Patents

Literature

129results about How to "Improve hydrogen embrittlement resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

HIGH STRENGTH STEEL PLATE WITH ULTIMATE TENSILE STRENGTH OF 900 MPa OR MORE EXCELLENT IN HYDROGEN EMBRITTLEMENT RESISTANCE AND METHOD OF PRODUCTION OF SAME

ActiveUS20120222781A1Reduce resistanceImprove plasticityHot-dipping/immersion processesSurface reaction electrolytic coatingCarbideUltimate tensile strength

High strength steel plate with an ultimate tensile strength of 900 MPa or more which is excellent in hydrogen embrittlement resistance characterized in that, in the structure of the steel plate, (a) by volume fraction, ferrite is present in 10 to 50%, bainitic ferrite and / or bainite in 10 to 60%, and tempered martensite in 10 to 50%, and (b) iron-based carbides which contain Si or Si and Al in 0.1% or more are present in 4×108 (particles / mm3) or more.

Owner:NIPPON STEEL CORP

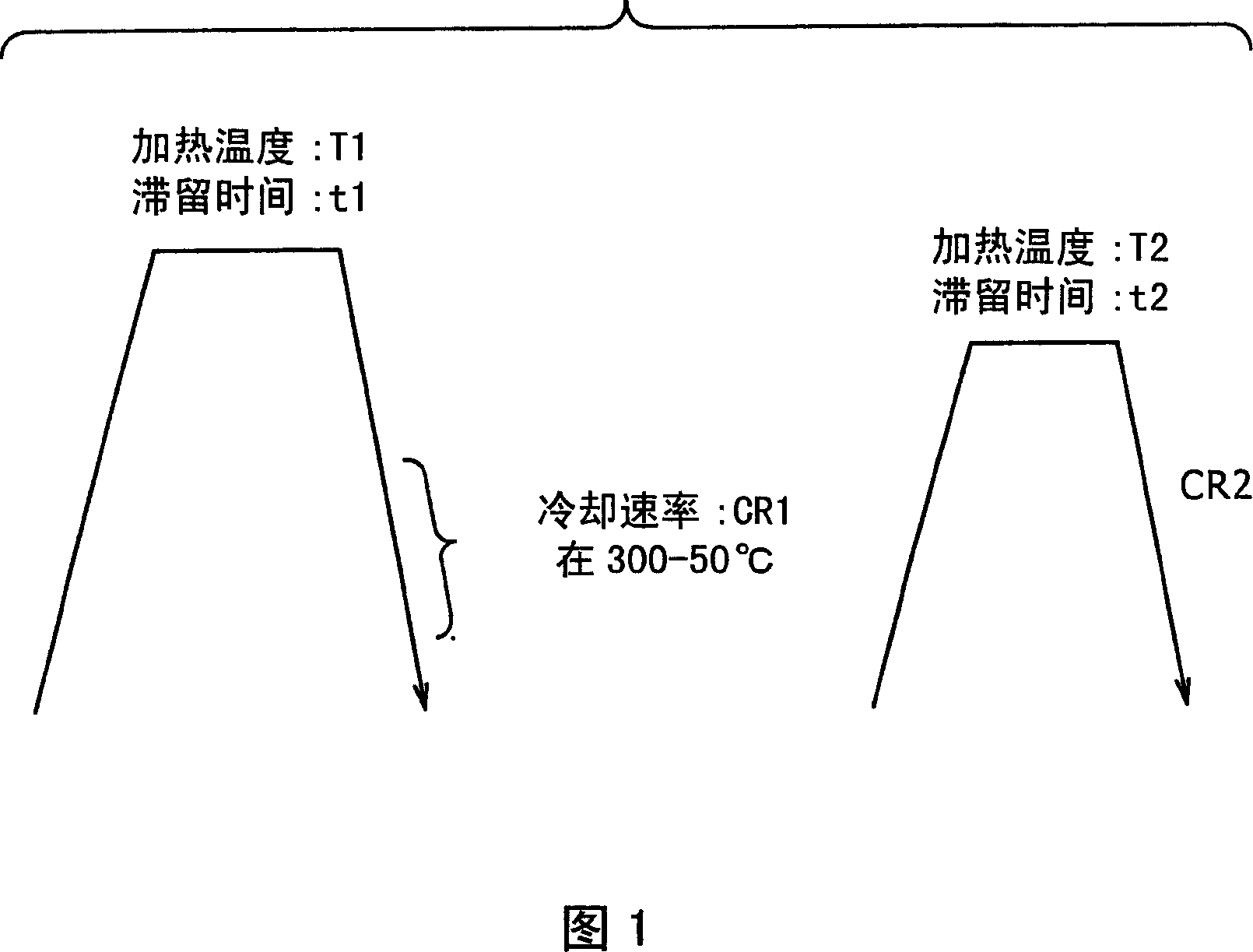

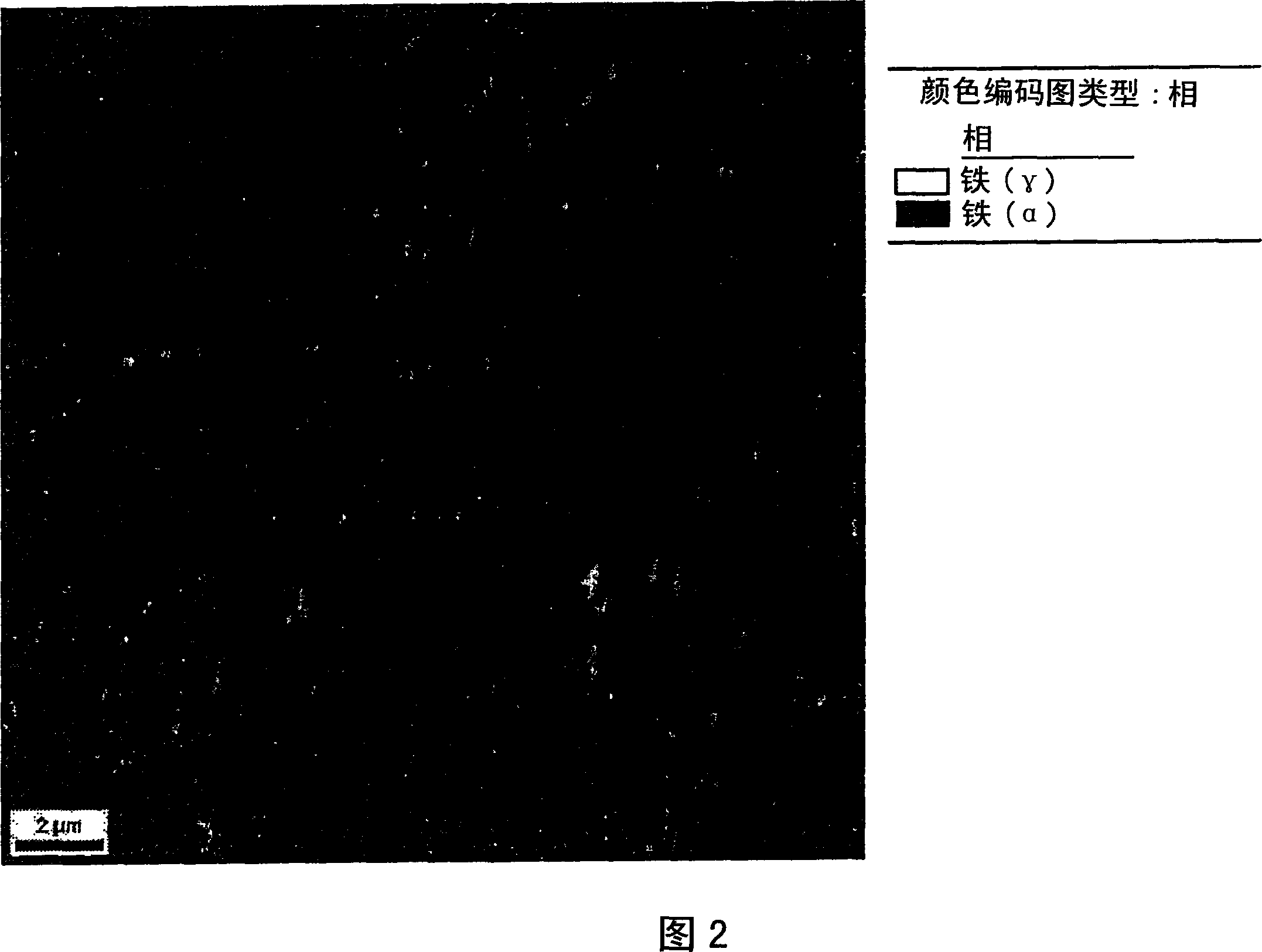

Ultrahigh-strength thin steel sheet

ActiveCN101351570AImprove corrosion resistanceReduce contentFurnace typesHeat treatment furnacesSheet steelUltimate tensile strength

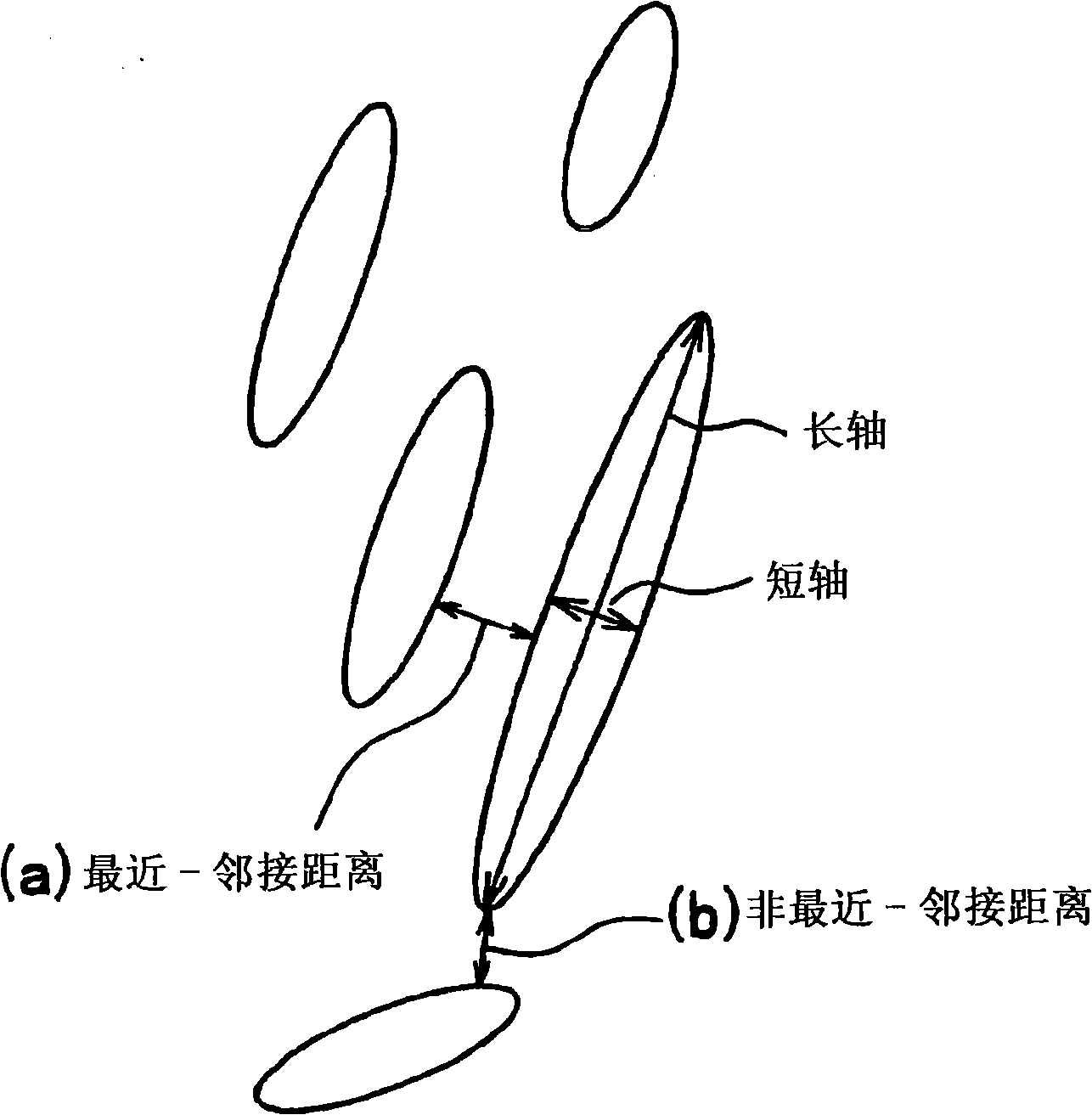

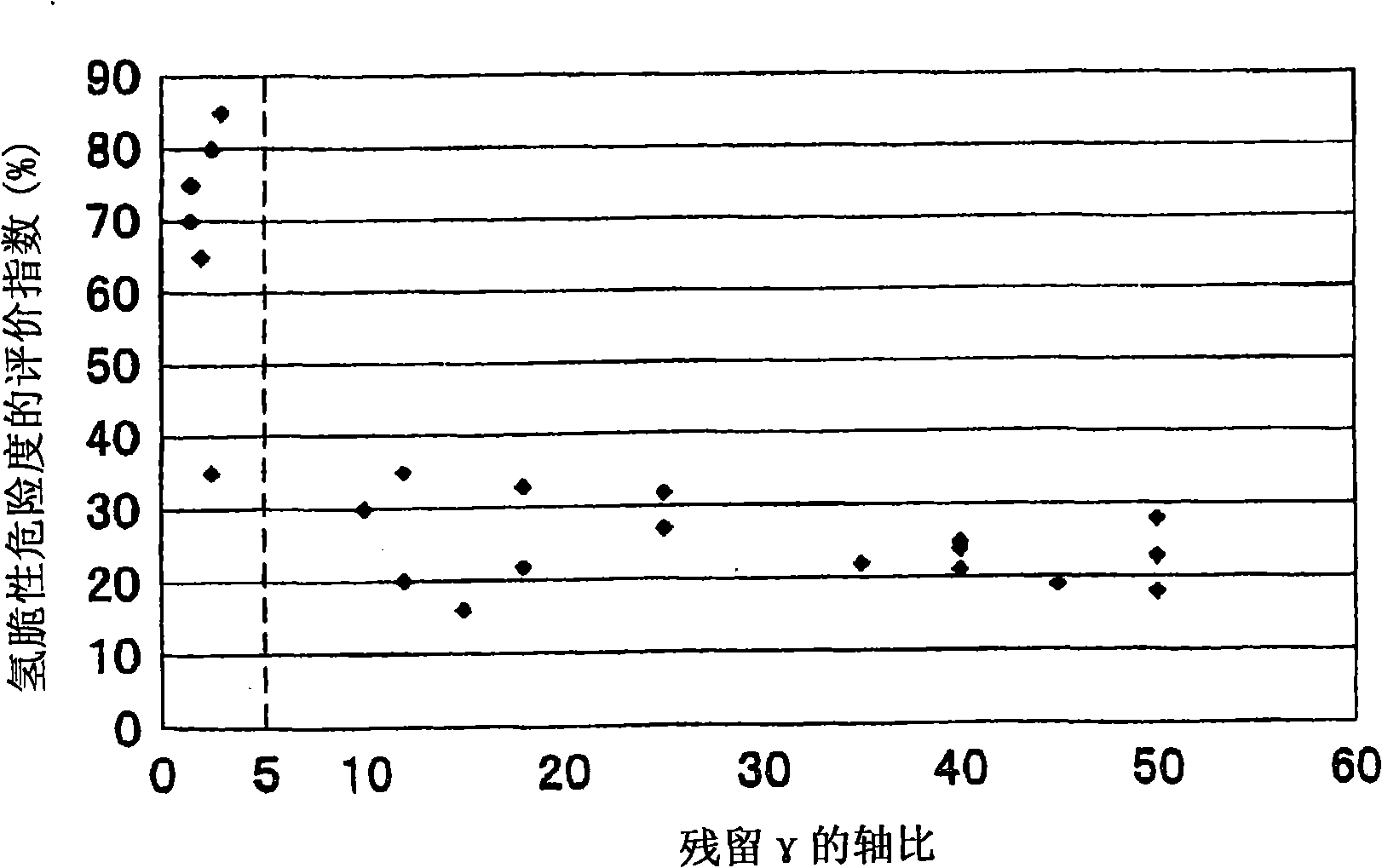

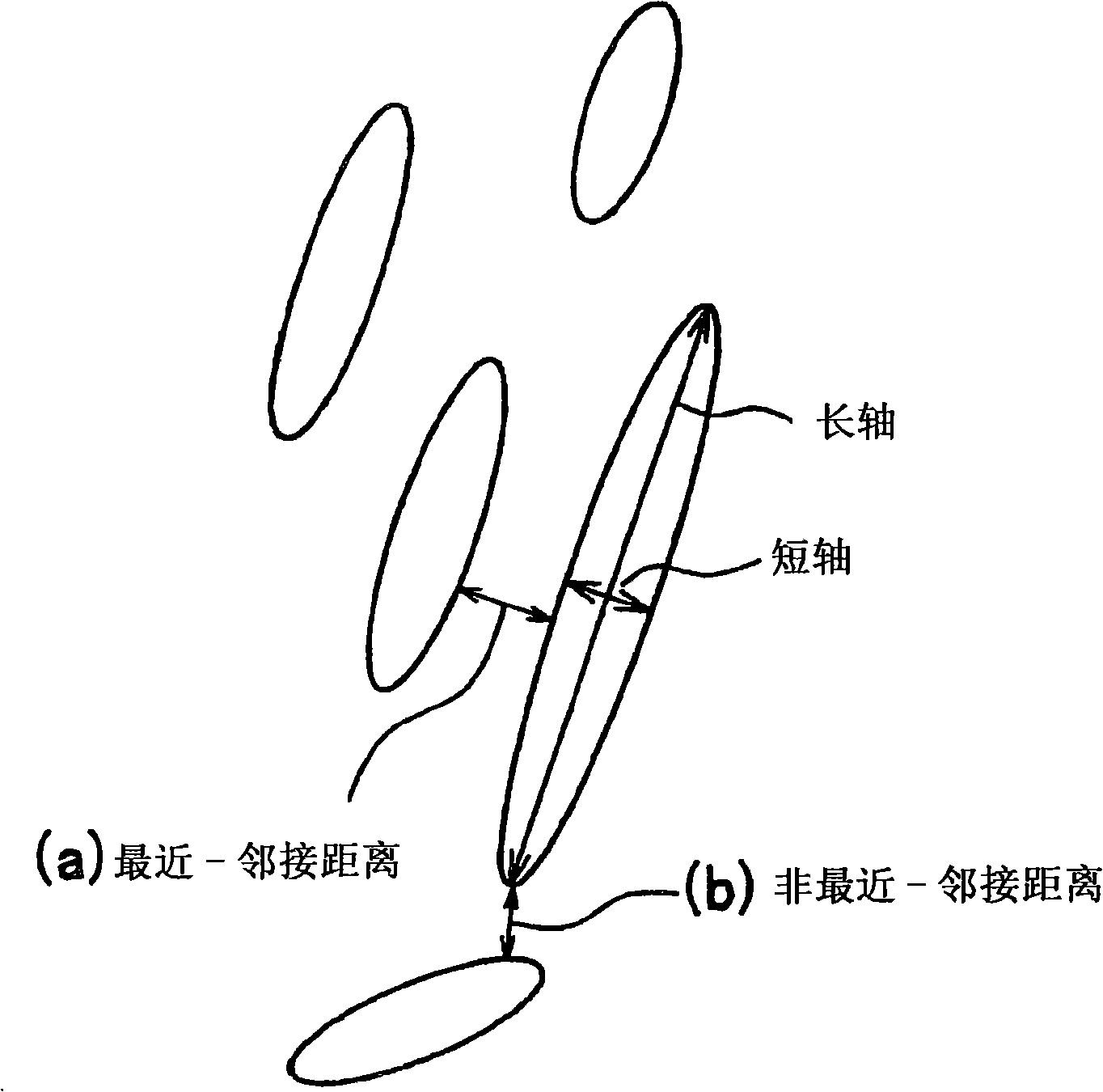

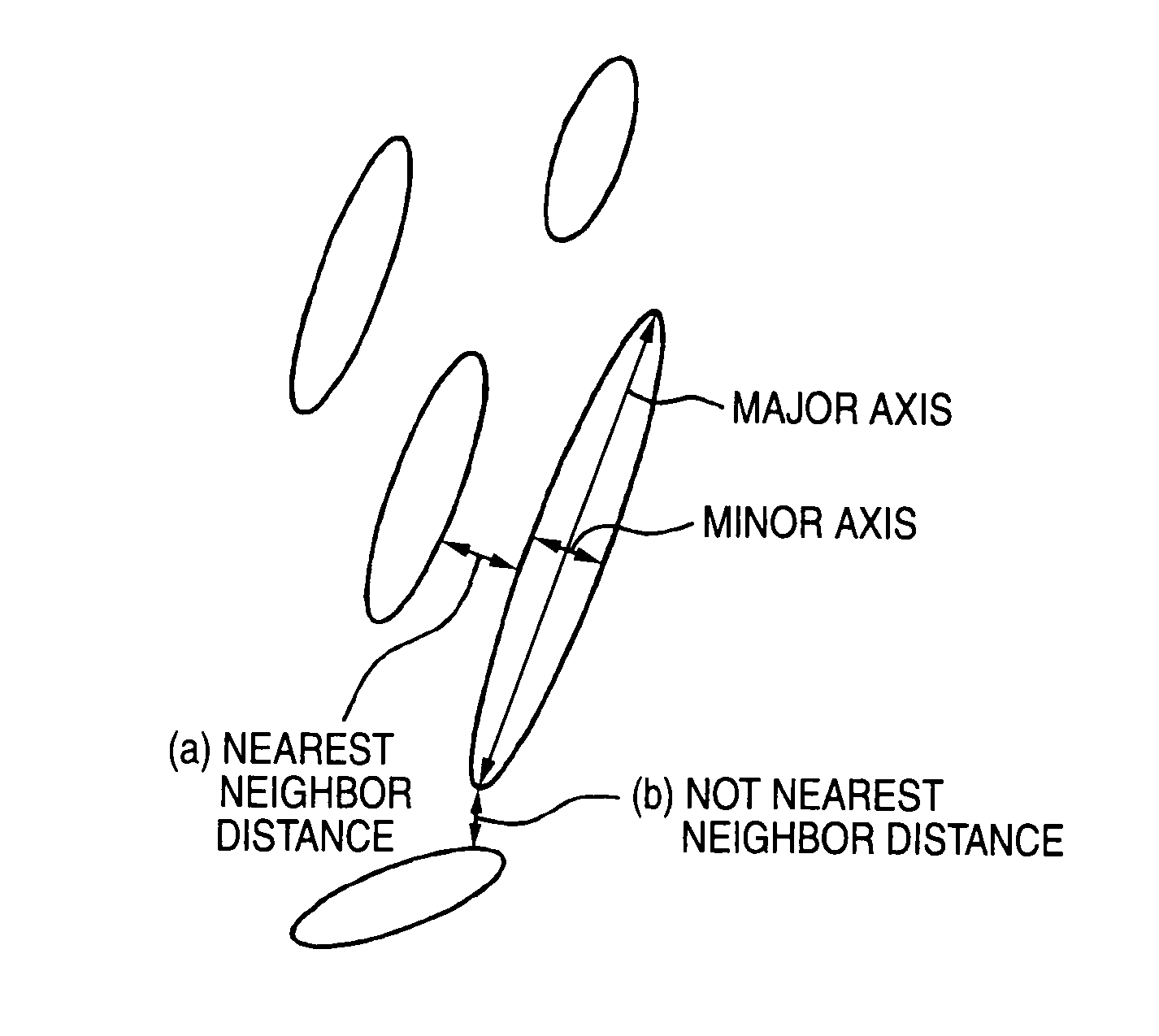

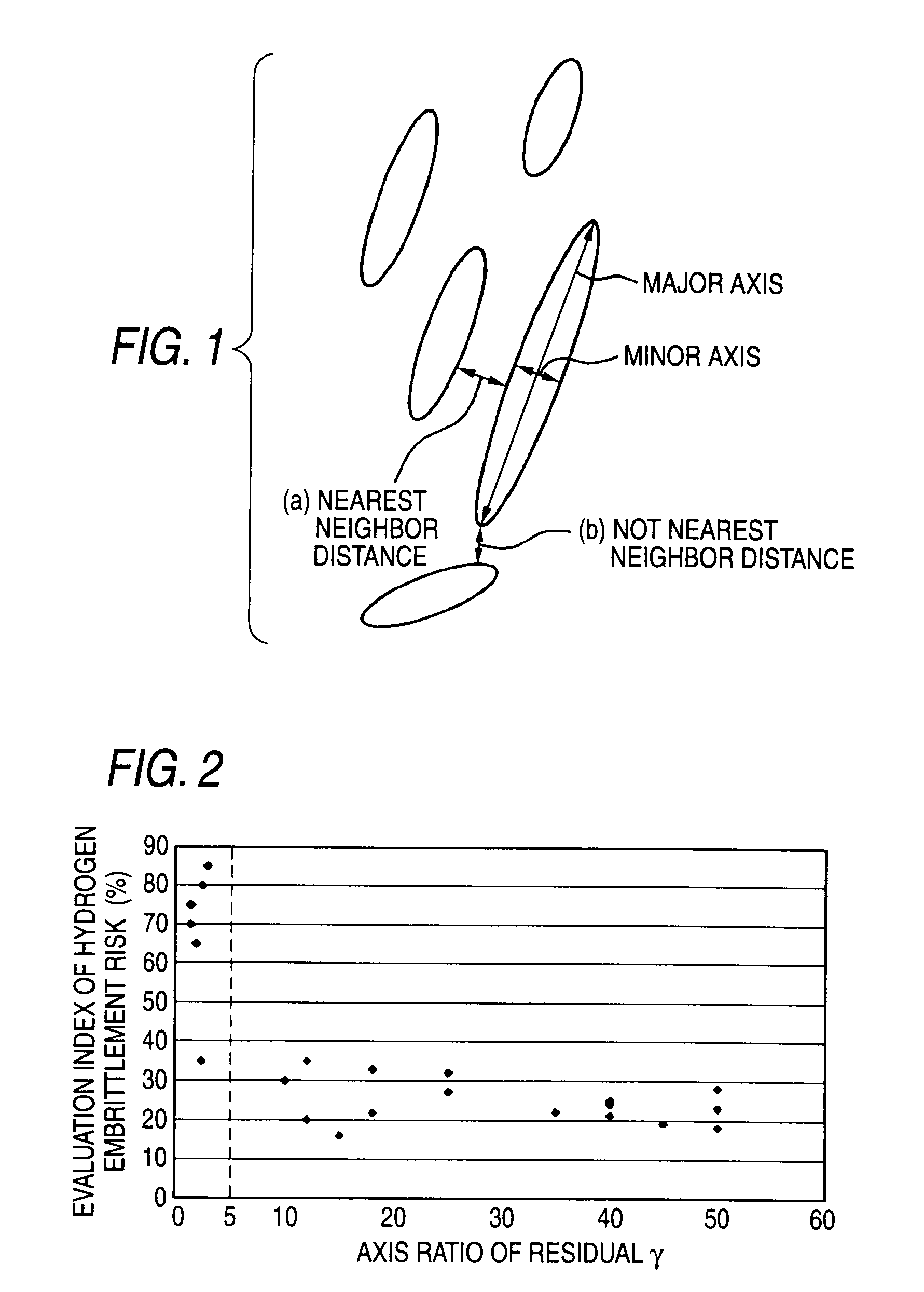

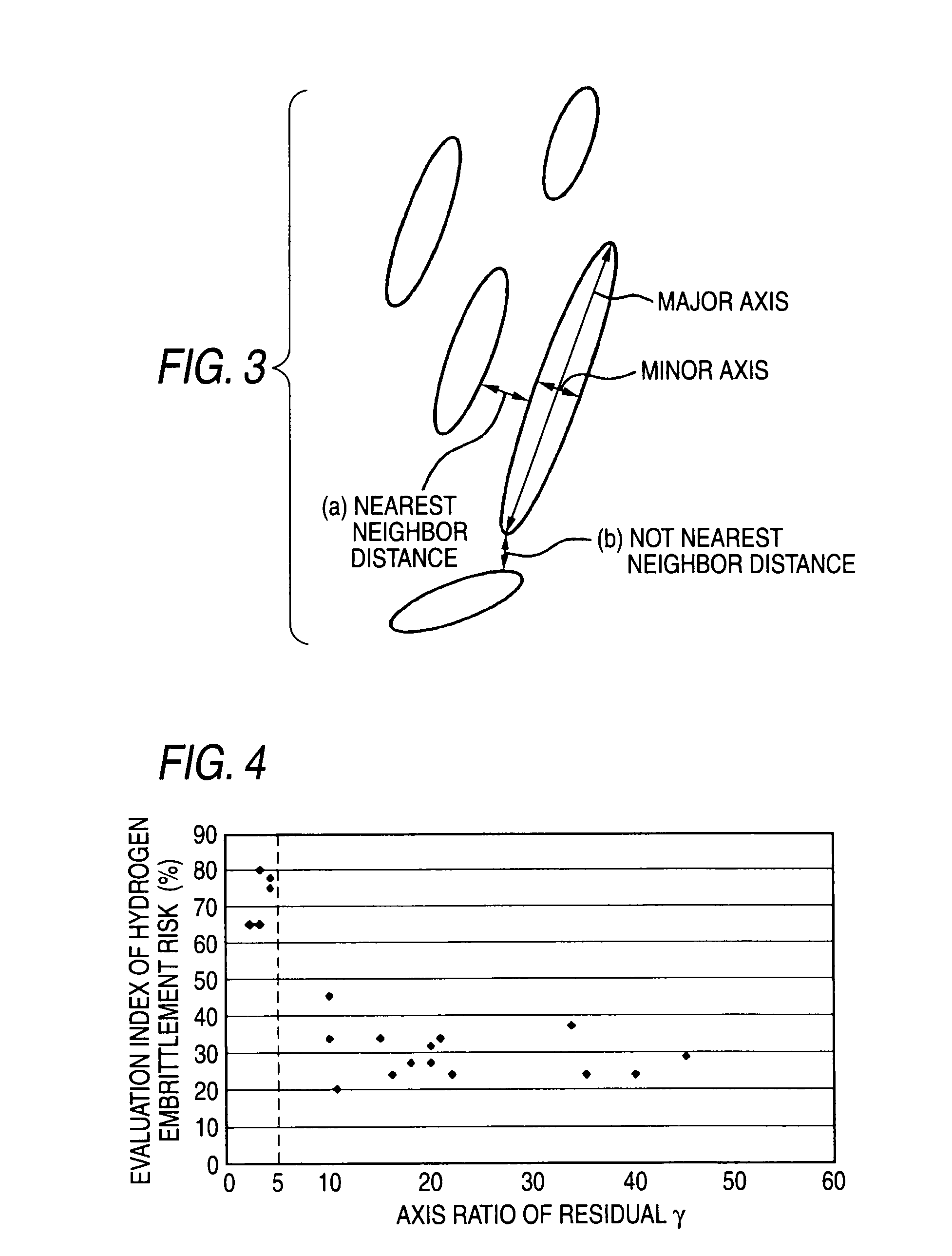

The present invention relates to an ultrahigh-strength steel sheet, which comprises, in terms of wt.%, 0.10-0.60% C, 1.0-3.0% Si, 1.0-3.5% Mn, up to 0.15% P, up to 0.02% S, up to 1.5% Al, and 0.003-2.0% Cr, with the remainder being iron and unavoidable impurities, and in which the crystal grains of residual austenite have an average aspect ratio (major axis / minor axis) of 5 or higher, an average minor-axis length of 1 [mu]m or shorter, and a minimum grain-to-grain distance of 1 [mu]m or shorter. It has excellent unsusceptibility to hydrogen embrittlement.

Owner:KOBE STEEL LTD

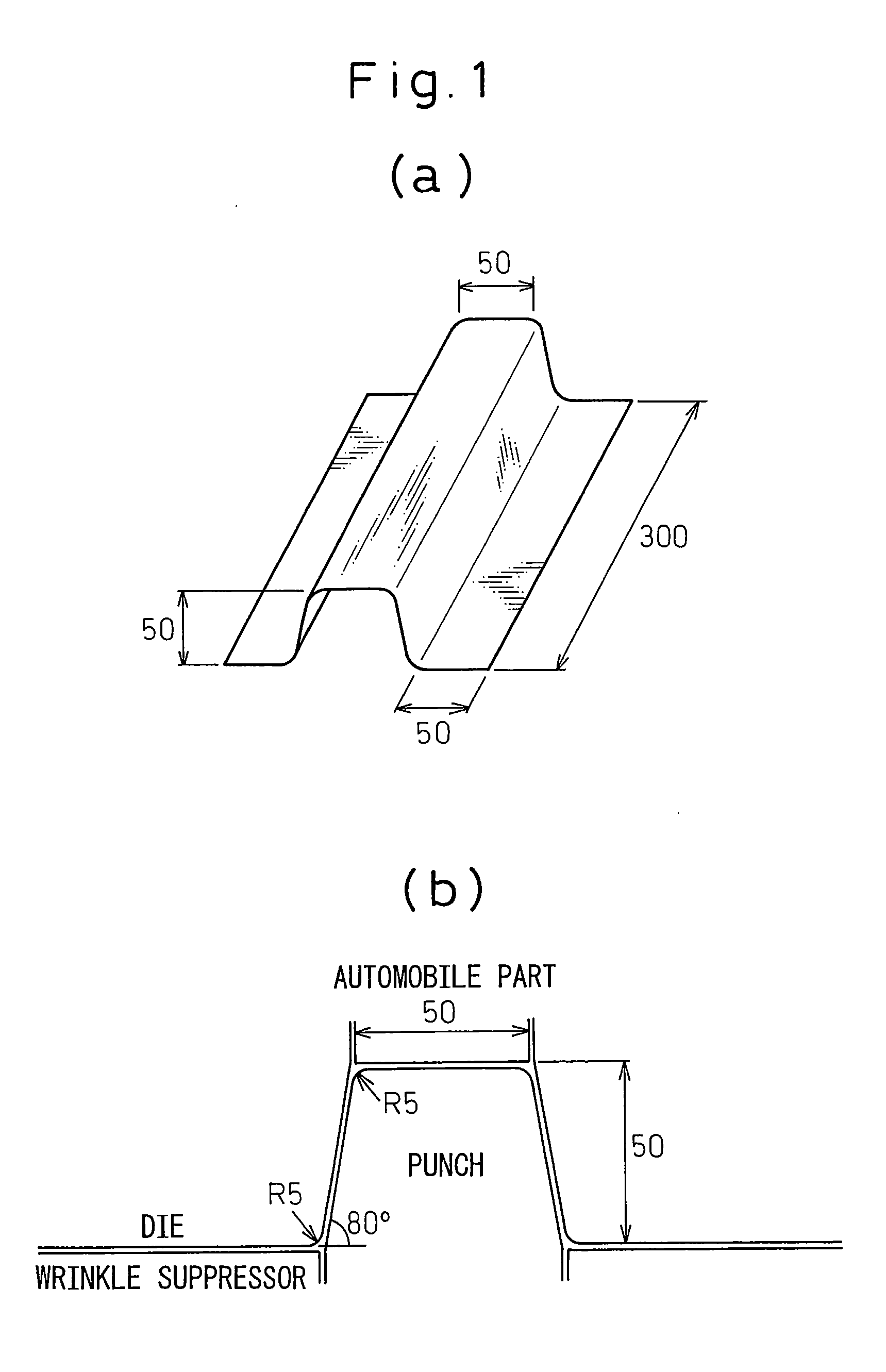

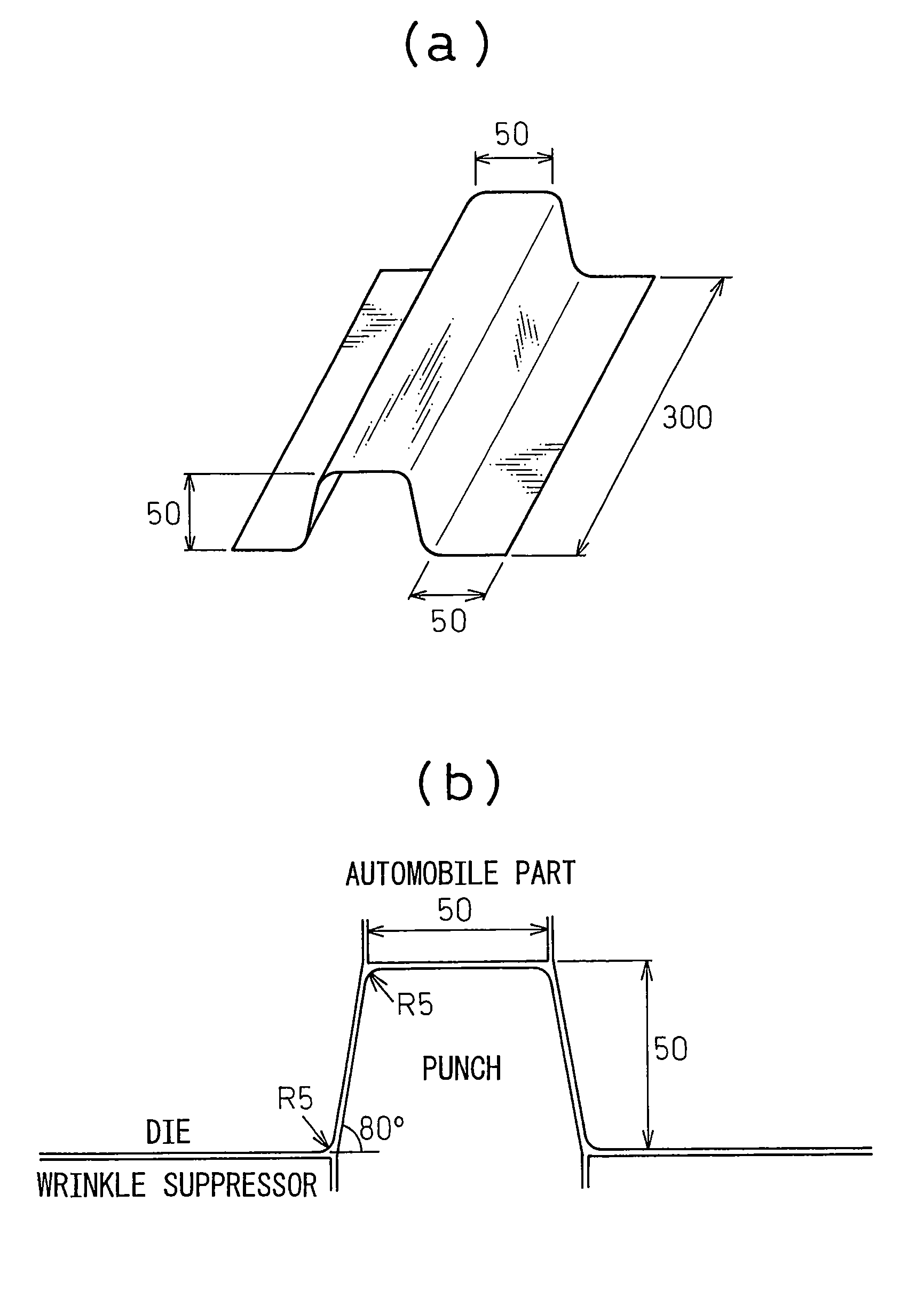

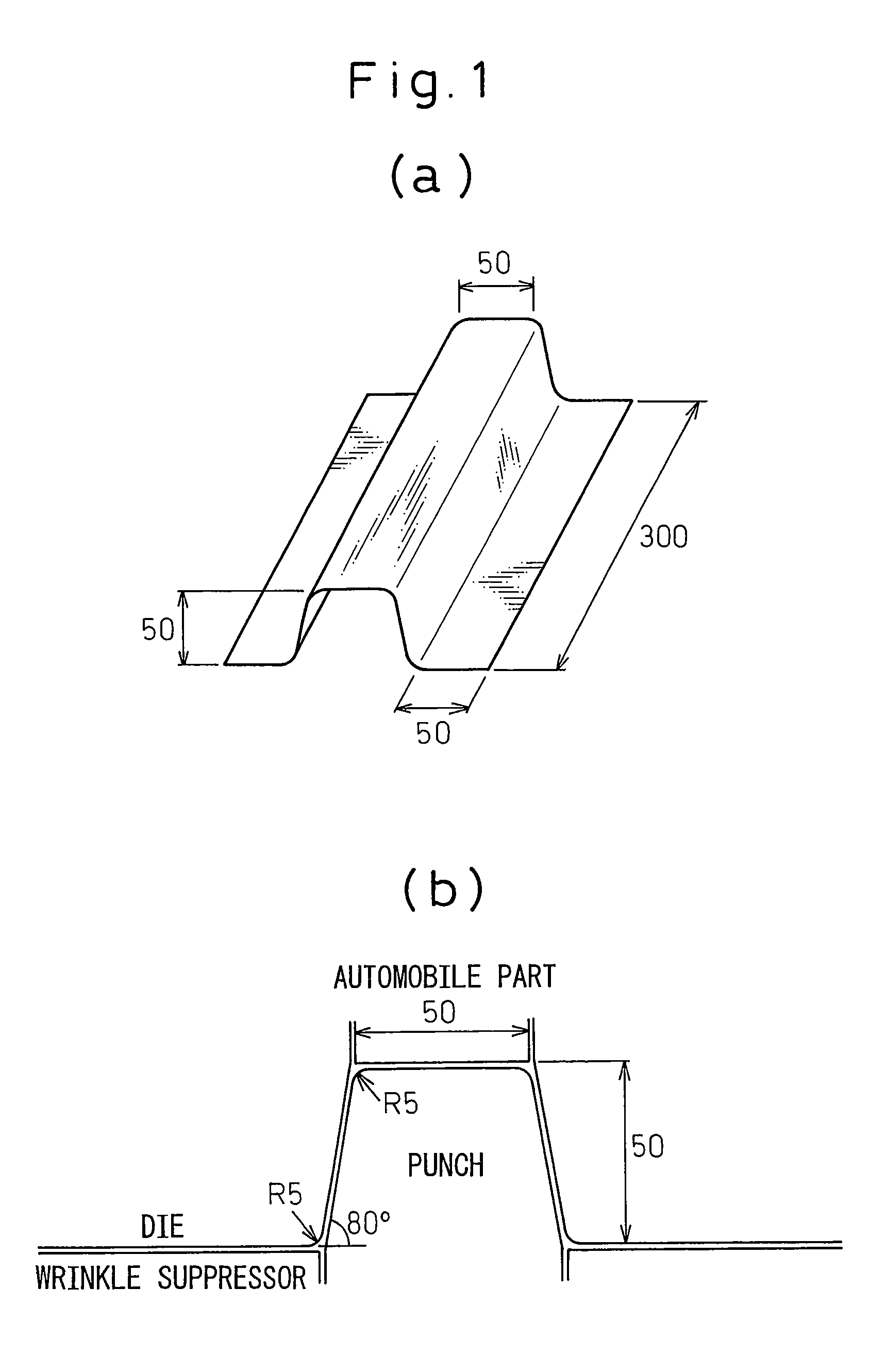

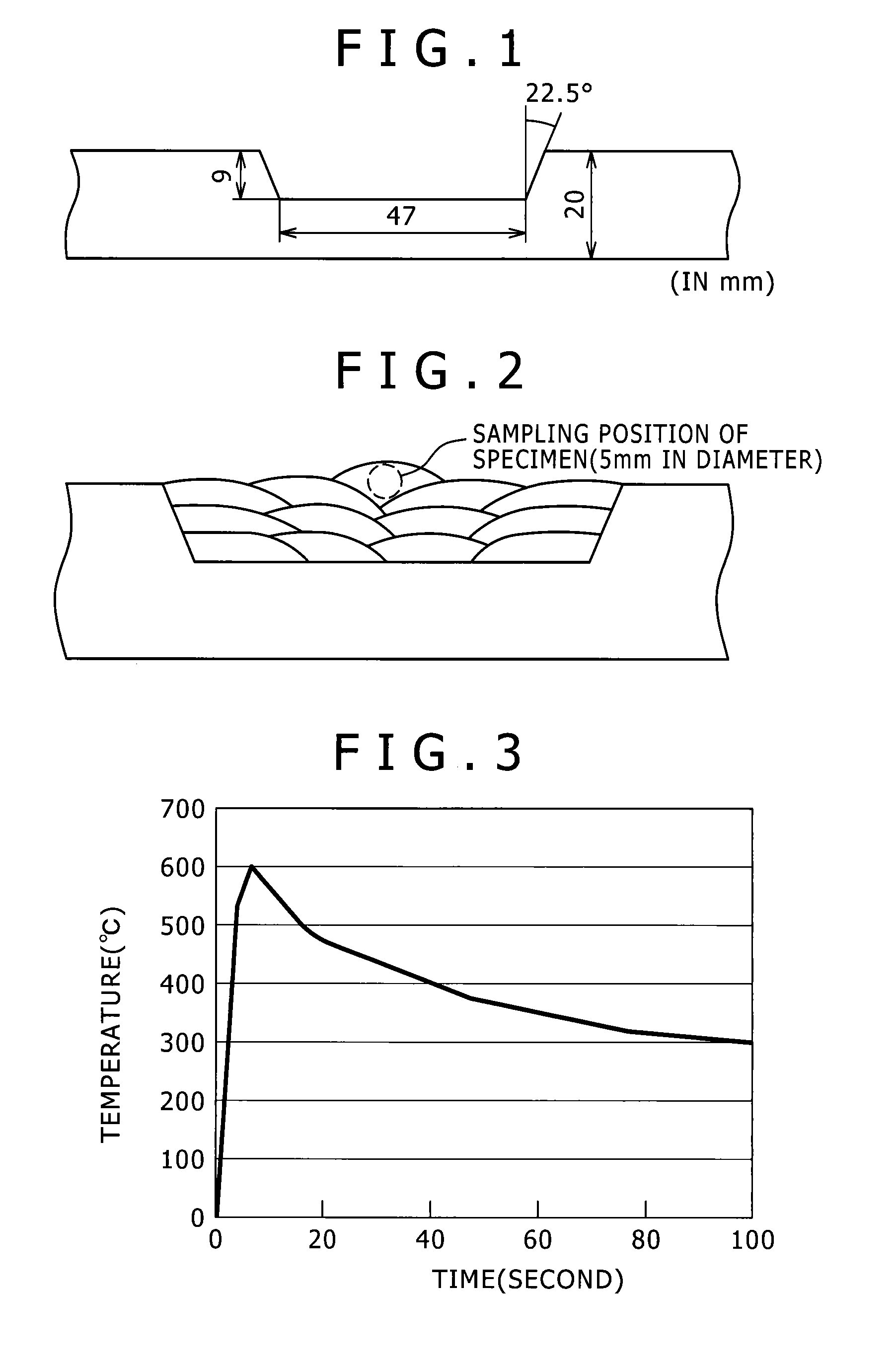

Hot pressing method for high strength member using steel sheet and hot pressed parts

ActiveUS20070163685A1Little riskImprove hydrogen embrittlement resistanceHot-dipping/immersion processesThin material handlingHydrogen concentrationHigh intensity

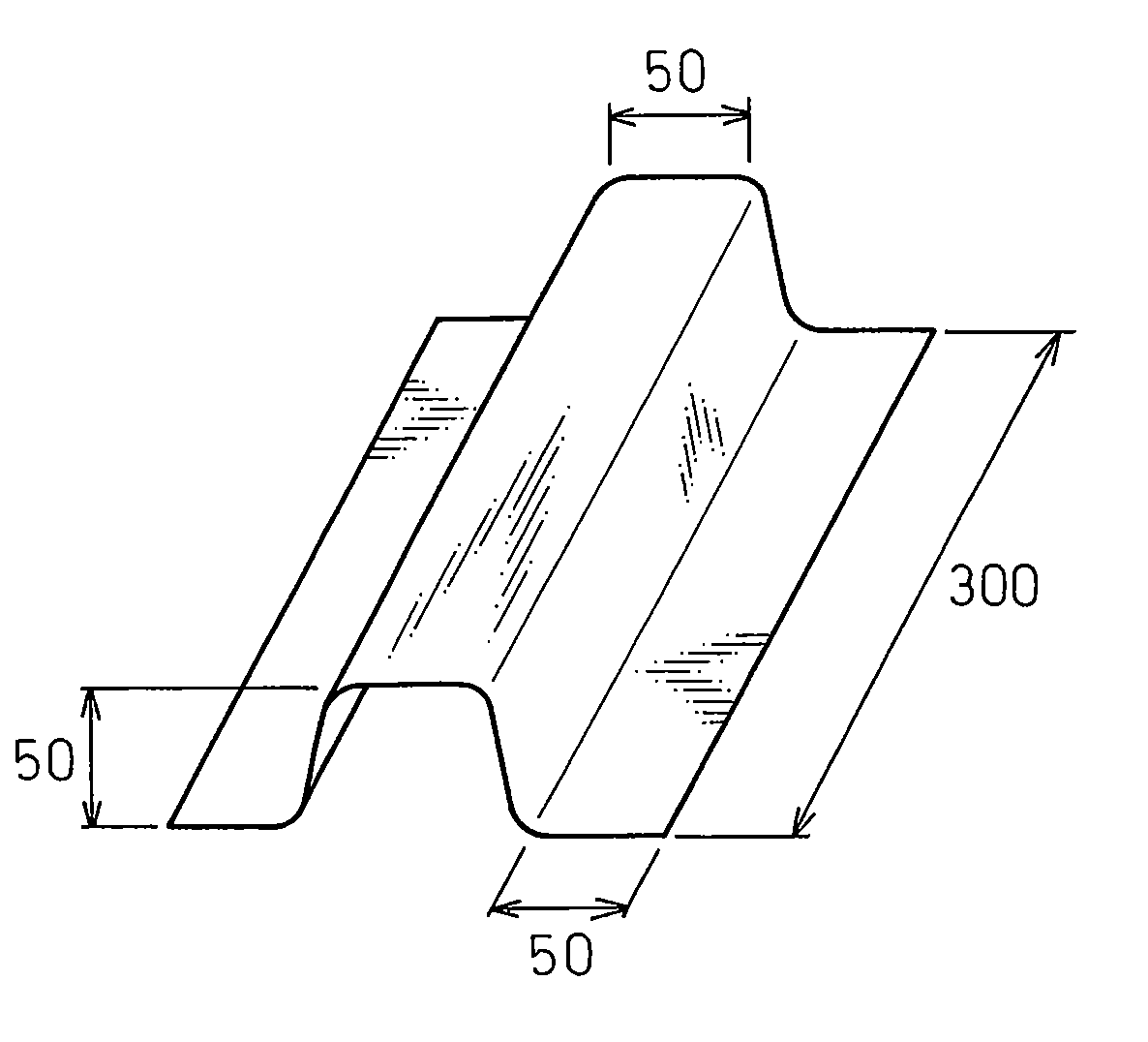

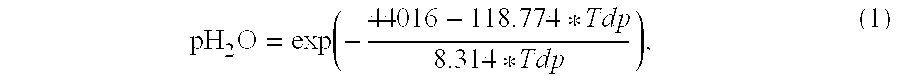

The present invention provides a method of hot pressing using hot rolled and cold rolled steel sheet or Al-based plated steel sheet or Zn-based plated steel sheet enabling a strength of at least 1200 MPa to be obtained after high temperature forming and with extremely little possibility of hydrogen embrittlement and such hot pressed parts, that is, a method of hot pressing a high strength automobile parts comprising using steel sheet containing as steel compositions by wt % C:0.05 to 0.5% or steel sheet plated mainly with Al or Zn to produce automobile members by hot pressing during which making the heating temperature before pressing Ac3 or more to 1100° C. or less, making the hydrogen concentration in the heating atmosphere 6 vol % or less, and making the dew point 10° C. or less and such hot pressed parts.

Owner:NIPPON STEEL CORP +1

Hot pressing method for high strength member using steel sheet and hot pressed parts

ActiveUS7867344B2Little riskImprove hydrogen embrittlement resistanceHot-dipping/immersion processesQuenching agentsSheet steelHigh intensity

A method is proved for hot pressing hot rolled steel sheet, cold rolled steel sheet, Al-based plated steel sheet or Zn-based plated steel sheet, where the hot pressed sheet can exhibit a strength of at least about 1200 Mpa, and my be prevented from exhibiting hydrogen embrittlement. The steel sheet may include between about 0.05 to 0.5 wt % C, and / or it may be plated with an Al-based or Zn-based plating material. The steel sheet may be heating to a temperature greater than an Ac3 temperature and not more than about 1100° C. before pressing. An atmosphere can be provided during heating which contains not more than about 6 vol % of hydrogen and a dew point of not more than about 10° C. The exemplary methods may be used to form high strength parts which may be used, e.g., in automobiles.

Owner:NIPPON STEEL CORP +1

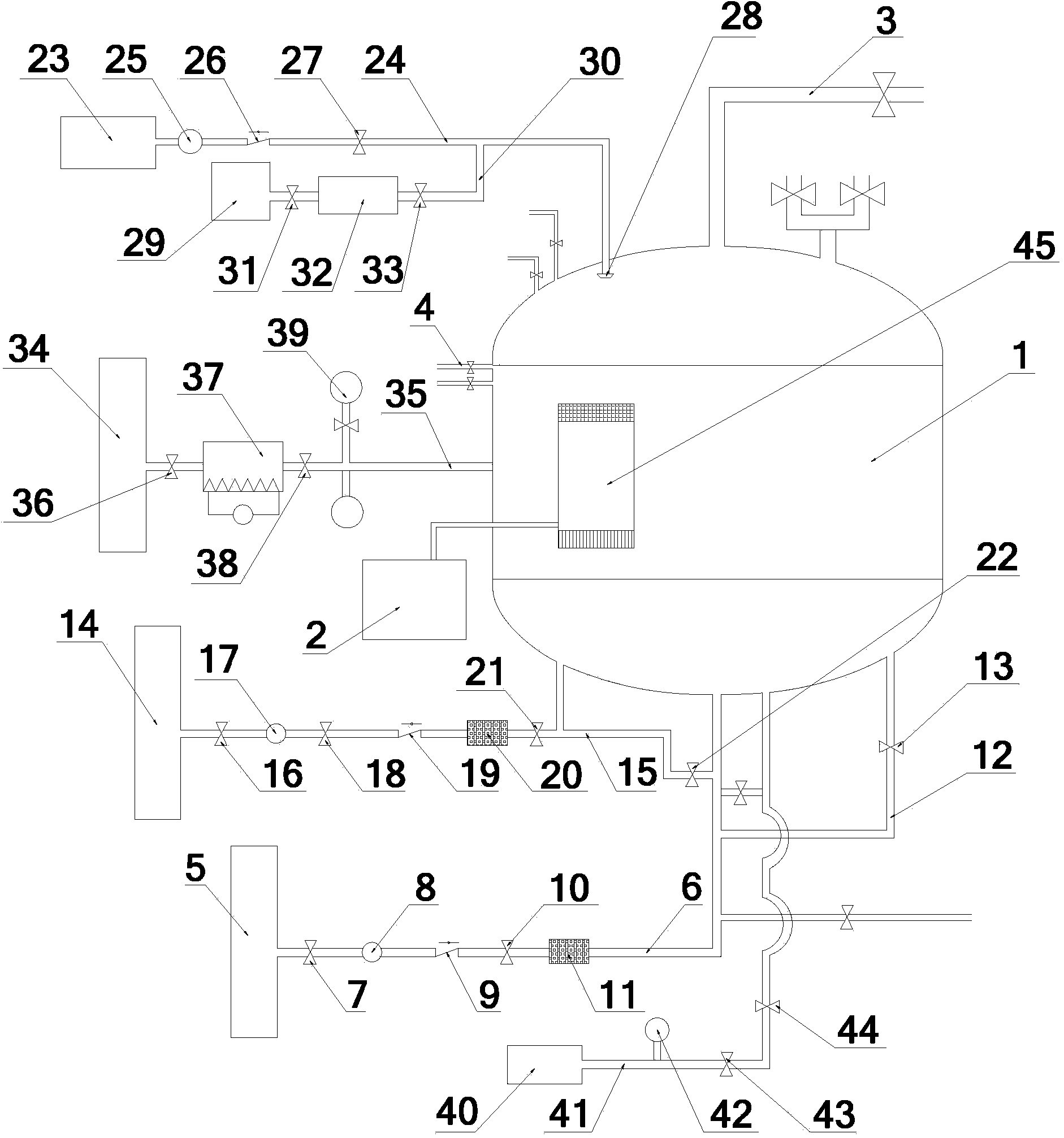

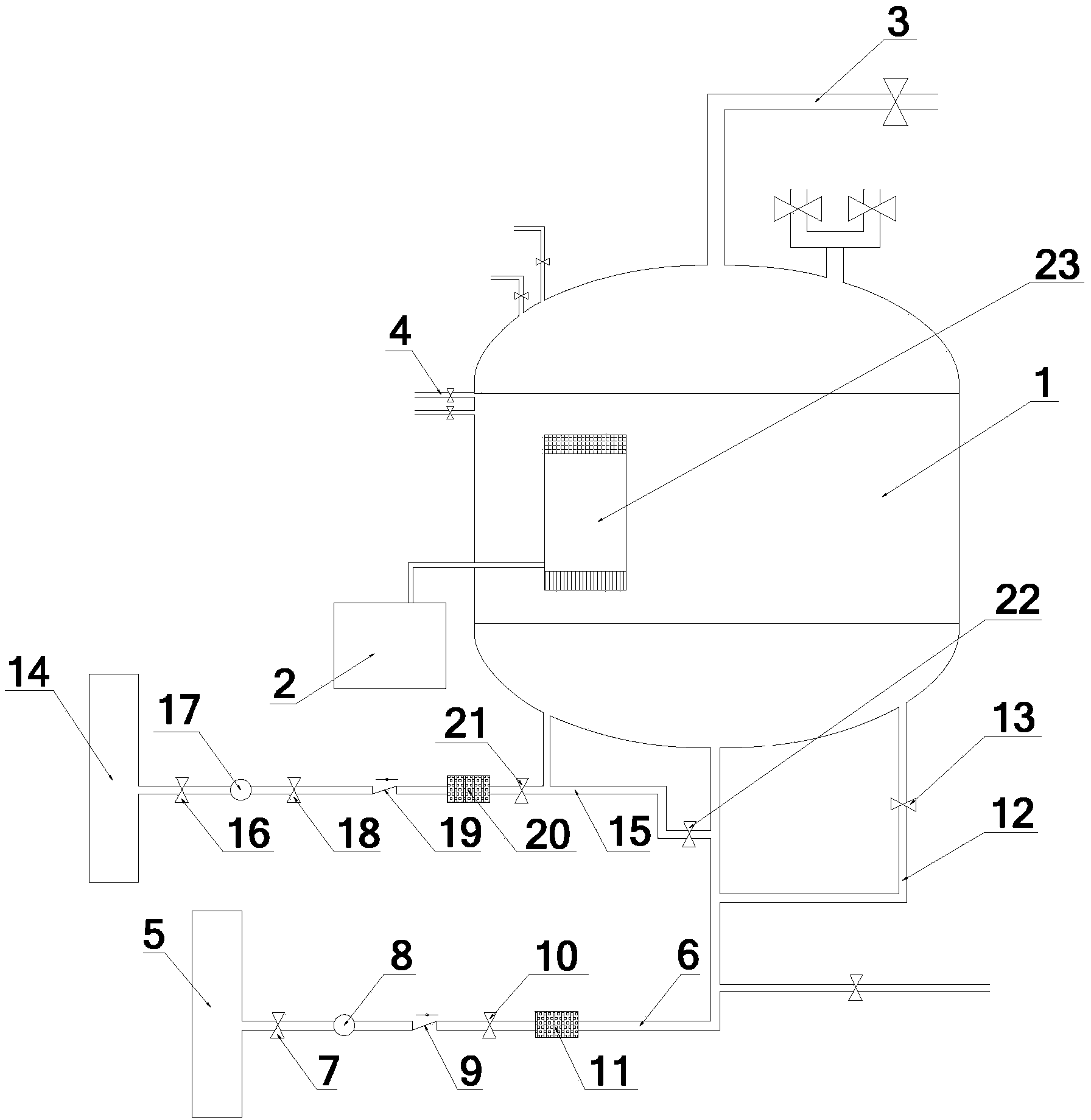

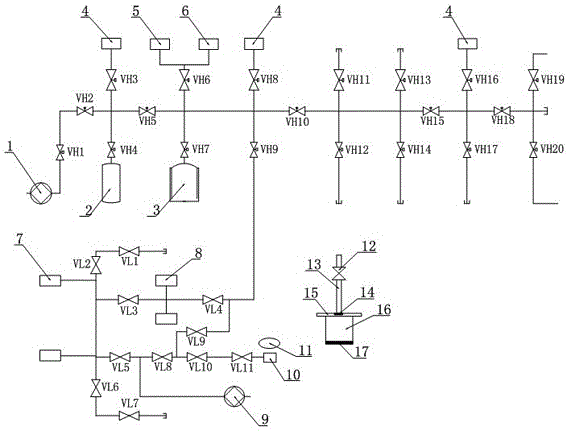

Experimental system used for simulating severe accident conditions of containment of nuclear power plant, and implementation method thereof

ActiveCN104392753ASimulate the realRealize simulationNuclear energy generationNuclear monitoringNuclear powerWater vapor

The invention discloses an experimental system used for simulating severe accident conditions of the containment of a nuclear power plant and an implementation method thereof to overcome the problem that comprehensive simulation of severe accident conditions of the containment of a nuclear power plant cannot be realized in the prior art. The experimental system comprises an experimental container, a first pressure sensor arranged in the experimental container, a data acquisition system, an exhaust pipeline, an air supply system, a hydrogen supply system, a spray system, an aerosol supply system, a cable combustion product supply system, a water vapor on-line supply system and at least four sampling pipelines, wherein the data acquisition system is connected with the experimental container through multipoint thermocouples; the exhaust pipeline, the air supply system, the hydrogen supply system, the spray system, the aerosol supply system, the cable combustion product supply system, the water vapor on-line supply system and the at least four sampling pipelines are connected with the experimental container; and the aerosol supply system is connected with the spray system. The experimental system provided by the invention has a reasonable structure, can authentically and comprehensively simulate severe accident conditions in the nuclear power plant and carries out hydrogen elimination performance testing on a passive hydrogen recombiner on the basis of simulation results; moreover, testing results approximately represent actual working conditions, so good reference standards are provided for researching and designing of the recombiner.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +2

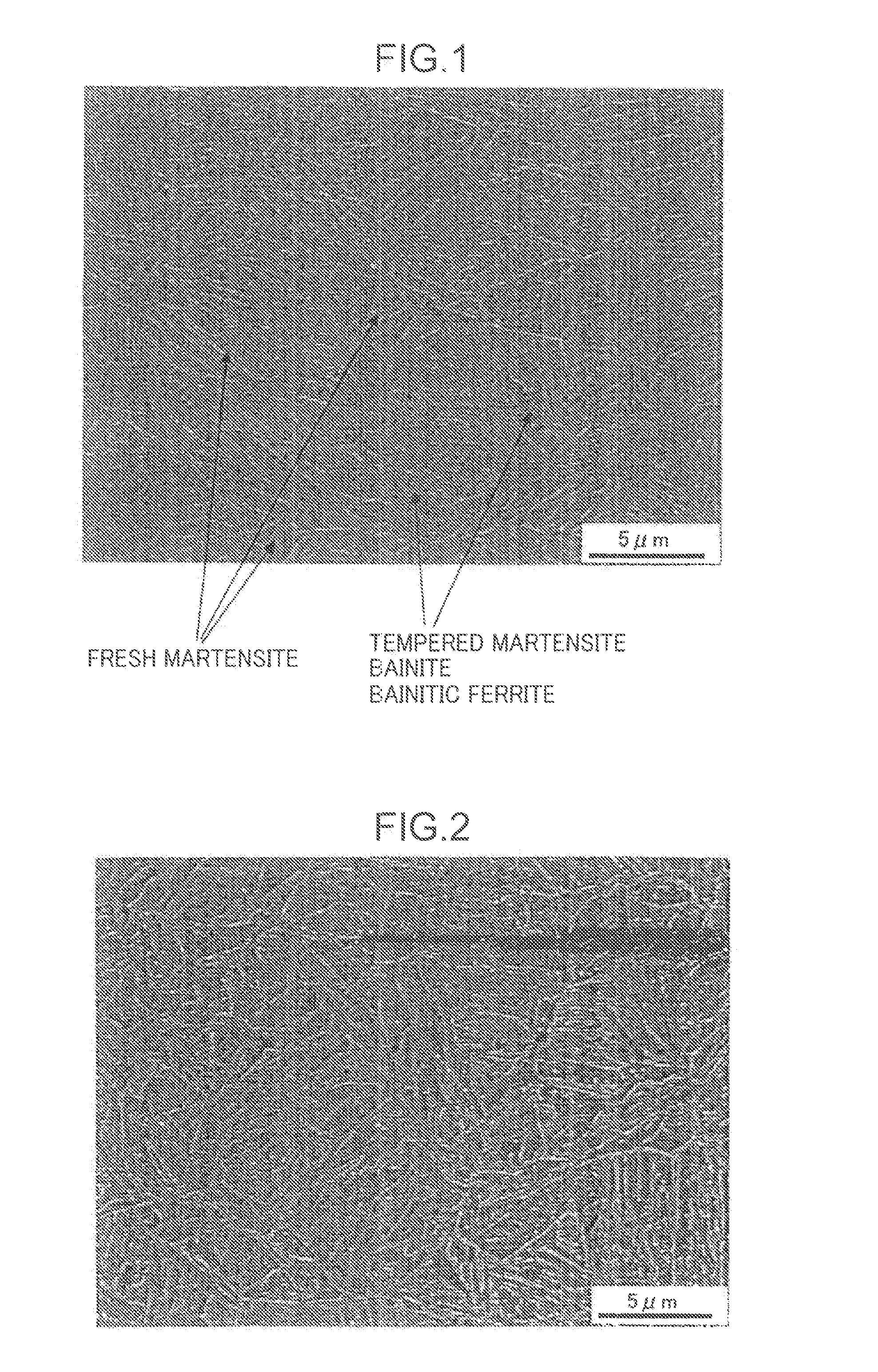

High strength steel sheet having excellent hydrogen embrittlement resistance

ActiveUS20120132327A1Improve hydrogen embrittlement resistanceHigh strengthFurnace typesHeat treatment furnacesHydrogen embrittlementBainite

Disclosed is a high strength steel sheet having excellent hydrogen embrittlement resistance. The steel sheet has a tensile strength of 1180 MPa or more, and satisfies the following conditions: with respect to an entire metallographic structure thereof, bainite, bainitic ferrite and tempered martensite account for 85 area % or more in total; retained austenite accounts for 1 area % or more; and fresh martensite accounts for 5 area % or less (including 0 area %).

Owner:KOBE STEEL LTD +1

High strength spring steel wire with excellent coiling properties and hydrogen embrittlement resistance

Disclosed herein is a high strength spring steel wire with excellent coiling properties and hydrogen embrittlement resistance. The steel wire comprises, by mass, 0.4 to 0.60% of C, 1.7 to 2.5% of Si, 0.1 to 0.4% of Mn, 0.5 to 2.0% of Cr, 0.015% or less of P (exceeding 0%), 0.015% or less of S (exceeding 0%), 0.006% or less of N (exceeding 0%), 0.001 to 0.07% of Al, and the remainder being Fe and unavoidable impurities. The steel wire has a structure wherein prior austenite has an average grain size of 12 mum or less, and retained austenite exists in an amount of 1.0 to 8.0 vol. % with respect to a whole structure of the steel wire. The retained austenite has an average grain size of 300 nm or less and a maximum grain size of 800 nm or less. The steel has a tensile strength of 1,900 MPa or more.

Owner:KOBE STEEL LTD

Experiment system for simulating nuclear containment benchmark accident condition and realizing method of experiment system

InactiveCN104269195AIncrease in sizeImprove hydrogen embrittlement resistancePower plant safety arrangementNuclear energy generationInternal pressureData acquisition

The invention discloses an experiment system for simulating a nuclear containment benchmark accident condition and a realizing method of the experiment system, and solves the problem that the nuclear containment benchmark accident condition cannot be simulated comprehensively in the prior art. The experiment system comprises an experiment container, a first pressure sensor, a data acquisition system, an exhaust pipeline, an air supply system, a hydrogen supply system and at least four sampling pipelines, wherein the experiment container is used for loading a complete machine of a passive hydrogen recombiner; the first pressure sensor is arranged in the experiment container and used for detecting inner pressure of the experiment container; the exhaust pipeline, the air supply system, the hydrogen supply system and at least four sampling pipelines are connected with the experiment container; and the experiment container is connected with the data acquisition system through a multi-point thermoelectric couple. According to the experiment system for simulating the nuclear containment benchmark accident condition and the realizing method of the experiment system, the structural design is reasonable, the nuclear containment benchmark accident condition can be simulated really and comprehensively, the hydrogen elimination performance of the passive hydrogen recombiner is tested, a test result is very close to the actual condition, and accordingly, a terrific reference standard is further provided for study and design of the recombiner.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +2

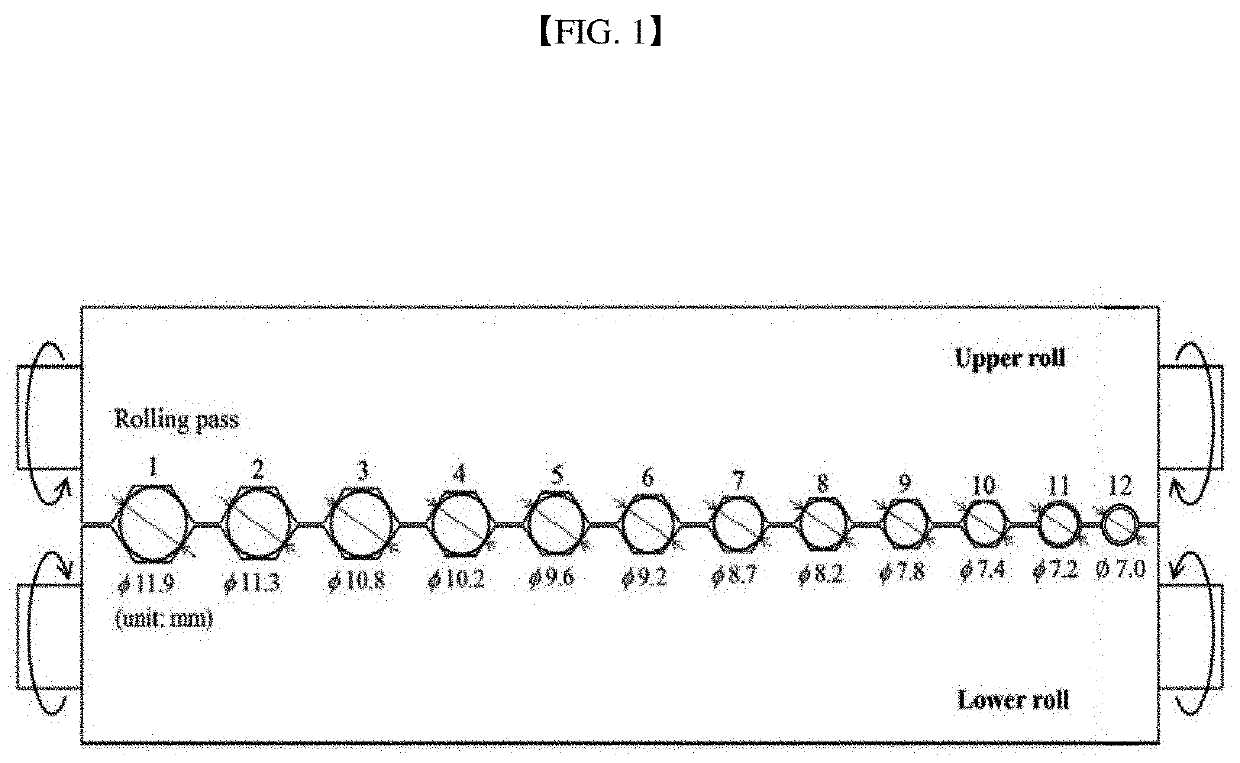

High-entropy alloy, and method for producing the same

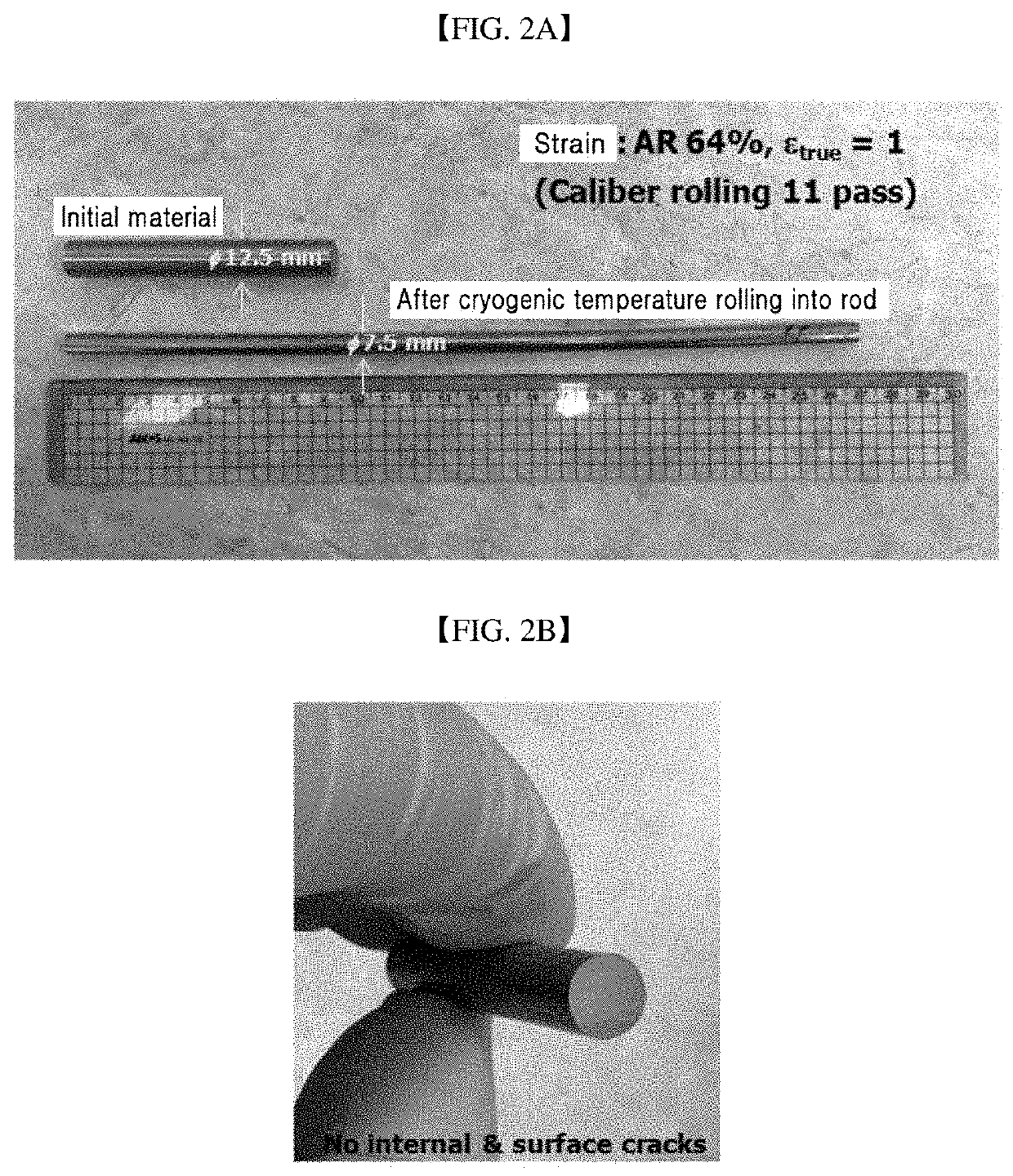

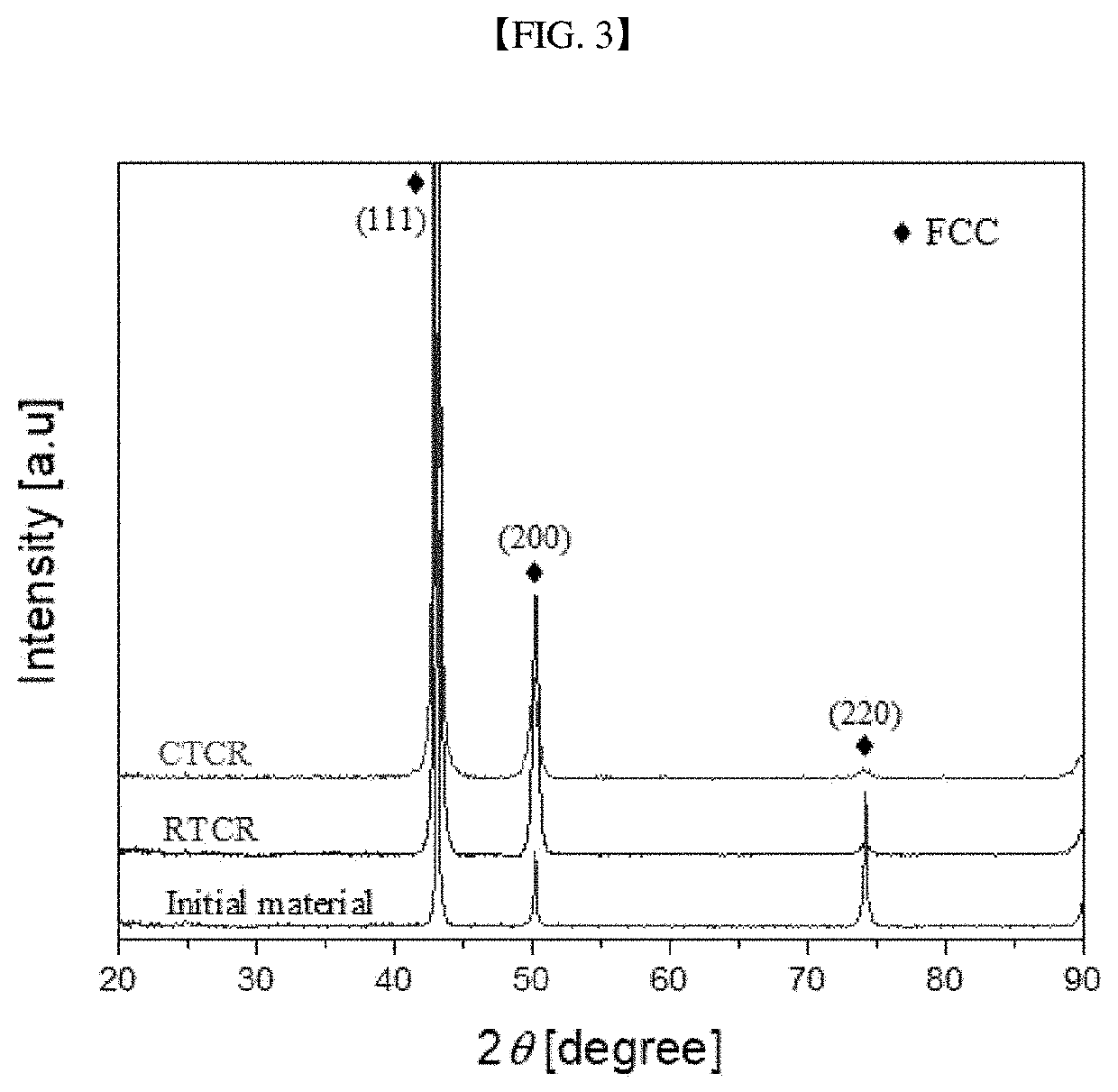

ActiveUS20200392613A1Effective segmentationImprove refinementMetal rolling arrangementsHigh entropy alloysUltimate tensile strength

A high-entropy alloy having ultra-high strength and high hydrogen embrittlement resistance due to formation of a microstructure at a low strain may be produced without a severe plastic deformation.A method for producing the high-entropy alloy includes (a) annealing and homogenizing an initial alloy material at 1000 to 1200° C. for 1 to 24 hours; and (b) rolling the annealed and homogenized initial alloy material into a rod, at a cryogenic temperature of −100 to −200° C. while pressing the initial alloy material in multi-axial directions at a strain of 0.4 to 1.2, thereby to produce the high-entropy alloy having intersecting twins as a microstructure, and secondary fine twins formed in the intersecting twins, wherein the initial alloy material contains Co of 5 to 35%, Cr of 5 to 35%, Fe of 5 to 35%, Mn of 5 to 35%, and Ni of 5 to 35%, based on weight %.

Owner:KOREA INST OF MATERIALS SCI

Hydrogen sensitive material for optical fiber hydrogen sensor and preparation method of hydrogen sensitive material

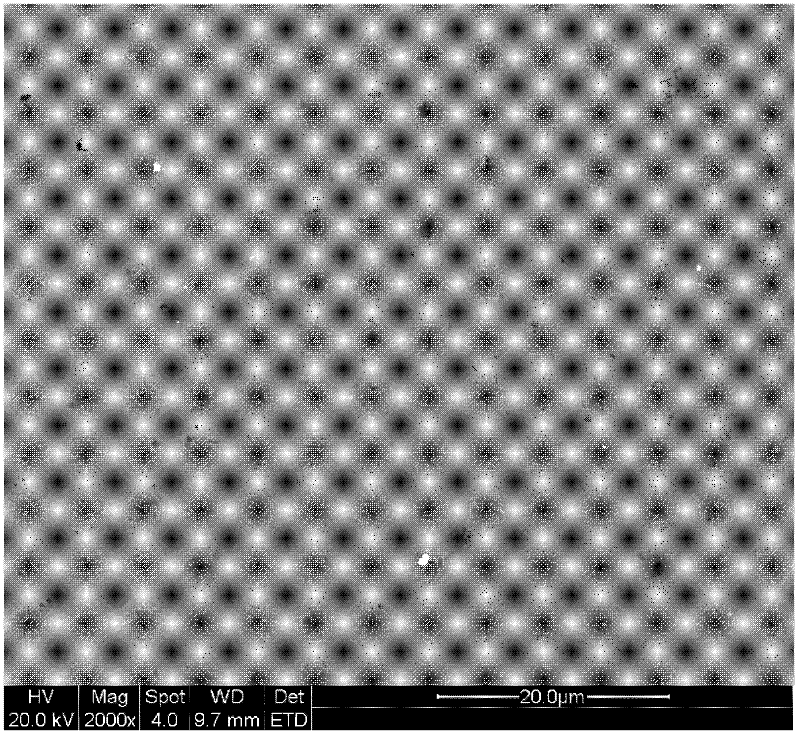

InactiveCN102495045AQuick responseHigh sensitivityVacuum evaporation coatingSputtering coatingChemical compositionGas phase

The invention discloses a hydrogen sensitive material for an optical fiber hydrogen sensor and a preparation method of the hydrogen sensitive material. The thin film material, namely the hydrogen sensitive material comprises a substrate and an alloy thin film, wherein the substrate is made of a metal, a semiconductor or an insulator material; the alloy thin film material comprises the basis components Pd and Y and has the chemical composition of Pd[1-x-y]Y[x]alpha[y], wherein alpha represents any one of Pt, Ag, Au, Ni, Cu, Al, Li and B, or at least one of La, Ru, Ce, Pr, Nd and Pm; x is more than 0 and is less than or equal to 0.3; and y is more than or equal to 0 and is less than or equal to 0.3. The alloy thin film material has the thickness of 2 to 1,000nm. The preparation method comprises the following steps of: firstly, prefabricating an alloy target by using an induction smelting or powder metallurgy method; then preparing the alloy thin film material on the substrate by a physical gas phase laminating method; or directly carrying out multitarget co-sputtering lamination on the substrate material by utilizing a plurality of pure targets to prepare the alloy thin film material. The optical fiber hydrogen sensor has the characteristics of strong anti-interference capability, high safety and high reliability and can be widely used for various conditions in which the hydrogen leakage needs to be detected.

Owner:HUAZHONG UNIV OF SCI & TECH

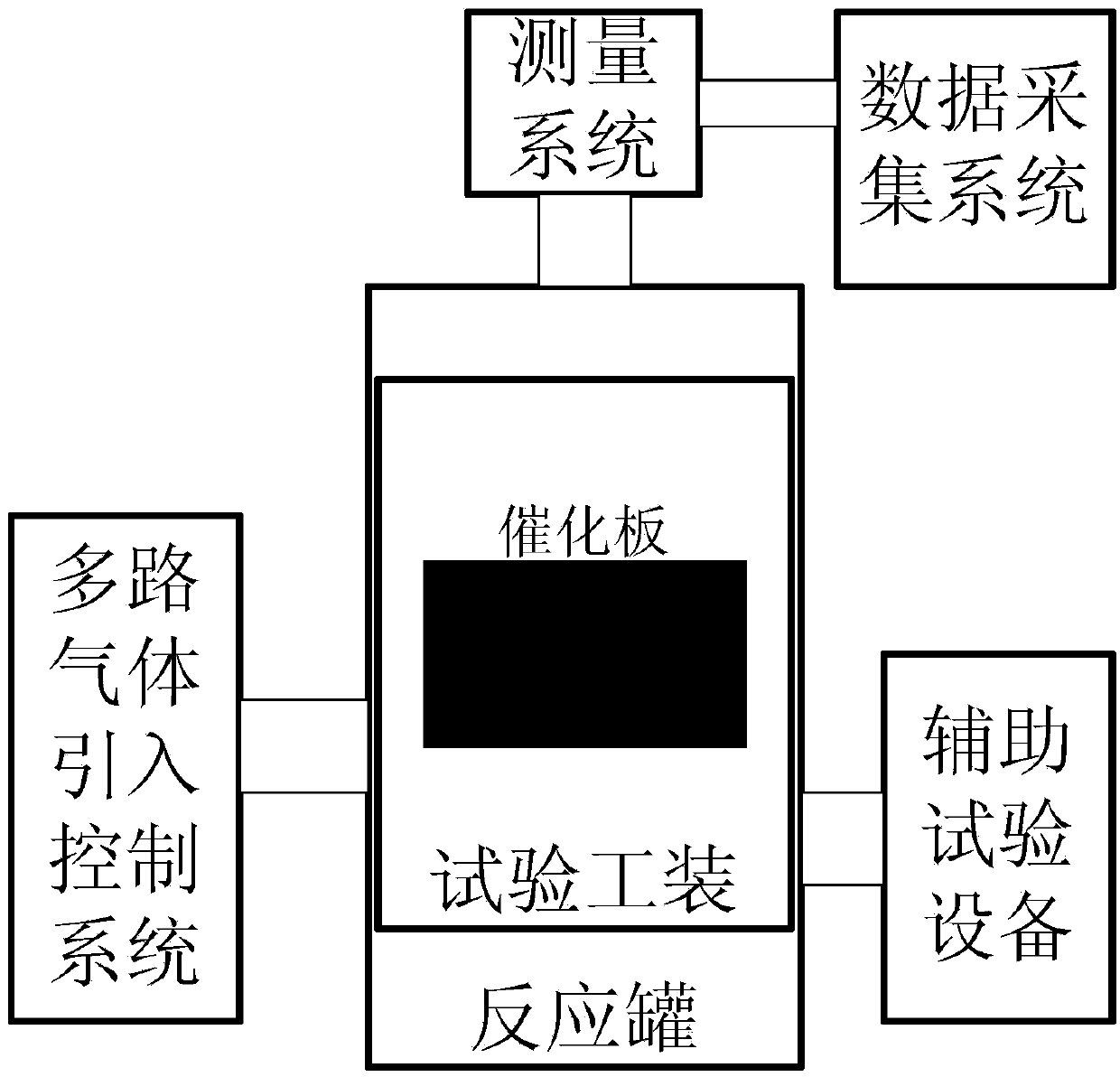

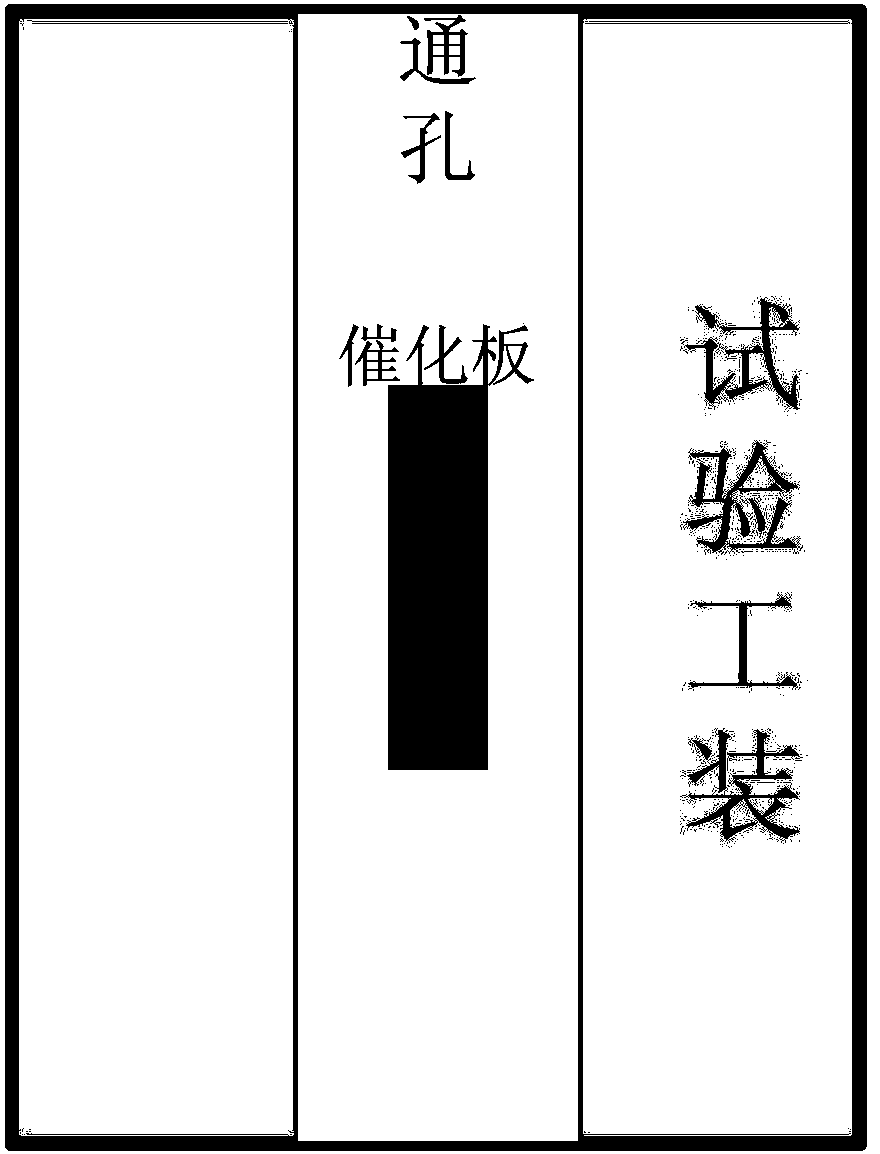

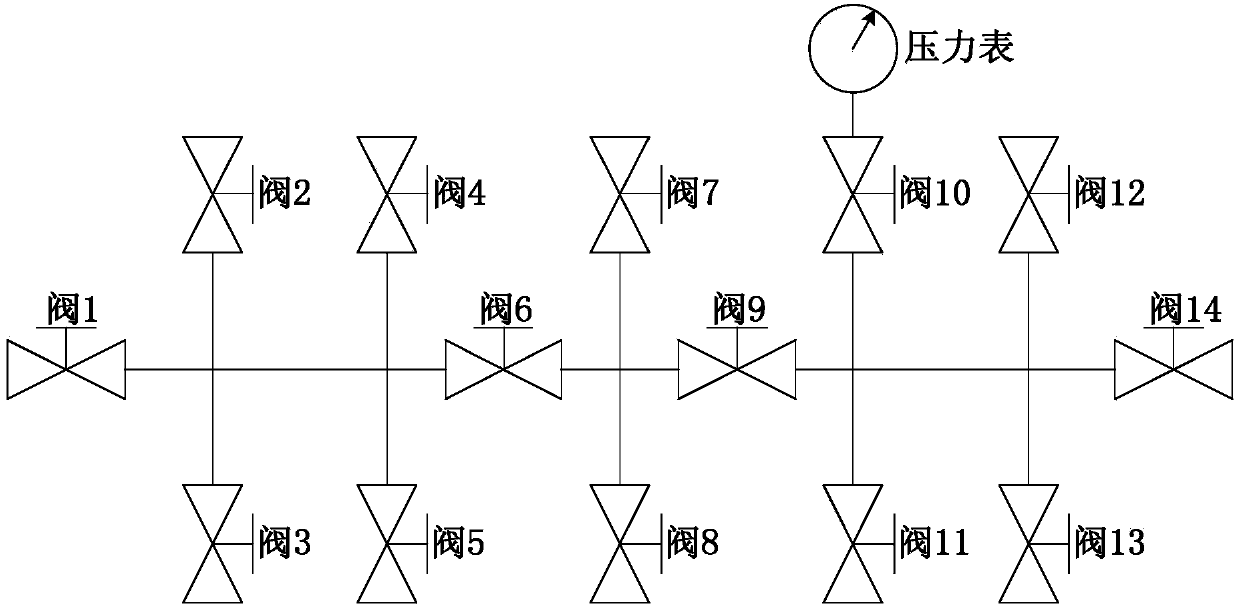

Comprehensive performance testing device for oxyhydrogen composite catalyst and application method thereof

InactiveCN104200856AAdjust environmental parameters at any timeIngenious designNuclear energy generationNuclear monitoringNuclear powerControl system

The invention discloses a comprehensive performance testing device for an oxyhydrogen composite catalyst and an application method thereof. The comprehensive performance testing device comprises a reaction tank, a test tooling, a measuring system, a data acquisition system, a multipath gas introduction control system and auxiliary testing equipment, wherein the test tooling is mounted in the reaction tank and is used for placing a catalytic board; the measuring system is mounted on the reaction tank and is used for detecting the concentration, the temperature, the pressure and other parameters of gas in the reaction tank; the data acquisition system is connected with the measuring system; the multipath gas introduction control system provides exogenous gas required by the test; the auxiliary testing equipment is connected with the reaction tank. According to the comprehensive performance testing device disclosed by the invention, the design is ingenious; the complex environment of a nuclear power station under the working condition of serious accidents is simulated by an oxyhydrogen composite catalytic board through special equipment, so that environment parameters of the catalyst can be adjusted at any time; all required data is accurately detected by the measuring system and various performance tests of the catalyst are realized; the transfer and the assembly of the catalytic board are eliminated, so that great human and material resources are saved; the time and the labor are saved; the comprehensive performance testing device is convenient and safe in use, simple and quick in debugging and comprehensive and sufficient in detection, and has high popularization and application values in the field.

Owner:SICHUAN INST OF MATERIALS & TECH +2

Weld metal excellent in hydrogen embrittlement resistance

InactiveUS20130315777A1Excellent hydrogen embrittlement resistanceExcellent low-temperature toughnessWelding/cutting media/materialsSoldering mediaNumber densityChemical composition

Owner:KOBE STEEL LTD

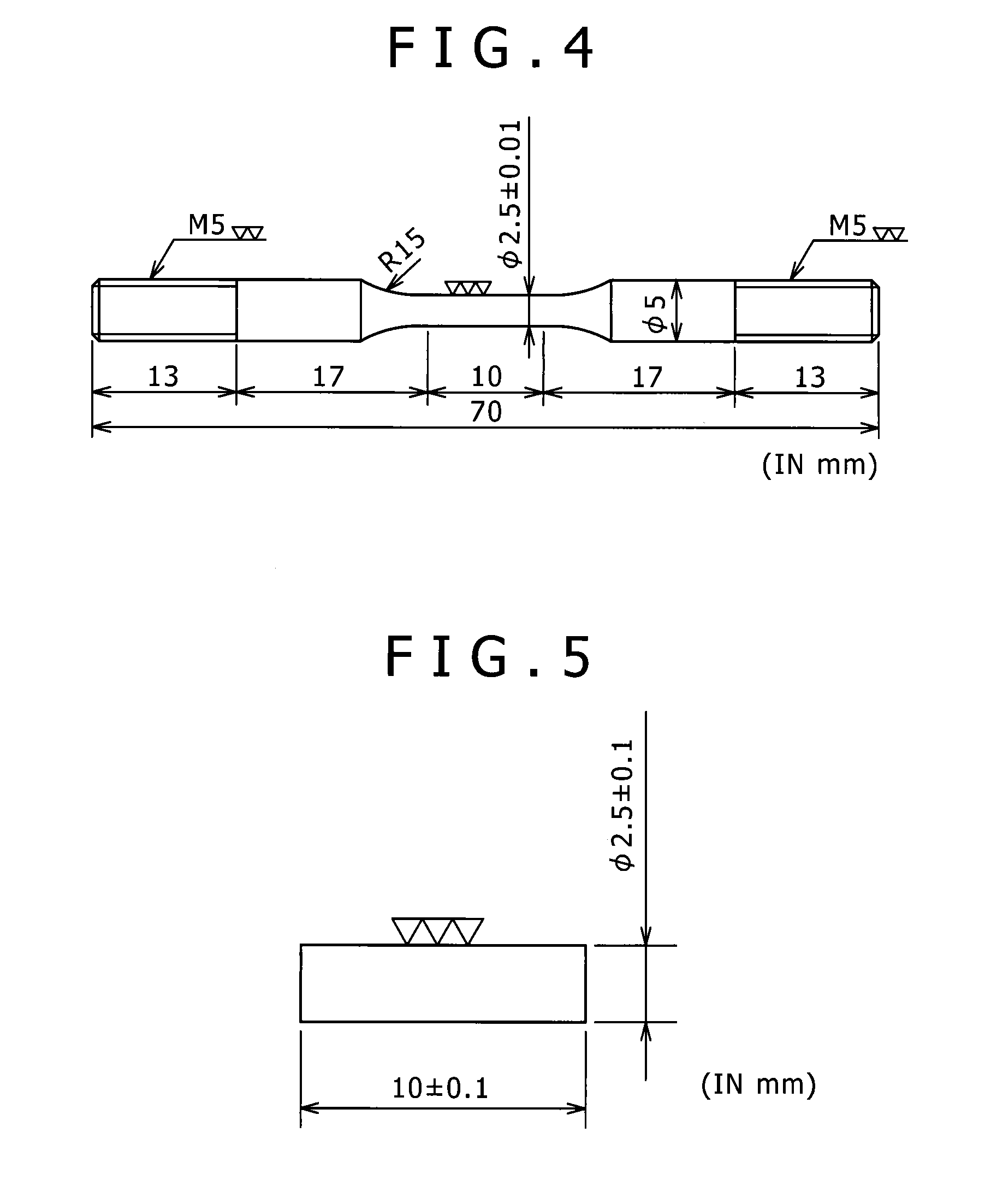

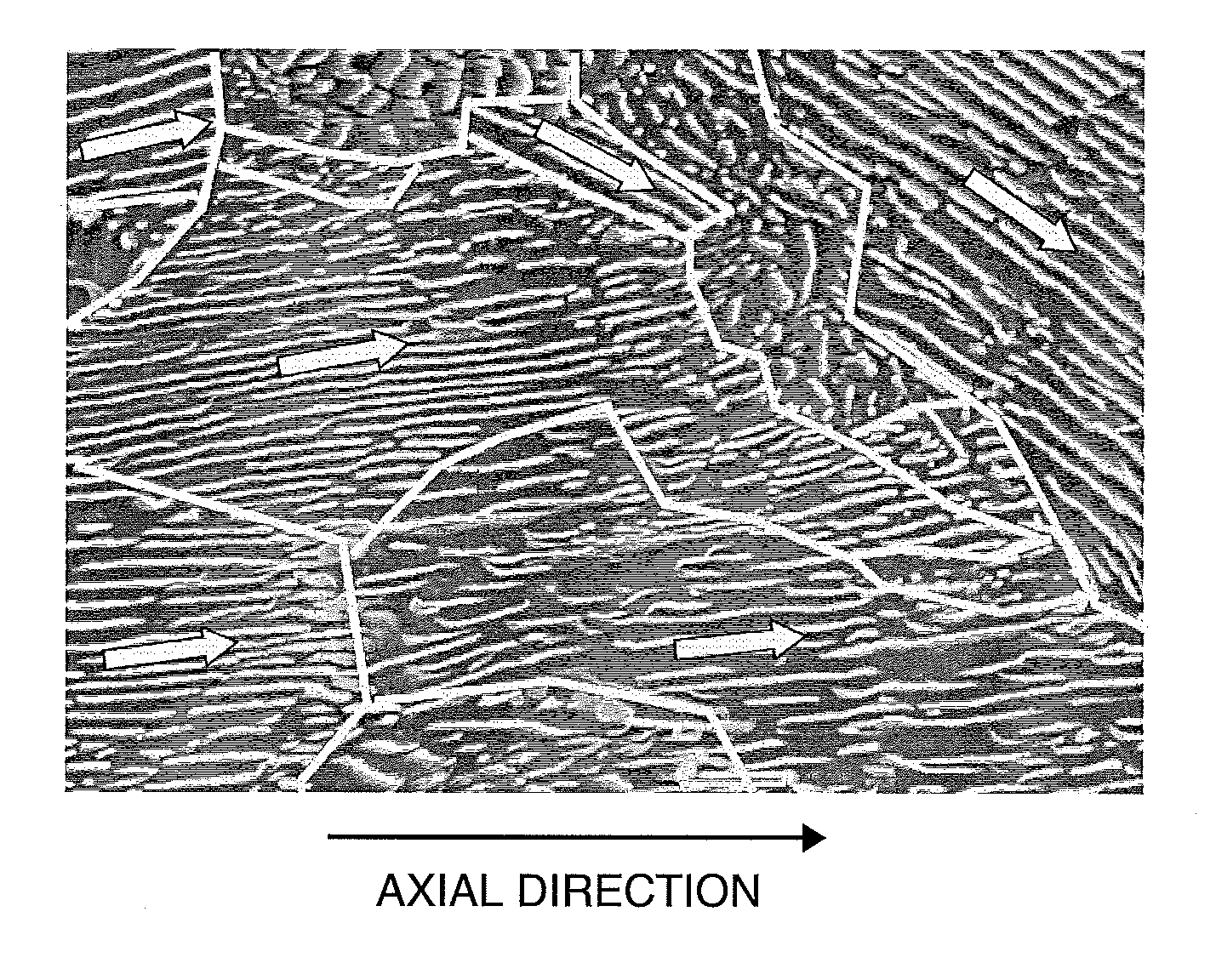

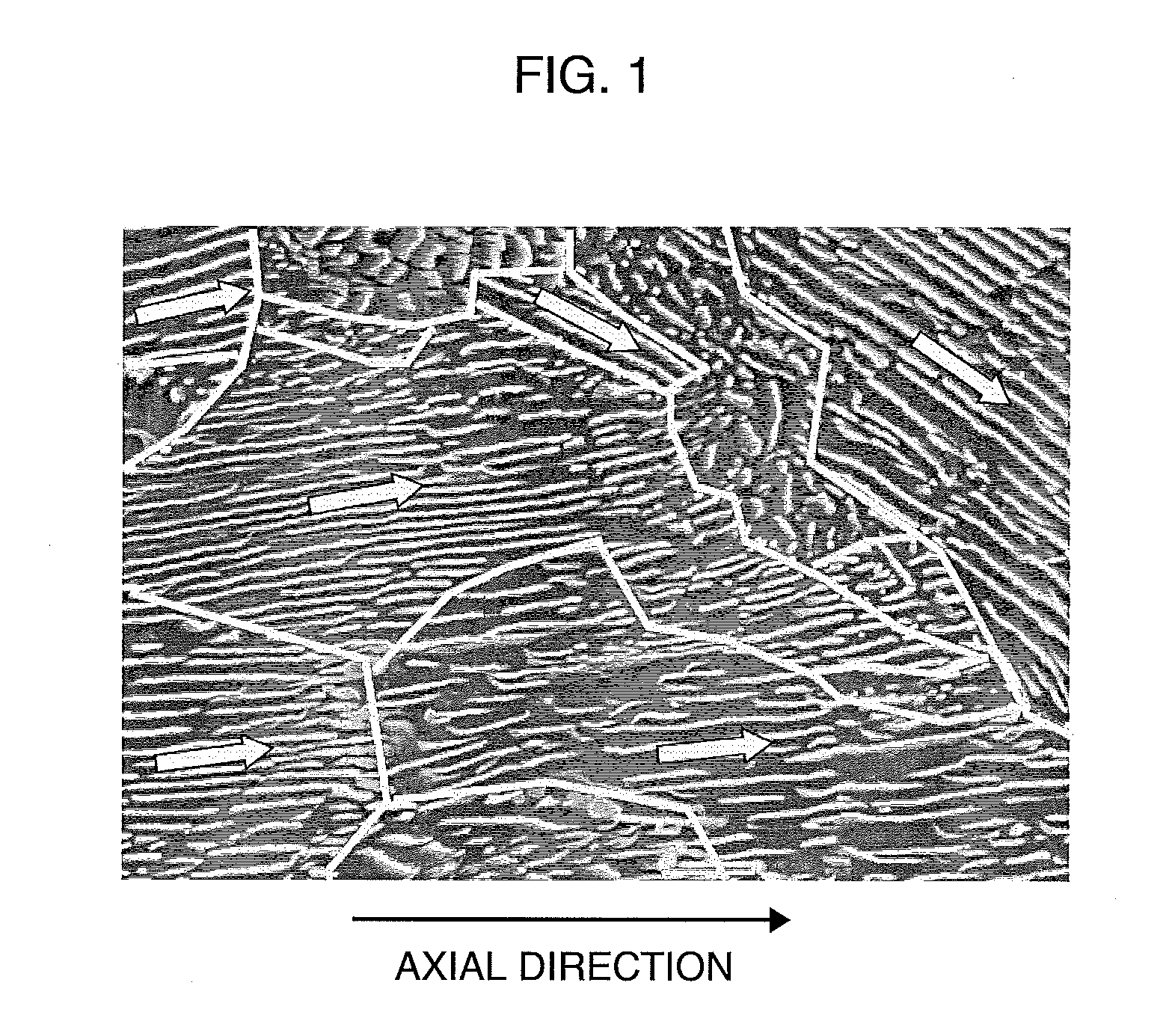

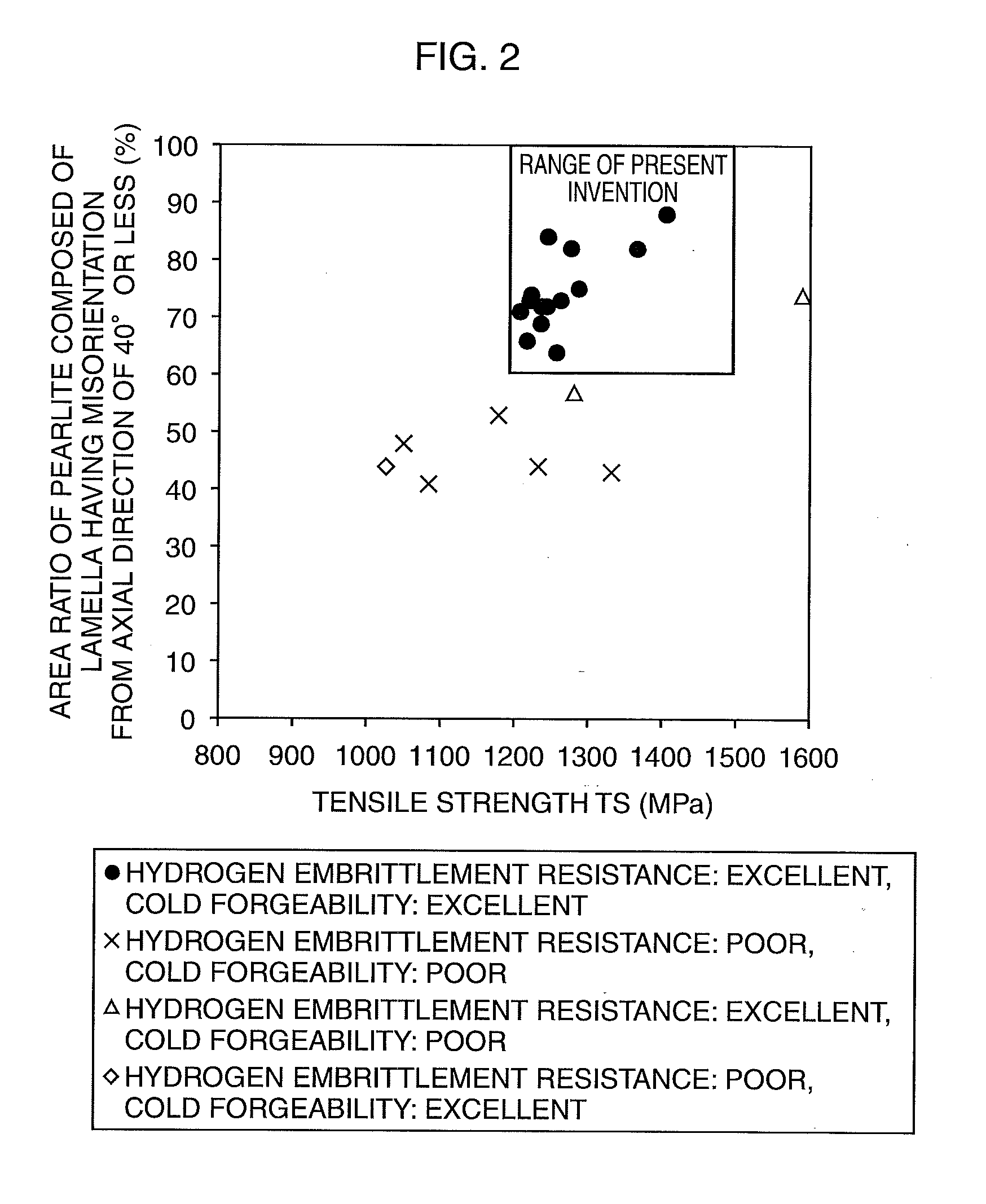

Steel wire of special steel and wire rod of special steel

ActiveUS20130133789A1Improve hydrogen embrittlement resistanceHigh strengthFurnace typesHeat treatment furnacesDEPBTMetallurgy

A predetermined composition is had, when a C content is represented by (C %), in a case of (C %) being not less than 0.35% nor more than 0.65%, a volume fraction of pearlite is 64×(C %)+52% or more, and in a case of (C %) being greater than 0.65% and 0.85% or less, the volume fraction of pearlite is not less than 94% nor more than 100%, and a structure of the other portion is composed of one or two of proeutectoid ferrite and bainite. Further, in a region to a depth of 1.0 mm from a surface, a volume fraction of pearlite block having an aspect ratio of 2.0 or more is not less than 70% nor more than 95%, and a volume fraction of pearlite having an angle between an axial direction and a lamellar direction on a cross section parallel to the axial direction of 40° or less is 60% or more with respect to all pearlite.

Owner:NIPPON STEEL CORP

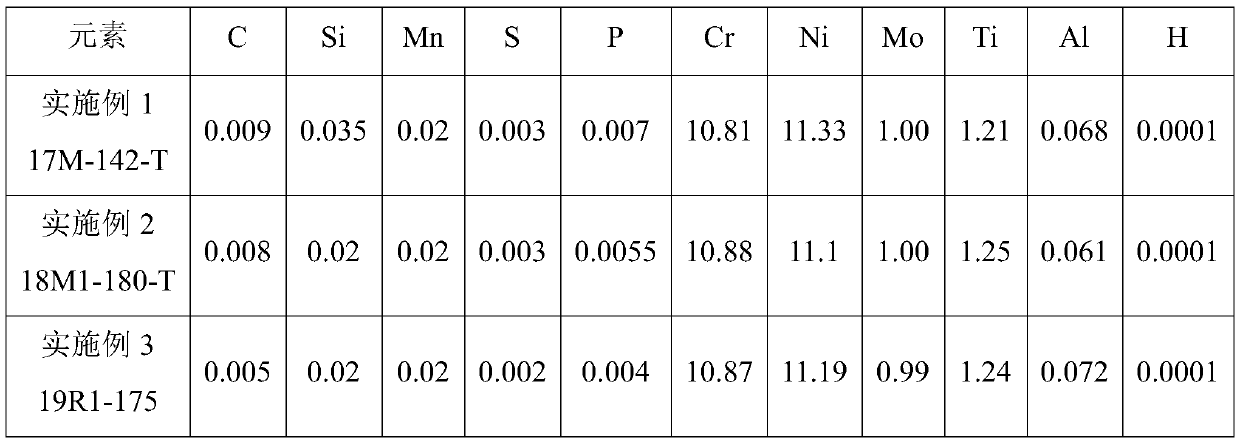

Anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for fastener, and manufacturing method thereof

ActiveCN111218618AIncrease chromium contentImprove hydrogen embrittlement resistanceMetallic materialsSS - Stainless steel

The invention relates to an anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for a fastener, and a manufacturing method thereof, belongs to the technical field of metal materials, and solves the problem of low matching degree of anti-hydrogen embrittlement property and high toughness of a fastener used in an aerospace environment. The anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for the fastener comprises the following elements in mass fraction: 0.0001%-0.01% of C, 0%-0.10% of Si, 0.01%-0.15% of Mn, 0%-0.005% of S, 0%-0.015%of P, 10.50%-12.50% of Cr, 10.70%-11.50% of Ni, 0.75%-1.25% of Mo, 1.20%-1.70% of Ti, 0%-0.10% of Al, not greater than 1.5ppm of H, and the balance iron and inevitable impurities. The stainless steelbar meeting the comprehensive performance of high strength, high toughness and anti-hydrogen embrittlement property simultaneously is prepared, and the use requirement of the fastener making contactwith a corrosive medium and used for the aerospace environment is met.

Owner:CENT IRON & STEEL RES INST

Ultrahigh-strength thin steel sheet

ActiveUS7887648B2Improve hydrogen embrittlement resistanceIncrease production capacityFurnace typesHeat treatment furnacesAustenite grainNear neighbor

Owner:KOBE STEEL LTD

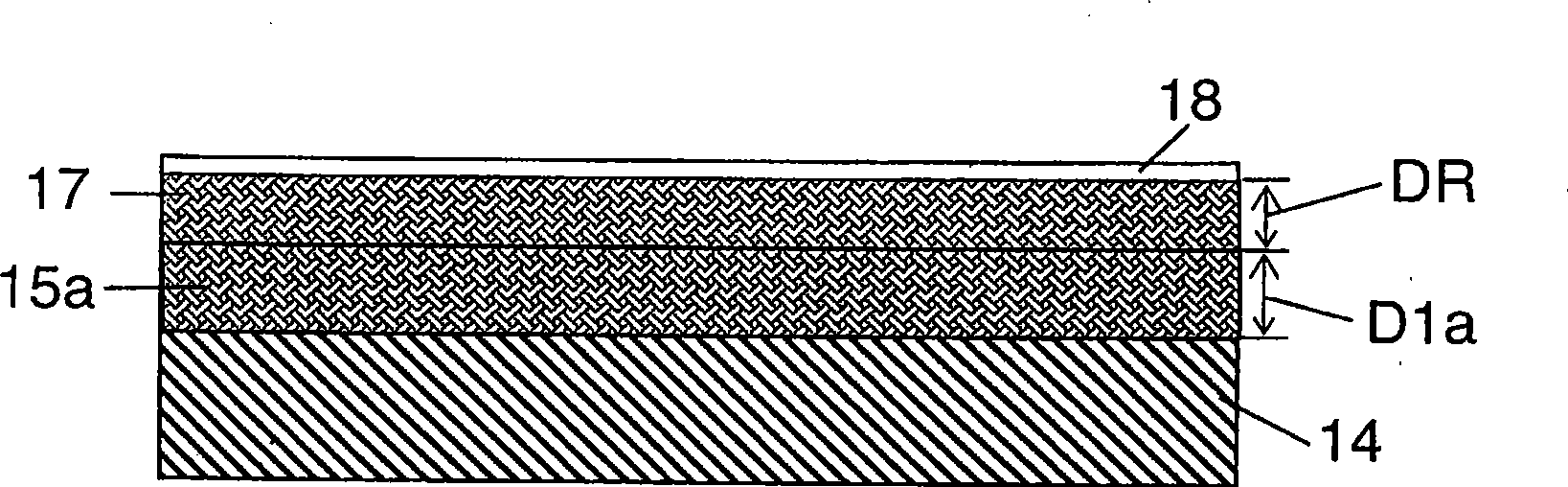

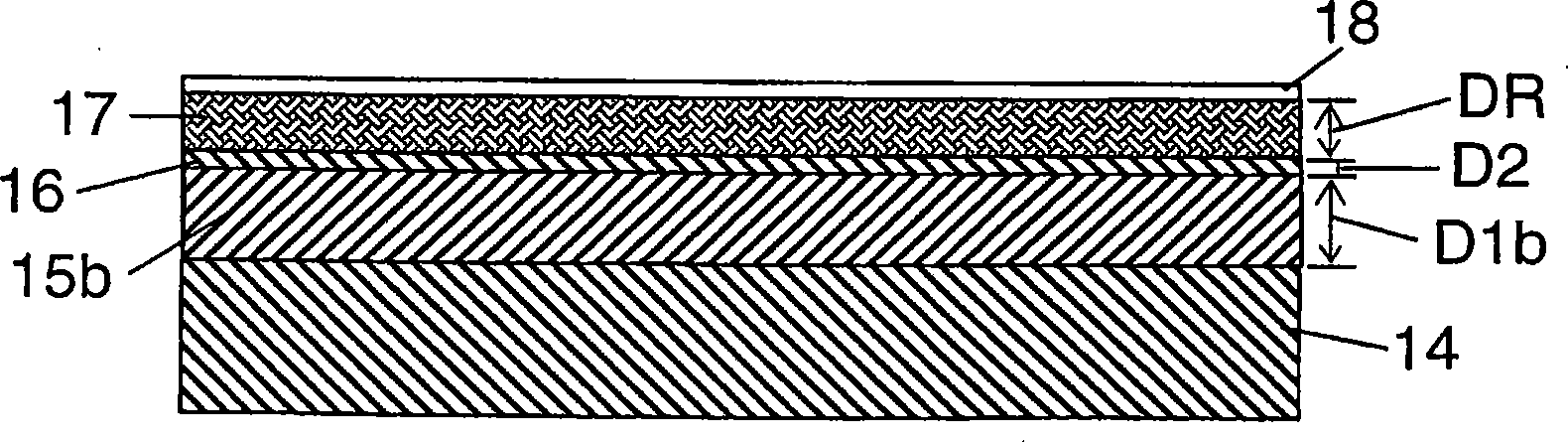

Fastening element

InactiveCN101382163AImprove hydrogen embrittlement resistanceProduction economyBoltsFurnace typesCarbon steelRivet

The invention relates to a fastening element, such as a pin bolt or a nail, an anchor rod, a screw or a rivet. The fastening element is provided with a core area (14) formed of relatively hard carbon steel and an edge area (17) positioned outside the core area (14) and formed of first low-carbon austenitic steel refined by adding a first alloy element. In order to improve the fastening element, the invention has such suggestion that an intermediate area (15a) at least formed of second low-carbon steel is arranged between the core area (14) and the edge area (17), wherein the second low-carbon steel has lower rigidity than the steel of the core area (14).

Owner:HILTI AG

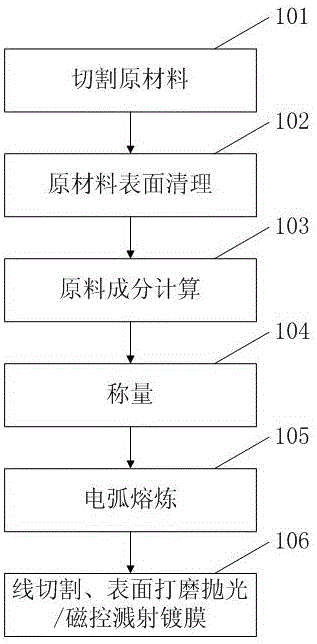

Nb based hydrogen permeation alloy doped with special elements and preparation method thereof

ActiveCN106834855AImprove hydrogen embrittlement resistanceUniform tissueVacuum evaporation coatingSputtering coatingRare-earth elementIngot

The invention provides a Nb based hydrogen permeation alloy doped with special elements and a preparation method thereof, the chemical general formula of the Nb based hydrogen permeation alloy doped with special elements is Nb100-(x + y + Z) MxNyPz; M is one or more than one element selected from Ti, Zr and Hf, N is one or more than one element selected from Ni or Co, P is one or more than one element selected from Cr, Fe, Cu, Al, Mo, Ru, Rh, W, Si, Mn, Sn, Zn and Mg, 20=<x=<30, 10=<y=<30, 5=<z=<20, and x, y and z are mole percentage. The preparation method comprises the following steps: cutting raw materials, cleaning raw material surface, calculating raw material composition, weighing the raw materials, and performing electric arc melting to obtain an alloy ingot. A hydrogen permeation alloy film material which has better hydrogen permeability and properties against hydrogen embrittlement and is doped with various rare earth elements can be prepared by a vacuum electric arc melting method.

Owner:SHANDONG UNIV OF SCI & TECH

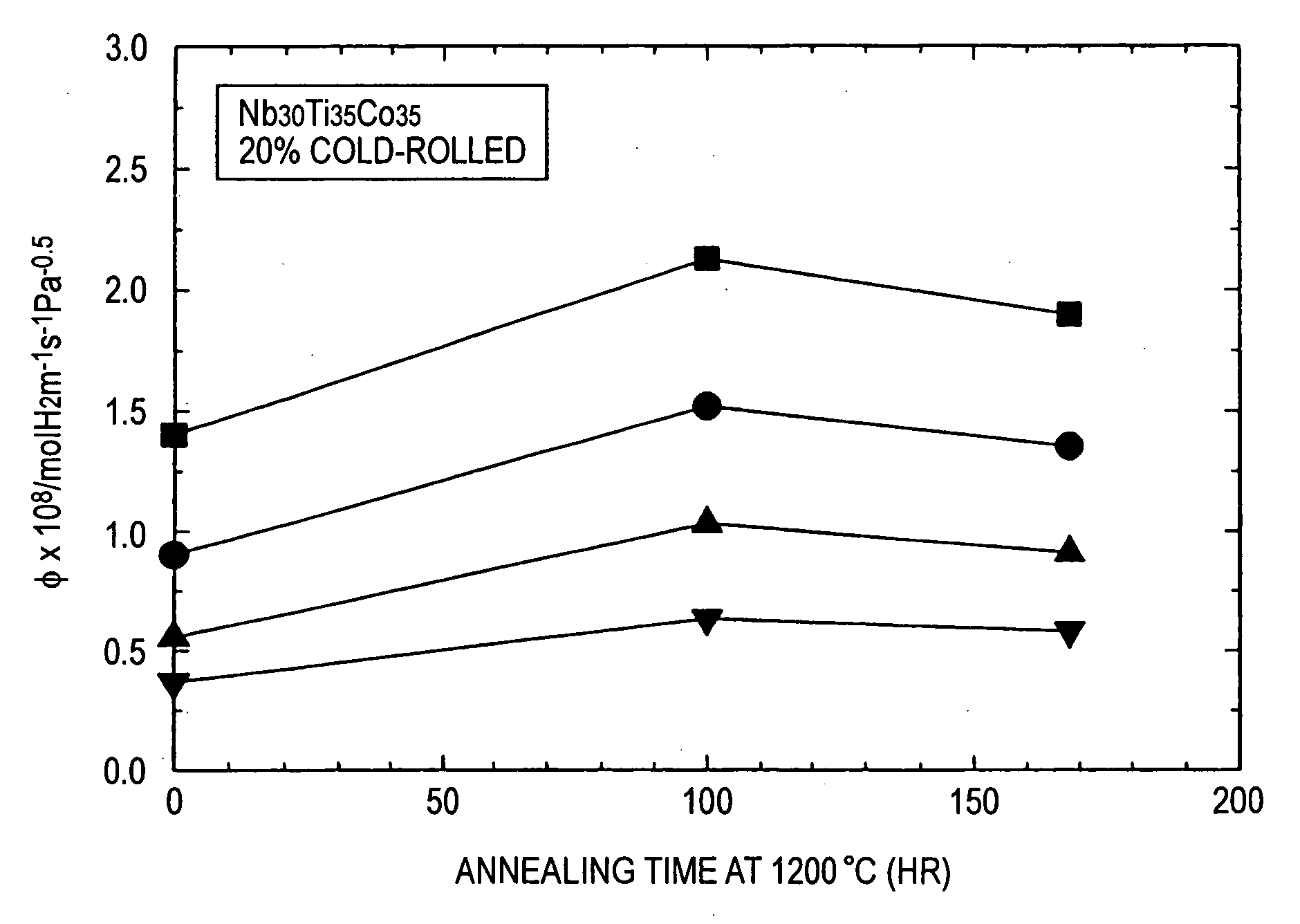

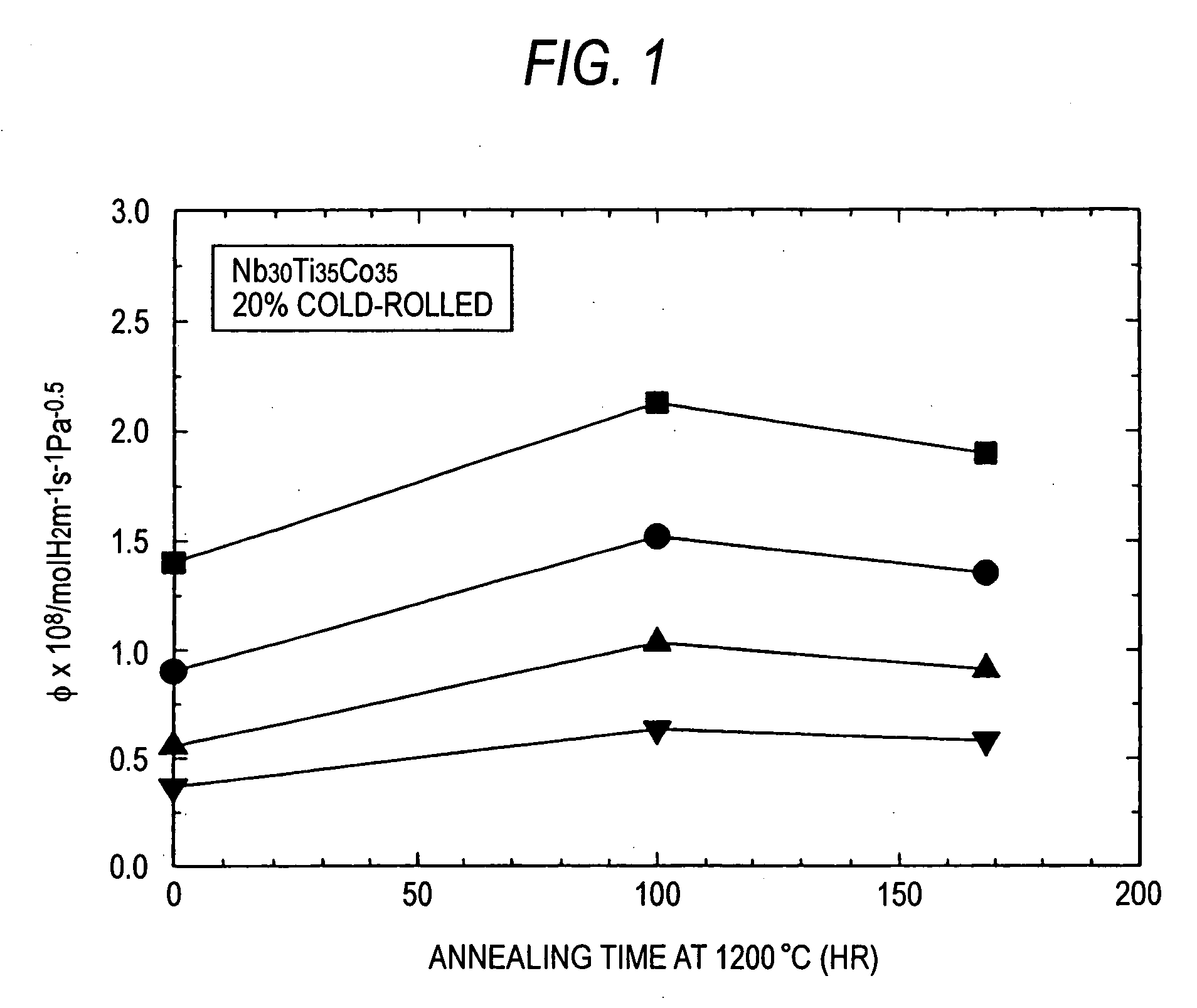

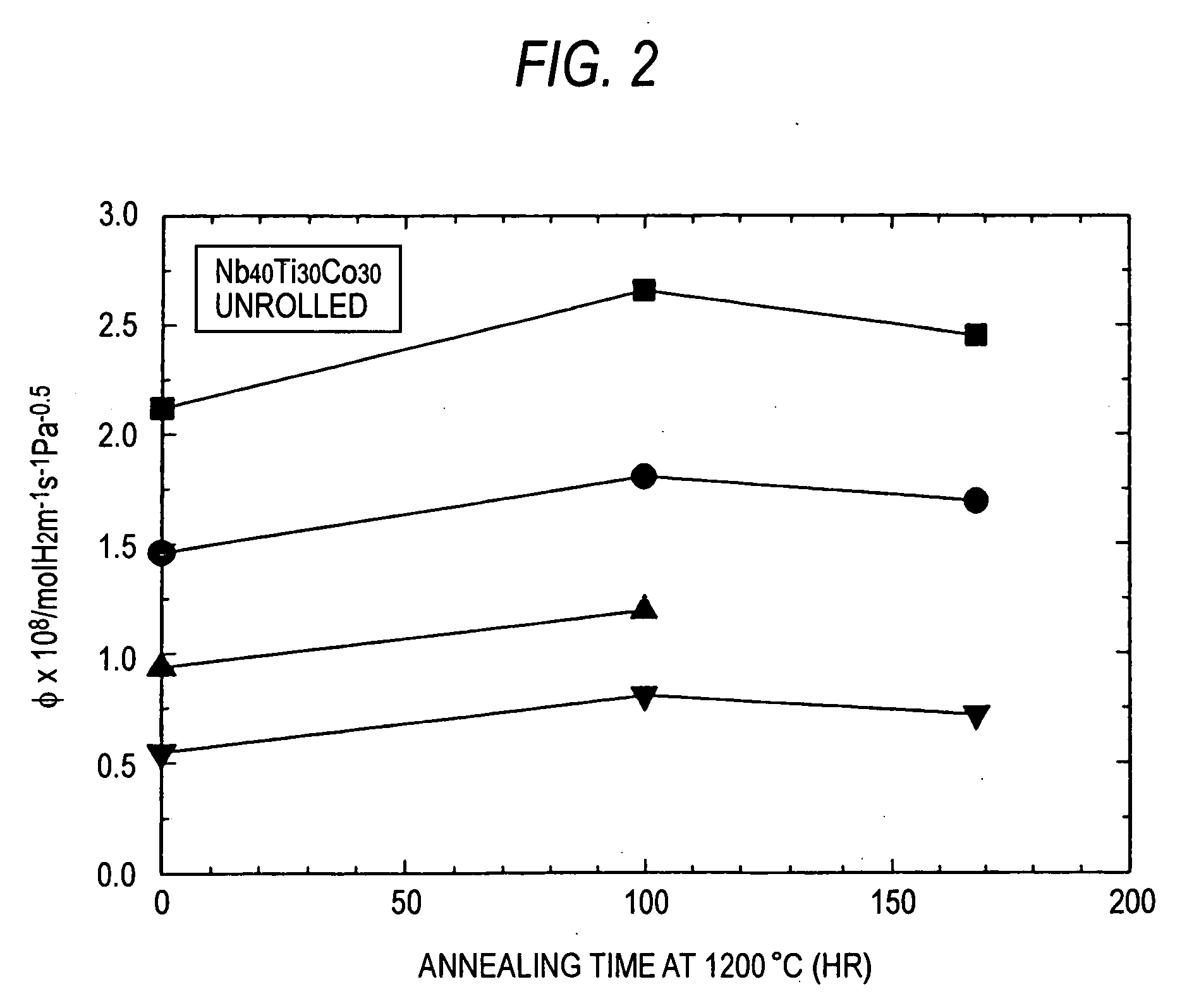

Hydrogen permeable alloy and method for producing the same

InactiveUS20070056660A1Improve permeabilityImprove hydrogen embrittlement resistanceSemi-permeable membranesReactant parameters controlAlloyTitanium

A (Nb, Ti) phase in an Nb—Ti—Co alloy is composed of a granular structure. The Nb—Ti—Co alloy is preferably subjected to heat treatment at 800° C. or more so that the eutectic structure in the casted state can be changed to a granular structure. The Nb—Ti—Co alloy used there is preferably NbxTi(100-x-y)Coy, (x≦70, 20≦y≦50 (mol %)). By properly predetermining the heating temperature and time, the resulting alloy exhibits improved hydrogen permeability in combination with a good hydrogen embrittlement resistance characteristic in the CoTi phase, making it possible to provide a practical hydrogen permeable membrane having an advantageously high performance.

Owner:JAPAN STEEL WORKS LTD +1

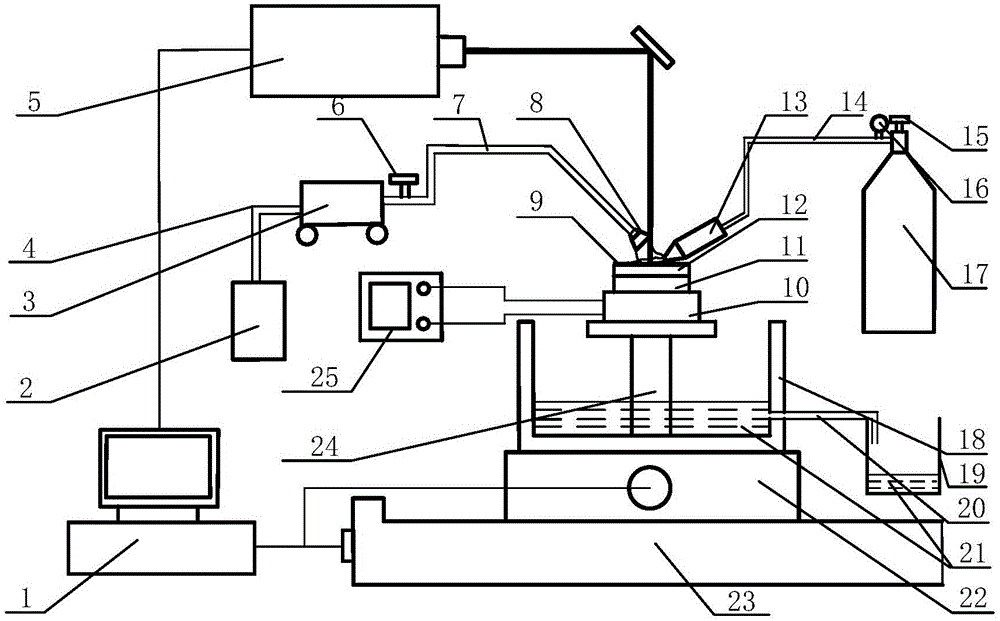

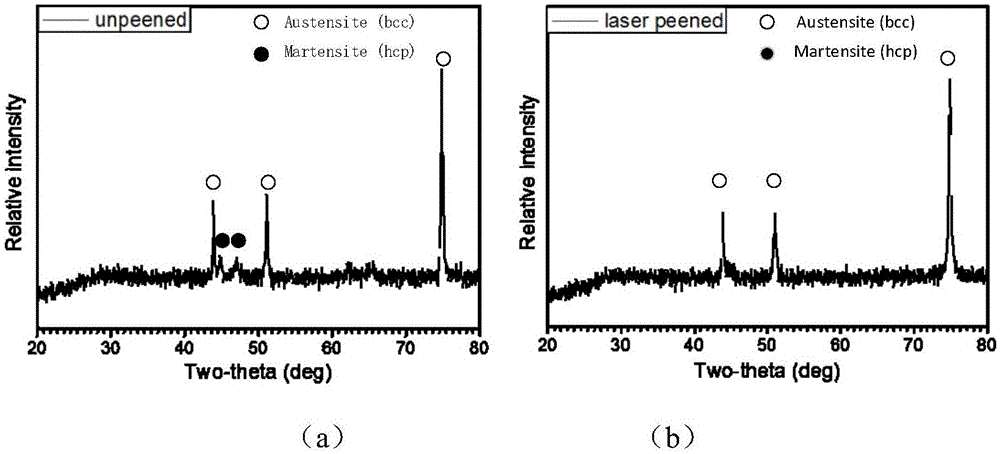

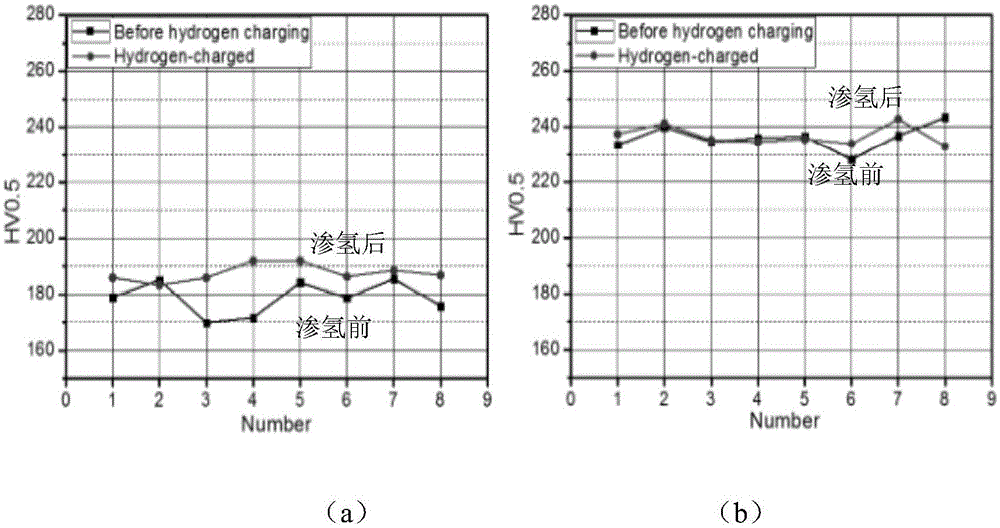

Method and device capable of improving hydrogen brittleness resistance of stainless steel materials substantially

The invention discloses a method and device capable of improving hydrogen brittleness resistance of 316L stainless steel substantially. The method comprises the steps that surface hydrogen atoms are promoted to separate out through high temperature (250-450 DEG C), and then laser shock is conducted at the dynamic strain aging temperature (300-450 DEG C); on the one hand, the precipitation of the hydrogen atoms is accelerated through plastic deformation, and on the other hand, secondary invasion of the hydrogen atoms in the cooling process is hindered; meanwhile, the hydrogen brittleness phenomenon caused by hydrogen atom evasion and hydrogen atom segregation in the hydrogen service environment is effectively hindered by utilizing the pinning effect of high-density dislocation and crystal boundary, the hydrogen-induced martensite phase change of the 316L stainless steel is reduced substantially, and the surface properties and fatigue properties of the 316L stainless steel in the hydrogen-type corrosion environment can be improved effectively by combining high-amplitude residual compressive stress induced by the laser shock. The device comprises core assemblies including a laser device, a heating platform, a moving platform, a restraint system and a nitrogen protection system. The method and device have the advantages of being simple in structure, controllable in process, low in cost and the like.

Owner:JIANGSU UNIV

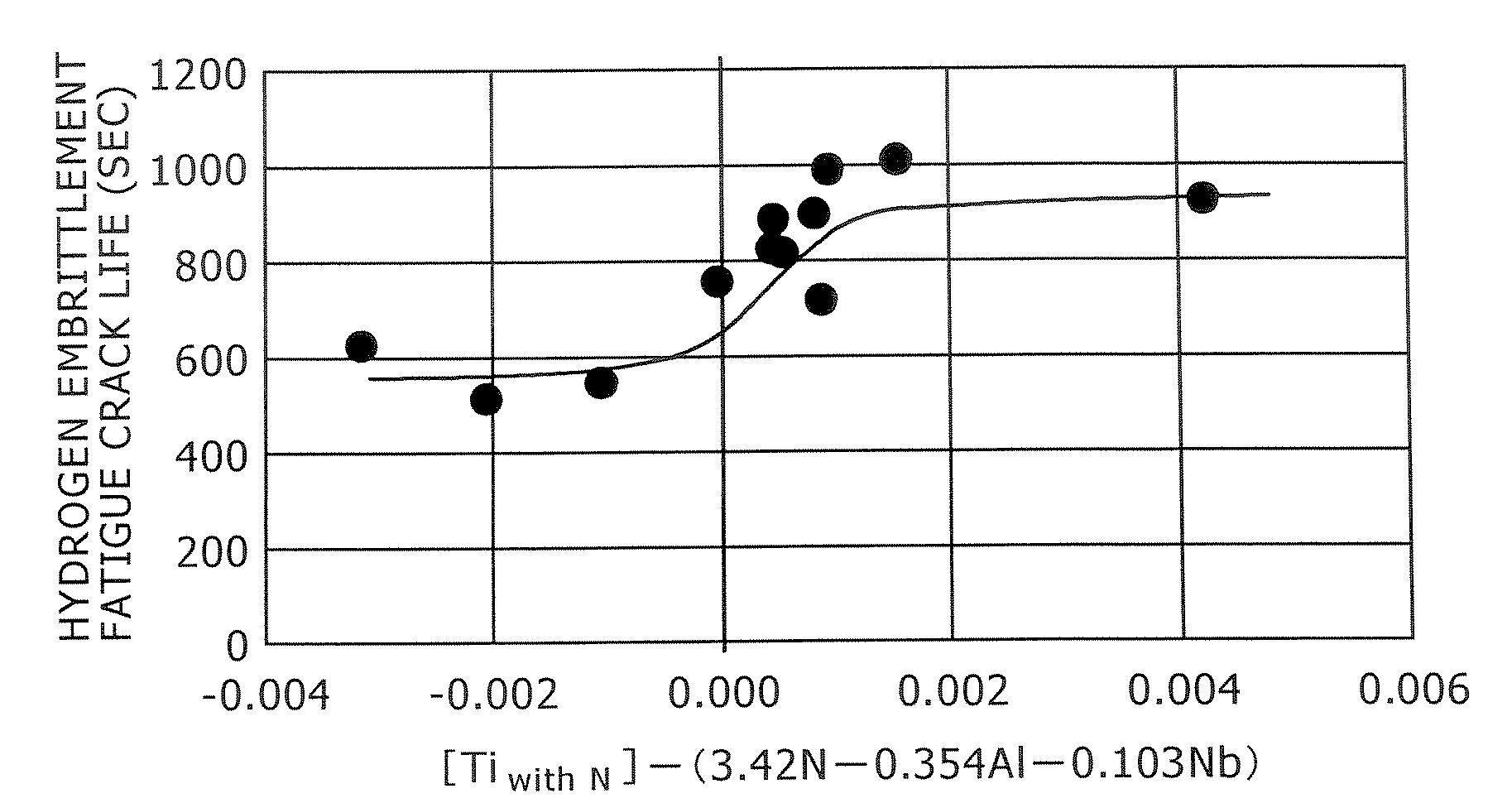

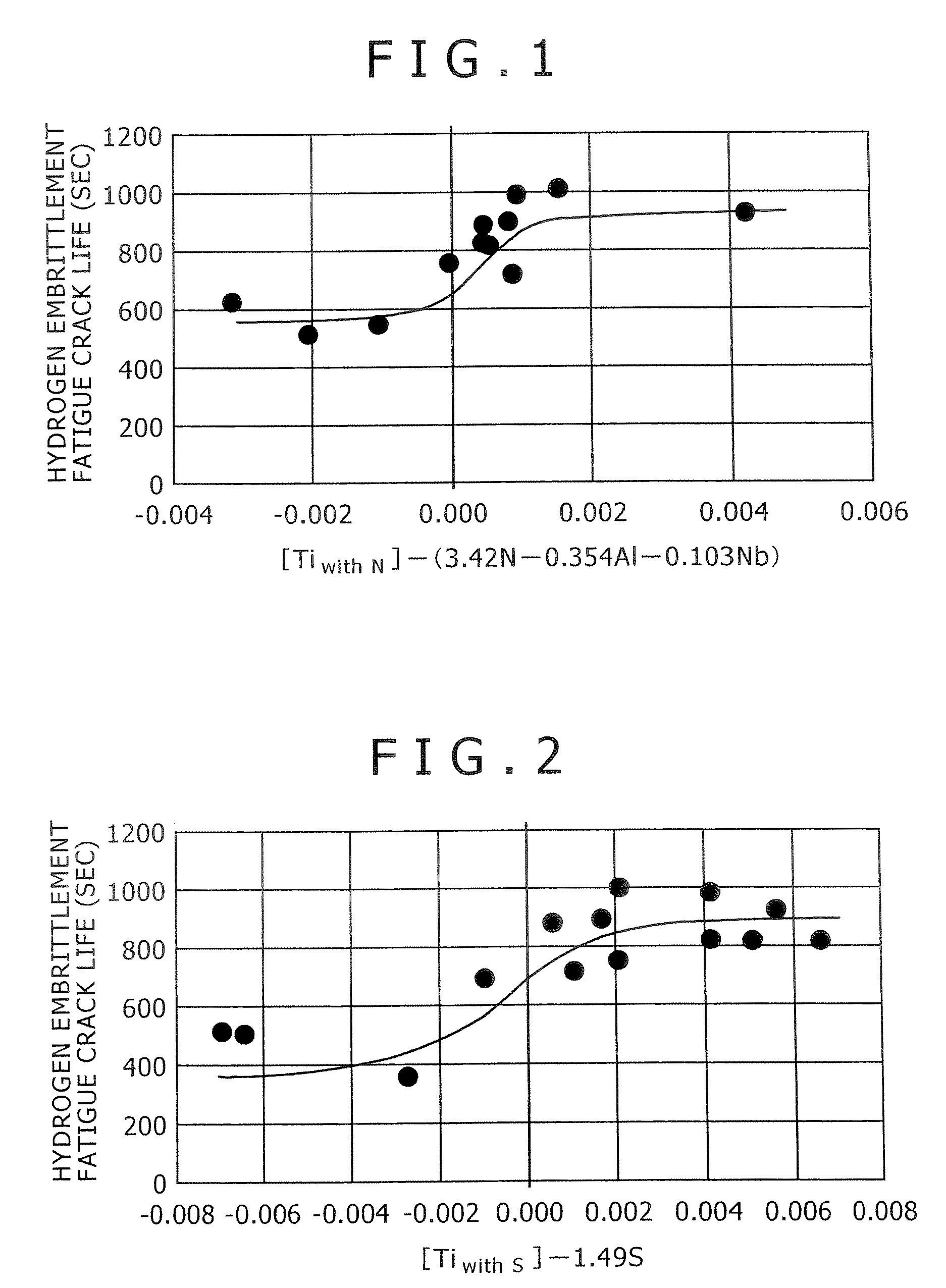

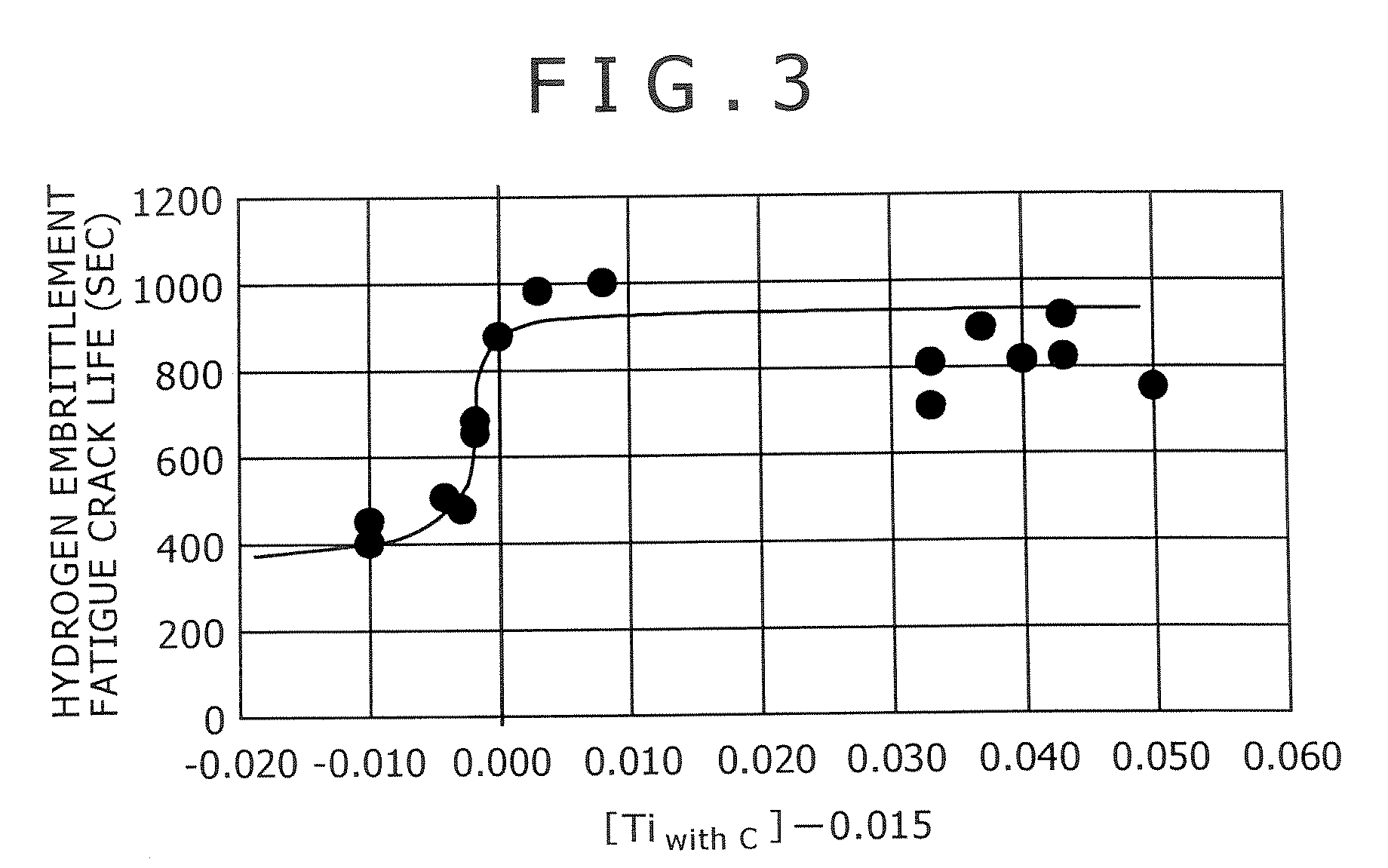

Spring steel with excellent resistance to hydrogen embrittlement and steel wire and spring obtained from the steel

InactiveUS20070095439A1Improve the immunityImprove machinabilityFurnace typesHeat treatment furnacesCarbideTitanium nitride

Disclosed is a spring steel, containing: C: 0.35-0.65% (the term “%” herein means “mass %”, the same is true hereinbelow), Si: 1.5-2.5%, Mn: 0.05-1%, Cr: 0.05-1.9%, P: 0.015% or less (exclusive of 0%), S: 0.015% or less (exclusive of 0%), Ti: 0.025-0.1%, Al: 0.05% or less (exclusive of 0%), and N: 0.01% or less (exclusive of 0%), wherein an amount of Ti nitride, an amount of Ti sulfide, and an amount of Ti carbide satisfy the following formulas (1), (2), and (3); [Tiwith N]≧3.42×[N]−0.354×[Al]−0.103×[Nb] (1) [Tiwith S]≧1.49×[S] (2) [Tiwith C]≧0.015 (3), in which [Tiwith N] represents the amount of Ti (mass %) forming Ti nitride, [Tiwith S] represents the amount of Ti (mass %) forming Ti sulfide, [Tiwith C9 represents the amount of Ti (mass %) forming Ti carbide, and [N], [Al], [Nb], and [S] represent an amount (mass%) of each element in the steel. The spring steel of the present invention shows excellent resistance to hydrogen embrittlement.

Owner:KOBE STEEL LTD

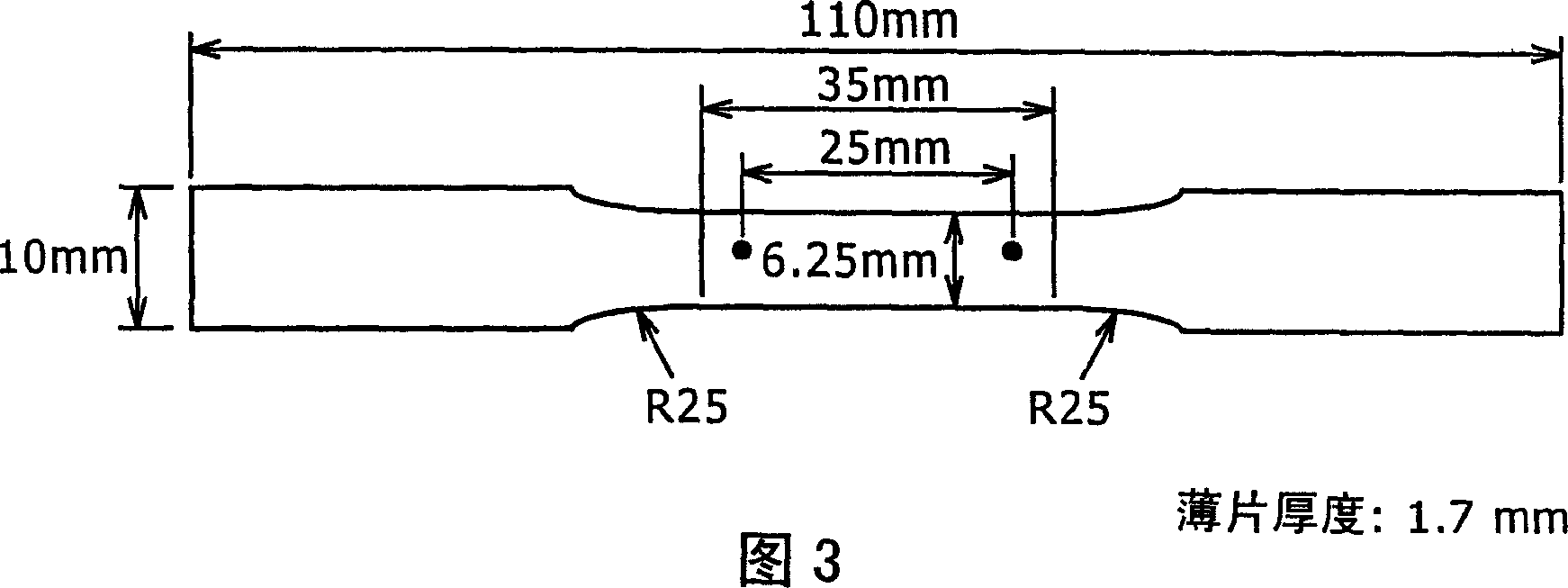

High strength bolt having excellent hydrogen embrittlement resistance

The present invention provides a high strength bolt that has excellent hydrogen embrittlement resistance. The high strength bolt having excellent hydrogen embrittlement resistance which bolt comprises 0.20 to 0.60% of C, 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, higher than 0% and not higher than 1.5% of Al, 0.15% or less P, 0.02% or less S, and balance of iron and inevitable impurities, and the structure includes: 1% or more residual austenite; 80% or more in total content of bainitic ferrite and martensite; and 10% or less (may be 0%) in total content of ferrite and pearlite in the proportion of area to the entire structure, and also the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher and the bolt has tensile strength of 1180 MPa or higher.

Owner:KOBE STEEL LTD +1

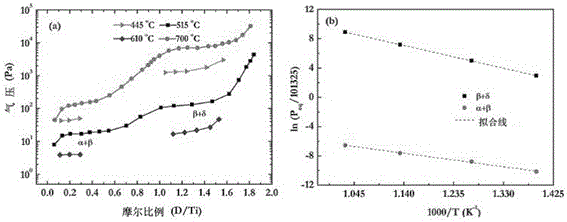

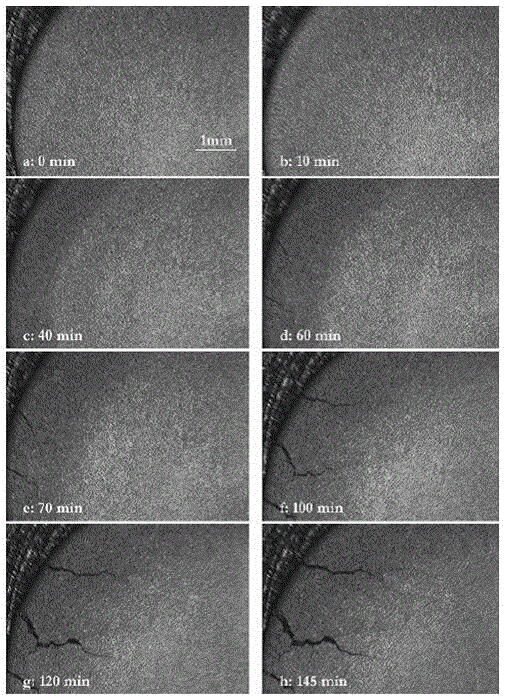

High vacuum-high pressure combined hydrogen storage property testing device for low hydrogen absorption equilibrium pressure material

InactiveCN105606767AIngenious designSave manpower and material resourcesMaterial analysisGas solidUltra high pressure

The invention discloses a high vacuum-high pressure combined hydrogen storage property testing device for a low hydrogen absorption equilibrium pressure material. The device comprises a high pressure gas introduction system, a high vacuum gas reaction and hydrogen storage sample real-time observation system, a measurement system, a data acquisition system and an auxiliary testing device. The device disclosed by the invention has the advantages that the design is smart; the device can be used for acquiring kinetic data and thermodynamic data of a gas-solid reaction of a hydrogen storage material, especially the low hydrogen absorption equilibrium pressure material, in hydrogen absorption and desorption processes, and further observing the change of the sample surface appearance in situ in the reaction process at the same time, therefore the hydrogen storage properties of these materials are overall obtained, and the research demands on the fields of fusion energy and hydrogen energy are met.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

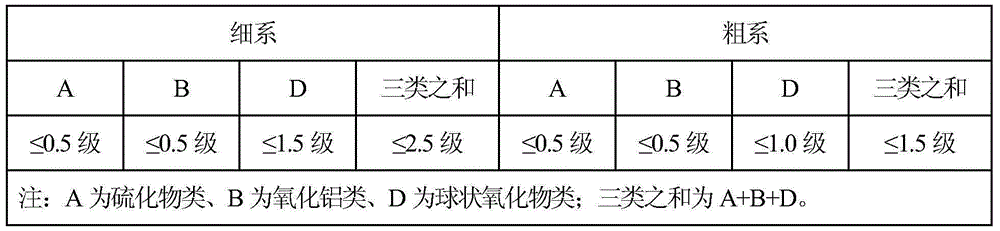

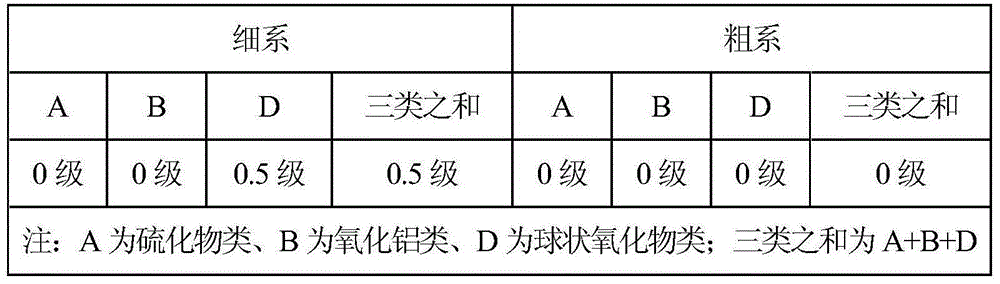

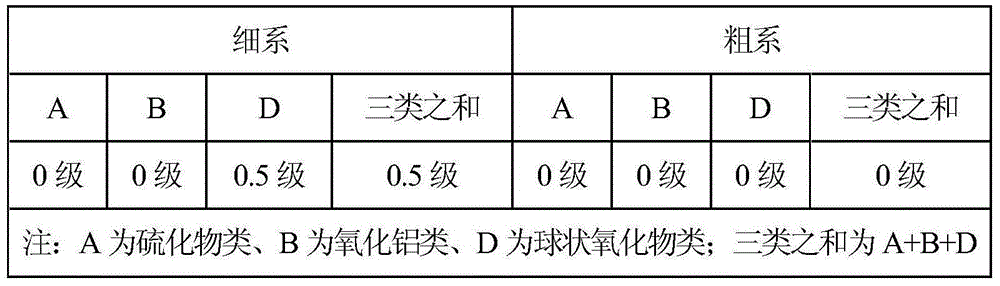

High-strength hydrogen-brittleness-resistant austenite alloy with mark of J75 and preparation method of high-strength hydrogen-brittleness-resistant austenite alloy

The invention relates to the field of precipitation strengthening austenite alloy, in particular to high-strength hydrogen-brittleness-resistant austenite alloy with the mark of J75 and a preparation method of the high-strength hydrogen-brittleness-resistant austenite alloy. The high-strength hydrogen-brittleness-resistant austenite alloy comprises, by weight, 0.0008-0.0025% of B, smaller than or equal to 0.020% of C, smaller than or equal to 0.006% of S, smaller than or equal to 0.006% of P, 0.10-0.30% of Si, 29.00-32.00% of Ni, 13.50-16.50% of Cr, 1.00-1.60% of Mo, 0.15-0.35% of V, 1.80-2.40% of Ti, 0.10-0.40% of Al, and the balance Fe. The alloy is formed by forging and / or rolling through vacuum induction and vacuum arc self-consuming smelting, hot-rolled bars with the diameters not larger than 80 mm is not lower than level 6, and hot-rolled bars and forged materials with the diameters larger than 80 mm are not lower than the level 5. The inspection result of bars with the diameters not larger than 65 mm needs to conform to the AA-level specification in GB / T 4162, and the inspection result of bars with the diameters larger than 65 mm needs to conform to the A-level specification in GB / T 4162.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

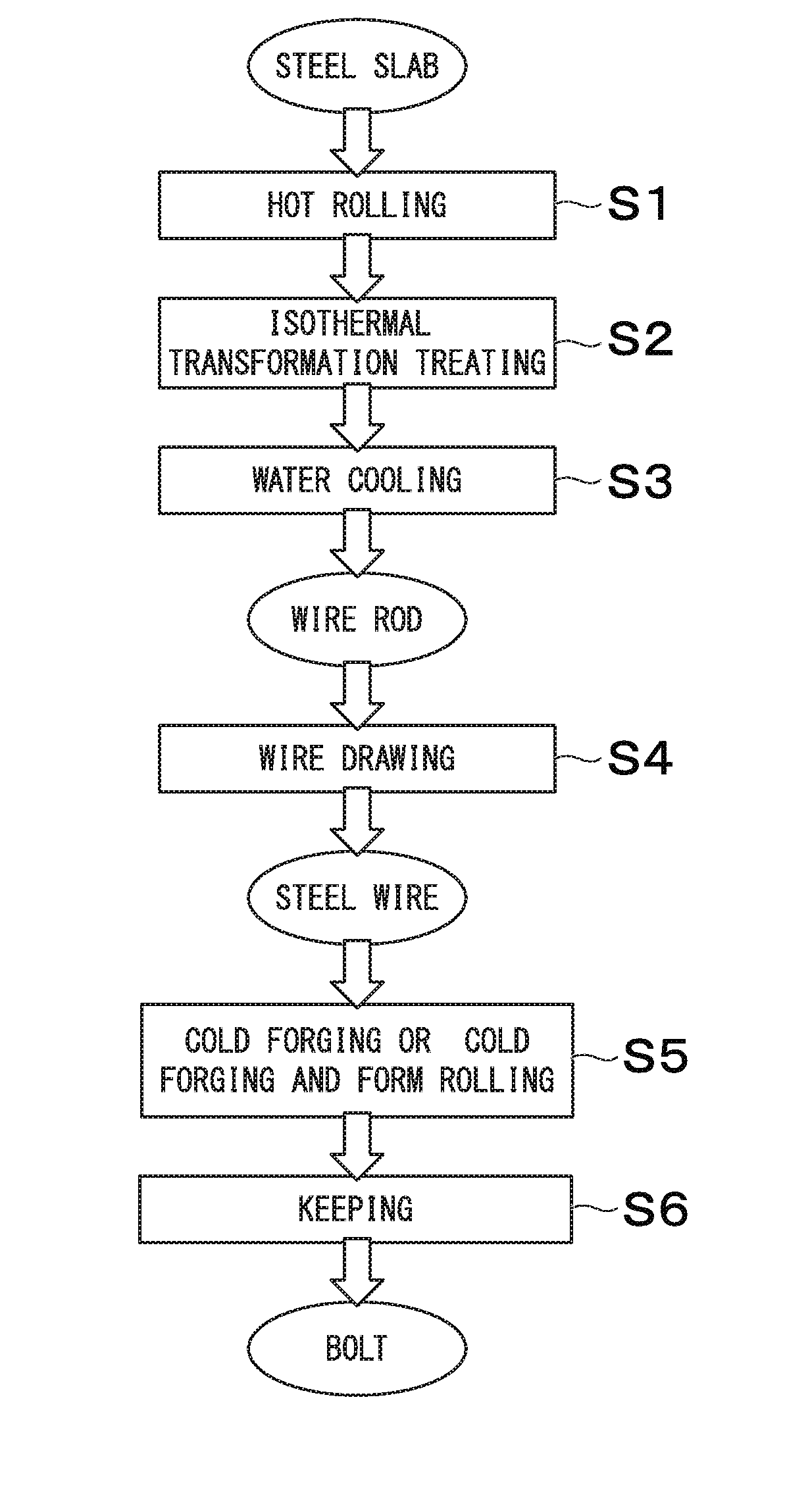

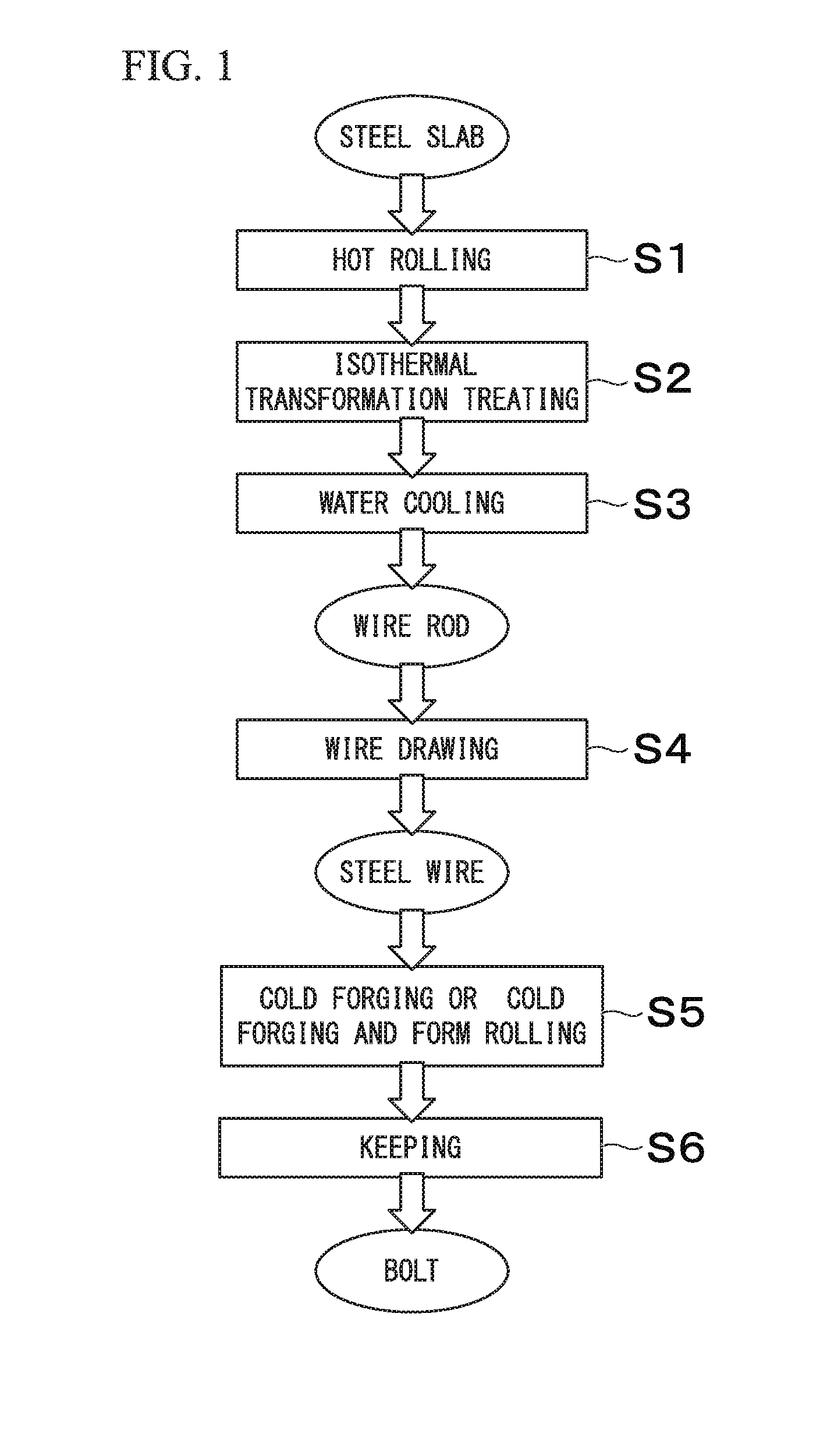

A WIRE ROD HAVING TENSILE STRENGTH OF 950 TO 1600MPa FOR MANUFACTURING A STEEL WIRE FOR A PEARLITE STRUCTURE BOLT, A STEEL WIRE HAVING TENSILE STRENGTH OF 950 TO 1600MPa FOR A PEARLITE STRUCTURE BOLT, A PEARLITE STRUCTURE BOLT, AND MANUFACTURING METHOD FOR THE SAME

InactiveUS20160129489A1Improved cold working propertiesHigh strengthWashersNutsWire rodChemical composition

A wire rod having a tensile strength of 950 to 1600 MPa for manufacturing a steel wire for a pearlite structure bolt according to the present invention includes a predetermined chemical composition and is manufactured by hot rolling and then direct isothermal transformation treating, in which when an amount of C in terms of mass % is indicated as <C>, a structure at an area from a surface of the wire rod to a depth of 4.5 mm includes 140×<C> area % or more of a pearlite structure, the average block size of a pearlite block at the area from the surface of the wire rod to the depth of 4.5 mm is 20 μm or less, in which the average block size is measured in a transverse section of the wire rod, and the average lamellar spacing of the pearlite structure at the area from the surface of the wire rod to the depth of 4.5 mm is more than 120 nm to 200 nm.

Owner:NIPPON STEEL CORP +1

High strength spring steel having excellent hydrogen embrittlement resistance

InactiveUS7438770B2High tensile strengthImprove hydrogen embrittlement resistanceFurnace typesOhmic-resistance heatingAustenite grainHigh intensity

The present invention provides a high strength steel used for spring steel that has excellent hydrogen embrittlement resistance.The high strength steel which spring steel having excellent hydrogen embrittlement resistance comprises 0.20 to 0.60% of C, 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, higher than 0% and not higher than 1.5% of Al, 0.15% or less P, 0.02% or less S, and balance of iron and inevitable impurities and the structure includes:1% or more residual austenite;80% or more in total of bainitic ferrite and martensite; and10% or less (may be 0%) in total content of ferrite and pearlite in the proportion of area to the entire structure, and also the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher and the steel tensile strength is 1860 MPa or higher.

Owner:KOBE STEEL LTD +1

Low alloy steel

InactiveUS20150047749A1Improve hydrogen embrittlement resistanceFurnace typesHeat treatment furnacesTitaniumSulfur hydride

A low alloy steel subjected to post weld heat treatment, containing, by mass percent, of C: 0.01 to 0.15%, Si: 3% or less, Mn: 3% or less, and Al: 0.08% or less, one or more kinds of elements selected from Ti, V and Nb: the range satisfying Formula (1), and the balance being Fe and impurities, wherein in the impurities, N: 0.01% or less, P: 0.05% or less, S: 0.03% or less, and O: 0.03% or less:0.1×[C(%)]≦[Ti(%)]+[V(%)]+0.5×[Nb(%)]≦0.2 (1)where, the symbol of element in the formula represents the content (mass %) of each element.In the alloy steel, a HAZ subjected to PWHT, especially short-time PWHT, has excellent hydrogen embrittlement resistance in wet hydrogen sulfide environments or the like.

Owner:NIPPON STEEL CORP

High-strength spring steel wire with excellent hydrogen embrittlement resistance, manufacturing process therefor, and high-strength spring

InactiveUS20150292052A1High strengthImprove hydrogen embrittlement resistanceFurnace typesIncreasing energy efficiencyAustenite grainChemical composition

A high-strength spring steel wire is provided which secures excellent hydrogen embrittlement resistance even when the adding amount of alloy elements is suppressed, and has 80 area % or more of tempered martensite and 1,900 MPa or more of the tensile strength, in which a predetermined chemical composition is satisfied, with C and Si satisfying the relation of the expression (1) below, with prior austenite grain size number being No. 10 or more, and with the hydrogen absorption amount being 14.0 ppm or more.0.73%≦[C]+[Si] / 8≦0.90% (1)where [C] and [Si] express the content (mass %) of C and Si respectively.

Owner:KOBE STEEL LTD

Steel for bolt use, bolt, and method for manufacturing bolt

A steel is used for providing a bolt that has a high strength and still exhibits excellent hydrogen embrittlement resistance. The steel contains C of 0.30% to 0.50%, Si of 1.0% to 2.5%, Mn of 0.1% to 1.5%, P of greater than 0% to 0.015%, S of greater than 0% to 0.015%, Cr of 0.15% to 2.4%, Al of 0.010% to 0.10%, N of 0.001% to 0.10%, Cu of 0.1% to 0.50%, Ni of 0.1% to 1.0%, Ti of 0.05% to 0.2%, and V of 0% to 0.2%, with the remainder including iron and inevitable impurities, in which a ratio [Ni] / [Cu] is 0.5 or more, and a total content [Ti]+[V] is 0.085% to 0.30%.

Owner:KOBE STEEL LTD

Rolled Rod for Cold-Forged Thermally Refined Article

InactiveUS20180347019A1Improve hydrogen embrittlement resistanceHigh strengthScrewsFurnace typesChemical compositionPearlite

The rolled rod for cold-forged thermally refined articles according to the present invention has a chemical composition consisting, in mass %: C: 0.22 to 0.40%, Si: 0.35 to 1.5%, Mn: 0.20 to 0.40%, P: less than 0.020%, S: less than 0.015%, Cr: 0.70 to 1.45%, Al: 0.005 to 0.060%, Ti: 0.01 to 0.05%, B: 0.0003 to 0.0040%, N: 0.0020 to 0.0080%, and O: 0.0020% or less, with the balance being Fe and impurities, and that satisfies Formula (1) and Formula (2), wherein a total area fraction of pro-eutectoid ferrite and pearlite is 90% or more, an area fraction of the pro-eutectoid ferrite is 30% or more, and the rolled rod has a tensile strength of 700 MPa or less.0.50≤C+Si / 10+Mn / 5+5Cr / 22≤0.85 (1)Si / Mn>1.0 (2)

Owner:NIPPON STEEL CORP

Austenitic stainless steel, preparation method thereof and application of austenitic stainless steel in hydrogen storage pressure vessel

ActiveCN114351051AReasonable design of ingredientsReduced ferrite contentFixed capacity gas holdersMetal rolling arrangementsMetallurgySS - Stainless steel

The invention belongs to the technical field of steel smelting, and relates to austenitic stainless steel, a preparation method thereof and application of the austenitic stainless steel in a hydrogen storage pressure container. The austenitic stainless steel provided by the invention comprises the following components in percentage by weight: 0.010%-0.030% of C, 0.40%-0.75% of Si, 1.3%-2.0% of Mn, 17.5%-18.0% of Cr, 13.05%-14.00% of Ni, 2.5%-3.0% of Mo, less than or equal to 0.030% of P, less than or equal to 0.002% of S, less than or equal to 0.06% of N, less than or equal to 0.5% of Cu, 0.002%-0.005% of B, 28.5%-35% of Nieq, and the balance of Fe and inevitable impurities. The austenitic stainless steel is stable in structure performance, low in ferrite content and good in hydrogen embrittlement resistance, the development requirement of a hydrogen storage pressure container of a hydrogen refueling station is met, and the austenitic stainless steel has important practical significance on safe and efficient development of the hydrogen energy storage technology.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com