Patents

Literature

66results about How to "Precise process parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

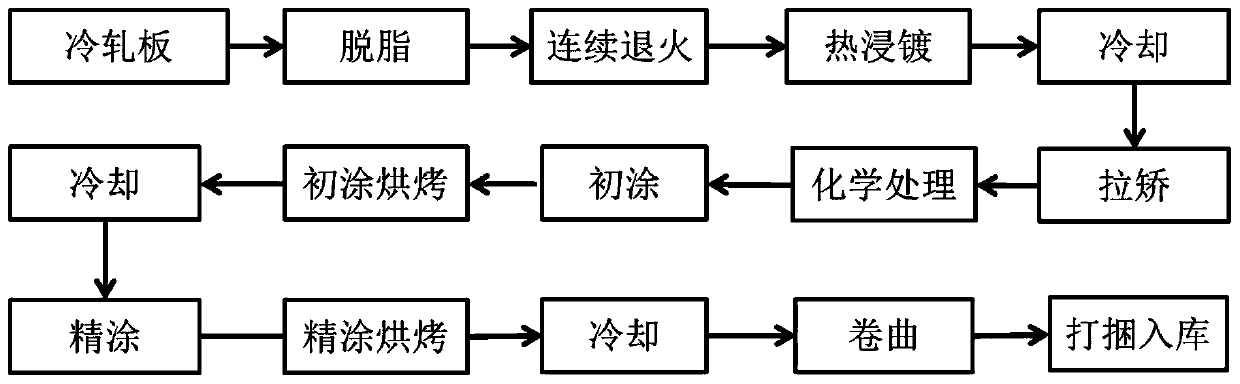

Aluminum foil and production method thereof

InactiveCN101956101AImprove surface qualityHigh strengthMetal rolling arrangementsHigh surfaceUltimate tensile strength

The invention discloses an aluminum foil and a production method thereof. The aluminum foil comprises the following components in percentage by weight: 0.57-0.63 percent of Si, 0.77-0.83 percent of Fe, not more than 0.05 percent of Cu, not more than 0.05 percent of Mn, not more than 0.05 percent of Mg, not more than 0.05 percent of Cr, not more than 0.05 percent of Zn, not more than 0.05 percent of Ti and the balance of Al. The method comprises the concrete steps of smelting, casting, cold rolling, intermediate annealing and foil rolling. The invention has the advantages that the aluminum foil for producing explosion foil can be produced according to the improvement on the production method and the accuracy of process parameters and has the advantages of high surface quality, high strength, favorable cracking strength and high stability for cold rolling as well as improved production efficiency and finished product rate.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Technology method for connecting three-body structure of titanium aluminum alloy turbine rotation shaft

InactiveCN101596665AAvoid shockAddress reliabilityBlade accessoriesMachines/enginesInterference fitImpeller

The invention relates to a technology method for connecting a three-body structure of a titanium aluminum alloy turbine rotation shaft, belonging to the technical field of mechanical processing technology design. The three-body structure of the titanium aluminum alloy turbine rotation shaft comprises a titanium aluminum alloy turbine impeller, a K418 high-temperature alloy transition sleeve and a 42 CrMo alloy steel shaft, wherein the K418 high-temperature alloy transition sleeve and the 42 CrMo alloy steel shaft rub through end surfaces and welded with each other, and then the K418 high-temperature alloy transition sleeve and the titanium aluminum alloy turbine rotation shaft are connected with each other through the interference fit of outside diameters and inside diameters. The invention has simple technology and stable and reliable stretch-proof strength and property.

Owner:CHINA NORTH IND GRP NO 70 RES INST +1

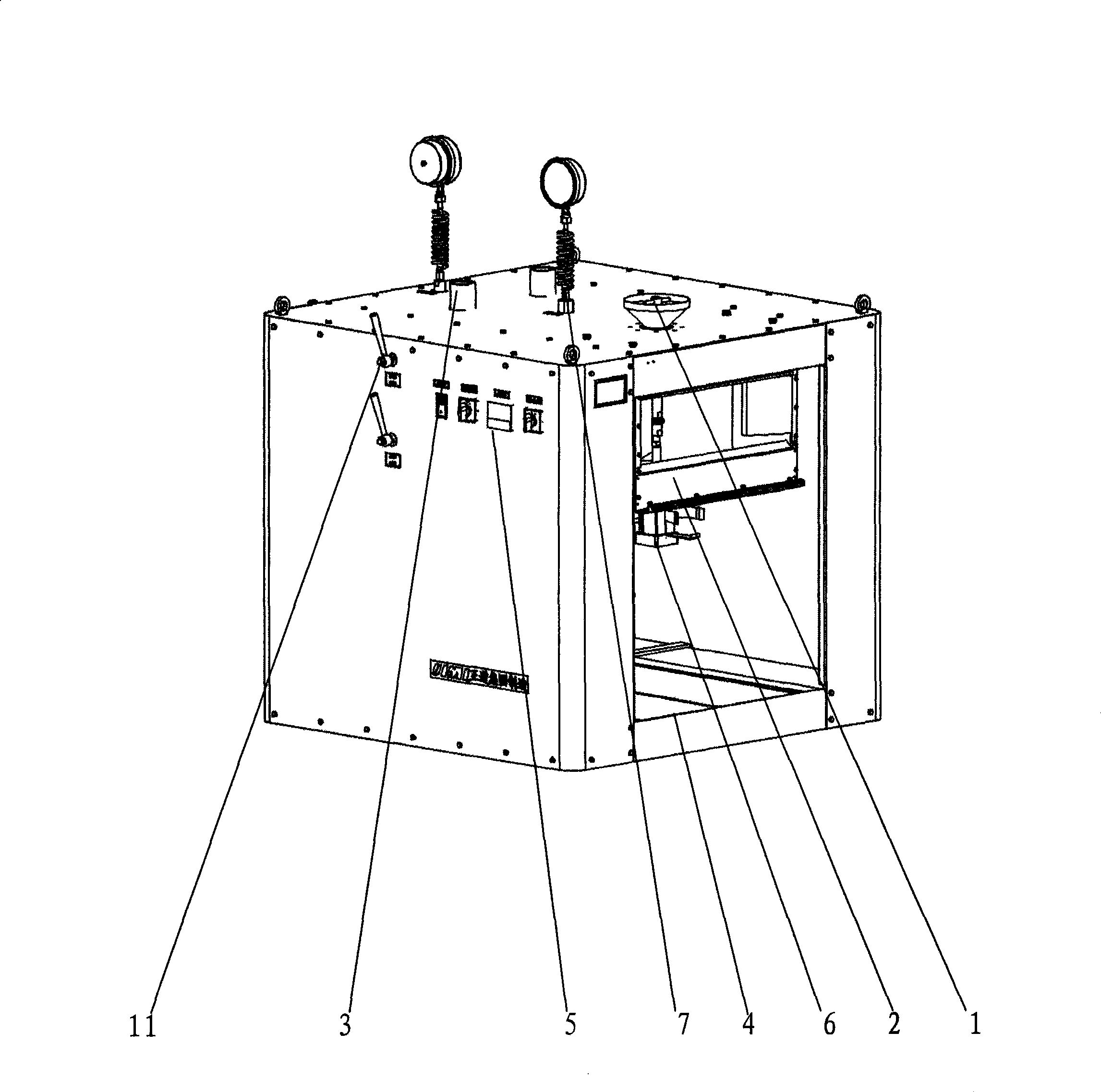

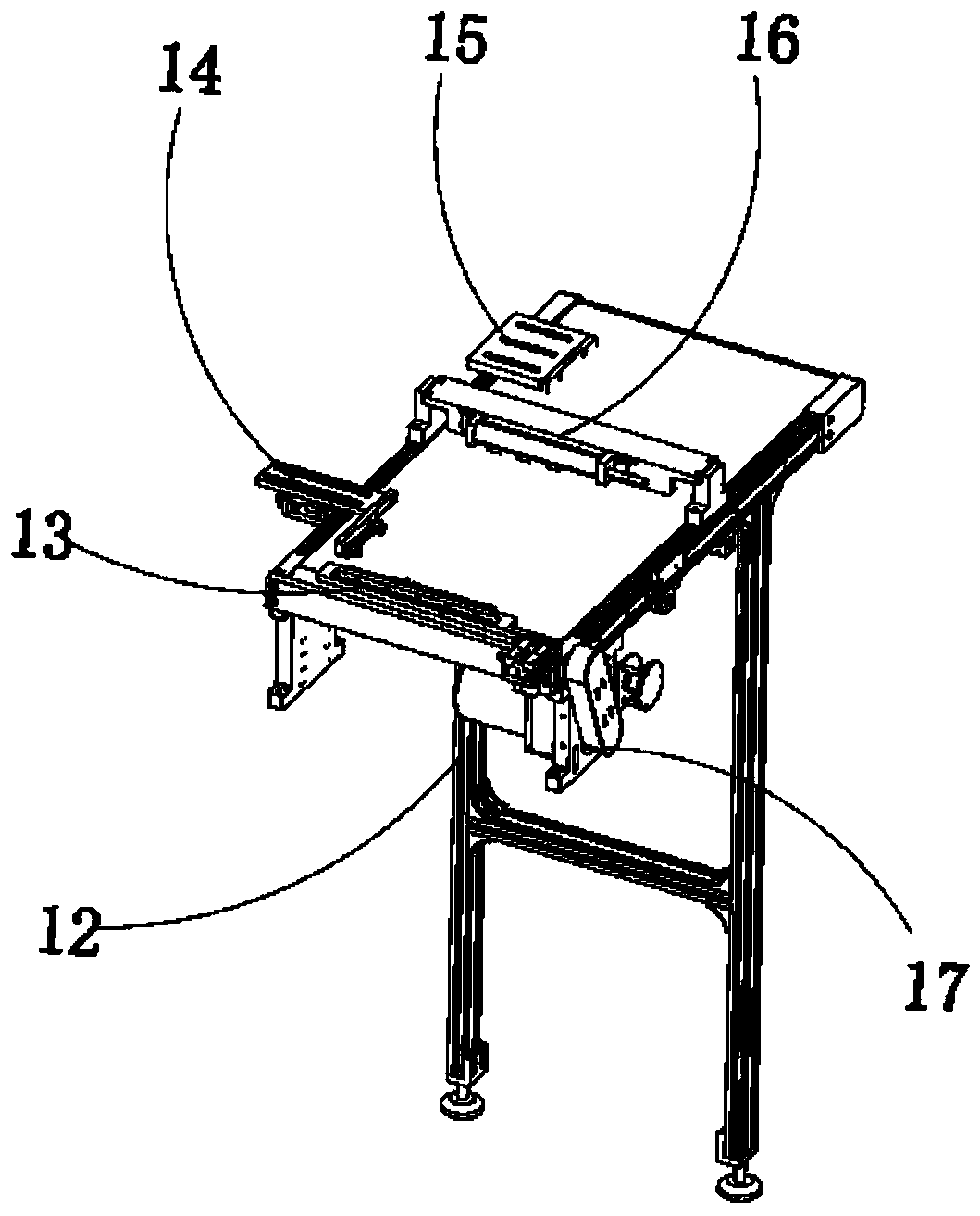

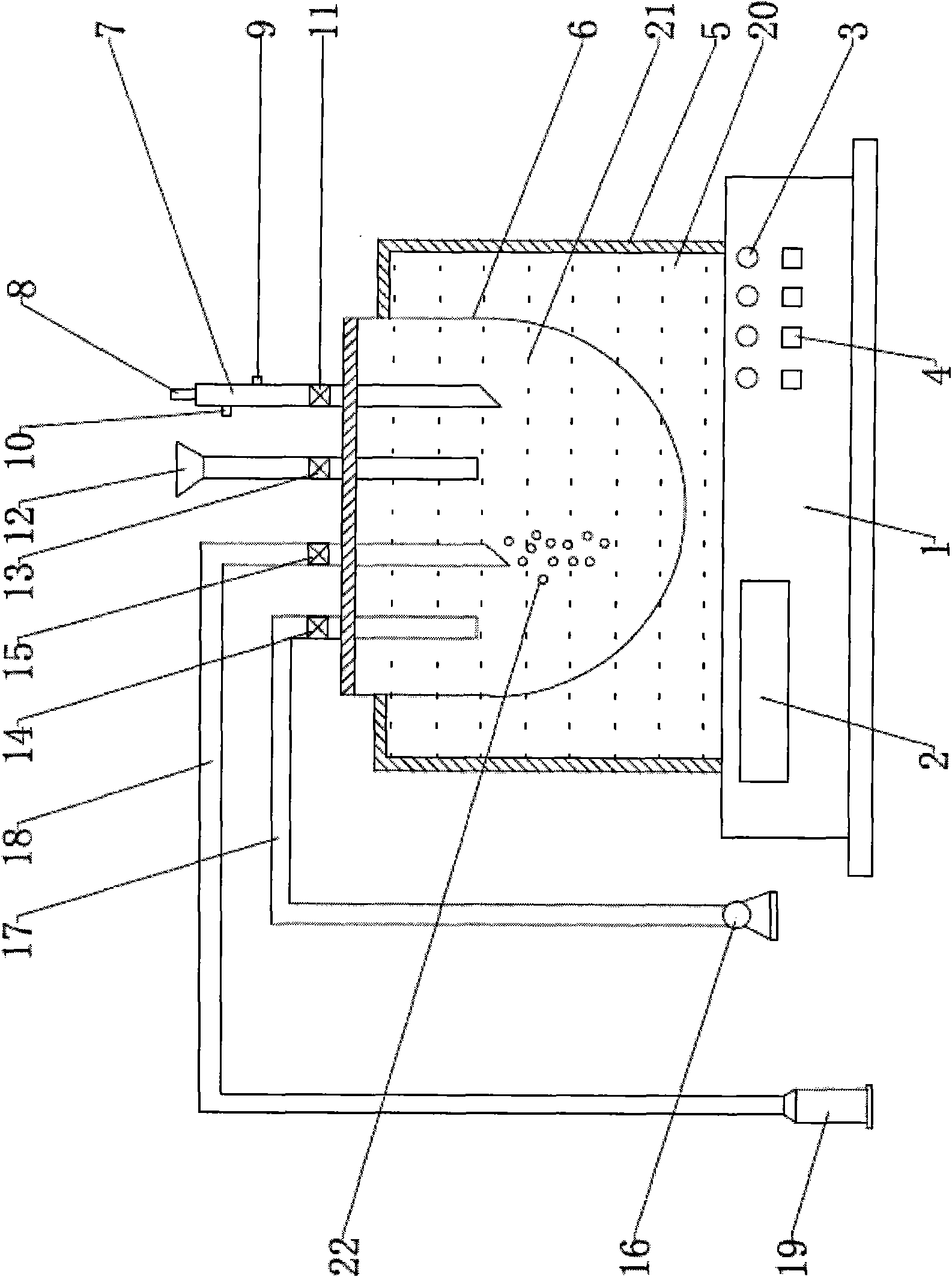

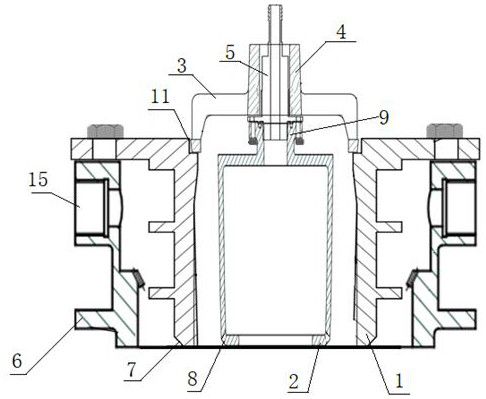

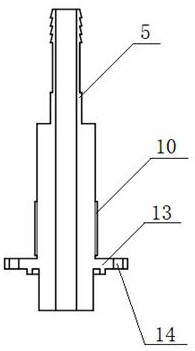

Steam explosion technique testing desk

InactiveCN101361588ADecompose fullyIncrease energy densityPressurized chemical processFood shapingFiberThermodynamics

The invention relates to a test device for determining parameters of steam explosion technology, belonging to physics test equipment. In the current technology mode, which realizes steam explosion through fast valve opening, long pressure release time reduces the energy density, so the material decomposition degree is low, little facilitating later enzymatic hydrolysis. The technological test bench based on the principle of cylinder explosion piston provided by the invention can finish the steam explosion within milliseconds, improving the energy density and fully decomposing the material. The technical principle of the test bench is also reflected in the design of industrial steam explosion devices, which accurately simulates the production environment for future industrialization of steam explosion and, thereby, accurately determining parameters of the steam explosion technology and providing fiber pretreatment materials for metaphase experiments of biochemical treatment such as enzymatic hydrolysis and the like. Experiments of the invention are relatively independent, creating conditions for contrast tests and final parameter determination.

Owner:于政道

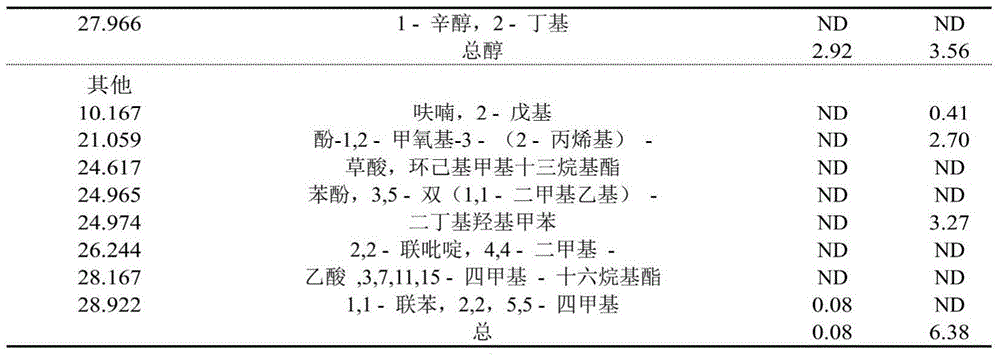

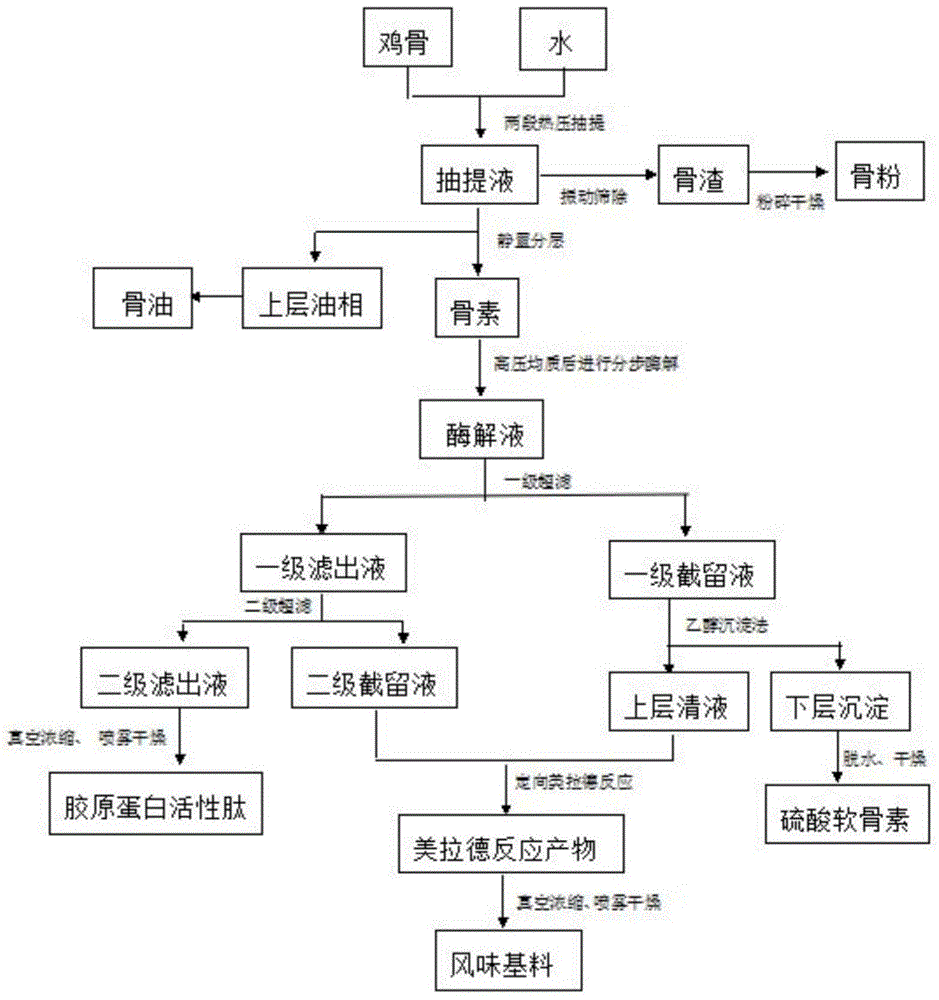

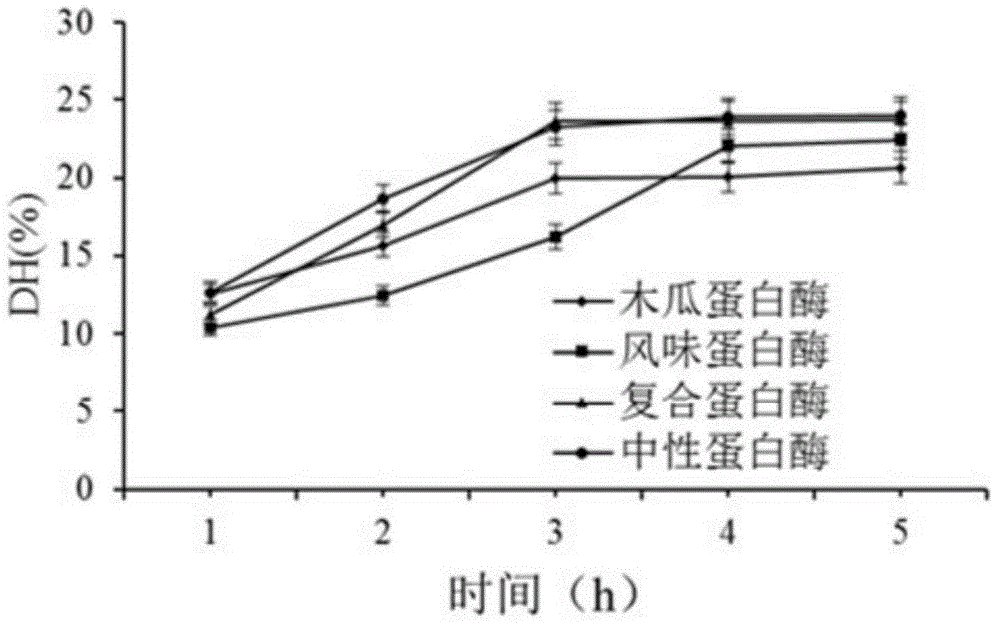

Method for coproducing collagen activity peptides and flavoured base materials with chicken bones

ActiveCN104095141AFacilitate physical disaggregationIncrease the degree of hydrolysisProtein foodstuffs working-upMaillard reactionFiltration

The invention discloses a method for coproducing collagen activity peptides and flavoured base materials with chicken bones. Through a two-step hot pressing and extracting method, and through slight pressure relief and pressure supplementation treatment, the yield of extracting the collagen activity peptides from the chicken bones is substantially increased. Through high-pressure homogenizing of osseins in extracting solutions before a step-by-step enzymolysis reaction of the osseins, the degree of hydrolysis of enzymolysis solutions is increased. In addition, two-step ultra filtration is performed on the enzymolysis solutions, and separation and purification of different products in the enzymolysis solutions are realized. Follow-up processing is performed aiming at the products of each molecule segment, different products of bone polysaccharide containing chondroitin sulfate, macromolecule polypeptide, micromolecule polypeptide and the like are obtained, making full use of ossein enzymolysis solutions is realized, and especially a Maillard reaction is performed on the macromolecule polypeptide, xylose, cysteine and thiamin to obtain the flavoured base material with a rich flavour.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

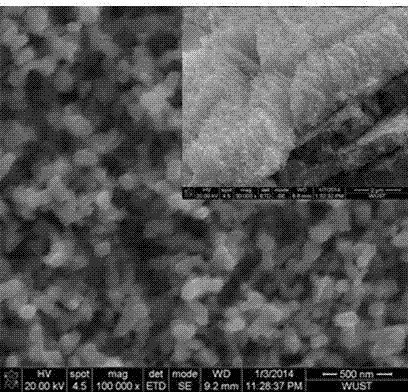

Pure iron based surface Fe3O4 nano-column array and preparation method thereof

InactiveCN104120481ANo pollution in the processSimple equipmentMaterial nanotechnologyAnodisationElectrolytic agentNanopillar

The invention particularly relates to a pure iron based surface Fe3O4 nano-column array and a preparation method thereof. The technical scheme of the invention is as follows: the method comprises the steps: carrying out anodic oxidation treatment on pure iron, which is subjected to surface pretreatment, in an ammonium fluoride-water-ethanediol system electrolyte; taking out, cleaning and drying through blowing; heating to the temperature of 400-800 DEG C from room temperature in a hydrogen atmosphere at the heating rate of 5-15 degrees centigrade per minute, carrying out heat preservation for 3-8 hours, and carrying out furnace cooling naturally, thereby preparing the pure iron based surface Fe3O4 nano-column array. The method is characterized in that in the ammonium fluoride-water-ethanediol system electrolyte, the mass percentage of ammonium fluoride is 0.2-0.5%, and the volume percentage of water is 1.5-3%; the anodic oxidation treatment is carried out under the conditions that the voltage is 20-60 voltage, the temperature is 20-60 DEG C and the time is 0.05-1 hour. The preparation method has the characteristics of simple process, environmental friendliness and low cost; the prepared pure iron based surface Fe3O4 nano-column array has the advantages that the structure is regular and orderly, the composition is uniform, the density of nano-columns is high, the specific surface area is large, the bonding with substrates is tight, and other impurity elements are not involved.

Owner:WUHAN UNIV OF SCI & TECH

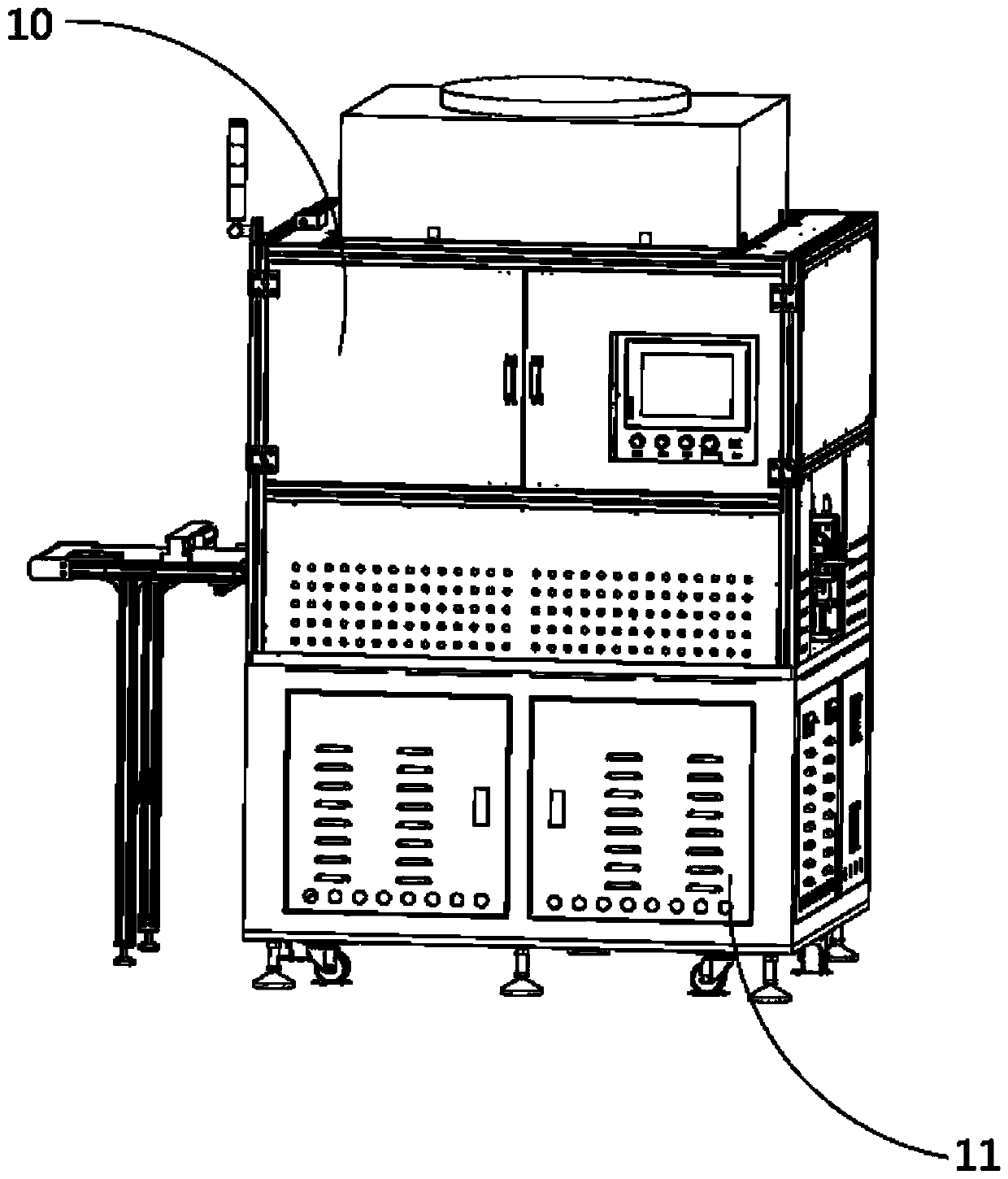

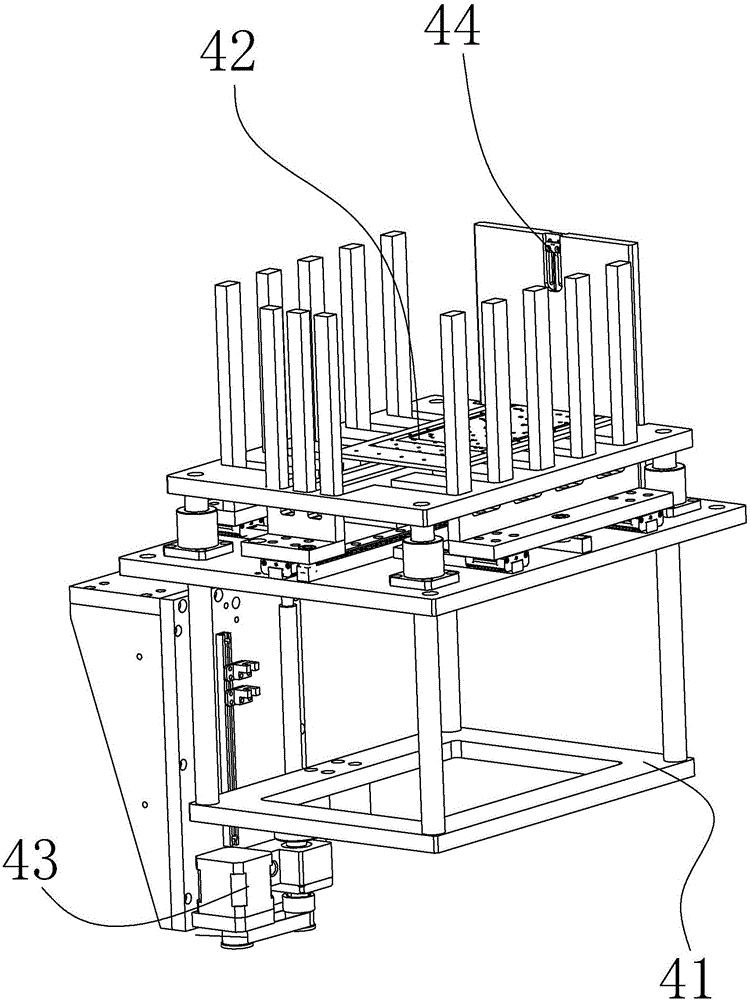

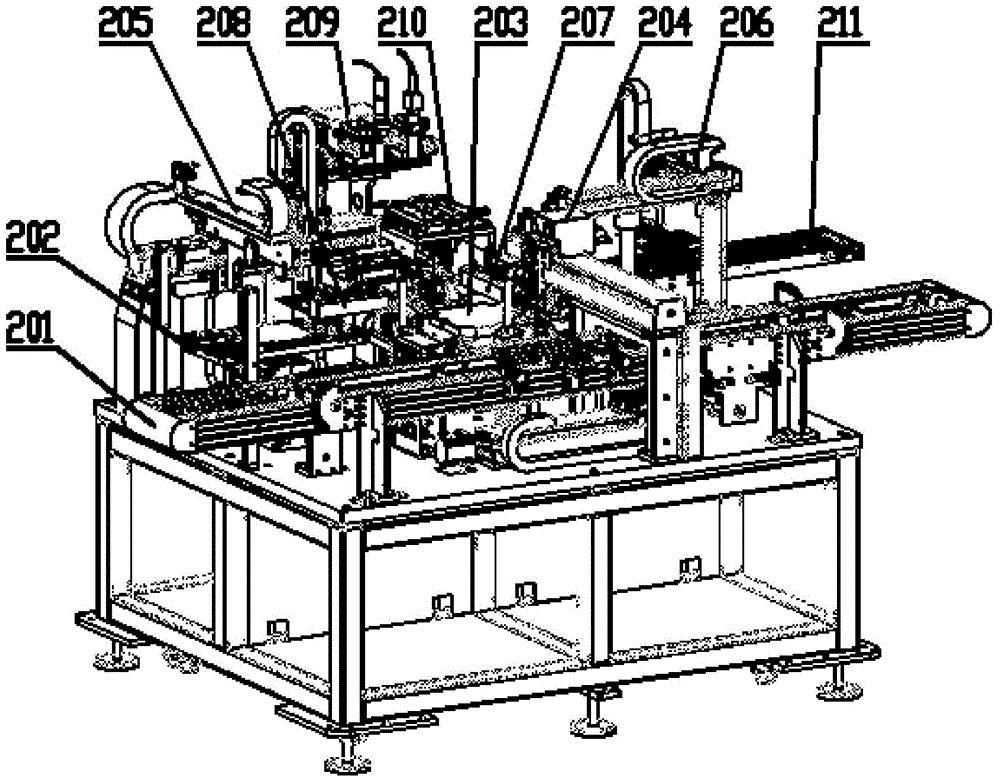

Device for tearing, cutting and pasting glass surface protection membrane

PendingCN110588125AImprove resection efficiencyHigh precisionLamination ancillary operationsLaminationTectorial membraneSeries production

The invention discloses a device for tearing, cutting and pasting a glass surface protection membrane. The device comprises a feeding mechanism, an alignment platform component, a working platform mechanism, a moving mechanism, a membrane tearing and pasting mechanism and a cutting mechanism, wherein the alignment platform component is used for holding glass to which a protection membrane is pasted and used for correcting and aligning the glass; the working platform mechanism is used for sucking the glass and used for moving the glass to a preset membrane tearing position; the moving mechanismis used for moving the glass on the feeding mechanism to the alignment platform component and used for moving the glass to the working platform mechanism after the glass is corrected; the membrane tearing and pasting mechanism is used for separating the glass from a part of the protection membrane on the glass and used for pasting the rest protection membrane to the glass; and the cutting mechanism is used for cutting a part of the protection membrane for a preset length. The device for tearing, cutting and pasting the glass surface protection membrane is beneficial to improvement of cuttingefficiency and cutting precision of the protection membrane, so that the purposes of lowering the labor cost,d improving the cutting quality and increasing the cutting speed can be achieved, in addition, the device is applicable to on-scale production, and the consistency of on-scale production can be improved.

Owner:SHENZHEN JIYIN TECH

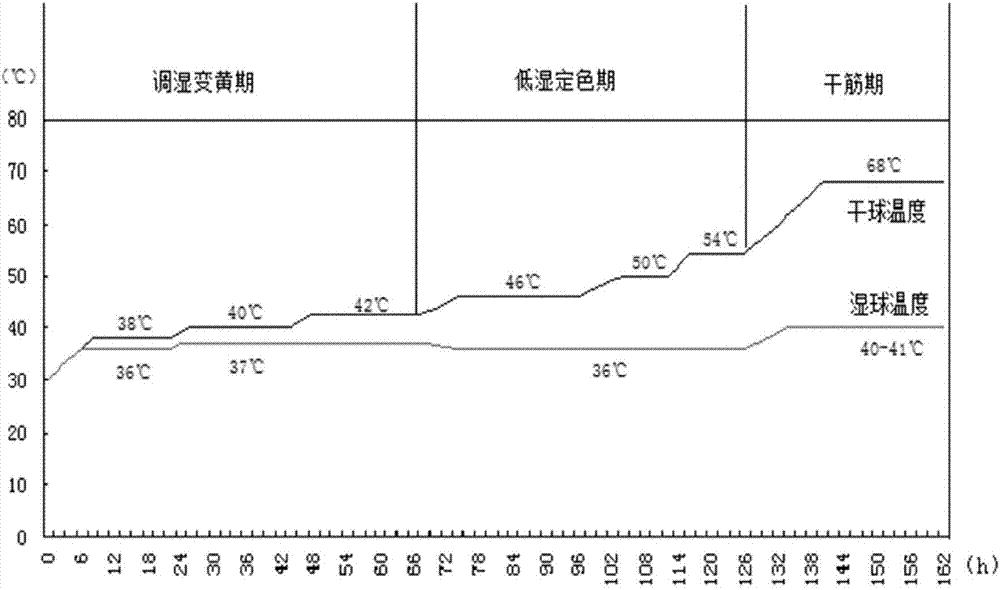

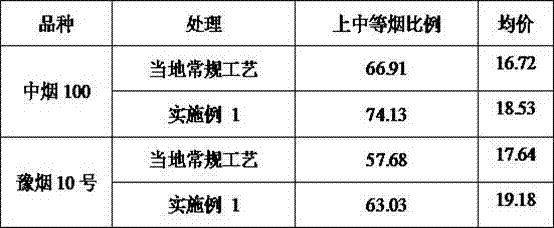

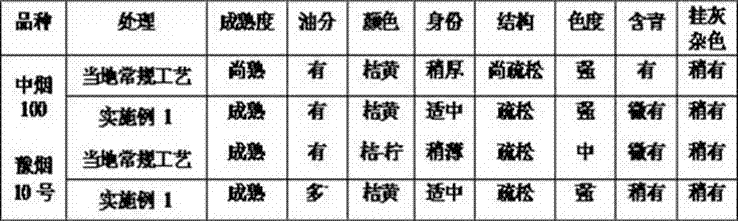

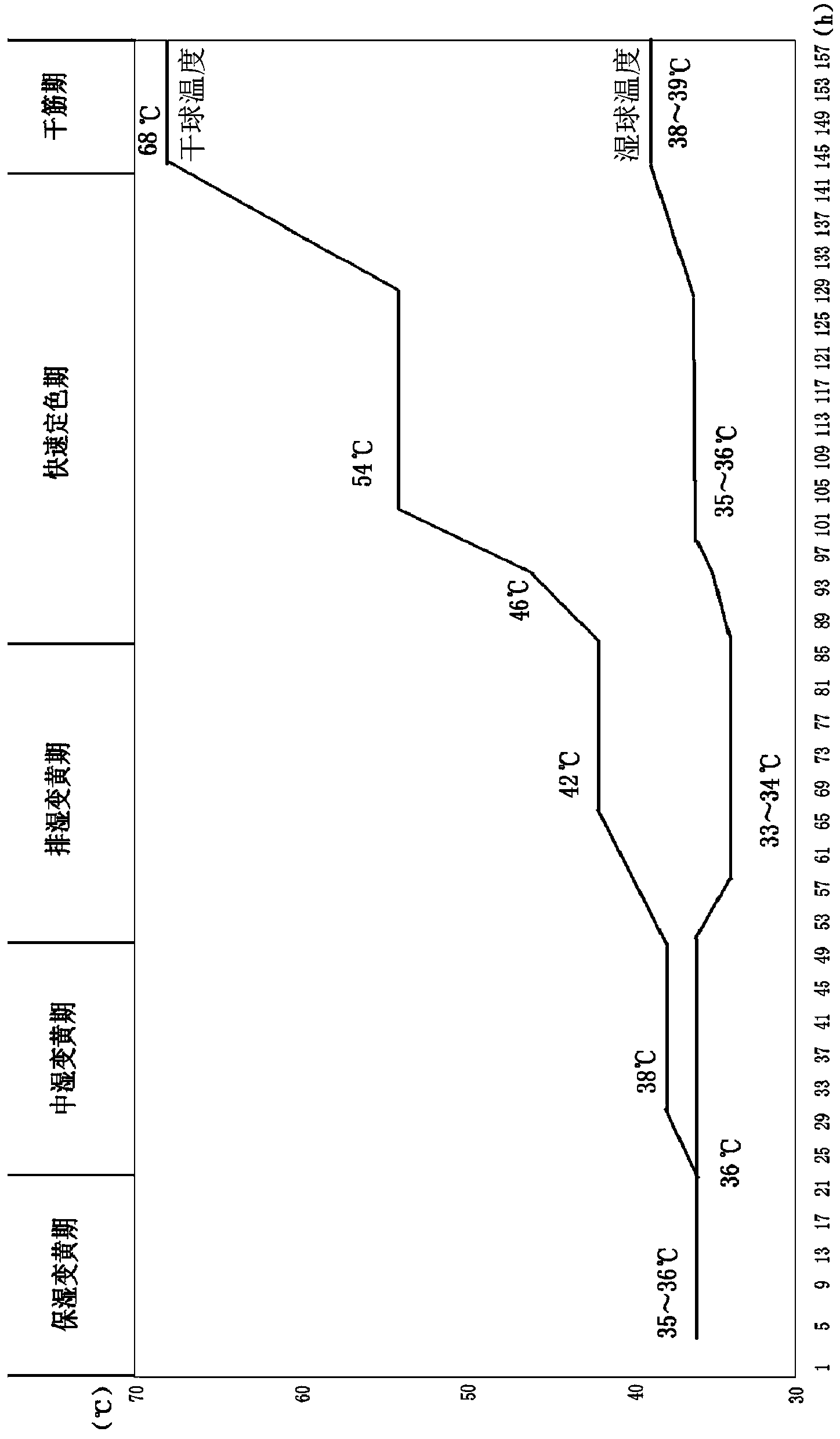

Special tobacco curing method for heat pump intensive curing barn

InactiveCN107348552ASolve the problem of difficult color settingPrecise process parametersTobacco preparationEngineeringMechanical engineering

The invention discloses a special tobacco curing method for a heat pump intensive curing barn. The special tobacco curing method for the heat pump intensive curing barn comprises the following steps of a humidifying and yellowing stage, a low-humidity color fixing stage and a rib-drying stage. After color fixing is finished, the temperature rises from 54 DEG C to 68 DEG C at a temperature rising speed of 1 DEG C / h and is kept stable, the wet-bulb temperature is kept stable at 40-41 DEG C until all tobacco leaves are rib-dried. The special tobacco curing method for the heat pump intensive curing barn has the positive beneficial effects that the specific technology parameters in all processes in the heat pump intensive curing process are precise, the curing procedures are simplified, and workload in the curing process is reduced; especially in the color fixing stage, the problem that color fixing is difficult in the prior curing process in a tobacco holding mode is solved effectively through the quick color fixing process, and operational implementation and popularization are easier.

Owner:TOBACCO RES INST HENAN ACADEMY OF AGRI SCI

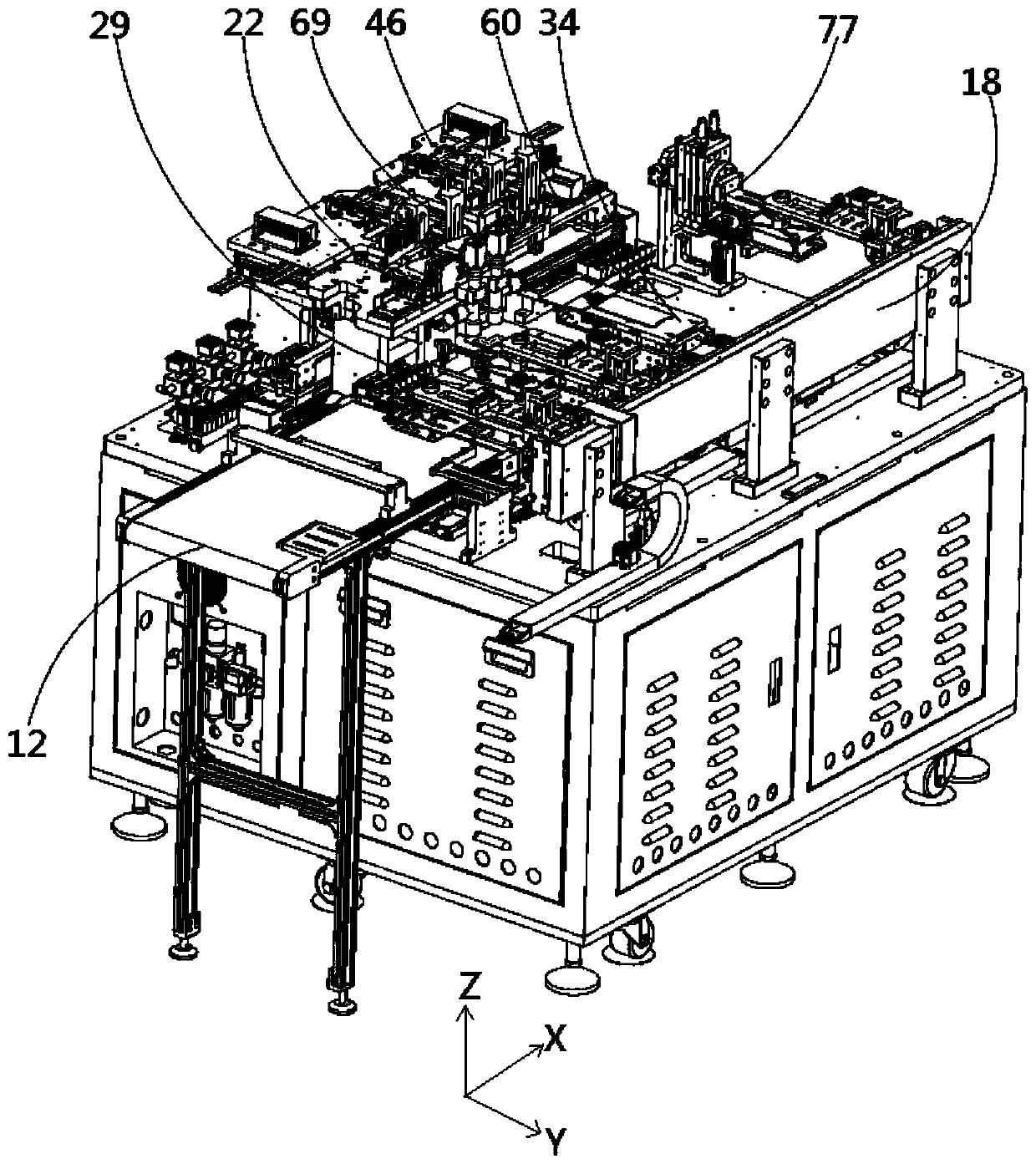

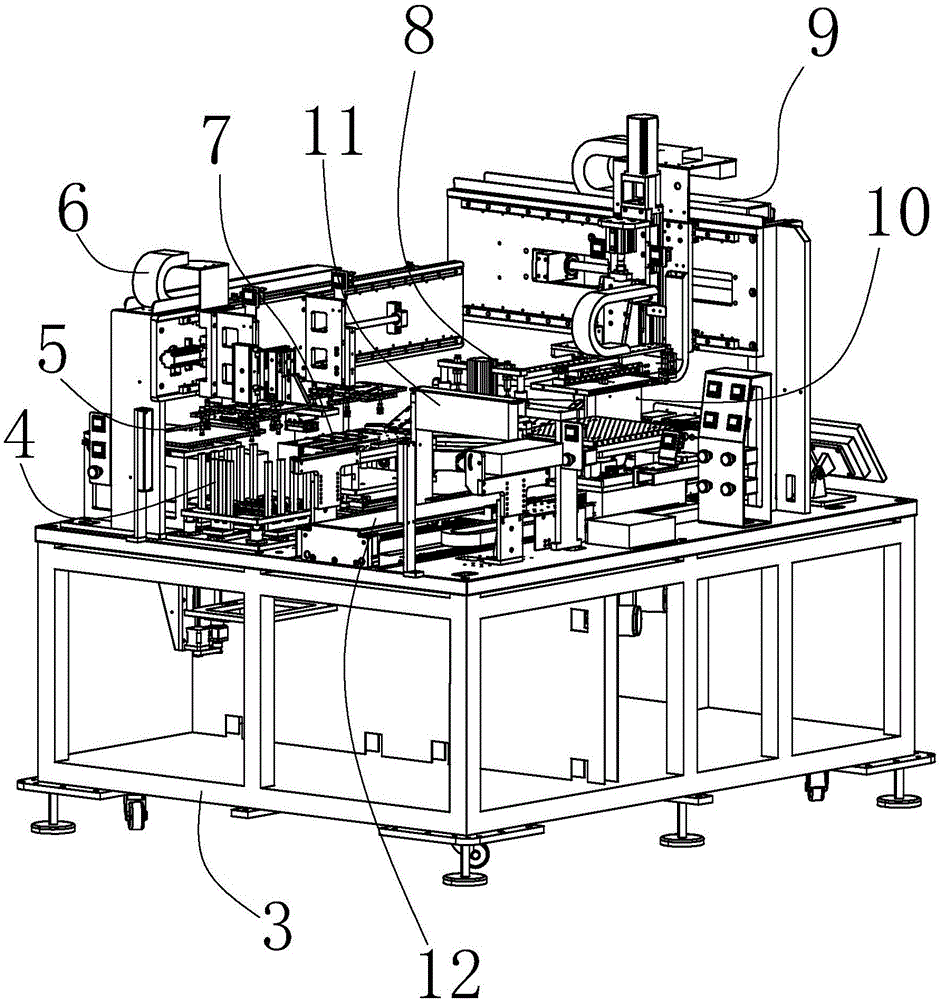

3D grating and LCD laminating machine, and laminating method using laminating machine

ActiveCN106379030AImprove consistencyPrecise process parametersLamination ancillary operationsControlling laminationGratingEngineering

The invention relates to a 3D grating and LCD laminating machine. The 3D grating and LCD laminating machine comprises an upper frame body, a lower frame body and a laminating rack, the upper surface of the laminating rack is respectively provided with a feeding mechanism, a single-piece detection and multiple-piece recovery mechanism, a fetching mechanism, a calibrating mechanism, a protection film tearing mechanism, a 3D grating and LCD laminating mechanism, a CCD image real-time contraposition mechanism, a bubble discharging mechanism and a discharging mechanism. The laminating machine can completely automatically substitute artificial operation without artificial lamination in use in order to obtain accurate technological parameters, so the manpower cost is reduced, and the laminating quality is improved; the laminating machine is suitable for batch production and realizes repeated dismounting and pasting, so improvement of the consistence of batch production is facilitated. Compared with laminating machines of the same products in the prior art, the laminating machine disclosed in the invention has the advantages of simplicity in operation, and convenience in realization of complete automation.

Owner:SHENZHEN JIYIN TECH

Stainless steel surface three-dimensional nanocarbon film and preparation method thereof

InactiveCN103882442ANo pollution in the processSimple structureAnodisationMetallic material coating processesCarbon filmArgon atmosphere

The invention relates to a stainless steel surface three-dimensional nanocarbon film and a preparation method thereof. According to the technical schem, the preparation method comprises the following steps: firstly, performing electrochemical anode oxidation treatment on stainless steel in a sodium dihydrogen phosphate solution, wherein the surface of the stainless steel is pretreated; then under a stirring condition, placing the stainless steel subjected to electrochemical anode oxidation treatment in a mixed solution of dopamine and trihytdroxy methyl-aminomethane for 4-24 hours, taking out and cleaning; then raising to 500-800 DEG C from a room temperature at a temperature raising rate of 5-15 DEG C / min in an argon atmosphere, insulating heat for 3-10 hours, and naturally cooling with a furnace to obtain the stainless steel surface three-dimensional nanocarbon film. The stainless steel surface three-dimensional nanocarbon film has the characteristics of simple process, environment friendliness and low cost; and the stainless steel surface three-dimensional nanocarbon film is regular and ordered in structure, uniform in components, high in nano hole density, large in carbon film specific surface area, controllable in pore diameter, pore depth and carbon film thickness, and compact in combination with a base material, and does not involve other impurity elements. According to the stainless steel surface three-dimensional nanocarbon film, the stainless steel corrosion resistance performance, the high temperature resistance, the electrochemical sensing performance and the biological medicine performance can be improved.

Owner:WUHAN UNIV OF SCI & TECH

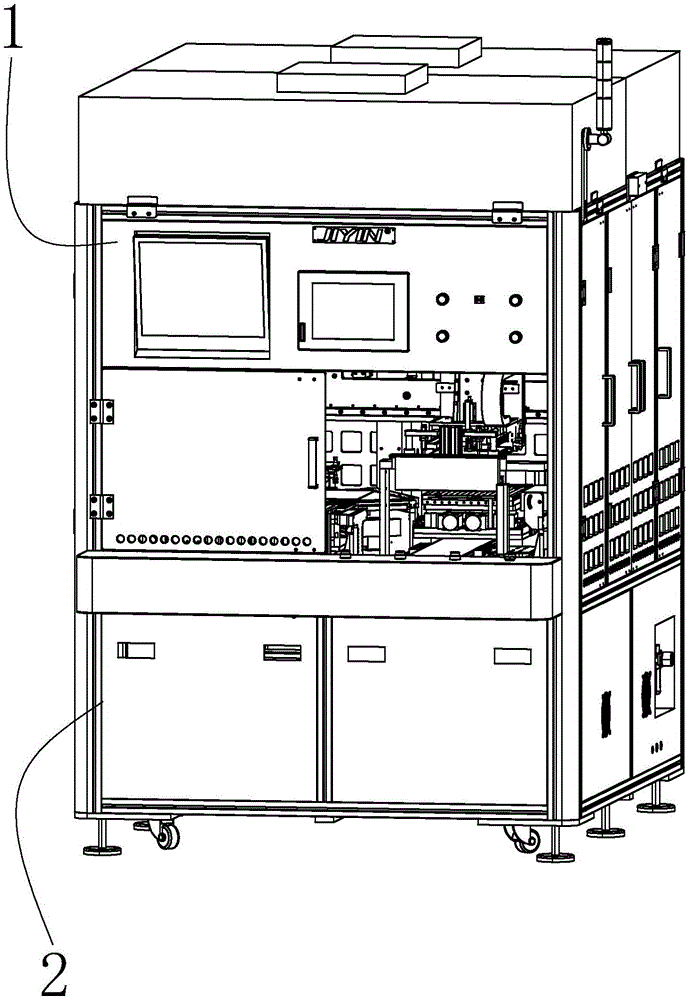

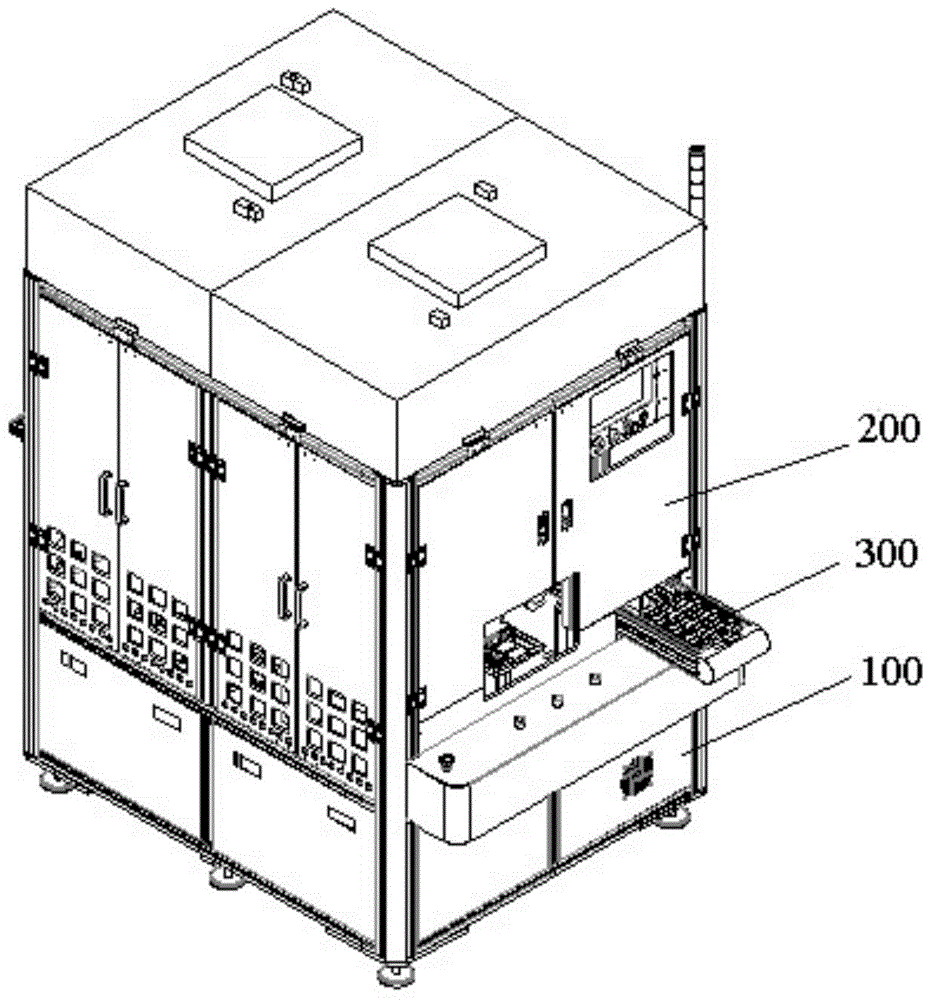

FPC light guide plate attaching machine

ActiveCN104816532ASolve the phenomenon of easy scratchesAdjustable pressureLaminationLamination apparatusLight guideEngineering

The present invention relates to the field of mobile phone backlight combination production equipment, particularly to an FPC light guide plate attaching machine, which comprises an upper cabinet and a lower cabinet, and comprises a first material feeding device fixedly arranged on the lower cabinet, a second material feeding device fixedly arranged on the lower cabinet, a third material feeding device fixedly arranged on the lower cabinet, a first material taking device fixedly arranged on the lower cabinet, a second material taking device fixedly arranged on the lower cabinet, a third material taking device fixedly arranged on the lower cabinet, a first destatic device fixedly arranged on the lower cabinet, a second destatic device fixedly arranged on the lower cabinet, a 2CCD image alignment device fixedly arranged on the lower cabinet, an FPC light guide plate attaching device fixedly arranged on the lower cabinet, a material discharge device fixedly arranged on the lower cabinet and an upper frame fixedly arranged on the lower cabinet, wherein the first material taking device, the second material taking device, the third material taking device, the 2CCD image alignment device, and the FPC light guide plate attaching device are positioned above the first material feeding device, the second material feeding device, and the third material feeding device. According to the FPC light guide plate attaching machine of the present invention, the technical disadvantages in the existing manual work can be overcome, and the productivity can be increased; the manual attaching is completely not required, the accurate parameters can be obtained, production switching is convenient, and the efficiency is high; and the problems of not high uniformity and low efficiency of the manual work can be solved.

Owner:SHENZHEN JIYIN TECH

Special tobacco curing method used for tobacco clamp packing mode in bulk curing barn

ActiveCN104366686ASimplify the baking processReduce workloadTobacco preparationCuring of tobaccoTobacco leaf

The invention belongs to the technical field of tobacco curing, and particularly relates to a special tobacco curing method used for a tobacco clamp packing mode in a bulk curing barn. The special tobacco curing method mainly includes a yellowing stage, a quick color fixing stage and a stem drying stage, wherein the yellowing stage comprises a moisture maintenance yellowing stage, a medium-moisture yellowing stage and a moisture eliminating yellowing stage; the quick color fixing stage comprises two temperature rising stages and a temperature stabilizing and color fixing stage. Process parameters in all stages of the curing process are made clear, indexes are clear, operations are easy and convenient, the difficult problems that tobacco leaves cannot become yellow sufficiently in a current production process and the color fixing process cannot be accurately controlled are solved, the technical difficulty of curing is further reduced and the method is convenient to master, use and widely popularize.

Owner:HENAN AGRICULTURAL UNIVERSITY

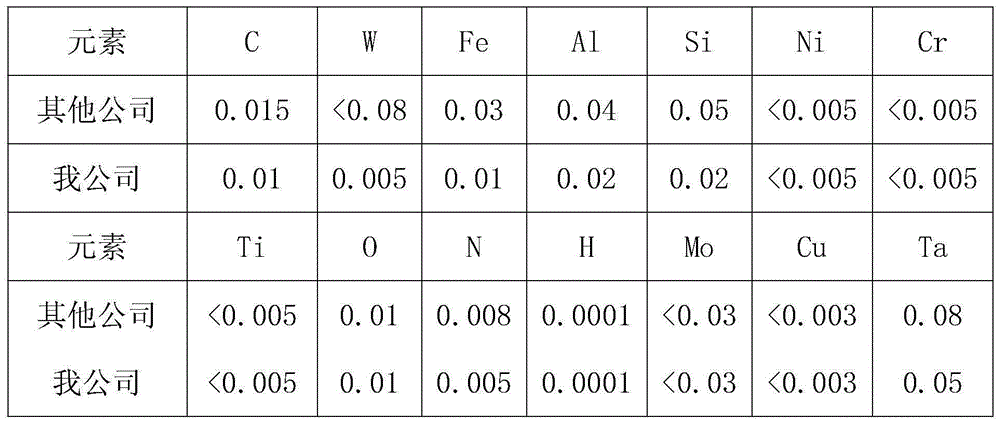

Pure niobium purification process

The invention relates to a pure niobium purification process including the steps of material preparation, material mixing, reduction furnace cleaning, reducing, discharging, crushing, screening, vacuum electron beam furnace cleaning, charging, primary smelting with a vacuum electron beam furnace, primary cooling, secondary smelting with the vacuum electron beam furnace, secondary cooling, discharging, sampling analysis and finished product obtaining. The process is rigorous in steps, the purification efficiency is high, and the purification purity is high.

Owner:江苏圣亚有色金属材料有限公司

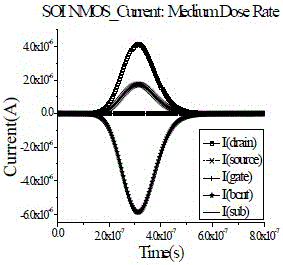

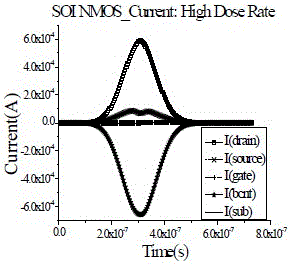

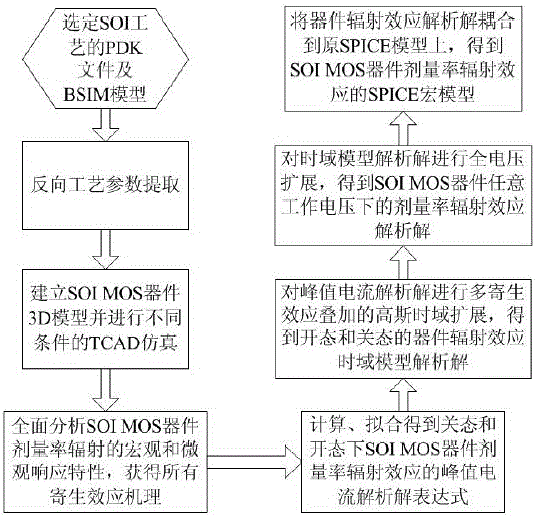

SPICE (Simulation Program for Integrated Circuit Emphasis) macro model molding method for SOIMOS (Silicon on Insulator Metal Oxide Semiconductor) transistor dose rate radiation

InactiveCN105740564AImprove simulation accuracyFull Radiation Response CharacteristicsSpecial data processing applicationsDose rateUnit model

The invention relates to a SPICE (Simulation Program for Integrated Circuit Emphasis) macro model molding method for SOIMOS (Silicon on Insulator Metal Oxide Semiconductor) transistor dose rate radiation. The method mainly comprises the following steps: coupling radiation response features of a device under different conditions to an original SPICE model under a non-radiation condition of the device through a macro model technology specific to a dose rate radiation effect of an SOI MOS device in order to form a basic device unit model including radiation responses; and predicting a radiation response feature of a whole integrated circuit by direct calling of the unit model and system simulation. Through adoption of the method, functions and performance of the designed integrated circuit under specific radiation conditions can be effectively simulated; a reference basis is provided for an anti-radiation SoC (System on Chip) design; the tape-out times are reduced; the cost is lowered greatly; the development period is accelerated; and the efficiency is increased.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

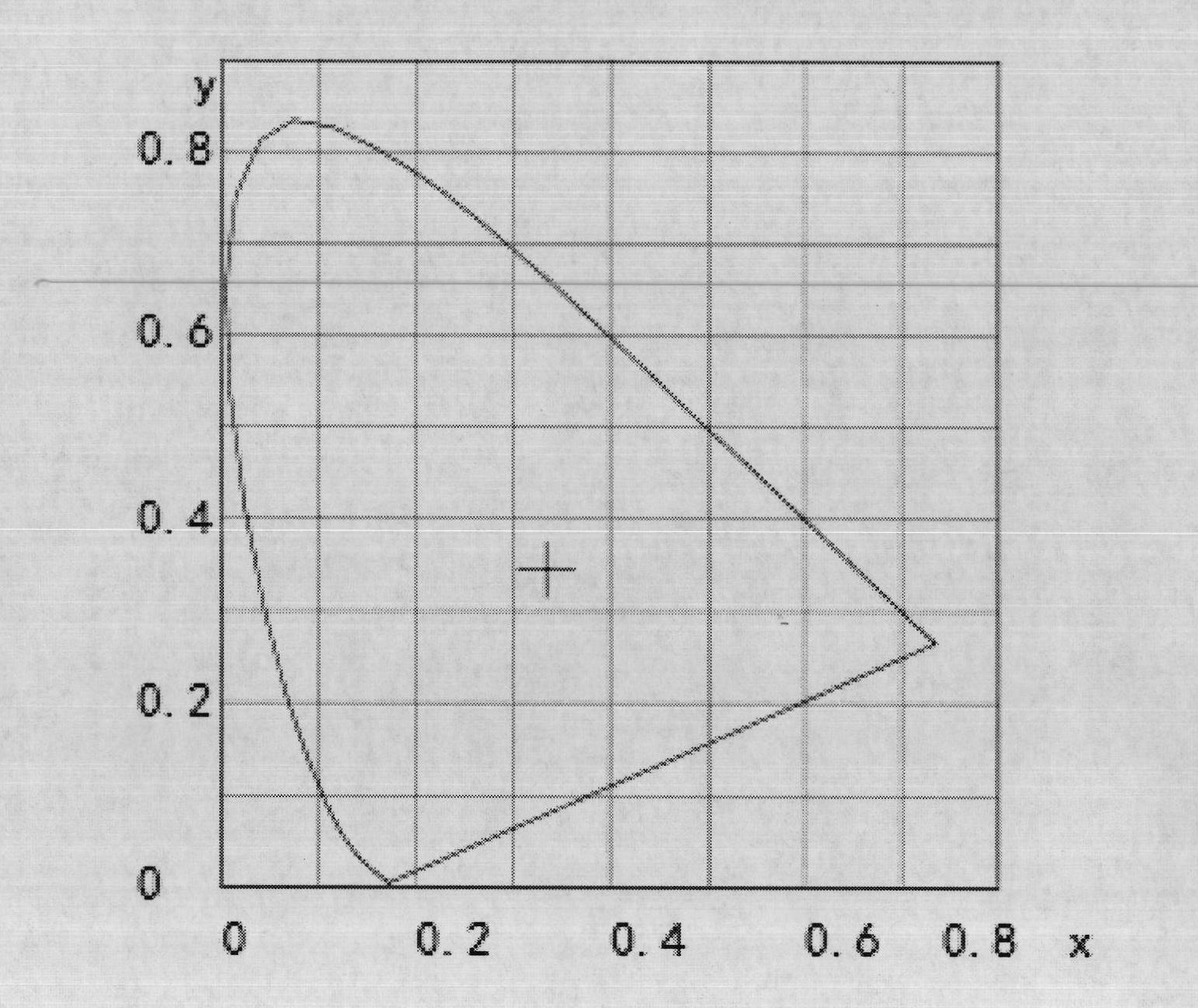

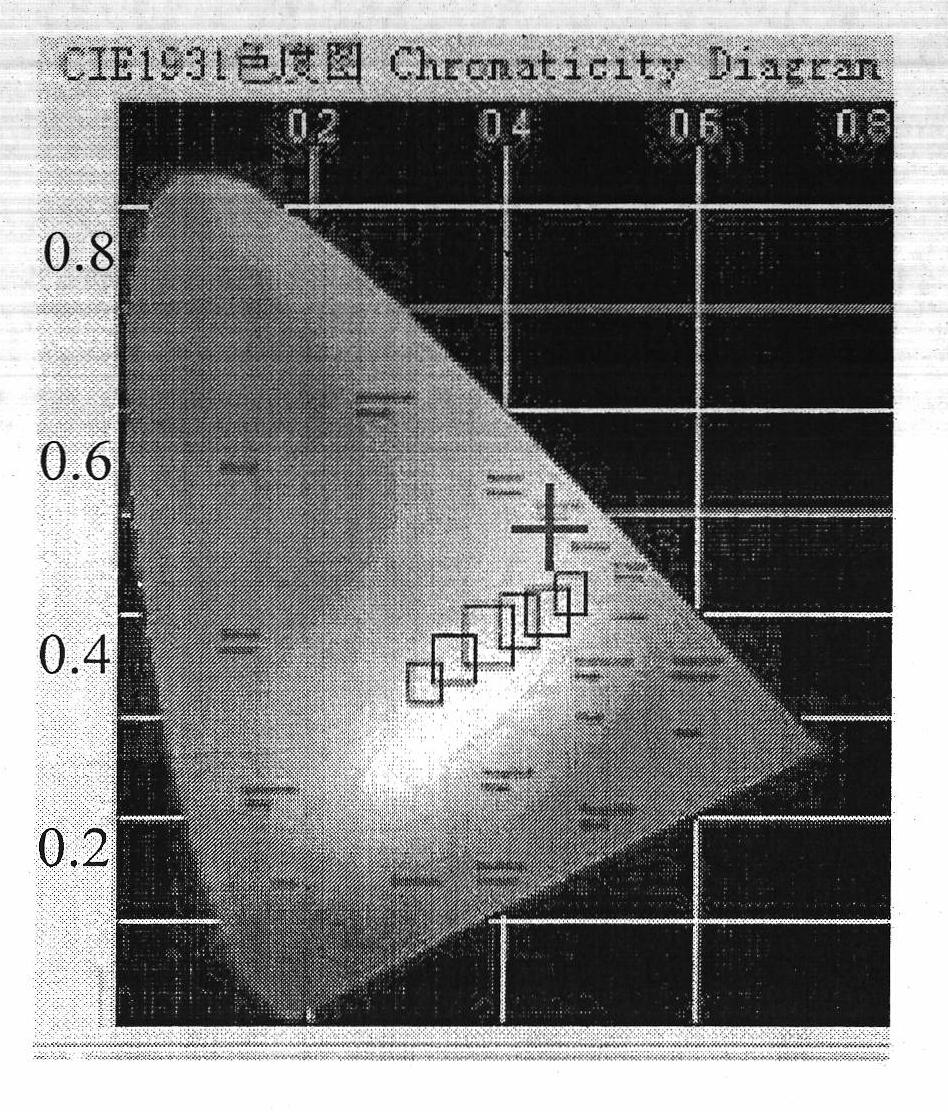

Method for synthetizing white light polymer

InactiveCN102120815AReasonable ratioAdvancedGas discharge lamp usageLuminescent compositionsSynthesis methodsFluorenone

The invention relates to a method for synthetizing a white light polymer. The method comprises the following steps of: firstly, synthesizing 2,7-dibromo-9,9-dioctyl fluorene, 2,7-dithienyl-9-fluorenone and 2,7-di-2'-(5'-bromine)-thiophene-9-fluorenone by using an organic material, an inorganic material and a solvent by a four-step synthesis method; and finally synthesizing 9,9-dioctyl fluorine and dithienyl fluorenone copolymer, wherein a product is yellow powder, has the number-average molecular weight of 10,102, the weight-average molecular weight of 17,198, high color purity and excellent light-emitting performance, emits white light and has the color coordinates that x is 0.3340 and y is 0.3447. The synthesis method is advanced in process; chemical substances are mixed reasonably; process parameters are accurate; and the synthesis method is a method for synthesizing the white light polymer by using the organic, inorganic and solvent substances and can be directly used for manufacturing organic white light light-emitting diodes.

Owner:TAIYUAN UNIV OF TECH

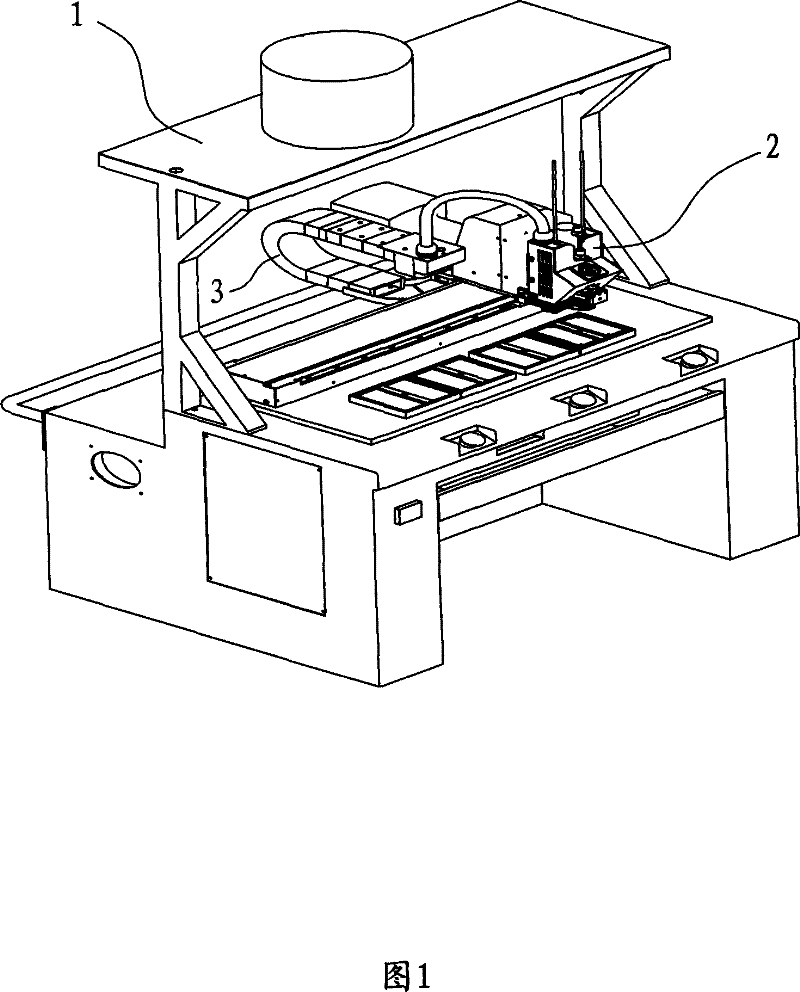

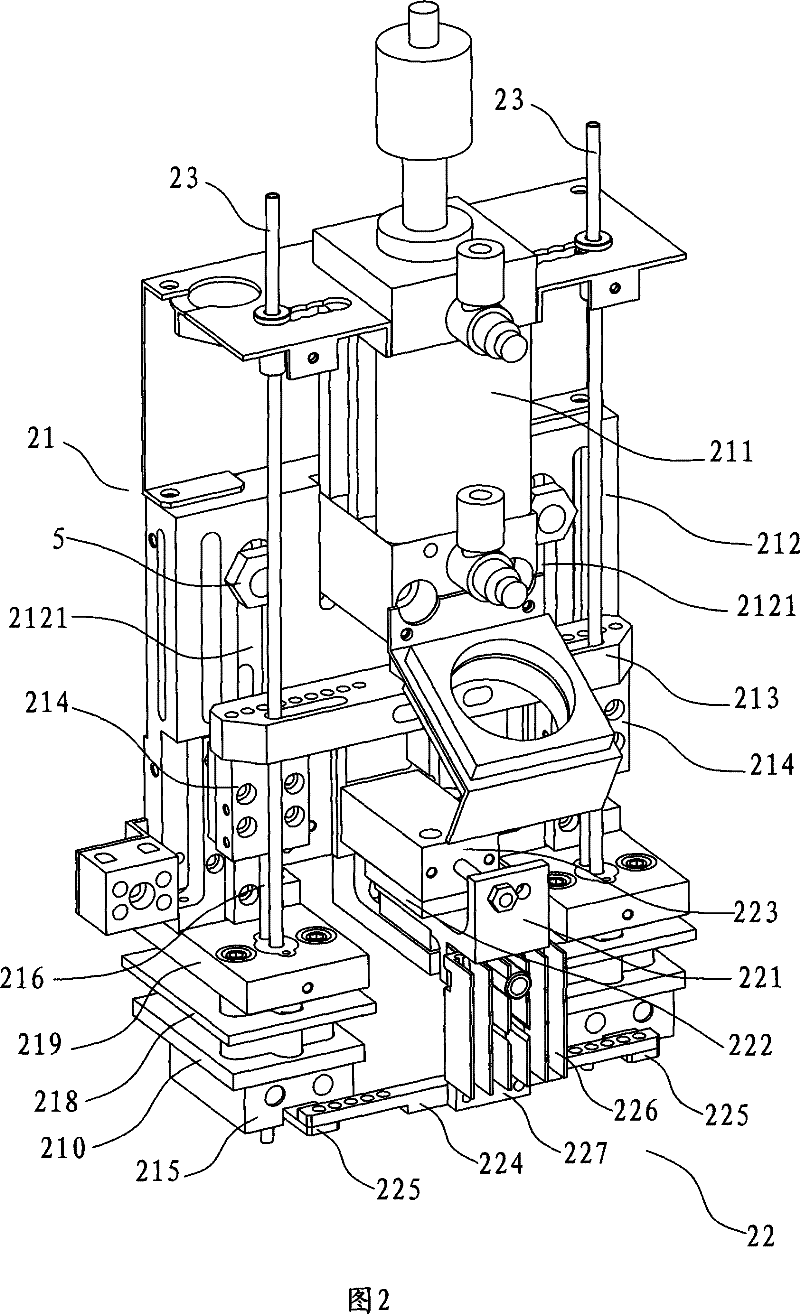

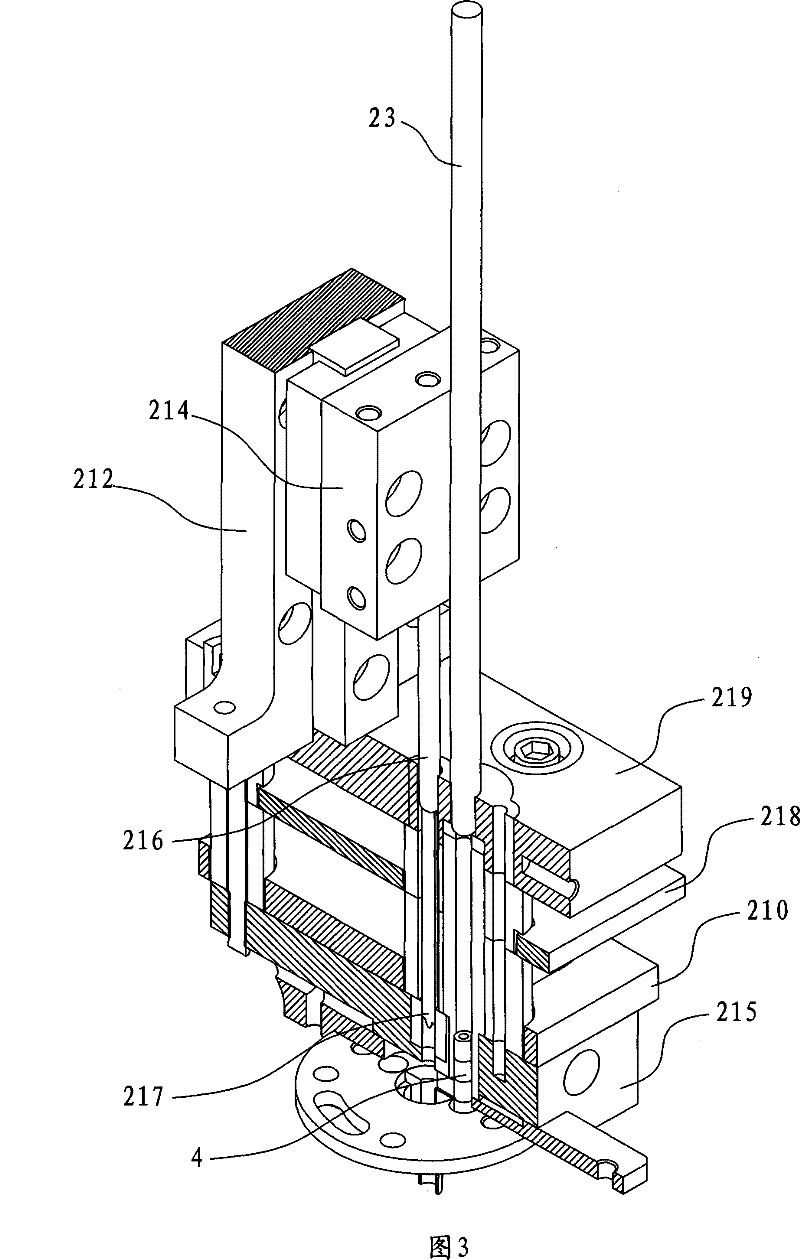

Nut implantation machine and implantation method thereof

InactiveCN101214728BNo warm-up time requiredIncrease production capacityMetallic materialsImplanted device

The invention discloses a nut implanting machine, which comprises: an implanting machine cabinet body and a machine head, the cabinet body is provided with a three-axis coordinate manipulator, and the machine head is arranged on its Z axis, wherein: the machine head is provided with an implanting device , the feeding device and the feeding tube that can withstand high temperature. The feeding tube is passed through the implanting device, and the nut to be used is installed in the feeding tube. The feeding device can push the nut into the implanting device; the feeding and implanting slide There are guide rails on both sides of the rail plate, and the nuts pass through the guide rails to connect them to the Z-axis; the invention can be used immediately, without preheating time, and can increase production capacity; it can obtain accurate process parameters without the need for manual nut placement. High pulling torque, convenient production and machine adjustment, convenient production change and high efficiency; in addition, it can solve the change of the thermal expansion coefficient of the metal material of the integrated machine head at a high temperature of 250°C-350°C to the width of the machine head.

Owner:SHENZHEN MIGHT TECH

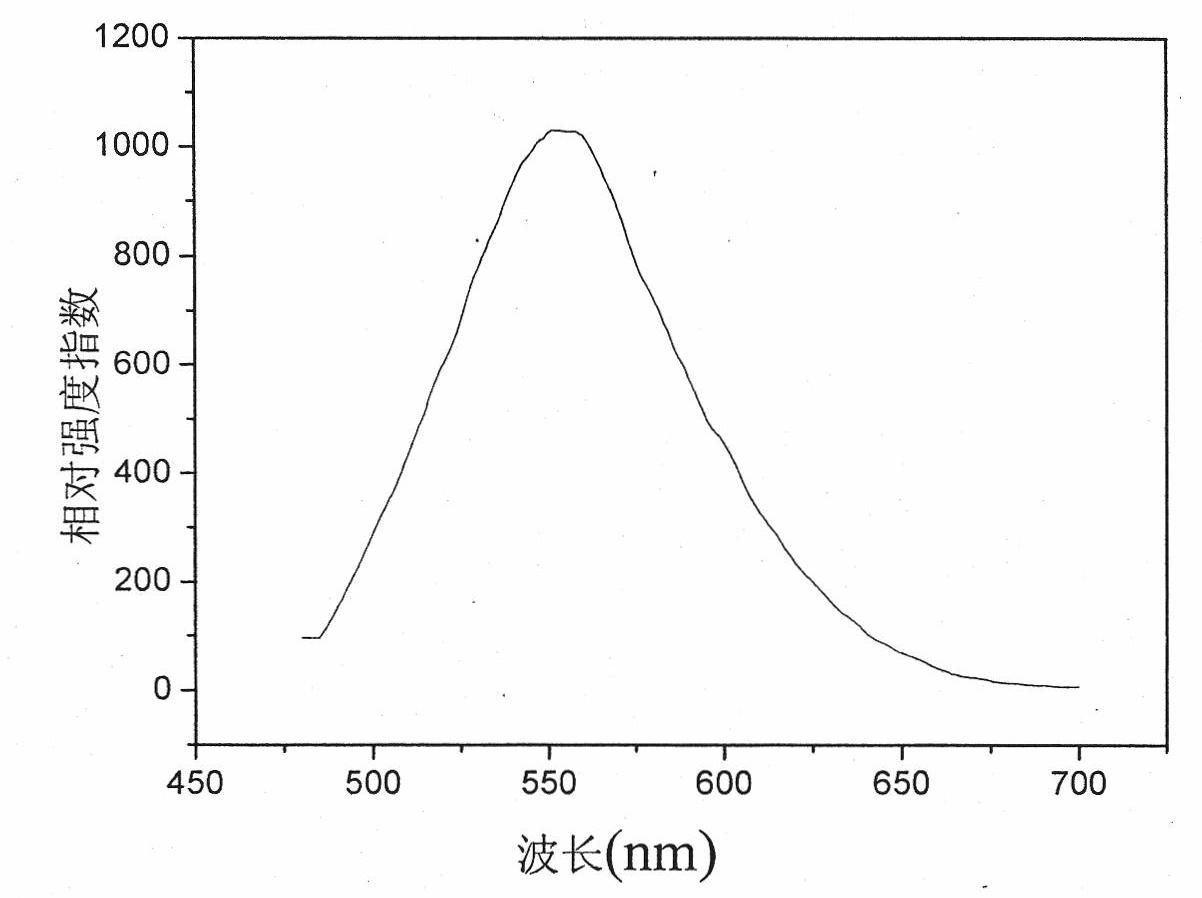

Quick synthesis method of reverse-2-(2-hydroxy styryl)-8-oxyquinoline zinc

InactiveCN102153570AHigh purityImprove luminosityLuminescent compositionsZinc organic compoundsSynthesis methodsQuinoline

The invention relates to a synthesis method of reverse-2-(2-hydroxy styryl)-8-oxyquinoline zinc. In the method, organic and inorganic and solvent materials are used and a two-step synthesis method is adopted to first synthesize reverse-2-(2-acetoxyl group styryl)-8-acetoxyl group quinoline and then directly synthesize reverse-2-(2-hydroxy styryl)-8- hydroxyquinoline zinc by ester exchange reaction. The product is yellow powder being kelly; the color coordinate is: X is equal to 0.4312 and Y is equal to 0.4861. The purity is good up to 99.1%, the light emission performance is excellent, and the yield is as high as 91.7%. The synthesis method is advanced in process, quick and simple with two steps of synthesis, reasonable in mixing rate of all chemical substances, and accurate in process parameters, being a method for synthesizing materials with kelly light by using organic and inorganic and solvent substances.

Owner:TAIYUAN UNIV OF TECH

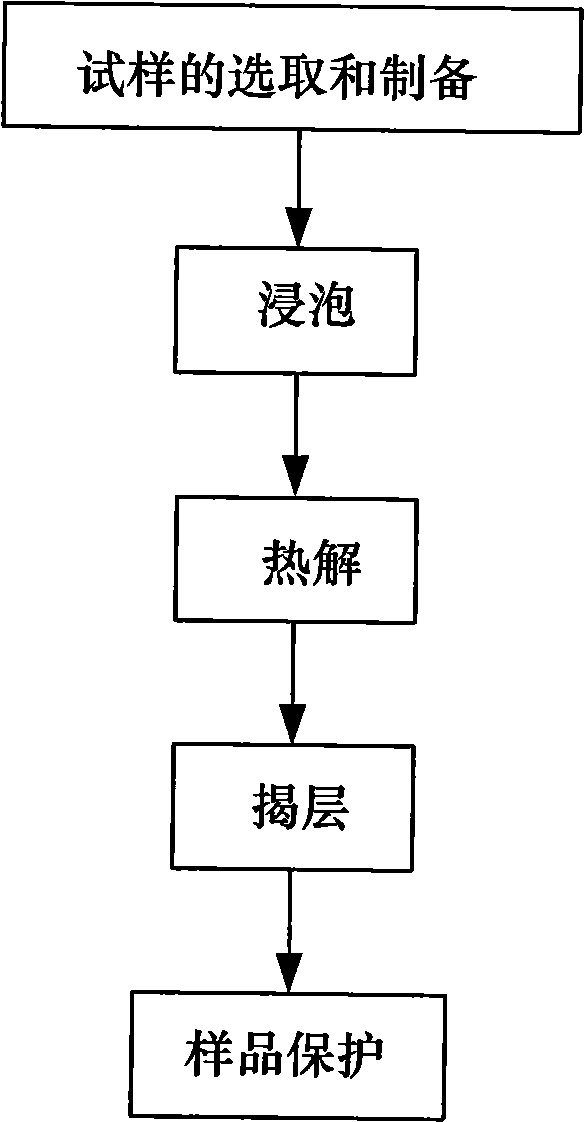

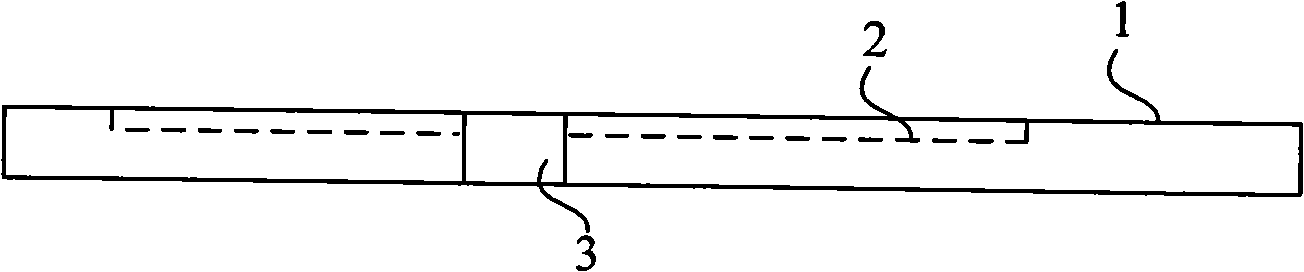

Defect hot-deply method of carbon fiber-reinforced modified bismaleimide laminates

InactiveCN101650272AUnique soaking methodNovel soaking methodPreparing sample for investigationNon destructiveLipid formation

The invention discloses a defect hot-deply method of carbon fiber-reinforced modified bismaleimide laminates. The method comprises the following steps: determining defects of a sample by non-destructive testing, preparing a label solution, soaking, pyrolyzing, deplying and protecting the sample. After being deplied, the sample keeps morphology features of a defect area, makes out the types, the sizes and the positions of the defects such as gap, delamination, poor (rich) lipid, matrix cracking and fiber bending (fracture), and provides the realest and most direct evidence for the further defect (breakage) forming mechanism analysis and the structural part failure analysis.

Owner:BEIHANG UNIV +1

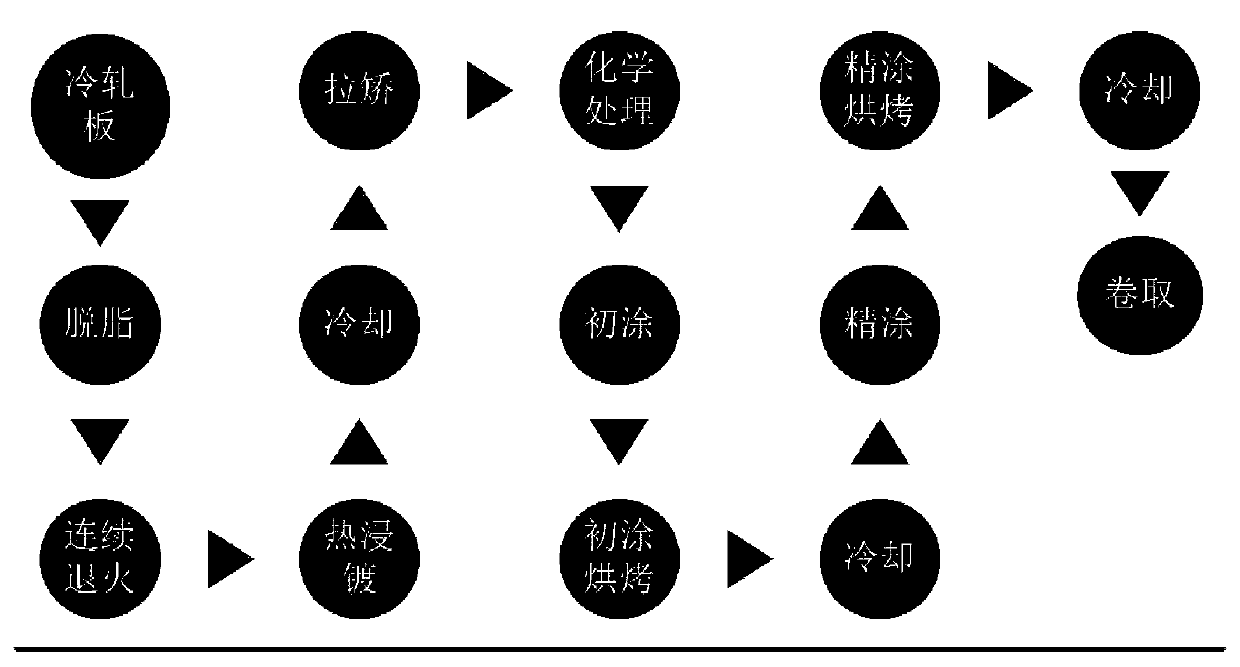

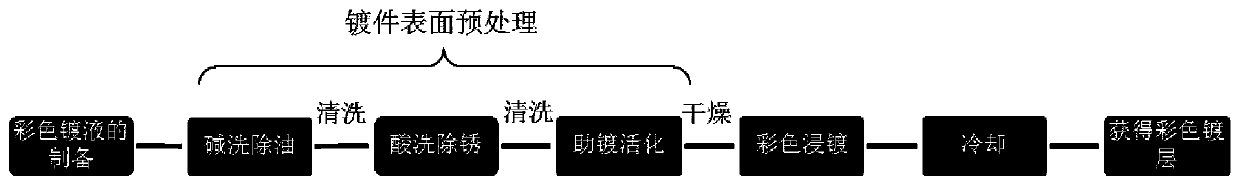

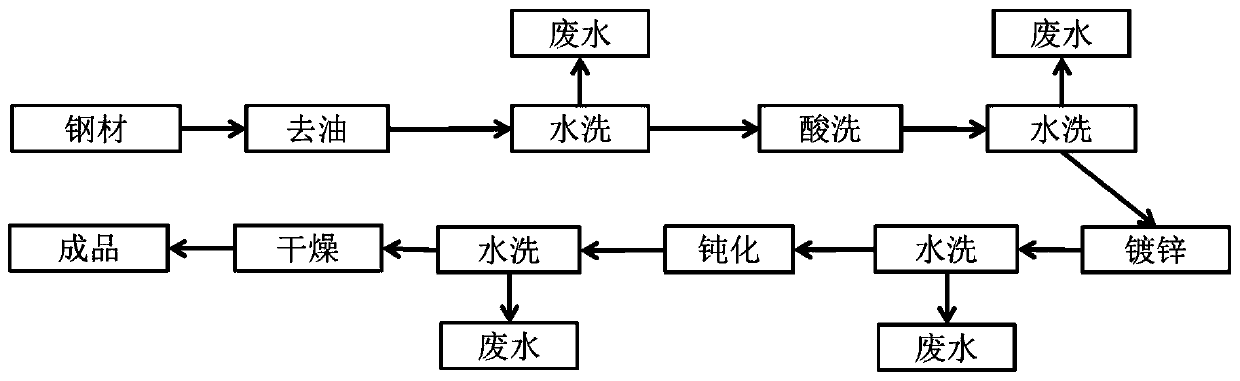

Hot-dip galvanizing method for obtaining colored plating on flat steel

The invention discloses a hot-dip galvanizing method for obtaining colored plating on flat steel. The method comprises the following steps of preparing alloy plating solution with special element proportion, placing the flat steel subjected to the surface pre-treatment in the hot plating solution at the rate of 0.01 m / s-0.03 m / s, carrying out immersion plating at the temperature of 430-560 DEG C for 0.5 min-10 min, taking out the flat steel from zinc liquid at the same rate, and carrying out air cooling and water cooling so as to obtain the colored coating which is uniform and single in color,good in surface smoothness and free of mixed color. According to the method, the steel can be divided into thin flat steel and thick flat steel according to the thickness of the steel, characteristics of a steel structure are fully analyzed, and technological parameters such as the immersion and leaching rate and the immersion plating temperature are regulated and controlled; the colored platingobtained through the colored hot-dip galvanizing carried out on the flat steep with different thickness and width is uniform in thickness, is stronger than that obtained through colored coating technology in terms of corrosion resistance and weather resistance, is stronger than that obtained through colored passivation technology in terms of adhesion and wear resistance, and is far higher than that obtained through original colored hot-dip galvanizing technology in terms of color uniformity; and the method is simple in process, easy to control, high in manufacturability, low in cost and wide in industrial popularization prospect.

Owner:NORTHEASTERN UNIV

7xxx series aluminum alloy large-specification hollow cast ingot production device and process thereof

The invention discloses a 7xxx series aluminum alloy large-specification hollow cast ingot production device and process. The device comprises a crystallizer, a water jacket, a core and a core support, wherein the core support is arranged above the crystallizer through an annular groove formed in the top of the crystallizer, the core support is a circular frame, and a protruding connecting opening is formed in the center of the core support; the connector is fixed to the edge of the core support through reinforcing ribs, a connecting sleeve connected with the core water inlet is arranged in the connector, the upper portion of the connecting sleeve is connected with the connector in a threaded fit mode and extends out of the connector, a lower end opening of the connecting sleeve is arranged in the core water inlet, a connecting plate matched with an end opening of the core is arranged on the outer side wall of the connecting sleeve, and a bolt hole is formed in the connecting plate. The 7xxx series aluminum alloy large-specification hollow cast ingot is prepared by smelting, refining and casting through a specific device and a bipolar uniform fire treatment process, and the formability and the structure of the cast ingot are ensured by utilizing accurate matching of process parameters.

Owner:西北铝业有限责任公司

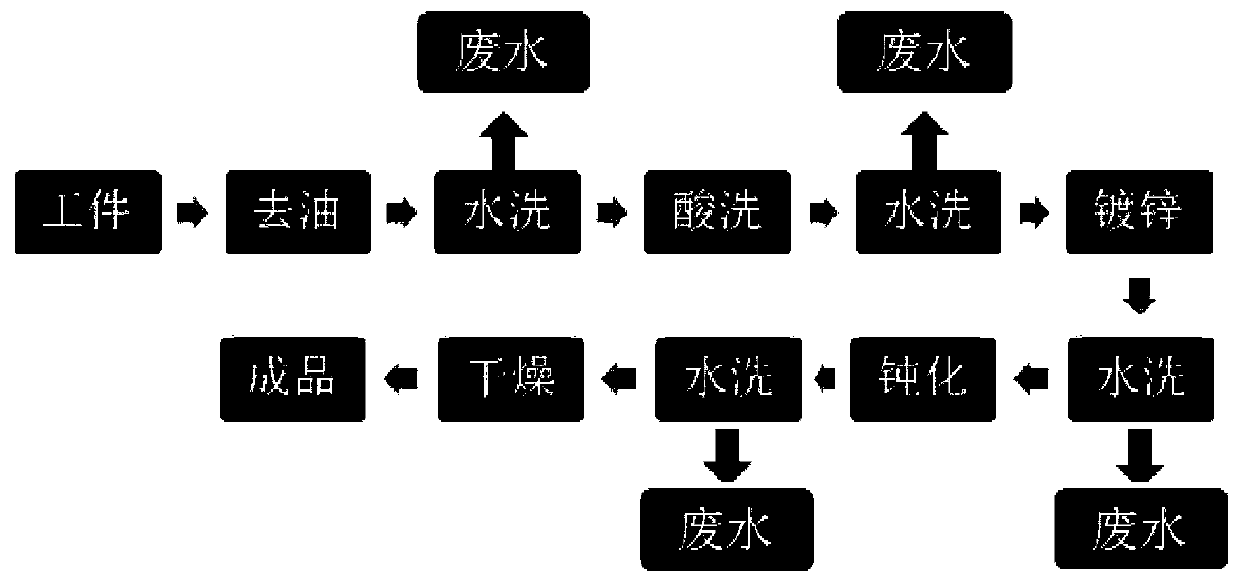

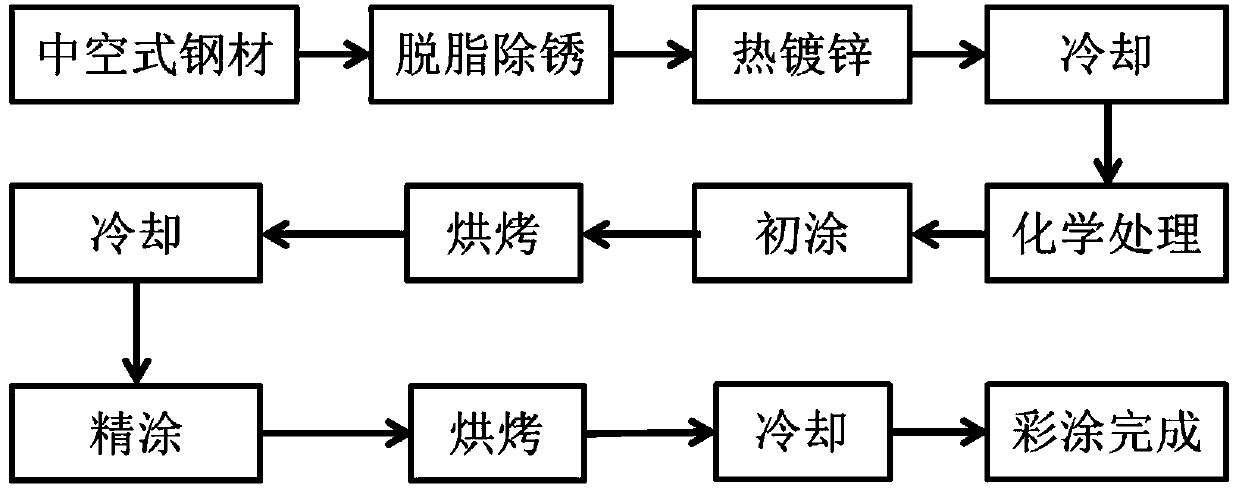

Method for coloration hot dip galvanization of hollow steel

The invention discloses a method for coloration hot dip galvanization of hollow steel and belongs to the technical field of steel surface treatment. The method comprises the following steps: firstly,preparing a zinc alloy plating solution (98.8 to 99.85 percent of Zn, 0.1 to 1 percent of Mn, 0 to 0.1 percent of Y, 0 to 0.08 percent of Ce and 0 to 0.05 percent of Cu); immersing hollow steel (suchas round tubes and square tubes) plated parts with pretreated surfaces into the zinc alloy plating solution by an angle of 10 to 15 degrees between the plated parts and the zinc alloy plating solutionat the rate of 0.002 to 0.015 m / s and the immersion plating temperature of 430 to 550 DEG C for 0.5 to 10 minutes; and secondly, extracting the plated parts from the zinc alloy plating solution by anangle of 10 to 15 degrees between the plated parts and the zinc alloy plating solution at the rate of 0.002 to 0.015 m / s, carrying out idle stop for 1 to 10 minutes and then carrying out water cooling to finally obtain coatings with various colors such as yellow, purple, blue, grass green and sandstone color and the advantages of uniform single colors, good surface smoothness and no mixed color.The process has the characteristics of simplicity, easiness in control, high manufacturability, low cost and the like, and thereby has a broad industrial popularization prospect.

Owner:NORTHEASTERN UNIV

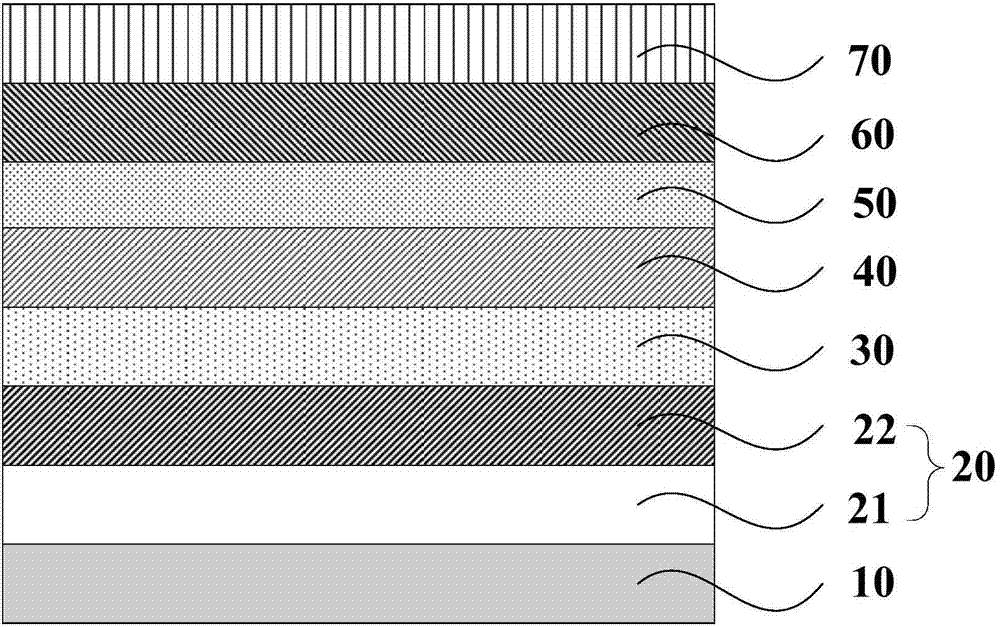

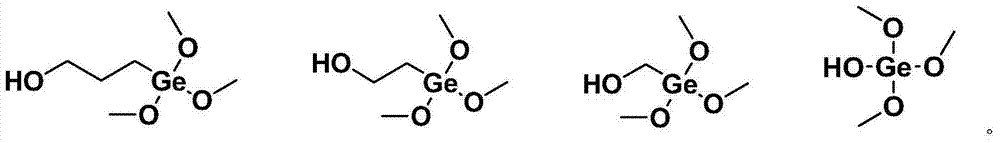

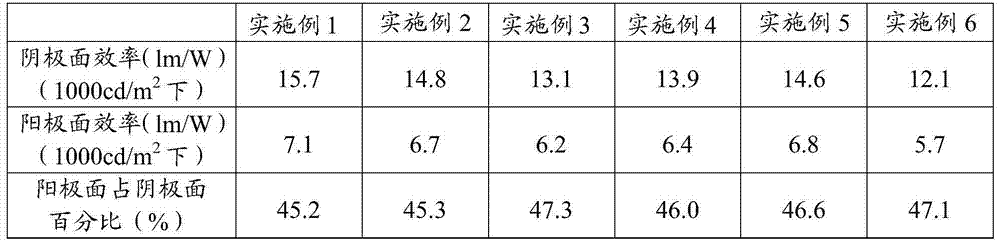

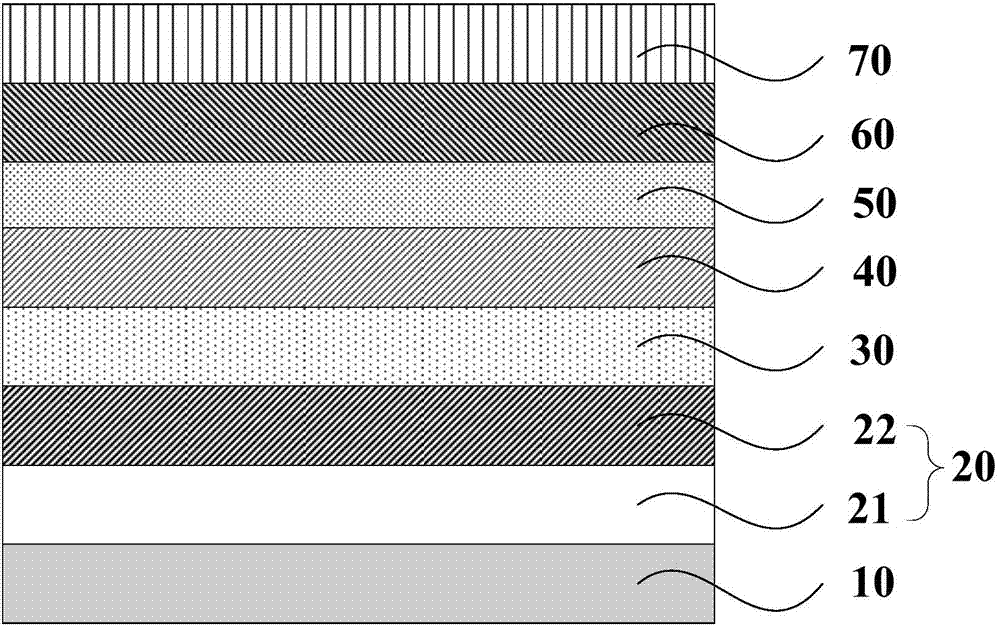

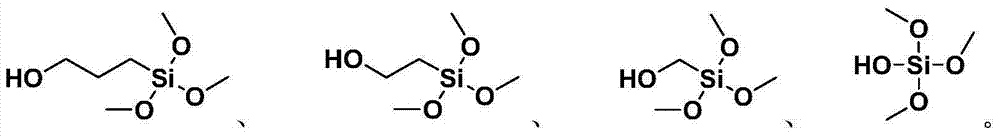

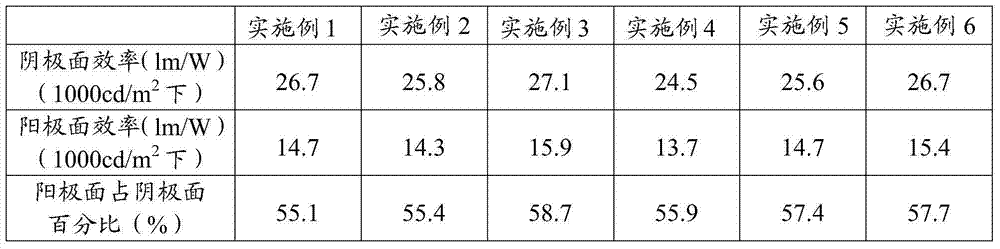

Transparent organic electroluminescent device and preparation method thereof

InactiveCN104518130AGood visible light transmittanceImprove antioxidant capacitySolid-state devicesSemiconductor/solid-state device manufacturingAlloyElectron transmission

The invention provides a transparent organic electroluminescent device comprising a glass substrate, and a transparent anode, a hole injection layer, a hole transmission layer, a green luminescent layer, an electron transmission layer, an electron injection layer and a transparent cathode which are arranged on the glass substrate in a laminating way in turn. The transparent anode comprises a hydroxy germane organic matter layer and a metal layer. Material of the hydroxyl germane organic matter layer is at least one type of (3-hydroxy propyl) trimethoxy germane, (3-hydroxy ethyl) trimethoxy germane, (3-hydroxy methyl) trimethoxy germane and O, O, O-trimethyl-hydroxy germane. Material of the metal layer is at least one type of a magnesium silver alloy, a lithium aluminum alloy, barium and calcium. According to the transparent organic electroluminescent device, light emergent efficiency of the anode surface is over 45% than light emergent efficiency of the cathode surface so that luminescent performance is excellent. The invention also provides a preparation method of the transparent organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

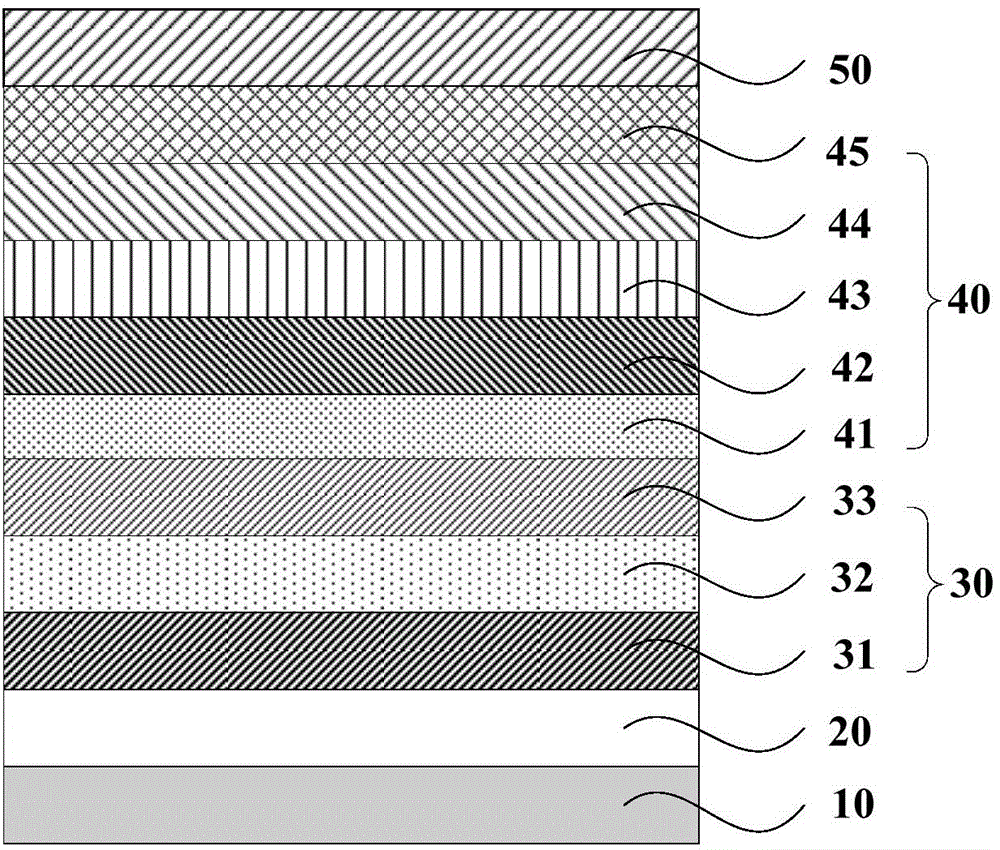

Organic electroluminescence device and manufacturing method thereof

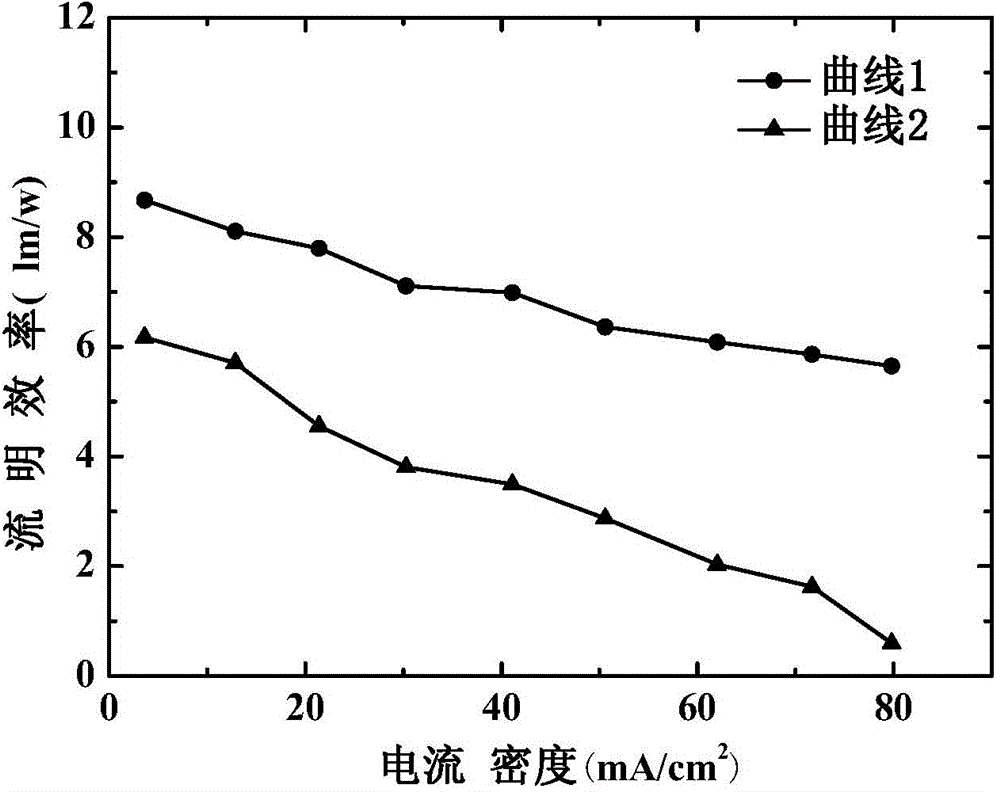

InactiveCN104425733AImprove light extraction efficiencyLight transmission loss is smallSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsOrganic electroluminescence

The invention provides an organic electroluminescence device. The organic electroluminescence device comprises a glass substrate, and an anode, a scattering layer, an organic light-emitting functional layer and a cathode which are sequentially arranged on the glass substrate in a stacked manner; the scattering layer comprises a first doped layer, a ferric salt layer and a second doped layer which are sequentially arranged on the anode in a stacked manner; the first doped layer is made of a mixed material of an organic material and ferric salt, and the second doped layer is made of a mixed material of the organic material and titanium dioxide; the organic material is one of 2, 3, 5, 6-tetrafluoro-7, 7, 8, 8, -tetracyano-benzoquinodimethane, 4, 4, 4-tri(naphthyl-1-phenyl-ammonio) triphenylamine and dinaphthyl-N, N'-diphenyl-4, 4'-benzidine. The scattering layer is additionally arranged in the structure of the organic electroluminescence device, so that the light-emitting efficiency and the luminous efficiency of the device can be improved. The invention also provides a manufacturing device of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

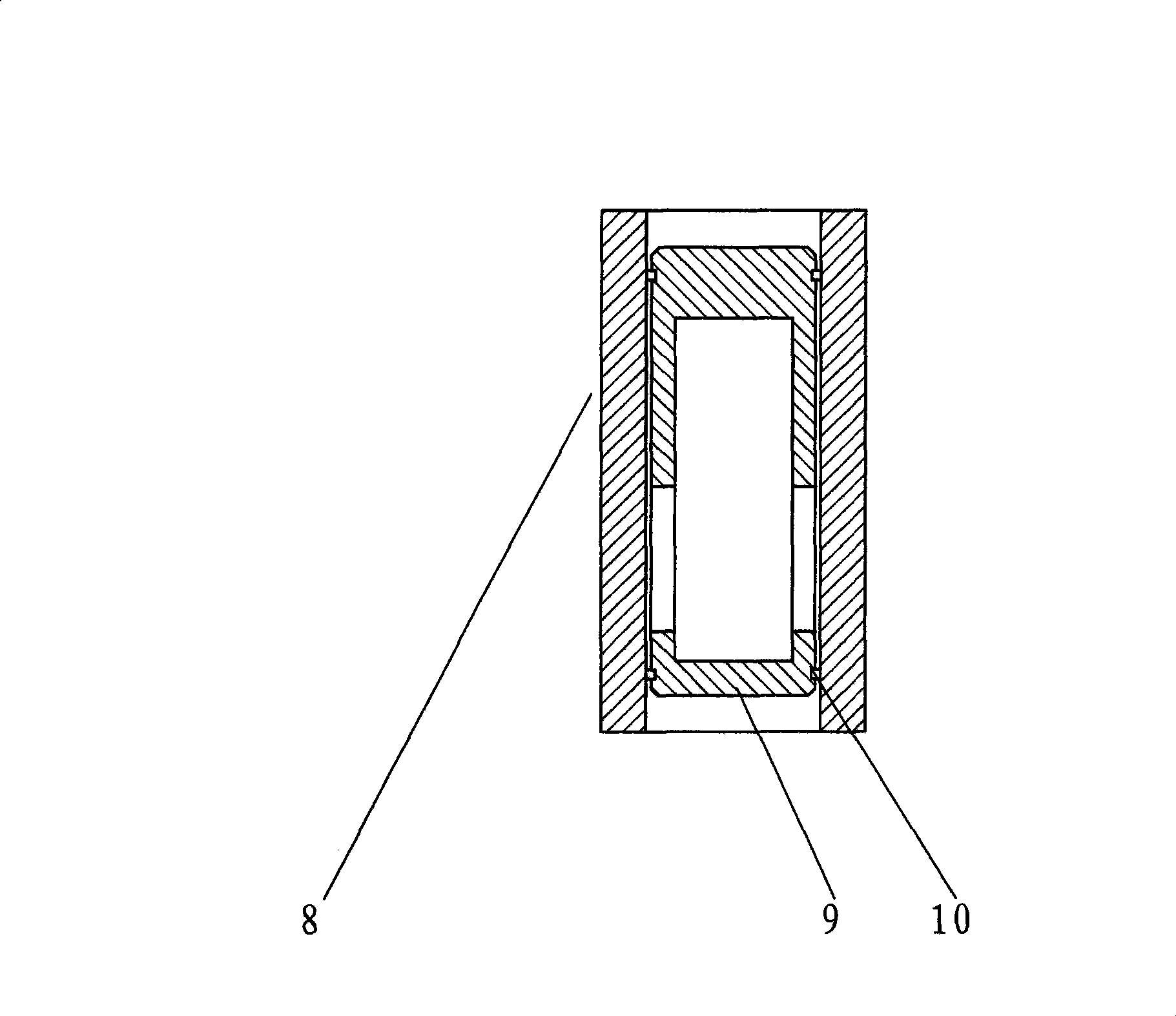

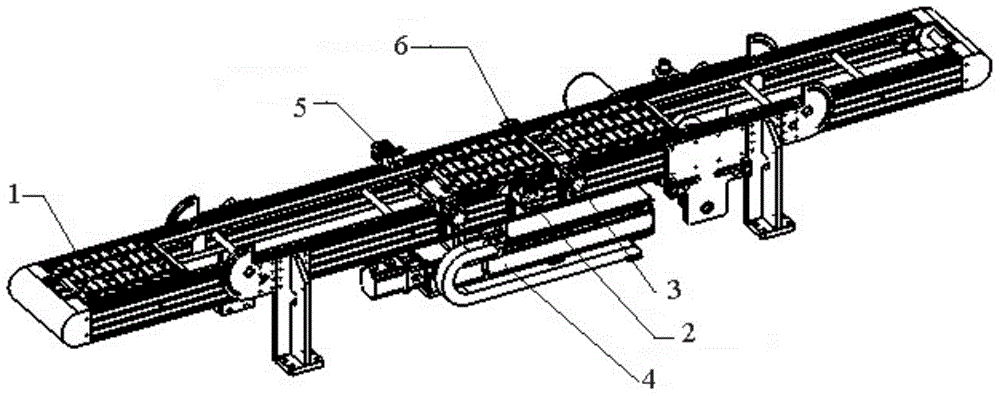

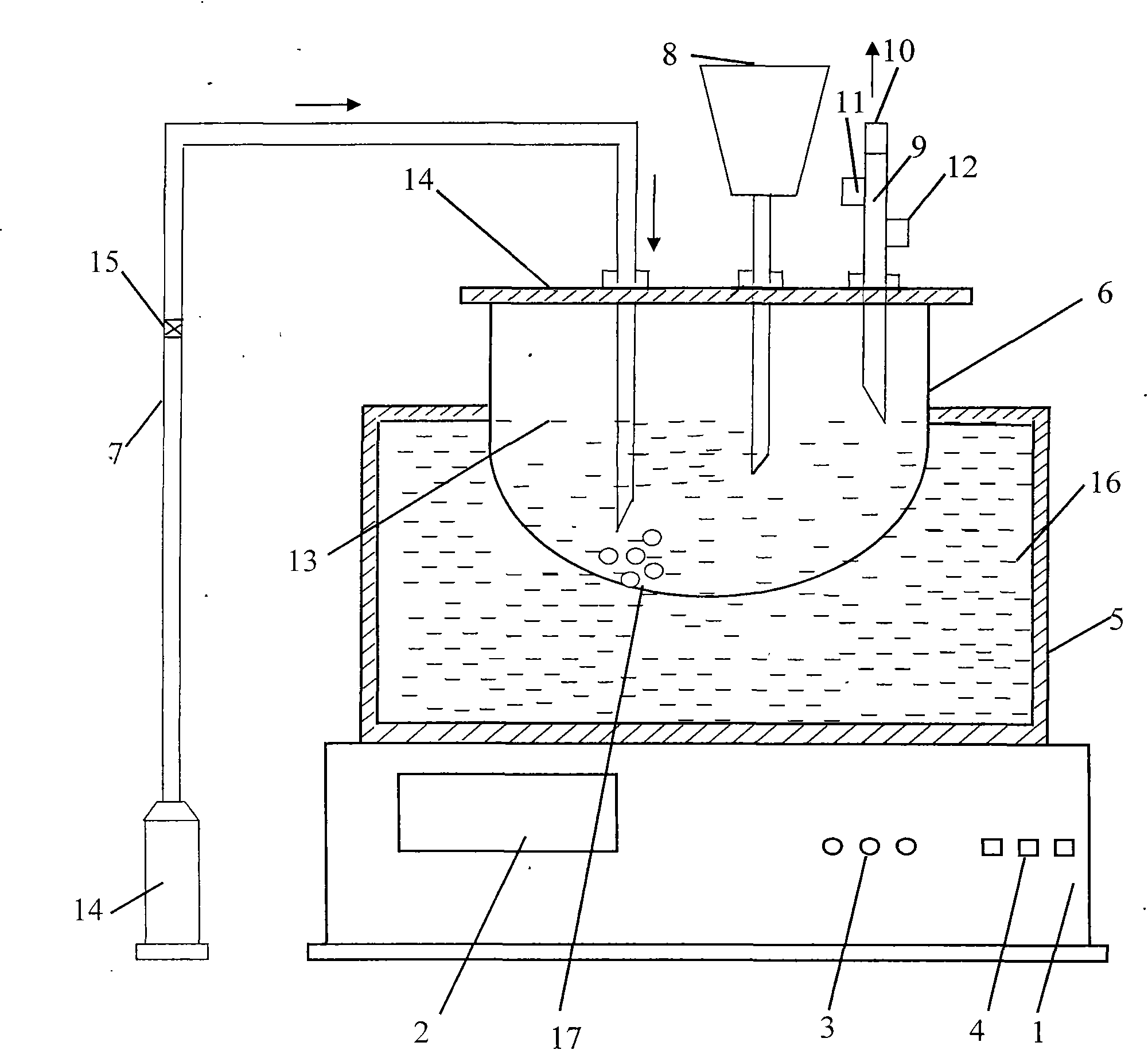

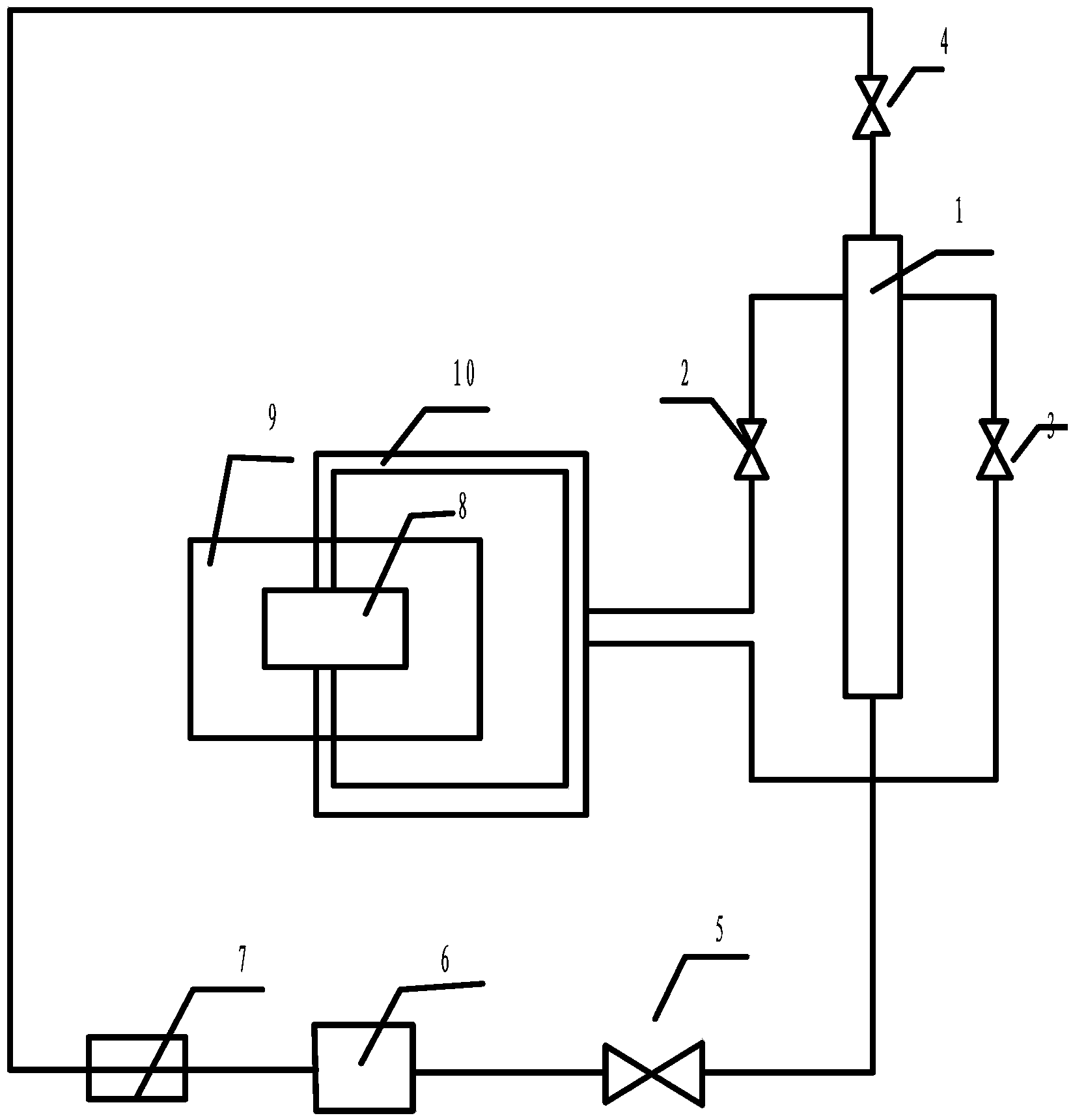

Heating circulating system of jig dyeing machine

InactiveCN103789954APrecise process parametersGuaranteed dyeing effectLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsWater circulationDyeing

The invention discloses a design method of a heating circulating system of a jig dyeing machine and belongs to the technical field of dyeing machinery. According to the design method, the heating circulating system of the jig dyeing machine is composed of, as shown in figure 1, a vertical type steam separating drum (1), an automatic ventilation valve (2), a manual control valve (3), a master valve (4), a drainage valve (5), a circulating water recycling tank (6), a hydraulic pump (7), a heating tube (8), a dye vat (9) and a steam inlet pipe (10). The heating circulating system achieves accurate technological parameters, solves the problem of uneven dyeing due to moisture absorption of dye liquor, ensures the dyeing effects, makes full use of circulating water, saves steam water, is simple in structure, convenient to maintain and low in cost, improves the dyeing quality and efficiency, omits thermal preservation pipes, thermal preservation layers or the like, avoids pollution and achieves circulation of airflow.

Owner:WUXI DANGKOU TONGHE TEXTILE MACHINERY PLANT

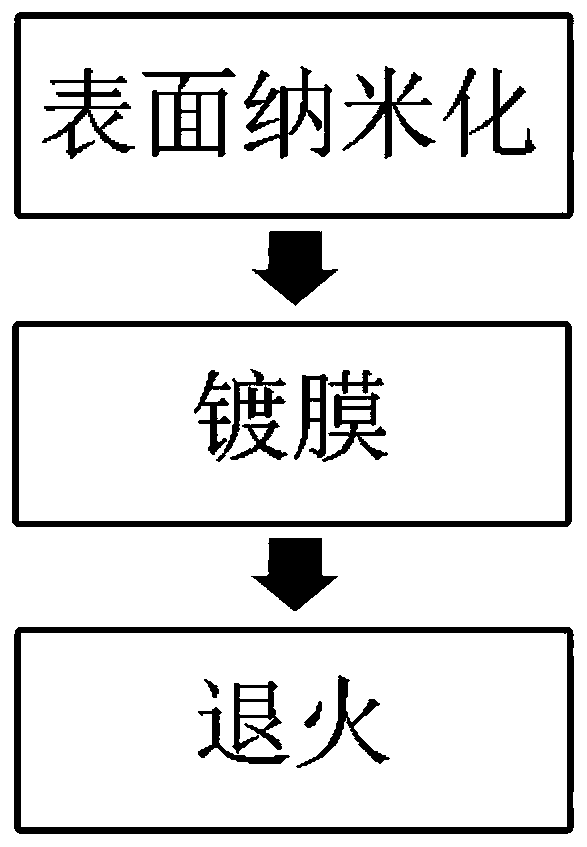

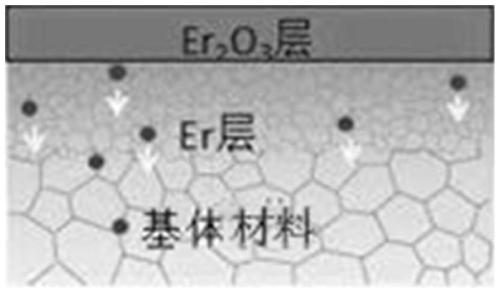

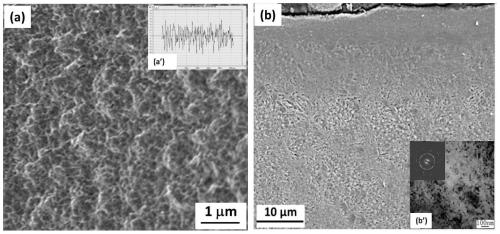

Preparation method and application of Er2O3 coating

InactiveCN111155052ASimple processMature technologyVacuum evaporation coatingSputtering coatingSputteringCoated membrane

The invention provides a preparation method and application of an Er2O3 coating. The preparation method of the Er2O3 coating comprises the following steps that firstly, peening treatment on a substrate is carried out by adopting a supersonic particle peening method; then a pure Er coating is plated and then the Er2O3 coating is plated on the matrix material by using a magnetron sputtering method;and finally annealing treatment is carried out. According to the invention, the problem that the coating is extremely prone to cracks, even spalling and poor bonding force under the long-term action of thermal stress is solved, and the effect of improving the binding force of the Er2O3 coating film is achieved. The coating is prepared by adopting a method of peening, magnetron sputtering and heattreatment, the process is simple and mature, the equipment is convenient to operate, the process parameters are accurate and controllable, and the method is suitable for mass production. The preparation method of the Er2O3 coating can be applied to a fusion reactor tritium proliferation cladding.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

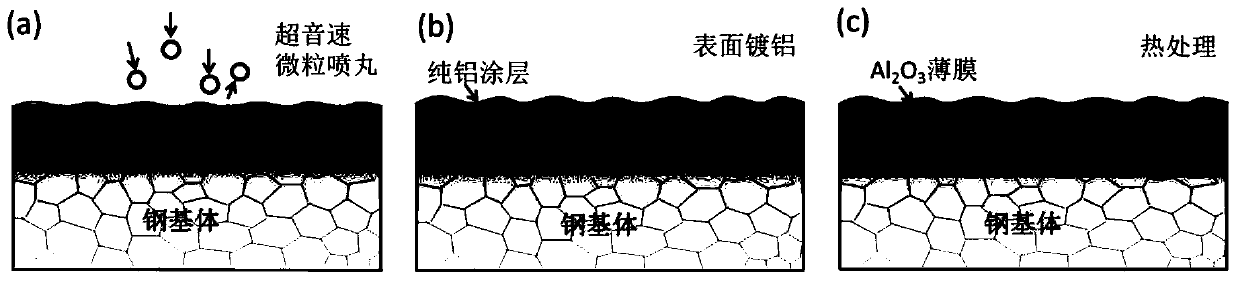

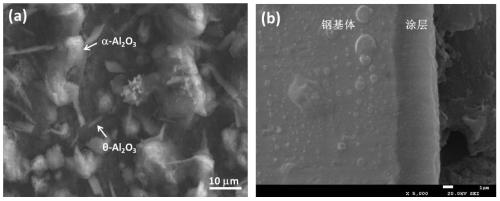

Fe-al/al for fusion reactor tritium breeding cladding 2 o 3 Tritium blocking coating and preparation method thereof

ActiveCN106048519BEnhanced resistance to peelingReduce contentVacuum evaporation coatingSputtering coatingDiffusion layerMaterials science

The invention discloses Fe-Al / Al for fusion reactor tritium breeding cladding 2 o 3 Tritium-blocking coating and preparation method thereof, coating of the present invention is formed by Fe-Al diffusion layer and its surface in situ oxidation-generated Al 2 o 3 film composition. The nano-grain boundary on the side of the steel matrix in the Fe-Al diffusion layer of the present invention can become a channel for Al atoms to diffuse to the inside of the steel matrix; during diffusion annealing, the Al atoms diffuse rapidly along the nano-grain boundary to the inside of the steel matrix, which will greatly reduce the The content of Al element in the coating and the interface can inhibit the high aluminum compound (Fe 2 Al 5 , FeAl 3 , FeAl 2 etc.); in the coating, the formation of low-aluminum compounds (FeAl) reduces the composition gradient of Fe and Al elements and inhibits the generation of Kirkendall voids.

Owner:SICHUAN UNIV

Transparent organic electroluminescent device and preparation method thereof

InactiveCN104518093AImprove light extraction efficiencyImprove removal efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerAlloy

The invention discloses a transparent organic electroluminescent device. The transparent organic electroluminescent device comprises a glass substrate, and a transparent anode, a cavity implantation layer, a cavity transmission layer, a green luminescent layer, an electron transmission layer, an electron injecting layer and a transparent cathode which are successively laminated on the glass substrate. The transparent anode comprises a hydroxysilane organic layer and a metal layer; the material of the hydroxysilane organic layer comes from at least one of (3-mercaptopropyl)trimethoxysilane, (3-mercaptoethyl)trimethoxysilane, (3-mercaptomethyl) trimethoxysilane and O,O,O-trimethyl-mercaptosilane; the material of the metal layer comes from at least one of a magnesium-silver alloy, a lithium-aluminum alloy, barium and calcium; and the material of the transparent cathode is indium tin oxide. According to the transparent organic electroluminescent device provided by the invention, the light emitting efficiency of an anode surface reaches more than 55% of the light emitting efficiency of a cathode surface, and the luminescence performance is excellent. The invention further discloses a preparation method of a transparent organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

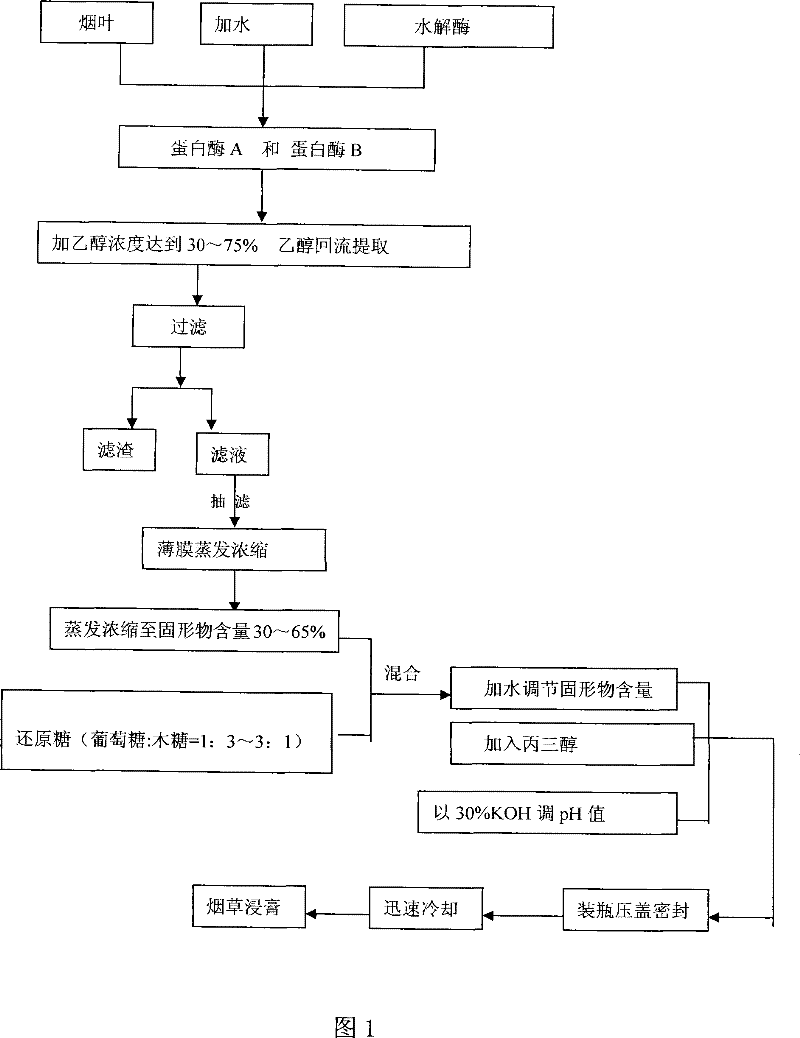

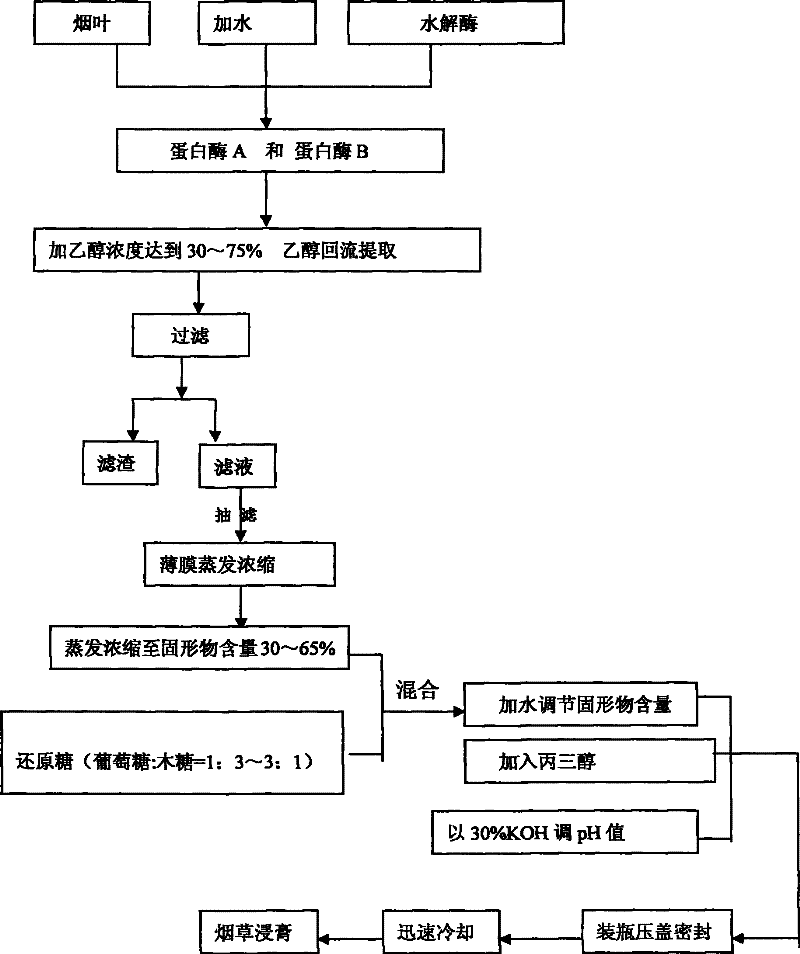

Preparation method for tobacco extract

The invention discloses a preparing method for a tobacco-made extract. The invention includes the following steps: tobacco leaves are firstly blended with water and enzyme for enzymolysis; and then ethanol is applied for extraction, filtration and concentration; and lastly the tobacco-made extract is obtained through maillard reaction. The invention utilizes the tobacco dust generated from the tobacco production, takes into full consideration the feasibility and operability of industrial production with respect to the preparing process, and furthermore, conducts a series of exploration on factors relating to the enzymolysis, extraction and maillard reaction forms the final preparing process and optimal technical parameters, and thereby the product quality reaches the requirements for adding fragrance to the tobacco-made extract with outstanding steadiness and repeatability.

Owner:CHINA TOBACCO GUANGDONG IND

Construction method for test section of earthwork backfill engineering

InactiveCN109778925AGuaranteed accuracyPrecise process parametersFoundation testingExcavationsEngineeringSlow speed

The invention discloses a construction method for a test section of earth-rock backfill engineering, and relates to the technical field of earthwork backfill construction. The construction method comprises the following steps: (1) selecting a typical roadbed with a length of not less than 100 m as a corresponding test section, and calculating main roadbed filling parameters; (2) conducting surveying and setting out, leveling a substrate, and conducting paving on site according to a test paving thickness; (3) conducting rough leveling by using a bulldozer, conducting leveling on site to adjustthe paving thickness, and conducting fine leveling by using a land leveler; (4) using a heavy vibratory roller for rolling compaction in a mode of first light pressing and then heavy pressing, first pressing at a slow speed and then pressing a high speed and from two sides to the middle, wherein wheel marks are required to be overlapped by 40-50 cm after two adjacent times of compaction; and (5) measuring the compaction degree of the roadbed after the sixth time in the step (4) by adopting a sand filling method, making detailed records, distinguishing the rolling compaction times with the compaction degree reaching 90% or above, and determining the technological parameters of earthwork backfill construction. The method has the advantages of accurate test result and prevention of problems in formal construction.

Owner:中冶成都勘察研究总院有限公司

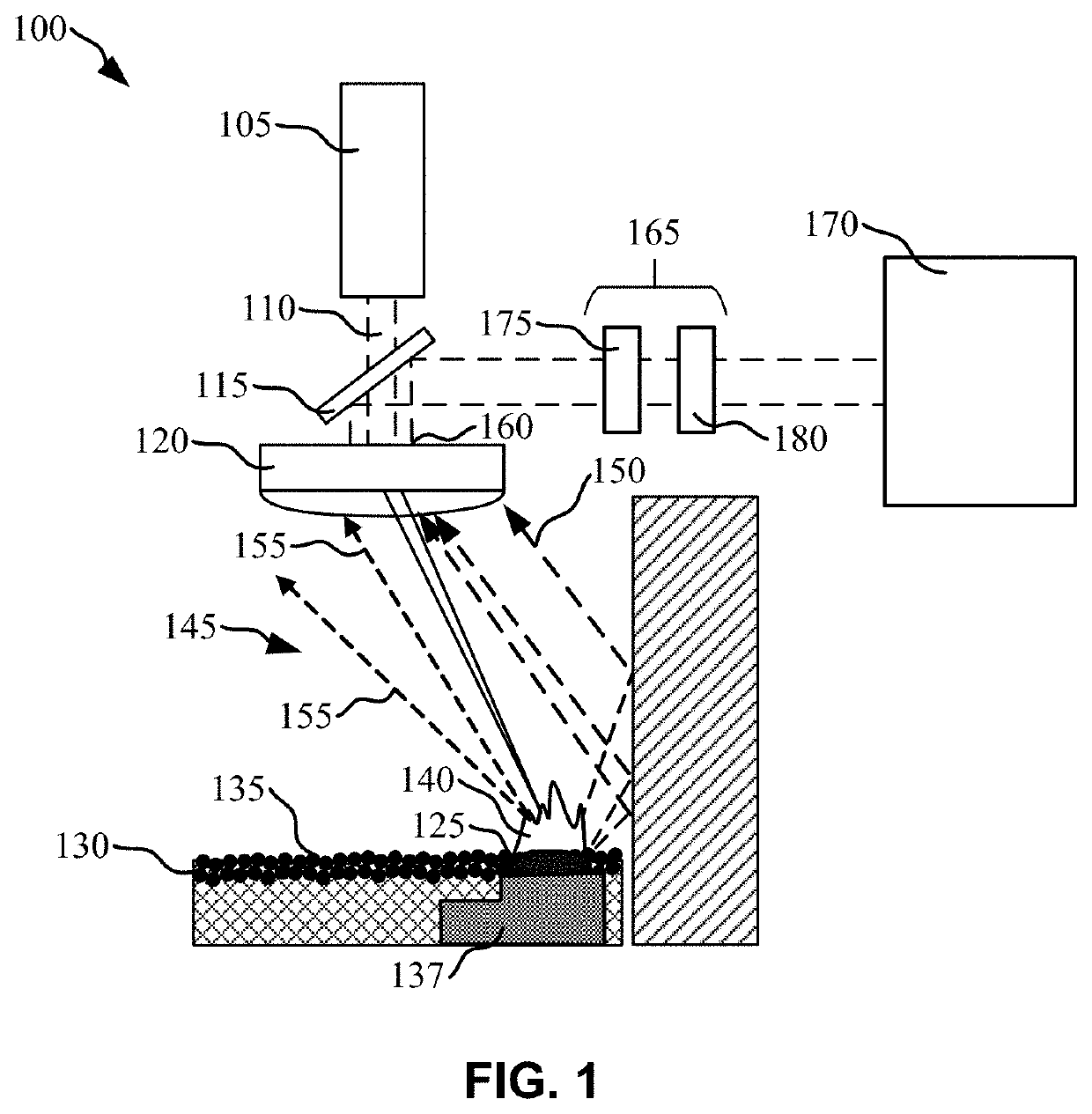

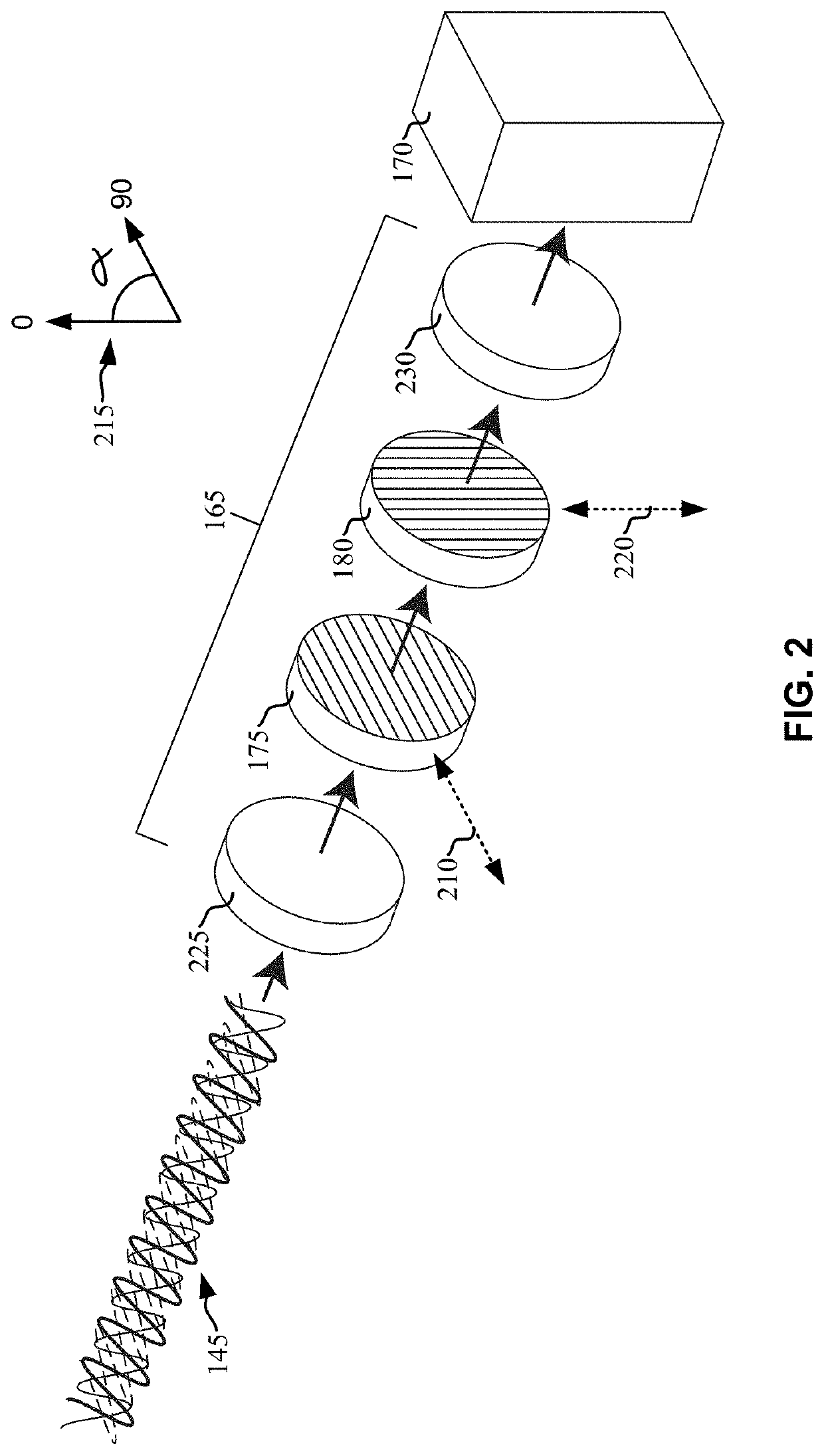

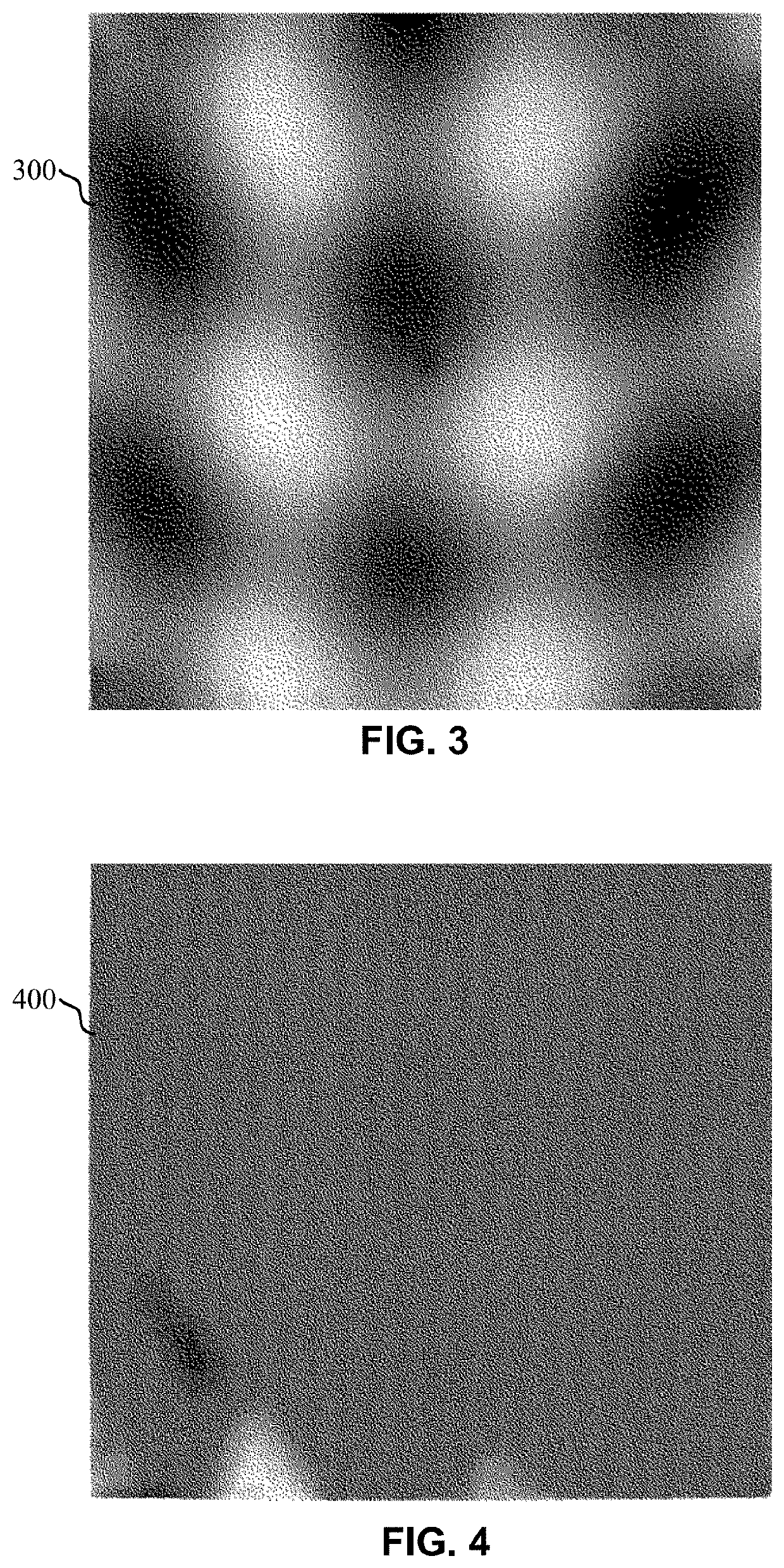

Optical filter having dual polarization

PendingUS20210138578A1Improved signal-to-noise ratio performancePrecise process parametersAdditive manufacturing apparatusPolarising elementsEngineeringOptical transducers

An additive manufacturing system comprises a build plane and an energy source configured to direct energy onto a work region of the build plane. An optical detector is configured to receive one or more optical signals from the work region. An optical filter is positioned between the work region and the optical detector, wherein the optical filter includes a first partially transmissive polarized filter having a first polarization axis and a second partially transmissive polarized filter having a second polarization axis. The first polarization axis is rotationally offset from the second polarization axis approximately 90 degrees. The optical filter improves the signal to noise ratio of the optical sensors.

Owner:SIGMA LAB OF ARIZONA

Method for producing bicycle wheel fellone using magnesium alloy section bar

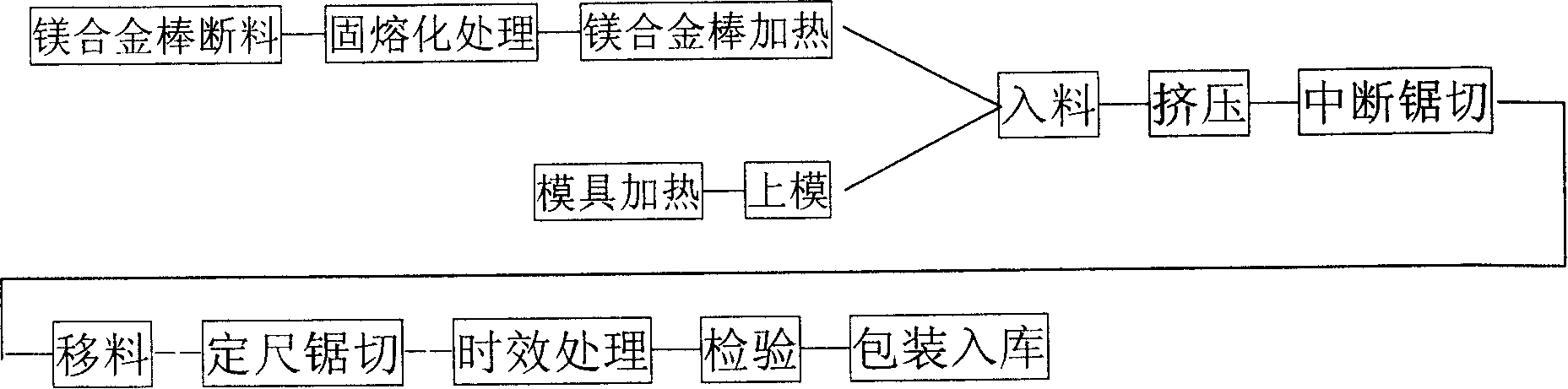

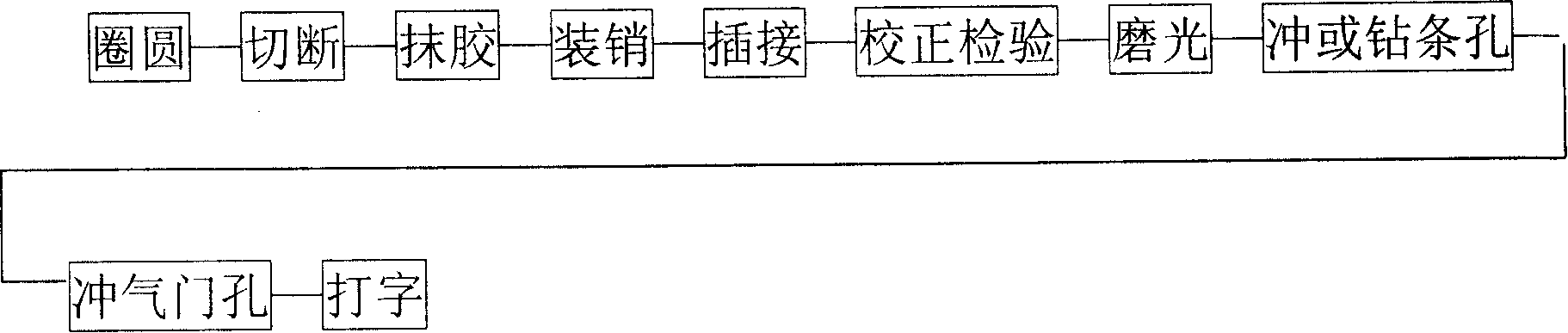

InactiveCN100386175CImprove plastic deformation abilityImprove corrosion resistanceExtrusion control devicesPunchingMagnesium alloy

The invention discloses a method for preparation of a bicycle rimmer, especially a method for preparation bicycle rimmer with a magnesium alloy sections. Said method contains two flow processes that are compression and formation: the compression technique containing cutting magnesium allay rod, solid fused treatment, heating the magnesium, heating the die, fixing the die, inputting the material, compressing, middle sawing, shifting the material, length sawing and aging treatment; the formation technique containing shaping, cutting, coating glue, fixing the pin, plugging in, correct checking, polishing, punching or drilling a strip hole, and punching gas inlet hole. With said method for preparation of bicycle rimmer with magnesium allay, the technique is simple, the operation is convenient, and the prepared bicycle rimmer is elegant and beautiful.

Owner:于克儒

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com