Special high impact resistant polypropylene pipe material

A special material for pipe materials, high impact resistance technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of nucleating agent agglomeration, dispersion and unevenness, and achieve improved impact strength, high retention rate, comprehensive Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

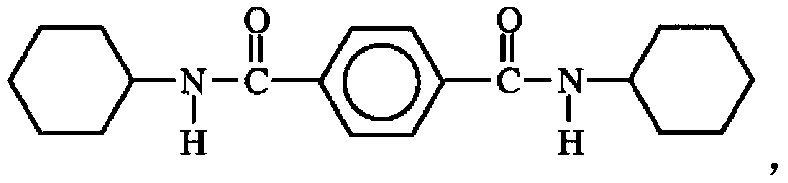

[0028] Use the surface modifier silane coupling agent to modify the surface of the β crystal nucleating agent 2,6-phthalic acid cyclohexanamide: add the β crystal nucleating agent into the reaction kettle, and then add a certain amount of silane coupling agent Coupling agent, under the condition of water bath temperature 60°C and magnetic stirring, after continuous reflux for 5 hours, filter, wash, and dry to obtain the β crystal nucleating agent; the amount of silane coupling agent is wt10 of the β crystal nucleating agent %.

[0029] 100 parts of polypropylene resin,

[0030] 0.125 parts of β crystal form nucleating agent after surface modification,

[0031] Antioxidant 1010 0.15 parts,

[0032] Antioxidant 168 0.15 parts,

[0033] Halogen absorbent calcium stearate 0.1 part;

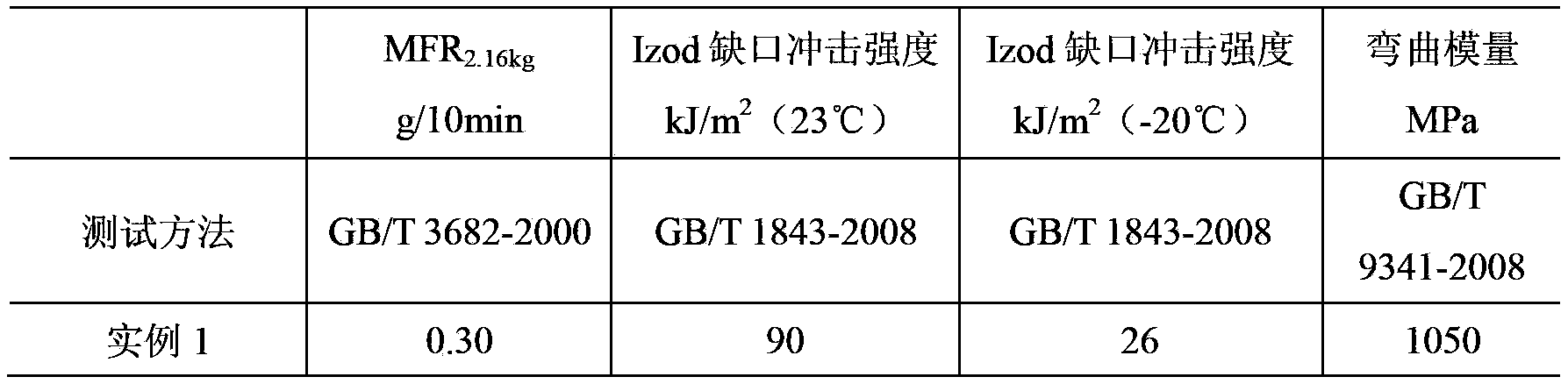

[0034] The above-mentioned components are added into a high-speed mixer, mixed for 5 minutes, and then extruded and granulated by a twin-screw extruder at a temperature of 190°C to 230°C to obtain...

specific Embodiment 2

[0035] The surface modifier lanthanum oxide sol is used to modify the surface of the β crystal nucleating agent 2,6-phthalic acid cyclohexanamide: add the β crystal nucleating agent into the reaction kettle, and then add a certain amount of oxidizing agent Lanthanum sol, under the condition of a water bath temperature of 50 ° C and magnetic stirring, continuously reflux for 6 hours, filter, wash, and dry to obtain a β crystal nucleating agent; the amount of lanthanum oxide sol is 10% by weight of the β crystal nucleating agent .

[0036] 100 parts of polypropylene resin,

[0037] 0.15 parts of β crystal form nucleating agent after surface modification,

[0038] Antioxidant 1010 0.1 parts,

[0039] Antioxidant 168 0.1 part,

[0040] Halogen absorbent zinc stearate 0.1 part;

[0041] The above-mentioned components are added into a high-speed mixer, mixed for 5 minutes, and then extruded and granulated by a twin-screw extruder at a temperature of 190°C to 230°C to obtain spec...

specific Embodiment 3

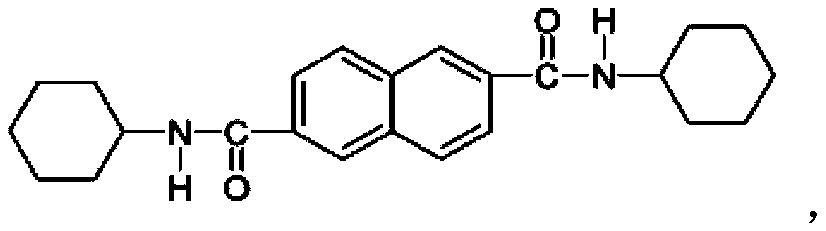

[0042]Surface modification of the β-crystal nucleating agent N,N'-dicyclohexyl-2,6-naphthalenediamide was carried out with the surface modifier octadecyltrichlorosilane: firstly, the β-crystal nucleating agent was added to A certain amount of heptane, and magnetically stirred. Draw a certain amount of octadecyltrichlorosilane with a micro syringe, inject it into the suspension at one time under stirring, stir until the nucleating agent is evenly dispersed in the solution, and continue stirring for 20 minutes. After filtration, wash with acetone and alcohol several times to remove free self-assembled modifier molecules. The modified nucleating agent was vacuum-dried to finally obtain the sample. The amount of octadecyltrichlorosilane is 15% of the mass of the β crystal form nucleating agent, and the amount of heptane is 10 times the mass of the β crystal form nucleating agent.

[0043] 100 parts of polypropylene resin,

[0044] 0.15 parts of β crystal form nucleating agent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com