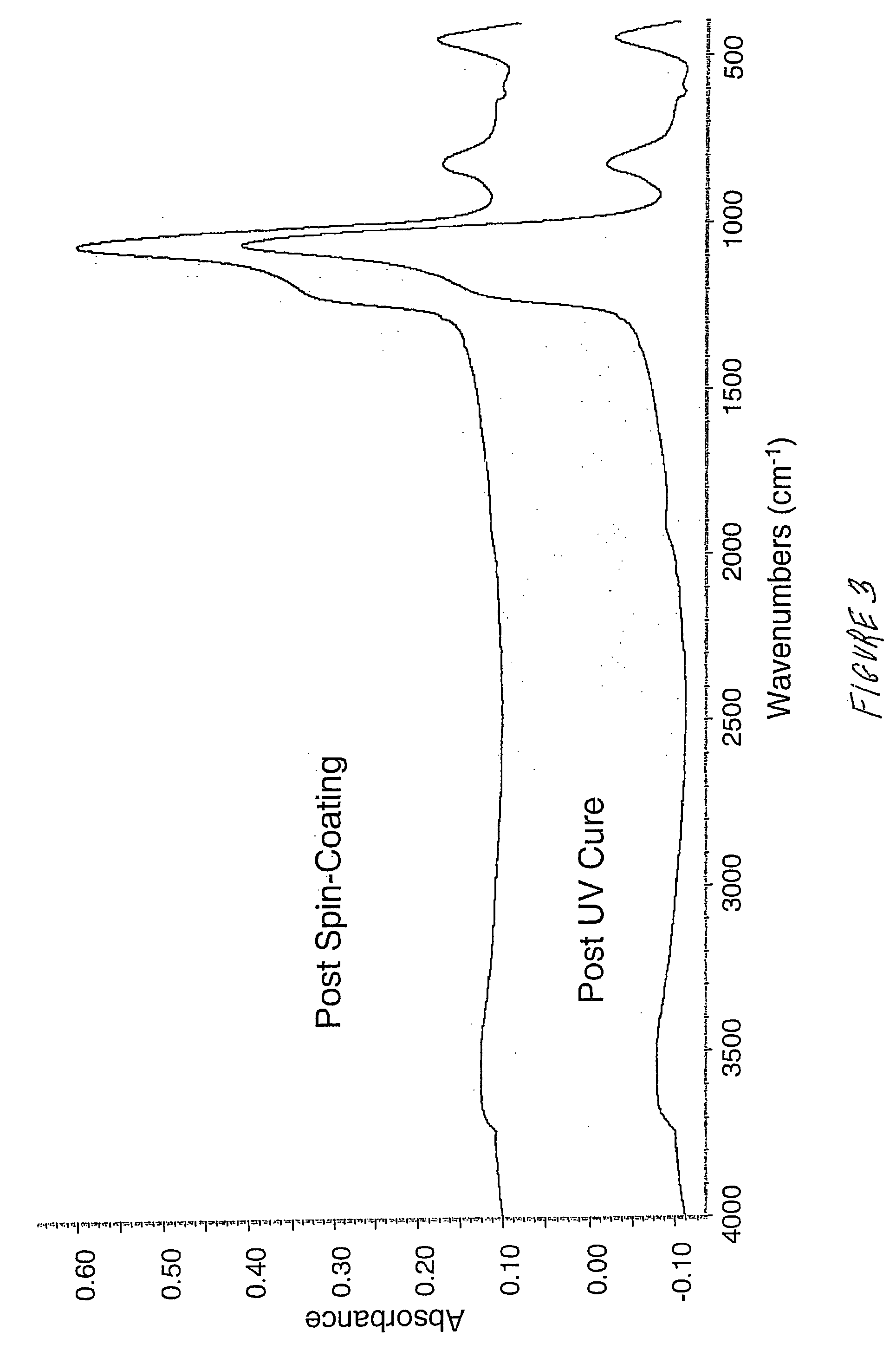

Ultraviolet curing process for spin-on dielectric materials used in pre-metal and/or shallow trench isolation applications

InactiveUS20050272220A1Reduce organic contentSemiconductor/solid-state device manufacturingUV curingUltraviolet radiation

A UV curing process for a dielectric material used in pre-metal and shallow trench isolation applications comprises coating a suitable dielectric material onto a substrate; and exposing the dielectric material to ultraviolet radiation in an amount effective to reduce an organic content and / or increase a density and. / or increase a wet etch resistance of the dielectric material. Optionally, the UV cured dielectric material may be exposed to multiple ultraviolet radiation patterns.

Owner:AXCELIS TECHNOLOGIES

Composition for pressure sensitive adhesive film, pressure sensitive adhesive film, and dicing die bonding film including the same

A composition, including a polymer binder resin A, a UV-curing acrylate B, a heat curing agent C, and a photopolymerization initiator D. The composition includes about 20 to about 150 parts by weight of the UV-curing acrylate B per 100 parts by weight of the polymer binder resin A, and the UV-curing acrylate B is a solid or near-solid at room temperature and has a viscosity of about 10,000 cps or more at 40° C.

Owner:CHEIL IND INC

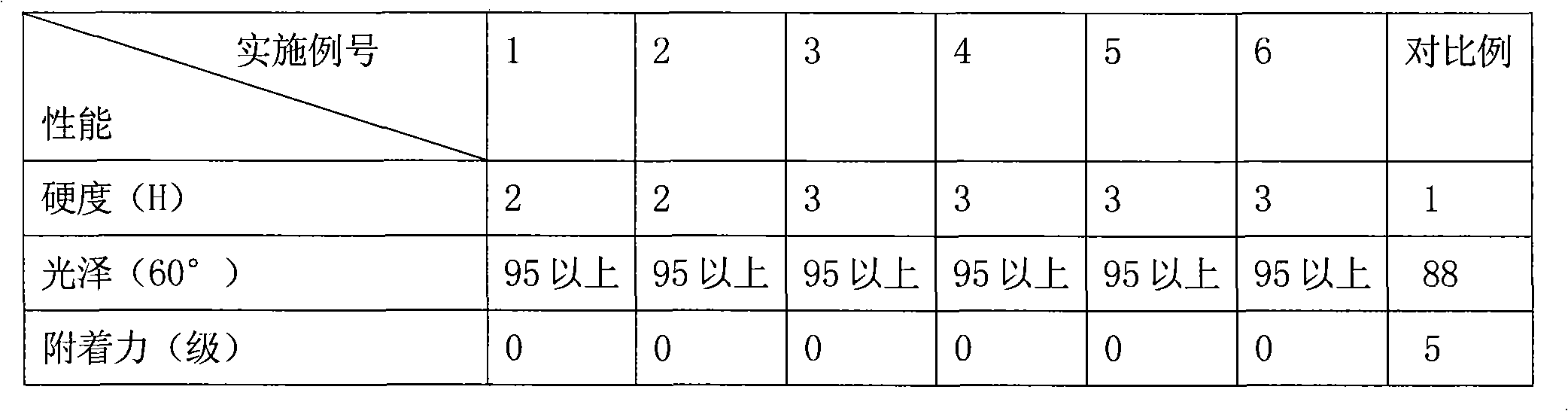

UV curing color decorative coating

InactiveCN101407651ASolve the problem of deep curingAvoid pollutionMulticolor effect coatingsPolyesterUltraviolet

The invention relates to an ultraviolet curing color decorative coating, the components of the coating and the parts by weight thereof are as follows: 5 to 25 parts of epoxy acrylate prepolymer, 5 to 30 parts of polyurethane acrylate prepolymer, 2 to 10 parts of polyester acrylate prepolymer, 15 to 70 parts of acrylate monomer, 1 to 10 parts of photoinitiator, 1 to 35 parts of pigment, 0.5 to 10 parts of dispersant and 0.1 to 2 parts of auxiliary agent, the acrylate monomer is a mixture of the monomer with bifunctionality and the monomer with high functionality, wherein, the mixture ratio of the monomer with high bifunctionality to the monomer with bifunctionality is 1: 0.3 to 8. Compared with an ultraviolet curing transparent varnish, the ultraviolet curing color decorative coating has stronger decorative effect and almost the same curing speed, paint film hardness, adhesion, paint film gloss, and the like; and compared with a traditional solvent based colored paint, the ultraviolet curing color decorative coating does not contain volatile organic solvent, thereby avoiding the pollution and greatly improving the production efficiency. The ultraviolet curing color decorative coating is applicable to the decoration of plastics, wood materials, metals and other base materials.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

Ink jet UV curing

InactiveUS7137696B2Avoid runningDrying solid materials with heatPretreated surfacesUV curingLed array

A method and apparatus for printing a product, article or other object at a printing station and for enhancing the application of UV light to UV photo initiators in a UV curable ink being applied to a product, article or other object at the printing station, comprising the steps for: printing a UV-curable ink with a printing head of a printer on a substrate, product, article or other object at a printing station; providing a primary light source of UV light preferably comprising at least one set of UV-LED arrays of UV-LED chips adjacent the printing head; and partially curing the ink dots by emitting light on the ink dots from the primary light source to set and partially polymerize, coalesce, coagulate and / or gel the ink dots so as to substantially inhibit the growth of the ink dots and prevent, running or smudging of the ink dots. The curing of the ink dots are completed by emitting light on the ink dots from a secondary light source, such as from one or more fluorescent lamps.

Owner:CON TROL CURE

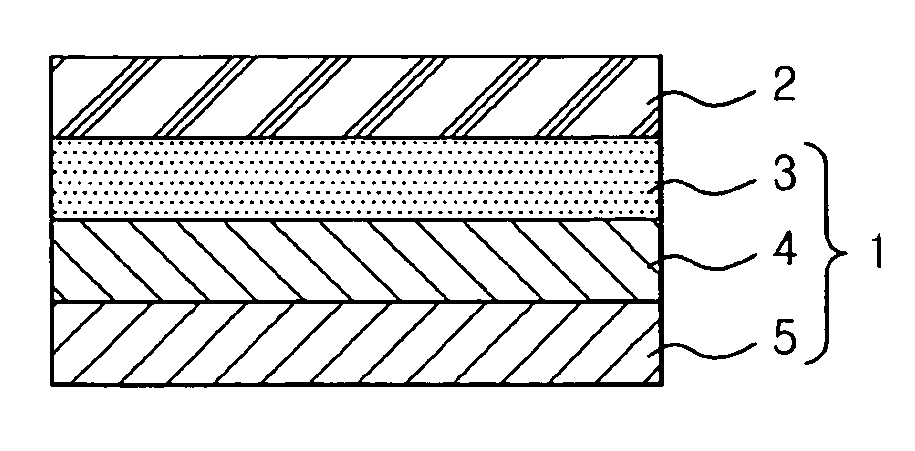

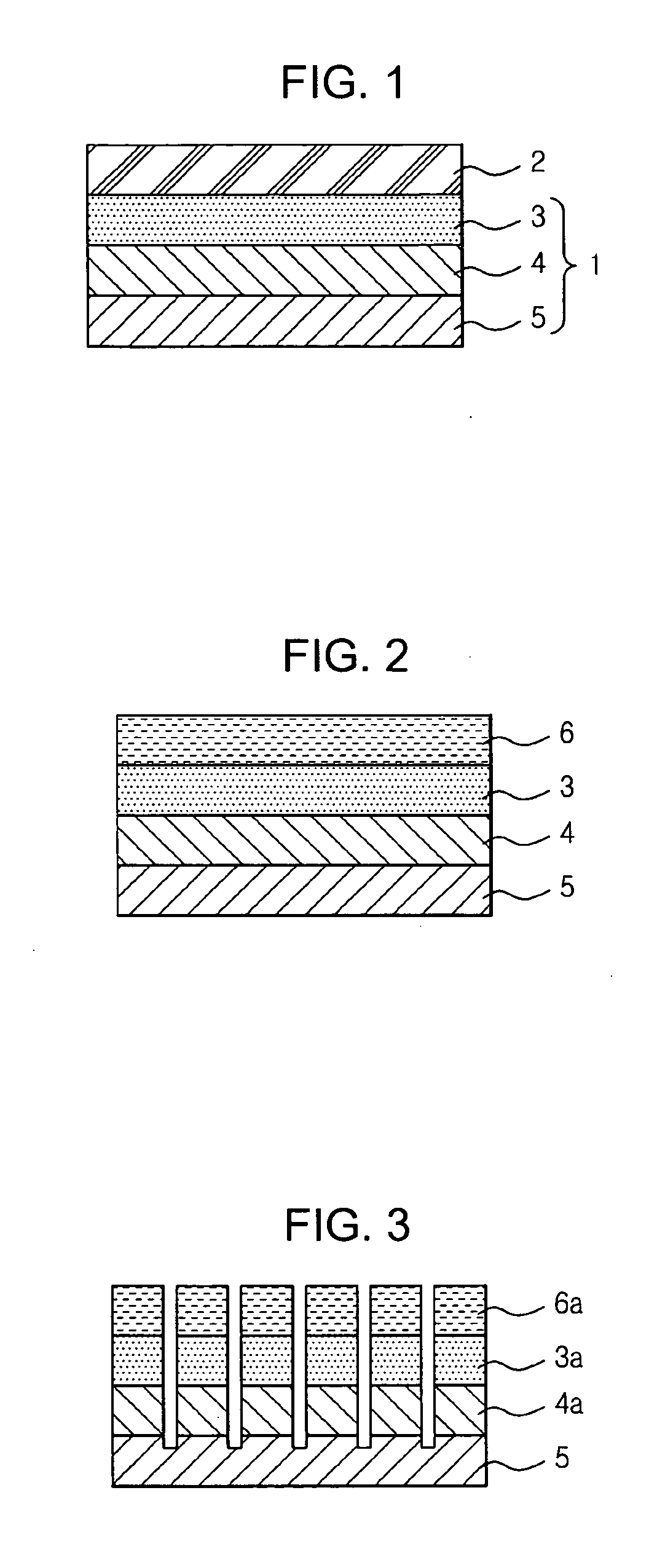

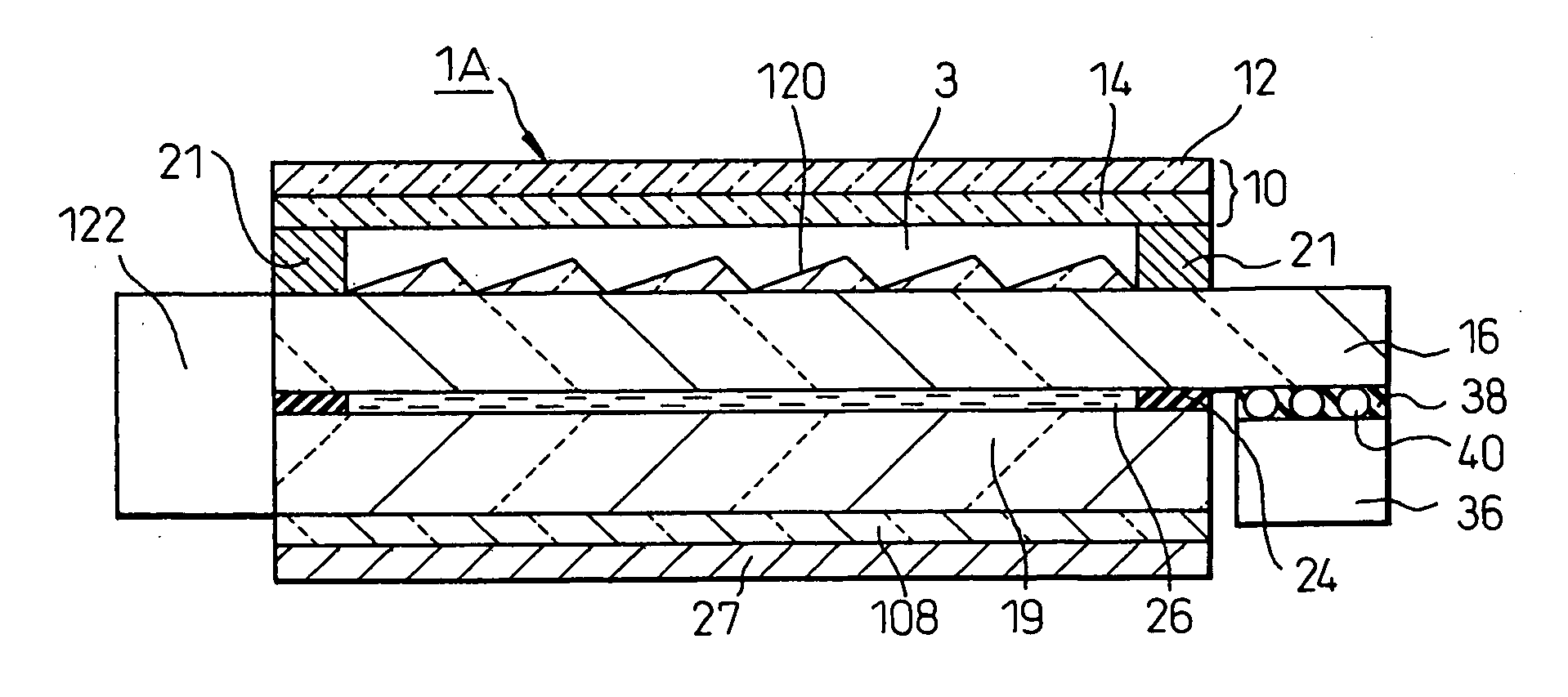

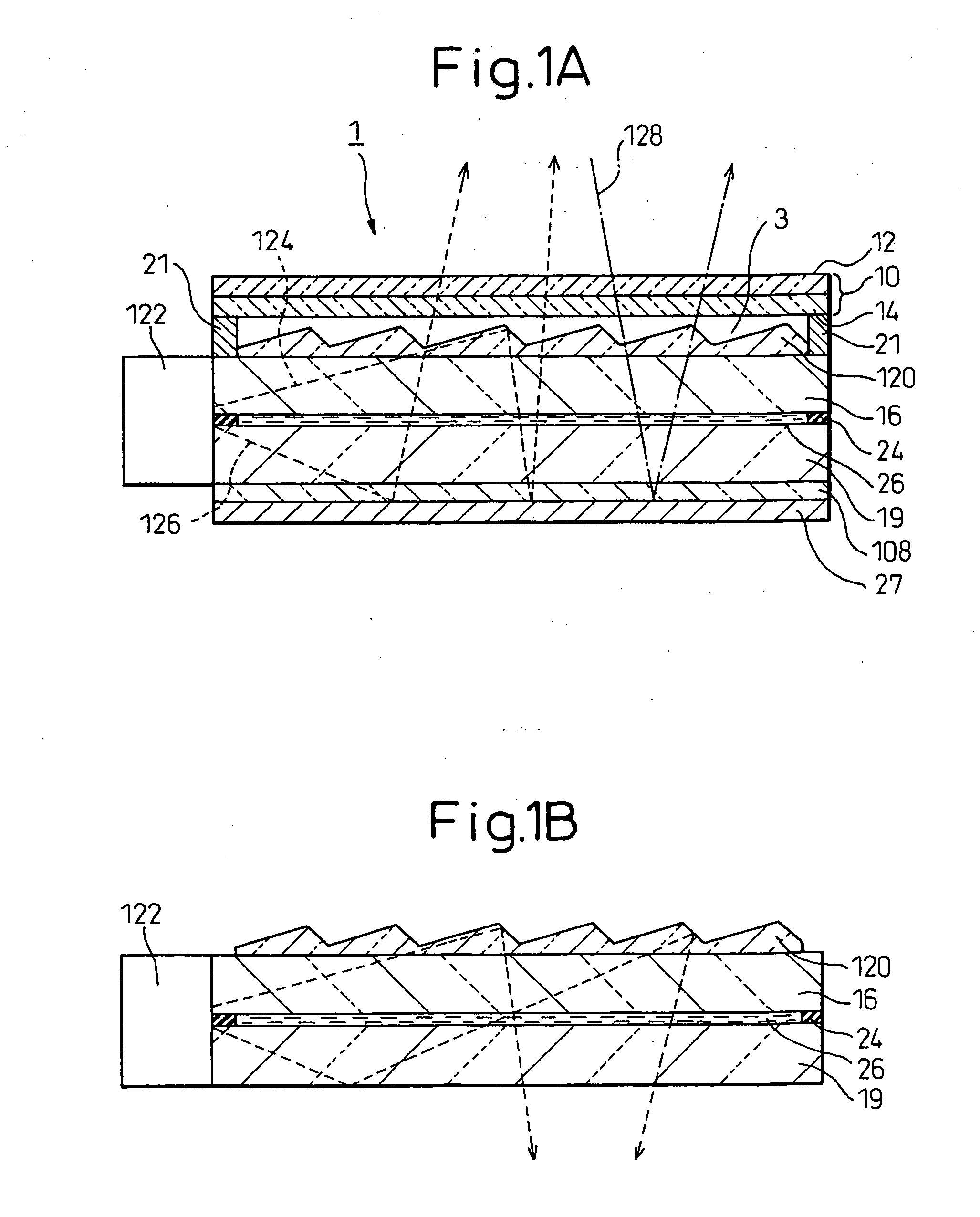

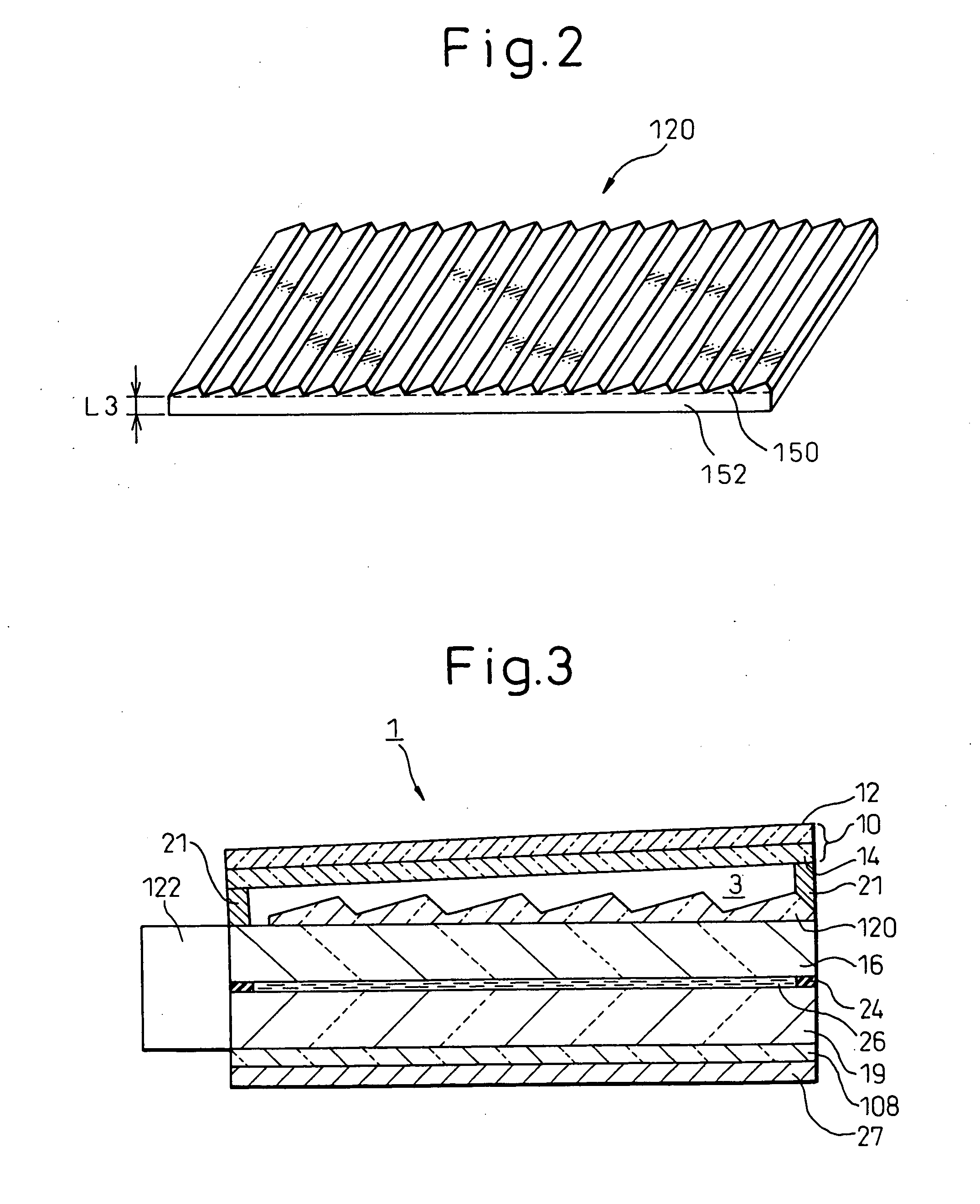

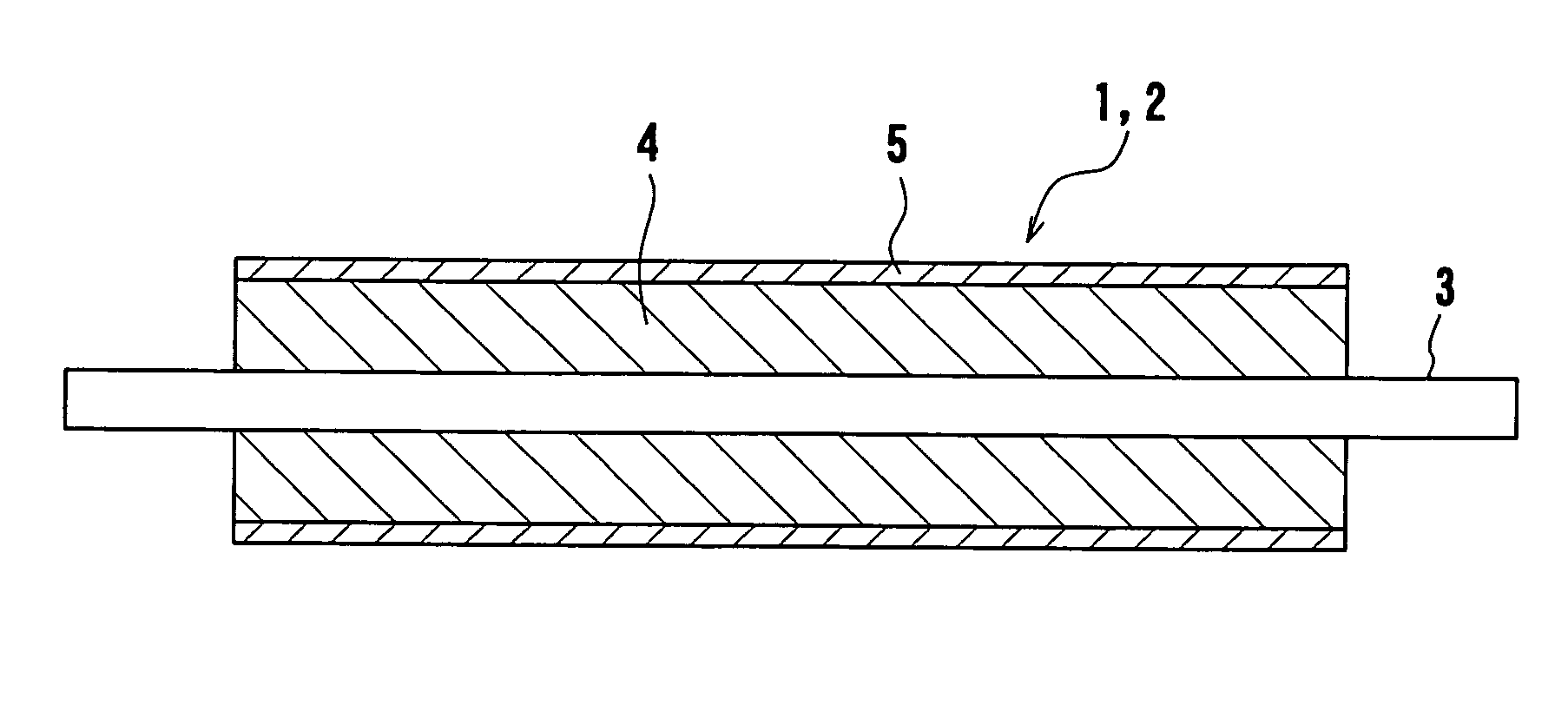

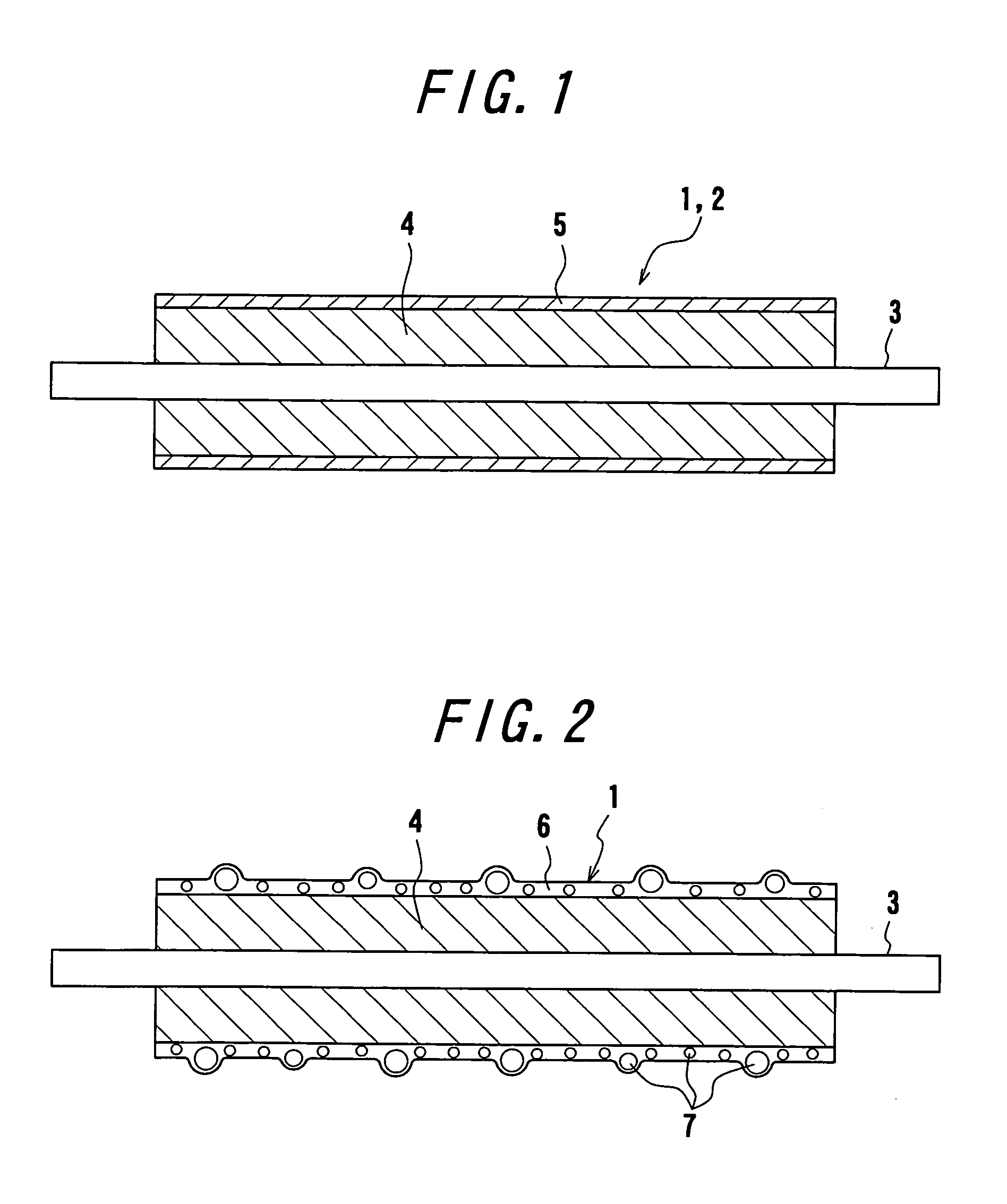

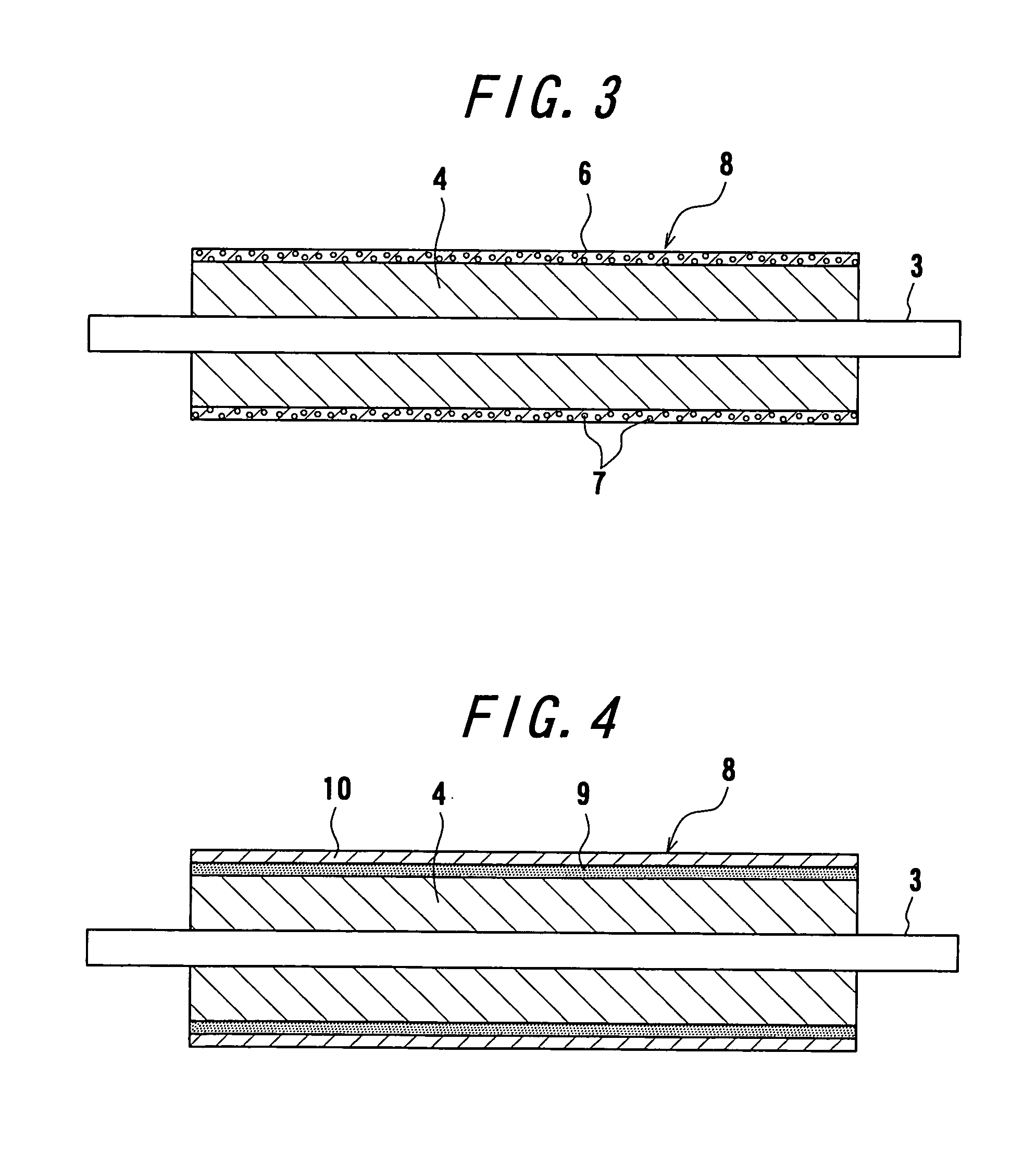

Display device employing light control member and display device manufacturing method

InactiveUS20050041175A1Prevent leakageReduce manufacturing costNon-linear opticsUV curingDisplay device

A liquid crystal is sealed with a sealing member between first and second transparent substrates, whereby a liquid crystal cell capable of transmitting ultraviolet light is produced. The liquid crystal cell is inserted into a mould into which an ultraviolet-setting resin is dropped and which is used to produce a light control member. The ultraviolet-setting resin is pressed to be bonded to the liquid crystal cell. In this state, ultraviolet light is irradiated to the liquid crystal cell in the mould from outside the mould. Thus, the ultraviolet-setting resin is set while bonding to the liquid crystal cell. Thereafter, the liquid crystal cell is removed from the mould. Consequently, the light control member is directly formed on the liquid crystal cell.

Owner:CITIZEN WATCH CO LTD

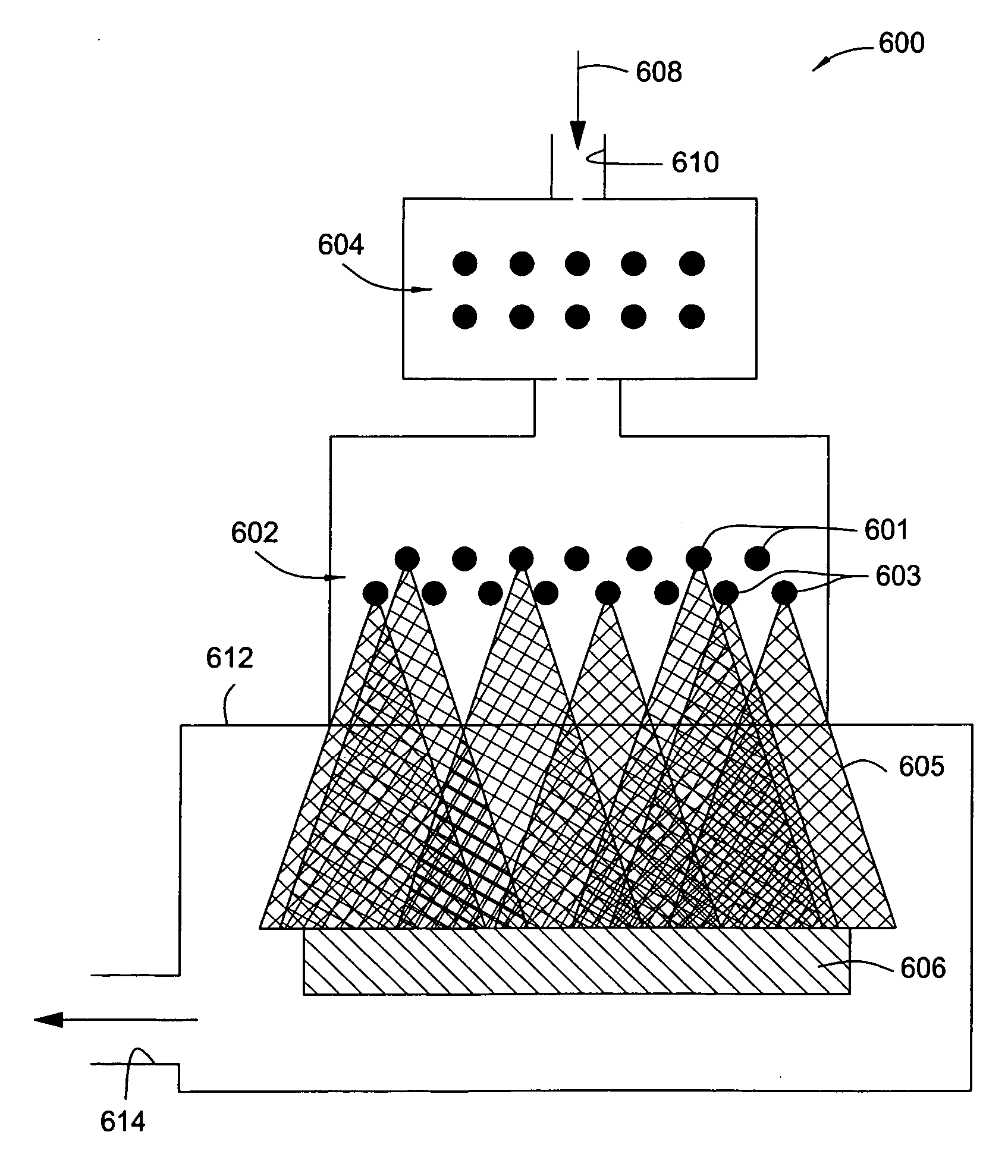

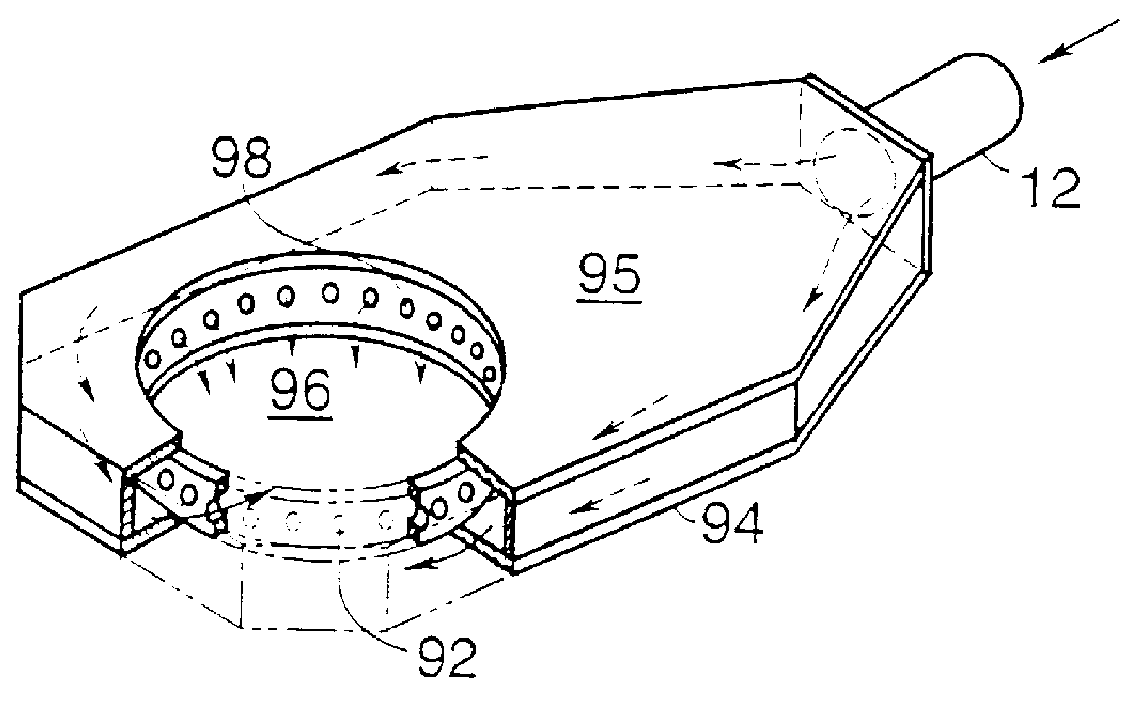

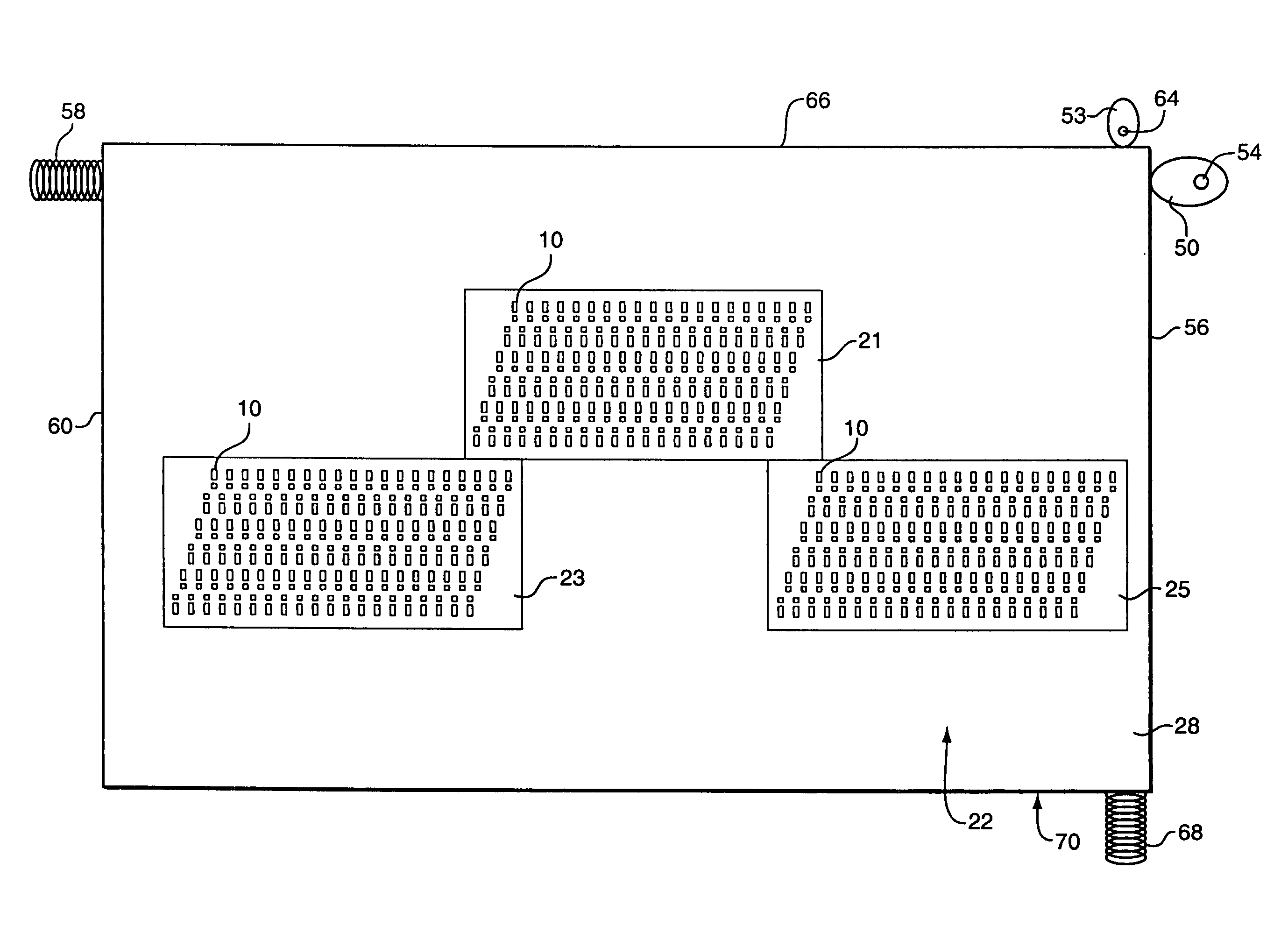

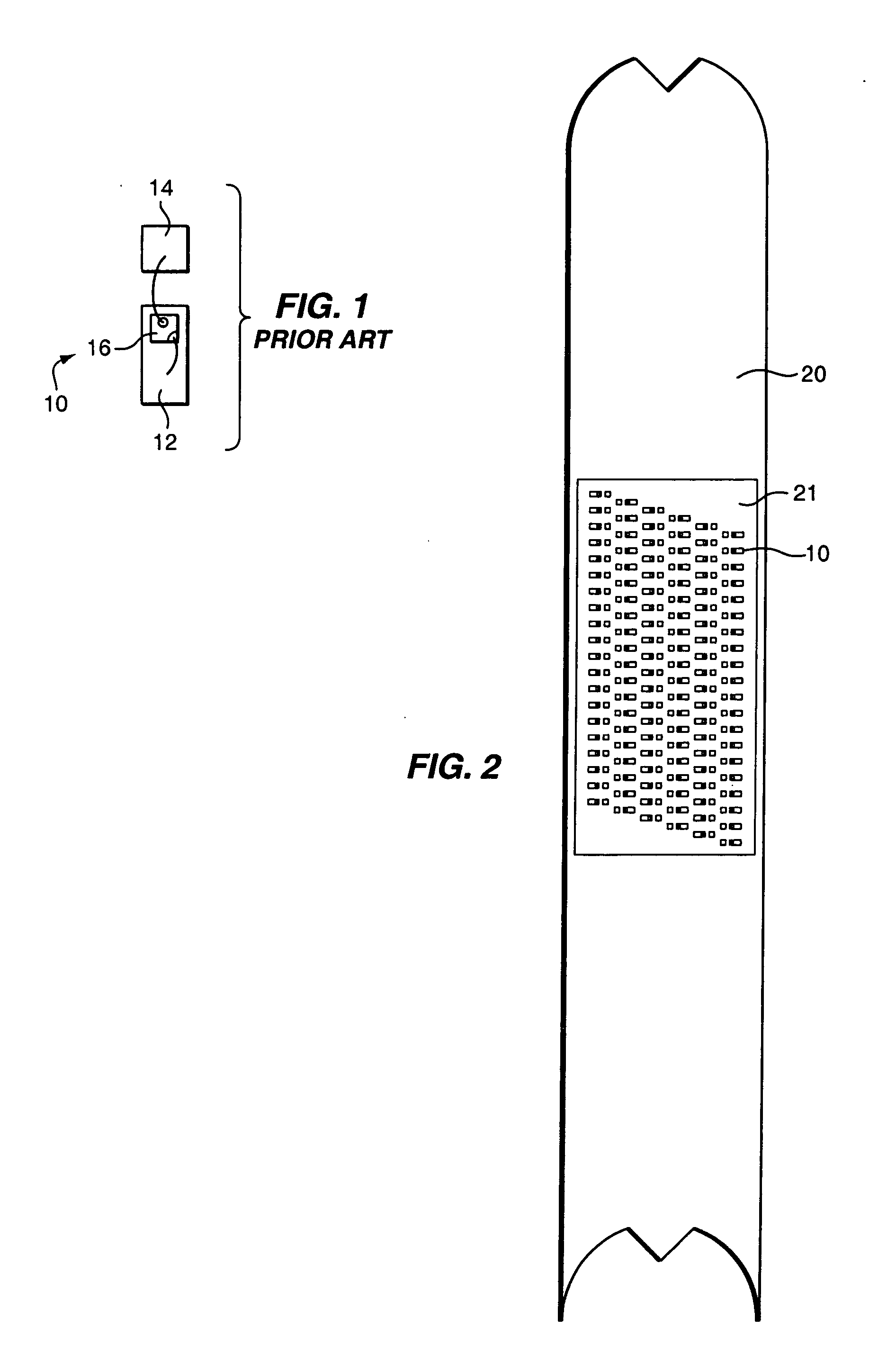

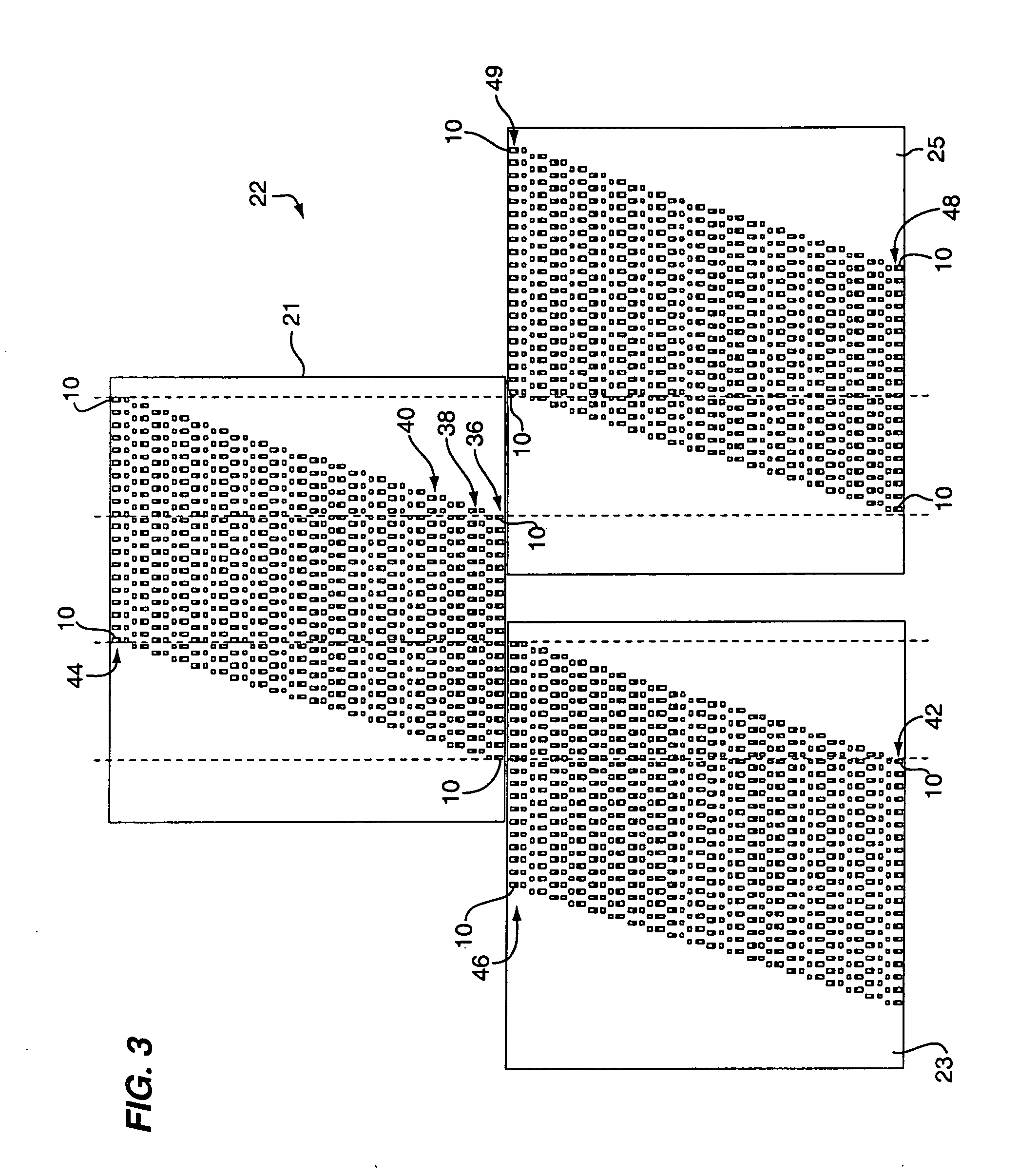

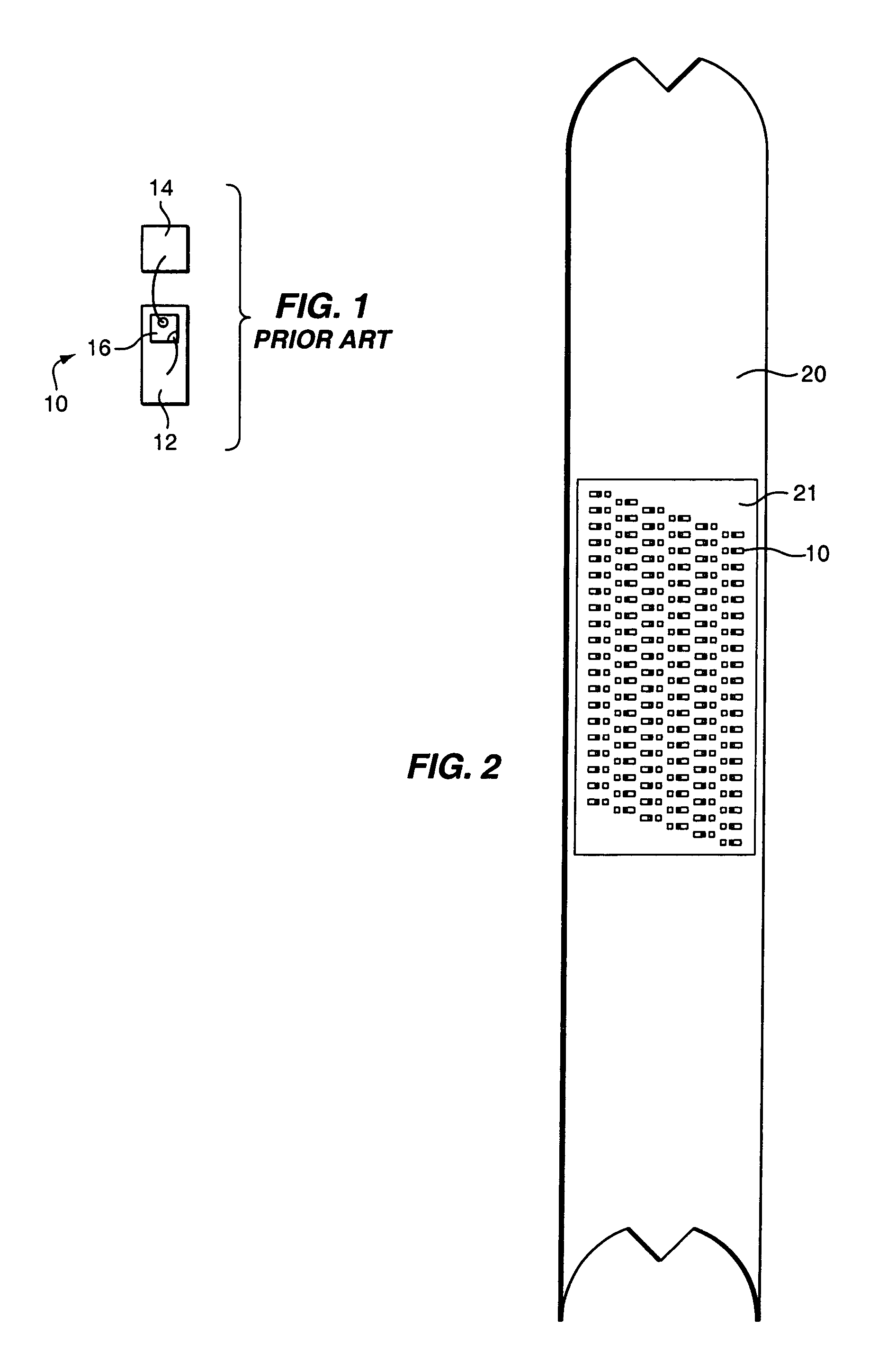

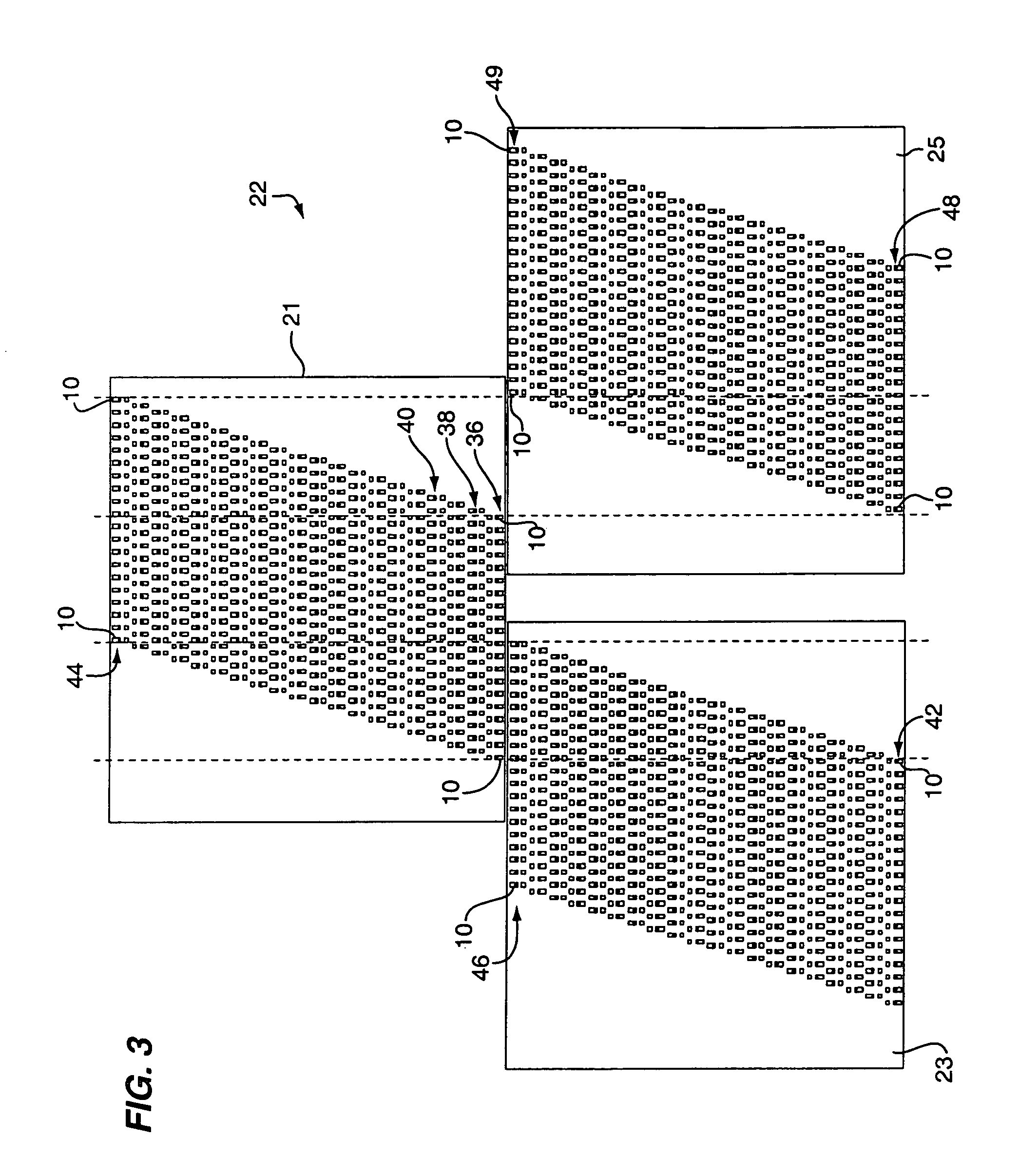

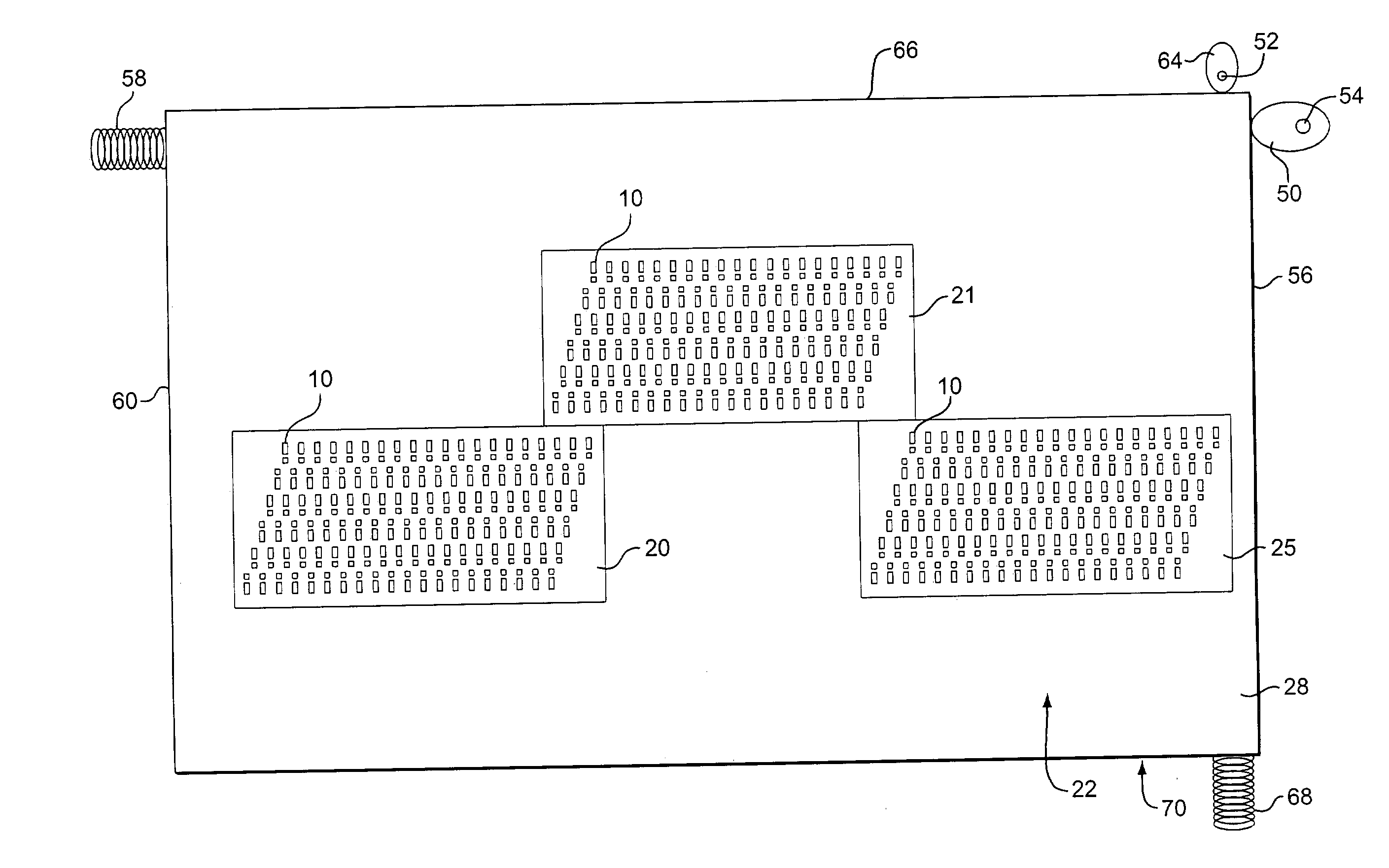

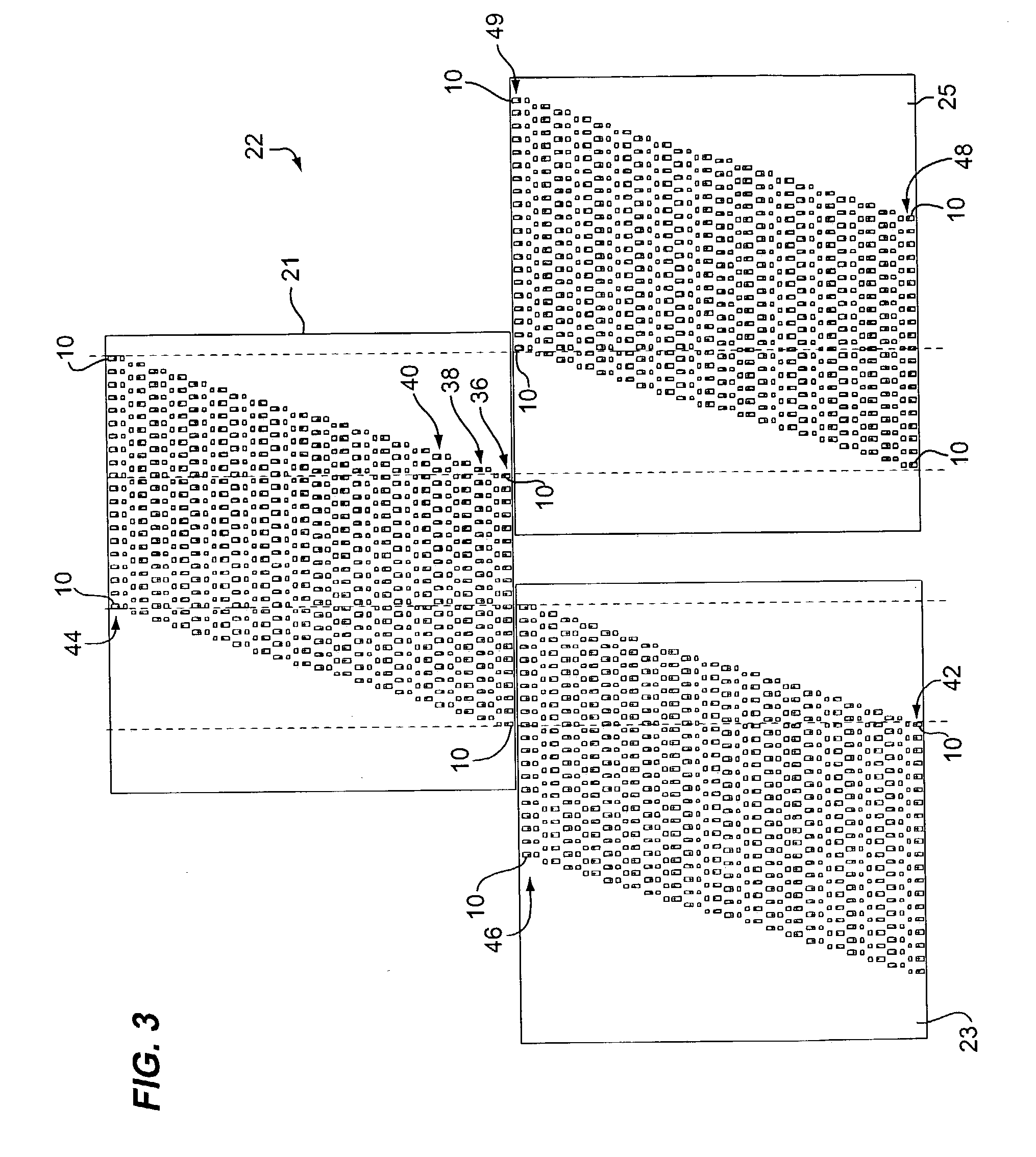

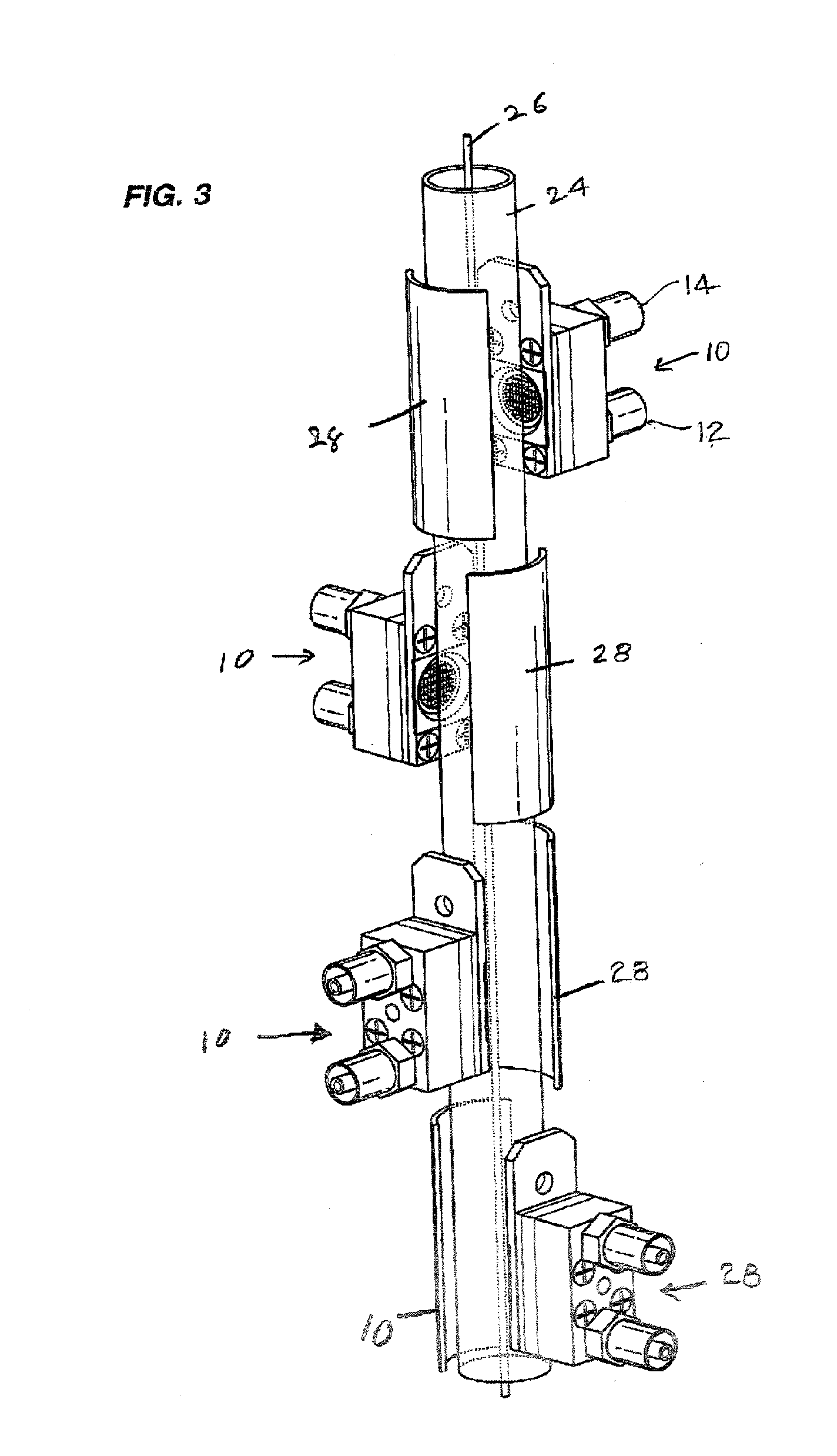

Light emitting apparatus and method for curing inks, coatings and adhesives

InactiveUS7175712B2Minimizing creationOptical radiation measurementDrying solid materials with heatUV curingEngineering

A UV curing apparatus and method is provided for enhancing the distribution and application of UV light to UV photo initiators in a UV curable ink, coating or adhesive. The UV curing apparatus and method comprises UV LED assemblies in a first row with the UV LED assemblies spaced from adjacent UV LED assemblies. At least one second row of a plurality of UV LED assemblies are provided next to the first row but with the UV LED assemblies of the second row positioned adjacent the spaces between adjacent UV LED assemblies in the first row thereby to stagger the second row of UV LED assemblies from the UV LED assemblies in the first row. Desirably, the rows of staggered UV LED assemblies are mounted on a panel. UV curable products, articles or other objects containing UV photo initiators that are in or on a web can be conveyed or otherwise moved past the rows of UV LED assemblies for effective UV curing. This arrangement facilitates more uniformly application of UV light on the UV curable ink, coating and / or adhesives in the UV curable products, articles or other objects. The apparatus can include one or more of the following: rollers for moving the web, mechanisms for causing the panel to move in an orbital or reciprocal path, and an injection tube for injecting a non-oxygen gas in the area of UV light curing.

Owner:CON TROL CURE

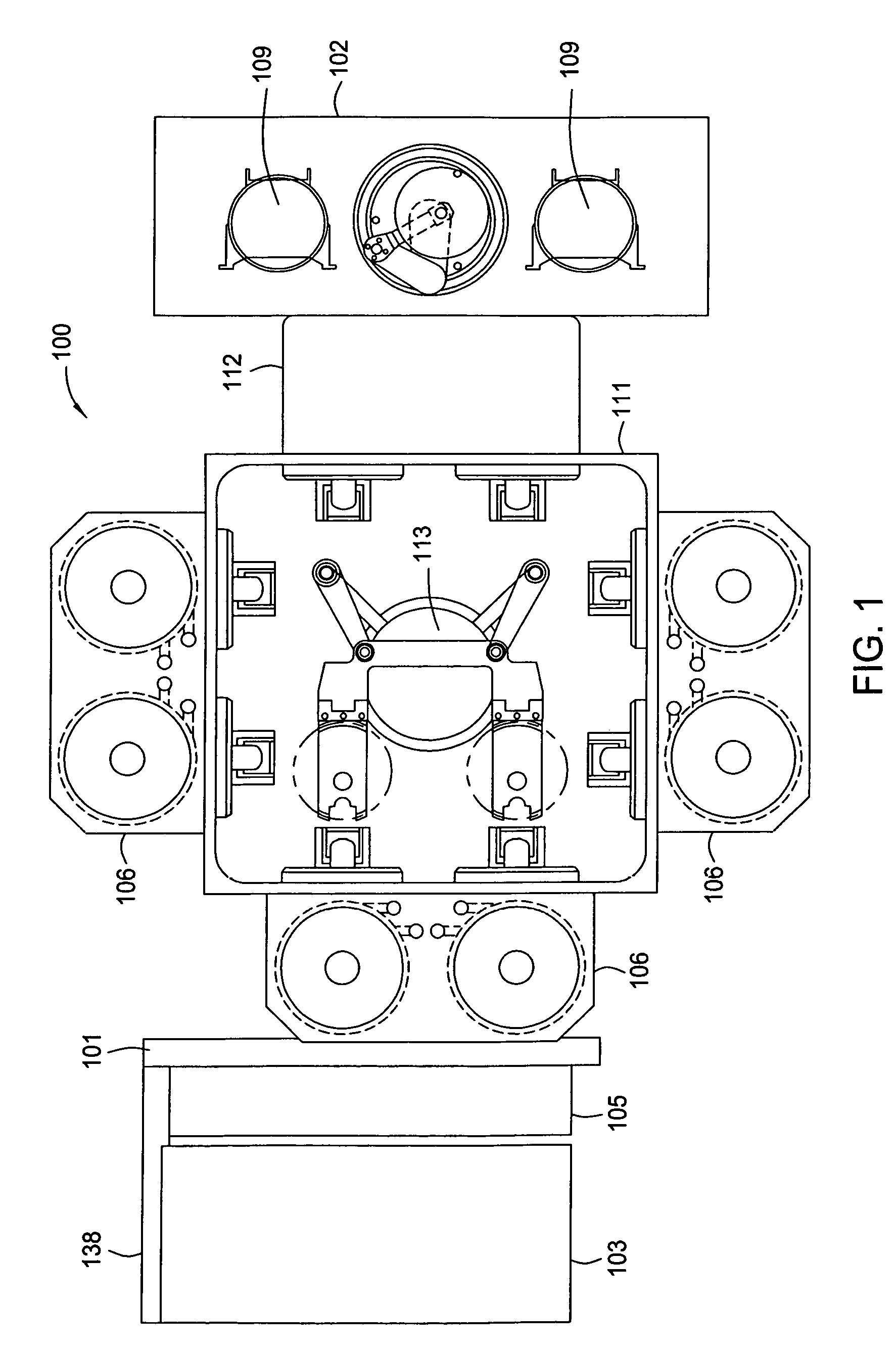

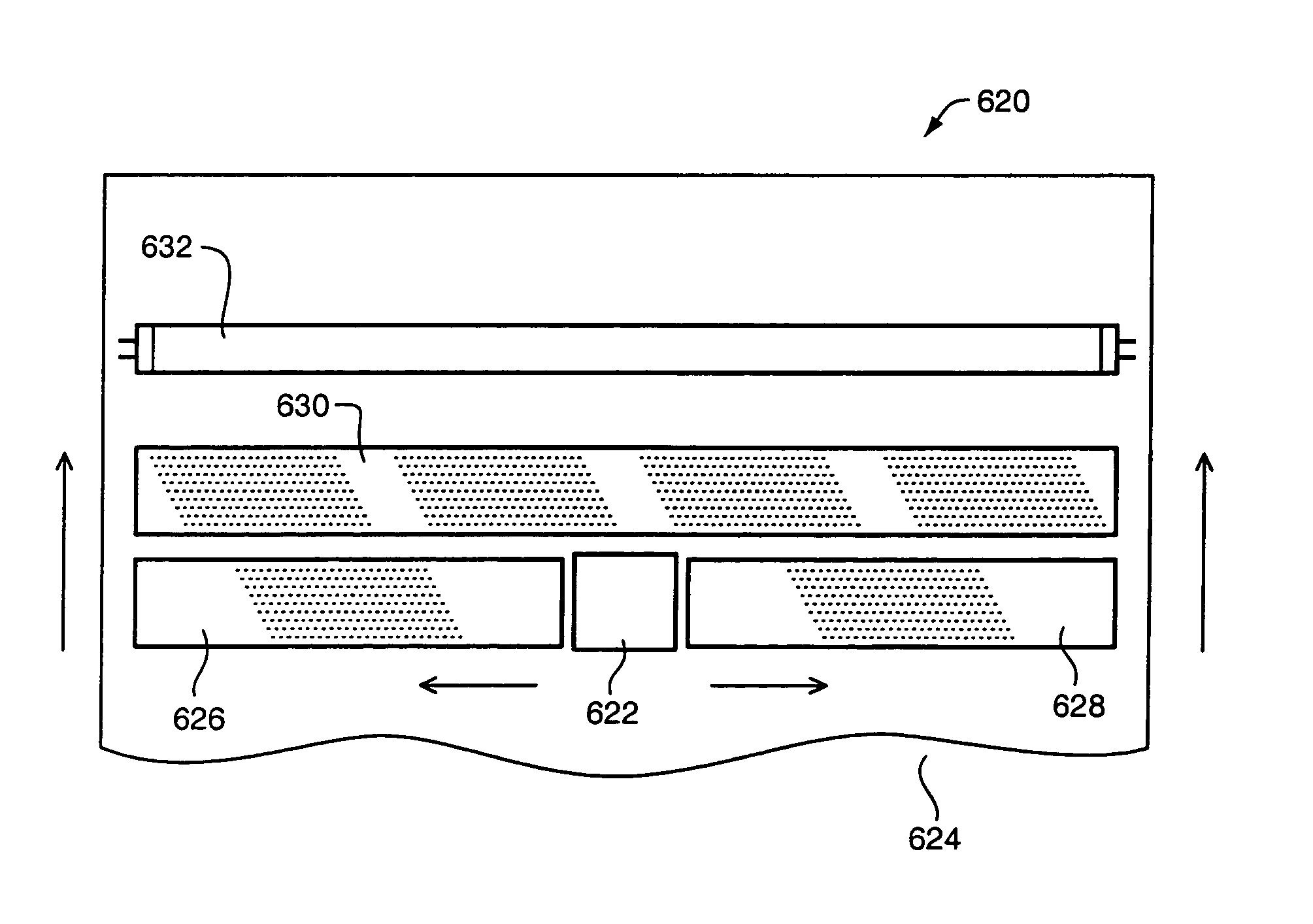

High efficiency UV curing system

ActiveUS20060249078A1Improve uniformityMaterial analysis using wave/particle radiationElectric discharge tubesUltravioletRelative motion

An ultraviolet (UV) cure chamber enables curing a dielectric material disposed on a substrate and in situ cleaning thereof. A tandem process chamber provides two separate and adjacent process regions defined by a body covered with a lid having windows aligned respectively above each process region. One or more UV bulbs per process region that are covered by housings coupled to the lid emit UV light directed through the windows onto substrates located within the process regions. The UV bulbs can be an array of light emitting diodes or bulbs utilizing a source such as microwave or radio frequency. The UV light can be pulsed during a cure process. Using oxygen radical / ozone generated remotely and / or in-situ accomplishes cleaning of the chamber. Use of lamp arrays, relative motion of the substrate and lamp head, and real-time modification of lamp reflector shape and / or position can enhance uniformity of substrate illumination.

Owner:APPLIED MATERIALS INC

UV Curing System and Process with Increased Light Intensity

InactiveUS20050222295A1Quickly and efficiently and cureImprove curingPhotomechanical apparatusMaterial analysis by optical meansUses eyeglassesUV curing

A special method is provided for more uniformly and quickly curing products with a scratch-resistant UV curable coating or UV curable printing thereon with high intensity UV light, such as for wires, cables, tubes, tubing, hoses, pipes, CDs, DVDs, golf balls, golf tees, eye glass lenses, contact lenses, string instruments, decorative labels, peelable labels, peelable stamps, doors, countertops, etc. The method can also be operated with one or more special UV curing apparatus equipped with a controller and one or more super high power UV-LED modules.

Owner:CON TROL CURE

Highly wearable vacuum coating ultraviolet curing coatings

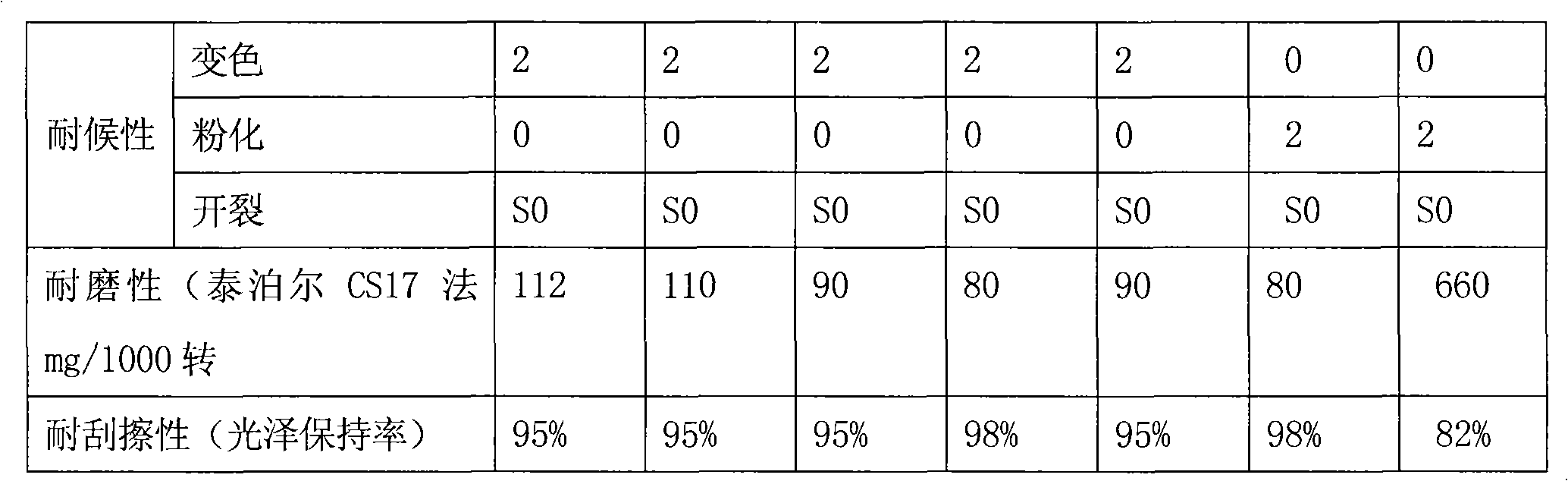

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

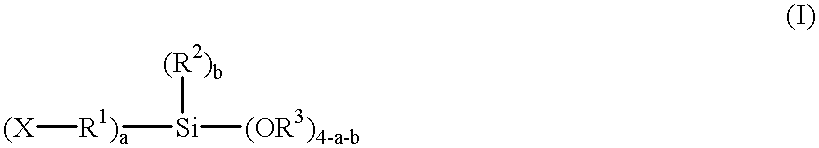

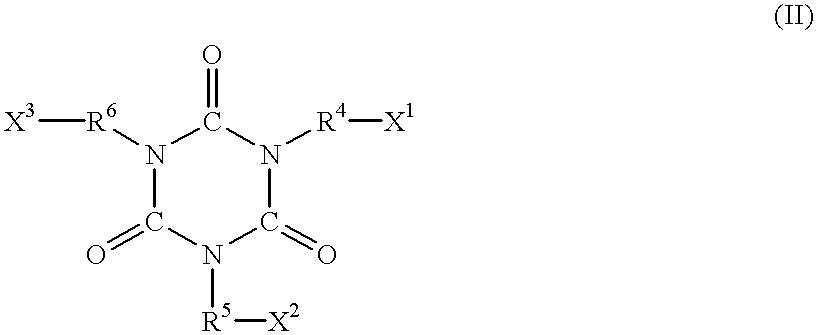

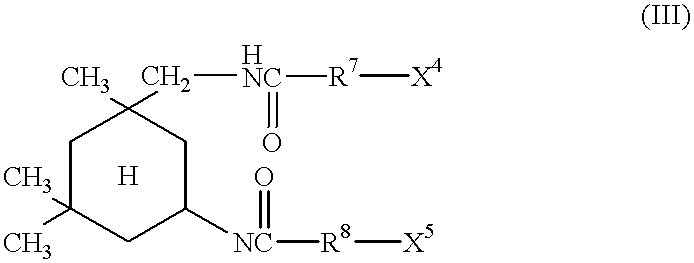

Coating composition forming wear-resistant coat and article covered with the coat

A coating composition forming a abrasion resistant coating comprising (A) an ultraviolet-curable silicone prepared by chemically modifying particulate colloidal silica with a specific silane compound, (B) a monomer mixture comprising a (meth)acrylate having a specific isocyanate skeleton and a urethane poly(meth)acrylate having an alicyclic skeleton, and (C) a photo-polymerization initiator. By using a urethane poly(meth)acrylate having an alicyclic skeleton as part of the component (B) and the component (A) having an enhanced reactivity of chemical modification, the compatibility of the component (A) with the component (B) is improved to give a cured coating with excellent wear resistance, weather resistance and durability.

Owner:MITSUBISHI RAYON CO LTD

On demand printer apparatus and method with integrated UV curing

InactiveUS6350071B1Premature curingInking apparatusOther printing apparatusUV curingUltraviolet radiation

The invention pertains to on demand printers such as thermal transfer, ink jet, laser, impact, and the like. More particularly, the invention discloses printers and methods for depositing an ultraviolet curable ink onto a printable item, and curing the ink with ultraviolet radiation emitted from the device. The ultraviolet light may be emitted from a curing station which is integral with or remotely connected to the printing apparatus.

Owner:INTERMEC IP

Developing Roller, Charging Roller, Conductive Roller and Method for Producing the Same

ActiveUS20080292366A1Improve propertiesImprove image qualityShaft and bearingsMetal-working apparatusUV curingUltraviolet

This invention relates to a conductive roller such as a developing roller, a charging roller or the like provided with a resin coating calyer on a surface of an elastic layer, and more particularly to a conductive roller having the resin coating layer using an ultraviolet-curing type resin or an electron beam curing type resin and being obtained by contriving a structure of the resin coating layer, rendering the resin coating layer to contain microparticles, controlling the particle size of the microparticles, or forming the resin coating layer after the outer peripheral surface of the elastic layer is subjected to surface treatment.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com