Patents

Literature

311 results about "Micro gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-film ultrasonic transducer and preparation method thereof

InactiveCN101712028AImprove emission efficiencyEnhance received signalMechanical vibrations separationUltrasonic sensorMicro gap

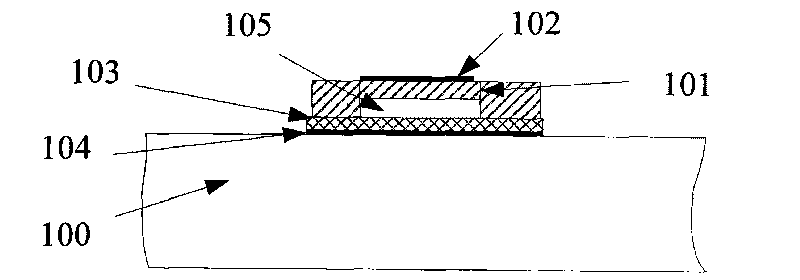

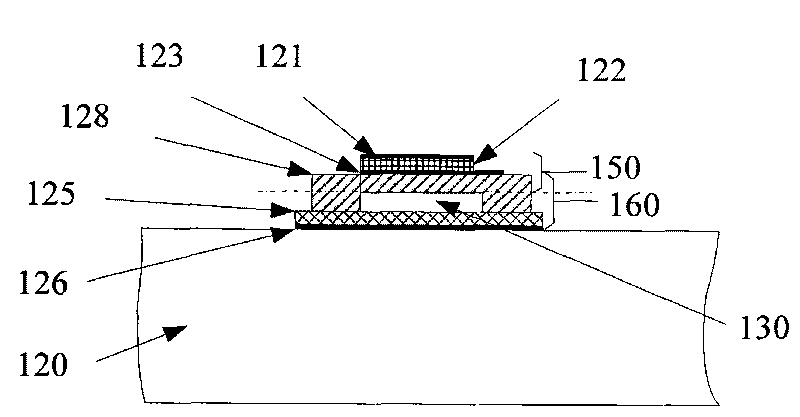

The invention relates to a thin-film ultrasonic transducer and a preparation method thereof. The thin-film ultrasonic transducer comprises a capacitance transducer unit, wherein the capacitance transducer unit comprises a capacitance second electrode (126), an insulating layer (125), an air micro-gap (130), a supporting component (128) and a piezoelectric first electrode (123) from bottom to top. The thin-film ultrasonic transducer is characterized in that the thin-film ultrasonic transducer also comprises a piezoelectric layer (122) positioned on the piezoelectric first electrode (123) and a piezoelectric second electrode (121) positioned on the piezoelectric layer (122) from bottom to top in turn; the supporting component (128) is a bendable piezoelectric vibrating diaphragm; and an inward-concave position in the lower center of the supporting component and the insulating layer (125) form a closed air micro-gap cavity. The invention also provides three methods for preparing the thin-film ultrasonic transducer, prepares all the components from bottom to top in turn, and particularly provides a plurality of modes for preparing the air micro-gap.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

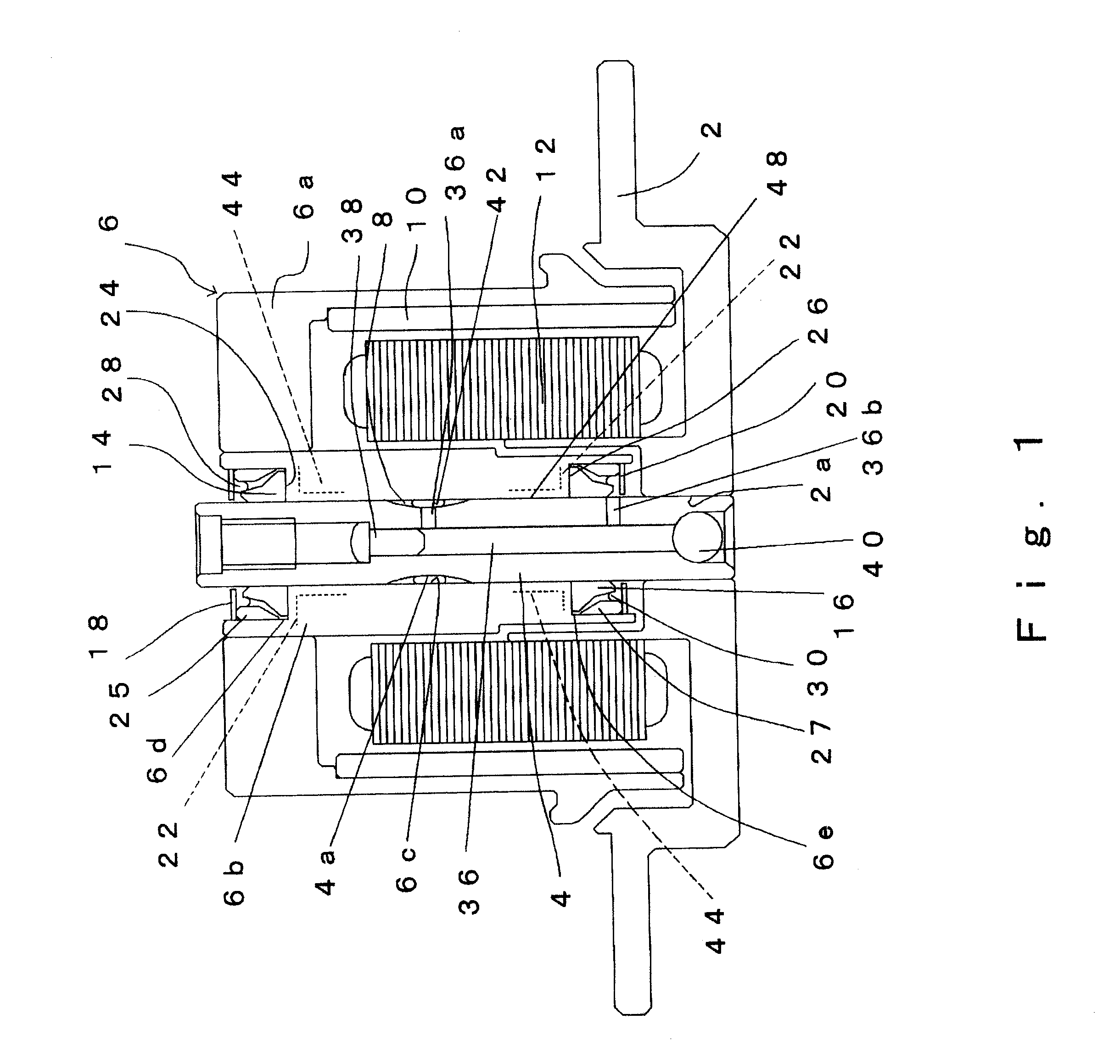

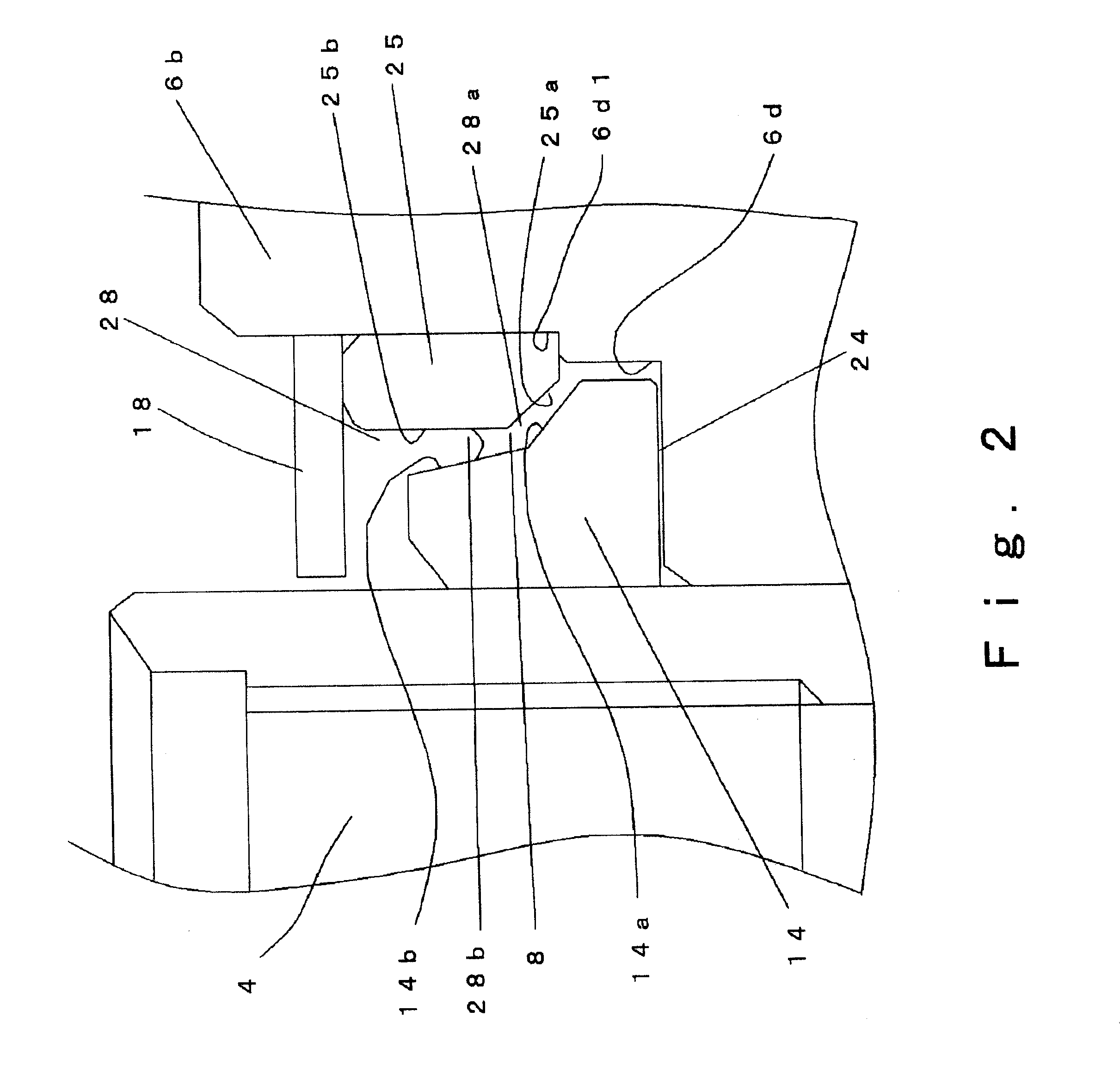

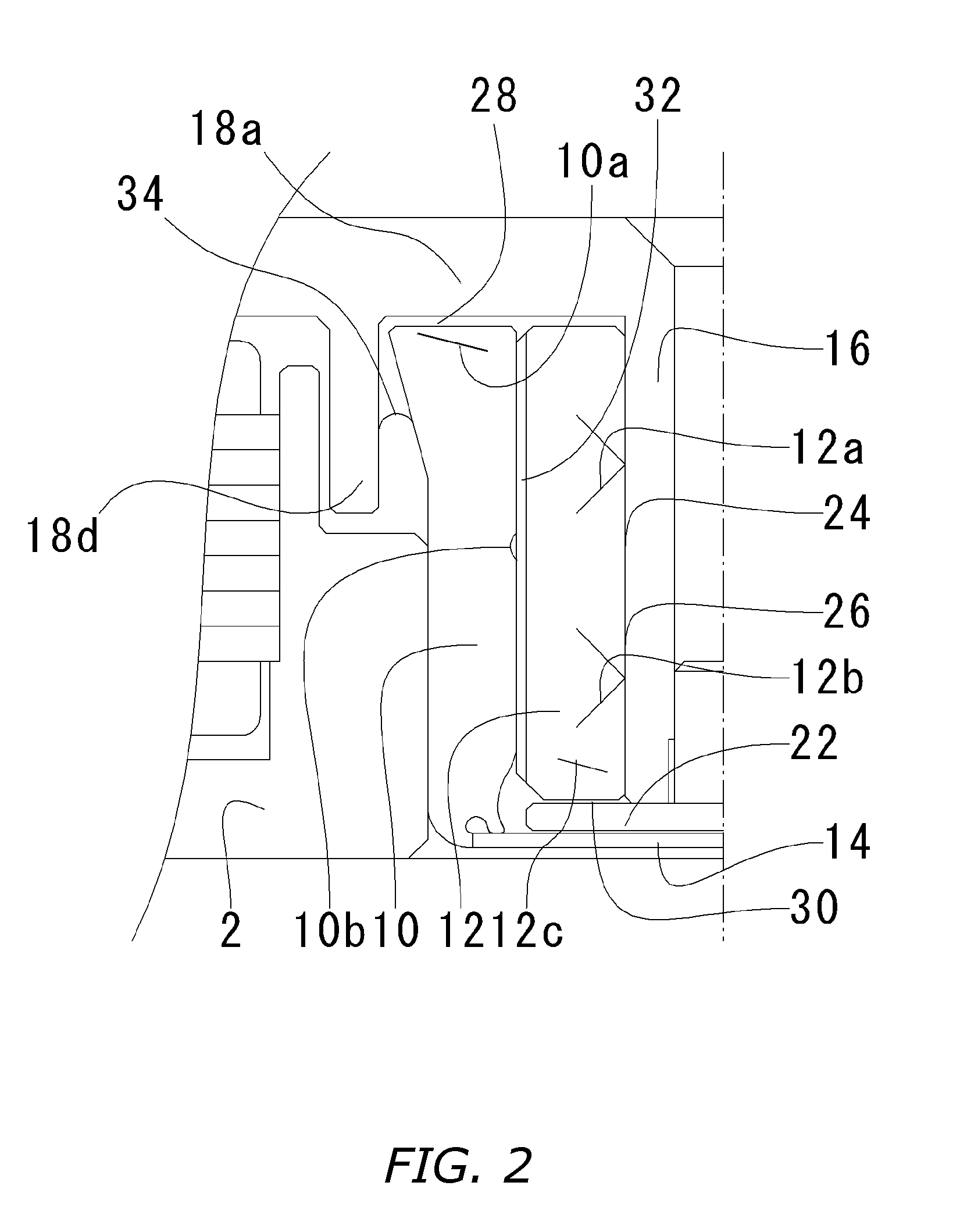

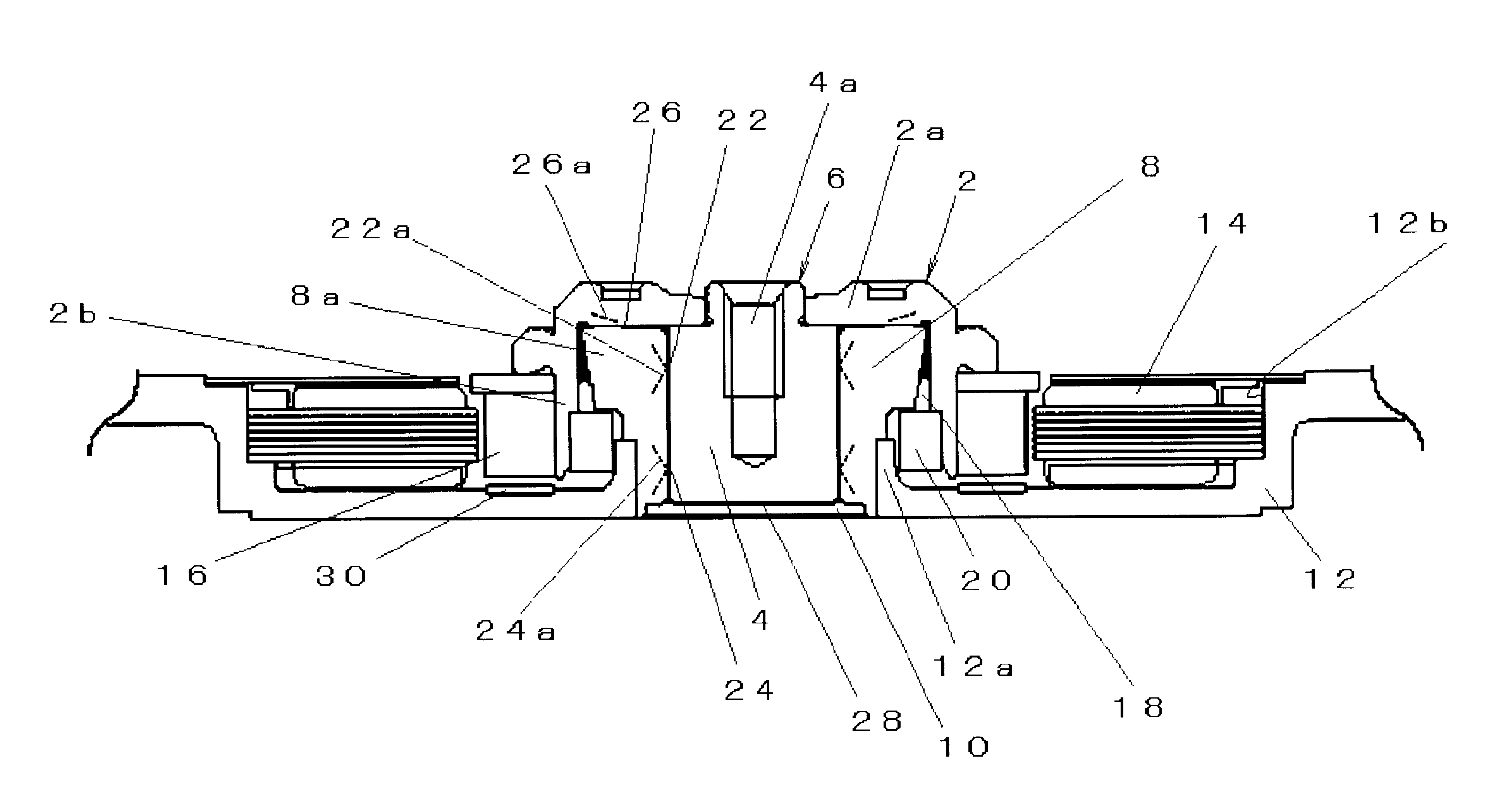

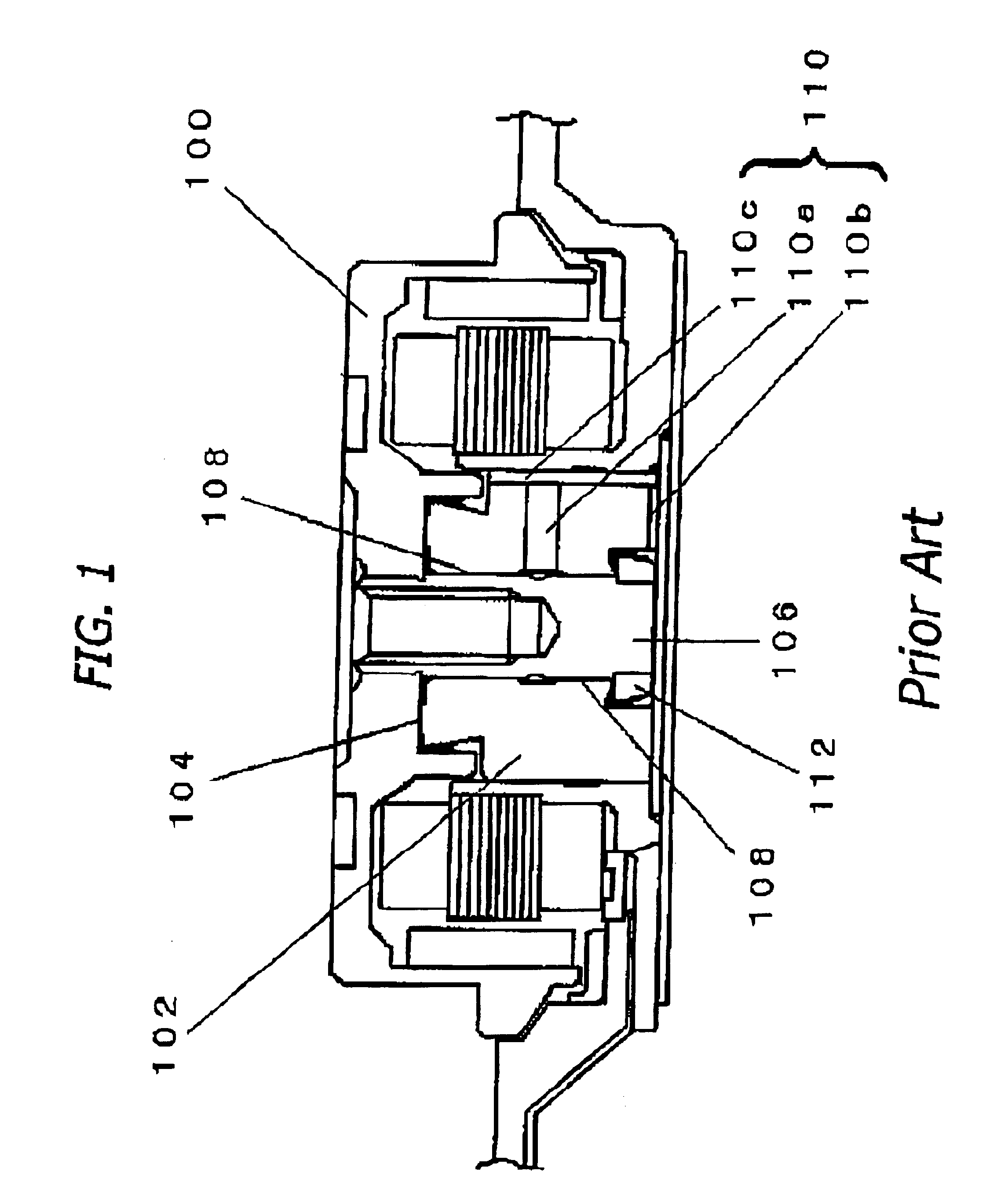

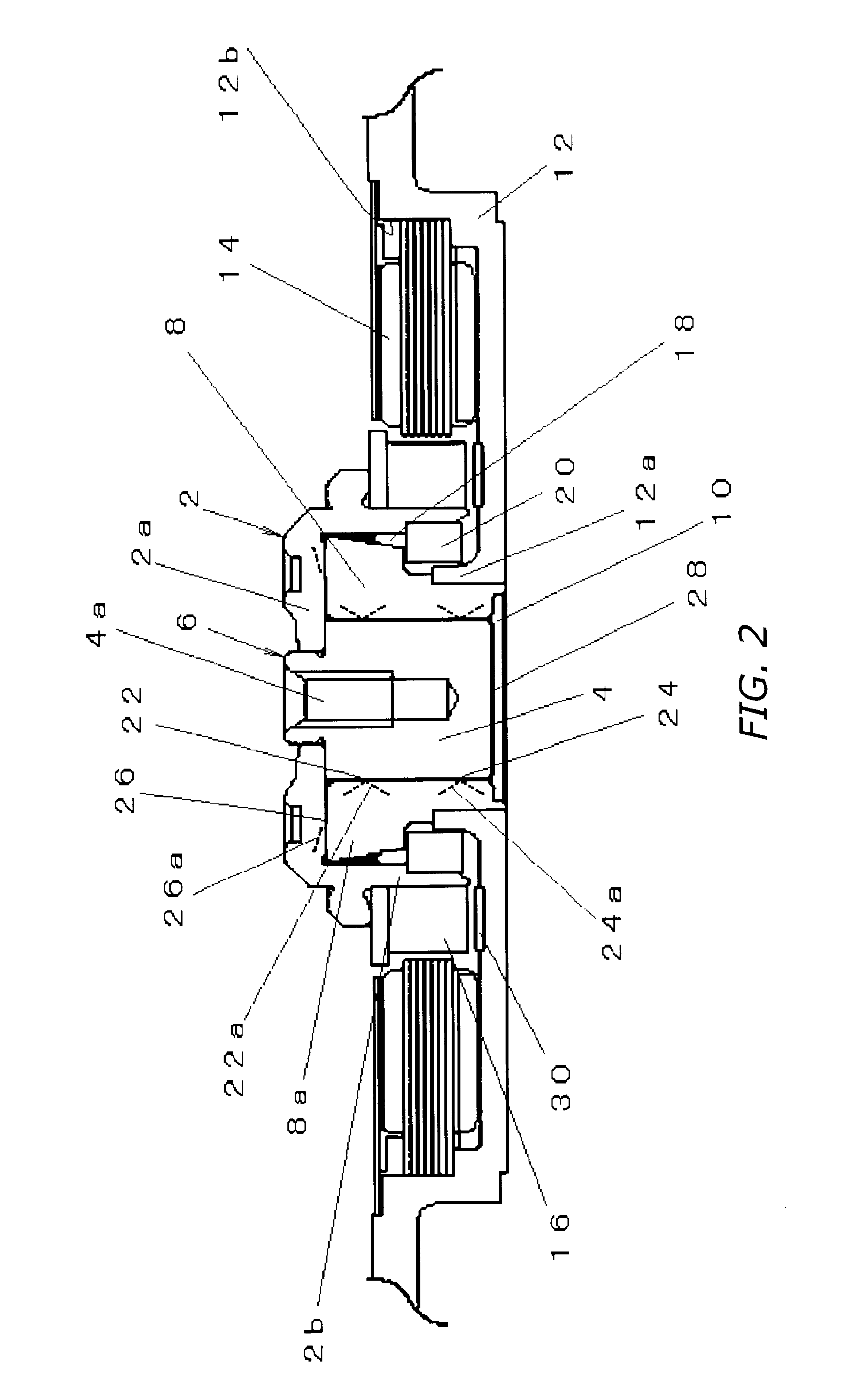

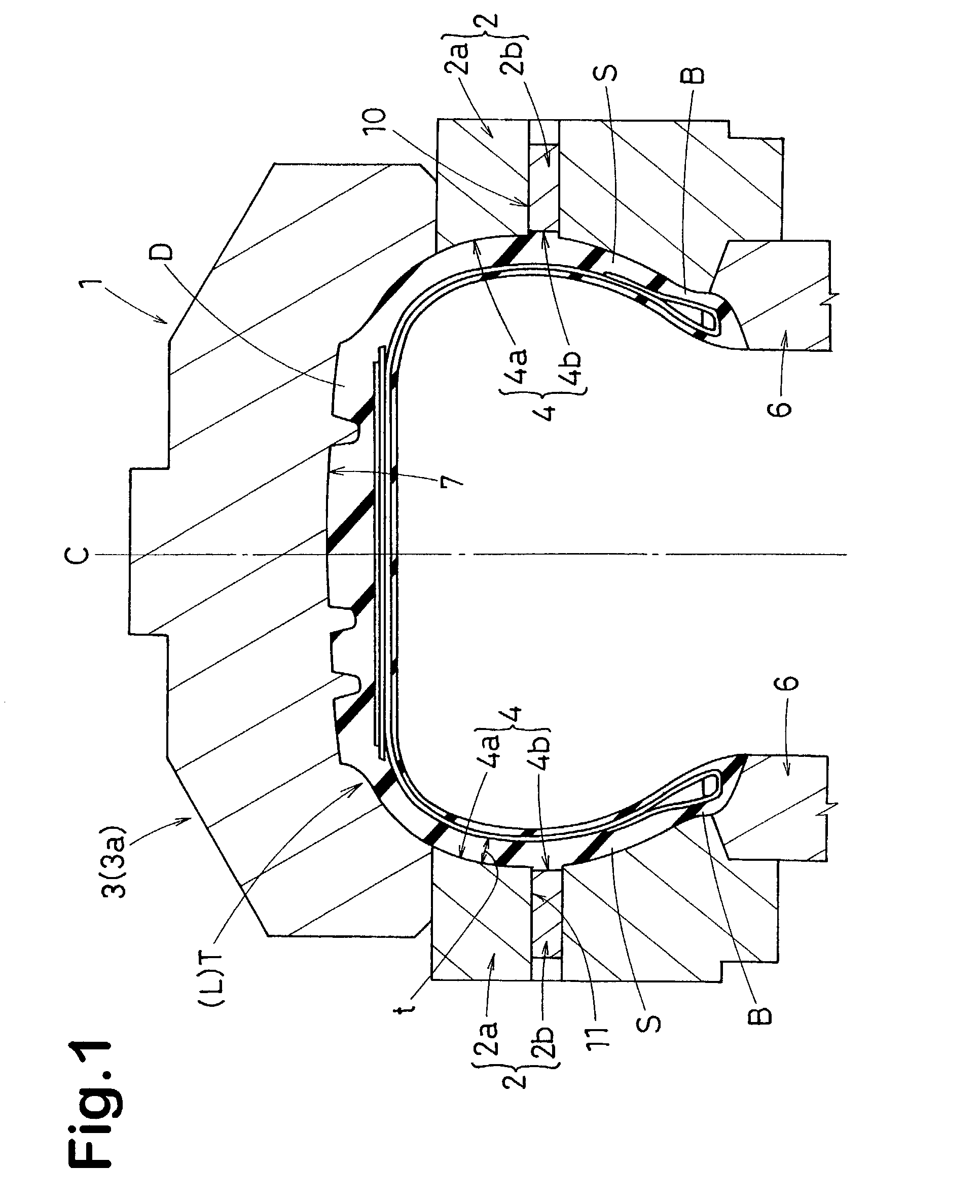

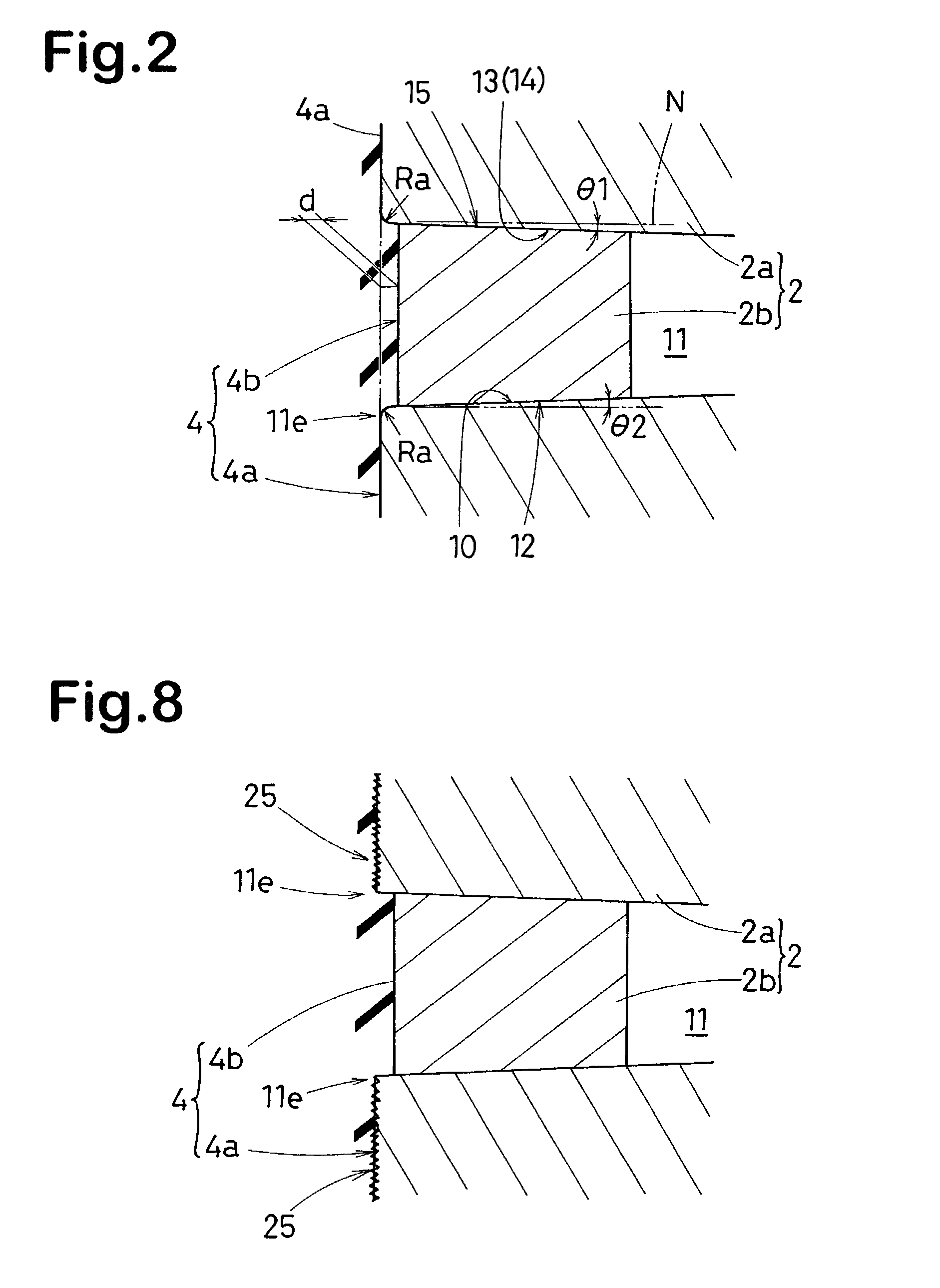

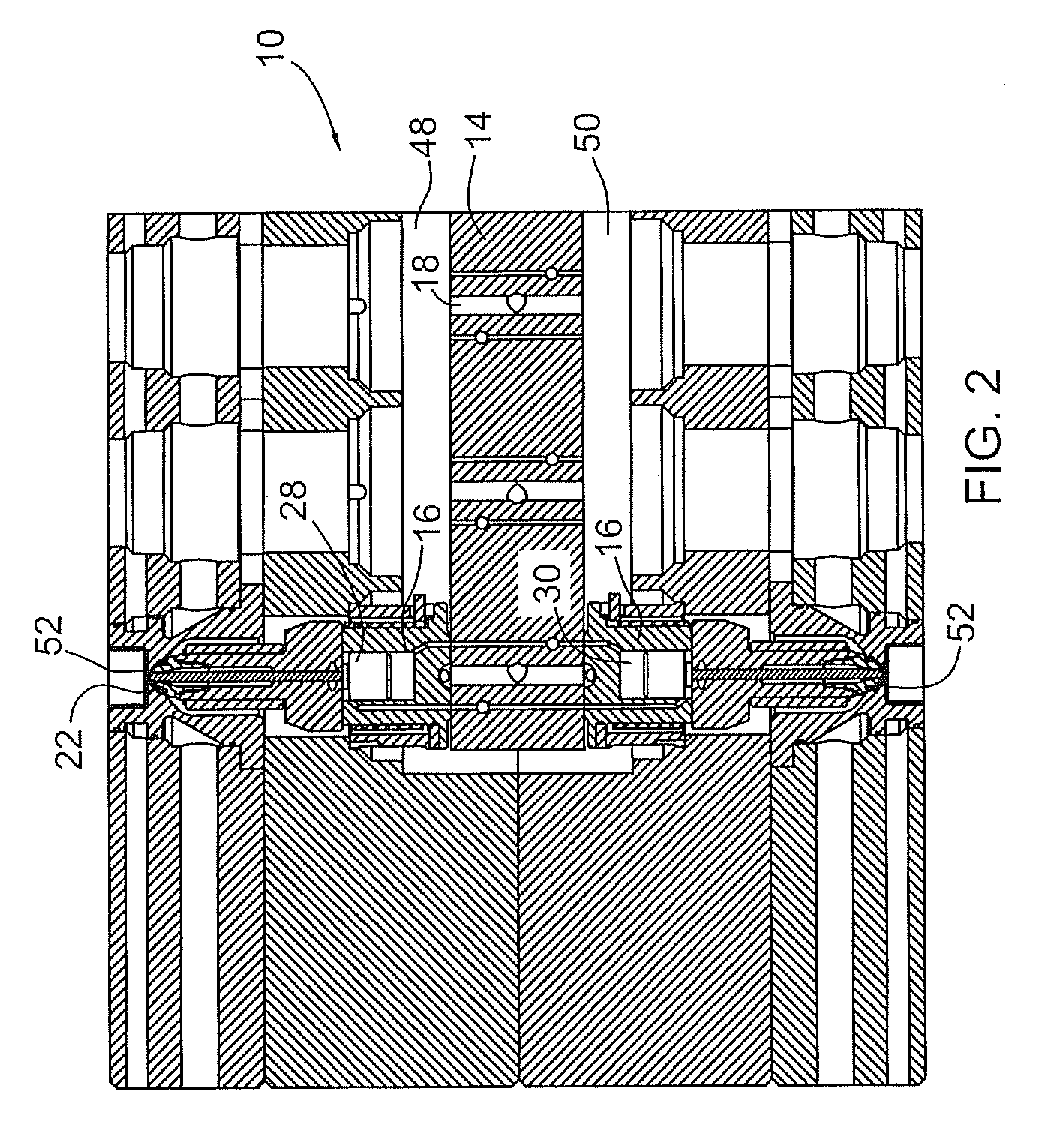

Hydrodynamic bearing, spindle motor using the same and disc drive apparatus provided with spindle motor

ActiveUS20040165797A1Increase capacitySufficient amount can be retainedShaftsRecord information storageWorking fluidCapillaria obsignata

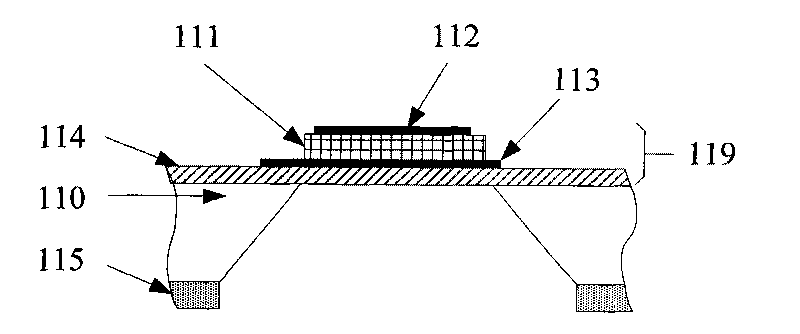

The present invention relates to a hydrodynamic bearing supporting a shaft and a sleeve so as to relatively rotate with respect to a rotation axis. In accordance with one example of the present invention, there is provided a hydrodynamic bearing in which a capillary seal portion is formed continuously in a bearing portion having a lubricating oil retained in a micro gap as a working fluid. The capillary seal portion is provided with a first capillary seal portion having a first radial gap, a dimension of the first radial gap being getting at least wider in accordance with increasing a distance from the bearing portion in the rotation axis, and a second capillary seal portion adjoining the first capillary seal portion and having a second radial gap, a dimension of the second radial gap being getting at least wider in accordance with increasing a distance from the bearing portion in the rotation axis. The second capillary seal portion is expanded progressively in accordance with getting toward an outer side in an axial direction.

Owner:NIPPON DENSAN CORP

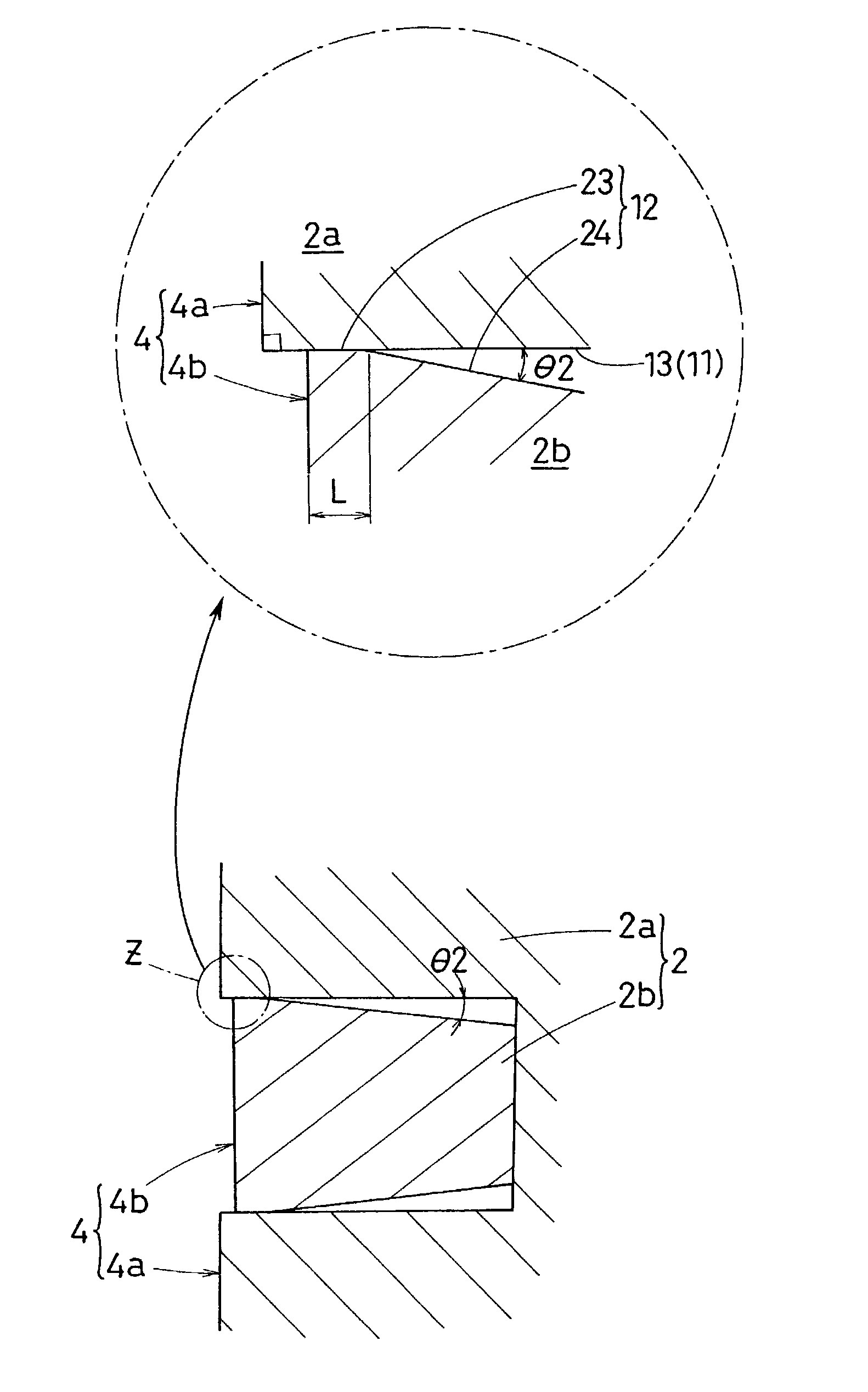

Fluid-dynamic-pressure bearing, spindle motor furnished with the fluid-dynamic-pressure bearing, method of manufacturing rotor assembly applied in the spindle motor, and recording-disk drive furnished with the spindle motor

ActiveUS7021829B2Reduced dimensionStress reliefShaftsMetal-working apparatusEdge surfaceThrust bearing

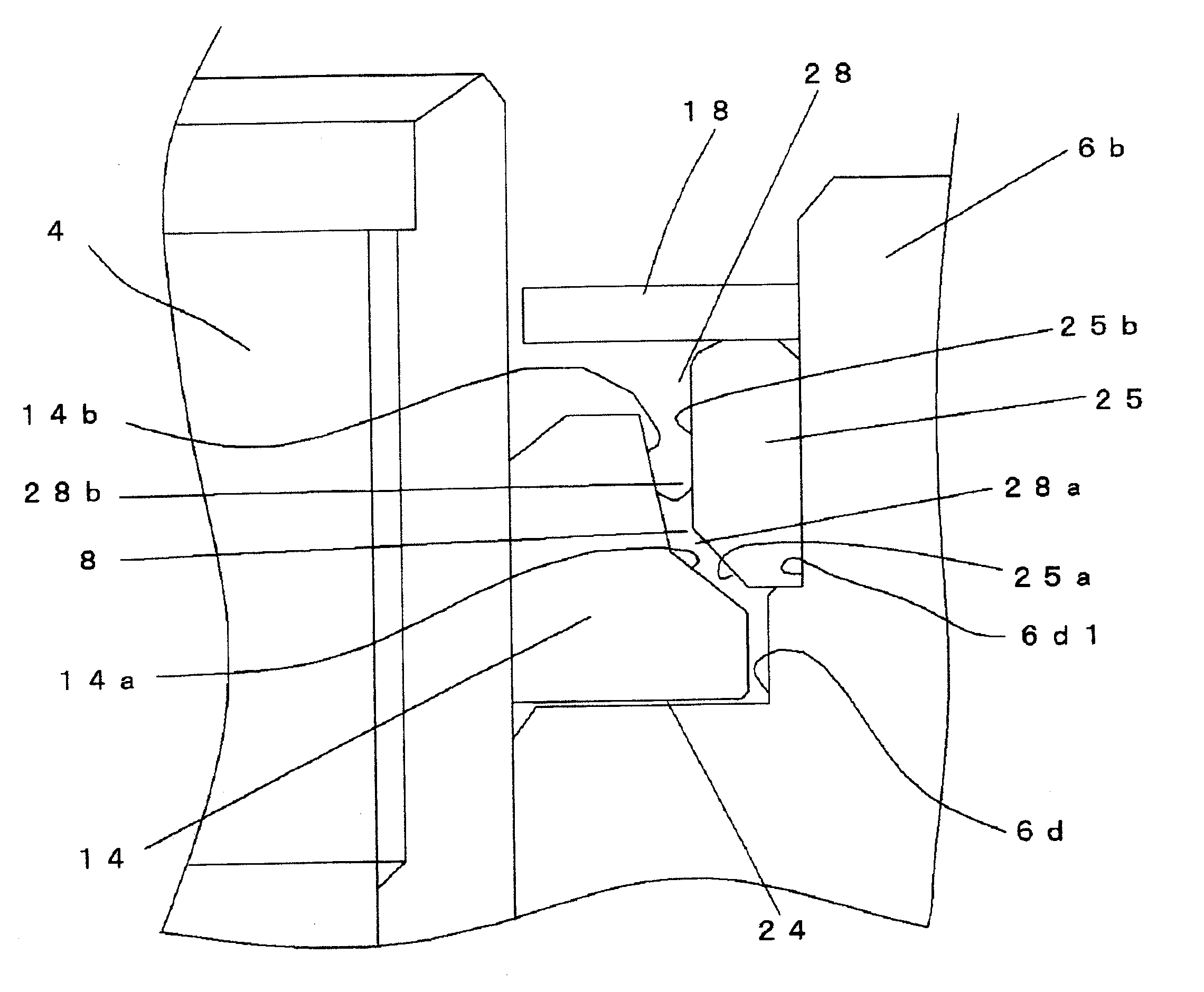

Fluid-dynamic-pressure bearing furnished with a shaft, a top plate fixed to an upper portion of the shaft, a thrust plate fixed to a lower portion of the shaft, a sleeve, and a cuplike bearing housing that along its inner periphery retains the sleeve. A lubricating-fluid-filled continuous micro-gap is formed in between the shaft and the sleeve and the top plate and the sleeve. Radial bearing sections are formed in between the shaft cylindrical outer surface and the sleeve cylindrical inner surface. An upper thrust bearing section is formed in between the undersurface of the top plate and the top-edge face of the bearing housing. A lower thrust bearing section formed in between the bottom margin of the sleeve and the top margin of the thrust plate. The bearing sections are each provided with dynamic-pressure-generating grooves for inducing dynamic pressure in the lubricating fluid when the shaft or sleeve spins.

Owner:NIDEC CORP

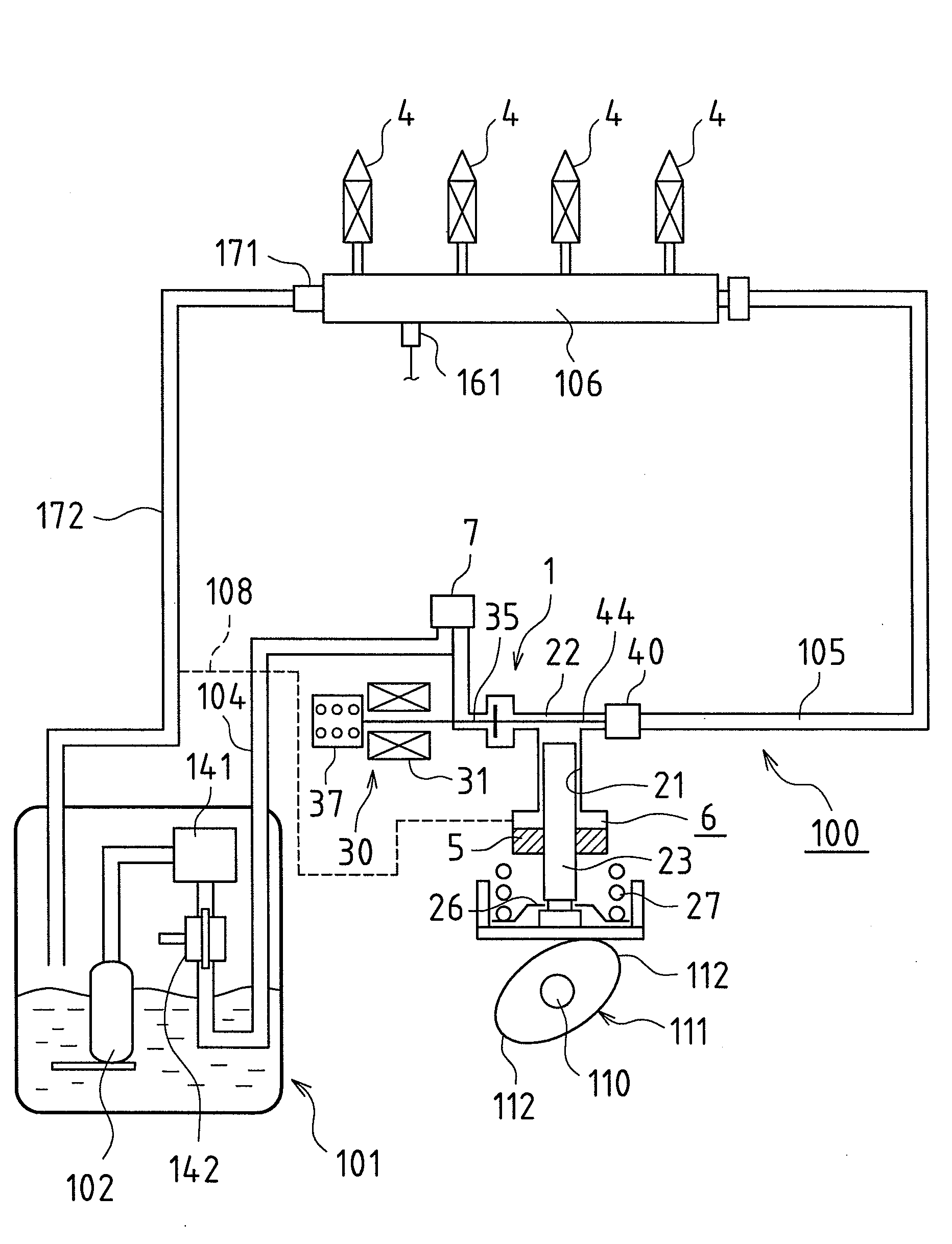

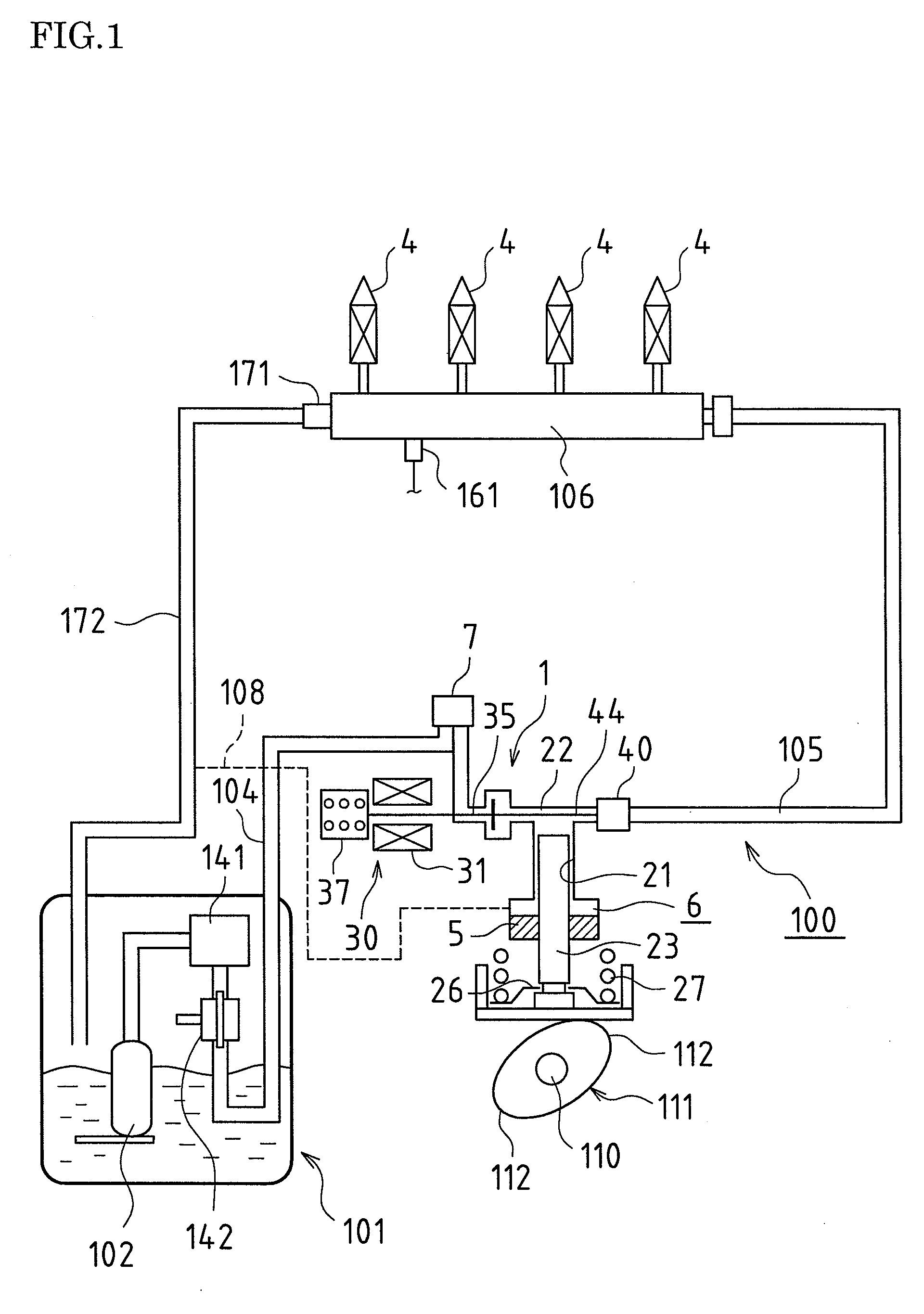

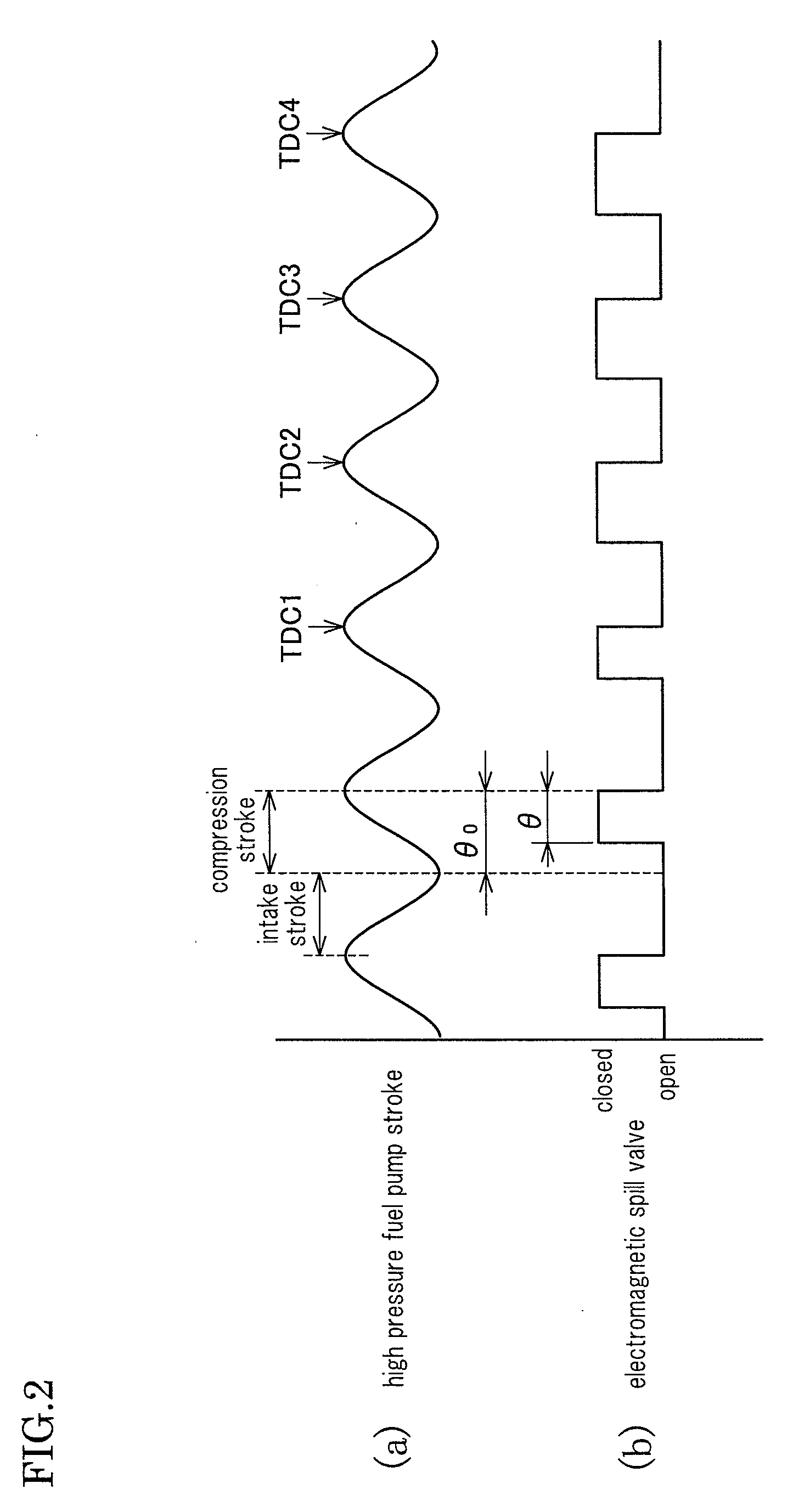

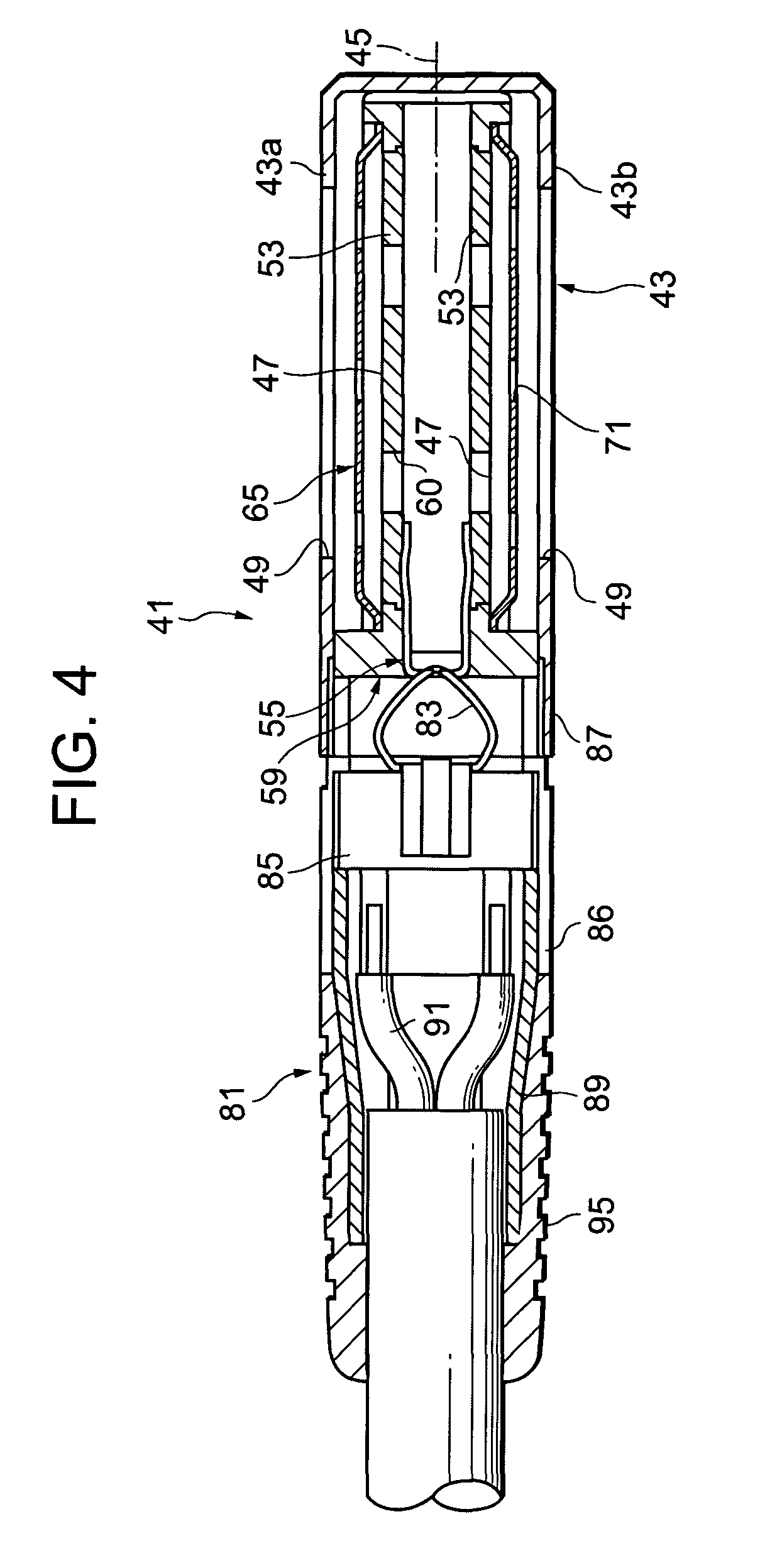

Fuel pump

InactiveUS20110129363A1Reduce fuel pressureImprove discharge efficiencyPositive displacement pump componentsFuel injecting pumpsMagnetic valveEngineering

In one embodiment, a small-diameter opening (42b) is formed in the central portion of a valve element (42) included in a check valve (40) of a high pressure fuel pump (1). A needle valve (44) is provided integrally with a valve element (35a) of an electromagnetic spill valve (30), and the opening (42b) of the valve element (42) can be opened and closed with a tip portion of the needle valve (44). When the high pressure fuel pump (1) switches from the drive state to the stopped state, the needle valve (44) retreats from the opening (42b) of the valve element (42) in conjunction with the movement of the valve element (35a) of the electromagnetic spill valve 30, thus forming a micro gap. When the high pressure fuel pump (1) is driven and the intake stroke is performed, the needle valve (44) obstructs the opening 42b of the valve element (42) in conjunction with the movement of the valve element (35a) of the electromagnetic spill valve 30, thus preventing the back-flow of fuel due to the existence of the micro gap.

Owner:TOYOTA JIDOSHA KK

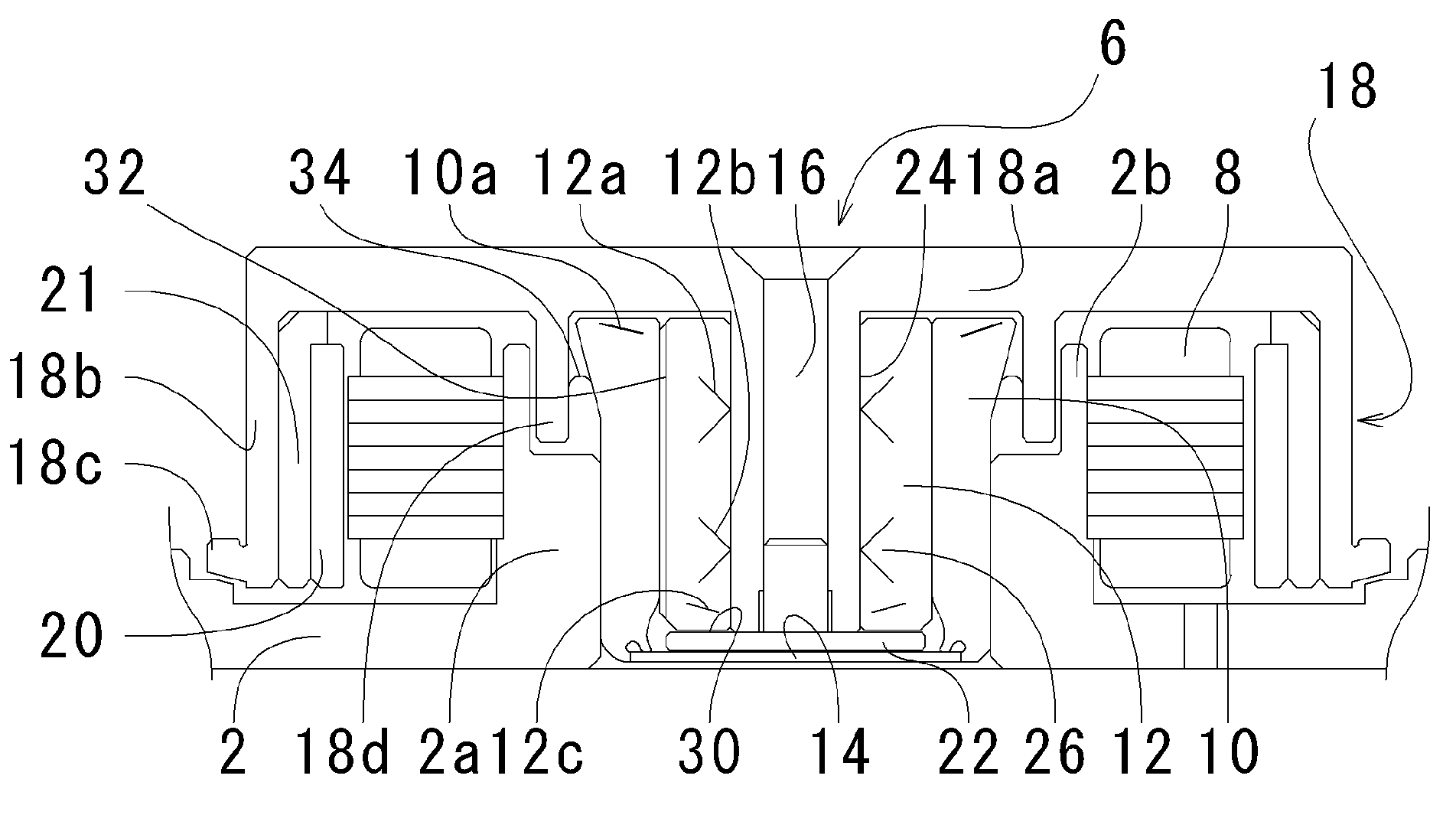

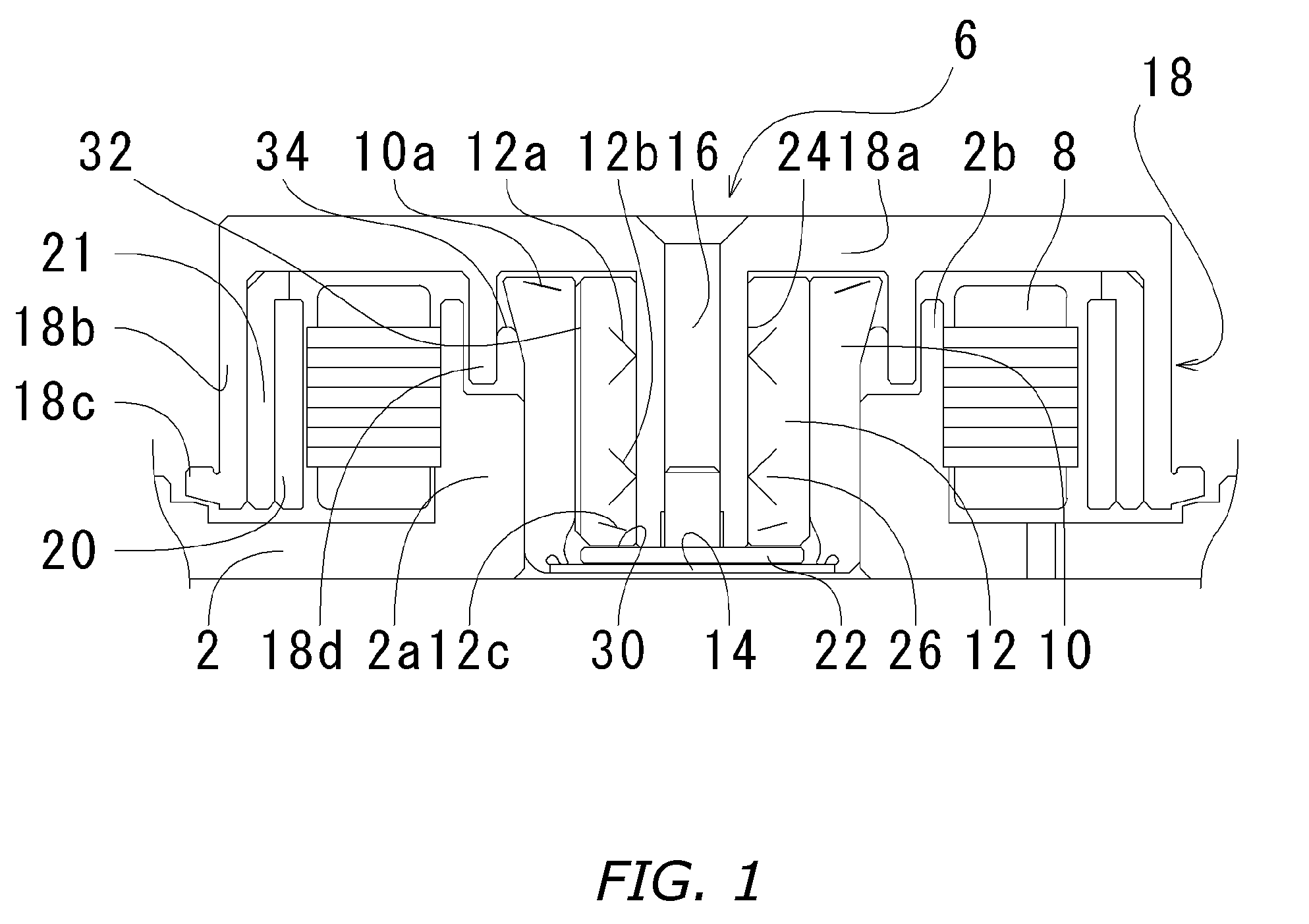

Spindle motor and disk drive utilizing the spindle motor

InactiveUS6888278B2Simplify and slim down structureMaintain relatively stableApparatus for flat record carriersShaftsThrust bearingEngineering

Low-profile spindle motor whose entire shaft length is utilized to configure, along an encompassing sleeve, a radial dynamic-pressure bearing section. One end of the shaft is unitary with the rotor, and a cover member closes the other end. Between the sleeve upper-end face and the rotor undersurface a thrust bearing section is configured. Micro-gaps are formed continuing between the sleeve upper-end face and the rotor undersurface; the sleeve inner-circumferential surface and the shaft outer-circumferential surface; and the cover member inner face and the shaft end face, where an axial support section is established. Oil continuously fills the micro-gaps, configuring a full-fill hydrodynamic bearing structure. Hydrodynamic pressure-generating grooves in the radial bearing section are configured either so that no axial flow, or so that a unidirectional flow that recirculates from one to the other axial end of the radial bearing section through a communicating pathway is induced in the oil.

Owner:NIDEC CORP

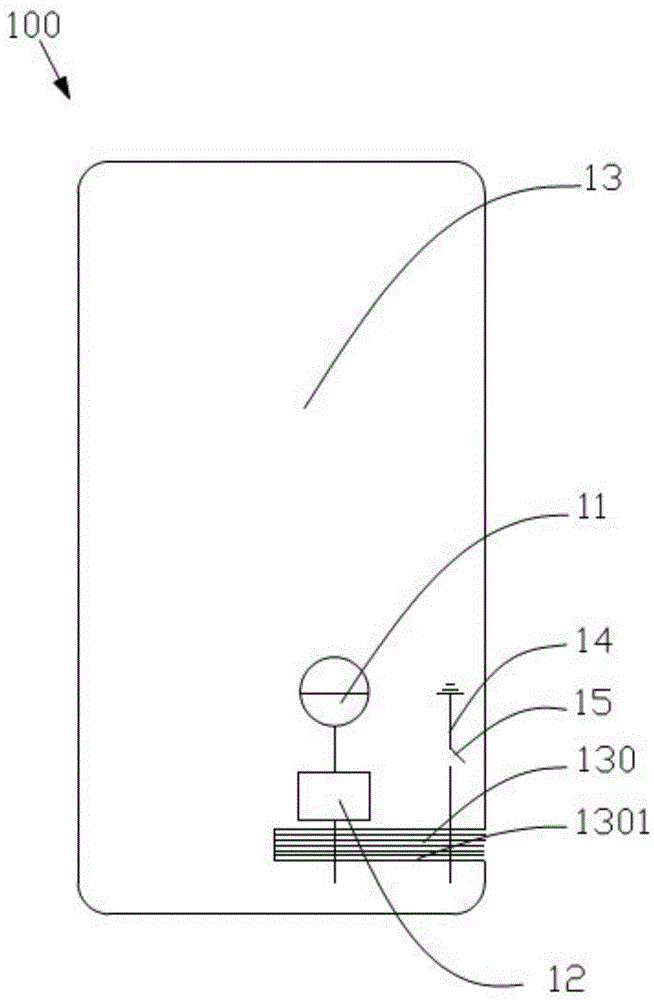

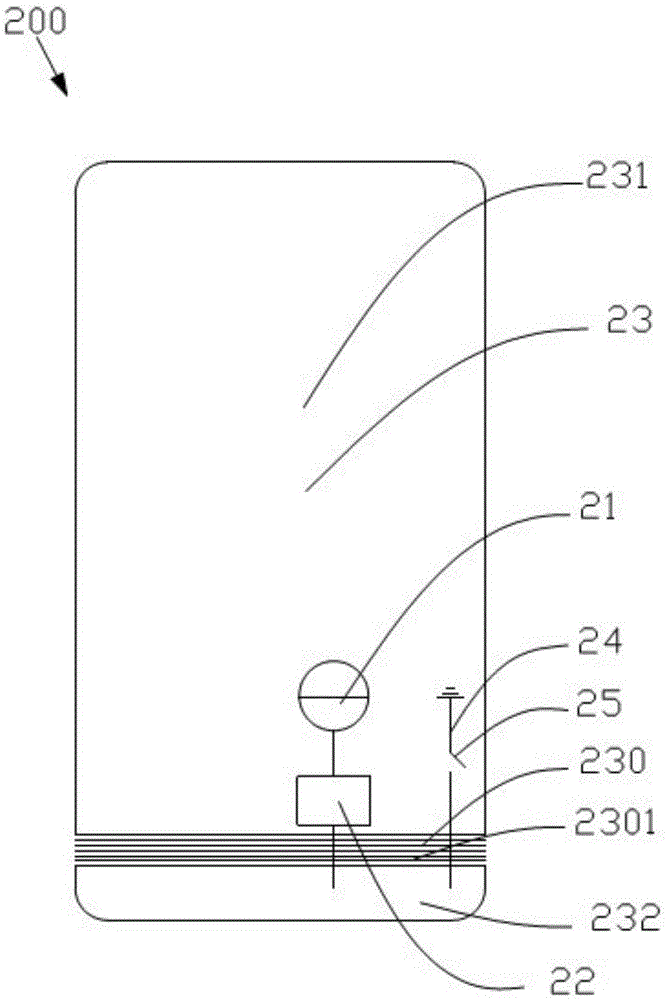

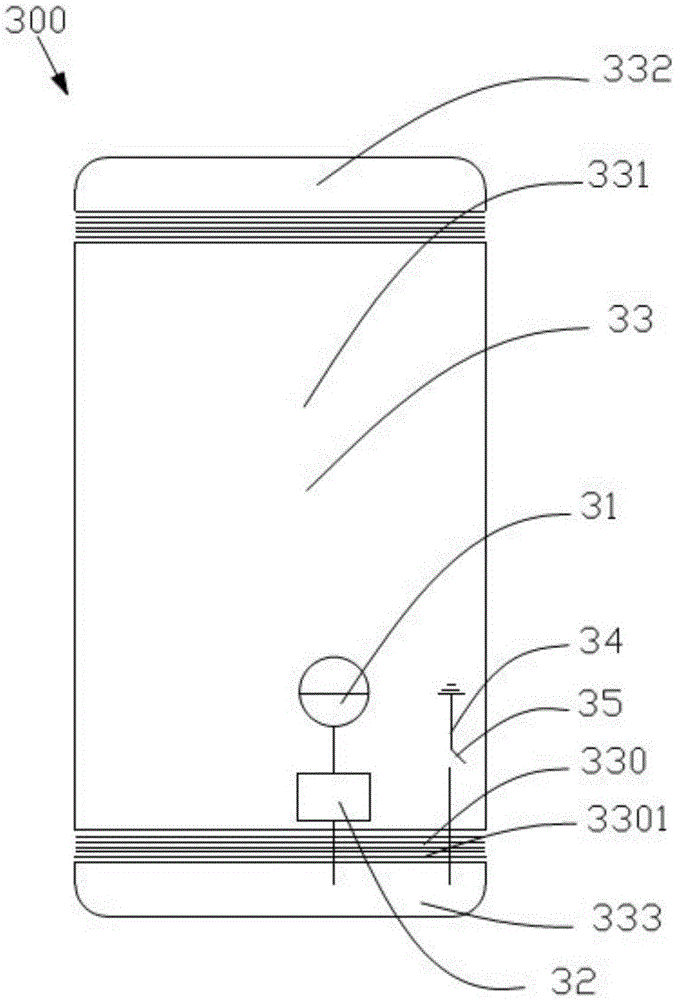

Antenna device and mobile terminal

ActiveCN105655704AGuaranteed integrityNot easy to attract attentionSimultaneous aerial operationsMetal casingsElectricityEngineering

The invention provides an antenna device. The antenna device comprises a radio frequency receiving and transmitting circuit, a match circuit electrically connected to the radio frequency receiving and transmitting circuit and a metal shell; the metal shell is provided with at least one micro gap tape, and the radio frequency receiving and transmitting circuit is electrically connected with the metal shell through the match circuit, so that the metal shell is used as a radiating body of the antenna device; the metal shell is grounded through a grounding wire, and the grounding wire is provided with a switch used for controlling on-off of the grounding wire. According to the antenna device, the overall appearance effect of a mobile terminal can be guaranteed, signals of the antenna device can be prevented from being interfered, and the bandwidth of the antenna device can be increased. The invention further provides the mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

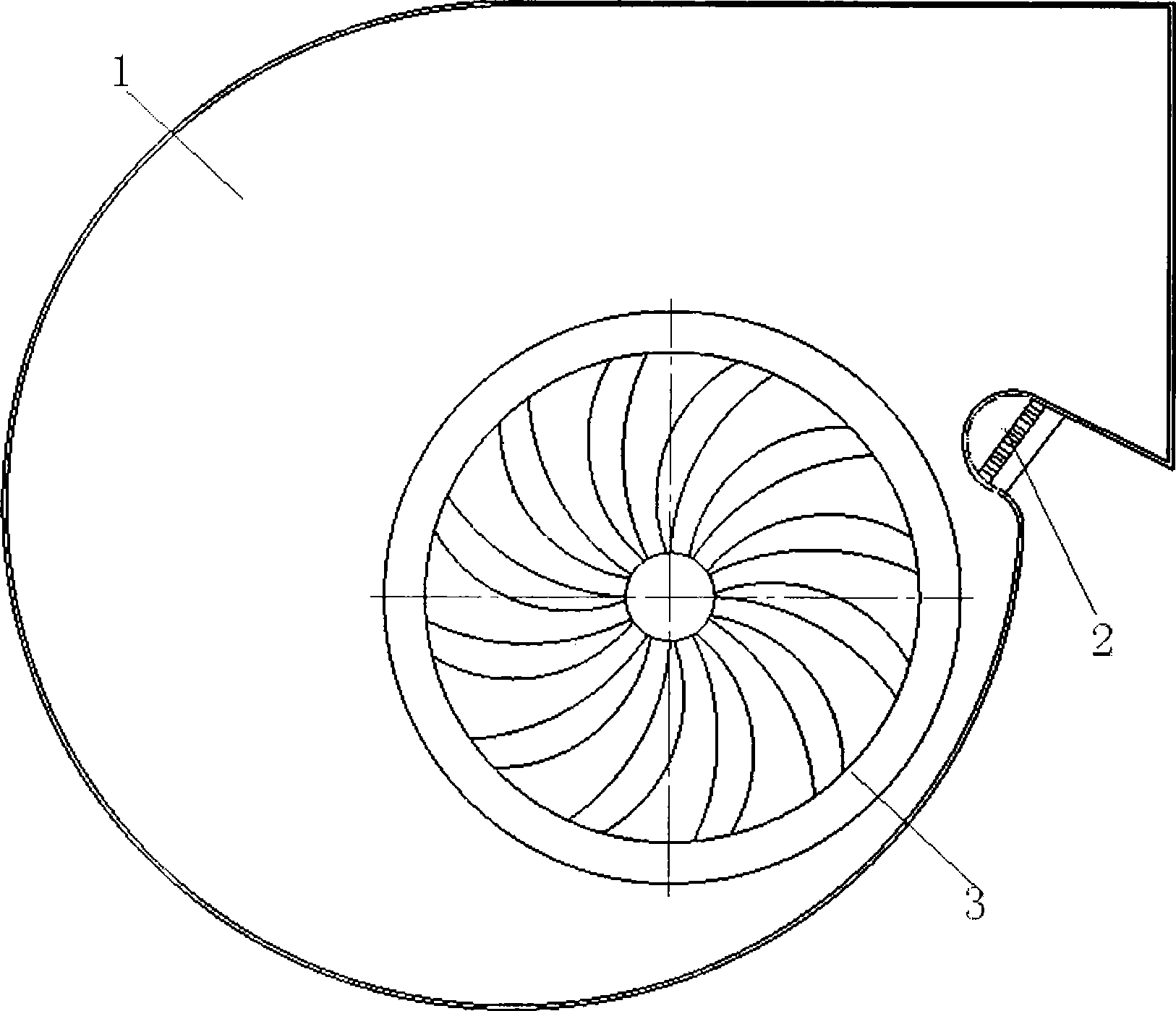

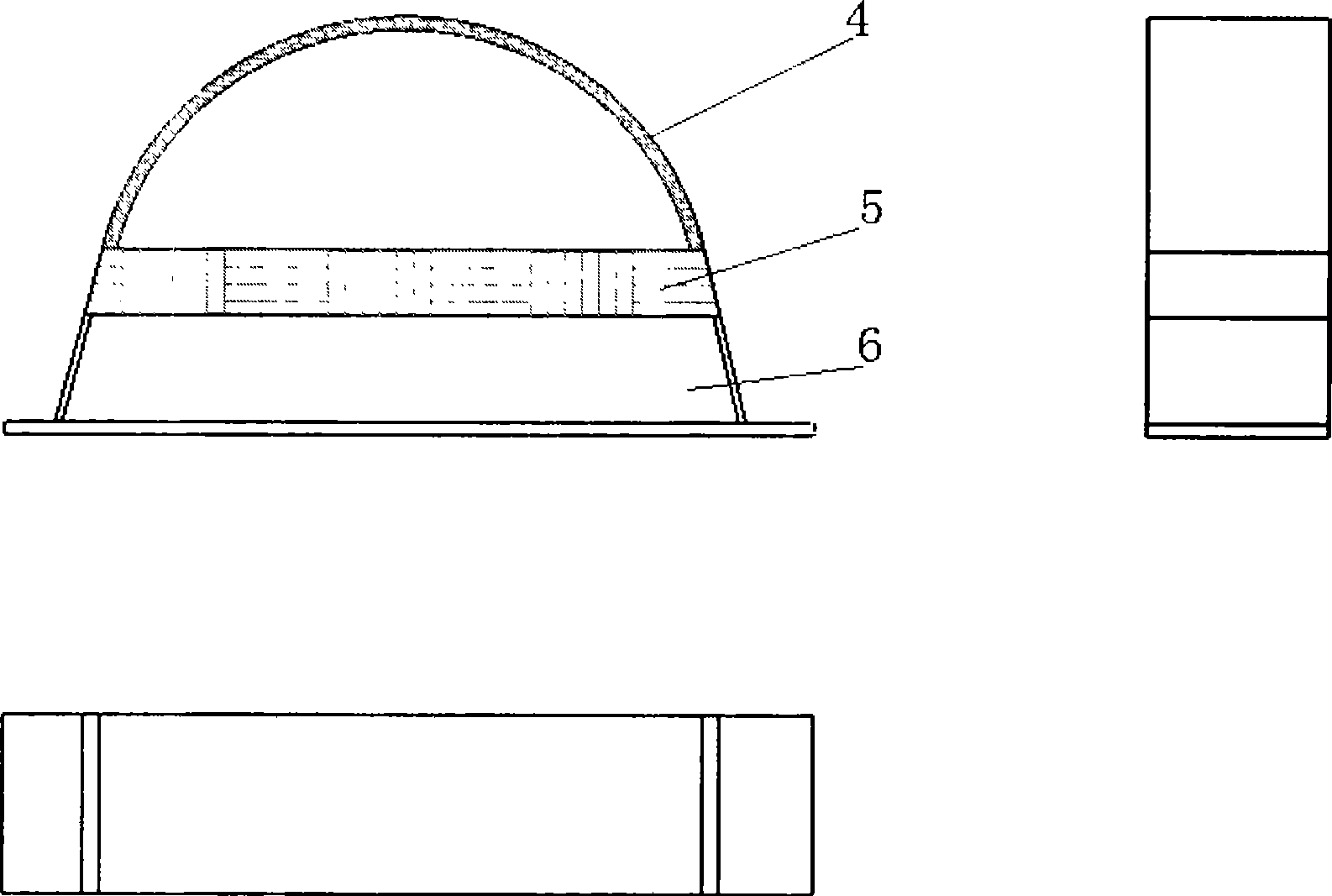

Bionic coupling noise elimination noise reduction spiral tougue

InactiveCN101509506AEasy to processReduced eddy current sheddingPump componentsPumpsNoise controlLow noise

The invention relates to a bionic coupling noise elimination volute tongue controlled by the aerodynamic noise of a centrifugal fan. The bionic coupling noise elimination volute tongue is arranged at a volute mouth of a volute casing. The bionic coupling noise elimination wolute tongue comprises a bionic coupling noise elimination volute tongue micro-gap ply, a bionic coupling noise elimination volute tongue micro-punch ply and an air chamber backing plate. A bionic coupling noise elimination volute tongue thin cavity layer is arranged between the bionic coupling noise elimination volute tongue micro-punch ply and the air chamber backing plate which is connected with the volute casing in a rivet welding way. The bionic coupling noise elimination volute tongue is simply processed and has the effects of sound absorption and noise reduction and rectification and noise reduction without needing changing the outline of the original fan volute casing. When air current flows through the surface of the bionic coupling noise elimination volute tongue, the bionic micro-gap ply contacted with the air current has the function of rectification and reducing the surface eddy shedding of the volute tongue. Experiments proves that the rotating speed of the fan selects the rotating speed of the working condition which is 1800r / min, for the original fan with higher noise lever, the noise can be reduced about by 3-5db (A), the noise reduction rate is 5%, for the original fan with lower noise lever, the noise can be reduced by 2-3db (A), and the noise reduction rate is 4.5%.

Owner:JILIN UNIV

Reusable air permeable packaging film

InactiveUS20050003150A1Improve alcohol resistanceGood oil resistancePackage recyclingPackage sterilisationMicrowaveEngineering

Owner:LIN IRENE

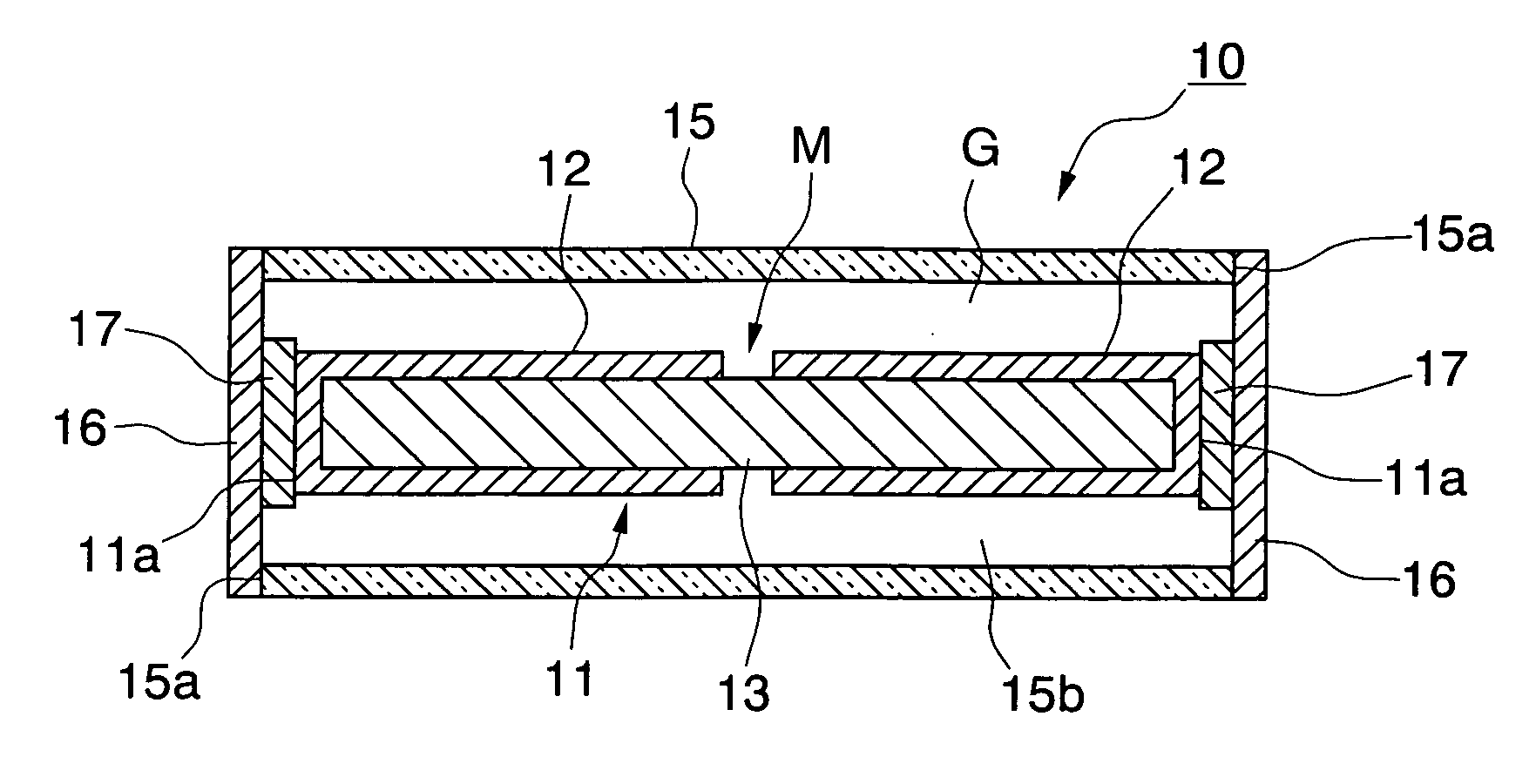

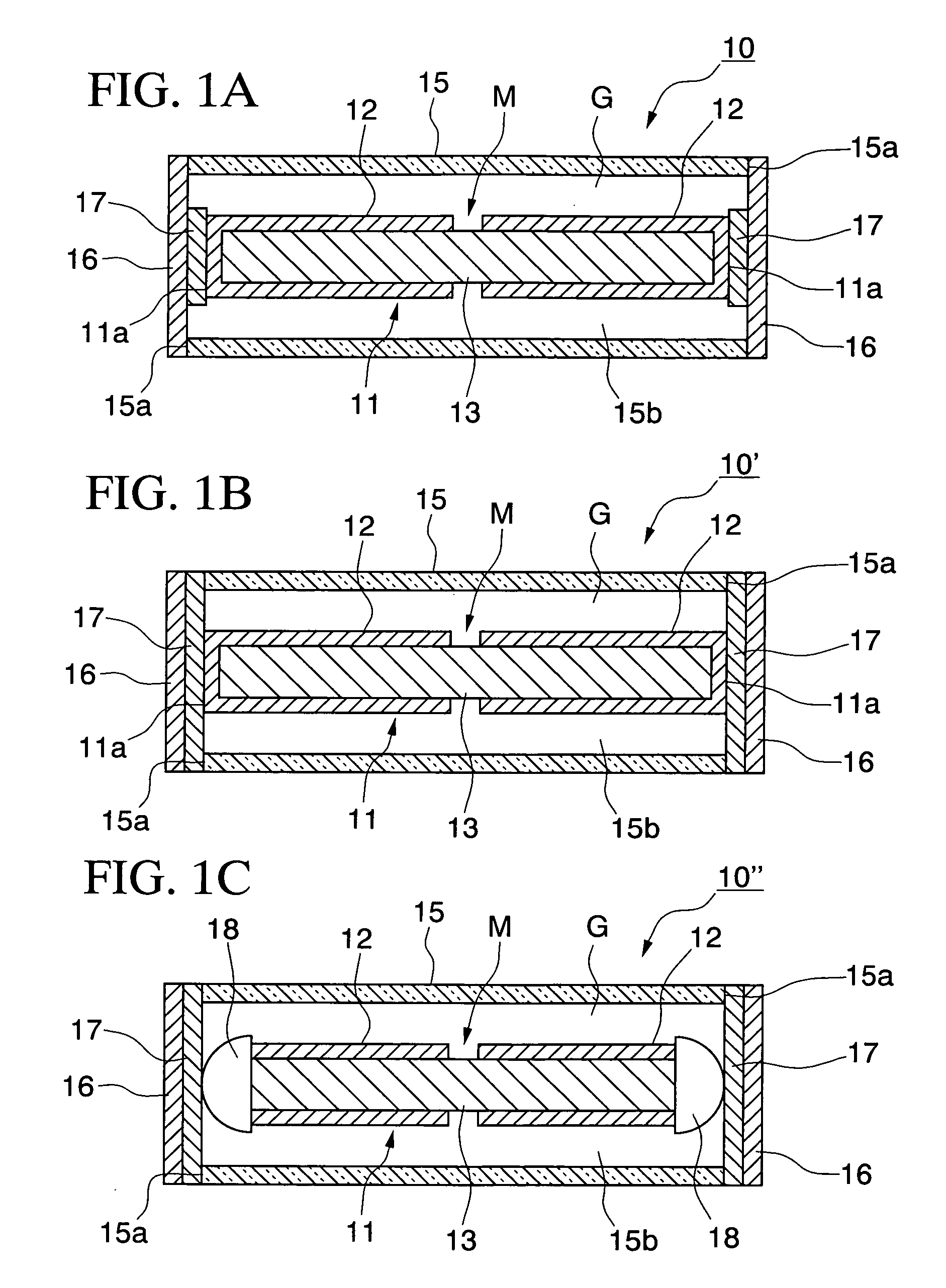

Surge Absorber and Production Method Therefor

ActiveUS20070285866A1Electrically stableAbsorb dimensional toleranceSparking plugsEmergency protective arrangement detailsMicro gapElectrical and Electronics engineering

This surge absorber includes an insulating part upon which is formed a conductive layer which is divided into two separate portions by a discharge gap (micro gap) around its circumferential surface; a pair of terminal electrodes which are arranged to oppose the insulating part, and contacts the conductive layer; an insulating tube at the ends of which the terminal electrodes are arranged, and which seals the insulating part in its interior along with seal gases; and a conductive portion provided at least between the terminal electrodes and the conductive layer. As a result, it becomes possible to provide a surge absorber of lower cost, and which is endowed with stabilized performance and high quality, while moreover it exhibits excellent durability.

Owner:MITSUBISHI MATERIALS CORP

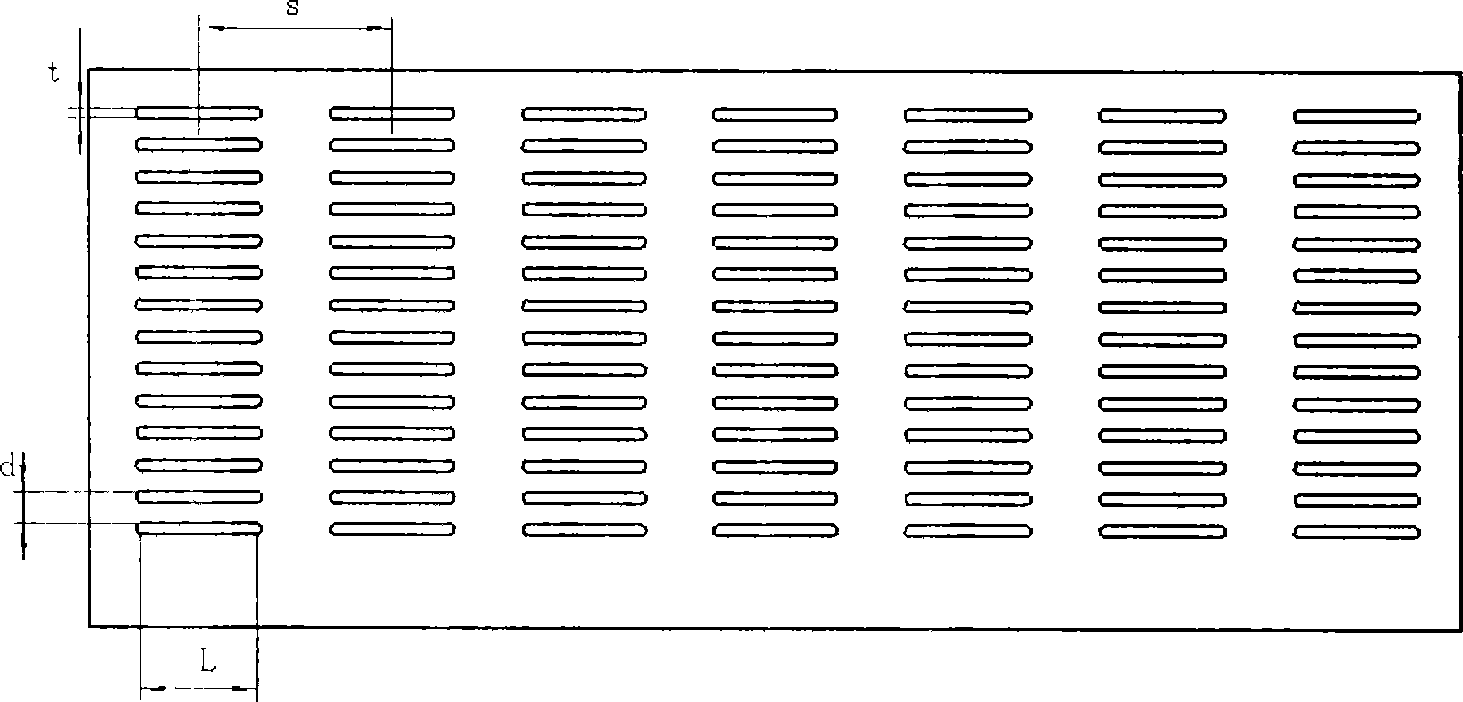

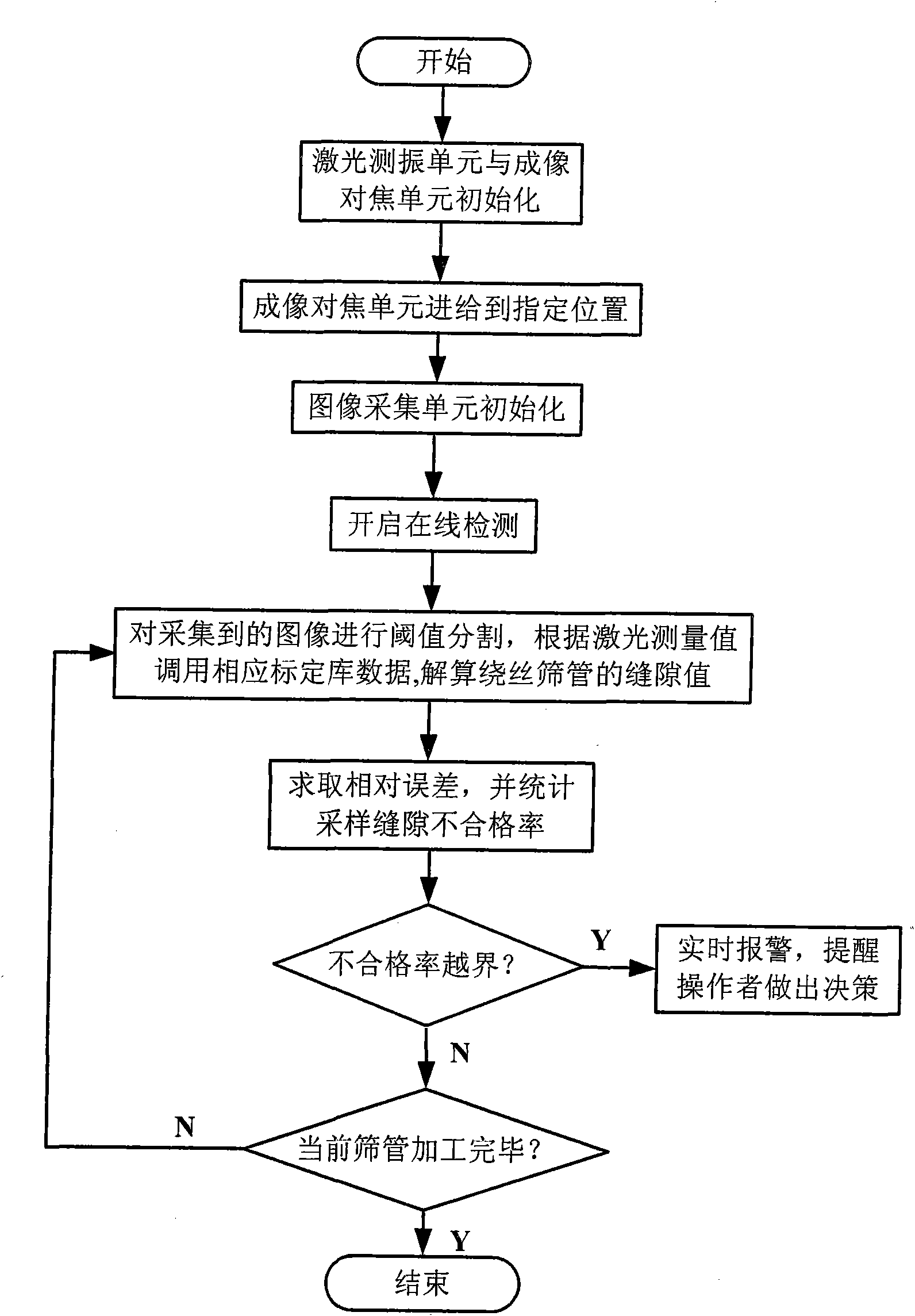

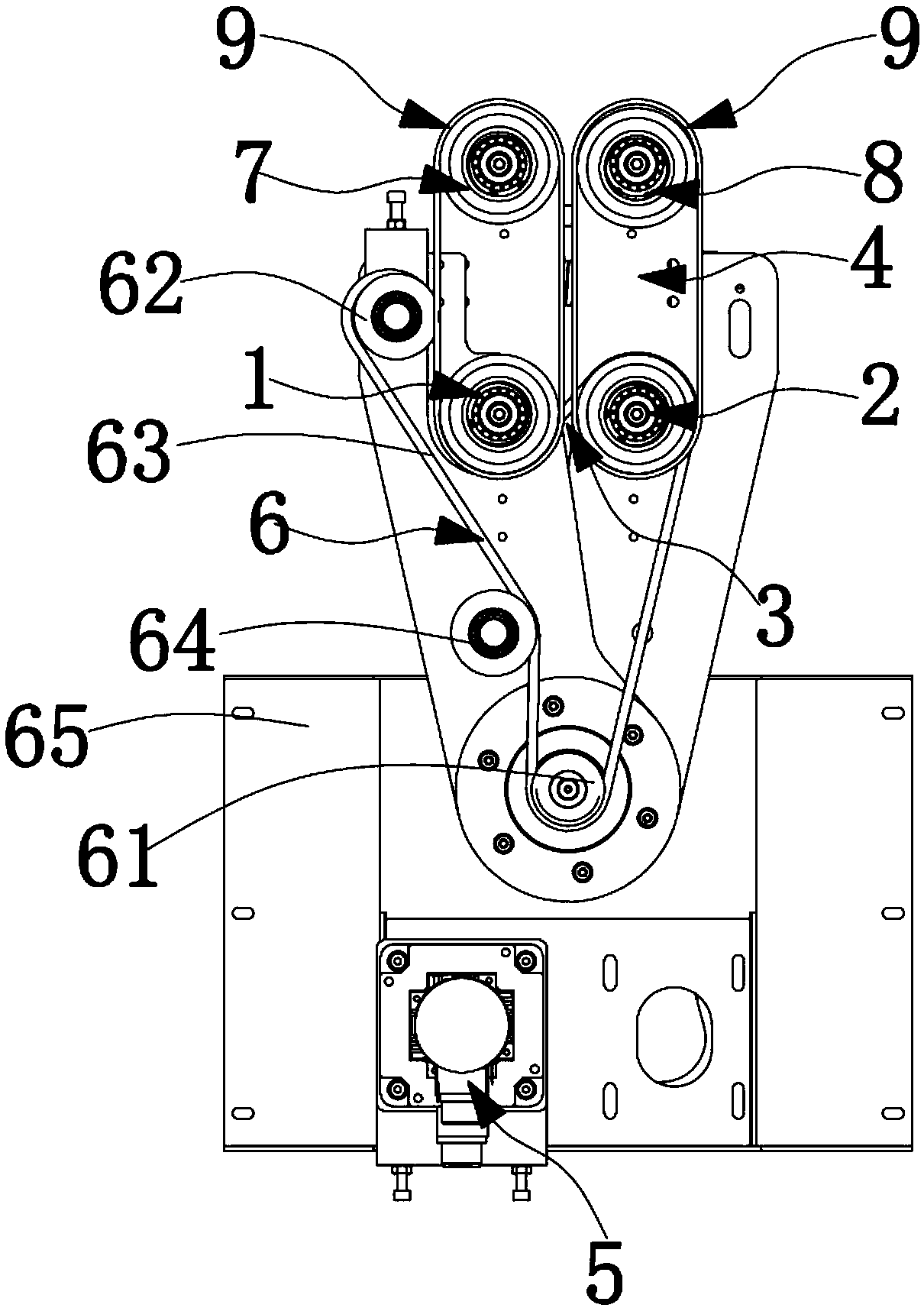

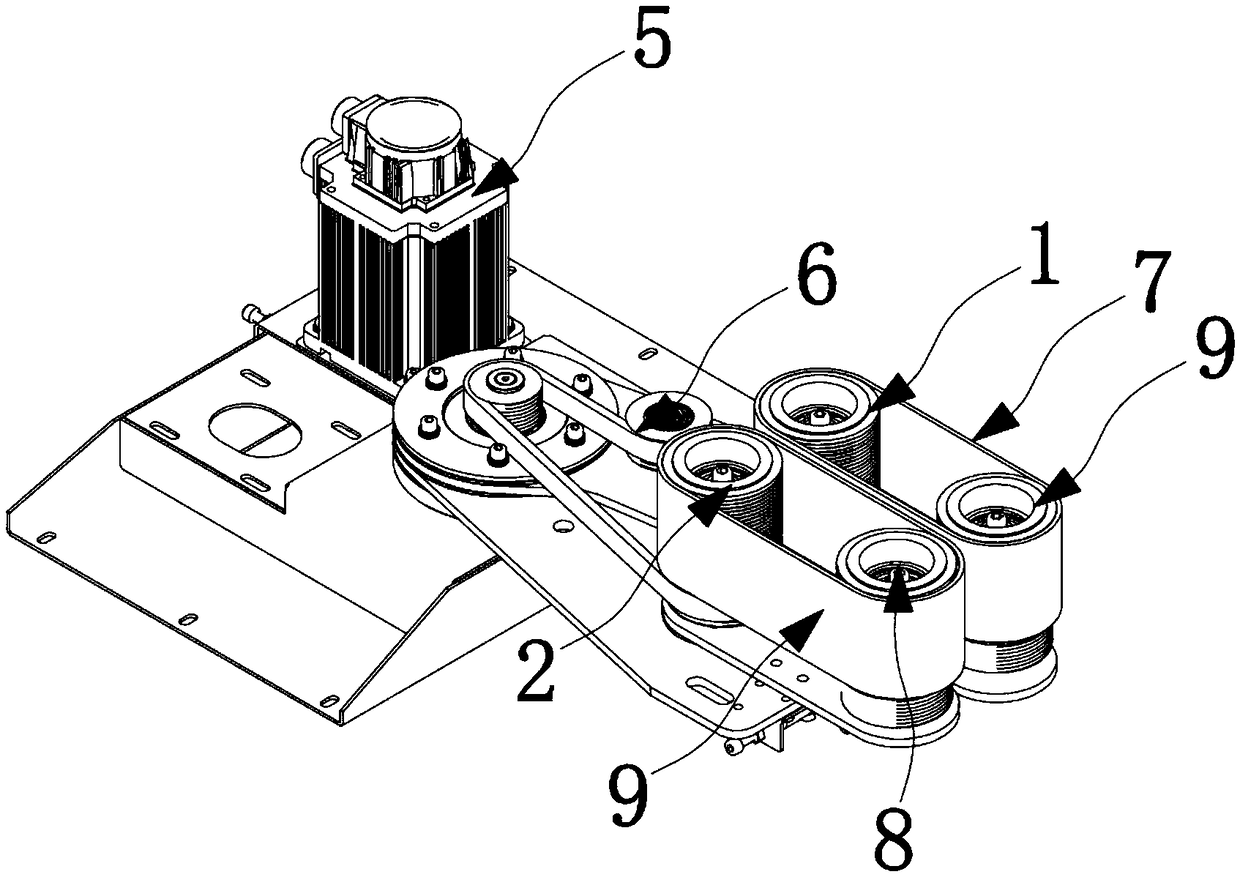

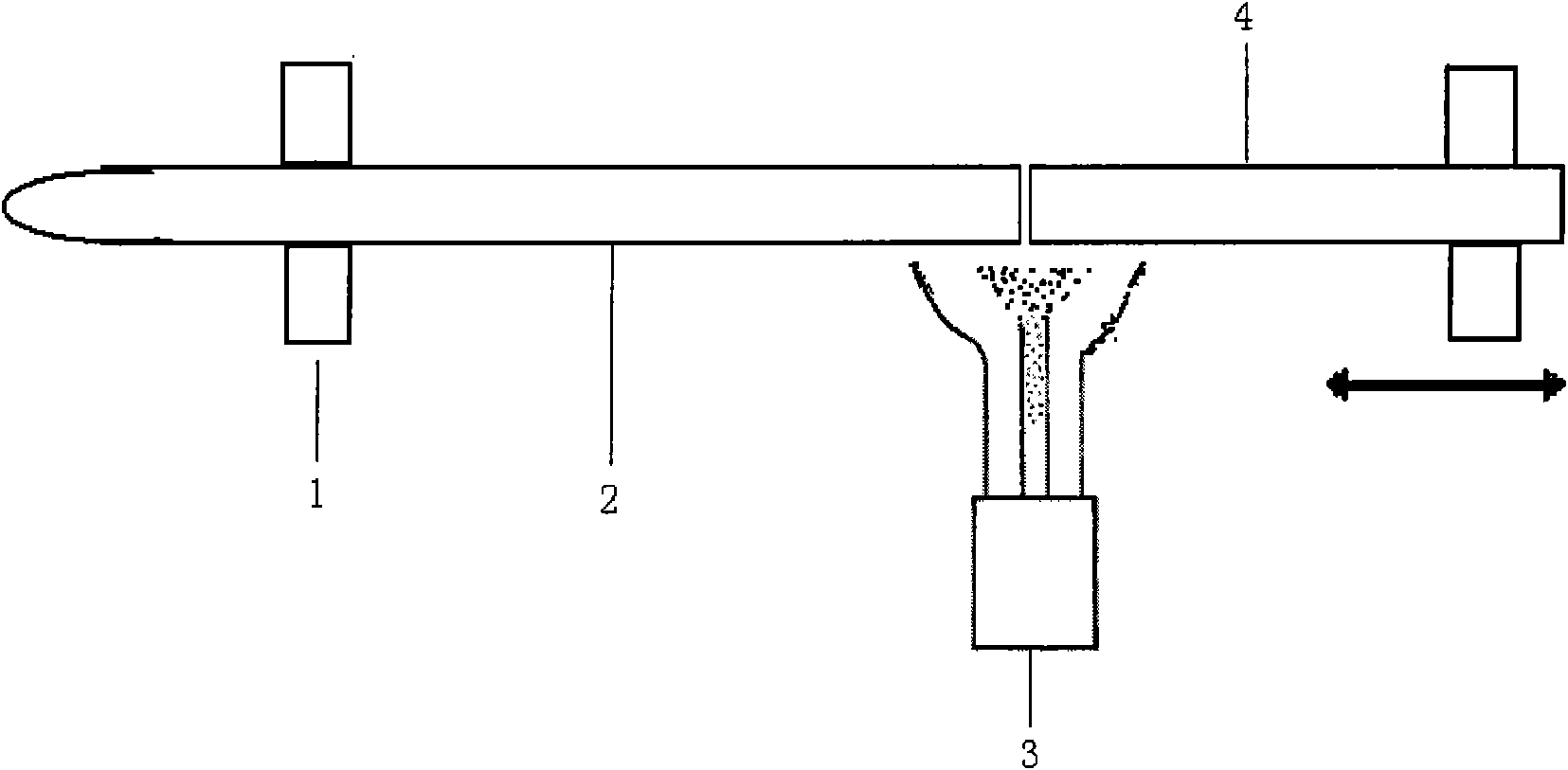

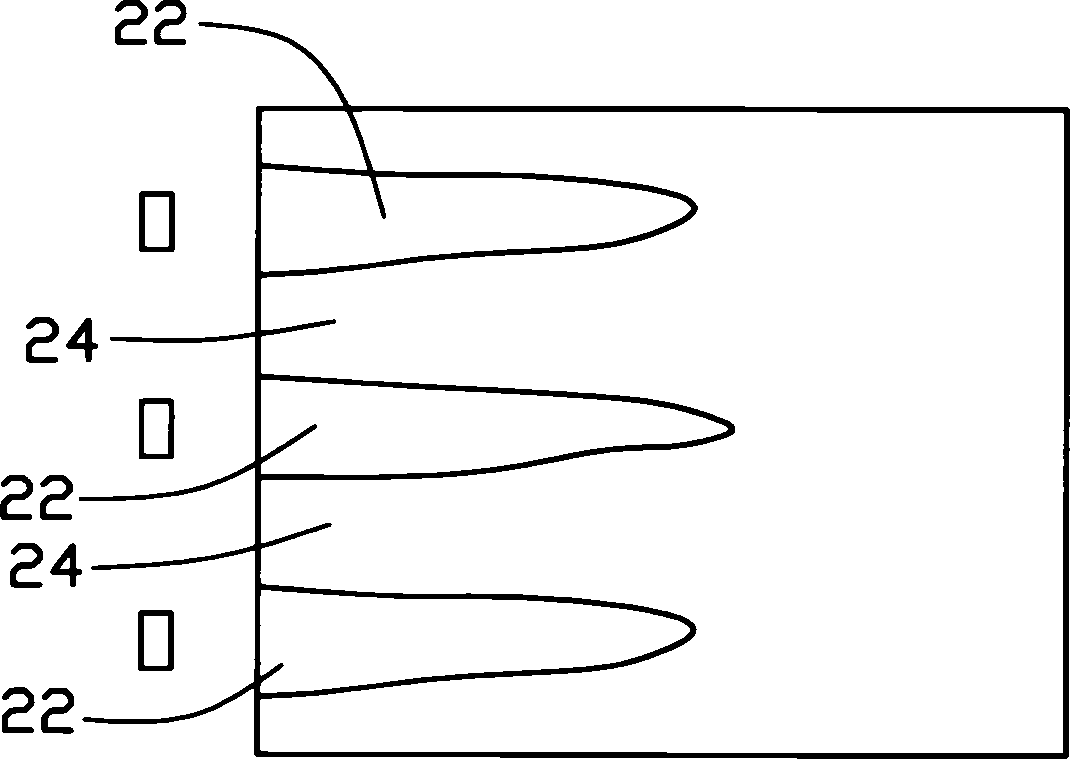

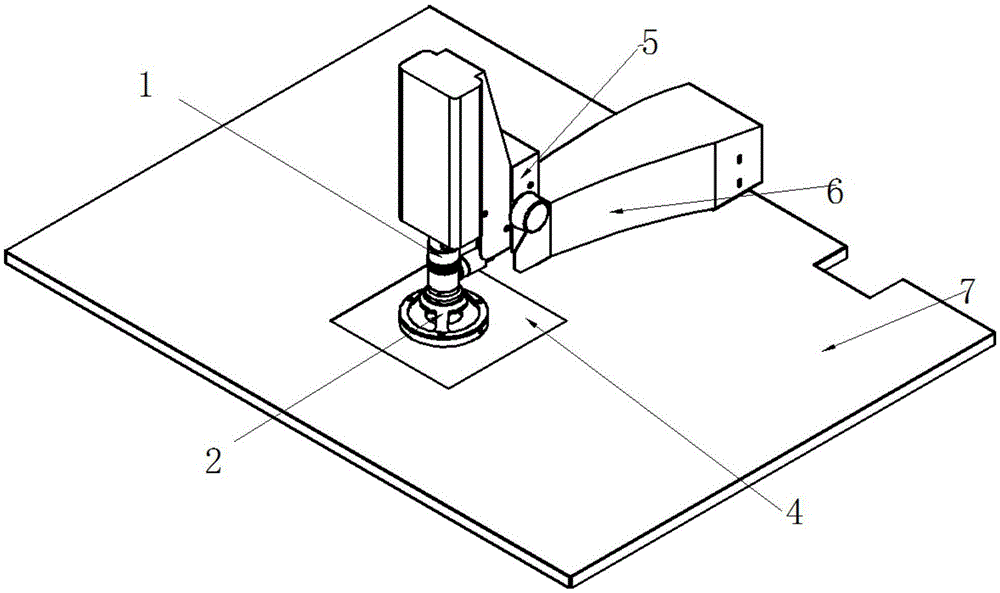

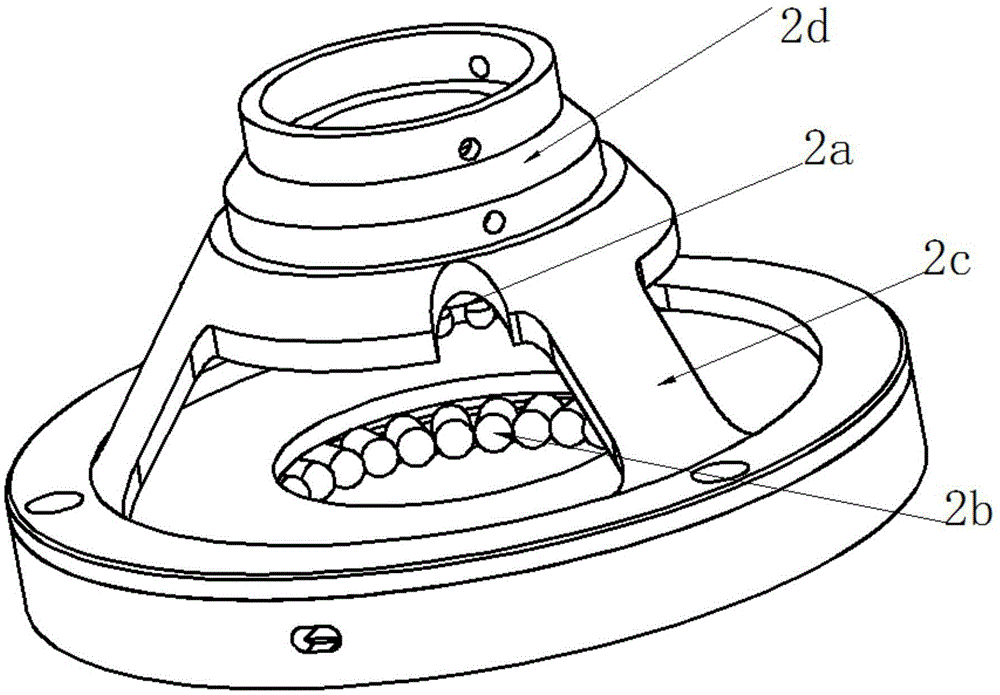

Non-contact on-line detection device of micro gap of wire wrapped screen

InactiveCN101915551AEasy to detectHigh degree of automationUsing optical meansProduction lineVibration measurement

The invention relates to a non-contact on-line detection device of a micro gap of a wire wrapped screen, mainly comprising an image collection unit, a laser vibration measurement unit, an imaging focusing unit and a host computer unit. The device uses the image collection unit to carry out real-time high-quality imaging on the micro gap of the wire wrapped screen, uses the laser vibration measurement unit to solve the influence of radial vibration on an imaging coefficient of the wire wrapped screen in the on-line processing process, calls an imaging coefficient base which is standardized in advance to resolve the micro gap of the wire wrapped screen, calculates a relative error, counts the unqualified rate of gap processing on line and judges whether the wire wrapped gap accords with an expected requirement or not. The imaging focusing unit is suitable for detecting screen gaps of various types. The invention forms a closed loop control processing system by butting an actual wire wrapped screen production line of a factory and has an important significance on on-line revising technological parameters of production, enhancing product indexes, abandoning an unqualified production section at an early date and reducing raw material waste.

Owner:BEIHANG UNIV

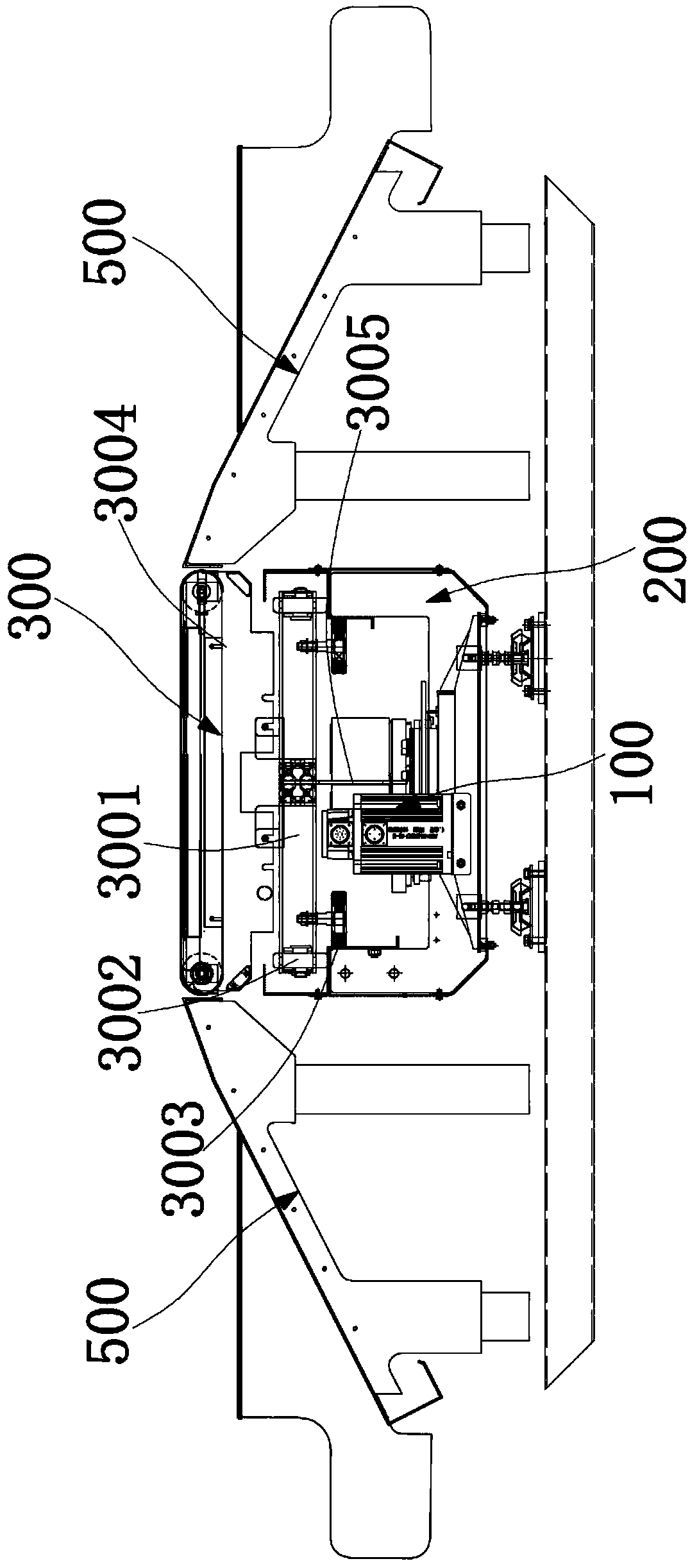

Friction drive device, cross-belt sorting machine and cross-belt sorting system

PendingCN109335568AReduce repair and replacement costsReduce energy consumptionConveyorsControl devices for conveyorsMotor driveDrive wheel

The invention discloses a friction drive device, a cross-belt sorting machine and a cross-belt sorting system. The friction drive device comprises at least one pair of drive wheels keeping a micro-clearance and provided with parallel axes, wherein the two drive wheels can be rotatably arranged on an installation plate and are driven by one same motor so as to self-rotate; and the self-rotation directions of the two drive wheels are opposite. The friction drive device with the scheme is ingenious in design and simple in structure; through arranging a special belt driving mechanism, one motor drives the two drive wheels to rotate, so that compared with an existing friction drive structure, one motor is omitted, the equipment cost is greatly reduced, meanwhile, the energy consumption of the single motor is low compared with the operation energy consumption of two motors, and meanwhile, a transmission mechanism is low in maintenance and replacement cost.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

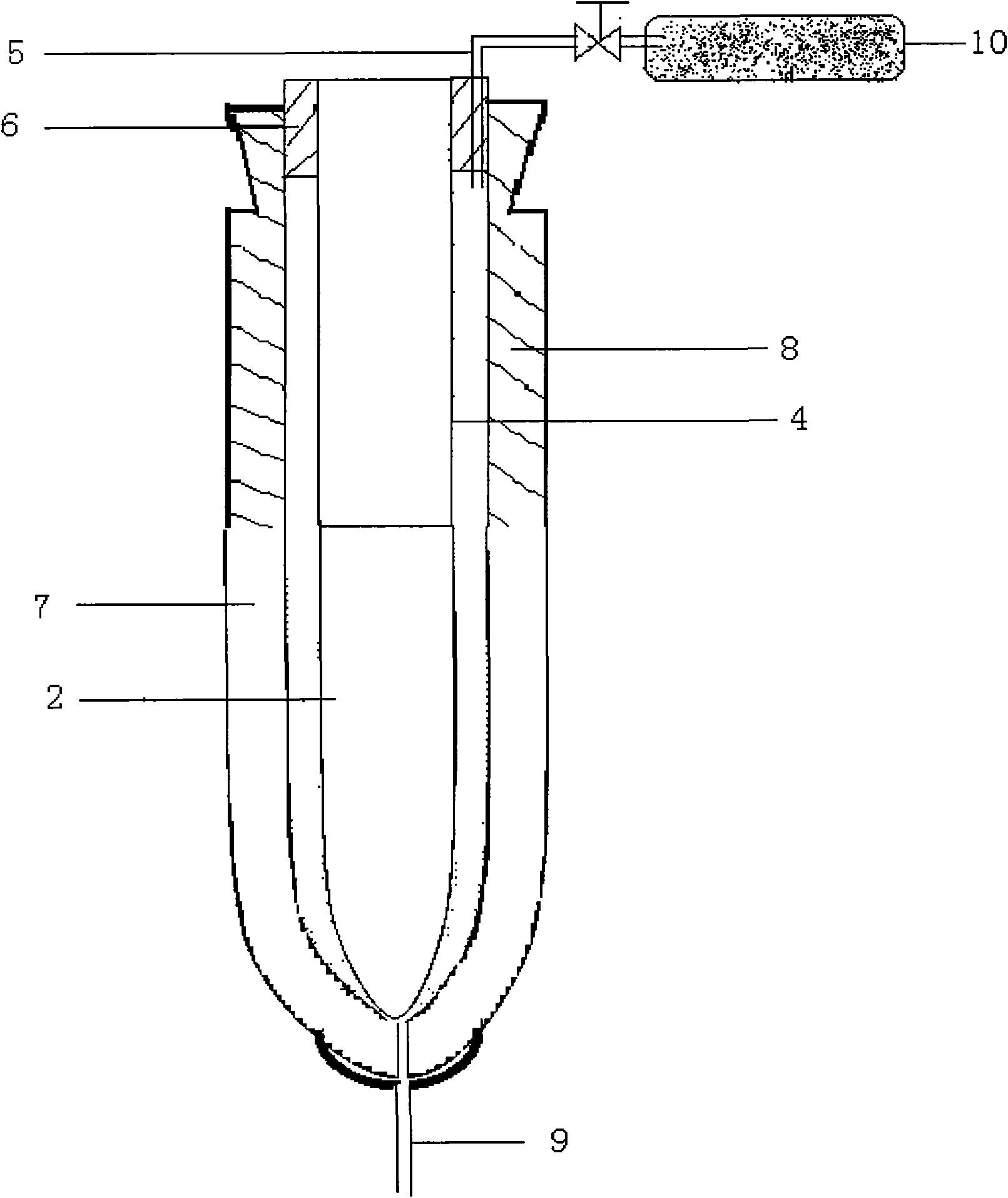

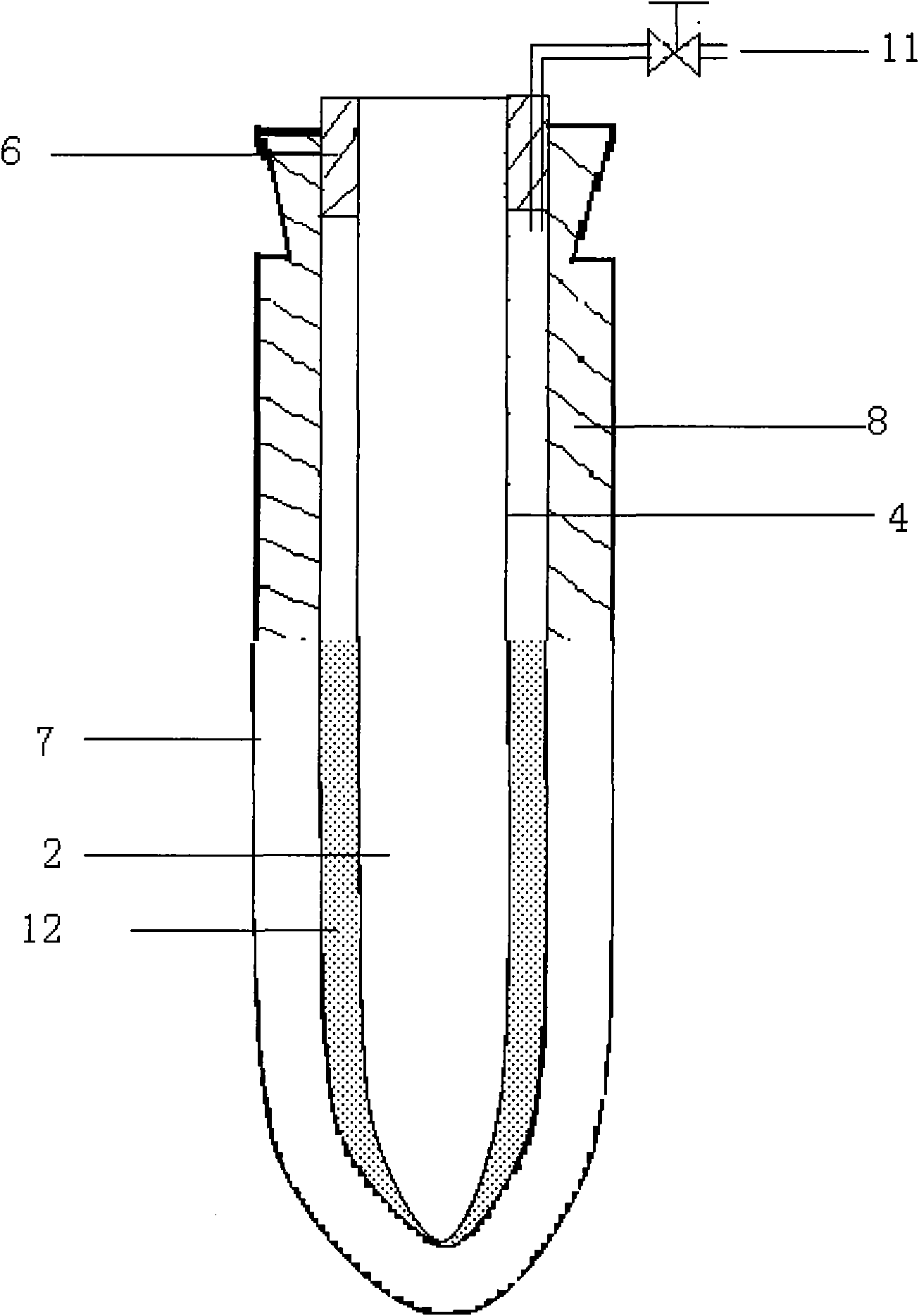

Method for preparing a microgap sleeve optical fiber prefabrication bar and method for drawing and preparing an optical fiber by microgap sleeve optical fiber prefabrication bar

ActiveCN101538113AThere will be no uneven shrinkageStable cladding geometryGlass fibre drawing apparatusGlass productionHydrofluoric acidMicro gap

The invention discloses a method for preparing a microgap sleeve optical fiber prefabrication bar and a method for drawing and preparing an optical fiber by the microgap sleeve optical fiber prefabrication bar and relates to the production of an optical fiber prefabrication bar and a method for drawing the wire by the optical fiber prefabrication bar. The method for preparing the microgap sleeve optical fiber prefabrication bar comprises the following steps: 1) a joint handle adopts a glass lathe and uses oxyhydrogen flame for separately abutting a core bar, a handle bar, a sleeve and a tail handle end face after high-temperature melting; 2) the joint handle is cleaned and dried, and 2-3 percent of hydrofluoric acid is used for cleaning the surfaces of the core bar and the sleeve for 2 hours so as to remove pollutants on the surfaces; and 3) in the assembly process, the cleaned and dried core bar is assembled into the sleeve, and then quartz sand is filled between the sleeve and the core bar so as to obtain the microgap prefabrication bar. The microgap sleeve optical fiber prefabrication bar is fixed on a collet of an optical fiber wire drawing tower and then molten so that an optical fiber can be drawn out from a lower opening of a wire-drawing stove and then is sequentially measured in diameter by a diameter measurer, cooled by a cooling pipe, coated, solidified by optical fiber coating and drawn by a main drawing device so as to reach a double-wire-collecting machine for optical fiber winding.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

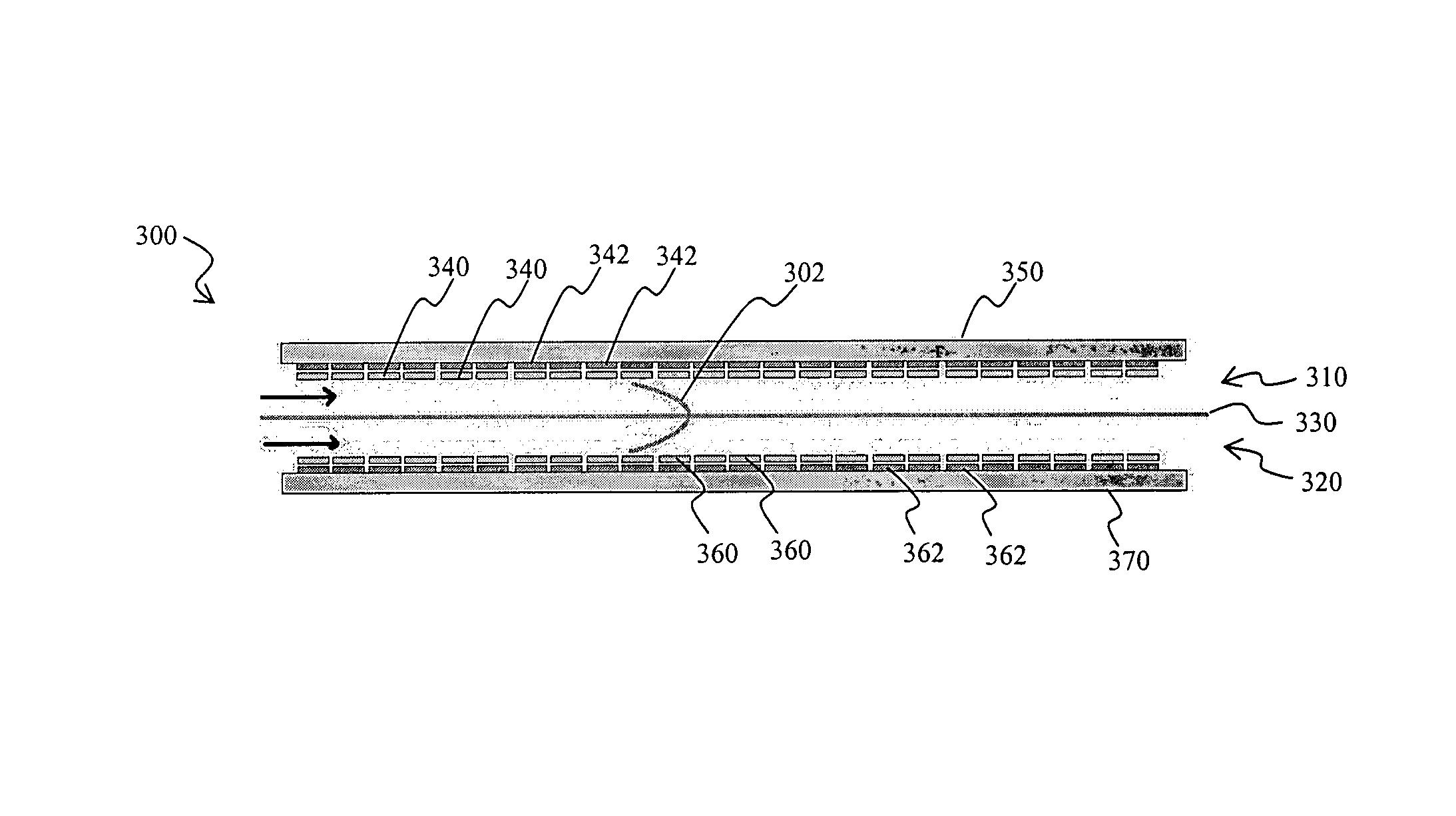

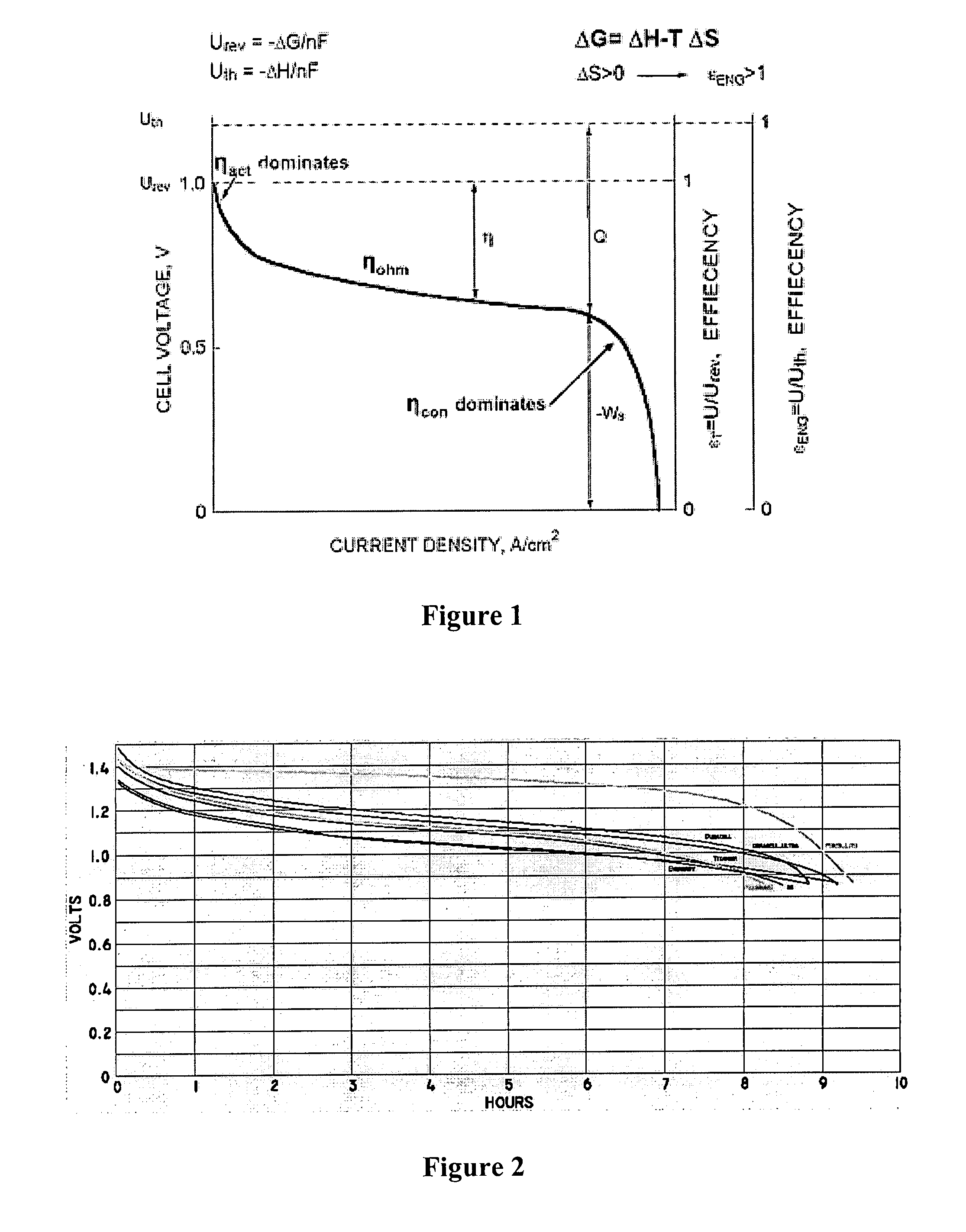

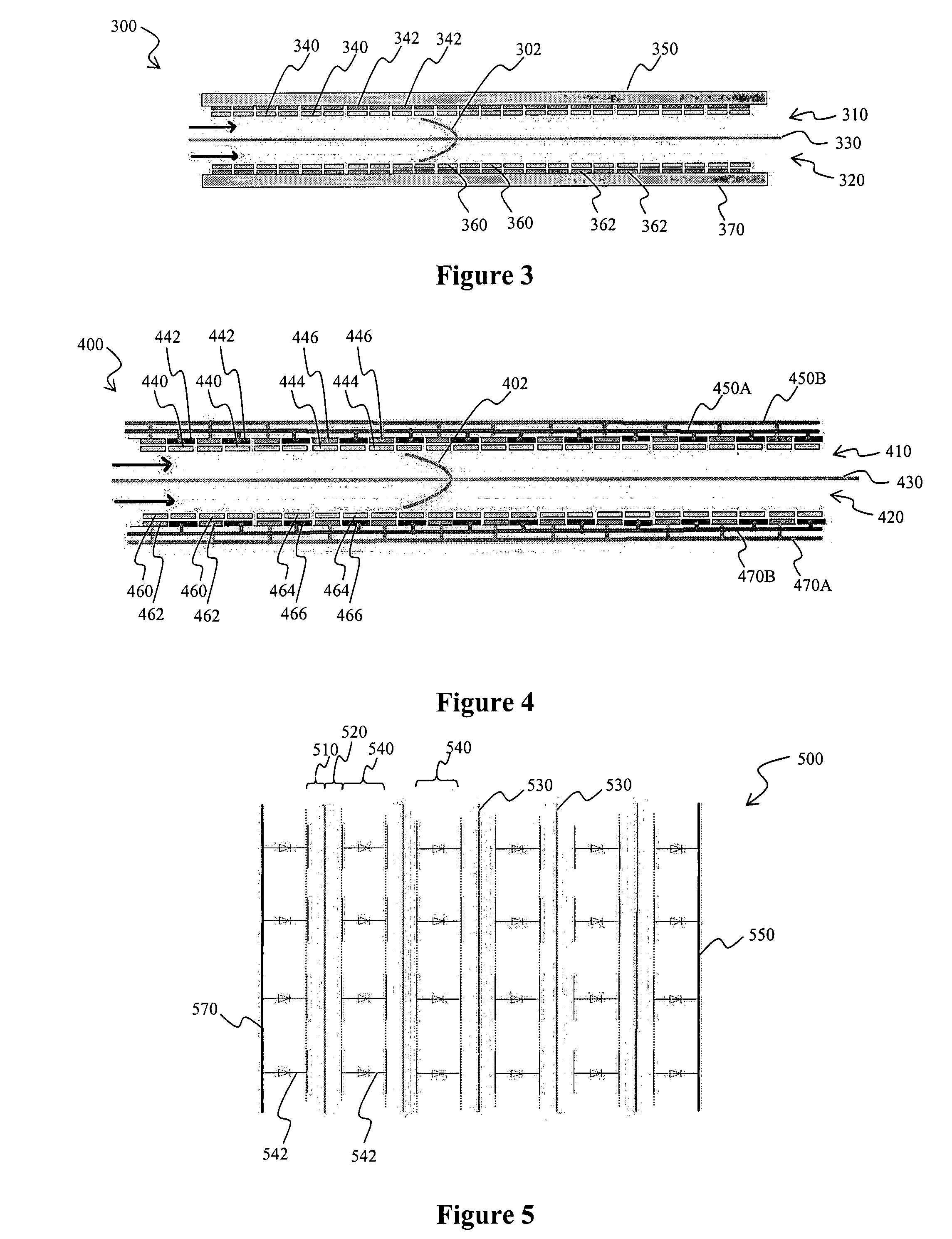

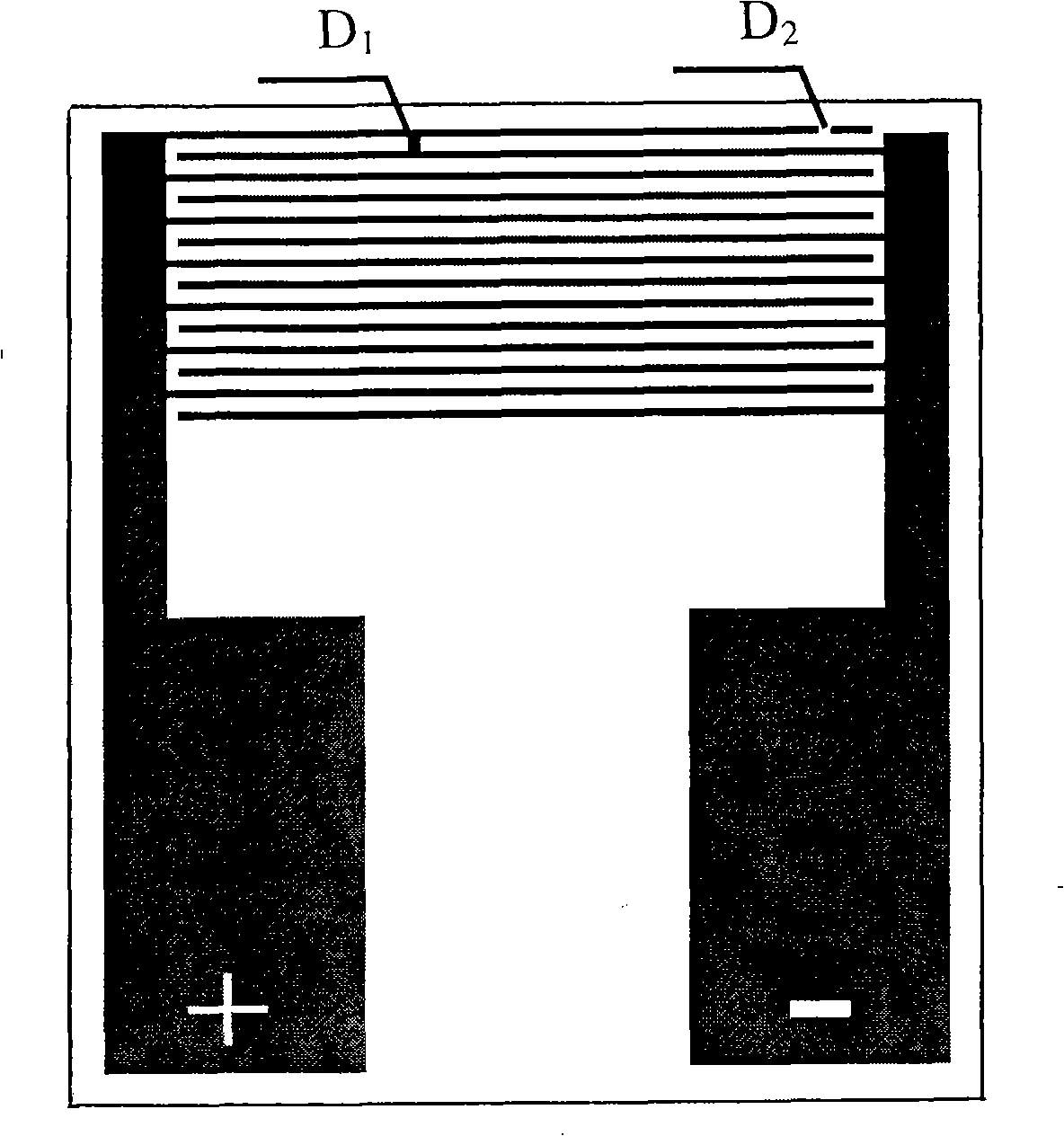

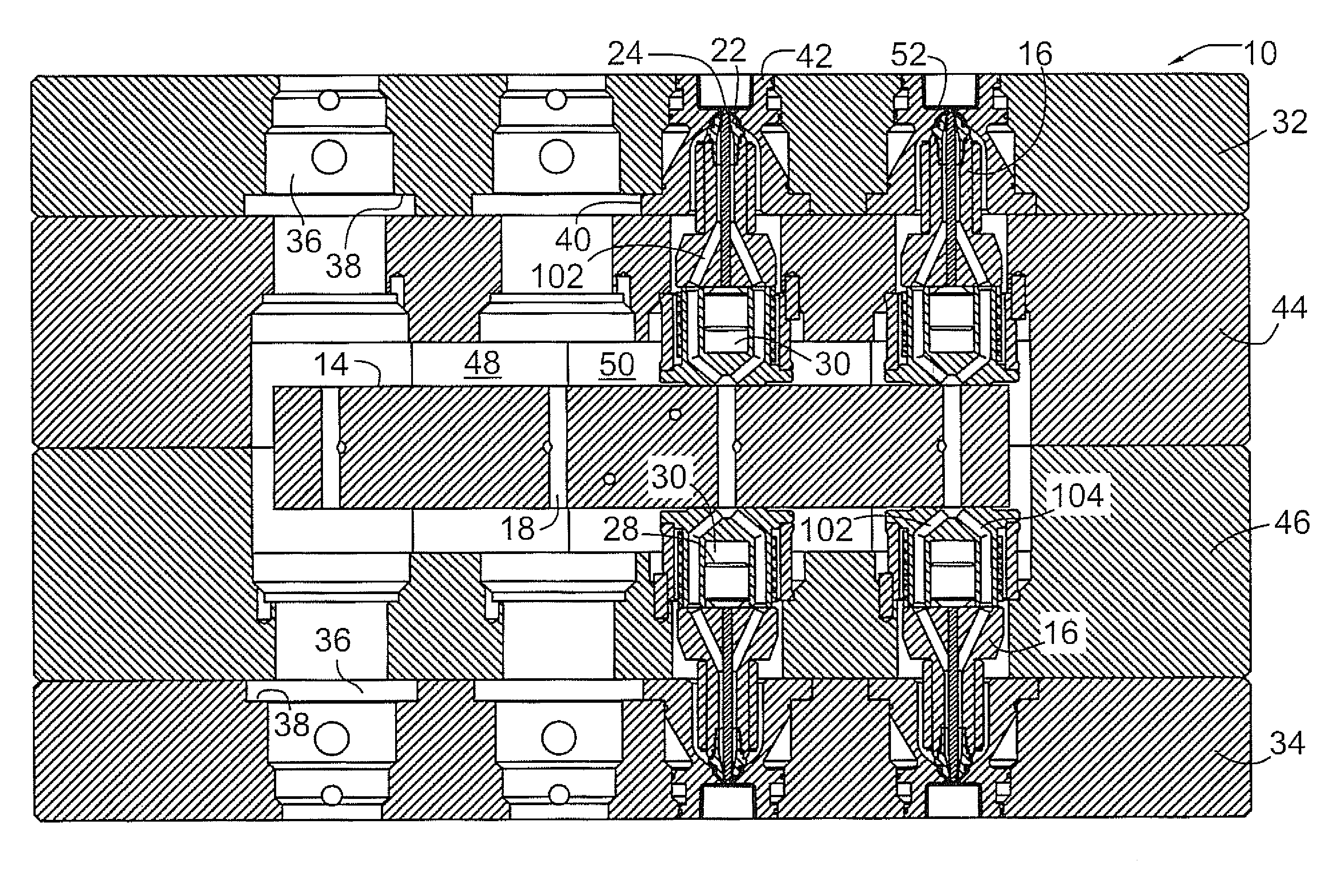

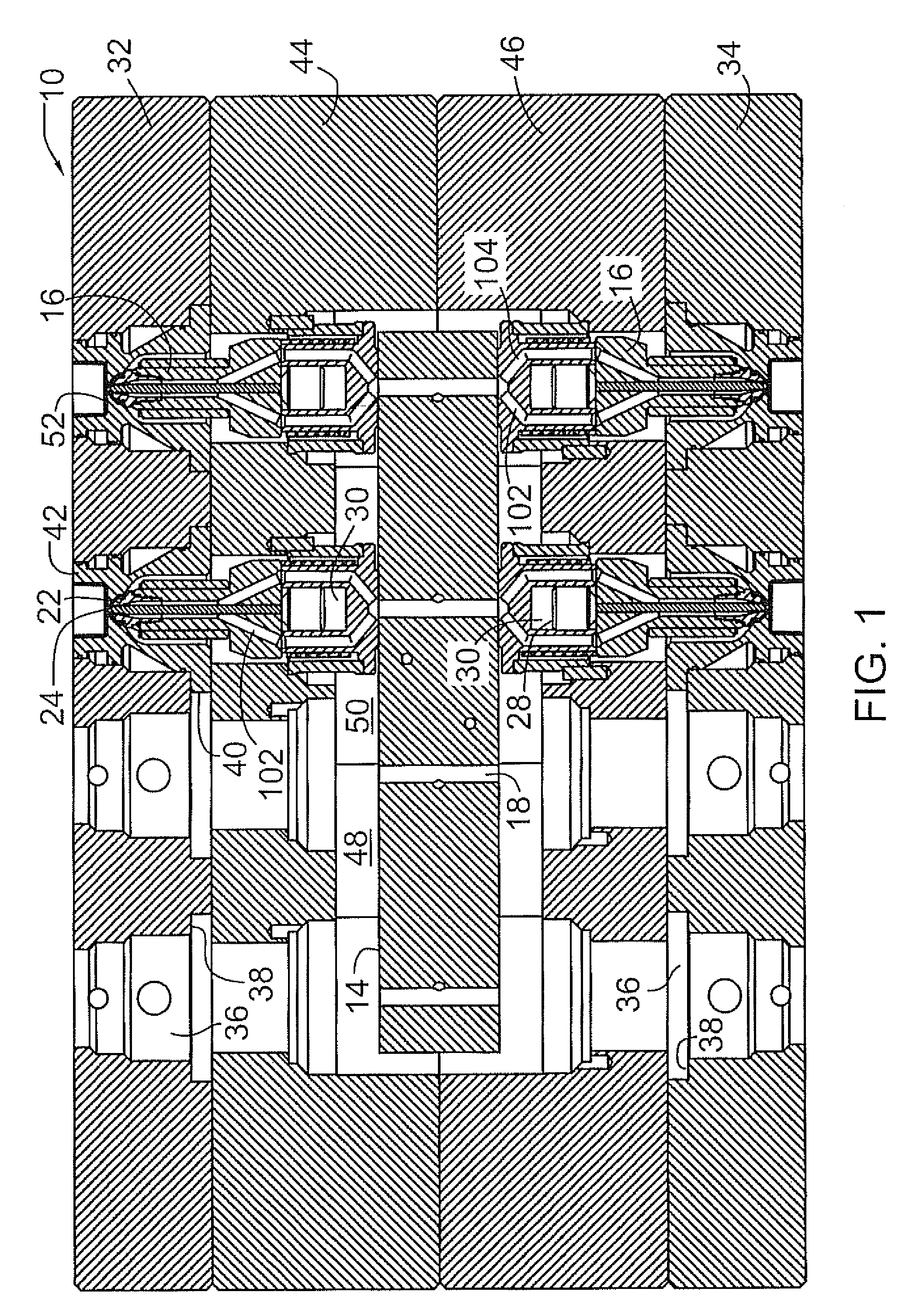

Micro gap flow through electrochemical devices with self adjusting reactive surfaces

Contemplated electrochemical devices and methods include an electrolyte flow path in which substantially all of the electrolyte has laminar flow. A segmented electrode contacts the electrolyte, and each of the segments in the segmented electrode is preferably coupled to a control device to provide control over the flow of current to and / or from the electrolyte. Thus, it should be appreciated that the redox state of the electrolyte can be changed in a single-pass through the flow path, which effectively eliminates problems associated with mass transport phenomena and reduced current efficiency.

Owner:CLARKE RICHARD

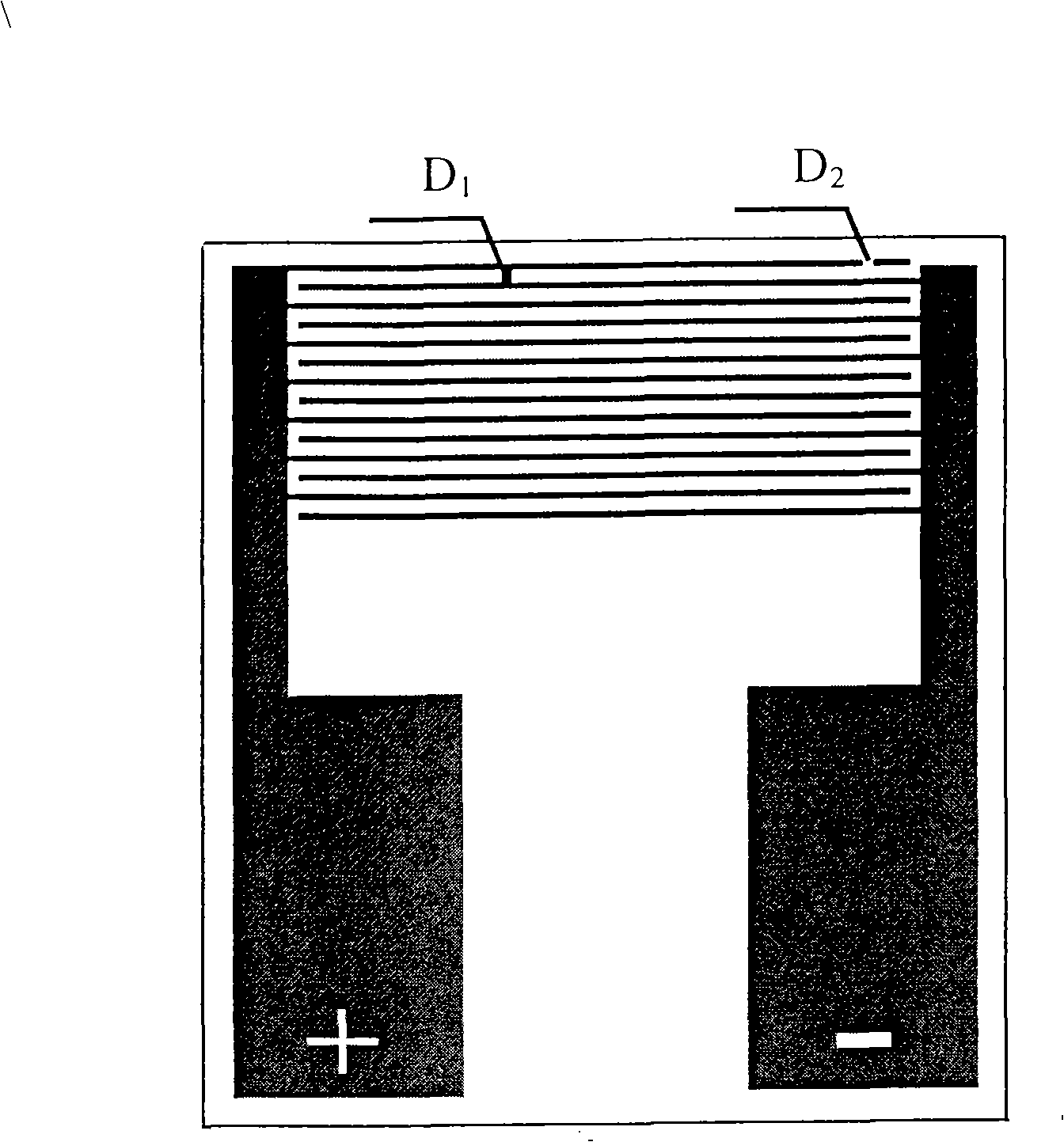

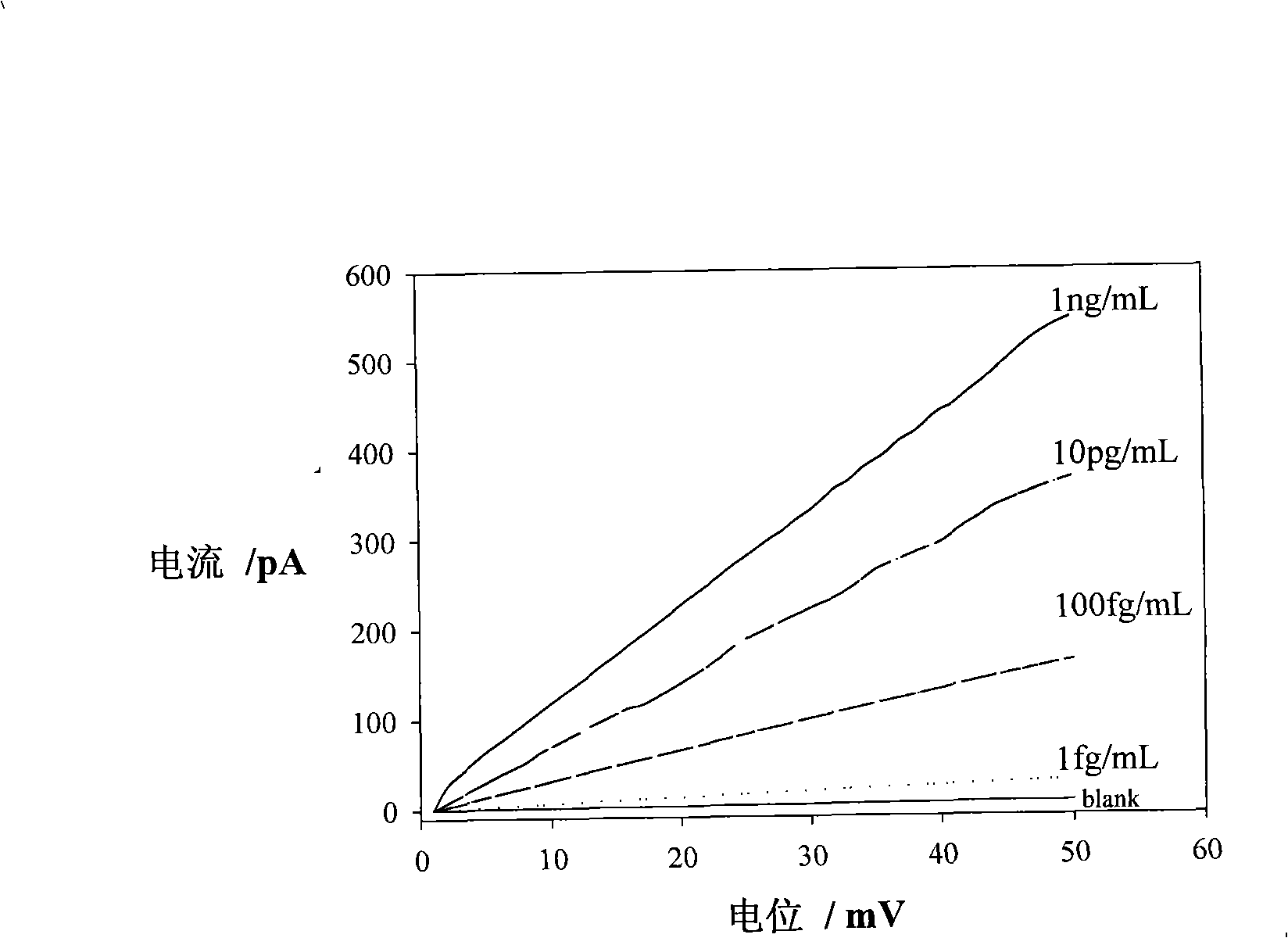

Enzyme catalysis conductance immune sensor and method for detecting food-borne causal agent

InactiveCN101275950AQuick checkRapid identificationMaterial analysis by electric/magnetic meansEscherichia coliFood borne

The present invention provides a micro-gap electrode array immune sensor which is used for detecting food-borne causal agent. The sensor comprises a micro-gap array electrode, an electrode substrate which is silylanized, an enzyme deposit which has excellent electric conductivity and an enzyme linked immunoreaction sensor based on the electrical conducting test. The invention also provides a detecting method. The invention uses the micro-gap electrode array immune sensor for detecting salmonella and bacillus coli O157:H7. The method has the advantages of high sensitivity, easy operation, portability and low cost. The invention can provide an immune detecting technique which has the advantages of high speed, practicability, low cost, high sensitivity and high flux for detection and determination of the food-borne pathogenic bacteria. The transmission of food-borne pathogenic bacteria can be controlled and prevented in time and effectively.

Owner:HUNAN UNIV

Organic silicon pouring sealant with thixotropy

InactiveCN104031604AMixed thixotropyExtend your lifeNon-macromolecular adhesive additivesOther chemical processesMicro gapMoisture

The invention relates to an organic silicon pouring sealant, and in particular relates to the organic silicon pouring sealant for insulation, moisture prevention, heat conduction and flame retardance of electronic and electrical appliances. The pouring sealant has the effects of performing insulation protection on each electronic component, rapidly conducting out work heat to prolong the service life, has rapid thixotropic property after being mixed, and is especially suitable for the occasions that to-be-sealed appliances have micro gaps.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

Enzyme catalysis electricity-conducting immunity sensor based on micro-gap array electrode and its immunity detecting method

InactiveCN101271114ARealize detectionHigh sensitivityMaterial analysis by electric/magnetic meansBiological testingElectricityMicro gap

The invention provides an enzyme-catalyzed conductivity immune sensor based on a micro-gap array electrode and an immune detection method thereof, the immune sensor comprises a micro-gap array electrode, an electrode substrate which is carried out the silanization treatment and enzyme sediments with great conductivity; the invention utilizes the micro-gap electrode array immune sensor, fixes the antibody of the object to be detected on the electrode gap substrate and utilizes an enzyme-labeled antibody sandwich to carry out the detection of the protein to be detected. The method of the invention has the advantages of high sensitivity and simple operation, the device is portable and the price is cheap, which possibly provides the immune detection technology with rapidity, practicality, low cost, high sensitivity and high throughput for the early and on-site detection and application of the diseases.

Owner:HUNAN UNIV

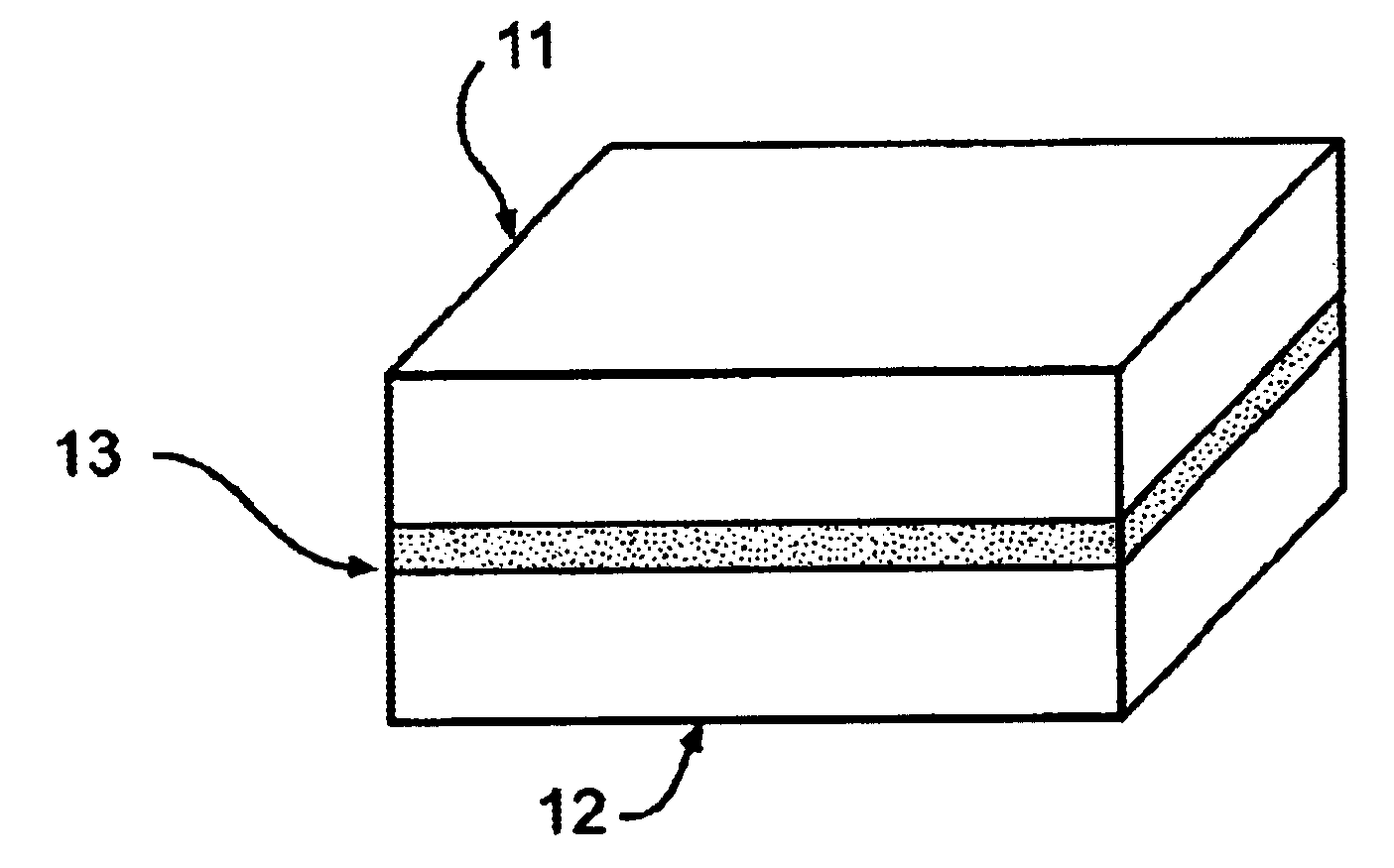

Micro-gap gas filled dielectric capacitor

InactiveUS6775124B2Improve performanceFixed capacitor dielectricStacked capacitorsDielectricPlanar electrode

The gas dielectric capacitor for high frequency applications. The capacitor has first and second planner electrodes separated by an adhesive having solid particles, which establish the distance between electrodes. An adhesive is formed along peripheral edges of the planner electrodes. The capacitor may include air, vacuum, or any number of other dielectric gases, which may be under pressure. A method is disclosed for manufacturing an array of capacitors having a pressurized gas dielectric.

Owner:MIND FUSION LLC

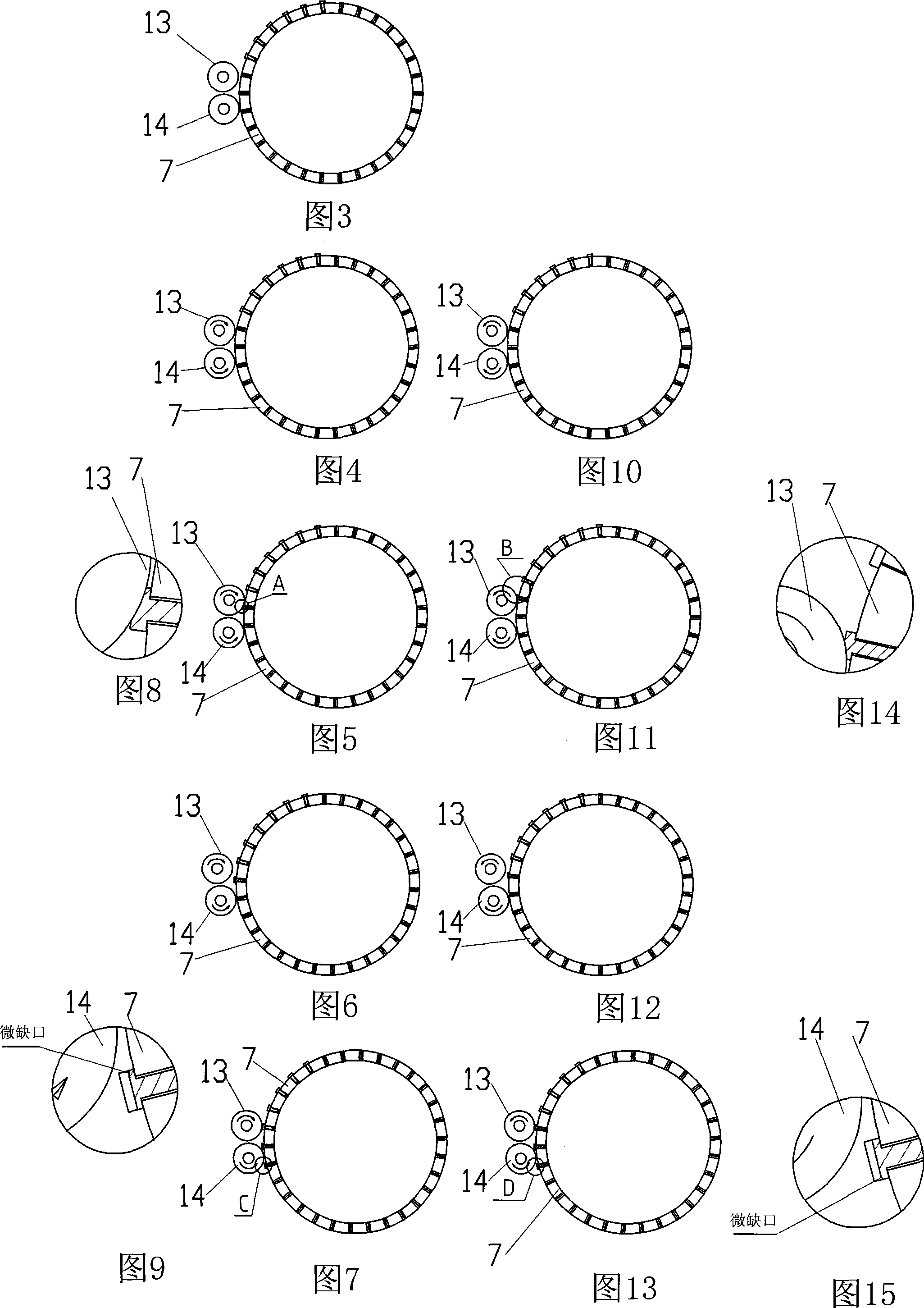

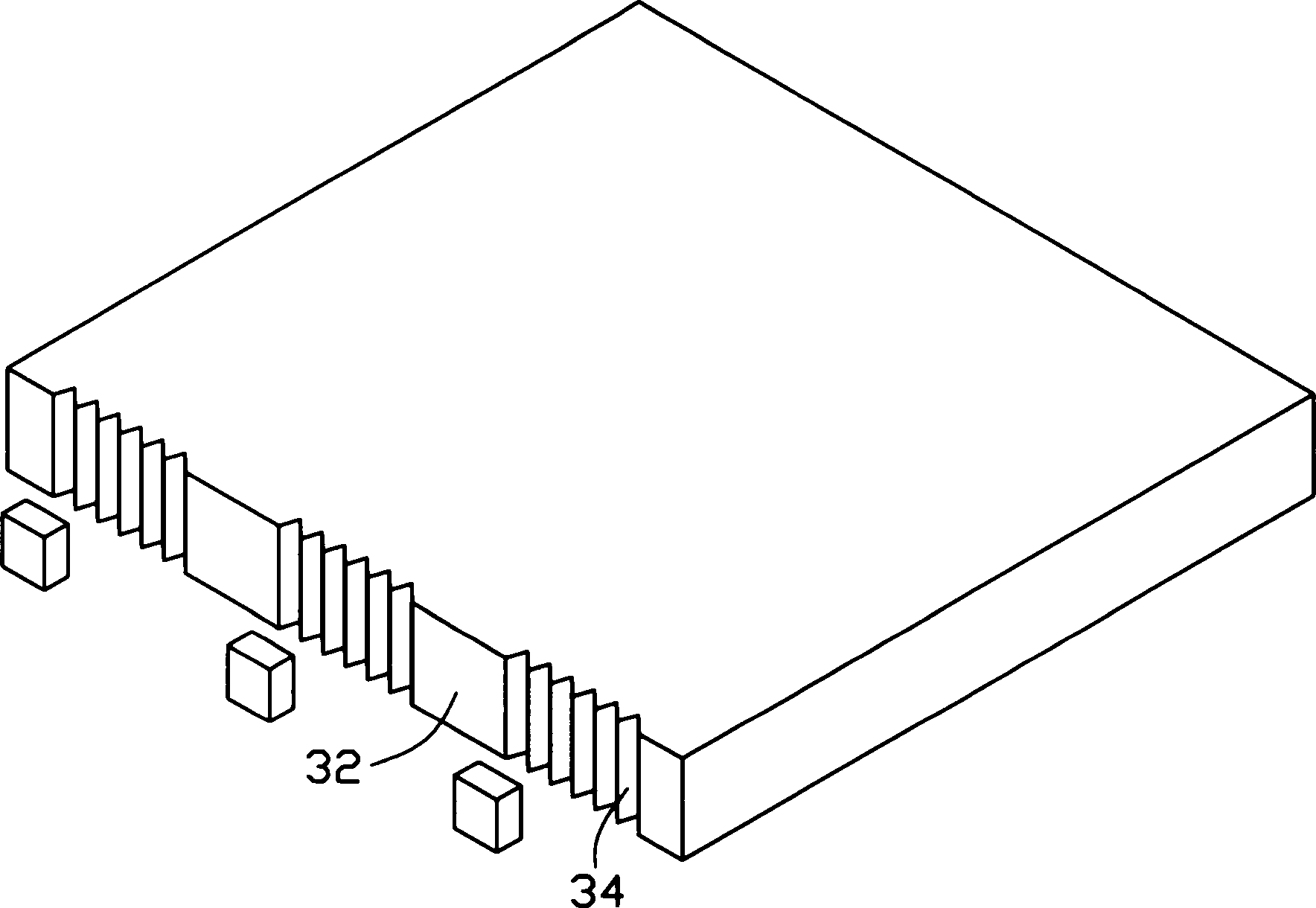

Tire mold

InactiveUS7021914B2Good lookingAvoid it happening againTyresPneumatic tyre reinforcementsMicrometerMicro gap

Owner:SUMITOMO RUBBER IND LTD

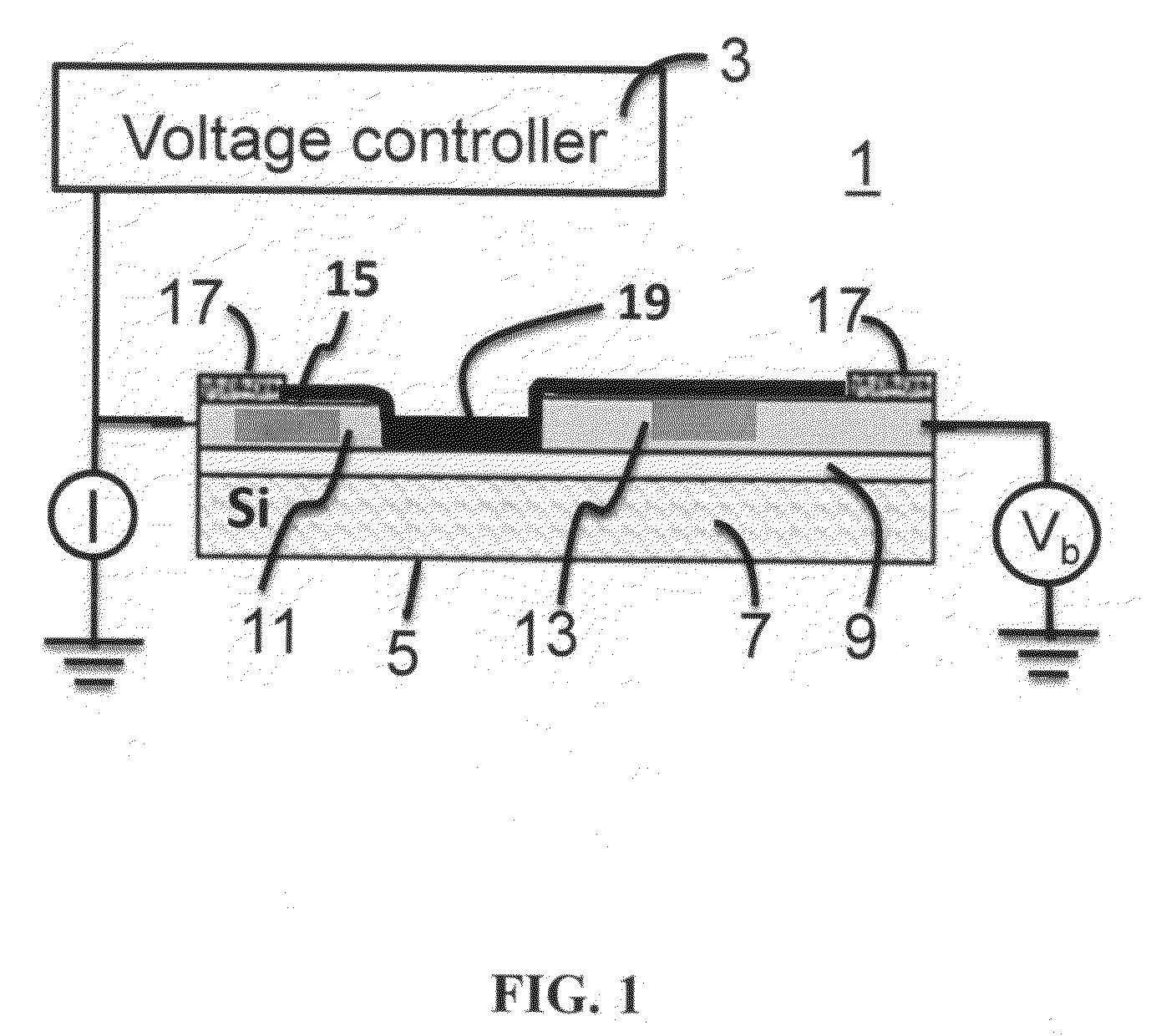

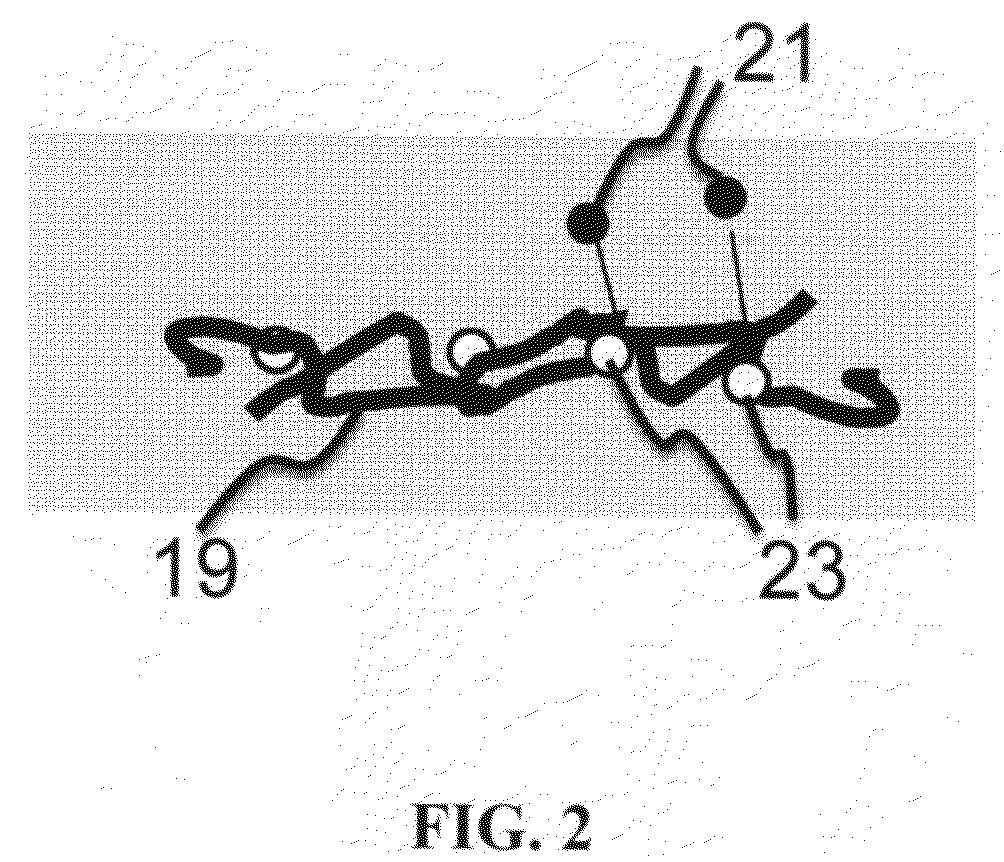

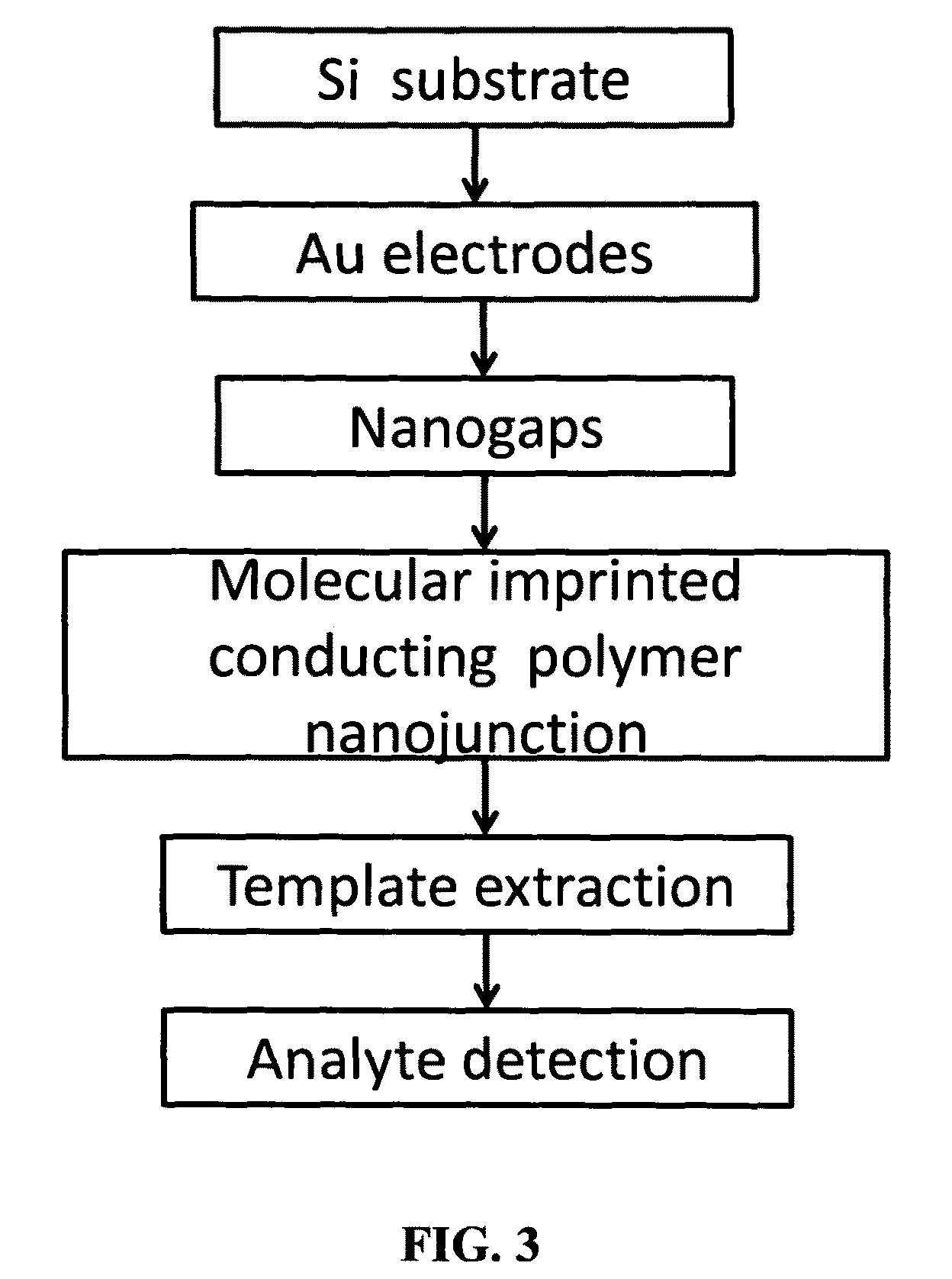

Molecular imprinted nanosensors and process for producing same

InactiveUS8313633B2Efficient extractionElectrophoretic coatingsSuperimposed coating processMetallic electrodeInsulation layer

A molecular recognition sensor system is provided incorporating a molecular imprinted nanosensor device formed by the process steps of:(a) fabricating using photolithography a pair of metallic electrodes separated by a microscale gap onto a first electrical insulation layer formed on a substrate;(b) applying a second electrical insulation layer on most of a top surface of said pairs of electrodes;(c) depositing additional metallic electrode material onto said electrode pairs using electrochemical deposition, thereby decreasing said microgap to a nano sized gap between said electrode pairs;(d) electrochemically polymerizing in said nanogap conductive monomers containing a target analyte, thereby forming a conducting polymer nanojunction in the gap between electrode pairs; and(e) immersing resultant sensor device in a solution which removes away the target analyte, and intermittently applying a voltage to the conducting polymer while it is immersed in said solution, thereby swelling and shrinking the conducting polymer to effect a more efficient extraction of target analyte from the conducting polymer.

Owner:POLESTAR TECH

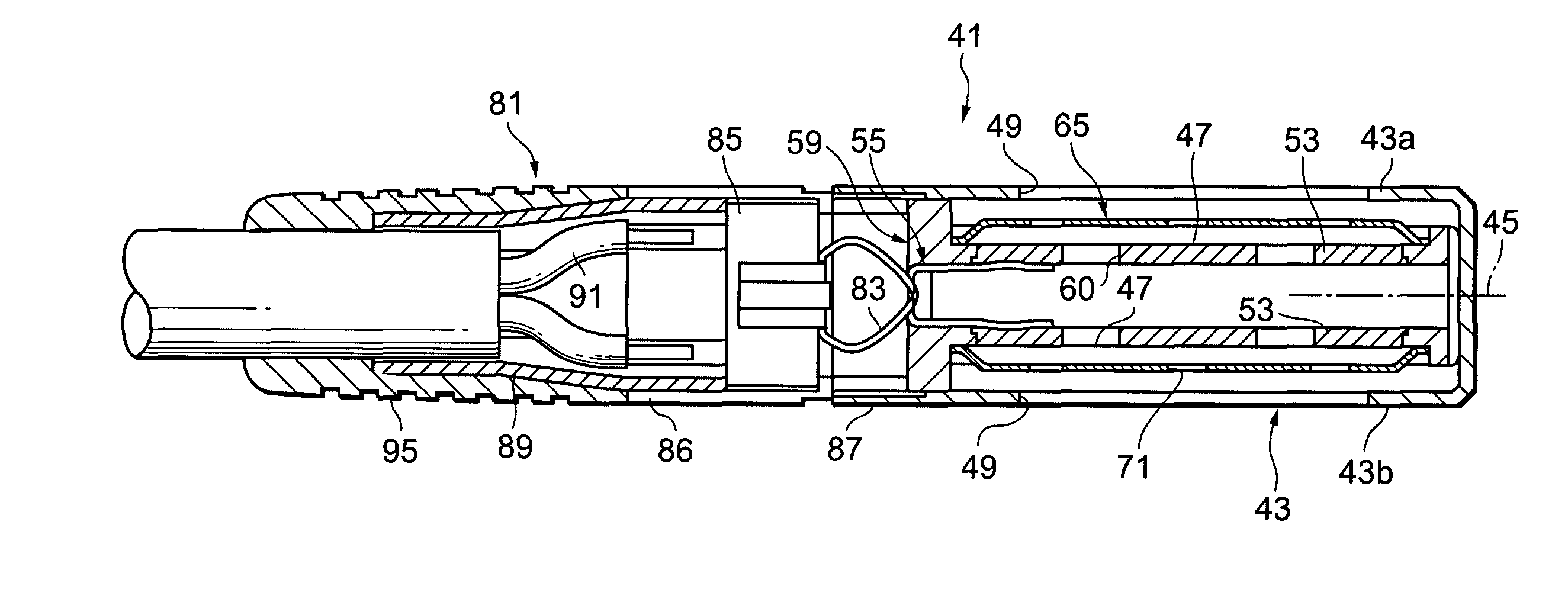

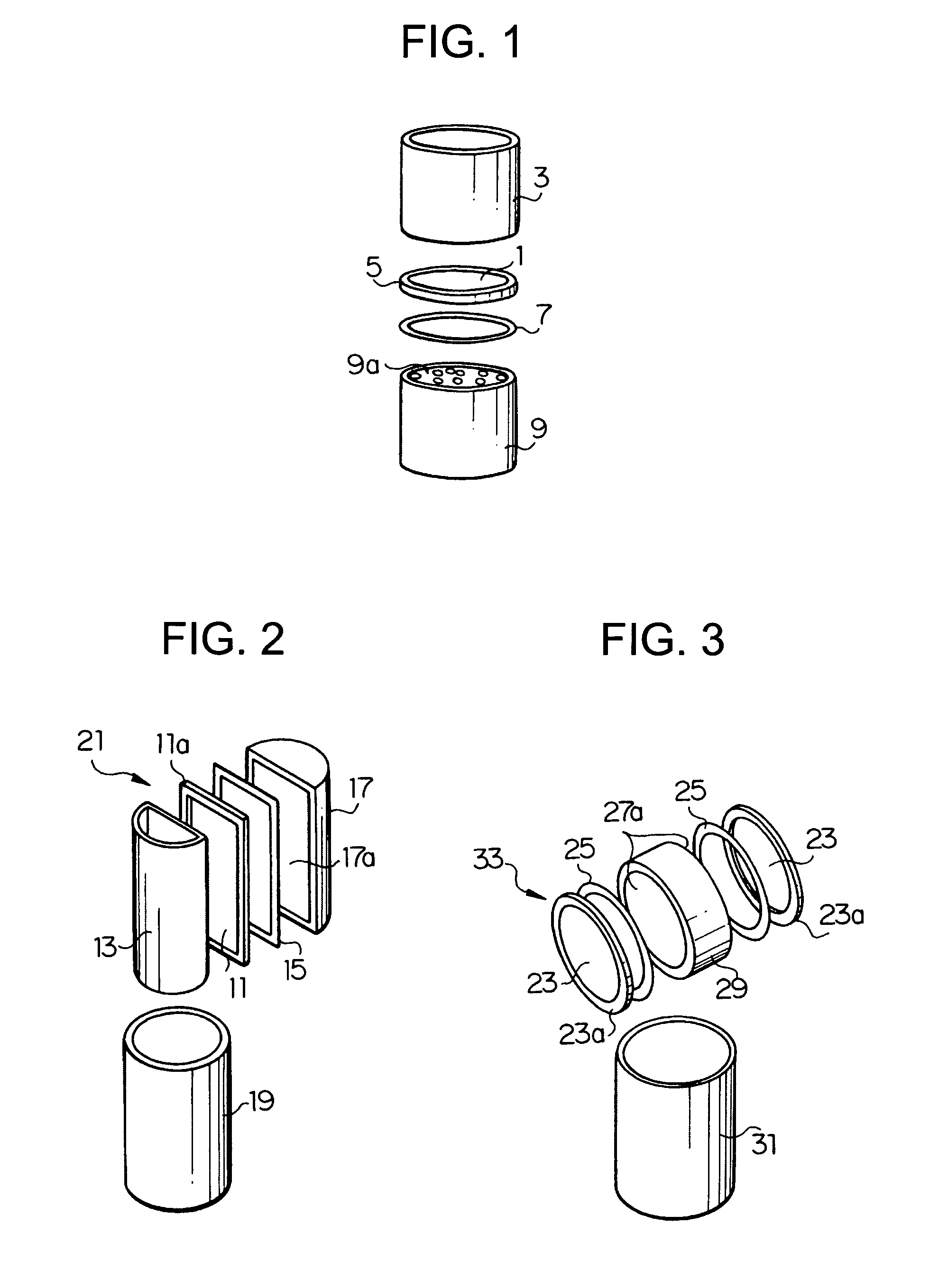

Condenser microphone

InactiveUS7106869B2Reduce the bodyEnlargement of vibration plate areaPiezoelectric/electrostrictive microphonesElectrets selectrostatic transducerCapacitanceBody axis

The present invention relates to a condenser microphone whose body can be miniaturized while keeping a property and a sound quality comparable to those of a conventional condenser microphone. The condenser microphone includes a cylindrical body, a plurality of vibration plates which are formed into the shapes of squares and placed in parallel to a body axis line within the body, acoustic holes formed on a body side wall in a direction vertical to the vibration plates and back pole plates which are placed on a side opposite to the acoustic holes with the vibration plate between and face on the respective vibration plates at an interval of a micro gap. A potential of the back pole plate is varied according to a vibration of the vibration plate.

Owner:SONY CORP

Modified formula for enhancing rapidly-dried silica sol

InactiveCN101885036AImprove wet strengthSpeed up evaporationFoundry mouldsFoundry coresFiberEvaporation

The invention relates to a modified formula for enhancing rapidly-dried silica sol. The technical scheme is that: the modified formula consists of the following components in part by weight: 8,500 to 9,800 parts of silica sol, 100 to 1,200 parts of emulsion, 80 to 160 parts of fiber, and 20 to 180 parts of antifoaming agent. The modified formula has the advantages that: by using the interpenetrating and complementary characteristics of the silica sol and the emulsion, coatings coated on the surface of a wax mold are in net distribution, the wet strength of the coatings is improved, and the next-layer sizing agent can be applied to the incompletely dried upper-layer sizing agent; by using the water conduction function of the fiber, the water inside and outside the coatings is balanced, the inner stress is reduced, the mold shell cracking probability is reduced, the evaporation of the water is accelerated, and the drying time is shortened; an ultra-micro gap of the fiber formed by high temperature carbonization can reduce the retained strength of the mold shell, also can improve the air permeability of the mold shell, and comprehensively improves the quality of casting products; and the period of shell making technology is shortened from 5-7 days to 1-2 days.

Owner:武汉市智发科技开发有限公司

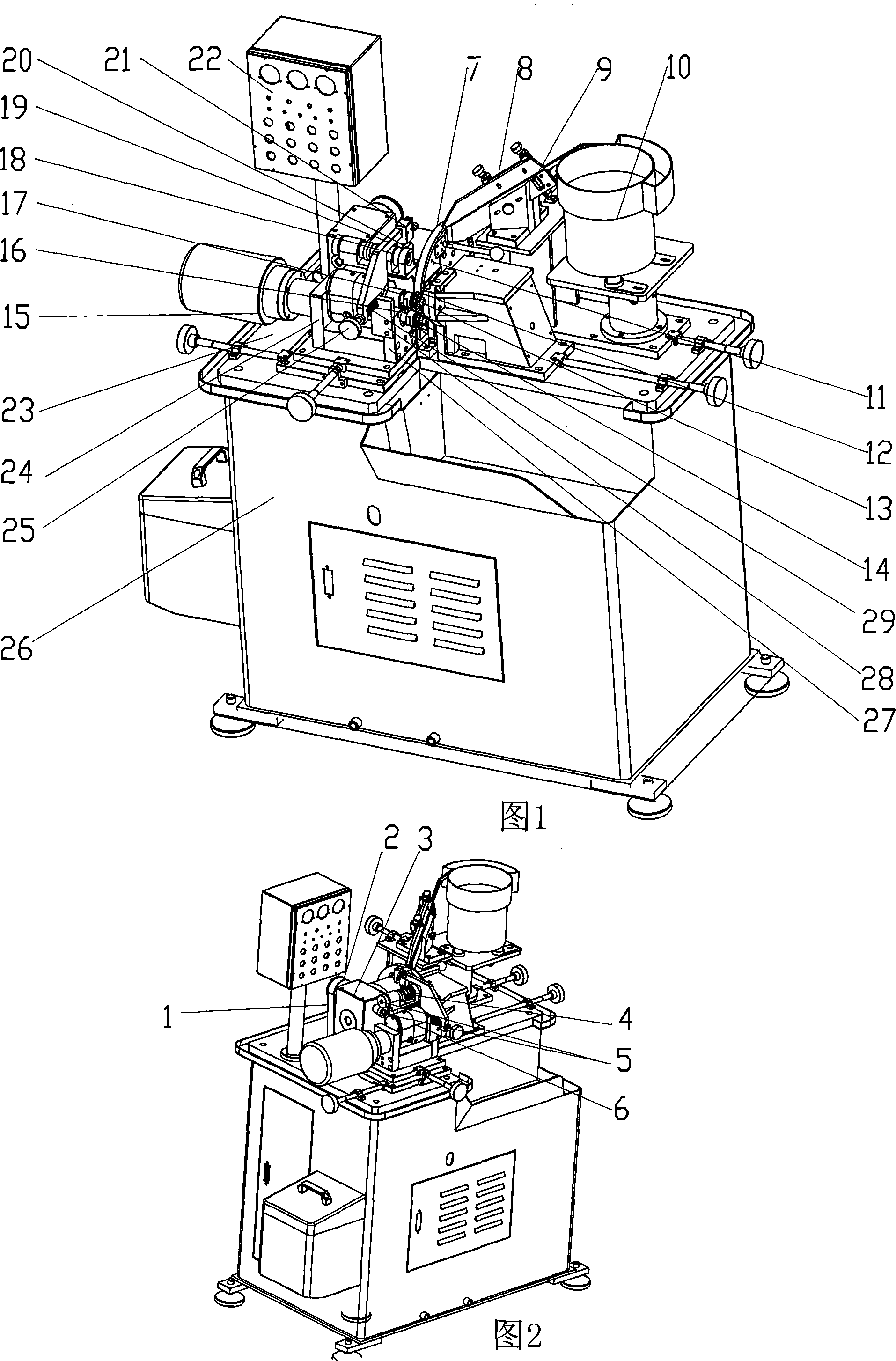

Processing method of slot for bolt micro-nick without burr and device thereof

ActiveCN101224509AGeneration and eliminationPrecise size controlMilling equipment detailsDriving apparatusCircular discMicro gap

The invention belongs to the screw head slotting technical field, in particular to a processing method and a device of a screw micro-gap I-shaped trough without burrs. A clamping disc and a milling blade are rotated under the driving of a power source; workpieces are uniformly distributed in the workpiece troughs on the circumference of the clamping disc along the clamping disc and cut by a first milling blade and a second milling blade sequentially under the driving of the clamping disc. The first milling blade withdraws the workpiece after an arc gap is milled; the outlet is arranged on the top of the workpiece but does not perforate the other port of the workpiece. The second milling blade cuts the I-shaped trough in the rotation direction which is reverse to that of the first milling blade. The milling tracks of the two milling blades on the I-shaped trough are crossed at the internal side of the notch, thus forming the micro-gap and generating no burrs at the two ports of the I-shaped trough. The finished workpiece continues to rotate and falls down when the workpiece trough faces downwards under the rotary driving of the clamping disc, thus achieving the milling trough process. The finished screw product of the invention generates no burrs at the two ends of the I-shaped trough, and has extremely high production efficiency.

Owner:罗锡锋

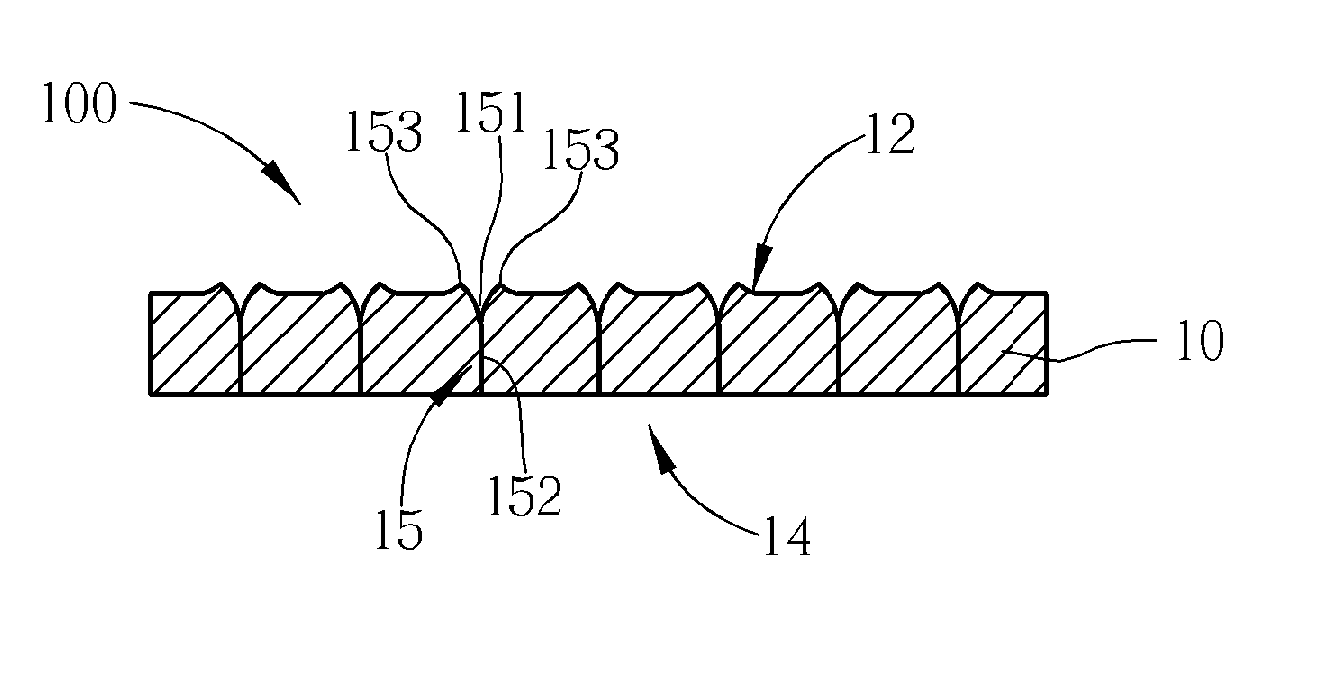

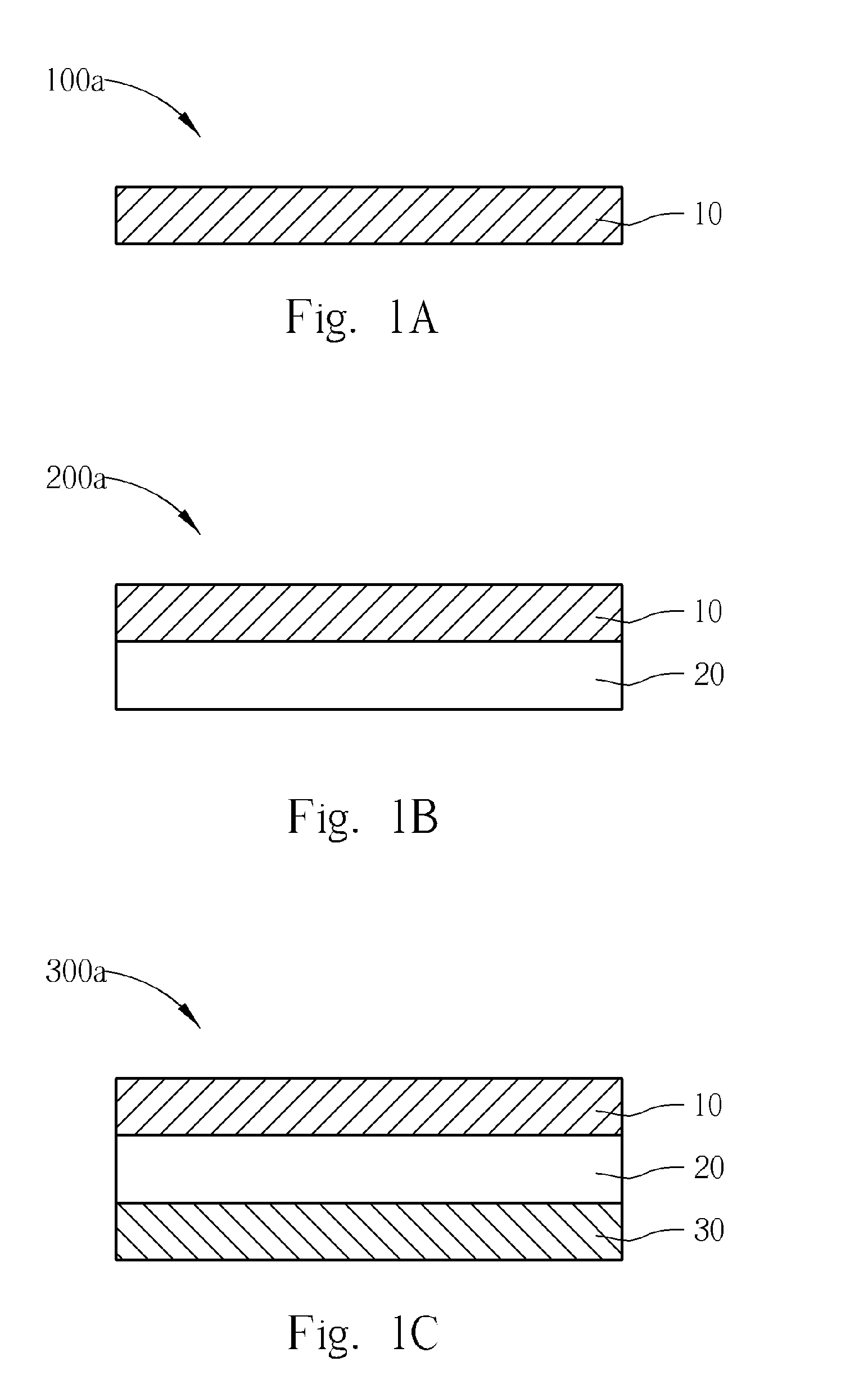

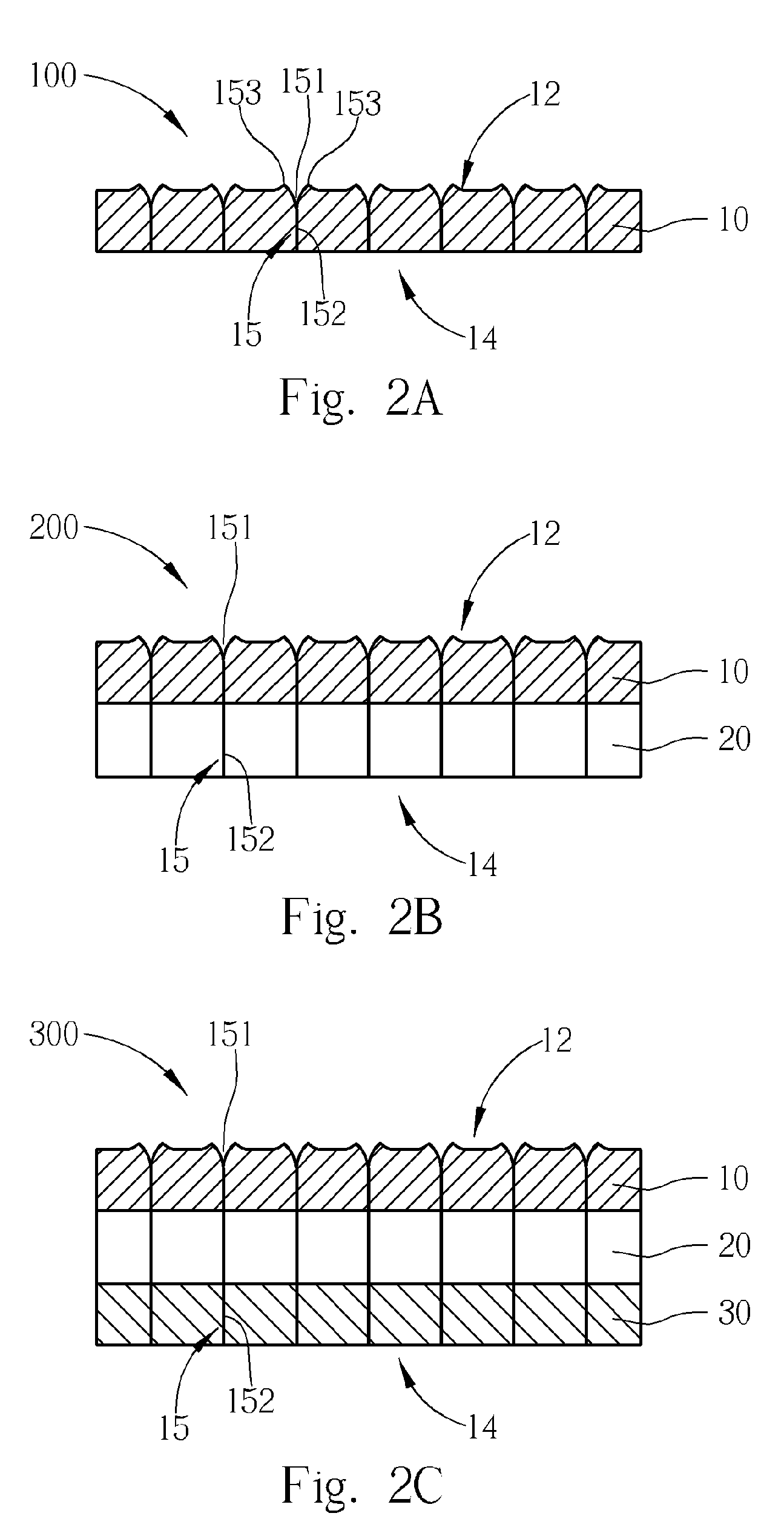

Efficient cooling system of graphene composite/silicon nitride/silicon chip

InactiveCN105514059AHigh thermal conductivityImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesGas phaseMicro gap

The invention provides a cooling system based on the multi-layer structure of a graphene composite / silicon nitride / silicon chip, and an establishing method of the cooling system, and belongs to the cooling technology of microelectronic devices. A cooling framework comprises a silicon-based heating device, a Si3N4 insulating layer, a graphene composite heat sink and a base plate. The dense Si3N4 insulating layer is deposited on the back face of a silicon wafer through a chemical gas-phase depositing method, a graphene composite and the Si3N4 insulating layer are connected through a chemical bond, and finally the silicon wafer with the cooling framework and the base plate are connected and packaged into a device. The silicon-based heating device, a thermal interface material and the heat sink are connected through chemical bonds, and therefore the distances of device layers are greatly reduced, thermal resistance caused by interlayer micro gaps is avoided, phonon thermal conductance is promoted, the cooling capacity of the whole cooling system is improved, and the chip can work at a severe high temperature. After package, the whole system is lighter and thinner and meets the development tendency of an up-to-date semiconductor device.

Owner:PEKING UNIV +1

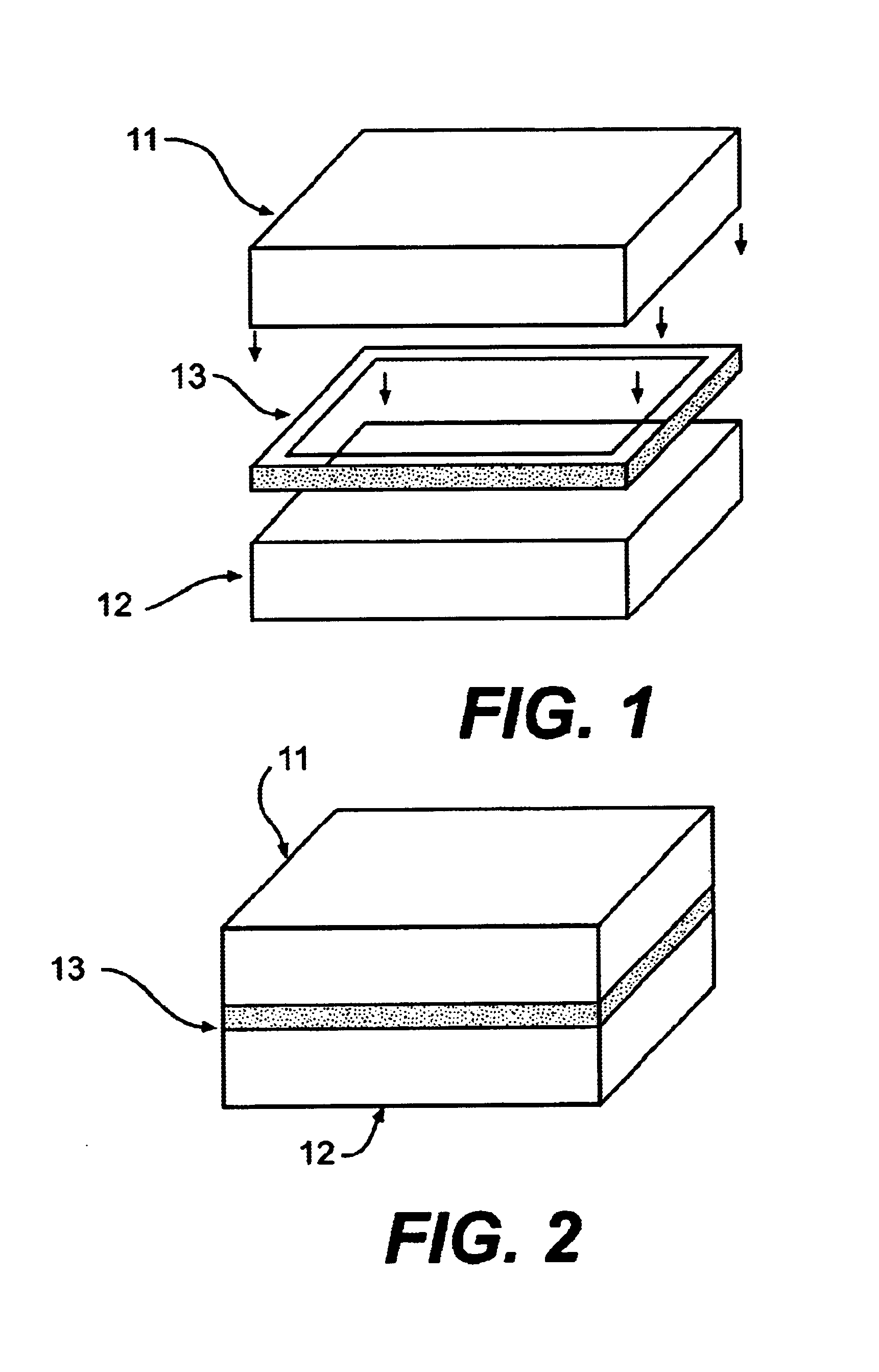

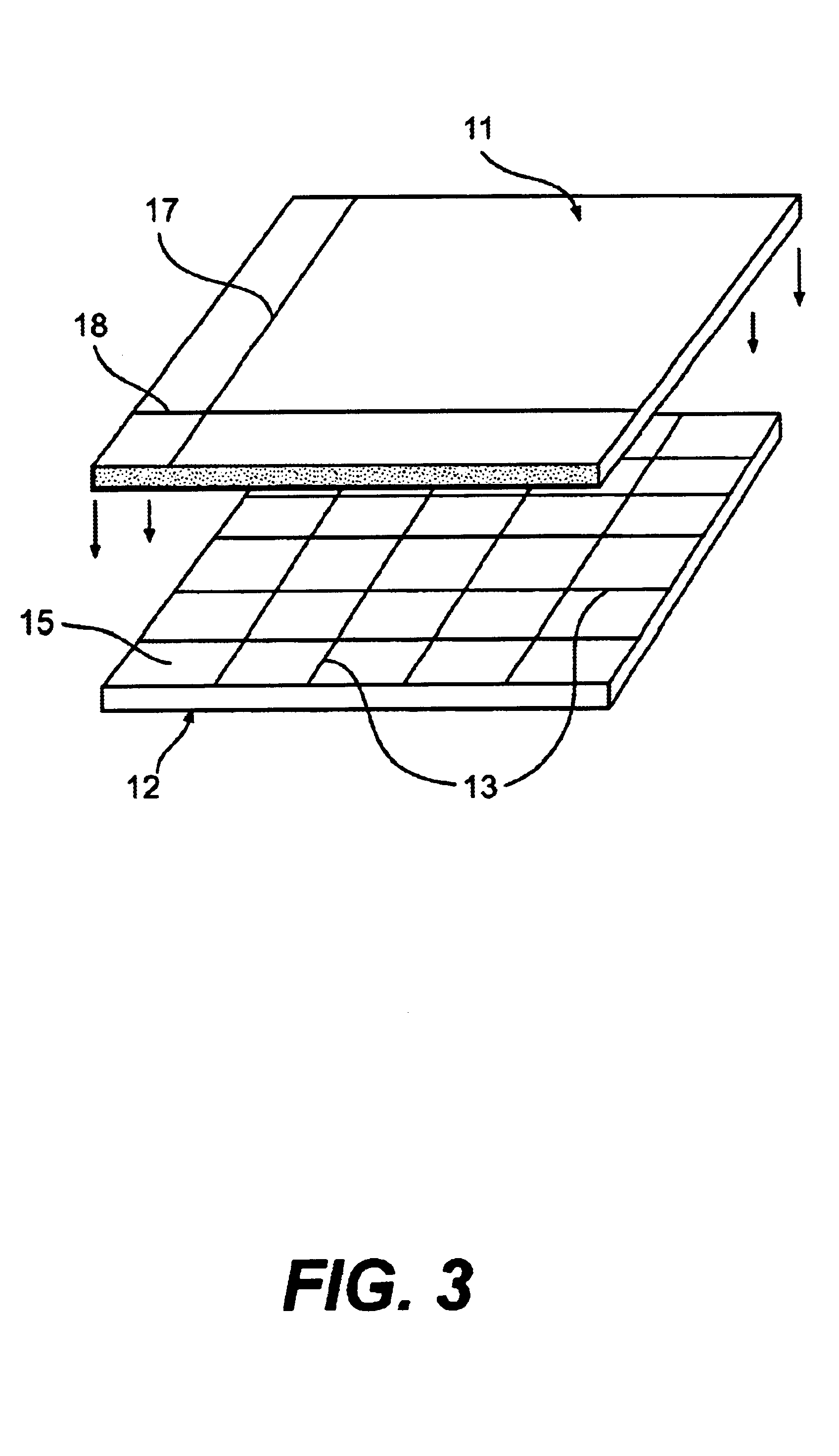

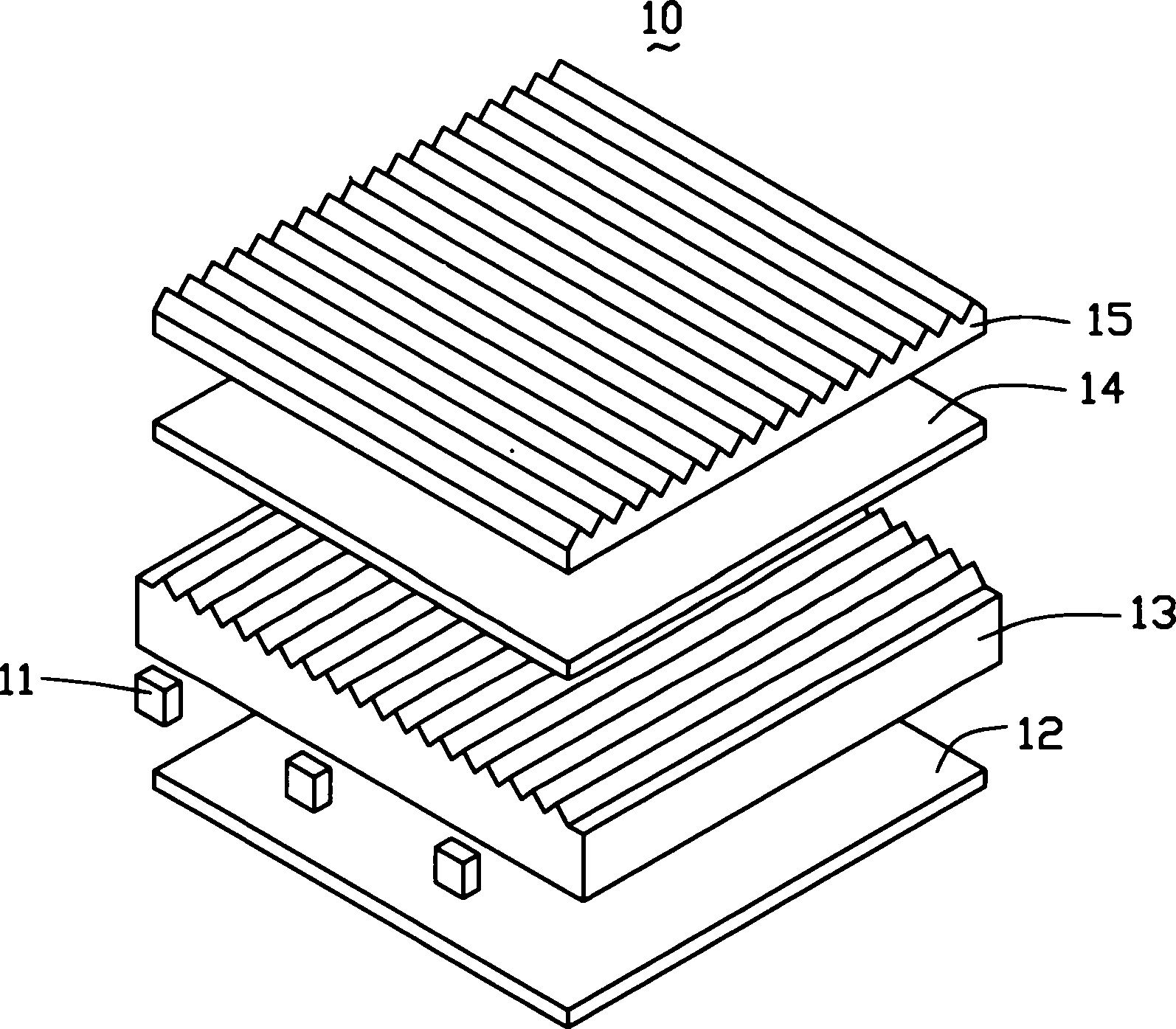

Backlight module assembly

ActiveCN1881023AImprove light energy utilizationAvoid prone to light column phenomenonPlanar/plate-like light guidesNon-linear opticsIn planeLight guide

The invention discloses an aphototropism module, which comprises the following parts: light conductive board, light source, reflecting lid and micro-reflecting mirror array, wherein the light conductive board contains a light-in plane, light-out plane in connection with light-in plane and reflecting plane corresponding to light-out plane; the light source contains luminous plane, which is set on one side of light-in plane of light conductive board with luminous plane opposing light-in plane; the reflecting lid is set on two sides of light source, which corresponds light-in plane; the micro-reflecting mirror array contains multiple micro-gap reflecting mirrors on the light-in plane to oppose luminous plane of light source, which reflects light beam from luminous plane of light source and incidences light beam to the light-in plane of light conductive board evenly.

Owner:TSINGHUA UNIVERSITY +1

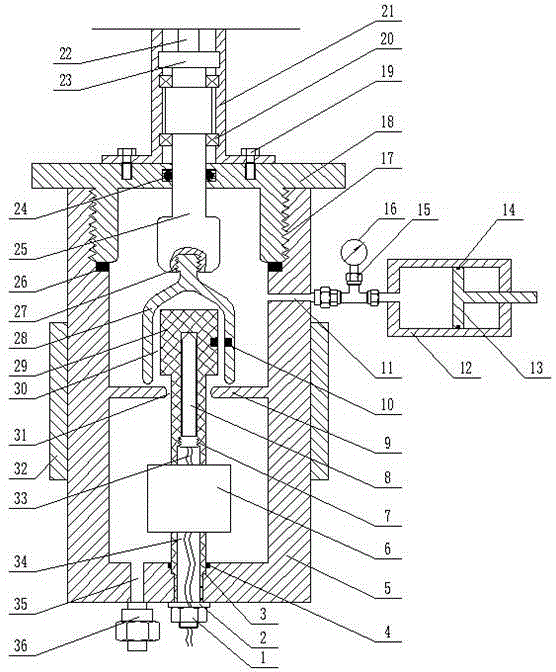

High-temperature high-pressure high-shear rate lubricating oil rheometer

The invention discloses a high-temperature high-pressure high-shear rate lubricating oil rheometer. The high-temperature high-pressure high-shear rate lubricating oil rheometer comprises a lock nut, a cylinder body, a static torque sensor, a temperature sensor, a splitter plate, a micro-gap measurer, a cylinder cover, a motor frame, a coupling, a rotating shaft sealing device, a rotating shaft, a threaded hole, an outer barrel, an inner barrel, a heater, an inner barrel hole, and the like. When the rheometer runs, the outer barrel rotates, and a lubricating oil sample is subjected to a shearing force, and then the shearing force of the lubricating oil sample acts on the inner barrel according to the principle of force balance; the micro-gap measurer is used for real-time measurement of the gap between the outer barrel and the inner barrel; the temperature sensor, the torque sensor, a pressure gage, a motor speed counter, and the like are connected with a computer, and data information is sent to the computer. Flow curves of the lubricating oil sample are drew by using a specific program in the computer, and constitutive equations of the lubricating oil sample is further determined, so that a relatively accurate lubricating oil rheological model is provided for theory and engineering practice.

Owner:SHANDONG UNIV OF TECH

Injection apparatus for injection molding of thermoplastic parts

An injection apparatus for injecting hot plastics material into an injection mold has an actuator section forming an actuator chamber and a nozzle member connected to the actuator section and extending to a nozzle tip having an injection aperture. The nozzle member includes an injection passage system for conducting the hot plastics material to the injection aperture. An elongate valve pin extends through a guide passage in the nozzle member and is movable between open and closed positions. A piston is connected to this pin, is slidably mounted in the actuator chamber and moves the valve pin between the open and closed positions. The piston and actuator section are machined to close tolerances so as to form a micro-gap between the wall of the piston and the wall of the chamber thereby avoiding fluid seals. The actuator is able to operate at temperatures ranging between 200 and 400° C.

Owner:WESTFALL ACQUISITION III INC

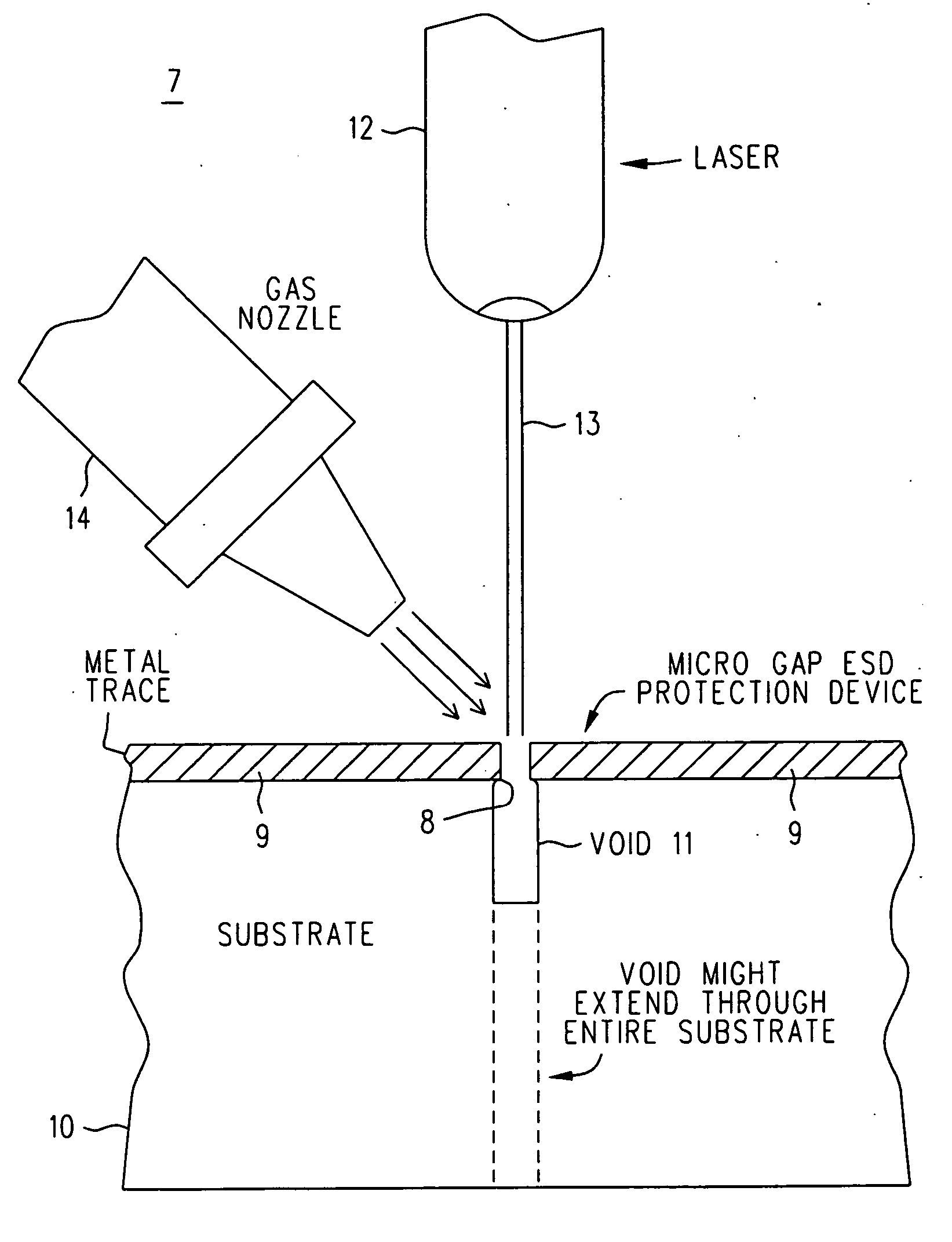

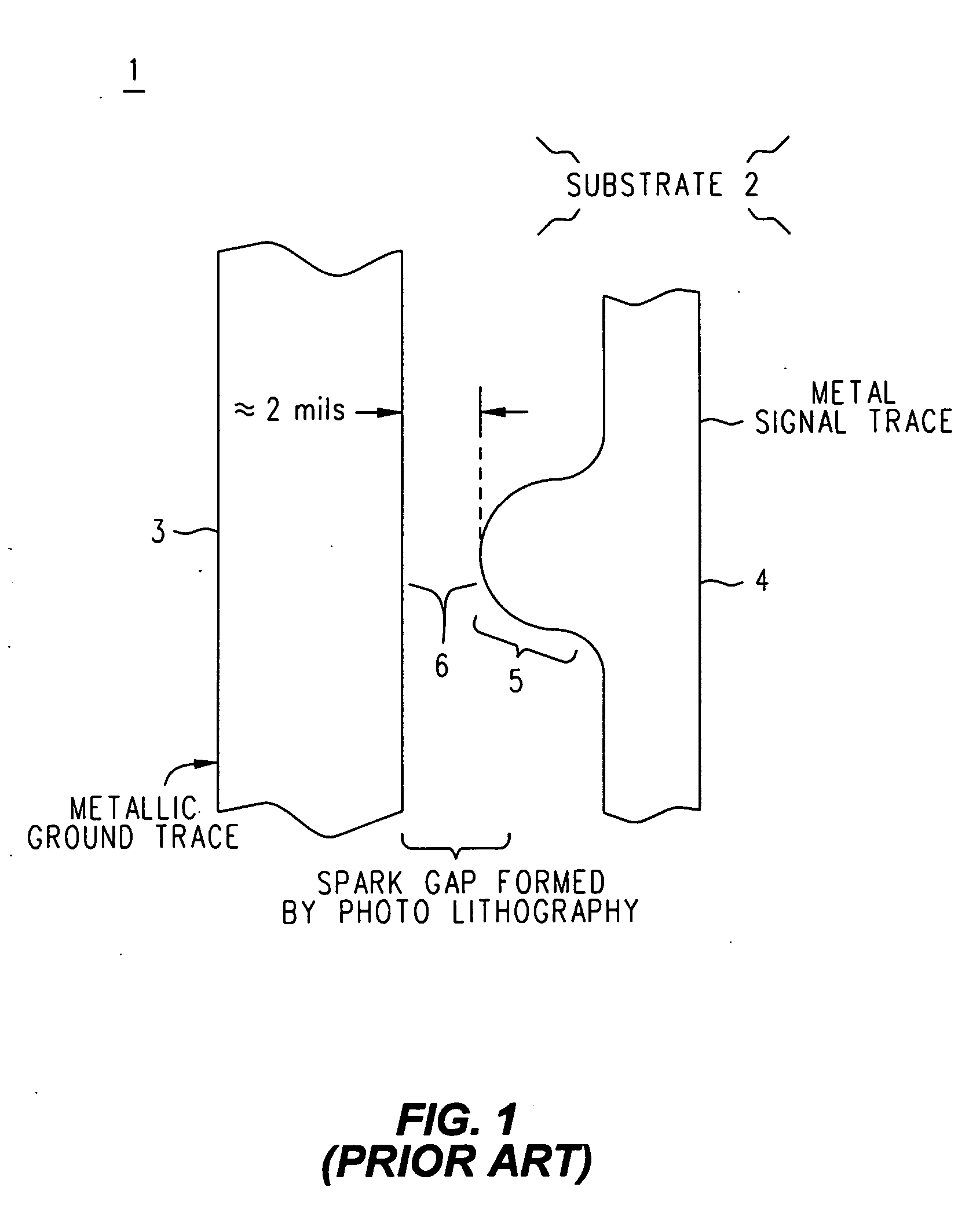

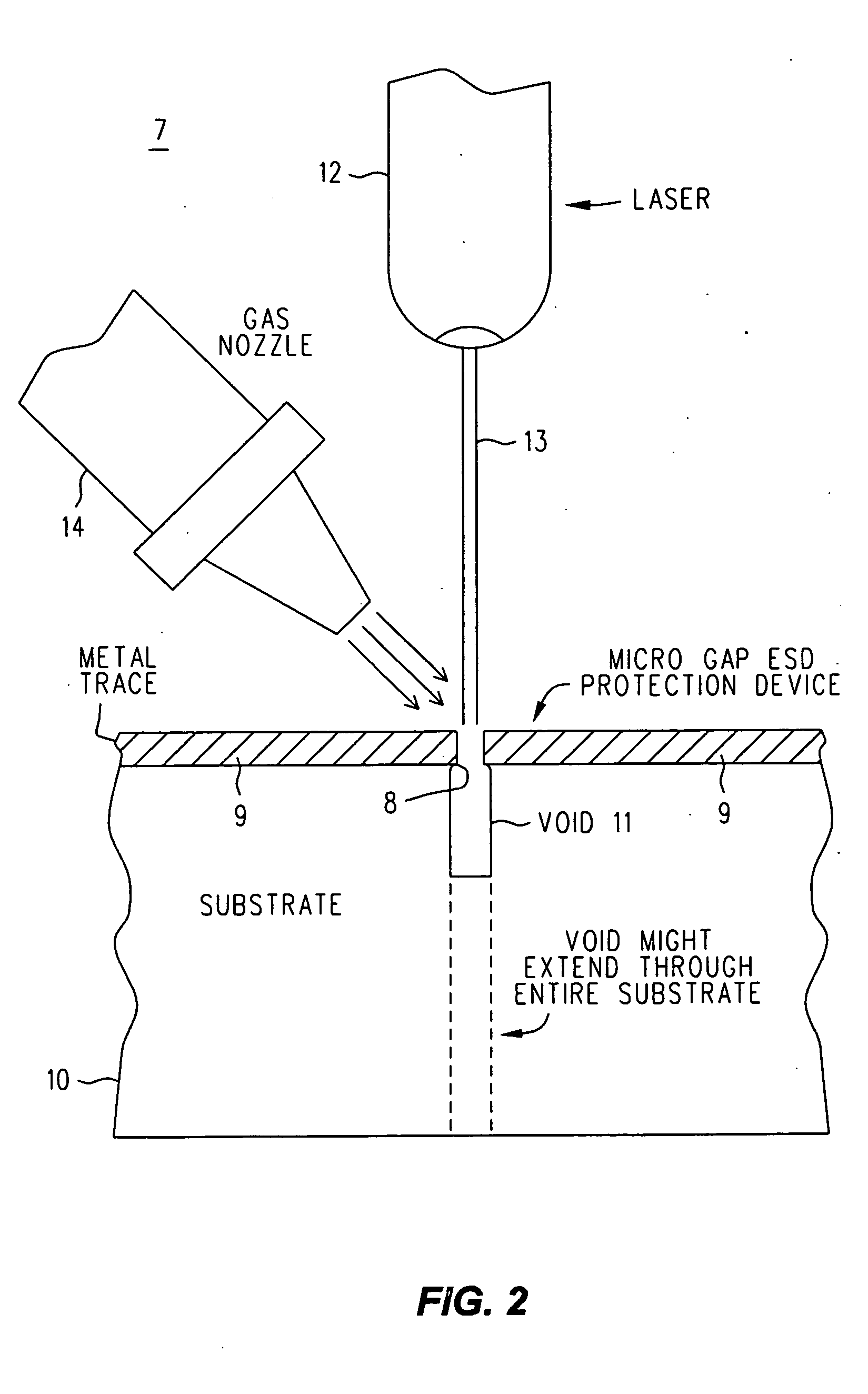

Micro gap method and ESD protection device

InactiveUS20060250744A1Lower breakdown voltageReduce capacitanceSolid-state devicesEmergency protective arrangement detailsCapacitanceMicro gap

ESD events on a hybrid circuit are suppressed with a high performance spark gap cut in a metal trace with a suitable laser micro machining technique. The trace can be carried by a conventional printed circuit board (using FR4), or a ceramic substrate. Gap size is reduced by flushing the cut with a flow of gas that removes the vaporized copper and prevents it from re-depositing upon the cut surfaces and bridging them. The gap can be as narrow as 0.4 mils (0.0004 inches) and can have very well defined features that include sharp corners that assist in lowering the breakdown voltage. In addition, dielectric material below and off to either side of the trace that would otherwise adjoin the metallic gap can also be removed, which lowers breakdown voltage and decreases capacitance across the gap. Breakdown voltages as low as 300 V can be achieved. Such a spark gap is used at the probe tip of an active oscilloscope probe to protect the delicate circuitry therein.

Owner:AGILENT TECH INC

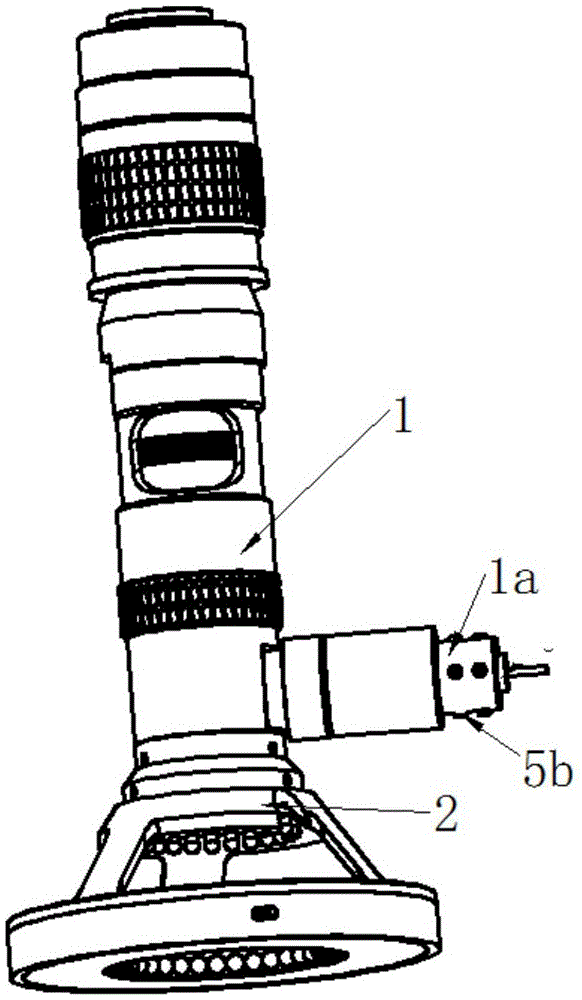

Device, method and system for detecting micro gap based on industrial equipment

The embodiment of the invention discloses a device, a method and a system for detecting a micro gap based on industrial equipment. A lens tube and a duel-light source assembly are included; the lower end of the lens tube is connected with the duel-light source assembly; the duel-light source assembly comprises an upper annular light source assembly and a lower annular light source assembly; and thus, irradiation of different light sources is realized for image processing on a PCB or a micro gap to-be-detected product; and subsequent industrial equipment-based micro gap detection is carried out. The subsequent industrial equipment-based micro gap detection device comprises the lens tube and the duel-light source assembly; the lower end of the lens tube is connected with the duel-light source assembly; and the duel-light source assembly comprises the upper annular light source assembly and the lower annular light source assembly.

Owner:GUANGDONG ZHENGYE TECH

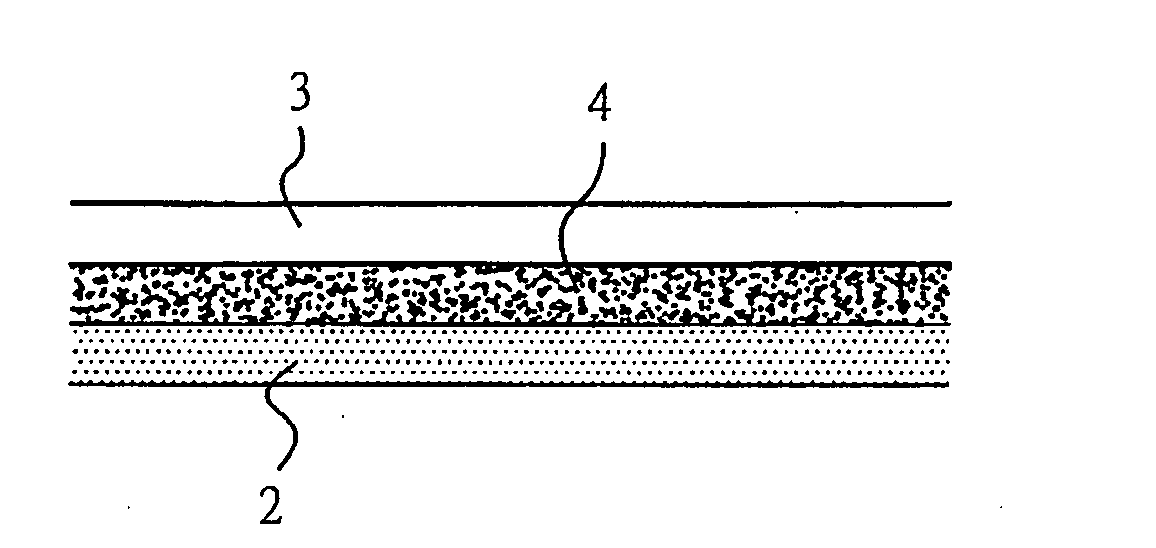

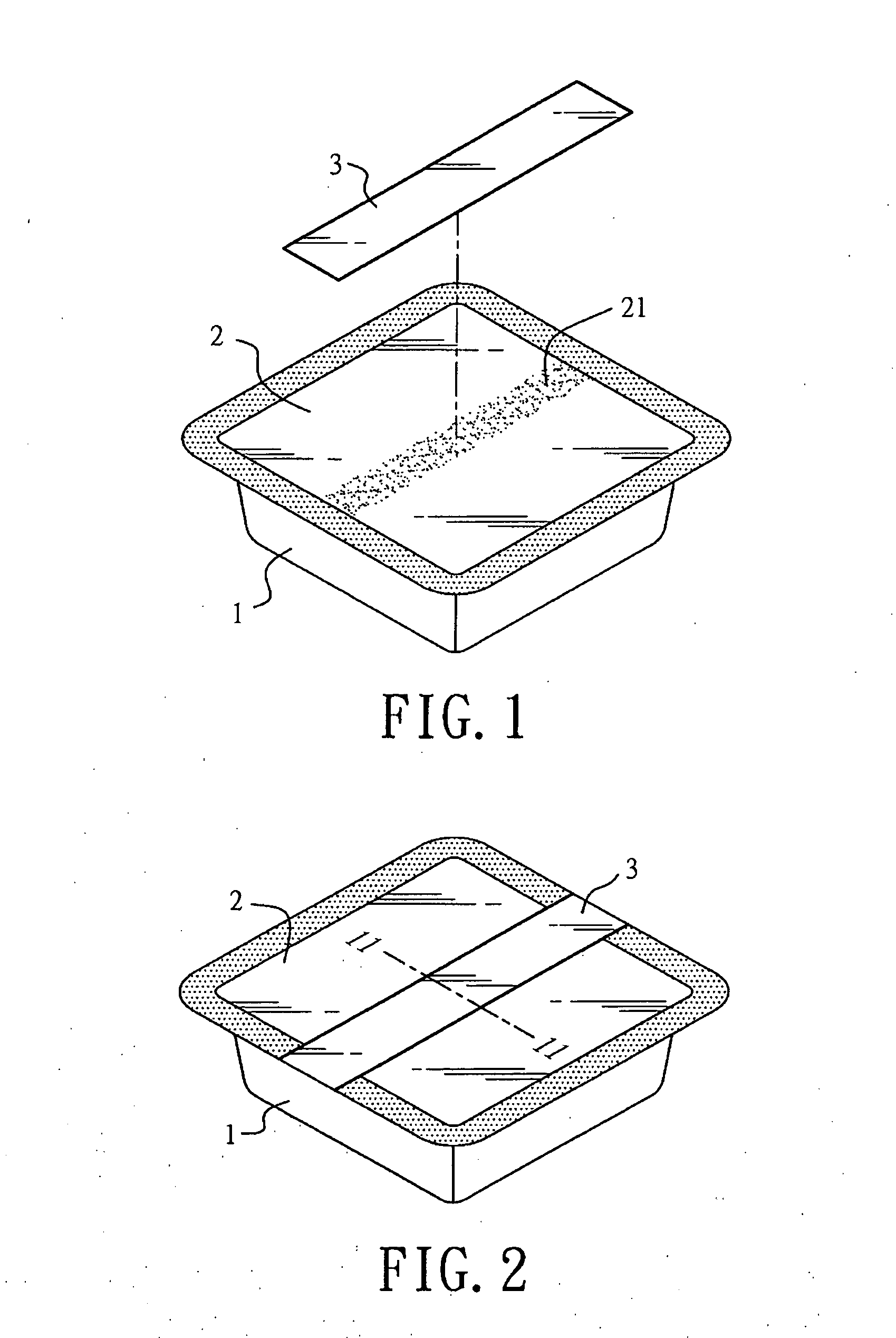

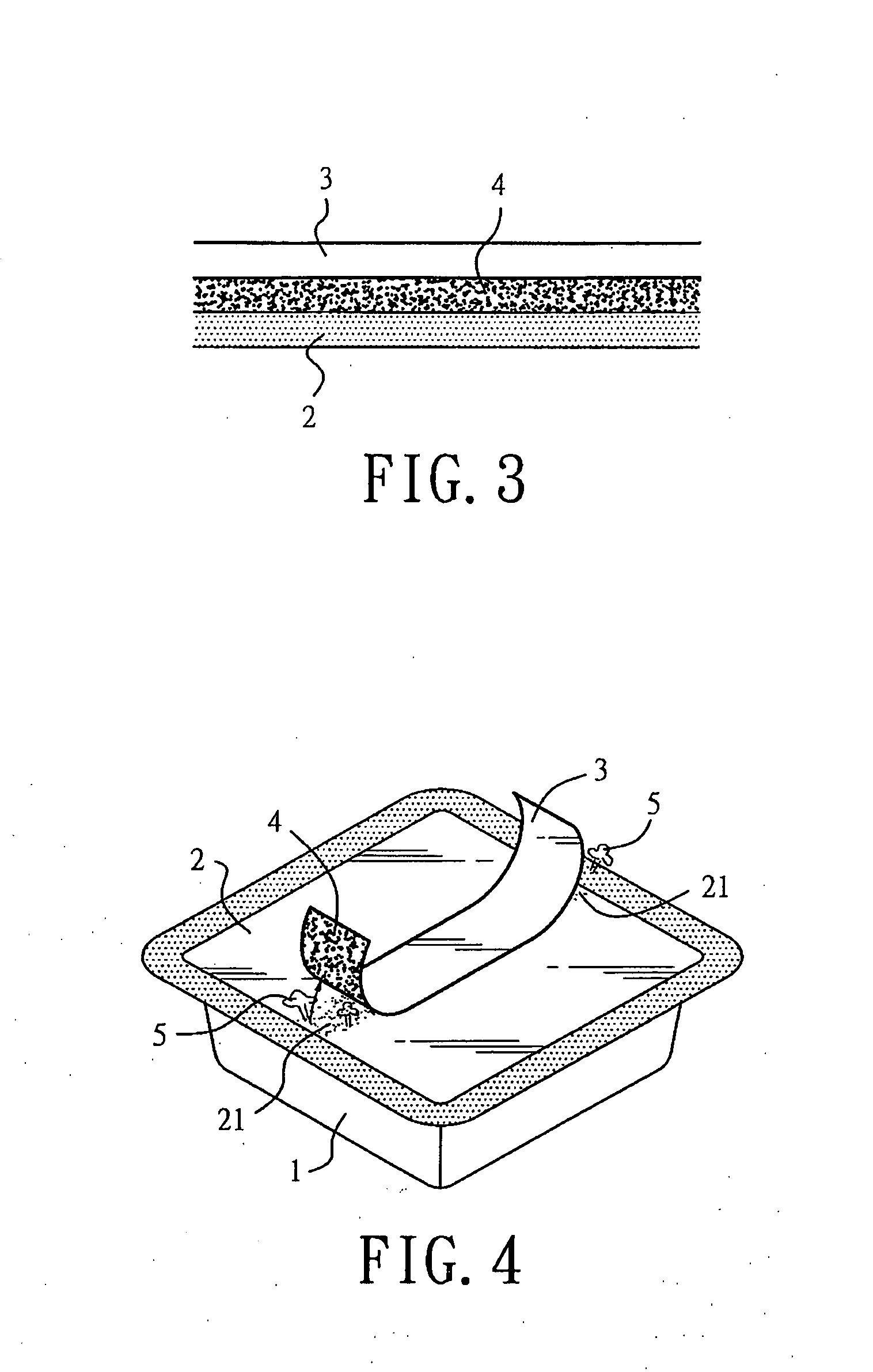

Composite Film for Packing Foods and the Process of Making it

InactiveUS20080220212A1Low peel strengthImprove the problemLamination ancillary operationsLaminationMicrowaveComposite film

A composite film for packaging foods enable to regulate pressure inside automatically when being heated and the progress of making it are provided. The composite film comprises a substrate film provided with a plurality of micro-gap regions processed by impressing process and an adhesive film attached to an airtight film. The composite film is applied to a food packaging devices which has an airtight structure. In use, the food packaging device can receive foods for microwave heating while the airtight film and the micro-gap region are used to prevent the food packaging device from breaking while preventing the steam vast losing and foods from becoming drier.

Owner:LIN DAVID

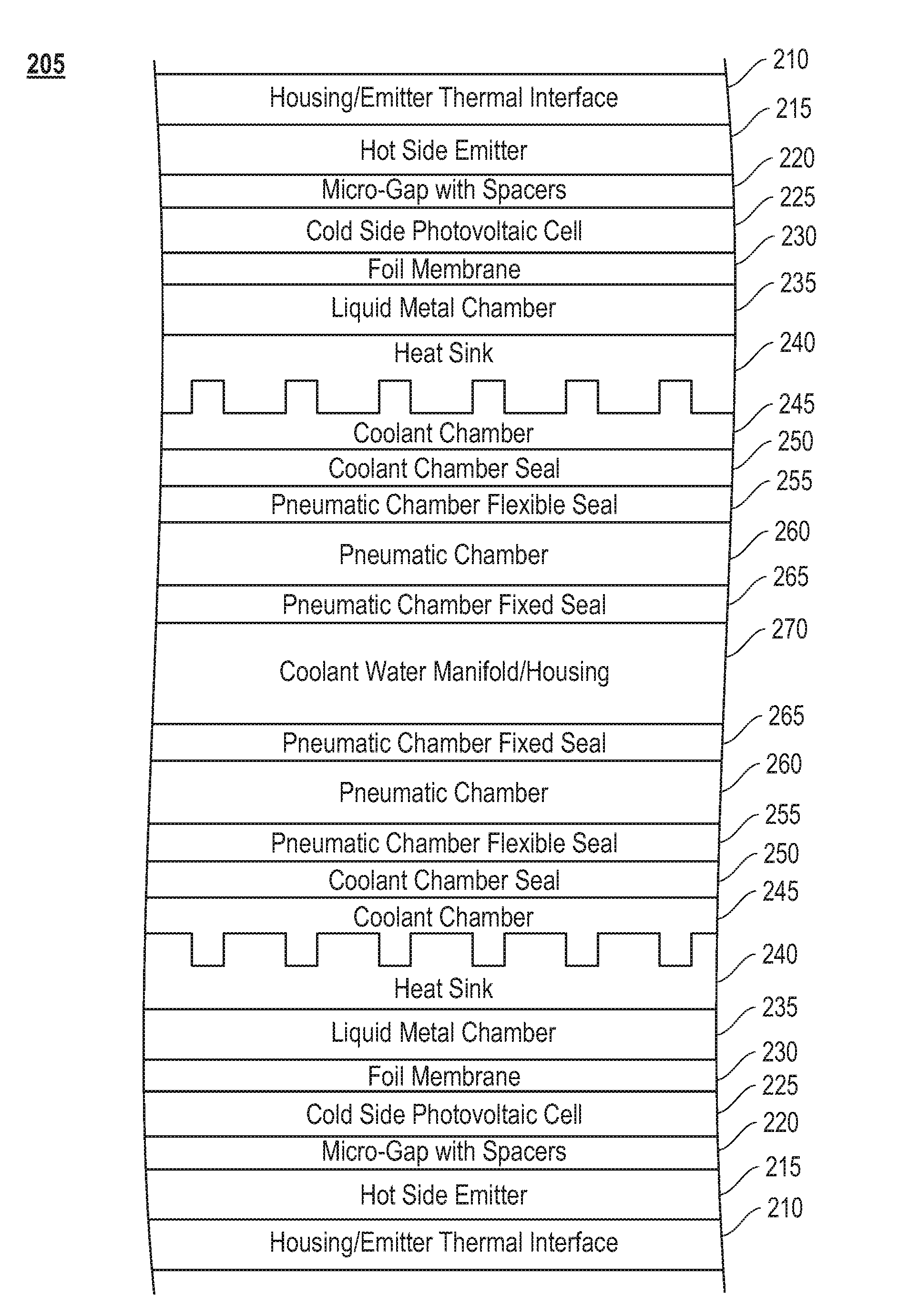

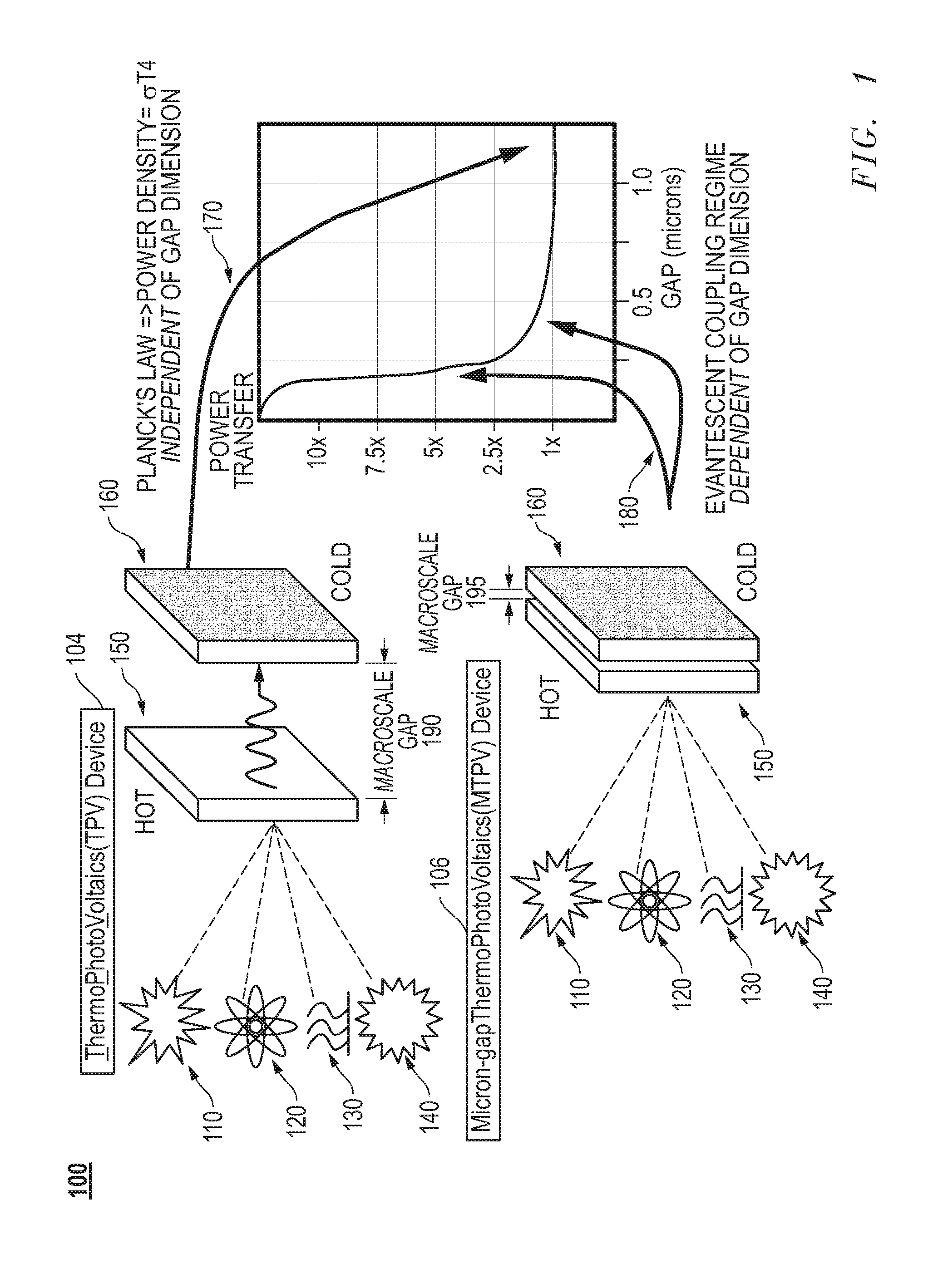

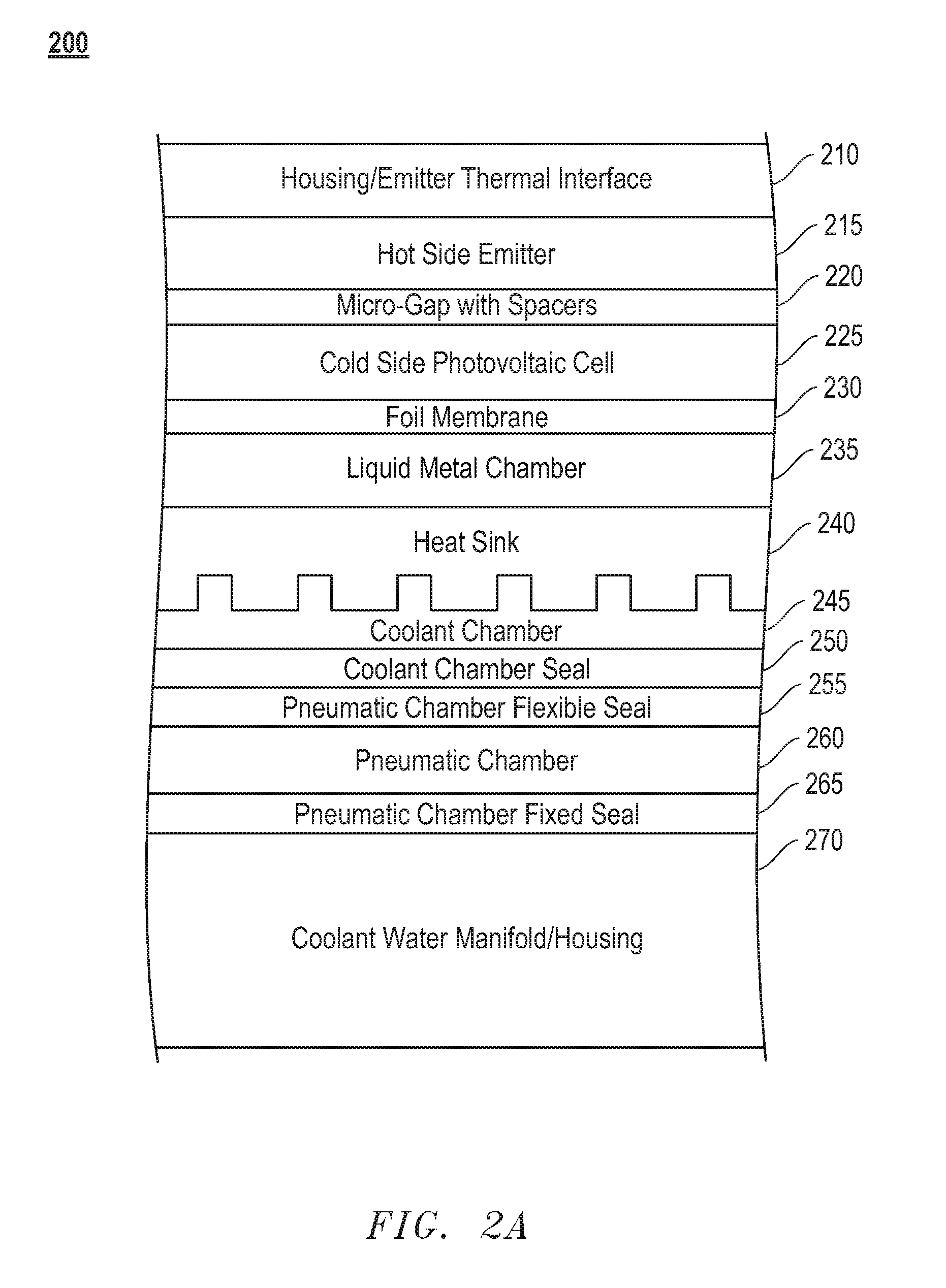

Micro-Gap Thermal Photovoltaic Large Scale Sub-Micron Gap Method and Apparatus

ActiveUS20110315195A1Easy to manufactureImprove heat insulationPV power plantsPhotovoltaic energy generationElectricityMicro gap

The present invention relates to micron-gap thermal photovoltaic (MTPV) technology for the solid-state conversion of heat to electricity. The problem is forming and then maintaining the close spacing between two bodies at a sub-micron gap in order to maintain enhanced performance. While it is possible to obtain the sub-micron gap spacing, the thermal effects on the hot and cold surfaces induce cupping, warping, or deformation of the elements resulting in variations in gap spacing thereby resulting in uncontrollable variances in the power output. A major aspect of the design is to allow for intimate contact of the emitter chips to the shell inside surface, so that there is good heat transfer. The photovoltaic cells are pushed outward against the emitter chips in order to press them against the inner wall. A high temperature thermal interface material improves the heat transfer between the shell inner surface and the emitter chip.

Owner:MTPV POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com