Patents

Literature

1896 results about "Ultrasonic testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion.

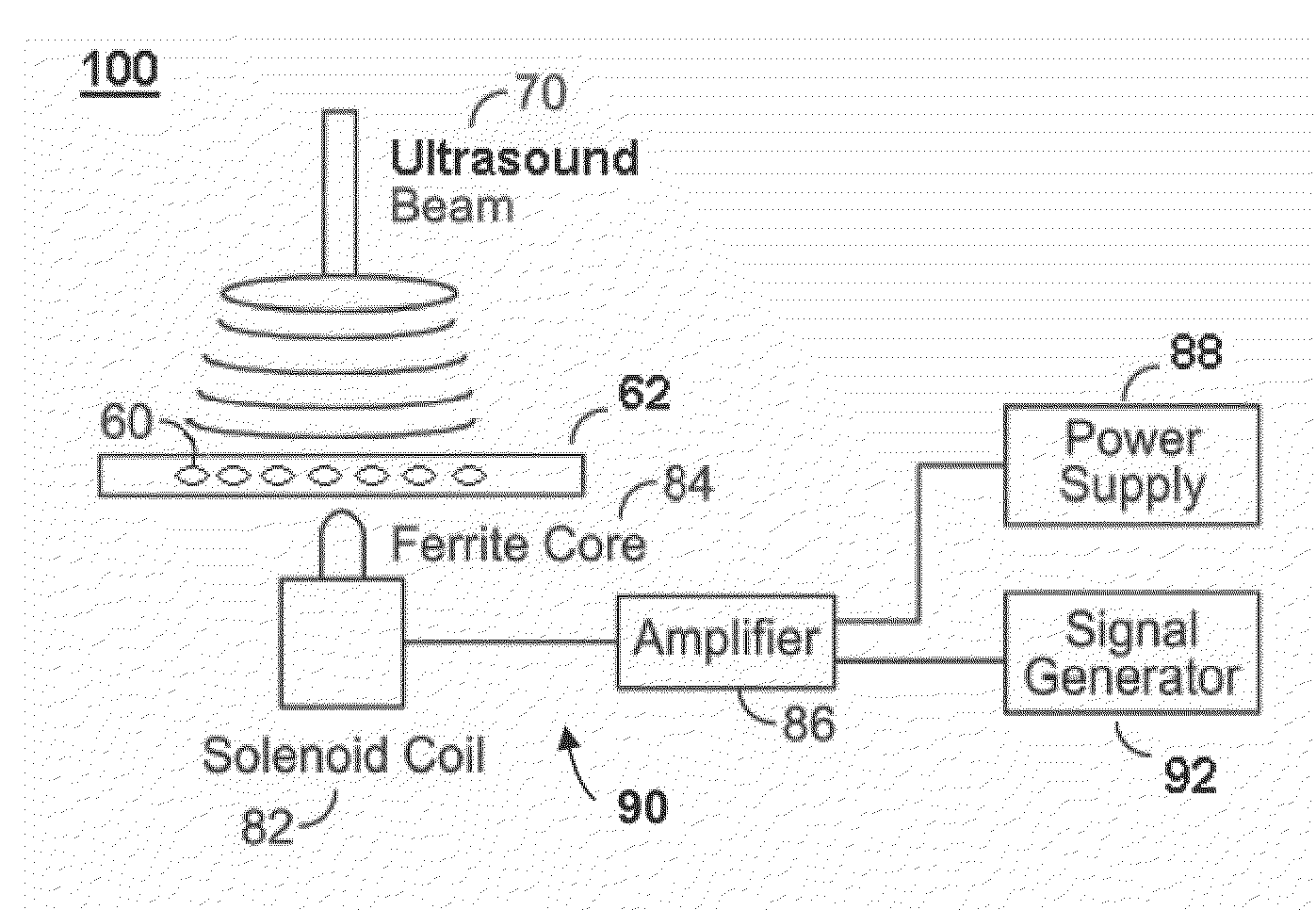

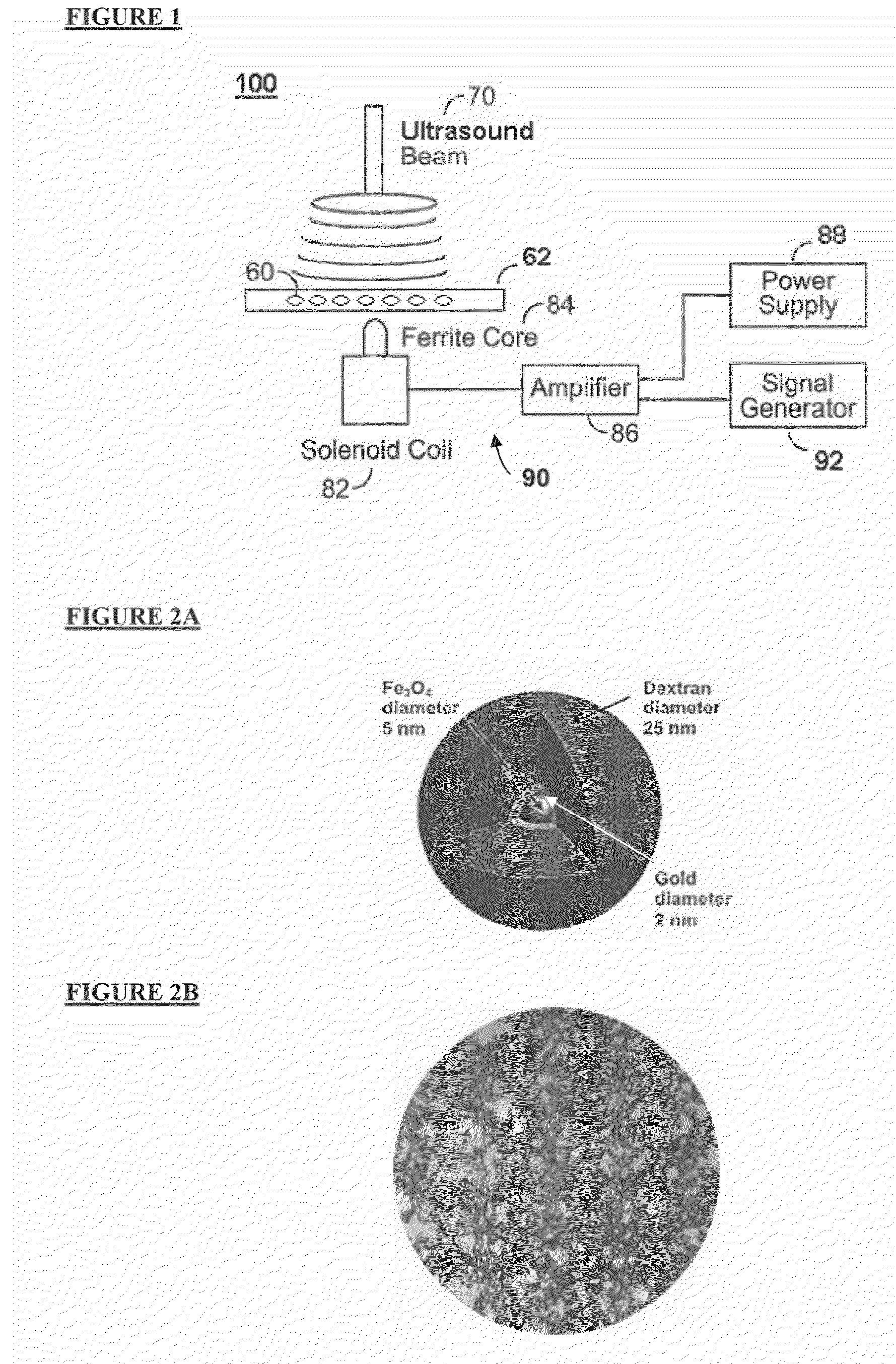

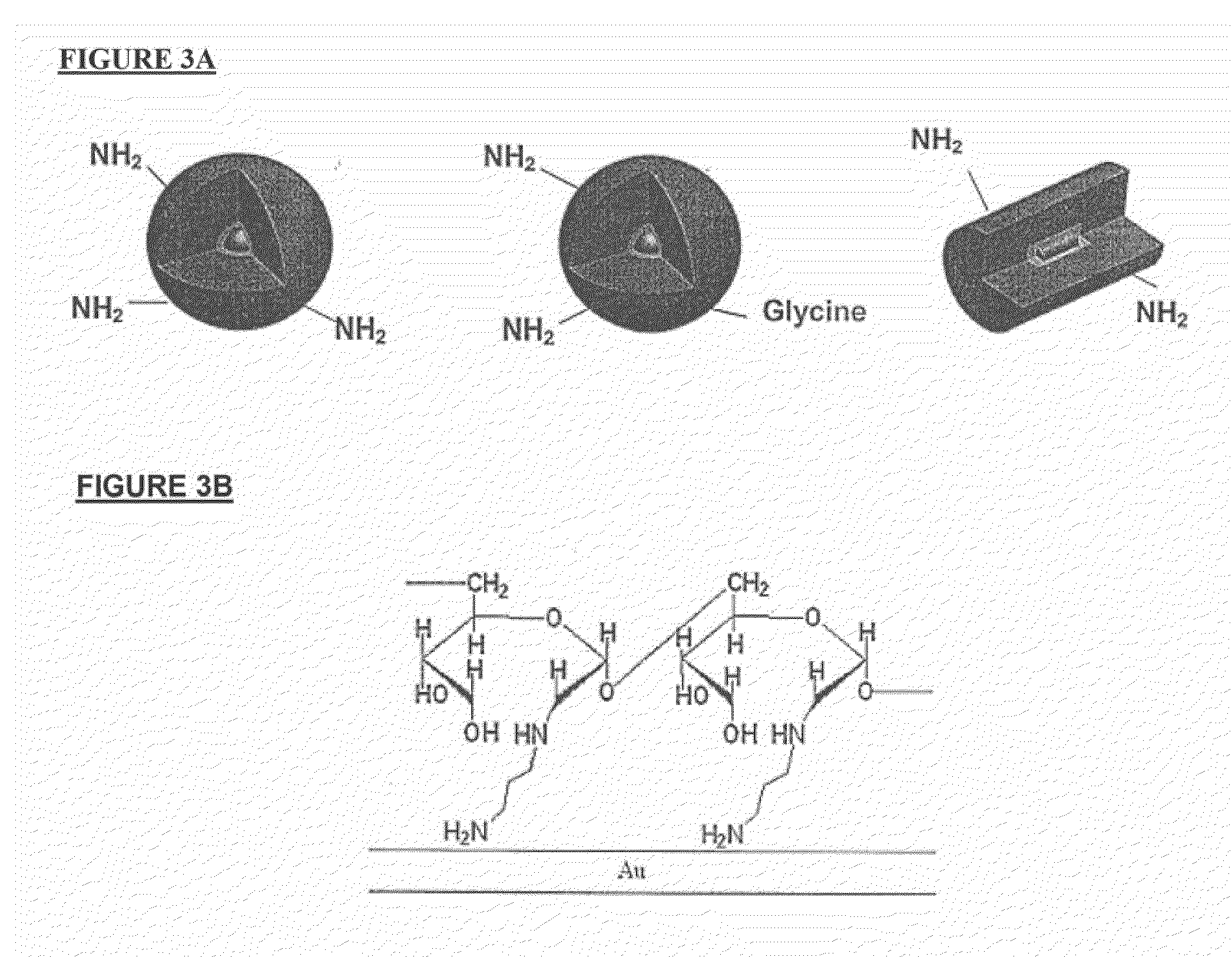

Magneto-motive ultrasound detection of magnetic nanoparticles

Provided herein are systems, methods and compositions for the use of ultrasound for detection of cells and nanoparticles.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

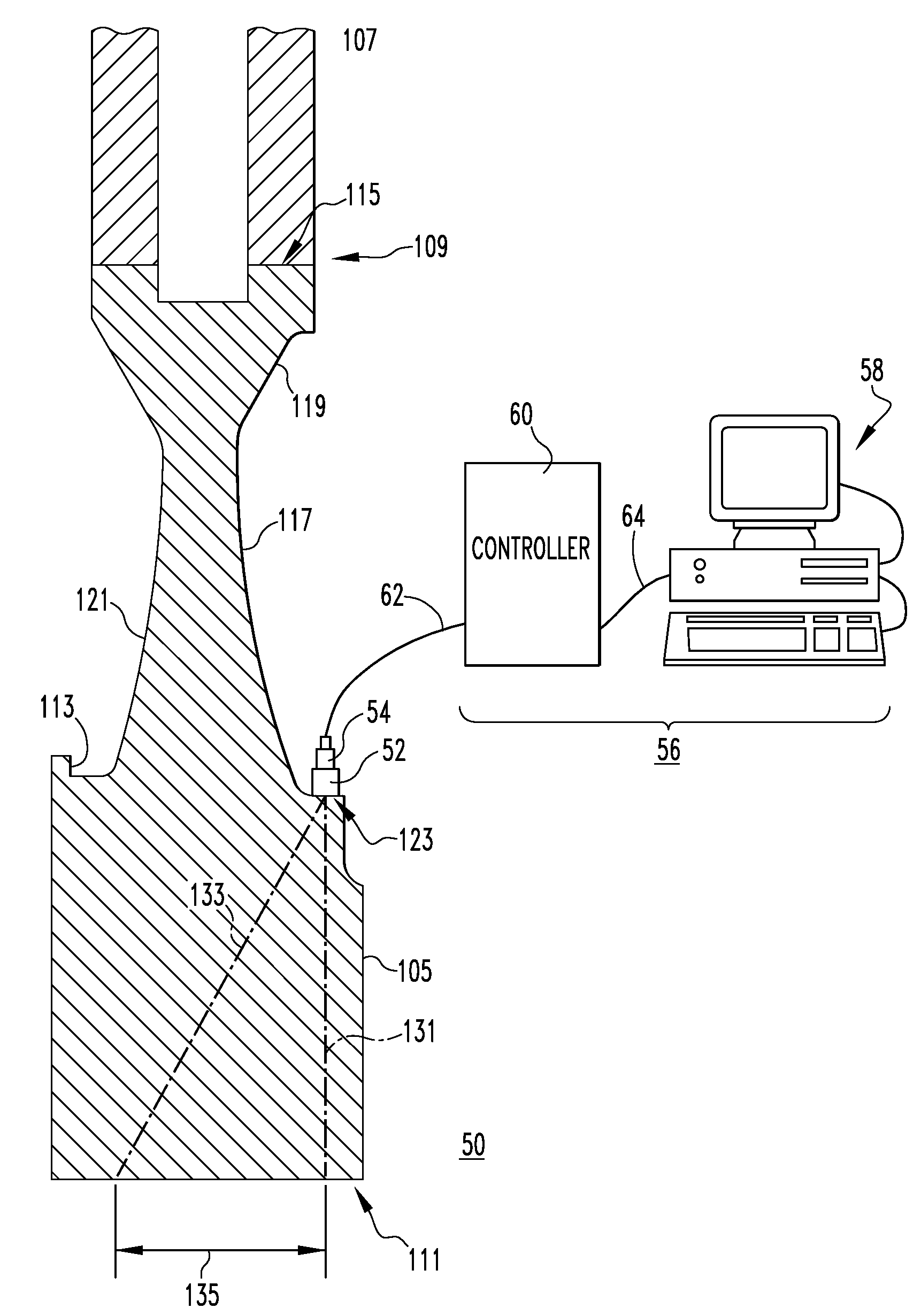

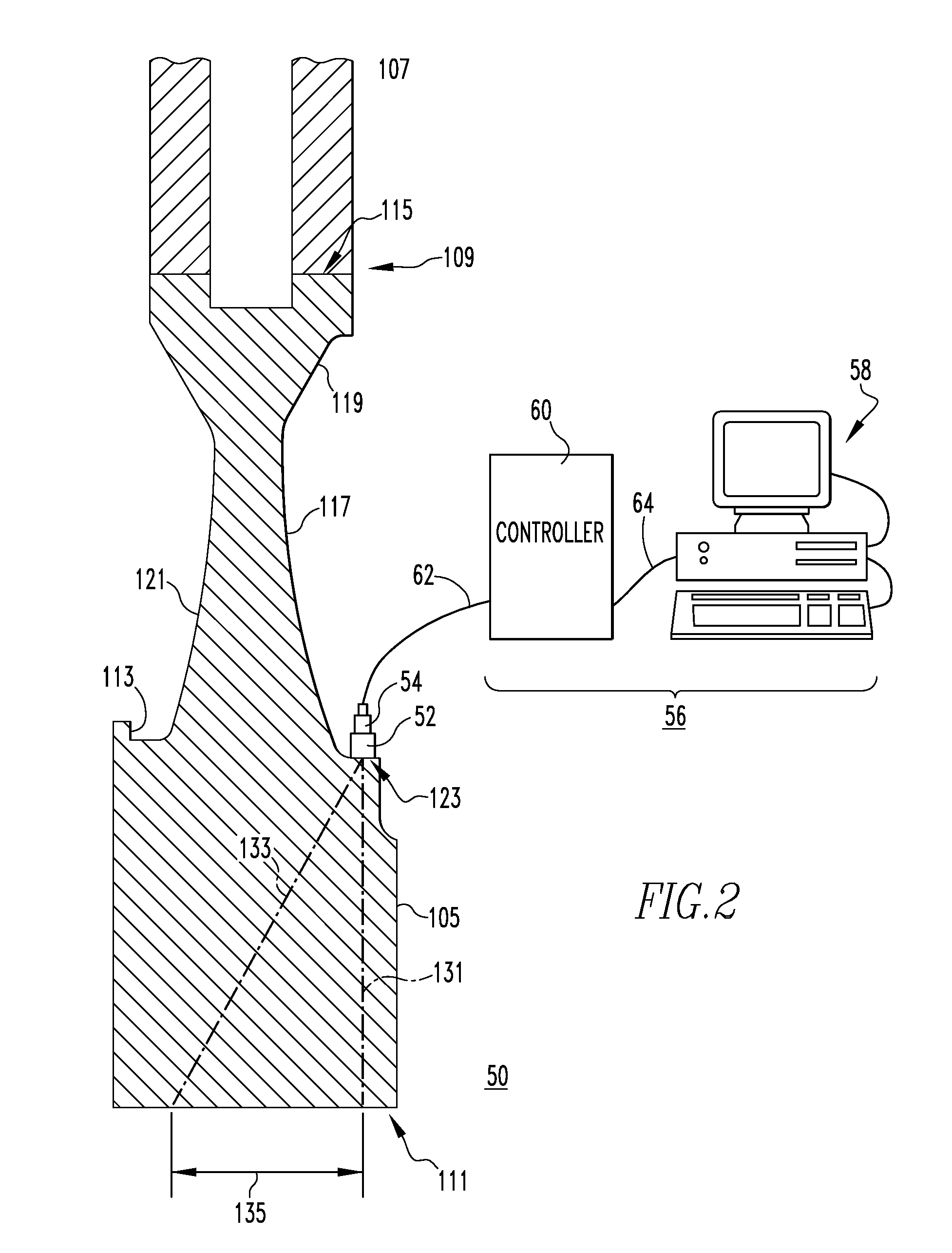

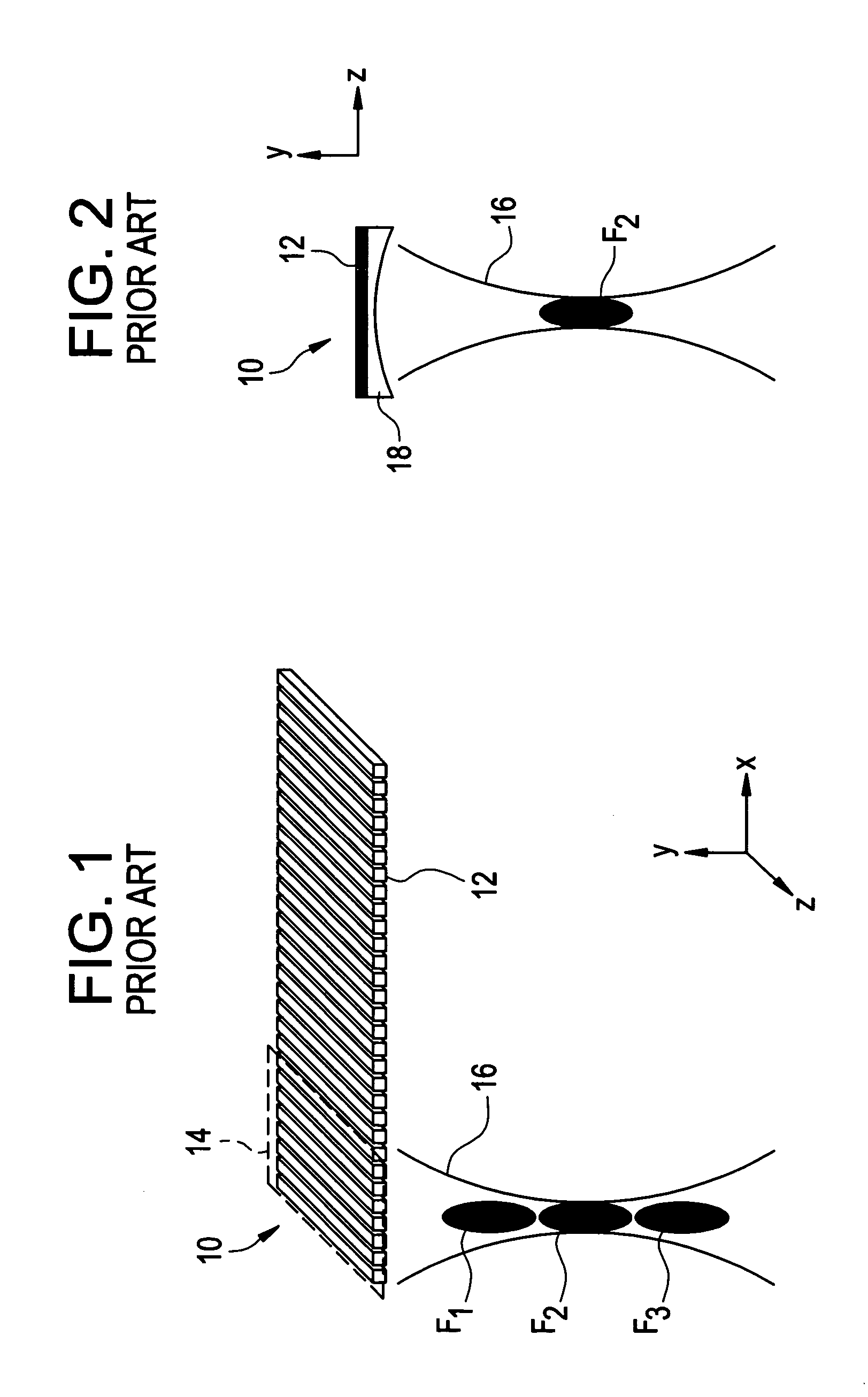

Angle beam shear wave through-transmission ultrasonic testing apparatus and method

InactiveUS7240556B2High resolutionPrevent and limit to regionAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsSonificationImage representation

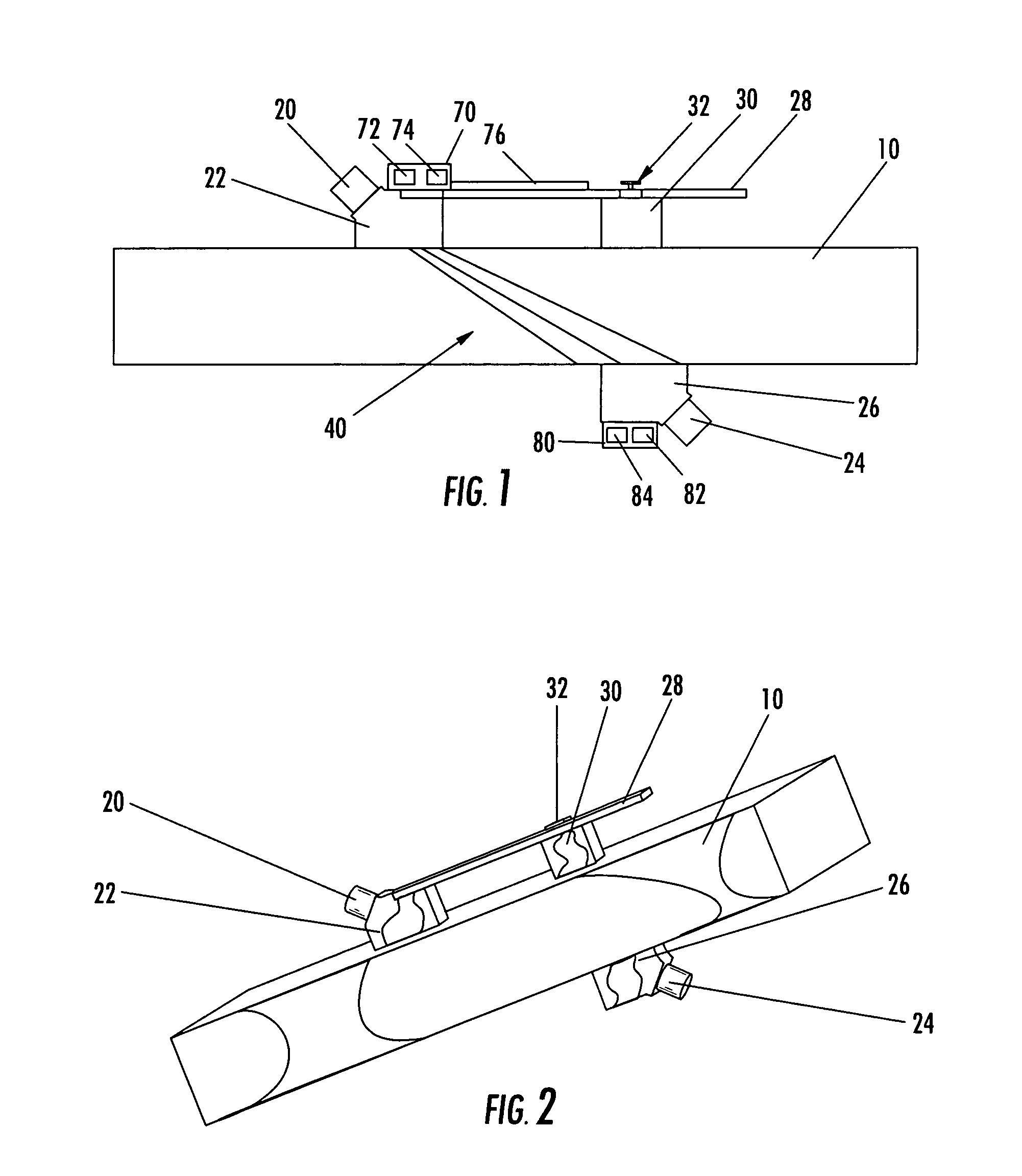

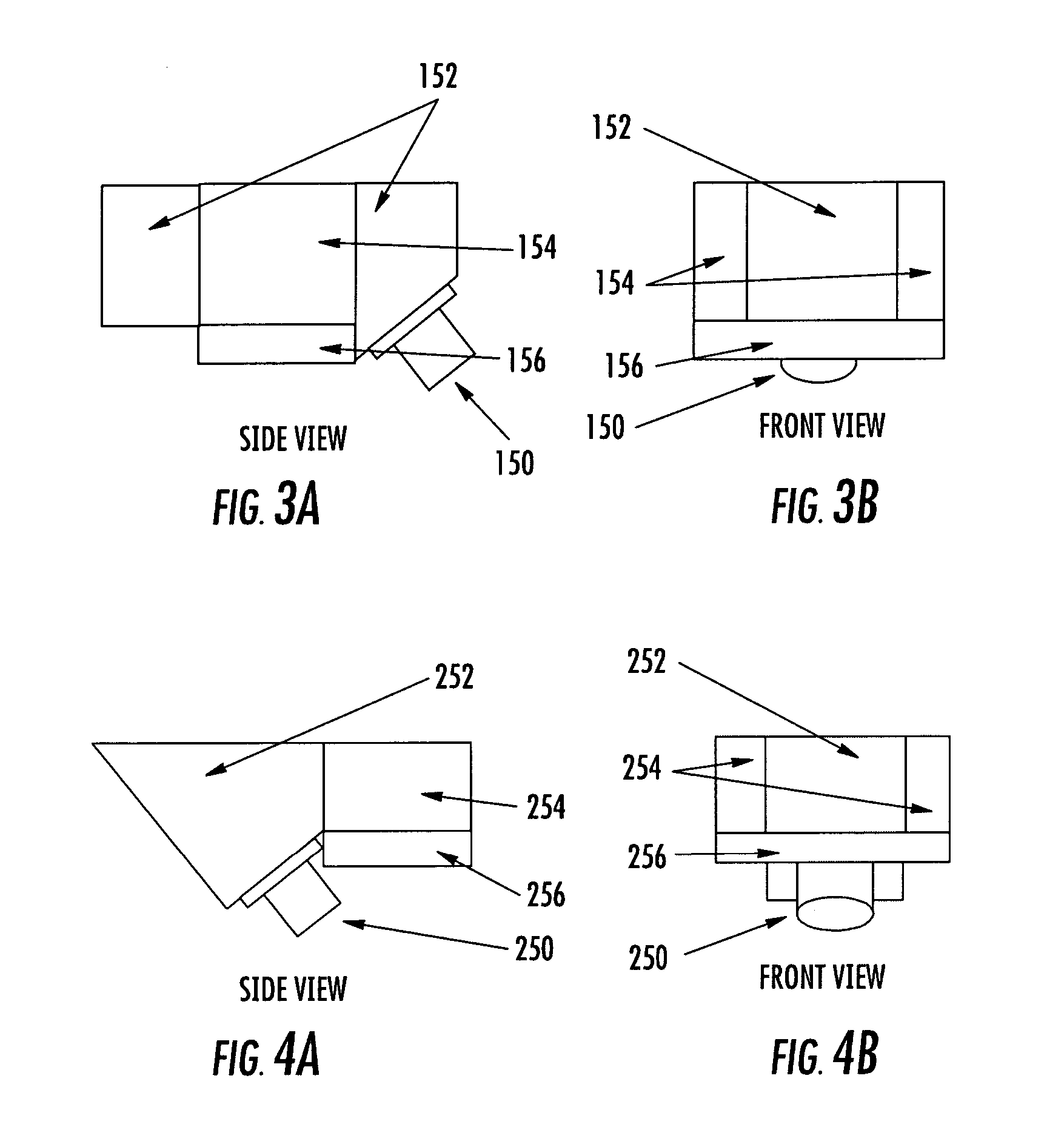

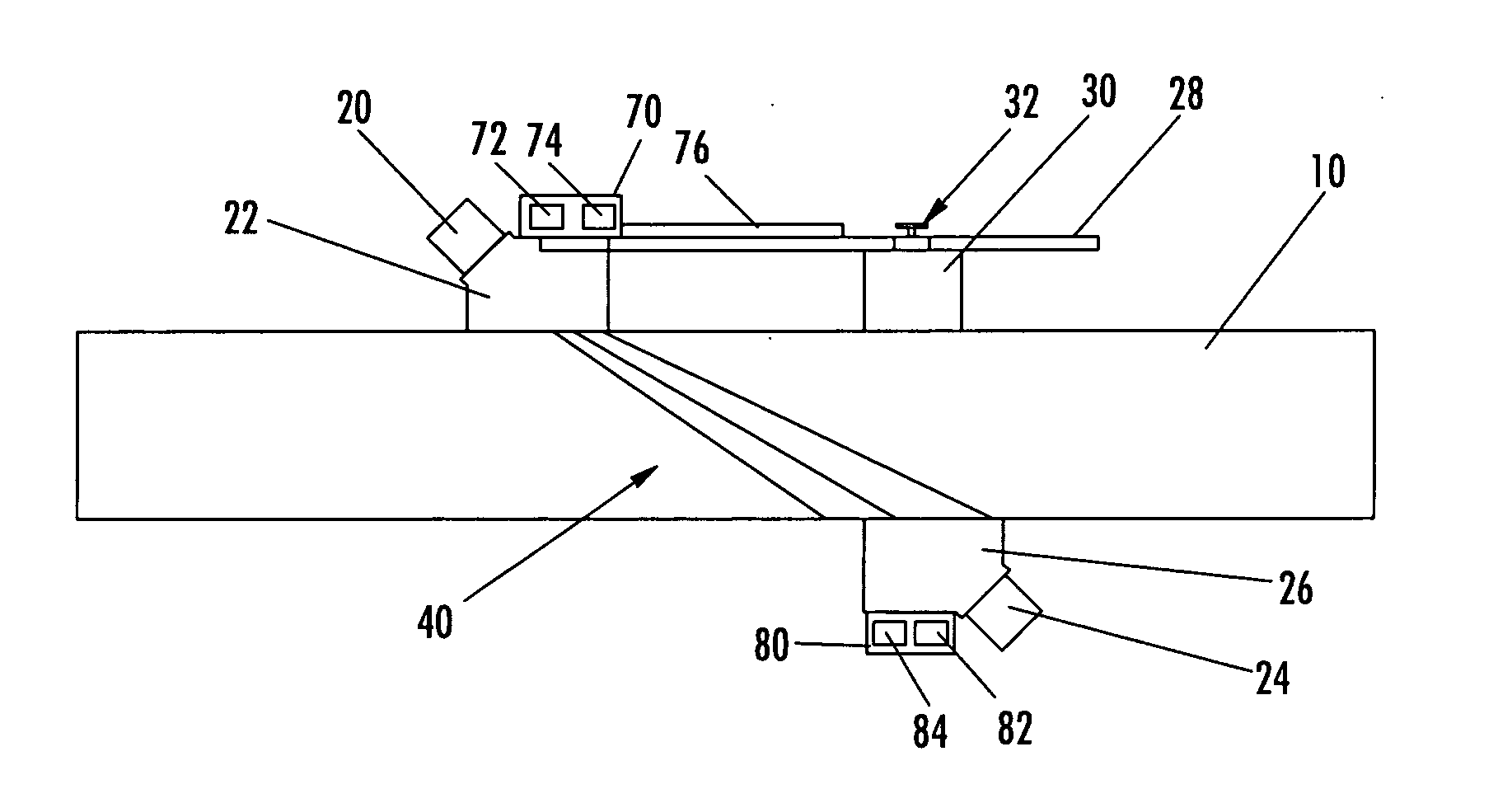

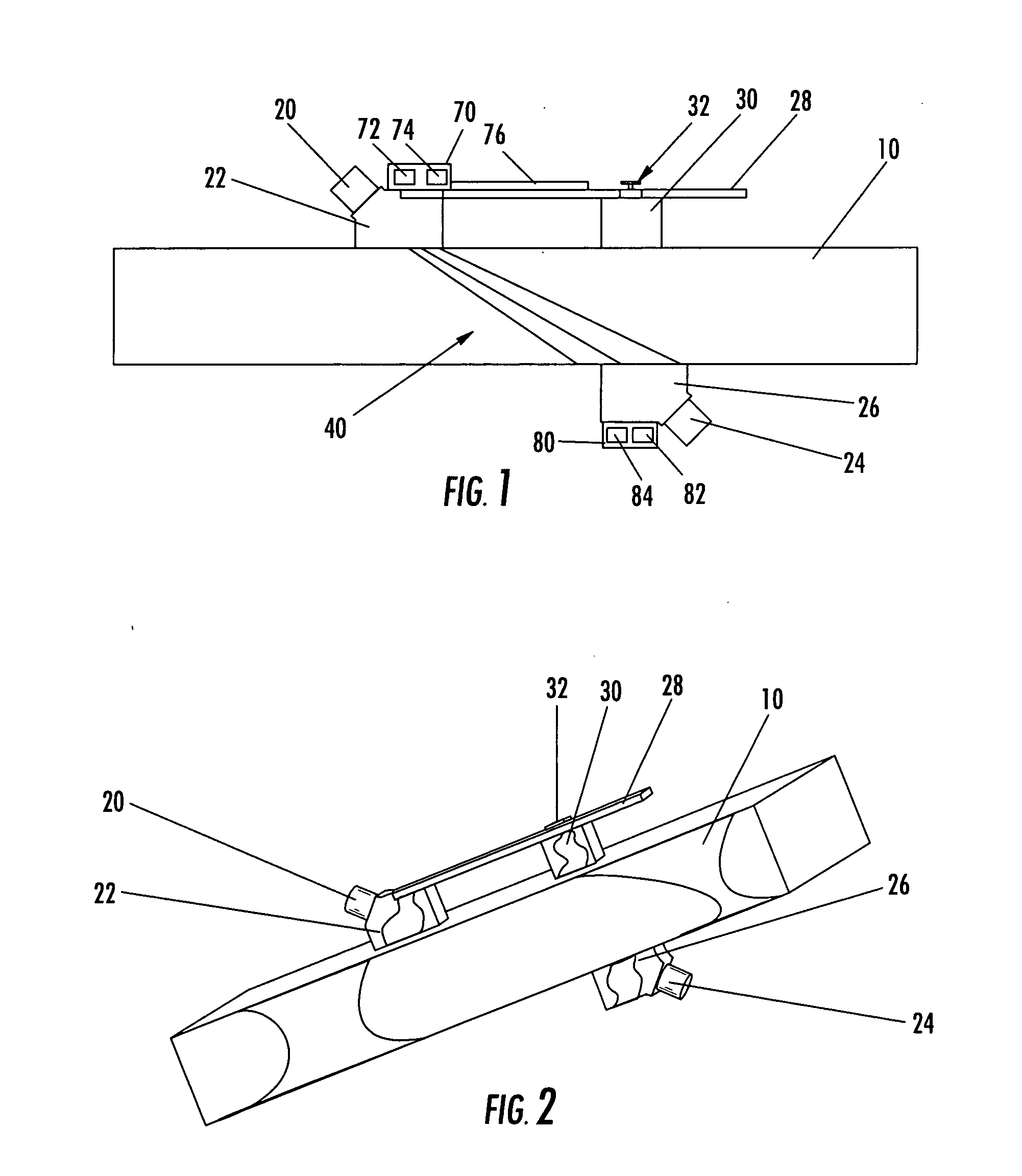

Improved methods, systems, and apparatus for inspecting a structure using angle beam shear wave through-transmission ultrasonic signals involves positioning transducers at offset positions on opposing sides of the structure and permits inspection of the inside of the structure beneath surface defects and features. Magnetic coupling can be used for supporting a pair of leader-follower probes and defining offset positions between angle beam shear wave transducers carried by the probes. Inspection data can be collected for supporting real-time generation of three-dimensional image representations of the structure and of internal defects and features of the structure. Image generation and resolution using inspection data from angle beam shear wave ultrasonic signals can be supplemented using pulse-echo ultrasonic inspection data.

Owner:THE BOEING CO

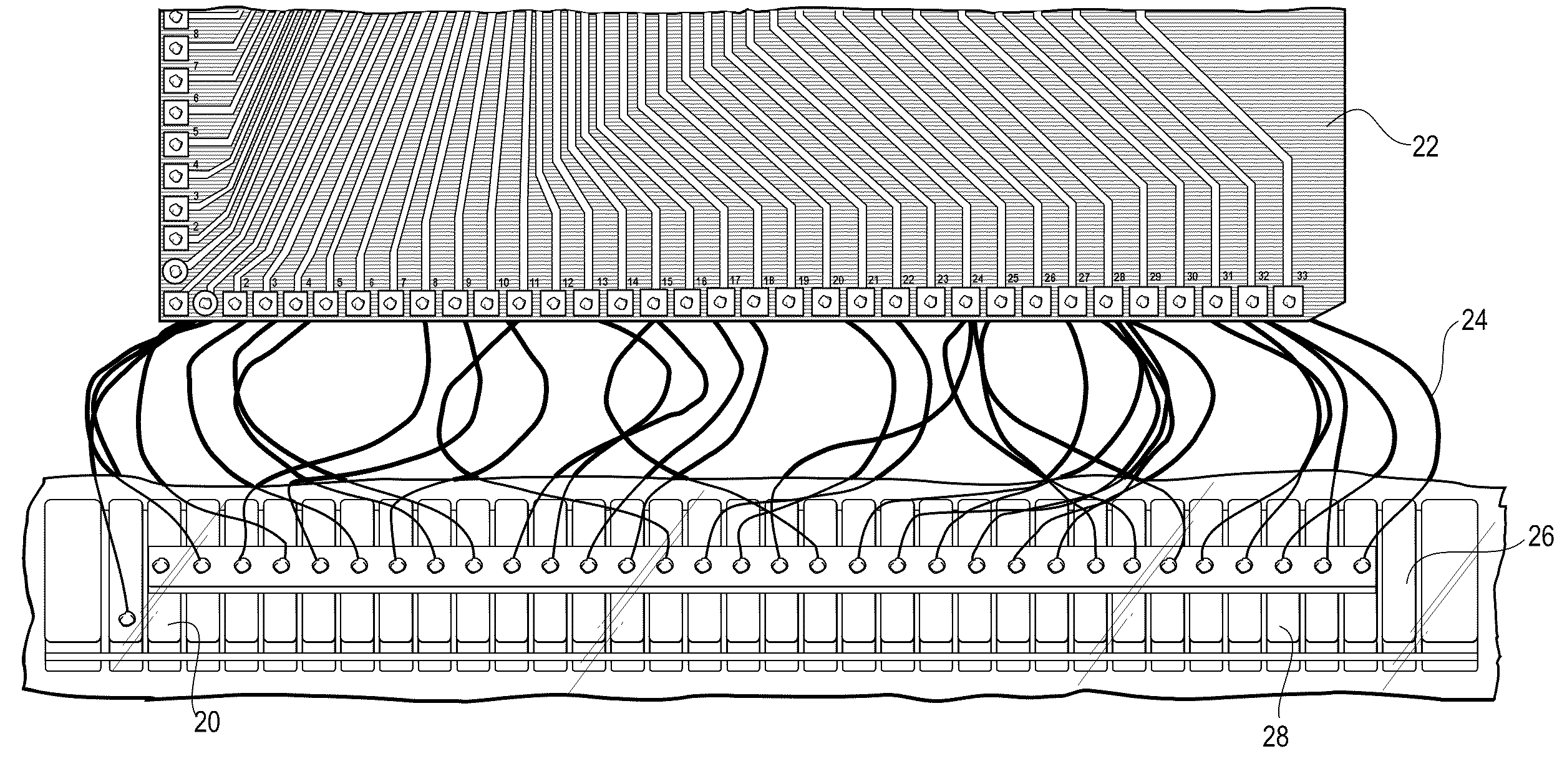

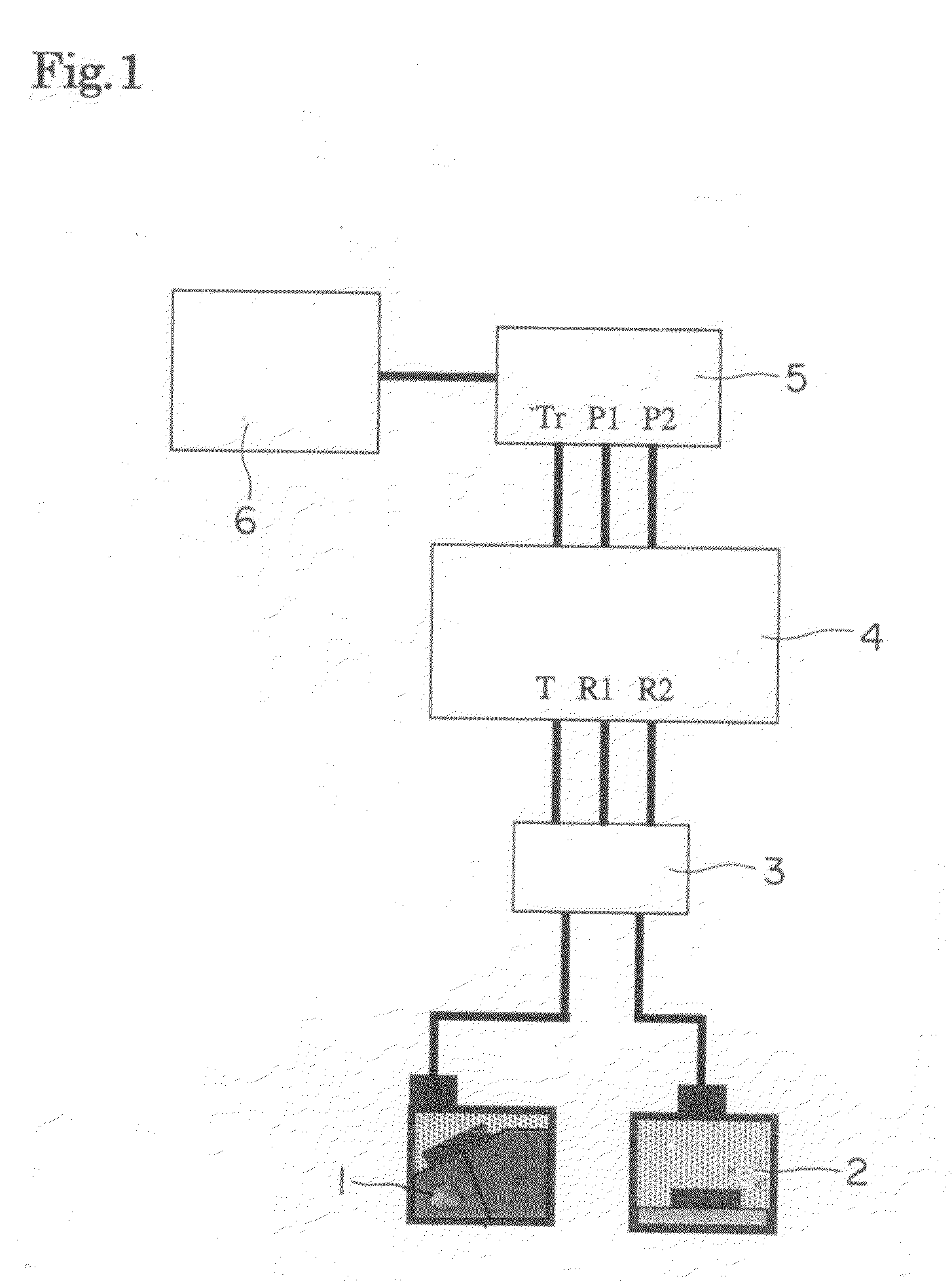

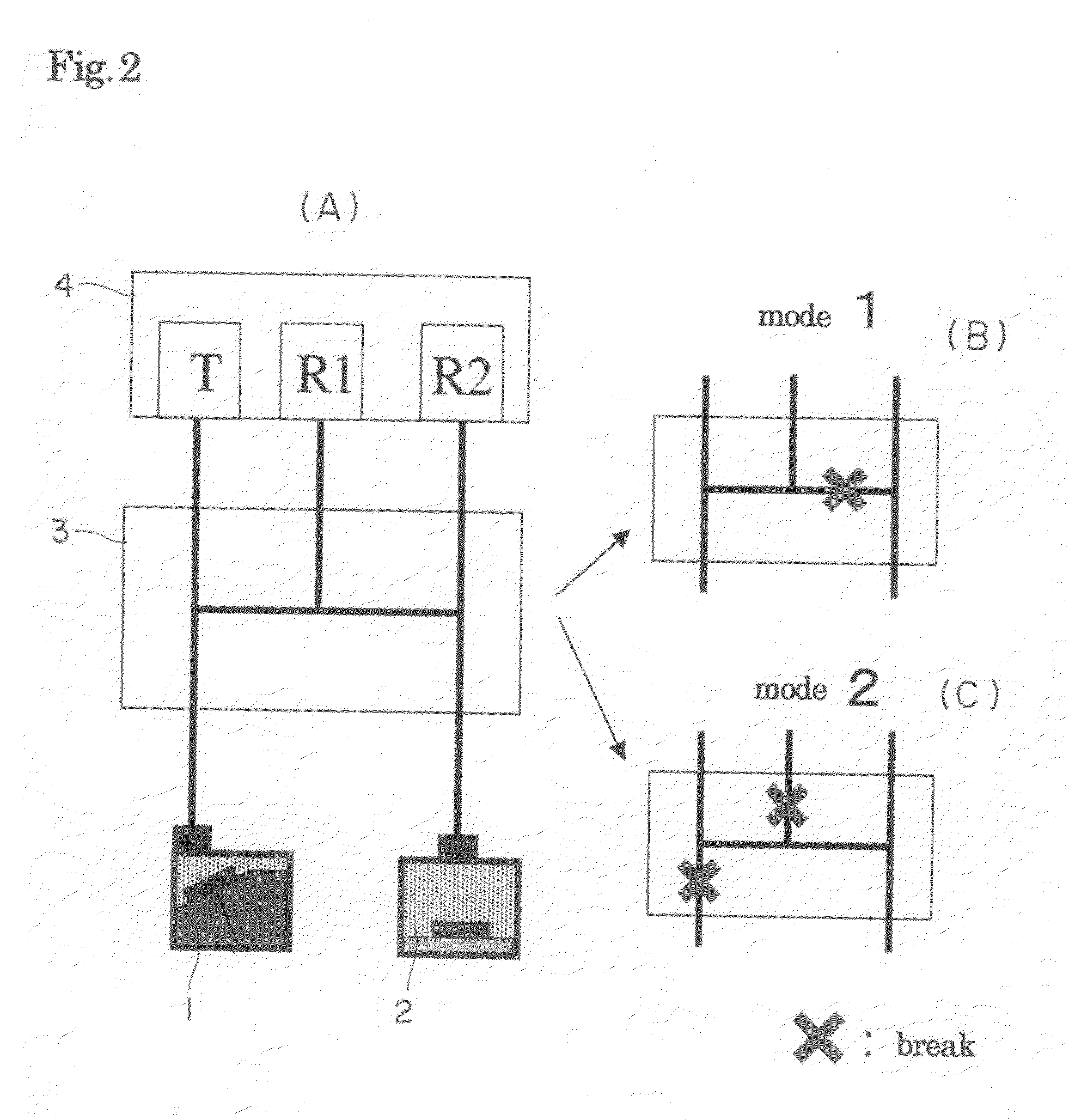

Apparatus and method for ultrasonic testing

InactiveUS20100106431A1RatioAnalysing solids using sonic/ultrasonic/infrasonic wavesSpecial data processing applicationsElectricityUltrasonic testing

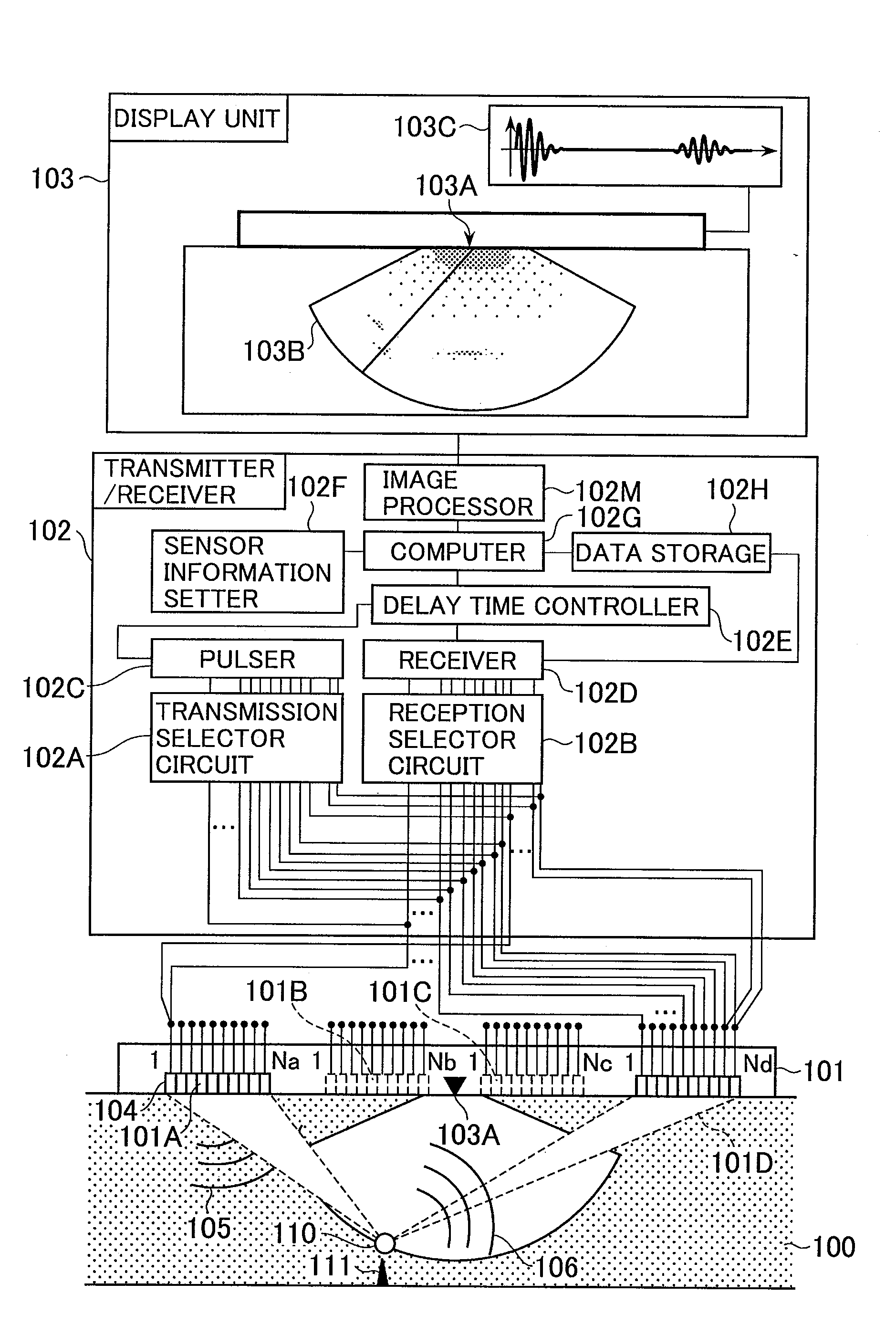

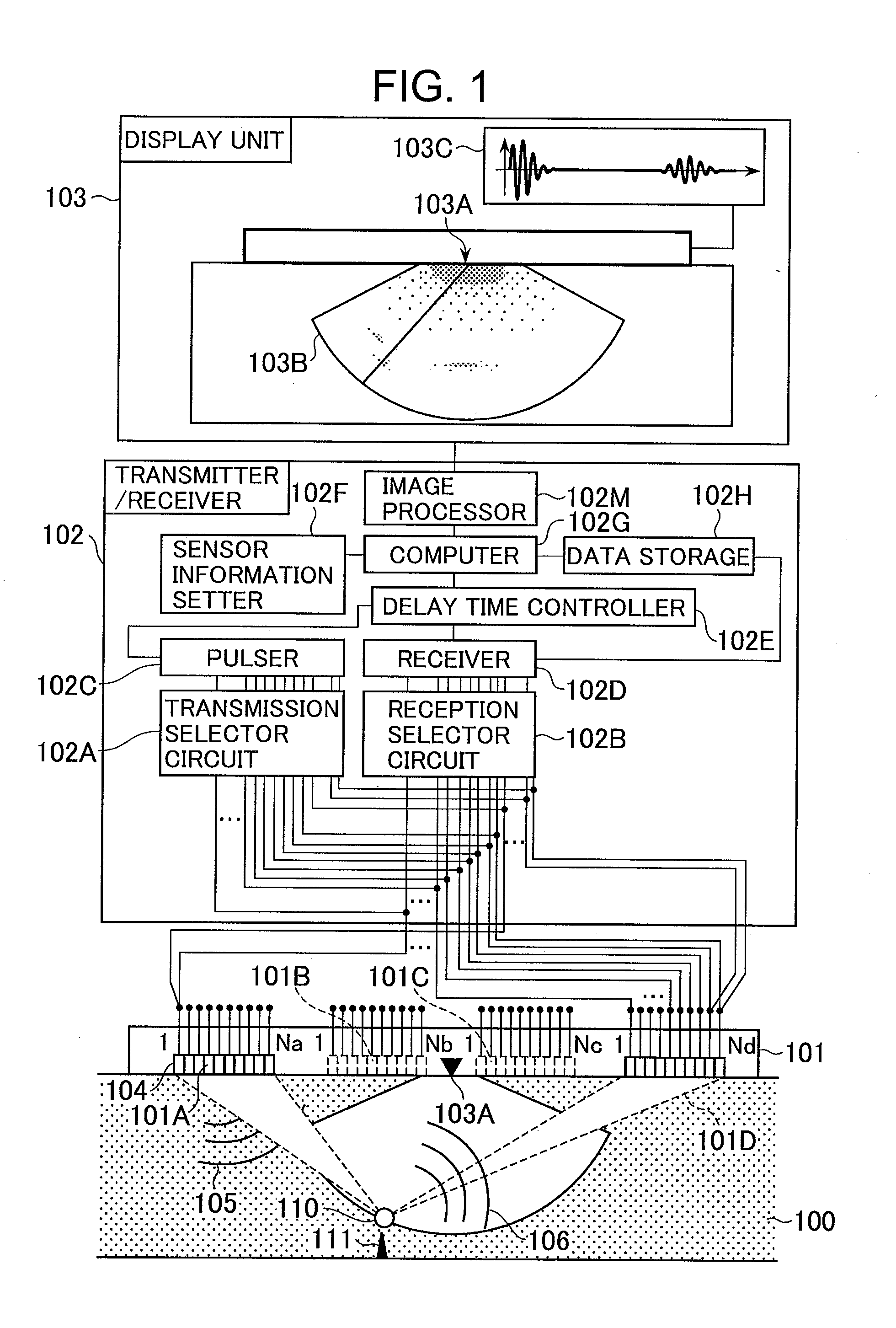

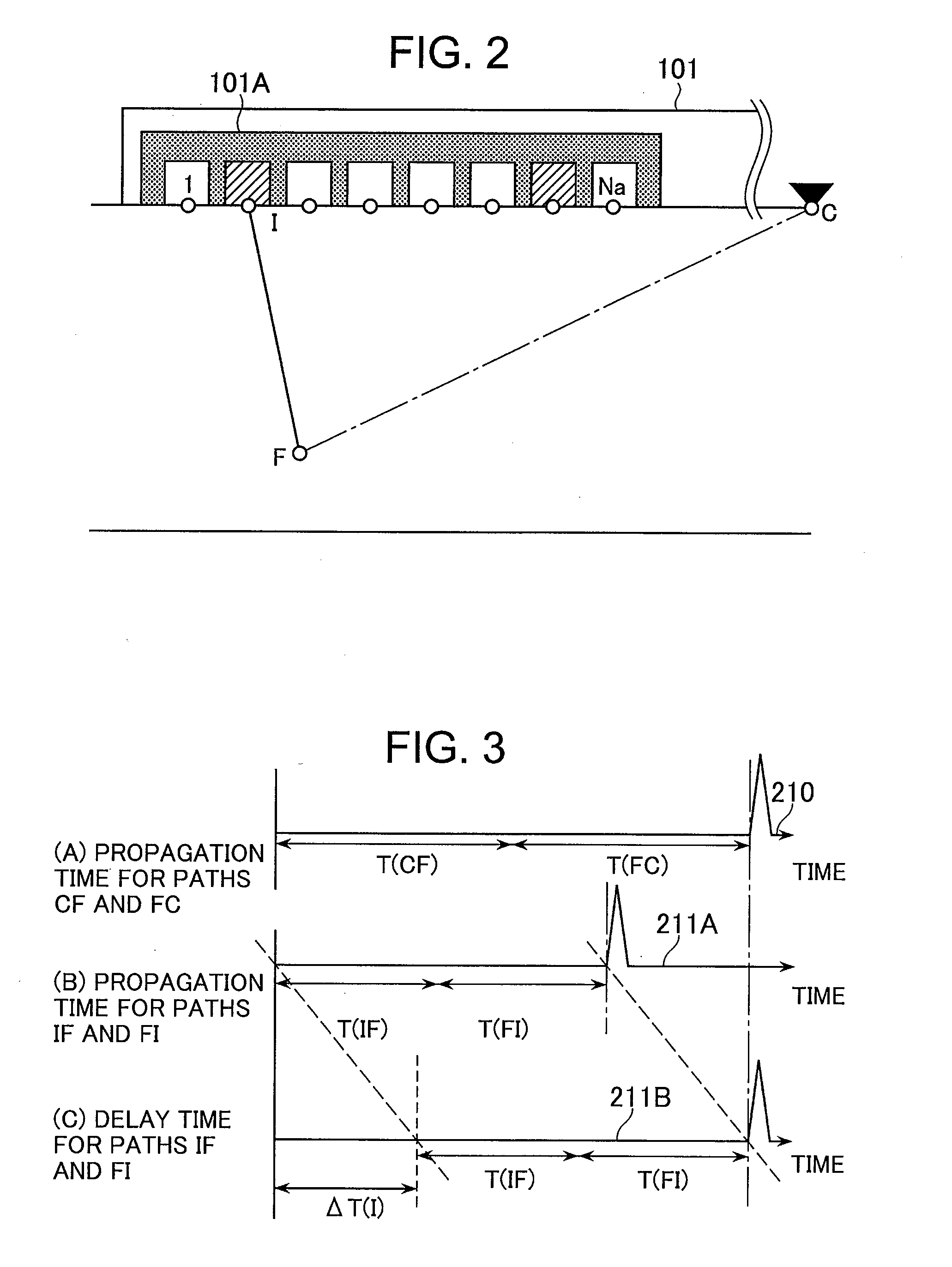

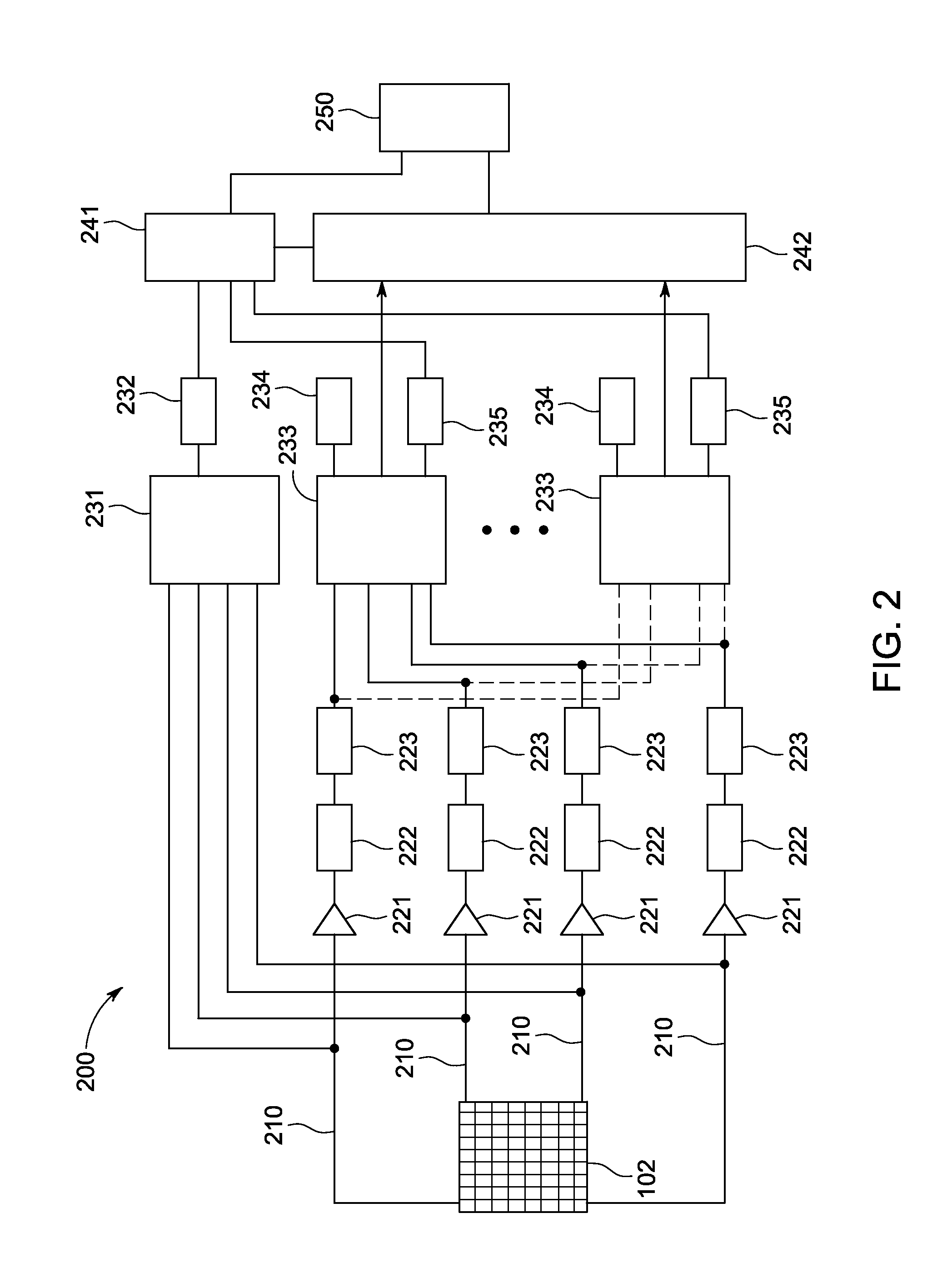

An apparatus and a method for ultrasonic testing obtains high-resolution and high-S / N ratio testing results by driving a number of piezoelectric elements using fewer pulsers and receivers in comparison with the number of elements composing an array transducer. A sensor information setter sets a plurality of piezoelectric element groups used for transmission and a plurality of piezoelectric element groups used for reception among the plurality of piezoelectric elements composing an ultrasonic array transducer. A computer transmits an ultrasonic wave from the element cluster set for transmission, and stores an ultrasonic wave received by the element cluster set for reception. The procedure is repeated including different element cluster sets for transmission and reception to obtain first receive signals. The first receive signals are summed to obtain a second receive signal; and the second receive signal is displayed with reference to the sensor center position on a display unit.

Owner:HITACHI LTD

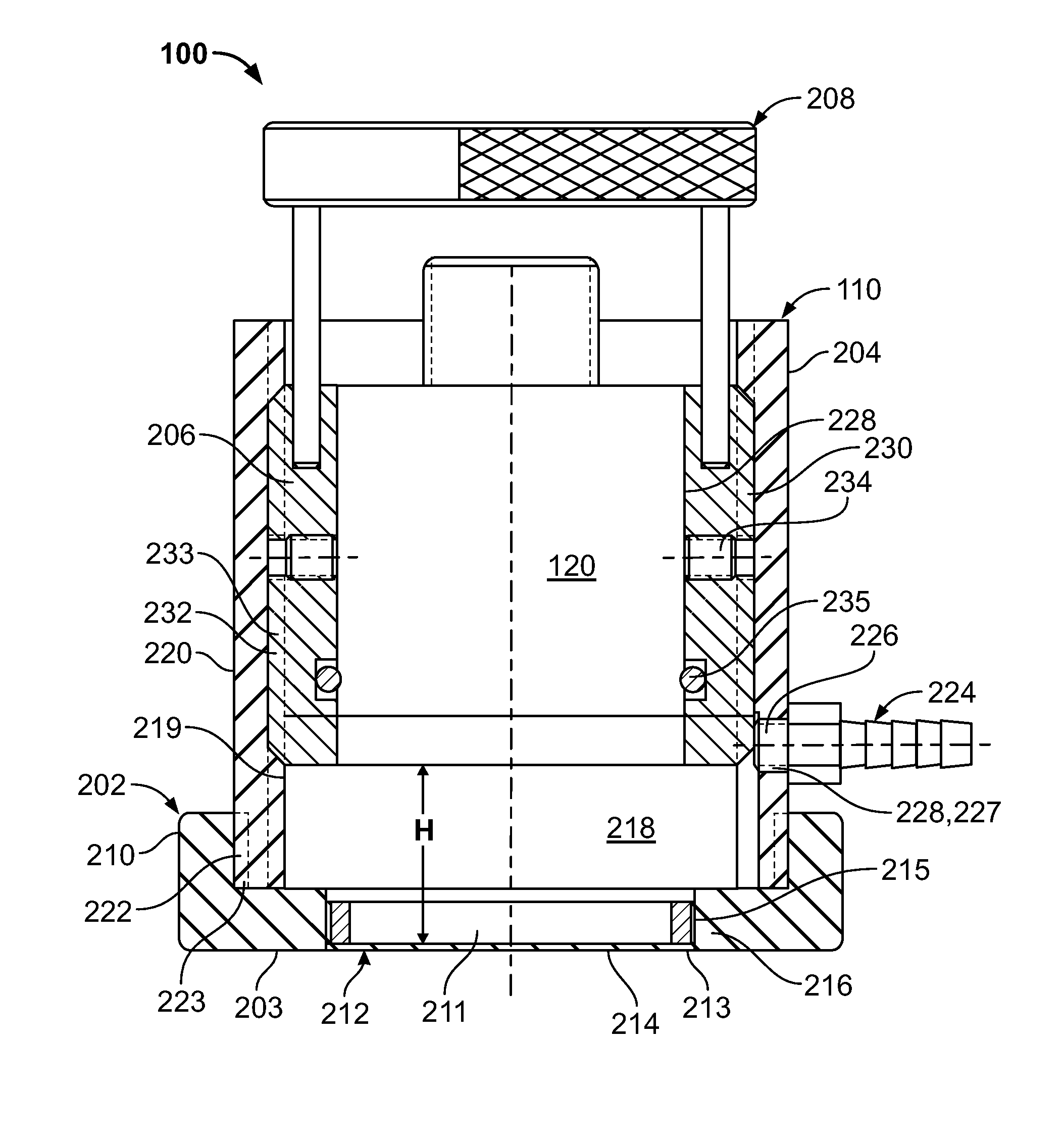

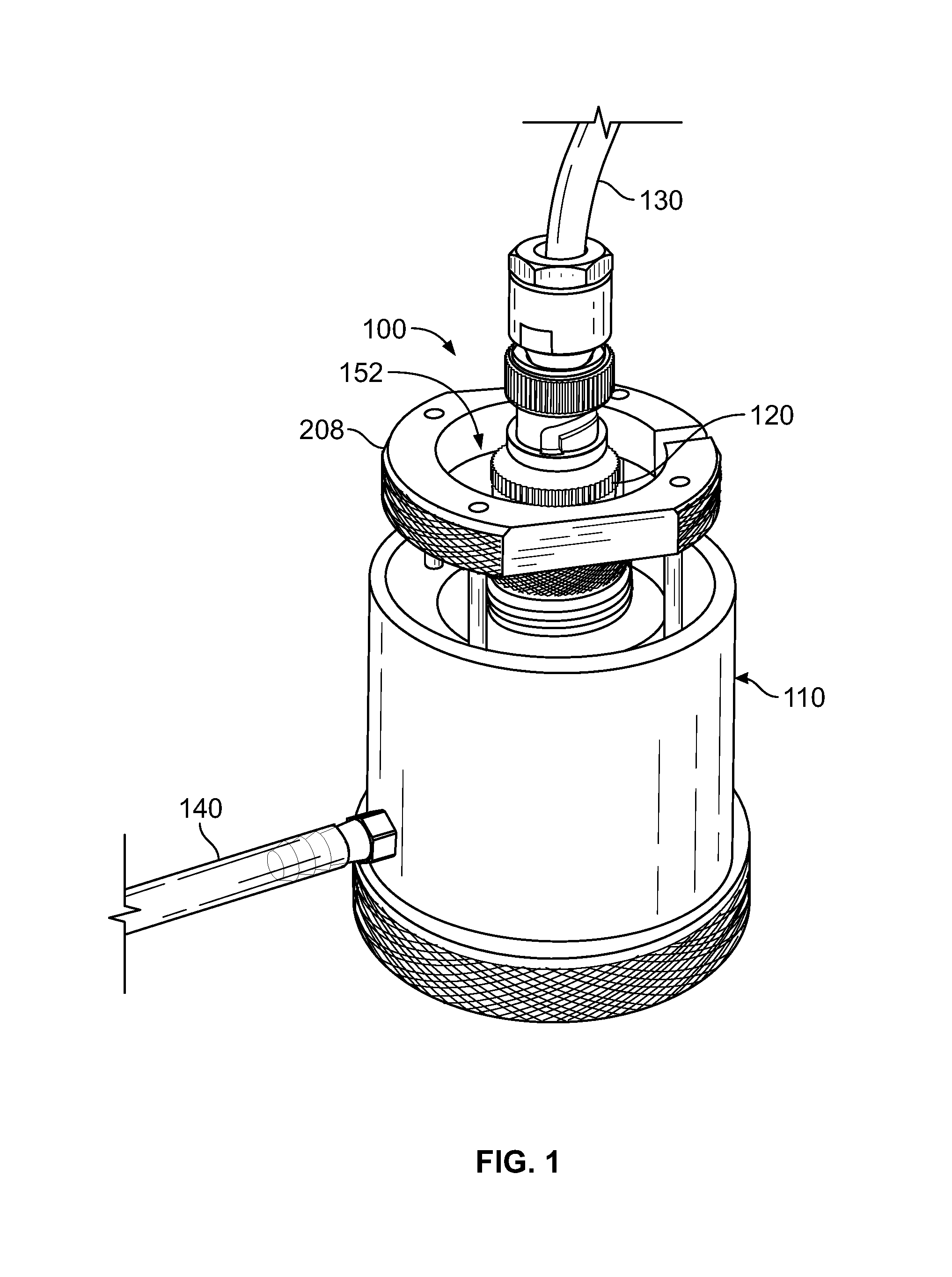

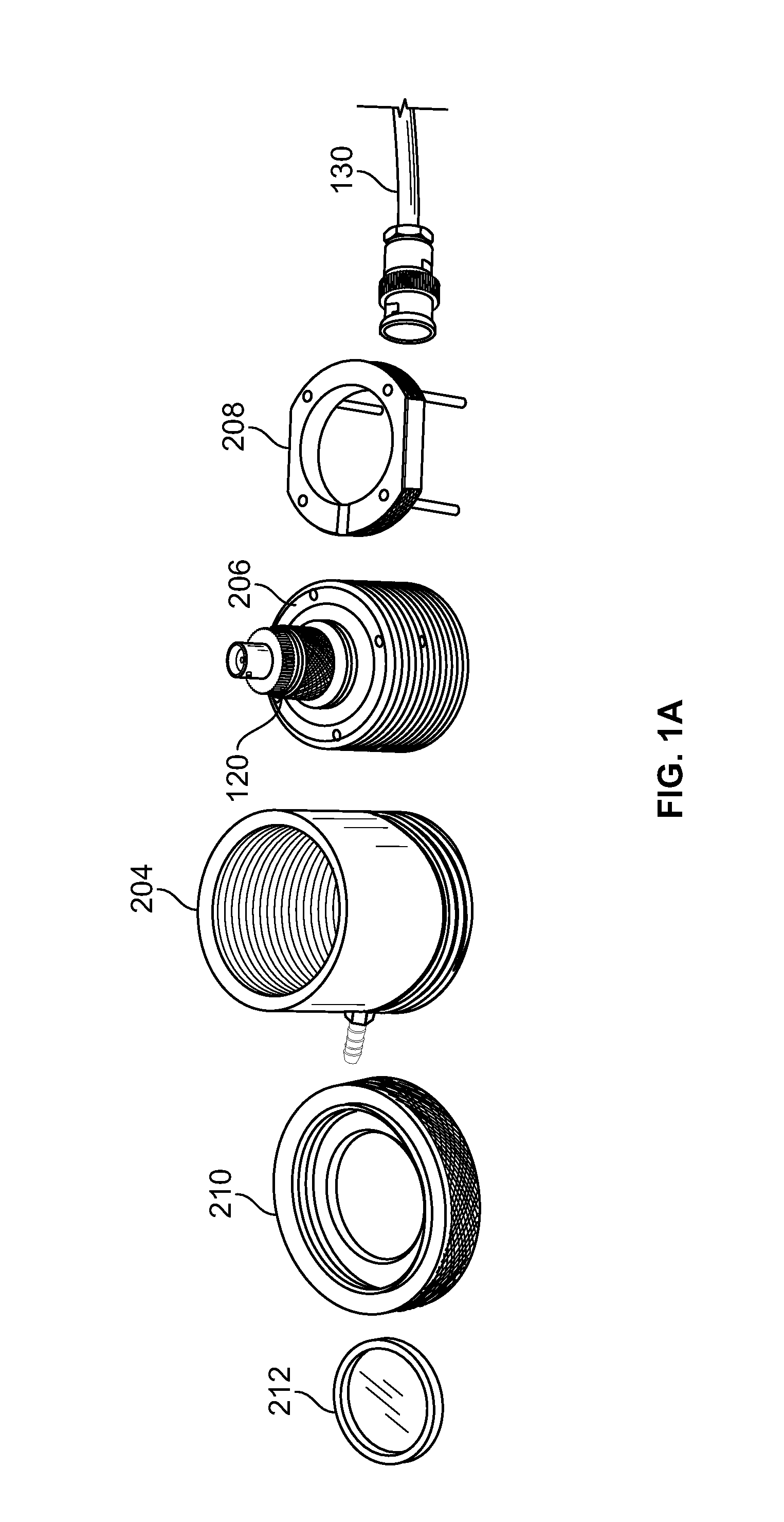

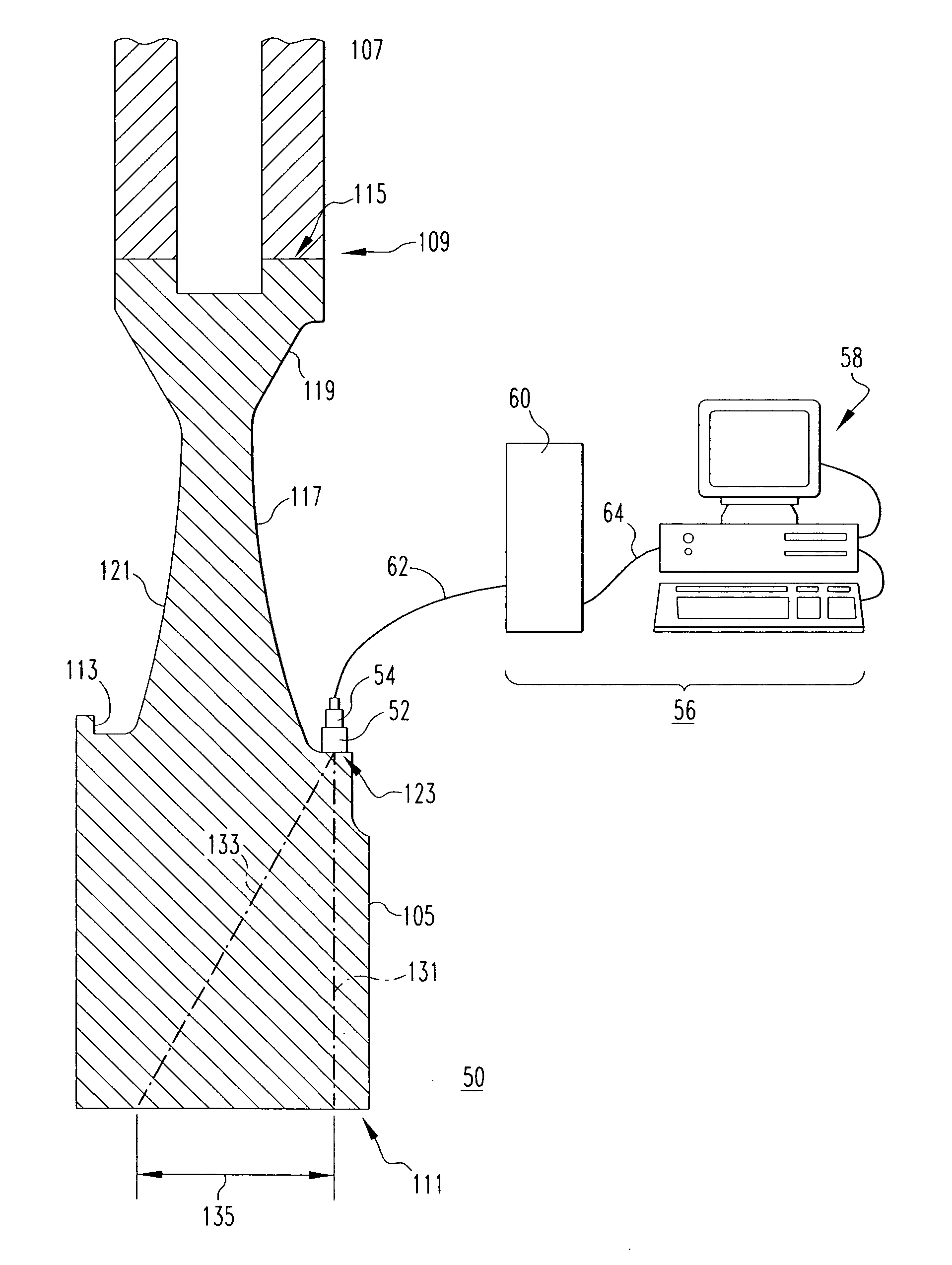

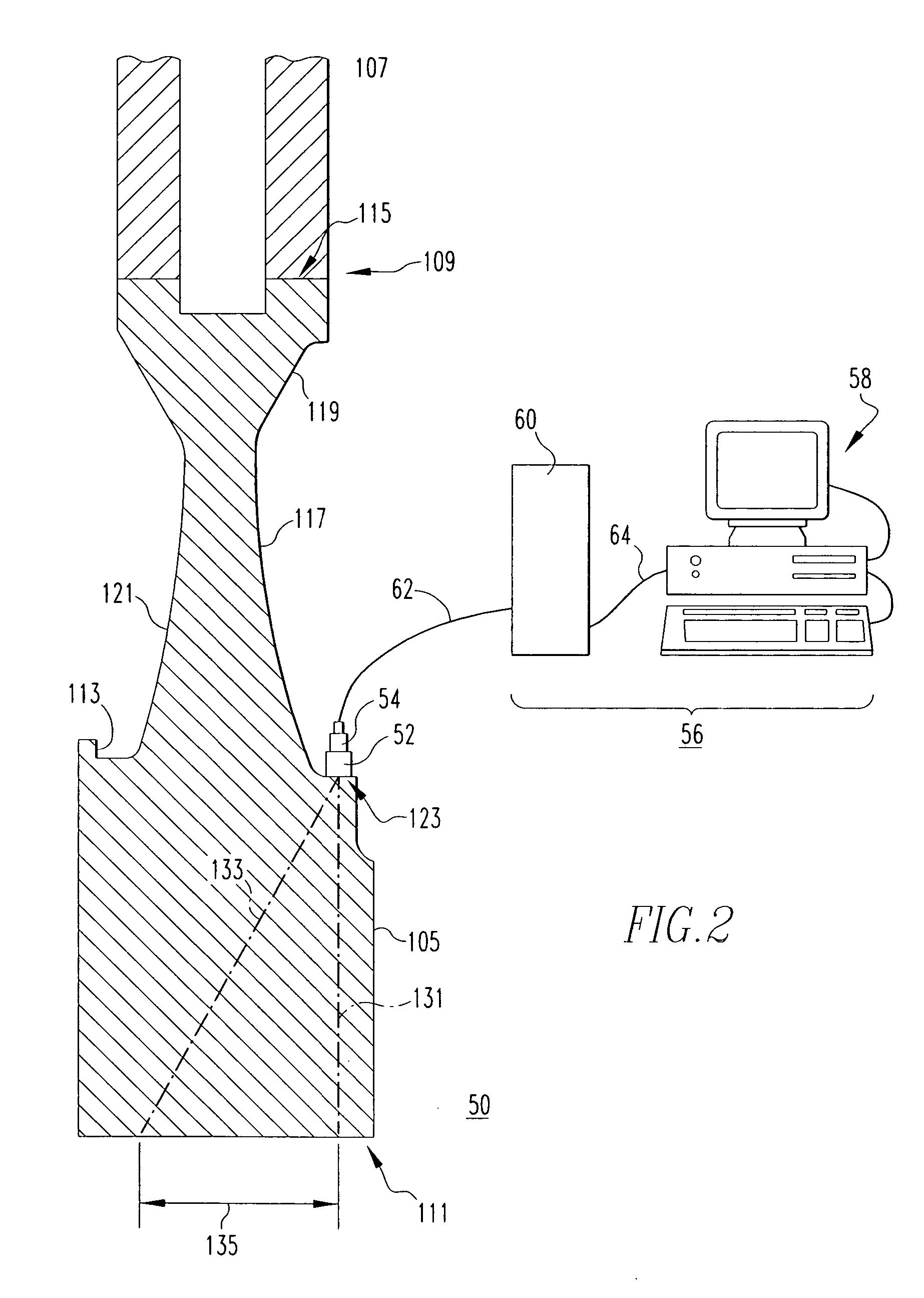

Ultrasonic testing device having an adjustable water column

ActiveUS9121817B1Quality improvementPromote quick completionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationUltrasonic testing

An ultrasonic testing device having a variable fluid column height is disclosed. An operator is able to adjust the fluid column height in real time during an inspection to to produce optimum ultrasonic focus and separate extraneous, unwanted UT signals from those stemming from the area of interest.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

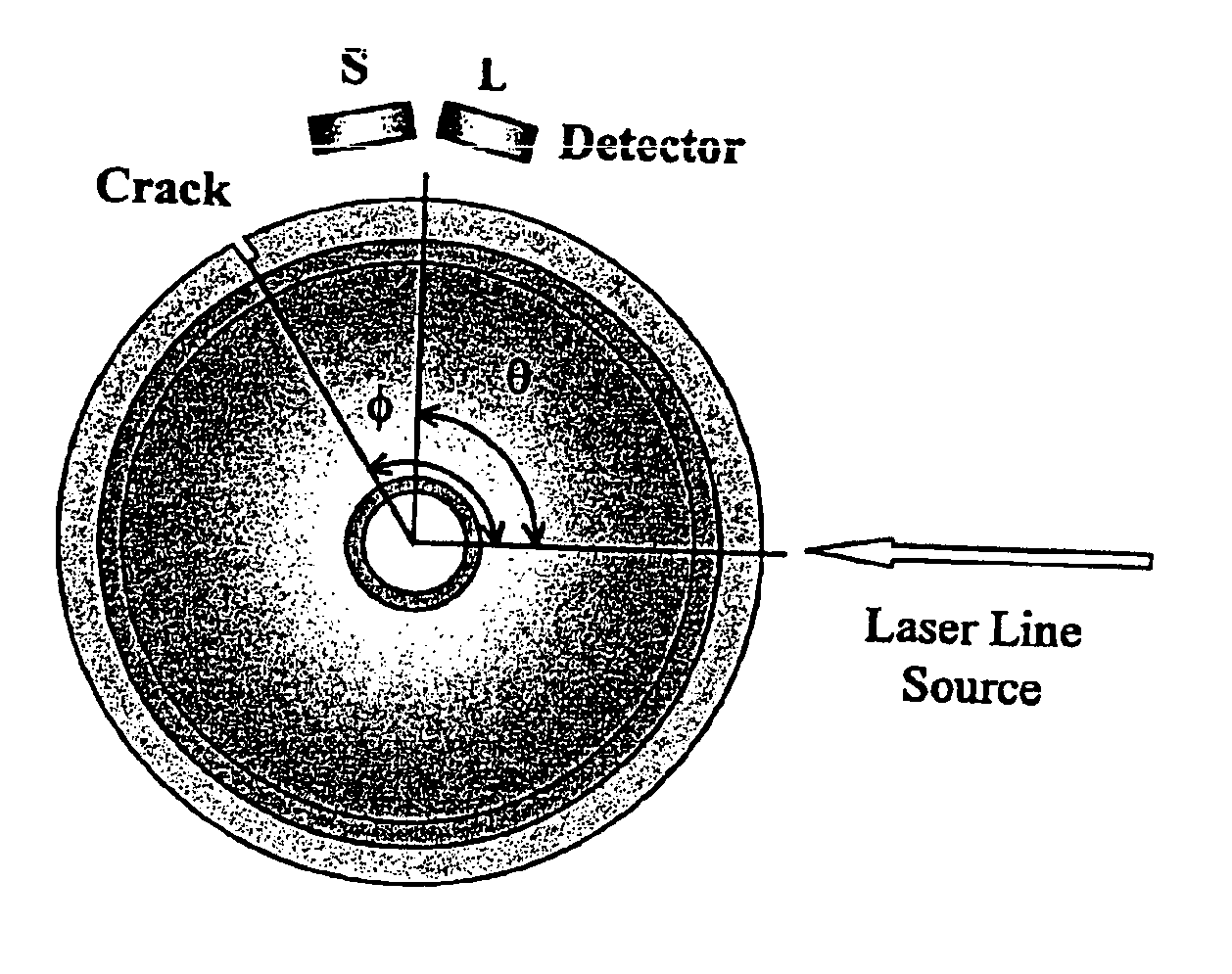

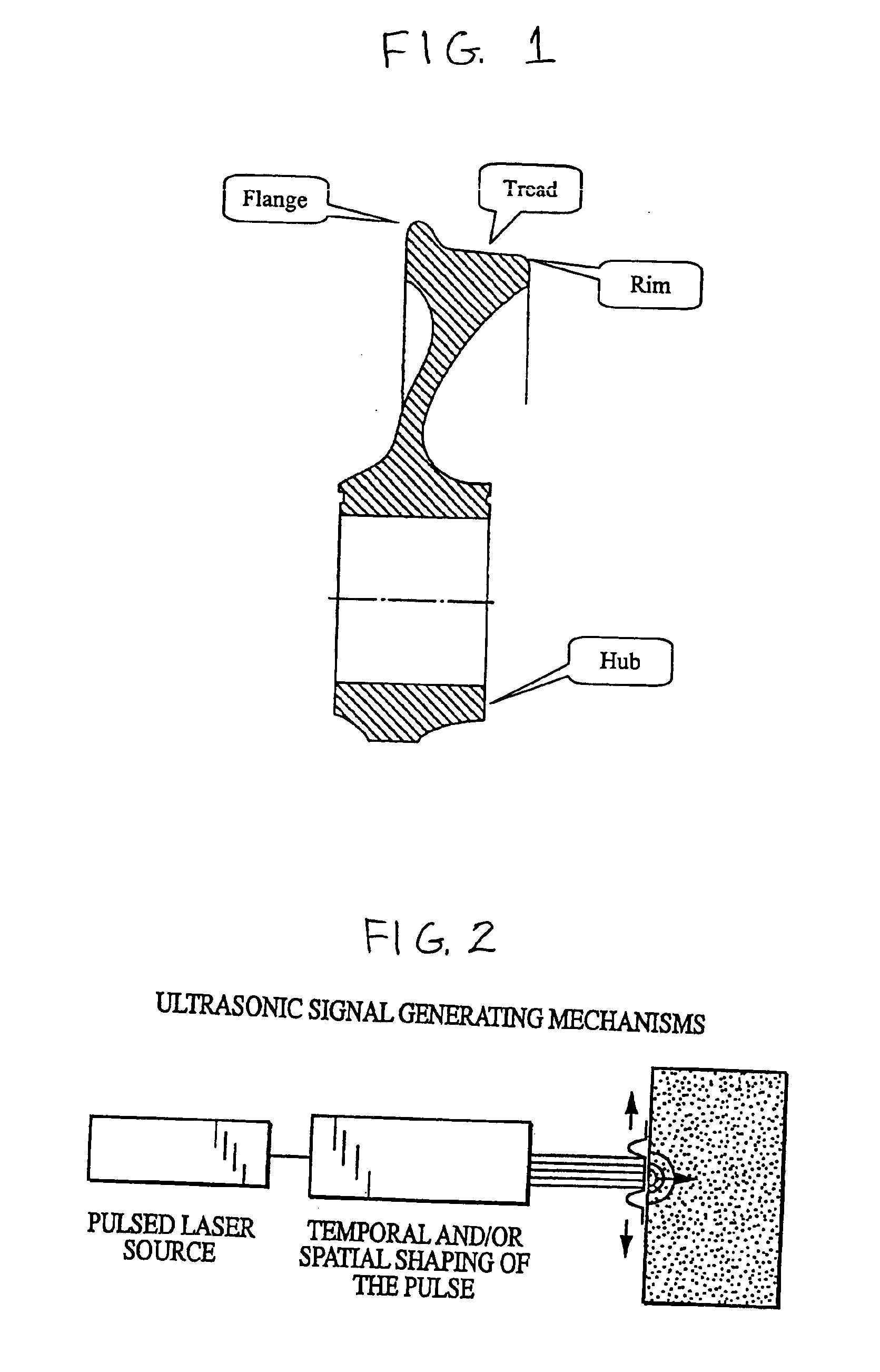

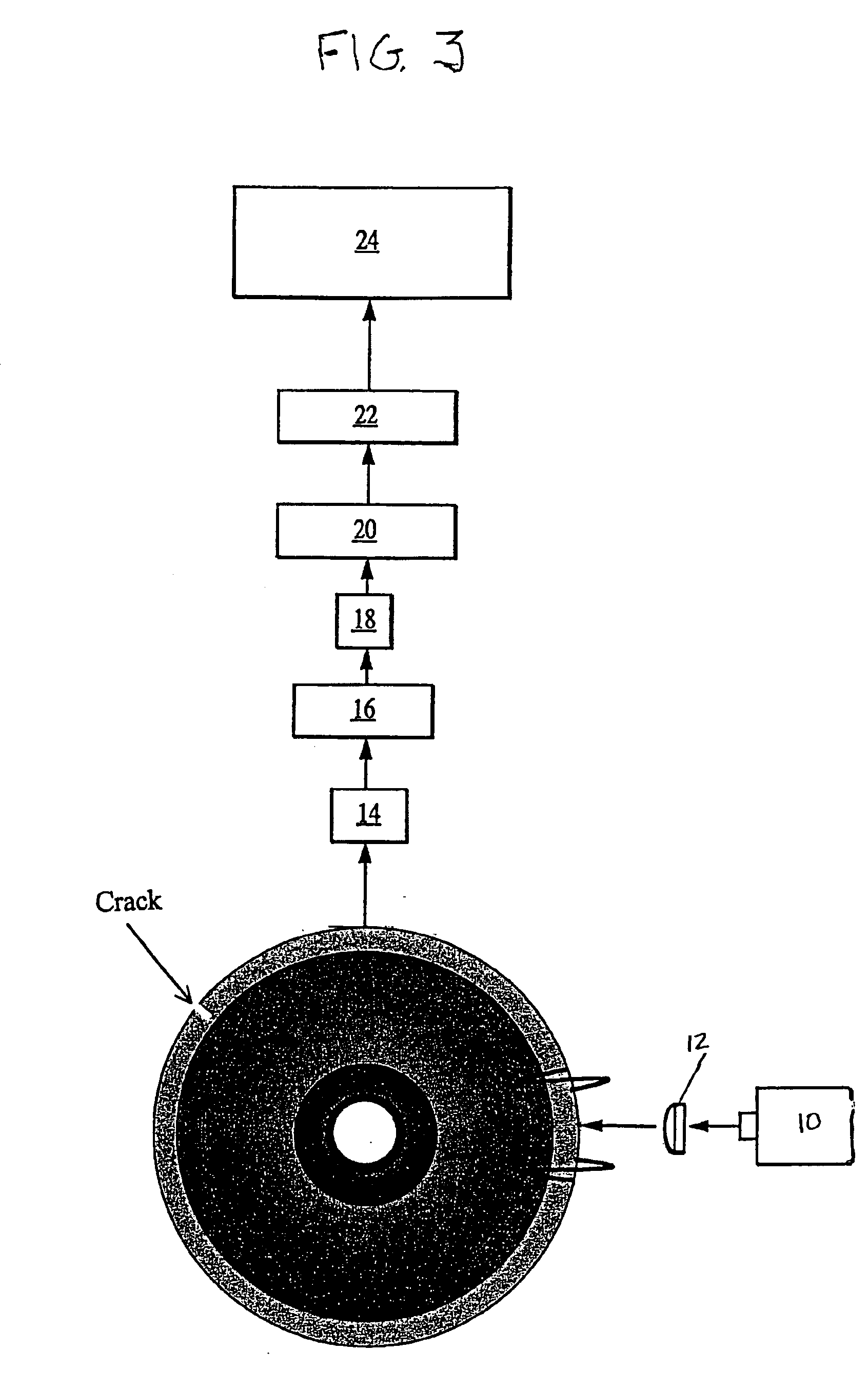

Laser-air, hybrid, ultrasonic testing of railroad wheels

InactiveUS6862936B2Rail-engaging wheelsAnalysing solids using sonic/ultrasonic/infrasonic wavesWavefrontRailroad wheel

A remote, non-contact system for detecting a defect in a railroad wheel as the wheel is stationary or moving along a railroad track includes; (1) a pulsed, laser light source for generating an ultrasonic wave in the wheel, the ultrasonic wave having a direct portion and reflected and transmitted portions if the direct portion encounters a defect in the wheel, (2) an optical component in the path of the light from the light source for forming the light into a specified illumination pattern so that the generated ultrasonic wave has a specified wavefront, (3) an air-coupled transducer or a group of transducers for sensing the acoustic signal emanating from the wheel that results from the ultrasonic wave traveling through the wheel, and (4) a signal processor, responsive to the sensed acoustic signal, capable of distinguishing whether the sensed signal has a component that indicates the existence of a reflected portion in the ultrasonic wave, wherein the presence of such a component in the acoustic signal indicates the existence of a defect in the railroad wheel.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

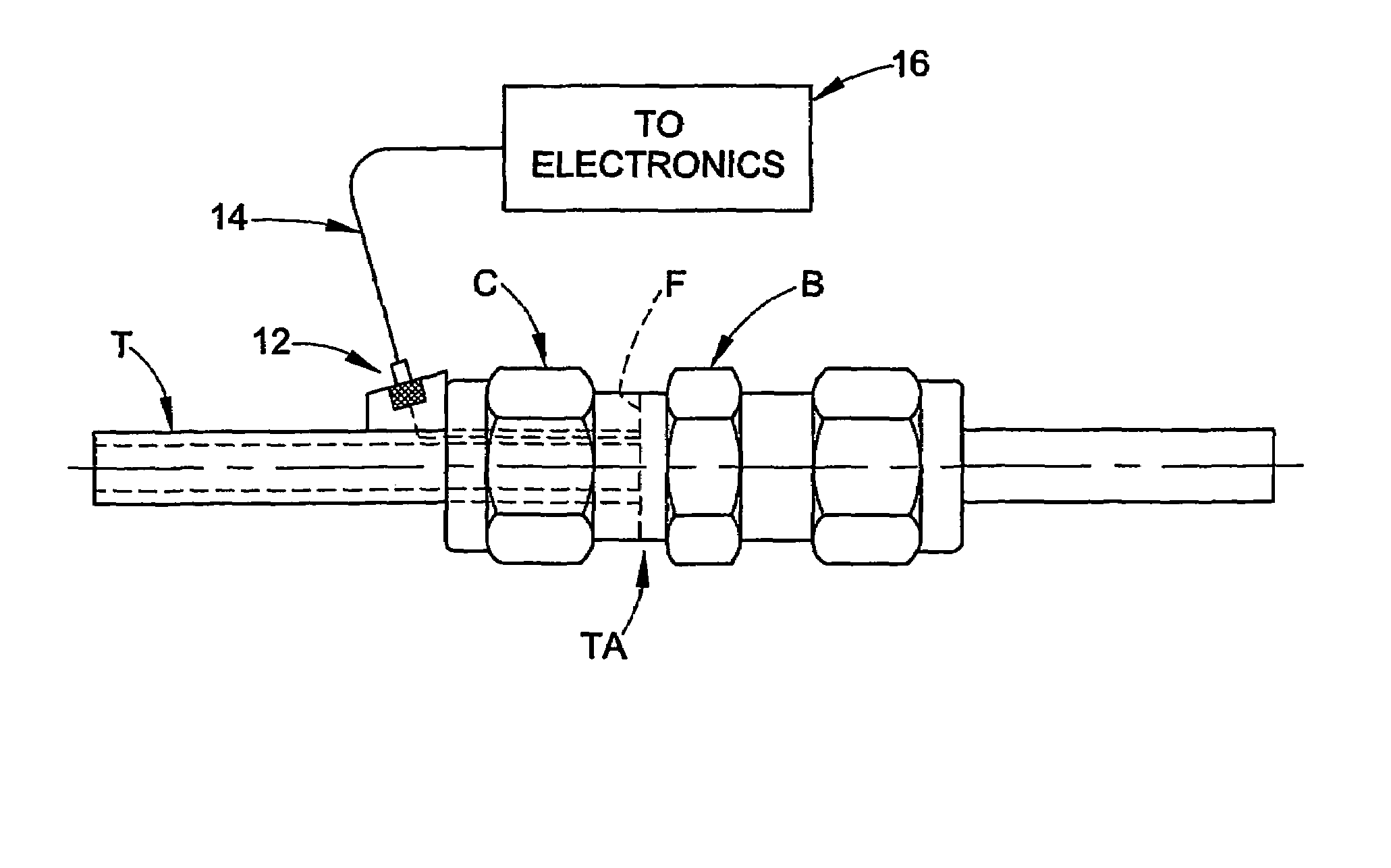

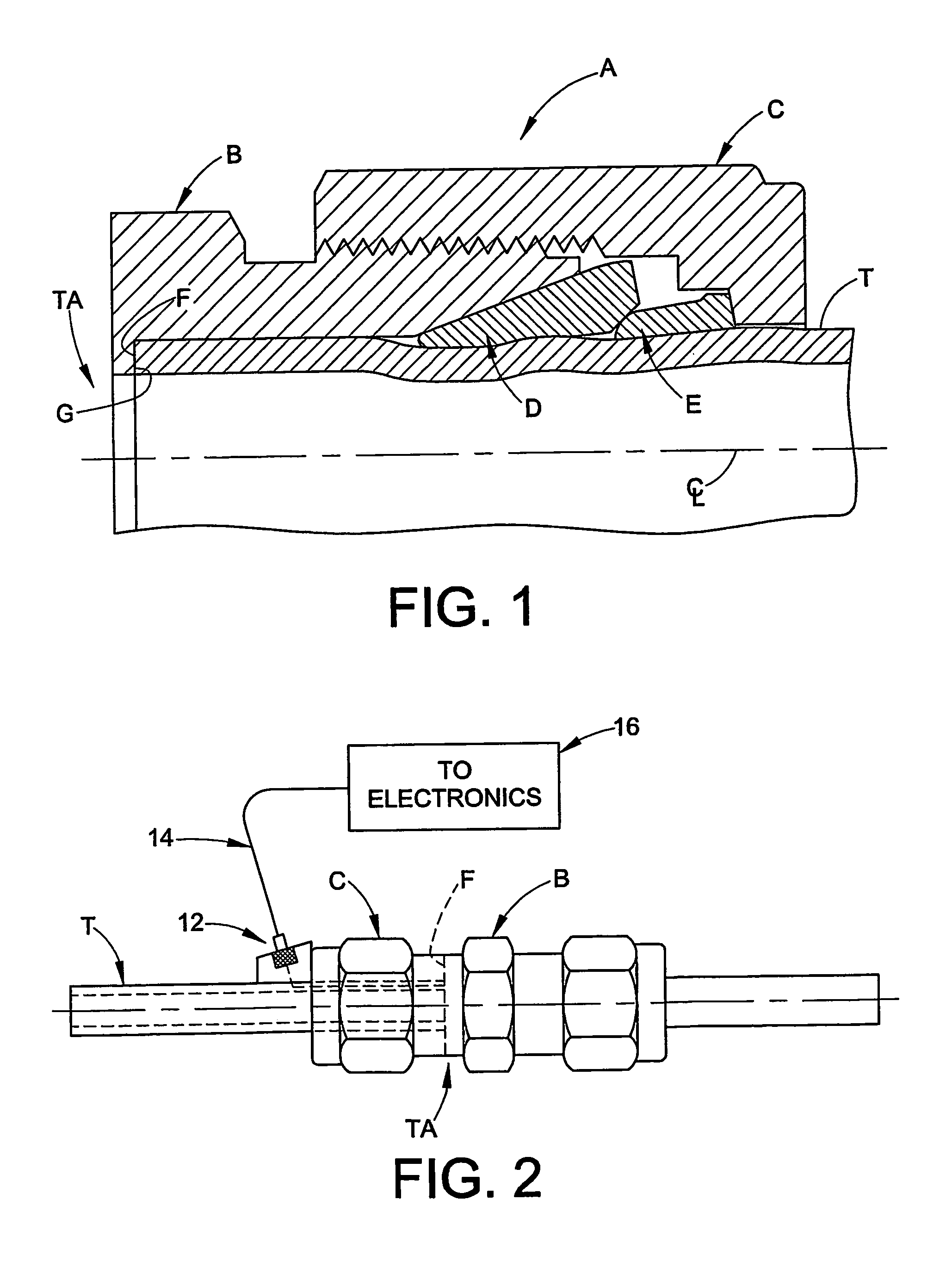

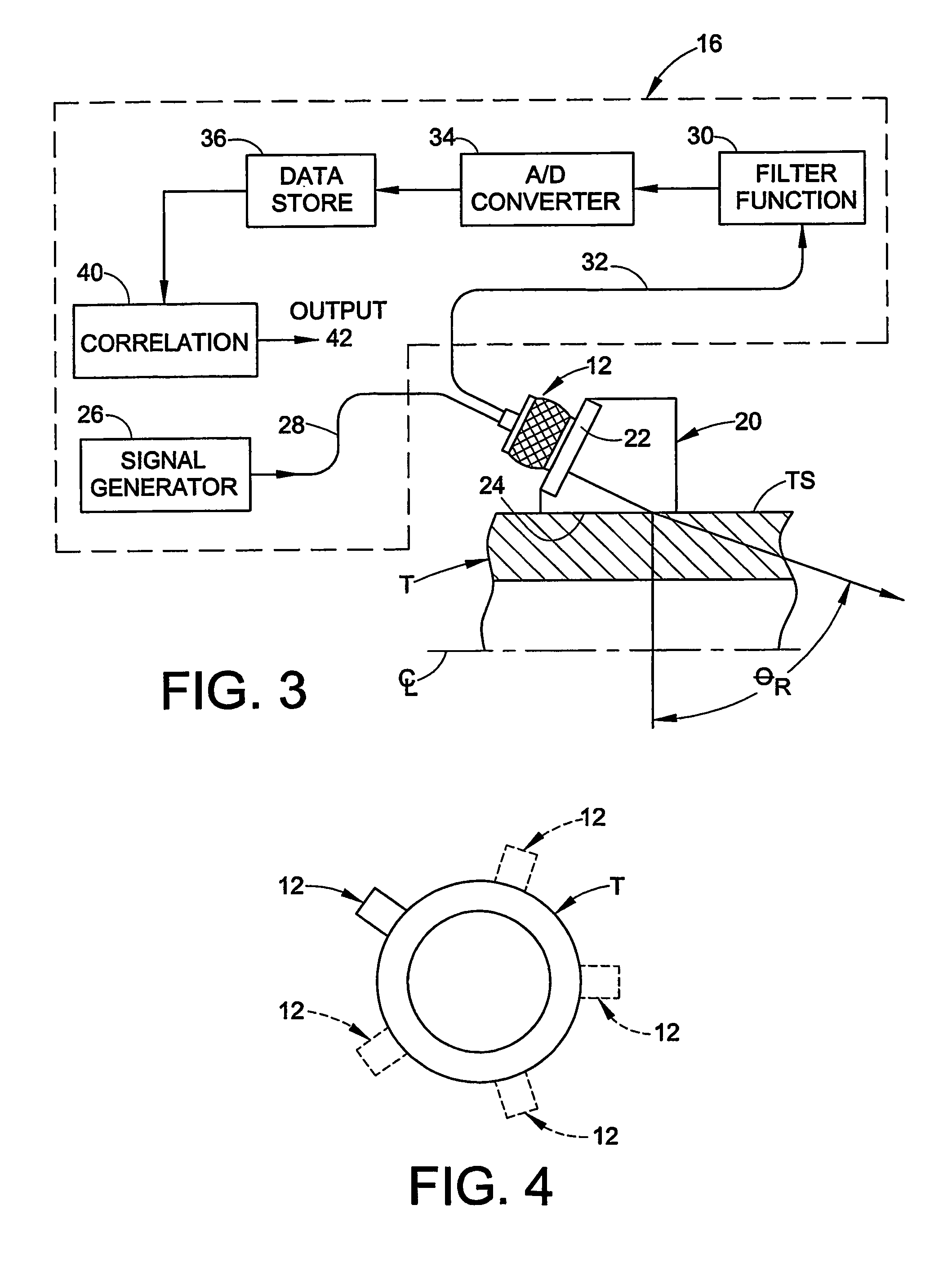

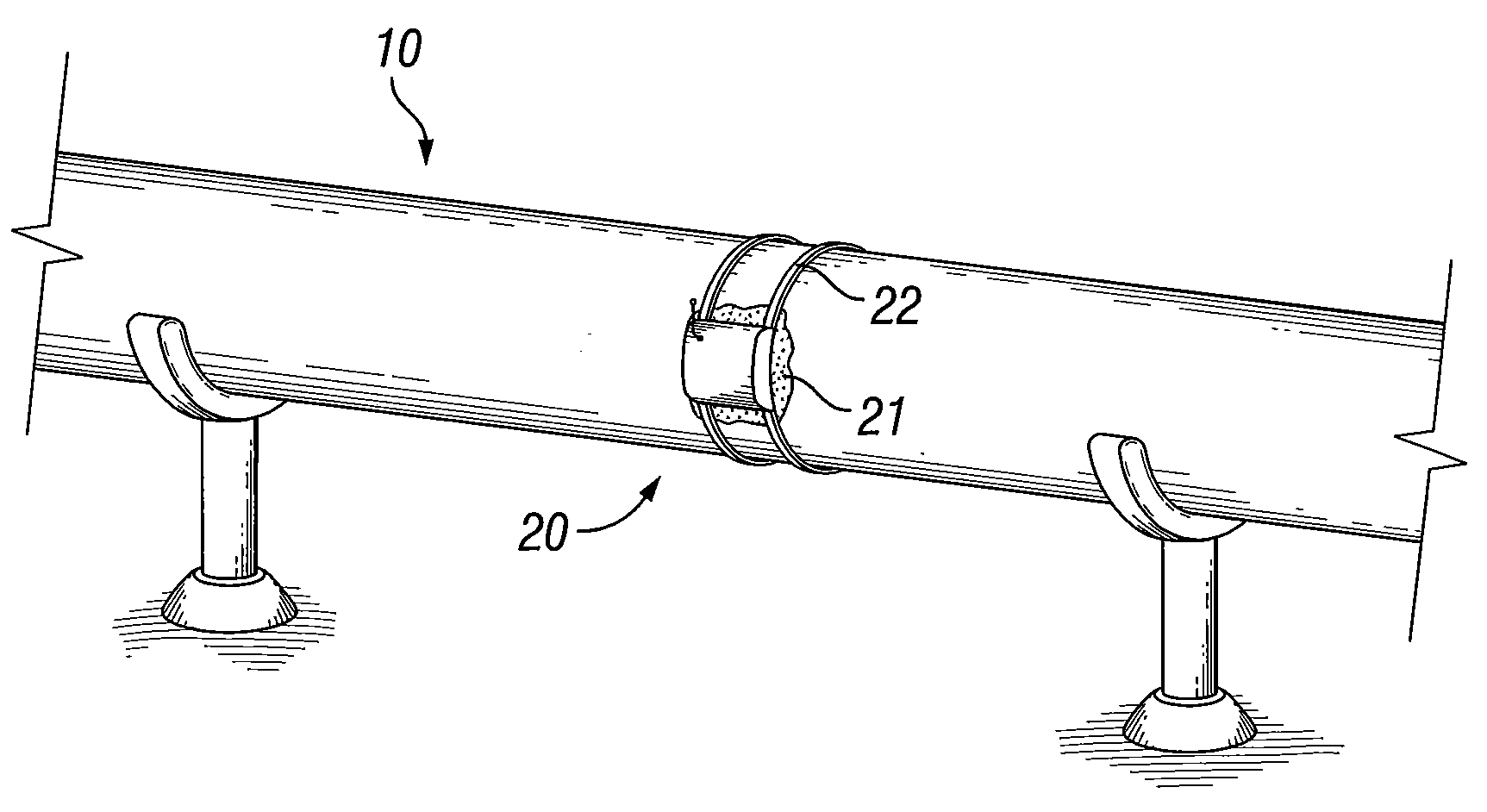

Ultrasonic testing of fitting assembly for fluid conduits with a hand-held apparatus

Hand-held apparatus and method for determining relative and / or absolute axial position of a conduit end within a fluid coupling includes application of input ultrasonic energy in the form of transient shear waves and analyzing the reflected energy. Application of the input energy collected at different radial positions about a first axial location is used with wavelet based correlation techniques to better analyze the reflected energy signals. Quality of the abutment between the conduit end and a surface associated with the coupling may also be determined as a separate or combined feature of the axial position determination.

Owner:SWAGELOK CO

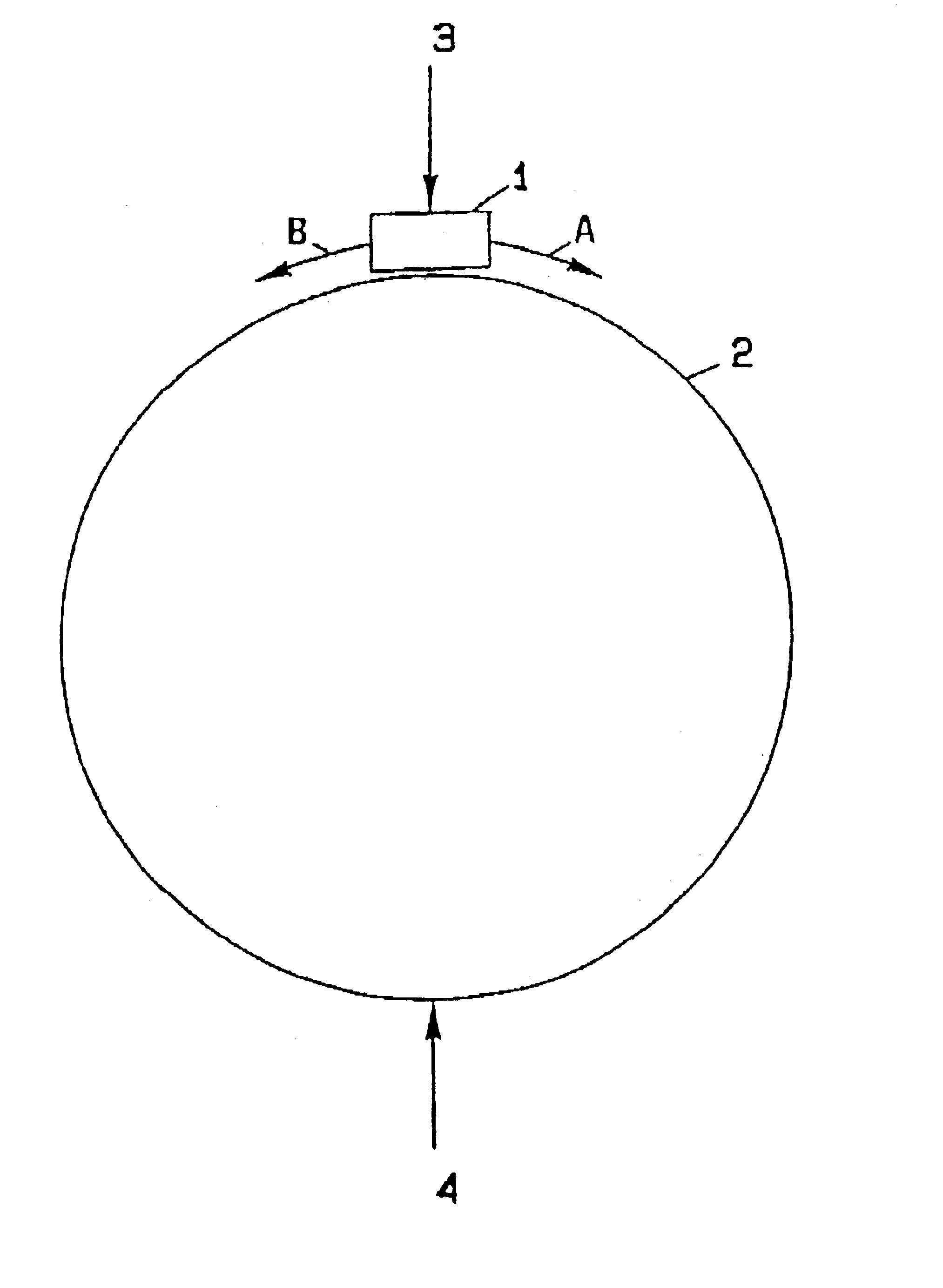

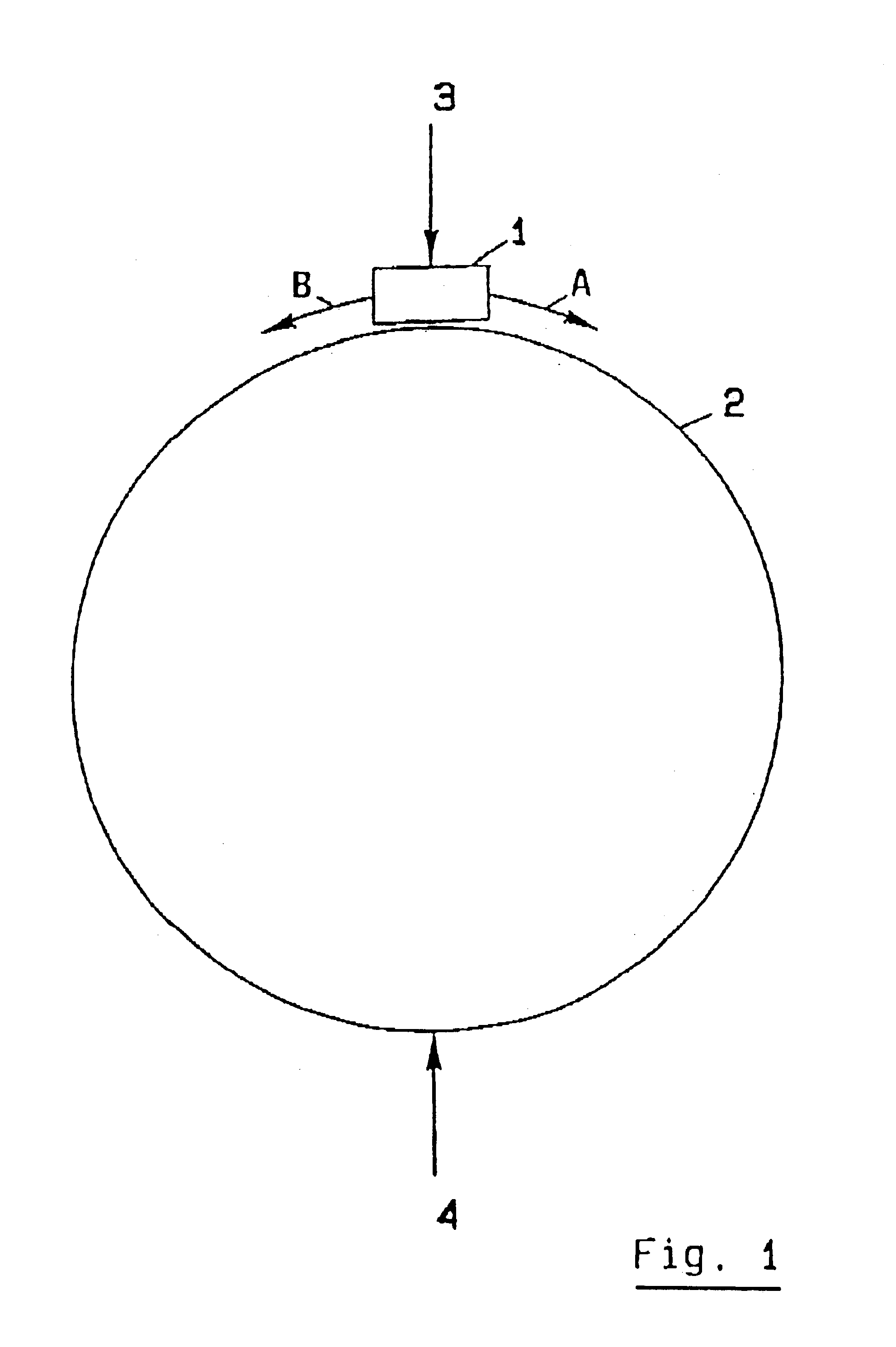

Method of detecting discontinuities on elongated workpieces

InactiveUS6843131B2Complex structureDetection securityAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationUltrasonic testingEngineering

In a method of detecting discontinuities on elongated workpieces, in particular tubes and bars, using ultrasonic testing system, a test object is positioned in relationship to a test head of the testing system, with the test object and the test head being moveable to one another. Signals from the test head are transmitted to an evaluation unit, where they are digitized and evaluated. The digitized signals of a test shot of a length position X are compared with digitized signals of a test shot of a length position X+ΔX, wherein ΔX is a multiple of a shot distance, and the difference is evaluated.

Owner:MANNESMANN ROHRENWERKE

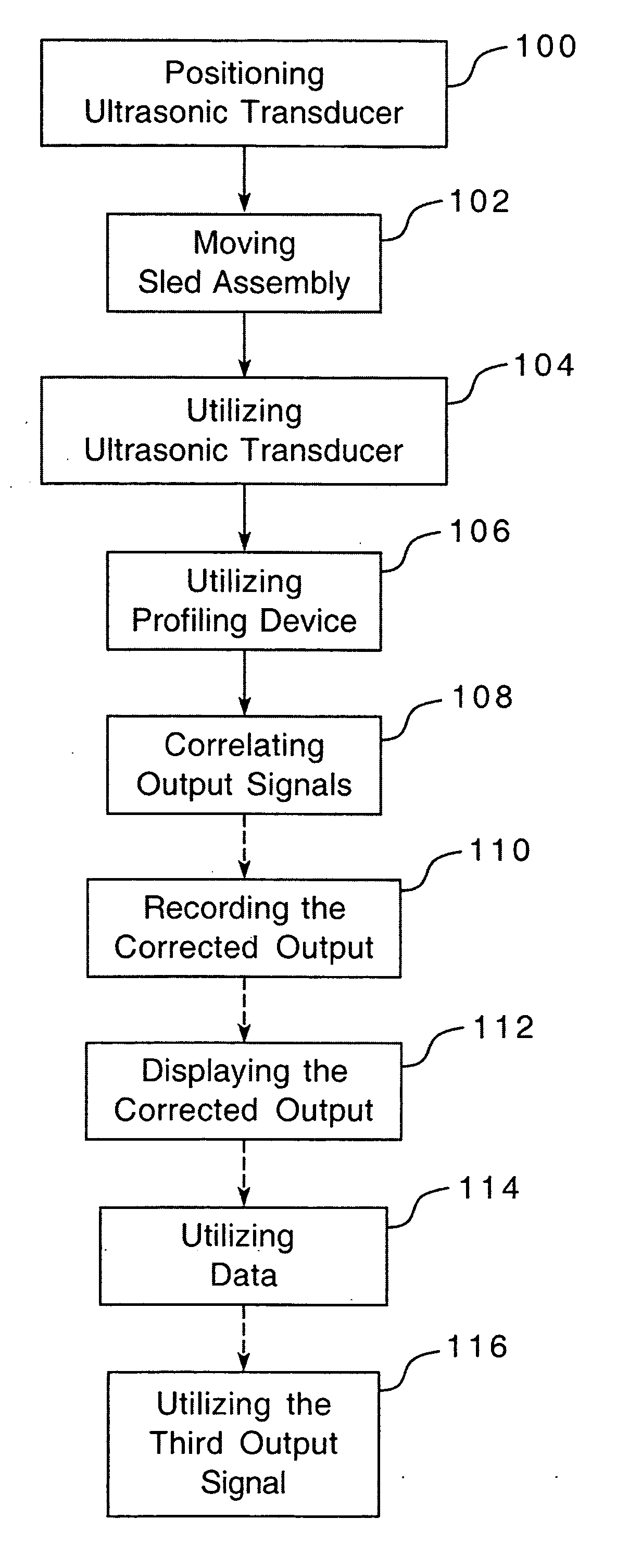

Device and method for ultrasonic inspection using profilometry data

ActiveUS20050150300A1Easy to determineAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsSonificationEngineering

An ultrasonic testing assembly structured to examine a test object, wherein the test object has a surface, and the examination examines the structure of the test object under the surface as well as the profile of the surface. The ultrasonic testing assembly includes a sled assembly structured to support a plurality of ultrasonic transducers, the sled assembly including at least one support member having a lower surface, at least one surface ultrasonic transducer coupled to the sled assembly and structured to extend below the support member lower surface and further structured to engage the test object surface, the surface ultrasonic transducer structured to examine internal structure of the test object and provide a first output, at least one profiling device coupled to the sled assembly, the profiling device structured to measure the profile of the test object surface and provide a second output, and a control device structured to correlate the first output and the second output and to calculate a corrected output.

Owner:WESTINGHOUSE ELECTRIC CORP

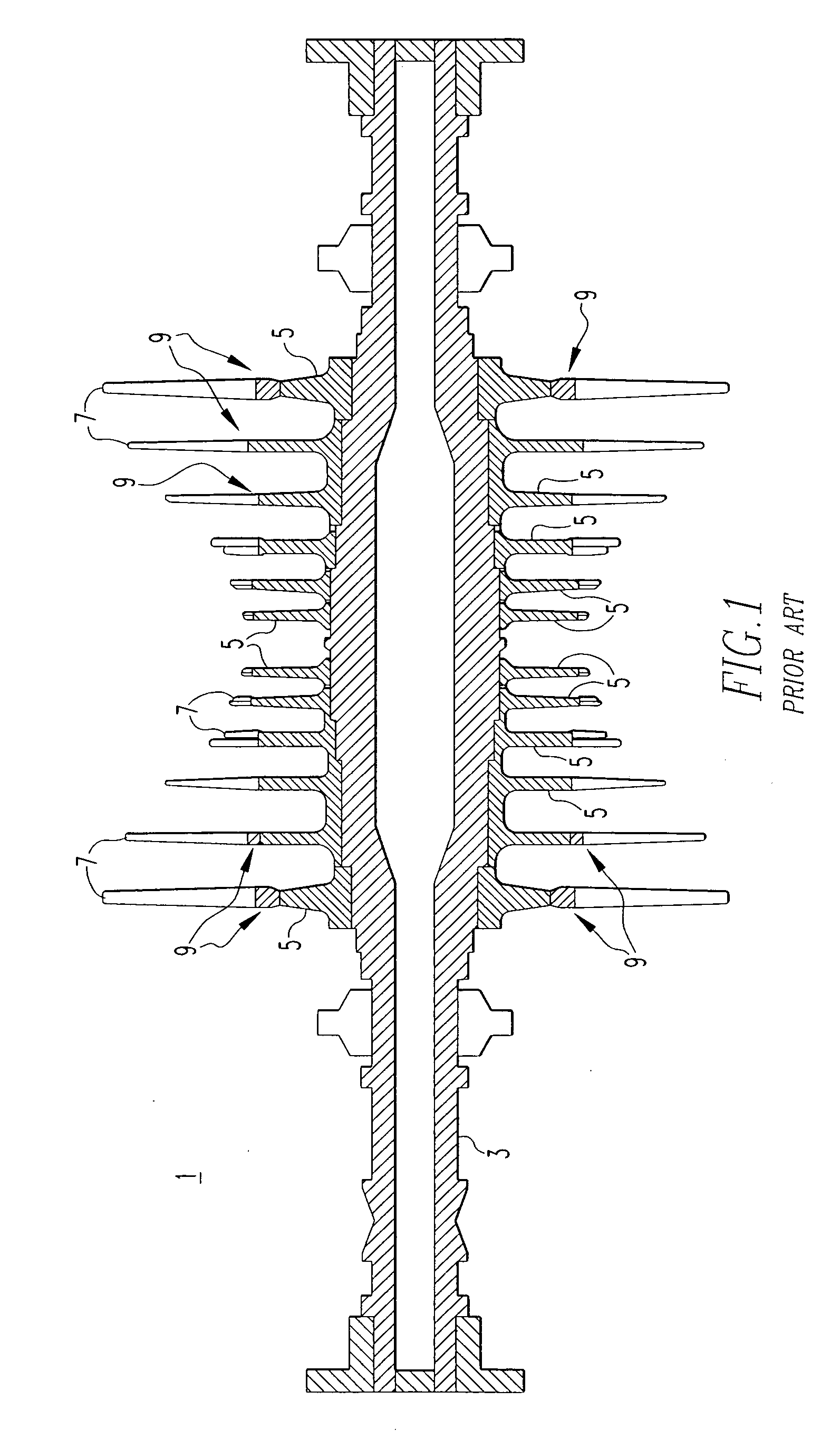

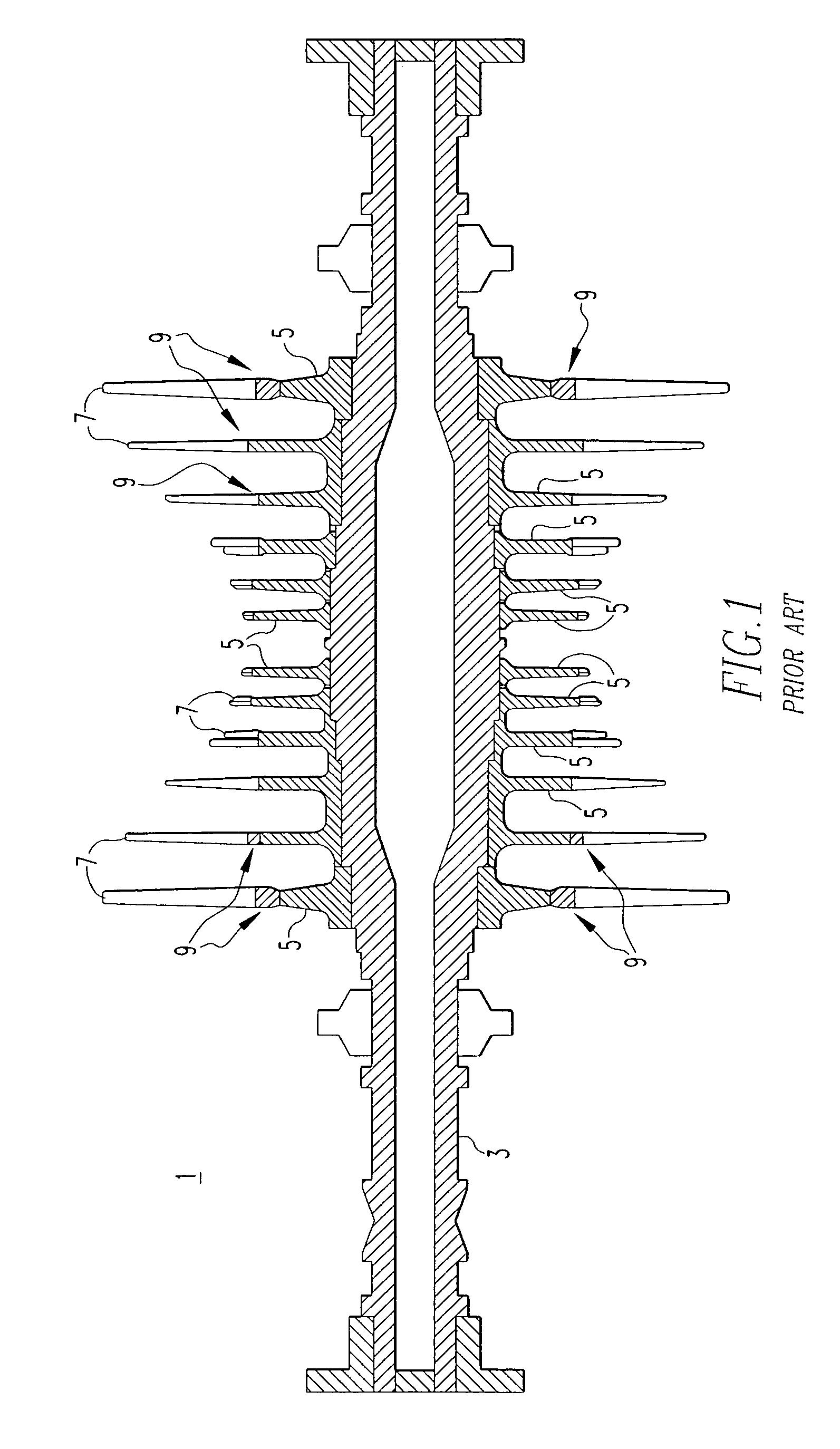

Phased array ultrasonic testing system and methods of examination and modeling employing the same

ActiveUS20060283250A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesCircular discSonification

A phased array ultrasonic testing system is for examining turbine disc bores and blade attachments for discontinuities, such as stress corrosion cracking. The system is particularly suited to perform an accurate and efficient inspection of components despite their having a relatively complex geometry, such as axial entry blade attachments and bores of associated discs. The system includes a control system with a computer and a controller for programming, emitting, and steering an ultrasonic beam via at least one two-dimensional phased array probe, thereby precisely inspecting the area of interest while simultaneously accommodating the aforementioned complex geometry of the disc or blade attachment. Computer control of the beam permits the number of inspection locations and the number of different probe wedges to be reduced providing for an efficient, timely inspection. Methods of profiling and examining turbine components of known and unknown geometries, are also disclosed.

Owner:SIEMENS ENERGY INC

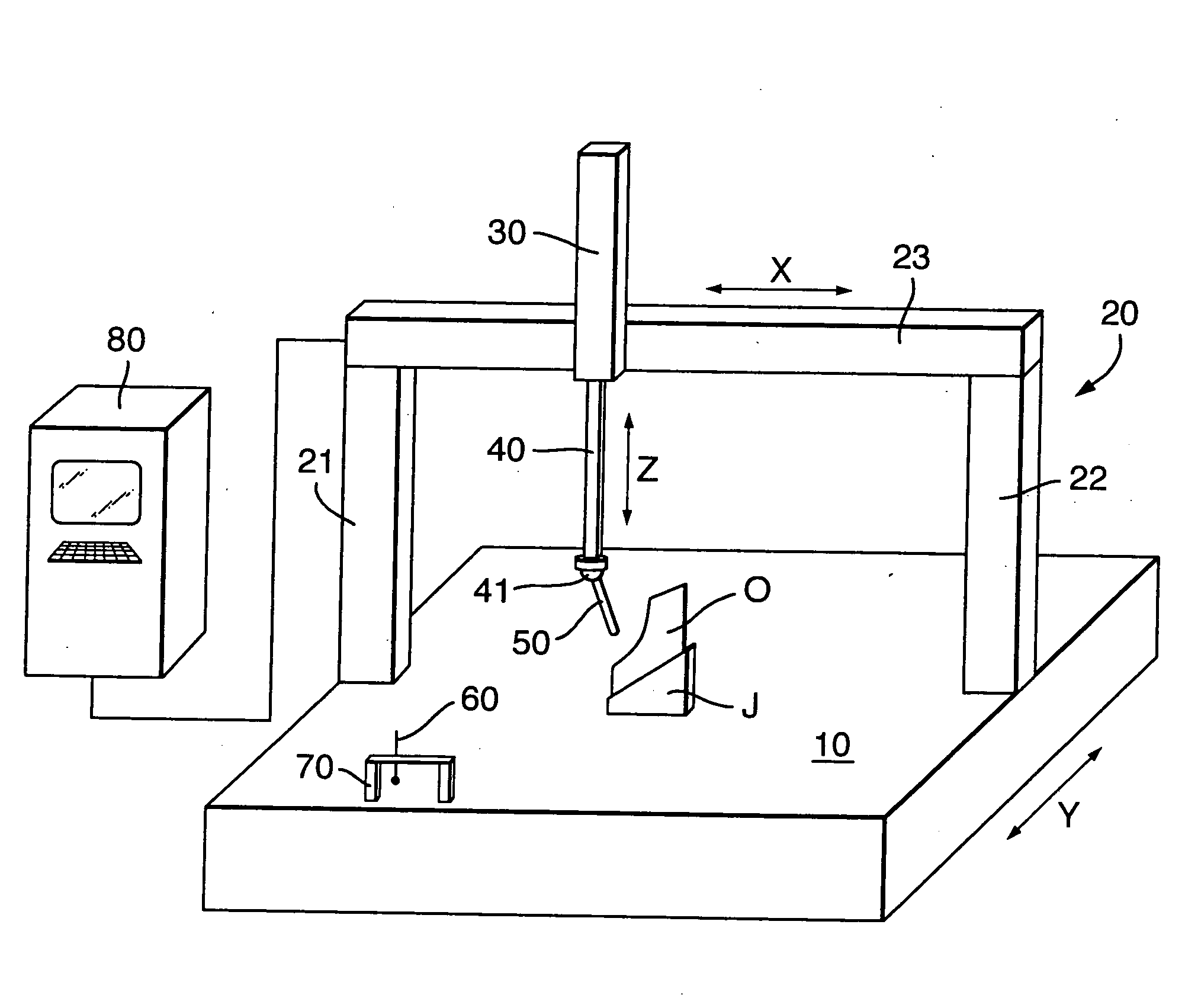

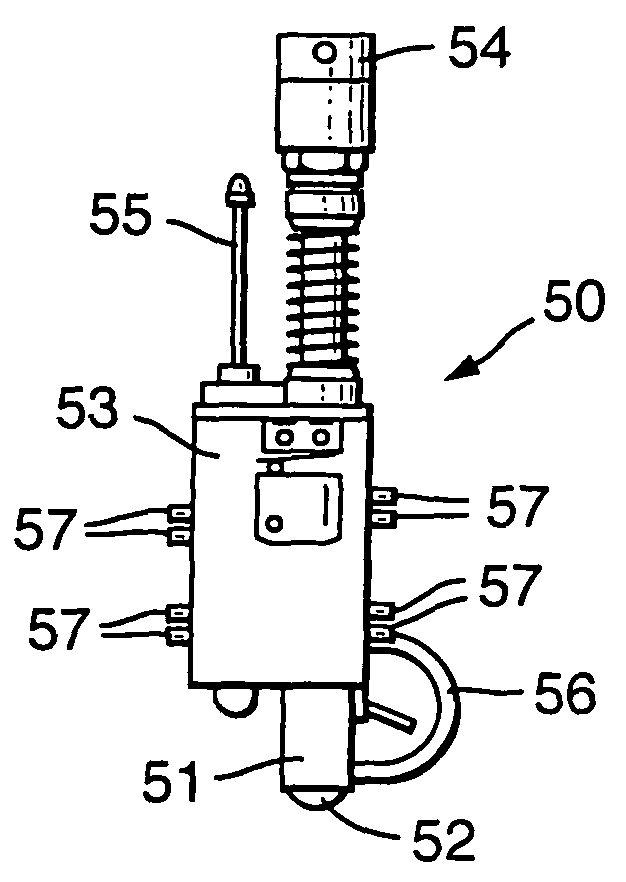

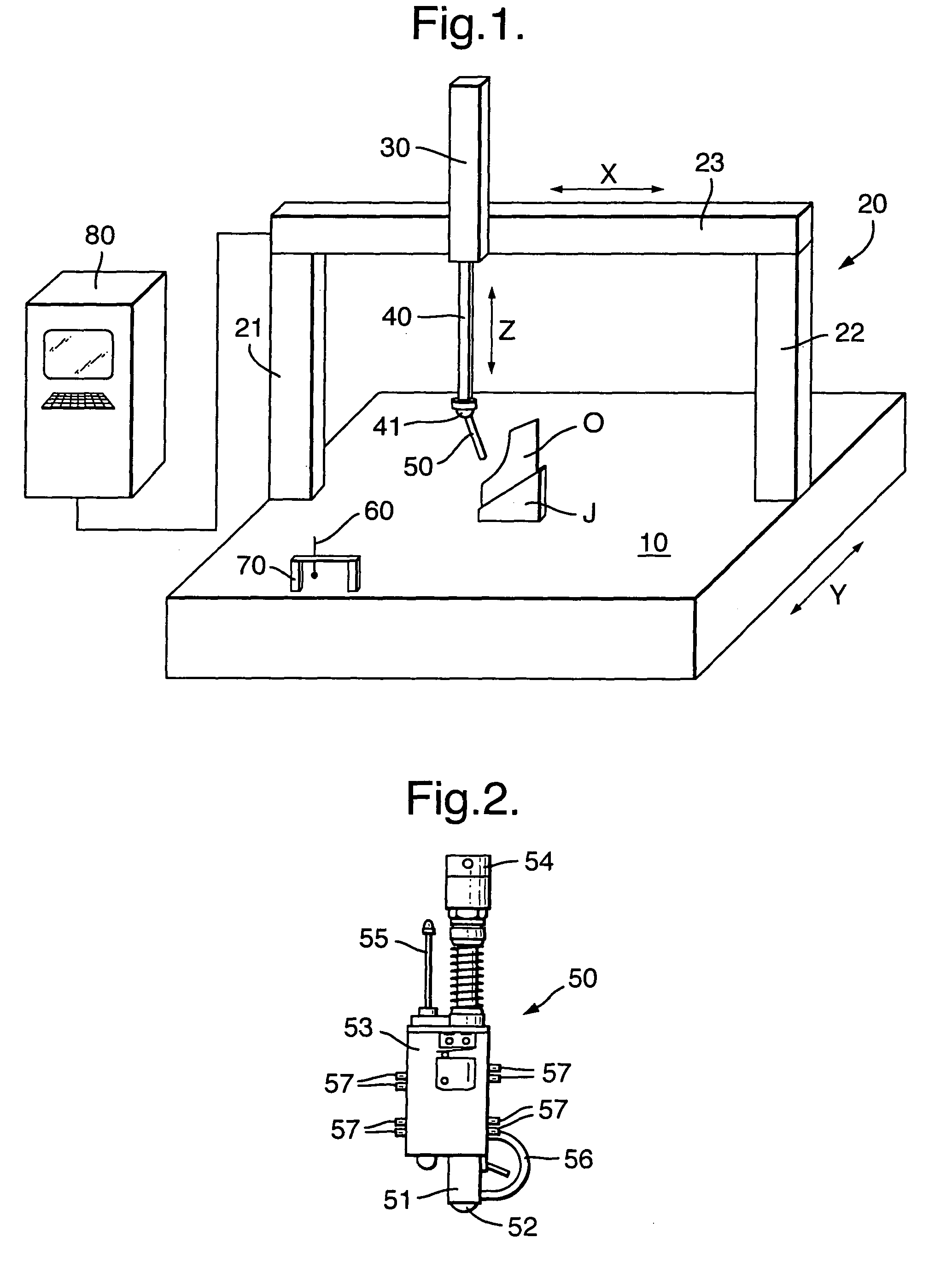

Apparatus for Measuring Wall Thicknesses of Objects

ActiveUS20090178482A1Correct misalignmentMultiple-port networksAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerUltrasonic testing

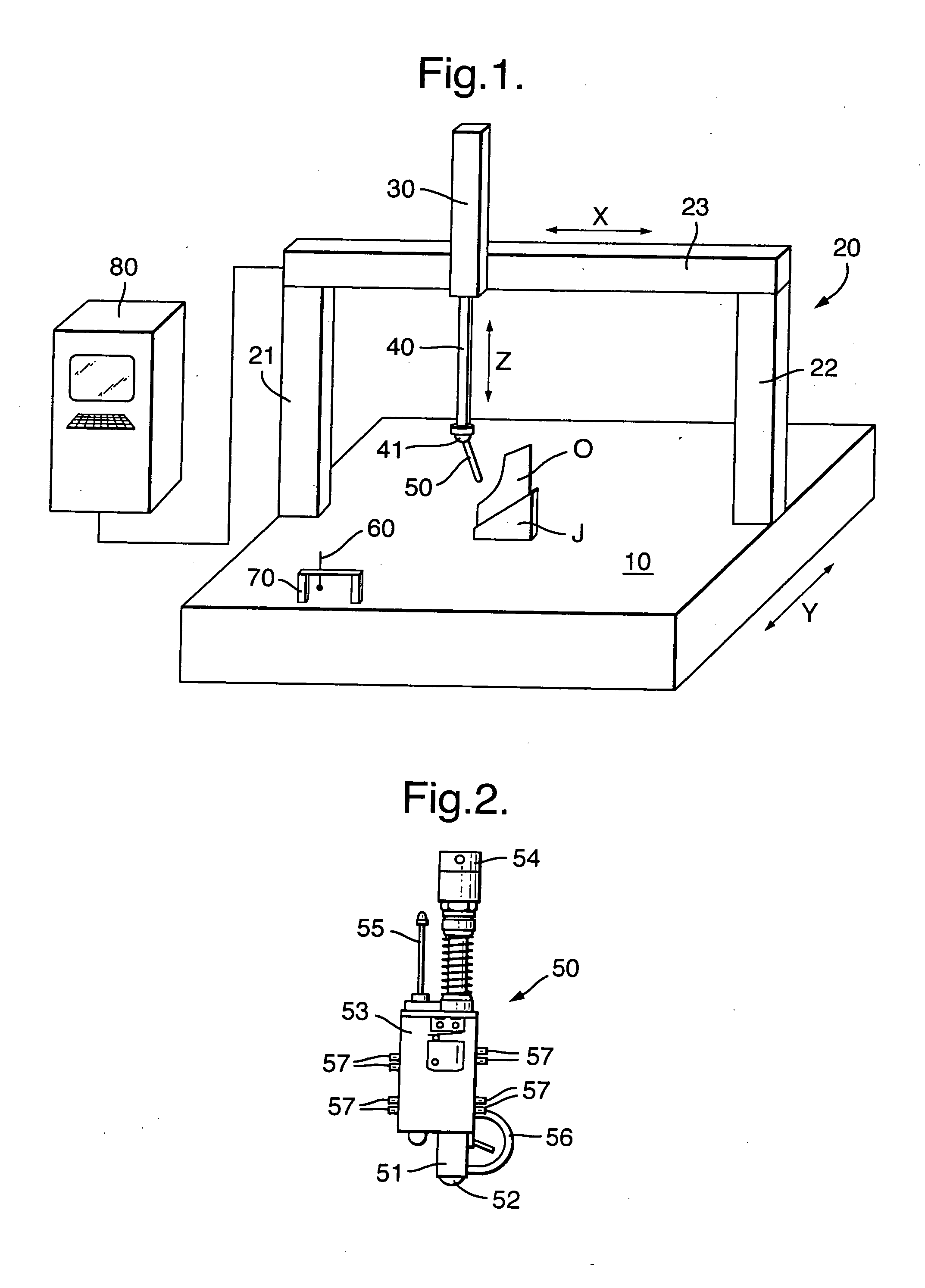

An apparatus for measuring wall thicknesses of objects, comprises: a coordinate measuring machine comprising a probe holder and an object support, the coordinate measuring machine being configured to provide relative movement between the probe holder and the object support in three dimensions; and an ultrasonic test probe which is held by the probe holder. The coordinate measuring machine brings the transducer of the ultrasonic test probe into contact with a position on a surface of an object at the object support so that the probe can measure an object wall thickness at the probe contact position.

Owner:ROLLS ROYCE PLC

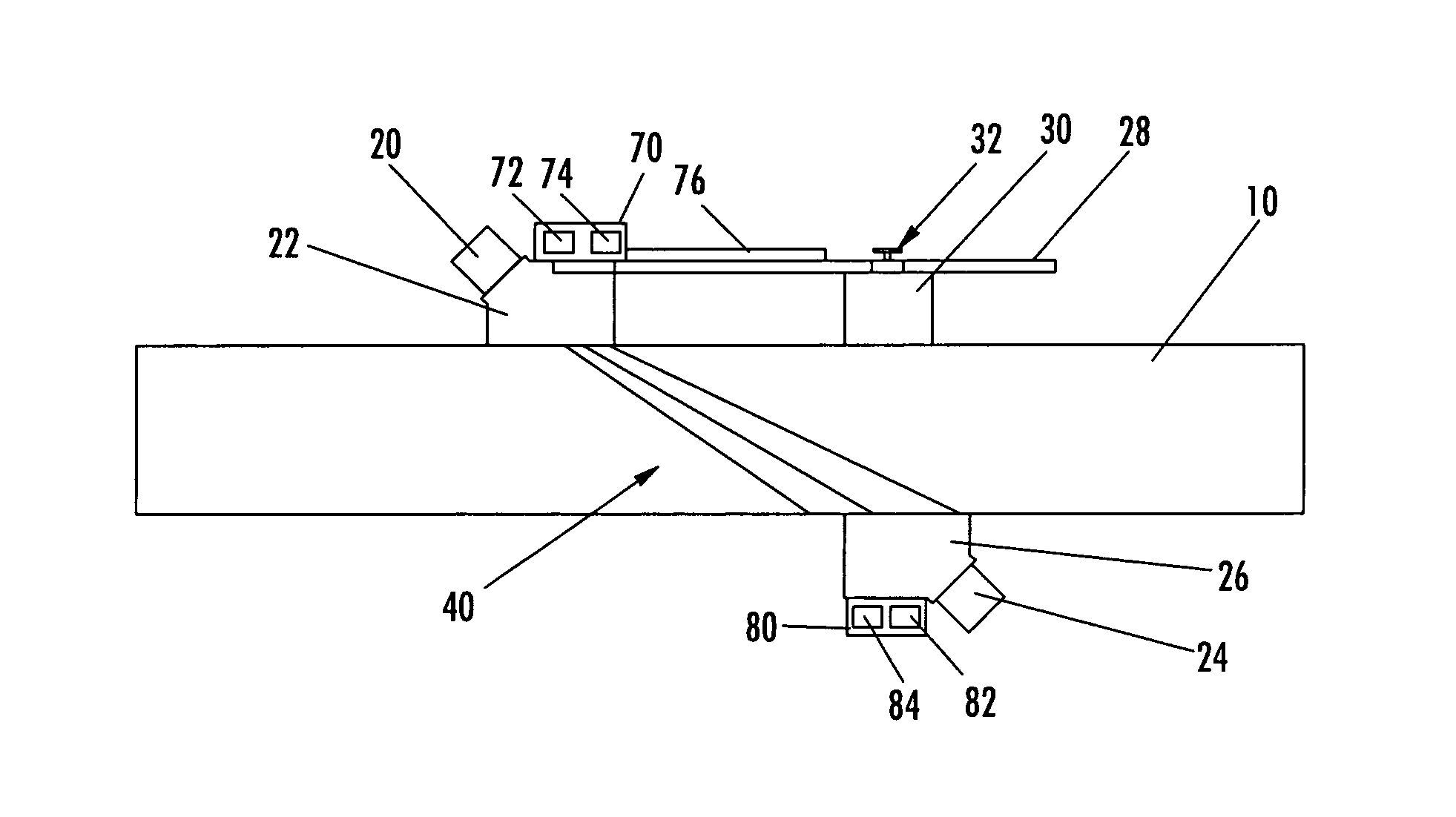

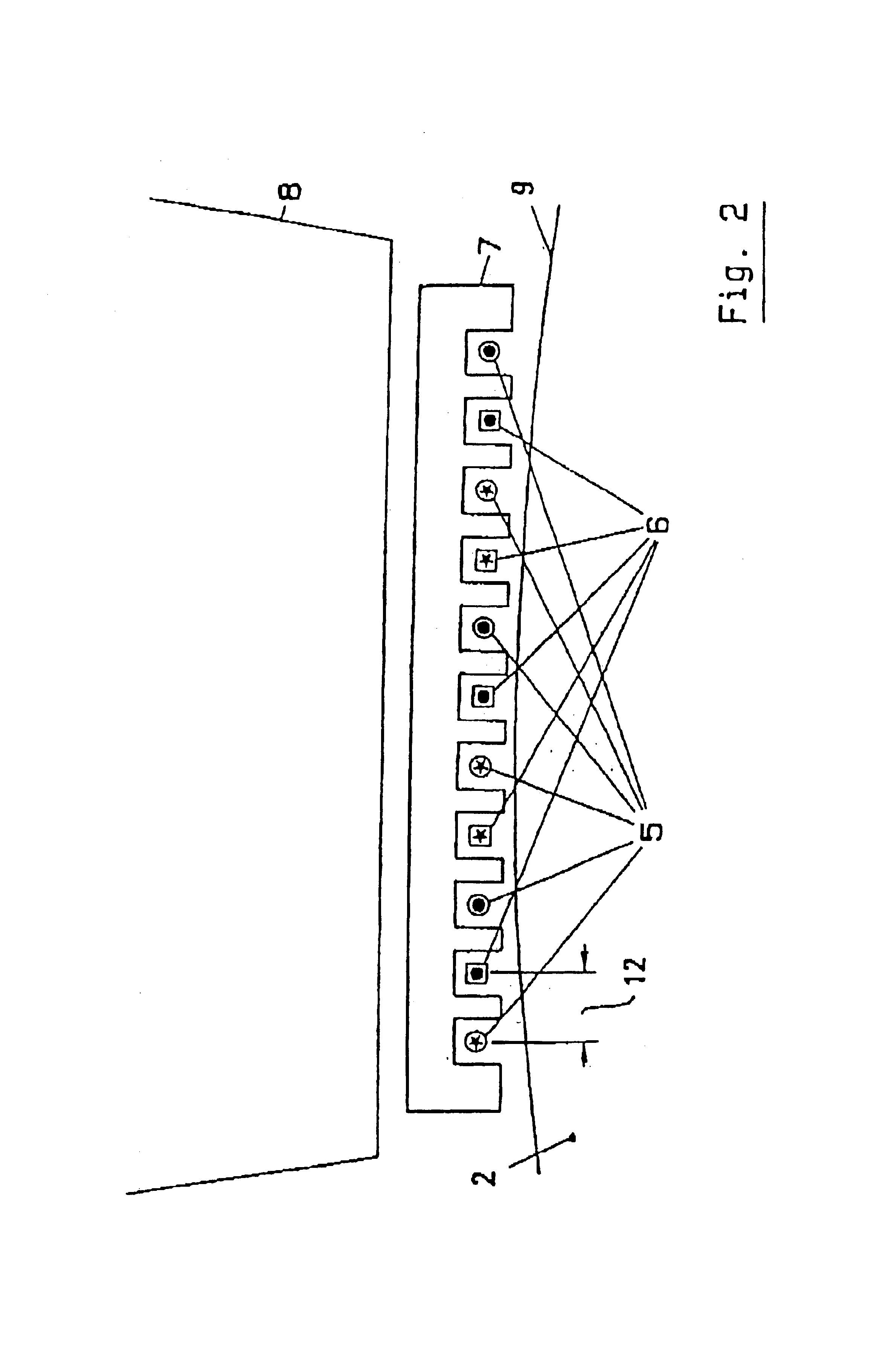

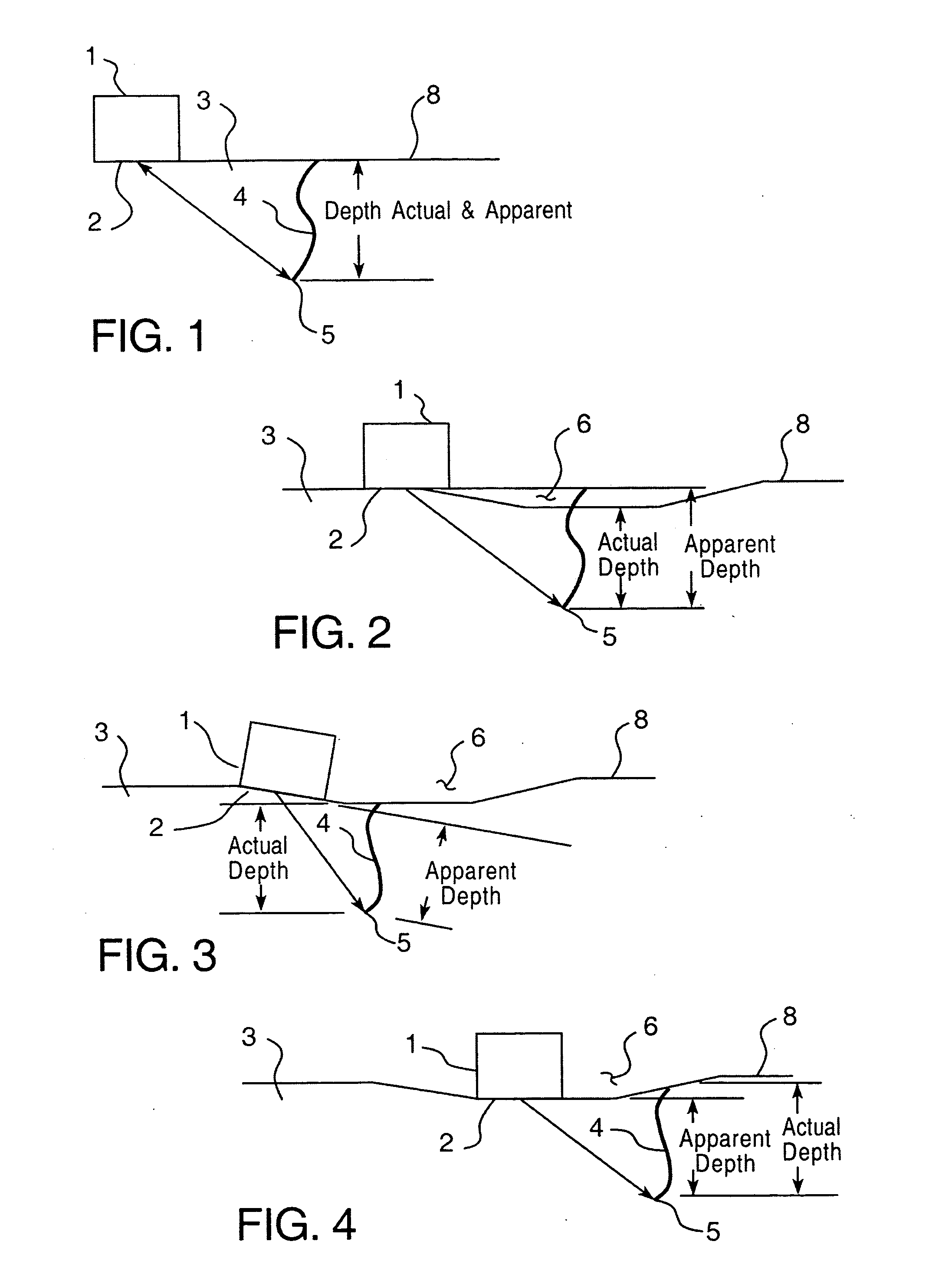

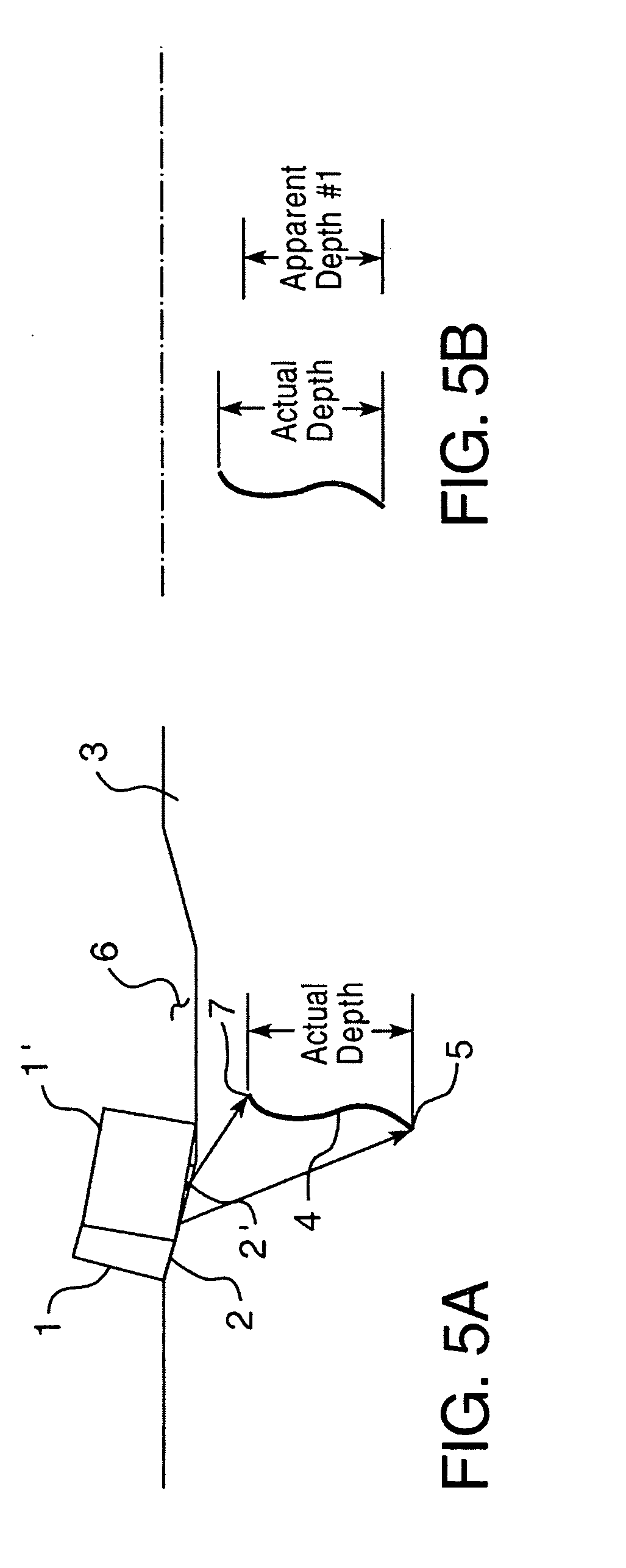

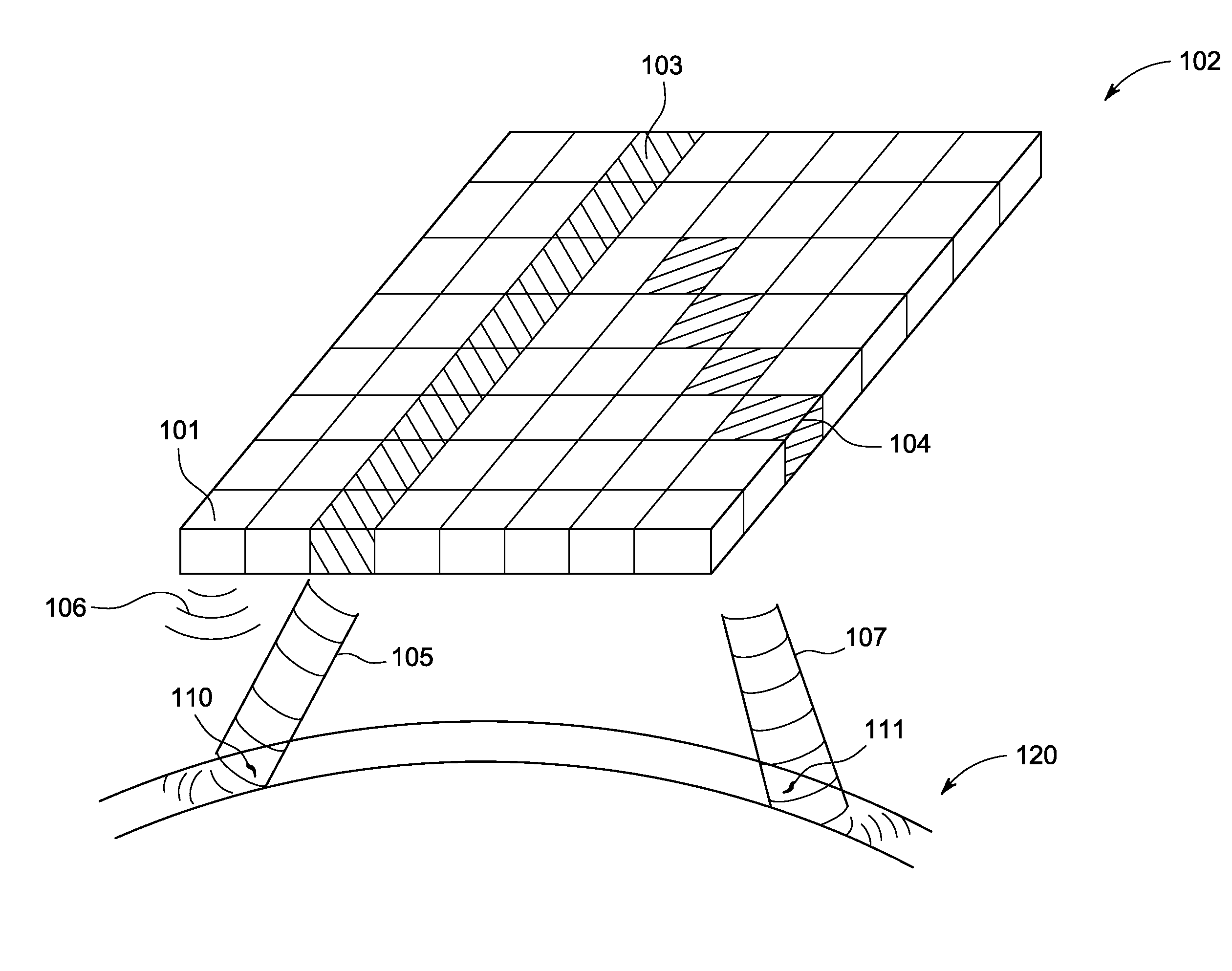

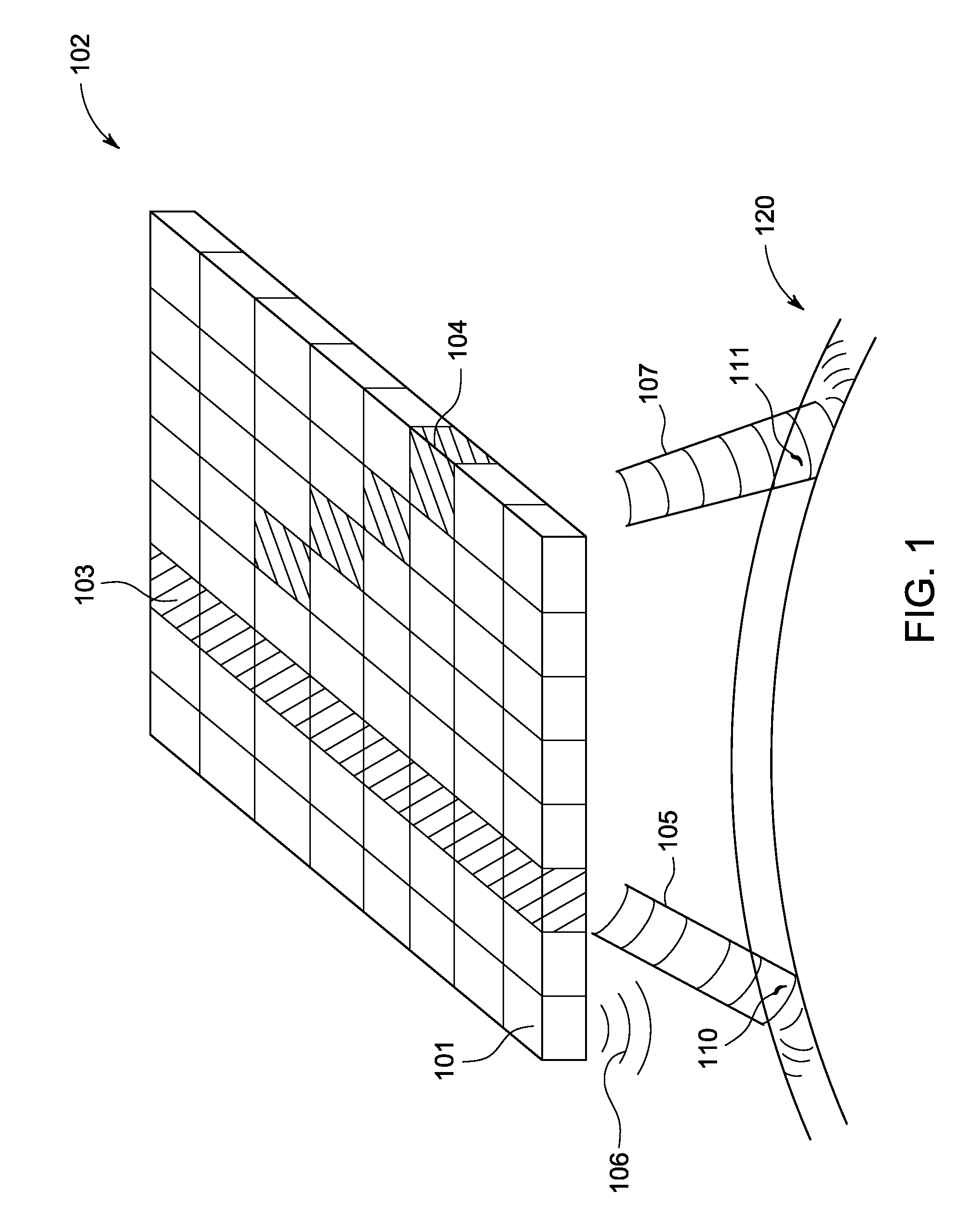

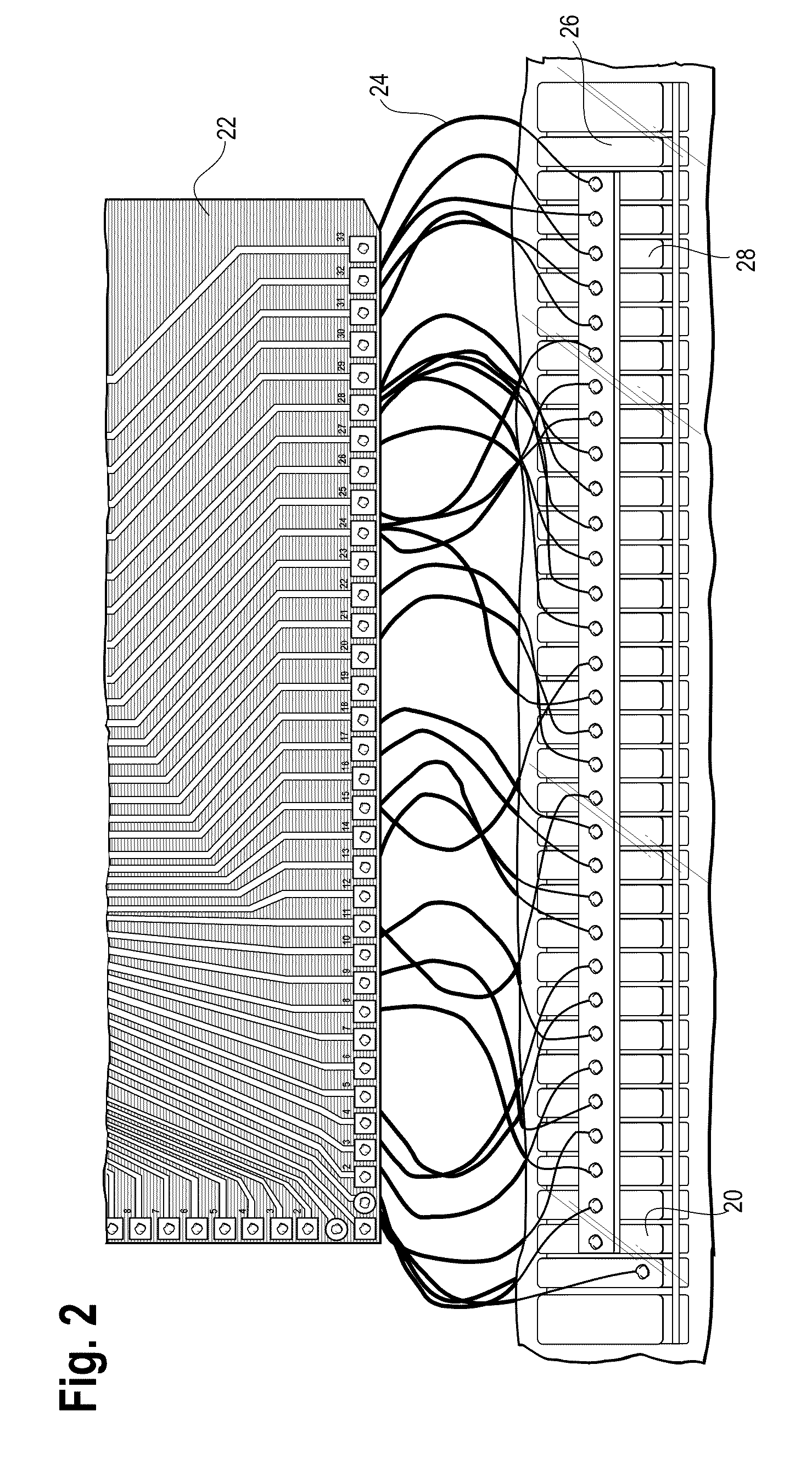

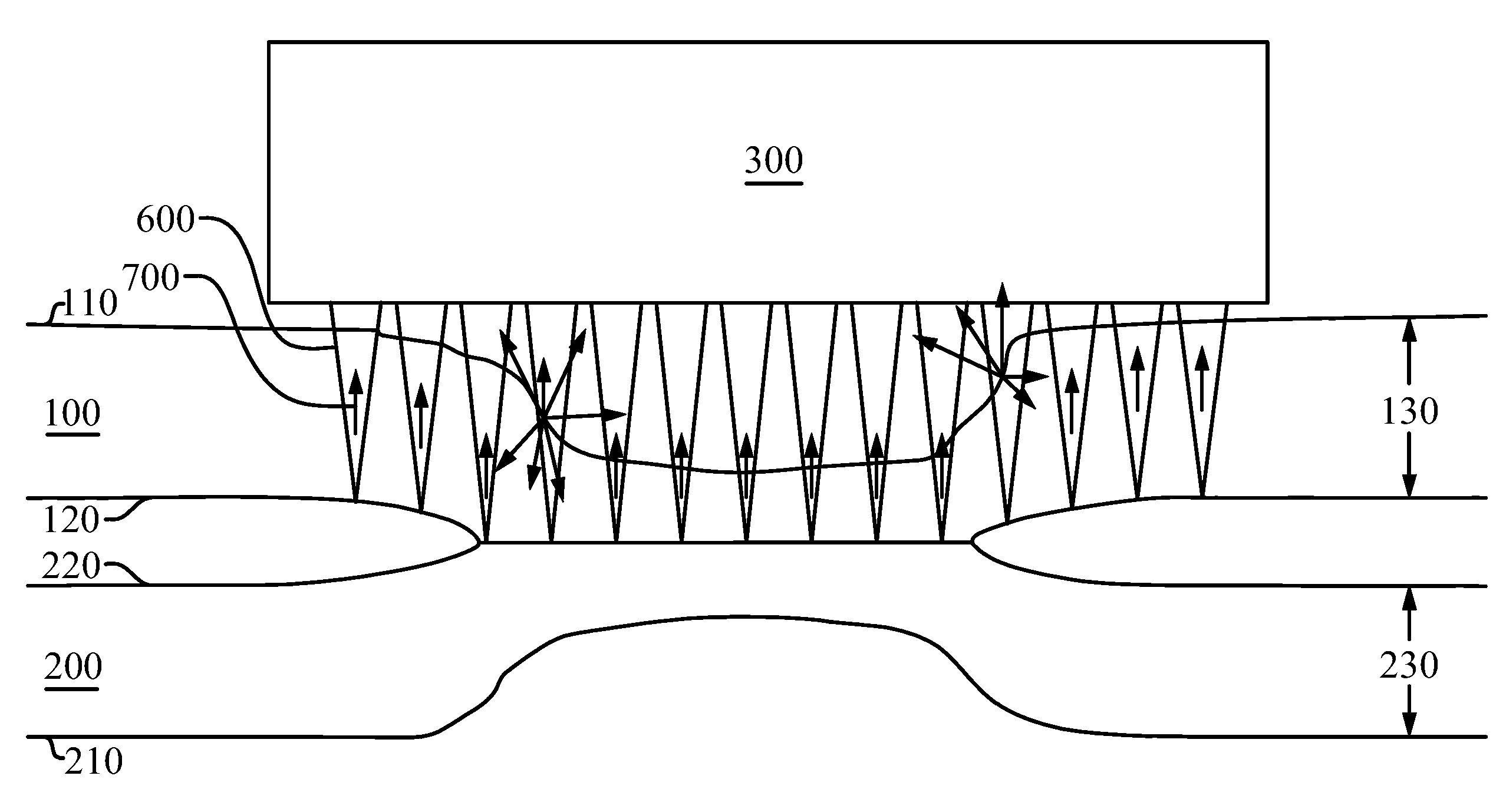

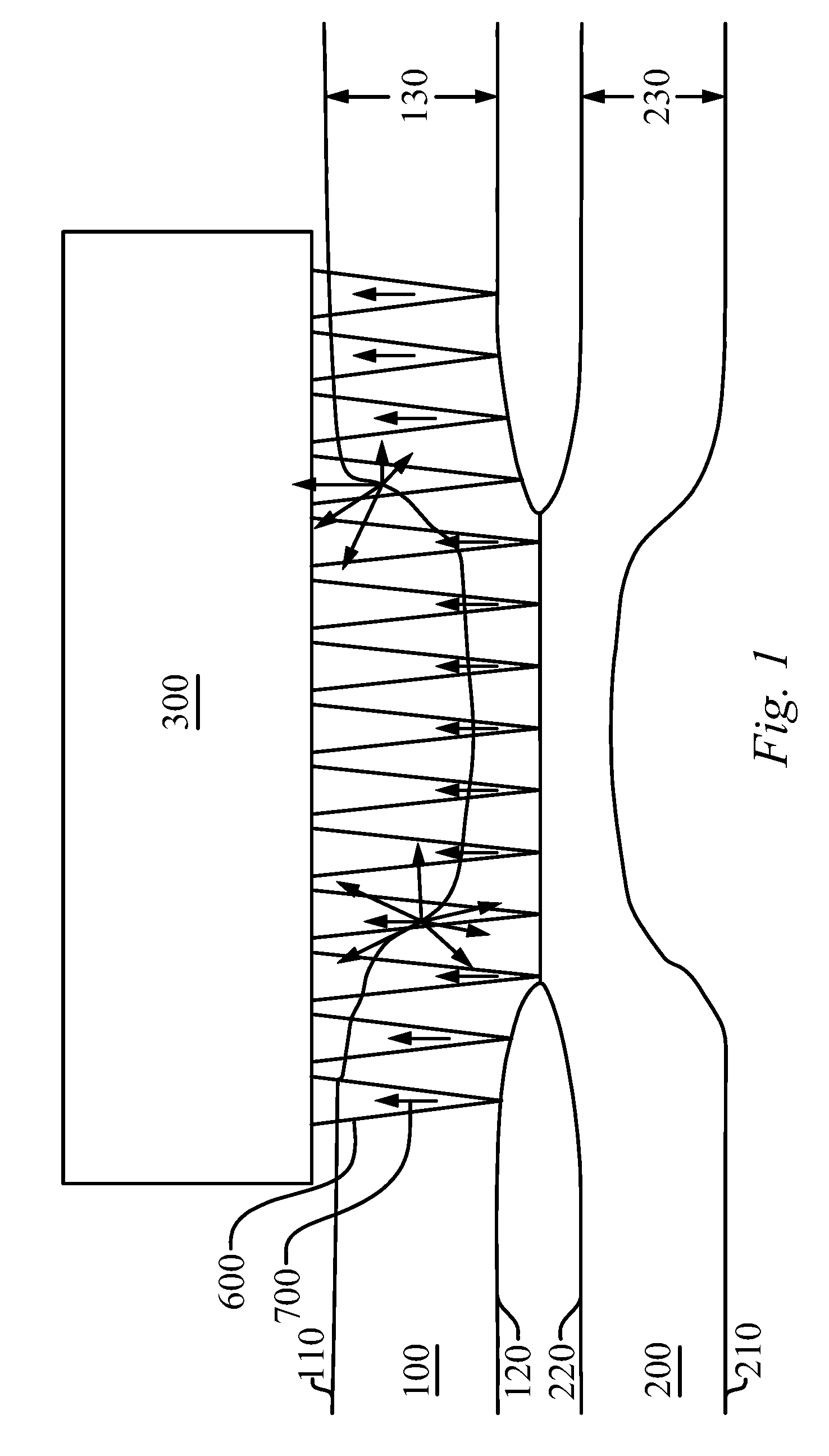

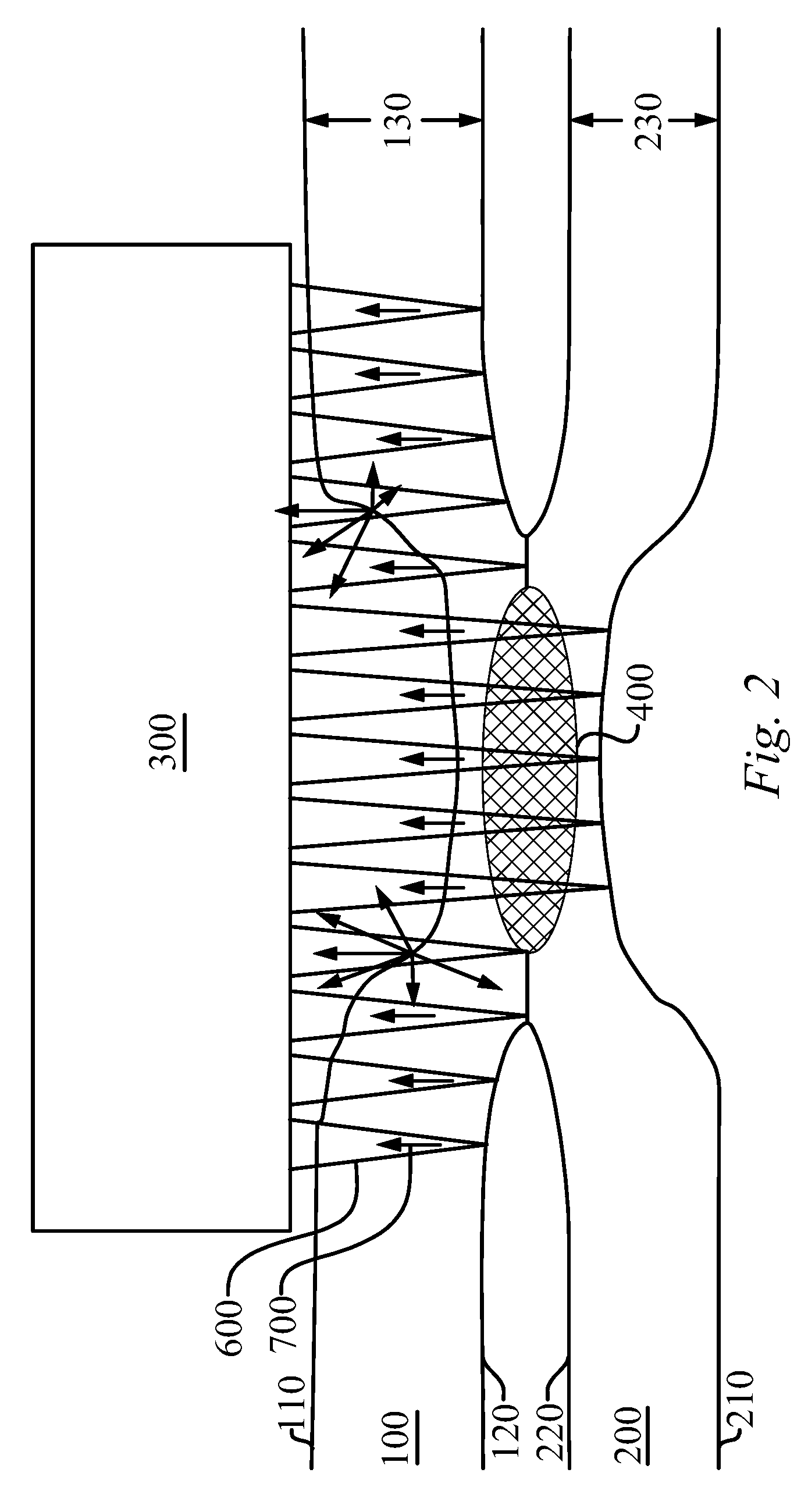

Angle beam shear wave through-transmission ultrasonic testing apparatus and method

InactiveUS20060201252A1Improve three-dimensional defect resolutionImproving depth measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsSonificationImage representation

Improved methods, systems, and apparatus for inspecting a structure using angle beam shear wave through-transmission ultrasonic signals involves positioning transducers at offset positions on opposing sides of the structure and permits inspection of the inside of the structure beneath surface defects and features. Magnetic coupling can be used for supporting a pair of leader-follower probes and defining offset positions between angle beam shear wave transducers carried by the probes. Inspection data can be collected for supporting real-time generation of three-dimensional image representations of the structure and of internal defects and features of the structure. Image generation and resolution using inspection data from angle beam shear wave ultrasonic signals can be supplemented using pulse-echo ultrasonic inspection data.

Owner:THE BOEING CO

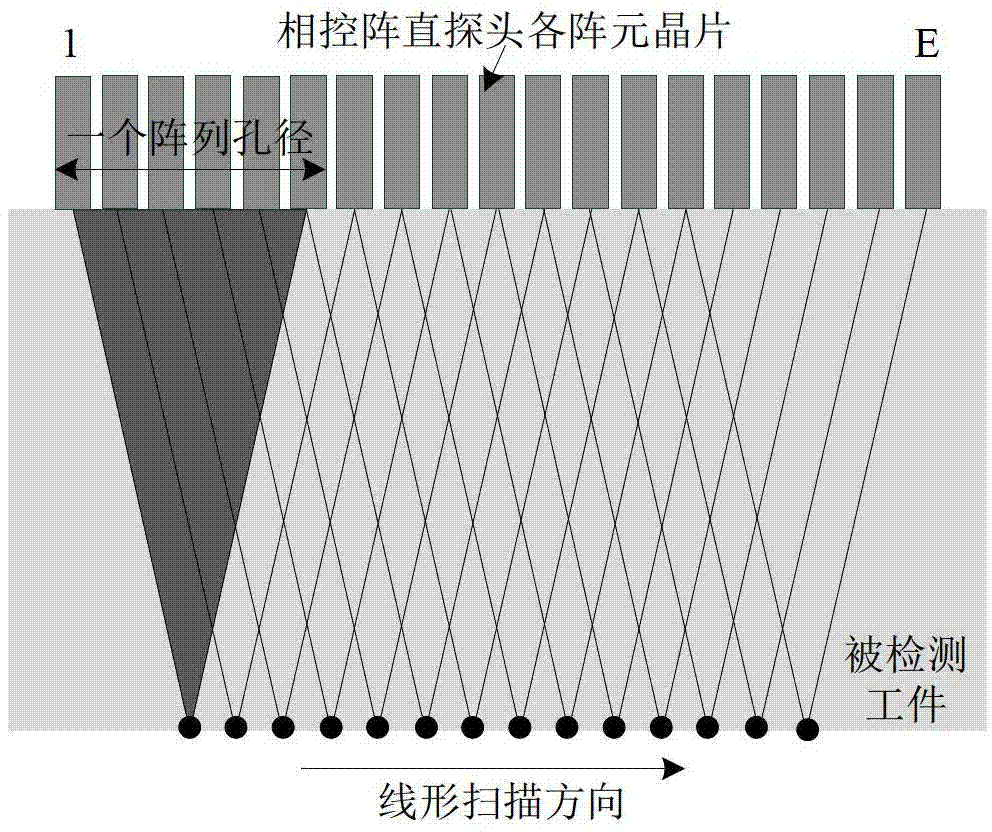

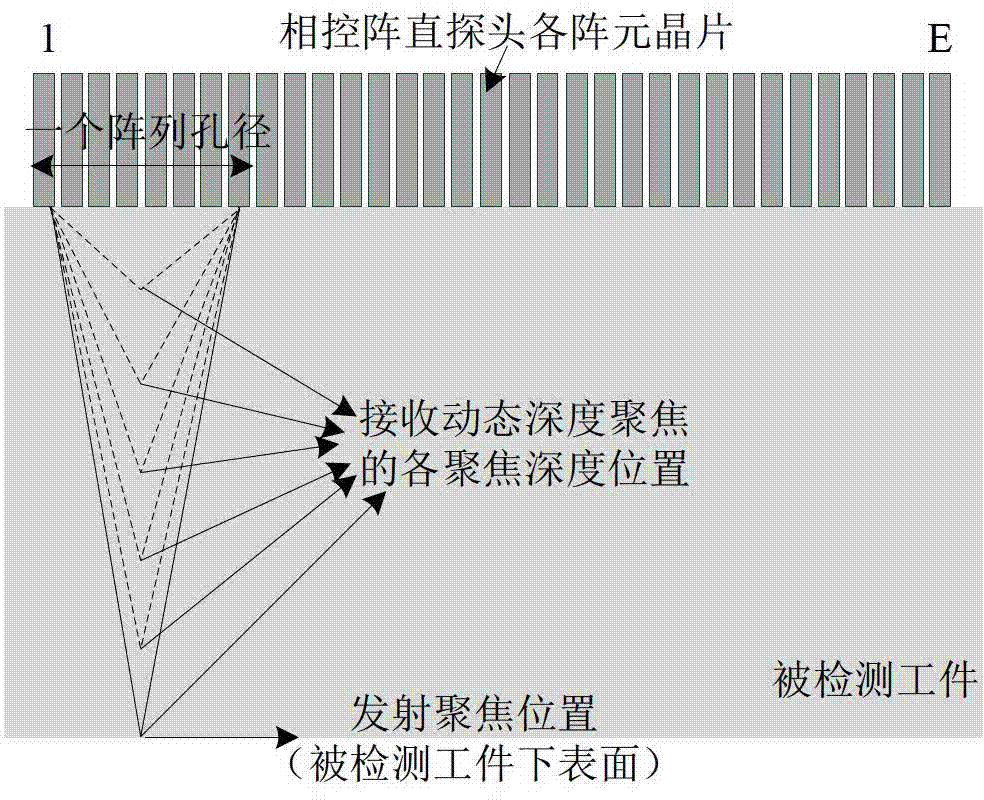

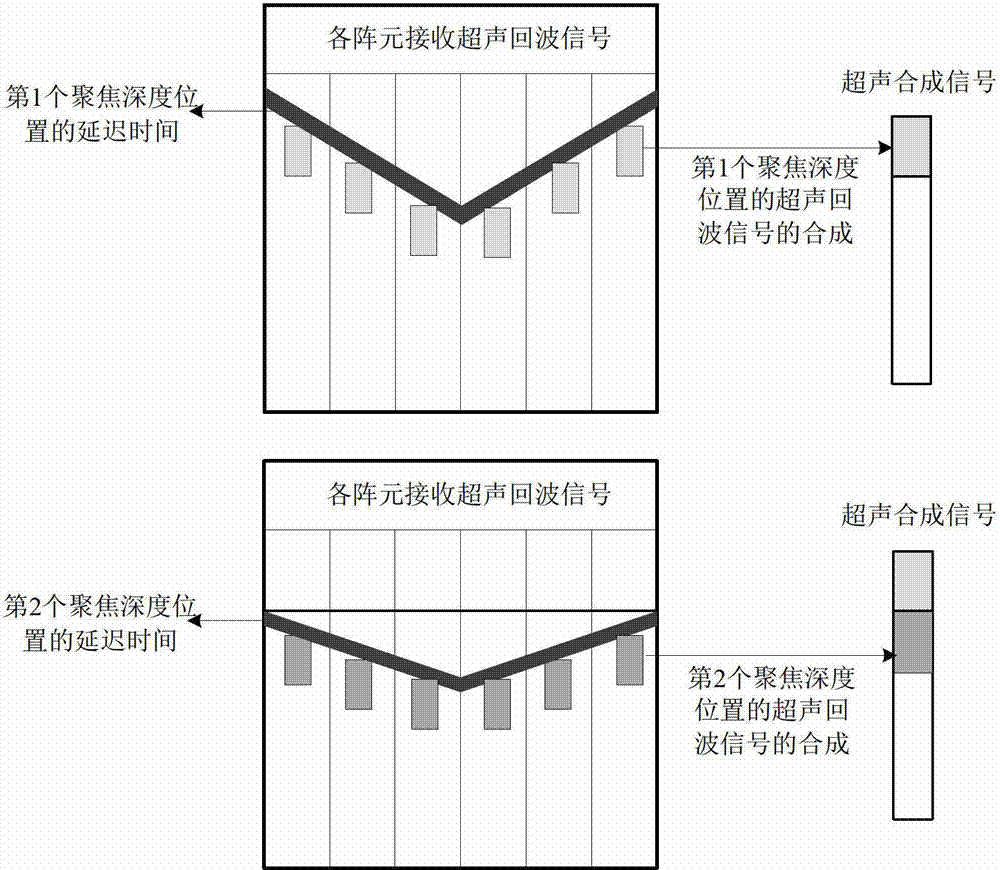

Phased array ultrasonic testing method based on improved dynamic depth focusing

InactiveCN102809610AAccurate focusSolve the problem of difficult defect identificationAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationUltrasonic transmission

The invention belongs to the technical field of non-destructive testing and particularly discloses a phased array ultrasonic testing method based on improved dynamic depth focusing. The method comprises the following five steps of: performing phased array ultrasonic transmission and reception, discriminating a defect, calculating delay time, post-processing echo signals and reconstructing a B type drawing. The ultrasonic echo signals are accurately focused to the position of the defect, so that the problem that the defect is difficult to identify when the signal-to-noise ratio of a reflection echo signal of the defect is too low can be solved; by the method, the problem that the deviation exists between an ideal focus and an actual focus because a material of a tested workpiece is nonuniform can be effectively solved, and the testing resolution of phased array ultrasonic testing of layered media and anisotropic media can be effectively improved; and by the method, the problems that ultrasonic imaging results are fuzzy and distorted due to errors of hardware systems such as phased array flaw detectors can also be solved, and the quality of phased array ultrasonic imaging can also be improved.

Owner:BEIHANG UNIV

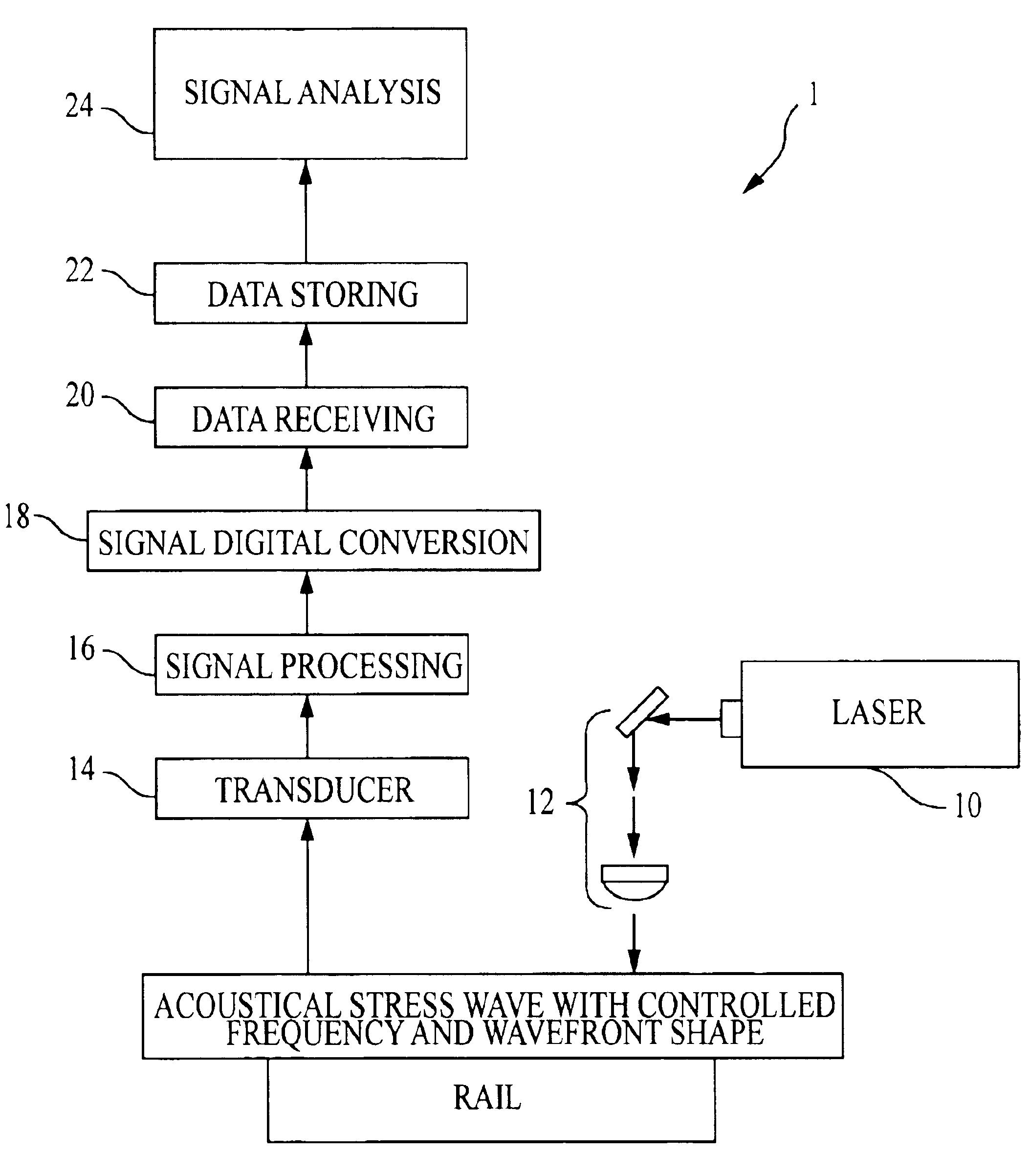

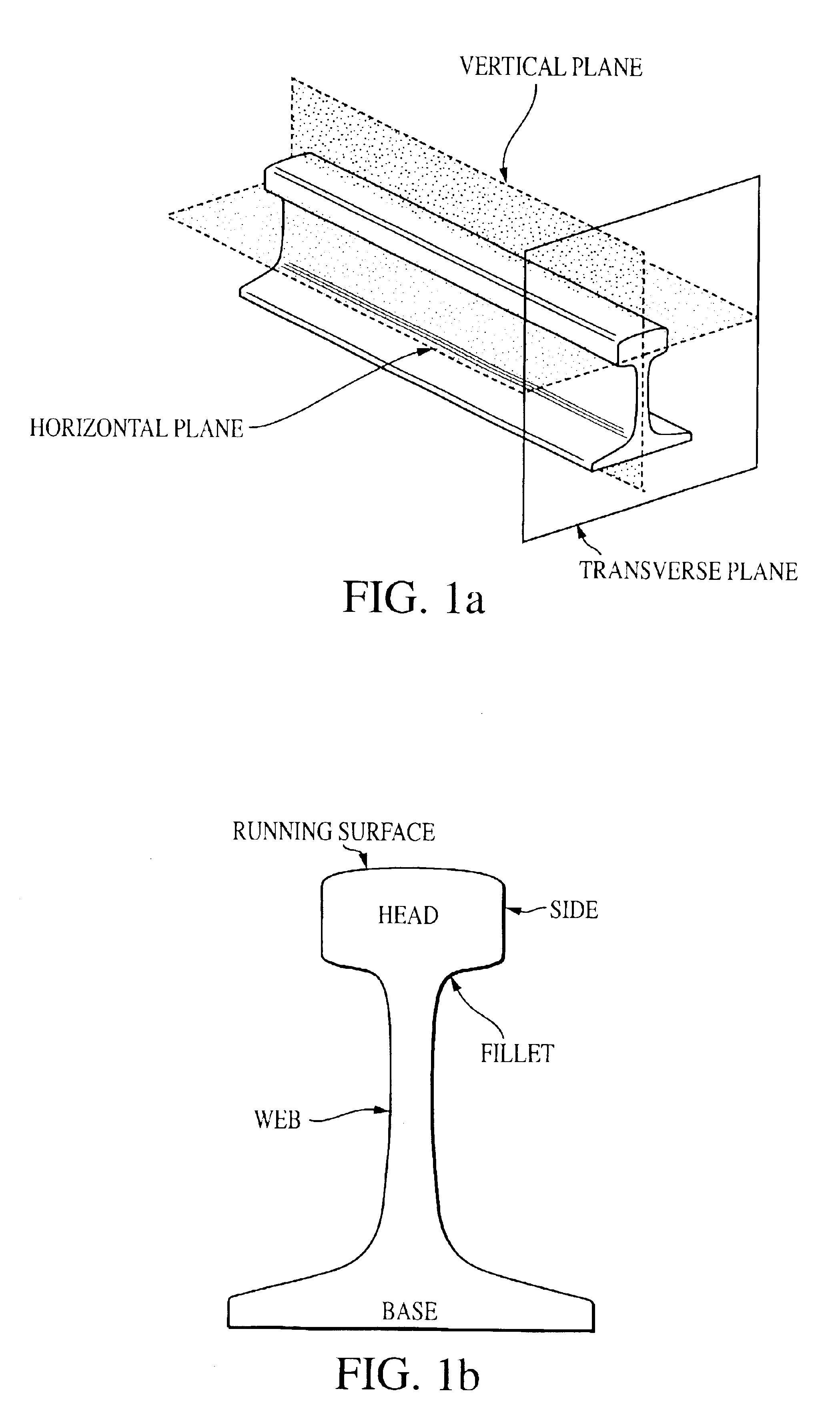

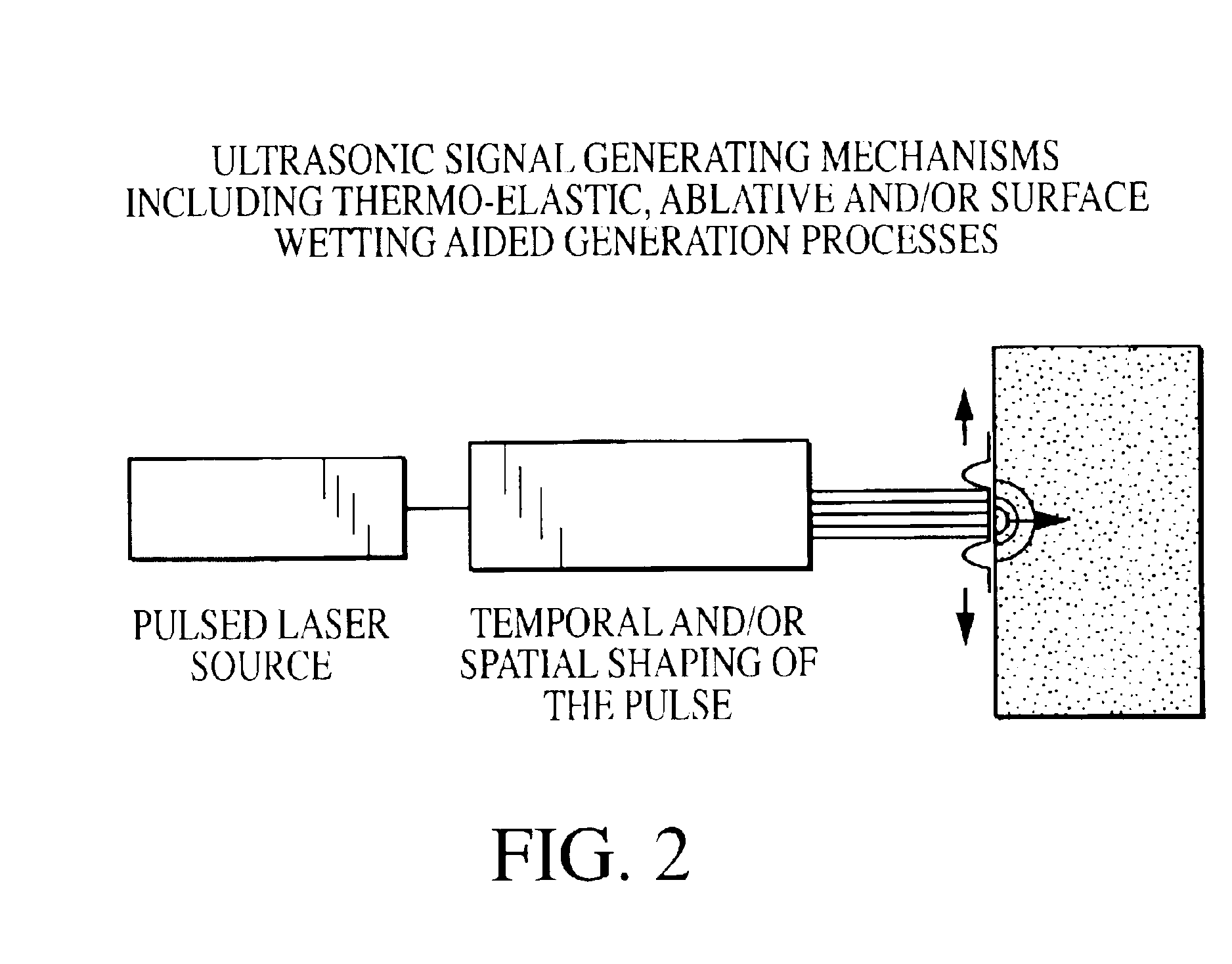

Laser-air, hybrid, ultrasonic testing of railroad tracks

InactiveUS6945114B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesRailroad industryWavefront

Formed Laser Sources (FLS) using pulsed laser light for generation of ultrasonic stress waves are combined with air-coupled detection of ultrasound to provide for the hybrid non-contact, dynamic and remote ultrasonic testing of structural materials, especially railroad tracks. Using this hybrid technique, multimode and controlled frequency and wavefront surface acoustic waves, plate waves, guided waves, and bulk waves are generated to propagate on and within the rail tracks. The non-contact, remote nature of this methodology enables high-speed, fill access inspections of rail tracks. The flexibility and remote nature of this methodology makes possible the detection of critical cracks that are not easy, or impossible to detect, with current inspection techniques available to the railroad industry.

Owner:MATERIALS & SENSORS TECH

Ultrasonic testing apparatus

InactiveUS20140060196A1Shorten inspection timeEfficient detectionMaterial analysis using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsUltrasonic testingTest object

A plurality of subsets of ultrasonic transducers in an array of ultrasonic transducers are configured to transmit ultrasonic waves at various angles simultaneously toward a test object so that an anomaly of any orientation in the test object can be detected efficiently.

Owner:GENERAL ELECTRIC CO

Phased array ultrasonic testing system and methods of examination and modeling employing the same

ActiveUS7428842B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationEngineering

A phased array ultrasonic testing system is for examining turbine disc bores and blade attachments for discontinuities, such as stress corrosion cracking. The system is particularly suited to perform an accurate and efficient inspection of components despite their having a relatively complex geometry, such as axial entry blade attachments and bores of associated discs. The system includes a control system with a computer and a controller for programming, emitting, and steering an ultrasonic beam via at least one two-dimensional phased array probe, thereby precisely inspecting the area of interest while simultaneously accommodating the aforementioned complex geometry of the disc or blade attachment. Computer control of the beam permits the number of inspection locations and the number of different probe wedges to be reduced providing for an efficient, timely inspection. Methods of profiling and examining turbine components of known and unknown geometries, are also disclosed.

Owner:SIEMENS ENERGY INC

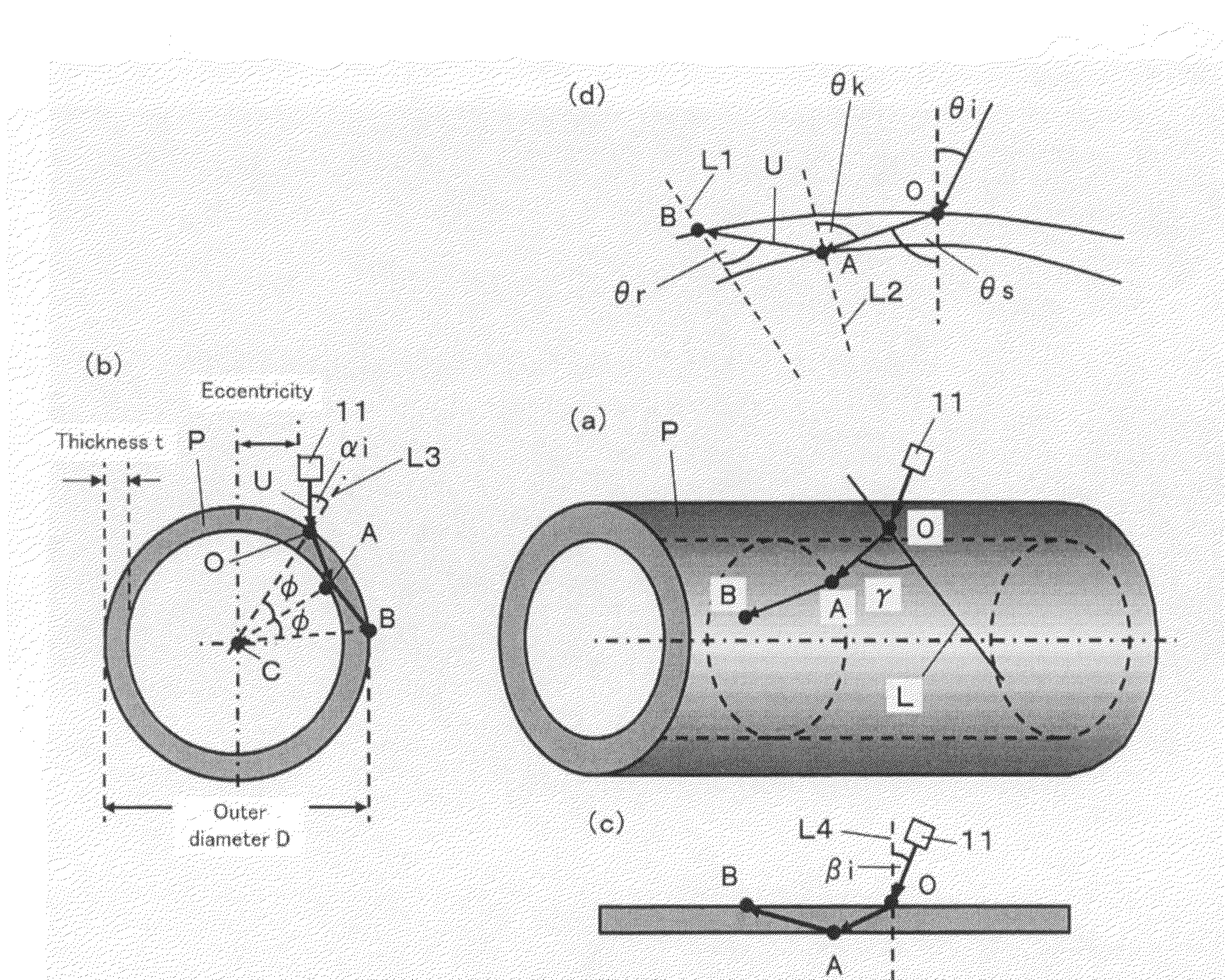

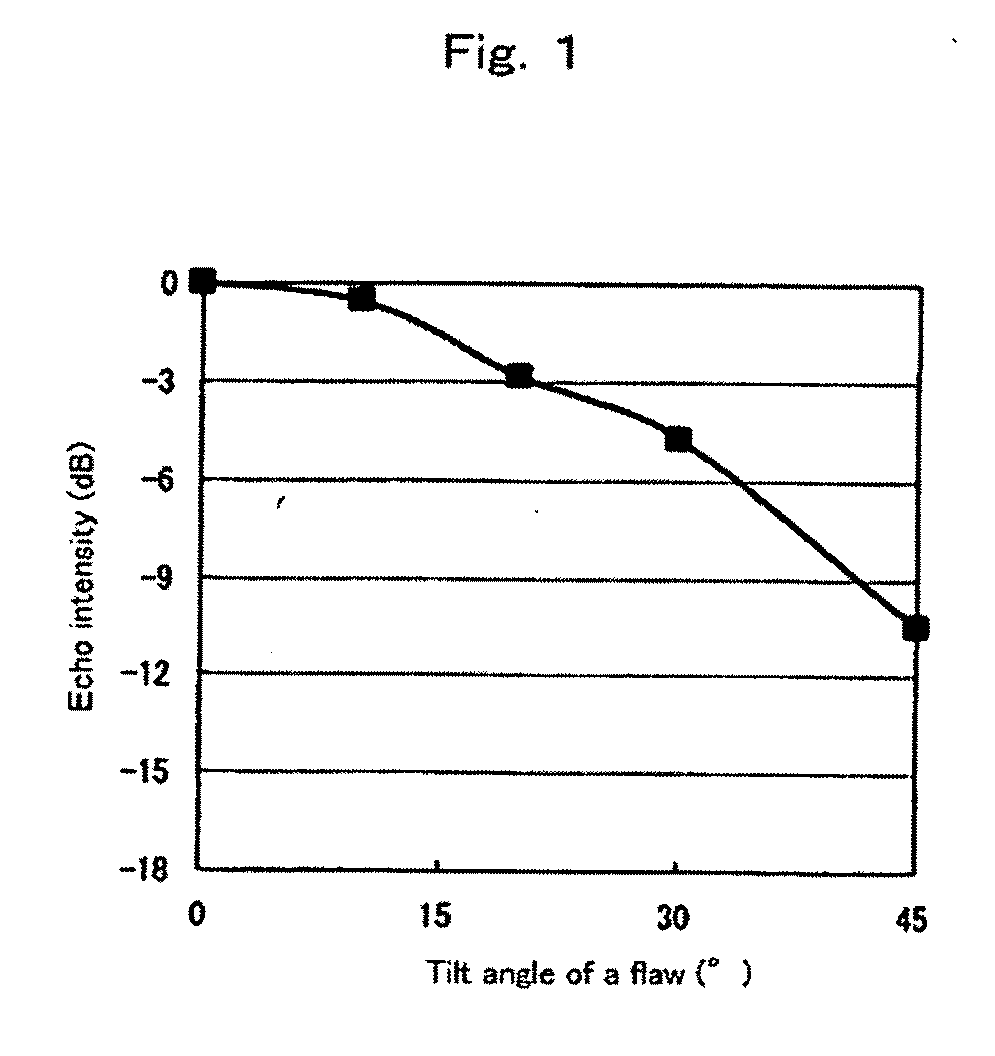

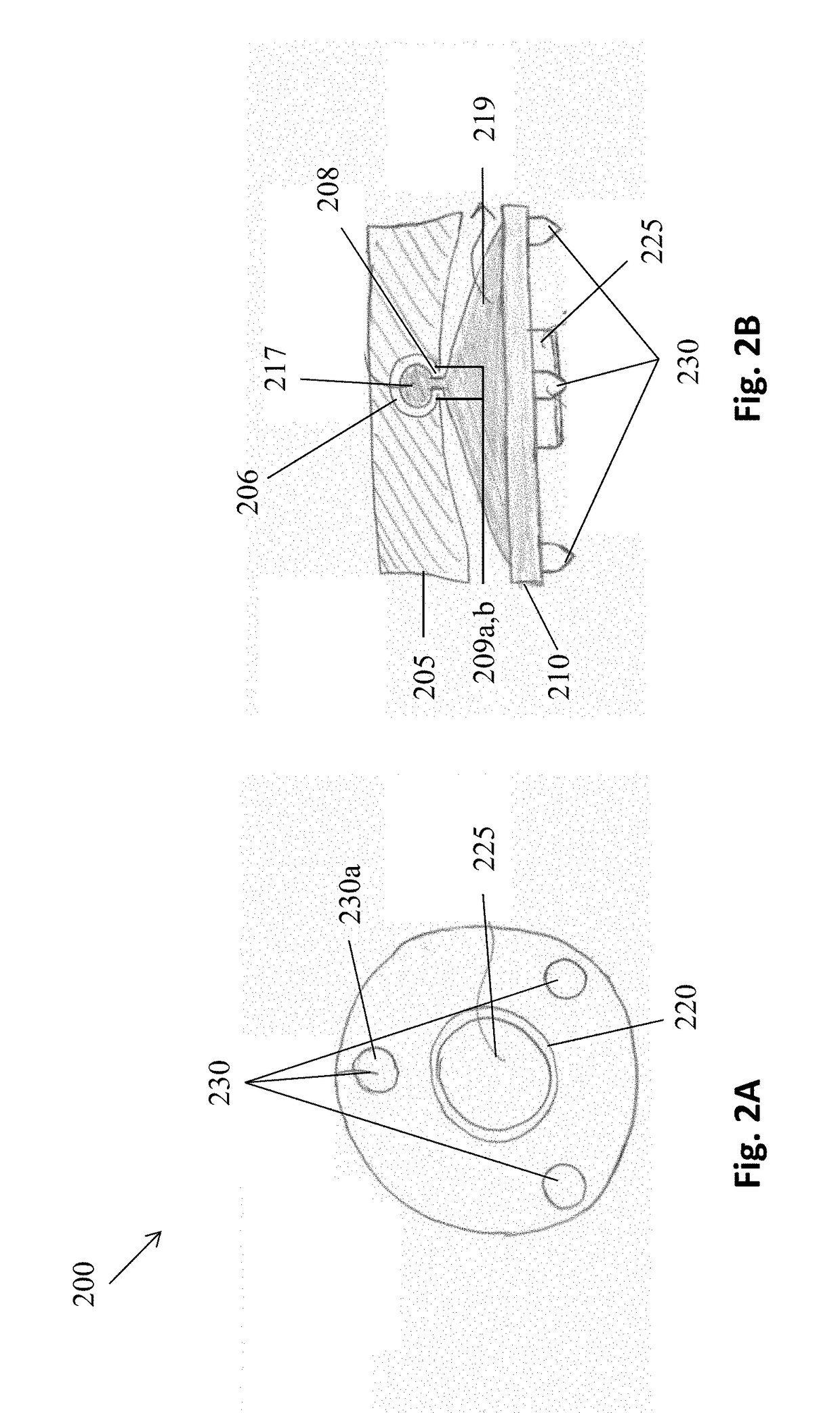

Ultrasonic probe, ultrasonic testing equipment, ultrasonic testing method, and manufacturing method of seamless pipe or tube

ActiveUS20090217763A1Improve accuracyHigh-precision detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansTransducerRefraction angle

The ultrasonic testing method according to the invention includes the steps of arranging an ultrasonic probe 1 having a plurality of transducers 11 so as to face a tubular test object P, and causing the transducers appropriately selected from the plurality of transducers to transmit and receive ultrasonic waves so that the ultrasonic waves are propagated in the tubular test object in a plurality of different propagation directions, wherein a ultrasonic testing condition by the ultrasonic probe is set so that respective external refraction angles θr of the ultrasonic waves in the plurality of propagation directions are approximately equivalent and / or respective internal refraction angles θk of the ultrasonic waves in the plurality of propagation directions are approximately equivalent.

Owner:NIPPON STEEL CORP

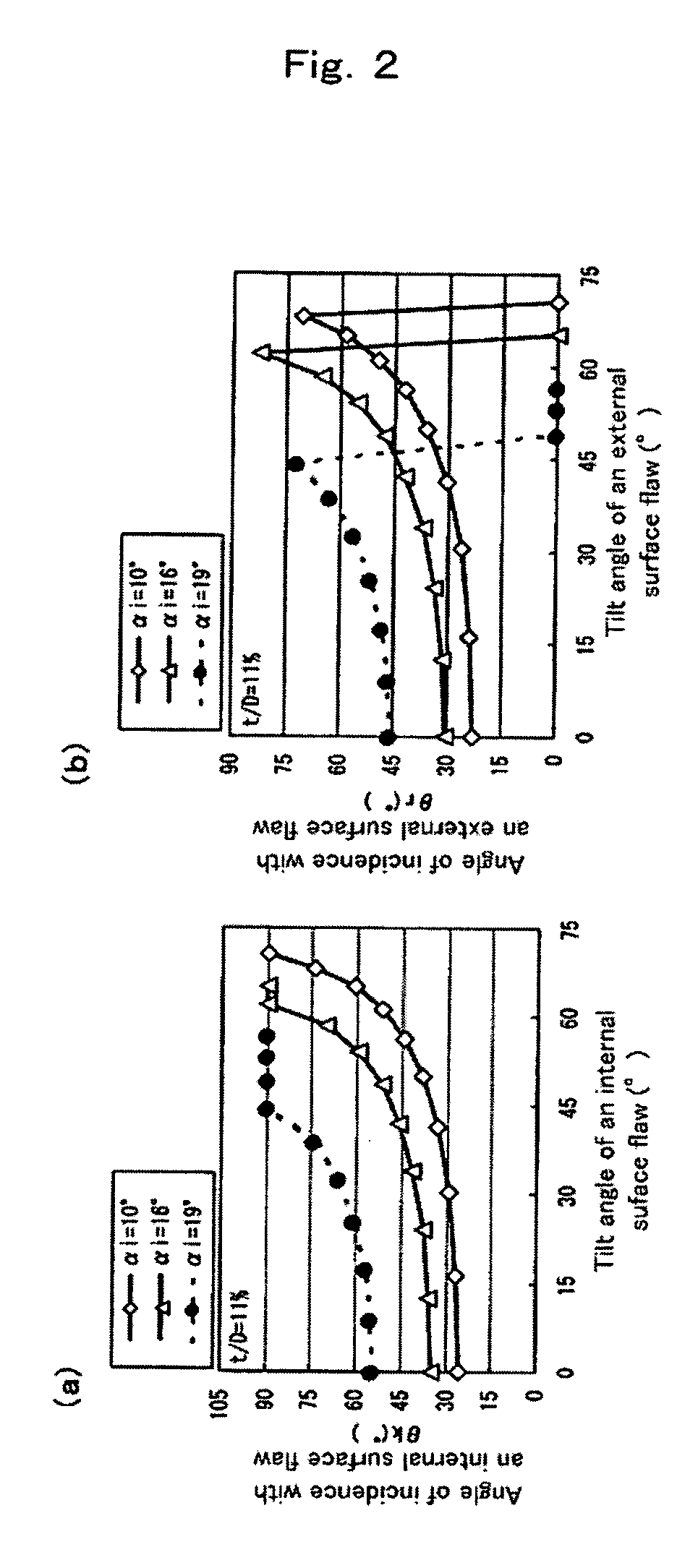

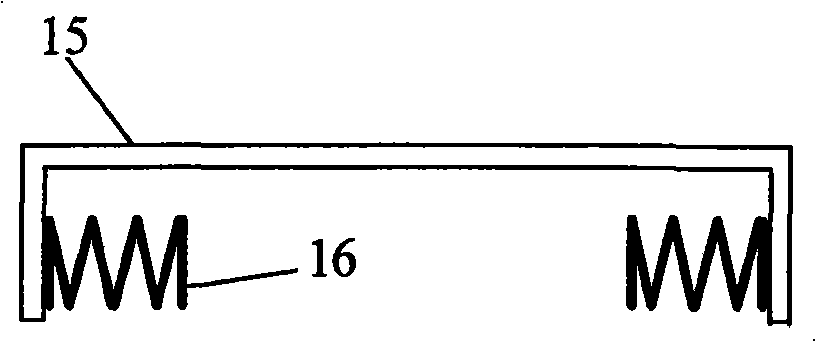

Experimental device for concrete multifactor permanent stability under co-action of pulling stress and surroundings

InactiveCN101271103AGeometrically accurateEasy to processMaterial testing goodsStrength propertiesConstant forceUltrasonic testing

The invention relates to a concrete multi-factor durability test device under the common effect of tensile stress and environment, wherein, the lower part of a pull rod (8) is connected with a lower pull plate (13), the upper part of the pull rod (8) penetrates an upper pull plate (7) and a limit plate (4), the upper pull plate (7) is penetrated on the pull rod (8) to be fixed by a lock nut (6), a screw cap (2) presses a stress sensor (3) on the limit plate by a spherical screw rod (1), a spring (5) is sheathed on the spherical screw rod (1) and is positioned between the limit plate and the upper pull plate, an upper stretching chuck (91) and a lower stretching chuck (92) are arranged between the upper pull plate and the lower pull plate (13), the upper stretching chuck (91) is connected with the spherical head part of the spherical screw rod (1), the lower stretching chuck (92) is connected with the spherical head part of a spherical pull rod (12), a dumbbell-shaped concrete sample (10) is positioned between the upper stretching chuck (91) and the lower stretching chuck (92), the dumbbell-shaped concrete sample is held by the stretching chucks, both sides of the dumbbell-shaped concrete sample (10) are provided with constant force holding instruments (11), and the constant force holding instruments are connected with a non-metallic ultrasonic testing instrument (14).

Owner:SOUTHEAST UNIV

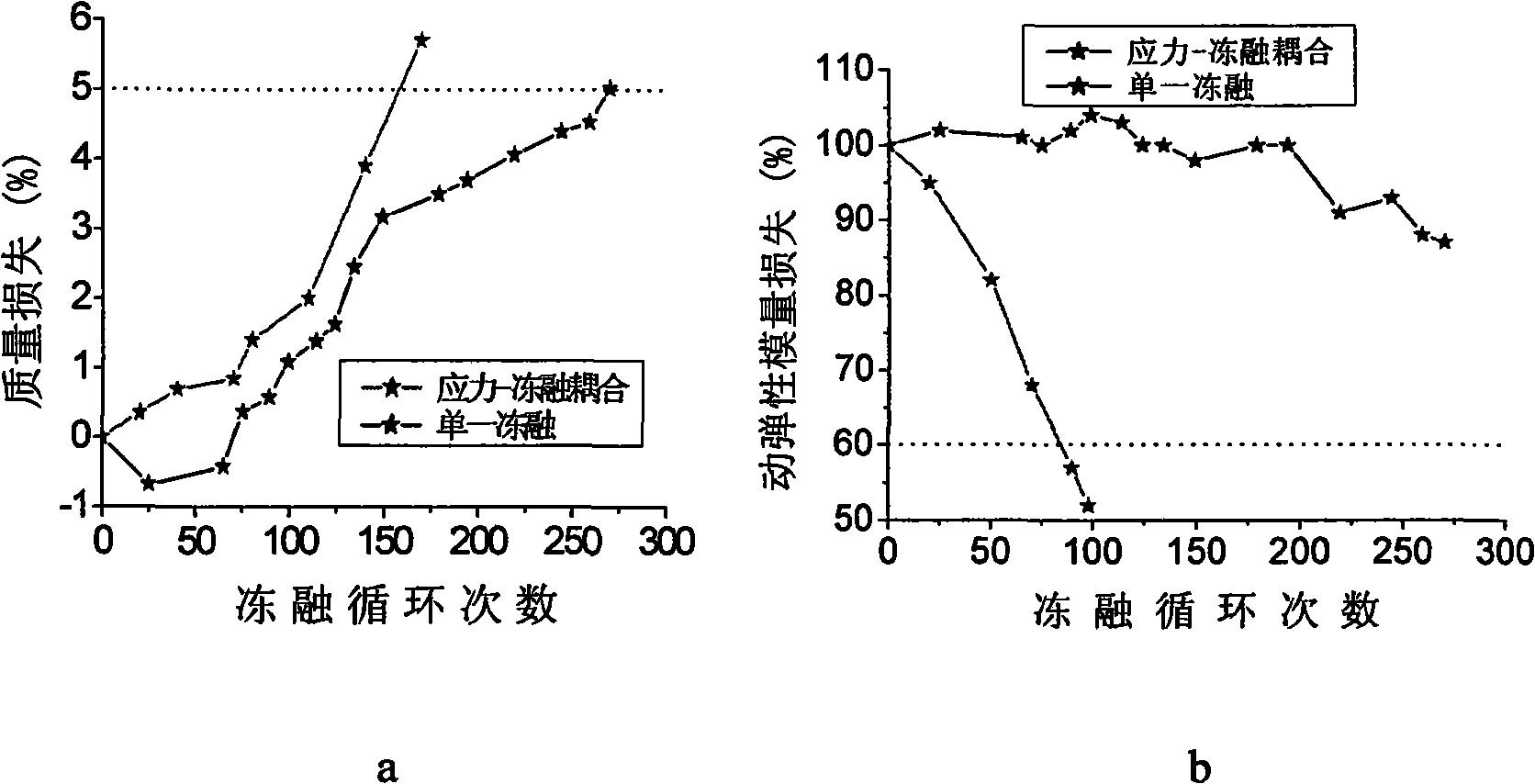

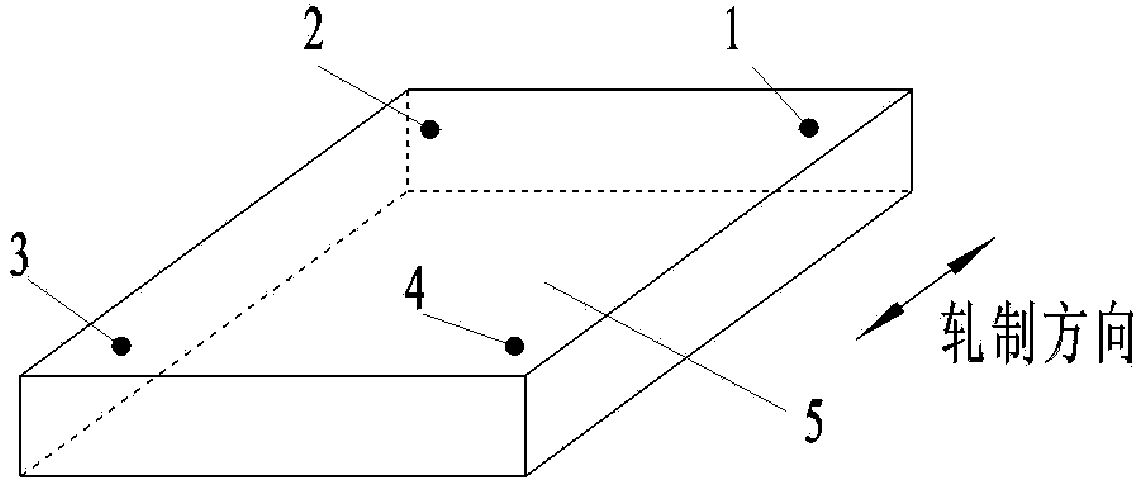

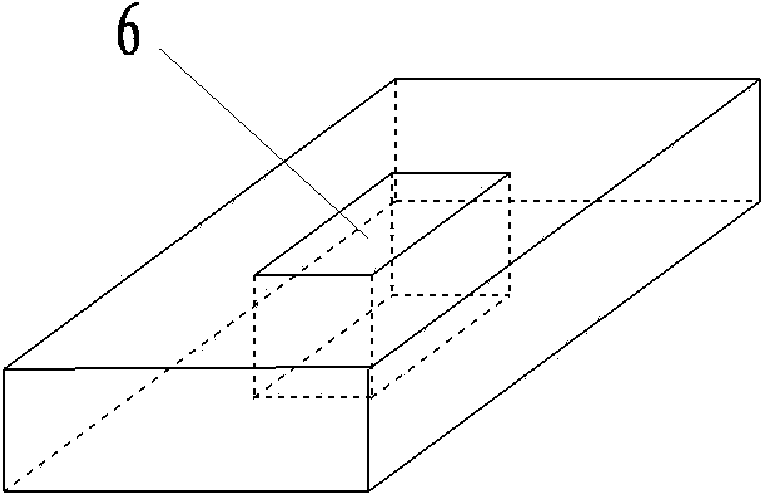

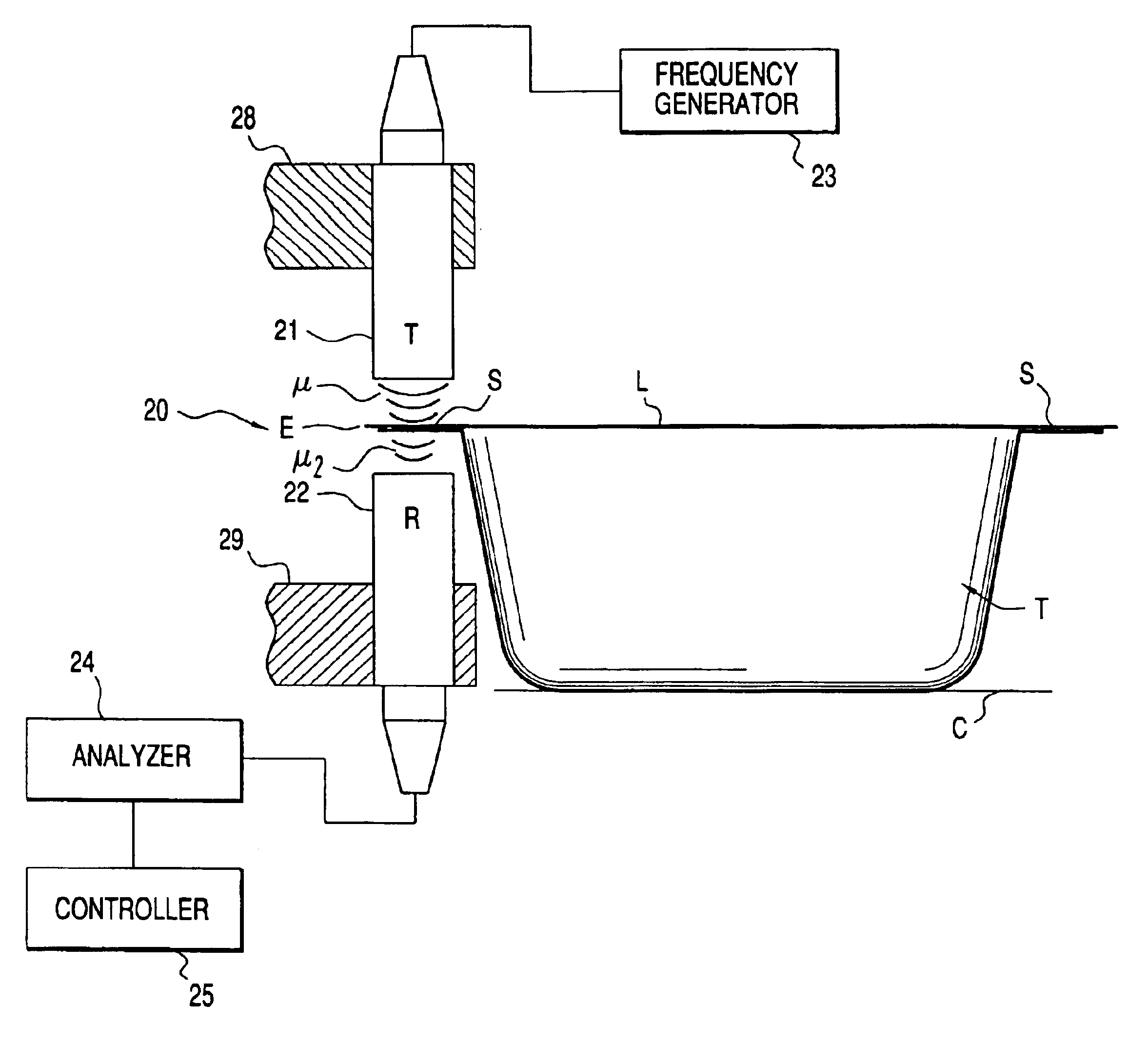

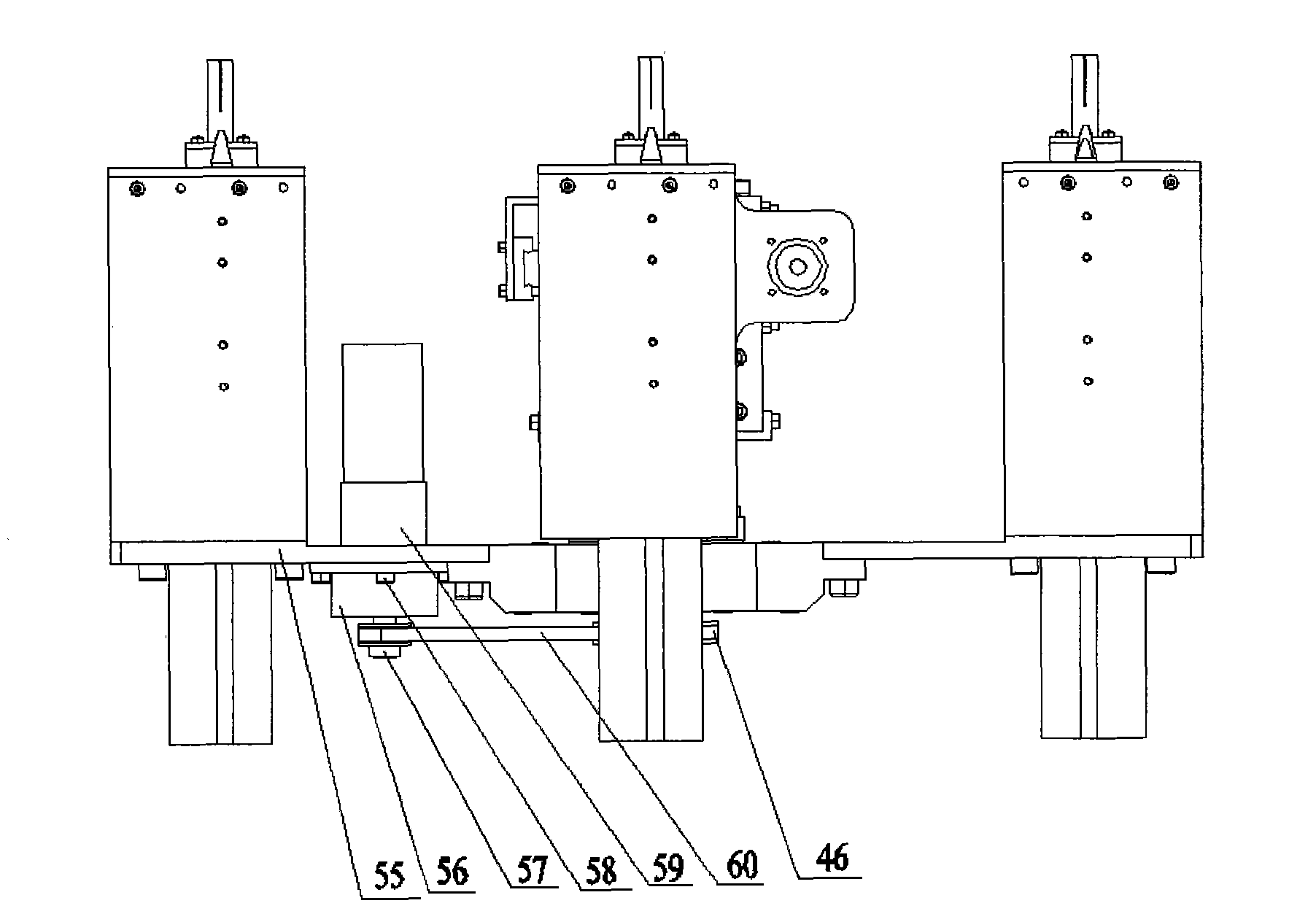

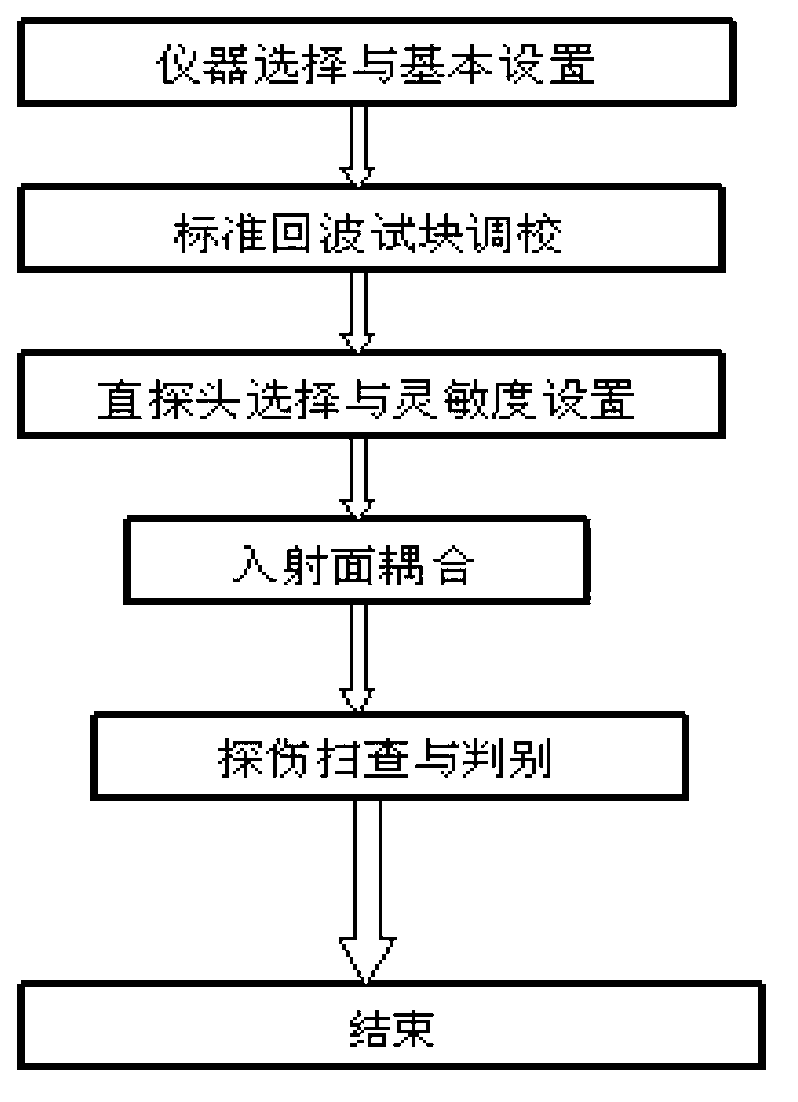

Method for carrying out ultrasonic inspection on residual stress of aluminium alloy pre-stretching board by water immersion

ActiveCN103543206AGood for non-destructive evaluationThe detection process is fastAnalysing solids using sonic/ultrasonic/infrasonic wavesStress measurementWater immersion

The invention provides a method for carrying out ultrasonic inspection on residual stress of an aluminium alloy pre-stretching board by water immersion, belonging to the field of non-destructive inspection. The method comprises the following steps of preparing a reference block; carrying out measurement and calibration; measuring the residual stress. In the method, the water immersion method is adopted, and the temperatures in stress calibration and stress measurement processes can be ensured to be consistent by controlling the water temperature not to be changed, thus eliminating the effects of temperature difference on the ultrasonic wave speed and eliminating temperature errors; besides, an automatic scanning frame is adopted instead of manual scanning, so that the distance between a probe and the surface of a material to be measured in the measurement process can be ensured not to be changed, thus eliminating the effects of coupling condition difference on sound propagation time and eliminating the coupling errors. The method is beneficial to non-destructive evaluation of the near surface residual stress of the aluminium alloy pre-stretching board.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

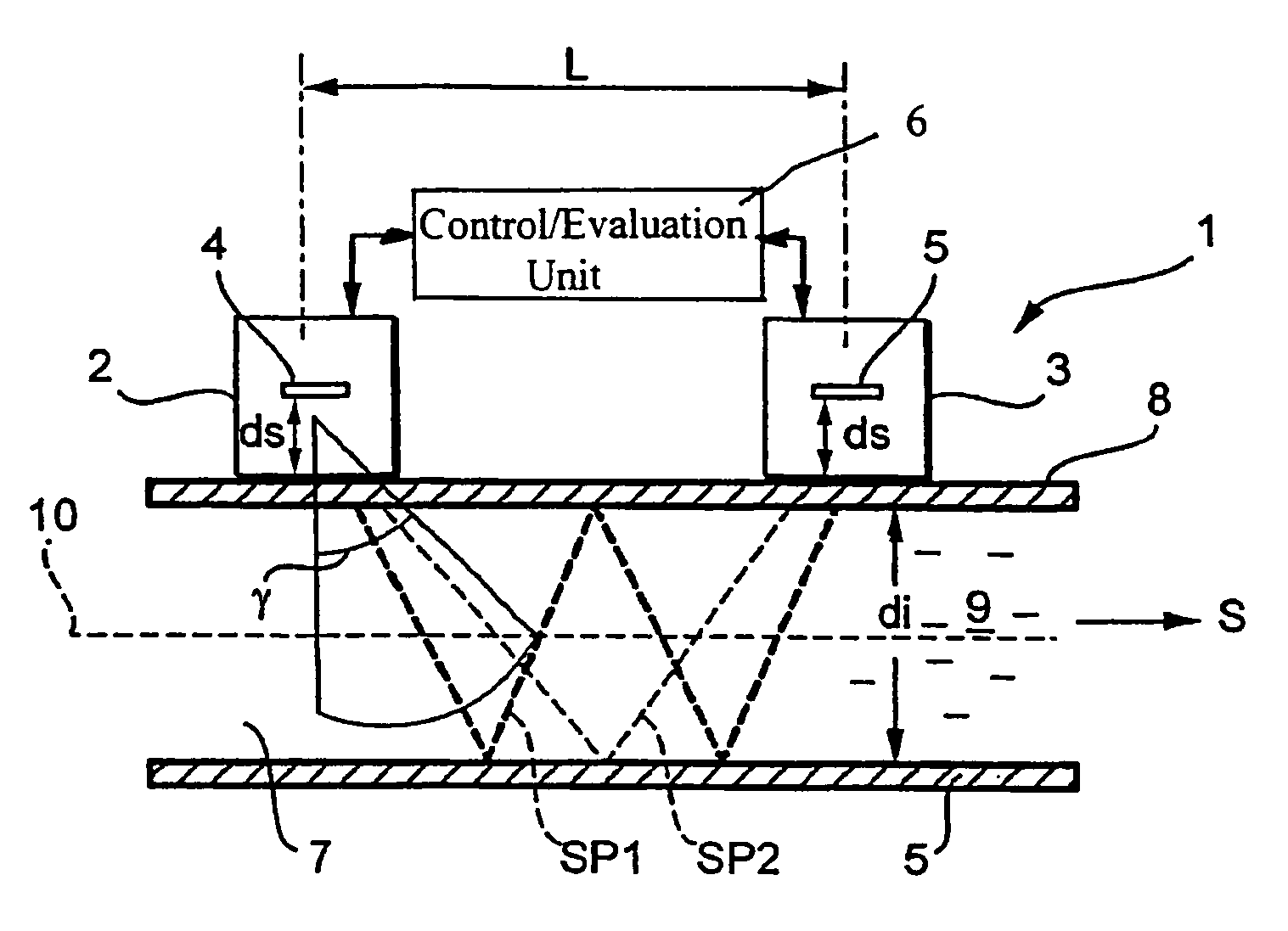

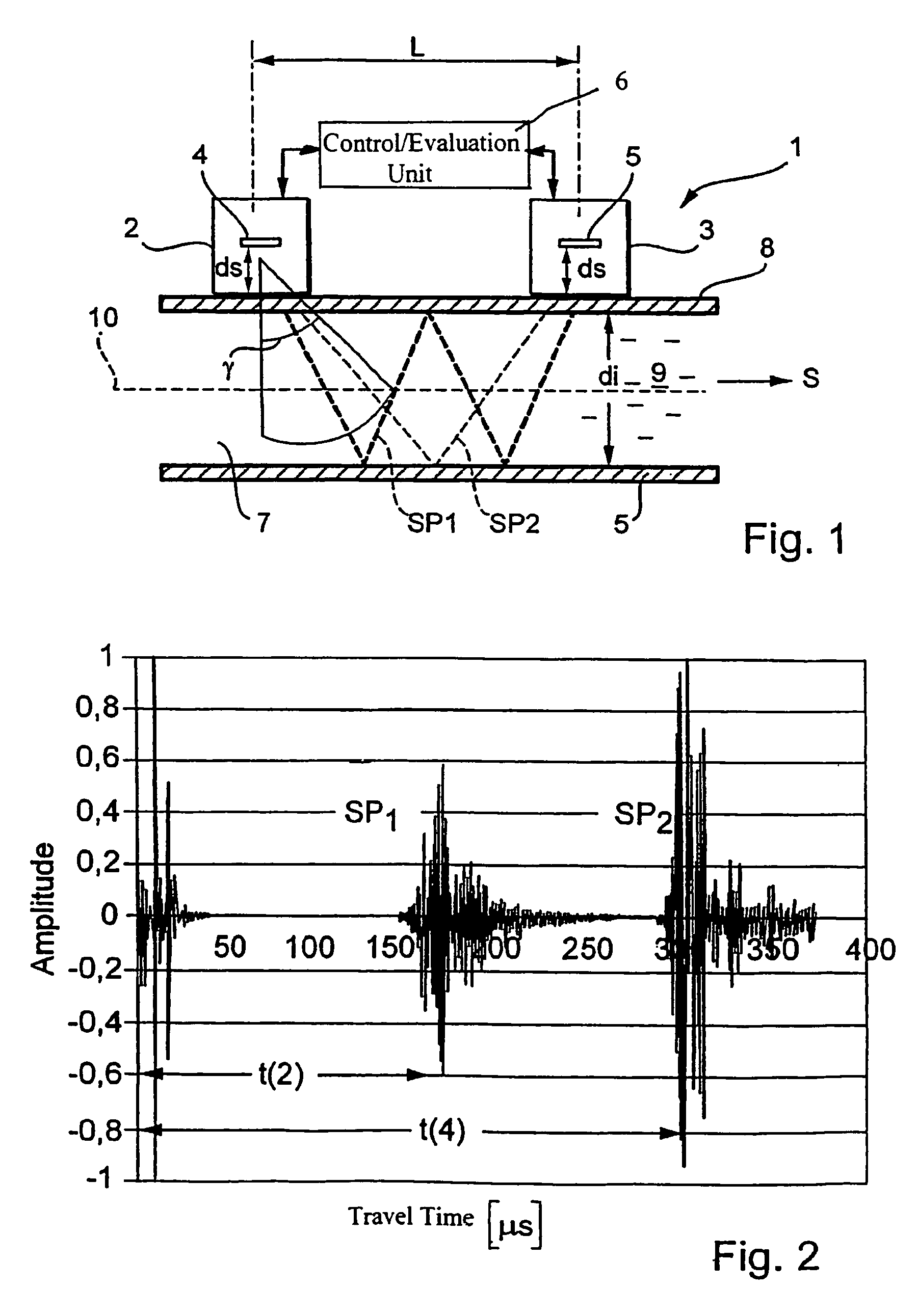

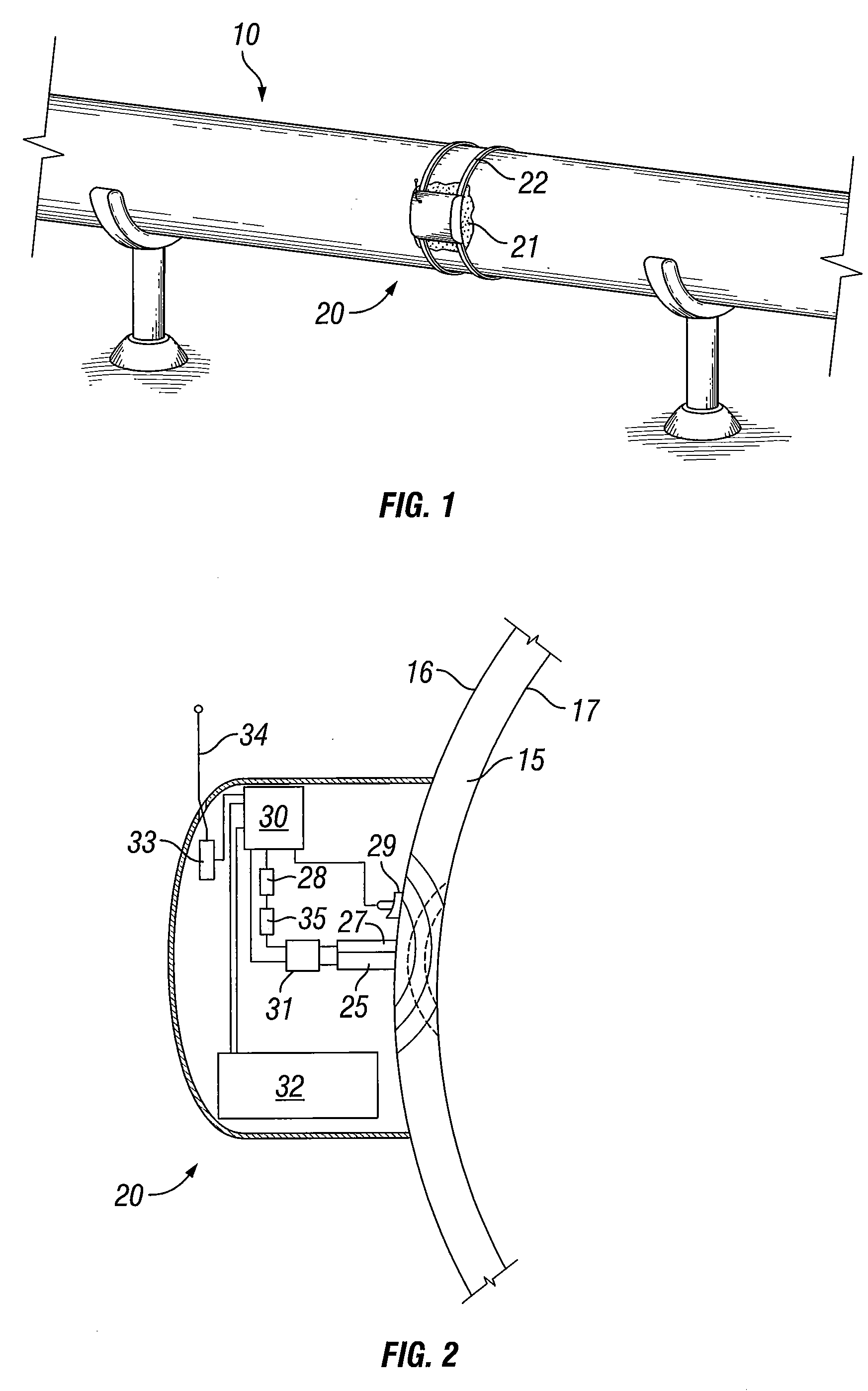

Flowmeter mounted on a containment

InactiveUS7469599B2The solution is simple and reliableHighly precise determining and monitoringVolume/mass flow measurementEngineeringUltrasonic testing

Flowmeter comprising at least two ultrasonic transducers that are mounted on a container which is penetrated by a medium in a certain direction of flow. The ultrasonic transducers alternately transmit and receive ultrasonic test signals in the direction of flow and counter to the direction of flow. The flowmeter further comprises a control / evaluation unit which determines and / or monitors the volume flow of the medium inside the container based on the difference in the travel time of the ultrasonic test signals propagating in the direction of flow and counter to the direction of flow. The ultrasonic transducers are configured such that they transmit and receive ultrasonic test signals or sound fields having a large aperture angle or a great beam expansion.

Owner:ENDRESS HAUSER FLOWTEC AG

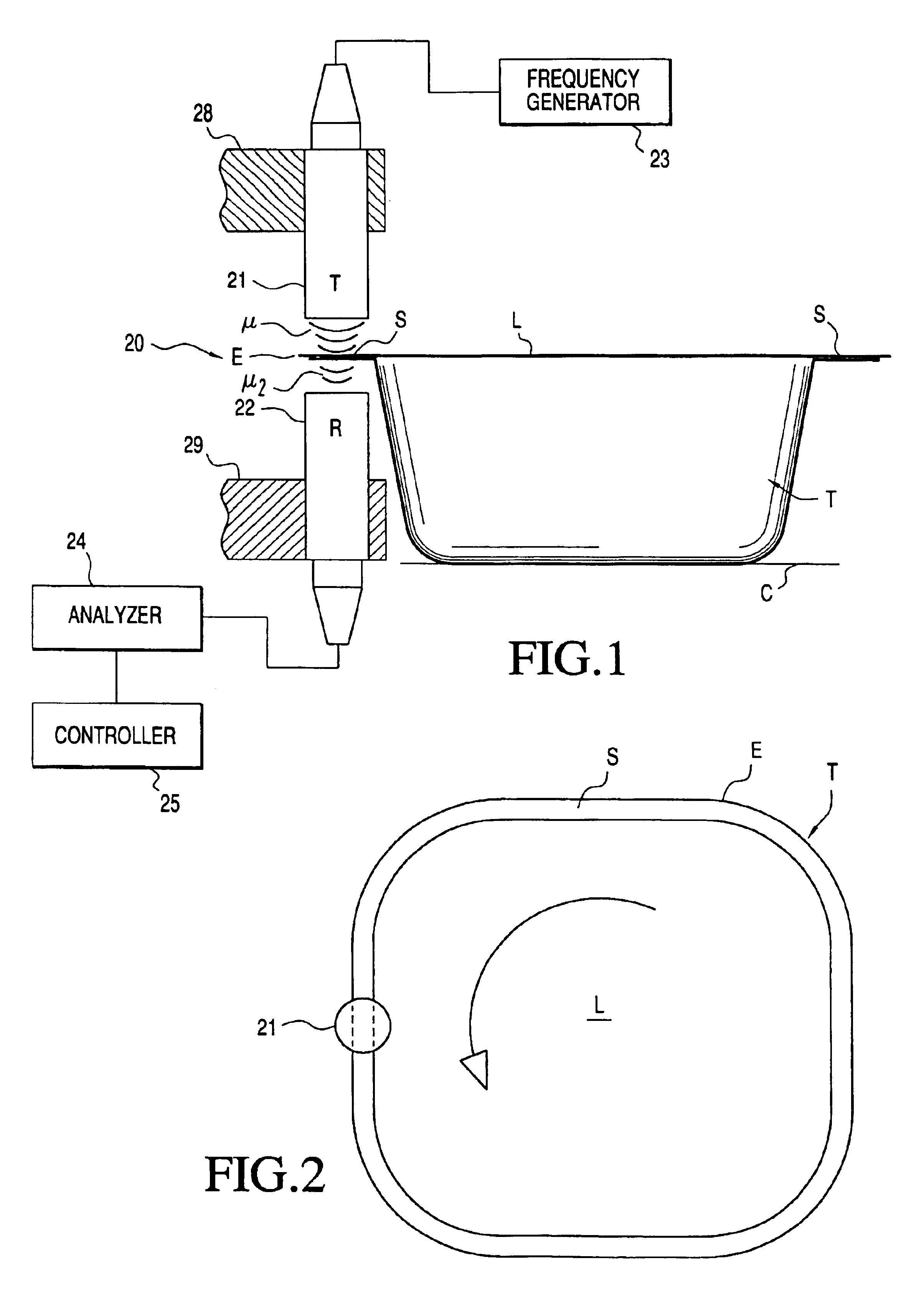

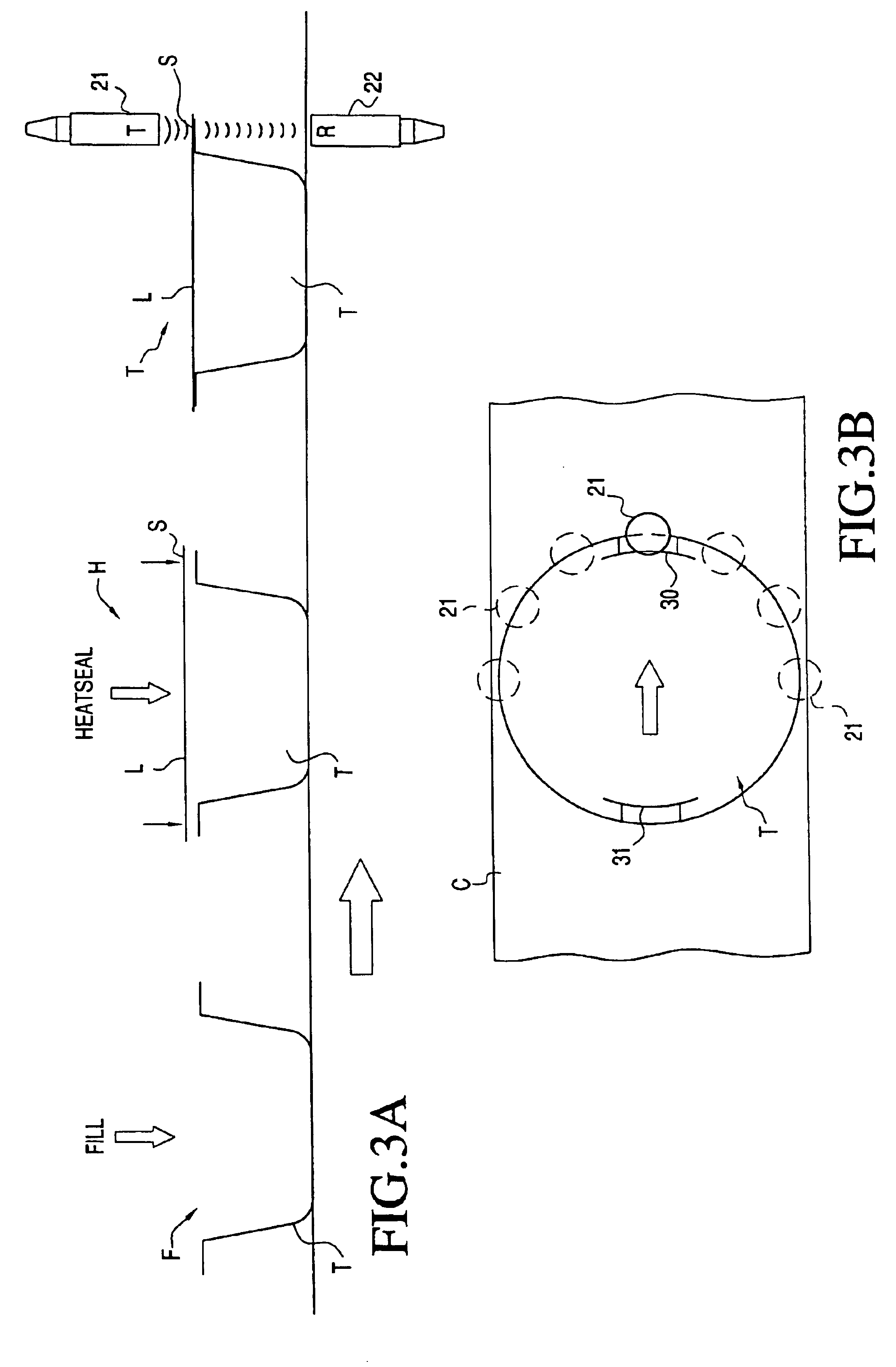

Method and apparatus for airborne ultrasonic testing of package and container seals

InactiveUS6840108B2Obstruct passageAvoid energyDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationNon-contact ultrasound

A method for testing or inspecting the integrity of package closure seals using contact and non-contact ultrasonic systems wherein a relative movement is created between a package seal and at least one ultrasonic transmitting transducer and at least one receiving transducer such that ultrasonic energy is focused so as to be transmitted toward and along a length of the seal from the transmitting transducer to the receiving transducer in a gaseous environment to thereby monitor energy signals which are analyzed to provide an indication of the seal integrity.

Owner:PACKAGING TECH & INSPECTION

Apparatus for measuring wall thicknesses of objects

ActiveUS7891248B2Correct misalignmentAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceTransducerUltrasonic testing

Owner:ROLLS ROYCE PLC

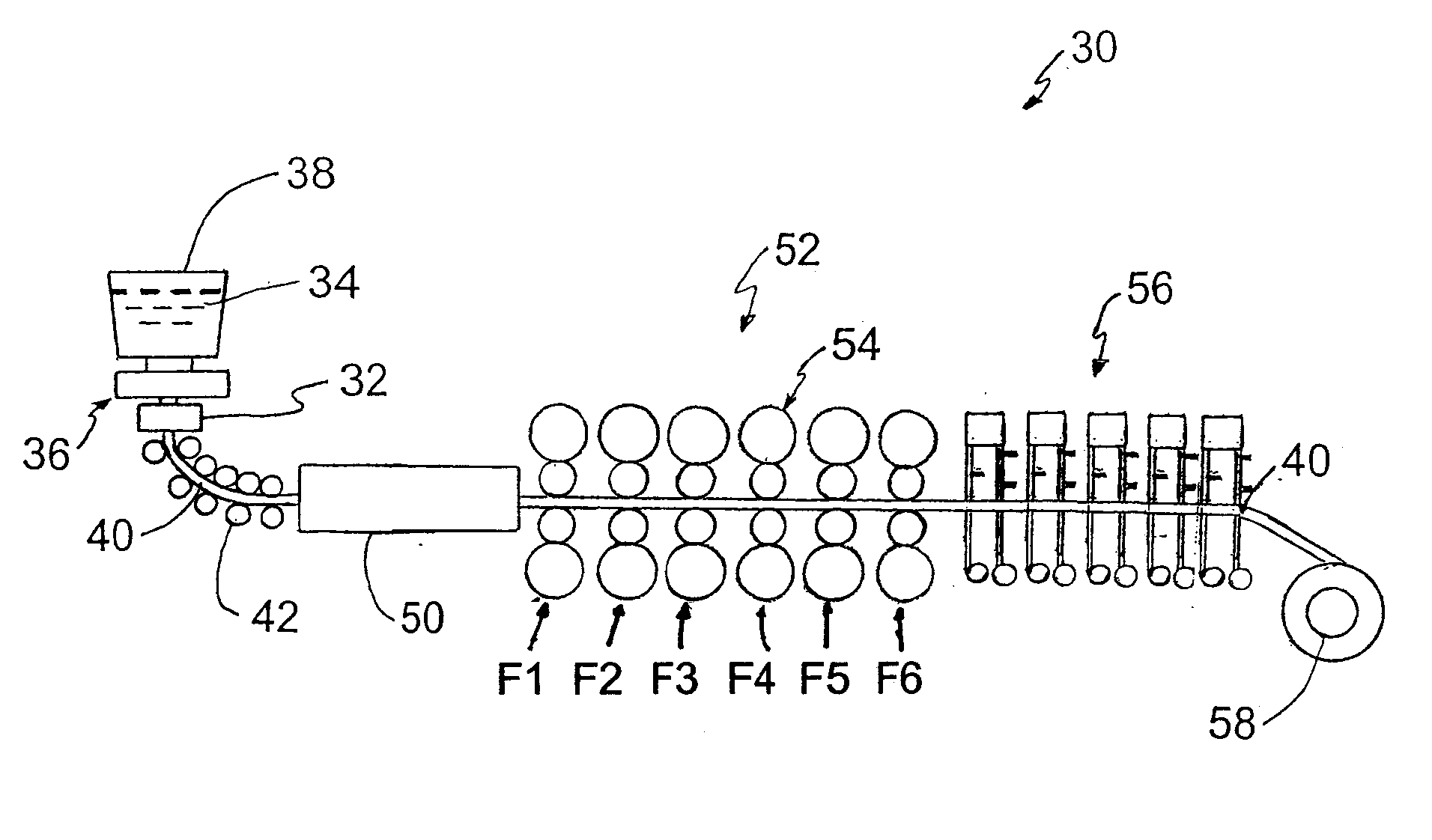

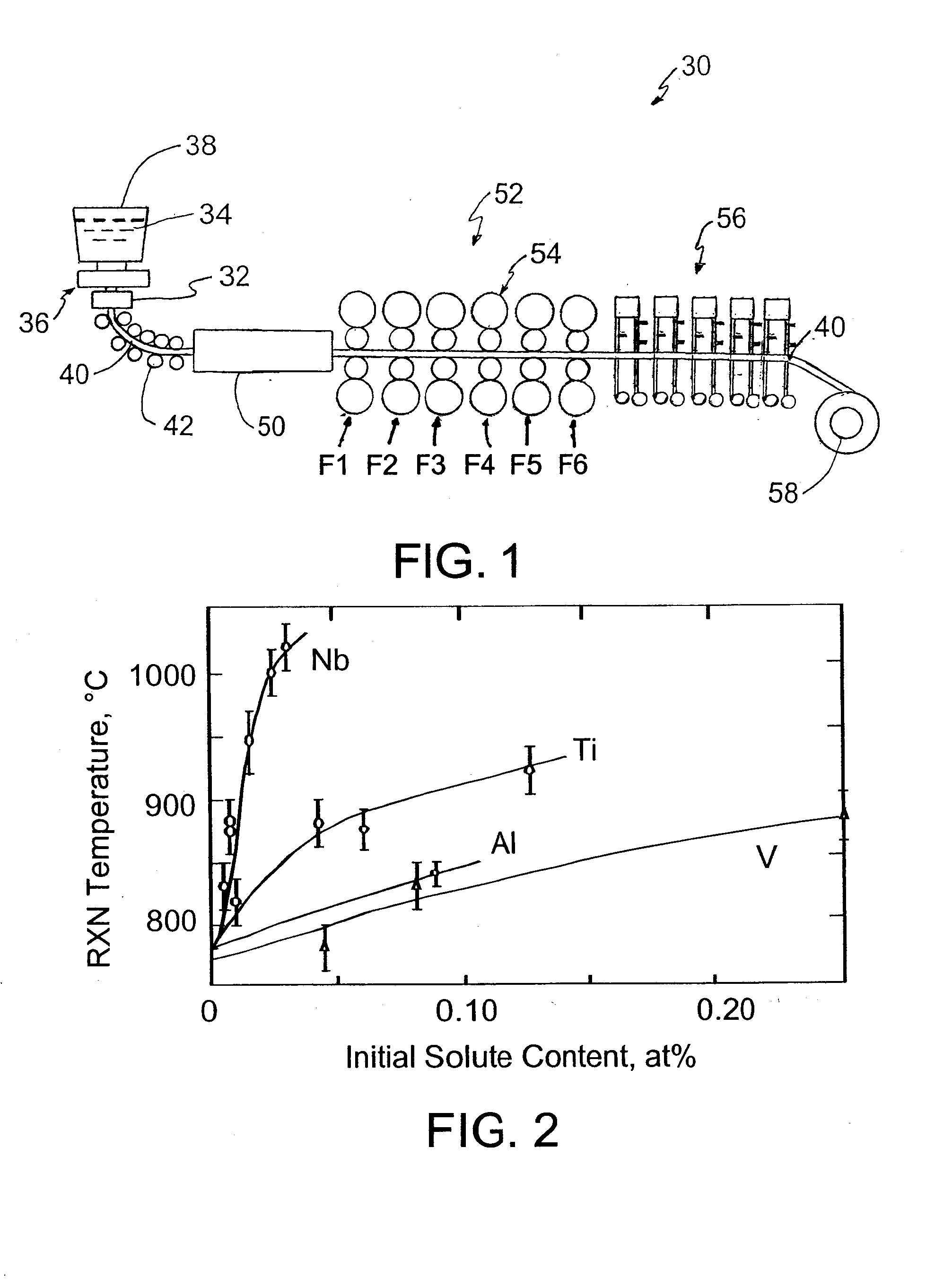

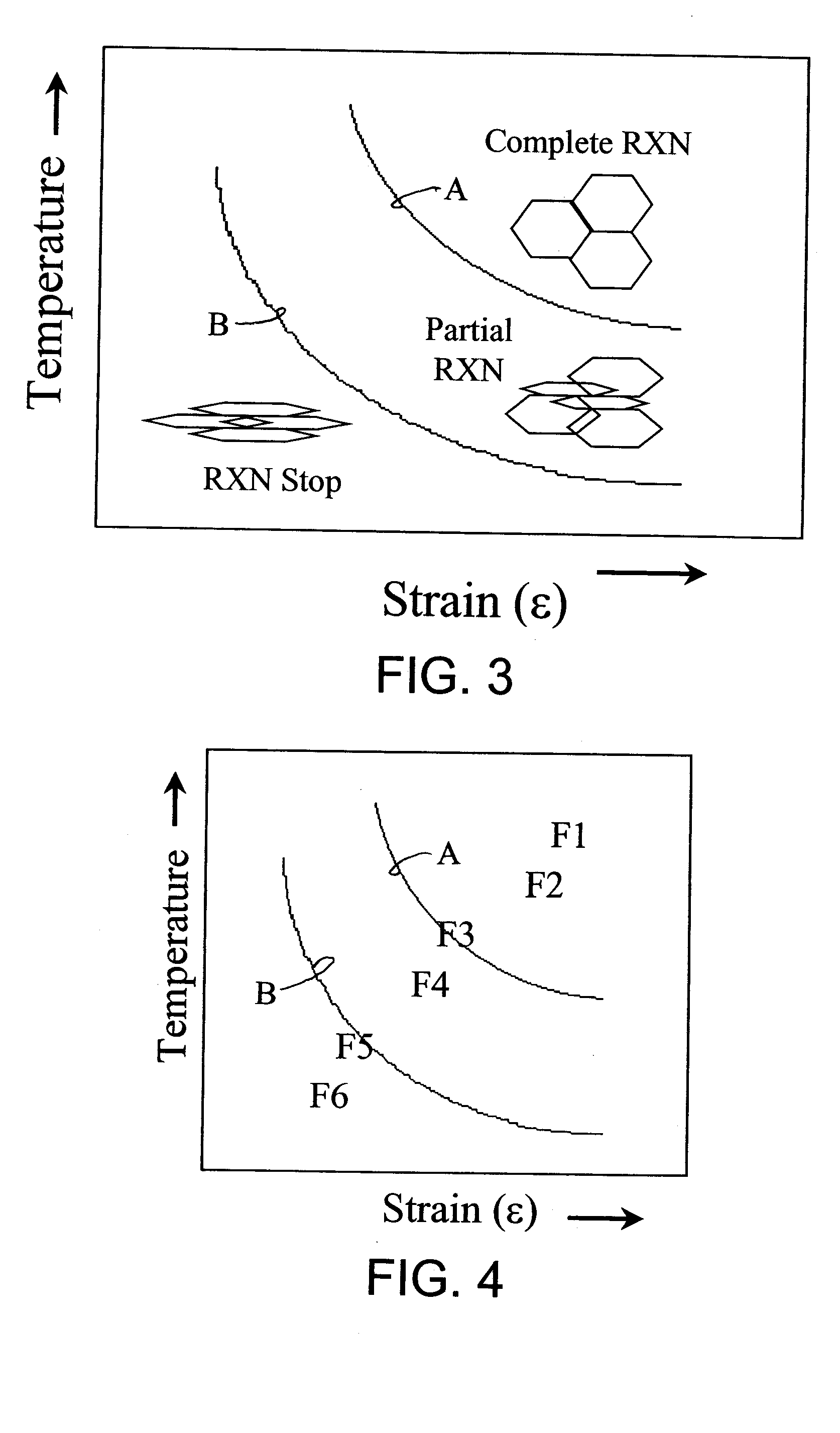

Thermomechanical processing routes in compact strip production of high-strength low-alloy steel

InactiveUS20050115649A1Accurate ultrasonic testingTime allowedMetal rolling arrangementsAustenite grainThin slab

Process for hot rolling of high-strength low-alloy steel cast in Compact Strip Production as a thin slab. The strain and temperature at initial roll stands where deformation occurs allows full recrystallization, and at latest roll stands where deformation occurs there is no recrystallization. Deformation is absent at strains and temperatures where partial recrystallization would occur, allowing increased recrystallization over conventional CSP rolling. The result may be beneficial for microalloyed high-strength low-alloy steel in permitting accurate ultrasonic testing of welds. The time allowed between deformation at passes through roll stands may be increased by eliminating deformation at one or more central roll stands. Combined with increased strain at the initial roll stands where the temperature of the steel is in the full recrystallization region, the process may result in a relatively fine and uniform austenite grain size.

Owner:NUCOR CORP

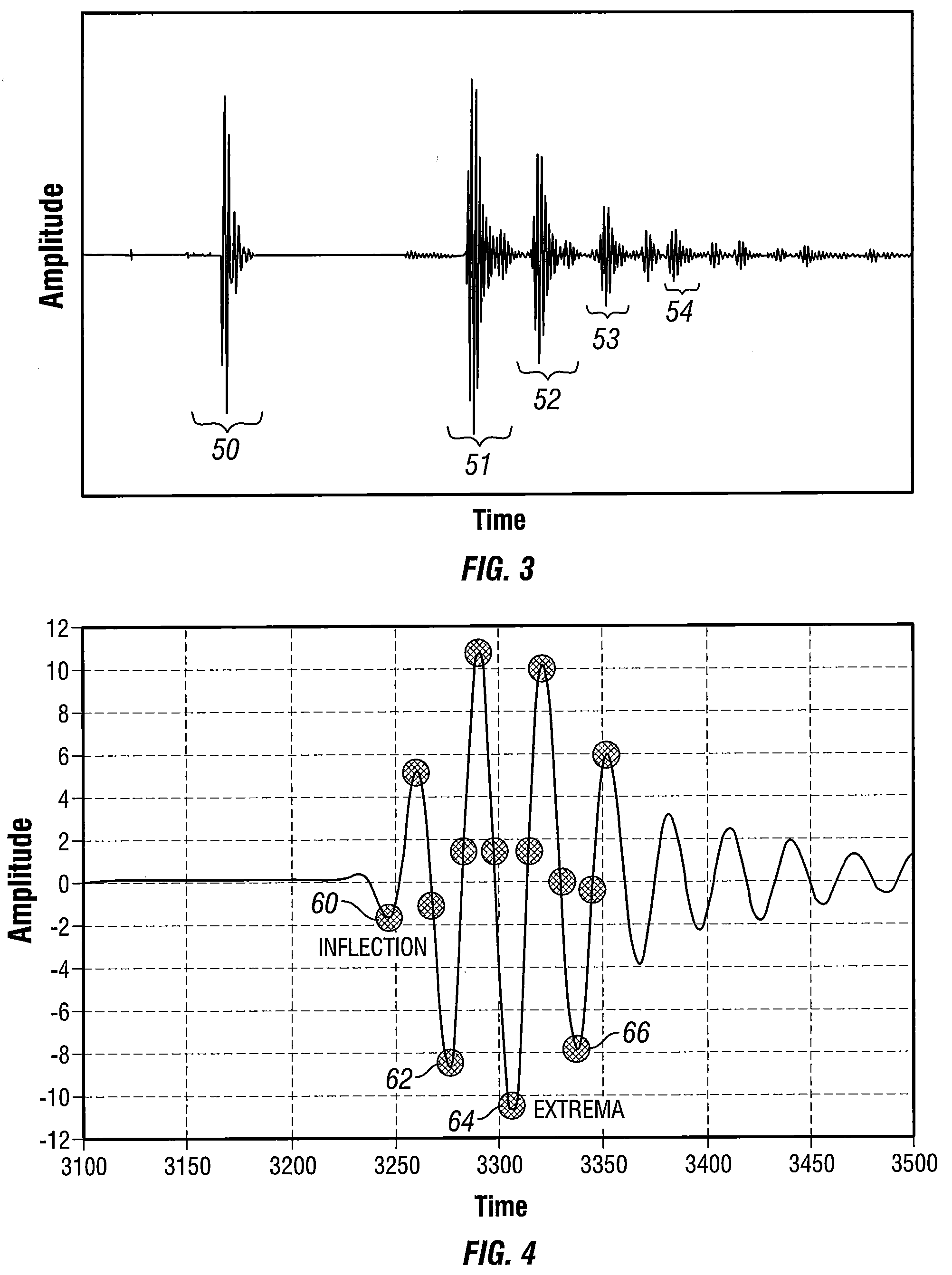

High precision ultrasonic corrosion rate monitoring

ActiveUS20110067497A1Analysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceUltrasonic testingPulse measurement

The invention relates to very precisely measuring changes in thickness of pipe walls to determine corrosion rate prior to any significant corrosion loss. The thickness is determined by ultrasonic testing where many measurements of the wall thickness are taken at the same spot by a fixed sensor and errors associated with noise and temperature changes are substantially eliminated. A highly sensitive receiver converts each reflected pulse to waves that are averaged with other pulse measurements. The resulting average wave is analyzed so that each waveform is analyzed to identify the extrema and inflection points of each reflected pulse. The resulting analysis provides a far more accurate determination of the time between reflected pulses. As a result, a far more accurate picture of corrosion at the location of the wall of the pipe can be determined within weeks with a high degree of confidence.

Owner:CONOCOPHILLIPS CO

Dry-coupled permanently installed ultrasonic sensor linear array

InactiveUS20100236330A1Analysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsProcess equipmentCoupling

This invention relates to permanent, ultrasonic, flexible, dry-coupled, linear arrays for the inspection of pipelines, process equipment, and the like. The permanent, ultrasonic, flexible, dry-coupled, linear arrays detect and / or measure corrosion wall loss, stress corrosion cracking, and / or internal initiated pipeline cracking. The apparatus for ultrasonically testing materials includes a linear array of ultrasonic sensors, and a flexible, acoustically transmissive, dry-coupling surrounding at least a portion of each of the ultrasonic sensors.

Owner:BP CORP NORTH AMERICA INC

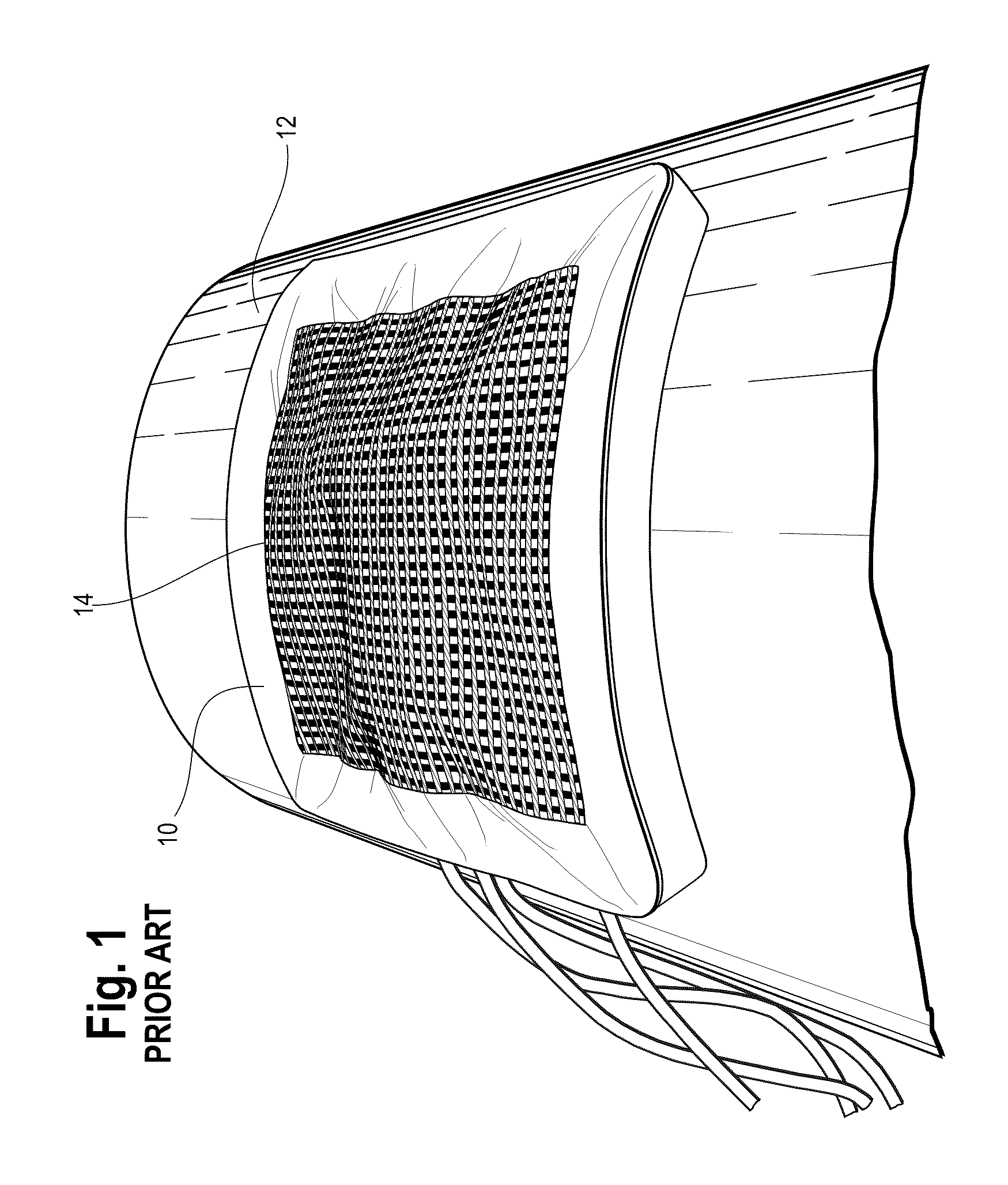

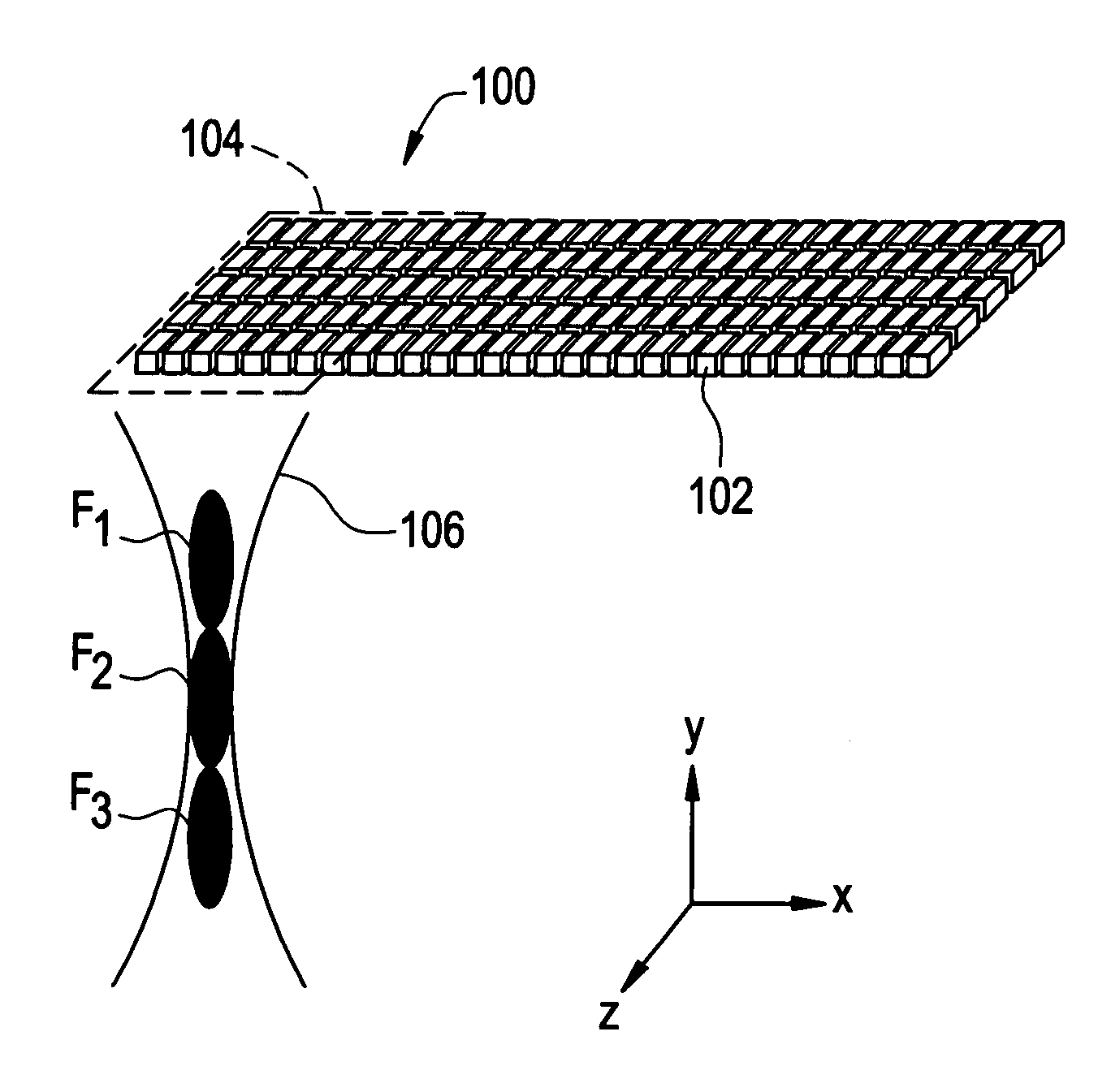

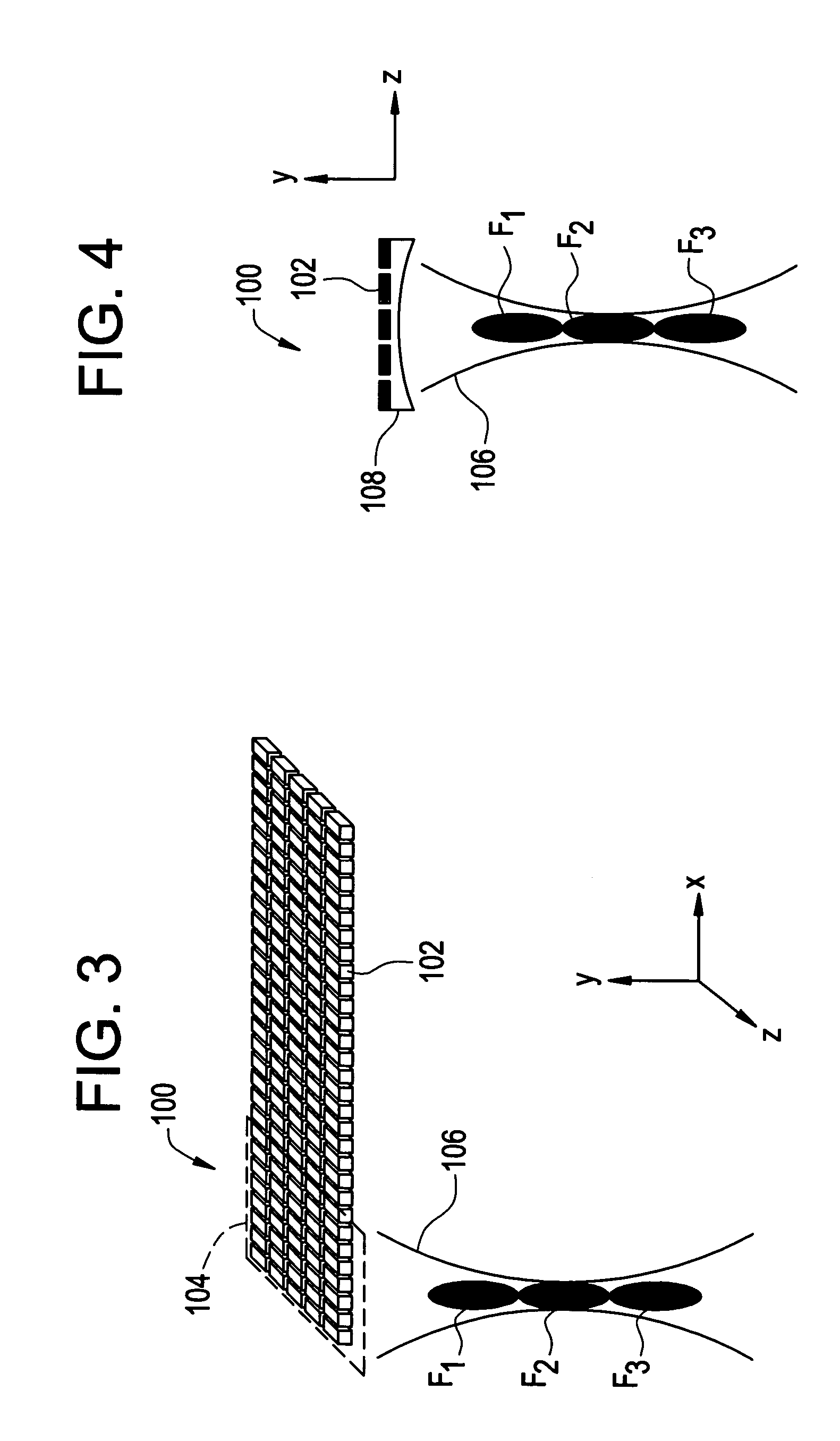

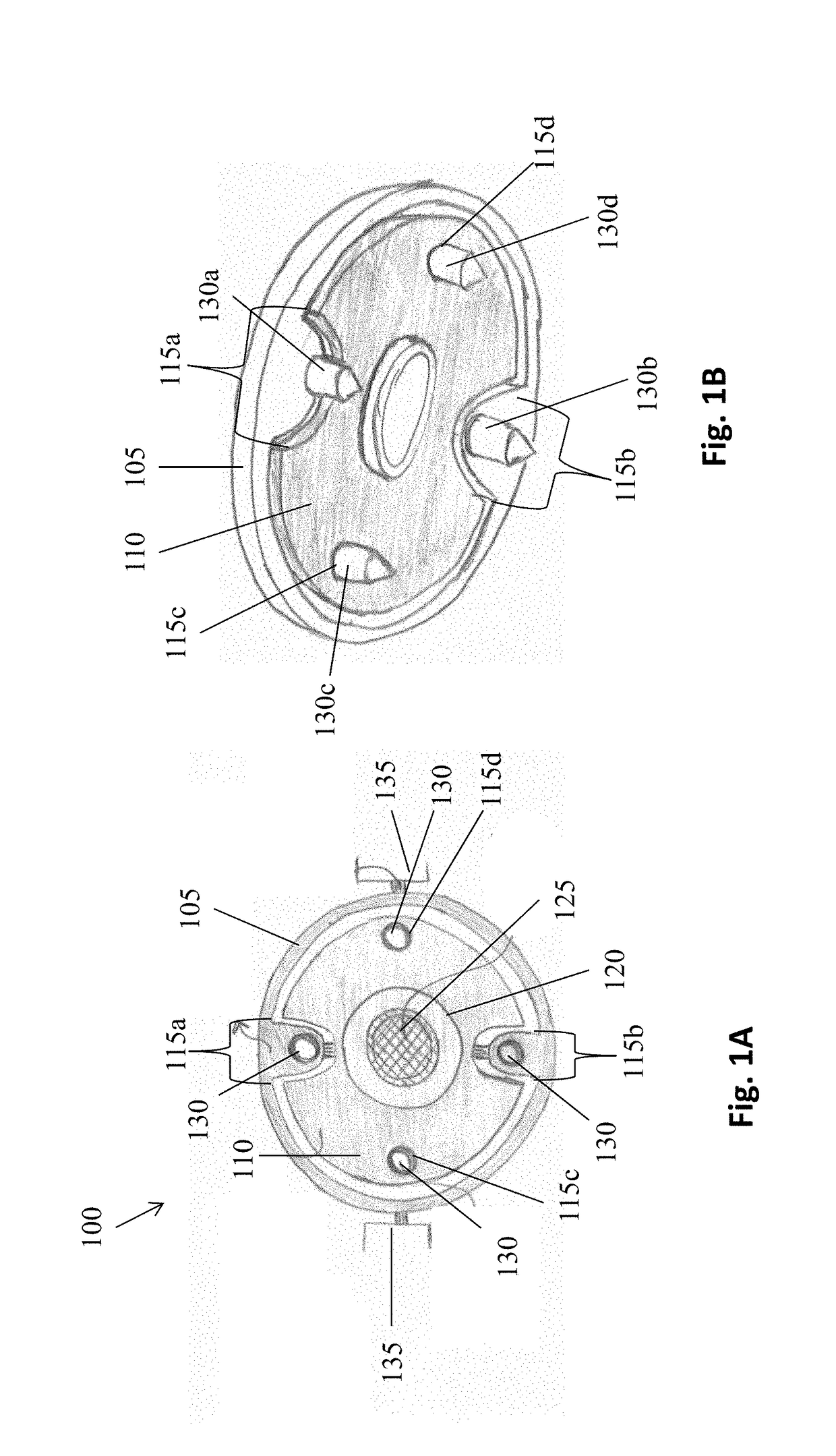

Two dimensional phased arrays for volumetric ultrasonic inspection and methods of use

ActiveUS20050081636A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerUltrasonic testing

The present disclosure provides for the application of a two-dimensional ultrasonic phased array (100), formed of a plurality of transducers (102) arranged in a rectilinear pattern, for material and volumetric component testing. The two-dimensional array enables electronic adjustment of the focal properties and size of the aperture in both the azimuthal and elevational directions such that uniform and / or specified sound field characteristics can be obtained at any or all locations in the component being tested.

Owner:GENERAL ELECTRIC CO

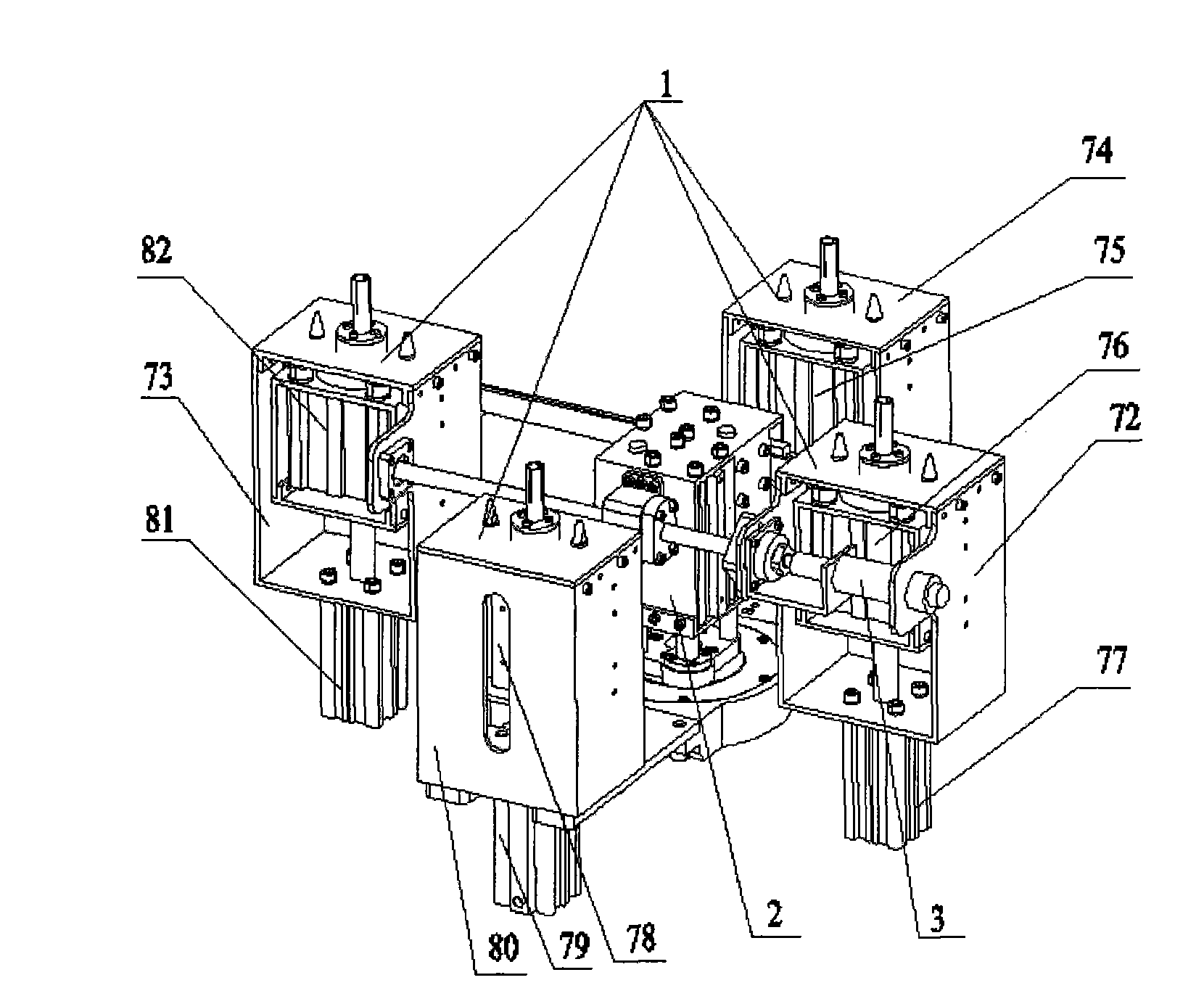

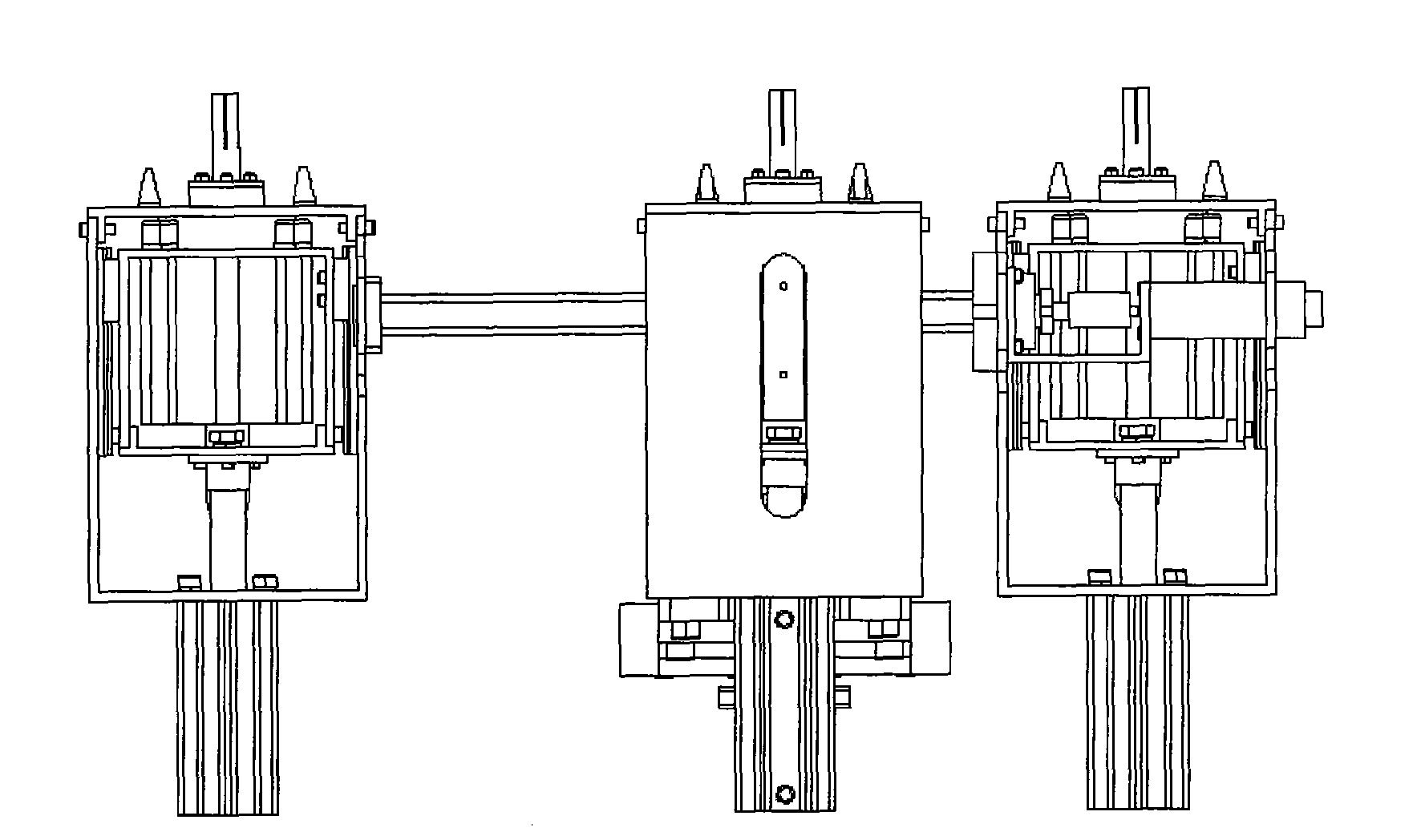

Robot for overhauling primary side of steam generator of nuclear power plant

InactiveCN101667465AReduce volumeReduce weightNuclear energy generationNuclear monitoringNuclear powerGas cylinder

The invention provides a robot for overhauling the primary side of a steam generator of a nuclear power plant, comprising a substrate unit, a rotating unit and a sliding unit. Each modularizing unit is internally provided with two gas cylinders capable of generating two lifting motions with different functions, wherein one pair of modularizing units can simultaneously provide loading spaces for adetecting device. When in use, a pneumatic self-locking expansion mechanism of a pair of modularizing units extends into a heat transfer pipe and is expanded, and a static friction force generated with the inner wall is used for supporting the total weight of the robot; the rotating unit is driven by one servomotor and two gas cylinders for respectively generating two motions of rotation and lifting; and the sliding unit converts the rotation motion of the servomotor into a rectilinear motion by a ball screw shaft and drives the modularizing unit to move on a tube plate hole. The invention isconvenient to be installed through a manhole of the steam generator so as to largely improve the overhauling efficiency, and can realize the fast replacement of operating apparatus for the eddy current inspection, the ultrasonic testing, the tube blockage detection, the water chamber surface condition detection and the like of the heat transfer tube.

Owner:HARBIN ENG UNIV

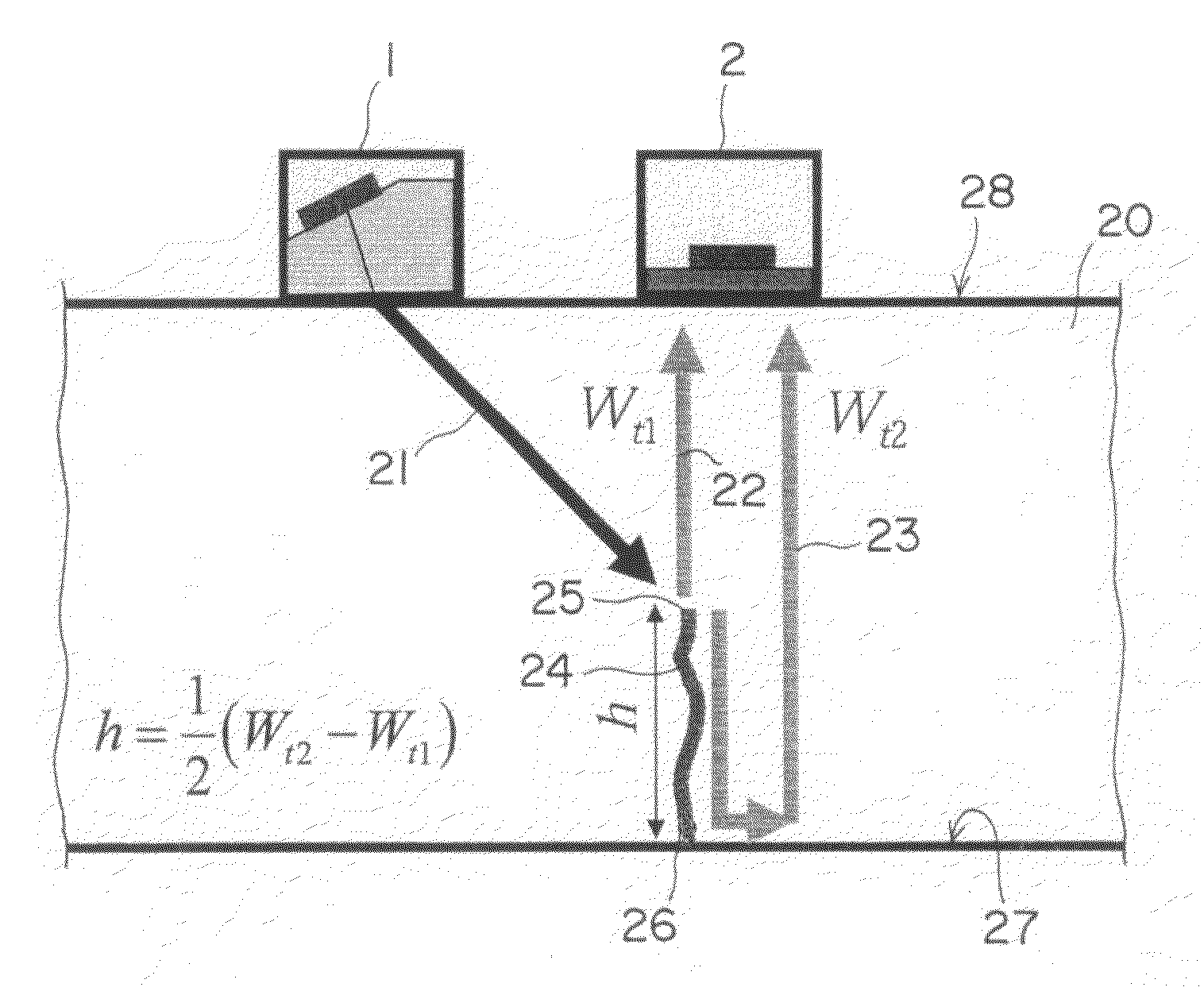

Method and apparatus for measuring flaw height in ultrasonic tests

InactiveUS20090007678A1Easy to practiceEasy and highly accurate measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsPropagation timeUltrasonic testing

The measurement of a flaw height in a thick welded portion of a stainless steel specimen, which is difficult to perform by the TOFD method, can be conducted with more ease, with higher accuracy and in a shorter time than in the case of using tip echo techniques. In addition, it is possible to reduce variations in measurement results among individual inspectors.An ultrasonic wave 21 is launched by a transmitting probe 1 into a specimen 20 in a direction oblique to a flaw 24 to generate diffracted waves at the tip 25 of the flaw 24, then a diffracted wave 22 propagating upward directly from the flaw 24 and a diffracted wave 23 propagating upwardly of the flaw 24 after once reflected off the back 27 are received by a receiving probe 2 disposed above the flaw 24, and the height of the tip of the flaw 24 from the back 27 is measured from the propagation time difference between the received diffracted waves.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

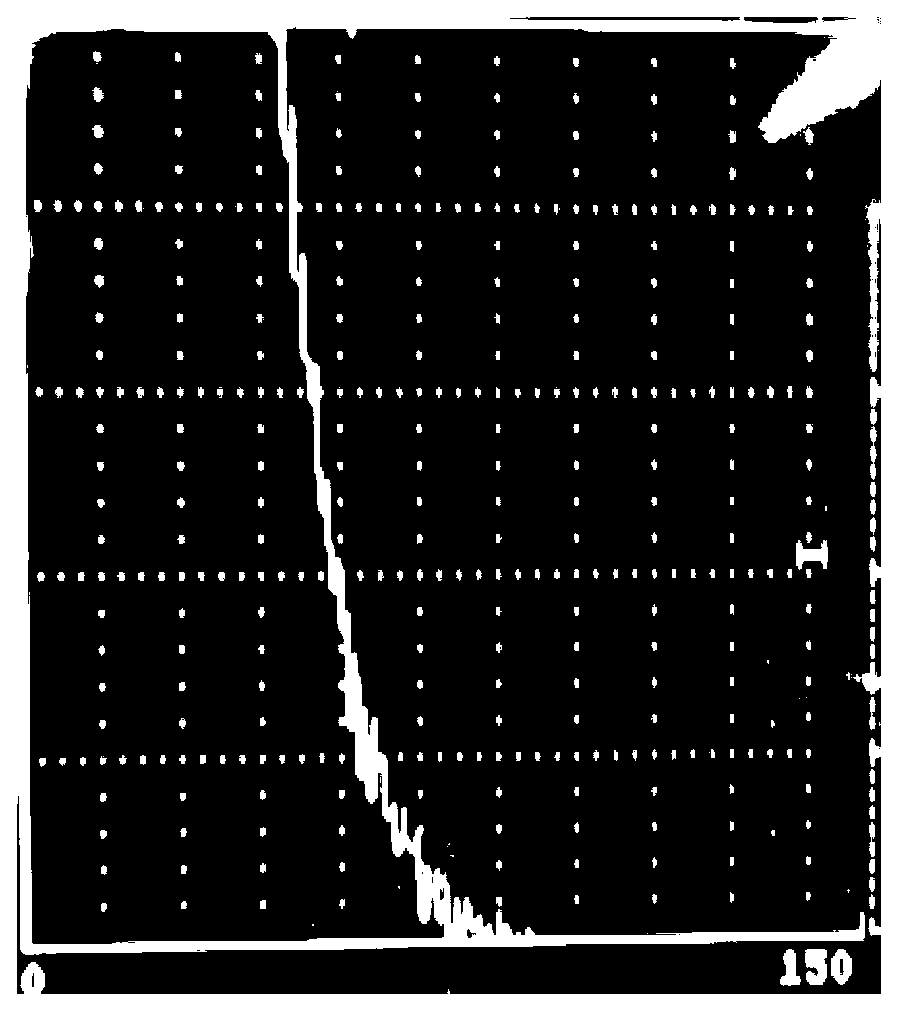

Ultrasonic testing method for bonding quality of coated steel sheet and rubber

The invention relates to an ultrasonic testing method for bonding quality of a coated steel sheet and rubber. The method comprises the following steps: conducting horizontal progressive scanning testing through a CTS-23 type pulse reflecting type ultrasonic tester, and by taking that the echo amplitude at the tenth horizontal grid on the display screen of the ultrasonic tester reaches or exceeds the longitudinal scale by 10% as benchmark, judging the bonding quality between the steel sheet with a resin coating and rubber according to the wave change on the screen of the ultrasonic tester; when no echo height exists at the tenth horizontal grid of the display screen of the ultrasonic tester or the echo height is lower than the longitudinal scale by 10%, judging the bonding between the steel sheet at the scanned position and the interface of the rubber to be good; and when the echo height at the tenth horizontal grid of the display screen reaches or exceeds the longitudinal scale by 10%, judging debonding, namely the steel sheet at the scanned position and the interface of the rubber are bonded badly. According to the method, the determination on the good bonding and debonding of an insulating layer can be realized through echo amplitude, and precise quantification can be conducted to the debonding area.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

Ut method of identifying a stuck joint

ActiveUS20100031750A1Quickly and easily identifyingAccurate identificationAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by using resonanceLight beamUltrasonic testing

An ultrasonic testing method to identify a stuck joint between two workpieces utilizing an ultrasonic probe to transmit ultrasonic (US) beams into the joint area and capture the associated US reflections. The method transmits two separate US beams fired in very close proximity to one another. The probe then captures a plurality of US reflections. The method looks for subtle variations in a high gain A-scan presentation of a high gain reflected beam, while using a low gain US beam to identify the particular region on the high gain A-scan presentation in which to look for signs of a stuck joint. Subtle variations within a particular region of the high gain A-scan presentation identify stuck joints. The method is applicable to metals and nonmetals and is not limited to fusion welding, but may also be used with solid state welds, brazed and soldered joints, and adhesively joined workpieces.

Owner:CUMBERLAND & WESTERN RESOURCES LLC

Integrated ultrasonic testing and cathodic protection measurement probe

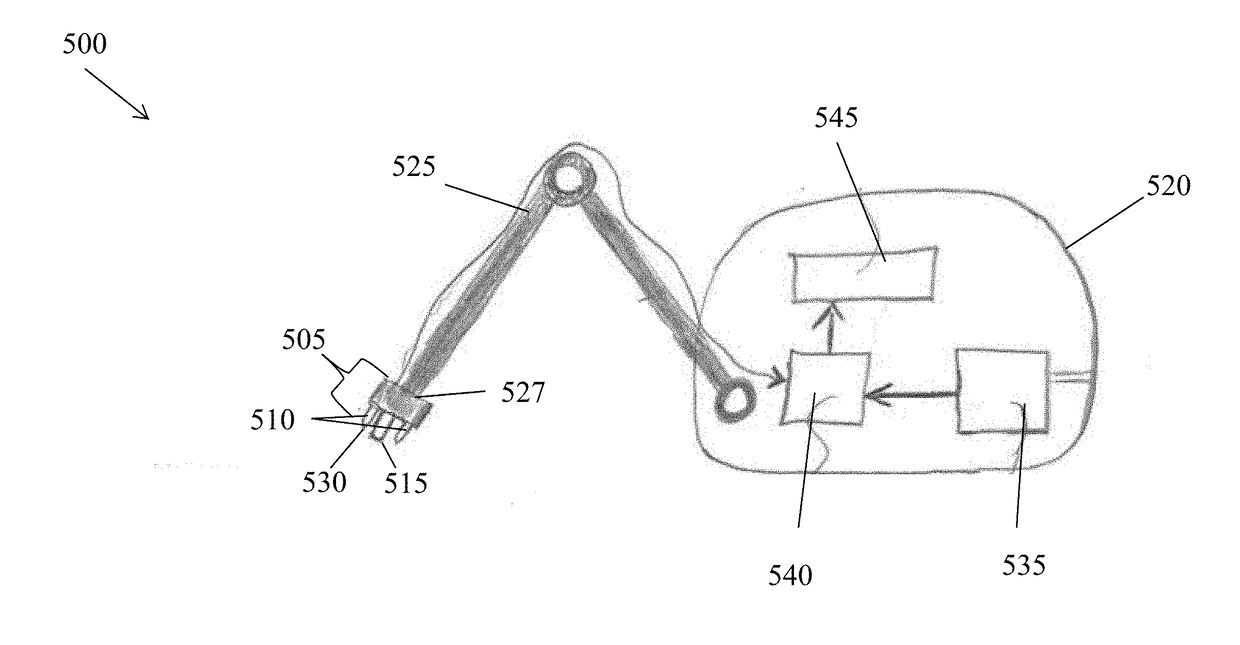

ActiveUS20180073975A1Material analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceRobotic armUltrasonic attenuation

This application discloses integrated probes and probe systems, which can be attached to the robotic arms of a remotely operated vehicle to perform both cathodic protection (CP) voltage measurements and ultrasonic testing (UT) thickness measurements at an underwater surface. In some embodiments, the integrated probe system couples an inner and outer gimbal together such that one or more electrically conductive legs pass from the outer gimbal through the inner gimbal. These legs are arranged about an ultrasonic sensor which extends from the front surface of the inner gimbal. When the integrated probe contacts the underwater surface, both the ultrasonic sensor and at least one leg contact the surface, thereby providing substantially simultaneous CP and UT measurements.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com