Ultrasonic detection method of scale thickness in pipeline

A detection method and ultrasonic technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve problems such as large damage, affecting the normal operation of equipment, and inability to effectively understand the scale of the inner wall of the pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in combination with specific embodiments.

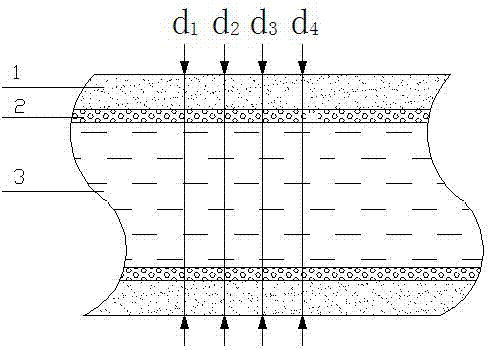

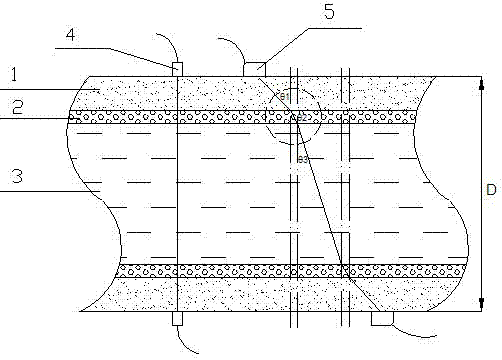

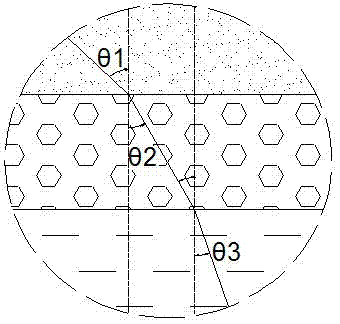

[0052] The concrete implementation method of the present invention is as follows:

[0053] (1) Use standard test block for zero point calibration

[0054] In actual testing, the ultrasonic wave has a propagation path in the probe, which will affect the accuracy of scale thickness measurement. Therefore, in order to improve the detection accuracy, we use standard test blocks for zero point calibration.

[0055] Select a standard test block with known sound velocity and known thickness to facilitate the determination of the propagation time required for ultrasonic waves to penetrate straight through the standard test block and obliquely penetrate in different paths; then calculate the total penetration time and corresponding The difference between the ultrasonic propagation time in the test block under the detection mode is the propagation time of the ultrasonic w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com