Patents

Literature

7278 results about "Anoxomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anoxomer is a food additive with E number E323. It is a non-digestible polymeric antioxidant. It was designed to allow the introduction of established antioxidants in a non-absorbable manner in order to avoid potential health risk associated with their digestion.

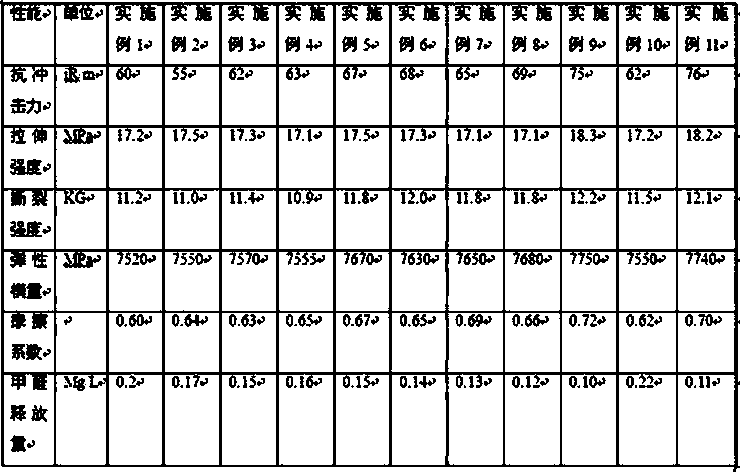

Thermoplastic elastomer composition for preparing flexible printing material for three-dimensional printing rapid prototyping

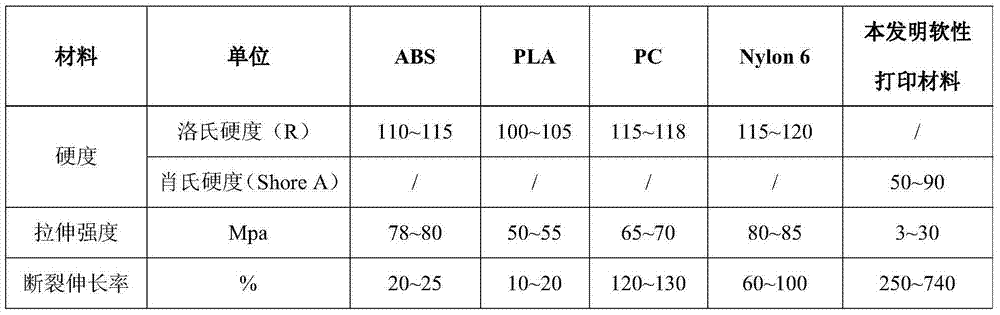

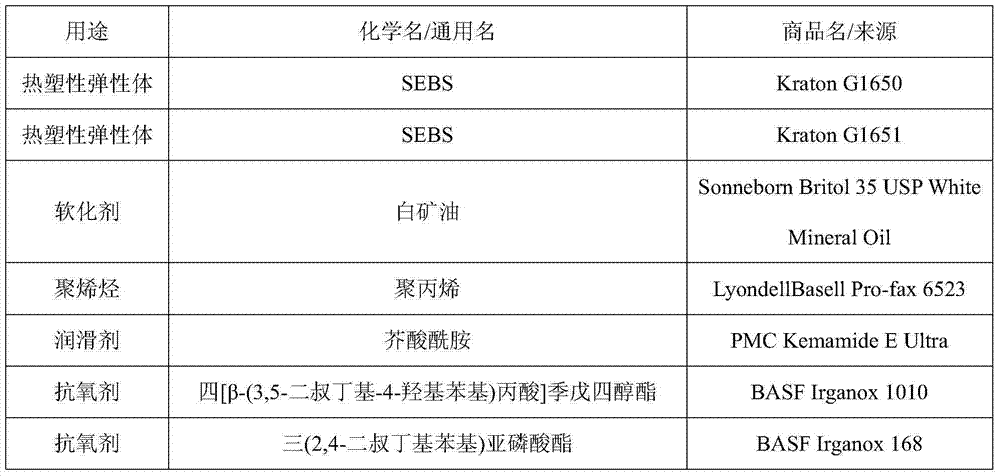

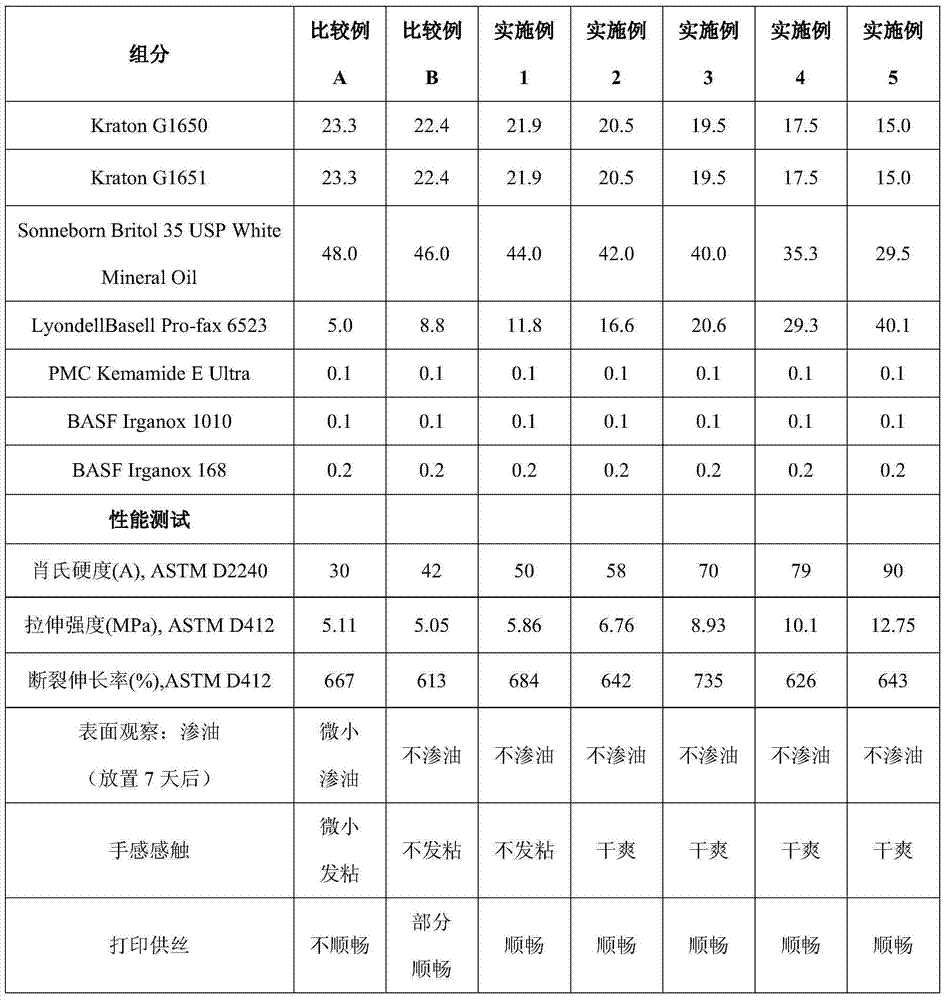

The invention discloses a thermoplastic elastomer composition for preparing a flexible printing material for three-dimensional printing rapid prototyping. The thermoplastic elastomer composition comprises the following components in percent by weight: 16.8-90.0% of thermoplastic elastomer, 1.0-49.8% of polyolefin, 0-44.0% of softening agent, 0.1-1.3% of lubricating agent and 0.2-0.3% of antioxidant. The hardness of the thermoplastic elastomer is Shore hardness of 50-90A, and the prepared flexible printing material is low in hardness, has outstanding flexibility and toughness and excellent handfeel and is particularly applied to the fields of special industrial design and consumer applications such as the manufacturing of toys, jewelries and fingerprints.

Owner:朱叶周

Antioxidant and ultravioresistant polypropylene woven bag raw material

InactiveCN102766918AImprove antioxidant capacityImproves UV resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureUv absorberStearic acid

The invention discloses an antioxidant and ultravioresistant polypropylene woven bag raw material. The polypropylene woven bag raw material is added with anti-oxidant B215, anti-oxidant 1010, auxiliary anti-oxidant DLTP (dilauryl thiodipropionate) or DSTP (distearyl thiodipropionate), ultraviolet absorber UV531, light stabilizer GW-480, stearic acid, calcium stearate, calcium carbonate, mono-alkoxy titanate coupling agent YDH-101, and zinc stearate in powdered polypropylene, and then subjected to wiredrawing treatment in a drawing machine. Compared with the prior art, the raw material provided by the invention has advantages of good antioxidant and ultravioresistant properties, the raw material is particularly suitable for being used as woven bag raw materials, especially for being used as the raw material for manufacturing container bags.

Owner:尚勇

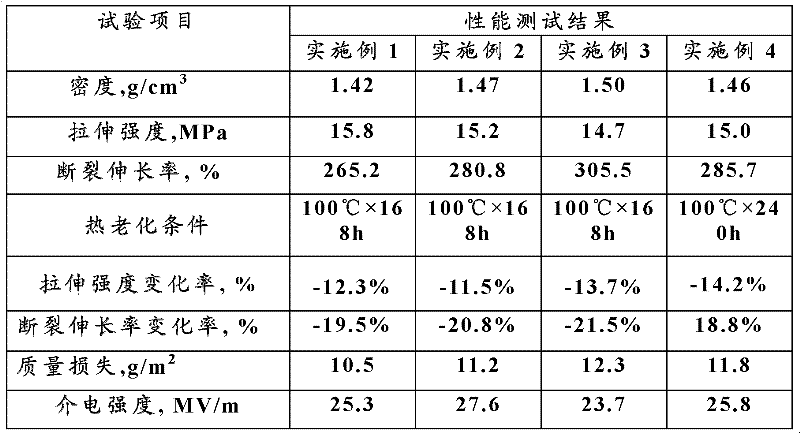

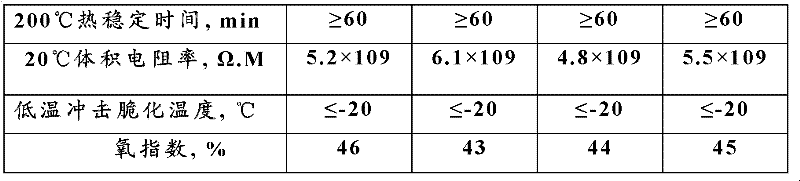

Chlorinated polrvinyl chloride modified material as well as preparation method and application thereof

ActiveCN102532763AGood physical and mechanical propertiesImprove brittlenessInsulated cablesInsulated conductorsAntioxidantShock resistance

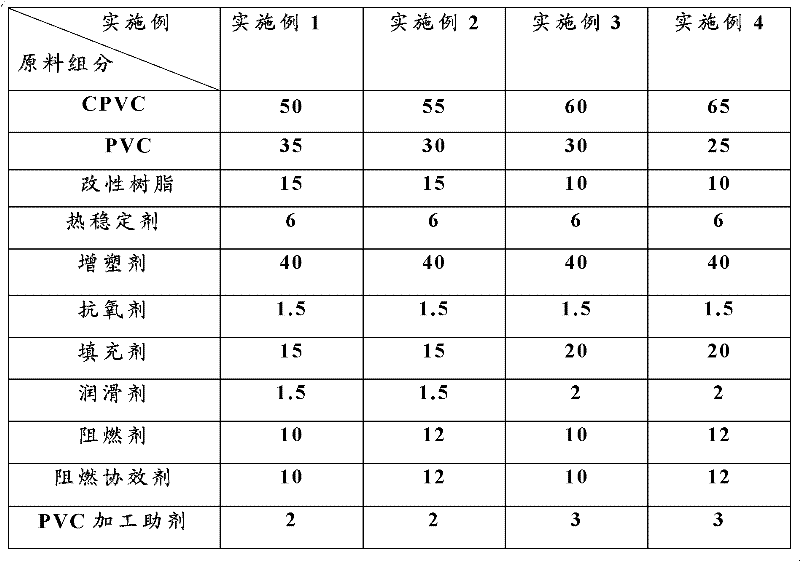

The invention relates to a chlorinated polrvinyl chloride modified material as well as a preparation method and application thereof. The raw material formula of the chlorinated polrvinyl chloride modified material comprises the following components in parts by weight: 40-90 parts of chlorinated polrvinyl chloride, 20-70 parts of polrvinyl chloride, 5-30 parts of modified resin, 1.5-10 parts of heat stabilizing agent, 20-60 parts of plasticizer, 1-10 parts of antioxidant, 1-10 parts of lubricating agent, 5-40 parts of filling agent, 8-40 parts of fire retardant, 8-40 parts of flame retardant synergist and 1-20 parts of polrvinyl chloride processing aid. Compared with the known CPVC (chlorinated polrvinyl chloride) modified plastic, the CPVC modified plastic disclosed by the invention is more excellent in physical and mechanical properties and is relatively reduced in cost; and compared with the known CPVC modified plastic, the CPVC modified material disclosed by the invention is obviously improved in heat resistance and flame retardant property (oxygen index can reach about 45%, and simple root of CPVC modified material can be vertically burnt) besides more excellent processabilityand obviously improved material brittleness and shock resistance. Thus, the CPVC modified material disclosed by the invention is suitable for being used as a wire and cable sheath material.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

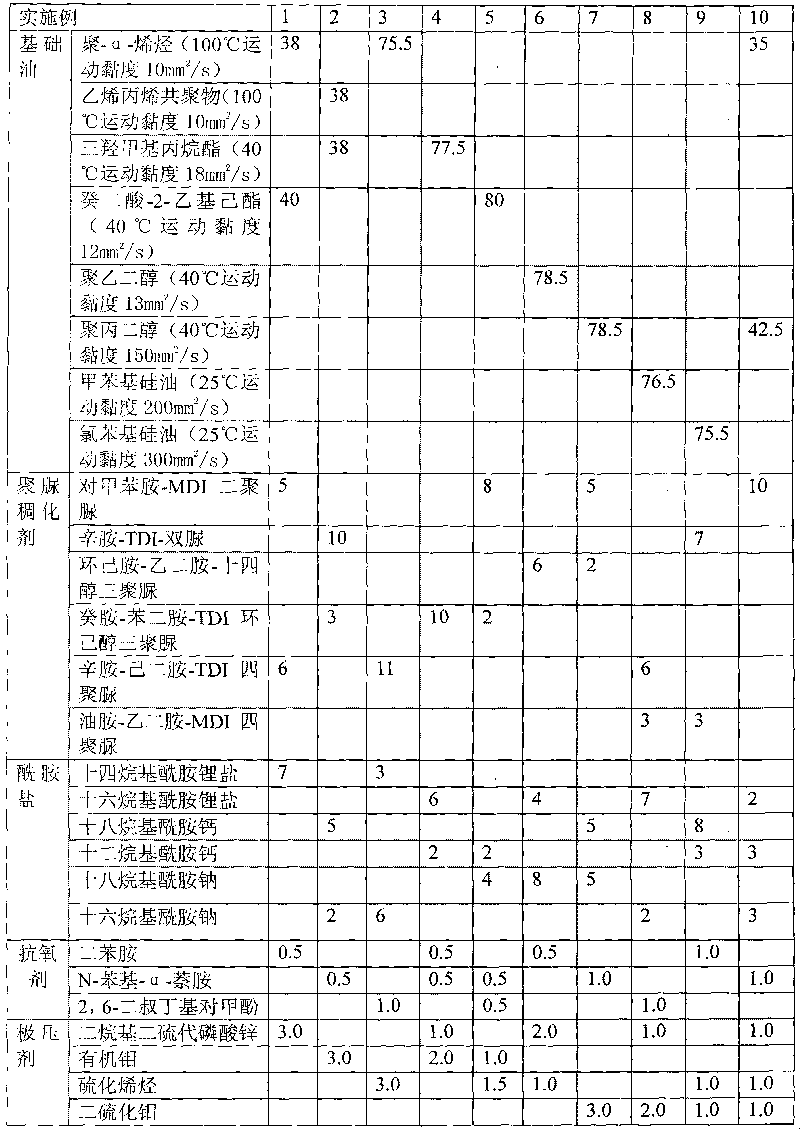

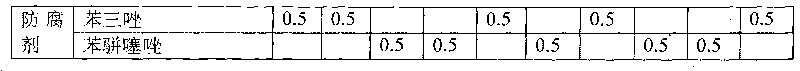

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

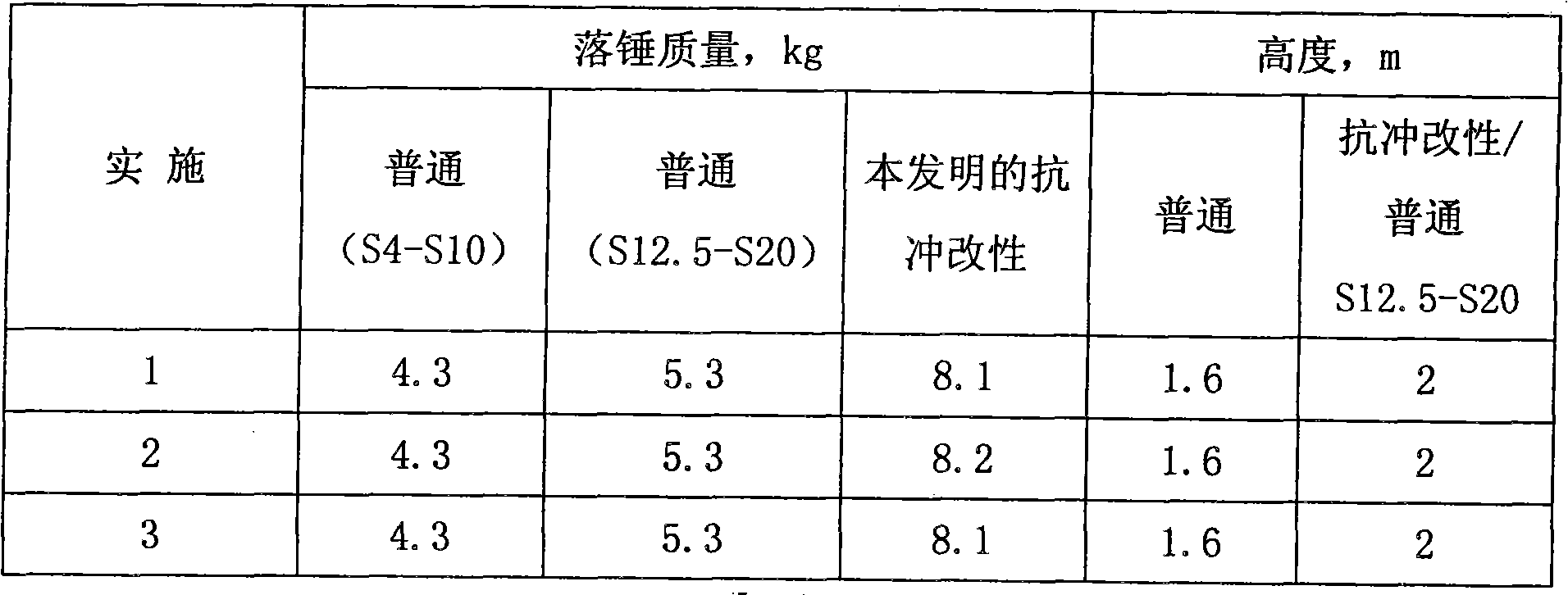

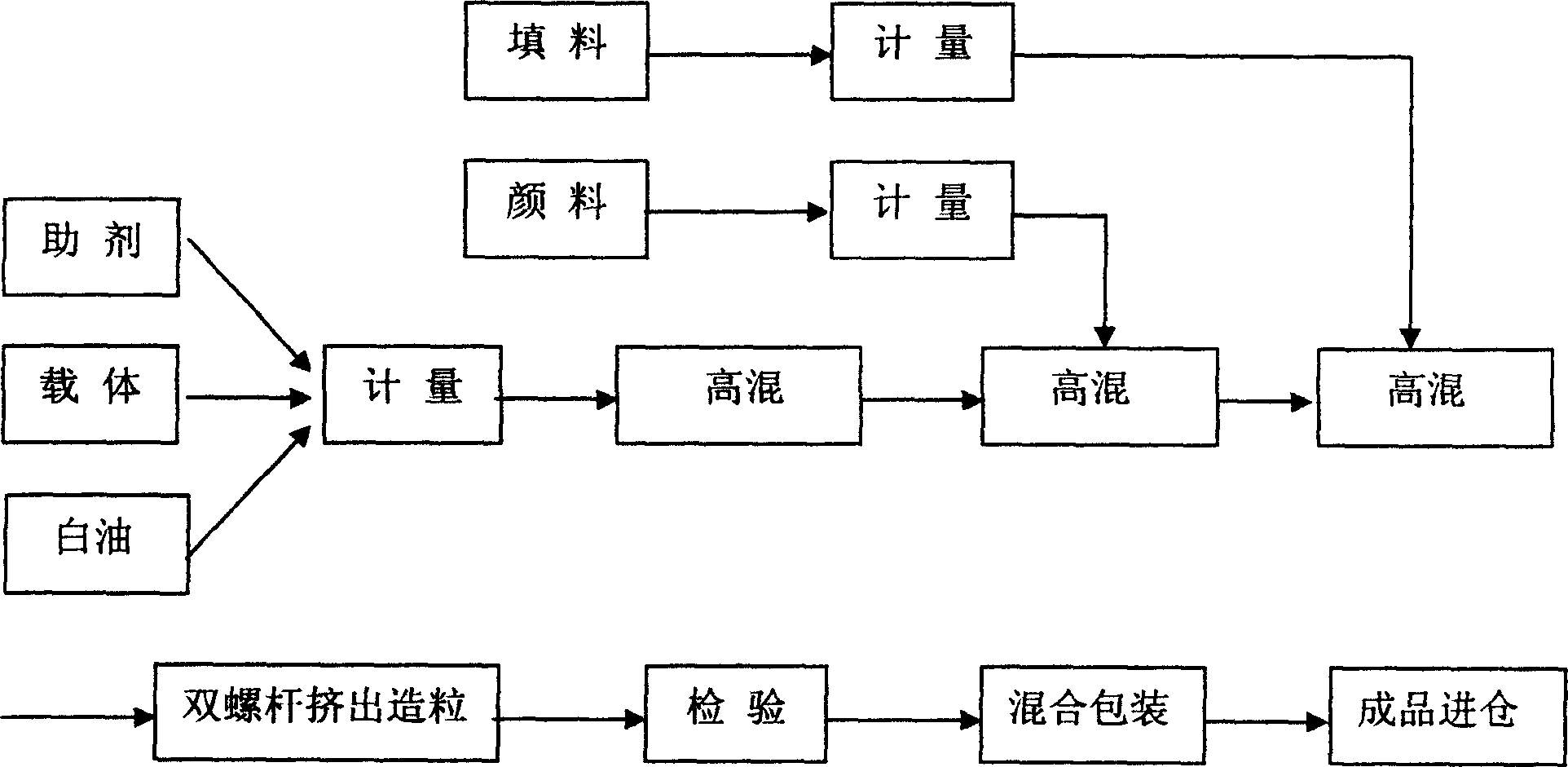

Impact-resistant modified polyvinyl chloride tube material and preparation process thereof

ActiveCN101775180AImprove mechanical propertiesCrack terminationRigid pipesAntioxidantPolyvinyl chloride

The invention discloses an impact-resistant modified polyvinyl chloride tube material, which is prepared from the following components in part by weight: 100 parts of polyvinyl chloride resin, 0.4 to 4.0 parts of stabilizing agent, 2 to 8 parts of toughening agent, 2 to 8 parts of rigid particles, 0.5 to 3.0 parts of processing aid, 1.1 to 2.5 parts of lubricant, 0.05 to 0.5 part of antioxidant, 0.03 to 3 parts of coloring agent and 0 to 5 parts of filling agent. A preparation process for the tube material comprises the following steps: mixing the components uniformly in a high-speed mixer, extruding the mixture to form the tube material by using a double-host single-screw extruder after the components are mixed uniformly in a cooling mixer, and modularizing, vacuuming and cooling-molding the tube material; and cutting and packing the tube material with fixed length. The impact-resistant modified polyvinyl chloride tube material uses a method of cooperative toughening of the toughening agent and the rigid particles, and solves the problem that the impact-resistant PVC tube material difficultly realizes rigidity balance so that the toughness of the tube material is obviously improved while the rigidity of the hard PVC tube material is kept.

Owner:山东华信塑胶股份有限公司

Low-emanation automobile inner fitting special-purpose material and preparation thereof

The invention relates to a kind of low emission type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, organic expellent of low molecule 1.0-3.0 parts, antioxidant 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and organic expellent of low molecule, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 3) three-stage vacuum extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

Compositely modified polypropylene and its prepn process

The composite modified polypropylene material has the raw material composition comprising polypropylene 100 weight portions, nanometer inorganic material 0.1-10 weight portions, elastomer 1-10 weight portions, beta-crystal nucleator 0.1-0.5 weight portions, antioxidant 0-1.5 weight portions, and compatibilizing agent 0.2-3 weight portions. The composite modified polypropylene material possesses raied tensile strength, high impact strength and high heat resistance.

Owner:ZHEJIANG UNIV

Low-odor low-VOC (volatile organic compound)-content styrene polymer composition and preparation method thereof

ActiveCN103044793AOvercome the shortcomings of not being able to directly add to raw materialsWon't overflowPolymer scienceAntioxidant

The invention discloses a low-odor low-VOC (volatile organic compound)-content styrene polymer composition and a preparation method thereof. The composition is prepared from the following components in percentage by weight: 70-99% of styrene polymer, 0.5-29% of strippant master batch and 0.01-1% of antioxidant. The preparation method comprises the following steps: preparing a strippant master batch, mixing the components in a high-speed mixer, adding the mixture into a screw extruder, carrying out melt extrusion, and granulating. The invention has the advantages of simple production technique and lower production cost, and effectively lowers the order and VOC content of the styrene polymer; and the prepared styrene polymer composition can be used in the field of materials with strict environmental requirements in packaging materials, daily necessities, home appliances, OA, toys, sports equipment, shoe materials, cables, instruments and meters, electronic components and equipment, construction materials and automobile materials.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

Method for producing wet-mixing, skid-resistance and noise-reduction asphalt road surface material

The invention relates to a method for producing an asphalt road surface material, in particular to a method for producing a wet-mixing, skid-resistance and noise-reduction asphalt road surface material. The invention is characterized in that the method comprises the following steps: 1) the production of modified asphalt: the modified asphalt consists of basic asphalt, modifying agent A, modifying agent B, stabilizing agent and antioxidant; and the mass ratio of the components is as follows: 100:2.0-6.5:1.6-9.4:0.18-0.45:0.1-0.6; 2) the production of wet-mixing asphalt: the wet-mixing asphalt consists of the modified asphalt, modifying agent C, sulfur and diatomite, and the mass ratio of the components is as follows: 100:1.5-6.0:1.0-10.0:1.0-8.5; 3) the selection of mineral aggregate graduation: the mineral aggregate consists of coarse aggregate, fine aggregate and stuffing, and the mass ratio of the components is as follows: 100:7.0-14.0:3.3-5.9; 4) the production of wet-mixing, skid-resistance and noise-reduction asphalt road surface material: the material consists of the mineral aggregate, wet-mixing modified asphalt and fiber, and the mass ratio of the components is as follows: 100:4.5-5.0:0.225-0.533. The asphalt road material produced by the method has lower construction temperature and has the functions of reducing noise and resisting skid.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Natural-like multifunctional color batch and use thereof

The present invention features that the color concentrate is prepared with main carrier resin A, matched carrier resin X, compatizer, pigment, inorganic stuffing, antistatic agent, light stabilizer, antioxidant and pigment lubricating dispersant. The main carrier resin an and the matched carrier resin X, which has obviously different compatibility and smelting behavior from that of the basic resin B in the product, may constitute alloy carrier resin. The said materials may be altered to result in various decoration effects.

Owner:GUANGDONG SHENGHENGCHANG CHEM IND

Polypropylene composite material and preparation method thereof

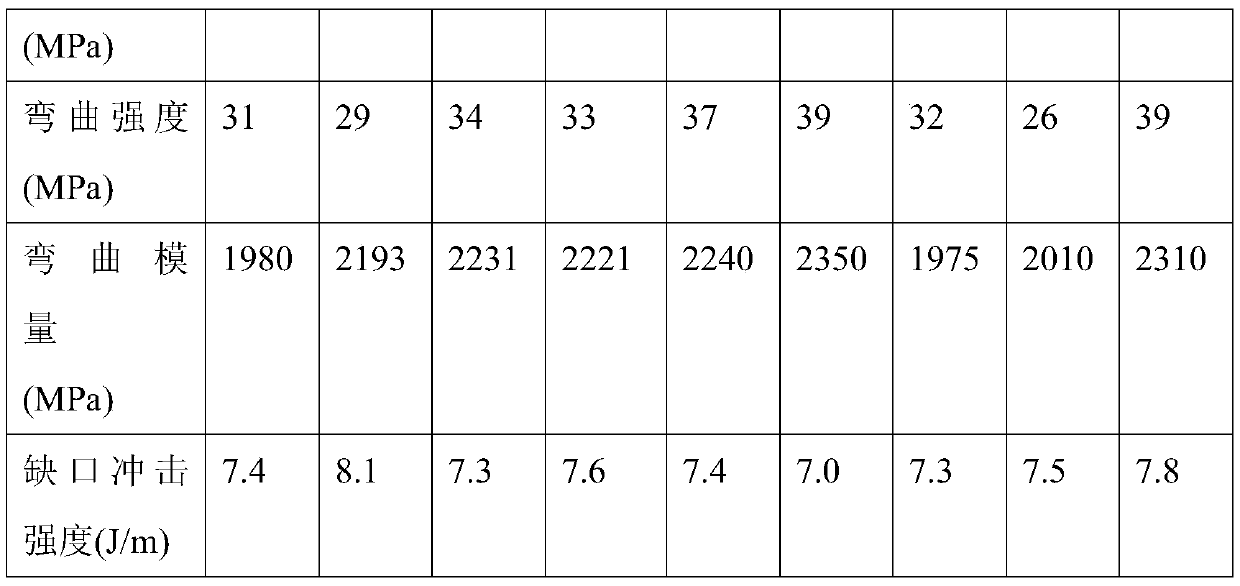

The invention discloses a composite polypropylene material. The composite polypropylene material contains polypropylene resin, glass fiber and an antioxidant, wherein the fiber length of the glass fiber is between 0.4 and 1 millimeter. The invention also discloses a method for preparing the composite polypropylene material. The mechanical properties of the composite polypropylene material such as the tensile strength, the impact strength, the bending strength, the flexural modulus and so on are between the mechanical properties of short glass fiber reinforced polypropylene material and the mechanical properties of long glass fiber reinforced polypropylene material, and the cost of raw materials and the manufacturing cost are low.

Owner:BYD CO LTD

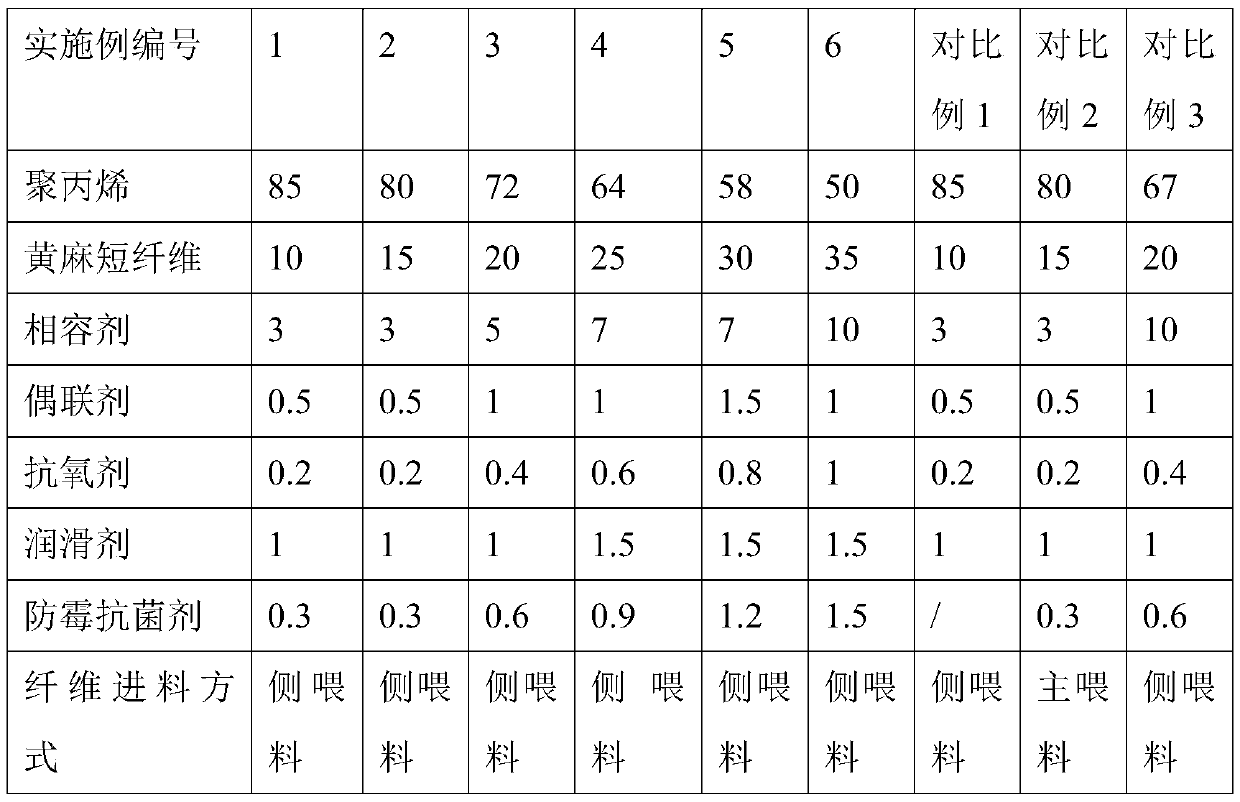

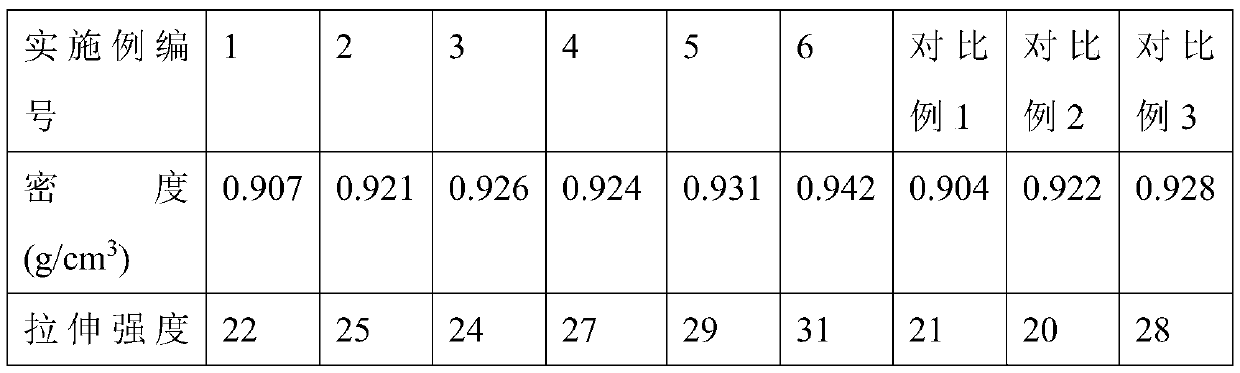

Natural-fiber-reinforced polypropylene composite material with mildewproof and antimicrobial properties and preparation method thereof

InactiveCN105504501ALow hygroscopicityImprove anti-mold and anti-bacterial propertiesNatural fiberAntibacterial action

The invention discloses a natural-fiber-reinforced polypropylene composite material with mildewproof and antimicrobial properties and a preparation method thereof. The natural-fiber-reinforced polypropylene composite material with mildewproof and antimicrobial properties comprises the following raw materials in parts by weight: 10-35 parts of natural fiber, 50-85 parts of polypropylene, 1-10 parts of compatilizer, 0.5-2 parts of coupling agent, 0.1-1 part of antioxidant, 0.5-2 parts of lubricant and 0.2-2 parts of mildewproof and antimicrobial agent. By using the natural fiber, which has the advantages of low price, abundant resources, high specific modulus and low density, to prepare the reinforced polypropylene composite material for vehicles, the production cost can be lowered. By using the combination of the alkali solution, coupling agent and compatilizer to treat the natural fiber, the hydroscopic property of the fiber is lowered. By adding the mildewproof and antimicrobial agent, the mildewproof and antimicrobial properties of the natural-fiber-reinforced polypropylene composite material with mildewproof and antibacterial functions can be greatly improved, so that the composite material is beneficial to human health in application, and has longer service life.

Owner:SHANGHAI PRET COMPOSITES

ABS//PET alloy and method for producing the same

The invention discloses an ABS / PET alloy and a preparation method thereof. The ABS / PET alloy comprises the components with the weight percentage as follows: 21-72 percent of ABS, 14-60 percent of PET, 3-10 percent of compatilizer, 0.4-0.6 percent of antioxidant, 5-15 percent of toughener and 0.3-1 percent of lubricant. In the invention, proper compatilizer and intensifier are selected to melt an ABS system and a PET system together very well and the material which has stable size, high strength, high modulus and high fluidity is produced. The ABS / PET alloy integrates the advantages of ABS and PET and improves the heat resistance, impact resistance, processability and the like of the PET. The method for manufacturing the ABS / PET alloy comprises the technical steps as follows: firstly, the raw materials are mixed in proportion as above and then are put into a plastic extruder to be granulated at the temperature controlled within 230 DEG C to 260 DEG C; and the ABS / PET alloy is obtained.

Owner:SHENZHEN KEJU NEW MATERIAL

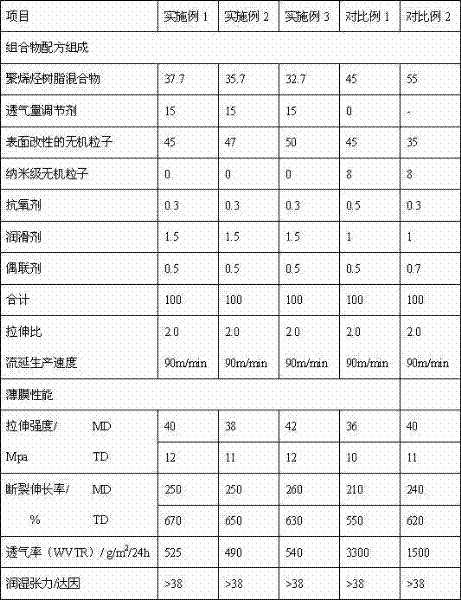

Composition of air-permeable film with low permeation volume and preparation method thereof

InactiveCN102336940AImprove mechanical propertiesGood compatibilityCoatingsPolymer sciencePolyolefin

The invention discloses a composition of an air-permeable film with a low permeation volume. The composition consists of the following components in percentage by weight: 30-60 percent of polyolefin resin mixture, 5-15 percent of permeation volume regulator, 30-55 percent of surface-modified nano-grade organic particles, 0.2-0.5 percent of antioxidant, 0.1-2.0 percent of lubricant and 1-3 percent of coupling agent. A preparation method of the composition comprises the following steps of: mixing a micro-grade inorganic filler with the coupling agent in a high-speed mixer to obtain a pretreated filler; feeding the pretreated filler, polyolefin resin, a modifier, the antioxidant and the lubricant into a double screw extruder by using a feeding system, extruding, cooling, pelletizing, drying, and packaging with an aluminum film bag in vacuum to obtain a finished air-permeable film composition with low permeation volume; and casting the prepared composite by using an extruder with a T-shaped film head, and stretching with a single shaft in two steps, wherein the stretching rate is 0.5-3.5. The invention has the advantages: 1, the nano inorganic filler is added, so that the mechanical property of the air-permeable film can be enhanced; 2, the surface of the inorganic particles is coupled, so that the compatibility with the polyolefin resin can be enhanced; 3, due to the adoption of the T-shaped film head, the drawing efficiency and the flatness can be fully enhanced; and 4, due to the adoption of the permeation volume regulator, the permeation volume of the air-permeable film can be lowered remarkably.

Owner:KINGFA SCI & TECH CO LTD +2

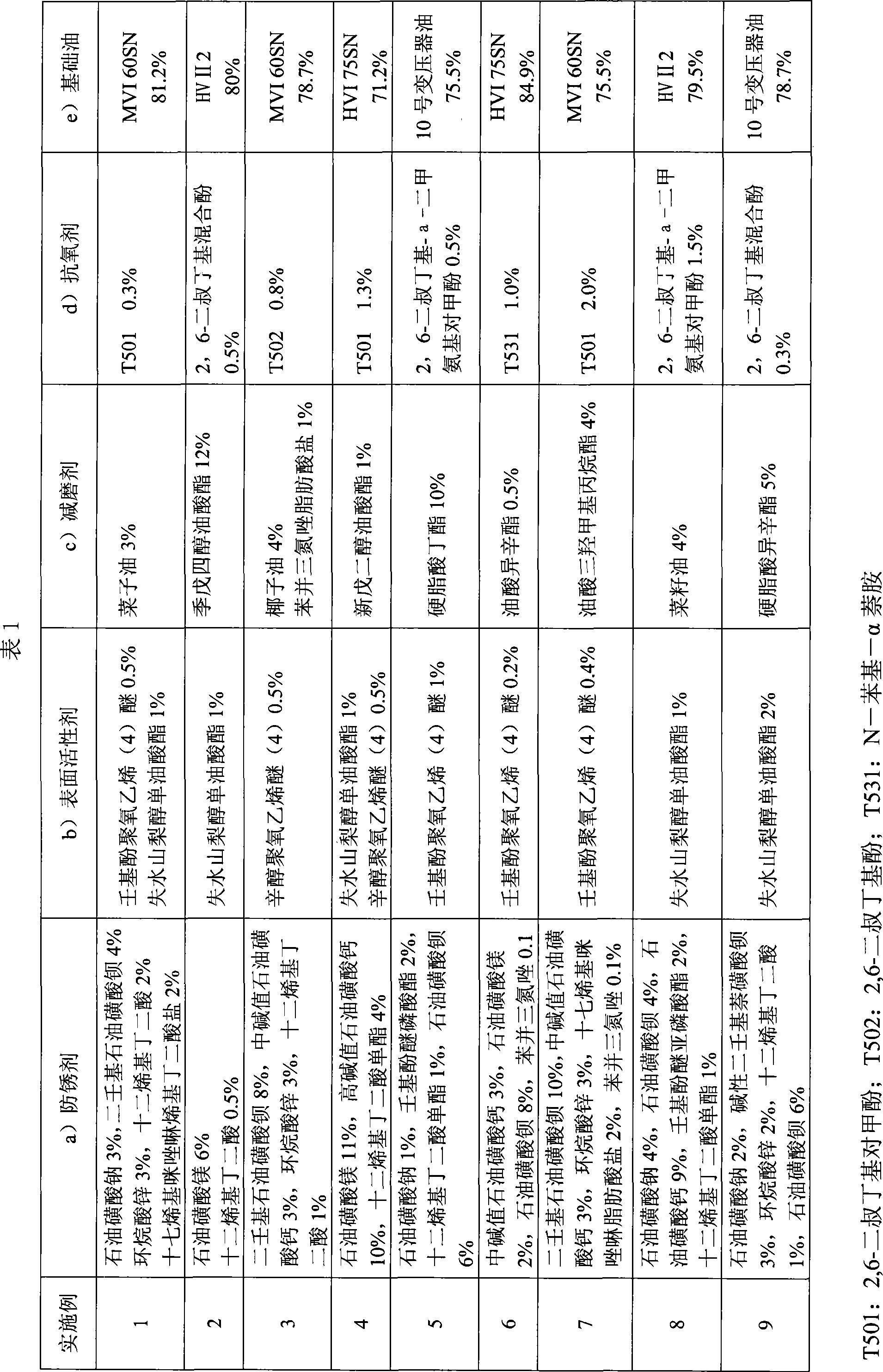

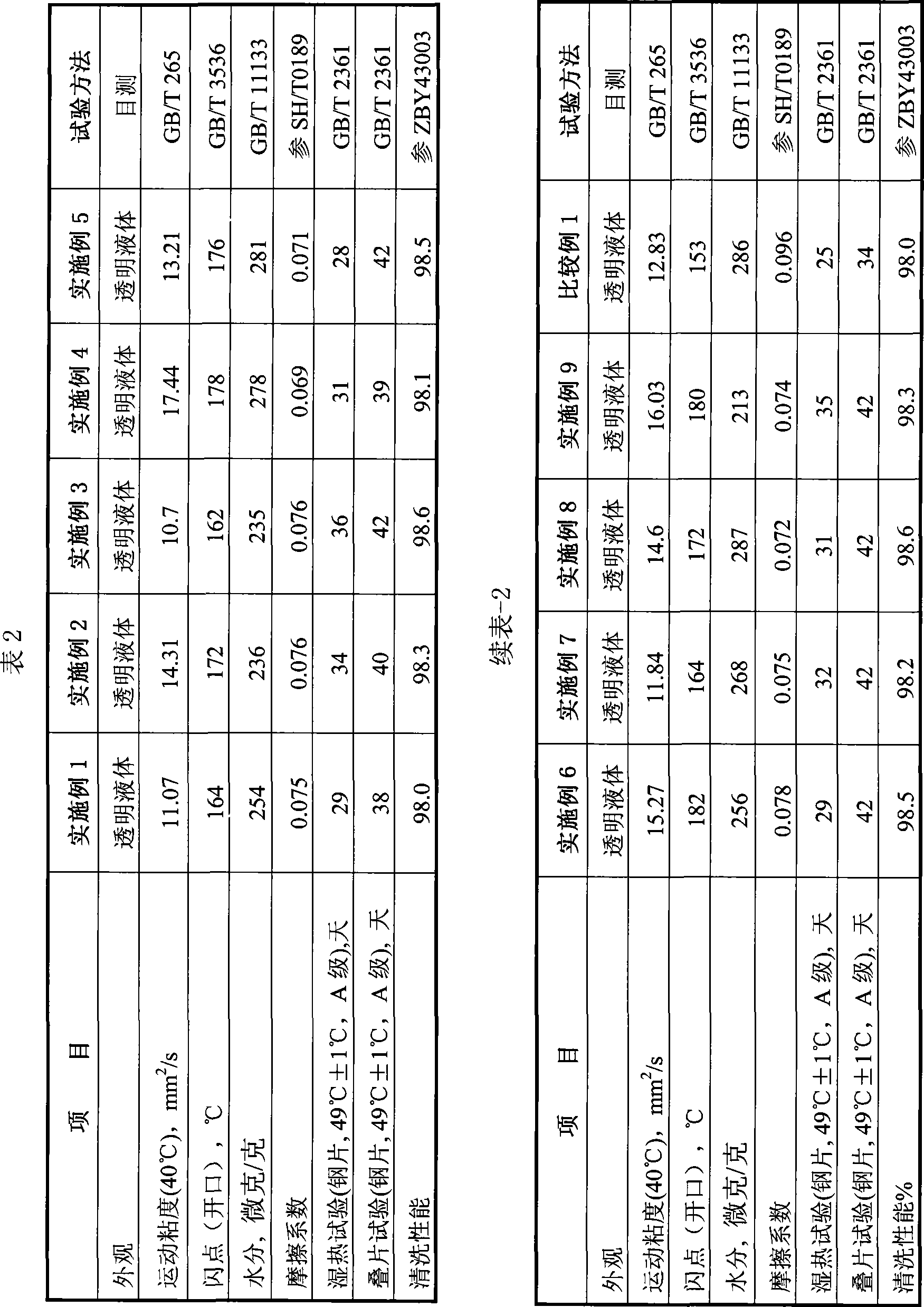

Electrostatic painting anticorrosive oil and production method thereof

ActiveCN101486945ADoes not affect post-processing effectsPost-processing effect is reducedAdditivesAntioxidantBase oil

The invention relates to electrostatic spraying anti-rust oil and a production method thereof, which essentially solves the problems of the prior art that the lubricating property of the anti-rust oil is poor; and interlayer sliding is caused due to larger tension during the reeling process of the steel plate, resulting in steel plate scratch and having impact on the surface quality of the steel plate. The electrostatic spraying anti-rust oil commendably solves the problems by using the technical proposal comprising components of weight percentages as follows: a) 5 to 30 percent of anti-rust agent, b) 0.1 to 5 percent of surface activator, c) 0.1 to 15 percent of anti-friction composition, d) 0.1 to 5.0 percent of antioxidant and e) 50 to 90 percent of base oil, and can be used for the electrostatic spraying rust resistance of the cold-rolled carbon steel plate, galvanized plate and aluminized zinc silicon plate of the steel enterprises.

Owner:CHINA PETROLEUM & CHEM CORP

High-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material and preparation method thereof

The invention relates to a high-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material which comprises the following raw materials in weight parts: 100 parts of chlorinated polyvinyl chloride, 1-50 parts of impact modifier, 1.5-10 parts of thermal stabilizer, 0.1-10 parts of lubricant, 0.5-15 parts of PVC processing aid, 0.1-0.5 part of antioxidant and 0-40 parts of filler. The invention solves the problems of low heat resistance and aging resistance while improving the tenacity of CPVC in the prior art; and the Vicat softening point can vary within the range of 104 to 119 DEG C, the tensile strength can reach 45-64 MPa, and the notch impact strength can be increased by more than 200 percent.

Owner:LIAOCHENG UNIV

Antimicrobial polyamide material and preparation method thereof

The invention relates to the technical field of polymer plastics and discloses an antimicrobial polyamide material and a preparation method thereof. The antibacterial polyamide material consists of the following components: polyamide resin, an antimicrobial agent, a compatibilizer and an antioxidant. One purpose of the invention is to provide the antimicrobial polyamide material which is non-toxic, antibacterial, natural and environmentally-friendly; and the other purpose of the invention is to provide the preparation method of the antimicrobial polyamide material, wherein the preparation method is simple and environmentally-friendly in process.

Owner:SHENZHEN KEJU NEW MATERIAL

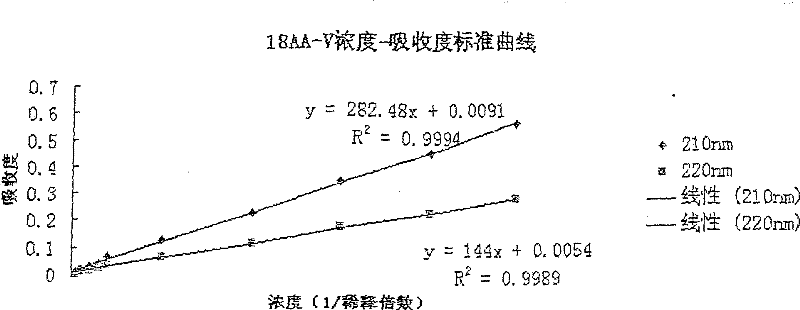

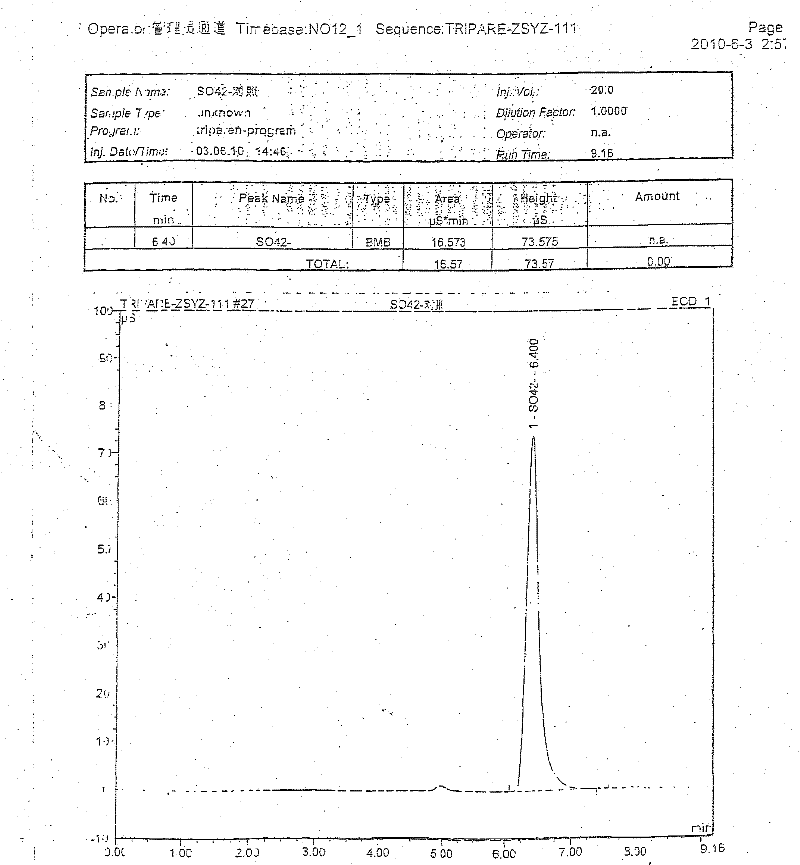

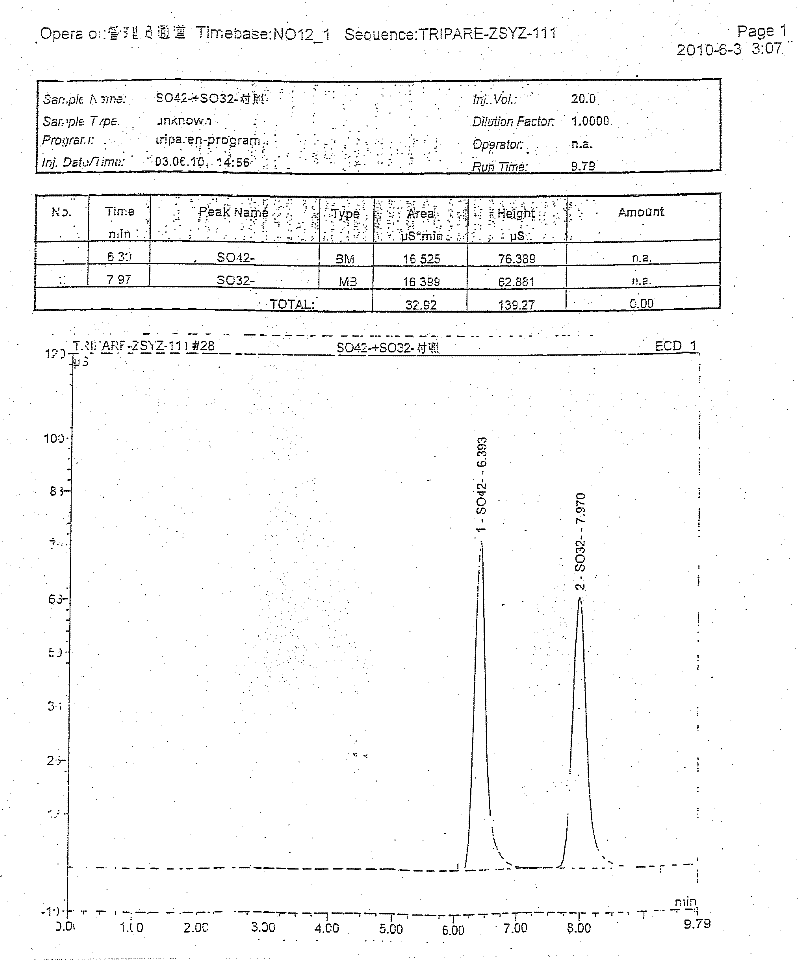

Compound amino acid injecta, and preparation method and detection method thereof

ActiveCN102440989AAccurate measurementExact reproductionOrganic active ingredientsMetabolism disorderIon chromatographySulfate radicals

The invention discloses compound amino acid injecta, which contains arginine hydrochloride, histidine monohydrochloride, leucine, isoleucine, lysine hydrochloride and the like; meanwhile, the invention further discloses a preparation method of the compound amino acid injecta (18AA); in the event of ensuring the product quality, the compound amino acid injecta has the characteristics of saving energy and enhancing efficacy; by means of repetitive verification on precision, detection limit, quantitation limit, linear range and the like, a simple, convenient, rapid and reliable method with cleaning verification is ensured; furthermore, the residual quantity of antioxygen, namely sodium hydrogensulfite, in the compound amino acid injecta and sulphate ion generated by degrading sodium hydrogensulfite are detected according to an ion chromatography principle, thus, the amount of the antioxygen charged in the raw material proportioning can be accurately measured, and the stability of the raw material proportioning process is judged according to the measurement result; and a detection method of the compound amino acid injecta provided by the invention is an online derivative amino acid content measuring method, the speed is rapid, and the method is applied to large-scale detection.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

PVC (polyvinyl chloride) micro-foam floor and preparation method thereof

Owner:安徽济峰节能材料有限公司

Butter inhibitor for ethylene unit alkaline washing tower

InactiveCN101838553ASuppress generationAntioxidantGaseous mixture working upTreatment apparatus corrosion/fouling inhibitionAnoxomerMaterials science

The invention relates to a butter inhibitor used for an ethylene unit alkaline washing tower. Problems of the background technology are solved, so the butter inhibitor has the performance of oxidation resistance, polymerization inhibition, cleanness, dispersion, metallic ion passivation and a better inhibition effect. The butter inhibitor is prepared from the following raw materials of: 1 to 30 percent of antioxidant, 5 to 40 percent of polymerization retarder, 2 to 30 percent of dispersant, 5 to 25 percent of metallic ion passivating agent and the balance of solvent; and the butter inhibitor is prepared by heating, uniformly mixing and cooling the materials.

Owner:浙江杭化科技股份有限公司

Polar monomer graft-modified amorphous poly-alpha-olefin and preparation method thereof

The invention discloses a polar monomer graft-modified amorphous poly-alpha-olefin and a preparation method thereof. The polar monomer graft-modified amorphous poly-alpha-olefin is prepared by carrying out grafting reaction on amorphous poly-alpha-olefin, a peroxide initiator, a polar monomer and an auxiliary grafting agent under molten or dissolved conditions. The polar monomer graft-modified amorphous poly-alpha-olefin is prepared from the following raw materials: 100 parts of amorphous poly-alpha-olefin, peroxide initiator accounting for 0.1-1 wt% of the amorphous poly-alpha-olefin, polar monomer accounting for 0.5-10 wt% of the amorphous poly-alpha-olefin, auxiliary grafting agent accounting for 0.1-5 wt% of the amorphous poly-alpha-olefin, solvent accounting for 0-300 wt% of the amorphous poly-alpha-olefin, and antioxidant accounting for 0.05-2 wt% of the amorphous poly-alpha-olefin. The amorphous poly-alpha-olefin has the characteristics of high grafting ratio, light color, high polarity, favorable flowability, favorable storage capability and no risk in moisture crosslinking.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

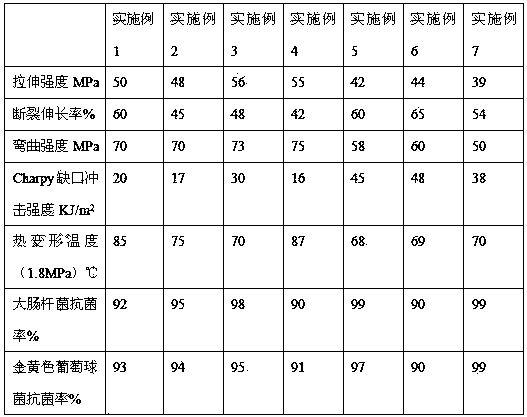

Antibacterial masterbatch, nano antibacterial super-tough plastic added with antibacterial masterbatch and preparation and application of plastic

The invention discloses an antibacterial masterbatch, nano antibacterial super-tough plastic added with an antibacterial masterbatch and preparation and an application of the plastic and relates to the technical field of high molecular materials. The nano antibacterial super-tough plastic is characterized by being prepared from the following raw materials in parts by weight through blending and extruding: 70-93 parts of resin, 2-10 parts of antibacterial masterbatch, 5-20 parts of a flexibilizer, 0.1-1.0 part of an antioxidant and 0.2-1.0 part of a lubricant. The preparation method comprises the following steps: firstly, preparing the antibacterial masterbatch, then, weighing the raw materials in proportion, adding into a high speed mixer and mixing for 2-10 minutes; and then, extruding and granulating the obtained mixture through a twin-screw extruder to obtain the nano antibacterial super-tough plastic. The nano antibacterial super-tough plastic disclosed by the invention has an efficient, lasting, broad-spectrum and safe antibacterial effect, can be applied to preparation of spectacle frames and can satisfy the requirements on characteristics of the spectacle frames such as great elasticity, strong toughness and difficulty in breakage.

Owner:HEFEI GENIUS NEW MATERIALS

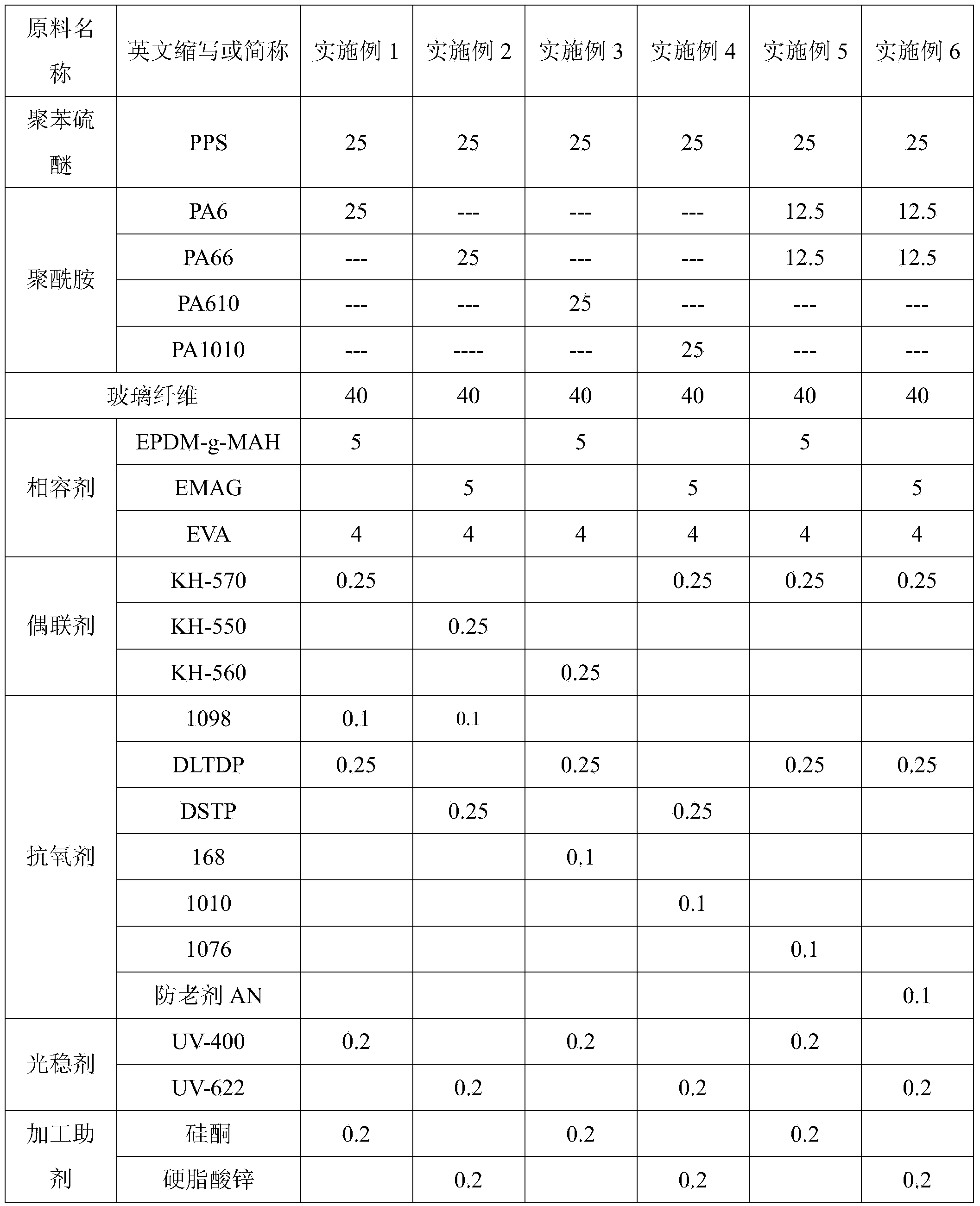

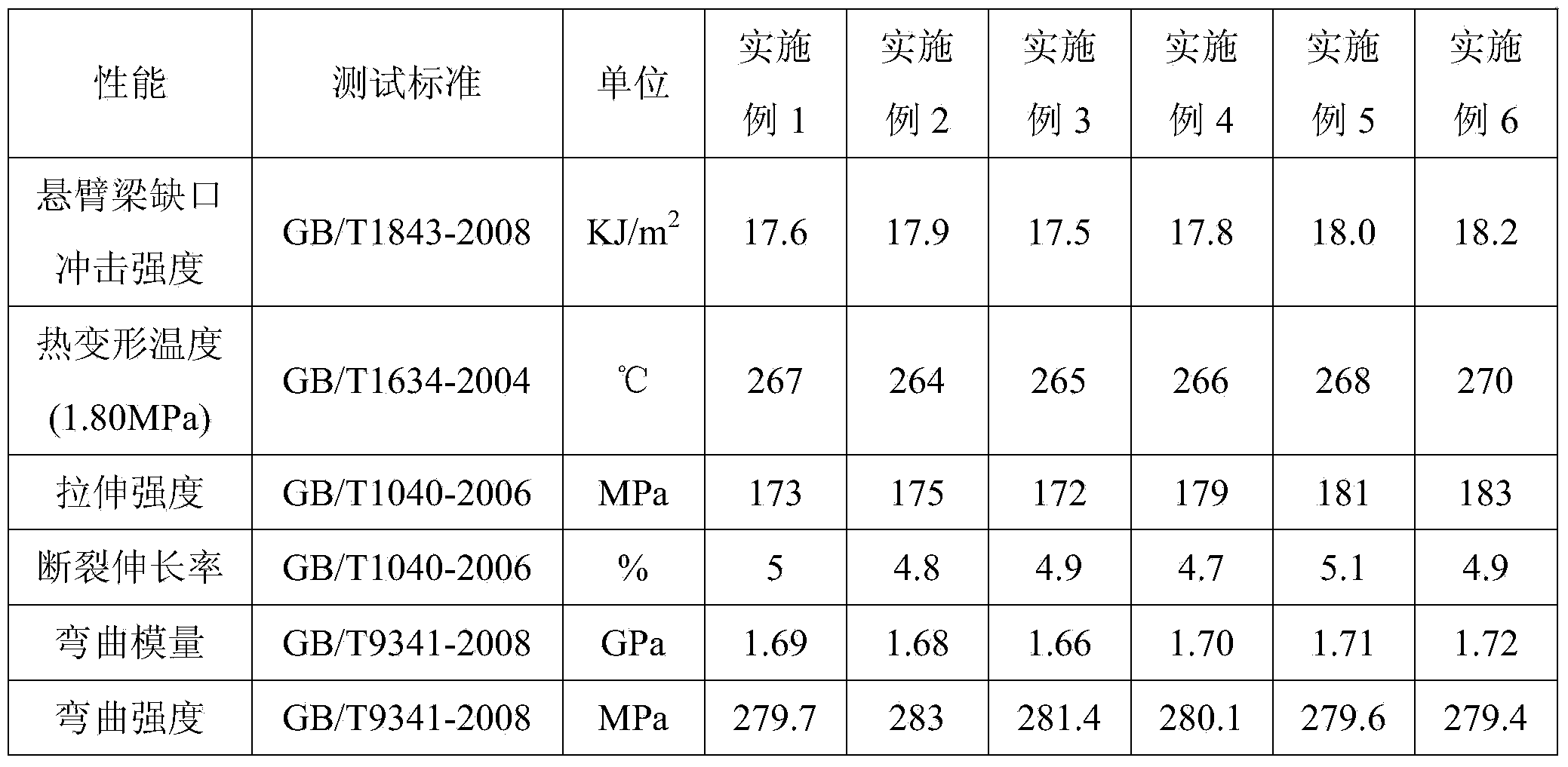

Polyphenylene sulfide composite material and preparation method thereof

The invention discloses a polyphenylene sulfide composite material which comprises the following components in percentage by weight: 10-40 percent of polyphenylene sulfide, 10-40 percent of polyamide, 5-30 percent of glass fiber, 5-20 percent of compatilizer, 0.2-1.5 percent of coupling agent, 0-1 percent of antioxidant, 0-1 percent of light stabilizer and 0-1 percent of processing aid. The method for preparing the polyphenylene sulfide composite material comprises the following steps: preparing various raw materials; sequentially adding polyphenylene sulfide, polyamide, the compatilizer, the coupling agent, the antioxidant, the light stabilizer and the processing aid into a high-speed mixer for dispersing and mixing; putting the mixed materials into an extruder after mixing is finished, independently introducing the glass fiber through a glass fiber port of the extruder during extrusion, and mixing, extruding and pelleting the materials to obtain granules of the polyphenylene sulfide composite material. The provided polyphenylene sulfide composite material has high rigidity, strength and toughness and can be widely applied to the fields of aerospace and aviation, chemical industry, electronic products, machinery, automobiles and railways.

Owner:宁波泛龙塑料新材料有限公司

High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

PC/PET alloy and manufacture method thereof

The invention discloses a PC / PET alloy and its producing method with a composite weight ratio (%): PC 65-87%; PET5-20%; elasticizer 6-10%; compatilizer 1-3%; antioxidant 0.2-0.6%; other assistant agents 0.1-2%. The inventive material has a high impacting strength, a high module, a high rigidity, a high surface gloss and a low density, which improves the PC resistance to solvent, abrasion resistance, resistance to stress cracking and processing fluidity. The plastic producing method contains following steps: firstly mixing the material according to above proportion, then entering into the plastic extruder at 245-280 DEG C, prilling, getting PC / PET alloy.

Owner:SHENZHEN KEJU NEW MATERIAL

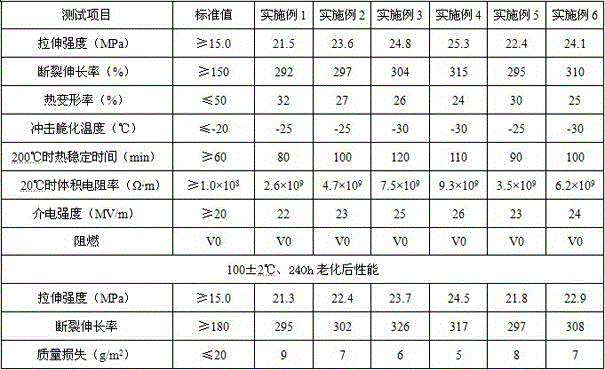

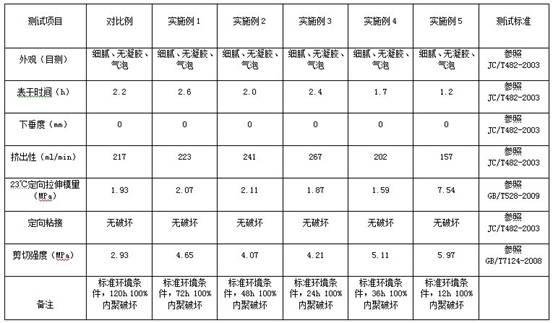

Polyurethane sealant with good initial adhesion

ActiveCN102504750AGood initial tackSolve the problem of prone to bond failureNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePlasticizer

The invention discloses a polyurethane sealant with good initial adhesion. The polyurethane sealant comprises the following ingredients in percentage by mass: 15 to 45 percent of polyurethane prepolymer, 10 to 40 percent of plasticizers, 0.5 to 15 percent of initial adhesion promoters, 1 to 10 percent of thixotropic agents, 5 to 30 percent of filling materials, 0.1 to 0.5 percent of light stabilizers, 0.1 to 0.5 percent of antioxidants, 0.5 to 3 percent of silane type bonding promoters and 0.1 to 1.5 percent of moisture removing agents, wherein the polyurethane prepolymer is obtained through preparation. Compared with the prior art, the polyurethane sealant has the following characteristics that: (1) the polyurethane sealant has good initial adhesion on the surfaces of imporous substrates such as glass, ceramics and the like, and the problems that the adhesion force in the initial curing period is poor and the adhesion damage is easy to occur when the polyurethane sealant receives external force effect are solved; and (2) no bubble exists in the sealant layer during the humid air curing, and the adhesion performance is good.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

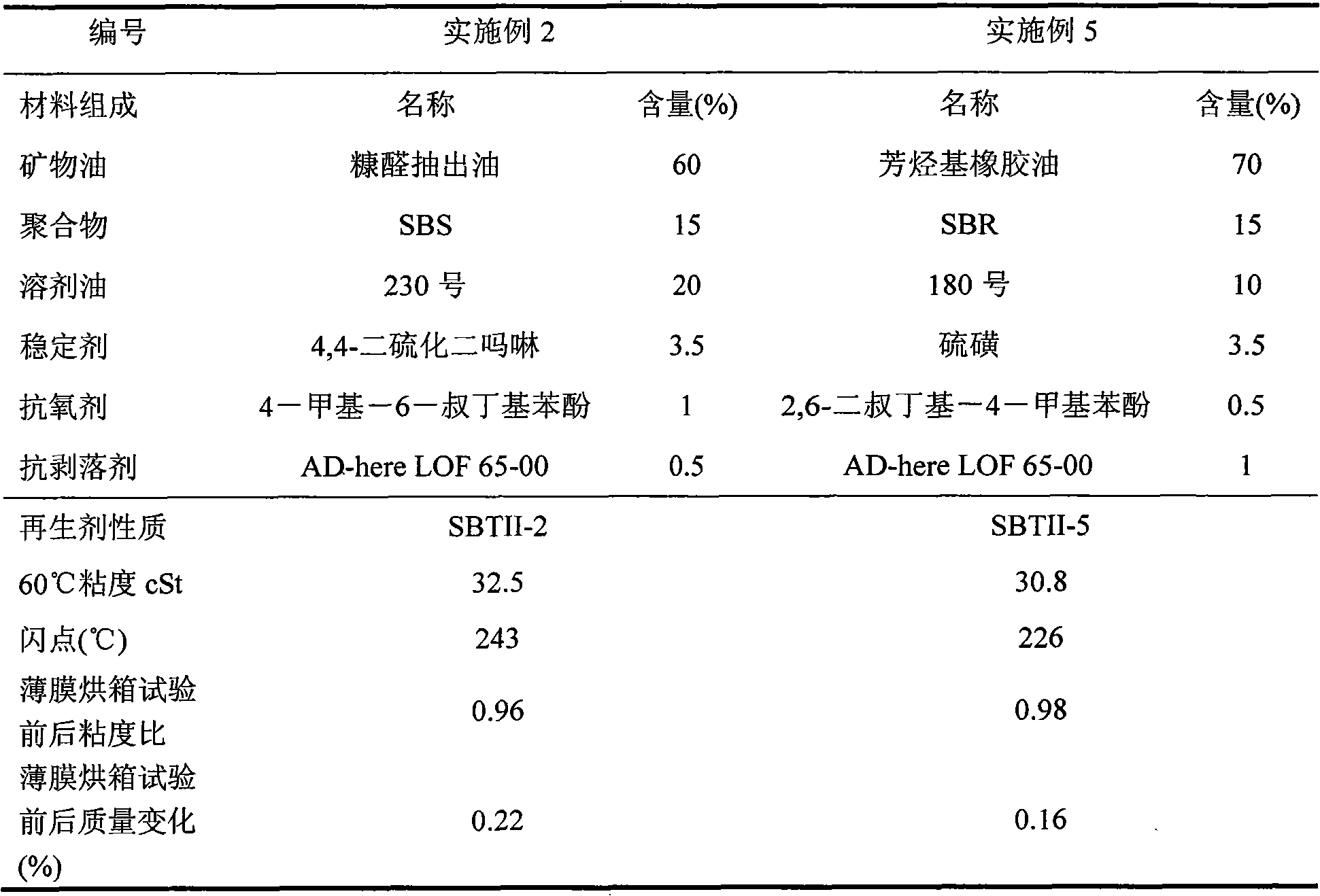

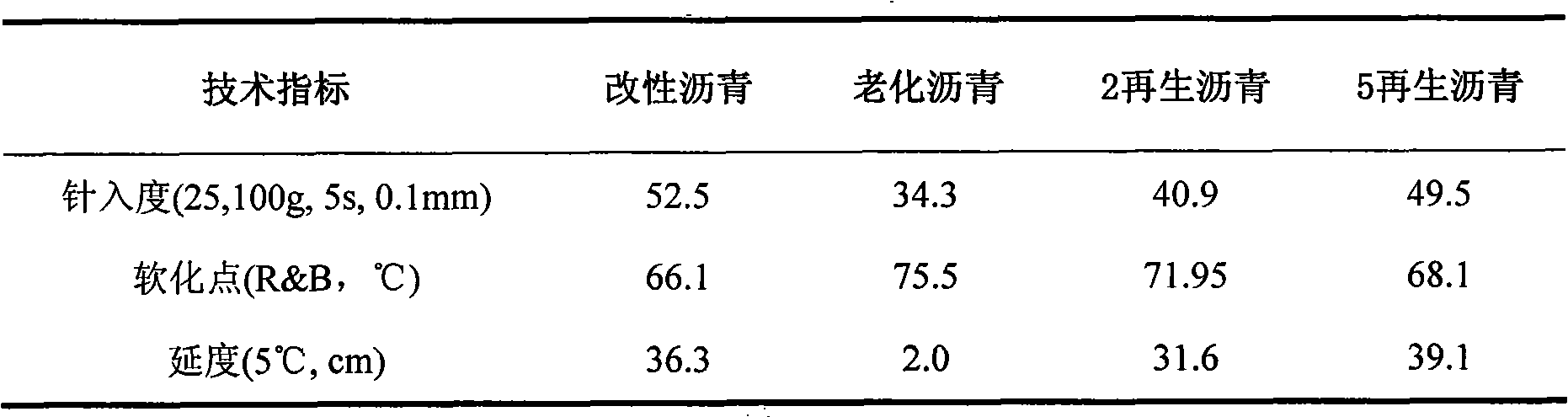

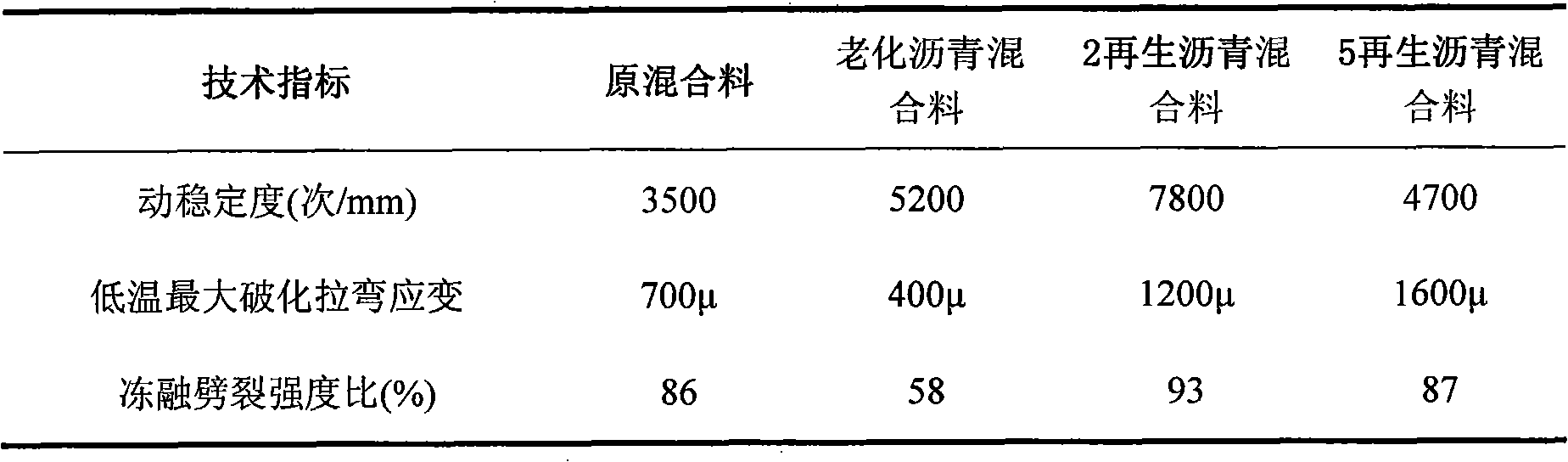

Special regenerant suitable for regenerating modified asphalt and prepared method thereof

InactiveCN101629020AImprove high temperature stabilityImprove low temperature crack resistanceBuilding insulationsBoiling pointAntioxidant

The invention relates to a special regenerant suitable for regenerating modified asphalt, prepared from the following components by weight percent: 50.0-80.0 percent of heavy mineral oil, 10.0-25.0 percent of rubber or thermoplastic elastomer, 10.0-30.0 percent of high-boiling-point solvent oil, 0.5-4.0 percent of stabilizer, 0.1-1.0 percent of antioxidant and 0.1-2.0 percent of antistripping agent. A preparation method of the special regenerant comprises the following steps: a. placing the heavy mineral oil into a reaction kettle, stirring and preheating to 100-130 DEG C; b. throwing the rubber or thermoplastic elastomer into the reaction kettle, stirring for 30 min, rising the temperature of the reaction kettle to 150-170 DEG C and quickly stirring for 15 min; and c. reducing the rotate speed of the reaction kettle to a normal stirring speed, cooling to 60-90 DEG C, adding the solvent oil, the stabilizer, the antioxidant and the antistripping agent, continuously stirring to be uniform and discharging. The regenerant for the modified asphalt belongs to an oiliness system, can be stably stored and used for regeneration of recovery asphalt of an asphalt road and especially for modified asphalt, and the regenerated asphalt can reach the level of new modified asphalt.

Owner:JIANGSU RES INST OF BUILDING SCI +1

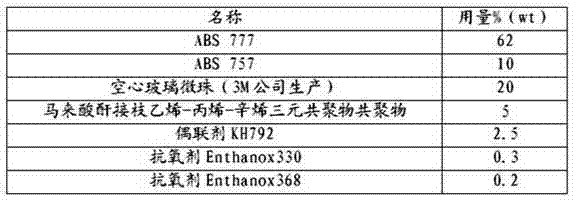

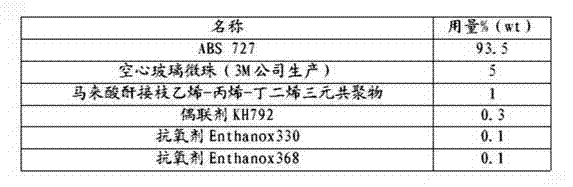

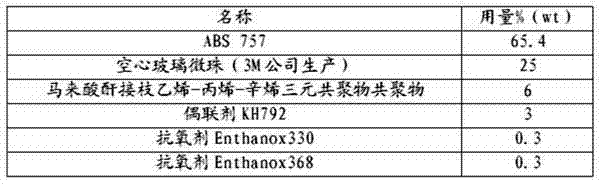

Lightweight noise-reduction modified ABS (Acrylonitrile Butadiene Styrene) material and preparation method thereof

The invention relates to a lightweight noise-reductio modified ABS (Acrylonitrile Butadiene Styrene) material which comprises the following raw materials in percentage by weight: 39-93.5% of ABS resin, 5-45% of inorganic filler, 1-10% of dispersing agent, 0.3-5% of coupling agent and 0.2-1% of antioxygen, wherein the inorganic filler is a hollow inorganic particle. Since the hollow inorganic particle is added to the formula of the material, the low density of the material is maintained while the mechanical property of the material is improved; meanwhile, the material is endowed with a certainnoise reduction function because of the special hollow particle structure, therefore, the material has a very high application value in lightweight automobile manufacture, damping and noise reductionand the like. The lightweight noise-reduction modified ABS material is prepared by the step of processing the inorganic filler fed into a screw extruder respectively from multiple lateral feeding ports arranged at different positions, so that the hollow structure of the inorganic filler is not damaged when the inorganic filler is melt and extruded, the inorganic filler can be dispersed more evenly in a substrate, and the prepared material is endowed with better properties.

Owner:辽宁金发科技有限公司

Thermoplastic elastomer material, preparation thereof and method for manufacturing medicinal bottle stopper by using the same

InactiveCN101376730ACreate pollutionWon't releasePharmaceutical containersMedical packagingRubber materialAntistatic agent

The invention provides thermoplastic elastomer materials used for a bottle cork for manufacturing medicines, a preparation method thereof and a method for applying the bottle cork for manufacturing medicines thereof. The materials are prepared by the following components: styrene copolymer or rubber materials as well as polyolefine matters. The styrene copolymer is PP or PE; besides, the materials also contain a plasticizer and a loading agent, contain or do not contain a compatibilizer, contain or do not contain an antioxidant, contain or do not contain an antistatic agent, contain or do not contain adhesion preventives. The preparation method thereof includes the steps of drying the materials, fusing a reaction kettle, using a plastic extruding machine to extrude the materials, using a cooling water slot to cool and shape the materials, using a hauling machine to haul and cut off the materials, and the like. The thermoplastic elastomer materials provided by the invention have the advantages of stable chemical property, no poison, low polarity and good rebound resilience.

Owner:谷其昌

Injection of 13 kinds complex vitamin and preparing technique thereof

InactiveCN101181289ASolve solubilityAvoid the trouble of reconstitution and reuseHydroxy compound active ingredientsMetabolism disorderSolubilityFreeze-drying

The invention discloses a preparation method and the production process of a complex injection of 13 vitamins. The injection adopts dual-injection type, the invention overcomes the problem of solubility of the fat-soluble vitamins in water, so the invention can be prepared into the water injection; the stability of the product is good, and various vitamins can not be affected mutually. The injection includes water-soluble vitamins, fat-soluble vitamins, surfactant, antioxidant, complexing agent and solvent, the injection water is added till the dissolution, the activated carbon is added for absorption, the pH value of the solution is regulated, and then the nitrogen filling and sterilization are carried out. The production process of the invention prepares the injection into dual-injection type, the vitamin B12, folic acid and biotin have an independent package, the process overcomes the problem of solubility of fat-soluble vitamins in water, the invention can be prepared into water injection, the stability of the product is good, and various vitamins can not be affected mutually, the vitamins can be added in a large infusion for usage, so as to avoid the trouble of redissolution and reuse of the freeze-dried powder injection.

Owner:NANJING HAILING TRADITIONAL CHINESE MEDICINE RES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com