Patents

Literature

361 results about "Refraction angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

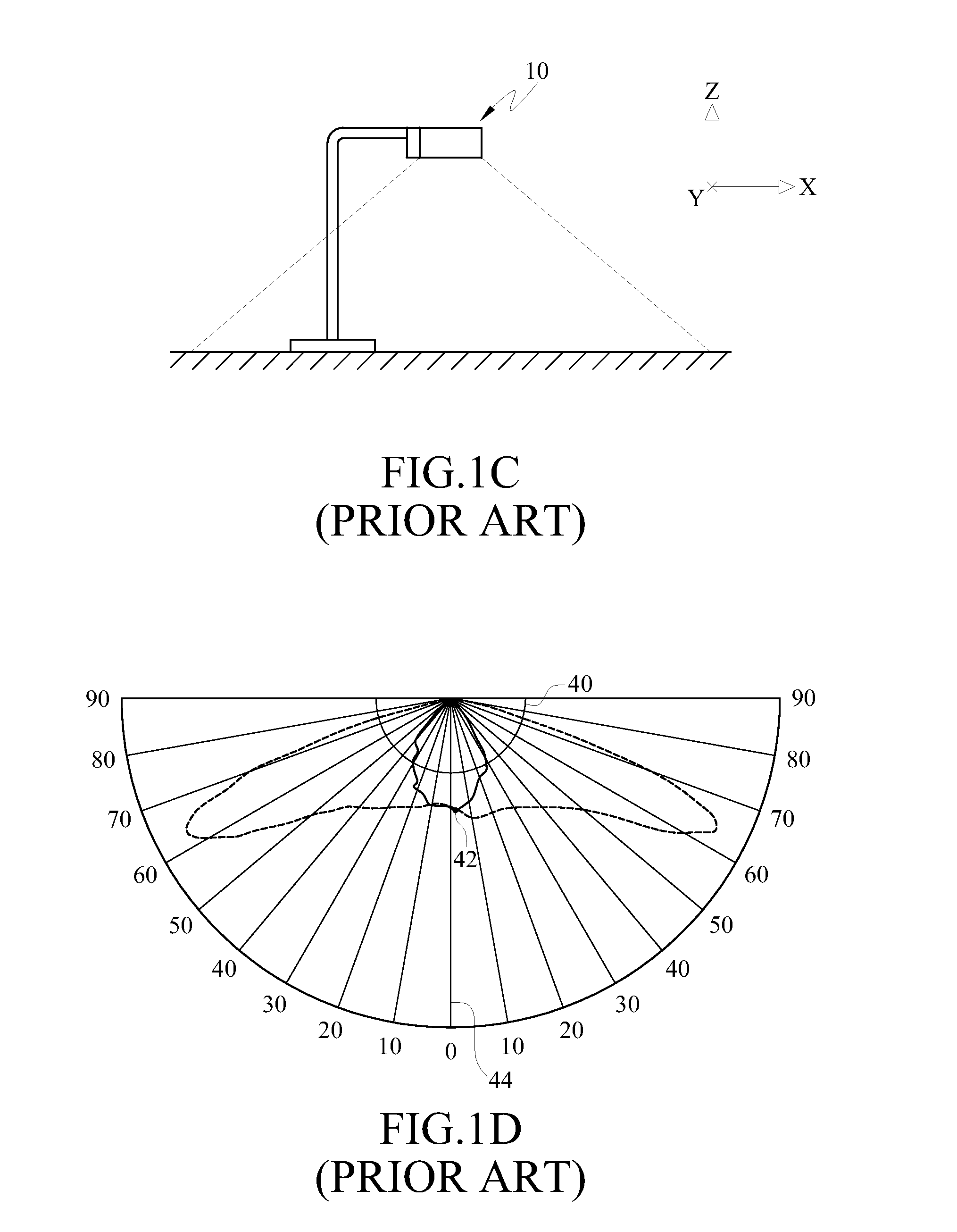

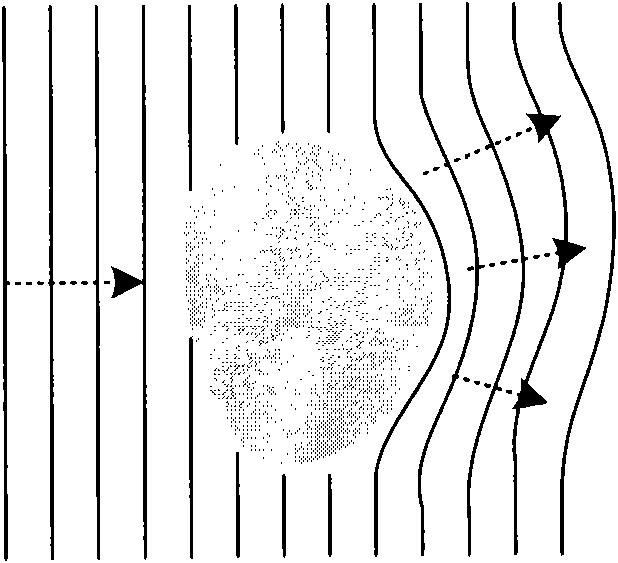

The angle of incidence in the water is approximately 39°. At this angle, the light refracts out of the water into the surrounding air bending away from the normal. The angle of refraction in the air is approximately 57°. These values for the angle of incidence and refraction are consistent with Snell's Law.

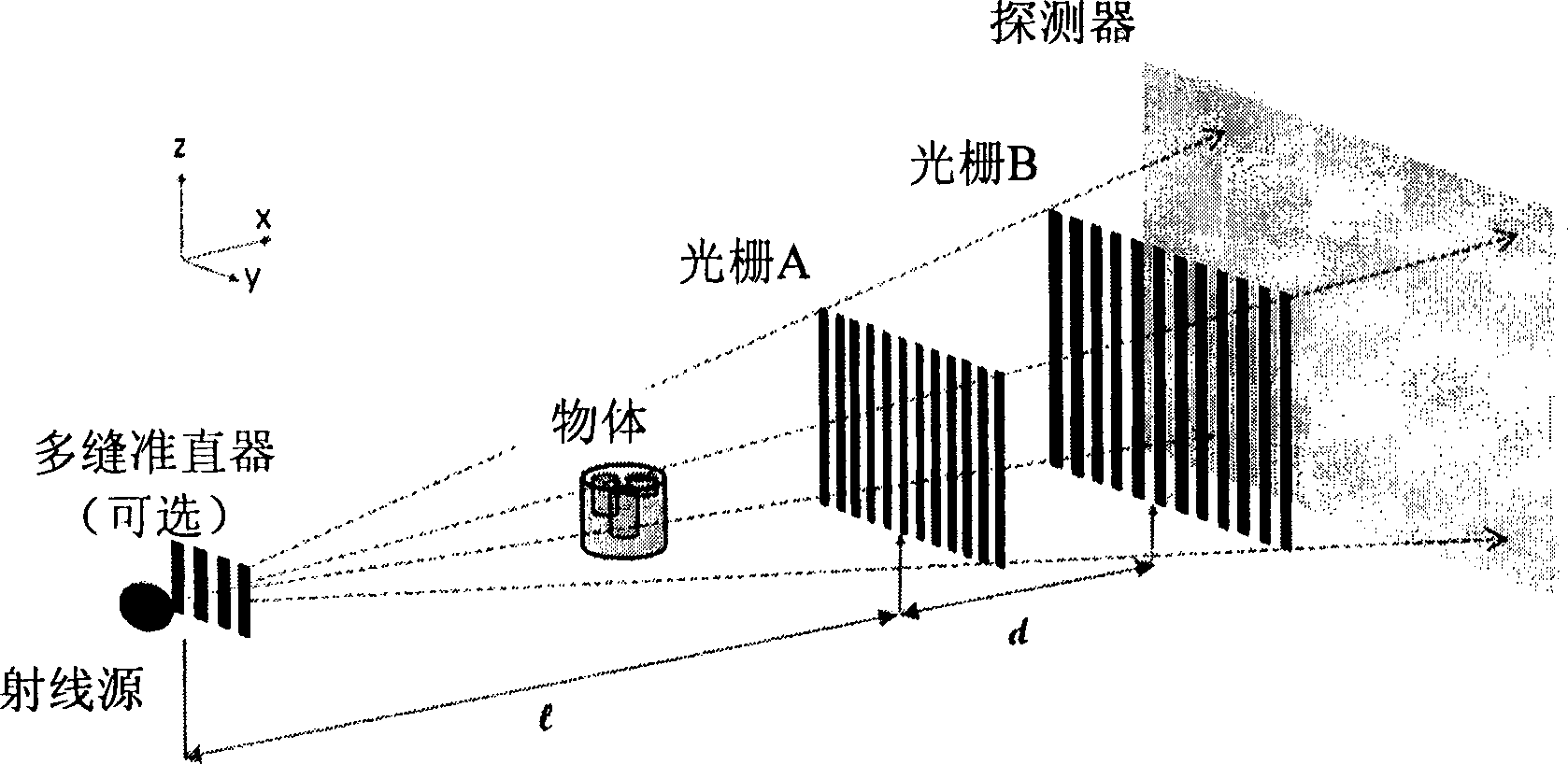

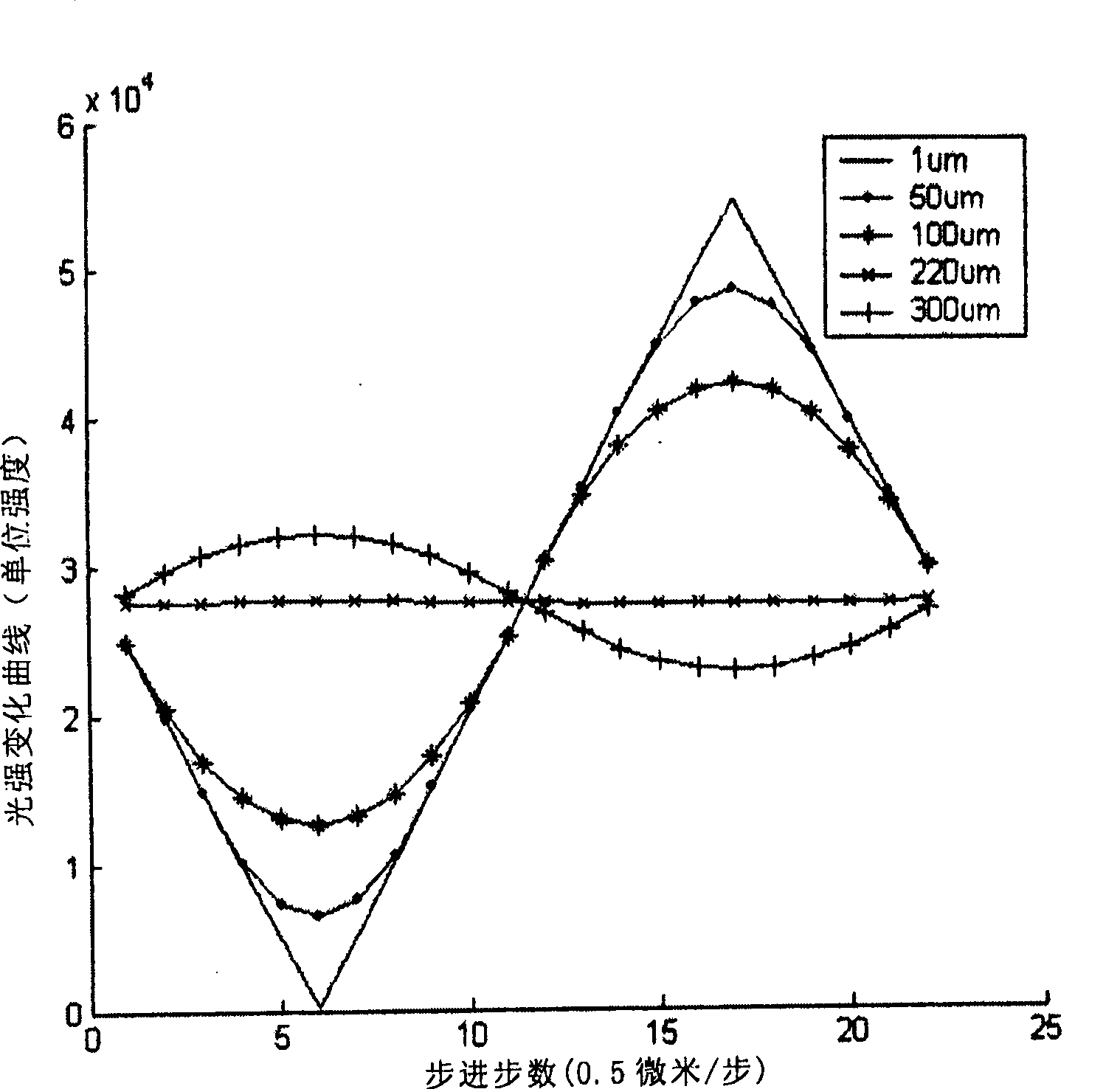

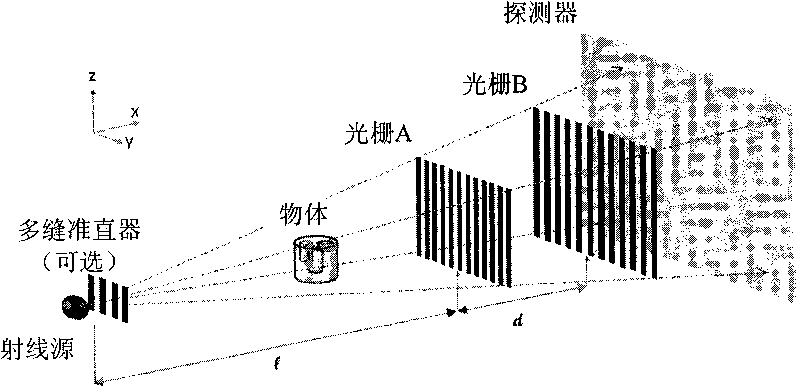

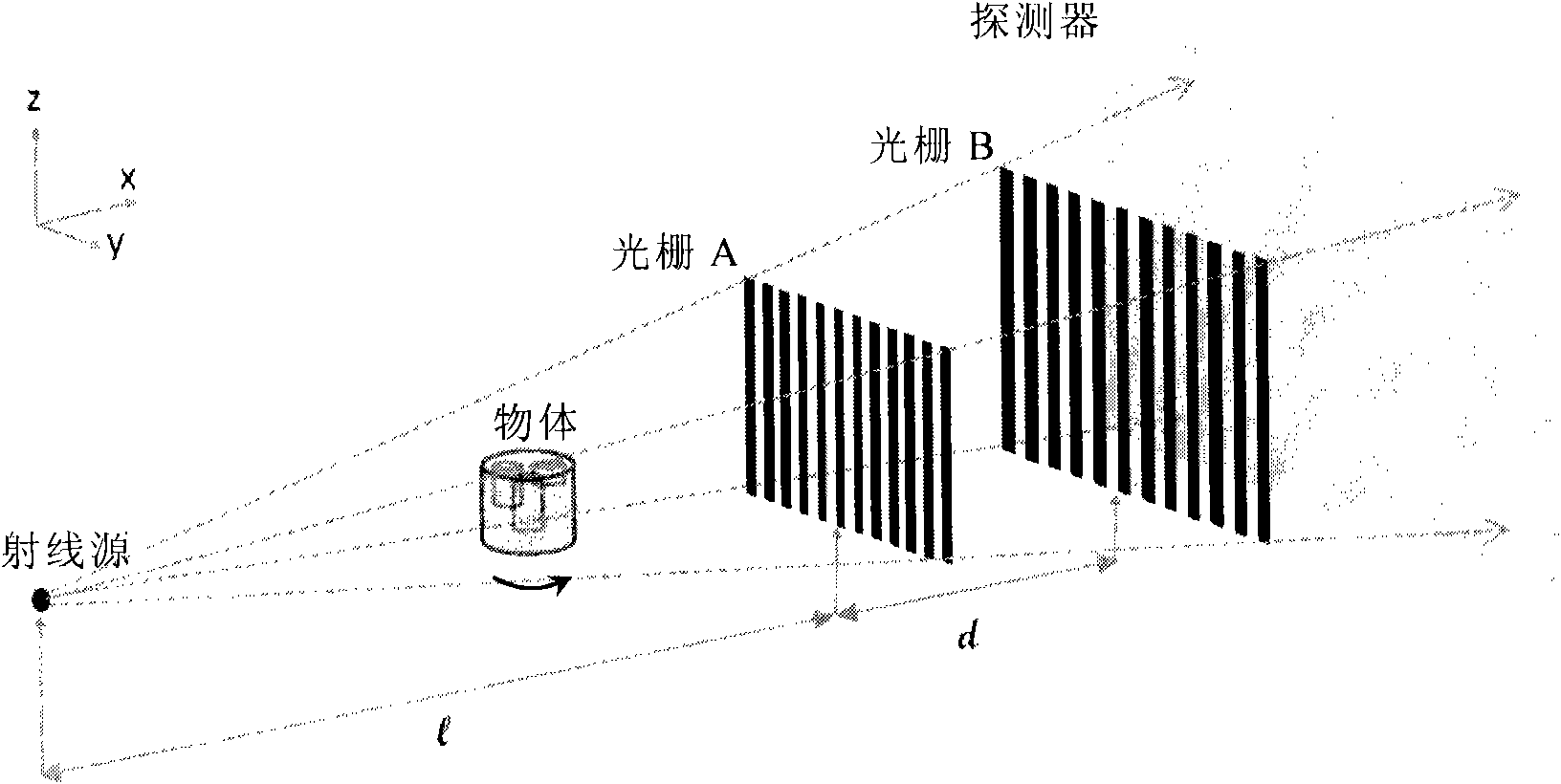

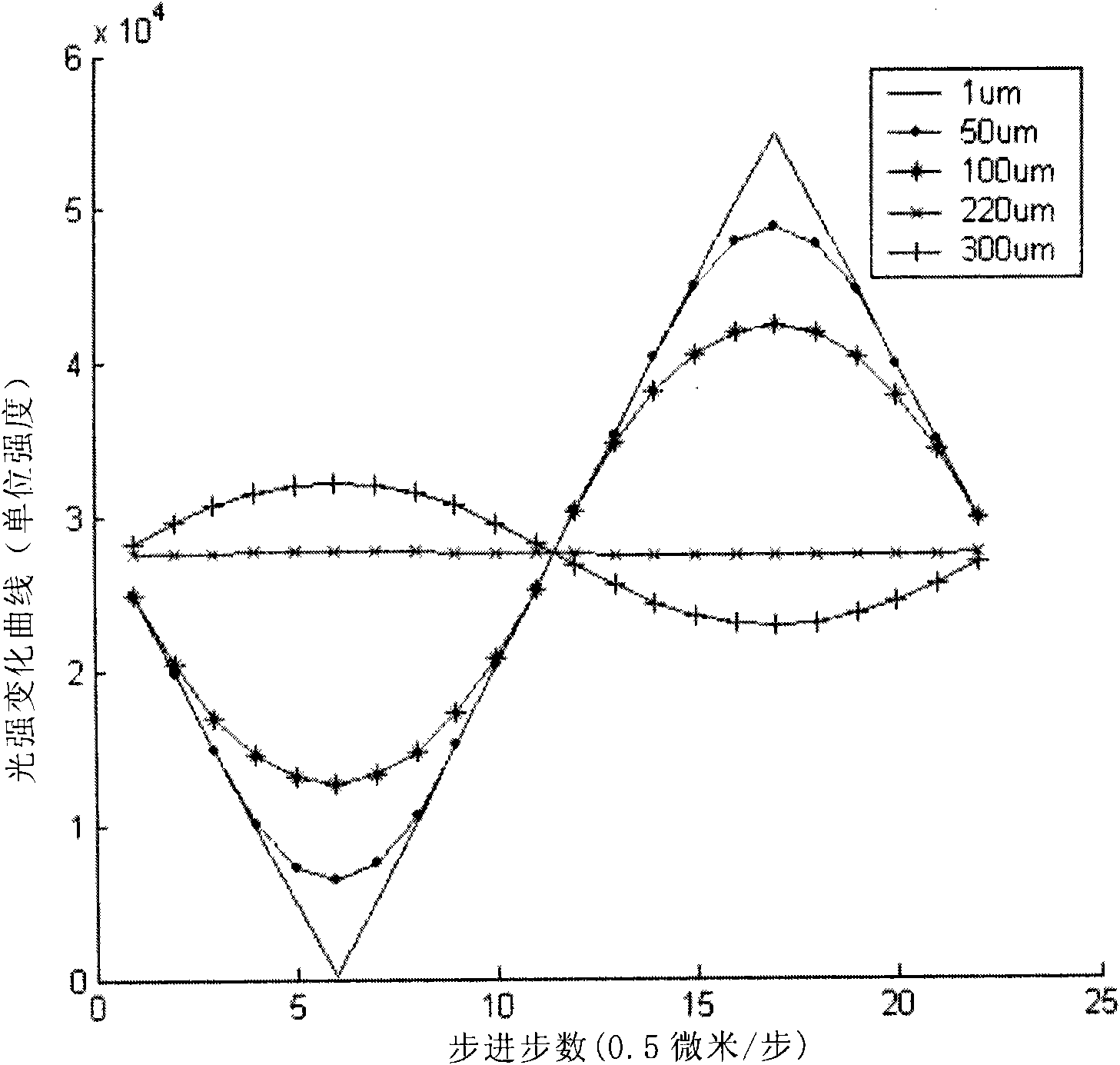

System and method for phase-contrast imaging by use of X-ray gratings

ActiveCN101532969AReduce production difficulty requirementsLower application thresholdComputerised tomographsTomographyGratingRefractive index

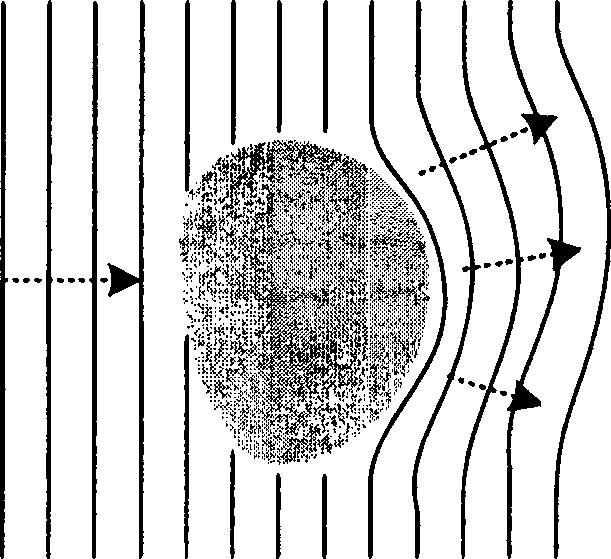

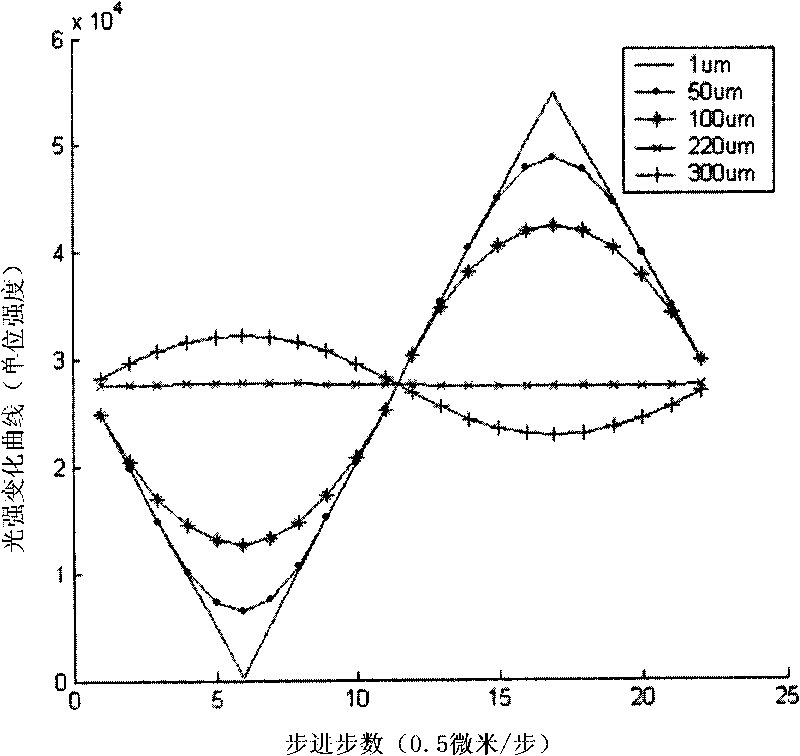

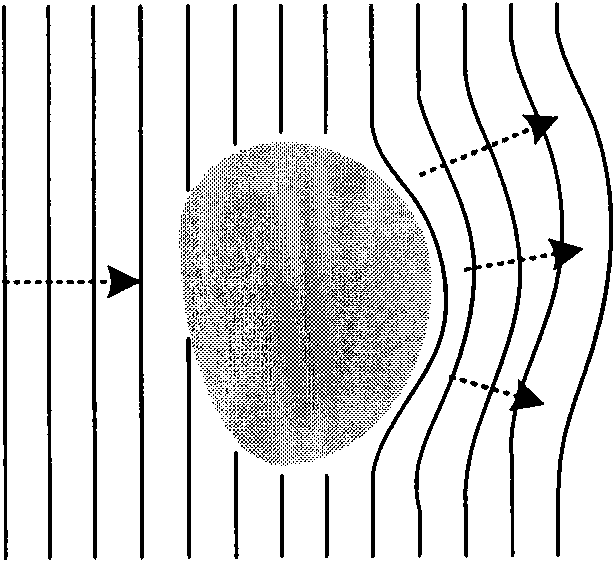

The application relates to a system and a method for the phase-contrast imaging by use of X-ray gratings. The system comprises an X-ray device, a first absorption grating, a second absorption grating, a detection unit, a data processing unit and an imaging unit, wherein the X-ray device transmits an X-ray bundle to a detected object; the first and second absorption gratings are positioned in the direction of the X-ray bundle; the X-ray refracted by the detected object forms an X-ray signal with variable intensity through the first absorption grating and / or the second absorption grating; the detection unit receives and converts the X-ray with variable intensity into an electrical signal; the data processing unit processes and extracts refraction-angle information in the electrical signal, and utilizes the refraction-angle information to figure out pixel information; and the imaging unit constructs images of the object. In addition, the system and the method can also realize CT imaging by using a rotating structure to rotate the object so as to obtain refraction angles in a plurality of projection directions and the corresponding images, and use CT reconstruction algorithm to figureout refraction-index fault images of the detected object. According to the invention, the phase-contrast imaging of approximate decimeter-magnitude viewing fields under incoherent conditions can be realized by use of common X-ray machines or multi-seam collimator such as source gratings, as well as two absorption gratings.

Owner:NUCTECH CO LTD +1

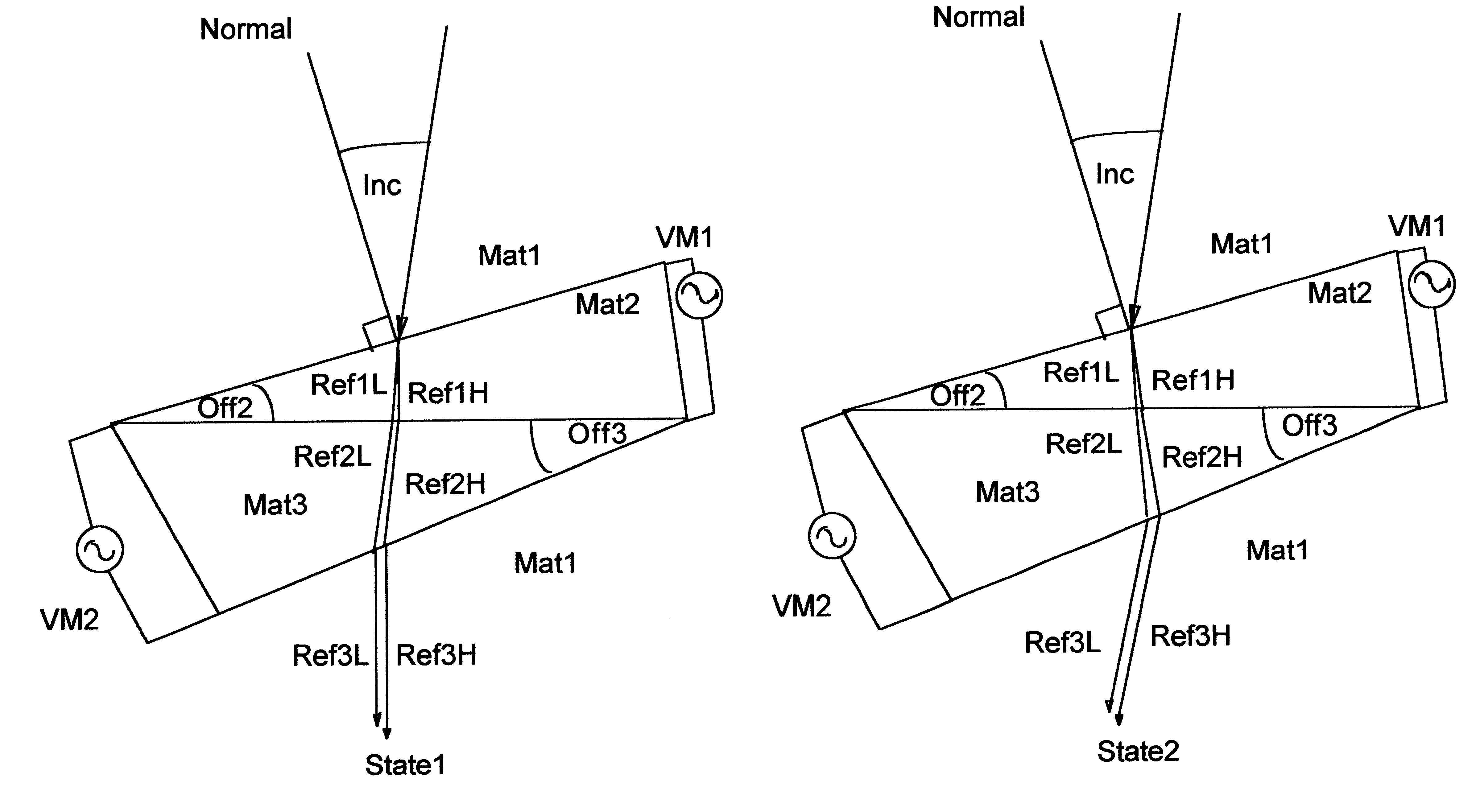

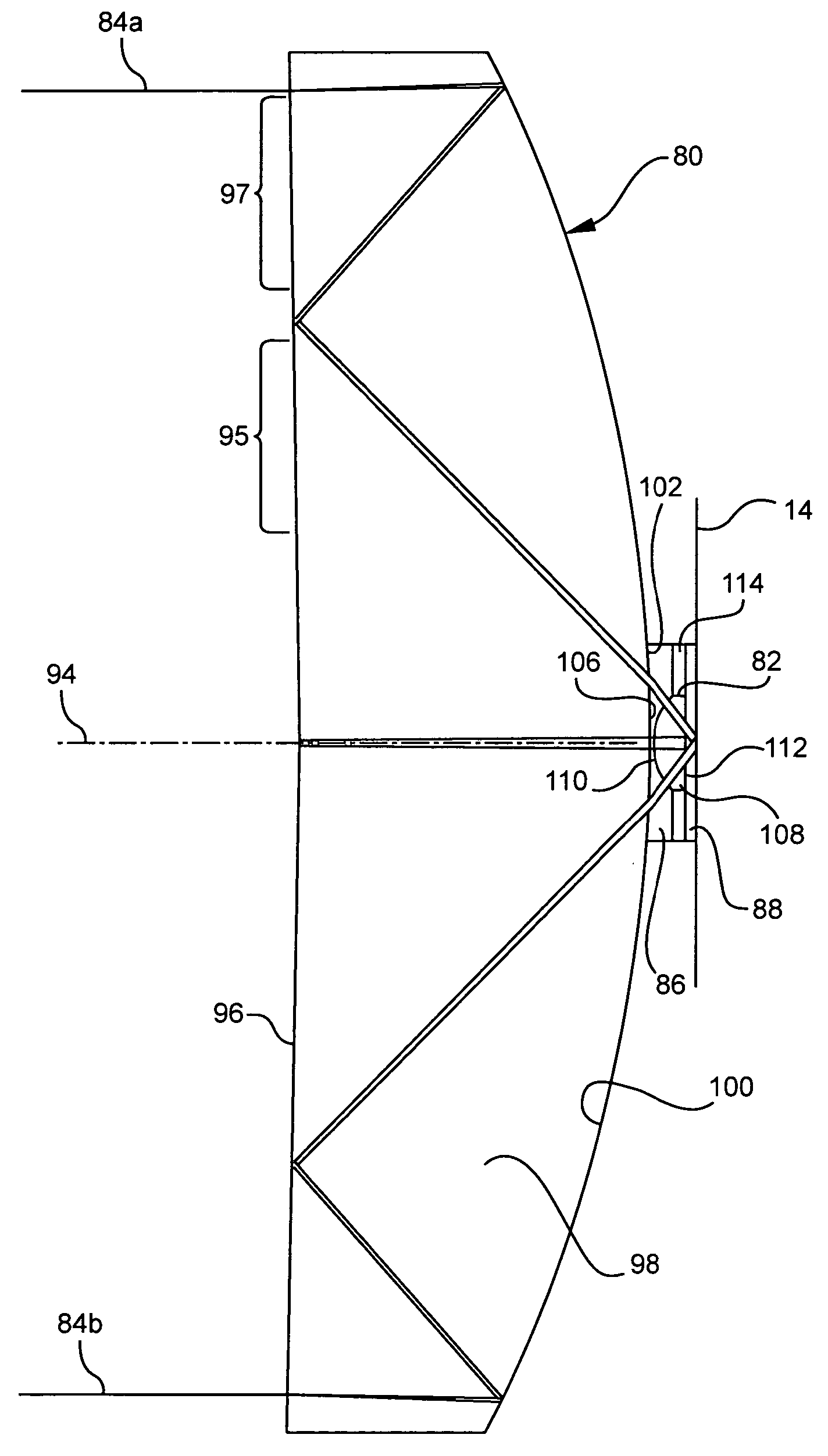

Electro-optic apparatus and process for multi-frequency variable refraction with minimized dispersion

InactiveUS6396622B1Minimal dispersionMinimizing dispersionStatic indicating devicesNon-linear opticsLight beamClassical mechanics

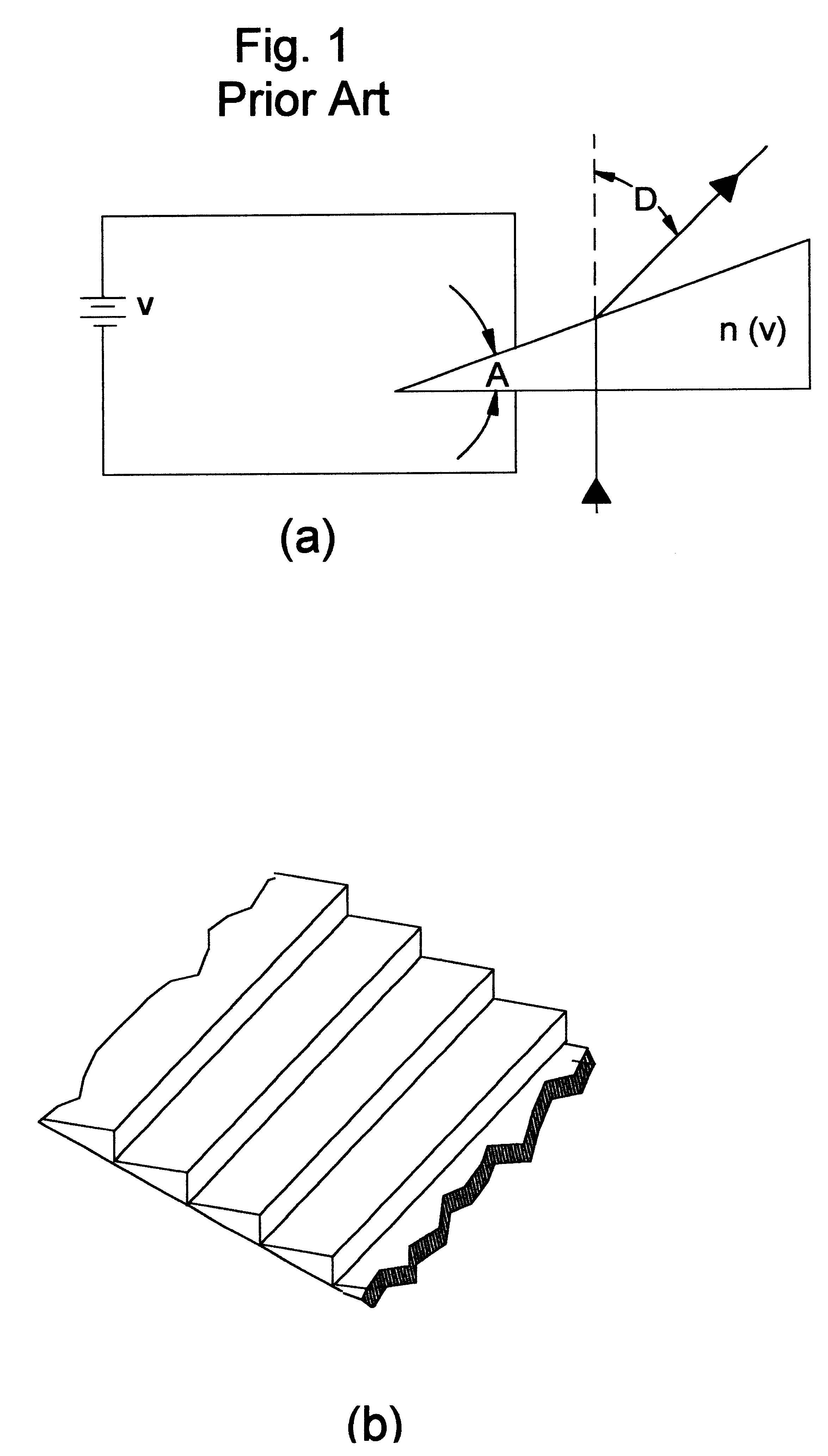

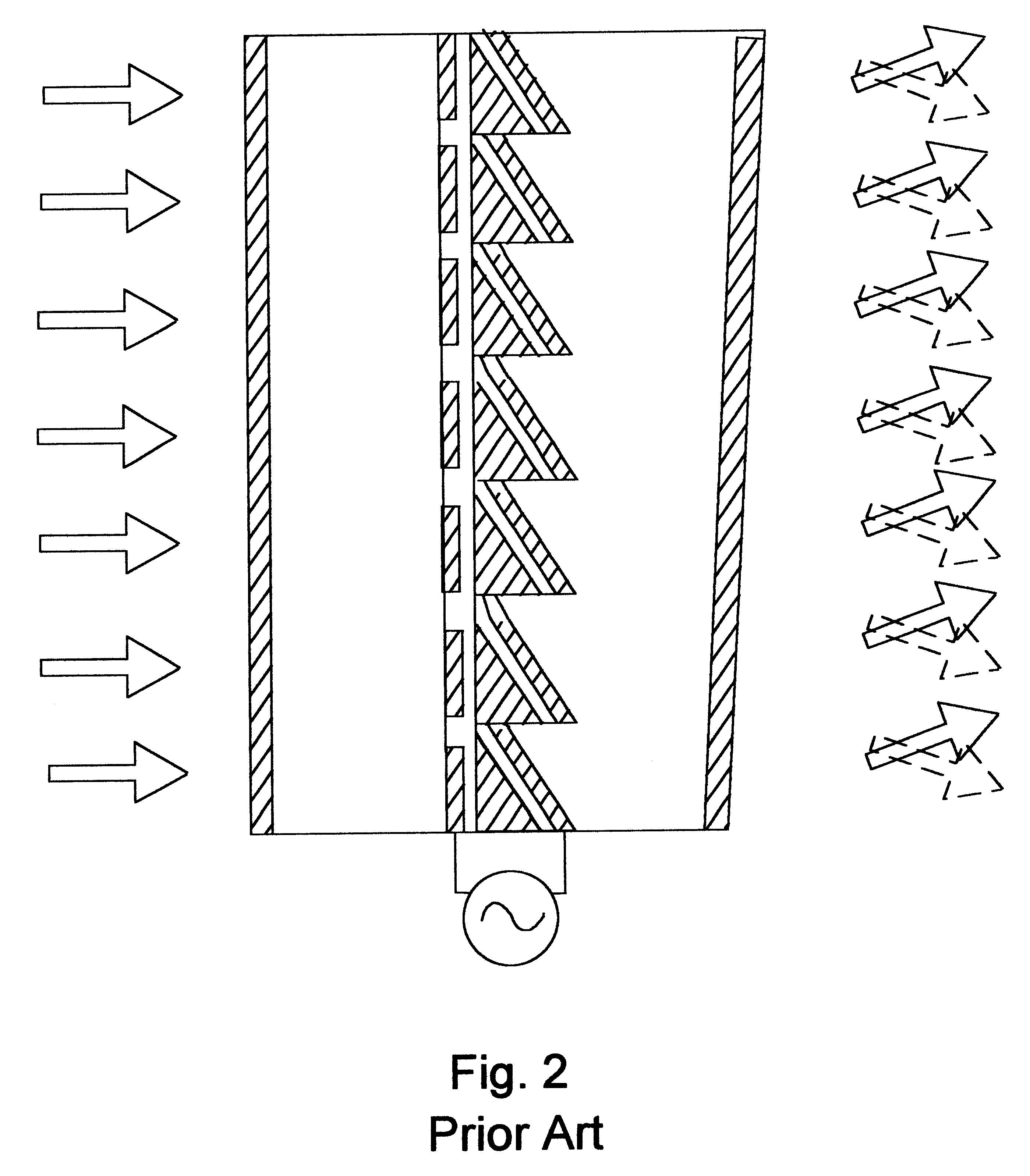

The object of the prevent invention is to provide an optical system for producing variable refraction with minimized dispersion. A first material with a first apex angle in a first state and a second material with a second apex angle in a first state produce a first net refraction angle in at least two frequencies of electromagnetic radiation such that the beams that entered parallel exit parallel (to within a controllable tolerance). Said first material with said first apex angle in a second state and said second material with said second apex angle in a second state produce a second net refraction angle in at least two frequencies of electromagnetic radiation such that the beams that entered parallel exit parallel (to within a controllable tolerance).

Owner:ALDEN RAY M

Optical lens and optical lens plate

InactiveUS20120307495A1Improve light utilizationLow utilization of lightPlanar light sourcesNon-electric lightingCamera lensRefraction angle

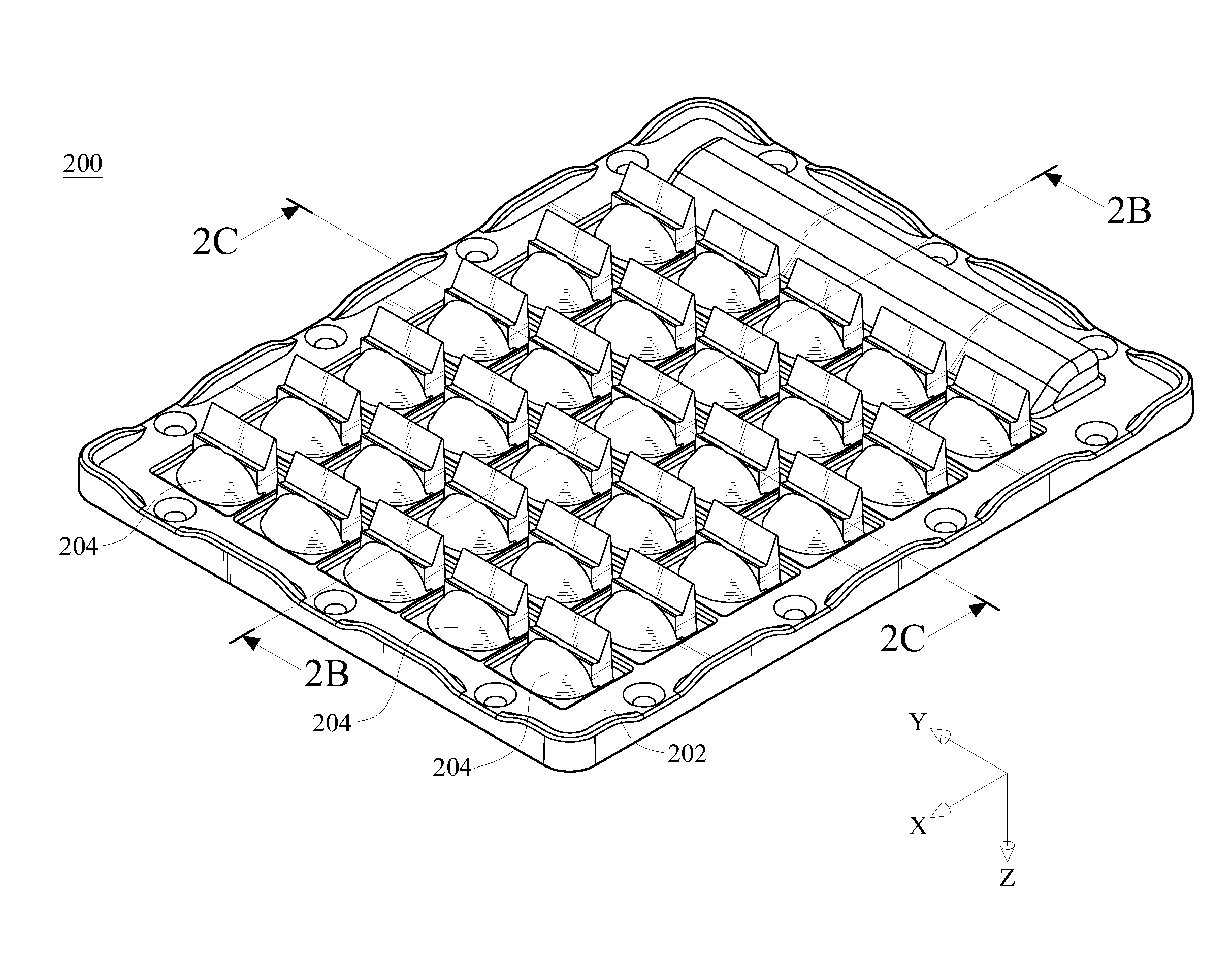

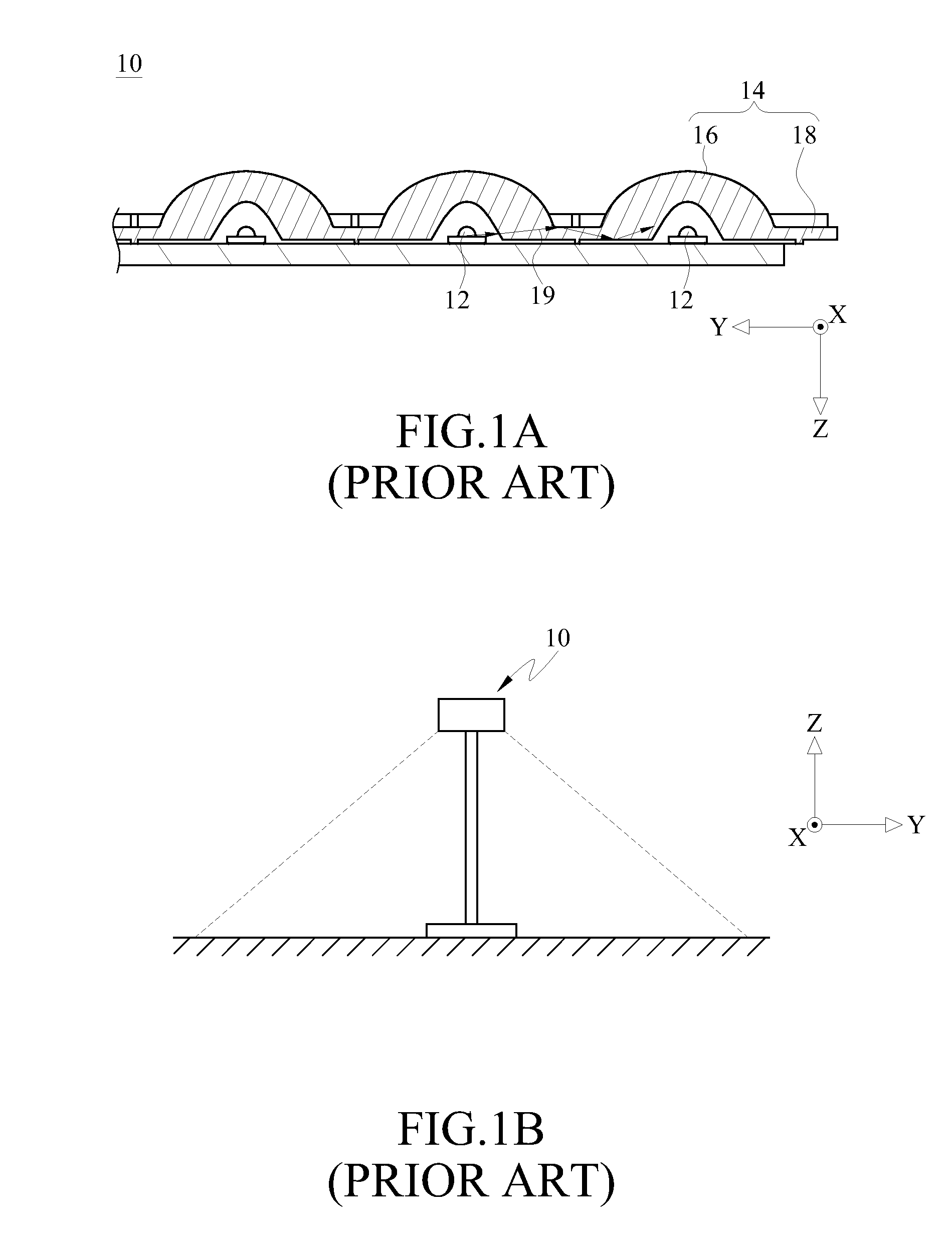

An optical lens includes a incident curved surface, a cone-shaped body, and a emitting curved surface. Light emitted from a light emitting diode (LED) has a first refraction angle on a first plane and a second refraction angle on a second plane after passing through the incident curved surface, the cone-shaped body, and the emitting curved surface. The first refraction angle is between 105 degrees and 145 degrees, and the second refraction angle is between 38 degrees and 65 degrees. The light is asymmetrically distributed on the second plane. Therefore, when the optical lens is applied to a street lamp, the light utilization on a road side may be increased.

Owner:LEOTEK ELECTRONICS

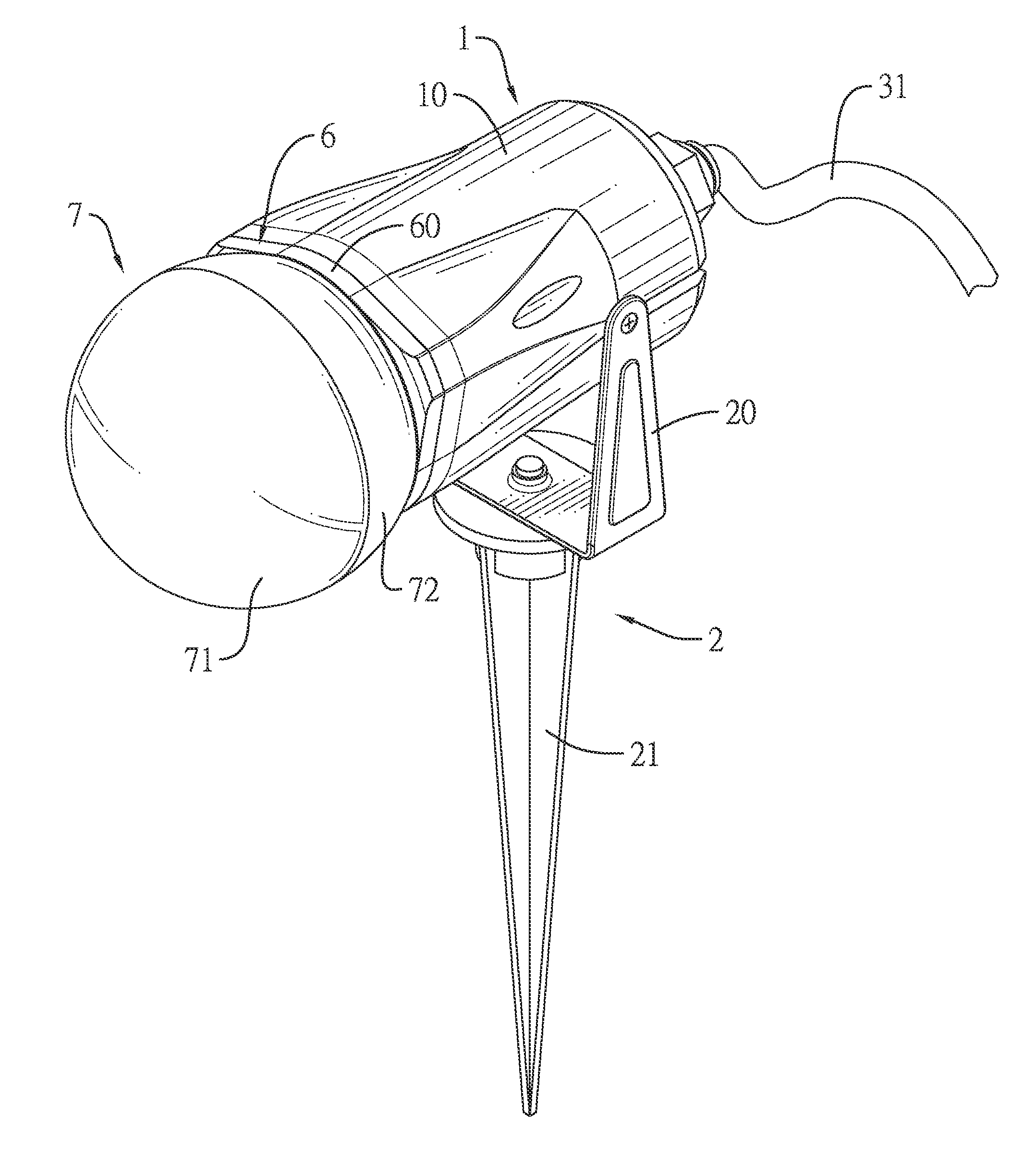

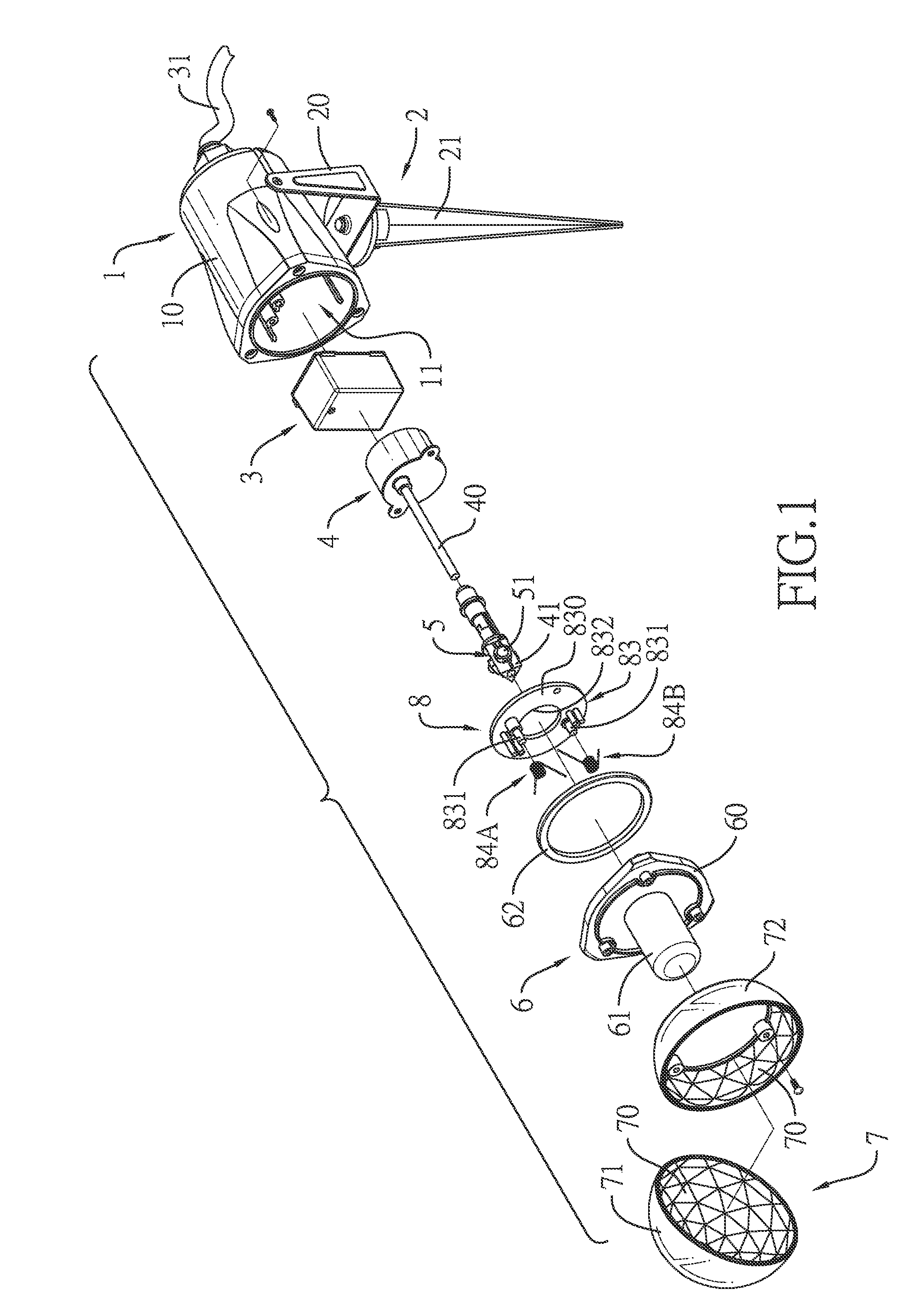

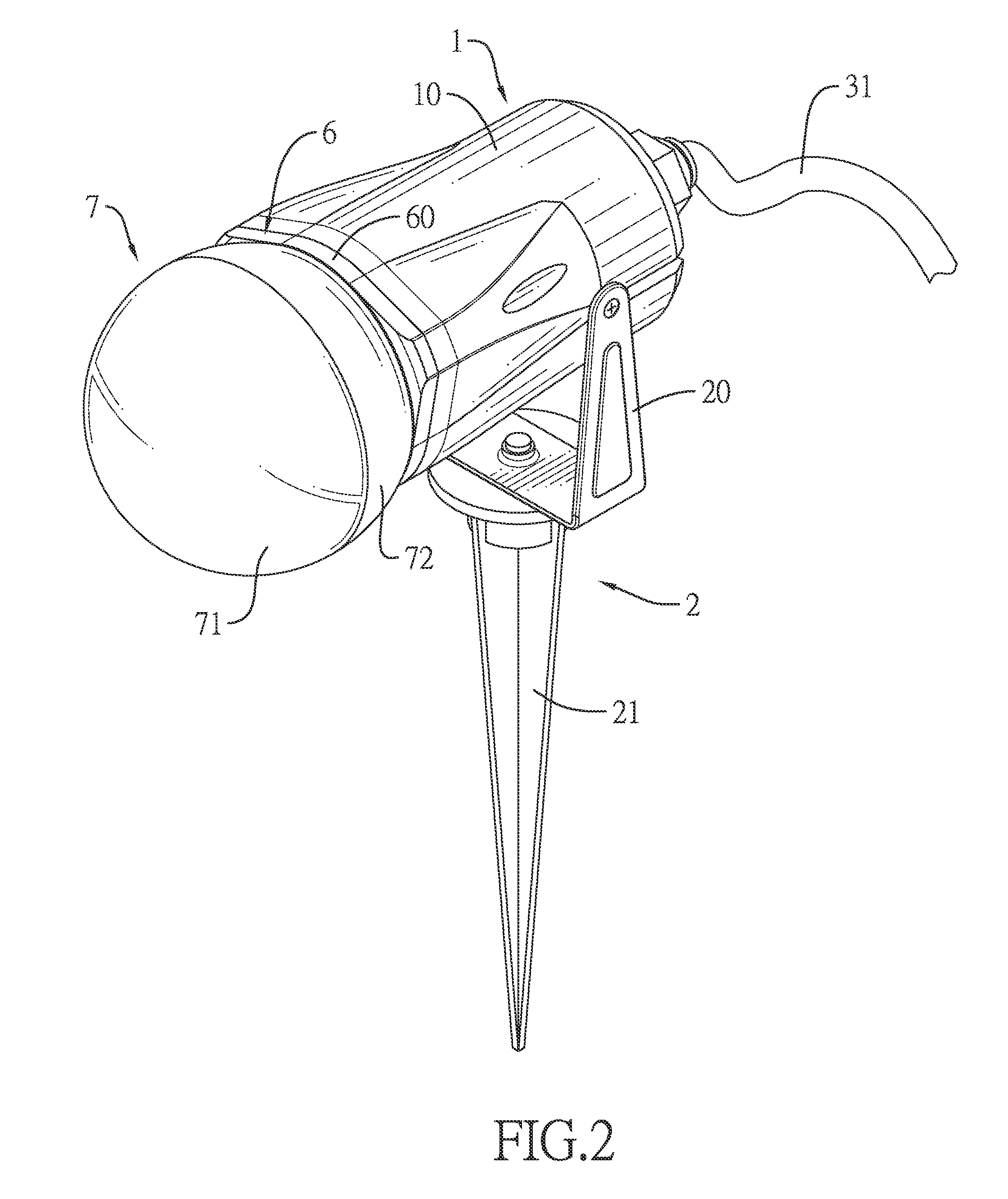

Rotary projector light

A rotary projector light can include a lamp case defining a hollow mounting chamber and having an open front end; a power supply located inside the lamp case, the power supply connected to a power cable adapted to connect to an external power source; a motor located inside the lamp case, the motor electrically connected to the power supply and having a spindle; a positioning seat mounted on the spindle; a plurality of light emitting diode (LED) elements located on the positioning seat, the LED elements electrically connected to the power supply; and a beam-splitting lens cover located on the open front end of the lamp case. The beam-splitting lens cover can have an inner surface with multiple convex lenses directed at multiple refraction angles.

Owner:GEMMY IND CORP

Robust Stereo Calibration System and Method for Accurate Digital Image Correlation Measurements

ActiveUS20100079598A1Maintain accuracyConvenient and accurateUsing optical meansTelevision systemsExplicit modelObject point

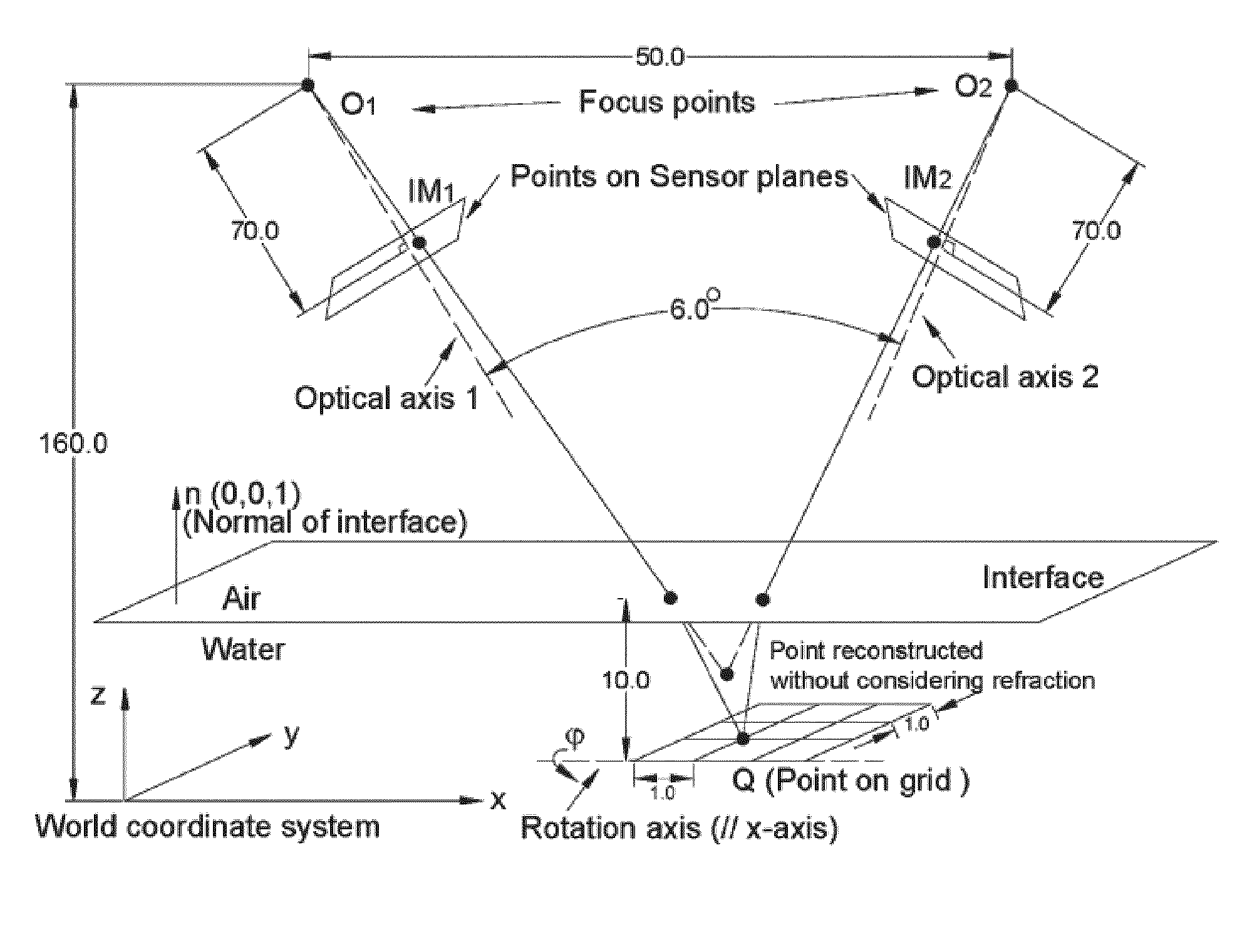

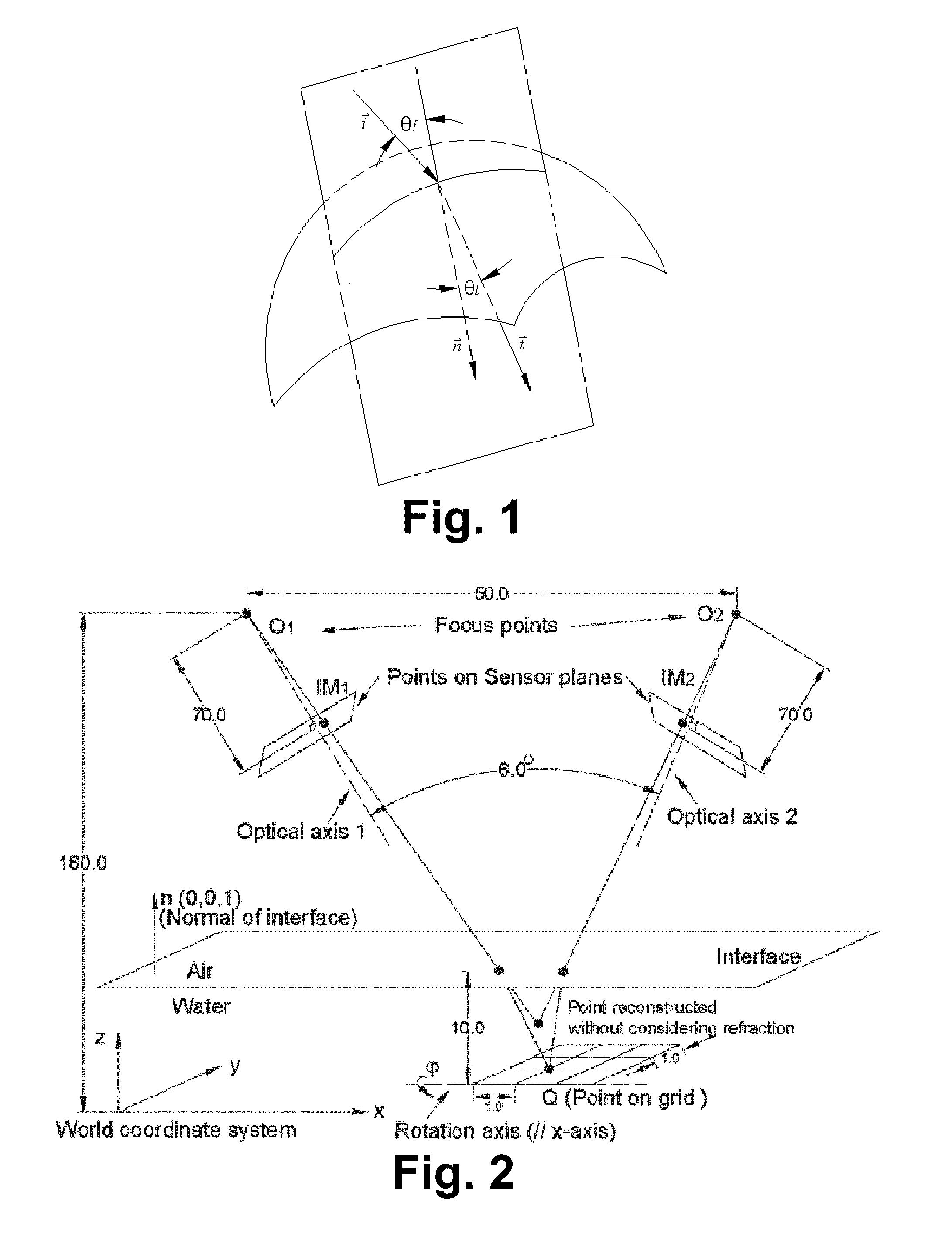

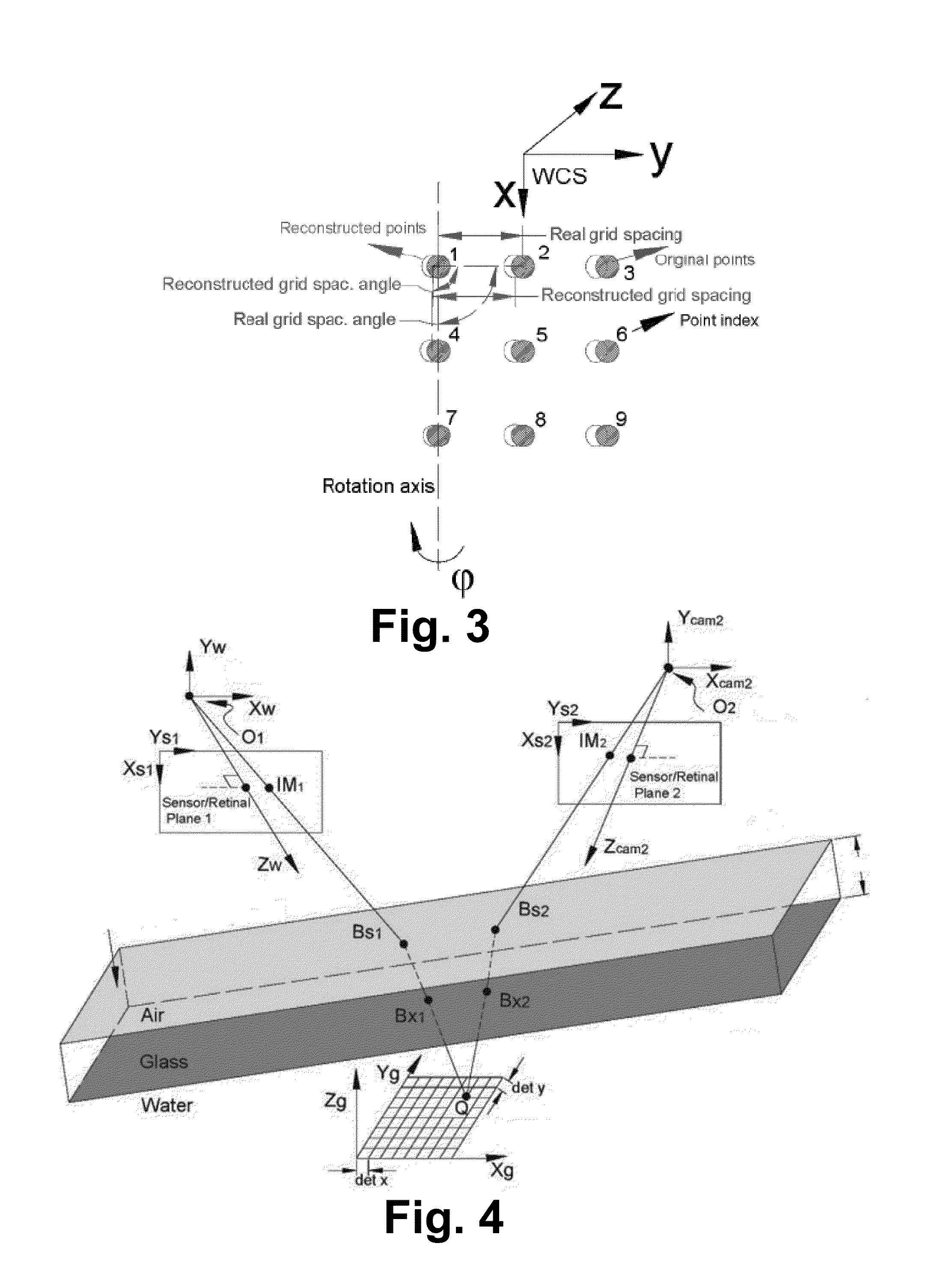

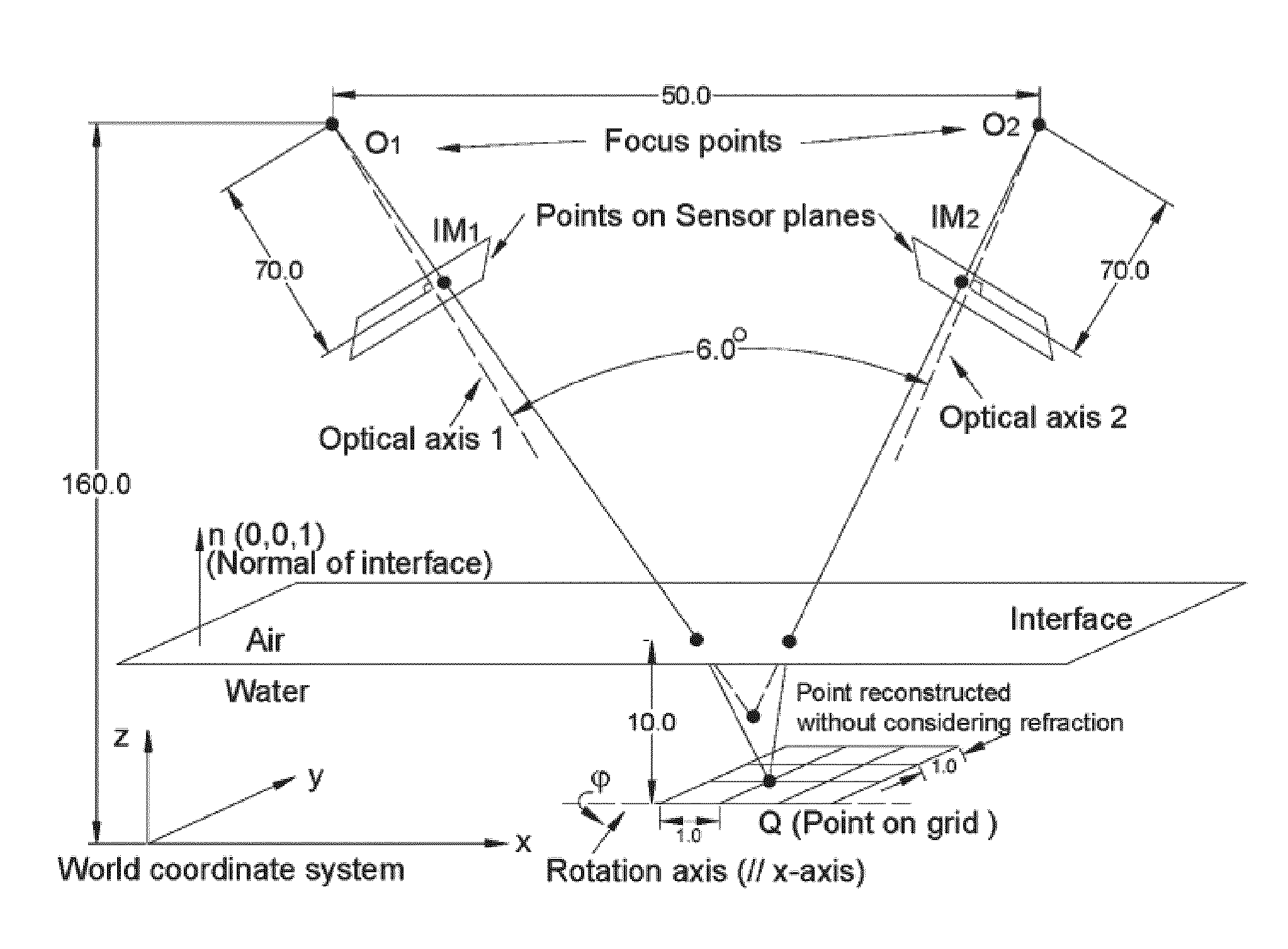

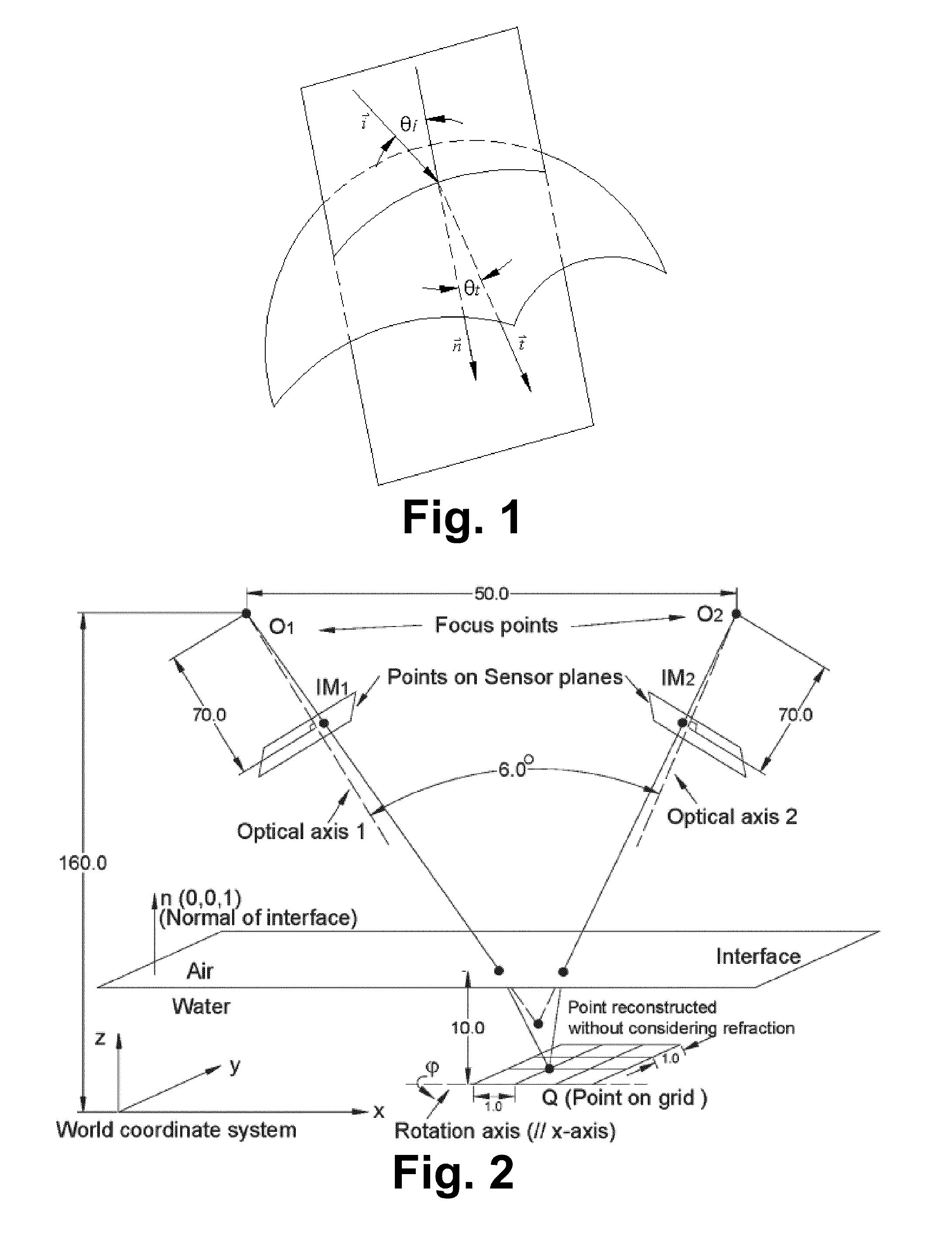

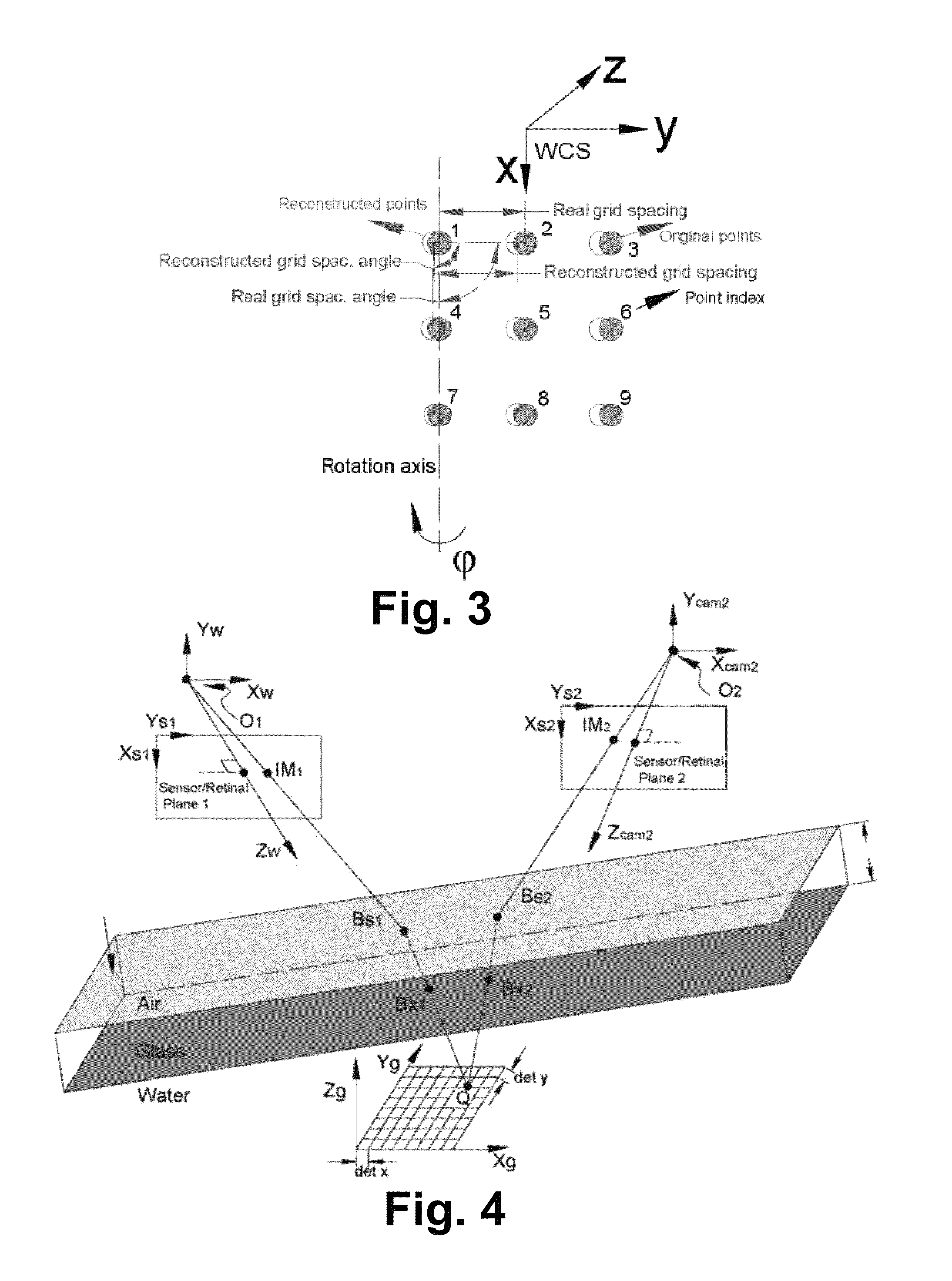

A stereo calibration method is proposed to calibrate an interface's shape and position when the measurement system is in one media and measures deformation and strain of an object that is submerged in a different media. After the interface's shape and position are modeled by parameters, an explicit model of object points as measurement is established taking account of refraction happening at the interface. Efficiency and convergence are assured by using measurement of object points to acquire initial estimates for refraction angles at the interface. Then, an optimization method is performed to get the optimized value of interface parameters. Last, based on the resulting interface parameters, 3-dimensional positions of object points in all the subsequent measurement could be reconstructed accurately. Therefore, the distortion induced by refraction in the measurement is corrected. Numerical simulations of the proposed calibration process confirm that it is both robust and accurate for a range of experimental conditions, even in the presence of Gaussian noise in the measurement.

Owner:UNIVERSITY OF SOUTH CAROLINA

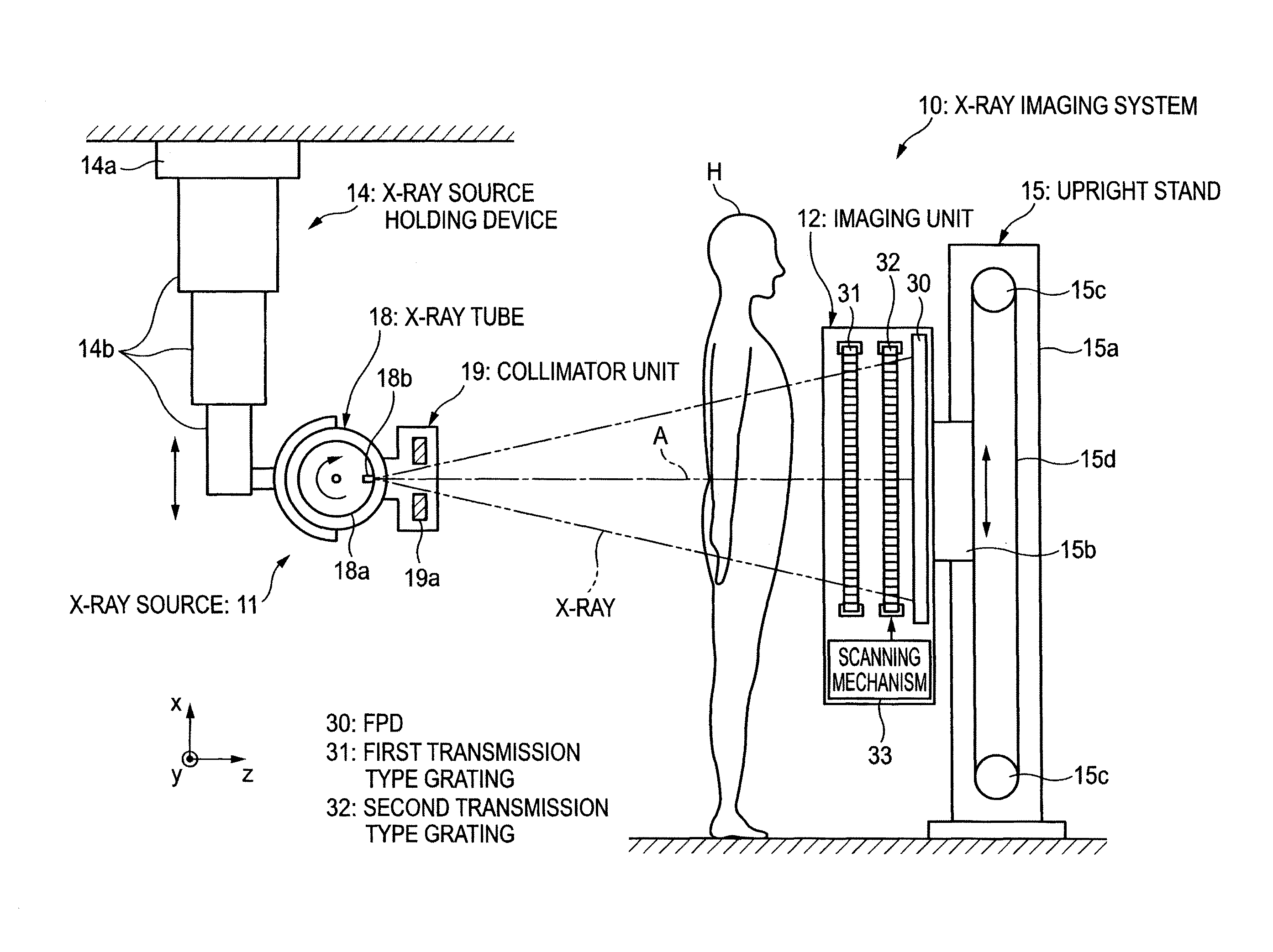

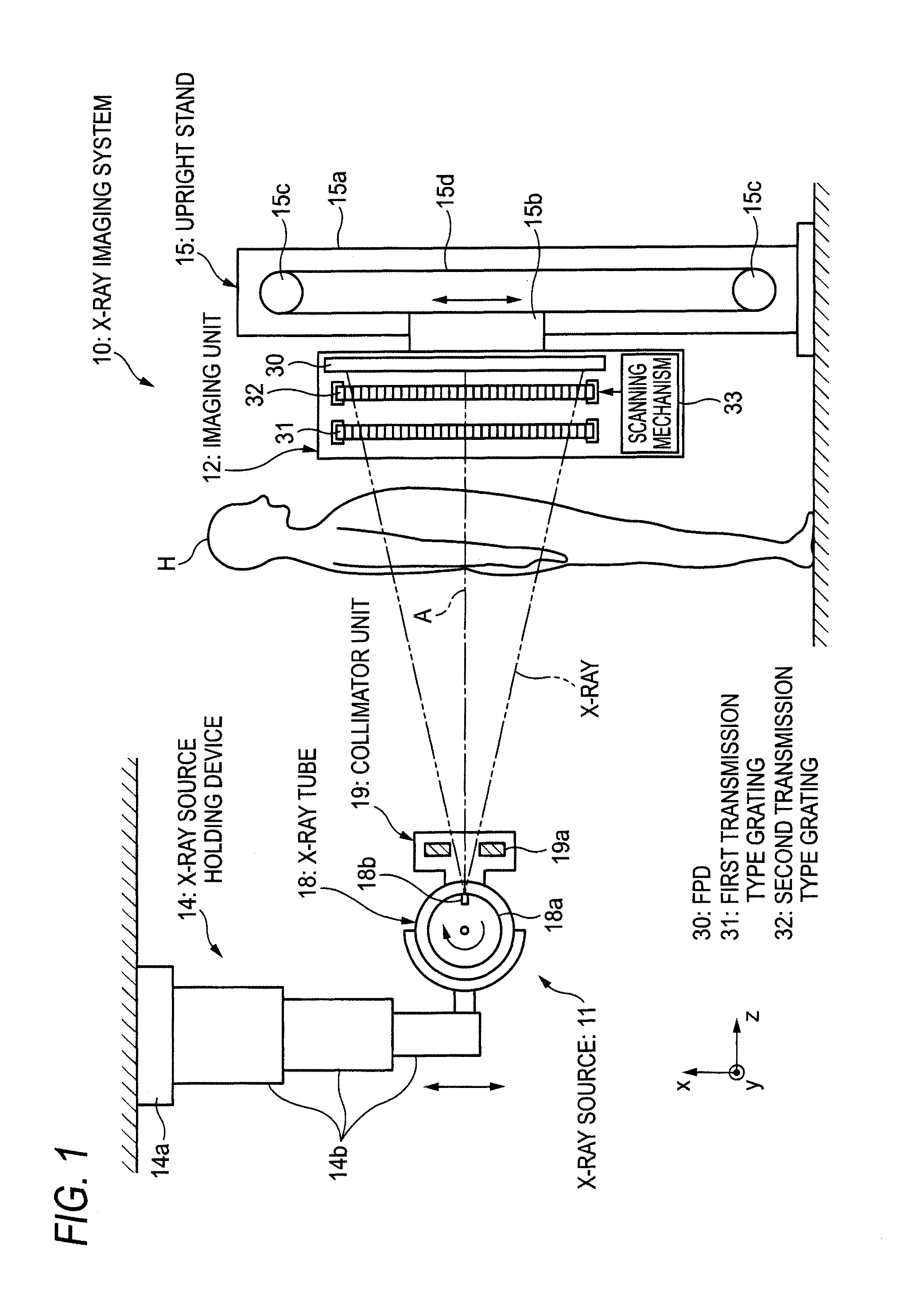

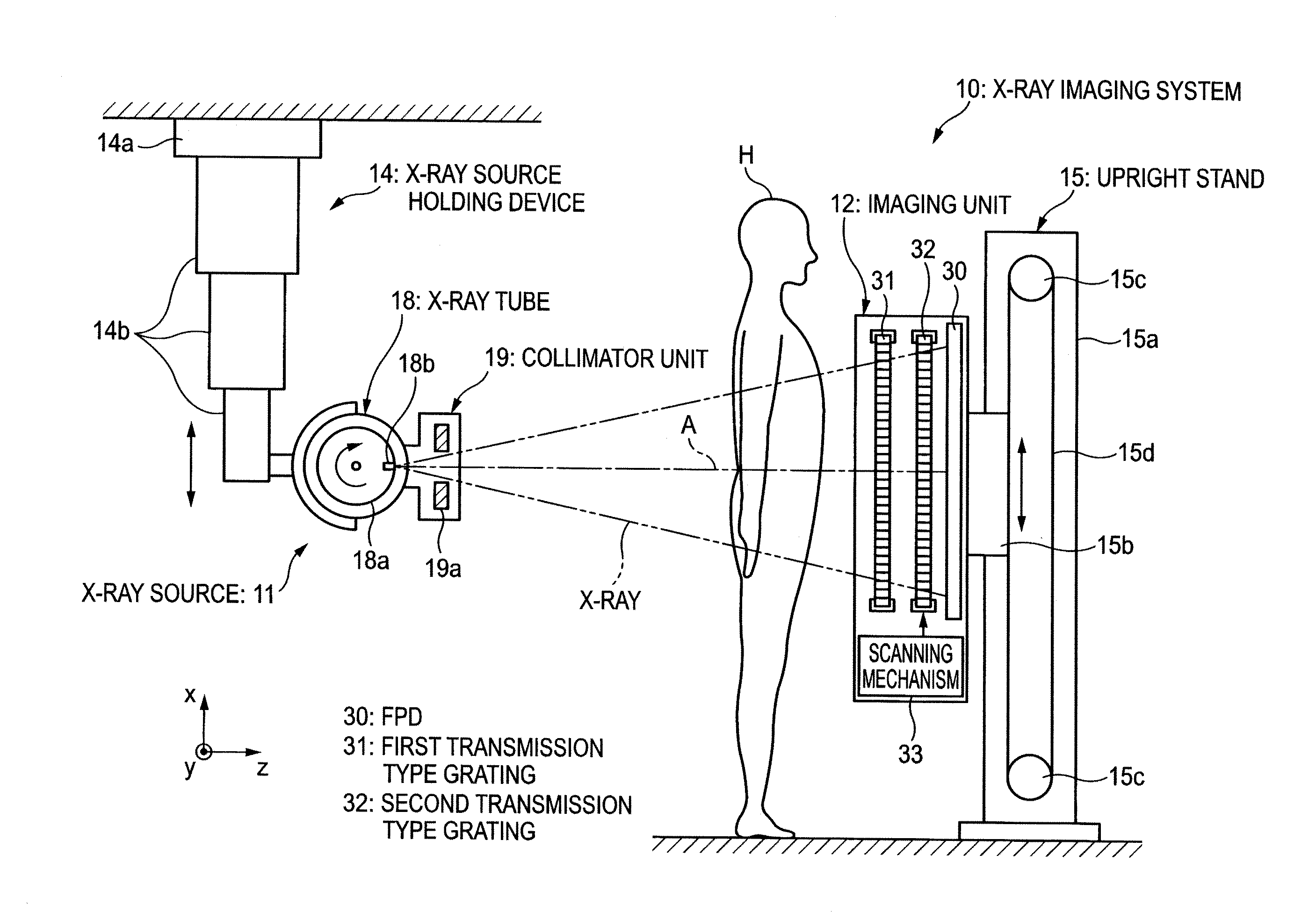

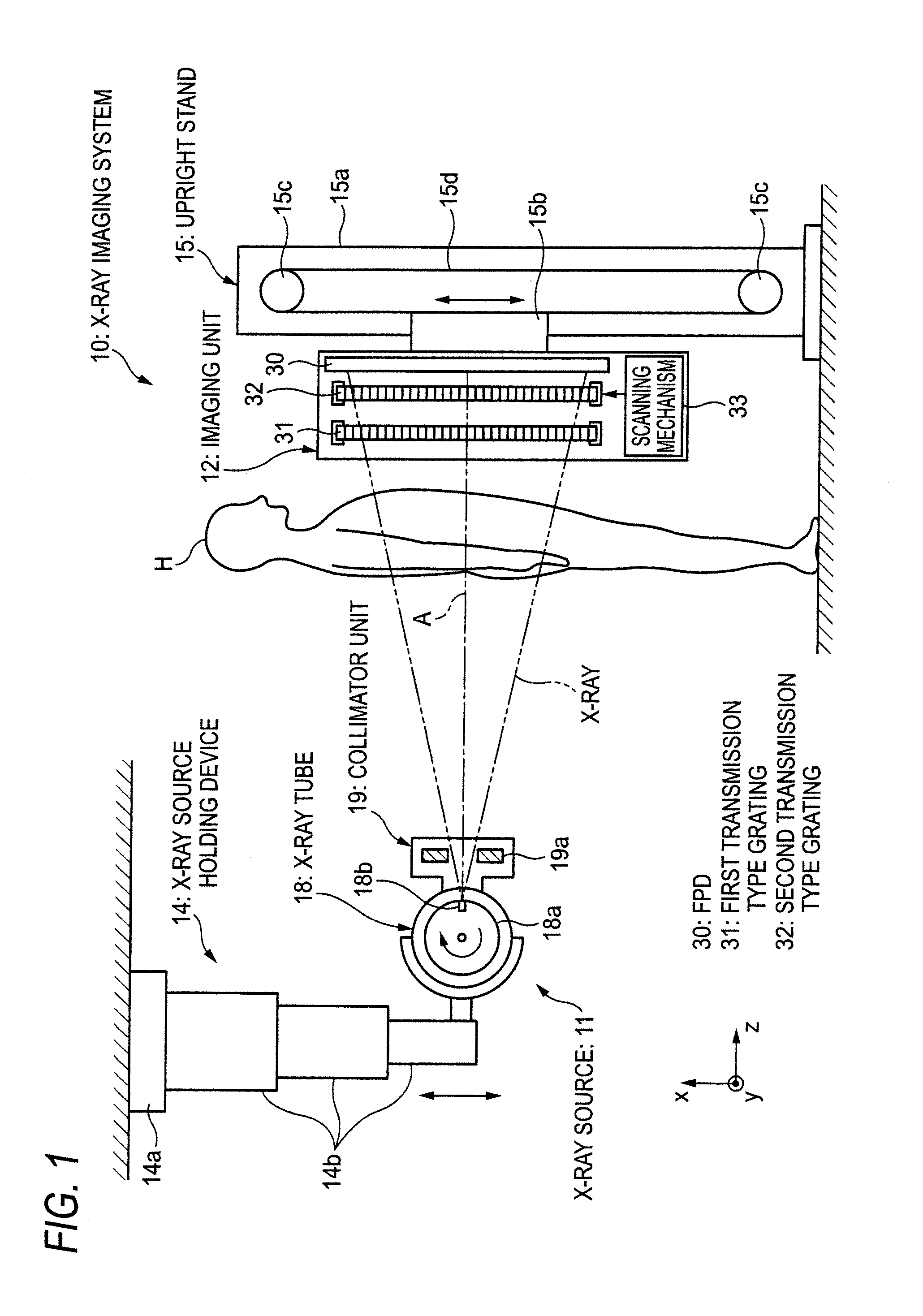

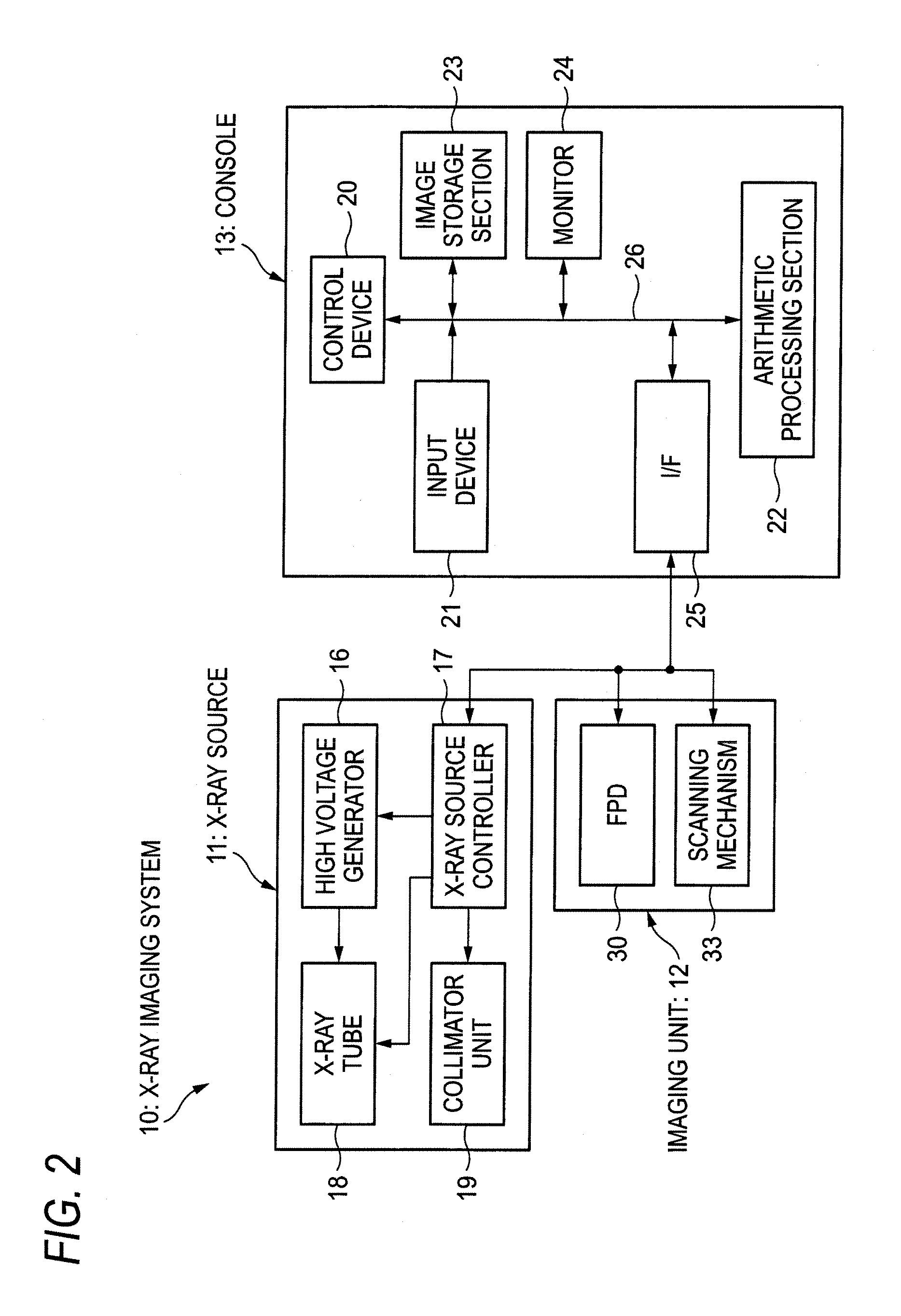

Radiographic system, radiographic method and computer readable medium

InactiveUS8451975B2High precisionEasy to correctMaterial analysis by transmitting radiationRadiation diagnosticsRefraction angleRadiography

A radiographic system which detects a radiation image transmitted through a subject with a radiation image detector and generates a phase contrast image of the subject, includes: a calculation section that calculates a distribution of refraction angles of radiation incident on the radiation image detector and generates the phase contrast image on the basis of the distribution of refraction angles; and a storage section that stores a correction coefficient of each pixel for making sensitivities of pixels equal. The calculation section performs sensitivity correction on a refraction angle of radiation incident on each pixel of the radiation image detector, which is calculated by imaging the subject, using the correction coefficient of the pixel stored in the storage section and generates the phase contrast image of the subject on the basis of the distribution of corrected refraction angles.

Owner:FUJIFILM CORP

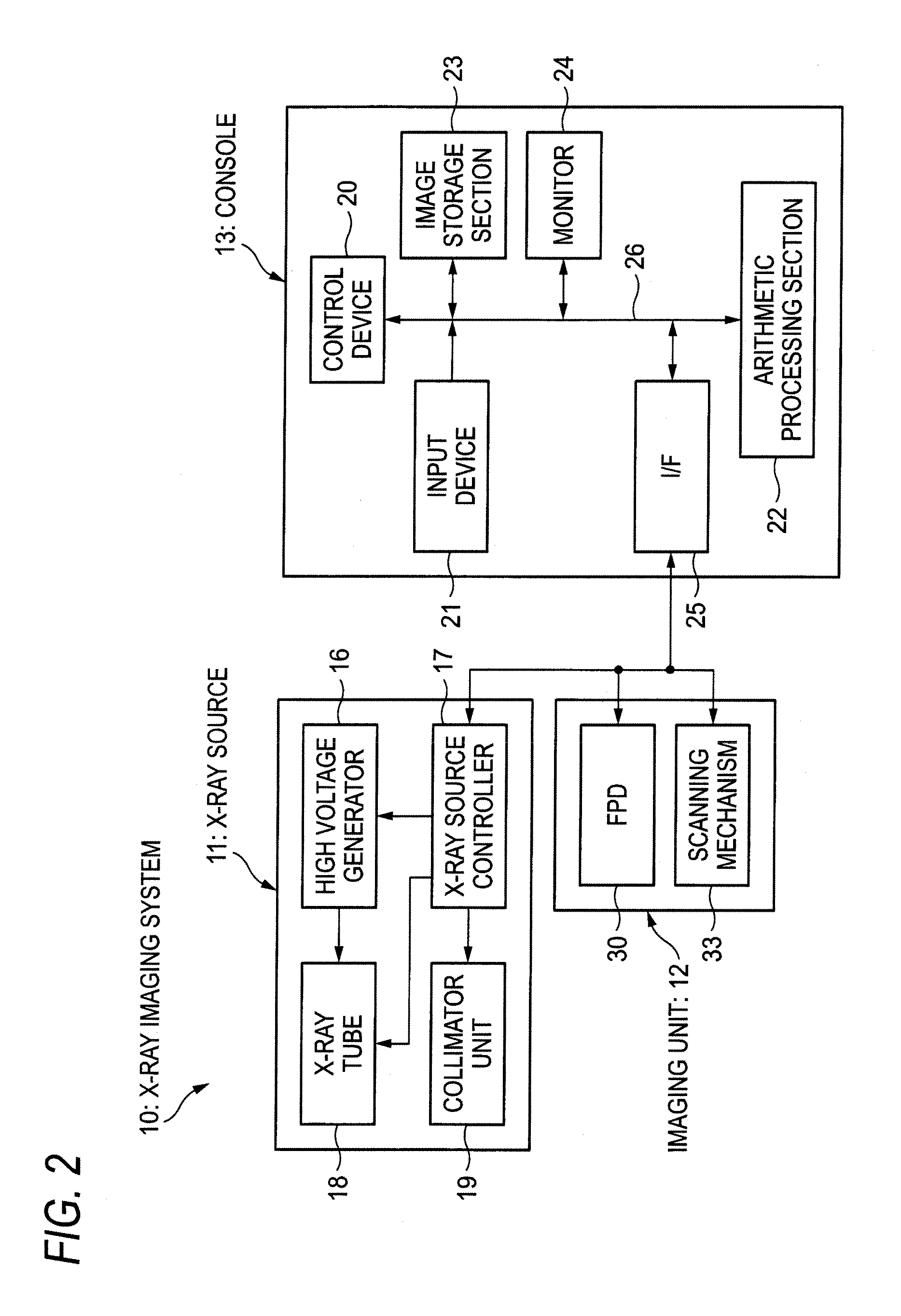

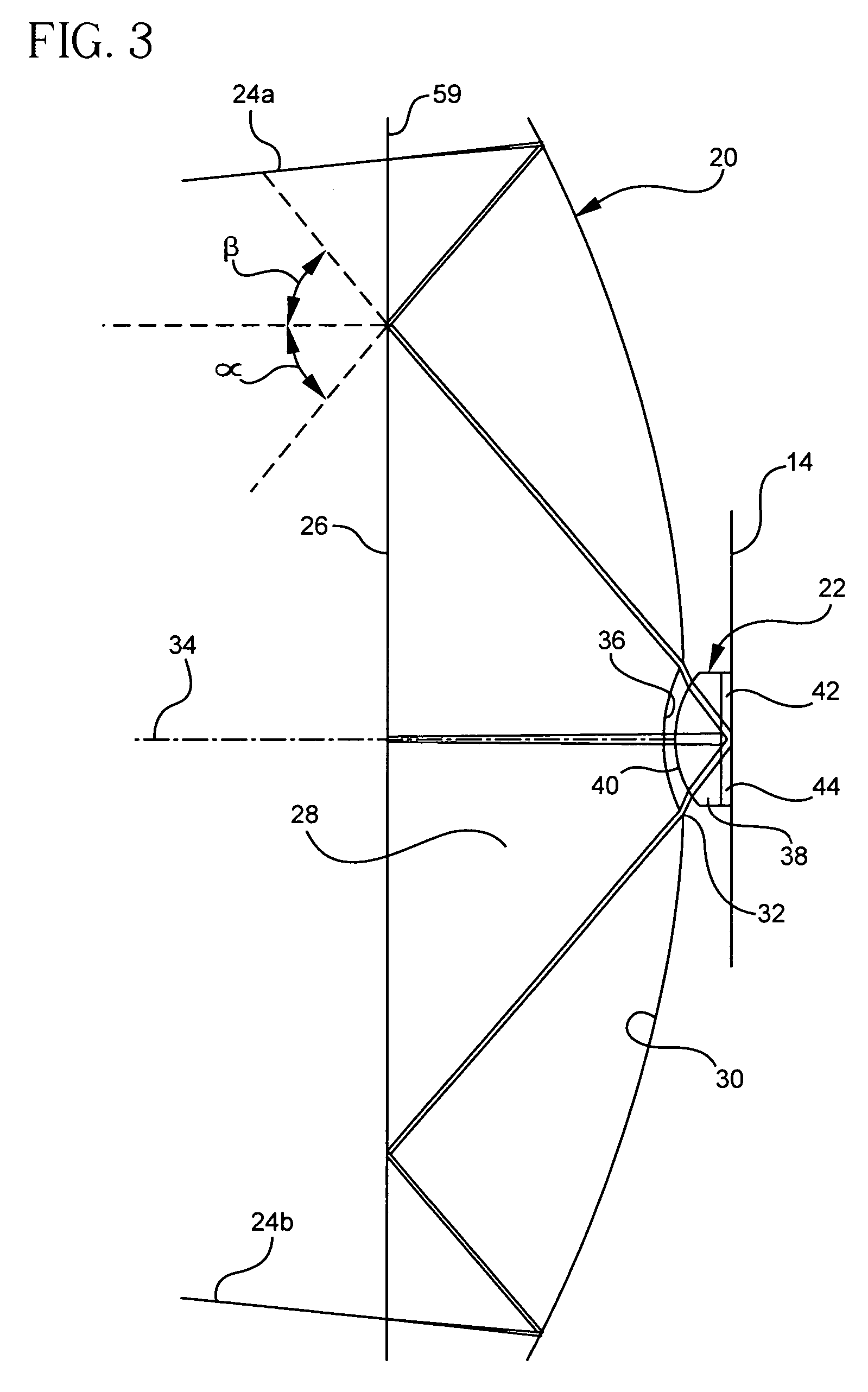

Catadioptric imaging system for high numerical aperture imaging with deep ultraviolet light

InactiveUS20050179994A1Reduces TM polarization componentReduce componentsPolarising elementsMicroscopesAngle of incidenceMangin mirror

A catadioptric imaging system for micro-lithographic projection features a high numerical aperture objective where most of the focusing power is produced by reflection and refraction angles are limited to avoid additional aberration. A field correcting optic is appended to a Mangin mirror in an immersive configuration for raising the numerical aperture. The optical connection between the Mangin mirror and the field correcting optic is arranged to control refraction angles by limiting angles of incidence or refractive index differences. A radially symmetric polarizing effect is achieved in a pupil to improve image contrast.

Owner:CORNING INC

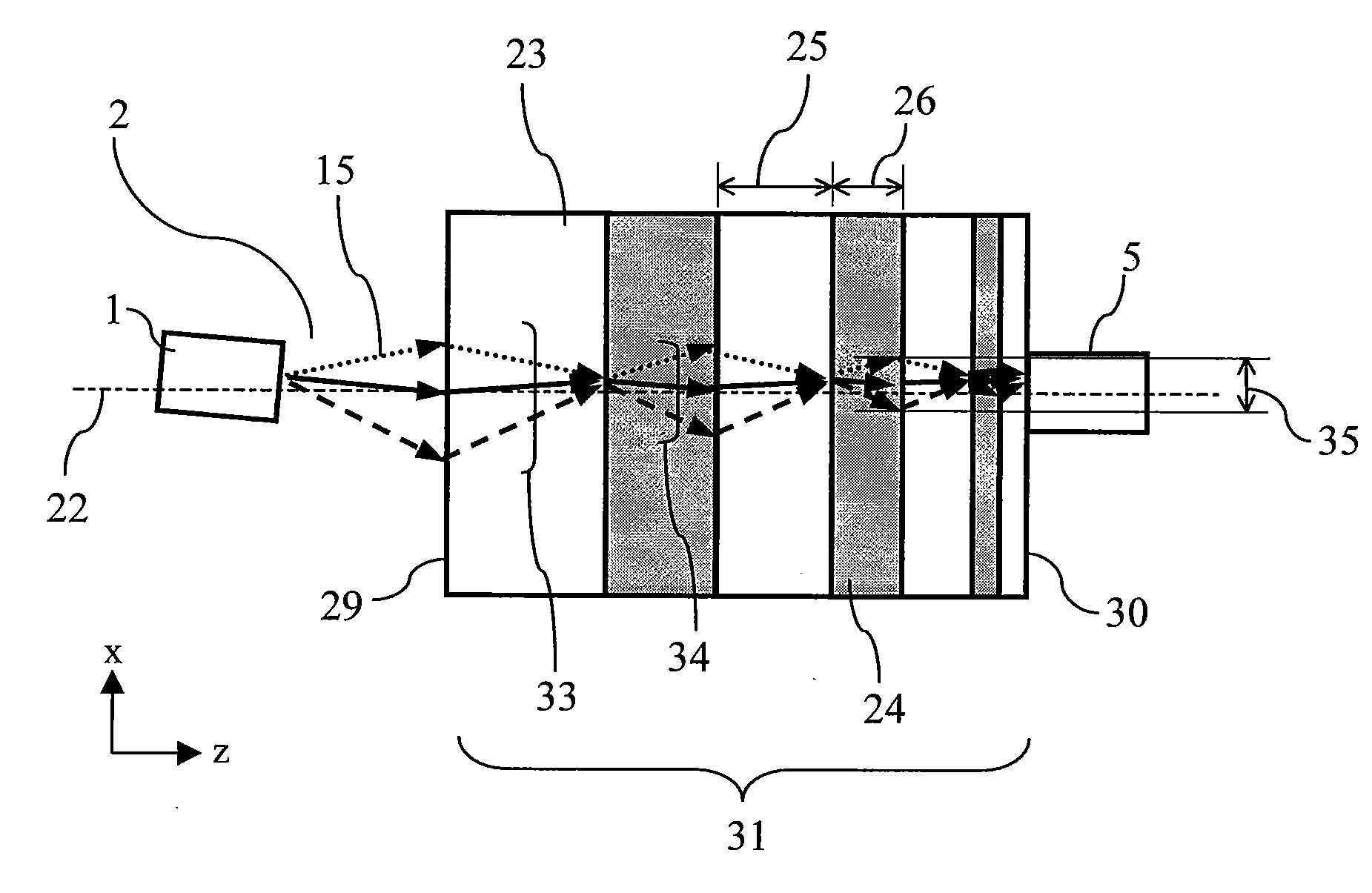

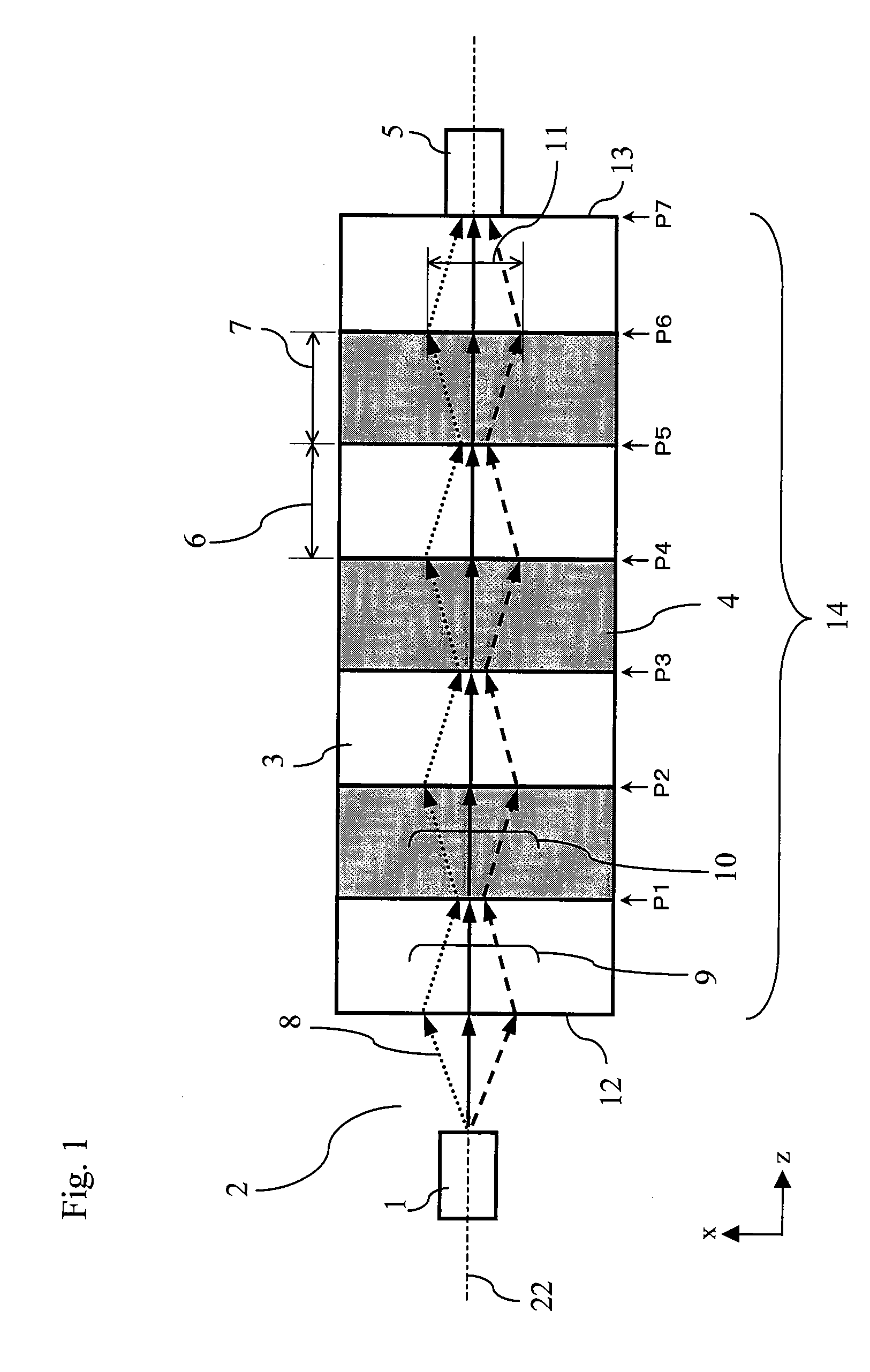

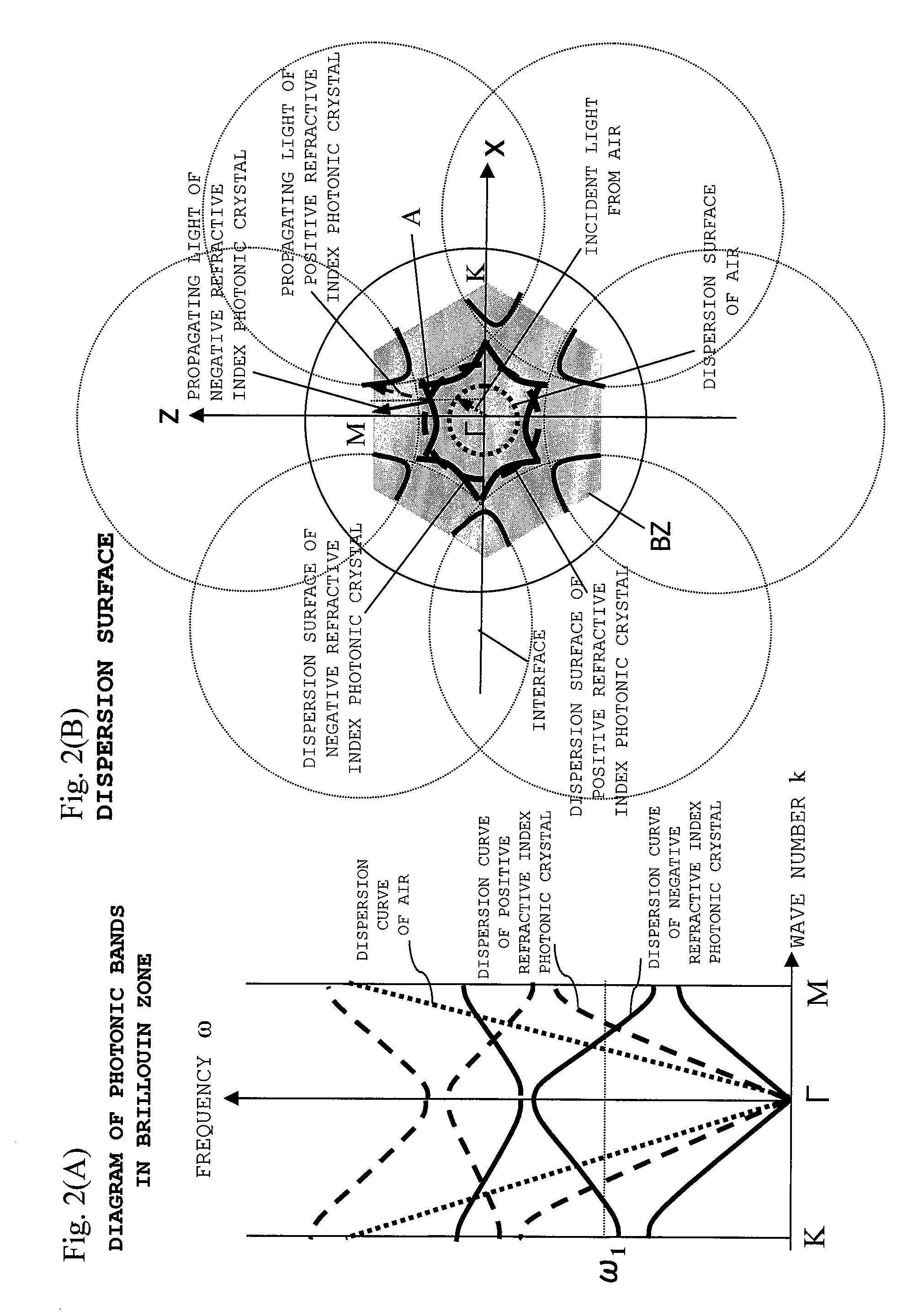

Optical transmission device and light-receiving module

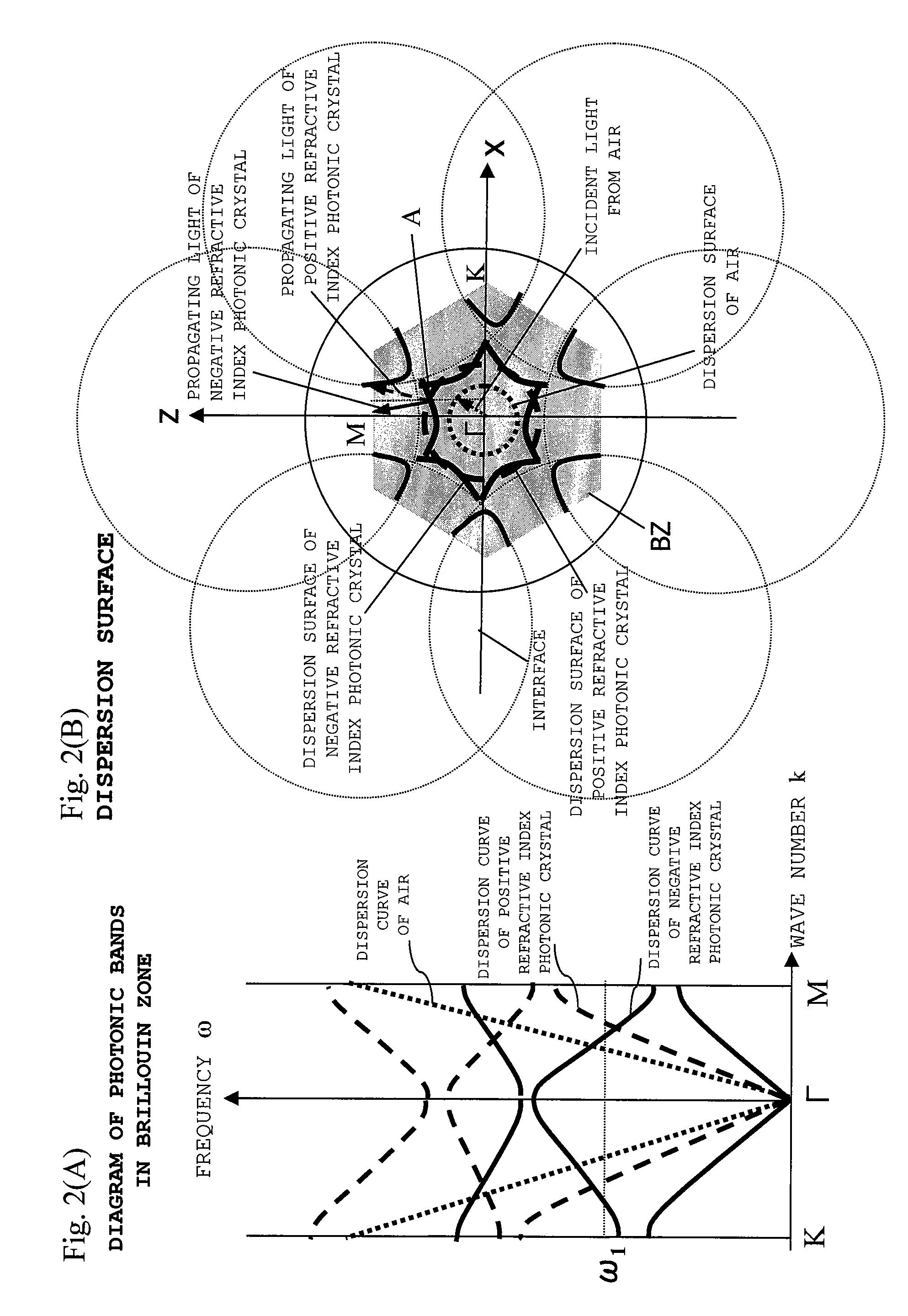

InactiveUS20070201805A1Easy to makeLarge caliberNanoopticsOptical waveguide light guideNegative refractionLight beam

An optical transmission device is provided with a first optical member having a negative refraction angle with respect to an incident angle of a beam and a second optical member having a positive refraction angle with respect to the incident angle, wherein the first and second optical members are arranged one each or more in tandem alternatively.

Owner:PANASONIC CORP

Radiographic system, radiographic method and computer readable medium

InactiveUS20110243305A1Easy to correctEasy to performMaterial analysis by transmitting radiationRadiation diagnosticsRefraction angleRadiography

A radiographic system which detects a radiation image transmitted through a subject with a radiation image detector and generates a phase contrast image of the subject, includes: a calculation section that calculates a distribution of refraction angles of radiation incident on the radiation image detector and generates the phase contrast image on the basis of the distribution of refraction angles; and a storage section that stores a correction coefficient of each pixel for making sensitivities of pixels equal. The calculation section performs sensitivity correction on a refraction angle of radiation incident on each pixel of the radiation image detector, which is calculated by imaging the subject, using the correction coefficient of the pixel stored in the storage section and generates the phase contrast image of the subject on the basis of the distribution of corrected refraction angles.

Owner:FUJIFILM CORP

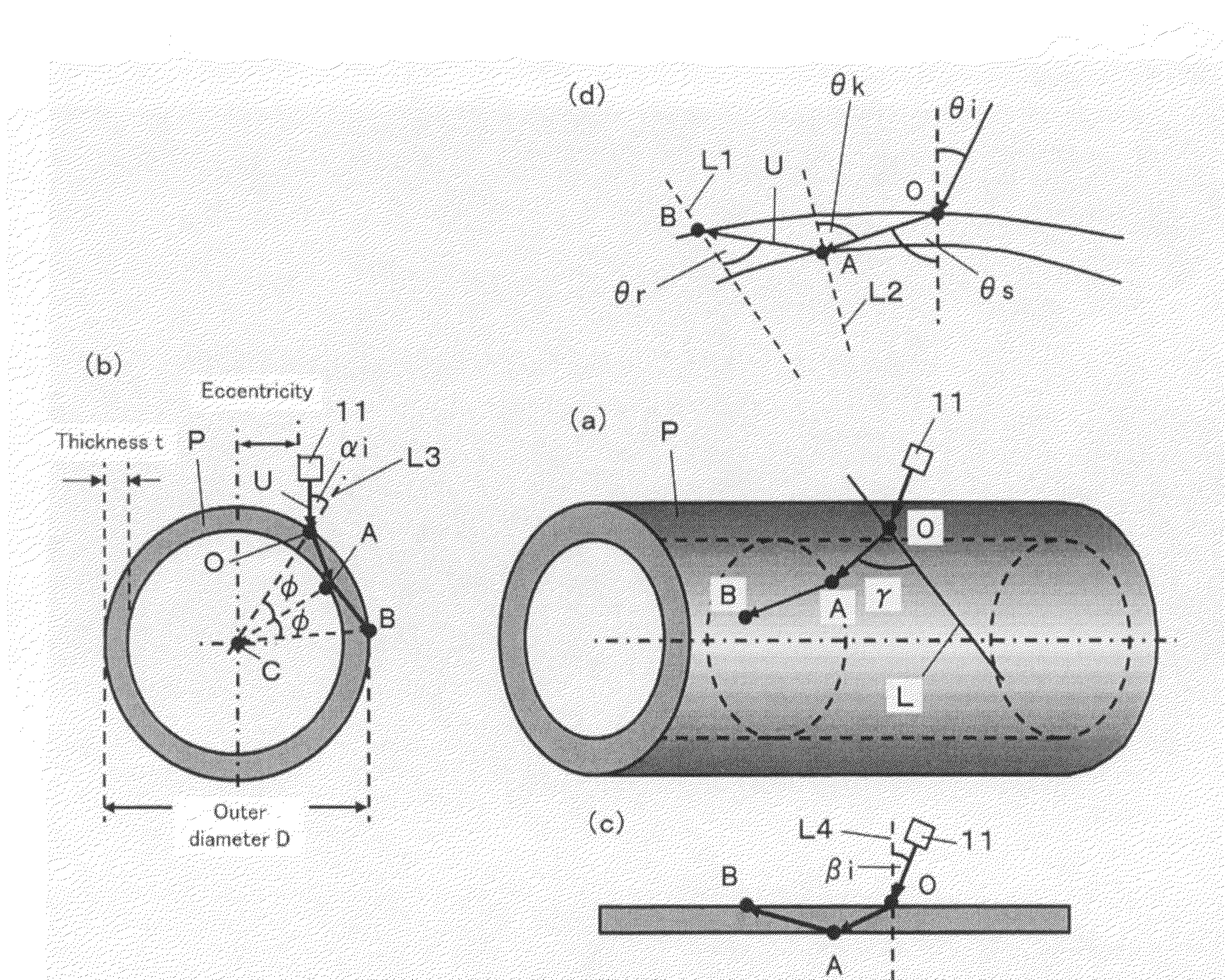

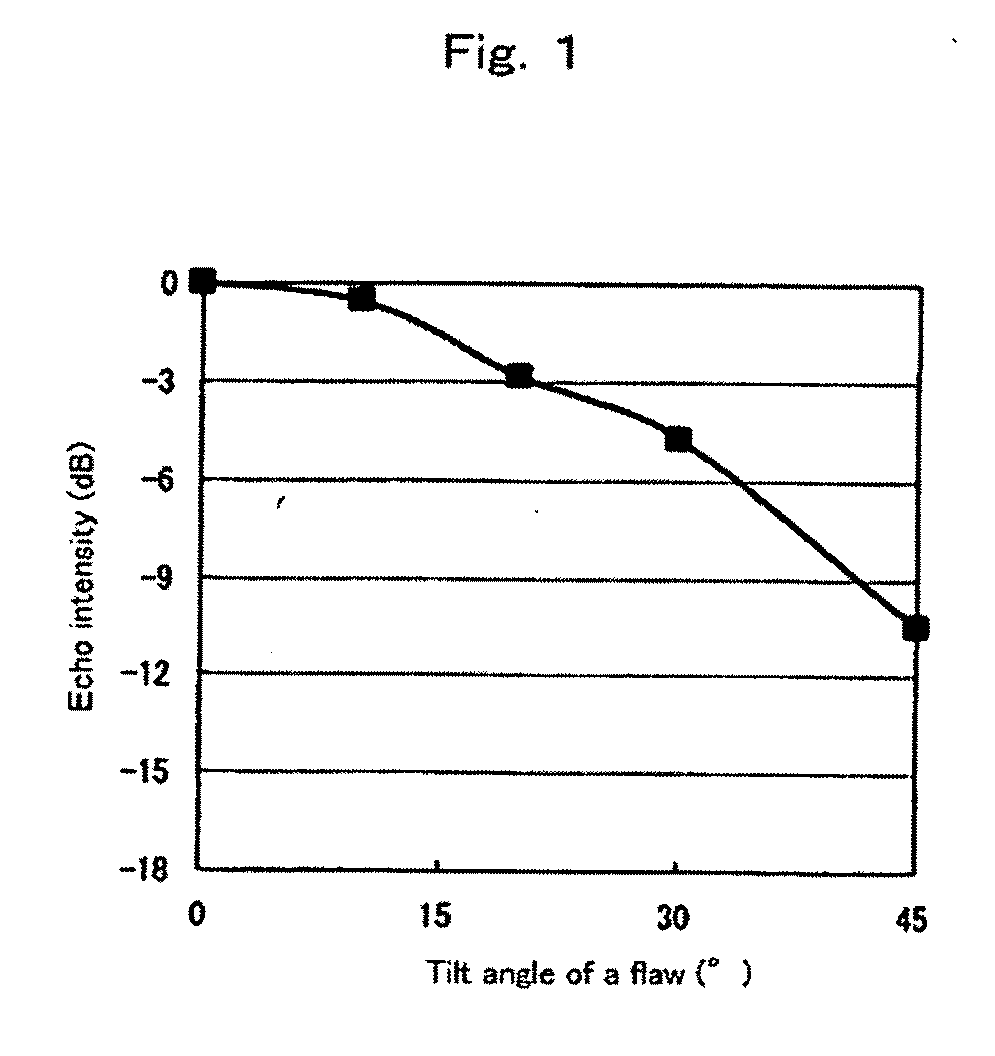

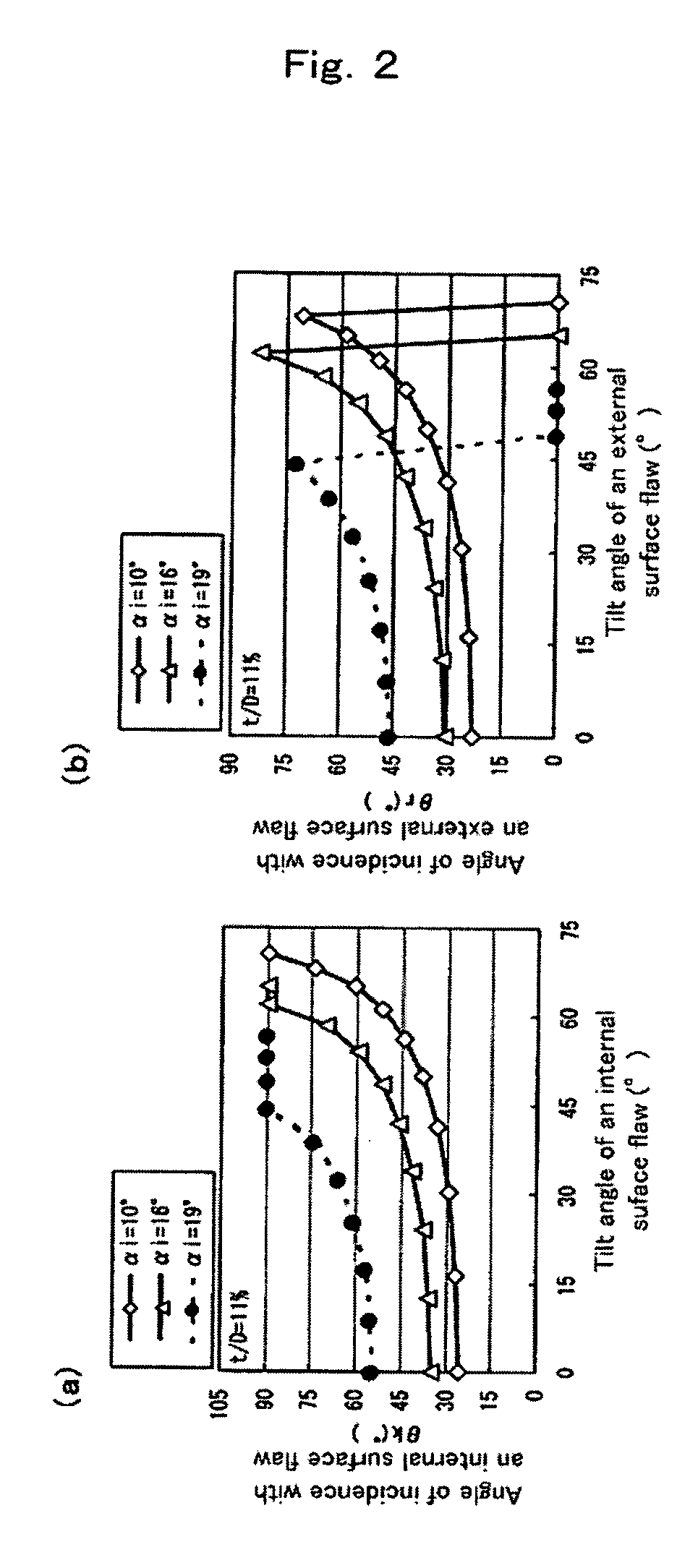

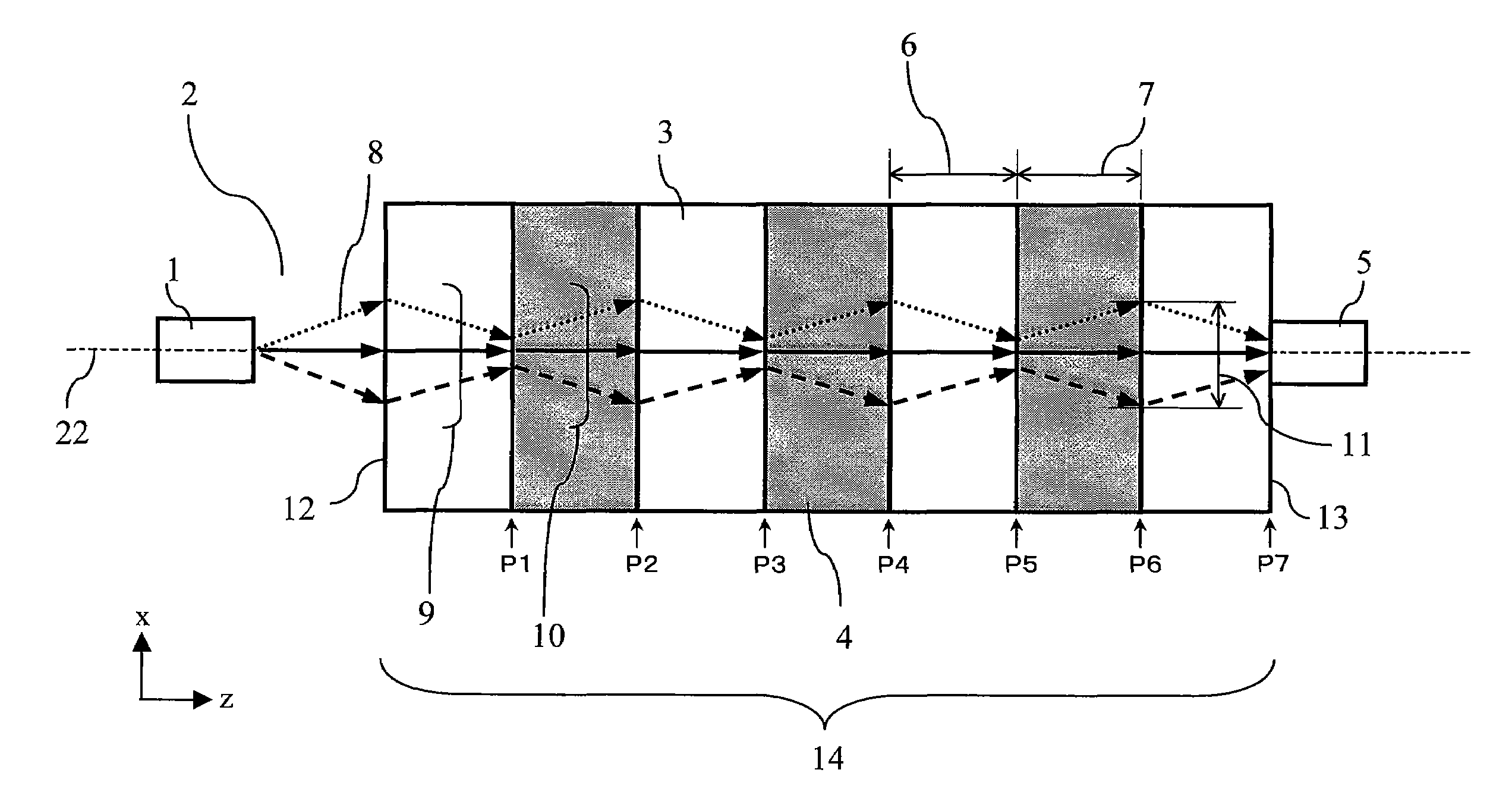

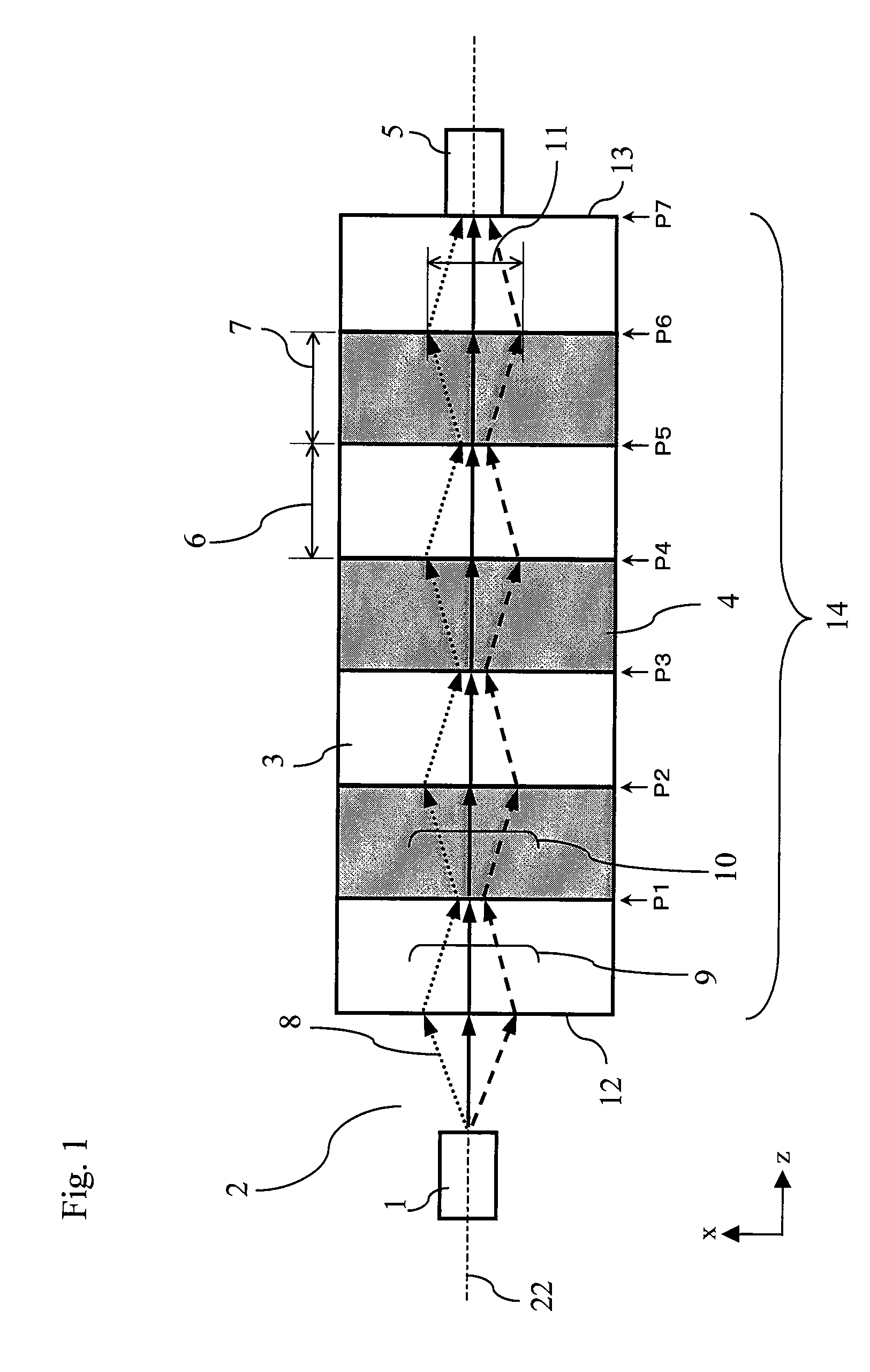

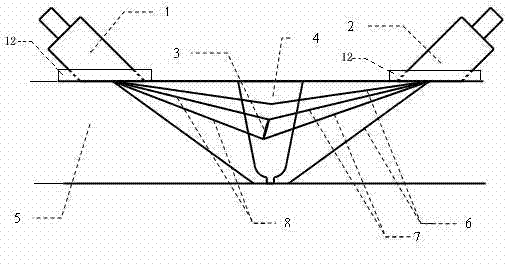

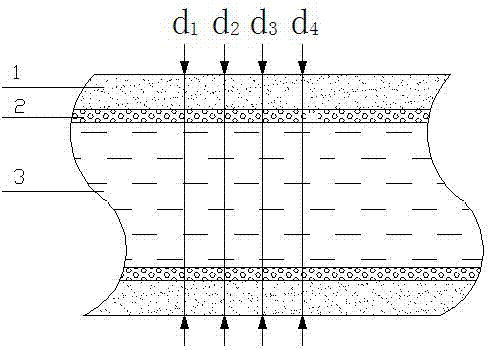

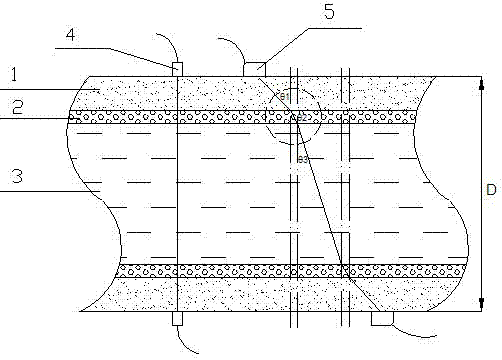

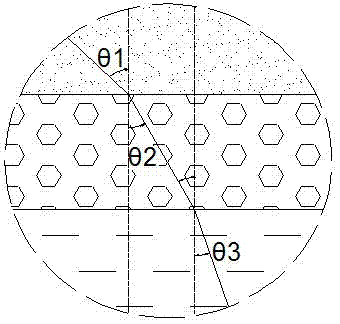

Ultrasonic probe, ultrasonic testing equipment, ultrasonic testing method, and manufacturing method of seamless pipe or tube

ActiveUS20090217763A1Improve accuracyHigh-precision detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansTransducerRefraction angle

The ultrasonic testing method according to the invention includes the steps of arranging an ultrasonic probe 1 having a plurality of transducers 11 so as to face a tubular test object P, and causing the transducers appropriately selected from the plurality of transducers to transmit and receive ultrasonic waves so that the ultrasonic waves are propagated in the tubular test object in a plurality of different propagation directions, wherein a ultrasonic testing condition by the ultrasonic probe is set so that respective external refraction angles θr of the ultrasonic waves in the plurality of propagation directions are approximately equivalent and / or respective internal refraction angles θk of the ultrasonic waves in the plurality of propagation directions are approximately equivalent.

Owner:NIPPON STEEL CORP

Optical transmission device and light-receiving module

InactiveUS7554741B2Easy to makeLarge caliberNanoopticsOptical waveguide light guideNegative refractionAngle of incidence

An optical transmission device is provided with a first optical member having a negative refraction angle with respect to an incident angle of a beam and a second optical member having a positive refraction angle with respect to the incident angle, wherein the first and second optical members are arranged one each or more in tandem alternatively.

Owner:PANASONIC CORP

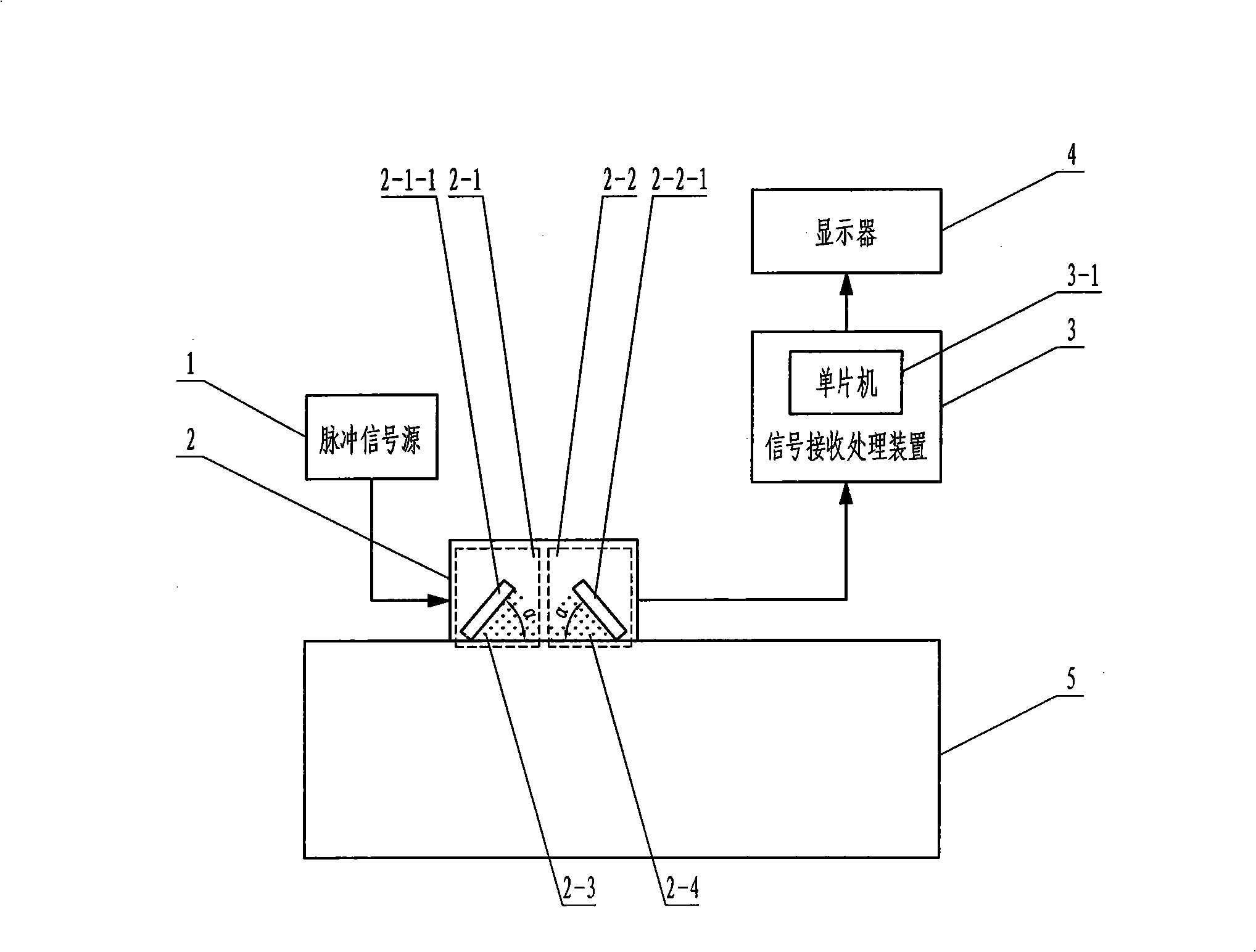

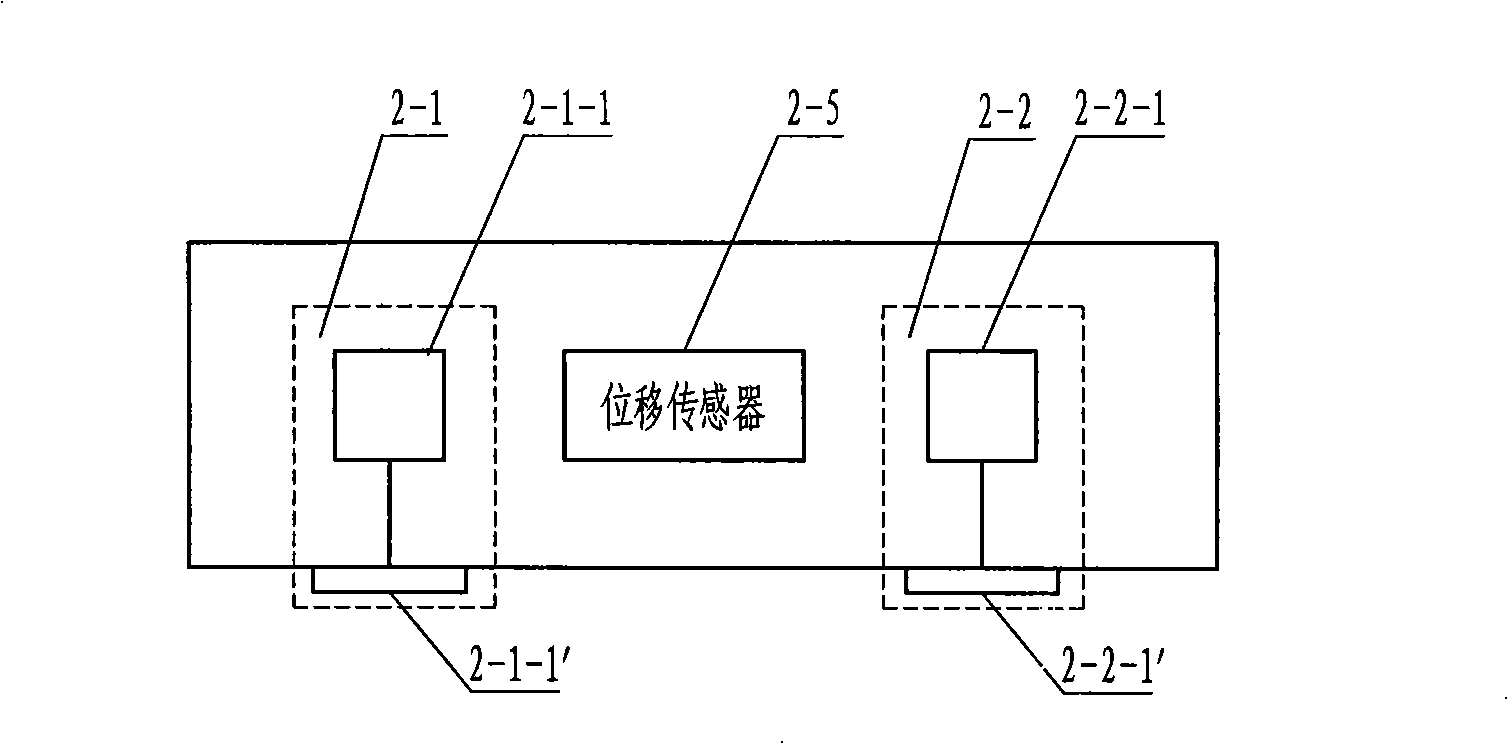

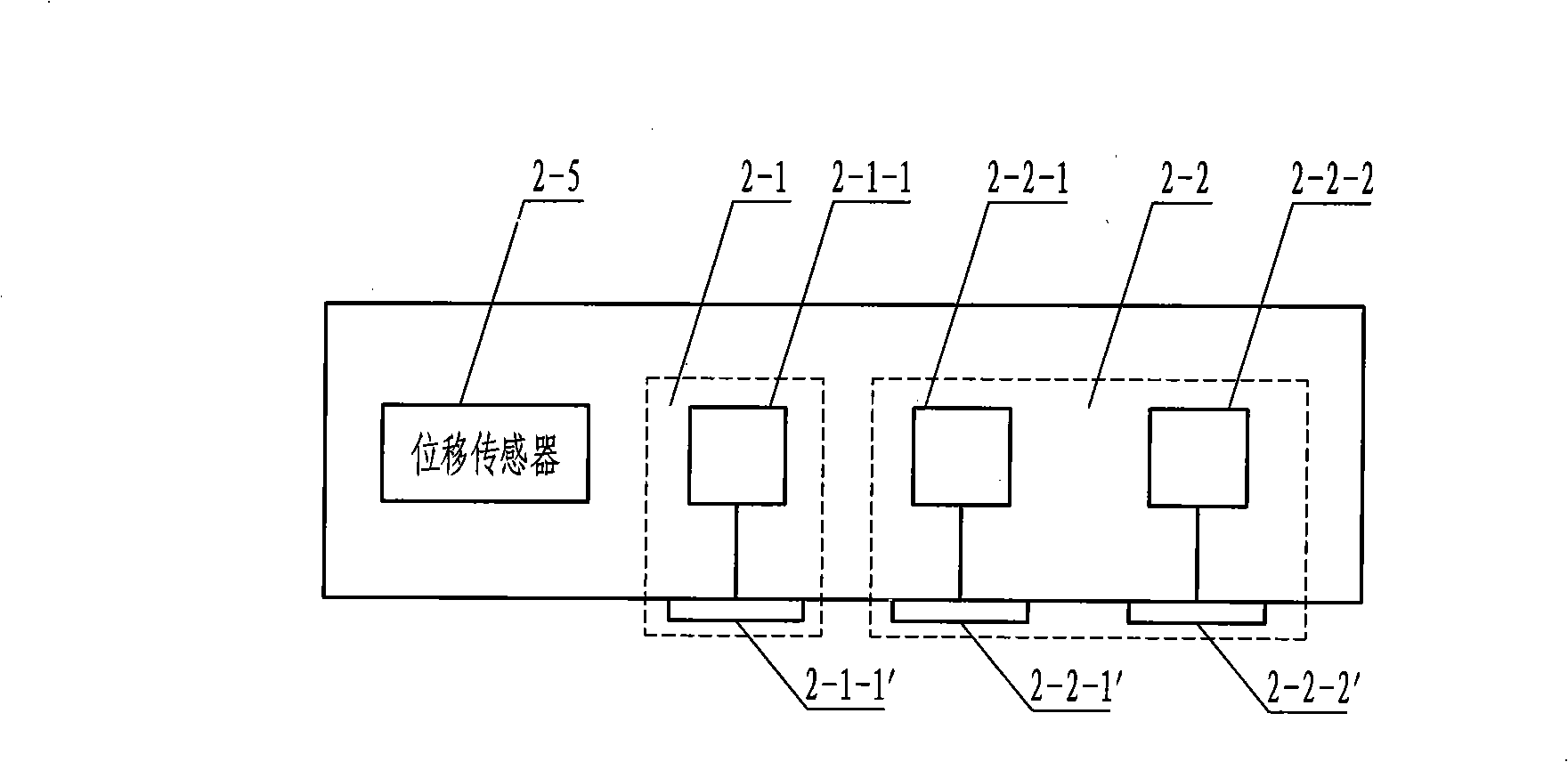

Ultrasonic wave nondestructive apparatus and method for measuring residual stress of welded structure

InactiveCN101320018AWill not be scrappedHigh measurement accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMicrocontrollerMeasurement device

The invention relates to a welding structure residual stress ultrasonic lossless measurement device and a method, in particular to a device and a method using ultrasonic for measuring the residual stress of a welding structure, belonging to the residual stress measurement field. The method aims at overcoming the problems of a traditional stress measurement method that work pieces are destroyed, time is consumed and the residual stress measurement can not be satisfied under the service condition of the welding structure. The two ends of a probe group of the invention are respectively connected with an impulse signal source and a signal receiving processing device which is connected with a display. And a microcontroller is embedded in the signal receiving processing device. In said method, the coordinate of a measured point is determined; the probe group emits impulse signals sent out from the impulse signal source into a work piece through a first critical refraction angle to generate critically refracted longitudinal waves, wherein, enveloping data are read by the signal receiving processing device and are discretized into digital signals and FIR filtering waves; total enveloping weight eigenvalue Mn is worked out; abnormal data are removed according to Brubbs criterion after one measured point is measured for a plurality of times, measuring position is changed for measuring again, and Mn and Mn+1 are worked out according to two measuring points to calculate the residual stress Delta of the work piece.

Owner:HARBIN INST OF TECH

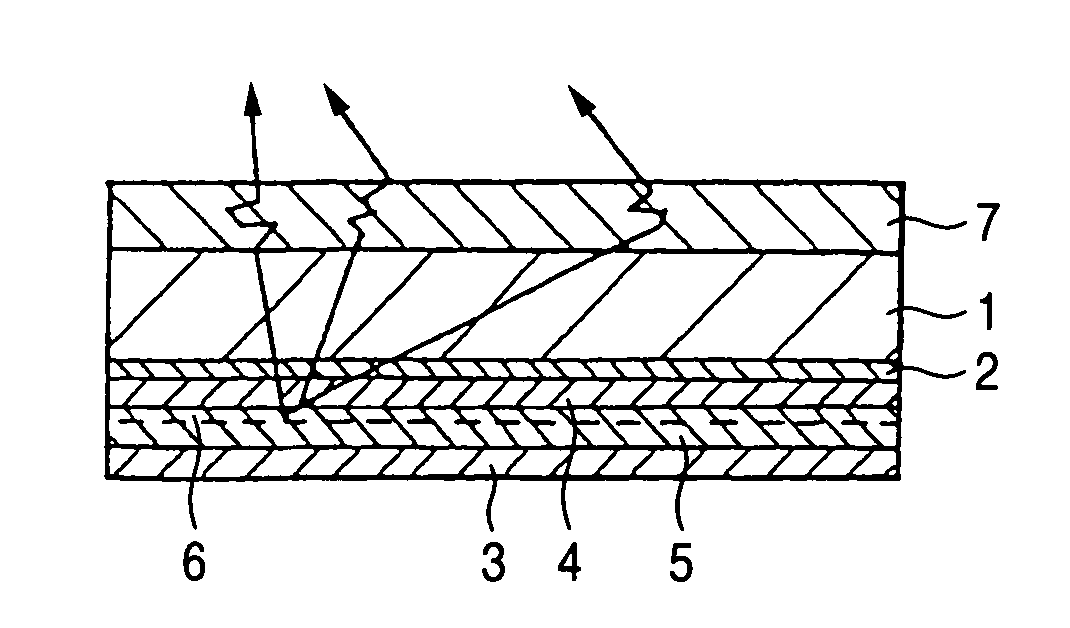

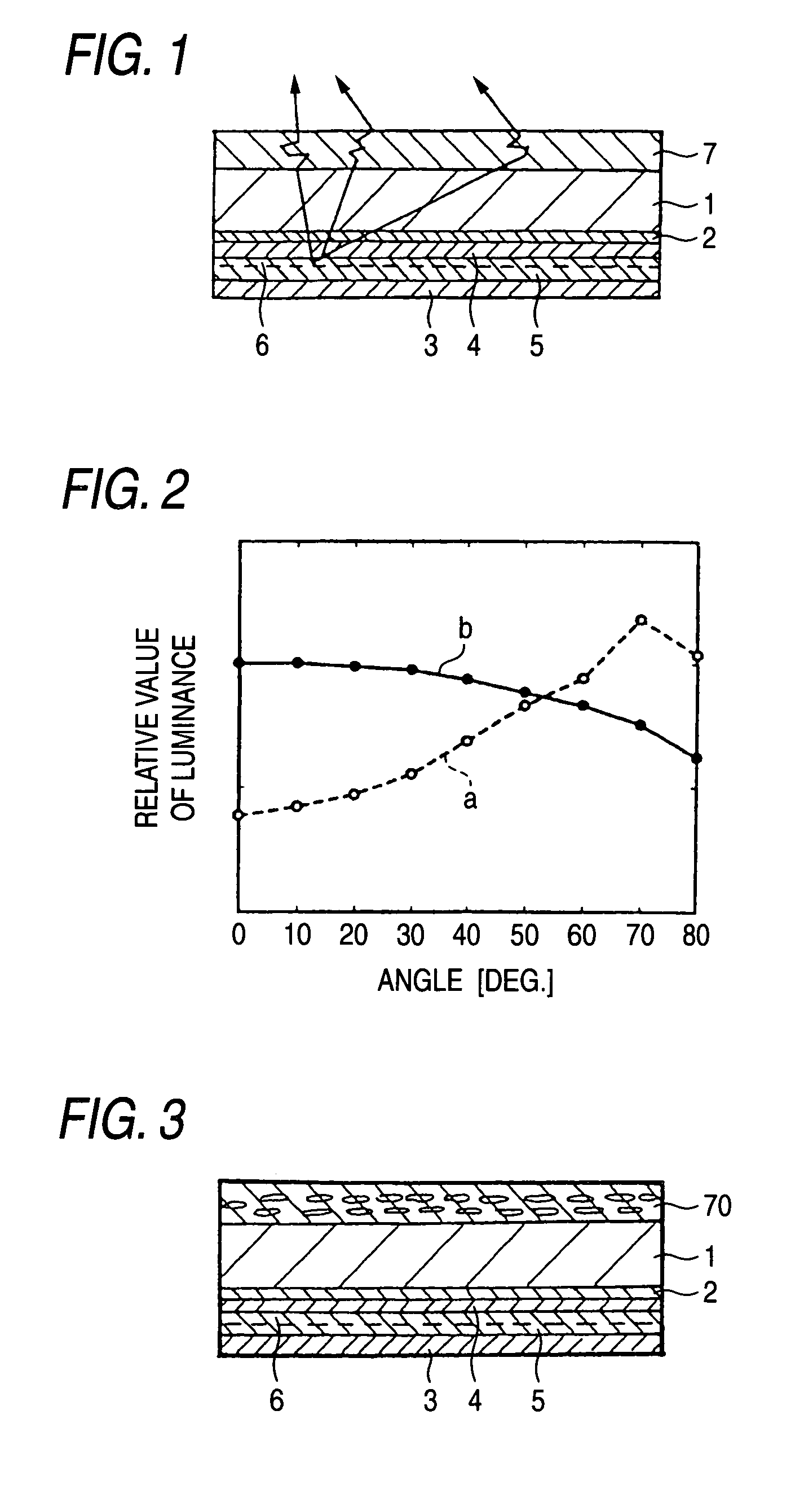

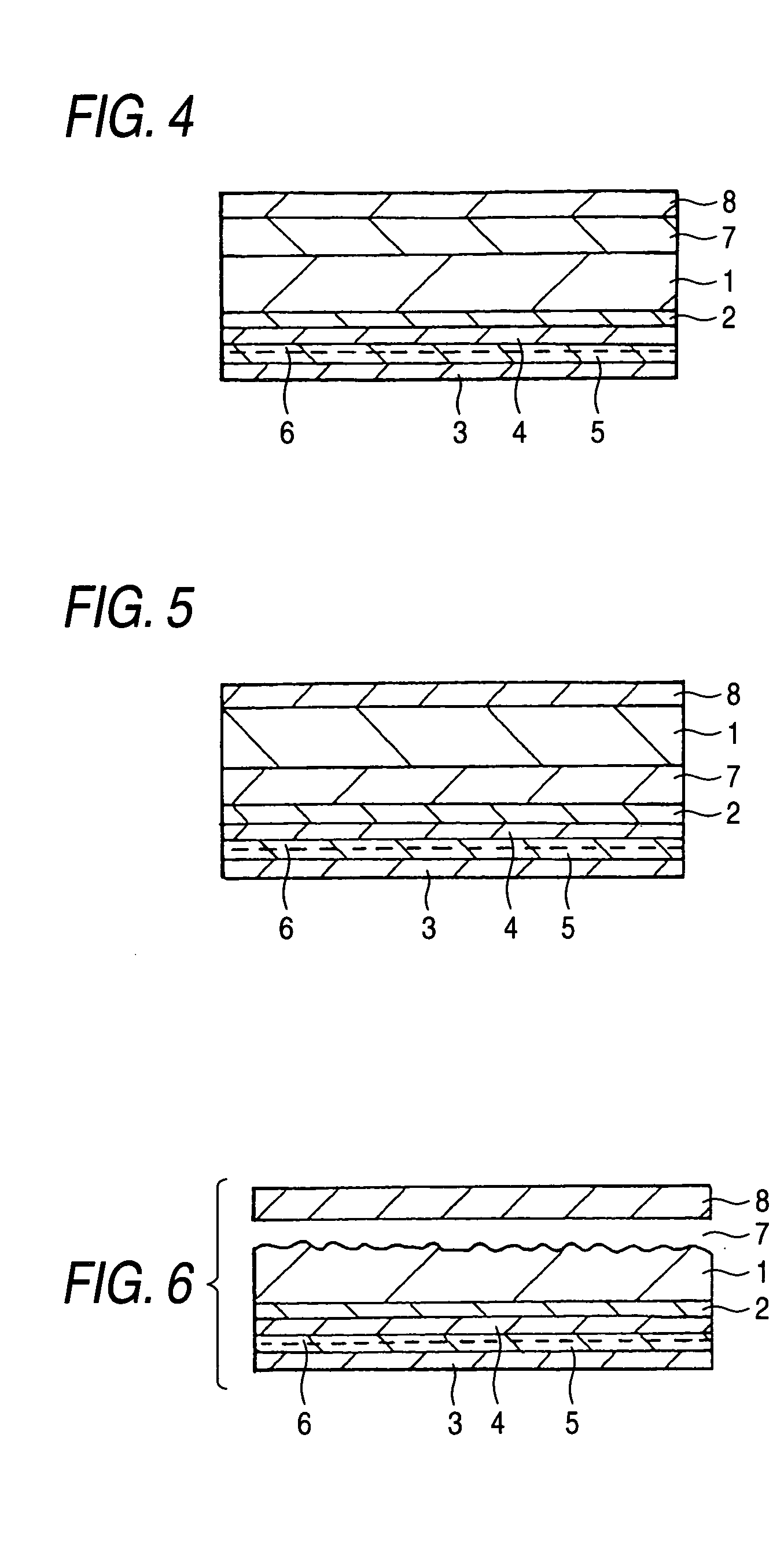

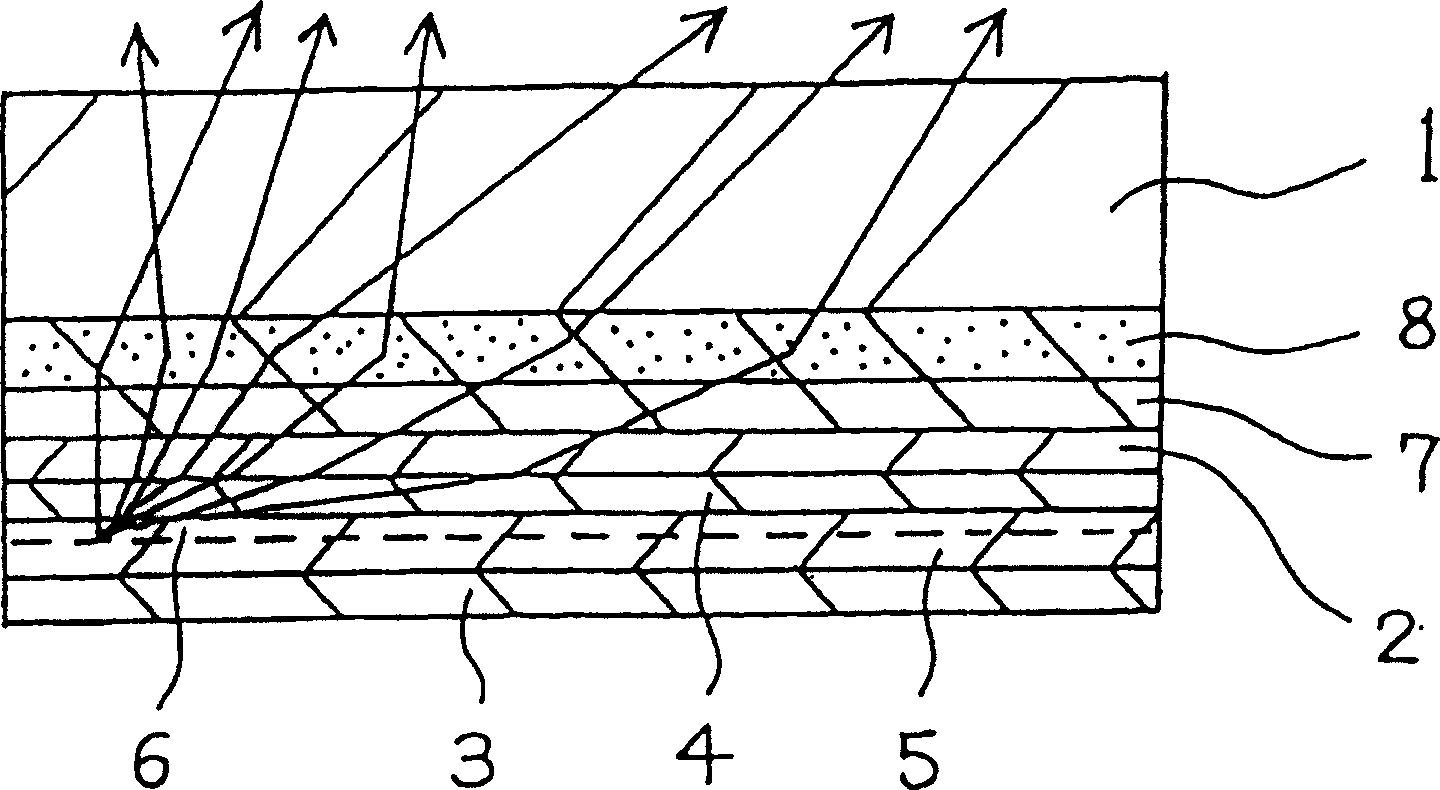

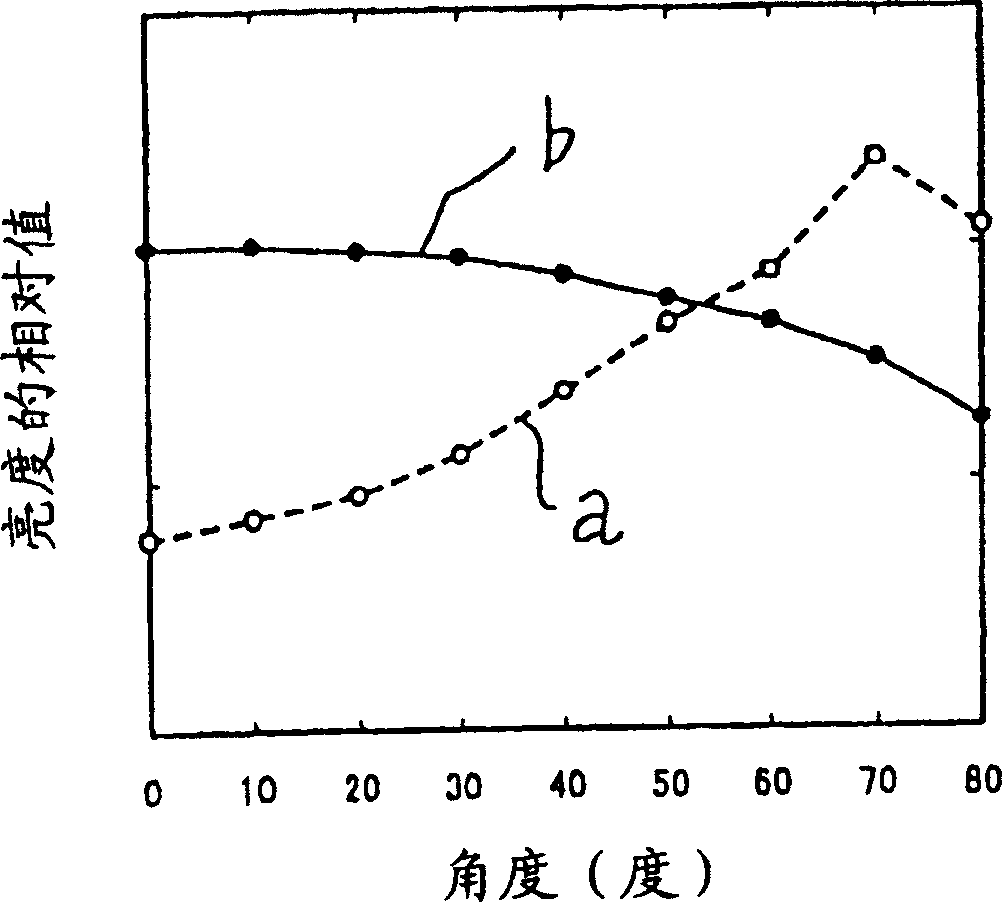

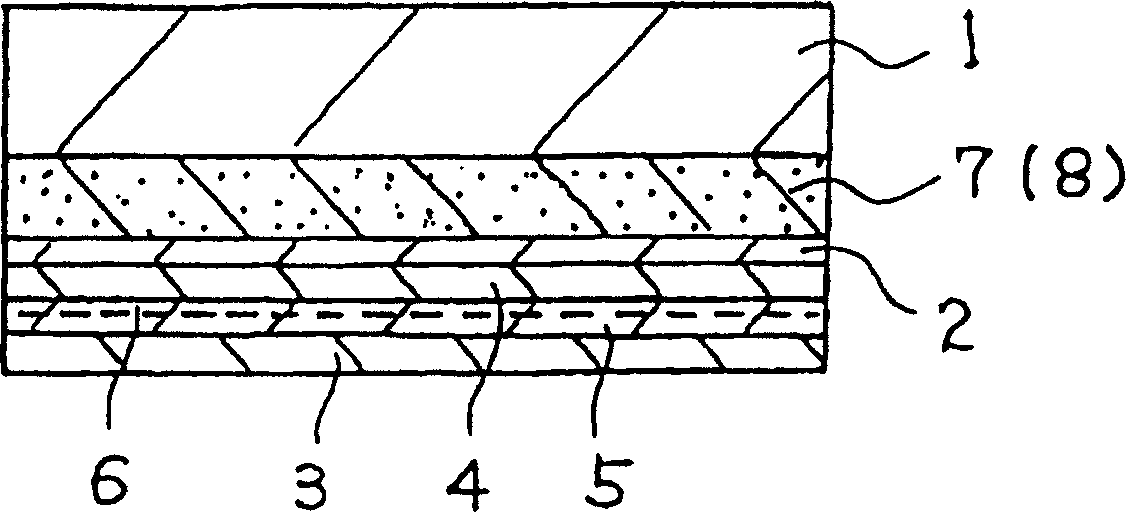

Organic electroluminescence cell, planar light source and display device

ActiveUS7109651B2Extend cell lifeTotal current dropIncadescent screens/filtersDischarge tube luminescnet screensOrganic layerDisplay device

An organic electroluminescence cell including at least one organic layer and a pair of electrodes, the organic layer including a light-emitting layer and sandwiched between the pair of electrodes, the pair of electrodes including a reflective electrode and a transparent electrode, the organic electroluminescence cell formed to satisfy the expression: B0<Bθ in which B0 is a frontal luminance value of luminescence radiated from a light extraction surface to an observer, and Bθ is a luminance value of the luminescence at an angle of from 50° to 70°, wherein a reflection / refraction angle disturbance region is provided so that the angle of reflection / refraction of the luminescence is disturbed while the luminescence is output from the light-emitting layer to the observer side through the transparent electrode.

Owner:NITTO DENKO CORP

X ray phase contrast tomography

ActiveCN101726503AAddressing organizational cascadingFix low contrastMaterial analysis by transmitting radiationPhase contrast tomographySoft x ray

The invention relates to an X ray phase contrast imaging system and an X ray phase contrast imaging method. The system comprises an X ray device, a grating system, a detection unit, a data processing unit and a relative shifting device, wherein the X ray device emits X ray bundles to a detected object; the grating system comprises a first absorption grating and a second absorption grating and is positioned on a direction of an X ray, and the X ray refracted by the detected object forms a variable-intensity X ray signal through the first absorption grating and the second absorption grating; the detection unit receives the variable-intensity X ray signal and converts the variable-intensity X ray signal into an electrical signal; the data processing unit processes and extracts the refraction angle information in the electrical signal and computes pixel information by utilizing the refraction angle information; and the relative shifting device is used for enabling the detected object to relatively shift relative to the imaging system. The imaging system carries out phase contrast imaging for the detected object within a certain relative shifting range of the imaging system and the detected object at a plurality of positions so as to obtain a plurality of images of the detected object. The images are converted into the images on the same reconstruction plane so as to carry out three-dimensional image reconstruction.

Owner:TSINGHUA UNIV +1

Star light refraction satellite autonomous navigation method based on single star sensor

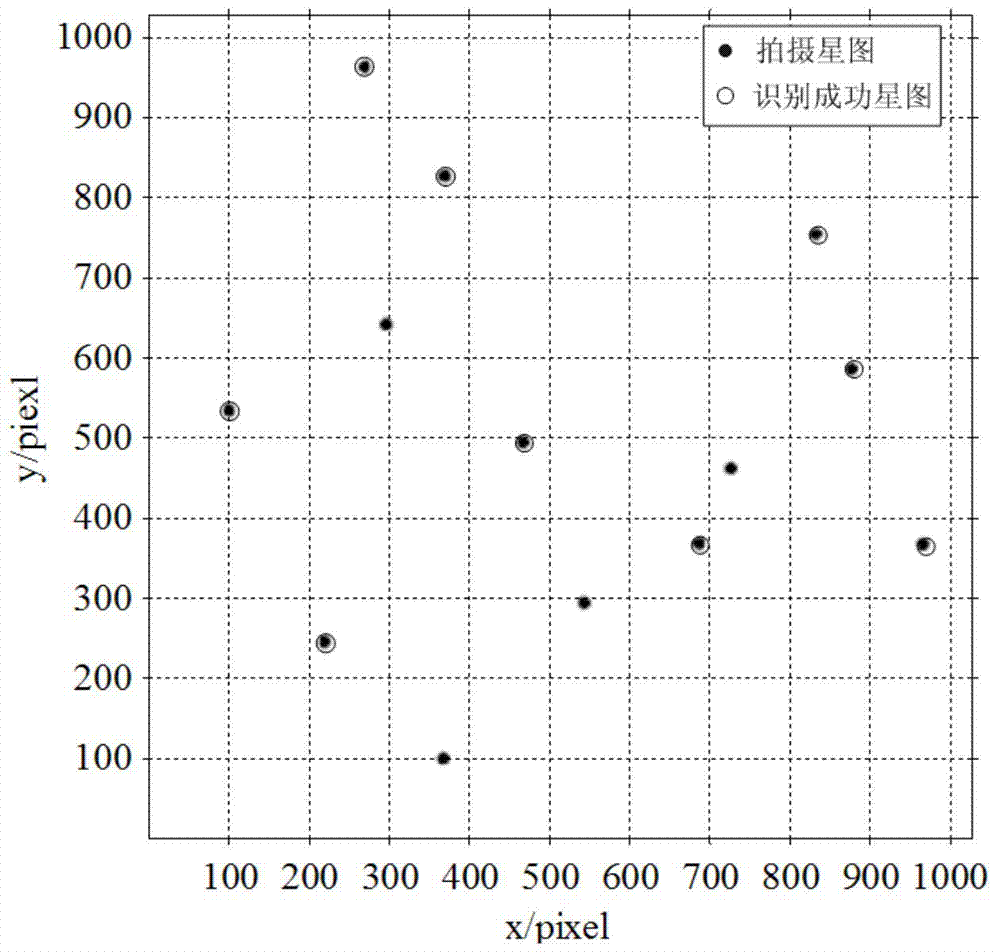

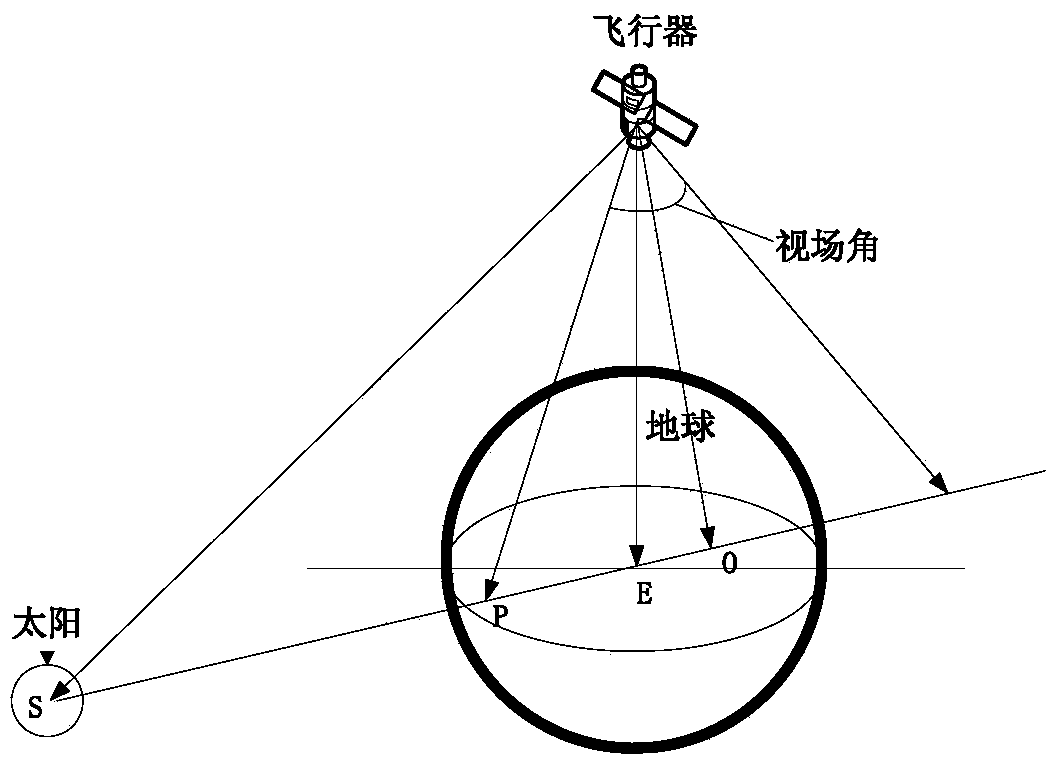

ActiveCN103616028AHigh precisionReduce the burden onNavigational calculation instrumentsInstruments for comonautical navigationNatural satelliteSingle star

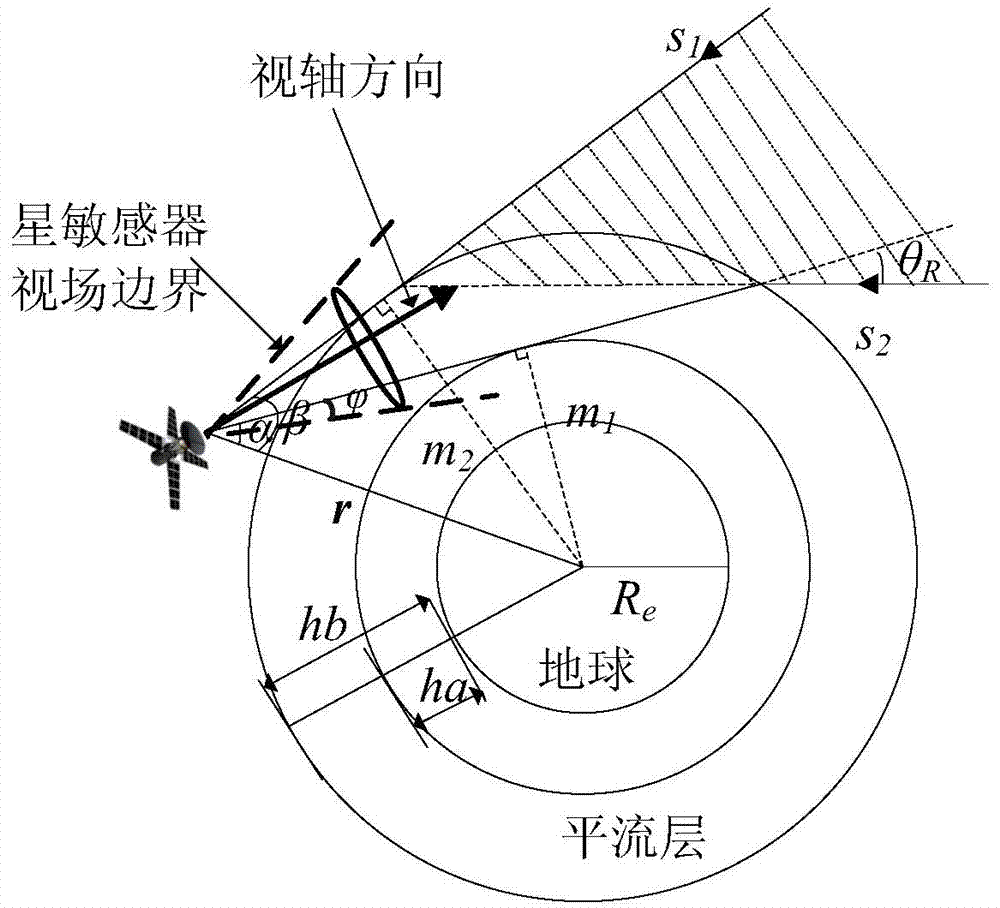

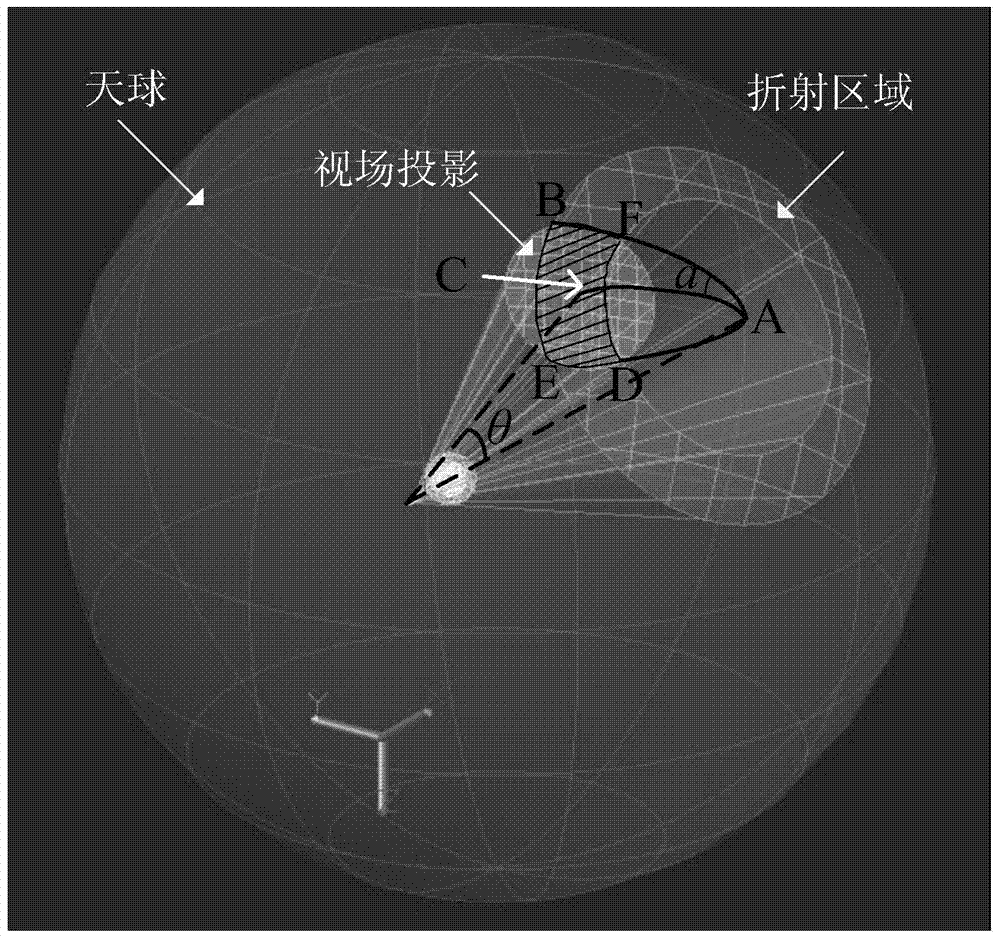

The invention discloses a star light refraction satellite autonomous navigation method based on a single star sensor. The star light refraction satellite autonomous navigation method comprises the following steps: 1, installing the star sensor on a satellite according to an optimal installation angle; 2, after the star sensor shoots a star map, identifying normal stars in the star map by using a triangle algorithm; 3, calculating an optical axis direction and a satellite gesture of the star sensor by using the identified star sensors; 4, selecting a star from the star map according to the optical axis direction of the star sensor to generate a stimulation refraction star map; 5, identifying a refraction star by using the stimulation refraction star map, and calculating a star light refraction angle according to an identification result; and 6, substituting the star light refraction angle into a system model, and obtaining navigation information of the satellite by using an optimum estimation method by a spaceborne computer. According to the star light refraction satellite autonomous navigation method, the precision of autonomous navigation of a star light refraction satellite is improved, and the design cost is lowered.

Owner:HARBIN ENG UNIV

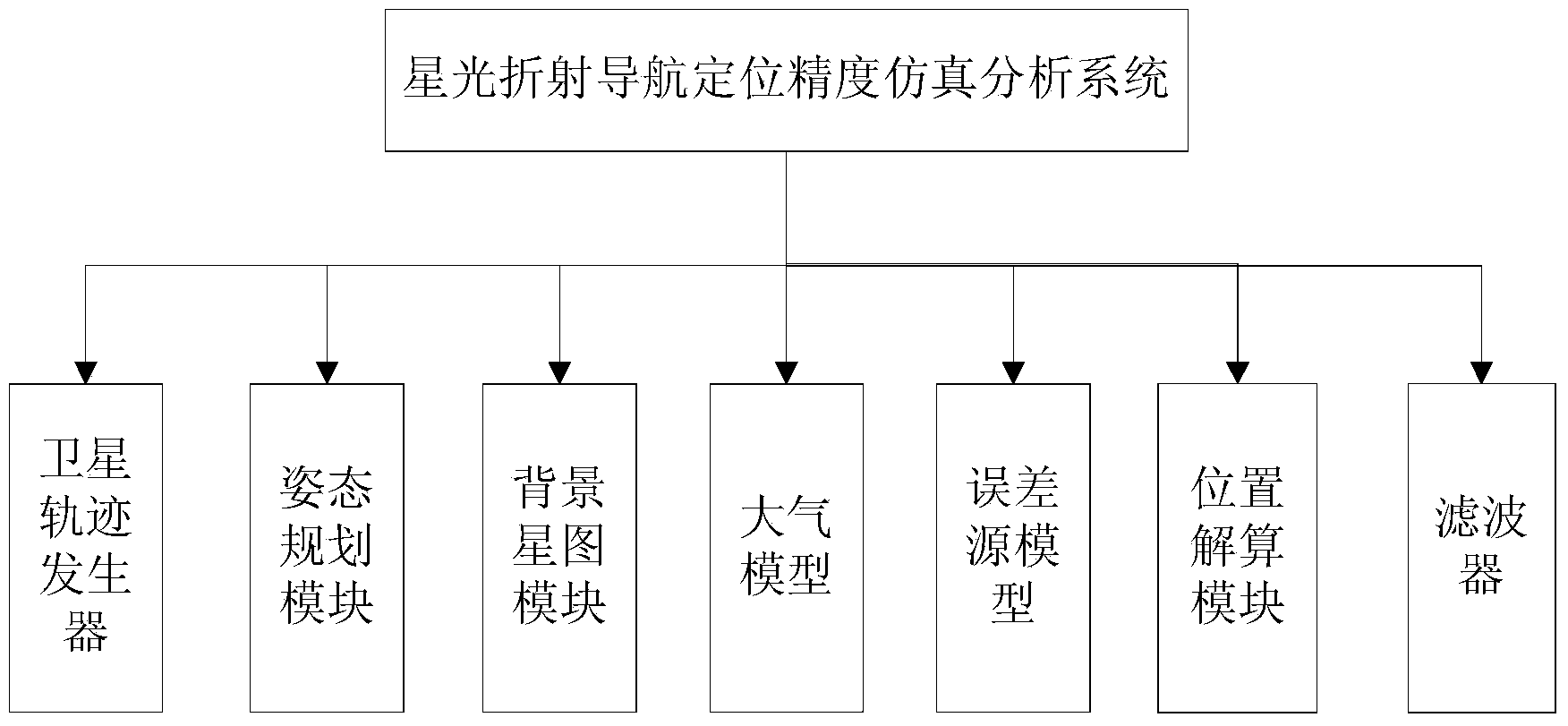

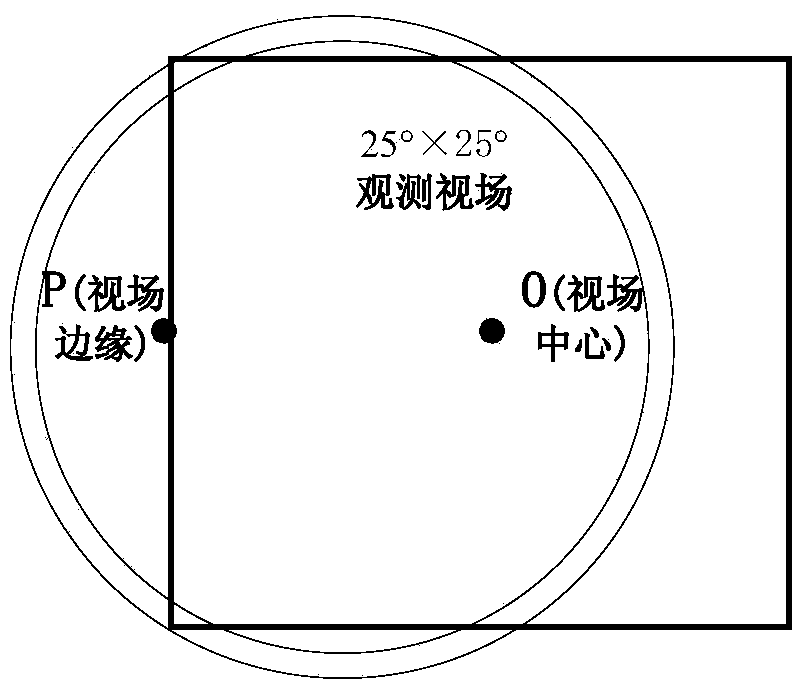

Satellite starlight refraction navigation error determination and compensation method

ActiveCN104236546AHigh positioning accuracyNavigation by astronomical meansRefraction angleAtmospheric models

The invention relates to a satellite starlight refraction navigation error determination and compensation method. The method comprises the following steps: firstly, generating data of a satellite orbit by virtue of STK software; establishing a satellite attitude planning model; determining an actual observation visual field, and simulating an observation star map comprising refraction stars and non-refraction stars; calculating to obtain the tangential height h of the refraction stars; calculating to obtain the tangential height h'' of the refraction stars with errors of refraction angles and errors of an atmospheric model, wherein tangential height errors are mainly caused by the measurement precision errors of the refraction angles and the errors of the atmospheric model; calculating to obtain the position of a satellite under a geocentric inertial coordinate system; and performing filtration by an extended Kalman filtration method, and outputting a starlight refraction navigation estimated position and position errors. The method provided by the invention can realize accurate prediction of navigation precision of a satellite starlight refraction navigation system, and is comprehensive in error analysis and accurate and reliable in results.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

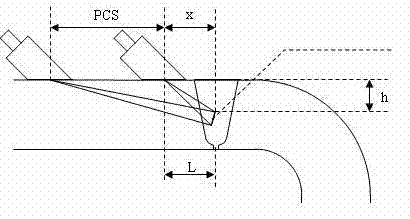

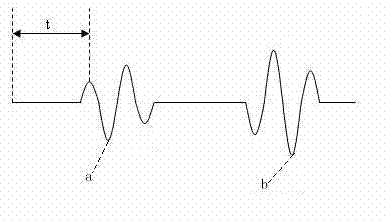

Ultrasonic time-of-flight diffraction (TOFD) detection method for weld seam

The invention relates to an ultrasonic time-of-flight diffraction (TOFD) detection method for a weld seam. The ultrasonic TOFD detection method comprises the following steps of: respectively taking two probes with different refraction angles as a transmitting probe and a receiving probe; arranging the transmitting probe and the receiving probe at the same side of the weld seam; connecting the transmitting probe and the receiving probe with a TOFD instrument; scanning the weld seam; carrying out interpretation on scanned images; finishing the scanning if no defected signal images are discovered; if defected signal images are discovered, changing probe clearance space (PCS), keeping the other settings and parameters unchanged, and carrying out scanning once again; calculating according to two-time scanned results; and achieving the positioned and quantitative detection of the defects of the weld seam. According to the ultrasonic TOFD detection method, a single-face one-sided scanning manner is adopted, the original advantages of TOFD detection are kept, meanwhile, the TOFD detection for the butt-jointed weld seams between a tube body of a pressure vessel and an end enclosure as well as between a pressure conduit and irregular members, such as an elbow, a pipe reducer or a tee joint and the like, is achieved, and thus, the ultrasonic TOFD detection method is wide in scope of application.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +1

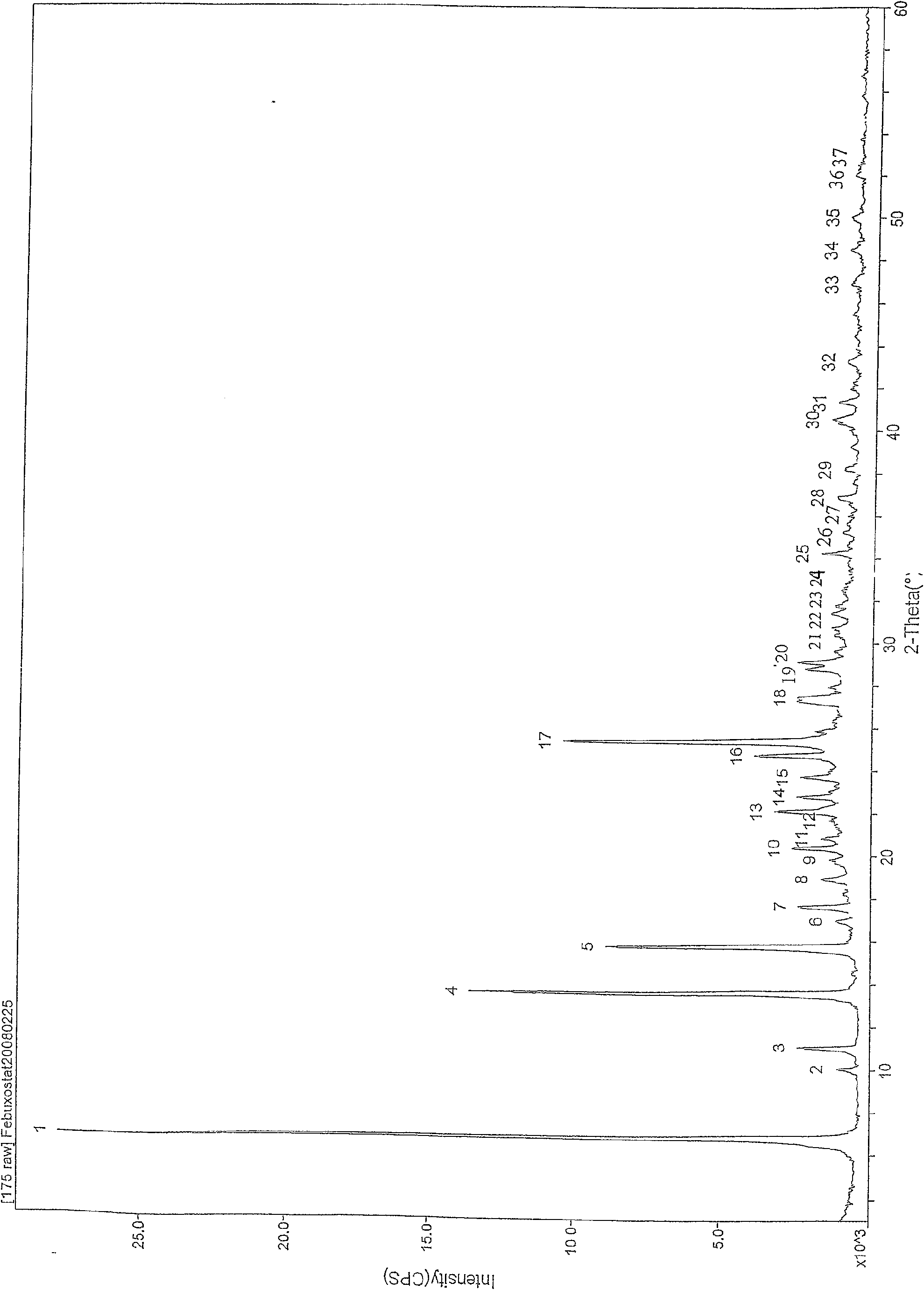

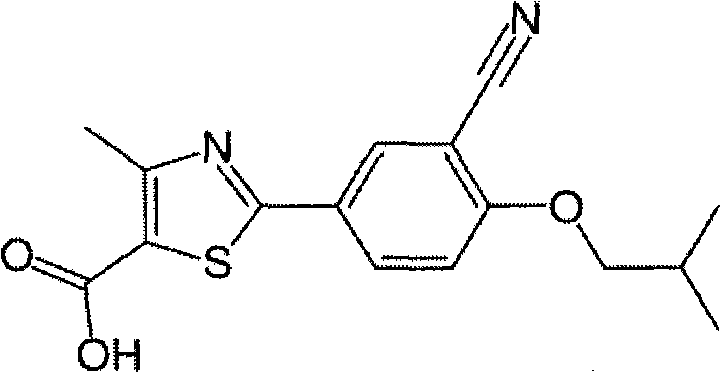

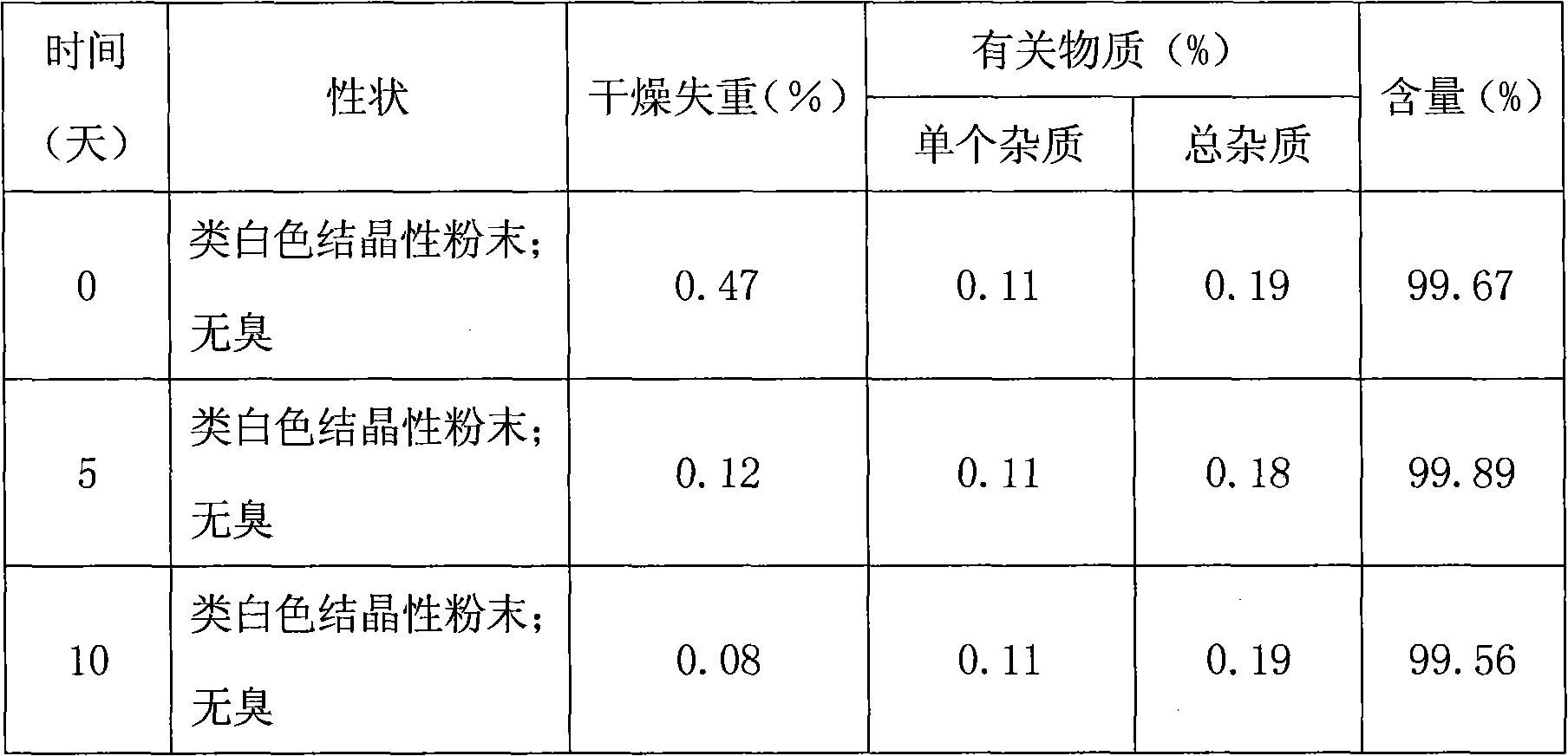

Febuxostat crystal form and preparation method thereof

The invention relates to a Febuxostat crystal form. The x-ray powder diffraction has characteristic peaks when a refraction angle 2 theta is at 6.80+ / - 0.2 degree, 11.04+ / - 0.2 degree, 13.56+ / - 0.2 degree, 15.74+ / -0.2 degree, 17.56+ / -0.2 degree, 20.36+ / -0.2 degree, 22.10+ / -0.2 degree, 24.72+ / - 0.2 degree, 25.38+ / - 0.2 degree, 28.80+ / -0.2 degree and 29.10 degrees+ / - 0.2 degree. The invention also provides a preparation method of the Febuxostat crystal form. The crystal form has better stability and is suitable for technically applying preparations and being stored in a long period.

Owner:CSPC OUYI PHARM CO LTD +1

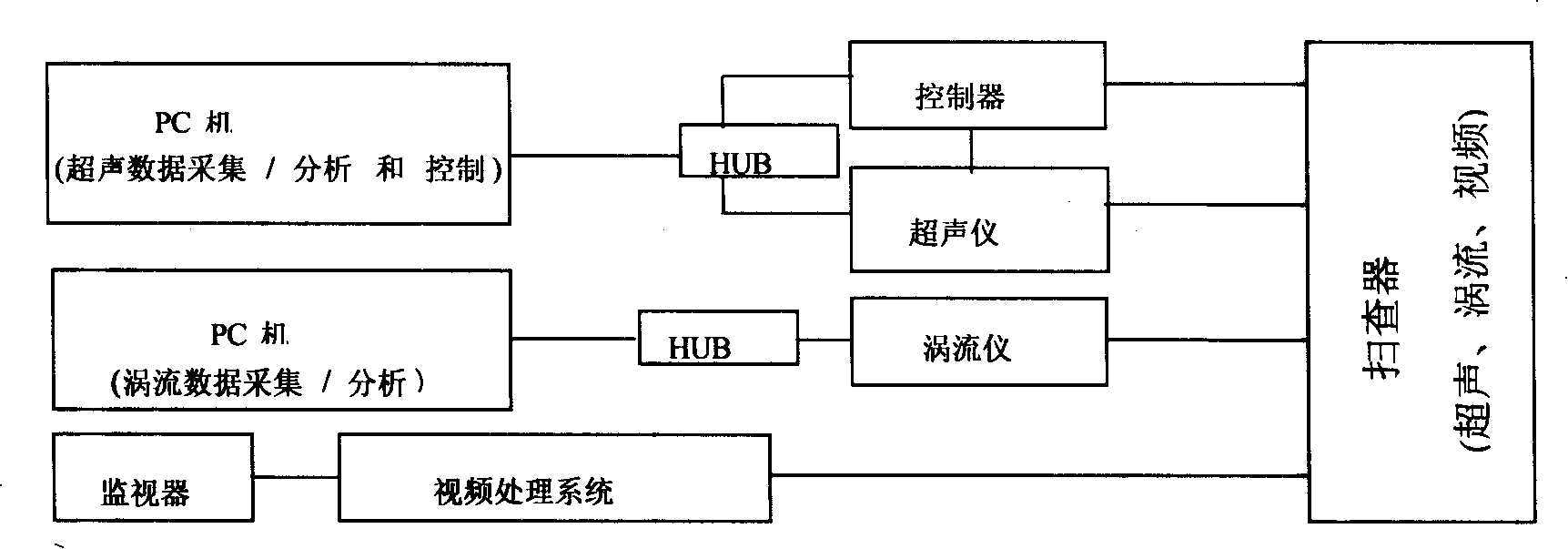

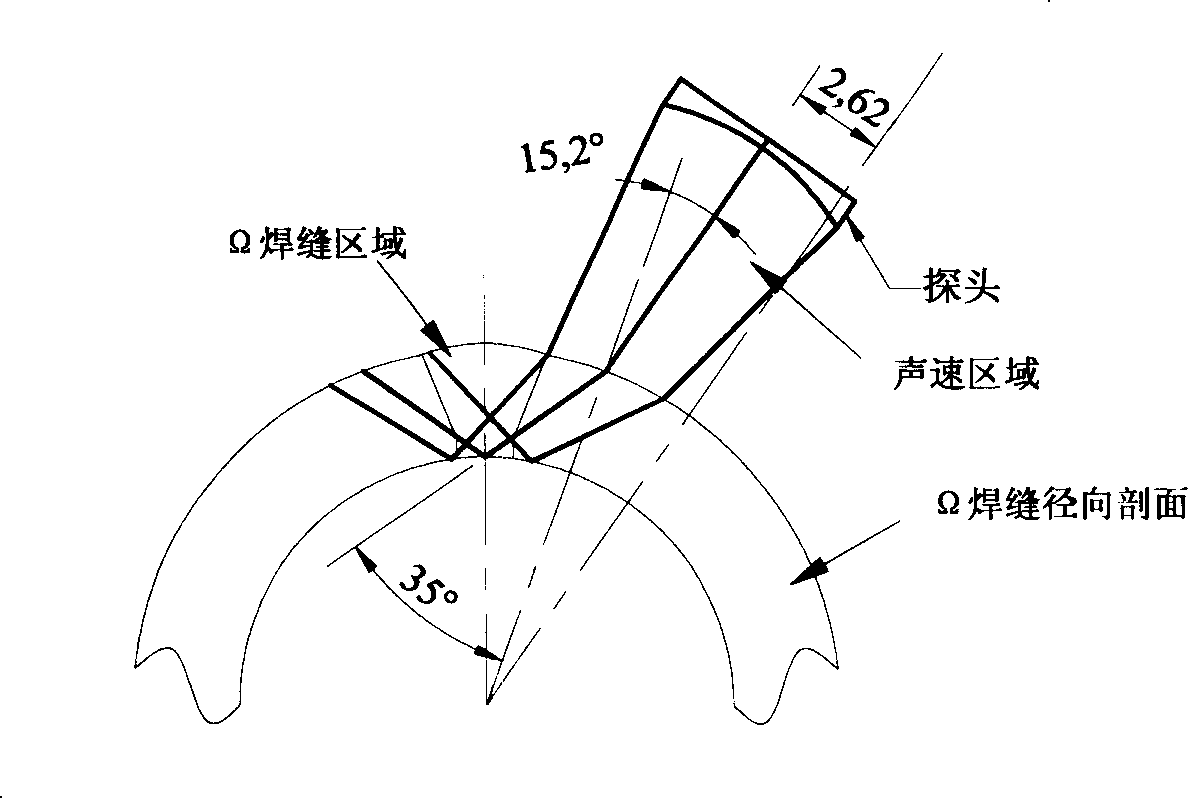

Pressure vessels top cover actuating device lower omega welding seam ultrasonic inspection method and device

ActiveCN101192458AGuaranteed accuracyGuaranteed reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationReactor pressure vesselSonification

The invention relates to an ultrasonic inspection method which refers to the specific ultrasonic inspection method for an Omega weld line beneath a driving mechanism of a reactor pressure vessel. In the method, the Omega weld lines is scanned with a ultrasonic probe, signals are collected through a digital ultrasonic device, then analyzed through a PC machine. During the inspection, four ultrasonic probes are used for scanning the weld lines and all the four probes enter with a refraction angle of transverse waves for 35-degree incidence. The focal point of the focusing probe falls on the axial lead of the Omega weld line that runs vertical to the vocal axis. In addition, a double crystal probe is used in the method to conduct a penetration scan of one deliver and one receive at the bottom and the medium parts of the Omega weld, and a eddy current probe is used for checking defects on the surface of the Omega weld line and the near surface. With the single sided array, the method can conduct overall ultrasonic inspection for the weld line beneath the driving mechanism of the pressure vessel cover for the reactor.

Owner:RES INST OF NUCLEAR POWER OPERATION

Electroluminescence device, planar light source and display using the same

InactiveCN1638585AGood light extraction efficiencyEfficient extractionElectroluminescent light sourcesSolid-state devicesClear LayerOrganic layer

The invention provides an organic electroluminescent device, comprising an organic layer, the organic layer includes an emission layer; a pair of electrodes sandwiching the above organic layer, consisting of a cathode and an anode, wherein at least one electrode is transparent a transparent layer disposed adjacent to the light extraction surface of the transparent electrode; a region, substantially interfering with the angle of reflection and refraction of light, disposed adjacent to or within the transparent layer, wherein the transparent layer's The refractive index is substantially equal to or greater than that of the emissive layer.

Owner:NITTO DENKO CORP

Horizontal surface plasmon resonance instrument with improved light path

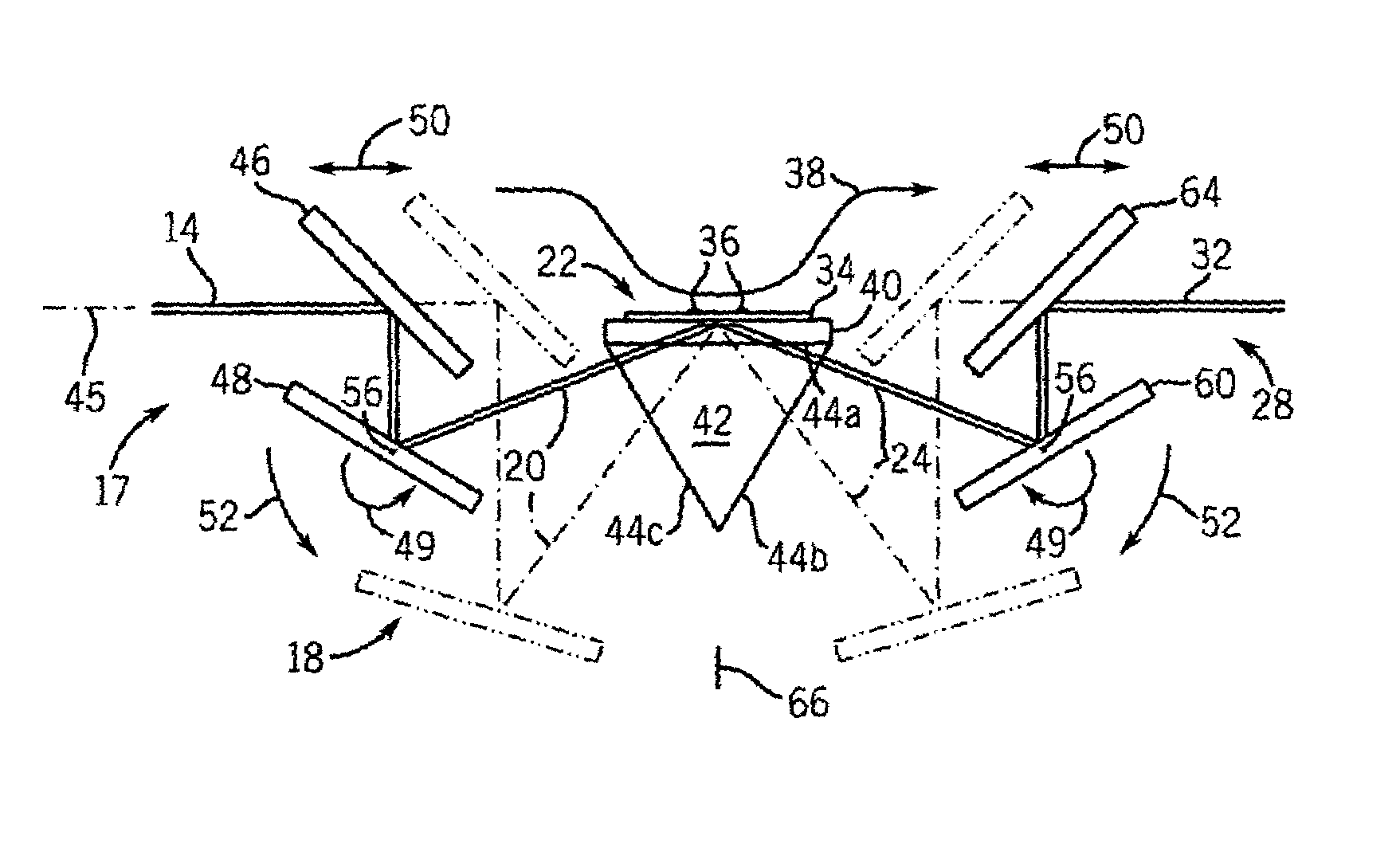

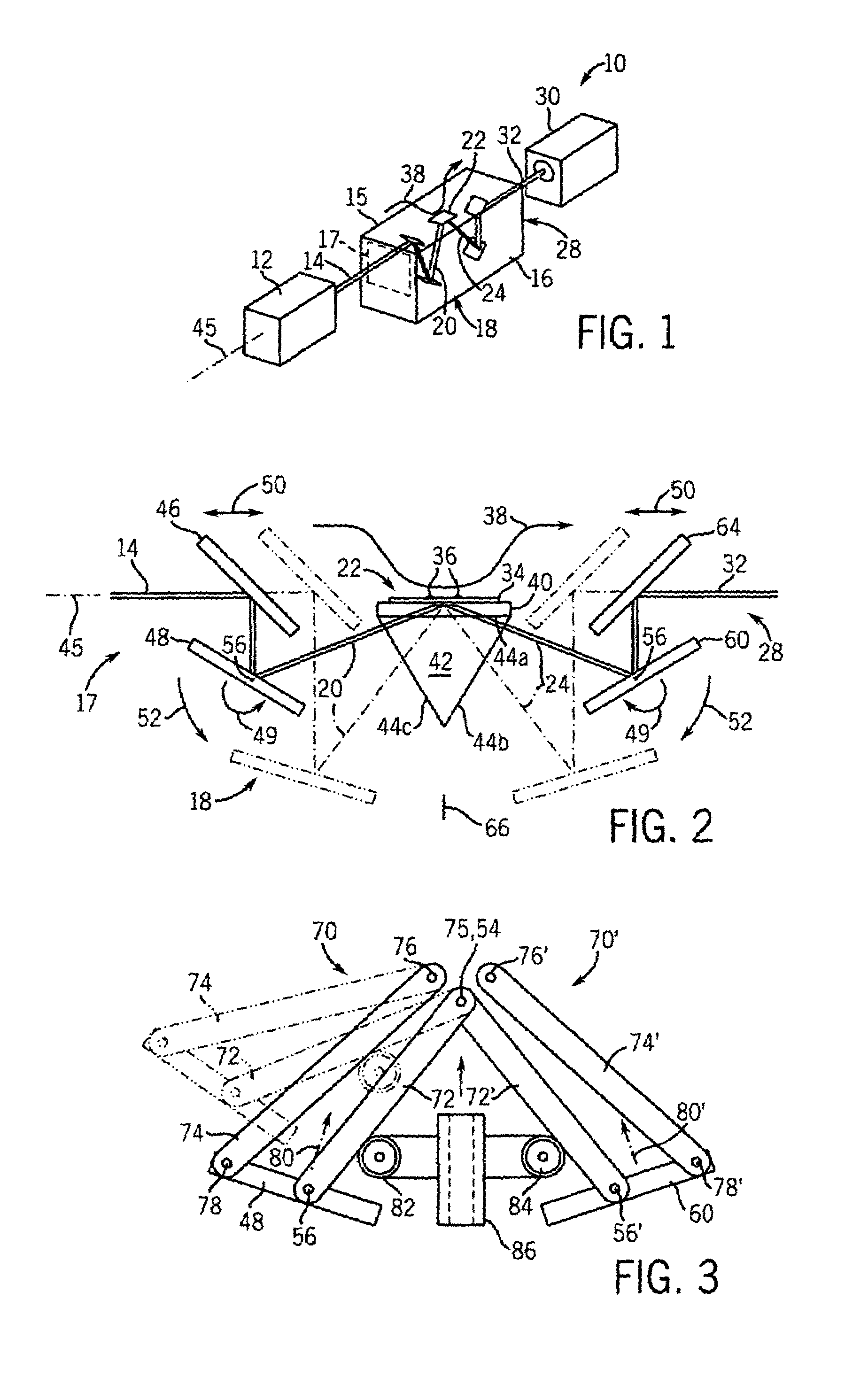

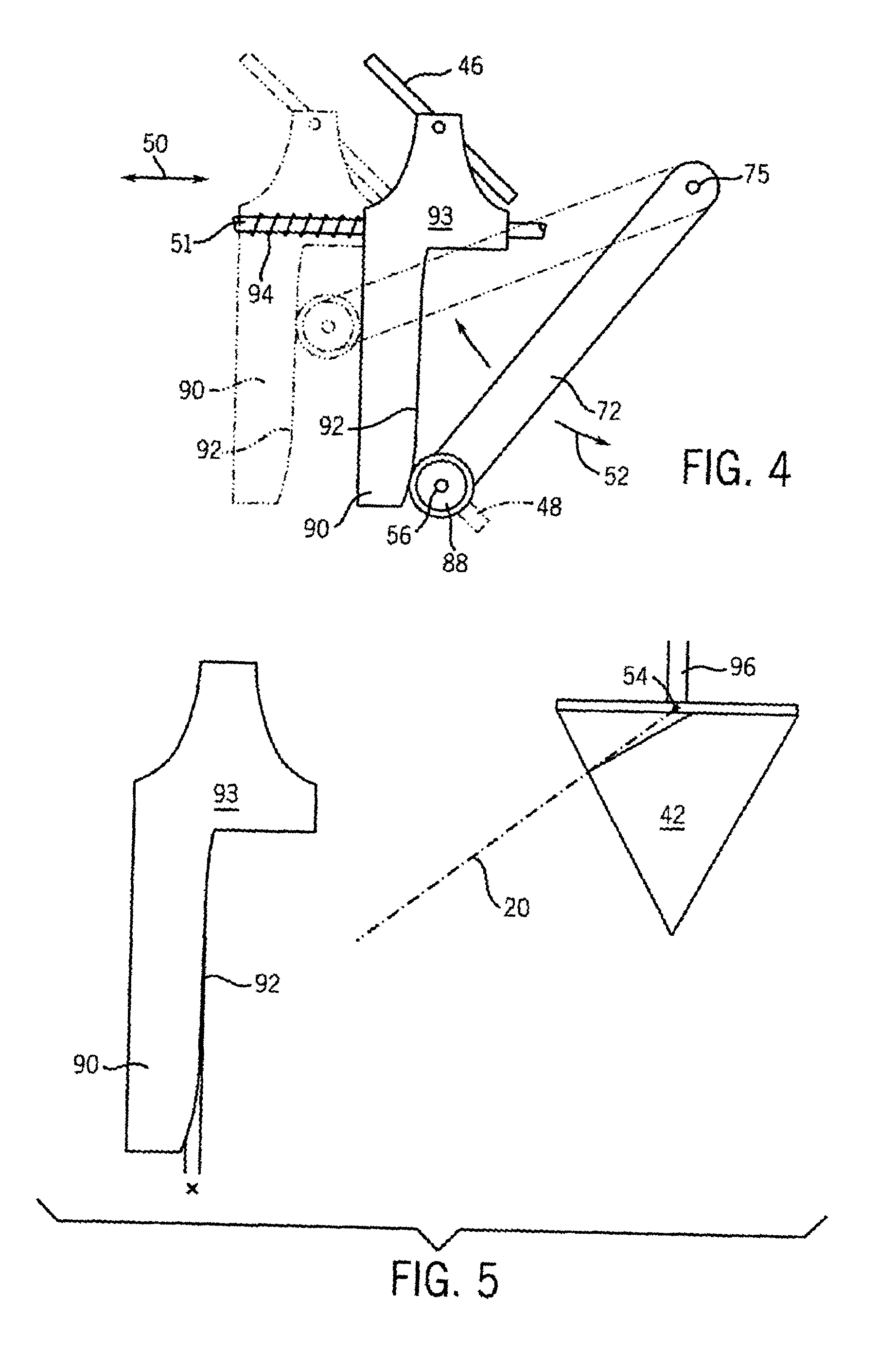

A surface plasmon resonance imaging apparatus provides an improved optical assembly allowing fixed source and detector operating with a horizontal test surface for a more compact design. In a preferred embodiment, a mechanical linkage of planar mirrors provides a single point adjustment of angle of incidence and angle of refraction while maintaining a constant optical axis of the source and detector.

Owner:WISCONSIN ALUMNI RES FOUND

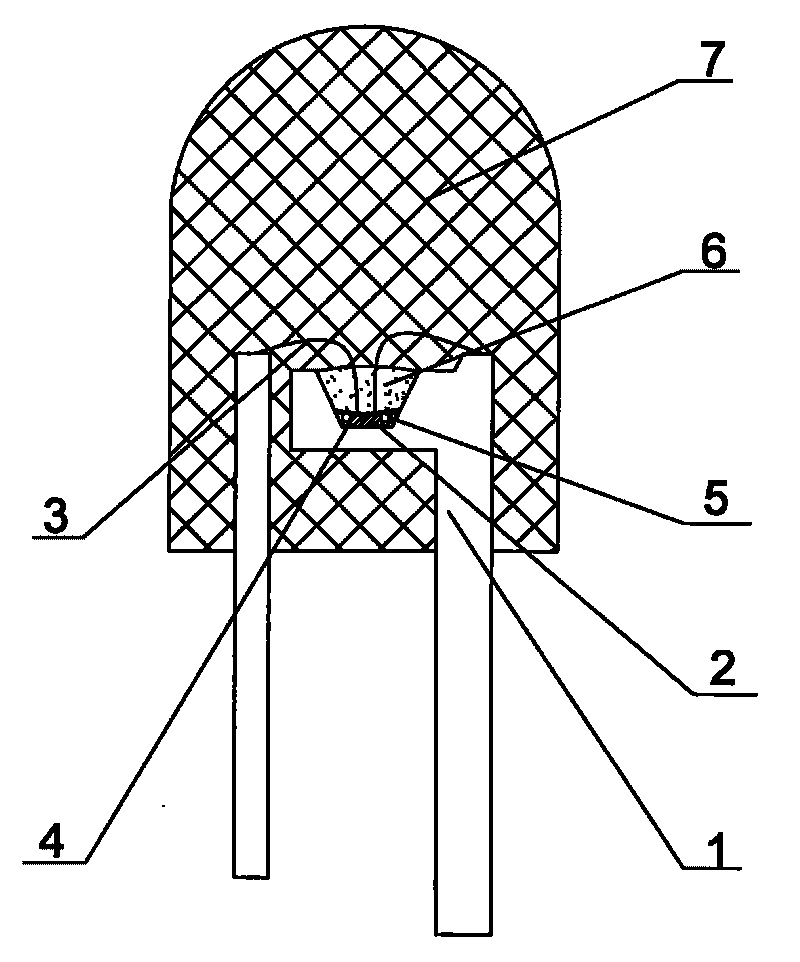

Manufacture method of low-attenuation white light LED

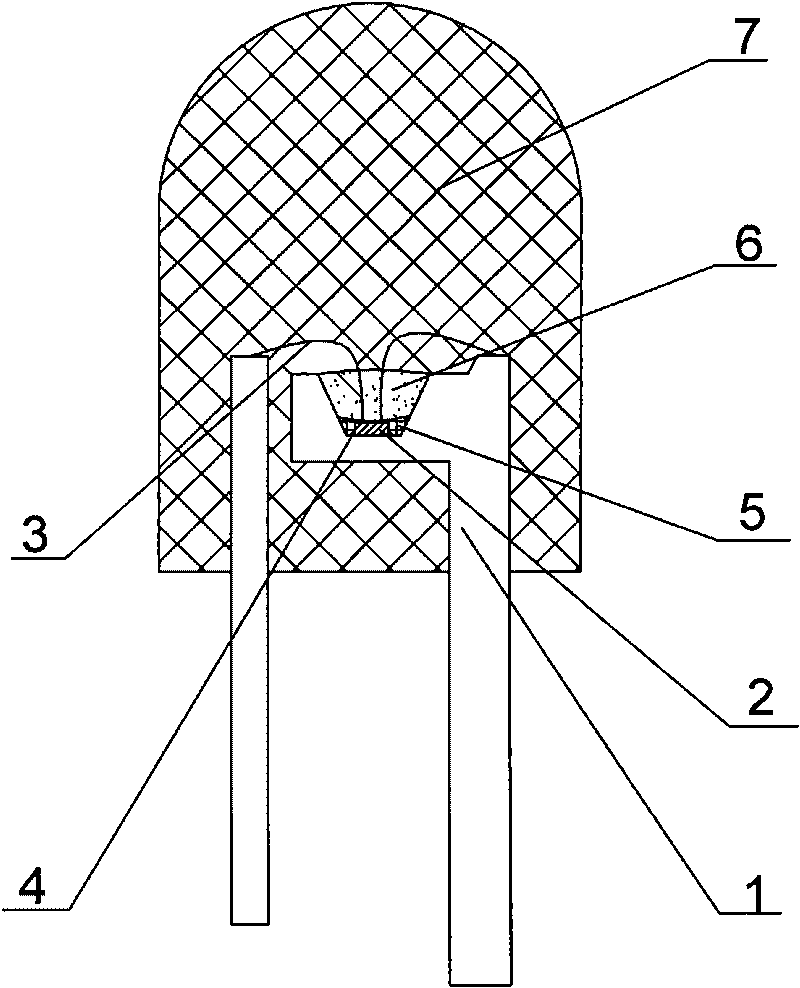

InactiveCN101694857AChange the angle of refractionReduce reflectivitySemiconductor devicesEpoxyUltrasound attenuation

The invention discloses a manufacture method of a low-attenuation white light LED, which comprises the following steps of (1), fixing a blue wafer in a base of a bracket, welding a line; (2), firstly adding inorganic filler in a main agent of silicon gel, uniformly stirring, then adding a curing agent to be uniformly mixed with the inorganic filler; (3), adding yellow fluorescent powder in the silicon gel containing two components, uniformly stirring and coating on the blue wafer to form a first coating layer, baking and curing;(4), adding a nano inorganic filler in a mixture of the silicon gel and epoxy glue, uniformly stirring, coating on the first coating layer to form a second coating layer, baking and curing; and (5), packing the periphery of the base by using the epoxy glue. A stress buffer layer is additionally arranged between the first coating layer and the externally packed epoxy glue, thereby changing the refraction angle of the light, reducing the reflection ratio of the light and the attenuation of the light, improving the light extraction efficiency of the white light LED, greatly improving the attenuation property of the product and ensuring the reliability of the product.

Owner:中外合资江苏稳润光电有限公司

Ultrasonic detection method of scale thickness in pipeline

ActiveCN102183229ASolving problems of unknown natureRealize in-service testingUsing subsonic/sonic/ultrasonic vibration meansSimultaneous equationsClassical mechanics

The invention discloses an ultrasonic detection method of scale thickness in a pipeline. The method comprises the following steps of: utilizing double incidences of ultrasonic waves at different angles, establishing simultaneous equations on the basis of propagation velocities of the known ultrasonic wave on the pipe wall and in the filled fluid and the relationship between an incident angle and a refraction angle of the ultrasonic wave by measuring the penetration time of the ultrasonic waves in the pipeline filled with fluid during the double incidences, and further calculating the velocity and the thickness of a scale layer in the pipeline. With the method, the scale thickness can be measured under the condition that the scale characteristic is unknown, the working detection of the pipeline can be achieved, and the method has reliable accuracy and no destructive effect.

Owner:常熟紫金知识产权服务有限公司

Robust stereo calibration system and method for accurate digital image correlation measurements

ActiveUS8248476B2Maintain accuracyConvenient and accurateUsing optical meansTelevision systemsExplicit modelObject point

Owner:UNIVERSITY OF SOUTH CAROLINA

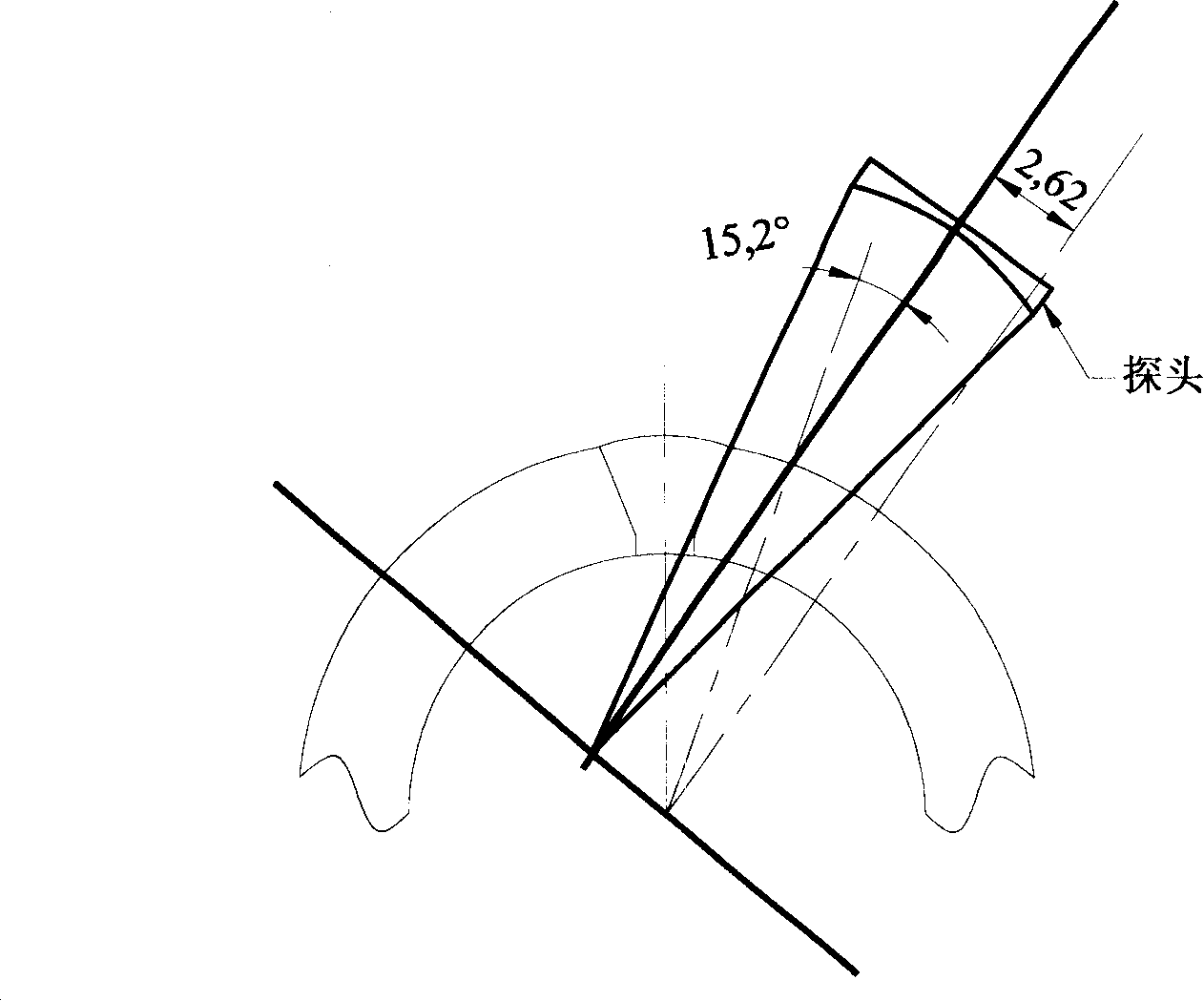

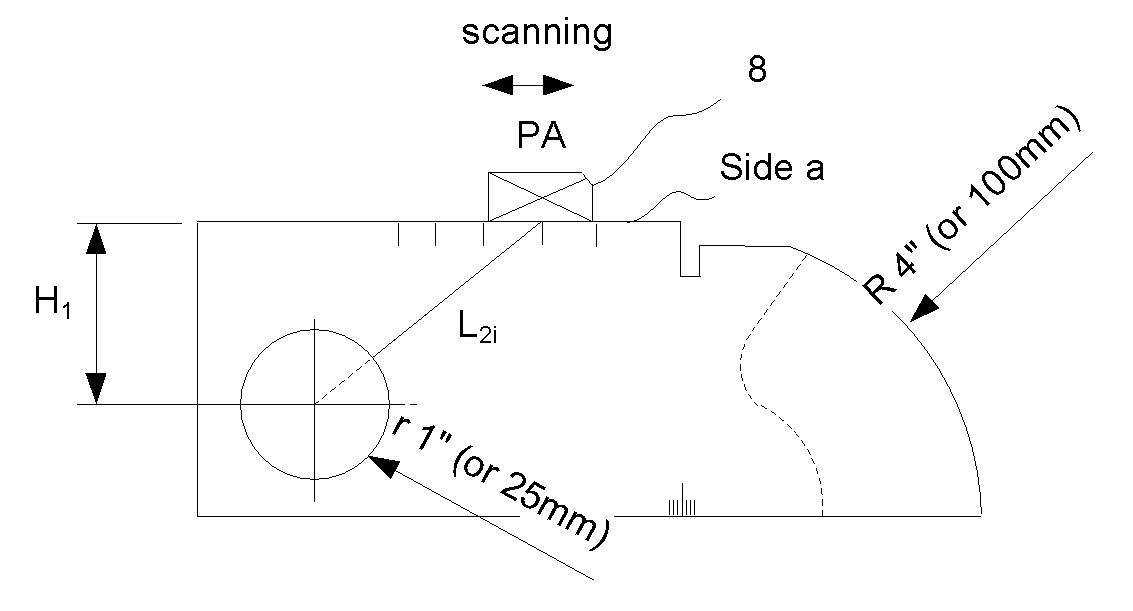

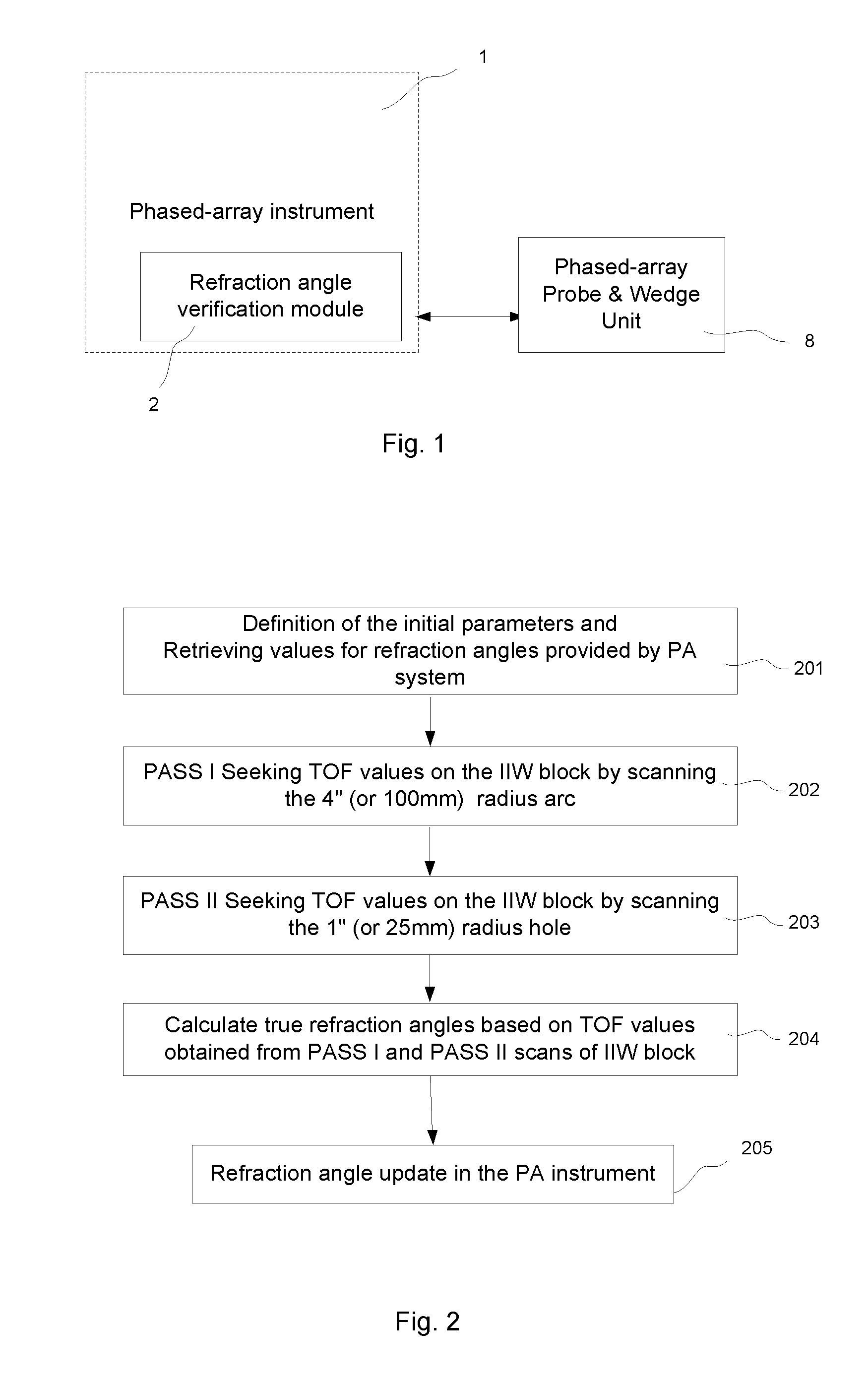

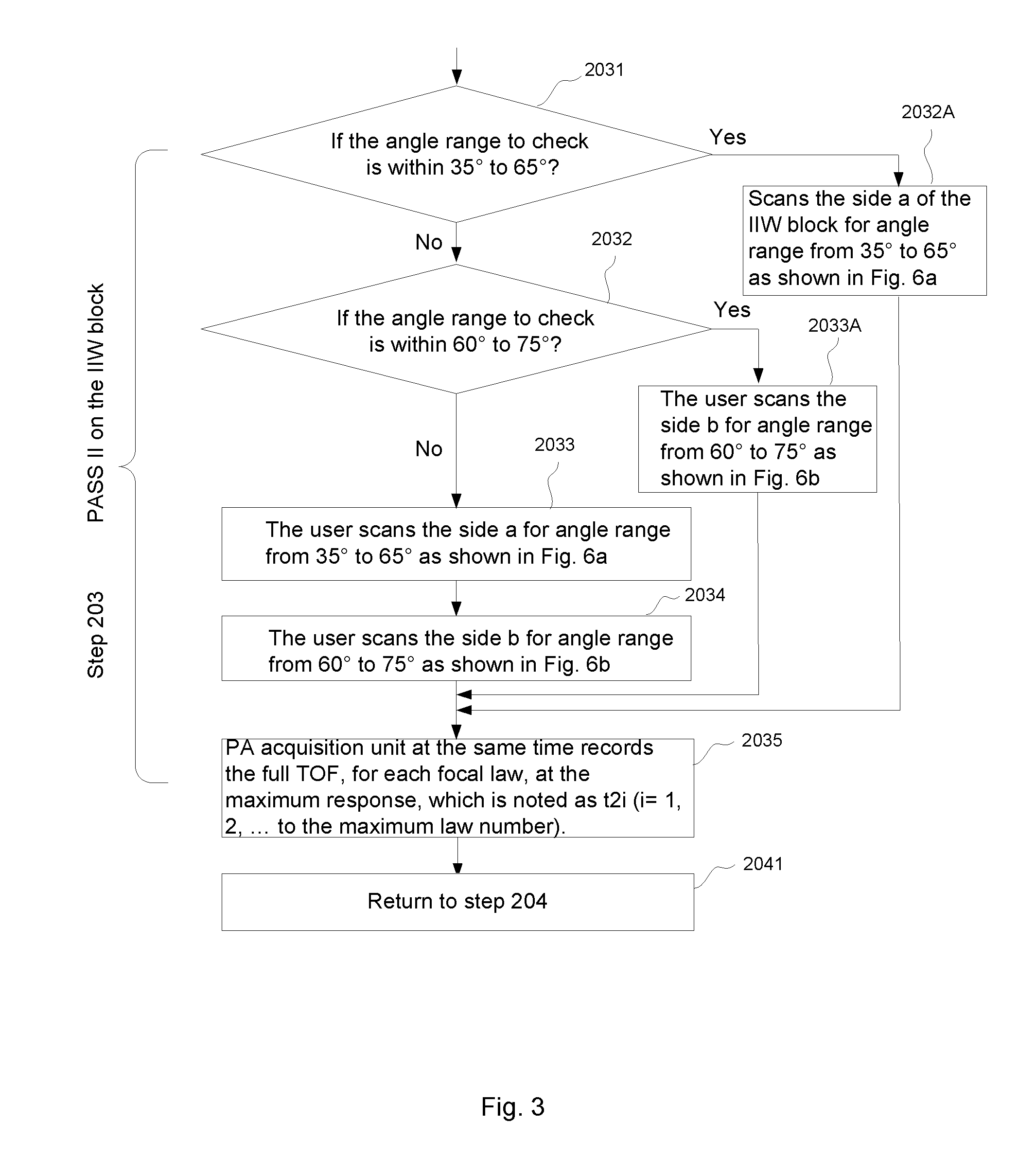

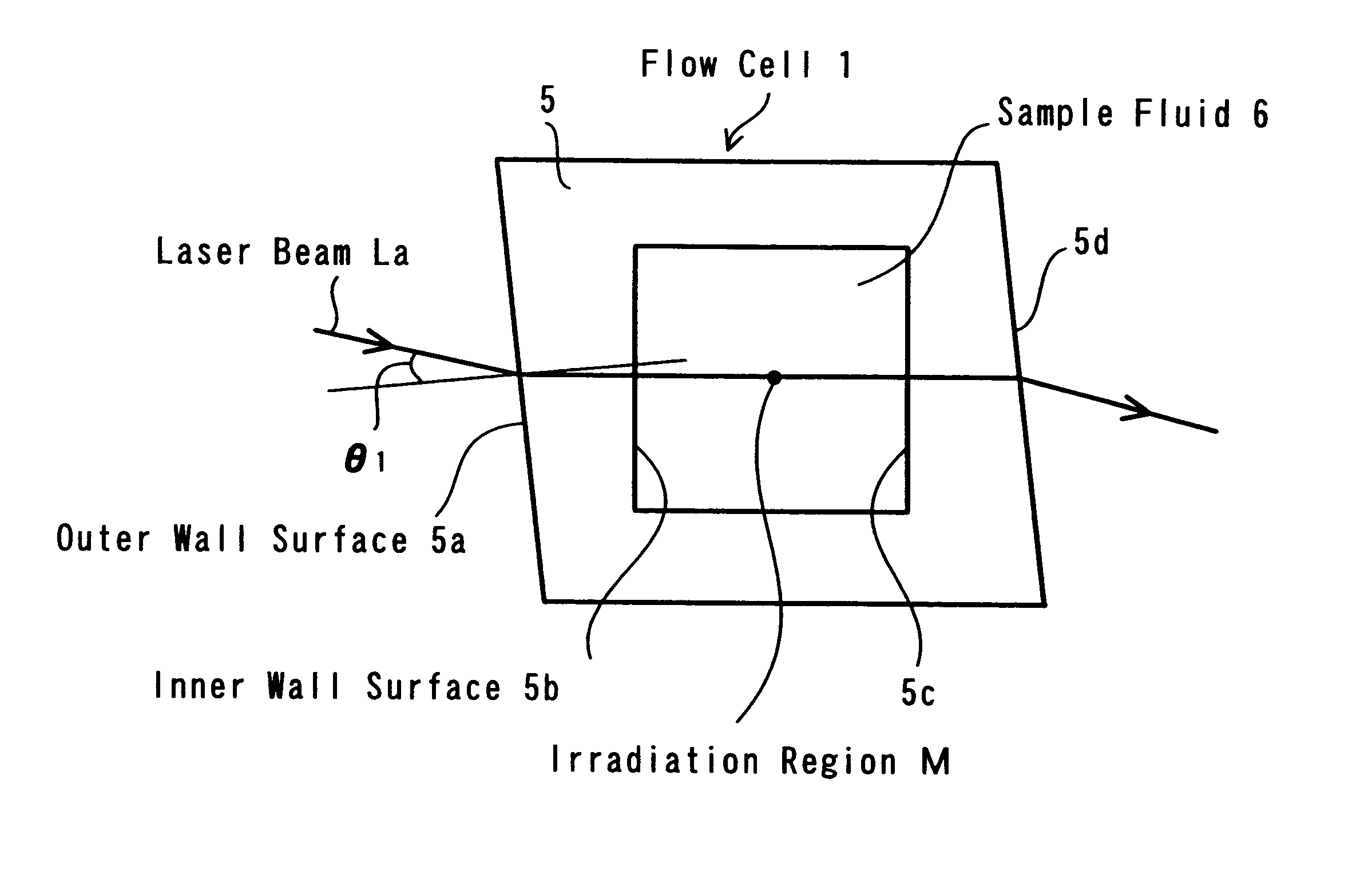

System and method of conducting refraction angle verification for phased array probes using standard calibration blocks

ActiveUS20120130653A1Easy to operateHighly accurate and consistent resultAnalysing solids using sonic/ultrasonic/infrasonic wavesFlow propertiesNon destructiveSonification

Disclosed is an ultrasonic phased array non-destructive inspection system that includes a PA probe, a conventional PA inspection unit and a refraction angle verification unit. The PA inspection unit is employed to emit ultrasonic angle beams into an AWS 11W Block and to receive a set of corresponding echo signals reflected from the calibration block and to provide time-of-flight (TOF) values corresponding to each angle beam. The refraction angle verification unit then provides a true angle for each of the angle beams based on the ultrasonic and geometric characteristics of the block and the measured TOF values. Other calibration blocks such as the DSC and Nayships blocks can also be used for this purpose.

Owner:OLYMPUS AMERICA

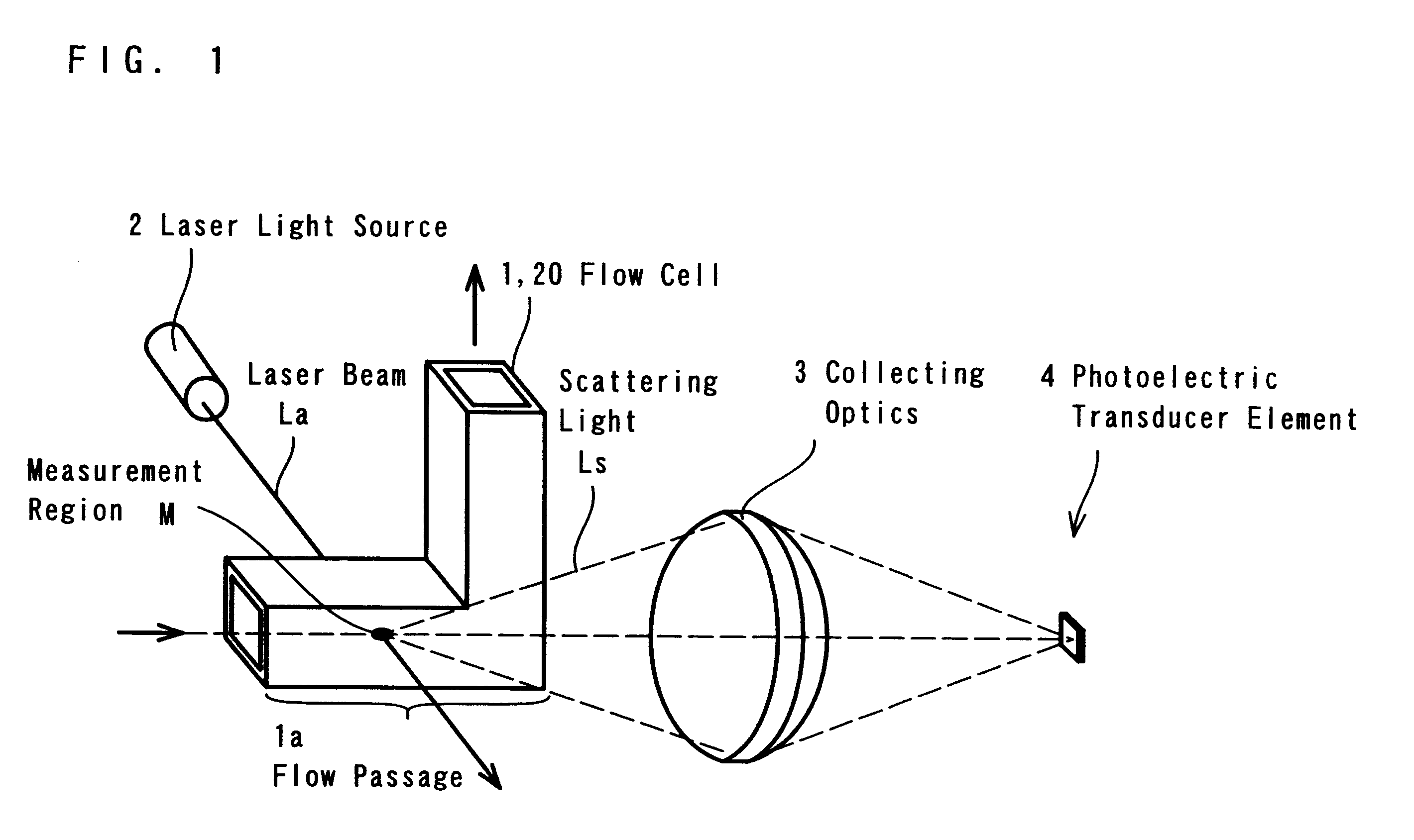

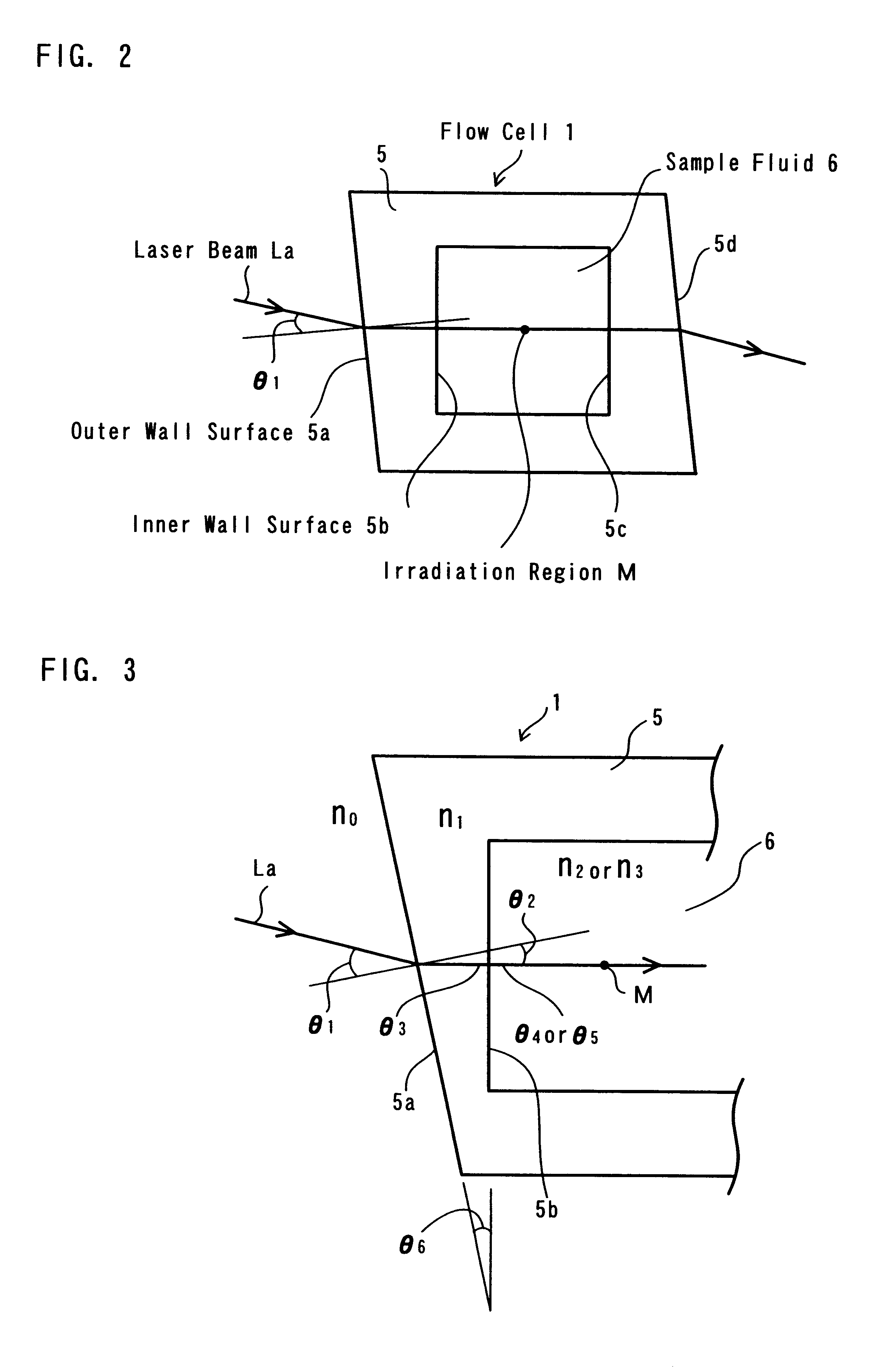

Particle measurement apparatus flow cell useful for sample fluids having different refractive indexes

InactiveUS6465802B1Prevents superposing of feedback noiseReduce noiseInvestigating moving fluids/granular solidsScattering properties measurementsFlow cellRefractive index

A flow cell for obtaining information on particles suspended in sample fluid, wherein an irradiation region M is defined in the flow cell for functioning as a particle detection portion to be irradiated with a laser beam La, and a wall portion of the flow cell is so adapted and arranged that the laser beam La becomes incident upon an outer wall surface of the flow cell 1 at a predetermined angle theta1 (theta1<> 0°) and exits from an inner wall surface 5b of the flow cell 1 into the sample fluid 6 at a refraction angle 0°.Further the wall portion 5 of the flow cell 1 is so arranged that the laser beam La becomes incident upon a boundary surface between the sample fluid and the opposite inner wall surface of the flow cell 1 at a predetermined incident angle alpha (alpha<> 0°) after being incident upon the sample fluid and passing through the irradiation region M.

Owner:RION COMPANY

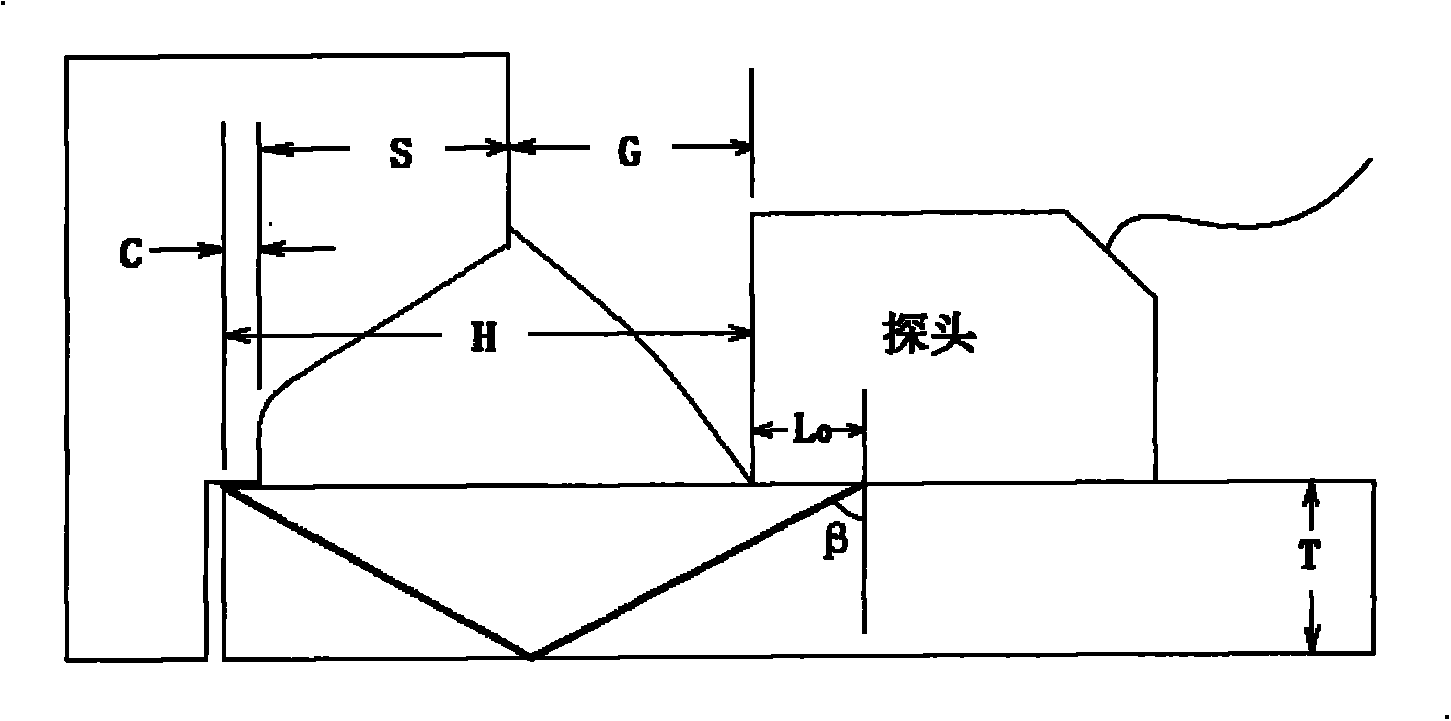

Ultrasonic detection method for weld joint of small-caliber pipe shelf angle

InactiveCN103439408AAccurate identificationImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesInsertion depthRefraction angle

The invention provides an ultrasonic detection method for a weld joint of a small-caliber pipe shelf angle. A digital ultrasonic fault detector is adopted to calculate and determine the refraction angle of a probe utilizing the formula that beta is equal to or larger than tan<-1>[(H+L0) / 2T] according to weld joints of pipe shelf angles in various specifications, so that the acoustic beam axis of the primary reflection wave can reach the end part of a pipe adapter, wherein H is the sum of the weld joint of the shelf angle, the depth of a header groove and the insertion depth of the pipe adapter, and T is the wall thickness of the pipe adapter; a monocrystal transverse wave angle probe with a corresponding refraction angle is adopted for detection from the outer side of the pipe shelf, so that a defect at the root part of the welt joint of the shelf angle can be effectively detected, a defect wave and structural wave can be accurately identified, missed detection and wrong detection during the detection of the workpieces can be reduced, and the accuracy of the detection work can be greatly improved.

Owner:TRANSTEK IND HK LTD KOWLOON

System and method for X-ray optical grating contrast imaging

ActiveCN101576515ALower application thresholdReduce production difficulty requirementsMaterial analysis using wave/particle radiationRadiation diagnosticsGratingRefractive index

The invention relates to a system and a method for X-ray grating contrast imaging. The system comprises an X-ray launching device, a first absorption grating, a second absorption, a detecting unit, a data processing unit and an imaging unit, wherein the X-ray launching device is used for launching X-ray beams to a detected article; the first absorption grating and the second absorption grating are positioned in the launching direction of the X-ray beams, and the X-ray refracted by the detected article forms X-ray signals with different intensity by the first absorption grating and the second absorption grating; the detecting unit is used for receiving the X-ray signals with changeable intensity and converting the X-ray signals into electric signals; and the data processing unit is used for processing and extracting the refraction angle information in the electric signals and calculating the pixel information through the refraction angle information; the imaging unit is used for constructing the image of the article. In addition, a rotating structure can also be utilized to rotate the article to realize a CT imaging mode so as to obtain refraction angles in a plurality of projection directions and the corresponding images and calculate the refraction index tomography image of the detected article by CT reconstruction algorithm. The system and the method adopt the common X-ray machine and the grating above a period of ten micron magnitude to realize the contrast imaging of a decimeter magnitude like viewing field.

Owner:NUCTECH CO LTD +1

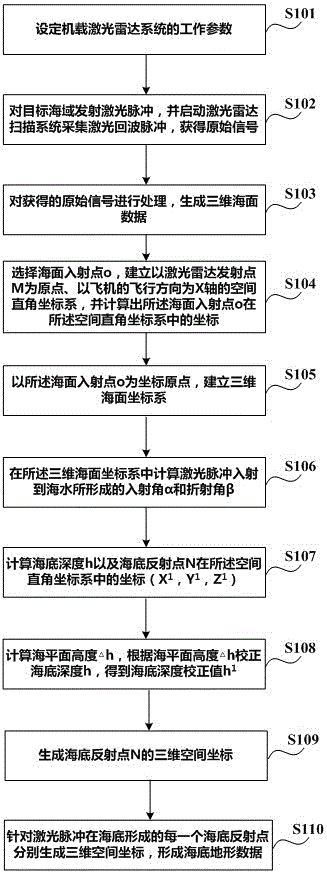

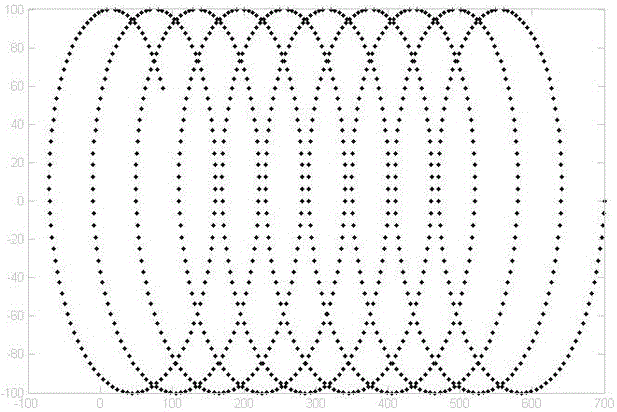

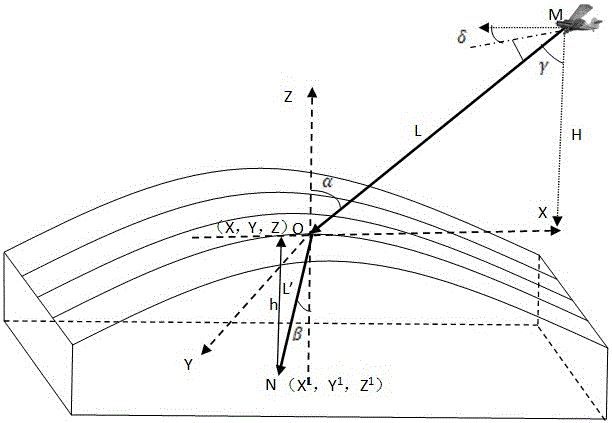

Sea surface error correction method for measuring submarine topography on basis of airborne laser radar

ActiveCN106199562AAccurate measurementImprove accuracyElectromagnetic wave reradiationOcean bottomRectangular coordinates

The invention discloses a sea surface error correction method for measuring the submarine topography on the basis of airborne laser radar. The method comprises the steps that three-dimensional sea surface data is generated according to sea return pulses, a space rectangular coordinate system taking a laser radar launching point M as an original point is established, and coordinates of a sea surface incidence point in the space rectangular coordinate system are calculated; a three-dimensional sea surface coordinate system taking the sea surface incidence point as a coordinate original point, an incidence angle alpha obtained when a laser is incident on sea water and a refraction angle beta are calculated, then the submarine depth h can be calculated according to the incidence angle alpha, the refraction angle beta and the incidence distance L' of refracted rays, the submarine depth h is corrected according to the sea surface height delta h to obtain a submarine depth correction value h1, and then submarine topography data can be formed. According to the sea surface error correction method, errors caused by sea heaving can be effectively corrected, the problem that the precision is poor when the submarine topography is measured by traditional airborne laser radar is solved, and precise measuring of the submarine topography is achieved.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Road reflective marker line coating

InactiveCN101338152AImprove compactnessImprove liquidityTraffic signalsRoad signsFluorescenceCalcite

The invention discloses a road light-reflective mark coating which comprises components in the following mass percent: 15 percent to 25 percent of C5 petroleum resin, 1 percent to 2 percent of ethylene-acetic acid polyvinyl, 1 percent to 1.5 percent of Tissuemat E, 3 percent to 5 percent of titanium white powder, 8 percent to 12 percent of quartz sand, 1.5 percent to 2 percent of di-1-octyl, 8 percent to 12 percent of 1.5RI glass beads, 8 percent to 12 percent of 1.93RI glass beads, 0.1 percent to 0.3 percent of calcium stearate, 36 percent to 46 percent of calcite powder, 0.25 percent to 0.29 percent of bentonite and 0.02 percent to 0.04 percent of optical brightener. The coating of the invention is fine; the coating interface of the glass beads is quite smooth and close to an ideal concave mirror, can focus the light and has good reflection effect. The glass beads which are added in have high refraction rate and small refraction angle of the light; the refraction angle for the reflected light to be obliquely incident from water into the air is small, and the return reflection effect in rainy nights is good.

Owner:潘东海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com