Thin-film ultrasonic transducer and preparation method thereof

A thin-film ultrasonic and transducer technology, applied in the direction of the fluid using vibration, can solve the problem of low sensitivity, and achieve the effect of increasing the received signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

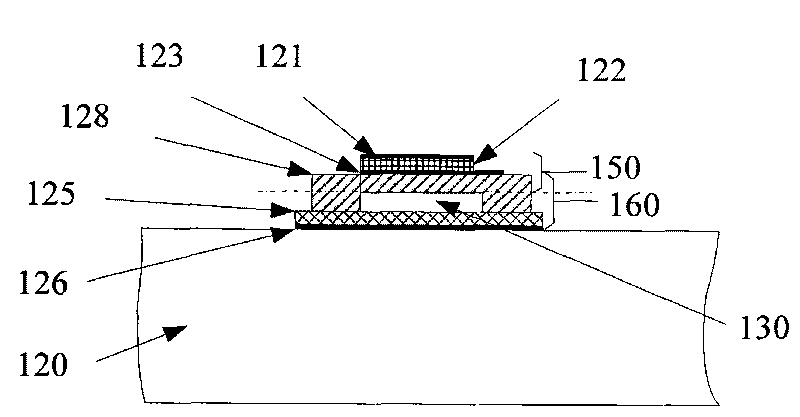

[0062] image 3 It is a structural schematic diagram of an embodiment of the thin-film piezoelectric ultrasonic transducer of the present invention. Its structure of thin-film acoustic transducer provided by the invention is as follows: image 3 As shown: it includes a flat part 150 containing a piezoelectric layer, a peripheral closed cavity 130 below the flat part 150 , and a capacitive second electrode 126 prepared with an insulating layer 125 on top. The flat part 150 containing the piezoelectric layer is a bendable piezoelectric vibrating membrane, including a support layer 128, a piezoelectric first electrode 123 located on the support layer 128, a piezoelectric first electrode 123 located on the piezoelectric first electrode 123 Layer 122 and the piezoelectric second electrode 121 positioned on the piezoelectric layer 122 constitute a piezoelectric acoustic transducer unit 150, so the function of a traditional piezoelectric thin film ultrasonic transducer can be realiz...

Embodiment 2

[0076] Figure 8 It is a structural schematic diagram of an embodiment of the thin-film piezoelectric ultrasonic transducer of the present invention. Its structure of thin-film acoustic transducer provided by the invention is as follows: Figure 8 As shown: it includes a flat part 250 containing a piezoelectric layer, a peripheral closed cavity 230 below the flat part 250, and a capacitive second electrode 226 prepared with an insulating layer 225 on the top, and the capacitive second electrode 226 is low. resistive silicon substrate. The flat member 250 containing a piezoelectric layer is a bendable piezoelectric vibrating membrane, including a support layer 228 , a piezoelectric first electrode 223 located on the support layer 228 , and a piezoelectric first electrode 223 located on the piezoelectric first electrode 223 . Layer 222 and the piezoelectric second electrode 221 positioned on the piezoelectric layer 222 constitute a piezoelectric acoustic transducer unit 250, s...

Embodiment 3

[0086] Figure 12 It is a structural schematic diagram of an embodiment of the thin-film piezoelectric ultrasonic transducer of the present invention. Its structure of thin-film acoustic transducer provided by the invention is as follows: Figure 12 As shown: it includes a flat part 350 containing a piezoelectric layer, a peripheral closed cavity 330 below the flat part 350, and a capacitive second electrode 300 prepared with an insulating layer 325 on the top, and the capacitive second electrode 300 is low. resistive silicon substrate. The flat member 350 containing a piezoelectric layer is a bendable piezoelectric vibrating membrane, including a support layer 328 , a piezoelectric first electrode 323 located on the support layer 328 , and a piezoelectric first electrode 323 located on the piezoelectric first electrode 323 . Layer 322 and the piezoelectric second electrode 321 positioned on the piezoelectric layer 322 constitute a piezoelectric acoustic transducer unit 350,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com