PVC (polyvinyl chloride) micro-foam floor and preparation method thereof

A technology of micro-foaming and PVC resin, applied in the field of PVC micro-foaming flooring and its preparation, can solve the problem of not having antibacterial and anti-aging, not having flame retardant and anti-aging, not having flame retardant, antibacterial, antistatic, etc. problem, achieve the effect of reducing production cost and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

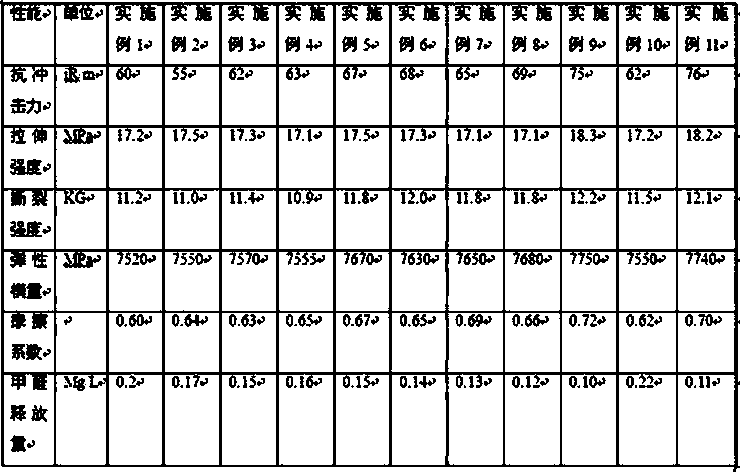

Examples

Embodiment 1

[0026] PVC micro-foam flooring, including the following components in parts by mass: 150 parts of PVC resin, 80 parts of diatomaceous earth, 20 parts of plant fiber, 10 parts of dioctyl phthalate, 5 parts of composite lead salt heat stabilizer, 3 parts of lead stearate, 2 parts of acrylate impact modifier, 3.5 parts of 2,6-di-tert-butyl-p-cresol, 1.2 parts of azodicarbonamide, 7 parts of TCEP, 7 parts of antibacterial agent, ultraviolet light Absorbent 4 parts.

[0027] The preparation method of PVC microfoaming floor, comprises the steps:

[0028] Step 1: Mix the dried diatomaceous earth and plant fiber evenly, and sieve through a 130-mesh sieve to obtain micropowder;

[0029] Step 2: Mix micropowder and PVC resin evenly, then add plasticizer, heat stabilizer, lubricant, foaming agent, impact modifier, antioxidant, flame retardant, antibacterial agent and UV absorber , mixing at a speed of 120 rpm and a temperature of 130°C for 15 minutes, followed by cooling, and dischargi...

Embodiment 2

[0033] PVC micro-foam flooring, including the following components in parts by mass: 120 parts of PVC resin, 40 parts of diatomaceous earth, 10 parts of plant fiber, 5 parts of dioctyl phthalate, 1 part of composite lead salt heat stabilizer, 0.5 parts of lead stearate, 0.7 parts of acrylate impact modifier, 1.5 parts of 2,6-di-tert-butyl-p-cresol, 0.5 parts of azodicarbonamide, 3 parts of TCEP, 2 parts of antibacterial agent, ultraviolet light Absorbent 1.5 parts.

[0034] The preparation method of PVC microfoaming floor, comprises the steps:

[0035] Step 1: Mix the dried diatomaceous earth and plant fiber evenly, and sieve through a 180-mesh sieve to obtain micropowder;

[0036] Step 2: Mix micropowder and PVC resin evenly, then add plasticizer, heat stabilizer, lubricant, foaming agent, impact modifier, antioxidant, flame retardant, antibacterial agent and UV absorber , mixing at a speed of 150 rpm and a temperature of 135°C for 20 minutes, followed by cooling, and when ...

Embodiment 3

[0040]PVC micro-foam flooring, including the following components in parts by mass: 125 parts of PVC resin, 46 parts of diatomaceous earth, 12 parts of plant fiber, 5.5 parts of dioctyl phthalate, 1.6 parts of composite lead salt heat stabilizer, 0.7 parts of stearic acid amide, 0.8 parts of acrylate impact modifier, 1.7 parts of 2,6-di-tert-butyl-p-cresol, 0.6 parts of azodicarbonamide, 3.4 parts of TCPP, 2.5 parts of antibacterial agent, ultraviolet light Absorbent 1.9 parts.

[0041] The preparation method of PVC microfoaming floor, comprises the steps:

[0042] Step 1: Mix the dried diatomaceous earth and plant fiber evenly, and sieve through a 150-mesh sieve to obtain micropowder;

[0043] Step 2: Mix micropowder and PVC resin evenly, then add plasticizer, heat stabilizer, lubricant, foaming agent, impact modifier, antioxidant, flame retardant, antibacterial agent and UV absorber , mixing at a speed of 135 rpm and a temperature of 132°C for 17 minutes, followed by cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com