Low-density high-plastic nial reinforced ultra-high-strength steel and its preparation method

A technology of ultra-high-strength steel and high plasticity, applied in the field of alloy steel, can solve the problems of limited size of parts, deterioration of steel plasticity, etc., and achieve the effect of high strength, good plasticity and excellent comprehensive performance

Active Publication Date: 2017-11-28

CENT IRON & STEEL RES INST

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

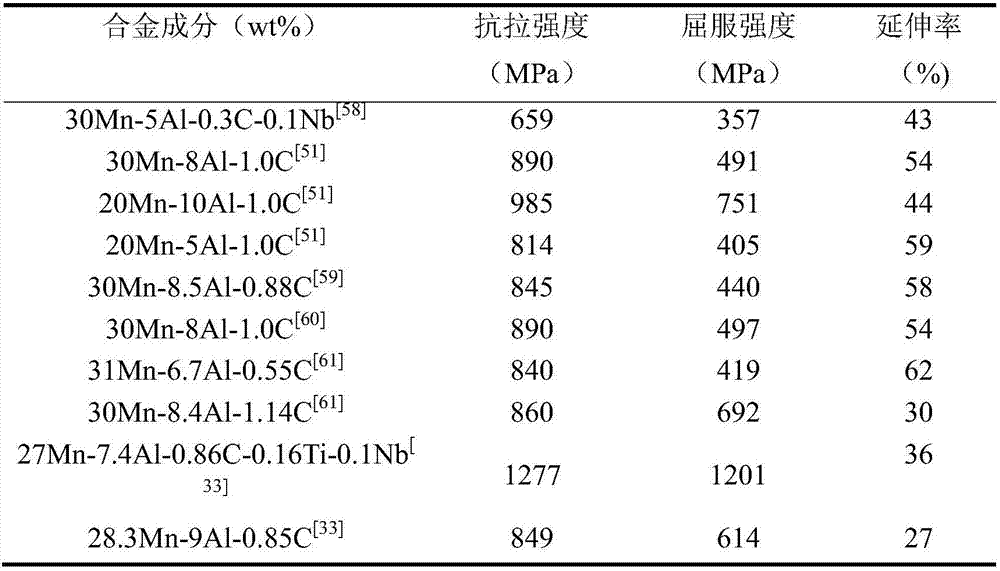

Since the main strengthening method of Fe-Mn-Al-C low-density steel is kapa-carbide precipitation strengthening, the improvement of kapa-carbide precipitation strengthening depends on the content of Al and C in the steel, but studies have shown that with the addition of Al, With the increase of C element composition ratio and content, к-carbide and some other carbide phases will appear in the structure, and even B2 (FeAl) and DO will appear. 3 (Fe 3 The second phase of intermetallic compounds represented by Al) may be in the form of ferrite, austenite or dual-phase matrix, which seriously deteriorates the plasticity of steel. Therefore, the traditional Fe-Mn-Al-C quaternary system The limit of Al content in low-density steel is 12%, and the limit of C content is 1.5-1.7%. In order to further increase the strength, it can only be strengthened by deformation. At the same time, it is imperative to increase the size of the parts and develop a new strengthening method that does not rely on rolling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

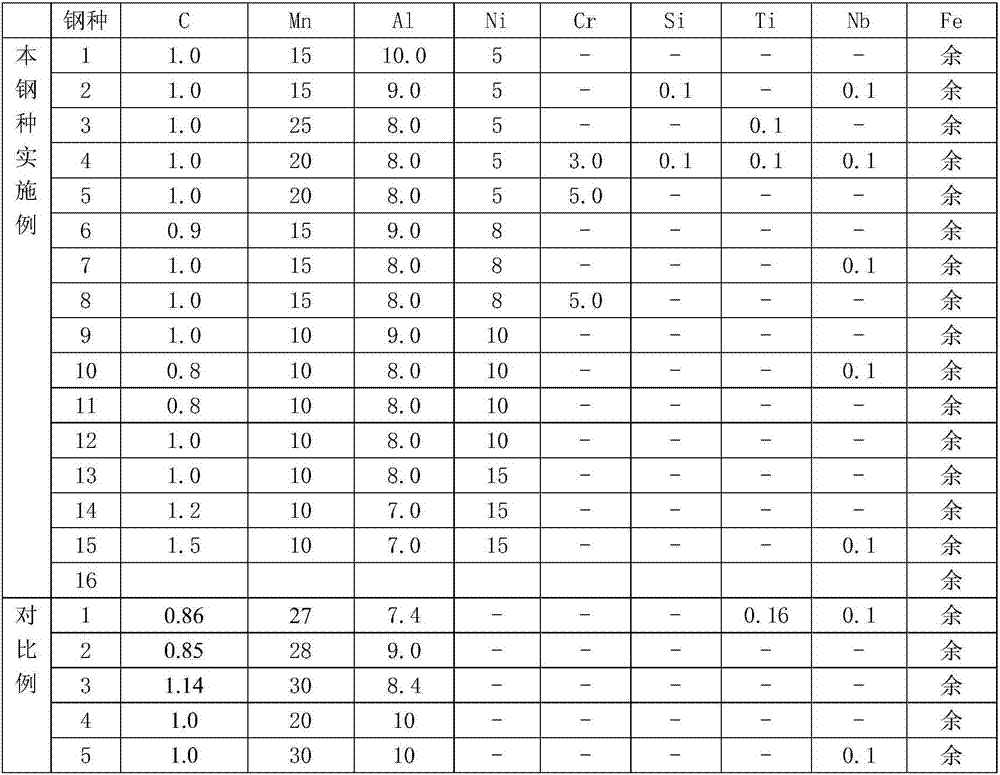

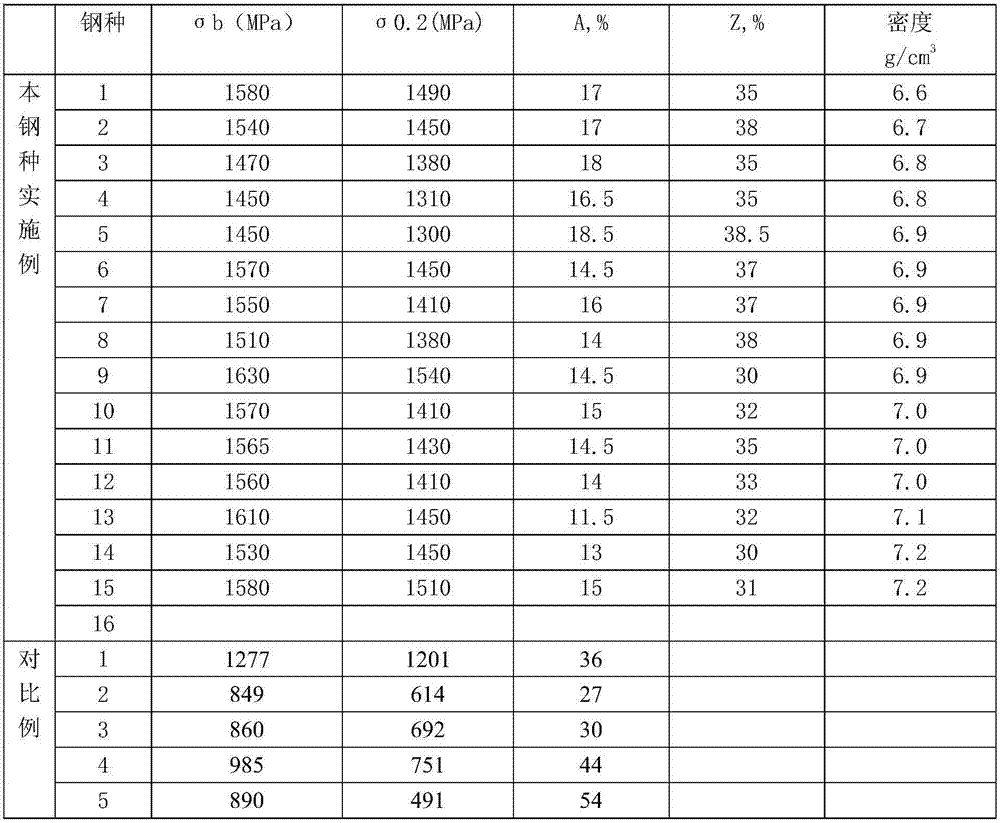

[0030] According to the scope of the chemical composition of the economical high-toughness, easy-spinning and easy-welding ultra-high-strength steel of the present invention, 25 kilograms of vacuum induction furnaces are used to prepare 15 furnaces of alloy ingots of 20 kilograms, and the specific chemical compositions are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a low-density high-plasticity NiAl-reinforced ultrahigh-strength steel and a preparation method thereof, belonging to the technical field of alloy steel. The alloy comprises the following components in percentage by weight: 0.5-1.5% of C, 10-30% of Mn, 5-12% of Al, 5-15% of Ni, 0-5% of Cr, 0-0.2% of Nb, and the balance of Fe and other inevitable impurity elements and minor elements, such as Si, Ti and the like. The preparation method adopts a vacuum induction+vacuum consumable remelting or electroslag remelting technique. Compared with the prior art, the low-density high-plasticity NiAl-reinforced ultrahigh-strength steel has the advantages of favorable comprehensive properties, low density, high plasticity, ultrahigh strength and the like. The density is up to 6.5-7.2 g / cm<3>, the tensile strength is up to 1350 MPa above, and the elongation percentage is up to 10% above.

Description

technical field [0001] The invention belongs to the field of alloy steel, and in particular relates to a low-density high-plastic NiAl reinforced ultra-high-strength steel DT550 and a preparation method thereof. The steel has excellent properties such as low-density high plasticity and ultra-high strength, and the density reaches 6.5-7.2g / cm 3 , The tensile strength reaches above 1350MPa, and the elongation reaches above 10%. The bar size reaches φ200mm or more. Background technique [0002] Ultra-high-strength steel has always been an indispensable material for the key load-bearing structures of aerospace. Reducing the density and increasing the strength-to-weight ratio have great significance for the development of steel for aviation and aerospace structural parts. According to relevant information, for a supersonic aircraft, if other conditions remain unchanged, if the empty weight of the aircraft increases by 1%, the commercial load of the aircraft will decrease by 2% t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/58C22C38/08C22C38/12C21D8/02

CPCC21D8/0247C22C38/04C22C38/06C22C38/08C22C38/12C22C38/18C22C38/40C22C38/48C22C38/58

Inventor 王春旭厉勇谭成文刘少尊于晓东王富耻黄顺喆韩顺刘宪民李国兰李玮戴意涛崔晓刚李建新庞学东

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com