Patents

Literature

680results about How to "Control generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

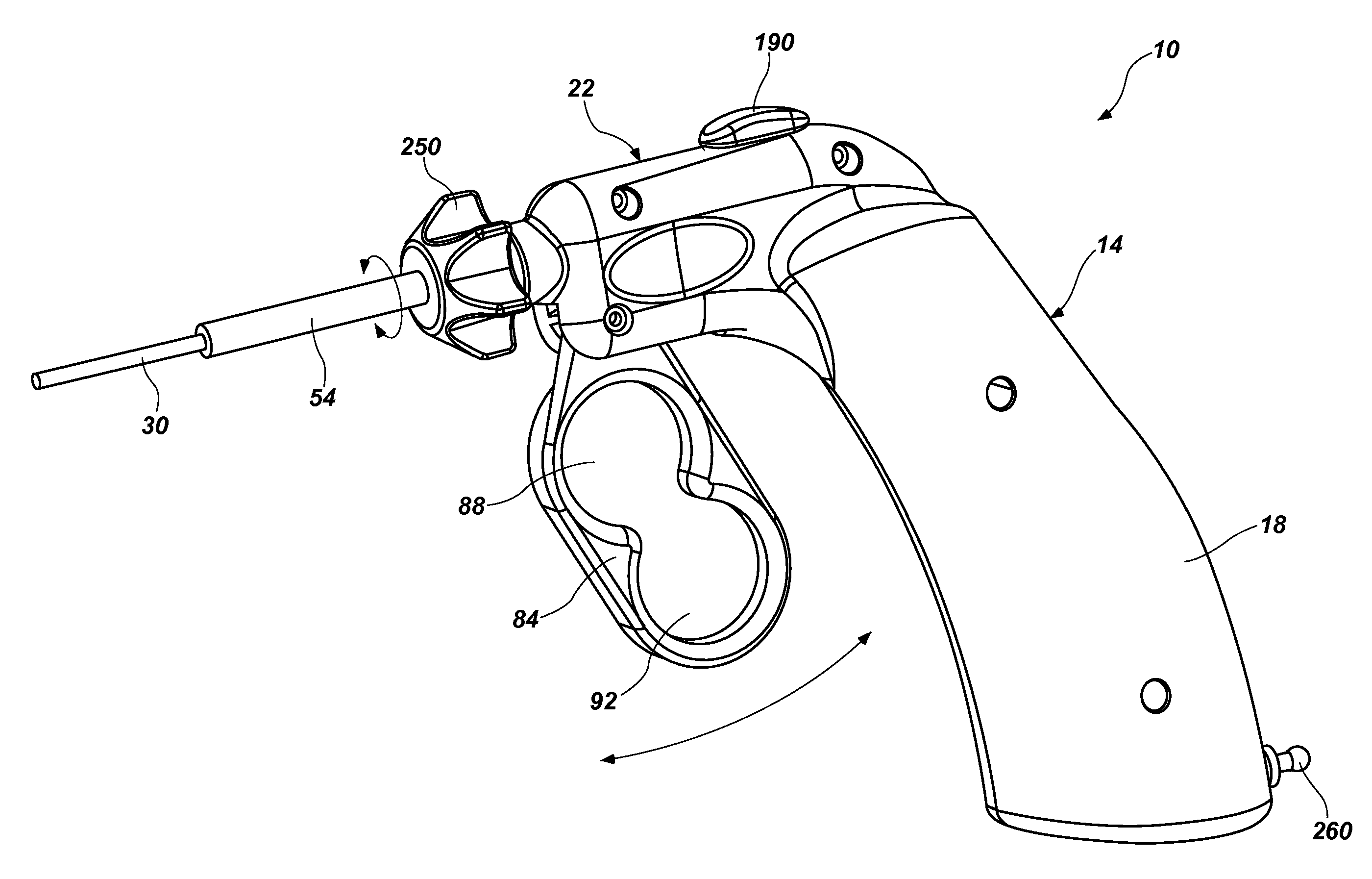

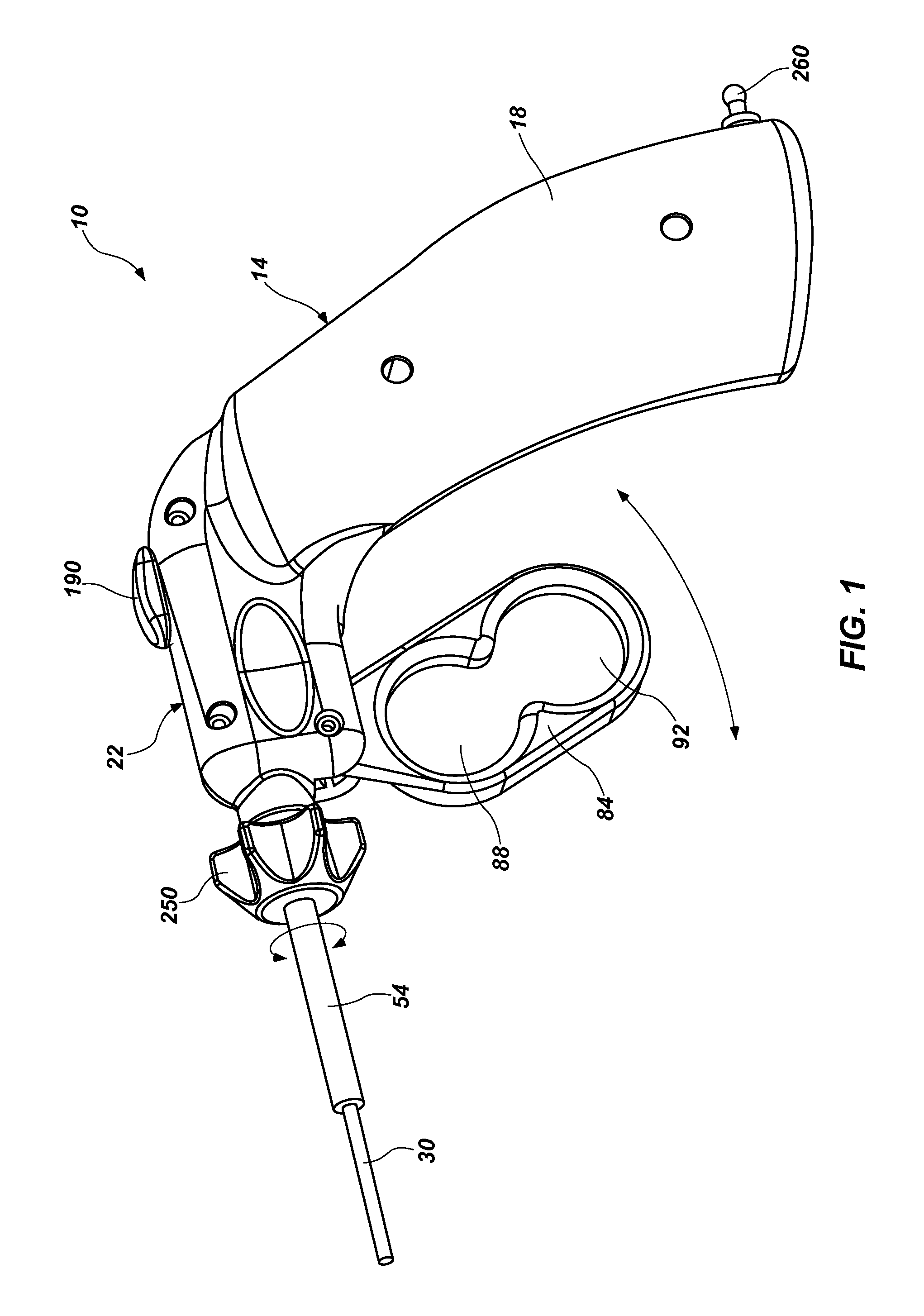

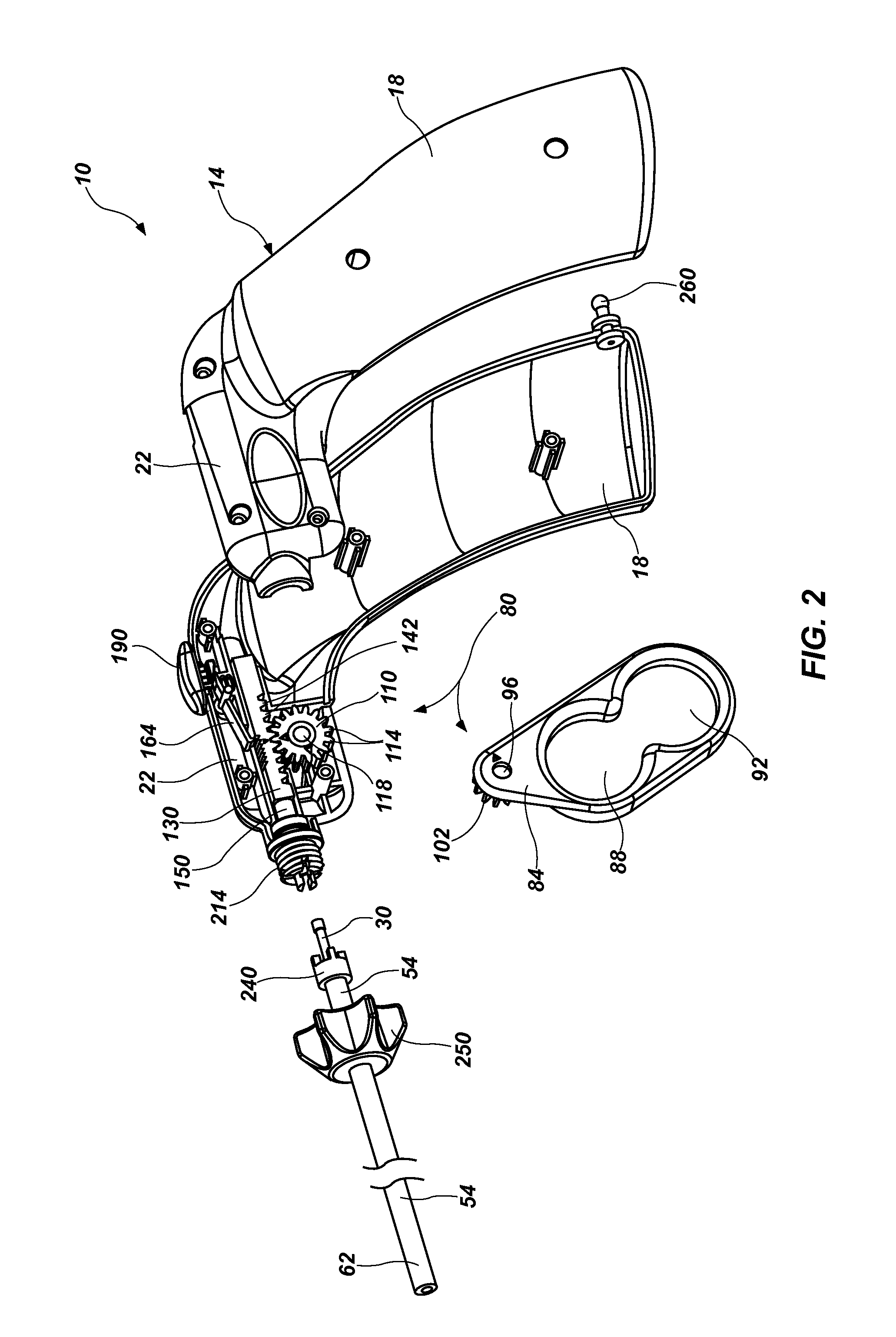

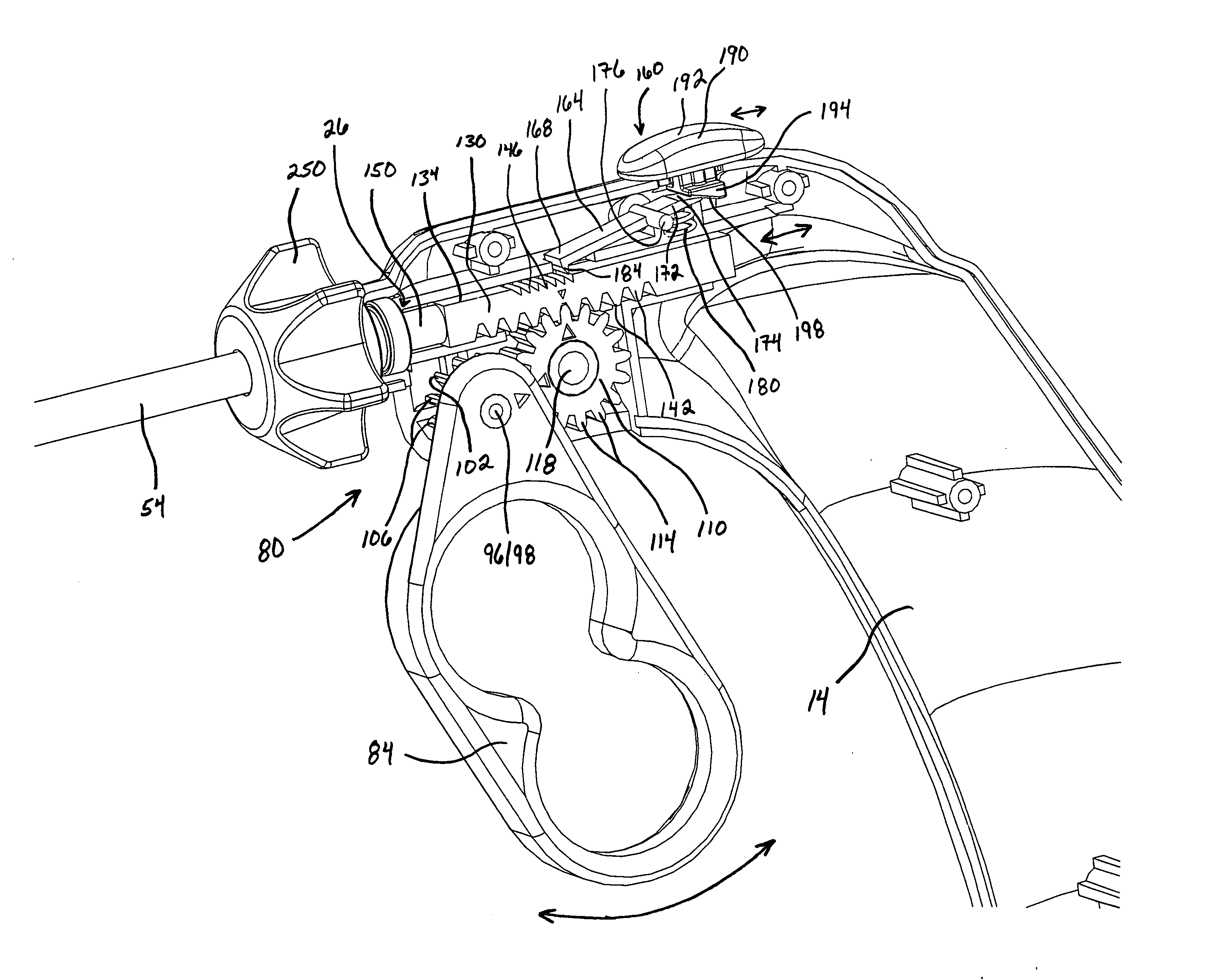

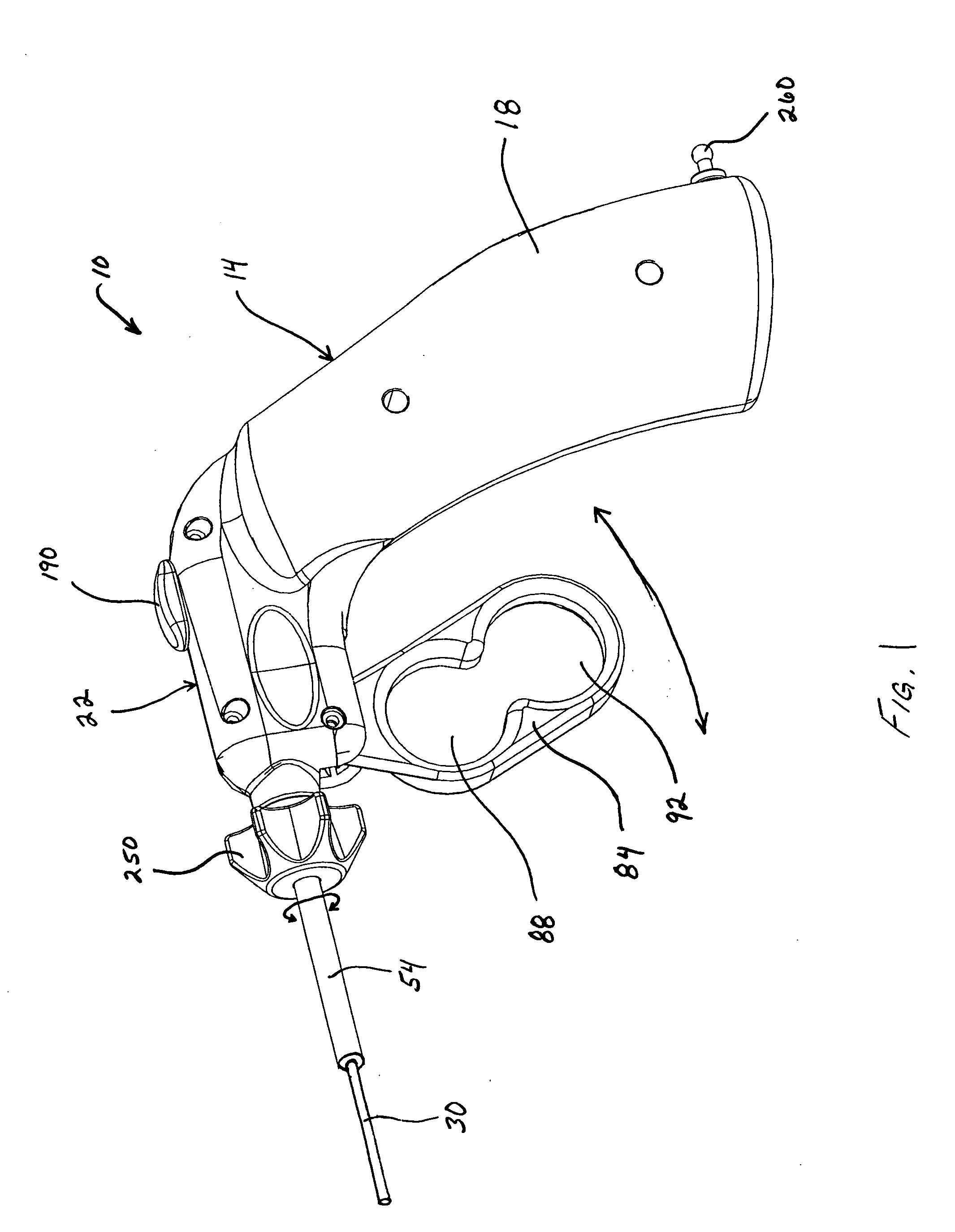

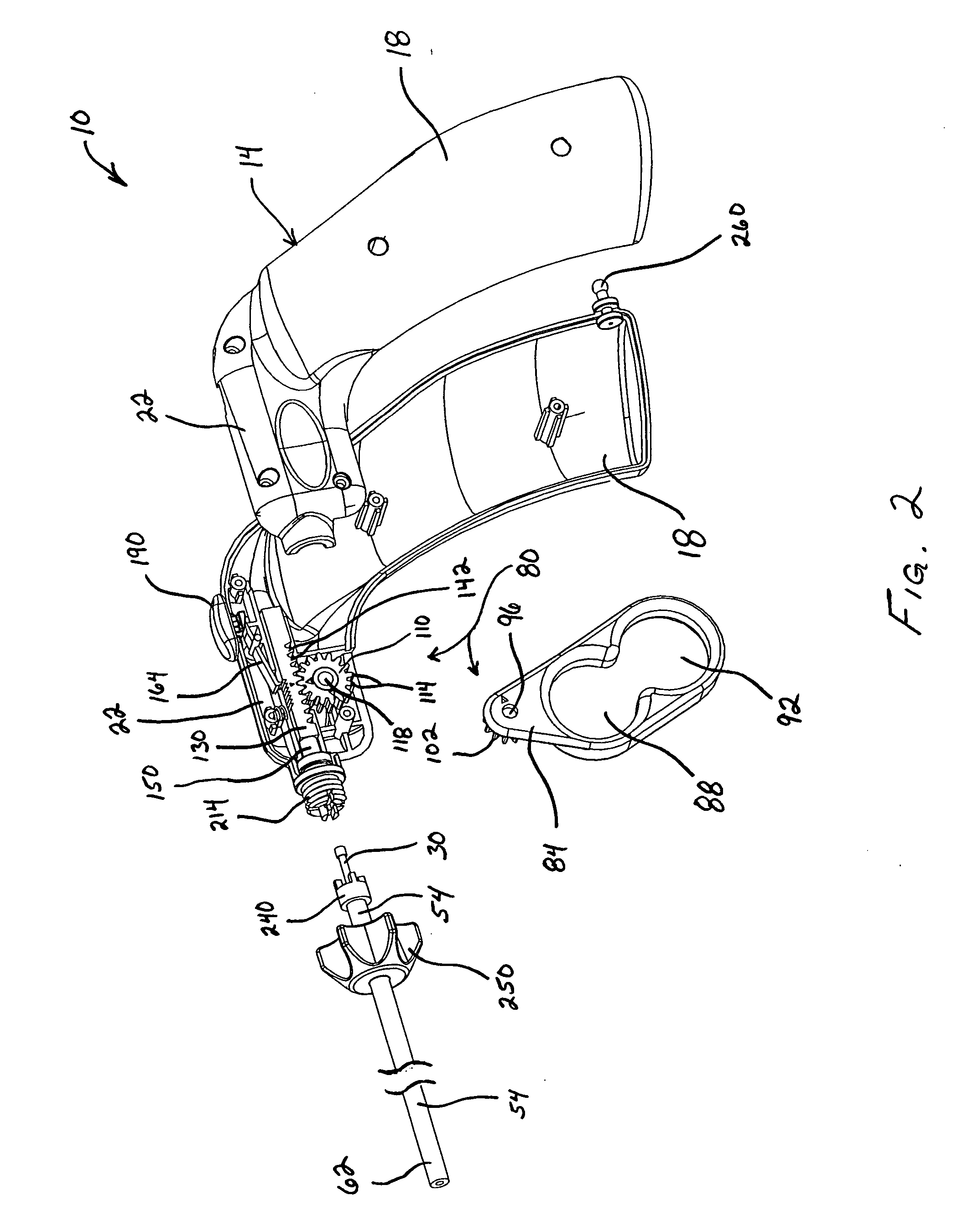

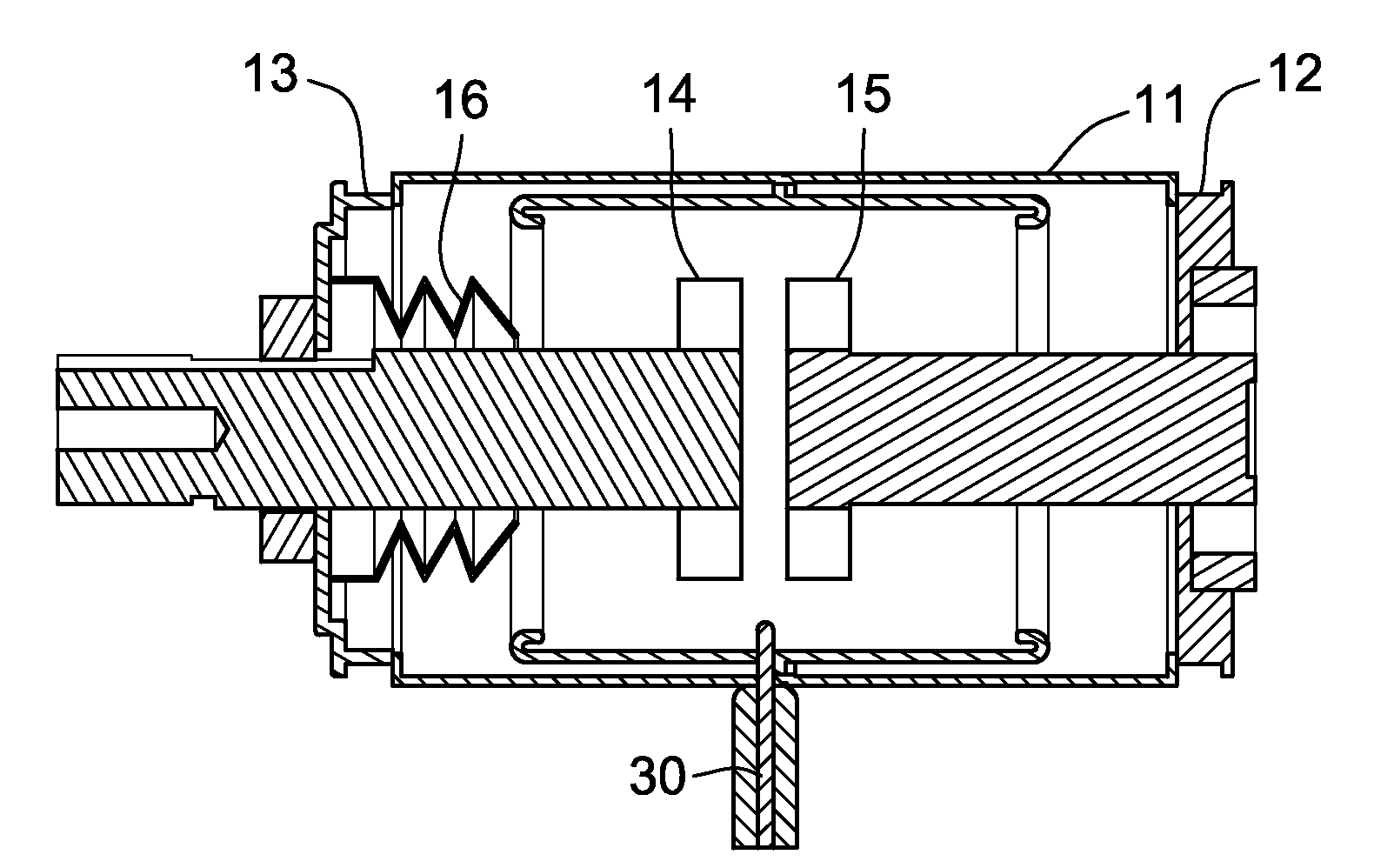

Laparoscopic surgical instrument

A laparoscopic surgical instrument configured to be ergonomic and anthropometrically correct, the laparoscopic surgical instrument comprising: (a) an ergonomic handle configured to orient a hand of a surgeon in a functional position, the handle comprising a handle grip; (b) an actuating mechanism actuatable by a finger and supported by the handle, the actuating mechanism comprising an actuator shaft and a gearing assembly operable to displace the actuator shaft with a mechanical advantage upon actuation of a trigger by the surgeon; (c) a locking mechanism configured to lock the actuating mechanism in one of a plurality of positions, the locking mechanism comprising a release located in an anthropometrically correct position; and (d) a working shaft having a proximal end coupled to and operable with the actuator shaft, the working shaft having an elongate configuration and a distal working end configured to couple a surgical tool to be manipulated by the surgeon via the handle and the actuating mechanism to perform a surgical function.

Owner:SHORTI RAMI +1

Laparoscopic surgical instrument

A laparoscopic surgical instrument configured to be ergonomic and anthropometrically correct, the laparoscopic surgical instrument comprising: (a) an ergonomic handle configured to orient a hand of a surgeon in a functional position, the handle comprising a handle grip; (b) an actuating mechanism actuatable by a finger and supported by the handle, the actuating mechanism comprising an actuator shaft and a gearing assembly operable to displace the actuator shaft with a mechanical advantage upon actuation of a trigger by the surgeon; (c) a locking mechanism configured to lock the actuating mechanism in one of a plurality of positions, the locking mechanism comprising a release located in an anthropometrically correct position; and (d) a working shaft having a proximal end coupled to and operable with the actuator shaft, the working shaft having an elongate configuration and a distal working end configured to couple a surgical tool to be manipulated by the surgeon via the handle and the actuating mechanism to perform a surgical function.

Owner:SHORTI RAMI +1

Methods for eyeglass lens curing using ultraviolet light

InactiveUS6022498AControl generationControl releaseOther chemical processesOptical articlesUV curingRadiation pulse

Method and apparatus for making [and coating] a plastic lens is provided. [Oxygen barrier containing photoinitiator is used to cure incompletely cured lens portions. Radiation pulses are used to control lens curing rate. Lens is postcured while in a mold cavity using a conductive heat source.] More particularly, the invention relates to applying alternating periods of ultraviolet light to lens forming composition. Such composition is cured while controlling the rate of heat generation and / or dissipation via manipulation of the duration of the radiation or the cooling in the curing chamber. The ultraviolet light is directed toward the lens forming composition which is preferably disposed in a mold cavity formed by two mold members. The ultraviolet light may be directed in pulses or continuously.

Owner:Q2100

Methods and apparatus for eyeglass lens curing using ultraviolet light and improved cooling

InactiveUS6086799AControl generationControl releaseOther chemical processesOptical articlesUltraviolet lightsRadiation pulse

Method and apparatus for making and coating a plastic lens. Oxygen barrier containing photoinitiator is used to cure incompletely cured lens portions. Radiation pulses are used to control lens curing rate. Lens is postcured while in a mold cavity using a conductive heat source. Air may be directed toward the mold cavity to help remove heat from the lens. An in-mold scratch resistant coating may be formed from two separate material which both contain a photoinitiator.

Owner:Q2100

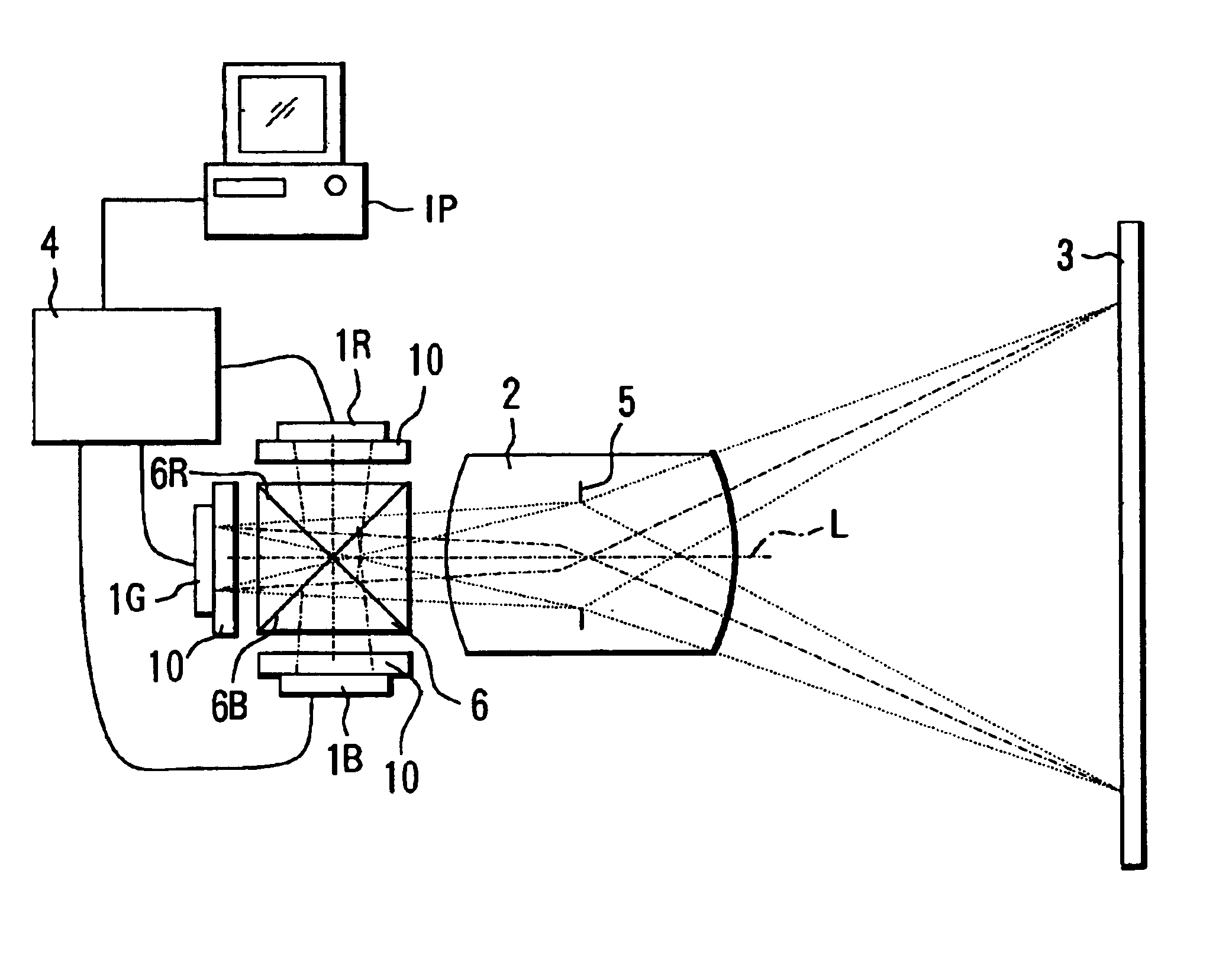

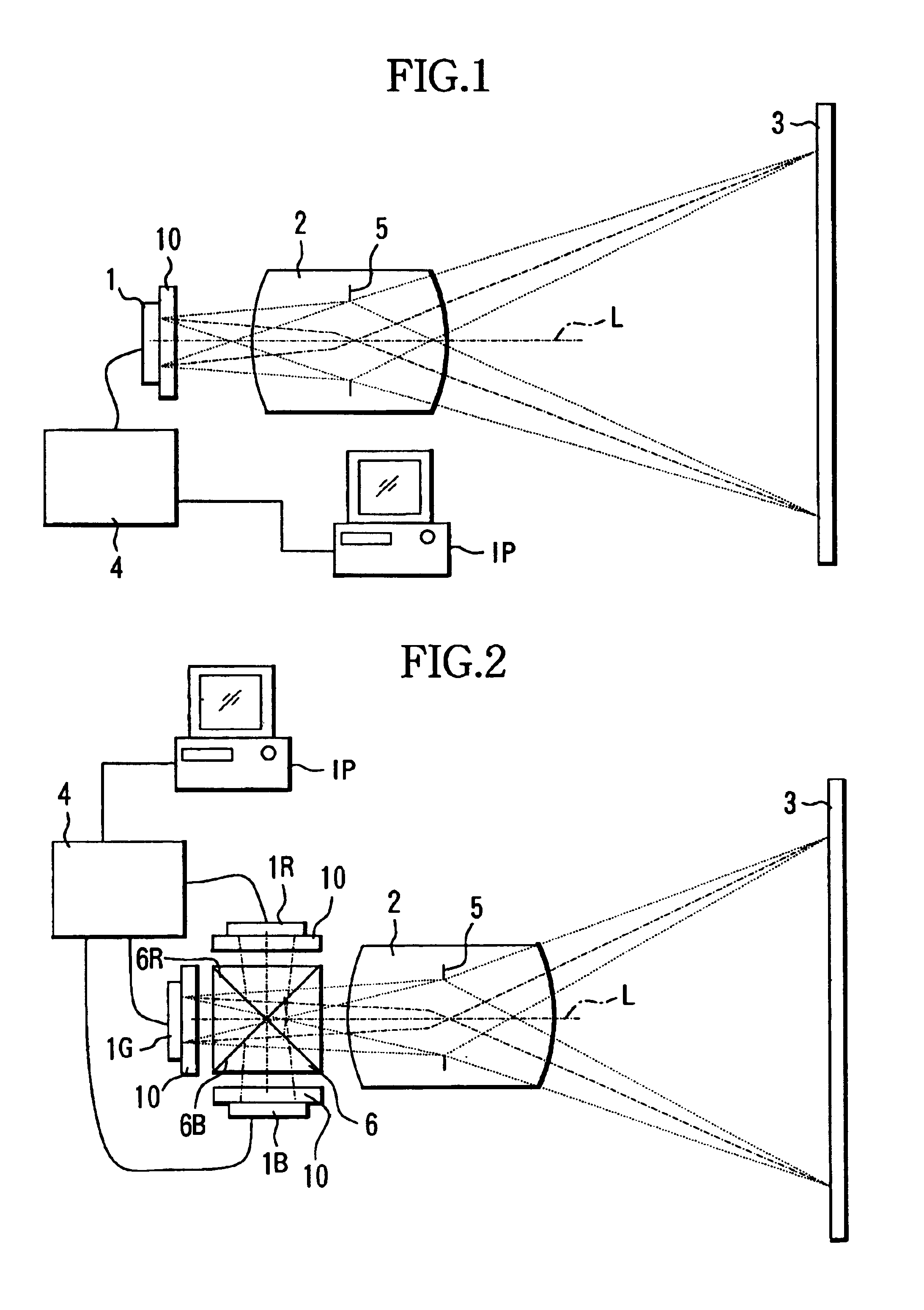

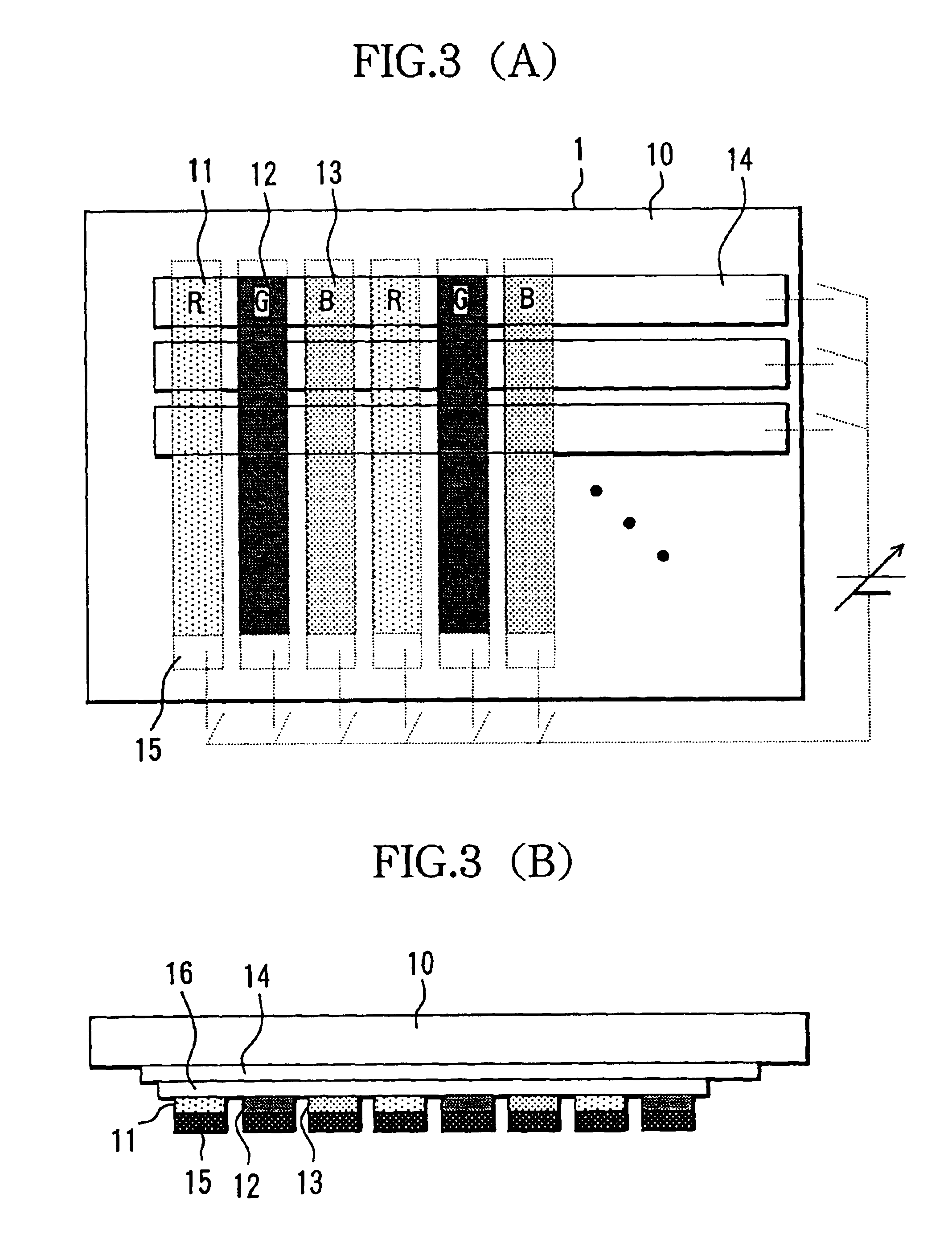

Projection type image display apparatus and image display system

InactiveUS6951393B2Efficient captureIncrease costStatic indicating devicesProjectorsProjection opticsOptical axis

A projection type image display apparatus includes a projection optical system the projects light emitted from an organic EL element onto a target object. The projection optical system has a characteristic non-telecentric toward the EL element with principal rays which pass through the median point of the aperture pupil that captures light diffusively emitted from the EL element converging when seen from the EL element at a pixel position where the object height on the EL element from the optical axis of the projection optical system reaches a maximum.

Owner:CANON KK

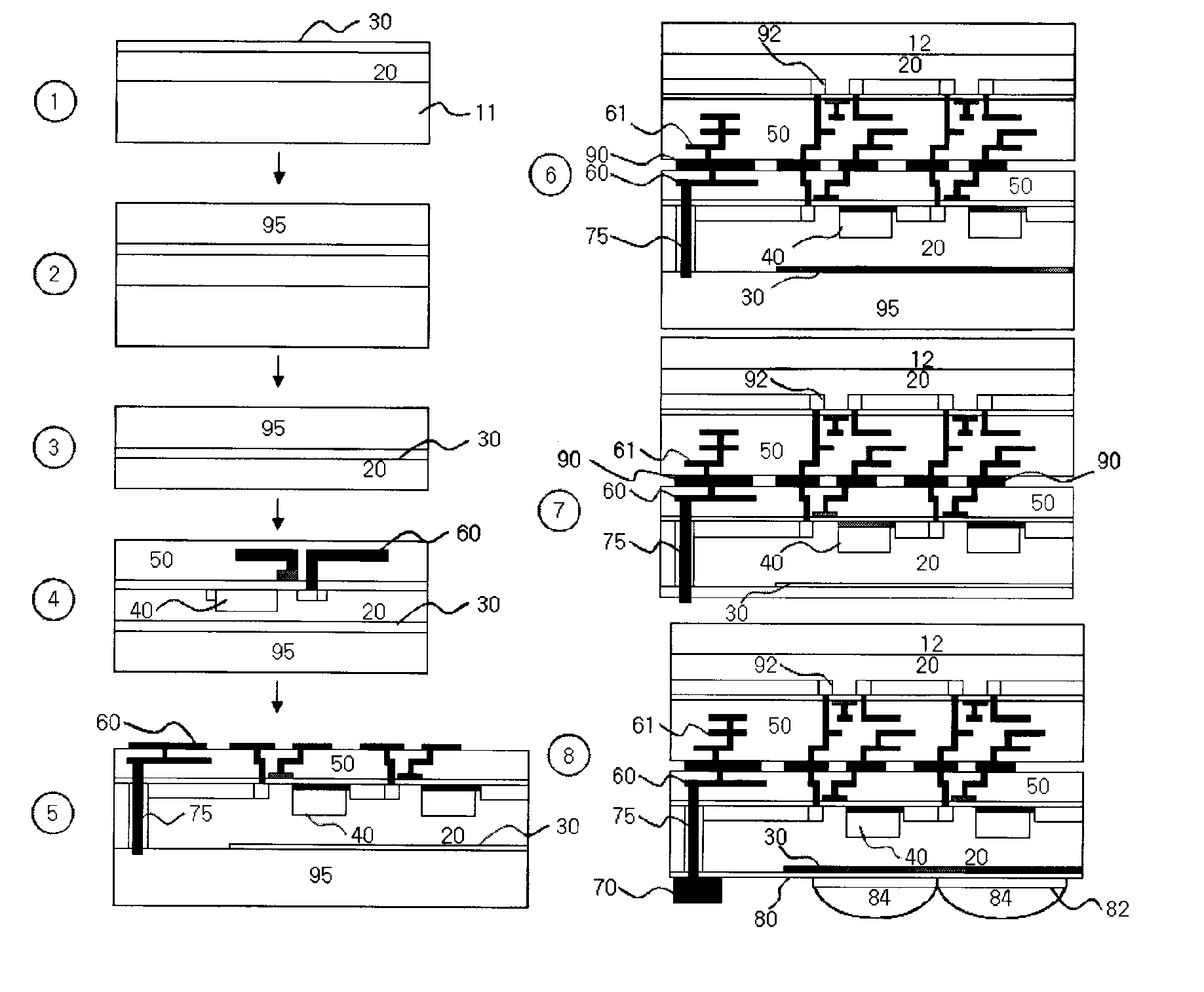

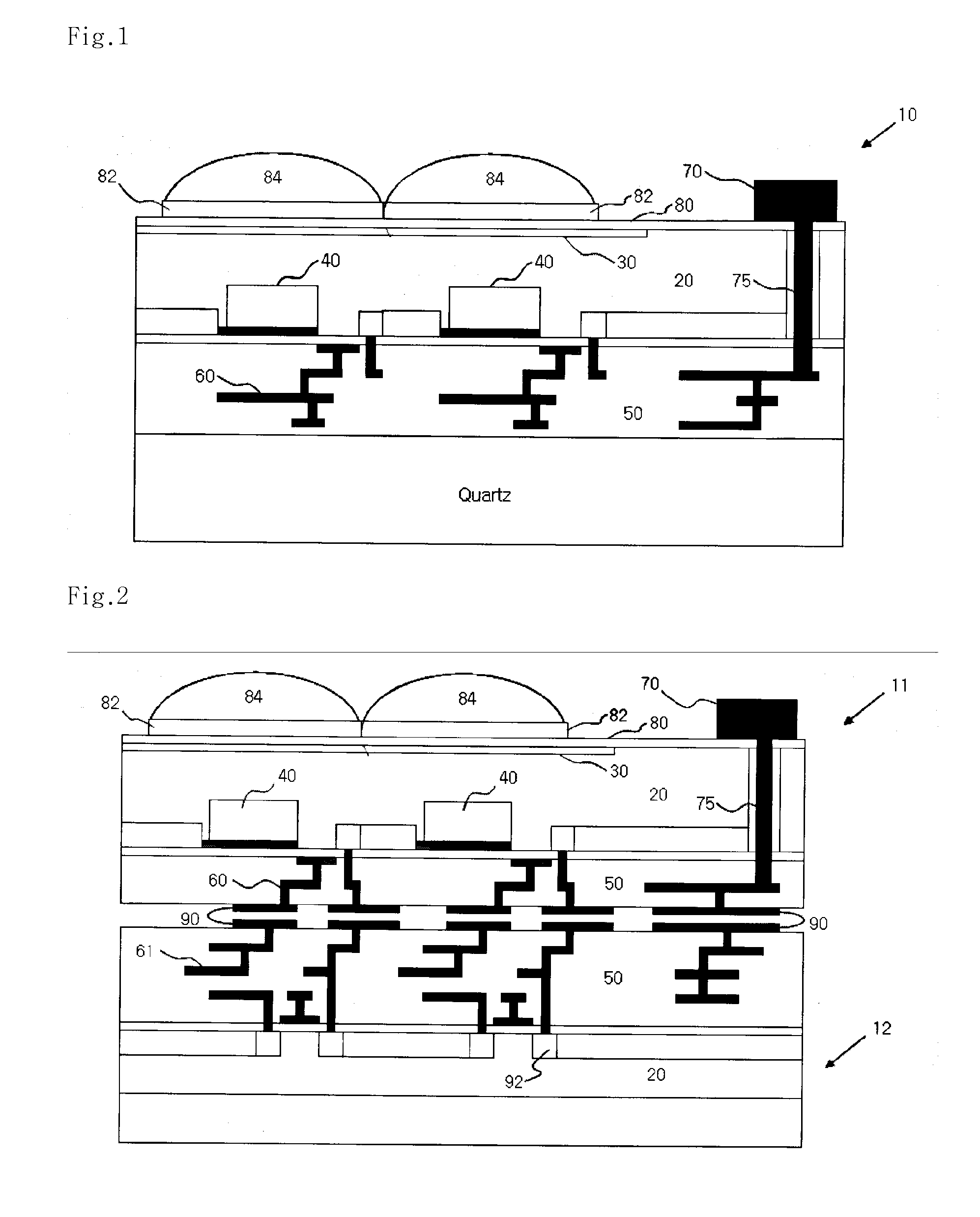

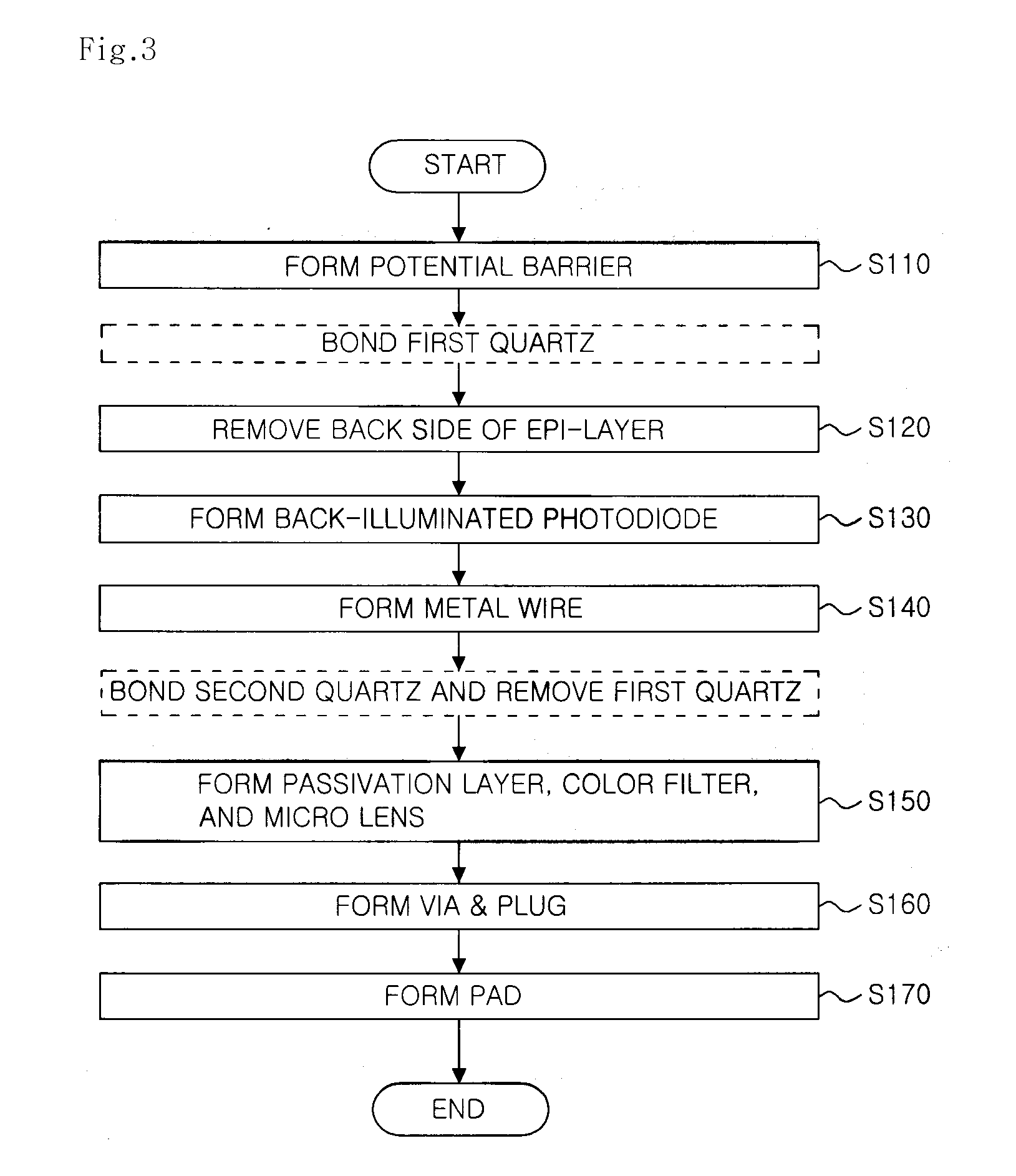

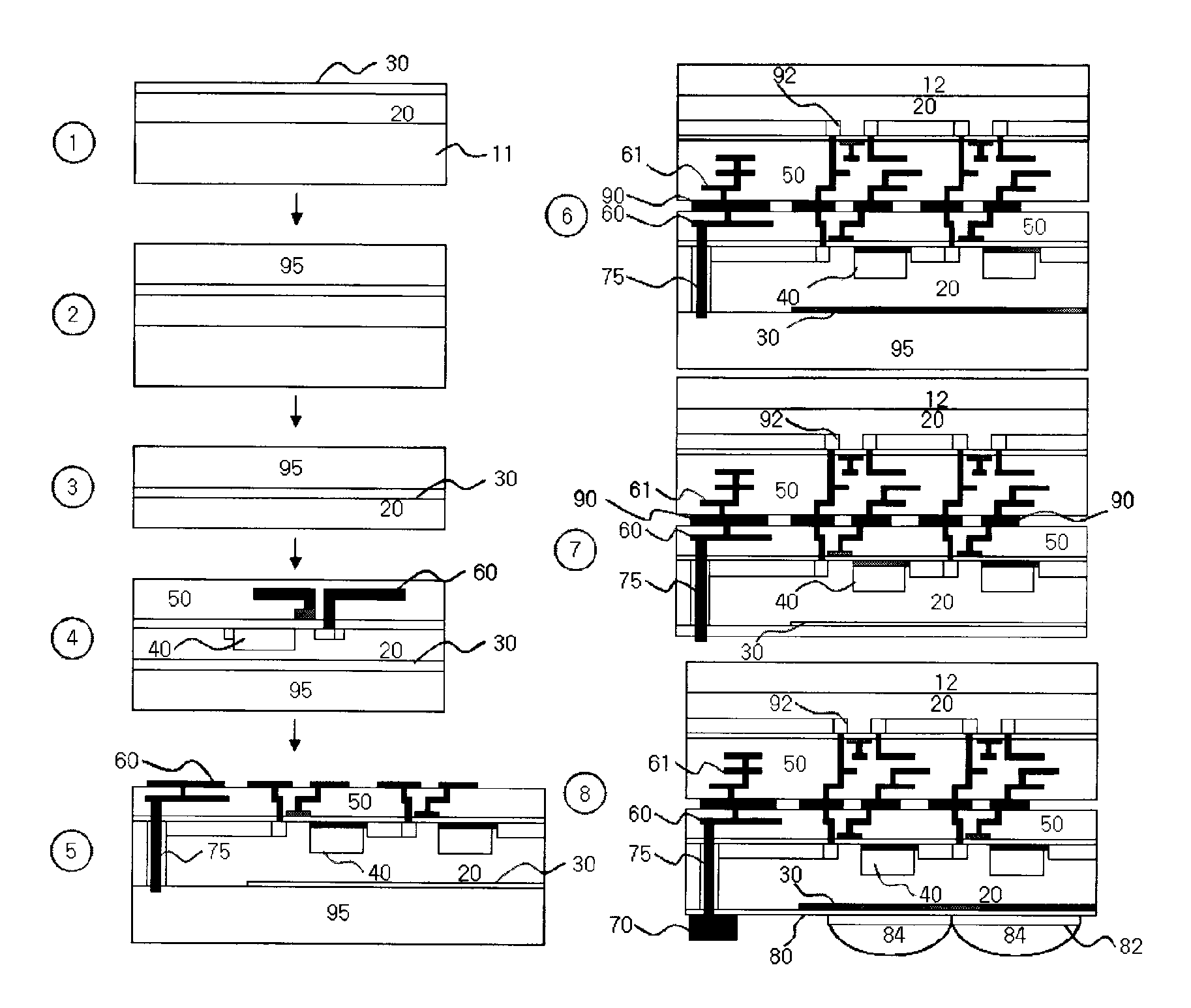

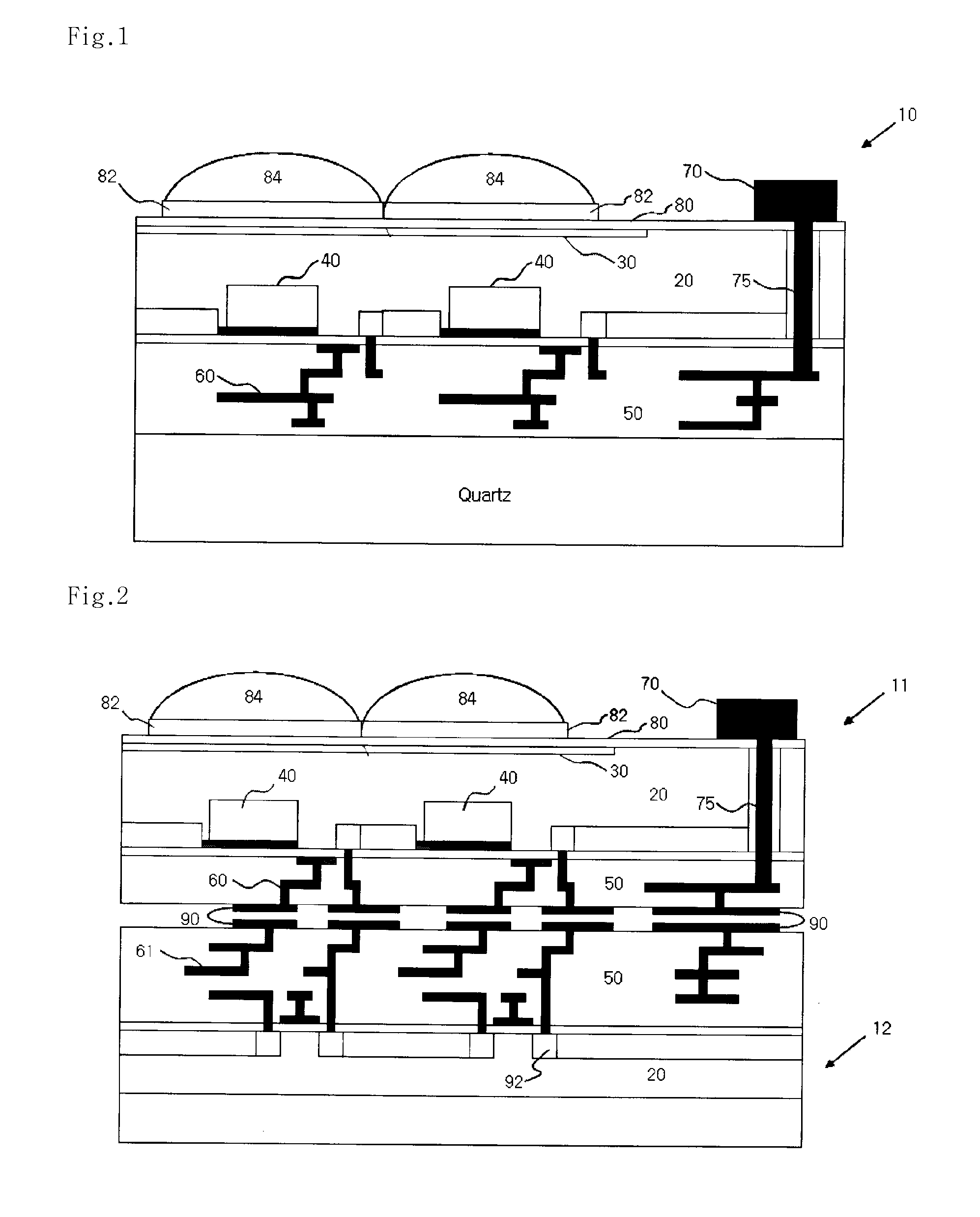

Image sensor using back-illuminated photodiode and method of manufacturing the same

ActiveUS20090224345A1Control generationHigh sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingHigh densityPhotodiode

An image sensor using a back-illuminated photodiode and a manufacturing method thereof are provided. According to the present invention, since a surface of the back-illuminated photodiode can be stably treated, the back-illuminated photodiode can be formed to have a low dark current, a constant sensitivity of blue light for all photodiodes, and high sensitivity. In addition, it is possible to manufacture an image sensor with high density by employing a three dimensional structure in which a photodiode and a logic circuit are separately formed on different substrates.

Owner:SK HYNIX INC

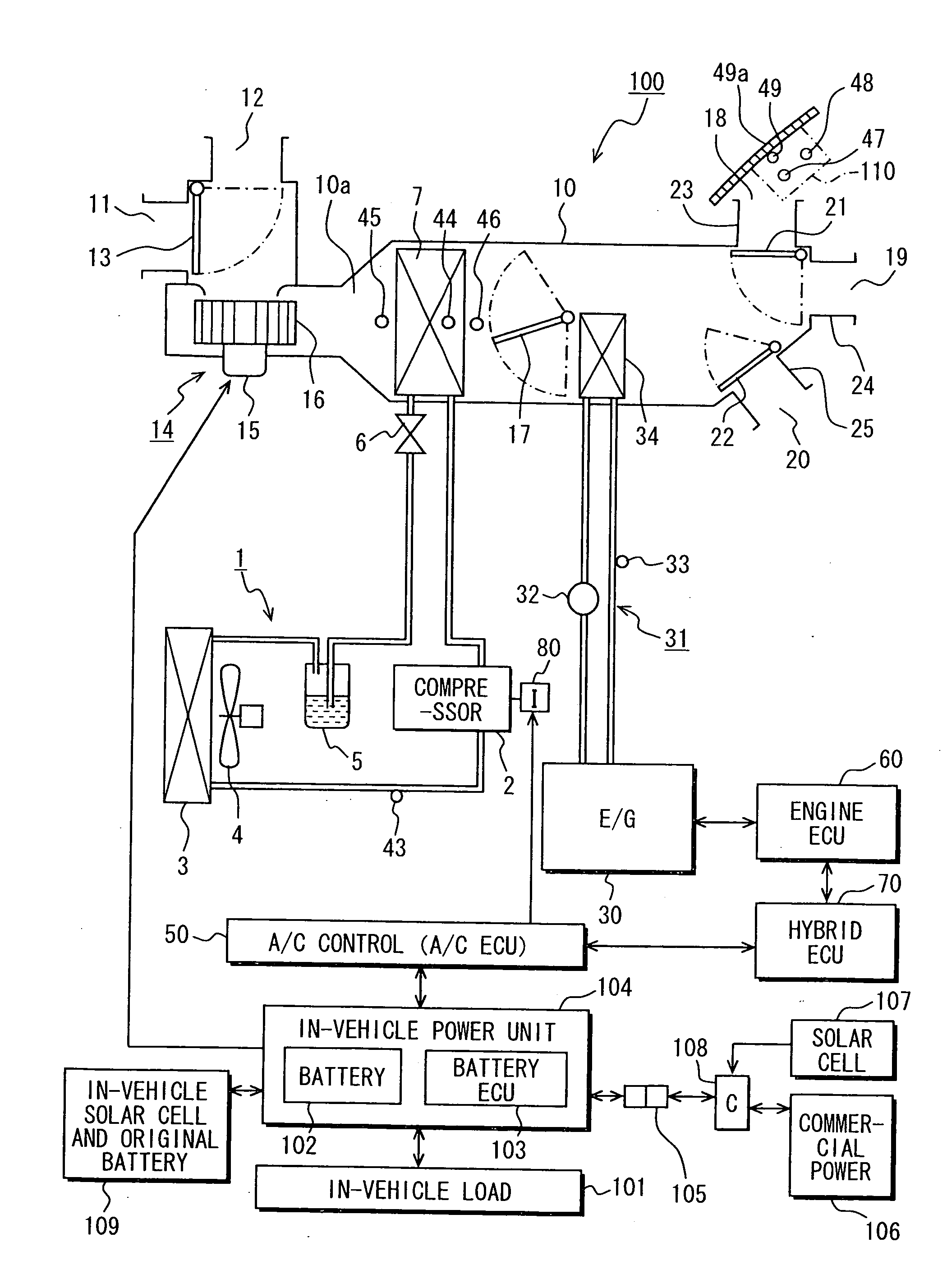

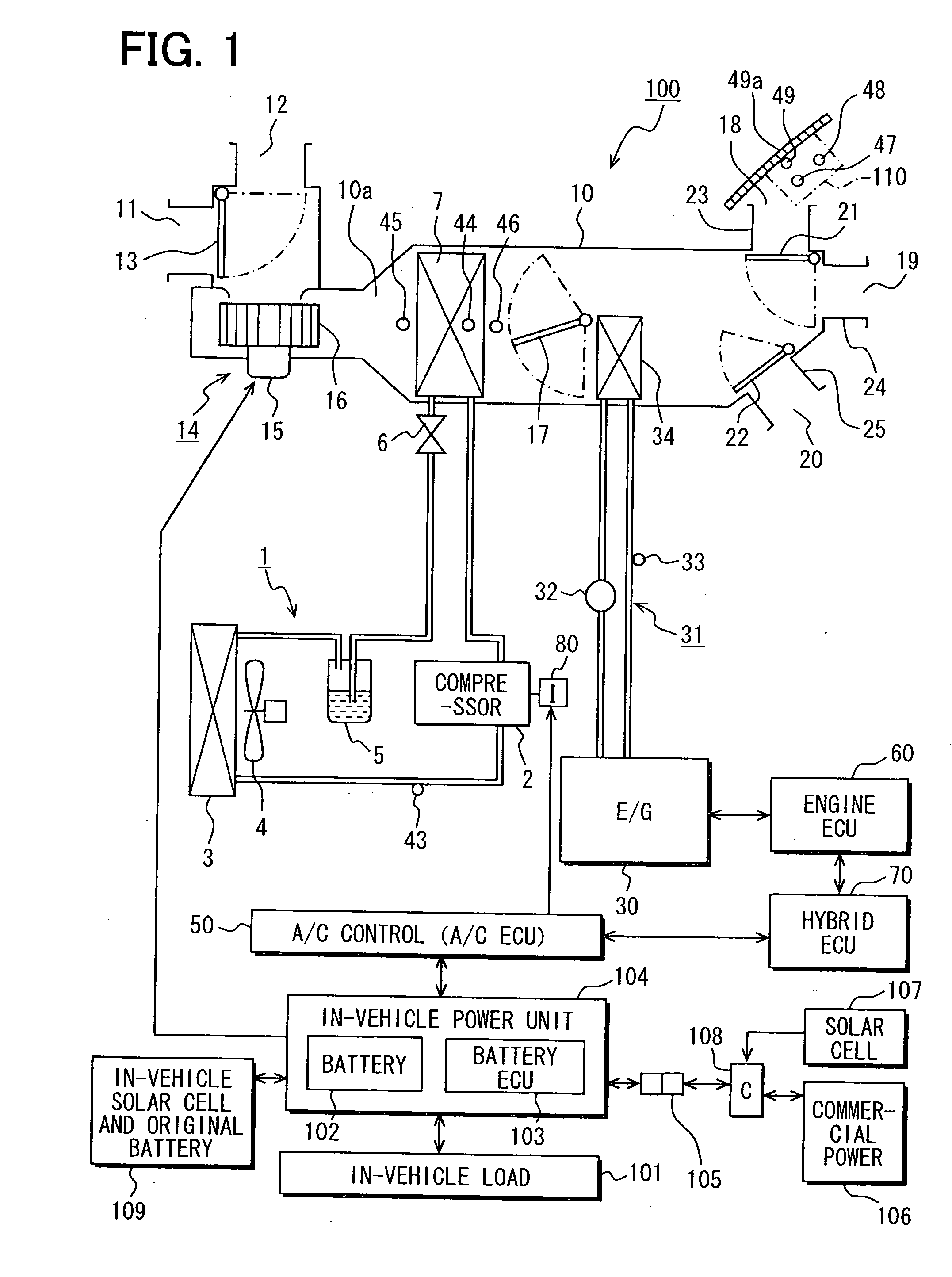

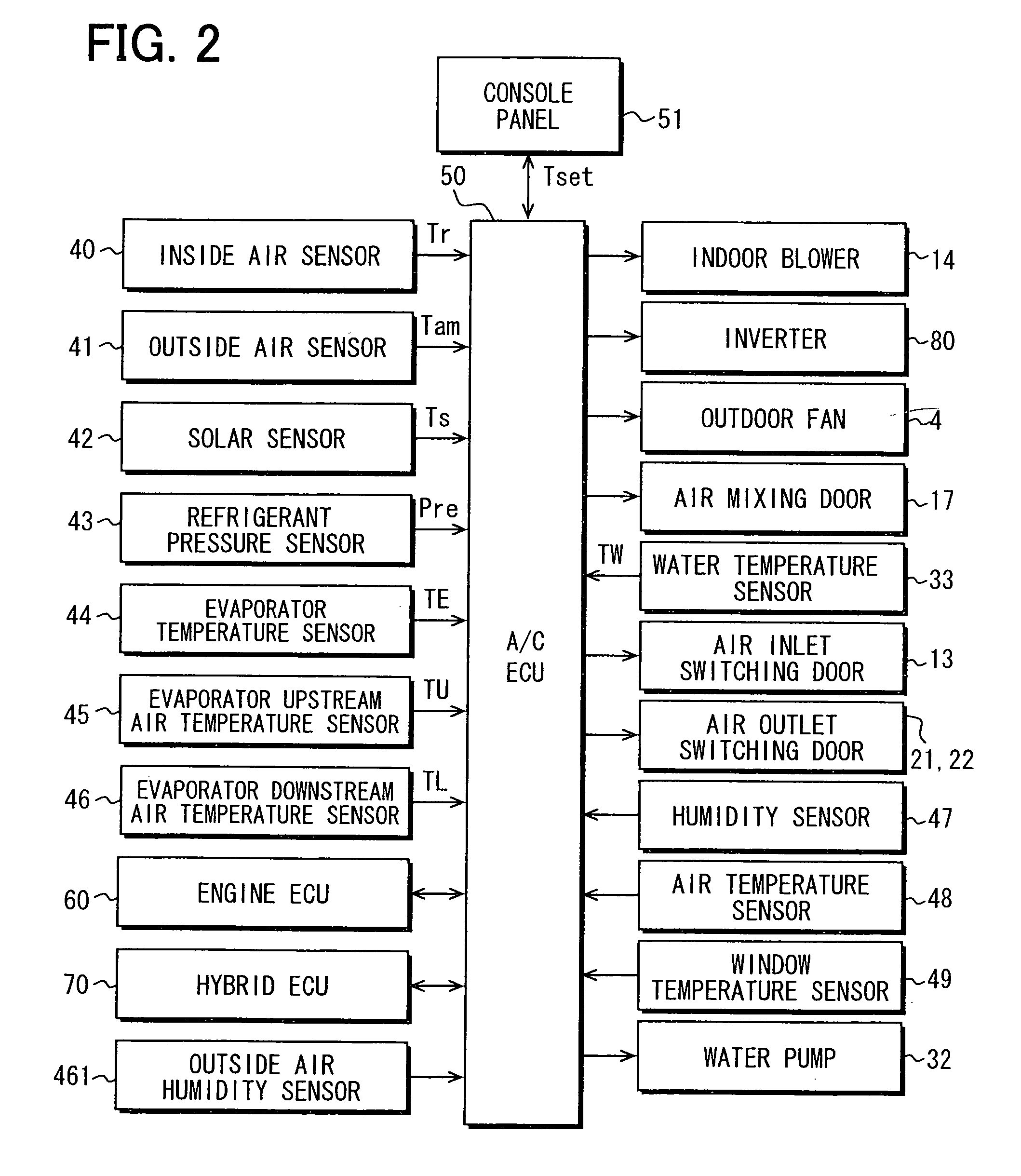

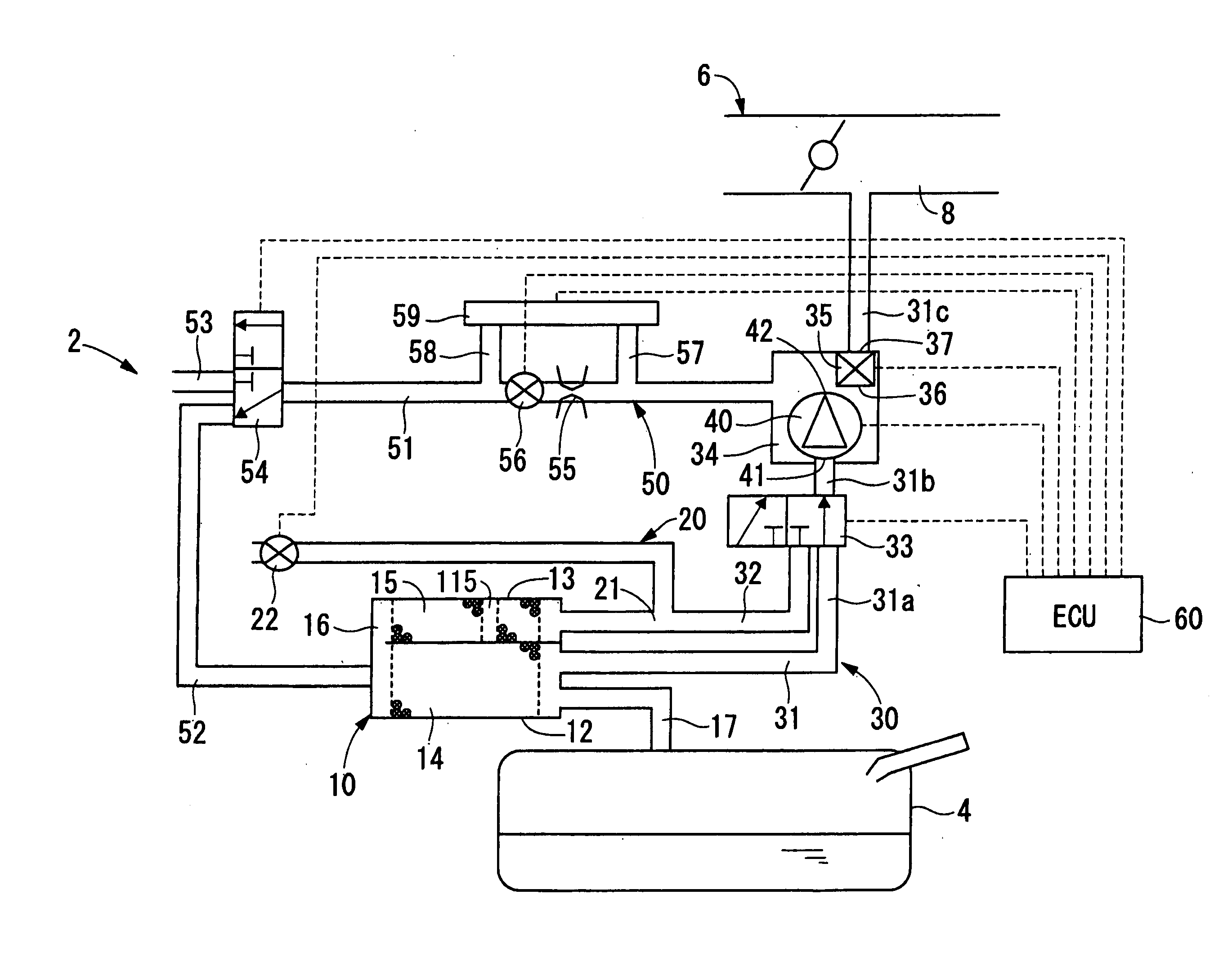

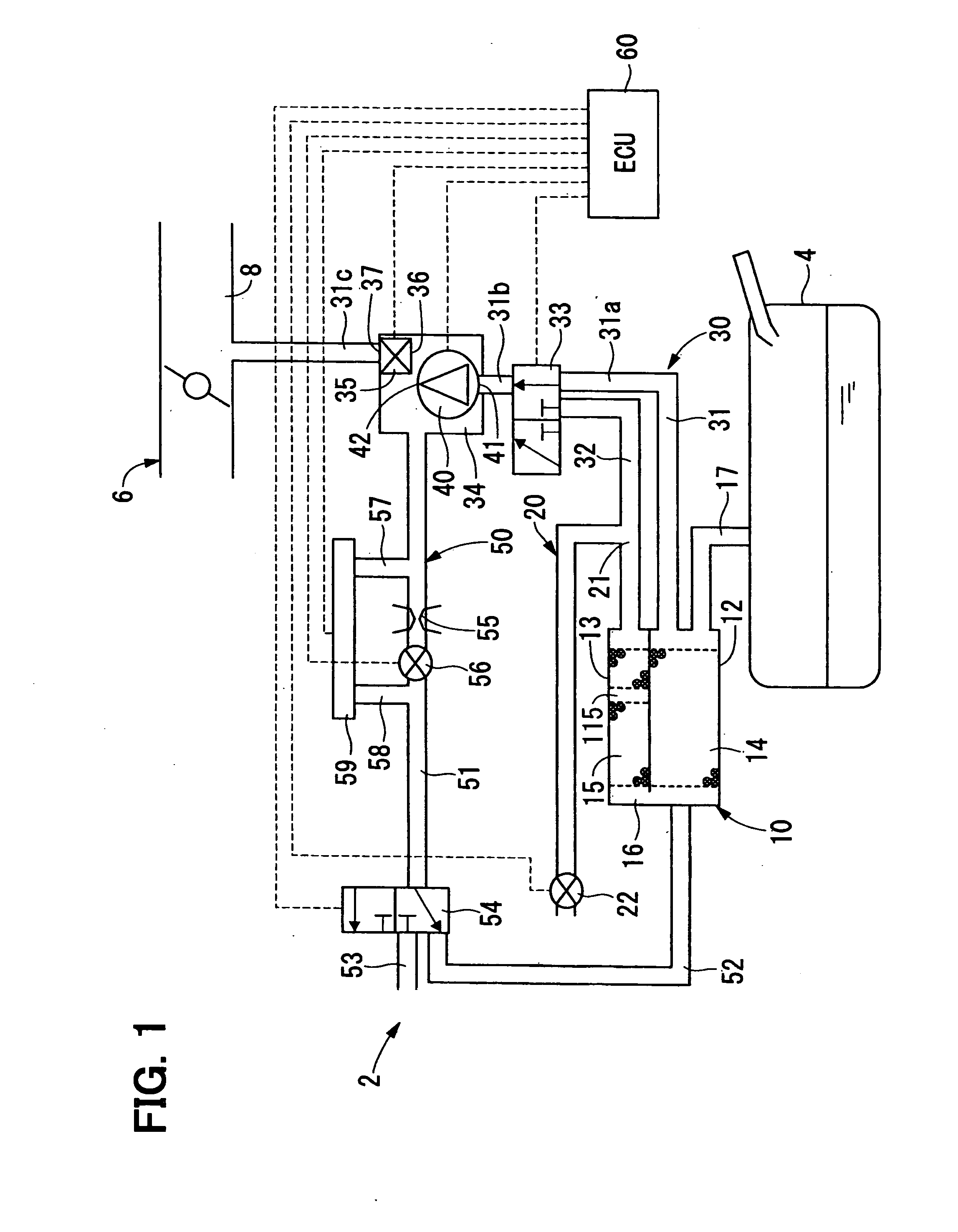

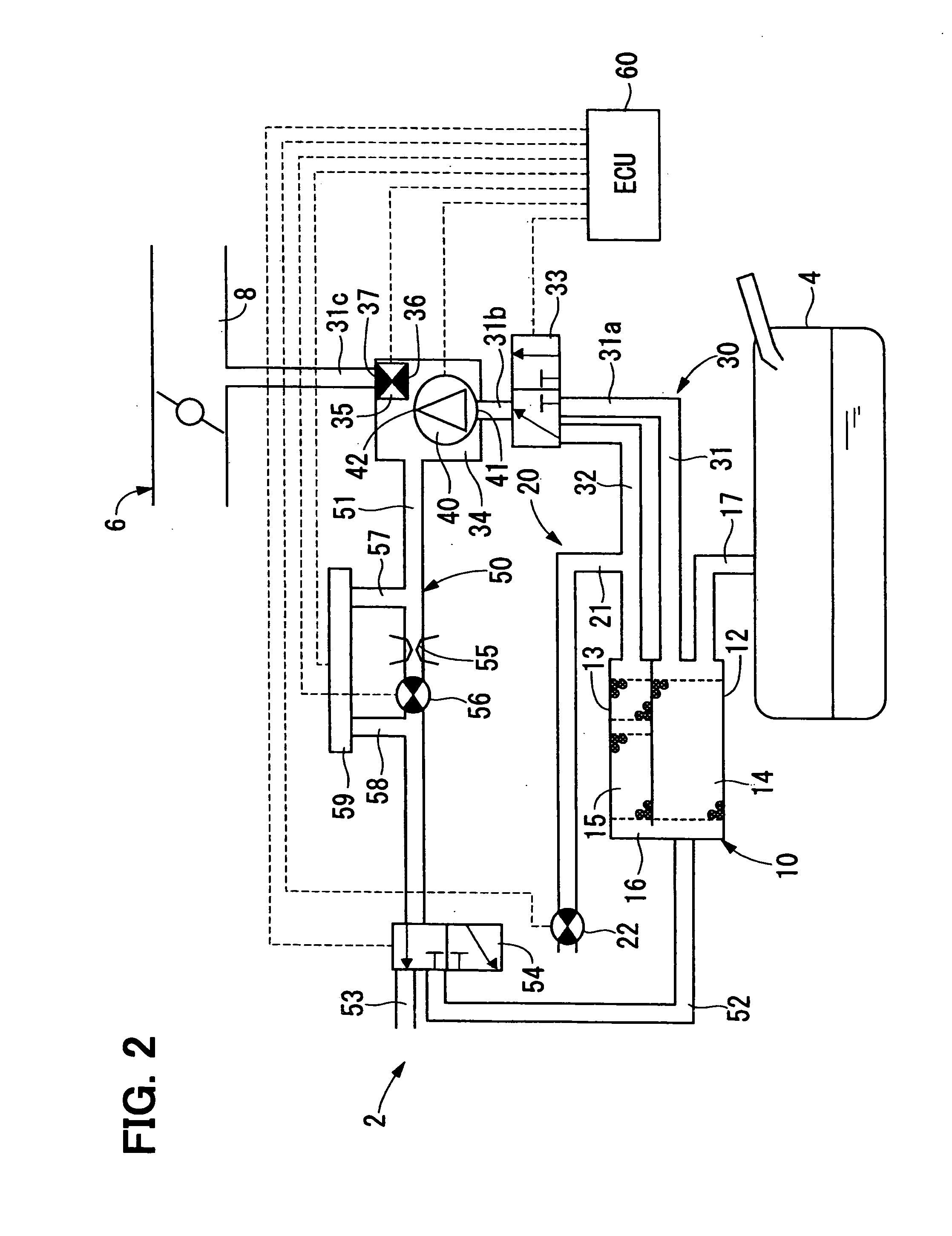

Air-conditioning device for vehicle

InactiveUS20110067422A1Control generationControl growthAir-treating devicesRefrigeration safety arrangementElectrical batteryIn vehicle

An air-conditioning device for a vehicle includes a blower and an estimating portion. The blower is disposed in an air-conditioning case, and performs a dry control for a heat exchanger arranged in a passenger compartment of the vehicle by sending air. The blower uses one of power supplied from an external power source, power supplied from the battery having residual quantity equal to or larger than a predetermined quantity, or power supplied from an in-vehicle solar cell, while the vehicle is parked. The estimating portion estimates an approximate elimination of odor generated from the heat exchanger by starting the sending of air, and stops the blower based on the estimation.

Owner:DENSO CORP

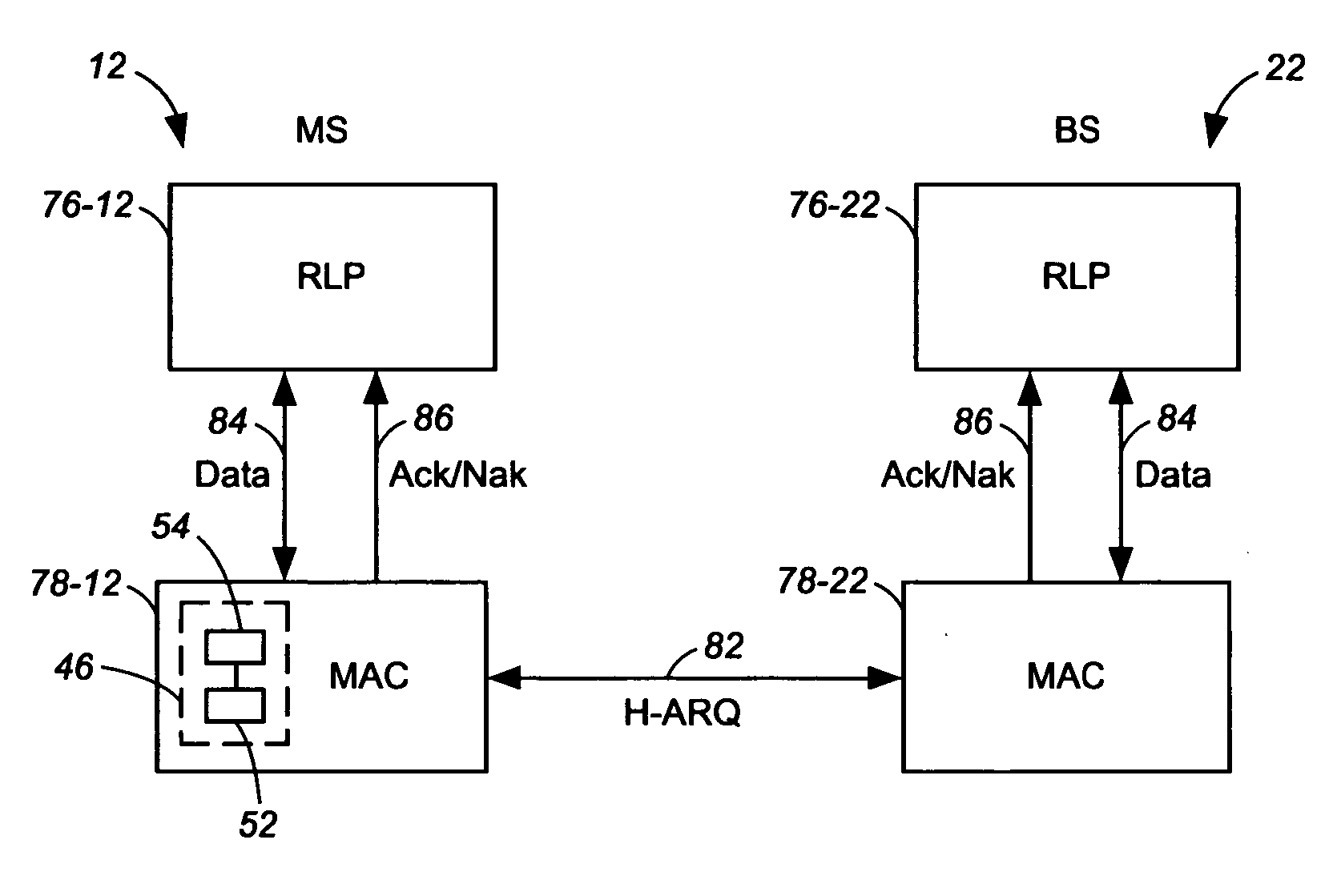

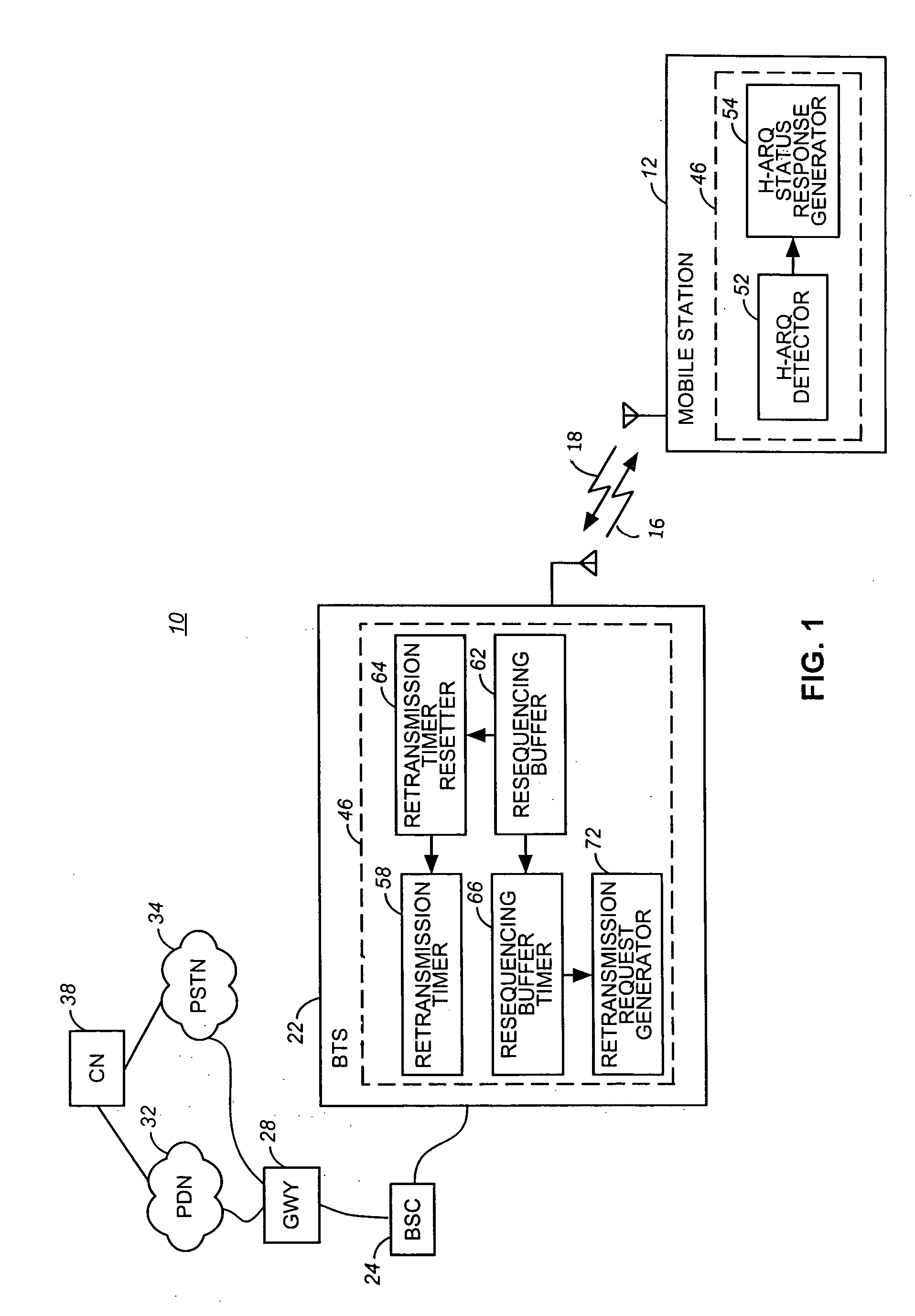

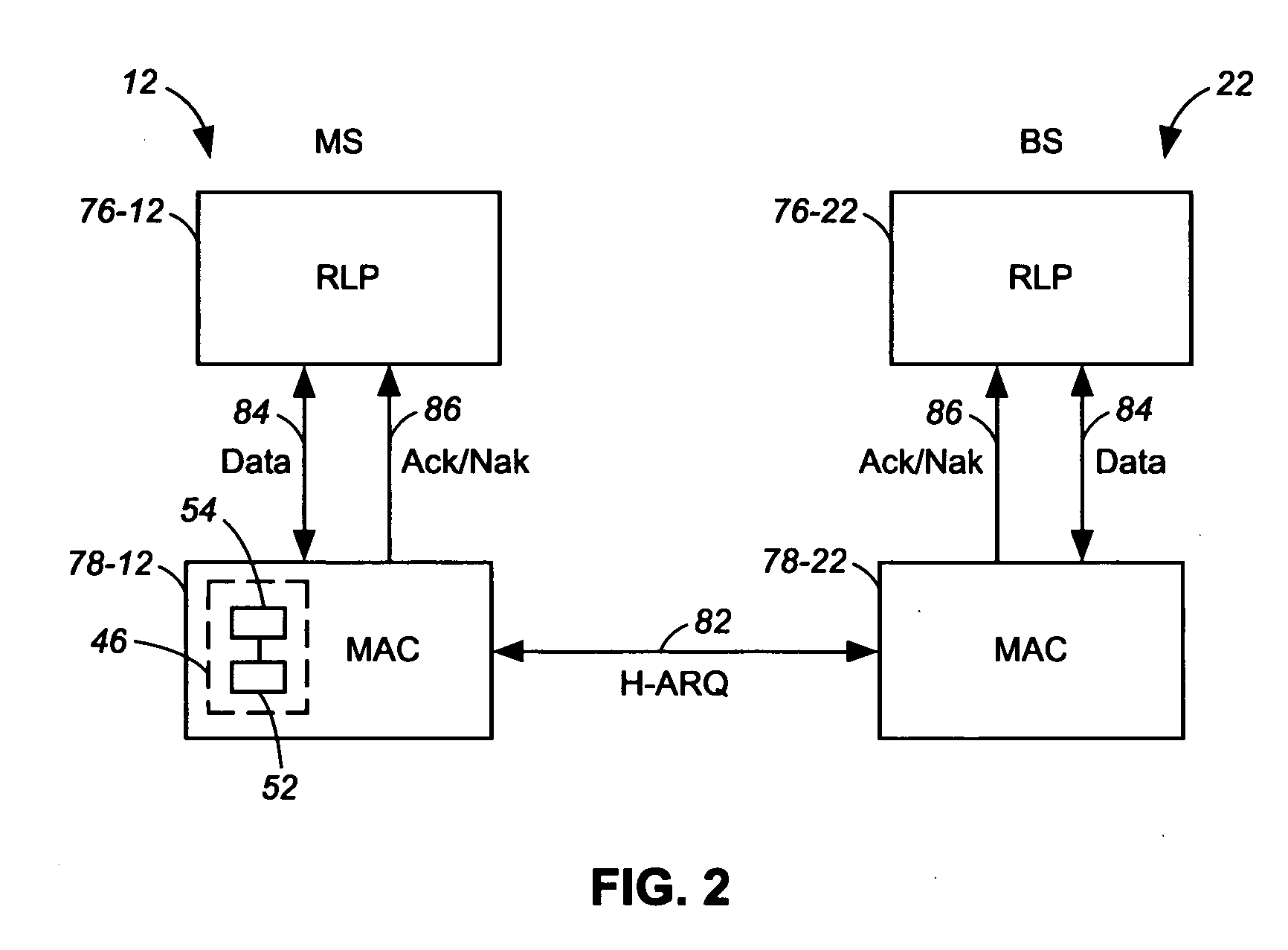

Apparatus, and associated method, for facilitating retransmission of data packets in a packet radio communication system that utilizes a feedback acknowledgment scheme

ActiveUS20050002363A1Improve communication performanceGood utilization of radio resourceError prevention/detection by using return channelFrequency-division multiplex detailsCommunications systemCorrelation method

Apparatus, and an associated method, for a frame-formatted radio communication system. Coordination is provided between MAC and RLP layers of a sending station through use of apparatus embodied at the MAC layer of the sending station. Also, apparatus is provided at a receiving station to reduce the generation of RLP layer NAK during segmented RLP frame retransmissions.

Owner:NOKIA TECHNOLOGLES OY

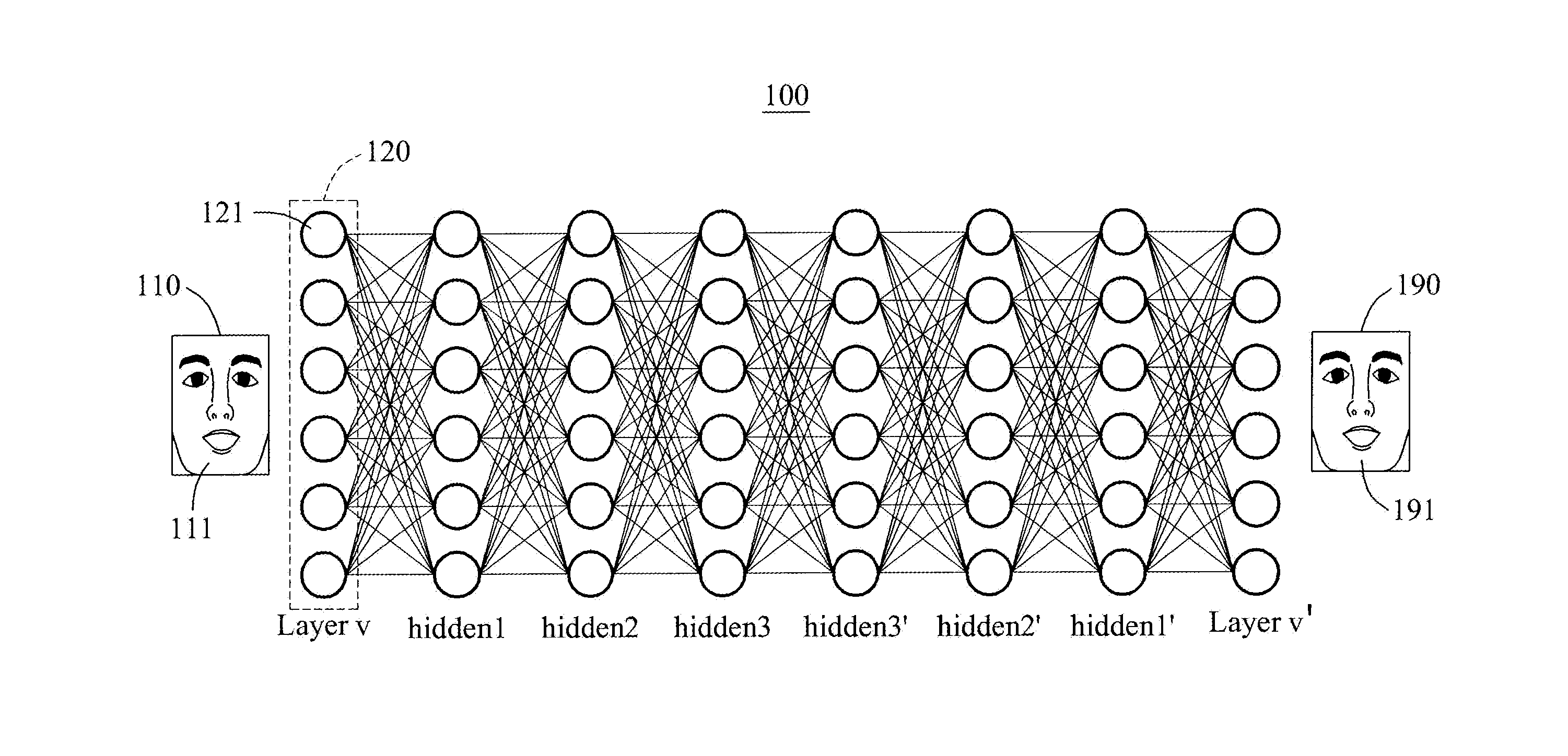

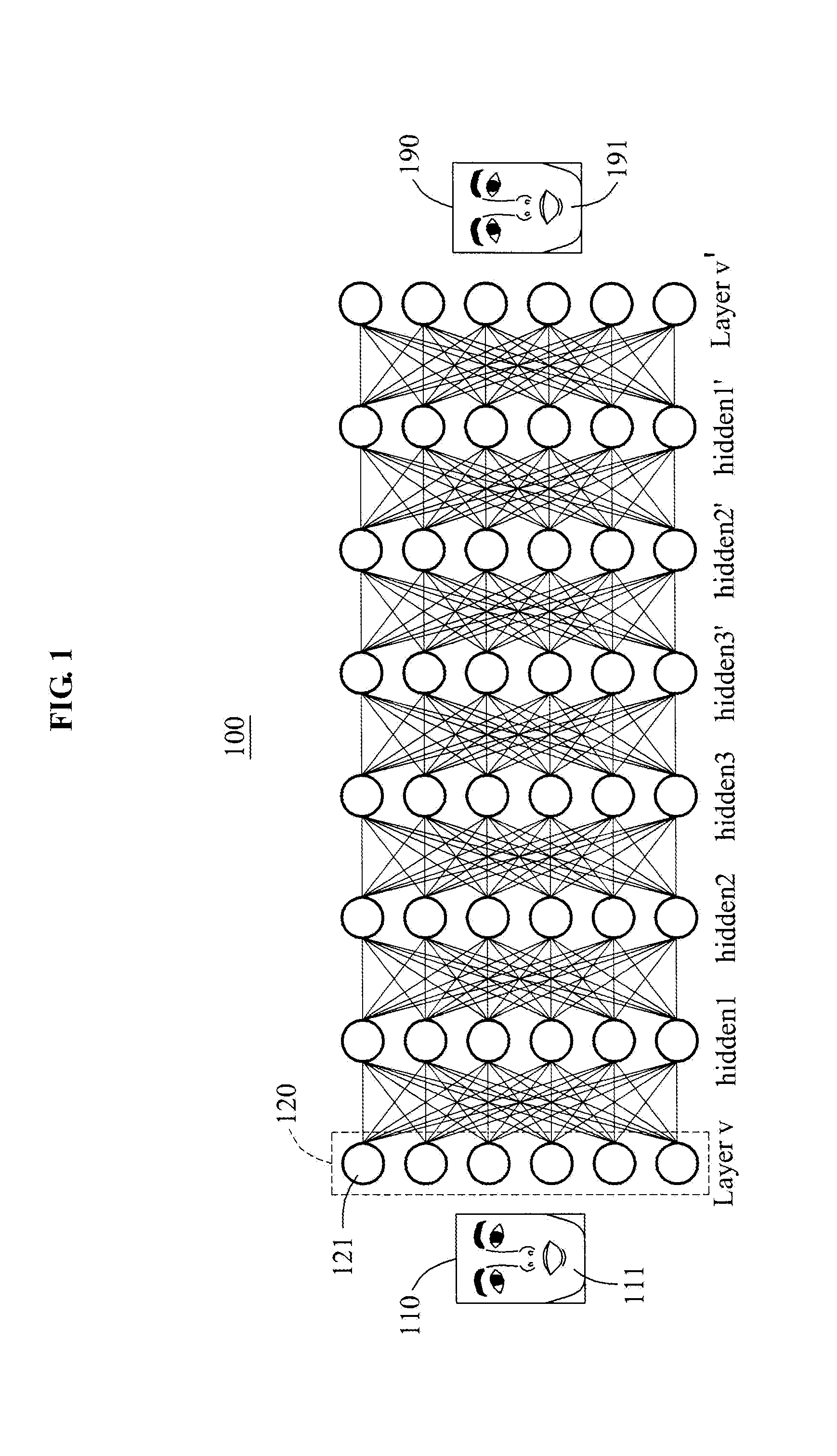

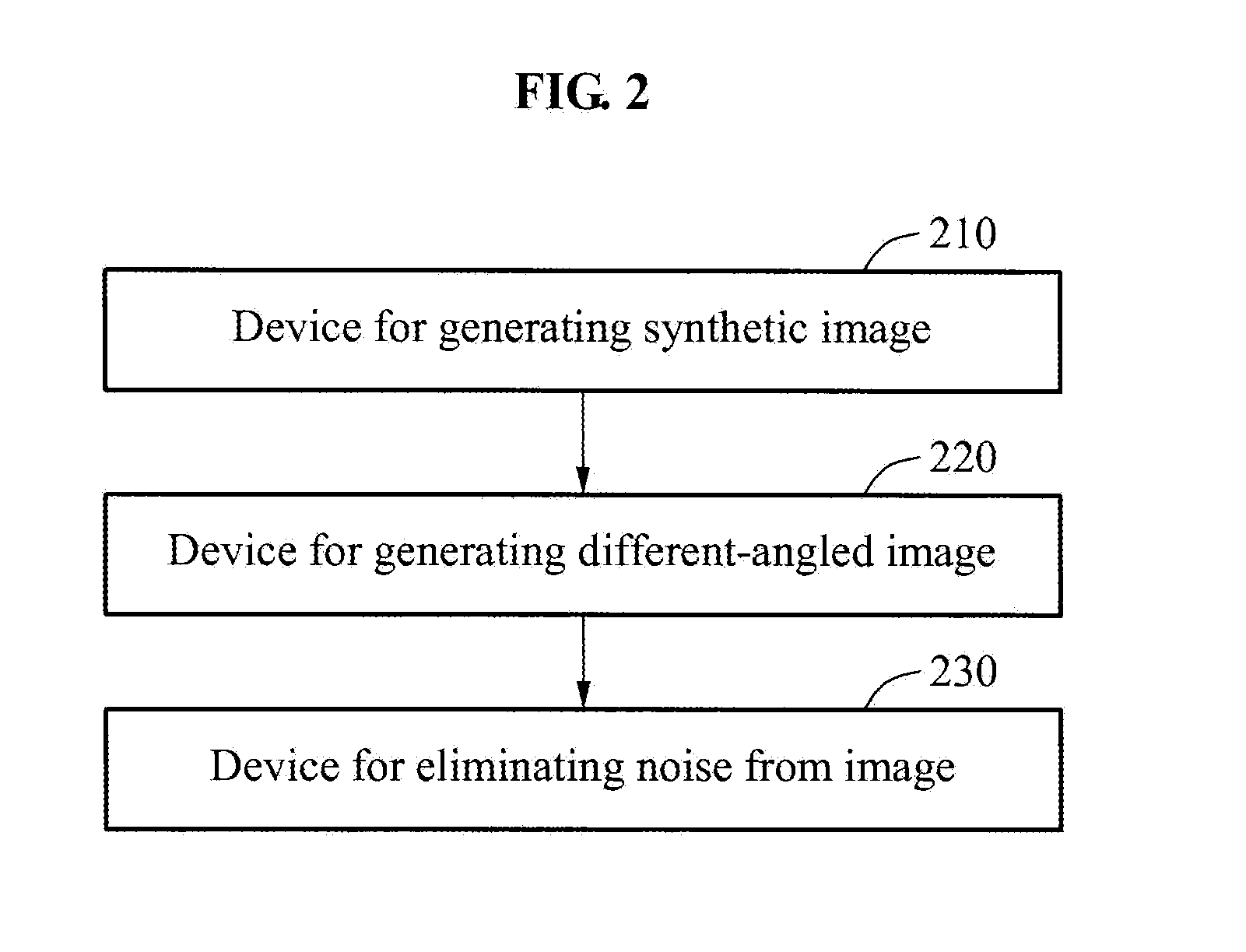

Device and method to generate image using image learning model

ActiveUS20160125572A1Taking imageCancel noiseImage enhancementImage analysisPattern recognitionMachine learning

Owner:SAMSUNG ELECTRONICS CO LTD +1

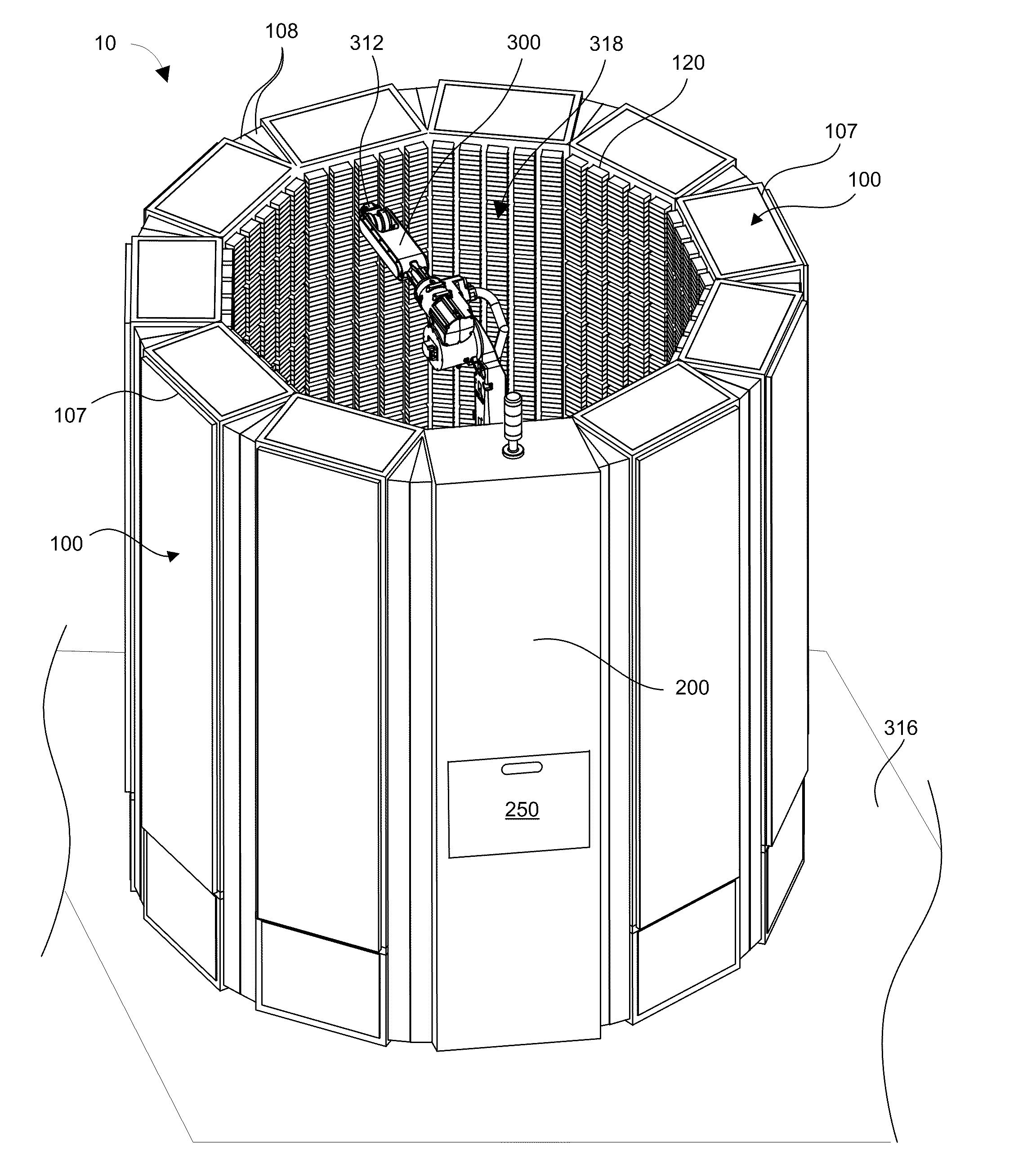

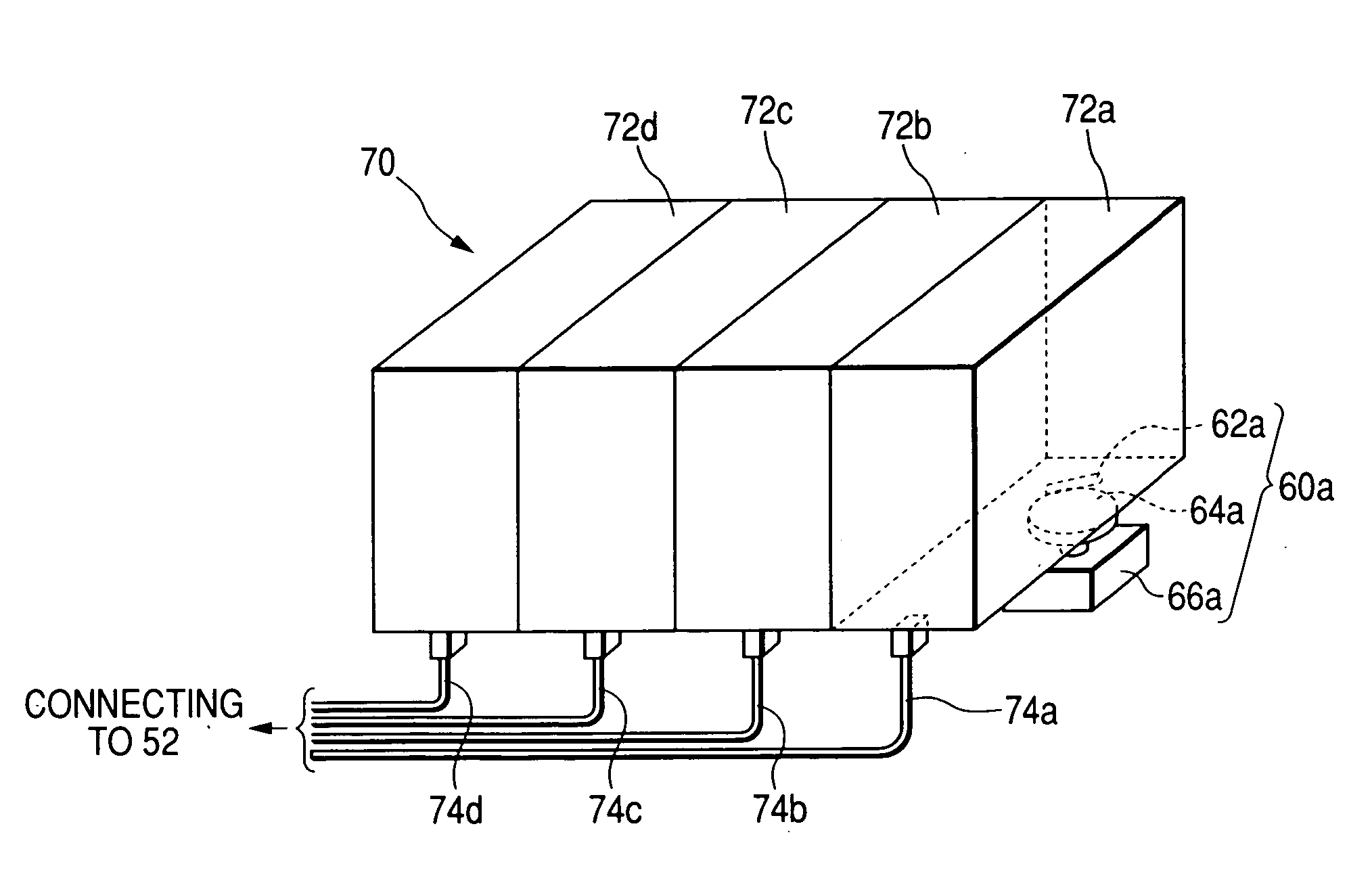

Conductive Heating

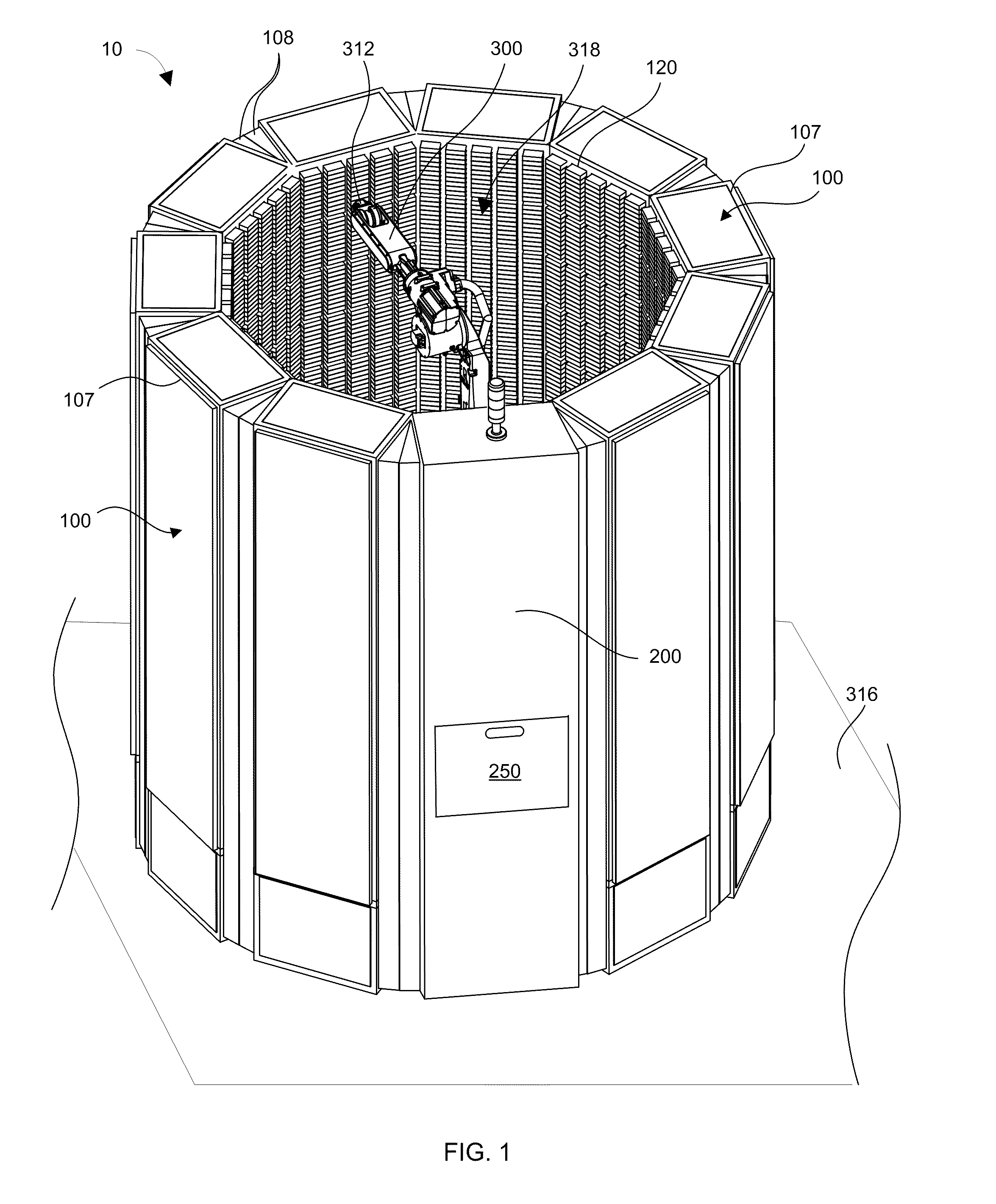

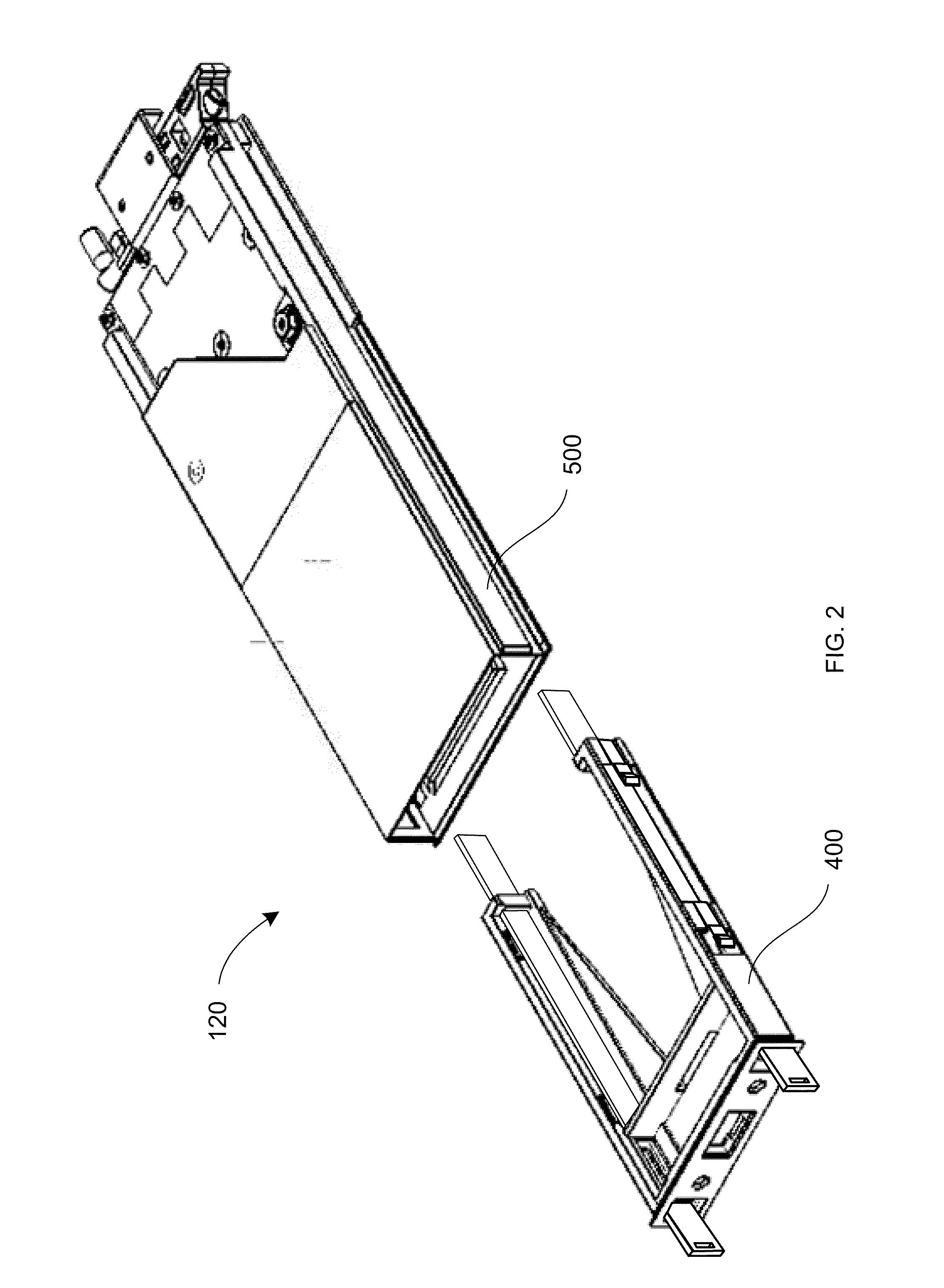

InactiveUS20110012632A1Reduce energy consumptionControl generationElectrical testingRecord information storageEngineeringElectrical and Electronics engineering

A test slot assembly is provided for testing a storage device. The test slot assembly is configured to receive and support a storage device, or a storage device supported by a storage device transporter. The test slot assembly also includes a conductive heating assembly. The conductive heating assembly is arranged to heat a storage device by way of thermal conduction.

Owner:TERADYNE

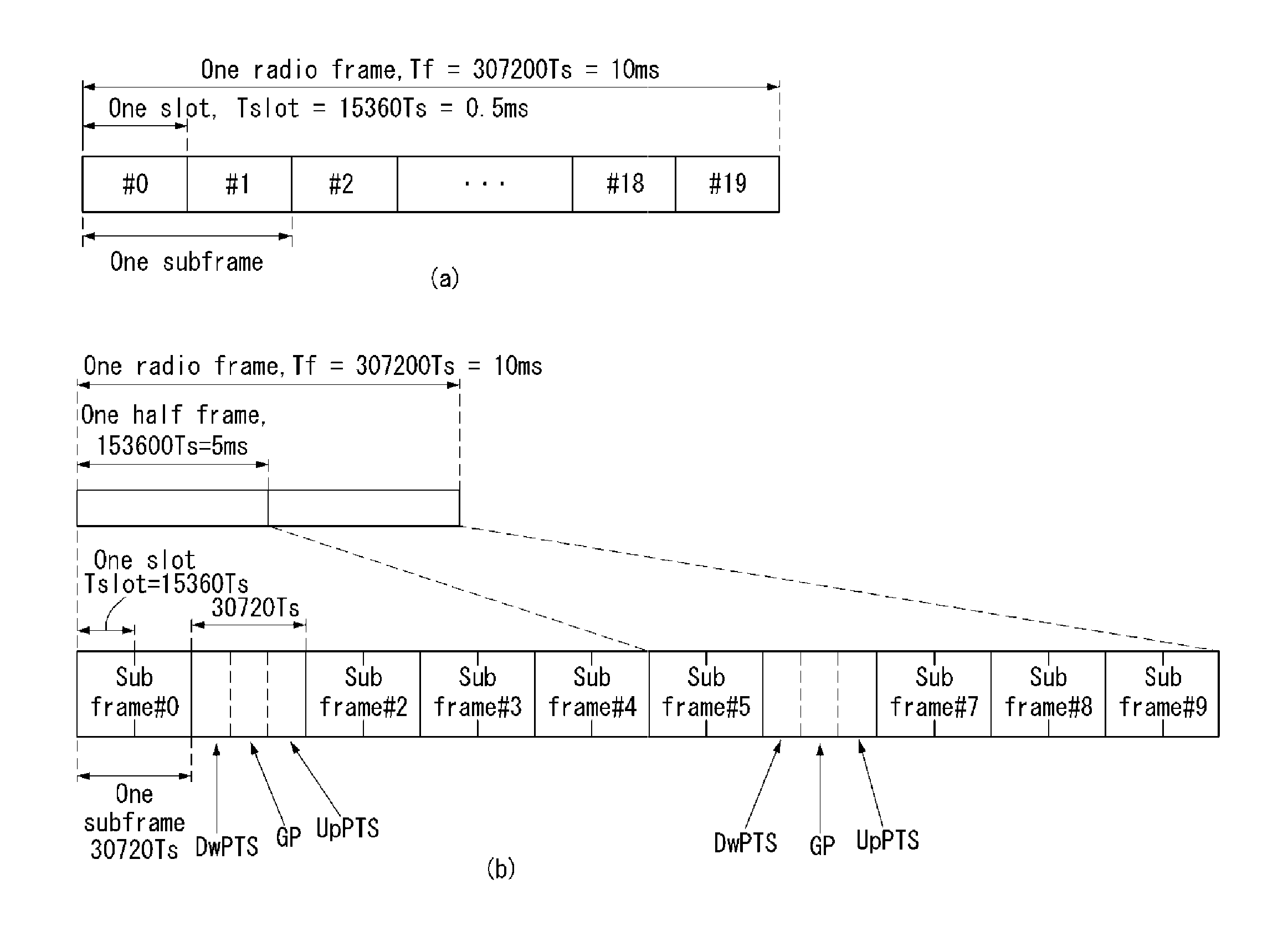

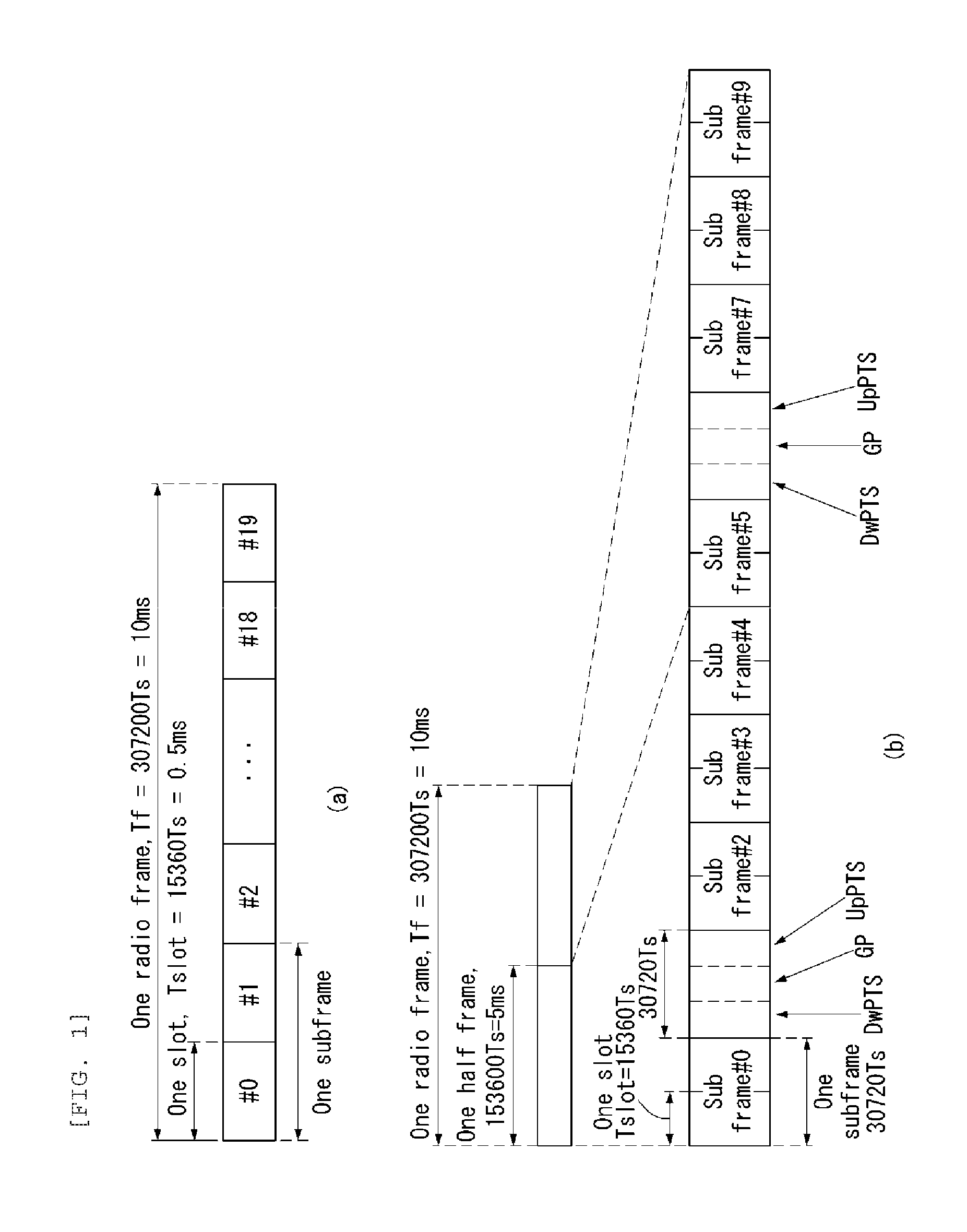

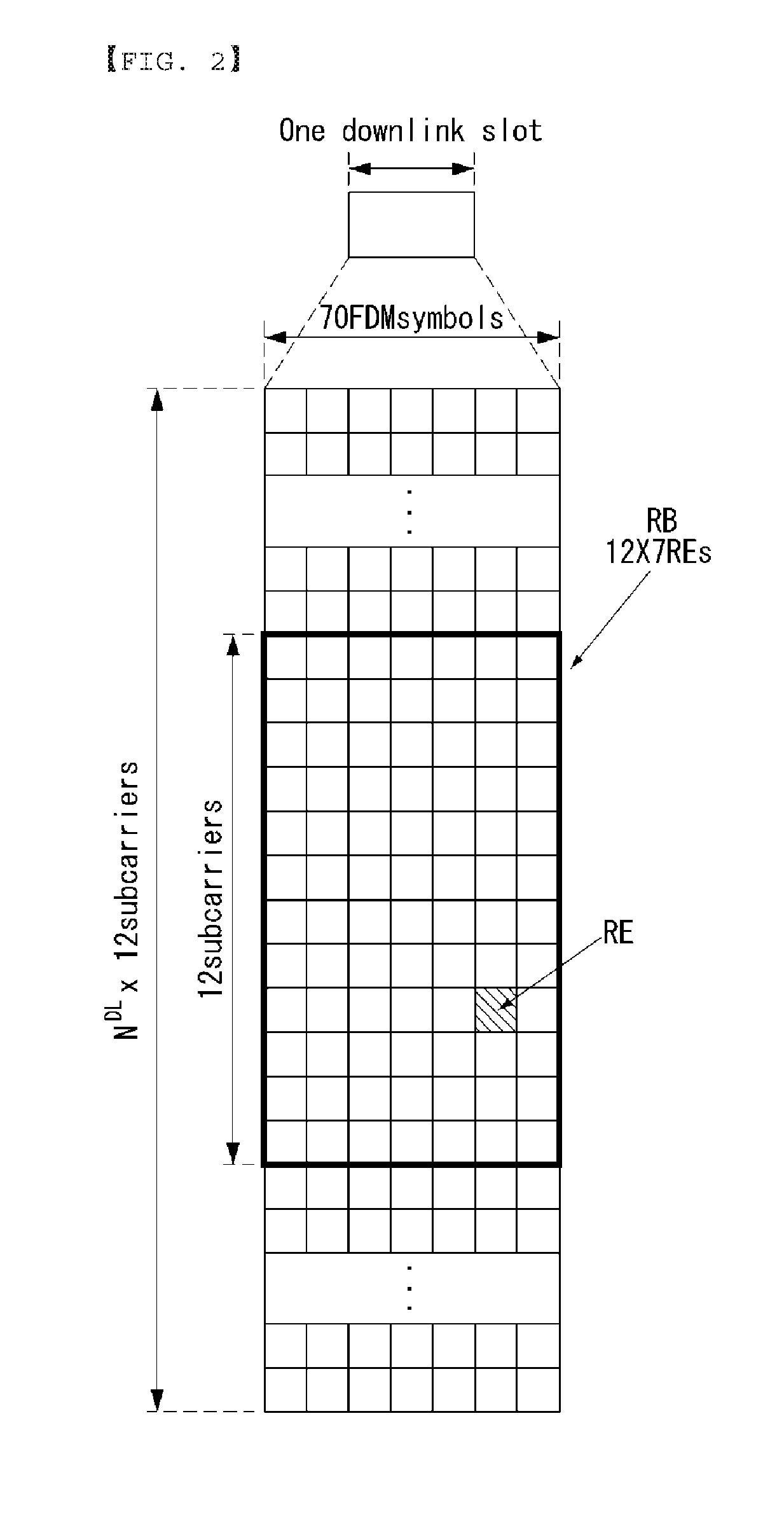

Method and device for performing synchronization between terminals in wireless communication system

ActiveUS20170034799A1Efficient executionControl generationSynchronisation arrangementCommunications systemSignal strength

The present invention relates to a method and apparatus for controlling a generation of synchronization signal in a wireless communication system that supports a device to device communication. The method includes searching a first synchronization signal for the D2D communication; comparing a reception signal strength of the searched first synchronization signal with a threshold value; and determining whether to transmit a second synchronization signal of the first UE according to a specific condition when the reception signal strength is smaller than the threshold value.

Owner:LG ELECTRONICS INC

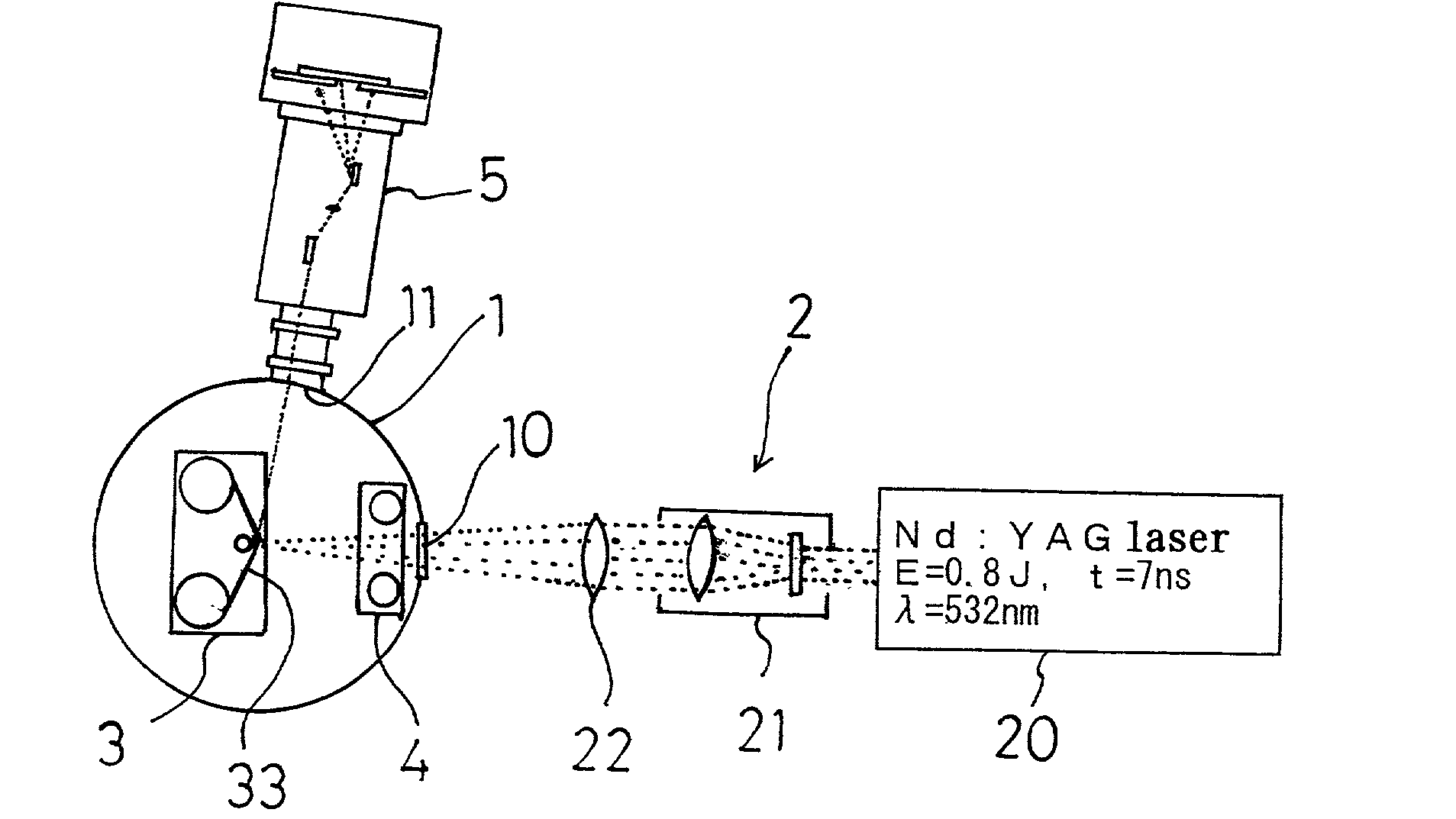

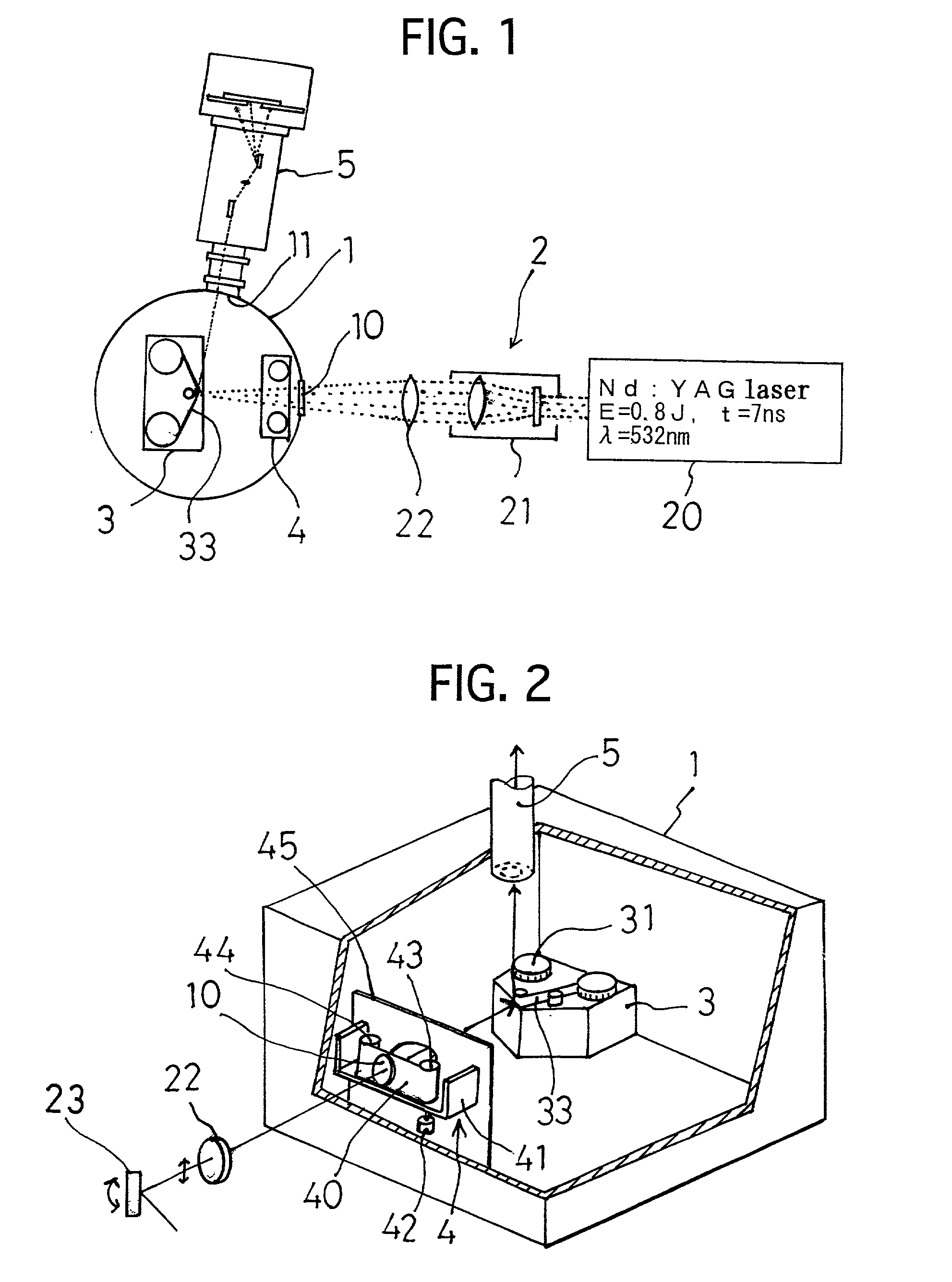

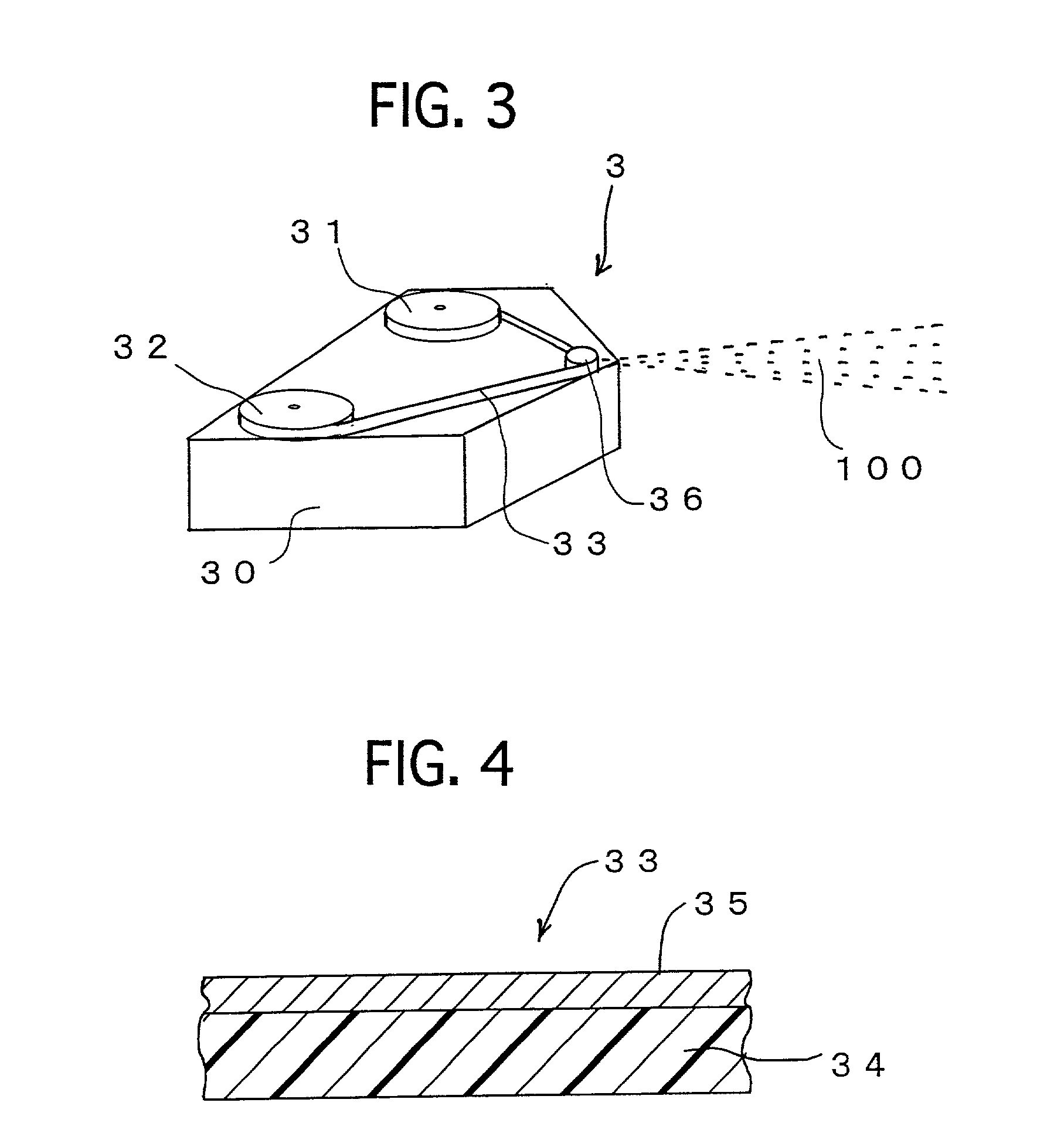

Laser plasma EUV light source apparatus and target used therefor

InactiveUS20020094063A1Control generationStable and long continuous drivingX-ray tube electrodesNanoinformaticsLength waveVacuum chamber

The present invention intends to generate an electromagneticwave of wavelength in an EUV area repeatedly by irradiating laser beam in high frequency more than few kHz. For such purpose, a laser plasma EUV light source apparatus is comprised of a vacuum chamber, a target disposed in the vacuum chamber, a beam irradiate means for irradiating energy beam to the target, an input optical system for introducing energy beam to the target, an output optical system being communicated with the vacuum chamber for introducing electromagneticwave generated from the target, a shield device for protecting at least one of the input optical system and output optical system from spattering particle, and a wave length select device for selecting from electromagneticwave an electromagneticwave at wavelength in the EUV area. By such construction, generation of the debris can be restricted, and generated debris is shielded by the shield device 4. In addition, the target can be supplied for long time and the laser plasma EUV light source apparatus can be made compact.

Owner:TOYOTA MACS

Fuel vapor treatment apparatus

InactiveUS20070137622A1Control generationImproved air-fuel ratio controlElectrical controlNon-fuel substance addition to fuelExternal combustion engineEngineering

A fuel vapor treatment apparatus is provided with a purging passage for introducing and purging fuel vapor produced in a fuel tank to an intake system for an internal combustion engine, a volume chamber located in the purging passage for enlarging a passage volume and a pump received in the volume chamber for generating a fluid flow in the purging passage.

Owner:DENSO CORP

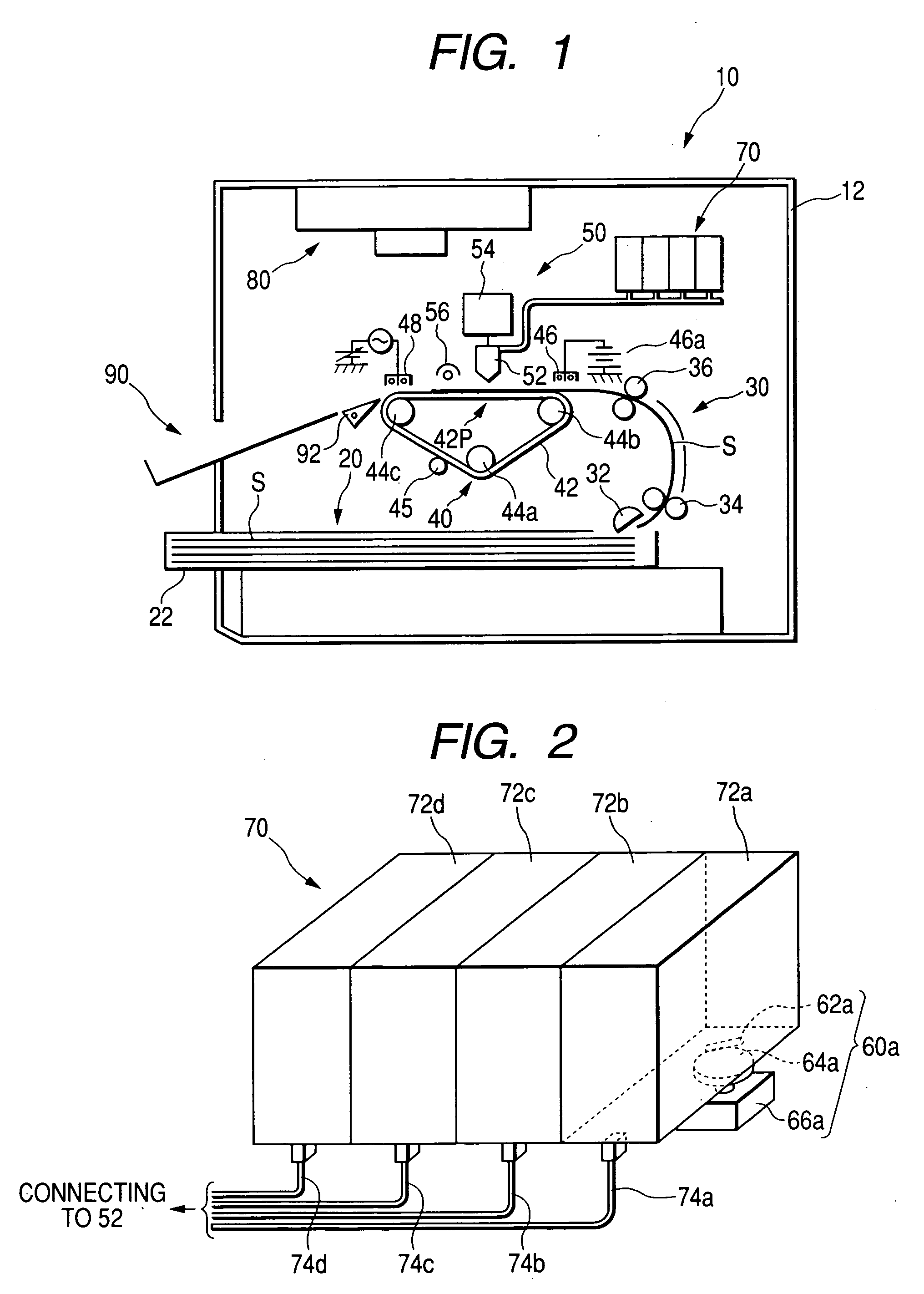

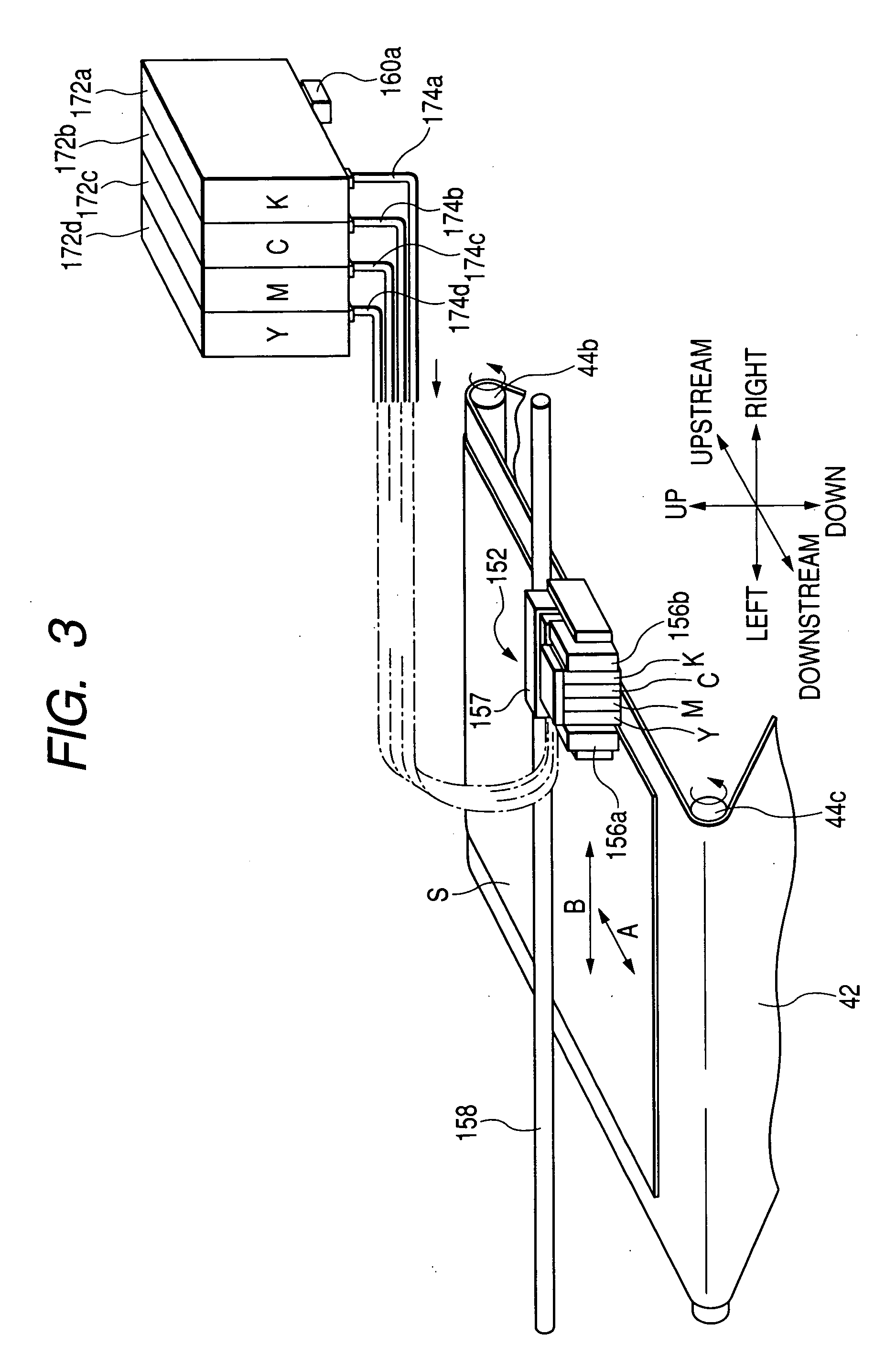

Ink cartridge and ink-jet recording device

InactiveUS20060268080A1Excellent in stability and run costRapid warm-upOther printing apparatusPhysicsEngineering

An ink recording device includes: an ink cartridge storing an ink curable by irradiation with an actinic energy ray, the ink cartridge having an ink stirring member inside thereof; and an drive section disposed lateral to the ink cartridge and in a position facing to the stirring member at a time installing the ink cartridge on the installing section.

Owner:FUJIFILM HLDG CORP +1

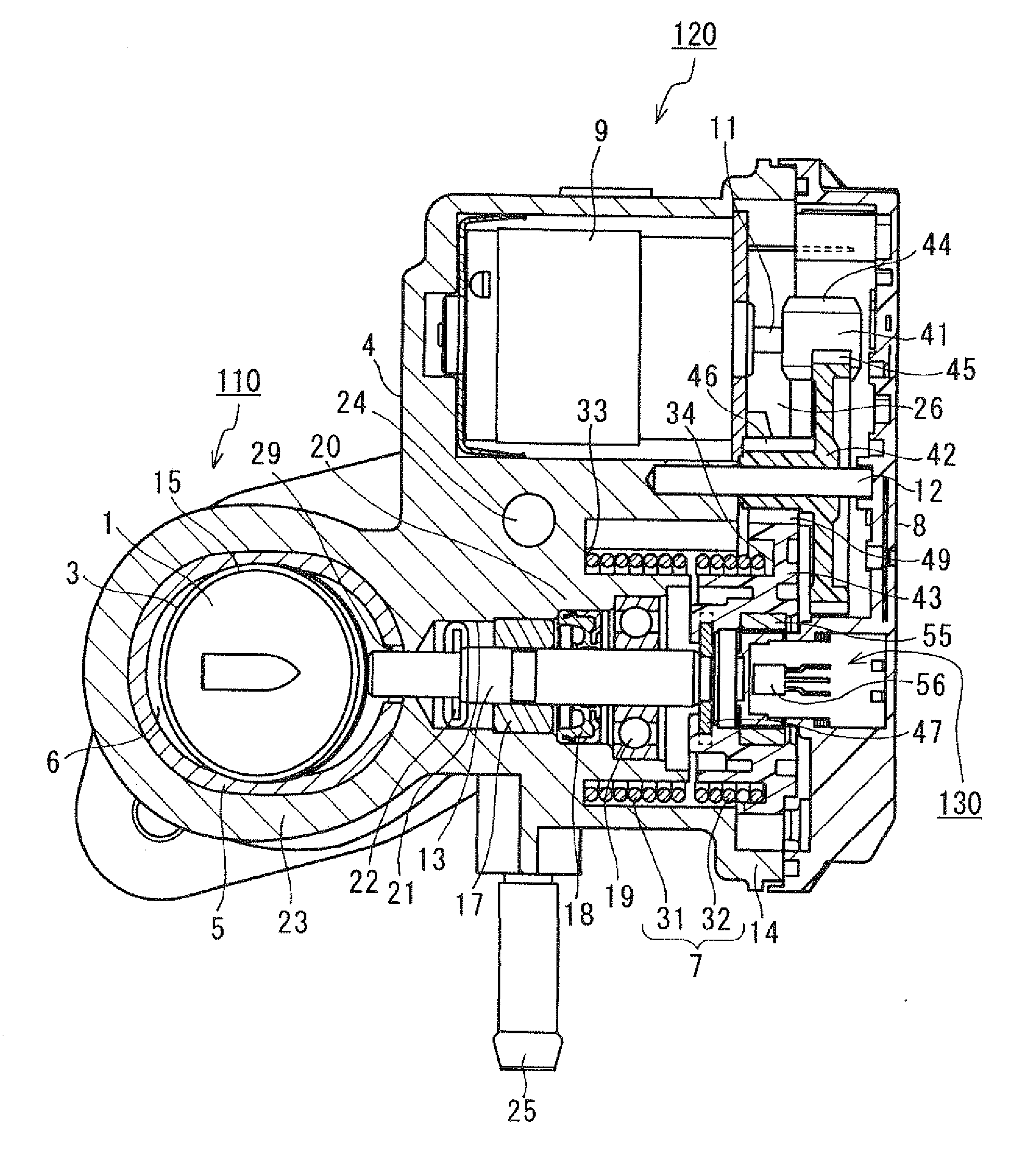

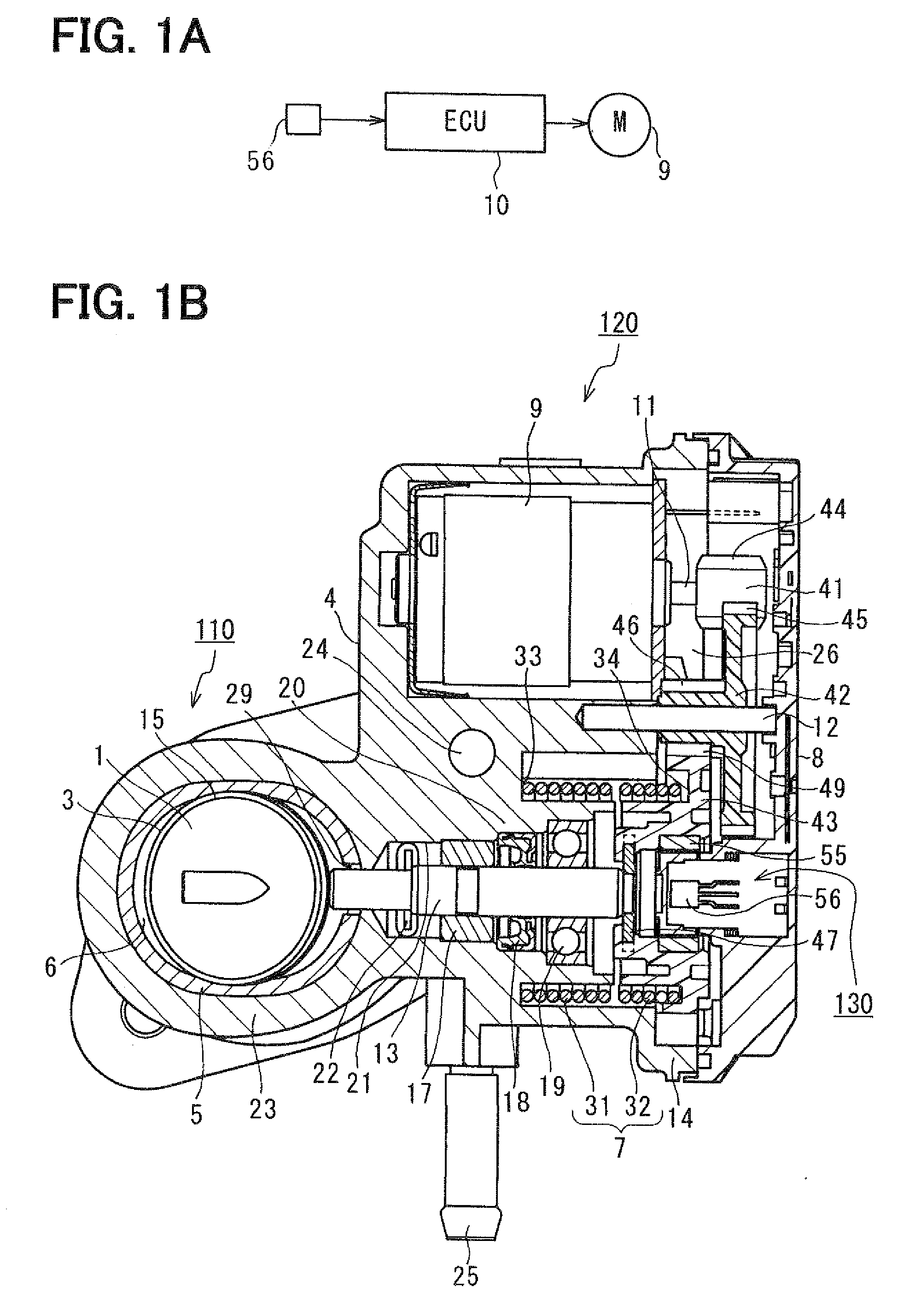

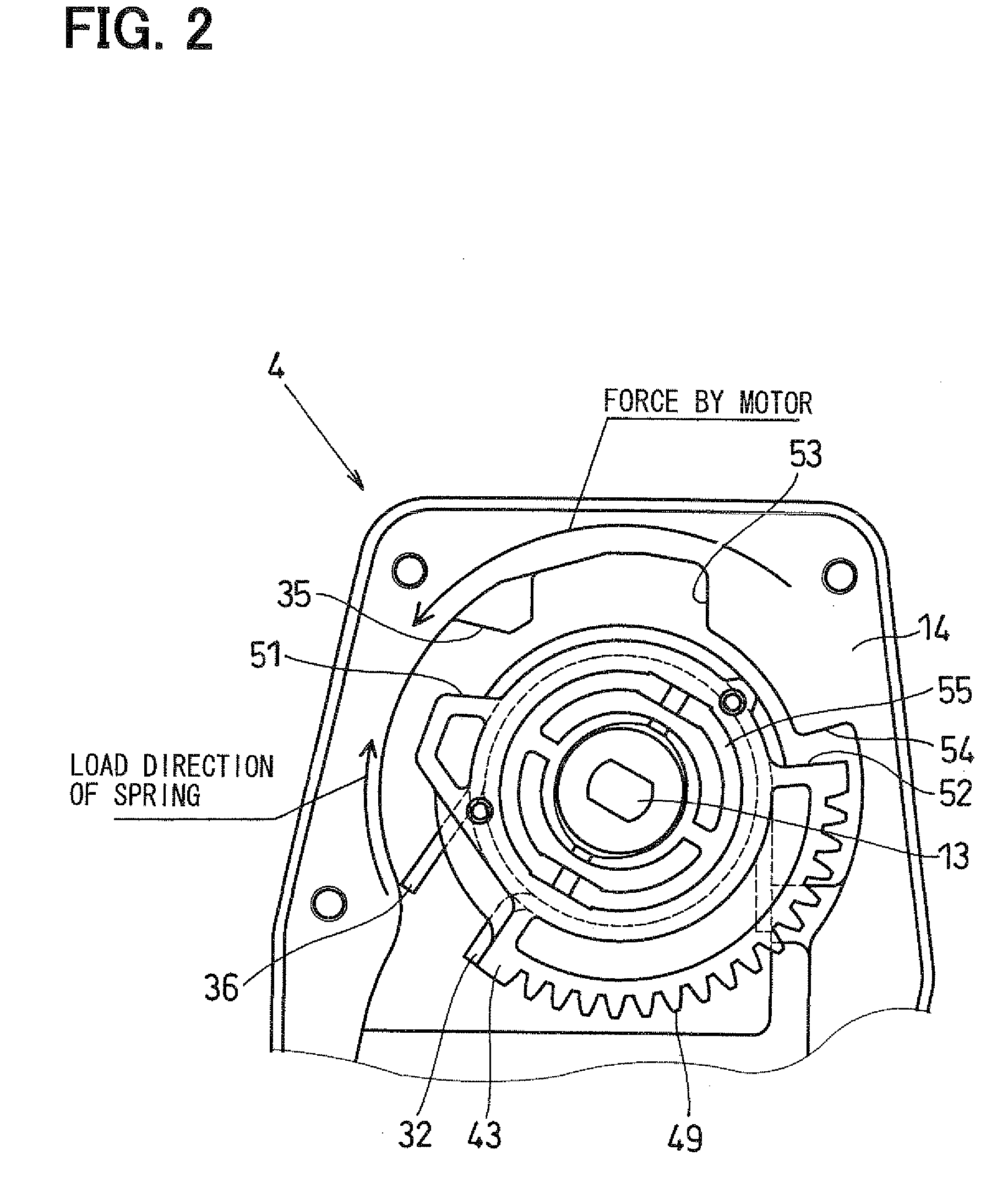

Valve opening and closing control apparatus

InactiveUS20090078898A1Control generationElectrical controlOperating means/releasing devices for valvesEngineeringElectric power

When a control unit variably controls an electric power supplied to an electric motor to repeat a valve opening and closing movement of a valve between a first intermediate position and a second intermediate position through a neutral position, the control unit initially sets the neutral position as a control target value until a valve position, which is sensed with a valve opening degree sensor, is located immediately before the neutral position. The control unit thereafter changes the control target value to the first intermediate position or the second intermediate position when the control unit determines that the valve position, which is sensed with the valve opening degree sensor, reaches the neutral position.

Owner:DENSO CORP

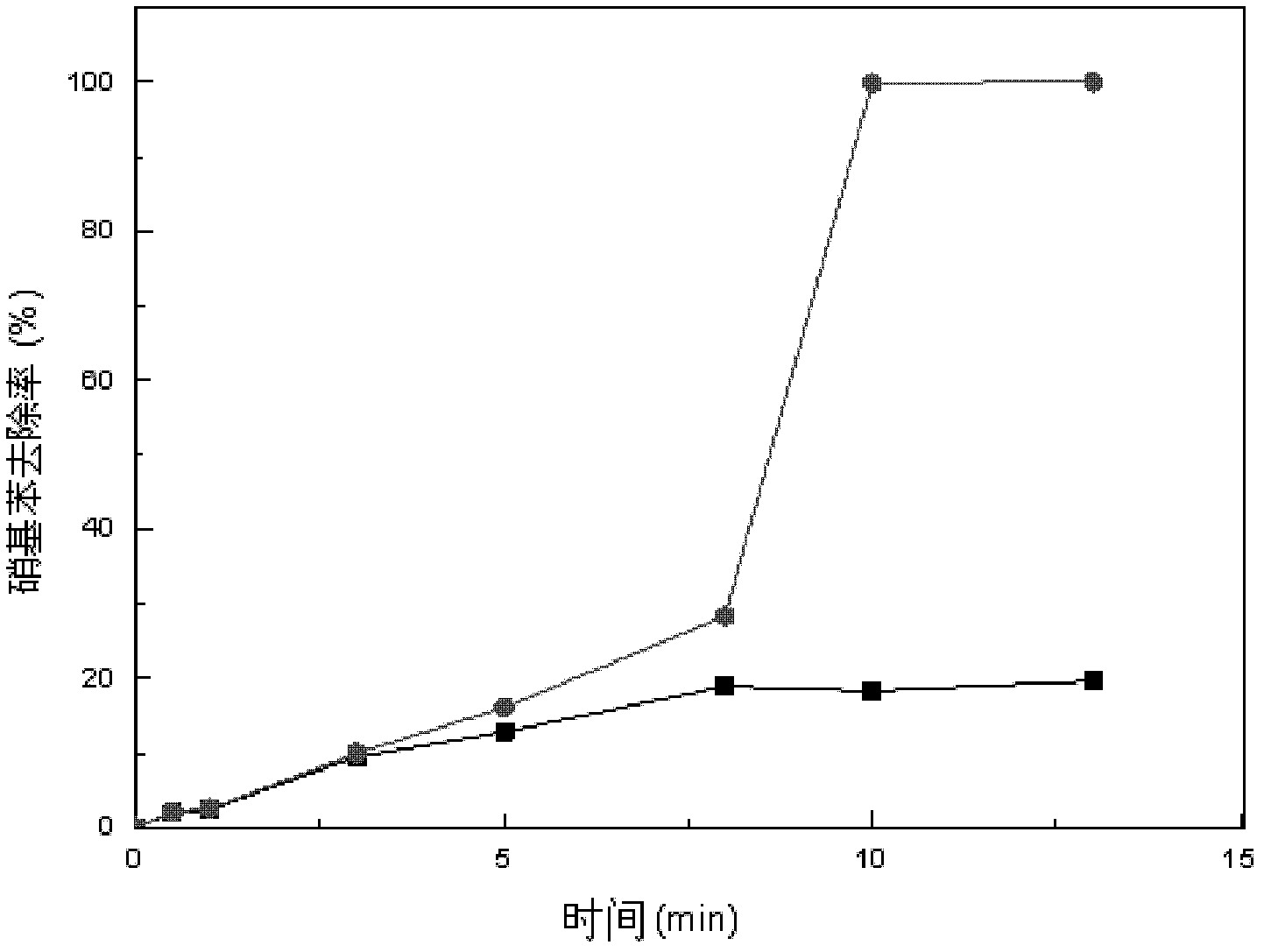

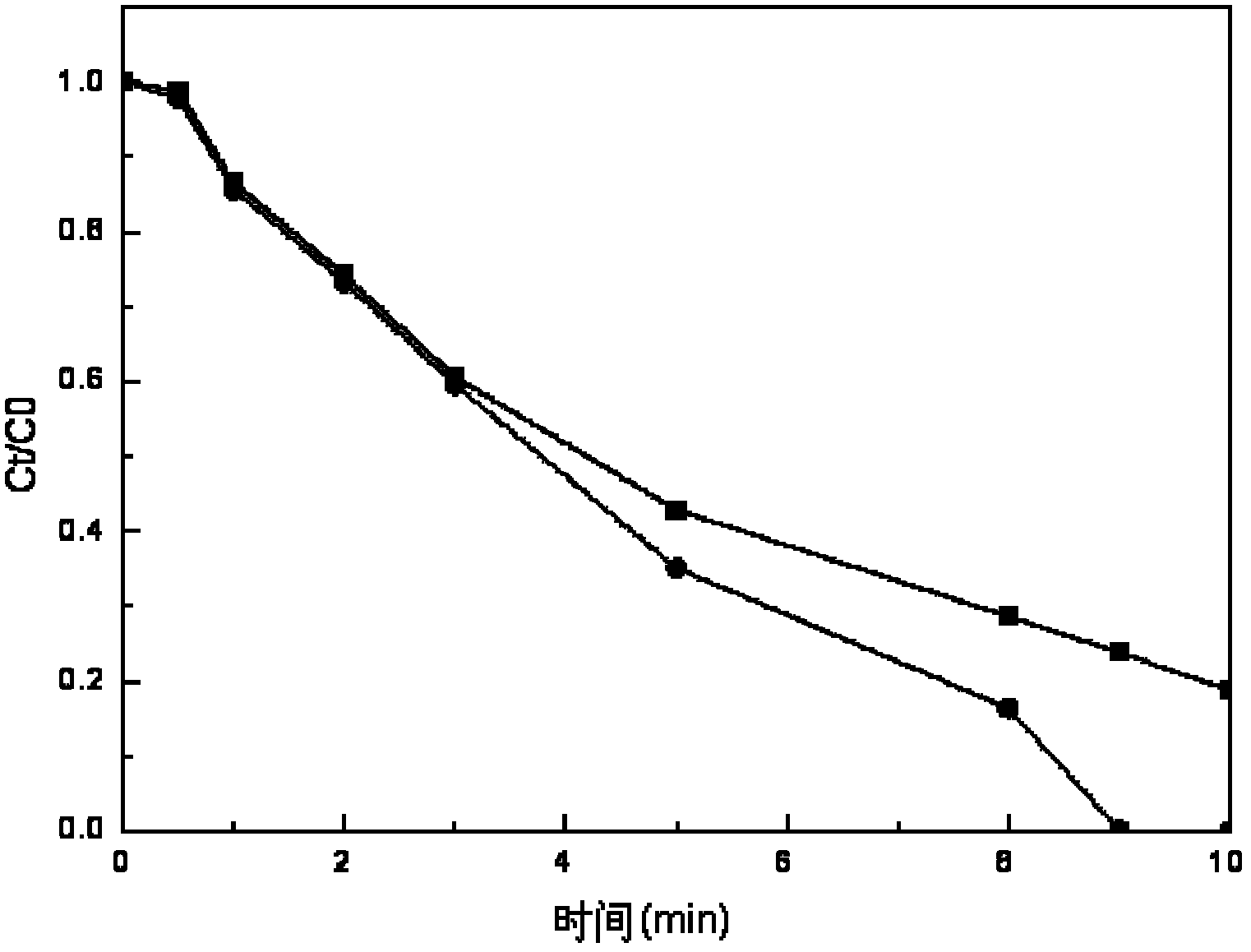

Gradient Ozone Catalytic Oxidation Method for Degrading Organic Pollutants in Water

ActiveCN102276095AAchieving Gradient OxidationControl contentMultistage water/sewage treatmentWater/sewage treatment by oxidationNitrosoCatalytic oxidation

The invention relates to a method for degrading organic pollutants in water by gradient ozone catalytic oxidation, and relates to a gradient ozone catalytic oxidation combination method for degrading organic pollutants in water. By the method, the problem that the conventional advanced oxidation technology has defects during individual use, the problem that the organic pollutants in the water cannot be removed efficiently, the problem that the influence of the pH value and temperature of the water on the method is large, and the problem that high-toxicity byproducts are formed are solved. In the method, water treatment is realized by combining two or three of a process for treating O3 individually, an enhanced catalytic oxidation process for O3 and an O3 / ultraviolet (UV) process sequentially. By the reasonable optimizing and gradient combination of the three treatment modes, the method is suitable for wide pH values and a wide temperature range, the pollutants with intermediate toxicity are controlled to be formed, the toxicity of the pollutants is reduced, the pollutants in the water is degraded efficiently and completely, and the content of oxidative species in effluent is controlled. An efficient oxidation treatment effect is kept at low temperature, and the generation of bromate, nitroso dimethylamine, chlorate, perchlorate, iodate and periodate can be controlled greatly.

Owner:哈尔滨工投环保产业有限公司

Water-soluble acrylic resin, resin composition containing the same for use in water-based coating composition, water-based coating composition and coating method by use of the same

A water-soluble acrylic resin which is prepared by neutralizing with a neutralizing agent an acrylic copolymer formed by copolymerizing (a) an alkylene oxide group-containing (meth)acrylate, (b) a cyclic saturated hydrocarbon group-containing (meth)acrylate, (c) a hydroxyl group-containing unsaturated monomer other than the monomer (a), and (d) other unsaturated monomer; a resin composition used for a water-based coating composition and containing, as a vehicle component, the above water-soluble acrylic resin; a water-based coating composition containing, as major components, (A) at Least one resin selected from the group consisting of a water-soluble resin and a water-dispersible resin and (B) a pigment, said pigment (B) being subjected to dispersion treatment; with a water-soluble acrylic resin (C), which is prepared by neutralizing with a neutralizing agent an acrylic copolymer formed by copolymerizing (a) an alkylene oxide group-containing (meth)acrylate, (b) a cyclic saturated hydrocarbon group-containing (meth)acrylate, and (e) other unsaturated monomer, followed by being mixed with the resin (A) to form a water-based coating composition; a coating method comprising coating a base coat coating composition onto a substrate followed by coating a top clear coating composition, the above water-based coating composition being used as the base coat coating composition.

Owner:KANSAI PAINT CO LTD

Image sensor using back-illuminated photodiode and method of manufacturing the same

ActiveUS7714403B2Control generationHigh sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingHigh densityPhotodiode

An image sensor using a back-illuminated photodiode and a manufacturing method thereof are provided. According to the present invention, since a surface of the back-illuminated photodiode can be stably treated, the back-illuminated photodiode can be formed to have a low dark current, a constant sensitivity of blue light for all photodiodes, and high sensitivity. In addition, it is possible to manufacture an image sensor with high density by employing a three dimensional structure in which a photodiode and a logic circuit are separately formed on different substrates.

Owner:SK HYNIX INC

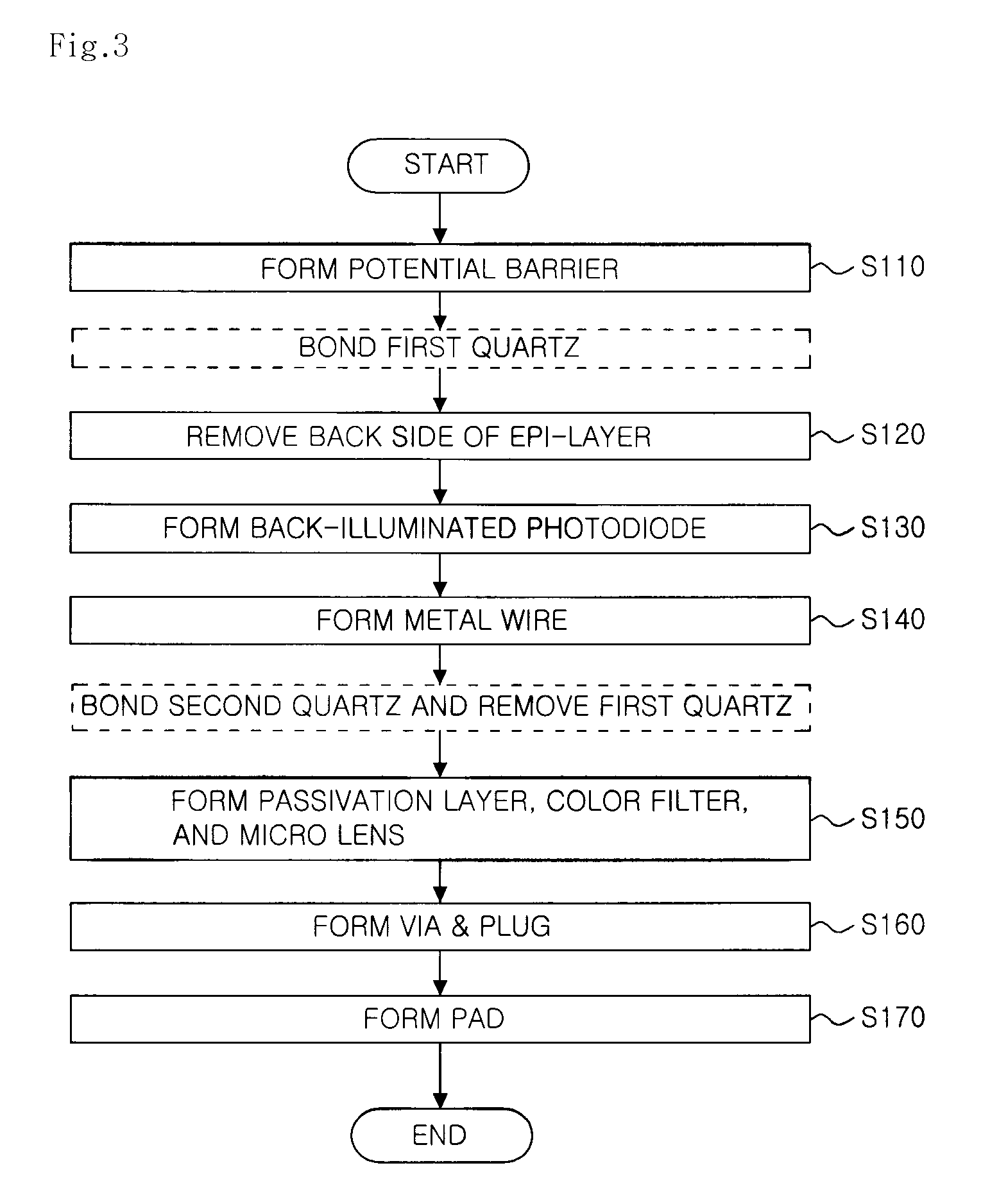

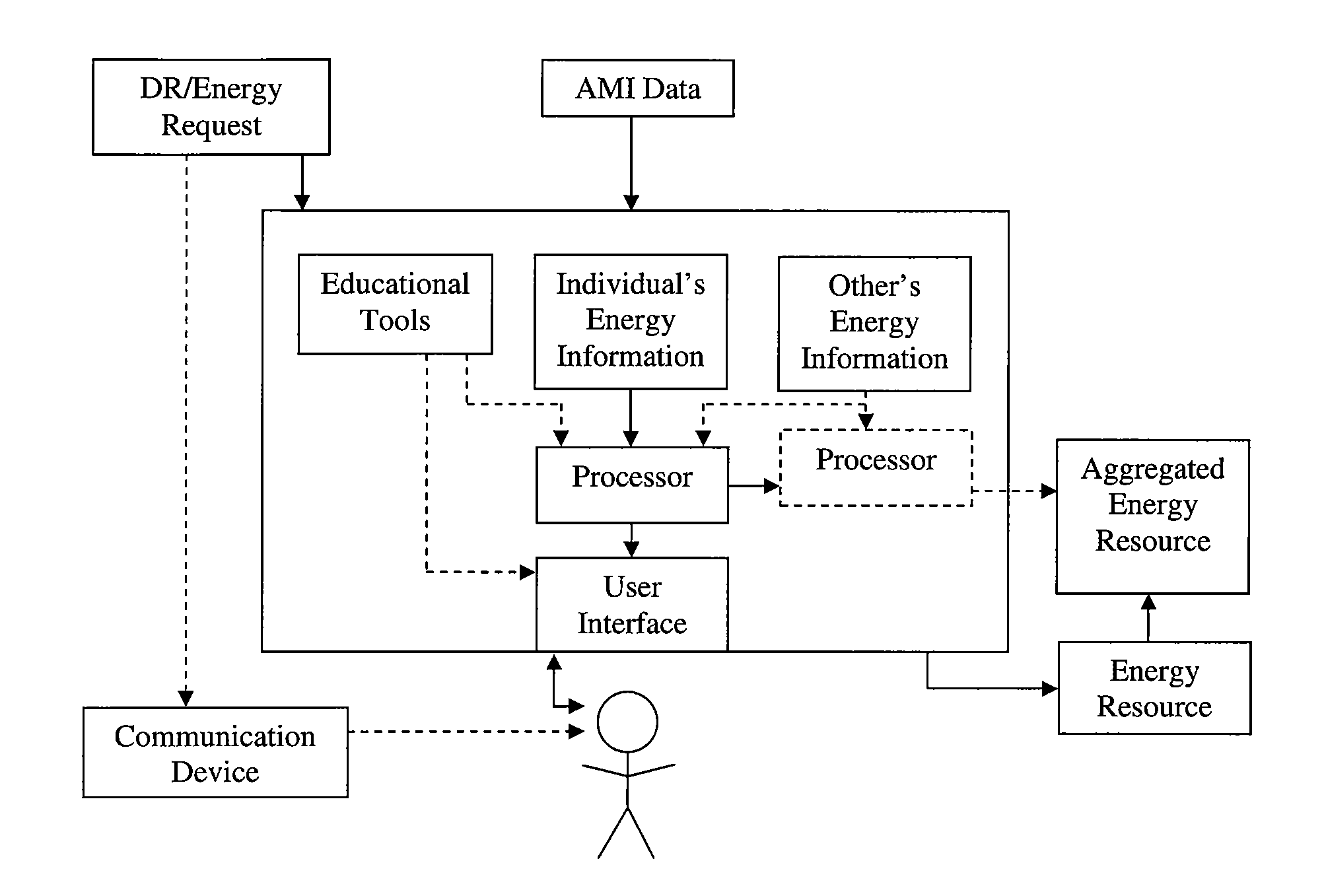

Coordinated energy resource generation

InactiveUS8489245B2Promoting and aggregating the demand response capabilitiesImprove welfareMechanical power/torque controlDiscounts/incentivesEngineeringEnergy expenditure

Demand response to reduce energy consumption by individual consumers is provided by aggregating individual consumers, and providing feedback to such consumers regarding their energy consumption relative to other energy consumers in a group. The resulting feedback may result in reduced energy consumption by the individual consumer.

Owner:CLEANTECH BUSINESS SOLUTIONS

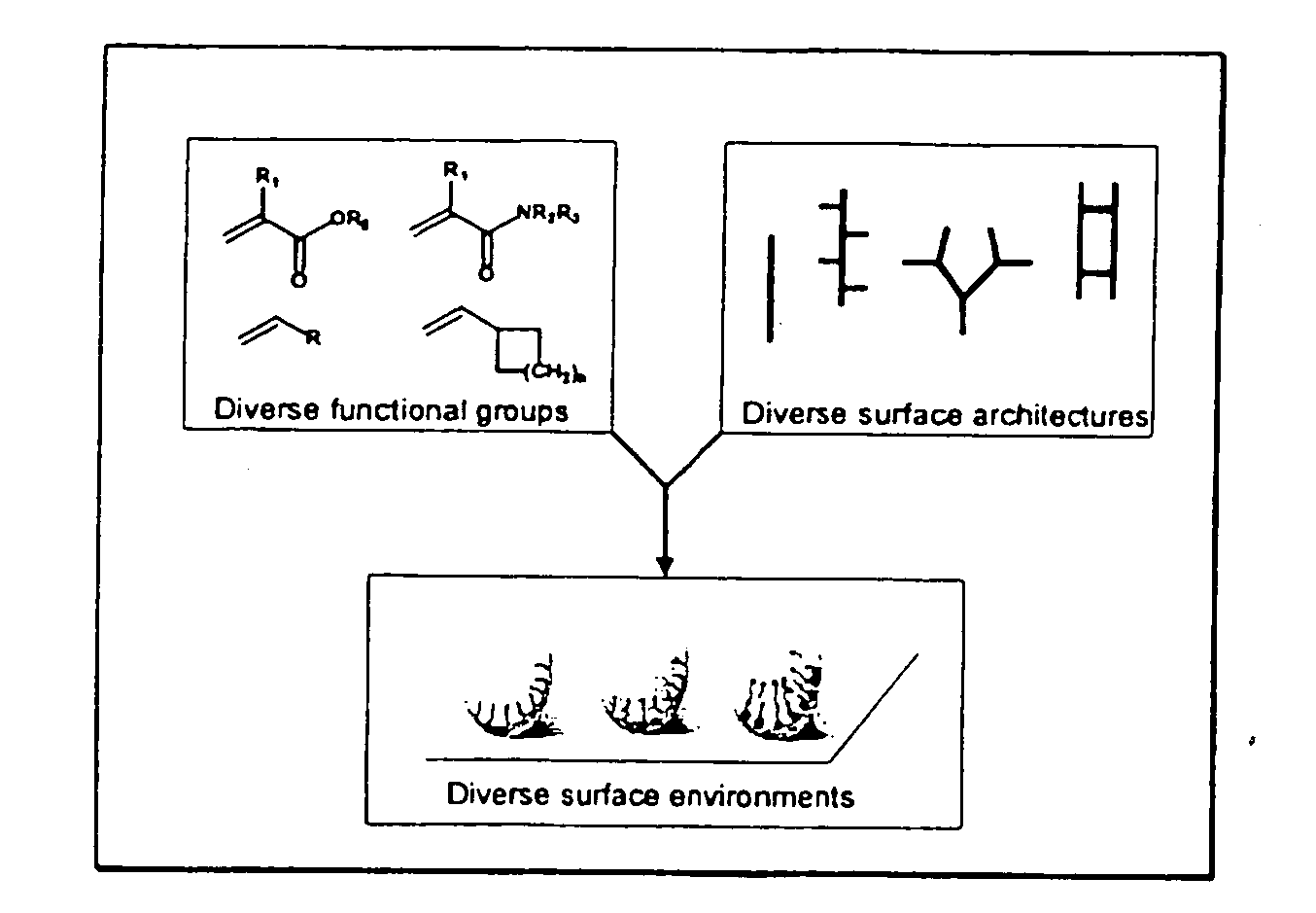

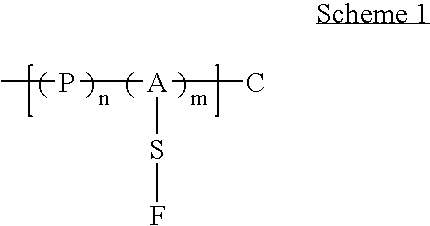

Generation of surface coating diversity

InactiveUS20060083858A1Generation of surfaceControl generationMembranesSequential/parallel process reactionsChemical compositionSynthon

The present invention relates to a surface discovery system comprising chemical compositions and high-throughput combinatorial synthesis methods for generating large numbers of diverse surface coatings on solid substrates. This surface discovery platform is built upon a fundamental chemical unit refereed to as a synthon. Each synthon comprises at least three elements: a chemical backbone coating on the solid substrate that comprises a passive (P) constituent and an active (A) constituent; a spacer unit (S) separating the backbone from a functional group; and a functional group (F). Variation of these synthon elements allows generation of large libraries surface coatings with a broad range of molecular and macroscopic properties. Further the spectrum of surfaces provided by the invention permits optimization of the wide range of solid-phase applications that involve surface immobilization of molecules.

Owner:ANTEO TECH

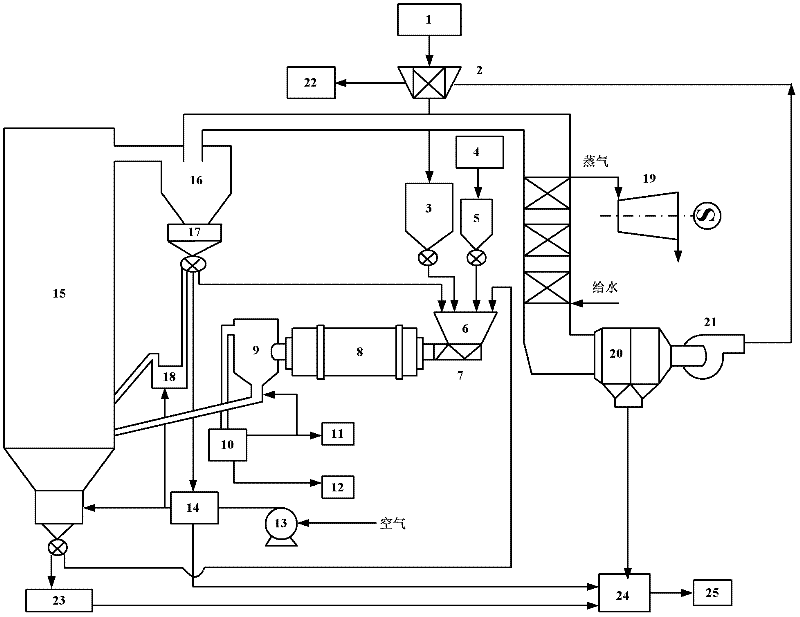

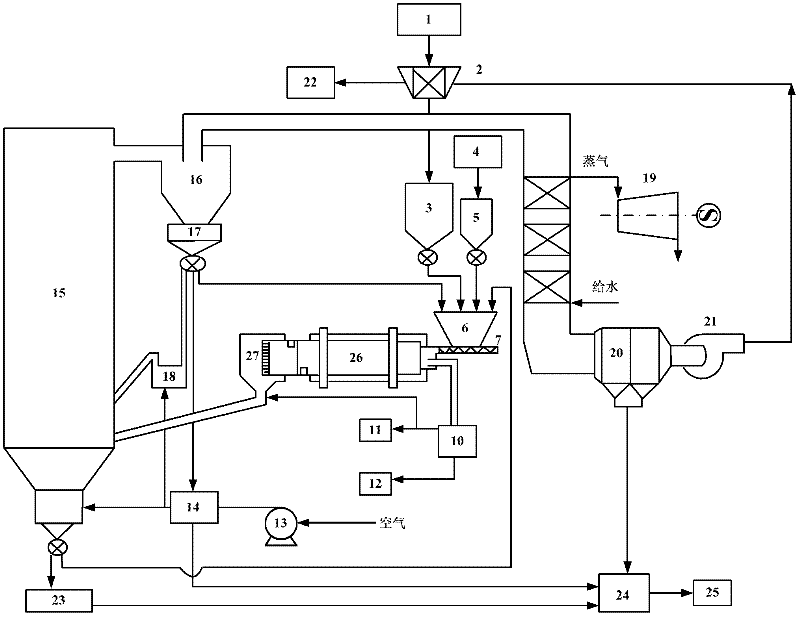

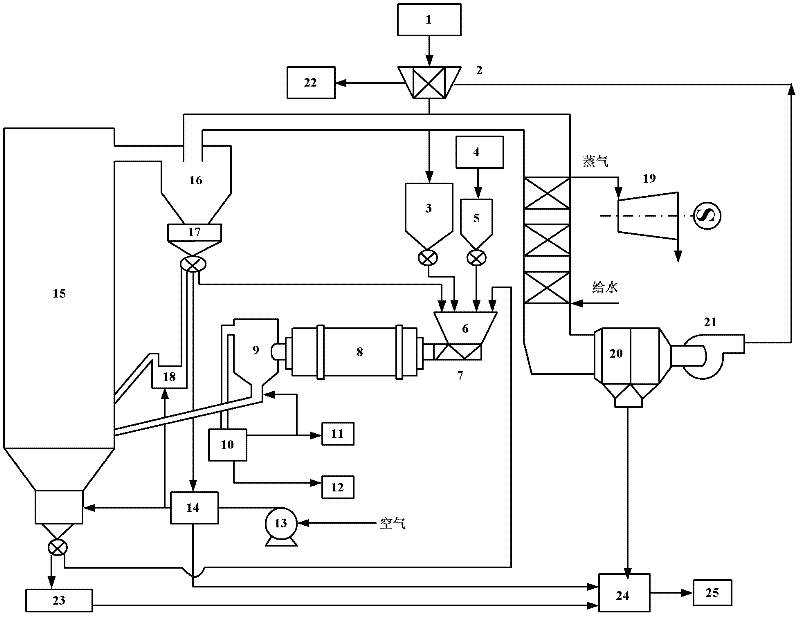

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

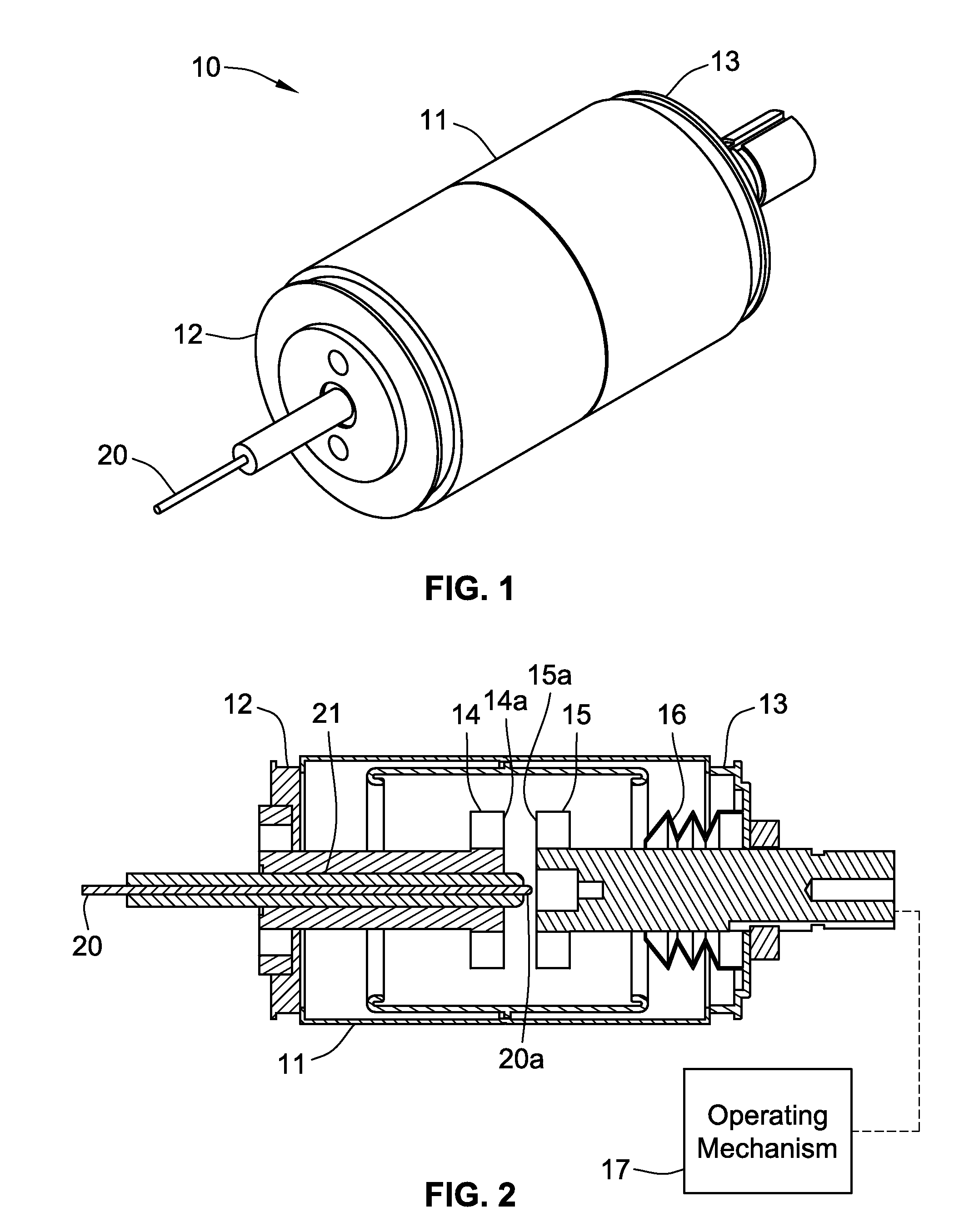

Arcing fault and arc flash protection system having a high-speed switch

ActiveUS8319136B2Control generationSwitchgear arrangementsProtective switchesArc flashElectrical conductor

A high-speed arc terminator for an electrical power distribution system includes a sealed, evacuated housing, and a controllable mechanical switch having first and second electrically conductive contacts enclosed within the housing and adapted to be coupled to the power distribution system outside the housing. A trigger conductor extends into the housing and has an exposed end near the gap between the contacts when the contacts are in the open position. At least one of the contacts is movable between an open position in which the contacts are separated by a gap, and a closed position in which the contacts engage each other, and an operating mechanism is provided for moving the at least one contact between the open and closed positions. A high voltage source is controllably coupled to the trigger conductor for supplying a high-voltage pulse to the trigger conductor in response to the detection of an arcing fault. The high-voltage pulse produces an arc within the gap between the contacts, to shunt fault current from the power distribution system across the gap, from one of the contacts to the other, before the contacts engage each other.

Owner:SCHNEIDER ELECTRIC USA INC

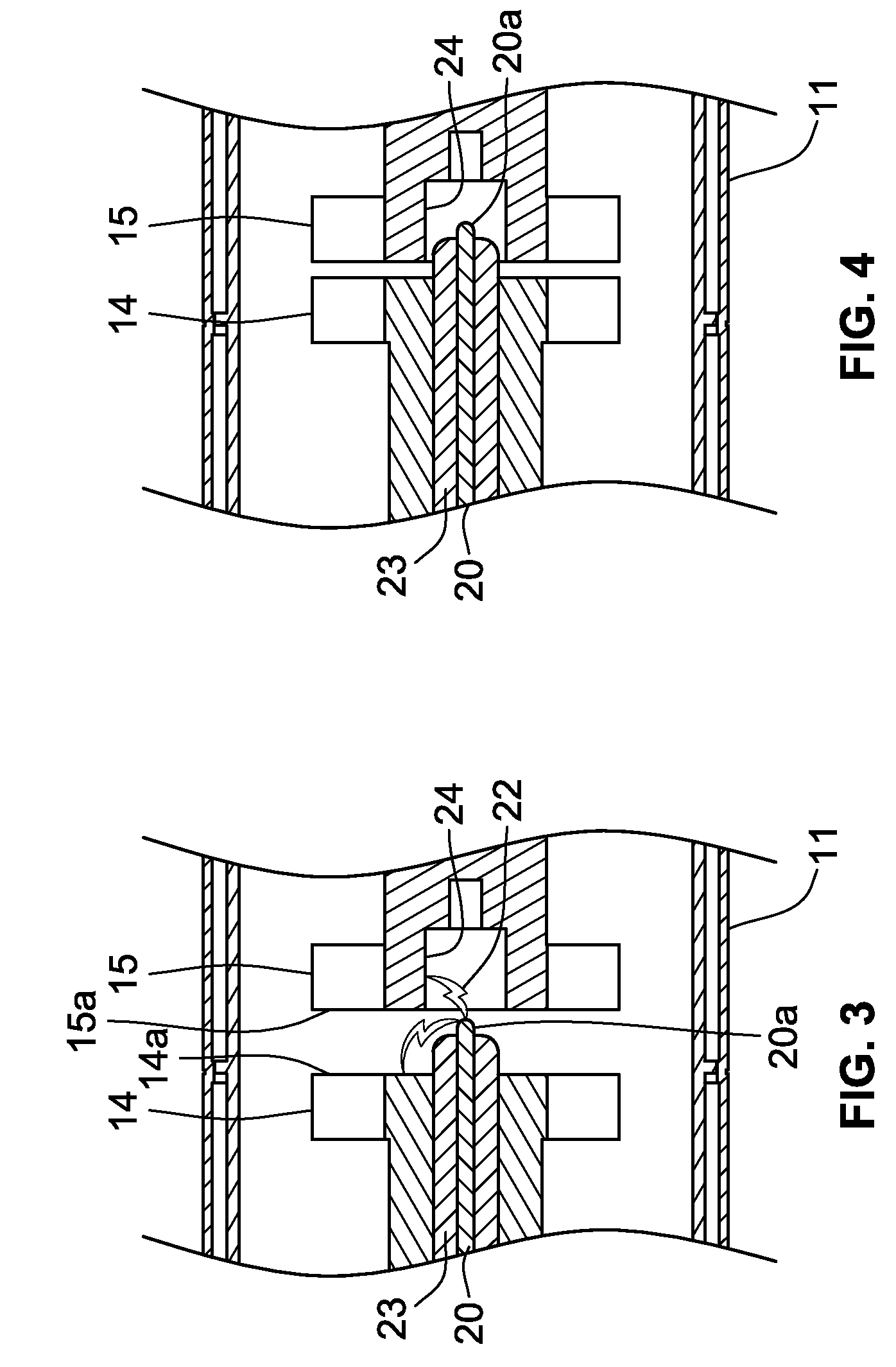

Process for separating and recovering valuable metals

InactiveUS7182926B2Control generationSuitable for useOther chemical processesTantalum compoundsAmmonium orthomolybdateAmmonium metavanadate

A process for economically separating and recovering valuable metal components, with few kinds of chemicals being used, with no waste water that causes environmental pollution being discharged, and also perfectly no by-products being formed by means of simple steps. The process includes a step of leaching a raw material containing at least vanadium oxides and molybdenum oxides with ammonia-containing leaching water to obtain a leached solution containing a vanadium compound and a molybdenum compound, a step of adding ammonium orthomolybdate to the leached solution to separate and recover the deposited ammonium metavanadate from a first solution for separation, a step of adding a water-soluble alcohol to the separated solution to separate and recover the deposited ammonium orthomolybdate from a second solution for separation, a step of distilling the second solution for separation to separate and recover the water-soluble alcohol and a residue solution, a step of adding at least a portion of the residue solution to the ammonia-containing leaching water as the portion thereof, and a step of returning a portion of the recovered ammonium orthomolybdate and a total of a recovered, water-soluble alcohol to the system for reusing.

Owner:Y K YSK TECHNOSYST

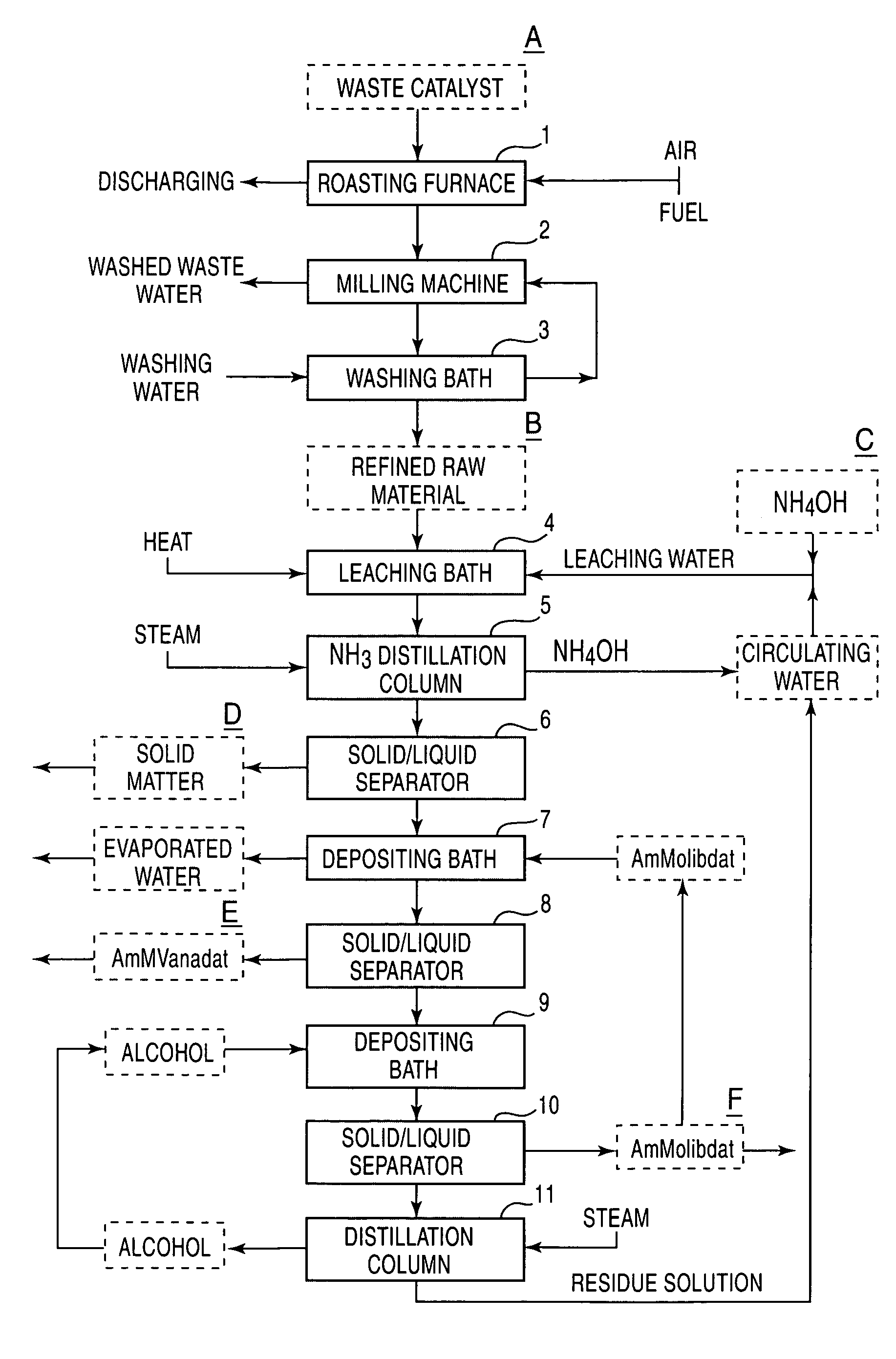

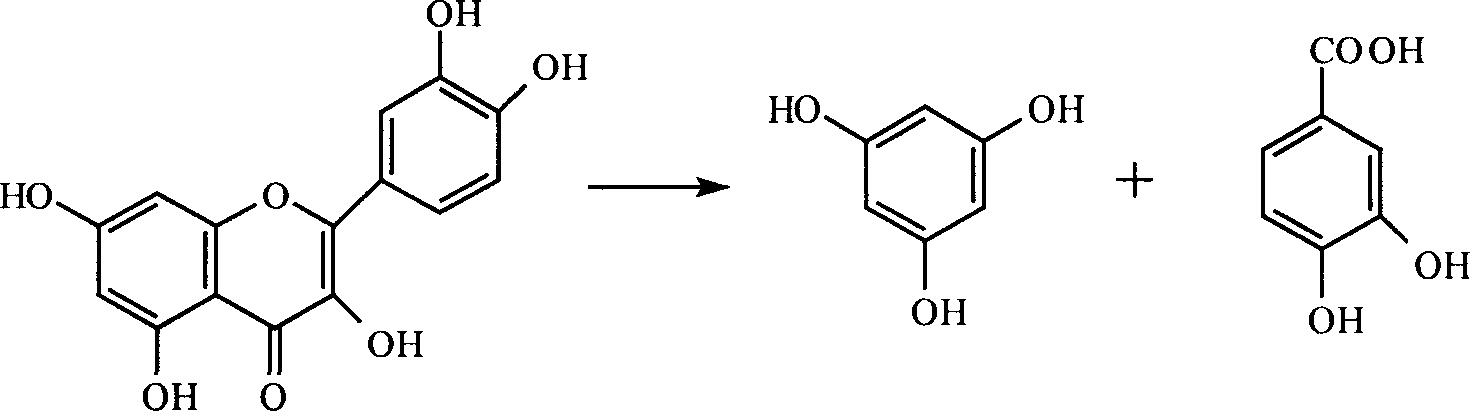

Method for preparing high-content troxerutin drug

ActiveCN1814613AHigh content and yieldReduce dosageOrganic active ingredientsSugar derivativesDrugSodium hydroxide

The invention offers 3', 4', 7-troxerutin synthetic method. It uses rutin and ethylene oxide to do hydroxyethylation reaction under the catalyzing of sodium hydroxide. Its features are that in the reaction, the weight ratio of rutin and water is 1:1-1:3; optimization is 1:1-1:1.5; the weight ratio of rutin and sodium hydroxide is 100:0.82-100:0.85; adding resin when the pH value of the reaction solution is 9.0-9.5 to adjust end point pH value to 9.5-10.3. The method can make high purity and high quality troxerutin. And its 3', 4', 7-troxerutin content is more than 78%; optimization is more than 80%; and the more optimization is more than 85%.

Owner:TOPFOND PHARMA CO LTD

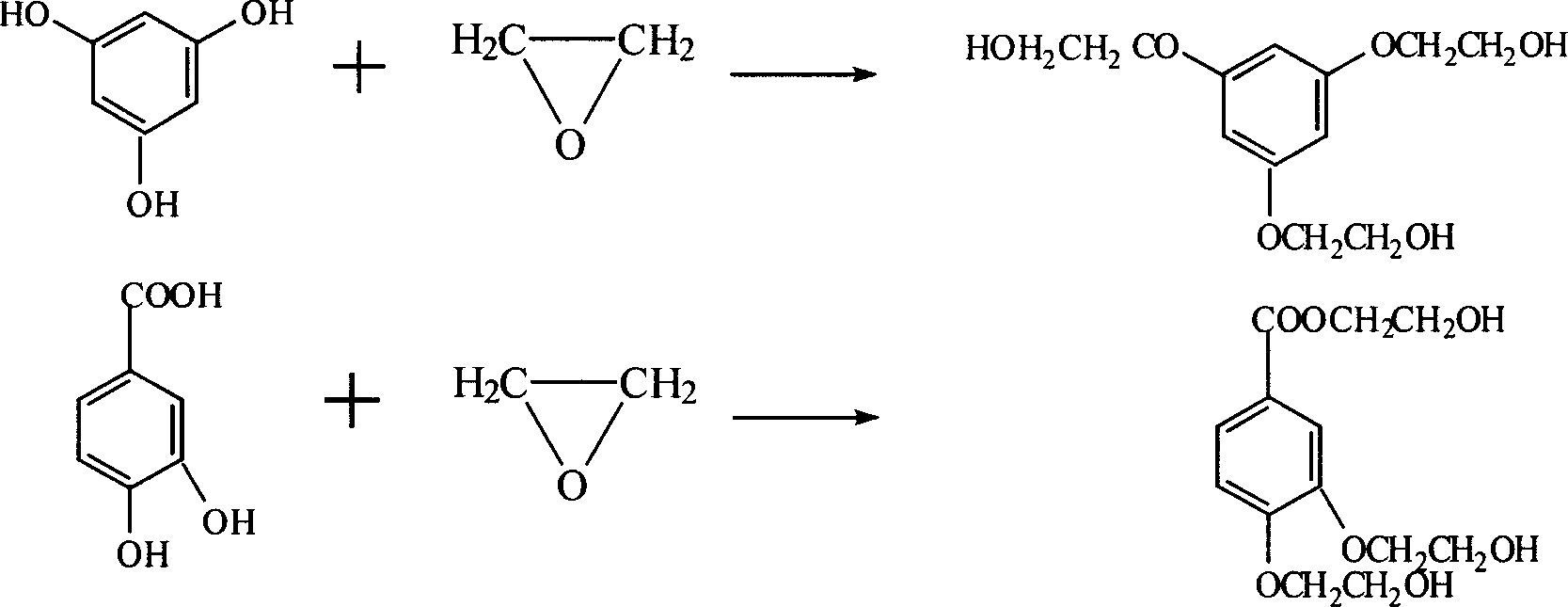

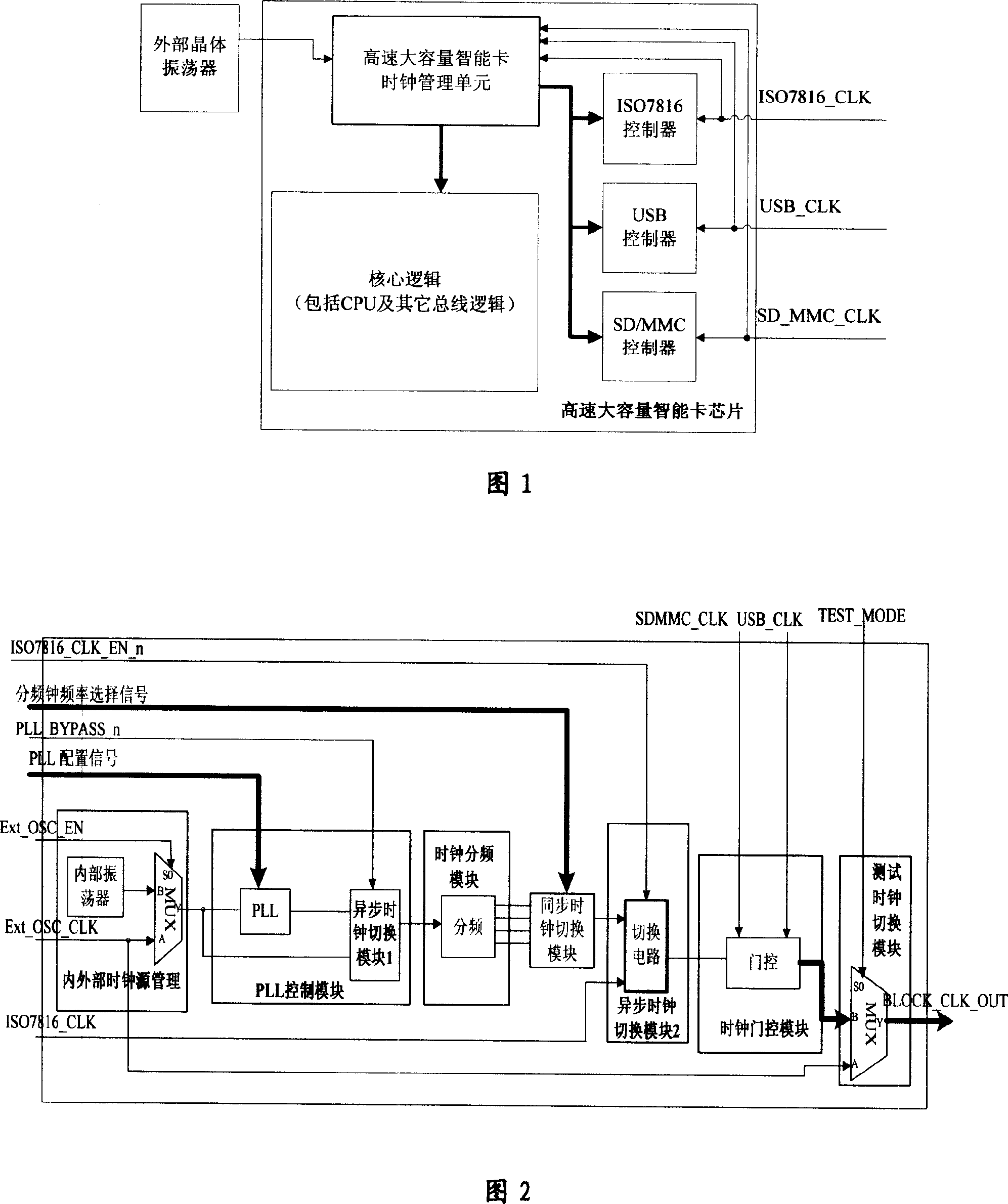

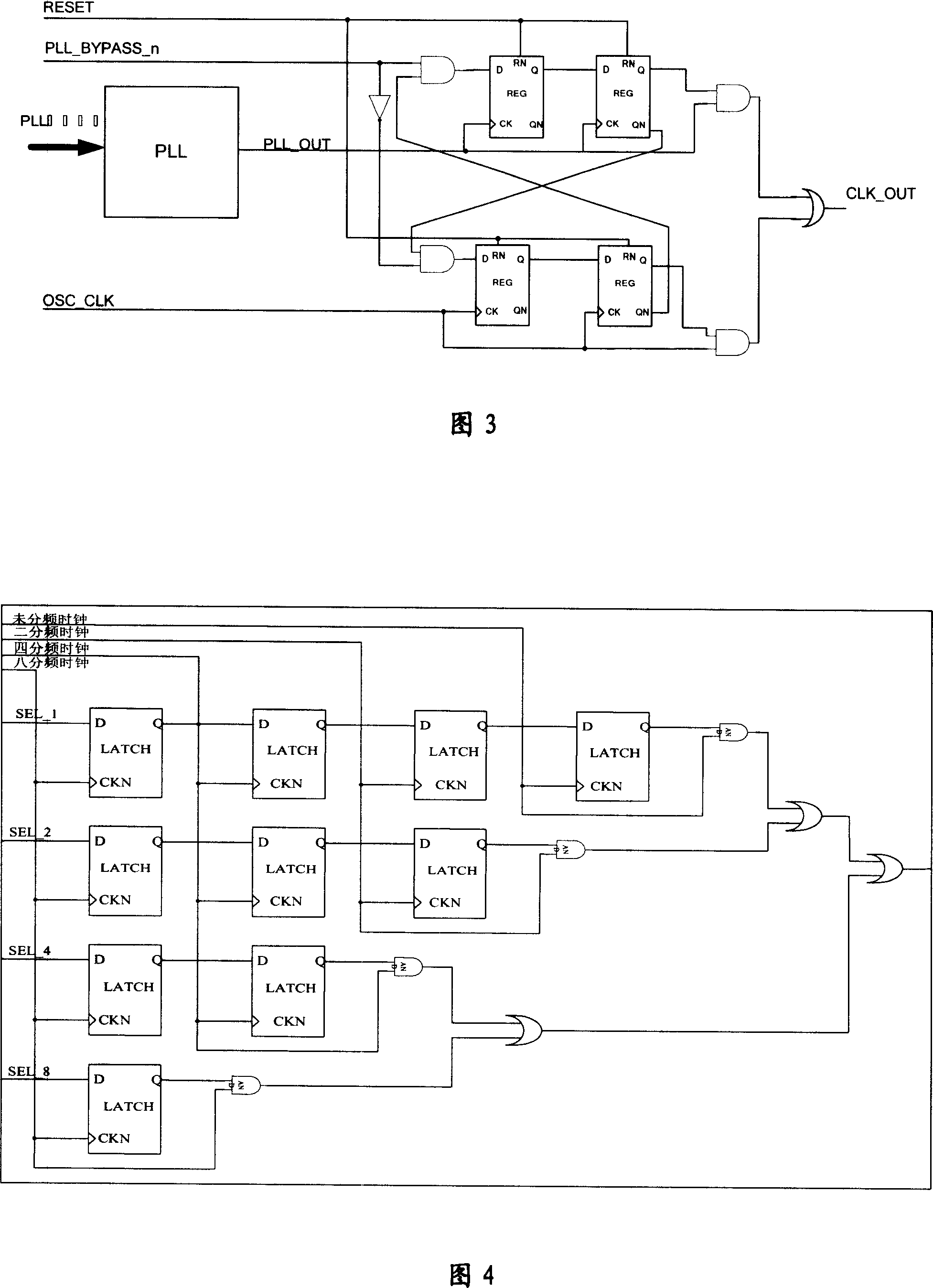

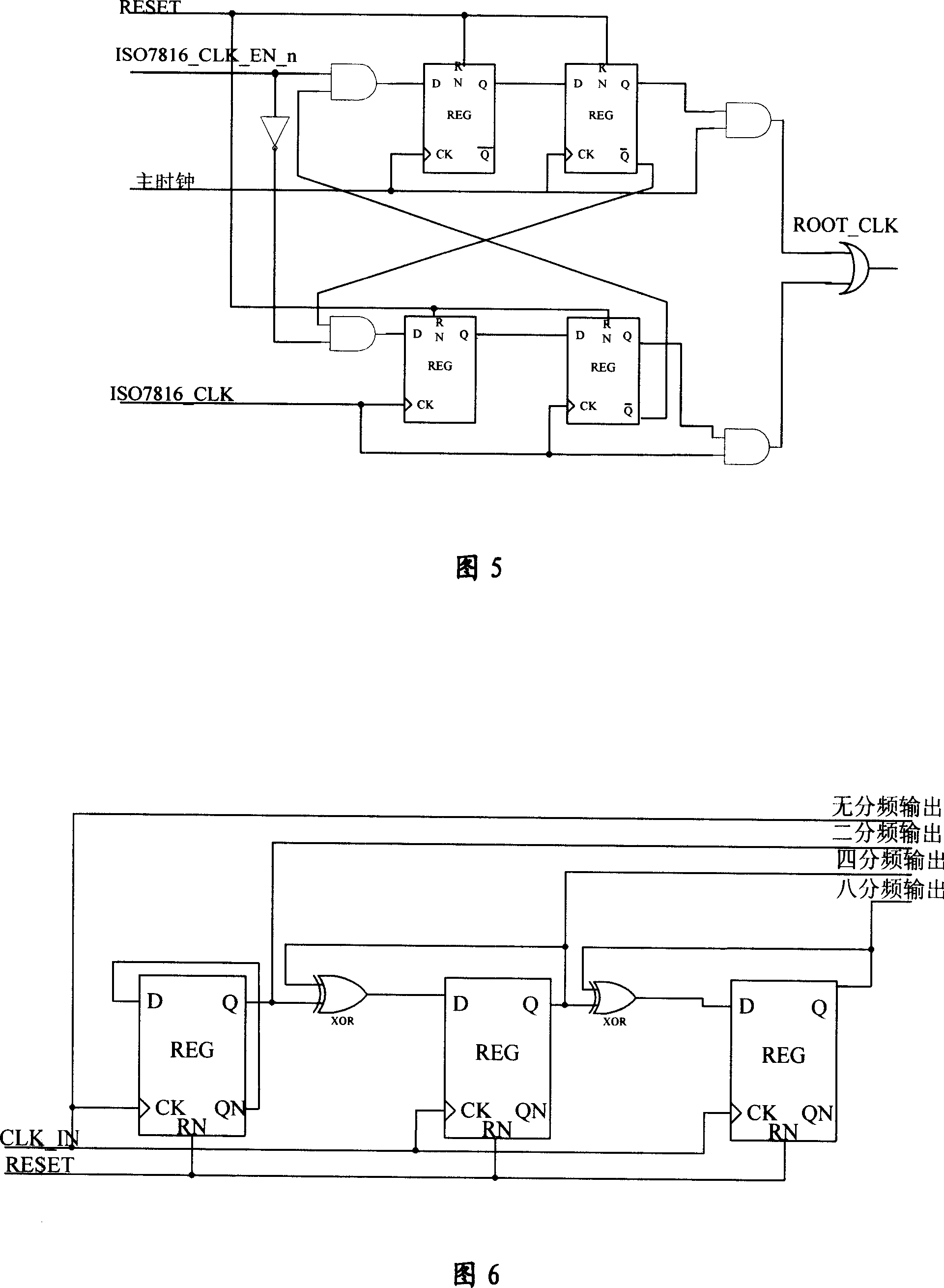

Unit and method for implementing clock management of high-speed high capacity smart card

ActiveCN101013477AImplement clock frequency selectionControl generationRecord carriers used with machinesDigital marking by punchingIndependent clockDynamic power dissipation

The invention belongs to the field of smart card technology, which involves smart card technology with high-speed interfaces, large storage capacity, specifically related to in a high-speed large-capacity smart card chip achieving clock switching and frequency control management modules and methods. The management unit includes internal and external clock source management module which select the clock source. The internal and external clock source management module connects with the PLL control module, the internal oscillator of the internal and external clock source management module and the PLL in the PLL control module constitute an internal independent clock source; PLL control module connects to clock frequency module, the clock frequency module connects to synchronous clock frequency switching module, the synchronous clock frequency switching module connects to the clock gating module through asynchronous clock switching module, the clock gating module connects to the testing clock switching module. The invention is a good solution to the dynamic power control and clock management problem in ultra high capacity smart card chip with multiple high-speed clocks.

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

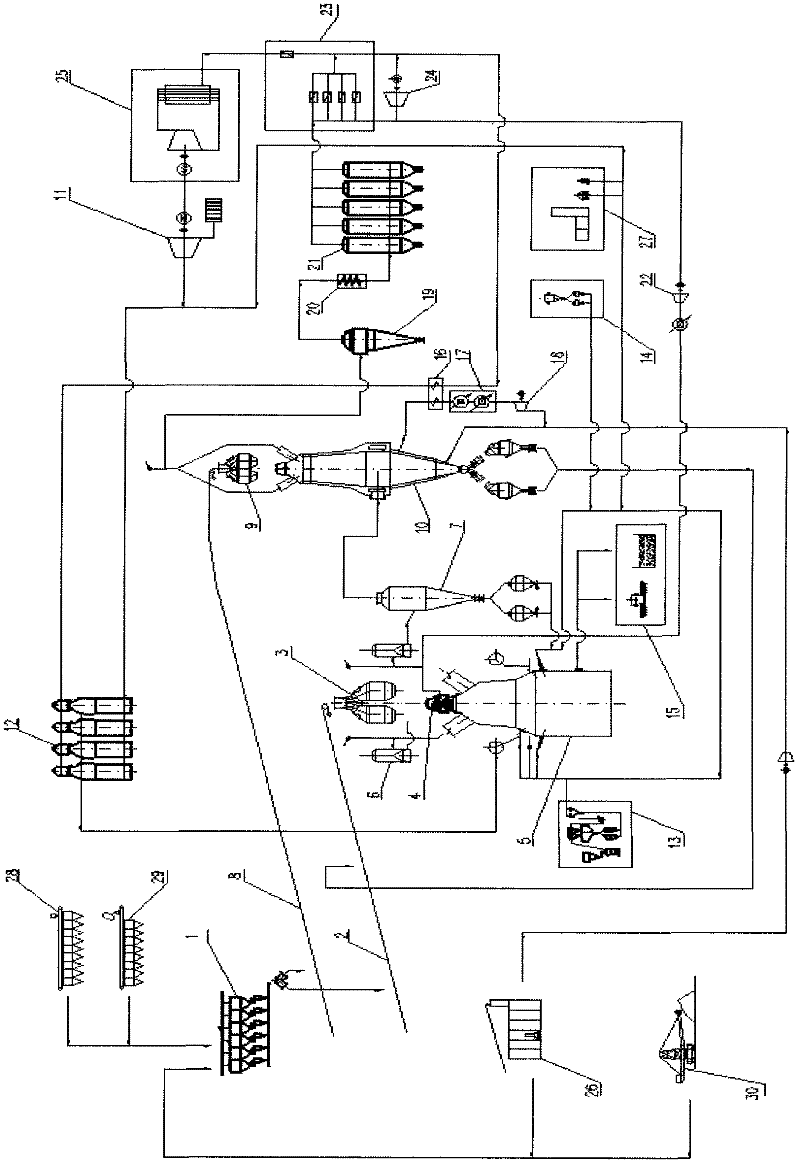

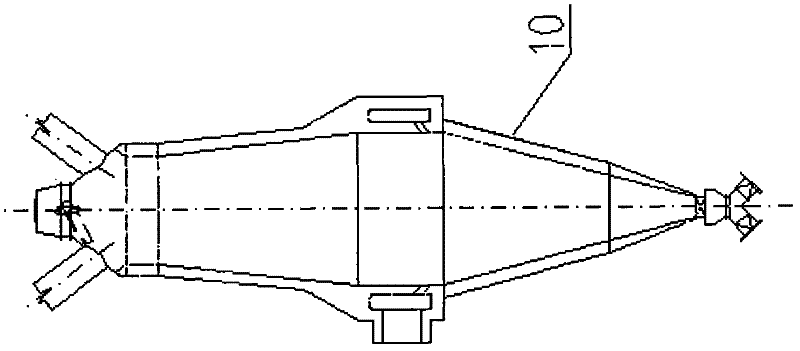

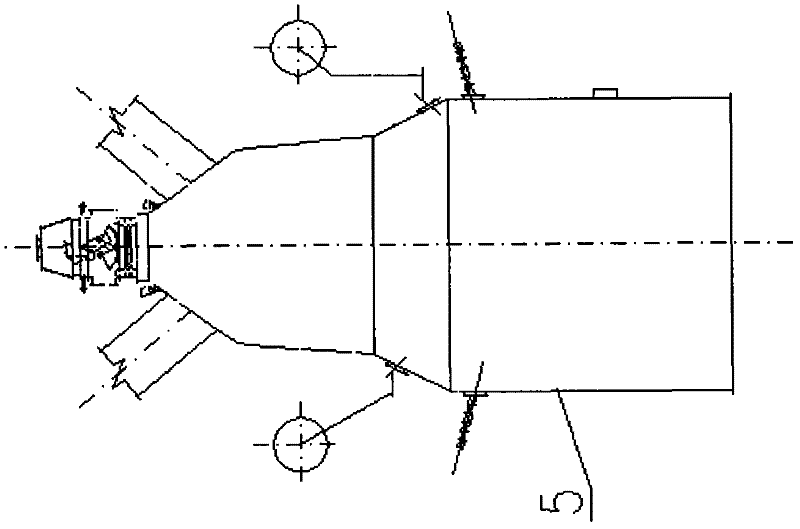

High-wind-temperature rotational flow injection disturbance melting reduction and prereduction combination device and method

ActiveCN102337369AGood for high pressure operationGood for material level controlShaft furnaceMetallurgyCogeneration

The invention discloses a high-wind-temperature rotational flow injection disturbance melting reduction and prereduction combination device and a method, which belong to the technical field of melting reduction. The device comprises a raw material system, a furnace top material charging and distributing system, a melting reduction furnace, a furnace top high-temperature gas system, a prereduction furnace, a semicoke gas recycling system, a coal dust preparing and spraying system, a molten iron desulfurizing agent preparing and jetting device, an oxygen and nitrogen supplying system, a residual iron treating system, a high-wind-temperature hot blast furnace, a melting reduction furnace blower, a furnace top gas dedusting and recycling system and a gas cogeneration device. The method comprises the following steps of: introducing high-temperature gas which is generated in a high-wind-temperature rotational flow injection disturbance melting reduction furnace into the prereduction furnace; directly reducing an iron-containing raw material in a solid phase state into a prereduction furnace material with a certain metallization rate; cooling, and then adding the cooled material and semicoke which serve as the furnace material and a fuel respectively into the melting reduction furnace; and finally producing molten iron by reduction. The device and the method have the advantages of high production efficiency and low energy consumption, are easy to operate and make industrialization easily realized.

Owner:BEIJING SHOUGANG INT ENG TECH

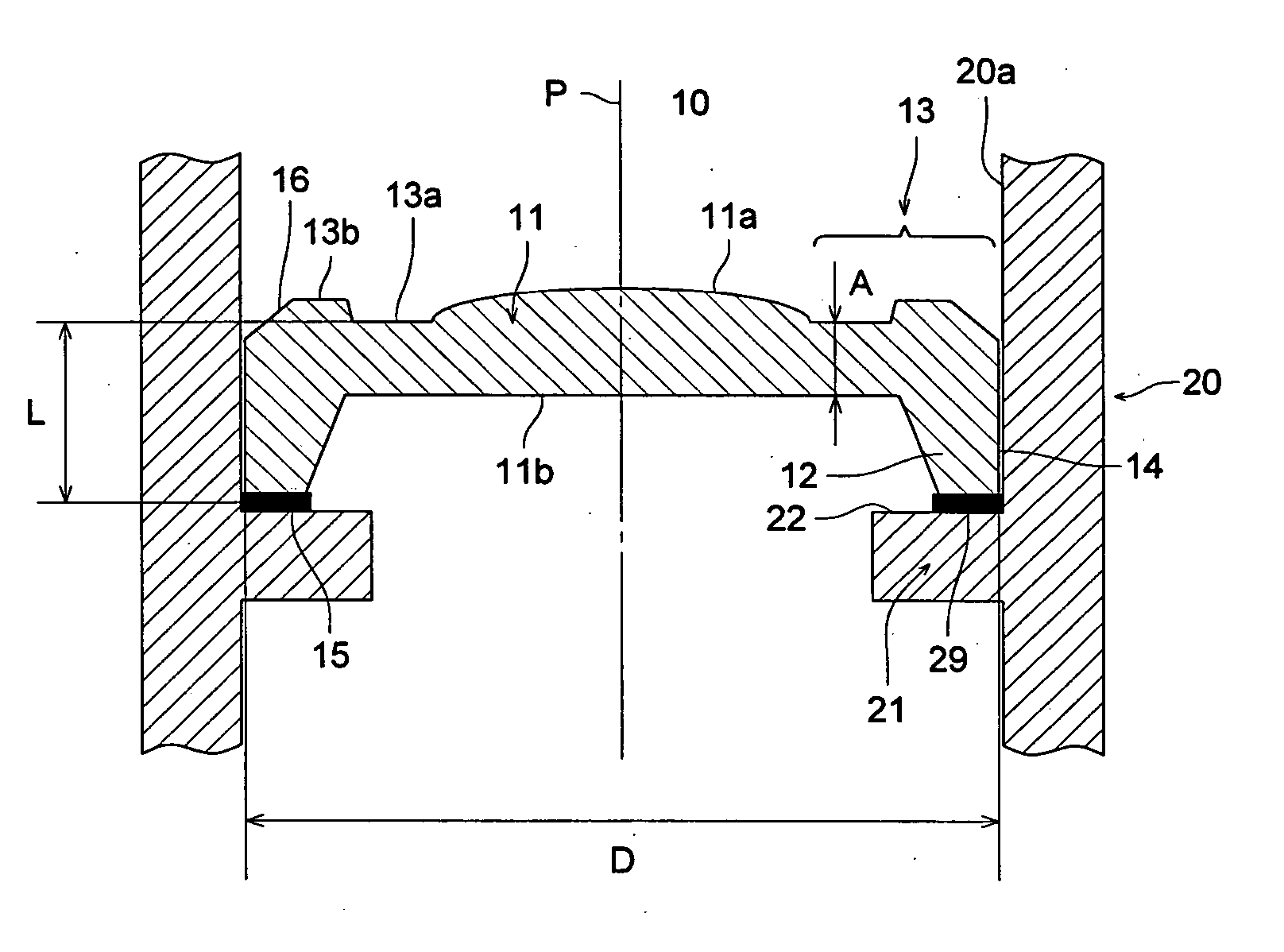

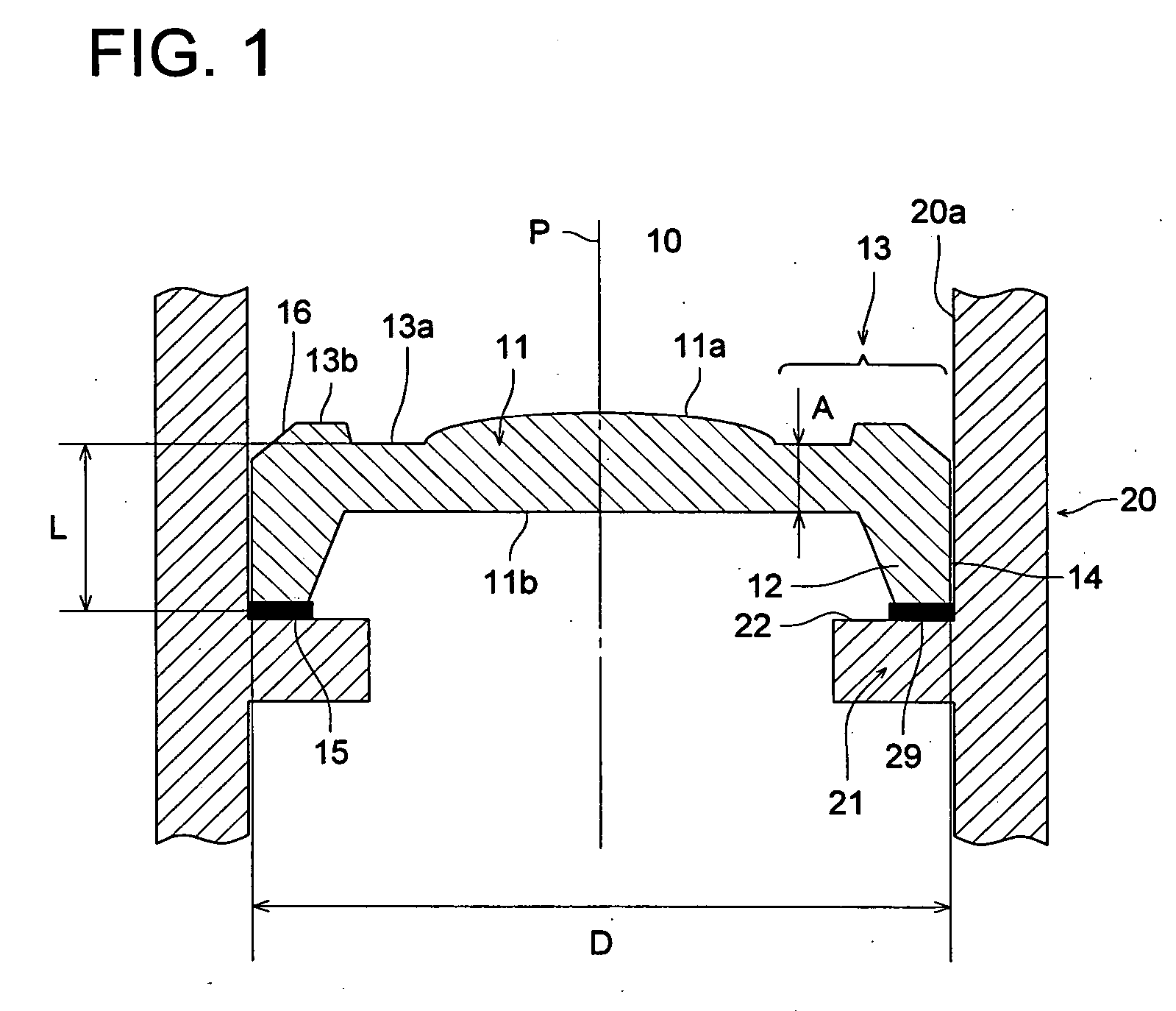

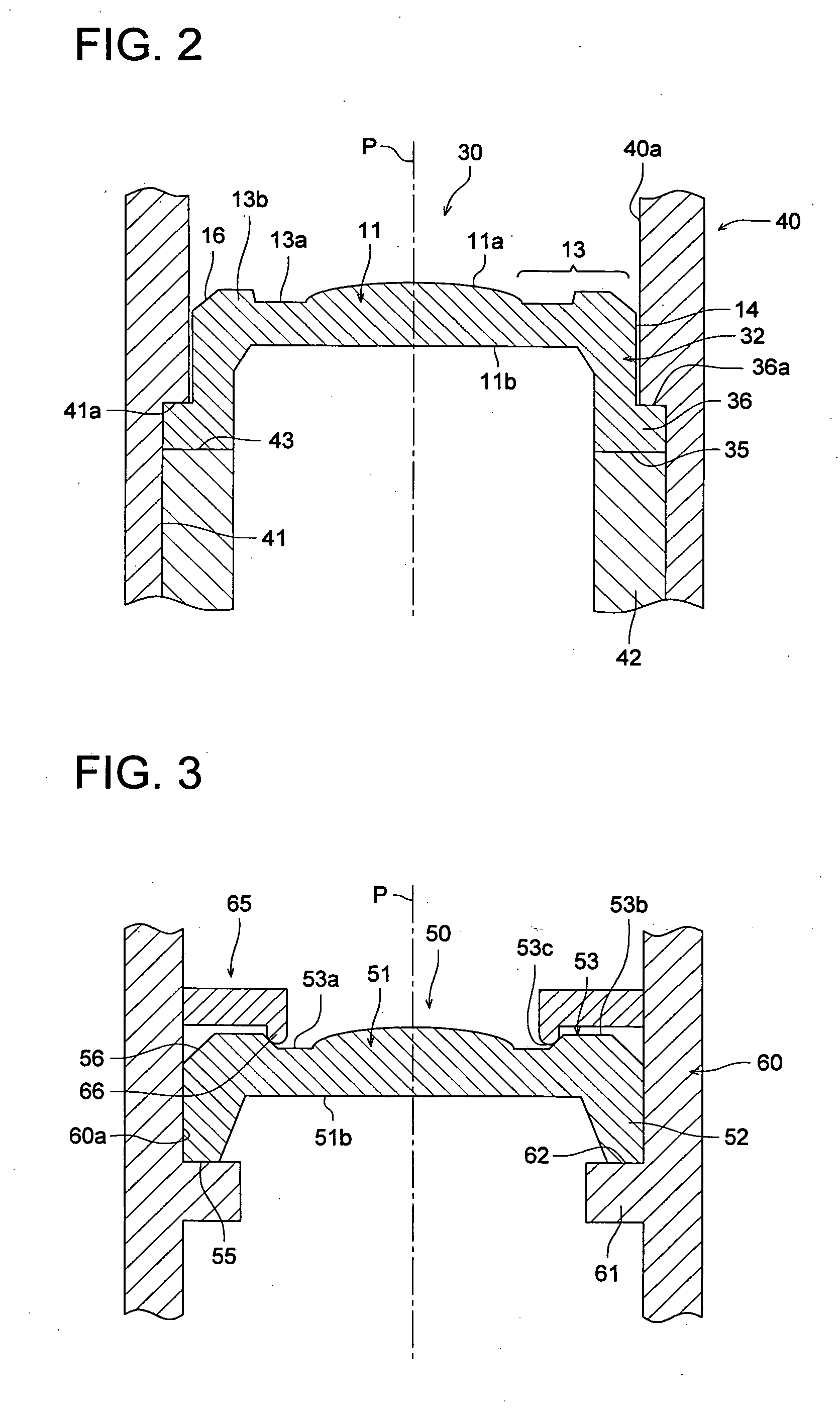

Optical element holding structure, optical element lens-barrel and optical communication module

InactiveUS20060114579A1Prevent movementControl deteriorationMountingsOptical light guidesOptical axisEngineering

An optical element holding structure, having: an optical element including an optical section having optical function, an outer peripheral portion which is positioned at the outer peripheral side of the optical section and a mounting portion which protrudes from the outer peripheral portion in a direction substantially parallel to the optical axis; and a lens barrel holding the optical element inside.

Owner:KONICA MINOLTA INC

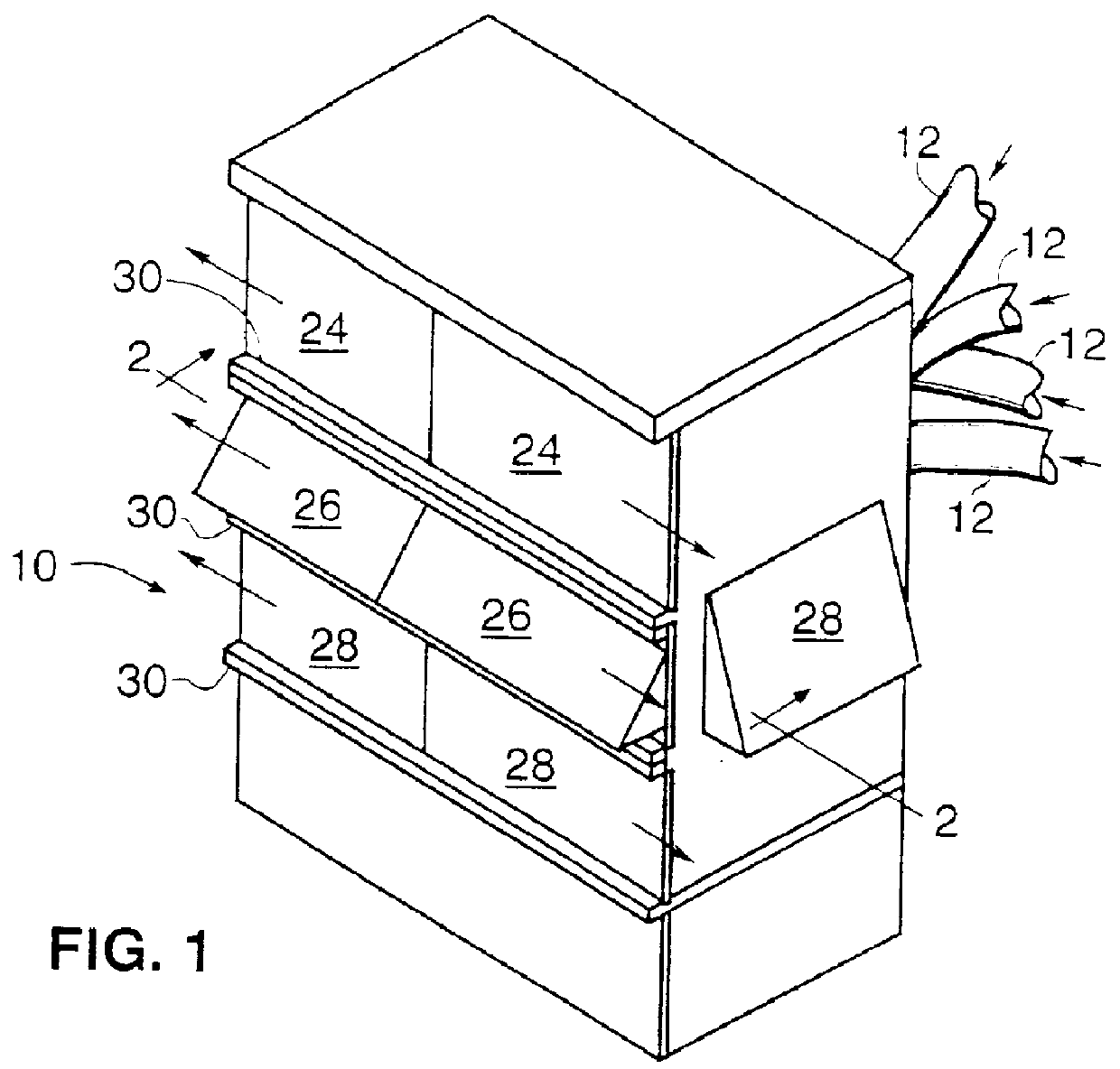

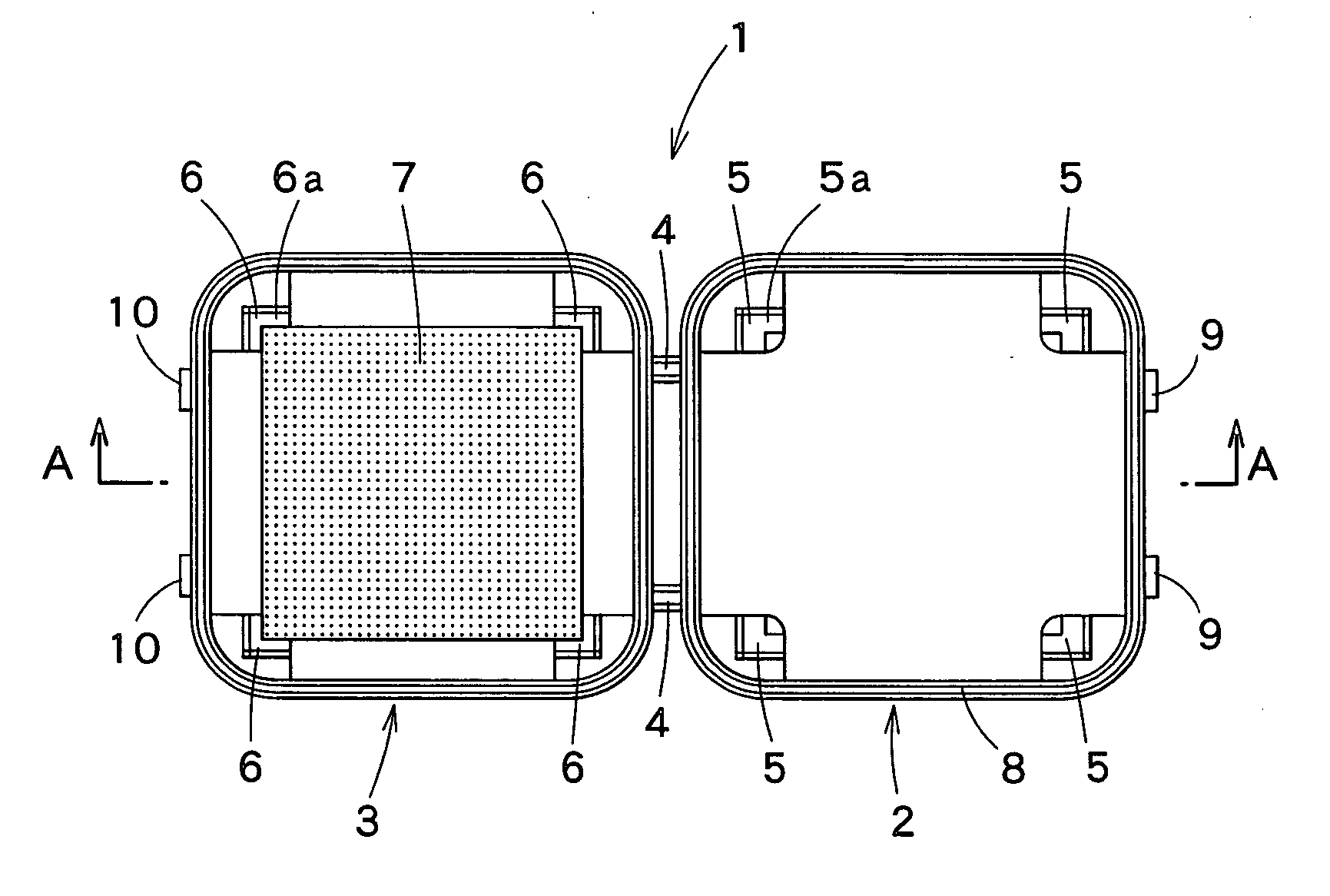

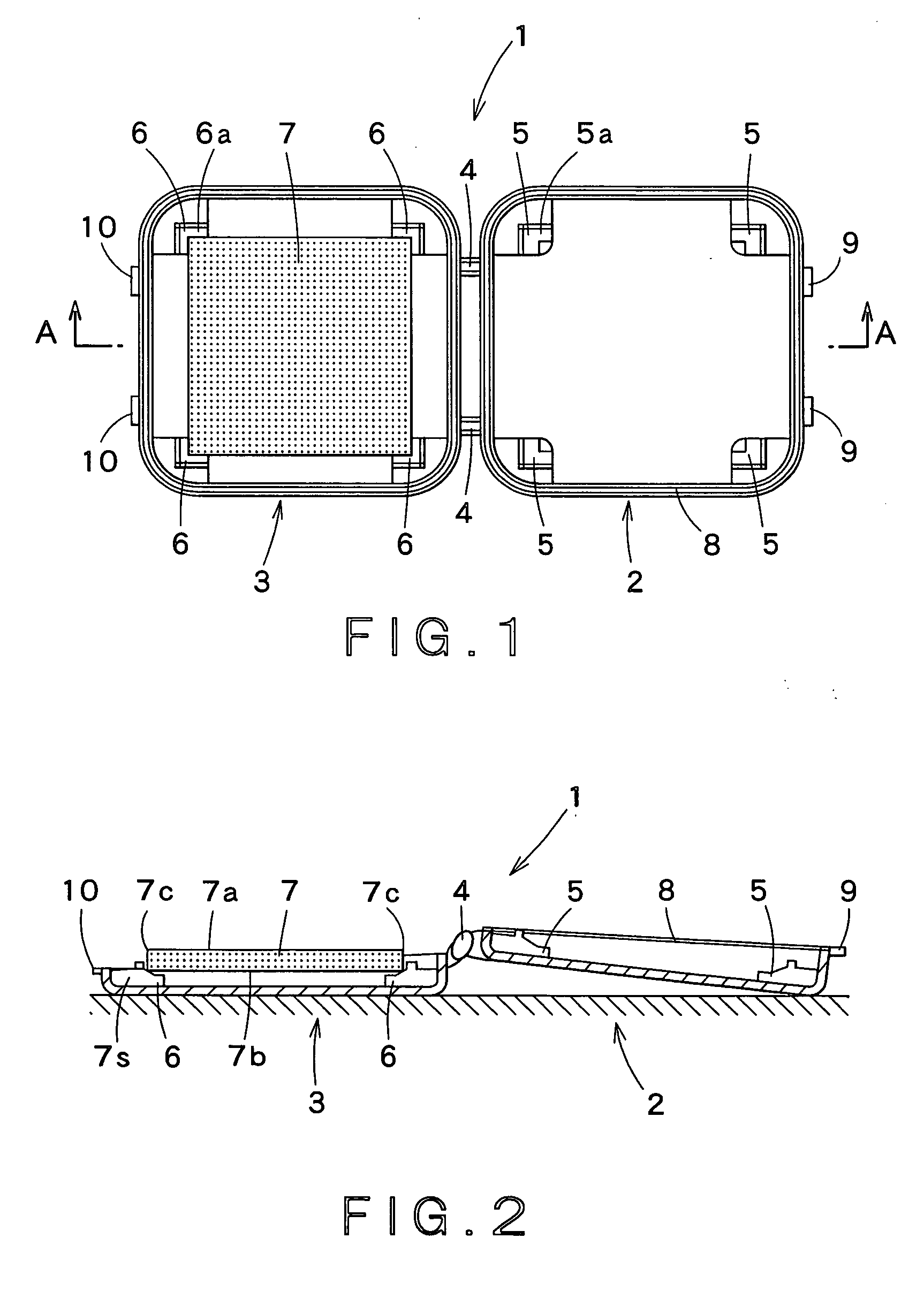

Substrate containing case

InactiveUS20060237338A1Avoid contaminationAvoid damageSemiconductor/solid-state device manufacturingPhotomechanical treatmentEngineering

Owner:DAI NIPPON PRINTING CO LTD

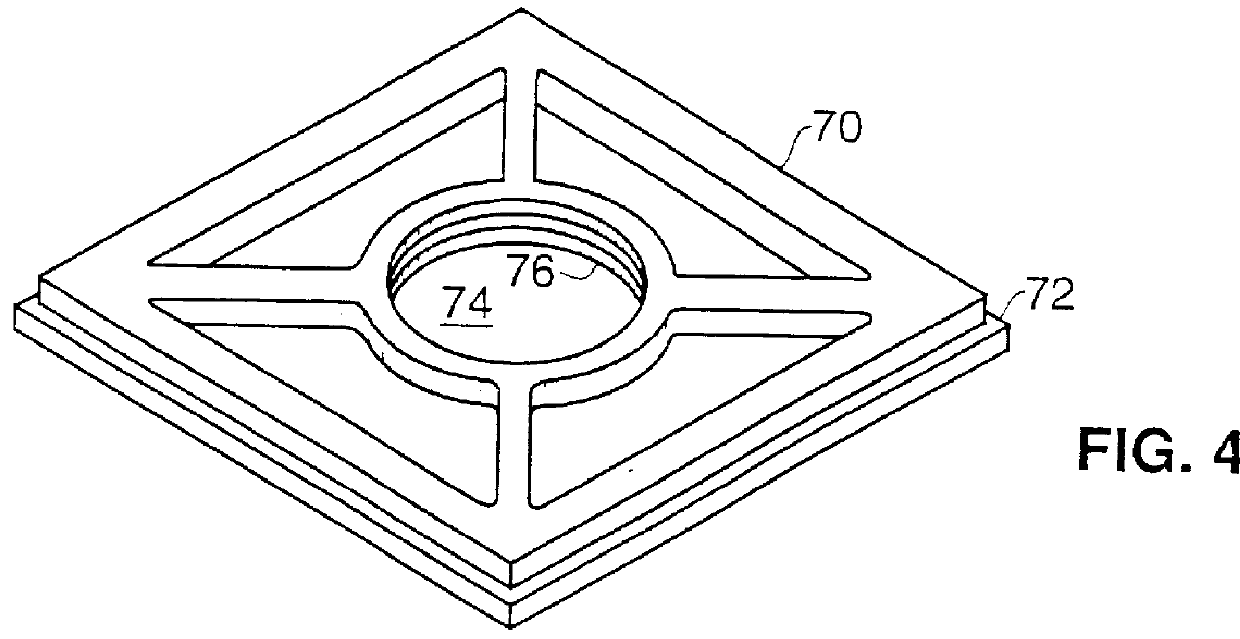

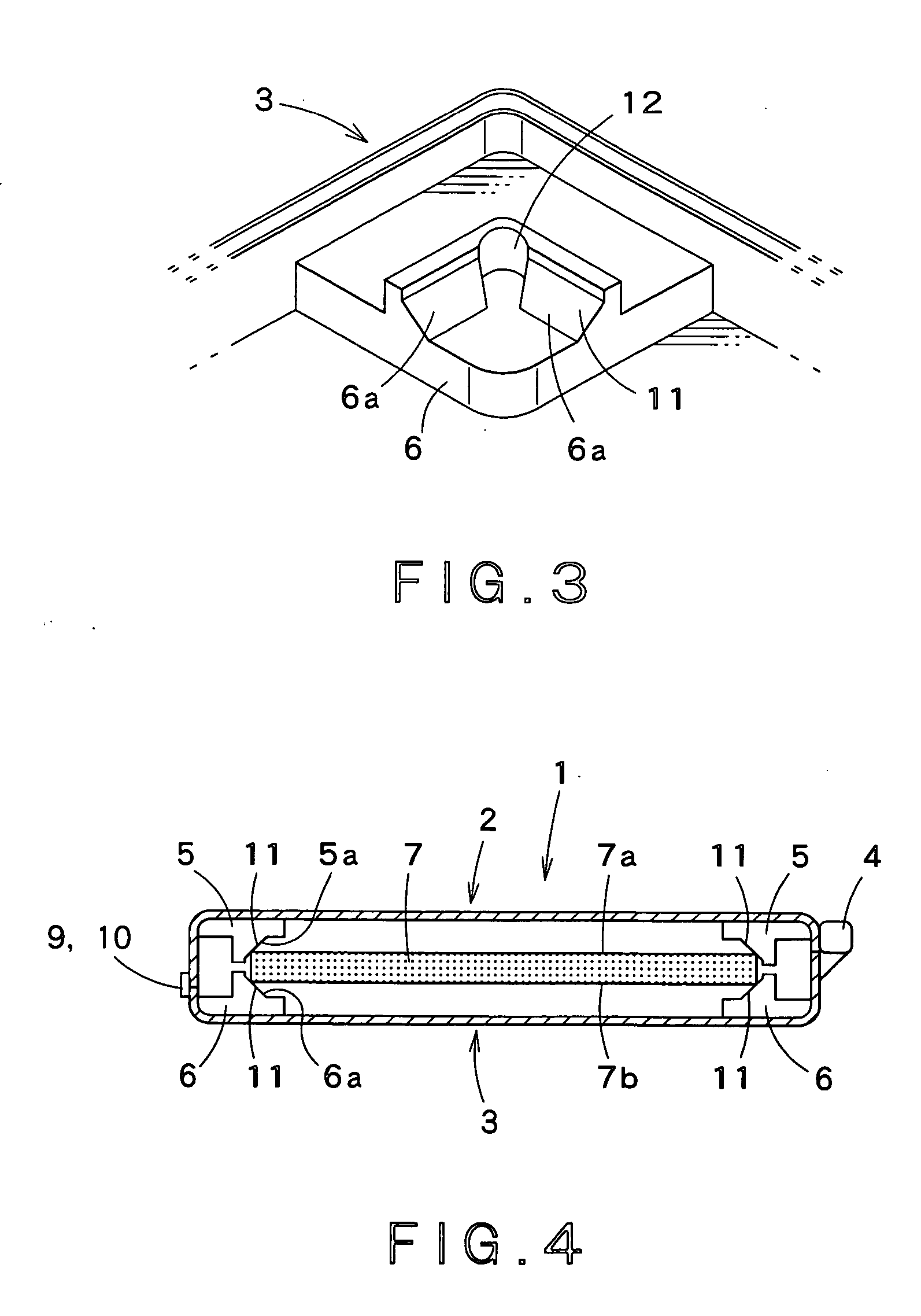

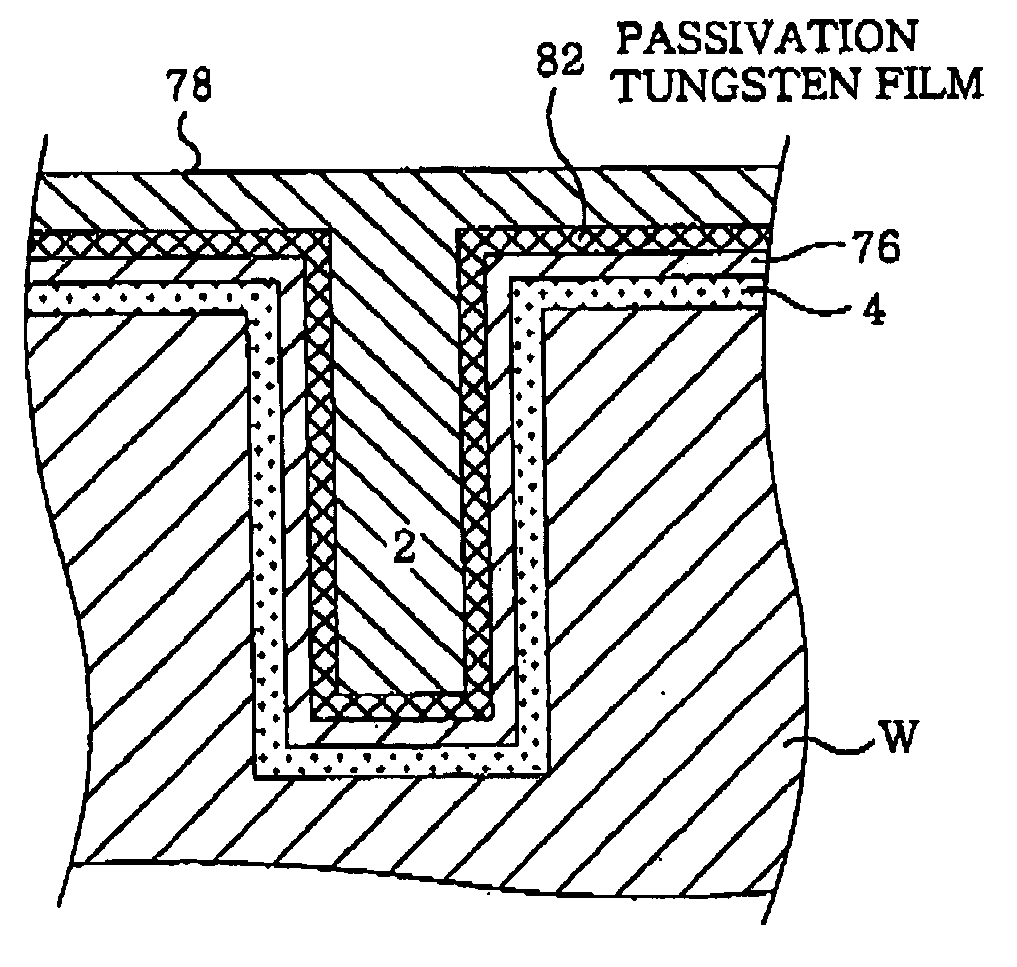

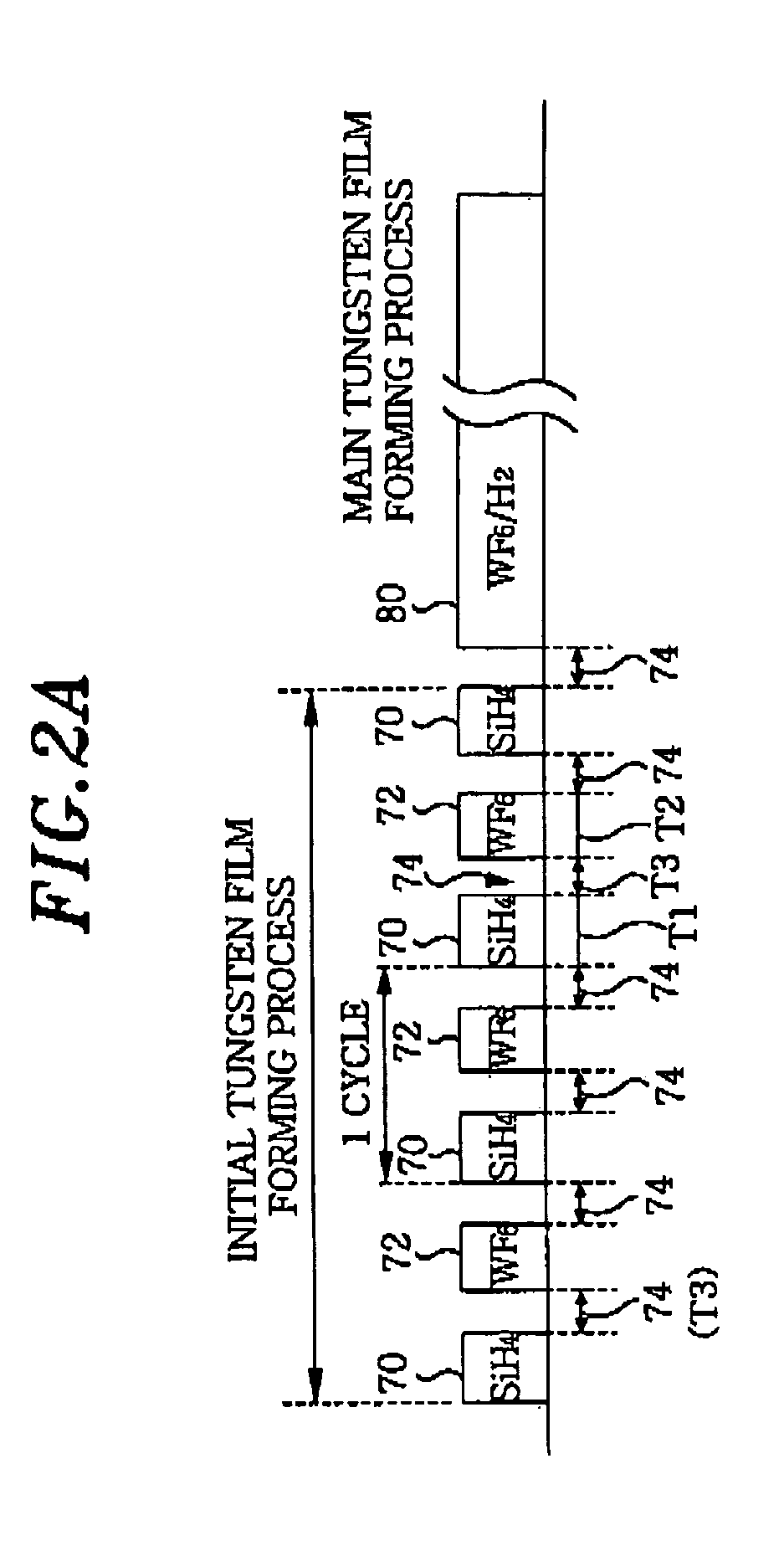

Method of forming tungsten film

InactiveUS20050032364A1Satisfactory characteristicAvoid it happening againSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNucleationVolcano

A method of forming a tungsten film, capable of restricting voids and volcanoes as large as adversely affecting characteristics despite the small diameter of a buried hole, and providing good burying characteristics. When forming a tungsten film on the surface of an object of treating (W) in a vacuumizing-enabled treating vessel (22), a reduction gas supplying process 70 and a tungsten gas supplying process 72 for supplying a tungsten-containing gas are alternately repeated with a purge process 74, for supplying an inert gas while vacuumizing, intervened therebetween to thereby form an initial tungsten film 76. Therefore, an initial tungsten film can be formed as a nucleation layer high in film thickness uniformity; and, accordingly, when main tungsten films are subsequently deposited, it is possible to restrict voids and volcanoes as large as adversely affecting characteristics despite the small diameter of a buried hole, and provide good burying characteristics.

Owner:TOKYO ELECTRON LTD

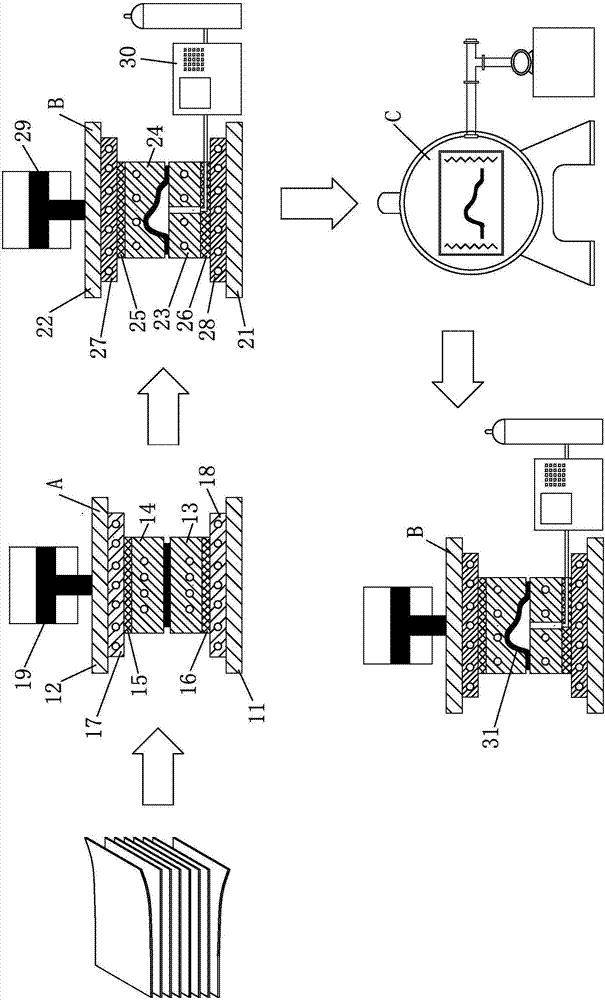

Synthesis, preparation and forming integrated method of NiAl alloy hook face plate component

The invention discloses a synthesis, preparation and forming integrated method of a NiAl alloy hook face plate component, relates to a synthesis, preparation and forming integrated method of an intermetallic compound hook face plate component, and aims to solve the technical problem that thermoforming of the hook face plate component is difficult because the existing NiAl alloy plate blank is poor in plasticity. The synthesis, preparation and forming integrated method comprises the following main steps: I, laminating and hot pressing Ni foils and Al foils alternately to obtain a Ni / Al lamination composite board; II, carrying out hot gas bulging forming on the Ni / Al lamination composite board to obtain the demanded shape and size, and enabling the Ni foils and the Al foils to react in a hot gas bulging forming die to synthesize a Ni-Al intermetallic compound; III, taking a forming piece out of the hot gas bulging forming die and putting the forming piece in a vacuum thermal treatment furnace for high-temperature vacuum thermal treatment to enable the generated Ni-Al intermetallic compound to completely react so as to generate NiAl alloy; and IV, putting the forming piece after thermal treatment in the hot gas bulging forming die, and carrying out densification treatment under the high-pressure gas bulging action. The synthesis, preparation and forming integrated method is suitable for preparation and forming of the NiAl alloy hook face plate component.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com