Hydrogen-oxygen mixed gas generator

A technology of mixed gas and generator, which is applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of small net electrolysis area of plates, increased electrolysis speed, low electricity utilization rate, etc., and achieves great heat dissipation effect, The effect of improving quality and increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

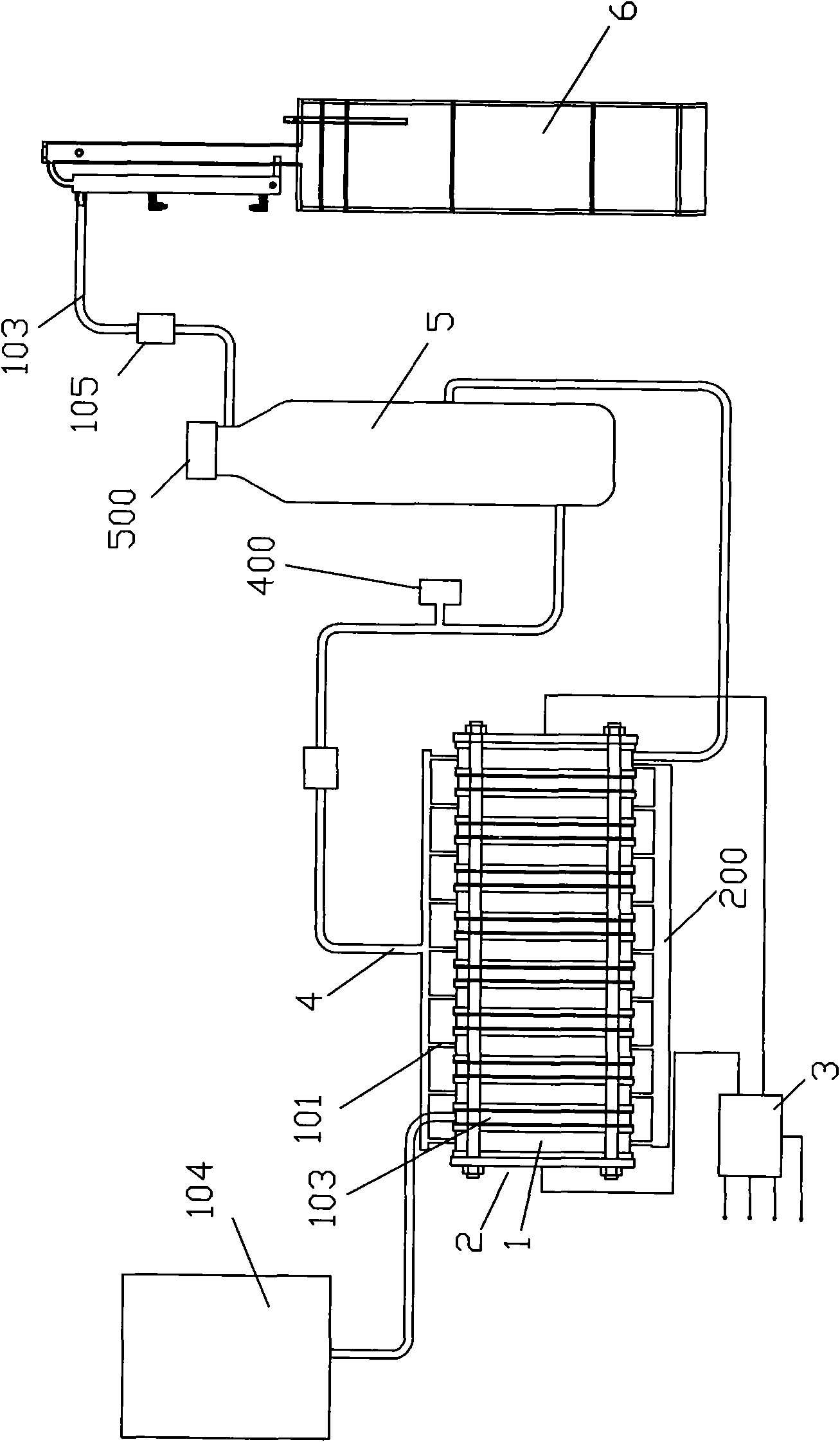

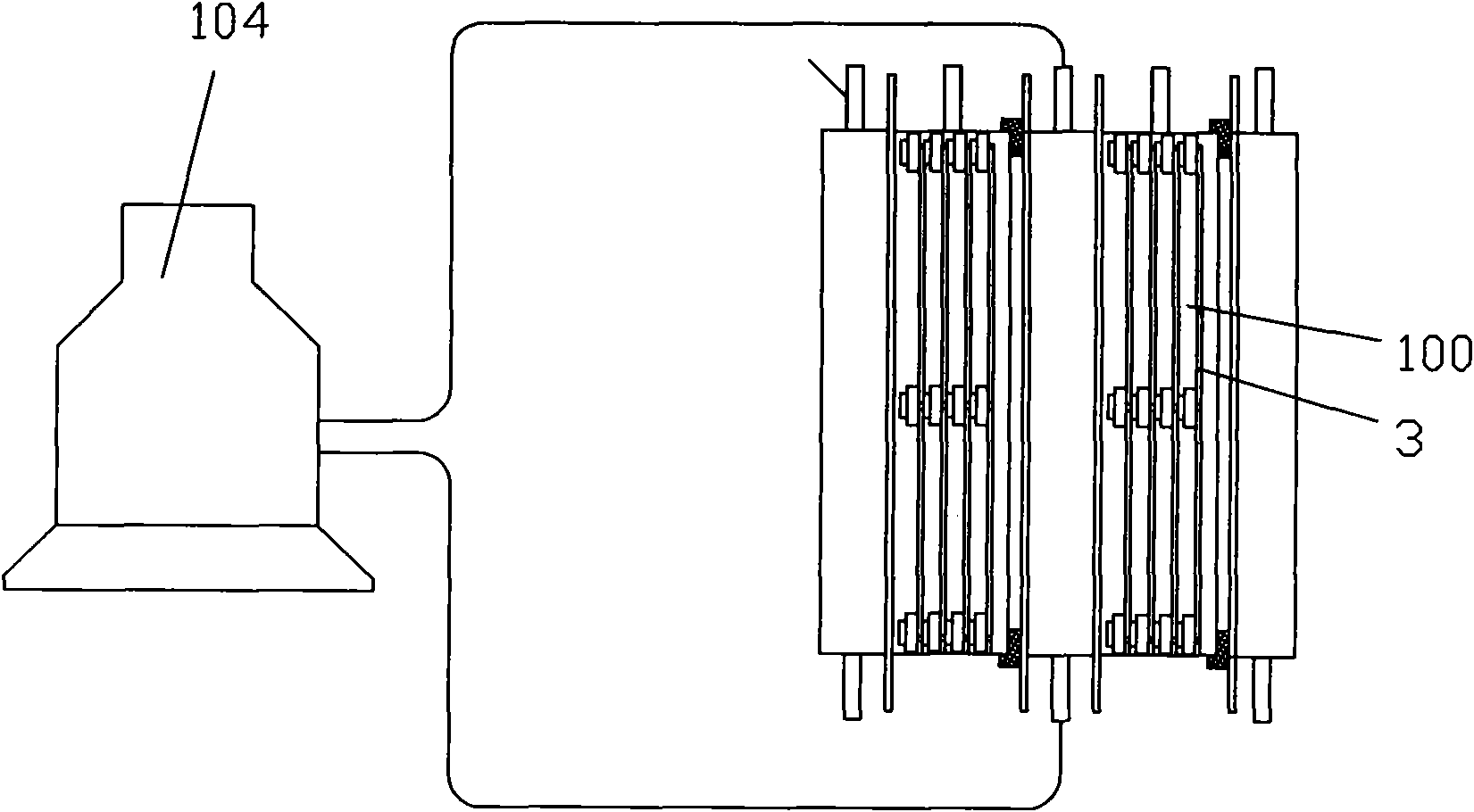

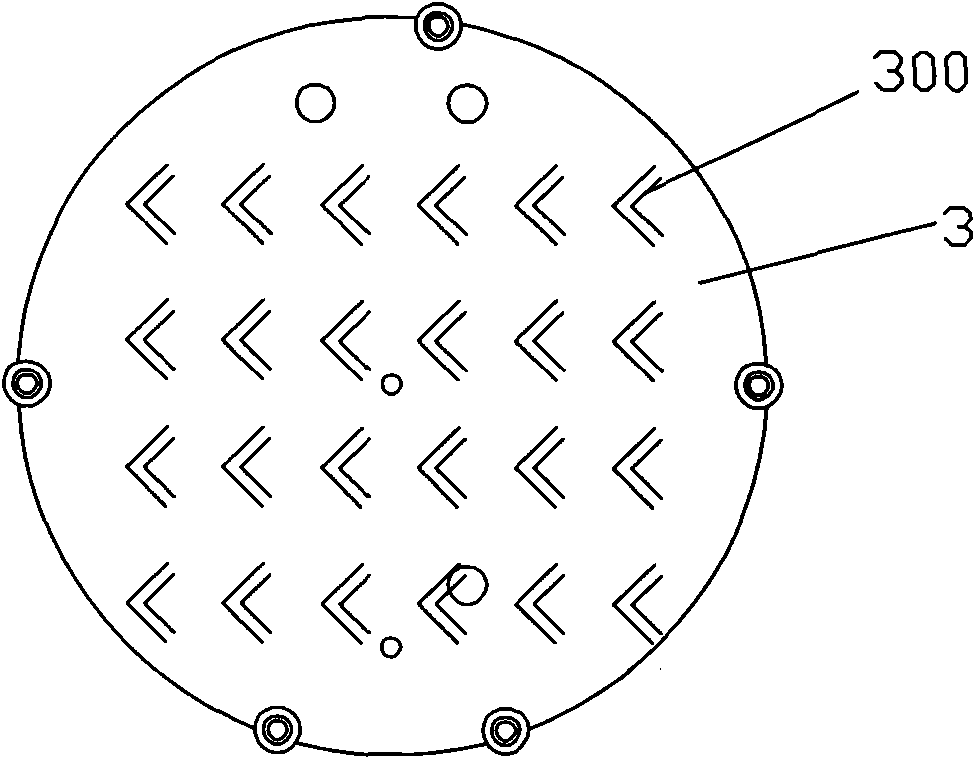

[0016] refer to figure 1 , figure 2 , a hydrogen-oxygen mixed gas generator, including an electrolytic cell 2 composed of a plurality of electrolytic chambers 1 connected in series, the electrolytic chamber 1 is divided into a plurality of electrolytic chambers 100 by a plurality of pole plates 3, and Concave and convex rough grooves 300 are provided; the positive and negative plates of the electrolytic cell are connected to the corresponding electrodes of the electrolysis power supply 3; the top of the electrolytic chamber 1 is provided with an exhaust pipe 101, and the exhaust pipe 101 is connected to the gas bus bar 4, The outlet end of the gas bus bar 4 is connected to the built-in water seal 5, and the built-in water seal 5 is connected to the external water seal 6 through the air guide tube 102; the outside of the electrolysis chamber 1 is provided with a cooling circulation device, so that a multi-chamber Electrolysis can make full use of electric energy efficiency. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com