Air-conditioning device for vehicle

a technology for air conditioning devices and vehicles, which is applied in the direction of domestic cooling devices, lighting and heating devices, and cooling fluid circulation, etc. it can solve the problems of insufficient inability to complete condensation water regeneration, and inability to use extra power and commercials to eliminate odors, etc., to achieve the effect of reducing mileage, reducing fuel consumption of vehicles, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

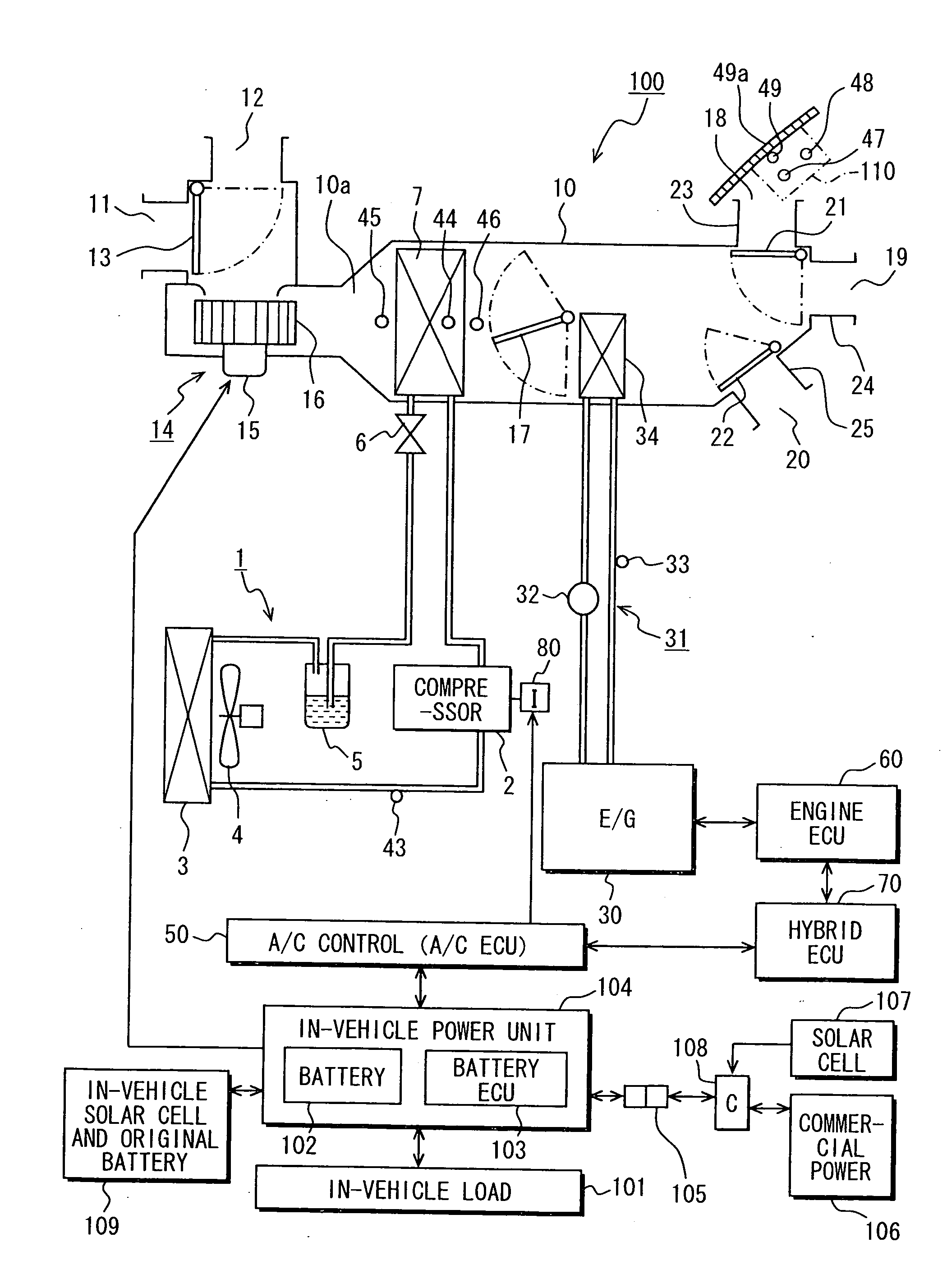

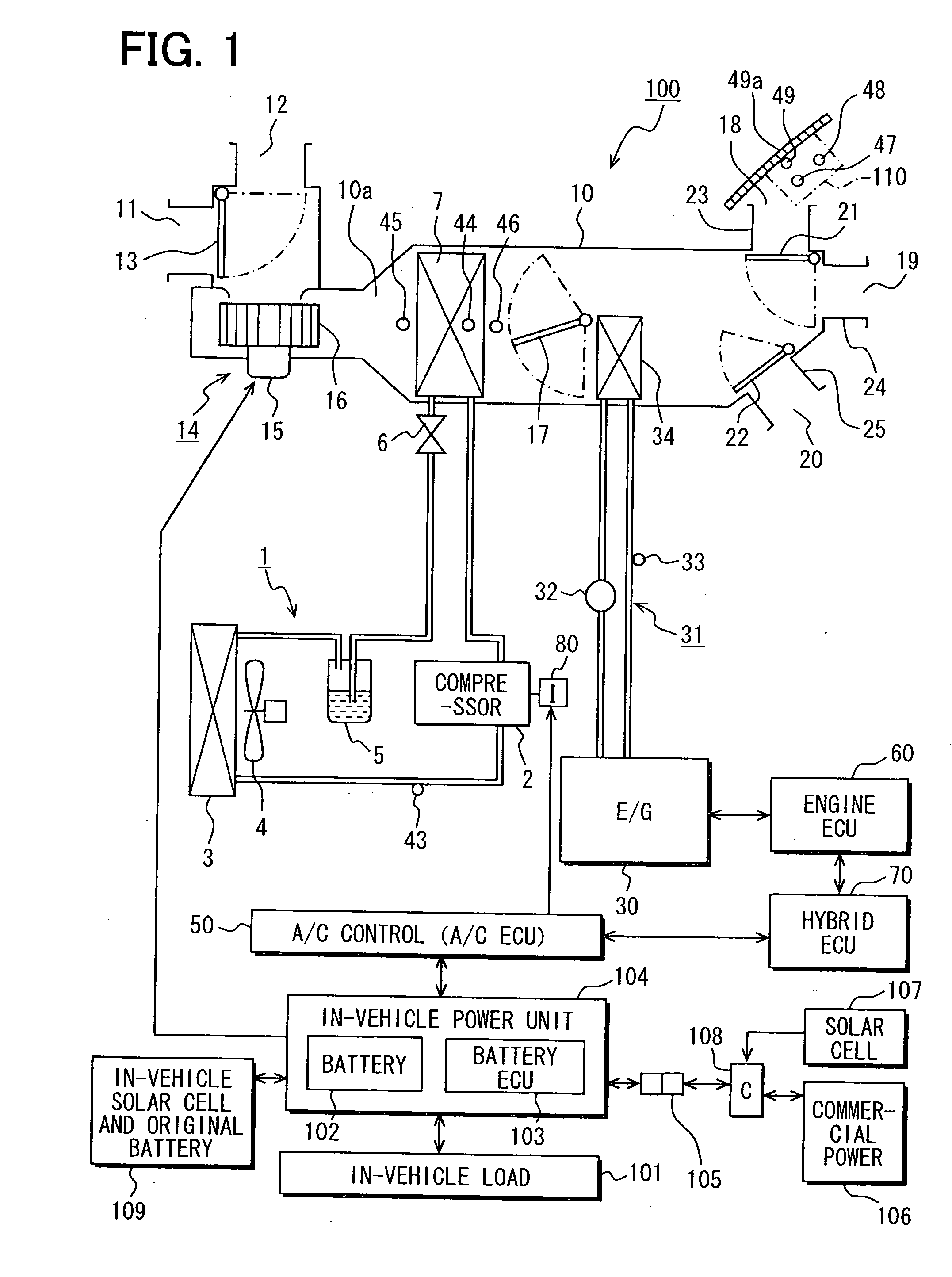

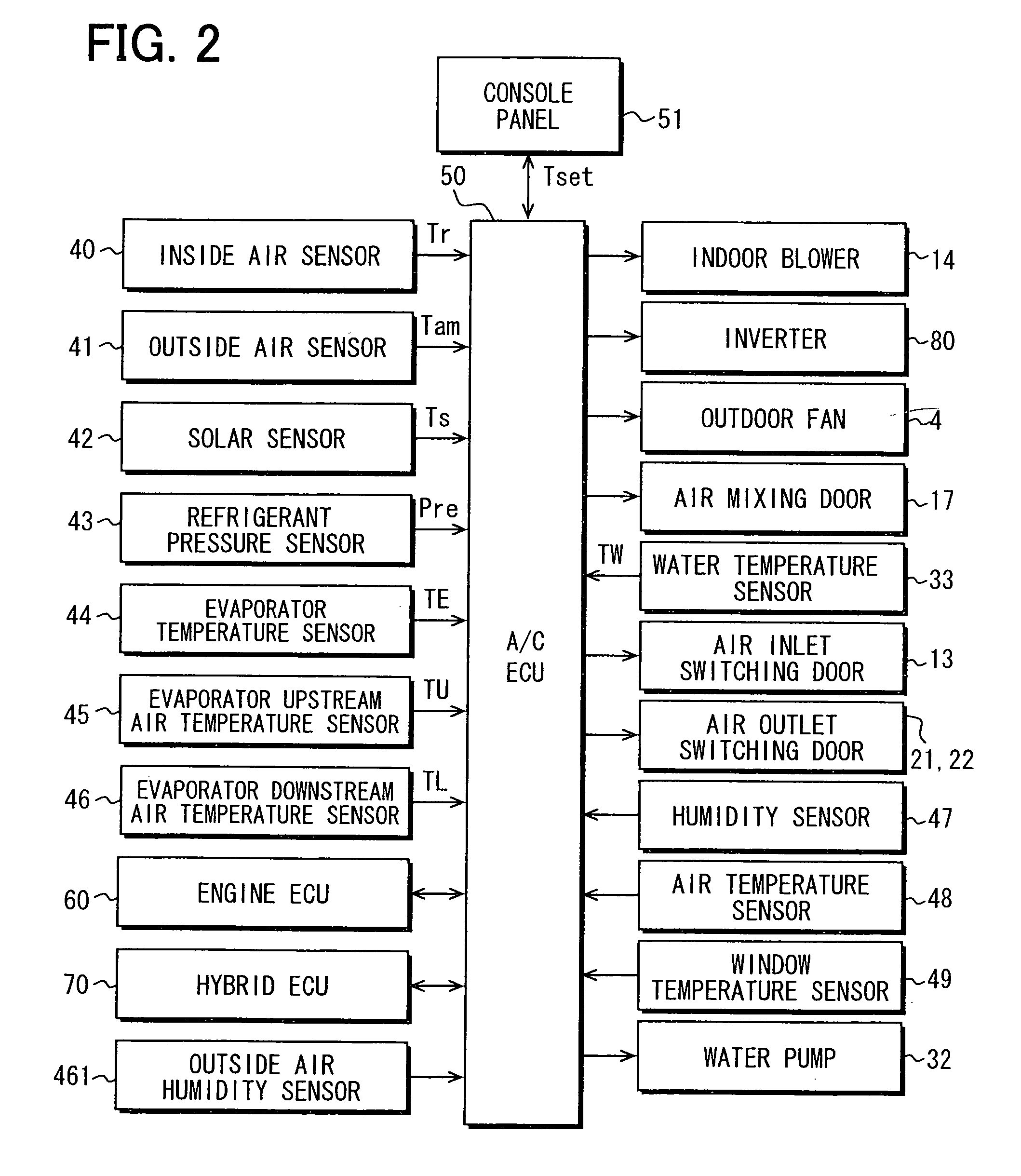

A first embodiment will be described with reference to FIGS. 1-6. An air-conditioning device 100 of FIG. 1 is used for a hybrid car in the first embodiment. FIG. 1 is a schematic diagram illustrating the air-conditioning device 100 and its power-source system. FIG. 2 is a block diagram illustrating peripherals of an air-conditioning control device of the air-conditioning device 100.

The hybrid car has an engine 30, an in-vehicle load 101, an engine electronic control device 60 (hereinafter referred as engine ECU 60), and a battery 102. The engine 30 generates power by combusting liquid fuel such as gasoline. The in-vehicle load 101 has motor function and generator function for assisting a driving of the car, and includes a non-illustrated drive-assisting motor generator. The engine ECU 60 controls fuel supply amount and ignition timing for the engine 30, for example. The battery 102 supplies electric power for the motor generator of the in-vehicle load 101, and the engine ECU 60, for...

second embodiment

Evaporation heat is emitted from the evaporator 7 of FIG. 1 while the condensation water is evaporated in the drying control of the evaporator 7, such that temperatures of the evaporator 7 and air downstream of the evaporator 7 are lowered. After the drying control is finished, the temperature of the air downstream of the evaporator 7 is raised to an approximately the same temperature as that of air upstream of the evaporator 7. Therefore, the finishing of the drying control of the evaporator 7 can be judged by this phenomenon.

In a second embodiment, the air-conditioning ECU 50 uses a temperature of a predetermined position of the evaporator 7 so as to judge a dryness degree of the evaporator 7. The dryness degree of the evaporator 7 is judged using a directly-detected temperature value of the evaporator 7 or around the evaporator 7.

Therefore, odor generated at a start time of air-conditioning can be properly prevented. The second embodiment will be described with reference to FIG. ...

third embodiment

In a third embodiment, the drying operation of the evaporator 7 of FIG. 1 is performed in a case where there is sufficient amount of electric power remained in the battery 102 or the original battery of the in-vehicle solar cell 109. An electronic control unit corresponding to the battery ECU 103 to control the in-vehicle battery 102 of FIG. 1 is mounted to an electric car or a hybrid car. The electronic control unit manages charge and discharge of the battery 102 and the original battery. In the third embodiment, information of battery residual quantity provided from the battery ECU 103 is used.

FIG. 8 is a flow chart showing details of blower voltage determination and evaporator dry control of the third embodiment. S80, S82, S83, S85 and S81 of FIG. 8 are similar to S40, S42, S43, S45 and S41 of FIG. 4.

At S84, the information of battery residual quantity is input from, the battery ECU 103 of FIG. 1 into the air-conditioning control device (air-conditioning ECU) 50 through multiplex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com