Patents

Literature

181results about How to "Improve fit quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

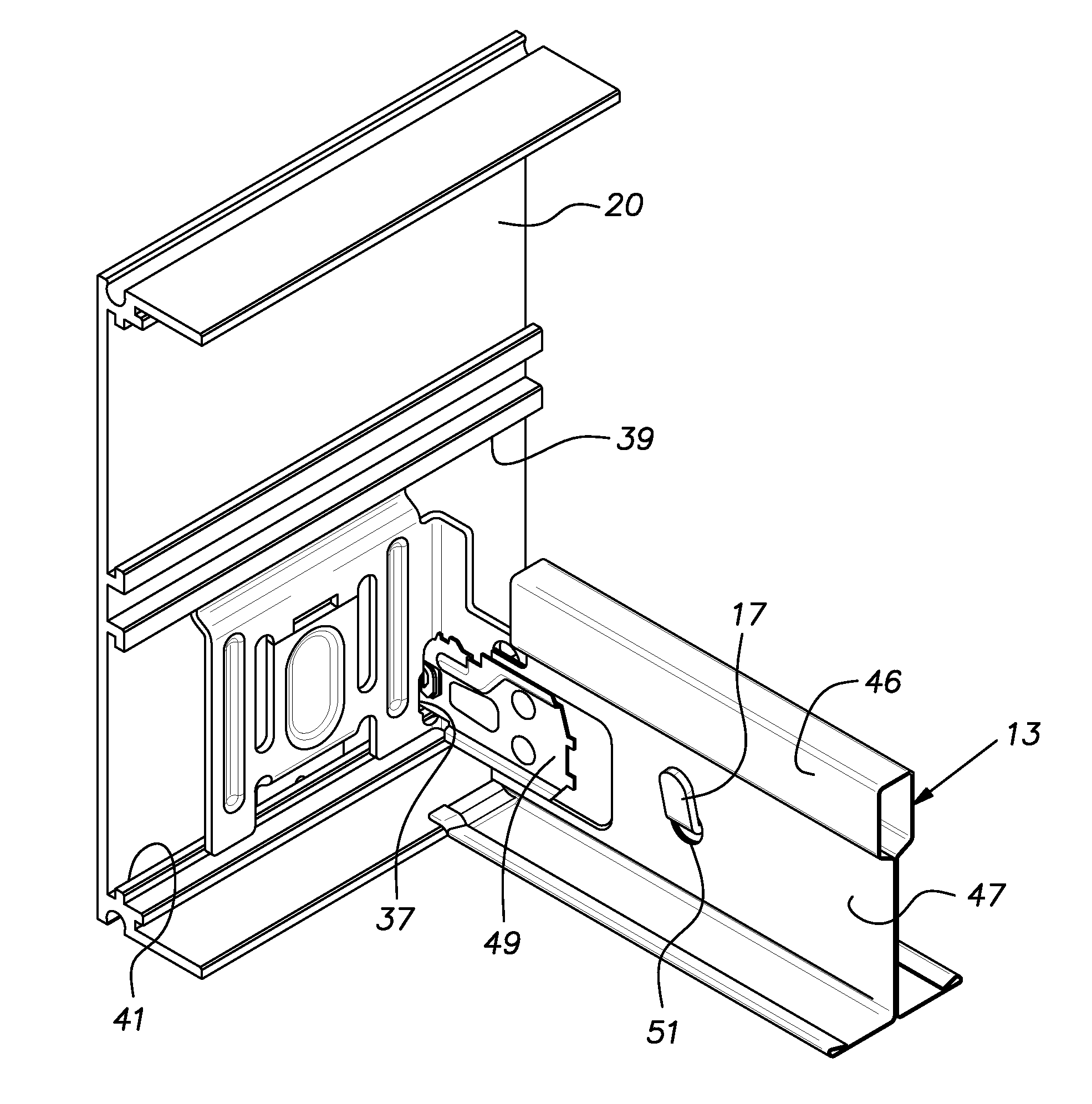

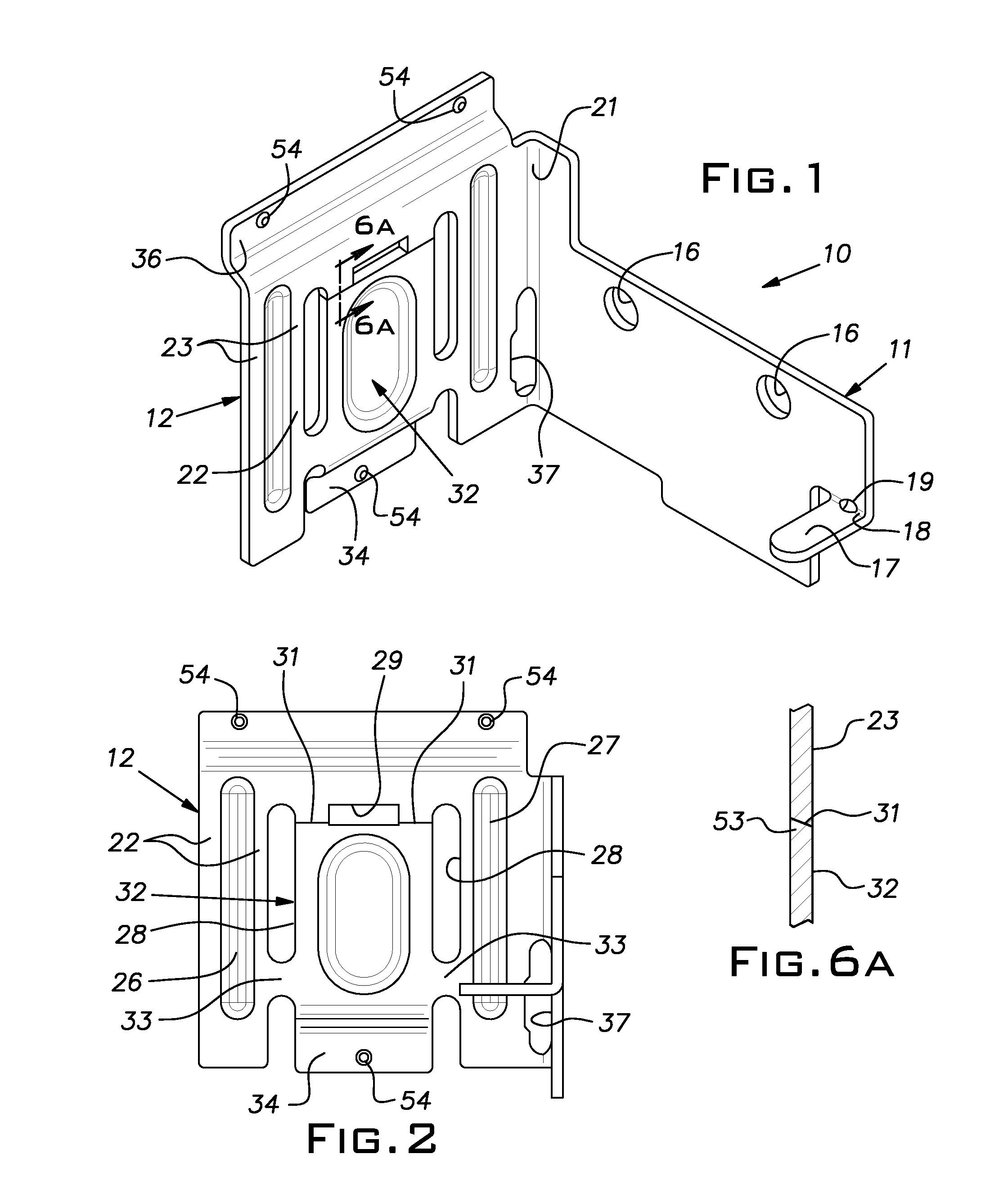

Grid runner to perimeter trim clip

InactiveUS20140000205A1Easy and fast assemblyMinimal dexterityCeilingsBuilding reinforcementsEngineeringMechanical engineering

Owner:USG INTERIORS INC

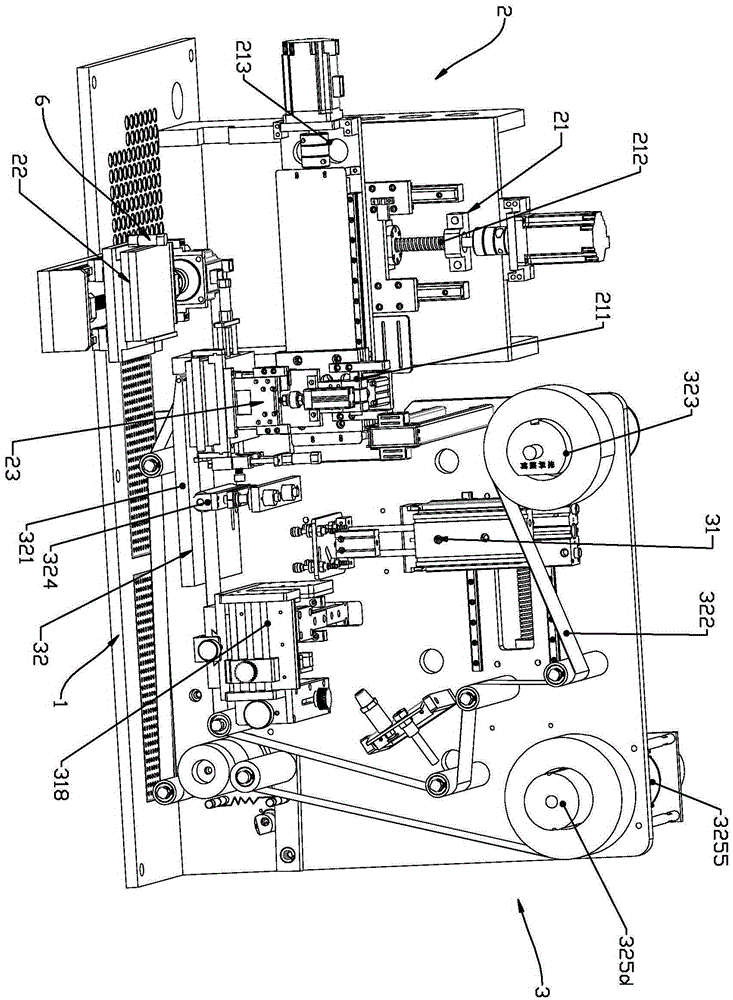

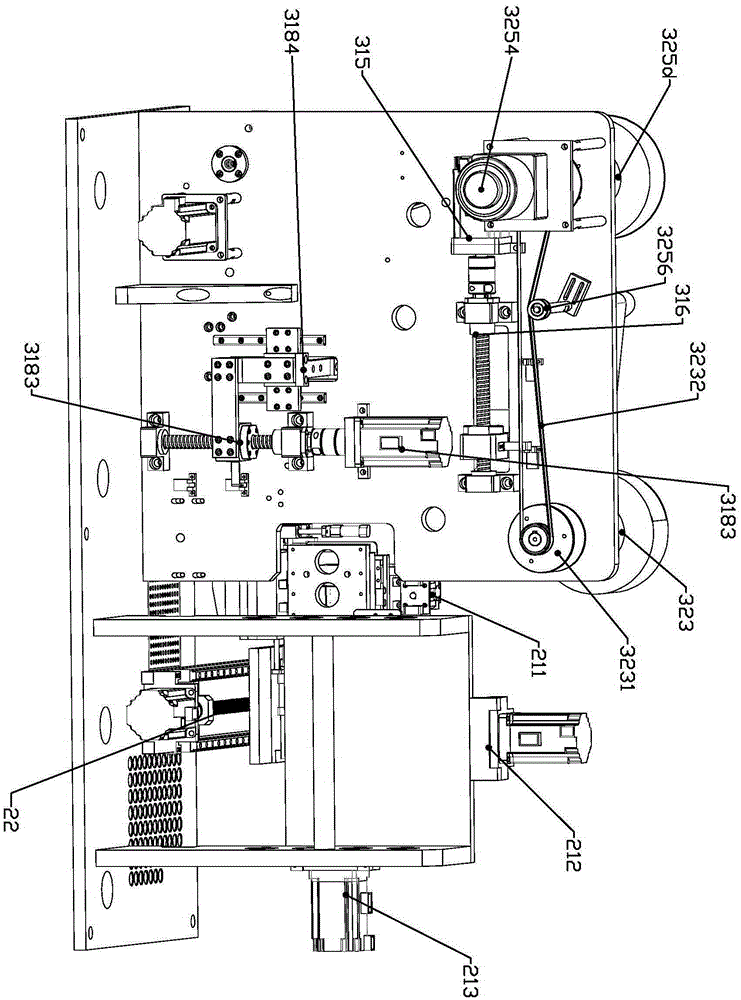

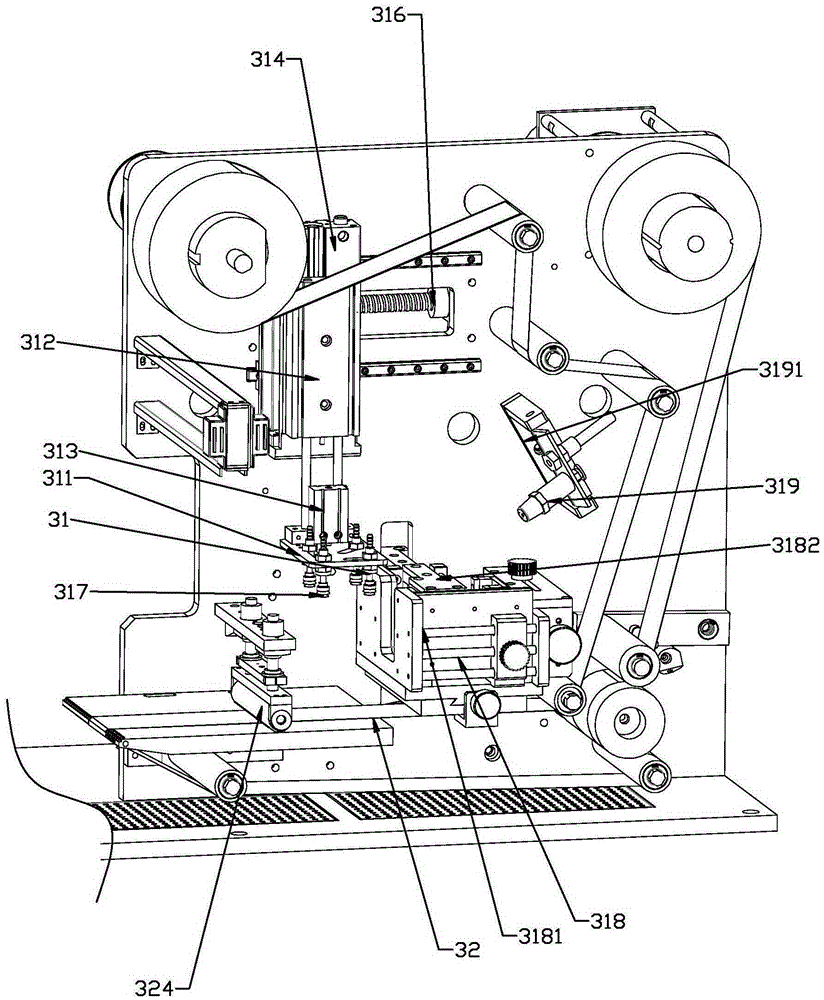

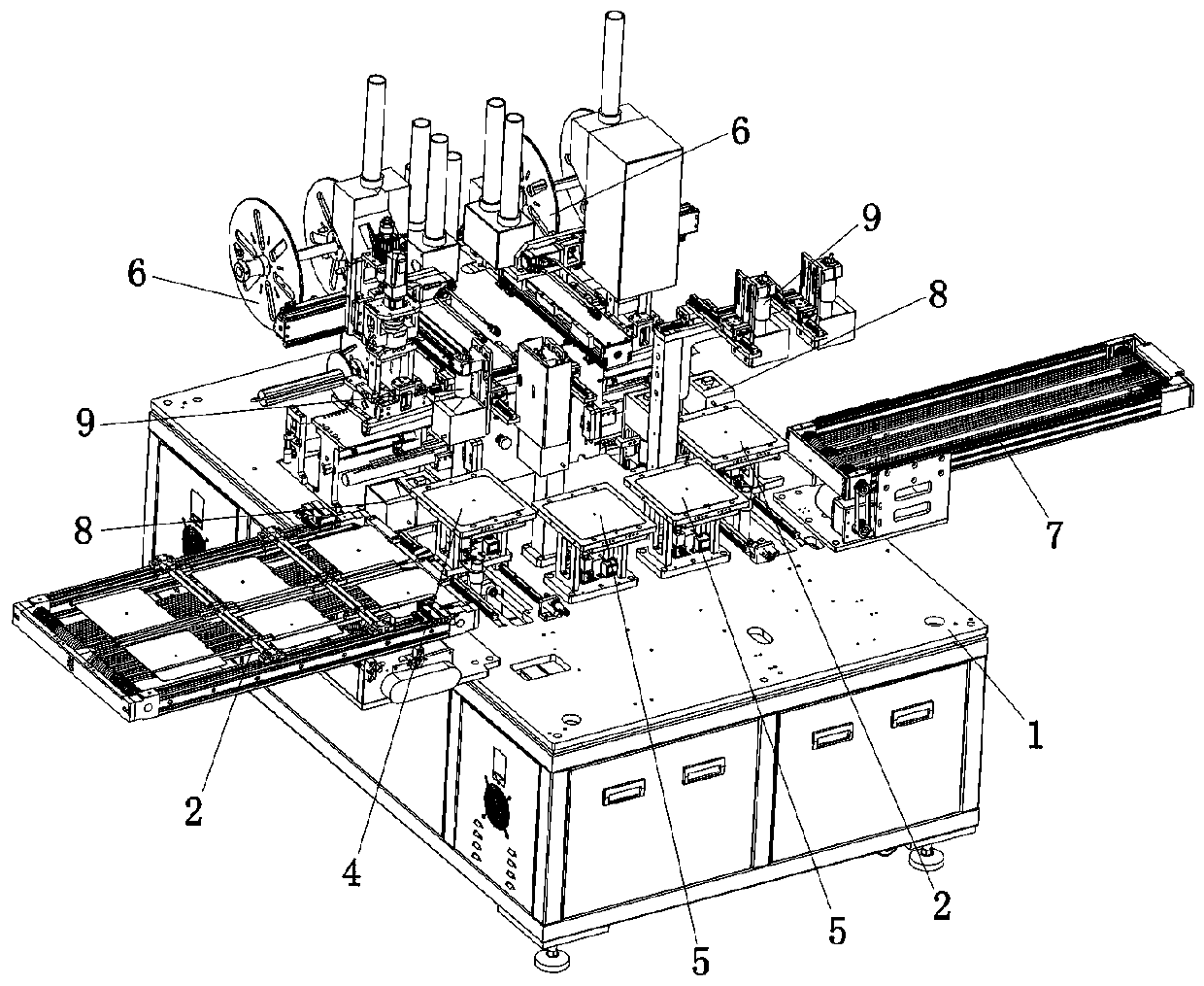

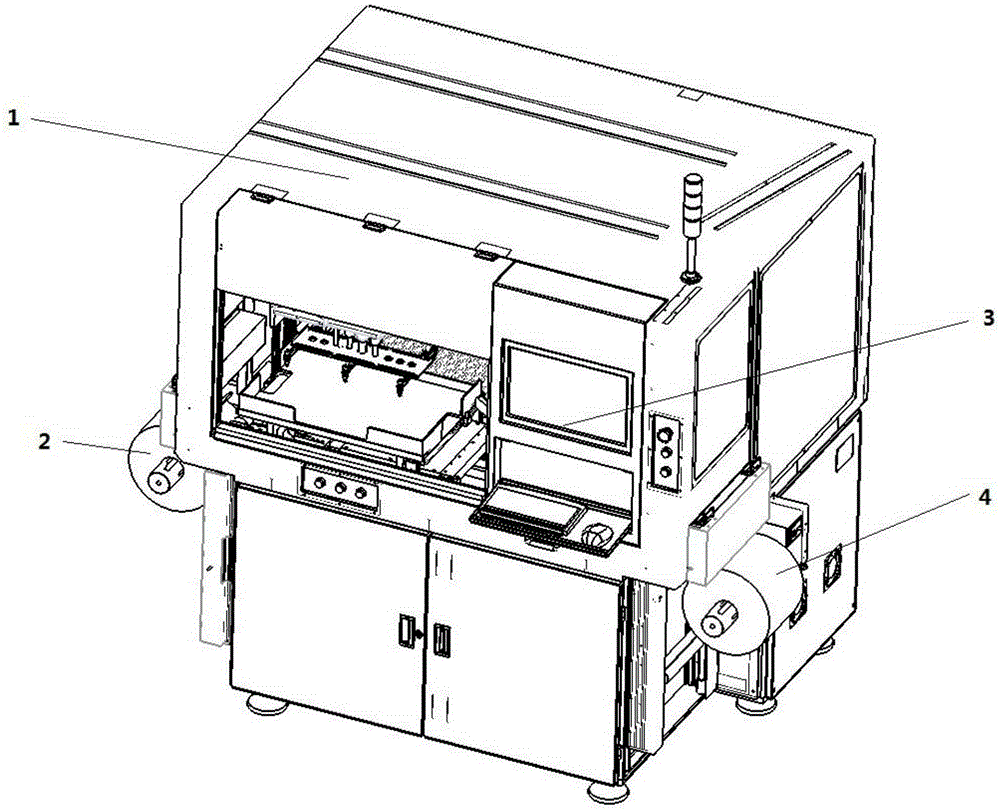

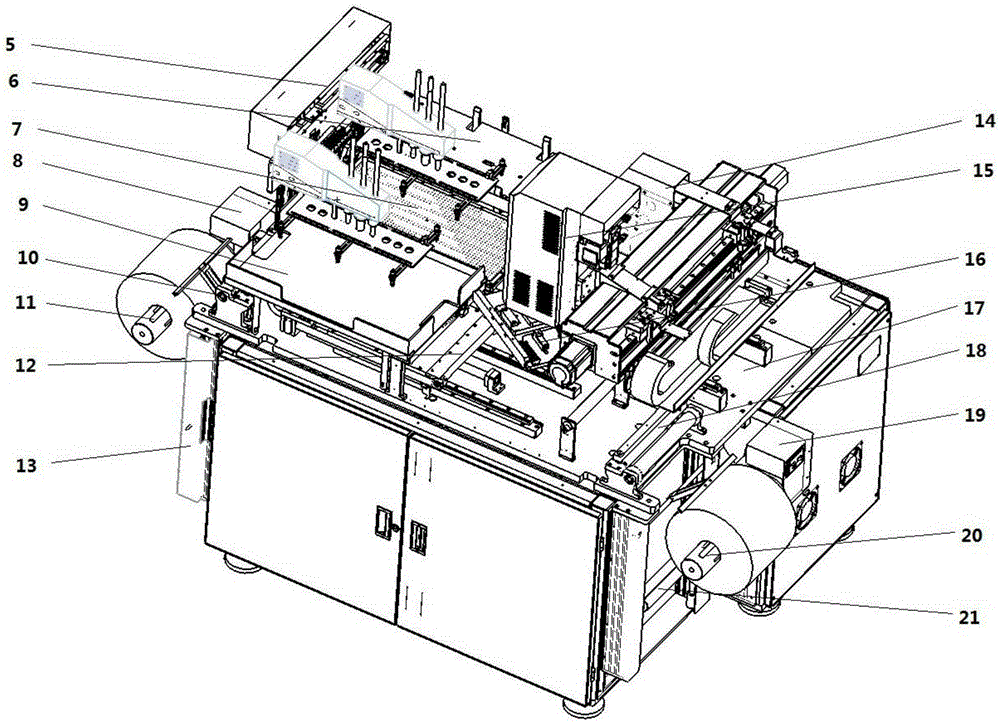

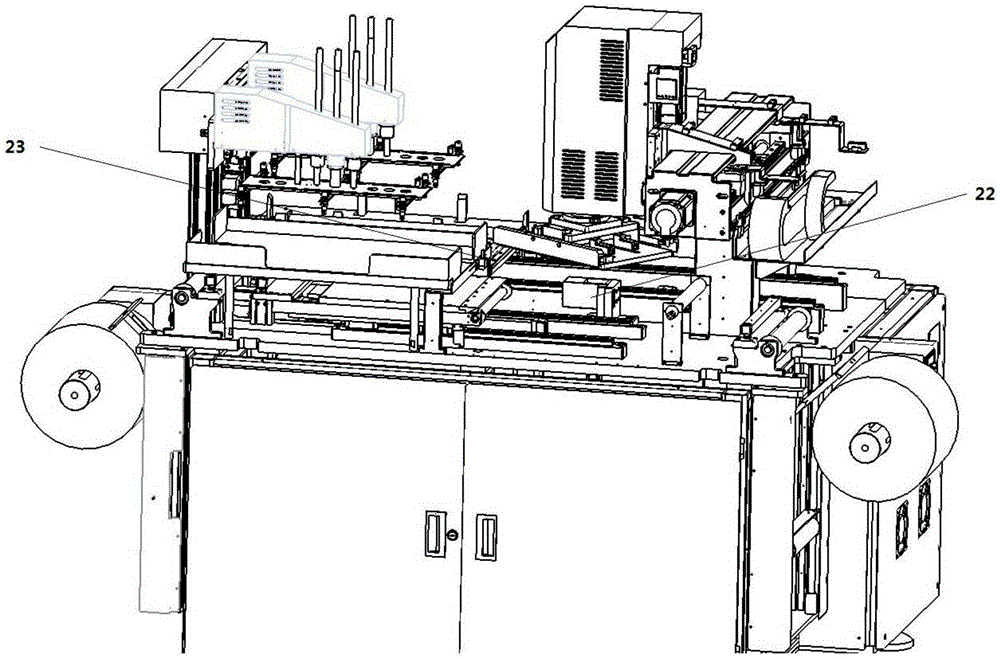

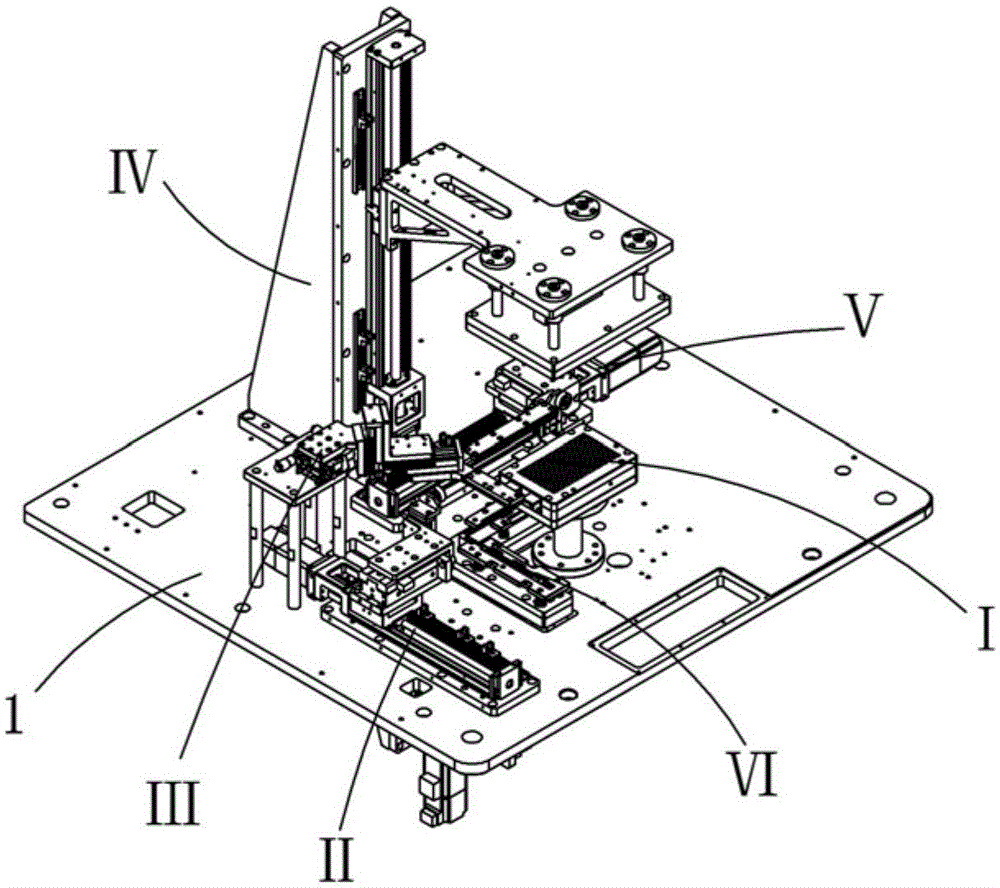

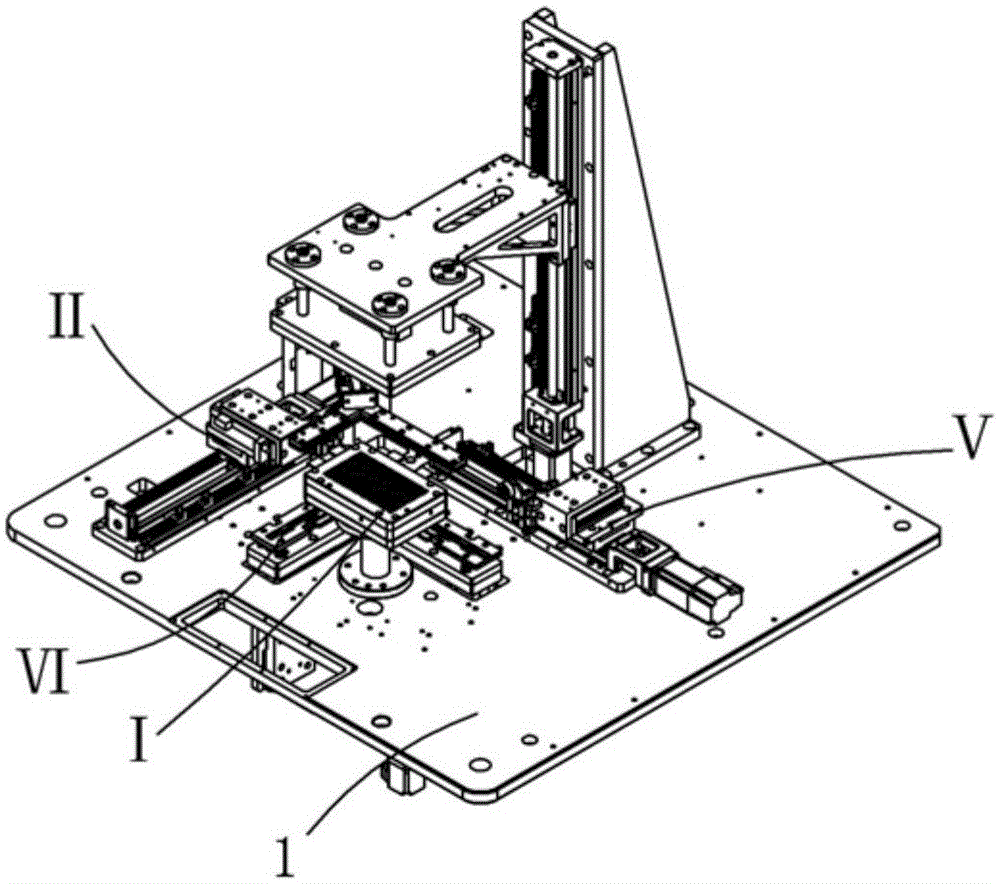

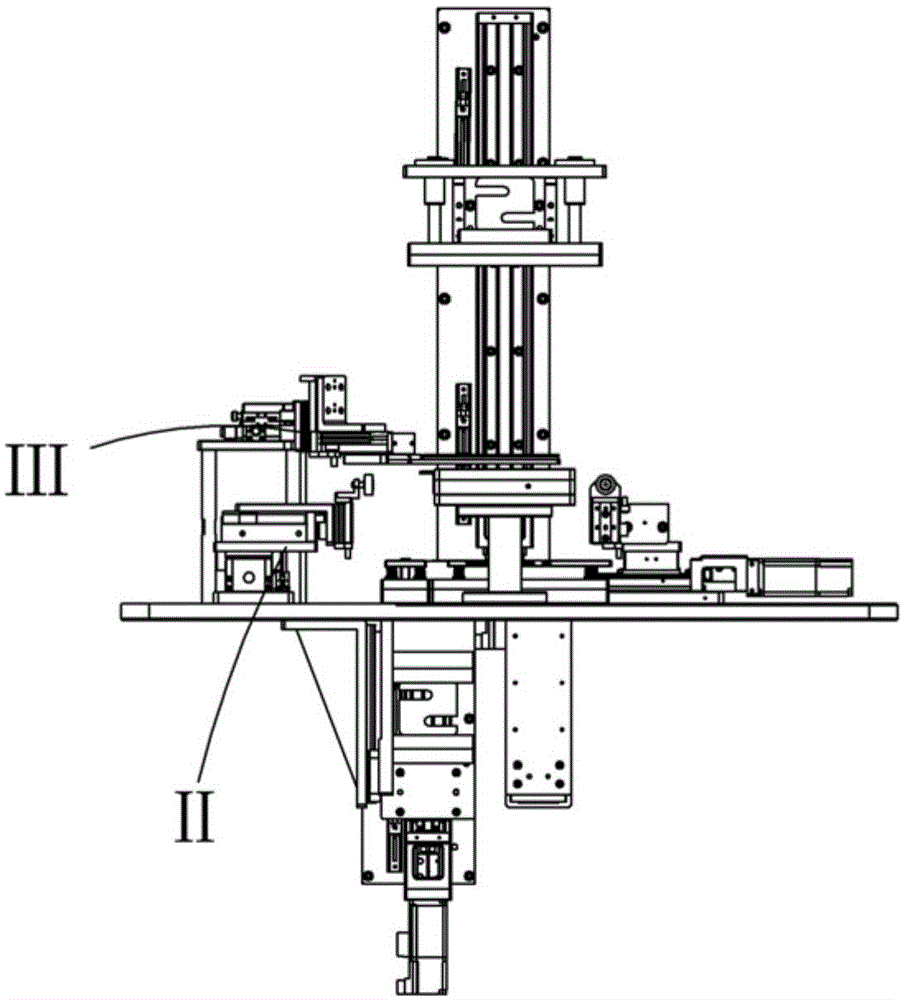

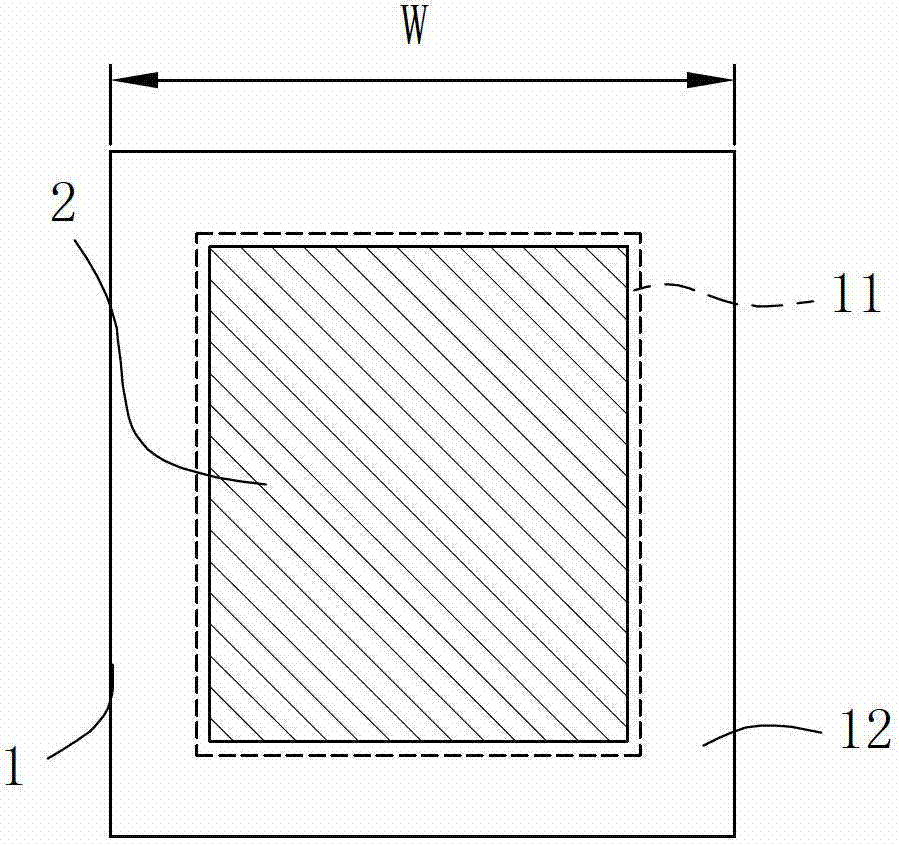

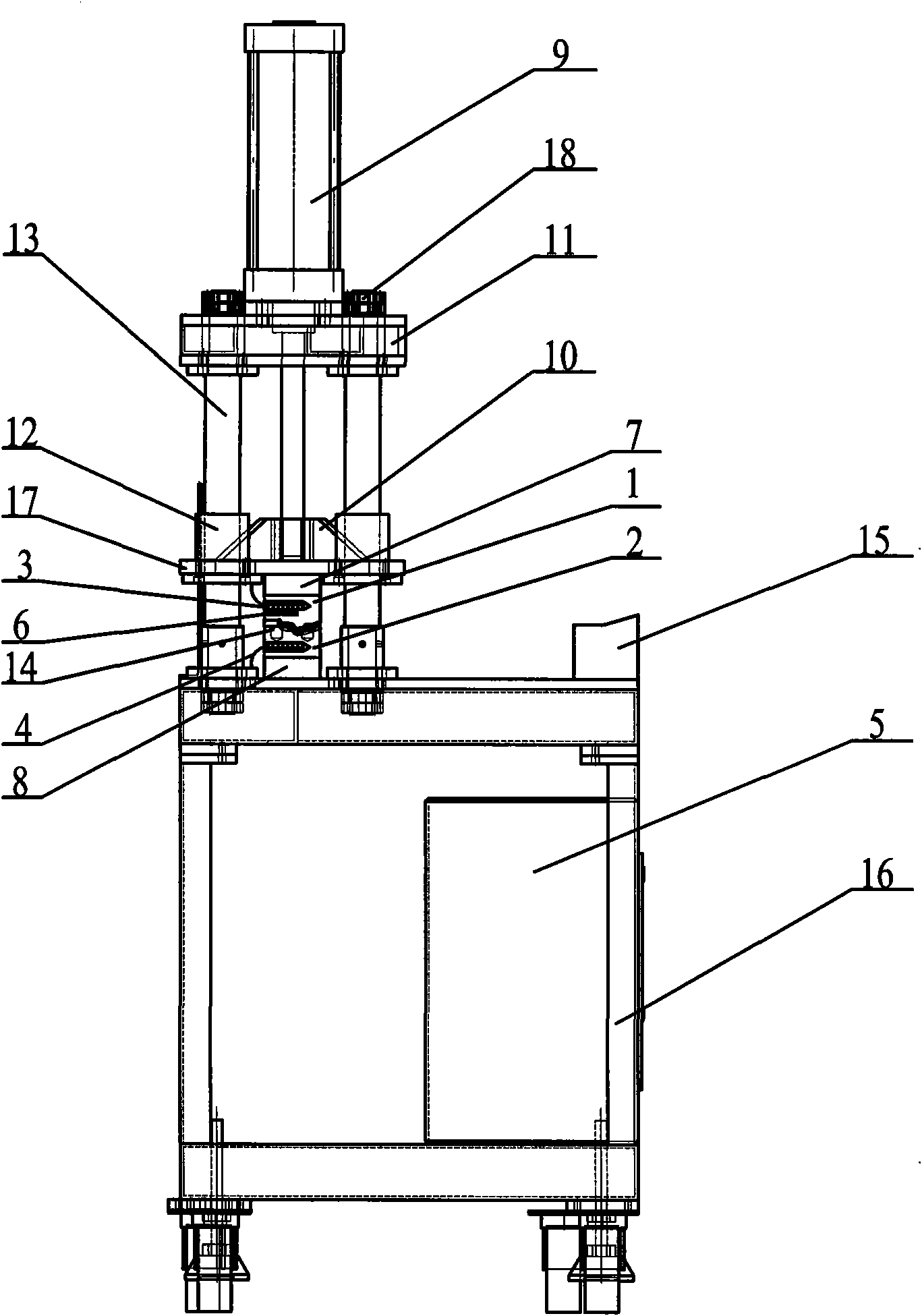

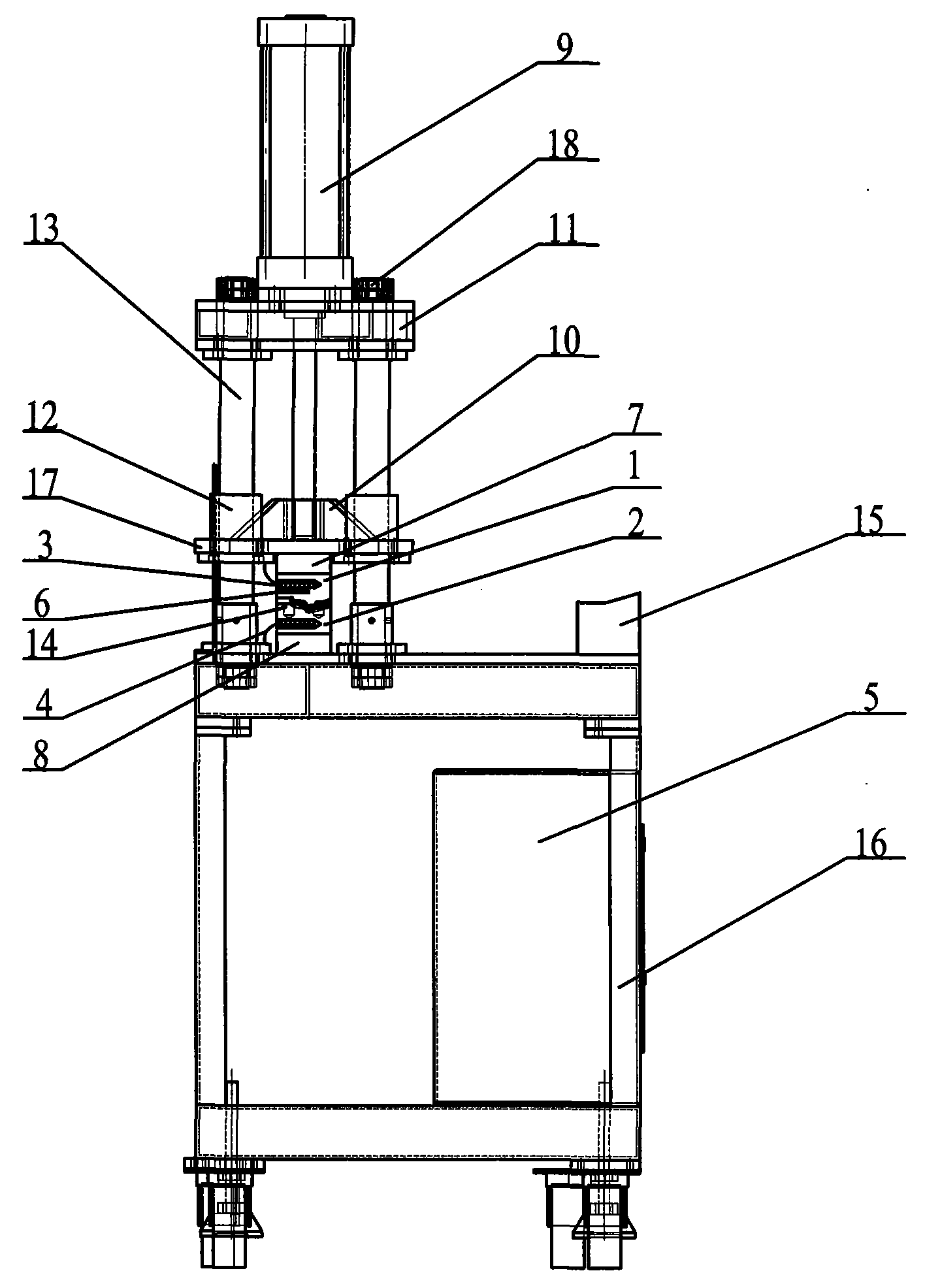

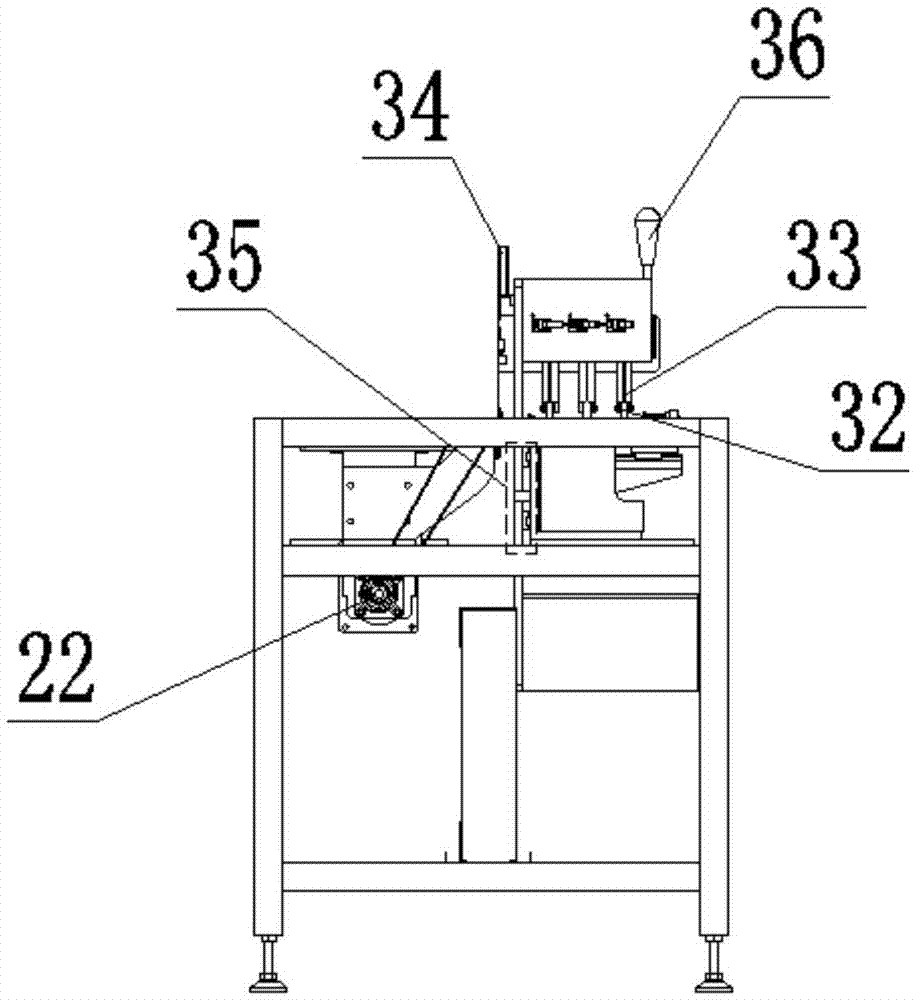

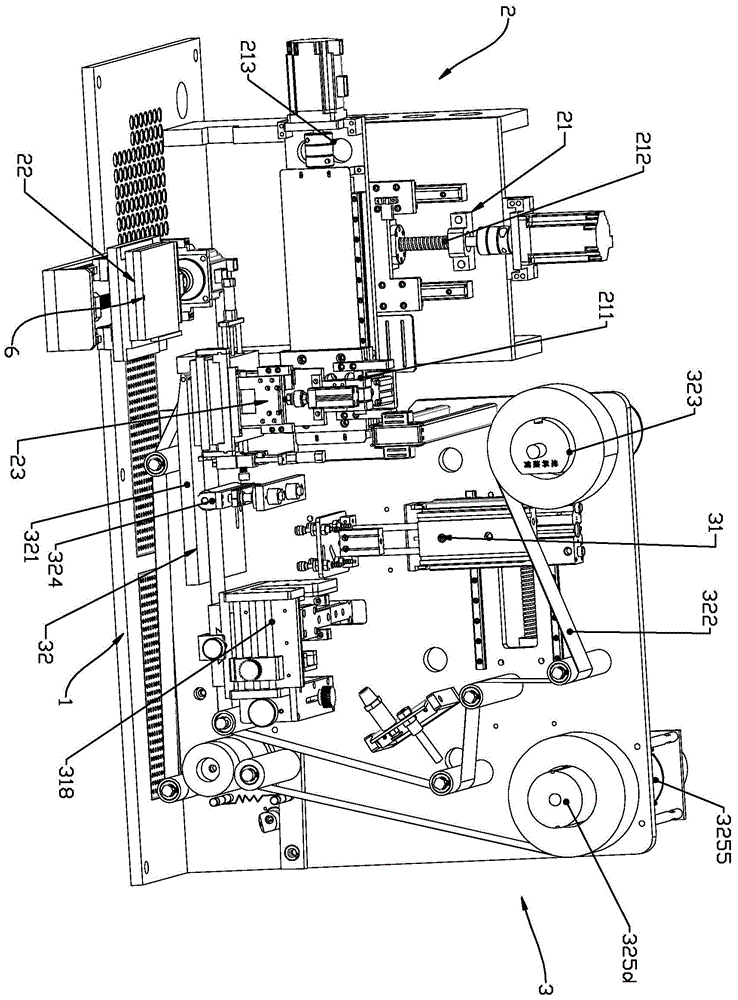

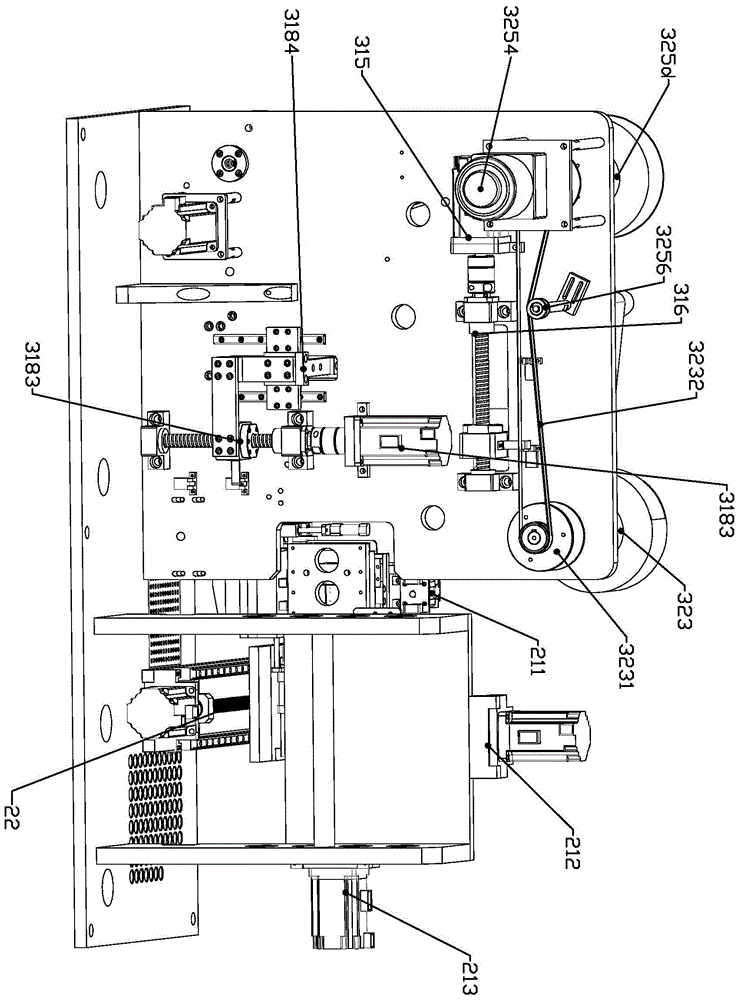

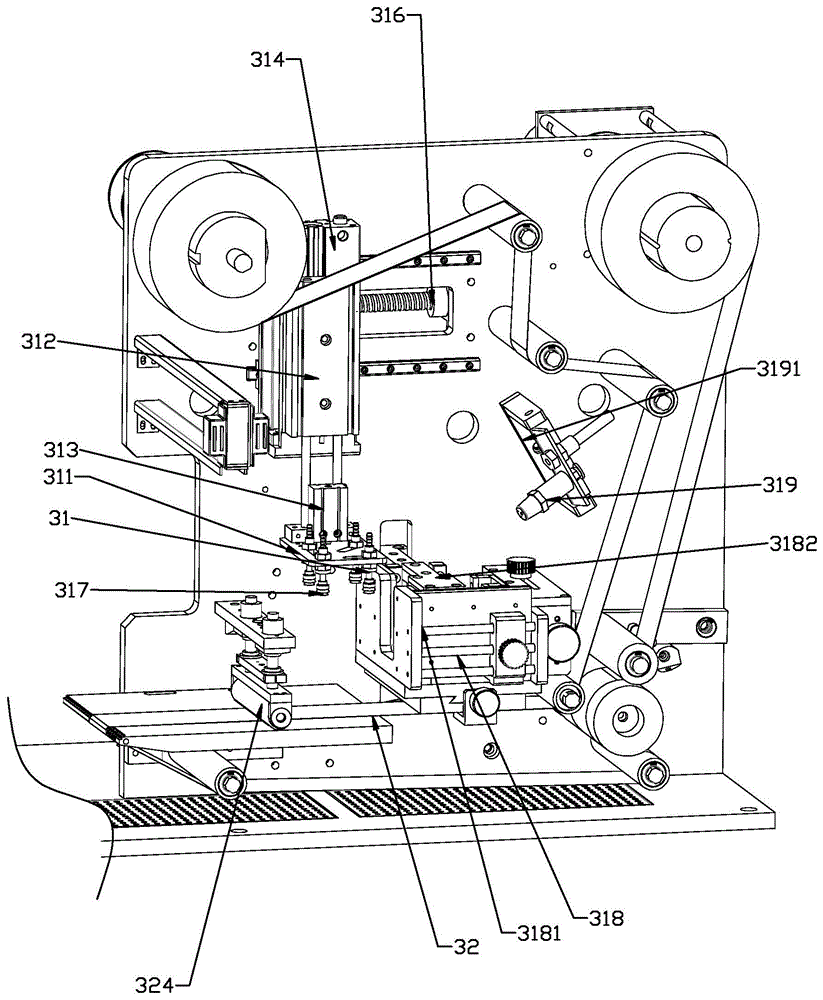

Mobile phone polaroid laminating machine capable of reliably laminating polaroid

InactiveCN105242419AGood for extrusionEasy to operateNon-linear opticsEngineeringMechanical engineering

The invention relates to a mobile phone polaroid laminating machine capable of reliably laminating a polaroid. A polaroid loading mechanism comprises a loading platform longitudinally lifting mechanism, a loading platform station switching mechanism installed on the loading platform longitudinally lifting mechanism and a polaroid loading platform installed on the loading platform station switching mechanism; the polaroid loading platform comprises a laminated polaroid transferring substrate and a laminated polaroid transferring hinged side panel which is installed on the loading platform station switching mechanism, the laminated polaroid transferring substrate is hinged to the bottom end of the laminated polaroid transferring hinged side panel, the side, opposite to the hinged point, of the laminated polaroid transferring substrate can longitudinally rotate around the laminated polaroid transferring hinged side panel, the laminated polaroid transferring substrate is connected with a laminated polaroid transferring cylinder which drives one side edge of the laminated polaroid transferring substrate to rotate, a polaroid aligning mechanism is installed on the laminated polaroid transferring substrate, a vacuum adsorption plate which can absorb and fix the polaroid is installed at the bottom of the laminated polaroid transferring substrate in an attached mode, and a high-speed camera is arranged on the side edge of a vacuum adsorption seat which is fixed through a glass substrate. The mobile phone polaroid laminating machine capable of reliably laminating the polaroid has the advantages of being reasonable in polaroid laminating action and good in polaroid laminating quality.

Owner:WENZHOU ZHIXIN ELECTROMECHANICAL TECH

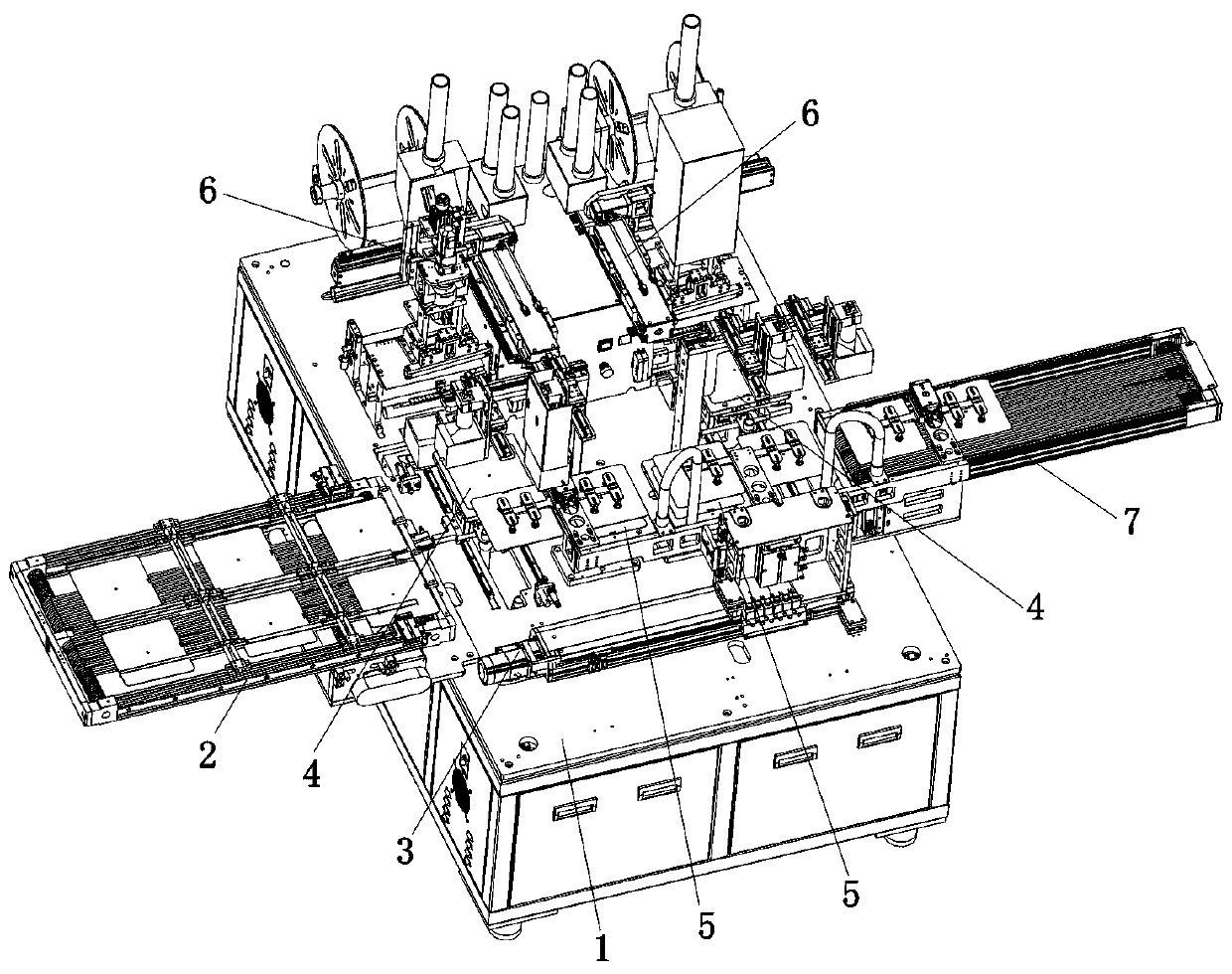

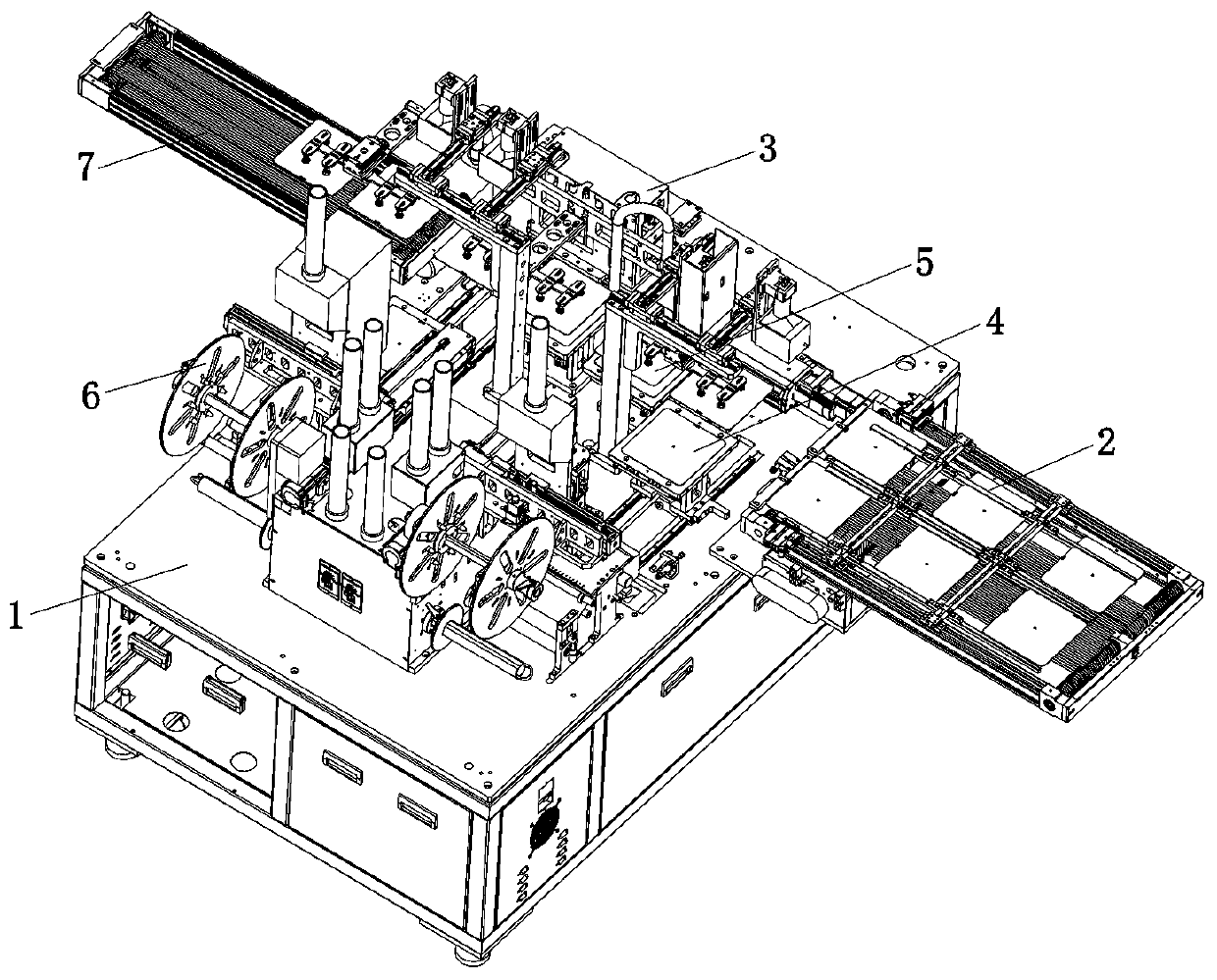

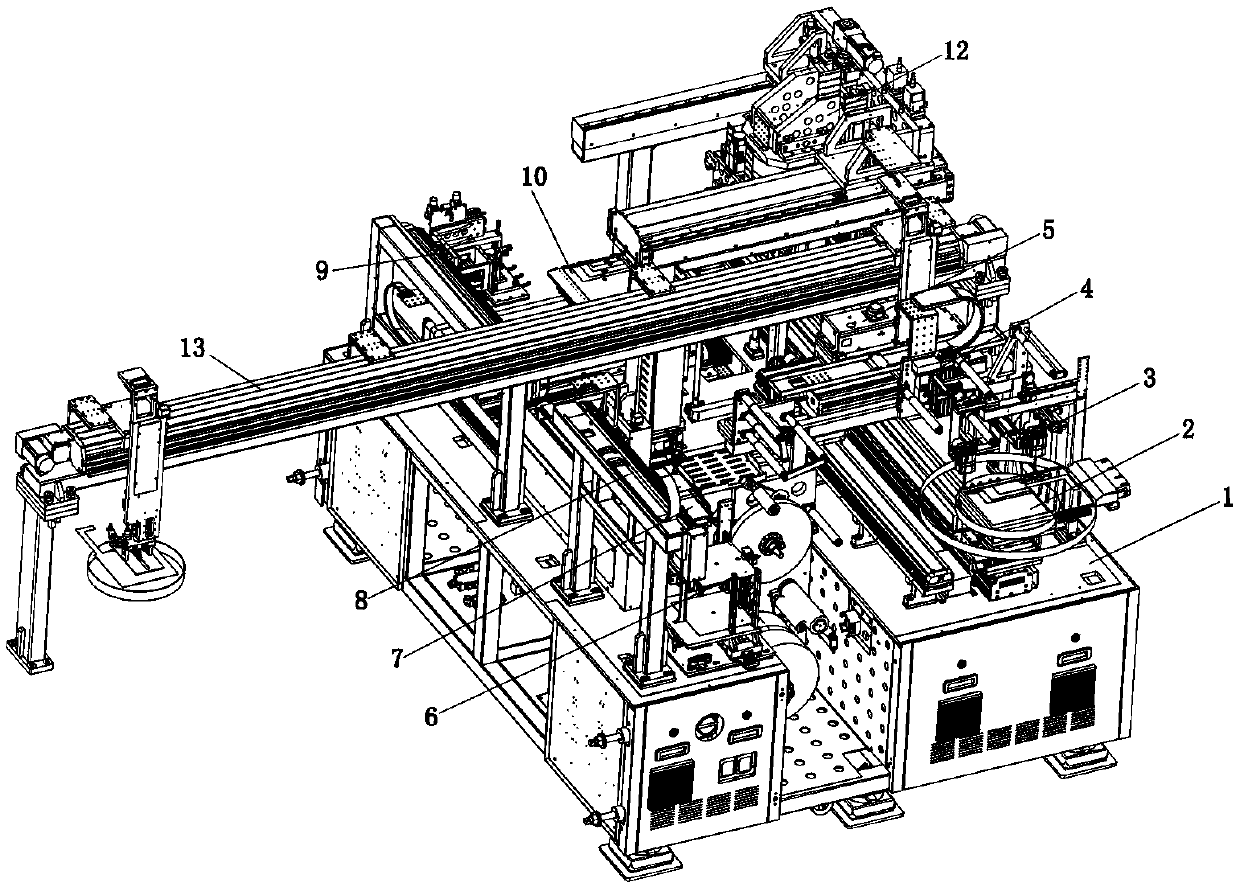

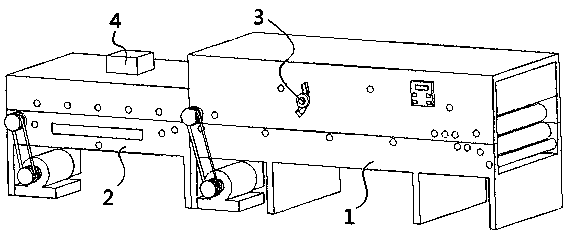

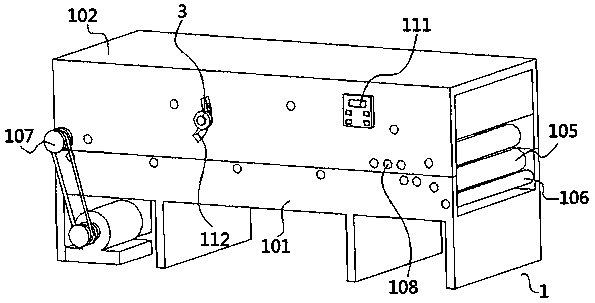

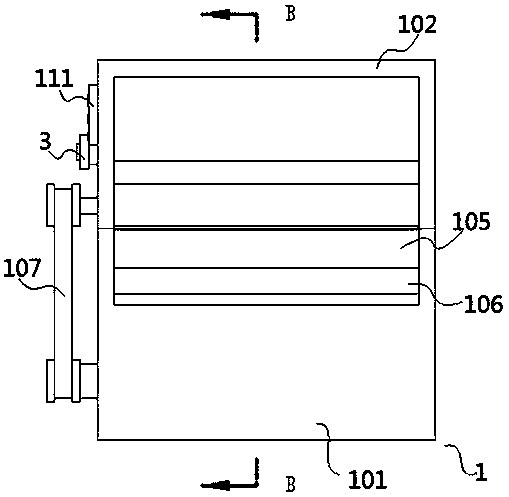

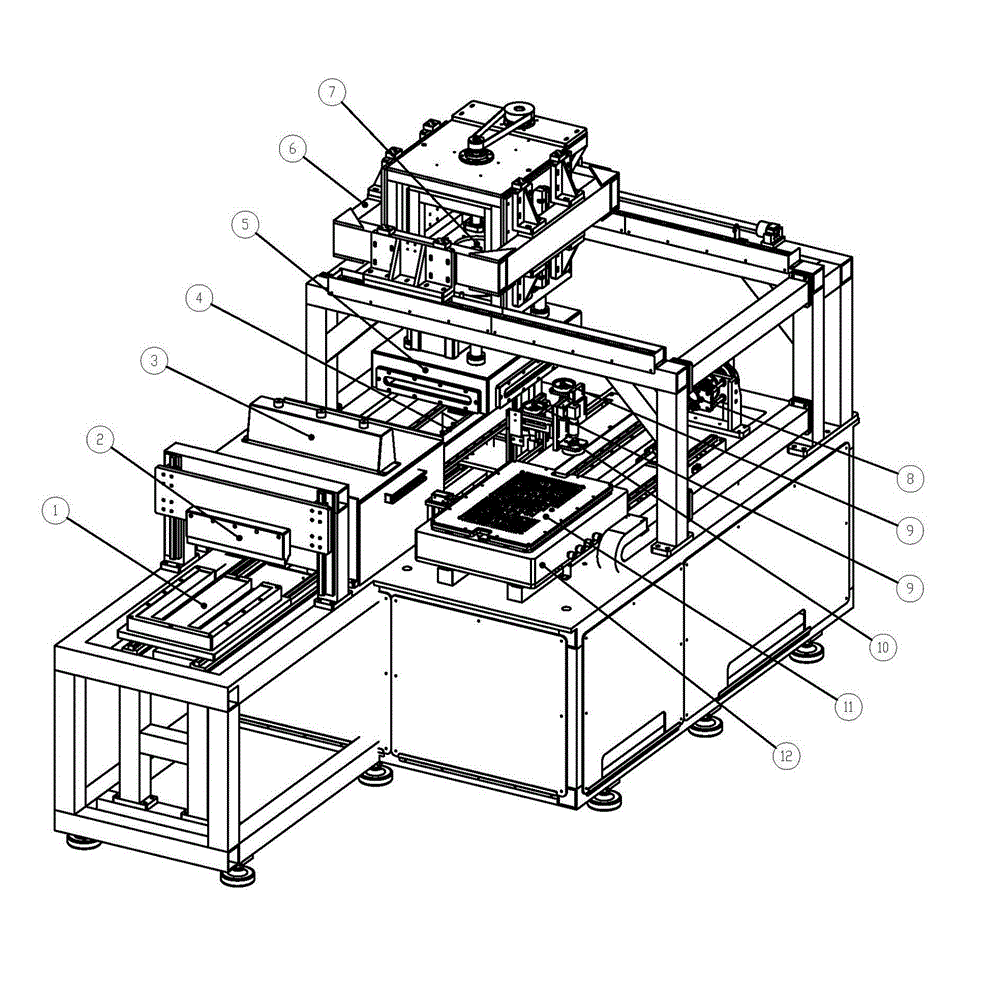

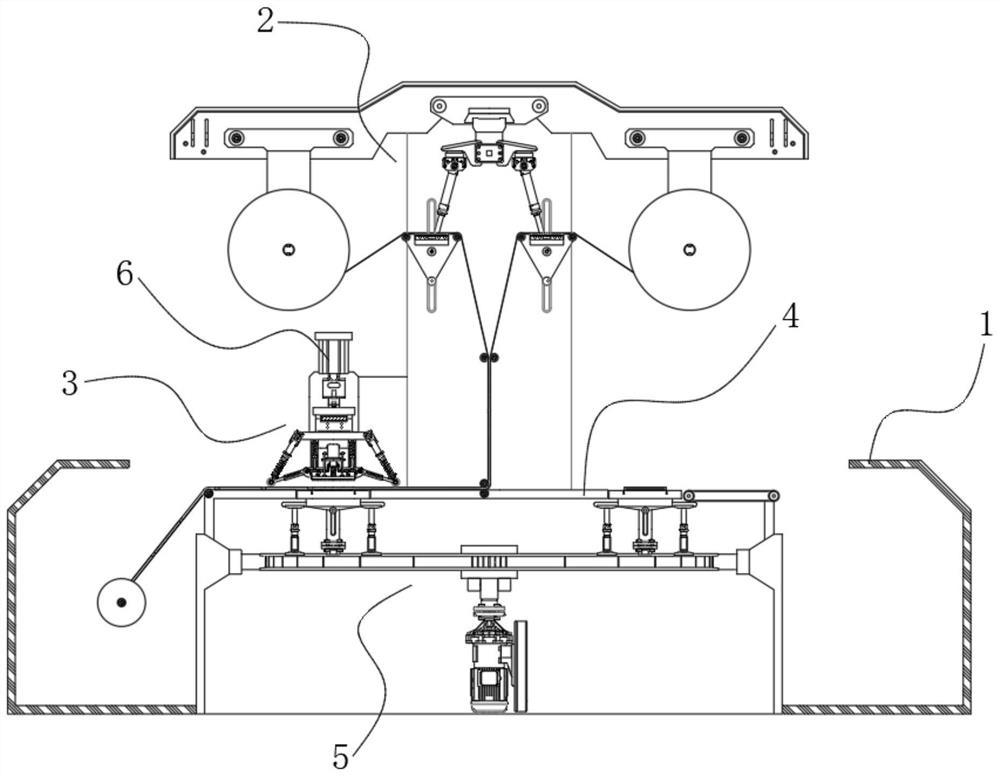

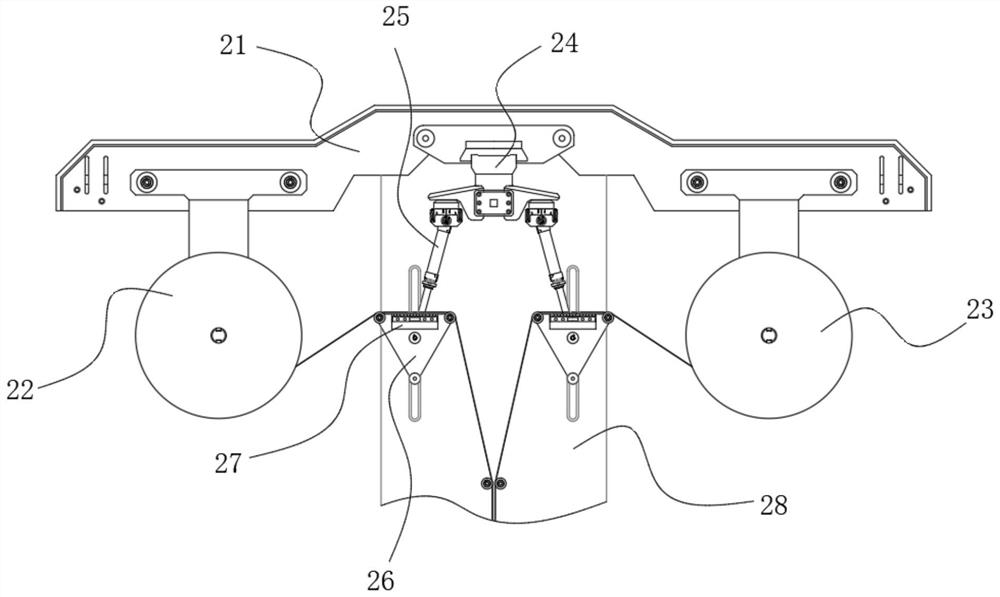

Two-in-one linkage film sticking production line and production process thereof

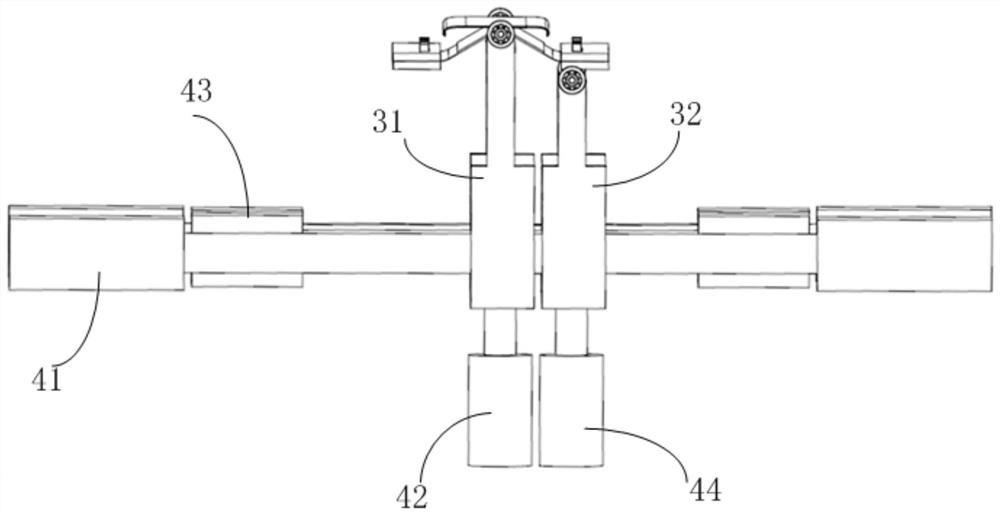

ActiveCN109533455AImprove film application efficiencyReduces fit bubblesPackagingProduction lineAgricultural engineering

The invention discloses a two-in-one linkage film sticking production line and a production process thereof. The two-in-one linkage film sticking production line comprises a feeding belt, a linkage carrying manipulator, a film sticking platform, a transfer platform film taking and sticking mechanism and a discharging belt, wherein the feeding belt and the discharging belt are respectively arrangedat the left end and the right end of a rack; the film sticking platform comprises two platforms; the transfer platform comprises two platforms; the linkage carrying manipulator is arranged at the front sides of the film sticking platform and the transfer platform along the left-right direction, and three sets of suction components are arranged on the linkage carrying manipulator; the film takingand film sticking mechanism comprises two sets, and the two sets of film taking and film sticking mechanisms are respectively arranged at the rear sides of the two film sticking platforms. According to the two-in-one linkage film sticking production line, the single film sheet is peeled off the peeling plate by pulling the discharge belt, the film pressing component is used for tearing off the film sheet from the mounting plate, meanwhile, the torn-off film sheet is roll-pressed on the glass plate to achieve the line contact type film sticking, the sticking air bubbles are effectively reduced,and through carrying the three sets of suction assemblies of the linkage carrying manipulator, the three groups of glass plates can be taken out and discharged, doubling the efficiency of the single-machine film sticking.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

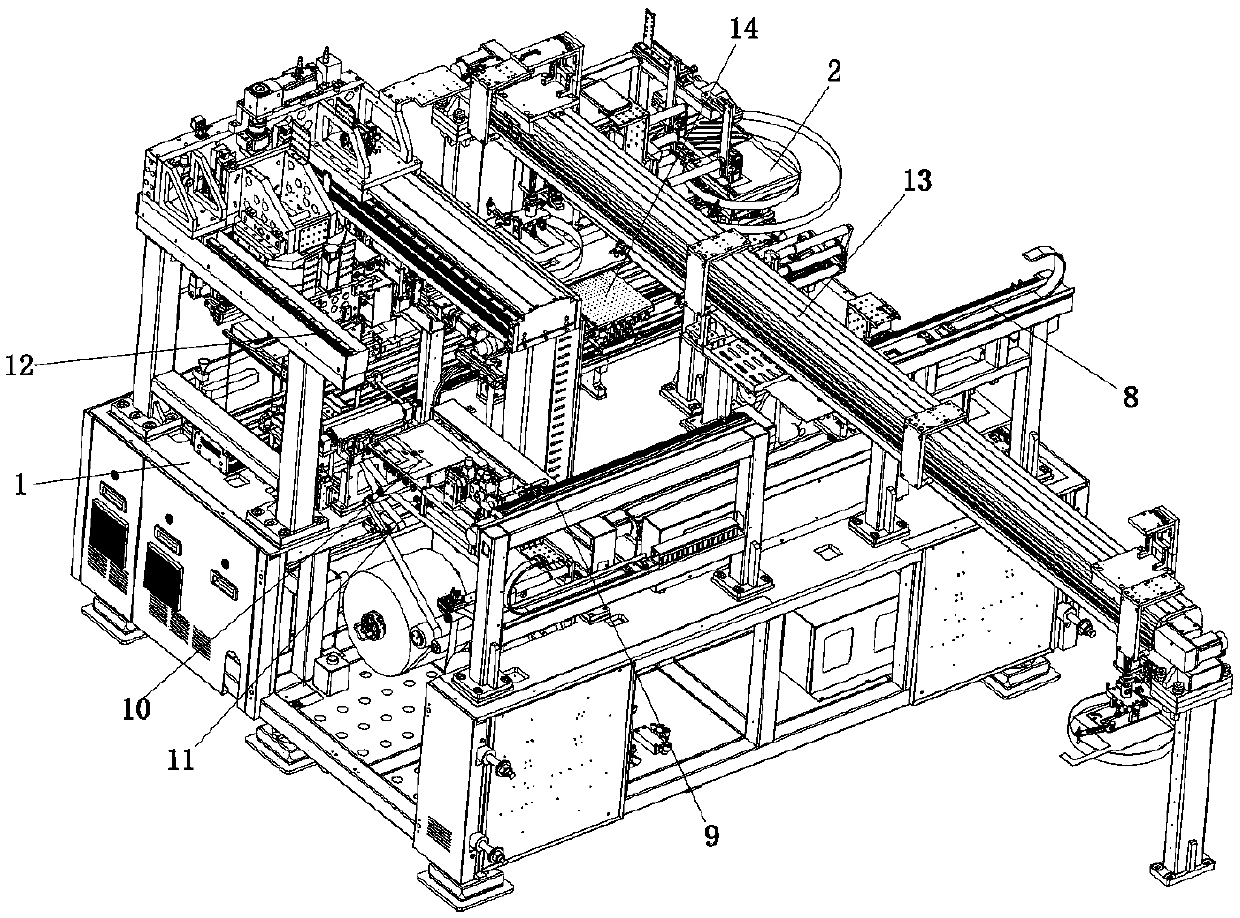

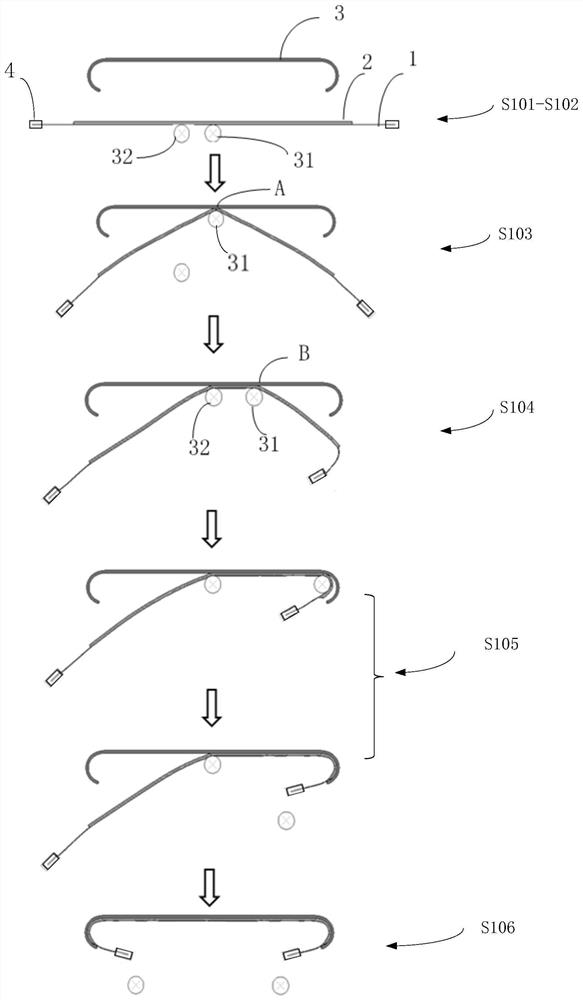

Automatic soft-to-soft flexible attaching machine and attaching process thereof

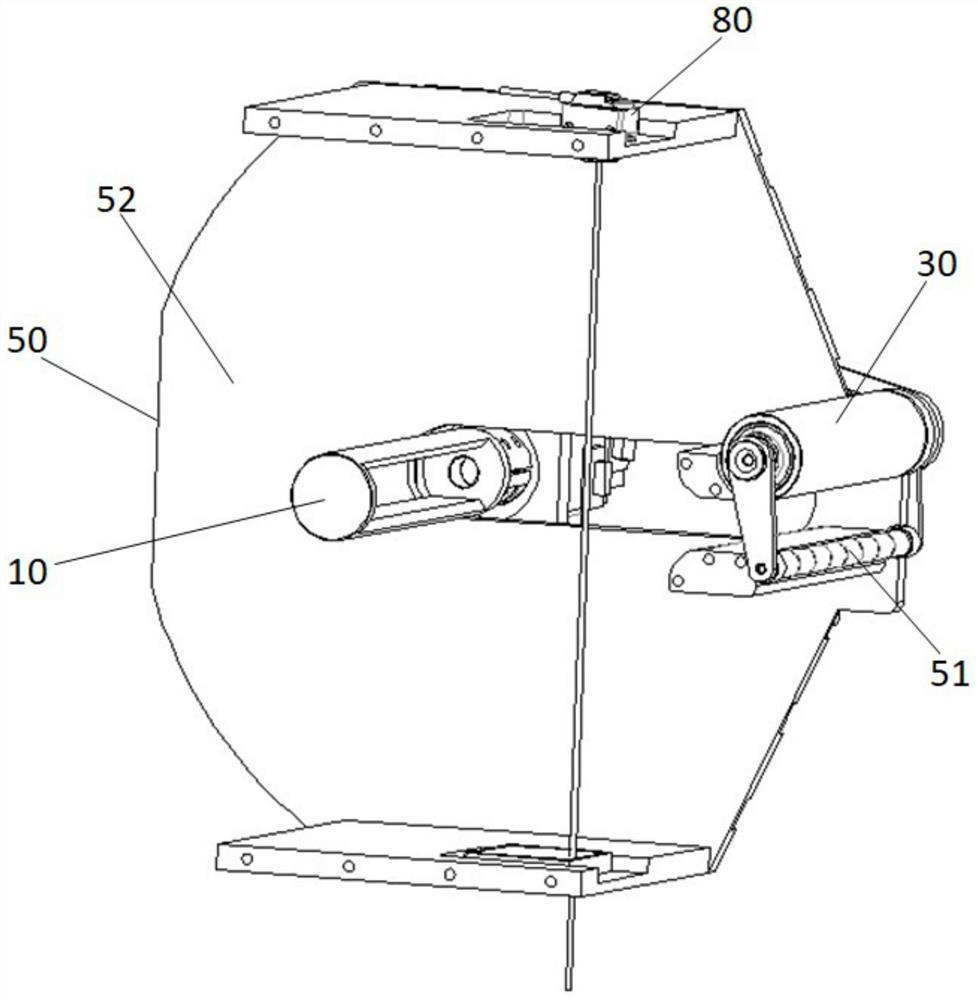

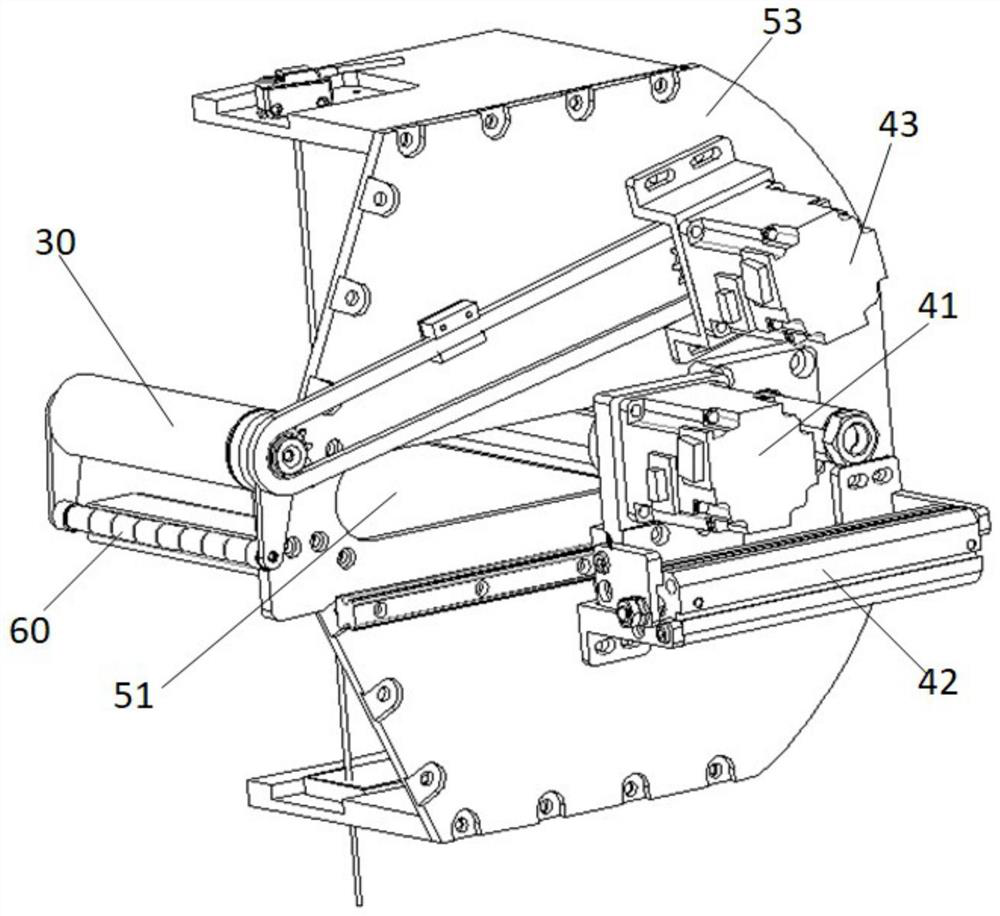

PendingCN109514969AControl tensionReduces fit bubblesLamination ancillary operationsLaminationArm movingEngineering

The invention discloses an automatic soft-to-soft flexible attaching machine and an attaching process thereof. The automatic soft-to-soft flexible attaching machine comprises an OLED adsorption and transfer platform, an OLED film tearing mechanism, a FILM feeding mechanism, a FILM transferring platform, a first carrying arm, a second carrying arm, a FILM tearing mechanism and an attaching mechanism. The OLED adsorption and transfer platform and the FILM transferring platform are horizontally arranged on a machine frame in the same direction at intervals, an OLED film is placed on the OLED adsorption and transfer platform, after initial positioning, the OLED film sequentially moves to the OLED film tearing mechanism and the attaching mechanism and the like to perform the film tearing action; and after a FILM is exported by the FILM feeding mechanism, the FILM is transported by the first carrying arm to the FILM transferring platform, the second carrying arm moves the FILM to the FILM tearing mechanism, the FILM tearing mechanism tears a film body at the bottom of the FILM, and the attaching mechanism attaches the FILM to the OLED film. The automatic soft-to-soft flexible attaching machine and the attaching process thereof solve the problems of bottom and surface film tearing of a flexible film, the adsorption stability during attaching and film tearing, the control over the angle change of the film or the film body during attaching and film tearing and the like.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

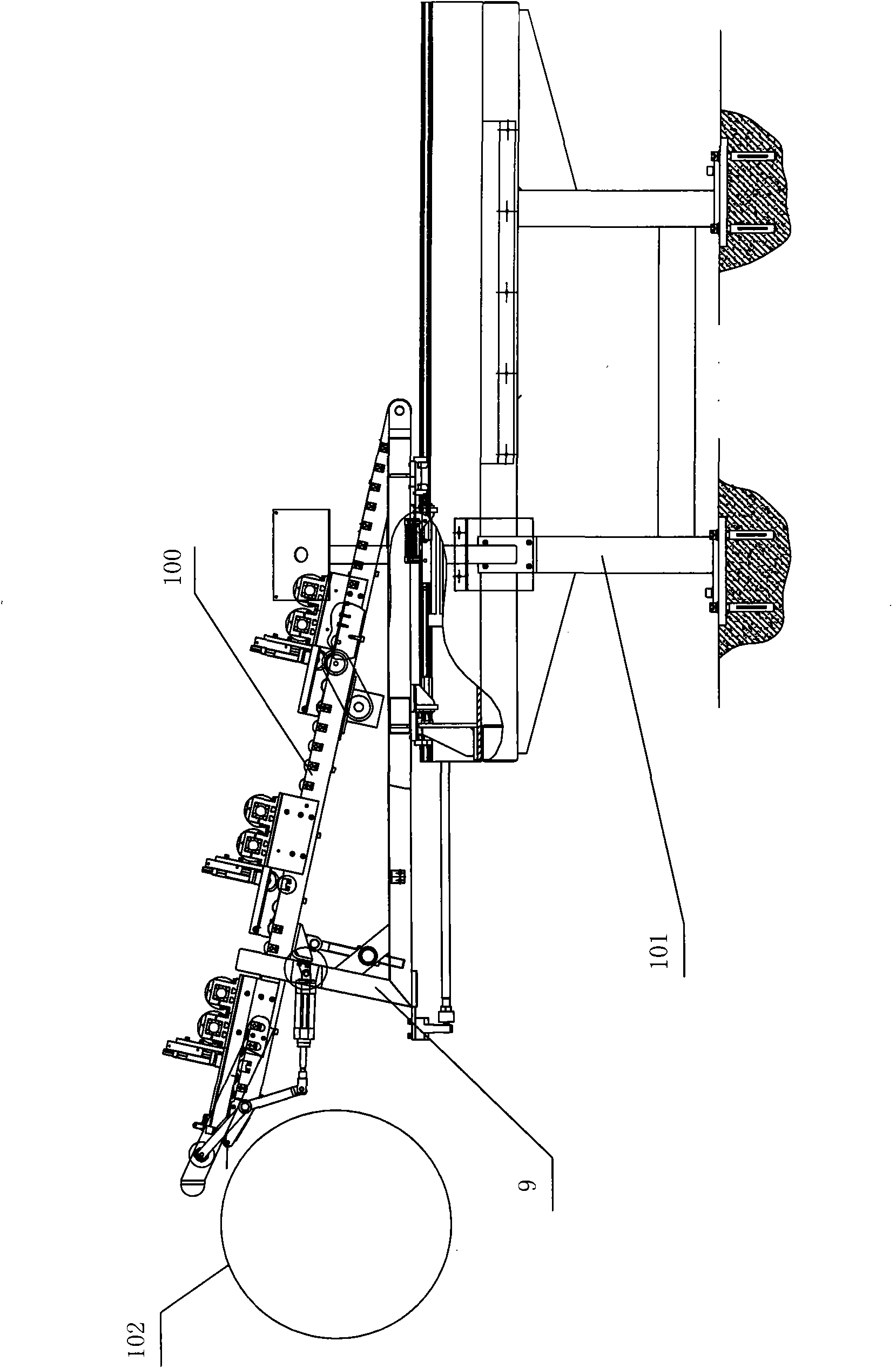

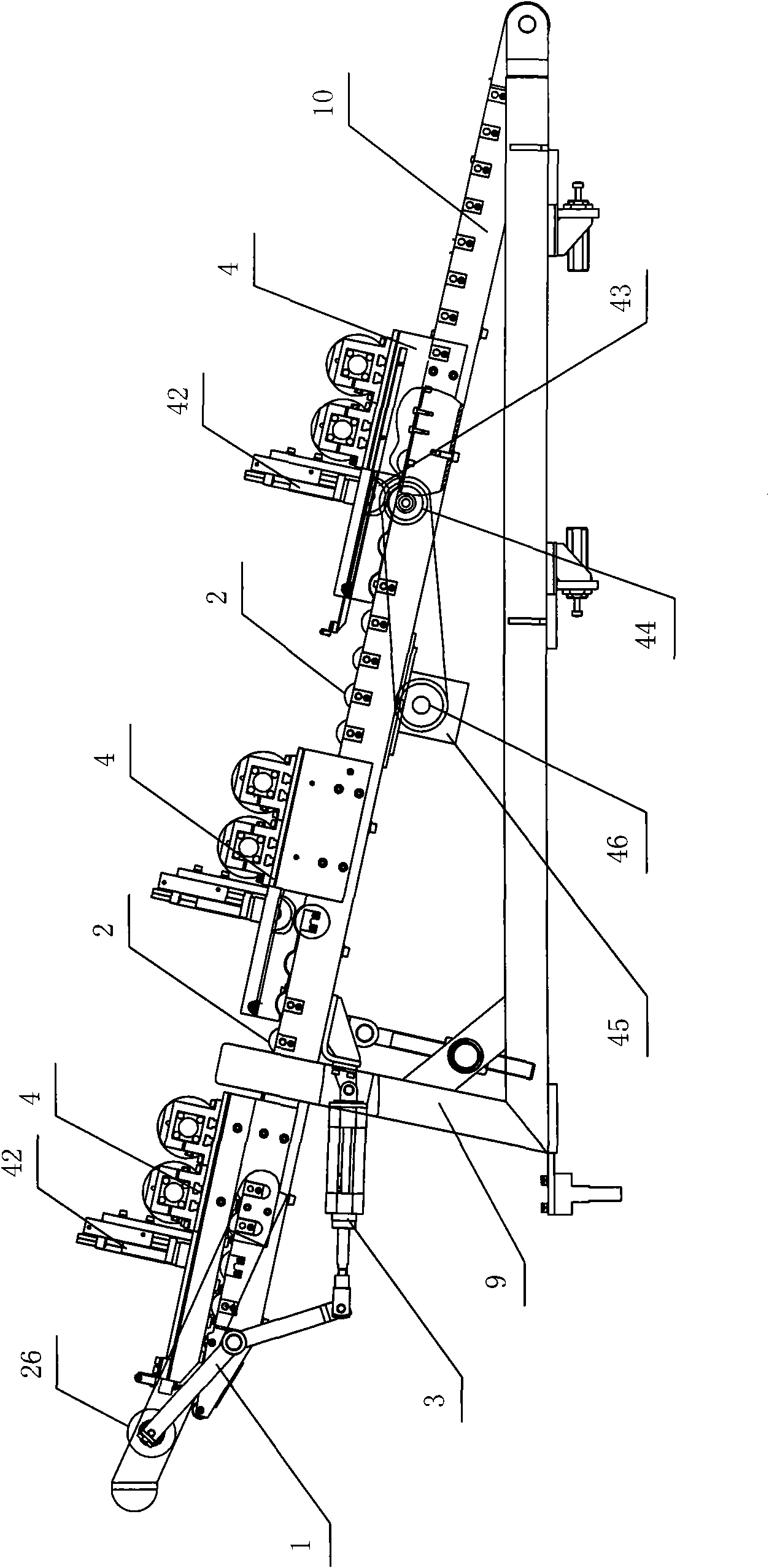

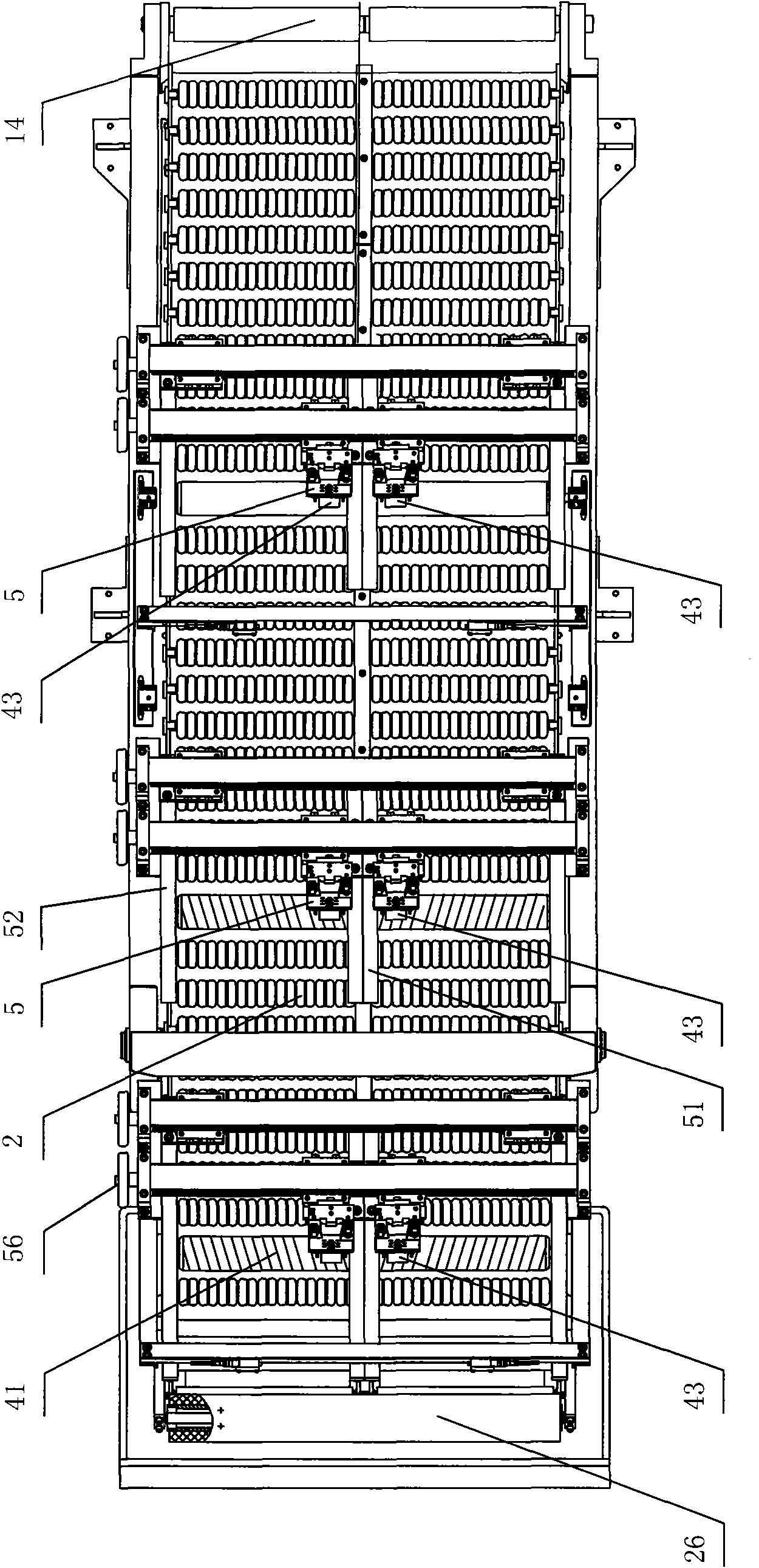

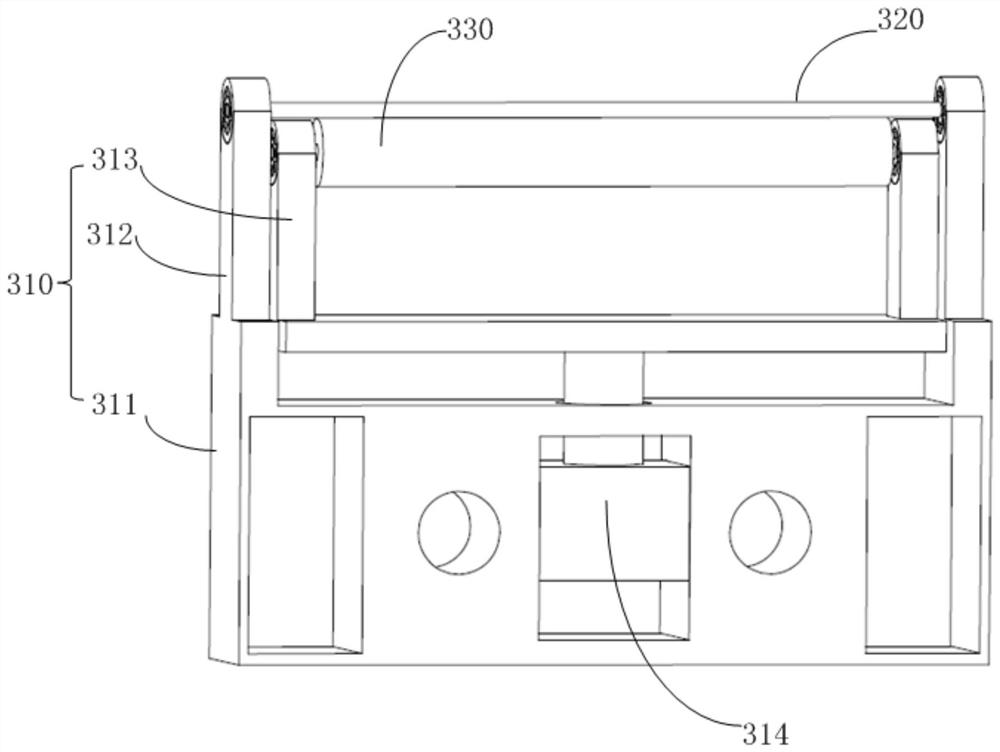

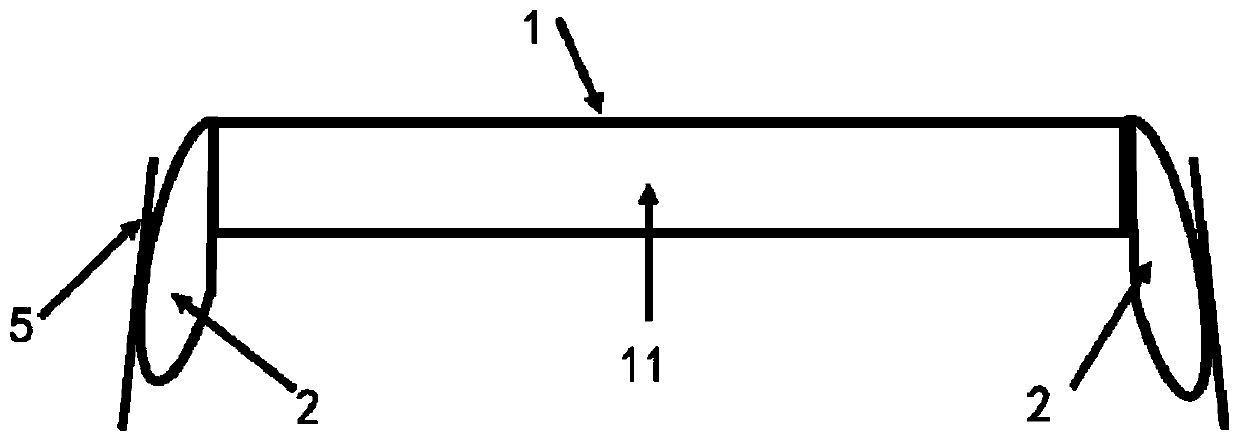

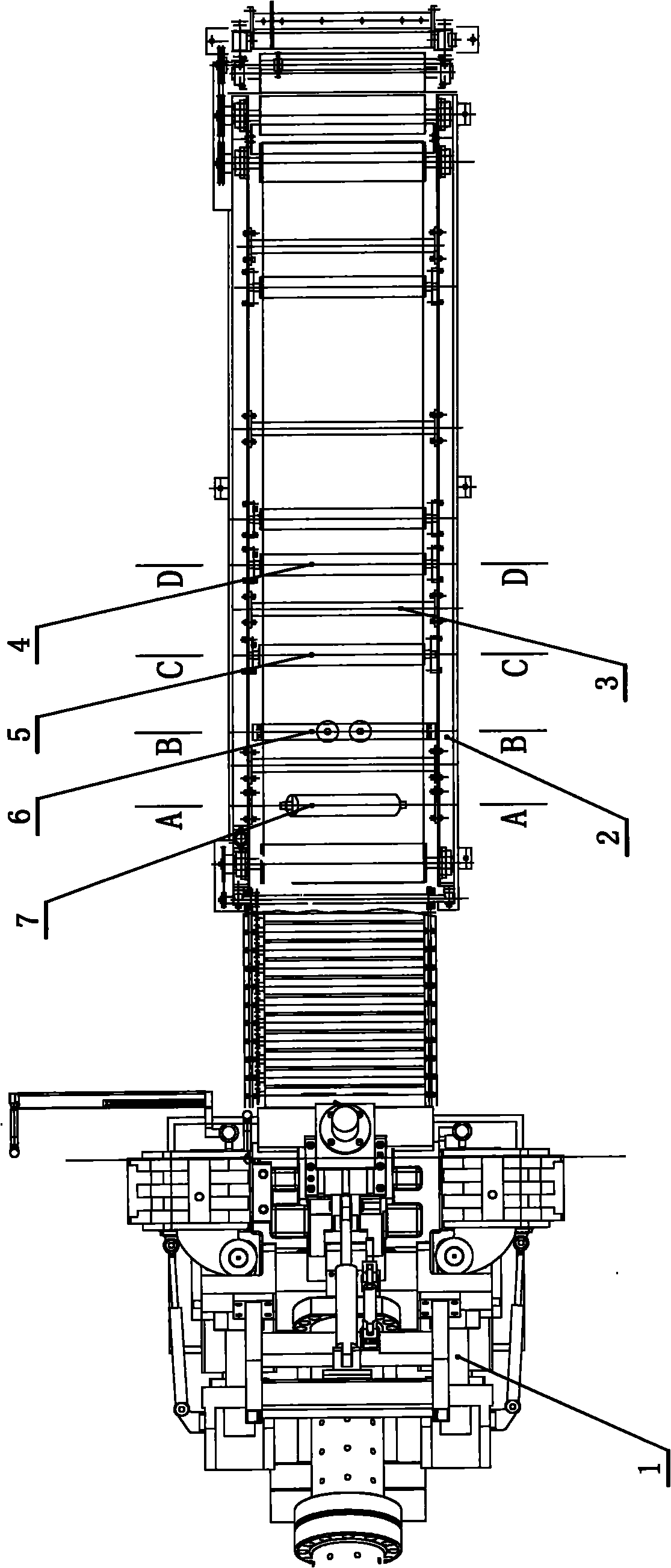

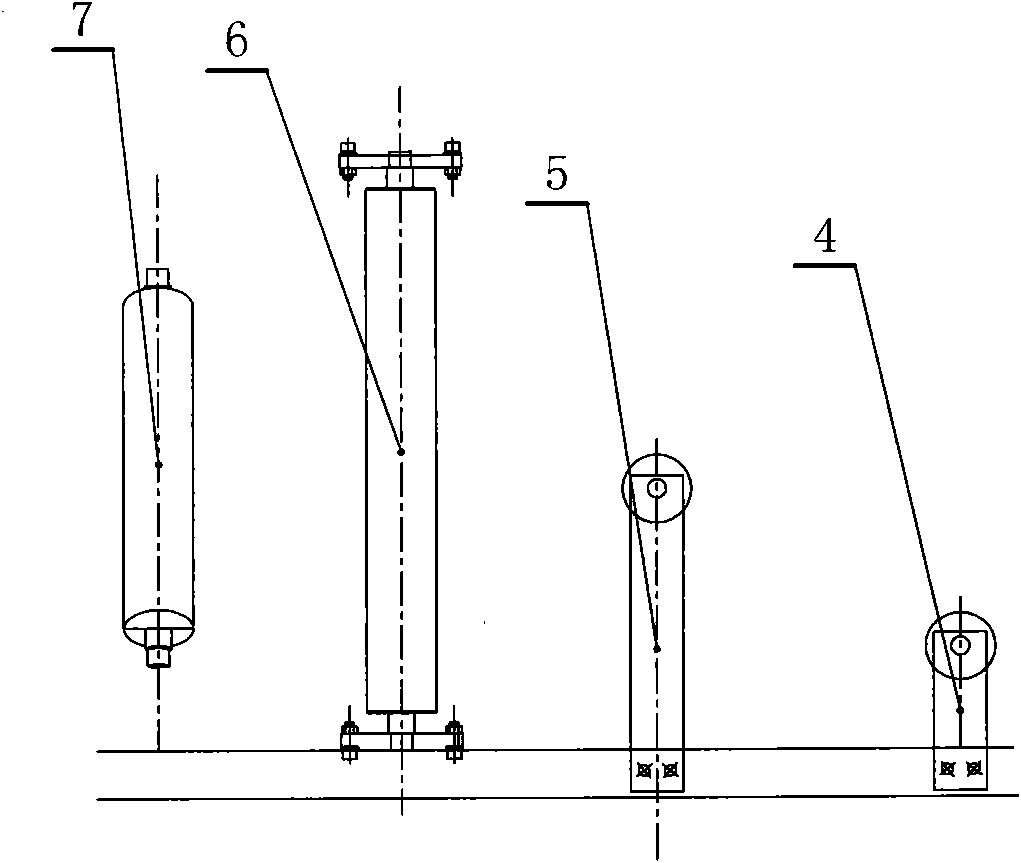

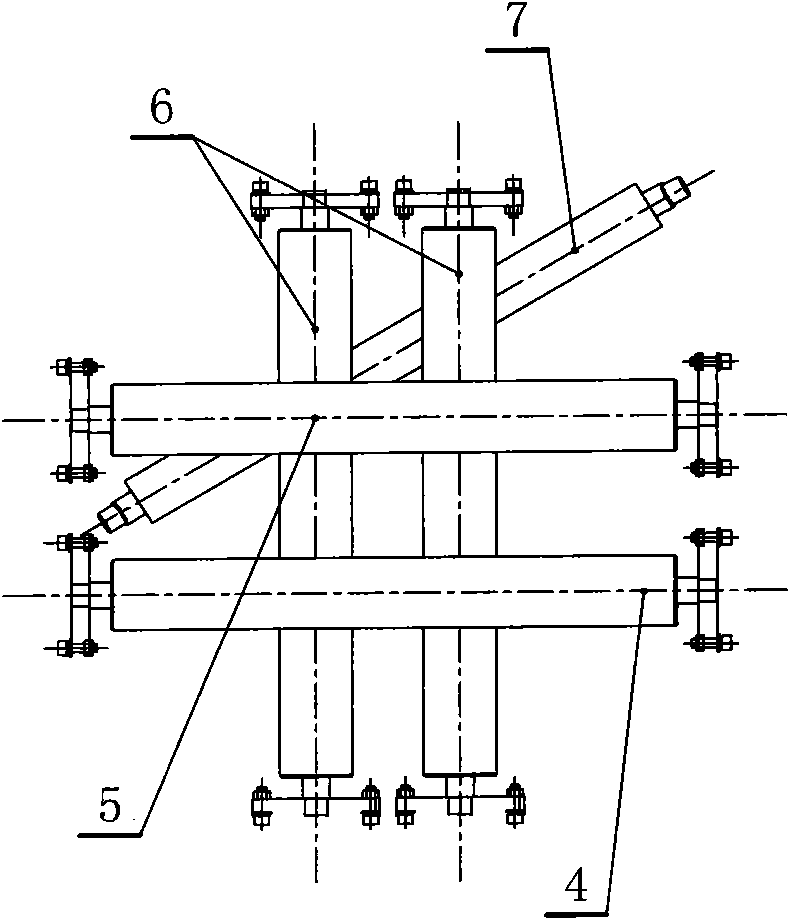

Shoulder wedge feeding frame and front guiding and positioning method thereof

ActiveCN101850628AOvercoming frictional resistancePrevent affecting the subsequent fit qualityTyresHelixSupport plane

The invention relates to a shoulder wedge feeding frame and a front guiding and positioning method thereof. A fixed edge guiding device and method capable of realizing the purpose of pressing downwards, rotating and pushing laterally simultaneously is used for realizing synchronous conveying of two shoulder wedges in limited conveying distance, thereby improving the conveying consistency of the two shoulder wedges to ensure that the two shoulder wedges can be accurately jointed on shoulder positions in parallel. The device is mainly provided with a conveying frame and a conveying template, wherein the conveying template is used for conveying shoulder wedges onto a forming drum and is installed on the conveying frame through a supporting frame. Different from the prior art, at least one group of fixed edge guiding mechanisms are arranged on brackets along the conveying direction of shoulder wedges. The fixed edge guiding mechanisms comprise at least one group of guiding rollers which are axially arranged between brackets at two sides and can axially rotate, and surface rollers of the guiding rollers are spirally arranged along the central line in the transverse direction and the brackets at two sides in the oblique direction. At least two groups of compression rollers which are driven by cylinders are arranged above the guiding rollers in the vertical direction, and the vertical central lines of the guiding rollers and the compression rollers are coincident.

Owner:MESNAC

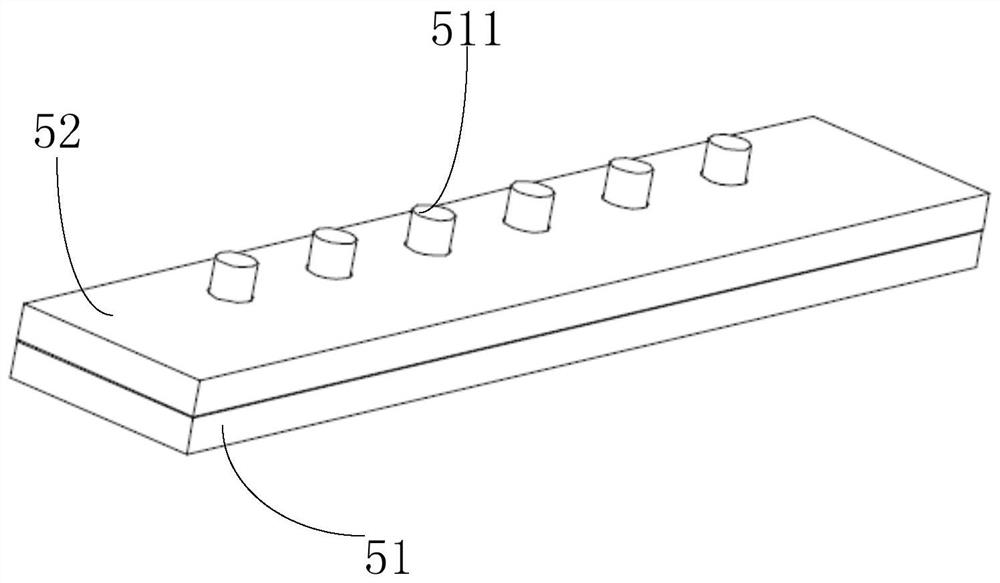

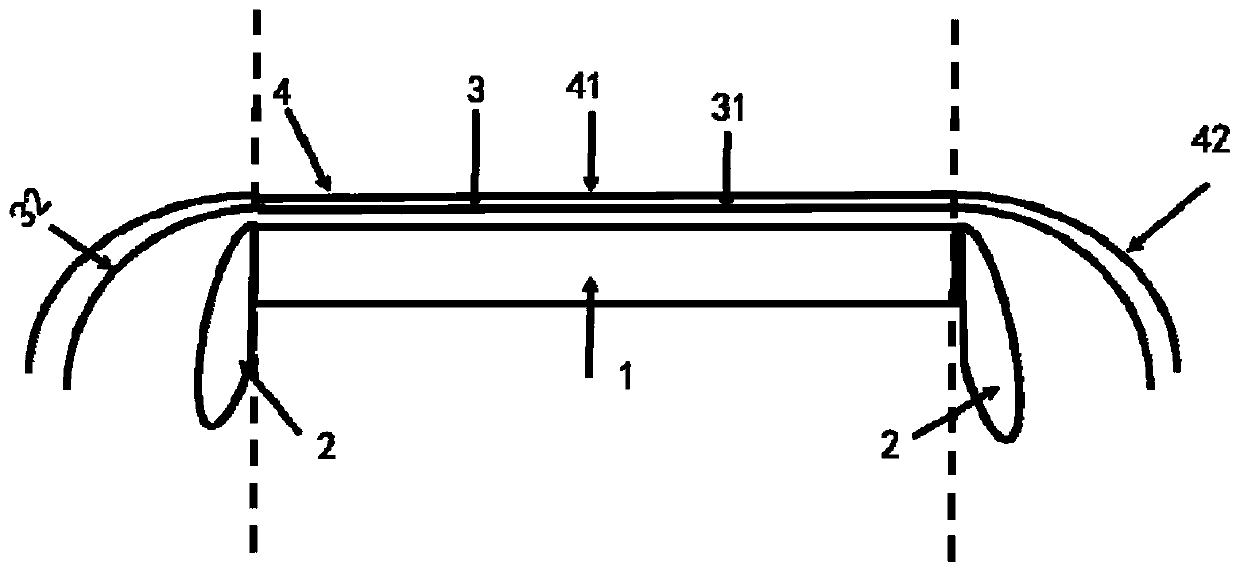

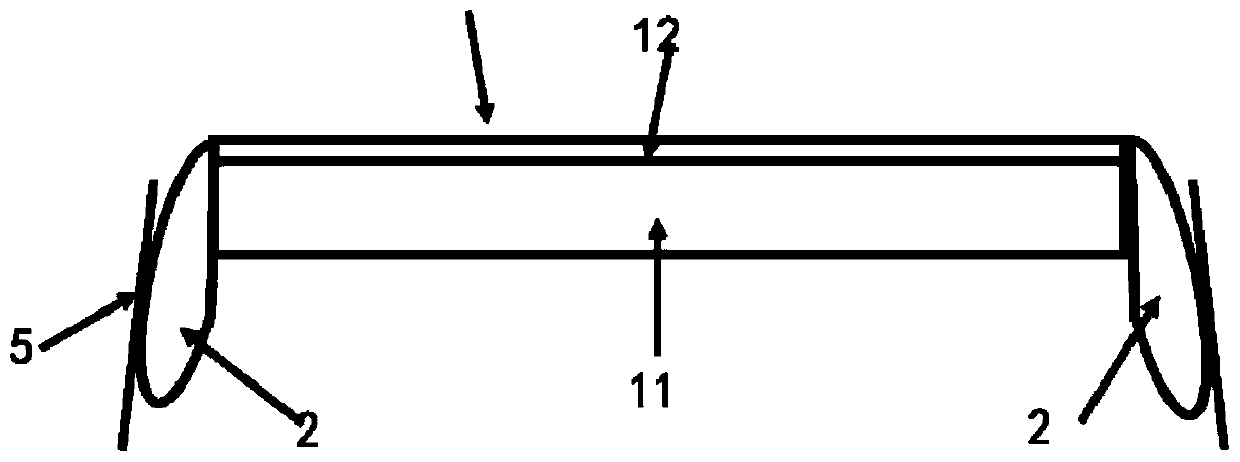

Fitting system

The embodiment of the invention provides a fitting system. The fitting system comprises a cover plate fixing part, a roller pressing mechanism and a bearing film control mechanism, wherein the cover plate fixing part is used for fixing a curved-surface cover plate; a flexible film is arranged on a bearing film; the bearing film control mechanism comprises a bearing film fixing device and a bearingfilm drive device; the bearing film fixing device is used for fixing and clamping two opposite ends of the bearing film; the bearing film drive device is used for driving two opposite ends of the bearing film to move; the roller pressing mechanism comprises roller pressing parts which are arranged side by side and two groups of roller drive devices; each roller pressing part comprises a first roller assembly; and the roller drive devices are used for driving the two roller pressing parts to independently move, so that the two first roller assemblies move towards arc-side areas of opposite twoside edges from the middle part of the curved-surface cover plate to press the flexible film and the curved-surface cover plate, and therefore, fitting is accomplished. The fitting system can be suitable for fitting flexible films on curved-surface cover plates of various shapes, and also can obtain high-quality high-efficiency fitting under a relatively great bending radian.

Owner:HUAWEI TECH CO LTD

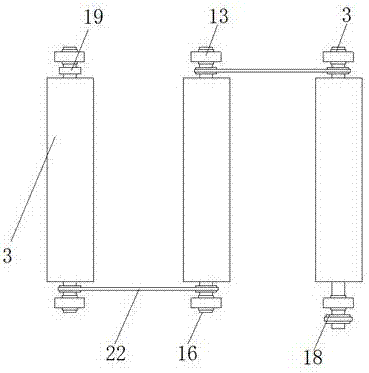

Laminating device used for identifying labels and operation method of laminating device

The invention discloses a laminating device used for identifying labels. The laminating device comprises a control console, a guide roller, bushings, transmission rollers, a motor, a top plate, an adjusting plate and a press roller and is characterized in that the operating console is arranged on a support, a bearing plate is arranged on the support, limit slots are arranged in vertical plates, the guide roller is arranged between fixing plates through a connecting shaft, the bushings are arranged in the corresponding limit slots, the connecting shafts are arranged at two ends of the transmission rollers, the motor is arranged on the bearing plate, the top plate is arranged on uprights, an air cylinder is arranged on the top plate, the adjusting plate is arranged on a piston rod, a positioning plate is arranged on the adjusting plate, and the press roller is arranged between positioning plates through the connecting shafts. The guide roller is arranged between the fixing plates, partition plates are arranged on the guide roller and can prevent a thin film skewing on the guide roller, and laminating quality in identifying the labels is improved.

Owner:ANHUI STARLIGHT LOGO SYST CO LTD

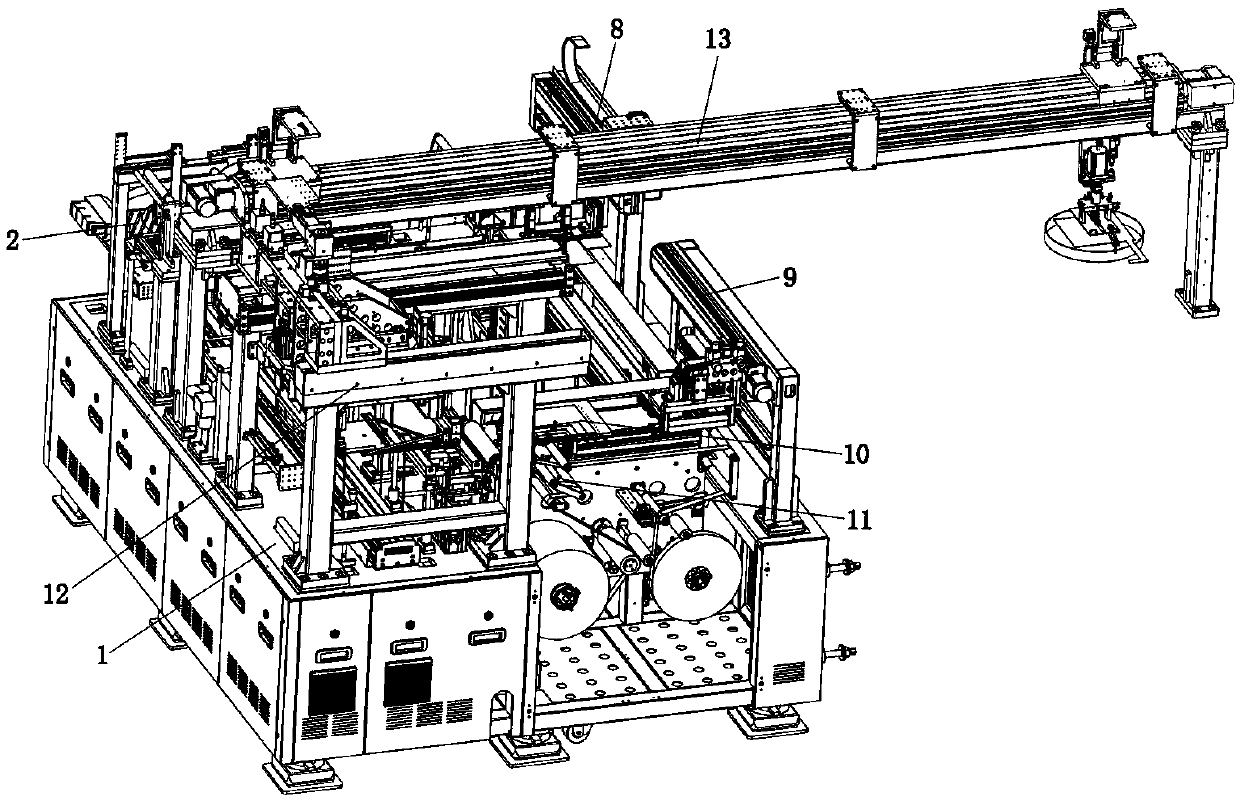

Full-automatic laminating machine

ActiveCN105328971AImprove fit qualityImprove fitting accuracyLamination ancillary operationsLaminationManipulatorDISC assembly

The invention provides a full-automatic laminating machine suitable for the technical fields of FPCs, liquid crystals and glass film laminating. According to the technical scheme, the full-automatic laminating machine comprises a base plate. An outer shell assembly, a feed and discharge mechanical arm assembly, a feed disc assembly, a carrying table module, a discharge disc, a discharge clamping assembly, a material stripping system assembly, an FPC CCD image system, an XZU axis movement system, a discharge clamping assembly and a cover film CCD image system. The full-automatic laminating machine is provided with a discharge end and a material collection end. The feed end is arranged on the left side of the full-automatic laminating machine, and the material collection end is arranged on the right side of the full-automatic laminating machine. By means of the technical scheme, the film laminating accuracy and quality are improved, and the production efficiency is improved.

Owner:SHENZHEN XINZHONGDA AUTOMATION TECH

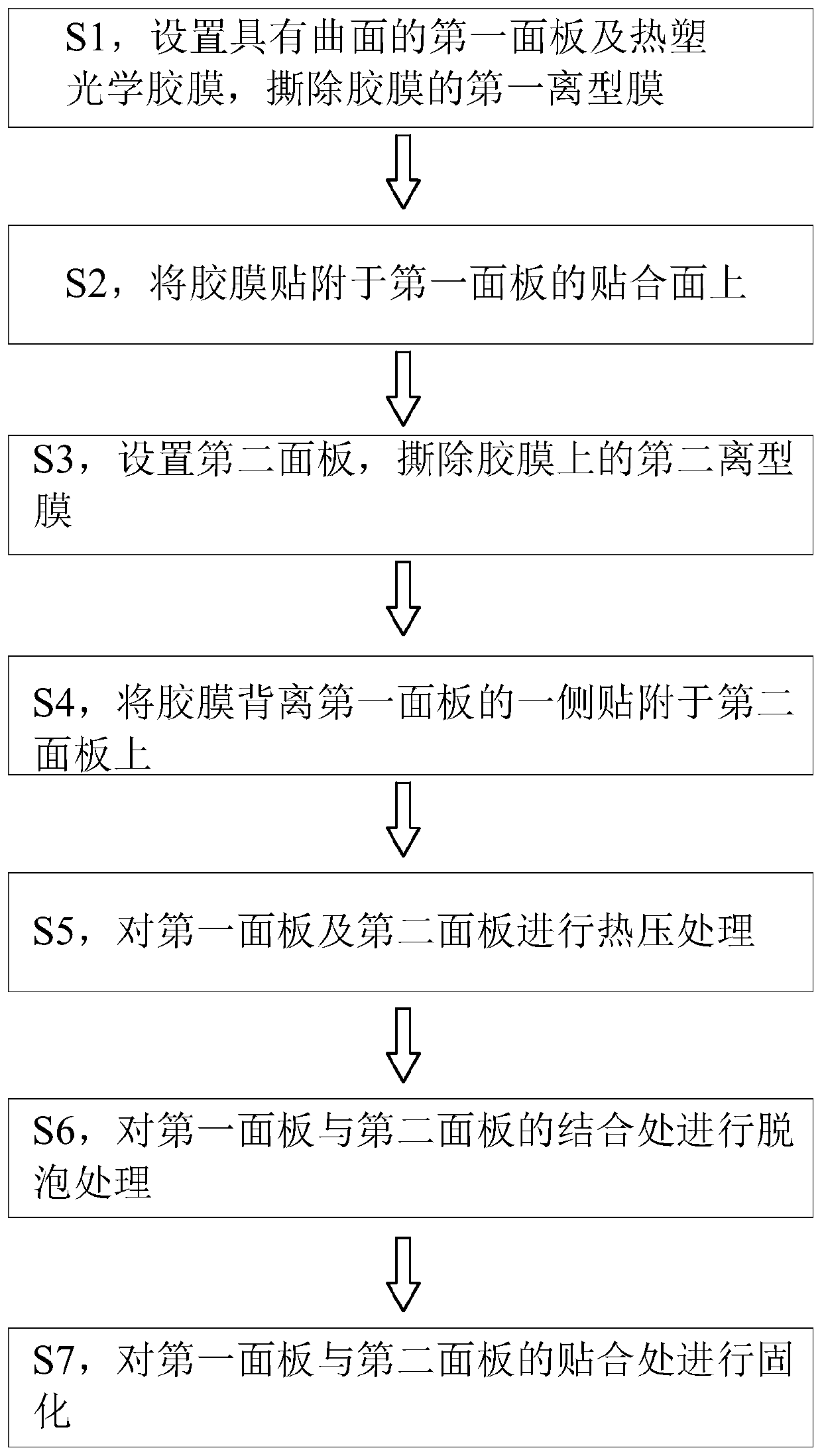

Adhesion method based on curved-surface flexible screen and display device

The invention relates to the technical field of displays and display adhesion. The invention relates to an Adhesion method based on a curved surface flexible screen. The adhesion method based on the curved surface flexible screen comprises the steps of providing a first panel with a curved surface and an optical thermoplastic adhesive film, tearing off the first release film of the adhesive film,attaching the adhesive film to the surface of the first panel, arranging a second panel, tearing off the second release film, attaching one side, opposite to the first panel, of the adhesive film to the second panel, carrying out hot pressing and defoaming treatment on the first panel and the second panel, and curing the joint of the first panel and the second panel. The display device is manufactured by the film adhesion method. The adhesive film provided by the invention can be quickly attached to the first panel and the second panel; according to the display device, bubbles generated in thehot pressing process of the adhesive film are eliminated, stress at the attaching position of the first panel and the second panel is absorbed, the adhesive film is prevented from rebounding, the first panel and the second panel are prevented from deforming, the attaching yield between the first panel and the second panel is increased, the display effect of the display device is improved, and theservice life of the display device is prolonged.

Owner:深圳一鑫新材料有限公司

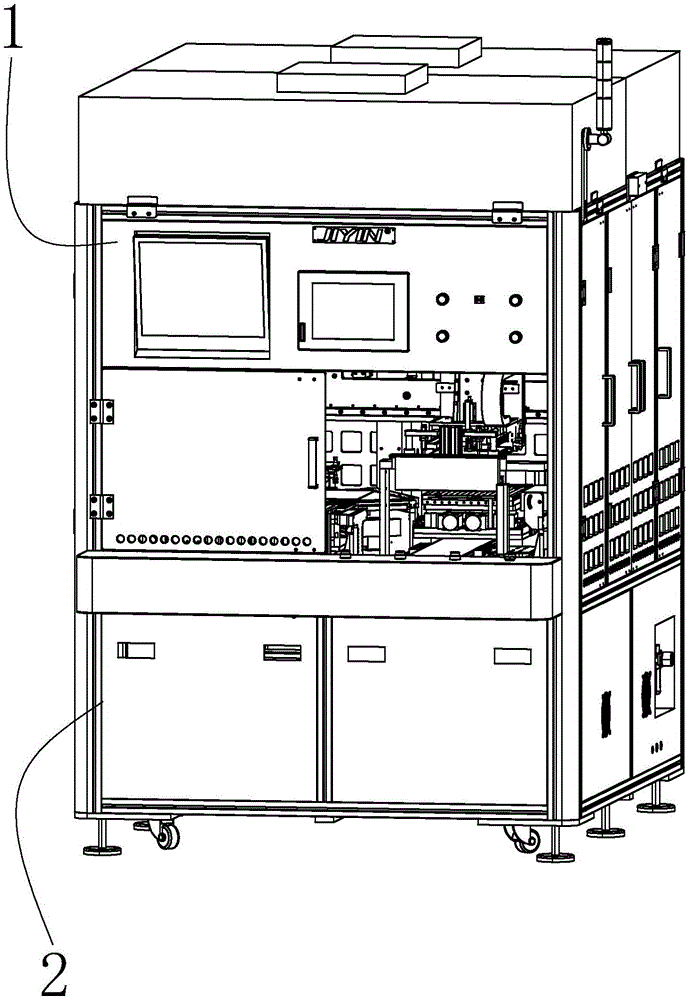

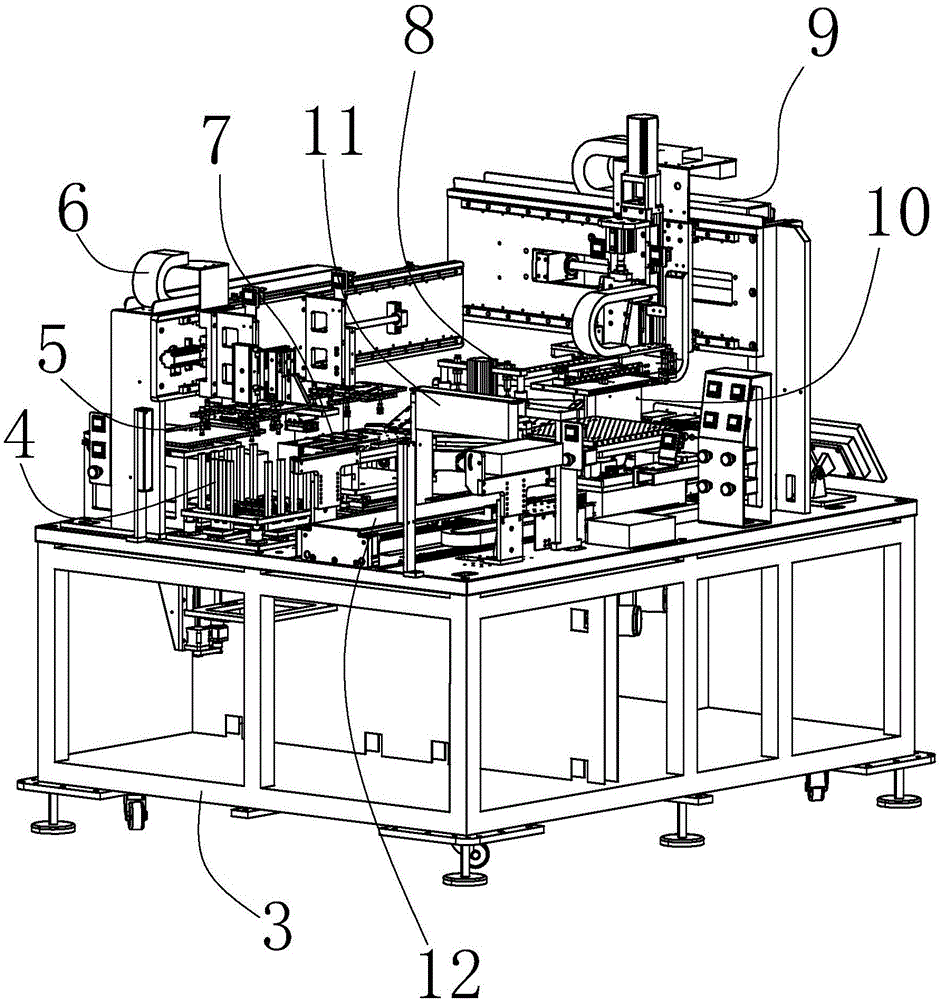

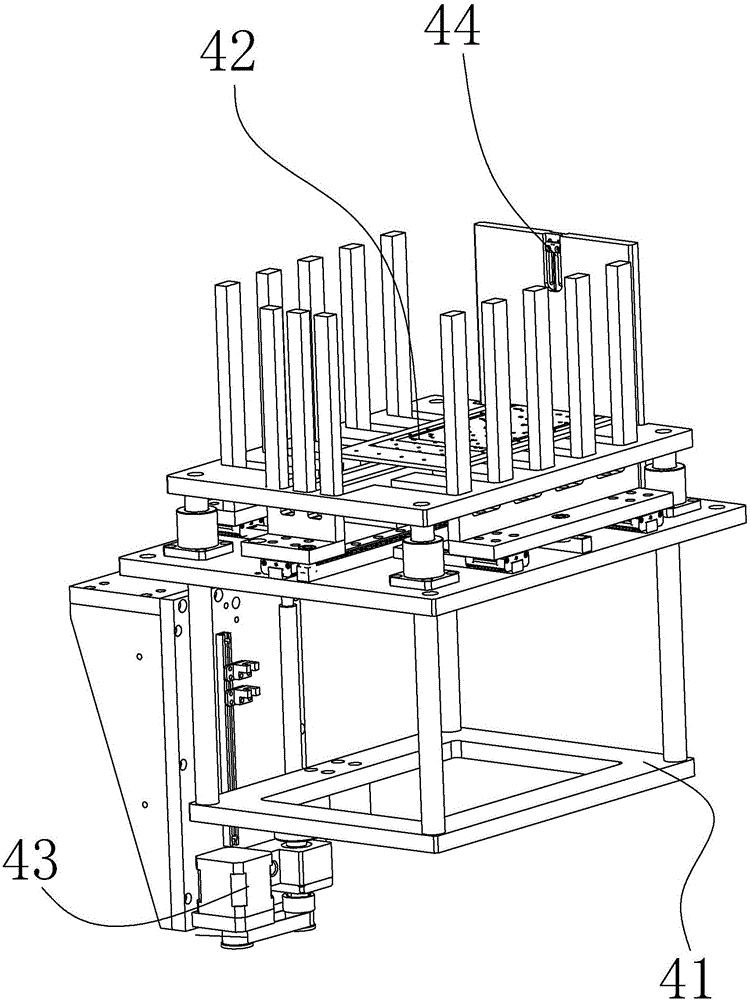

3D grating and LCD laminating machine, and laminating method using laminating machine

ActiveCN106379030AImprove consistencyPrecise process parametersLamination ancillary operationsControlling laminationGratingEngineering

The invention relates to a 3D grating and LCD laminating machine. The 3D grating and LCD laminating machine comprises an upper frame body, a lower frame body and a laminating rack, the upper surface of the laminating rack is respectively provided with a feeding mechanism, a single-piece detection and multiple-piece recovery mechanism, a fetching mechanism, a calibrating mechanism, a protection film tearing mechanism, a 3D grating and LCD laminating mechanism, a CCD image real-time contraposition mechanism, a bubble discharging mechanism and a discharging mechanism. The laminating machine can completely automatically substitute artificial operation without artificial lamination in use in order to obtain accurate technological parameters, so the manpower cost is reduced, and the laminating quality is improved; the laminating machine is suitable for batch production and realizes repeated dismounting and pasting, so improvement of the consistence of batch production is facilitated. Compared with laminating machines of the same products in the prior art, the laminating machine disclosed in the invention has the advantages of simplicity in operation, and convenience in realization of complete automation.

Owner:SHENZHEN JIYIN TECH

Full-automatic jacking attaching device

ActiveCN104999771AAvoid not being perpendicular to each otherPrecise positioningLamination ancillary operationsLaminationEngineeringLoad cell

Owner:BOZHON PRECISION IND TECH CO LTD

Functional membrane, mobile terminal, hot pressing molding method of functional membrane and tool for hot pressing molding

InactiveCN106738804AImprove bonding yield and finished product qualityReduce processDigital data processing detailsTelephone set constructionsHot pressingCivil engineering

The invention relates to a functional membrane, a mobile terminal, a hot pressing molding method of the functional membrane and a tool for hot pressing molding. The functional membrane is applied to a curved surface cover plate and is provided with a shading region and a light transmitting region, one surface of the cover plate back to a user is the back surface of the cover plate, when the functional membrane is attached to the back surface of the cover plate, the region, corresponding to the shading region, on the cover plate forms a non-display region, the region, corresponding to the light transmitting region, on the cover plate forms a display region, and the shape of the functional membrane is matched with the shape of the back surface of the cover plate. The mobile terminal applies the functional membrane above. The hot pressing molding method of the functional membrane is used to manufacture the functional membrane. The tool for hot pressing molding is used to implement the hot pressing molding method of the functional membrane. The functional membrane is prefabricated into a curved surface model suitable for the curved surface cover plate before attaching, which is favorable for solving the defect problem occurring when a flat functional membrane is attached, such that the attaching yield and finished product quality are improved.

Owner:VIVO MOBILE COMM CO LTD

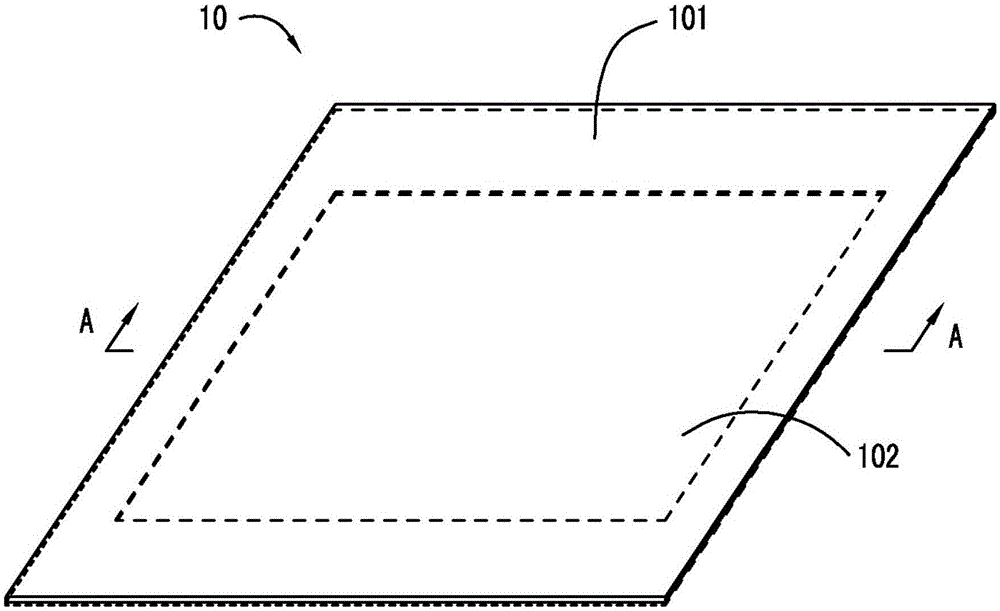

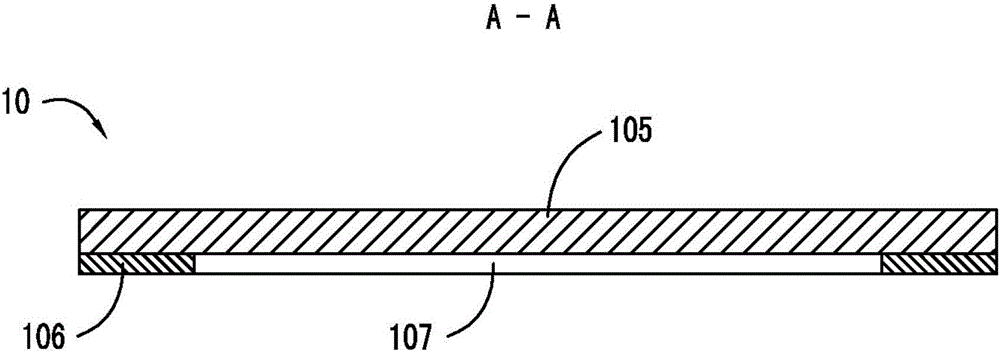

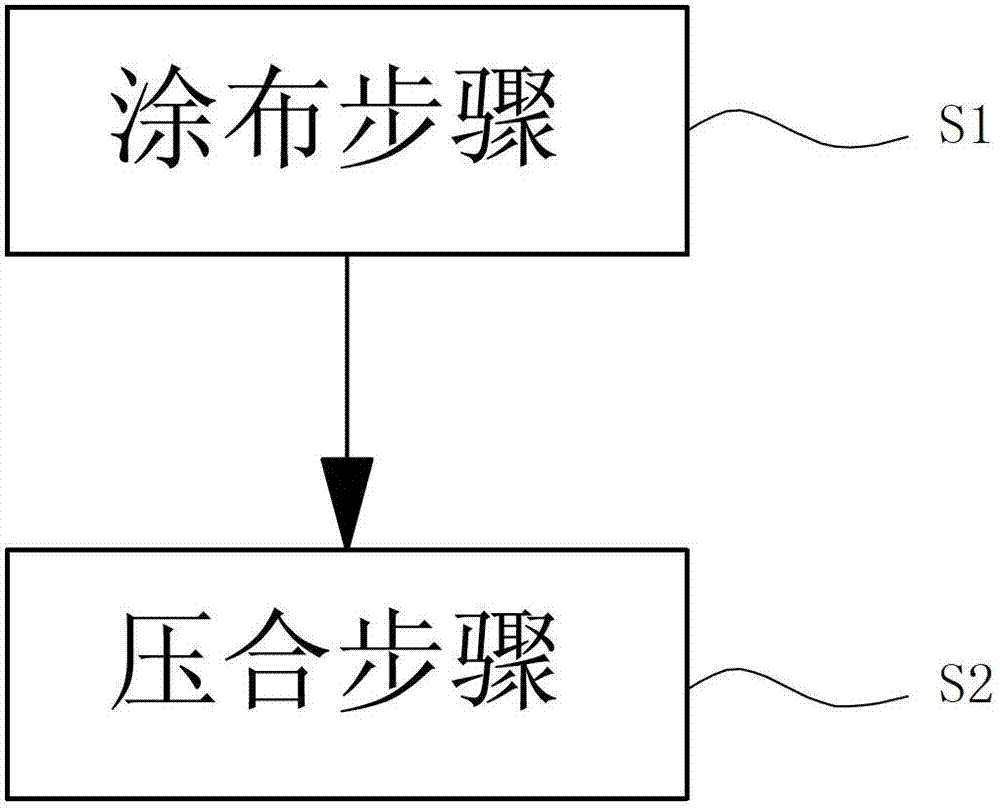

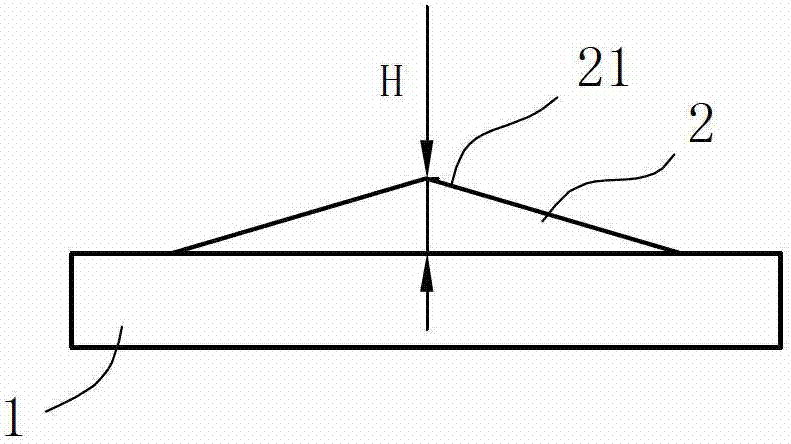

Rigid panel adhesion method and smearing module utilized thereby

InactiveCN102815080AAvoid air bubblesImprove fit qualityAdhesive processesLiquid surface applicatorsAdhesion processEngineering

The invention discloses a rigid panel adhesion method including a smearing step and a pressing step. The smearing step smears glue on a surface of a first rigid panel to form a glue layer. The glue layer has a single contact portion being in one-dimensional form of a dot or line. The glue layer has a coverage ratio of no less than 50% over the surface of the first rigid panel. The pressing step touches the contact portion of the glue layer with a second rigid panel, and slowly presses the first and second rigid panels together to discharge gases between the first and second rigid panels, thereby adhering the first and second rigid panels to each other and preferably the glue layer has a coverage ratio of 50% to 70% over the surface of the rigid panel. The rigid panel adhesion method can control the contact between glue and two rigid panels to prevent bubbles from forming during the adhesion process of the rigid panels, thereby improving the adhesion quality and product yield rate.

Owner:METAL INDS RES & DEV CENT

Hot-press laminating mechanism for overlapping front edge of sun shield of automobile

InactiveCN101987526AImprove fit qualityReduce labor intensityLaminationLamination apparatusEngineeringFront edge

The invention relates to a hot-press laminating mechanism for overlapping the front edge of a sun shield of an automobile. The mechanism comprises a base, wherein the base is provided with fixedly connected lift guide pillars; each lift guide pillar is provided with a fixed plate corresponding to the other end connected with the base; the fixed plate is provided with a lift air cylinder; a piston rod of the lift air cylinder passes through the fixed plate, and is connected with a connecting plate under the lift air cylinder; two ends of the connecting plate are sleeved on the corresponding lift guide pillars respectively, and can move relative to the lift guide pillars; an upper profile heating mould is fixedly connected with the connecting plate corresponding to the other side which is provided with a connecting block, and a lower profile heating mould is arranged under the upper profile heating mould and fixed on the base; and a plurality of uniformly distributed heat pipes are arranged in the lower profile heating mould and the upper profile heating mould respectively. The hot-press laminating mechanism is simple, compact and reasonable, has high automation degree, can improve the production efficiency, reduce labor intensity and save energy, and has stable drying temperature without polluting the ambient environment.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

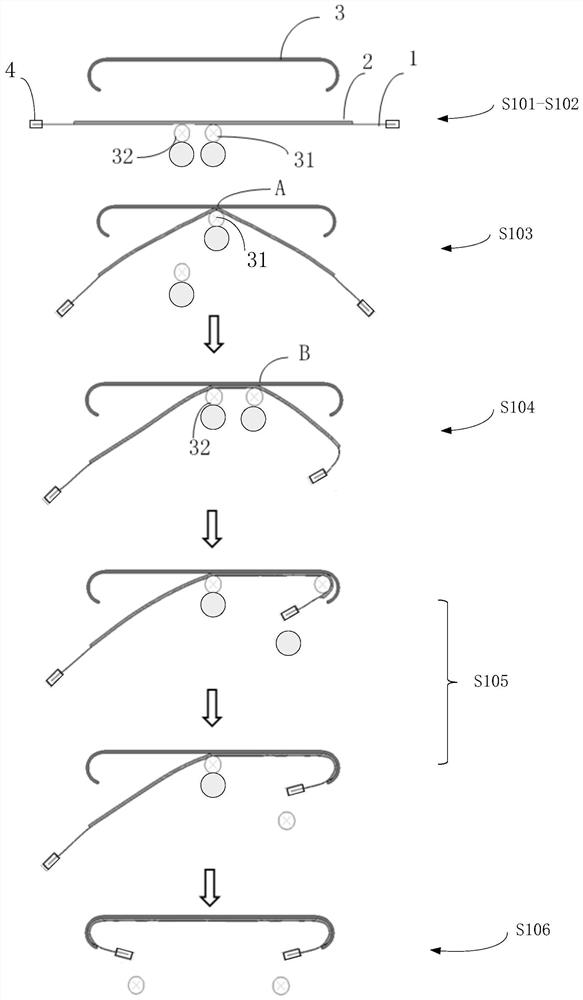

Laminating process for curved surface cover plate and flexible film

The embodiment of the invention provides a laminating process for a curved surface cover plate and a flexible film. The process comprises the steps that the curved surface cover plate is fixed, the flexible film is arranged on a bearing film, and the two ends of the bearing film is fixed, so that the flexible film is opposite to the inner surface of the curved surface cover plate; a first roller is adopted to abut against an initial position of the middle of the bearing film, so that the middle of the flexible film and the middle of the curved surface cover plate are subjected to laminating atfirst, and then the first roller is moved towards an arc edge area of one side of the curved surface cover plate by a preset distance; a second roller is adopted to move from the initial position tothe arc edge area of the other side of the curved surface cover plate; the first roller is continued to move towards the arc edge area of one side of the curved surface cover plate, so that the flexible film and the curved surface cover plate are subjected to laminating completely; and in the whole laminating process, the two opposite ends of the bearing film are controlled to do matched movementin the direction of reducing the tensile force of the bearing film. The laminating process is suitable for laminating of flexible films on curved surface cover plates in various shapes, and the high laminating quality and high laminating efficiency are achieved even for cover plates with large curved radian.

Owner:HUAWEI TECH CO LTD

Display screen pasting device and display screen pasting method

InactiveCN110682651AInnovative wayLow costLaminationLamination apparatusComposite materialEngineering

The invention provides a display screen pasting device and a display screen pasting method. A display screen comprises a planar substrate and a curved surface substrate, wherein the curved surface substrate is arranged on the outer side of the planar substrate; the planar substrate comprises a screen planar part and a cover plate planar part; and the curved surface substrate comprises a screen curved surface part and a cover plate curved surface part. The display screen pasting device comprises a straight part pasting mechanism and airbag pasting mechanisms, wherein the straight part pasting mechanism is used for pasting the screen planar part and the cover plate planar part as a whole; the airbag pasting mechanisms are arranged on both sides of the straight part pasting mechanism; and theairbag pasting mechanisms are used for exerting pressure to the screen curved surface part from inside to outside from one side, close to the planar substrate, of the curved surface substrate to paste the cover plate curved surface part under the action of pressure of gas. With the combined structure of the straight part pasting mechanism and the airbag pasting mechanisms, the planar substrate and the curved surface substrate of the display screen are separatelypasted, the mode is novel, pasting bubbles betweena screen and a cover plate can be reduced, the pasting quality can be improved, meanwhile, the breakage rate of the screen and the cover plate can be reduced, and the yield loss can be reduced.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

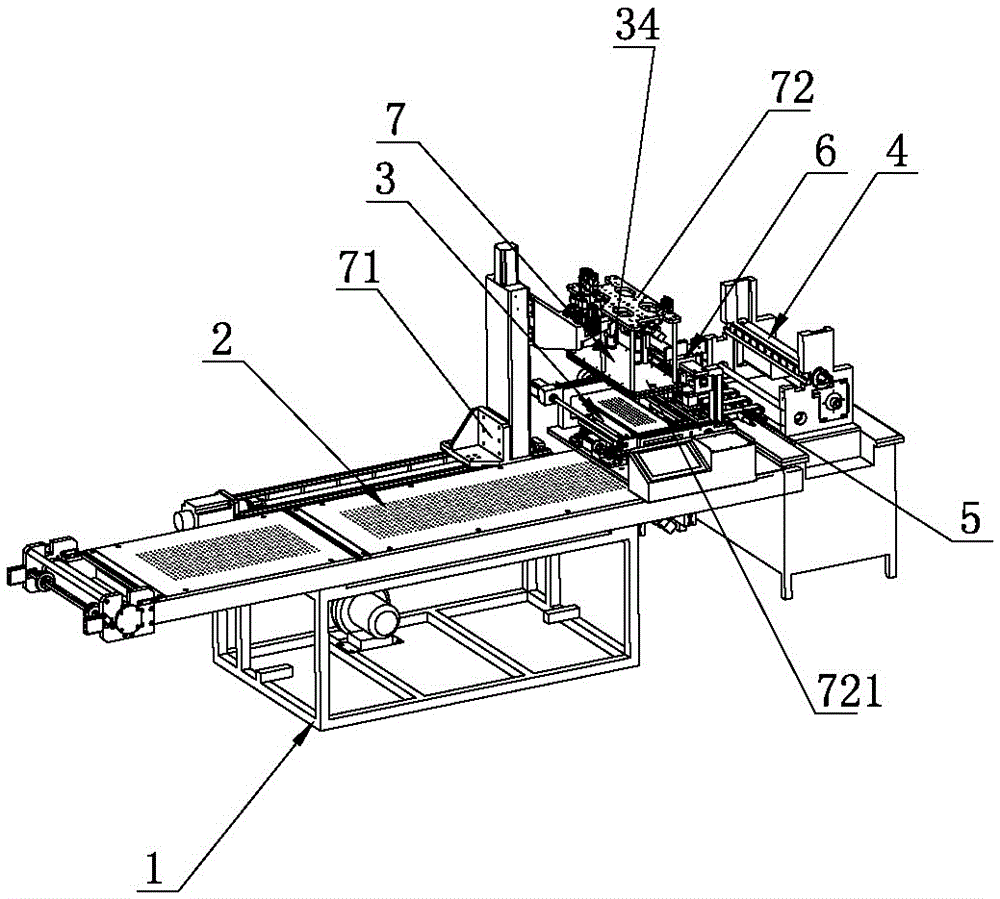

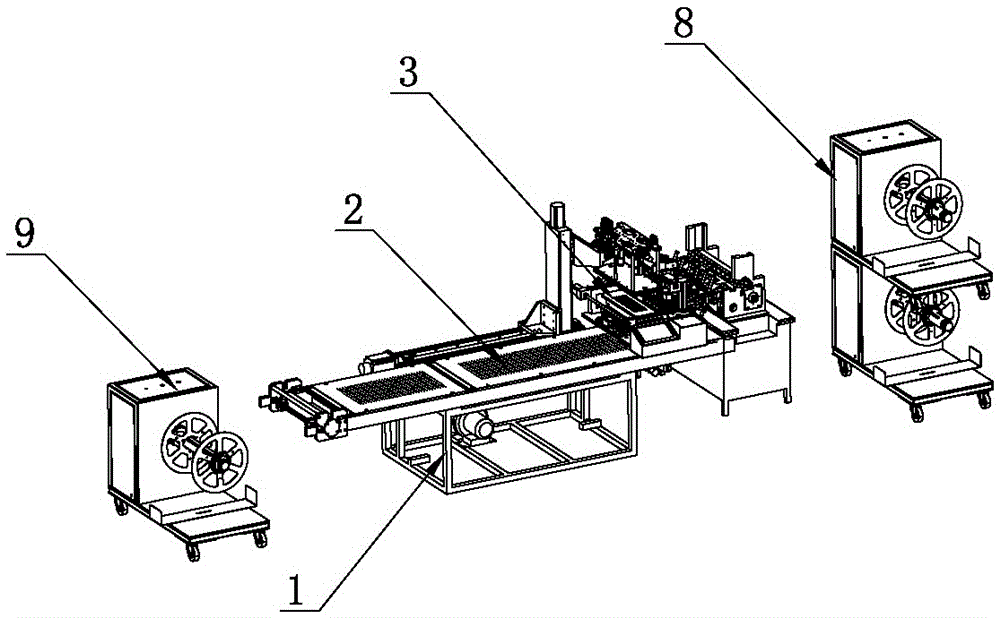

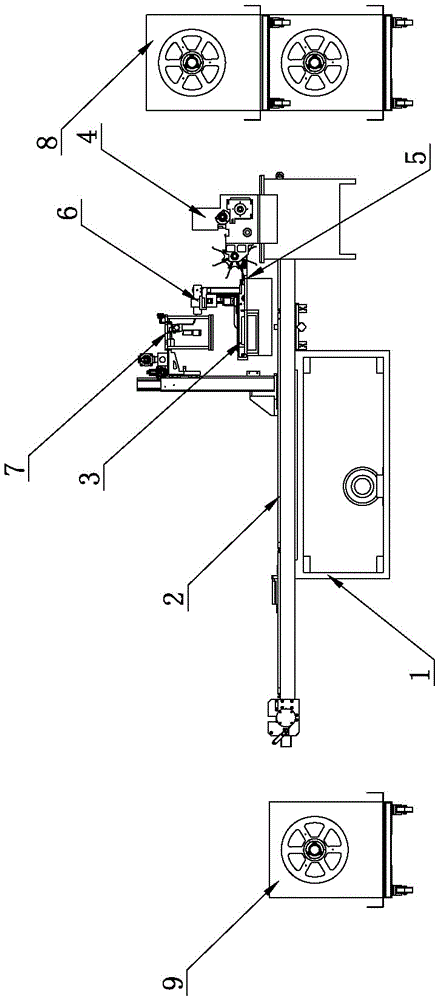

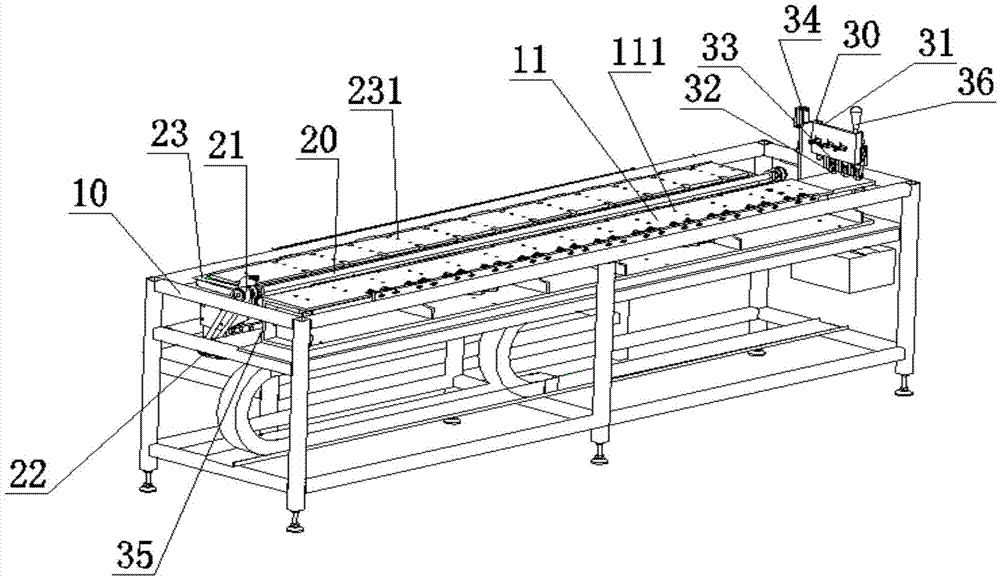

Coil material fitting system

ActiveCN105555042AReduce labor costsHigh degree of automationPrinted circuit manufactureEngineeringManipulator

The invention relates to the technical field of automatic fitting device, and in particular relates to a coil material fitting system, comprising a rack, wherein the rack is provided with a suction and fitting platform, an automatic aligning platform is arranged on one side of the suction and fitting platform, a cutting device is arranged on one side of the automatic aligning platform, and a material suction mechanical arm is arranged between the cutting device and the automatic aligning platform; and a fitting mechanical arm is arranged between the automatic aligning platform and the suction and fitting platform. With the automatic aligning of the automatic aligning platform, the coil material can be continuously fit, the degree of automation is high, and the labor cost of the enterprise is greatly saved, and the fitting quality of the product is improved. When multiple layers of material need to be fit, the plurality of coil material fitting system can be sequentially connected in series according to the number of layers of material to be fit; according to the flexible combined manner, the coil material fitting system can be applicable to fitting of different layers of material, and is simple and convenient to use.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

Corrugated board production line double-face machine

InactiveCN108284646ASpeed up heat dissipationEven heat dissipationMechanical working/deformationLaminationProduction lineFixed frame

The invention discloses a corrugated board production line double-face machine and relates to the technical field of corrugated board production equipment. The corrugated board production line double-face machine comprises a thermal attaching device and a cooling device which are arranged sequentially in the paper discharge direction of a corrugated board production line. The thermal attaching device comprises an attaching support. A fixed frame is fixed to the top of the attaching support. A first transmission mechanism is rotationally connected in the fixed frame. A tensioning mechanism is arranged in the fixed frame. The cooling device comprises a conveying table. A second transmission mechanism is rotationally connected in the conveying table. A support box is fixed to the top of the conveying table. An air blasting mechanism is fixed to the top of the inner wall of the support box. According to the corrugated board production line double-face machine, through matched use of the cooling device and the air blasting mechanism, the heat dissipation speed of an attached corrugated board is increased, thus heat dissipation is more uniform, the warping phenomenon of the corrugated board during cooling is avoided, and work efficiency and production quality are improved.

Owner:张志锋

Assembly repairing device

InactiveCN105449047AReduce the chance of occurrenceImprove rework efficiencyFinal product manufactureSemiconductor devicesEngineeringVertical displacement

The invention provides an assembly repairing device, which comprises a rack, a reversal mechanism and a lamination mechanism, wherein the reversal mechanism and the lamination mechanism are arranged on the rack; the reversal mechanism comprises a reversal shaft, two bearing pedestals, a reversal motor and a reversal table top; the two bearing pedestals are independently arranged on two ends of the rack; the reversal shaft passes through the two bearing pedestals; one end of the reversal shaft is connected with the reversal motor; the reversal shaft is also connected with the reversal table top; the reversal table top is provided with a plurality of vacuum suction nozzles; the vacuum suction nozzles are connected with a vacuum system; the rack is also provided with an operating table top; the operating table top is arranged on one side which is opposite to the reversal table top; the lamination mechanism comprises a longitudinal frame and a lateral frame, wherein the lateral frame is arranged on the longitudinal frame and realizes vertical displacement through a lifting motor arranged on the upper part of the lateral frame; the bottom of the lateral frame is provided with a lamination roller; the longitudinal frame is arranged in a slideway; and the slideway penetrates through two ends of the rack.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

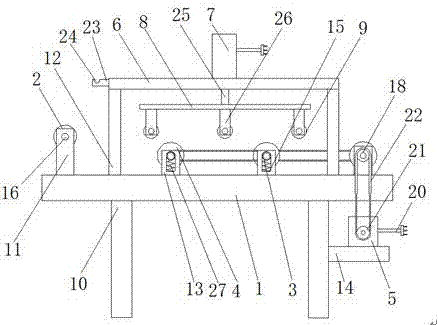

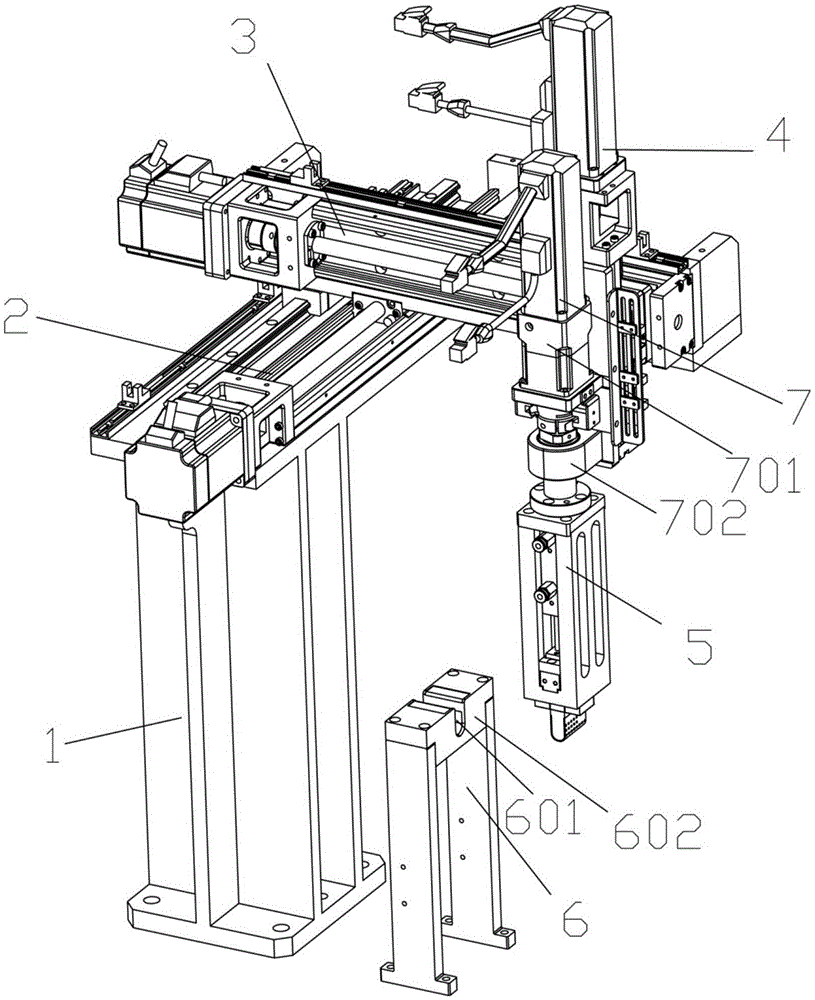

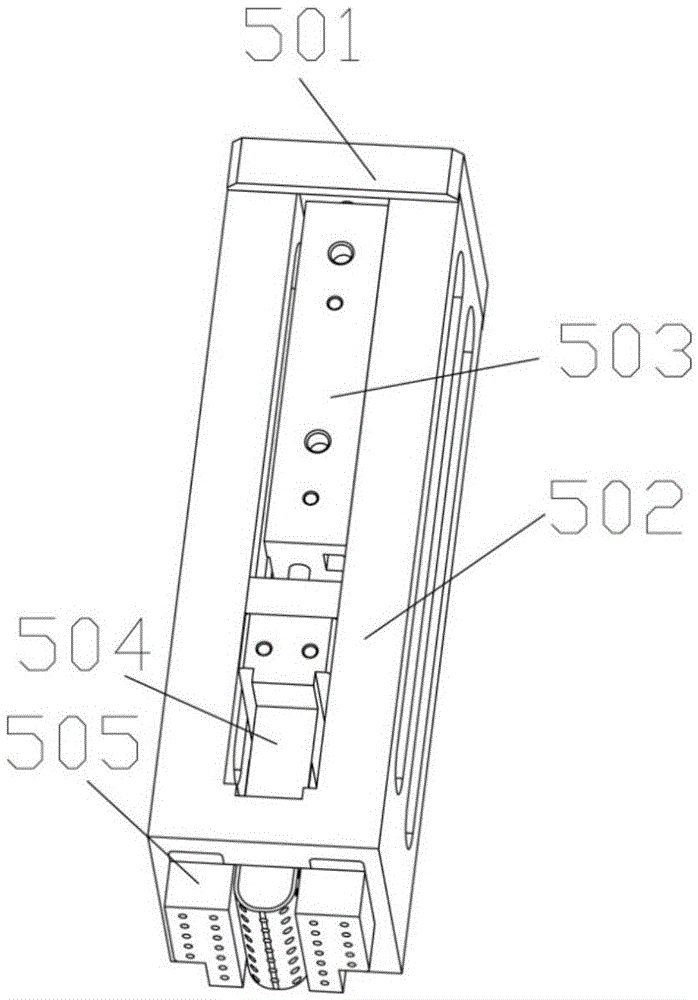

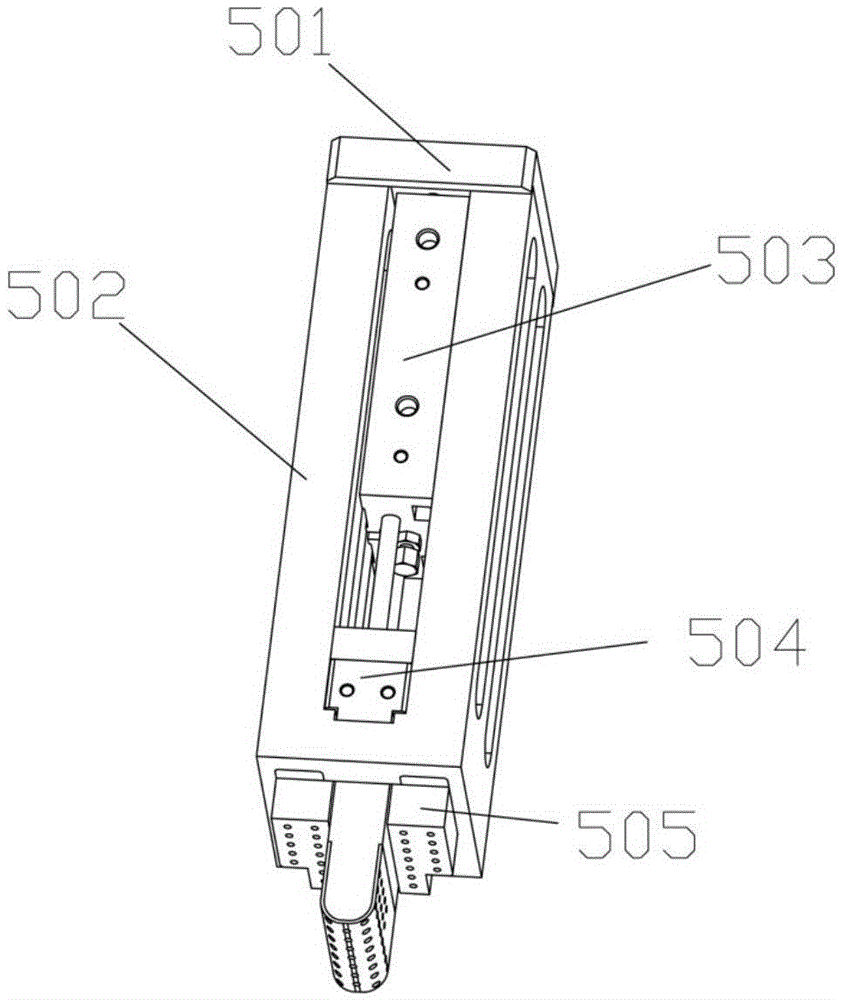

Glue laminating machine

InactiveCN103818096AImprove fitting accuracyImprove fit qualityControlling laminationLaminationReciprocating motionEngineering

The invention relates to a laminating machine and in particular relates to a glue laminating machine. The glue laminating machine comprises a stander, wherein an upper panel Y-axis conveying mechanism, a lower panel Y-axis conveying mechanism, a manipulator, an upper panel X-axis conveying mechanism, a Z-axis laminating mechanism, an upper panel CCD (charge coupled device) image sensor and a lower panel CCD image sensor are arranged on the stander; the manipulator comprises an upper panel clamping part, an upper panel rotating mechanism and a manipulator Y-axis conveying mechanism; the manipulator Y-axis conveying mechanism is connected with the upper panel rotating mechanism; the upper panel rotating mechanism is connected with the upper panel clamping part; the manipulator Y-axis conveying mechanism drives the upper panel clamping part to perform reciprocating motion between the upper panel Y-axis conveying mechanism and the upper panel X-axis conveying mechanism; the upper panel X-axis conveying mechanism is connected with the Z-axis laminating mechanism. The glue laminating machine has the benefits of improving the laminating precision, the laminating quality and the laminating beat.

Owner:深圳市创造机电有限公司

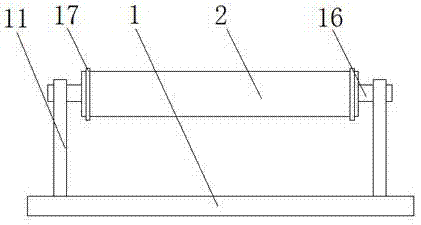

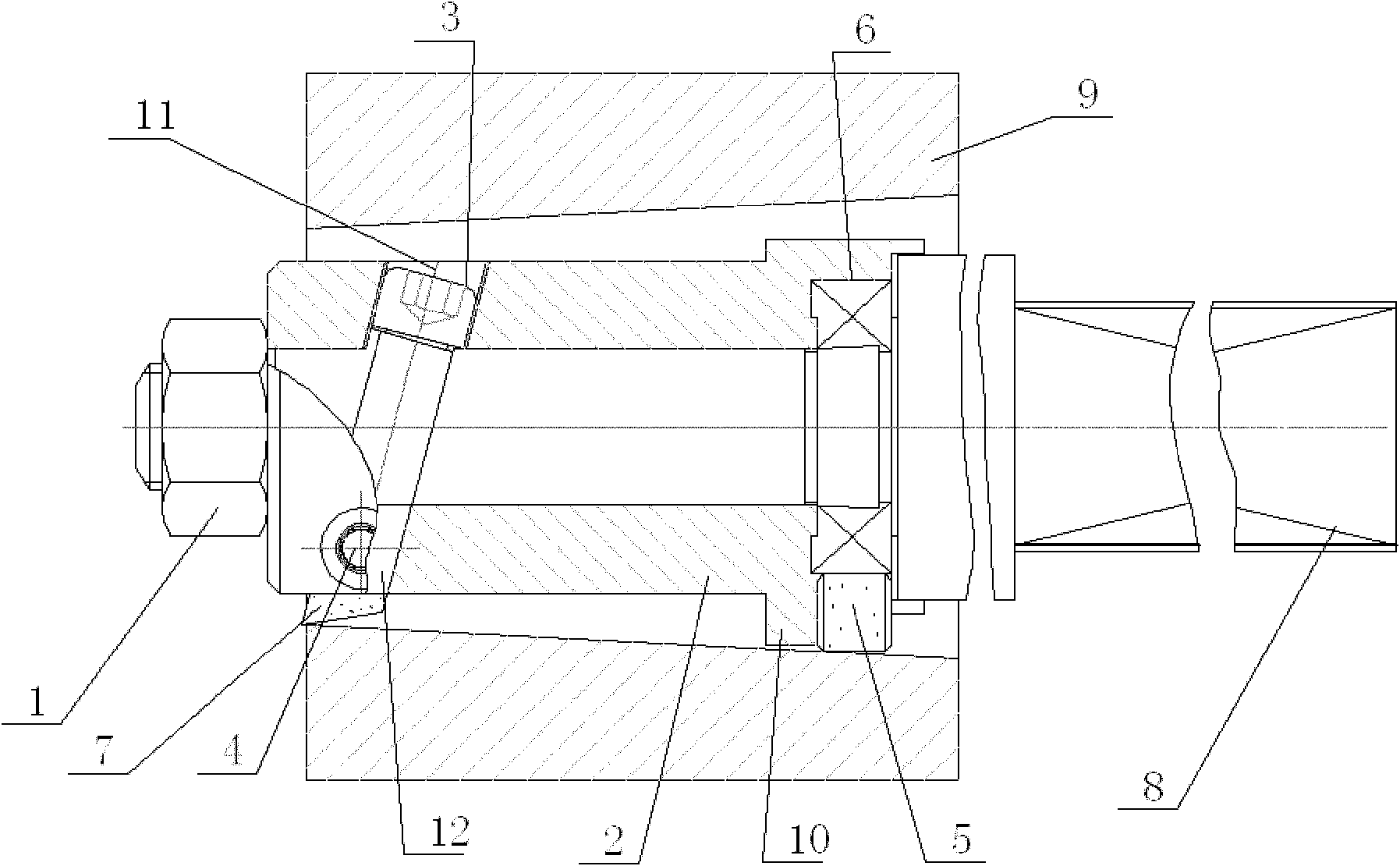

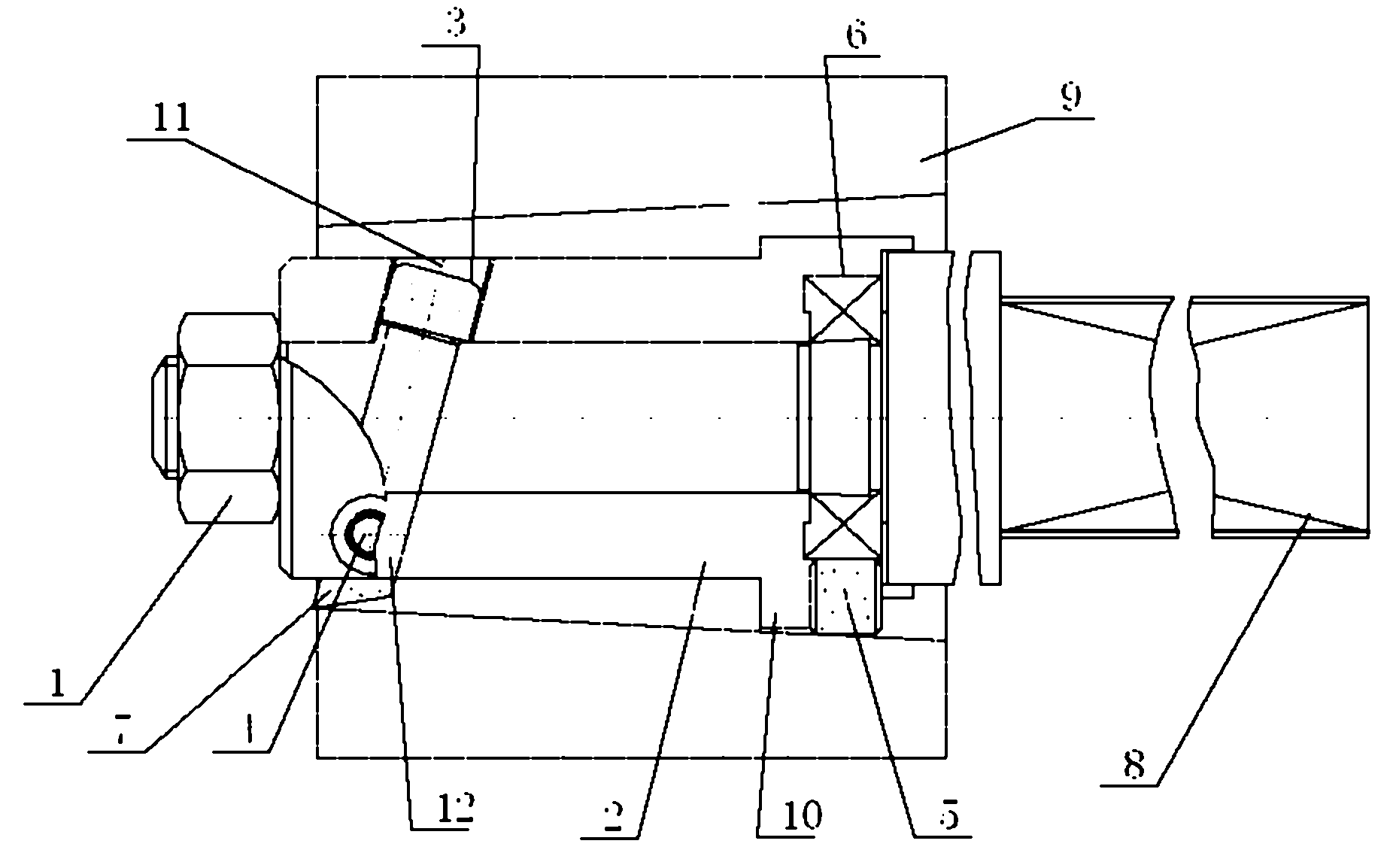

Combined turning rolling device used for processing taper hole

InactiveCN102107359AExtended service lifeGood size consistencyOther manufacturing equipments/toolsSurface roughnessProcessing cost

The invention relates to a combined turning rolling device used for processing a taper hole, wherein, two mechanically processing procedures are combined reasonably, so that the turning technology and the rolling technology can be achieved in the processing procedures during one cutting feed process, the matching quality can be improved, and processing cost is lowered; in addition, the surface roughness of an inner wall of the taper hole can be reduced to one to two stages by adopting the rolling technology, and the rigidity and the fatigue strength of an inner surface of the taper hole can be improved.

Owner:SHANDONG DONGYI MACHINERY MFG

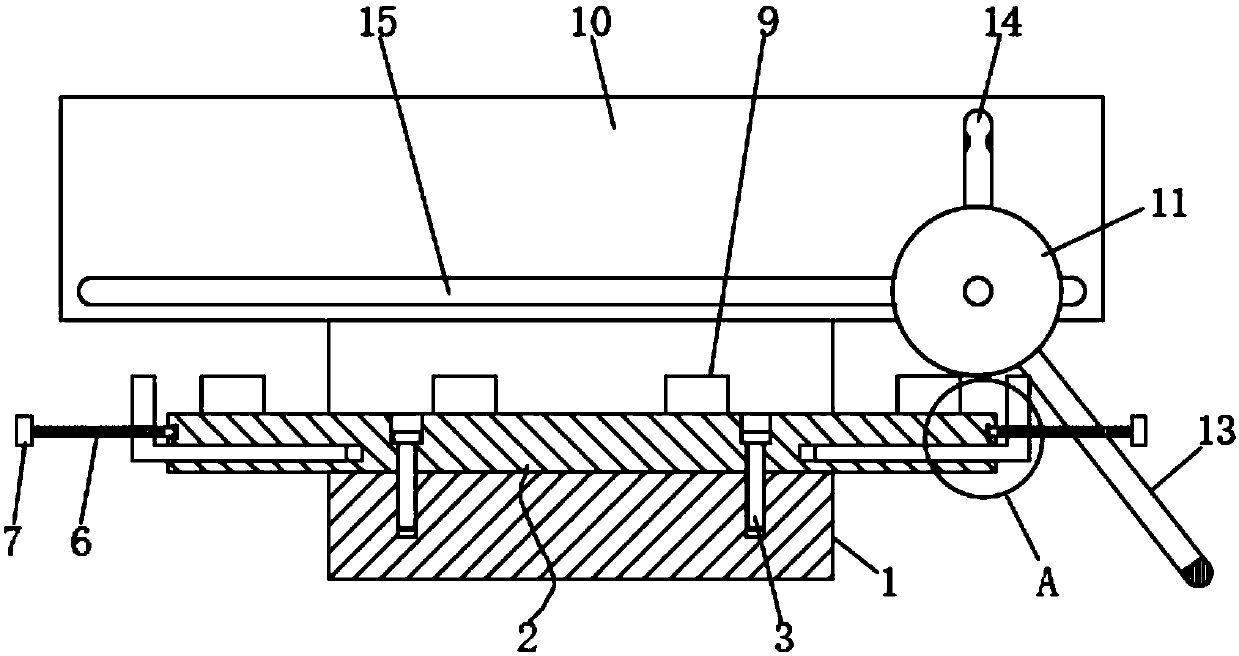

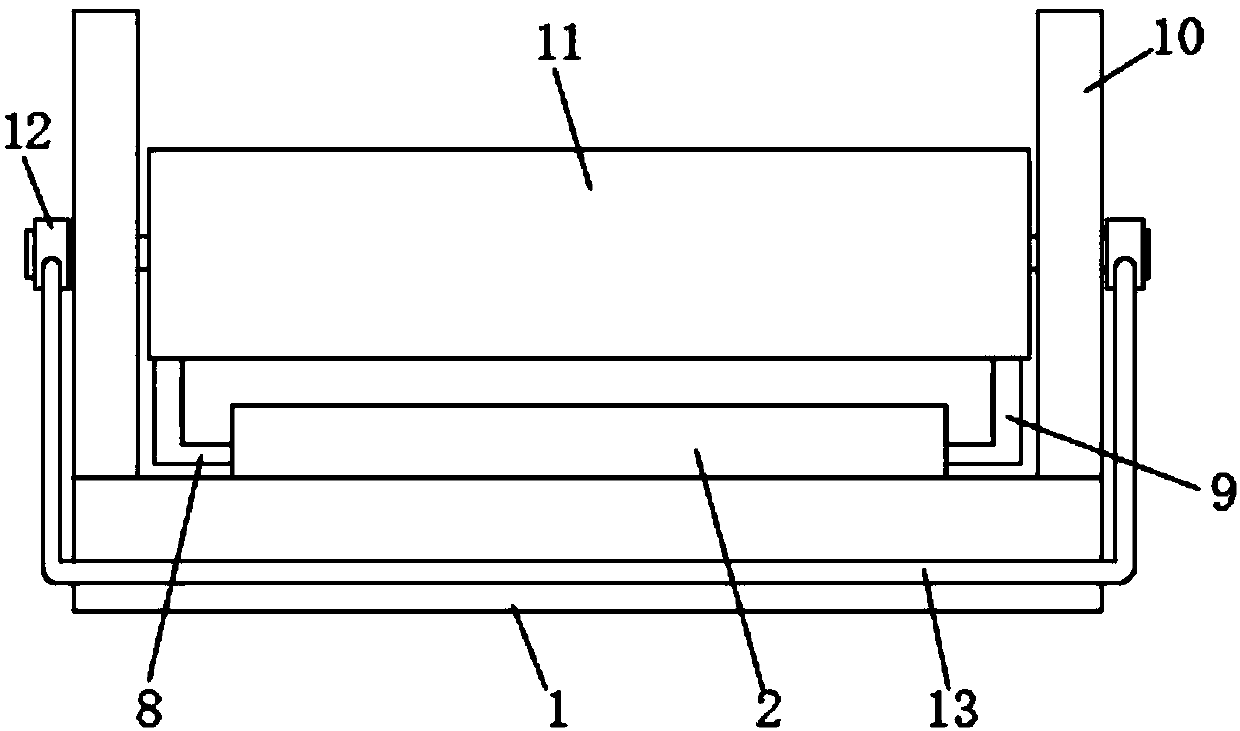

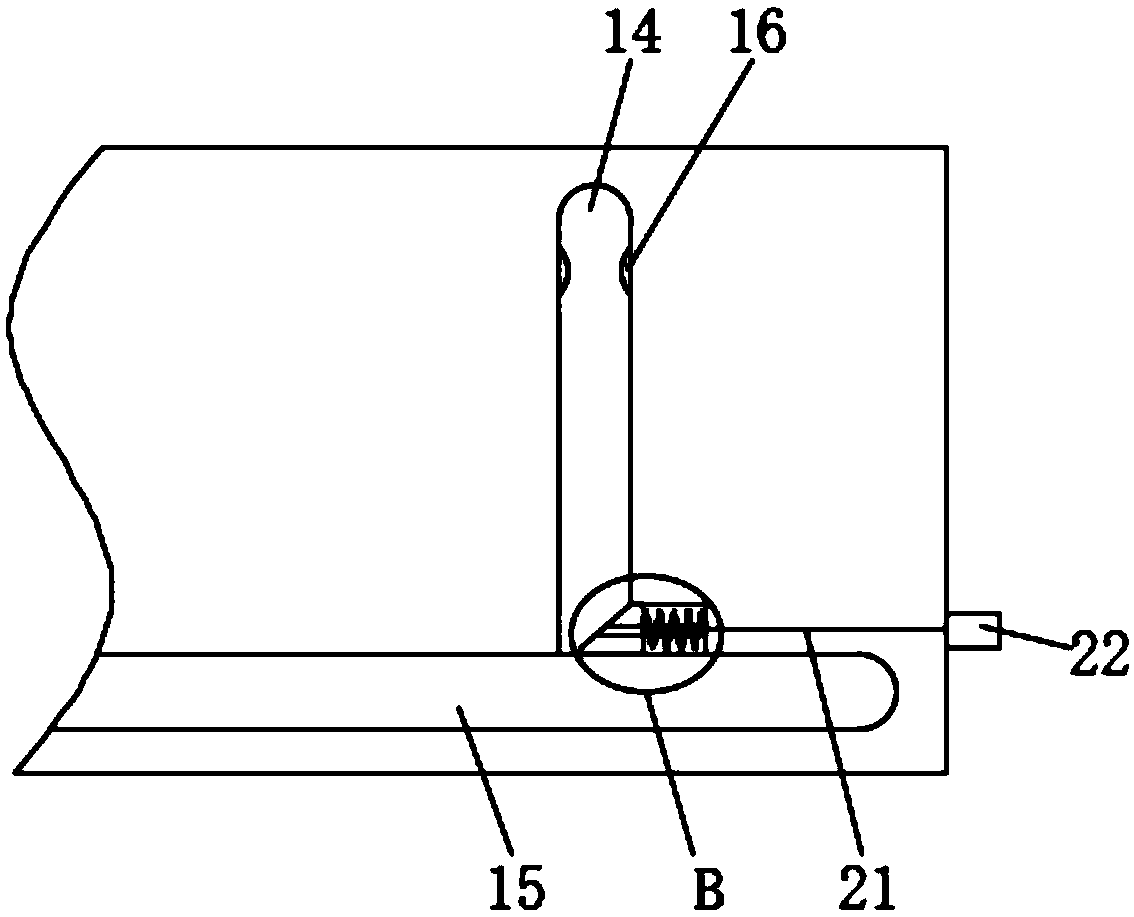

Lining machine for mobile phone polarizer with reliable alignment

The invention relates to a lining machine for a mobile phone polarizer with reliable alignment. A polarizer loading mechanism comprises a loading platform longitudinal lifting mechanism, a loading platform station switching mechanism and a polarizer loading platform, wherein the loading platform station switching mechanism is mounted on the loading platform longitudinal lifting mechanism; the polarizer loading platform is mounted on the loading platform station switching mechanism; the polarizer loading platform comprises a lining transferring base plate and a lining transferring hinge lateral plate; the lining transferring hinge lateral plate is mounted on the loading platform station switching mechanism; the lining transferring base plate is hinged with the bottom end of the lining transferring hinge lateral plate; a lateral edge of the lining transferring base plate opposite to a hinge point can be rotated along the longitudinal direction of the lining transferring hinge lateral plate; a lining transferring cylinder which is used for driving the lateral edge of the lining transferring base plate to rotate is connected with the lining transferring base plate; a polarizer aligning mechanism is mounted on the lining transferring base plate; a vacuum absorbing plate which is used for absorbing and fixing a polarizer is lined at the bottom of the lining transferring base plate; a high-speed camera is arranged on the lateral side of a vacuum absorbing base fixed by the lining transferring base plate. The lining machine for the mobile phone polarizer with reliable alignment has the advantages of reasonable lining action and high lining quality.

Owner:WENZHOU ZHIXIN ELECTROMECHANICAL TECH

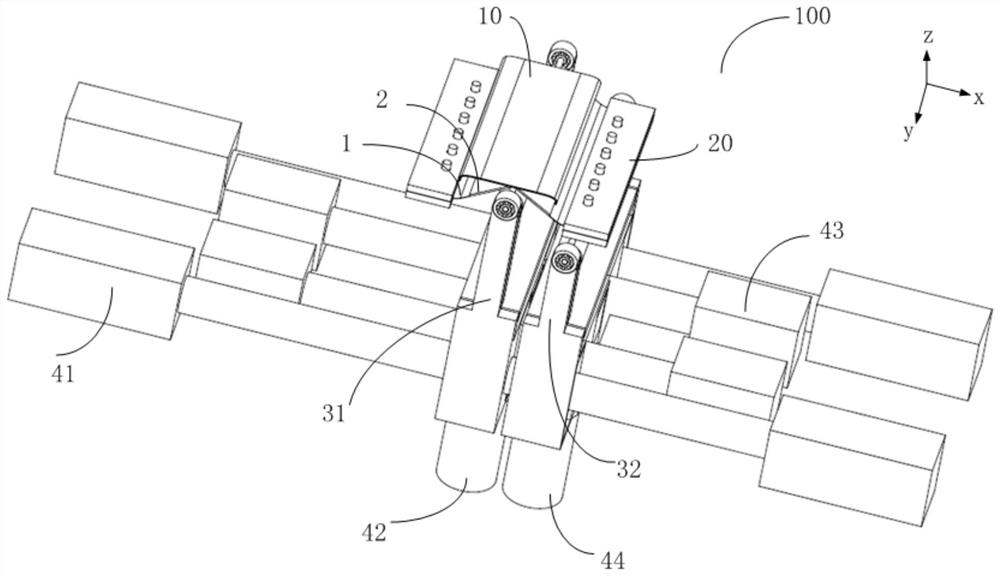

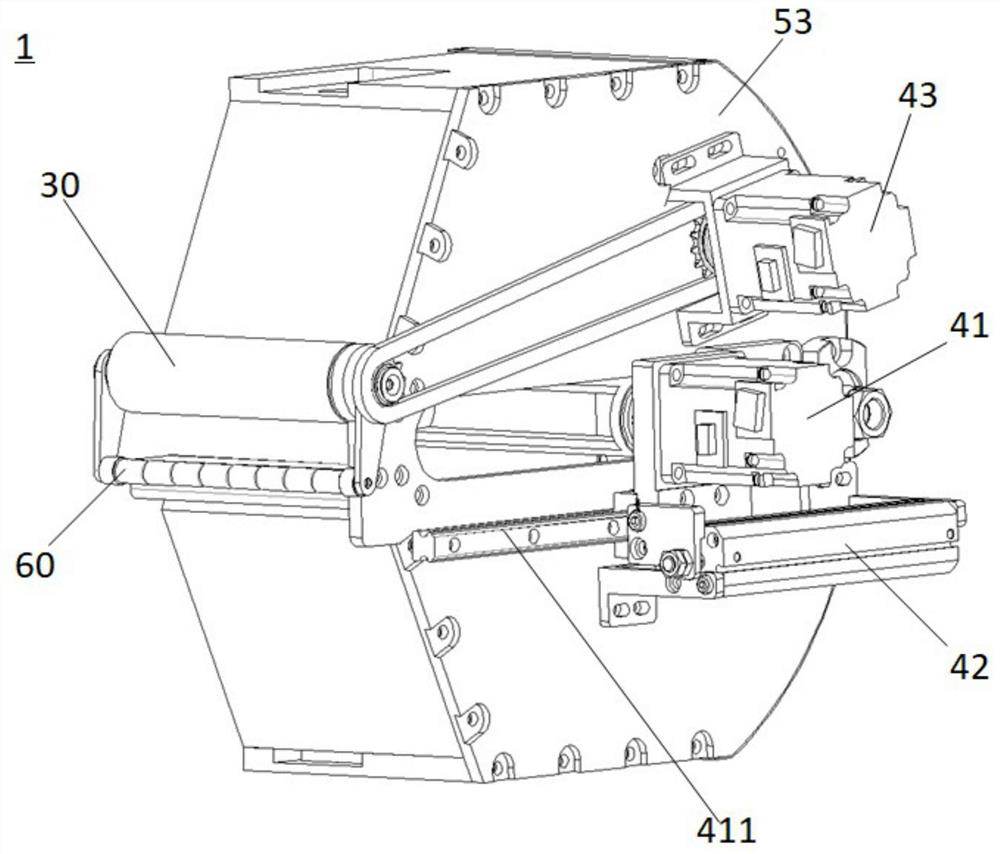

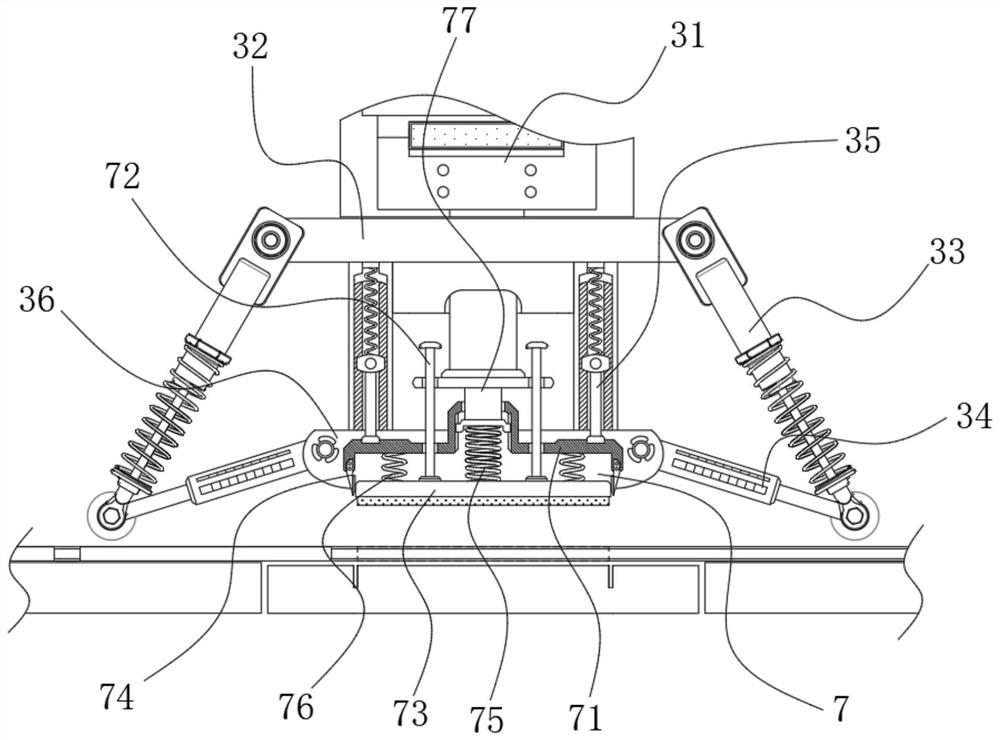

Attaching assembly, equipment and method for applying sound damper to inner surface of tire

The invention discloses an attaching assembly for applying a sound damper to the inner surface of a tire. The attaching assembly comprises a material receiving component, used for fixing a material head of the sound damper and storing a material, a pressing piece, used for pressing the material tail of the sound damper on the inner surface of the tire; and a first driving source, used for providing power to drive the material receiving component to rotate, wherein when the material receiving component receives the sound damper, the material head of the sound damper is fixed firstly, and then the first driving source drives the material receiving component to rotate so as to wind the sound damper into a roll; and when the sound damper is attaching, the sound damper wound into the roll may be released to attach the sound damper to the inner surface of the tire. The brand-new attaching assembly provided with the material receiving component, the first driving source and the pressing piece is designed, so that the strip-shaped sound damper is automatically received, wound into the roll, and unwound and attached, and the technical effects of being simple in structure, convenient to use, low in cost, high in mute material attaching quality and the like are achieved.

Owner:LINK-ASIA SMART TECH (SUZHOU) CO LTD

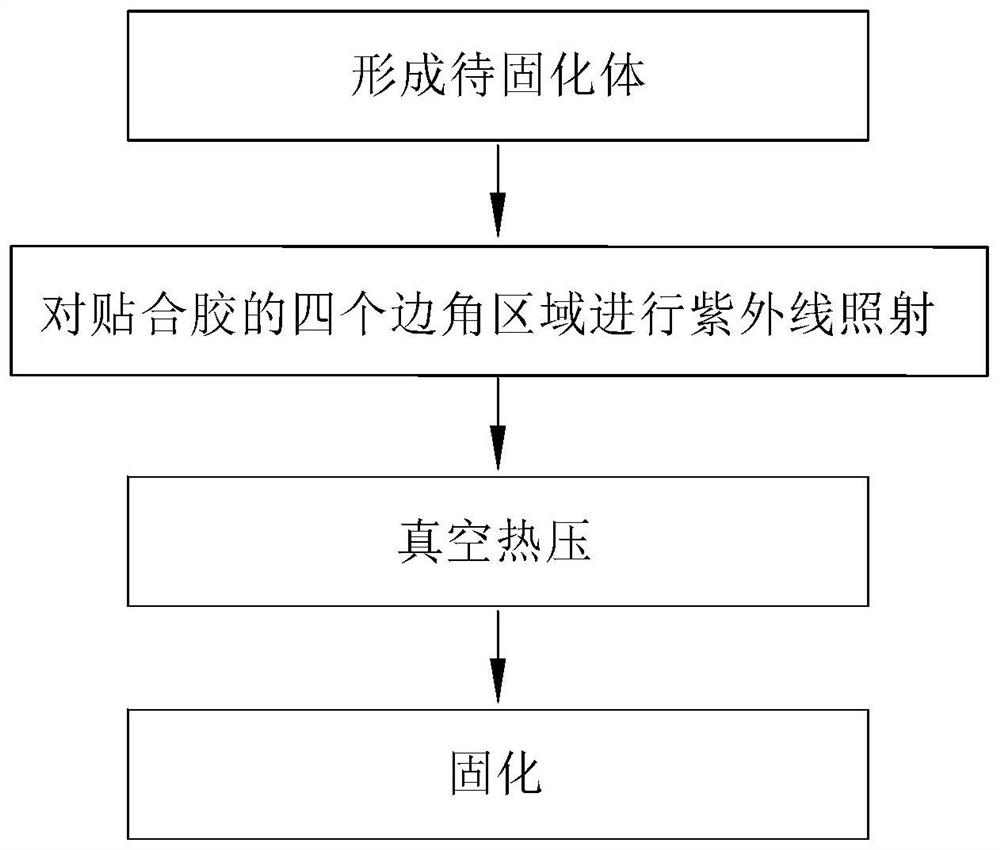

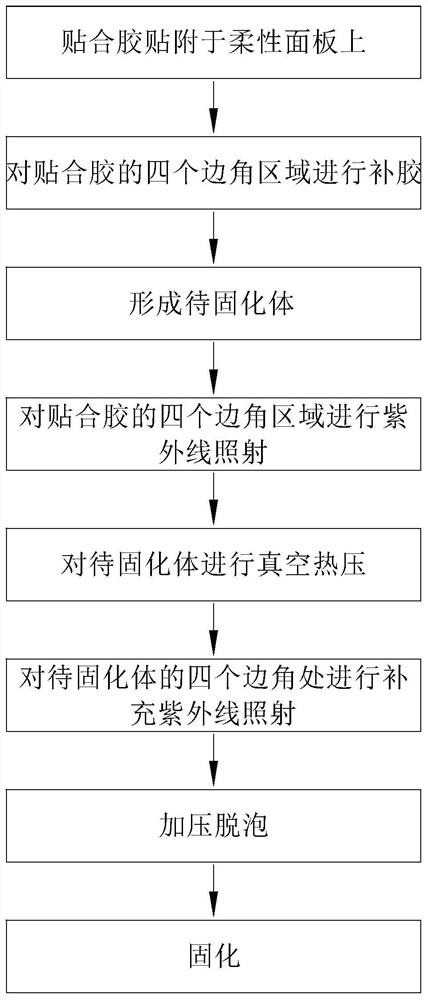

Four-side curved display screen laminating process

ActiveCN112652243AImprove fit qualityImprove the display effectIdentification meansAdhesiveMechanical engineering

The invention discloses a four-side curved display screen laminating process which comprises the following steps: attaching a flexible panel and a protective panel to two sides of a laminating adhesive to form a to-be-cured body, and before vacuum hot pressing of the to-be-cured body, carrying out ultraviolet irradiation on four corner areas of the laminating adhesive to cure the to-be-cured body. According to the four-side curved display screen laminating process, before vacuum hot pressing, ultraviolet irradiation is carried out on the four corner areas of the laminating adhesive firstly, so that the laminating adhesive in the areas has certain bonding force, rebound of the laminating adhesive is avoided, the flowability of the laminating adhesive in the areas after melting is reduced, and the laminating glue in other areas continuously flows and fills the four corners to discharge bubbles at the corners, so that the flexible panel and the protective panel are laminated more smoothly, and the laminating quality and the display effect of a four-sided curved display screen are improved.

Owner:深圳一鑫新材料有限公司

Curved label sticking mechanism and sticking method thereof

ActiveCN105600049AImprove bonding efficiencyImprove fit qualityLabelling machinesEngineeringMotor module

The invention relates to a curved label sticking mechanism which comprises a mounting rack, a triaxial adjusting module arranged on the mounting rack, a rotary motor module connected to the triaxial adjusting module, a profile sticking device connected to the rotary motor module and a profile modeling device matched with the profile sticking device for use. The invention relates to a curved label sticking mechanism and a sticking method thereof. The curved label sticking mechanism is capable of automatically performing profile modeling on curved labels, and the profile sticking device is utilized for sticking the profiled curved labels, so that the sticking efficiency and the sticking quality are improved.

Owner:BOZHON PRECISION IND TECH CO LTD

Double-plex extrusion linkage production line with turnover device

The invention discloses a double-plex extrusion linkage production line with a turnover device, which has good product quality and high production efficiency. The double-plex extrusion linkage production line comprises a double-plex extruder unit which comprises a first extruder, a second extruder and a complex head, the back side of the complex head is provided with a track which is connected with a receiving roll in a relative rotation way, the tract at the back side of the complex head is sequentially provided with a pre-turnover roll, a turnover roll, a leveling roll and a belt pressing roll in a relative rotation way, the pre-turnover roll, the turnover roll, the leveling roll and the belt pressing roll are all positioned above the receiving roll, the pre-turnover roll is slantly arranged, the turnover roll is vertically arranged, the leveling roll and the belt pressing roll are horizontally arranged, and the horizontal position of the leveling roll is higher than that of the belt pressing roll. The pre-turnover roll is arranged on the tract through a pre-turnover roll connecting seat which is provided with a plurality of pre-turnover roll regulation holes. The turnover roll is arranged on the tract through the turnover roll connecting seat which is provided with a carrier roll in a relative rotation way.

Owner:八亿橡胶有限责任公司

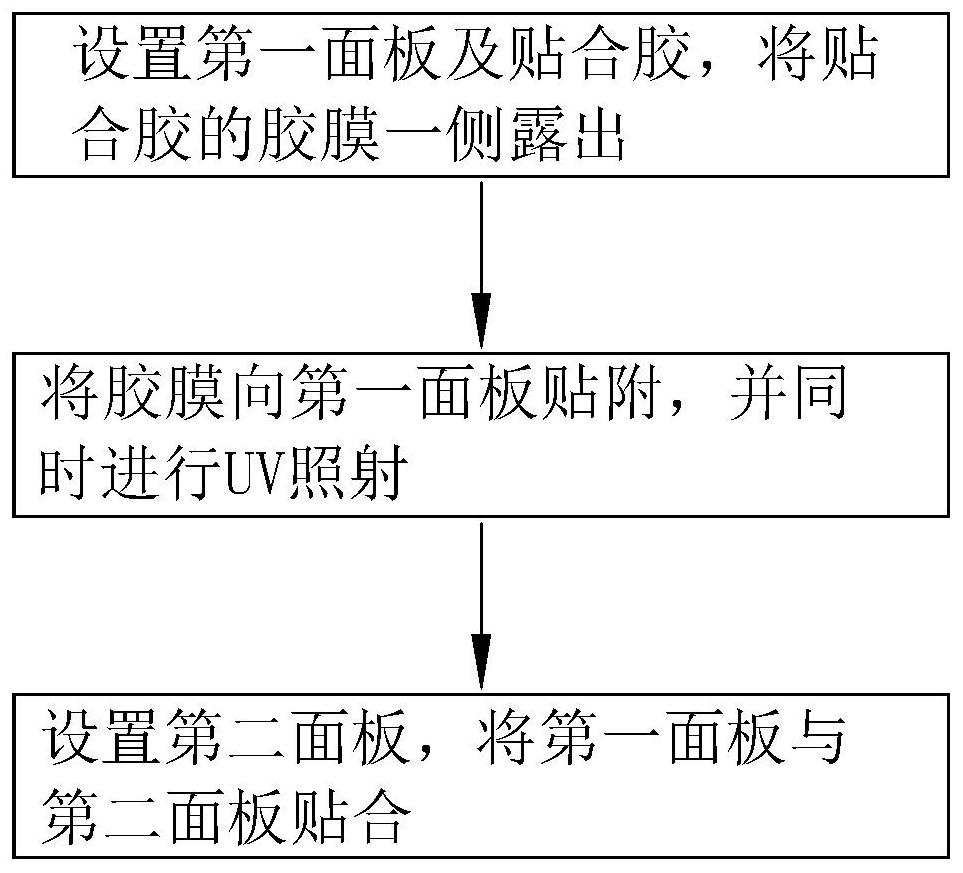

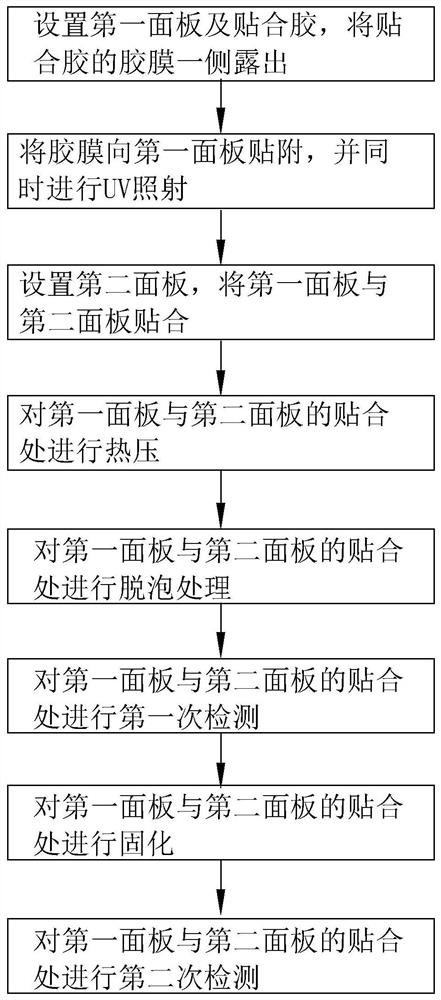

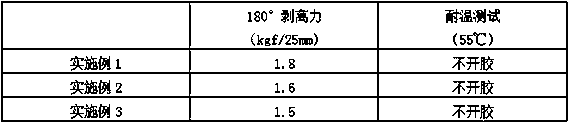

Display screen laminating process and display screen

ActiveCN111806052ASelf-adhesivePrevent overflowLaminationLamination apparatusMembrane surfaceEngineering

The invention discloses a display screen laminating process and a display screen. The display screen laminating process comprises the steps that: arranging a first panel and an attaching glue, whereinthe attaching glue comprises a release film with a glue film attached to the surface of the glue film, the release film on one side of the attaching glue is torn off to expose the glue film, the gluefilm is attached to the first panel, UV irradiation is conducted on the glue film at the same time; arranging a second panel, and attaching the first panel and the second panel together; preparing the display screen by using the above process. According to the display screen laminating process, the glue film can be excited in advance, the adhesive force and the bonding degree between the glue film and the first panel are improved, and the glue film is prevented from being taken away from the first panel in the release film tearing process; besides, in the hot pressing process of the glue film, after a hot pressing plate is lifted up, the edge of the glue film is prone to rebounding to cause excessive glue on the edge of the panel, UV irradiation is conducted on the glue film in advance, on one hand, certain adhesive force exists between the glue film and the panel, rebounding of the glue film is avoided, on the other hand, overflowing of the glue film can be avoided, and the attachingquality of the display screen is improved.

Owner:深圳全息界科技有限公司

Environment-friendly slowly-cured TPU hot melt glue film for insole and production method of environment-friendly slowly-cured TPU hot melt glue film

InactiveCN109679557AImprove fit qualityAvoid harmPolyureas/polyurethane adhesivesMacromolecular adhesive additivesEnvironmentally friendlyMelt flow index

The invention relates to an environment-friendly slowly-cured TPU hot melt glue film for an insole and a production method of the environment-friendly slowly-cured TPU hot melt glue film, and belongsto the field of TPU new materials. The TPU hot melt glue film is prepared from the following components in percentage by weight: 50%-90% of TPU particles, 10%-40% of tackifying resin, and 4%-10% of afunctional additive, wherein the hardness of the TPU particles is 60-90 A, the melting point of the TPU particles is 50-100 DEG C, and the melt flow index of the TPU particles is 10-60 g / 10min@150 DEGC; the tackifying resin is C5 resin or C9 resin, the softening point of the tackifying resin is 80-100 DEG C, and the viscosity of the tackifying resin at 160 DEG C is 1000-6000 CPS; the functional additive is an antioxidant and an ultraviolet absorber; and all the components of the TPU hot melt glue film are placed in an extruder proportionally, and extruded by the extruder and then release paper is coated with all the components , rolling-up is conducted, and thus the TPU hot melt glue film can be prepared. The environment-friendly slowly-cured TPU hot melt glue film for the insole adopts environment-friendly TPU materials and is environmentally friendly, harm of white glue and yellow glue to the body of workers is avoided, the curing speed is low while the cost is saved, and thus the attaching quality between all layers of the insole is improved.

Owner:江苏和和新材料股份有限公司

Forming structure on packaging bag production device

InactiveCN113184249APrevent looseningNeat edgesWrapper twisting/gatheringSuccessive articlesEngineeringRoll film

The invention discloses a forming structure on a packaging bag production device. The forming structure comprises a shell frame, a tensioning device, a sealing device, a supporting flat plate, a conveying device and a main lifting machine; the tensioning device is arranged above the shell frame and used for fixing a packaging roll film and adjusting the tension degree of the film; the shell frame is arranged at the bottom end; the supporting flat plate is fixed to the upper end face of the shell frame; multiple sets of square holes are formed in the supporting flat plate in a circumferential arrangement manner; the sealing device is arranged over the square hole close to the left side; the main lifting machine drives the sealing device to be integrally pressed downwards and lifted upwards, and the packaging film is subjected to heat sealing and cutting; the conveying device is arranged below the supporting flat plate and used for rotationally conveying packaging bags; and a leftover material collecting chamber and a packaging bag collecting chamber are arranged on the left side and the right side of the shell frame correspondingly.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Glass-to-glass bonding device produced on basis of capacitive touch screen.

ActiveCN109605903AThe limit effect is stable and reliableImprove fit qualityLaminationLamination apparatusEngineeringMechanical engineering

The invention discloses a glass-to-glass bonding device produced on the basis of a capacitive touch screen. The device comprises a base seat and a bonding platform, the bonding platform is fixedly installed on the top wall of the base seat, two ends of the bonding platform are separately and movably provided with one first movable plate in an insertion manner, opposite ends of the two first movable plates are separately and vertically equipped with one first limiting plate, the two limiting plates are separately equipped with one adjusting bolt, and one end of each adjusting bolt is movably embedded on the bonding platform; and each adjusting bolt is in thread engagement with one corresponding first limiting plate, opposite ends of the two adjusting bolts are separately equipped with one rotary knob, and the outer side walls of two sides of the bonding platform are equidistantly and movably provided with a plurality of second movable panels in an insertion manner. According to the device disclosed in the invention, the high-efficiency and convenient bonding device is provided for the bonding process of a touch screen, the device has a wide application range, and can bond glass withdifferent sizes; and meanwhile the device is simple to operate, flexible and reliable when being used, reduces equipment outlay and improves working efficiency.

Owner:青岛欣晶玻璃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com