Patents

Literature

112results about How to "Improve fit tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

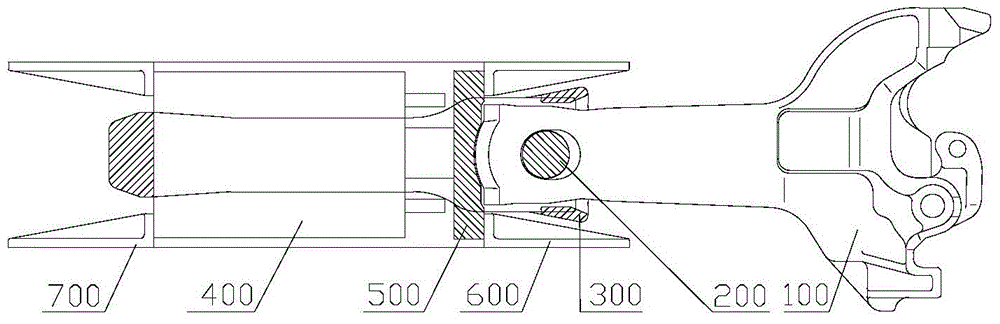

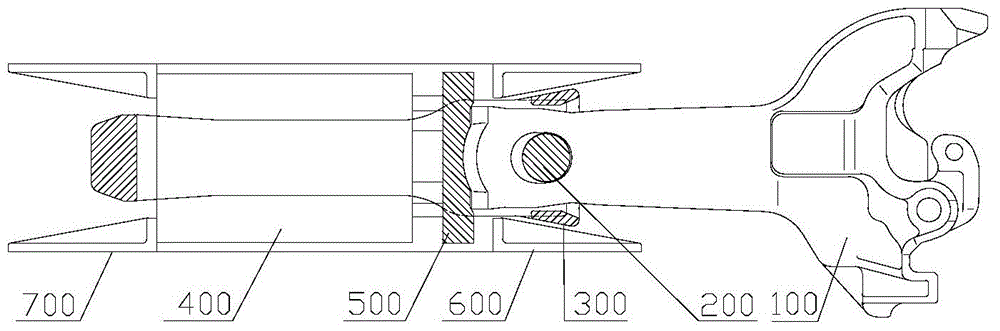

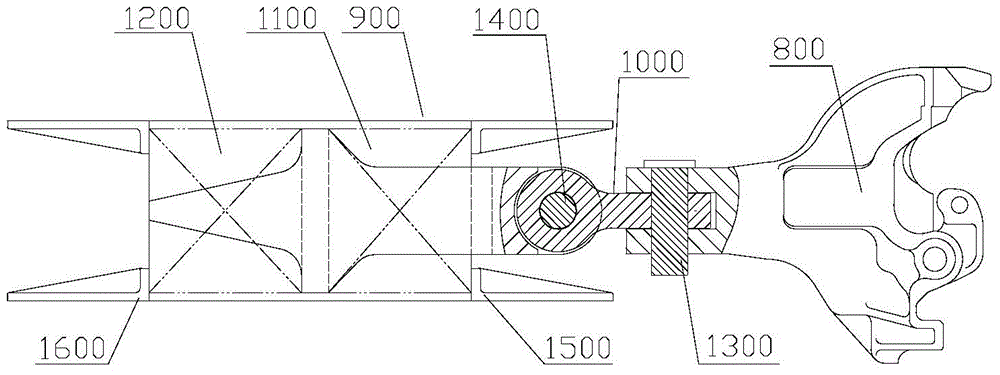

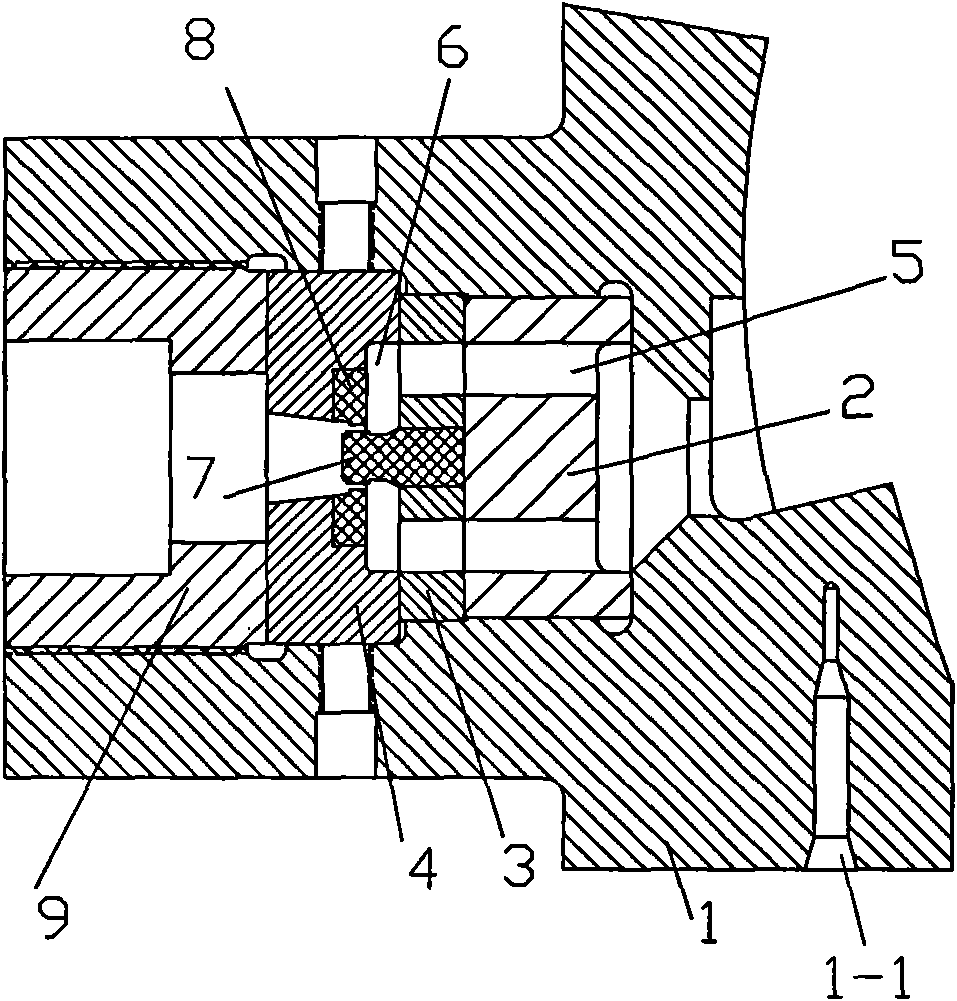

Railway vehicle and hook buffer device thereof

ActiveCN104401348ASolve the problem of excessive longitudinal fit clearanceFew partsDraw-gearRelative displacementVertical plane

The invention provides a railway vehicle and a hook buffer device thereof. While curve pass is realized, a connecting structure is simplified, a fit clearance is reduced, and the fitting tightness between a tail hook pin and a pin hole is improved. The hook buffer device comprises a front slave plate base, a rear slave plate base and a bidirectional buffer, wherein the front slave plate base and the rear slave plate base are connected with a vehicle body; the bidirectional buffer is fixedly connected between the front slave plate base and the rear slave plate base and is provided with a carrying body with a buffering function and a connecting component acting on the carrying body; the connecting component is hinged to a vehicle hook through the tail hook pin; the tail hook pin extends up and down; a rotating component is assembled between at least one of the connecting component and the vehicle hook, and the tail hook pin, so that the connecting component and the vehicle hook relatively rotate in a vertical plane; the rotating component is matched with the connecting component and the vehicle hook, so that relative displacement between the connecting component and the vehicle hook in the front-back direction is limited. Due to the fact that the vehicle hook and the connecting component can be relatively fixed in the front-back direction, no matter in an assembling state or various working states, the longitudinal impact caused in a vehicle driving process can be obviously reduced, the usability of the vehicle is improved, and the abrasion is reduced.

Owner:CHINA RAILWAYS CORPORATION +1

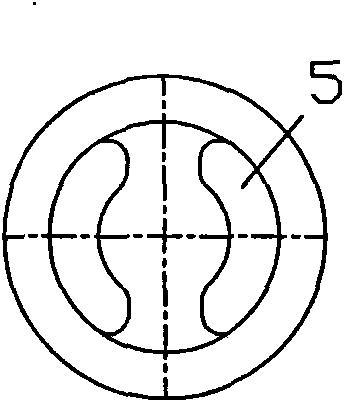

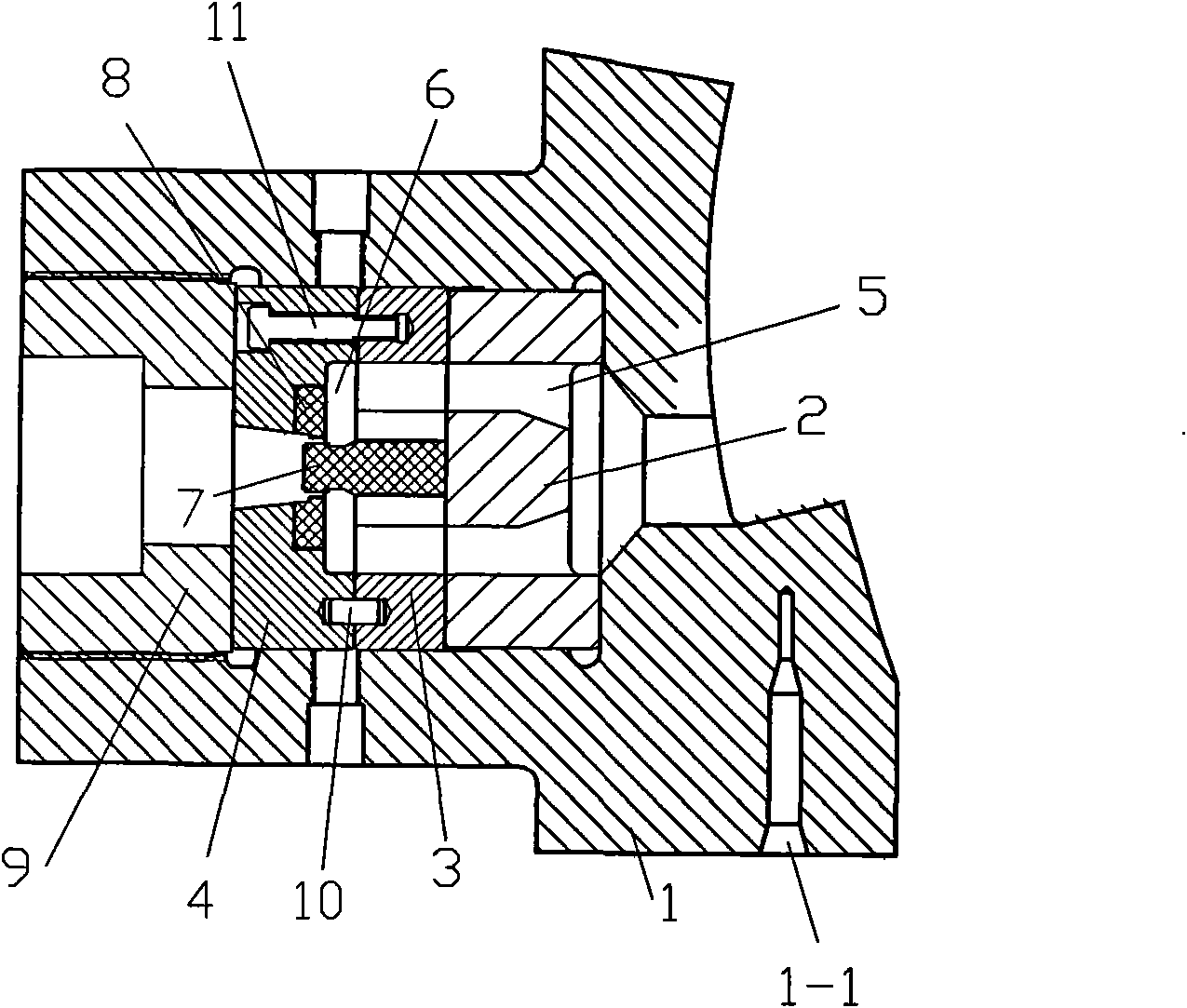

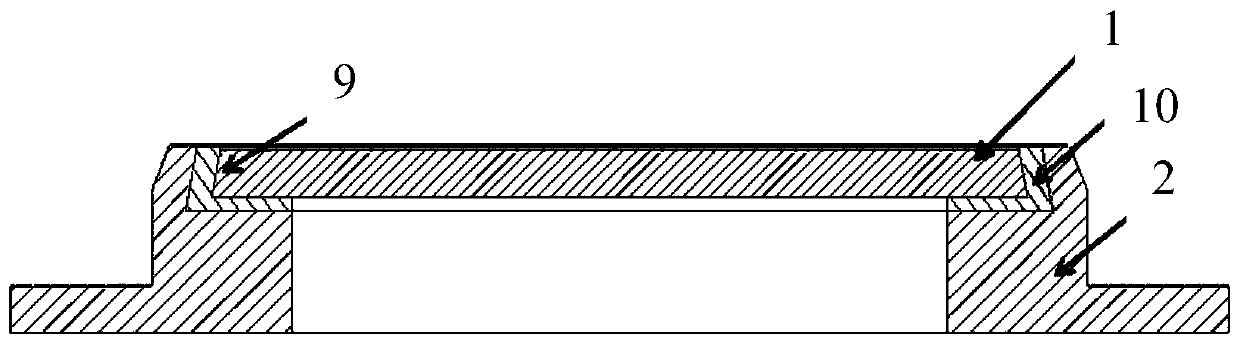

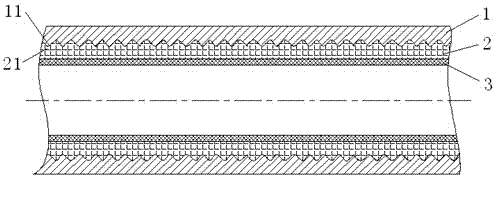

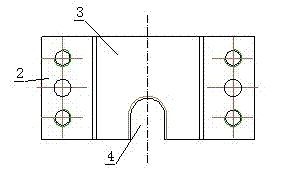

Novel die for continuously extruding aluminum pipes, aluminum alloy pipes and special-shaped hollow profiles

InactiveCN101618408ASpeed up the flowReasonable structureExtrusion diesEconomic benefitsAluminium alloy

The invention relates to a novel die for continuously extruding aluminum pipes, aluminum alloy pipes and special-shaped hollow profiles, comprising a die arranged in a cavity in an integral structure. A front deflector of the die, which is provided with at least three special-shaped shunt holes, is connected with an upper die of the die; the shunt holes of the front deflector form an inclined angle; a die core arranged on the upper die forms the inside diameter of a pipe, and a lower die connected with the upper die is provided with a welding cavity and a mold; the shunt holes of the front deflector form the angle of 18-20 degrees; the upper die and the lower die of the die are positioned by pins and are connected by screws; the die is connected with the cavity by a locking nut; the diameters of the upper die and the lower die are from 60*52-0.1mm to 60*52+0.1mm; and the mold and the die core are made of hard alloy materials. The invention improves the production efficiency of the aluminum alloy extrusion pipes or the special-shaped profiles by approximate 15 percent, decreases the production cost, prolongs the service life longer than twice, can produce the aluminum alloy pipes and the special-shaped profiles in various shapes and specifications and has good product quality and wide economic benefits.

Owner:佛山市禅城区南庄兴顺精密模具有限公司

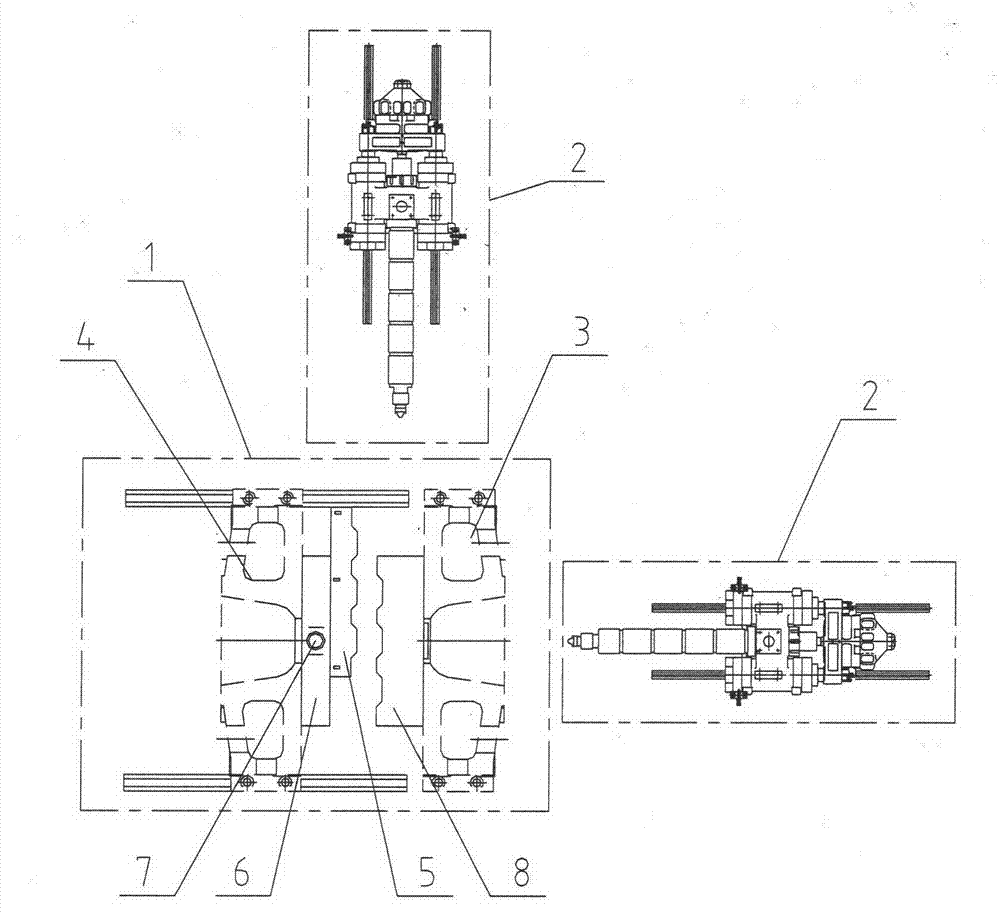

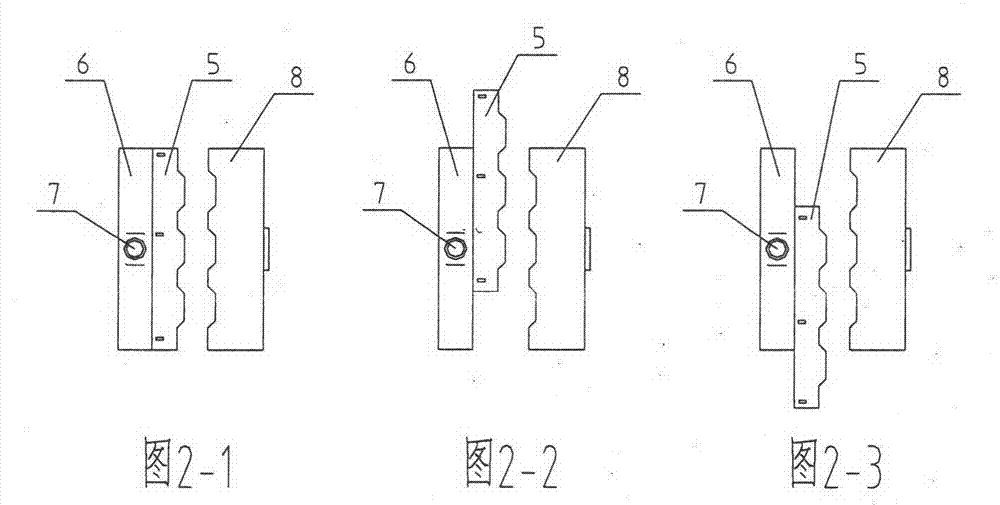

In-mold multi-station injection molding machine

The invention relates to an in-mold multi-station injection molding machine comprising a mold locking mechanism, an injection stage mechanism, and related driving and controlling mechanisms. A fixed plate and a moving plate are arranged on the mold locking mechanism. The fixed plate matches and is fixed with a fixed mold, and the moving plate matches and is fixed with a moving mold. A sub mold is arranged on the moving mold. The sub mold can perform relative movement on the moving mold through a sliding or rolling mechanism or other motion pair mechanisms. The relative movement of the sub mold is driven by a sub mold driving mechanism. The sub mold driving mechanism drives the sub mold, such that different station requirements are satisfied. Therefore, production processes such as in-mold assembling and multi-color multi-material injection are realized. According to the invention, some processes requiring secondary processing, especially movable parts, are executed in the mold. When a plastic product leaves the mold cavity, the product is already a finished product. Therefore, product assembling quality stability and fit compactness are improved, labor and material resources are saved, and factory spaces are saved.

Owner:BORCH MACHINERY

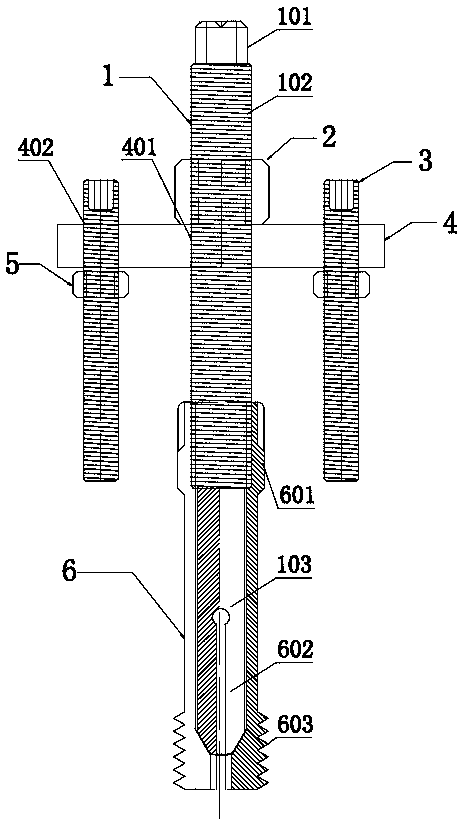

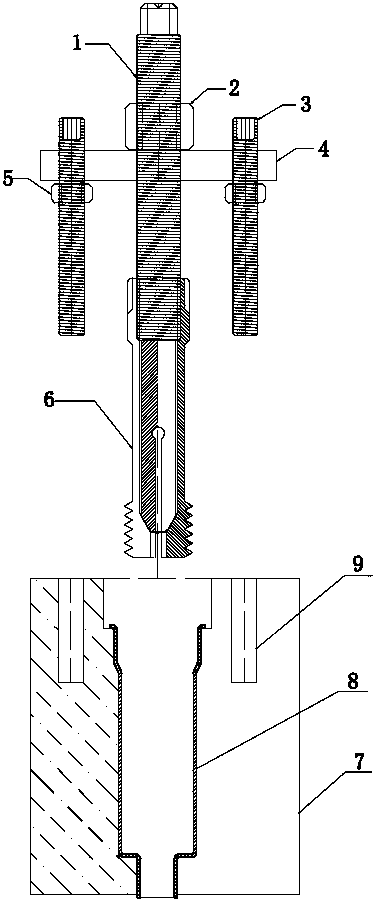

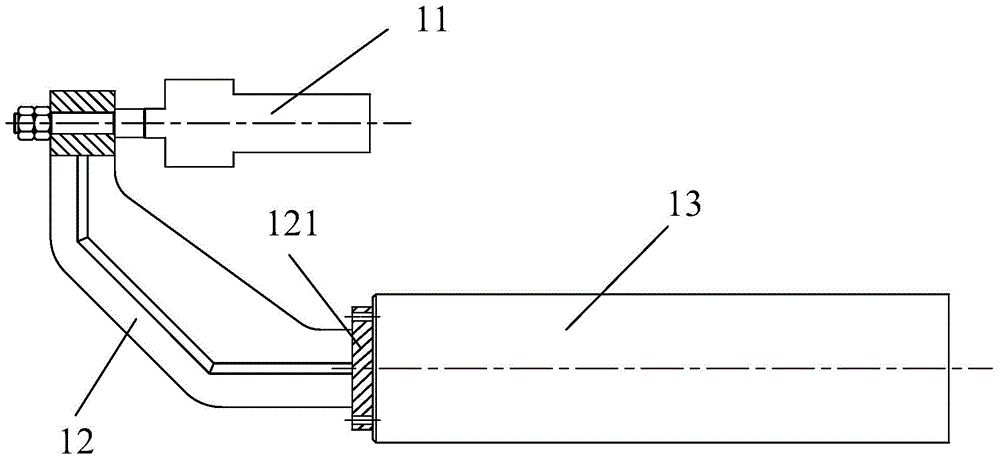

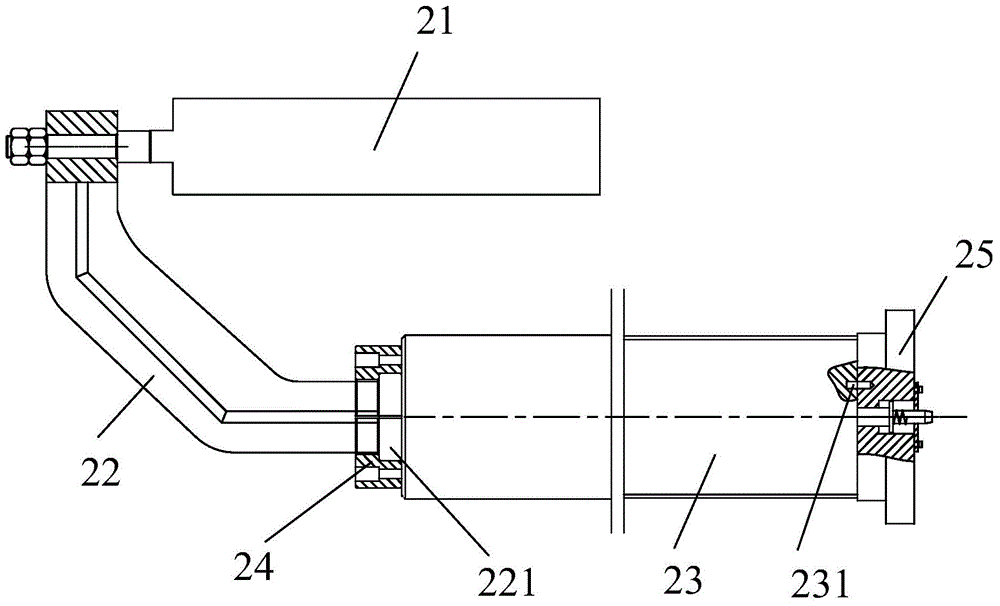

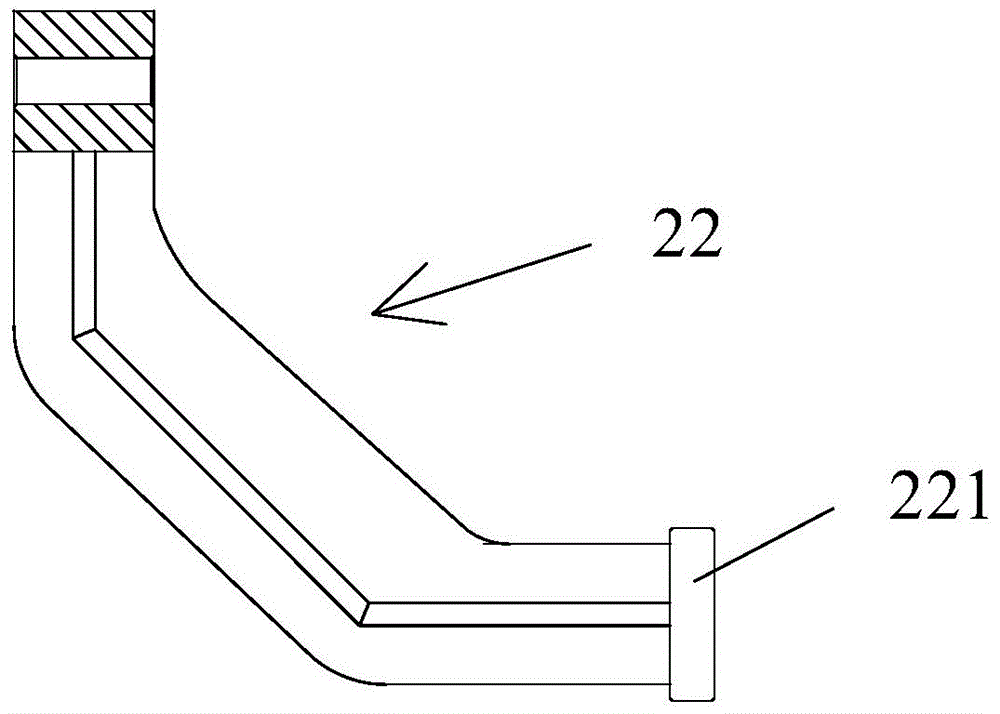

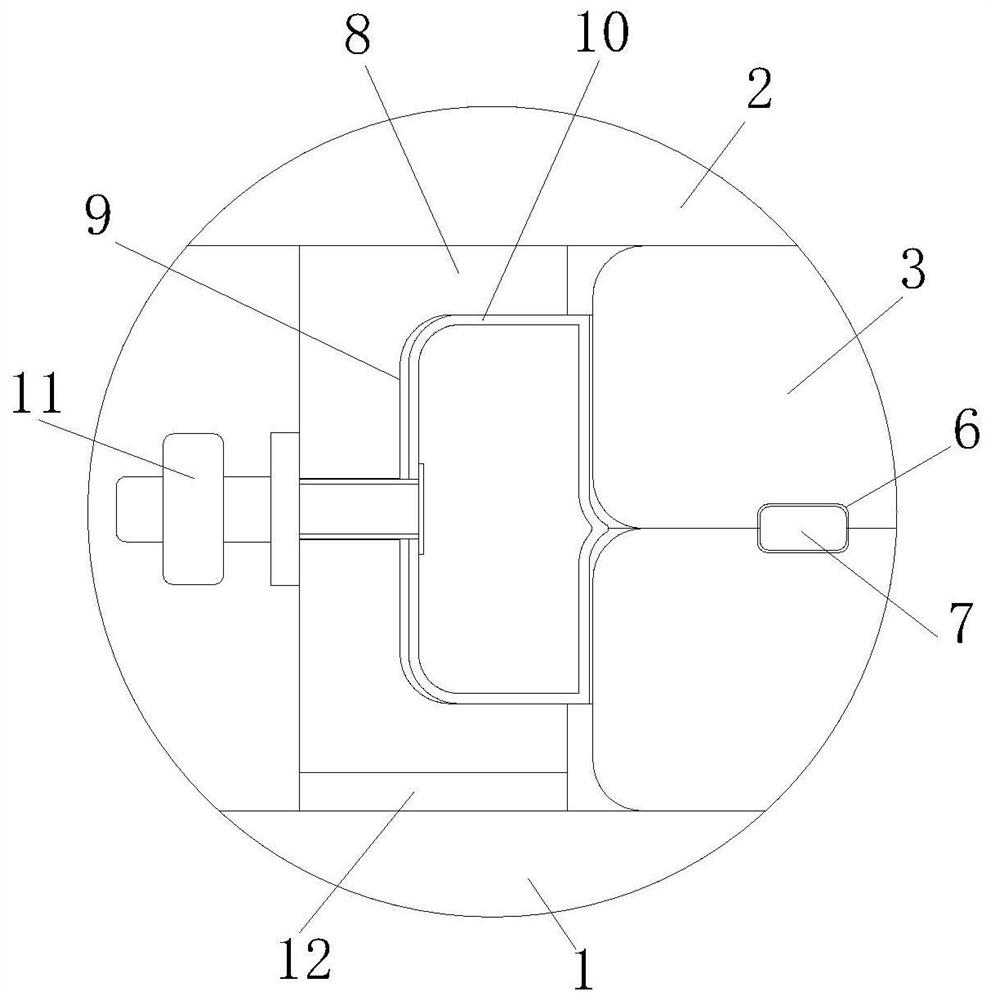

Diesel engine injector water spacer extractor

ActiveCN103753487AImprove removal effectPrevent slipping outMetal-working hand toolsWater jacketDiesel engine

The invention belongs to the technical field of diesel engine maintenance tools and relates to a diesel engine injector water spacer extractor comprising a support beam and support screws arranged on the support beam. The support beam is further provided with a pull screw connected with an expansion pull sleeve; the expansion pull sleeve is composed of a connecting part and an expansion pull part; the connecting part matches with the pull screw; the expansion pull bar is connected with a water spacer. The water spacer is extracted by: inserting the expansion pull sleeve into the water spacer, tightening the pull screw into the expansion pull sleeve to expand the expansion pull sleeve and tightly combine with the water spacer, and downwardly turning a pull nut on the pull screw to downwardly separate the expansion pull sleeve from the pull screw and to drive the water spacer to constantly move down. The diesel engine injector water spacer extractor has the advantages that the water spacer is more convenient to extract, operating efficiency is improved, the water spacer is also protected from damage, and the diesel engine injector water spacer extractor is applicable to popularization and application in extracting water spacers from diesel engine injectors.

Owner:DEQING FANGSHAN HARDWARE TOOL

Camera decoration assembly and electronic equipment

ActiveCN109714506ANot easy to break awayImprove fit tightnessTelevision system detailsColor television detailsEngineeringBearing surface

The invention provides a camera decoration assembly and electronic equipment. The camera decoration assembly comprises a lens, the whole decorative ring is annular, the decorative ring comprises a central hole, and an opening part which is communicated with the central hole and has a radial size larger than that of the central hole is formed at the top end of the decorative ring; The opening partcomprises a bearing surface which is arranged around the central hole and is perpendicular to the axis of the central hole, and a side surface which is connected with one end, far away from the central hole, of the bearing surface and extends to the top end of the decorative ring, and the bearing surface and the side surface are matched to form a circular-truncated-cone-shaped containing space with a narrow top and a wide bottom; The lens is arranged in the circular-truncated-cone-shaped containing space and fixedly connected with the decorative ring in an injection molding mode, the matchingtightness between the assemblies is improved, and the overall structural strength is enhanced.

Owner:VIVO MOBILE COMM CO LTD

Screw machine barrel of extruder

The invention discloses a screw machine barrel of an extruder. The screw machine barrel comprises a machine barrel body, a heat-insulating block and an abrasion-resistant sheet, wherein the outer surface of the heat-insulating block is in interference fit with the inner surface of the machine barrel body; the abrasion-resistant sheet is adhered to the inner surface of the heat-insulating block; and wave-shaped bulges are uniformly distributed on the inner surface of the machine barrel body, wave-shaped grooves are uniformly distributed in the outer surface of the heat-insulating block, and the wave-shaped bulges positioned on the inner surface of the machine barrel body are matched with the wave-shaped grooves formed in the outer surface of the heat-insulating block. By adopting the mode, the screw machine barrel disclosed by the invention can be used for enhancing the abrasion-resistant property and the heat-resistant property so that the machine barrel is difficult to abrade and can also be used for prolonging the service life, reducing the replacement frequency and cost and improving the working efficiency.

Owner:JIANGSU HONGYUAN NEW MATERIAL TECH

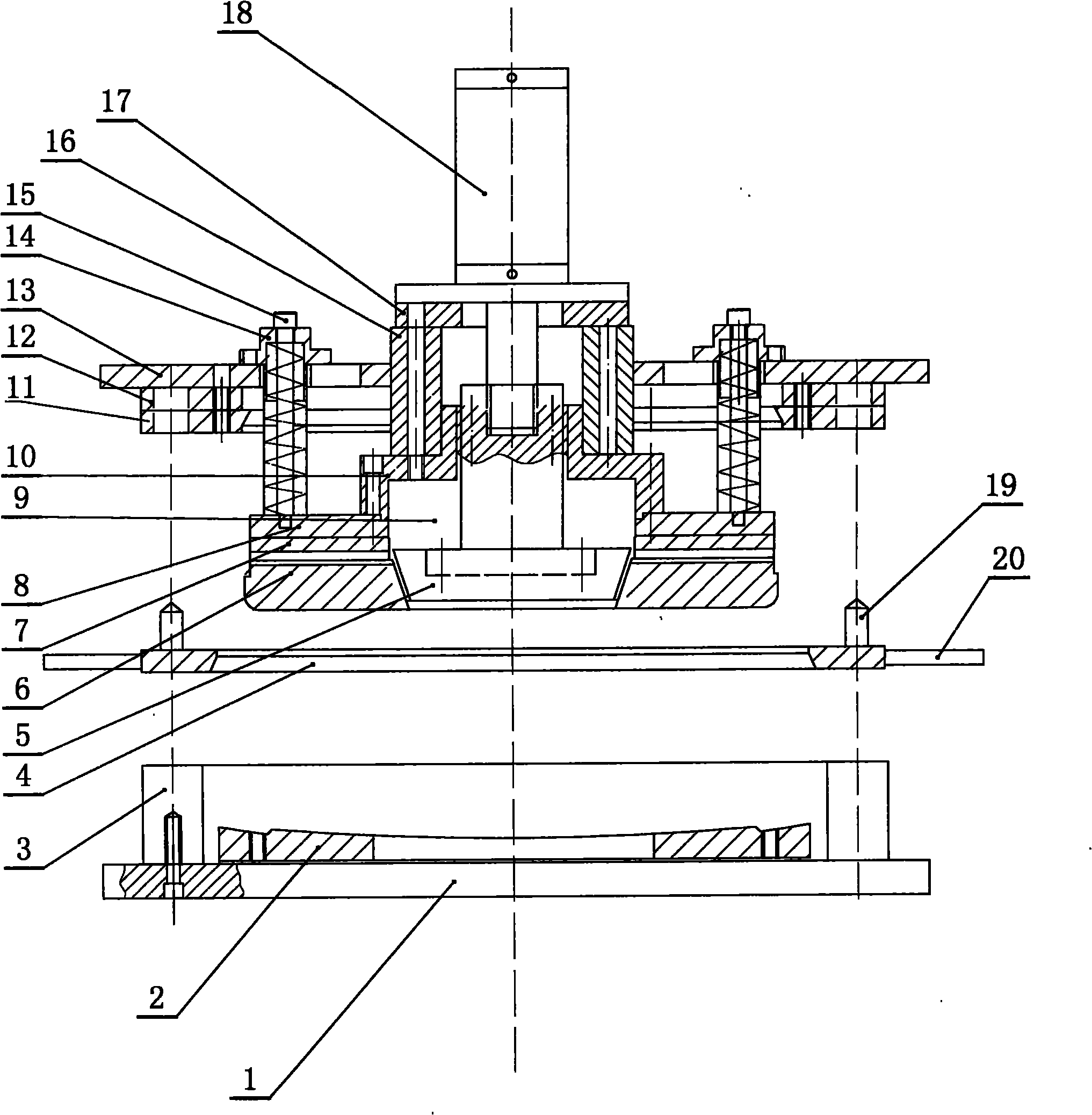

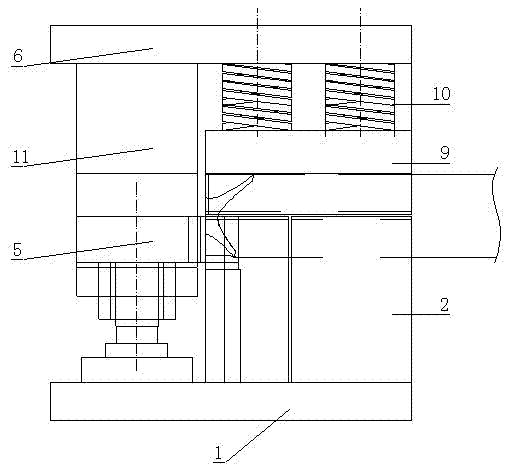

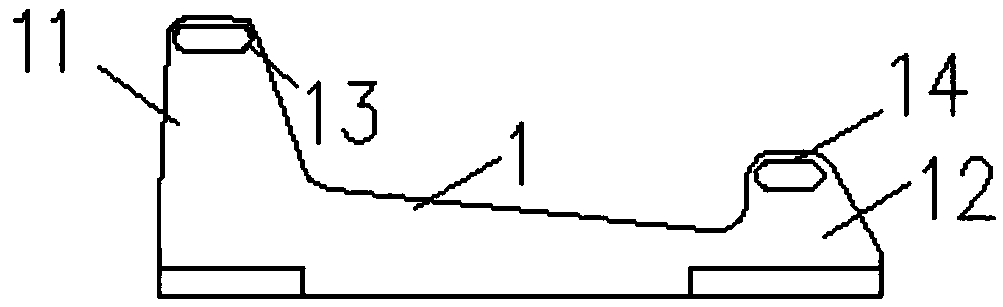

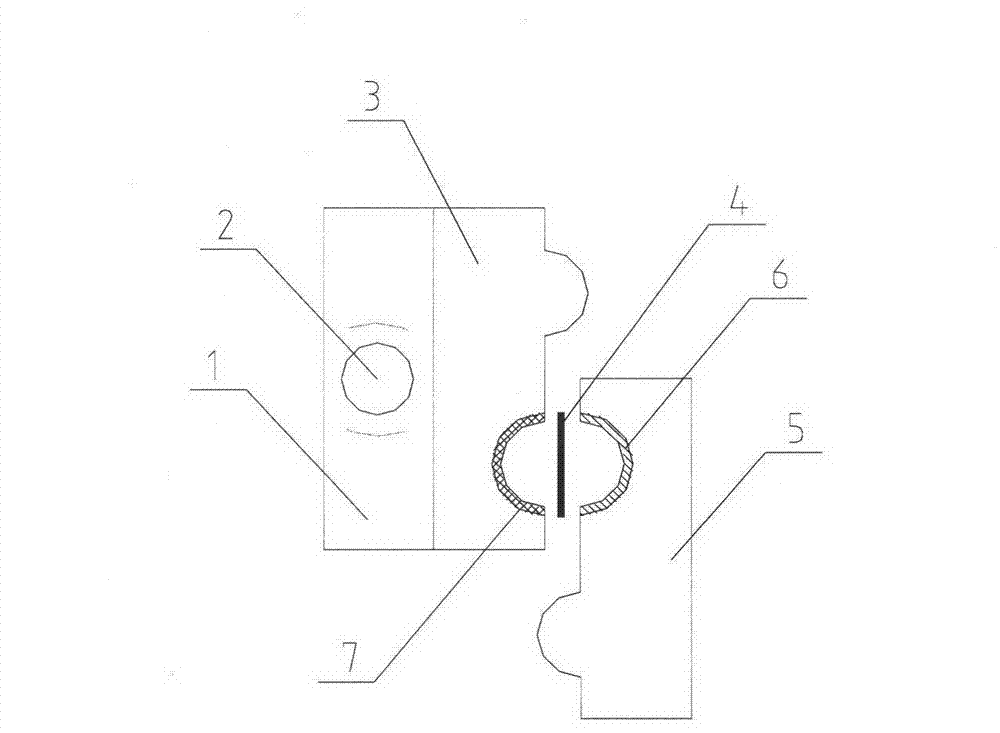

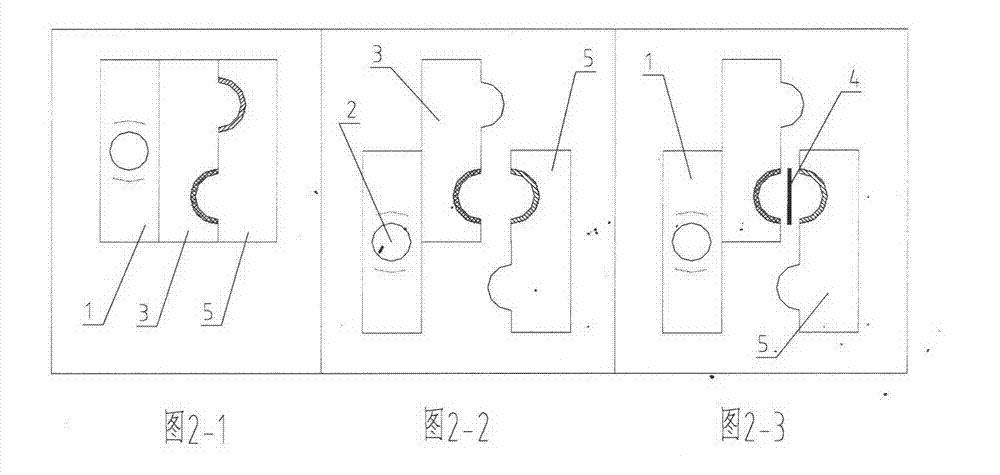

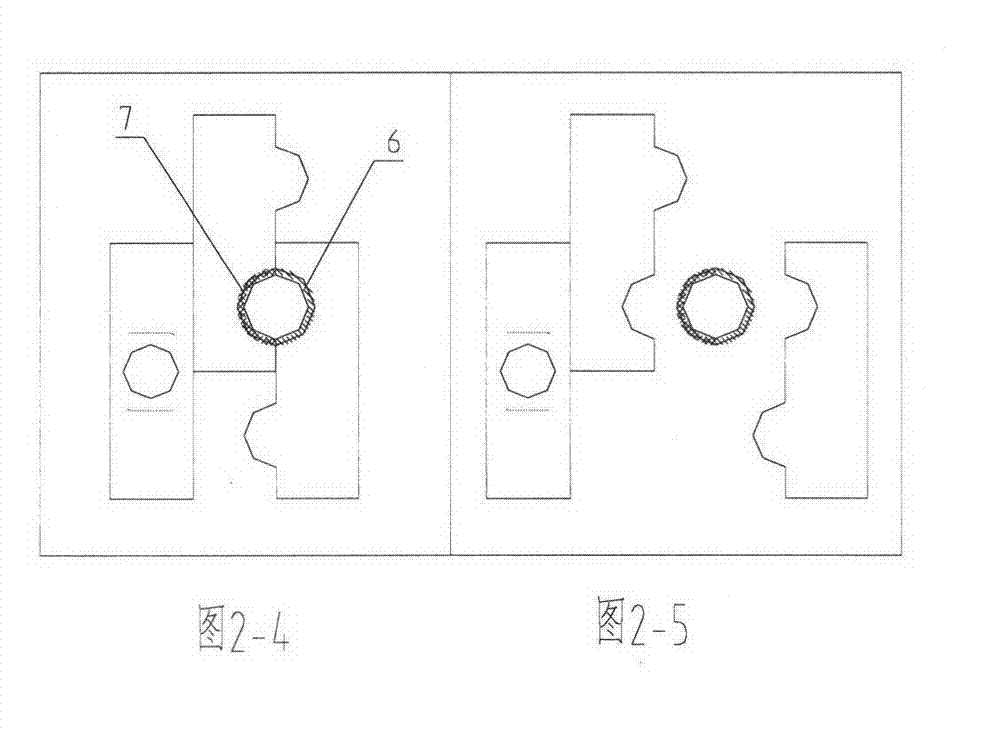

Closing-in and forming stamping die for close over of automobile fuel tank

InactiveCN102114509ASolve the disadvantages of oil leakageImprove fit tightnessShaping toolsFuel tankEngineering

The invention relates to a closing-in and forming stamping die for a close cover of an automobile fuel tank, which has good sealing property of a product. The closing-in and forming stamping die comprises a lower die, an upper die and a movable cone die, wherein the movable cone die is in a ring structure and is positioned between the lower die and the upper die; the lower die comprises a lower die plate on which a lower die cushion and a lower open die are fixedly installed; the lower open die is in a ring structure; the lower die cushion is positioned in the lower open die; the movable cone die and the lower open die are corresponding to each other up and down; the upper die comprises an upper die plate below which a closing-in backing plate is fixedly installed; a forming open die is fixedly installed below the closing-in backing plate; the forming open die, the closing-in backing plate and the movable cone die are corresponding to each other up and down; a connecting cushion cover is installed in the middle of the upper die plate; an air cylinder is fixedly installed on the connecting cushion cover; a conical rod is fixedly installed at the lower end of the piston rod of the air cylinder; a conical head is fixedly installed at the lower end of the conical rod; a die plate flange is installed below the connecting cushion cover; a dovetail die plate is fixedly installed below the die plate flange; and a slide block die plate is arranged on the dovetail die plate.

Owner:SHANDONG JINHUA FEISHUN VEHICLES

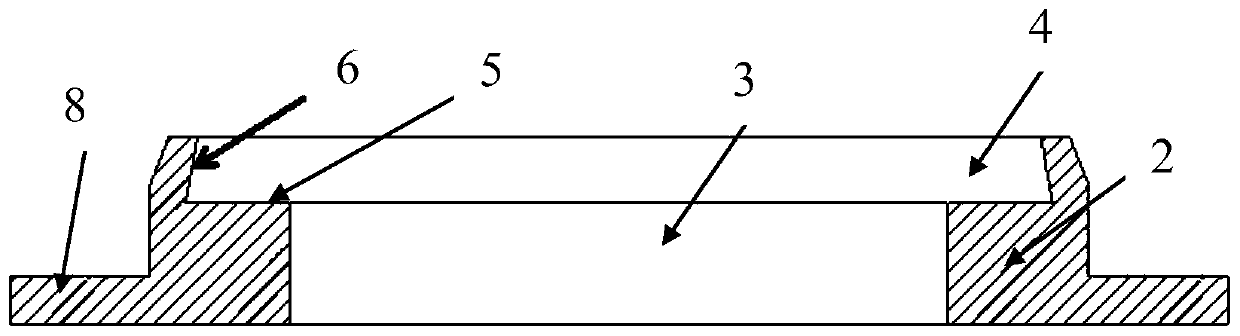

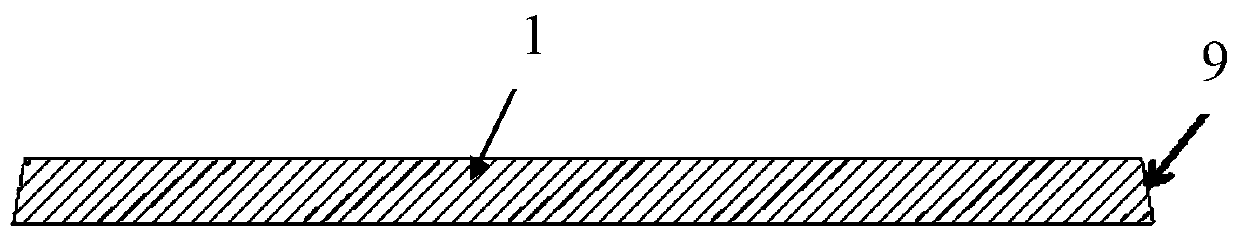

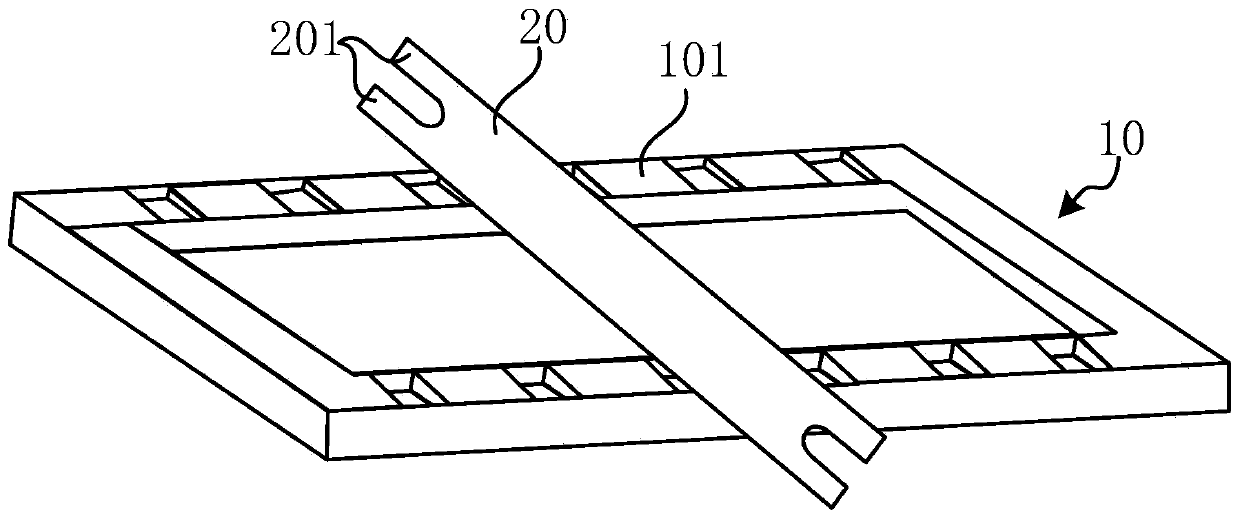

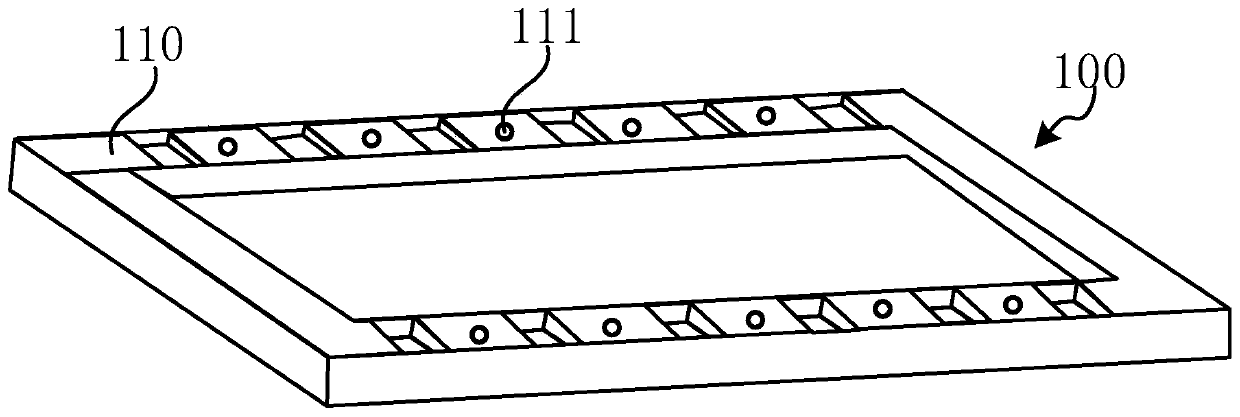

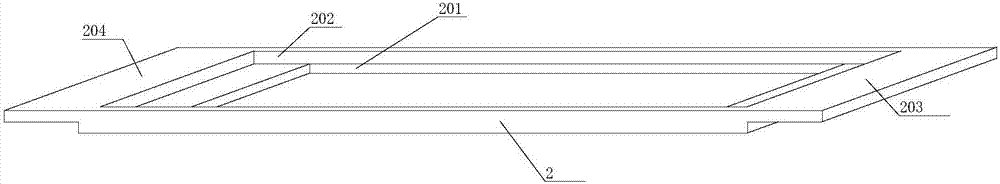

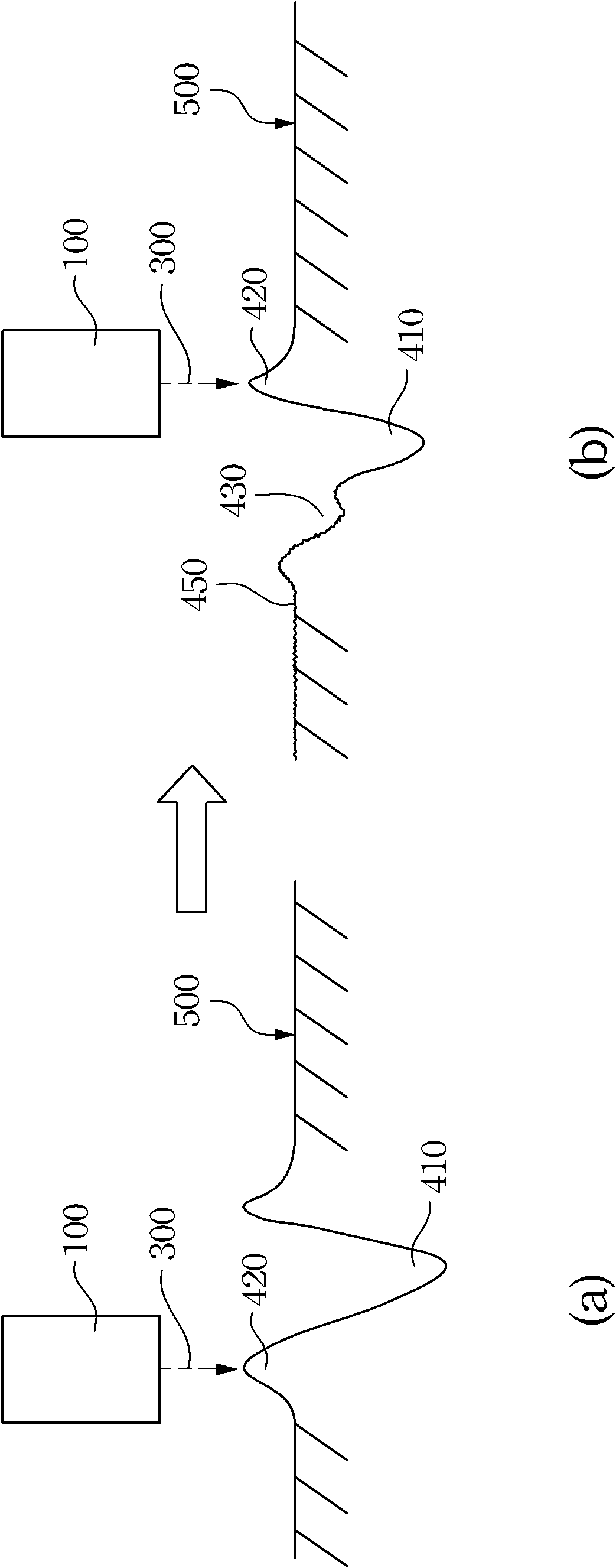

Mask fixing device, mask plate, and manufacturing method of mask plate

InactiveCN110359011AImprove fitReduce wrinklesVacuum evaporation coatingSputtering coatingEngineeringColor mixing

The invention discloses a mask fixing device, a mask plate and a manufacturing method of the mask plate. The mask fixing device comprises a bearing part, wherein one or more adsorption air holes for adsorbing the mask are arranged on the bearing part. Through arranging one or more adsorption air holes for adsorbing the mask on the bearing part, the adsorption air holes generate adsorption force toadsorb the mask in the process of mask attaching; the mask is better attached to the bearing part; folding risk of the mask is reduced; attaching tightness of the mask and the bearing part is improved; and fixing strength of the mask is guaranteed. In addition, the reduced folding risk of the mask can improve alignment precision of the mask and further improve precision of the mask plate. According to the device, when the mask plate is used for evaporating luminous materials with different colors of the display panel; and risks like color deviation and color mixing of the display panel can bereduced.

Owner:YUNGU GUAN TECH CO LTD

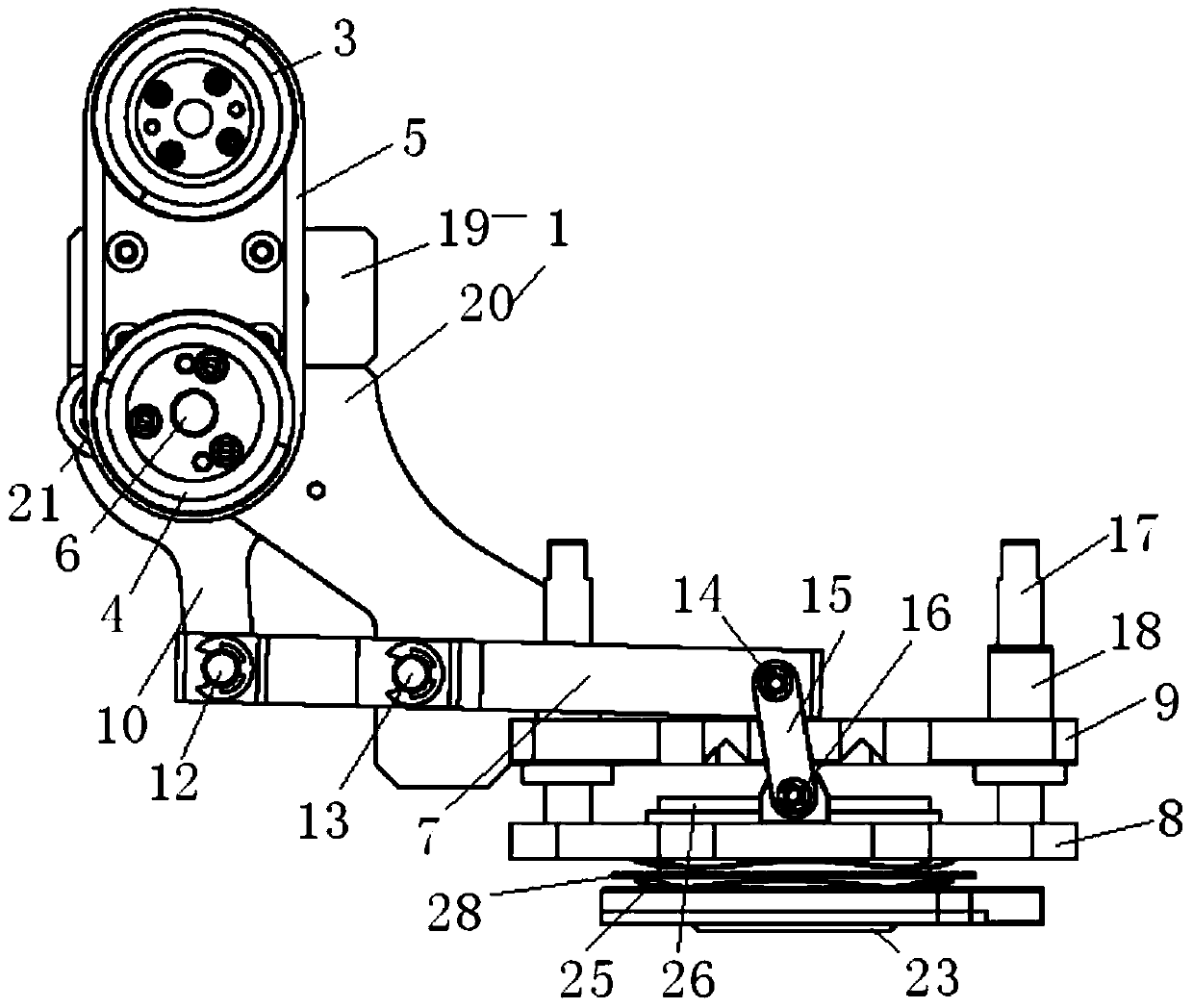

Weld seam detection device

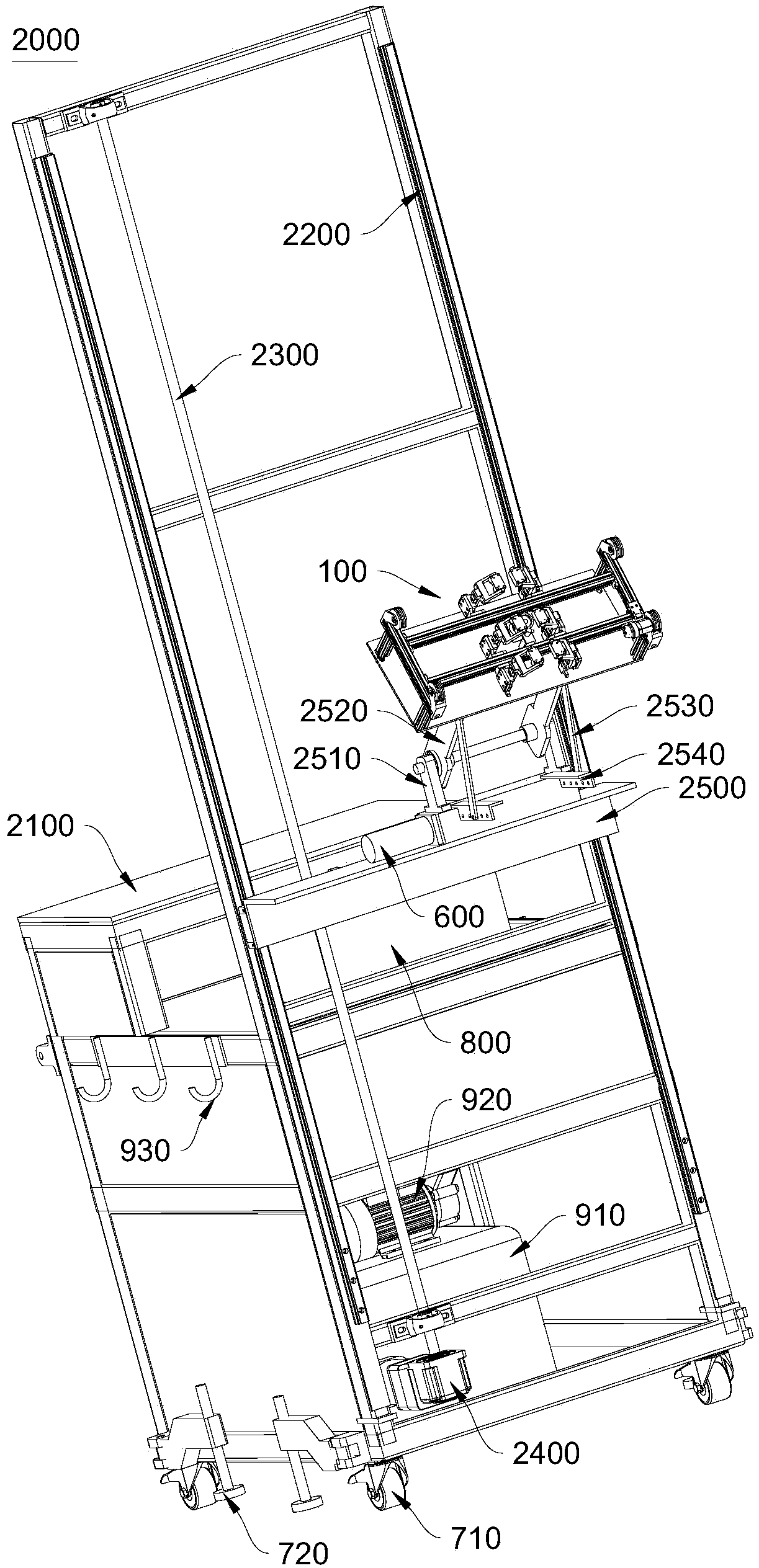

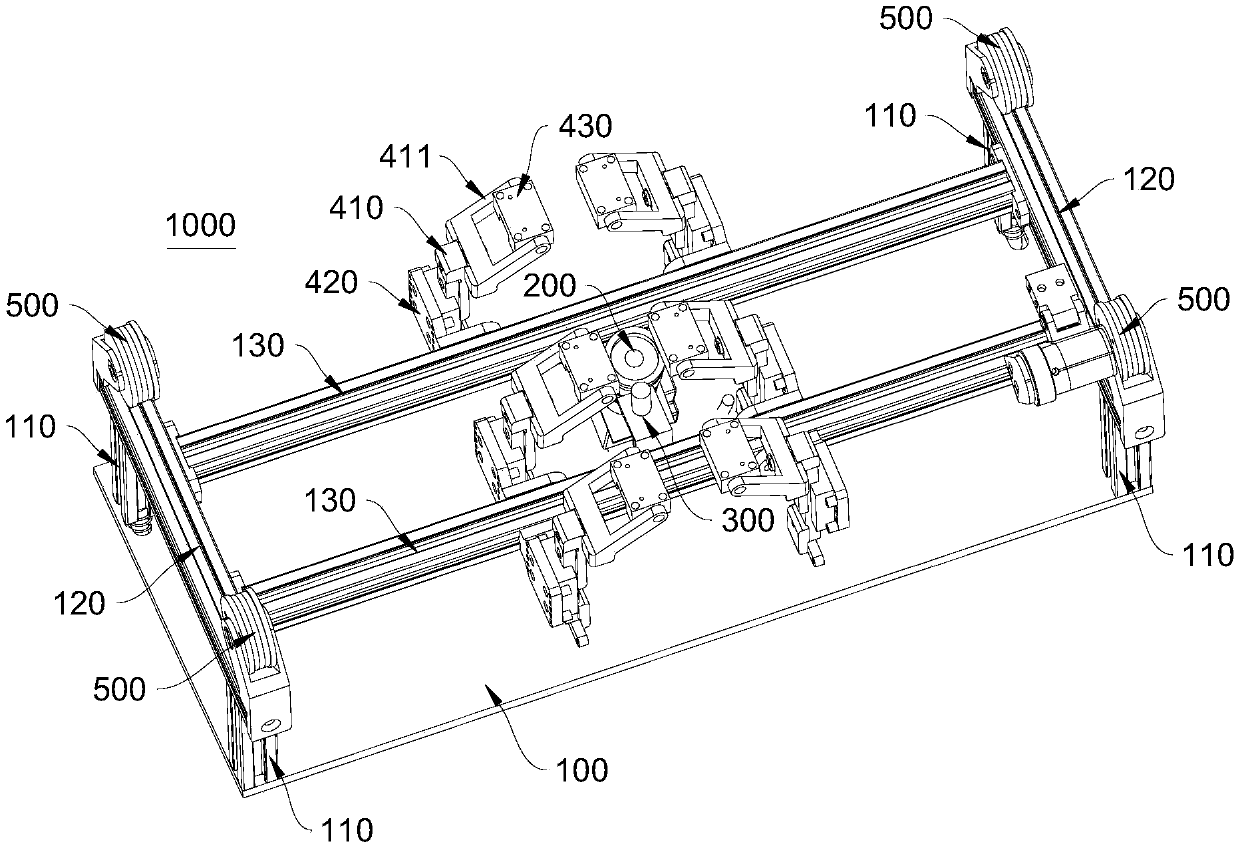

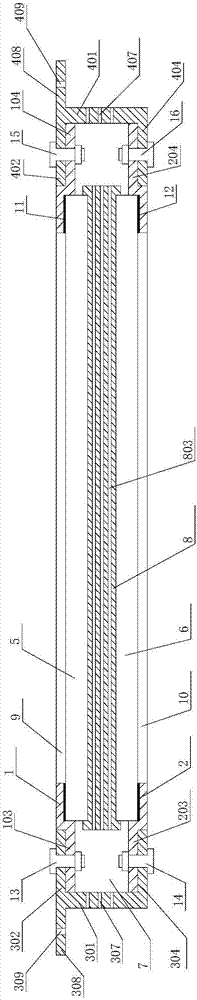

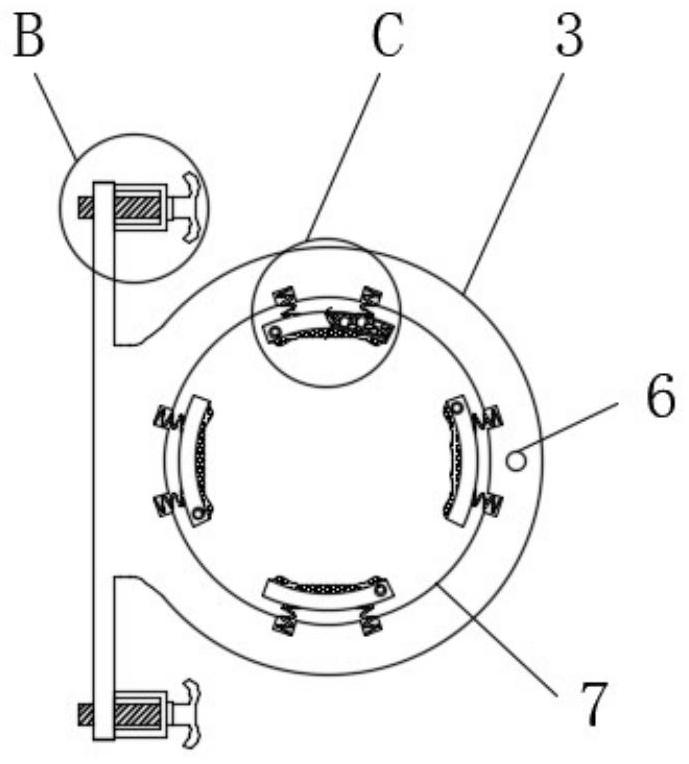

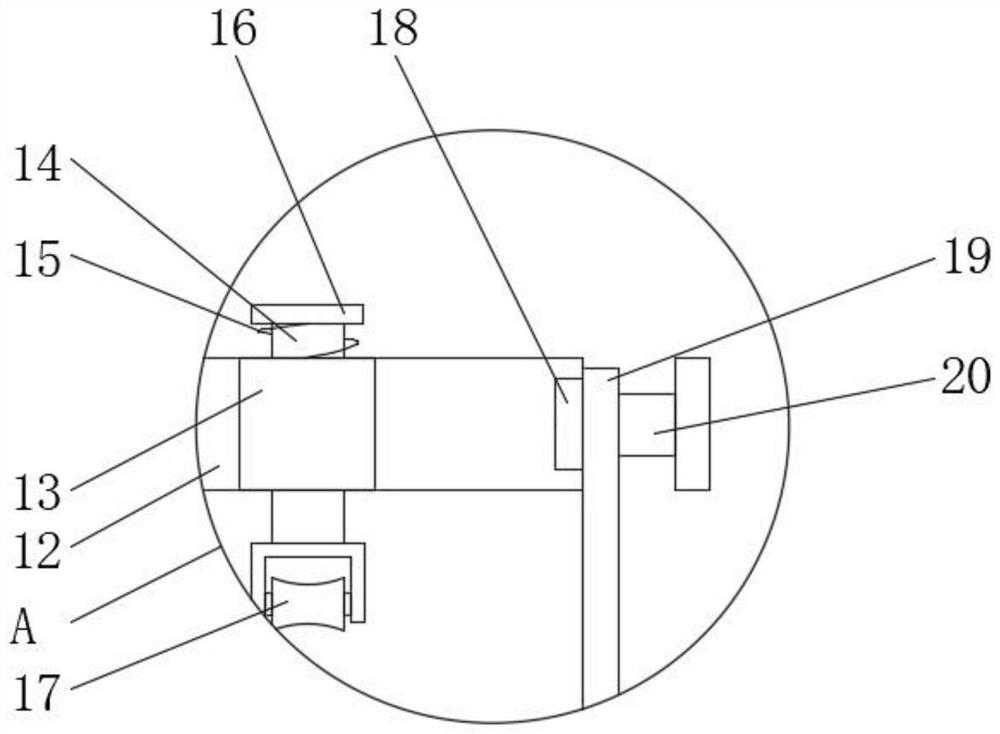

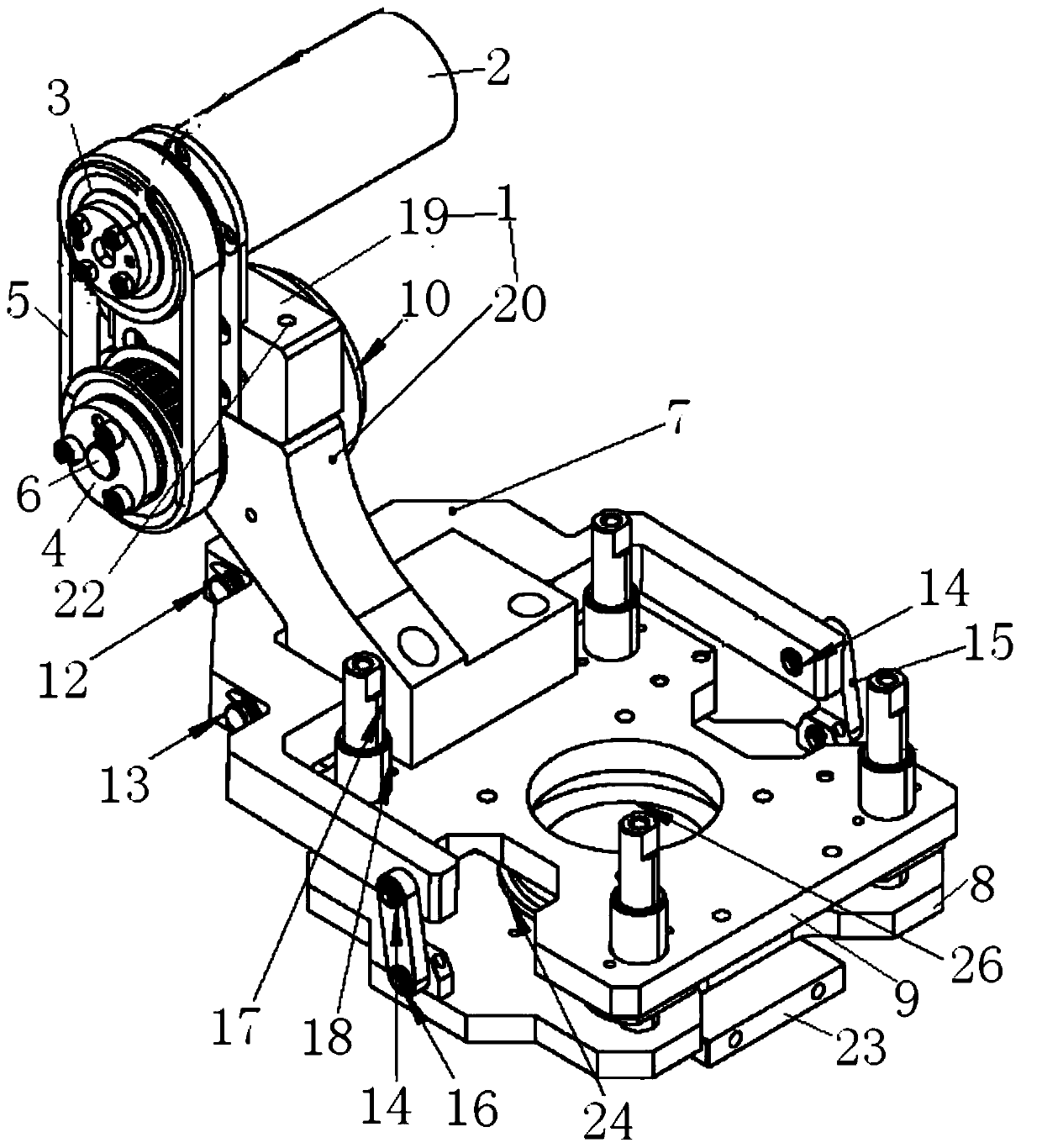

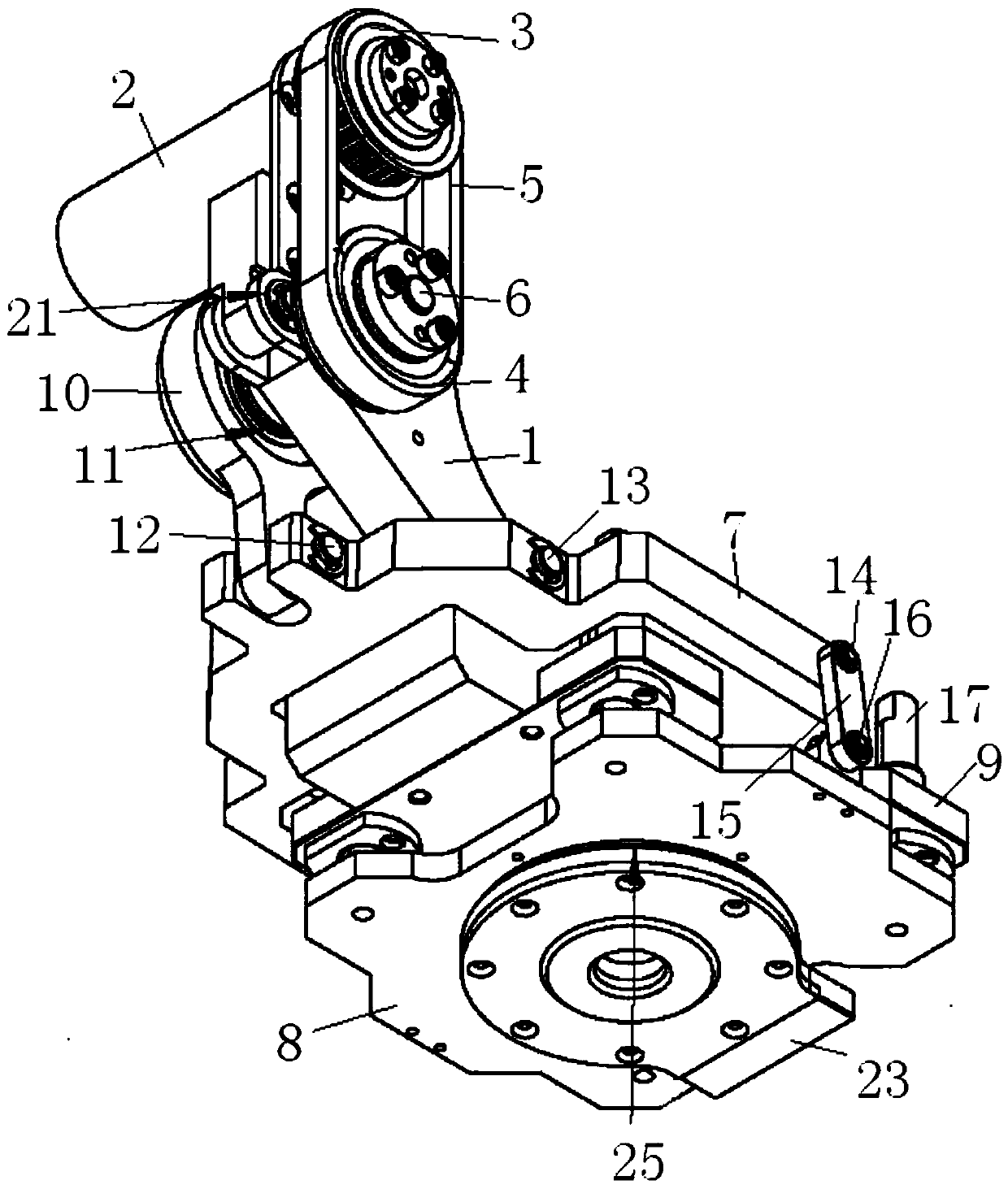

PendingCN109596799AAccurate detectionStable detectionOptically investigating flaws/contaminationTesting metalsWeld seamMechanical engineering

A weld seam detection device relates to the field of pipeline detection. The weld seam detection device comprises a substrate, support columns, cross beams, connecting rods, a camera, a laser pen anddetection components, wherein each of the detection components includes two groups of detection heads; each of the detection heads includes a slide rail, a slider and a probe; the support columns arearranged at four corners of the substrate; the cross beams are disposed in parallel and are respectively disposed at two ends of the substrate; the cross beams are connected between the support columns; the multiple connecting rods are disposed in parallel and are connected between the cross beams; each of the connecting rods is connected with the detection components; two groups of detection heads of each of the detection components are spaced apart; the slider is slidably matched with the slide rail and is fixedly connected to the connecting rods; the probe is connected to an end part, away from one end of the substrate, of the slide rail; a tension spring is connected between one end, close to the substrate, of the slide rail and the slider; rollers are disposed at two ends of the cross beams; rotational axial lines of the rollers are parallel to the connecting rods; and the camera and the laser pen are disposed on the substrate and toward the probe. The weld seam detection deviceis high in measurement accuracy and is capable of performing comprehensive detection on a weld seam rapidly and accurately.

Owner:四川纽赛特工业机器人制造有限公司

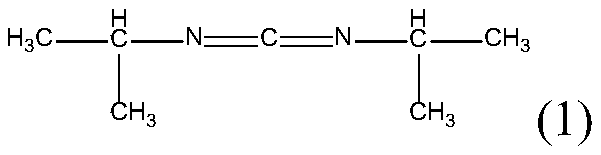

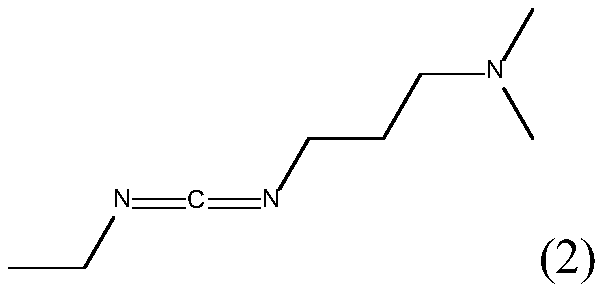

Wear-resistant cloth

ActiveCN110205707AGood weather resistanceImprove water resistanceConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolypropylene glycolPolytrimethylene terephthalate

The invention provides a monofilament and wear-resistant cloth containing the same and belongs to the field of special textile cloth. The monofilament is composed of polytrimethylene terephthalate, polypropylene glycol naphthalate, polytrimethylene terephthalate modified by dicarboxylic acid, polypropylene glycol naphthalate modified by dicarboxylic acid or polyester raw material combined thereby,thermoplastic elastomer segmented copolymer, polyacrylate modified by organosilicon and carbodiimide stabilizer selected from DIC and EDC. A wear-resistant agent is smeared on the surface of the wear-resistant cloth after being dyed. The monofilament and the wear-resistant cloth have the advantages that the monofilament and the wear-resistant cloth have excellent weatherability, hydrolysis resistance, wear resistance and stain resistance, can be applied in all industrial fields and especially is expected to have high-wear and high-pollution application in hygrothermal environment.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

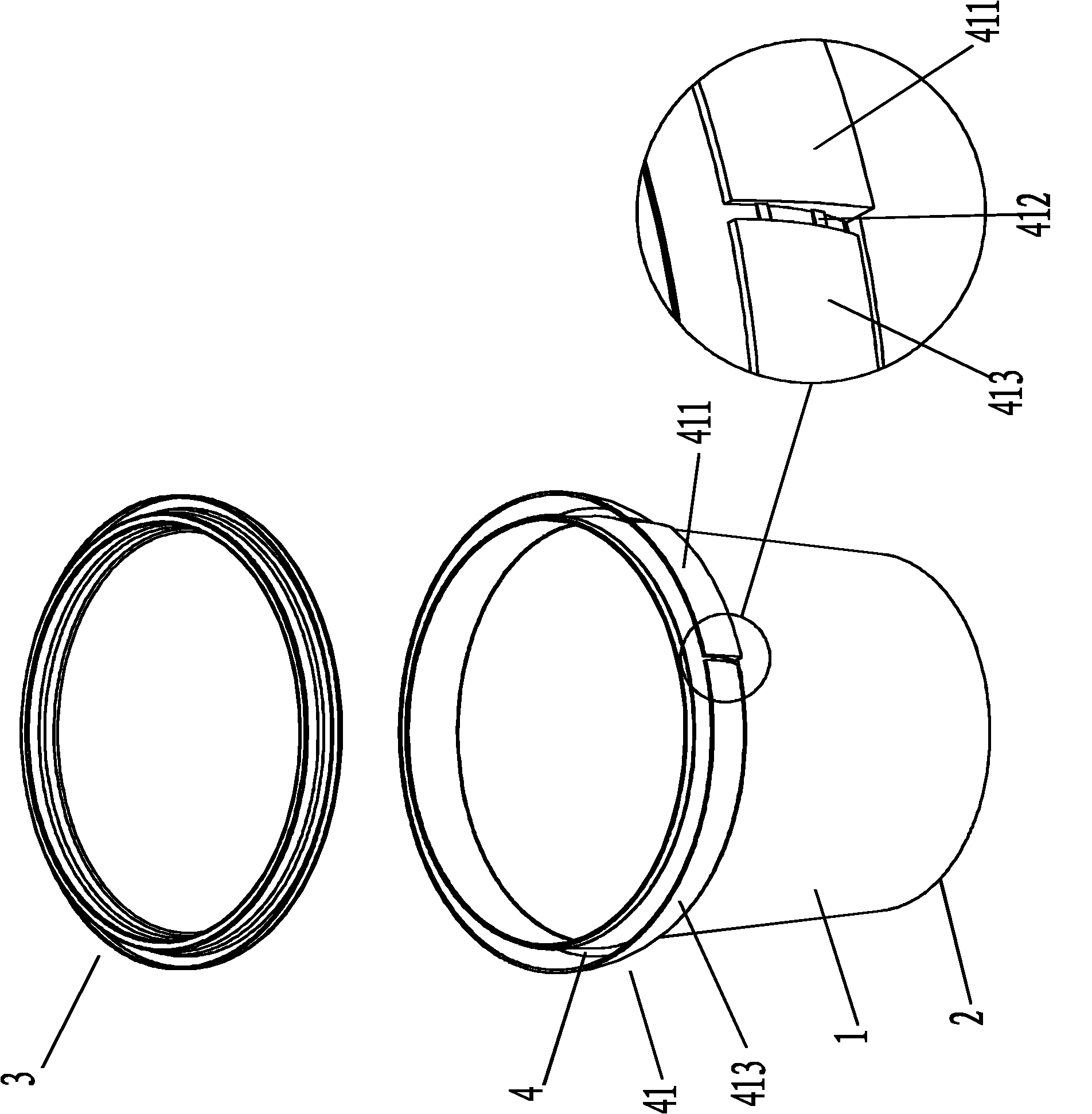

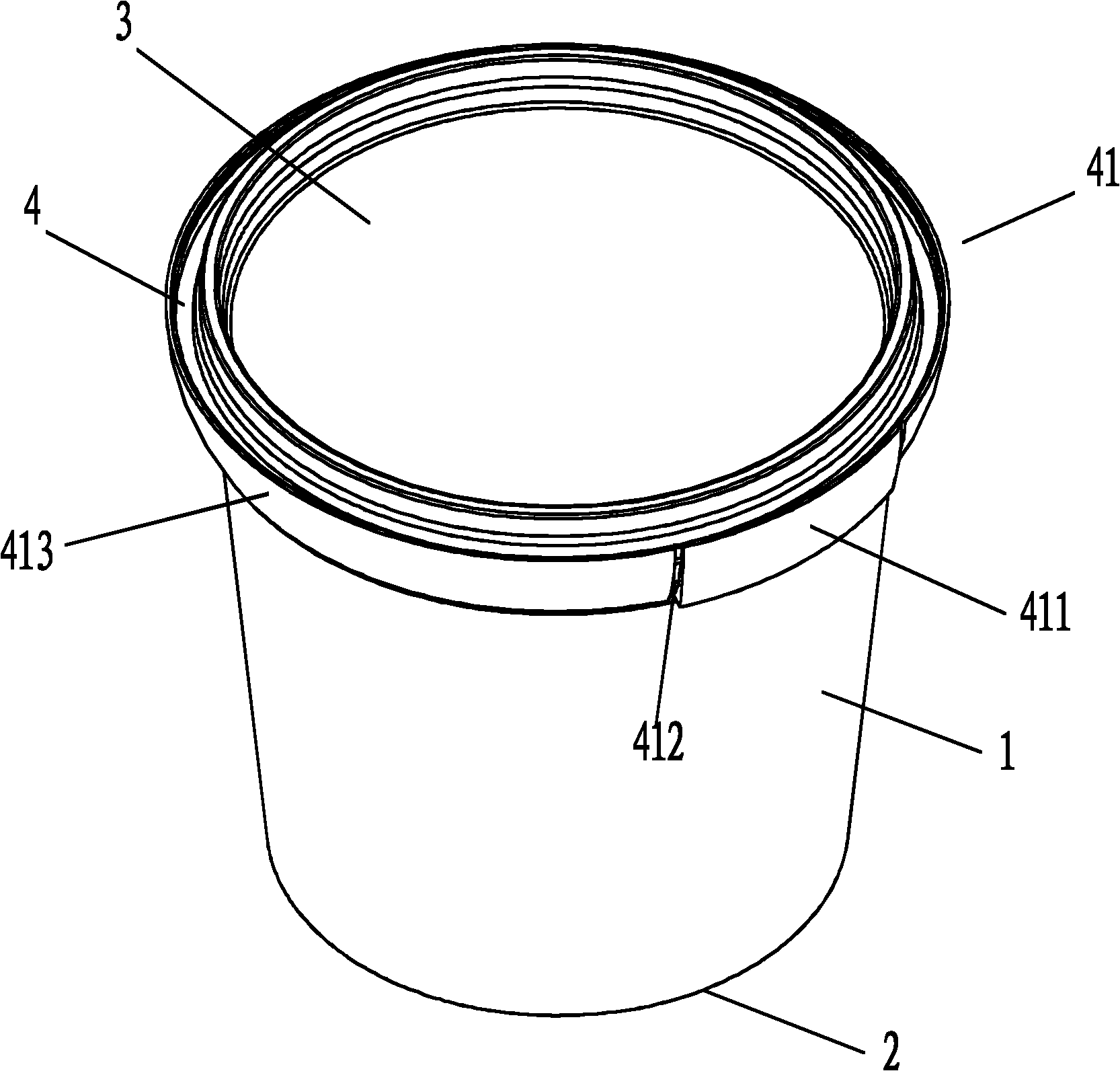

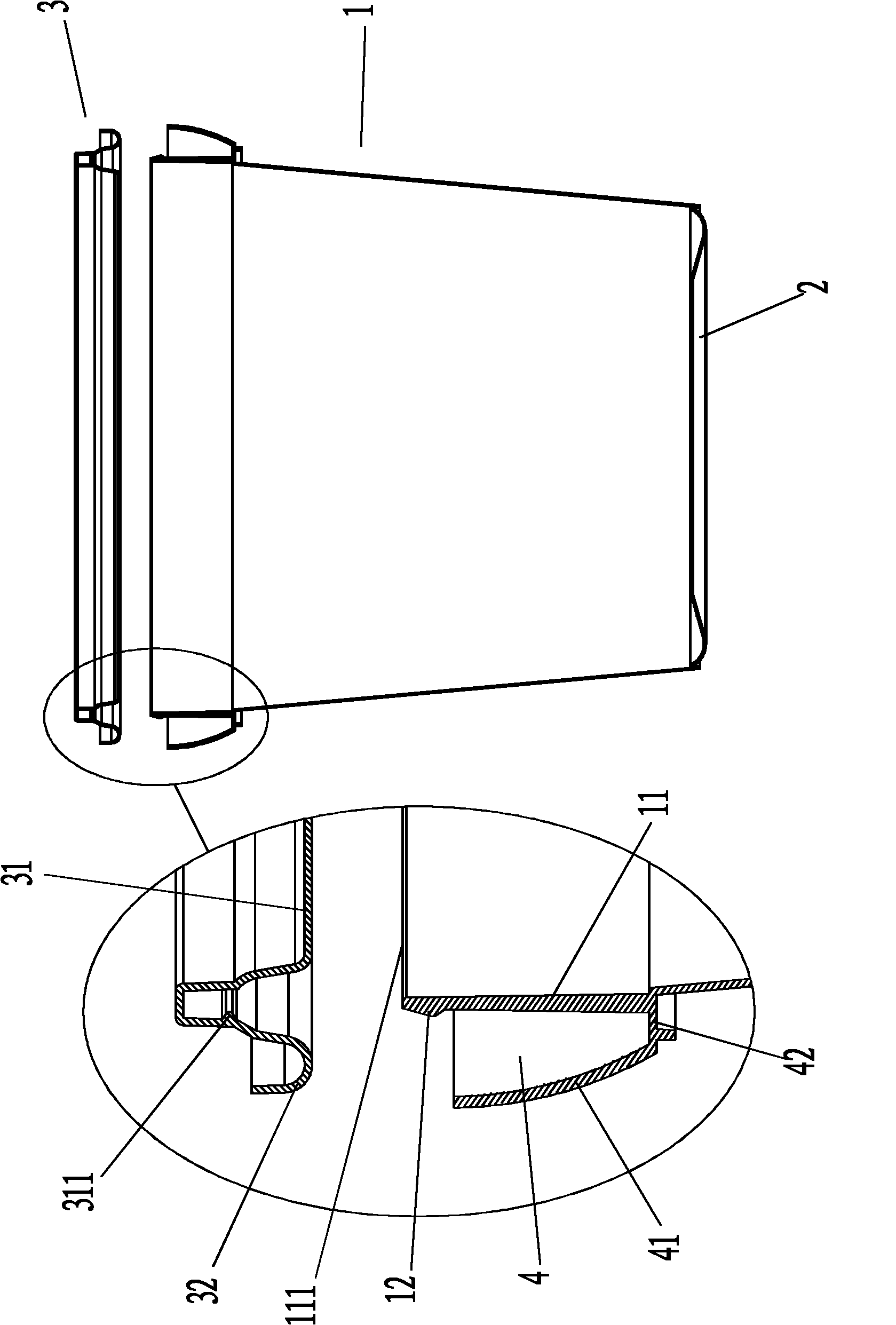

Anti-counterfeit sealed package box

InactiveCN102020055AIncrease elasticityStrong toughnessRemovable lids/coversLocking devicesEngineeringHermetic packaging

The invention discloses an anti-counterfeit sealed package box, which comprises a box bottom, a box body and a box cover, wherein a surrounding groove which is open upwards is formed on the outer wall of the box body close to the edge of the opening of the box body; the box cover is arranged on the opening of the box body, the lower edge of the box cover is embedded in the groove completely, and a zip part which can destructively tear part or all of the outer groove wall to expose part or all of the lower edge of the box cover is arranged on the outer groove wall of the groove; and the box cover comprises a box cover body and an ejecting part which surrounds the peripheral edge of the box cover body and ejects against the inner side face of the outer groove wall of the groove in a tensioned state. When the scheme is adopted, based on the conventional anti-counterfeit sealed package box, the anti-counterfeit sealed package box disclosed by the invention has the ejecting part which is arranged on the peripheral edge of the box cover body and ejects against the inner side face of the outer groove wall of the groove of the box body in a tensioned state, so that it is impossible for lawless person to pull the box cover out of the surrounding groove by inserting a fingernail or other sheetlike objects into the space between the peripheral edge of the box cover and the surrounding groove; and thus, the anti-counterfeit sealed package box has a better anti-counterfeit effect.

Owner:MEIYANG PLASTIC METALS PRODS QUANZHOU

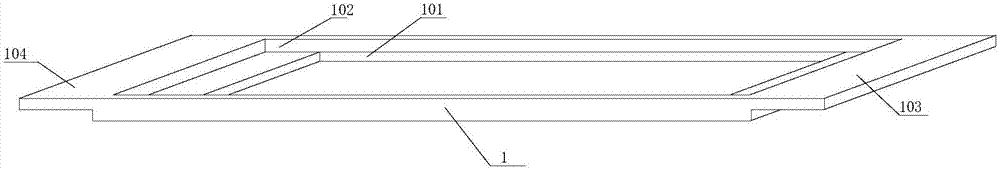

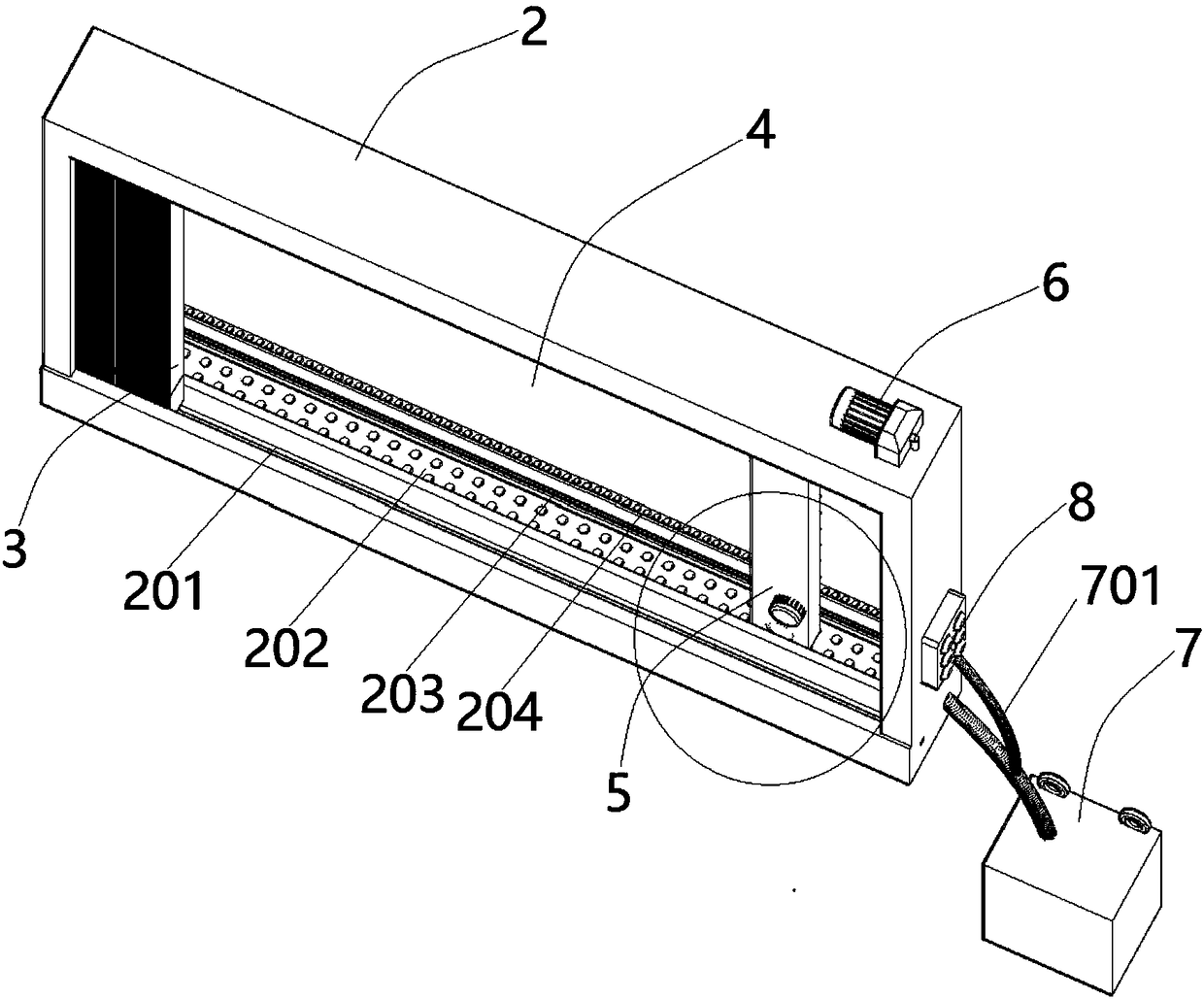

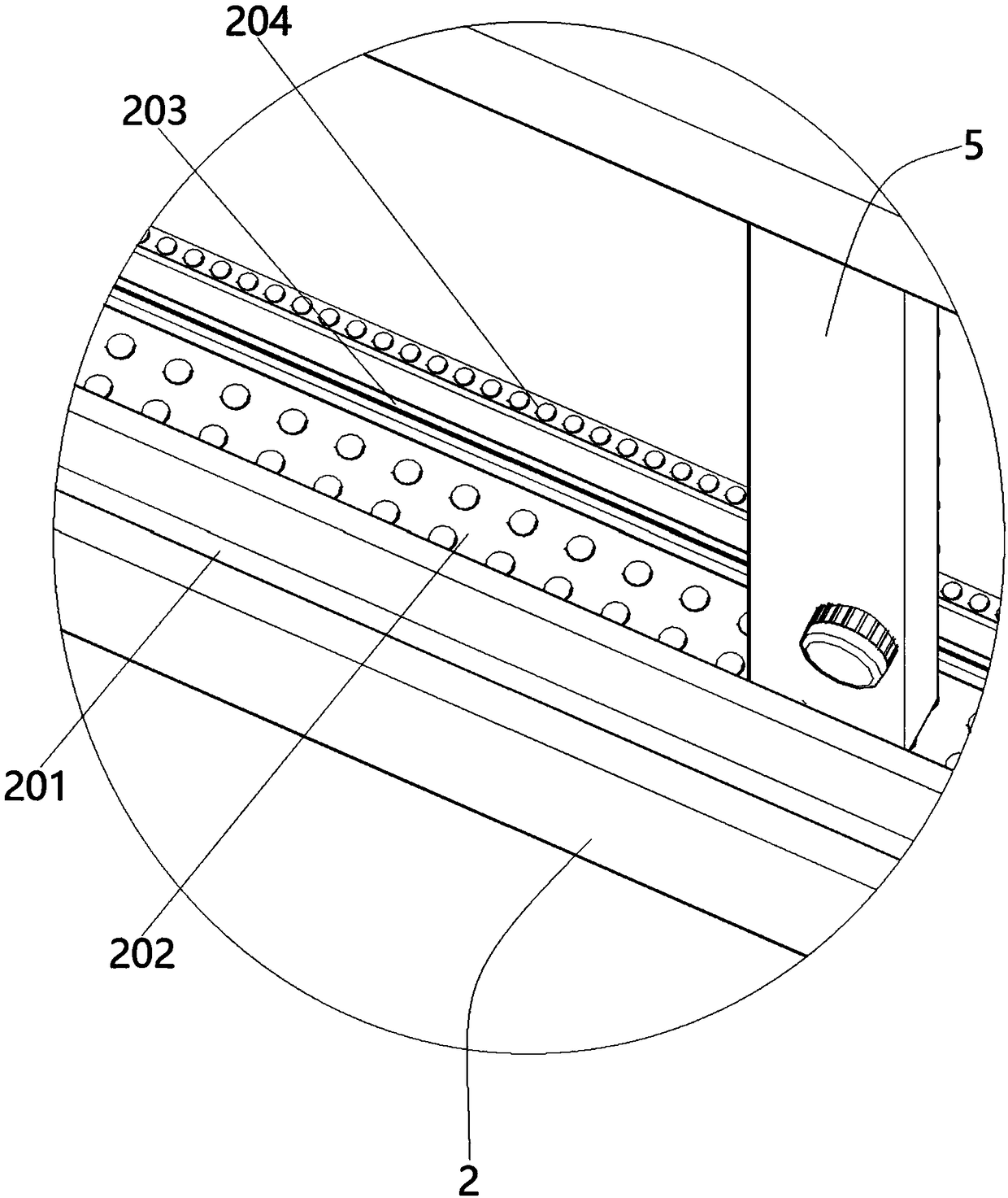

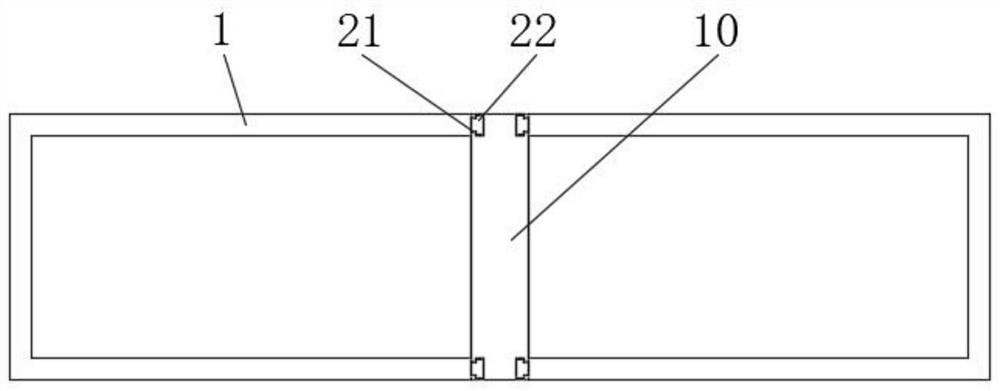

LED display screen fixing structure for intelligent public transportation

InactiveCN107146536AExtend the life cycleExtended maintenance cycleVehicle componentsIdentification meansLED display

The invention provides an intelligent public transportation with LED display screen fixing structure, including a first shell, a second shell, a first cover body, a second cover body, a first display screen and a second display screen. The first shell and the second shell are oppositely arranged. The first cover body and the second cover body are oppositely arranged in the length direction of the first shell and the second shell. An installation cavity is formed between the first shell, the second shell, the first cover body and the second cover body. The first display screen and the second display screen are all arranged in the installation cavity. The first display screen is arranged on one end of the mounting cavity near the first housing. The second display screen is connected on one end of the mounting cavity near the second housing. A support plate for supporting the first display screen and the second display screen is arranged between the first display screen and the second display screen. The LED display screen fixing structure for intelligent public transportation is convenient to install, stable in structure, waterproof and shockproof. And LED display screen fixing structure for intelligent public transportation the prolongs the service life of the display and maintenance cycle and improves the coordination between the first and the second shells close by setting the first cover, the second cover body.

Owner:ANHUI FUHUANG TECH CO LTD

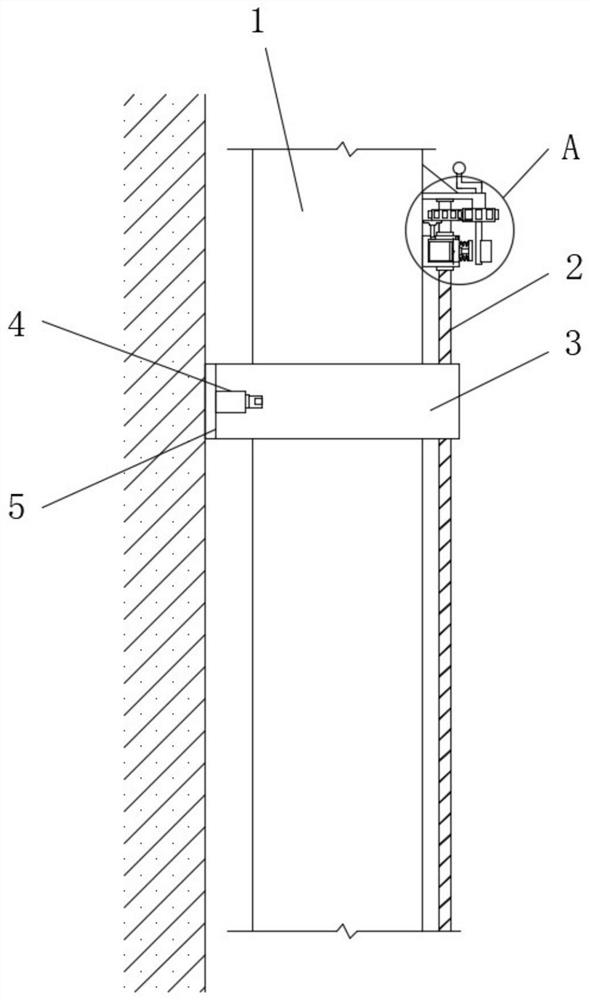

Heating and ventilation pipeline fixed installing structure realizing tight attachment

InactiveCN112503260AEasy to adjustGuaranteed smoothness and lubricationPipe supportsGear lubrication/coolingEngineeringThermodynamics

Owner:温州港臣信息科技有限公司

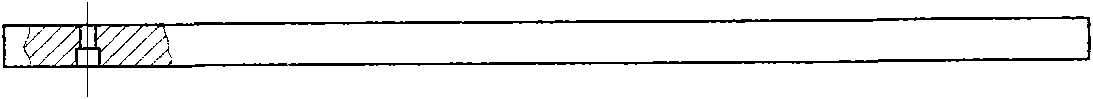

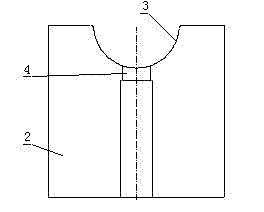

Method for processing and forming pipe fitting connection end of motorcycle frame

The invention discloses a method for processing and forming a pipe fitting connection end of a motorcycle frame. The method comprises the following steps: a, a notch is pre-processed, namely, the notch is processed at the pipe fitting connection end, wherein the depth of the notch is not less than that of arched grooves in the need of being processed; and b, the arched grooves are processed by adopting a die, a punching die is adopted for carrying out punching from top to bottom;, when the punching die is used for carrying out punching, the cutting edge at the lower end cuts in from the innermost edge of the notch, and the two needed arched grooves are punched at the pipe fitting end to be processed after being punched by the punching die. The method disclosed by the invention is capable of greatly increasing the bonding tightness when one pipe fitting is connected with another pipe fitting, so that the welding quality is improved, and the connection intensity is increased; furthermore, the method is suitable for pipe fittings connected in any angle; the pipe diameter application range about the pipe fittings is also very wide; meanwhile, the method disclosed by the invention has the characteristics of high efficiency and low cost and is applied to large-scale popularization and application.

Owner:重庆建设·雅马哈摩托车有限公司

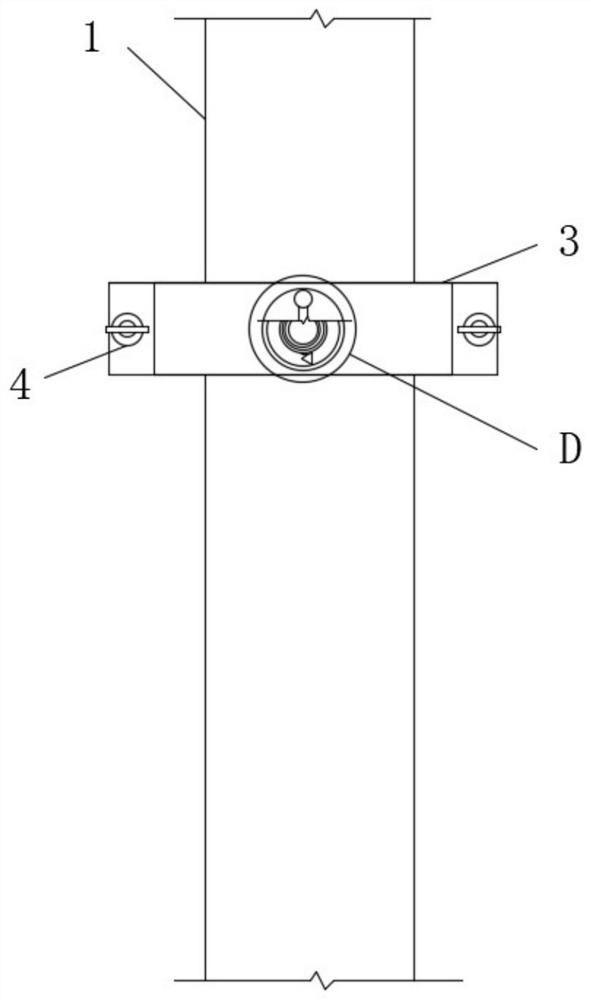

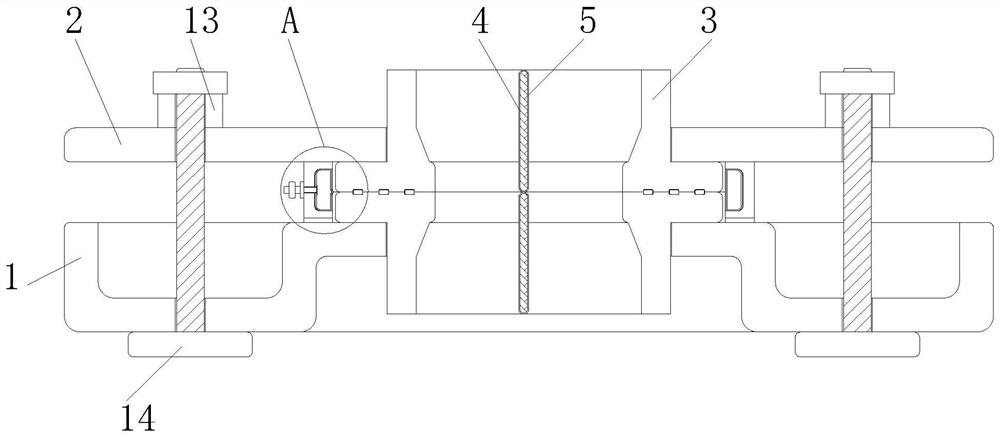

Tiebar fixing device for die casting machine and die casting machine including same

The invention discloses a tiebar fixing device for a die casting machine and the die casting machine including the same. The tiebar fixing device comprises a support base component, wherein the two ends of the support base component are respectively connected with an oil cylinder component and a tiebar; a connecting part is arranged at the end part, connected with the tiebar, of the support base component; and an outer edge of the connecting part is projected at the outer edge of the end part of the support base component. The tiebar fixing device further comprises a gland; a step through hole is formed in the gland; the end part of the support base component and the connecting part are inserted into the step through hole of the gland in a gap fit manner; gland is fixedly connected with the end part of the tiebar; and the die casting machine comprises the tiebar fixing device. When the oil cylinder component pulls out or inserts in the tiebar, the tiebar cannot rotate along with the rotation of the support base component, so that the fit tightness of parts of the die casting machine is improved, and the pass percent of products produced by the die casting machine is improved.

Owner:上海一达机械有限公司

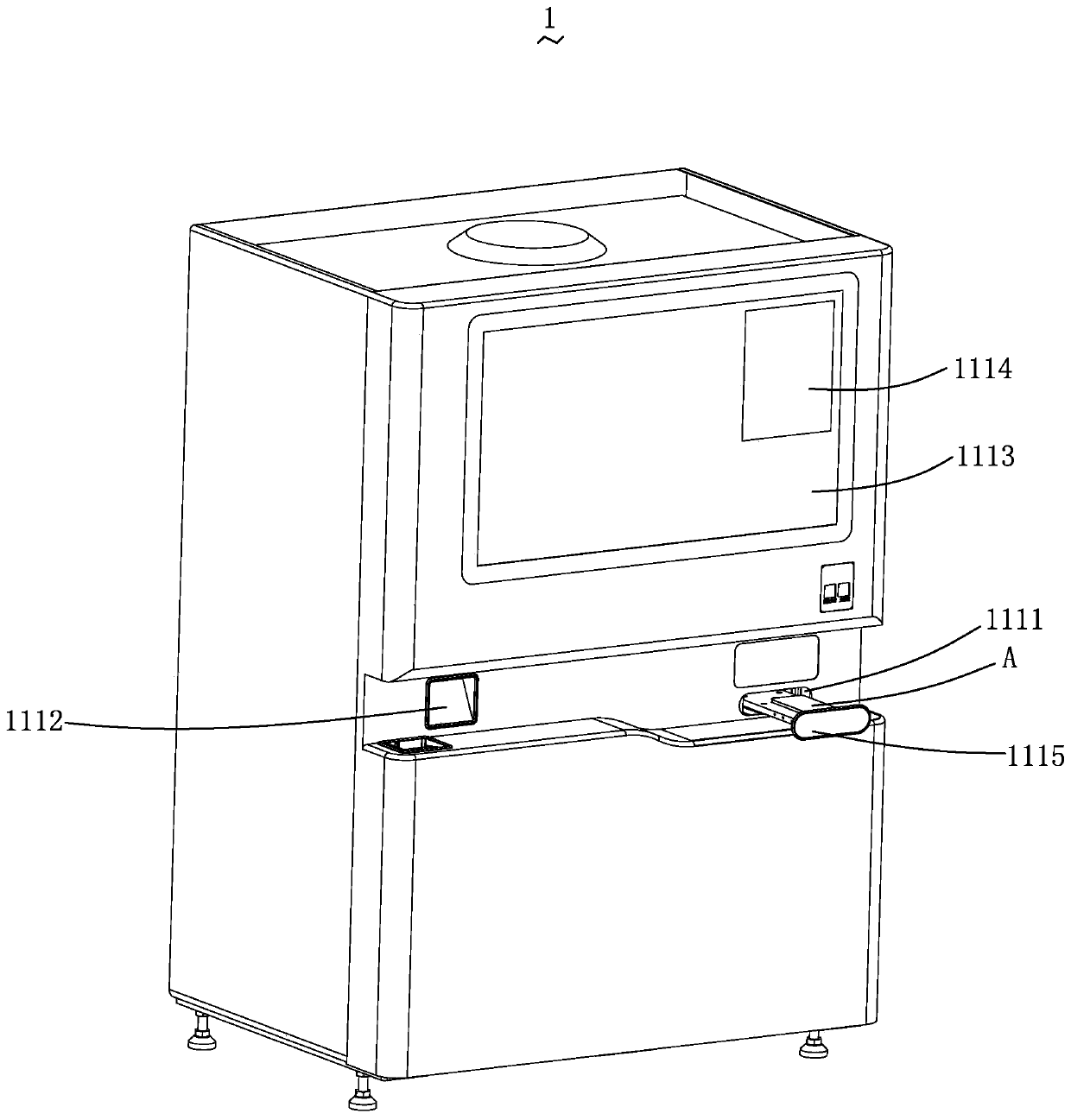

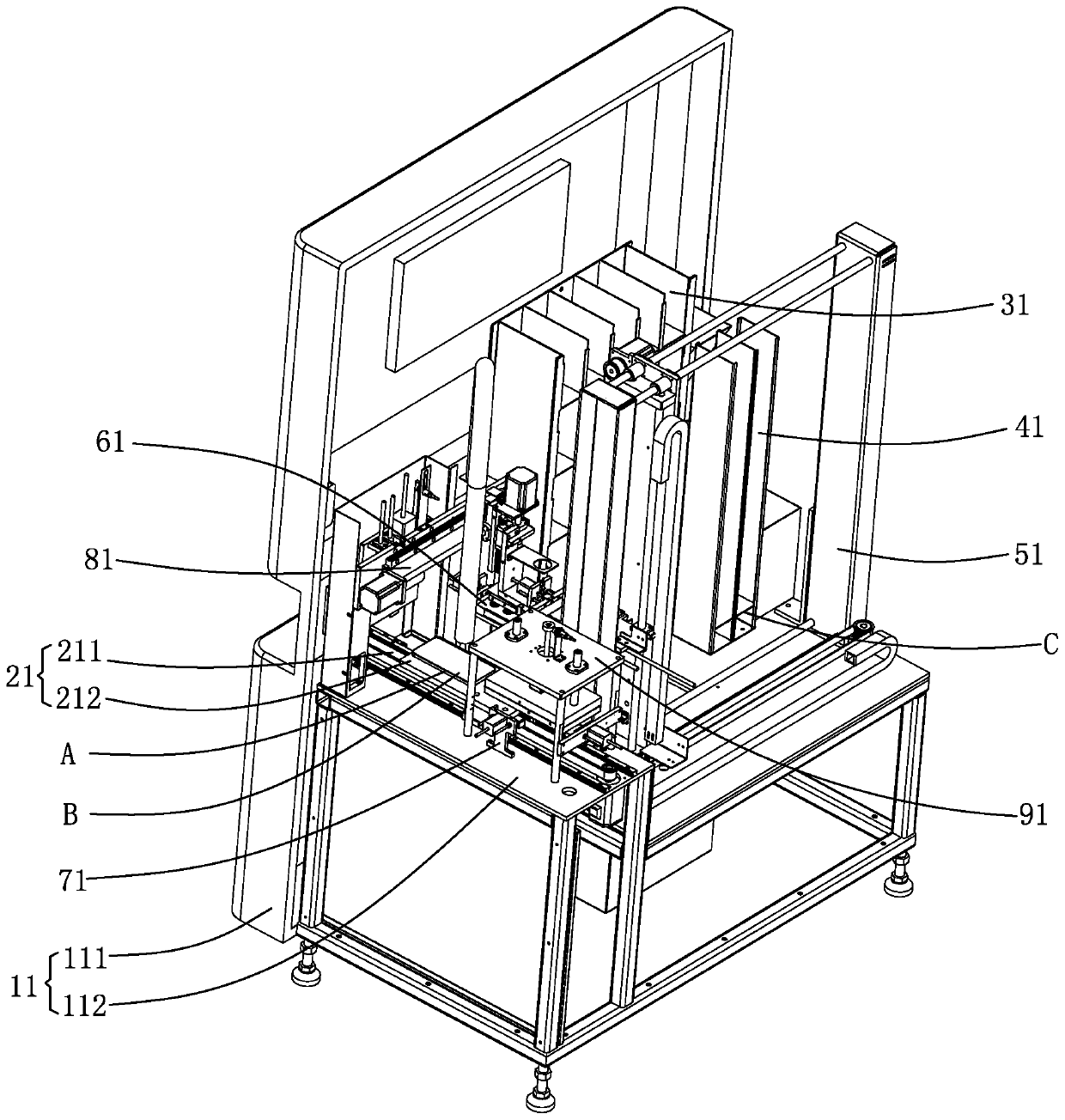

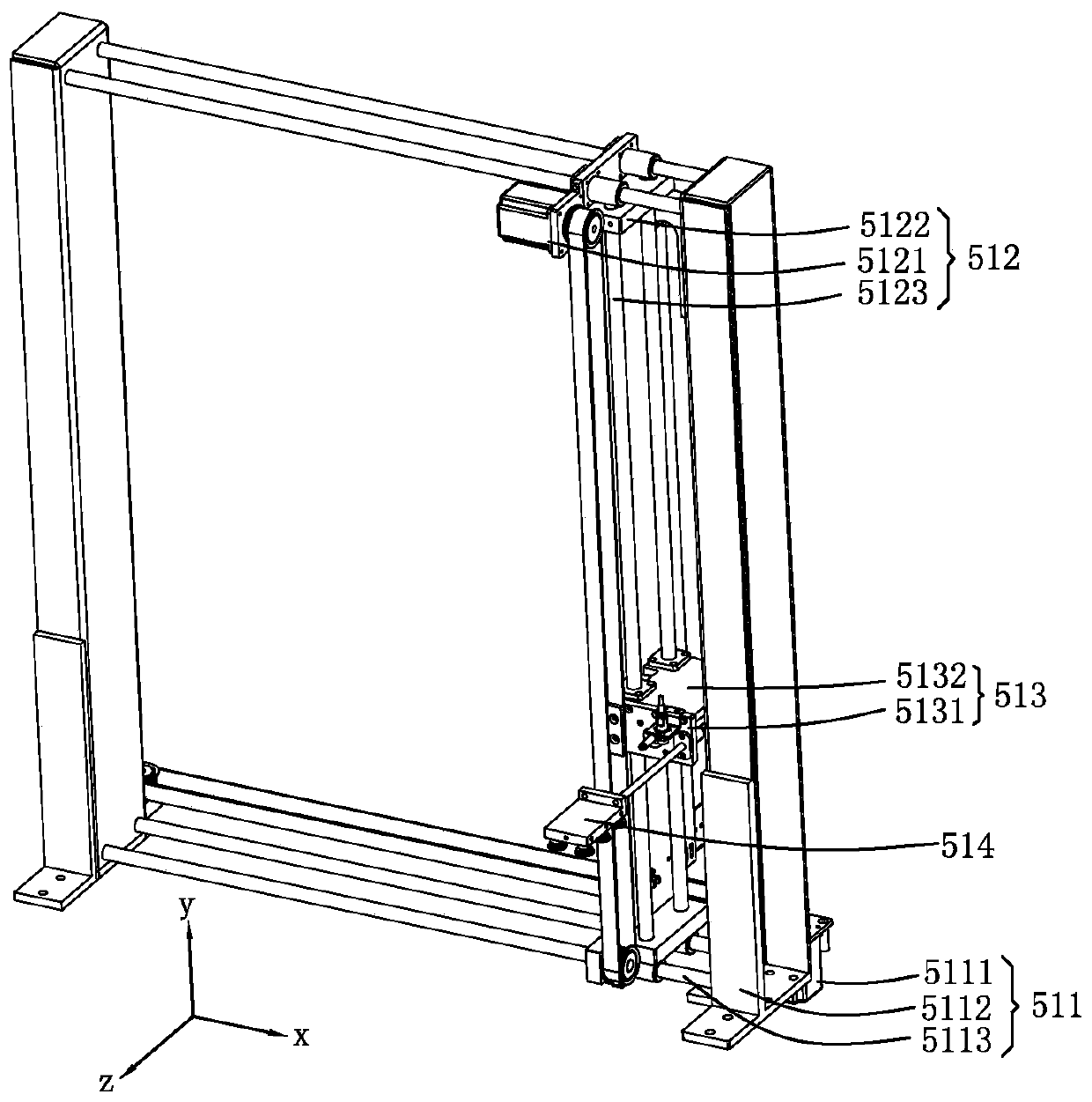

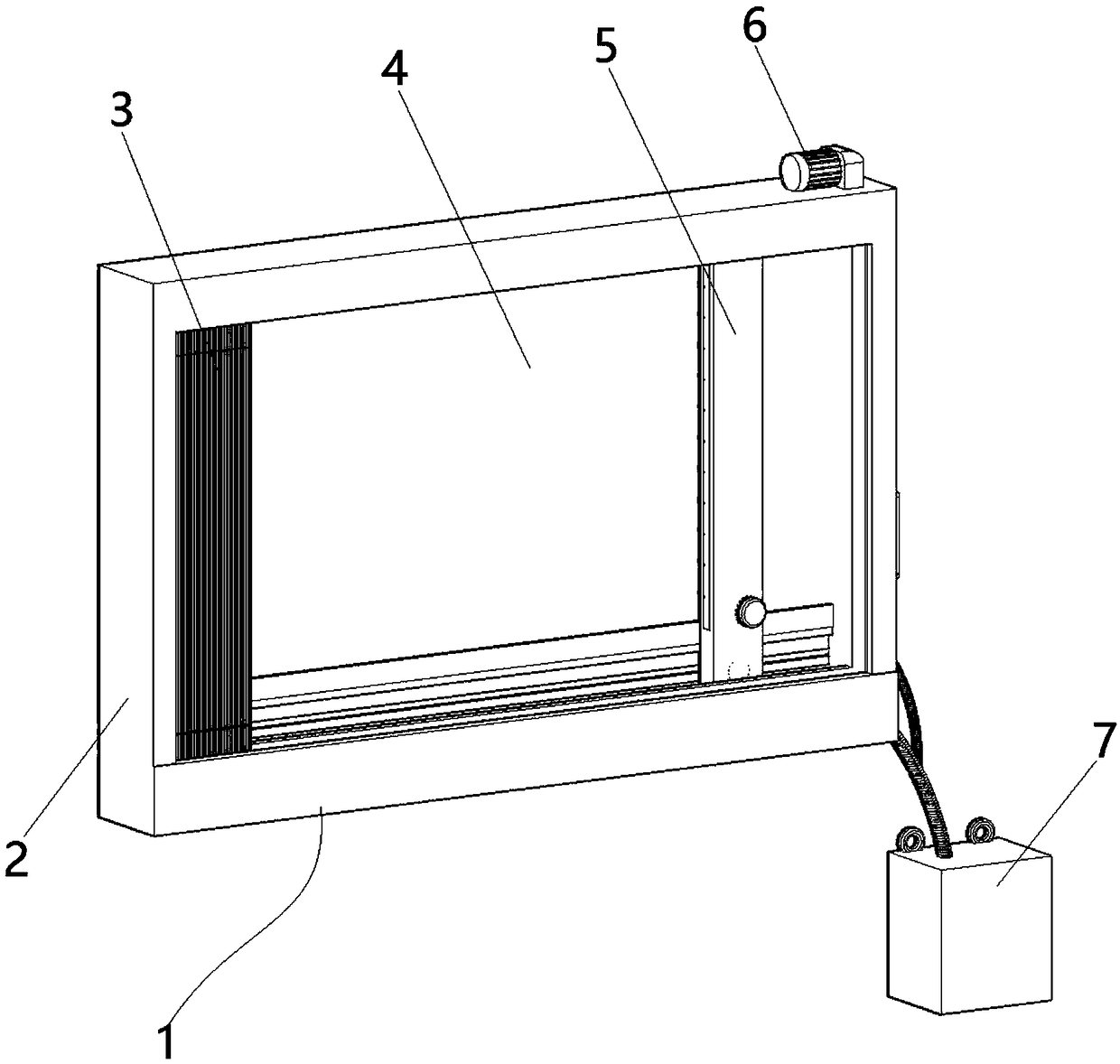

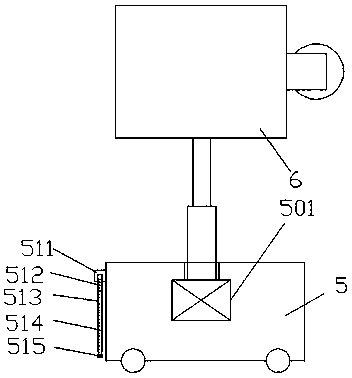

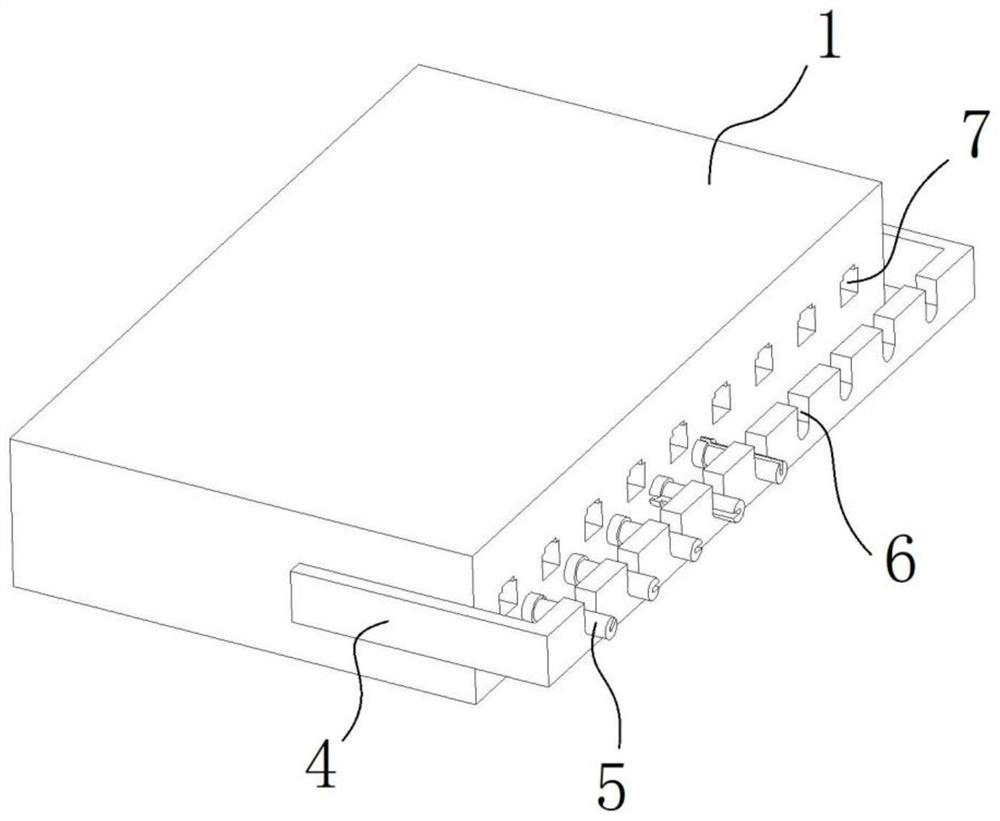

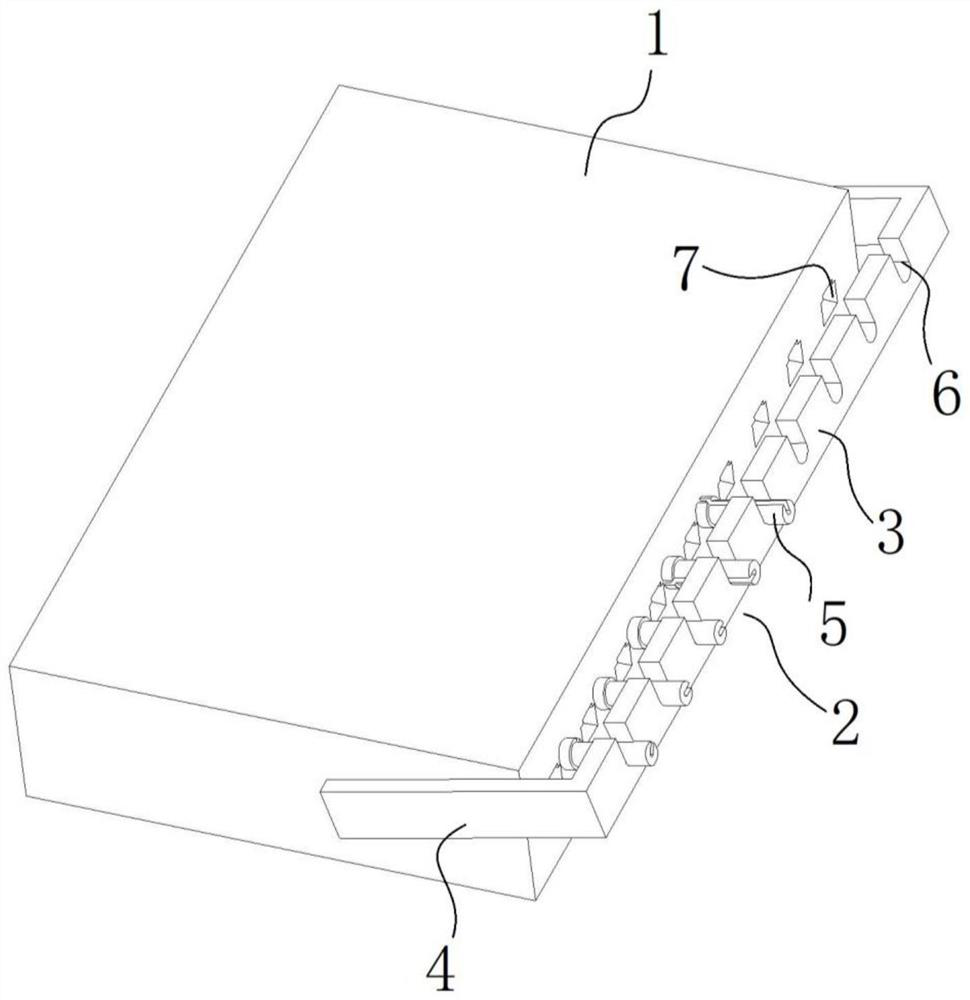

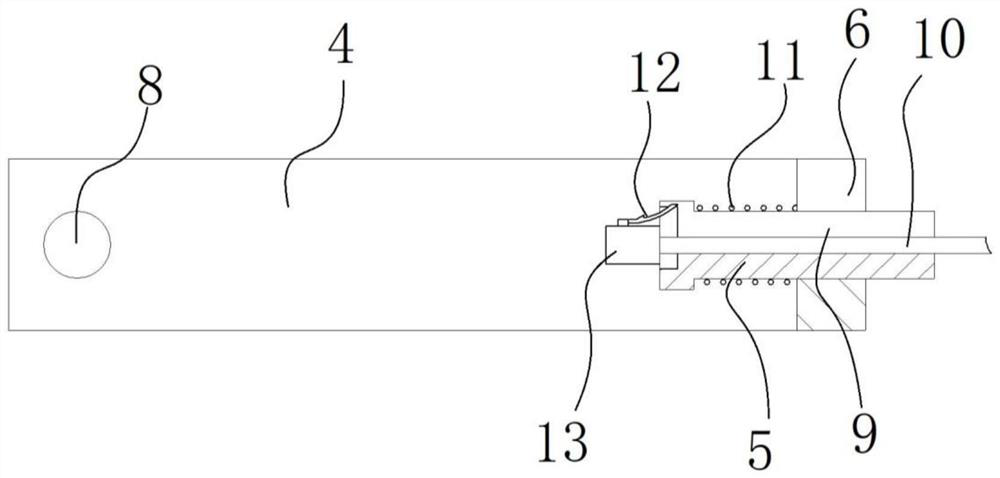

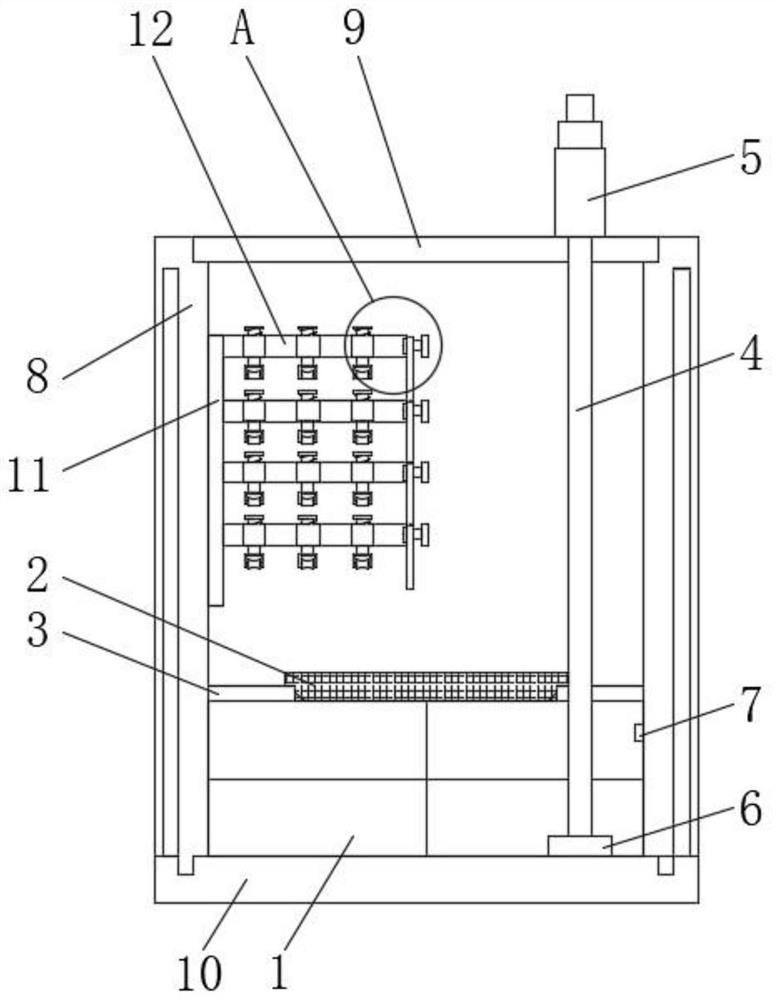

Self-service film pasting machine and film pasting method thereof

ActiveCN111113881AUniform extrusion forceImprove fit tightnessFinal product manufactureEngineeringService mode

The invention relates to a self-service film pasting machine which is used for pasting protective layers to different electronic equipment in a self-service mode. The self-service film pasting machinecomprises a first positioning device, a second positioning device, a first film pasting device and a second film pasting device, wherein the first positioning device and the second positioning deviceare mutually independent, and the first film pasting device and the second film pasting device are mutually independent; the first positioning device is used for positioning the protective layer, andthe second positioning device is used for positioning the electronic equipment; the first film pasting device obtains the protective layer from the first positioning device and pastes the protectivefilm to the positioned electronic equipment to complete primary pasting of the protective layer and the electronic equipment; and the second film pasting mechanism comprises a cavity cover, a cavity capable of containing different electronic equipment is formed in the cavity cover, and an air bag is arranged in the cavity to extrude the protective layer on the electronic equipment contained in thecavity so as to carry out secondary pasting. The invention further provides a film pasting method of the self-service film pasting machine, and the self-service film pasting machine and the film pasting method thereof have the advantages of being tight in pasting, free of bubbles and the like.

Owner:SHENZHEN BNT INTELLIGENT TECH CO LTD

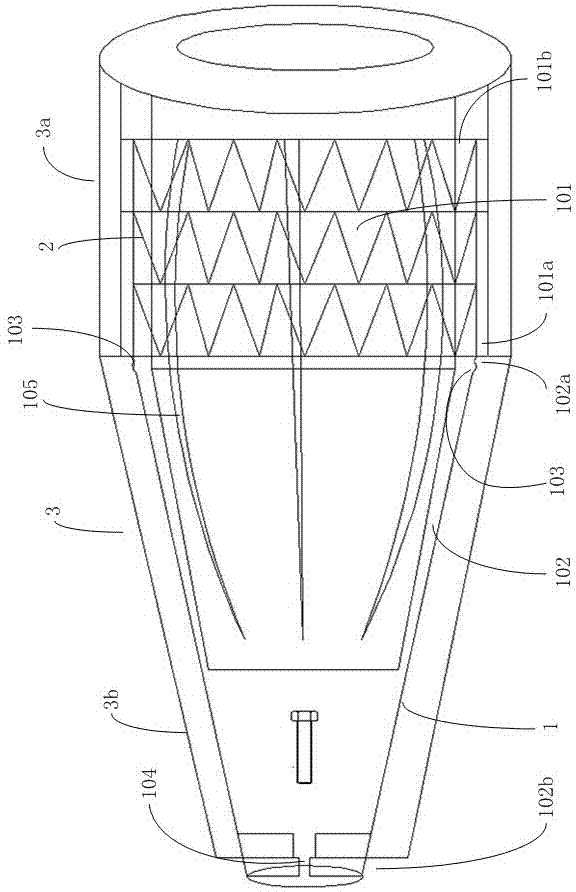

Quick coupler for in-out cables of high- voltage switch cabinet

ActiveCN105449391AQuick insertEasy to insertCouplings bases/casesClamped/spring connectionsElectrical conductorSoft materials

The invention relates to the electrical equipment field, especially a quick coupler for in-out cables of a high- voltage switch cabinet which is characterized by comprising a hollow inner conductor; the hollow inner conductor comprises a columnar part and a tapered part; the tapered part and the columnar part are equipped with oppositely arranged first ends and second ends; the end of the tapered part connected with the columnar part is constructed into the first end; the other end is constructed into the second end; an externally convex clamping structure is arranged at the periphery of the tapered part close to its first end; an elastic slot is arranged at the port of the second end of the tapered part; the end of the columnar part connected with the tapered part is constructed into the first end; the other end is constructed into the second end; a number of shrinkage slots are evenly arranged on the inner conductor along the periphery; the invention also comprises an elastic element sleeving the periphery of the columnar part, and hollow insulation sleeves coating the peripheries of the inner conductor and the elastic element; the insulation sleeves are made of an insulation soft material. The invention can quickly connect the cables, saves connecting time and is good in insulation performance and sealing performance.

Owner:HUBEI XIANGKAI POWER EQUIP CO LTD

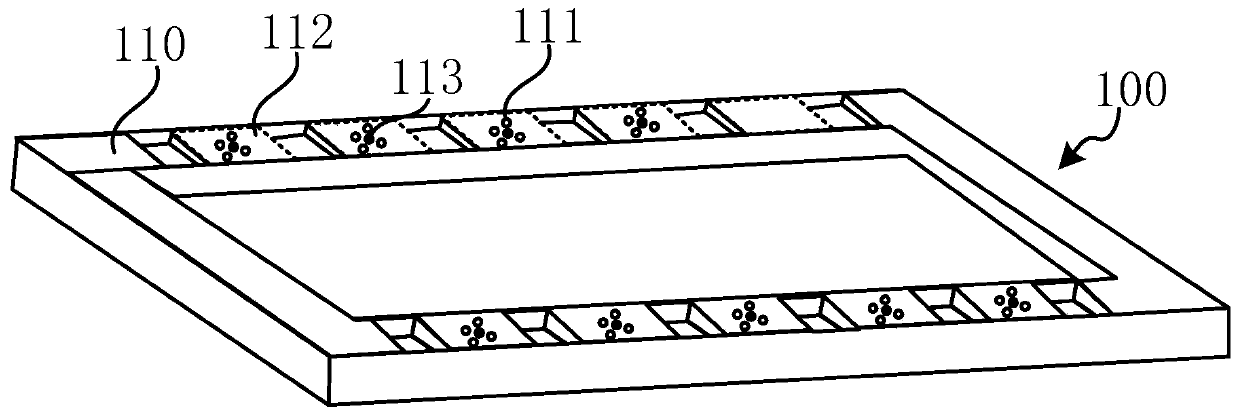

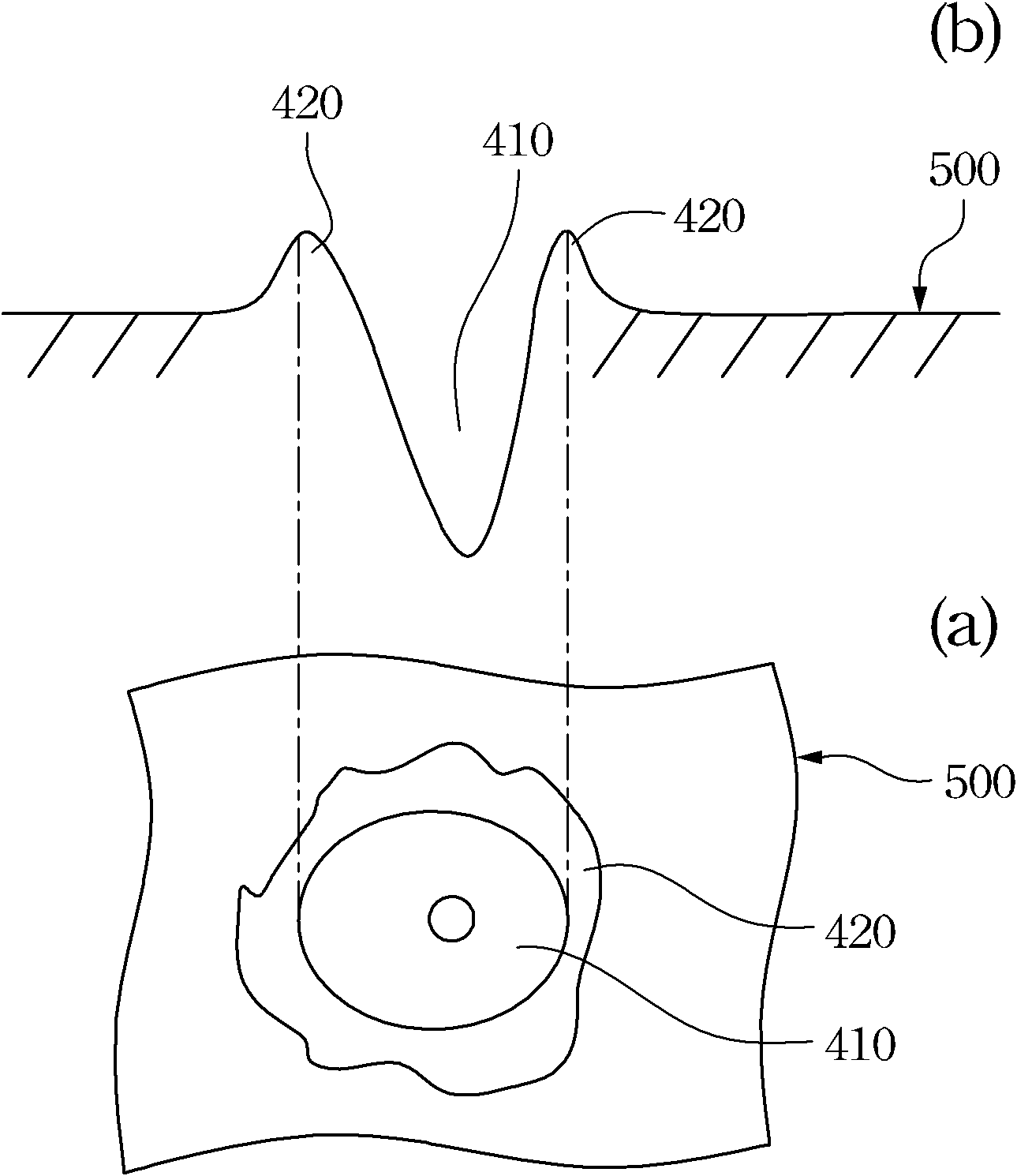

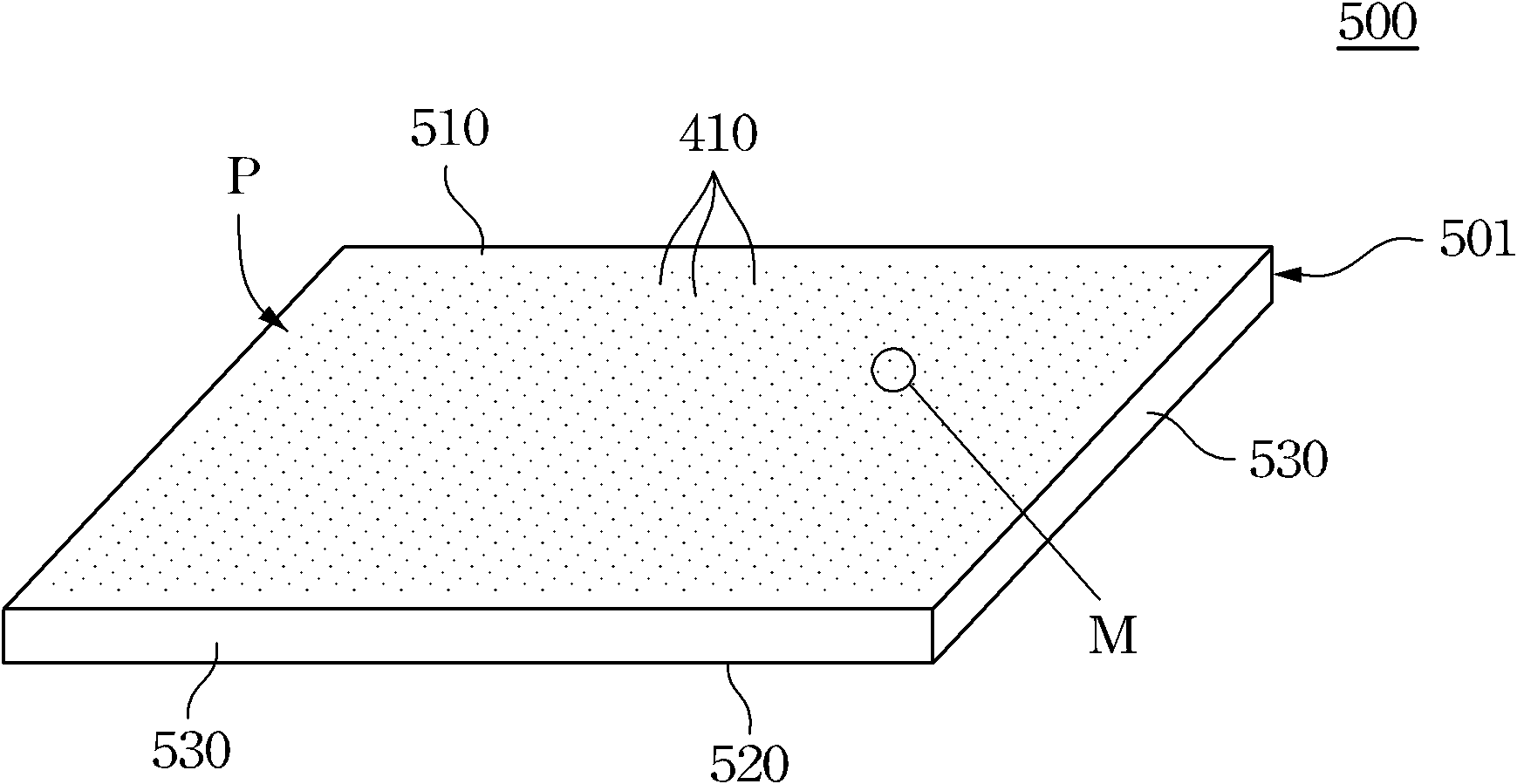

Light guide plate, backlight module and display device thereof

InactiveCN102073091AAvoid destructionImprove fit tightnessMechanical apparatusLight guides for lighting systemsLight guideDisplay device

The invention relates to a light guide plate, a backlight module and a display device thereof. The light guide plate comprises a plate body and an optical microstructure pattern, wherein the optical microstructure pattern is distributed on the surface of the plate body and comprises a plurality of micro concave holes; the periphery of each of the micro concave holes is provided with at least one recessed part having a molten surface; and the depth of each recessed part is smaller than that of each micro concave hole. The invention has the advantages that: the possibility for protrusions at the peripheries of the micro concave holes to fall off to fill the micro concave holes can be reduced or avoided, and the optical guide rotation performance of the optical microstructure is prevented from being degraded after the light guide plate is manufactured. In addition, after the light guide plate is arranged in a display, the joint tightness of the light guide plate and an optical film is improved, the excellent light-extraction efficiency is kept, the optical film is prevented from being broken, and the service life of the product is prolonged.

Owner:苏州茂立光电科技有限公司

Dust-free multifunctional blackboard

PendingCN108146113AImprove sealingPrevent environmental sanitationBoard cleaning devicesWriting boardsEngineeringNozzle

The invention discloses a dust-free multifunctional blackboard. The blackboard comprises a dustproof curtain cover, a blackboard body and a blackboard wiping device, wherein the blackboard is arrangedon the blackboard body; a blackboard functional frame is arranged on the periphery of the blackboard, and a curtain groove is formed in the outer side of a sliding groove; the inner side of the curtain groove is provided with a dustproof curtain cover through a sliding rod; gas nozzles are further symmetrically arranged on the adjacent inner side of the sliding groove at the top side of the blackboard functional frame; an air pump is further fixedly arranged on the upper side of the top end of the blackboard functional frame; and the air pump communicates with the gas nozzles, and a controller is further arranged on the side wall of the blackboard functional frame. The dust-free multifunctional blackboard is provided with wiping brushes which are arranged on the side wall of a wiping device box body in a two-row structure, the two rows of wiping brushes are designed in a crossed structure, so that the wiping brushes can be mutually crossed and wiped to enable the wiping path to extendto the surface of the whole blackboard, and the phenomenon that the wiping is not clean due to the fact that a gap is reserved is avoided.

Owner:王芳

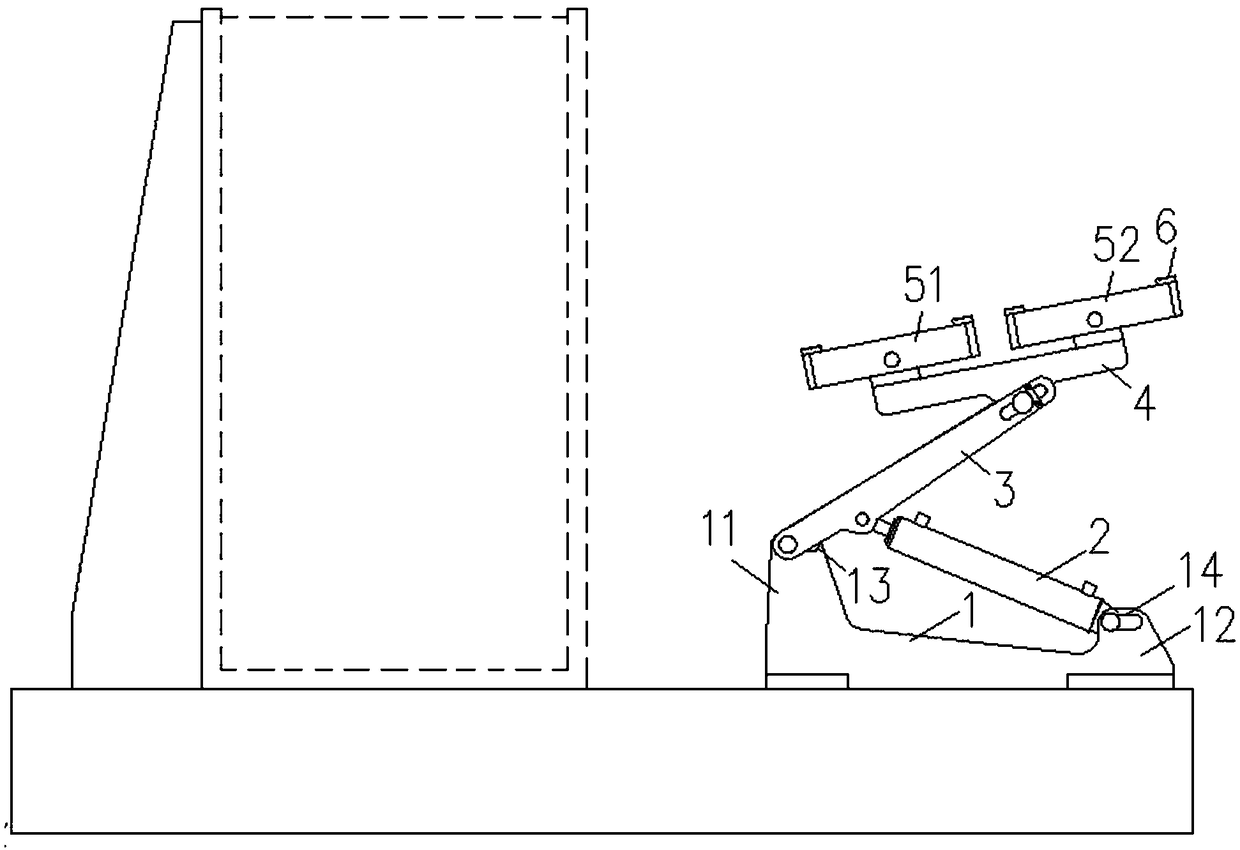

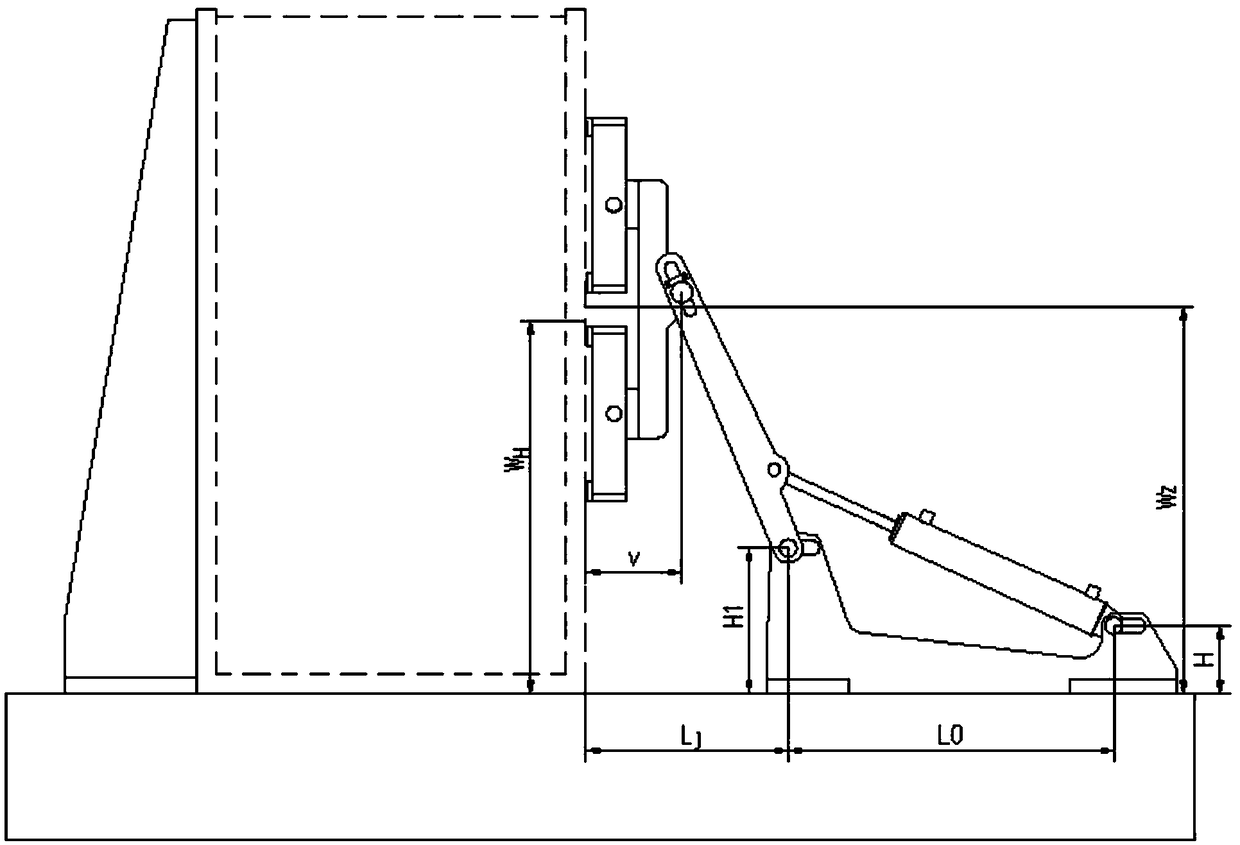

Press machine tailor-welding clamping device and application method thereof

PendingCN108772657AIncrease flexibilityGuaranteed continuityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPiston rod

The invention discloses a press machine tailor-welding clamping device. The press machine tailor-welding clamping device comprises a base, an oil cylinder, a front arm, a rear arm and a pressing device. The pressing device comprises a first pressing base and a second pressing base. The base is fixedly mounted on a tailor-welding reference station on one side of a to-be-assembled side plate. The end, close to the to-be-assembled side plate, of the base extends upwards to form a first lug plate. The end, away from the to-be-assembled side plate, of the base extends upwards to form a second lug plate. A lug plate of the oil cylinder is hinged to the second lug plate. The top end of a piston rod of the oil cylinder is hinged to the middle of the front arm. One end of the front arm is hinged tothe first lug plate. The other end of the front arm is hinged to the middle of the rear arm. The first pressing base is arranged at the end, close to the to-be-assembled side plate, of the rear arm.The second pressing base is arranged at the end, away from the to-be-assembled side plate, of the rear arm. The oil cylinder is used for pushing the front arm so as to drive the rear arm, the pressingplate is closely attached to the side plate, manual force is replaced by hydraulic force of the oil cylinder, and thus the pressing force to the side plate is kept continuous and stable.

Owner:WORLD PRECISE MACHINERY CO LTD CHINA

Intramode butt fusion type secondary processing method

InactiveCN103112172AImprove fit tightnessSave manpower and material resourcesCoatingsInjection - actionMaterial resources

The invention relates to an intramode butt fusion type secondary processing method comprising a movable mould, an auxiliary mould driving device, an auxiliary mould, a heating butt fusion device and a fixed mould. The intramode butt fusion type secondary processing method is characterized in that after the movable mould, the auxiliary mould and the fixed mould are closed, an injection molding machine performs an injection action and opens the moulds to necessary distances after the injection procedure, the movable mould drives the auxiliary mould to match a next working station through the auxiliary mould driving device, and then, the heating butt fusion device enters the mould region to heat originally separated and different component products, the heating butt fusion device retreats, and finally, the injection molding machine closes the moulds to fuse the originally separated and different component products together so as to finish the intramode butt fusion type secondary processing procedure and assemble plastic products. According ot the intramode butt fusion type secondary processing method, the procedures needing secondary processing, particularly, components needing butt fusion, are designed to be executed in the moulds, so that the plastic products are finished products when leaving the die cavity, which improves the assembly quality, stability and cooperation firmness of the products and saves the manpower and material resources and the factory building space.

Owner:BORCH MACHINERY

New-energy automobile cleaning device

InactiveCN107901888ASimple structureEasy to operateCleaning apparatus with conveyorsCleaning apparatus for vehicle exteriorsNew energyEngineering

The invention discloses a new energy automobile cleaning device, which comprises a cleaning frame body and a walking body. A flange is installed, and the flange is hingedly installed with a support sleeve. A spiral chamber with an opening facing downward is arranged in the support sleeve. A spiral column is installed in the spiral cavity, and the bottom of the spiral column has an extended tail. A supporting protrusion is slightly fixedly installed, and a receiving and embedding groove is provided in the front end surface of the cleaning rack body, and a control chamber that is expanded left and right is arranged in the inner wall of the cleaning rack on the rear side of the receiving and embedding groove. There is a control plate connected smoothly in the cavity; the invention has simple structure, convenient operation, convenient storage, convenient movement and transportation, and meanwhile, improves cleaning efficiency and effect.

Owner:HAINING JINXIN BEARING CO LTD

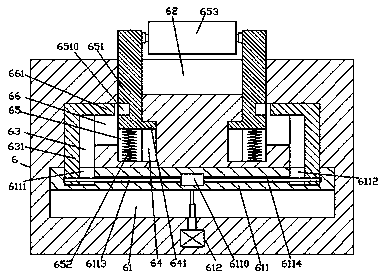

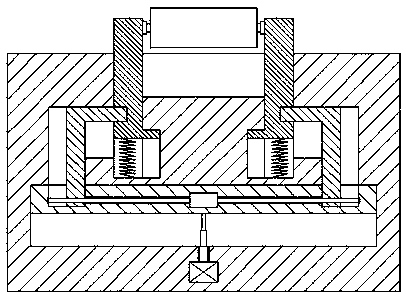

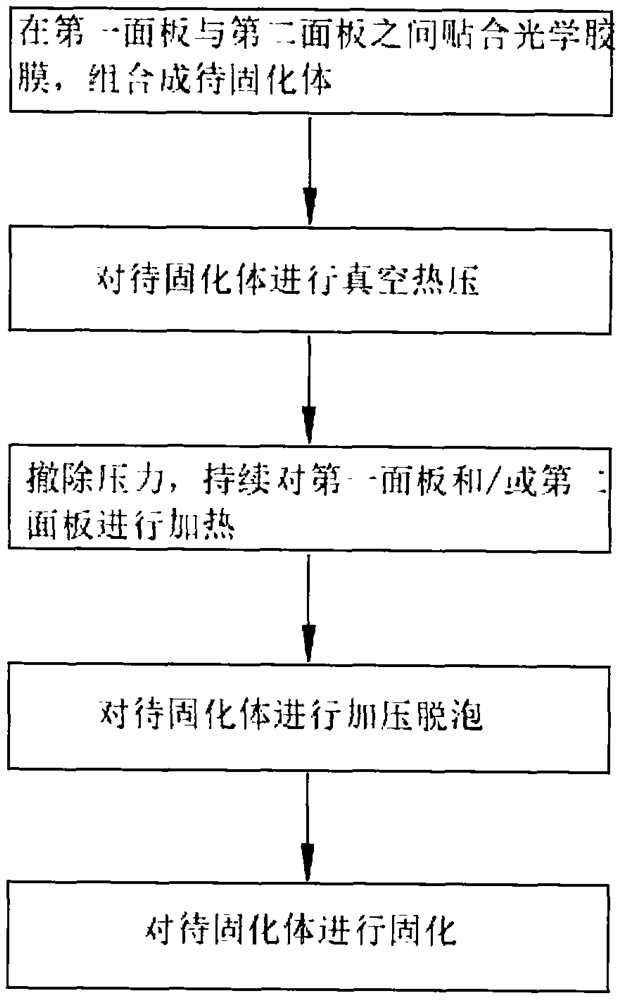

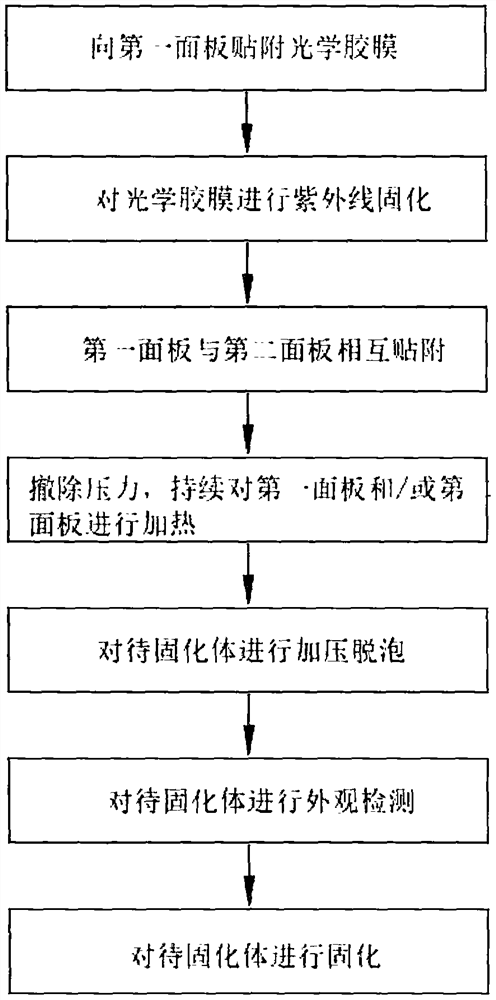

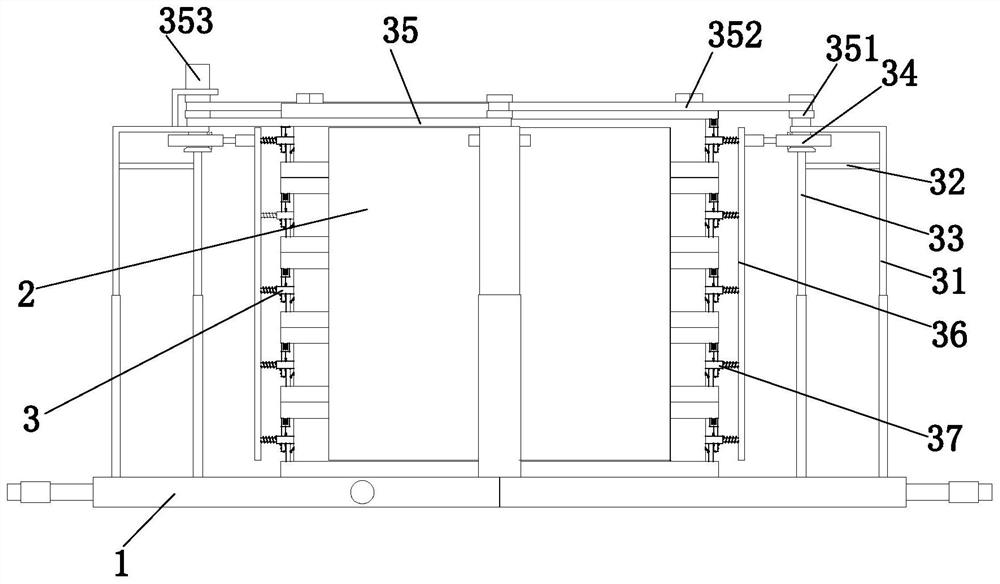

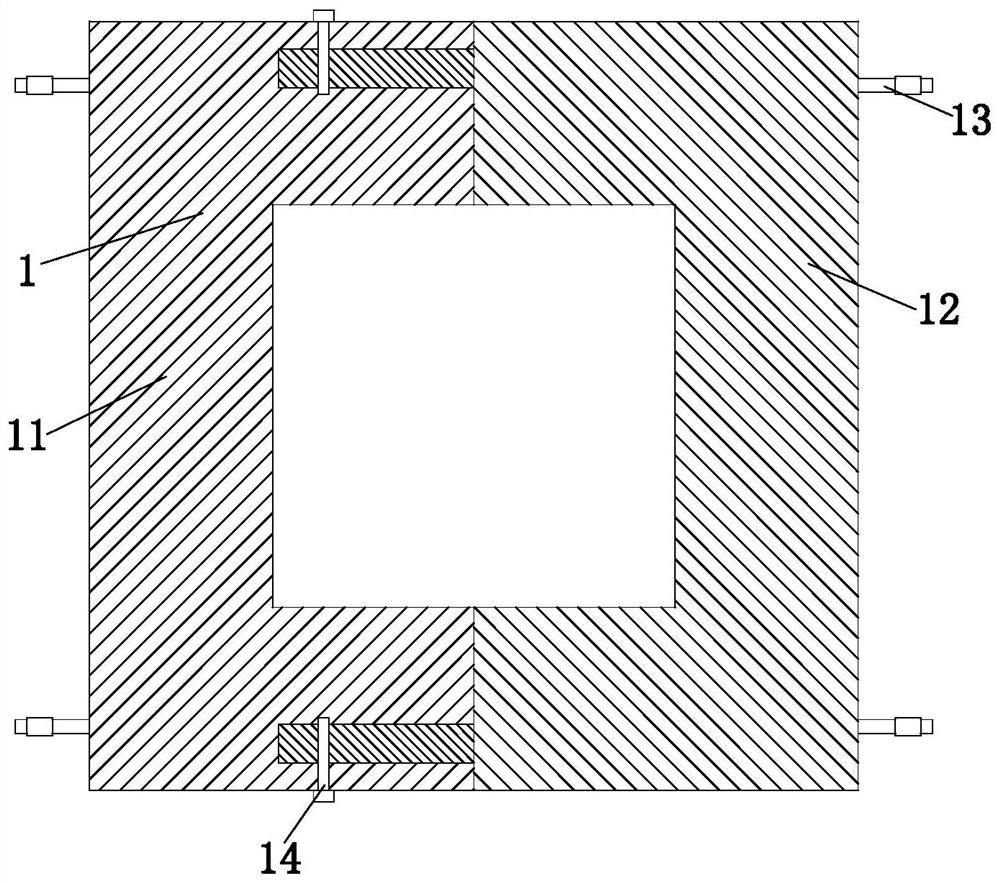

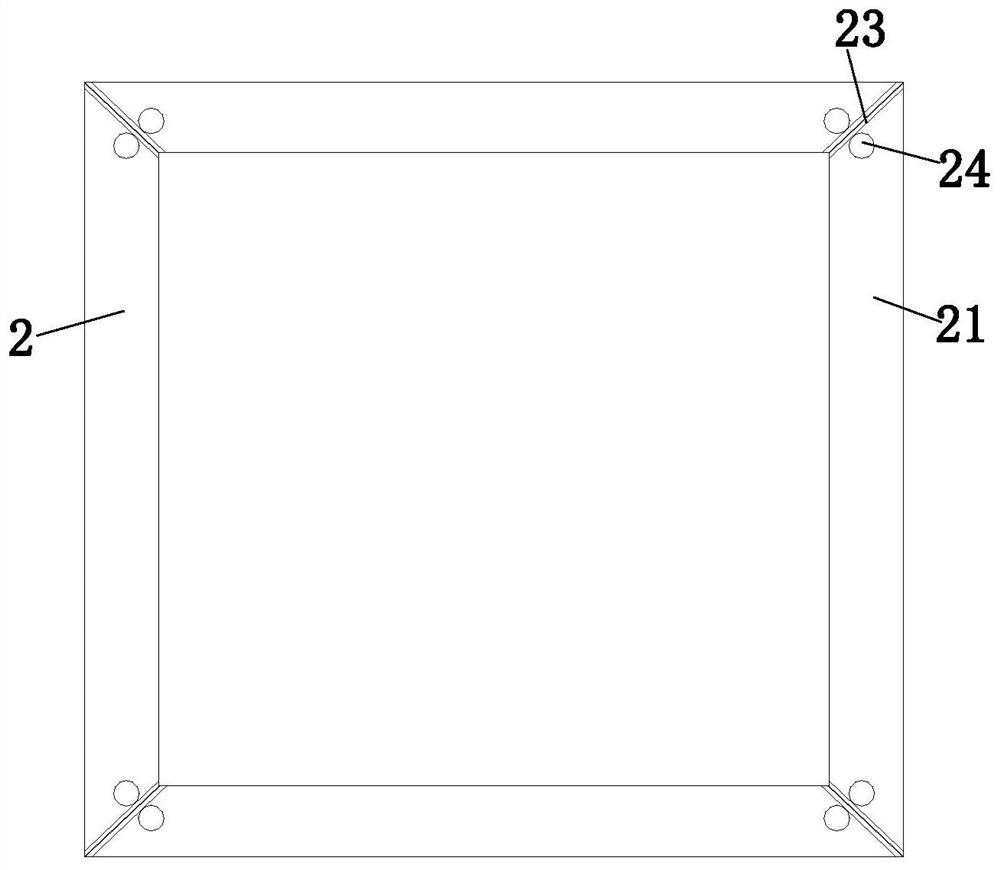

Large-size display screen laminating process

PendingCN113409690AImprove fit qualityImprove fit tightnessIdentification meansMechanical engineeringHot press

The invention discloses a large-size display screen laminating process which comprises the following steps: laminating an optical adhesive film between a first panel and a second panel, combining to form a to-be-cured body, carrying out vacuum hot pressing on the to-be-cured body, removing pressure, continuously heating the to-be-cured body, and curing the to-be-cured body. According to the large-size display screen laminating process provided by the embodiment of the invention, in the process of continuously heating the to-be-cured body, the first panel and the second panel release the stress and freely recover the stress, meanwhile, the optical adhesive film is gradually converted into a molten state, the optical cement freely flows between the first panel and the second panel and gradually fills the gap between the first panel and the second panel, so that the space between the two panels is filled with the optical cement, the attaching flatness of the first panel and the second panel is improved, and the attaching quality of the large-size display screen is improved.

Owner:深圳全息界科技有限公司

Building steel formwork structure

ActiveCN112942804AReduce the difficulty of transportationImprove fit tightnessForming/stuttering elementsForm treatmentCamStructural engineering

The invention relates to a building steel formwork structure. The building steel formwork structure comprises a bottom plate, a formwork main body and a demolding device, wherein the demolding device comprises a mounting frame, a connecting plate, a lifting frame, a vibration cam, a transmission mechanism, a vibration plate and a vibration rod, and the formwork main body comprises a plurality of side plates, sealing pieces, rubber gaskets and connecting rods which are arranged from top to bottom. According to the building steel formwork structure, both the formwork main body and the bottom plate are of a detachable structure, the formwork main body can be separately conveyed in a transferring process, compared with an overall conveying mode, the transportation difficulty is obviously reduced, after concrete is formed, the side wall of the formwork main body is evenly knocked through the demolding device, and the knocking force tends to be large from small, so that the formwork main body or concrete is prevented from being damaged by sudden increase of the knocking force, and additionally, the condition that the separation speed of the formwork main body and the concrete cannot be increased due to small knocking force is avoided.

Owner:浙江隆曦建筑工程有限公司

Switches for easy network connection

InactiveCN110247861BImprove stabilitySmooth transmissionData switching networksSelection arrangementsControl theoryMechanical engineering

Owner:陈建新

Cable trench convenient for cleaning and treating rain sewage

ActiveCN112267539ALife expectancyAvoid accumulationCable installations on groundSewerage structuresPower stationTelecommunications cable

The invention discloses a cable trench convenient for cleaning and treating rain sewage, and belongs to the field of power equipment. The cable trench comprises a plurality of water collection modules, wherein the adjacent water collection modules are movably connected, the water collection modules on two adjacent sides communicate with each other, a partition plate is fixedly connected to one side of the top of an inner cavity of each water collection module, a water pump is fixedly connected to the bottom of each water collection module, and a drainage pipeline communicates with a water outlet in the top of the water pump. According to the cable trench convenient for cleaning and treating rain sewage, whether a drainage device is started or not can be controlled according to the water level in the cable trench and monitoring data within a set range around the cable trench, so that automatic drainage of accumulated water in the cable trench is realized, the service life of a cable inthe cable trench is not influenced by excessive accumulated water, and the cable trench can be applied to places where power or telecommunication cable facilities are laid and replaced under power plants, power substations and sidewalk.

Owner:JIANGSU HUASHIYUAN ELECTRIC POWER TECH CO LTD

Electric material beating device

PendingCN110421852ACoherent and smooth transmissionRealize high-frequency beatingAdditive manufacturing apparatus3D object support structuresDrive wheelEngineering

Owner:上海酷鹰机器人科技有限公司

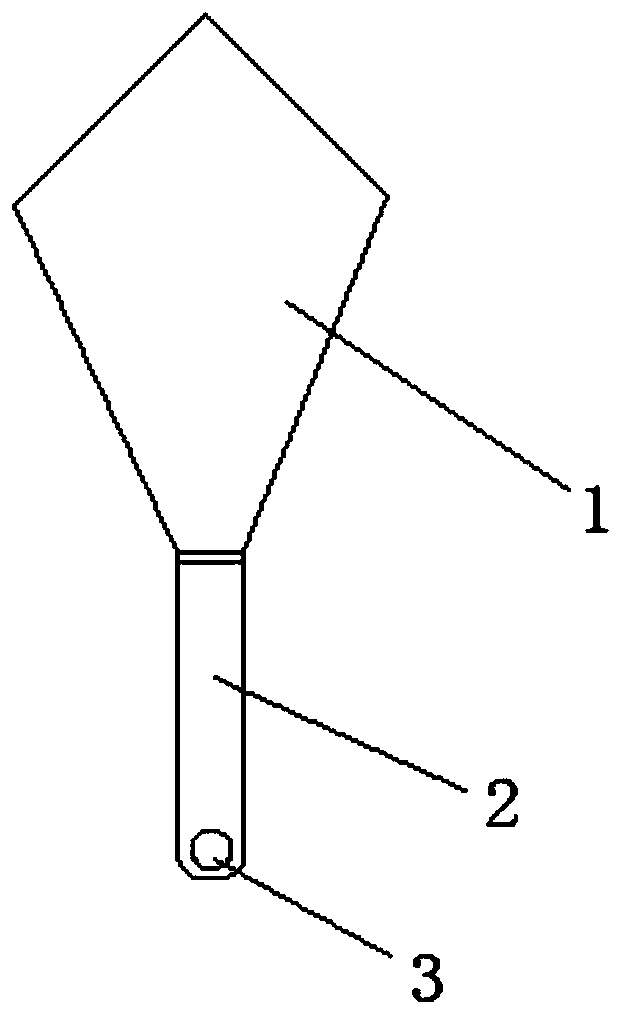

Dragon fruit grafting method and special cutter thereof

The invention discloses a dragon fruit grafting method which comprises the following steps: I, selecting varieties of a rootstock and a scion; II, performing rootstock treatment, namely cutting a section of a plant twig as the rootstock, cutting off mesophyll tissue at the root part of the rootstock, exposing wooden white vascular bundles which are base parts of the rootstock, and cutting a stair-shaped grafting hole of which the cut surface is flat on the ridge of a rootstock stem; III, performing double-bud scion treatment, namely cutting a scion with double buds, wherein the cut part of thescion takes the shape of a Chinese word Ao and has a size corresponding to that of the grafting hole; IV, performing grafting treatment, namely aligning the cut part of the scion to the grafting holeof the rootstock, pressing the scion till the cut part is completely fitted to the grafting hole, and performing bundling and fixing, so as to obtain a grafting seedling; and V, performing grafting seedling culture, namely inserting the base part of the rootstock of the grafting seedling into soil, and performing culture, wherein it means grafting succeeds after the rootstock has roots and scionbuds germinate. The grafting method disclosed by the invention is high in survival rate, rapid in grafting speed and small in workload, the grafting time can be shortened, and the yield and the growthspeed of a scion dragon fruit variety can be effectively increased.

Owner:GUANGXI JINSUI ECOLOGICAL TECH CO LTD

Press key without need of hot melting

InactiveCN101430978AReduce processImprove fit tightnessElectric switchesEngineeringMechanical engineering

The invention provides a key without the requirement of hot melt, consisting of a key and a rear cover; the structure of the rear cover is matched with the key; five plastic rubber clamp columns are arranged below a key hole at the internal side of the rear cover; the key is provided with five special semiround structures which can be closely matched with the five clamp columns; the close matching strength needs no hot melt, thus reducing the working procedure during the assembly process and increasing the matching compactness; the key of the invention can be disassembled and maintained.

Owner:SUZHOU SUPPORT IND

Novel loose flange

InactiveCN112377689AImprove sealingIncrease frictionFluid pressure sealed jointsPipe elementsFlangeFriction force

The invention relates to the technical field related to flange connection, and discloses a novel loose flange. The novel loose flange comprises a lower flange and an upper flange, wherein flanging flange plates are movably inserted into the hollow inner sides of the lower flange and the upper flange in a penetrating mode; the lower flange and the upper flange are connected with each other througha tightening mechanism; the plate surfaces of the two flanging flange plates are in contact with each other and are attached to each other; three corresponding annular embedding grooves are formed inthe attached surfaces of the two flanging flange plates; annular sealing rings are embedded into the two flanging flange plates through the annular embedding grooves; and hollow flow dividing plates are installed at the centers of the inner sides of the two flanging flange plates. According to the novel loose flange, the sealing performance of the flanging flange plates in use is effectively improved, on the premise that the structural matching sealing performance is not influenced, the friction force of the upper flange and the lower flange during movable rotation is effectively increased, the stability of matching installation between the structures is guaranteed, noise generated by flow dividing in the flanging flanges is effectively absorbed and reduced, and the noise of the flange connecting end is reduced.

Owner:江阴犇源精密零部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com