Patents

Literature

117results about How to "Improve interface effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

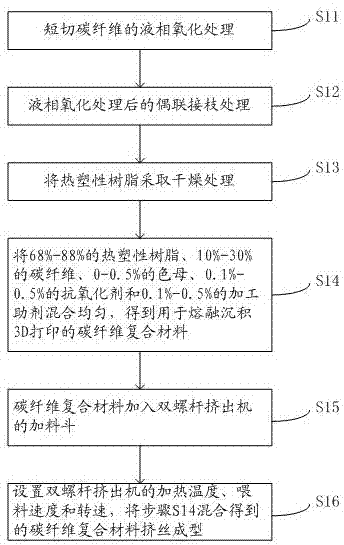

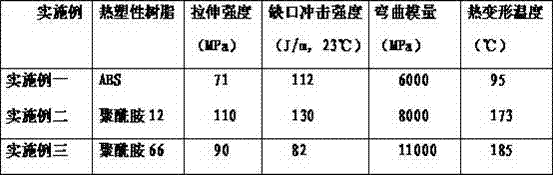

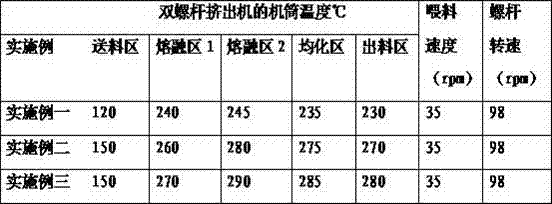

Carbon fiber composite material for fused deposition 3D printing and preparation method thereof

InactiveCN105440560AImprove interface effectThe process is simple and effectiveCarbon fiber compositeFlexural strength

The invention provides a carbon fiber composite material for fused deposition 3D printing and a preparation method thereof. The preparation method comprises the following steps: subjecting chopped carbon fibers to a liquid phase oxidation treatment and a coupling grafting treatment, then evenly mixing 10 to 30 wt% of chopped carbon fiber, 68 to 88 wt% of dried thermoplastic resin, 0 to 0.5 wt% of color master batch, 0.1 to 0.5 wt% of antioxidant, and 0.1 to 0.5 wt% of processing aid, heating, and extruding the mixture into filaments by a double screw extruder so as to obtain the carbon fiber composite material for fused deposition 3D printing. Compared with the prior art, the products made of the provided carbon fiber composite material has the advantages that impact strength, bending strength, and tensile strength are all prominently improved.

Owner:QINGDAO UNIQUE PRODS DEV

Nanometer deodorant for purifying air and preparing method thereof

A nano-class deodoring agent for cleaning air is prepared from TiO2 nanoparticles, tourmalinite nanoparticles, muscovite nanoparticles, sodium silicate, sodium benzoate, sodium chloride, polyacrylamide, hydroxyethylene cellulose and propanetriol through ball grinding and baking. Its advantages are high effect to remove benzene, ammonia and formaldehyde by 60-80%, and short time (24hr).

Owner:万意群

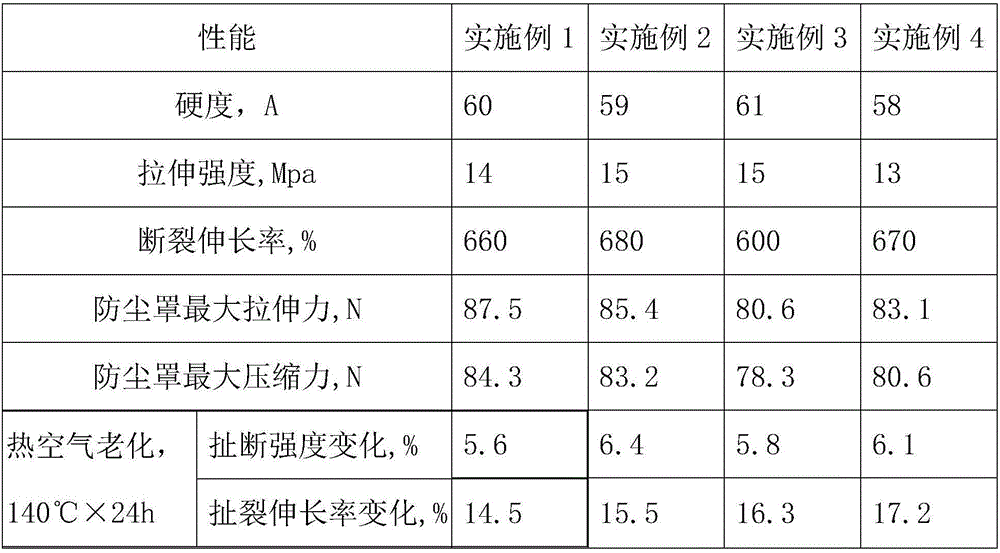

Thermoplastic vulcanized rubber material for automobile turning dust cover and preparation method of thermoplastic vulcanized rubber material

ActiveCN105860284AImprove blow molding processabilityMeet performance requirementsRubber materialThermoplastic

The invention discloses a thermoplastic vulcanized rubber material for an automobile turning dust cover and a preparation method of the thermoplastic vulcanized rubber material. The thermoplastic vulcanized rubber material is prepared from, by weight, 100-300 parts of EPDM, 20-80 parts of polypropylene, 10-50 parts of linear low density polyethylene, 40-100 parts of thermoplastic polyurethane elastomers, 5-15 parts of ethylene-octylene copolymers, 5-15 parts of compatilizer, 10-80 parts of inorganic filler, 3-5 parts of silane coupling agent, 0.2-10 parts of cross-linking agent, 1-5 parts of activated zinc oxide, 1-3 parts of primary antioxidant, 0.5-1 part of auxiliary antioxidant, 1-3 parts of ultraviolet light absorber, 20-100 parts of processing oil and 2-6 parts of lubricating oil. The thermoplastic vulcanized rubber material has excellent strength, high temperature resistance, flexibility and blow molding performance.

Owner:ANHUI ZHONGDING RUBBER PLASTIC PROD CO LTD

Waterproof high-hardness waterborne polyurethane coating

InactiveCN104312411AImprove thermal stabilityHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesCarbon nanotube

The invention discloses a waterproof high-hardness waterborne polyurethane coating which is characterized by comprising the following components in parts by weight: 65-80 parts of modified waterborne polyurethane, 20-35 parts of waterborne polyaniline, 3-6 parts of polyisocyanate, 5-20 parts of nano-silica, 3-9 parts of isopropanol, 5-10 parts of ethylene glycol propyl ether, 0.5-1.6 parts of dipentaerythritol, 15-20 parts of polydimethylsiloxane, 3-8 parts of gamma-isocyanate propyl triethoxy silane, 3-8 parts of polytetrafluoroethylene, 0.5-3 parts of modified carbon nanotubes, 5-20 parts of precipitated barium sulphate, 2-6 parts of amino resin, 3-8 parts of zinc powder and 30-60 parts of water. The waterproof high-hardness waterborne polyurethane coating is good in water resistance, high in harness and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

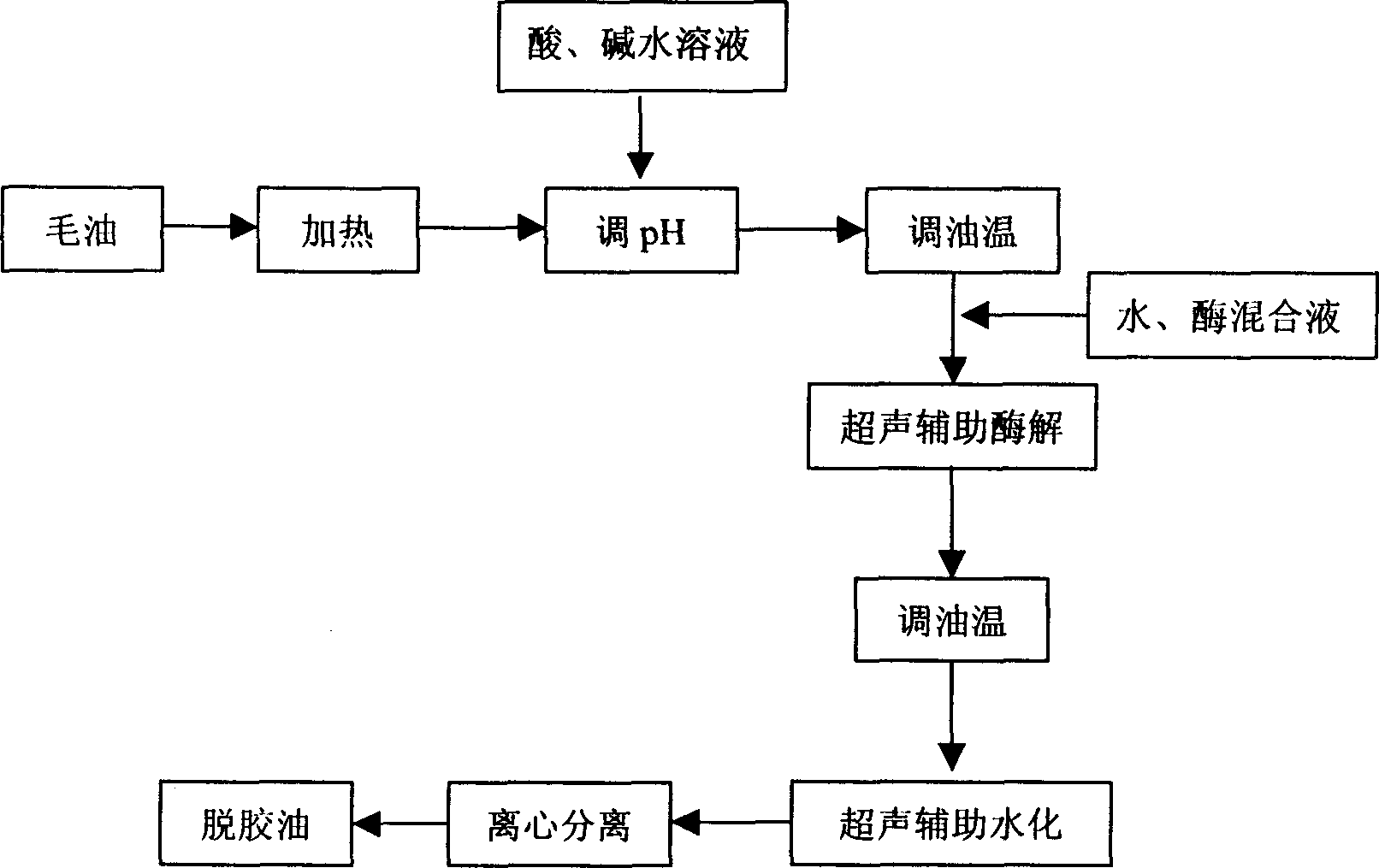

Supersonic wave intensified bioenzyme grease degumming method

ActiveCN1884459AWill not destroy the spatial structureHigh catalytic activityFatty-oils/fats refiningEmulsionBoundary effects

The invention relates the ultrasonic degumming method, comprising adjusting emulsion, hypersonic auxiliary enzymolysis and hypersonic auxiliary hydrating. The method comprises the following steps: after biological enzyme treatment fat, carrying out low water hydrated phase, carrying out ultra-audio wave radiation, and then carrying out water-oil separating. The invention can shorten treatment time and enzyme content, improves the boundary effect between oil and water, reduces biological enzyme density, advances the gelatinous hydrating, improves detaching efficiency, modifies weight of boil-off gum content, and reduces equipment investment and oil consumption, reduces cost.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Preparation method of carbon brake disk

ActiveCN102643103AExtended service lifeOptimizing Growth PatternsBraking discsFiberCarbon composites

The invention discloses a preparation method of a carbon brake disk. The invention combines heat treatment and chemical vapor deposition fiber surface treatment to obtain the improved carbon fiber preform. The fiber surface CVD modification and secondary heat treatment process reinforces the fiber modification result, increases the base nucleation points on the fiber surface, enhances the interfacial effect of carbon / carbon composite treatment, and increases the shear resistance force of bulges on the friction surface; and meanwhile, the deposition efficiency of the carbon disk is enhanced, the deposition period of the carbon brake disk is shortened from 800-1200 hours to 450-600 hours, and the preparation cost is saved. The technical scheme adopted by the invention can enhance the interfacial bonding strength and the interfacial effect, improve the base growth pattern and prolong the service life of the carbon brake disk under low-speed low-energy conditions.

Owner:XIAN AVIATION BRAKE TECH

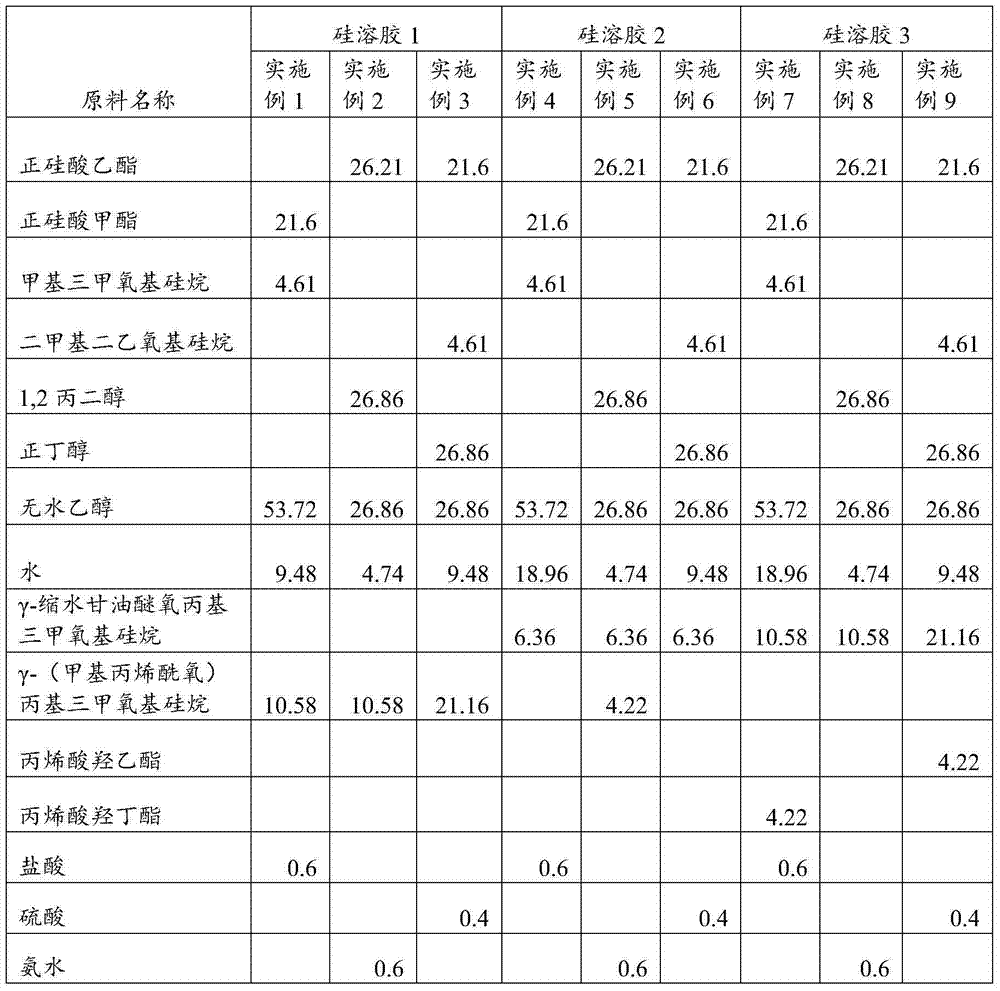

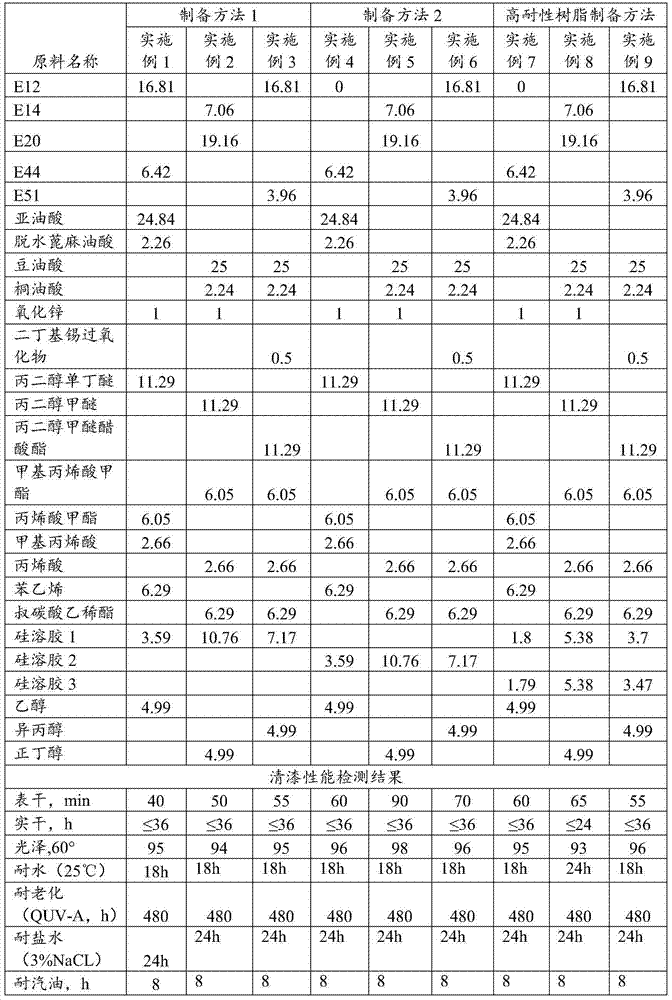

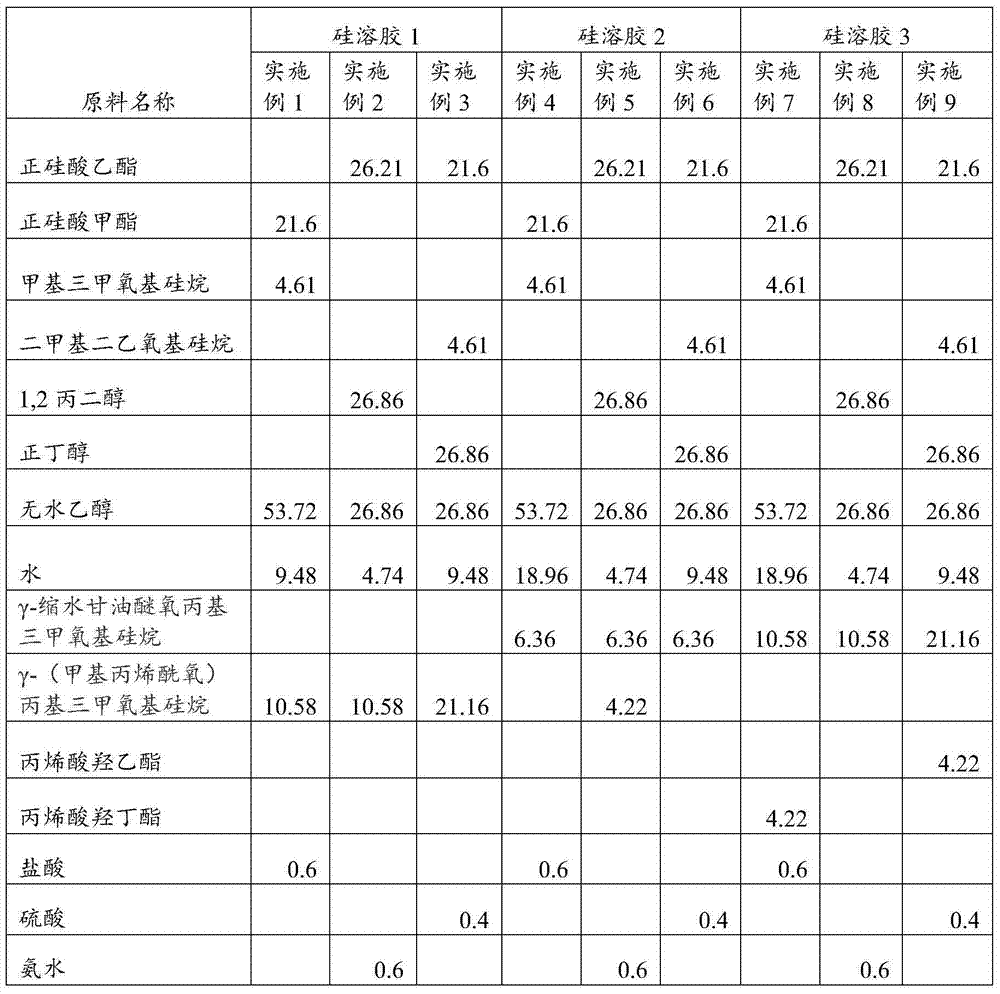

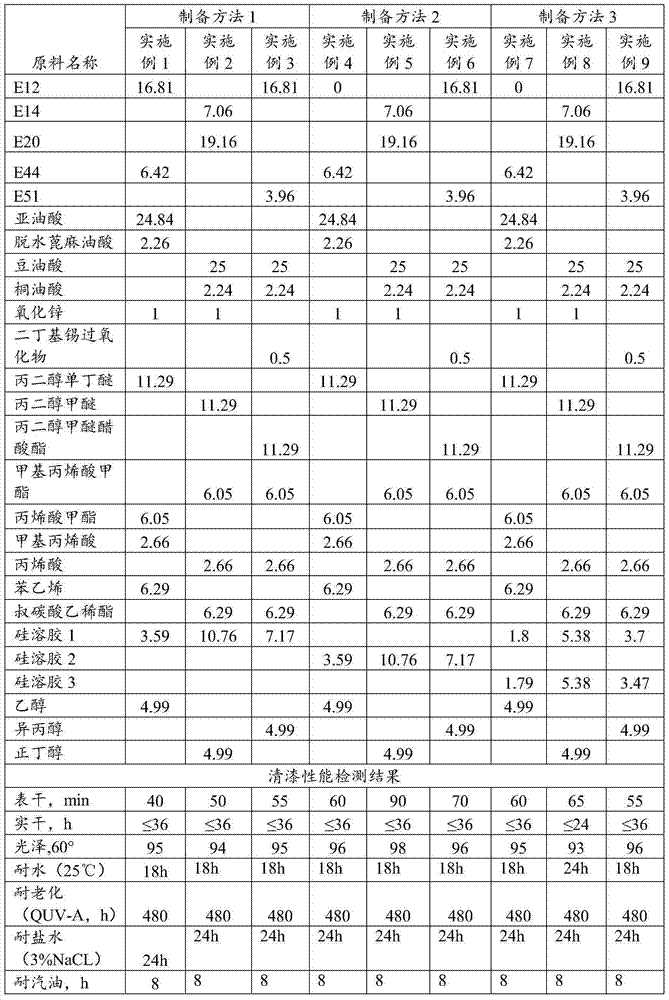

Organic-inorganic compound modified waterborne acrylic epoxy ester resin and preparation method thereof

The invention belongs to the field of waterborne coatings, and relates to an organic-inorganic compound modified waterborne acrylic epoxy ester resin and a preparation method thereof. The organic-mineral compound modified waterborne acrylic epoxy ester resin is synthesized by using the following raw materials in parts by weight: 30-70 parts of an epoxy ester, 5-50 parts of an acrylic monomer and 5-25 parts of silica sol, wherein the epoxy ester is prepared by carrying out catalytic reaction on 40-70 parts of an epoxy resin and 20-60 parts of an unsaturated fatty acid; the acrylic monomer comprises 20-60 parts of a vinyl monomer and 40-70 parts of an acrylic monomer; and the silica sol is obtained by reacting 10-50 parts of an organosilicone intermediate, 5-50 parts of a silane coupling agent, 20-70 parts of a cosolvent, 0.2-5 parts of a pH regulator and 5-15 parts of water. The nano silicon sol improves the tolerance and dryness of films; secondary crosslinking is formed along with pH value changes, so that the crosslinking density after film formation is increased; a structure taking the nano silicon sol as a core and taking an organic resin as a shell increases the stability of silicon hydroxyl; and the waterborned epoxy ester resin reduces the VOC content.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Zirconia dental implant surface treatment method

InactiveCN105854080AIncrease roughnessImprove bindingTissue regenerationCoatingsAcid etchingSand blasting

The invention discloses a zirconia dental implant surface treatment method which comprises the steps of cleaning, sand blasting treatment, acid etching, soaking and sintering. In the invention, the zirconia dental implant surface is dipped with a ball-milled zirconia suspension; the pore diameter of pores in the zirconia dental implant surface is controlled by use of different particle sizes of the ball-milled zirconia powder; meanwhile, due to the sand blasting and acid etching treatment before soaking, the surface roughness of false teeth is increased to certain degree; with later sintering, the surface roughness of false teeth is remarkably increased; and thus, the interfacial effect between the implant material and the host bone can be improved, the binding capacity between the implant and the bone is enhanced, and clinical success rate of dental implant is increased. The zirconia dental implant surface treatment method is simple in operation, convenient in treatment, low in cost and suitable for industrialized large-scale production.

Owner:CHENGDU BESMILE BIOTECH

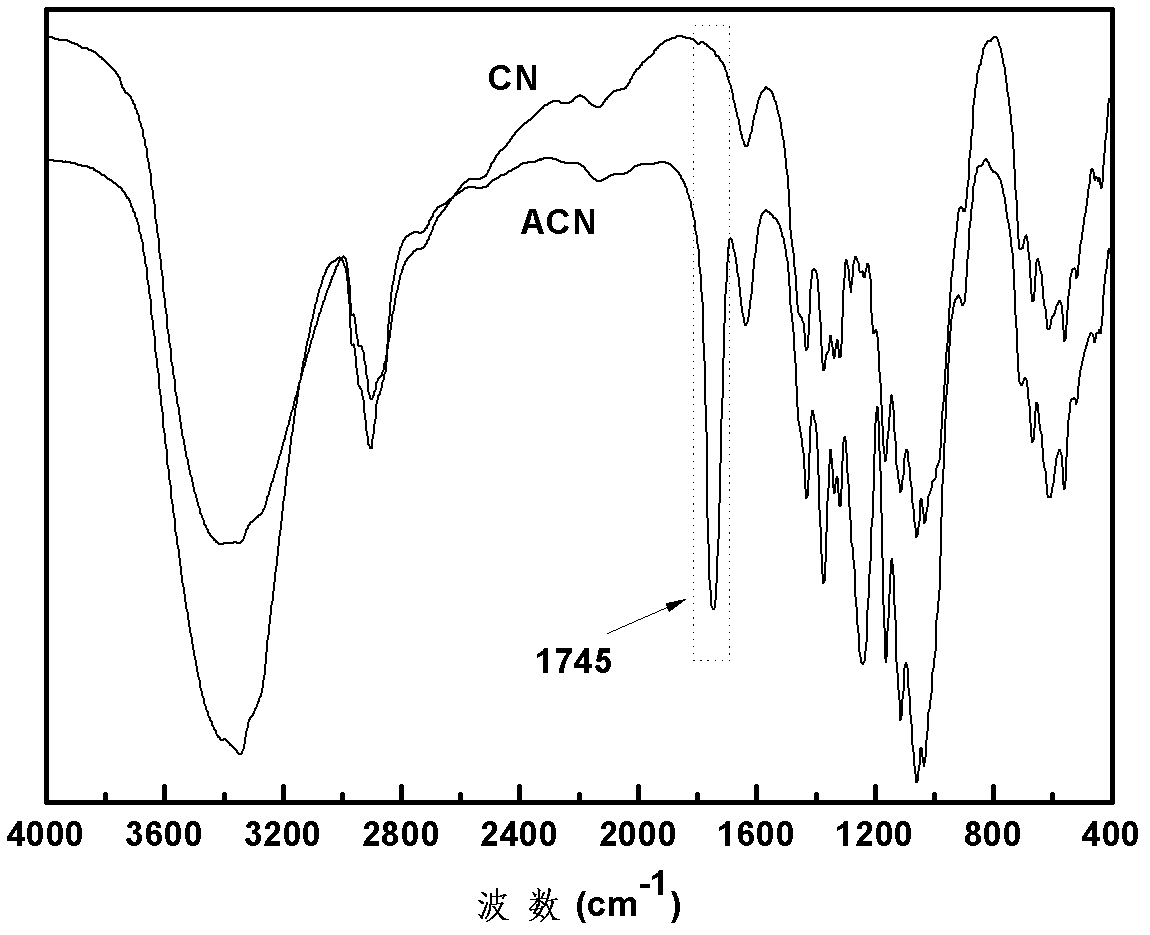

Preparation method of polyurethane nanometer composites

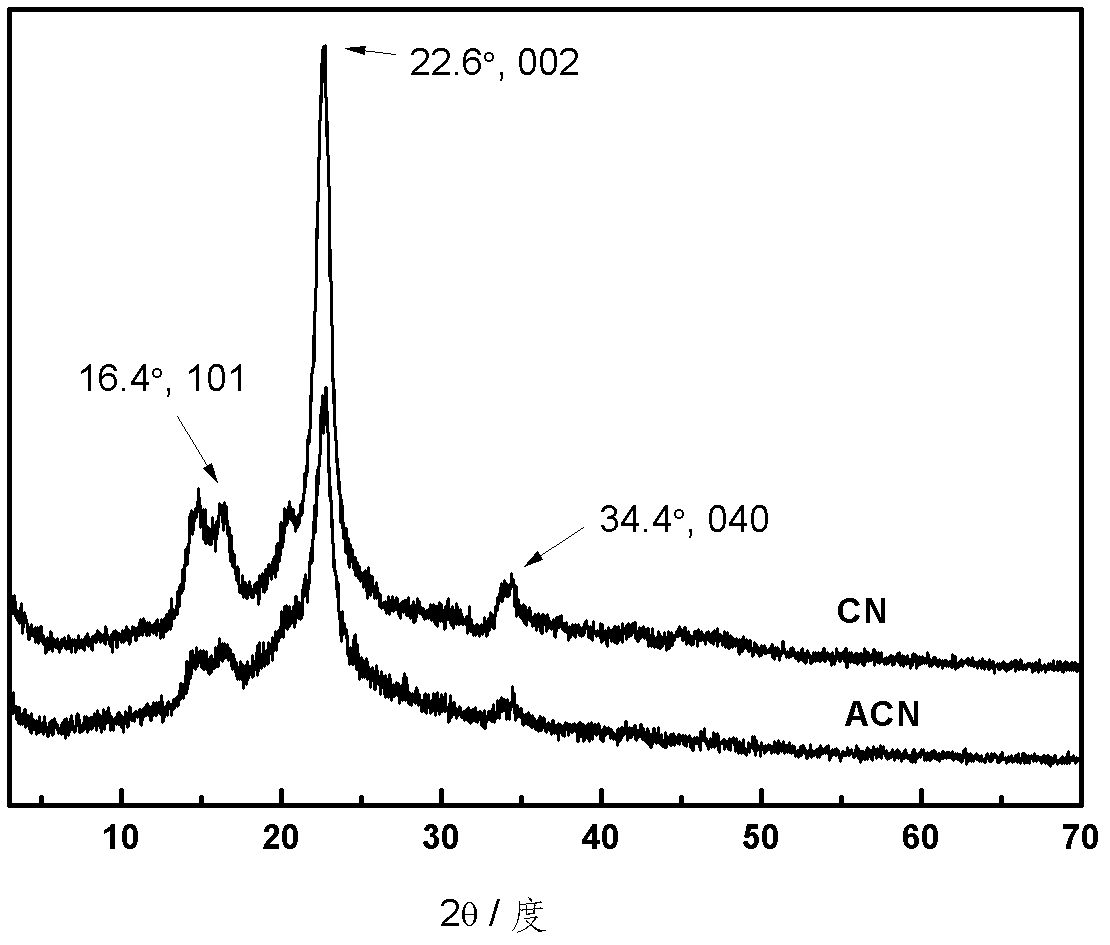

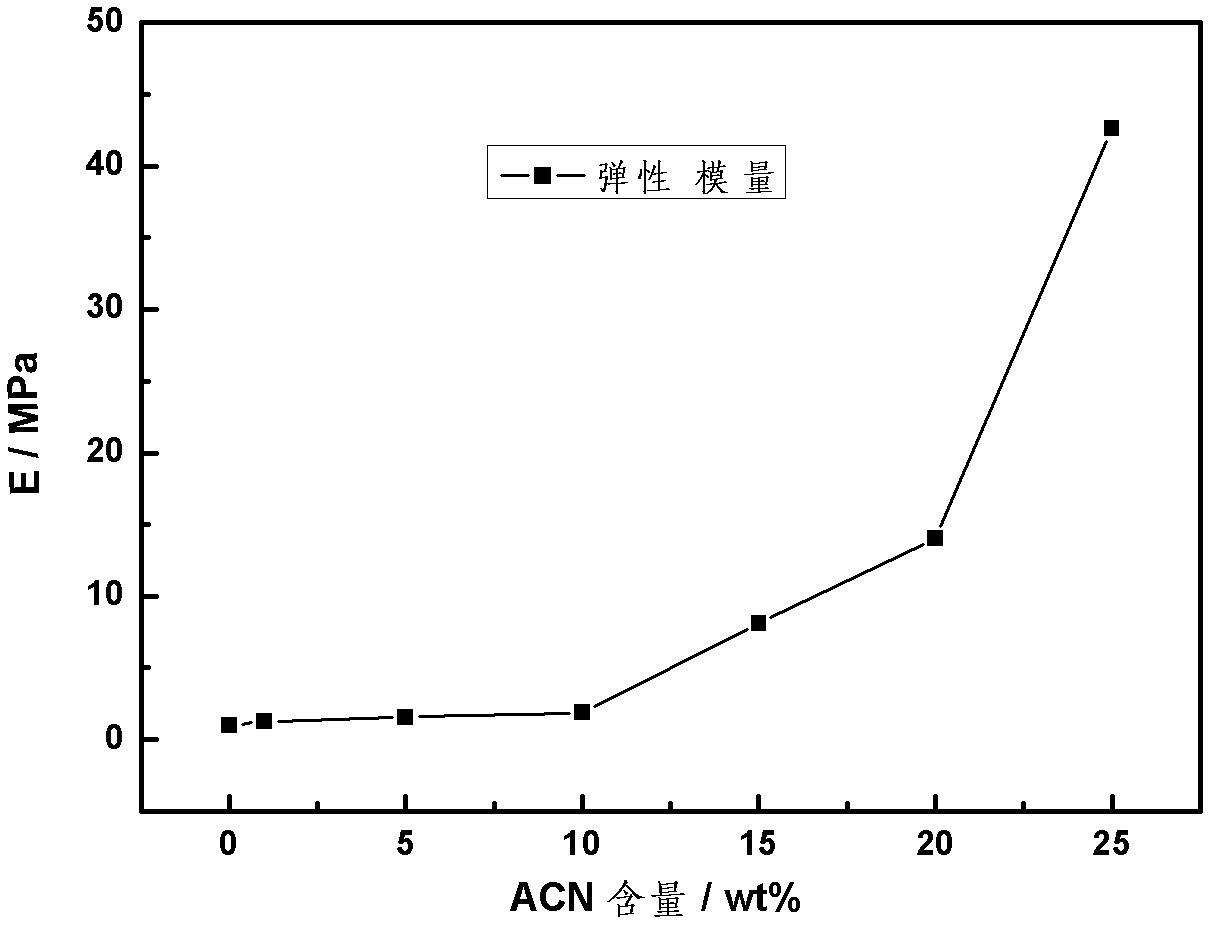

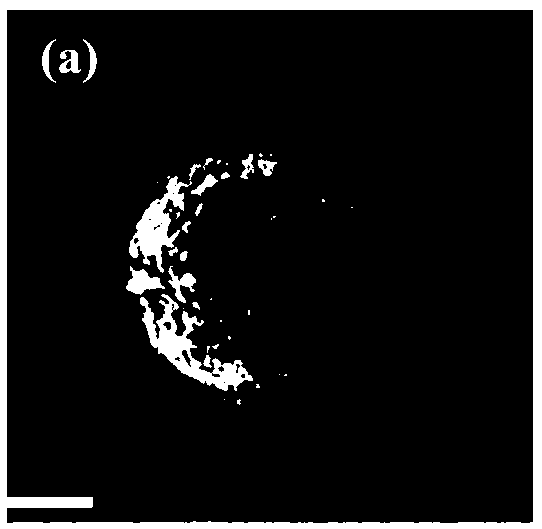

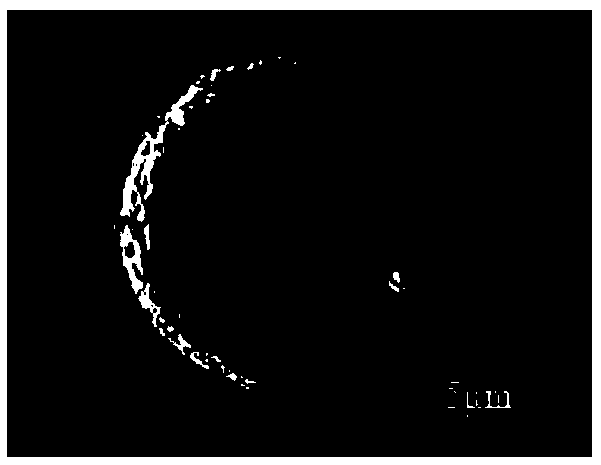

The invention relates to a preparation method of polyurethane nanometer composites, which belongs to the field of natural high-polymer nanometer composites. The preparation method is characterized by including the following steps of 1) finishing the surface of nanometer particles, utilizing cellulose nanocrystalline (CN) as nanometer filler of polyurethane, introducing -C(=O)CH3 functional group having excellent surface compatibility with oily polyurethane by one-step finishing to obtain finished nanometer particles; 2) compounding the finished nanometer particles with castor-oil based polyurethane to obtain the polyurethane nanometer composites. The polyurethane nanometer composites have high elasticity modulus (E), tensile strength (ob) and breakage elongation (epsilon b). The preparation method is low in cost and simple in process.

Owner:重庆盾之王安防设备技术研究院有限公司

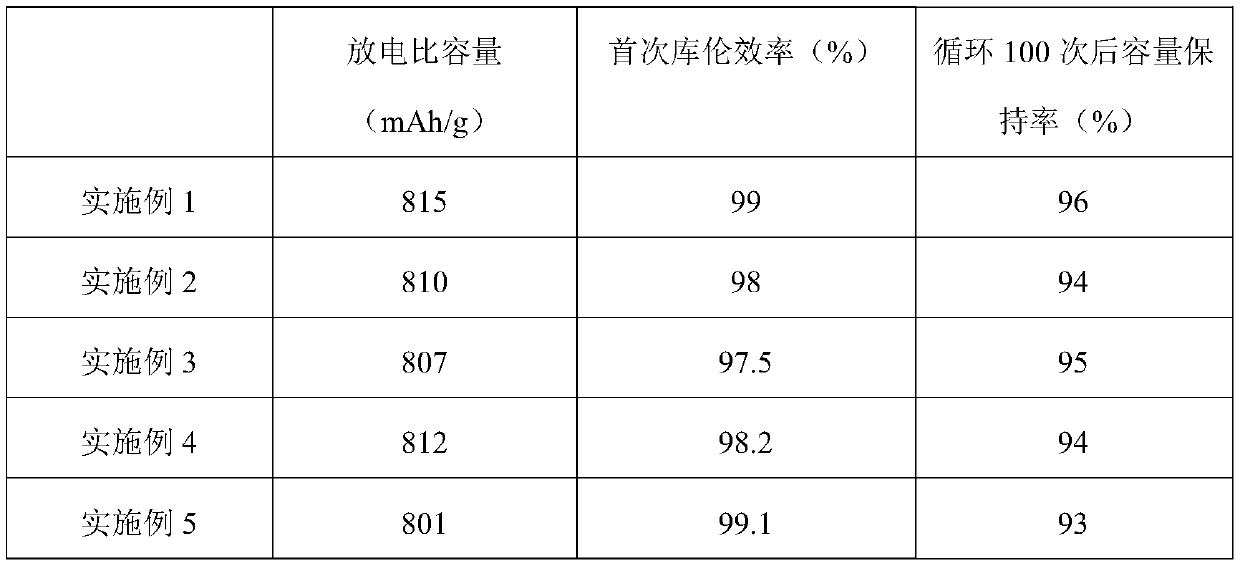

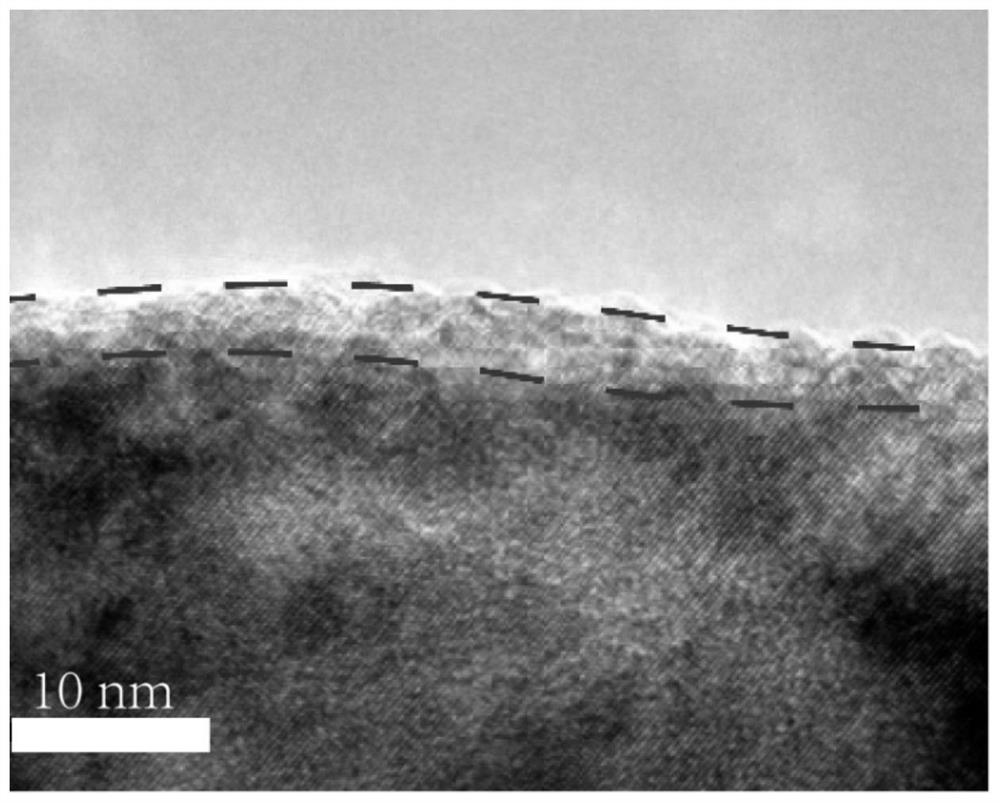

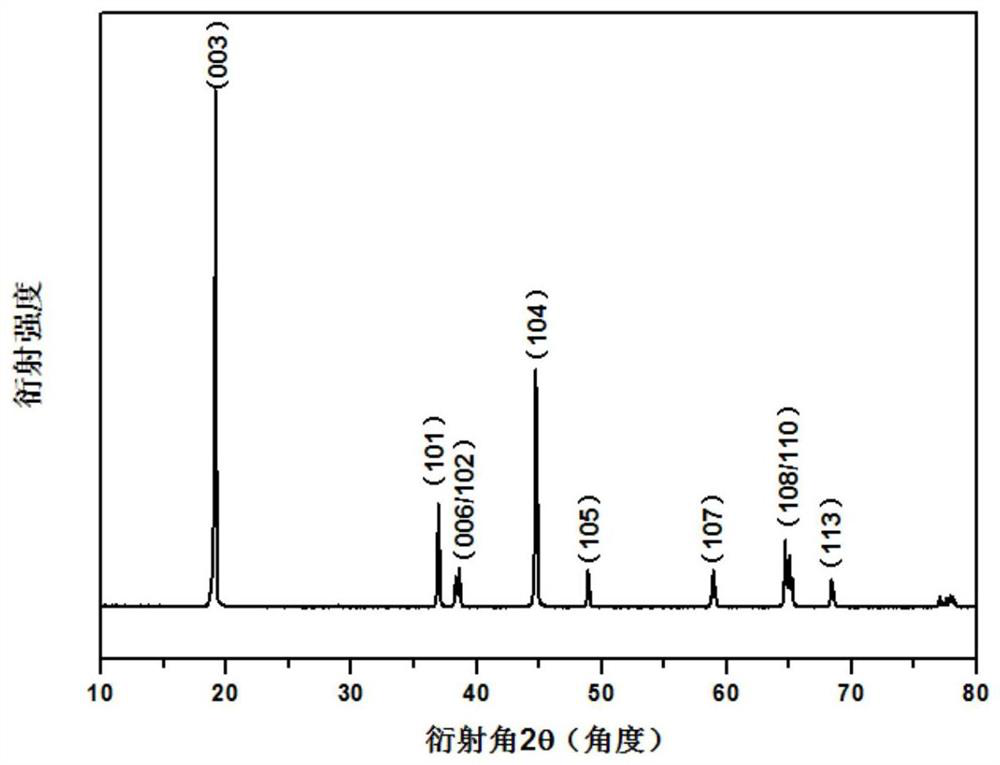

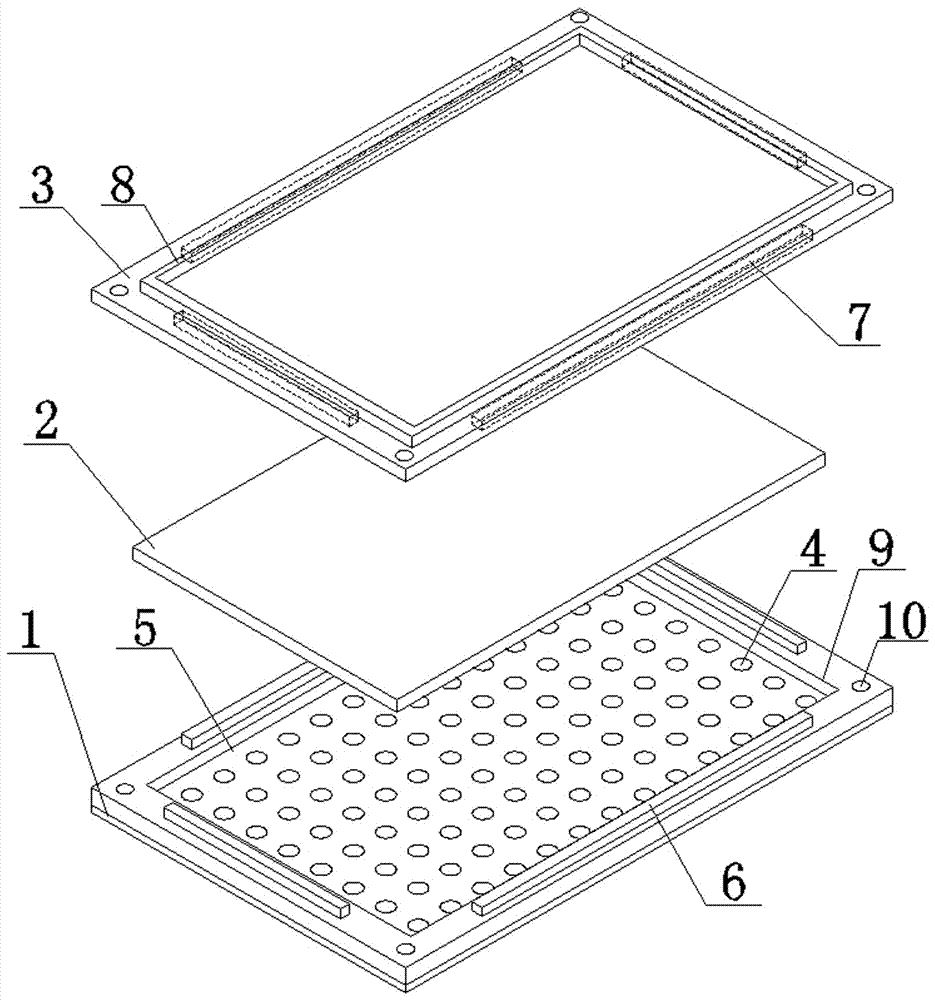

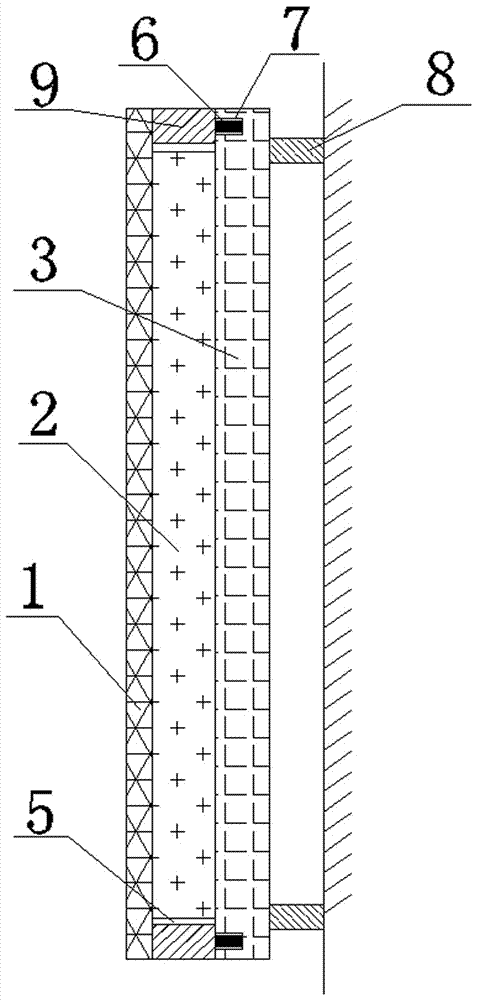

Wrapping method of nickel-cobalt-aluminum ternary positive electrode material and application

ActiveCN108807964AImprove interface effectImprove cycle stabilityCell electrodesInternal resistanceFreeze-drying

The invention provides a wrapping method of a nickel-cobalt-aluminum ternary positive electrode material and an application. The wrapping method is a surface wrapping method on a base material of thenickel-cobalt-aluminum ternary positive electrode material LiNi0.8Co0.15Al0.05O2 by a solvothermal method and a freeze-drying method. The invention further provides an application of the wrapping method to a lithium ion battery, and particularly relates to a preparation method of the lithium ion battery. According to the method, the nickel-cobalt-aluminum ternary positive electrode material LiNi0.80Co1.5Al0.05O2 wrapped with TiO2 is prepared by the freeze-drying method and can effectively improve interface effect of the material, so that the internal resistance of the battery is reduced, the cyclic stability of the material can be greatly improved when a charging cut-off potential is high, the heat stability of the material is improved, charge and discharge performances of the material under high current are improved, overlaying reunion of a wrapping modified material can be effectively avoided by the freeze-drying method, and the modified material uniformly wraps the surface of a material to be modified.

Owner:桑顿新能源科技(长沙)有限公司

Surface treatment method of fiber for carbon brake disc

The invention discloses a surface treatment method of fiber for a carbon brake disc. The fiber is subjected to surface modification, and the sectional deposition is combined with the heat treatment, and then the low-wear-rate aircraft carbon brake disc modified by a chemical vapor deposition method is obtained. By adopting the technical scheme of the invention, a pyrolytic carbon interfacial layer different from a deposition pyrolytic carbon matrix is added and increases the interfacial effect; the interfacial deposition efficiency is improved by the pyrolytic carbon interface, the deposition temperature and the subsequent deposition or thermal treatment temperature are set according to the kind of the selected gas, the deposition period of the carbon brake disc is shortened, and the final density of the obtained carbon brake disc is up to more than 1.72g / cm<3>. The carbon fiber surface treatment method mitigates the defect of an isothermal vapor phase chemical vapor deposition method that the attenuation of the density increase rate is too fast along with the deposition time; and moreover, the interface bonding strength and the growth mode of the matrix are improved, and the service life of the brake disc is prolonged.

Owner:XIAN AVIATION BRAKE TECH

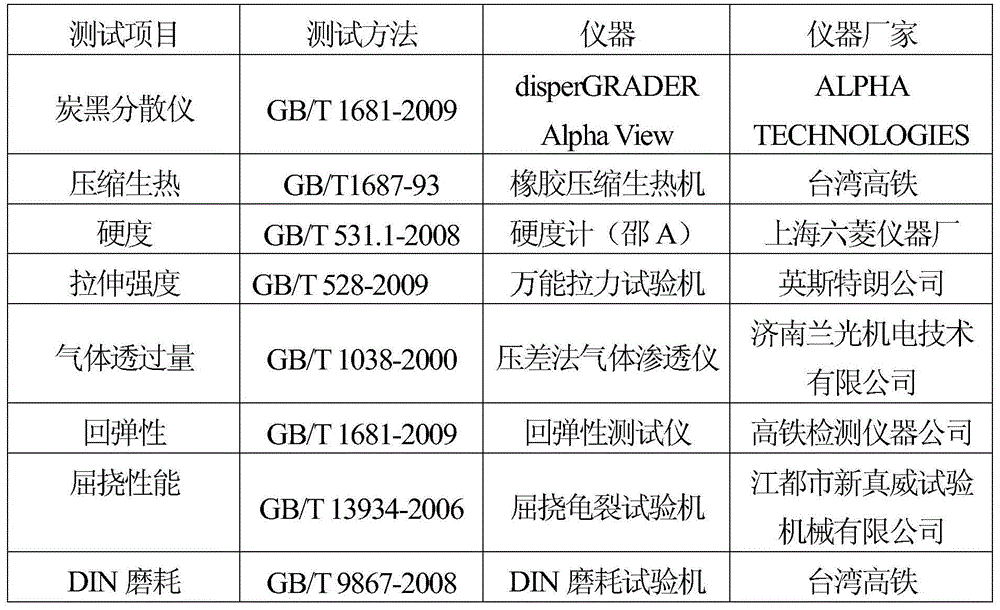

Method for preventing packing in rubber blend from migration

InactiveCN104356407AImprove interface effectGuaranteed dimensional stabilityPolymer scienceIrradiation

The invention relates to a method for improving the interaction of packing rubber, preventing packing in rubber blend from migration and maintaining the good initial dispersion state of packing. The method comprises the following steps: for rubber blend consisting of two-component or multi-component rubber, a reinforcing filling agent and other ingredients, firstly, mixing each rubber component with the reinforcing filling agent and any irradiation sensitizing agent respectively so as to prepare rubber master batch; subsequently mixing the rubber master batch of different rubber components with ingredients such as an anti-aging agent, a vulcanizing agent and oil so as to prepare a rubber compound; performing electronic irradiation treatment on the rubber compound; vulcanizing the rubber compound, so as to obtain the rubber.

Owner:EVE RUBBER RES INST

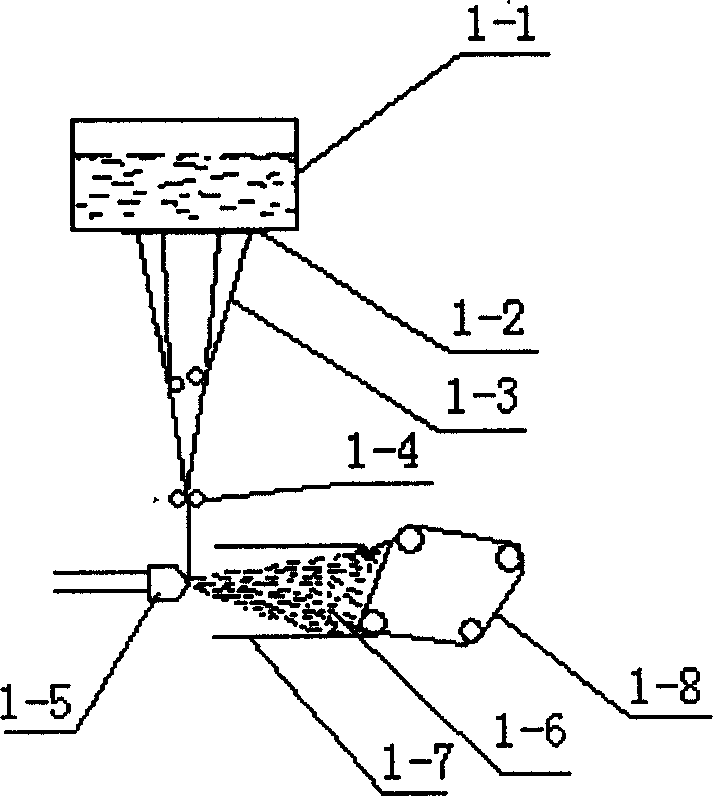

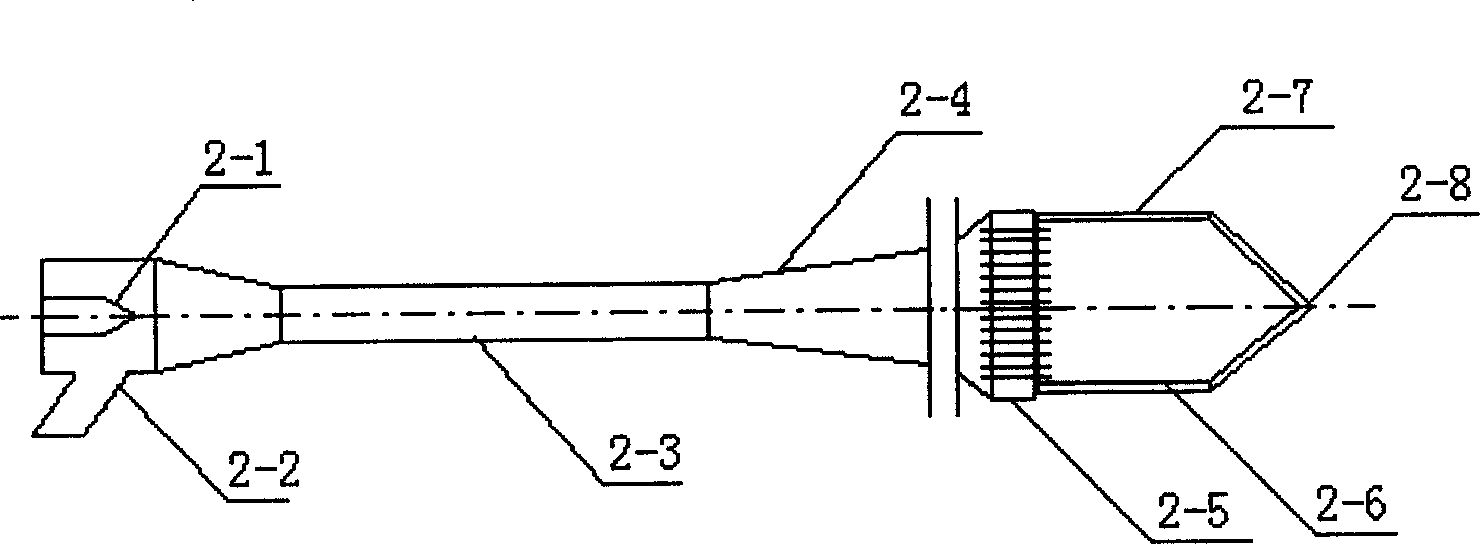

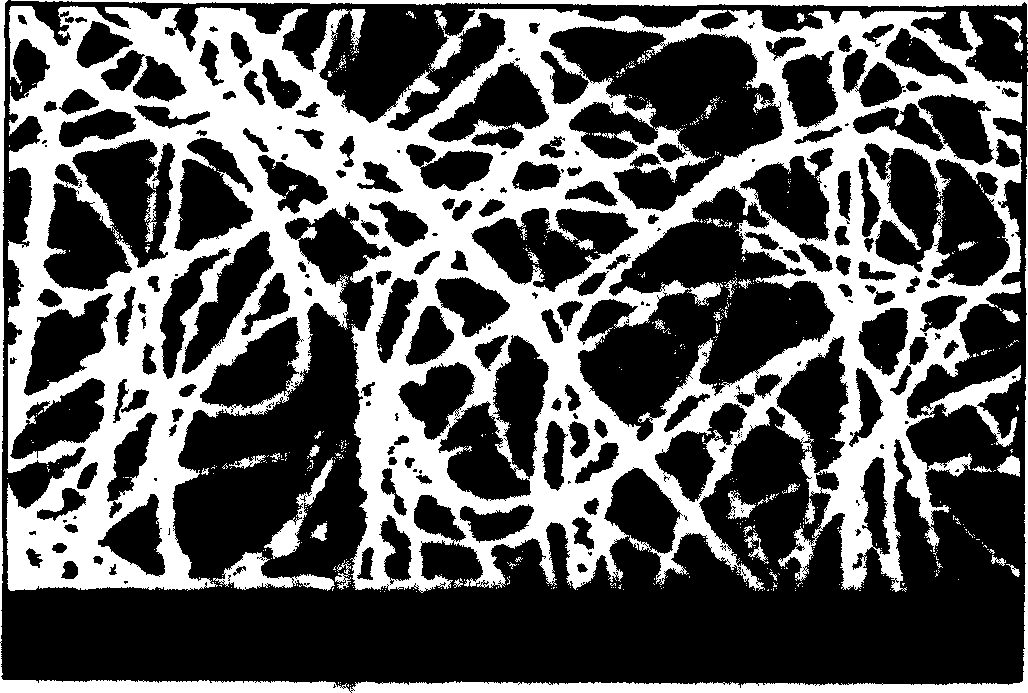

Nano-grade glass fibre cotton and mfg. technology and apparatus thereof

InactiveCN1623945AHigh sound absorption coefficientHigh-quality sound-absorbing materialGlass making apparatusGlass fiberFiber

Owner:HOHAI UNIV

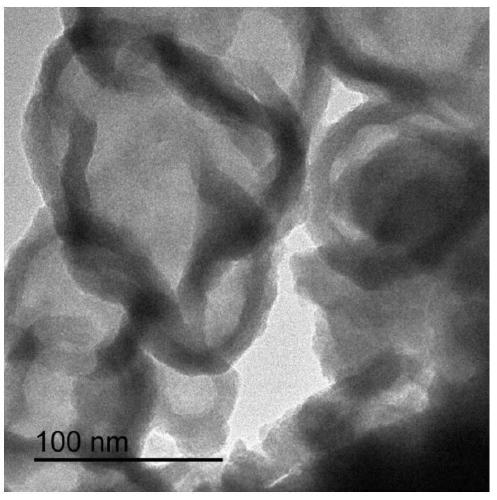

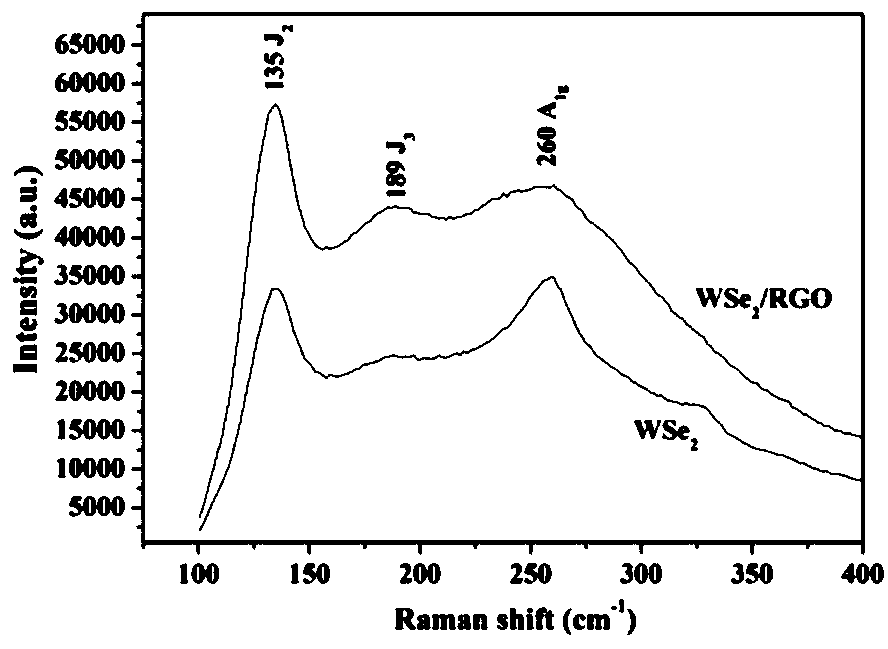

Metal structure tungsten diselenide/redox graphene composite structure and preparation method thereof

ActiveCN110240148ALow costReduce energy consumptionMaterial nanotechnologyPhotometryTungsten diselenideMaterials science

The invention relates to a metal structure tungsten diselenide / redox graphene composite structure and a preparation method thereof. Firstly, a precursor aqueous solution of a WSE2 film is prepared; a monolayer graphene oxide aqueous solution and citric acid are added into the precursor aqueous solution of the WSE2 film to obtain a WSe2 / RGO precursor aqueous solution; then, after hydrothermal treatment at 165-180 DEG C, a thin-film metal structure tungsten diselenide / redox graphene composite structure is obtained on a polyethylene naphthol substrate inserted into the WSe2 / RGO precursor aqueous solution, and a precipitate in a residual solution after the hydrothermal treatment is filtered, washed and dried to obtain a powder metal structure tungsten diselenide / redox graphene composite structure. According to the invention, the preparation of metal structure tungsten diselenide can be realized through a one-step synthesis process through a hydrothermal method, and the preparation method is not only simple in process, but also has the excellent characteristics of low cost of used raw materials and equipment, low energy consumption, high efficiency and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Hindered-phenol-quaternary-ammonium-salt-modified-imvite-modified PP-R pipe

The invention relates to a material special for a hindered-phenol-quaternary-ammonium-salt-modified-imvite-modified PP-R pipe. The material special for the hindered-phenol-quaternary-ammonium-salt-modified-imvite-modified PP-R pipe is prepared from, by mass, 80-120 parts of PPR, 0.5-10 parts of hindered-phenol-quaternary-ammonium-salt-modified imvite and 1-30 parts of a compatilizer, wherein the compatilizer is one or more of maleic anhydride (MAH) grafted by elastomer, HDPE, LDPE and PP or acrylonitrile (SAN) or glycidyl methacrylate (GMA). According to the material, the hindered-phenol-quaternary-ammonium-salt-modified imvite and the compatilizer are compounded, then the mixture and the PPR resin are blended and modified, and the material special for the PPR pipe is prepared; the material special for the PPR pipe has the advantages of being excellent in low-temperature performance, stable in size and good in antibacterial performance and weather resistance.

Owner:LIANSU TECH DEV GUIYANG

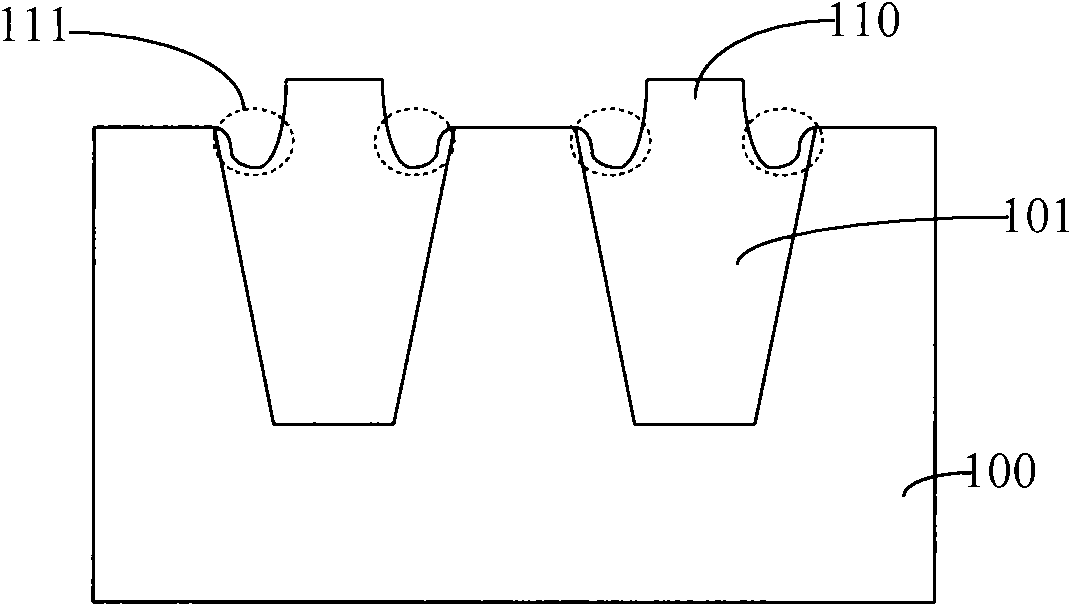

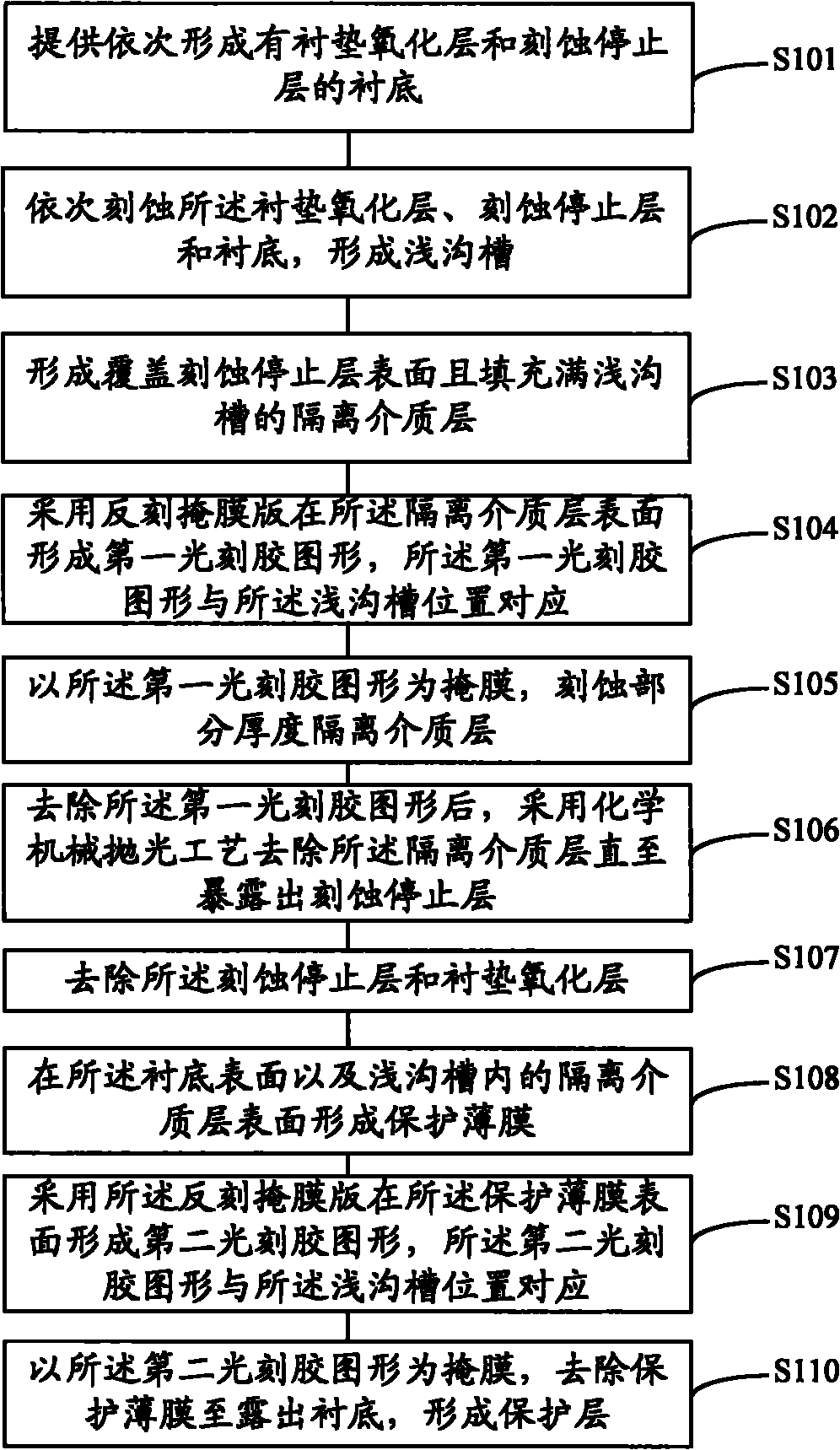

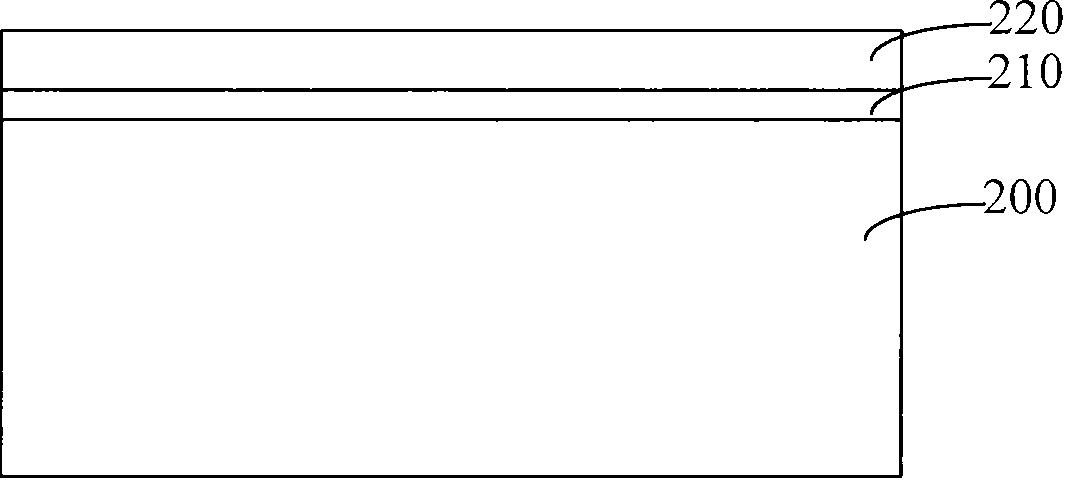

Method for forming shallow trench isolation structure

ActiveCN102148181AImprove corrosion resistanceGood interface effectSemiconductor/solid-state device manufacturingEngineeringProtection layer

The invention discloses a method for forming a shallow trench isolation structure. The method comprises the following steps of: providing a substrate on which a gasket oxide layer and an etching stopping layer are formed sequentially, and forming a shallow trench in the substrate; forming an isolation medium layer which fills the shallow trench on the surfaces of the etching stopping layer and the gasket oxide layer; forming a first photoresist pattern on the surface of the isolation medium layer by using an active reverse mask; etching the isolation medium layer of partial thickness by using the first photoresist pattern as a mask; removing the isolation medium layer until the isolation medium layer is exposed out of the etching stopping layer by adopting a chemical mechanical polishing process after removing the first photoresist pattern; removing the etching stopping layer and the gasket oxide layer; forming a protection film which covers the isolation medium layer on the surface of the substrate; forming a second photoresist pattern on the surface of the protection film by using the active reverse mask; and removing the protection film until the protection film is exposed out of the substrate by using the second photoresist pattern as the mask to form a protection layer. A divot situation does not exist in the isolation of the shallow trench which is formed by the method.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Preparation method for high-resistance inorganic-organic composite modified acrylic epoxy ester resin

The invention belongs to the field of water-based paints, and discloses a high-resistance inorganic-organic composite modified acrylic epoxy ester resin. The high-resistance inorganic-organic composite modified acrylic epoxy ester resin is synthesised from the following raw materials in parts by weight: 30-70 parts of epoxy ester, 5-50 parts of acrylic monomers and 5-25 parts of silica gel, wherein the epoxy ester is prepared by carrying out a catalytic reaction on 40-70 parts of epoxy resin and 20-60 parts of unsaturated fatty acid; the acrylic monomers comprise 20-60 parts of vinyl monomers and 40-70 parts of acrylic acid monomers; the silica gel is prepared by reacting 10-50 parts of an organic silicon intermediate, 5-50 parts of a silane coupling agent, 20-70 parts of a cosolvent, 0.2-5 parts of a pH value regulator and 5-15 parts of water; the nanoscale silica gel is capable of improving the resistance and dryness of a paint film; secondary crosslinking is formed along with the changes of a pH value, thus increasing the crosslinking density after film formation; the structure taking the nanoscale silica gel as a core and the organic resin as a shell is capable of improving the stability of silicon hydroxyl; the water-based epoxy ester resin is capable of reducing a VOC content.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

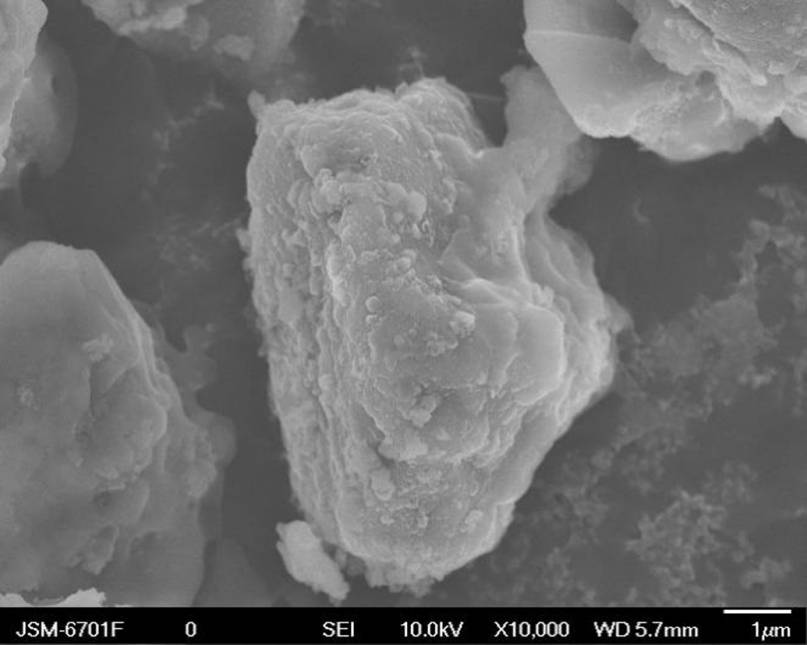

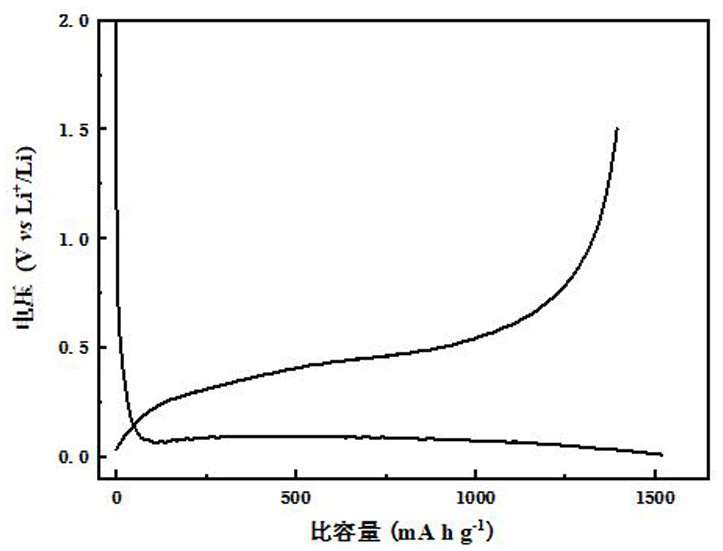

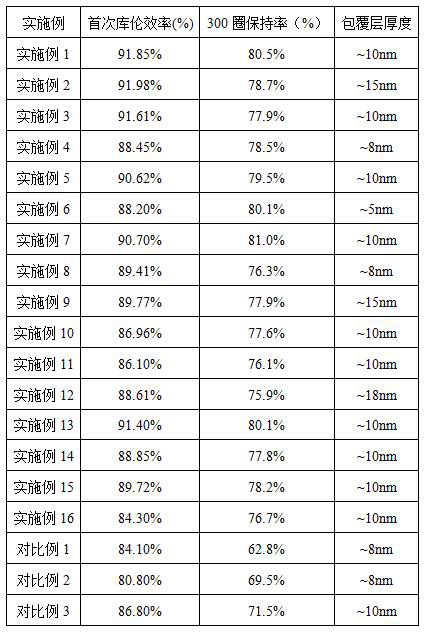

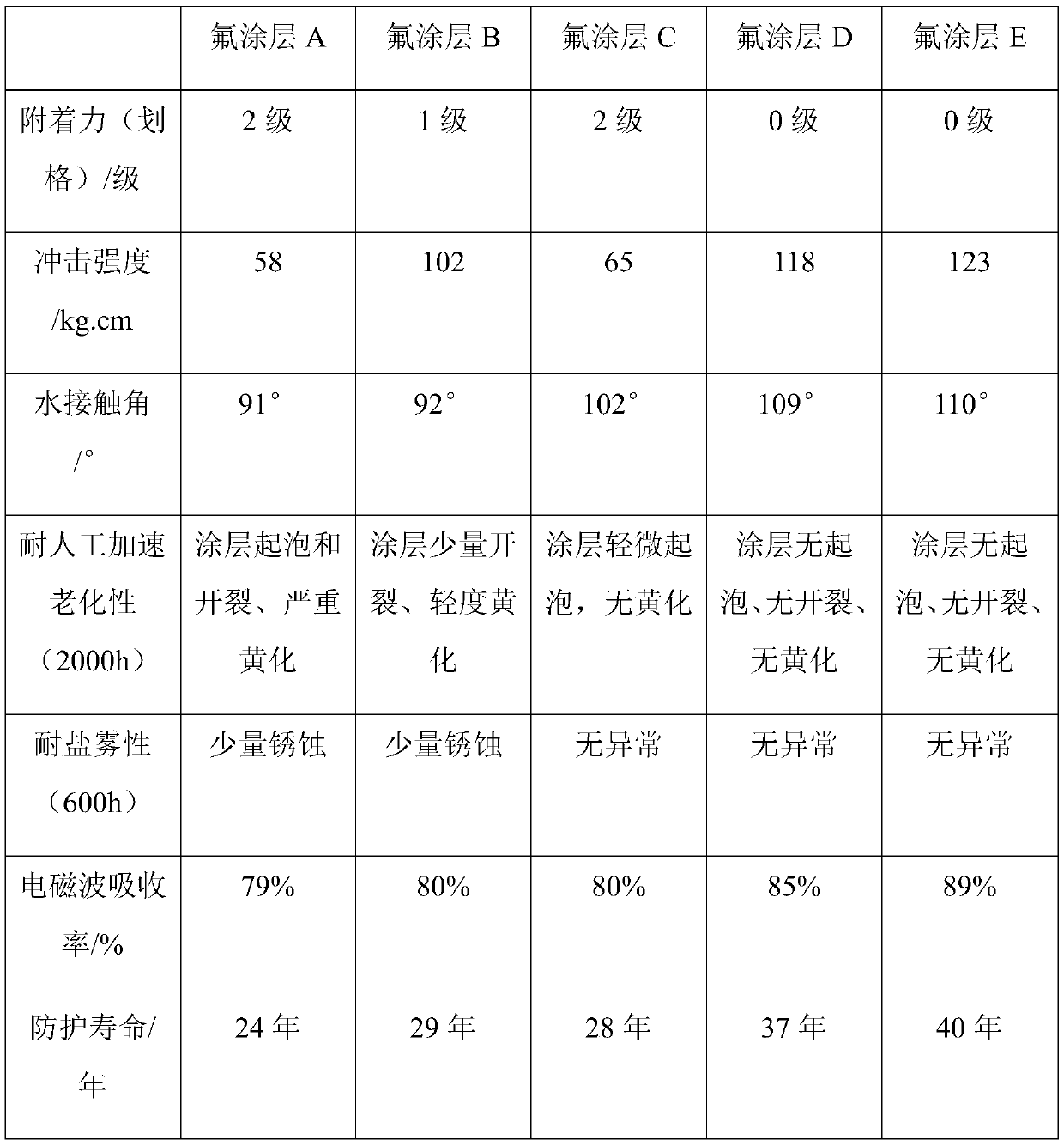

Preparation and application of in-situ polymerization coated modified silicon-based negative electrode material

ActiveCN113270586AAvoid uneven coating, increase of inactive substances, etc.Improve interface effectSecondary cellsNegative electrodesIn situ polymerizationPhysical chemistry

The invention discloses preparation and application of an in-situ polymerization coating modified silicon-based negative electrode material, the surface of a silicon-based material is coated with a composite coating layer of an inorganic matter and a polymer, and through the effect of a deep eutectic solvent, the silicon-based negative electrode material enables monomers of the polymer to be subjected to in-situ polymerization reaction on the surface of the silicon-based material to obtain a composite coating layer in which inorganic matters are uniformly distributed in the polymer; the inorganic matter is lithium salt, and the thickness of the composite coating layer is 5-15 nm. According to the composite coating layer, an organic-inorganic composite coating layer is constructed on the surface of the material in an in-situ polymerization manner of a polymeric monomer doped with an inorganic substance. According to the negative electrode material, in the initial lithiation / delithiation process, a layer of organic-inorganic composite artificial solid electrolyte interface (SEI) is formed in situ, the structural integrity in the lithium intercalation / delithiation process is maintained, the irreversible consumption of lithium ions is reduced due to the addition of the lithium-rich inorganic matter, and the first coulombic efficiency and the cycle stability of the negative electrode material are improved.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

Method for preparing high-electric energy density high polymer composite film

The invention provides a method for preparing a high-electric energy density high polymer composite film. Hydrochloric acid-doped polyaniline (PANI) is chemically grafted to a molecular chain of polyolefin, a polyurethane (PU) elastomer, epoxy resin (EP) or an acrylic resin elastomer (AE) at first, and a solution casting film-hot pressing method is then utilized to prepare the high-electric energy density high polymer composite film. A chemical method is utilized to graft polyaniline to high polymer, interface bonding strength between two components is improved, the polyaniline particle size is reduced, and furthermore, an interfacial effect between a high polymer basal body and polyaniline particles is fully utilized, so that a composite material with both excellent electrical performance and mechanical performance is obtained. When 50% of ceramic particle is added into a traditional high polymer, the dielectric constant is only about 100; the high polymer-based composite material which is prepared by the method and has the polyaniline content of 12-14% has the dielectric constant of above 380 when the room temperature frequency is 1000Hz; and the electric energy density is above 2.8J / cm<3> in an electric field of 20MV / m.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

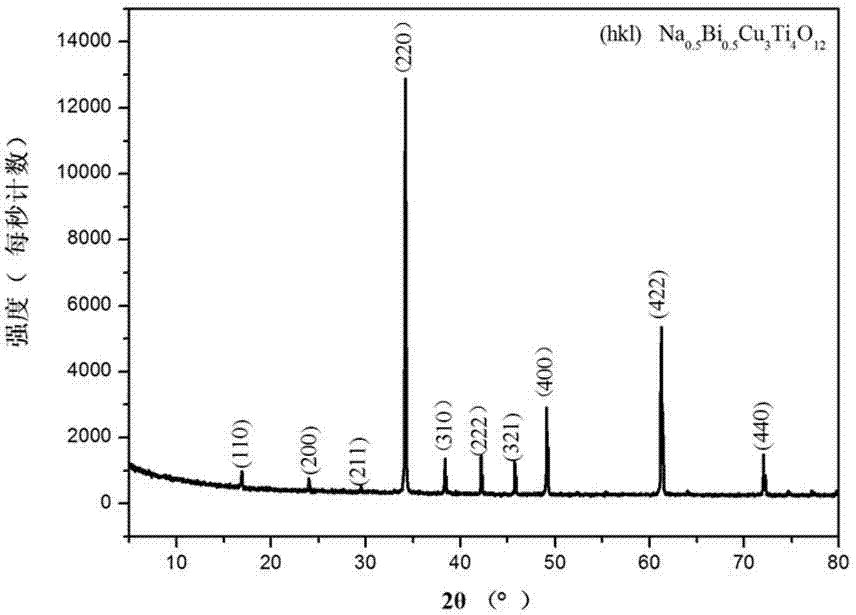

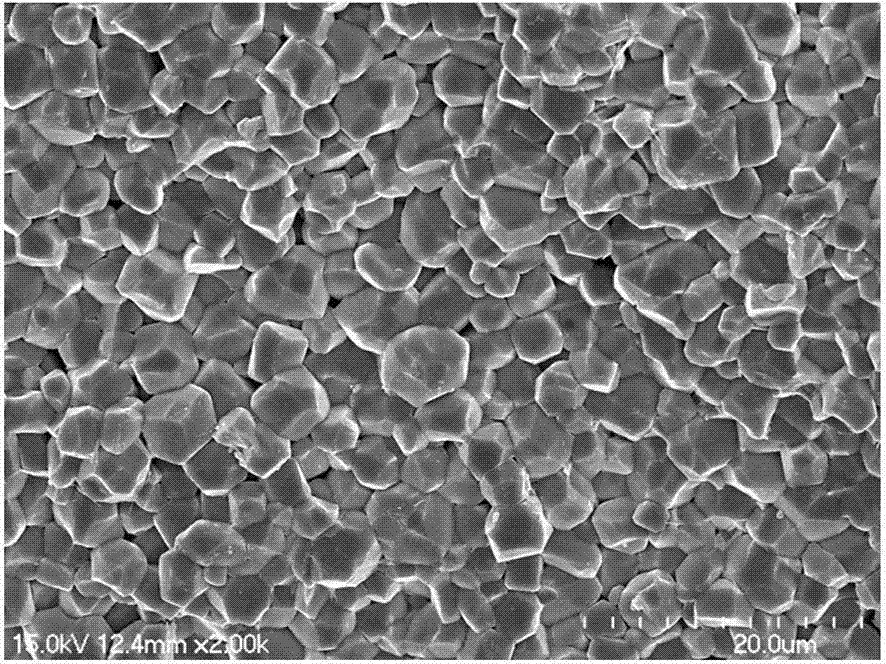

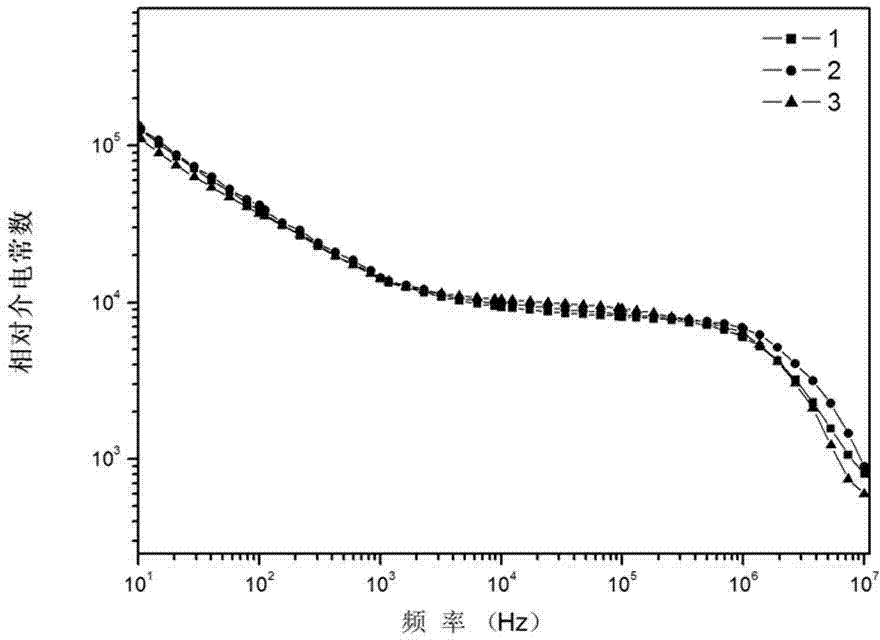

Method for preparing copper titanate bismuth sodium ceramic

The invention relates to a method for preparing a Na0.5Bi0.5Cu3Ti4O12 ceramic. Na2CO3, Bi2O3, CuO and TiO2 serve as raw materials, NaCl and KCl are added into the raw materials, and the raw materials are ball-milled, pre-burned, formed and sintered to form a product. By the method, the raw materials can react at low temperature, a synthetic product is high in purity and small in grain size and has a great value in the field of high dielectric constant materials, the microscopic structure of the copper titanate bismuth sodium ceramic can be obviously improved, and further dielectric property is improved.

Owner:SUZHOU UNIV

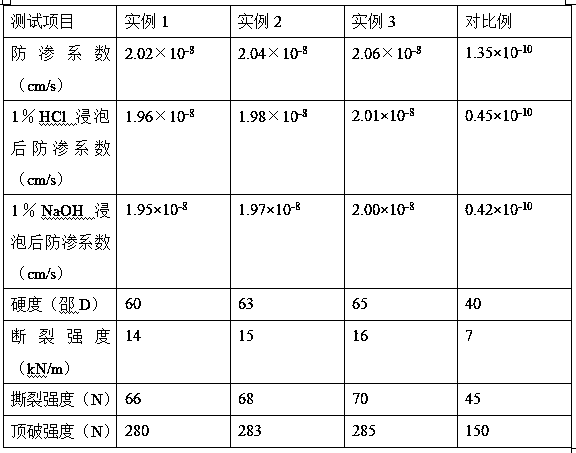

Preparation method of acid and alkali resistant anti-puncture anti-seepage material

InactiveCN108751907AImprove liquidityBroad application prospectsNon-macromolecular adhesive additivesProtective foundationIonCalcium hydroxide

The invention discloses a preparation method of an acid and alkali resistant anti-puncture anti-seepage material, and belongs to the technical field of preparation of environmental protection materials. Since fumed silica particles have large surface defects, many unpaired atoms and high surface activity, a large interfacial effect is generated on the surface of double-layered glass wool, and thefumed silica is dispersed in the gap of a polyester molecular chain, so that the elasticity of polyester resin and a fumed silica system is improved and resistant to plant root tip puncture. Quick lime reacts with water to form calcium hydroxide that reacts with sulfate in the manganese residue to form unite particles in the anti-seepage material. The heavy metal ions in the clay slurry componentmanganese slag are mostly in the form of sulfate, and the heavy metal ions of a landfill can be in complexing with modified polyester, hydrated silicate is insoluble under alkaline conditions, a claylayer in the anti-seepage material can be used as a protective film to make the clay slurry have acid and alkali resistance, so that the material has broad application prospects.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Preparation method of in-situ polymerized type halogen-free flame retardant nylon material for selective laser sintering

A preparation method of an in-situ polymerized type halogen-free flame retardant nylon material for selective laser sintering comprises the following steps: carrying out in-situ polymerization of nylon monomers, melamine, cyanuric acid, a light absorbent, a molecular weight regulator and a first antioxidant to obtain a halogen-free flame retardant nylon material; and crushing the halogen-free flame retardant nylon material to obtain a halogen-free flame retardant nylon powder. The prepared in-situ polymerized type halogen-free flame retardant nylon material for selective laser sintering not only makes a flame retardant chemically bonded into the nylon monomers or uniformly dispersed in the nylon monomers, so as to achieve a good flame retardant effect, namely meet the requirements of the aviation flame retardant standard FAR25.853; and because the light absorbent is added in the polymerization process and the light absorbent can be uniformly dispersed in a base material, the laser energy in the selective laser sintering process can be better absorbed, melt processing of materials can be effectively promoted, and thus the utilization rate of laser energy and the mechanical performance of sintering parts are improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Nano grade condiment micro emulsion and its preparing method

InactiveCN1561815ALarge specific surface areaImprove surface activityEmulsion deliveryFood preparationSolubilityEmulsion

A nano-class spice's microemulsion is prepared from deionized water, spice's oil, emulsifier bone marrow oil, salt and sugar through proportionally mixing and high-pressure homogenizing. It has high water solubility, dispesity and penetrability.

Owner:毛一鹏

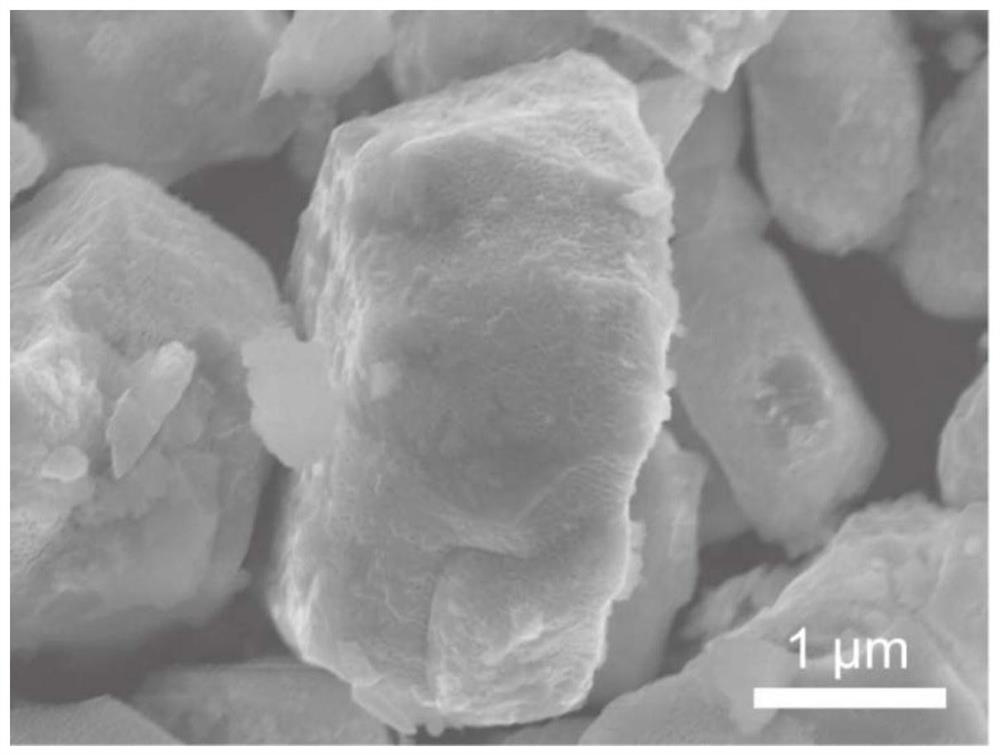

Silicon-based negative electrode material and preparation method and application thereof

ActiveCN110993925AAlleviate volumetric deformation effectsImprove structural stabilityNegative electrodesSecondary cellsCarbon layerDoped graphene

The invention relates to a silicon-based negative electrode material and a preparation method and application thereof. The silicon-based negative electrode material comprises a silicon-based inner core and a shell coating the surface of the silicon-based inner core. The shell comprises a first coating material and a second coating material, wherein the first coating material is composed of a compound of nitrogen-doped graphene, a nitrogen-doped hydrogen-containing lithium titanium oxide compound and nitrogen-doped hexagonal phase tungsten oxide, and the second coating material is composed of amesoporous carbon layer. The preparation method comprises the following steps: (1) dispersing a silicon-based material and a first coating material in a solvent to obtain a dispersion liquid, and carrying out spray drying to obtain an inner core material; (2) dispersing a triblock copolymer, amino alcohol and the core material in the step (1) in a solvent to obtain a dispersion liquid; and (3) adding dopamine into the dispersion liquid obtained in the step (3), carrying out a polymerization reaction, and then carbonizing in an inert atmosphere to obtain the silicon-based negative electrode material. The structure and the cycling stability of the silicon-based negative electrode material are obviously improved, and the cycling performance of the silicon-based negative electrode material isalso obviously improved.

Owner:LANGFANG GREEN IND TECH CENT +1

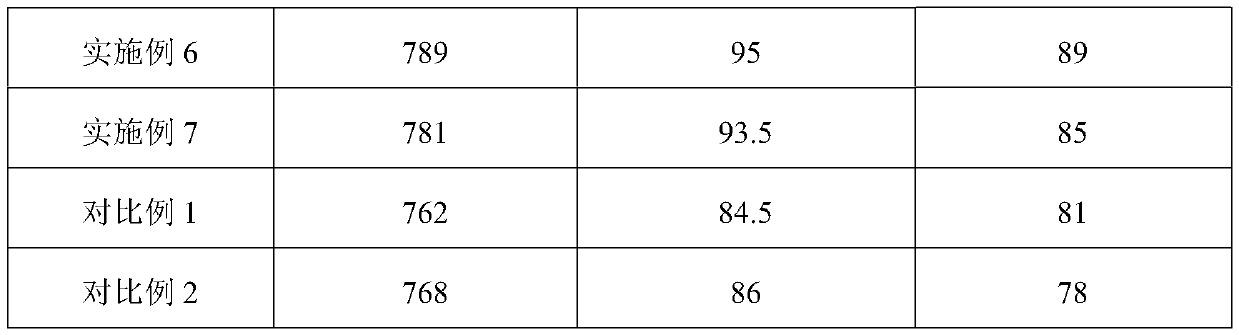

Fluorine-containing coating material for outdoor protection of 5G communication base station and preparation method thereof

ActiveCN111363423AExtended service lifeMany active sitesAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyFiber

The invention discloses a fluorine-containing coating material for outdoor protection of a 5G communication base station and a preparation method thereof. The fluorine-containing coating material comprises a substrate material layer, a functional material layer and a maintenance material layer, wherein the substrate material layer is formed by mixing a nano-fiber dispersion liquid consisting of electrostatic spinning fibers with epoxy resin; the functional material layer is mainly formed by wrapping wave-absorbing nano particles with a fluorine-containing polymer, and is further connected withthe substrate material layer in a crosslinking manner through a ring-opening catalyst, so that the connecting strength of the coating and a substrate is greatly improved while the excellent weather resistance and radiation resistance are improved. The maintenance material layer is mainly composed of a mixed solution of hydroxyapatite nano particles and polyvinyl butyral, has excellent corrosion resistance, softness and flexibility, can well protect the functional material layer, and prolongs the service life of the coating.

Owner:无锡市恒创嘉业纳米材料科技有限公司

Bifunctional interface lithium ion battery nickel-rich single crystal positive electrode material and preparation method thereof

ActiveCN112864372AImproved magnification performanceImprove cycle stabilitySecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention provides a bifunctional interface lithium ion battery nickel-rich single crystal positive electrode material and a preparation method thereof. According to the method, a certain amount of aluminum source and phosphate are added into a nickel-rich single crystal positive electrode material, and a bifunctional coating layer of AlPO4 and Li3PO4 is formed while surface residual alkali (Li2CO3 / LiOH) is consumed. By controlling the adding amount of the aluminum source and the phosphate and adjusting and controlling the adding mode and the calcining method, the direct contact between the active material and an electrolyte can be reduced, gas production is inhibited, and the thermal stability of the material is improved; and the transmission of ions between the positive electrode and the electrolyte can be accelerated, the stress change in a charging and discharging process is relieved, and the rate capability of the material is improved. According to the method, a bifunctional interface modification layer is obtained, the electrochemical performance of the nickel-rich single crystal positive electrode material is improved through the synergistic effect of the bifunctional interface modification layer; operation is easy and convenient; and raw materials are cheap and easy to obtain. The method is suitable for large-scale commercialization of the nickel-rich single crystal positive electrode material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

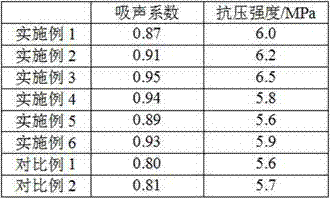

Micro hole-aluminum silicate fiber sandwich type composite sound absorption board

The invention discloses a micro hole-aluminum silicate fiber sandwich type composite sound absorption board and belongs to the field of noise control devices. The micro hole-aluminum silicate fiber sandwich type composite sound absorption board comprises a micro perforation board body, an aluminum silicate fiber mat and an aluminum silicate fiber board body which are sequentially arranged from outside to inside. The micro perforation board body is provided with a plurality of penetrating holes, and the periphery of the inner surface of the micro perforation board body is provided with baffles to form a first groove, and the first groove is matched with the aluminum silicate fiber mat. The periphery of the inner surface of the micro perforation board body is provided with a plurality of protrusions, and the periphery of the aluminum silicate fiber board body is provided with second grooves matched with the protrusions. The periphery of the inner surface of the aluminum silicate fiber board body is provided with a frame. According to the sound absorption board, through hole diameter resistance, material sound absorption, the interfacial effect between high-low volume weight materials and the like, the sound absorption frequency band of the sound absorption board is greatly widened, the sound absorption coefficient of the sound absorption board is 0.87-0.95, the compressive strength is high, and the fireproof grade is A; and the sound absorption board is suitable for absorbing of low-frequency electromagnetic noise of equipment such as a transformer and an electric reactor and high-frequency aerodynamic noise of a cooling fan.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +3

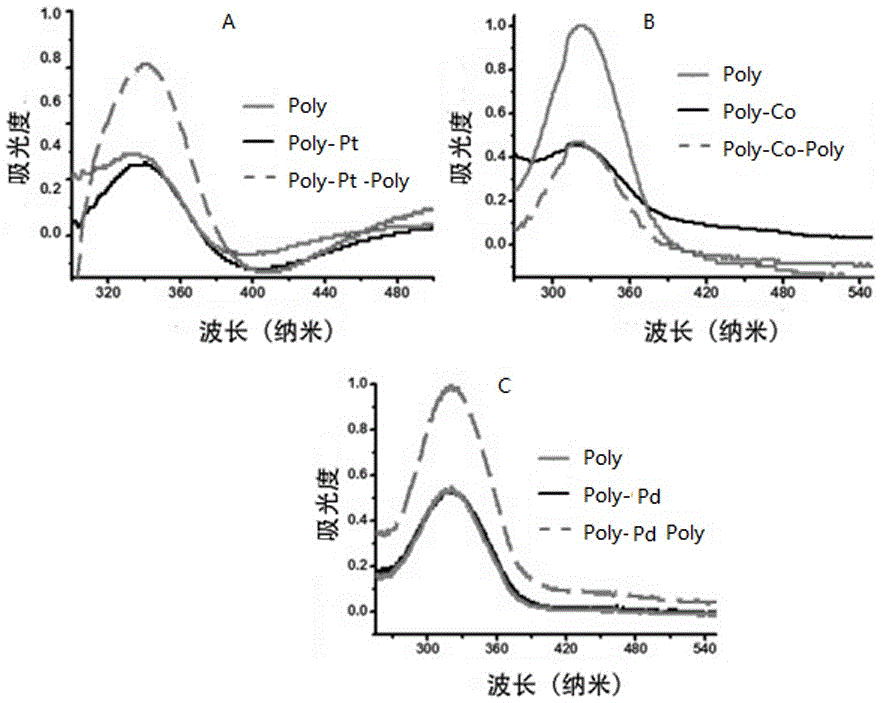

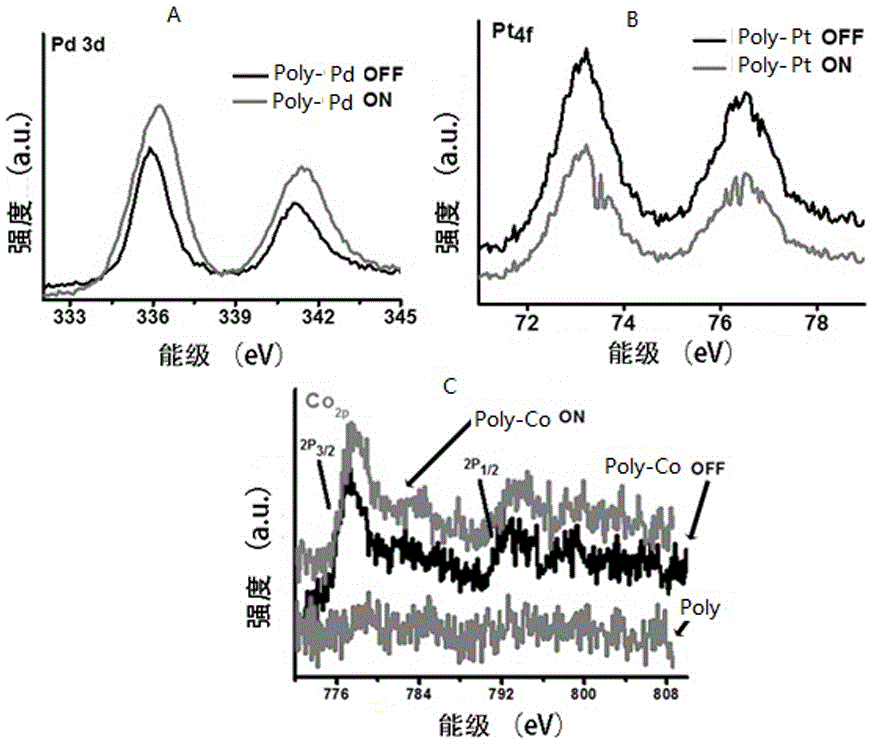

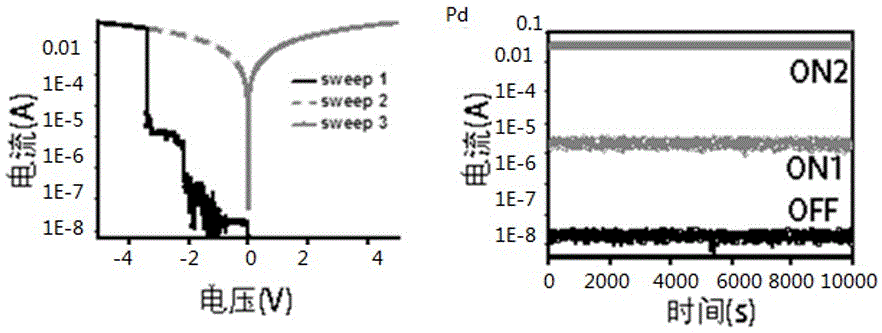

Active layer material and application of active layer material in preparing ternary memory device

ActiveCN106449975AMeet application needsEasy transitionSolid-state devicesSemiconductor/solid-state device manufacturingPolymeric surfacePolymer thin films

The invention discloses an active layer material and an application of the active layer material in preparing a ternary memory device. A thin film is prepared by synthesizing poly4-(4-methylacryloyloxy)-azo) pyridine with a solution spinning method; a metal complex layer is assembled on the surface of the polymer with a molecular self-assembly method; a polymer thin film is prepared with the solution spinning method, and an active layer is obtained. According to the device prepared from the active layer, stable multi-system storage is achieved; particularly, as the complex layer is introduced between the polymers with the molecular self-assembly method, transition of binary storage to ternary storage of the device is achieved.

Owner:SUZHOU UNIV

Strontium carbonate-modified silk fibroin composite material and preparation method thereof

InactiveCN106730020AAchieve in situ mineralizationImprove mechanical propertiesPharmaceutical delivery mechanismTissue regenerationFiberStrontium chloride

The invention relates to a strontium carbonate-modified silk fibroin composite material and a preparation method thereof. The method comprises the steps of dissolving a high polymer material into formic acid to obtain a polymer material formic acid solution; degumming silk and then obtaining a silk fibroin fiber; dissolving the silk fibroin fiber into a strontium chloride formic acid solution to obtain a silk fibroin solution; adding the polymer material formic acid solution again; mixing and drying to obtain a strontium-containing regenerated fibroin membrane; putting the strontium-containing regenerated fibroin membrane into a close container for mineralization in the presence of ammonium carbonate or ammonium bicarbonate to obtain a mineralized membrane; putting the mineralized membrane into deionized water; and carrying out drying treatment to obtain the strontium carbonate-modified silk fibroin composite material. The breaking strength of the prepared composite material is 70-100MPa, the breaking elongation is 6-10%, the Young modulus is 3-5GPa and the composite material can be applied to preparation of a bone repair material.

Owner:宁波芸生纺织品科技有限公司

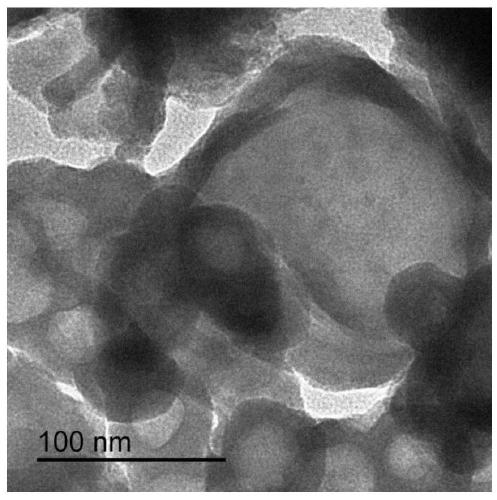

Core-shell nanoparticle/polyvinylidene fluoride composite material and preparation method thereof

The invention provides a core-shell nanoparticle / polyvinylidene fluoride composite material and a preparation method thereof and belongs to the technical field of composite materials. The core-shell nanoparticle / polyvinylidene fluoride composite material is compounded by doping three-layer core-shell nanoparticles into polyvinylidene fluoride, wherein the core of the three-layer core-shell nanoparticles is silicon dioxide, the first-layer shell is reduced graphene oxide, and the second-layer shell is chitosan. The preparation method comprises the following steps of: grafting a silane couplingagent KH550 to the surfaces of SiO2 nanoparticles, coating by the graphene oxide, preparing the three-layer core-shell nanoparticles, adding the three-layer core-shell nanoparticles into a mixed solution of the polyvinylidene fluoride and N-N-dimethylformamide, removing bubbles, heating and preparing films and the like. The core-shell nanoparticle / polyvinylidene fluoride composite material prepared by the invention has the characteristics of high dielectric constant and low dielectric loss; the preparation method has the advantages of simple process and low cost and is suitable for industrialproduction and application of various types of factories.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com