Patents

Literature

80results about How to "Improve impact strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Fast cure epoxy adhesive with enhanced adhesion to toughened sheet molding compound

ActiveUS20080199717A1Improve impact strengthEnhance substrate adhesionPlastic/resin/waxes insulatorsFilm/foil adhesivesPolyamidePliability

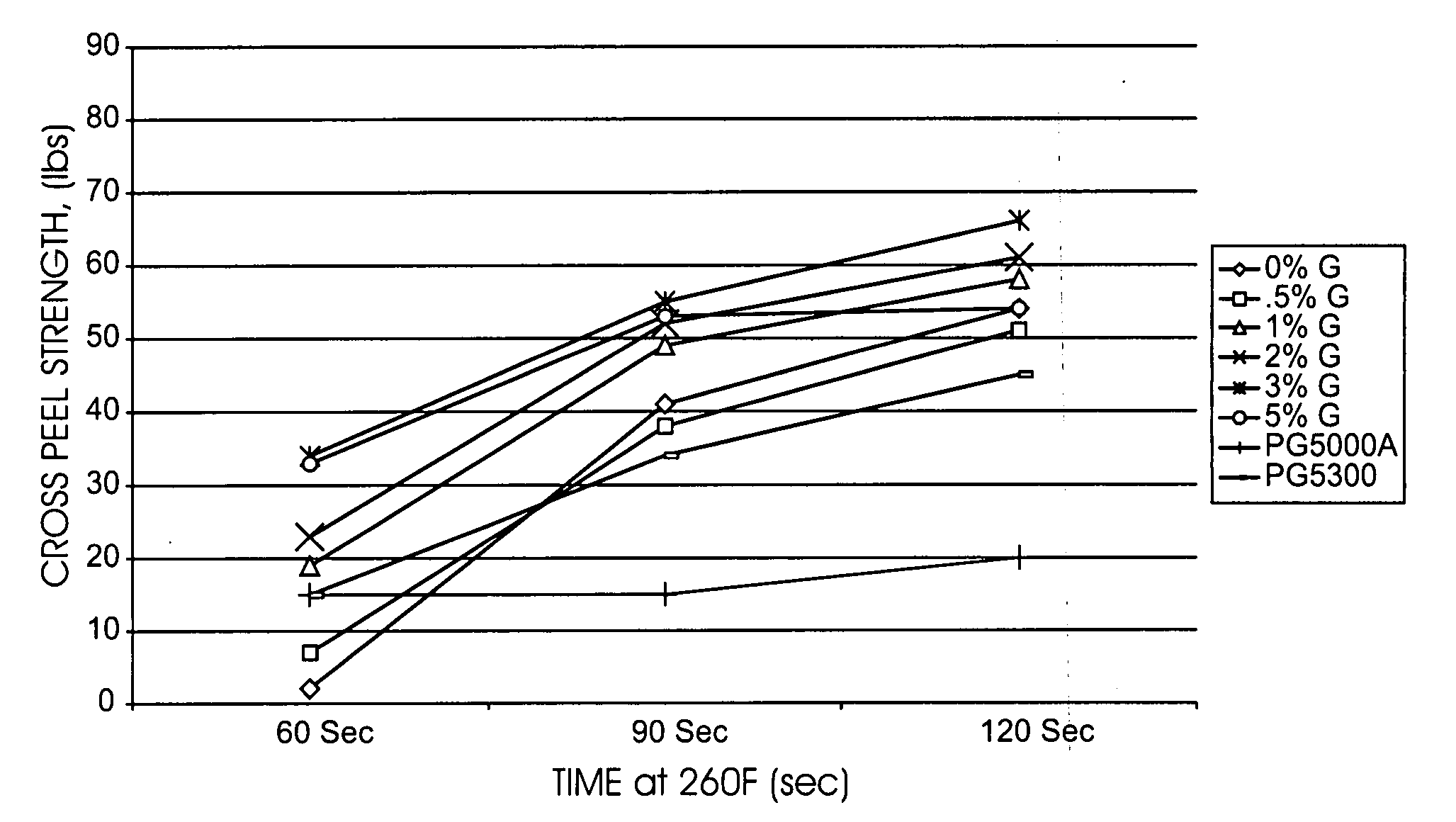

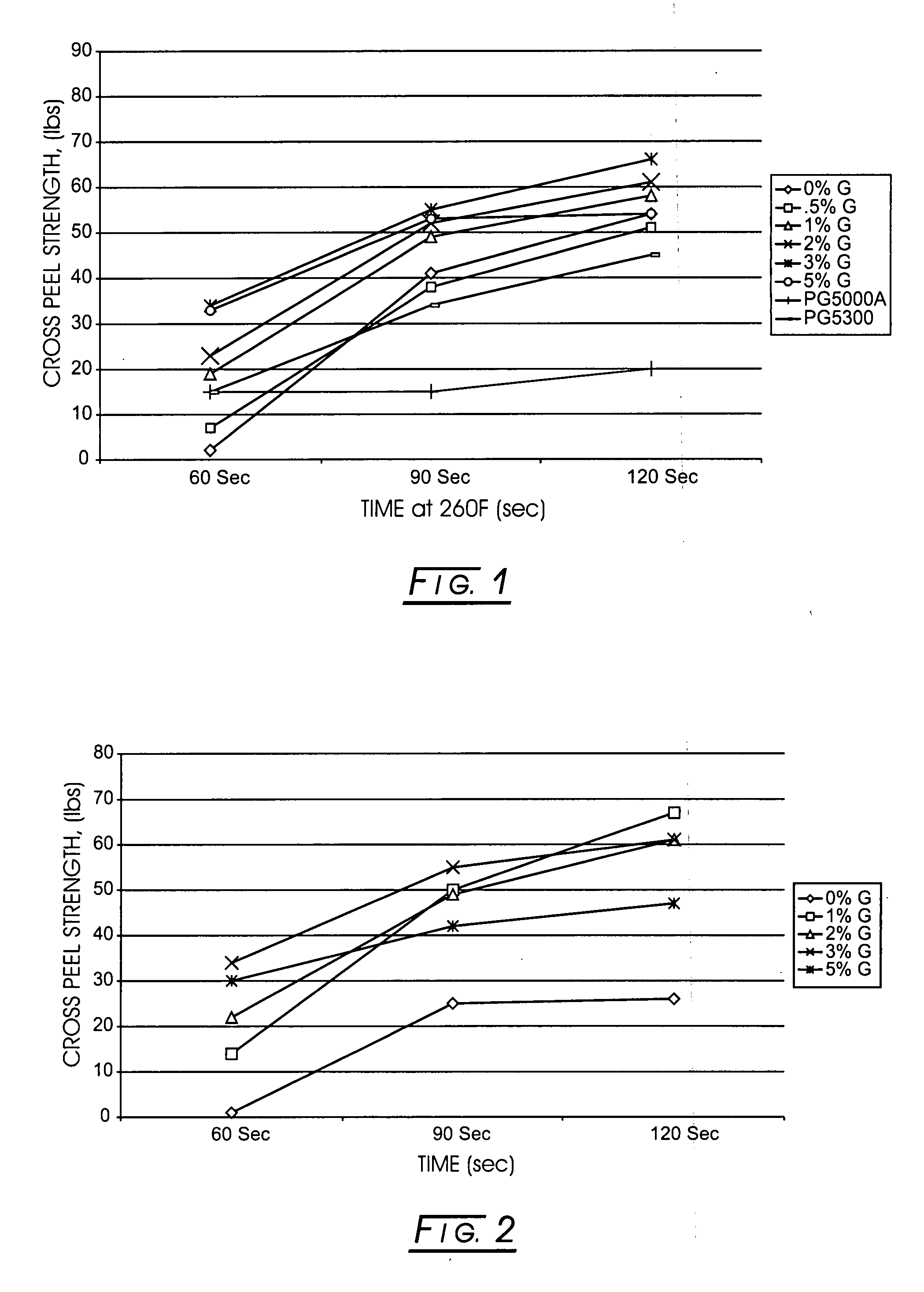

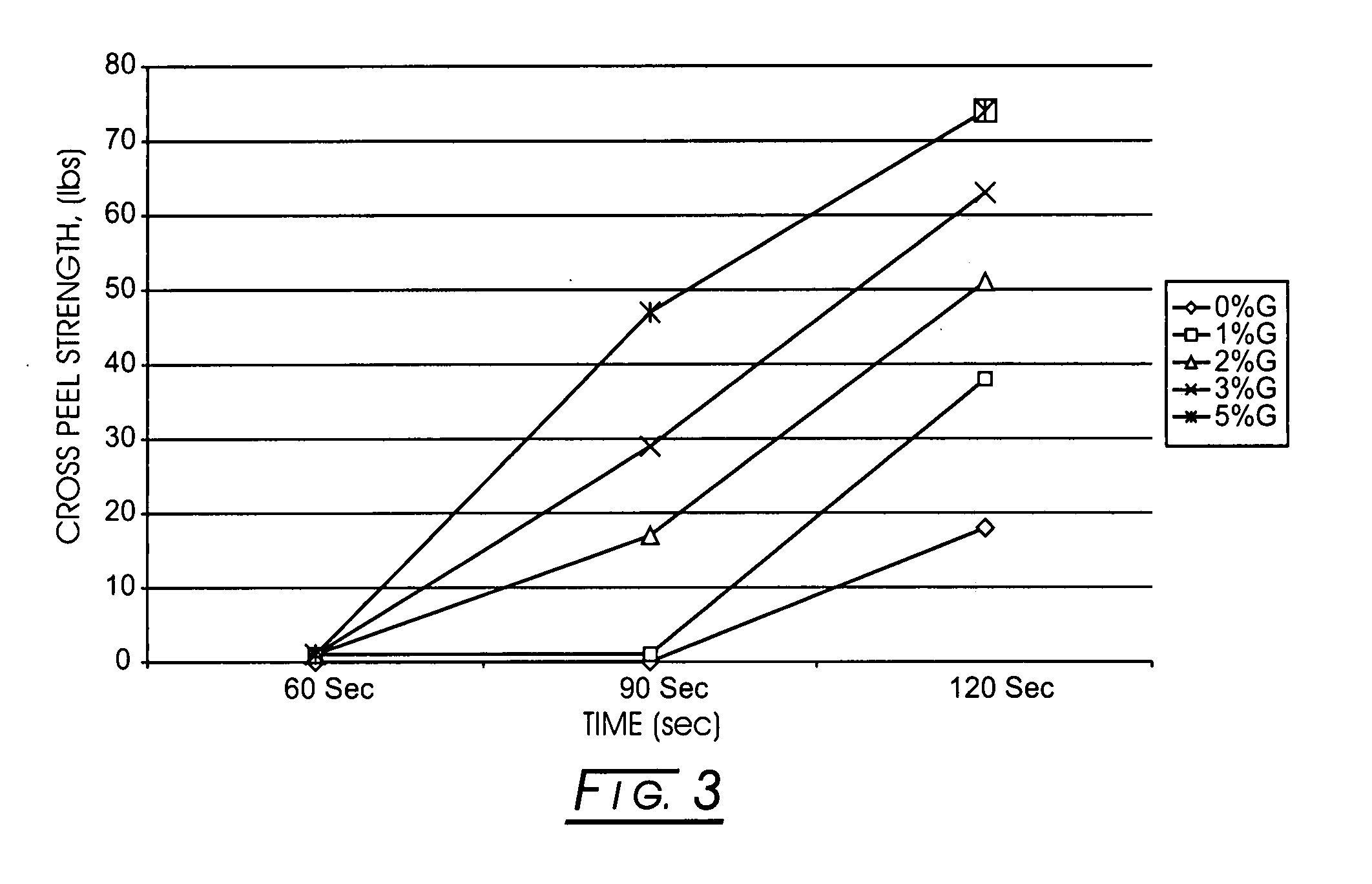

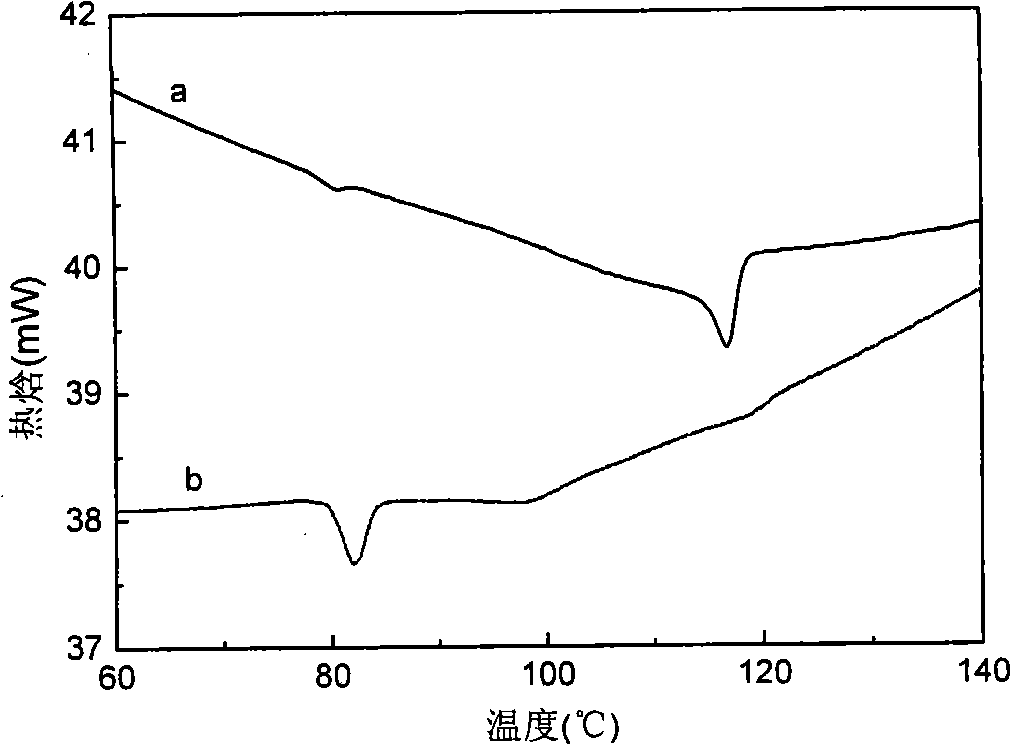

An epoxy adhesive composition of an epoxy resin, an epoxy terminated liquid rubber, filler, and an amine curing package for said epoxy resin is disclosed. Advantageously, a short chain diol will be incorporated into the adhesive in order to enhance reactivity and strength build. Advantageously, a mixture of amines will be used in the curative including multifunctional aliphatic amines that improve adhesion and strength build; tertiary amines which are used to enhance adhesion and strength build, polyamides which can be used to provide flexibility; and amine-terminated rubbers (ATBN) which can improve toughness and impact resistance to the cured system. The preferred short chain diol is glycerin. Surfaces of adherends are joined with the dried residue of the epoxy adhesive composition by applying the epoxy resin composition to one or both surfaces, joining the surfaces, and applying pressure, optionally with heating.

Owner:ARKEMA FRANCE SA

Method for preparing high impact modified material with waste and old polystyrene plastics

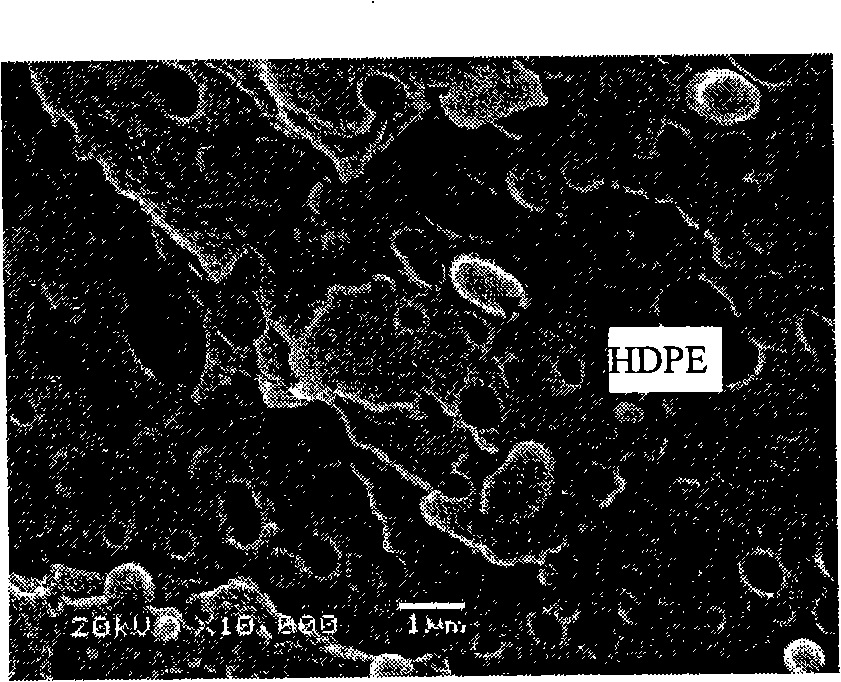

The invention discloses a method for preparing high-impact modified material from waste polystyrene plastic, which comprises the following steps: uniformly mixing 60 to 80 parts of waste polystyrene, 5 to 10 parts of polyethylene, 10 to 30 parts of elastomer, compatibilizer, etc. by stirring, adding to a screw extruder, and melting and blending at 150 to 210 DEG C, wherein the melt index ratio of polyethylene to polystyrene is equal to or less than 0.5. Due to the addition of small amount of polyethylene, the viscosity ratio of polyethylene to polystyrene and the crystallization behavior and the phase size of polyethylene can be controlled by restricting the melt index of waste polystyrene and polyethylene, so that the obtained modified material has a notched impact strength 8 to 10 times as high as that of original waste polystyrene and can maintain or even improve the tensile strength of polystyrene. The prepared modified polystyrene can be used for producing parts of middle- and high-level household appliances such as computer and air conditioner as the substitute of high-impact polystyrene new material, thus achieving remarkable social and economic benefits.

Owner:SICHUAN UNIV

Flame-retardant polycarbonate resin composition

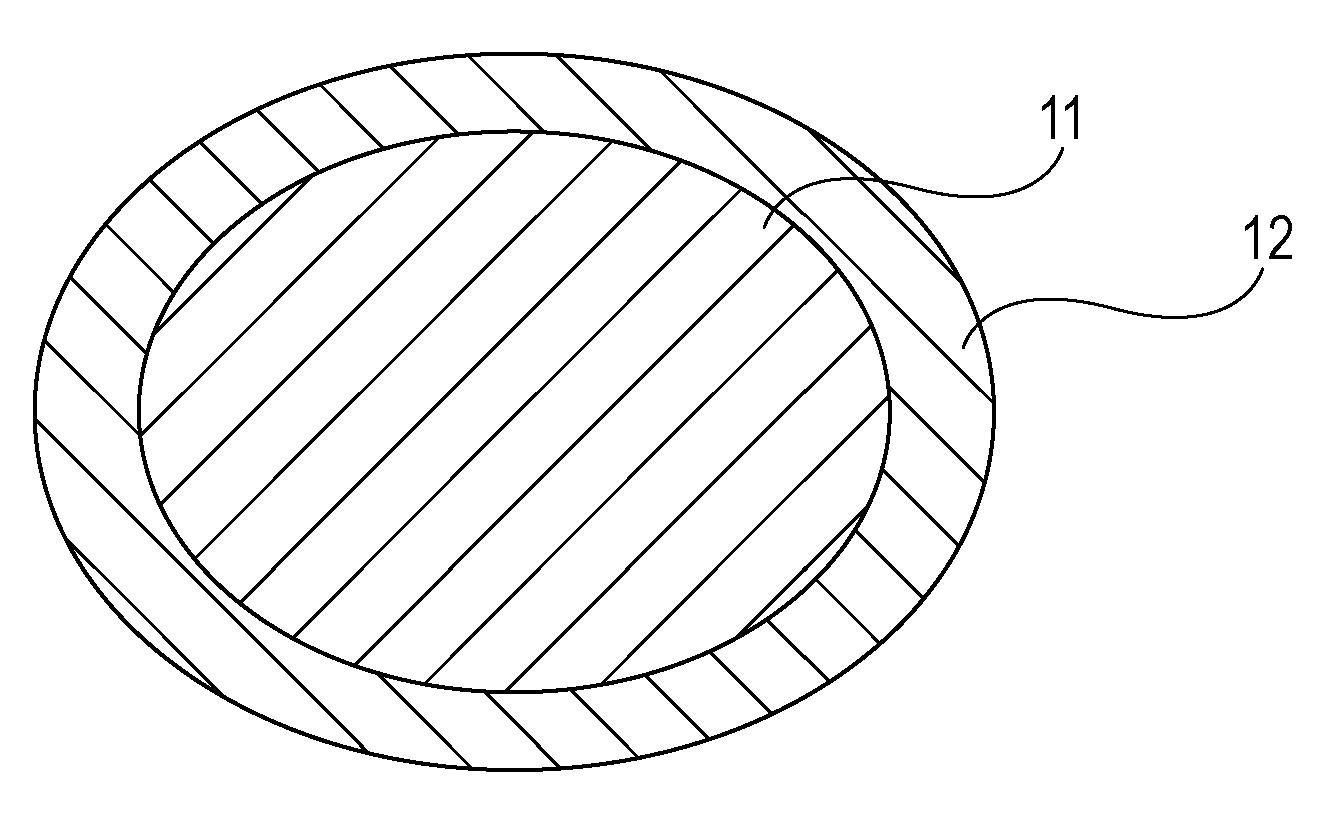

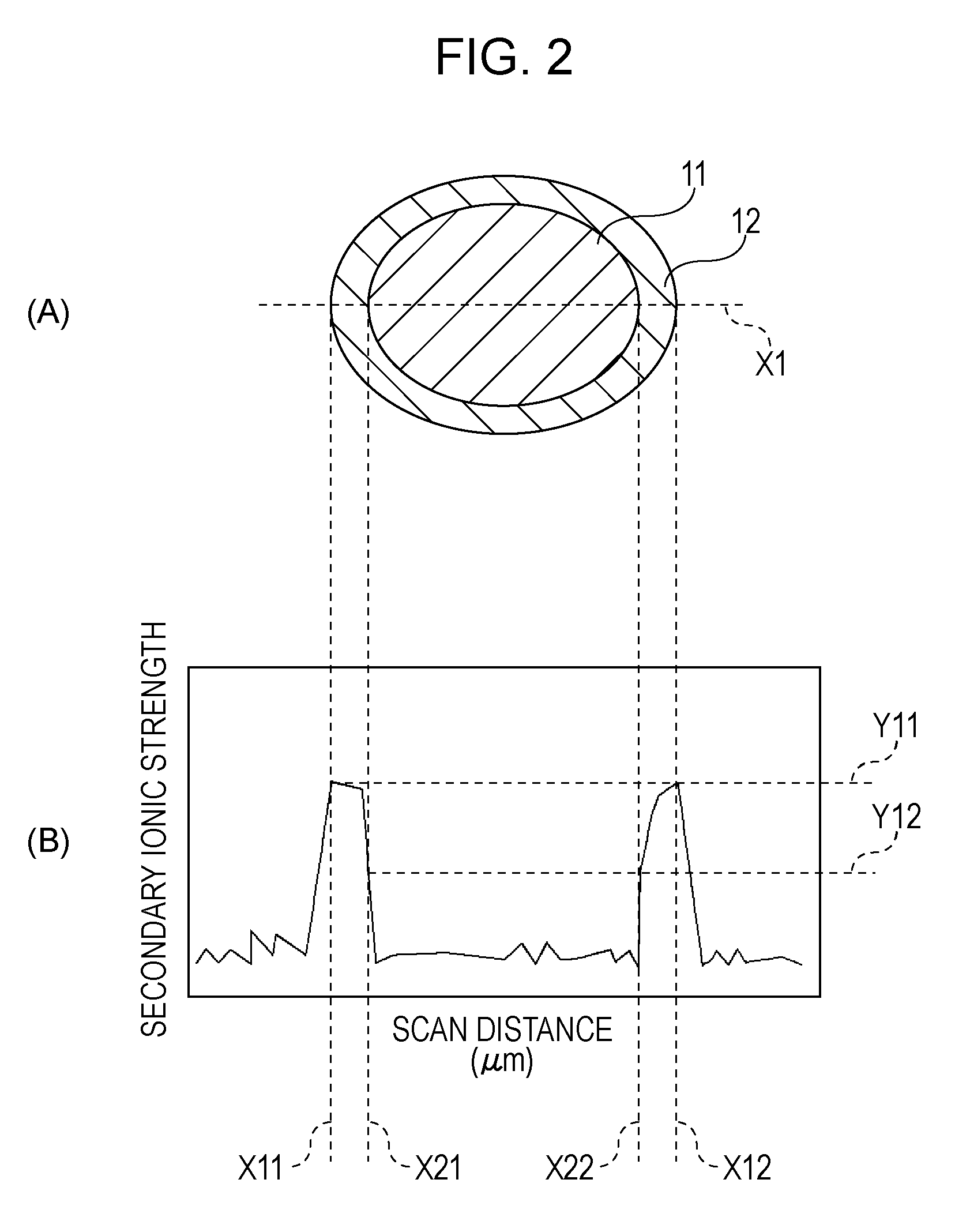

ActiveUS20090306275A1Improve impact strengthImprove dynamic characteristic and formabilityPolycarbonateBisphenol-A-polycarbonate

Five to eighty-five percent by weight of an aromatic polycarbonate resin (A component) having a weight-average molecular weight (polystyrene equivalent) of 27000 to 35000, to 10 percent by weight of an impact strength improver (D component), 0.05 to 4 percent by weight of a core-shell-type styrene-based polymer flame retardant (E component) having a sulfonate group bonded to a particle surface layer portion, 5 to 20 percent by weight of an inorganic filler (F component), and 0.1 to 0.5 percent by weight of a polyfluoroolefin resin (G component) are mixed.

Owner:SONY CORP

High-toughness, wear-resistant, self-lubricating polyamide material and preparation thereof

The invention discloses a polyamide material with high tenacity, wear-resisting capacity and self-lubricating property and a method for preparing the same. The compositions by weight percentage of the polyamide material are: 65 to 80 percent of polyhexamethylene adipamide, 15 to 23 percent of wear-resistant agent, 0 to 0.5 percent of lubricating agent, 0 to 3 percent of coupling agent, 0 to 0.5 percent of antioxidant, and 5 to 10 percent of toughener. The method improves wear-resisting property and self-lubricating property of the product mainly through auxiliary materials, thereby enlarging the application range of polyamide modified engineering plastics. The product of the invention has the advantages of good toughness, high impact strength, good surface glossiness, excellent chemical resistance and good dimension stability; a part of wear-resisting agent is added in the polyamide material, so the wear-resisting property of the material can be greatly improved; because the application range of the polyamide material is enlarged, wear-resisting requirements of partial transmission parts, shuttle wear parts and anti-sand-scraping parts can be met; and the polyamide material can be widely used for transmission components of an engine, an outer housing of a roller, an outer housing of an engine, a mechanical socket connector and transmission accessories, and can be used in positions which are often contacted and abraded in other transmission devices.

Owner:SHENZHEN KEJU NEW MATERIAL

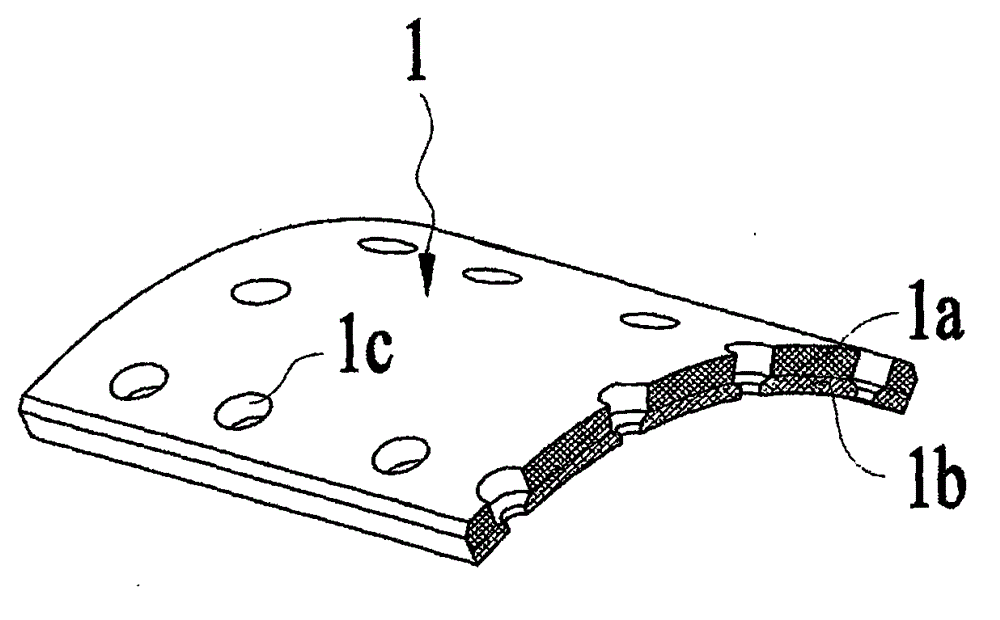

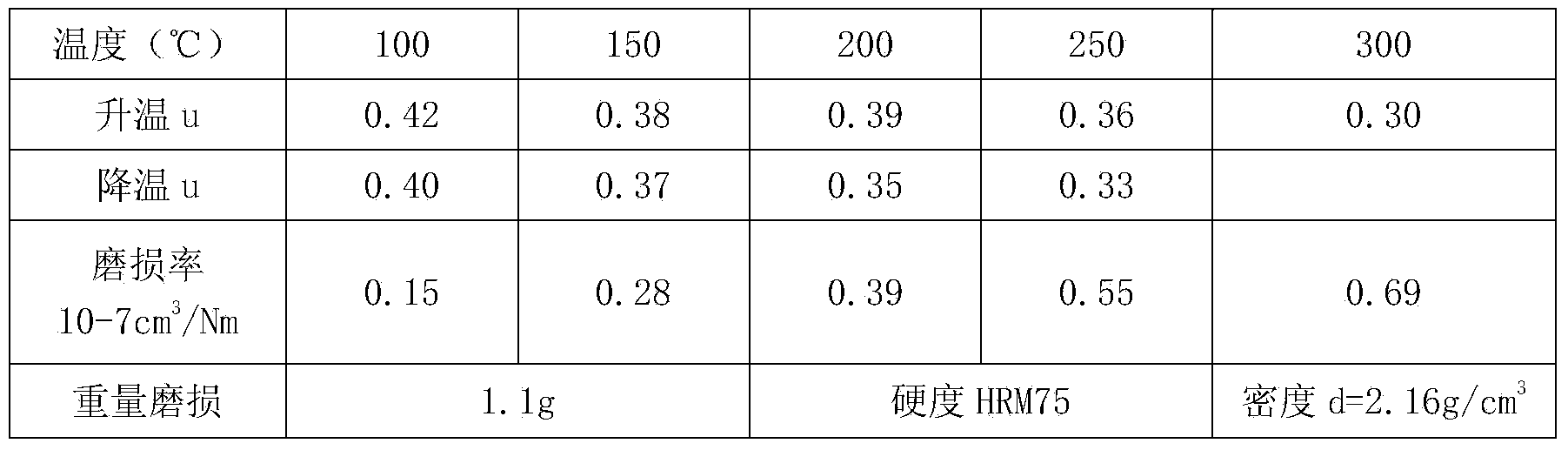

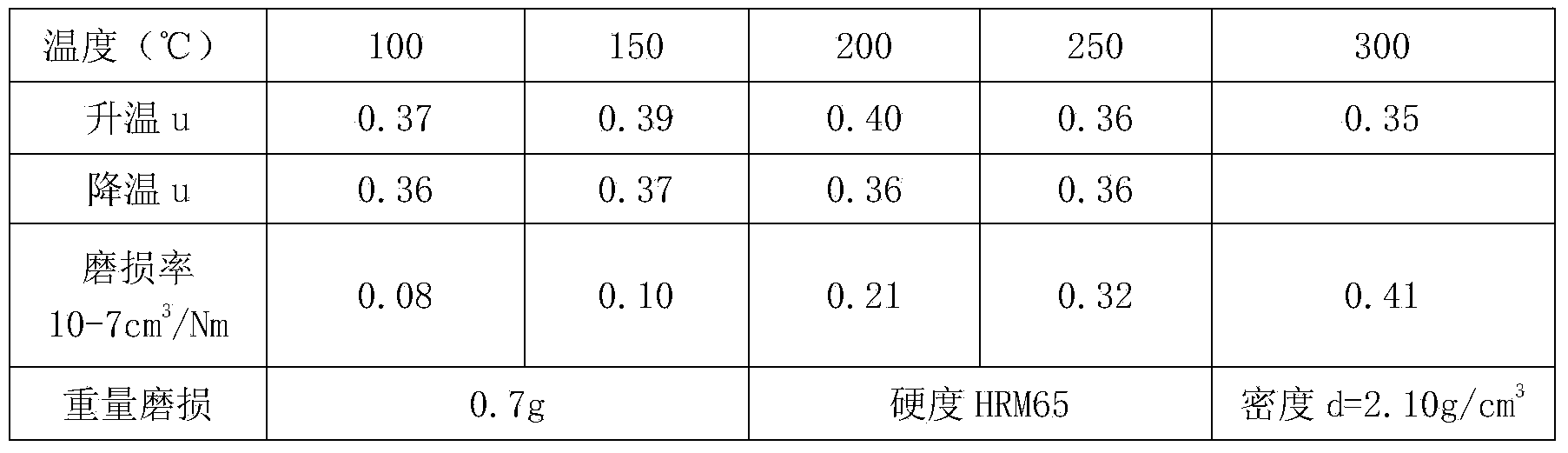

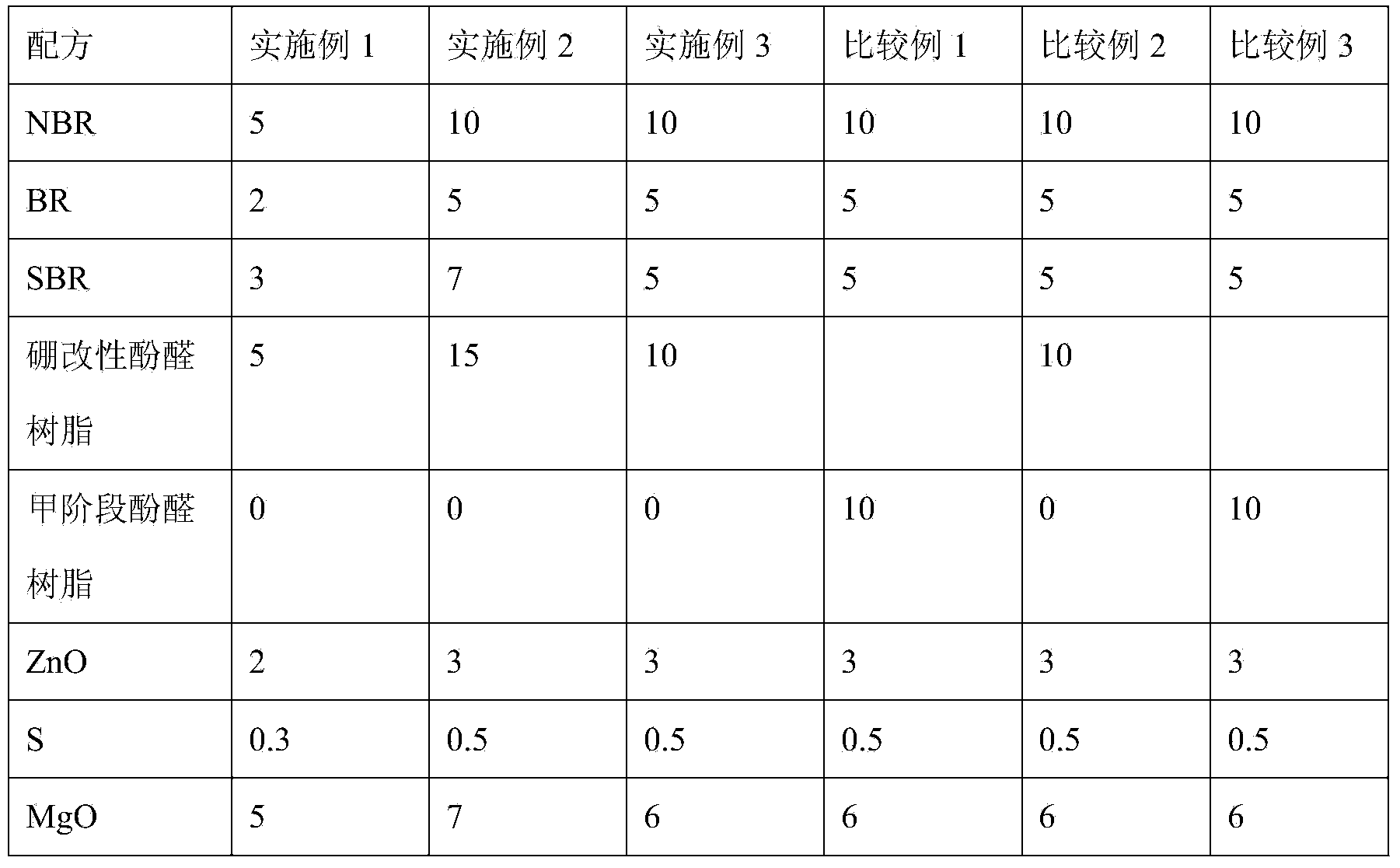

Automobile brake lining and fabrication method thereof

InactiveCN103148139AHigh friction coefficientImprove impact strengthDomestic articlesFriction liningBrake liningAdhesive

The invention provides an automobile brake lining which comprises a friction part and a connecting part, wherein the friction part comprises the following components by mass percentage: 10-20% of adhesive, 25-35% of composite fiber, 2-10% of carbon fiber, 5-10% of glass fiber, 2-10% of aramid fiber, 5-15% of friction increasing agent, 2-15% of friction reducing agent, 20-25% of filler, 1-2% of releasing agent, and 0-5% of colorant. The connecting part comprises the following components by mass percentage: 10-20% of adhesive, 30-40% of composite fiber, 0-15% of mineral fiber, 0-15% of friction increasing agent, 0-15% of friction reducing agent, 30-45% of filler, 1-2% of releasing agent, and 0-5% of colorant. With the adoption of the automobile brake lining, the connection between the brake lining and a brake assembly is firmer and more reliable, the material cost of the connecting part is lowered greatly, and great resource waste caused by replacement of the brake lining is reduced effectively.

Owner:SHANDONG LIANGSHAN SHENLI AUTO PARTS

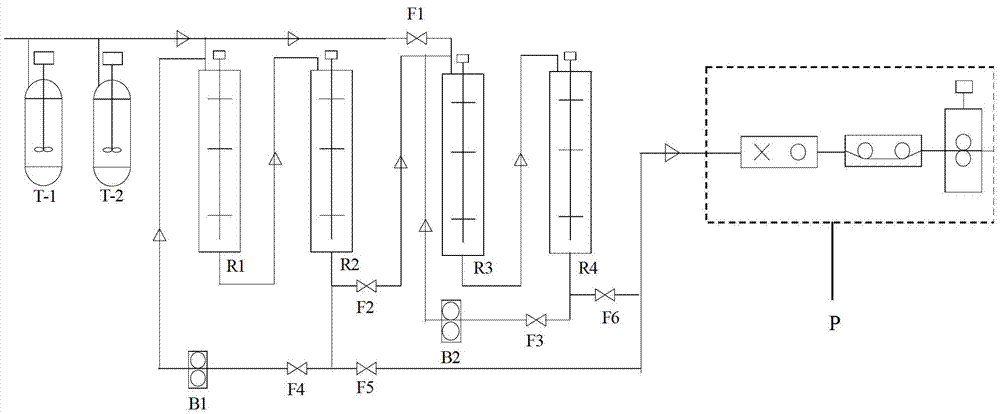

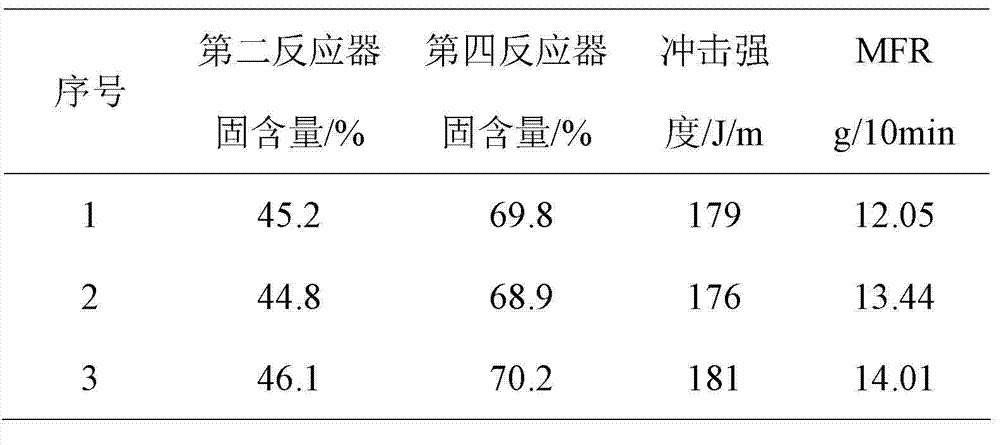

Continuous pipe type flexible plug flow reactor and method for preparing mass ABS resin or SAN resin

ActiveCN103030743ANarrow molecular weight distributionImprove impact strengthChemistryWeight distribution

The invention relates to a continuous pipe type flexible plug flow reactor and a method for preparing mass ABS (acrylonitrile butadiene styrene) resin or SAN (styrene acrylonitrile plastic) resin. The process comprises the following four parts: a raw material preparation system, a polymerization reaction system, a vacuum-pumping system and an extrusion granulation system. The reaction system includes four plug flow reactors and different material loops. The four plug flow reactors can be connected in series for producing the ABS resin with a continuous mass method by controlling the different material loops. One or two double tandem plug flow reactor sets with reflux systems can be also connected in parallel for producing the SAN resin with the continuous mass method. When the SAN resin is prepared, the reflux ratio of the reflux systems of the double tandem plug flow reactor sets is controlled so as to control the polymerization degree of the polymerization reaction of the SAN resin. The ABS or SAN resin products prepared with the flexible device and the production process capable of producing the continuous mass ABS resin or SAN resin have the characteristics of controllable molecular weight, narrower molecular weight distribution, excellent product performance and good device process stability.

Owner:NORTH HUAJIN CHEM IND CO LTD +1

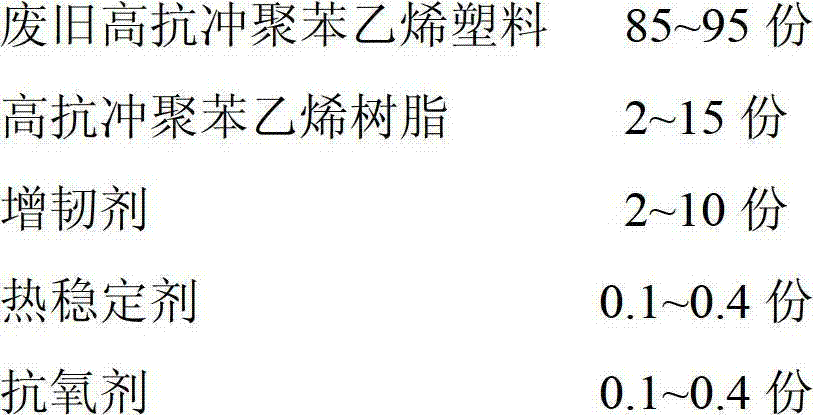

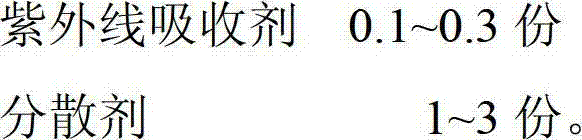

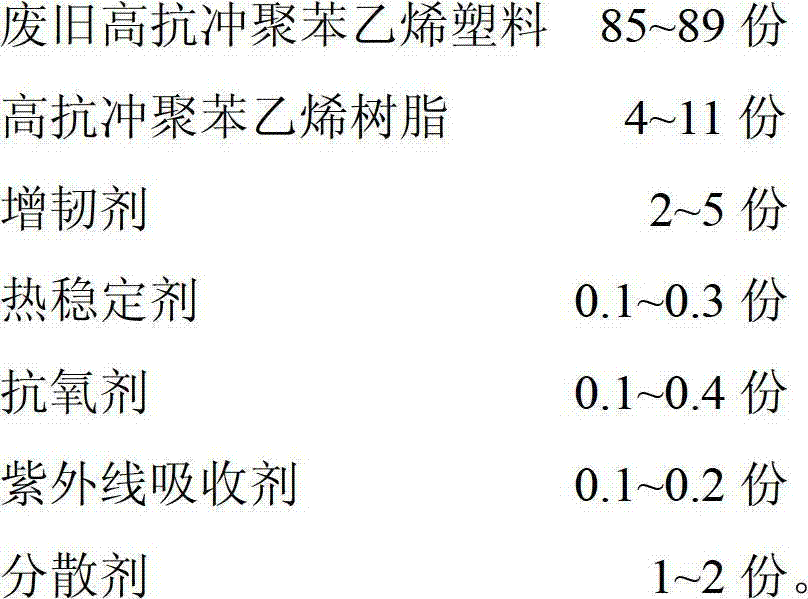

Modified high-impact polystyrene plastic

InactiveCN102786761AImprove impact strengthGuaranteed tensile strength and flexural strengthPlastic recyclingFlexural strengthAntioxidant

The invention relates to the technical field of modification treatment of waste plastics, in particular to modified high-impact polystyrene plastic. The modified high-impact polystyrene plastic comprises, by weight, 85-95 parts of waste high-impact polystyrene plastics, 2-15 parts of high-impact polystyrene resin, 2-10 parts of flexibilizers, 0.1-0.4 part of heat stabilizers, 0.1-0.4 part of antioxidants, 0.1-0.3 part of ultraviolet absorbers and 1-3 parts of dispersing agents. By adding certain quantities of novel high-impact polystyrene and plastic additives, the impact resistance of the waste HIPS (high-impact polystyrene plastic) is increased while the tensile strength and the flexure strength of the plastic are guaranteed, mechanical properties of the plastic reach standards of fresh materials, the waste HIPS plastic can be recovered effectively, and affection to environments is low.

Owner:四川长虹格润环保科技股份有限公司

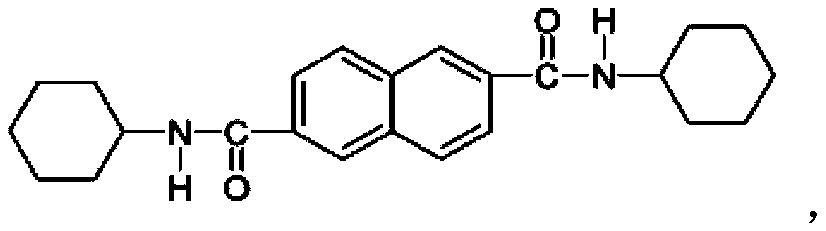

Special high impact resistant polypropylene pipe material

The invention relates to a special high impact resistant polypropylene pipe material, which comprises polypropylene resin, an antioxidant, a halogen absorbent, and a beta crystal form nucleating agent subjected to chemical surface modification. The special beta crystal form polypropylene pipe material is prepared by: mixing the polypropylene resin, the surface modified beta crystal form nucleating agent, the antioxidant and the halogen absorbent evenly, and carrying out extrusion granulation. The special polypropylene pipe material has greatly improved impact strength, especially the low temperature impact resistance, and at the same time, the tensile strength and the bending modulus retention rate are high, thus well achieving comprehensive balance of rigidity and toughness.

Owner:CHINA PETROLEUM & CHEM CORP +1

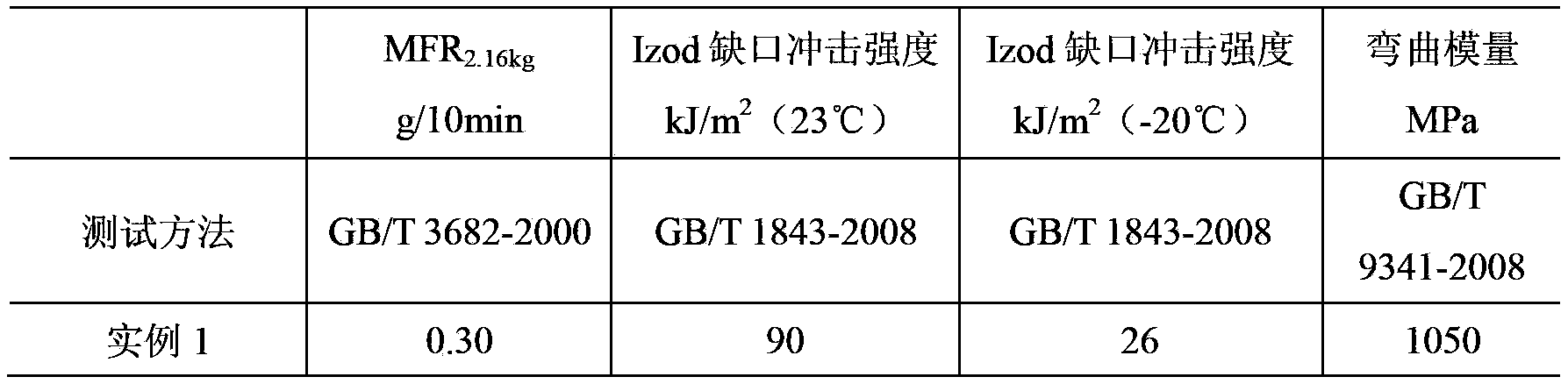

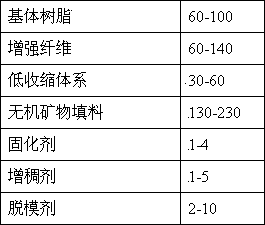

Toluene diisocyanate (TDI)-thickening-modified BMC (Bulk Molding Compound) material and preparation method thereof

The invention discloses a toluene diisocyanate (TDI)-thickening-modified BMC (Bulk Molding Compound) material and a preparation method thereof. The BMC material is prepared from vinyl resin, reinforcing fibers, a low-shrink agent, inorganic mineral filler, a curing agent, a thickener, a demolding agent and the like. The thickener is TDI which is commonly-used polyisocyanate, is white liquid, is easy to disperse and can be excellently blended with unsaturated polyester resin, the viscosity of resin paste can be lowered effectively, and then, the immersion of glass fibers is facilitated. The method comprises preparing the resin paste and kneading, and the prepared BMC material has the characteristics of low shrinkage, high impact strength and high toughness and can be applied to the fields of automobiles, buildings, electronics, electrical appliances and the like.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

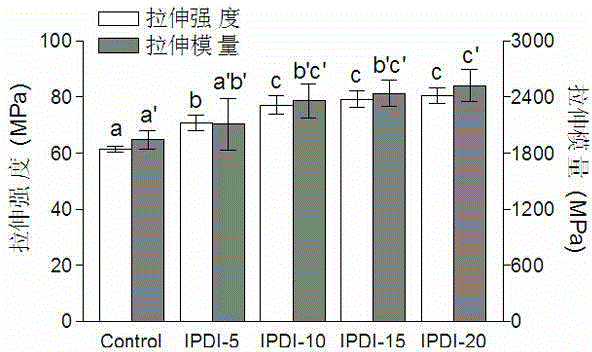

Plant fiber reinforced modified soy-based resin composite material

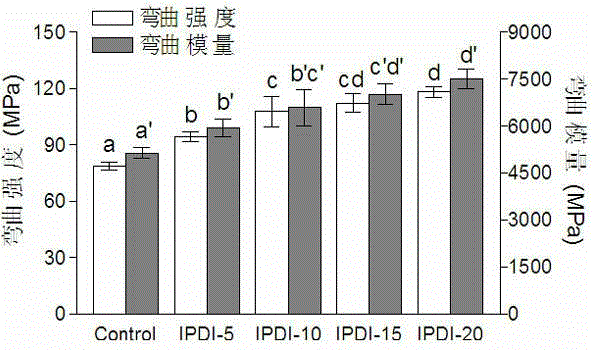

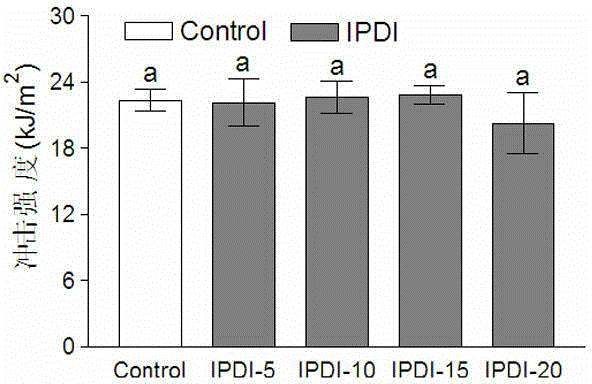

ActiveCN104448793AImprove impact strengthImprove mechanical propertiesSynthetic resin layered productsLaminationChemistryResin composite

The invention discloses a plant fiber reinforced modified soy-based resin composite material and a preparation method thereof. Cross-linking agents and epoxidized soybean oil acrylate are blended to prepare soy-based resin, the soy-based resin is modified by modifiers to obtain modified soy-based resin, and plant fibers, the modified soy-based resin and initiators are hot-pressed to obtain the plant fiber reinforced modified soy-based resin composite material. The plant fiber reinforced modified soy-based resin composite material has excellent tensile strength, tensile modulus, bending strength, bending modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

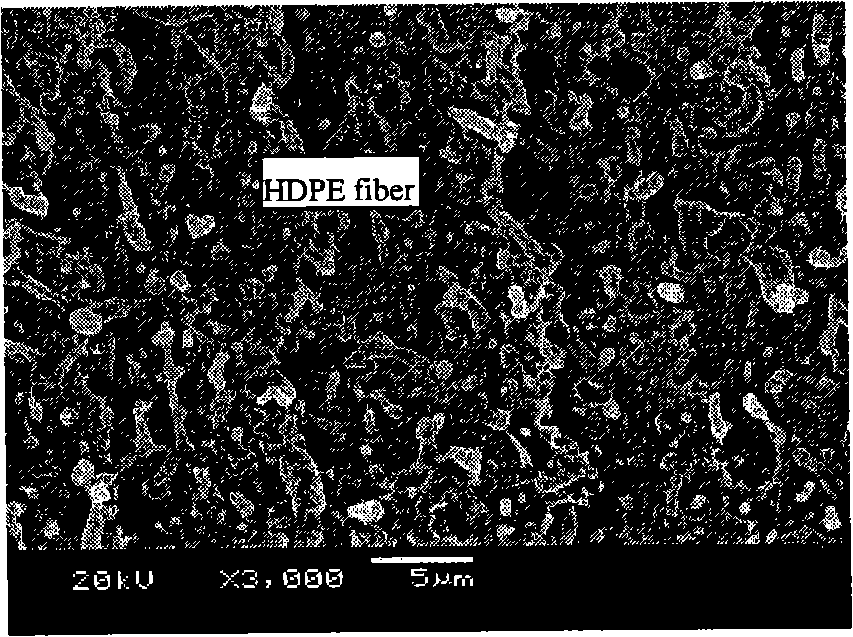

Organic fiber reinforced polypropylene composite material and LFT-D forming process thereof

InactiveCN106009246AImprove impact strengthAchieving a balance of rigidity and toughnessFibre reinforcementPolypropylene composites

The invention discloses an organic fiber reinforced polypropylene composite material and an LFT-D forming process thereof. The polypropylene composite material is formed by compounding of a polypropylene composition and organic fiber, and the polypropylene composition is prepared from the following components by weight: 80-100 parts of polypropylene, 0.1-3 parts of a compatilizer, 0.1-0.5 part of an antioxidant, and 0-20 parts of other assistants. The LFT-D forming process of the organic fiber reinforced polypropylene composite material includes: subjecting a polypropylene composite material to melting plastification by a first-order screw extruder, then subjecting the treated polypropylene composite material and organic fiber together to melting plastification again, then performing block cutting, and finally putting the block melt into a die to conduct die pressing, thus obtaining a finished product. The LFT-D production process of the organic fiber reinforced polypropylene has short forming cycle, and the formed product has the advantages of complex structure, large size, high strength, and good toughness.

Owner:HEFEI GENIUS NEW MATERIALS

High-temperature resistant composite type function brake shoe and production method thereof

ActiveCN104059260AImprove impact strengthReduce labor intensityBraking membersDecompositionCarbon black

The invention provides a high-temperature resistant composite type function brake shoe with excellent metal adhesiveness. Phenolic resin and white carbon black are adopted for promoting an H system to generate a synergistic effect, so that adhesiveness of the brake shoe and a steel backing is improved. The phenolic resin is boron-modified phenolic resin, due to the fact that a B-O bond is contained in the resin, heat resistance of the resin is improved, escape of low molecular materials and gas in the friction process can be reduced through increase of decomposition temperature, the phenomenon of heat fading is avoided, and friction is stable.

Owner:扬中市检验检测中心

Method for preparing nano ceric oxide/epoxy resin composite material

The invention relates to a method for preparing a nano ceric oxide / epoxy resin composite material and belongs to the technical field of preparation processes for nano inorganic rare earth oxide and organic resin composite materials. The method mainly comprises the following steps: mixing nano ceric oxide and an organic solvent and uniformly dispersing the nano ceric oxide, wherein the weight volume ratio of using amount of the nano ceric oxide to the organic solvent is 1:5-1:30 (g / ml); pre-processing a certain amount of epoxy resin by heating the epoxy resin for 4 to 8 hours at the temperature of 80 to 120 DEG C under vacuum, adding the nano ceric oxide into the heated epoxy resin, and processing the mixture by ultrasonic waves; processing the mixture for 10 to 24 hours at the temperature of 50 to 120 DEG C in a vacuum oven; and adding a certain amount of curing agent into the mixture to cure the mixture for 24 hours or raising the temperature at the temperature of 80 to 160 DEG C section by section to cure the mixture to obtain the nano ceric oxide / epoxy resin composite material. In the method, the content of the nano ceric oxide in the composite material is 0.5 to 5 weight percent; and the nano ceric oxide is uniformly dispersed, so the mechanical properties of the composite material are relatively good.

Owner:SHANGHAI UNIV

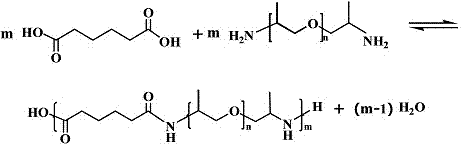

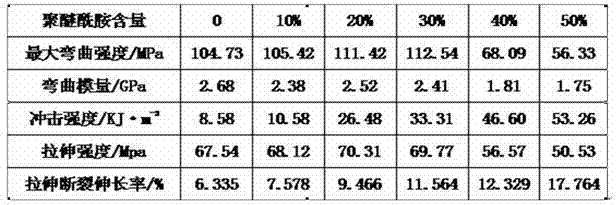

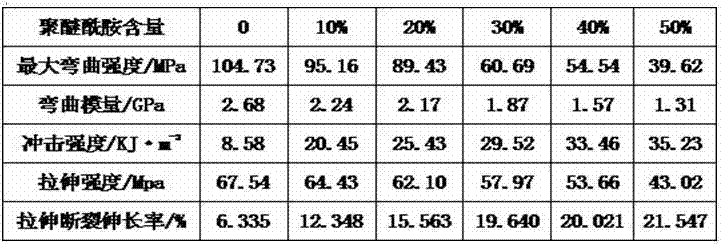

Polyetheramide toughened epoxy resin

The present invention provides a polyetheramide-containing epoxy resin composition and a preparation method thereof, and relates to the technical field of epoxy resin toughening modification. The epoxy resin composition comprises an epoxy resin, polyetheramide, a curing agent, a promoter, and a solvent or a diluent, wherein amino-terminated polyether and a dibasic acid are polymerized at a high temperature to obtain the polyetheramide, and a ratio of the total mass of the polyetheramide to the total mass of the epoxy resin is (1-90):100. According to the present invention, the impact strength of the epoxy resin composition containing different molecular weights or different contents of the polyetheramide can be remarkably improved after the curing, and optimally the improving can achieve more than 500%; and by rationally adjusting the ratio of the polyetheramide to the epoxy resin, the toughness of the epoxy resin can be well improved while the strength of the resin can be ensured so as to broaden the application field of the epoxy resin.

Owner:HUNAN NORMAL UNIVERSITY

Nano-composite material containing organic sepiolite and its preparation method

The present invention relates to a nano composite material containing organic sepiolite and its preparation method. It is technically characterized by that its main components are organic sepiolite, epoxy resin and solidifying agent. Its preparation method includes the following steps: making crude sepiolite undergo the process of organization treatment, adding organic exchange agent, mixing organic sepiolite and epoxy resin according to the ratio of 1-10:100, and adopting melting intercalation polymer method to prepare invented product. The described epoxy resin can adopt liquid bisphenol A, glycidyl ether type, glycidyl ester type, glycidyl amine type, alicyclic epoxide or linear type fatty epoxide, etc.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

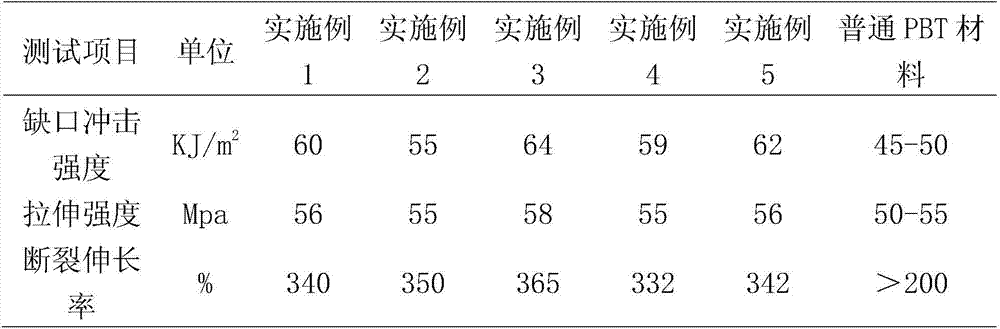

PBT material and preparation method thereof

The invention relates to a PBT material and a preparation method thereof, belonging to the technical field of high polymer materials. The PBT material comprises the following raw materials by weight: 55 to 75% of polybutylene telephthalate, 15 to 35% of TPEE, 0.2 to 1.0% of calcium carbonate, 2.0 to 5.0% of 1,4-butylene glycol, 0.5 to 2.0% of an anti-oxidant, 0.5 to 3.0% of dicumyl peroxide, 2.0 to 5.0% of a cross-linking agent, 0.2 to 1.5% of a light stabilizing agent and 0.2 to 1.0% of an anti-hydrolysis agent. The invention also discloses the preparation method for the PBT material. According to the invention, TPEE and the anti-oxidant 1010 are used for the PBT material, so the prepared PBT material has good elasticity and improved impact strength, toughness and ageing resistance, and thus, the PBT material has more excellent mechanical and machining properties, enables a product to have prolonged service life and better stability and is widened in the application scope; the PBT material and the preparation method overcome the technical problem that the mechanical strength of conventional PBT resin cannot meet usage requirements after toughening; and the preparation method is simple in process and easy to realize industrial production.

Owner:XINJIANG BLUE RIDGE TUNHE POLYESTER CO LTD

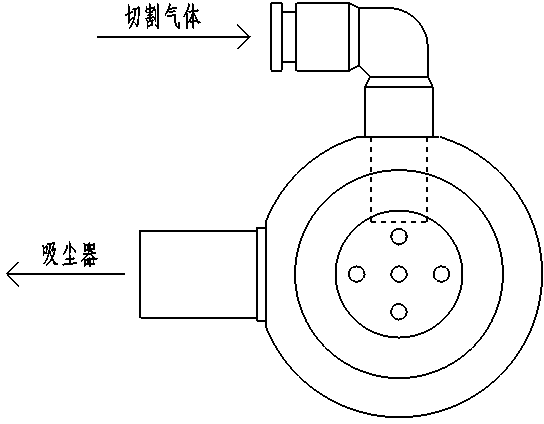

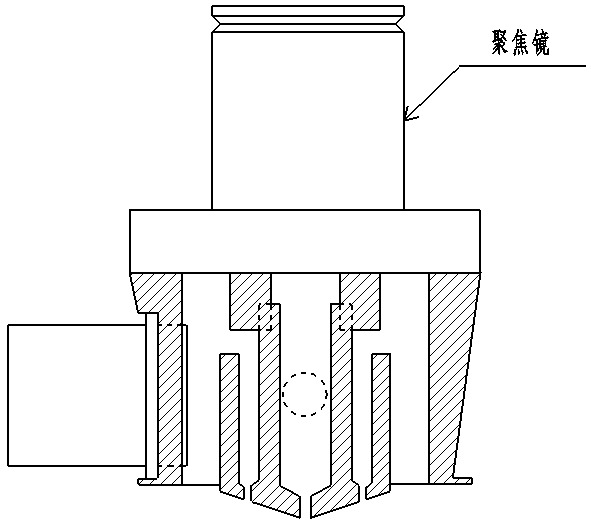

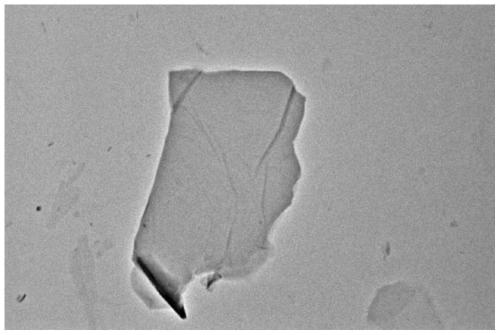

Fiber laser device and cutting method for cutting sapphire glass

InactiveCN103586588AImprove impact strengthAccelerateGlass severing apparatusLaser beam welding apparatusCutting-plane methodWear resistant

The invention discloses a fiber laser device and a cutting method for cutting sapphire glass. According to the fiber laser device, a single-mode continuous pulse fiber laser for cutting a mouth is arranged at an emitting outlet of the laser device. The cutting method includes the following steps that firstly, the sapphire glass with the surface coated by absorbing agents is placed on a jig, and the height of a cutting head is debugged according to the thickness of the sapphire glass; secondly, the pressure of cutting gas is debugged; thirdly, the focusing height, the speed, the pulse width and the power of the device are debugged; fourthly, laser beams of a single-mode continuous pulse are focused in a high power mode and vertically emitted to the surface of a sapphire glass sample to be processed; fifthly, the sapphire glass is cut. With the cutting method flaws of processed products and the processing cost can be greatly reduced. Produced sapphires are high in electrical performance, wear-resistant and free of sticking of films and other coatings.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

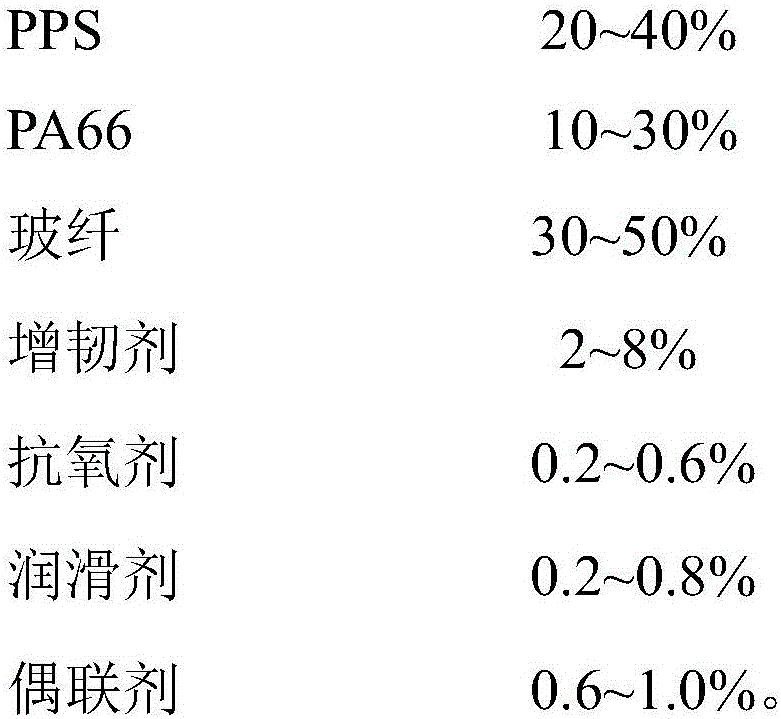

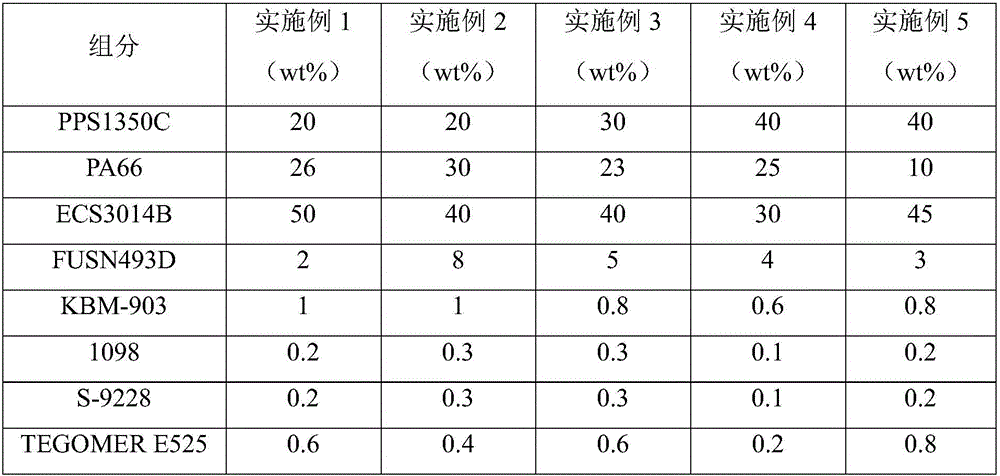

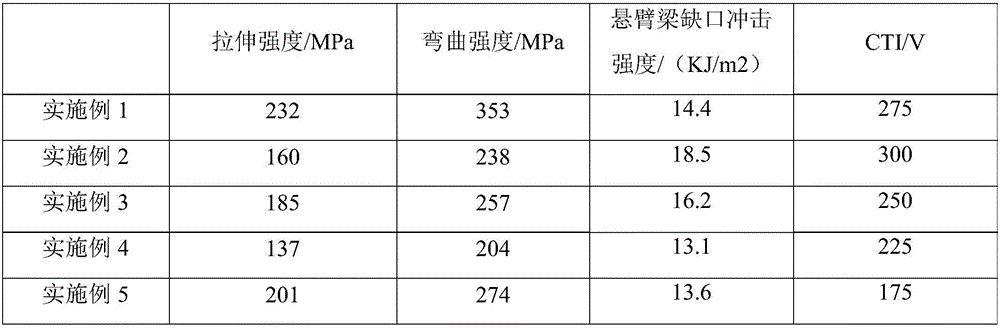

Polyphenylene sulfide composite material with high impact and high CTI and preparation method and application thereof

The invention belongs to the field of modified plastics, particularly discloses a polyphenylene sulfide composite material with high impact and high CTI, a preparation method and application thereof. the composite material is prepared from polyphenylene sulfide, nylon 66, toughening agent, glass fiber, antioxidant, lubricating agent and coupling reagent. Aiming at the defect that PPS resin is prone to tracking failure, PA66 resin with high CTI is added, and the addition of PA66 not only improves the CTI of the PPS composite material, but also improves the impact strength of the PPS composite material, and the PPS composite material with high impact and high CTI is obtained through further toughening effect of PA66 high-efficiency toughening agent. According to the preparation method, the operation is simple, the obtained PPS composite material with high impact and high CTI is low in cost, and has a very good prospect for popularizing in the market. The composite material has excellent impact resistance and excellent tracking failure resistance, and can be used in electrical and electronic and other related fields where the above performance requirements are higher.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Modified polypropylene complex with low warpage and high impact strength and preparation method of modified polypropylene complex

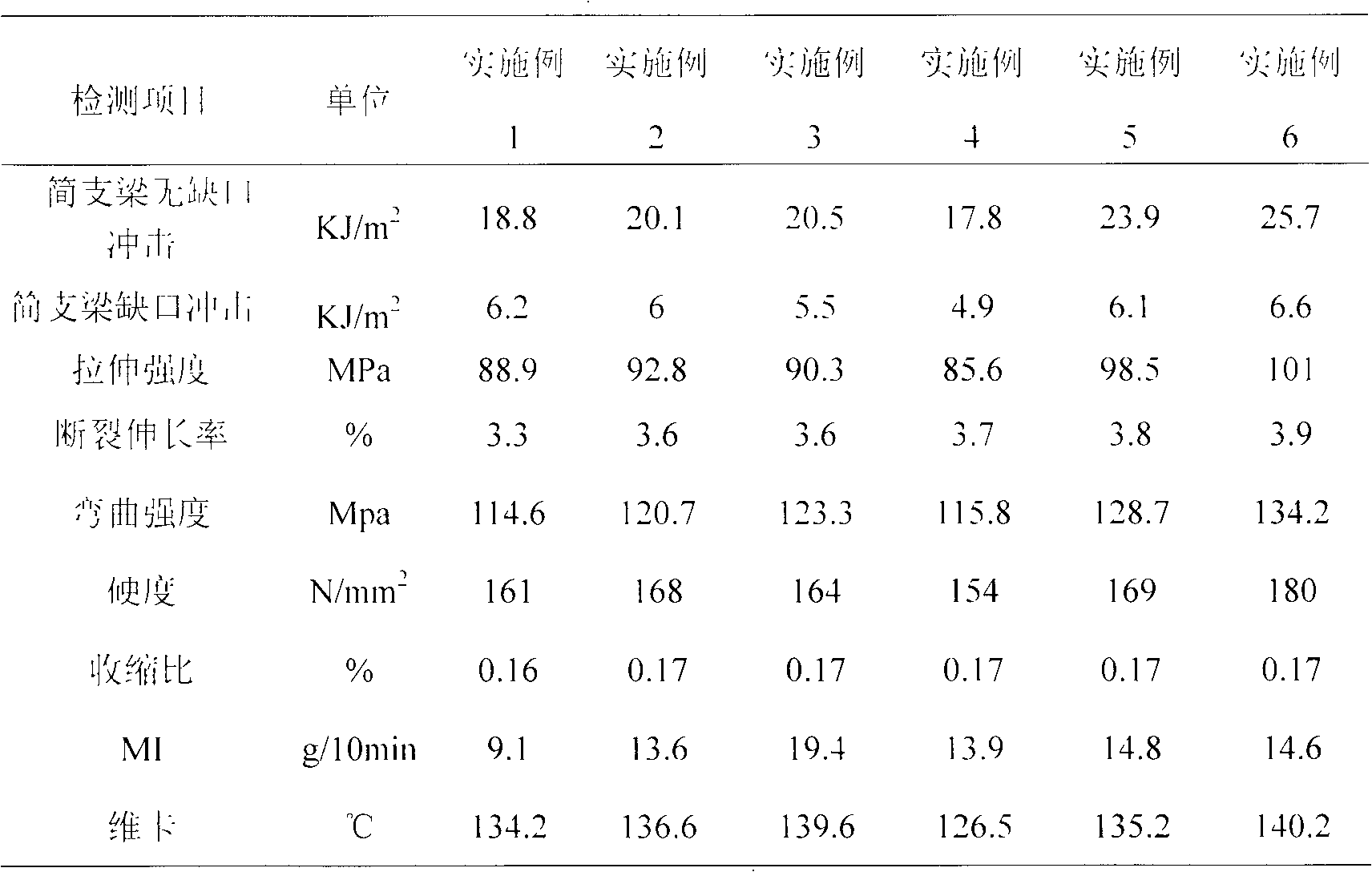

The invention relates to the field of polymer plastic modification, and discloses a modified polypropylene complex with low warpage and high impact strength and a preparation method of the modified polypropylene complex. The modified polypropylene complex with the low warpage and the high impact strength is prepared from the following components in percentage by weight: 50-75% of polypropylene, 3-10% of a beta-modified mica modifier, 10-20% of modified alkali-free flat fiberglass, 5-10% of a flexibilizer, 5-9.5% of a compatibilizer, 0.1-0.6% of an antioxidant, and 0.2-0.9% of other auxiliaries. According to a prepared product, the simply supported beam notched impact strength can reach 36 KJ / m<2> or above, the bending modulus can reach 3000 MPa or above, meanwhile, the product further hasgood fluidity and low warping performance, and the product can be applied to large workpieces with high strength requirements.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

High-heat resistance and high-weatherability material specially for heat radiation grid

The invention discloses a high-heat resistance and high-weatherability material specially for a heat radiation grid, and a preparation method thereof. The high-heat resistance and high-weatherability material specially for a heat radiation grid is prepared from main raw materials of 20 to 70 parts of an acrylonitrile-styrene-acrylate copolymer (ASA), 20 to 50 parts of polybutylene terephthalate (PBT) and 10 to 30 parts of long glass fibers (GF), and additives of appropriate amounts of one or more compatilizers, a glass fiber rich surface resistant agent, one or more lubricants, a dispersing agent, one or more antioxidants and a coupling reagent. The raw materials are weighted according to the ratio and are blended and extruded by a twin-screw extruder to form an ASA / PBT / GF composite material. The invention provides the ASA / PBT / GF composite material having good heat resistance, chemical resistance and weather resistance. Compared with common ABS or PC / ABS and PC / PET alloys used for automobiles, the ASA / PBT / GF composite material has the advantages of high heat resistance, high weatherability, high chemical resistance, easy coloring and low cost, and is particularly popular with clients.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Antistatic functional masterbatch, production process thereof, and production process of polyethylene pipes

The invention relates to an antistatic functional masterbatch, comprising, by weight, 15-30% of superconducting carbon black, 0.1-10% of a lubricant, 0.5-5% of a coupling agent, 3-11% of a dispersant, and 30-80% of linear low-density polyethylene (LLDPE). The antistatic functional masterbatch has the advantages that the addition of the antistatic functional masterbatch produced through the process to coal mine polyethylene pipes may be decreased to 18-25% so that impact strength of the mine pipes is greatly improved which is 24% higher, and product cost is greatly lowered; by using the process, a processing scheme is provided particularly for the production of antistatic functional masterbatch with pigment carbon black; the antistatic functional masterbatch produced through the process is mixed well with 75% high-density polyethylene DGDB2480 to produce coal mine polyethylene pipes, the surface resistance of the pipes may reach 2.5*10<5> Omega, with breaking elongation reaching 520%, both the surface resistance and the breaking elongation meet the standard requirements, and the pipes have smooth surface and high brightness.

Owner:SHANDONG DONGHONG PIPE IND

Ivory tint handicraft wood fan blank bleaching technique

InactiveCN1528575AColor fast to lightImprove impact strengthUmbrellasWood treatment detailsChemistryMetal

The invention is an ivory technical wooden fan blank bleaching technique, technical steps: (1), weight percent of each component in bleacher solution: 20-50% concentration oxydol 0.93457-0.71428, 5-30% concentration sodium hydroxide solution 0.01869-0.21428 and industrial alcohol 0.04674-0.071428; (2), bleaching: soaking separated fan blanks in the oxydol and sodium hydroxide solution for 5-10 hours, and fan edge in the oxydol, sodium hydroxide solution and alcohol solution for 10-12 hours; (3), washing: washing qualified fan blanks and edges by clear water to eliminate the solutions; (4)separating: making the fan blanks and edges whose whiteness is lower than 70% repeat the step (2); (5), drying: cold-placing the fan blanks and edges to dry, where water ratio is up to 12-14%. It keeps original property of timber, strong color lightfastness, etc.

Owner:NANJING FORESTRY UNIV +1

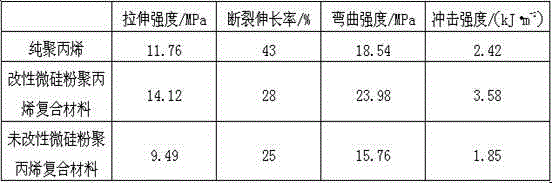

Preparation method of silica fume polypropylene composite material

The invention relates to a preparation method of a silica fume polypropylene composite material, and relates to the field of polypropylene material preparation. Aiming at problems of easy low-temperature embrittlement and poor impact resistance of current polypropylene, the invention provides the silica fume polypropylene composite material with significantly improved mechanical properties. According to the preparation method, silica fume is used as inorganic particles for filling polypropylene; and silica fume is subjected to surface modification with a silane coupling agent Si69. The preparation method comprises the steps of 1, silica fume pretreatment and 2, composite material preparation. The preparation method and process are simple. The mechanical properties of the prepared silica fume polypropylene composite material are significantly improved. The silica fume polypropylene composite material has a good application prospect.

Owner:贺灿辉

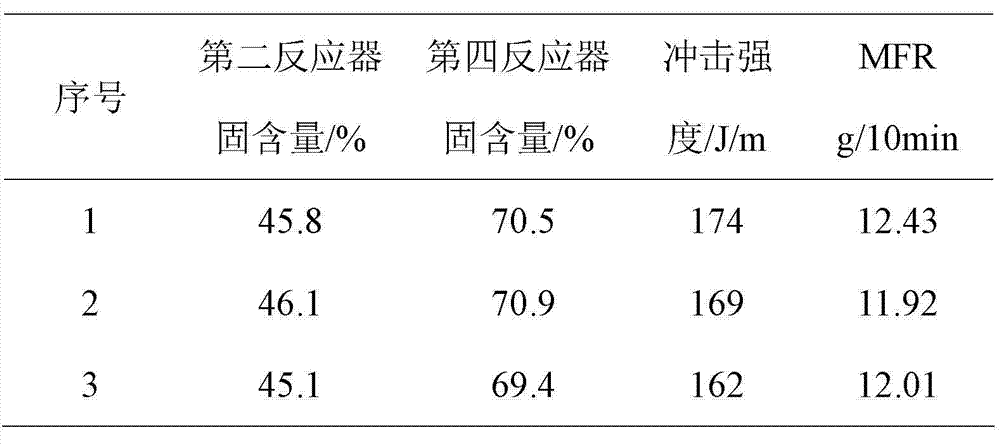

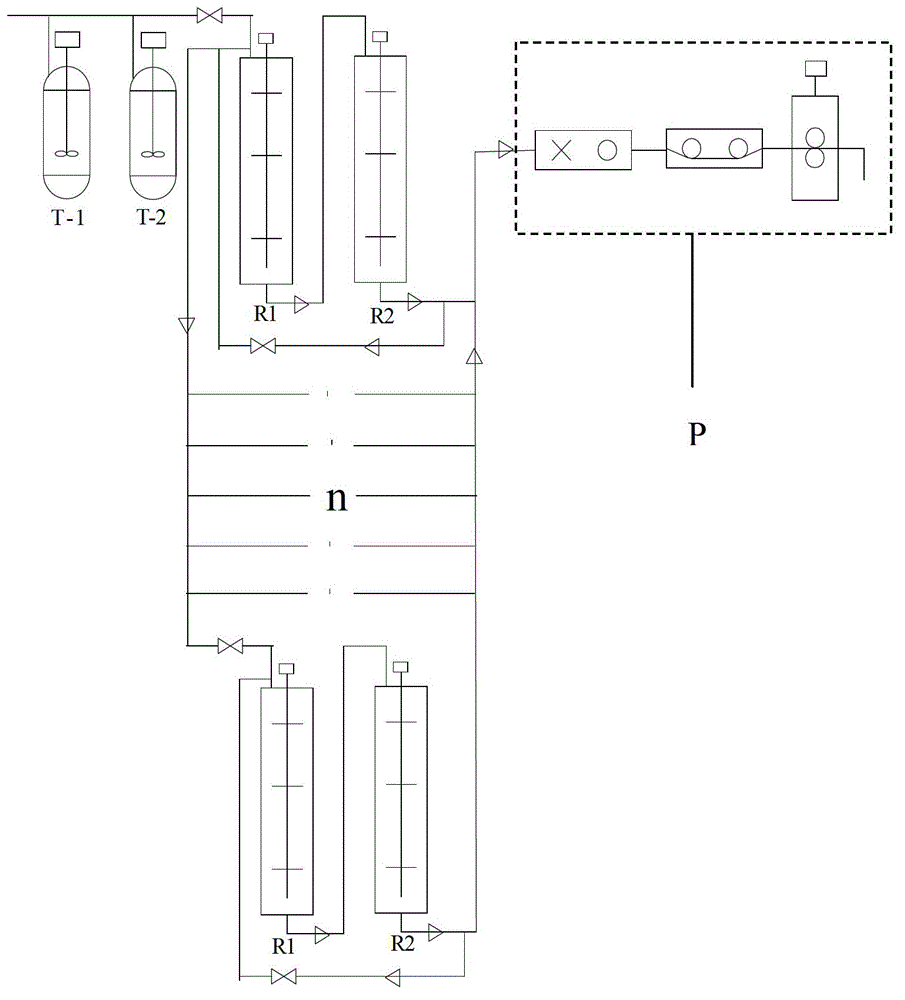

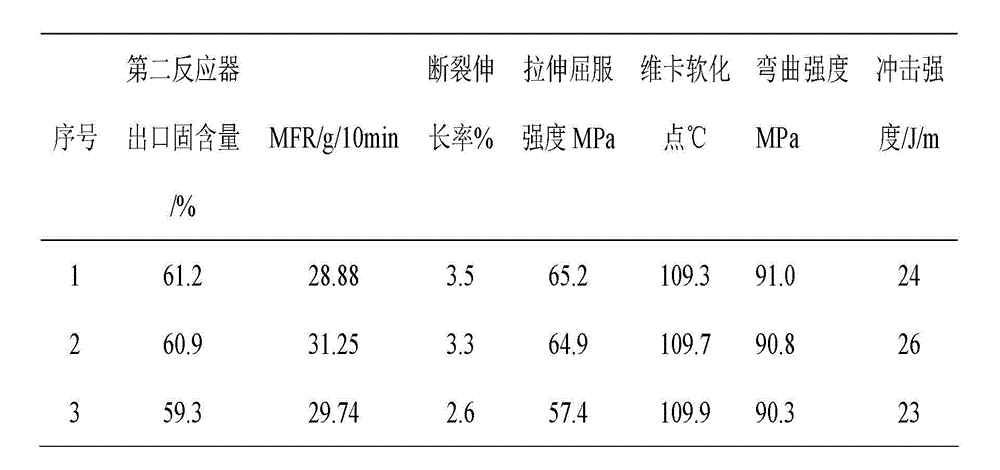

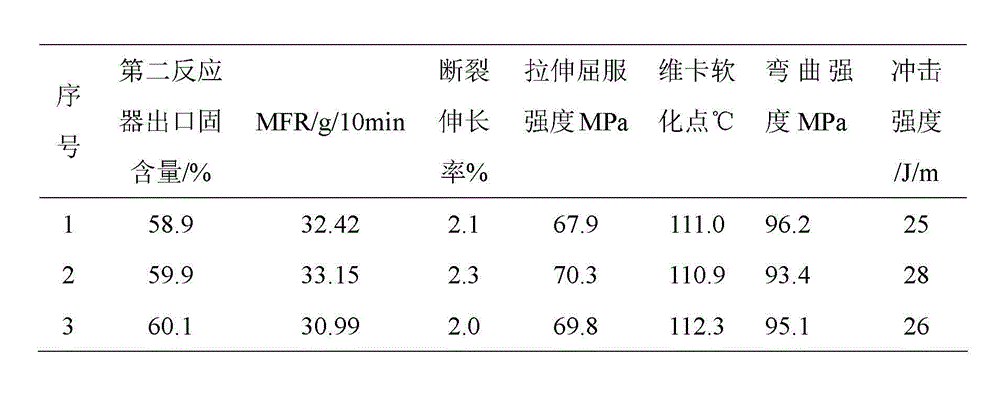

Continuous tubular plug flow reactor and preparation method for preparing continuous bulk SAN (Styrene-Acrylonitrile) resin

ActiveCN102977246ANarrow molecular weight distributionImprove impact strengthWeight distributionChemistry

The invention relates to a continuous tubular plug flow reactor and a preparation method for preparing continuous bulk SAN (Styrene-Acrylonitrile) resin. The two-stage continuous tubular plug flow reactor for producing the SAN resin has the process advantages that material staying time is consistent, the product has uniform molecular weight, good color appearance and excellent performance, and the production process is free of a wall hanging phenomenon. The two-stage continuous tubular plug flow reactor system which is connected in parallel in a multiple manner is adopted, so that the yield of the product can be increased by increasing the quantity of the parallel-connected two-stage continuous tubular plug reactors. The two-stage continuous tubular plug flow reactors which can be connected in parallel in a multiple manner have completely consistent process conditions, the materials are in similar parallel flow, the staying time is consistent, the production process is simple, the process is compact, the molecular weight distribution of the SAN resin is narrow, and the process is green and environment-friendly. The two-stage continuous tubular plug flow reactors are connected in series, so that the material at the outlet of the second reactor is controlled to circulate and reflow to the inlet of the first reactor for keeping good stability of the polymerization system.

Owner:NORTH HUAJIN CHEM IND CO LTD +1

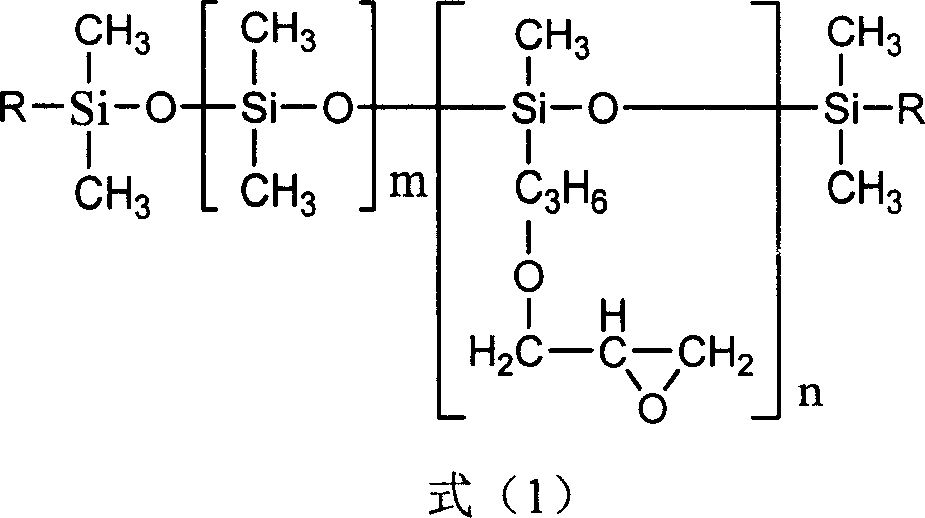

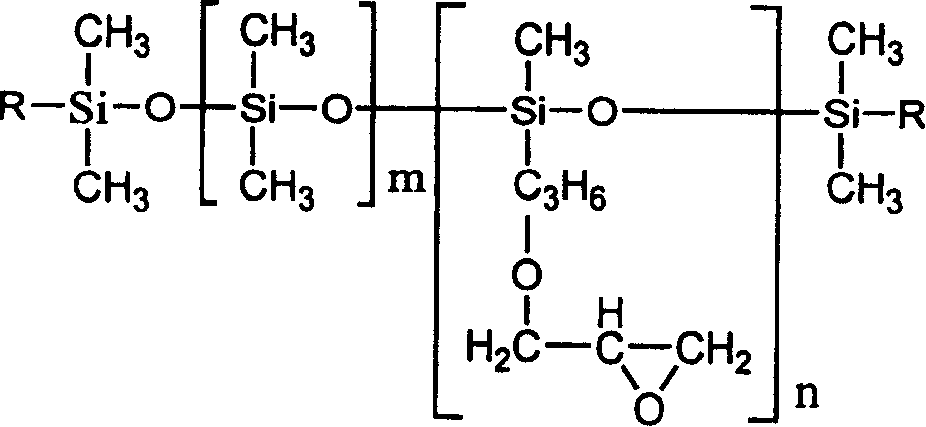

Epoxidation silicon oil modified three kinds of composite material of epoxy resin

This invention involves three processes for preparing epoxy resin composites modified with epoxy silicone oil, characteristic of mixing epoxy silicone oil with epoxy resin followed by solidification with the solidified agent to obtain epoxy resin composites modified with epoxy silicone oil. The first process is mixing epoxy silicone oil with epoxy resin directly; the second process is modifying epoxy silicone oil with the solidified agent and then mixing with epoxy resin; and the third is mixing coupled epoxy silicone oil with epoxy resin, thus obtaining three new epoxy resin composites modified with epoxy silicone oil. Compared with unmodified epoxy resin, these three epoxy resin composites exhibit higher impact strength, tensile strength, rupture extension rate and vitrification temperature, and thus can be used as high-performance materials, e.g., paints, structural adhesives and electronic packaging materials.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

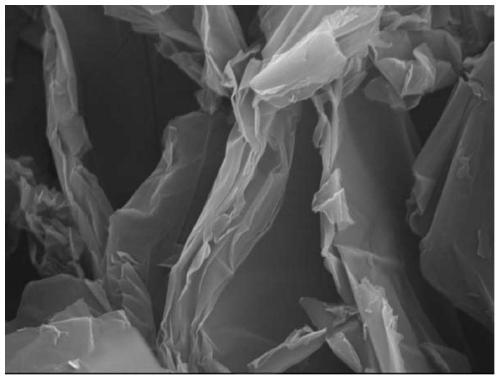

Preparation method of aminated graphene oxide

PendingCN111232967ADispersion effect is stableImprove impact strengthCarbon compoundsChemistryGraphite oxide

The invention relates to a preparation method of aminated graphene oxide, which solves the technical problem of different sizes of material lamellas prepared by the existing preparation method, and comprises the following steps: weighing graphite flakes, and preparing graphene oxide dispersion liquid from the graphite flakes by an improved Hummers method; performing cell disruptor treatment and ultrasonic treatment on the obtained graphene oxide dispersion liquid, and performing freeze drying to obtain graphene oxide powder; adding the obtained graphene oxide powder into an organic solvent, carrying out ultrasonic treatment, and then adding a small molecular amine compound and a dehydration condensing agent for treatment; and carrying out centrifugation and suction filtration on the reaction product through a centrifuge to obtain aminated graphene oxide dispersion liquid with different lamellar sizes, and carrying out freeze drying to obtain aminated graphene oxide powder. The preparation method can be used for preparing aminated graphene oxide.

Owner:BEIJING UNIV OF CHEM TECH

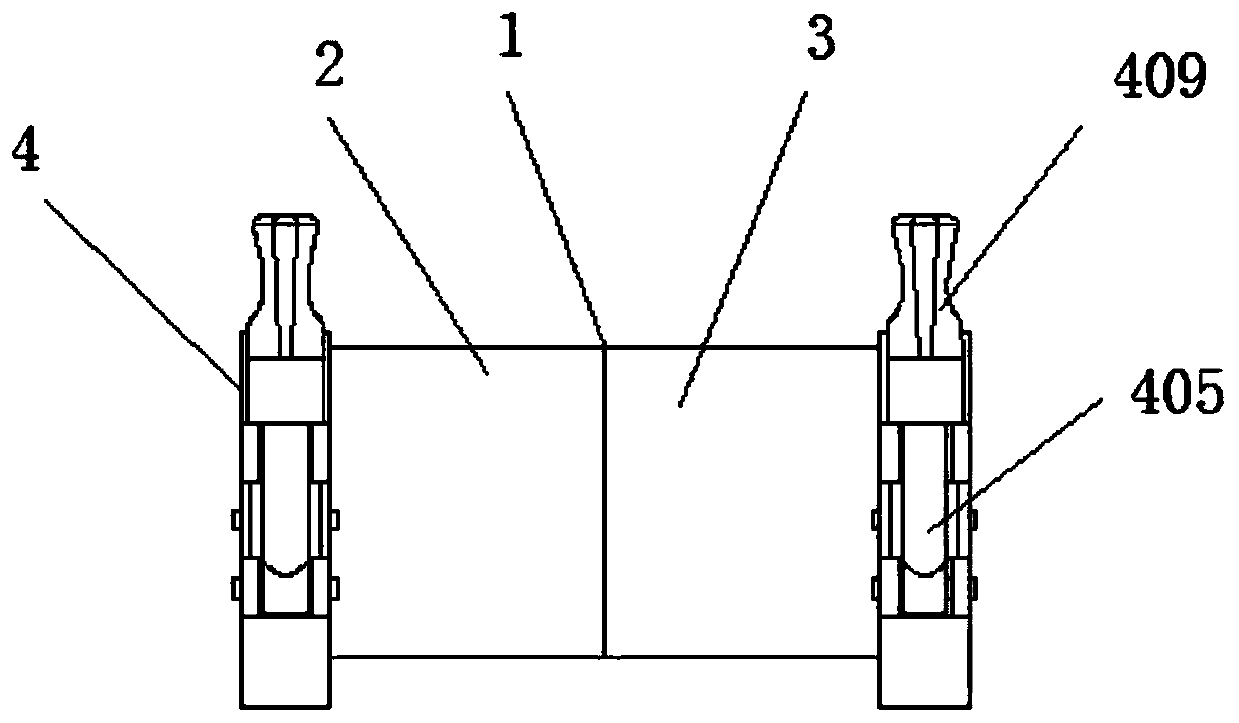

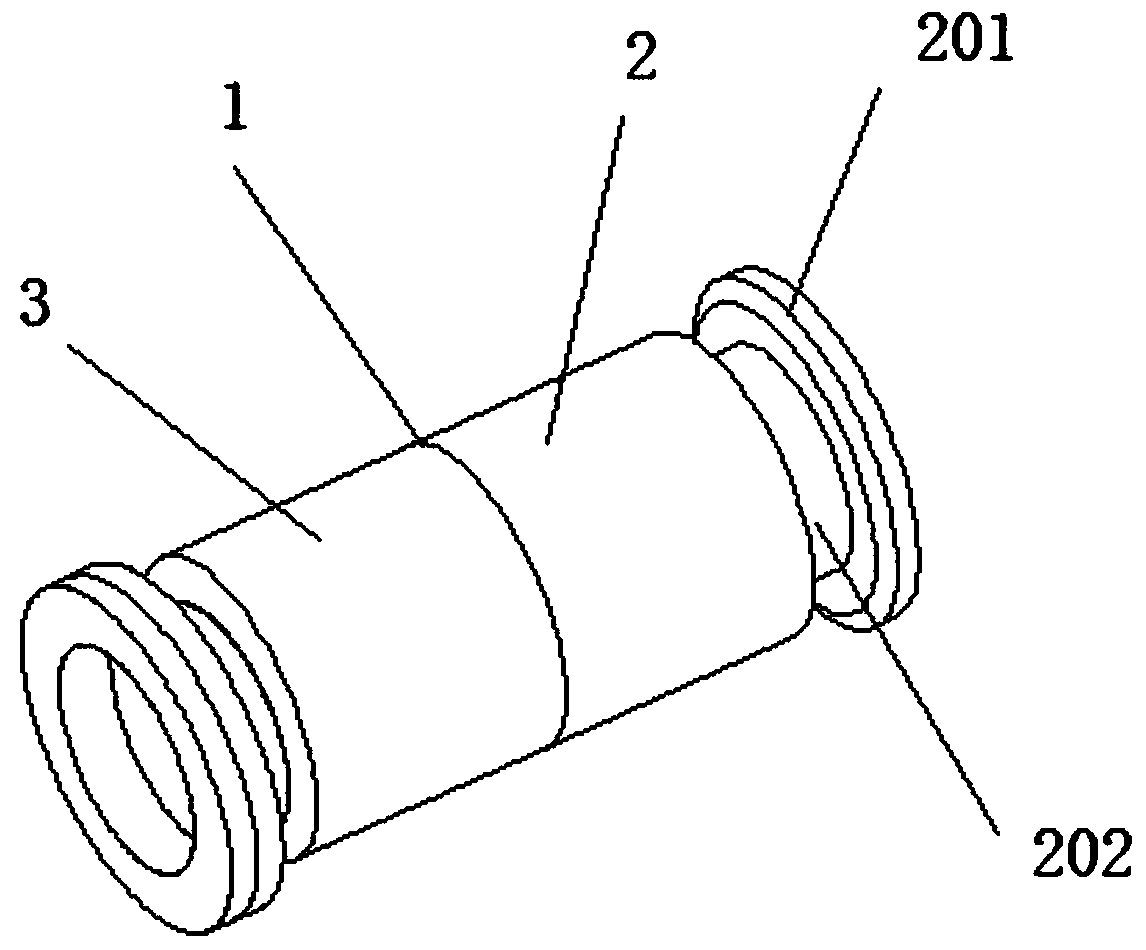

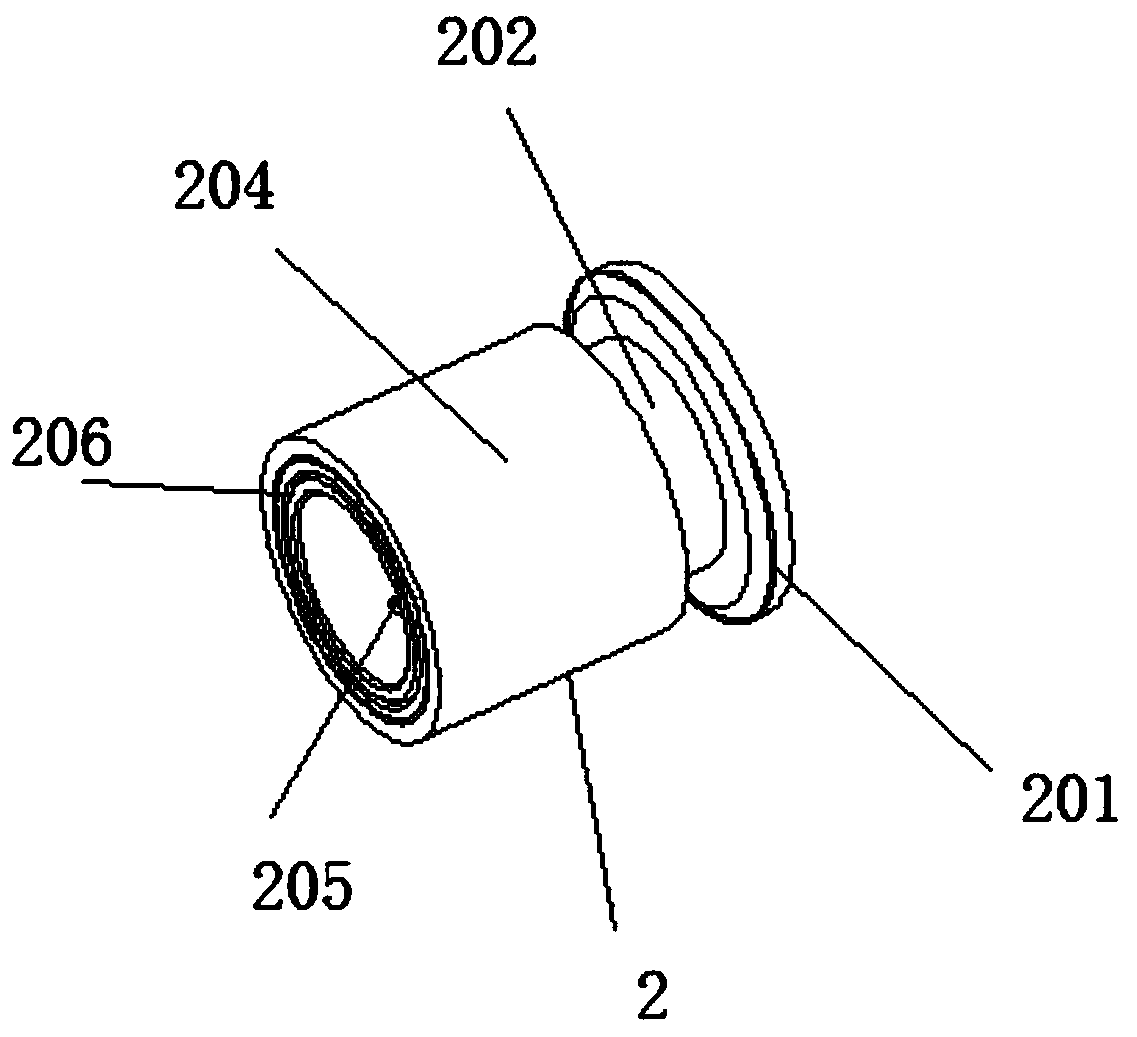

MPP power cable protection pipe, and connection assembly of protection pipe

InactiveCN110760127AImprove mechanical propertiesImprove impact strengthCable installations in underground tubesPolypropyleneCalcium carbonate

The invention discloses an MPP power cable protection pipe, and a connection assembly of the protection pipe. The MPP power cable protection pipe comprises the following raw materials in parts by weight: 70-80 parts of polypropylene, 15-20 parts of ultra-high molecular weight polyethylene, 6-8 parts of nano calcium carbonate, 3-5 parts of modified talc powder, 3-5 parts of glass fiber, 1-2 parts of a coupling agent, 2-3 parts of an antibacterial agent, 3-5 parts of a plasticizer, 1-3 parts of an antioxidant, and 1-2 parts of a compatibilizer. Polypropylene as a matrix, and the added ultra-highmolecular weight polyethylene and modified talc powder are used as a preparation base material of the MPP power cable protection pipe, and the rose crystalline nanometer calcium carbonate and other processing aids are matched to form a multi-dimensional MPP power cable protection pipe material. The connection assembly of the MPP power cable protection pipe comprises a connection sleeve body and fixing sleeves, and the connection operation of the MPP power cable protection pipe is simple and fast through the connection assembly, so that the fast construction of a power cable in the power engineering is facilitated.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Glass fiber reinforced NPG-PETG transparent composite material and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to a glass fiber reinforced NPG-PETG transparent composite material and a preparation method thereof. The glass fiber reinforced NPG-PETG transparent composite material is prepared from, by weight, 50-95 parts of NPG-PETG, 5-50 parts of modified glass fiber, 0.1-3 parts of an antioxidant and 0.3-2 parts of a lubricant; the NPG-PETG used in the invention is prepared by esterification and polycondensation of three monomers of neopentyl glycol (NPG), ethylene glycol and terephthalic acid, and has good fluidity and high gloss. The modified glass fiber is blended into the NPG-PETG, so that the prepared glass fiber reinforced NPG-PETG composite material keeps transparent while having high impact strength, heatresistance, high modulus, high rigidity and high surface gloss.

Owner:腾龙特种树脂(厦门)有限公司

Modified AS resin and preparation method thereof

The invention belongs to the field of macromolecule composite materials, and particularly relates to modified AS resin. The resin is prepared from, by weight, 40-55 parts of AS resin, 5-7 parts of addition agent, 15-20 parts of glass fiber, 10-25 parts of EPDM and MAH graft copolymer, 5-9 parts of MBS, 15-20 parts of CPE, 35-40 parts of triisopropanolamine and 10-15 parts of thioglycollic acid. According to the modified AS resin, the problem is solved that in the prior art, after the glass fiber is added, products can be in a white mist shape and are not transparent.

Owner:CHENGDU KALEFU HIGH POLYMER MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com