Patents

Literature

60 results about "Nial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nial (from "Nested Interactive Array Language") is a high-level array programming language developed from about 1981 by Mike Jenkins of Queen's University, Kingston, Ontario, Canada. Jenkins co-created the Jenkins–Traub algorithm.

Bond or overlay MCrAIY-coating

It is disclosed a bond or overlay MCrAlY-coating for the use within a high temperature environment for the protection of the base alloy of turbine blades and vanes. The MCrAlY-coating having a gamma or gamma / gamma'-structure comprises a dispersion of beta-NiAl and / or y / beta-MCrAlY particles. This provides a reservoir of aluminum reservoir to coatings wherein the reservoir replenish the aluminum lost due to oxidation and interdiffusion during service. The beta-NiAl and / or y / beta-MCrAlY is the aluminum reservoir and is applied by mixing appropriate powders with gamma or gamma / gamma' powders.

Owner:ALSTOM TECH LTD

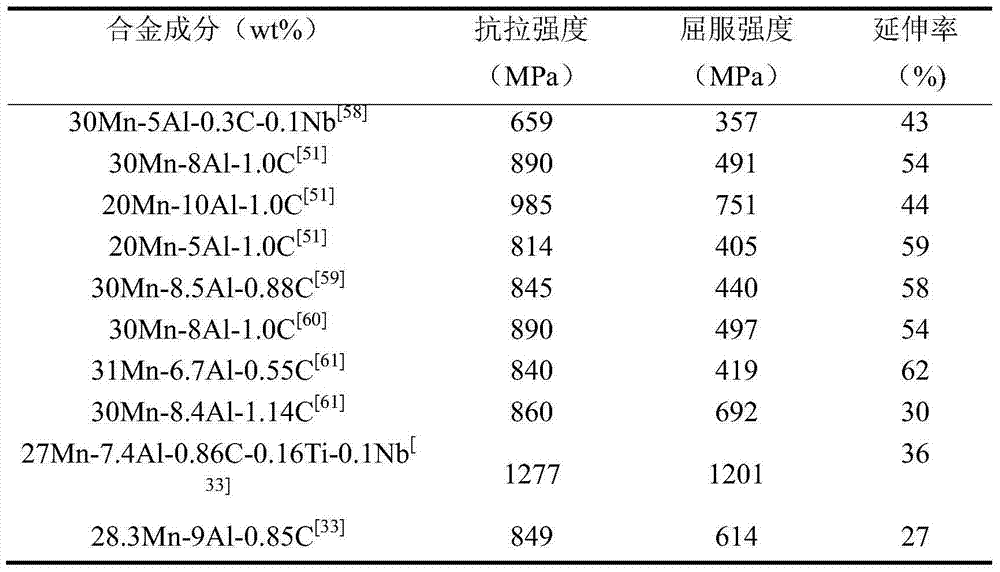

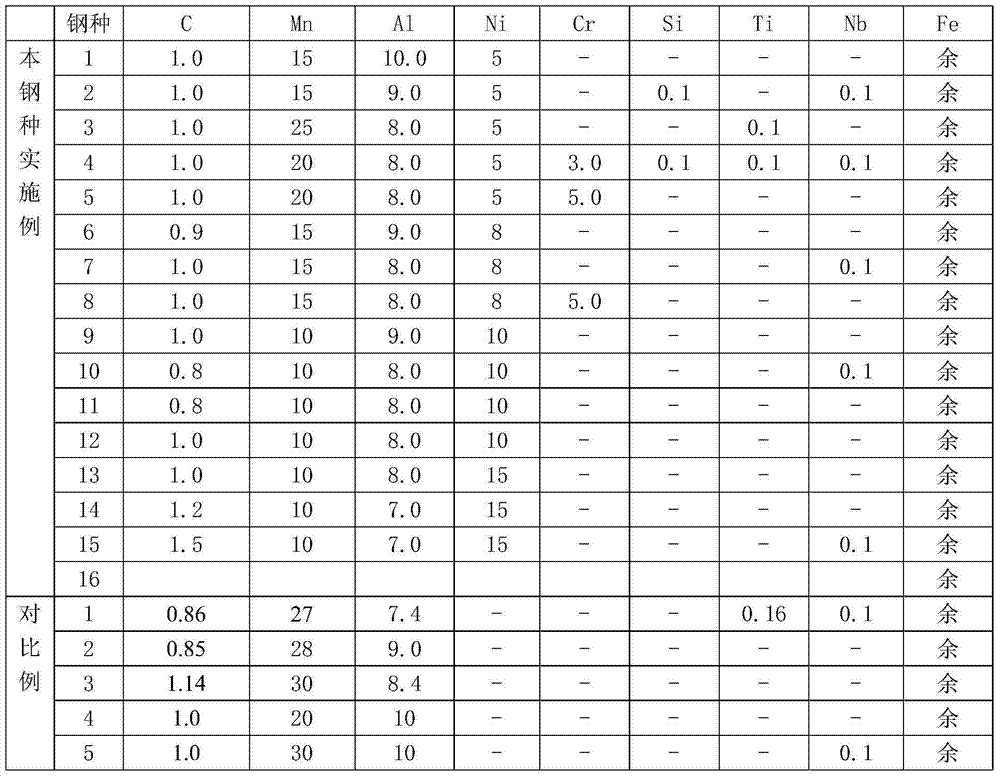

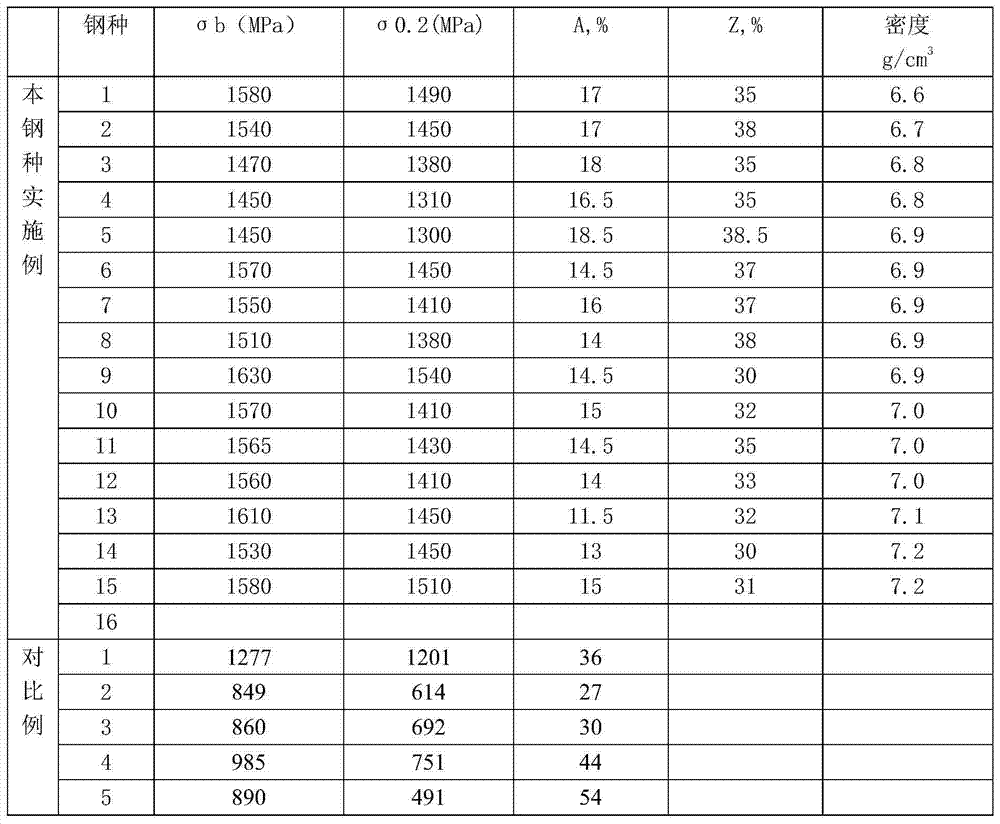

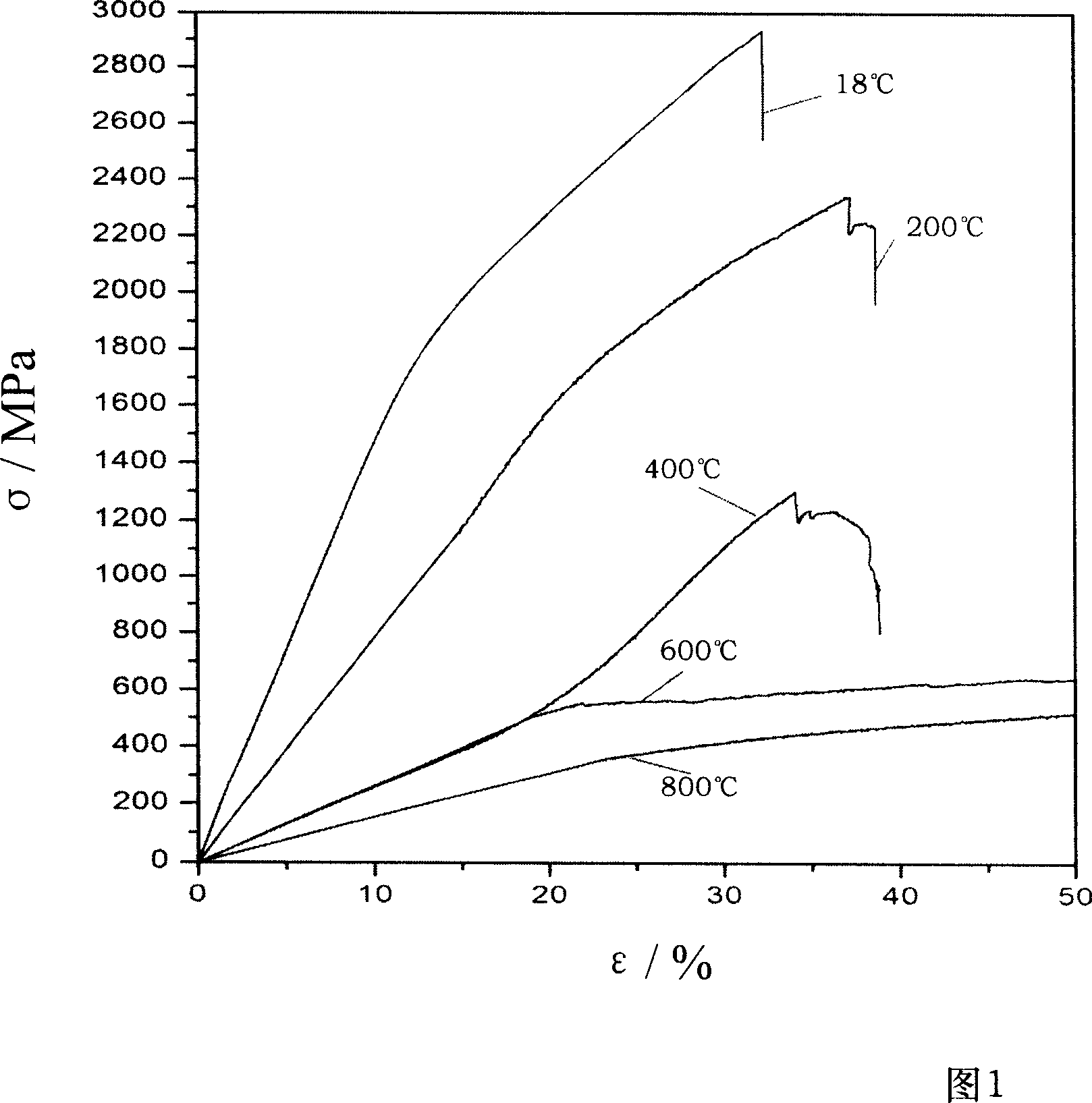

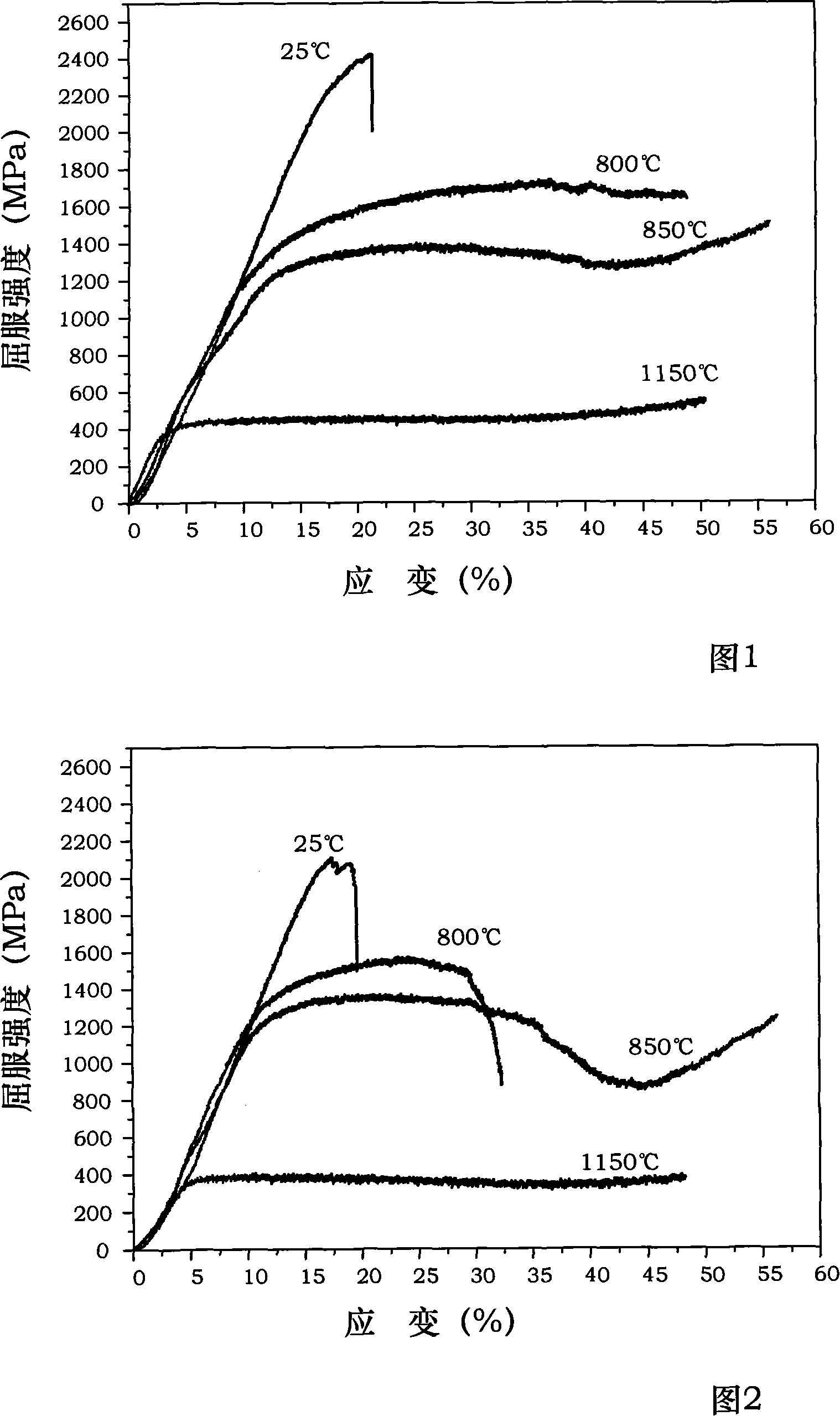

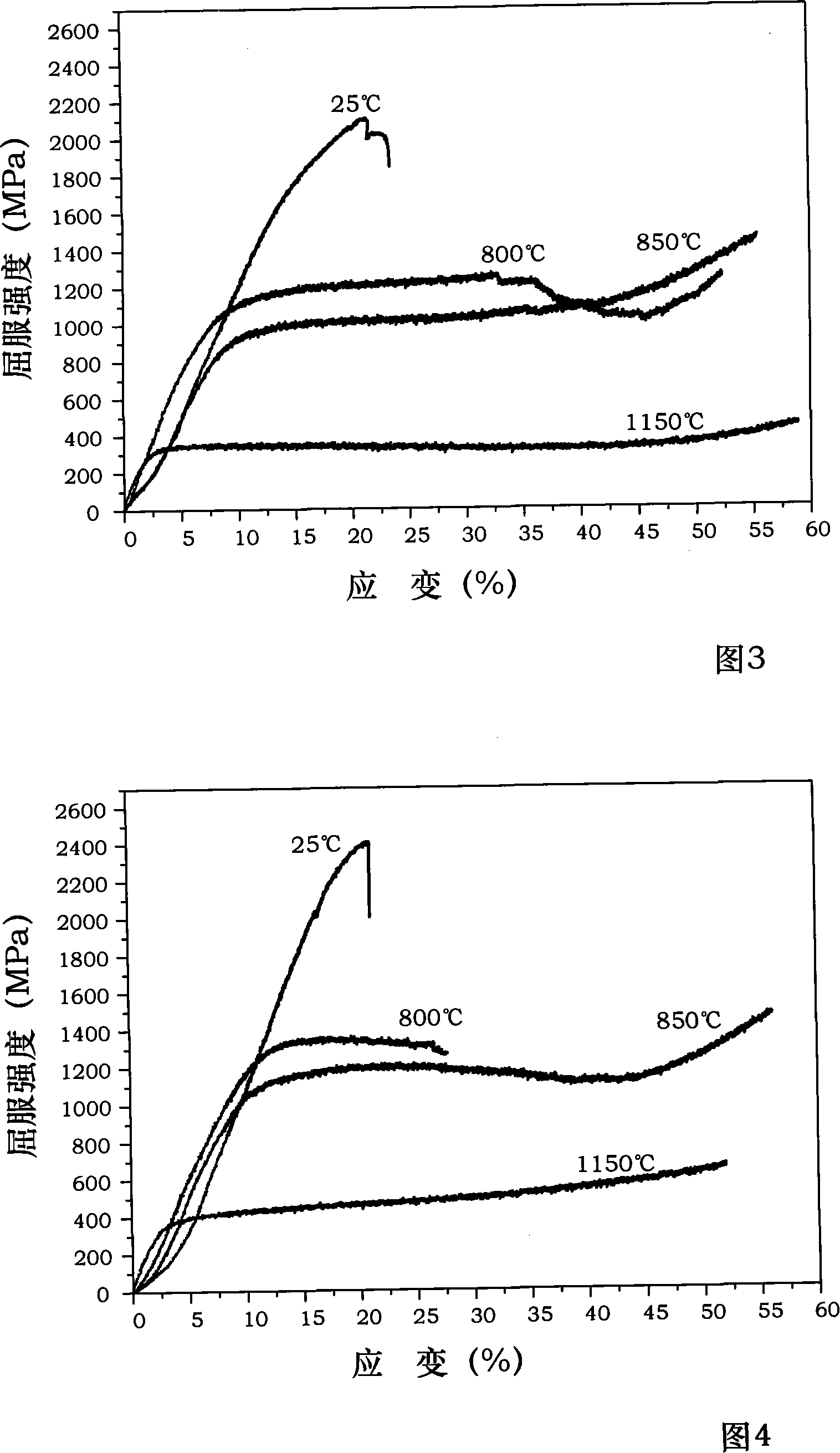

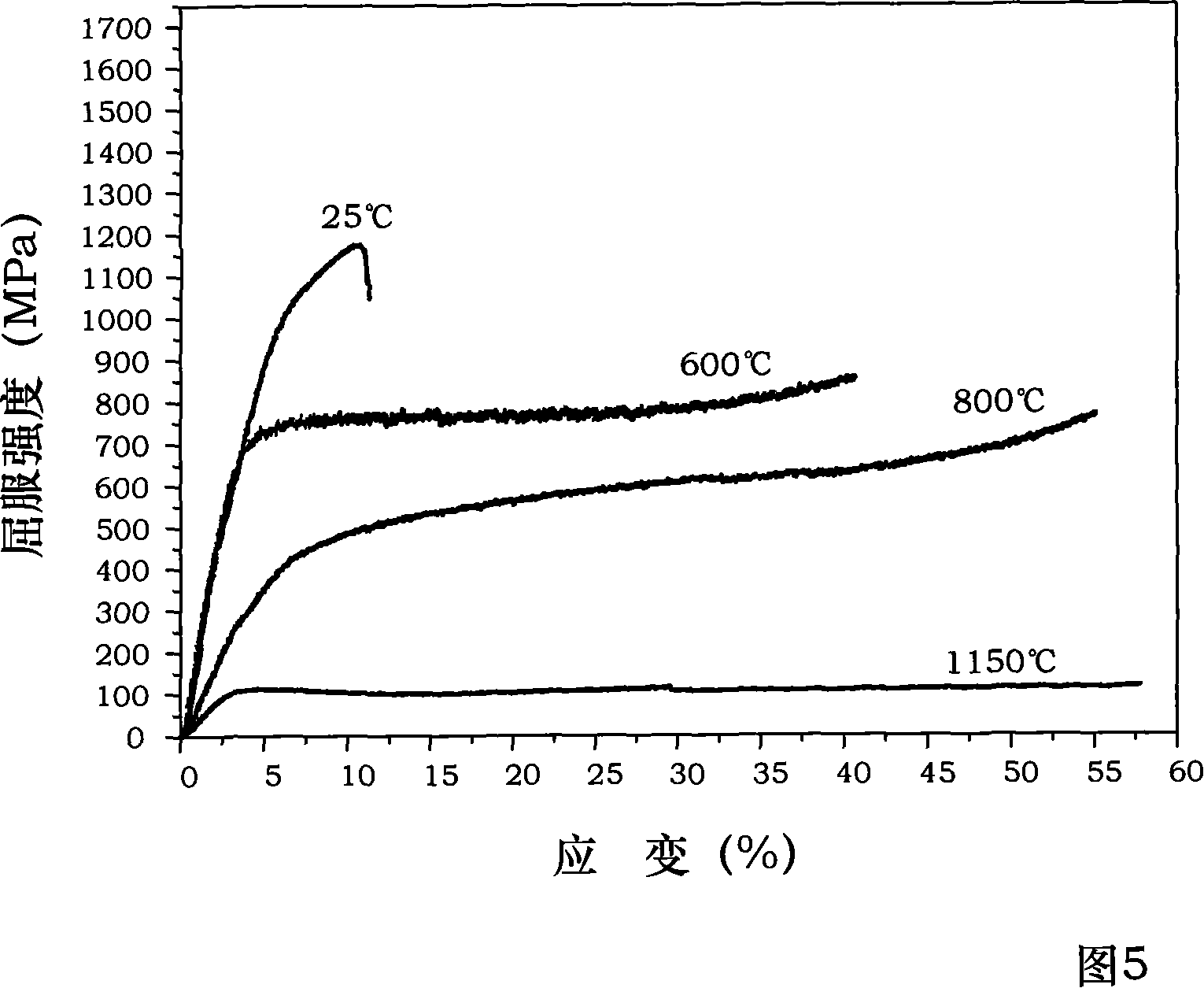

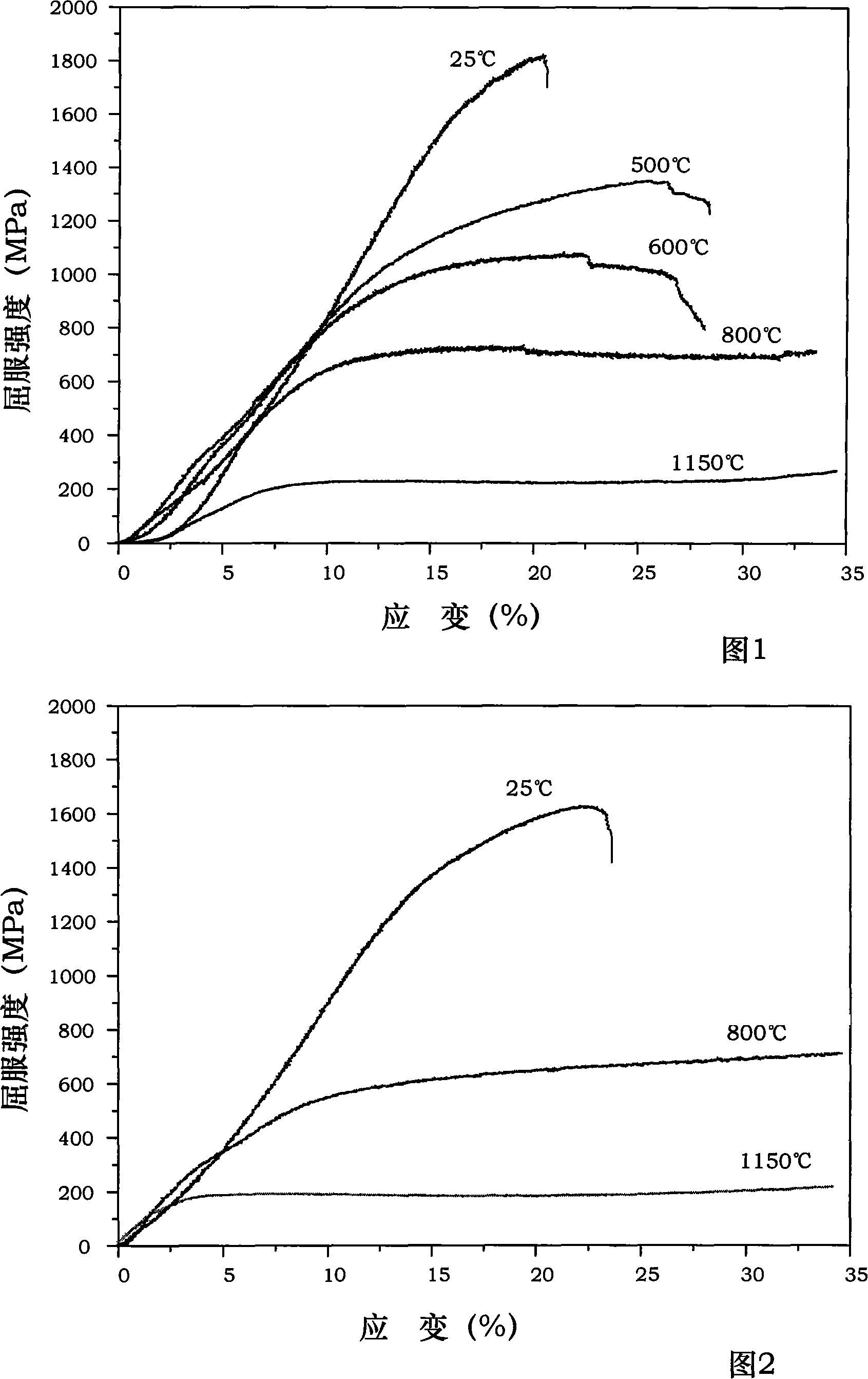

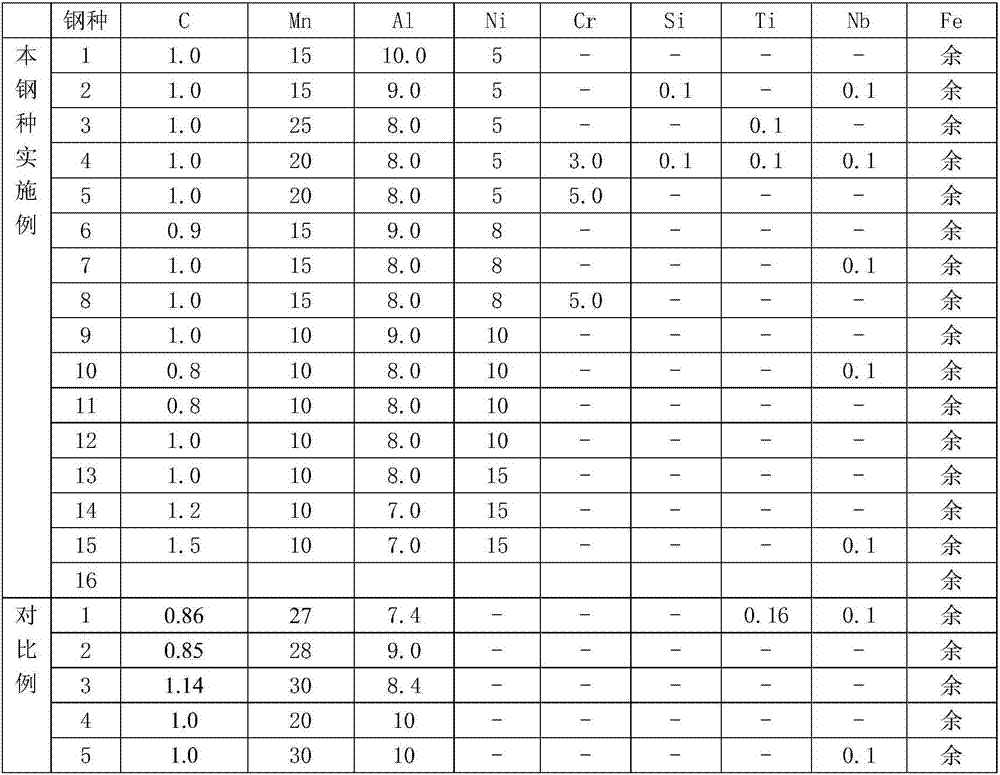

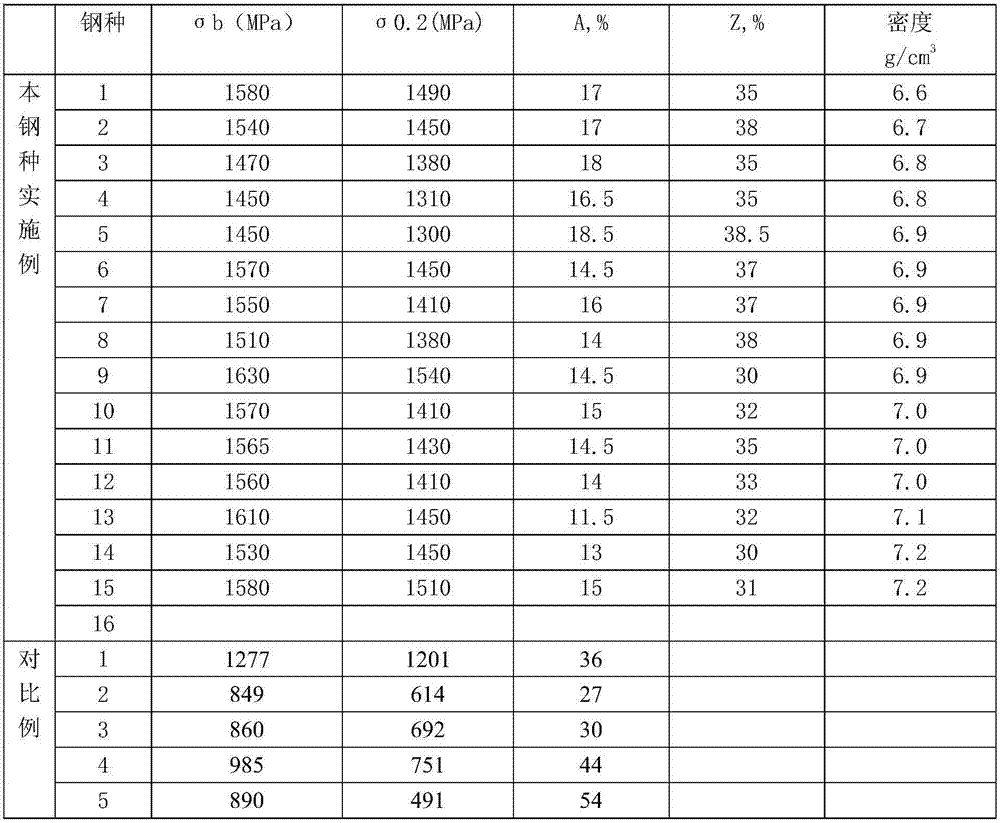

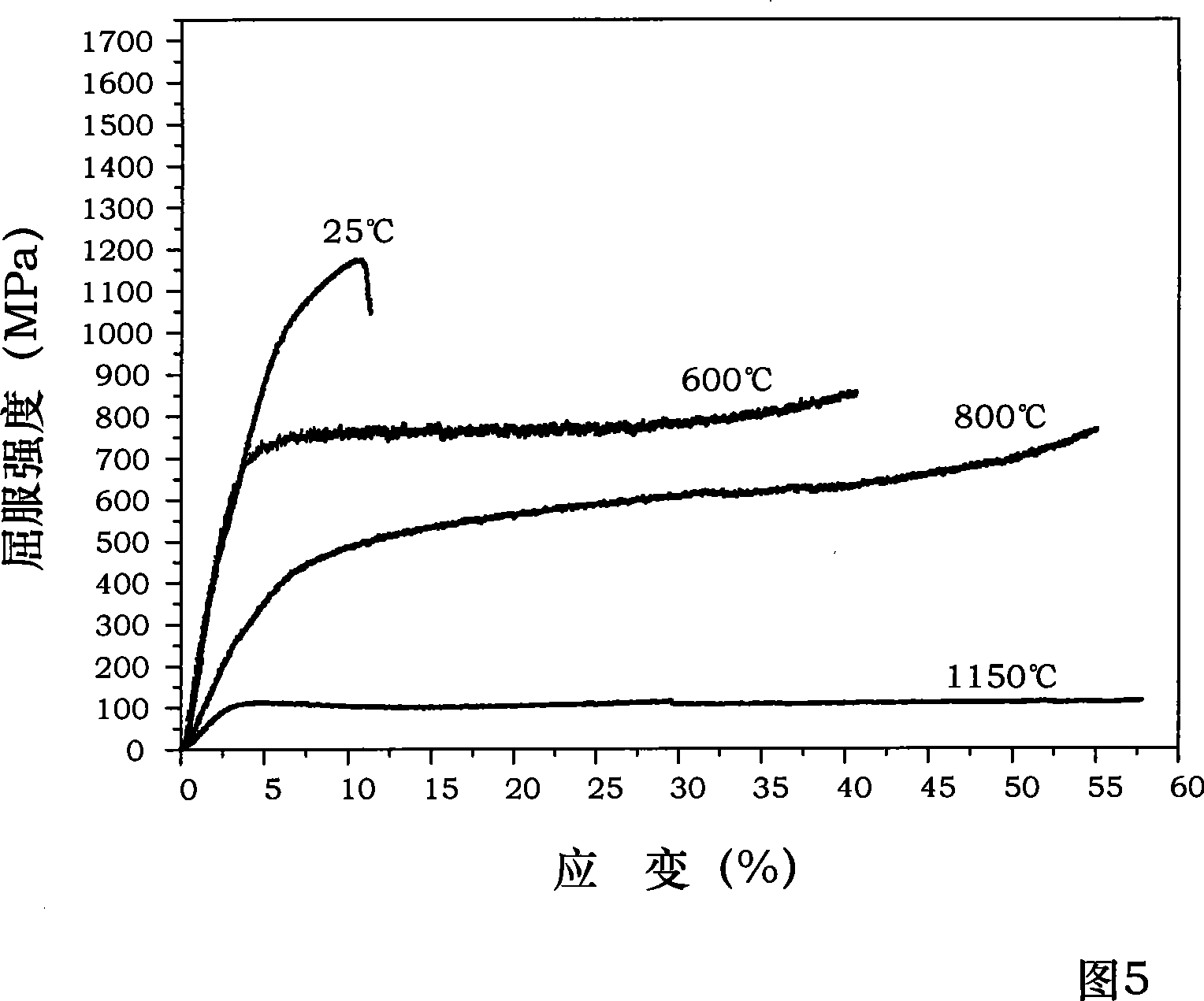

Low-density high-plasticity NiAl-reinforced ultrahigh-strength steel and preparation method thereof

The invention relates to a low-density high-plasticity NiAl-reinforced ultrahigh-strength steel and a preparation method thereof, belonging to the technical field of alloy steel. The alloy comprises the following components in percentage by weight: 0.5-1.5% of C, 10-30% of Mn, 5-12% of Al, 5-15% of Ni, 0-5% of Cr, 0-0.2% of Nb, and the balance of Fe and other inevitable impurity elements and minor elements, such as Si, Ti and the like. The preparation method adopts a vacuum induction+vacuum consumable remelting or electroslag remelting technique. Compared with the prior art, the low-density high-plasticity NiAl-reinforced ultrahigh-strength steel has the advantages of favorable comprehensive properties, low density, high plasticity, ultrahigh strength and the like. The density is up to 6.5-7.2 g / cm<3>, the tensile strength is up to 1350 MPa above, and the elongation percentage is up to 10% above.

Owner:CENT IRON & STEEL RES INST

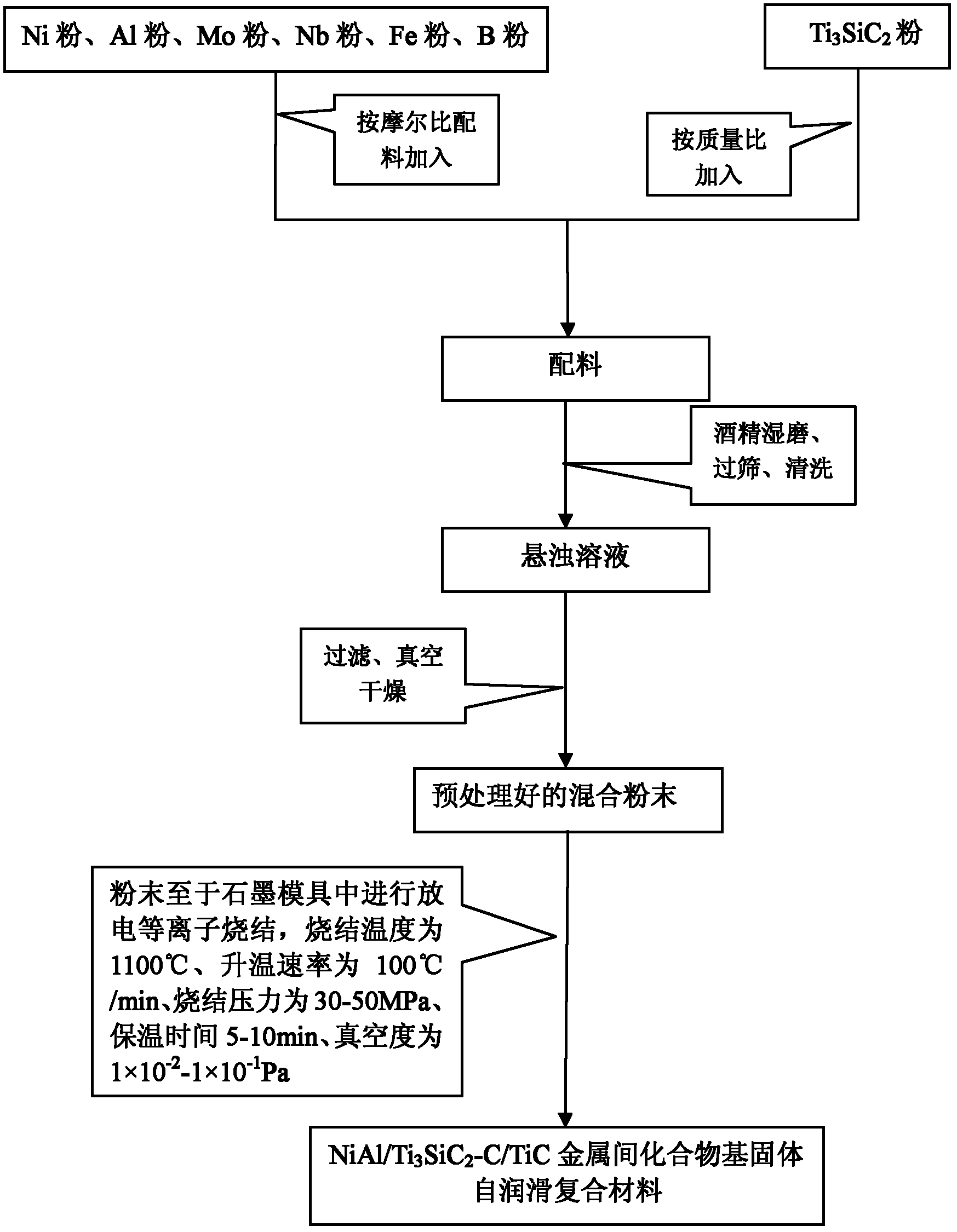

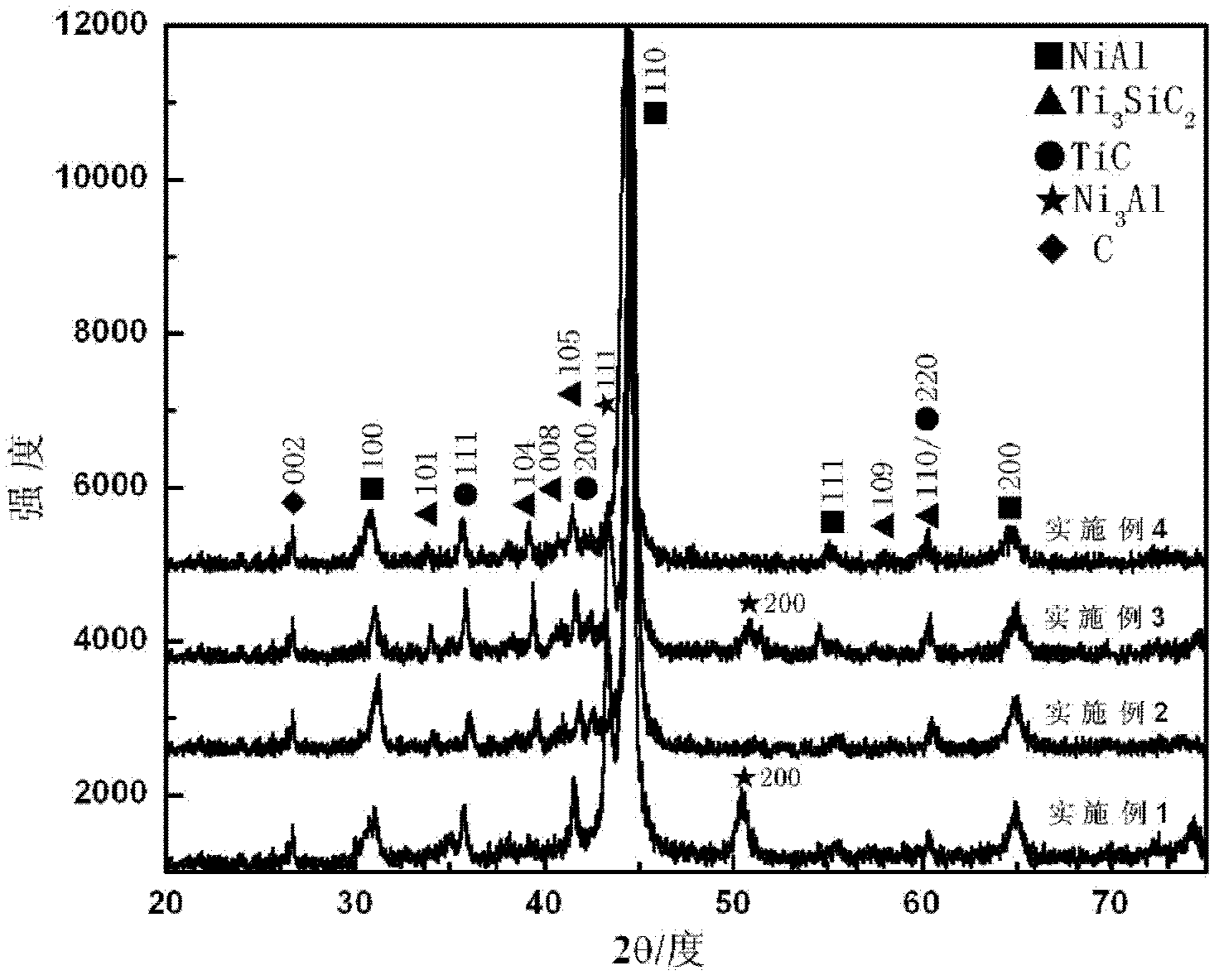

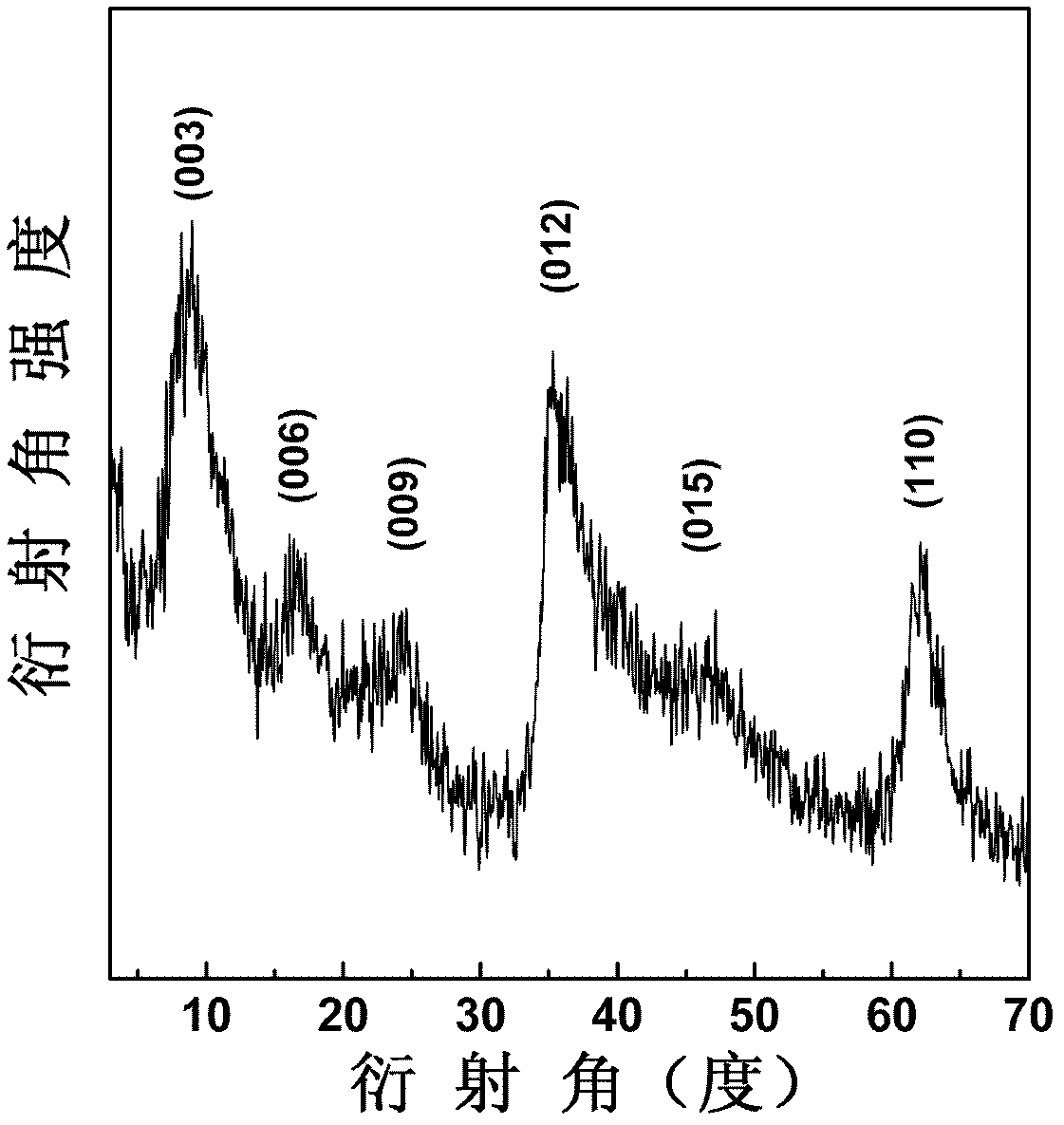

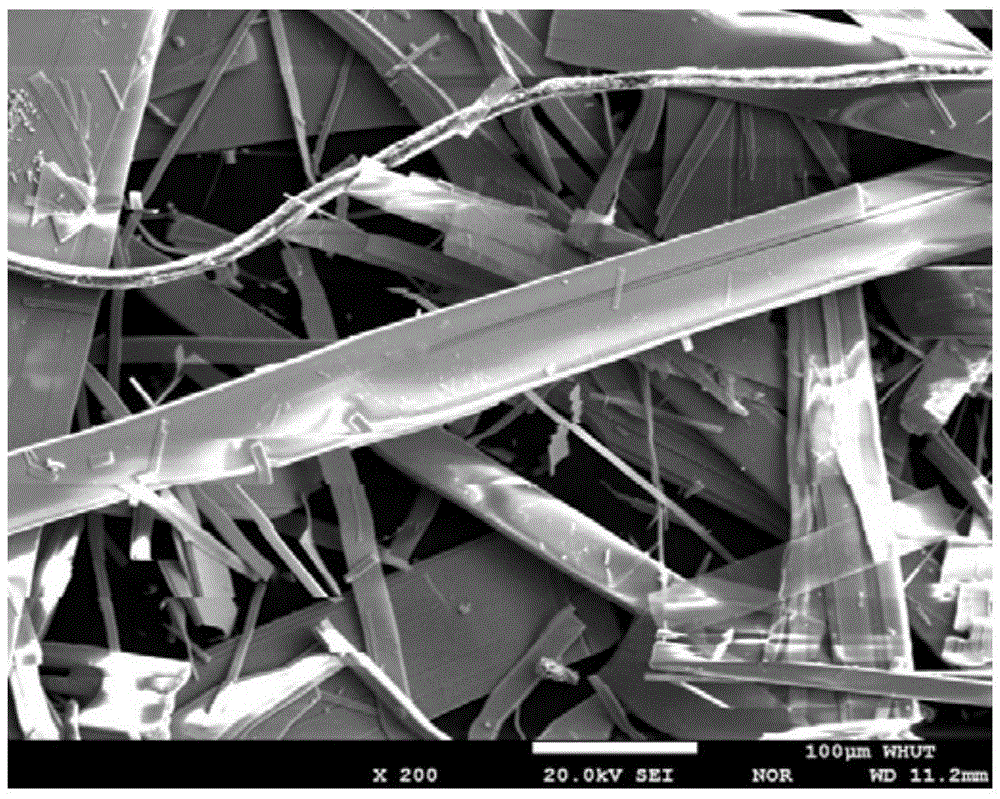

NiAl intermetallic base solid self-lubricating composite material and preparation method thereof

The invention relates to a preparation method of a NiAl intermetallic base solid self-lubricating composite material containing Ti3SiC2 and C binary composite lubrication phase and wild phase TiC. The NiAl intermetallic base solid self-lubricating composite material is prepared from Ni powder, Al powder, Mo powder, Nb powder, Fe powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ni: Al: Mo: Nb: Fe: B=48: 50: 1: 1: 0.5: 0.02, and the addition quantity of the Ti3SiC2 powder is 5-20 weight percent of the total weight of the Ni powder, the Al powder, the Mo powder, the Nb powder, theFe powder and the B powder. The NiAl / Ti3SiC2-C / TiC intermetallic base solid self-lubricating composite material synthesized by the method has novel component design (intermetallic matrix+ composite lubrication phase+ wild phase), high density, good tribological properties and stable technological parameters. The preparation process is fast and simple, and the method is easily operated and is suitable for preparing NiAl intermetallic base solid self-lubricating composite materials with high performance.

Owner:WUHAN UNIV OF TECH

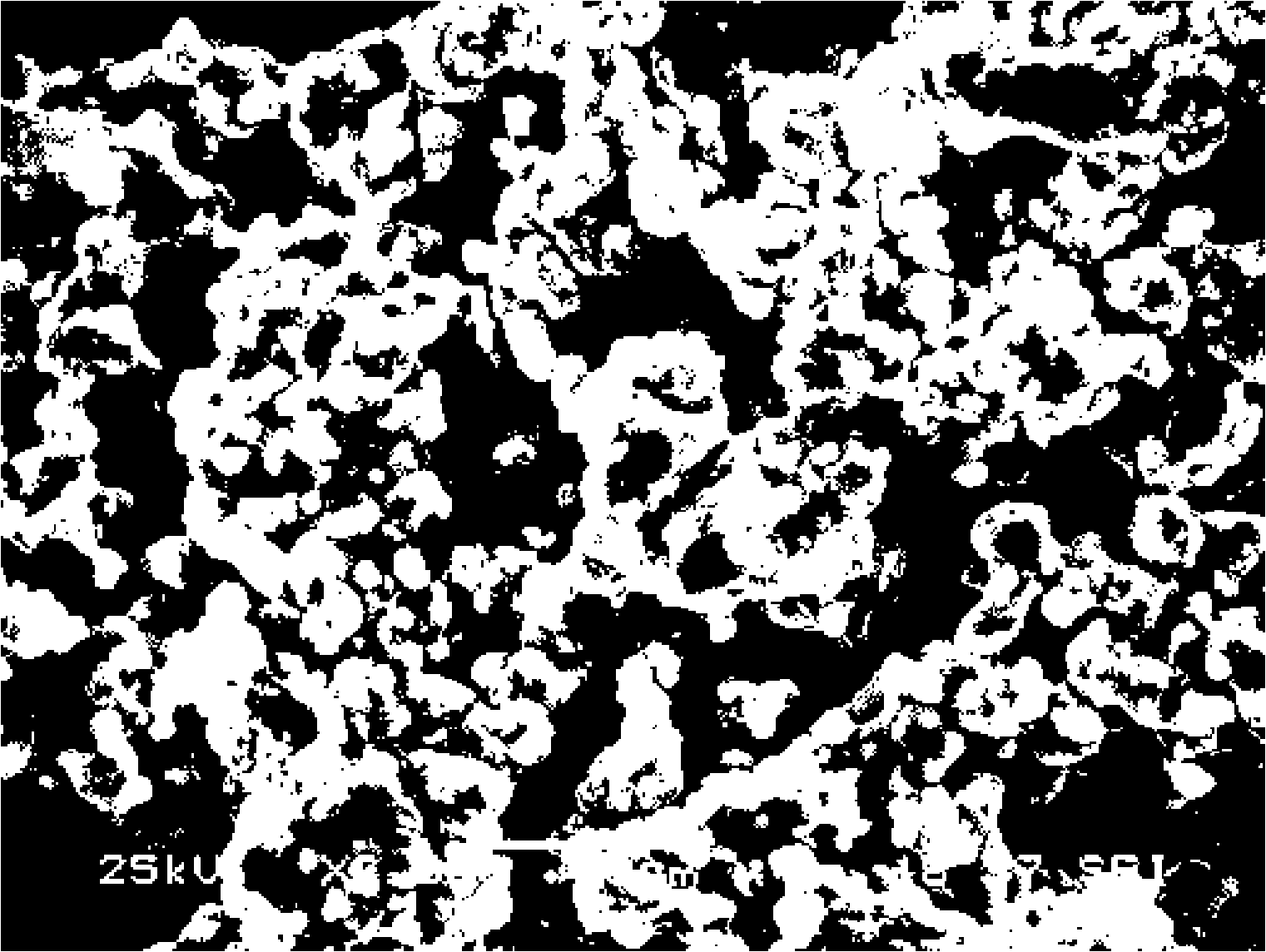

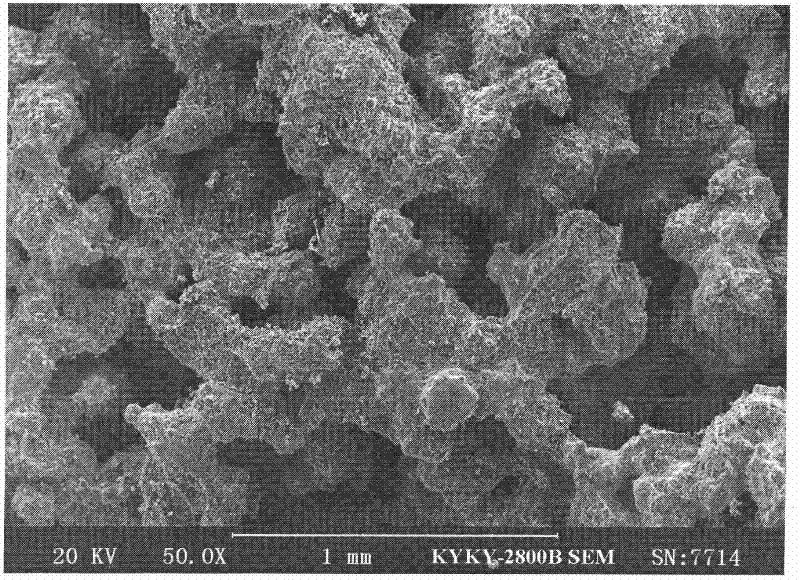

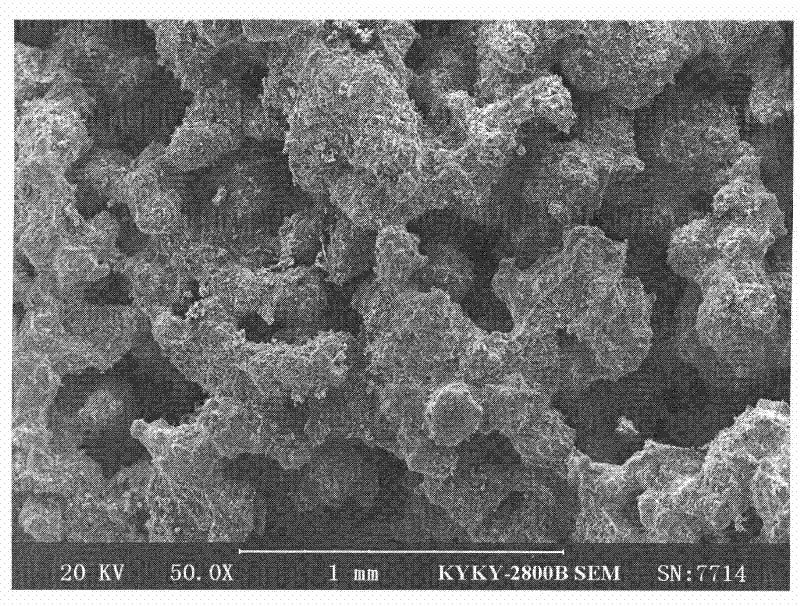

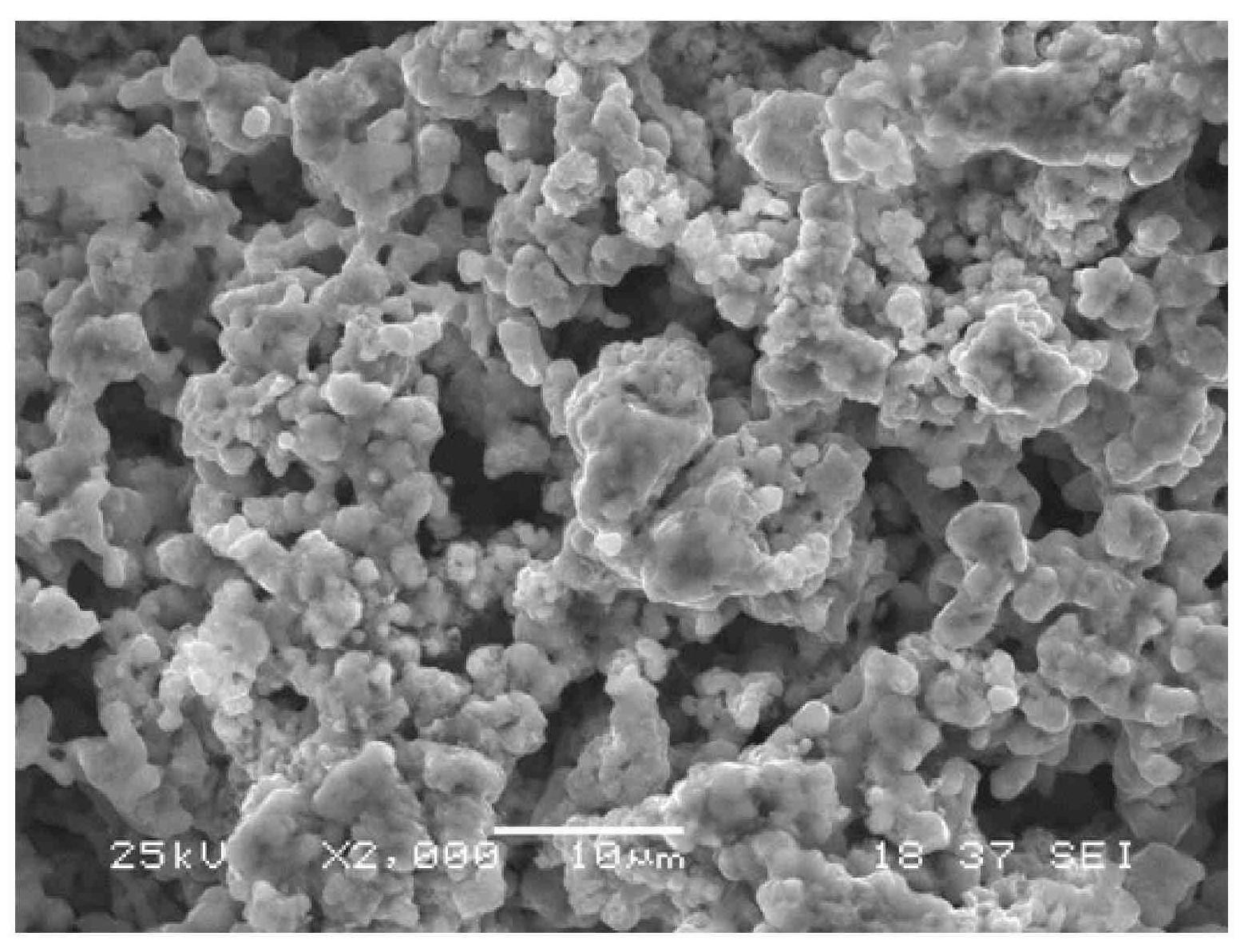

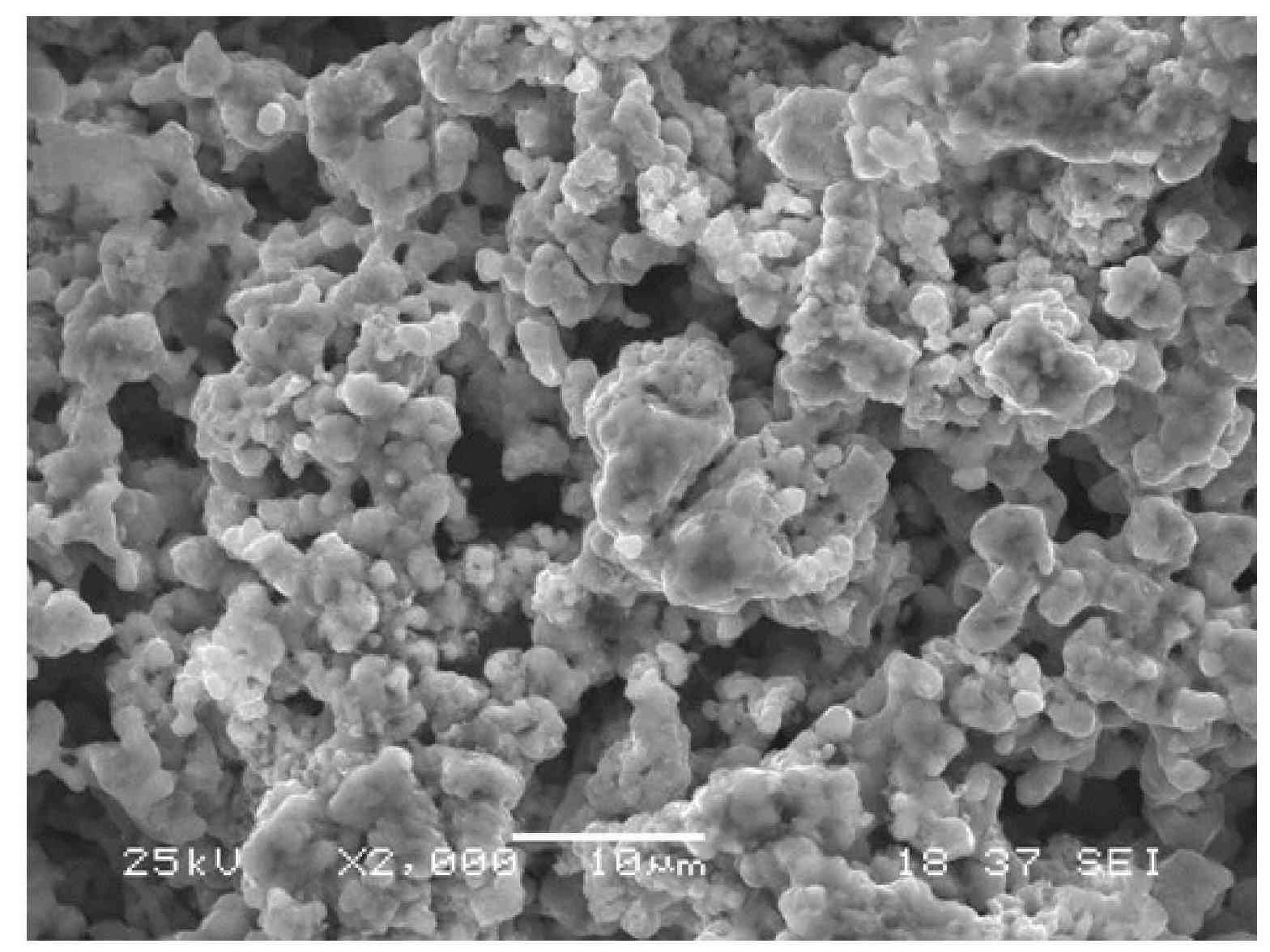

NiAl intermetallic compound porous material and preparation method thereof

The invention relates to a NiAl intermetallic compound porous material and a preparation method thereof, which belong to the field of inorganic materials. The invention provides a NiAl intermetallic compound porous material with good combination property and a preparation method thereof. The novel NiAl intermetallic compound porous material has communicated three-dimension solid network apertures and the porosity of 30 percent and 55 percent, the biggest pore is from 5 microns and 50 microns; wherein, the atom weight portions of Ni and Al in the material is equal to 60 to 90 : 10 to 40. The preparation method is that Ni and Al powders with a certain granularity are firstly mechanically mixed evenly, and then go through compression molding cold forming, finally the porous material is obtained by a sectional type vacuum pressureless sintering mode. The method has low energy consumption and almost no contamination, and the porous structures can be controlled independently. The NiAl intermetallic compound porous material of the invention has excellent high-temperature mechanical properties, good acid-resistance and alkali-resistance properties, high-temperature oxidation resistance property and excellent filtering quality, and can be used in the fields such as high temperature, separation and the like.

Owner:CHENGDU INTERMENT TECH

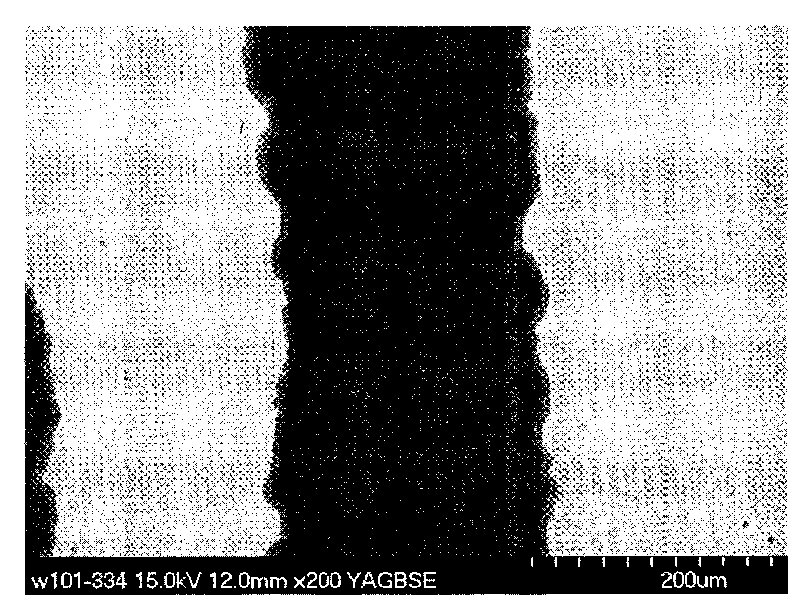

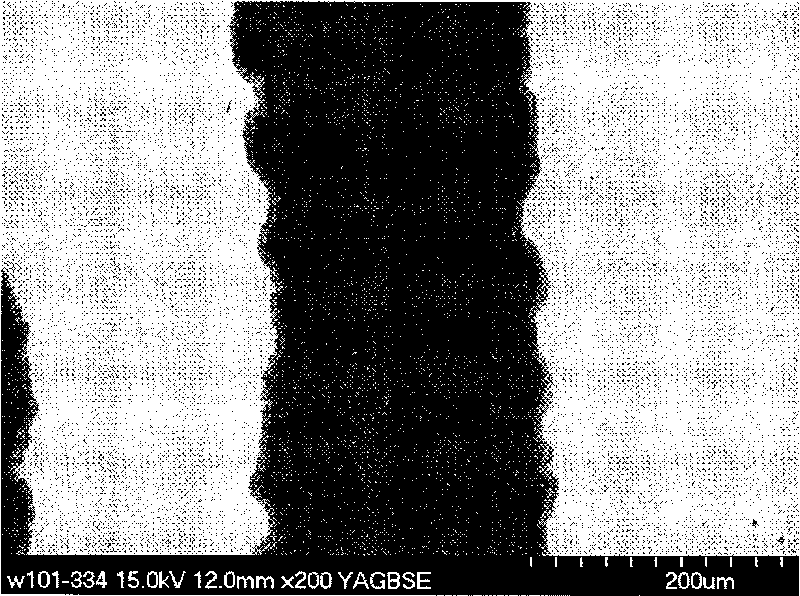

Roll forming technique of board made of NiAl-based composite material

InactiveCN101760674AFix production issuesSolve deformation coordination problemsMetal rolling arrangementsRoll formingAluminum composites

The invention relates to a preparation process of a novel composite material, in particular to a roll forming technique of a board made of an NiAl-based composite material, which comprises the following steps of: (1) preparing a board made of an aluminium base composite material reinforced by ceramic particles; (2) preparing a nickel-aluminum composite board; and (3) carrying out heat treatment on the nickel-aluminum composite board. The invention solves the preparation problem of the board of the NiAl-based composite material and is mainly applied to the roll forming of the board made of the NiAl-based composite material.

Owner:HARBIN INST OF TECH

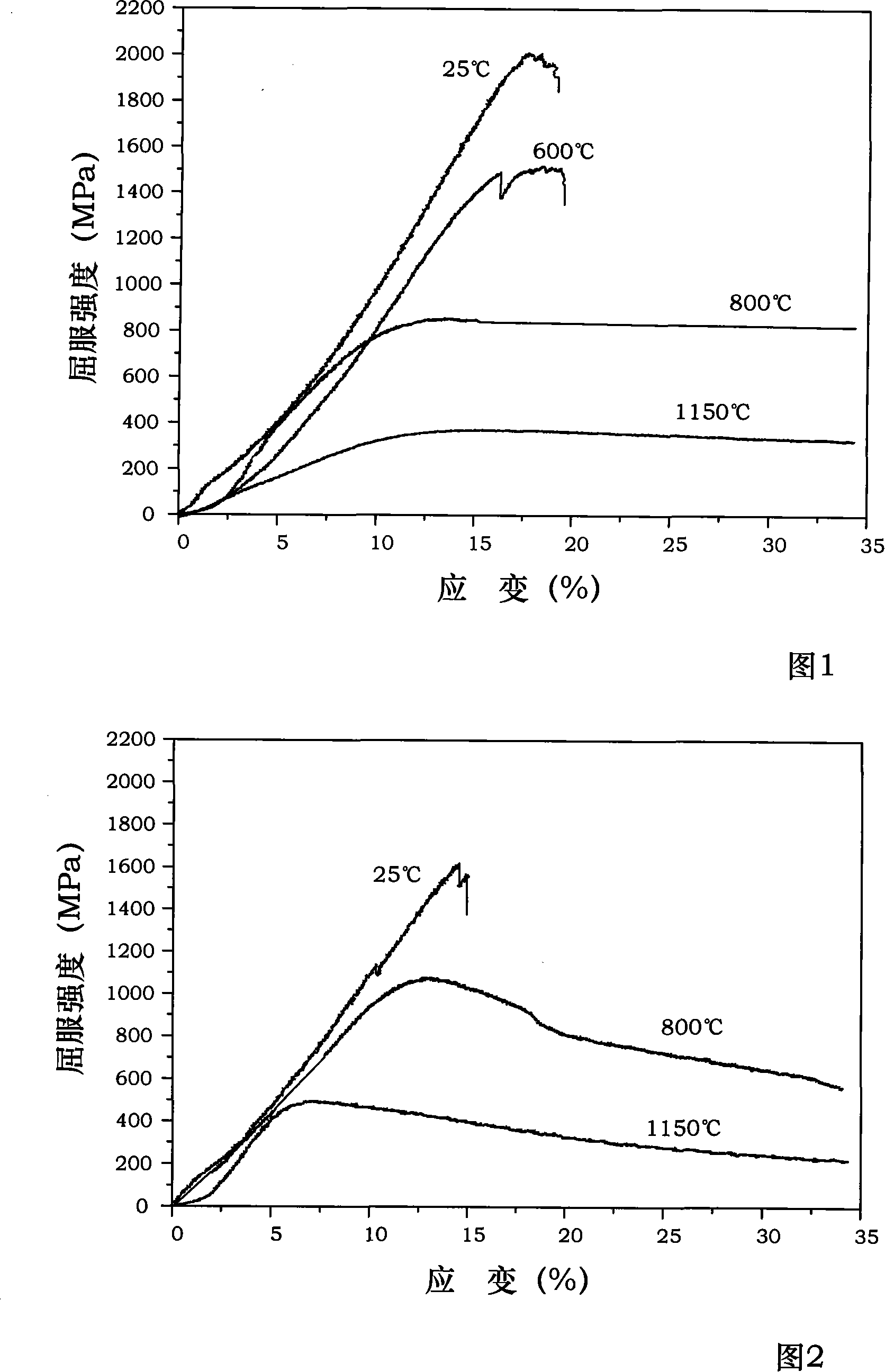

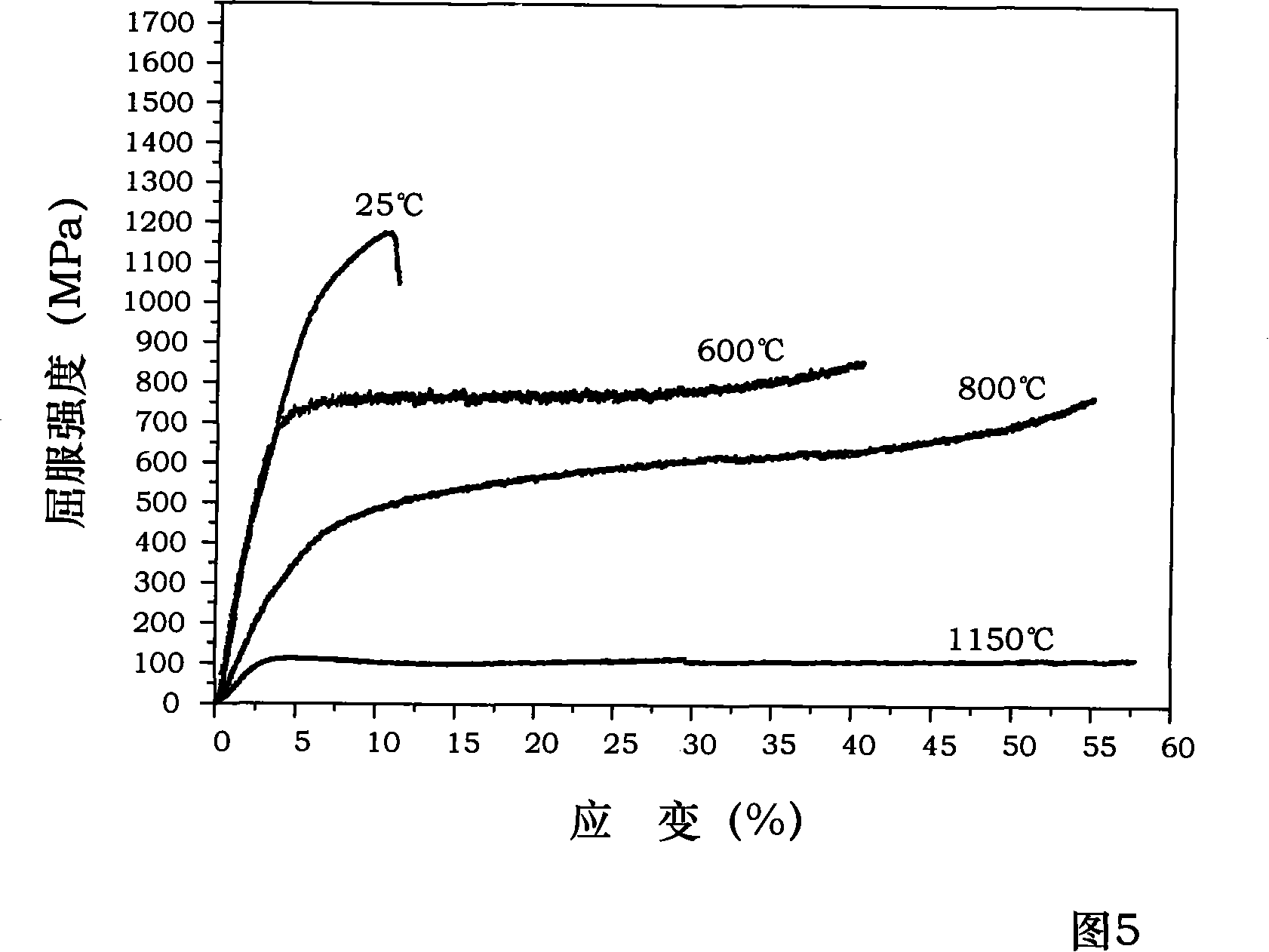

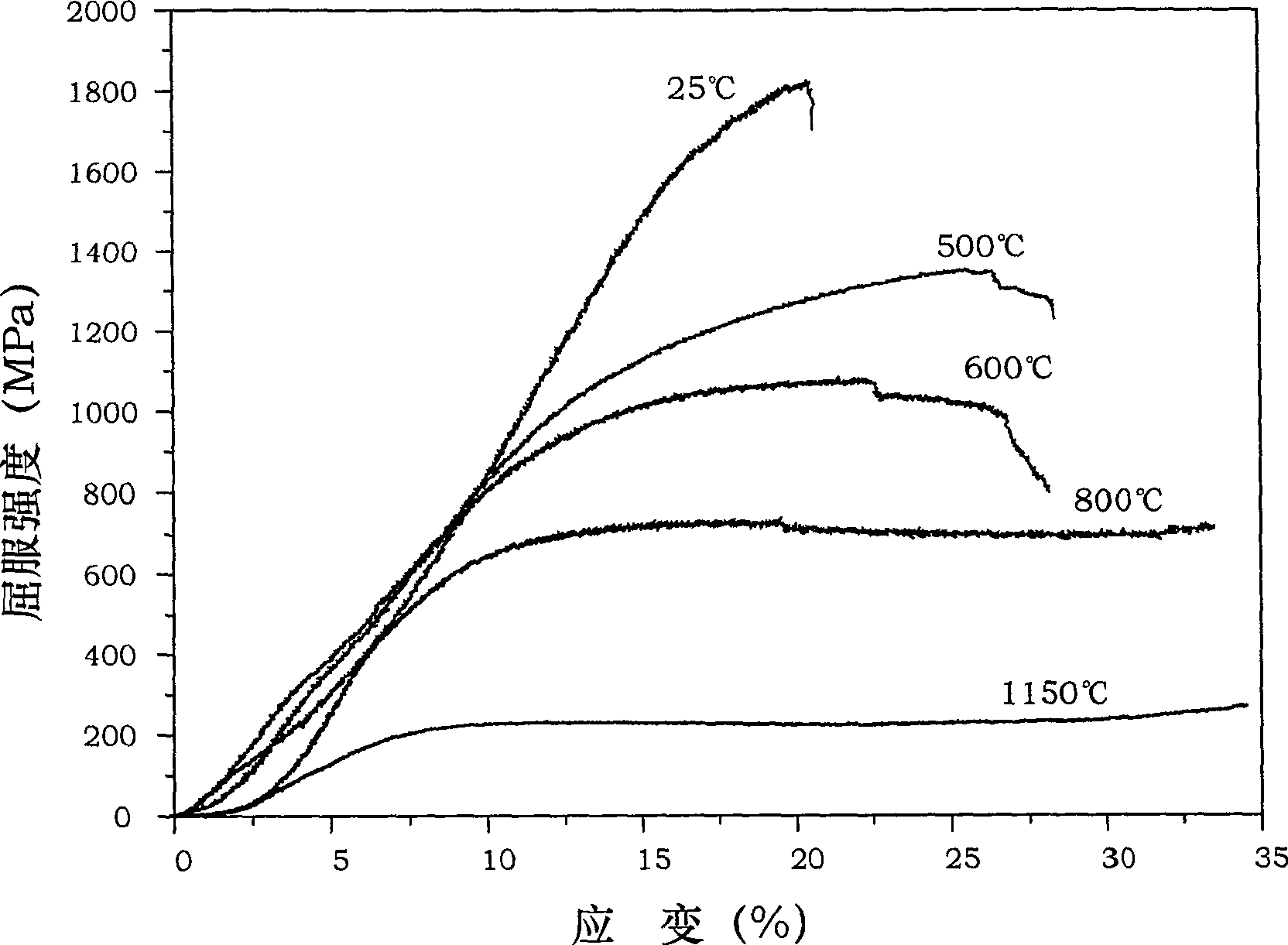

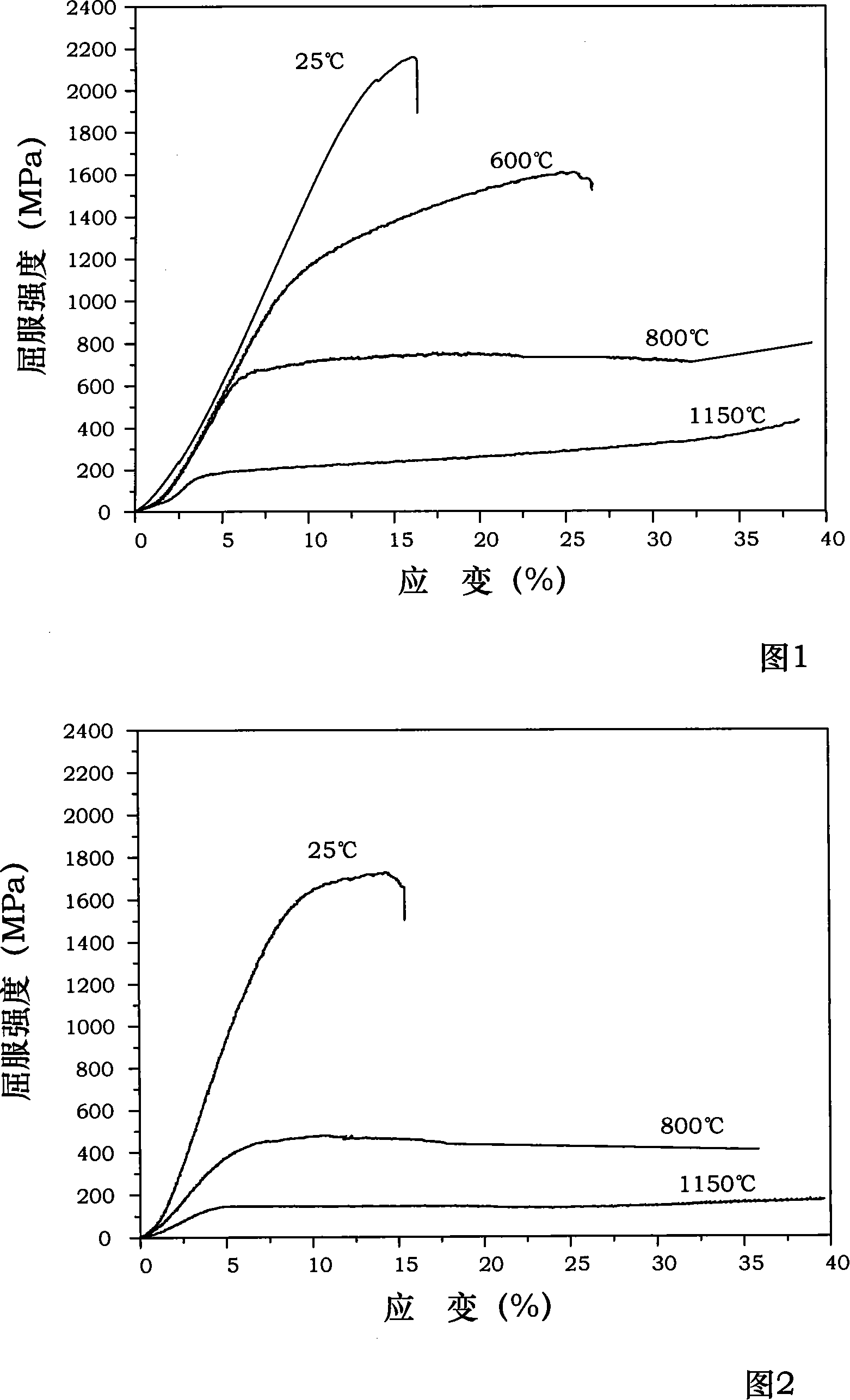

Fe-modified NiAl-Cr(Mo) polyphase eutectic intermetallic compound

InactiveCN1970804AImprove high temperature strengthHigh temperature strengthSolid solution strengtheningUltimate tensile strength

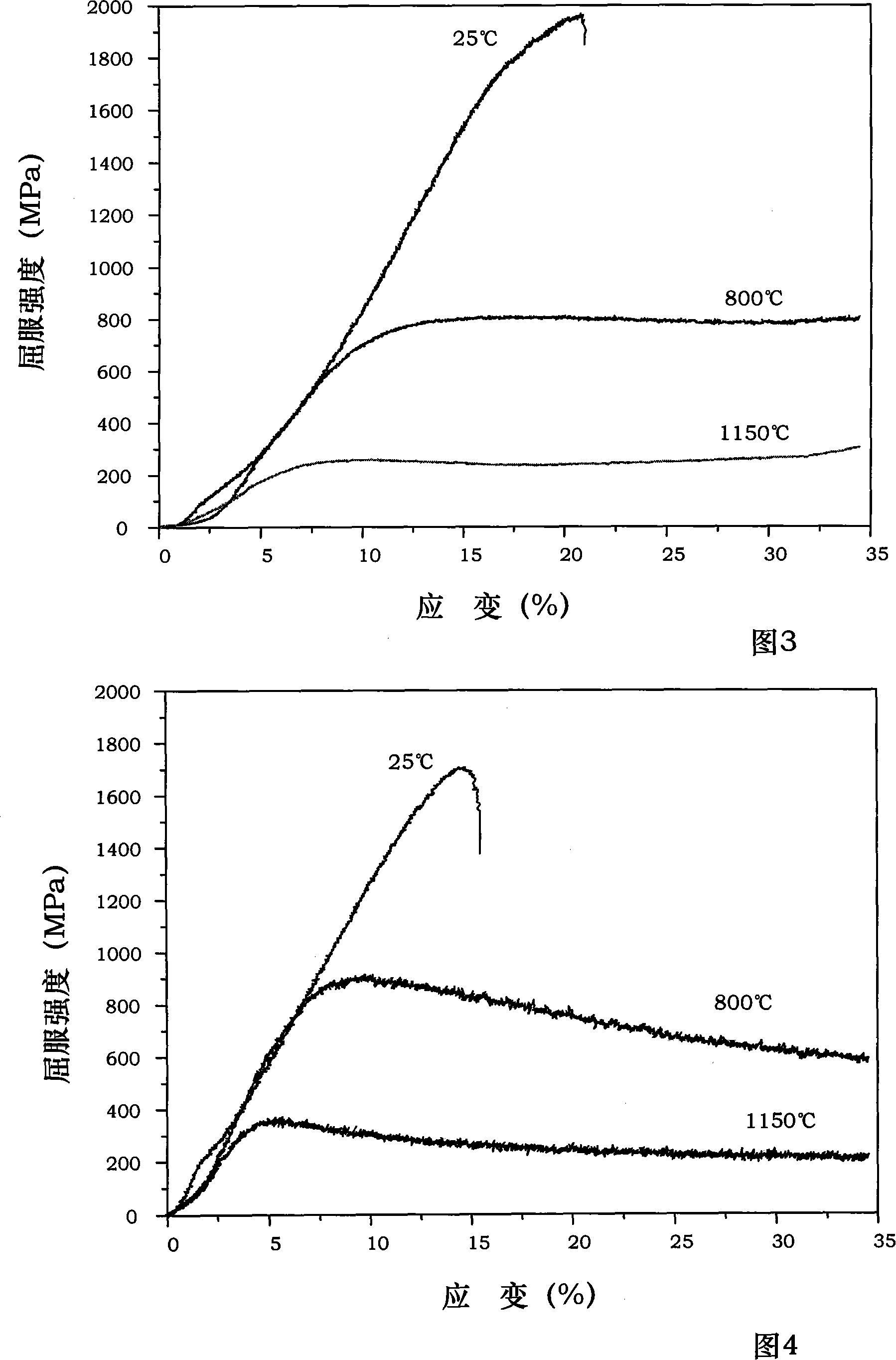

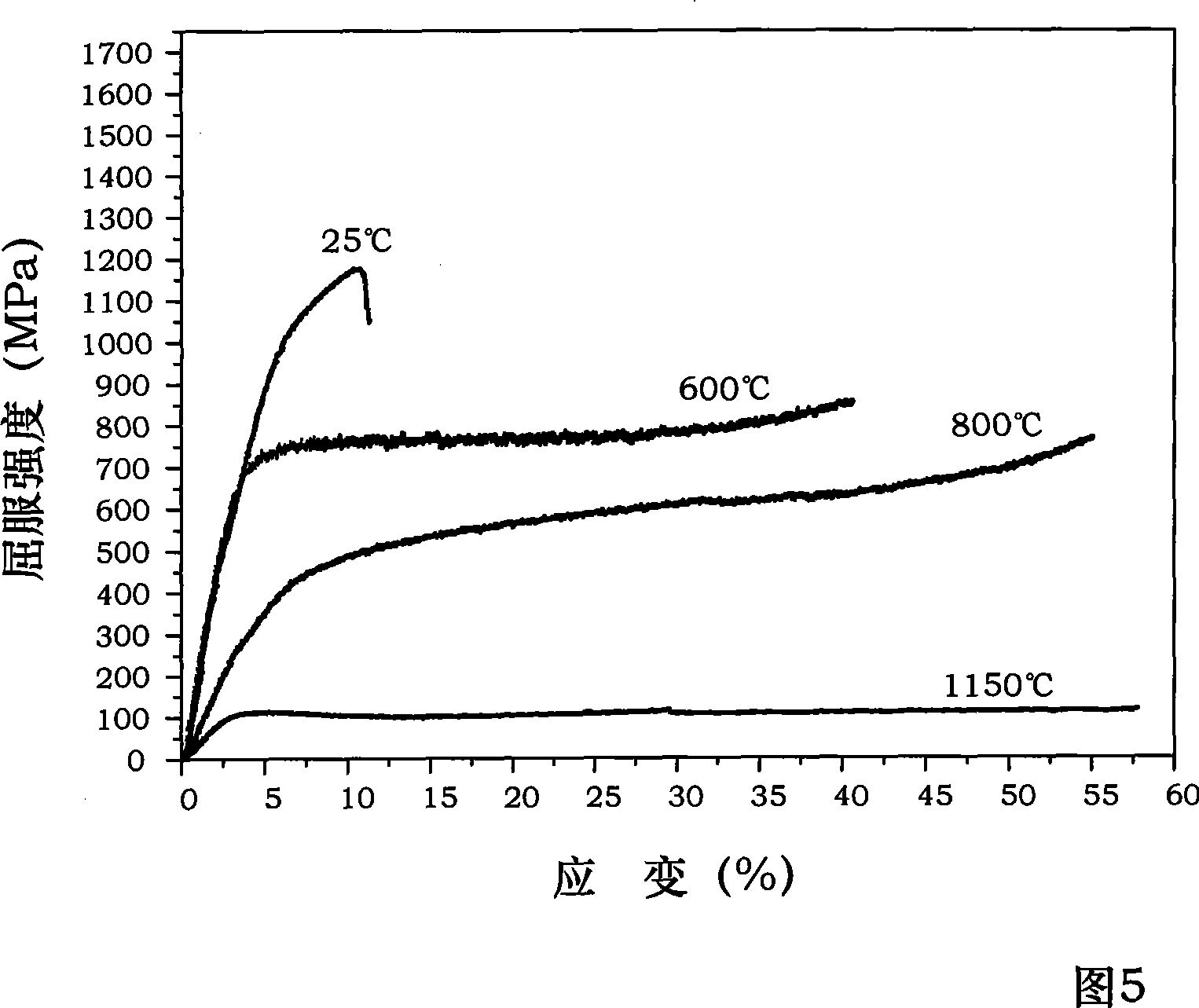

The invention discloses a new-typed structure metal compound of Fe modified NiAl-Cr (Mo) polyphase eutectic crystal, which comprises the following parts: 33at% Ni,30at% Cr,4at% Mo,1-17at% Fe and Al, wherein the NiAl-Cr (Mo) polyphase alloy is modified by Fe, which induces plastic third phase gamma-phase and gamma'-phase to improve high-temperature strength and indoor temperature flexibility and plasticity.

Owner:BEIHANG UNIV

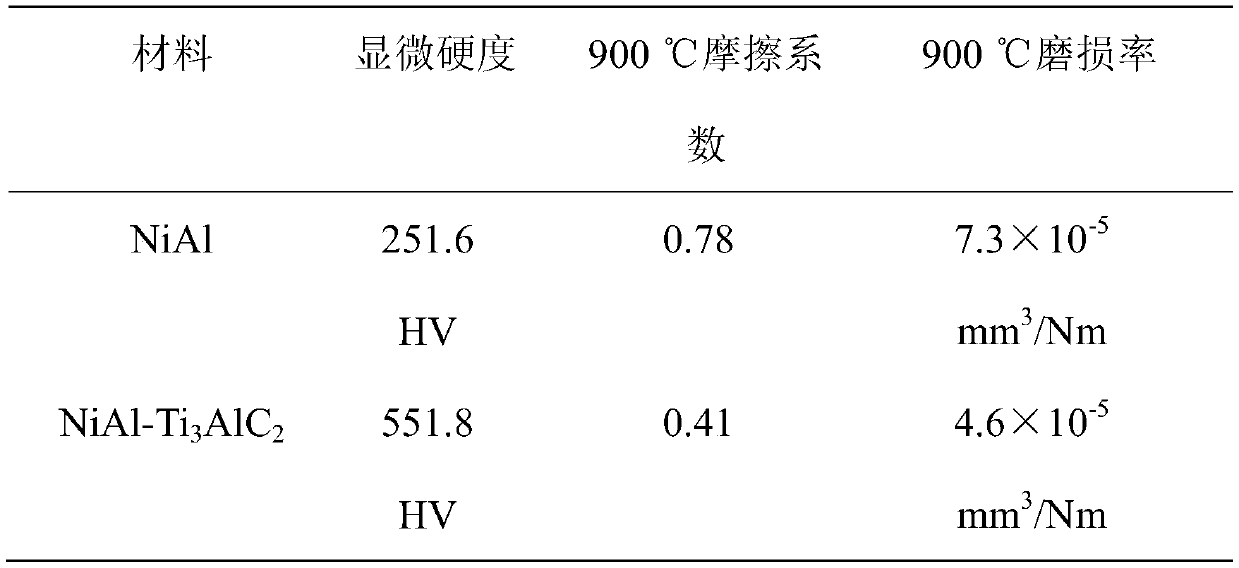

Preparation method and application of MAX-phase enhanced nickel-based high-temperature lubricating composite material

ActiveCN109666815AHigh bonding strengthGood self-lubricating performanceCylinder headsGas turbine plantsAlloyGraphite

The invention discloses a preparation method and application of a MAX-phase enhanced nickel-based high-temperature lubricating composite material. The preparation method comprises the following steps:carrying out mechanical mixing on Ti powder, Si powder and TiC powder; preparing loose block-shaped Ti3SiC2 ceramic through a powder metallurgy method; then carrying out crushing and ball-milling treatment on the prepared loose block-shaped Ti3SiC2 ceramic, so as to obtain Ti3SiC2 ceramic powder; then carrying out mechanical mixing on the sieved Ti3SiC2 powder and NiAl powder; compacting and molding; and finally, preparing a block-shaped NiAl-Ti3SiC2 composite material through hot-pressing sintering, wherein the phase content of NiAl and Ti3SiC2 in the block-shaped NiAl-Ti3SiC2 composite material is 60 to 90 percent and 10 to 40 percent respectively. The NiAl composite high-temperature lubricating material is prepared by adopting the powder metallurgy method and the self-lubricating performance of hot-pressing sintering and synthesis in the composite material is better than that of Ti3SiC2-phase ceramic of graphite and MoS2; and meanwhile, an NiAl alloy has excellent corrosion resistance and abrasion resistance, and has good sintering performance, so that NiAl alloy powder is selected as a matrix of the composite material.

Owner:咸阳瞪羚谷新材料科技有限公司

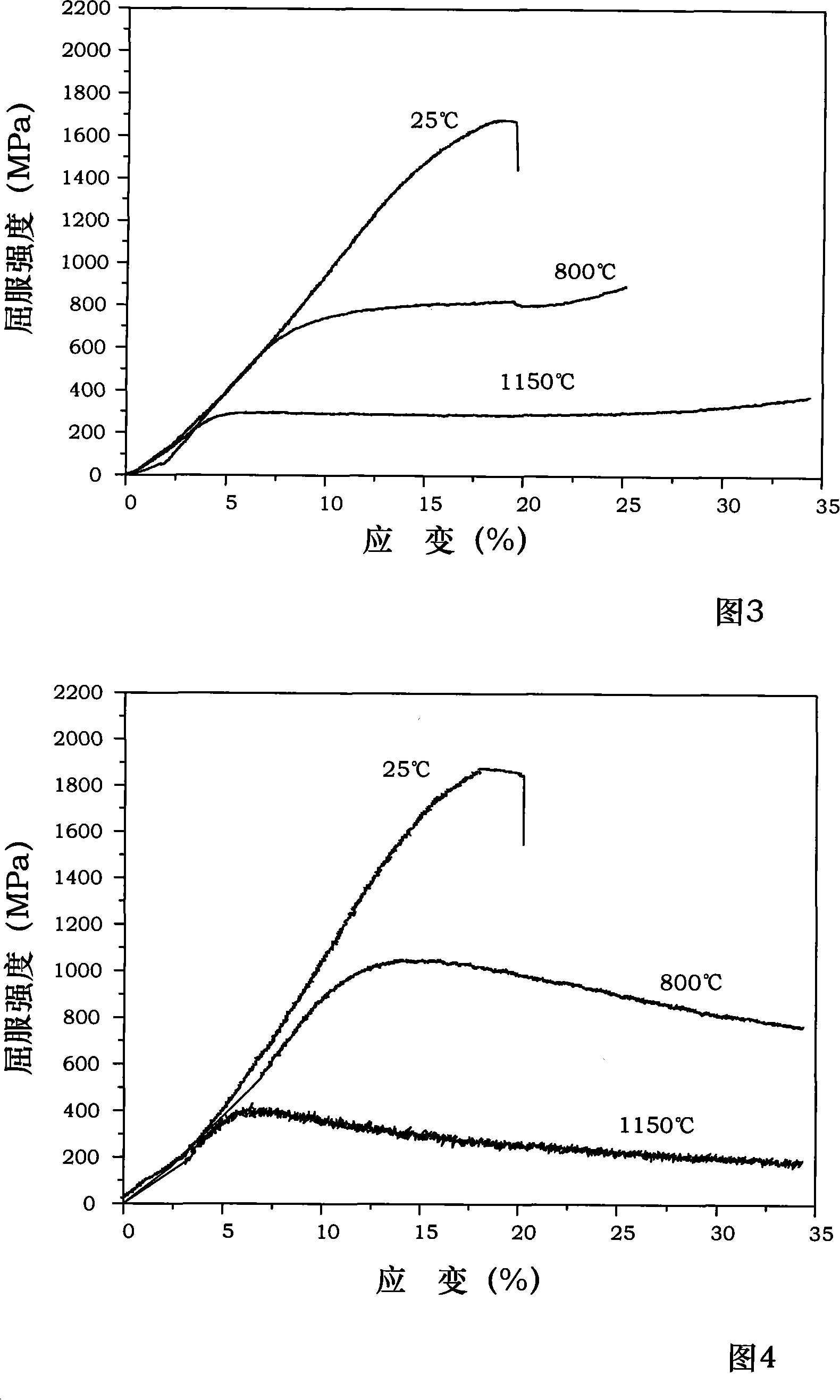

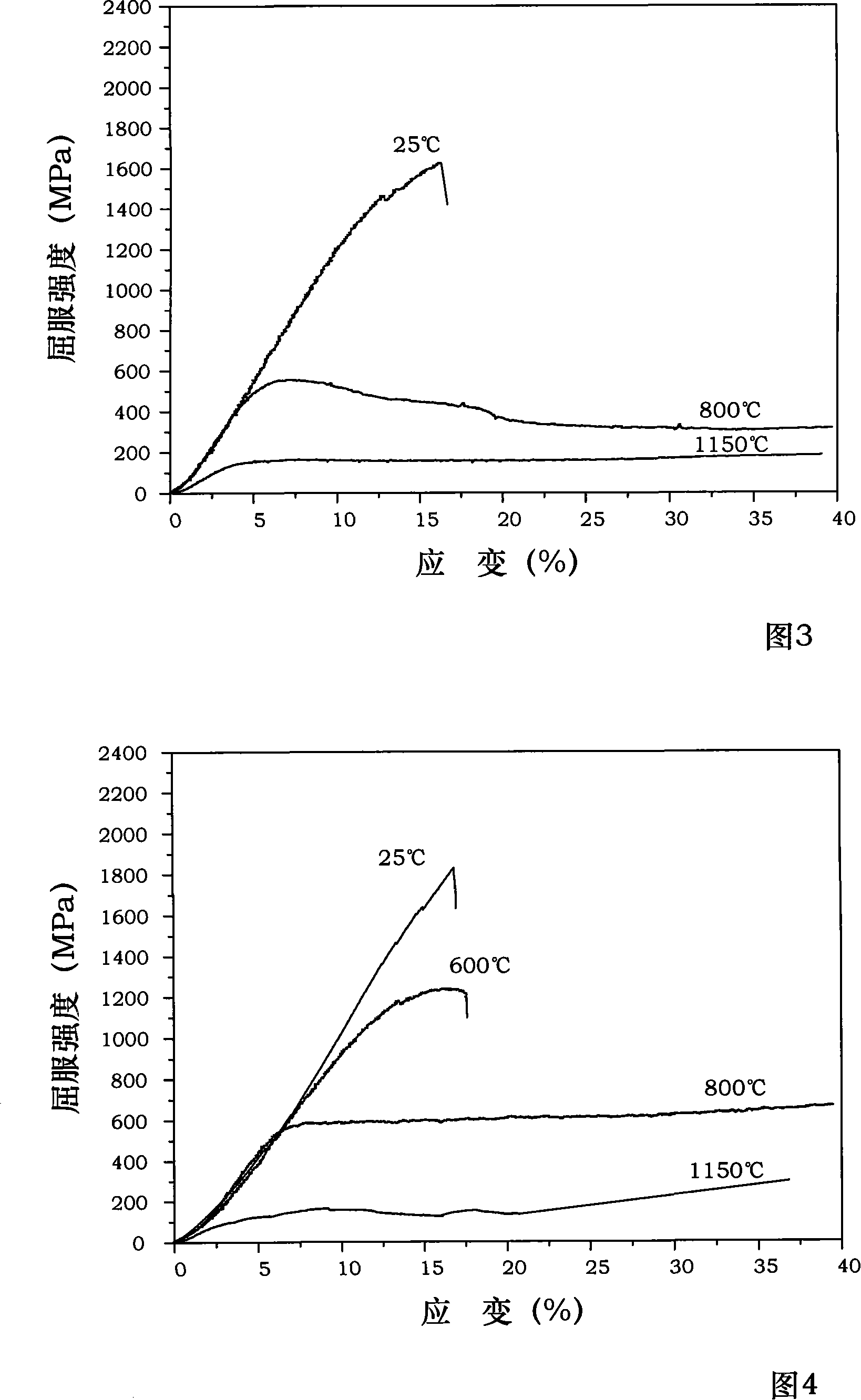

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Hf

InactiveCN101148727AImprove high temperature strengthImprove performanceRoom temperatureUltimate tensile strength

The present invention discloses one kind of Hf modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Hf in 0.1-11 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Hf element to modify and form one Heusler (L21-Ni2AlHf) phase with NiAl, the Hf modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Hf modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 300-420 MPa and density of 6.02-7.66 g / cu cm.

Owner:BEIHANG UNIV

Loading nano Ni-B type catalyst by using Al2O3 and C as carrier, and preparation method thereof

InactiveCN102872872AImprove catalytic performanceGood dispersionHydrocarbon from halogen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsChlorobenzeneActive component

The invention provides a loading nano Ni-B type catalyst by using Al2O3 and C as a carrier, and a preparation method thereof. The active components of the catalyst is a B-doped metal Ni-based catalyst by embedding B in crystal lattice of Ni; and the carrier is co-formed by Al2O3 and C. The method comprises the steps of preparing a layered precursor of borate-intercalation NiAl-BO3-LDHs through supramolecular intercalation; forming a hybrid composite of NiAl-BO3-LDHs / C by using a hydrothermal carbonization method of carbohydrate molecules; and finally preparing the uniformly-dispersed and unagglomerated Ni-B nanocatalyst loaded by Al2O3 and C through a temperature programming in-situ reduction method in an inert atmosphere. The high-dispersed loading nano Ni-B type catalyst has good catalytic hydrogenation performance when being used in the hydrogenation dechlorination reaction of chlorobenzene.

Owner:BEIJING UNIV OF CHEM TECH

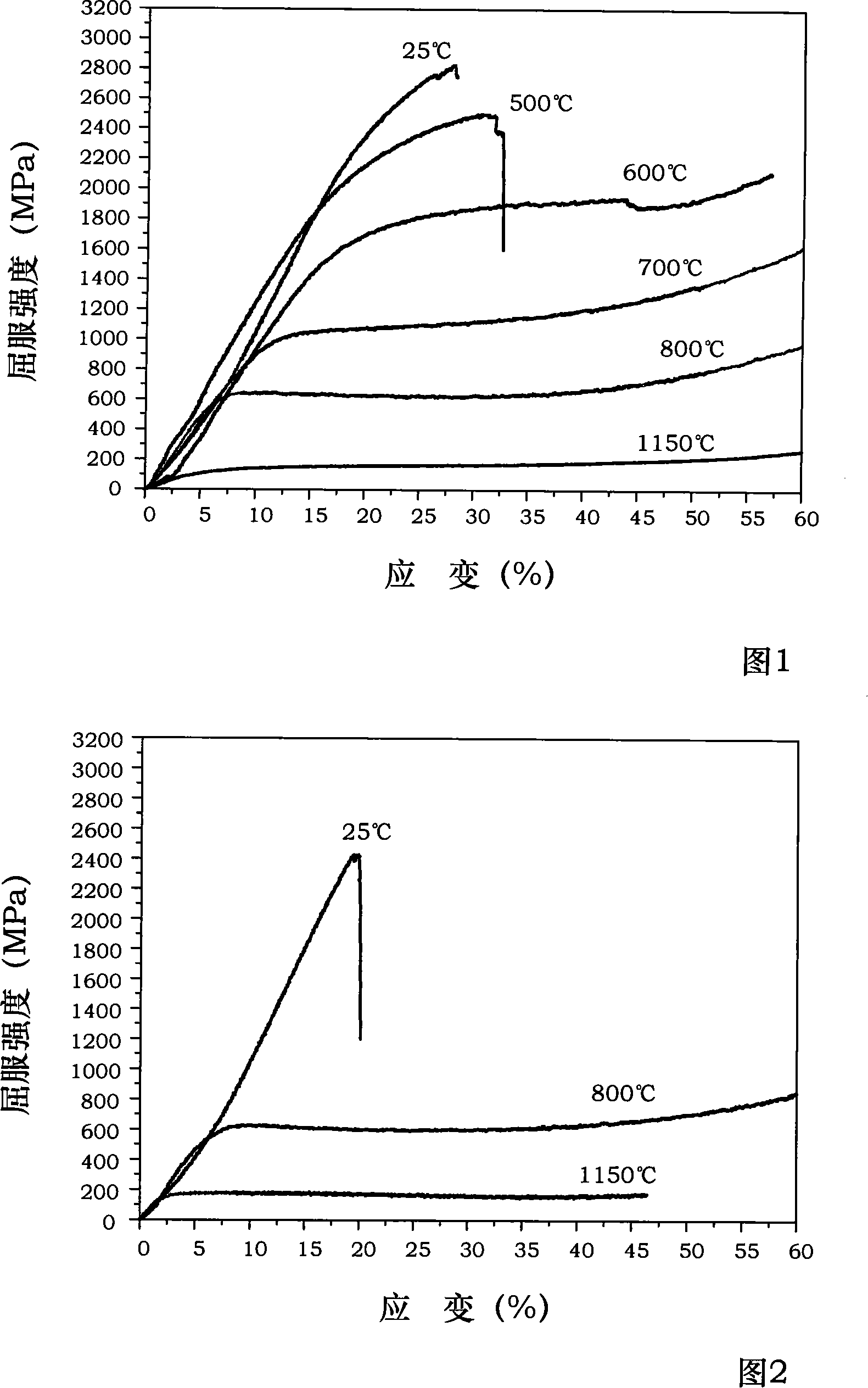

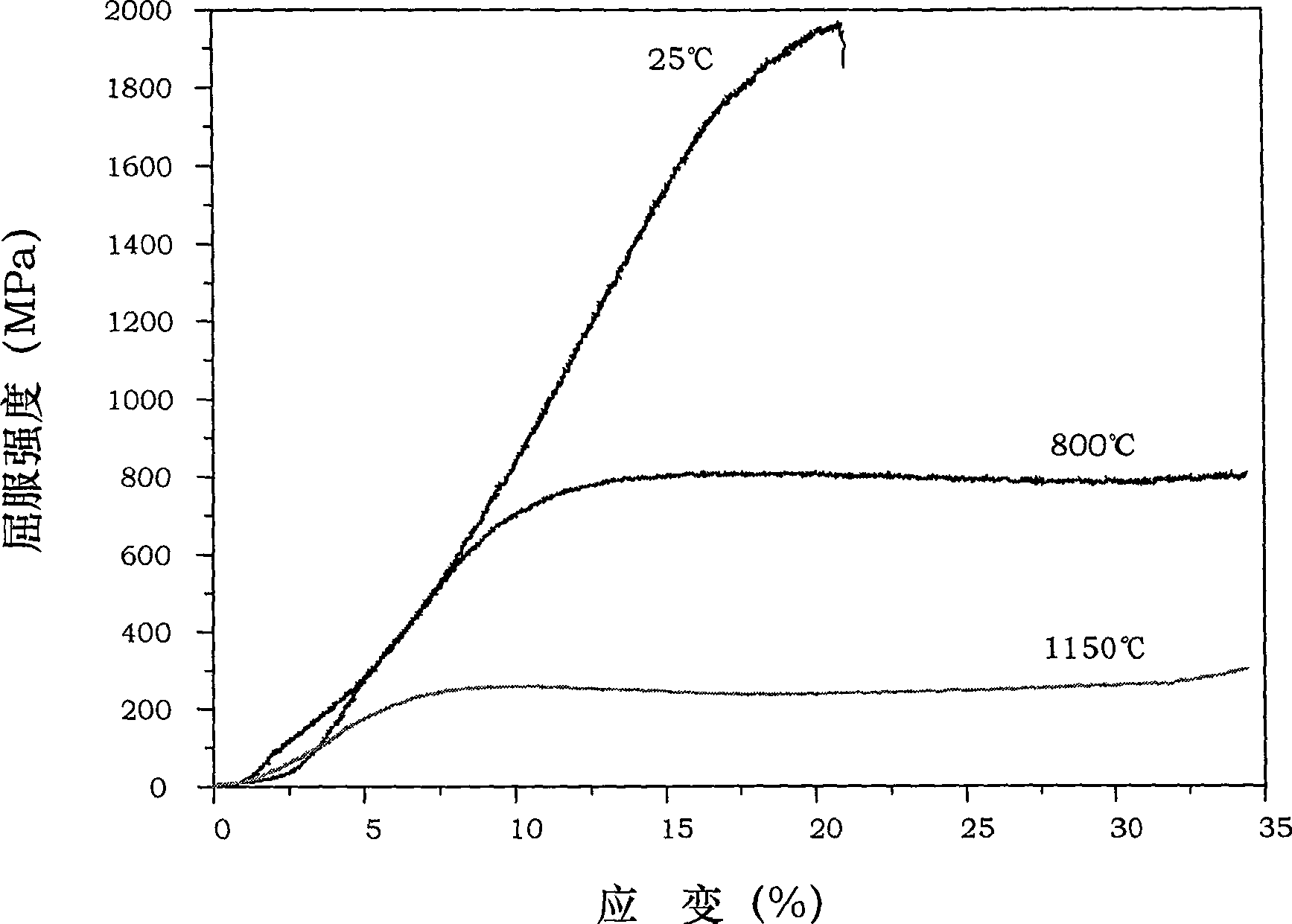

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Nb

The present invention discloses one kind of Nb modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Nb in 1-13 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Nb element to modify and form one strong Laves(Cr2Nb) phase with Cr, the Nb modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has effectively raised high temperature strength. The Nb modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 150-400 MPa and density of 6.1-6.7 g / cu cm.

Owner:BEIHANG UNIV

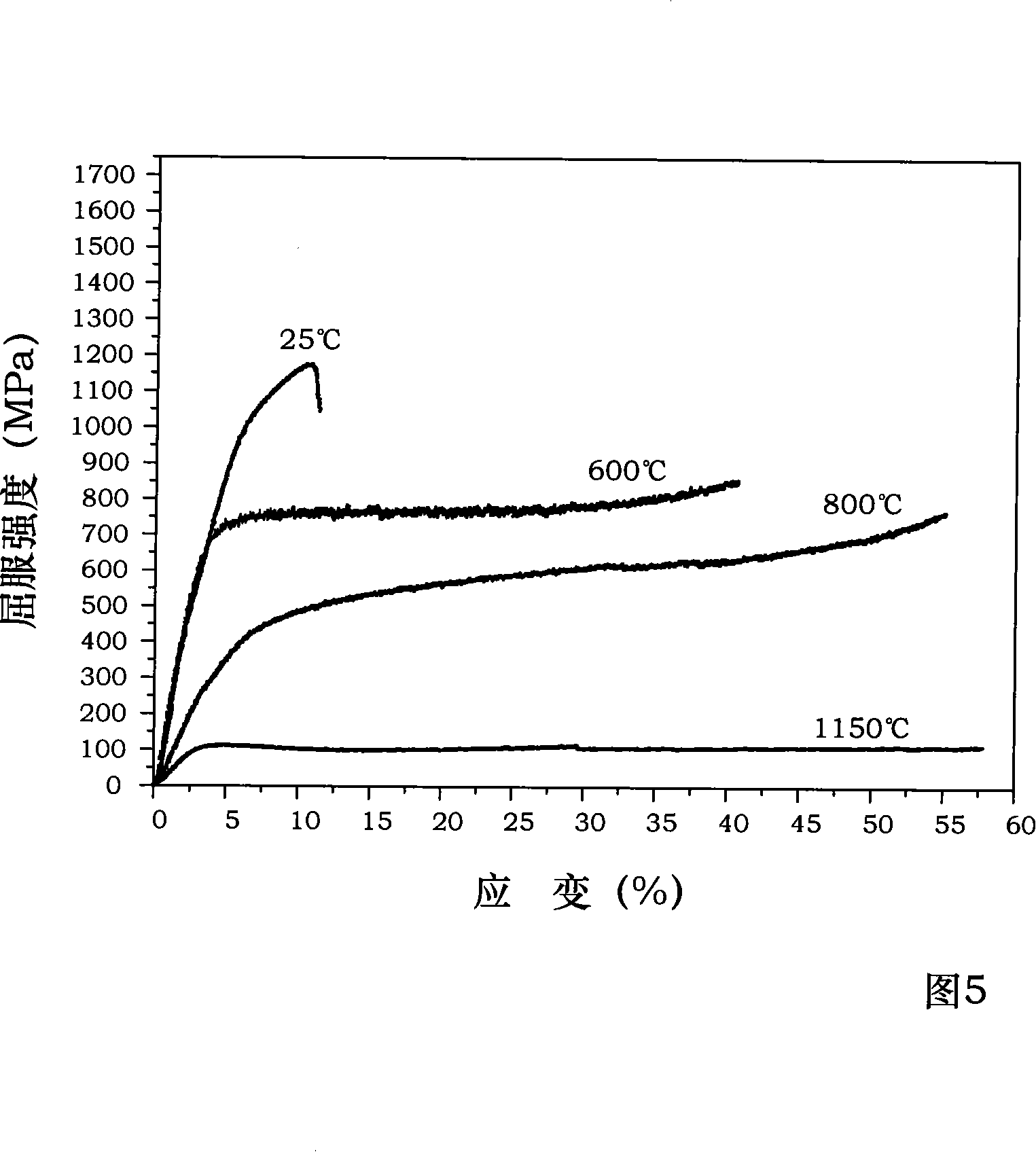

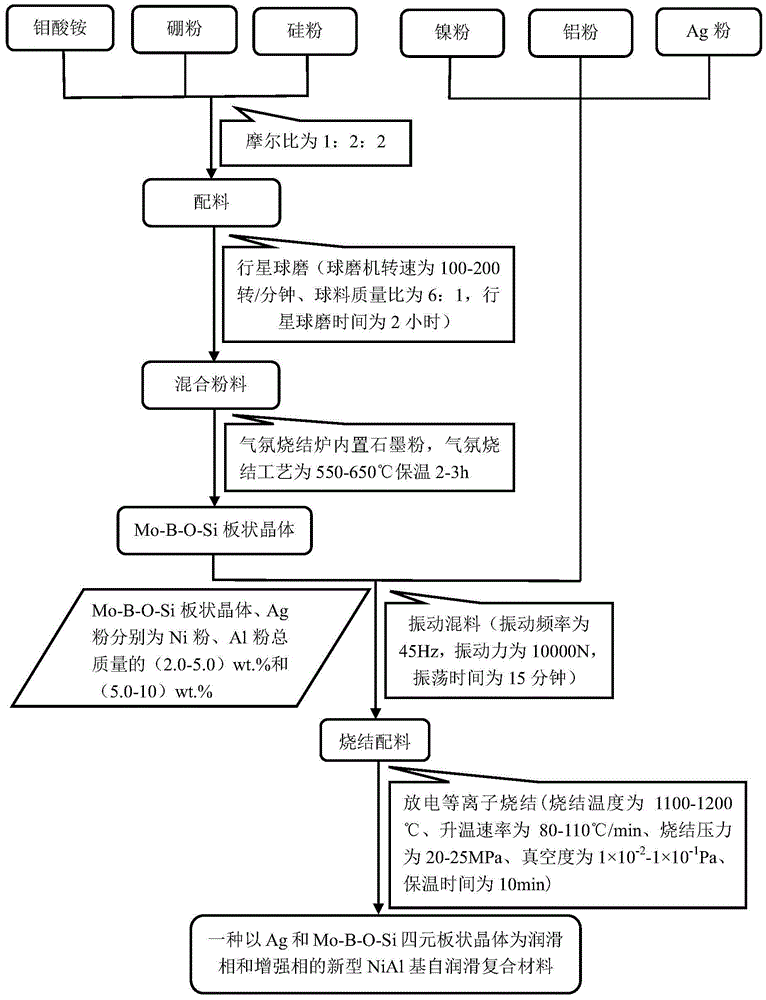

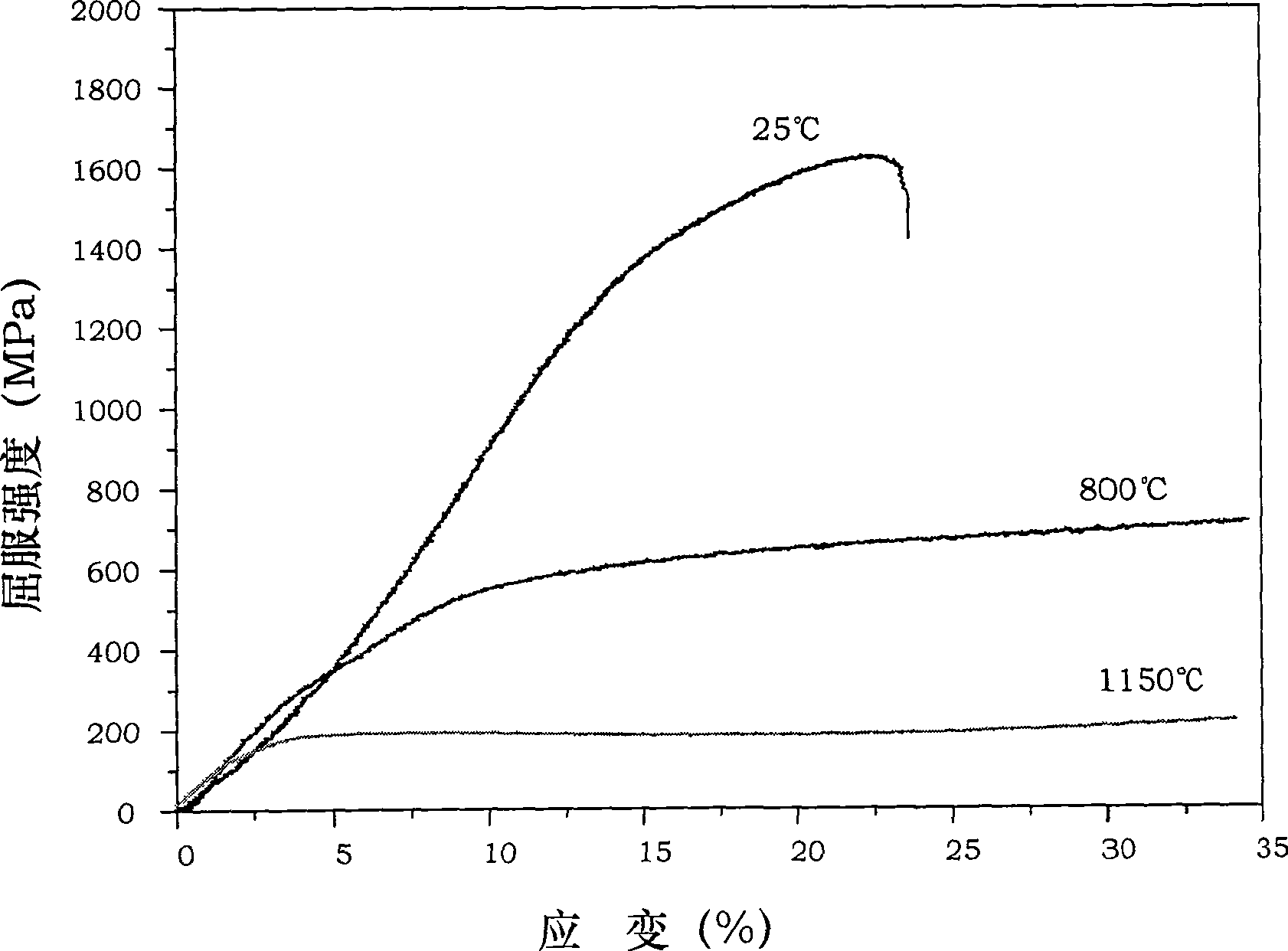

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Co

InactiveCN101148726AHigh temperature strengthImprove toughnessRoom temperatureSolid solution strengthening

The present invention discloses one kind of Co modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Co in 1-16 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Co element with solid solution reinforcing effect to modify and introduce one third plastic phase, the Co modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has further raised high temperature strength and room temperature toughness and plasticity. The Co modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 110-130 MPa and density of 6.02-7.06 g / cu cm.

Owner:BEIHANG UNIV

Cooking UItensils with Metallic Non-Stick Coating and Methods for Making the Same

InactiveUS20080073357A1Limited temperature toleranceImprove impact performanceCooking-vessel materialsMolten spray coatingChromium carbideHeat resistance

Disclosed is a cooking utensil coated with a metallic non-stick coating made of a nickel-aluminum-molybdenum (NiAlMo) alloy mainly composed of nickel aluminum (NiAl), and / or a nickel-chrome-chromic carbide (NiCr—Cr3C2) alloy mainly composed of chromic carbide (Cr3C2). A method for coating a cooking utensil with a metallic non-stick coating is also provided. The metallic non-stick coating of the invention possesses high impact, heat and abrasion resistances.

Owner:QIN RAYMOND +1

Aggregation-type composite powder for high-temperature abradable seal coating layer and preparing method of aggregation-type composite powder

The invention relates to aggregation-type composite powder for a high-temperature abradable seal coating layer and a preparing method of the aggregation-type composite powder. The aggregation-type composite powder which has good spraying technology adaptability is prepared through the method of mechanical milling, room-temperature binding and aggregation. The powder comprises MCrAlY alloy powder, alloy powder with beta-NiAl intermetallic compounds as a main phase, polybenzoate powder, boron nitride, binding agents and the like. Raw materials can be the combination of the materials, and the binding agents can be inorganic matter or organic matter. The powder comprises beta-NiAl intermetallic compound high-temperature-resisting components, heat-resisting temperature of an existing metal-based seal coating layer can be raised, and compared with a ceramic seal coating layer, the coating layer has great thermal shock resistance and can be used under the working condition of the high temperature of 1000 DEG C for a long time. The powder has wide application in gas channel sealing of a combustion gas turbine high-temperature part, especially of a high-pressure turbine.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

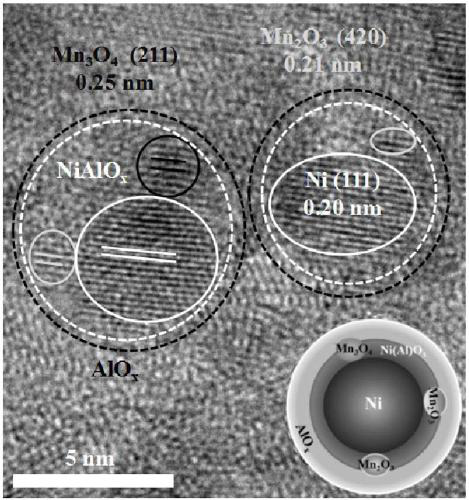

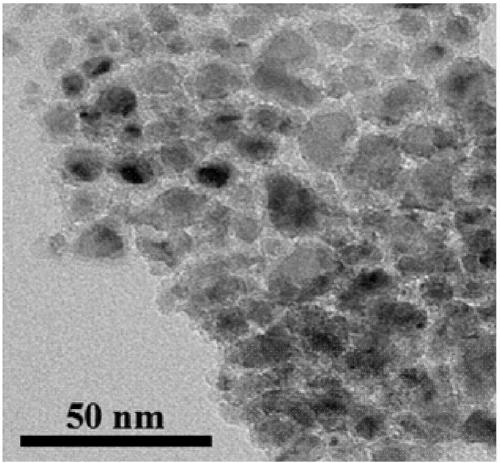

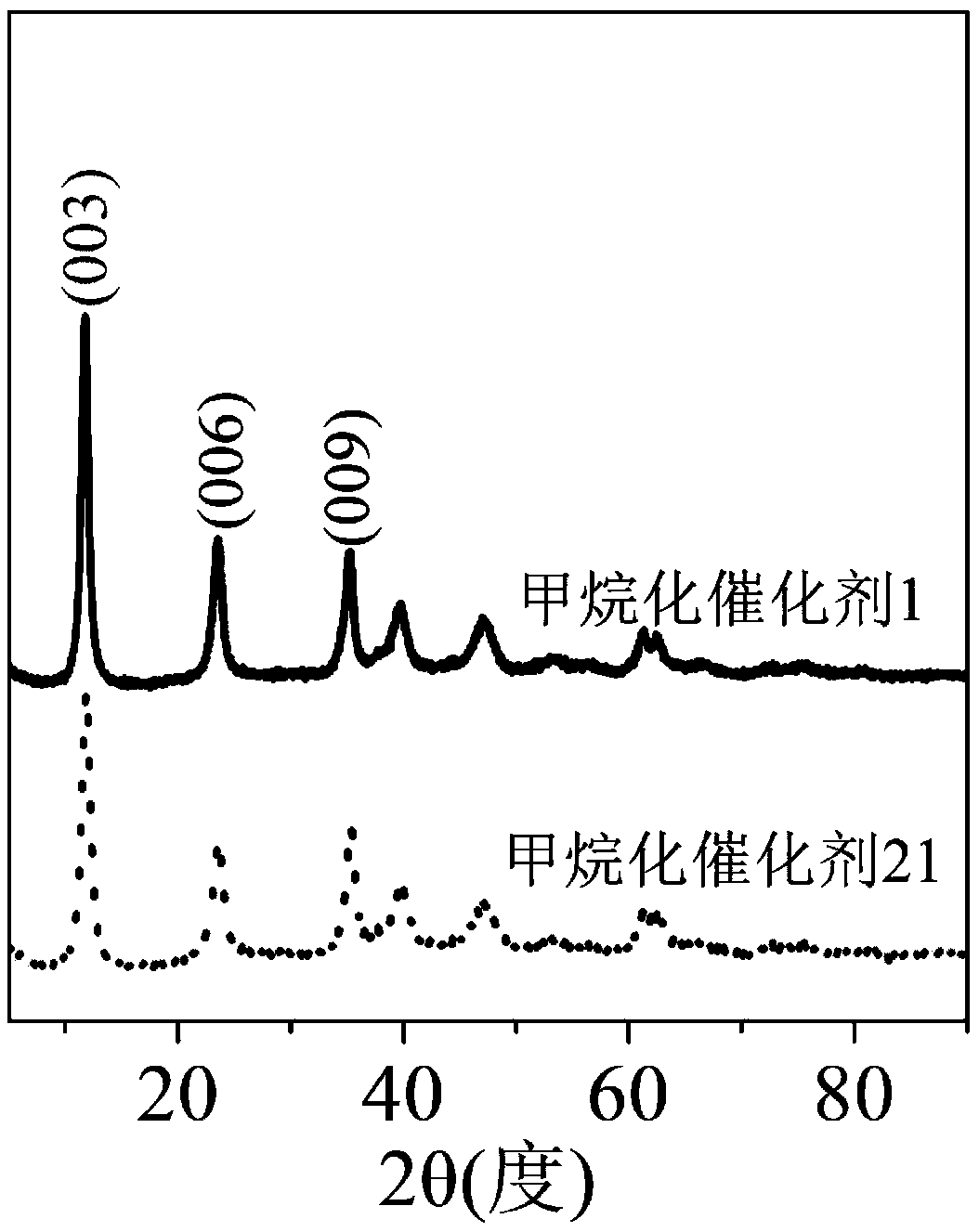

Methanation catalyst, preparation method thereof and method for using methanation catalyst to prepare methane

ActiveCN109395735ALarge specific surface areaImprove permeabilityHydrocarbon from carbon oxidesCatalystsMethanationOxidation state

The invention provides a methanation catalyst, a preparation method thereof and a method for using the methanation catalyst to prepare methane. The methanation catalyst is obtained by reducing metal hetero-atom doped NiAl hydrotalcite directly, the metal hetero-atom is doped into the NiAl hydrotalcite by replacing a nickel atom in a NiAl hyrotalcite crystal lattice, and the atomic radius ratio ofthe metal hetero-atom to the nickel atom is between 0.75 and 1.6, and the oxidation state is valence +2 and above. The obtained methanation catalyst has high specific surface area, permeability and pore volume, activation temperature is between 220 and 230 DEG C, the conversion rate of CO between 270 and 280 DEG C can reach 100%, the selectivity to CH4 can reach 97%, the product catalytic effect is stable, the service life is long, and the catalytic activity, the stability and the carbon deposition resistance of the methanation catalyst are all apparently superior to an existing commercializedcatalyst.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Nanosized intermetallic powders

InactiveUS7547344B2Material nanotechnologyNanomagnetismElectrical resistance and conductanceNano size

Nanoparticles of intermetallic alloys such as FeAl, Fe3Al, NiAl, TiAl and FeCoV exhibit a wide variety of interesting structural, magnetic, catalytic, resistive and electronic, and bar coding applications. The nanosized powders can be used to make structural parts having enhanced mechanical properties, magnetic parts having enhanced magnetic saturation, catalyst materials having enhanced catalytic activity, thick film circuit elements having enhanced resolution, and screen printed images such as magnetic bar codes having enhanced magnetic properties. In contrast to bulk FeAl materials which are nonmagnetic at room temperature, the FeAl nanoparticles exhibit magnetic properties at room temperature.

Owner:PHILIP MORRIS USA INC

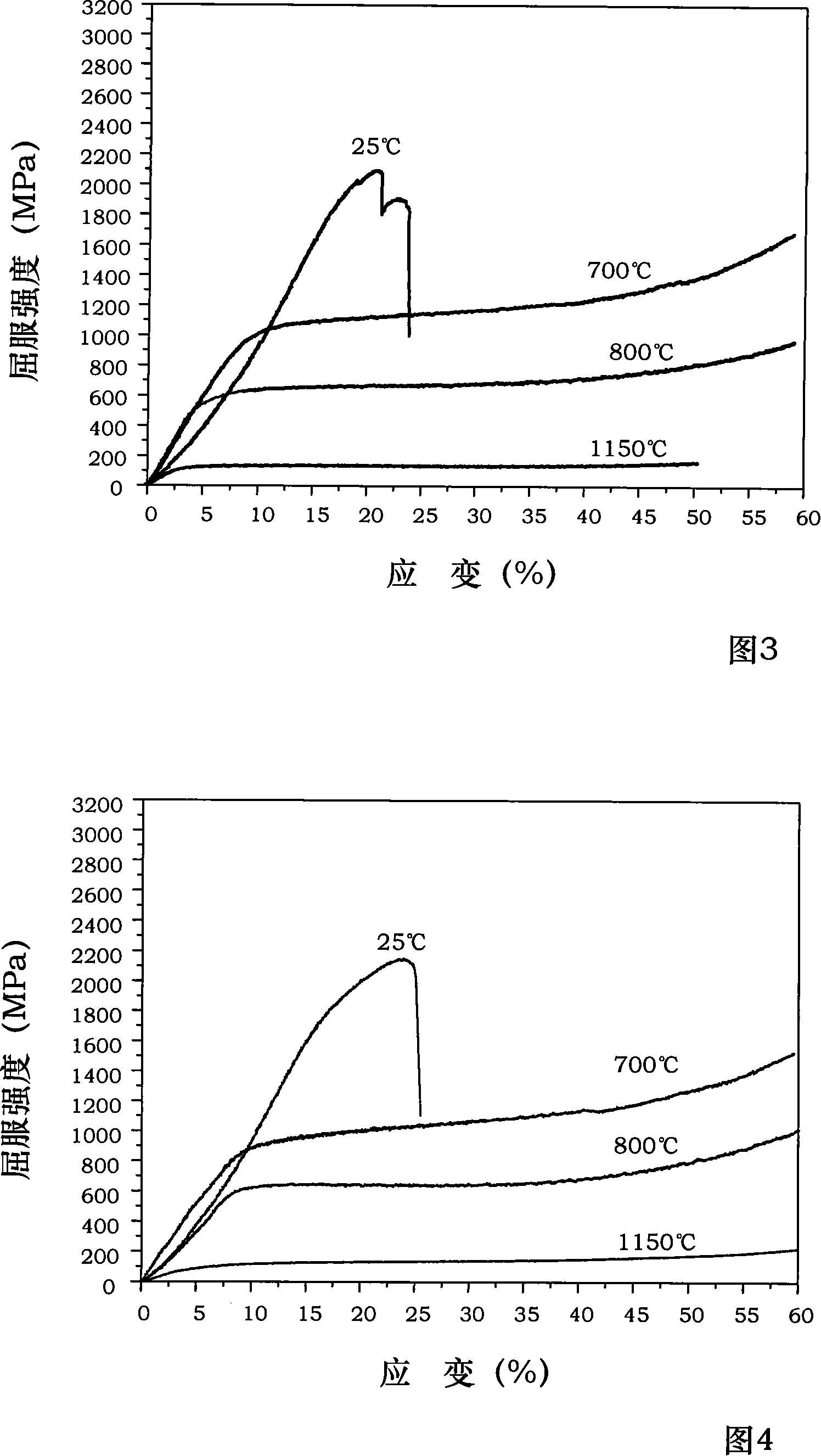

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Ta

InactiveCN101148728AImprove high temperature strengthImprove performanceRoom temperatureUltimate tensile strength

The present invention discloses one kind of Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Ta in 1-13 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Ta element to modify and form one Laves(Cr2Ta) phase with Cr, the Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 120-400 MPa and density of 6.1-6.9 g / cu cm.

Owner:BEIHANG UNIV

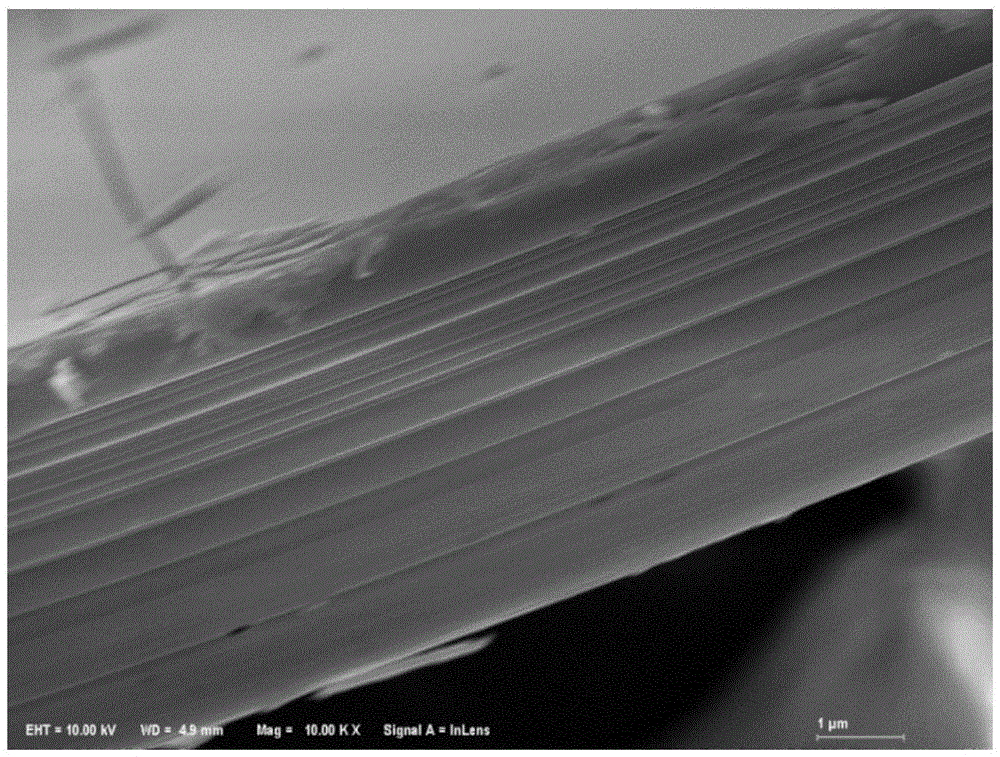

Novel NiAl-based self-lubricating material using Ag and Mo-B-O-Si four-element platy crystal as composite lubricating phase and reinforcing phase and preparation method of novel NiAl-based self-lubricating material

The invention relates to a novel NiAl-based self-lubricating material using Ag and Mo-B-O-Si four-element platy crystals as a composite lubricating phase and a reinforcing phase and a preparation method of the novel NiAl-based self-lubricating material. The preparation method includes following steps: preparing the Mo-B-O-Si four-element platy crystals; selecting Ni powder and Al powder according to a molar ratio of Ni:Al=1:1, selecting the Mo-B-O-Si four-element platy crystals and Ag powder, and mixing the Mo-B-O-Si four-element platy crystals with the Ni powder, the Al powder and the Ag powder to obtain an ingredient; disposing the ingredient in a vibration mixing machine for dry mixing to obtain a sintered ingredient; subjecting the sintered ingredient to discharging plasma sintering to obtain the novel NiAl-based self-lubricating material. The self-lubricating material is low in friction coefficient and wear rate in the process of friction and wear and has excellent tribological performance, the preparation method is simple and novel, and process parameters are easy to control in the preparation process.

Owner:WUHAN UNIV OF TECH

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Ta

InactiveCN100497700CImprove high temperature strengthImprove performanceRoom temperatureUltimate tensile strength

The present invention discloses one kind of Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Ta in 1-13 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Ta element to modify and form one Laves(Cr2Ta) phase with Cr, the Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Ta modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 120-400 MPa and density of 6.1-6.9 g / cu cm.

Owner:BEIHANG UNIV

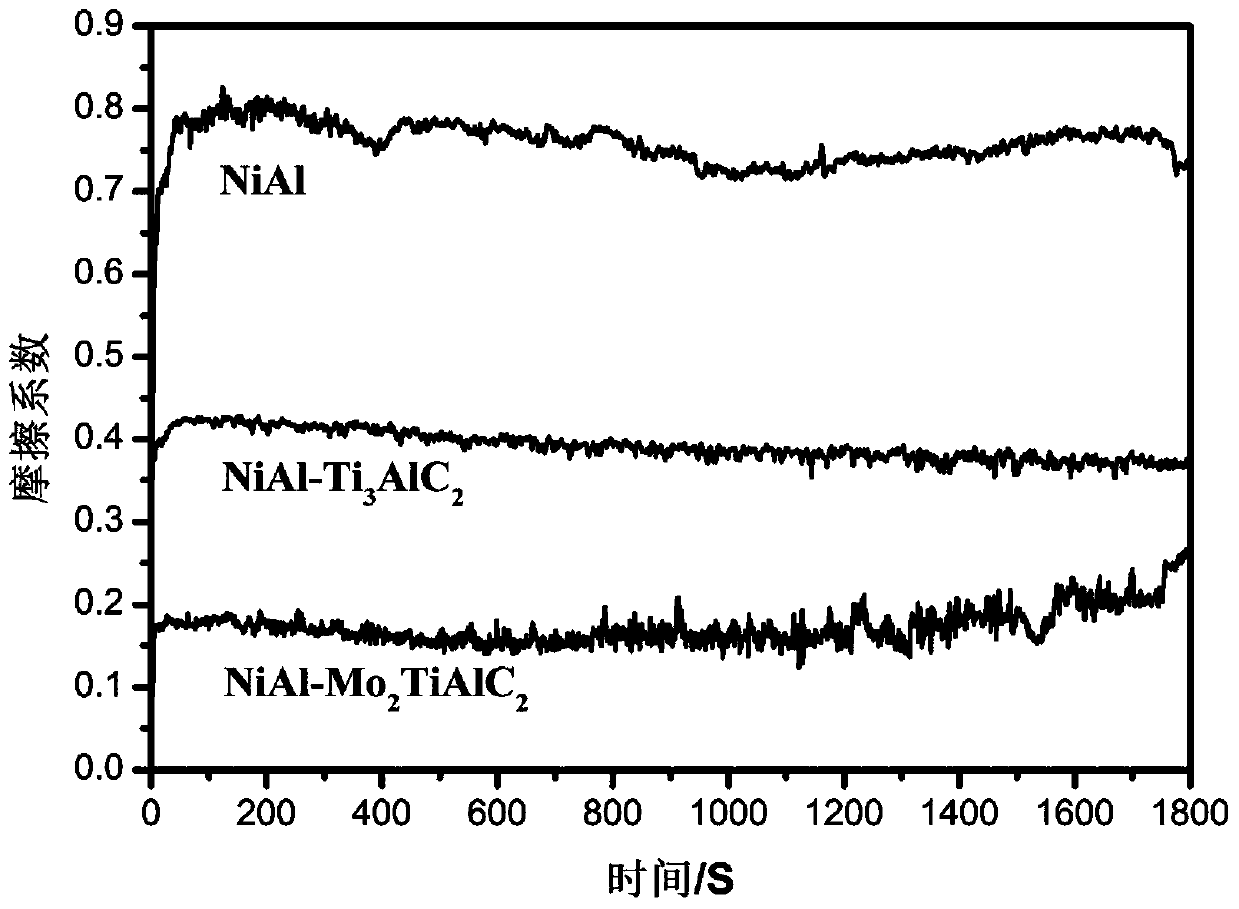

Quaternary MAX phase reinforced NiAl-based high-temperature lubricating composite and preparation method thereof

The invention discloses a quaternary MAX phase reinforced NiAl-based high-temperature lubricating composite and a preparation method thereof. The preparation method comprises the following steps of respectively weighing NiAl powders, Mo podwers, Ti powders, Al powders and C powders in proportion, and then putting the weighed powders into a high-energy ball mill for ball milling to prepare nano-structure mixed powders uniformly mixed; and putting the mixed powders into a graphite grinding tool for cold pressing treatment, and carrying out vacuum hot pressing sintering in a vacuum hot pressing sintering furnace after cold pressing is finished to obtain the NiAl-Mo2TiAlC2 composite. According to the quaternary MAX phase reinforced NiAl-based high-temperature lubricating composite and the preparation method thereof, a novel quaternary MAX phase (Mo2TiAlC2) is generated by the in-situ reaction of Mo, Ti, Al and C in the sintering process, so that the high-temperature lubricating performanceof the composite is achieved, and the wettability between the MAX phase and a NiAl matrix and the structure of the composite are effectively improved at the same time, therefore, the strength of thecomposite is effectively improved, and the excellent lubricating performance of the composite under the condition of higher temperature is achieved.

Owner:XI AN JIAOTONG UNIV +1

Manganese oxide catalyst as well as preparation method and application thereof

InactiveCN109939692AEvenly dispersedExtended use timeDispersed particle separationCatalyst activation/preparationManganese oxideHigh activity

The invention discloses a manganese oxide catalyst as well as a preparation method and application thereof. According to the manganese oxide catalyst, nickel-aluminum composite metal oxide is taken asa carrier, manganese oxide is taken as an active component, and the mass percentage of manganese oxide is 1%-20%. A series of nickel-aluminum lamellar composite metal hydroxide (NiAl-LDHs) materialsare prepared by virtue of a hydrothermal synthesis method, manganese nitrate (50% water solution) is added for modification, the materials are roasted at a high temperature to be converted into corresponding composite metal oxides, and the high-activity loaded manganese oxide catalyst is prepared. The catalyst is applied to a formaldehyde degradation process, and a result shows that the degradation removal rate of the catalyst to formaldehyde reaches over 90% under normal-temperature and normal-pressure natural conditions.

Owner:北京氦舶科技有限责任公司

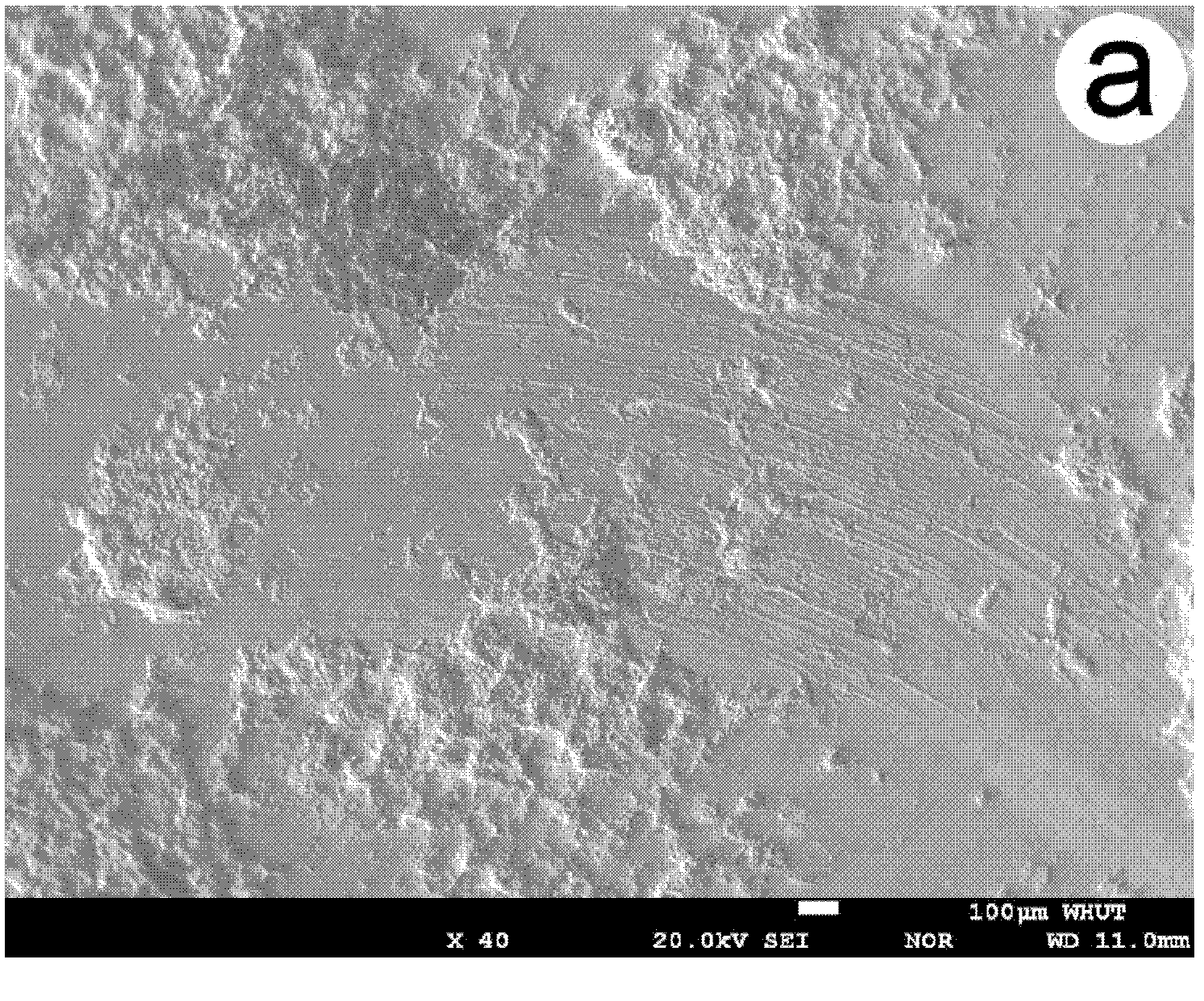

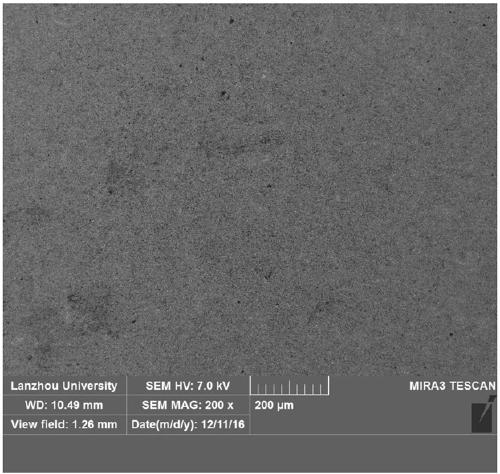

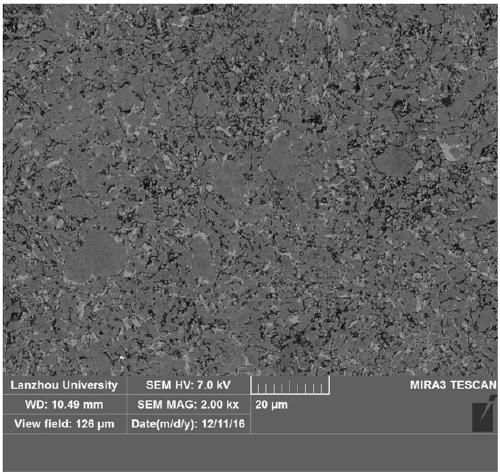

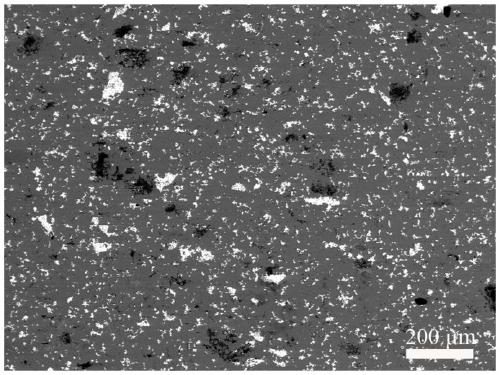

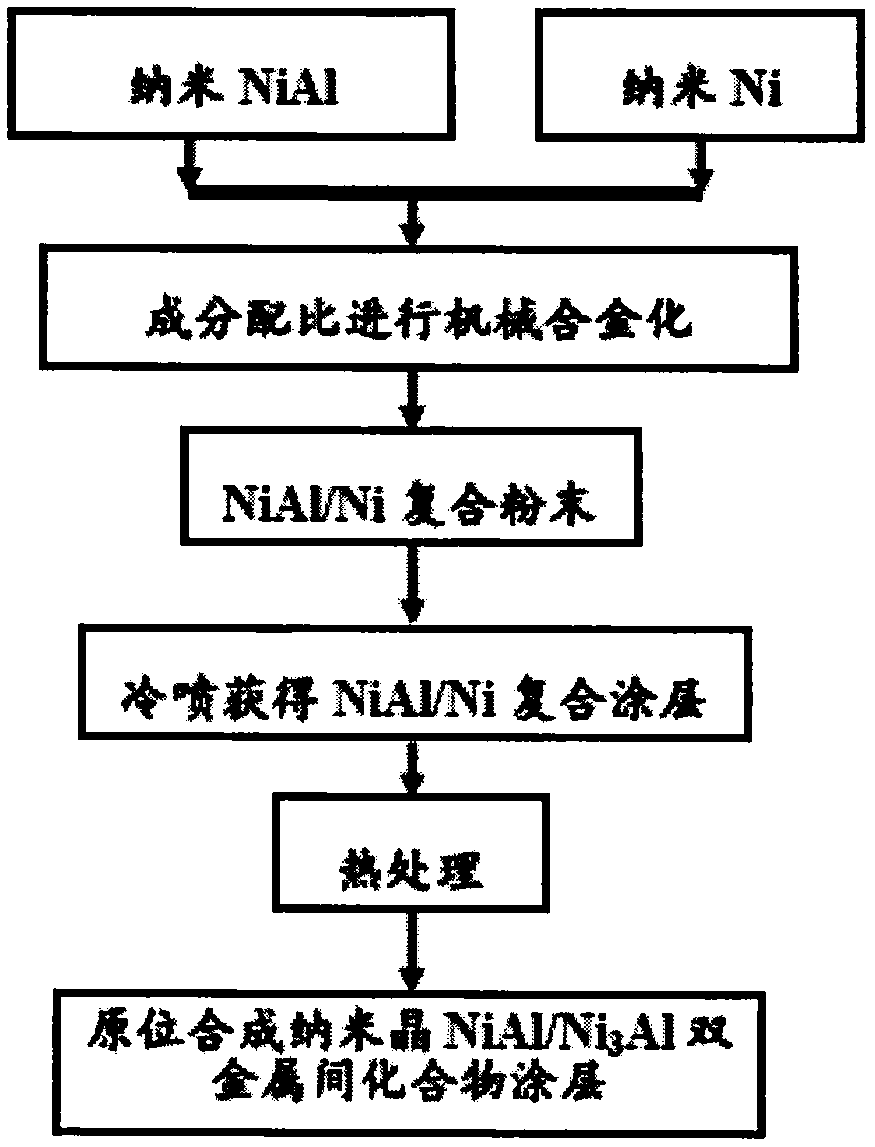

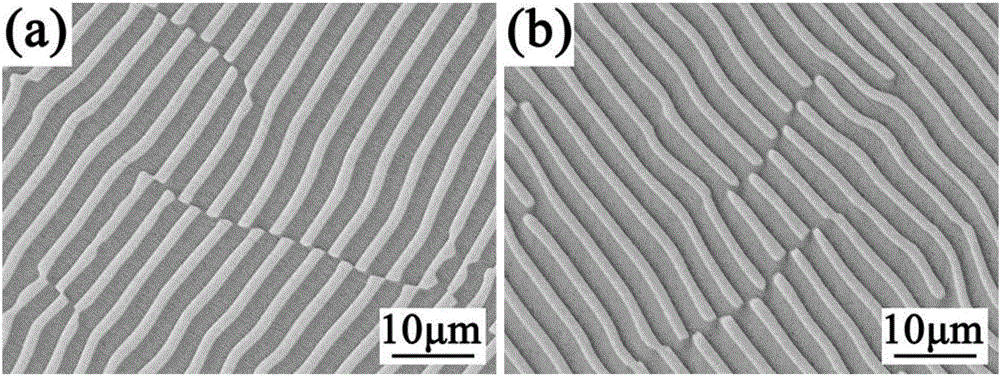

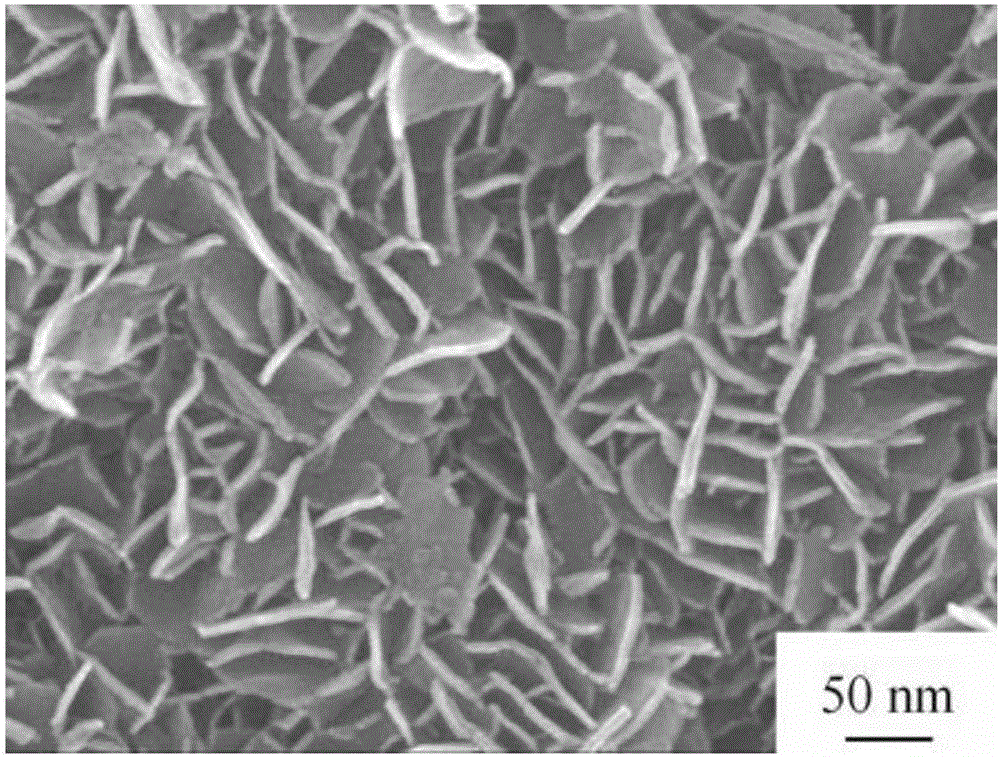

Preparation method for in-situ synthesized nano-crystalline NiAl/Ni3Al intermetallic compound coating

ActiveCN108866536AImprove bindingImprove compactnessPressure inorganic powder coatingNano structuringSand blasting

The invention discloses a preparation method for an in-situ synthesized nano-crystalline NiAl / Ni3Al intermetallic compound coating. The preparation method comprises the following steps of preparing NiAl / Ni composite powder with the NiAl content of 20 vol.%-40 vol.% by using nano-structure NiAl and Ni powder under the inert gas protection through a mechanical alloying technology, screening the NiAl / Ni composite powder, and collecting the NiAl / Ni composite powder with the size of 30-50 [mu]m; performing sand blasting and coarsening pretreatment to base materials, and then preparing a NiAl / Ni composite coating with the thickness of 200 [mu]m-300 [mu]m through deposition on the surface of the pretreated base materials with a cold spraying system; and then placing the coating in inert gas environment for heat treatment for 5-15 hours. The preparation method benefits control over interparticle bonding, particle size and distribution of intermetallic compounds; and the compactness of the prepared coating is high; and the preparation method is easy to operate and lower in cost, and is especially suitable for industrial application and promotion.

Owner:XINYU UNIV

Porous NiAl/Al2TiO5 composite material and preparation method thereof

ActiveCN102212735ATake full advantage of performanceSmall coefficient of thermal expansionCatalyst carriersExhaust apparatusSelf-propagating high-temperature synthesisThermal expansion

The invention discloses a porous NiAl / Al2TiO5 composite material and a preparation method thereof. Industrially pure Ni, Al, TiO2 and Al2O3 powder are used as raw materials of the composite material. The preparation method comprises the following steps of: performing high-temperature sintering reaction (TiO2+Al2O3=Al2TiO5) to synthesize Al2TiO5, mixing the crushed Al2TiO5 and Ni and Al powder, adding C powder serving as a pore forming agent and a heat generating agent, uniformly mixing the raw materials, pressing the mixture into a blank, and performing self-propagating high-temperature synthesis reaction to generate the porous composite material consisting a NiAl phase and a Al2TiO5 phase. The adjustable ranges of the strength, the porosity and the thermal expansion coefficient of the porous composite material are large; and the production process is simple, the yield is high, and the porous composite material can be used as a carrier and a filter in catalysis and environmental purification.

Owner:SHANDONG UNIV OF SCI & TECH

NiAl intermetallic compound porous material and preparation method thereof

The invention relates to a NiAl intermetallic compound porous material and a preparation method thereof, which belong to the field of inorganic materials. The invention provides a NiAl intermetallic compound porous material with good combination property and a preparation method thereof. The novel NiAl intermetallic compound porous material has communicated three-dimension solid network aperturesand the porosity of 30 percent and 55 percent, the biggest pore is from 5 microns and 50 microns; wherein, the atom weight portions of Ni and Al in the material is equal to 60 to 90 : 10 to 40. The preparation method is that Ni and Al powders with a certain granularity are firstly mechanically mixed evenly, and then go through compression molding cold forming, finally the porous material is obtained by a sectional type vacuum pressureless sintering mode. The method has low energy consumption and almost no contamination, and the porous structures can be controlled independently. The NiAl intermetallic compound porous material of the invention has excellent high-temperature mechanical properties, good acid-resistance and alkali-resistance properties, high-temperature oxidation resistance property and excellent filtering quality, and can be used in the fields such as high temperature, separation and the like.

Owner:CHENGDU INTERMENT TECH

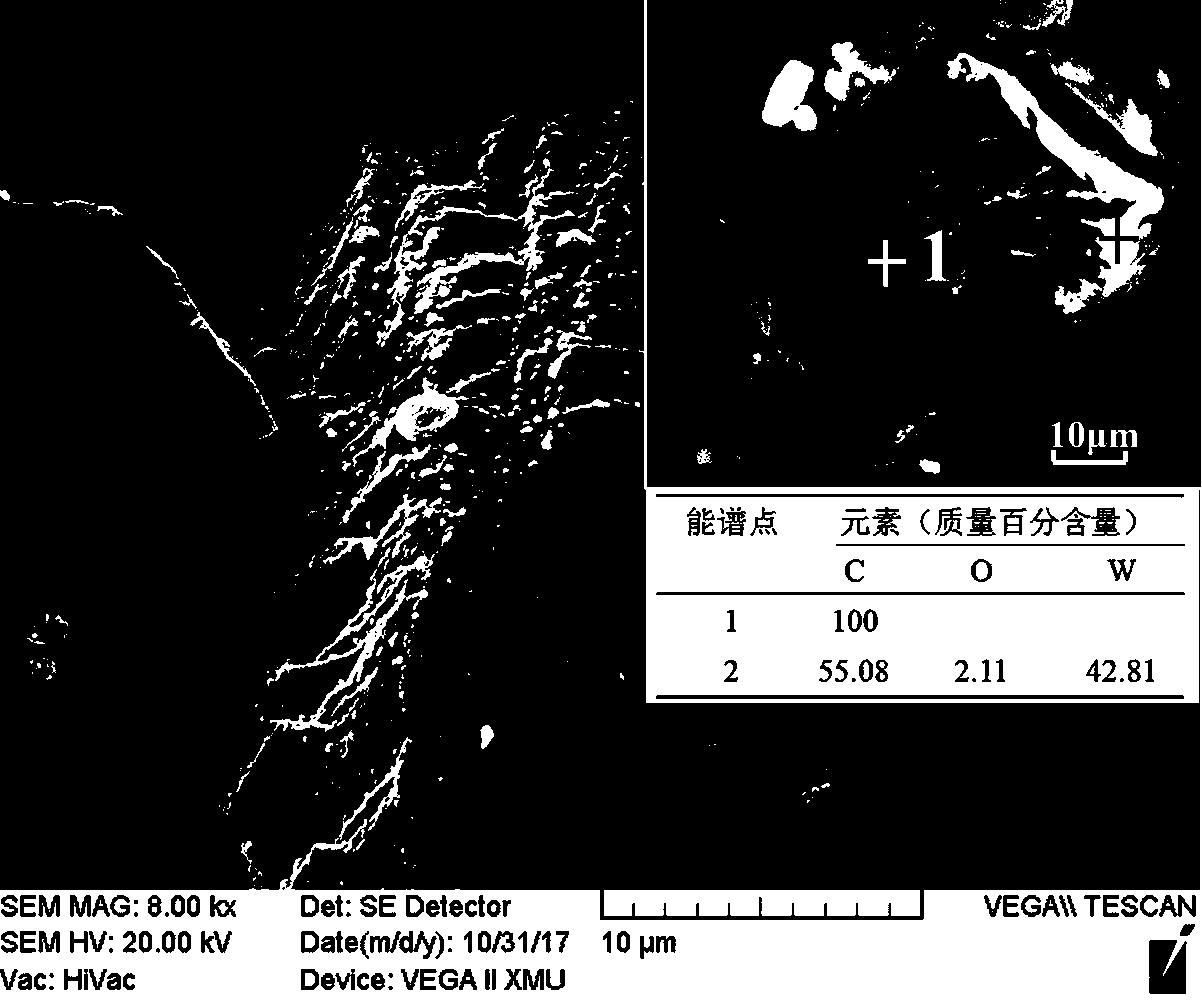

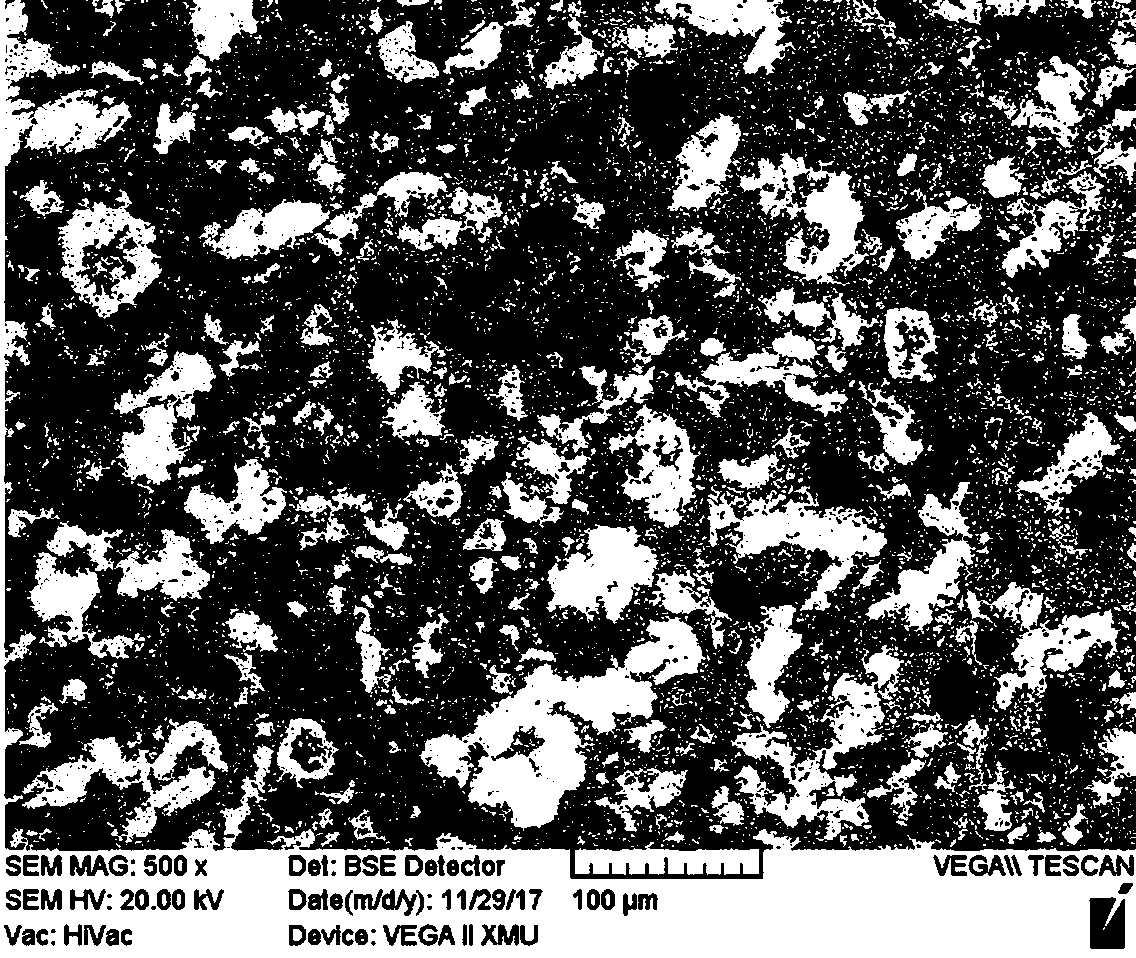

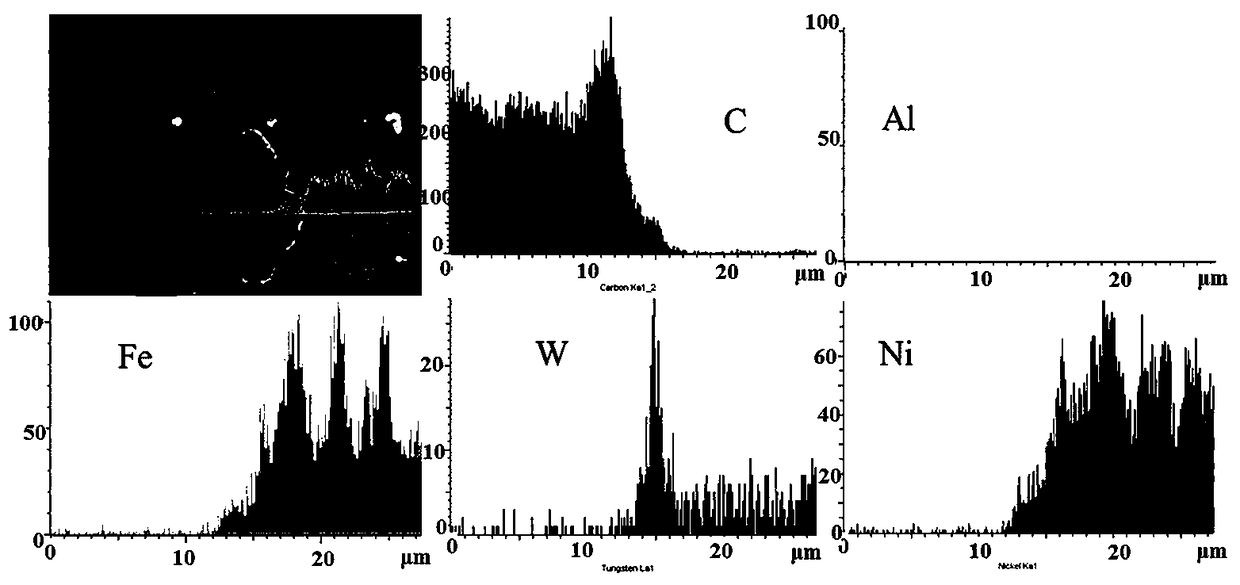

Low-density heat-resistant iron-based alloy and preparation method thereof

ActiveCN108588530ASmall particle sizeThorough responseTransportation and packagingMetal-working apparatusAl powderAlloy composite

The invention relates to a low-density heat-resistant iron-based alloy and a preparation method thereof. The NiAl powder particles with the ordered structure of nano B2 which are generated in the process of reacting between a Ni powder mechanical alloy and an Al powder mechanical alloy is adoptd, diamond is pretreated by a proper technology to enable the surface of the diamond form a uniform tungsten coating layer, and then the NiAl powder and the pretreated diamond powder are filled into a ball milling tank, and a Fe powder is continuously mixed with the NiAl powder and the pretreated diamondpowder in an uniform mode to obtain a fine and uniform NiAl or diamond-reinforced Fe-based alloy composite powder, and hot-pressing sintering is carried out to obtain a block composite material so asto obtain a high-density heat-resistant NiAl or diamond-reinforced Fe-based material, that is the low-density heat-resistant iron-based alloy. According to the alloy and the method, a mechanical alloying technology is combined with the hot-pressing sintering technology, a developed novel low-density heat-resistant NiAl or diamond-reinforced Fe-based alloy product is low in cost, high in purity, low in density, high in heat conductivity and has the application potential of being applied to a high-power-density diesel engine cylinder cover material.

Owner:XIAN TECH UNIV

Method for preparing nickel-aluminum-chromium-molybdenum eutectic alloy with outstanding structure heat stability

Owner:XIAN UNIV OF TECH

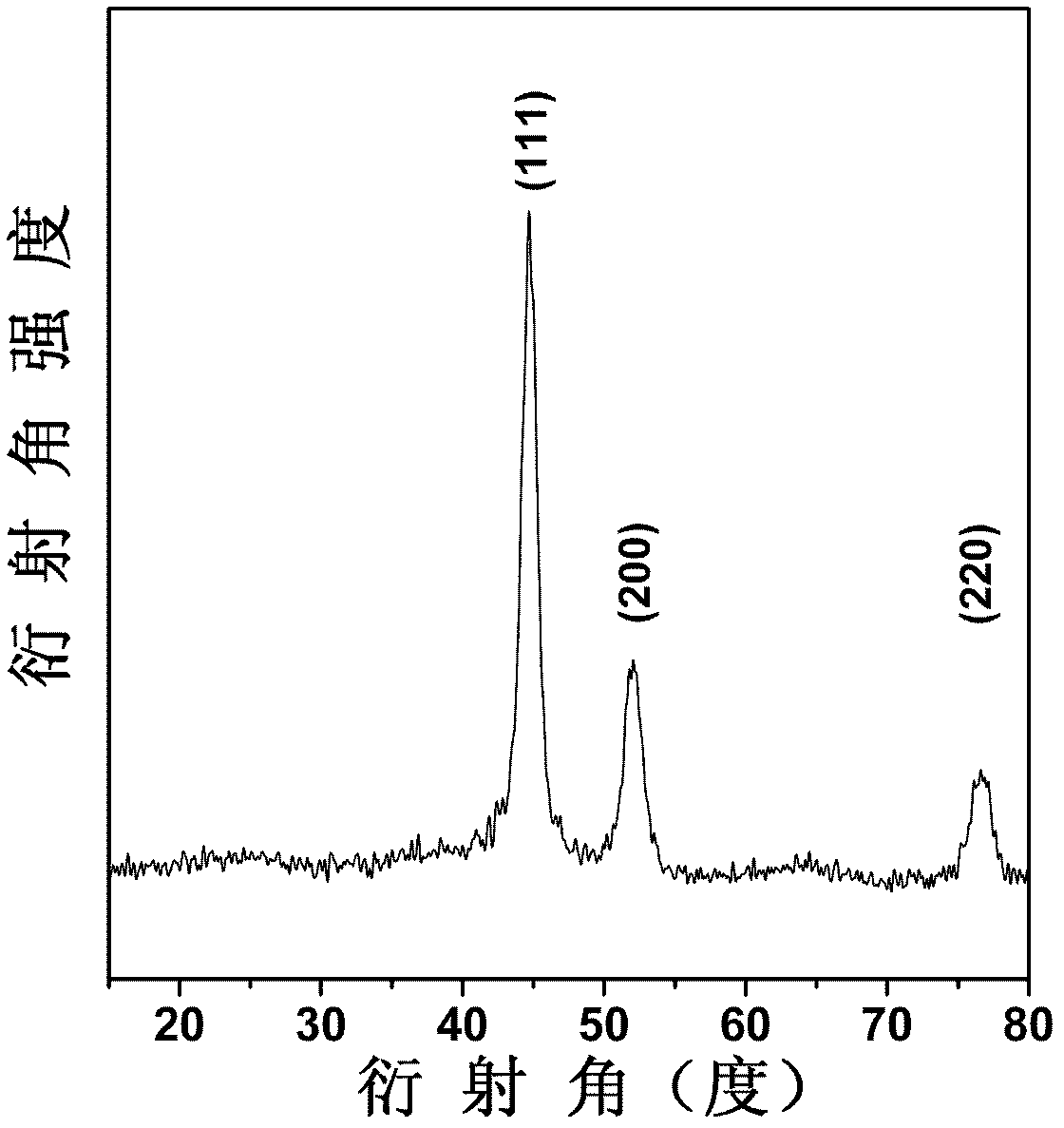

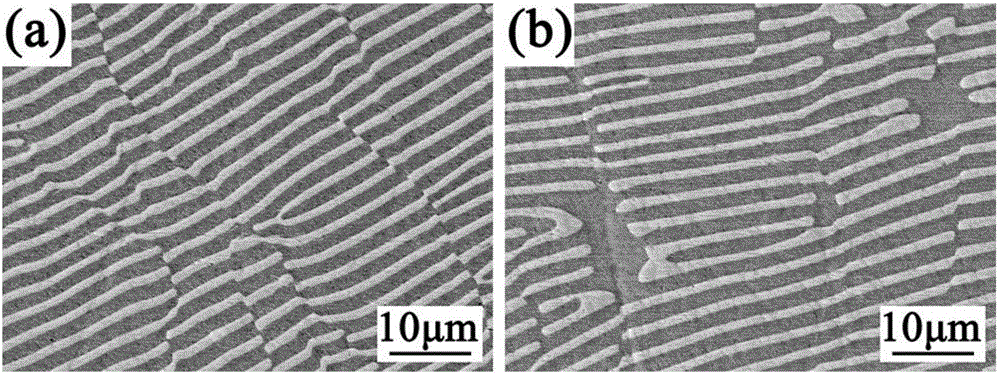

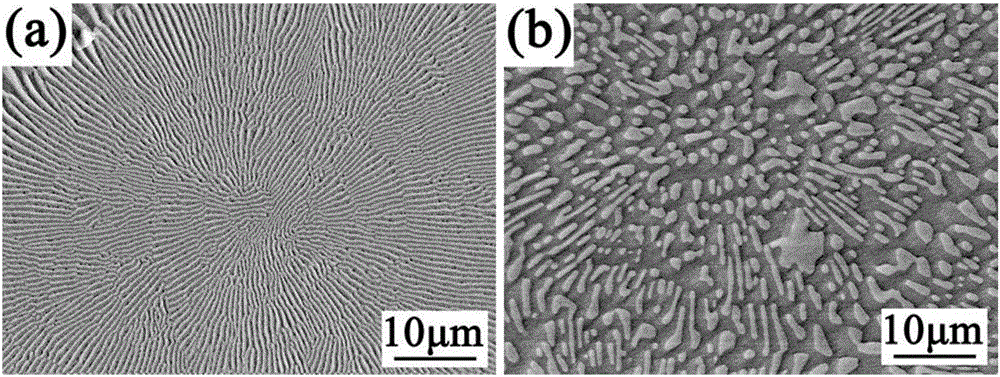

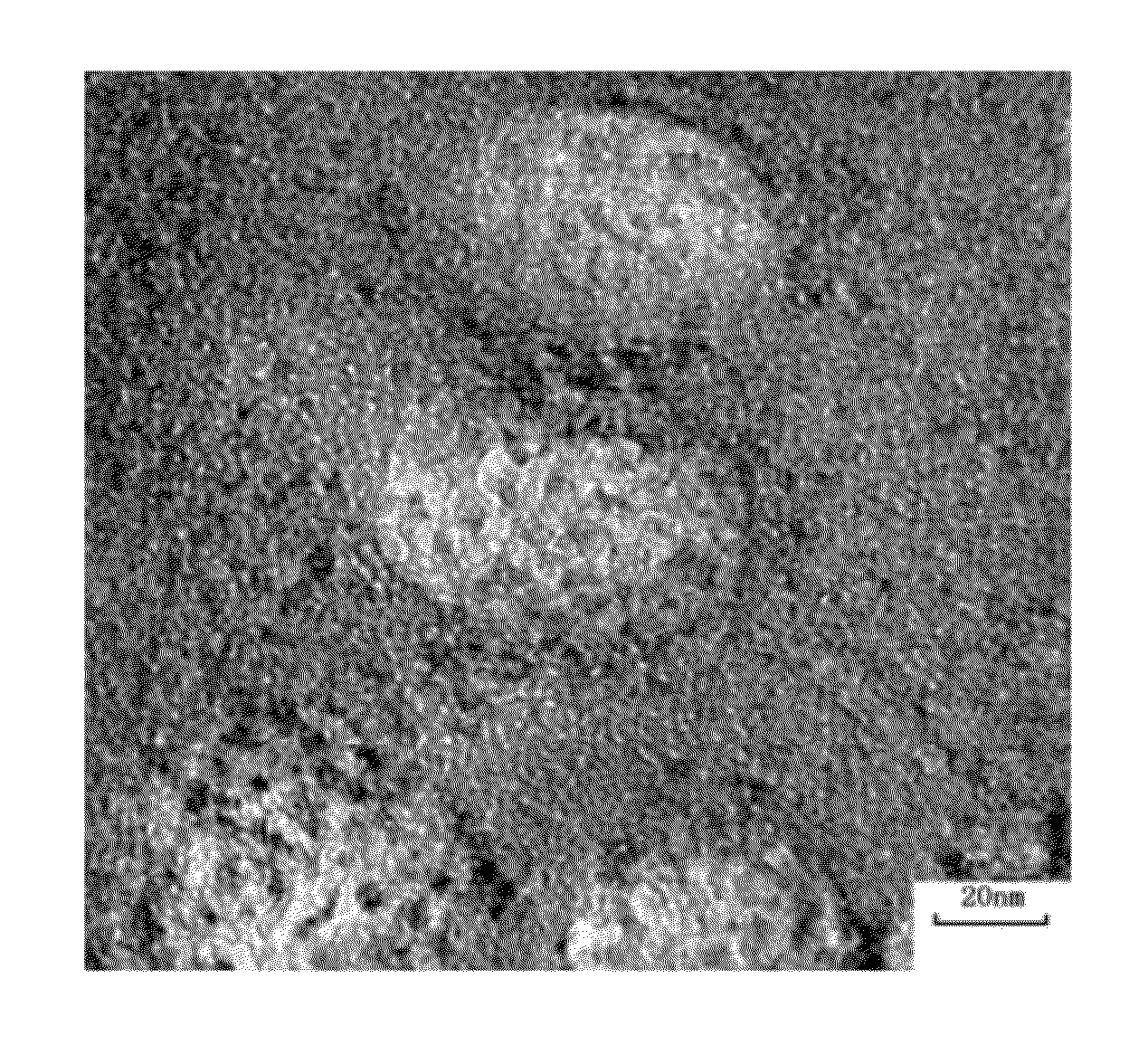

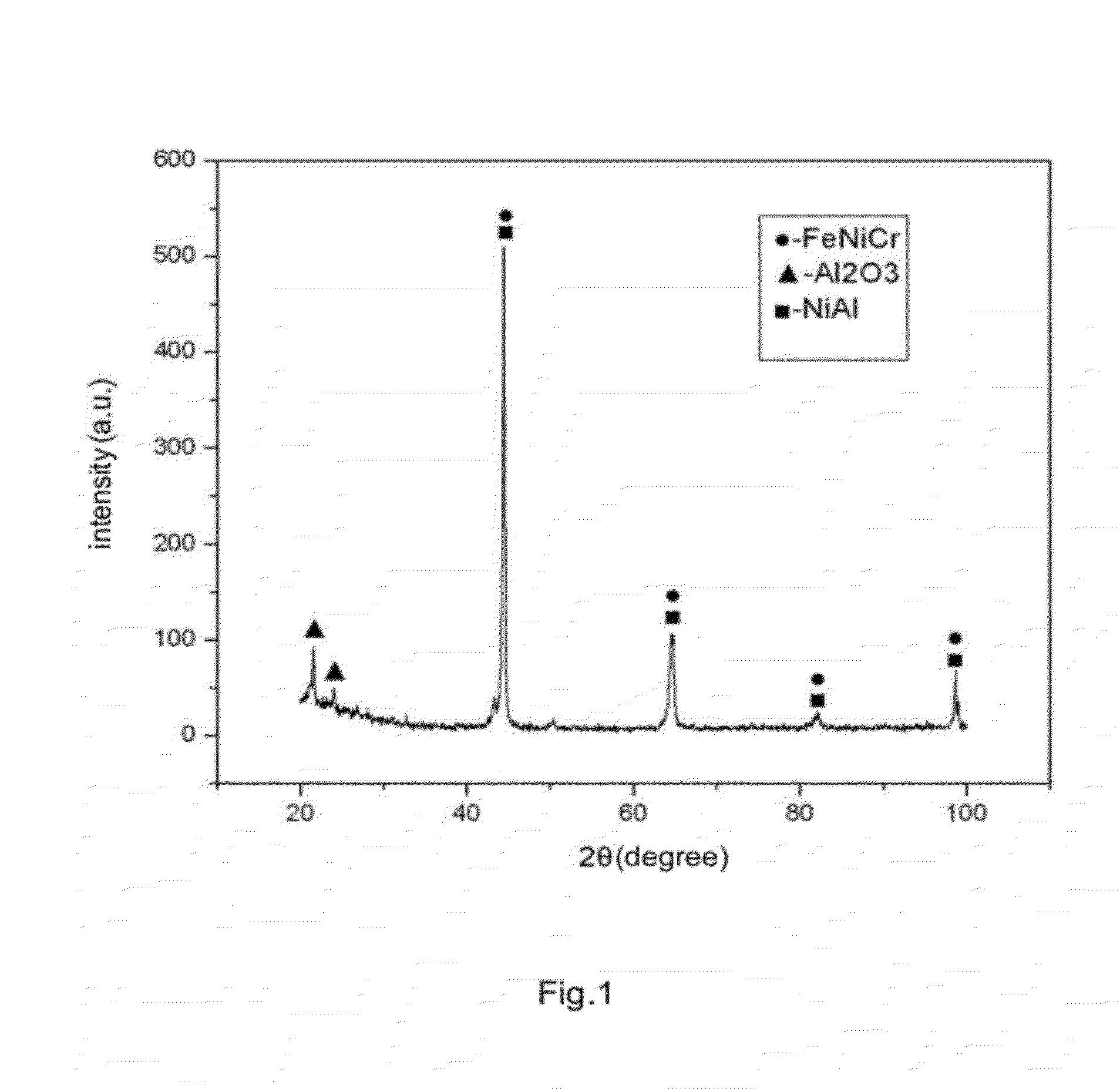

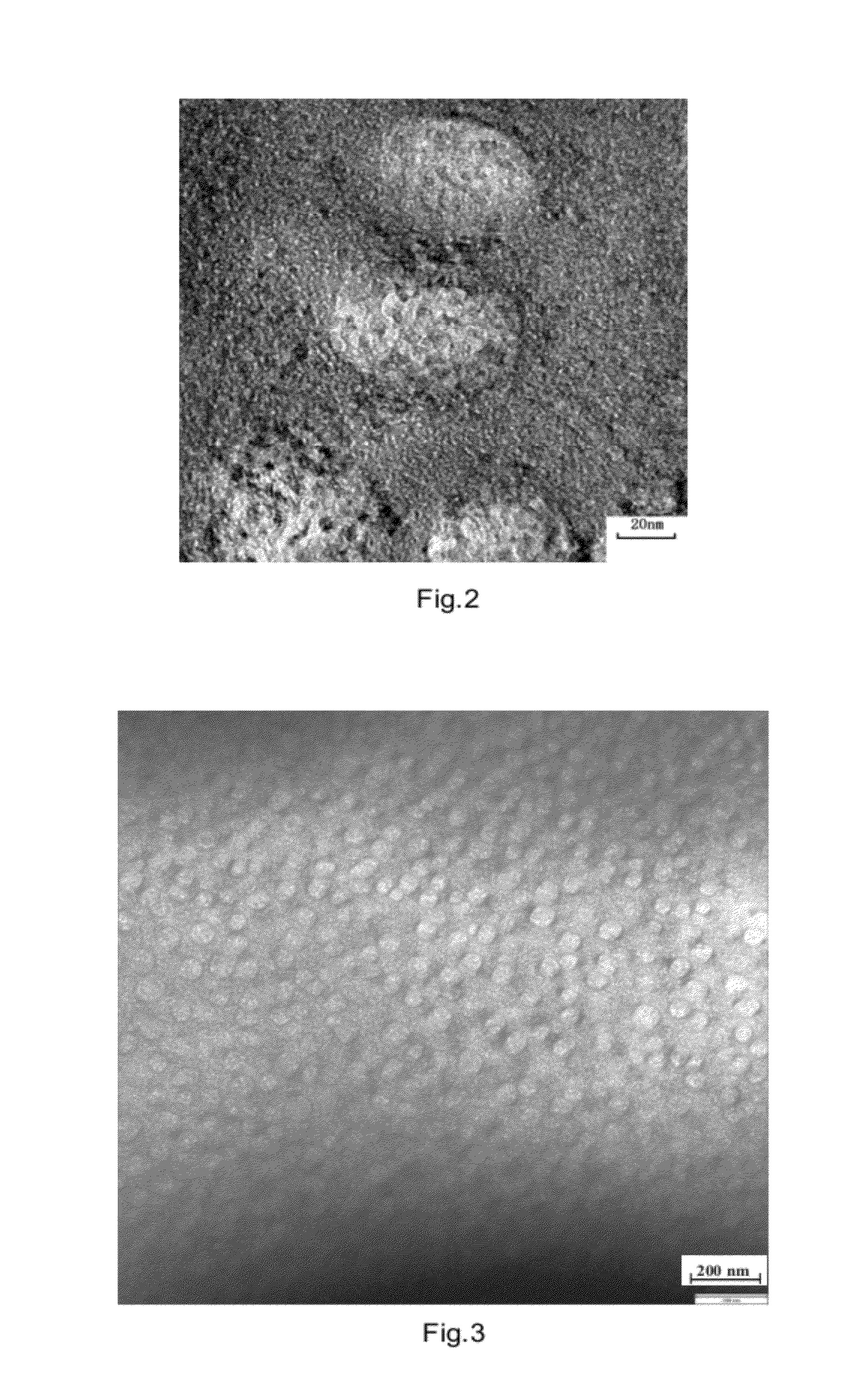

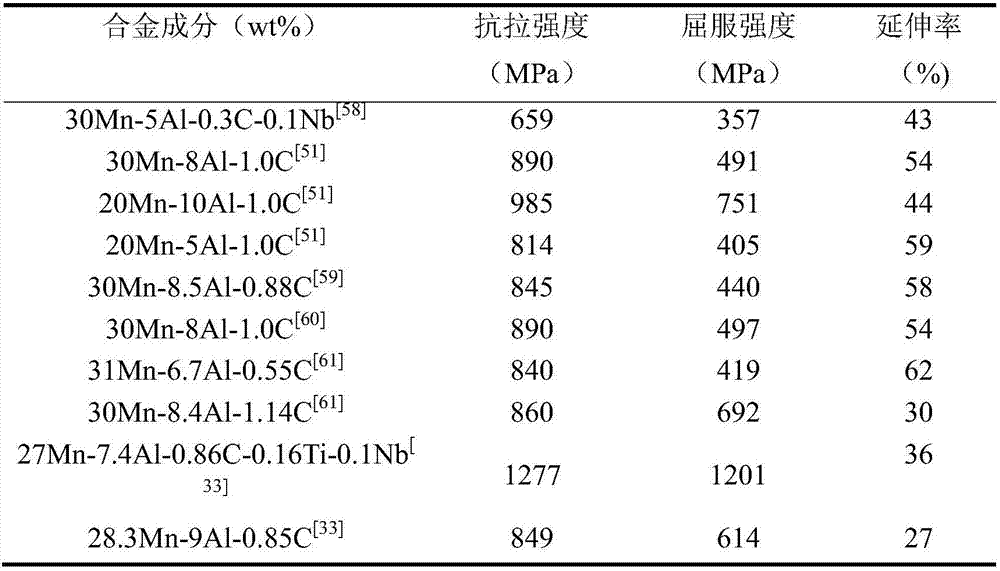

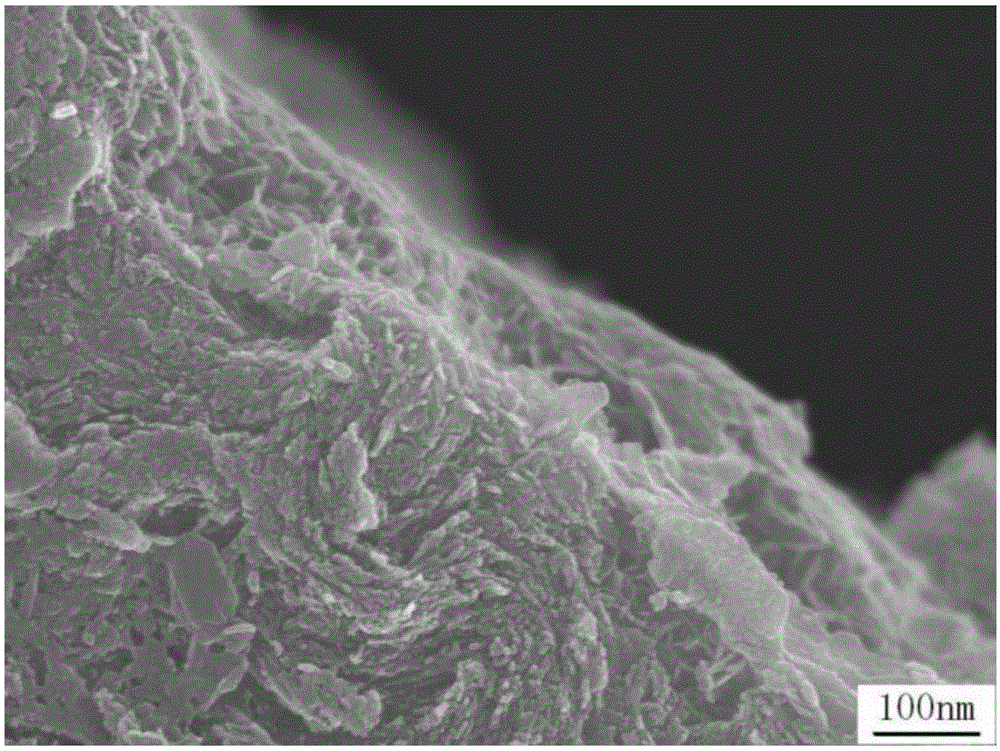

Method of in situ synthesis by thermite reaction with sol-gel and FeNiCrTi/NiAl-A12O3 nanocomposite materials prepared by the method

The invention prepares FeNiCrTi / NiAl-A12O3 nanocomposite materials by a method of in situ synthesis by thermite reaction with sol-gel. The nanocomposite material has high intensity at high temperature, high tenacity at room temperature, good oxidation resistance and good resistance to thermal corrosion. The method of the invention comprises: igniting thermite mixture to produce a high temperature melt and putting the high temperature melt into a fast-cooling mold, thereby obtaining the FeNiCrTi / NiAl—Al2O3 nanocomposite material. The thermite mixture contains Fe2O3, NiO, Cr2O3, CrO3, Al and TiO2 gel. The composite material is featured by small size of grains.

Owner:XI WENJUN +2

Low-density high-plastic nial reinforced ultra-high-strength steel and its preparation method

The invention relates to a low-density high-plasticity NiAl-reinforced ultrahigh-strength steel and a preparation method thereof, belonging to the technical field of alloy steel. The alloy comprises the following components in percentage by weight: 0.5-1.5% of C, 10-30% of Mn, 5-12% of Al, 5-15% of Ni, 0-5% of Cr, 0-0.2% of Nb, and the balance of Fe and other inevitable impurity elements and minor elements, such as Si, Ti and the like. The preparation method adopts a vacuum induction+vacuum consumable remelting or electroslag remelting technique. Compared with the prior art, the low-density high-plasticity NiAl-reinforced ultrahigh-strength steel has the advantages of favorable comprehensive properties, low density, high plasticity, ultrahigh strength and the like. The density is up to 6.5-7.2 g / cm<3>, the tensile strength is up to 1350 MPa above, and the elongation percentage is up to 10% above.

Owner:CENT IRON & STEEL RES INST

Catalyst for preparing synthetic gas by reforming methane and carbon dioxide and preparation method thereof

InactiveCN106040243AStrong interactionProcess stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrotalciteNickel

The invention provides a catalyst for preparing synthetic gas by reforming methane and carbon dioxide and a preparation method thereof. The catalyst related herein is obtained by: synthesizing nickel-containing hydrotalcite lamellar precursor NiAl-LDH / Gamma-Al2O3 in situ in surface pores of a support, and calcining at 500-800 DEG C; a chemical formula of the catalyst is NiO / Gamma-Al2O3, wherein NiO is distributed evenly on the inner surface of the Gamma-Al2O3 support, Ni accounts for 0.5-5% of total weight of the catalyst, and the support is spherical Gamma-Al2O3, having a specific surface area of 100-300 m<2> / g and a particle size of 0.84-2 mm.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Zr

The present invention discloses one kind of Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Zr in 1-13 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Zr element to modify and form one Heusler(L21-Ni2AlZr) phase with NiAl, the Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has high room temperature toughness and plasticity and further raised high temperature strength. The Zr modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 110-130 MPa and density of 6.1-6.7 g / cu cm.

Owner:BEIHANG UNIV

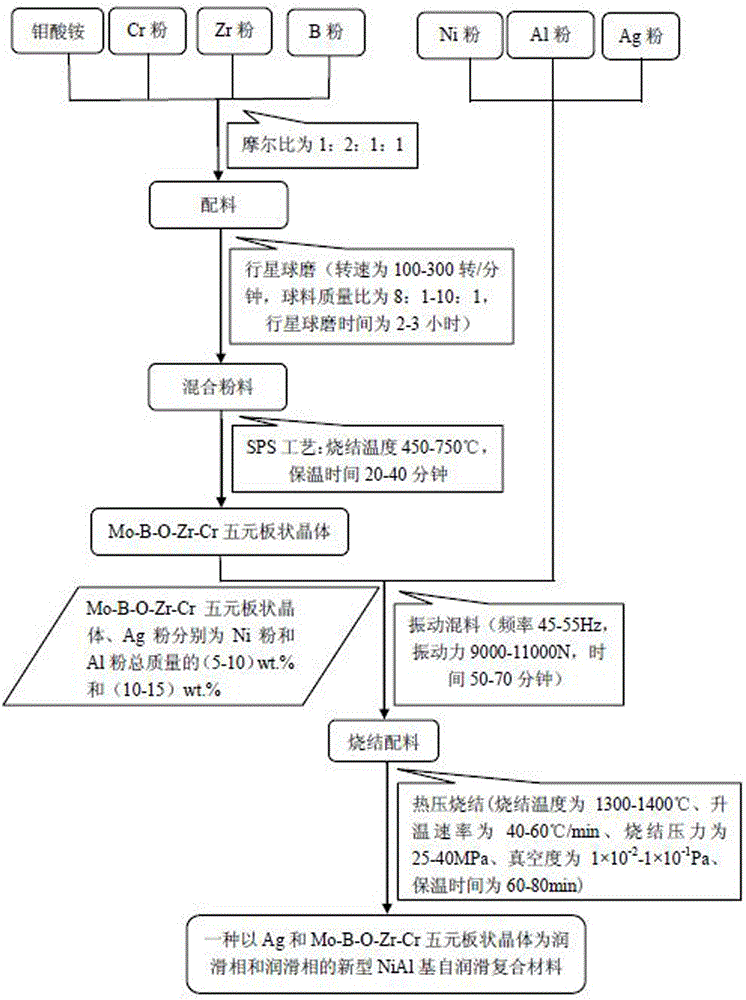

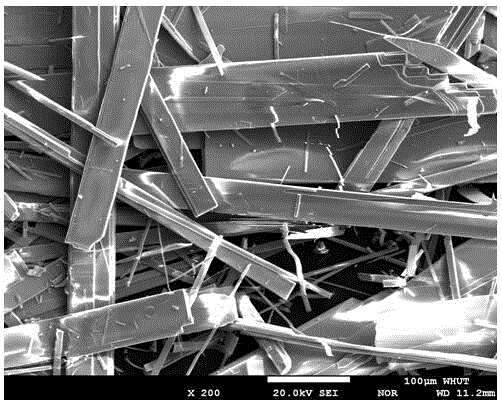

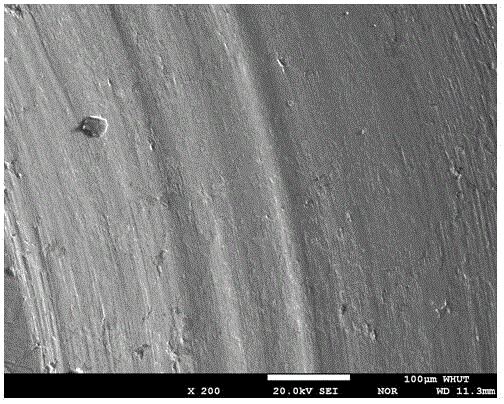

Novel NiAl-based solid self-lubricating composite material and preparation process thereof

ActiveCN105483449AHigh synthesis efficiencyStable and excellent tribological propertiesLubricationMole ratio

The invention discloses a novel NiAl-based solid self-lubricating composite material and a preparation process thereof. The preparation process comprises the following steps of preparing Mo-B-O-Zr-Cr pentabasic clintheriform crystals; selecting Ni powder and Al powder according to the mole ratio of Ni to Al, namely 1: 1, selecting the Mo-B-O-Zr-Cr pentabasic clintheriform crystals and Ag powder according to the weight ratio of (10-15)% of the total mass of the Ni powder and (5-10)% of the total mass of the Al powder respectively, and mixing, compounding and placing the Mo-B-O-Zr-Cr pentabasic clintheriform crystals, the Ni powder, the Al powder and the Ag powder in a vibrating mixer for uniform mixing, so that a sintering compound is obtained; sintering the sintering compound with spark plasma sintering equipment, and preparing the novel NiAl-based solid self-lubricating composite material with the Mo-B-O-Zr-Cr pentabasic clintheriform crystals as the solid lubrication phase. The preparation process is novel, and the composite material is easy, fast and convenient to prepare, is excellent in performance and has stable and excellent tribological performance.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com