Patents

Literature

4737 results about "High strength steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

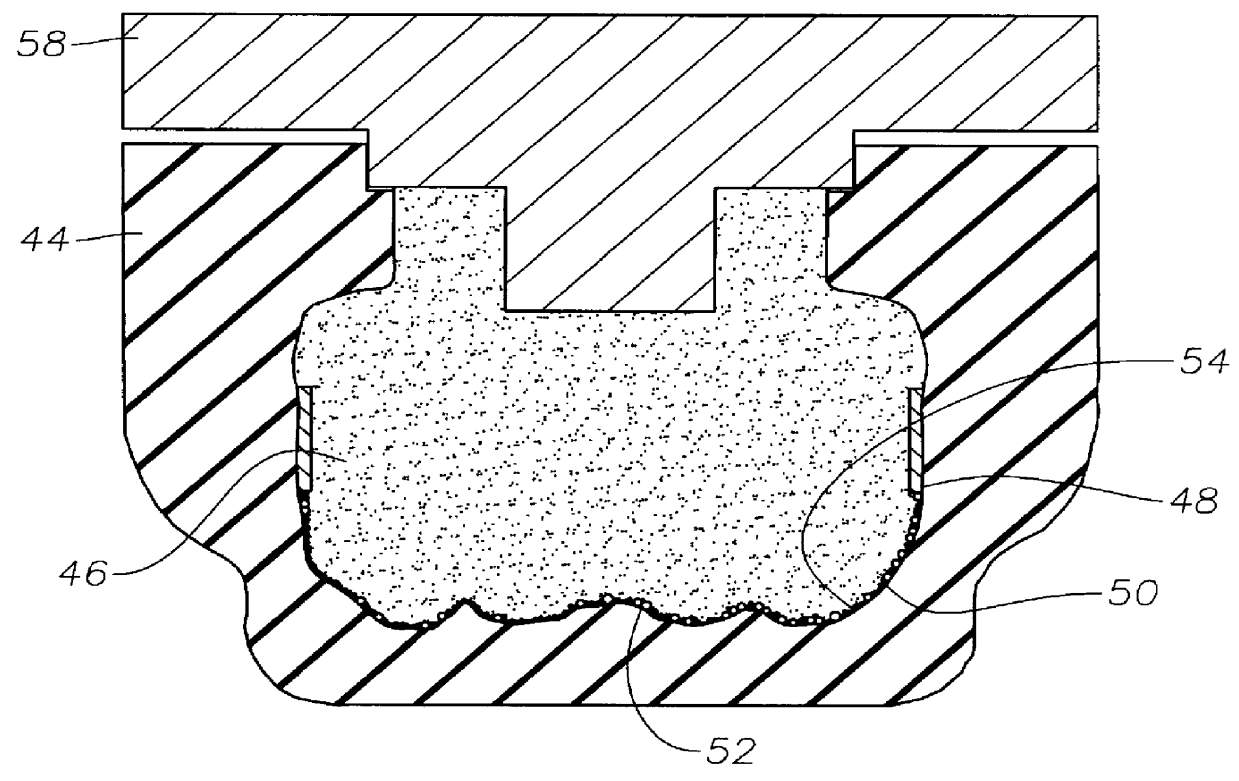

High-strength/high-toughness alloy steel drill bit blank

Drill bit reinforcing members or blanks of this invention are formed from high-strength steels having a carbon content less than about 0.3 percent by weight, a yield strength of at least 55,000 psi, a tensile strength of at least 80,000 psi, a toughness of at least 40 CVN-L, Ft-lb, and a rate of expansion percentage change less than about 0.0025% / ° F. during austenitic to ferritic phase transformation. In one embodiment, such steel comprises in the range of from about 0.1 to 0.3 percent by weight carbon, 0.5 to 1.5 percent by weight manganese, up to about 0.8 percent by weight chromium, 0.05 to 4 percent by weight nickel, and 0.02 to 0.8 percent by weight molybdenum. In another example, such steel comprises in the range of from about 0.1 to 0.3 percent by weight carbon, 0.9 to 1.5 percent by weight manganese, 0.1 to 0.5 percent by weight silicon, and one or more microalloying element selected from the group consisting of vanadium, niobium, titanium, zirconium, aluminum and mixtures thereof.

Owner:SMITH INT INC

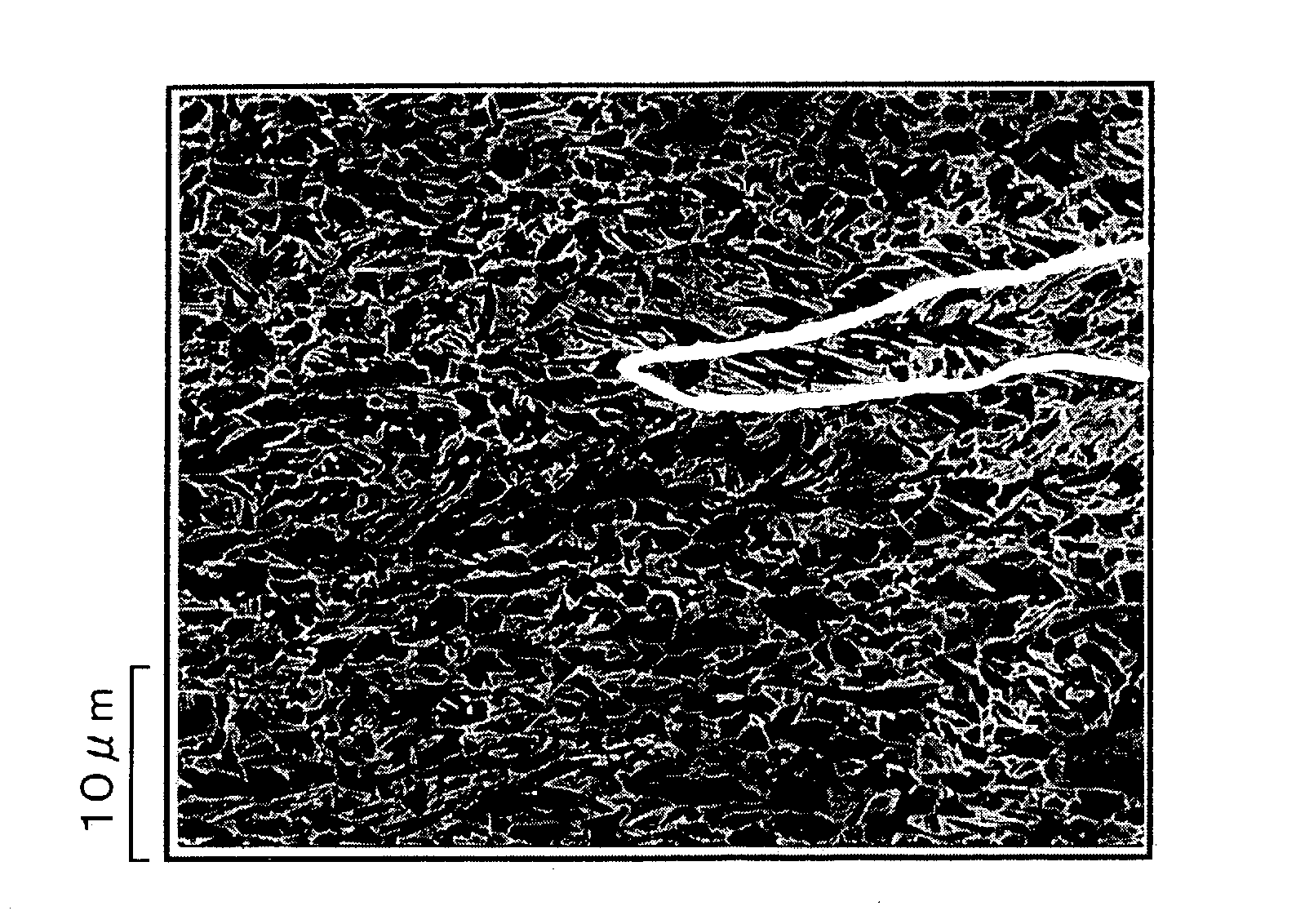

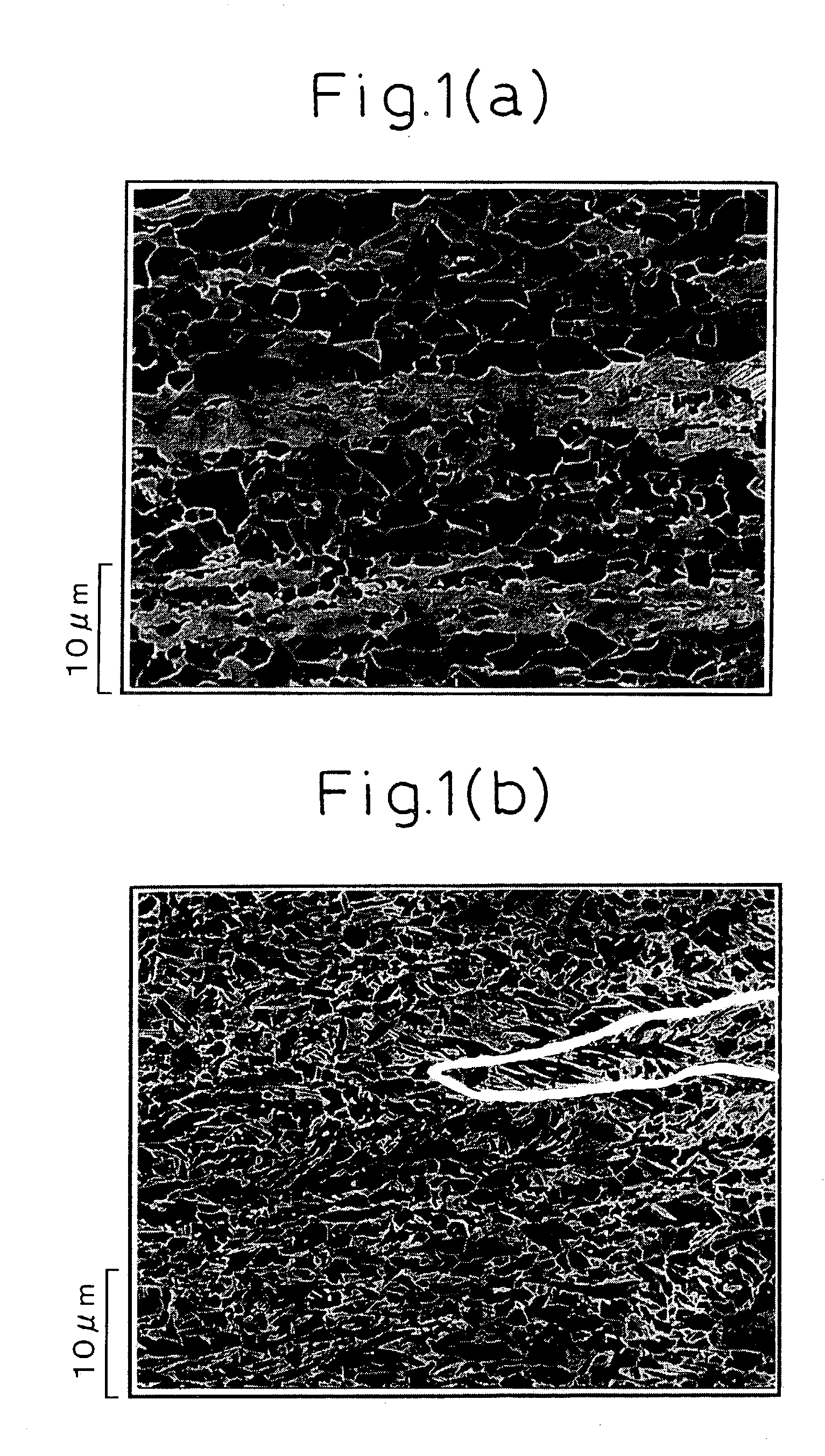

High strength steel sheet having excellent formability and method for production thereof

InactiveUS7090731B2Good molding effectHigh strengthHot-dipping/immersion processesFurnace typesHigh intensityHardness

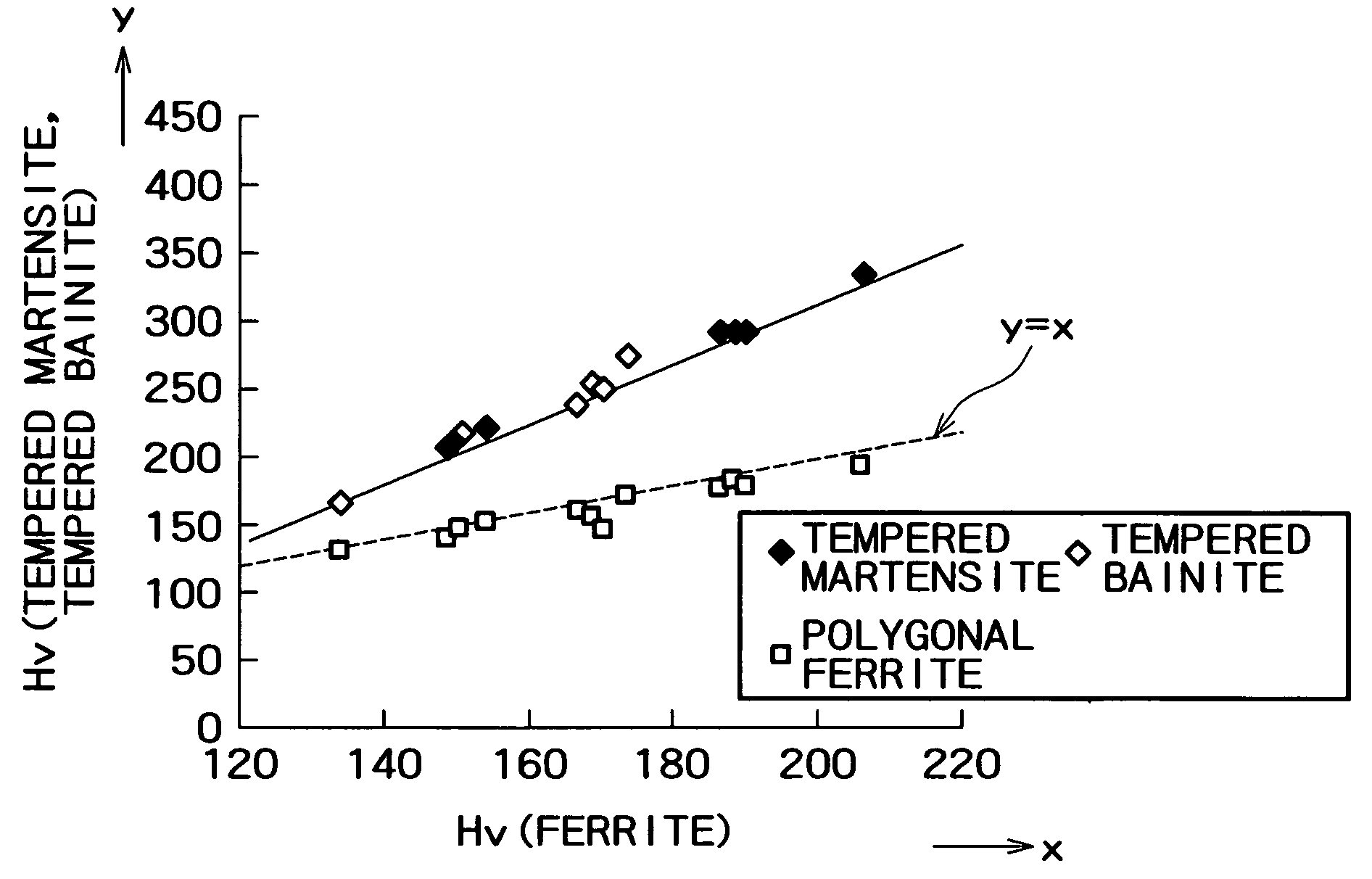

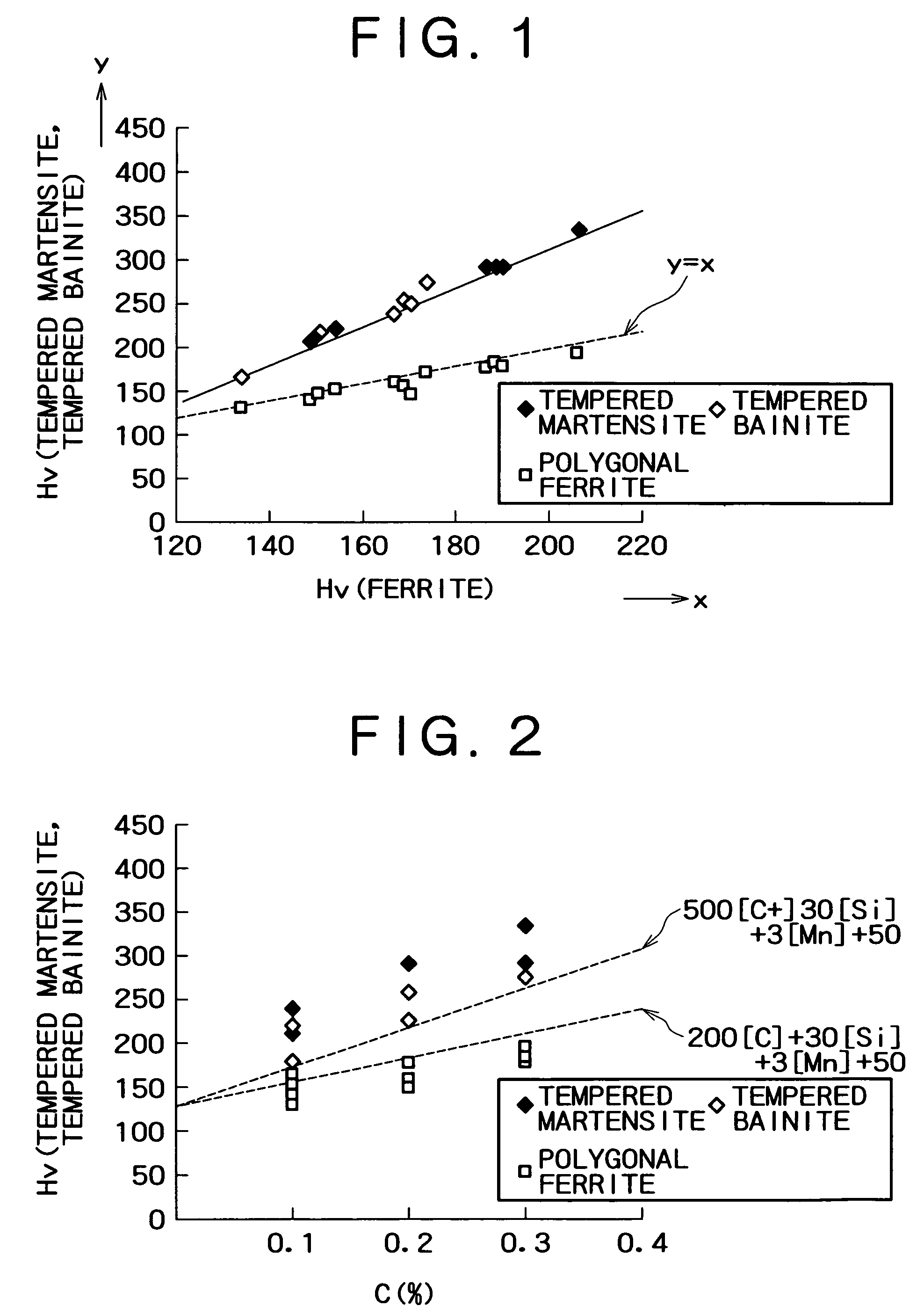

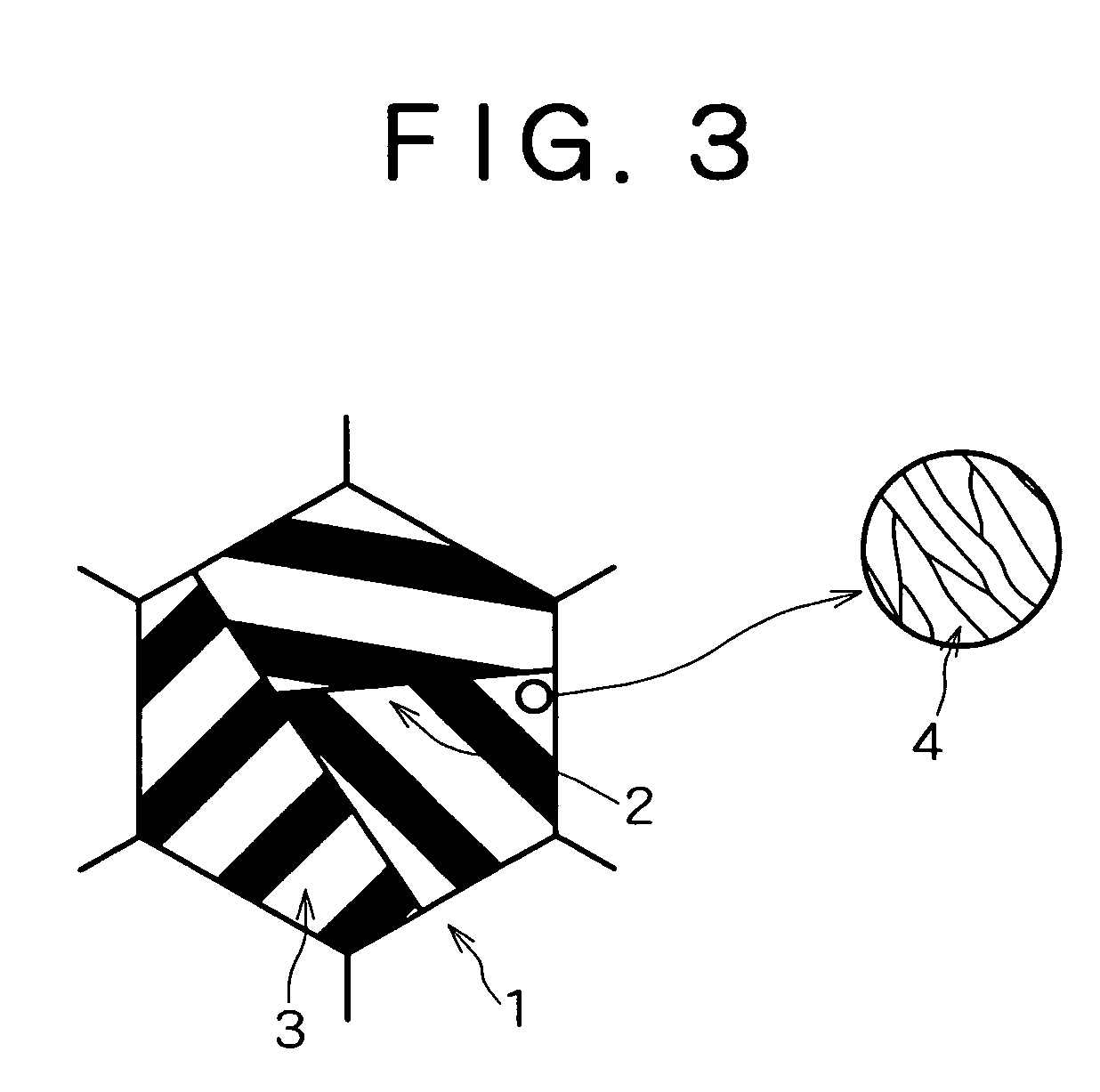

A high strength steel sheet having (2-1) a base phase structure, the base phase structure being tempered martensite or tempered bainite and accounting for 50% or more in terms of a space factor relative to the whole structure, or the base phase structure comprising tempered martensite or tempered bainite which accounts for 15% or more in terms of a space factor relative to the whole structure and further comprising ferrite, the tempered martensite or the tempered bainite having a hardness which satisfies the relation of Vickers hardness (Hv)≧500[C]+30[Si]+3[Mn]+50 where [ ] represents the content (mass %) of each element, and (2-2) a second phase structure comprising retained austenite which accounts for 3 to 30% in terms of a space factor relative to the whole structure and optionally further comprising bainite and / or martensite, the retained austenite having a C concentration (CγR) of 0.8% or more.

Owner:KOBE STEEL LTD

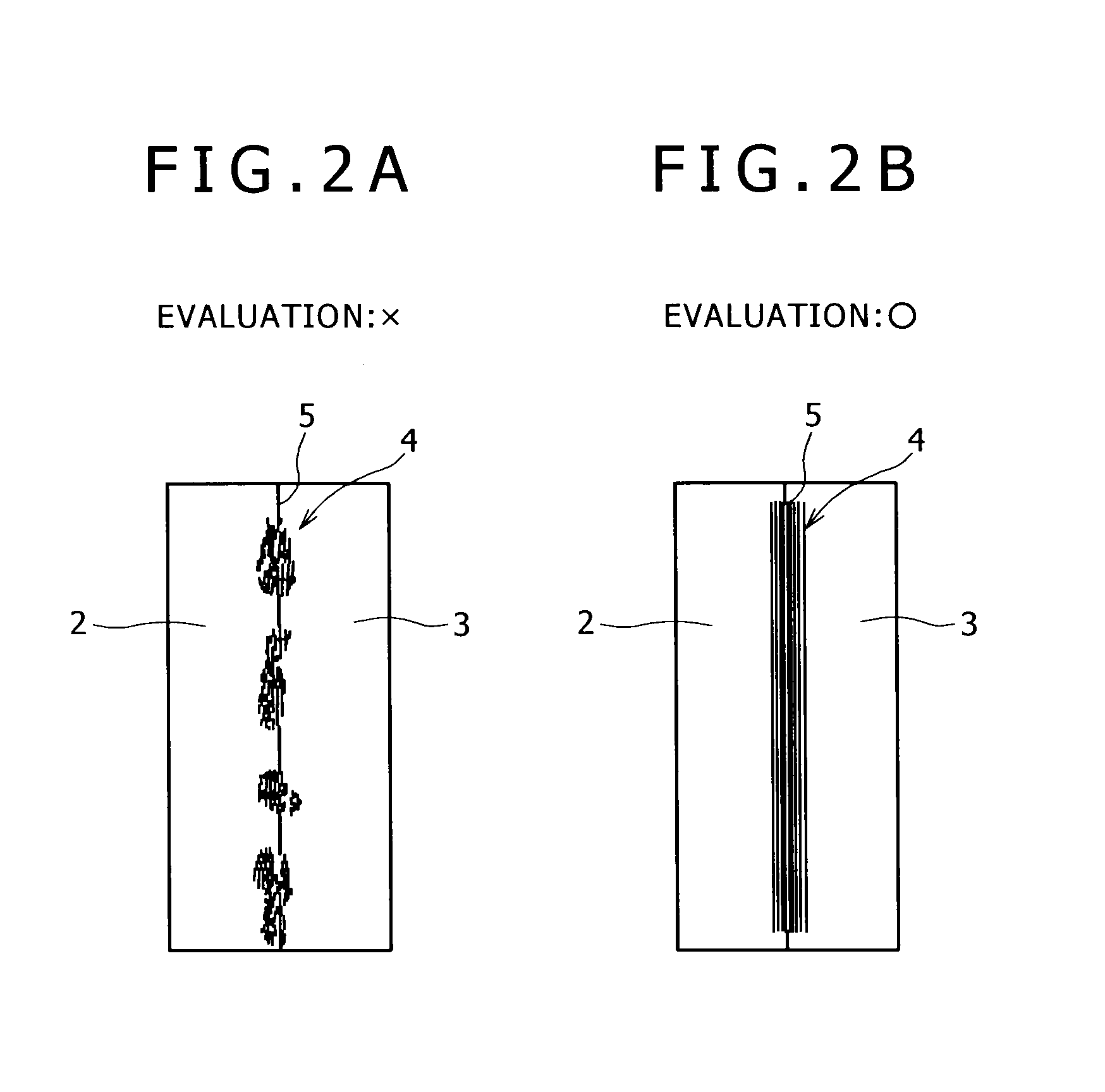

Flux-cored wire for different-material bonding and method of bonding different materials

InactiveUS20090017328A1High bonding strengthRaise checkHot-dipping/immersion processesArc welding apparatusHigh intensityChloride

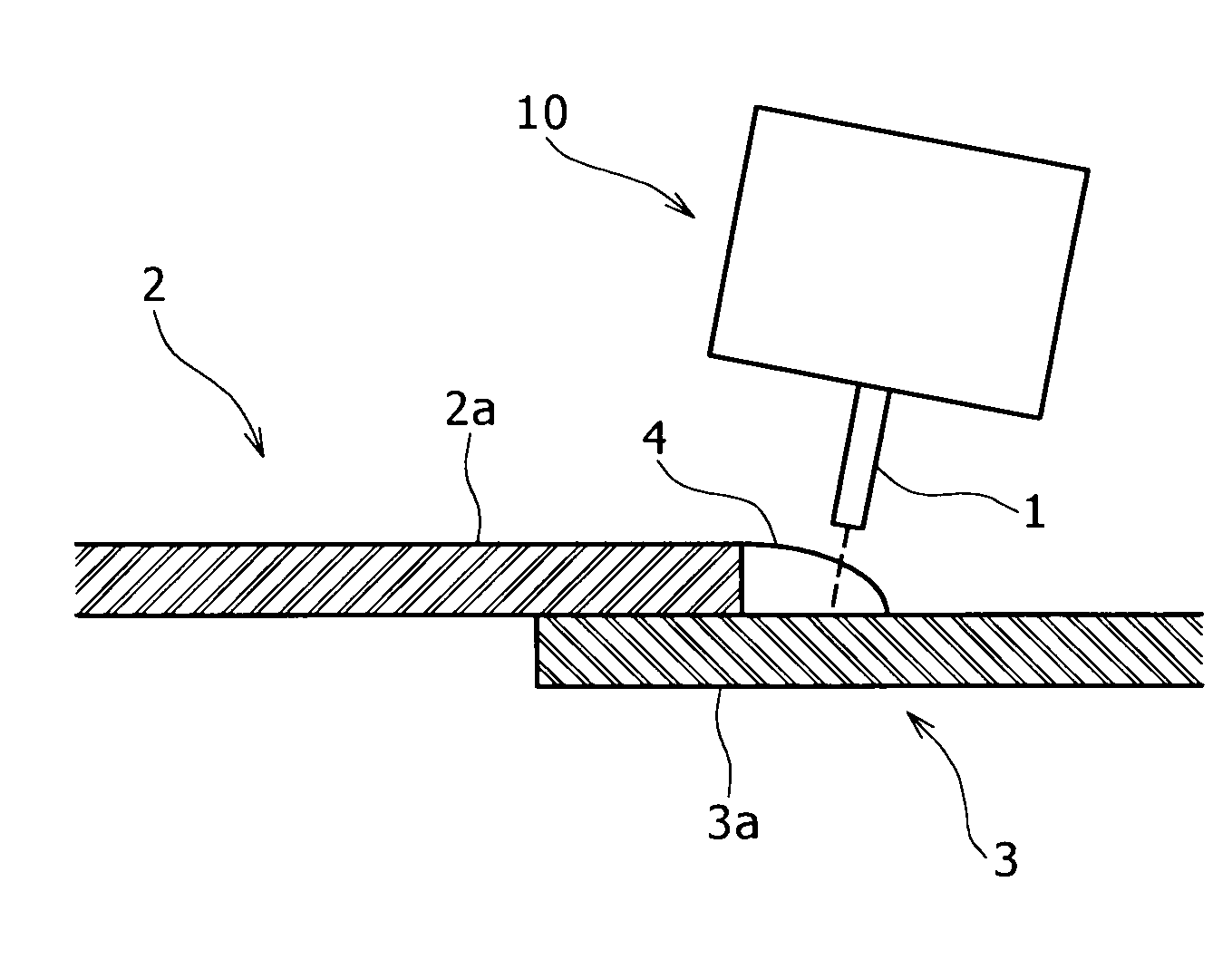

There are provided a flux cored wire for joining dissimilar materials with each other, capable of enhancing a bonding strength upon joining an aluminum-base material with a steel-base material, and excellent in bonding efficiency, a method for joining the dissimilar materials with each other, and a bonded joint obtained by the method. In particular, there is provided a method for joining dissimilar materials with each other, in the case of melt weld-bonding of high-strength dissimilar materials with each other, that is, the high-strength steel member with the high-strength 6000 series aluminum alloy member and in the case of the steel member being a galvanized steel member. In one mode, use is made of a flux cored wire wherein the interior of an aluminum alloy envelope is filled up with a flux, the flux has fluoride composition containing a given amount of AlF3 without containing chloride, and the aluminum alloy of the envelope contains Si in a range of 1 to 13 mass %. If such a flux cored wire is use, it is possible to obtain a high bonding strength in the case of melt weld-bonding of high-strength dissimilar materials with each other, that is, the high-strength steel member with the high-strength 6000 series aluminum alloy member.

Owner:KOBE STEEL LTD

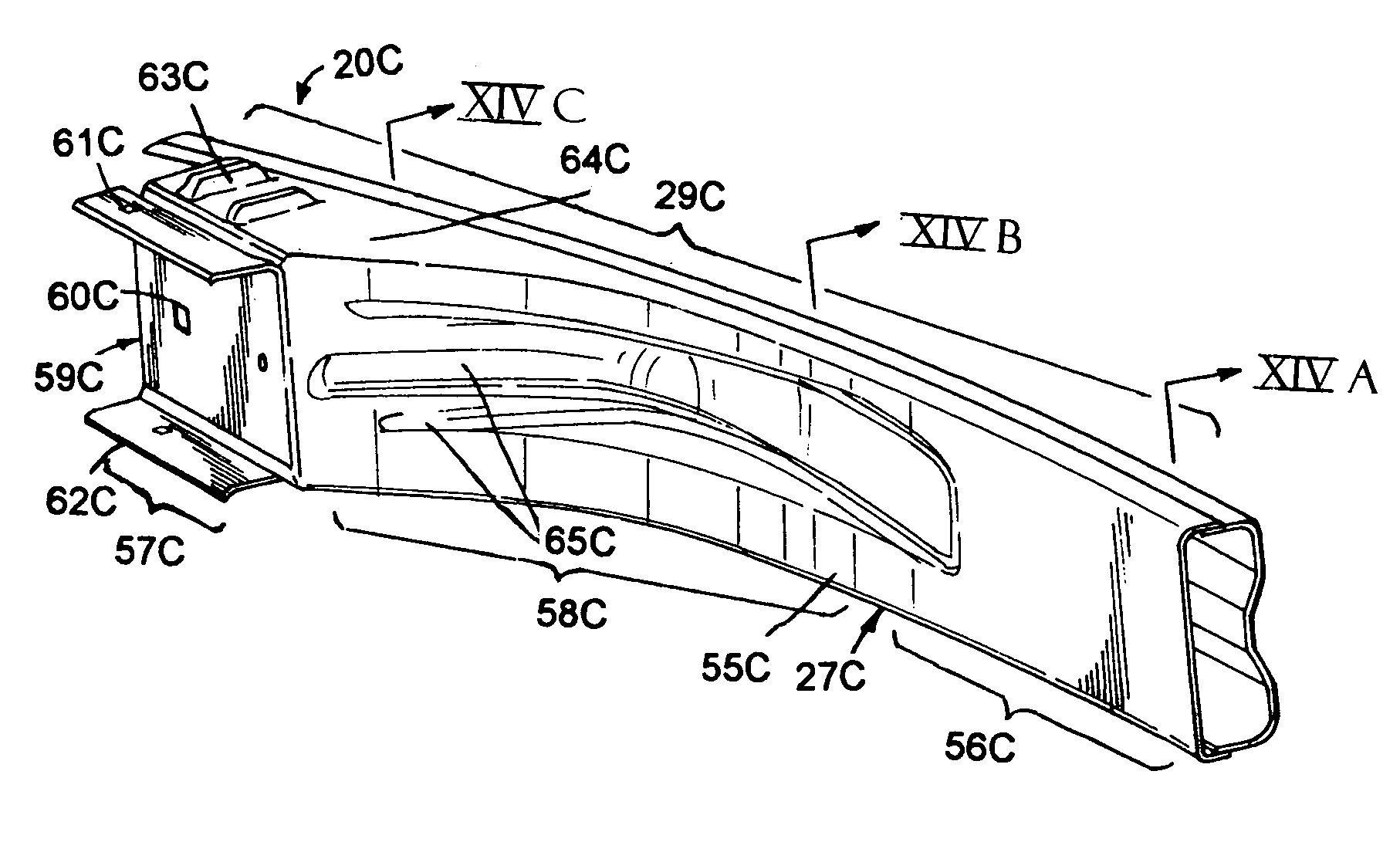

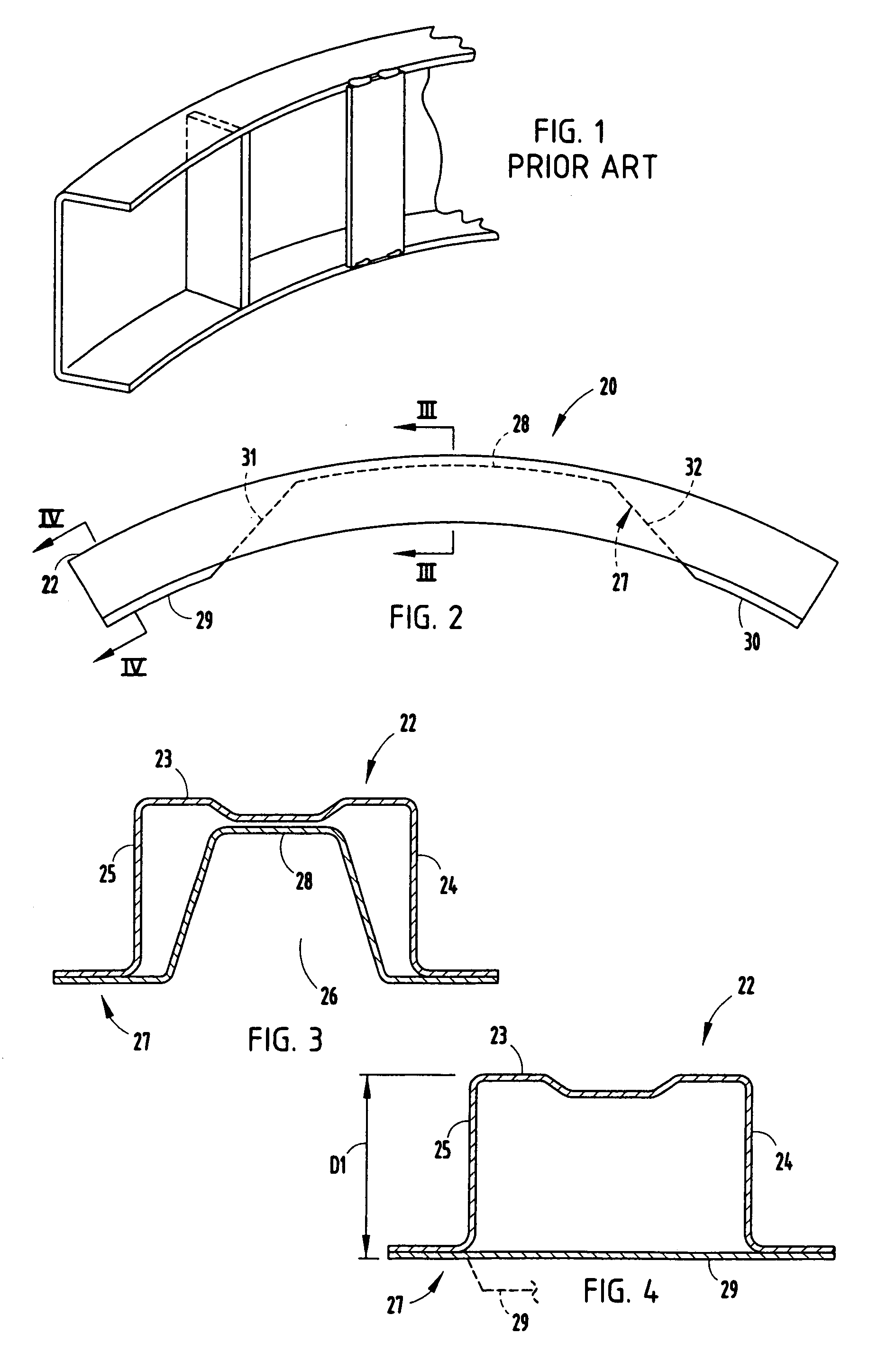

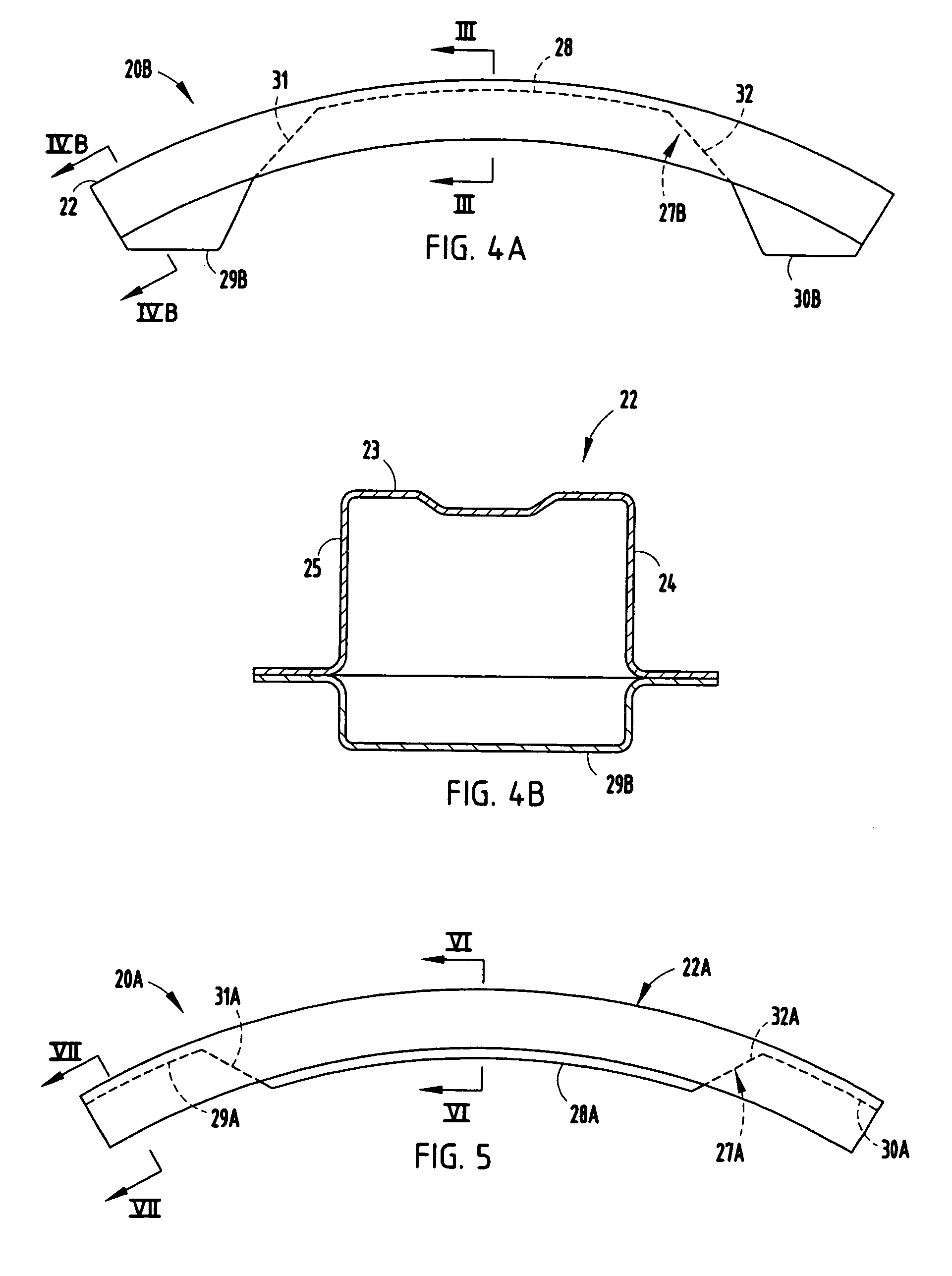

Vehicle bumper beam

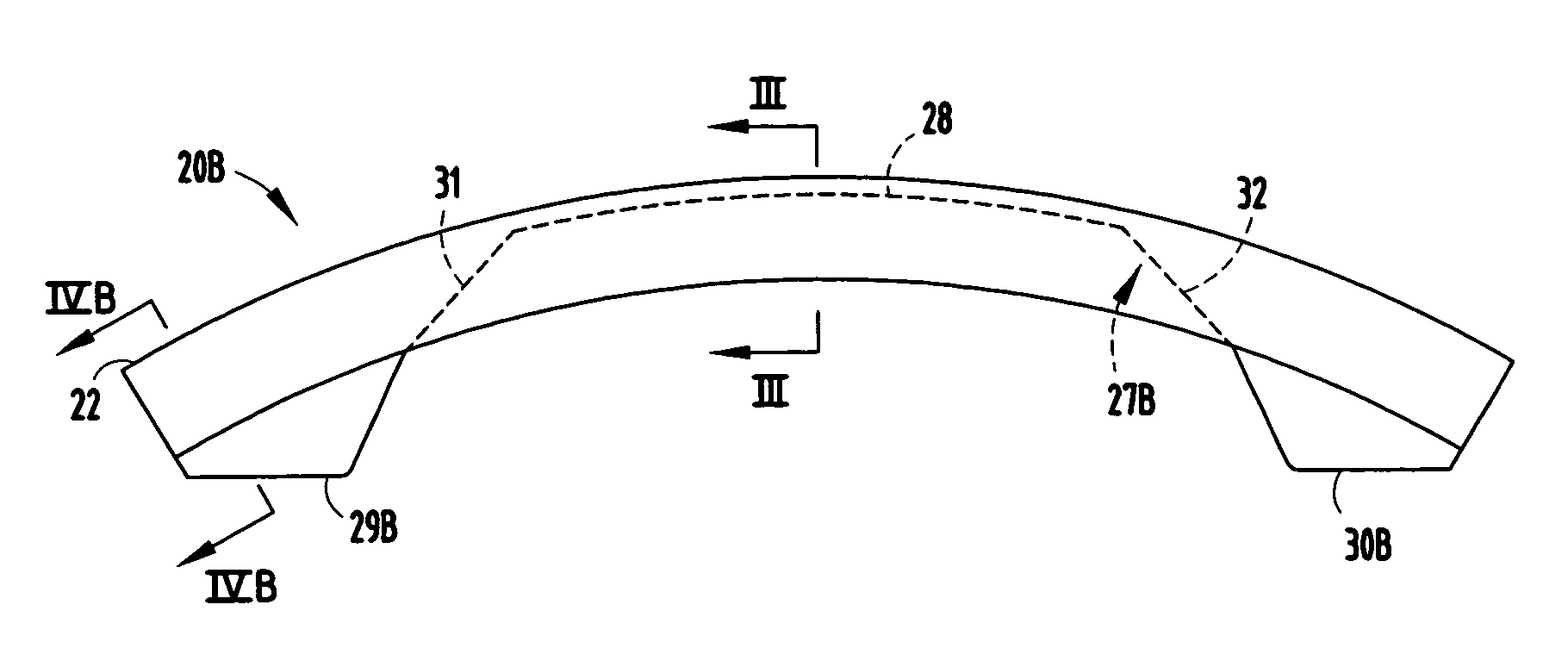

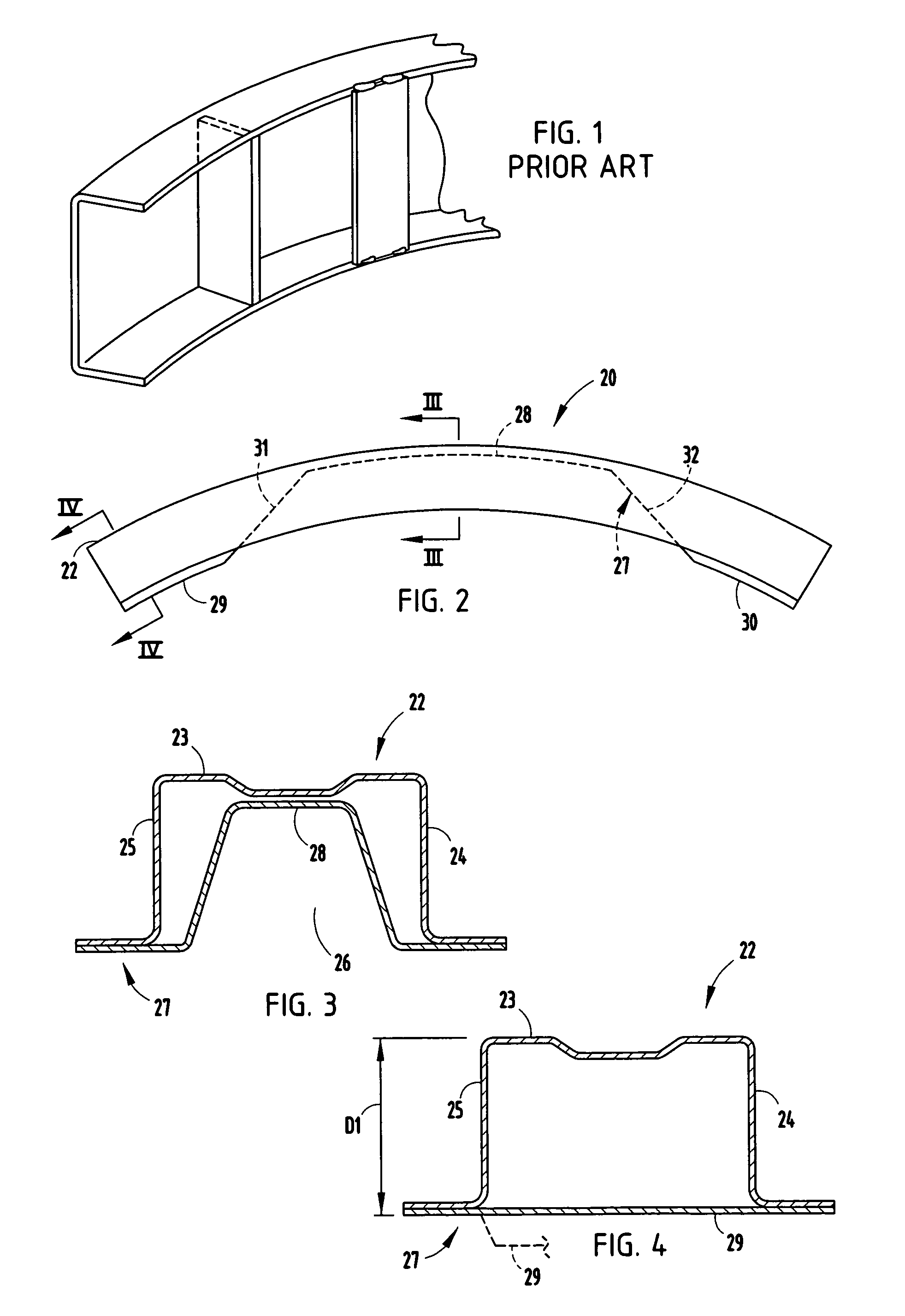

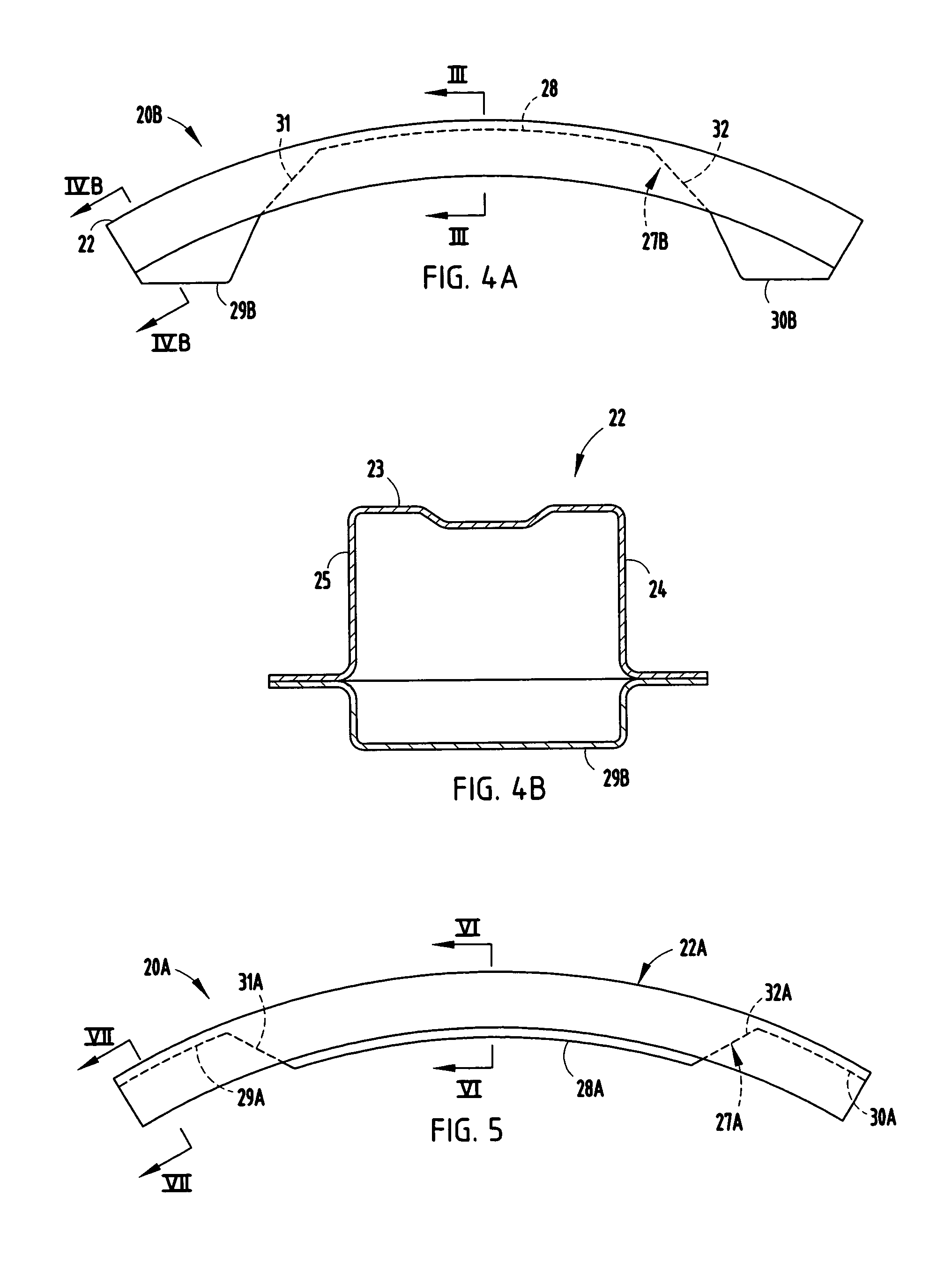

A bumper beam includes an open front section made from a high-strength material such as ultra-high-strength steel (UHSS) material, and further includes a mating back section made of lower-strength material attached to a rear side of the front section along abutting flanges. The front and back sections combine to define different tubular cross sections. The front section can be roll-formed, and the back section can be stamped, thus taking advantage of roll-forming processes' ability to form high-strength materials, while allowing the back section to have a more complicated shape and be stamped. The abutting flanges telescopingly overlap in a fore-aft direction of the vehicle and are welded together at locations that potentially experience shear upon impact, but the flanges of the front section are captured within the flanges of the backs section, thus providing impact strength even if the attachment locations shear off.

Owner:SHAPE CORP

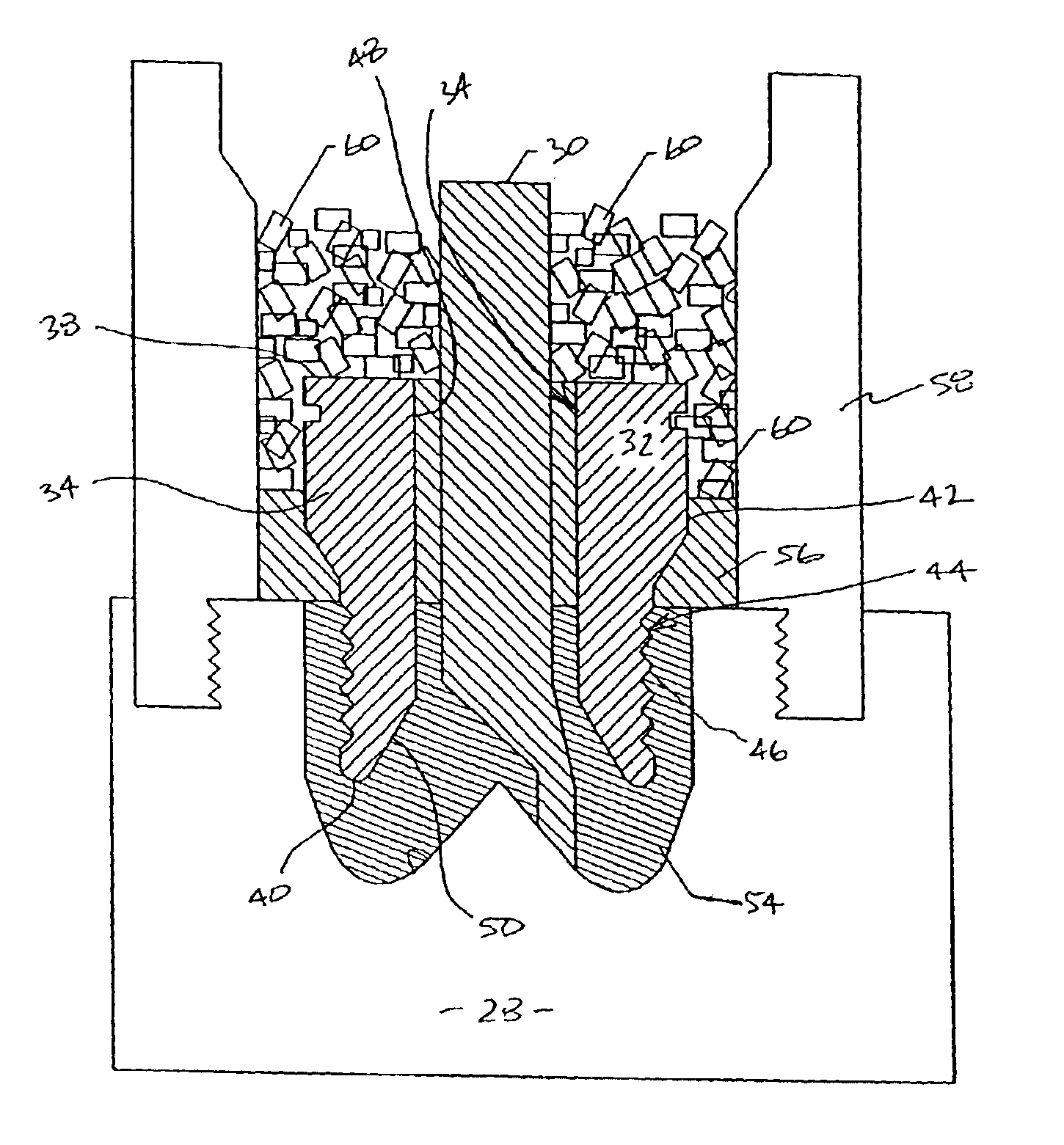

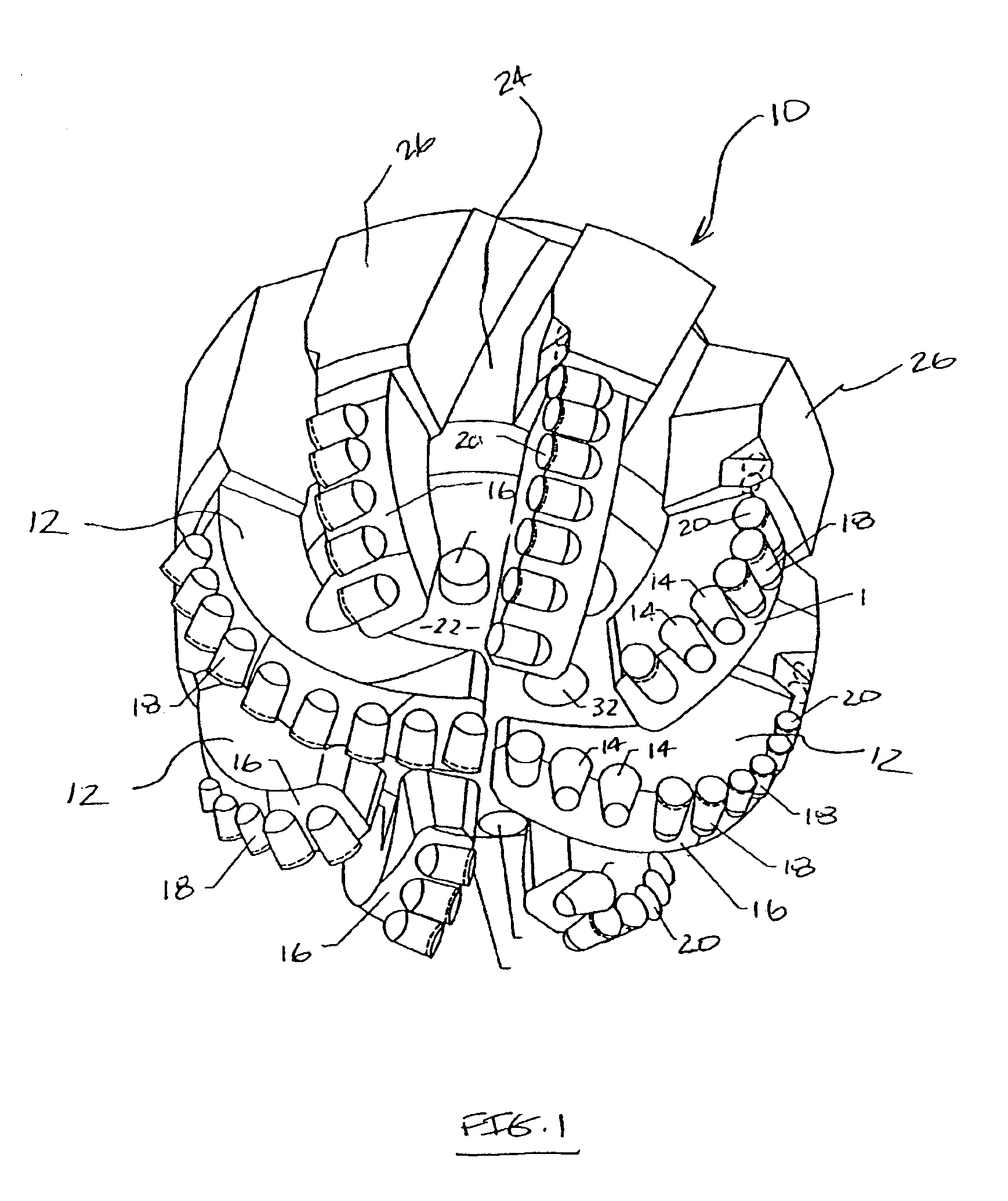

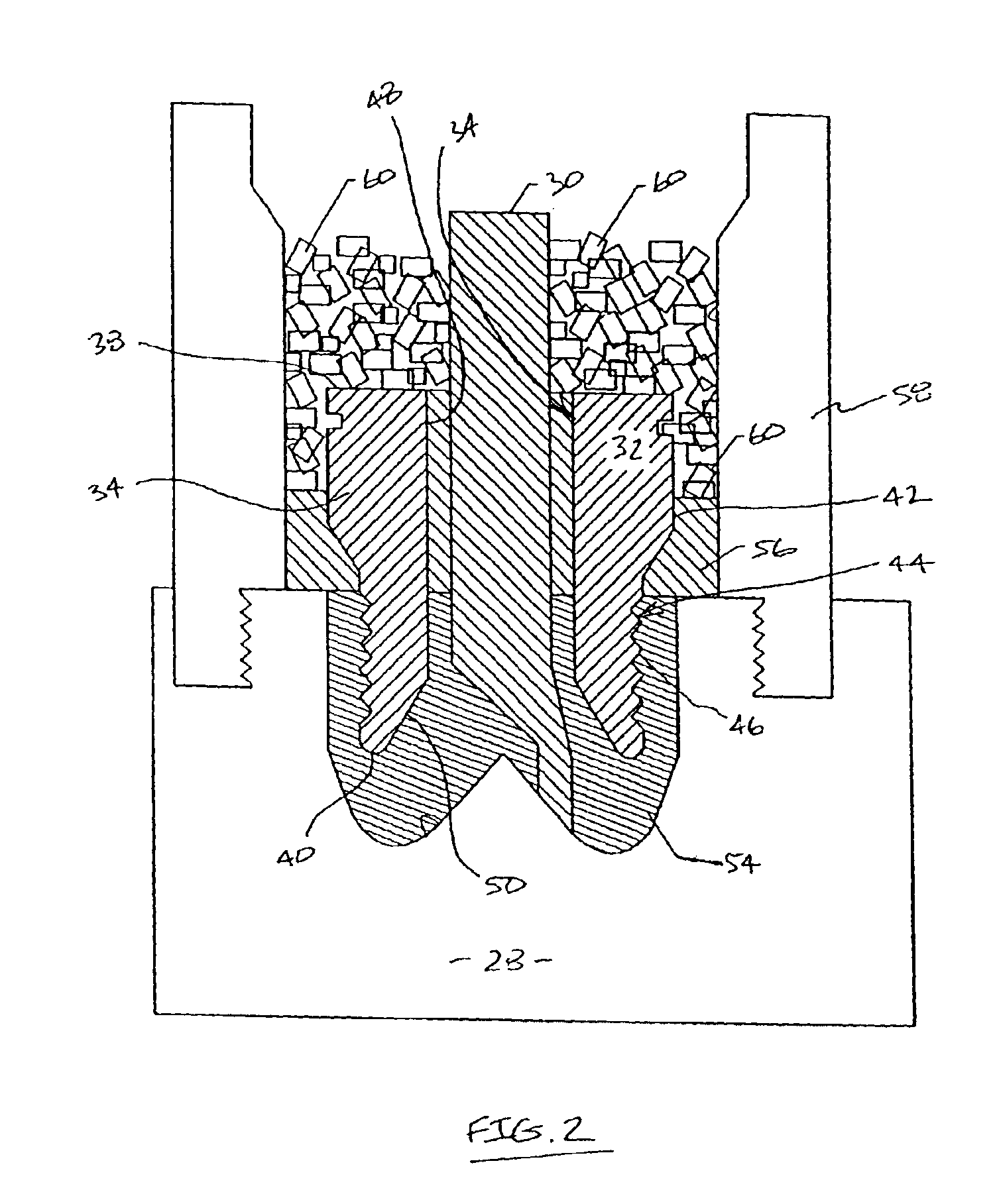

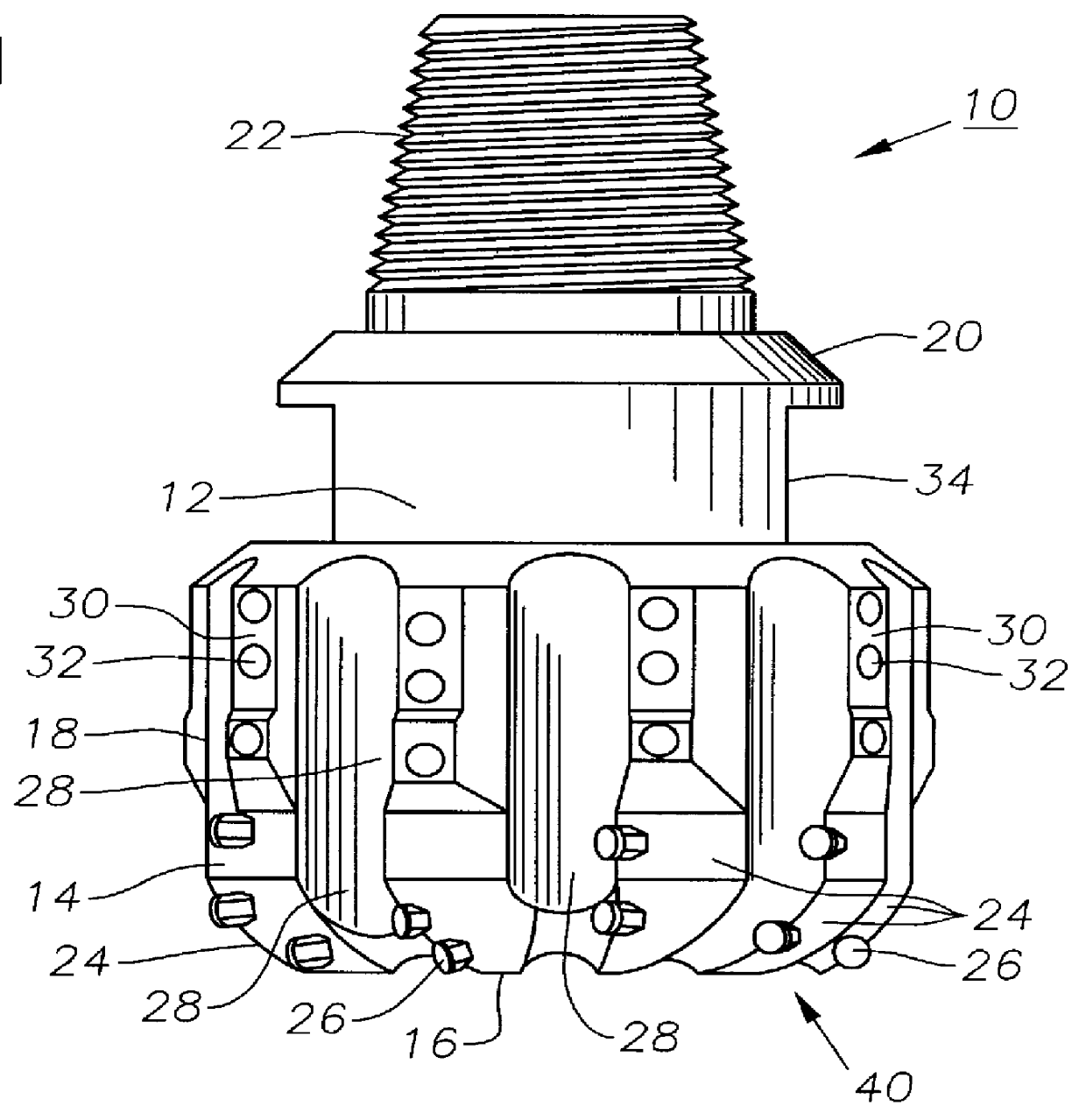

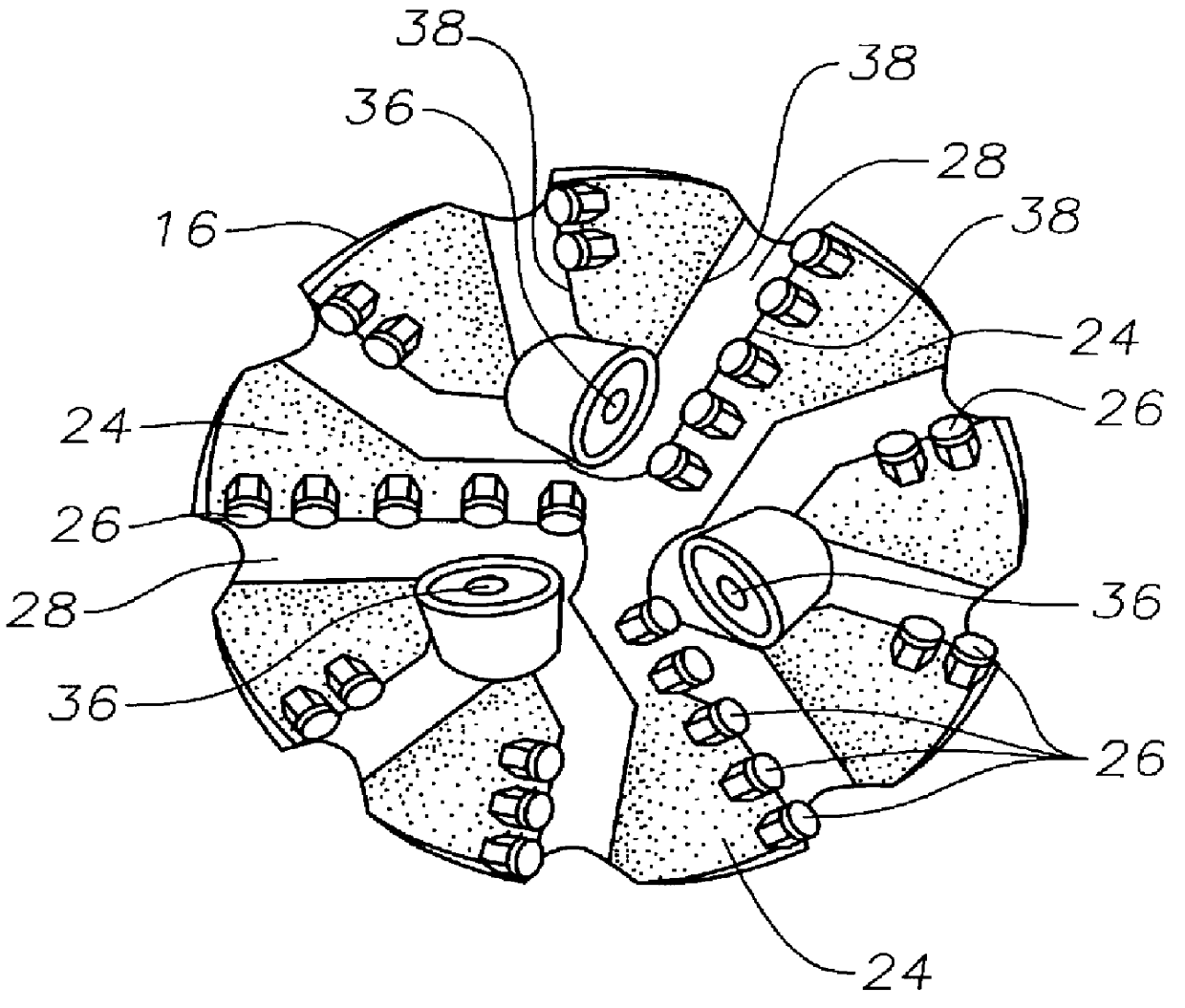

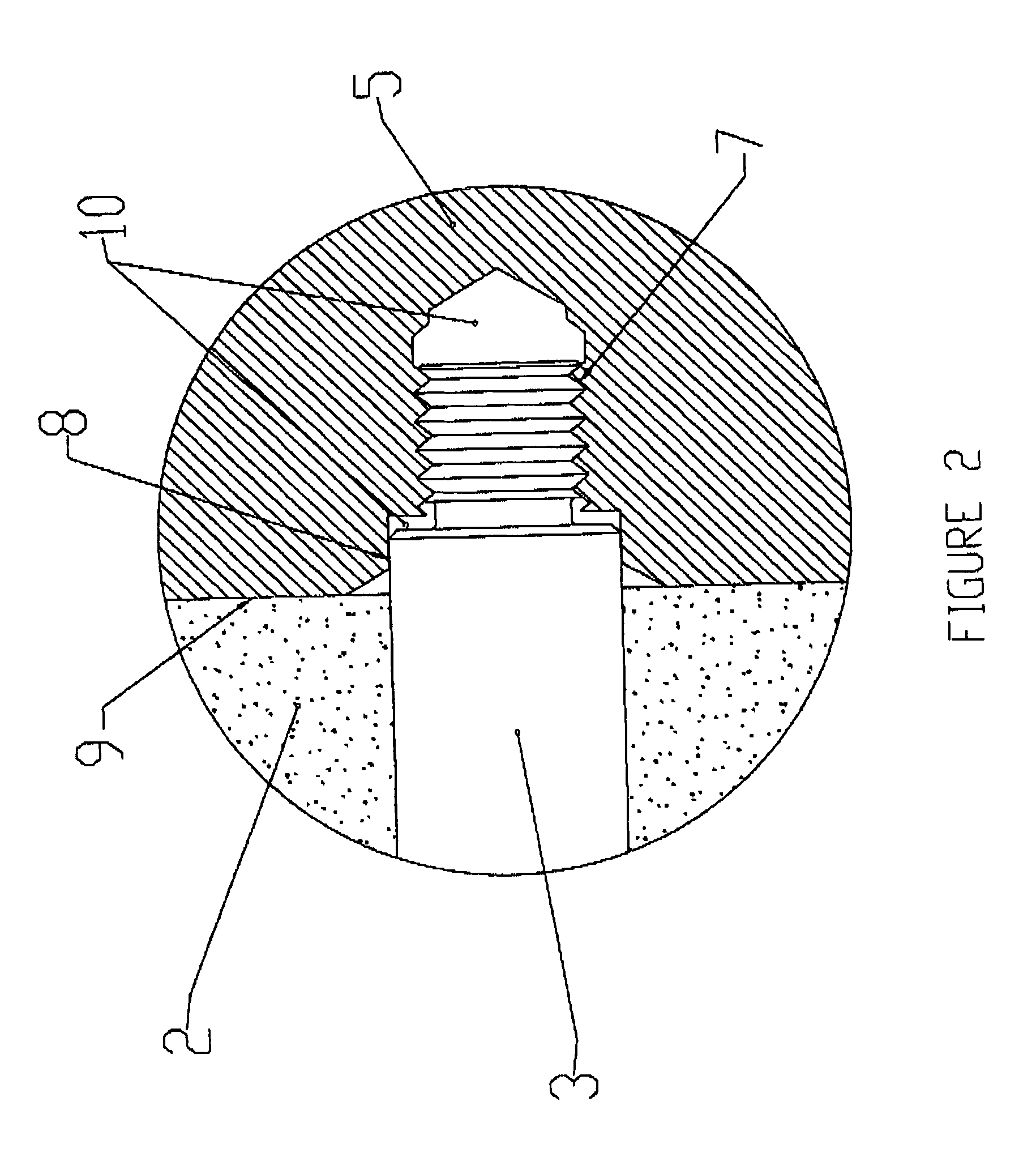

Fixed cutter drill bits with thin, integrally formed wear and erosion resistant surfaces

A fixed-cutter drill bit for boring through earth has a body made predominately of high strength steel with thin erosion and abrasion resistant surfaces integrally formed in the steel in areas likely to encounter abrasive or erosive conditions. The drill bit may be formed by a rapid solid state densification (RSSDPM) process. The drill bit combines the high strength of conventional steel bits with design freedom and hardness equal to or greater than conventional matrix bits. Due to the manner in which the hard particles, such as tungsten carbide, are integrally held in a steel matrix, aggressive fluid hydraulics may be employed with the drill bit without unduly limiting the performance of the drill bit.

Owner:REEDHYCALOG LP

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

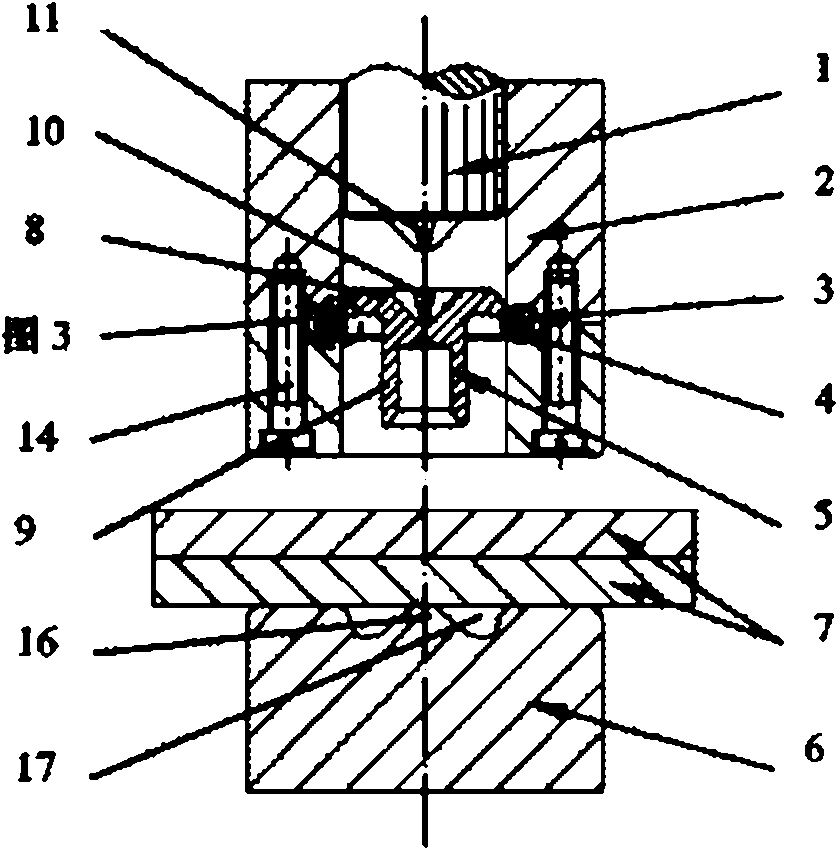

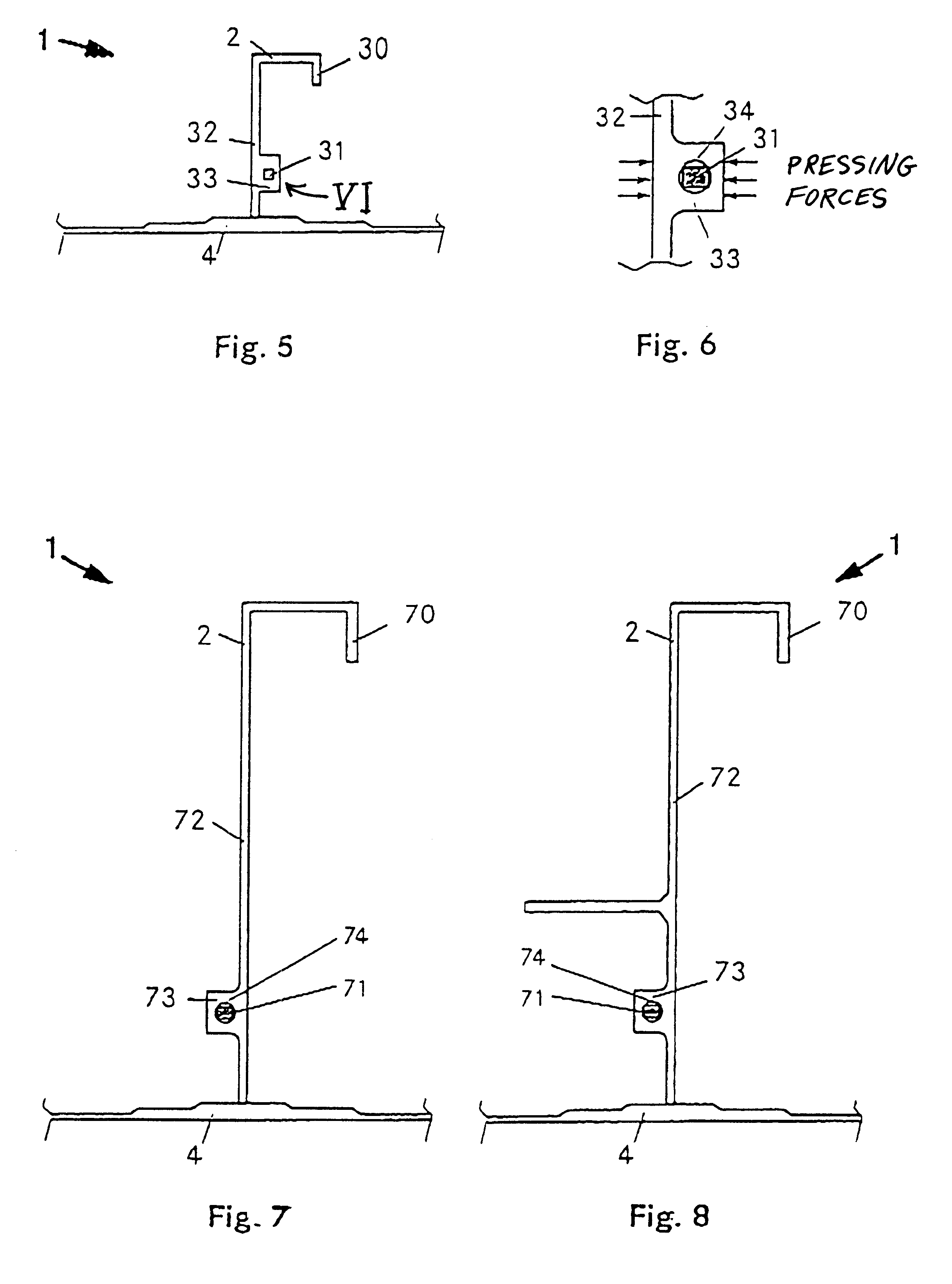

Self-piercing frictional rivet welding connecting device

InactiveCN101817142AHigh elongationImprove connection efficiencyOther manufacturing equipments/toolsNon-electric welding apparatusEngineeringAlloy

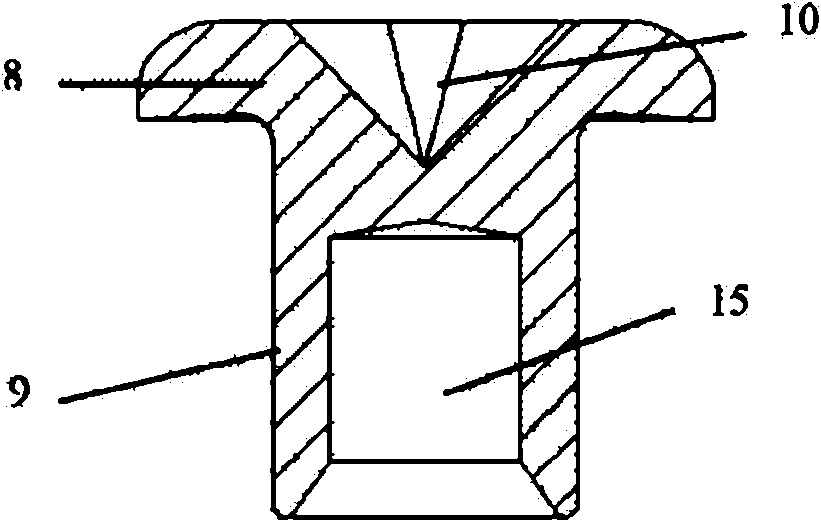

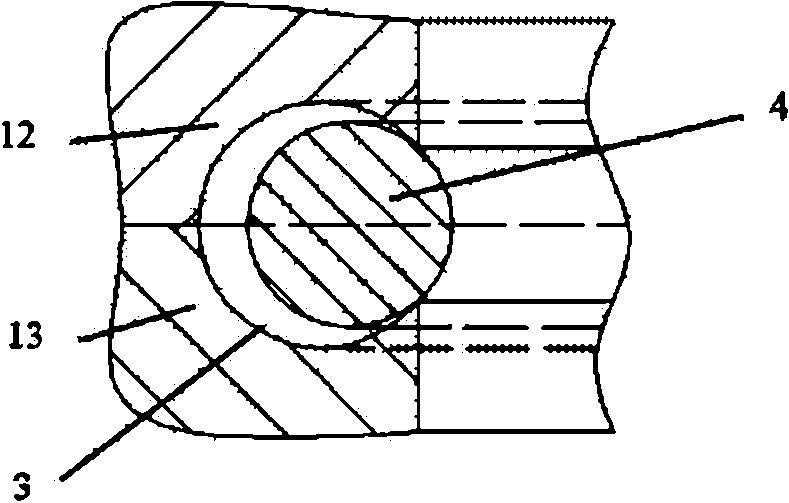

The invention relates to a self-piercing frictional rivet welding connecting device which belongs to the technical field of rivet welding. The device comprises a driving needle, a blank holder, an annular guide slot, an annular positioning spring, a semi-tubular rivet and a female die, wherein the driving needle is sleeved in the blank holder; the semi-tubular rivet is positioned below the driving needle; the annular guide slot is formed in the blank holder; the annular positioning spring is arranged in the annular guide slot; the semi-tubular rivet is positioned on the annular positioning spring; and the female die is arranged below the semi-tubular rivet. The high-strength steels are softened by using the friction heat generated by speedily rotating the rivet so the percentage of elongation of the high-strength steel is increased, the riveting force and the rigid requirement on equipment are reduced, the joint efficiency of friction stir spot welding is improved, the technical shrinkage pool is eliminated, the joint strength is efficiently increased, the mechanical-solid phase double joint is realized and the static and dynamic mechanical properties of the joint are greatly improved. The connecting device of the invention is applied to the connection between the light alloy and the high-strength steel and is also applied to the connection between the different light alloys and between different high-strength steels.

Owner:SHANGHAI JIAO TONG UNIV +1

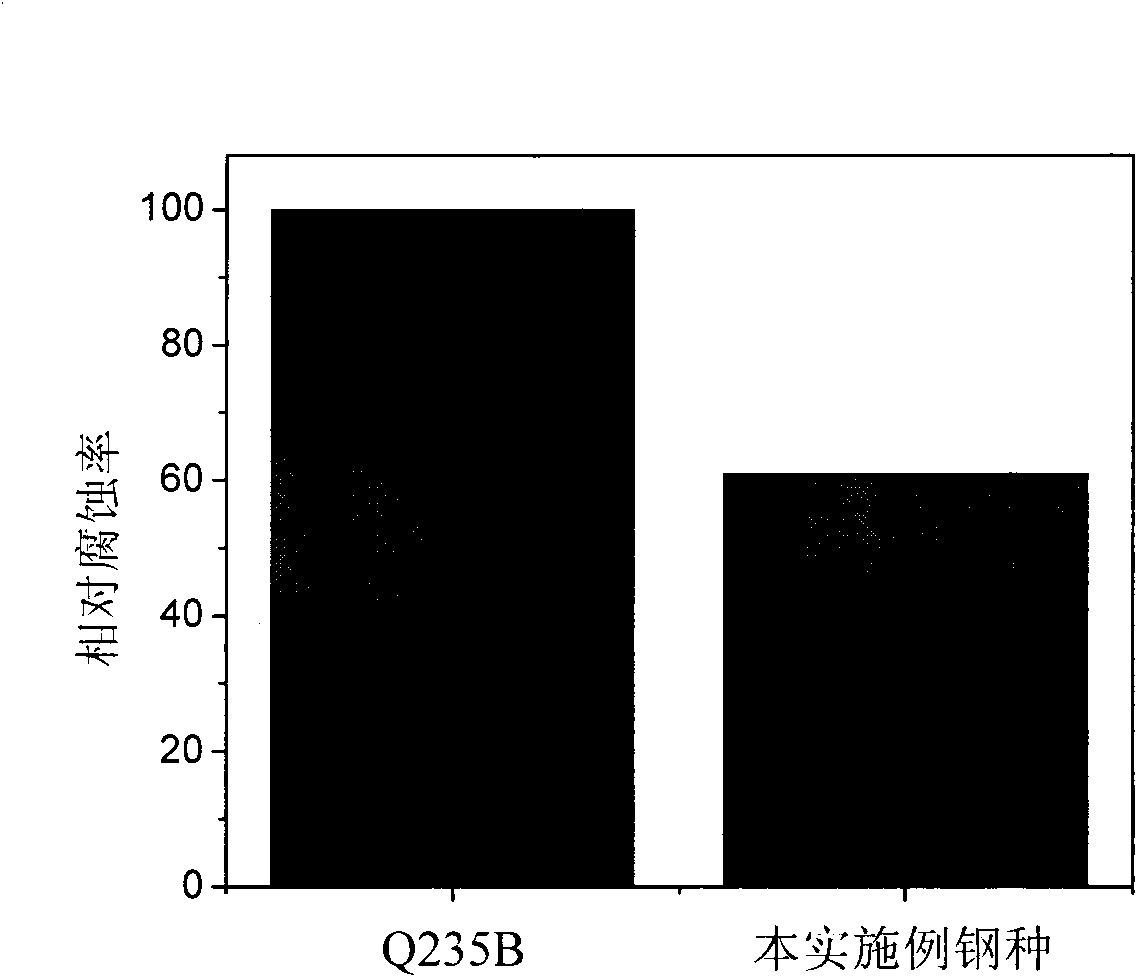

High strength low alloy hot rolling ferrite bainite weathering resistant steel and production method thereof

ActiveCN101660099AHigh strengthImprove toughnessTemperature control deviceManufacturing convertersNiobiumManganese

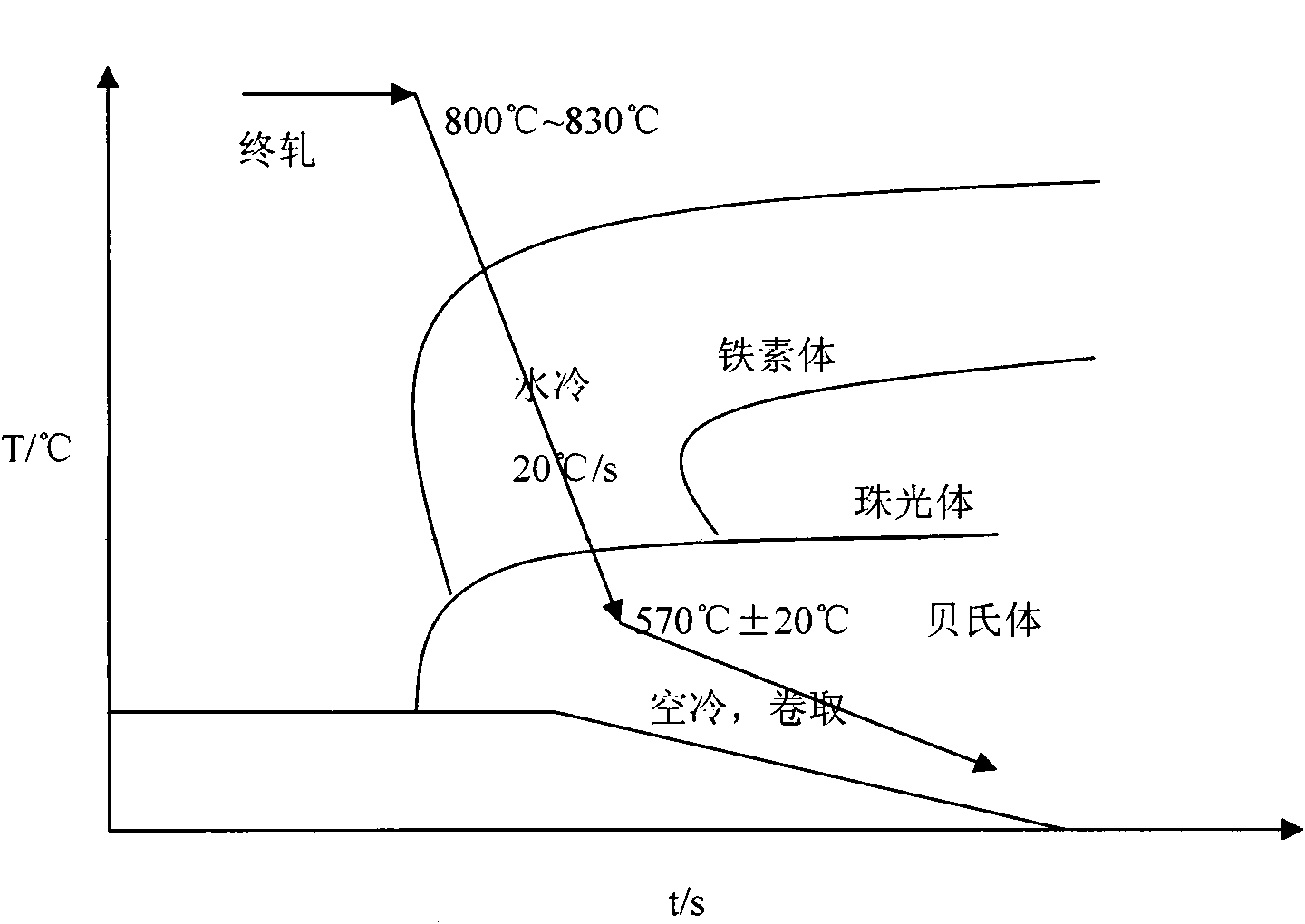

The invention relates to a high strength low alloy hot rolling ferrite bainite weathering resistant steel and a production method thereof. The steel comprises the components by weight percent: 0.05-0.10% of C, 0.30-0.45% of Si, 1.00-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, 0.50-0.70% of Cr, 0.20-0.30% of Ni, 0.20-0.40% of Cu, less than or equal to 0.05% ofAl, 0.01-0.025% of Ti, 0.03-0.05% of Nb and the rest of Fe and impurities; and the yield strength is more than or equal to 450MPa, and the welding cold crack susceptibility coefficient is less than orequal to 0.2. The invention has the advantages of low cost, high strength, low yield ratio, high weatherability, excellent weldability and low temperature toughness, simple process flow of the preparation technique and easy operation. Therefore, the invention can be widely applied to the fields such as bridges, buildings, containers, railway coaches, etc.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

HIGH STRENGTH STEEL PLATE WITH ULTIMATE TENSILE STRENGTH OF 900 MPa OR MORE EXCELLENT IN HYDROGEN EMBRITTLEMENT RESISTANCE AND METHOD OF PRODUCTION OF SAME

ActiveUS20120222781A1Reduce resistanceImprove plasticityHot-dipping/immersion processesSurface reaction electrolytic coatingCarbideUltimate tensile strength

High strength steel plate with an ultimate tensile strength of 900 MPa or more which is excellent in hydrogen embrittlement resistance characterized in that, in the structure of the steel plate, (a) by volume fraction, ferrite is present in 10 to 50%, bainitic ferrite and / or bainite in 10 to 60%, and tempered martensite in 10 to 50%, and (b) iron-based carbides which contain Si or Si and Al in 0.1% or more are present in 4×108 (particles / mm3) or more.

Owner:NIPPON STEEL CORP

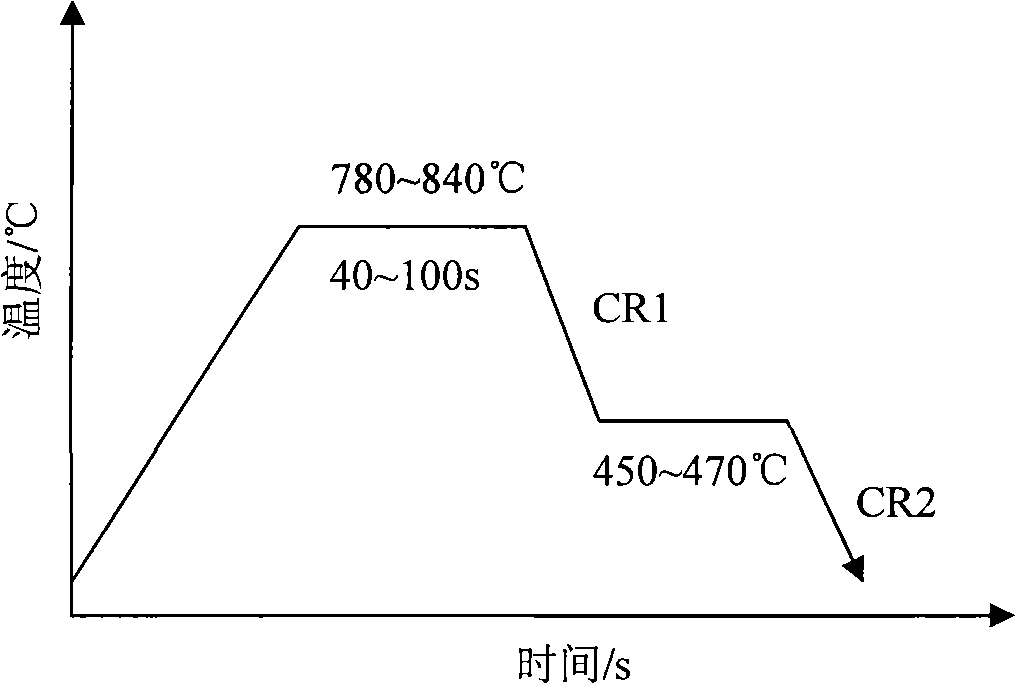

1000MPa grade cold rolling hot dip galvanizing two-phase steel and manufacturing method thereof

The invention provides 1,000 MPa cold-rolled hot-dip galvanized dual-phase steel and a manufacturing method thereof, belonging to the technical field of cold-rolled hot-dip galvanized high-strength steel plates. The chemical components in mass percentage of the cold-rolled hot-dip galvanized dual-phase steel are: 0.06 to 0.18 percent of C, less than or equal to 0.1 percent of Si, 1.2 to 2.5 percent of Mn,0.05 to 0.5 percent of Mo, 0.05 to 0.6 percent of Cr, 0.005 to 0.05 percent of Al, 0.01 to 0.06 percent of Nb, 0.01 to 0.05 percent of Ti, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.005 percent of N, the balance being Fe and inevitable impurities. The manufacturing method adopts Cr or Mo to replace Si, so as to enlarge an austenitic and ferritic two-phase region and improve the hardenability of the dual-phase steel, and meanwhile, the manufacturing method improves the strength of toughness of the steel by adding Nb or Ti refined grains, so as to ensure that the steel has good weldability and usability, and the strength grade of the steel can reach over 1,000 Mpa.

Owner:UNIV OF SCI & TECH BEIJING +1

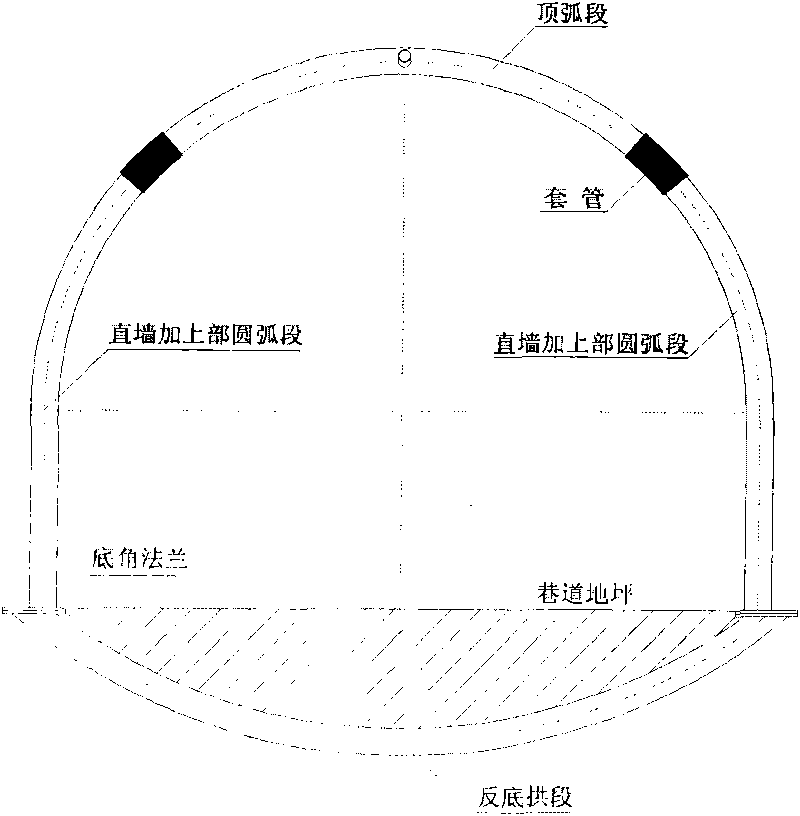

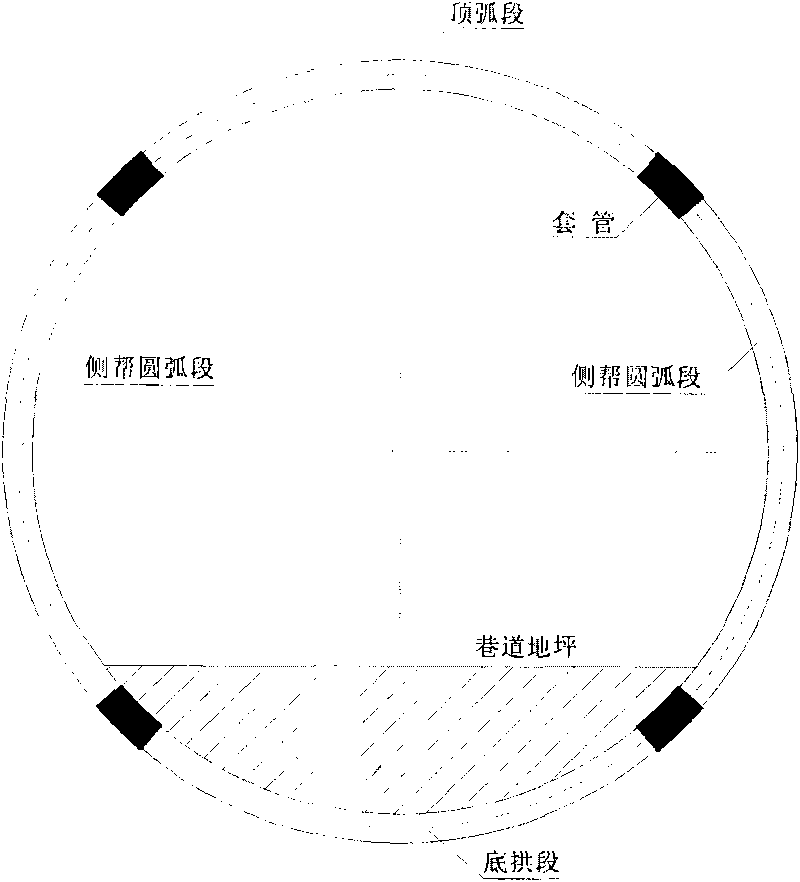

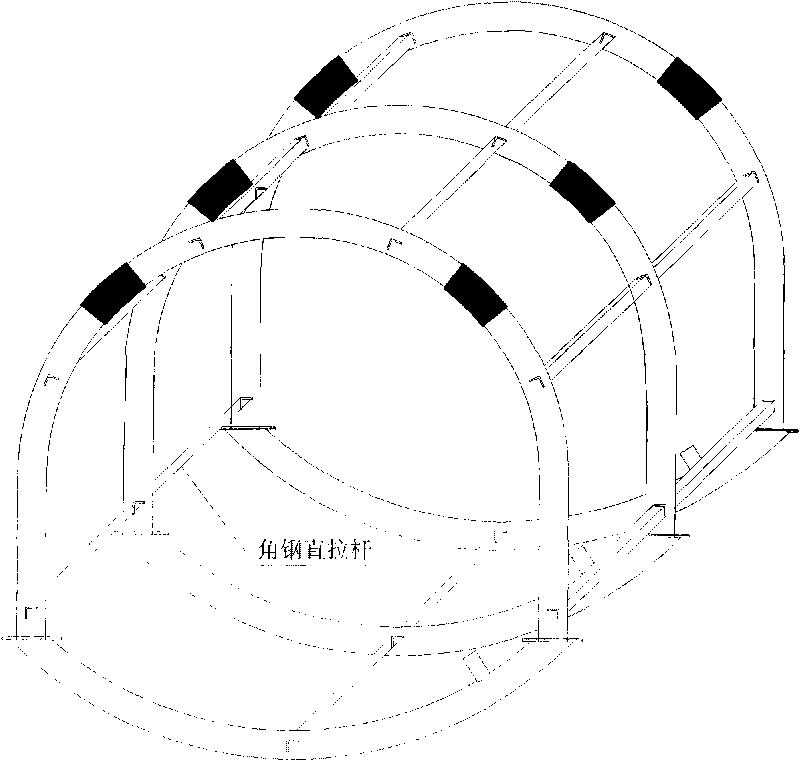

Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

InactiveCN101725362AControl deformationSimple structureProps/chocksAnchoring boltsSupporting systemHardness

The invention relates to a composite support device of a dynamic pressure softrock tunnel based on a steel pipe concrete bracket, which comprises a steel pipe concrete bracket, wherein a flexible pressure sharing and releasing layer is arranged between the steel pipe concrete bracket and supported surrounding rock. The composite support device also comprises a surrounding rock grouting and reinforcing device, wherein the surrounding rock grouting and reinforcing device comprises a plurality of hollow surrounding rock grouting anchor rods, and the surrounding rock is grouted by the hollow anchor rods; after being injected with a concrete layer, the surrounding rock is covered by a flexible seal layer; and the steel pipe concrete bracket is provided with a vertical column shaped or Y-shaped or T-shaped high-strength steel pipe concrete strut. The high-strength steel pipe concrete bracket and the flexible pressure sharing and releasing layer are two necessary technologies; and the flexible seal layer, the surrounding rock grouting and reinforcement and the high-strength steel pipe concrete strut are three optional technologies. The flexible pressure sharing and releasing layer is combined with the steel pipe concrete bracket so that the whole support system combines hardness with softness, has simple structure, low cost and high support resistance and can effectively control the stability of large deformed tunnels of deep well softrock dynamic pressure, and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

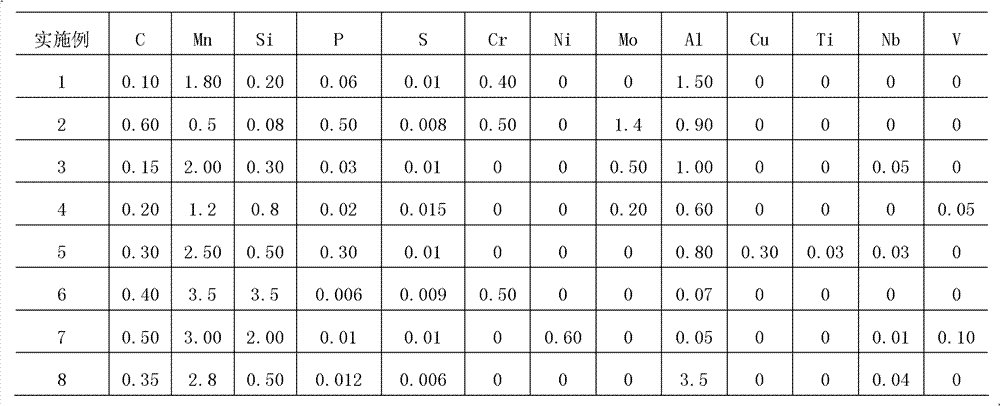

Production method of ultrahigh strength steel plate for cold forming and steel plate

The invention provides a production method of an ultrahigh strength steel plate for cold forming and the steel plate. The method comprises the steps of smelting, casting, hot rolling, cold rolling, heating the cold-rolled steel plate through a continuous annealing production line with rapid cooling treatment to the austenite temperature, holding the temperature for a certain time, carrying out quenching treatment, obtaining a steel plate with the main structure of M+A and carrying out distribution treatment in a bell type annealing furnace. The steel plate comprises the following components in percentage by mass: 0.02-0.60% of C, 0.05-3.5% of Si, 0.20-3.50% of Mn, P more than or equal to 0.005 but less than or equal to 0.50%, S not more than 0.05%, 0.02-3.00% of Al, Cr not more than 0.50%, Ni not more than 3.00%, Cu not more than 0.50%, Mo not more than 1.50%, V not more than 0.50%, Ti not more than 0.20%, Nb not more than 0.20% and the balance of Fe and unavoidable impurities. The steel plate produced by adopting the method provided by the invention has the advantages of high strength and capability of cold forming and the process route of Q&P steel industrial production is effectively solved.

Owner:ANGANG STEEL CO LTD

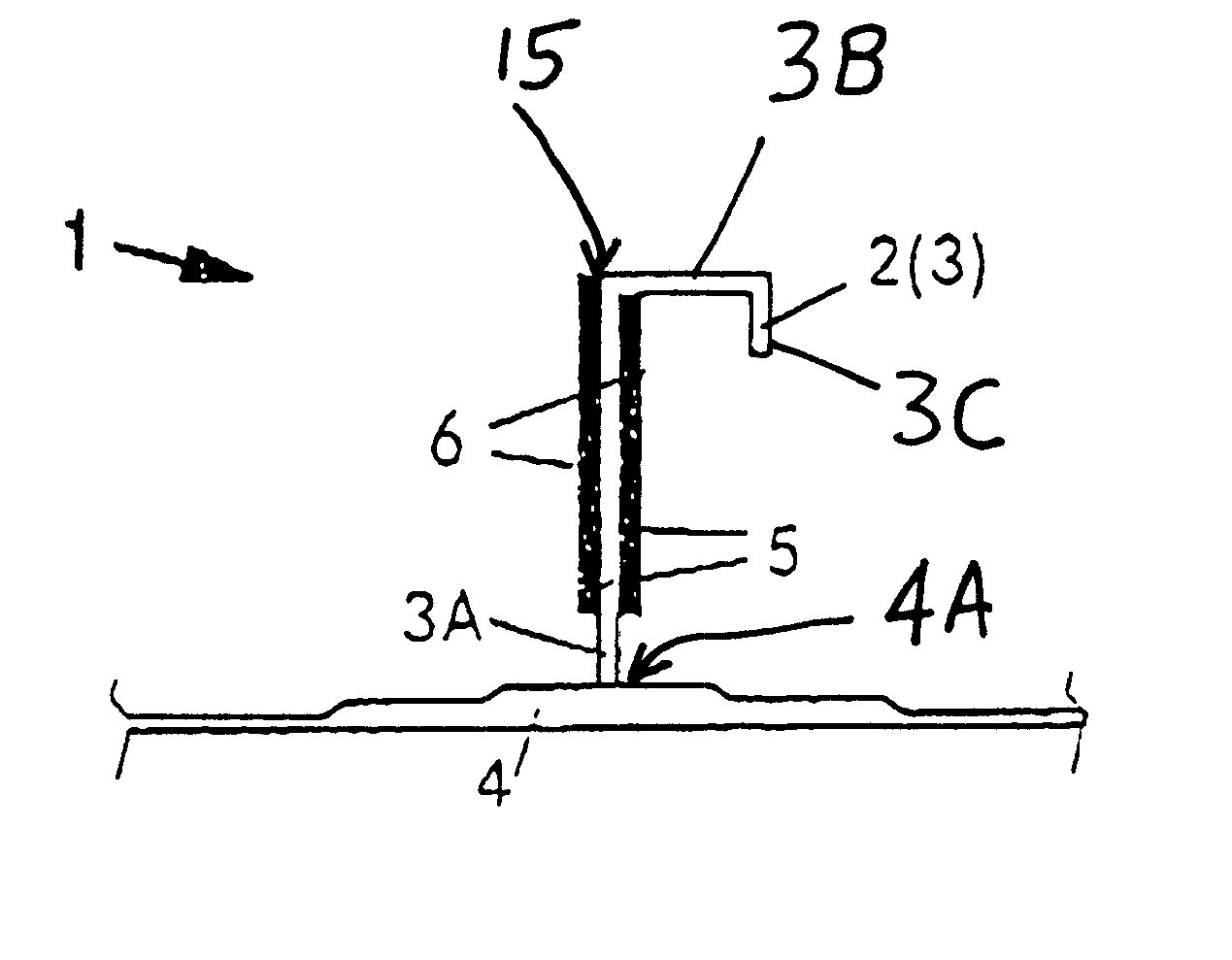

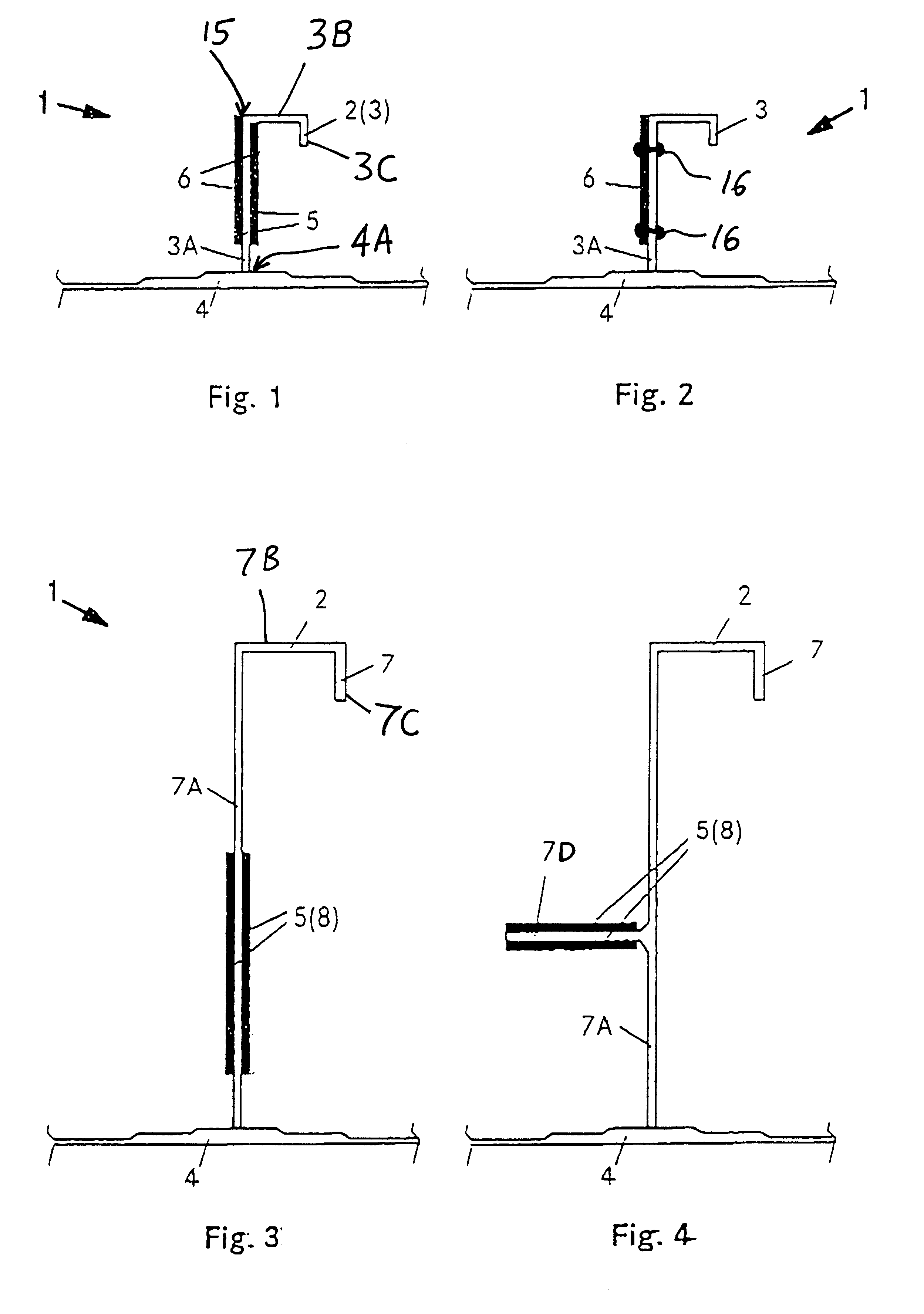

Aircraft fuselage shell component with crack propagation resistance

InactiveUS6595467B2Increasing weight and costEasy to crackFuselage bulkheadsWelding apparatusResidual strengthFiber-reinforced composite

Owner:AIRBUS OPERATIONS GMBH

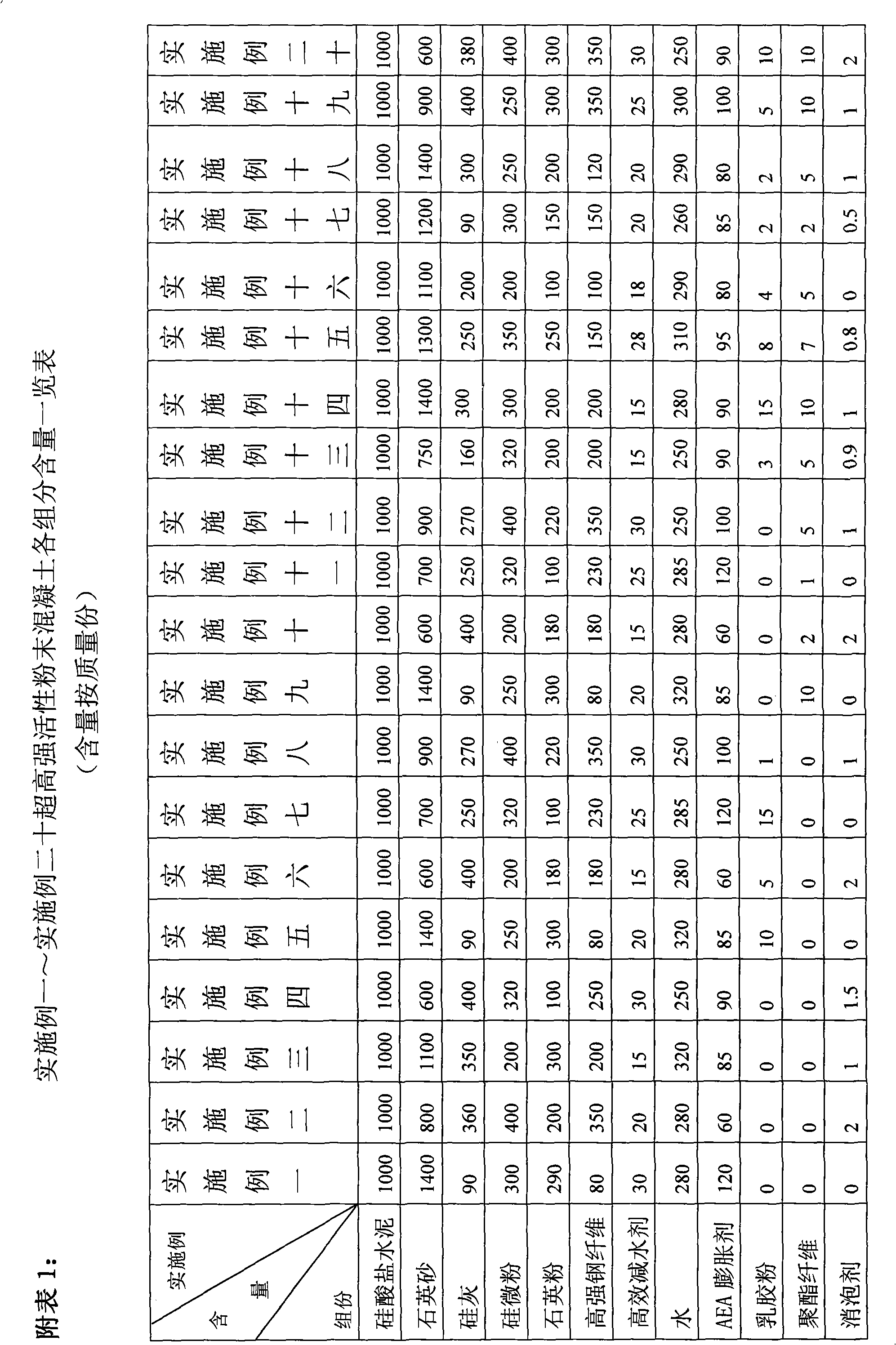

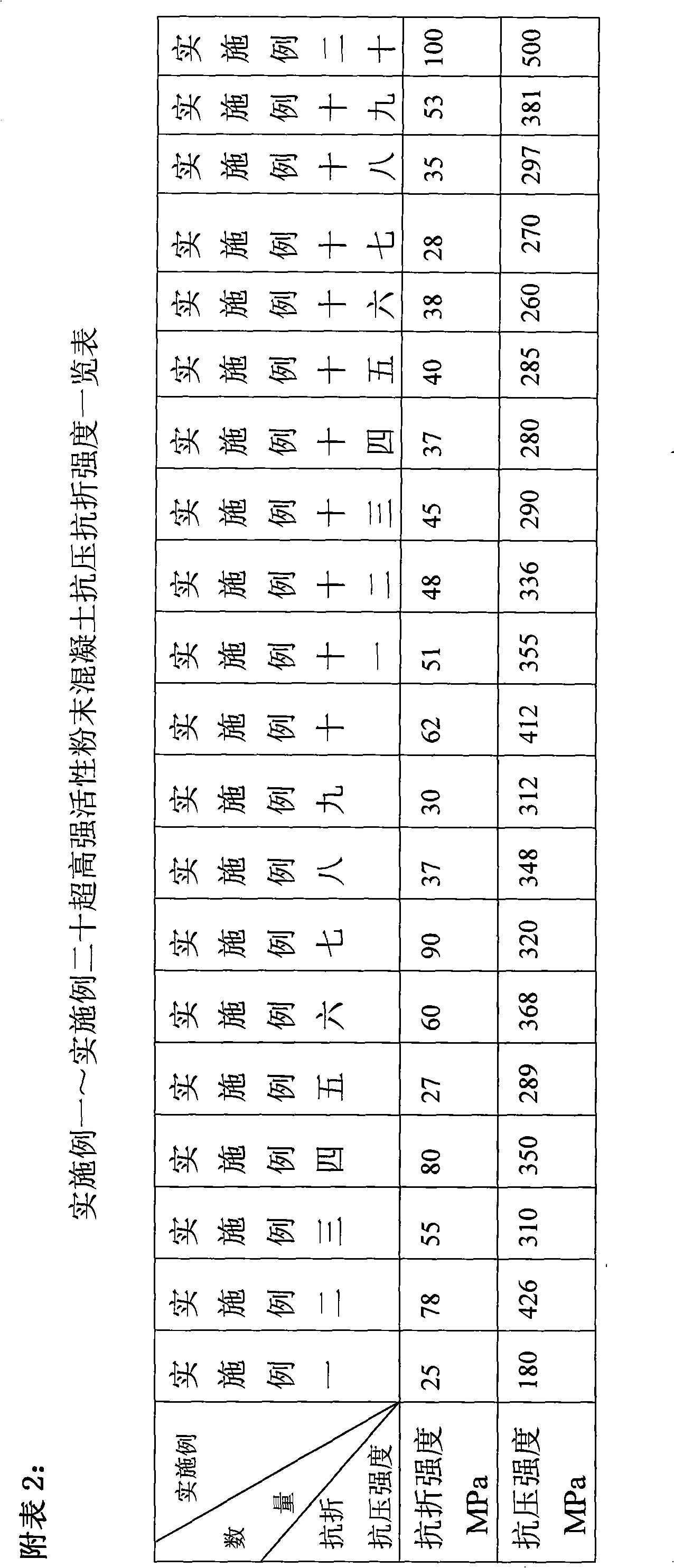

Ultrahigh-strength active powder concrete and preparation method thereof

An ultrahigh-strength active powder concrete is a mixture prepared by mixing the following materials according to weight portion: 1000 portions of Portland cement, 600-1400 portions of quartz sand, 90-400 portions of siliceous dust, 200-400 portions of silicon powder, 100-300 portions of quartz powder, 80-350 portions of high-strength steel fiber, 15-30 portions of high-efficiency water reducing agent, 250-320 portions of water, 60-120 portions of AEA expanding agents, 0-15 portions of latex powder, 0-10 portions of polyester fiber and 0-2 portions of antifoam agents. The preparation method comprises the following steps: preparing the materials according to the weight proportion, firstly mixing water, cement, quartz sand, siliceous dust, silicon powder, quartz powder, AEA expanding agents, high-efficiency water reducing agent, latex powder, polyester fiber, and antifoam agents into pasty state; then adding high-strength steel fiber, and mixing for 4-6 minutes. The prepared active powder concrete has super-high compressive and bending strengths, high mechanical property and high durability.

Owner:LIUZHOU OVM MASCH CO LTD

High-strength steel sheet and process for production thereof

ActiveCN101932745AHigh strengthHelps to reduce weightHot-dipping/immersion processesFurnace typesSheet steelCarbide

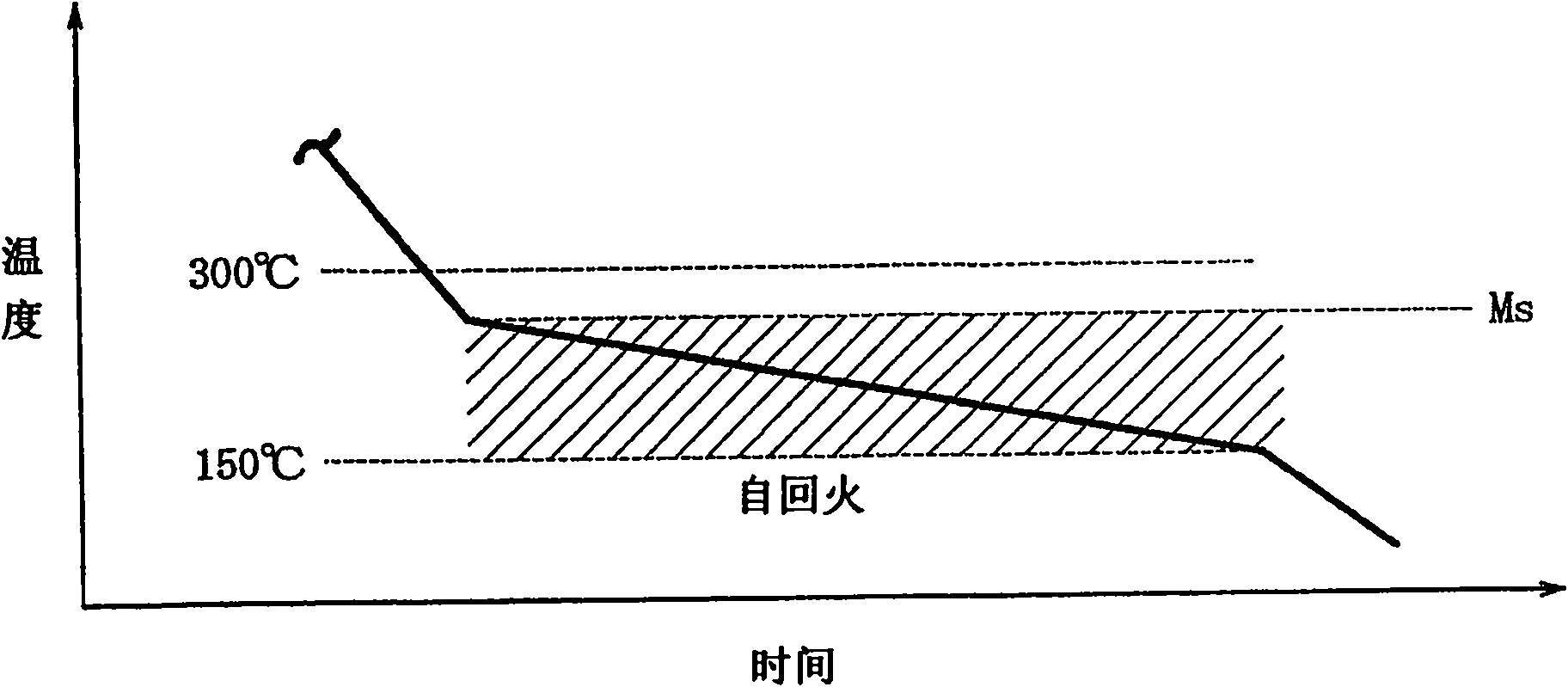

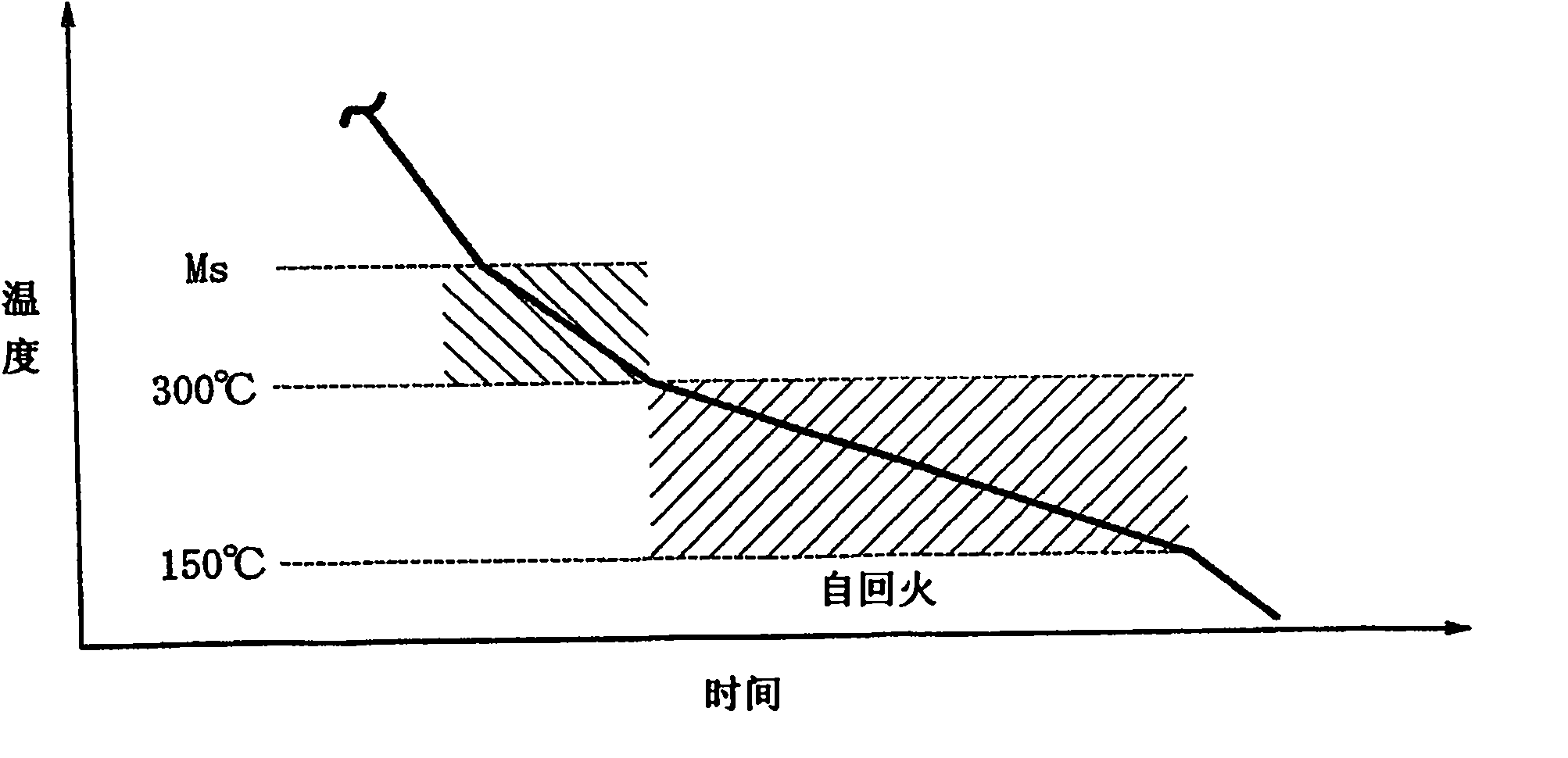

Disclosed are an ultra-high-strength steel sheet having both a tensile strength of as high as 1400MPa or above and excellent formability and an advantageous process for manufacturing the same. A high-strength steel sheet having both a composition which contains by mass C: 0.12 to 0.50%, Si: 2.0% or less, Mn: 1.0 to 5.0%, P: 0.1% or less, S: 0.07% or less, Al: 1.0% or less, and N: 0.008% or less with the balance being Fe and unavoidable impurities, and a structure which comprises, in terms of area fraction, autotempered martensite: 80% or more, ferrite: less than 5%, bainite: 10% or less, and retained austenite: 5% or less and in which the average number of precipitated iron carbide particles of 5nm to 0.5[mu]m in the autotempered martensite is 5OE04 or above per mm2.

Owner:JFE STEEL CORP

Permanent magnet rotor construction wherein relative movement between components is prevented

ActiveUS7042118B2Simple methodHigh strengthMagnetic circuit rotating partsPropulsion systemsInterference fitPermanent magnet rotor

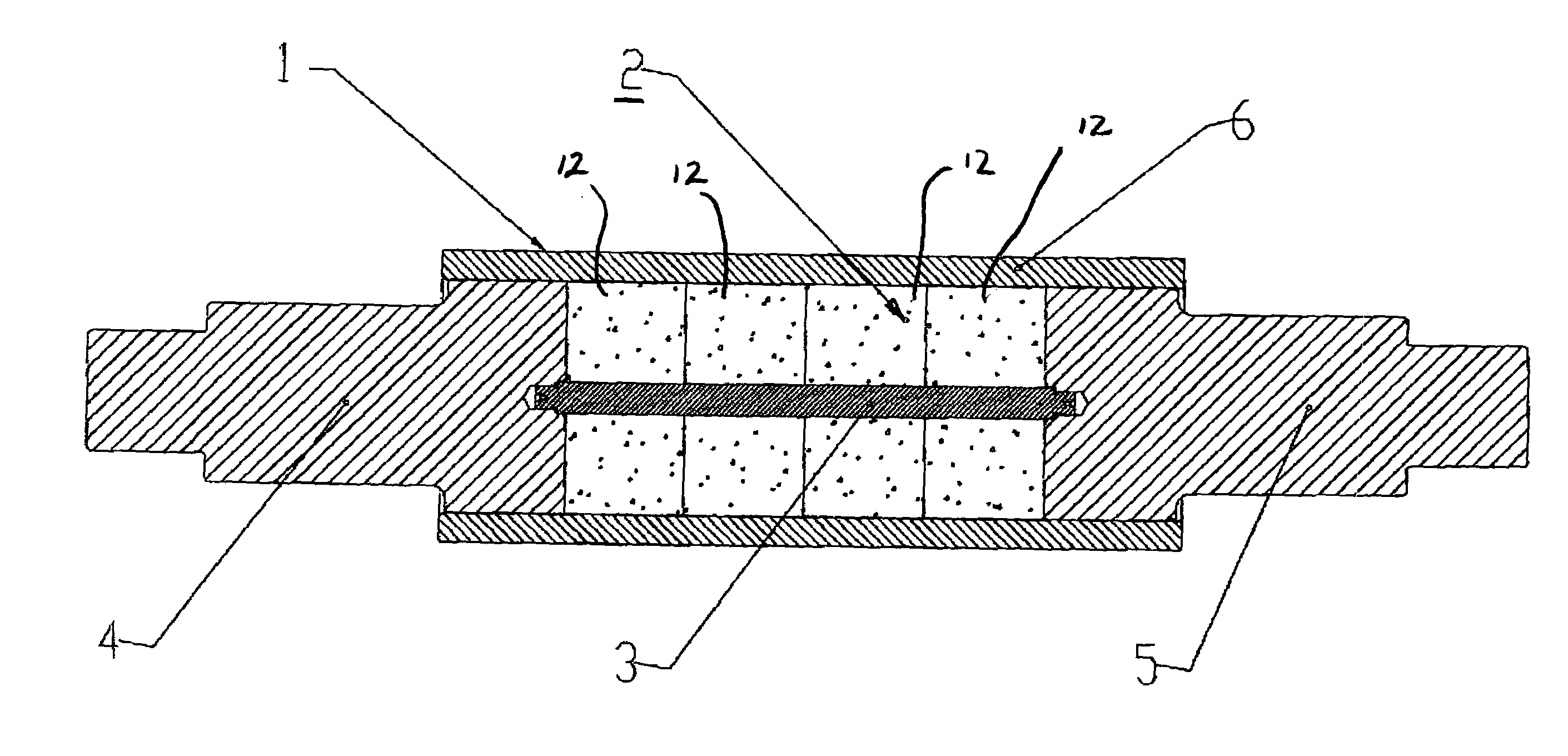

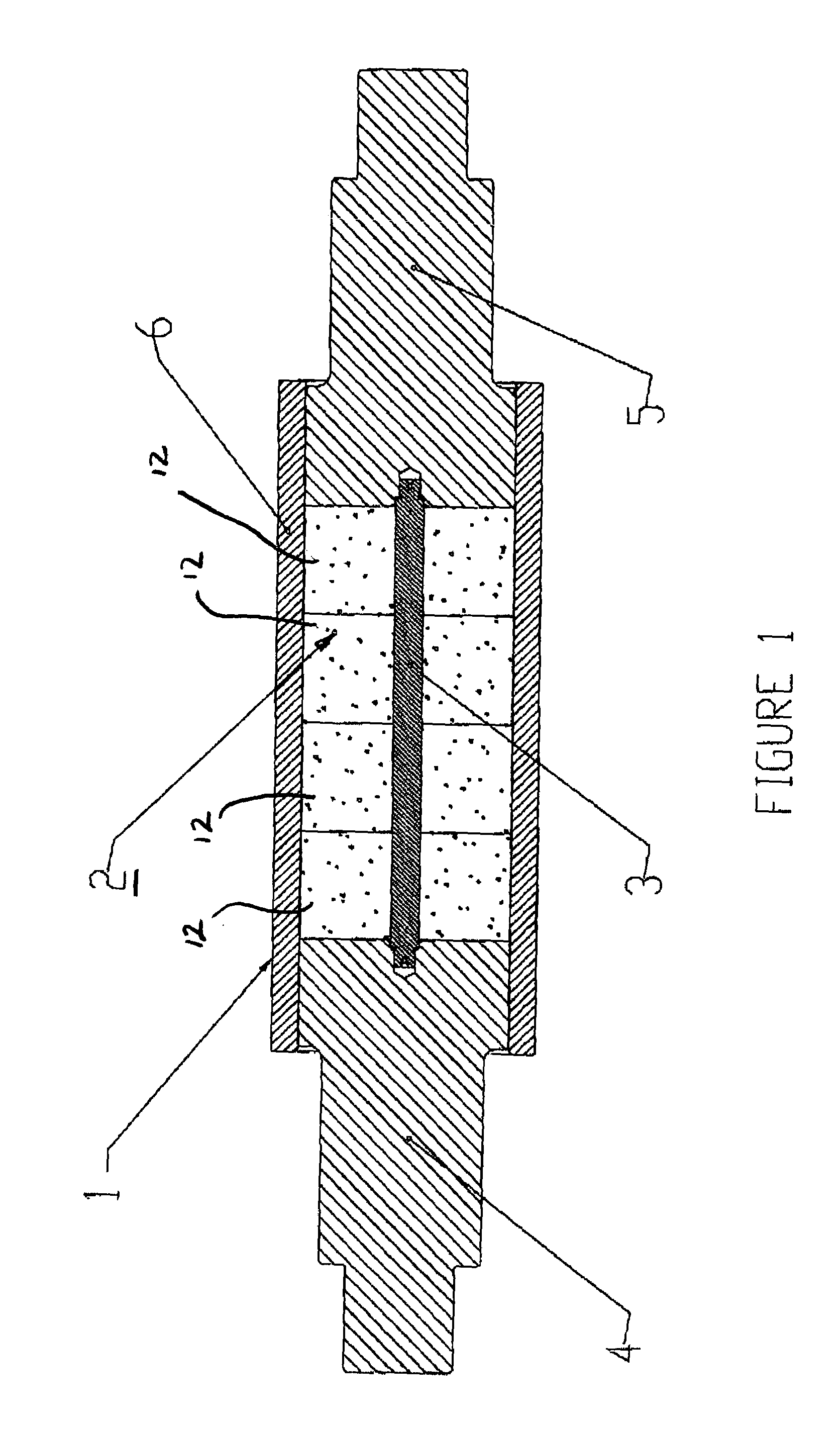

A rotor construction may comprise a rotor with a centrally located permanent magnet section having aligned magnet segments and having a central hole throughout its length. A thin rod of magnetic steel is located in this central hole to support the permanent magnets from within. At each end of the rod are located threaded sections for attachment to supporting end stubs. A high strength steel sleeve is interference fit over both the magnets and the end stubs to provide a mechanical link from stub to stub. The guide rod insures that the end stubs and central magnet are concentric during initial processing, prevents relative motion between the rotor components and provides support for the magnet once the sleeve is installed.

Owner:CALNETIX TECH

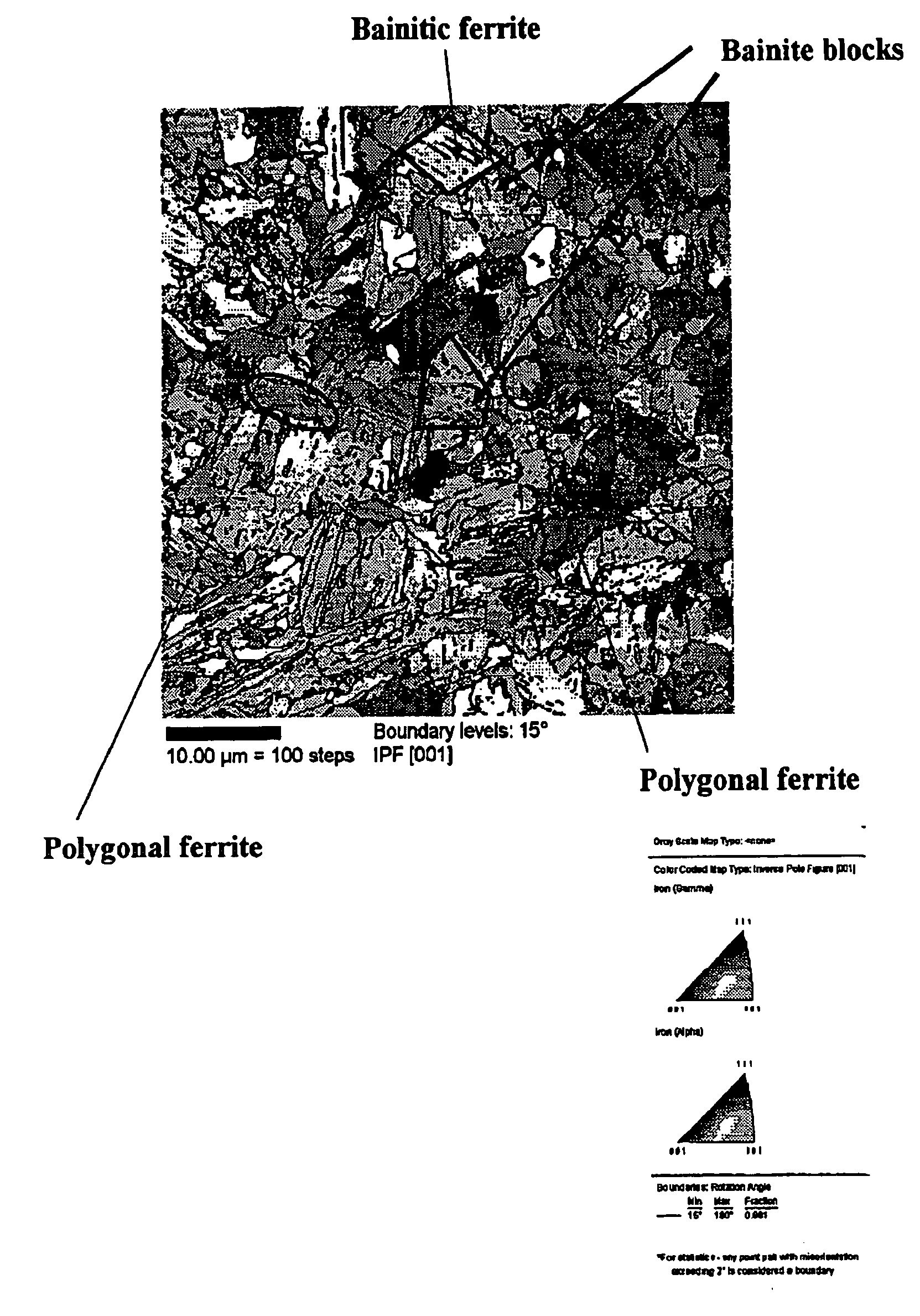

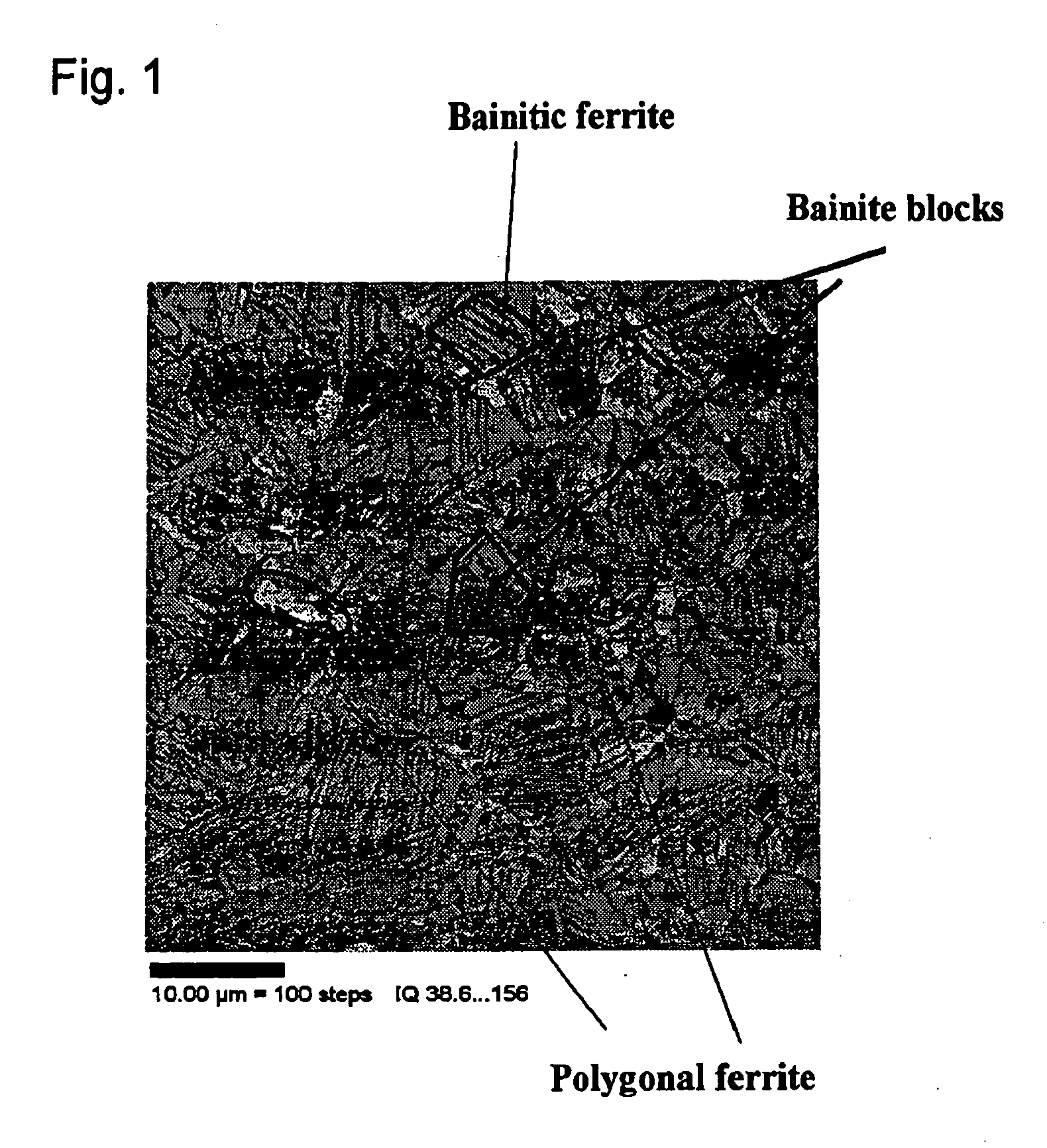

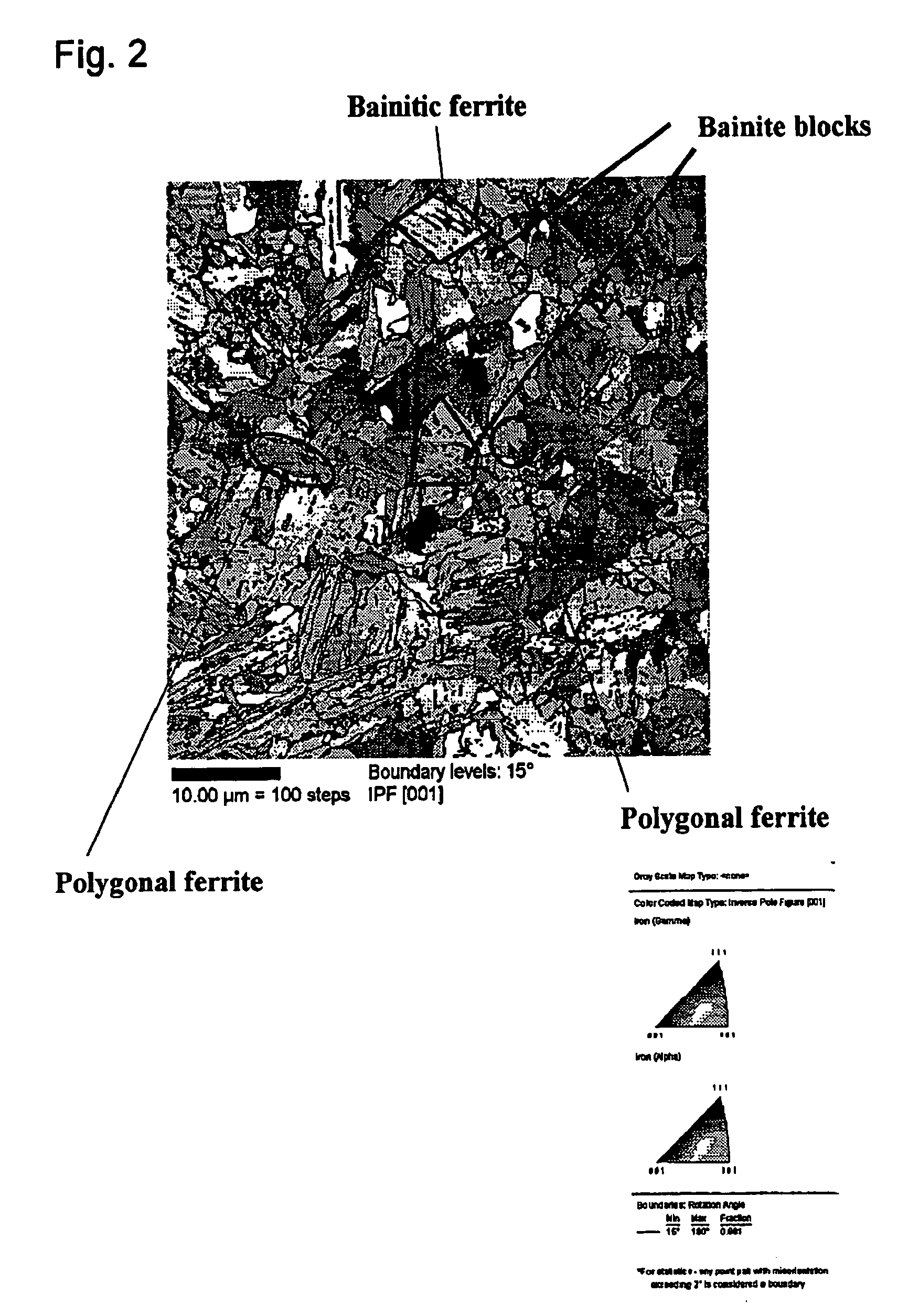

Ultra-high strength steel sheet having excellent hydrogen embrittlement resistance, and method for manufacturing the same

InactiveUS20050150580A1High strengthImprove hydrogen embrittlement resistanceManganeseUltimate tensile strength

The present invention provides an ultra-high strength steel sheet having excellent hydrogen embrittlement resistance, which includes: 0.06 to 0.6% of C; 0.5 to 3% of Si+Al; 0.5 to 3% of Mn; 0.15% or lower of P; and 0.02% or lower of S in terms of mass percentage, and also includes 3% or higher of residual austenite structure, 30% or higher of bainitic ferrite structure, and preferably 50% or lower of polygonal ferrite in terms of an areal ratio to the entire structure, wherein a mean grain size of bainite blocks is smaller than 20 μm as determined by comparing observations of the same region of the bainitic ferrite structure by EBSP (electron back scatter diffraction pattern) and SEM.

Owner:KOBE STEEL LTD

High strength cold-rolled plate with excellent formability and production method thereof

The invention provides a high strength cold-rolled plate with excellent formability, containing: no more than 0.0040% of C, 0.02-0.15% of Si, 0.20-1.00% of Mn, 0.02-0.09% of P, 0.015-0.06% Ti, 0.01-0.05% of Nb, and the rest being Fe. The production method comprises: smelting, continuous casting, hot-rolling, cold rolling and continuous annealing, wherein the heating temperature of the hot-rolled billet is 1170-1270 DEG C, the finishing temperature of hot-rolling is 850-960 DEG C, and the coiling temperature is 650-760 DEG C; the cold rolling reduction percent is 60-82%; the annealing temperature is 760-880 DEG C, the thermal insulation time is 60-210s, the slow-cooling segment temperature is 630-700 DEG C, and the fast-cooling exit temperature is 300-500 DEG C; and the levelling elongationrate is 0.5-1.0%. The high strength steel plate containing phosphorus of the invention has the features of low carbon, microalloying and purity. The steel added with a certain amount of Nb and Ti hashigher plasticity. Using relevant rolling and annealing technique, the indexes of performance of the steel achieves the demand of high strength automobile stamping parts.

Owner:ANGANG STEEL CO LTD

Low-yield ratio and high-strength steel for bridges and manufacturing method thereof

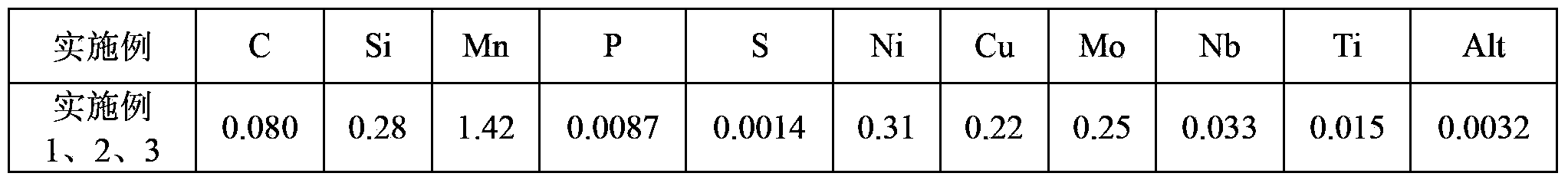

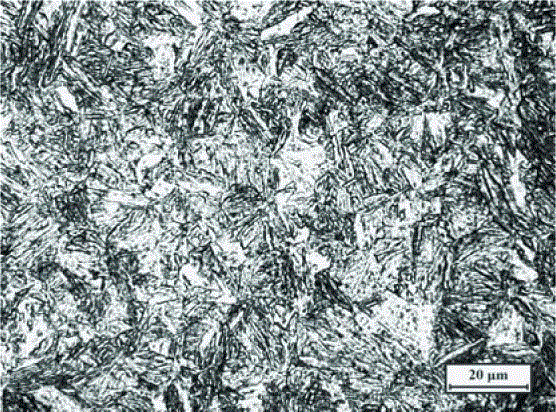

The invention discloses low-yield ratio and high-strength steel for bridges and a manufacturing method thereof. The steel comprises the following chemical components by weight percent : 0.06-0.10 percent of C, 0.20-0.45 percent of Si, 1.20-1.50 percent of Mn, no more than 0.010 percent of P, no more than 0.0020 percent of S, 0.30-.060 percent of Ni, 0.20-0.50 percent of Cu, 0.15-0.50 percent of Mo, 0.025-0.060 percent of Nb, no more than 0.035 percent of Ti, 0.020-0.040 percent of Alt, and Fe and unavoidable impurities in balancing amount. According to the invention, through smelting, refining, performing a reasonable thermo-mechanical control process (TMCP) and optimizing tempering heat treatment production, the tensile strength of the steel is 700-780 MPa, the yield strength is 530-600MPa, the extensibility is greater than or equal to 18 percent, the yield ratio is less than or equal to 0.80, and 40 below zero DEG C low-temperature longitudinal impact is greater than or equal to 100 J, so that the steel is good in obdurability matching and low in the yield ratio, is provided with excellent performance of shock prevention, and is stable in production process and strong in operability.

Owner:NANJING IRON & STEEL CO LTD

High-strength steel sheet with yield strength of 1100MPa and manufacturing method thereof

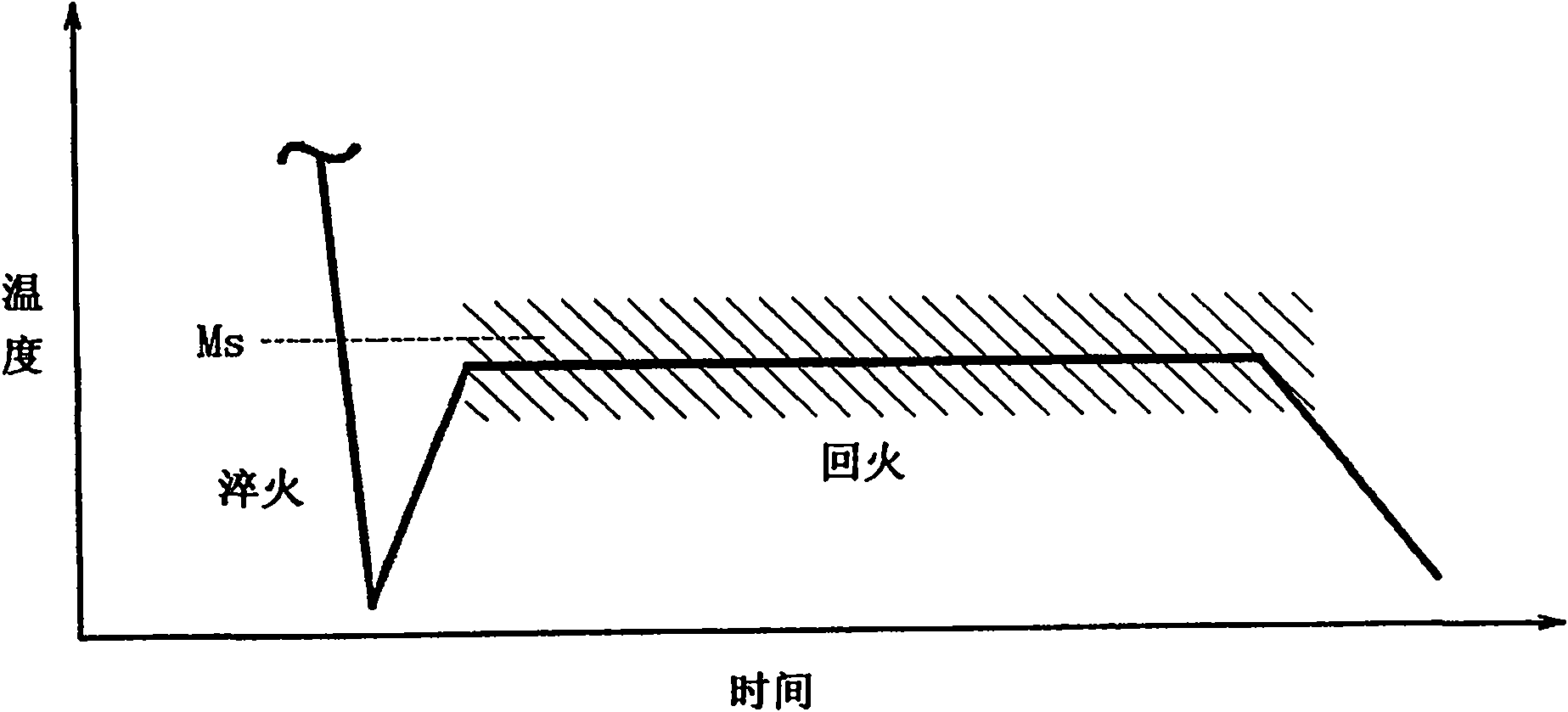

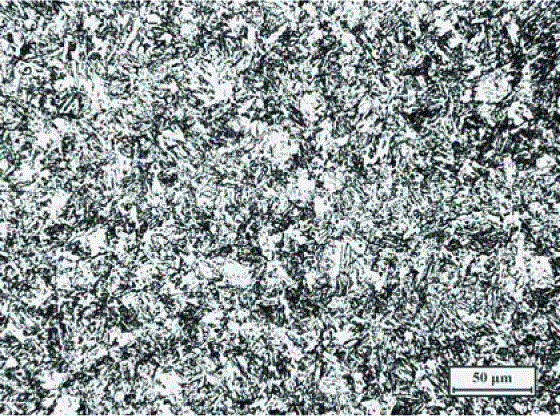

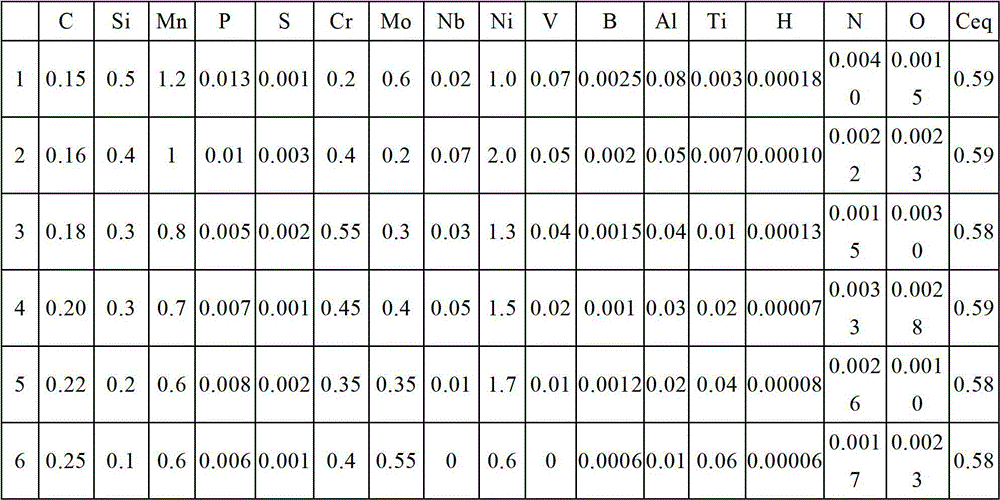

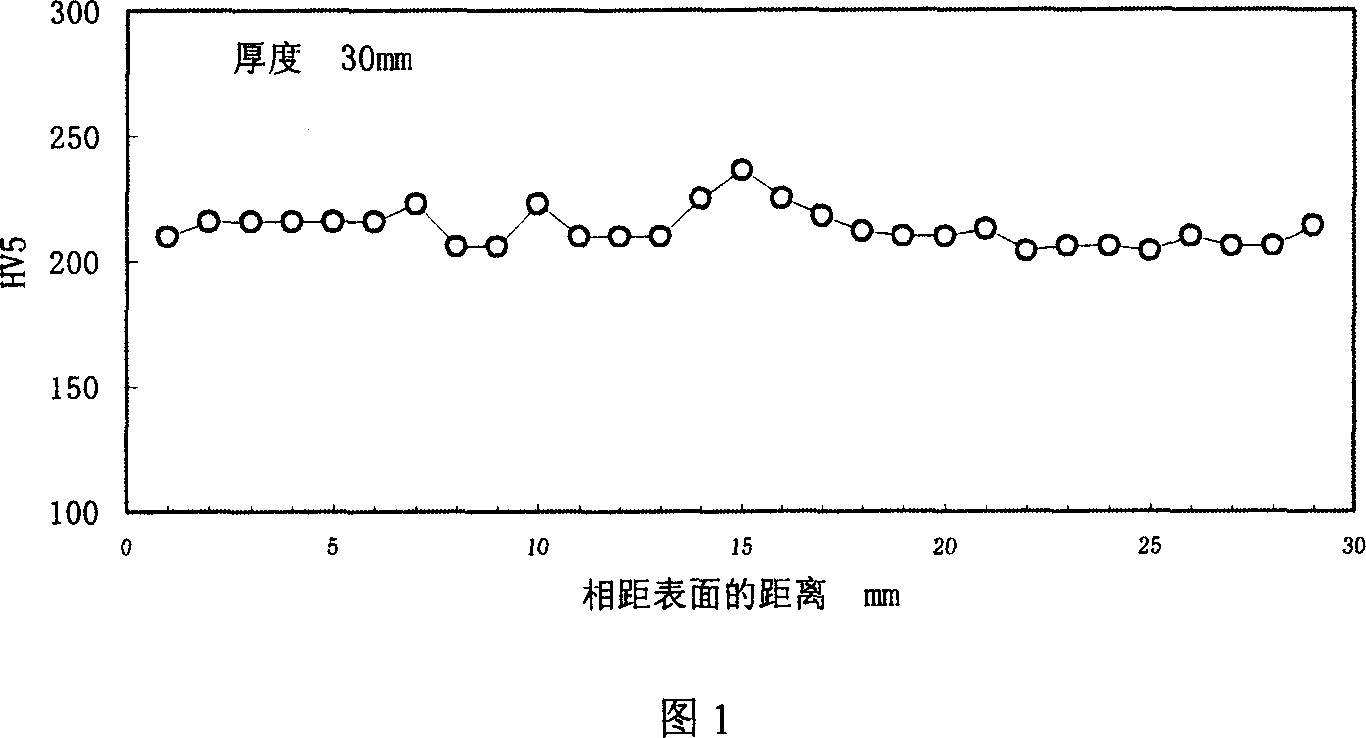

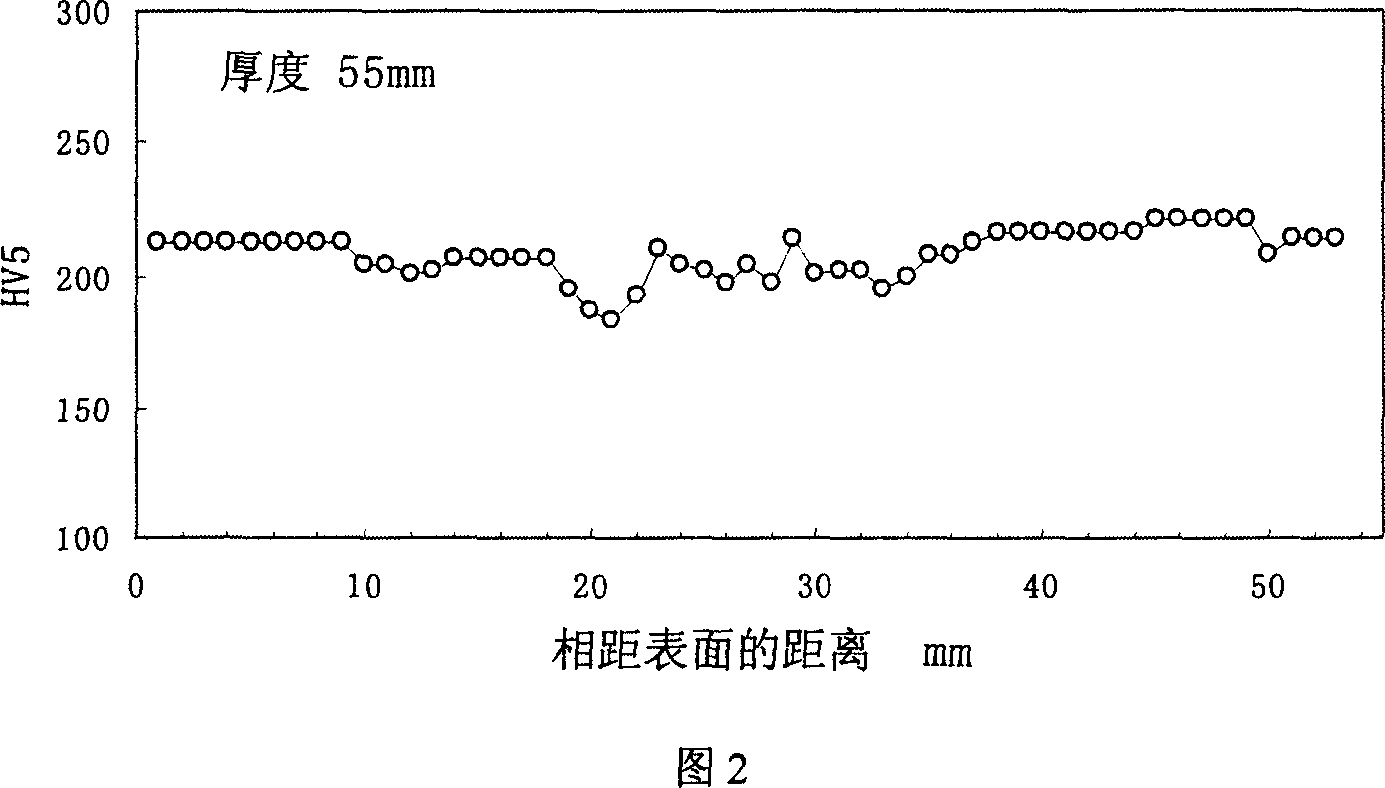

A high-strength steel sheet with yield strength of 1100MPa and a manufacturing method thereof. The high-strength steel sheet comprises, based on the weight percentage, 0.15-0.25% of C, 0.10-0.50% of Si, 0.60-1.20% of Mn, no more than 0.013% of P, no more than 0.003% of S, 0.20-0.55% of Cr, 0.20-0.70% of Mo, 0.60-2% of Ni, 0-0.07% of Nb, 0-0.07% of V, 0.0006-0.0025% of B, 0.01-0.08% of Al, 0.003-0.06% of Ti, no more than 0.00018% of H, no more than 0.0040% of N, no more than 0.0030% of O, and the balance of Fe and inevitable impurities; and the carbon equivalent CEQ is no more than 0.60%. A quenching and a tempering heat treatment are employed to obtain a tempered martensite tissue. The steel provided by the present invention has yield strength no less than 1100MPa, tensile strength no less than 1250MPa, Charpy ballistic work Akv (-40 DEG C) no less than 50J, and good strength and toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

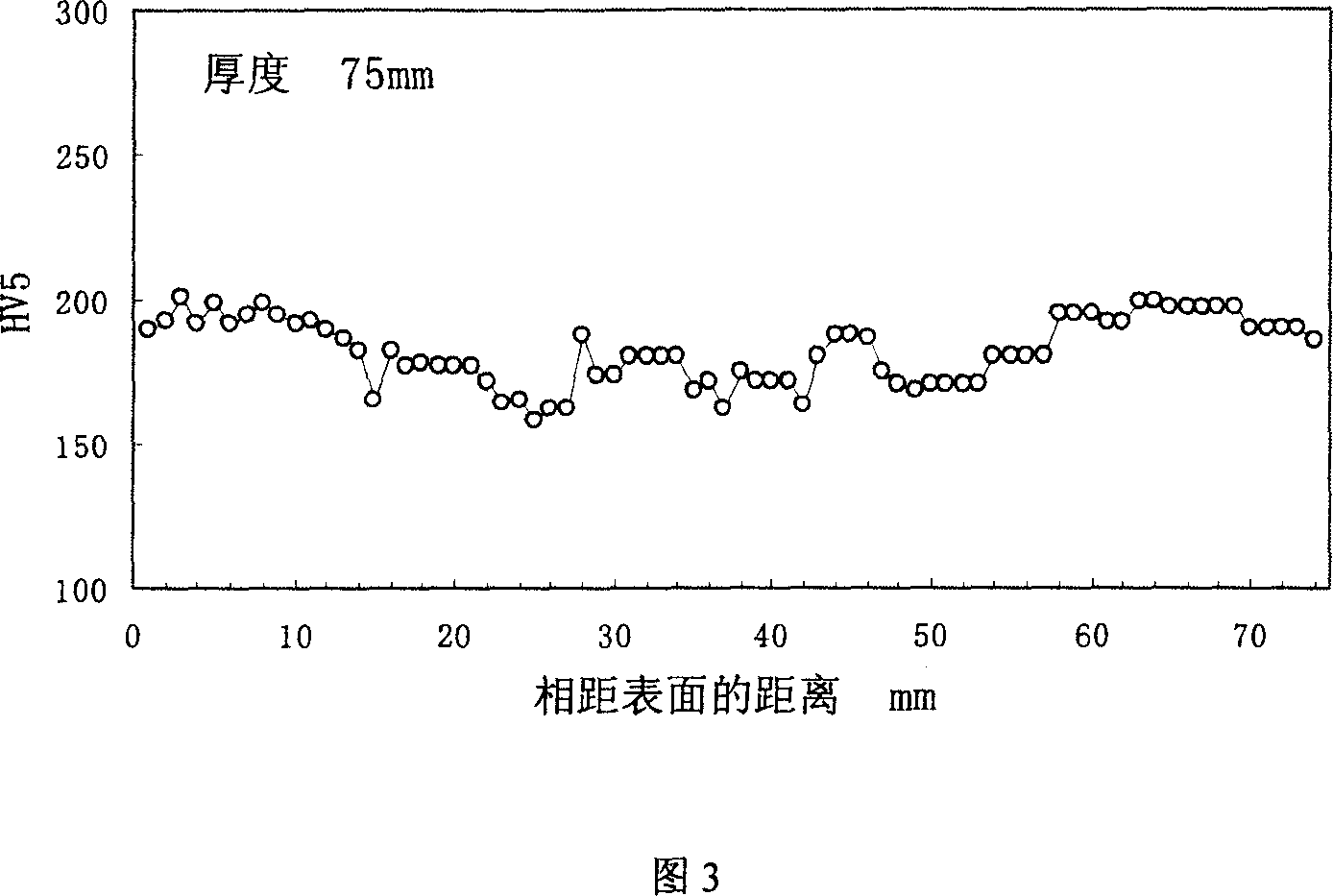

Thick steel plate with high strength and low welding crack sensitivity and its production process

InactiveCN1932063ASimple designGuaranteed performanceTemperature control deviceSheet steelChemical composition

The present invention discloses one kind of thick steel plate with high strength and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.09 wt%, Si 0.15-0.55 wt%, Mn 1.00-1.60 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo not more than 0.30 wt%, Cu not more than 0.30 wt%, V 0.02-0.06 wt%, Nb 0.005-0.05 wt% and Als 0.010-0.04 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 % and Ceq not higher than 0.42 %. The production process includes two stage controlled rolling, on-line laminar flow cooling, off-line tempering and other steps. The produced steel plate has thickness up to 75mm, tensile strength not lower than 610 MPa and very low welding crack sensitivity.

Owner:ANGANG STEEL CO LTD

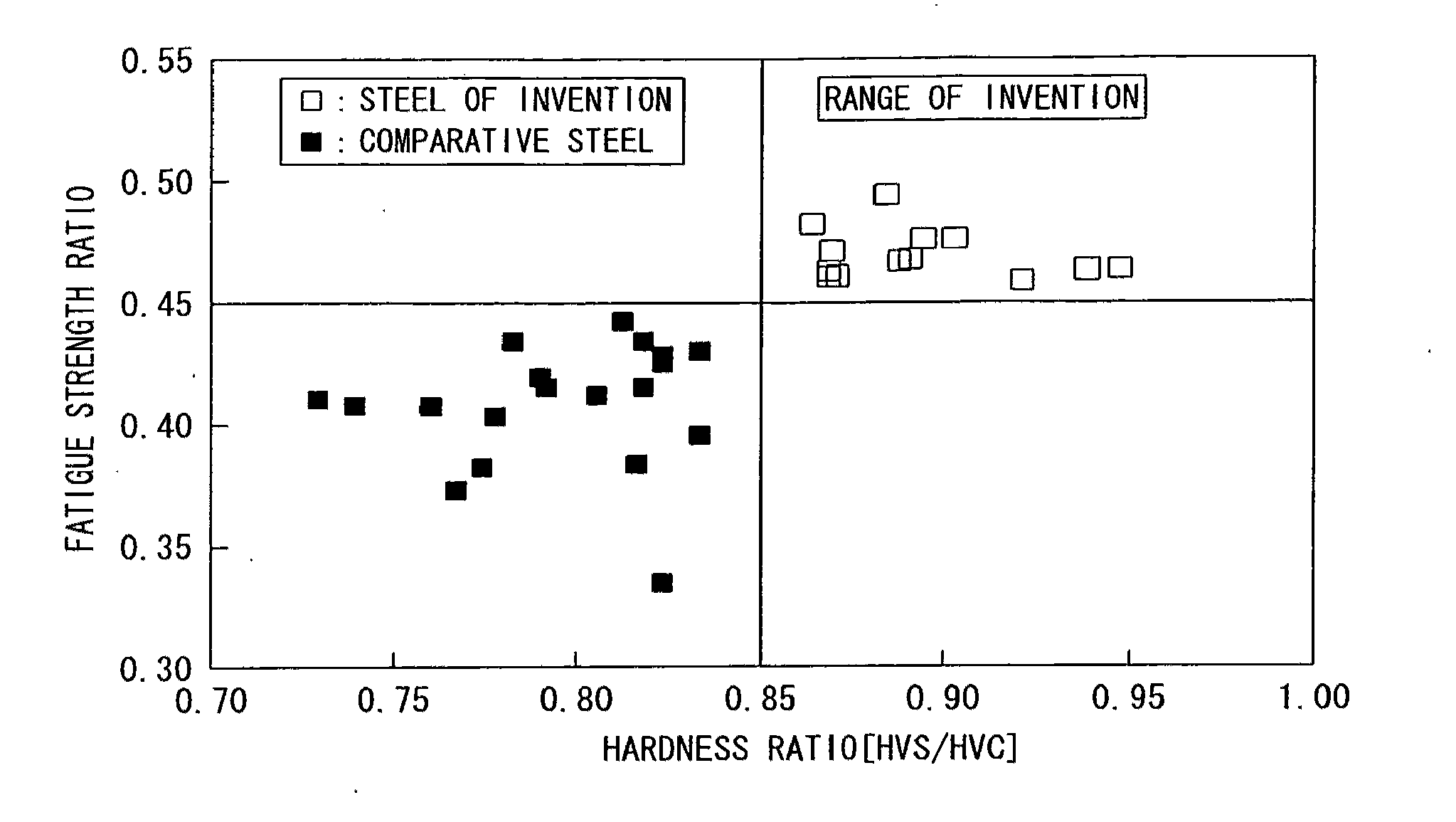

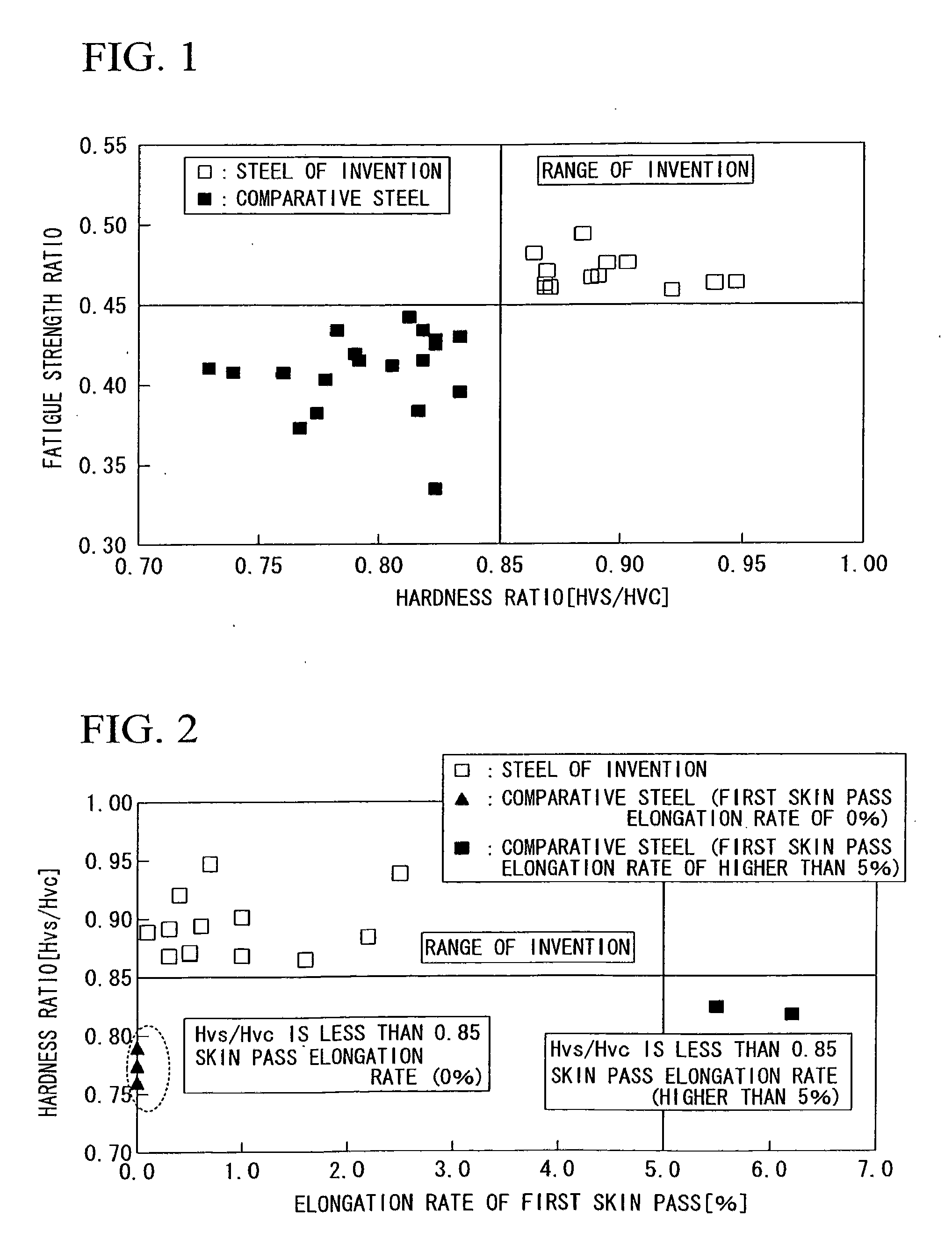

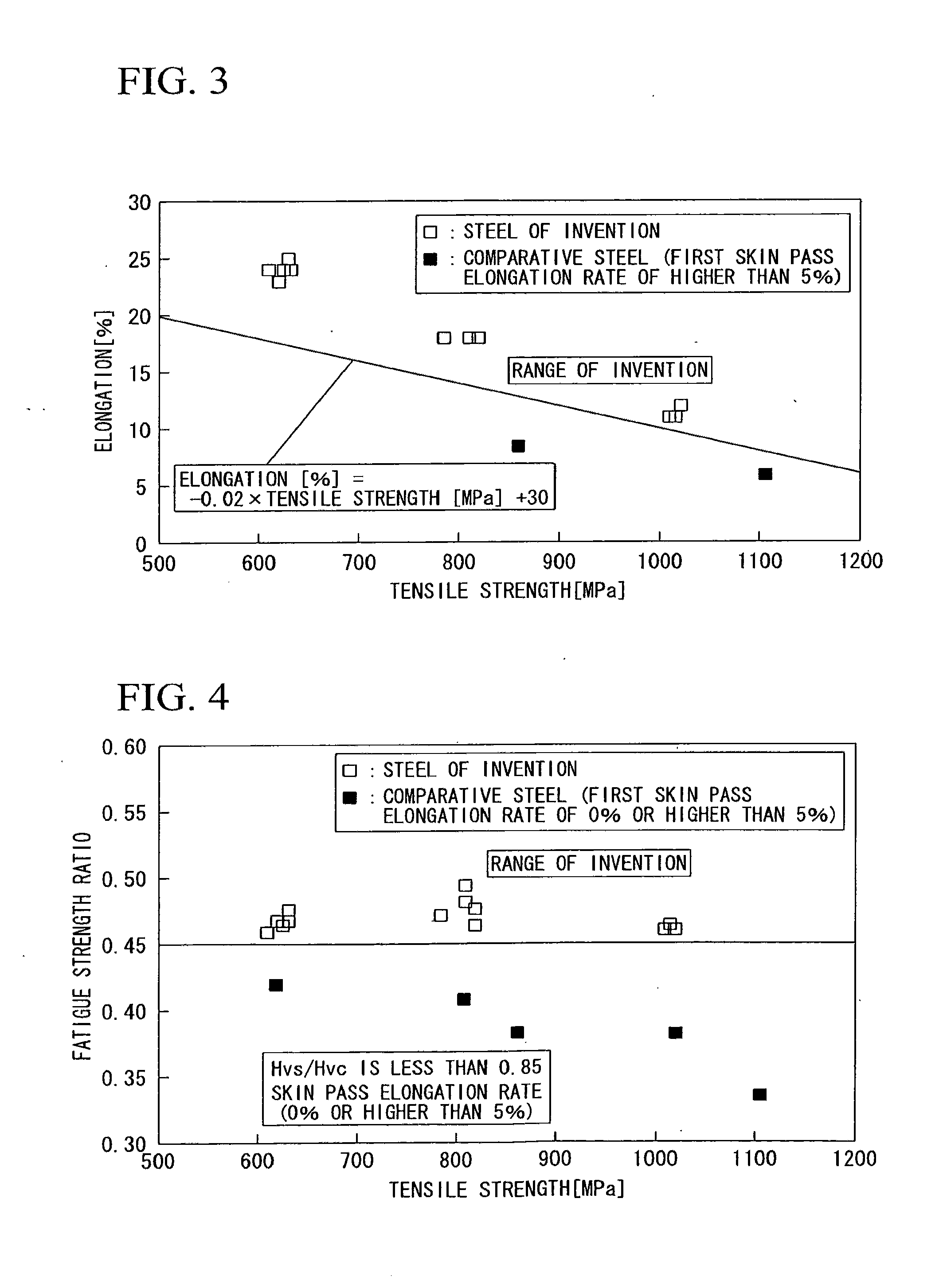

High-strength steel sheet, hot-dipped steel sheet, and alloy hot-dipped steel sheet that have excellent fatigue, elongation, and collision characteristics, and manufacturing method for said steel sheets

ActiveUS20120031528A1Improve crash performanceHigh yield stressHot-dipping/immersion processesFurnace typesUltimate tensile strengthImpurity

This high-strength steel sheet includes: in terms of percent by mass, 0.03 to 0.10% of C; 0.01 to 1.5% of Si; 1.0 to 2.5% of Mn; 0.1% or less of P; 0.02% or less of S; 0.01 to 1.2% of Al; 0.06 to 0.15% of Ti; and 0.01% or less of N; and contains as the balance, iron and inevitable impurities, wherein a tensile strength is in a range of 590 MPa or more, and a ratio between the tensile strength and a yield strength is in a range of 0.80 or more, a microstructure includes bainite at an area ratio of 40% or more and the balance being either one or both of ferrite and martensite, a density of Ti(C,N) precipitates having sizes of 10 nm or smaller is in a range of 1010 precipitates / mm3 or more, and a ratio (Hvs / Hvc) of a hardness (Hvs) at a depth of 10 μm from a surface to a hardness (Hvc) at a center of a sheet thickness is in a range of 0.85 or more.

Owner:NIPPON STEEL CORP

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

Vehicle bumper beam

A bumper beam includes an open front section made from a high-strength material such as ultra-high-strength steel (UHSS) material, and further includes a mating back section made of lower strength material attached to a rear side of the front section along abutting flanges. The front and back sections combine to define different tubular cross sections along their length, thus providing selected stiffness and strength at critical areas of the bumper beam. The front section can be roll-formed, and the back section can be stamped, thus taking advantage of roll-forming processes' ability to form high-strength materials, while allowing the back section to have a more complicated shape and be stamped. For example, the back section can be made from a material selected from a group consisting of HSLA steel, aluminum, and / or polymeric material. The back section is attached to the beam using welding or mechanical attachment.

Owner:SHAPE CORP

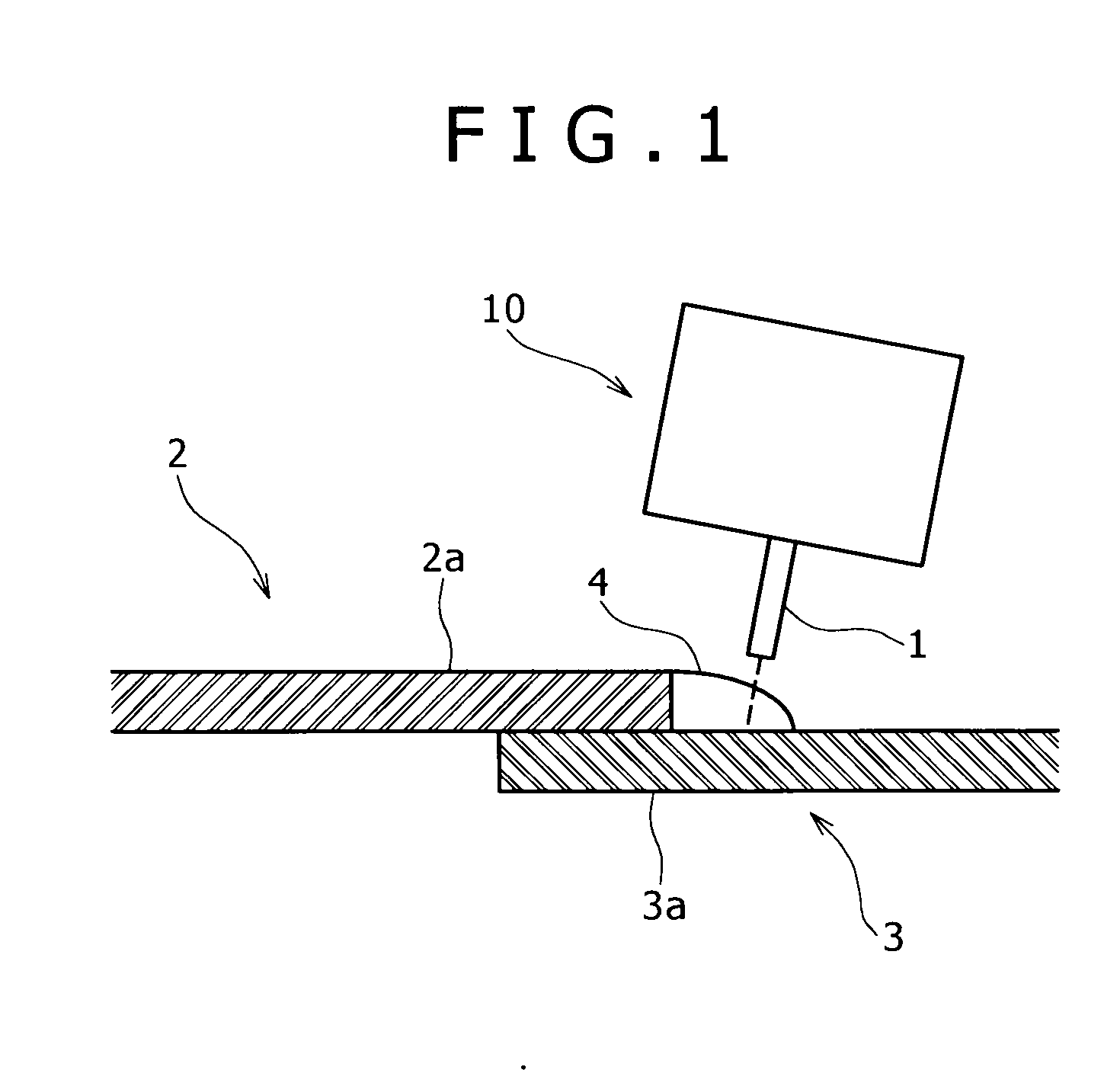

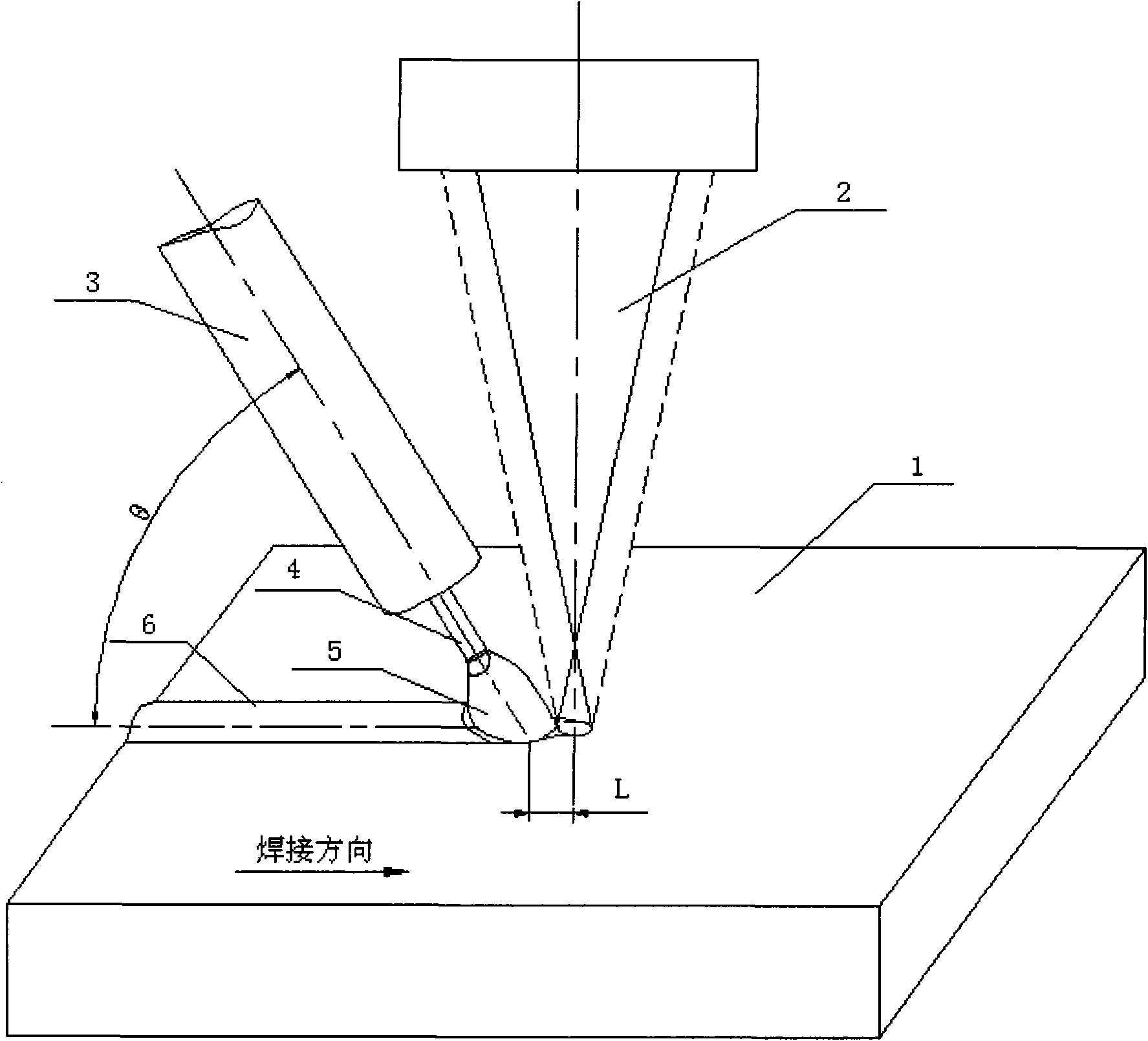

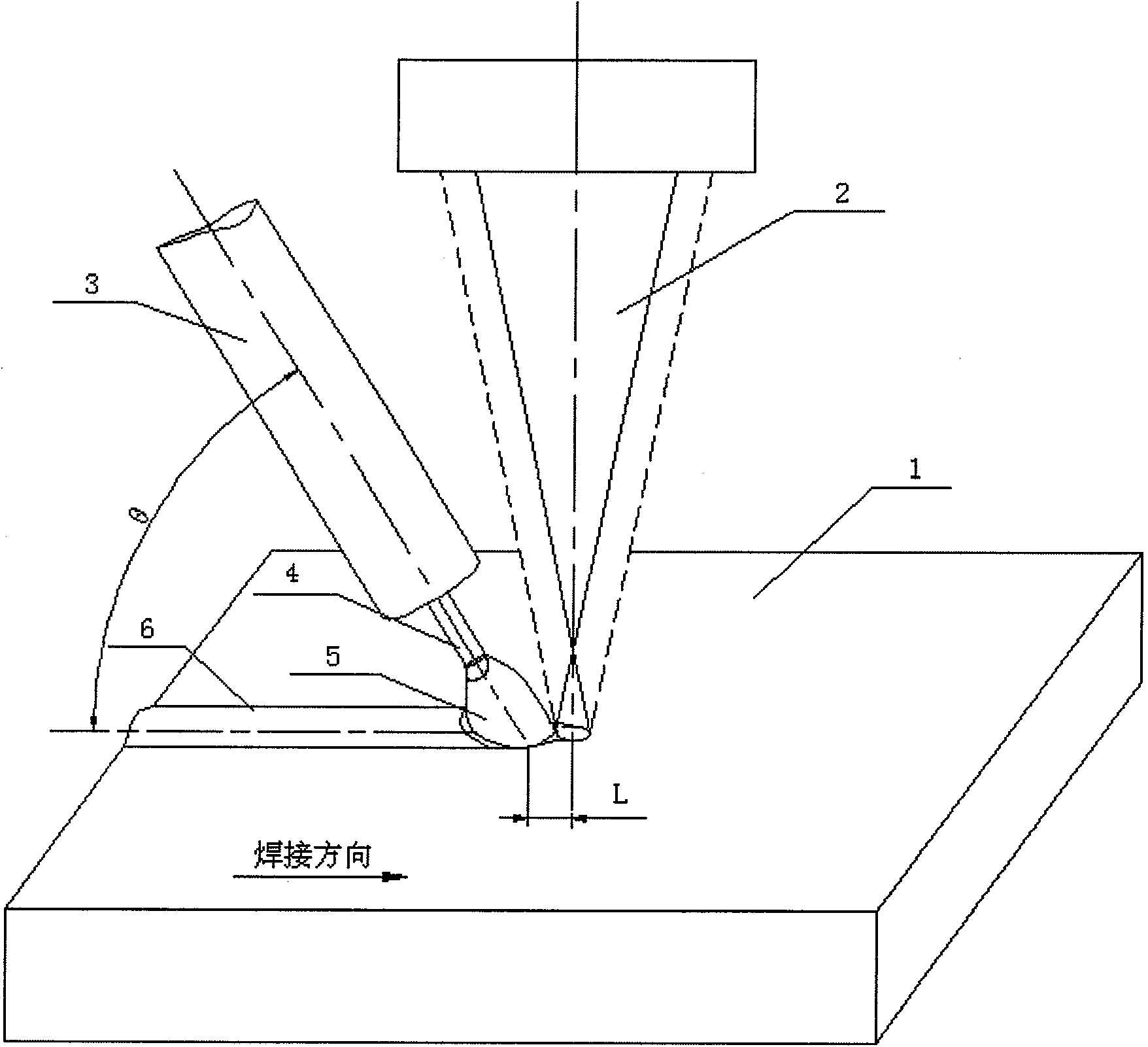

Method for welding with laser-cold metal transferred arc composite heat source

ActiveCN101811231ASolve the problem of poor spreadabilityImprove stabilityLaser beam welding apparatusArc stabilityAlloy

The invention provides a method for welding with a laser-cold metal transferred arc composite heat source, and belongs to the technical field of composite heat sources. The welding method solves the technical problems of low-quality welding lines and low arc stability of the pure Ar-protected cold metal transferred arc welding. The method comprises the following steps of: using pure Ar gas for protection during welding, and forming a novel composite heat source by using the cold metal transferred arc(5) and a laser beam (2) of which the power is more than or equal to 800, wherein the laser beam (2) is defocused, the diameter of a laser spot formed by the laser beam (2) on the surface of a workpiece (1) to be welded is 1 to 4mm, a spot of the cold metal transferred arc (5) can be arranged in front of or behind the spot of the laser beam (2), the central distance of the two spots is 0 to 8mm, and an included angle between a welding torch(3) of the cold metal transferred arc(5) and the horizontal plane is 45 and 75 degrees. The composite heat source is mainly used for welding plates and tubes made of stainless steel, high-strength steel and nickel-based alloy.

Owner:HARBIN WELDING INST LTD

High-strength steel sheet and high-strength steel pipe excellent in deformability and method for producing the same

The present invention provides a line pipe of, e.g., the API standard X60 to X100 class. The line pipe has an excellent deformability, as well as excellent low temperature toughness and high productivity, a steel plate used as the material of the steel pipe. Methods for producing the steel pipe and the steel plate are also provided. In particular, a high-strength steel plate excellent in the deformability has a ferrite phase is dispersed finely, and accounts for 5% to 40% in area percentage in a low temperature transformation structure mainly composed of a bainite phase. For example, most grain sizes of the ferrite phase are smaller than the average grain size of the bainite phase. A high-strength steel pipe excellent in deformability is also provided, in which a large diameter steel pipe is produced through forming the steel plate into a pipe shape. The steel pipe has the above-referenced structure, and satisfies the conditions that YS / TS is 0.95 or less and YSxuEL is 5,000 or more. Methods for producing such steel plate and steel pipe are also provided.

Owner:NIPPON STEEL CORP

Ultrahigh-strength steel laser tailor welded blank and forming process thereof

InactiveCN102162574AGood formabilityReduce weightSheets/panelsLaser beam welding apparatusHot stampingRoom temperature

The invention relates to an ultrahigh-strength steel laser tailor welded blank and a forming process thereof. The forming process provided by the invention comprises the following steps: carrying out the laser tailor welding on ultrahigh-strength steel and high-strength steel according to the needed shape; then, delivering the obtained welded blank to a furnace filled with a protective gas and heating to 920-940 DEG C to be continued for at least 5 minutes; fully austenitizing; transferring the austenitized welded blank to a press machine to be rapidly molded and formed; cooling to 100-150 DEG C through pressurization quenching; and cooling along room temperature to obtain the needed parts. The hot stamping process of the laser tailor welded blank provided by the invention has the double advantages of the forming and hot stamping forming of the laser tailor welded blank and simultaneously solves the problems that the ultrahigh-strength steel is difficultly applied to the production ofautomobile structural components / framework components in a laser tailor welded blank mode.

Owner:SHANDONG JIANZHU UNIV

Ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process

InactiveCN1888120ARaise Strength IndexMeet manufacturing requirementsRoll mill control devicesHeat treatment process controlHeat sensitiveUltimate tensile strength

The present invention discloses one kind of ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process. The ultra-high strength steel consists of C 0.05-0.12 wt%, Si 0.05-0.50 wt%, Mn 1.10-1.70 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Nb 0.025-0.070 wt%, V 0.005-0.080 wt%, Mo 0.20-0.50 wt%, Ni 0.30-0.80 wt%, Ti 0.005-0.025 wt%, Cu 0.25-0.80 wt%, B 0.0005-0.0020 wt%, and Cr 0.10-0.70 wt%, except Fe and inevitable impurities. It has carbon equivalent not lower than 0.65 % and heat sensitive coefficient not lower than 0.30 %. Its making process includes the steps of smelting, desulfurizing molten iron, combined blowing in converter, vacuum treatment, casting into plate blank, etc. It has yield strength not lower than 880 MPa, tensile strength not lower than 980 MPa and V-shaped notch Charpy absorbed-in-fracture energy at -20 deg.c not lower than 100J.

Owner:武钢集团有限公司

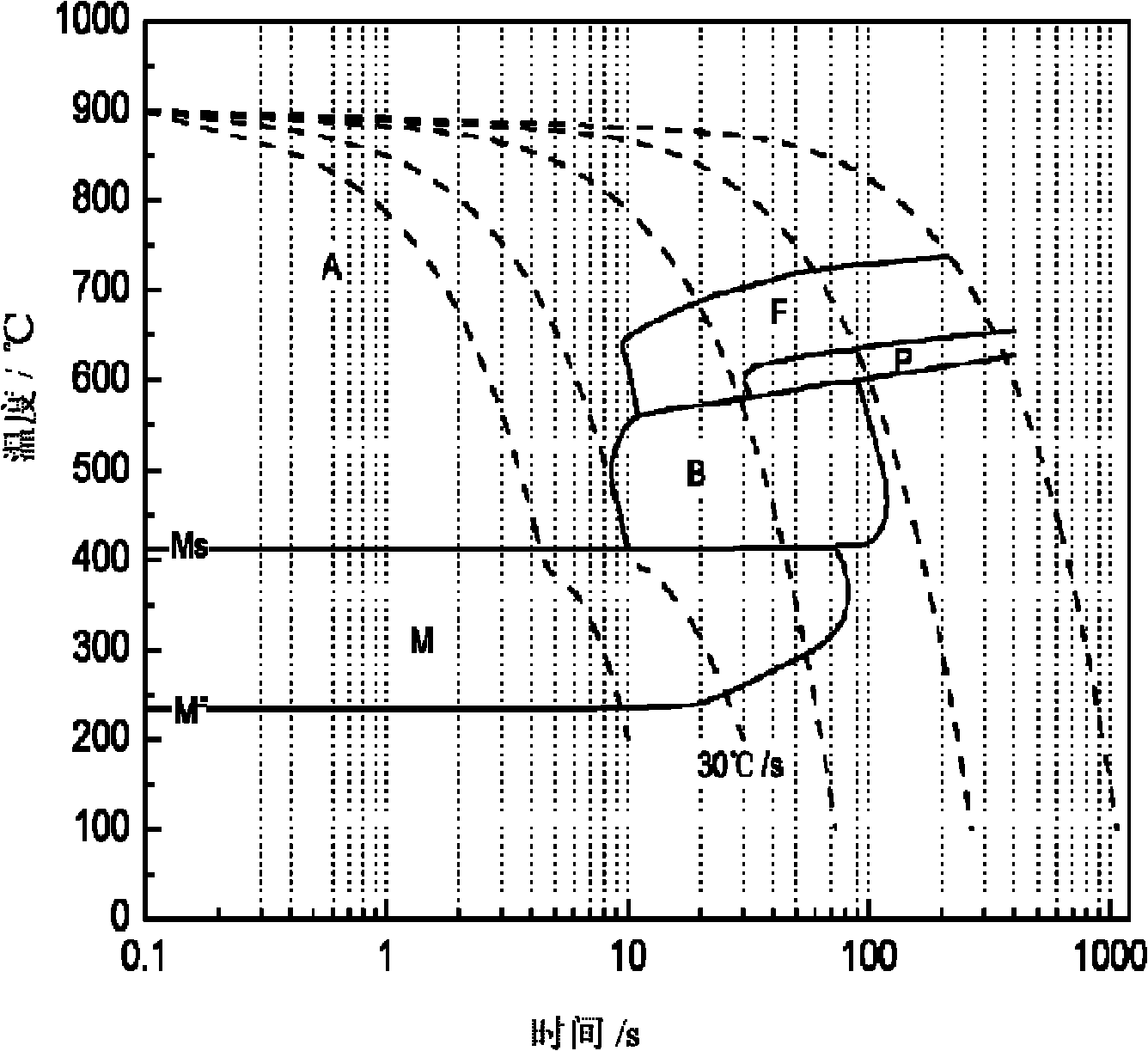

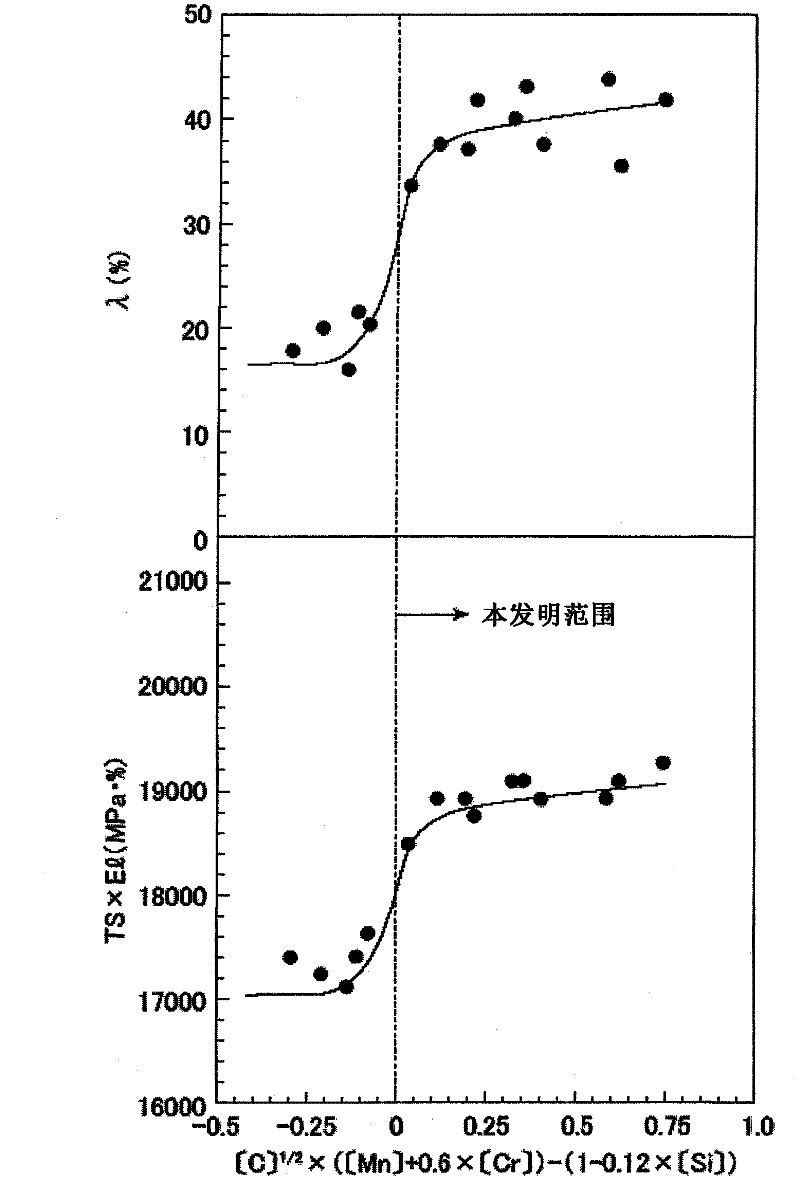

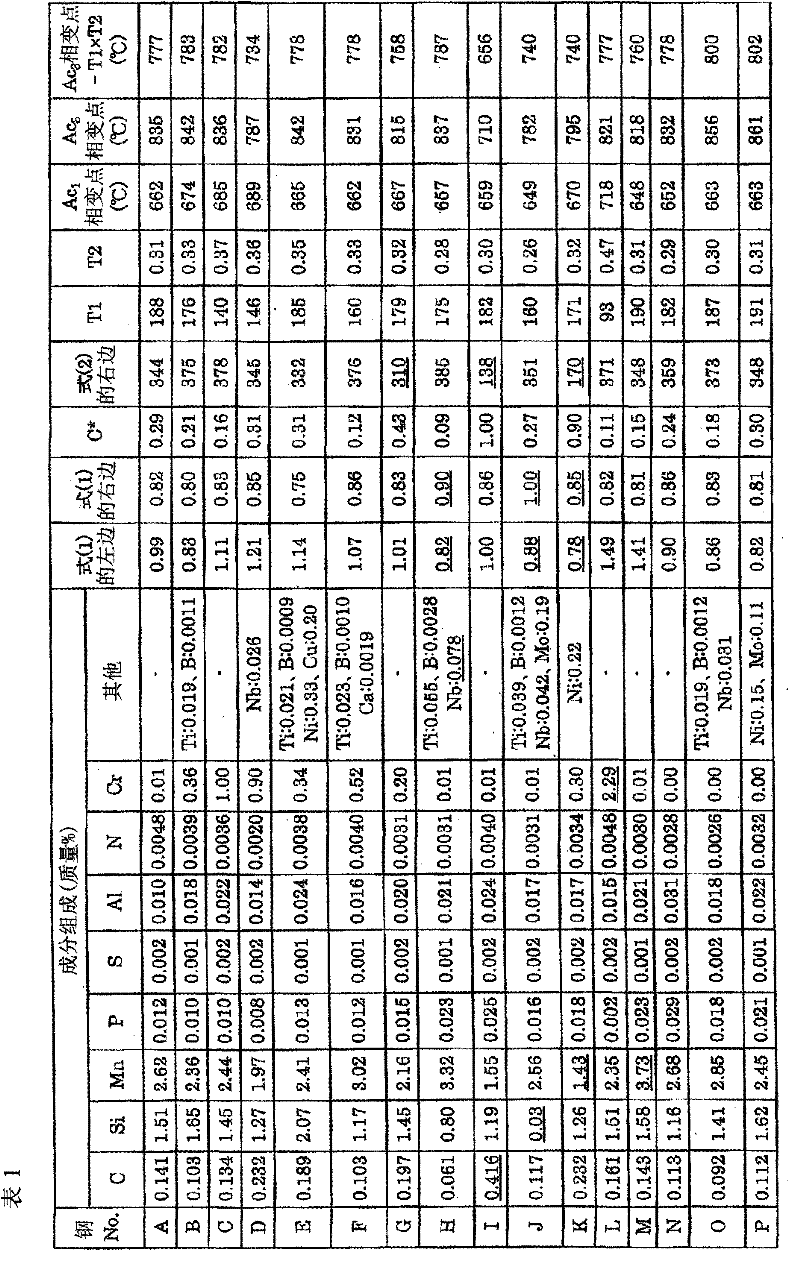

High-strength cold-rolled steel sheet having excellent workability, molten galvanized high-strength steel sheet, and method for producing same

ActiveCN102227511AExcellent hole expandabilityImprove bending performanceHot-dipping/immersion processesFurnace typesUltimate tensile strengthMartensite

The invention provides a high-strength cold-rolled steel sheet having a TS of 1,180 MPa or greater and excellent workability, such as stretch flange workability and bendability. Also provided are a molten galvanized high-strength steel sheet, and a method for producing the same. The high-strength cold-rolled steel sheet having excellent workability has a composition that comprises, by mass%, C: 0.05 to 0.3, Si: 0.5 to 2.5, Mn: 1.5 to 3.5, P: 0.001 to 0.05, S: 0.0001 to 0.01, Al: 0.001 to 0.1, N: 0.0005 to 0.01, and Cr: 1.5 or less (including 0) and satisfies formulas (1) and (2), with the balance being Fe and inevitable impurities. The steel sheet has a microtexture wherein there is a ferrite phase and a martensite phase, the percentage of the texture total surface area occupied by martensite phase is 30% or greater, (the surface area occupied by martensite phase) / (surface area occupied by ferrite phase) exceeds 0.45 but is less than 1.5, and the average particle diameter of the martensite phase is 2 microns or larger. [C]1 / 2*([Mn]+0.6*[Cr])> / =1-0.12*[Si] (1), and 550-350*C*-40*[Mn]-20*[Cr]+30*[Al]> / =340 (2), wherein C*=[C] / (1.3*[C]+0.4*[Mn]+0.45*[Cr]-0.75).

Owner:JFE STEEL CORP

Low alloy high-strength steel plate capable of being welded in large energy input and method of producing the same

ActiveCN101153370AImprove toughnessSimple designRoll mill control devicesHeat treatment process controlHeat-affected zoneSheet steel

The invention provides a high strength low alloy steel plate suitable for high heat input welding and is characterized in that the chemical composition (wt percent) of steel comprises 0.04 percent to 0.16 percent of C, 0.10 percent to 0.50 percent of Si, 0.40 percent to 1.8 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.006 percent to 0.030 percent of Ti, 0.0030 percent to 0.010 percent of N, 0.015 percent to 0.060 percent of Al and the rest, Fe and other inevitable impurities; meanwhile, C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14 is less than or equal to 0.45 percent and the total amount of Ti and the total amount of N are that [Ti percent]T is more than or equal to 2.667[N percent]T-0.004667 percent; moreover, Ti microalloying is adopted to ensure that the Ti / N ratio in the second sort of particle generated ranges between 2.4 and 3.2. The manufacture method of the steel plate adopts austenite recrystallization zone and austenite non-recrystallization zone rolling and forced water cooling after rolling; moreover, when the steel plate is under 50 KJ / cm to 150 KJ / cm high heat input welding, the welding heat affected zone has excellent toughness. The invention has the advantages of simple production process, low cost and wide applicability.

Owner:ANGANG STEEL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com