Preparation method of aminated graphene oxide

A technology of amination and graphene, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of different sizes of material sheets, achieve good compatibility, simple preparation method, and improved impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The selected graphite flakes in this embodiment are 300 meshes, and the selected small molecule amine is triethylenetetramine.

[0026] The present embodiment prepares a large sheet of aminated graphene oxide from the above raw materials, and its specific steps are as follows:

[0027] Weigh 5g of 300 mesh graphite flakes, and obtain a graphene oxide dispersion by improving the Hummers method and dialysis with deionized water. The improved Hummers method is as follows: add 2.5g sodium nitrate and 120ml concentrated sulfuric acid to 5g flake graphite, then add 15g potassium permanganate, after 2 days of reaction, take a mixed solvent of 30ml hydrogen peroxide and 300ml deionized water, slowly add the reacted system until no gas is released. Then, through deionized water dialysis and ultrasound, two kinds of graphene oxide dispersions were obtained.

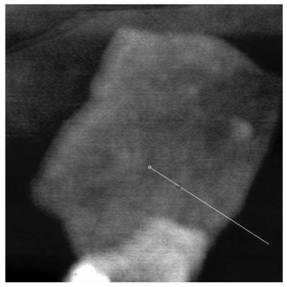

[0028] The obtained graphene oxide dispersion was processed by a cell disruptor in an ice-water bath for 15 minutes, fol...

Embodiment 2

[0033] The selected graphite flakes in this embodiment are 300 meshes, and the selected small molecule amine is triethylenetetramine.

[0034] The present embodiment prepares a kind of larger lamellar aminated graphene oxide from the above raw materials, and its specific steps are as follows:

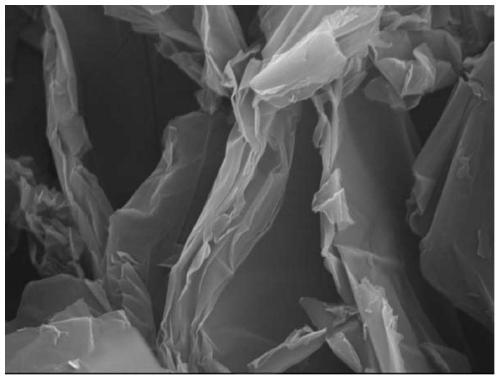

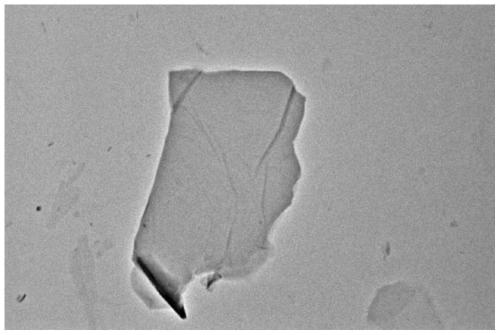

[0035]Weigh 5g of 300-mesh graphite flakes, and obtain a graphene oxide dispersion by improving the Hummers method and dialysis with deionized water. The graphene oxide dispersion is treated by a cell disruptor in an ice-water bath for 45 minutes, followed by ultrasonication for 2 hours. After freeze-drying, graphene oxide powder is obtained. First, 1g of graphene oxide powder and 200ml of DMSO were added to the beaker, followed by 5g of triethylenetetramine and 1g of diisopropylcarbodiimide. After condensing and refluxing at 120°C for 12 hours, adding ethanol to make it layered, centrifuging at a speed of 8000rpm / min for 5 minutes, and freeze-drying the supernatant to obtain a large l...

Embodiment 3

[0040] The selected graphite flakes in this embodiment are 3000 meshes, and the selected small molecule amine is triethylenetetramine (TETA).

[0041] The present embodiment prepares a kind of smaller lamellar aminated graphene oxide from above raw material, and its specific steps are as follows:

[0042] Weigh 5g of 3000-mesh graphite flakes, and obtain a graphene oxide dispersion by improving the Hummers method and dialysis with deionized water. The graphene oxide dispersion is treated by a cell disruptor in an ice-water bath for 20 minutes, followed by ultrasonication for 2 hours. After freeze-drying, graphene oxide powder is obtained. First 1g graphene oxide powder and 200ml THF are added in the beaker, followed by adding TETA5g and N-N'-dicyclohexylcarboimide 1g. After condensing and reflux for 24 hours at 120°C, add ethanol to make it layered, centrifuge at a speed of 8000rpm / min for 10min, and then freeze-dry the supernatant to obtain medium-layer triethylenetetramine-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com