Transparent organic electroluminescent device and preparation method thereof

An electroluminescence, electromechanical technology, applied in the fields of electric solid state devices, semiconductor/solid state device manufacturing, electrical components, etc., which can solve the problems of difficulty in carrier injection and disparity in light extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

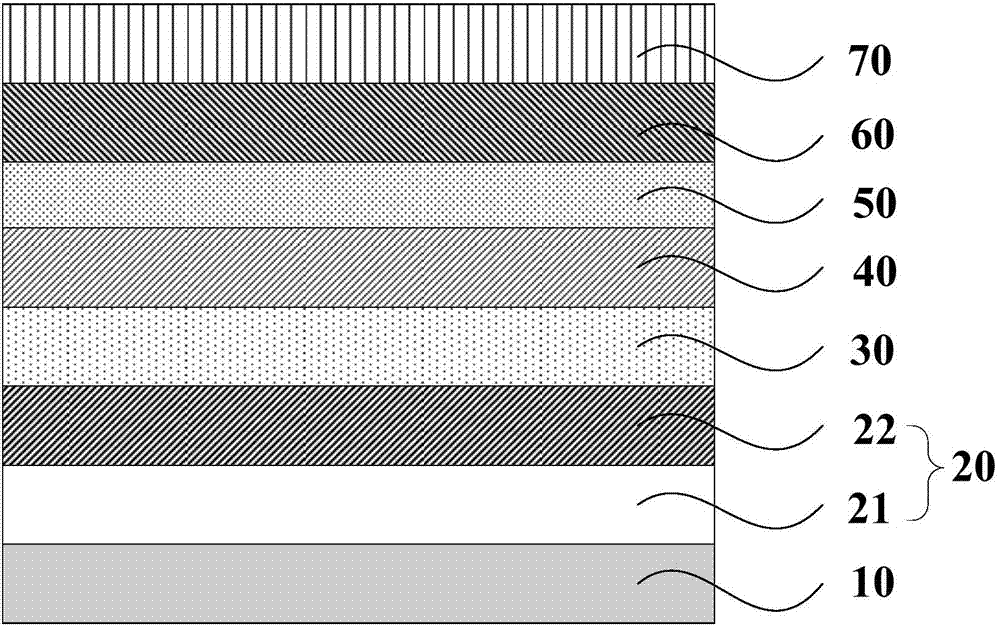

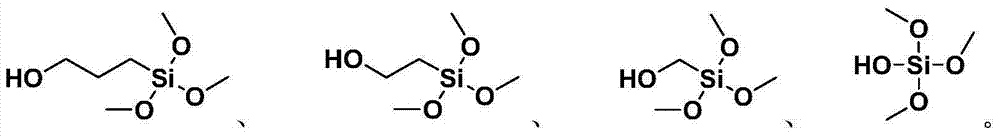

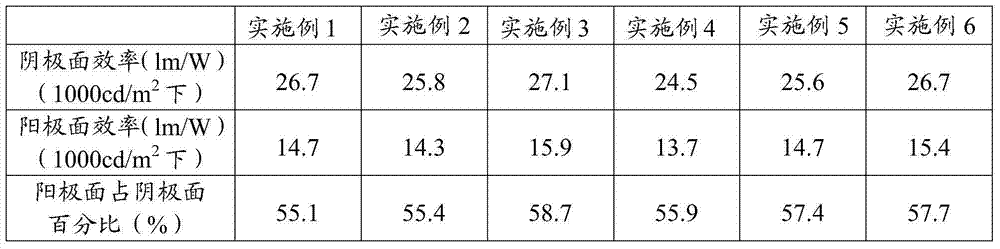

[0048] Example 1: Preparation of a transparent organic electroluminescent device; the device structure is glass substrate / (3-hydroxypropyl)trimethoxysilane / Mg:Ag (10:1) / NPB:MoO 3 / NPB / TCTA:Ir(ppy) 3 / Bphen / Bphen:LiF:Li 2 SO 4 / ITO. Its preparation method is as follows:

[0049] (1) Provide glass substrate: take a piece of white glass, wash it with detergent, deionized water, acetone, and ethanol in sequence. This operation is carried out in an ultrasonic cleaning machine. Each washing takes 5 minutes and stops for 5 minutes. , Repeat the method 3 times respectively, and then dry it in an oven for use.

[0050] (2) Prepare a transparent anode on the glass substrate. The transparent anode includes a hydroxysilane organic layer and a metal layer sequentially stacked on the glass substrate. The material of the hydroxysilane organic layer is (3-hydroxypropyl) trimethoxy Silane, produced by spin coating, with a rotational speed of 2000rpm and a thickness of 4nm; a metal layer wa...

Embodiment 2

[0053] Example 2: Preparation of a transparent organic electroluminescent device; the device structure is a glass substrate / (3-hydroxyethyl)trimethoxysilane / Li:Al(0.6%Li) / TCTA:WO 3 / TCTA / mCP:Ir(ppy) 2 (acac) / BCP / BCP:LiN 3 :Na 2 SO 4 / ITO. Its preparation method is as follows:

[0054] (1) Provide glass substrate: take a piece of white glass, wash it with detergent, deionized water, acetone, and ethanol in sequence. This operation is carried out in an ultrasonic cleaning machine. Each washing takes 5 minutes and stops for 5 minutes. , Repeat the method 3 times respectively, and then dry it in an oven for use.

[0055] (2) Prepare a transparent anode on the glass substrate. The transparent anode includes a hydroxysilane organic layer and a metal layer sequentially stacked on the glass substrate. The material of the hydroxysilane organic layer is (3-hydroxyethyl)trimethoxy Silane is produced by spin coating with a rotating speed of 5000rpm and a thickness of 2nm; a metal la...

Embodiment 3

[0058] Embodiment 3: the preparation of a kind of transparent organic electroluminescent device; Device structure is glass substrate / (3-hydroxymethyl)trimethoxysilane / Ba / CBP:V 2 o 5 / CBP / CBP:Ir(mppy) 3 / BAlq:Li 3 N:K 2 SO 4 / ITO. Its preparation method is as follows:

[0059] (1) Provide glass substrate: take a piece of white glass, wash it with detergent, deionized water, acetone, and ethanol in sequence. This operation is carried out in an ultrasonic cleaning machine. Each washing takes 5 minutes and stops for 5 minutes. , Repeat the method 3 times respectively, and then dry it in an oven for use.

[0060] (2) Prepare a transparent anode on the glass substrate. The transparent anode includes a hydroxysilane organic layer and a metal layer sequentially stacked on the glass substrate. The material of the hydroxysilane organic layer is (3-hydroxymethyl)trimethoxy Silane is produced by spin coating with a rotating speed of 2000rpm and a thickness of 4nm; a metal layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com