Patents

Literature

732 results about "Oxyhydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxyhydrogen is a mixture of hydrogen (H₂) and oxygen (O₂) gases. This gaseous mixture is used for torches to process refractory materials and was the first gaseous mixture used for welding. Theoretically, a ratio of 2:1 hydrogen:oxygen is enough to achieve maximum efficiency; in practice a ratio 4:1 or 5:1 is needed to avoid an oxidizing flame.

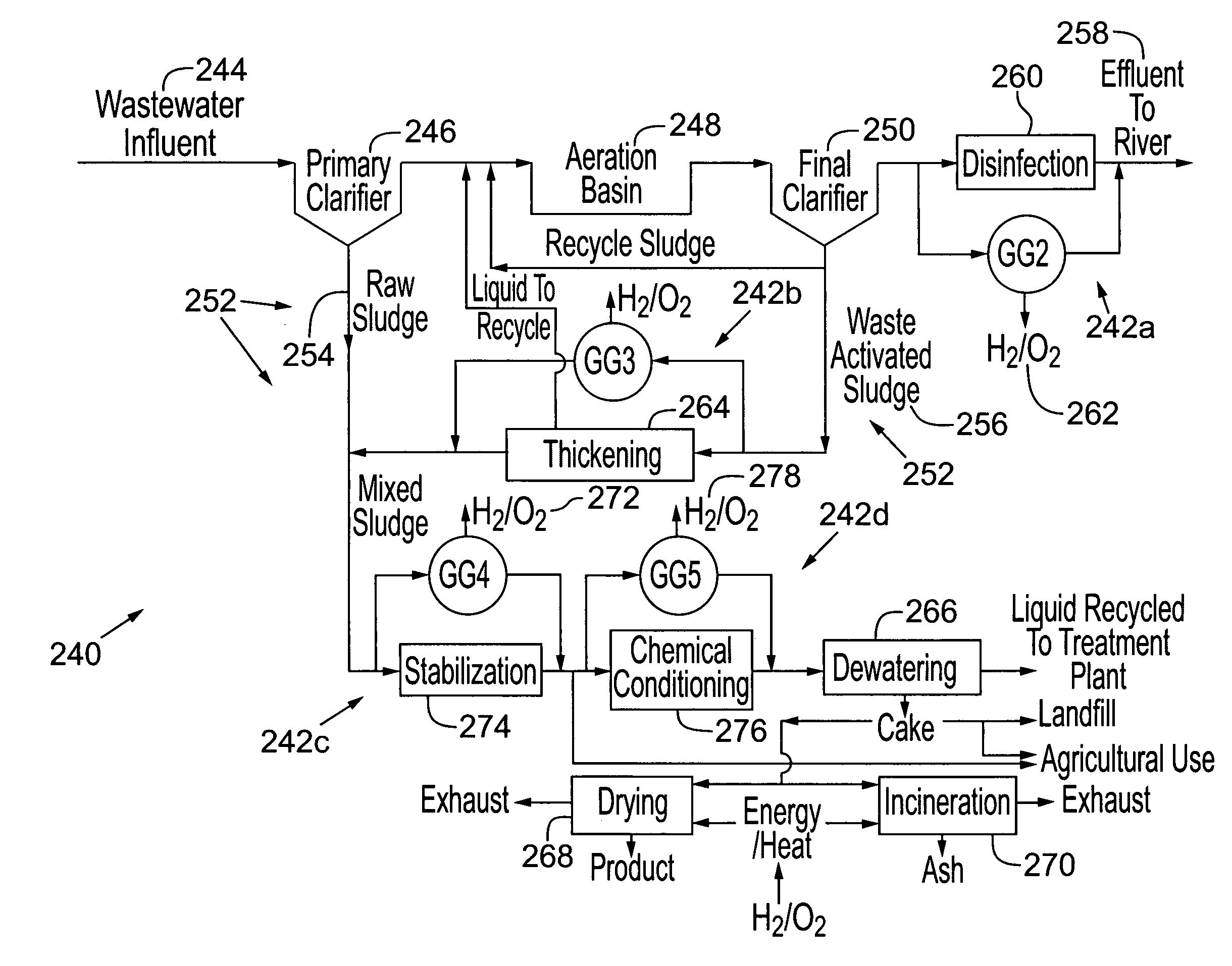

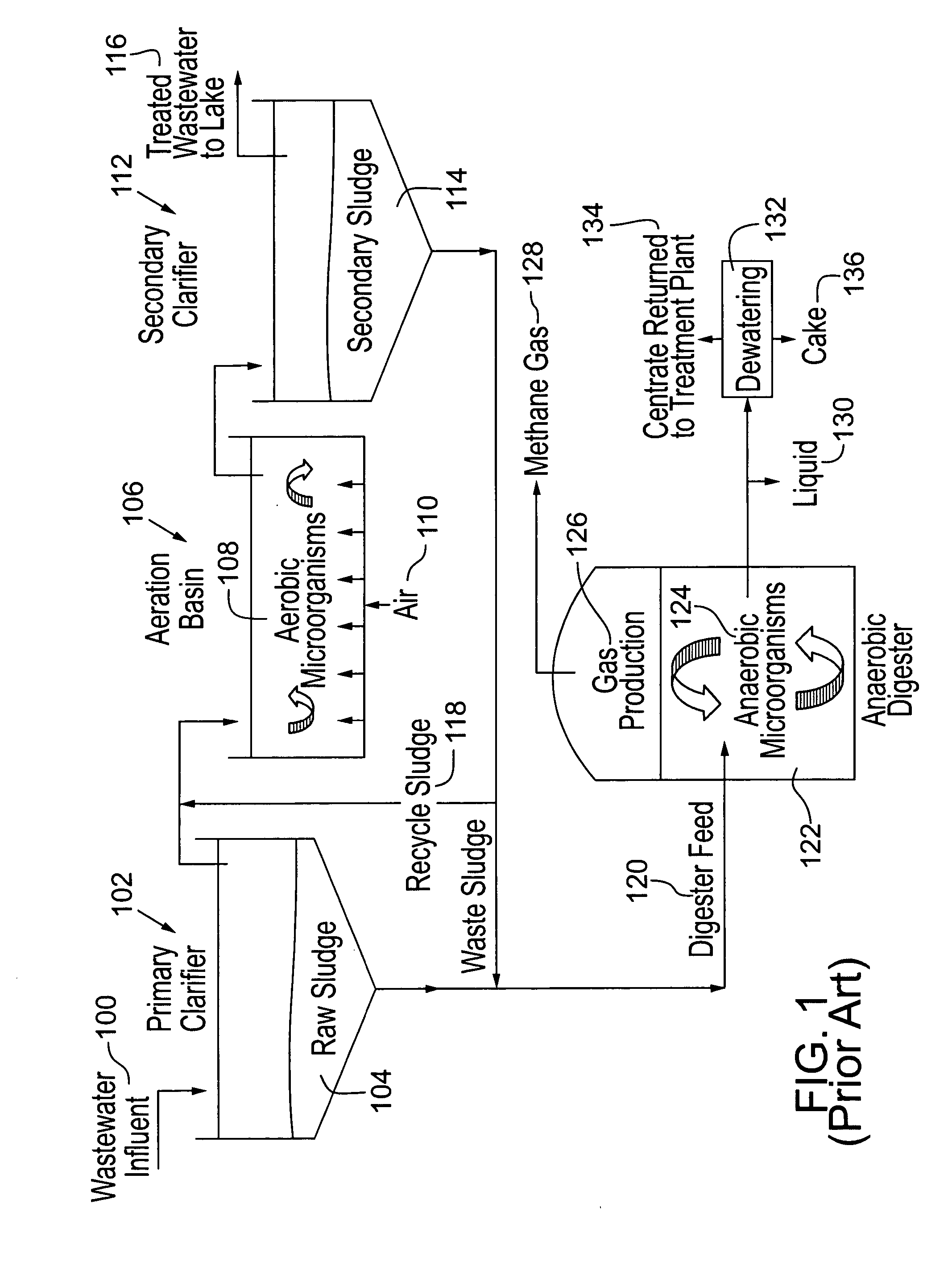

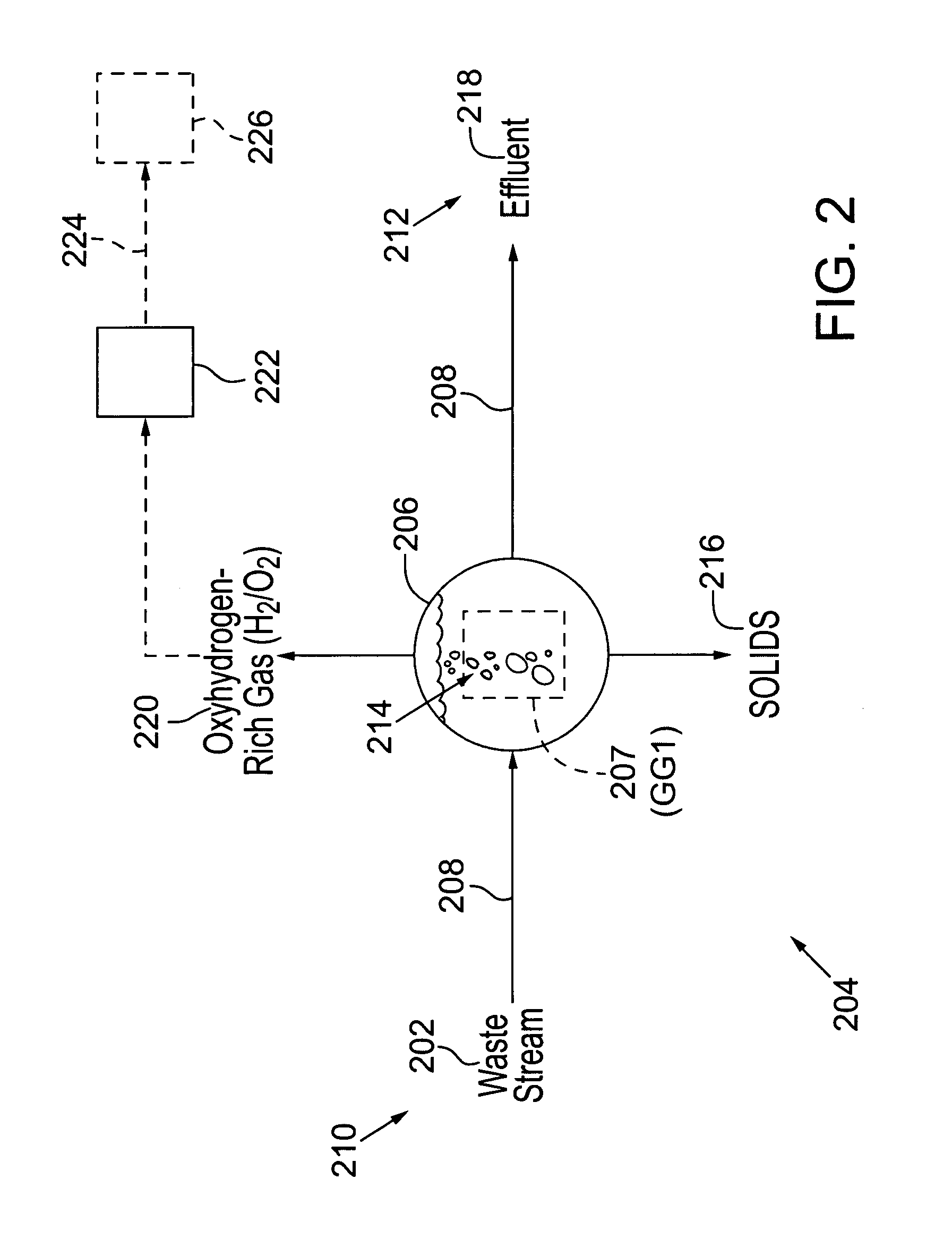

Treatment of a waste stream through production and utilization of oxyhydrogen gas

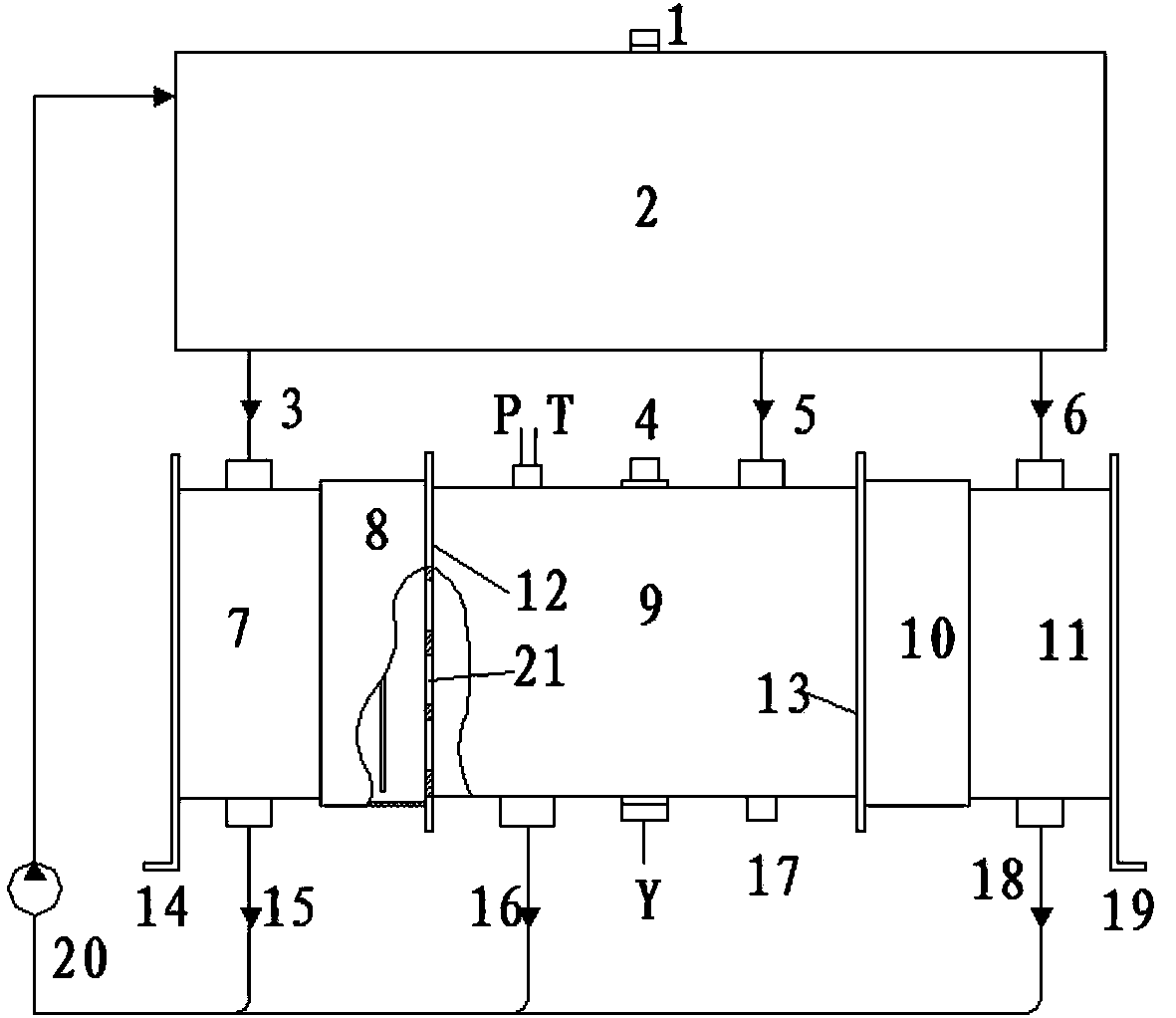

Methods and systems for treating a waste stream in a waste treatment system involve performing a unit process of the waste treatment system by contacting the waste stream with oxyhydrogen-rich gas generated on-site by an oxyhydrogen gas generator that implements water dissociation technology. In a preferred embodiment, the oxyhydrogen gas generator involves applying a pulsed electrical signal to a series of closely-spaced electrodes that are submerged in the waste stream to produce oxyhydrogen-rich gas from a water component of the waste stream. Operation of the oxyhydrogen gas generator in the waste stream may accomplish one or more unit processes for waste treatment, such as conditioning, stabilization, thickening, and dewatering, among others. At least a portion of the oxyhydrogen-rich gas can be conveyed for a second use in the waste treatment system, such as a source of combustible fuel for incineration or power generation, for example.

Owner:XOGEN TECH

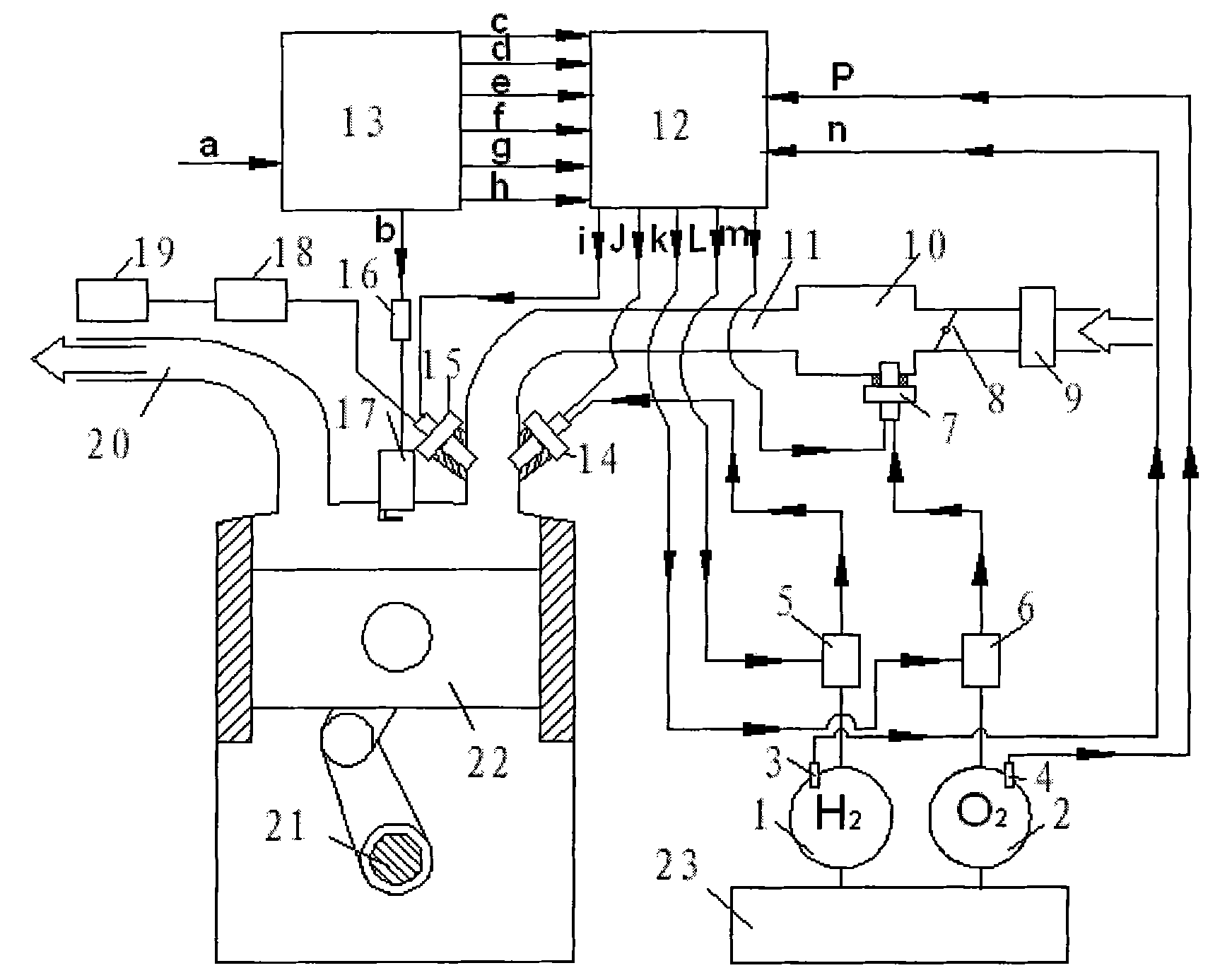

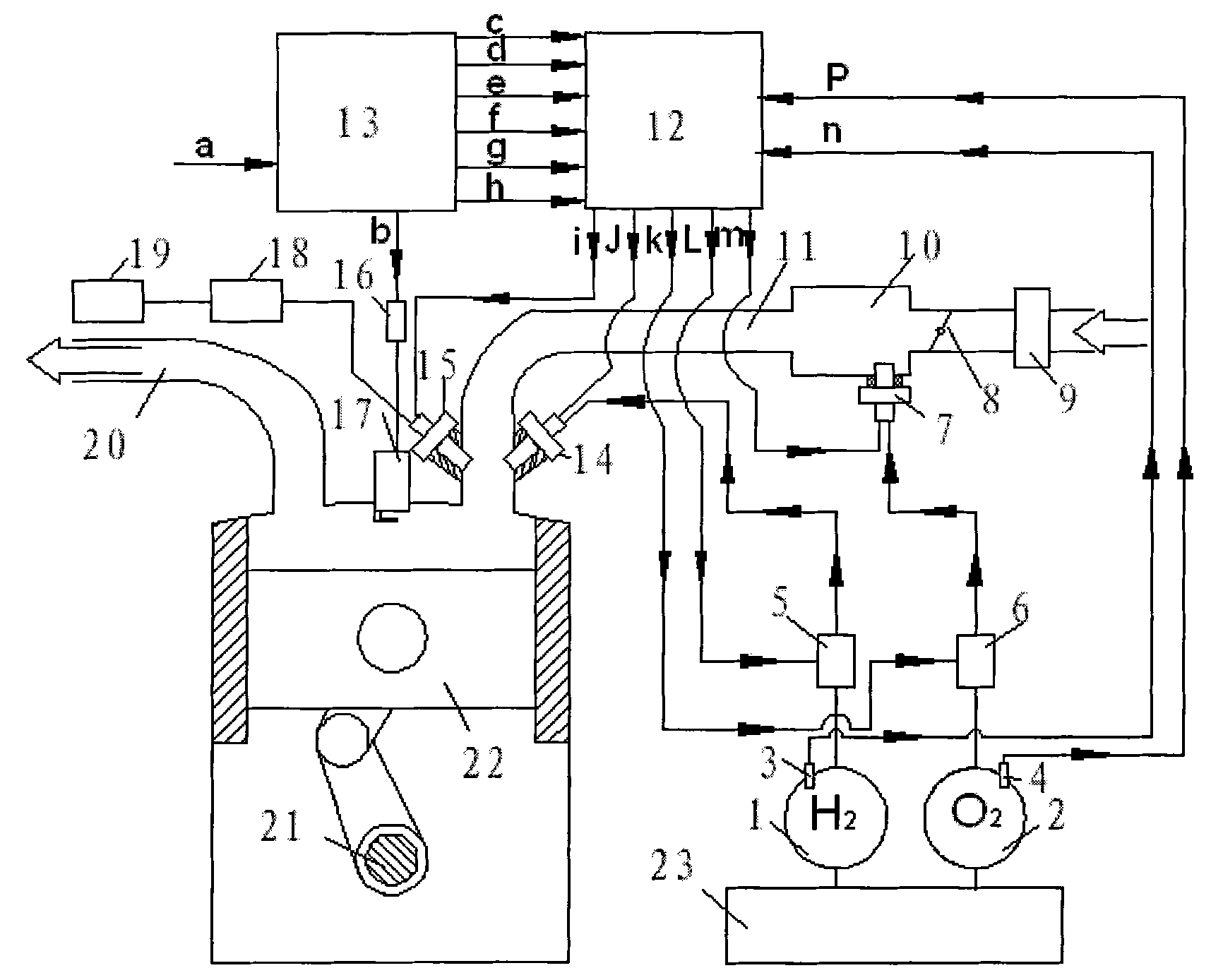

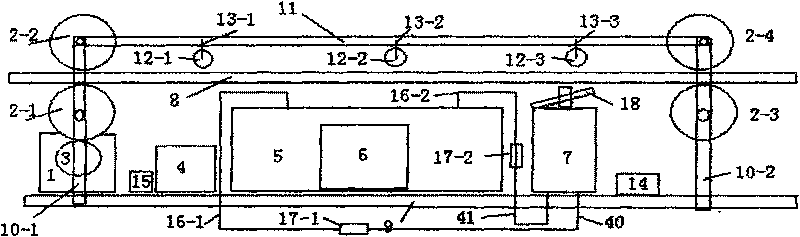

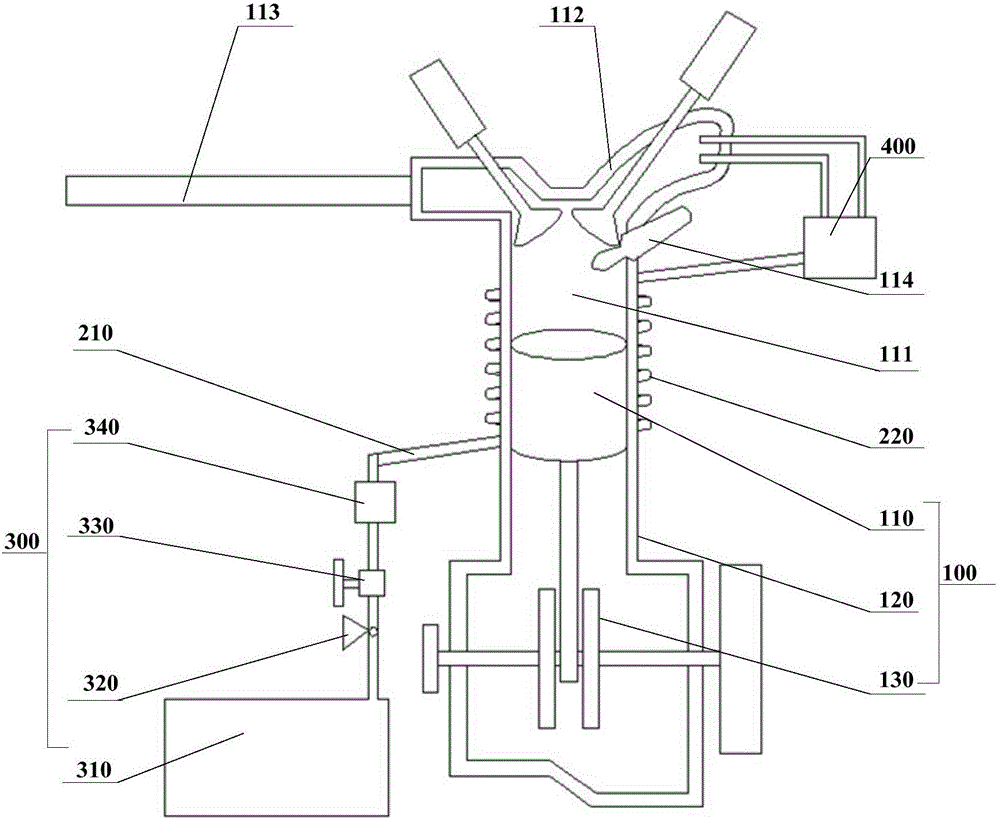

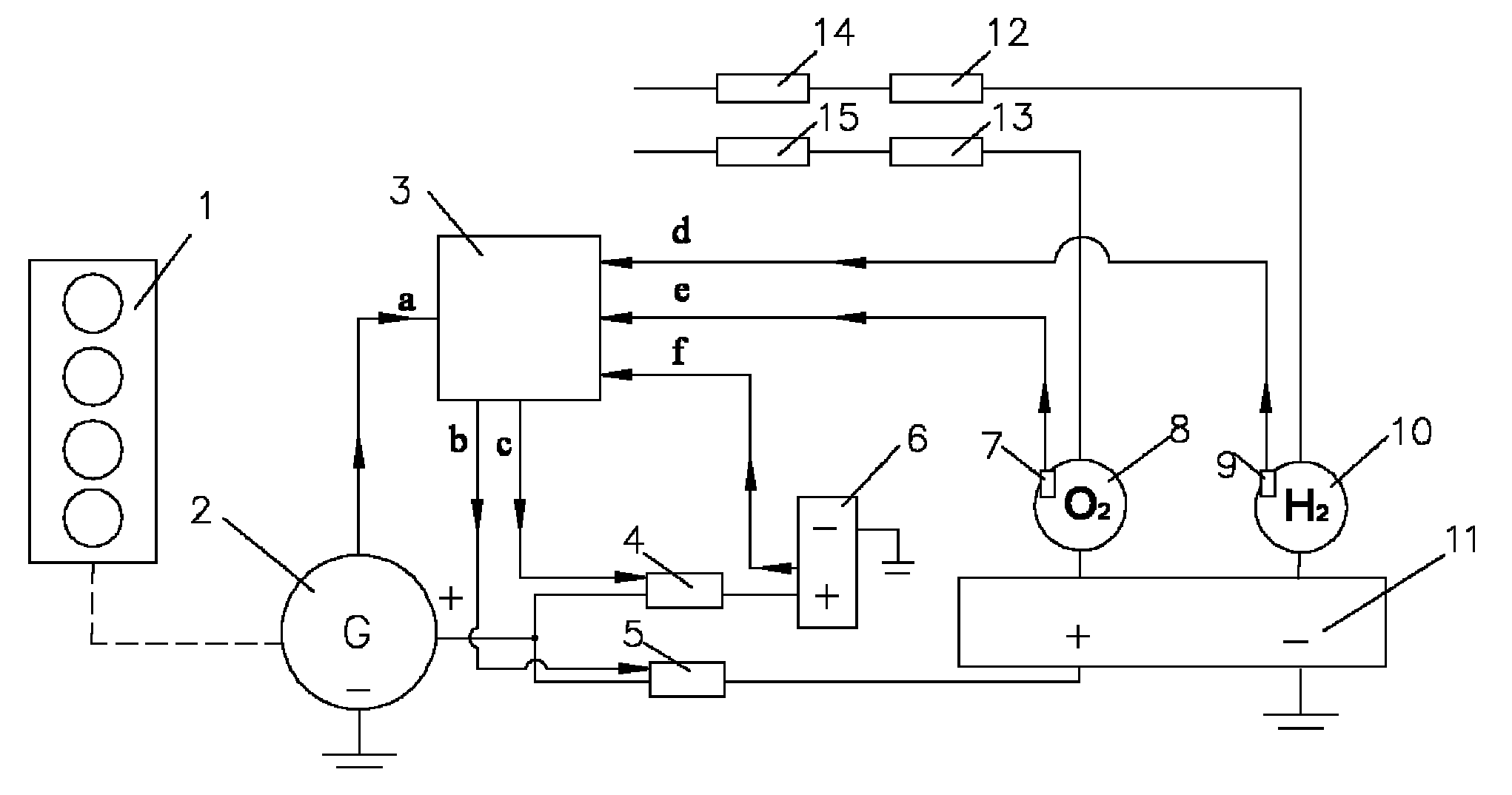

Hydrogen-oxygen-mixed high-octane fuel ignition combustion engine and control method thereof

ActiveCN101975108AReduce consumptionImprove economyElectrical controlInternal combustion piston enginesOn boardLow load

The invention provides an ignition combustion engine by the mode of mixing hydrogen and oxygen with high-octane fuel and a control method thereof, and particularly relates to a fuel storage and supply system of the ignition combustion engine by the mode of mixing the hydrogen and the oxygen with the fuel, fuel proportional distribution and combustion process control, wherein, a set of on-board hydrogen and oxygen production, a storage and supply device is added to the system on the basis of retaining main parts and an electronic control unit of the original engine. The hydrogen and oxygen mixed fuel electronic control unit (12) can control the opening and closing of a hydrogen nozzle and an oxygen nozzle according to sensor signals c-h so that the engine can run in three combustion modes such as pure hydrogen and oxygen mixed gas, hydrogen-oxygen-high-octane fuel mixed gas and pure high-octane fuel according to different operating conditions, thus greatly lowering HC and CO emission in the case of cold starting and idling of the high-octane fuel combustion engine and improving the thermal efficiency and emission level of the high-octane fuel combustion engine in middle and low load stages.

Owner:BEIJING UNIV OF TECH

On demand hydrogen enhancement system for internal and external combustion engine

InactiveUS20100206721A1Increased flame speedImprove performanceCellsInternal combustion piston enginesExternal combustion engineInternal combustion engine

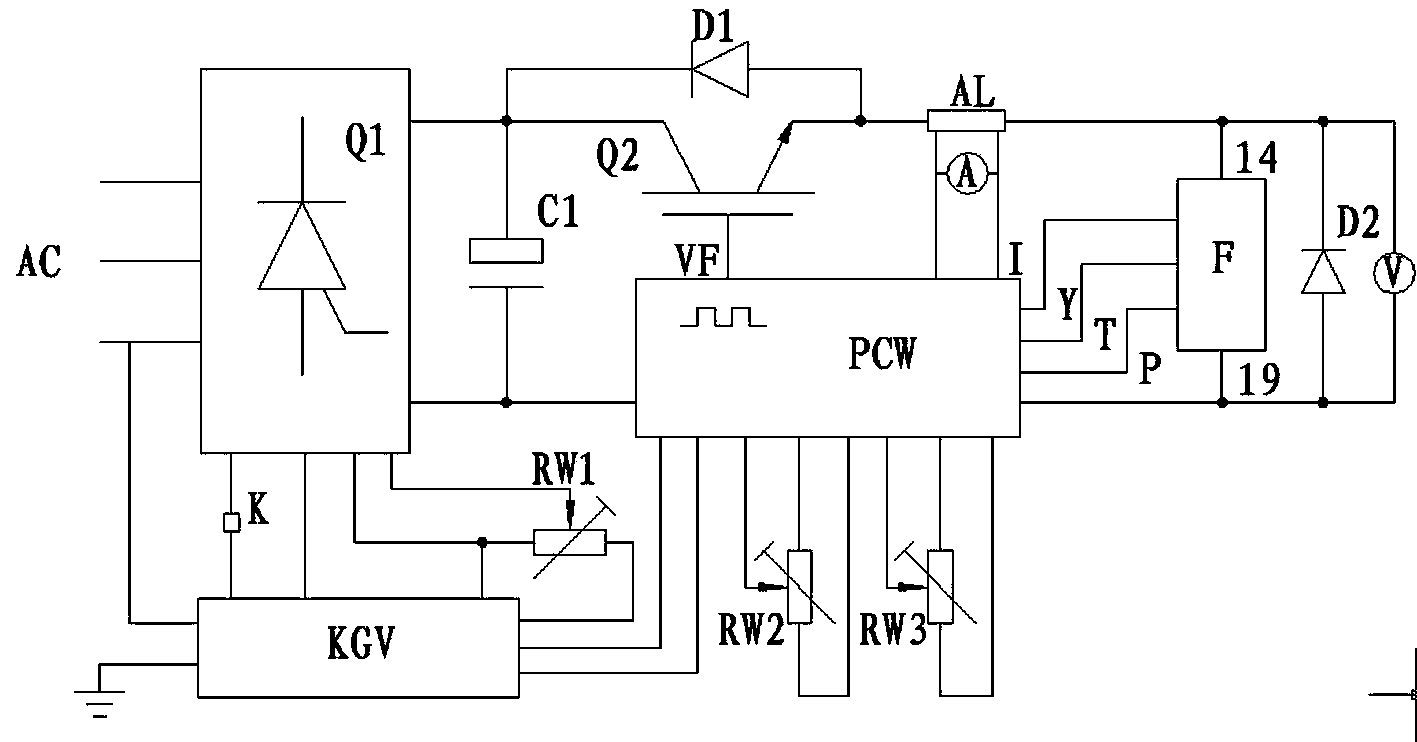

The objective of this invention, on demand hydrogen enhancement system for internal and external combustion engine, is to develop a continuous non pressurized water electrolyzer from clean water (not pure water or distil water) generator system. The mixed hydrogen gas and oxygen gas called “Oxyhydrogen”. Oxyhydrogen use as catalyse for internal and external combustion engine to increase fuel flame speed. It can use with variety fuels such as Ethanol, Methanol, Gasohol, Gasoline, Diesel, Bio Diesel, LPG, CNG, and LNG. This system can reduce fuel consumption, increase fuel efficiency, increase torque, reduce emissions, and reduce engine temperatures. The system required no cooling fan and electrolytic solution circulating pump. The system has less heat loss and very low electrical consumption. Oxyhydrogen will produce on demand as the engine RPM and load of generator. The control unit detects signal frequency from the alternator. Gas production rate low at low RPM and use less current and gas production will high at high RPM and use higher current. This can save lot of energy for the electrolysis process. In the past, water electrolysis use direct current (D.C.). In this invention the inventor uses D.C. with Frequency Modulate (FM) pulse width modulator (PWM) instead of Amplitude Modulator (AM) to control the electrolyzer (FMPWM). This circuit had current detector for automatic current adjustment and over current protection.

Owner:SNIDVONGS SURAVUT

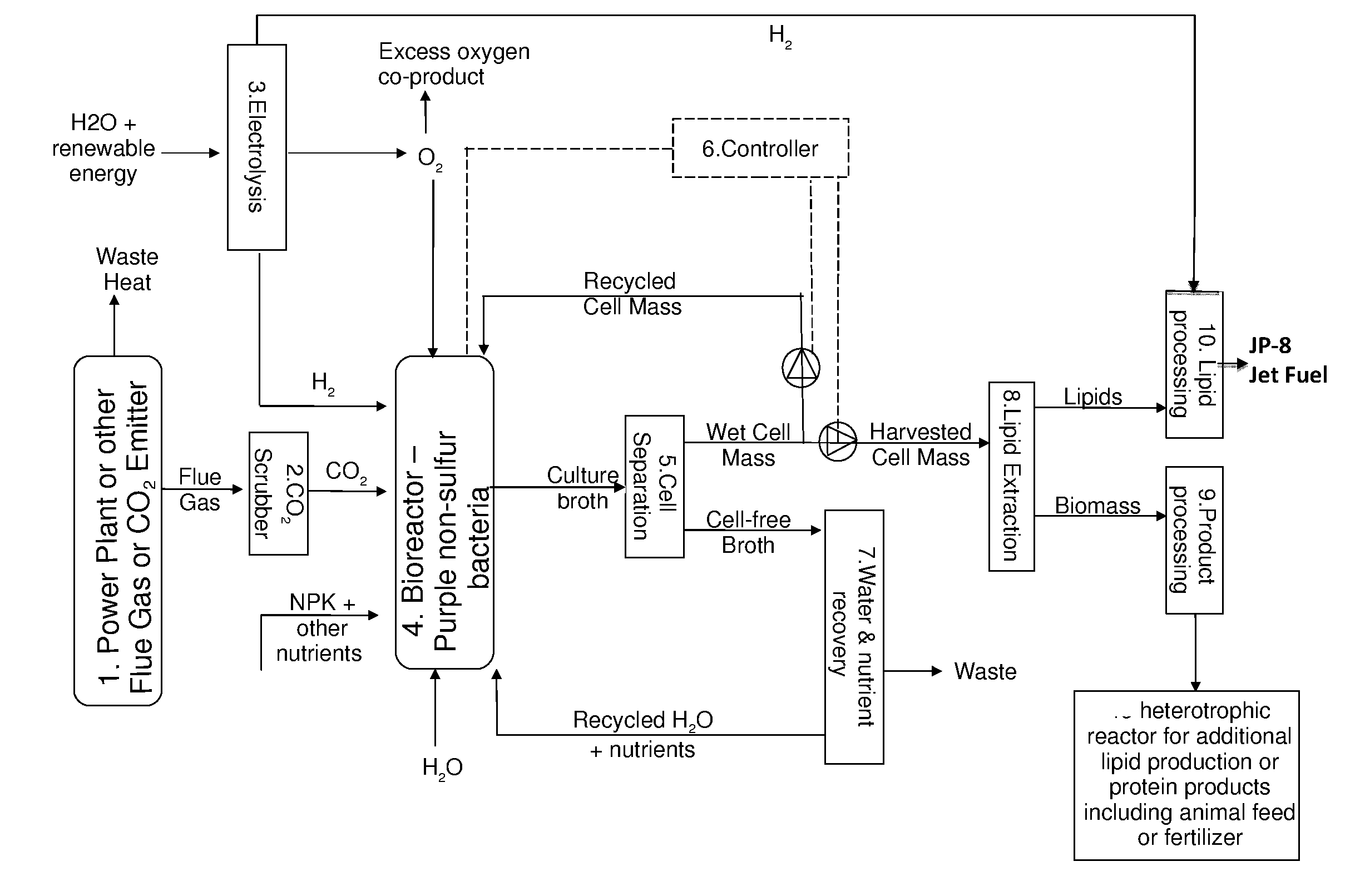

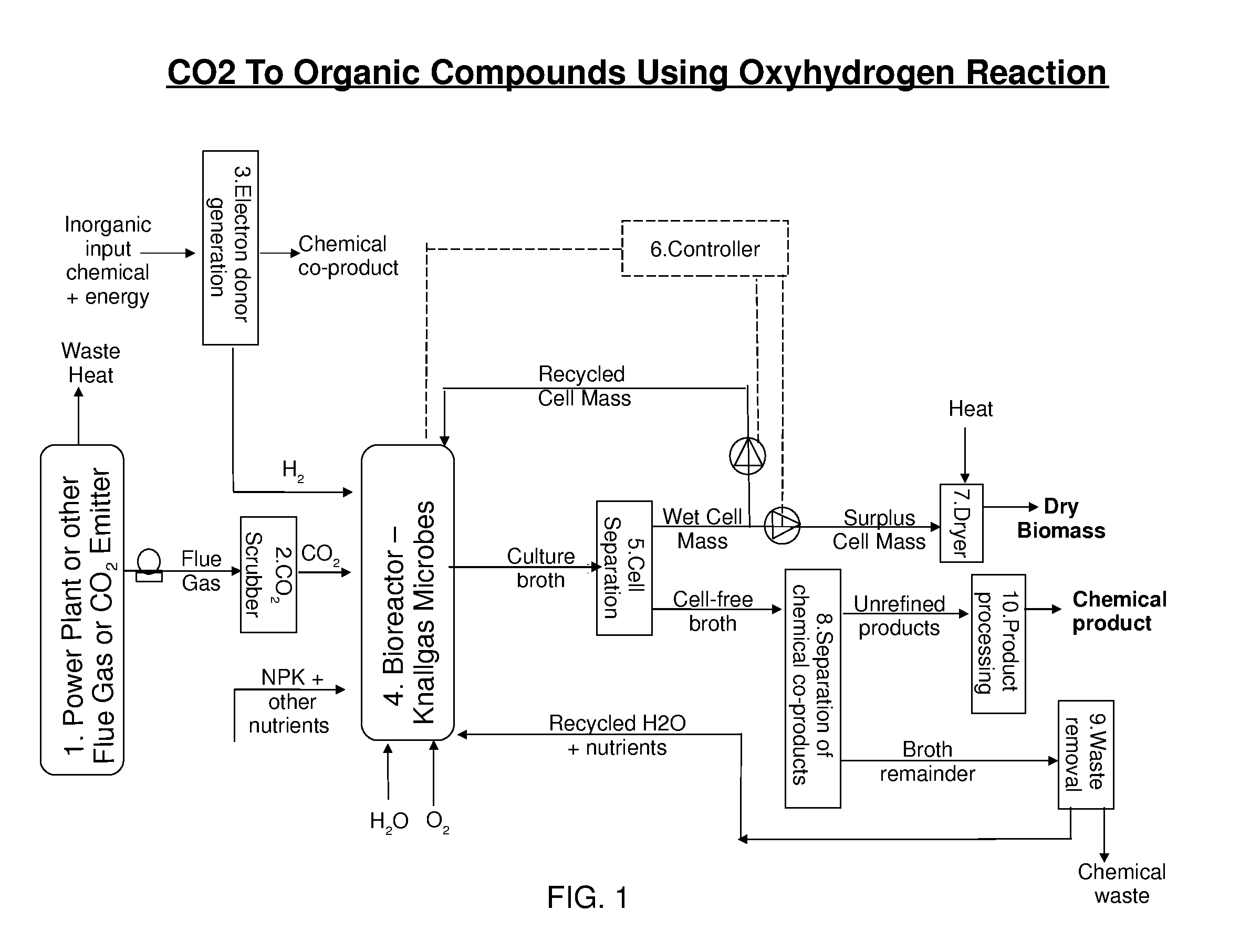

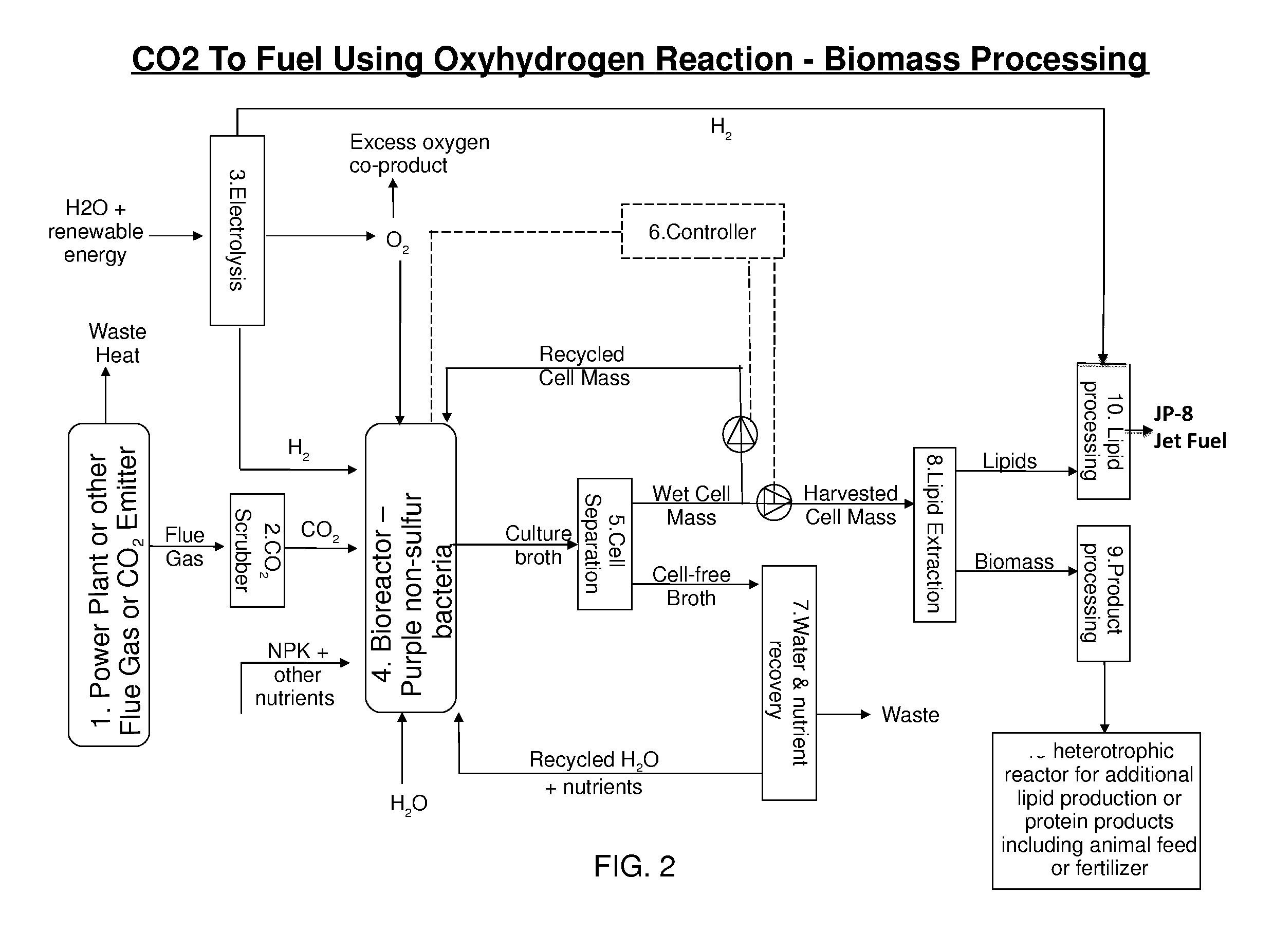

Use of oxyhydrogen microorganisms for non-photosynthetic carbon capture and conversion of inorganic and/or c1 carbon sources into useful organic compounds

InactiveUS20130149755A1Increase incomeEfficient productionBioreactor/fermenter combinationsBiological substance pretreatmentsFormateBiofuel

Compositions and methods for a hybrid biological and chemical process that captures and converts carbon dioxide and / or other forms of inorganic carbon and / or CI carbon sources including but not limited to carbon monoxide, methane, methanol, formate, or formic acid, and / or mixtures containing CI chemicals including but not limited to various syngas compositions, into organic chemicals including bio-fuels or other valuable biomass, chemical, industrial, or pharmaceutical products are provided. The present invention, in certain embodiments, fixes inorganic carbon or CI carbon sources into longer carbon chain organic chemicals by utilizing microorganisms capable of performing the oxyhydrogen reaction and the autotrophic fixation of CO2 in one or more steps of the process.

Owner:KIVERDI INC

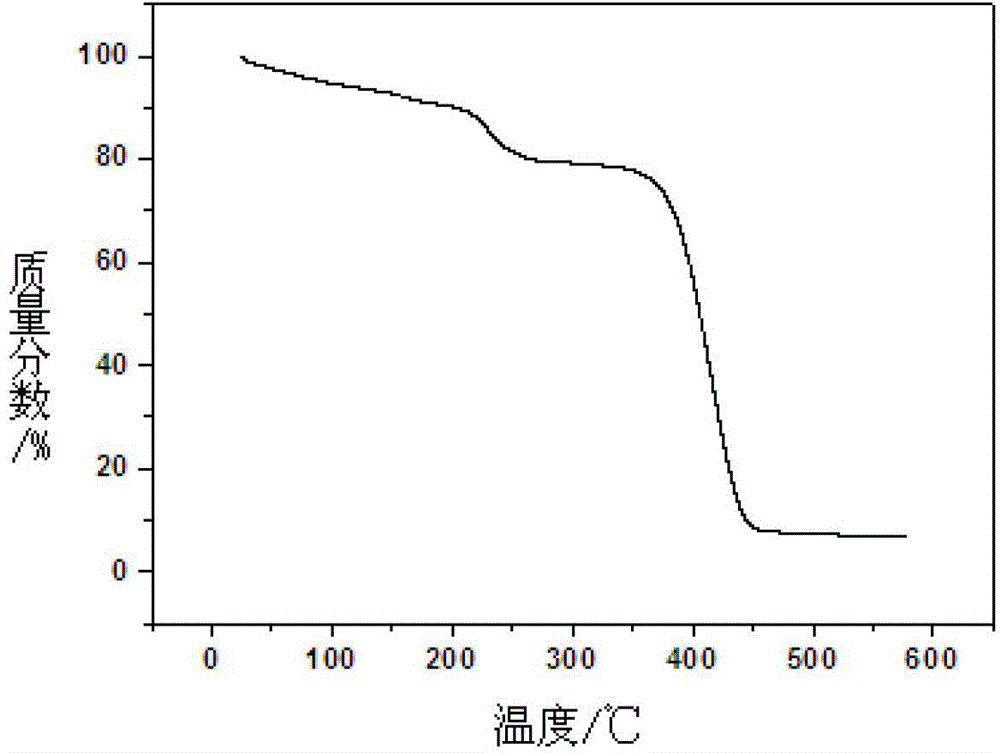

Alkaline calcium bentonite and its preparation method

InactiveCN1803294AGood anion exchange functionIncrease spacingCation exchangersSilicon compoundsSodium BentoniteWater quality

The invention discloses an alkaline calcium bentonite and making method, which comprises the following steps: adapting active carclazyte and calcium oxide as raw material; mixing the raw material evenly; reacting the calcium oxide and water to produce calcium hydroxide; diffusing the calcium hydroxide in the active carclazyte layers; reacting one of two oxyhydrogen base with hydrogen of active carclazyte to produce the alkaline calcium bentonite with anion exchanging function. The invention can react with organic acid to prepare composite layered nanometer material, which can be applied in the coating, plastic and new adsorptive material domain.

Owner:GUANGXI UNIV

Process for preparing regenerated cellulose films and wires

The invention discloses a method for manufacturing cellulose film and silk. The cellulose is dissolved in mixed liquid 5-12wt% natrium oxyhydrogen and 8-20wt% ureophil, gets the cellulose liquid, then carries on film scratching and silk spraying to the cellulose, they are solidified in the solidifying bath, then the regenerated cellulose film and silk will be got after being cleaned. The cellulose thick liquid has excellent fiber textile performance and compactibiity of film, the regenerated cellulose has excellent light transmission and mechanical performance, the silk also has good mechanical performance. The method can obtain cellulose thick liquid by dissolving cellulose in room temperature. It has no contamination and its price is low, it is a kind of green manufacturing process.

Owner:WUHAN UNIV

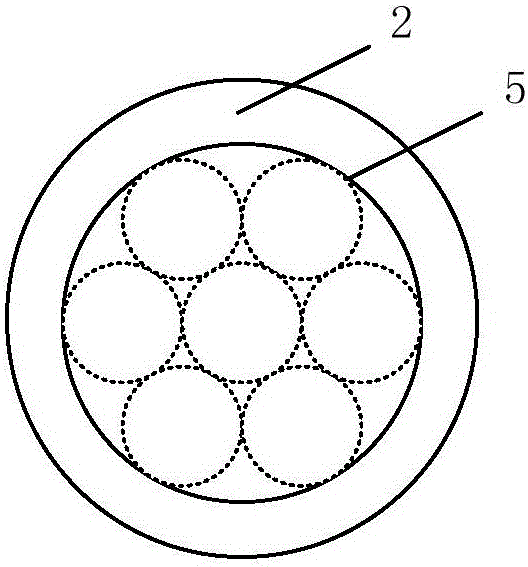

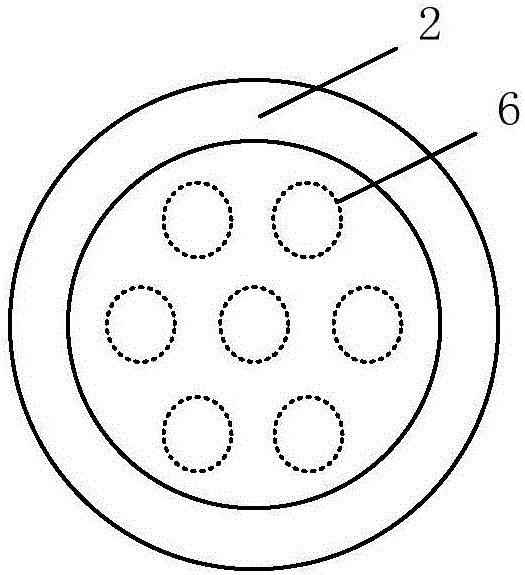

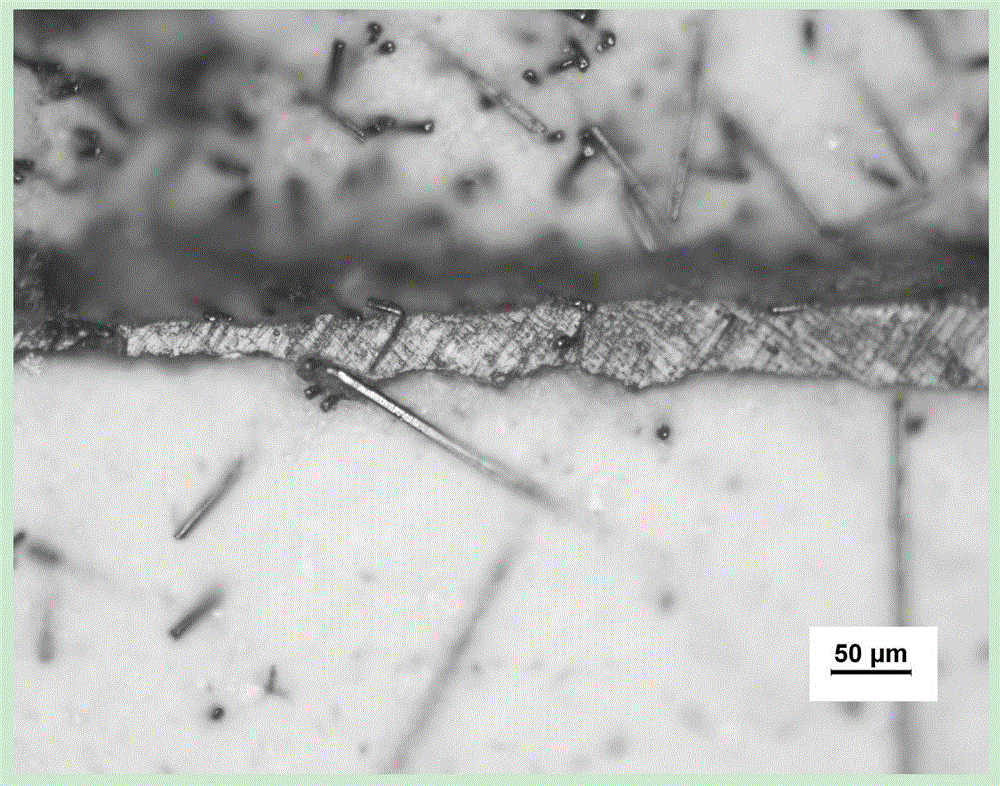

Method for preparing multi-core optical fiber coupler based on tapering self-assembly

ActiveCN105785511AThere is no situation where the fiber insertion is easy to breakImprove yieldCoupling light guidesFiber bundleEngineering

The invention discloses a method for preparing a multi-core optical fiber coupler based on tapering self-assembly. The method comprises following steps: single mode fiber pretreatment, single mode fiber bundle end preparation, glass bushing tapering, and glass bushing cutting and welding; inserting single mode fiber into the glass bushings entirely, wherein the front ends of the single mode fiber are corroded but the rear ends are still coated with coating; then placing the glass bushing vertically and tapering the glass bushing by use of oxyhydrogen flame, wherein the tapering position is the part which is corroded of the single mode fiber; then cutting and polishing the tapered zones; finally, welding the glass bushing with multi-core optical fiber to complete the preparation of the multi-core optical fiber coupler. The provided method for preparing the multi-core optical fiber coupler based on tapering self-assembly has good scalability and high yield rate, concise process and simple operation.

Owner:HUAZHONG UNIV OF SCI & TECH

Deicer for high-voltage power transmission line and deicing method thereof

InactiveCN101707339ASignificant progressSignificant positive effectOverhead installationElectrolysis componentsHigh pressureSolar cell

The invention relates to a deicing method for a high-voltage power transmission line and a device. The device is located on a supporting plate of a travel carriage on the high-voltage power transmission line and fixedly provided with an electrolytic cell filled with strong electrolyte solution and the like. The storage battery is charged continuously through electromagnetic inducing electrical energy which is from a solar cell panel and is generated under wind power or movement of three electromagnetic induction coils that are suspended on a beam and from a solar cell plate. The storage battery is connected with the electrolytic cell. Hydrogen and oxygen generated by the electrolytic cell enter a combuster through a delivery pipe, a one-way valve, a polycarbonate pipe and a lock net adaptor, respectively; a spring sheet metal and a thin plate that form an ice and snow detector as well as an electrode connected with a power line of a high-voltage boosting circuit below the reed pipe are arranged at the top of the combuster below the high-voltage transmission line. When the thin plate is covered by ice, and elastic metal and thin plate bend downwards, the free end and the magnetic block at the top of the combuster attract each other, and the power line of a high-voltage boosting circuit is switched on. Mixture of hydrogen and oxygen in the combuster combusts so that the piston body in the combuster strikes the high-voltage transmission line to enable the ice and snow to fall off.

Owner:NORTHEAST DIANLI UNIVERSITY

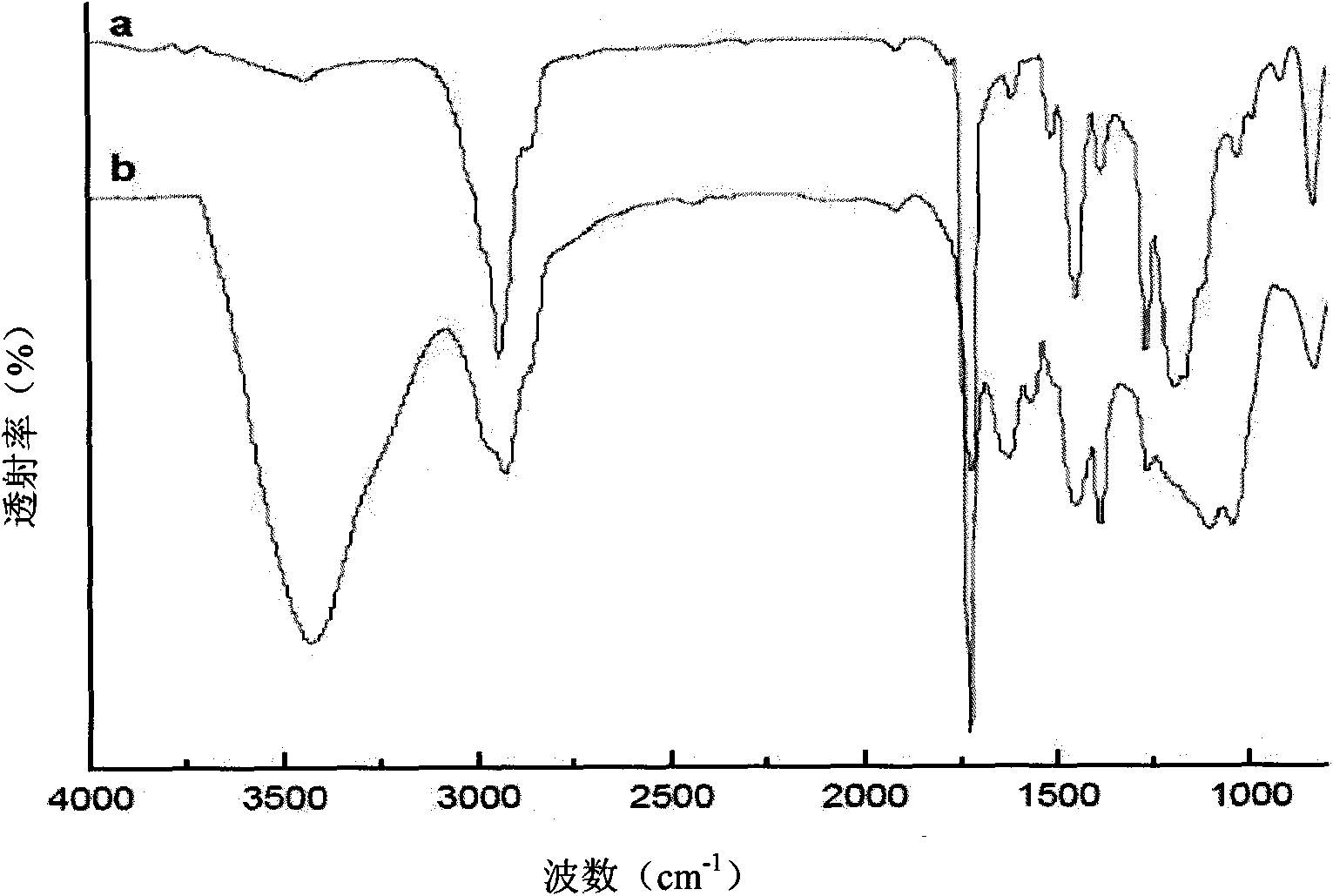

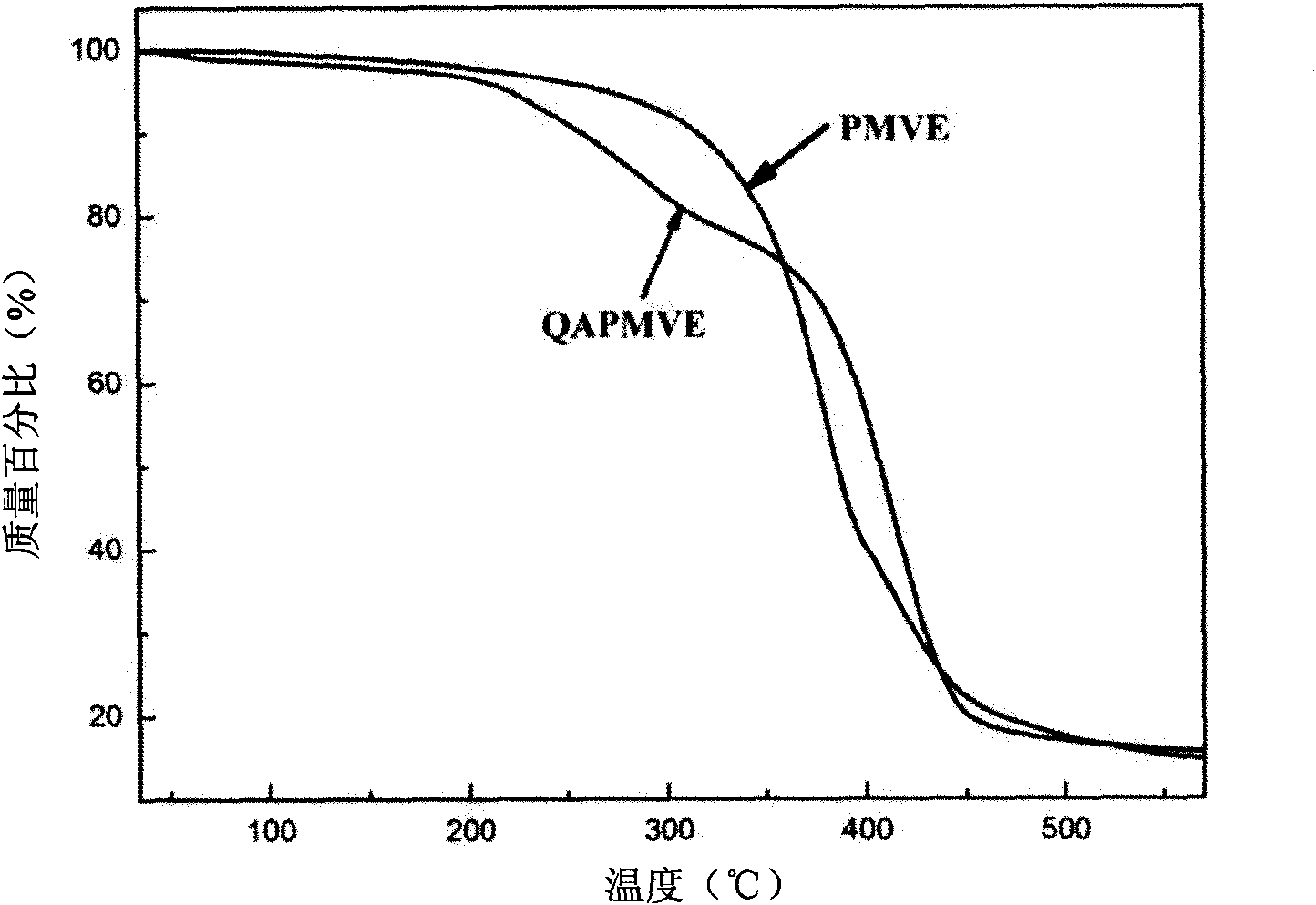

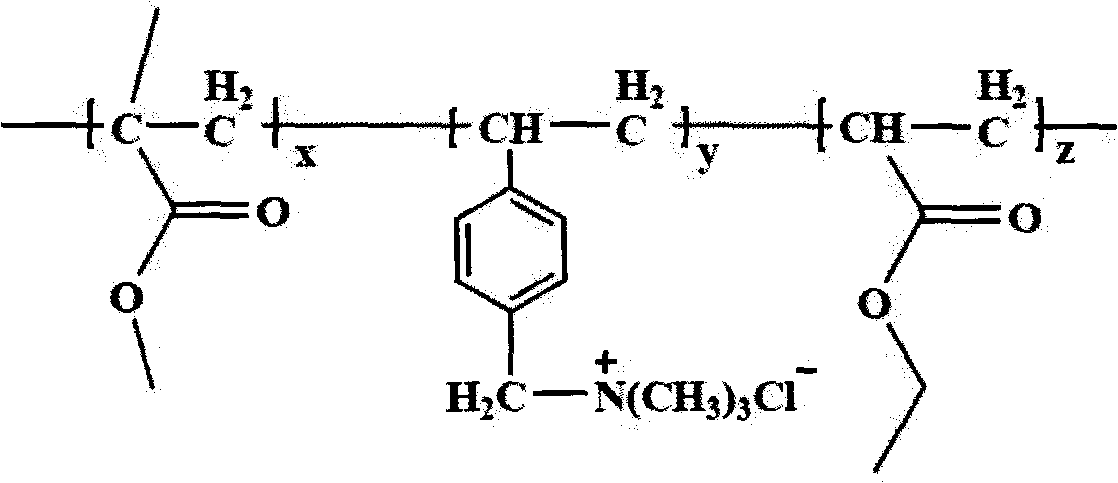

Preparation method of QAS polymer anion exchange membrane

InactiveCN101850218AReduce usageAvoid harmSemi-permeable membranesPolymer sciencePotassium hydroxide

A preparation method of a QAS polymer anion exchange membrane relates to an ion exchange membrane, which provides a preparation method of a QAS polymer anion exchange membrane. The reaction process has no obvious harm on human body and environment. The prepared anion exchange membrane has high electrical conductivity and good mechanical performance. Monomer, solvent and evocating agent are added into a reactor. Reflowing reaction is carried out under the protection of inert gas. The obtained copolymer is deposited in methyl alcohol, washed and dried for standby. The copolymer is dissolved in the organic solvent to prepare polymer solution which is cast into the membrane with a phase inversion method and is dried for standby. The cast membrane is dipped in low-grade tertiary amine water solution, quaternized, and washed to obtain the QAS anion exchange membrane. If the membrane is dipped in hydrochloric acid water solution, a chloride anion exchange membrane is obtained and if the membrane is dipped in potassium hydroxide water solution, an oxyhydrogen anion exchange membrane is obtained.

Owner:XIAMEN UNIV

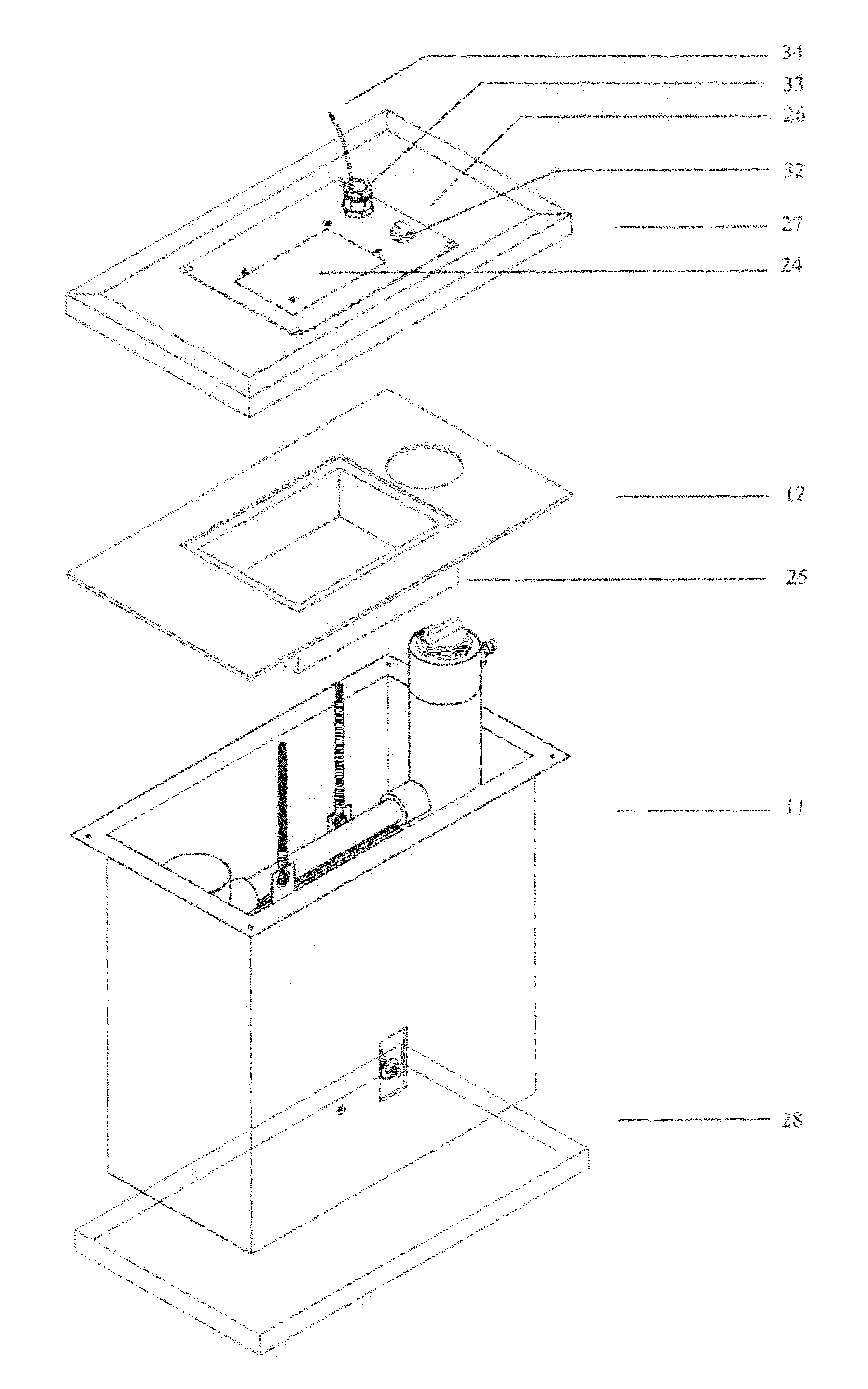

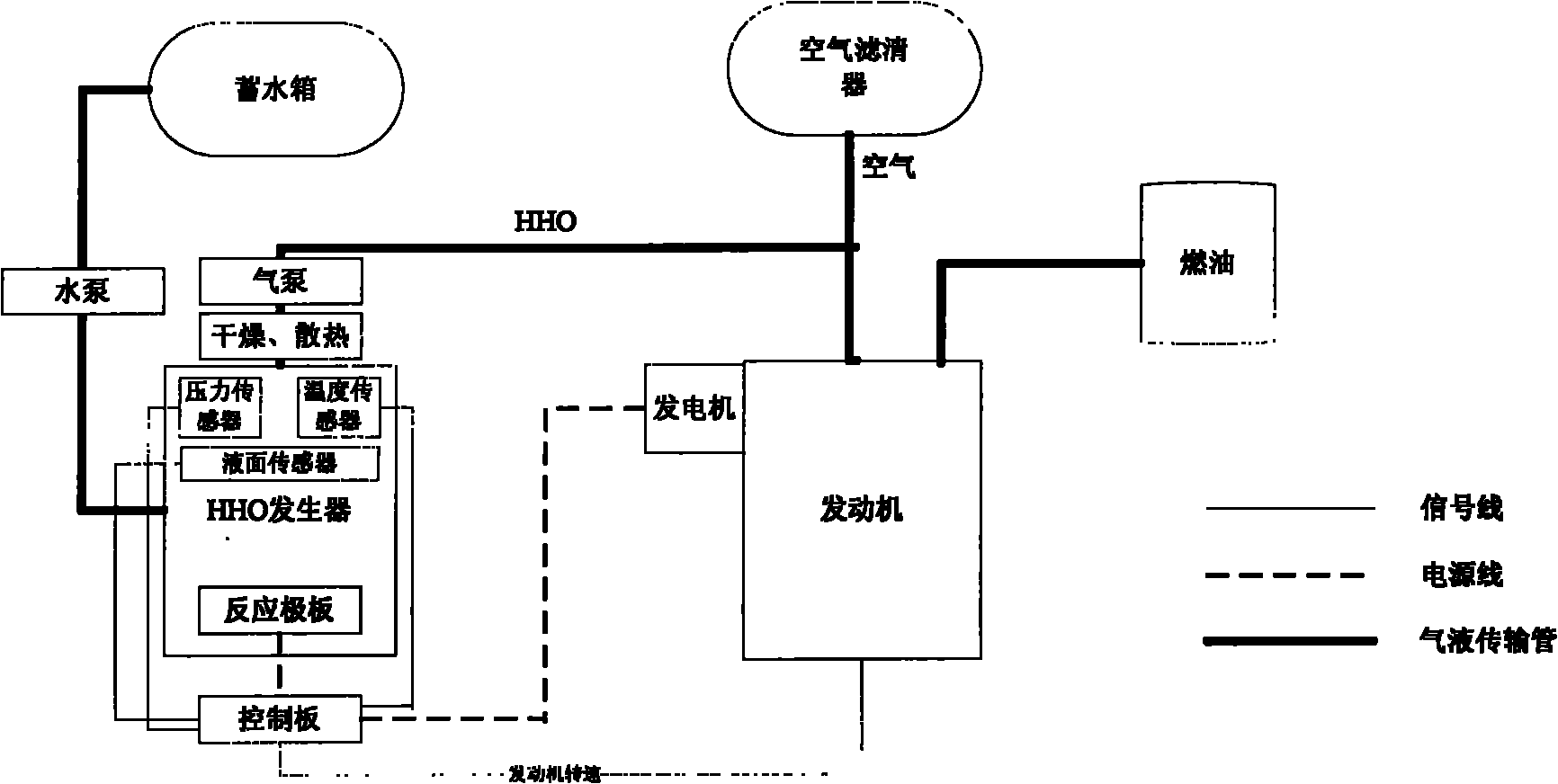

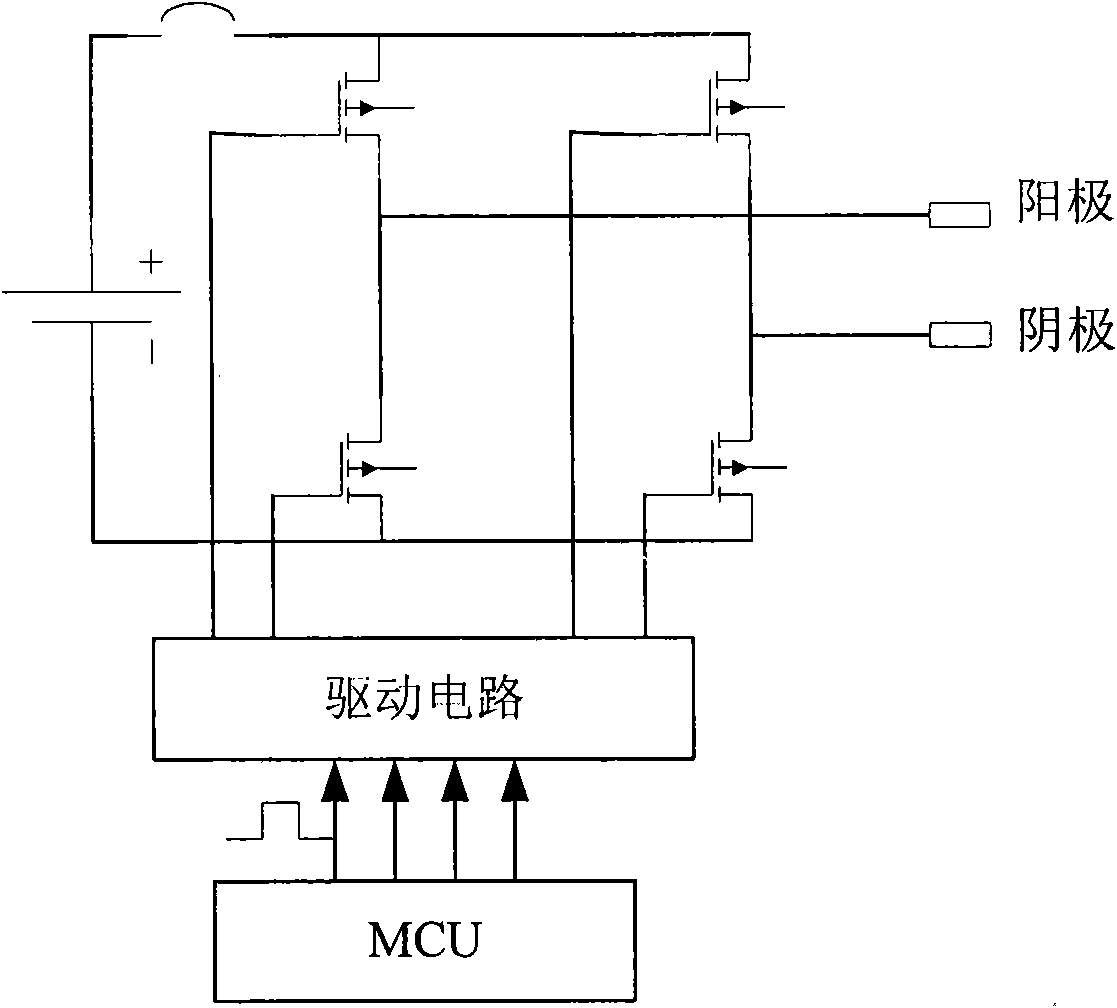

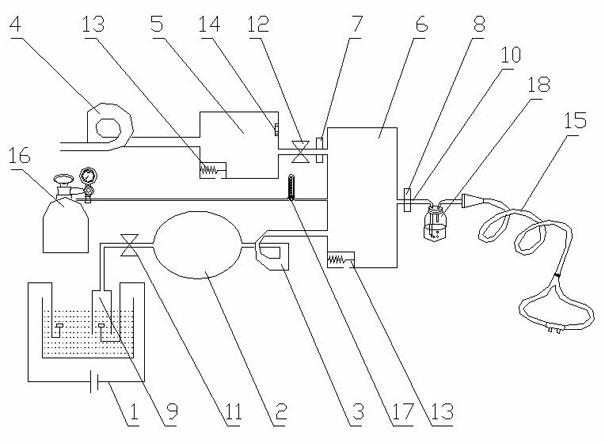

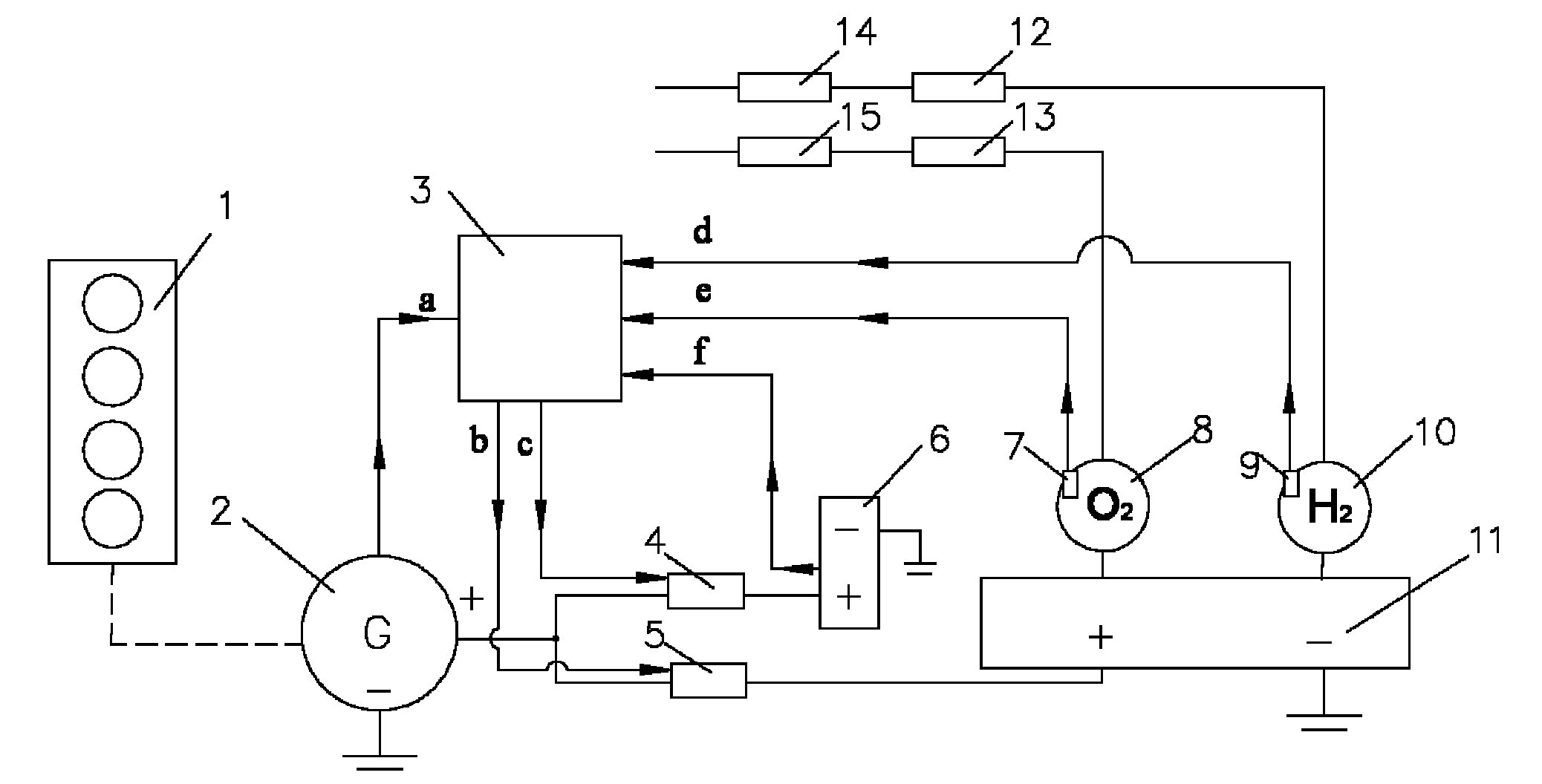

Auxiliary combustion system of vehicle-mounted hydrogen and oxygen generator

ActiveCN101900059AImprove efficiencyImprove electrolysis efficiencyElectrolysis componentsNon-fuel substance addition to fuelElectrolysisWater storage tank

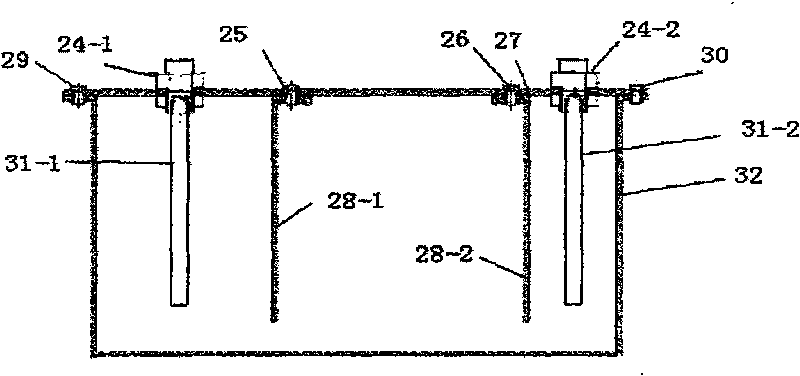

The invention discloses an auxiliary combustion system of a vehicle-mounted hydrogen and oxygen generator. The auxiliary combustion system comprises a hydrogen and oxygen mixed gas generator, a pulse power supply control board, a water storage tank and a pulse power supply; the hydrogen and oxygen mixed gas generator is an airtight metal container, plugged with a positive metal electrode and a negative metal electrode, filled with electrolyte and connected with a gas inlet of an engine through a gas guide tube; the water storage tank is connected with the hydrogen and oxygen mixed gas generator; the pulse power supply control board is respectively connected with the metal electrodes and the pulse power supply; the pulse power supply generates controllable alternating current through the pulse power supply control board, and the alternating current is added onto the electrodes in the hydrogen and oxygen mixed gas generator; and hydrogen and oxygen which are separated out by electrolyzing are together injected into the engine for assisting combustion. In the invention, the alternating current pulse power supply is adopted as an electrolysis power supply, thus the electrolysis efficiency is effectively improved; and closed-loop control is formed by adopting pressure, temperature and oxygen sensors so as to improve the efficiency of the engine, reduce the power consumption and reduce the discharge value.

Owner:NINGBO INTELLIGENT MFG IND RES INST

Hydrogen therapeutic apparatus

The invention discloses a hydrogen therapeutic apparatus which comprises a water-electrolysis hydrogen generator, an air chamber, an air blower I, an air blower II, an air storage chamber, a mixing chamber, a flow sensor and a hydrogen concentration monitor, wherein a hydrogen collecting conduit of the water-electrolysis hydrogen generator is communicated with the air chamber; the air chamber is communicated with an air inlet of the air blower I; an air outlet of the air blower I is communicated with the mixing chamber; an air outlet of the air blower II is communicated with the air storage chamber; an air outlet of the air storage chamber is communicated with the mixing chamber; the mixing chamber is provided with a conveyer pipe; the flow sensor is arranged on a pipeline connecting the air storage chamber and the mixing chamber; and the hydrogen concentration monitor is arranged on the conveyer pipe. Through the invention, the hydrogen generated by the water-electrolysis hydrogen generator is blown into the mixing chamber, and air is blown into the air storage chamber and then conveyed into the mixing chamber; the hydrogen / oxygen mixed gas is introduced into a conduit at a patient end and used for treating the patient; and the hydrogen therapeutic apparatus takes full advantage of the antioxidant, anti-inflammation and anti-necrosis effects of hydrogen and can be used for treating and preventing multiple diseases.

Owner:THE FIRST AFFILIATED HOSPITAL OF CHONGQING MEDICAL UNIVERSITY

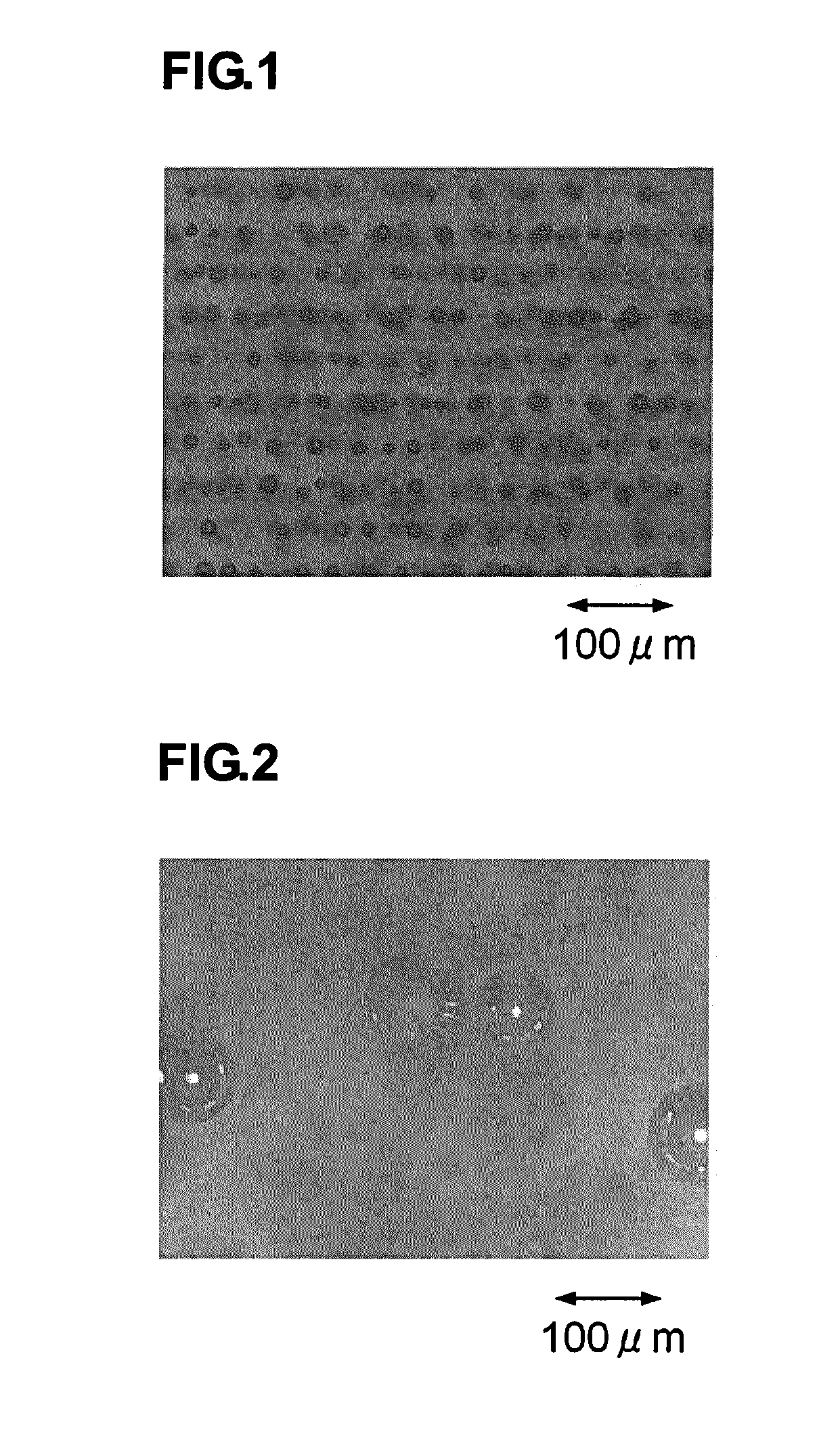

Synthetic opaque quartz glass and method for producing the same

ActiveUS20100316858A1High puritySimple methodGlass shaping apparatusGlass/slag layered productsQuartzSilicon

Provided is a method for producing a synthetic opaque quartz glass where flame processing can be performed in high purity with a simple way and even a large sized one can be produced, and the synthetic opaque quartz glass.A method for producing a synthetic opaque quartz glass which comprises the step of heating and burning a quartz glass porous body under a pressure of from 0.15 MPa to 1000 MPa at a temperature of from 1200° C. to 2000° C. The quartz glass porous body is prepared by depositing quartz glass particles which are produced by hydrolyzing a silicon compound with an oxyhydrogen flame.

Owner:SHIN ETABU QUARTZ PRODS

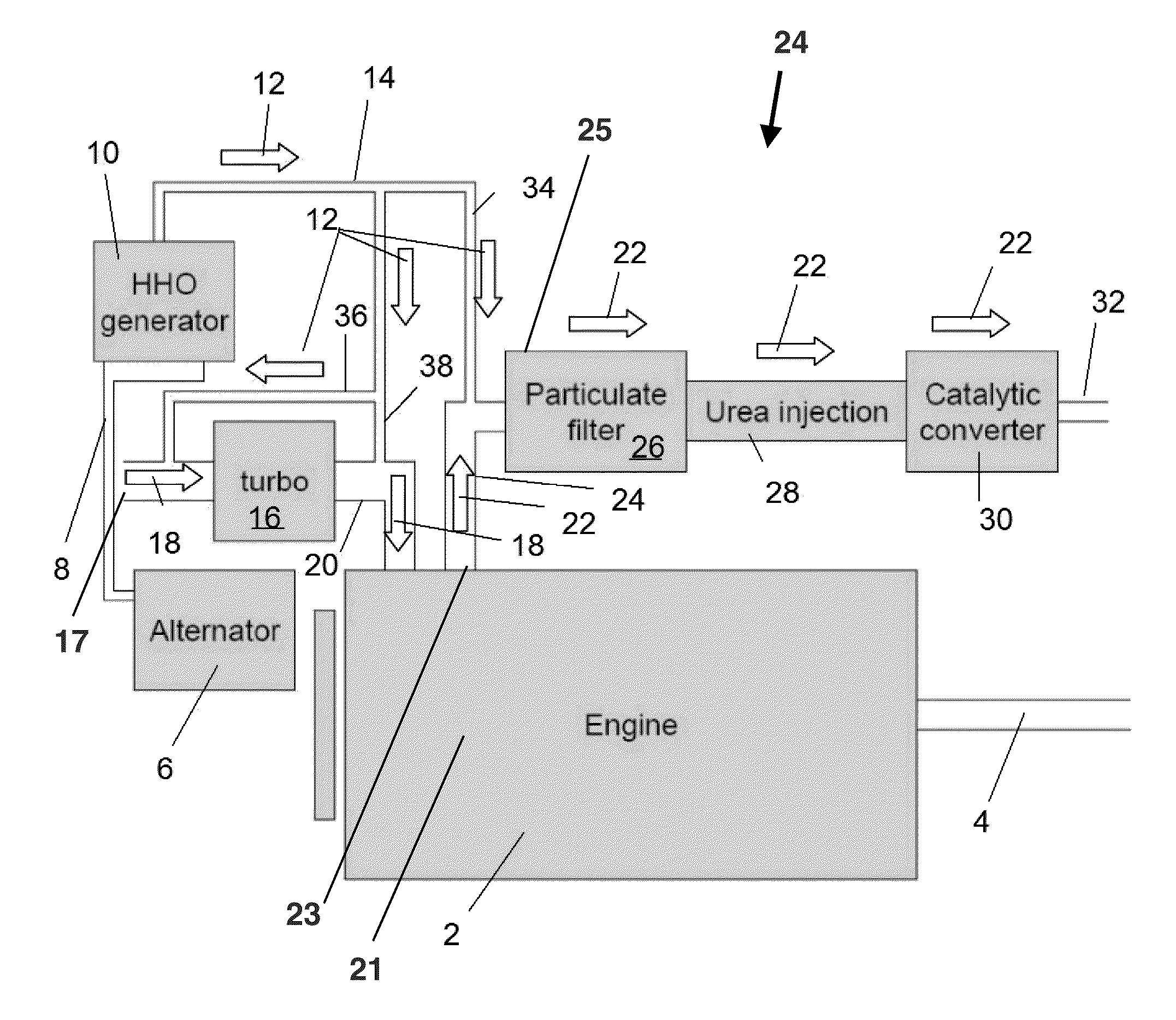

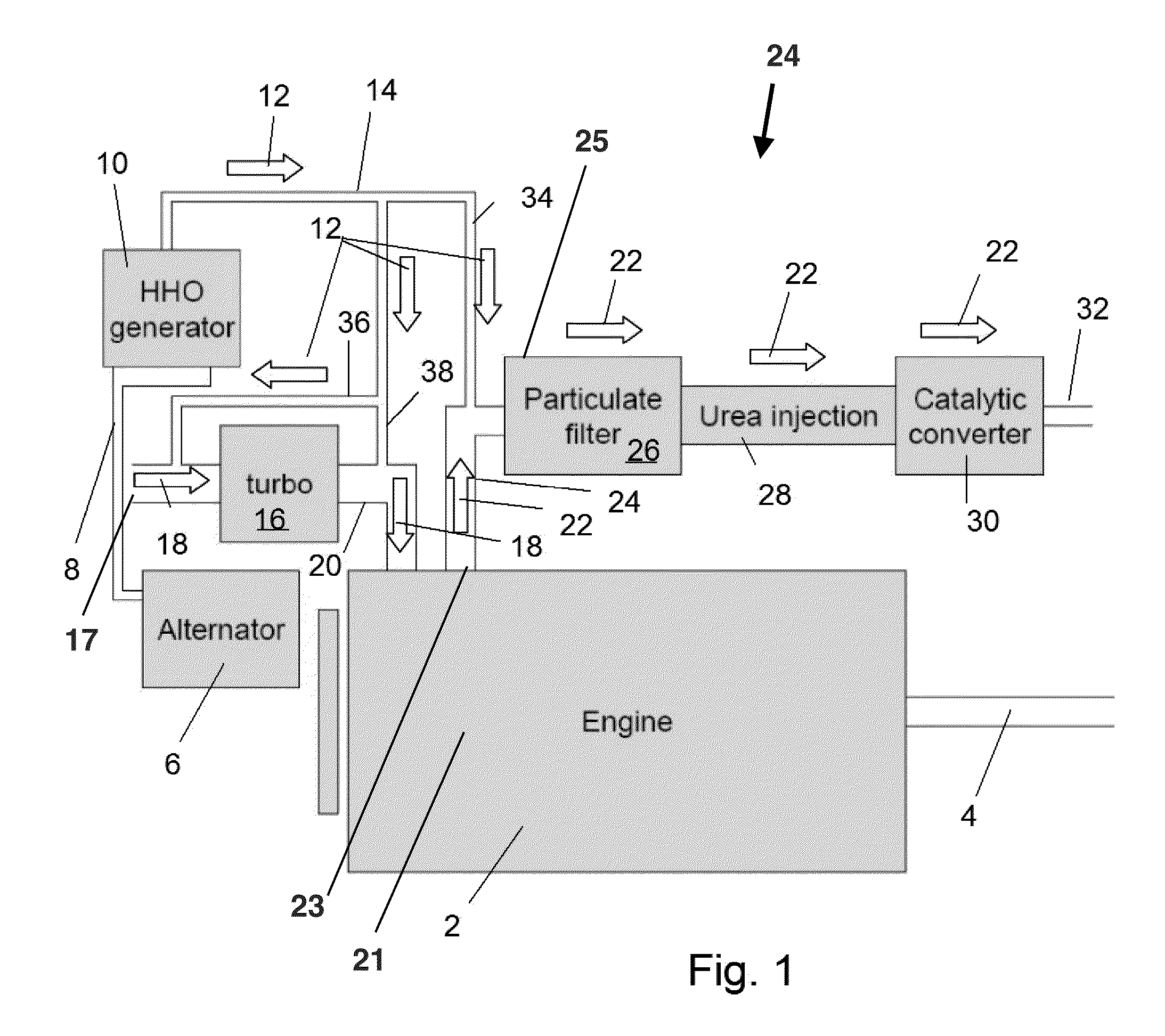

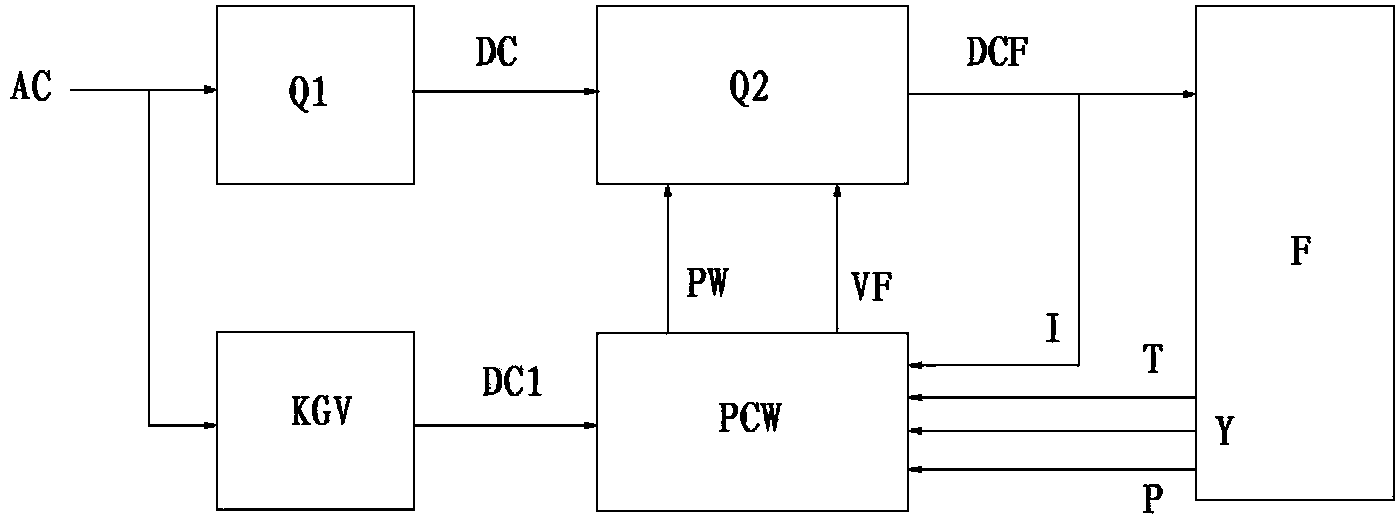

System and method of improving efficiency of combustion engines

InactiveUS20110303194A1Less fuelEfficient combustionInternal combustion piston enginesNon-fuel substance addition to fuelCombustionInternal combustion engine

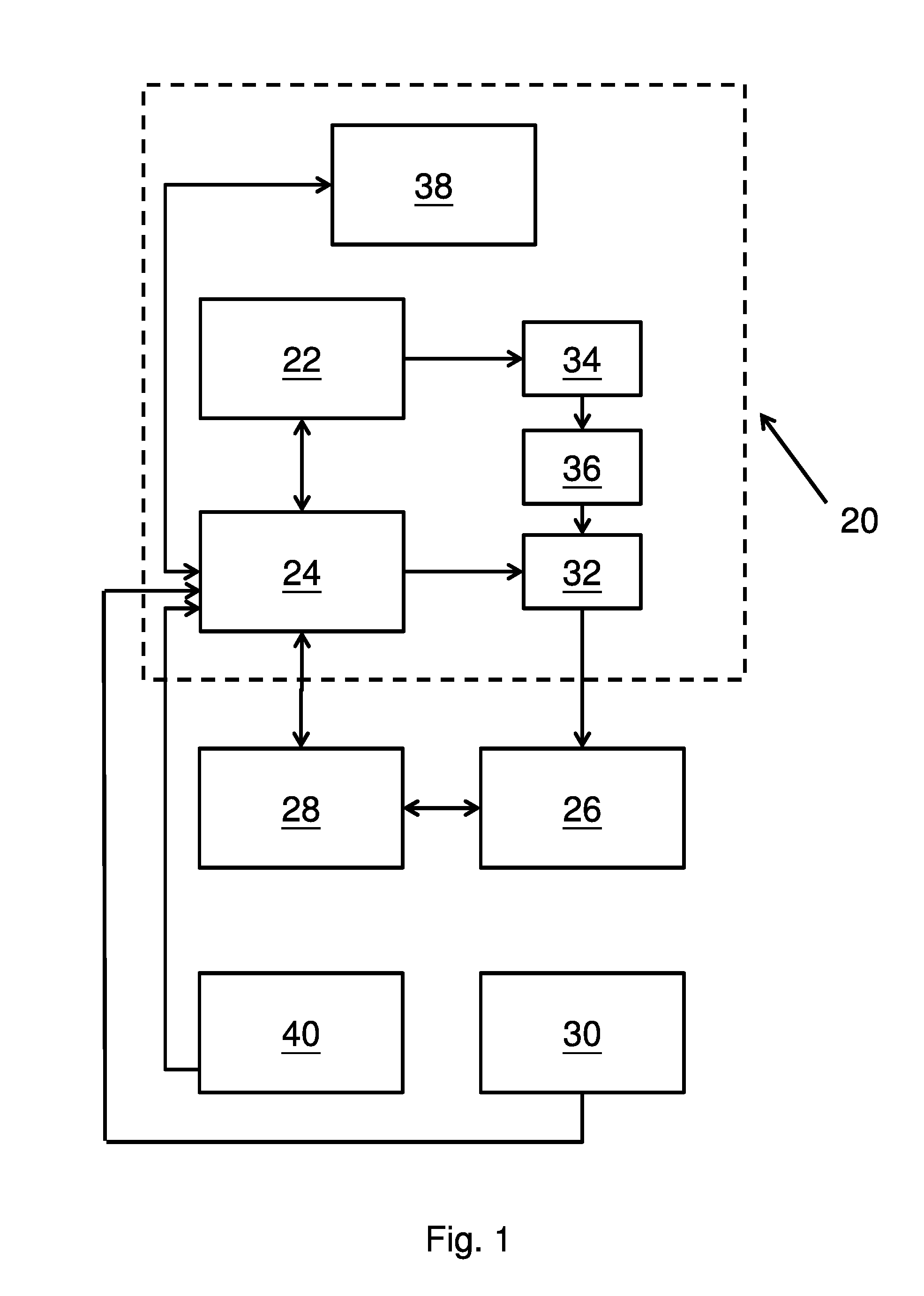

A system for improving the performance of a combustion engine comprising a system control unit is disclosed. The system control unit comprises an input module, a transform module and a control module all interconnected to each other. The input module obtains a first set of combustion parameters of the engine through at least one sensor. The transform module transforms the first set of combustion parameters into a second set of combustion parameters. The control module controls fuel injection of the engine based on the second set of combustion parameters, and controls oxyhydrogen production and injection based on the second set of combustion parameters. The controlled fuel injection and the controlled oxyhydrogen production and injection contribute to an improved performance of said engine during combustion. A method of improving the performance of a combustion engine and a method of injecting oxyhydrogen into a combustion engine are also disclosed.

Owner:HANDSOME VIVA INVESTMENTS

Two-stage light gas gun driven through hydrogen energy

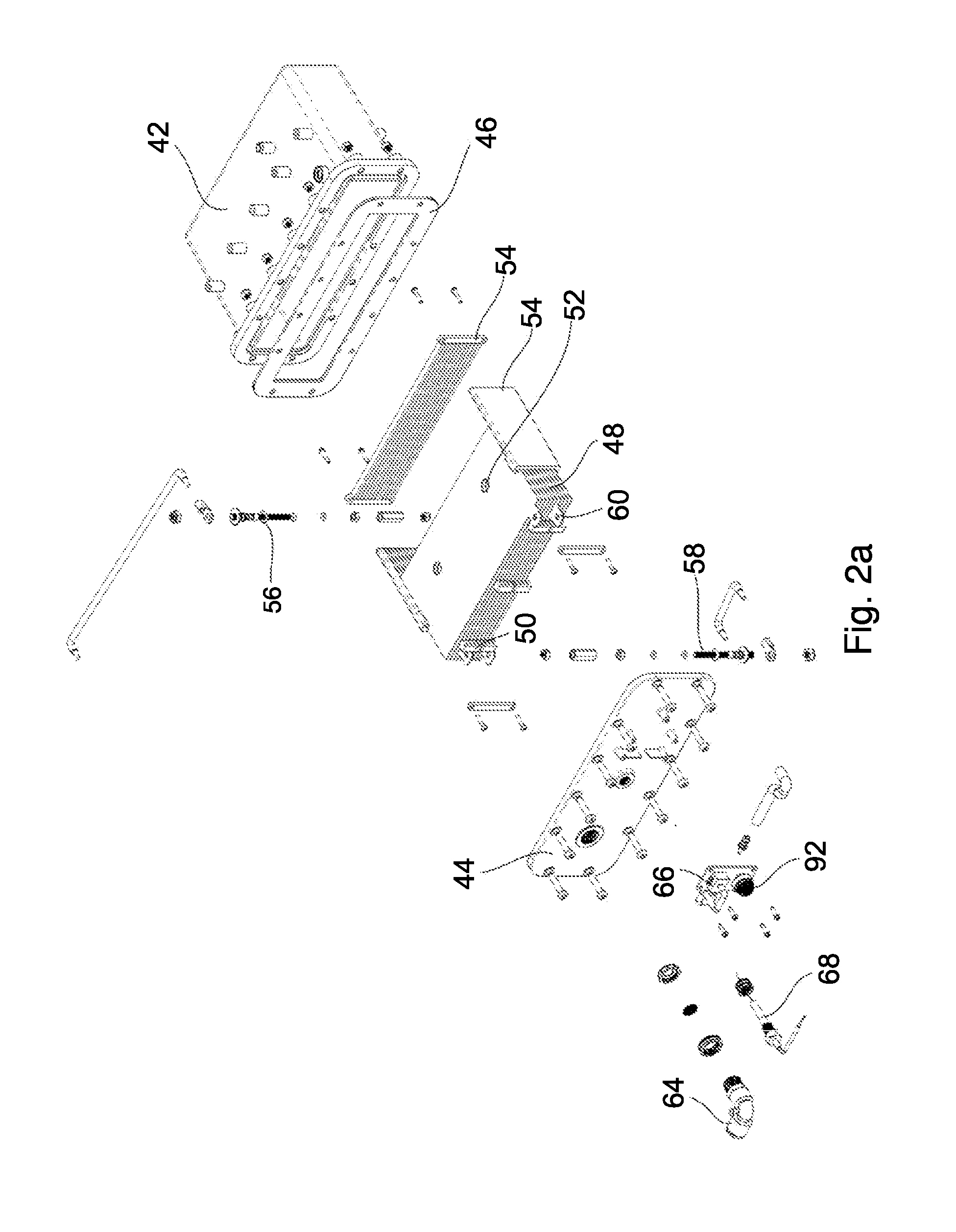

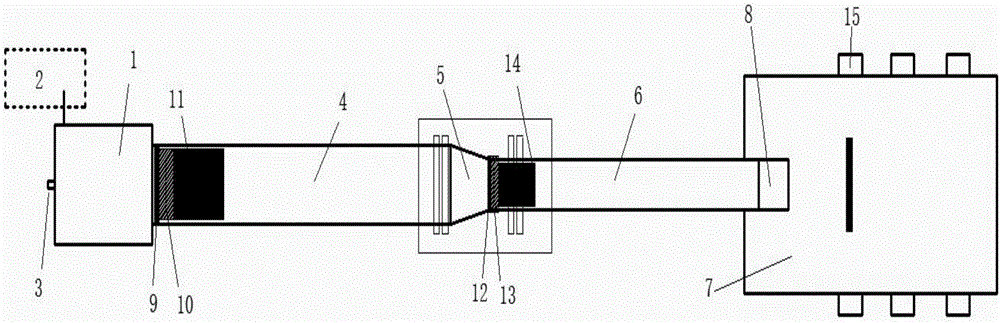

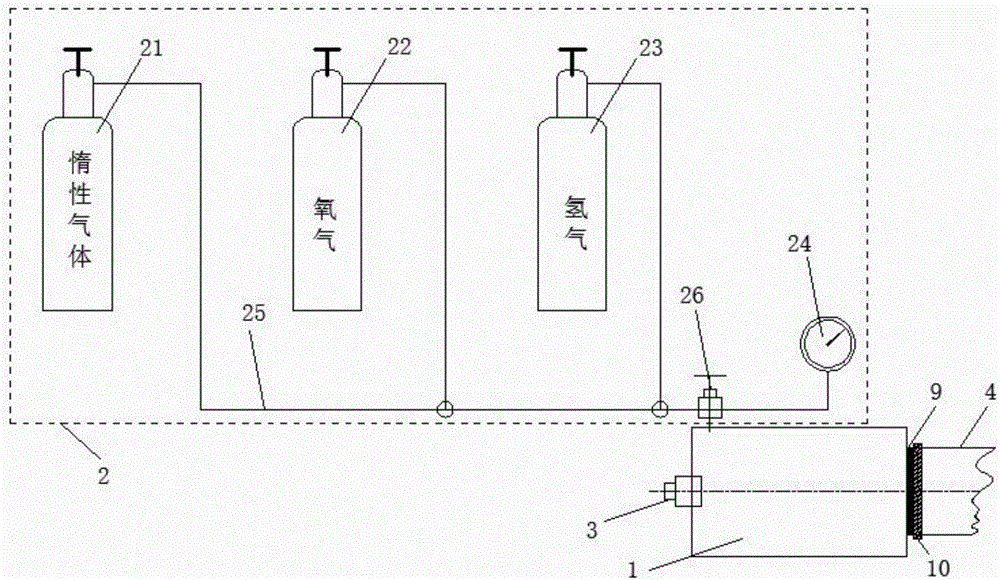

The invention belongs to the technical field of light gas gun experiments, and particularly relates to a light gas gun driven through hydrogen and oxygen mixed gas detonation, in particular to a two-stage light gas gun driven through hydrogen energy. According to the technical scheme, the two-stage light gas gun driven through hydrogen energy comprises a combustor, a gas injection device, an ignition device, a pump pipe, a high-pressure cone section, a transmitting pipe, a target chamber and a magnetic speed testing device, wherein the ignition device is installed at one end of the combustor, the other end, opposite to the end with the ignition device, of the combustor is connected with the pump pipe, and a pump pipe membrane and a pump pipe membrane breaker are arranged at the junction; the gas injection device is used for injecting hydrogen, oxygen and inert gas into the combustor; a piston is arranged in the pump pipe; the large-diameter portion of the high-pressure cone section is connected with the pump pipe; the small-diameter portion of the high-pressure cone section is connected with the transmitting pipe, and a transmitting pipe membrane and a transmitting pipe membrane breaker are arranged at the junction; shots are arranged in the transmitting pipe, and one end of the transmitting pipe is located in the target chamber; and the magnetic speed testing device is installed at the tail end of the transmitting pipe and connected with an oscilloscope. The two-stage light gas gun is driven through hydrogen energy instead of gunpowder, damage to the gun is small, no particular product is generated, and a gun barrel can be cleaned conveniently after experiments.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Internal combustion engine and vehicle

InactiveCN106677930ATake advantage ofIncrease temperatureInternal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineControlled combustion engine

The invention relates to the technical field of energy conservation and environmental protection, in particular to an internal combustion engine and a vehicle. The internal combustion engine comprises an internal combustion engine body, a pipe body assembly, an oxyhydrogen generating device and a water supply system; the internal combustion engine body is provided with an exhaust system and an air intake system; the exhaust system comprises an exhaust branch and an exhaust pipeline connected with each other; the exhaust branch is connected with the external part; the pipe body assembly comprises a first pipe body part and a second pipe body part; the first pipe body part is connected with the water supply system; the second pipe body part is connected with the exhaust branch in a winding manner in the length direction of the exhaust branch to be used for having thermal transmission with the exhaust branch; one end of the oxyhydrogen generating device is connected with the second pipe body part; and the other end of the oxyhydrogen generating device is connected with the air intake system. The internal combustion engine alleviates the technical problem that the existing internal combustion engine adopts petroleum for combustion to pollute the environment, generate haze and seriously consume the petroleum resources.

Owner:宽城天宇鹿业有限公司

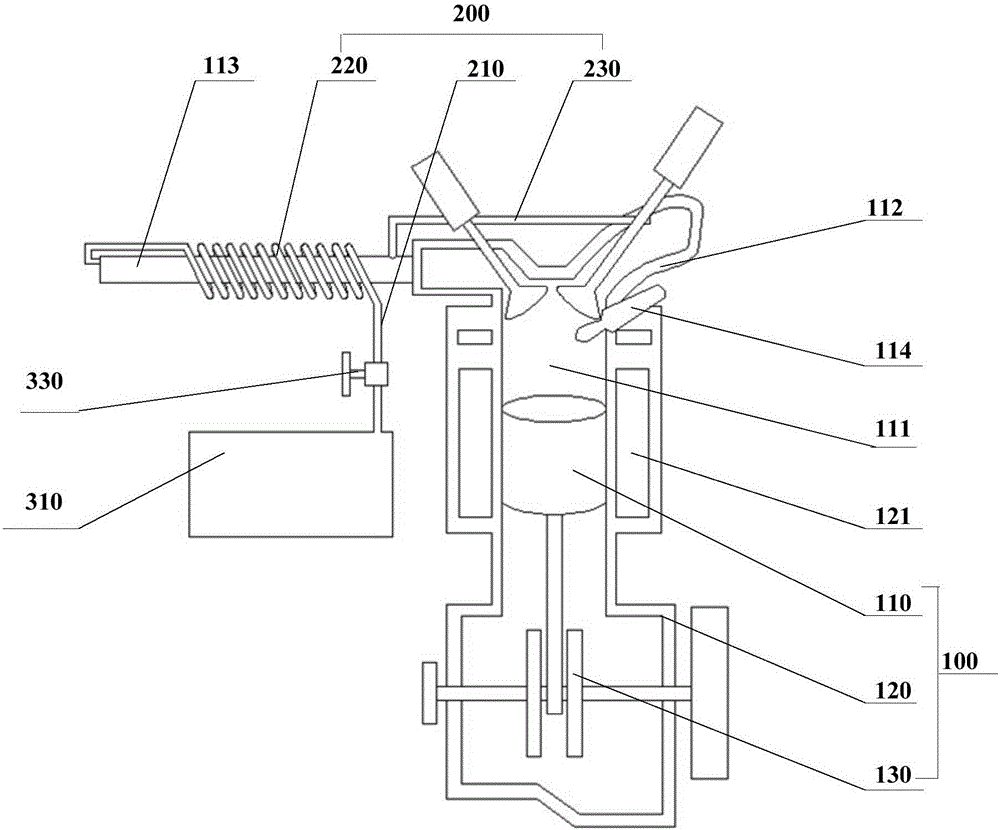

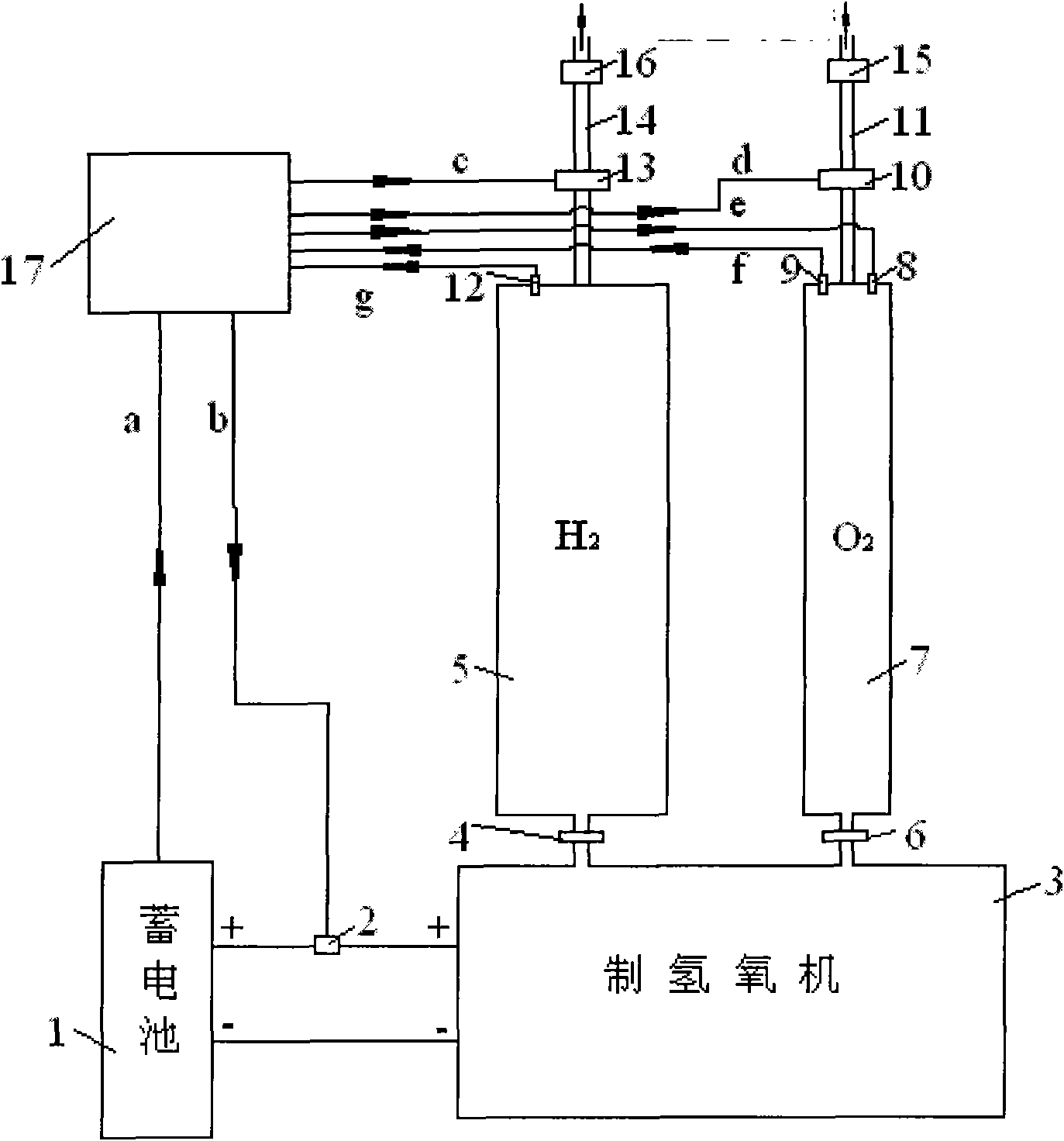

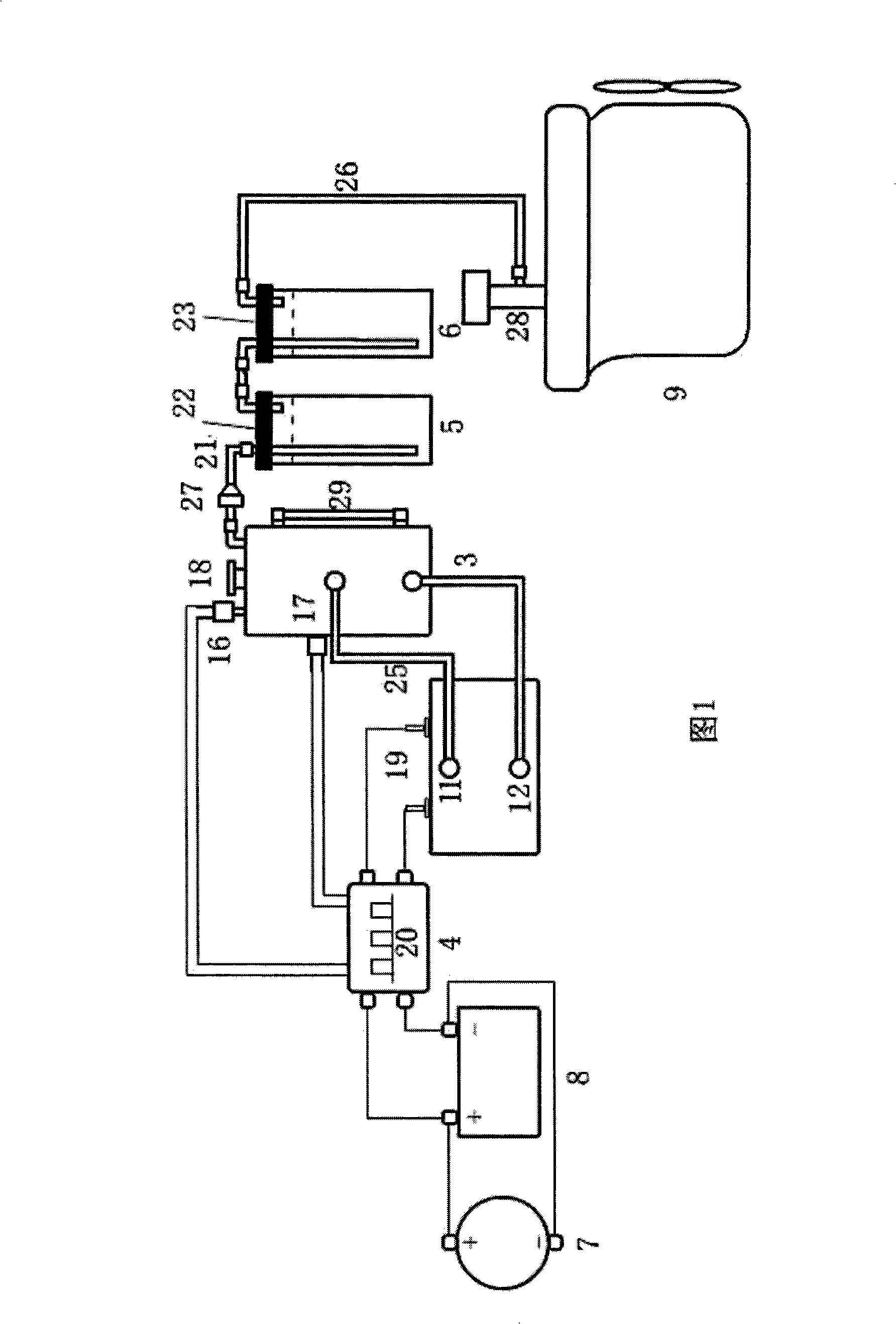

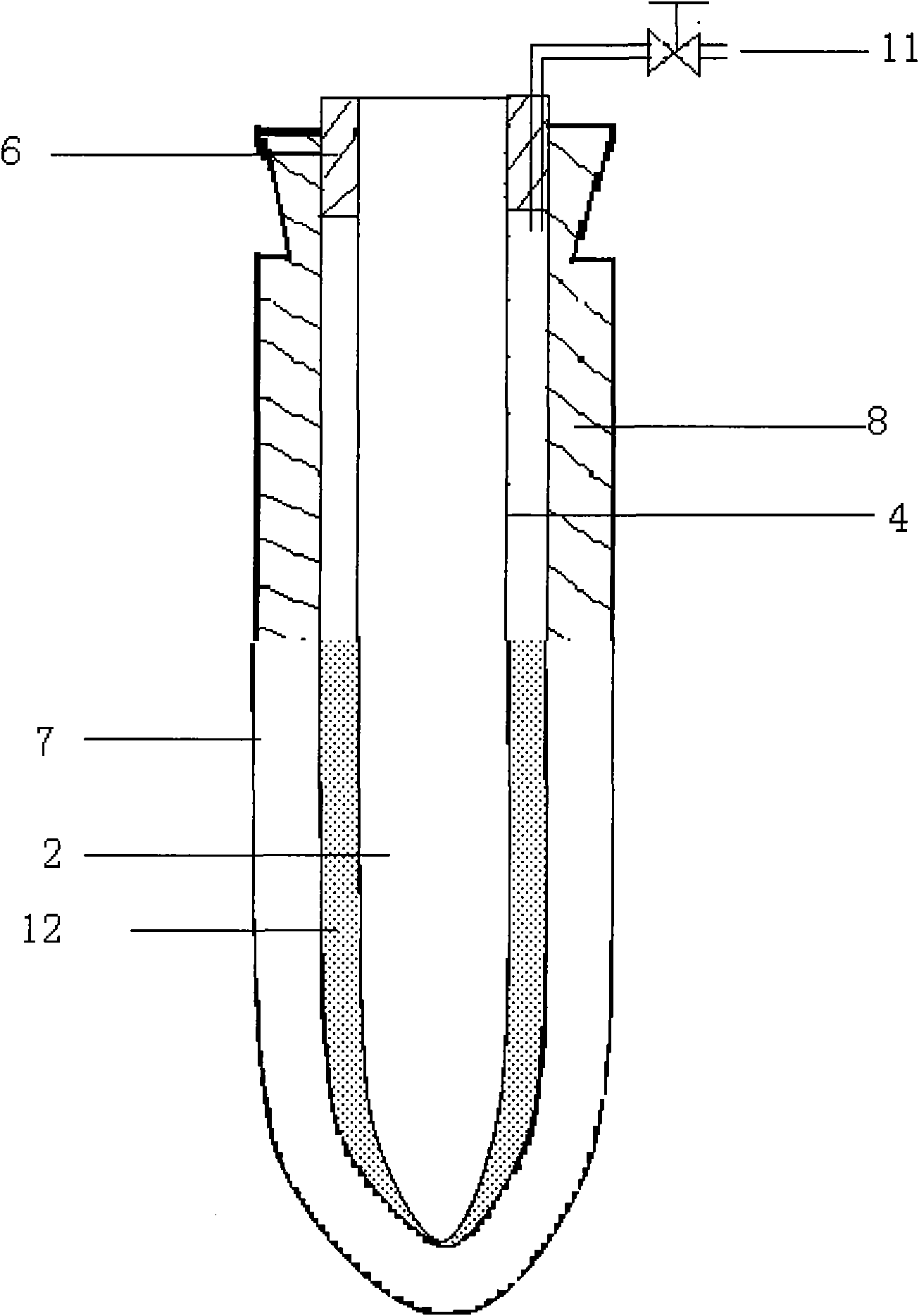

Device for preparing, storing and feeding vehicle-mounted hydrogen/oxygen and control method thereof

ActiveCN101956634AReduce weightReduce manufacturing costNon-fuel substance addition to fuelInternal combustion piston enginesOxygen tankSolenoid valve

The invention discloses a device for preparing, storing and feeding vehicle-mounted hydrogen / oxygen and a control method thereof, particularly relating to prepare, store and feed the hydrogen and the oxygen on a vehicle. In the system, based on reserving an engine storage battery, a vehicle-mounted hydrogen and oxygen preparing device, a hydrogen and oxygen storing device, a hydrogen and oxygen preparing, storing and electronicaly control unit are increased, wherein, according to an accumulator voltage signal, and a hydrogen and oxygen storage tank pressure signal, the electronicaly control unit controls opening and closing of a hydrogen and oxygen preparing machine switch relay, an oxygen tank unidirectional gas discharging valve, an oxygen supply linear solenoid valve and a hydrogen supply pipeline solenoid valve, thus realizing the preparation, storing, feeding, and controlling of the hydrogen and the oxygen on the vehicle. The system has the advantages of realizing the preparation and storing of the hydrogen and the oxygen on the vehicle, ensuring that the vehicle can utilize the hydrogen and the oxygen prepared by the system in the last-time operation when in cold starting, so as to realize the starting of pure hydrogen or pure hydrogen-oxygen gas mixture for the increasing of the hydrogen and oxygen storing device, thereby greatly reducing HC and CO emission when a gasoline engine is started.

Owner:BEIJING UNIV OF TECH

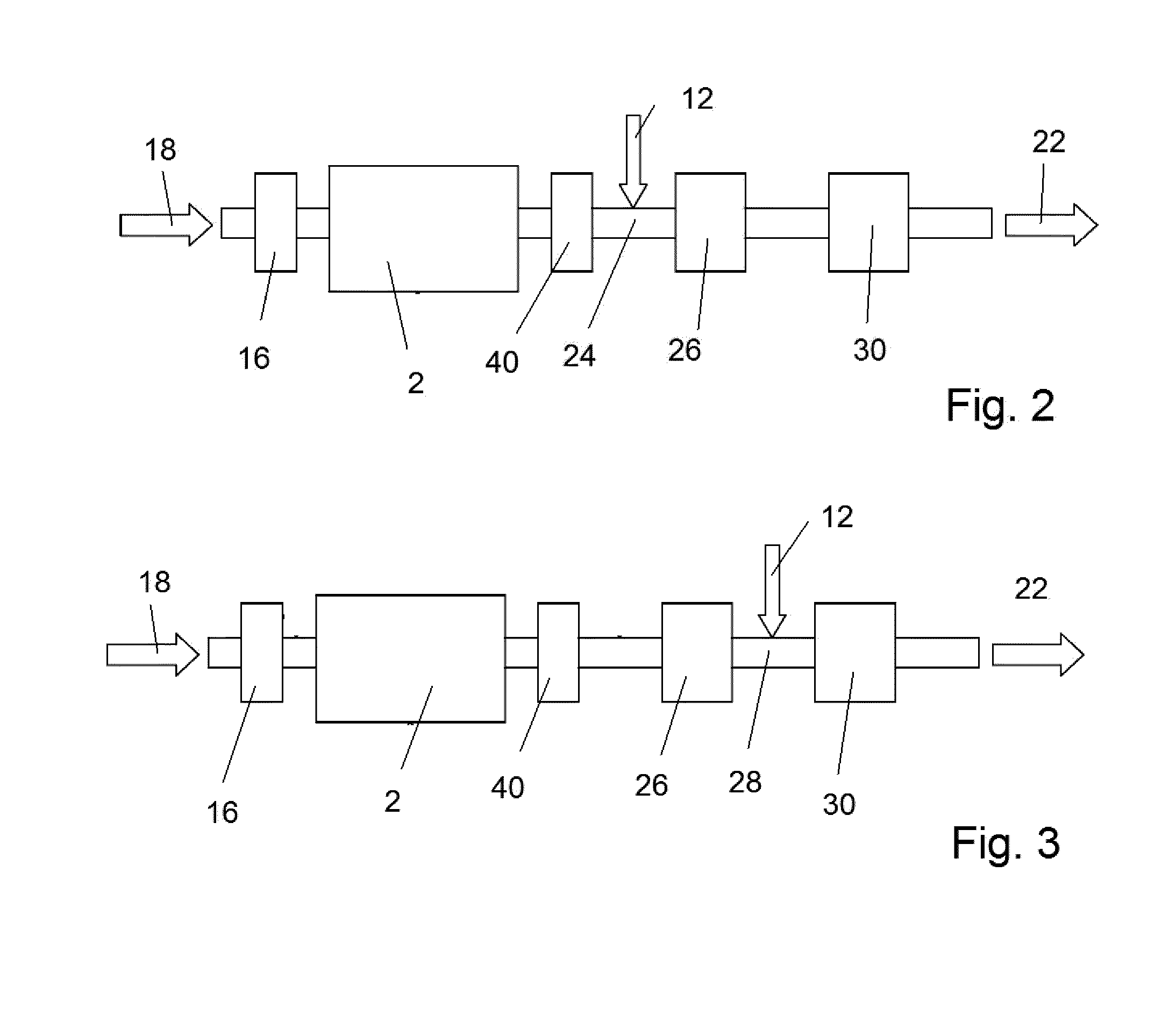

Apparatus and Method for Preventing and Removing Carbon Deposits

InactiveUS20160047284A1Increase pressure dropElimination of urea injectionInternal combustion piston enginesNon-fuel substance addition to fuelParticulatesSolid carbon

Oxyhydrogen (HHO) generated by an HHO generator hydrogenates solid carbon to liquid and gaseous hydrocarbons in the exhaust system of an internal combustion engine, such as in the particulate filter of a diesel engine to clean the solid carbon from the particulate filter without conventional regeneration. Discharge of the HHO to the exhaust system also reacts with NOx in the exhaust gas to reduce the NOx. The HHO may be discharged to a plurality of locations to clean solid carbon and reduce NOx emissions from a diesel engine.

Owner:TURGEON LUKE J +1

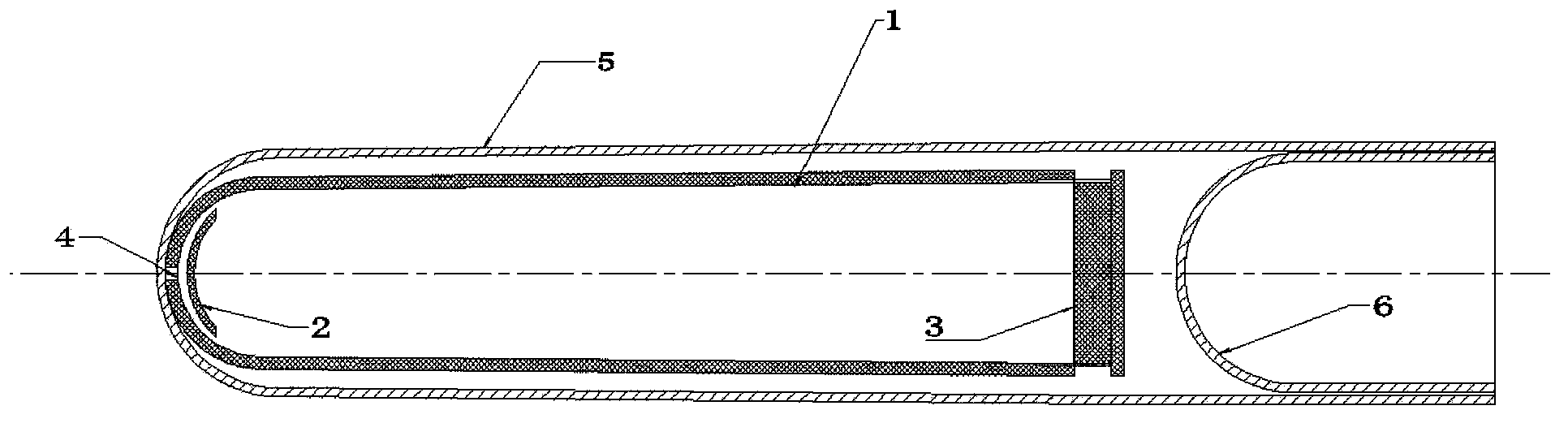

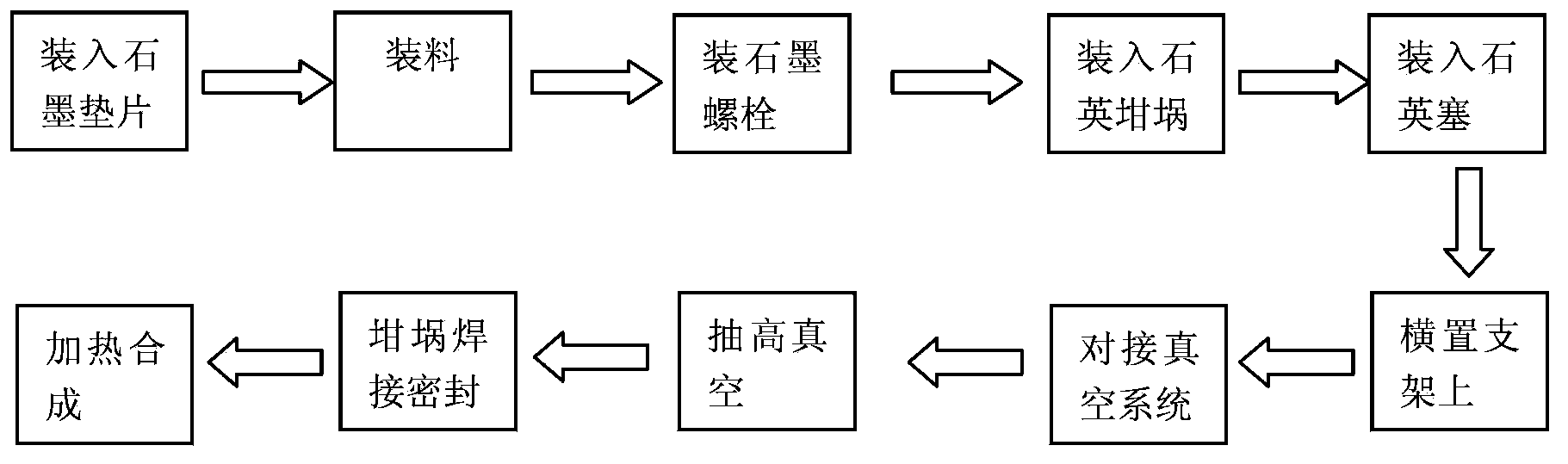

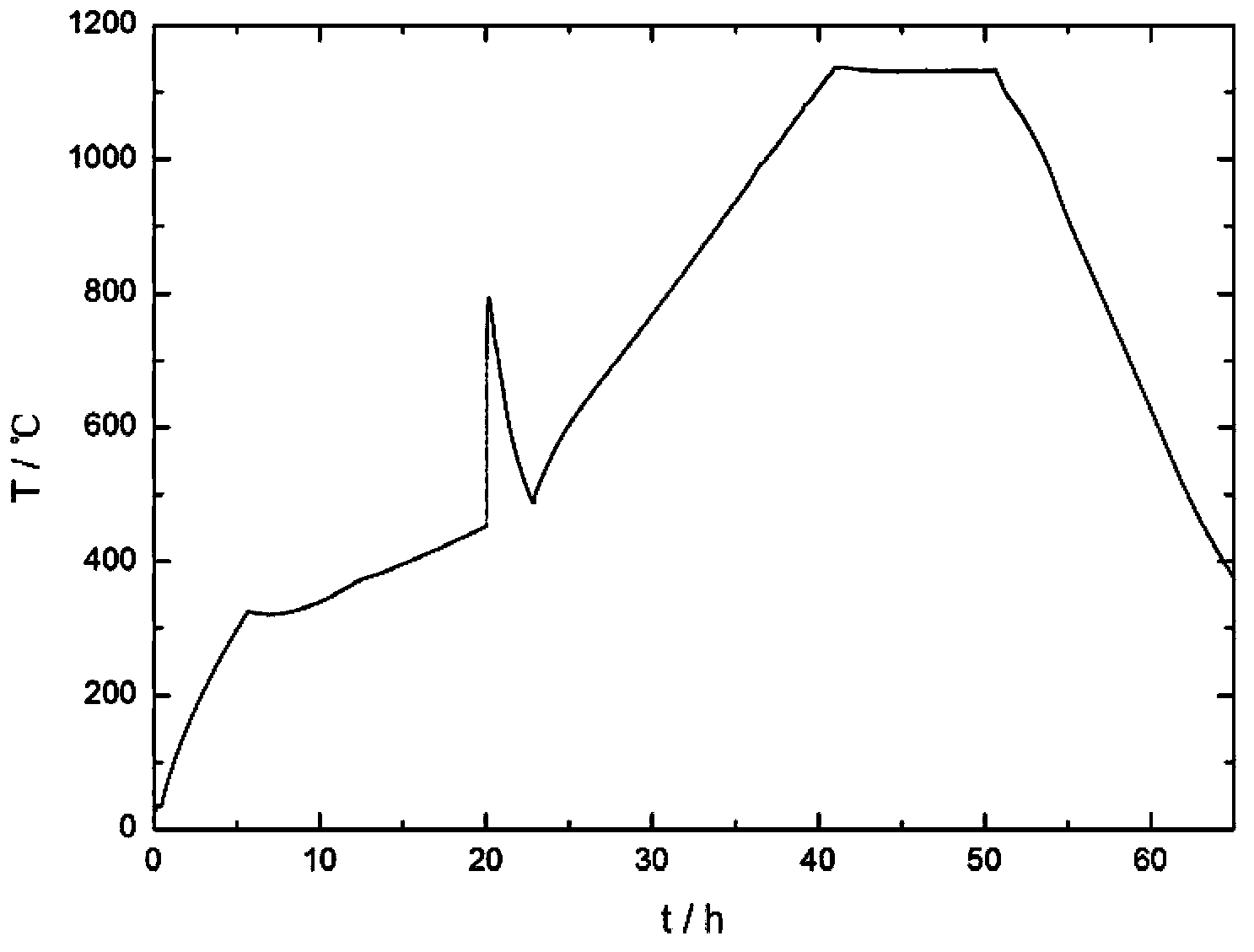

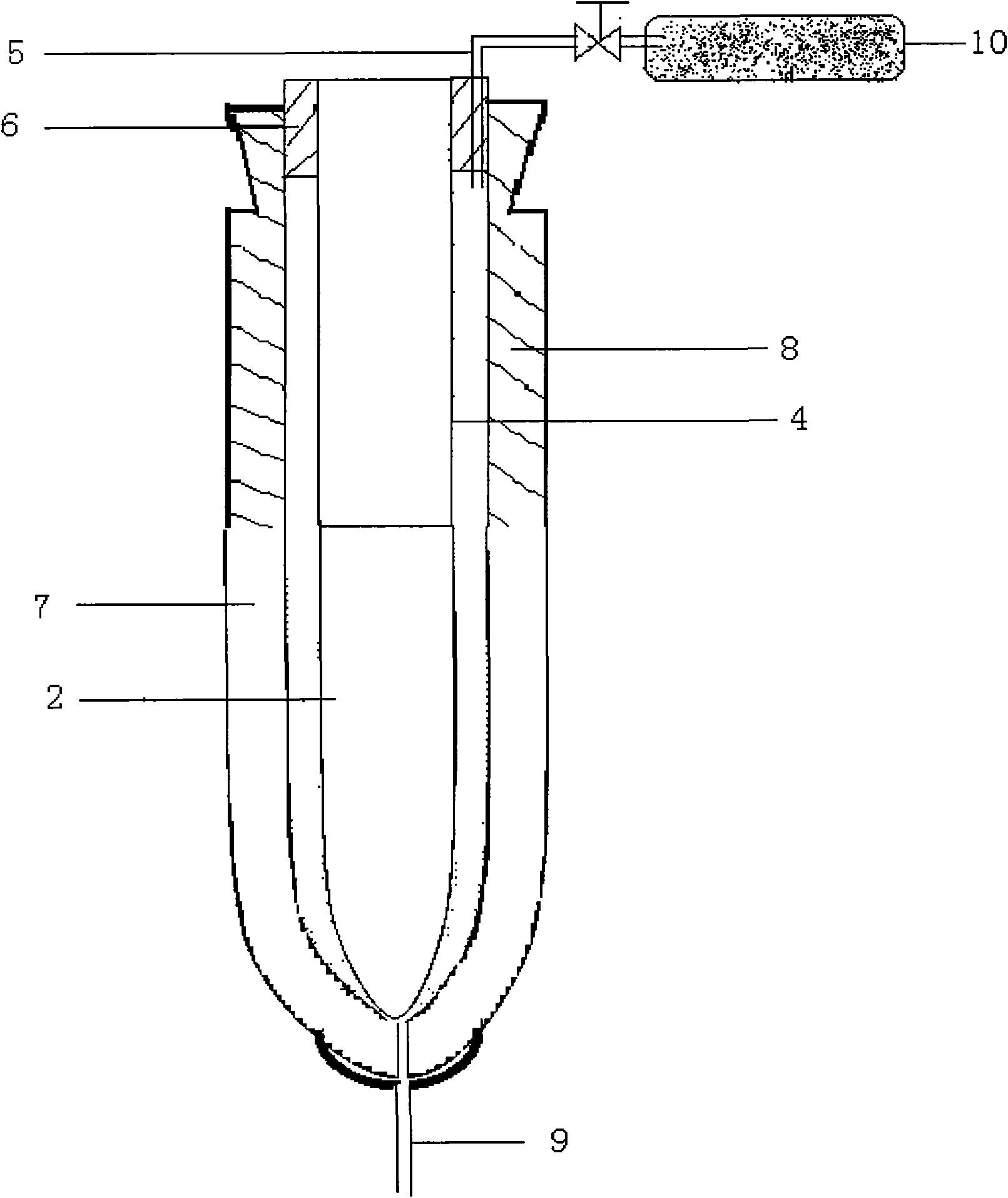

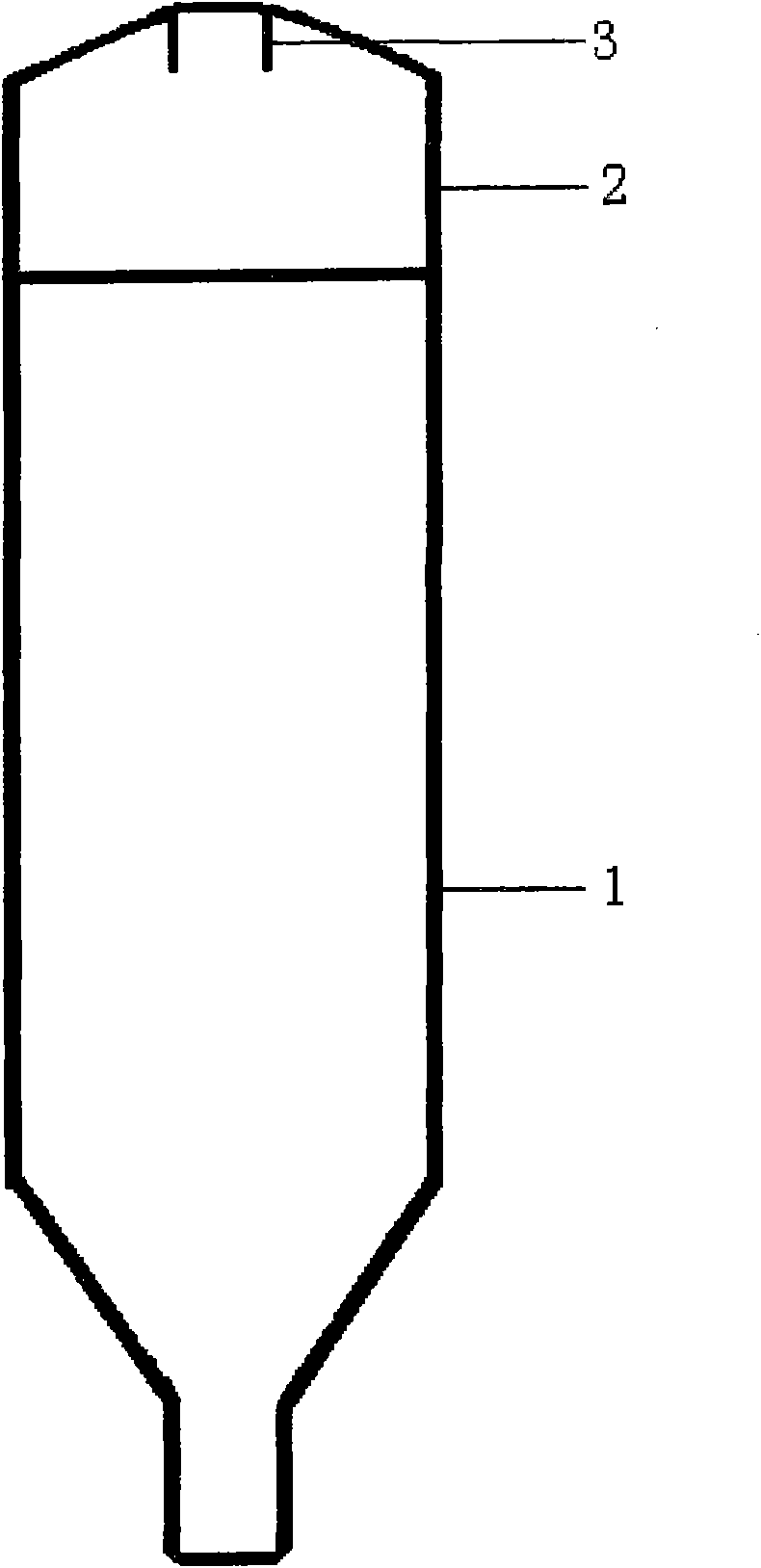

Large-diameter CdTe or CdZnTe polycrystalline rod synthesis apparatus and preparation method thereof

ActiveCN103409800AAvoid pipe cracking or even pipe explosionAvoid damagePolycrystalline material growthSingle crystal growth detailsChemical combinationLatent heat

The invention discloses a large-diameter CdTe or CdZnTe polycrystalline rod synthesis apparatus and a preparation method thereof. The apparatus is characterized in that an aspirating hole is arranged at the bottom of a graphite crucible, a graphite pad is placed at the bottom of the graphite crucible, a graphite cover is positioned at the mouth of the graphite crucible, the whole graphite crucible is placed in a quartz crucible and has a corresponding gap with a quartz plug, and the quartz plug is positioned at the mouth of the quartz crucible. The quartz crucible and the quartz plug are sealed through welding by adopting oxyhydrogen flame; the obtained quartz crucible is sent to a synthesis furnace and is heated to realize a raw material synthesis technology in order to prepare CdTe or CdZnTe polycrystalline rods; and the graphite crucible is completely sealed in the quartz crucible to make the solid material in graphite crucible in a high vacuum state at normal temperature, so the violent release and the heat impact of latent heat in a raw material mixture chemical-combination process can be effectively born during the heating synthesis, the frequent-appearing quartz crucible explosion or cracking event is completely avoided in the highly-pure raw material mixture synthesis process, and the highly pure graphite crucible can be repeatedly used, thereby the batch production cost is reduced.

Owner:WUHAN GAOXIN TECH

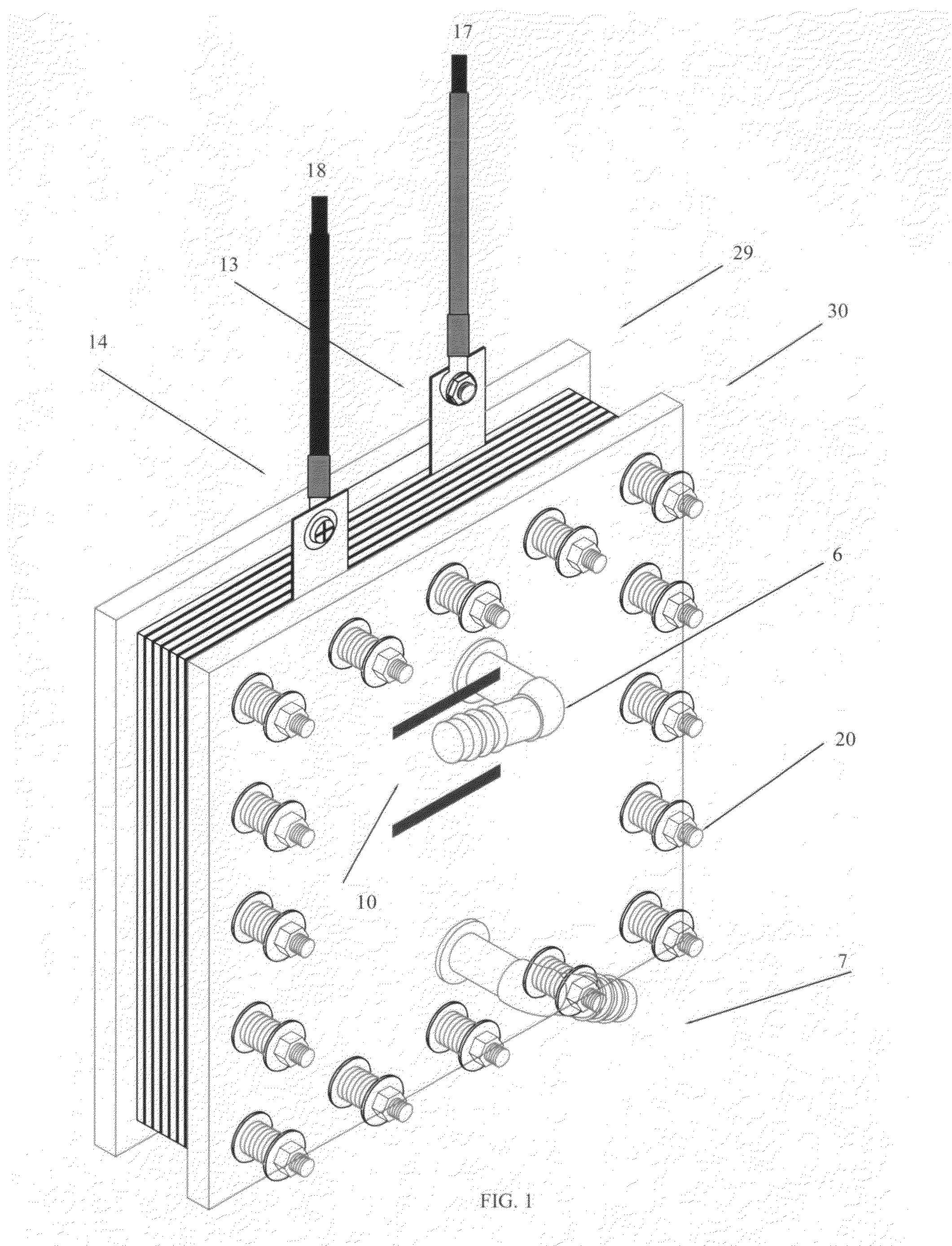

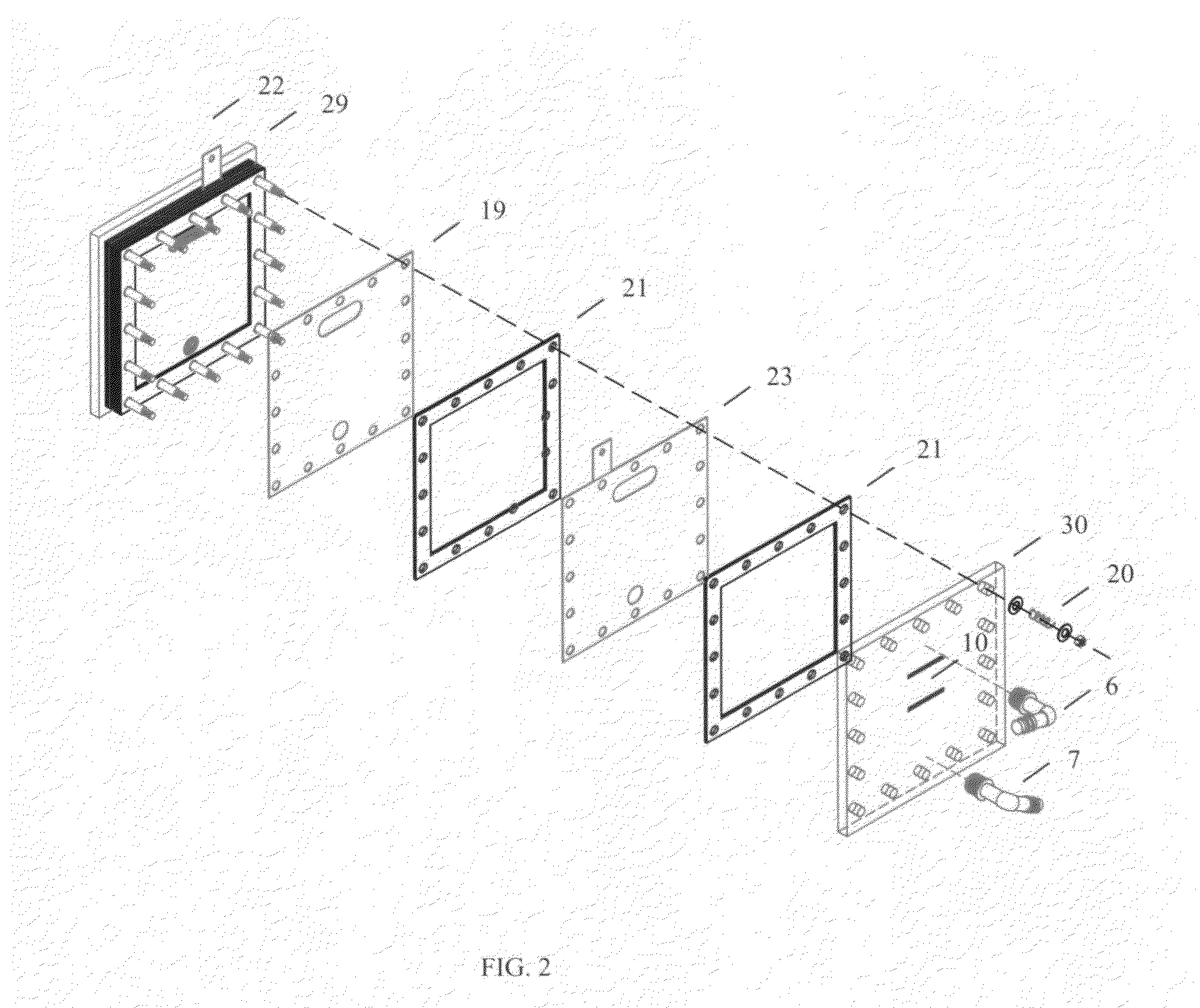

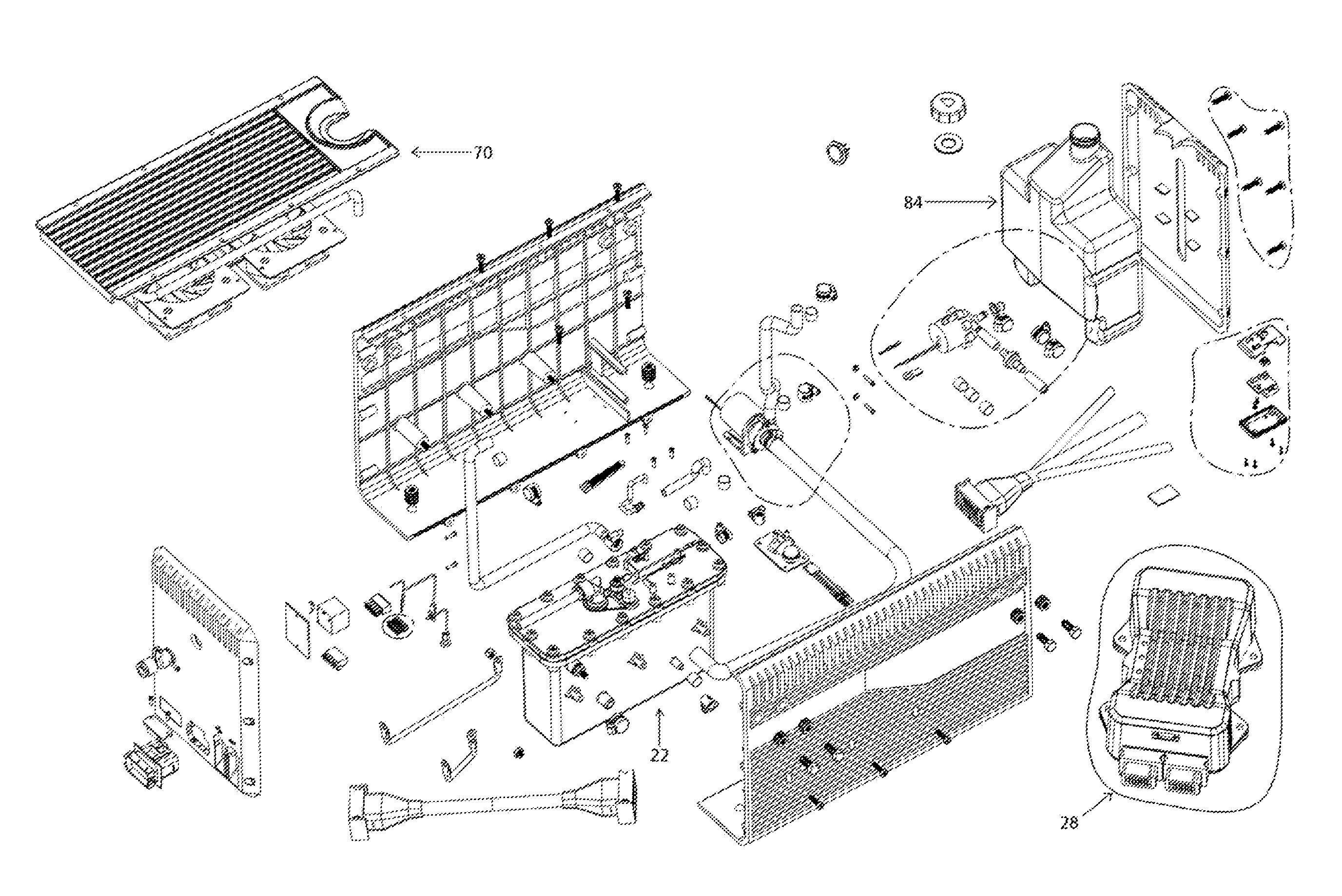

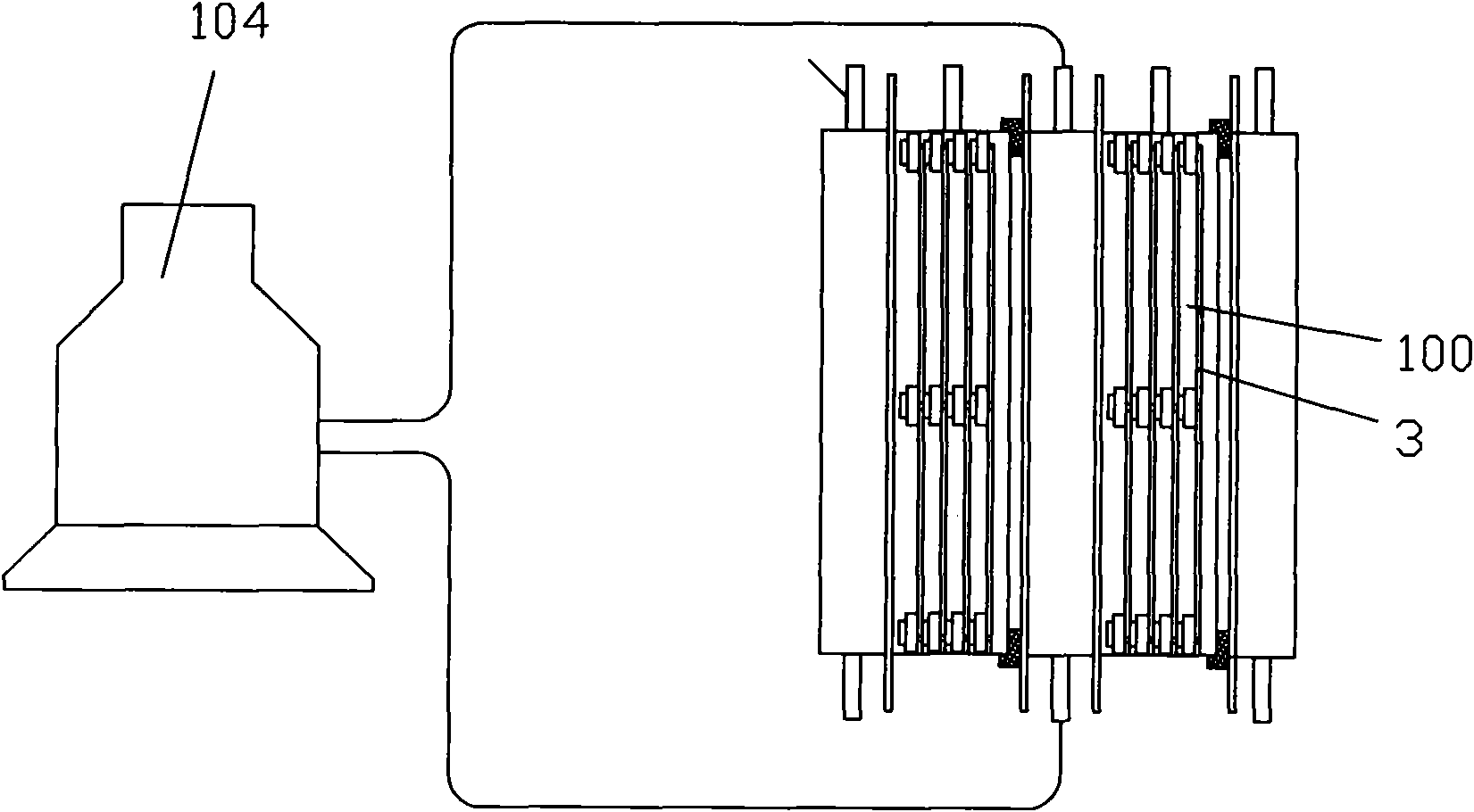

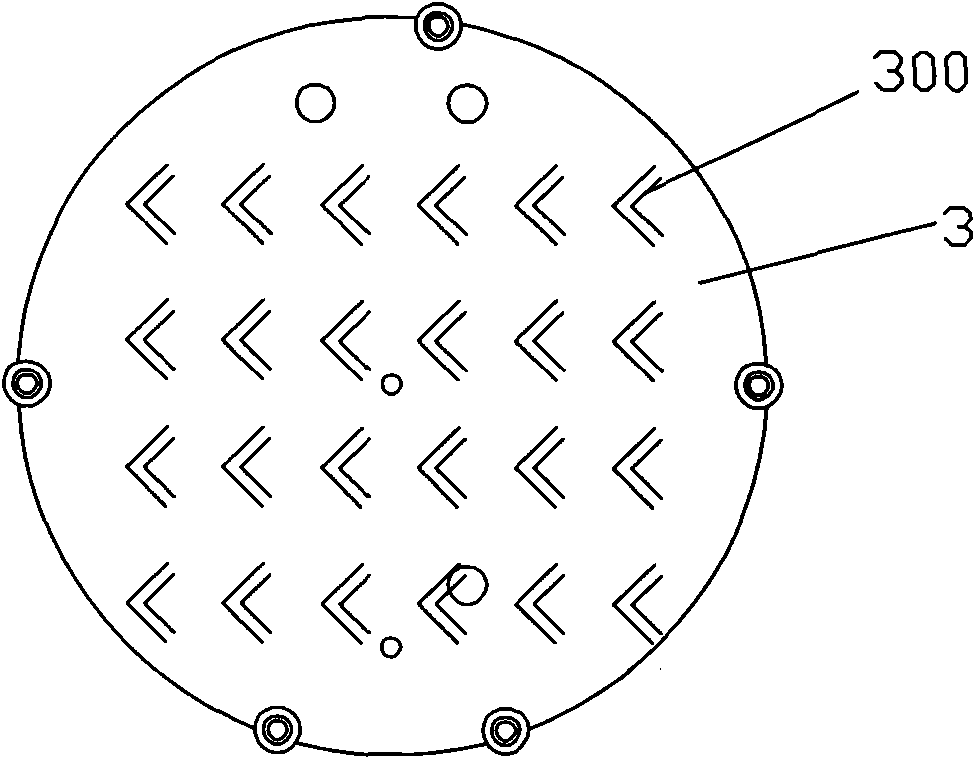

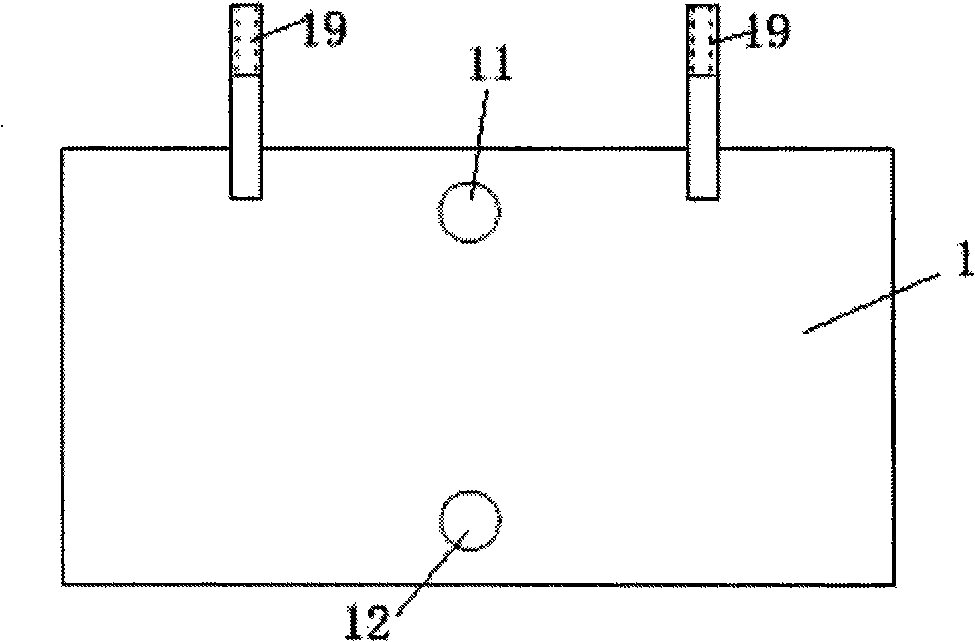

Hydrogen-oxygen mixed gas generator

The present invention discloses a hydrogen-oxygen mixed gas generator, including electrolytic tank combined by a plurality of electrolytic chambers connecting in series, the electrolytic chamber is cut into a plurality of small electrolytic chambers by a plurality of polar plates, on which is provided with rhombic concave-convex groove; positive and negative polar plate of the electrolytic tank is connected with corresponding electrode of the electrolysing power supply; top of the electrolytic chamber is arranged with vent-pipe which connecting to gas busbar, air-out end of the gas busbar is connected with built-in water block, which is connected with external water block via airway; external side of the electrolytic chamber is arranged with cooling cycle apparatus. Employing multi-chamber electrolysis can make full use of electric energy efficiency, and heating dissipating impression of the water-cooling circulating device set outside the electrolytic tank is obvious, improving quality of hydrogen-oxygen mixture, assuring stabilization of working level, assuring use impression of long time machine opening. The electrolytic tank of entrails uses easily broken bubbles, and electrode plate of concave-convex rough groovy for increasing electrolysis effective area, large gas production.

Owner:广州中氢能源科技有限公司

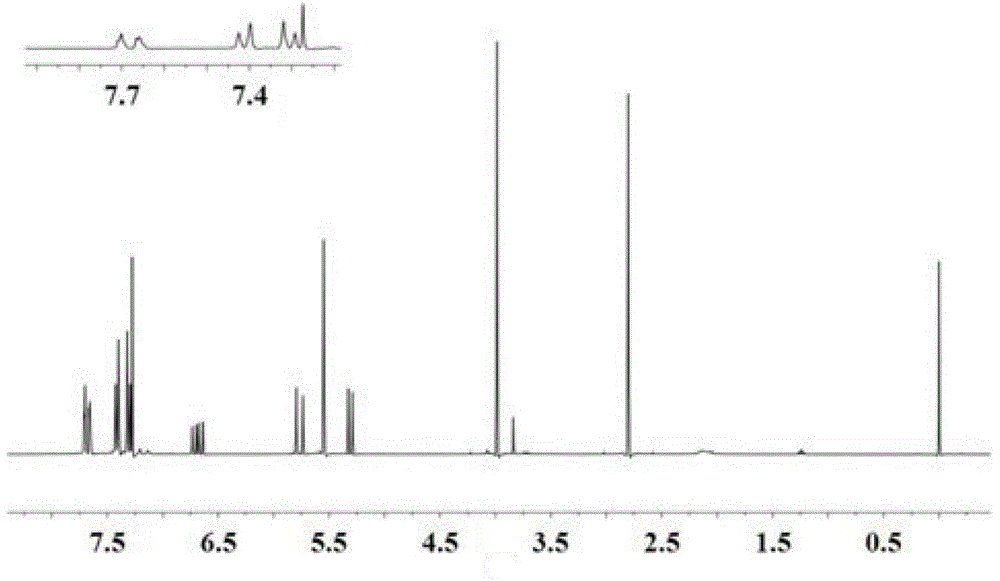

Imidazolyl ionic liquid and application thereof in alkaline anion exchange membrane

ActiveCN104447560AImprove stabilityOpen loop degradationOrganic chemistryFinal product manufactureCross-linkAlcohol fuel

The invention relates to an imidazolyl ionic liquid and preparation of an alkaline anion exchange membrane with the same. The preparation includes the following three steps: synthesis of an imidazolium salt, synthesis of imidazolyl cross-linked copolymer, and preparation of an imidazolyl cross-linked type alkaline anion exchange membrane, and at the same time on the basis, the step of preparation of an oxyhydrogen type imidazolyl cross-linked alkaline anion exchange membrane can be added so as to further improve the conductivity of the membrane. The ionic liquid involved in the invention substitutes the 2-position of an imidazole ring, thus avoiding imidazole group ring opening and degradation occurring under the attack of hydroxyl ions, and enhancing the stability of the imidazole group. And the method of applying the imidazolyl ionic liquid to preparation of the alkaline anion exchange membrane has the advantages of environmental friendliness, simple process, and can realize large-scale production. The prepared imidazolyl cross-linked alkaline anion exchange membrane has a uniform, smooth and compact surface, and has good conductivity, good thermal stability and chemical stability. By applying the alkaline anion exchange membrane to alkaline direct alcohol fuel cells, a single battery has the advantages of high performance, and obvious performance advantages, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

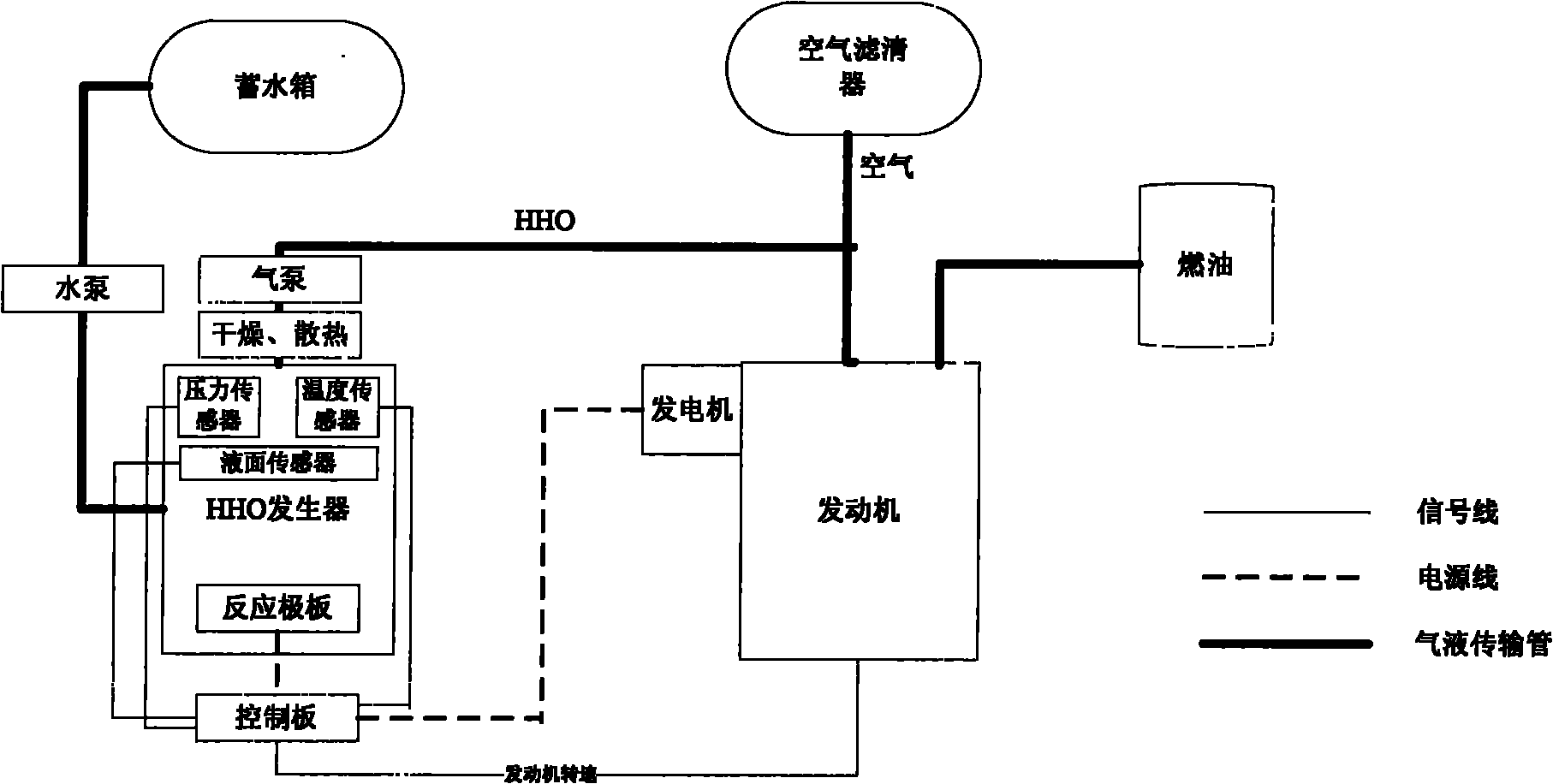

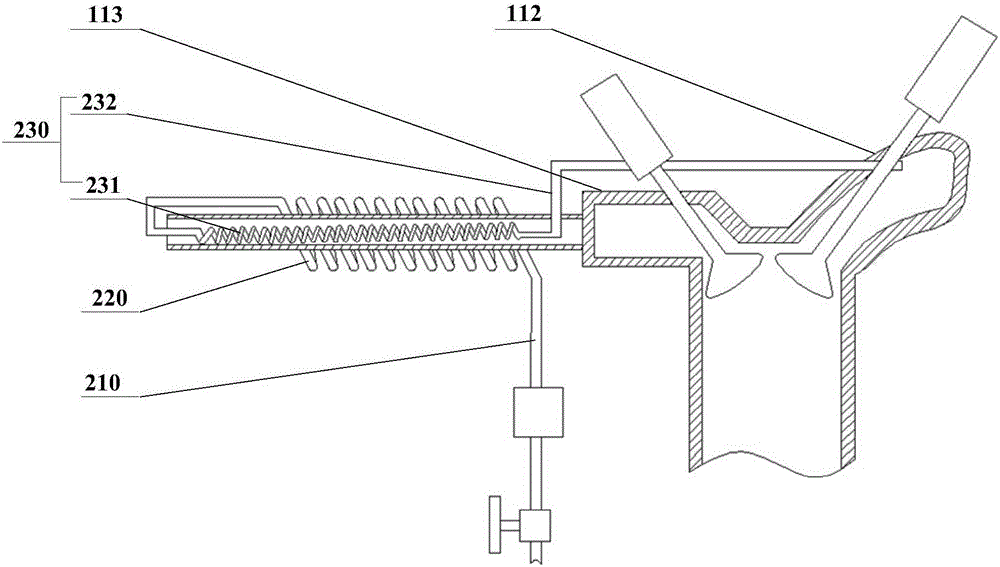

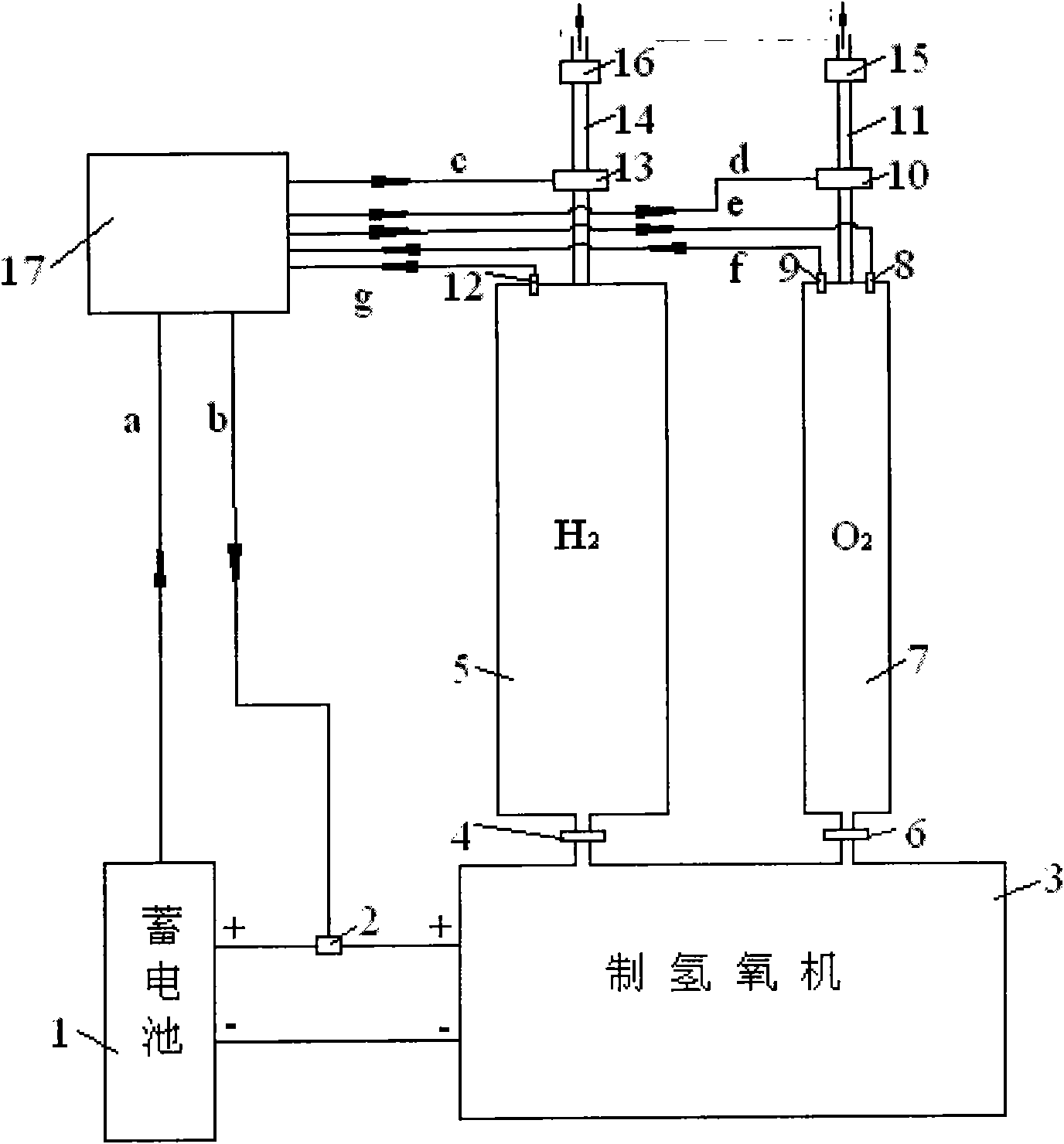

Device and method for producing oxyhydrogen through vehicle-mounted oxyhydrogen producer using residual electricity supplied by internal combustion engine

ActiveCN102128107AAvoid hazards such as flashbackImprove stabilityElectrolysis componentsInternal combustion piston enginesHydrogen pressureExternal combustion engine

The invention relates to a device and method for producing oxyhydrogen through a vehicle-mounted oxyhydrogen producer using residual electricity supplied by an internal combustion engine. The system keeps the entire main body and a control system of the original internal combustion engine, one set of vehicle-mounted oxyhydrogen producer control system and one set of oxyhydrogen production, storage and supply system are added. The device mainly comprises the vehicle-mounted oxyhydrogen producer, a hydrogen storage tank, a hydrogen pressure reducer, a hydrogen flame retarding valve, an oxygen storage tank, an oxygen pressure reducer, an oxygen flame retarding valve, a storage battery loop relay connected between the engine and a storage battery, an oxyhydrogen producer loop relay connected between the engine and the oxyhydrogen producer, an electronic control unit and the like, wherein the hydrogen storage tank, the hydrogen pressure reducer and the hydrogen flame retarding valve are connected with a hydrogen outlet of the vehicle-mounted oxyhydrogen producer; and the an oxygen storage tank, the oxygen pressure reducer and the oxygen flame retarding valve are connected with an oxygen outlet of the vehicle-mounted oxyhydrogen producer. The electronic control unit controls the operation of the oxyhydrogen producer according to the relationship between the engine and the voltage ofthe storage battery and the pressure of hydrogen and oxygen in the storage tanks, preferably ensures the charge of the storage battery and stops the operation of the oxyhydrogen producer when the gases in the hydrogen and oxygen storage tanks have overpressure.

Owner:南通秀丽环保科技发展中心(有限合伙)

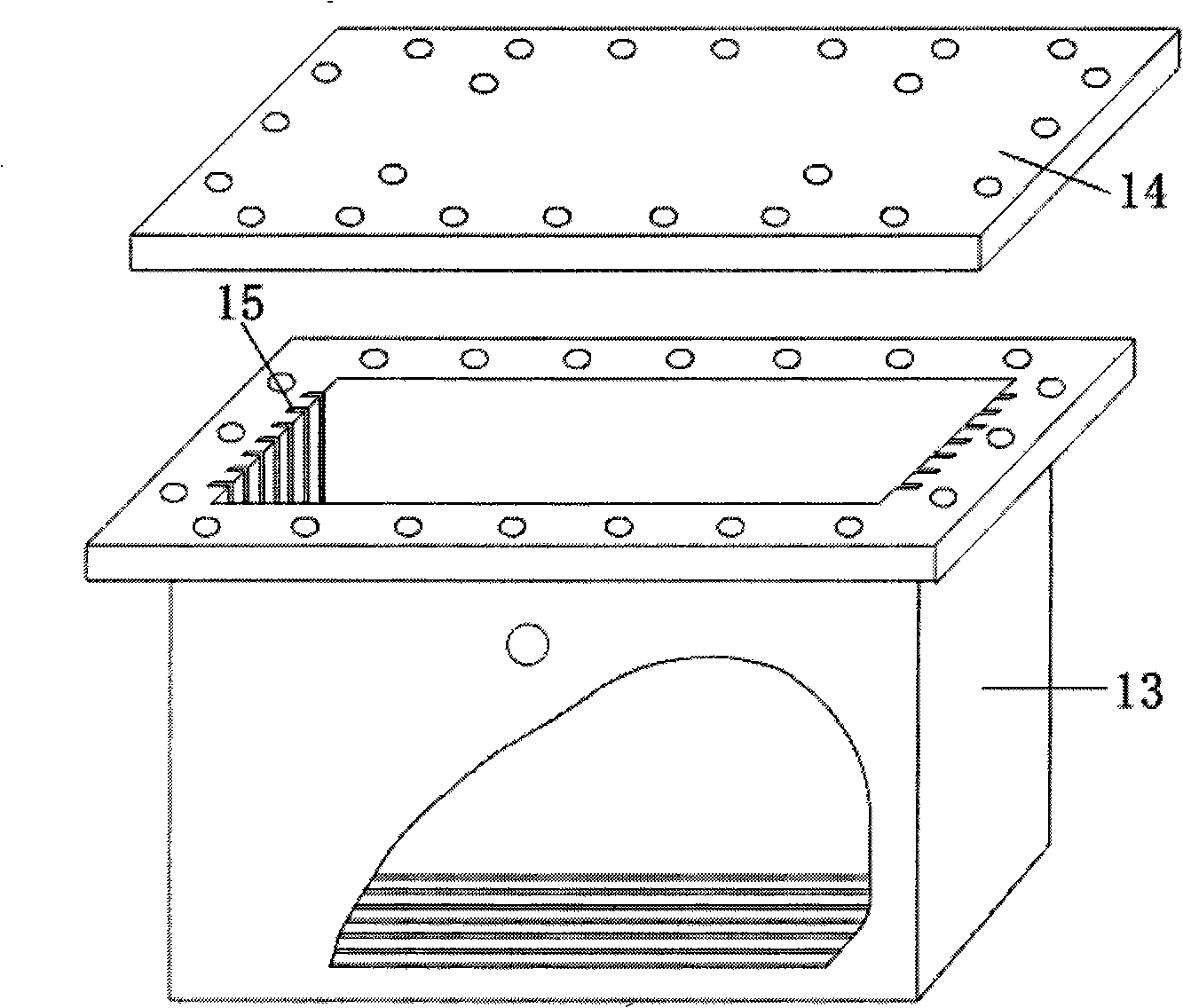

Hydrogen generator

InactiveCN103451671AChange designGive full play to work efficiencyElectrolysis componentsSignal onControl cell

The invention discloses a hydrogen generator comprising a hydrogen generating device and a controller part, wherein the controller comprises three phases of electricity respectively connected to input ends of a rectifying circuit and a switch power supply; output ends of the rectifying circuit and the switch power supply are respectively connected to input ends of a direct current switch circuit and an intelligent program control unit; the output end of the intelligent program control unit is connected with the hydrogen generating device through the direct current switch circuit; a current signal, a temperature signal and a pressure signal on the hydrogen generating device are connected with the intelligent program control unit; the hydrogen generating device comprises an electrolytic bath and a cooling system; heat exchangers are respectively arranged on two sides of the electrolytic bath; the heat exchangers are provided with inlets / outlets for circulating cooling water; the inlets / outlets of the heat exchangers, together a cooling system, form a circulating cooling system through pipelines and a water pump; an oxyhydrogen gas outlet is formed in the upper part the heat exchanger close to the electrolytic bath. The hydrogen generator, through organically combining the electrolytic bath and the cooling system, changes a normal direct current power supply way on an aspect of electric control.

Owner:侯艳杰

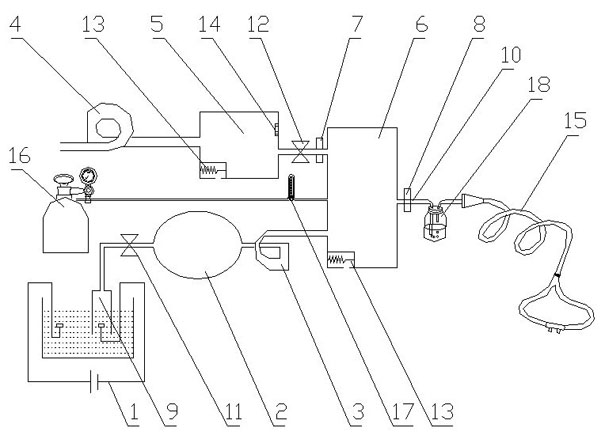

Micro-hydrogen injection energy-saving exhaust-reduction device of internal combustion engine

ActiveCN101403354ASuitability for useSuitable for maintenanceInternal combustion piston enginesNon-fuel substance addition to fuelElectrolysisExternal combustion engine

The invention relates to an energy conservation and emission reduction device for internal-combustion engine micro-hydrogen jet, which comprises an oxyhydrogen electrolysis pool, an electrolyte reservoir, a current pulse width modulation volume control and safety protection circuit, a gas washing tank, a water seal anti-backfire pot, a generator and a multiple-connected battery; the current pulse width modulation volume control and safety protection circuit and the positive and negative electrodes of a conductive electrode plate of the oxyhydrogen electrolysis pool are connected into a loop; the case of the oxyhydrogen electrolysis pool is provided with two holes, and pipelines led out of the two holes of the oxyhydrogen electrolysis pool are sequentially connected with the electrolyte reservoir, the gas washing tank, the water seal anti-backfire tank and an internal-combustion engine. The device injects the mixed oxyhydrogen gas after water electrolysis into a combustion chamber of the internal-combustion engine to accelerate fuel oil or fuel gas combustion and realizes the full combustion of the fuel oil or fuel gas, thus improving the thermal efficiency, reducing the consumption of the fuel oil or fuel gas, and reducing the emissions of greenhouse gases, harmful gases and solid particles. The device is used for various vehicles, ships, generator sets and the like which take the internal-combustion engine as power.

Owner:WUHAN MICRO HYDROGEN NEW ENERGY CO LTD

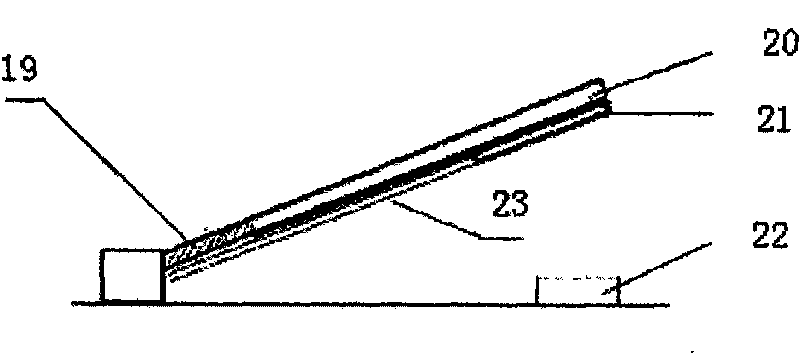

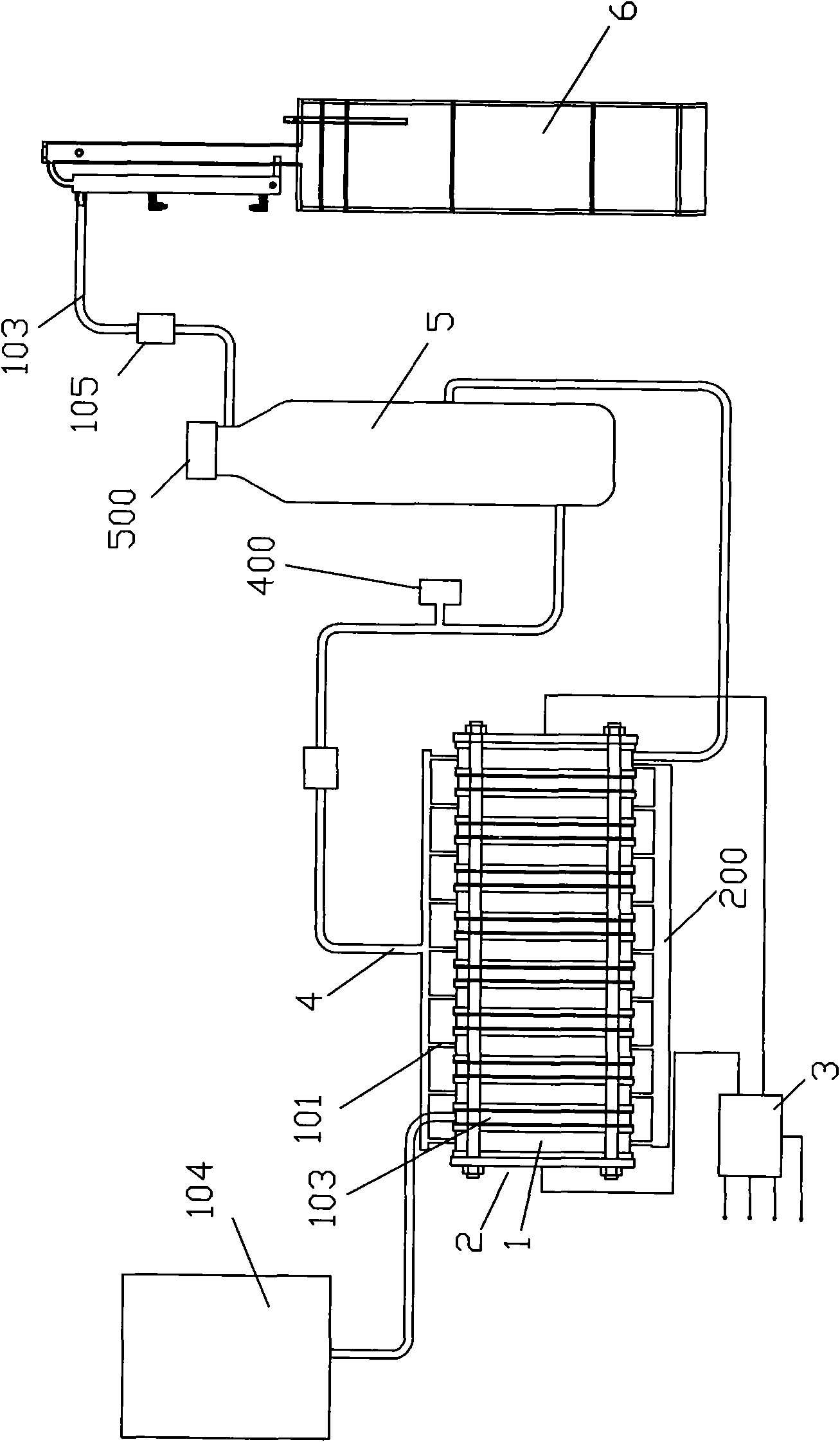

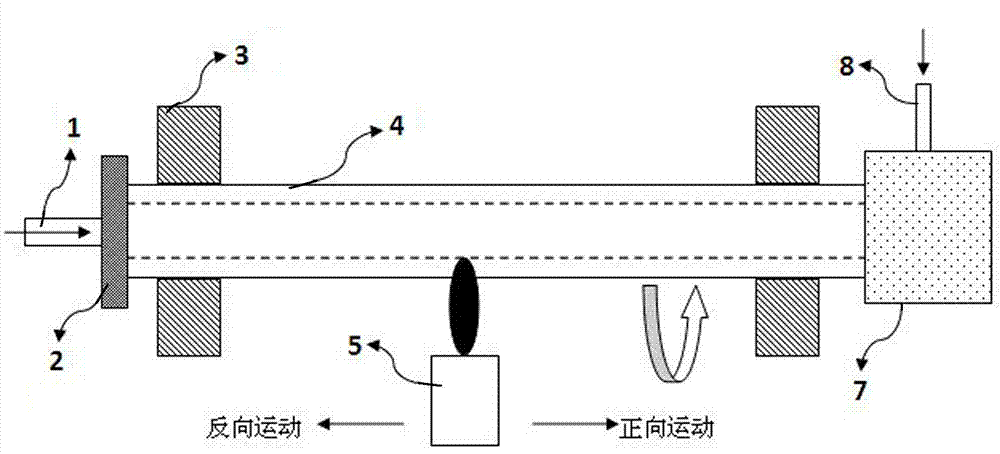

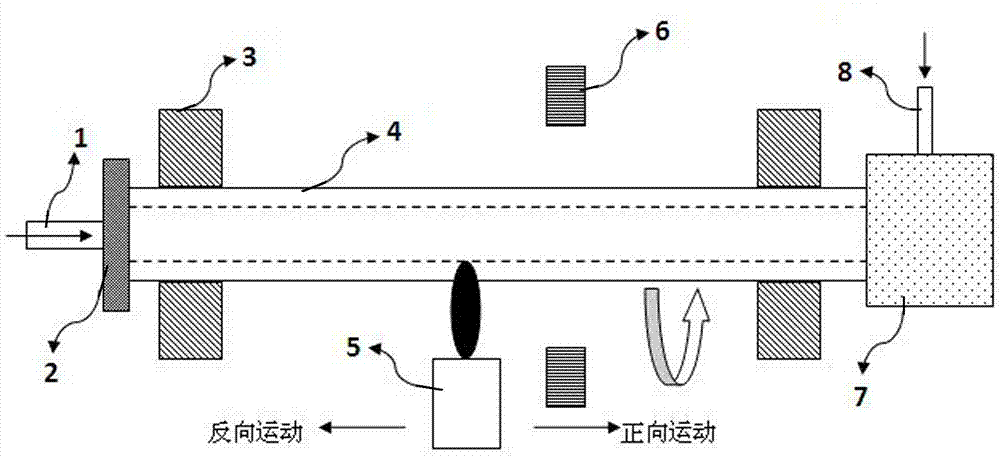

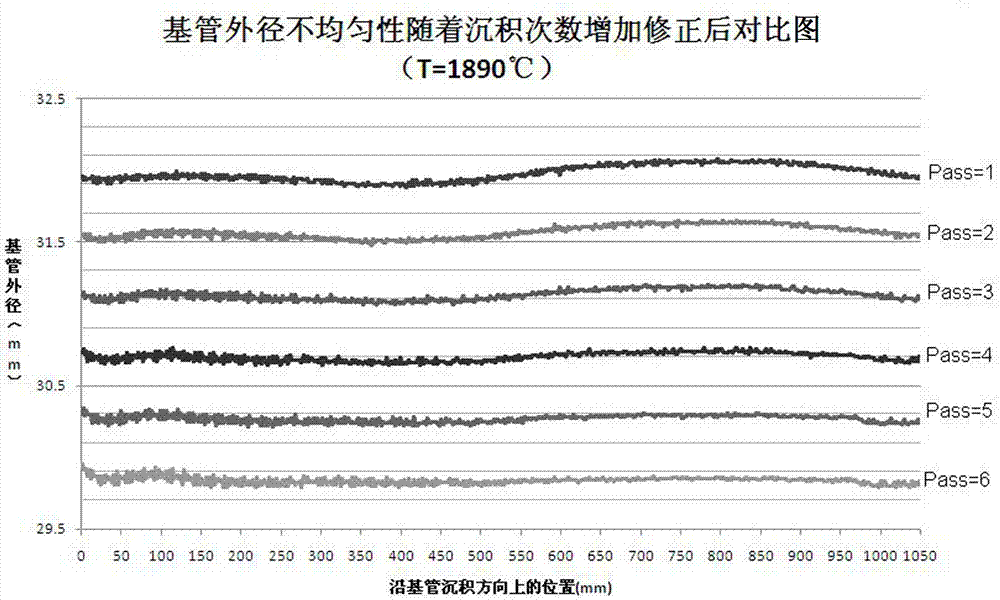

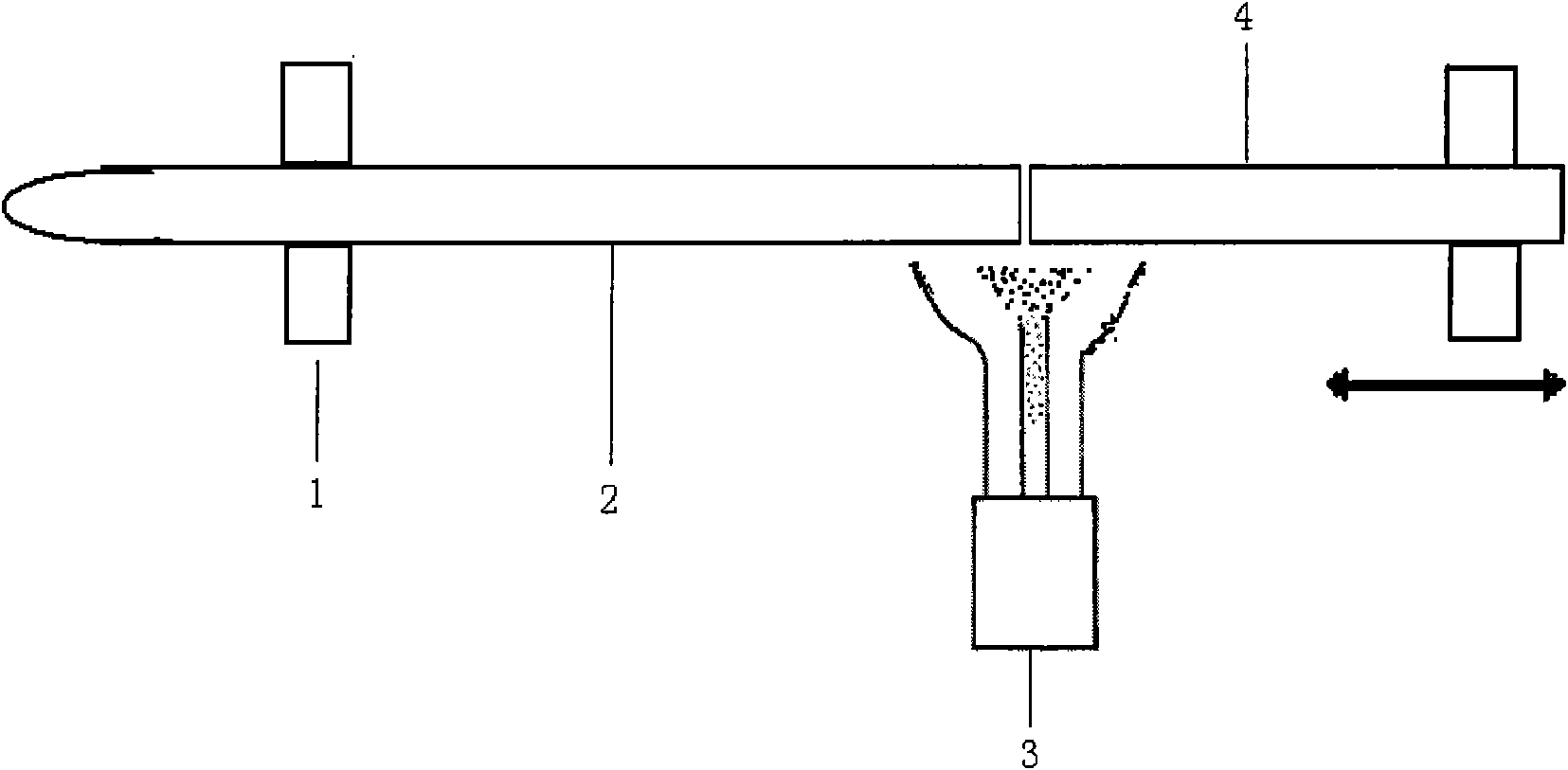

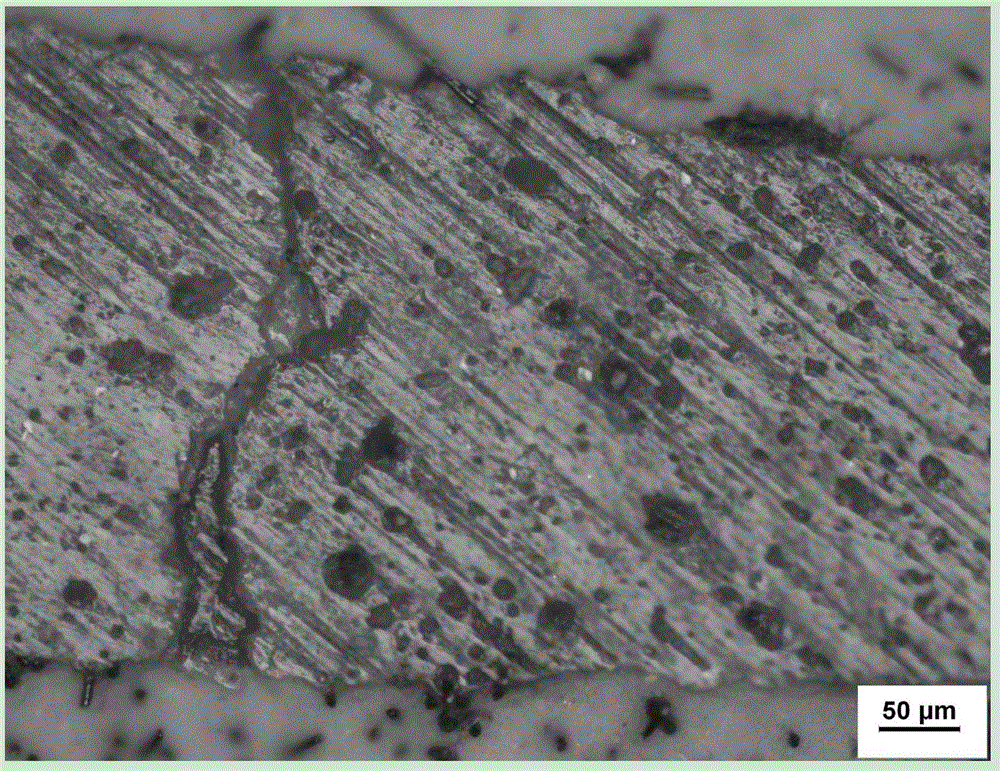

Device for manufacturing prefabricated optical fiber core rod based on base pipe outer diameter maintaining and correcting control and method for manufacturing prefabricated optical fiber core rod by device

ActiveCN103922579AReduce or even eliminate hydroxyl contentReduce biasGlass making apparatusGas phaseNitrogen

The invention relates to a device for manufacturing a prefabricated optical fiber core rod based on base pipe outer diameter maintaining and correcting control and a method for manufacturing the prefabricated optical fiber core rod by the device. In an improved chemical vapor deposition process, the correction of the axial outer diameter change and the maintenance of the outer diameter uniformity and the roundness of a base pipe are realized by controlling the outer diameter of the base pipe during deposition at the high temperature, so that the uniformity of the axial and radial deposition rates is ensured, and the manufactured core rod and a drawn optical fiber have uniform radial and axial geometric characteristics and refractivity profiles. The device comprises a raw material feeding pipeline, a rotary connector, a chuck, a quartz base pipe, an oxyhydrogen flame blow lamp, an outer diameter measurement instrument, a waste residue collection box and a nitrogen pipeline, wherein the raw material feeding pipeline is connected with the rotary connector and is mounted in the quartz base pipe on the chuck of a lathe during chemical vapor deposition; the outer diameter measurement instrument is mounted on a base of the oxyhydrogen flame blow lamp; the waste residue collection box is mounted at the tail end of the chuck of the lathe during chemical vapor deposition; the nitrogen pipeline is connected to the waste residue collection box.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

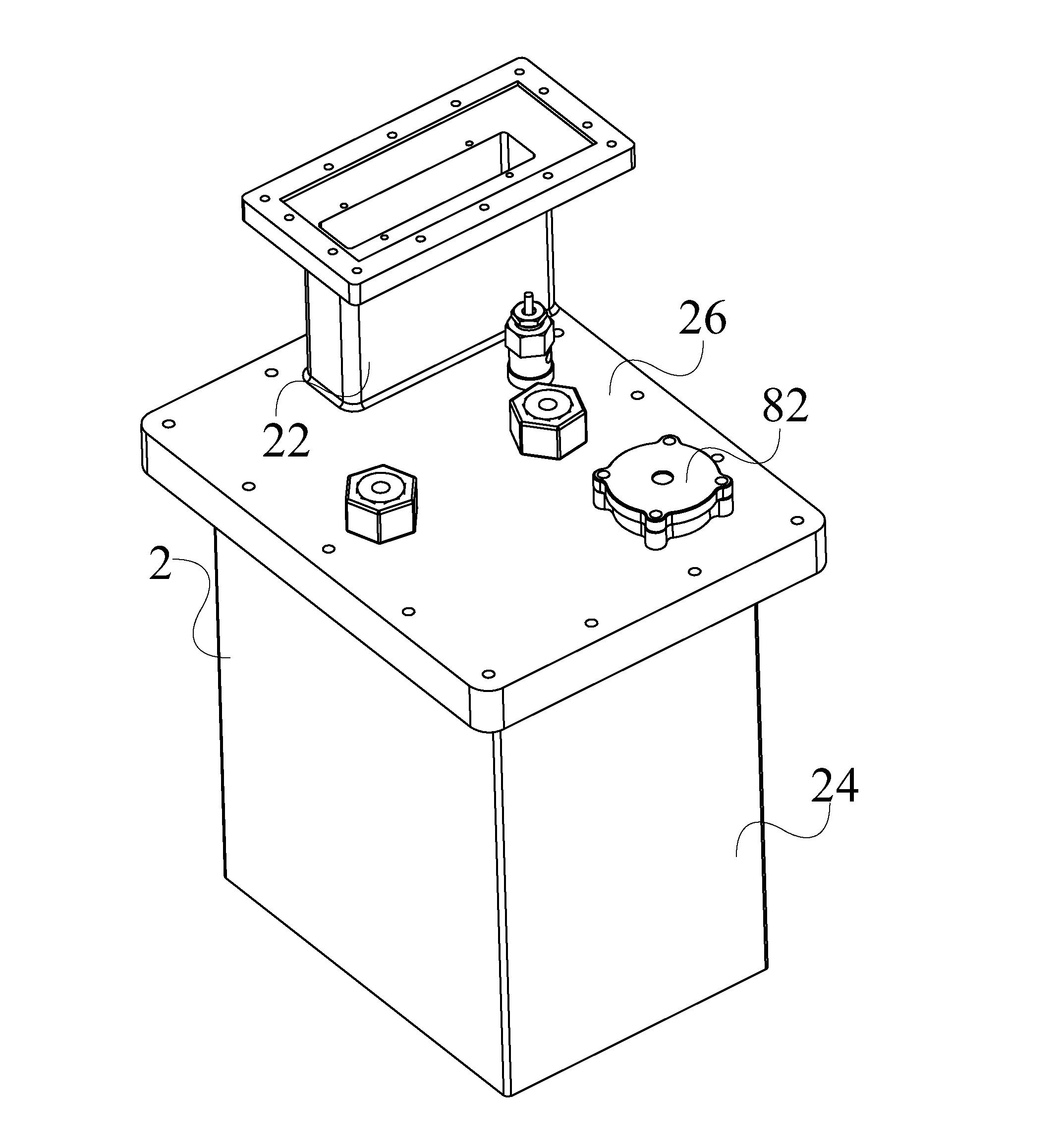

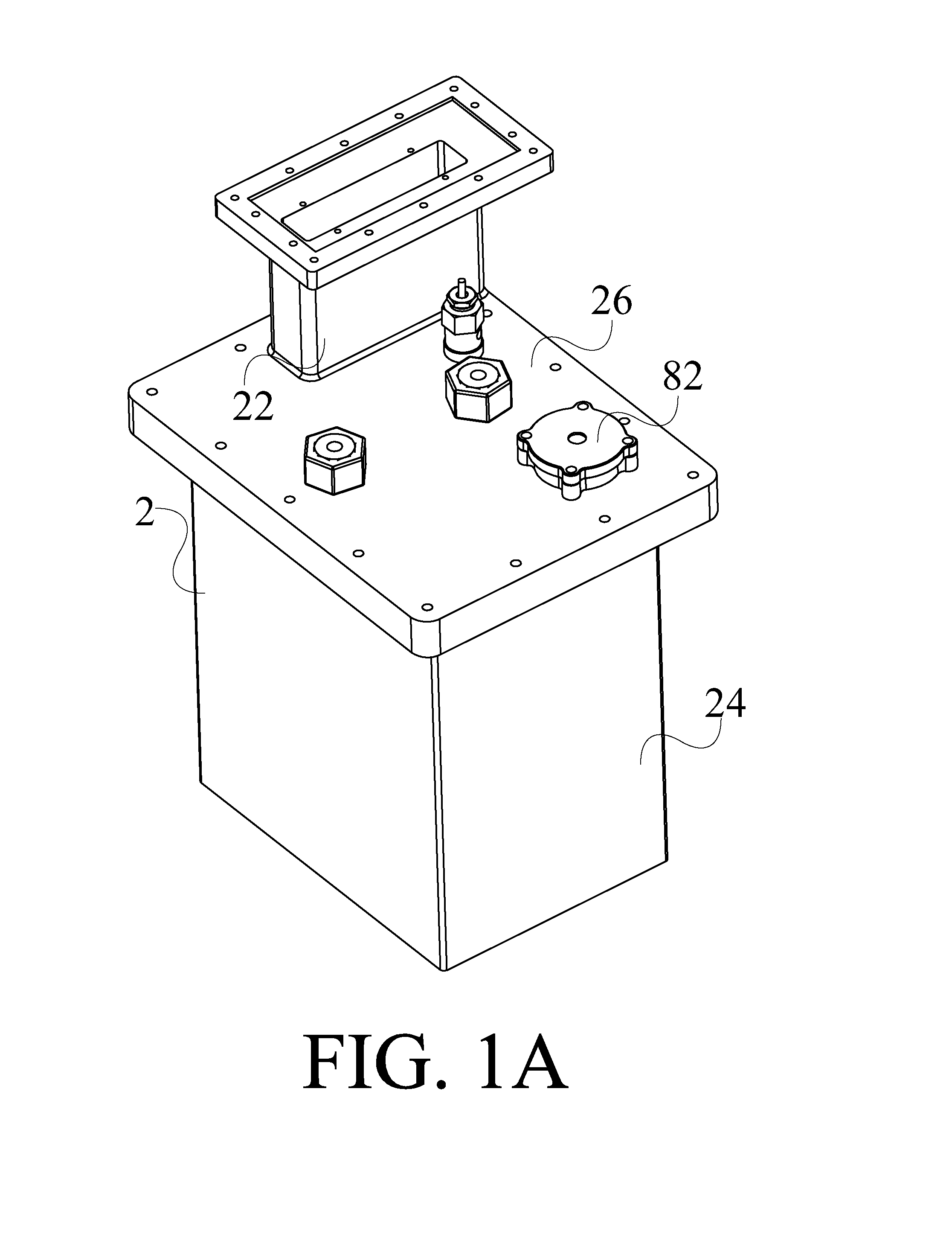

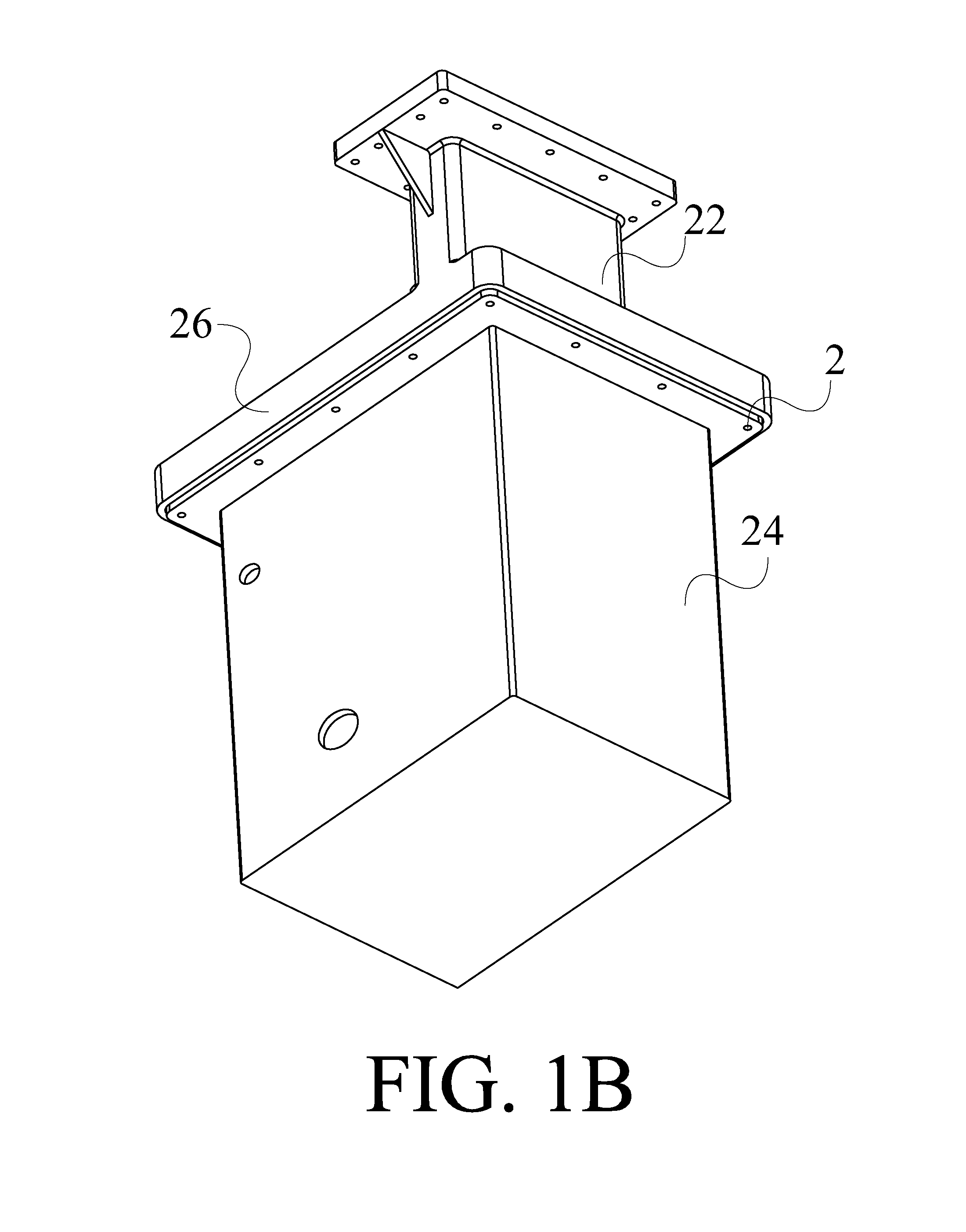

Gas generator

The present invention provides a gas generator, comprising a water tank and an electrolysis device. The water tank has a first hollow portion for containing electrolyzed water. The electrolysis device is disposed inside the first hollow portion of the water tank for electrolyzing the electrolyzed water to generate a hydrogen-oxygen mixed gas. When the electrolysis device starts to electrolyze the electrolyzed water, the first hollow portion of the water tank is filled with the electrolyzed water for standing at a full level of water. And after the electrolysis device electrolyzed the electrolyzed water, the level of water for the electrolyzed water filled into the first hollow portion of the water tank is higher than 95% of the full level of water. The gas generator of the present invention provides the design for saving space and nearly a zero gas chamber to reduce the possibility of explosions resulting from hydrogen-oxygen mixed gas.

Owner:LIN HSIN YUNG

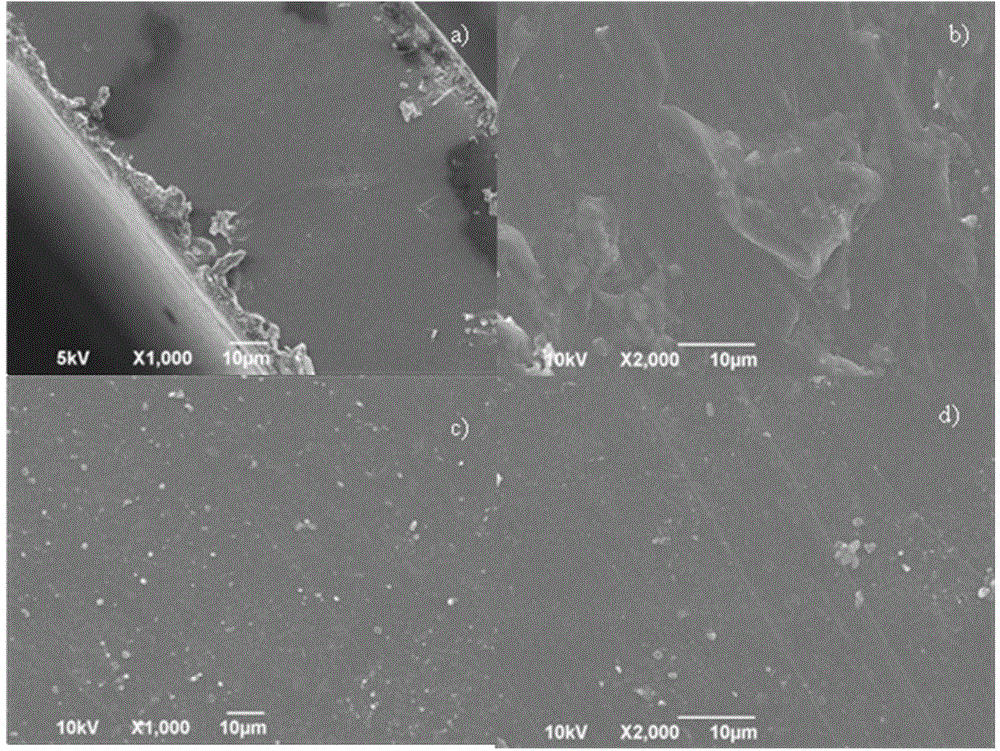

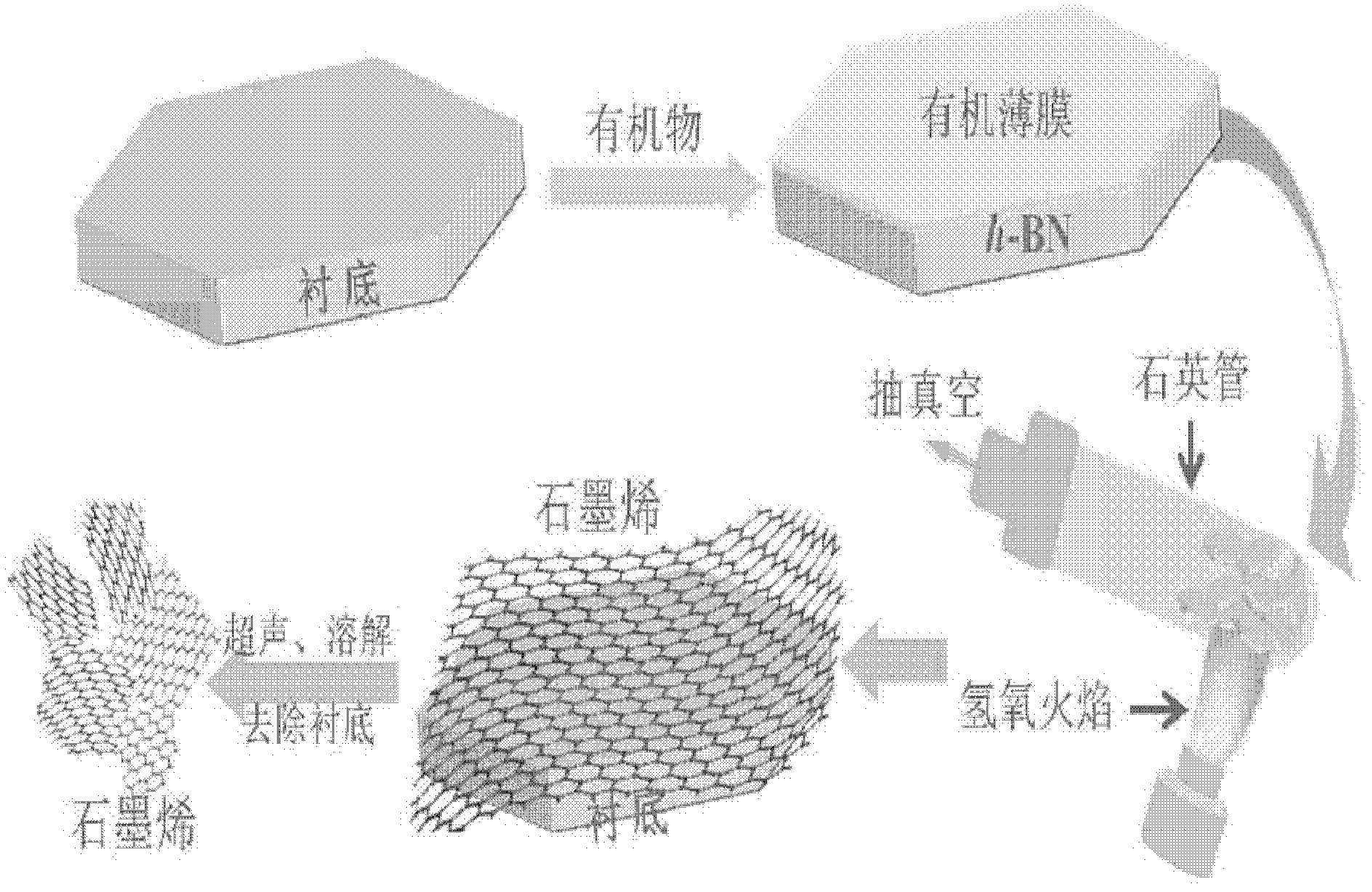

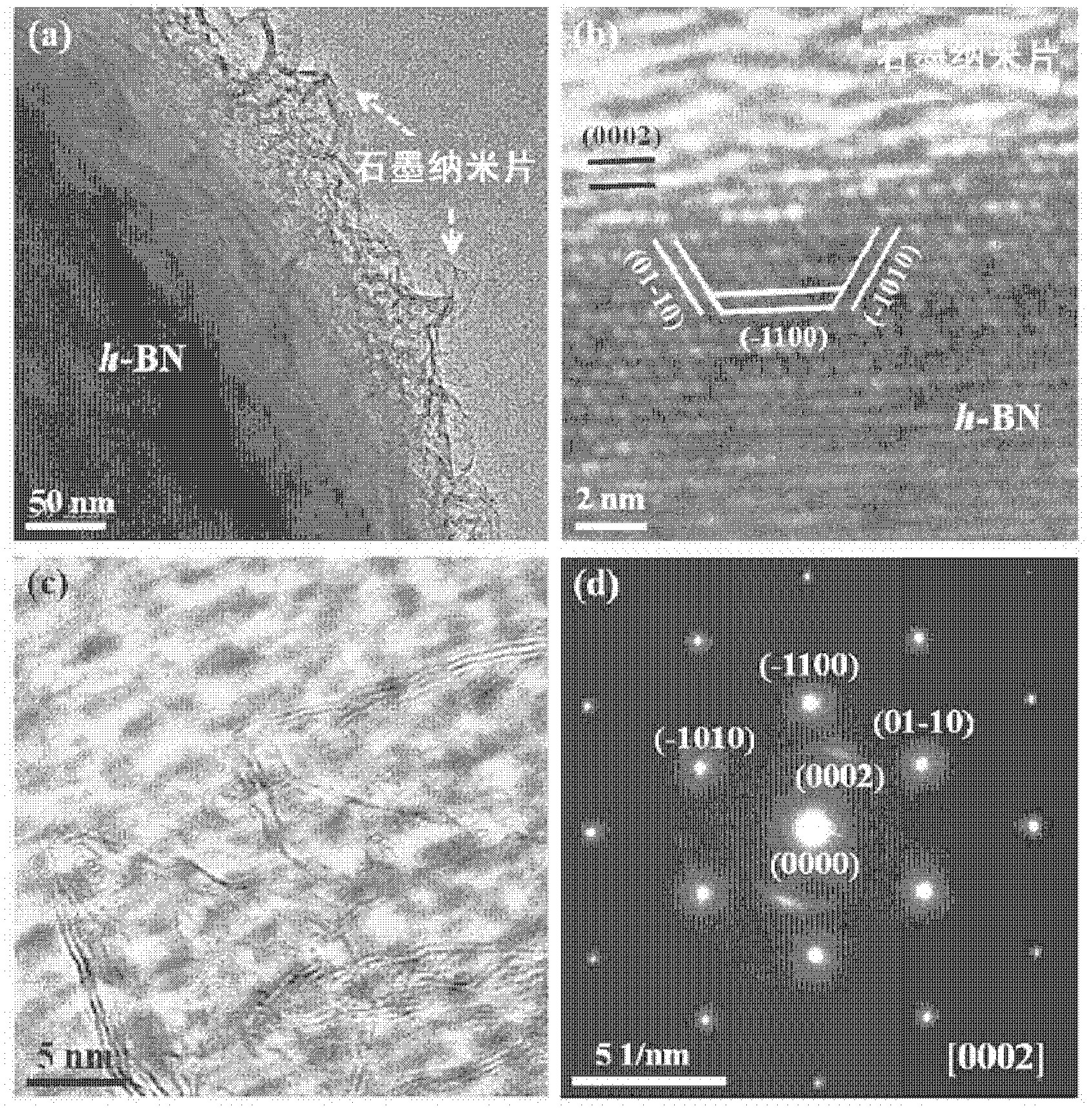

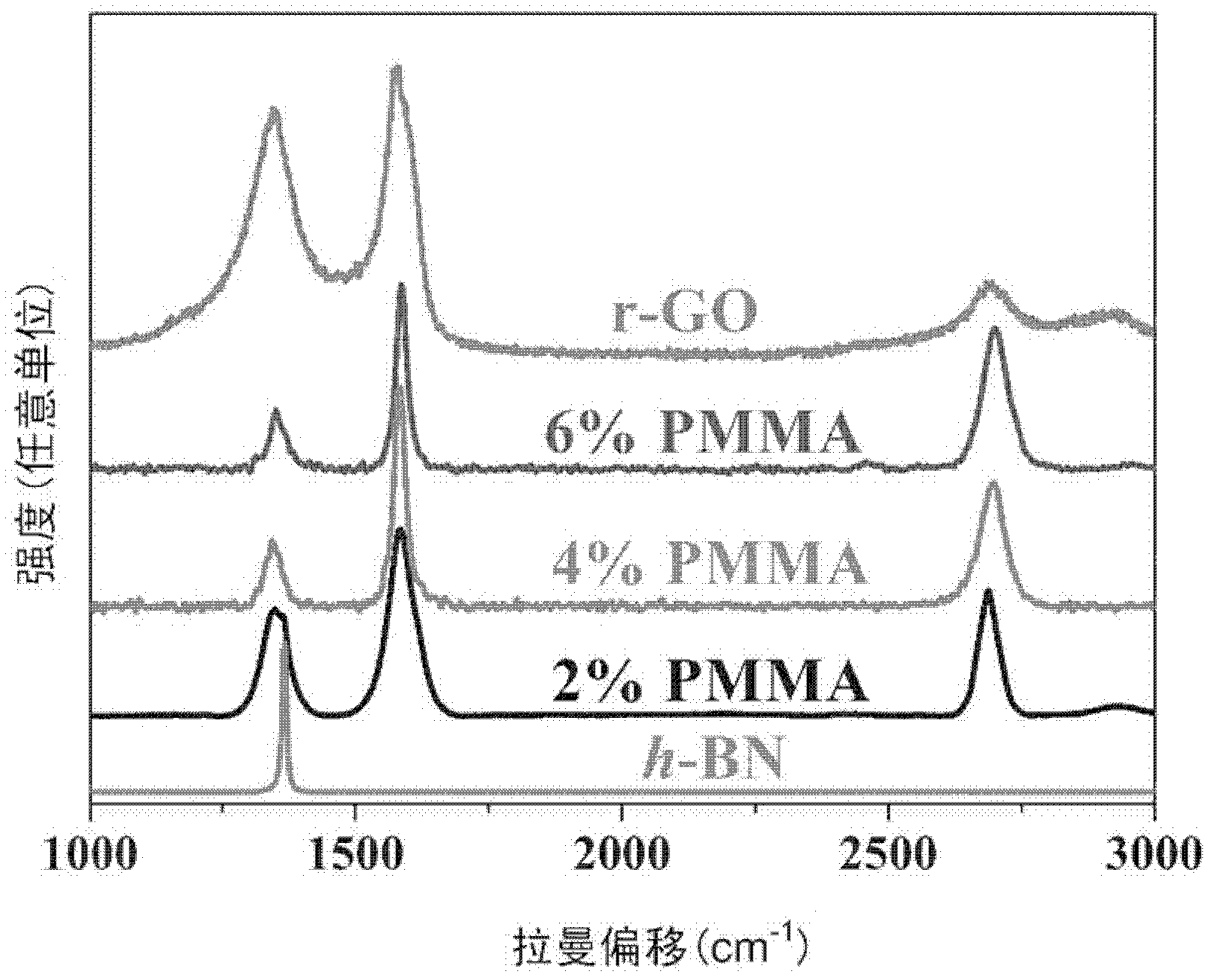

Method for preparing graphene powder and graphene transparent conductive film by oxyhydrogen flame method

The invention discloses a method for preparing high-quality graphene powder and a graphene transparent conductive film. The method comprises that through an oxyhydrogen flame rapid heating method, organics are decomposed into high-activity carbon atoms; and the high-activity carbon atoms are re-configurated into graphene on an insulating substrate or a catalyst substrate. Through the method, high-quality graphene can directly grow on the insulating substrate, and through an ultrasonic method, high-quality graphene powder without a support substrate is obtained. Compared with the traditional chemical stripping method for preparing graphene, the method has simple processes, a low cost, less defects and good conductivity and can produce high-quality graphene. The method can be used for preparing the graphene transparent conductive film on a catalyst film substrate. The graphene transparent conductive film has quality and conductivity approximate to the optimal values of a graphene transparent conductive film obtained by the traditional CVD method. Graphene obtained by the method has wide application prospects in fields of photoelectric devices such as copper indium gallium diselenide, cadmium telluride and dye-sensitized solar cells, panel displays, super capacitors, field emission materials, and lithium ion batteries.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing a microgap sleeve optical fiber prefabrication bar and method for drawing and preparing an optical fiber by microgap sleeve optical fiber prefabrication bar

ActiveCN101538113AThere will be no uneven shrinkageStable cladding geometryGlass fibre drawing apparatusGlass productionHydrofluoric acidMicro gap

The invention discloses a method for preparing a microgap sleeve optical fiber prefabrication bar and a method for drawing and preparing an optical fiber by the microgap sleeve optical fiber prefabrication bar and relates to the production of an optical fiber prefabrication bar and a method for drawing the wire by the optical fiber prefabrication bar. The method for preparing the microgap sleeve optical fiber prefabrication bar comprises the following steps: 1) a joint handle adopts a glass lathe and uses oxyhydrogen flame for separately abutting a core bar, a handle bar, a sleeve and a tail handle end face after high-temperature melting; 2) the joint handle is cleaned and dried, and 2-3 percent of hydrofluoric acid is used for cleaning the surfaces of the core bar and the sleeve for 2 hours so as to remove pollutants on the surfaces; and 3) in the assembly process, the cleaned and dried core bar is assembled into the sleeve, and then quartz sand is filled between the sleeve and the core bar so as to obtain the microgap prefabrication bar. The microgap sleeve optical fiber prefabrication bar is fixed on a collet of an optical fiber wire drawing tower and then molten so that an optical fiber can be drawn out from a lower opening of a wire-drawing stove and then is sequentially measured in diameter by a diameter measurer, cooled by a cooling pipe, coated, solidified by optical fiber coating and drawn by a main drawing device so as to reach a double-wire-collecting machine for optical fiber winding.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

Silica tube for growing semi-insulated gallium arsenide and method for doping carbon in gallium arsenide

InactiveCN101603208AGood electrical uniformityC concentration is easy to controlPolycrystalline material growthDiffusion/dopingCrucibleGraphite

The invention relates to a method for doping carbon in the gallium arsenide by using a silica tube for growing semi-insulated gallium arsenide. The method comprises the following steps: step 1: polycrystally synthesizing 7N Ga and 7N As to form a GaAs polycrystal; step 2: putting the synthesized GaAs polycrystal, seed crystal and B2O3 in a PBN crucible; step 3: putting the PBN crucible in a quartz body of the silica tube; step 4: fixing pure graphite in a silica groove on a silica cap of the silica tube; step 5: covering the quartz body and the silica cap, vacuumizing and welding the quartz body and the silica cap of the silica tube on oxyhydrogen flame; step 6: putting the welded silica tube in a VGF single crystal furnace for atmosphere doping and single crystal growth; and step 7: soaking the PBN crucible in methanol after the single crystal growth to obtain a GaAs single crystal and finish the preparation of the GaAs single crystal.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Ceramic/ceramic connection method for regulating and controlling middle solder layer through multi-physical-field coupling

Provided is a ceramic / ceramic connection method for regulating and controlling a middle solder layer through multi-physical-field coupling. According to the ceramic / ceramic connection method, a heat source is adopted to fuse solder or solder and a part of base metal, meanwhile physical fields are additionally applied, the solder is a non-crystalline material or a mixed material of the non-crystalline material and a reinforcement phase, an outer heating source is acetylene flame or oxyhydrogen flame, electric arcs, laser, electron beams or a resistance heating method for melting metal through heat conduction and heat radiation is adopted, and the additionally-applied physical fields are one or more than two of ultrasonic waves, magnetic fields and electric fields which are simultaneously applied. The ceramic / ceramic connection method has the advantages of effectively controlling interface reaction, strengthening liquid metal flowing, regulating and controlling weld joint substance distribution, regulating the metallurgical welding process, controlling a weld joint organization structure, eliminating weld joint defects, reducing residual waste heat stress, improving weld joint toughness, promoting interface bonding, improving the mechanical property of welded joints, decreasing the material using amount and reducing environmental pollution through the additionally-applied physical fields and being widely applied to the fields of aviation, aerospace, electronic devices, fuel cells and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

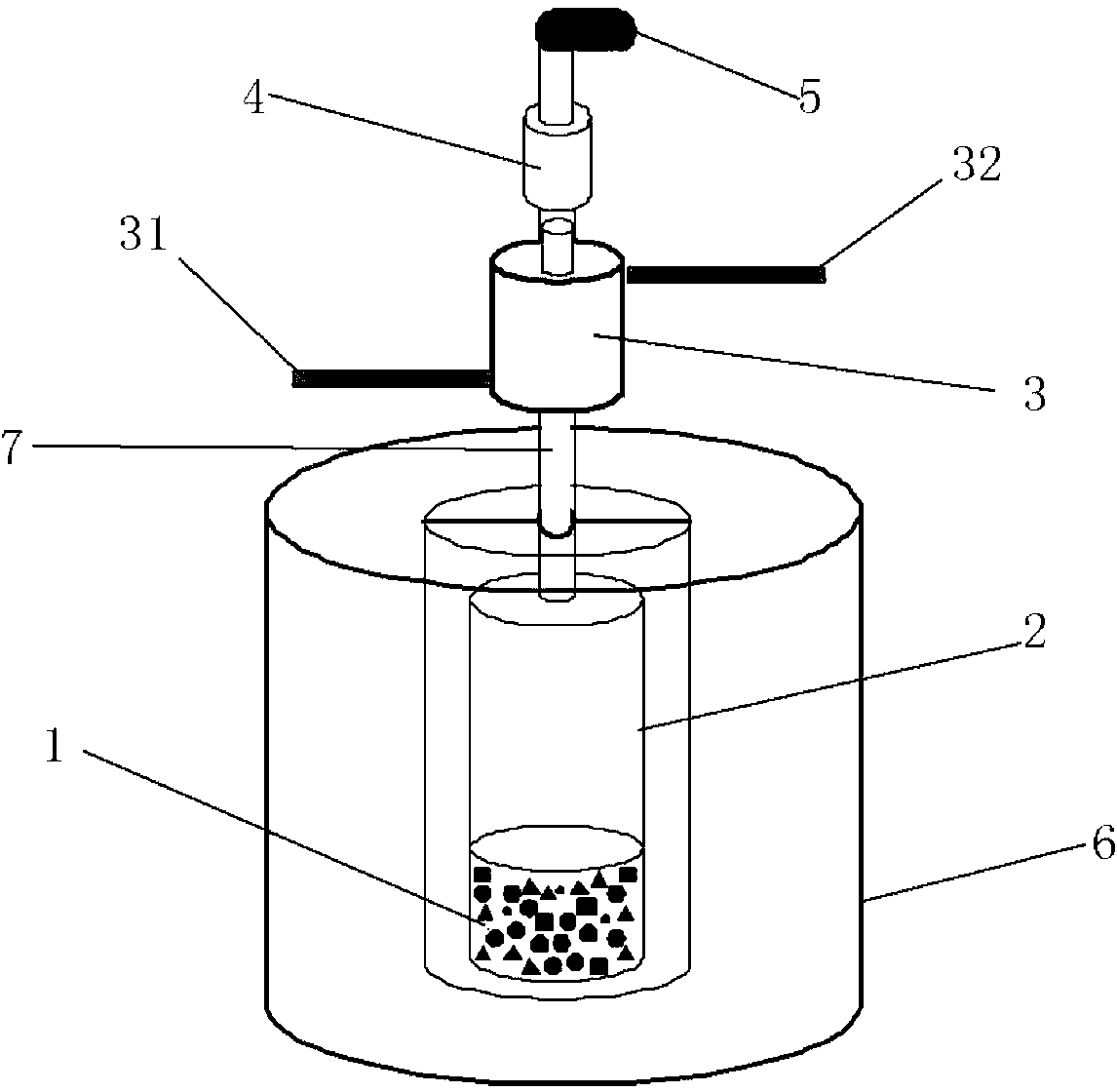

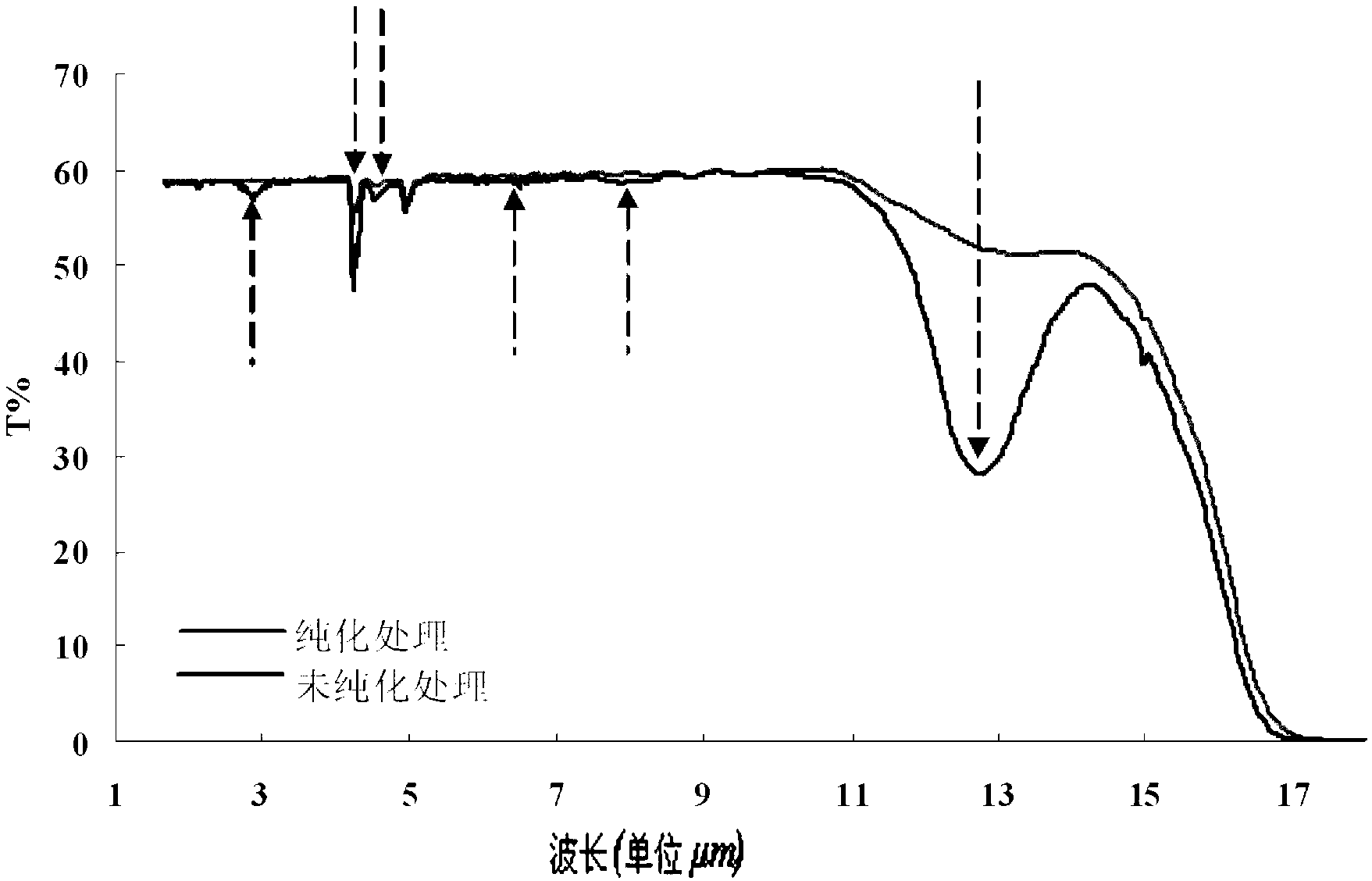

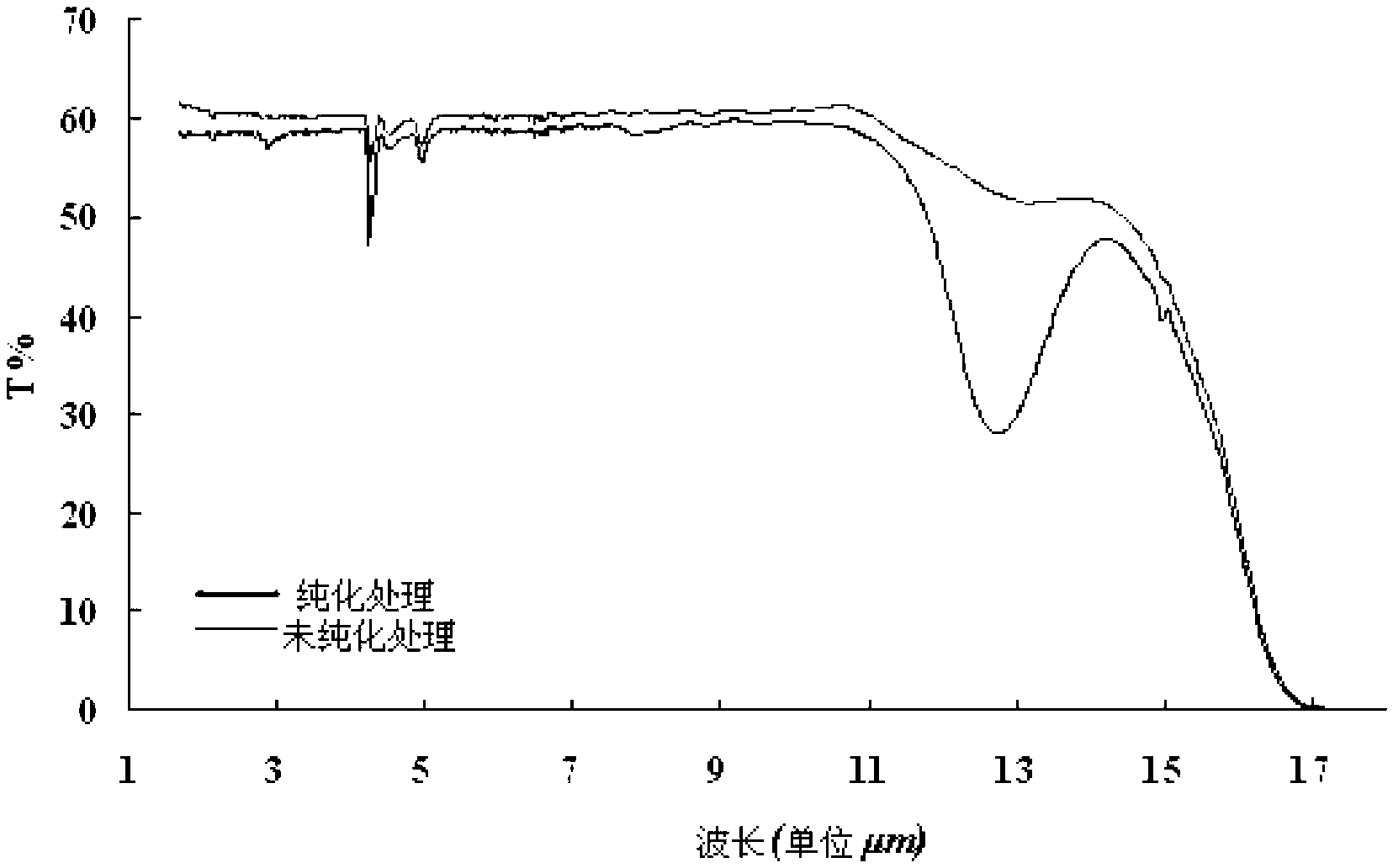

Purification method for preparing high-purity infrared chalcogenide glass, and apparatus thereof

The invention discloses a purification method for preparing high-purity infrared chalcogenide glass, and an apparatus thereof. The purification method comprises the following steps: 1, fully mixing a chalcogenide glass raw material and a deoxidant to obtain a mixture, placing the mixture in a quartz ampoule, and pre-evacuating the quartz ampoule until the vacuum degree is less than or equal to 5*10<-4>Pa; 2, placing the evacuated quartz ampoule in a purifying furnace, carrying out raw material entirety purification at 200-400DEG C for 1-6h, and cooling the portions of the quartz ampoule outside the purifying furnace for solidifying volatile components; and 3, cooling the quartz ampoule to room temperature after the purification is completed, carrying out 900-950DEG C high-temperature melting of the quartz ampoule melt-sealed by the oxyhydrogen flame in a rocking furnace, carrying out heat insulation for 6-20h, cooling to 500-650DEG C, and quenching to obtain a chalcogenide glass blank. The method can effectively eliminate impurity peaks in a 1-13mum infrared area range of the chalcogenide glass.

Owner:CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com