Synthesis, preparation and forming integrated method of NiAl alloy hook face plate component

An alloy and component technology, which is applied in the field of preparation and forming of intermetallic compound surface plate components, can solve the problems of difficult hot forming and poor plasticity, and achieve the effects of overcoming secondary deformation, convenient acquisition and streamlining of processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

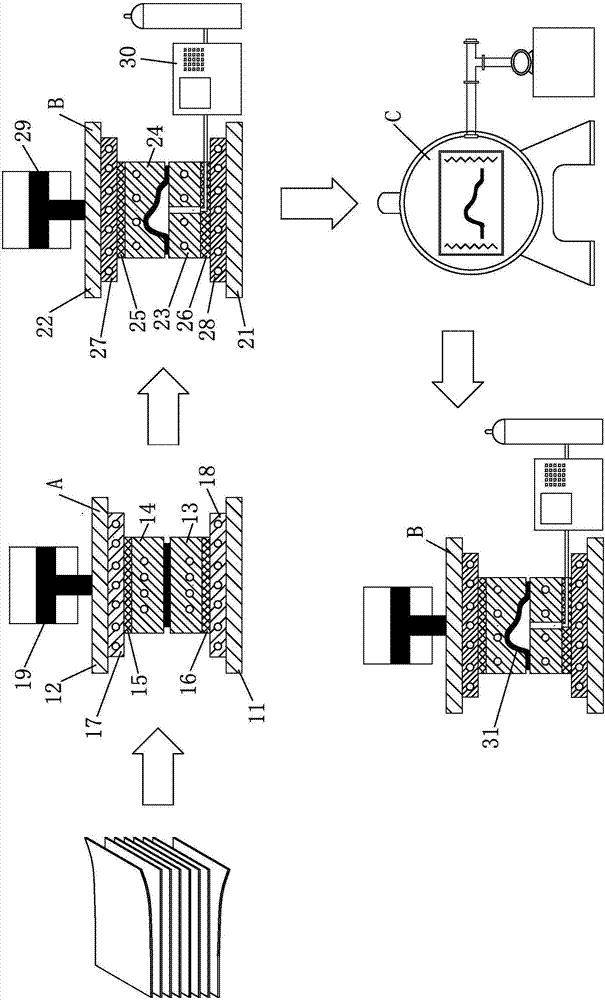

[0020] Specific implementation mode one: combine figure 1 To illustrate, the integrated method for the synthesis, preparation and forming of a NiAl alloy curved plate component in this embodiment includes the following steps:

[0021] Step 1, raw material thickness ratio design: according to the atomic number ratio of Ni atoms and Al atoms in the NiAl alloy, calculate the thickness ratio of Ni foil and Al foil;

[0022] Step 2, surface pretreatment: surface cleaning treatment of Ni foil and Al foil;

[0023] Step 3, hot pressing: alternately stack several Ni foils and several Al foils treated in step 2 on the lower mold 13 of the hot pressing mold A, and apply a pre-pressure of 3-5 MPa to the stacked foil layers, When the temperature of the hot-pressing mold A is raised to 500°C-600°C, the pressure on the acting foil layer is increased to 5-20MPa, and the temperature is kept for 0.5-2h. laminated composite panels;

[0024] Step 4. Inflatable forming and reaction synthesis: ...

specific Embodiment approach 2

[0042] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 2, Ni foil and Al foil are polished with fine sandpaper, then put them into acetone solution for ultrasonic cleaning, and then soak in distilled water 1min, take it out and dry it with cold air. Such setting ensures that the surface of Ni foil and Al foil is clean. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: after the Ni foil and Al foil are polished with fine sandpaper in step 2, the Ni foil is treated with a NaOH solution with a volume percentage of 5% to 15%. After cleaning, perform ultrasonic cleaning in acetone solution, then soak in distilled water for 1 min, take it out and dry it with cold air; wash Al foil with a volume percentage of 5% to 15% HF solution, then perform ultrasonic cleaning in acetone solution, and then place Soak in distilled water for 1 min, take it out and dry it with cold air. Such setting ensures that the surface of Ni foil and Al foil is clean. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com