Modified AS resin and preparation method thereof

A resin and modification technology, applied in the field of modified AS resin and its preparation, can solve the problems of high bending strength and notched impact strength, limited improvement of impact strength, affecting the use range of materials, etc., so as to improve hardness and improve impact strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

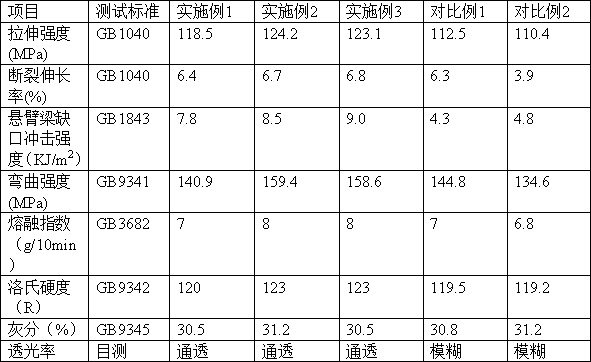

Examples

Embodiment 1

[0026] A preparation method of modified AS resin, comprising the following steps:

[0027] 1) Weigh 40 parts of AS resin, 15 parts of glass fiber, 10 parts of EPDM and MAH graft copolymer, 5 parts of MBS, 15 parts of CPE, 35 parts of triisopropanolamine, and 10 parts of thioglycolic acid in a high mixer and mix them , the temperature is 220°C to obtain the premix; 2) Add the premix to the main feeding port of the extruder, add 5 parts of PMMA from the side feeding port of the extruder, and melt and extrude the pellets through the extruder to obtain .

Embodiment 2

[0029] A preparation method of modified AS resin, comprising the following steps:

[0030] 1) Weigh 48 parts of AS resin, 18 parts of glass fiber, 12 parts of EPDM and MAH graft copolymer, 8 parts of MBS, 18 parts of CPE, 38 parts of triisopropanolamine, 12 parts of thioglycolic acid and mix them in a high mixer , the temperature is 230°C to obtain the premix; 2) Add the premix to the main feeding port of the extruder, add 6 parts of polystyrene from the side feeding port of the extruder, melt and extrude the pellets through the extruder , that is.

Embodiment 3

[0032] A preparation method of modified AS resin, comprising the following steps:

[0033] 1) Weigh 55 parts of AS resin, 20 parts of glass fiber, 25 parts of EPDM and MAH graft copolymer, 9 parts of MBS, 20 parts of CPE, 40 parts of triisopropanolamine, and 15 parts of thioglycolic acid in a high mixer and mix them , the temperature is 240°C to obtain the premix; 2) Add the premix to the main feeding port of the extruder, add 7 parts of polystyrene from the side feeding port of the extruder, and melt and extrude the pellets through the extruder , that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com