Method for preparing nickel-aluminum-chromium-molybdenum eutectic alloy with outstanding structure heat stability

A thermally stable, eutectic alloy technology, applied in the field of nickel-aluminum-based eutectic alloy and its preparation, can solve the problems of unstable performance, reduced high temperature strength, shortened service life of the alloy, etc., and achieve the effect of excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

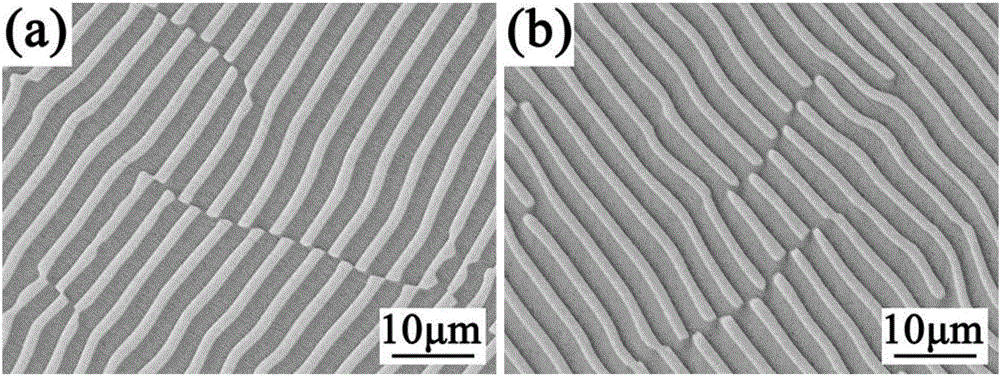

Embodiment 1

[0039] A nickel-aluminum-chromium-molybdenum eutectic alloy with excellent thermal stability is prepared by the following method:

[0040] Step 1, raw material ratio: select Ni block with a purity of 99.96wt%, high-purity Al rod with 99.99wt%, Cr sheet with 99.9wt%, and Mo wire with 99.95wt%, according to the atom of 33Ni-33Al-28Cr-6Mo Percentage ingredients are proportioned.

[0041] In step 2, the metal raw materials are pretreated, the Mo wire and the Ni blocks are polished, and the Al rods are pickled to remove the scale on the surface of the raw materials.

[0042] In step 3, mass compensation is performed on Al and Cr before smelting. Specifically, 2.9 wt% of Al and 0.45 wt% of Cr need to be compensated.

[0043] Step 4, put the metal raw material to be smelted into the smelting equipment, and pump the vacuum of the furnace chamber to 5.9×10 -3 Pa and filled with high-purity argon; then smelted and cast into a master alloy; the smelting equipment is a high-vacuum non-c...

Embodiment 2

[0048] A nickel-aluminum-chromium-molybdenum eutectic alloy with excellent thermal stability is prepared by the following method:

[0049] Step 1, raw material ratio: select Ni block with a purity of 99.96wt%, high-purity Al rod with 99.99wt%, Cr sheet with 99.9wt%, and Mo wire with 99.95wt%, according to the atom of 33Ni-33Al-32Cr-2Mo Percentage ingredients are proportioned.

[0050] In step 2, the metal raw materials are pretreated, the Mo wire and the Ni blocks are polished, and the Al rods are pickled to remove the scale on the surface of the raw materials.

[0051] Step 3, performing mass compensation on Al and Cr before smelting, specifically, 3.0 wt% of Al mass compensation and 0.5 wt% of Cr mass compensation are required.

[0052] Step 4, put the metal raw material to be smelted into the smelting equipment, and pump the vacuum of the furnace chamber to 5.8×10 -3 Pa and filled with high-purity argon; then smelted and cast into a master alloy; the smelting equipment is...

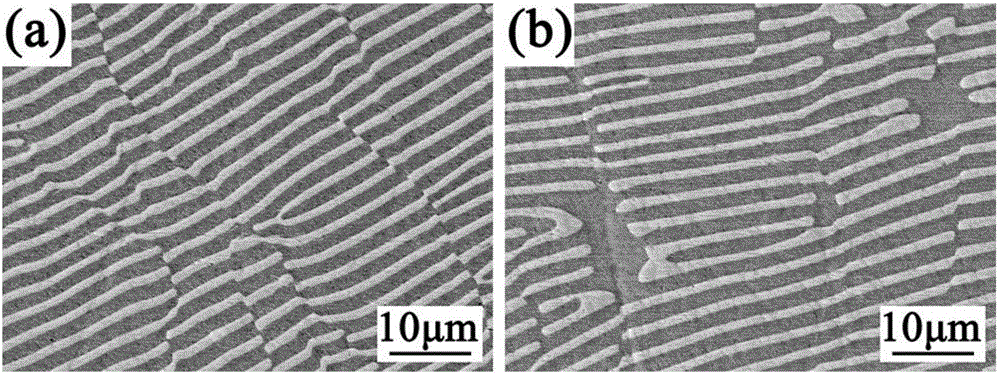

Embodiment 3

[0057] A nickel-aluminum-chromium-molybdenum eutectic alloy with excellent thermal stability is prepared by the following method:

[0058] Step 1, raw material ratio: select Ni block with a purity of 99.96wt%, high-purity Al rod with 99.99wt%, Cr sheet with 99.9wt%, and Mo wire with 99.95wt%, according to the atom of 33Ni-33Al-26Cr-8Mo Percentage ingredients are proportioned.

[0059] In step 2, the metal raw materials are pretreated, the Mo wire and the Ni blocks are polished, and the Al rods are pickled to remove the scale on the surface of the raw materials.

[0060] In step 3, mass compensation is performed on Al and Cr before smelting. Specifically, 3.1 wt% of Al mass compensation is required, and 0.55 wt% of Cr mass compensation is required.

[0061] Step 4, put the metal raw material to be smelted into the smelting equipment, and pump the vacuum of the furnace chamber to 5.7×10 -3 Pa and filled with high-purity argon; then smelted and cast into a master alloy; the sme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com