Patents

Literature

87results about How to "Reduce interface effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

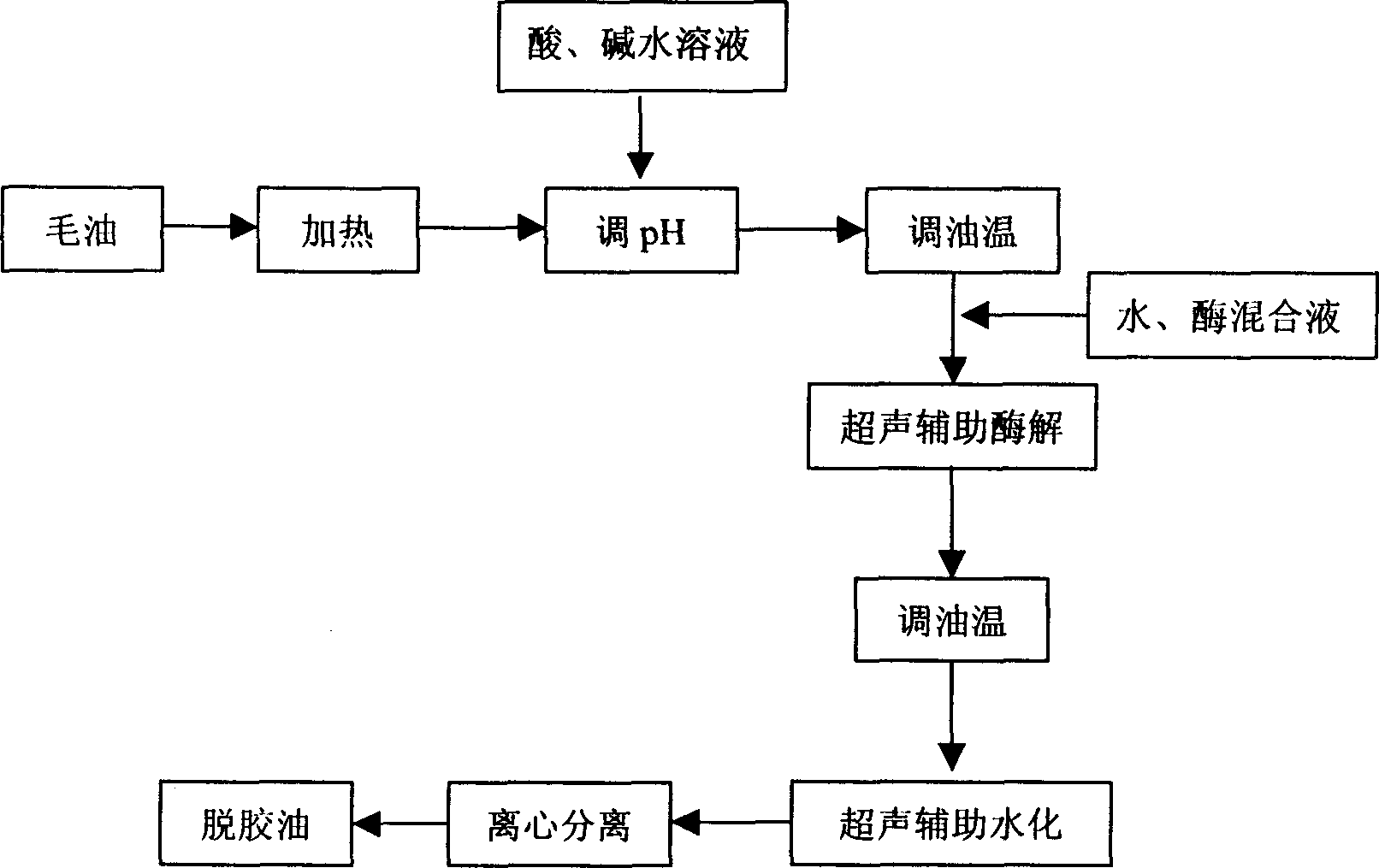

Supersonic wave intensified bioenzyme grease degumming method

ActiveCN1884459AWill not destroy the spatial structureHigh catalytic activityFatty-oils/fats refiningEmulsionBoundary effects

The invention relates the ultrasonic degumming method, comprising adjusting emulsion, hypersonic auxiliary enzymolysis and hypersonic auxiliary hydrating. The method comprises the following steps: after biological enzyme treatment fat, carrying out low water hydrated phase, carrying out ultra-audio wave radiation, and then carrying out water-oil separating. The invention can shorten treatment time and enzyme content, improves the boundary effect between oil and water, reduces biological enzyme density, advances the gelatinous hydrating, improves detaching efficiency, modifies weight of boil-off gum content, and reduces equipment investment and oil consumption, reduces cost.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

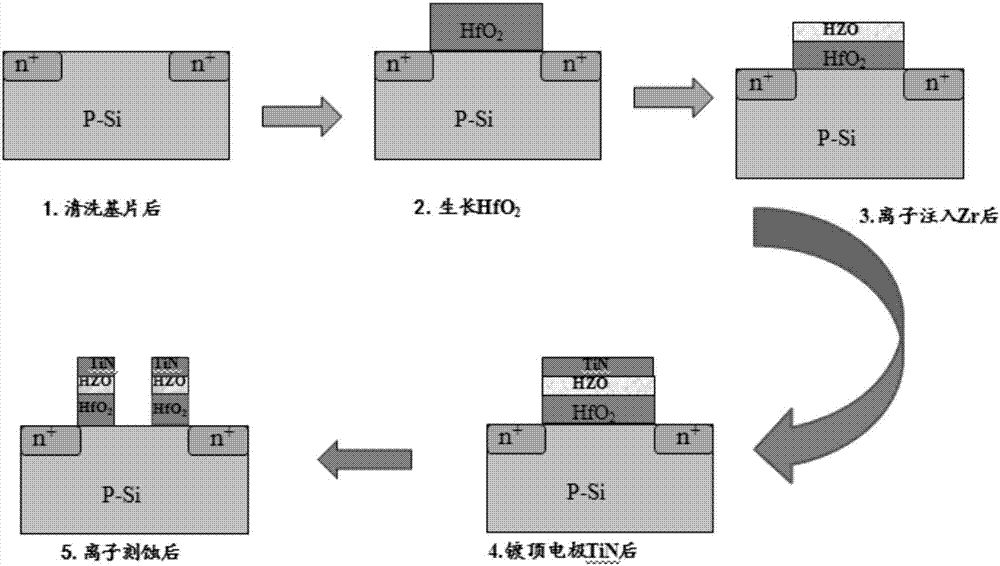

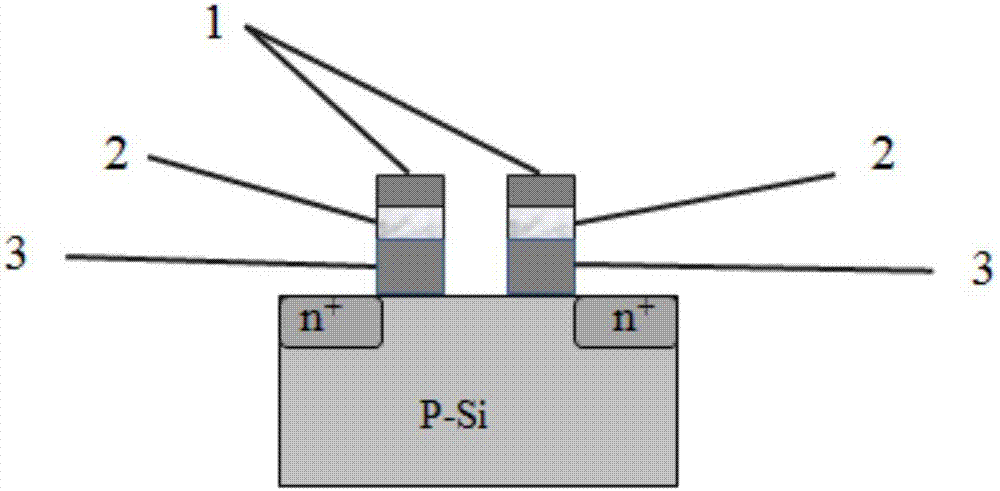

Ion implantation doping-based preparation method of hafnium oxide ferroelectric gate

ActiveCN107146759APrecise control of concentrationReduce interface effectsSemiconductor/solid-state device manufacturingSemiconductor devicesFerroelectric thin filmsThermal treatment

The invention provides an ion implantation doped HfO2 based preparation process of an HfO2 MIFS ferroelectric gate. The preparation process comprises the steps of firstly, cleaning a P-Si or n-Si substrate by a standard cleaning process to remove particles and other pollutants on a Si surface, afterwards depositing an appropriate thickness of HfO2 on a silicon wafer, and performing annealing; secondly, doping HfO2 by an ion implanter, and annealing the doped HfO2; thirdly, depositing a top electrode on the doped HfO2, namely halfnium oxide ferroelectric thin film, and performing rapid thermal treatment on the electrode; and finally, etching an MFIS multi-layer thin film structure to form an MFIS array unit which is matched with the sizes of a source, a drain and a channel by a reactive ion etching method. By the preparation process, the doping concentration of the HfO2 ferroelectric gate thin film can be accurately controlled, and the preparation process is a mature operation process for preparing the thin film relatively simple to prepare and with lower preparation temperature.

Owner:XIANGTAN UNIV

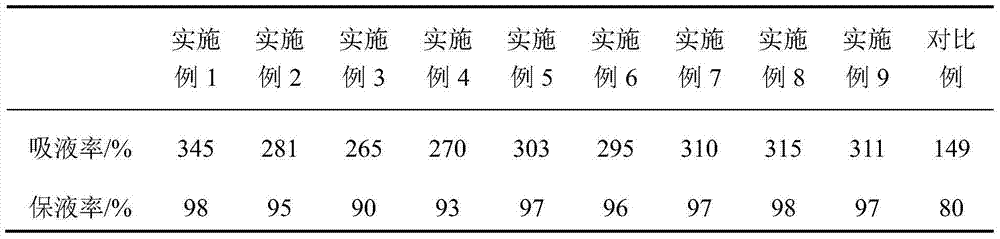

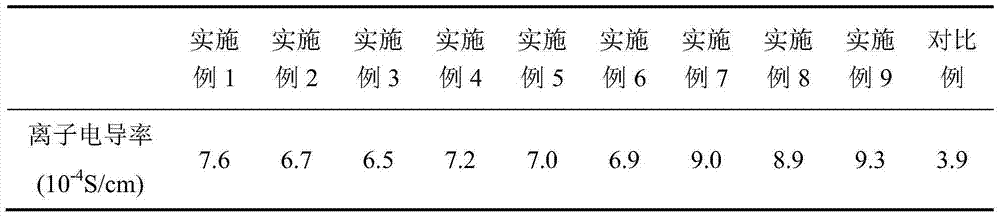

Lithium ion battery composite separation membrane and preparation method thereof

ActiveCN103715384ASimple methodSuitable for large-scale industrial production applicationsCell component detailsPolyolefinCrystallinity

The present invention discloses a lithium ion battery composite separation membrane and a preparation method thereof, and belongs to the technical field of lithium ion batteries, wherein at least a surface of a polyolefin separation membrane is coated with a modified natural rubber polymer coating. According to the invention, the polyolefin separation membrane and the modified natural rubber are combined to form the composite separation membrane, such that mechanical properties of the natural rubber can be improved, and the original pore closing characteristic of the polyolefin separation membrane can be maintained and utilized so as to improve safety of the battery, enhance bonding force between the separation membrane and the positive electrode and bonding force between the separation membrane and the negative electrode, eliminate the interface effect, and improve cycle stability of the battery; and the inorganic nanoparticles are added to the modified natural rubber latex, such that the crystallinity of the polymer can be reduced to a certain extent, the mechanical strength of the separation membrane and the carrier concentration can be increased, the interface compatibility between the separation membrane and the lithium electrode can be effectively improved, and the interface is stable.

Owner:HENAN NORMAL UNIV

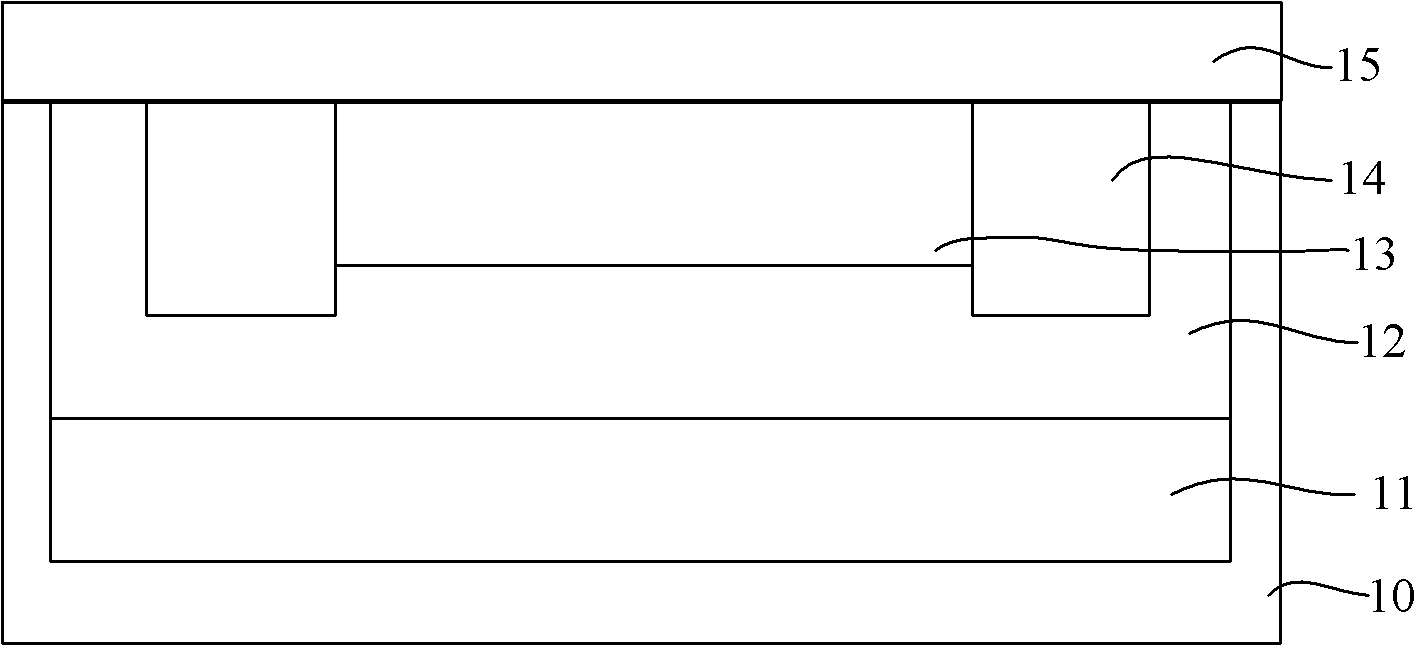

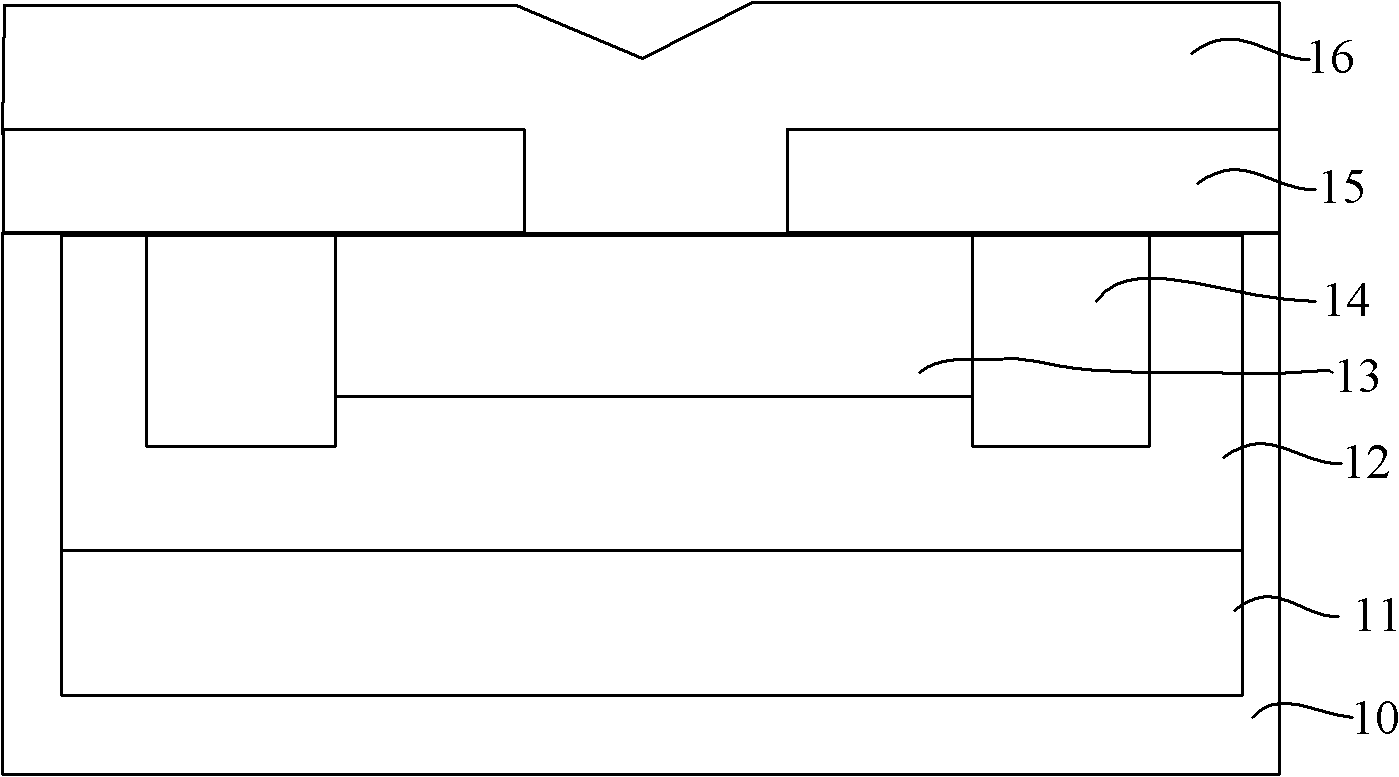

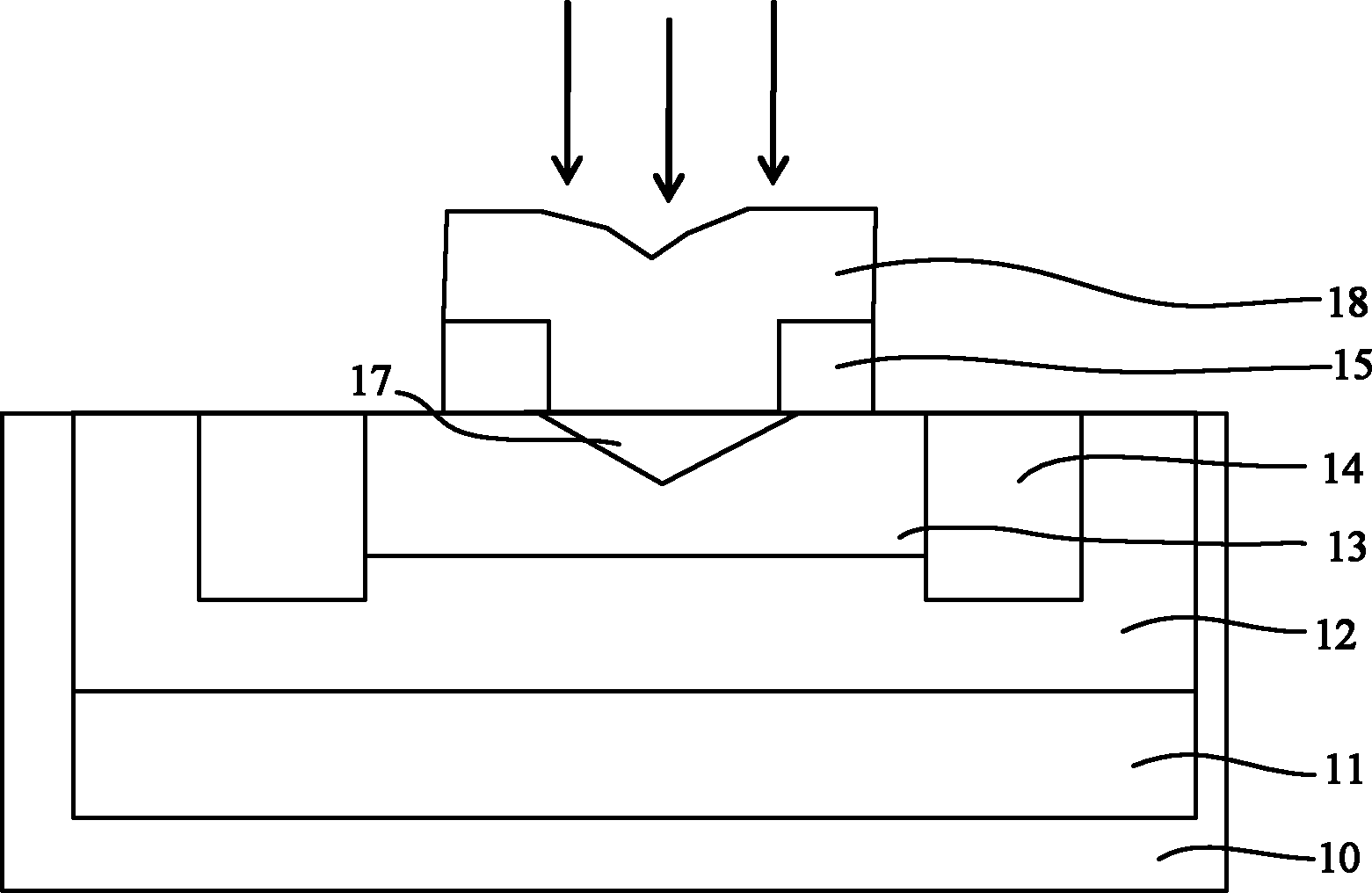

Method for manufacturing bipolar junction transistor

ActiveCN102122643AUniform thicknessReduce interface effectsSemiconductor/solid-state device manufacturingCMOSBoundary effects

The invention relates to a method for manufacturing a bipolar junction transistor, which is compatible with a process for preparing a complementary metal oxide semiconductor (CMOS) transistor. In the method, an emitter is formed in a bipolar junction transistor preparation region while gate polycrystalline silicon is formed in a CMOS transistor preparation region; high doping is generally required to be performed on an extrinsic base region in the bipolar junction transistor so as to form good ohmic contact with an electrode; a self-aligned extrinsic base region is realized by means of self-aligned high-doping ion implantation of the CMOS transistor; and doping ions are implanted and propelled to the emitter, so that the doping ions are uniformly propelled to the base region to form an emitter junction, the thickness of the emitter junction is more uniform, and etching damage is repaired by means of a rapid thermal oxidation process of a CMOS polycrystalline silicon gate after a polycrystalline silicon layer is etched; therefore, the boundary effect is reduced and the leakage current is reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

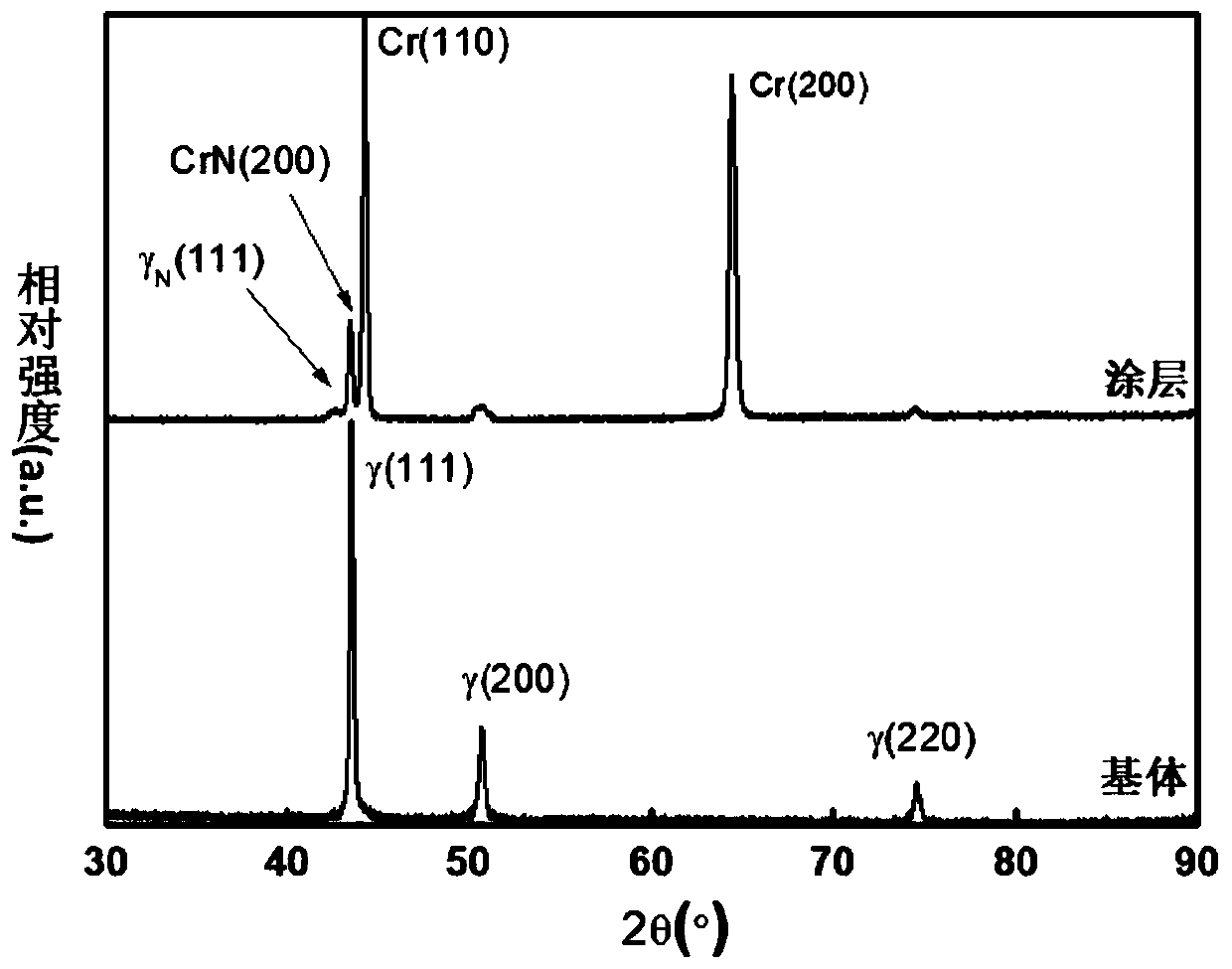

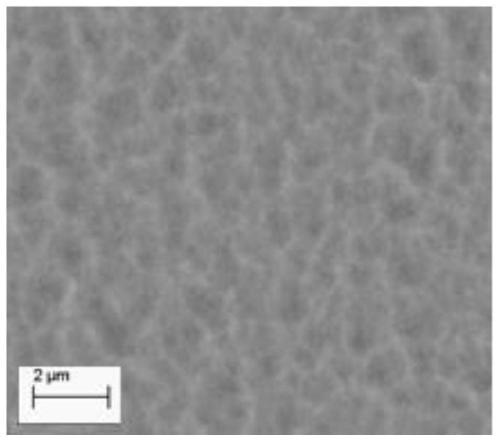

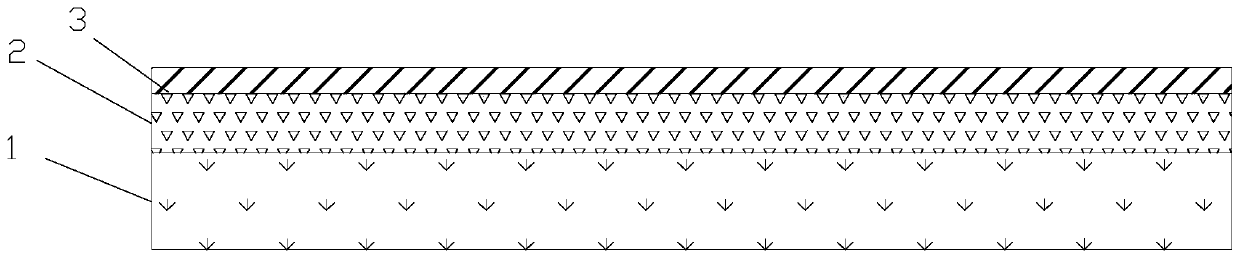

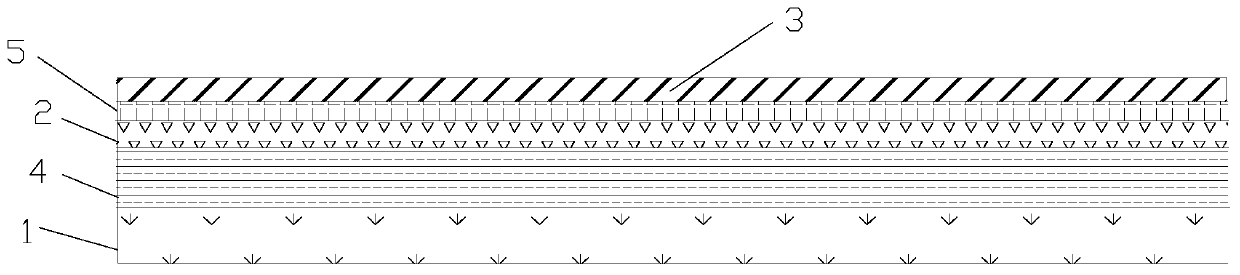

In-situ preparation method of composite modified layer on surface of stainless steel bipolar plate of proton exchange membrane fuel cell

ActiveCN111224121AReduce interface effectsExtended service lifeFinal product manufactureVacuum evaporation coatingSputteringMetallurgy

The invention relates to an in-situ preparation method of a composite modified layer on the surface of a stainless steel bipolar plate of a proton exchange membrane fuel cell. The in-situ preparationmethod comprises the steps of pre-treating at an earlier stage, vacuumizing and preheating, conducting plasma cleaning, preparing a pure metal Cr layer by non-equilibrium magnetron sputtering, performing plasma in-situ nitriding treatment, cooling and then taking out. The prepared composite modified layer on the surface of the stainless steel bipolar plate is a nitriding / CrNx composite modified layer, the inner layer is a nitriding layer, and the surface layer is a CrNx layer. According to the invention, a plasma enhanced magnetron sputtering system is adopted, in-situ nitriding is carried outon a pure metal Cr layer and a base body at the same time, and nitrogen atoms are diffused into the base body from the Cr layer, so that the pure metal Cr layer and the base body are enabled to havecontinuous gradient distribution. Compared with a traditional nitriding-coating composite treatment process, the composite modified layer has more excellent electrical conductivity, wear resistance and film-substrate bonding strength, so that the service life of the bipolar plate is prolonged.

Owner:UNIV OF SCI & TECH LIAONING

High-quality polycrystalline diamond compact and preparation method thereof

InactiveCN110143021AImprove high temperature resistanceInhibit sheddingAdditive manufacturing apparatusIncreasing energy efficiencyPolycrystalline diamondCobalt

The invention relates to the technical field of super-hard composite materials, particularly to a high-quality polycrystalline diamond compact and a preparation method thereof. According to the invention, the high-quality polycrystalline diamond compact is manufactured by using double-beam 3D printing equipment which performs processing with high-power continuous beams and ultra-fast pulsed laserbeams alternately; and gradual transition layers are formed among layers, so bonding between a matrix and diamond and between the diamond and nickel is firm, and an interlayer interface is free of sudden changes in thermal and mechanical quantities. The polycrystalline diamond compact of the invention comprises, arranged from bottom to top, the matrix, a matrix-diamond gradual transition layer, adiamond layer, a diamond-nickel gradual transition layer, a nickel layer and a cobalt-free binder. The diamond-nickel gradual transition layer improves the heat dissipation performance of the polycrystalline diamond compact, prevents thermal stress corrosion from generating cracks on the surface of the diamond layer, and greatly improves the thermal stability of the polycrystalline diamond compact. Double-beam 3D printing technology used in the invention makes D-D bonding firm and ultra-high hardness to be obtained, so the polycrystalline diamond compact has high heat resistance, wear resistance and impact toughness, and thus has prolonged service life.

Owner:上海梁为科技发展有限公司

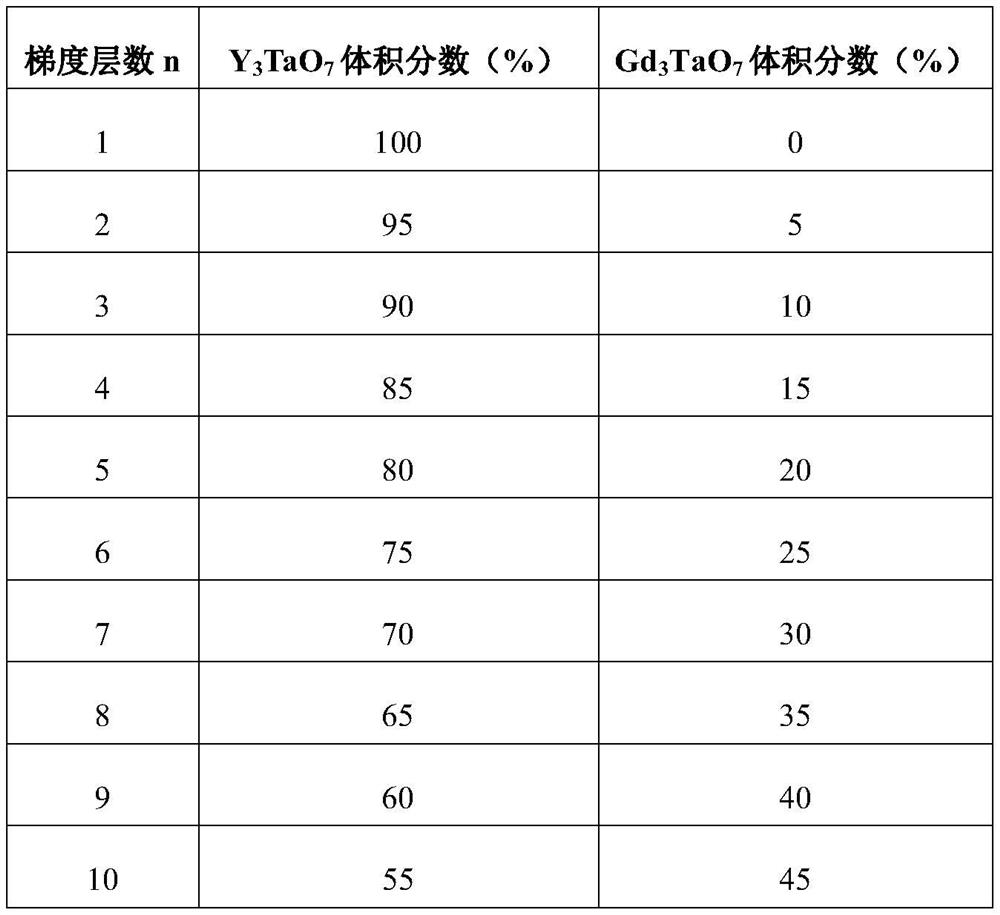

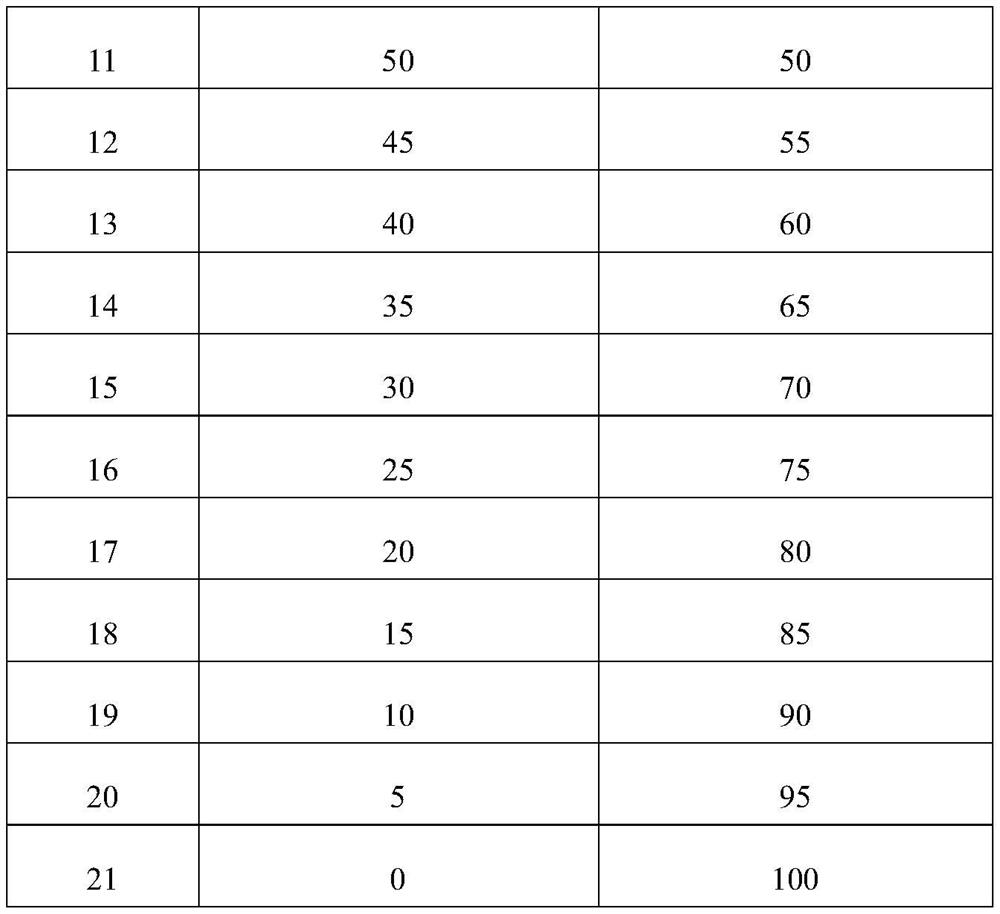

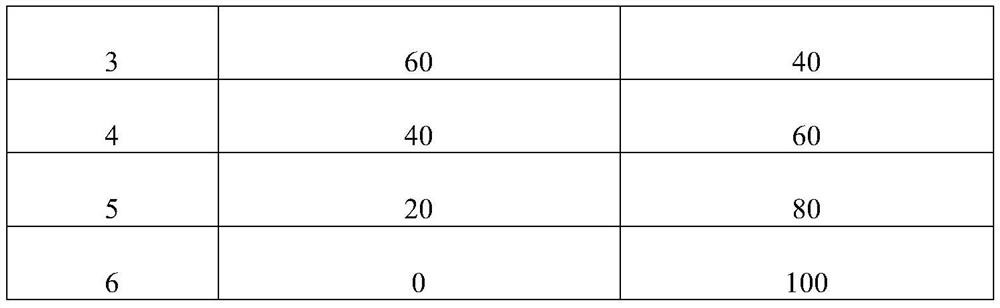

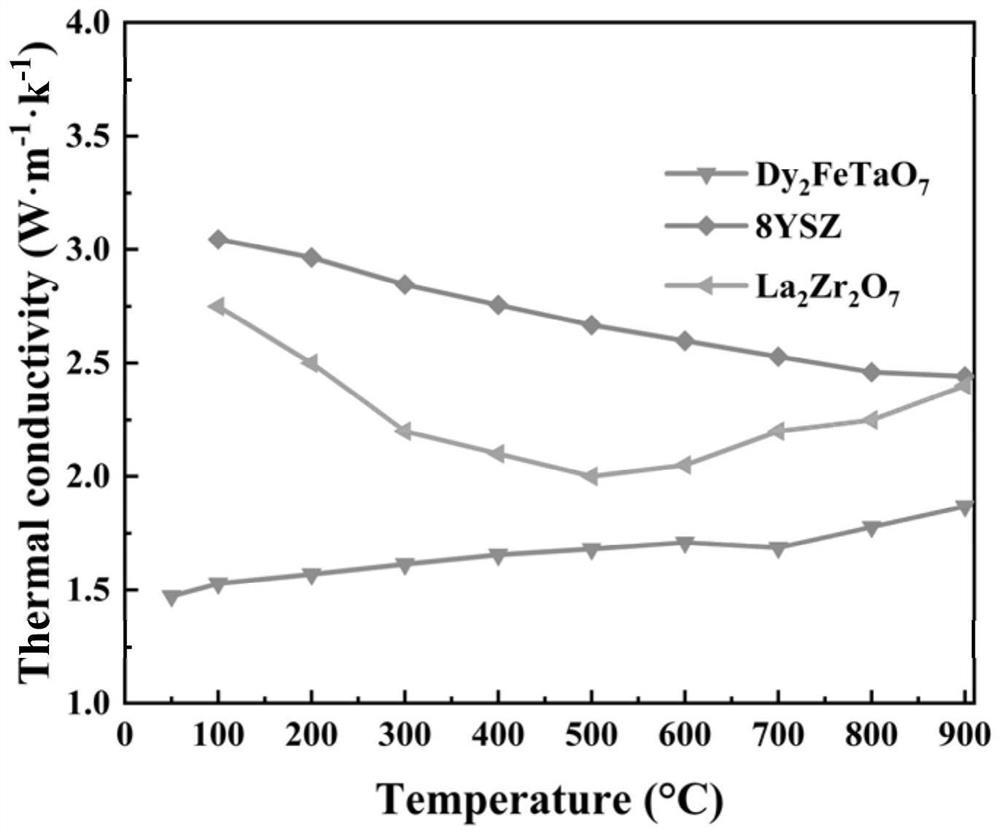

Rare earth tantalate (RE3TaO7) thermal barrier coating and preparation method thereof

ActiveCN111908921ALow thermal conductivityMeet the need for low thermal conductivityMolten spray coatingRare-earth elementThermal barrier coating

The invention relates to the technical field of thermal barrier coatings, and particularly discloses a rare earth tantalate (RE3TaO7) thermal barrier coating and a preparation method thereof. Tantalate ceramic powder of more than two different rare earth elements is taken and mixed into n parts of mixed ceramic powder; the volume fraction of at least more than one tantalate ceramic component in the n parts of mixed ceramic powder is continuously increased or decreased; and sequentially depositing n parts of mixed ceramic powder on the base material to obtain the multi-gradient rare earth tantalate thermal barrier coating. The multi-element gradient coating is obtained by designing tantalate ceramic powder of more than two different rare earth elements, that is, the volume fraction of at least one ceramic component in the coating is continuously increased or continuously decreased, so that the thermal barrier coating has a high expansion coefficient of the original rare earth tantalate(RE3TaO7). Meanwhile, the heat conductivity is also greatly reduced.

Owner:KUNMING UNIV OF SCI & TECH +1

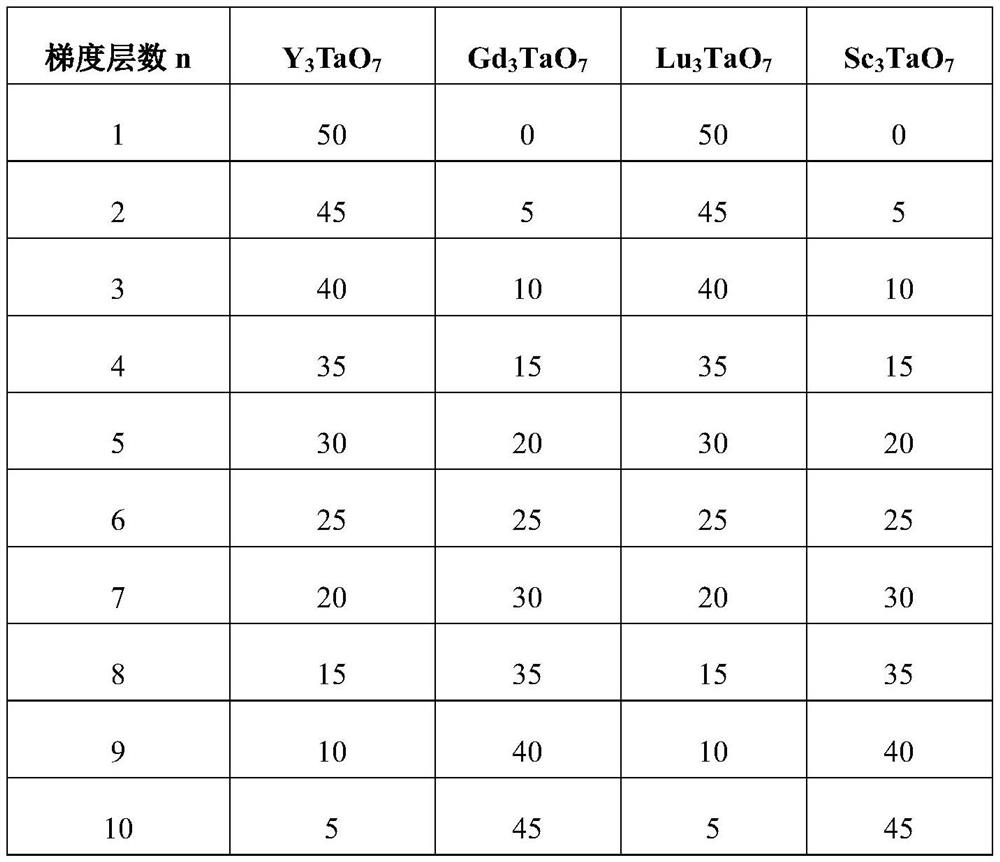

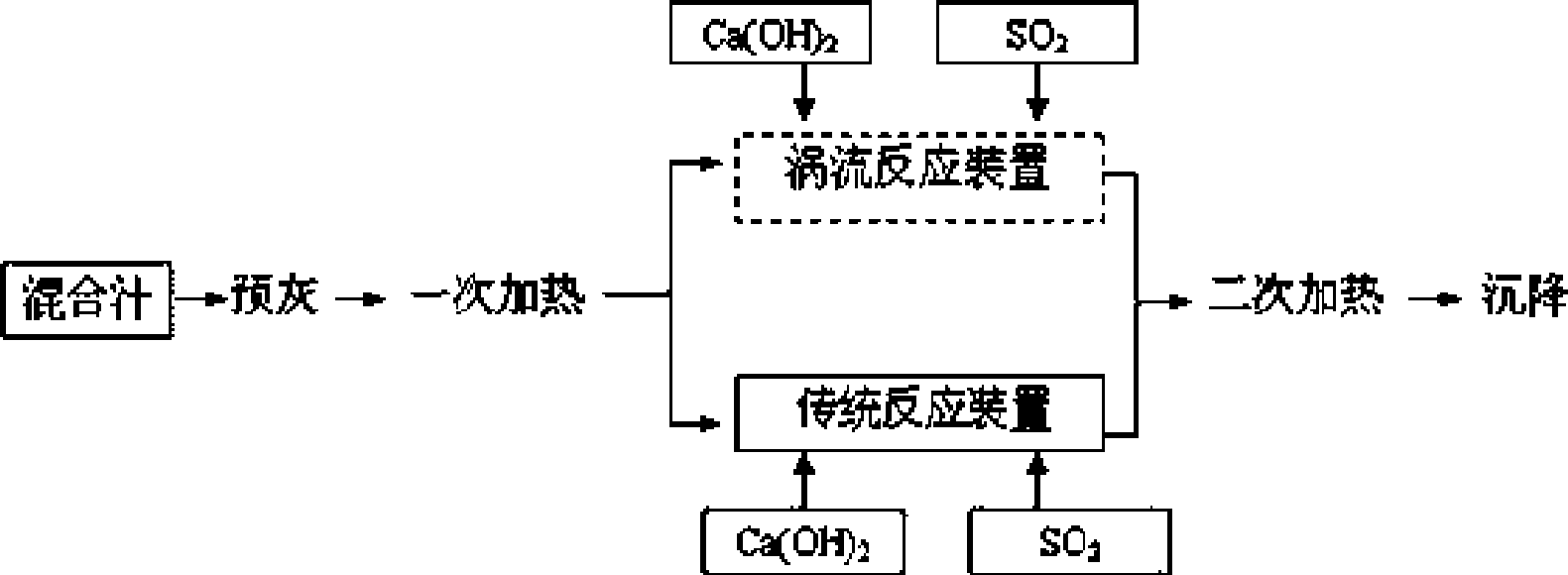

Sugarcane juice clarification method with intensified sulfitation-neutralization reaction

InactiveCN101485409AReduce contentSulfur dioxide content requirements are reducedFood preparationJuice clarificationReaction speed

The invention provides a cane juice clarification method for a reinforced sulfur fumigation neutralization reaction, which relates to a clarification process method for sugar processing. The method adopts the sulfurous method clarification process which comprises preliming, first heating, sulfur fumigation neutralization, secondary heating and settlement procedures; the sulfur fumigation neutralization procedure comprises a reinforced sulfur fumigation neutralization reaction step in which the cane juice is filled in a vortex reaction device for reaction; and at the reinforced sulfur fumigation neutralization reaction step, the full or partial mixing of the cane juice is performed by the combination of the sulfur fumigation neutralization procedure, namely the mixed cane juice after the preliming and the first heating is fully or partially filled in the vortex reaction device, lime milk and SO2 are simultaneously added to the vortex reaction device, so that the reinforced sulfur fumigation neutralization reaction is carried out in the vortex reaction device, or in the prior sulfurous method clarification process; and the cane juice after the sulfur fumigation neutralization is fully or partially filled in the vortex reaction device to reinforce the sulfur fumigation neutralization reaction. The method has the advantages of improving the reaction speed and the reaction extent of the sulfur fumigation neutralization reaction, improving the decolorization effect, and reducing the residual sulfur content in white granulated sugar.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

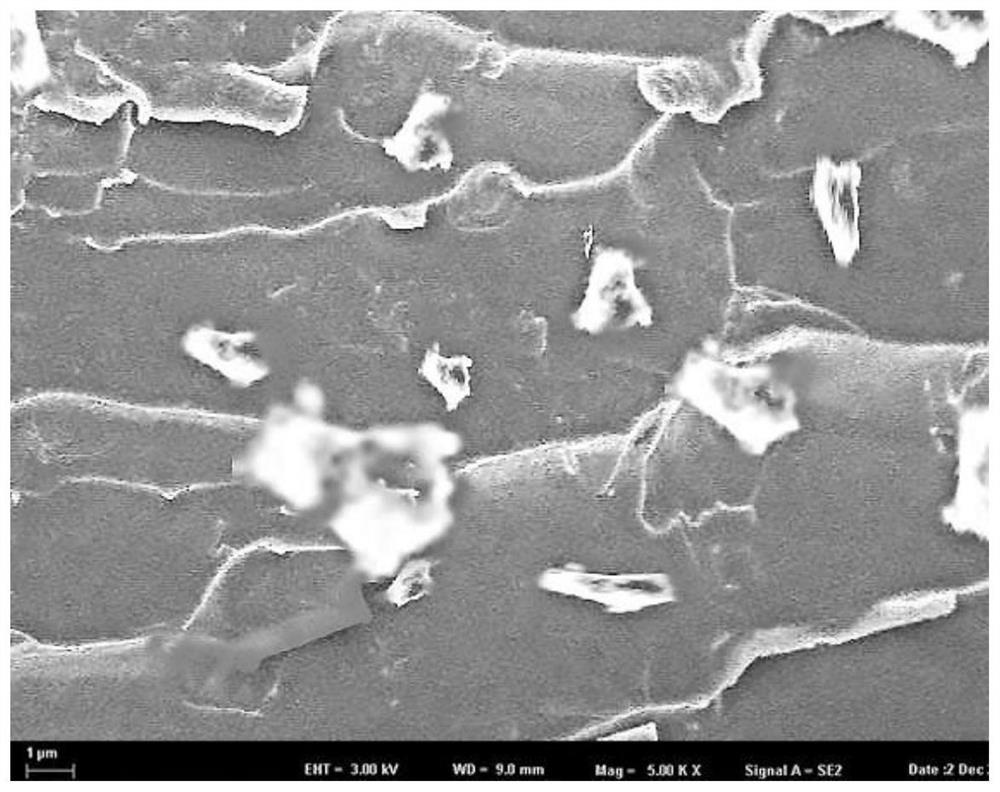

Graphite-based high-strength heat-conducting epoxy resin adhesive and preparation method thereof

InactiveCN111621253AImprove adhesionImprove insulation performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesHexadecanePolymer science

The invention relates to the technical field of adhesives, and discloses a graphite-based high-strength heat-conducting epoxy resin adhesive and a preparation method thereof. The adhesive comprises the following components in parts by weight: bisphenol A type epoxy resin, calcium carbonate, modified graphite, composite glass fibers, 1, 4-butanediol diglycidyl ether, a curing agent polydiphenyl substituted cetane dicarboxylic anhydride, a curing accelerator pyridine and absolute ethyl alcohol. The preparation method comprises the following steps: performing ultrasonic oscillation dispersion onmodified graphite to obtain a graphite suspension; adding bisphenol A epoxy resin, calcium carbonate, composite glass fibers and 1, 4-butanediol diglycidyl ether into the graphite suspension, and uniformly mixing to obtain a premix; and adding polydiphenyl substituted hexadecane dicarboxylic anhydride and pyridine into the premix, pouring into a metal mold, and standing while keeping the temperature, thereby obtaining the graphite-based high-strength heat-conducting epoxy resin adhesive. The adhesive prepared by the method has high mechanical strength and excellent heat-conducting property, and the application range of the epoxy resin adhesive is expanded.

Owner:李磊

Ternary composite material and preparation method thereof and lithium-ion battery

InactiveCN106654201AAvoid direct contactInhibition of catalytic decomposition reactionsCell electrodesSecondary cellsOxalateCatalytic decomposition

The invention discloses a ternary composite material and a preparation method thereof and a lithium-ion battery. The method comprises the steps of adding a vanadium source to an oxalic acid solution, adding a phosphorus source and a lithium source, adding a ternary material for stirring evenly and then dropwise adding ethylene glycol and ethanediamine for reaction at 150-200 DEG C for 2-4 hours to obtain a precursor; carrying out vacuum drying on the precursor at 80-120 DEG C for 6-10 hours, grinding the precursor evenly and then sintering at 800-860 DEG C for 8-15 hours; and carrying out furnace cooling to obtain NLiNi<x>Co<y>Mn<z>O<2> / (1-N)Li<3>V<2>(PO<4>)<3> / C, wherein x+y+z is equal to 1 and N is smaller than 1 and greater than or equal to 0.5. A coating layer is formed on the surface of the ternary material, so that direct contact of the ternary material and an electrolyte can be blocked and catalytic decomposition of the ternary material on the electrolyte is inhibited. Catalytic reaction of the ternary material on the electrolyte is retarded by the coating layer, instantaneous accumulation of heat is relieved and a dangerous condition of the battery is inhibited.

Owner:深圳市鑫永丰科技有限公司

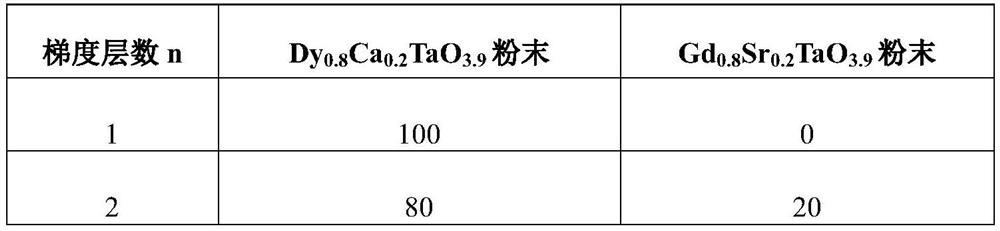

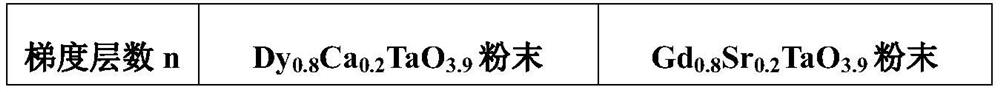

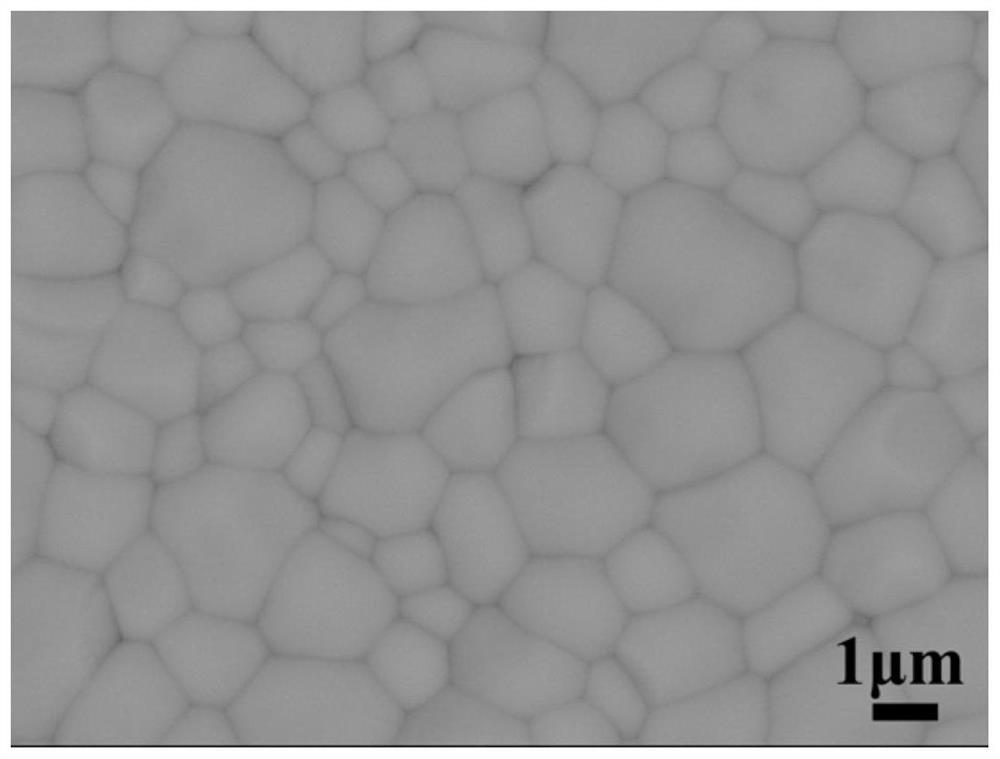

Alkaline earth metal ion doped rare earth tantalate or niobate thermal barrier coating and preparation method thereof

ActiveCN111960823AHigh thermal conductivityLow thermal conductivityMolten spray coatingAlkaline earth metalPhysical chemistry

The invention relates to the technical field of thermal barrier coatings and particularly discloses an alkaline earth metal ion doped rare earth tantalate or niobate thermal barrier coating and a preparation method thereof. The coating is a multi-element gradient coating and comprises two or more different ceramic components, the volume fraction of at least one or more ceramic components is continuously increased or decreased along the gradient of the coating, the chemical general formula of the ceramic components in the coating is RE1-xM1xM2O4-x / 2 (0<x<1), and M1 is one of Mg, Ca, Sr or Ba; M2 is Ta or Nb. According to the scheme, it can be guaranteed that the thermal barrier coating has a high expansion coefficient of original alkaline earth metal doped rare earth tantalum / niobate, meanwhile, the thermal conductivity of the thermal barrier coating is greatly reduced, the thermal conductivity detected in an experiment does not exceed 1.10 W.m<-1>.K<-1>, and the requirement of the thermal barrier coating for the low thermal conductivity is met.

Owner:KUNMING UNIV OF SCI & TECH +1

A2B2O7 type rare earth tantalate ceramic and preparation method thereof

ActiveCN111925211ALow thermal conductivityMeet the need for low thermal conductivityWater bathsGraphite

The invention relates to the technical field of thermal barrier coatings, and particularly discloses an A2B2O7 type rare earth tantalate ceramic and a preparation method thereof. The preparation method comprises the following steps: respectively dissolving RE2O3 and M2O3 into concentrated nitric acid according to the structural formula of RE2MTaO7 to react and adjusting the pH value to be not lessthan 1.5, dropwise adding a TaOCl3 solution, continuously stirring, adding ammonia water to stabilize the pH value of the system at 9-10, continuously stirring in a water bath environment, washing the precipitate with deionized water until the pH value is 7, drying the obtained filter cake in a drying oven, and screening for later use; and placing the powder in a graphite grinding tool, performing spark plasma sintering in a sintering furnace, then performing annealing and carbon removal on a sintered sample to obtain a compact RE2MTaO7 block. The material has the characteristics of low heatconductivity, high hardness, fracture toughness and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

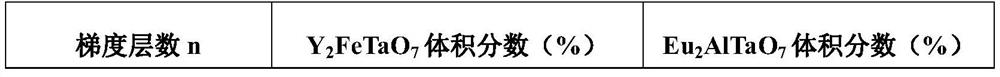

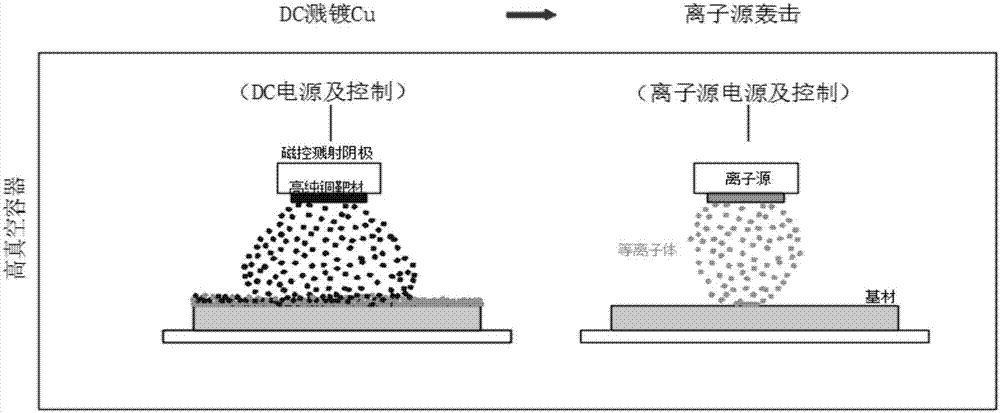

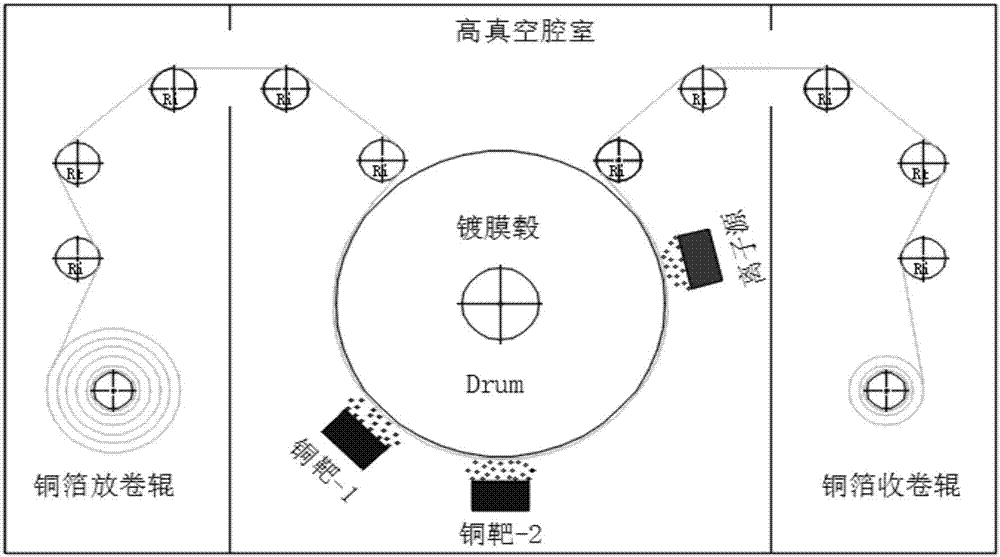

Method for improving electric performance of copper foil collector of battery cathode

InactiveCN107452964AImprove adhesionImprove the conductivity of the negative electrodeMaterial nanotechnologyElectrode carriers/collectorsNanometreElectricity

The invention discloses a method for improving the electric performance of a copper foil collector of a battery cathode. The method is characterized in that a nano-copper film is deposited on the copper foil of the collector of a lithium battery cathode by utilizing a vacuum plasma plating technology, and the copper film surface is subjected to ion source bombardment for improving the adhesion of the lithium battery cathode material with the copper foil of the collector, the interface effect is reduced, and the electric performance of the lithium battery is improved.

Owner:惠州市烯谷新能源产业技术研究院有限公司

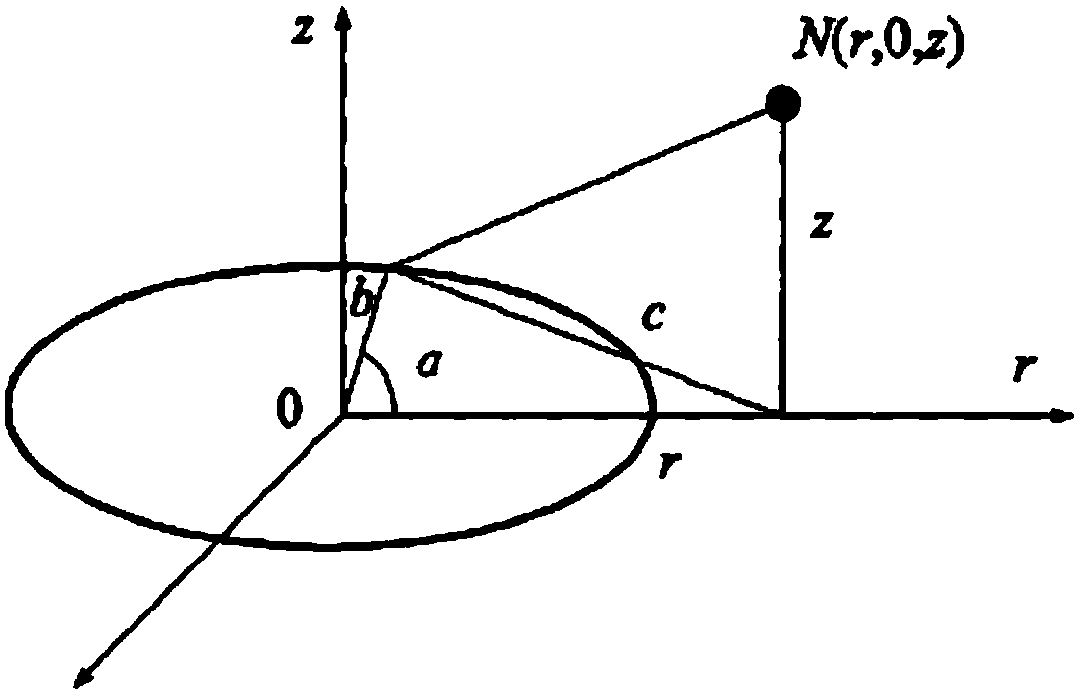

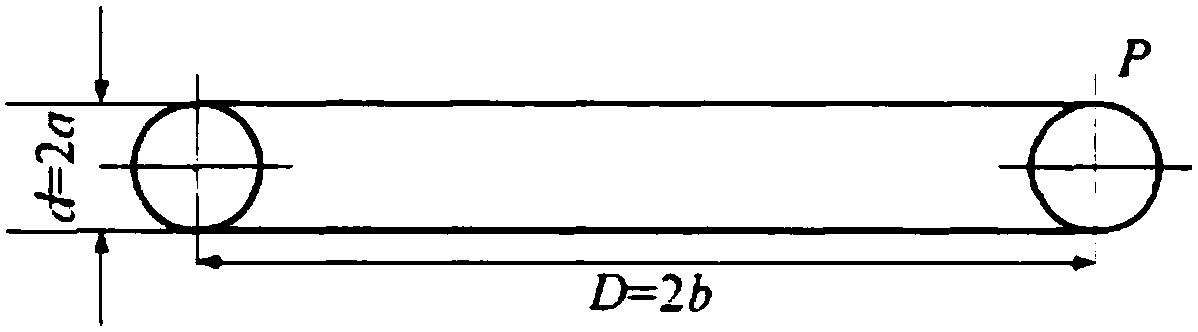

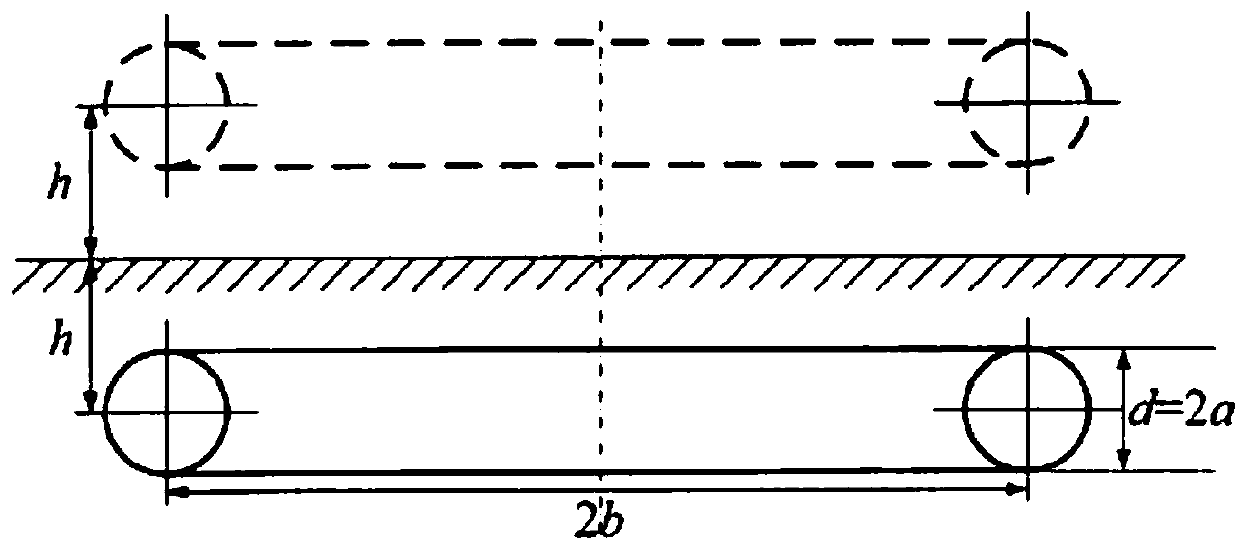

Novel step voltage calculation method based on circular ring-shaped DC power transmission earth electrode different buried depths

ActiveCN107831353AReduce corrosionReduce step voltageVoltage measurements onlyEarth surfaceCalculation methods

The present invention discloses a novel step voltage calculation method based on circular ring-shaped DC power transmission earth electrode different buried depths. The method comprises the followingtwo situations of (1) analyzing the potential distribution that the homogeneous medium circular ring-shaped earth electrodes are not buried at the equal depth to obtain a calculation expression of a step voltage on an earth surface; (2) analyzing the potential distribution that the horizontal dual-layer medium circular ring-shaped earth electrodes are not buried at the equal depth to obtain a calculation expression of the step voltage on the earth surface; utilizing a MALTAB software to simulate to obtain the results and the influence of different earth electrode ring numbers and different buried depths on a surface potential, thereby demonstrating that the method provided by the present invention enables the step voltage to be reduced. The present invention creatively provides the thoughtthat the dual-circular ring-shaped earth electrodes are not buried at the equal depth, the calculation is simple, and the operation speed is fast.

Owner:JIANGSU UNIV

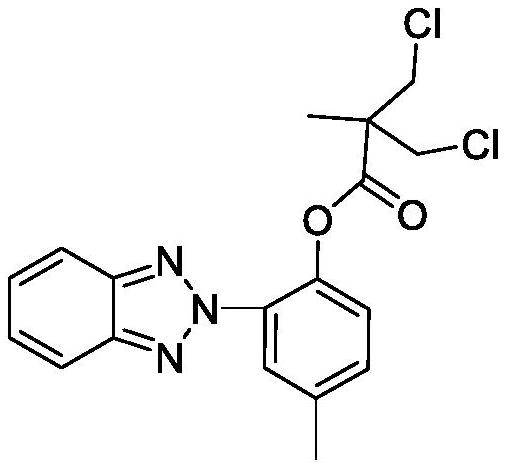

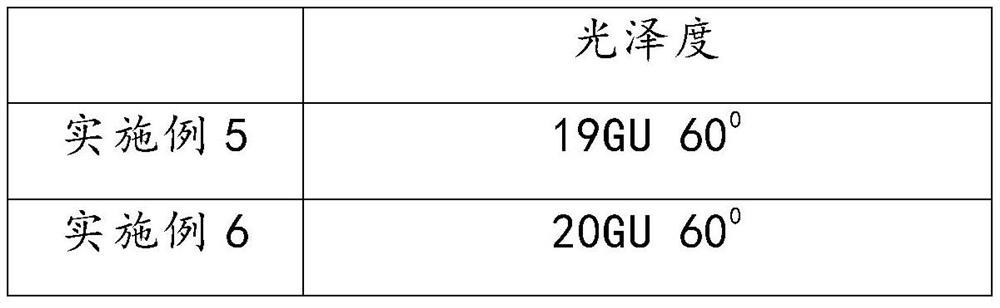

Delustering master batch for plastic and preparation method thereof

The invention relates to a matting master batch for plastic and a preparation method of the matting master batch, and belongs to the technical field of plastic processing. The matting master batch for plastics comprises the following raw materials: matrix resin, a composite matting agent, a lubricant and a compatibilizer, the composite delustering agent is an inorganic delustering agent (titanium dioxide) of which the surface is grafted with a delustering hyperbranched polymer, and the delustering hyperbranched polymer contains a large amount of light absorption structures of pyridine rings and benzotriazole, so that the reflected light of the master batch is greatly reduced, and the delustering performance of the master batch is improved; thirdly, the dull hyperbranched polymer is grafted on the surface of titanium dioxide, so that the titanium dioxide is promoted to be uniformly dispersed in the master batch base material, and meanwhile, the grafted dull hyperbranched polymer and the master batch base material can generate the action of a polymer molecular chain, so that the migration of the titanium dioxide in the dull master batch base material is reduced; the effect of enhancing the matting performance and the mechanical performance of the matting master batch by the composite matting agent is promoted.

Owner:JIESHOU JINFENG PLASTIC

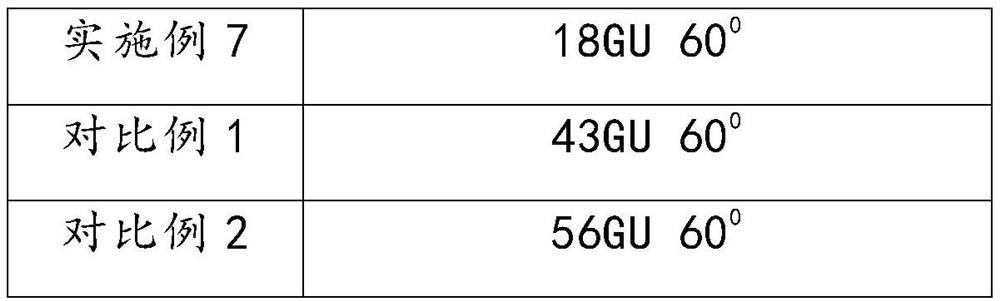

Essence for improving skin aging and damage and preparation method thereof

InactiveCN113274312AAccelerated agingEasily damagedCosmetic preparationsToilet preparationsBenzoic acidArginine

The invention discloses essence for improving skin aging and damage, and belongs to the technical field of skin care product processing. The essence is prepared from the following ingredients including 1, 3-propanediol, glycerol, isononanoate cetearyl stearate, cetostearyl alcohol, ceteareth-20, glyceryl stearate, ceteareth-12, cetyl palmitate, serum protein, acetyl hexapeptide-8, hydrolyzed sodium hyaluronate, glyceryl acrylate / acrylic acid copolymers, propanediol, PVM / MA copolymers, sodium hyaluronate, lactose, milk protein, oligopeptide-1, arginine / lysine polypeptide, polyacrylate cross-linked polymers-6, tert-butyl alcohol, 1, 2-hexanediol, caprylyl glycol, benzoic acid, ethylhexylglycerin, p-hydroxyacetophenone and water. A preparation method of the essence comprises the following steps of (1) raw material weighing; (2) stirring treatment; (3) cold plasma-ultraviolet light circulation alternate treatment; (4) micro jet high-pressure homogenizing treatment; and (5) quality inspection and packaging. The finally prepared essence has the obvious anti-aging effect.

Owner:上海活彩生物科技有限公司

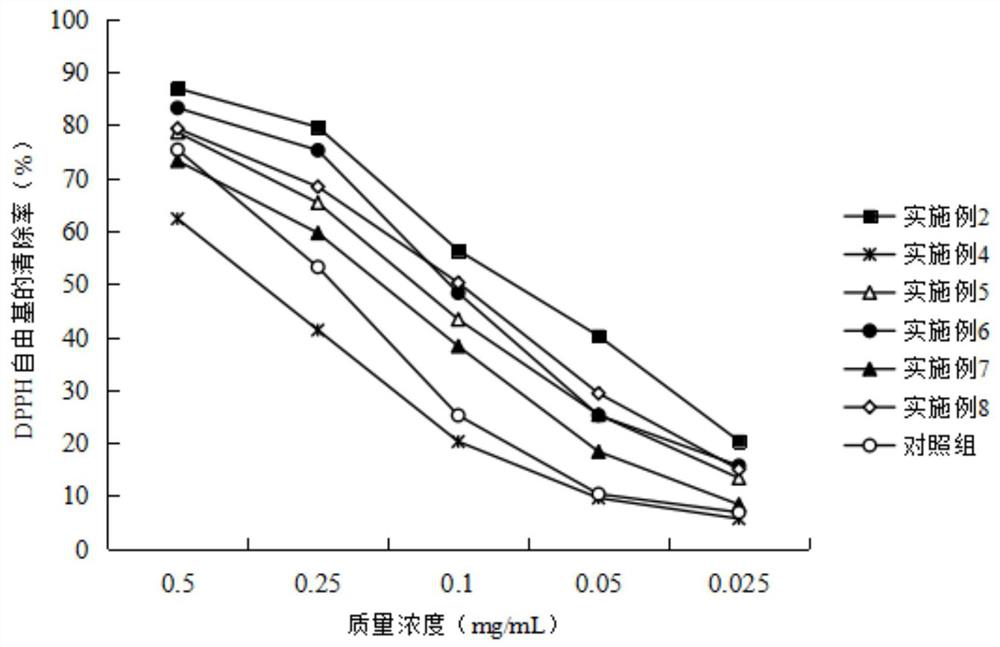

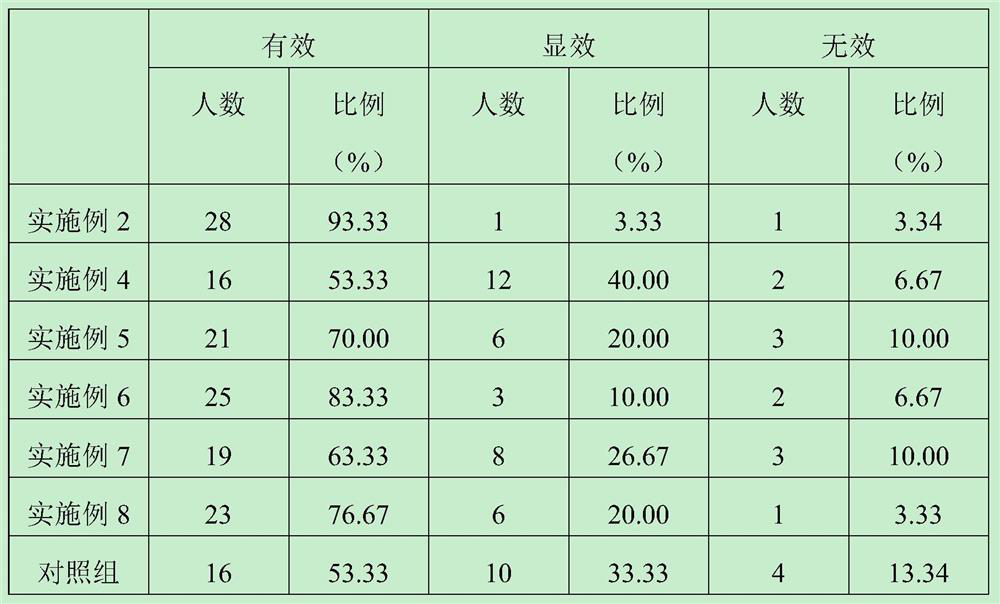

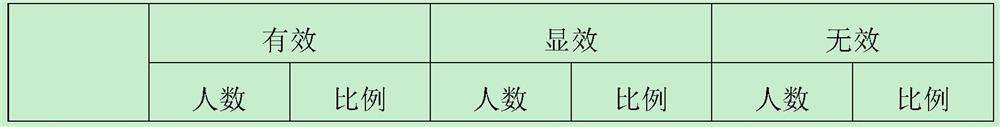

Composition for treating chloasma and preparation method thereof

InactiveCN113908191AImprove surface wettabilityImprove bioavailabilityDermatological disorderGinkgophyta medical ingredientsMagnetic field couplingBioavailability

The invention discloses a composition for treating chloasma and a preparation method thereof, and belongs to the technical field of chloasma treatment preparations. The preparation method comprises the following steps of: (1) preparing extract paste; (2) performing steam flash explosion; (3) performing micro-jet high-pressure homogenization treatment; and (4) performing ultrasonic-ultraviolet-magnetic field coupling treatment. According to the composition for treating chloasma and the preparation method thereof, firstly, the selected raw materials are traditional Chinese medicines, vegetables and fruits with mild temperament, and the raw materials are safe; secondly, by combining and applying the technologies of cryogenic grinding, cold plasma treatment, steam flash explosion, micro-jet high-pressure homogenization treatment, ultrasonic waves and the like, the fusion among the raw materials is promoted, the bioavailability of the raw materials is improved, the interaction among the raw materials is promoted, the finished product is refined while sterilization is performed, and the composition is easy to absorb, so that the raw materials can synergistically act on the skin, and the composition has a remarkable treatment effect on chloasma.

Owner:杨业 +1

Compound anode material used for lithium ion battery, preparation method of compound anode material, and lithium ion battery

ActiveCN106410169AIncrease contact interfaceGood synergyCell electrodesSecondary cellsLithium iron phosphatePhysical chemistry

The invention discloses a compound anode material used for a lithium ion battery, a preparation method of the compound anode material, and a lithium ion battery. The preparation method comprises the following steps: according to a situation that the molar ratio of Ni to Co to Mn is equal to X to Y to Z, preparing solution, and carrying out coprecipitation to prepare precursor oxide under an alkaline condition; preparing an Li source and the precursor oxide; after the above materials are evenly mixed, carrying out high-temperature sintering to obtain an Li-rich ternary material; carrying out coprecipitation on a P source and an Fe source to prepare FePO4; preparing the Li-rich ternary material and the FePO4 according to a certain molar ratio, evenly mixing in a solvent, and evenly grinding after drying; sintering the above mixed powder at a high temperature; cooling with a furnace to obtain the compound anode material used for the lithium ion battery. According to a compound system of the ternary material and lithium iron phosphate, a contact interface for material compounding is effectively improved, and the synergistic effect of the compound material is better performed. Meanwhile, side reaction generated by the contact of the ternary material and electrolyte is inhibited, and the safety of the lithium ion battery is greatly improved.

Owner:深圳市鑫永丰科技有限公司

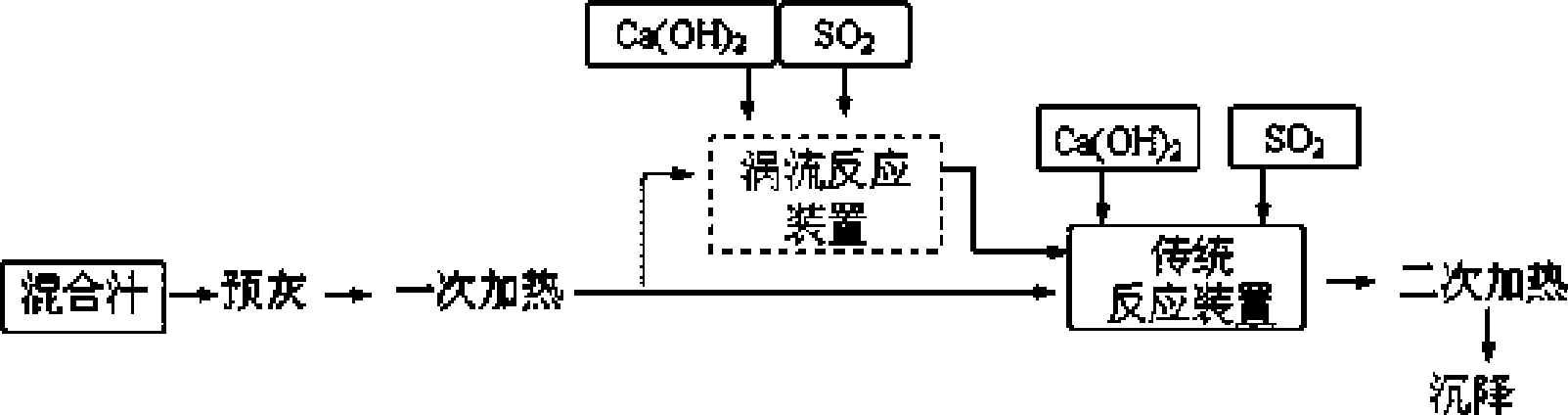

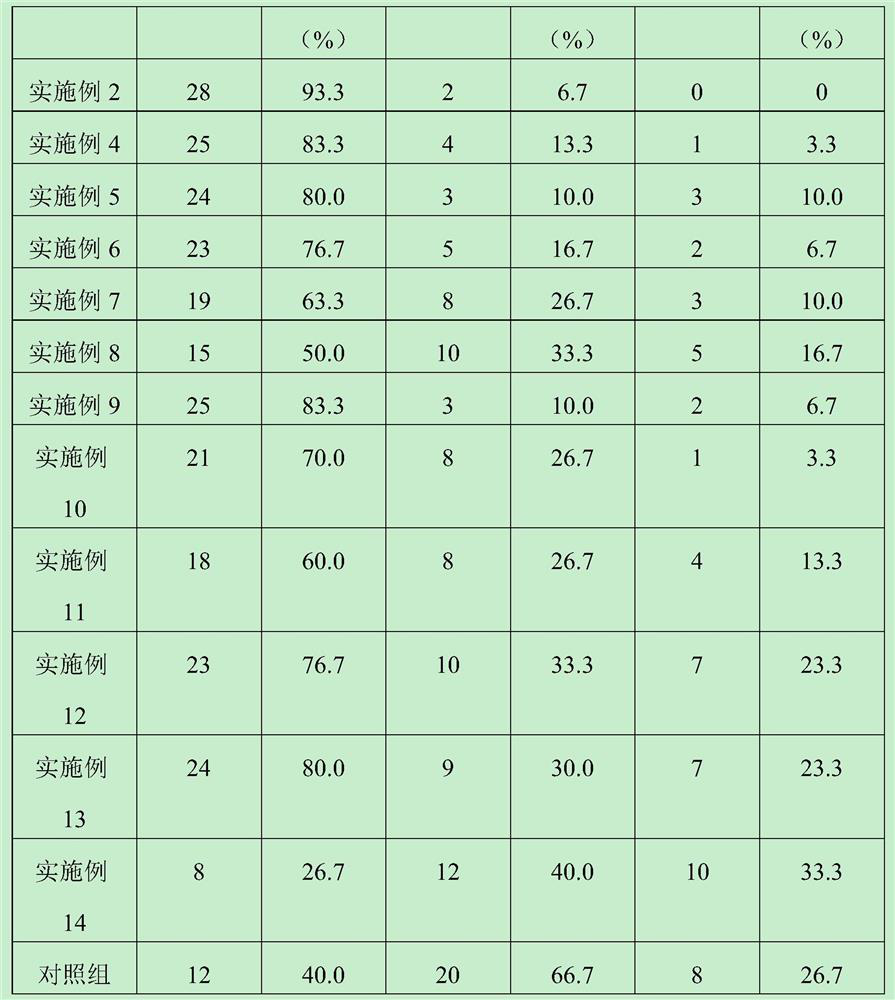

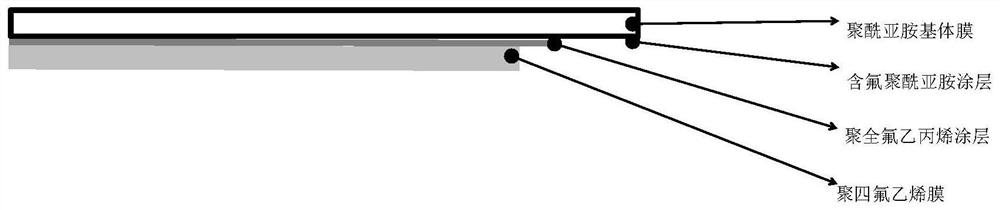

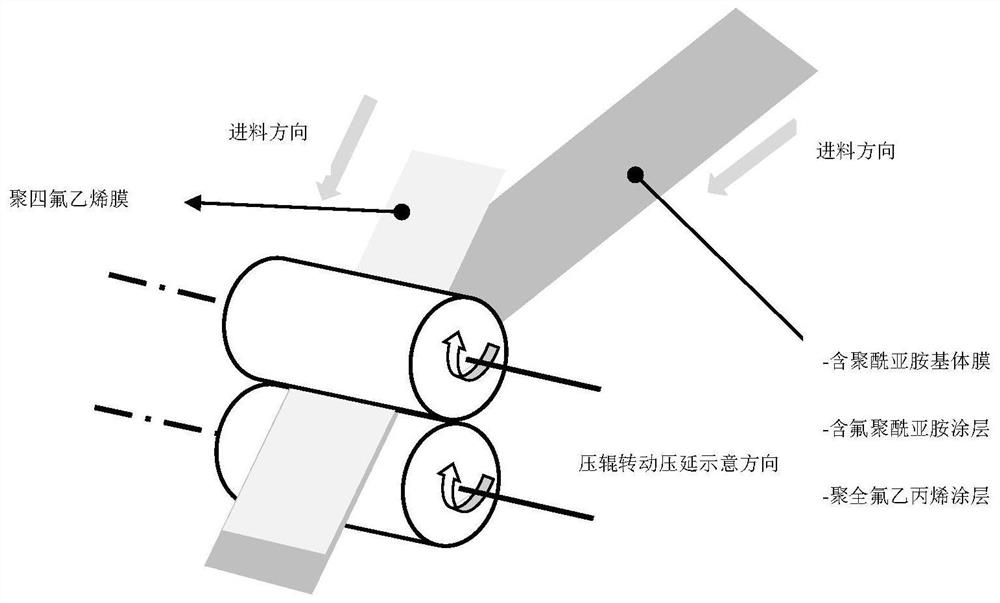

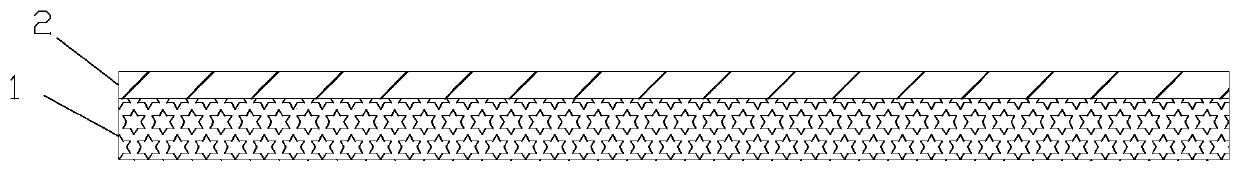

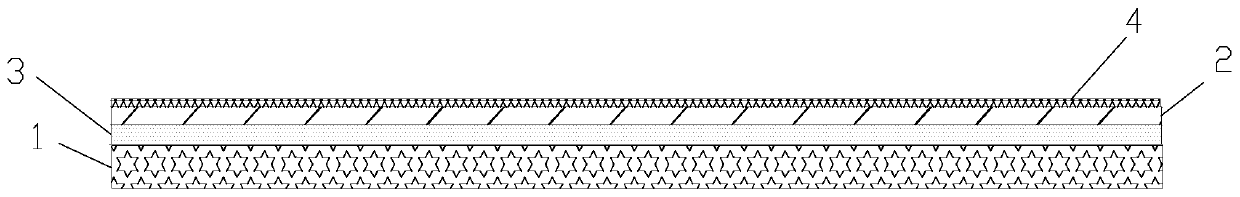

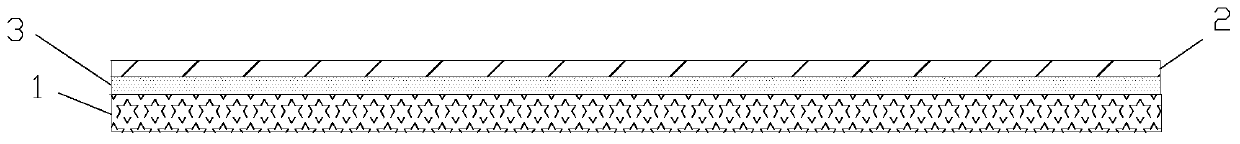

Polyimide composite film as well as preparation method and application thereof

The invention provides a polyimide composite film as well as a preparation method and application thereof, belonging to the technical field of insulating materials for aerospace cables. According to the invention, a fluorine-containing polyimide coating and a polyimide matrix film are connected through covalent bonds, so the fluorine-containing polyimide coating and the polyimide matrix film form a whole; and meanwhile, the fluorine-containing polyimide coating contains fluorine atoms and has good affinity with a fluorinated ethylene propylene coating, and due to the existence of the fluorine-containing polyimide coating, the interface affinity between polyimide and the fluorinated ethylene propylene coating is greatly improved, and interface effect is remarkably reduced; and a tetrafluoroethylene-hexafluoropropylene copolymer coating can be effectively adhered to a polytetrafluoroethylene film in a hot pressing process, so interfaces among different films in the composite film are greatly improved, and the problem that the composite film is easy to crack in a use process is solved.

Owner:DONGHUA UNIV

Self-lubricating metal ceramic bearing with high bending resisting strength and preparing method of self-lubricating metal ceramic bearing

InactiveCN105385967AMagneticHigh bonding strengthTransportation and packagingMetal-working apparatusIodideBoron fiber

The invention discloses a self-lubricating metal ceramic bearing with high bending resisting strength. The bearing is prepared from raw materials including, by weight, 2.3-2.4 parts of ferric citrate, 3.1-3.5 parts of basic nickel carbonate, 1.1-1.3 parts of cuprous iodide, 25-30 parts of water, a proper amount of ammonium hydroxide, 2.9-3 parts of TiH2, 5-5.6 parts of TiC, 3-4 parts of Mo2C, 3-4 parts of WC, 0.9-1.1 parts of LaB6, 0.6-0.8 part of germanium dioxide, 0.6-0.8 part of nanometer boron fibers, 0.7-0.9 part of a lubricating agent, 1-1.1 parts of C, 8.6-9 parts of W, 6.1-6.3 parts of Mo, 3.1-3.3 parts of V and 65-66 parts of Fe. By means of the Mo2C, the WC, the LaB6, the germanium dioxide and the nanometer boron fibers, the thermal resistance and bending resisting strength of the bearing are improved, the bearing has the characteristics of high hardness, high strength and high tenacity, and cracking is prevented.

Owner:ANHUI SILVER BALL BEARING

Method for prolonging endurance life of diamond compact and diamond compact

The invention relates to the technical field of super-hard composite materials, in particular to a method for prolonging the endurance life of a diamond compact and the diamond compact. The method forprolonging the endurance life of the diamond compact includes the steps: irradiating an interface between a substrate and a diamond layer and the surface of the diamond layer by ultra-fast pulse laser beams; polishing the surface of the diamond layer. The diamond compact is manufactured by the ultra-fast pulse laser beams, a gradient transition layer is generated between layers, so that the substrate and the diamond layer are firmly combined, and sudden change of a thermal quantity and a mechanical quantity on the interlayer interface is avoided. The surface (cold annealing) of the diamond layer is irradiated by the ultra-fast pulse laser beams, thermal stress concentration and lattice defects of the diamond layer can be eliminated, D-D bonds on the surface of the diamond layer can be firmly bonded, cobalt atoms are 'extruded' to the surface of the diamond layer, a rich cobalt layer is removed by polishing, ultra-high surface smoothness is realized, the high-temperature resistance ofthe diamond compact is improved, and the service life of the diamond compact is prolonged.

Owner:上海梁为科技发展有限公司

Iron, lithium and manganese phosphate composite material, method for preparing same and lithium ion battery

ActiveCN106450239AReduce solubilityImprove charge and discharge specific capacityCell electrodesSecondary cellsEthylenediamineManganese

The invention discloses an iron, lithium and manganese phosphate composite material, a method for preparing the same and a lithium ion battery. The method includes dispersing lithium sources, iron sources, manganese sources and phosphorus sources in deionized water; adding citric acid into the deionized water to obtain sol; stirring the sol to form gel, drying and grinding the gel and then pre-sintering the gel to form LiFe<0.5-x>Mn<0.5+x>PO<4>; adding vanadium sources into oxalic acid solution, then adding phosphorus sources, lithium sources and the LiFe<0.5-x>Mn<0.5+x>PO<4> into the oxalic acid solution, uniformly stirring the vanadium sources, the phosphorus sources, the lithium sources, the LiFe<0.5-x>Mn<0.5+x>PO<4> and the oxalic acid solution to obtain mixtures, dropwise adding ethylene glycol and ethylenediamine into the mixtures and carrying out reaction to obtain precursors; drying the precursors under vacuum conditions, uniformly grinding the precursors and then sintering and cooling the precursors to obtain the iron, lithium and manganese phosphate composite material YLiFe<0.5-x>Mn<0.5+x>PO<4> / (1-Y)Li<3>V<2>(PO<4>)<3> / C. The X is larger than or equal to 0.1 and is smaller than or equal to 0.4, and the Y is larger than or equal to 0.5 and is smaller than 1. The iron, lithium and manganese phosphate composite material, the method and the lithium ion battery have the advantages that dissolution of manganese in the iron, lithium and manganese phosphate composite material can be relieved, and the ionic conductivity and the electronic conductivity can be improved.

Owner:深圳市鑫永丰科技有限公司

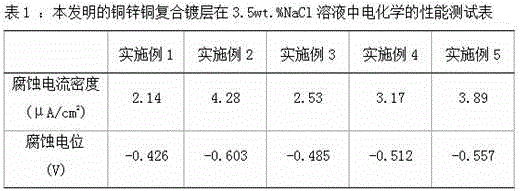

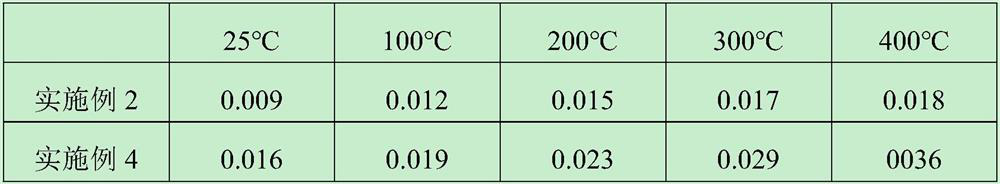

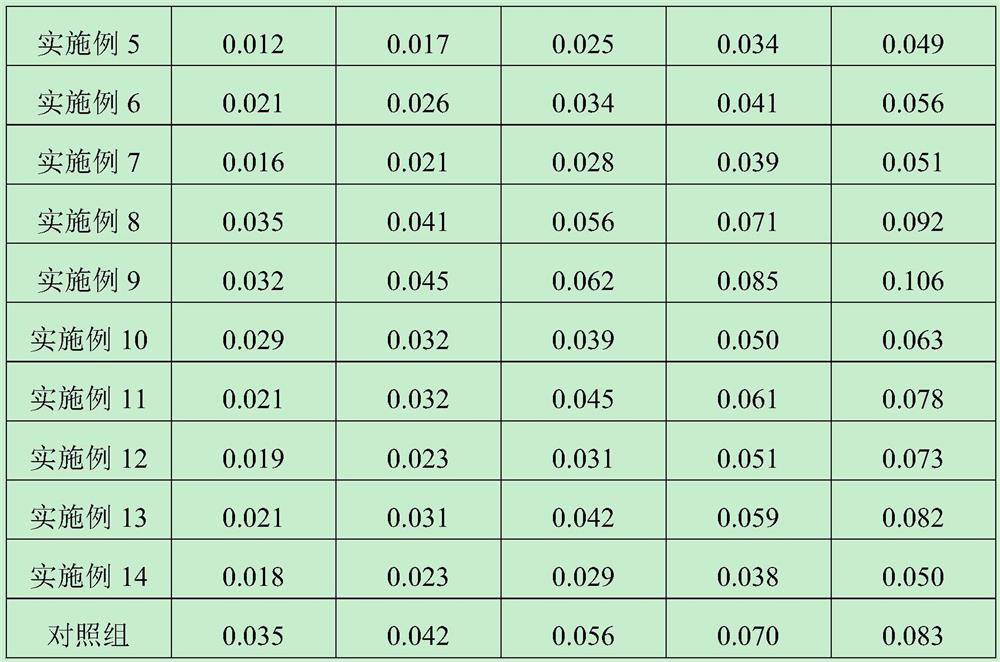

Method of preparing copper-zinc-copper composite coating with high corrosion resistance on surface of low-carbon steel

The invention discloses a method of preparing a copper-zinc-copper composite coating with high corrosion resistance on the surface of low-carbon steel. The method comprises the following steps of: (1) carrying out oil removal treatment on the surface of the low-carbon steel; (2) carrying out pulse copper plating electroplating treatment on the pretreated low-carbon steel; (3) carrying out electrogalvanizing electroplating treatment on the low-carbon steel subjected to pulse copper plating; (4) carrying out alkaline copper plating electroplating treatment on the low-carbon steel subjected to electrogalvanizing; (5) carrying out electrocoppering electroplating treatment on the low-carbon steel subjected to alkaline copper plating; and (6) putting the low-carbon steel subjected to electrocoppering in an alloying furnace, and alloying the low-carbon steel in a protective nitrogen atmosphere, wherein the alloying temperature is 250-400 DEG C, and the heating rate is 0.01-50 DEG C / S; carrying out heat preservation for 2 to 50 hours, then carrying out fast cooling to a room temperature, wherein the cooling rate is 0.01-50 DEG C / S; and finally obtaining the copper-zinc-copper composite coating with the high corrosion resistance on the surface of the low-carbon steel. The copper-zinc-copper composite coating prepared on the surface of the low-carbon steel by using the method is uniform and compact and can obviously improve the corrosion resistance of metals. The method has the advantages of simple operation, large electric current density and fast electrodeposition rate.

Owner:SHANGHAI UNIV

Preparation method of liquid pasty thermal insulation material

InactiveCN113683864AReduce the degree of aggregationImprove surface activityThermal insulationSuperfine grinding

The invention discloses a preparation method of a liquid pasty thermal insulation material, and belongs to the technical field of thermal insulation material processing. The method comprises the following steps: (1) corona treatment; (2) calcining treatment; (3) ionization infiltration-ultrasonic coupling treatment; (4) bead milling treatment; (5) dispersion treatment; (6) subzero treatment; (7) superfine grinding treatment; and (8) uniform stirring and mixing. According to the preparation method of the liquid pasty thermal insulation material provided by the invention, all the steps have a synergistic effect, and the finally prepared thermal insulation material is relatively stable in heat conductivity coefficient along with temperature rise, relatively small in temperature change and very good in thermal insulation effect.

Owner:CHANGZHOU UNIV

High-strength self-lubricating metal ceramic bearing and preparation method thereof

The invention discloses a high-strength self-lubricating metal ceramic bearing. The high-strength self-lubricating metal ceramic bearing is prepared from, by weight, 2.3-2.4 parts of ferric citrate, 3.1-3.5 parts of basic nickel carbonate, 25-30 parts of water, an appropriate amount of ammonium hydroxide, 2.9-3 parts of TiH2, 1.1-1.3 parts of nanocarbon, 15-15.4 parts TiC, 0.7-0.9 part of lubricant, 1-1.1 parts of C, 3.9-4.1 parts of Cr, 5.8-6 parts of W, 5.1-5.3 parts of Mo, 3.1-3.3 parts of V and 65-66 parts of Fe. Ferric citrate and basic nickel carbonate are used for carrying out coating modification on TiC, the bonding strength of a ceramic phase and a metal phase is improved, and the strength and the toughness of the bearing are greatly improved. Nanocarbon, ferrocene acetyenic ketone and ferric alginate are adopted, so that the lubricating performance and compactness in the pressing process are improved, the pore connectivity of sintered materials is good, the show porosity is improved, and the wear resistance of the bearing is extremely good.

Owner:ANHUI SILVER BALL BEARING

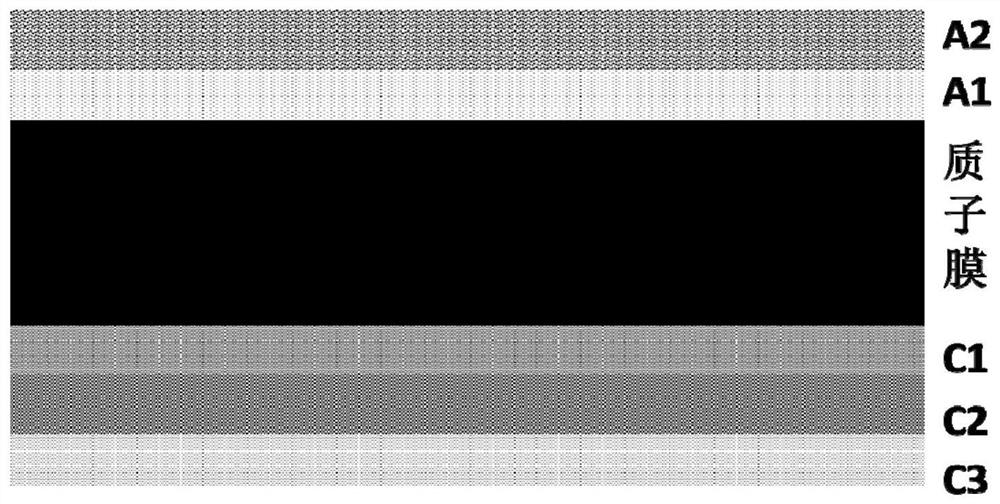

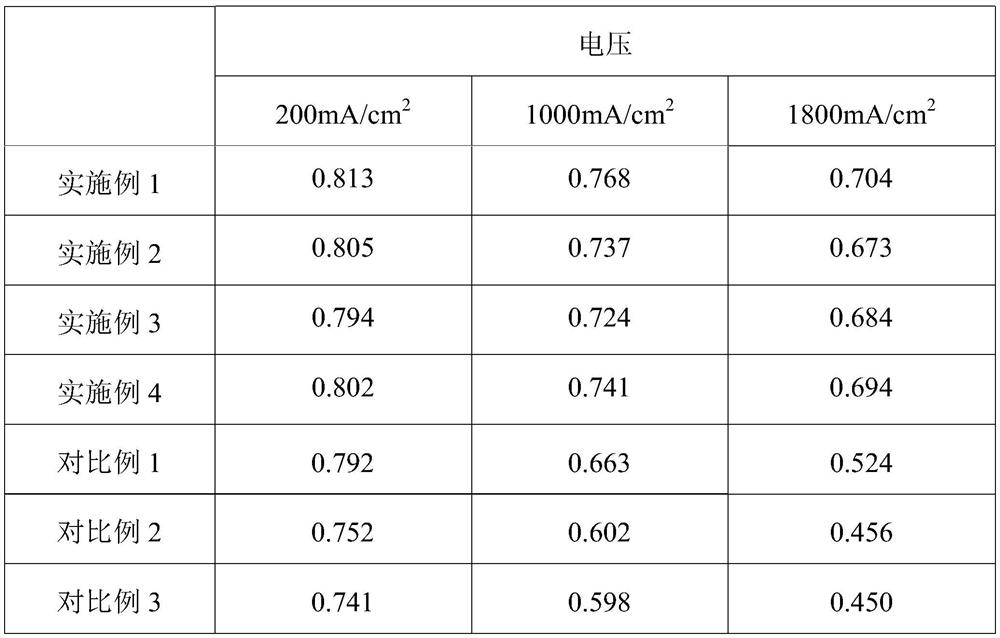

Membrane electrode of gradient proton exchange membrane fuel cell as well as preparation method and application of membrane electrode

ActiveCN113991126AIncrease profitReduce dosageFinal product manufactureCell electrodesPtru catalystCarbon nanomaterials

The invention provides a gradient proton exchange membrane fuel cell membrane electrode as well as a preparation method and application thereof. The gradient proton exchange membrane fuel cell membrane electrode comprises a cathode catalyst layer and an anode catalyst layer, the cathode catalyst layer comprises a first catalyst layer, a second catalyst layer and a third catalyst layer, and the slurry of the third catalyst layer contains a carbon nanomaterial; the anode catalyst layer comprises a first catalyst layer and a second catalyst layer. According to the gradient proton exchange membrane fuel cell membrane electrode, gradient design is carried out on the catalyst layers, the mass fraction of platinum, the mass fraction of ionomer and the EW value in the cathode catalyst layer and the anode catalyst layer are distributed in a segmented mode, the utilization rate of platinum is increased, the content of platinum is reduced, the electrode is suitable for low-humidity and high-current-density working conditions, and the production cost is reduced.

Owner:FAW JIEFANG AUTOMOTIVE CO

Flame-retardant light-transmittance sheet resin and preparation method thereof

The invention relates to flame-retardant light-transmittance sheet resin. The flame-retardant light-transmittance sheet resin comprises raw materials in parts by mass as follows: 40-50 parts of HET acid, 12-19 parts of propylene glycol, 9-13 parts of ethylene glycol, 10-15 parts of maleic anhydride, 15-20 parts of phthalic anhydride, 40-70 parts of styrene and 0.01-0.03 parts of hydroquinone. During preparation, HET acid, propylene glycol, ethylene glycol, hydroquinone and phthalic anhydride are added to a reaction kettle, a mixture is heated to 200 DEG C, reacts and is dehydrated until an acid value reaches 45 mgKOH / g, and nitrogen is introduced for protection in the reaction process; introduction of nitrogen is stopped, and vacuumization is performed for further dehydration until the acid value reaches 30 mgKOH / g; the mixture is cooled to 160 DEG C, and polyester after reaction is sucked into a dilution kettle containing styrene for dilution; the dilution temperature does not exceed 80 DEG C. The flame-retardant light-transmittance sheet resin has good flame retardance and high light transmittance and has a refraction rate approaching to that of glass fiber, and the technological performance is good.

Owner:美高微球(南通)科技有限公司

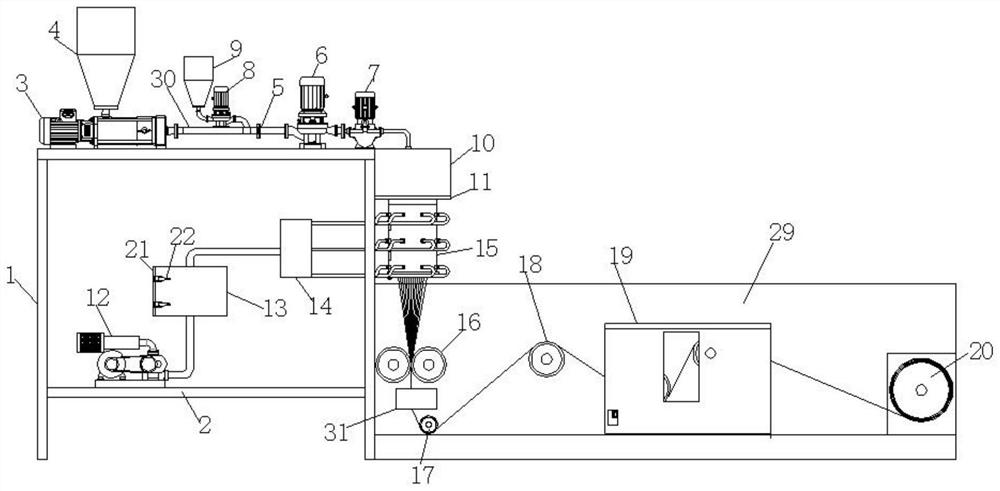

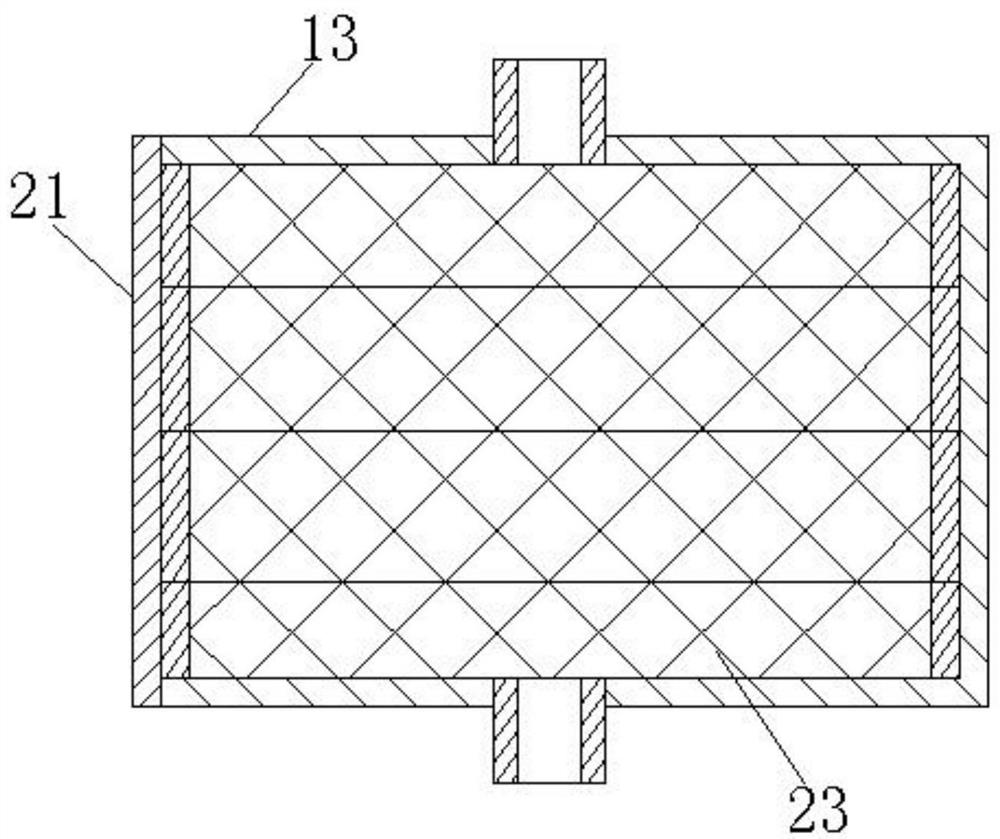

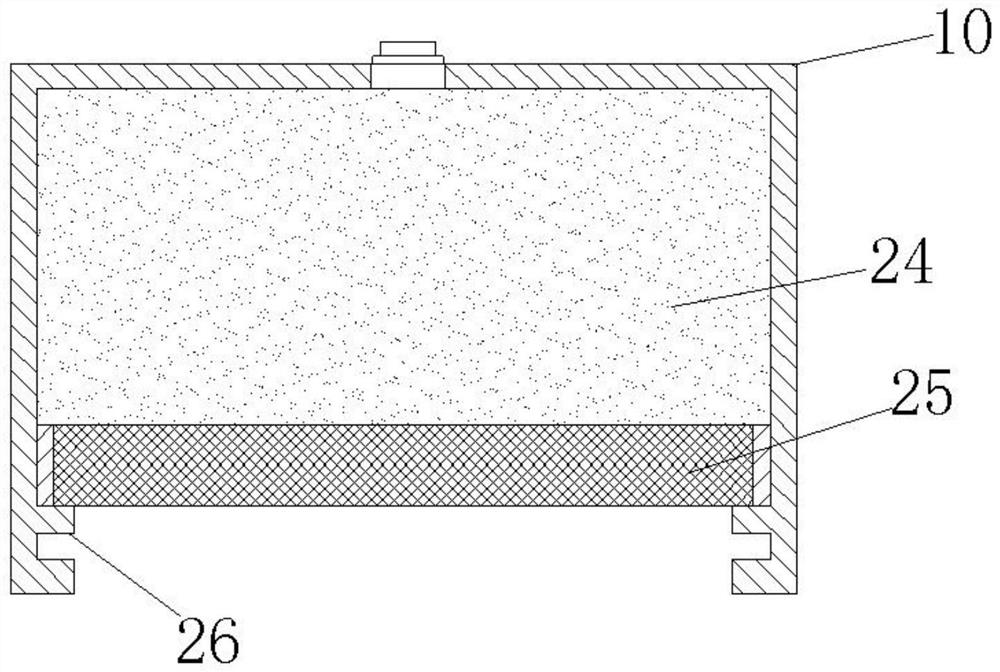

Production and processing equipment and method for high-glossiness draw-textured yarn

InactiveCN113969452AHigh glossBright colorFilament/thread formingMonocomponent polyesters artificial filamentPolymer dissolutionYarn

The invention provides production and processing equipment and method for high-glossiness draw-textured yarn, and relates to the technical field of spinning. The production and processing equipment for the high-glossiness draw-textured yarn comprises a rack, a mounting plate fixedly connected to the side wall of the rack and a cross beam fixedly connected to the inner side of the rack. According to the production and processing equipment and method for the high-glossiness draw-textured yarn, the refractive index and transmissivity of fiber are ensured through four-leaf spinneret orifices, polymer dissolution caused by nano Ag2O during modification, addition and blending in the later stage can be prevented by using a chemical coprecipitation method, the interfacial effect of solid-liquid reflection is reduced through pulping operation, and the esterification rate in the polymerization process is improved. A pressurized esterification processing technology is adopted, the reaction activity is guaranteed, the reaction rate is increased, air is blown by an air blower to enter an annular blowing channel to cool tows, the air filtered by an air filter box is free of impurities, tow surface pollution is avoided, and meanwhile air pressure is adjusted by an air pressure adjusting box. The problems of many broken filaments and easy end breakage of the tows are greatly reduced.

Owner:江苏嘉通能源有限公司

Self-lubricating metal ceramic bearing good in abrasion resistance and preparing method of self-lubricating metal ceramic bearing

InactiveCN105385929AReduce interface effectsHigh bond strengthTransportation and packagingMetal-working apparatusCeramic particleBonding strength

Ferric citrate and basic nickel carbonate are used for carrying out wrapping modification on TiC, the surface of a ceramic phase is wrapped by iron and nickel, and ceramic particles have magnetism and are prone to being combined with a metal phase. The interracial effect is reduced, the bonding strength between the ceramic phase and the metal phase is improved, and the strength and the tenacity of a bearing are greatly improved. By means of gallium trichloride and cadmium selenide, grain refinement is achieved, the bonding performance between the metal and the ceramic is improved, and tenacity is improved. By means of nanometer tungsten trioxide and zirconium oxide powder, the abrasion resistance and thermal resistance of the bearing are improved, and the bearing does not deform and is not prone to abrasion under the high-temperature condition.

Owner:ANHUI SILVER BALL BEARING

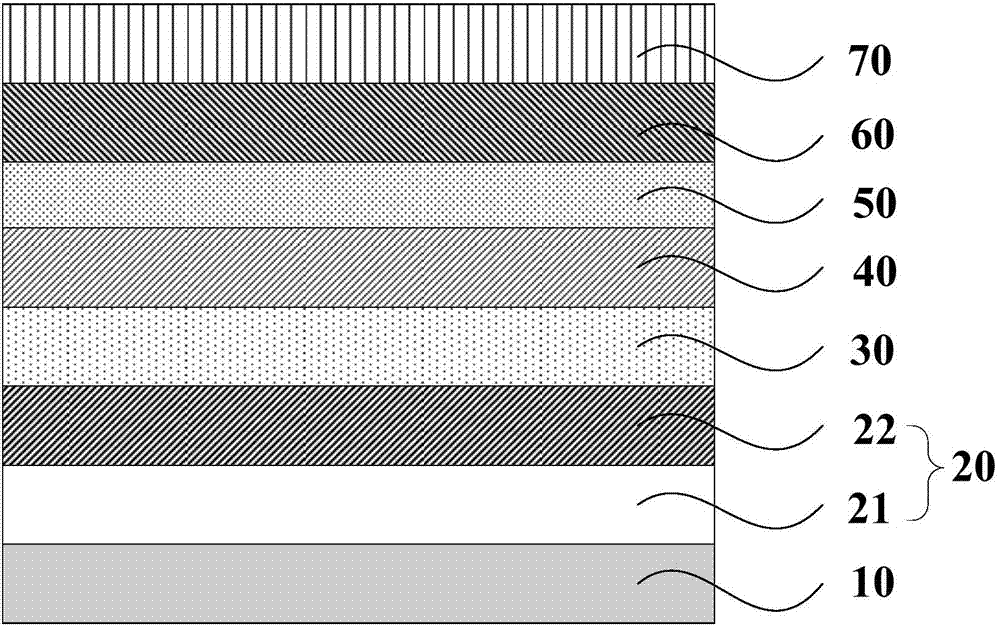

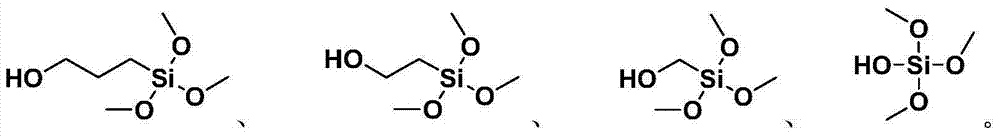

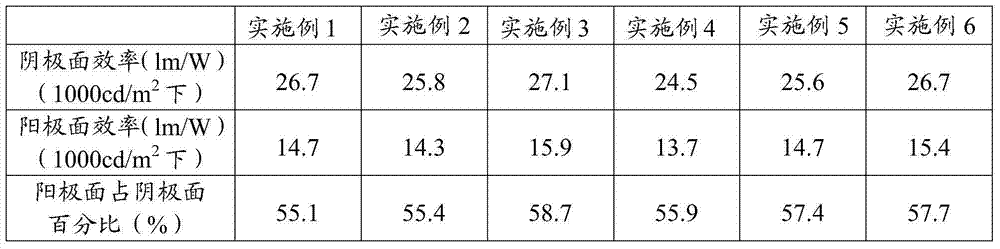

Transparent organic electroluminescent device and preparation method thereof

InactiveCN104518093AImprove light extraction efficiencyImprove removal efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerAlloy

The invention discloses a transparent organic electroluminescent device. The transparent organic electroluminescent device comprises a glass substrate, and a transparent anode, a cavity implantation layer, a cavity transmission layer, a green luminescent layer, an electron transmission layer, an electron injecting layer and a transparent cathode which are successively laminated on the glass substrate. The transparent anode comprises a hydroxysilane organic layer and a metal layer; the material of the hydroxysilane organic layer comes from at least one of (3-mercaptopropyl)trimethoxysilane, (3-mercaptoethyl)trimethoxysilane, (3-mercaptomethyl) trimethoxysilane and O,O,O-trimethyl-mercaptosilane; the material of the metal layer comes from at least one of a magnesium-silver alloy, a lithium-aluminum alloy, barium and calcium; and the material of the transparent cathode is indium tin oxide. According to the transparent organic electroluminescent device provided by the invention, the light emitting efficiency of an anode surface reaches more than 55% of the light emitting efficiency of a cathode surface, and the luminescence performance is excellent. The invention further discloses a preparation method of a transparent organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com