Patents

Literature

61results about How to "Good light extraction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

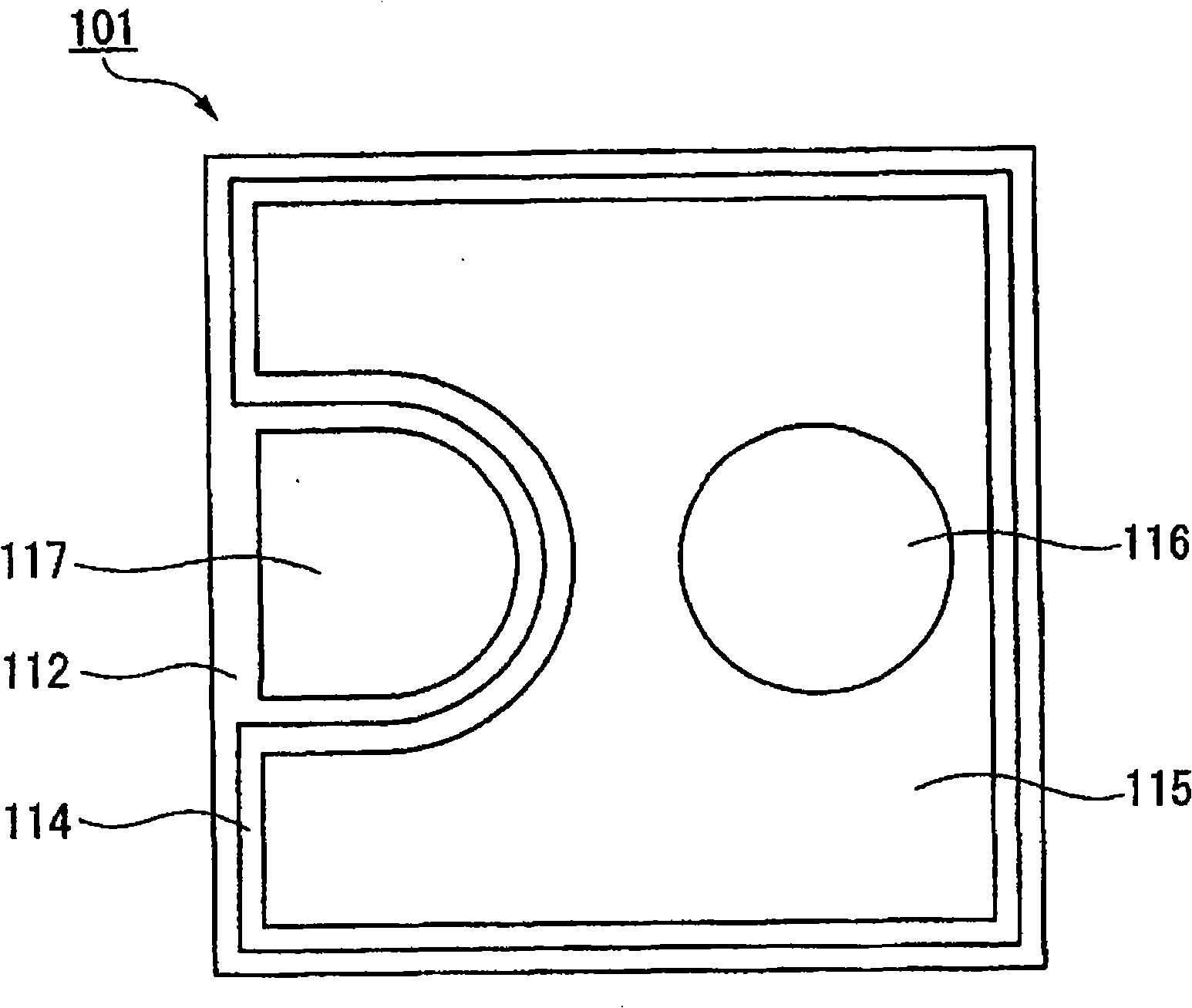

Electroluminescence device, planar light source and display using the same

InactiveCN1638585AGood light extraction efficiencyEfficient extractionElectroluminescent light sourcesSolid-state devicesClear LayerOrganic layer

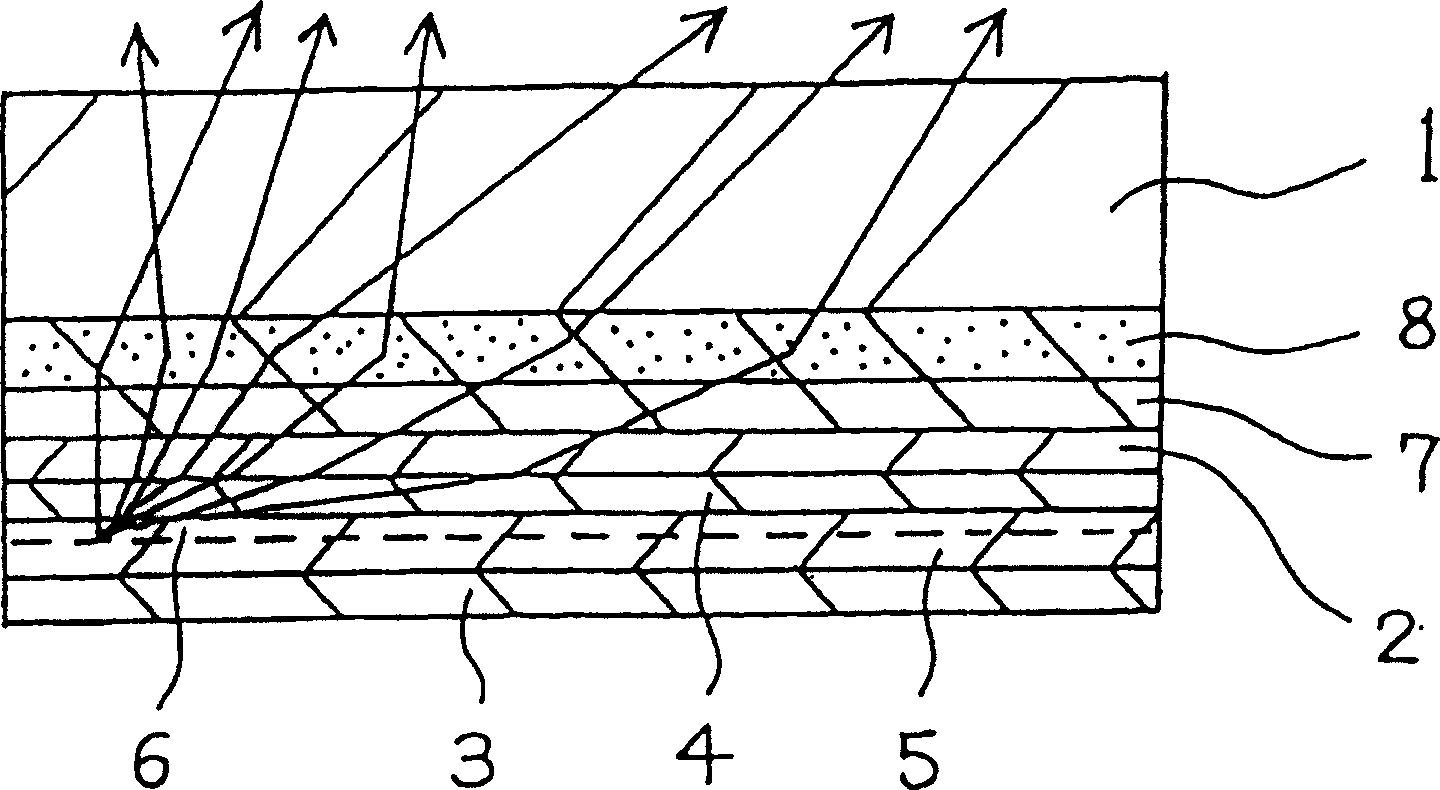

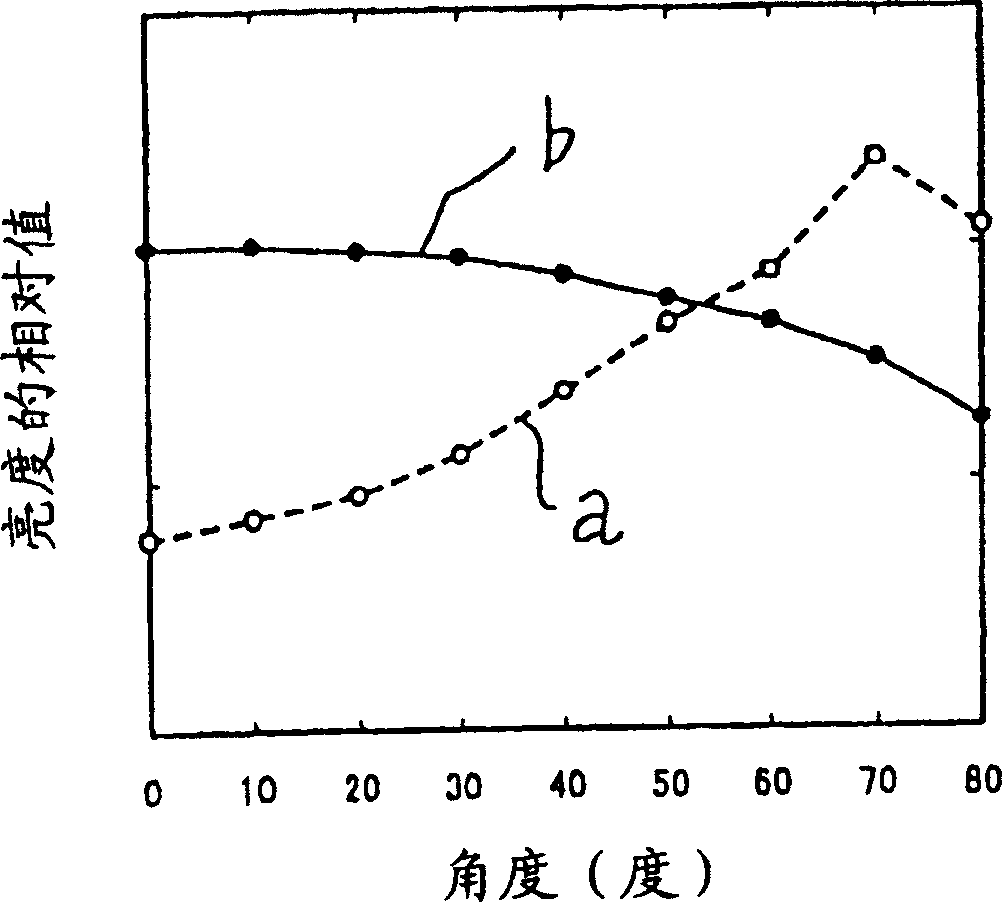

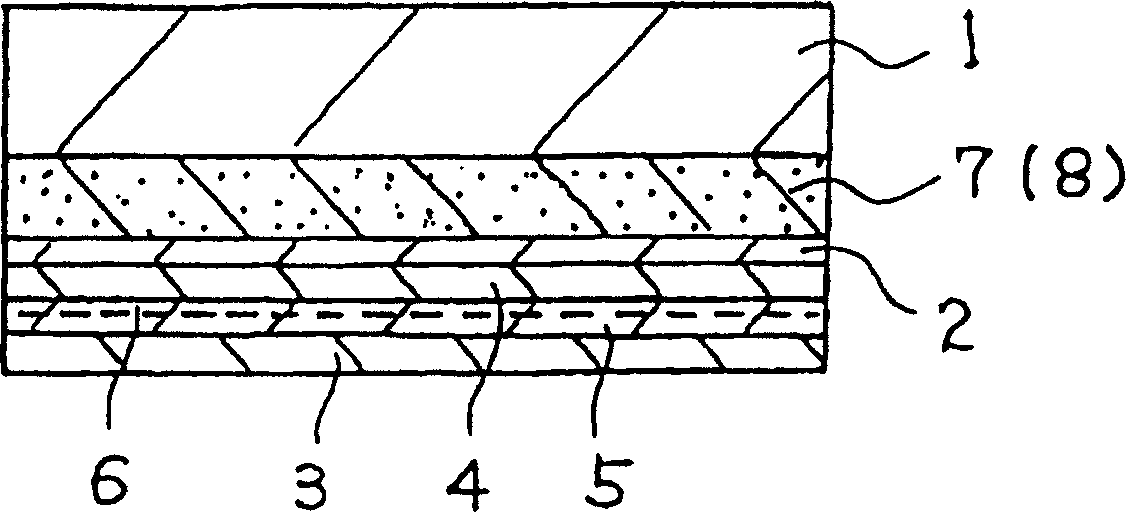

The invention provides an organic electroluminescent device, comprising an organic layer, the organic layer includes an emission layer; a pair of electrodes sandwiching the above organic layer, consisting of a cathode and an anode, wherein at least one electrode is transparent a transparent layer disposed adjacent to the light extraction surface of the transparent electrode; a region, substantially interfering with the angle of reflection and refraction of light, disposed adjacent to or within the transparent layer, wherein the transparent layer's The refractive index is substantially equal to or greater than that of the emissive layer.

Owner:NITTO DENKO CORP

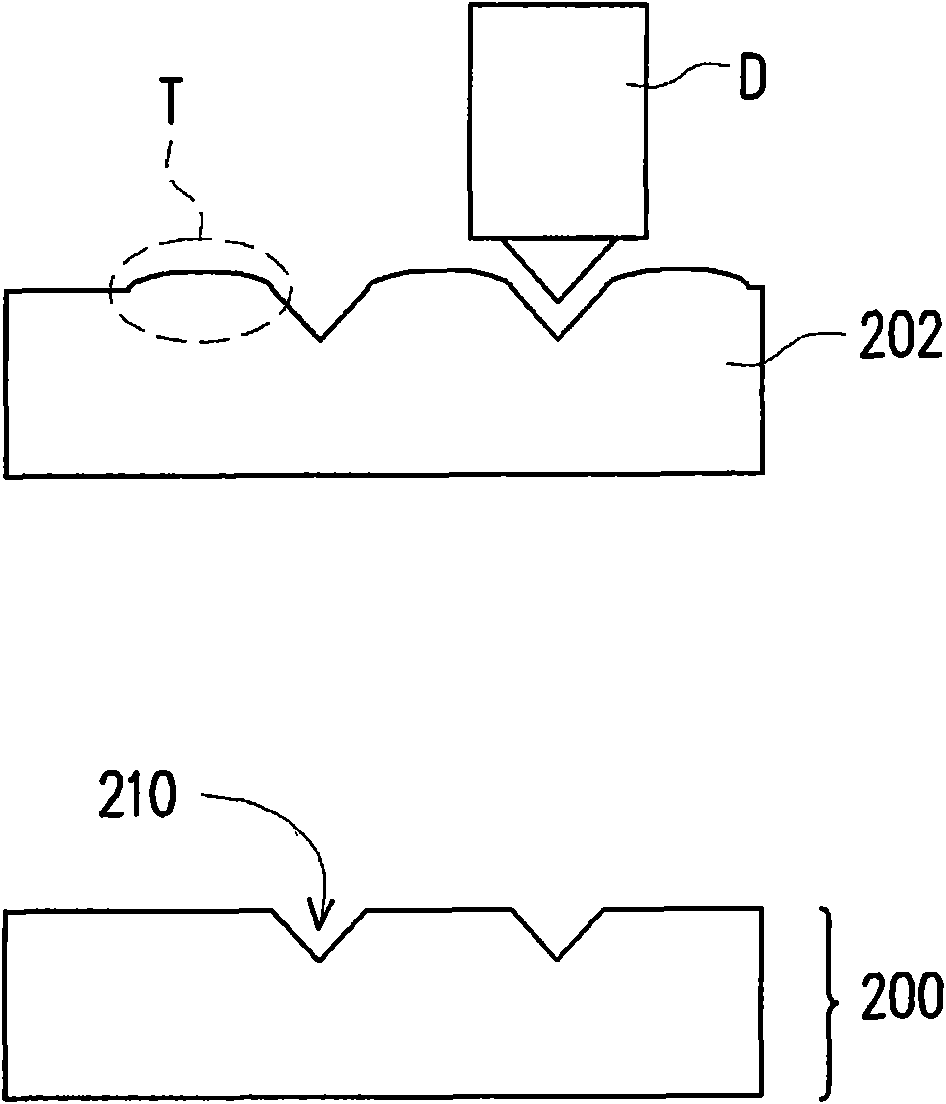

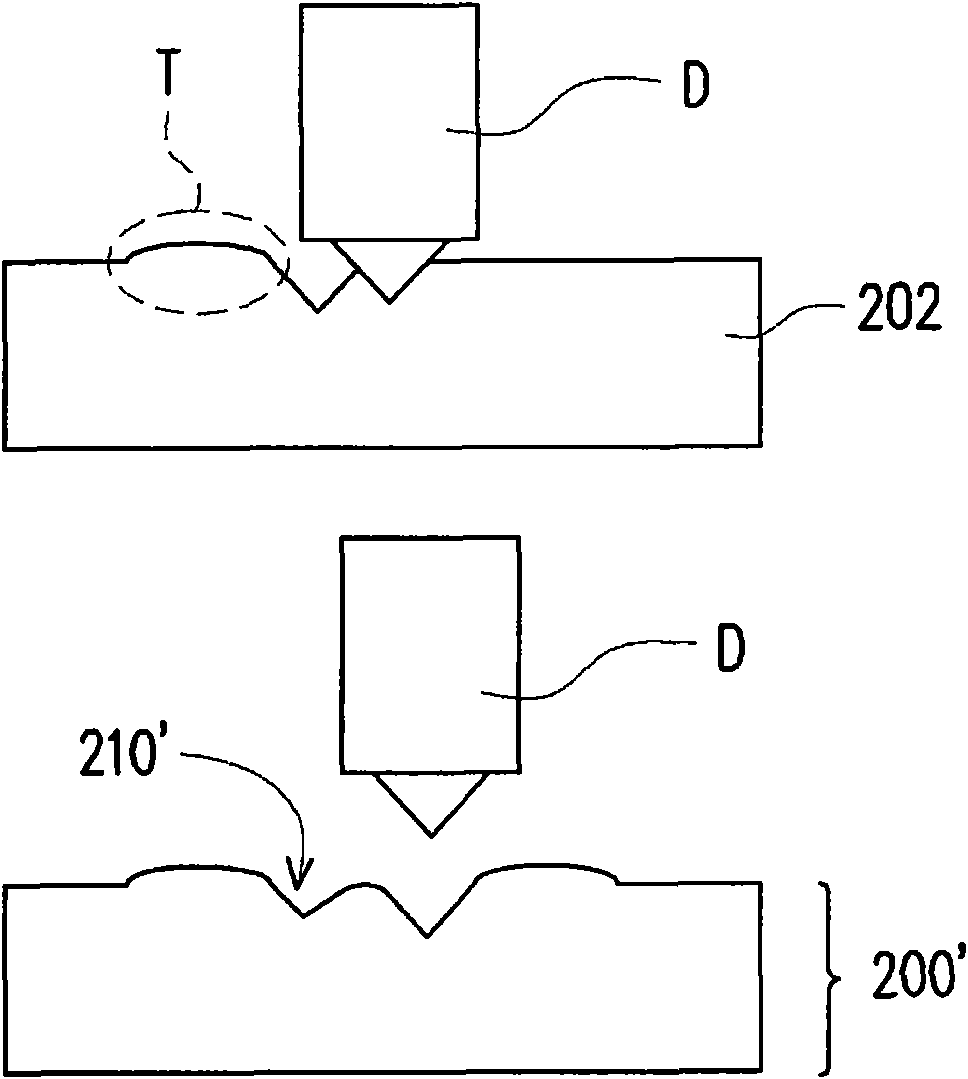

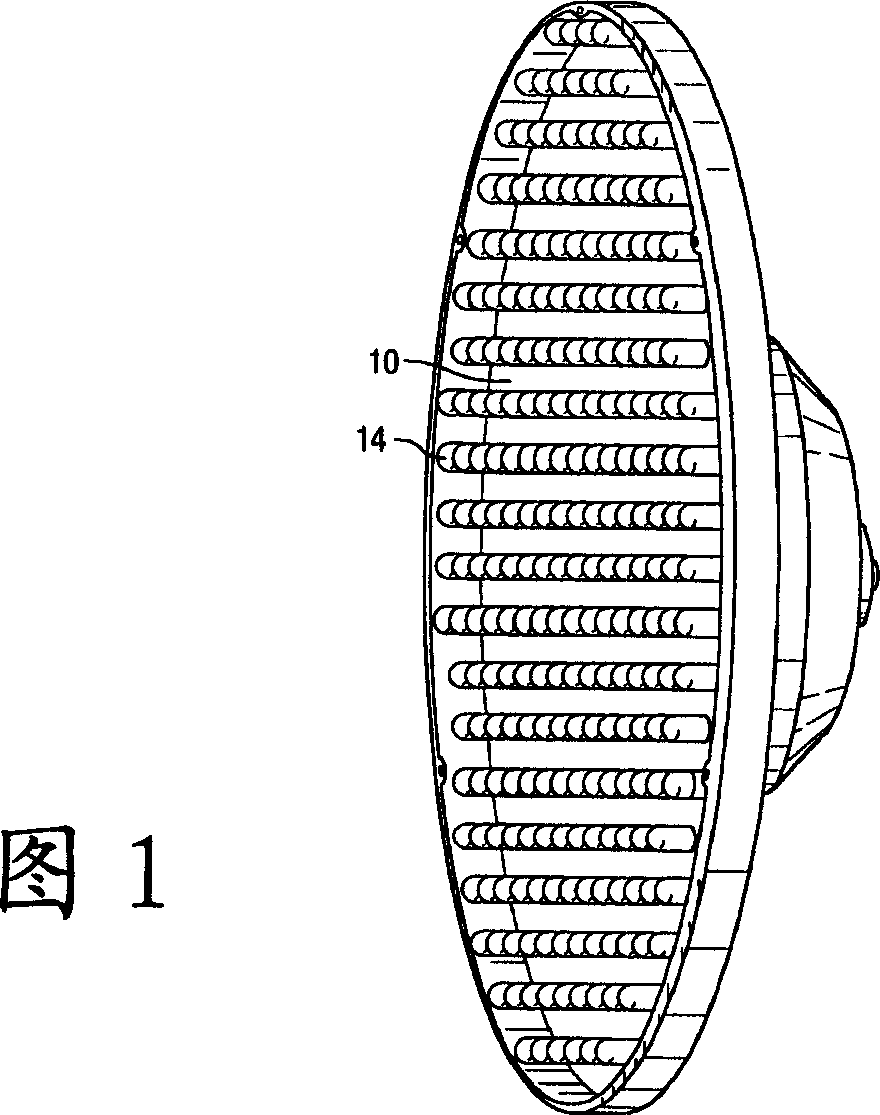

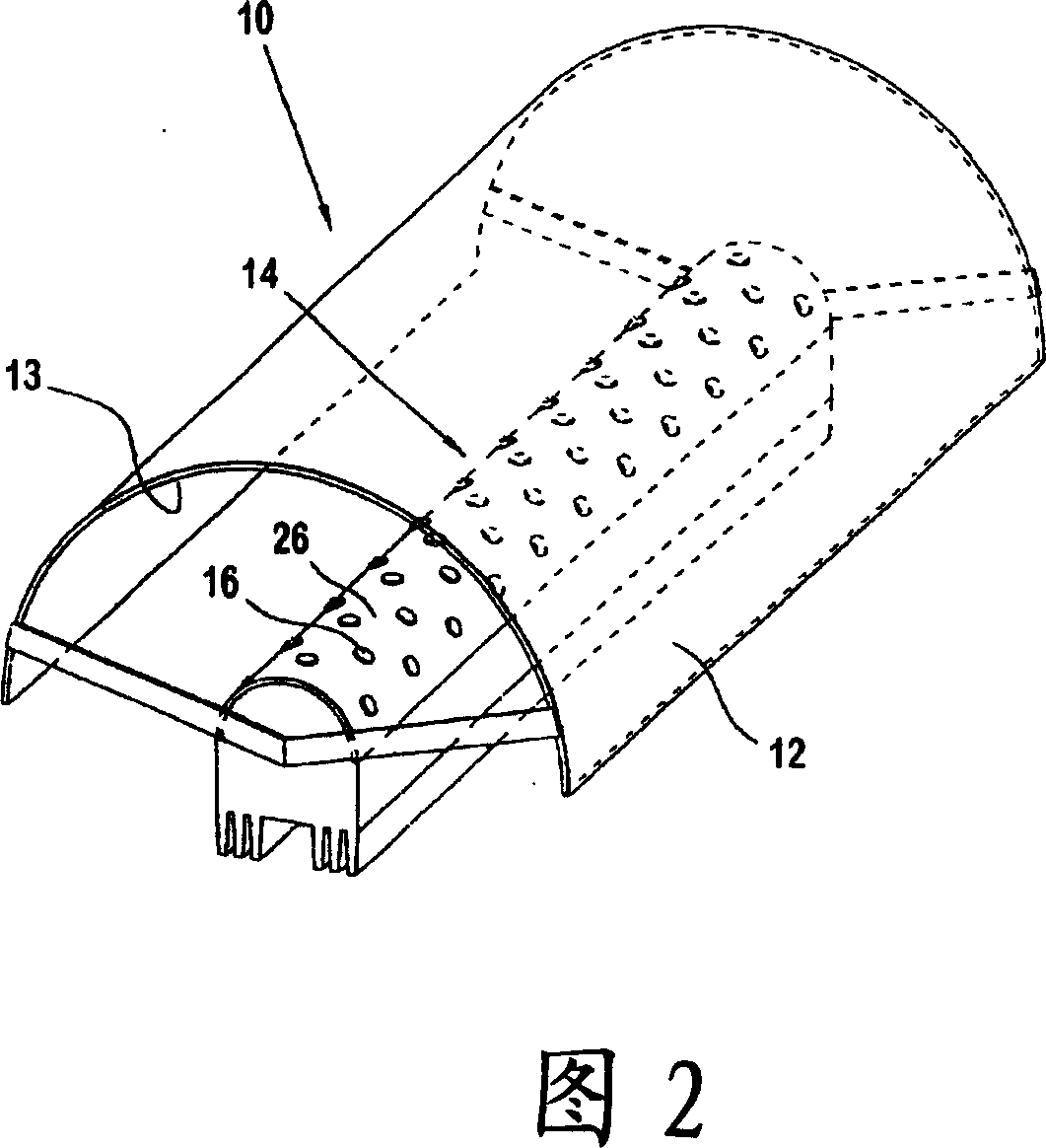

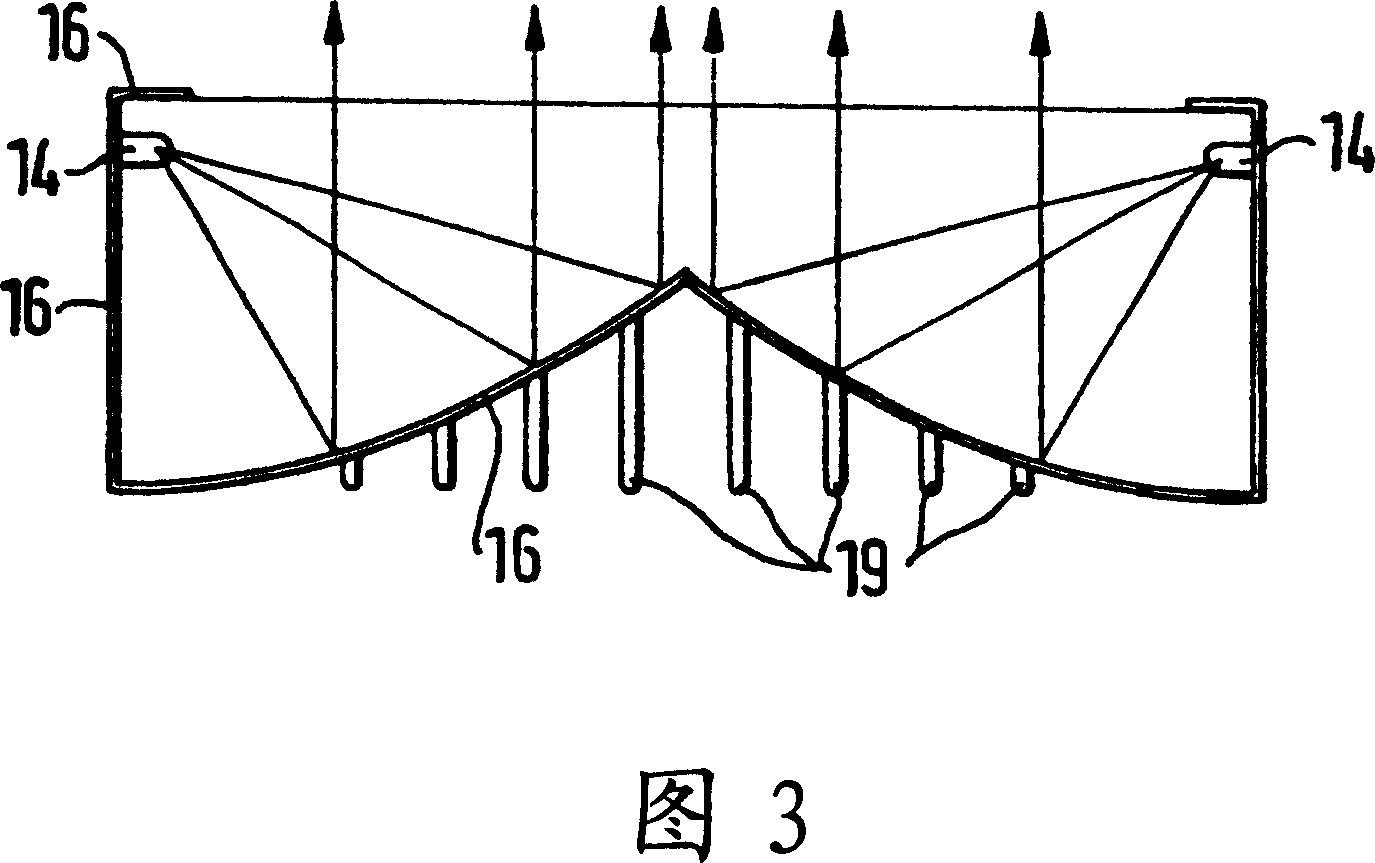

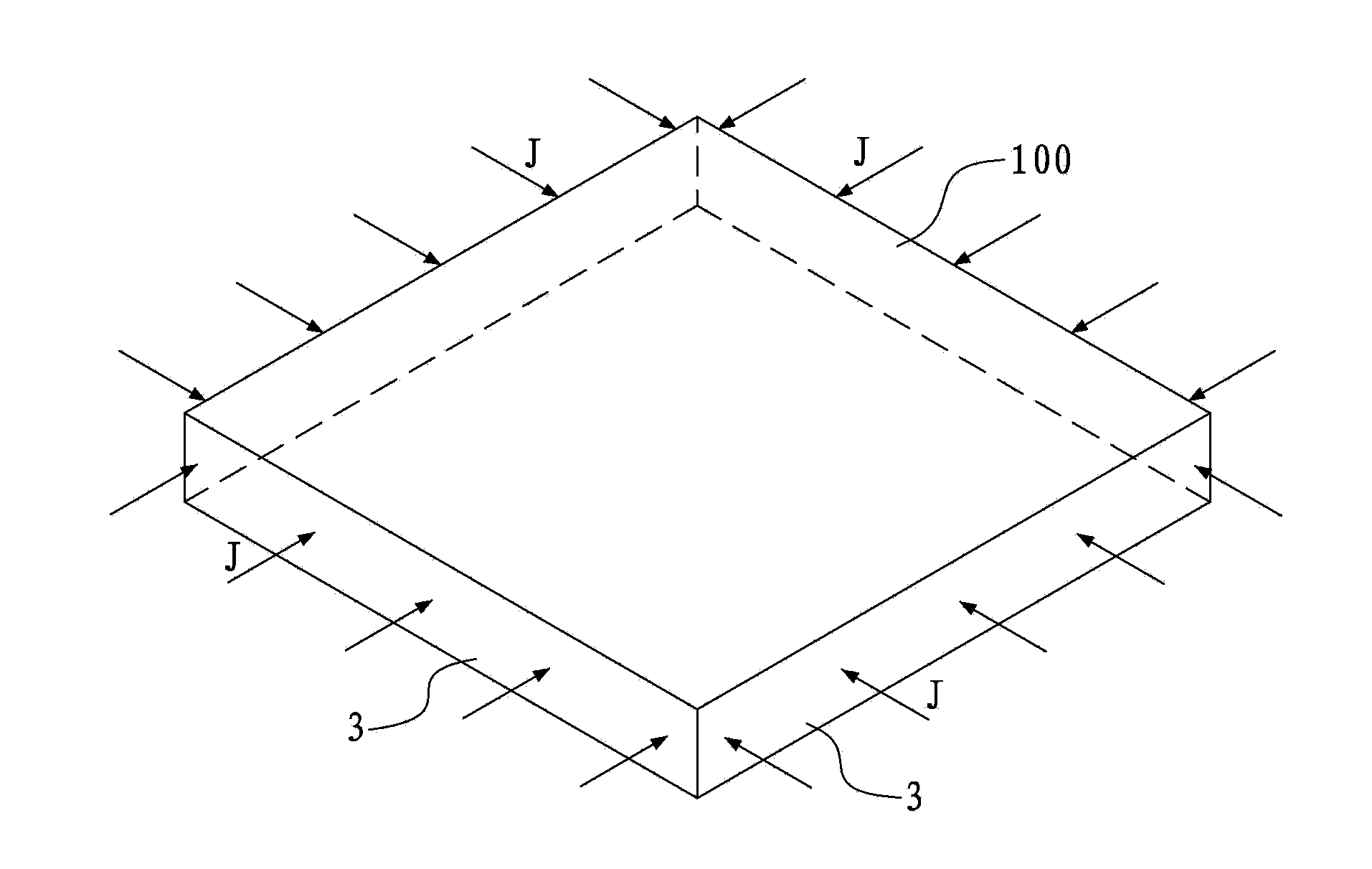

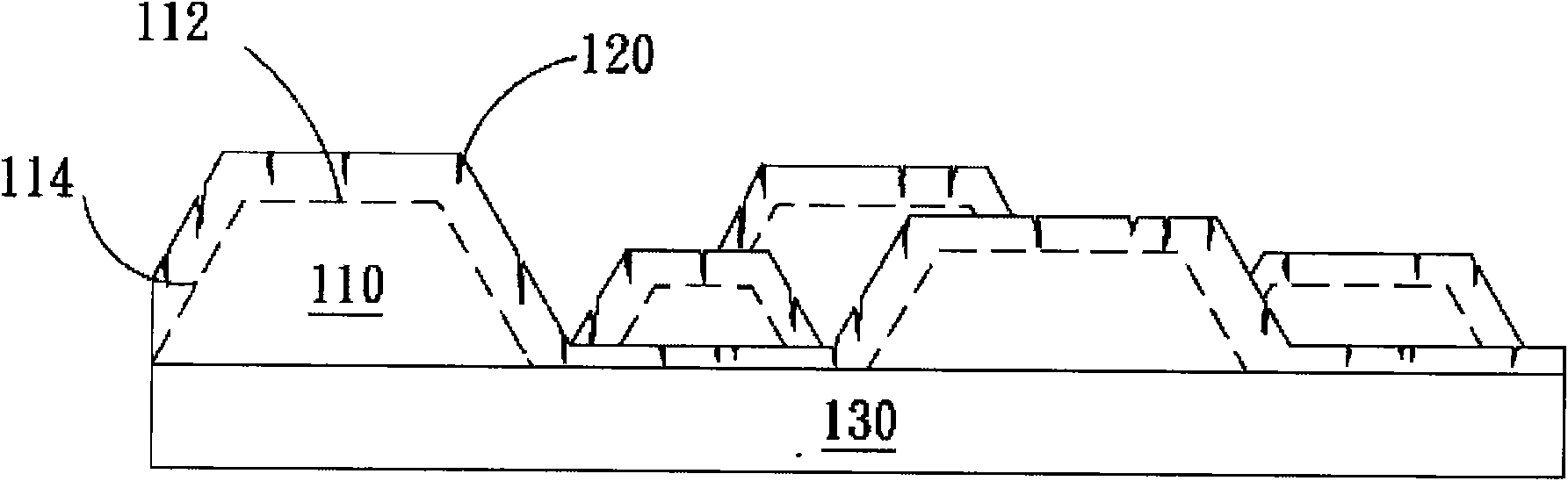

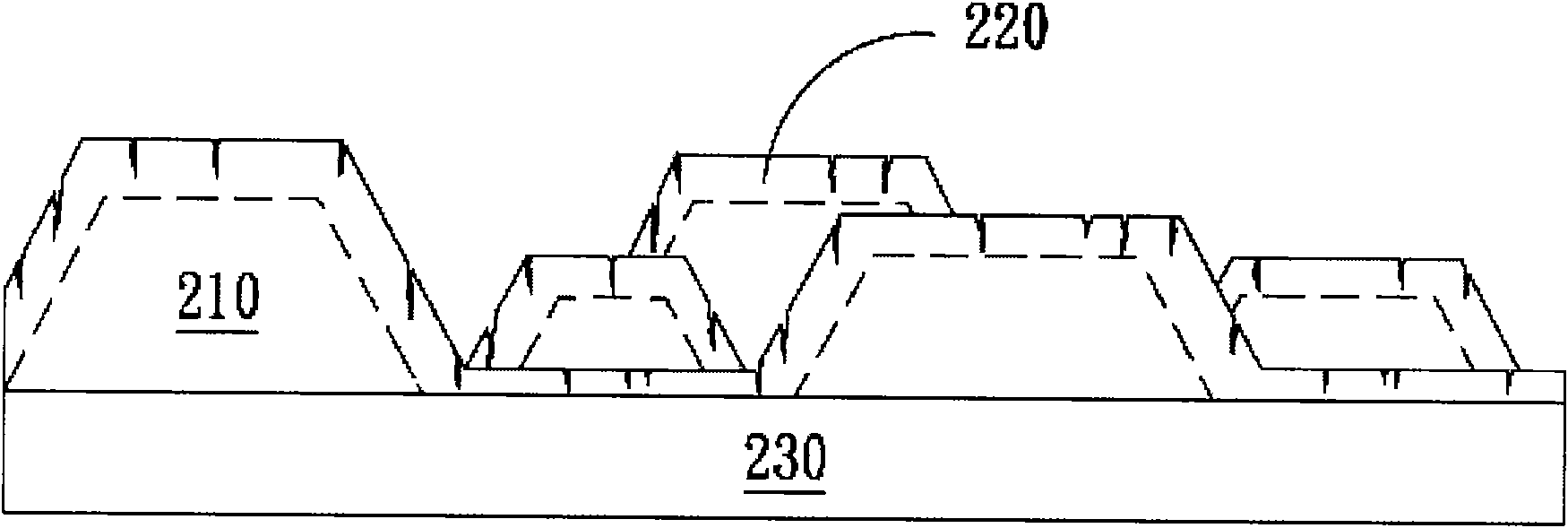

Manufacturing method of light source module, optical plate, and master mould and sub-mould of the optical plate

InactiveCN101571246AAvoid damageGood light extraction efficiencyMechanical apparatusElectric lightingComputer moduleEngineering

The invention discloses a manufacturing method of a light source module, an optical plate, and a master mould and a sub-mould of the optical plate. The optical plate comprises a substrate, a plurality of first microstructures, a plurality of second microstructures and a plurality of third microstructures. The substrate has a first area, a second area and a third area, and the second area is between the first area and the third area. A plurality of the first microstructures are arranged on a surface of the substrate in the first area at a predetermined spacing. A plurality of the second microstructures are arranged on the surface of the substrate in the second area. A plurality of the second microstructures have paired mutual connection at least, and a connection and the surface of the substrate are coplanar. A plurality of the third microstructures are arranged on the surface of the substrate in the third area, and a plurality of the third microstructures have paired partial superposition at least; wherein, the first microstructures, the second microstructures and the third microstructures have circular arc-shaped tips respectively. The method can help prevent moire generation, provide uniform and concentrated beams and be used for manufacturing a concaved microstructure mould and a convex microstructure mould with circular arc-shaped tips, and the optical plate with high light extraction efficiency.

Owner:AU OPTRONICS CORP

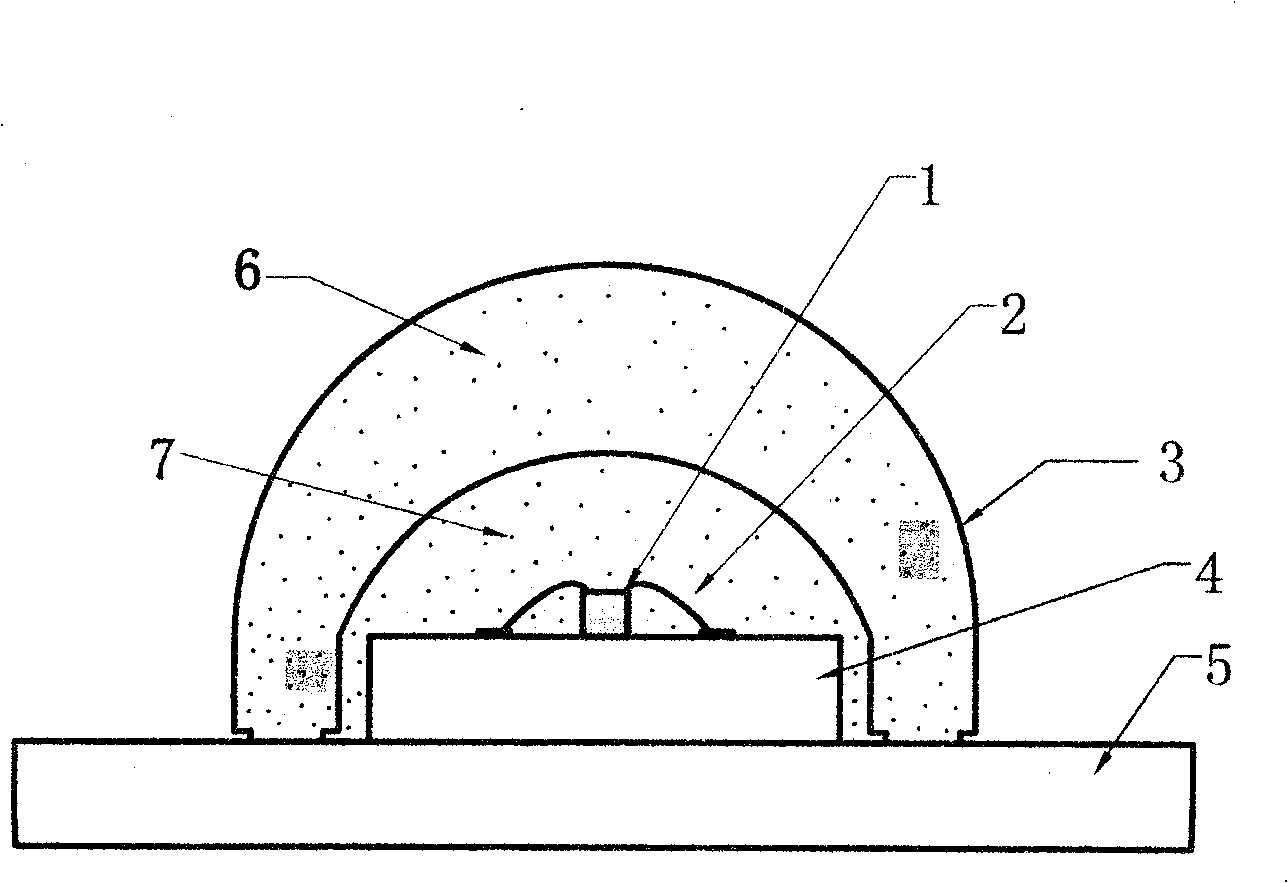

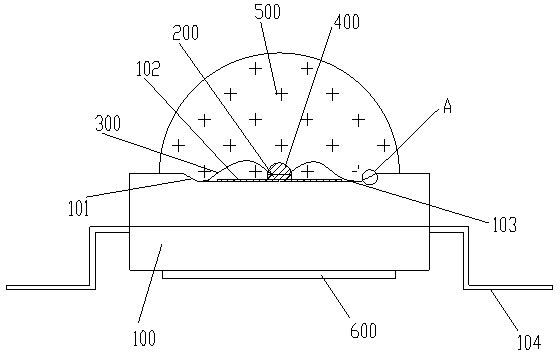

Low attenuation high light efficiency LED illuminating apparatus and preparation method

InactiveCN101338865AImprove light extraction efficiencyGood light extraction efficiencyLighting support devicesPoint-like light sourceUltrasound attenuationFilling materials

The invention discloses a low-attenuation high-lighting effect LED lighting device and a preparation method thereof, and relates to a semiconductor LED lighting device and a preparation method thereof. The lighting device comprises a heat dissipation plate is equipped with an aluminum basal plate, a blue LED chip is fived on the aluminum basal plate and the outer cover of the blue LED chip is a transparent cover. The preparation process is as follows: bonding material is filled on the aluminum basal plate; the luminescent material is fixedly positioned on the bonding material of the aluminum basal plate; the bonding material is baked and dried; a gold wire is used to connect the electrode; the transparent cover material and the fluorescent powder are molded to form the transparent cover; the transparent cover is fixed on the aluminum basal plate; the aluminum basal plate is fixed on a heat-dissipating aluminum plate; the filling material is filled into the space between the aluminum basal plate and the transparent cover; the LED lighting device is baked or dried at ambient temperature; The invention can prolong the service life of the LED lighting device, and promote the luminescence efficiency and the consistency of light and color.

Owner:段永成

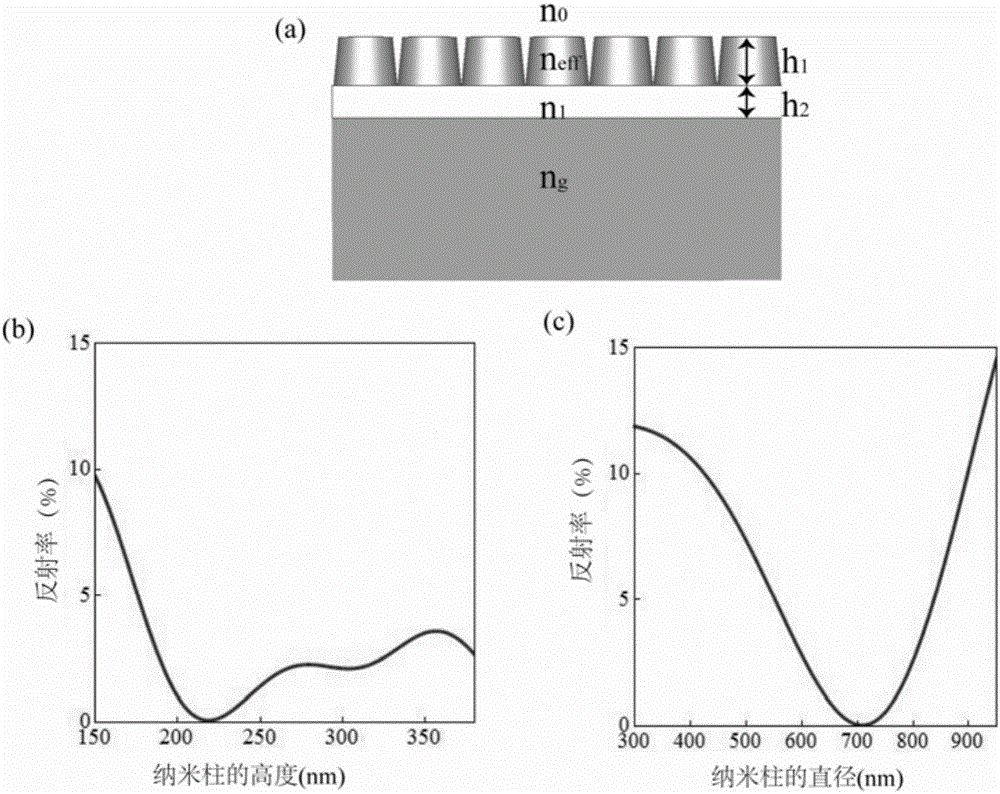

High-efficiency nano-structure light emitting diode (LED) and design and fabrication methods thereof

InactiveCN105845791AReduce reflectivityImprove light extraction efficiencySemiconductor devicesTransmittanceNanometre

The invention discloses a high-efficiency nano-structure light emitting diode (LED) and design and fabrication methods thereof. The design method comprises the following steps of 1) designing a period of a nanopillar array by a Bragg diffraction theory; 2) designing the diameter and the height of a nanopillar by an effective refractive index and enhanced thin film transmittance; and 3) fabricating a nanopillar array structure by nanosphere mark etching or other nanometer technologies. The high-efficiency nano-structure LED is ingenious in design and can be produced at a large scale, and a planar-structure LED chip with high efficiency is fabricated by optimally designing the nanopillar structure. With the design and fabrication methods of the high-efficiency LED, disclosed by the invention, the nanopillar array structure is designed on an ITO layer of a transparent electrode of the LED, and the high-efficiency planar-structure LED is fabricated.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

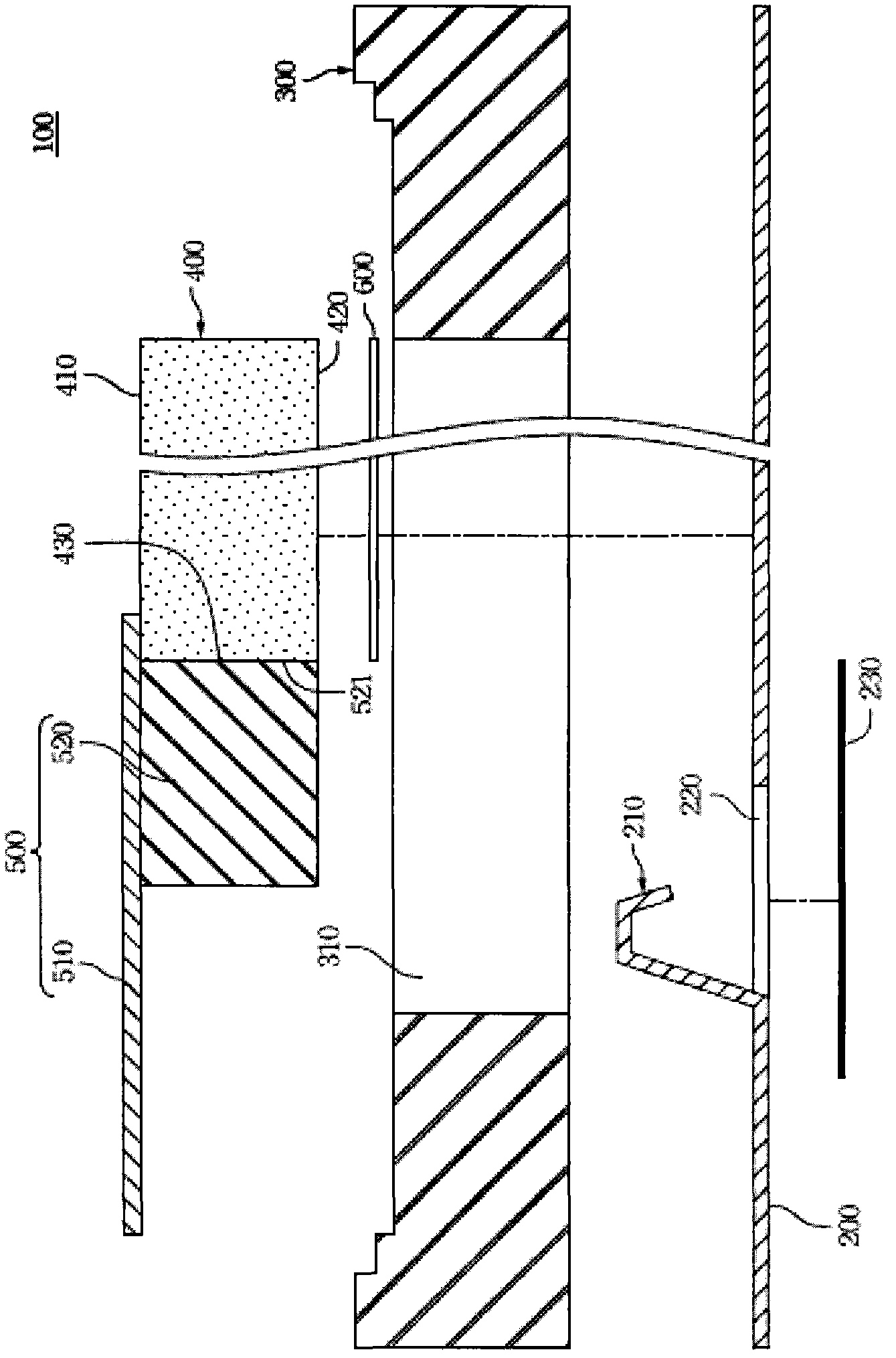

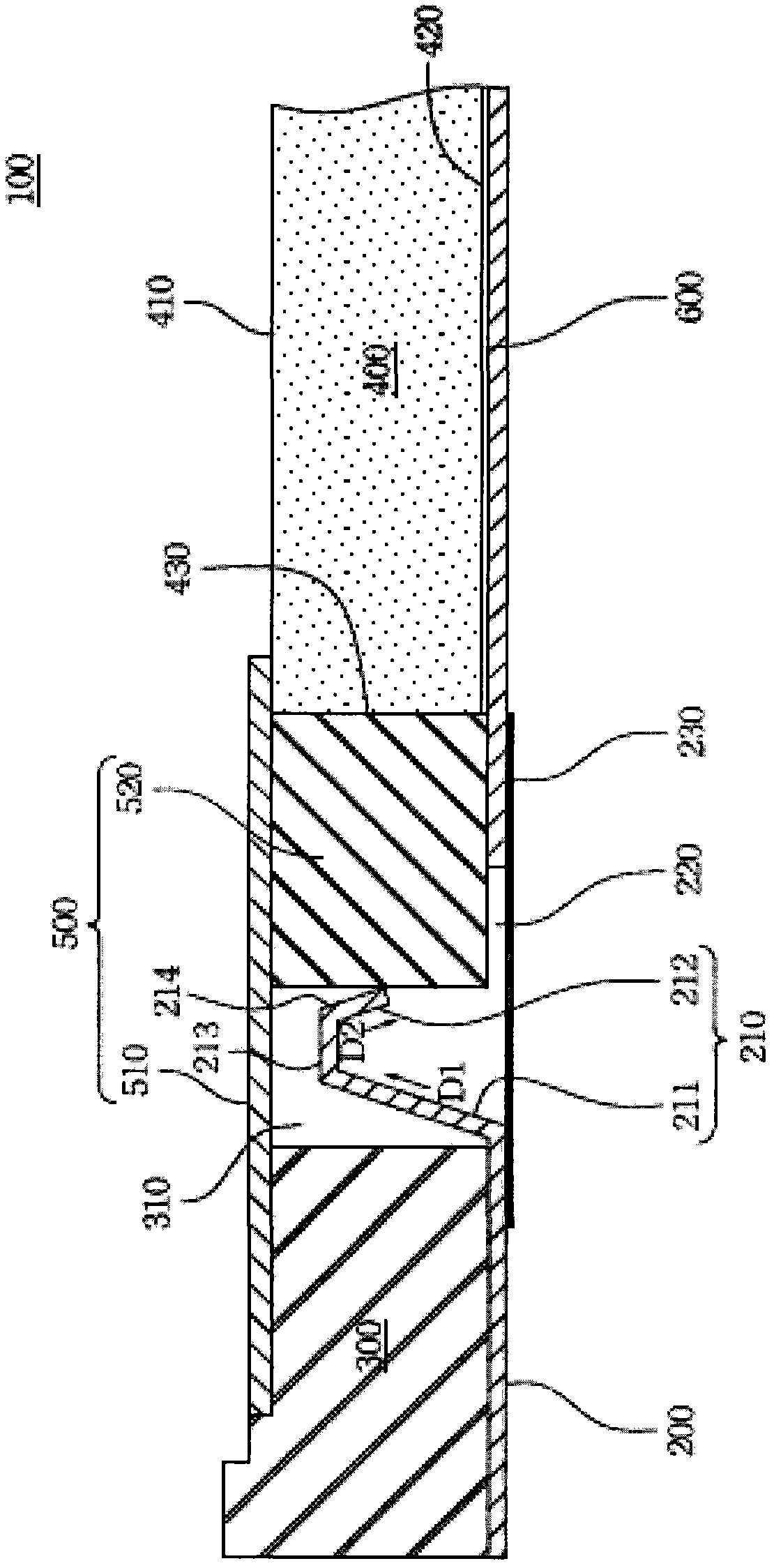

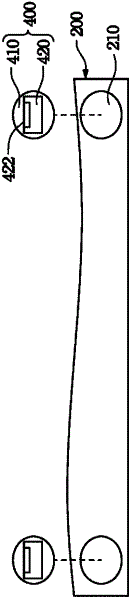

Liquid crystal display device and backlight module thereof

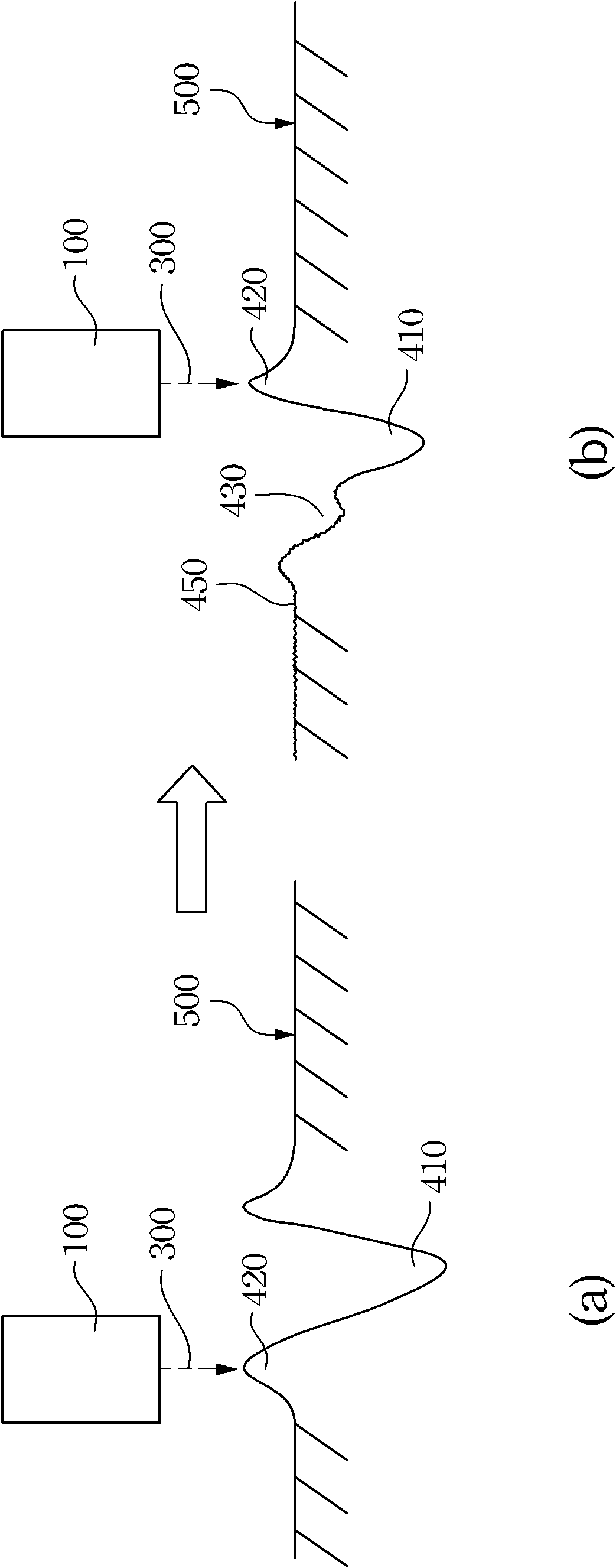

InactiveCN101818874AReduce gapGood light extraction efficiencyMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

The invention relates to a liquid crystal display device and a backlight module thereof. The backlight module comprises a light guide panel, a light emitting module and a plurality of elastic elements, wherein the light emitting module comprises a plurality of light emitting diodes; the light emitting diodes emit light towards a light incident surface on the lateral side of the light guide panel; and both ends of each elastic element are respectively connected with the light guide panel and the light emitting module, so that the light guide panel abuts against the light emitting diodes. The liquid crystal display device and the backlight module thereof in the invention can reduce the clearance between the lateral side of the light guide panel and the light source as much as possible, and even achieve zero clearance to realize ideal light emergent efficiency of the light guide panel, thereby providing sufficient illuminating rays for the display panel.

Owner:AU OPTRONICS CORP

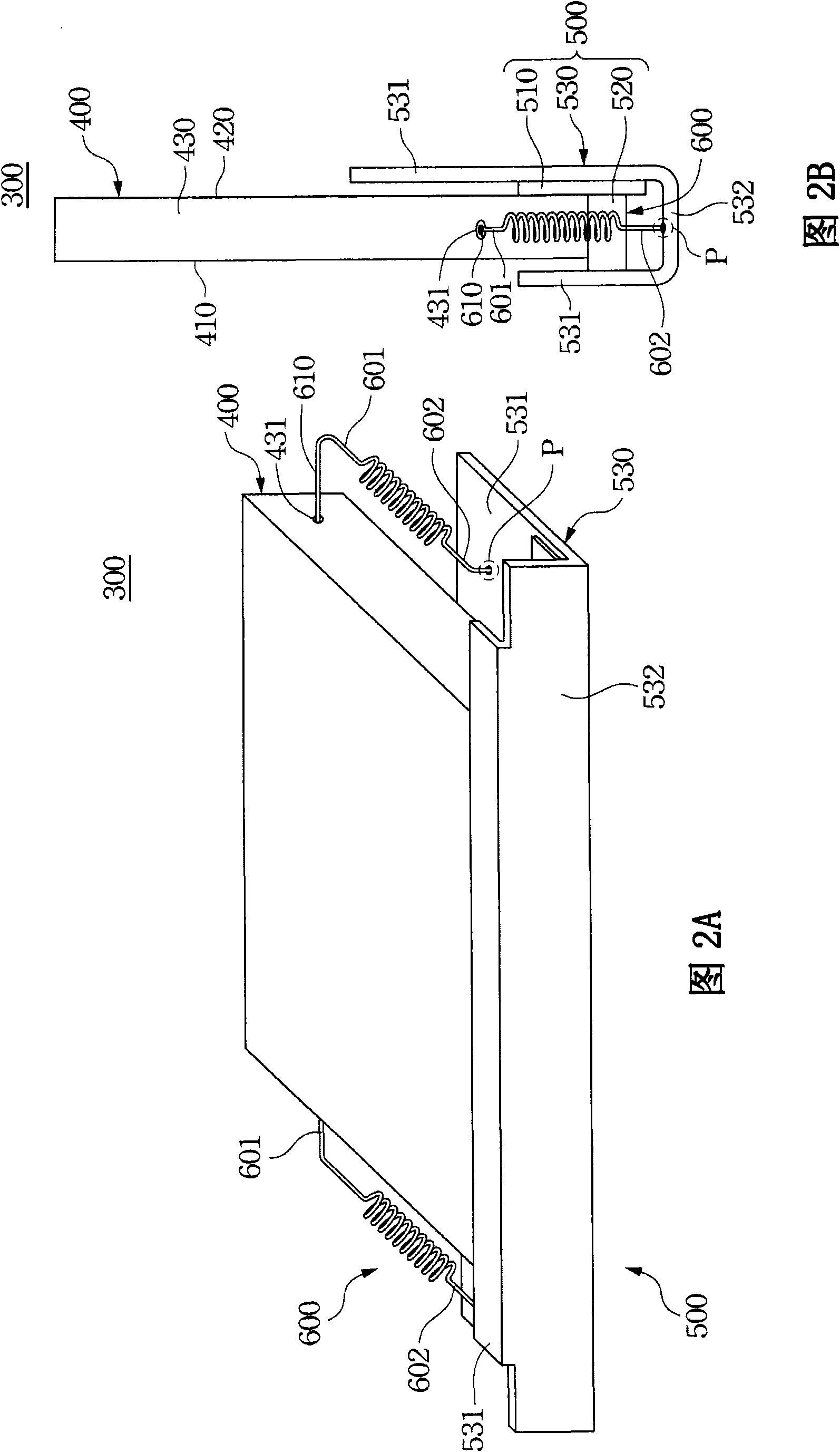

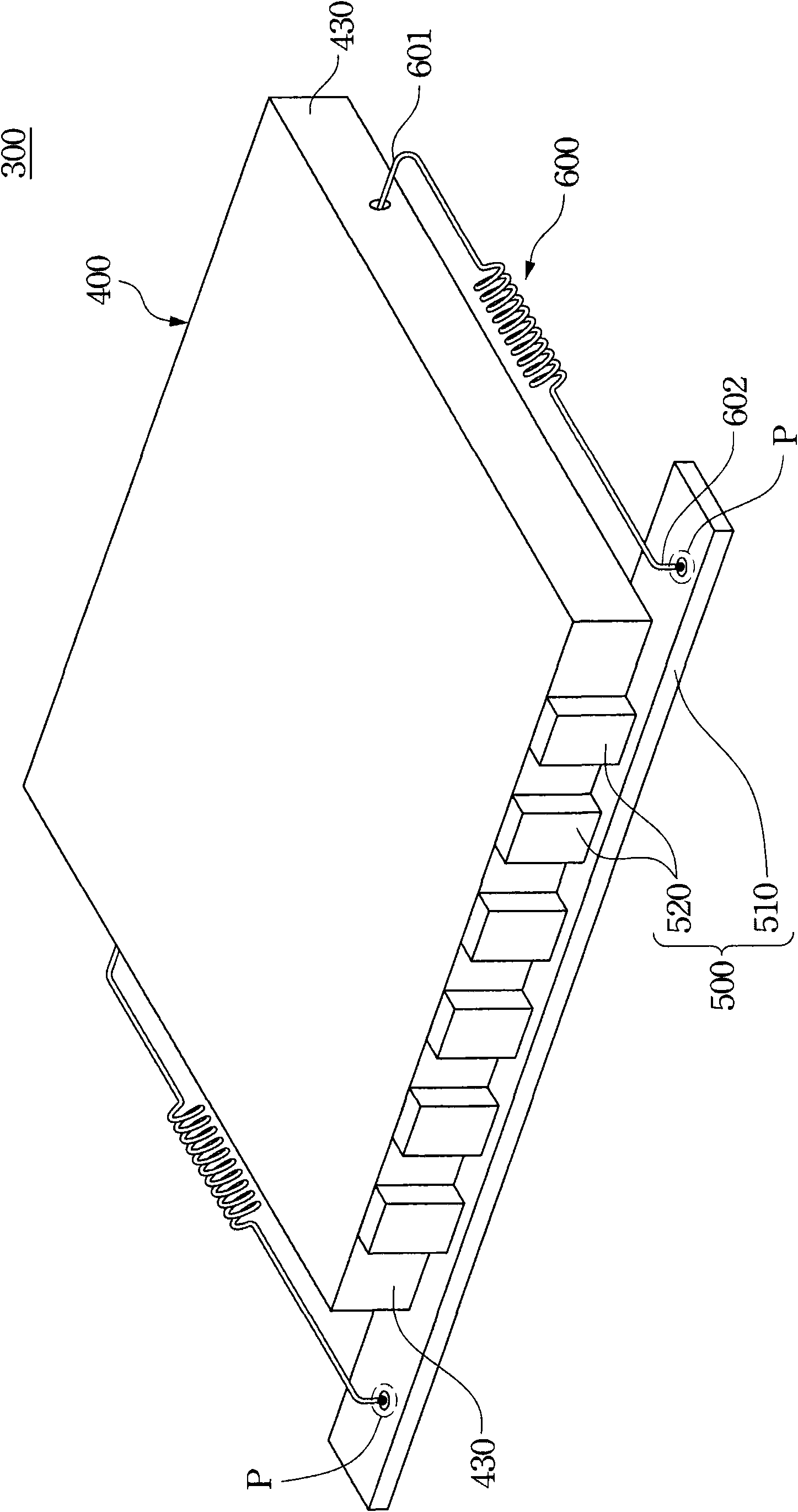

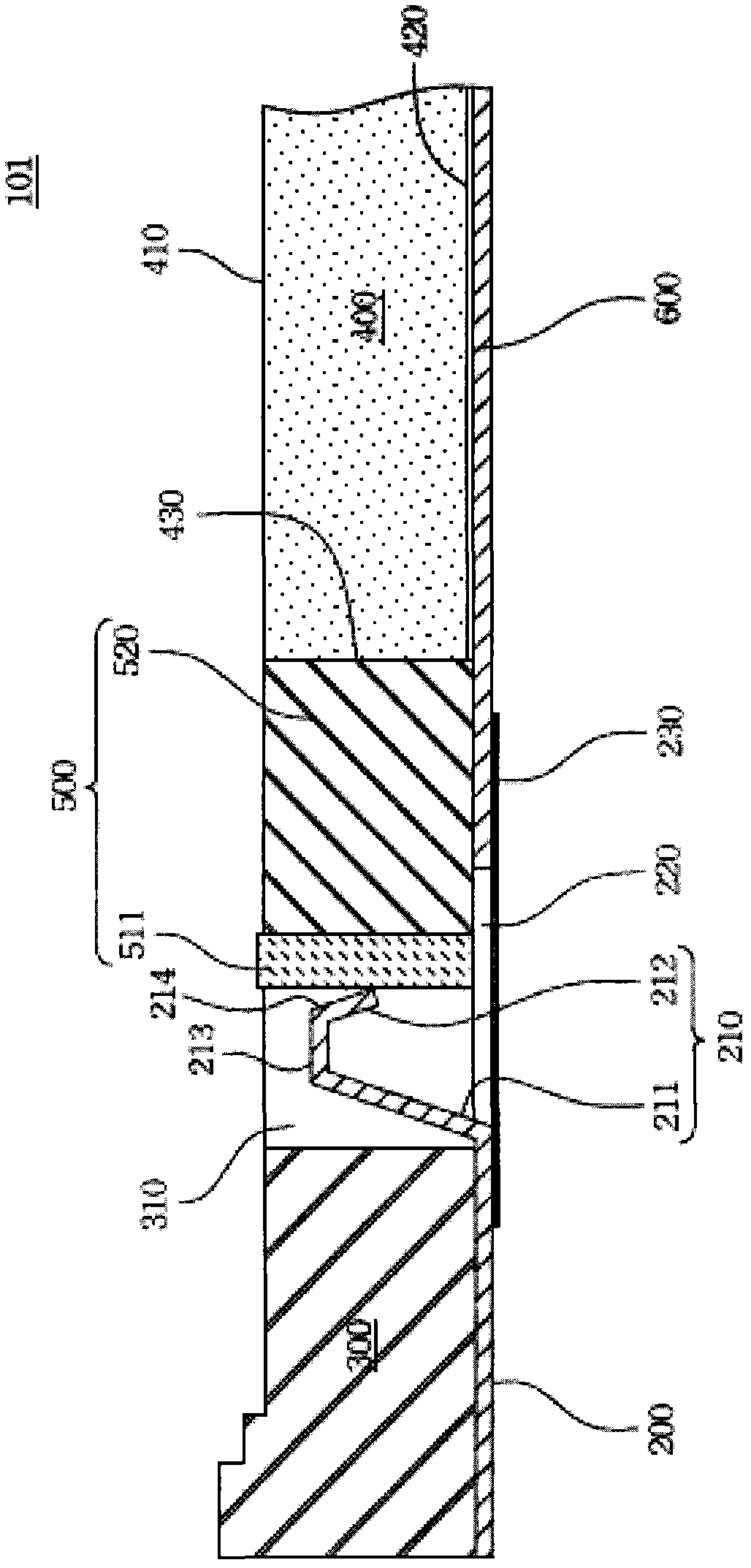

Display device and backlight module thereof

InactiveCN102563469AReduce gapGood light extraction efficiencyMechanical apparatusPoint-like light sourceLight guideComputer module

The invention discloses a display device and a backlight module of the display device. The backlight module comprises a base plate, a frame, a light guide plate, a light source and a bent elastic piece. The frame is located at one side of the base plate to form a containing space. The light guide plate is arranged in the containing space and comprises a light inlet surface. The light source is arranged at one side of the light inlet surface in the containing space for emitting light towards the light inlet surface. One end of the bent elastic piece is connected with the base plate, and the other end extends into the containing space and elastically presses the light source to abut against the light inlet surface of the light guide plate. With the adoption of the invention, the distance between the side of the light guide plate and the light source is shortened so as to realize the perfect light emitting efficiency of the light guide plate and therefore, enough illuminating light is provided to the liquid crystal panel.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

Nano-patterned substrate and manufacturing method thereof

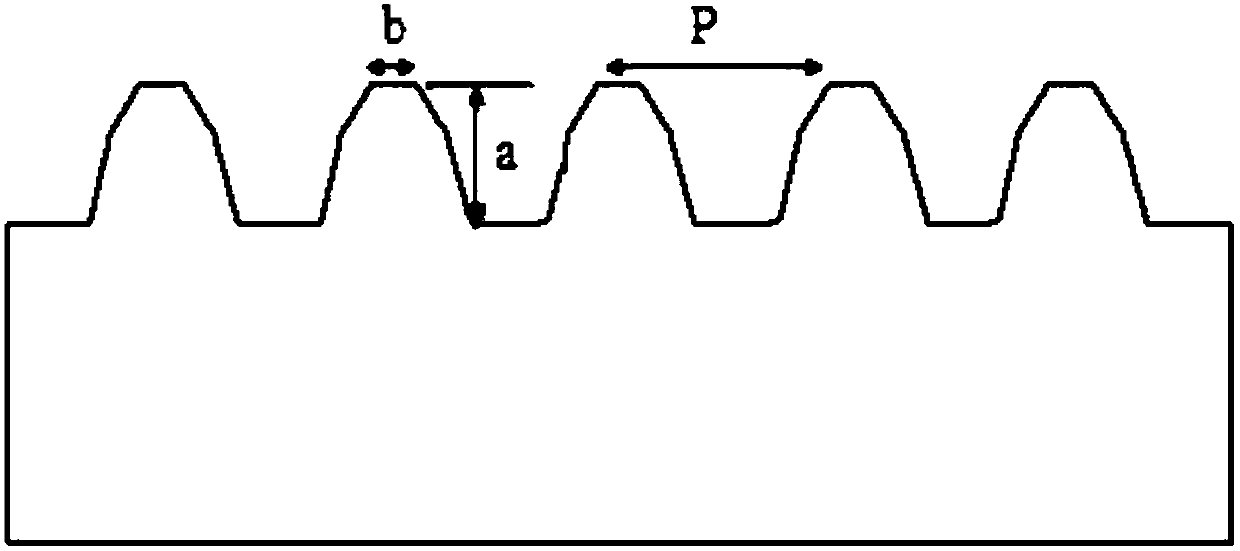

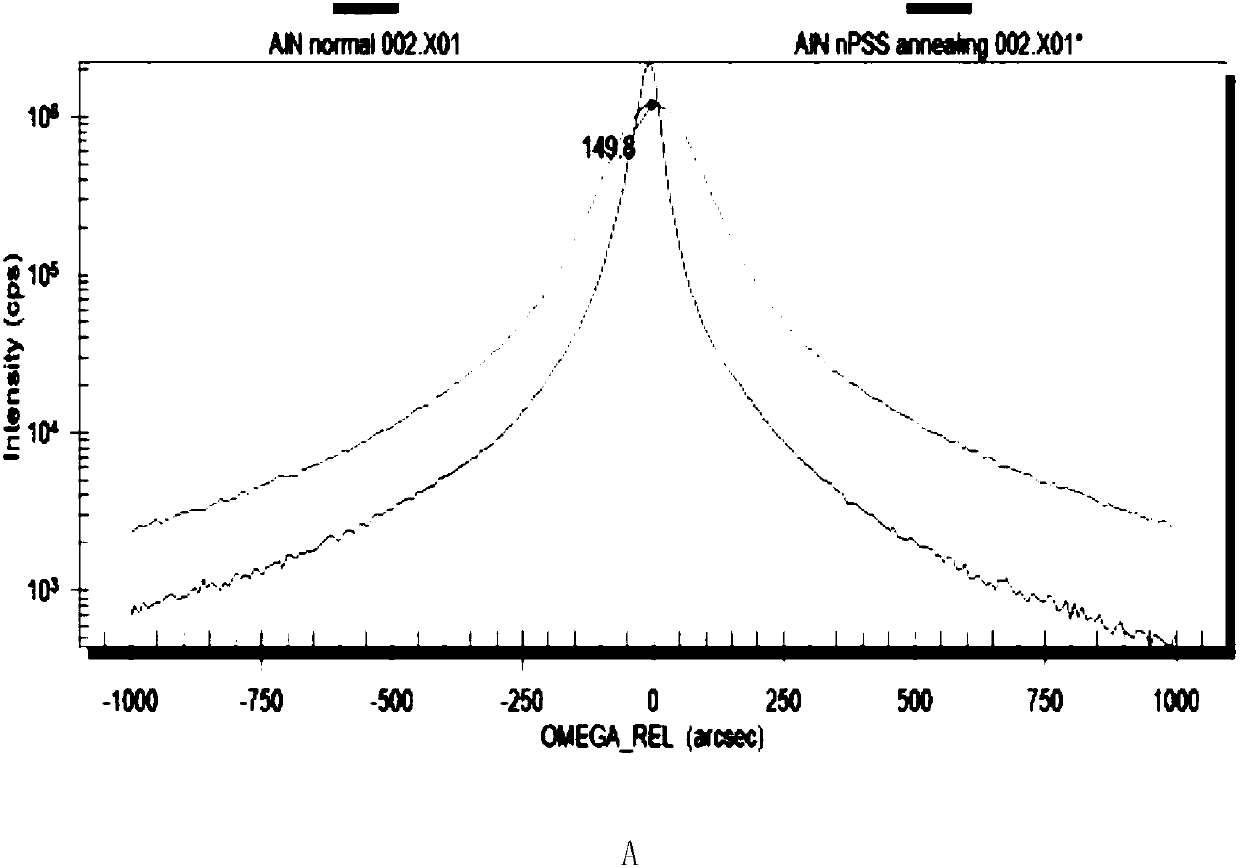

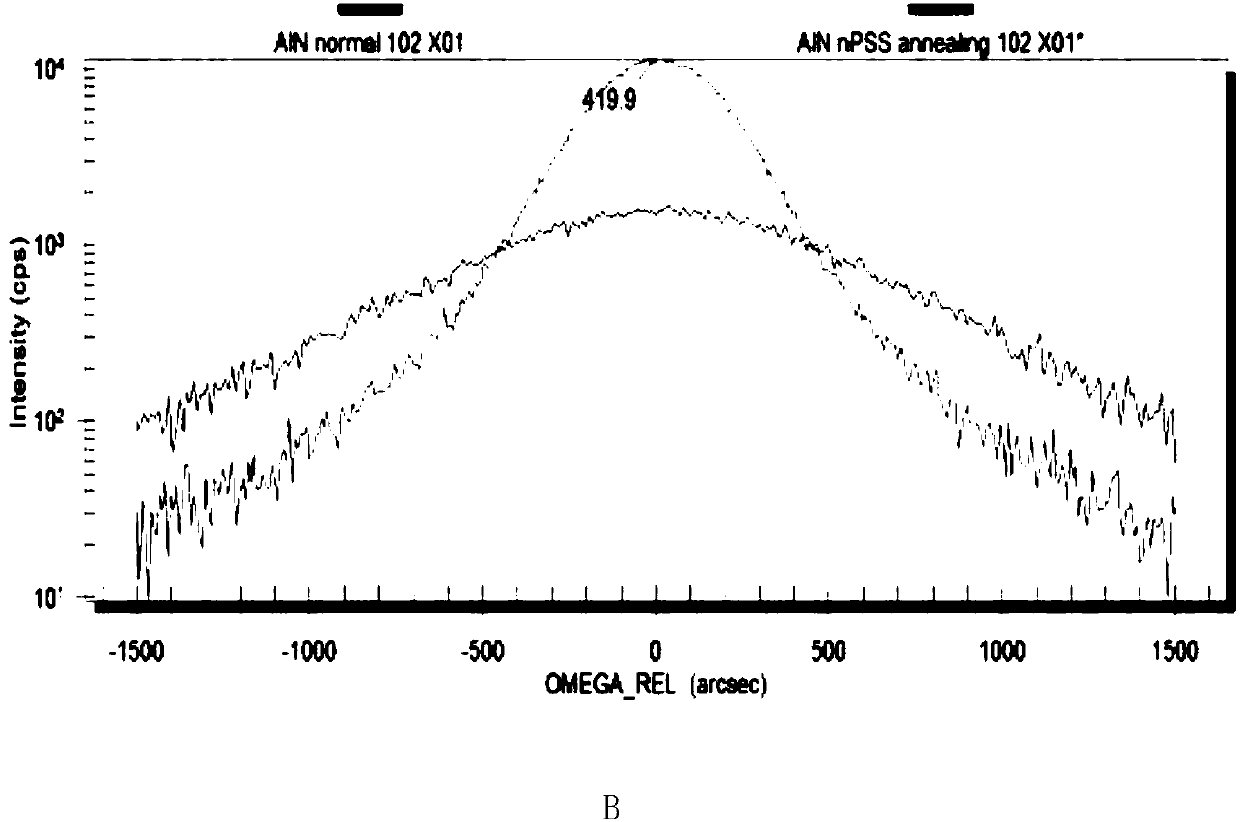

PendingCN107863428AImprove light extraction efficiencyPromote growthSemiconductor devicesPatterned substrateUltraviolet light emitting diodes

The invention discloses a nano-patterned substrate and a manufacturing method thereof. The nano-patterned substrate is manufactured through sputtering an AlN layer on a sapphire substrate; annealing the AlN layer and then forming a nano-pattern on the annealed AlN layer. The substrate has the characteristics of being simple in manufacturing process and low in cost, the quality of AlN crystal and the light extraction efficiency of a UV-LED (deep ultraviolet light-emitting diode) can be greatly improved, and the nano-patterned substrate is a necessary product for later growth of the deep ultraviolet LED.

Owner:山西中科潞安紫外光电科技有限公司

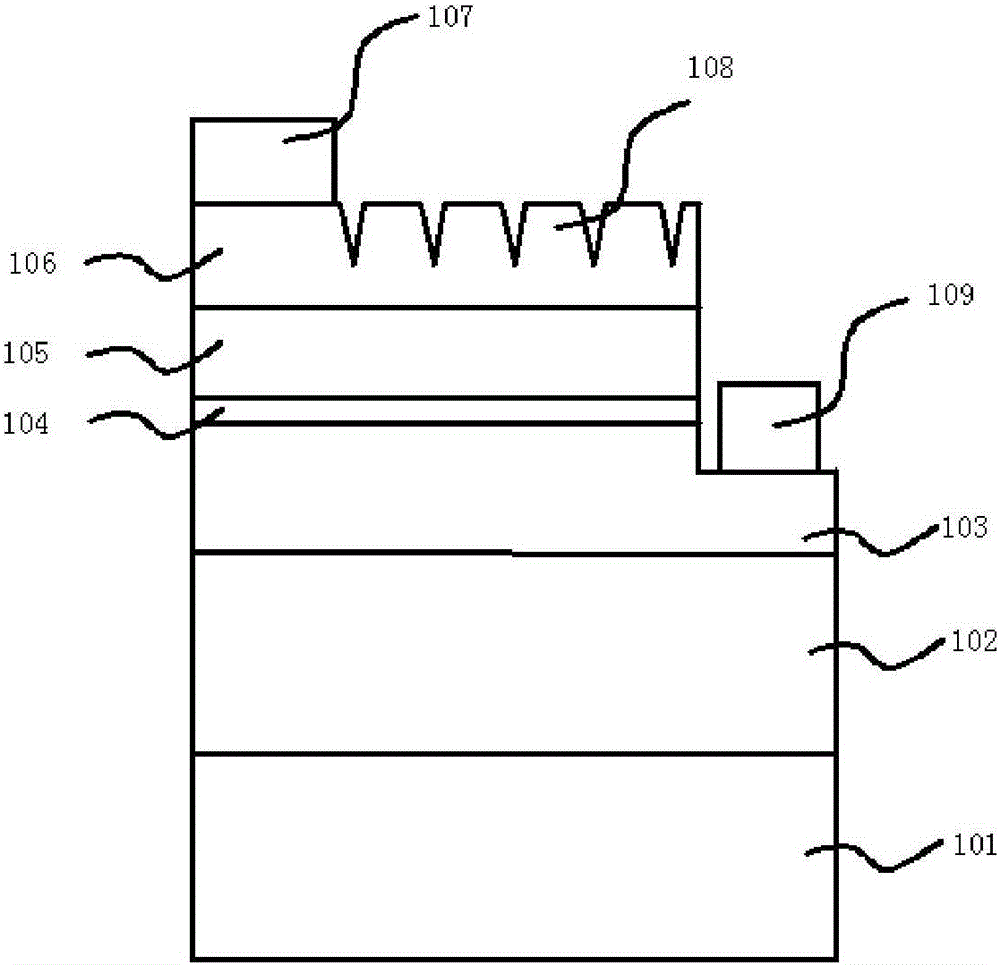

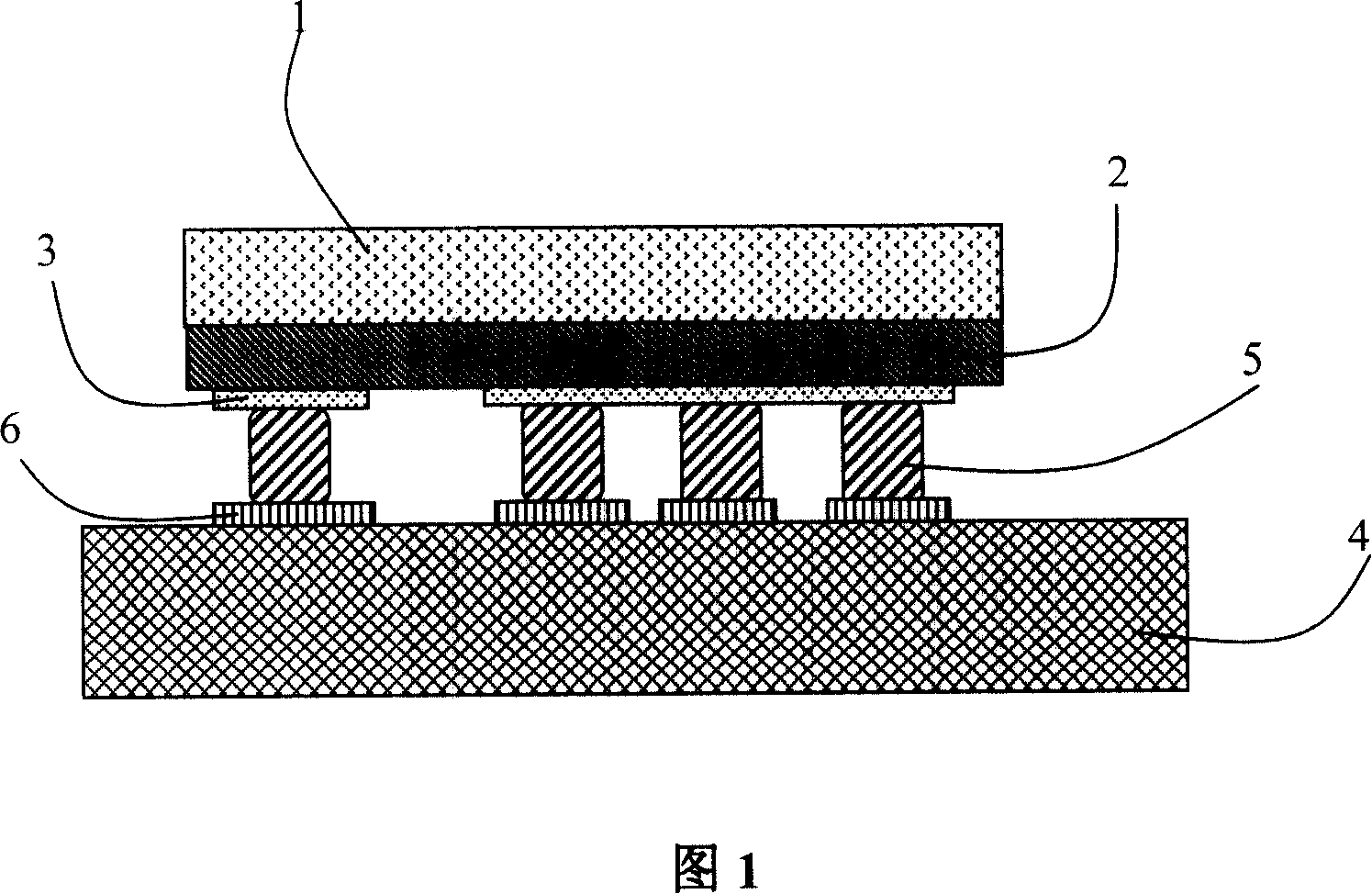

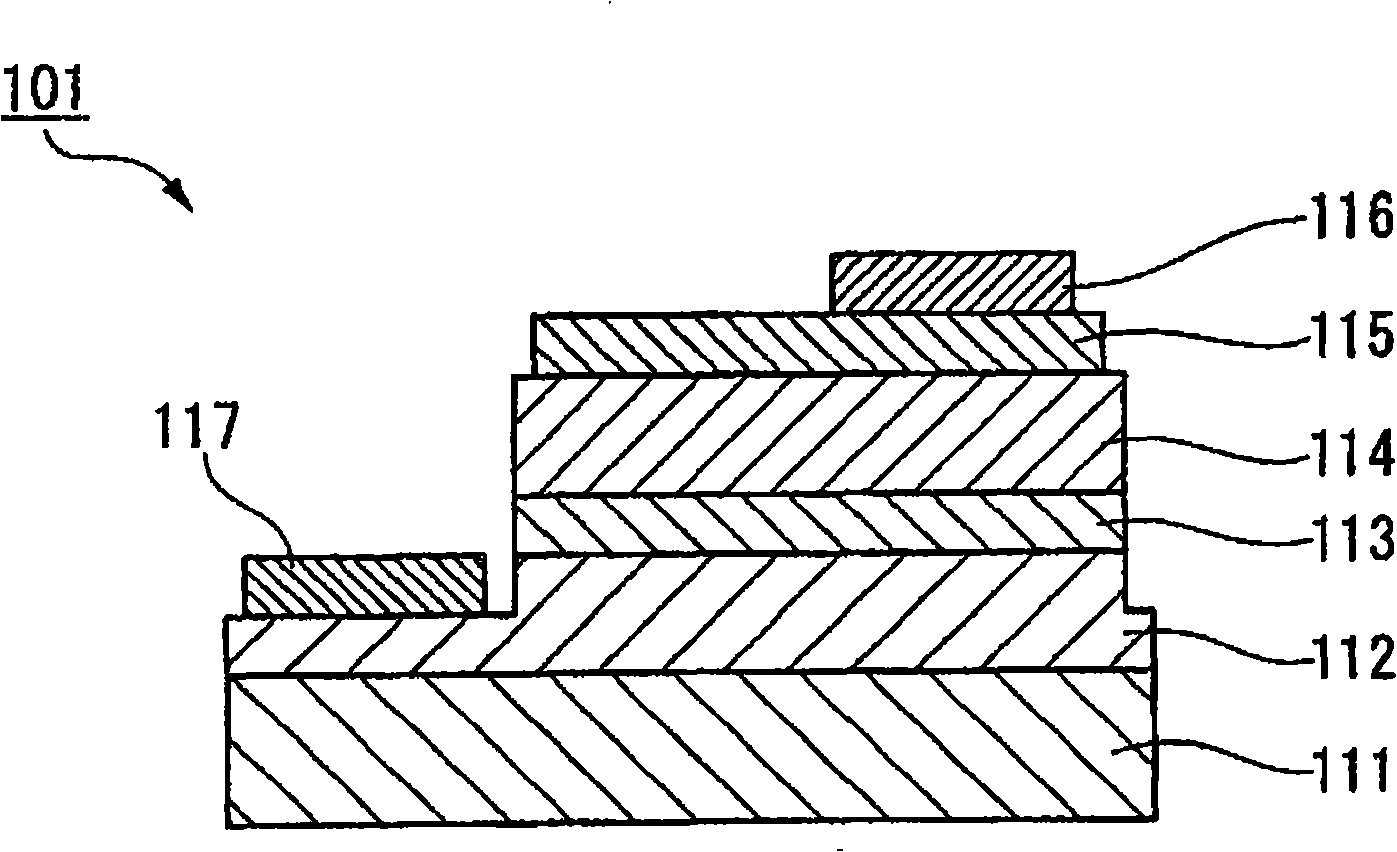

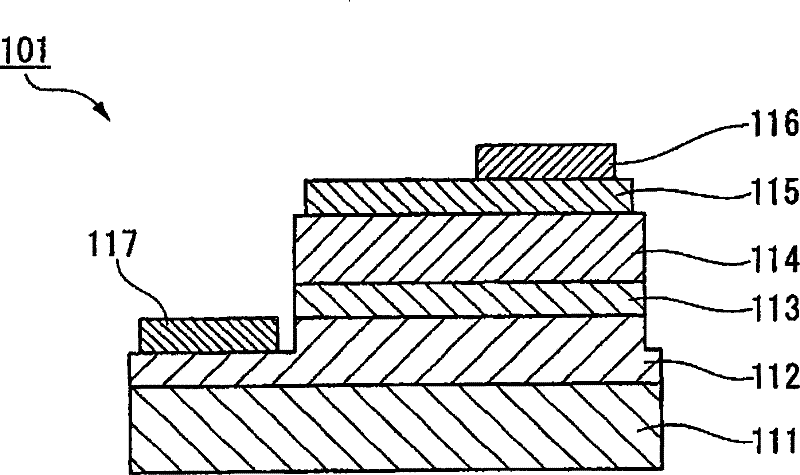

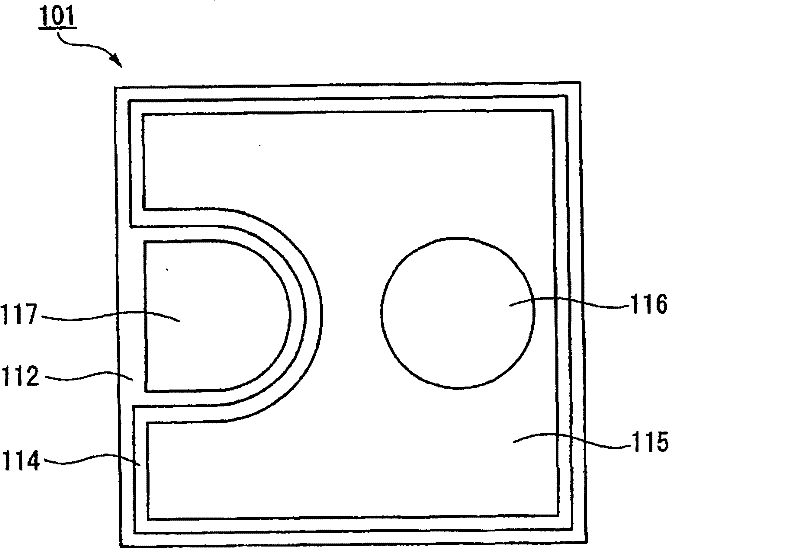

Light emitting diode chip and method for manufacturing the same

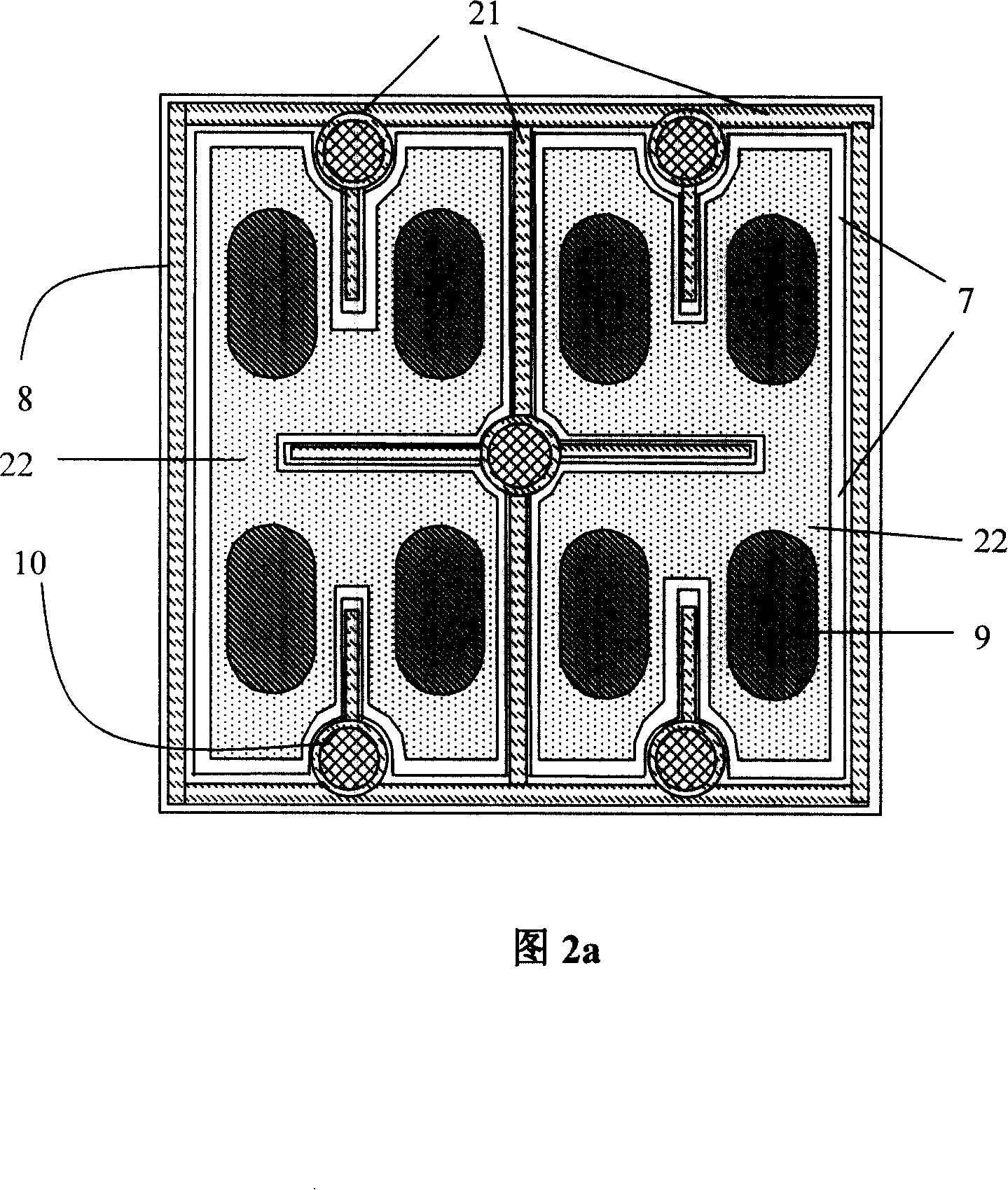

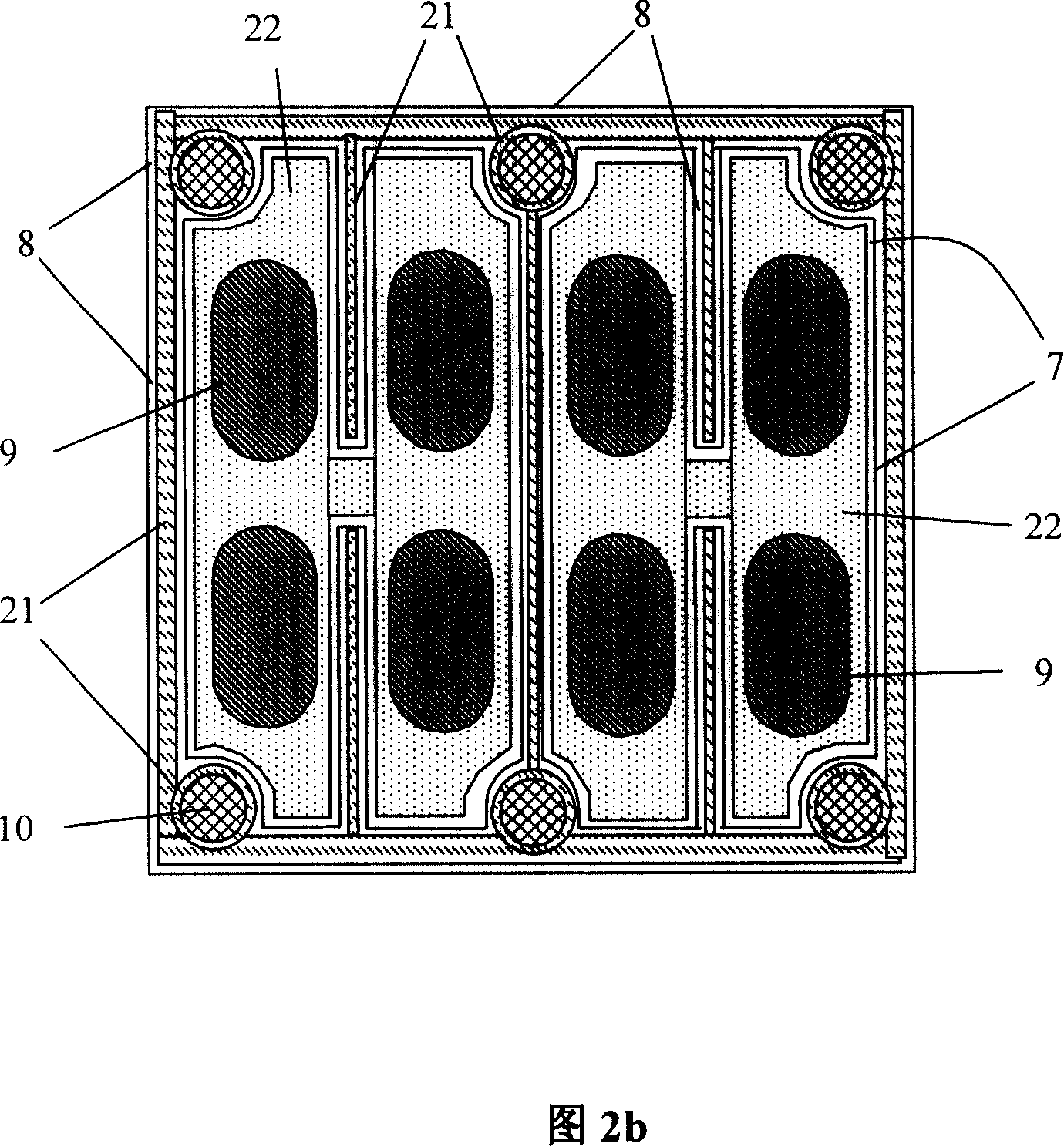

ActiveCN101154697AImprove device performanceImprove current distributionSolid-state devicesSemiconductor devicesPhysicsThermal conductivity

The invention discloses a light emitting diode chip and making method thereof, wherein, the chip comprises an external spreading wafer which is formed on a sapphire substrate, an N type zone and a P type zone of the external spreading wafer are covered with a metal electrode layer which comprises a transparent metal layer and a reflection layer and has a metal layer under convex points and metal convex points; a soleplate for flip chip which is provided with a metal line layer and convex points formed on the metal line layer; wherein, the N type zone surrounds the P type zone as large as possible, and the N type zone is communicated with the metal electrode layer covered on the N type zone and P type zone is divided into a plurality of zones by the N type zone and the metal electrode layer. The metal convex points of the P type zone are evenly distributed on a plurality of divided zones. The invention improves the current distribution conditions by optimized design for device electrode so as to improve the performance and life-span of devices. In addition, the flip chip joint point strength on the electrode and thermal conductivity performance of the device are further improved.

Owner:APT ELECTRONICS

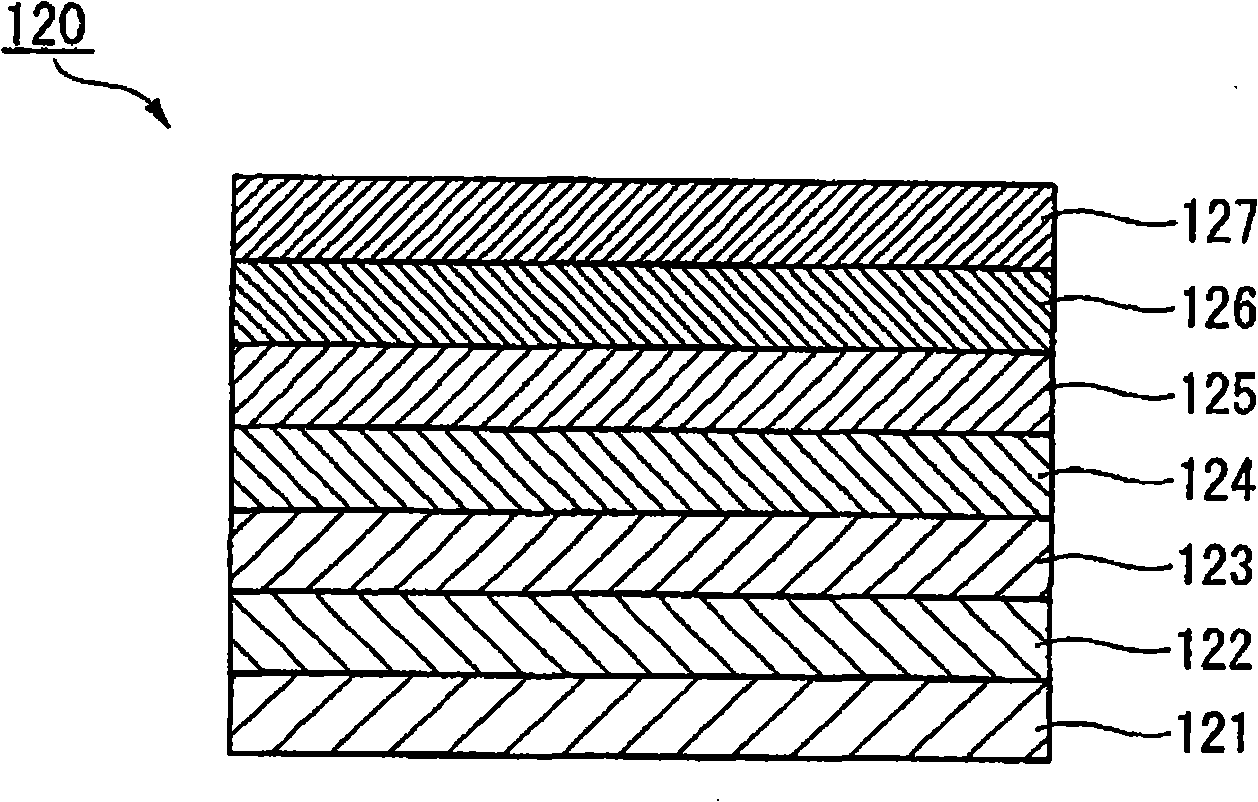

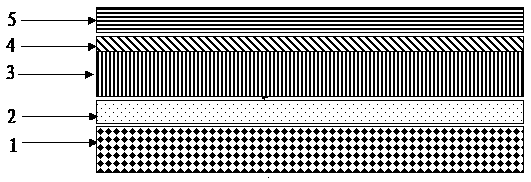

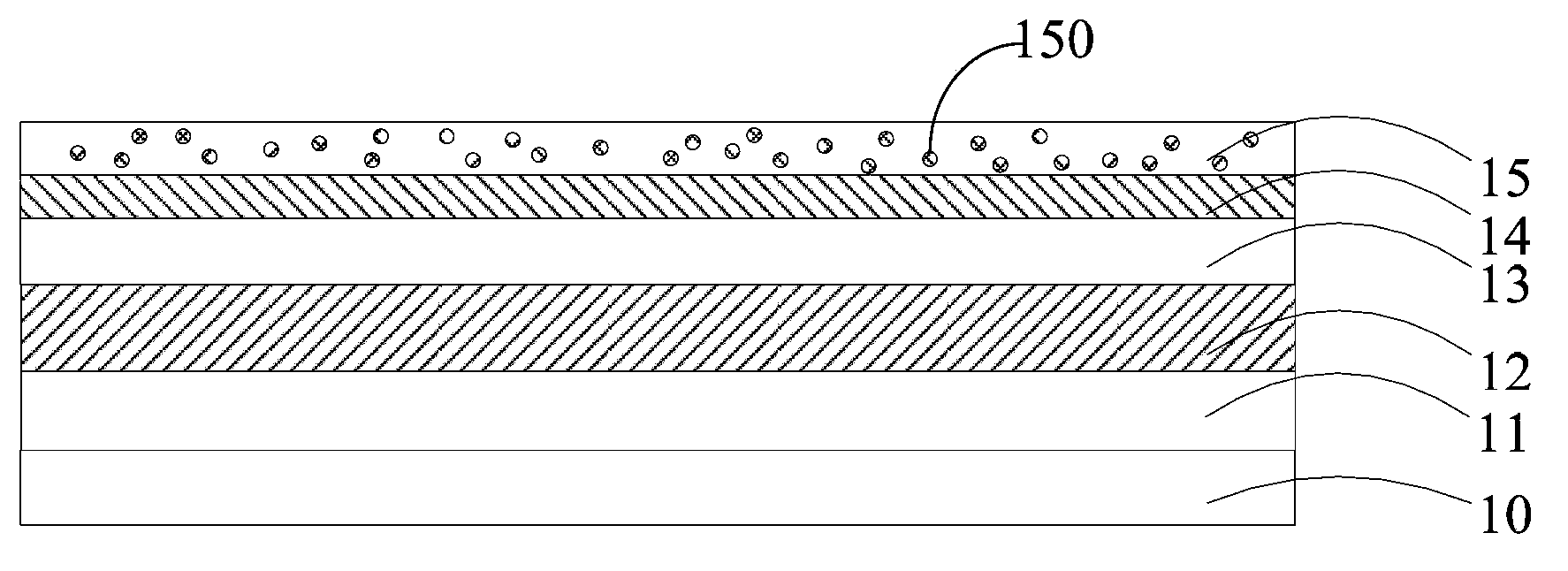

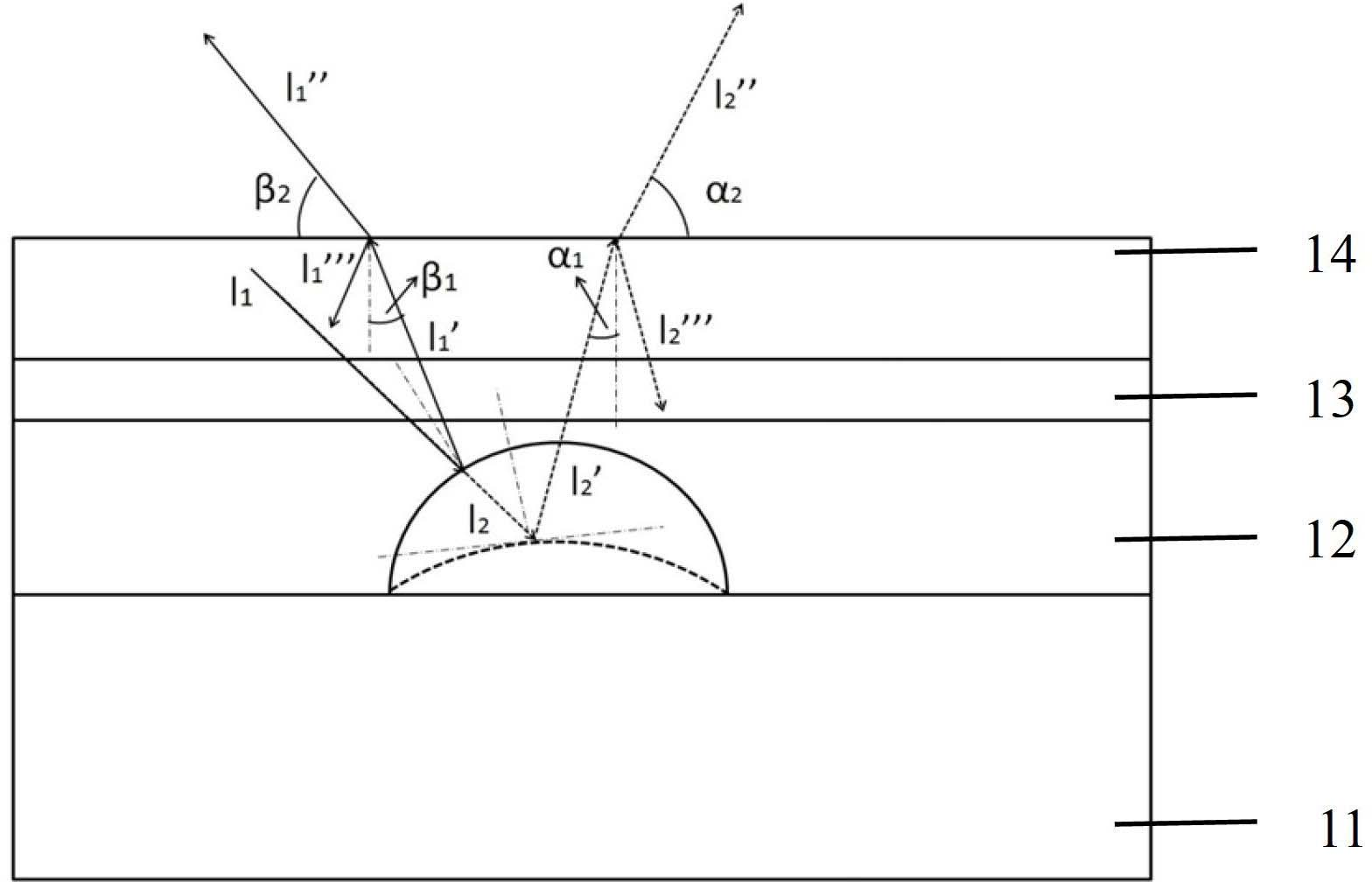

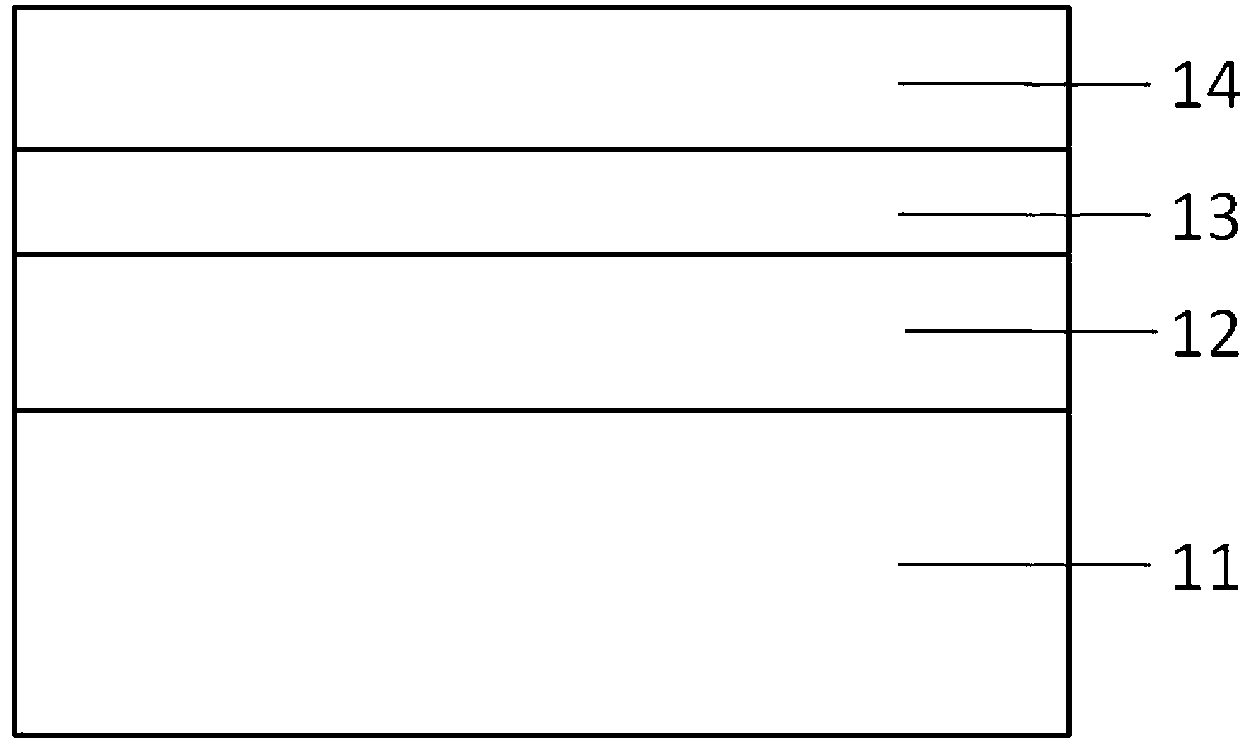

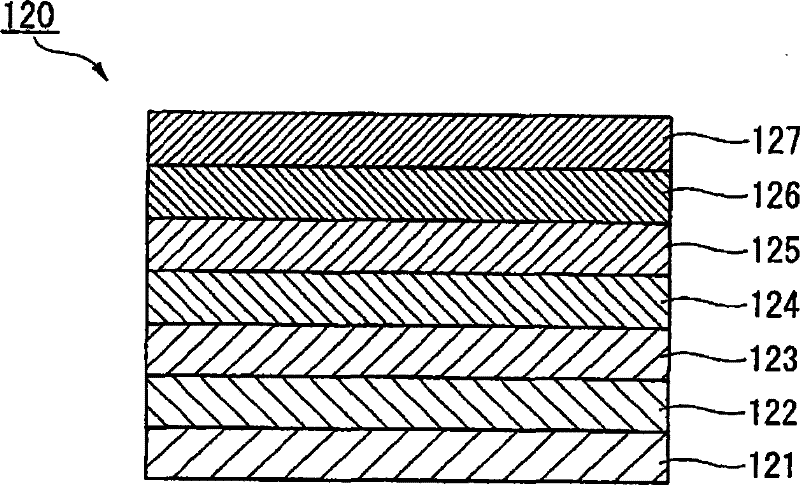

Organic electroluminescent device and preparation method thereof

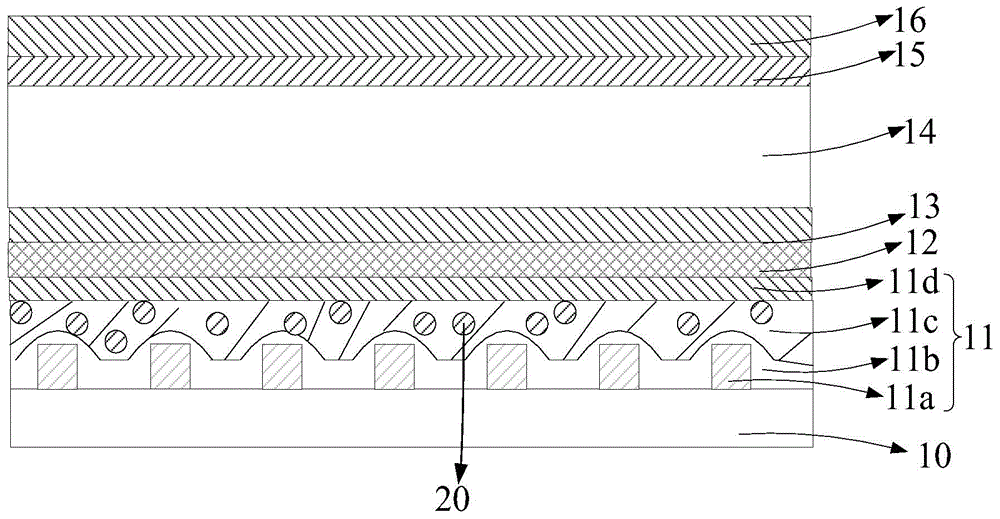

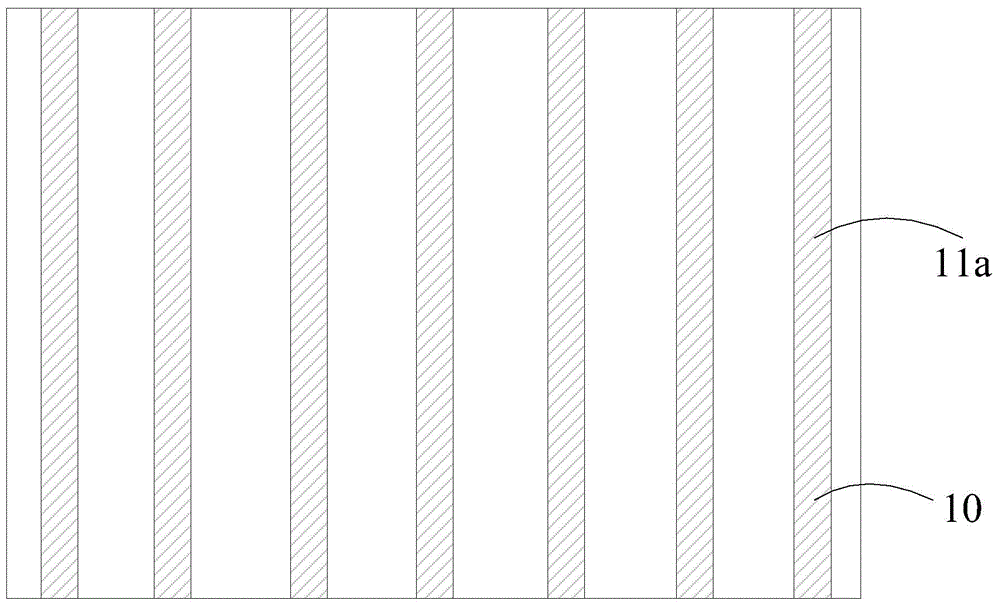

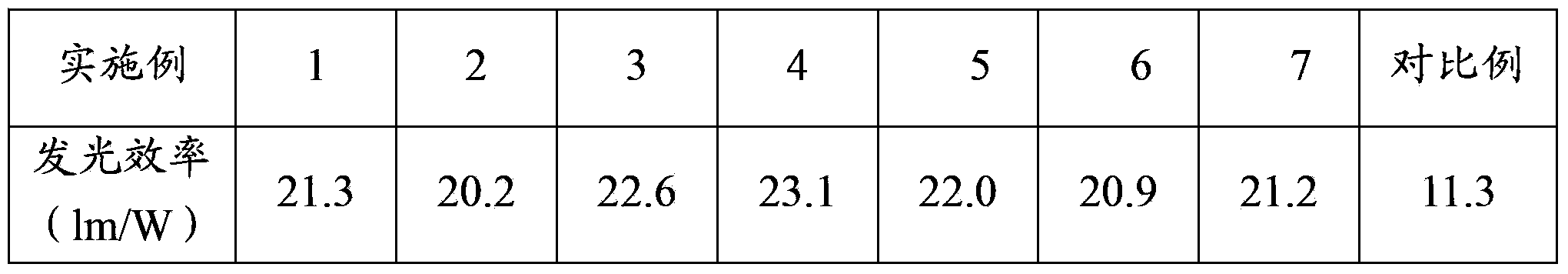

InactiveCN104425720AImprove light extraction efficiencyGood light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingWave shapeOrganic electroluminescence

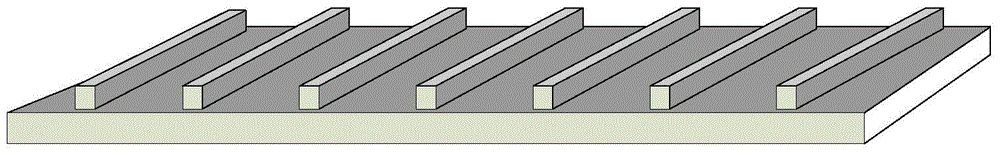

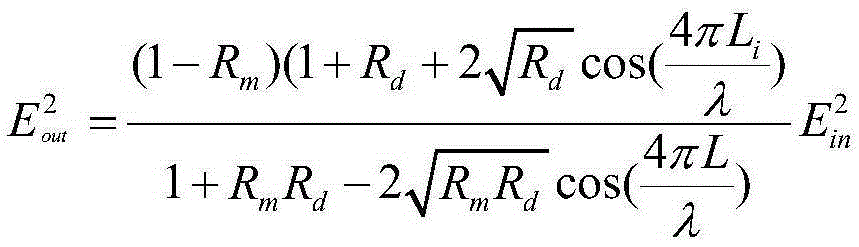

The invention provides an organic electroluminescent device, including a light transmission substrate, and a light extraction layer, an anode, an organic luminous functional layer and a cathode which are stacked on the light transmission substrate in sequence. The light extraction layer includes a plurality of oxide layers parallelly arranged on the surface of the light transmission substrate at intervals, a sulfide layer that covers the surfaces of the light transmission substrate and the oxide layers, and a transparent polymer film that covers the surface of the sulfide layer, the oxide layers are in the shapes of long strips, oxides are one or more of titanium dioxide, silicon dioxide and zirconium dioxide, the thickness of the oxide layers is 5 to 10 [mu]m, and the sulfide layer is a continuous thin film layer and has a wave-shaped curved surface structure. According to the organic electroluminescent device, through the arrangement of the light extraction layer, a critical angle of total reflection of an interface of the light transmission substrate is increased, thereby increasing the light extraction efficiency between the light transmission substrate and the anode, and improving the luminous efficiency of the device. The invention also provides a preparation method of the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

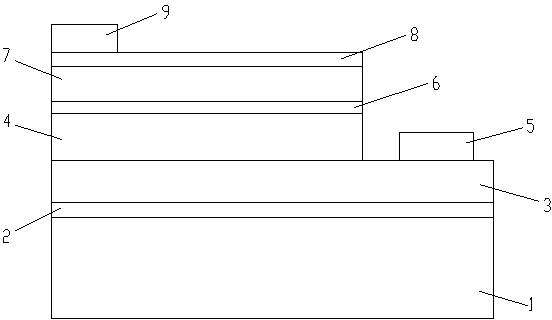

Organic light-emitting device

ActiveCN105428550ABest light efficiencySimple device structureSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceReflectivity

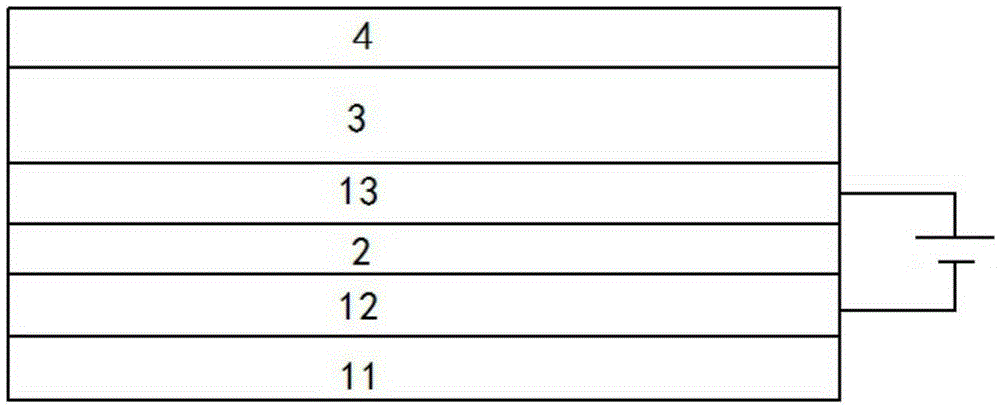

The invention discloses an organic light-emitting device. The organic light-emitting device comprises a substrate, and a first electrode, a luminous layer and a second electrode that are stacked on the substrate in sequence; the first electrode comprises an electronic control birefringent material film layer and multiple conductive film layers that are arranged in a laminated manner; and the conductive film layers are partially arranged on the same side of the electronic control birefringent material film layer. The organic light-emitting device provided by the invention can regulate and control the reflectivity of the first electrode through the electronic control birefringent material film layer for regulating and controlling a microcavity length so as to realize high luminous efficiency; a method for regulating and controlling the microcavity length through a multi-layer luminous layer structure in the prior art is also avoided; meanwhile, the device is simple in structure and mature in technology; and the production cost is effectively reduced and the product yield is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

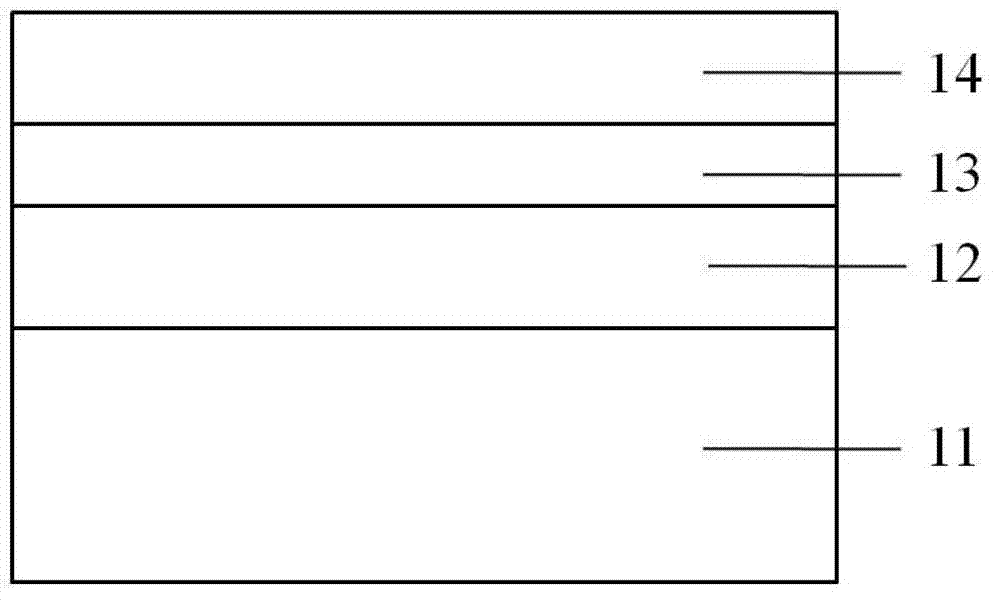

LED (Light Emitting Diode) chip manufacturing technology, LED chip structure and LED chip packaging structure

ActiveCN103441212AWon't stainAvoid yellowingSolid-state devicesSemiconductor devicesManufacturing technologyTemperature resistance

The invention relates to an LED (Light Emitting Diode) chip manufacturing technology, an LED chip structure and an LED chip packaging structure. According to the manufacturing technology, wolfram-molybdenum-copper alloy (WMoCu) is used as a substrate. The wolfram-molybdenum-copper alloy substrate is a good choice for a high-power LED chip heat dissipation substrate as the wolfram-molybdenum-copper alloy substrate has the thermal conductivity second only to that of a silicon carbide substrate, the cost of the wolfram-molybdenum-copper alloy substrate is far lower than that of the silicon carbide substrate, and meanwhile the wolfram-molybdenum-copper alloy substrate has the advantages of high temperature resistance, low expansion factor, high specific heat capacity, good mechanical machining property, easiness in manufacturing of mirror surfaces and the like. An LED chip in the invention sequentially comprises a wolfram-molybdenum-copper substrate layer, a U-GaN buffer layer and a N-type GaN layer from bottom to top, wherein an InGaN / GaN multiple-quantum well luminous layer and an N-electrode are arranged on the surface of the N-type GaN layer, and a P-type AlGaN layer, a P-type GaN layer, a current expanding layer and a P-electrode are also sequentially arranged above the InGaN / GaN multiple-quantum well luminous layer. Correspondingly, the LED chip has the advantages that the currents of the LED chip are vertically distributed, the substrate has high thermal conductivity and high reliability, the back surface of the luminous layer is a metal reflecting mirror, the surface has a coarsening structure, and the extraction efficiency is high.

Owner:江西量一光电科技有限公司

Gallium nitride compound semiconductor light-emitting device and method for manufacturing same

ActiveCN101331616AImprove light extraction efficiencyReduce contact resistanceSemiconductor devicesDopantGallium nitride

Disclosed is a gallium nitride compound semiconductor light-emitting device having high light extraction efficiency and low driving voltage (Vf). Specifically disclosed is a gallium nitride compound semiconductor light-emitting device wherein a light-transmitting conductive oxide film containing a dopant is arranged on a p-type semiconductor layer. In this gallium nitride compound semiconductor light-emitting device, the dopant concentration at the interface between the p-type semiconductor layer and the light-transmitting conductive oxide film is set higher than the bulk dopant concentration of the light-transmitting conductive oxide film, thereby reducing the contact resistance between the p-type semiconductor layer and the light-transmitting conductive oxide film.

Owner:TOYODA GOSEI CO LTD

Reflection type light projector device

InactiveCN101063518AReduce the volume of lampsGood collimationMechanical apparatusPoint-like light sourceFresnel lensCollimated light

The invention is a reflection-type light-projecting device, comprising a light-guiding cover with reflecting characteristic and a directional light source, wherein the light-guiding cover has a reflection surface of Fresnel structure which uses Fresnel lens principle and converts the geometrical reflection surface to an equivalent reflection surface to be a plane, a chamber or a combination, the reflection surface of Fresnel structure is arranged at the bottom of the light-guiding cover, the light source is arranged on the side wall of the light-guiding cover, adjusting the light direction to form a certain engageable angle with the Fresnel structure can make the reflecting light emitted in certain angle from the light-guiding cover, to generate collimated light with high efficiency and high alignment.

Owner:IND TECH RES INST +1

SiC-substrate-based perpendicular structural GaN-based ultraviolet LED (Light Emitting Diode) and production method thereof

InactiveCN103730549AImprove growth qualityEvenly distributedSemiconductor devicesUltraviolet lightsMetal electrodes

The invention belongs to the technical field of semi-conductor luminescent devices and production thereof and discloses a SiC-substrate-based perpendicular structural GaN-based ultraviolet LED (Light Emitting Diode) and a production method thereof. The production method of the SiC-substrate-based perpendicular structural GaN-based ultraviolet LED comprises firstly producing a GaN-based ultraviolet LED structure on a SiC substrate; producing an ohm reflecting layer and a metal bonding layer on a p-GaN layer; performing thermocompression bonding on prepared epitaxial wafer and electric and thermal conductive substrate of the metal bonding layer; thinning the SiC substrate and removing the SiC substrate; performing shape photoetching on a n-ALGaN layer, evaporating metal electrodes and producing into the ultraviolet LED. According to the production method of the SiC-substrate-based perpendicular structural GaN-based ultraviolet LED, material growing quality is good due to the fact that the substrate of the ultraviolet LED is made of SiC materials; current distribution of the ultraviolet LED is more uniform due to the fact that the electric and thermal conductive substrate can be served as the p-GaN electrode and can provide support; technological difficulties in epitaxial technology are solved, SiC negative influences to ultraviolet light absorption are avoided and the external quantum efficiency of the devices are improved by a large margin due to the fact that the substrate stripping technology can completely strip the SiC substrate which is strong in function of absorbing the ultraviolet light.

Owner:DALIAN UNIV OF TECH

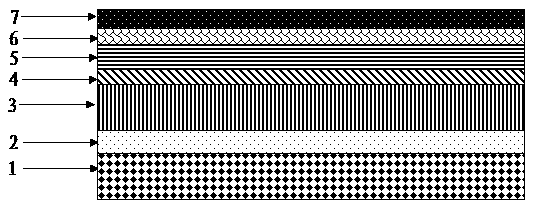

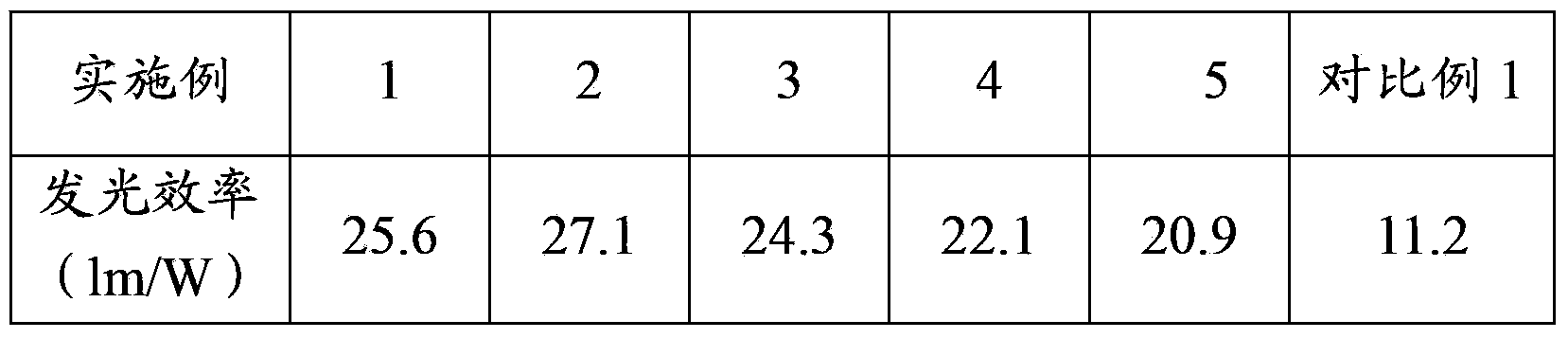

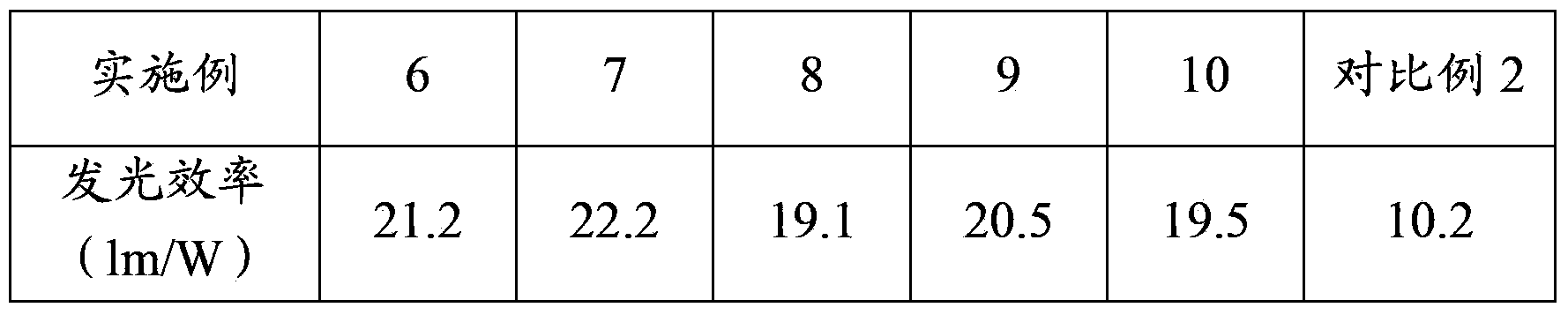

Organic light emission diode device and fabrication method thereof

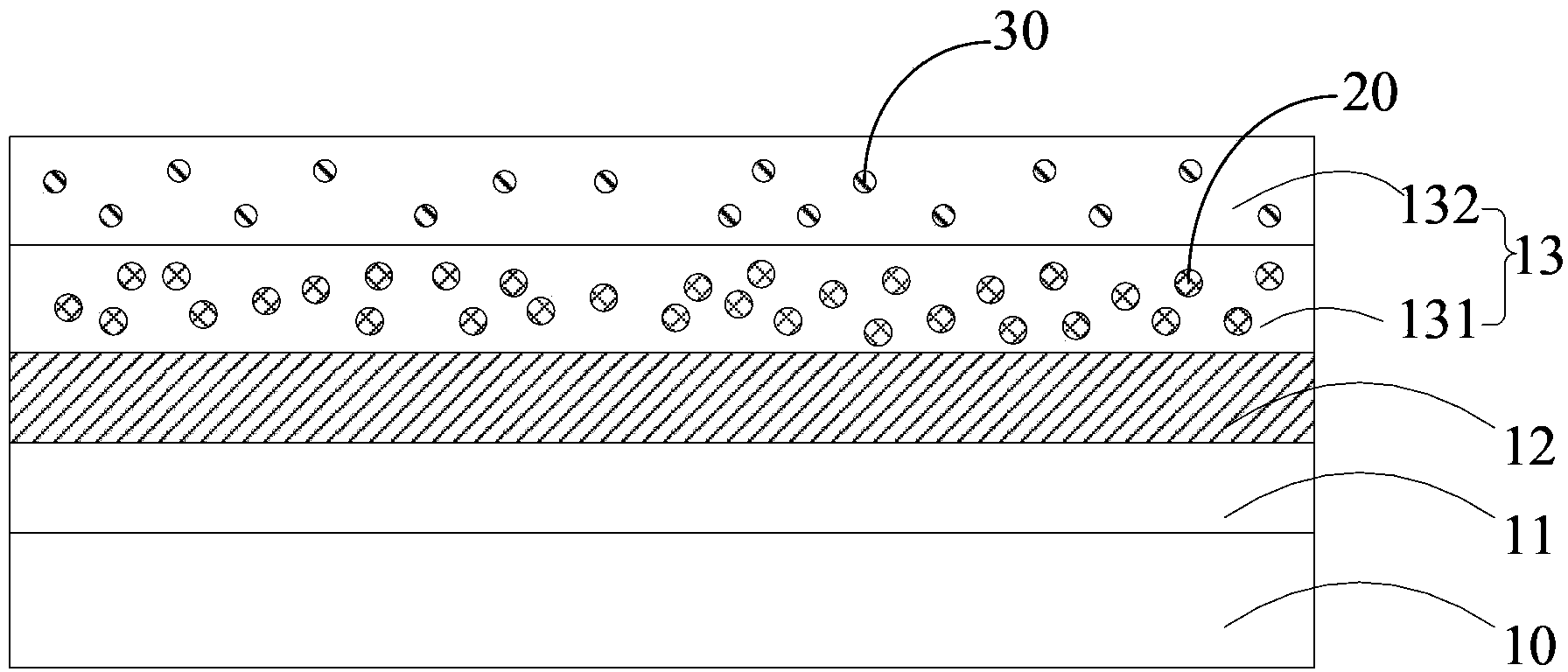

InactiveCN104218173AImprove light extraction efficiencyGood light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMicrosphereMixed materials

The invention provides an organic light emission diode device. The organic light emission diode device comprises a substrate and an anode, a light emission functional layer and a cathode which are sequentially laminated on the substrate, a light matching layer and a light extraction layer are sequentially arranged on the surface of the cathode, the material of the light extraction layer comprises nanoparticles and a polymer material, the nanoparticles are ceramic or high-polymer material particles with the grain size of 50 to 1,500 nanometers, the polymer material is a heat cured polymer or photo cured polymer material, the thickness of the light extraction layer is 10 to 100 micrometers, the material of the light matching layer is a mixed material formed by metal and an organic material, the metal is silver, aluminum or magnesium, and the organic material is N,N'-diphenyl-N,N'-bis(1-naphthyl)-1,1'-biphenyl-4,4'-diamine, copper phthalocyanine or 8- hydroxyquinoline aluminum. The luminous efficiency of the cathode of the organic light emission diode device is high, so that the luminous efficiency of the device is improved. The invention also provides a fabrication method of the organic light emission diode device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

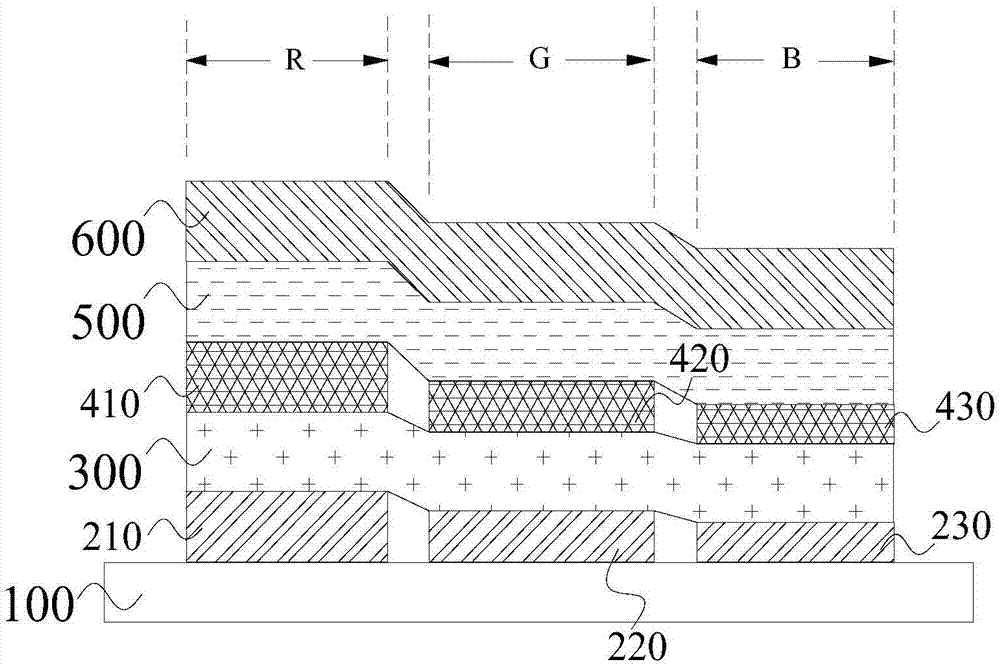

Display back plate and manufacturing method and display device thereof

ActiveCN107994125AImprove the display effectGood light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSingle processDisplay device

The invention provides a display back plate and a manufacturing method and a display device thereof. The display back plate comprises a plurality of pixel units which are arranged in array, each pixelunit comprises a plurality of sub-pixels, each sub-pixel comprises a base plate, a first electrode, a first organic functional layer, an illuminating layer, a second organic functional layer and a second electrode, wherein illuminating colors of the plurality of sub-pixels are different, the thickness of the plurality of first electrodes of the plurality of sub-pixels is different, and the thickness of the first electrodes and the thickness of the first organic functional layers are used for making illuminating dipole moments of the sub-pixels located on second standing wave nodes of the first electrode side. According to the display back plate, the thickness of the first electrodes of different sub-pixels is different, so that the illuminating dipole moments of the different sub-pixels are installed on the second standing wave nodes of respective first electrode side, therefore the illuminating efficiency of the display back plate can be greatly improved, so that each other layer outside the illuminating layer in the display back plate is formed through a single process.

Owner:BOE TECH GRP CO LTD

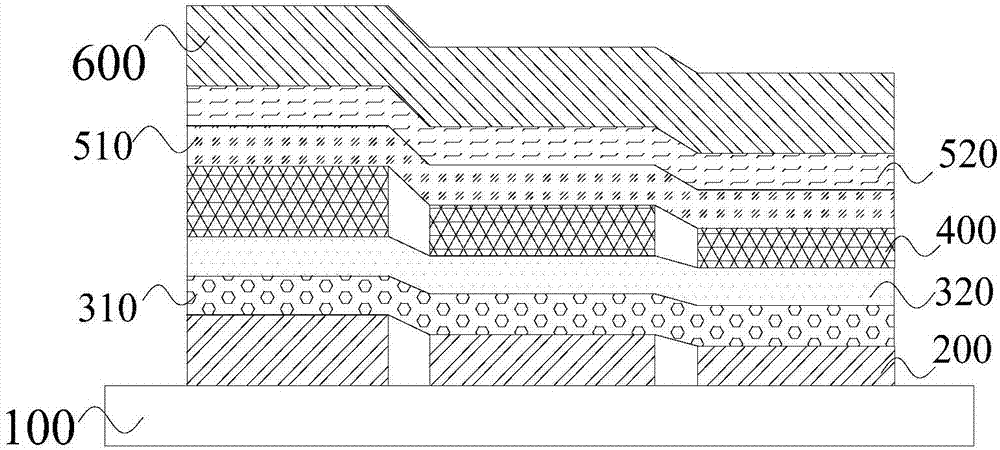

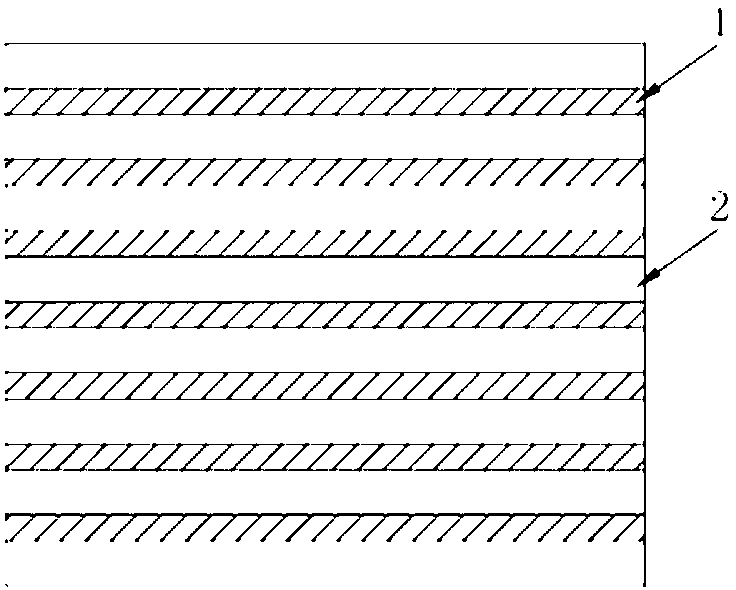

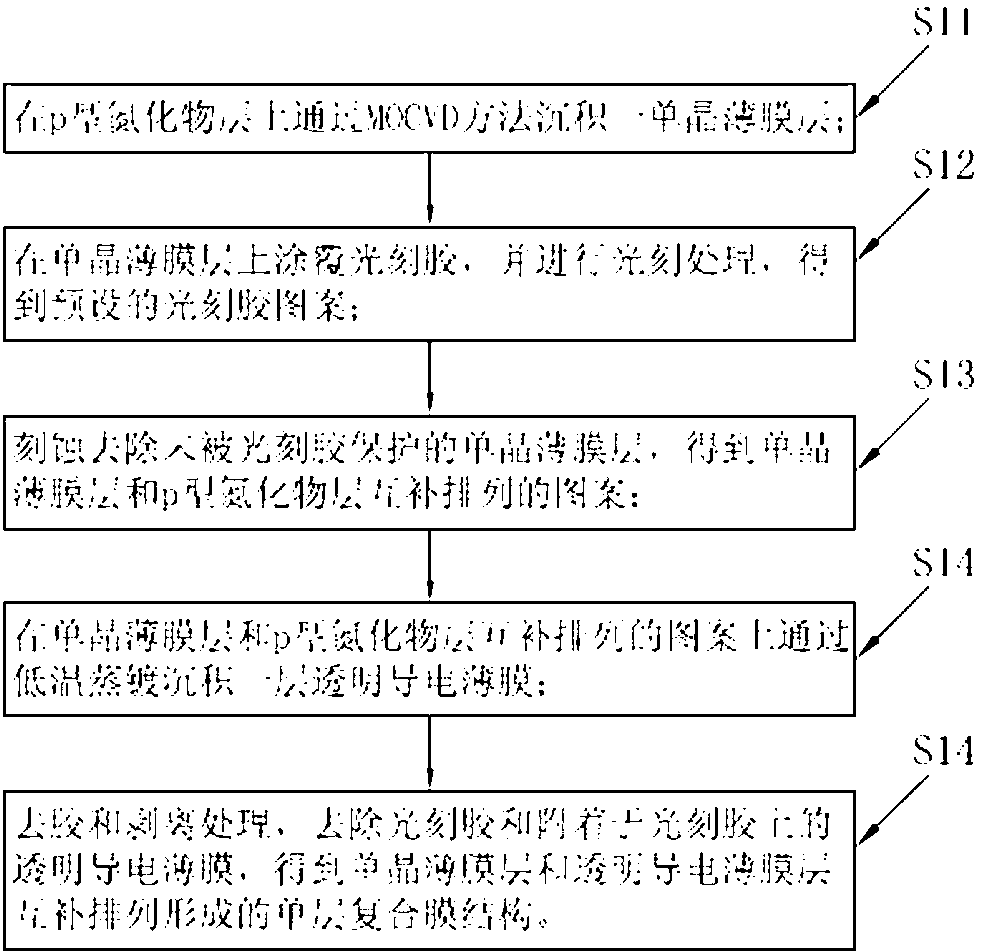

Current diffusion electrode, semiconductor emitting device, method for manufacturing current diffusion electrode and method for manufacturing semiconductor emitting device

ActiveCN102810613AEasy ohmic contactReduce contact resistanceSemiconductor devicesOhmic contactConductive oxide

The invention provides a current diffusion electrode, which comprises single crystal film layers and transparent conductive film layers. The single crystal film layers and the transparent conductive film layers are arranged in a complementary manner so as to form a single-layer composite film; the single-layer composite film can be in contact with a p-type nitride layer; and the single crystal film layers are made of transparent conductive oxide. The invention also provides a method for manufacturing the current diffusion electrode, a semiconductor emitting device with the current diffusion electrode, and a method for manufacturing the semiconductor emitting device. The single crystal film layers and the transparent conductive film layers are arranged in the complementary manner so as to form the single-layer composite film; the single-layer composite film can be in contact with the p-type nitride layer; if the single crystal film layers are in contact with a p-type nitride semiconductor, ohmic contact is easy to form, contact resistance is low, current diffusion is uniform, and electric properties of a nitride semiconductor device are improved; and besides, light transmission of the transparent conductive film layers is good, light penetration rate and light emergent efficiency of the transparent conductive film layers are high, and optical properties of the nitride semiconductor device are improved.

Owner:BYD SEMICON CO LTD

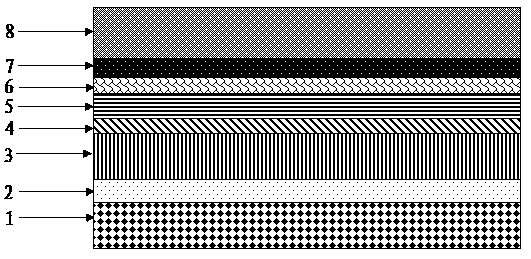

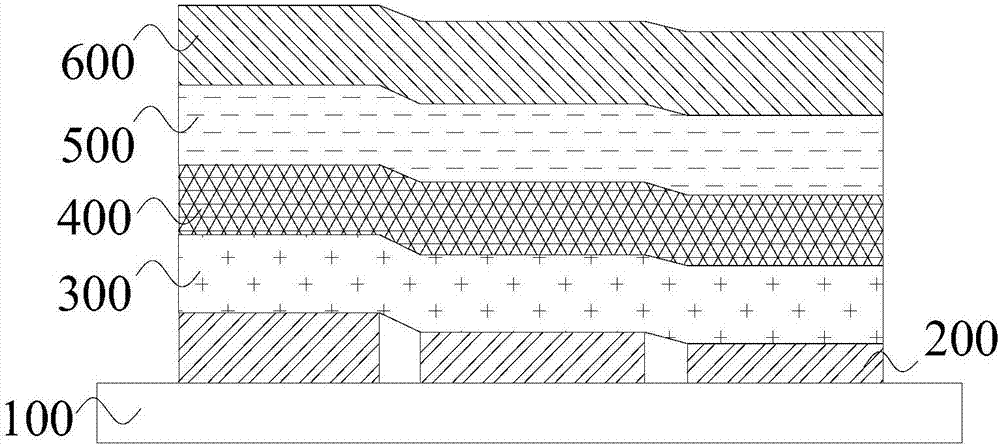

Organic light emission diode device and fabrication method thereof

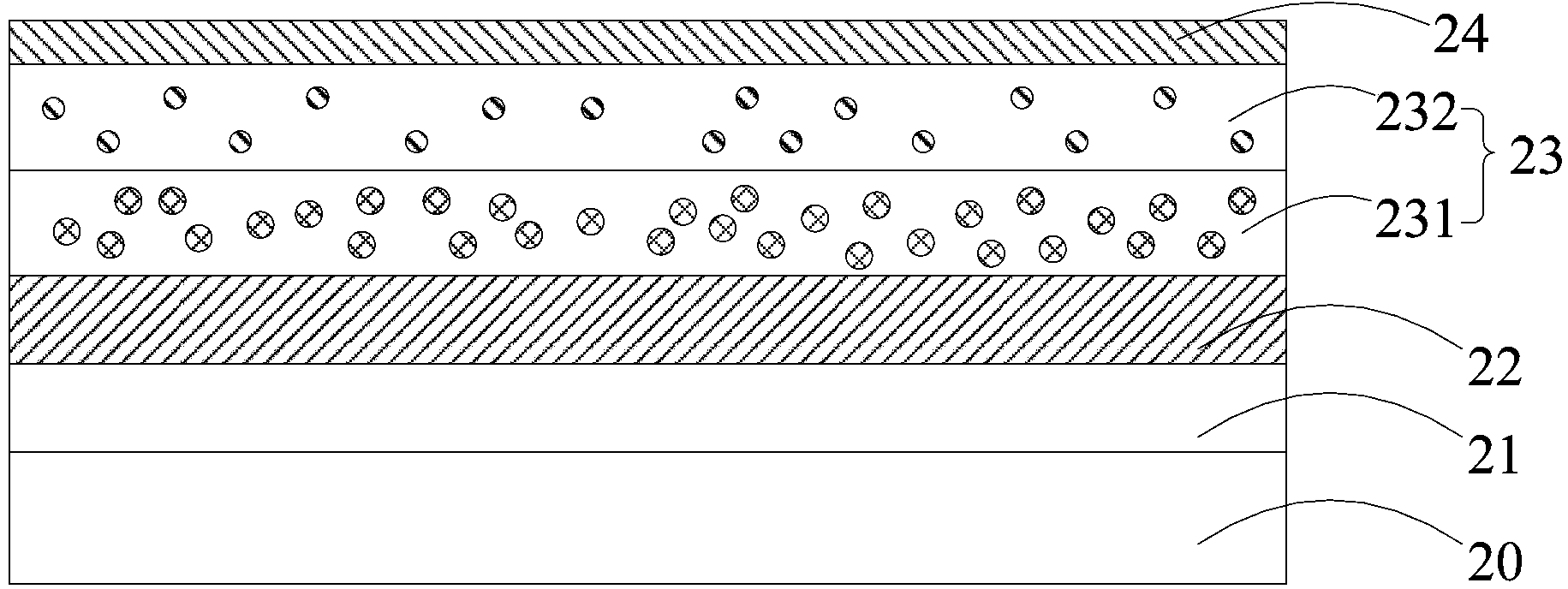

InactiveCN104218155APlay the role of light scatteringChange the refractive indexSolid-state devicesSemiconductor/solid-state device manufacturingSilicon monoxideMicroparticle

The invention provides an organic light emission diode device which comprises a substrate, an anode, a light emission functional layer and a cathode, the cathode comprises a first doping layer and a second doping layer which are sequentially laminated, the material of the first doping is a mixed material formed by organic particles and metal, the mass rate of the organic particles to the metal is (0.6-1.2):1, the grain size of the organic particles is 10 to 100 nanometers, the organic particles are an electron-transmitted organic material, the material of the second doping layer is a mixed material formed by inorganic particles and metal, the mass rate of the inorganic particles to the metal is (0.02-1):1, the grain size of the inorganic particles is 10 to 50 nanometers, the inorganic particles are one or more of silicon monoxide, silicon dioxide, titanium dioxide and tungsten oxide, and the metal is elementary substance of gold, silver, aluminum or magnesium. The luminous efficiency of the cathode of the organic light emission diode device is high, therefore, the luminous efficiency of the device is improved. The invention also provides a fabrication method of the organic light emission diode device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

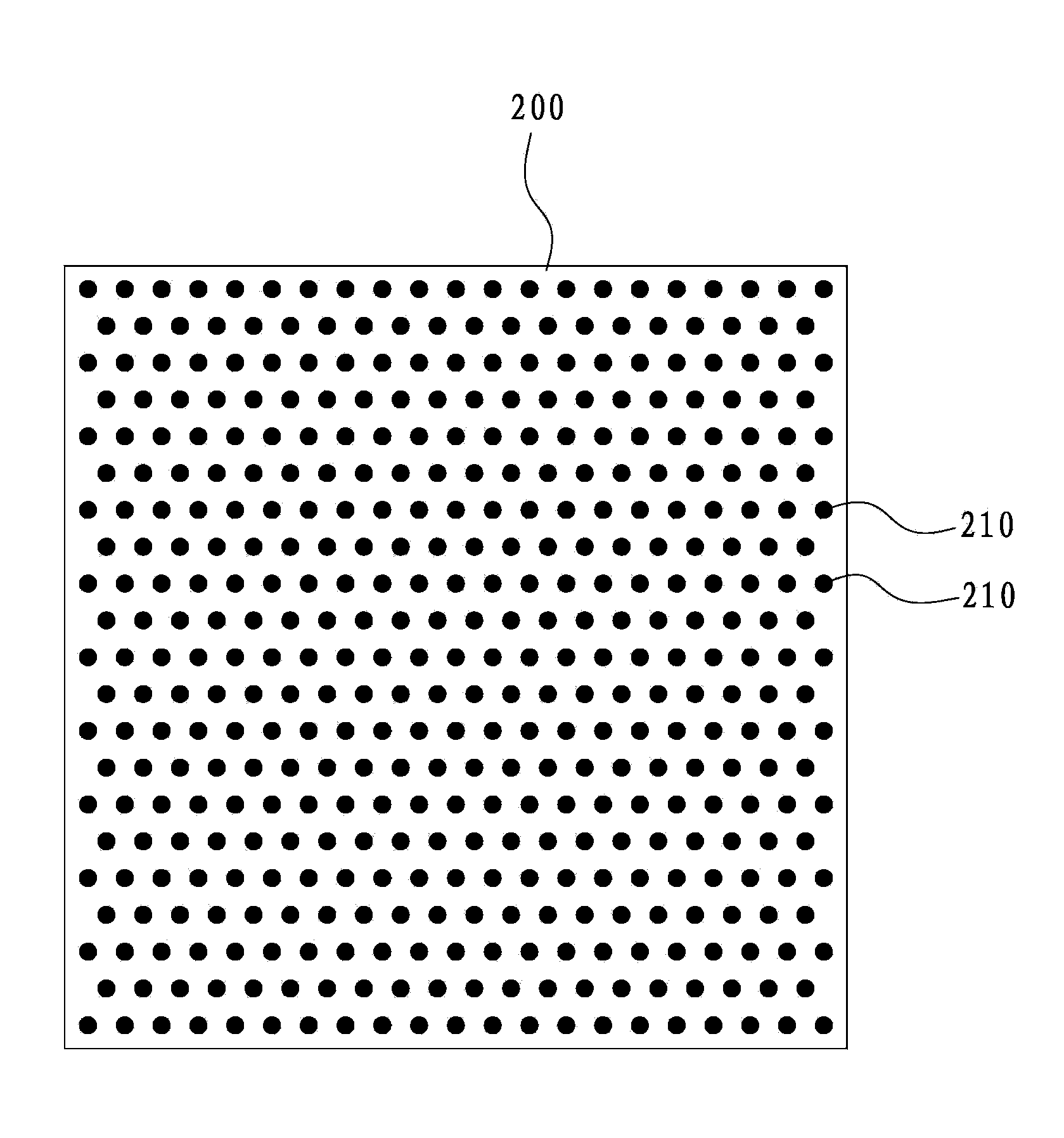

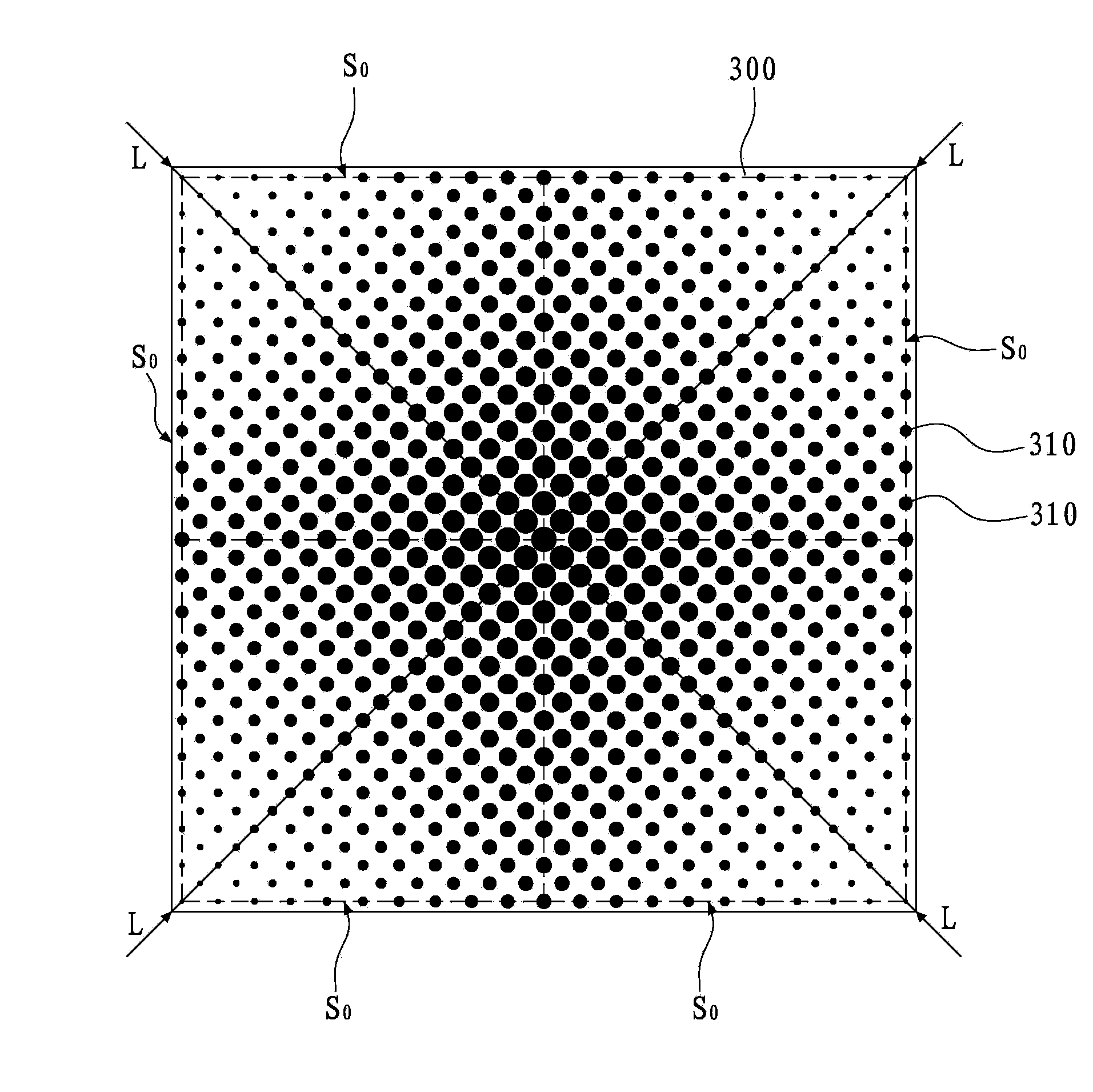

Large-size light guide plate

InactiveCN103543487AGood light extraction efficiencyConsider flexibilityOptical light guidesRight triangleEngineering

The invention discloses a large-size light guide plate. A plate body is equally divided into four parts. Silk-screen lattice points on the plate body are divided into four point units. The reflecting face of each plate part is divided into an L-shaped area and a large rectangular area. The L-shaped area is located at the connection of the plate part and the adjacent plate body. The large rectangular area is divided into a first right triangle area and a second right triangle area. Each point unit comprises silk-screen graded area in the first right triangle area, a silk-screen snap in the second right triangle area and an invariable area in the L-shaped area. Lattice points in the graded area and the snap area are arrayed and distributed on the light entering direction of two sides; wherein, diameters of the lattice points are increased gradually along the light entering direction of the two sides, and change values of the graded area are smaller than that of the snap area. Diameters of the lattice points in the invariable area are increased gradually on the direction of the light entering direction of the contacting side face of each area, and the diameters of the lattice points are constant on the direction of the light entering direction of the non-contacting side face. By the aid of the large-size light guide plate, light irradiating effect and light irradiating efficiency are guaranteed.

Owner:厦门伟然科技股份有限公司

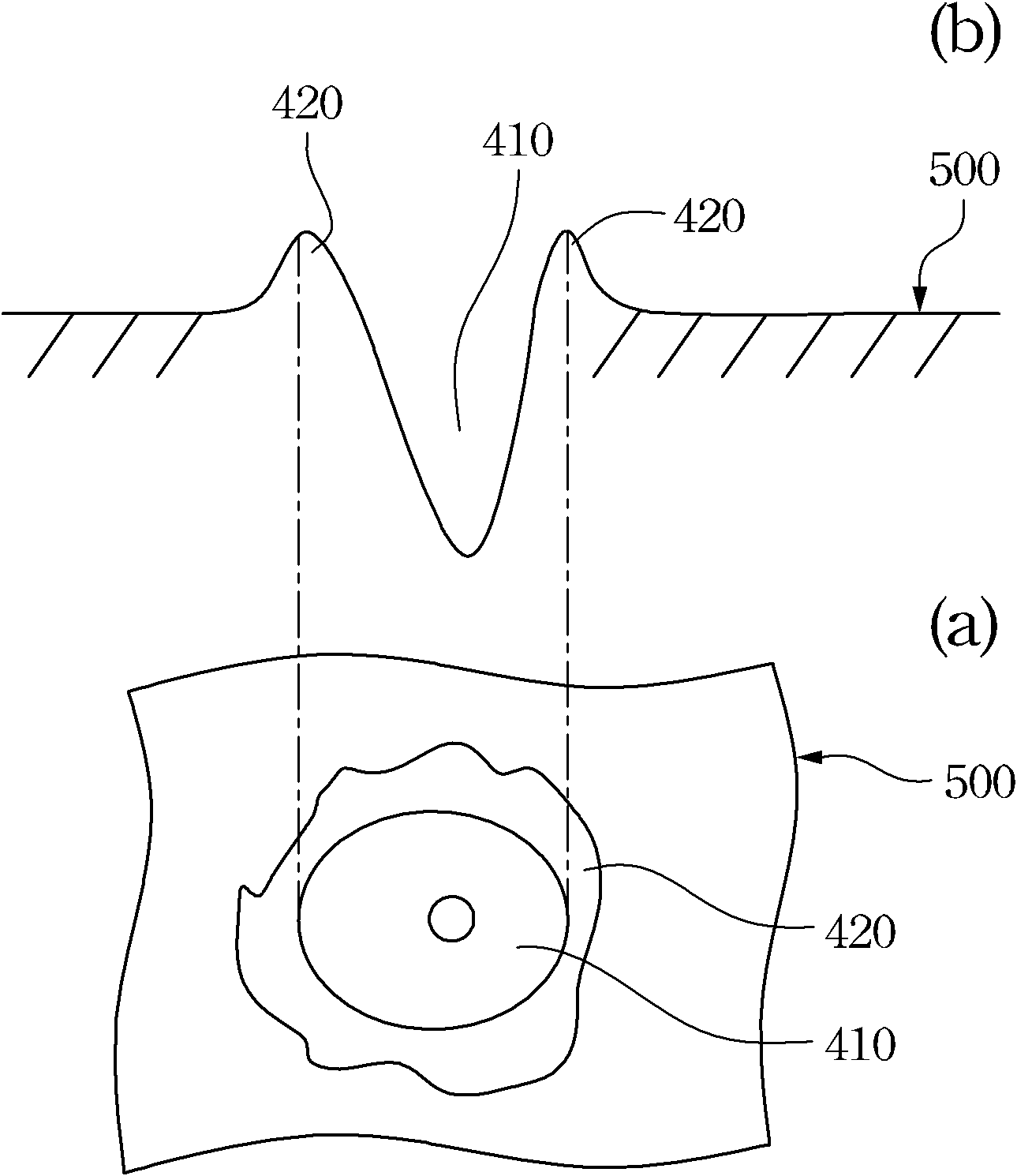

Coarsening structure, coarsening surface and coarsening layer of optoelectronic element and manufacturing method of optoelectronic element

The invention provides a coarsening structure, a coarsening surface and a coarsening layer of an optoelectronic element and a manufacturing method of the optoelectronic element. The optoelectronic element with double-scale coarsening structures is characterized in that: impurities are doped in an extension process of a semiconductor of the optoelectronic element to allow the semiconductor to growa plurality of island bodies; subsequently, the extension temperature is lowered so as to continuously form a plurality of pin holes on the plurality of island bodies, wherein the pin holes are distributed on the top parts and side faces of the island bodies, so the total internal reflectivity of rays in the optoelectronic element is greatly reduced and the light intensity performance of the optoelectronic element is enhanced. Compared with the conventional art, the process of the invention has the advantages of low pollution, simple process, low cost, better light extraction efficiency, bigger effective area of double-scale light scattering surface and the like.

Owner:ZHANJING TECH SHENZHEN +1

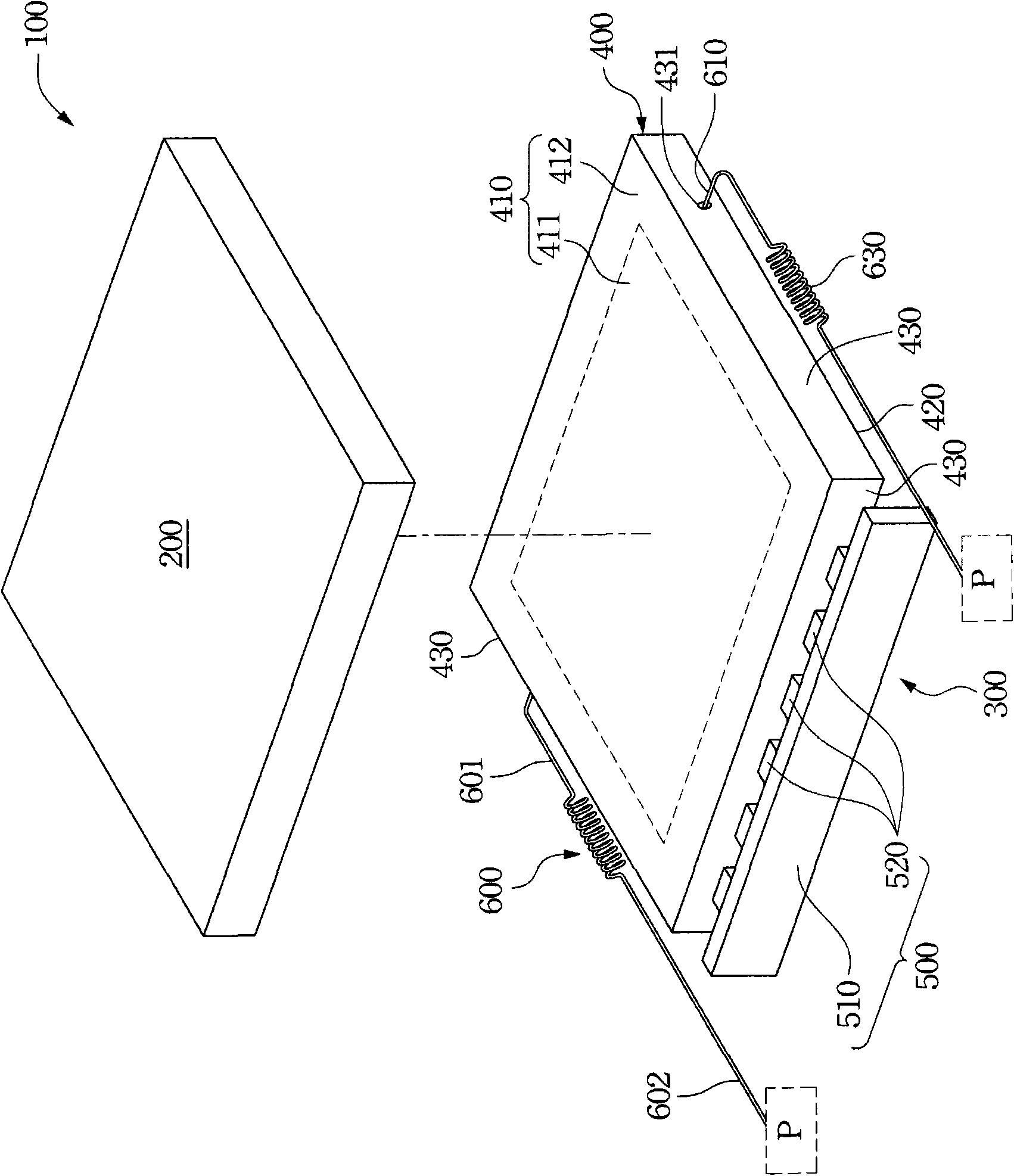

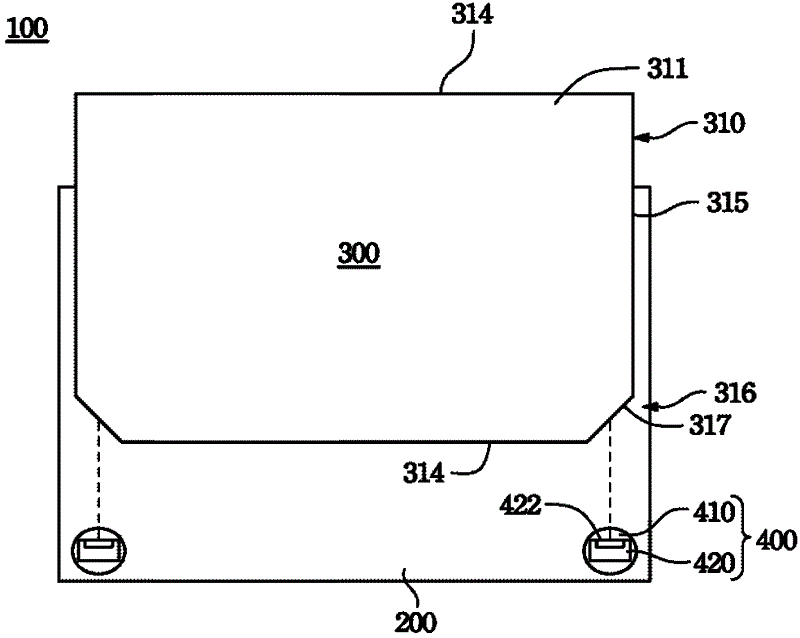

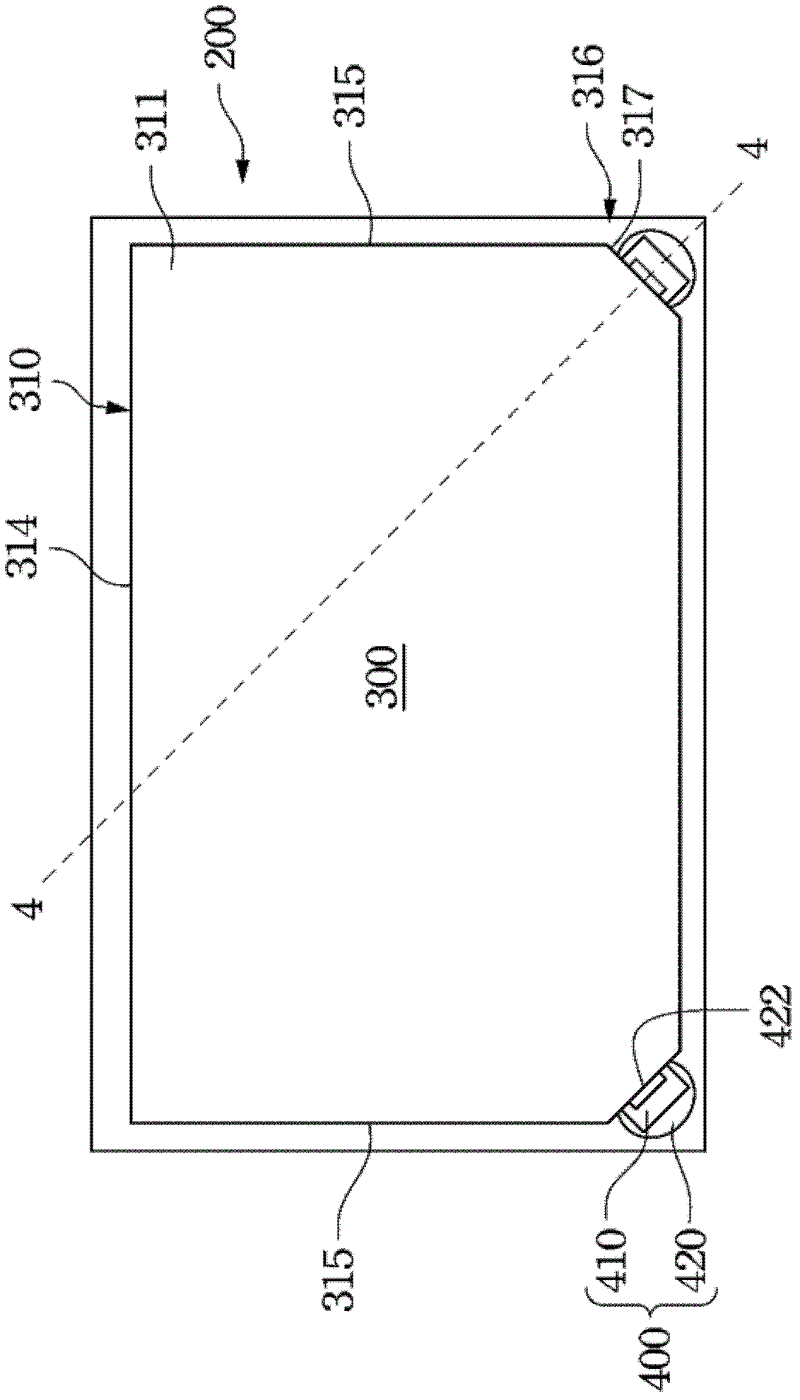

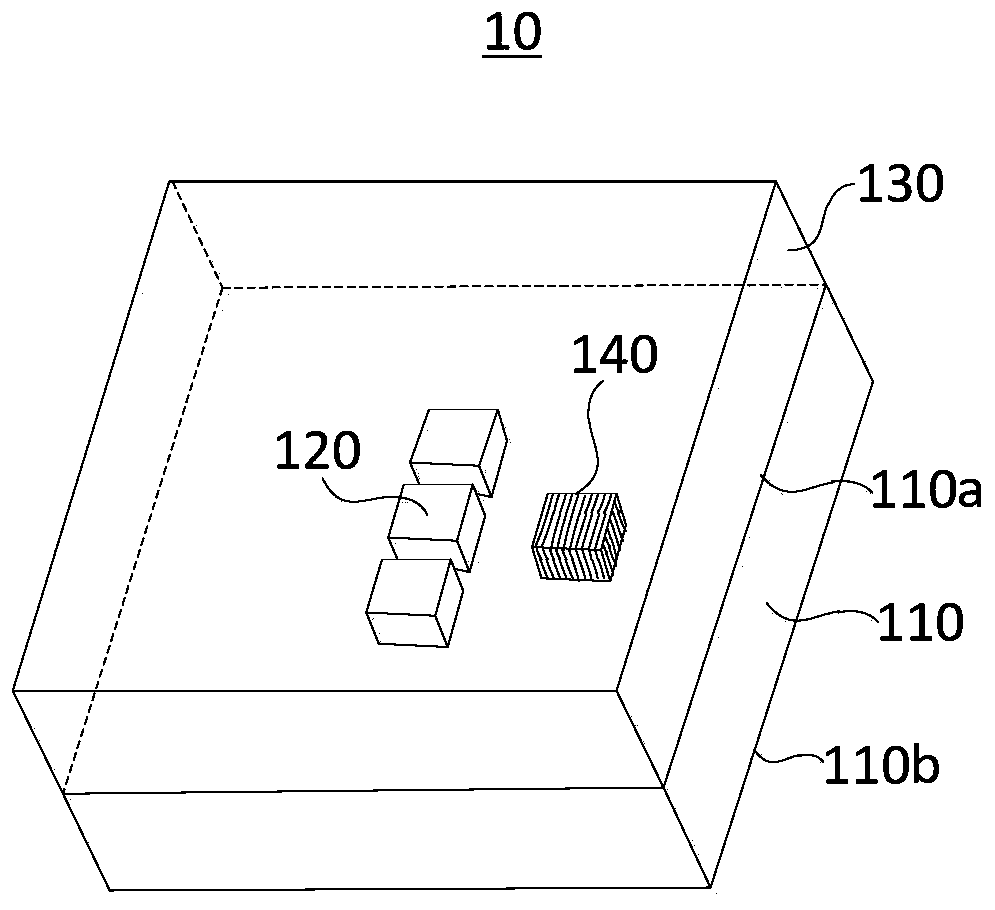

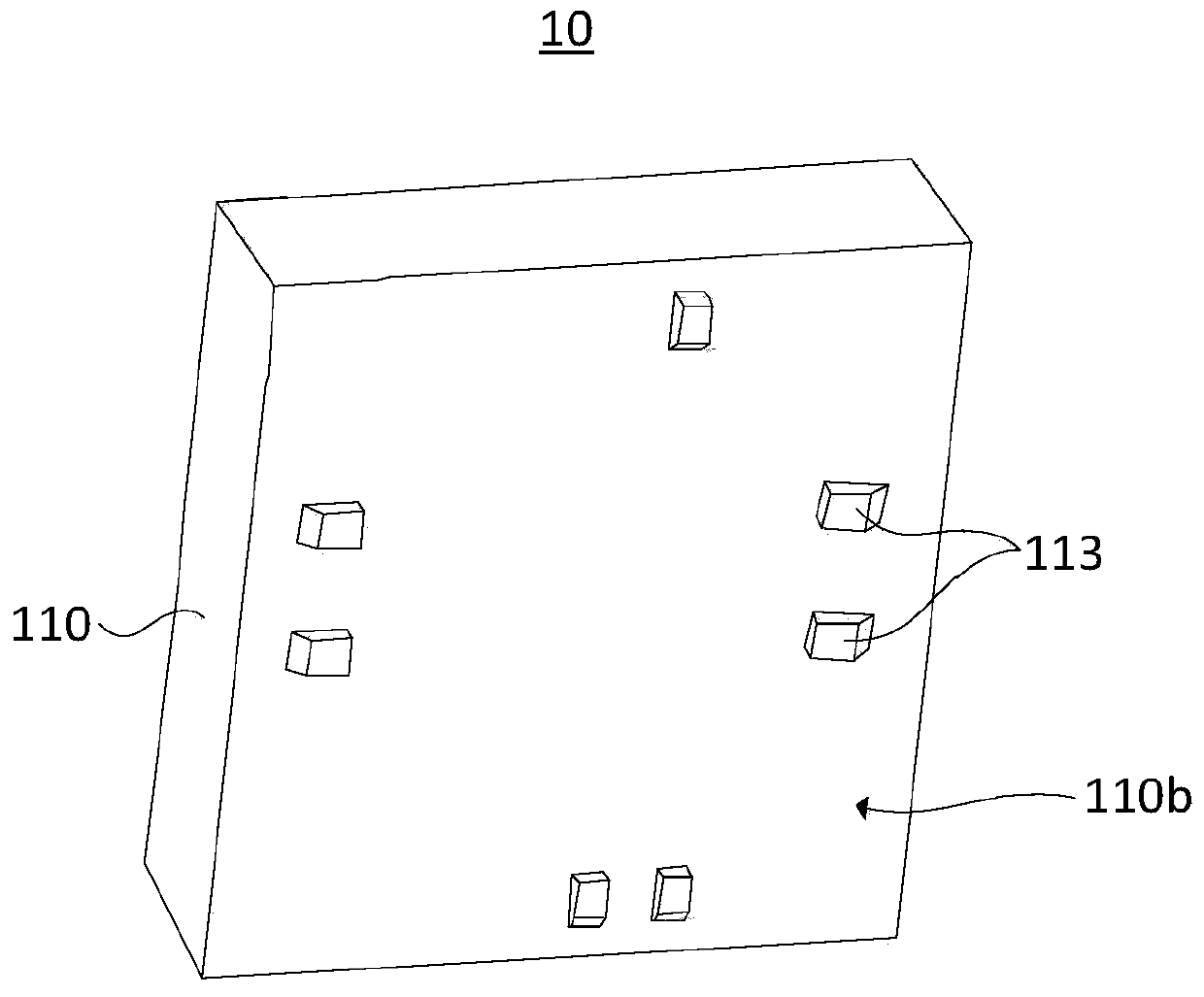

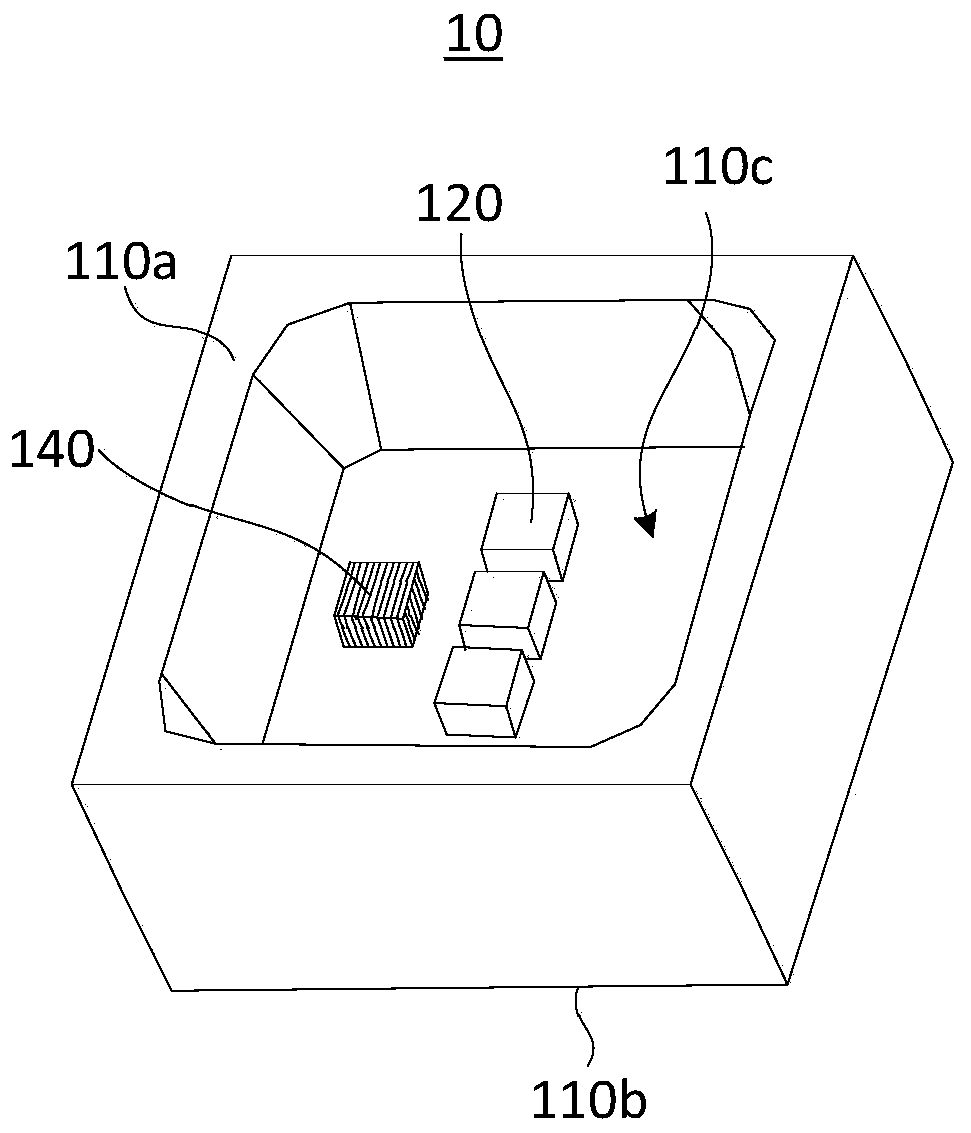

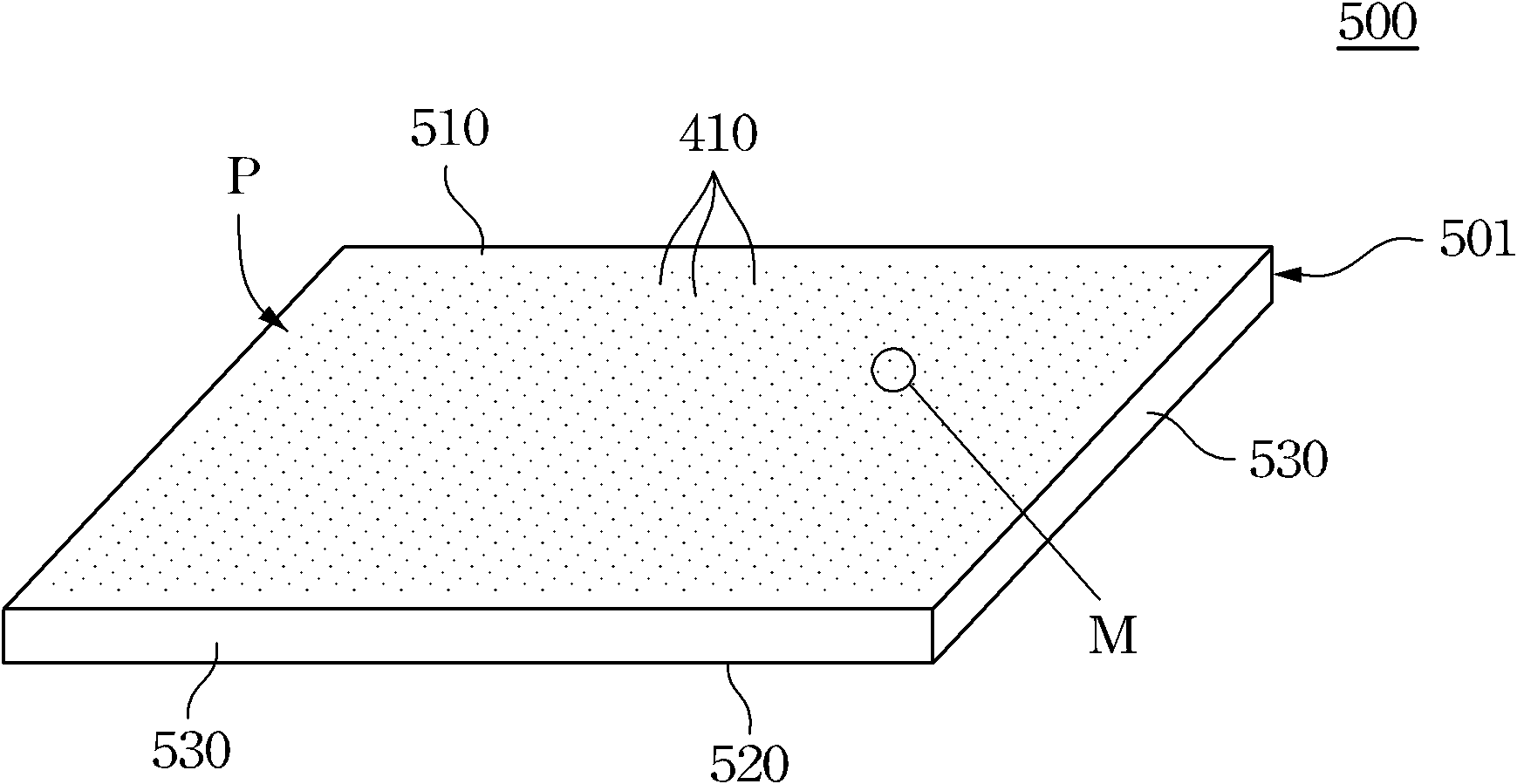

Display apparatus, backlight module thereof, and method for assembling backlight module

ActiveCN102620192AGood light extraction efficiencyEnough lighting lightMechanical apparatusLight guides for lighting systemsOptoelectronicsLight guide

The invention discloses a display apparatus, a backlight module thereof, and a method for assembling the backlight module. The backlight module comprises a pedestal, a light guide plate, and a light source, wherein the light guide plate comprises a corner-lacking portion; the light source can be arranged upon the pedestal in a rotary manner; and one lighting surface of the light source is applied to one light-incoming surface of the corner-lacking portion.

Owner:AU OPTRONICS CORP

LED lamp bead capable of improving display effect and LED display screen

ActiveCN111029333AStrong brightnessLuminous Intensity ControlSolid-state devicesSemiconductor devicesLuminous intensityLED display

The invention relates to an LED lamp bead capable of improving a display effect and an LED display screen. The lamp bead comprises a lamp body, a primary color light-emitting device, an ultraviolet LED chip, pins and a packaging layer, wherein the primary color light-emitting device and the ultraviolet LED chip are arranged on the lamp body, and the packaging layer packages the primary color light-emitting device and the ultraviolet LED chip on the lamp body; the primary color light-emitting device and the ultraviolet LED chip are electrically connected with the pins; the packaging layer comprises a photochromic material, and when the ultraviolet LED chip does not emit light, the packaging layer is transparent; when the ultraviolet LED chip emits ultraviolet light, the photochromic material absorbs the ultraviolet light and becomes black, and the packaging layer becomes black gradually. The photochromic material is transparent, the packaging layer has good light emitting efficiency, the light emitting brightness can be improved without increasing the size and current of the light emitting device, the power consumption is low, and the problem of temperature rise does not exist; thelight emitting intensity of the ultraviolet LED chip is controlled, the blackening degree of the packaging layer can be controlled, the contrast ratio is controlled, and the display effect is improved.

Owner:SHENZHEN AOTO ELECTRONICS

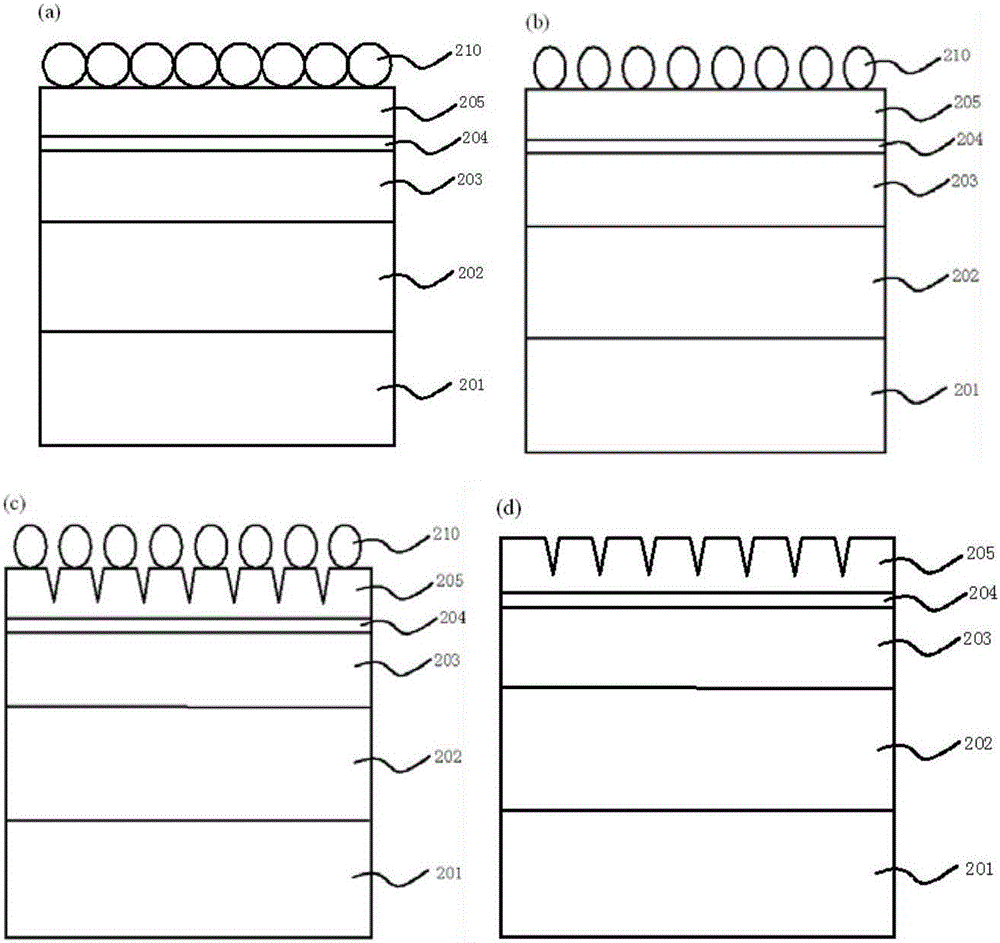

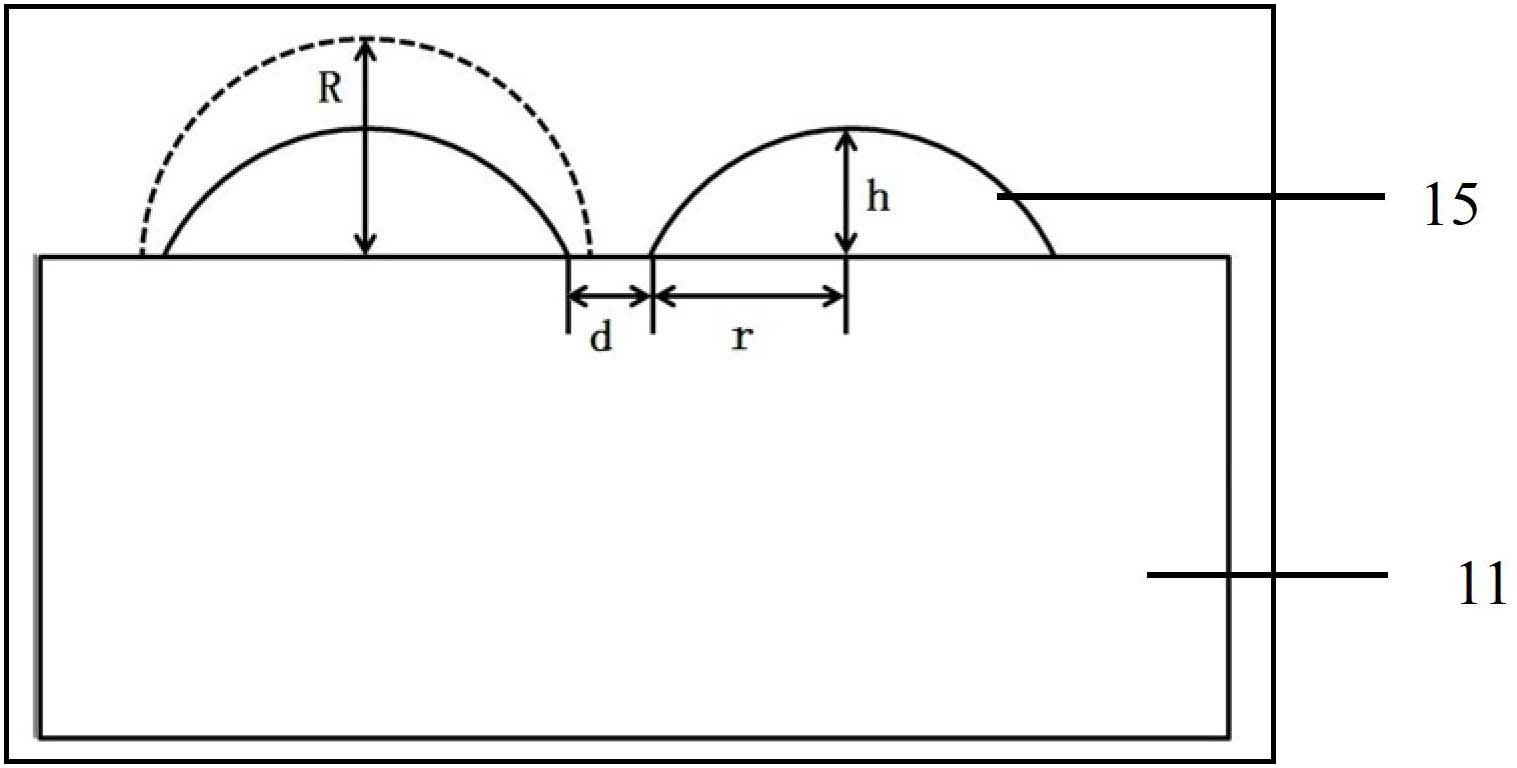

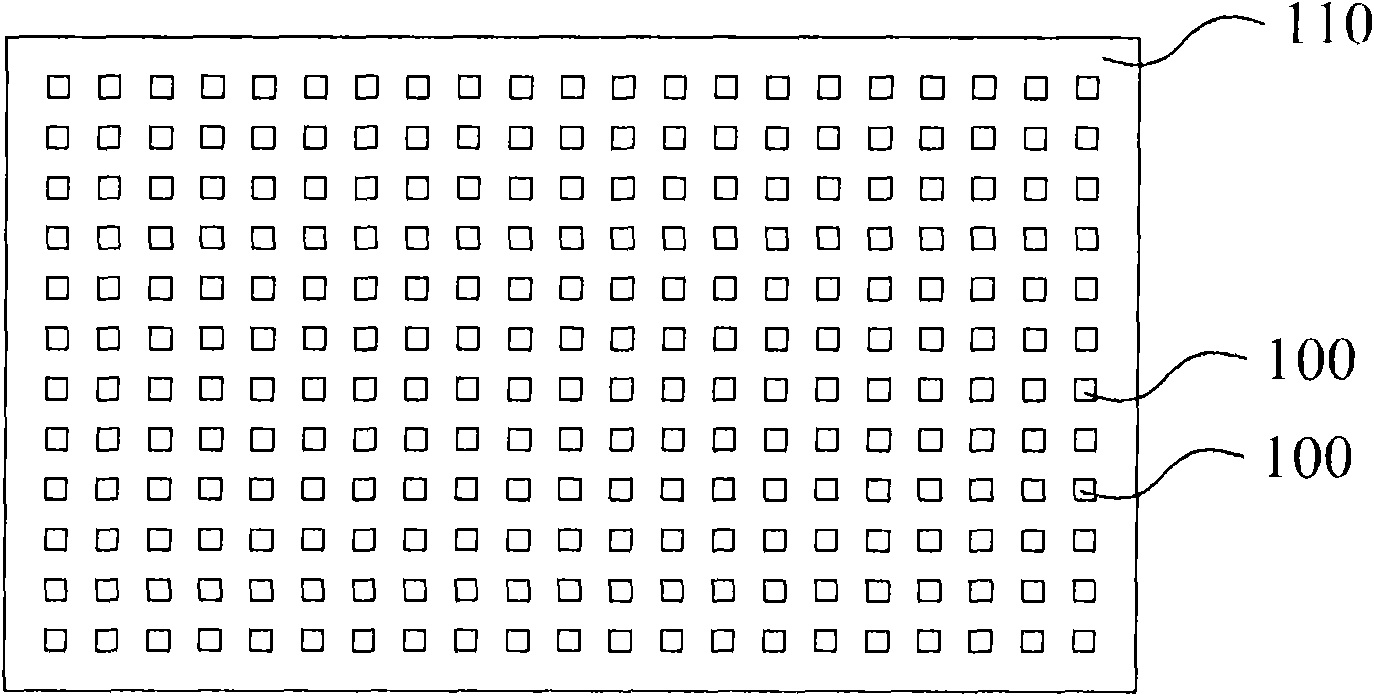

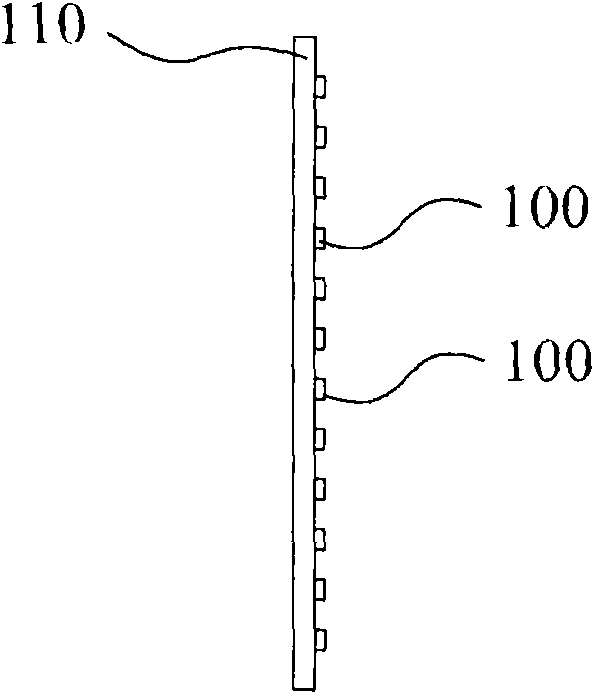

Patterned substrate of LED chip and LED chip

InactiveCN102694086AIncreased Scatter ChanceImprove light extraction efficiencySemiconductor devicesOptoelectronicsPatterned substrate

The invention discloses a patterned substrate of an LED chip and an LED chip. Patterns of the substrate consist of a plurality of identically-shaped spherical caps arranged on the surface of the substrate, the height h of each spherical cap is 75-85 percent of the radius R of the sphere corresponding to the spherical cap, and the distance d between the edges of the adjacent spherical caps is 30-50 percent of the radius r of the bottom surface of the spherical caps. Compared with the prior art, the patterned substrate has better light extraction efficiency than a substrate with hemispherical patterns with the same bottom surface radius, is simpler in actual processing and facilitates popularized application.

Owner:SOUTH CHINA UNIV OF TECH

Light guide plate, backlight module and display device thereof

InactiveCN102073091AAvoid destructionImprove fit tightnessMechanical apparatusLight guides for lighting systemsLight guideDisplay device

The invention relates to a light guide plate, a backlight module and a display device thereof. The light guide plate comprises a plate body and an optical microstructure pattern, wherein the optical microstructure pattern is distributed on the surface of the plate body and comprises a plurality of micro concave holes; the periphery of each of the micro concave holes is provided with at least one recessed part having a molten surface; and the depth of each recessed part is smaller than that of each micro concave hole. The invention has the advantages that: the possibility for protrusions at the peripheries of the micro concave holes to fall off to fill the micro concave holes can be reduced or avoided, and the optical guide rotation performance of the optical microstructure is prevented from being degraded after the light guide plate is manufactured. In addition, after the light guide plate is arranged in a display, the joint tightness of the light guide plate and an optical film is improved, the excellent light-extraction efficiency is kept, the optical film is prevented from being broken, and the service life of the product is prolonged.

Owner:苏州茂立光电科技有限公司

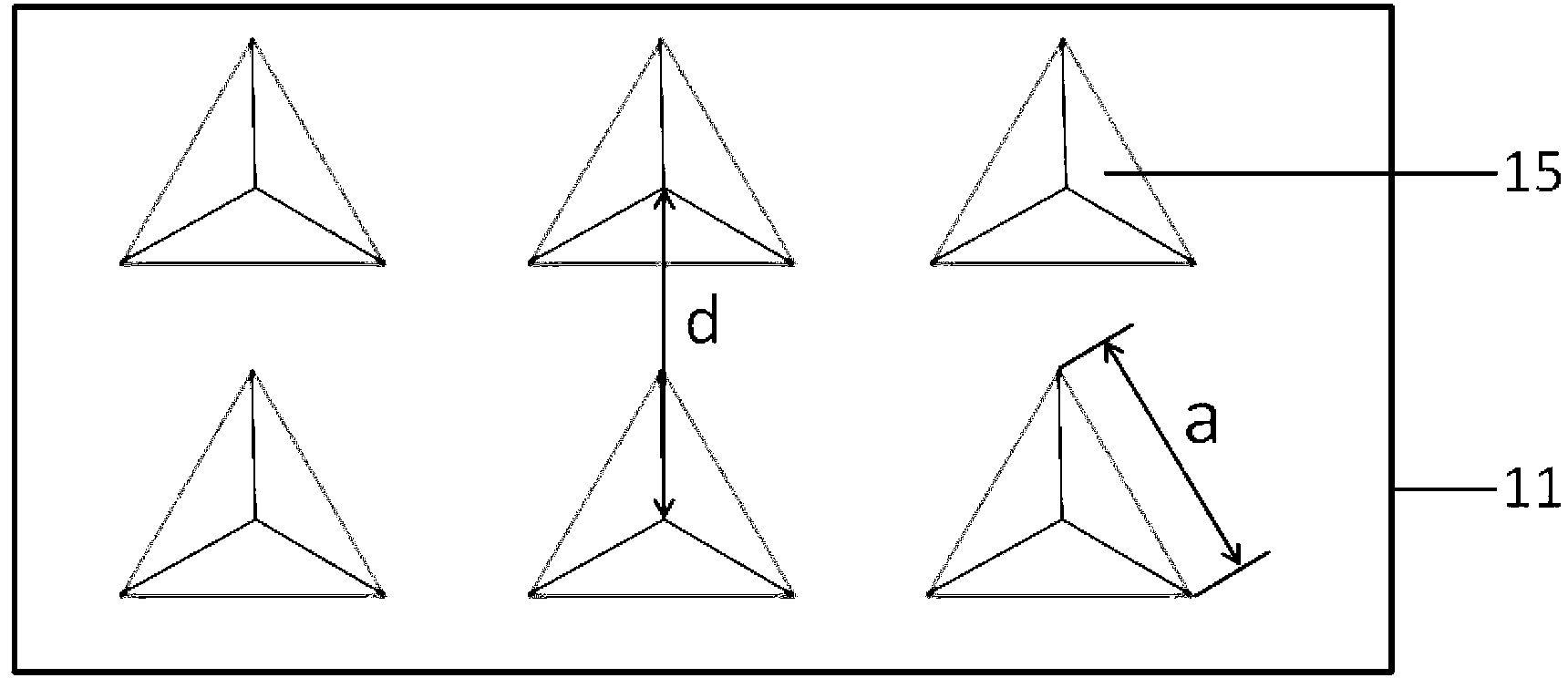

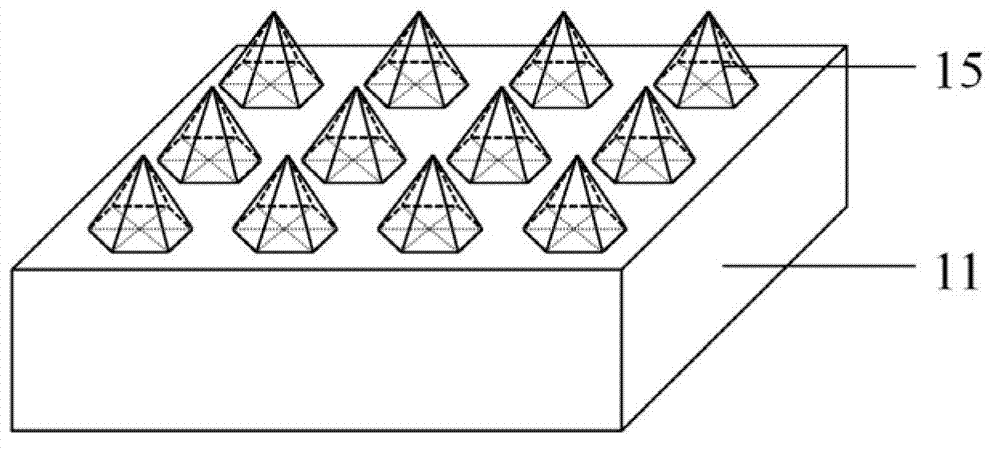

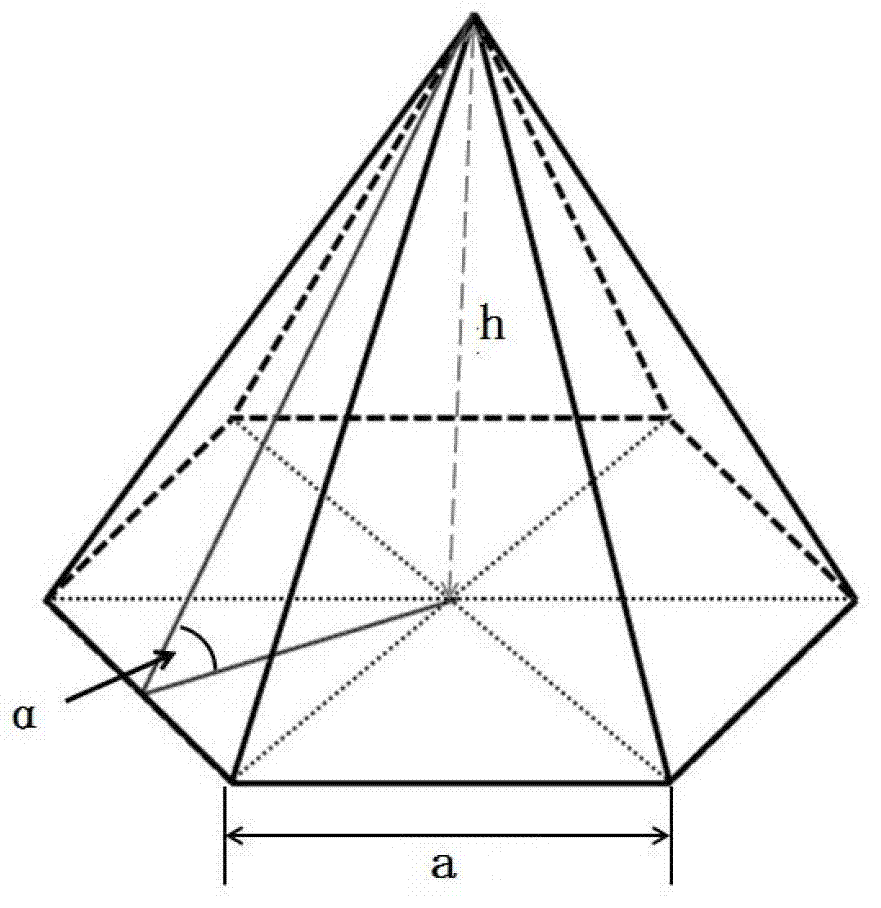

Patterned substrate of pattern improved LED chip and LED chip containing the same

InactiveCN103022302AImproved ability to reach the top of the LED chipImprove light extraction efficiencySemiconductor devicesState of artOptoelectronics

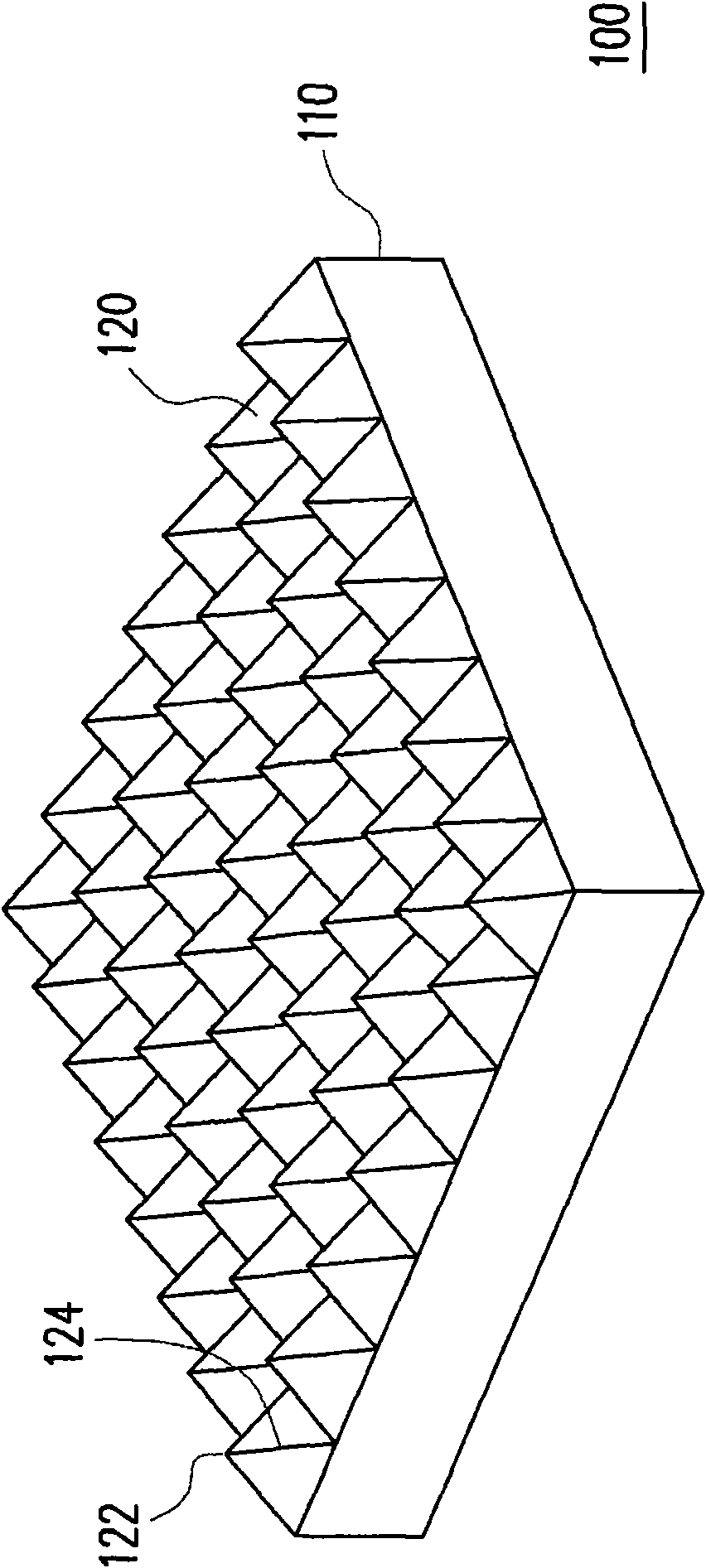

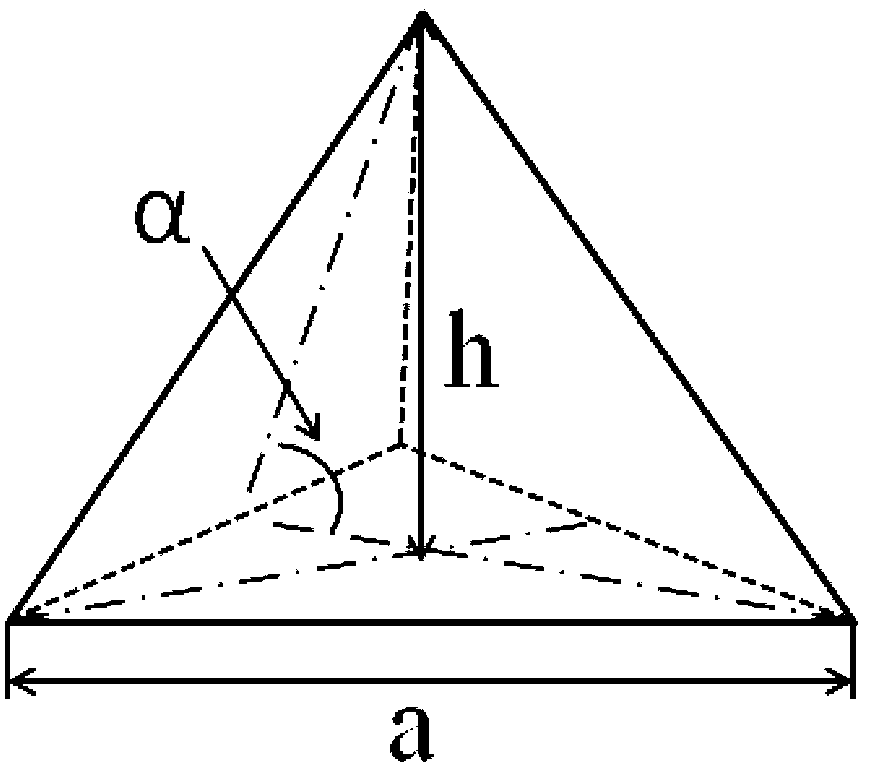

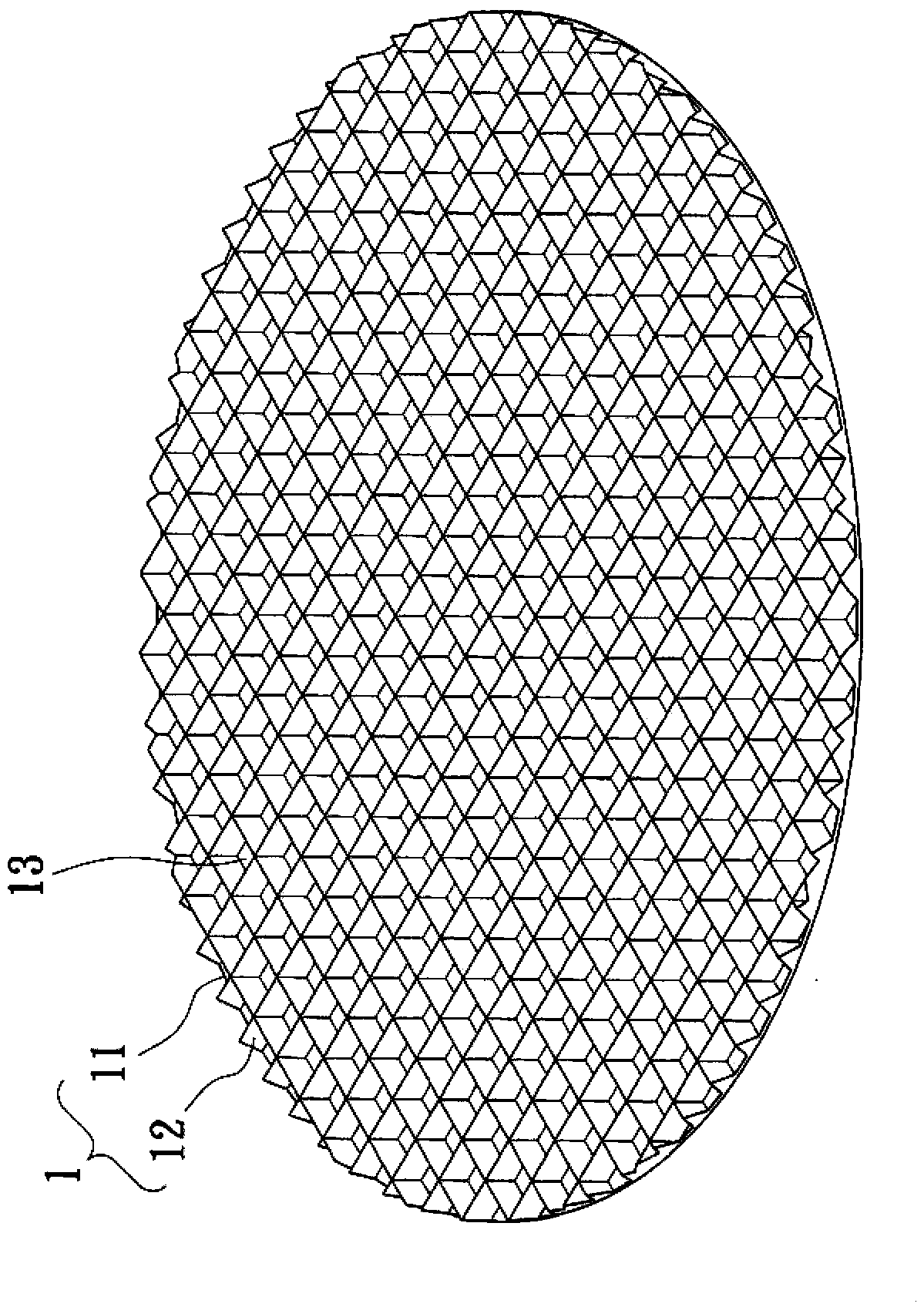

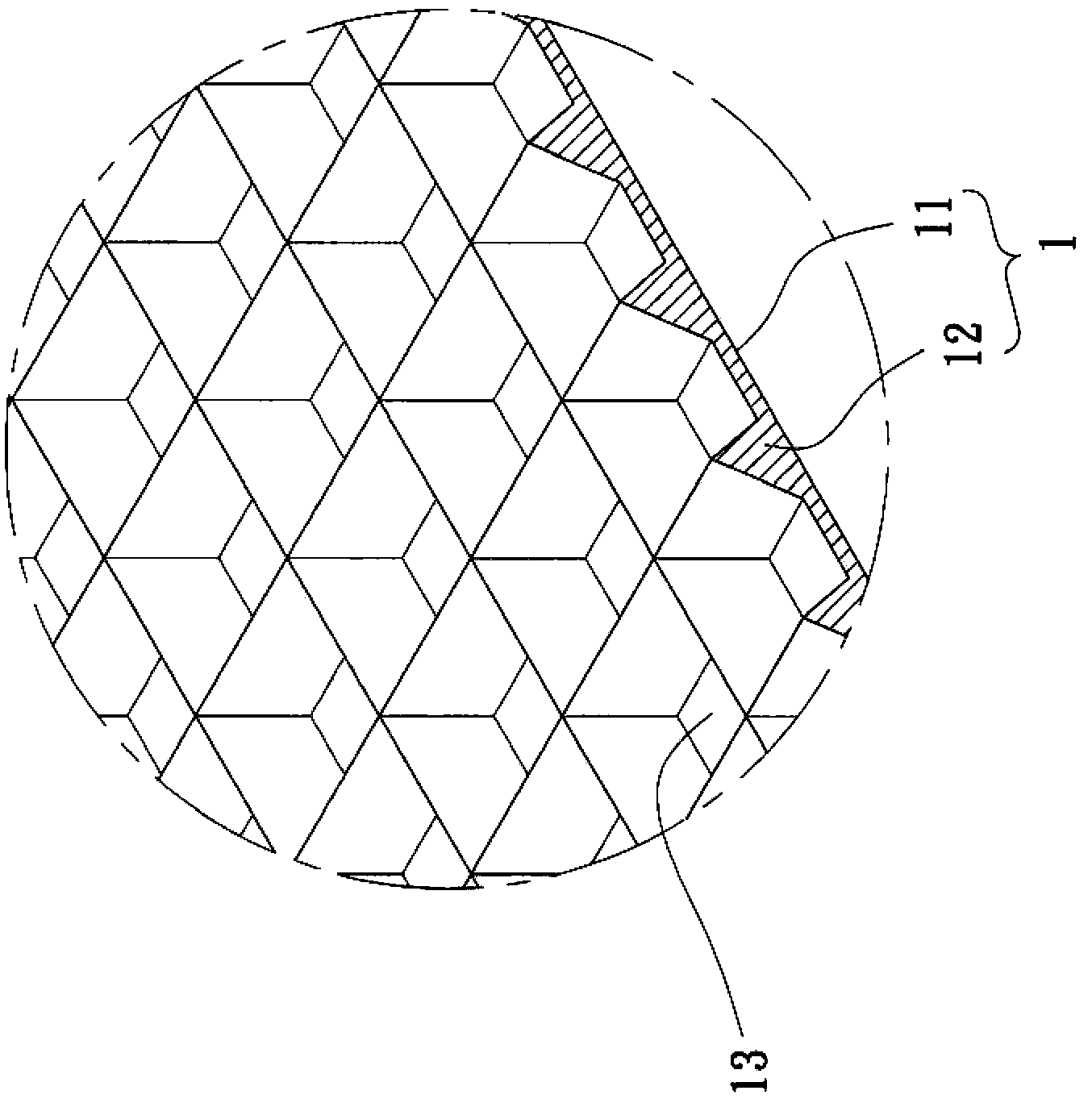

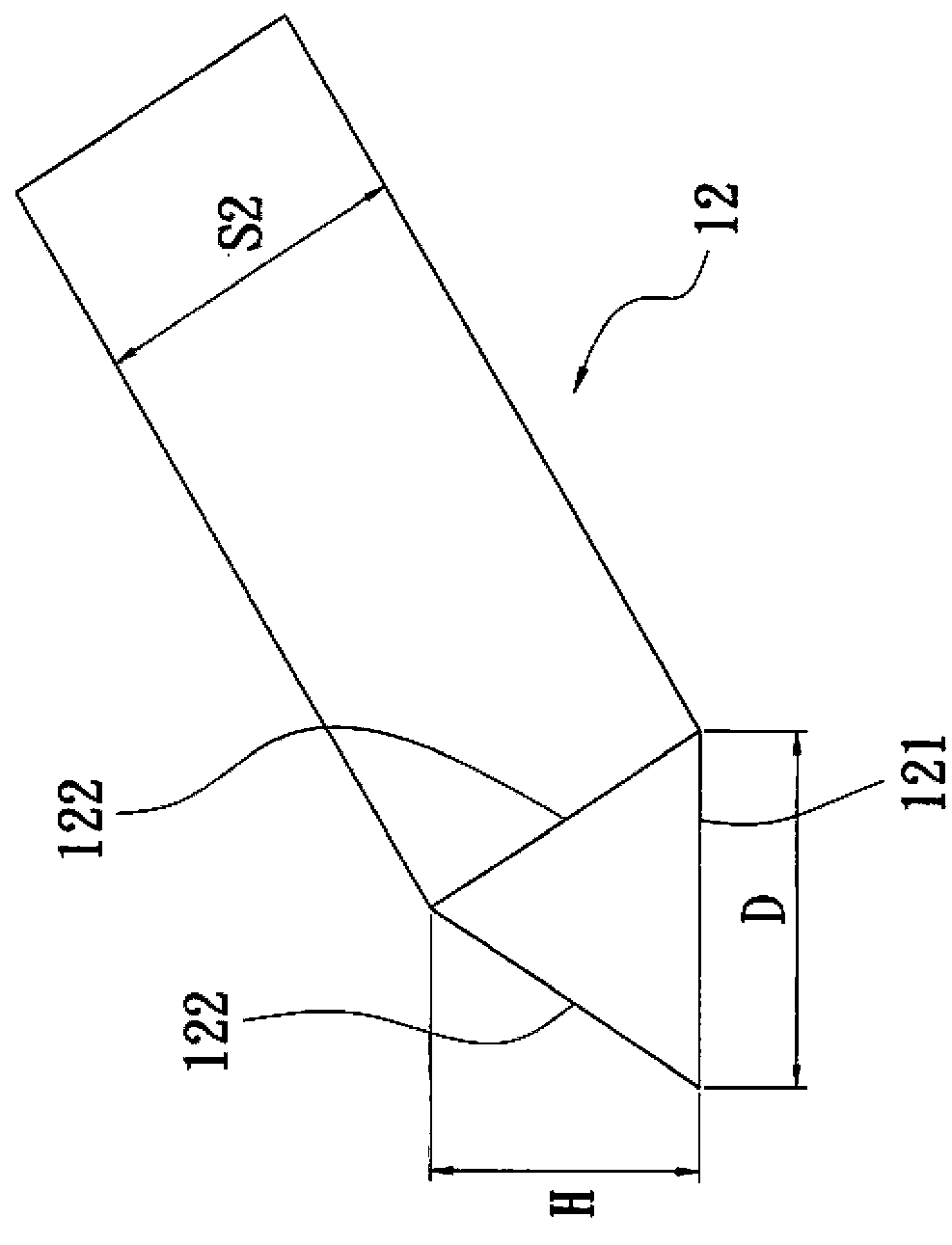

The invention discloses a patterned substrate of pattern improved LED chip. The pattern of the substrate is composed of a plurality of regular triangular pyramids with the same shape which are arranged on the surface of the substrate, and the inclination angle alpha of the regular triangular pyramids is 60 DEG to 65 DEG. The space D of the adjacent regular triangular pyramids is 1 to 1.4 times the length A of the side of the regular triangular pyramids. The invention further discloses a LED chip containing the patterned substrate of pattern improved LED chip. Compared with the prior art, the LED chip containing the patterned substrate of pattern improved LED chip has better extraction efficiency than a LED chip with a common substrate, and is convenient in popularization and application. According to the patterned substrate of pattern improved LED chip and LED chip containing the same, the regular triangular pyramids graph accords with the crystal lattice structure of GaN, and the target pattern can be easily obtained in practical processing.

Owner:SOUTH CHINA UNIV OF TECH

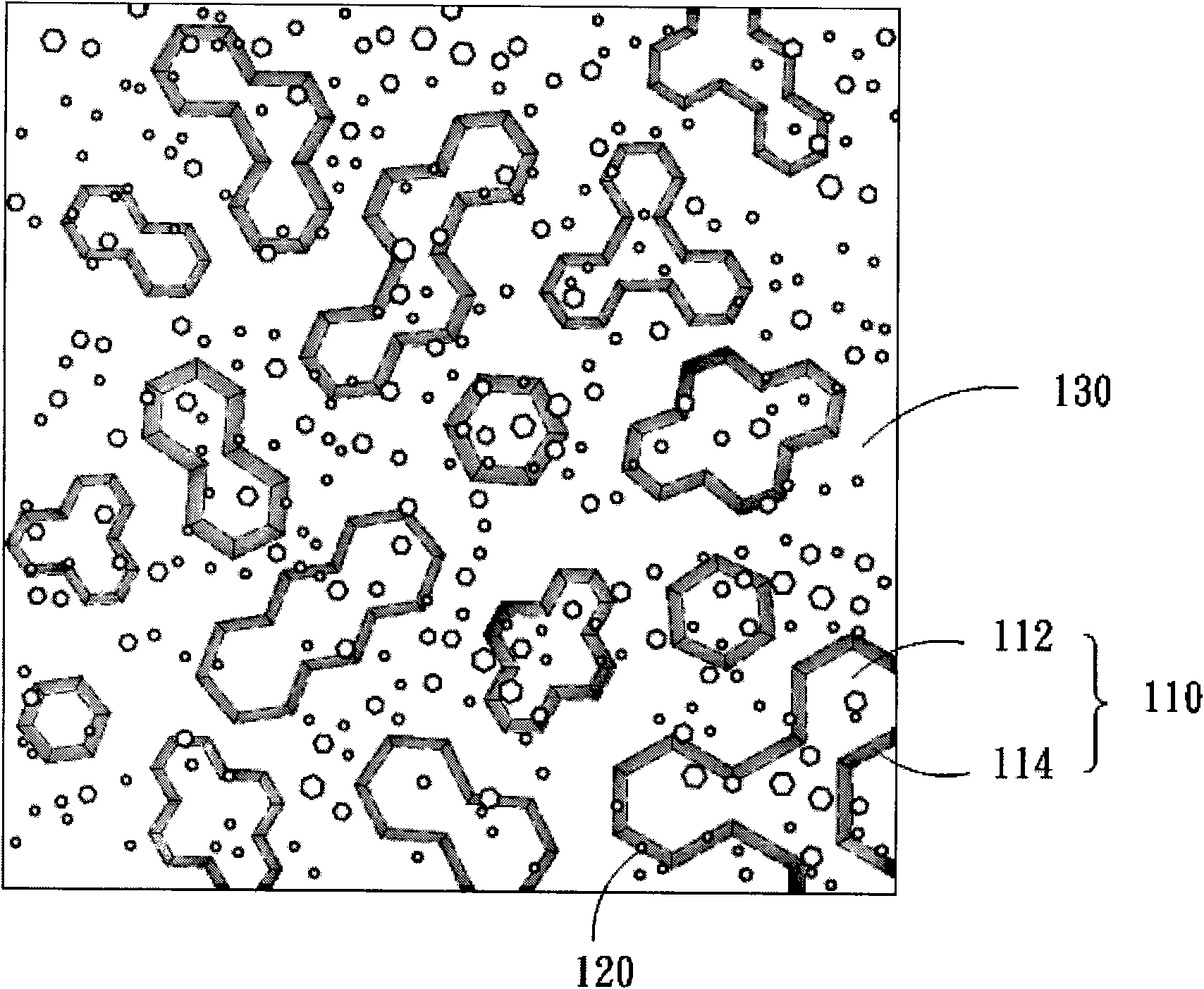

Patterned base material with emitting angle convergent and light-emitting diode element

InactiveCN103390706AImprove misalignment and misalignmentAvoid absorptionSemiconductor devicesLight reflectionPatterned substrate

The invention discloses a patterned base material with the emitting angle convergent and a light-emitting diode element. According to the patterned base material, a plurality of closed geometric-shape regions are arranged on the surface of a substrate and are formed by being defined by at least three strip-shaped bodies, and therefore the effect of light reflection is achieved through the non-smoothness of the surface of the substrate to ensure that light is emitted from the light-emitting diode element at 100-110 degrees, perfect directivity can be achieved, and light-emitting efficiency of the light-emitting diode element made of the patterned base material can be effectively improved.

Owner:GENESIS PHOTONICS

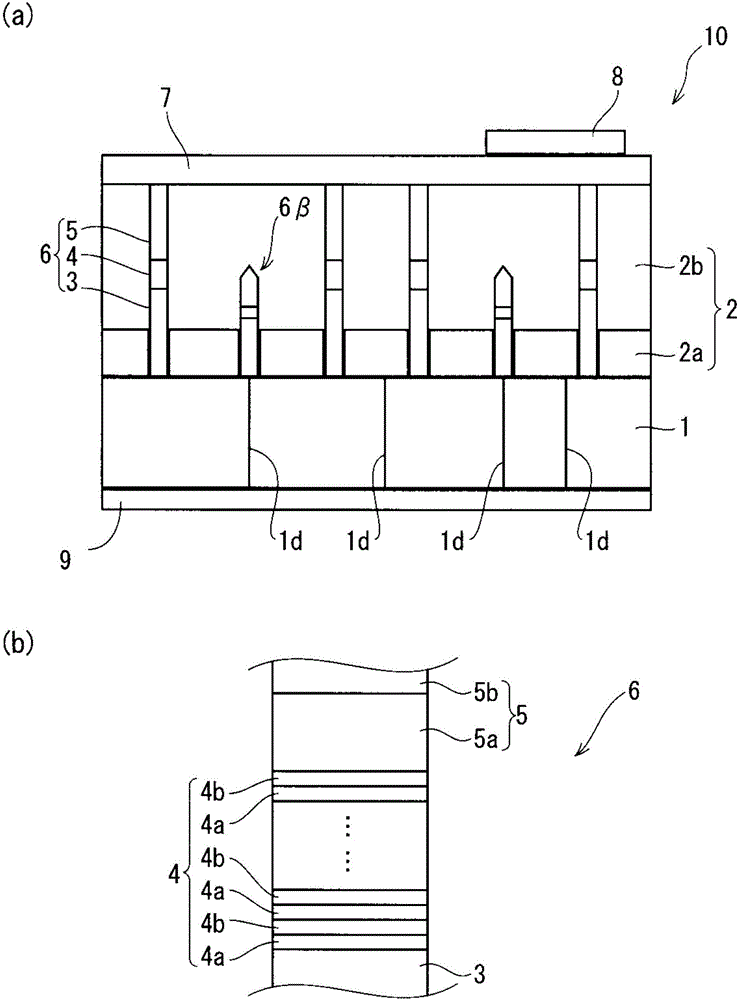

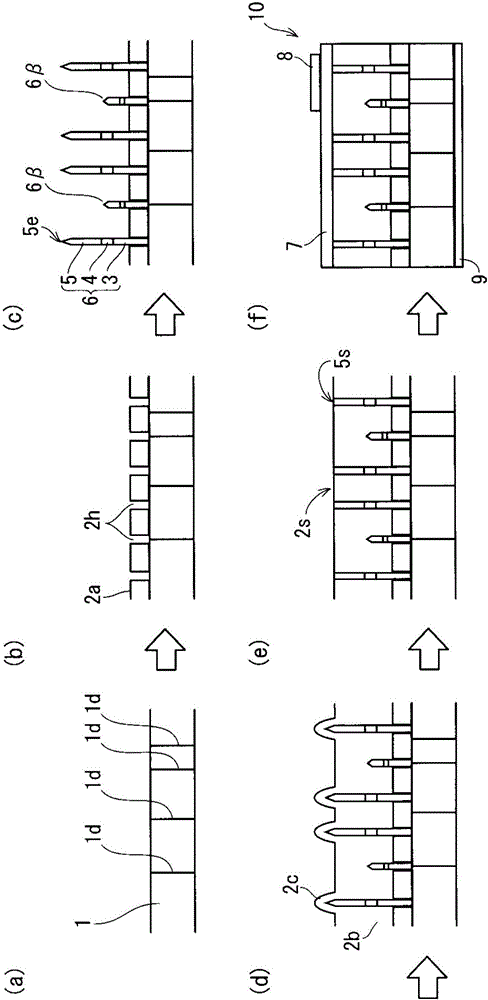

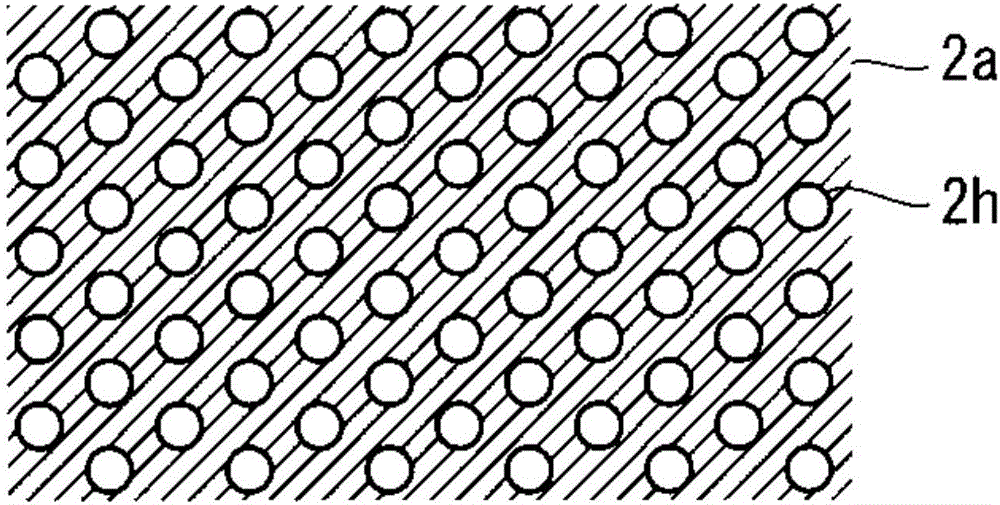

Light-emitting element and method for manufacturing light-emitting element

ActiveCN106716650AEasy to manufactureGood light extraction efficiencySemiconductor devicesTrappingRefractive index

Provided is a light-emitting element that is inexpensive, easy to manufacture, and has superior light extraction efficiency. This light-emitting element is equipped with: an oriented polycrystalline substrate comprising multiple oriented crystal grains; multiple columnar light-emitting parts, which are discretely provided above a region on one primary surface of the oriented polycrystalline substrate in a region where no crystal defects exist, and each of which has a lengthwise direction in the normal line direction of the oriented polycrystalline substrate; and a light-trapping layer formed of a material with a lower refractive index than the constituent material of the columnar light-emitting parts, and provided above the oriented polycrystalline substrate so as to surround the multiple columnar light-emitting parts.

Owner:NGK INSULATORS LTD

Optimized light-emitting diode (LED) chip patterned substrate and LED chip

InactiveCN103035792AImprove light extraction efficiencyImprove external quantum efficiencySemiconductor devicesEngineeringPatterned substrate

The invention discloses an optimized light-emitting diode (LED) chip patterned substrate. A Pattern of the LED chip patterned substrate is composed of a plurality of regular hexagonal pyramids with the same shape, the regular hexagonal pyramids are arranged on the surface of the LED chip patterned substrate, dip angles Alpha of the regular hexagonal pyramids are 55 degrees to 60 degrees, and edge distances between regular hexagonal pyramids next to each other are 1.0-1.2 Mum. Compared with the prior art, the LED chip patterned substrate has the advantages that luminous efficiency of the patterned substrate LED chip is greater than that of a ordinary patterned substrate LED chip, available effective light rays are increased greatly, and external quantum efficiency of the LED chip is improved. What is more, the pattern of regular hexagonal pyramids is coincident with a lattice structure of GaN, so the LED chip patterned substrate is beneficial for epitaxial growth of high quality GaN crystals, quality of epitaxy is further improved, and accordingly internal quantum efficiency of the LED chip is improved.

Owner:SOUTH CHINA UNIV OF TECH

Method for manufacturing gallium nitride compound semiconductor light-emitting device and lamp

ActiveCN101331616BImprove light extraction efficiencyReduce contact resistanceSemiconductor devicesDopantGallium nitride

Disclosed is a gallium nitride compound semiconductor light-emitting device having high light extraction efficiency and low driving voltage (Vf). Specifically disclosed is a gallium nitride compound semiconductor light-emitting device wherein a light-transmitting conductive oxide film containing a dopant is arranged on a p-type semiconductor layer. In this gallium nitride compound semiconductor light-emitting device, the dopant concentration at the interface between the p-type semiconductor layer and the light-transmitting conductive oxide film is set higher than the bulk dopant concentrationof the light-transmitting conductive oxide film, thereby reducing the contact resistance between the p-type semiconductor layer and the light-transmitting conductive oxide film.

Owner:TOYODA GOSEI CO LTD

Method for improving uniform distribution of light sources and structure thereof

InactiveCN102147102APromotes even distributionCost controlPoint-like light sourceLight fasteningsLight beamOptoelectronics

The invention relates to a method for improving the uniform distribution of light sources and a structure thereof. The method for improving the uniform distribution of the light sources and the structure thereof are that through arranging a plurality of light source chips on a base of at least one curved surface, each light beam emitted by each light source chip can be partially superposed and are further mutually compensated in light shape to obtain the uniform and bright light sources. Therefore, through the method, the uniform light sources can be obtained without optical element, so that the cost can be effectively controlled, and good light emitting efficiency can be maintained.

Owner:MILLENNIUM COMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com