Graphite-based high-strength heat-conducting epoxy resin adhesive and preparation method thereof

A technology of epoxy resin and adhesive, applied in the direction of epoxy resin glue, adhesive, non-polymer adhesive additive, etc., can solve the problem of poor impact resistance and thermal conductivity of adhesive, and insignificant improvement of thermal conductivity of epoxy resin , the limited effect of epoxy resin reinforcement, etc., to achieve excellent thermal conductivity and mechanical strength, shorten the preparation time, and strong bonding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

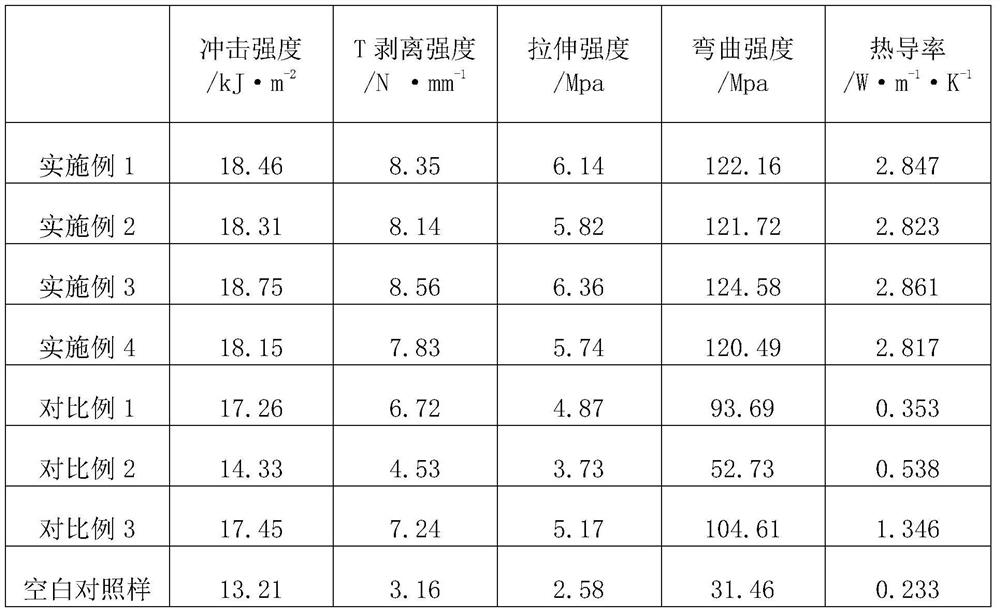

Examples

Embodiment 1

[0029] The preparation method of modified graphite comprises the following steps:

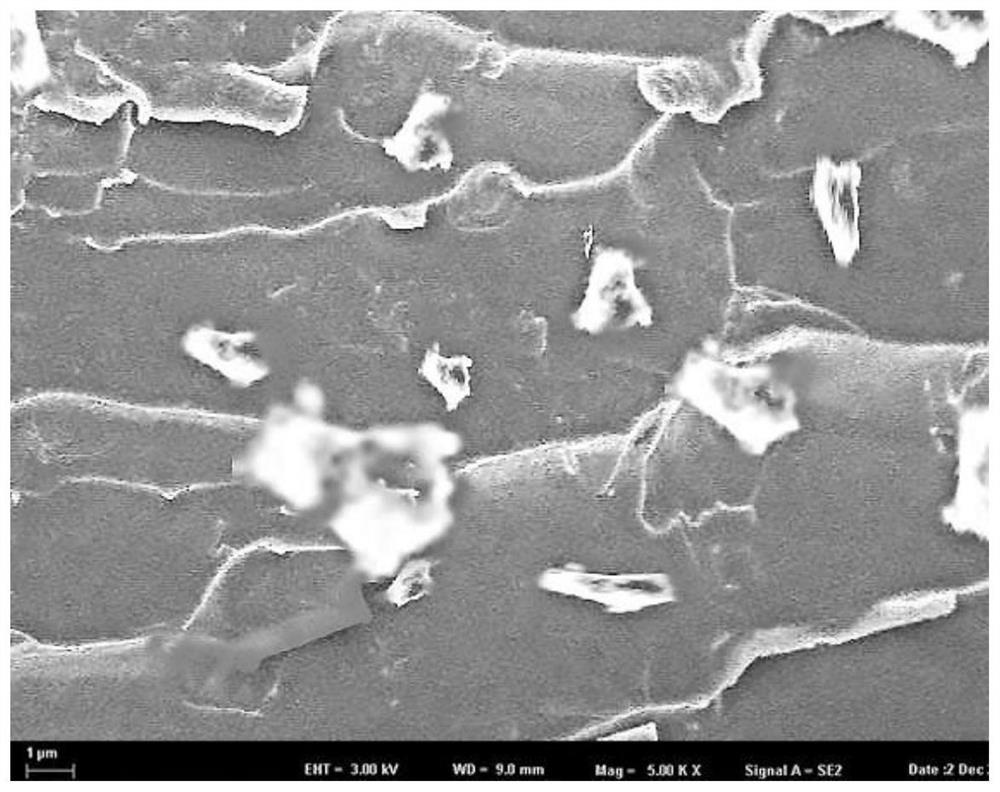

[0030] Take the graphite powder and place it in a microwave oven for 2 minutes at 1000W for microwave treatment to obtain expanded graphite. Put the expanded graphite into the methylpyrrolidone dispersing solvent according to the mass volume ratio of 1g / 50mL for ultrasonic peeling and dispersing. The ultrasonic peeling and dispersing power is controlled at 700W , ultrasonic peeling and dispersion time is 30h, after centrifugation, washing and drying, graphene is obtained, polyethyleneimine and sodium lauryl sulfate are added to deionized water and stirred to dissolve to obtain polyethyleneimine solution, in which polyethyleneimine The mass ratio of amine, sodium lauryl sulfate, and deionized water is 1:0.05:60. Put the graphene into the polyethyleneimine solution and perform ultrasonic oscillation treatment at 100W power for 10min, and then add the homogeneous mass The n-hexane solution of trim...

Embodiment 2

[0040] The preparation method of modified graphite comprises the following steps:

[0041] Take graphite powder and place it in a microwave oven at 500W for microwave treatment for 5 minutes to obtain expanded graphite. Put the expanded graphite in a methylpyrrolidone dispersion solvent at a ratio of 1g / 50mL by mass to volume for ultrasonic peeling and dispersing. The power of ultrasonic peeling and dispersing is controlled at 800W , ultrasonic peeling and dispersion time is 20h, after centrifugation, washing and drying, graphene is obtained, polyethyleneimine and sodium lauryl sulfate are added to deionized water and stirred to dissolve to obtain polyethyleneimine solution, in which polyethyleneimine The mass ratio of amine, sodium lauryl sulfate, and deionized water is 1:0.05:60. Put graphene into polyethyleneimine solution and perform ultrasonic oscillation treatment at 100W power for 5min, and then add a uniform mass The n-hexane solution of trimesoyl chloride with a conce...

Embodiment 3

[0051] The preparation method of modified graphite comprises the following steps:

[0052] Take graphite powder and place it in a microwave oven for 3 minutes at 800W for microwave treatment to obtain expanded graphite. Put the expanded graphite into a methylpyrrolidone dispersing solvent at a ratio of 1g / 50mL by mass to volume for ultrasonic peeling and dispersing. The power of ultrasonic peeling and dispersing is controlled at 750W , ultrasonic stripping and dispersion time is 25h, after centrifugation, washing and drying, graphene is obtained, polyethyleneimine and sodium lauryl sulfate are added to deionized water and stirred to dissolve to obtain polyethyleneimine solution, in which polyethyleneimine The mass ratio of amine, sodium lauryl sulfate, and deionized water is 1:0.05:60. Put the graphene into the polyethyleneimine solution and perform ultrasonic oscillation treatment at 100W power for 8min, and then add a uniform mass The n-hexane solution of trimesoyl chloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com