Carbon fiber composite material for fused deposition 3D printing and preparation method thereof

A 3D printing and fused deposition technology, which is applied in the field of carbon fiber composite materials for fused deposition 3D printing and its preparation, can solve the problems of complex molding process, high cost, and difficulty in molding large-scale products, and achieves simple and effective process. Effects of interfacial interaction, flexural strength and tensile strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

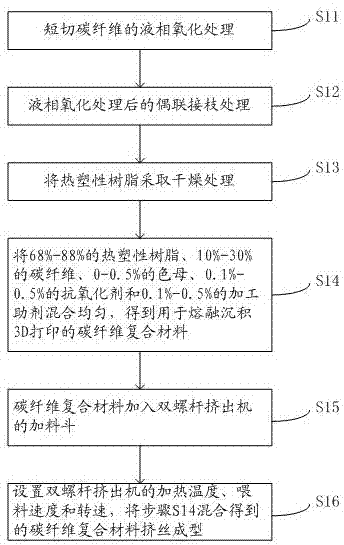

[0021] Such as figure 1 As shown, the preparation method of the carbon fiber composite material for fused deposition 3D printing comprises the following steps:

[0022] Step S11: Liquid-phase oxidation treatment, including liquid-phase oxidation treatment of carbon fibers, including putting chopped carbon fibers in 68% concentrated nitric acid, heating in a water bath at 80°C for 2 hours, and then rinsing with distilled water until the pH of the distilled water is 7 Or so, finally put the carbon fiber in a 105°C oven to dry for 2 hours.

[0023] Step S12: Coupling and grafting treatment, including coupling and grafting the carbon fibers treated in step S11, including coating with a 2% ethanol solution of a titanate coupling agent or a 1% acetone solution of a silane coupling agent After coating, the carbon fiber is allowed to air dry.

[0024] Step S13: Drying the thermoplastic resin.

[0025] The thermoplastic resin raw material was put into a drier and dried at 100° C. fo...

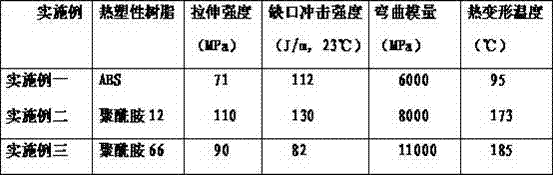

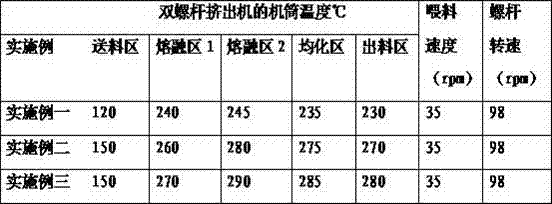

Embodiment 1

[0034] The carbon fiber reinforced ABS resin composite material is composed of the following components by mass percentage:

[0035]ABS resin: 68%-88%; carbon fiber: 10%-30%; masterbatch 0-0.5%; antioxidant: 0.1%-0.5%; dispersant (processing aid) 0.1%-0.5%.

Embodiment 2

[0037] The carbon fiber reinforced polyamide 12 resin composite material is composed of the following components by mass percentage:

[0038] Polyamide 12 resin: 68%-88%; carbon fiber: 10%-30%; masterbatch 0-0.5%; antioxidant: 0.1%-0.5%; dispersant (processing aid) 0.1%-0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com