Glass fiber reinforced NPG-PETG transparent composite material and preparation method thereof

A technology of glass fiber and composite materials, which is applied in the field of glass fiber reinforced NPG-PETG transparent composite materials and its preparation, which can solve the problems of low toughness and achieve the effects of high fluidity, high surface gloss and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

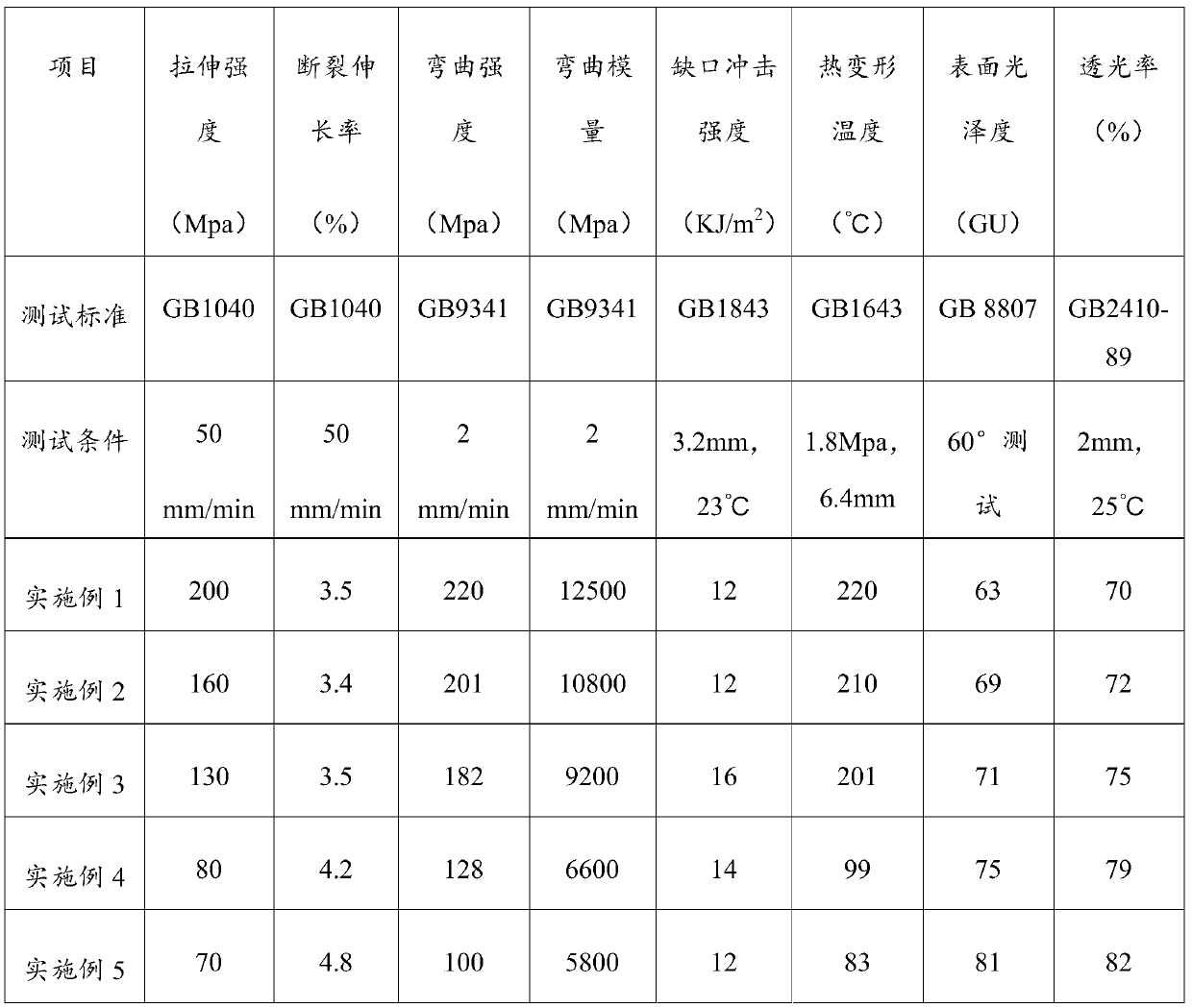

Examples

Embodiment 1

[0034] A glass fiber reinforced NPG-PETG transparent composite material. The components in the raw material include 50 parts of NPG-PETG, 50 parts of modified glass fiber, 0.9 part of antioxidant and 0.3 part of lubricant.

[0035] The above-mentioned NPG-PETG is formed by esterification and polycondensation of neopentyl glycol, ethylene glycol and terephthalic acid.

[0036] Above-mentioned lubricant selects stearate for use.

[0037] The above antioxidant is selected from phenolic antioxidant 1010.

[0038] The preparation method of above-mentioned modified glass fiber comprises the following steps:

[0039] S1: Take an appropriate amount of glass fiber with a length of 3-4.5mm and a single filament diameter of 8-17μm, add it to a 9.5mol / L phosphoric acid solution, where the mass ratio of glass fiber to phosphoric acid solution is 1:25, and stir at room temperature for 3 minutes;

[0040] S2: Filter the treated glass fiber from the phosphoric acid solution, wash it with de...

Embodiment 2

[0049] A glass fiber reinforced NPG-PETG transparent composite material. The components in the raw material include 60 parts of NPG-PETG, 40 parts of modified glass fiber, 0.1 part of antioxidant and 0.6 part of lubricant.

[0050] The above-mentioned NPG-PETG is formed by esterification and polycondensation of neopentyl glycol, ethylene glycol and terephthalic acid.

[0051] Above-mentioned lubricant selects fatty alcohol diacid ester for use.

[0052] The above-mentioned antioxidant is selected from phosphite lipid antioxidant 168.

[0053] The preparation method of above-mentioned modified glass fiber comprises the following steps:

[0054] S1: Add an appropriate amount of glass fiber with a length of 3-4.5mm and a single filament diameter of 8-17μm into a 9.5mol / L phosphoric acid solution, where the mass ratio of glass fiber to phosphoric acid solution is 1:26, and stir at room temperature for 6 minutes;

[0055] S2: Filter the treated glass fiber from the phosphoric acid ...

Embodiment 3

[0064] A glass fiber reinforced NPG-PETG transparent composite material. The components in the raw material include 75 parts of NPG-PETG, 30 parts of modified glass fiber, 1.8 parts of antioxidant and 0.5 part of lubricant.

[0065] The above-mentioned NPG-PETG is formed by esterification and polycondensation of neopentyl glycol, ethylene glycol and terephthalic acid.

[0066] The above-mentioned lubricants are selected from stearic acid ester and fatty alcohol diacid ester, and the ratio of the two is 1:1.

[0067] The above antioxidants are selected from phenolic antioxidant 1010 and phosphite antioxidant 168, in which 1010 and 168 are 1:2.

[0068] The preparation method of above-mentioned modified glass fiber comprises the following steps:

[0069] S1: Take an appropriate amount of glass fiber with a length of 3-4.5mm and a single filament diameter of 8-17μm, add it to a 9.5mol / L phosphoric acid solution, where the mass ratio of glass fiber to phosphoric acid solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com