Patents

Literature

651results about "Three-dimensional effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

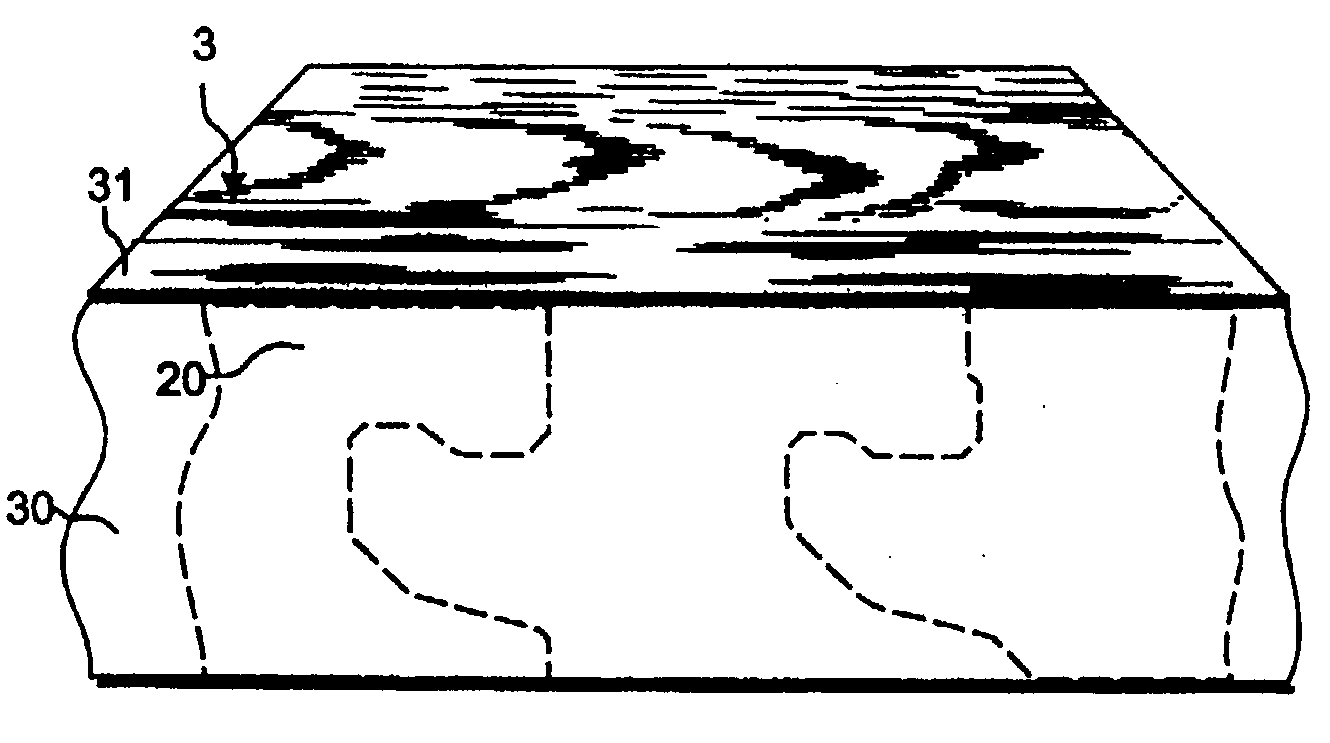

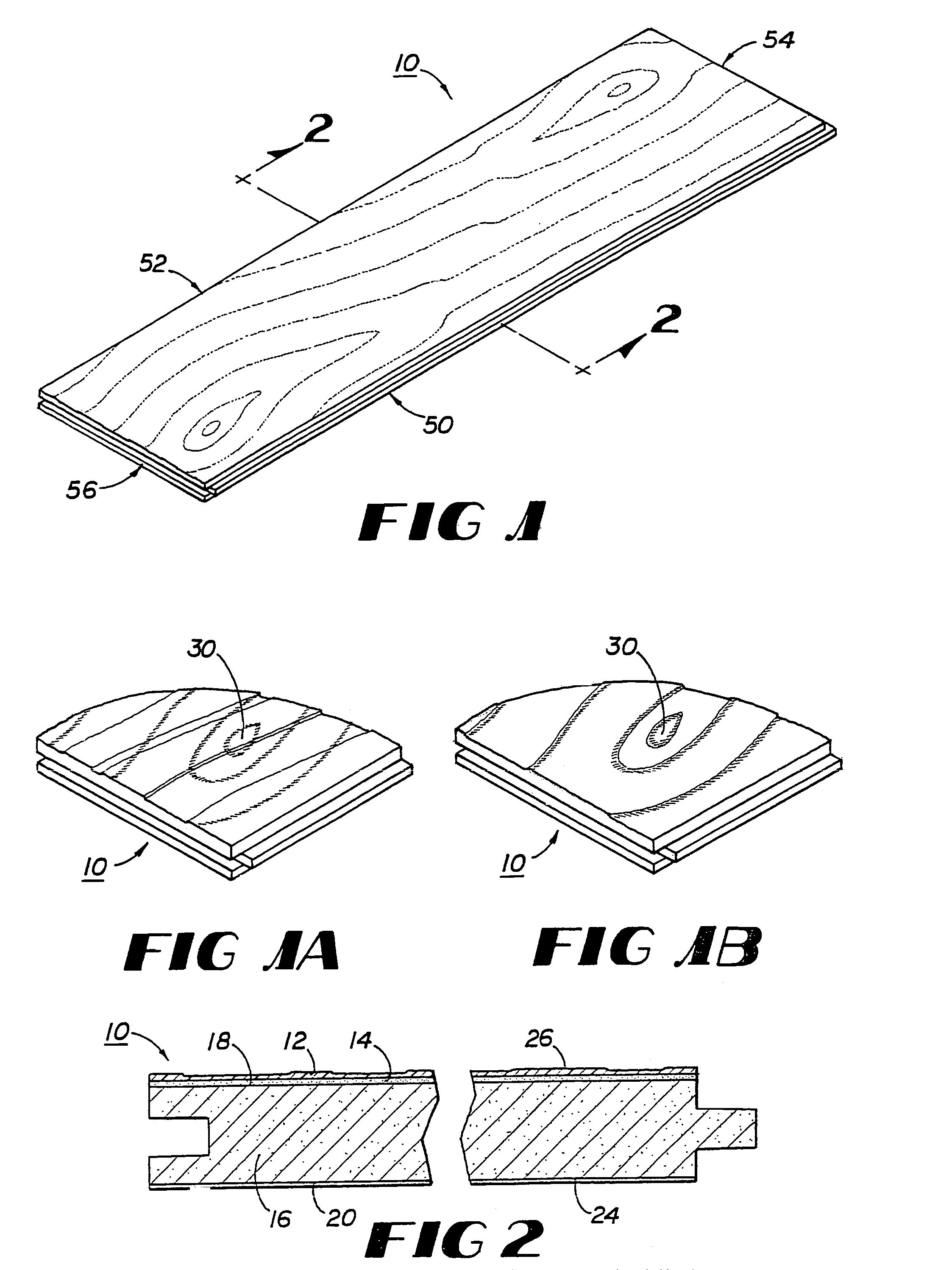

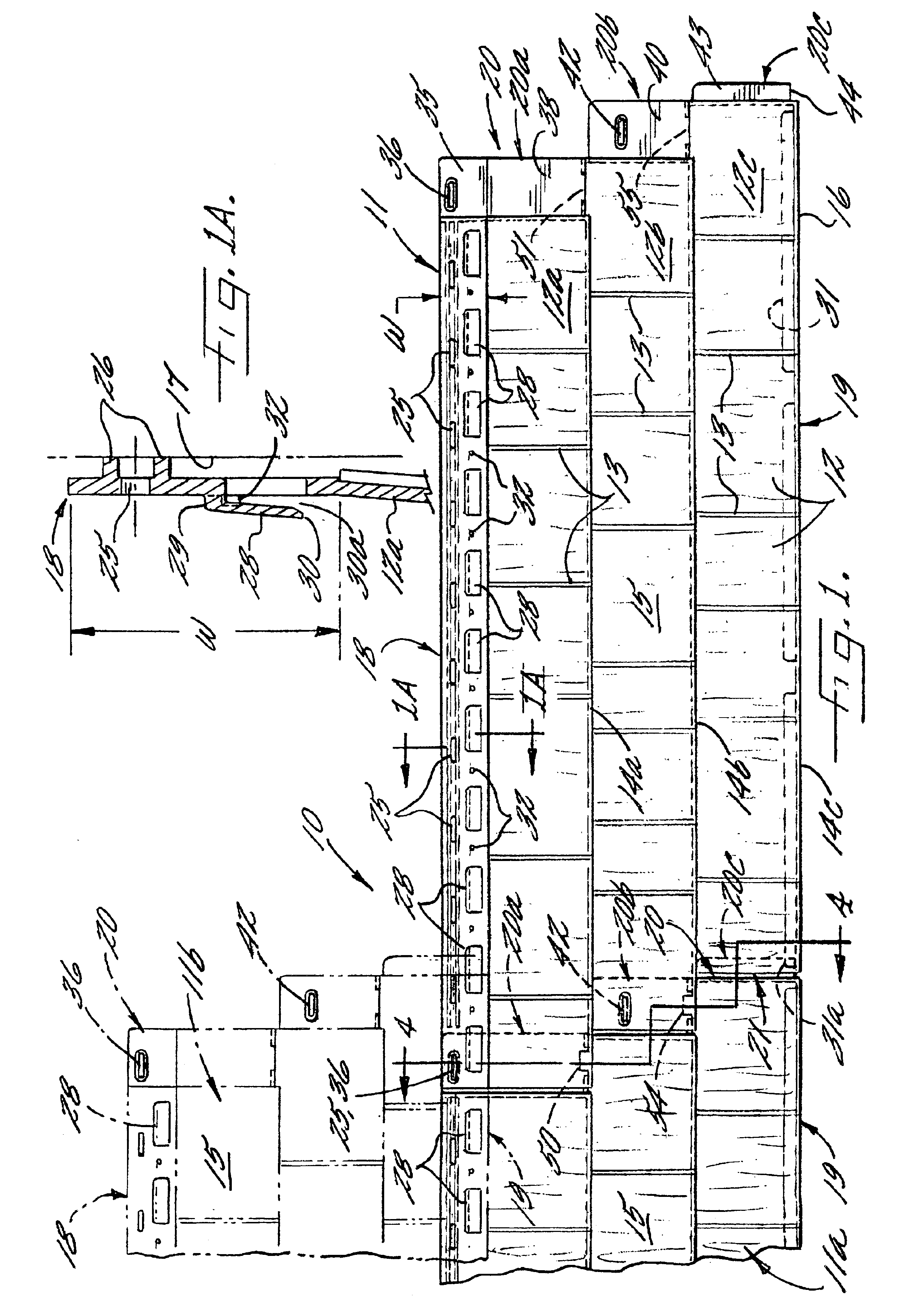

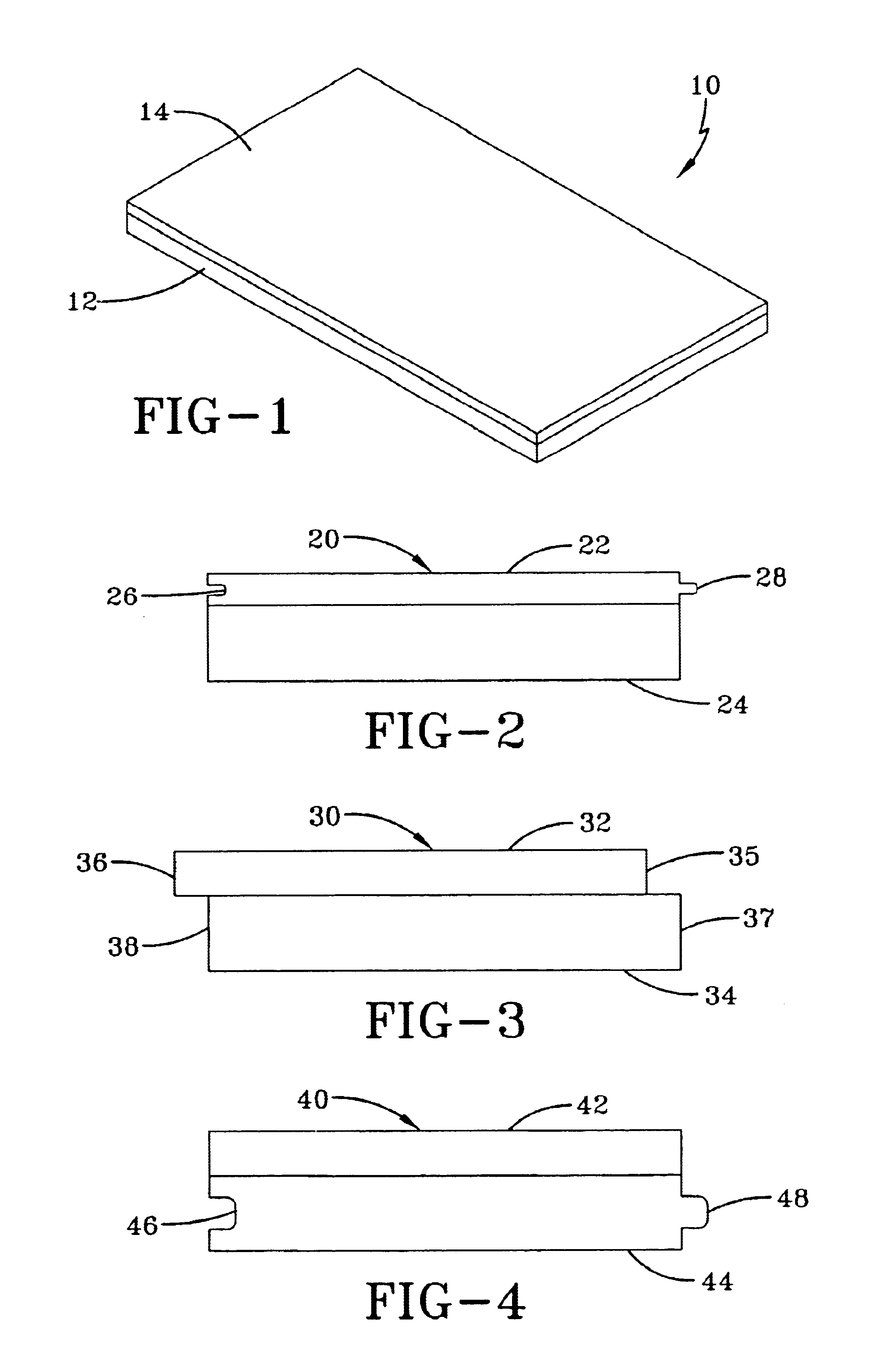

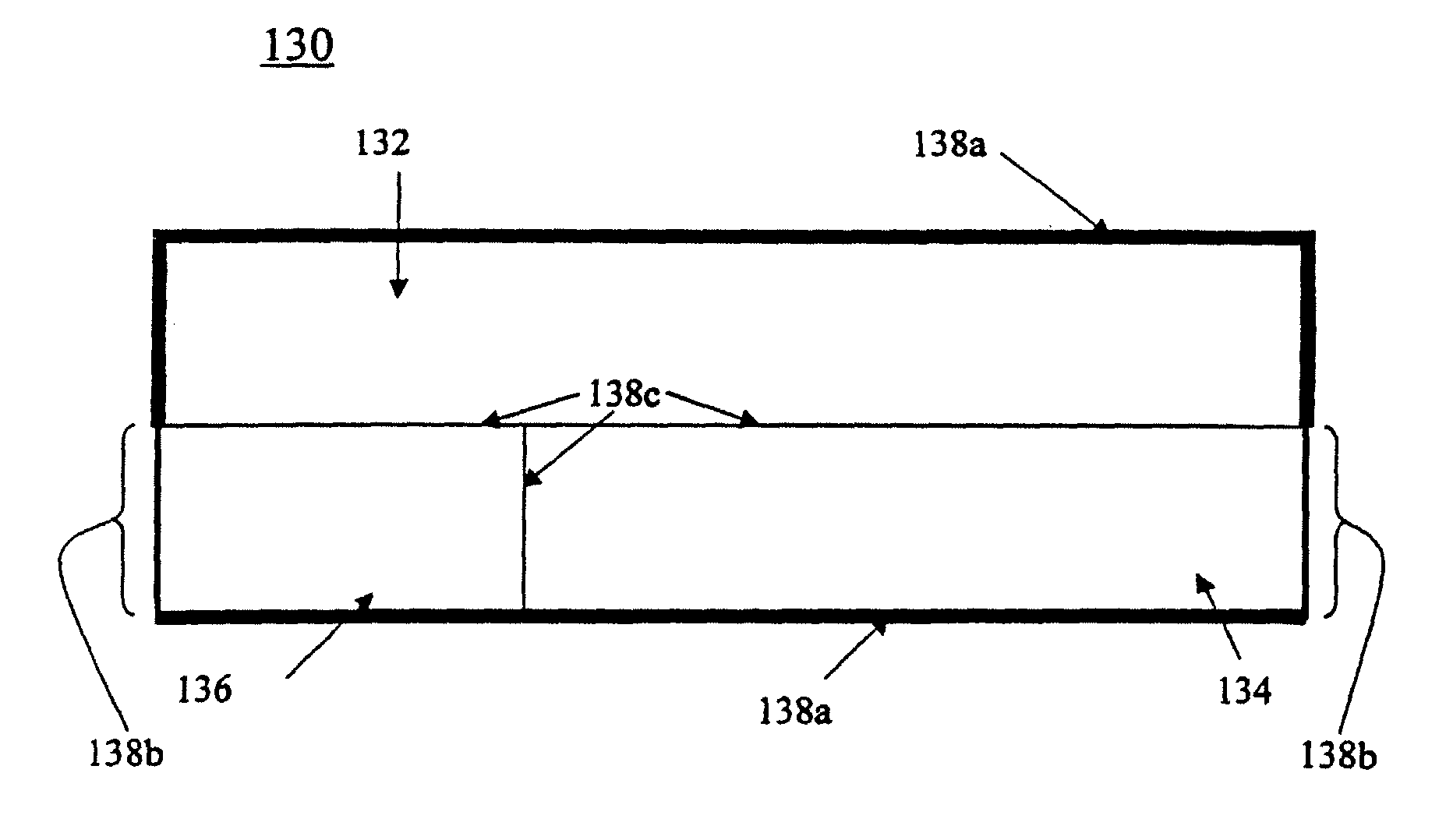

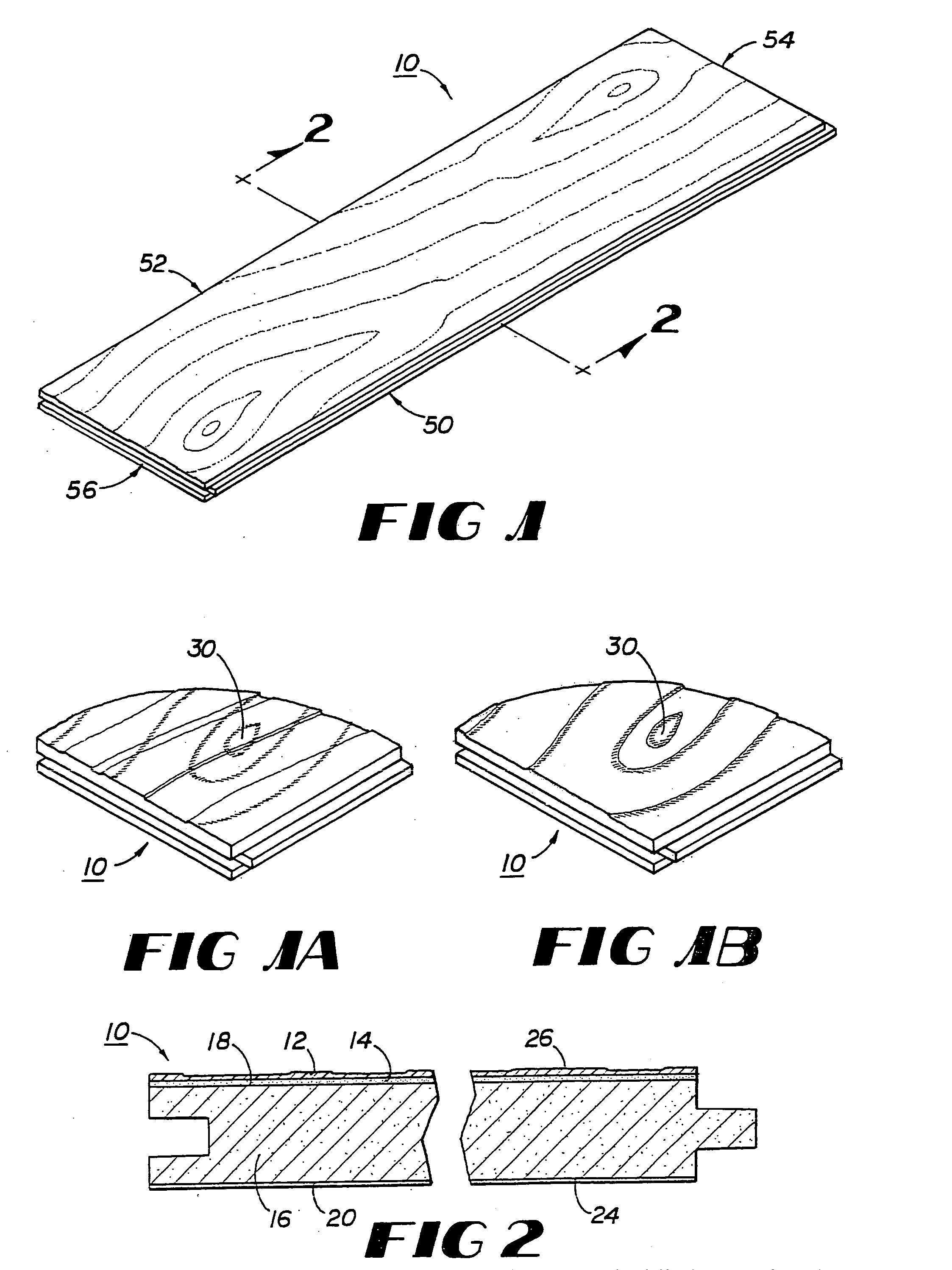

Floorboards with decorative grooves

InactiveUS20040035078A1Provides appearance and durabilityNatural appearanceCovering/liningsTongue/grooves making apparatusSurface layerEngineering

Floorboards consisting of a core and a surface layer with decorative joint edge portions which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

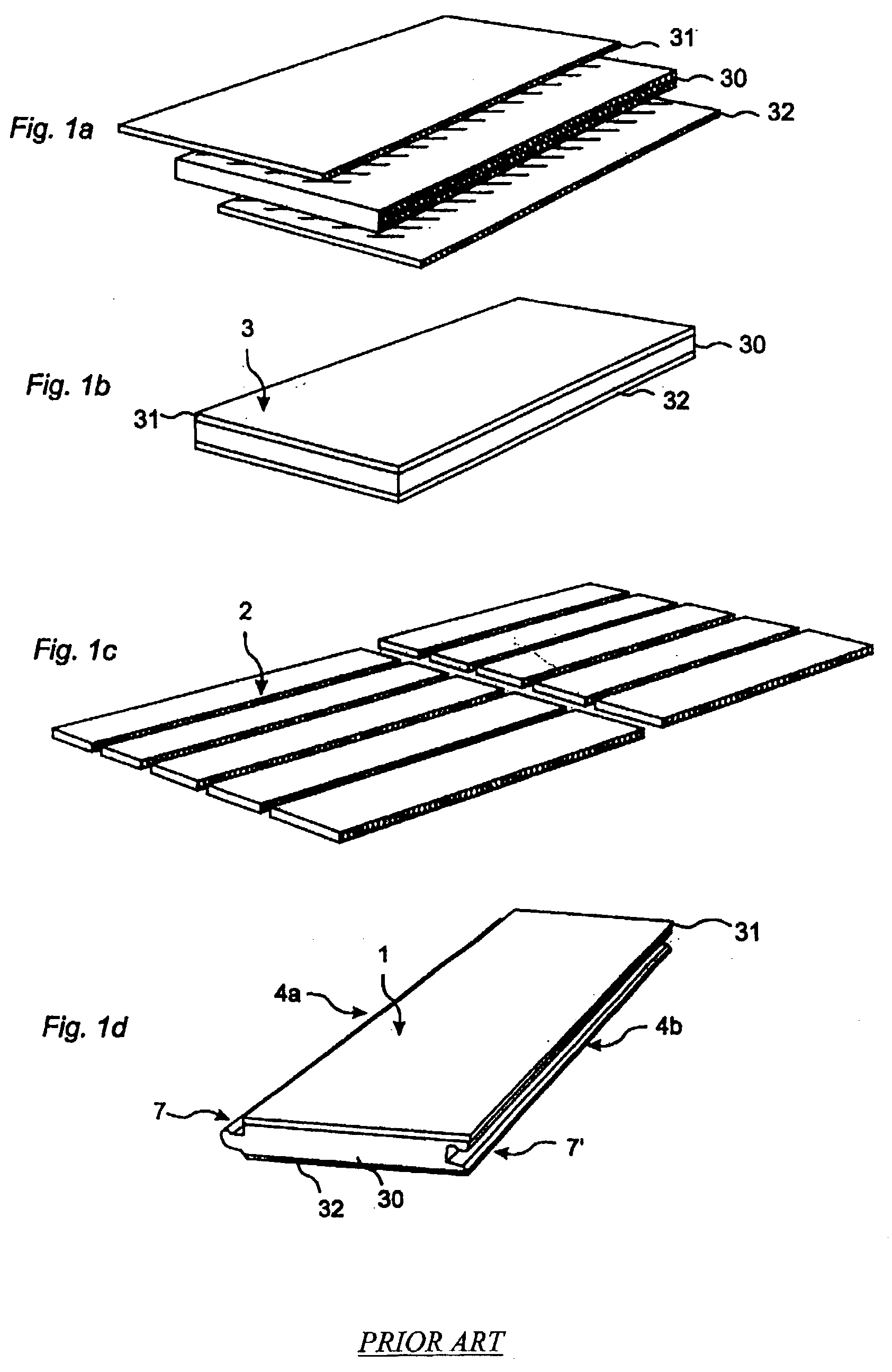

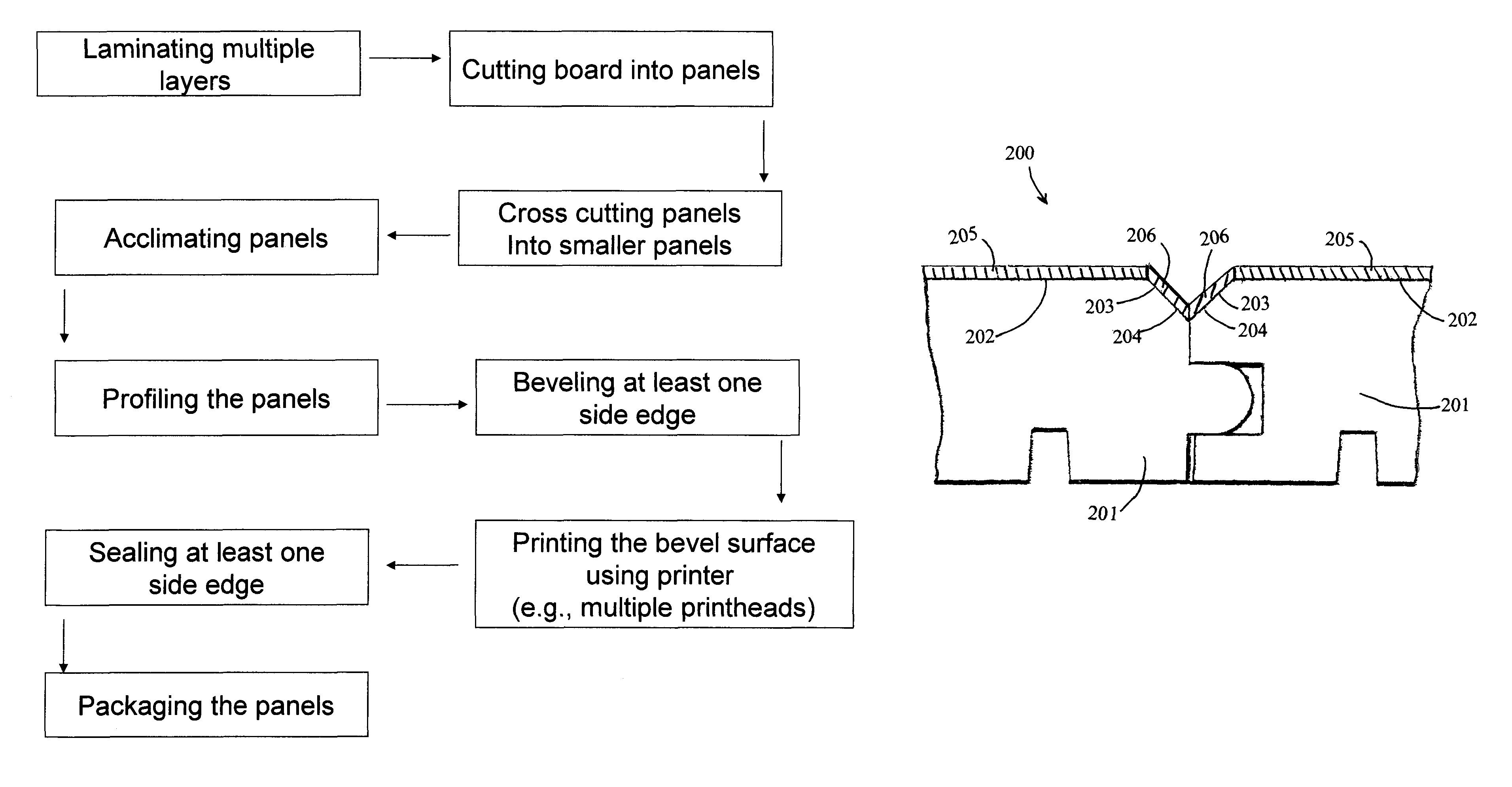

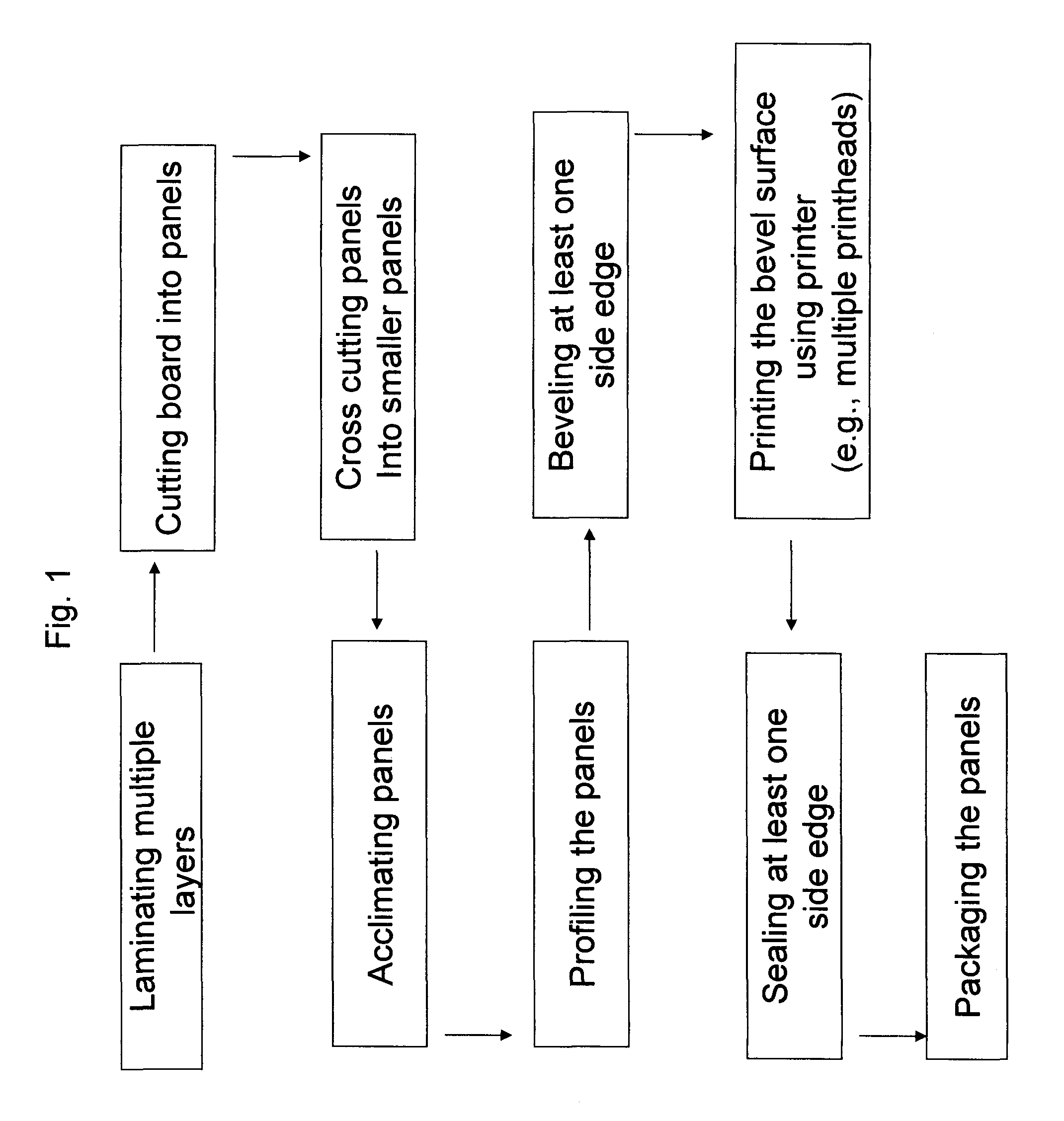

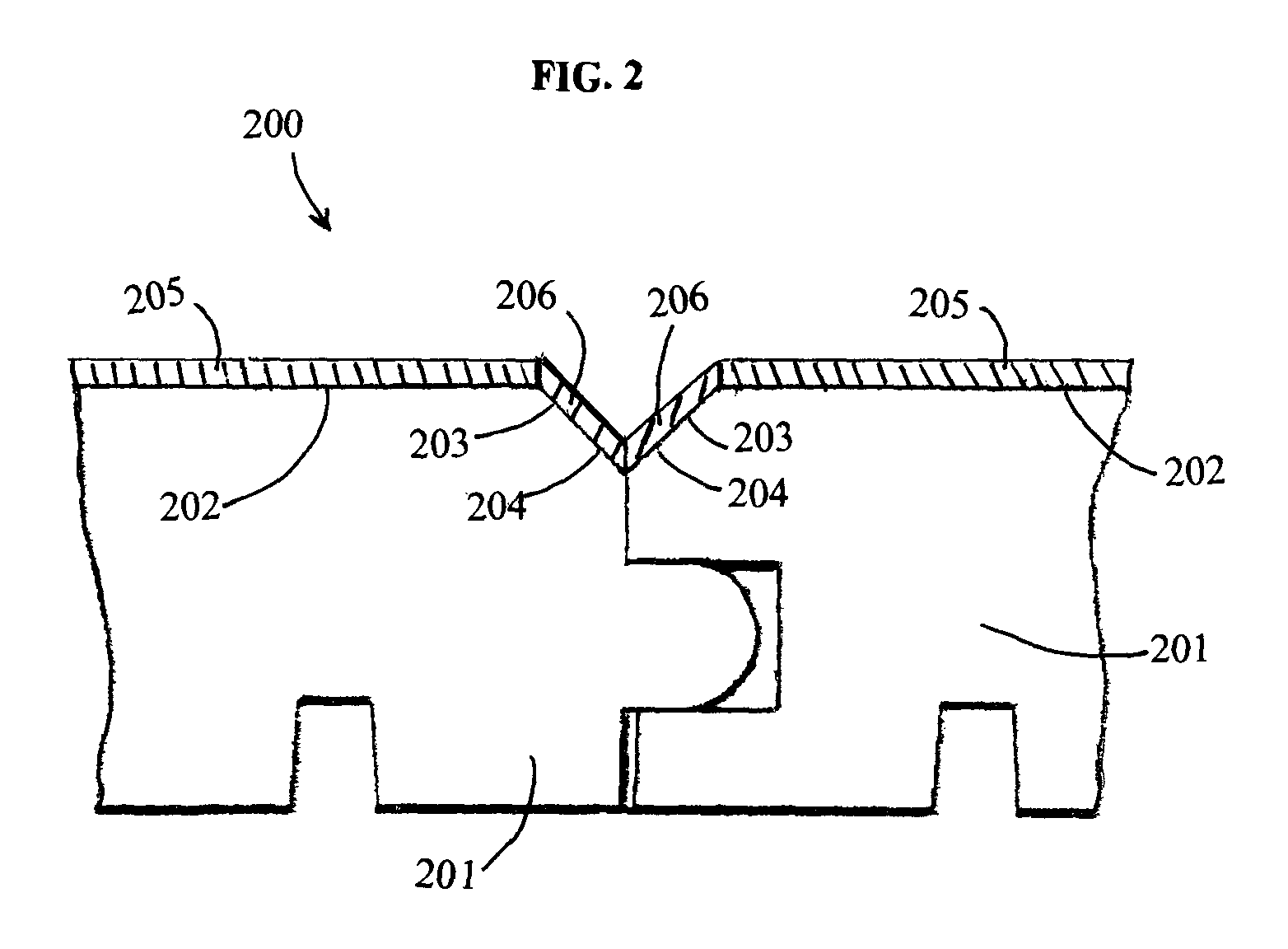

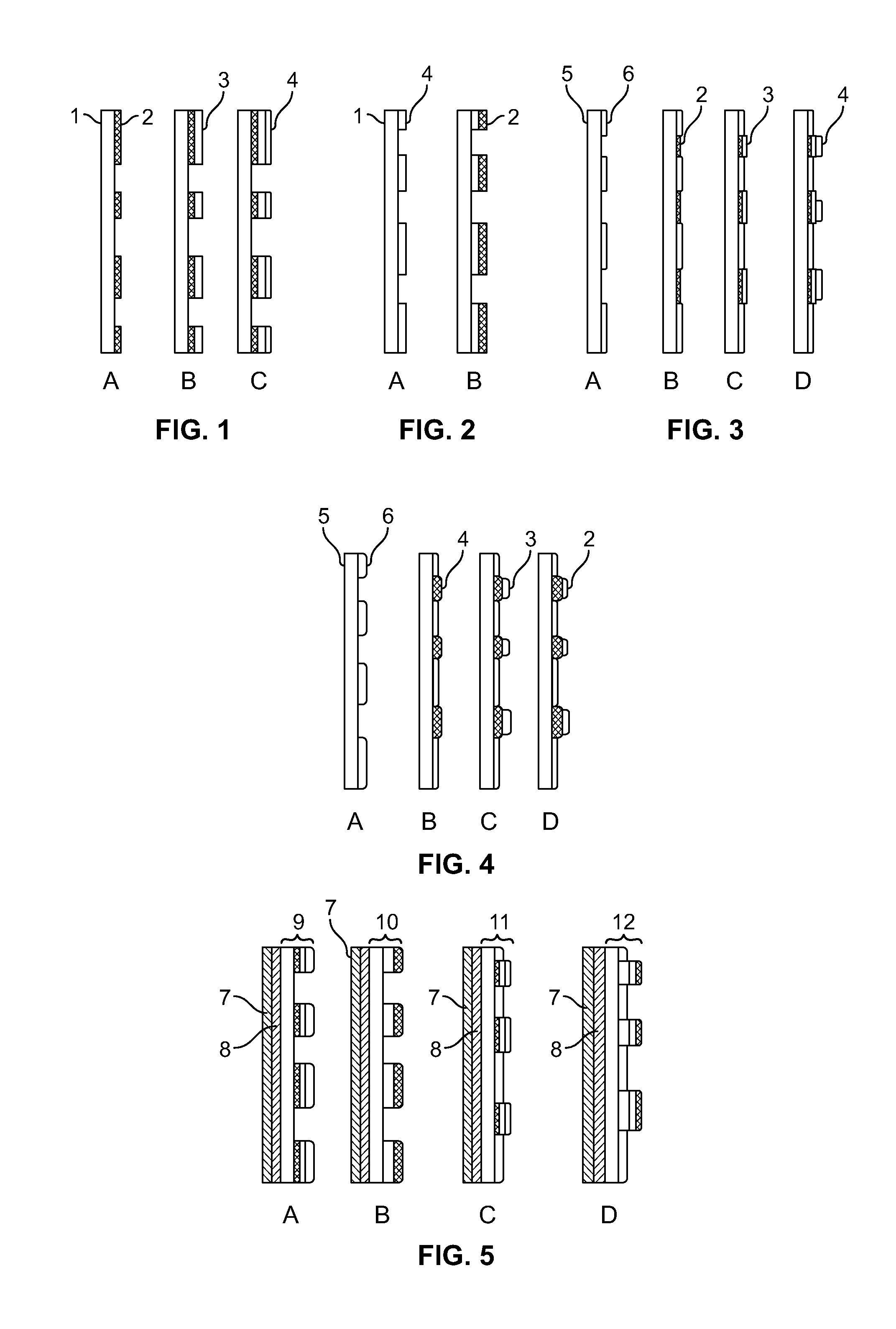

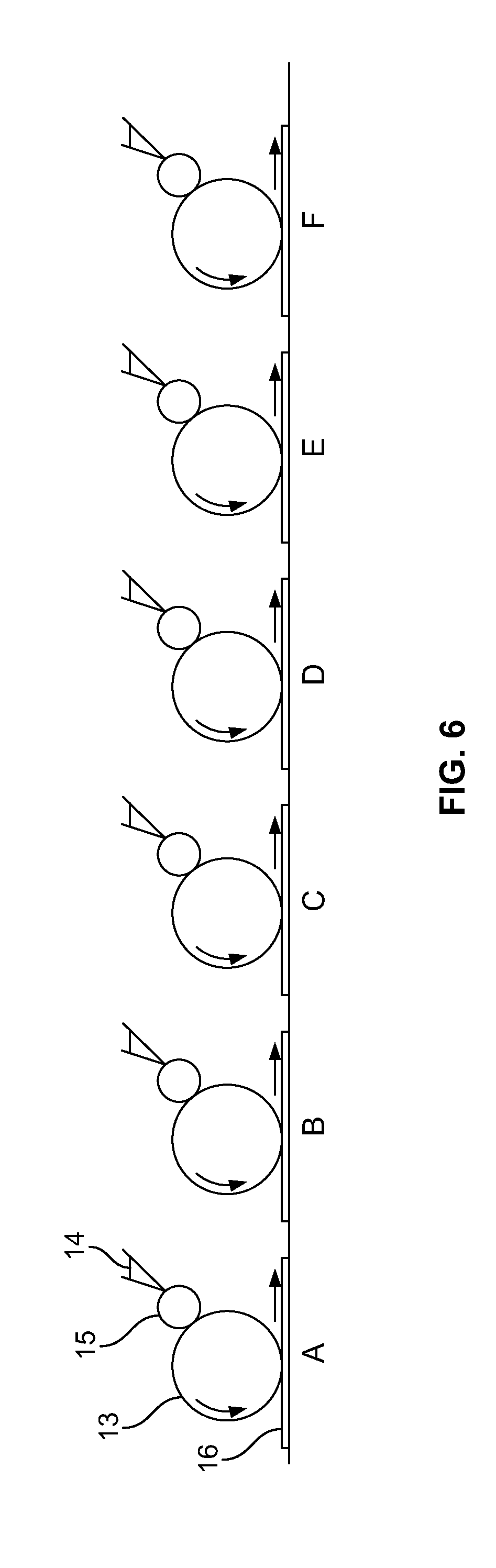

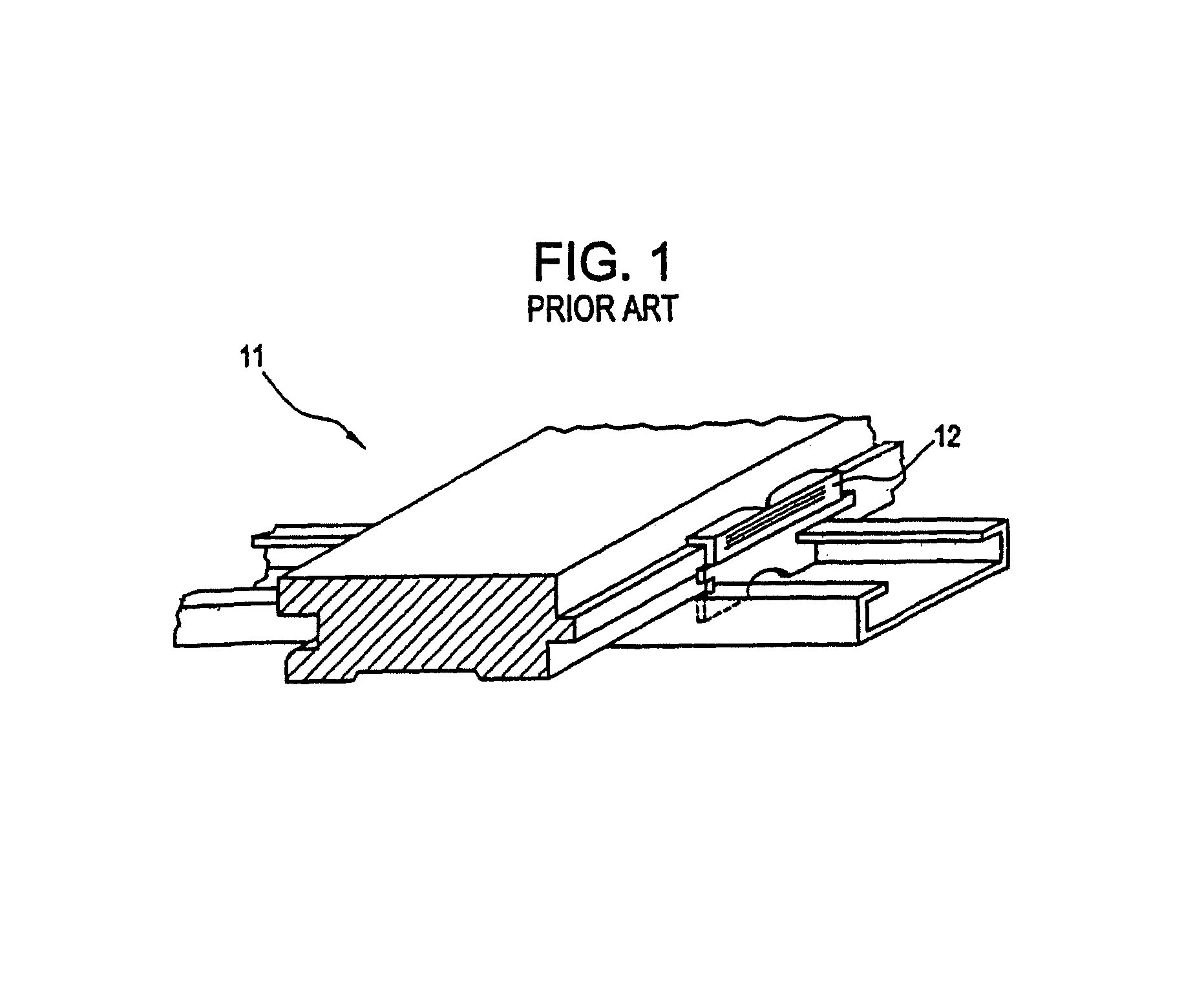

Methods and systems for decorating bevel and other surfaces of laminated floorings

ActiveUS20070283648A1Eliminate needEnhance the imageCovering/liningsWallsEngineeringDigital printing

Methods and systems for decorating at least one bevel surface or other surface of a laminated flooring are described. The bevel surface can be decorated by non-transfer printing such as digital printing. The digital printer can be an ink jet printer such as a piezoelectric drop-on-demand (DOD) printer that allows a color and pattern to be placed on the bevel surface that matches the print design (décor pattern or face design) of the laminated flooring. Other devices are provided such as a device that takes a picture of or scans an image of the print design, and modifies the taken picture or the scanned image so that the edge pattern thereof matches with an edge pattern of the print design.

Owner:FLOORING IND LTD

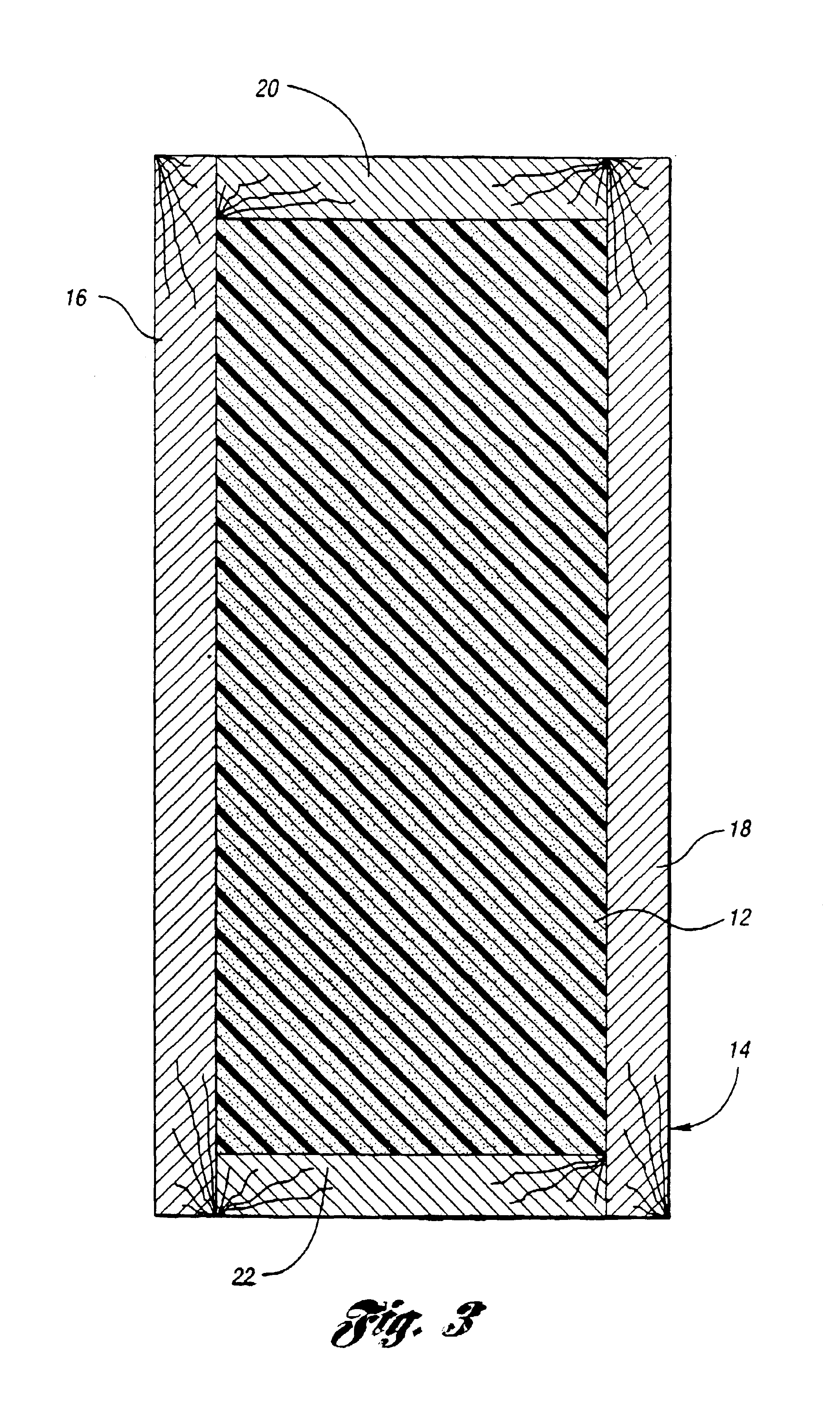

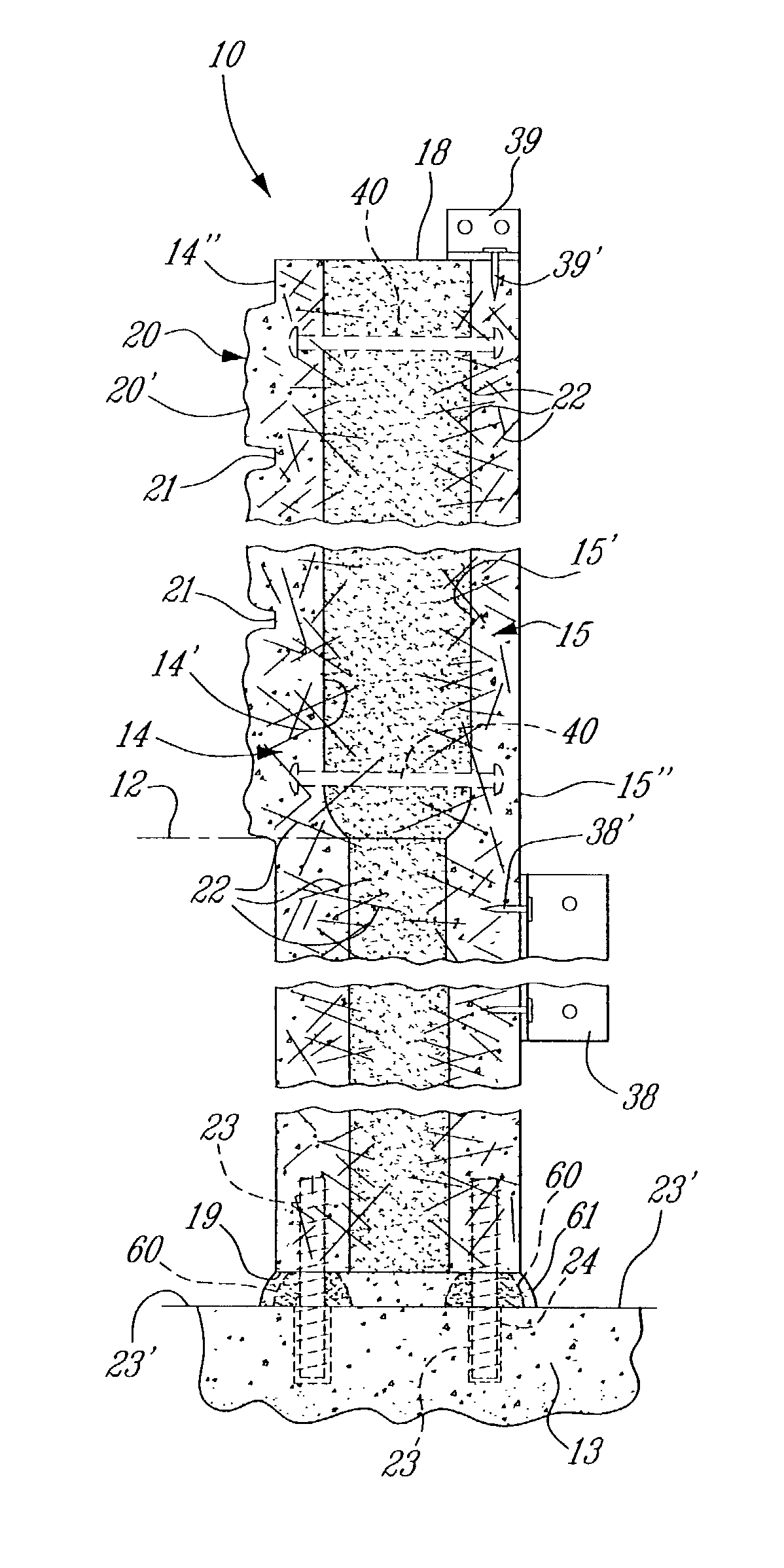

Foaming of simulated stone structures

InactiveUS20090056257A1Improve insulation performanceImprove sound insulationConstruction materialCovering/liningsBrickThermal insulation

Simulated stone, masonry, and brick textured products such as siding having a foam backing or with the hollow parts injected with foam or molded with foam in one or more steps, obtained when specially selected materials are properly admixed and formed via molding techniques. The foam backing is applied to the product in either a one or two step process. The foam backing may be used on panels, wall structures, and other products that may have contoured and textured surfaces and may simulate the appearance of conventional building and construction materials including, but not limited to, stone, brick, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials are disclosed. The foam backing provides improves thermal insulation, improved sound reduction, improved rigidity, and improved dimensional stability. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:EXTERIOR PORTFOLIO

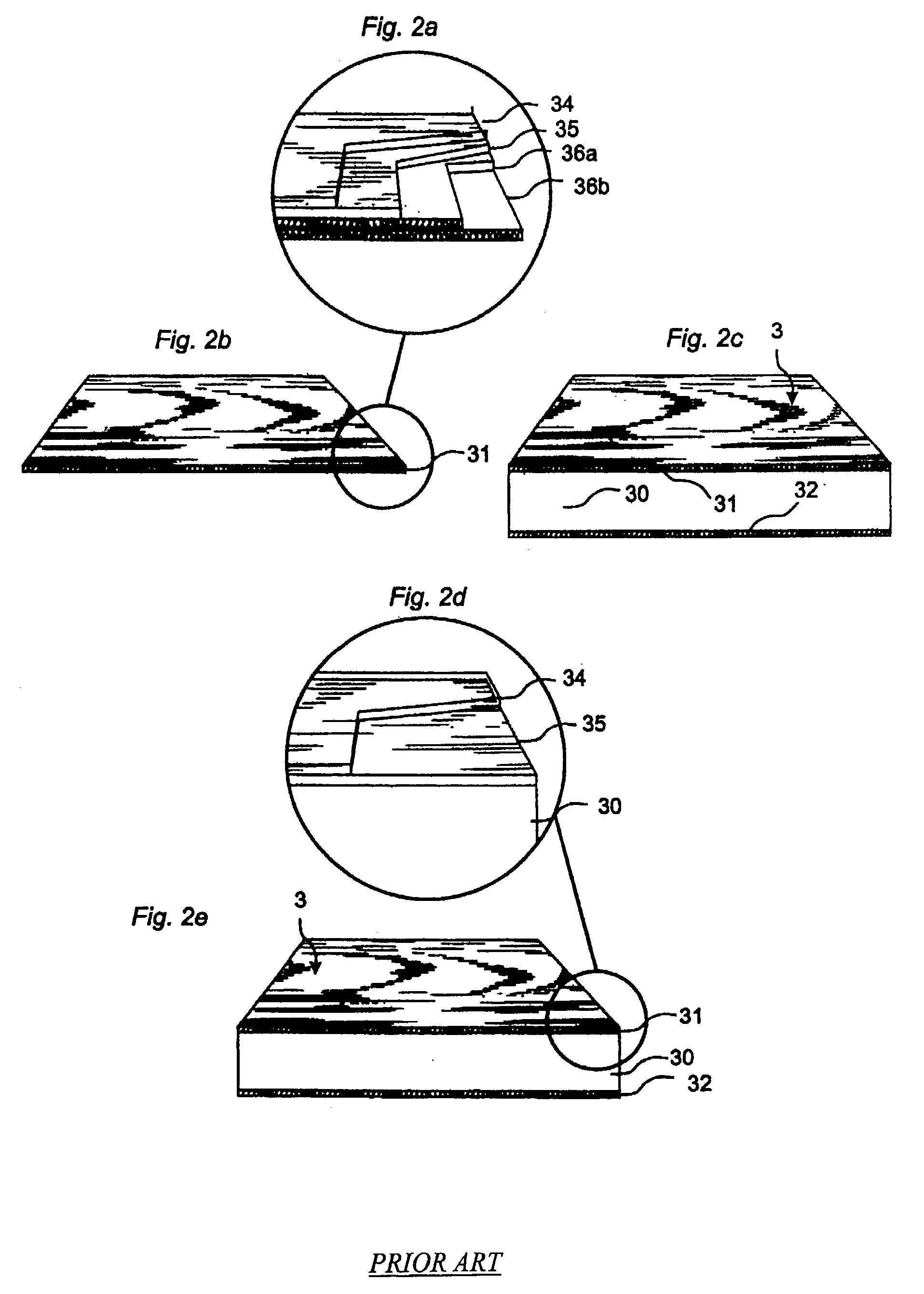

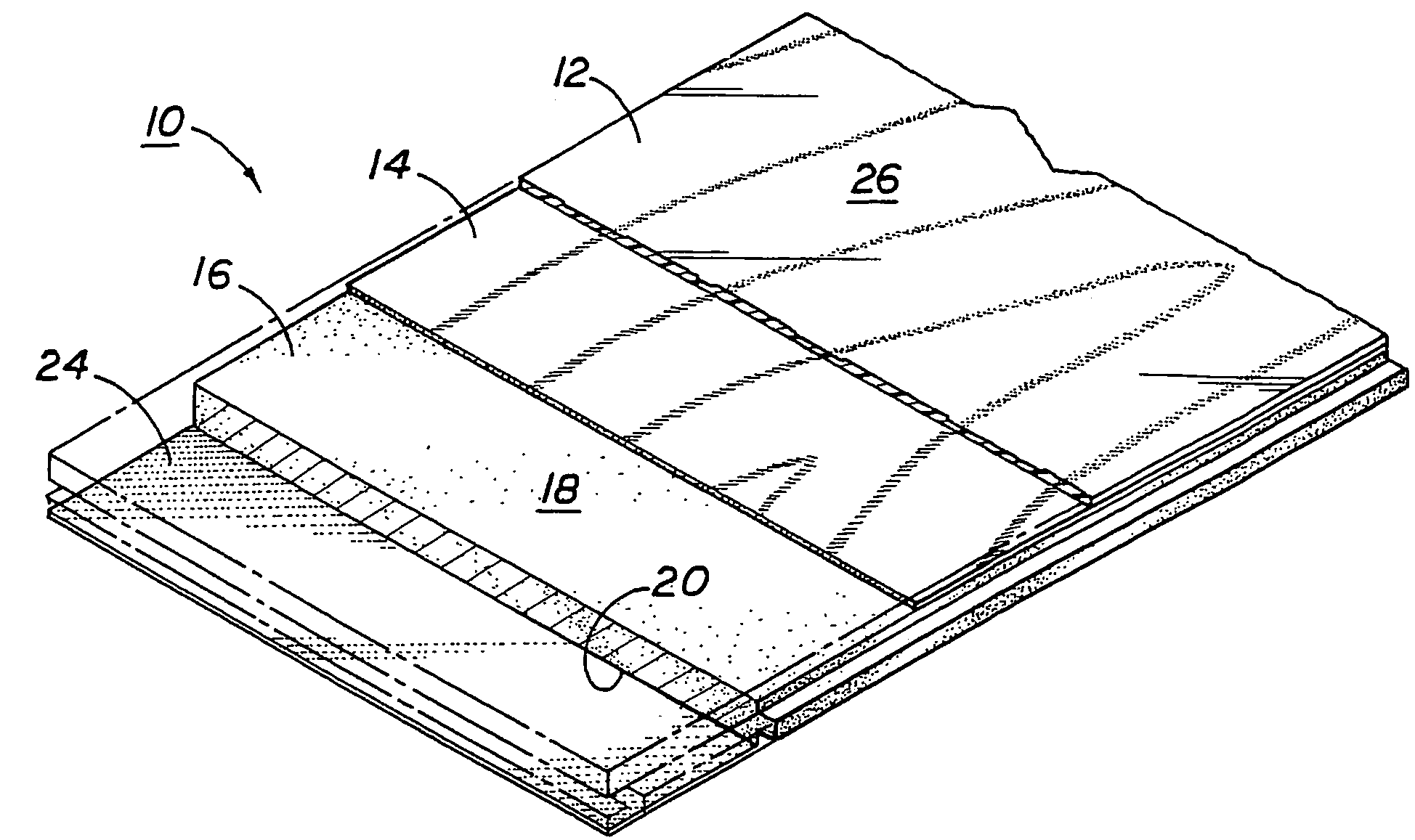

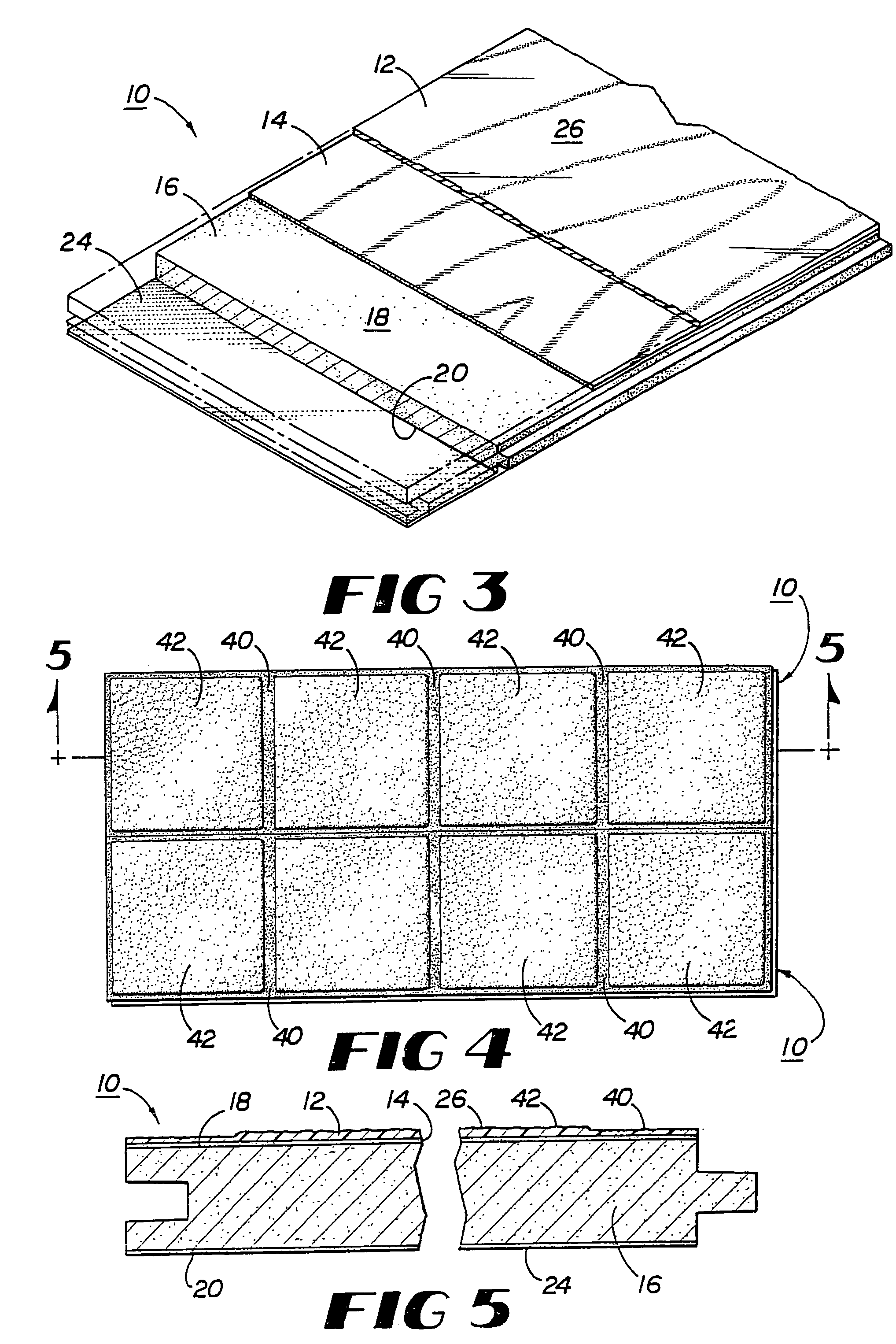

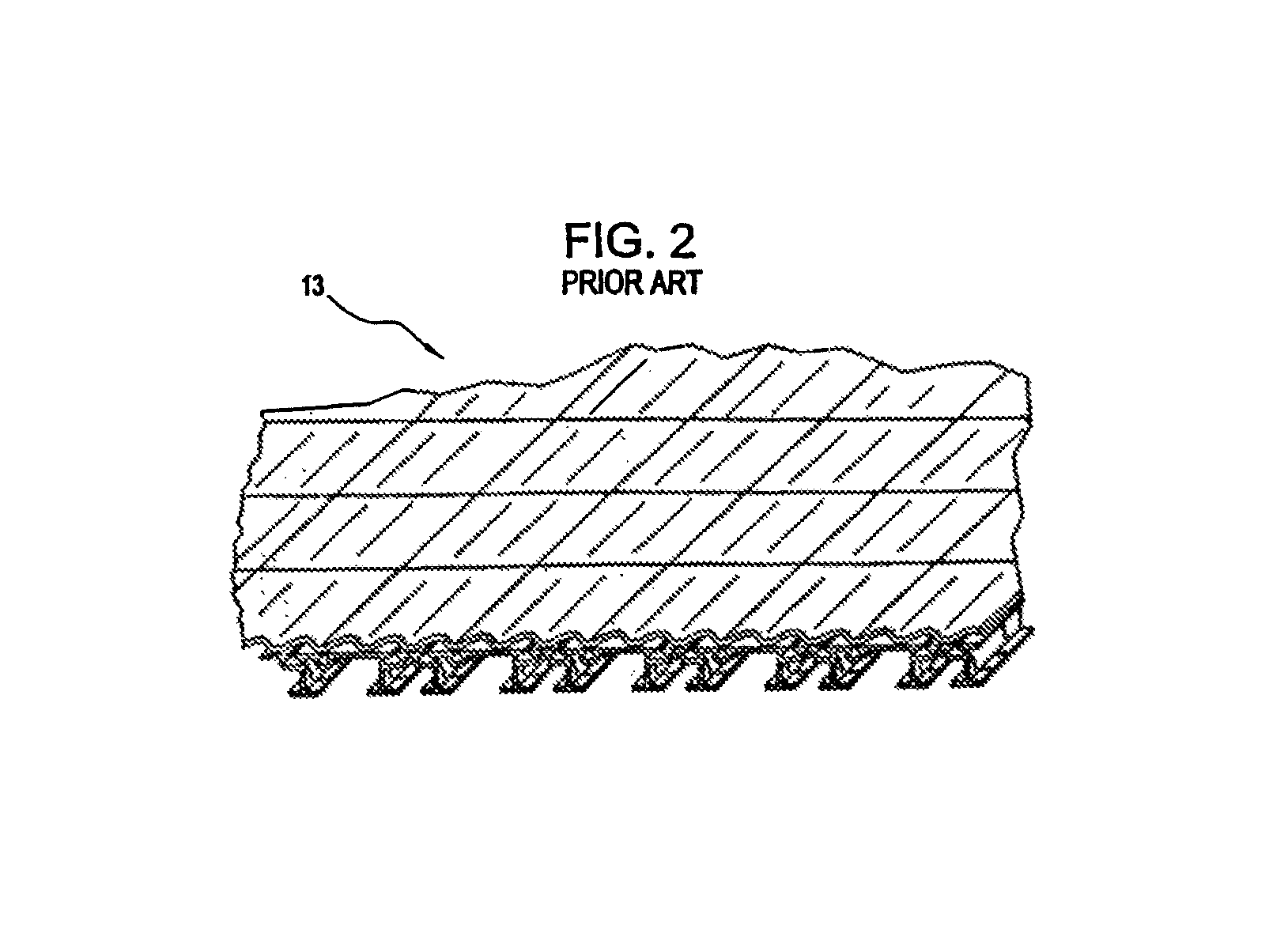

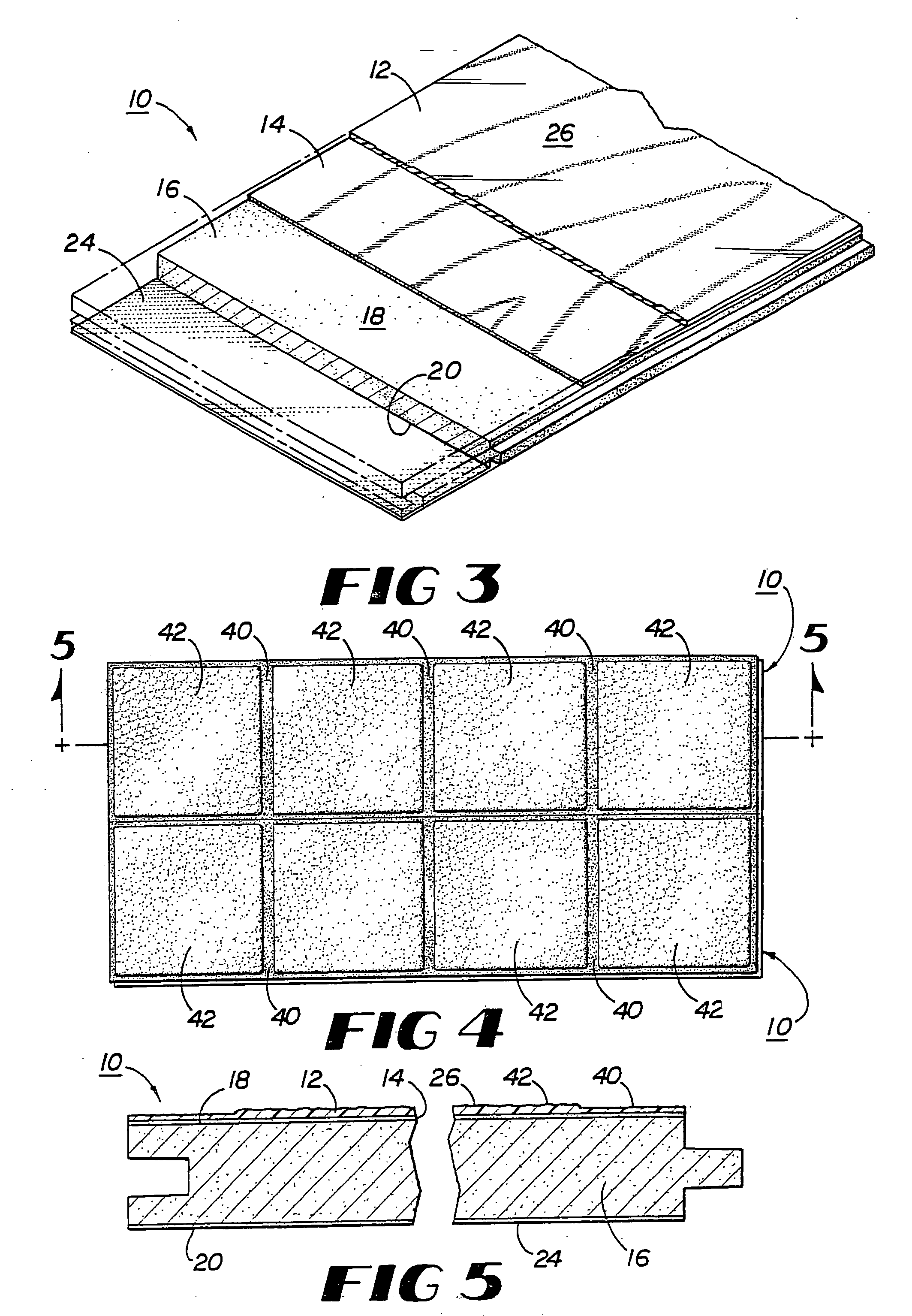

Textured laminate flooring

InactiveUS7243469B2Provide protectionImprove aestheticsCovering/liningsSpecial paperSubject matterEngineering

A decorated floor panel having a core with a top surface and an opposite bottom surface; a decorative layer coupled to the top surface of the core, the decorative layer having a desired aesthetic appearance; and a wear layer coupled to and substantially covering the decorative layer for protecting the decorative layer. The wear layer has an exposed wear surface with depressions therein of a variable depth below the wear surface, the depressions being arranged to display a desired texture pattern. It is noted that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to ascertain quickly the subject matter of the technical disclosure. The abstract is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims pursuant to 37 C.F.R. § 1.72(b).

Owner:COLUMBIA INSURANCE CO

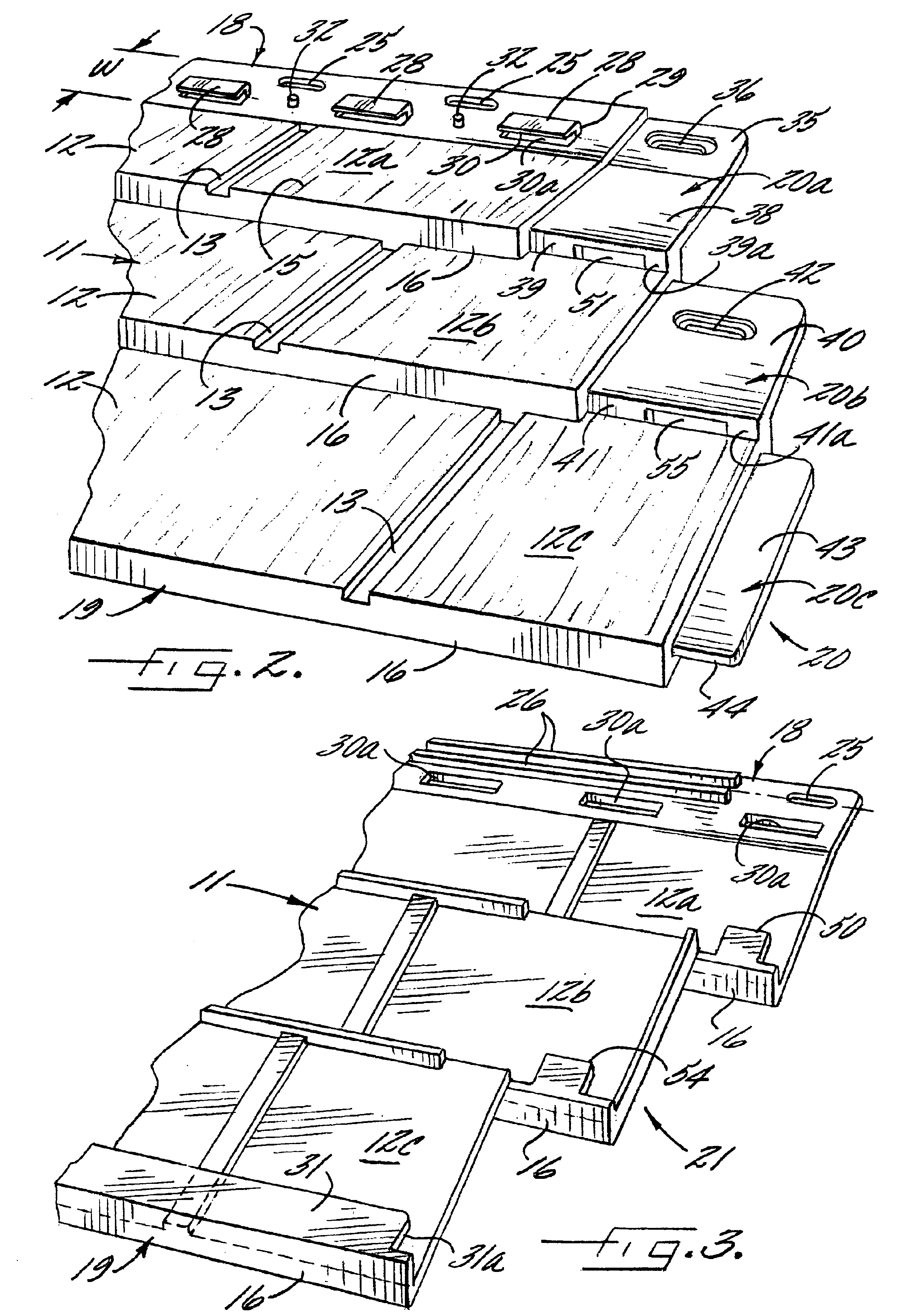

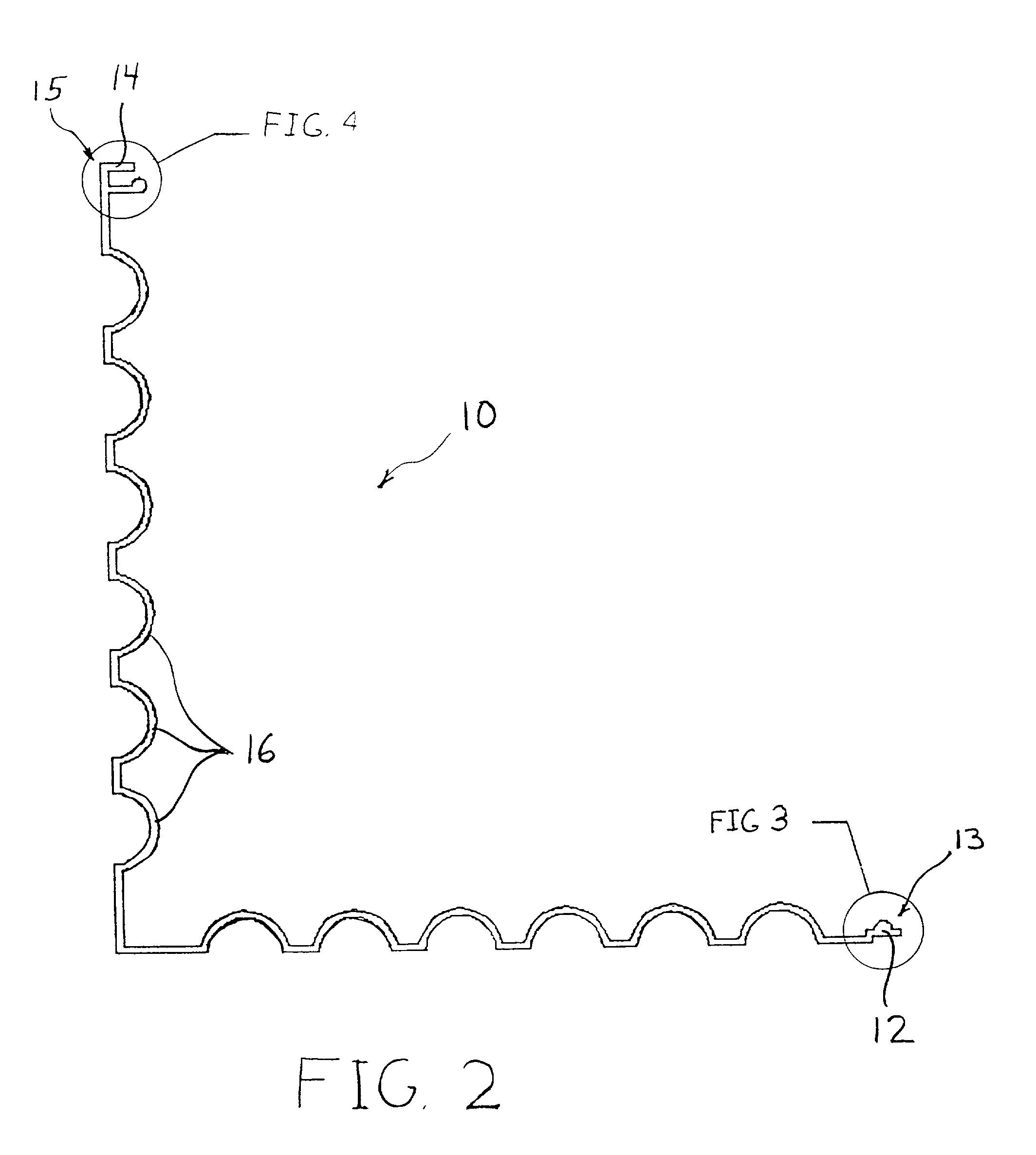

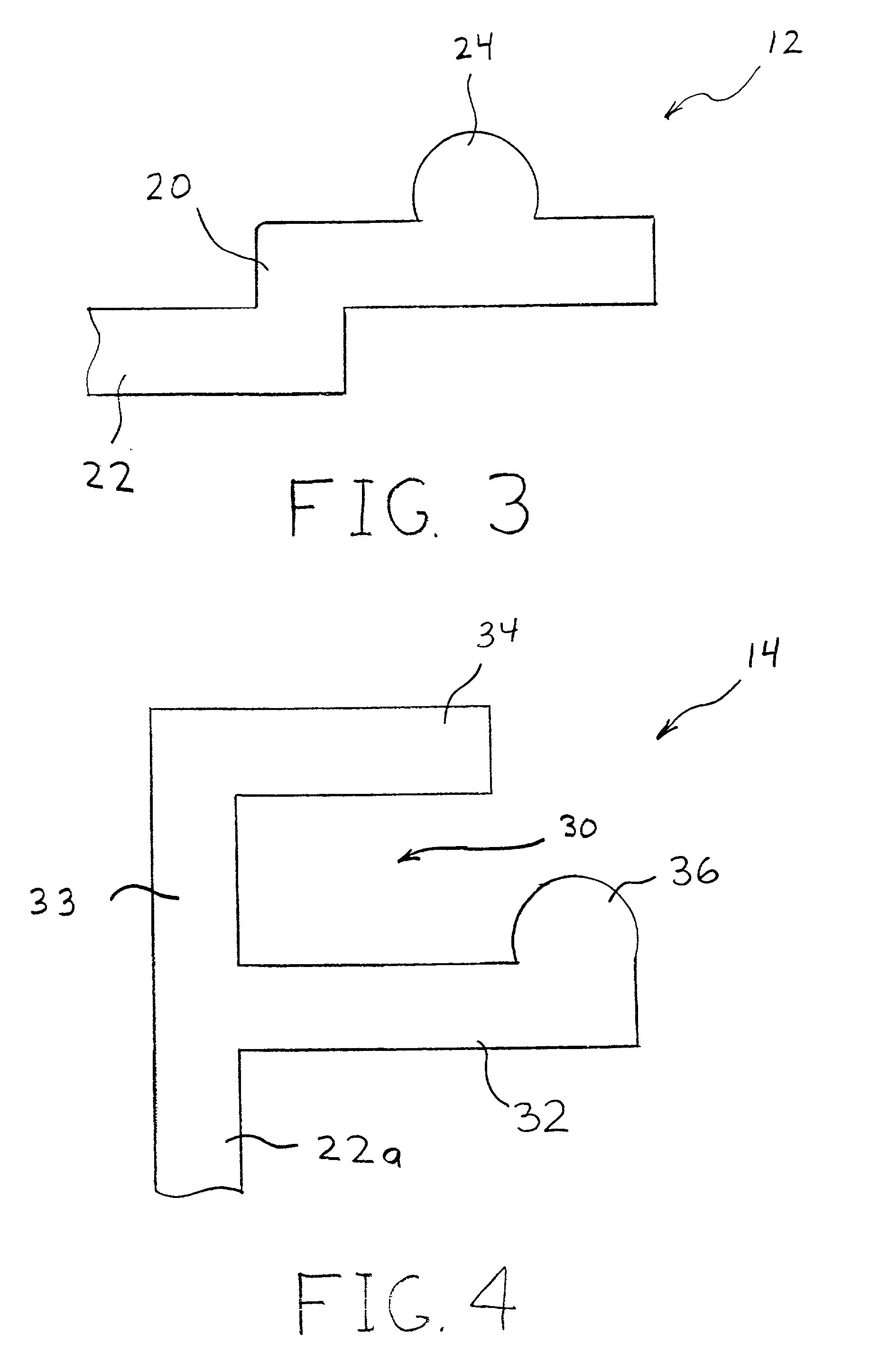

Paving system for floor tiles

ActiveUS7197855B2Reduce paving costsRoof covering using tiles/slatesStrutsCeramic tilesCivil engineering

Owner:CLICKN WALK +1

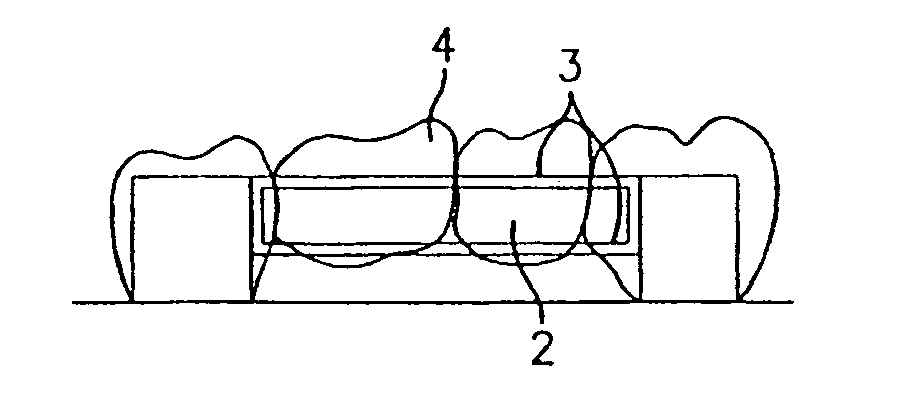

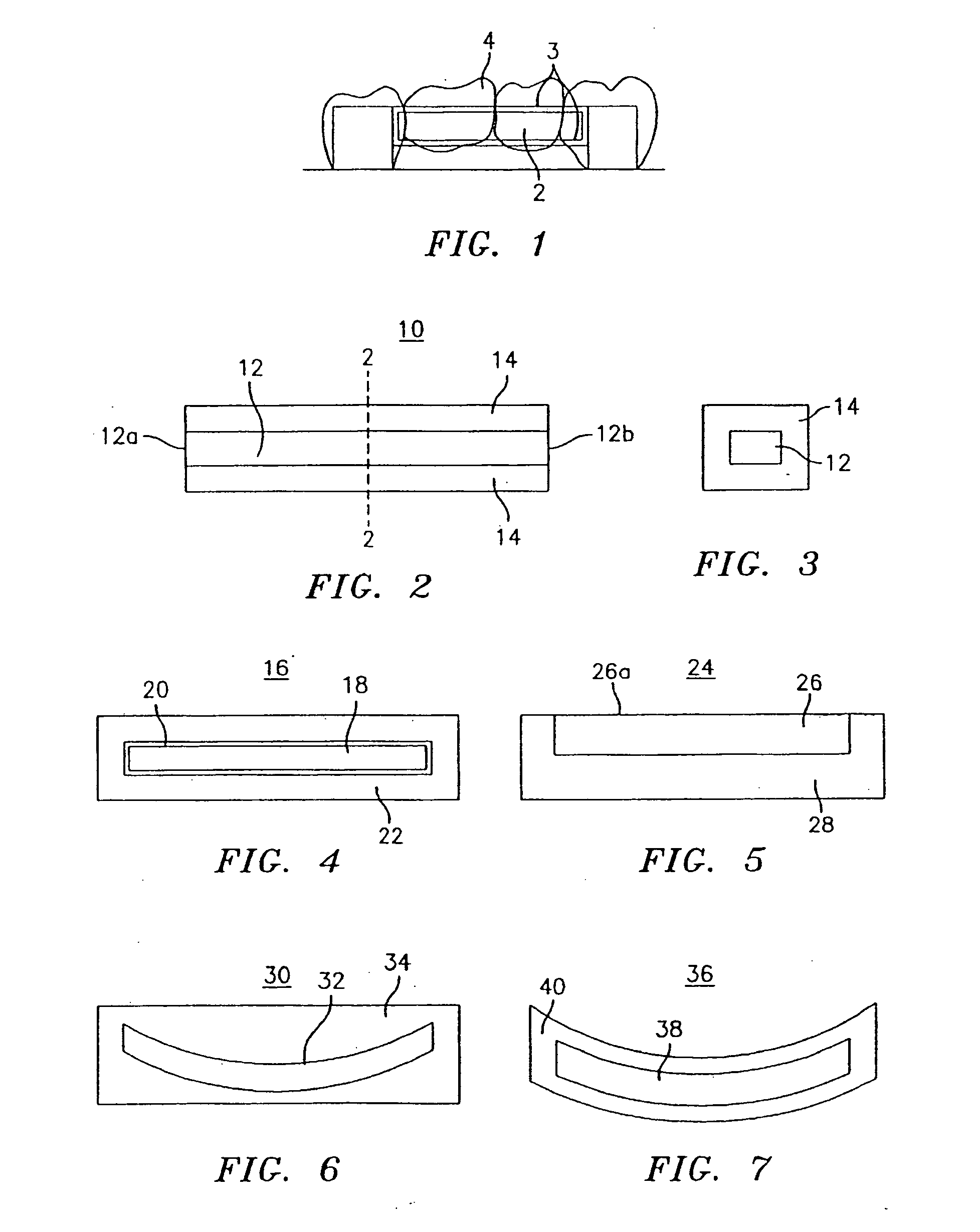

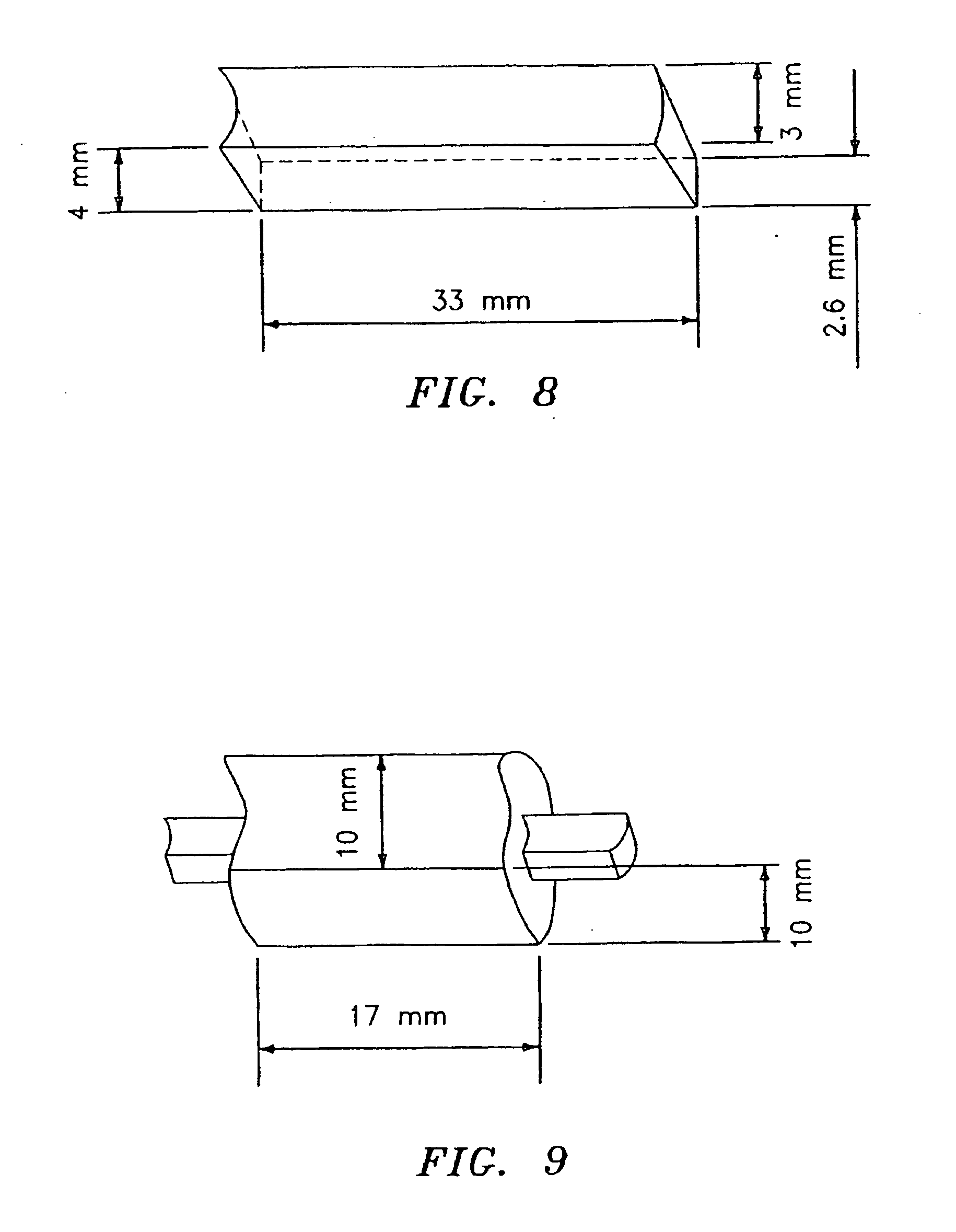

High-strength dental restorations

InactiveUS20050127544A1Improve adhesionHigh strengthHair accessoriesImpression capsDental ProductHigh intensity

Lithium disilicate based glass-ceramics contain high strength ceramic components for use in the manufacture of dental products. The glass-ceramics have good pressability, i.e., the ability to be formed into dental products by heat-pressing using commercially available equipment. The strength of the dental articles is increased with the inclusion of the high strength ceramic components.

Owner:ARDENT

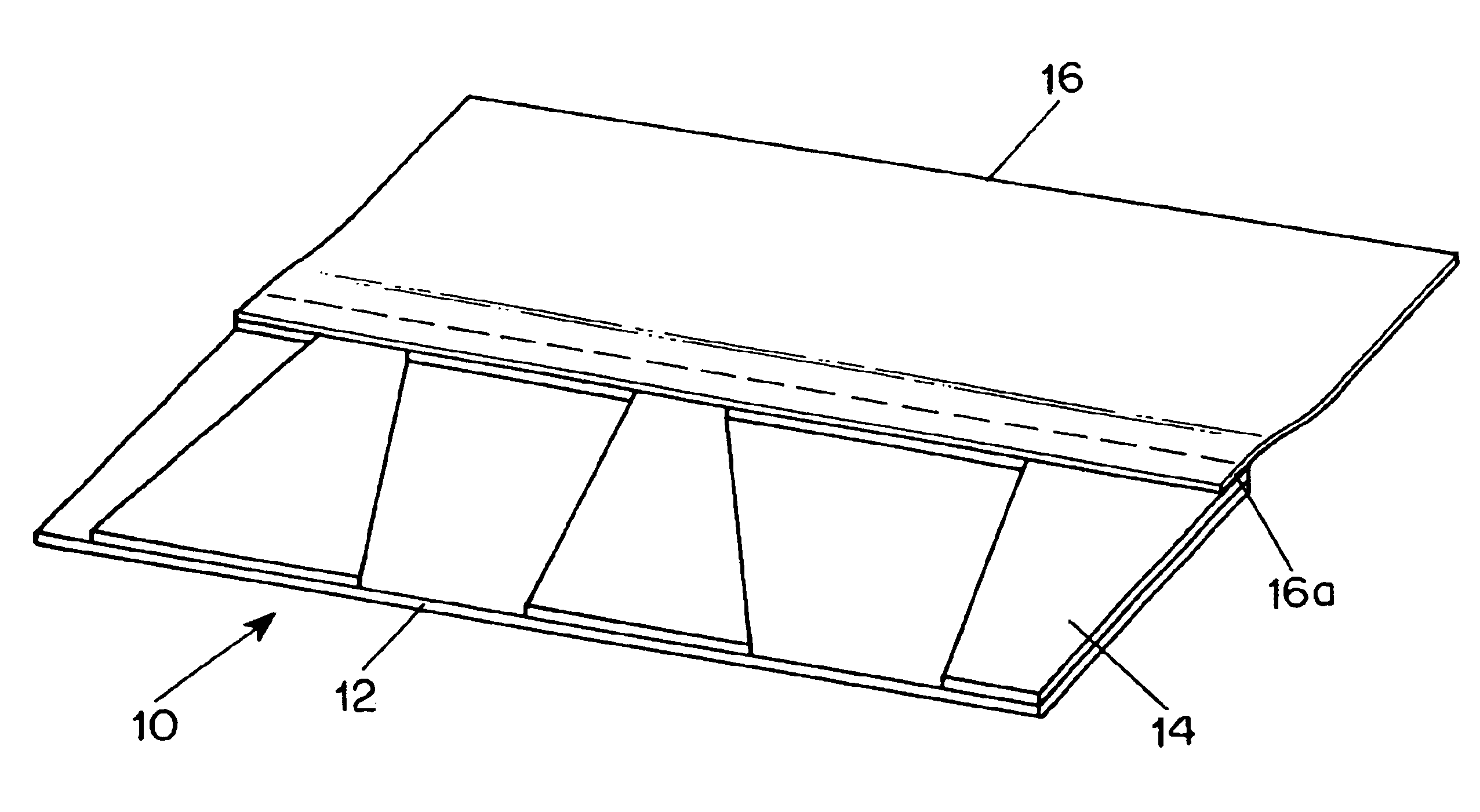

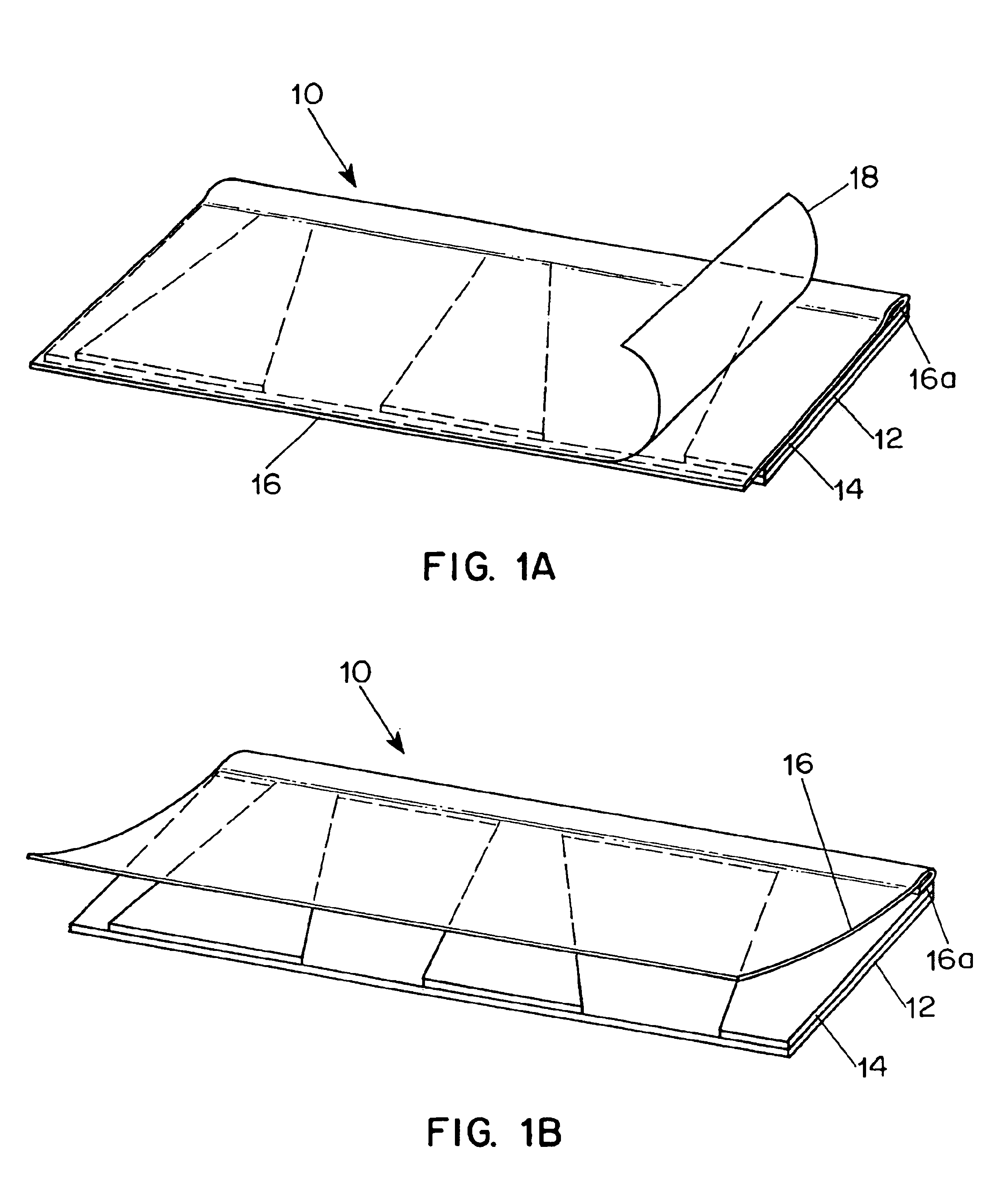

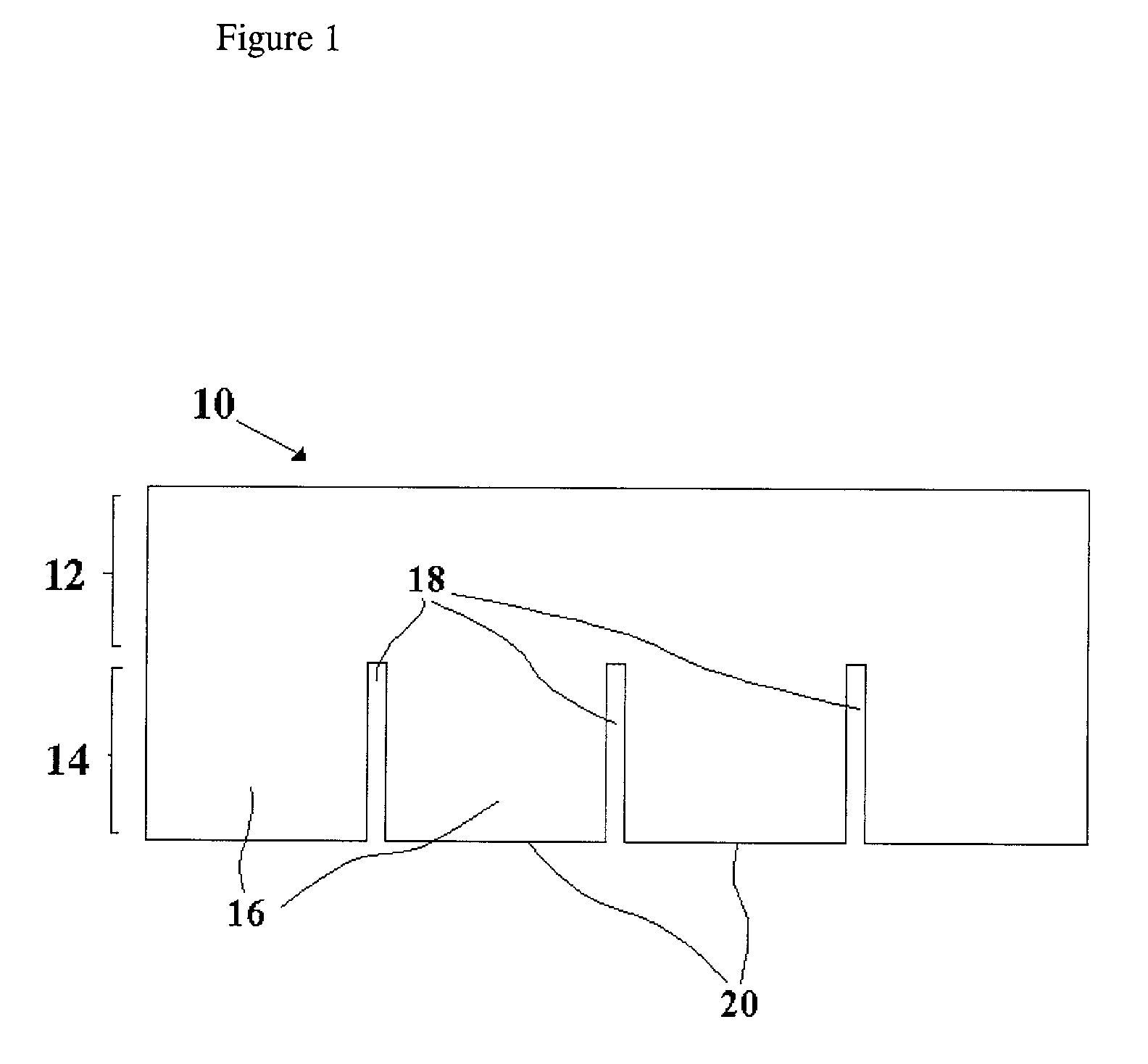

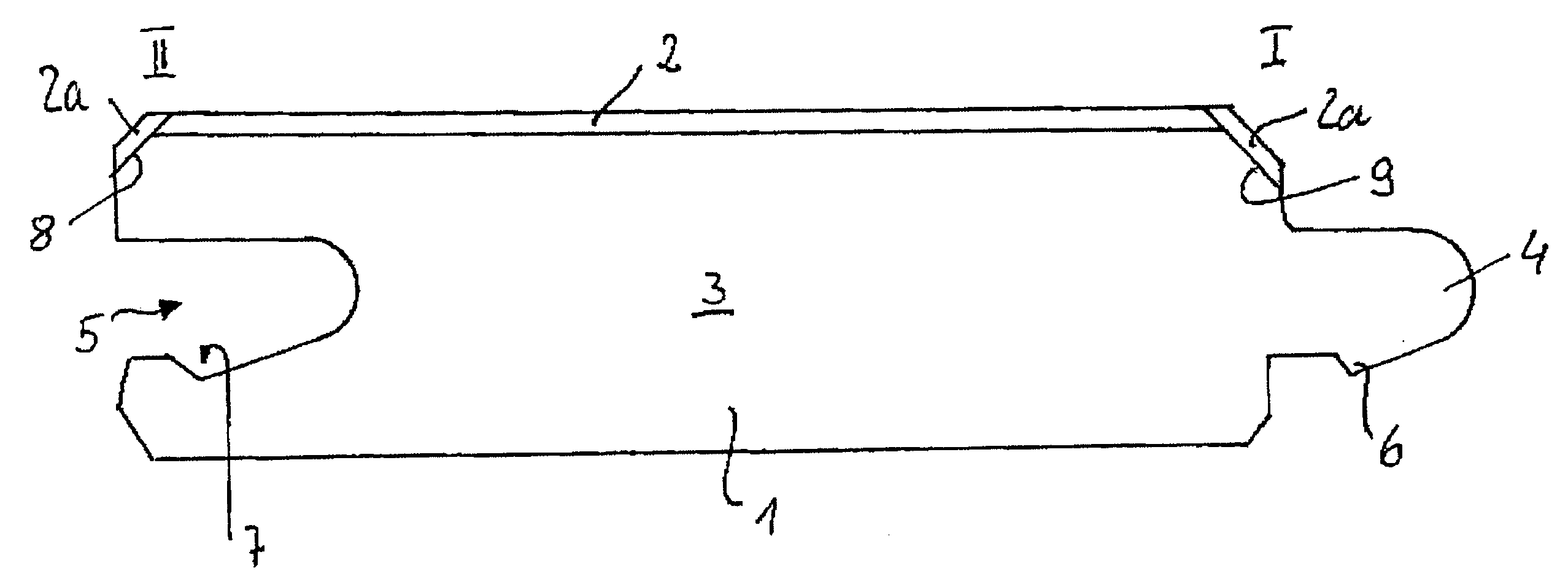

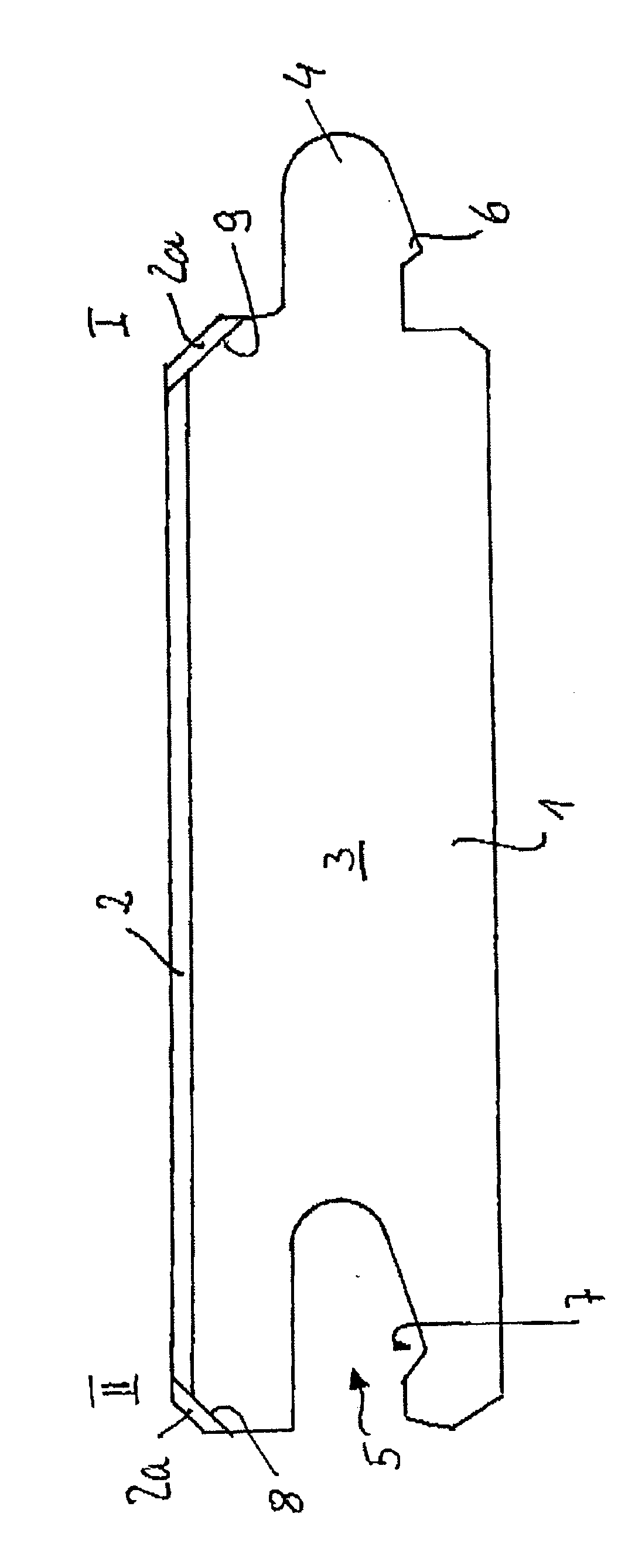

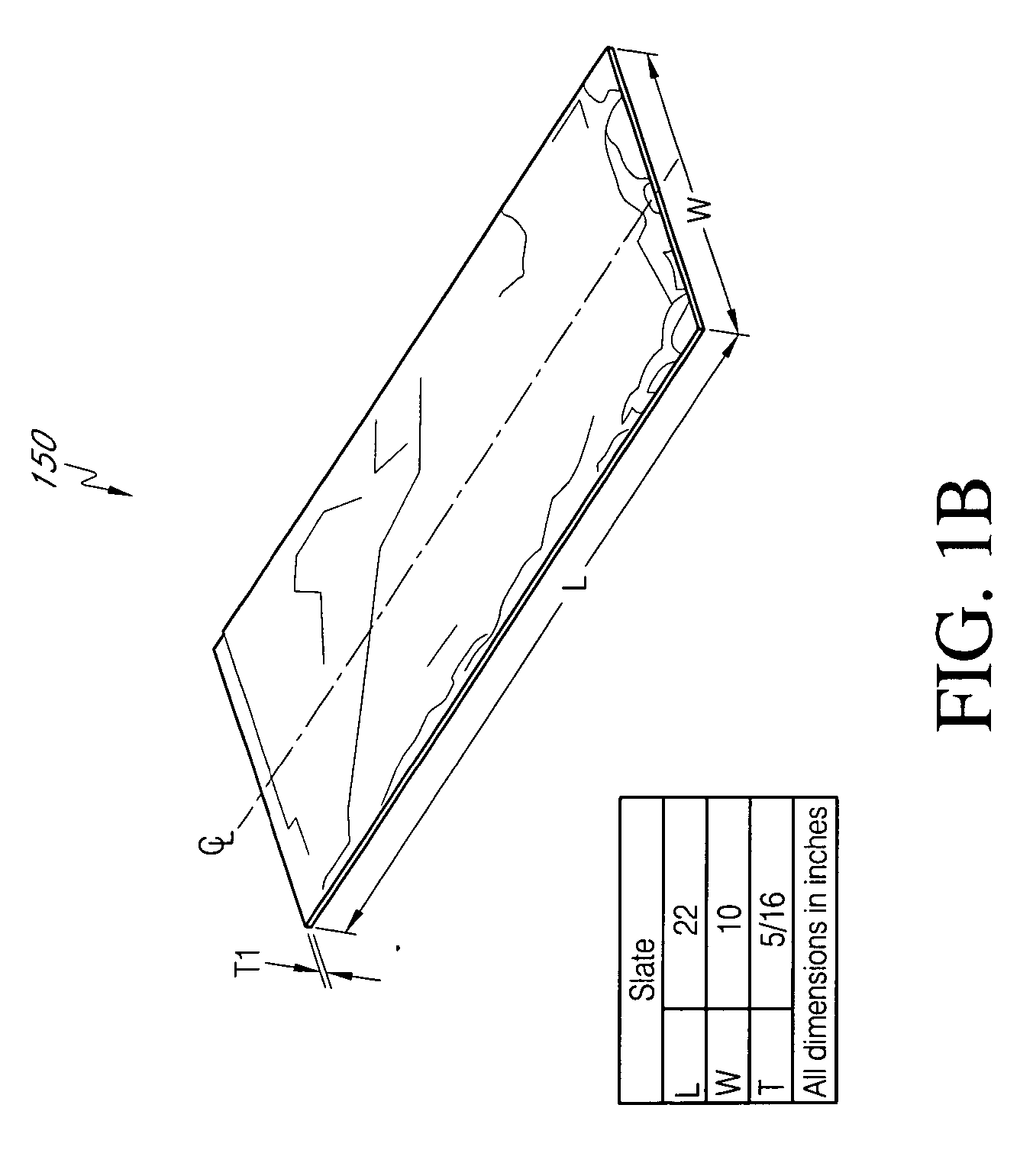

Fastener-free composite roofing product

InactiveUS6936329B2Wider exposed surfaceRecord information storageMagnetic recordingAdhesiveWater resistant

A fastener-free composite roofing product comprising a roofing material and an interply material attached to the roofing material, wherein the interply material includes an adhesive coating on one side. The interply material is attached adjacent to an edge of the roofing material to permit a major portion of the interply material to be folded away from the roofing material for application to a roof. The adhesive is effective to secure the roofing product to the roof without the use of nails or other fasteners. The roofing material may be a roofing shingle or roll roofing, and the interply material is comprised of a water resistant material.

Owner:ELCOR CORP

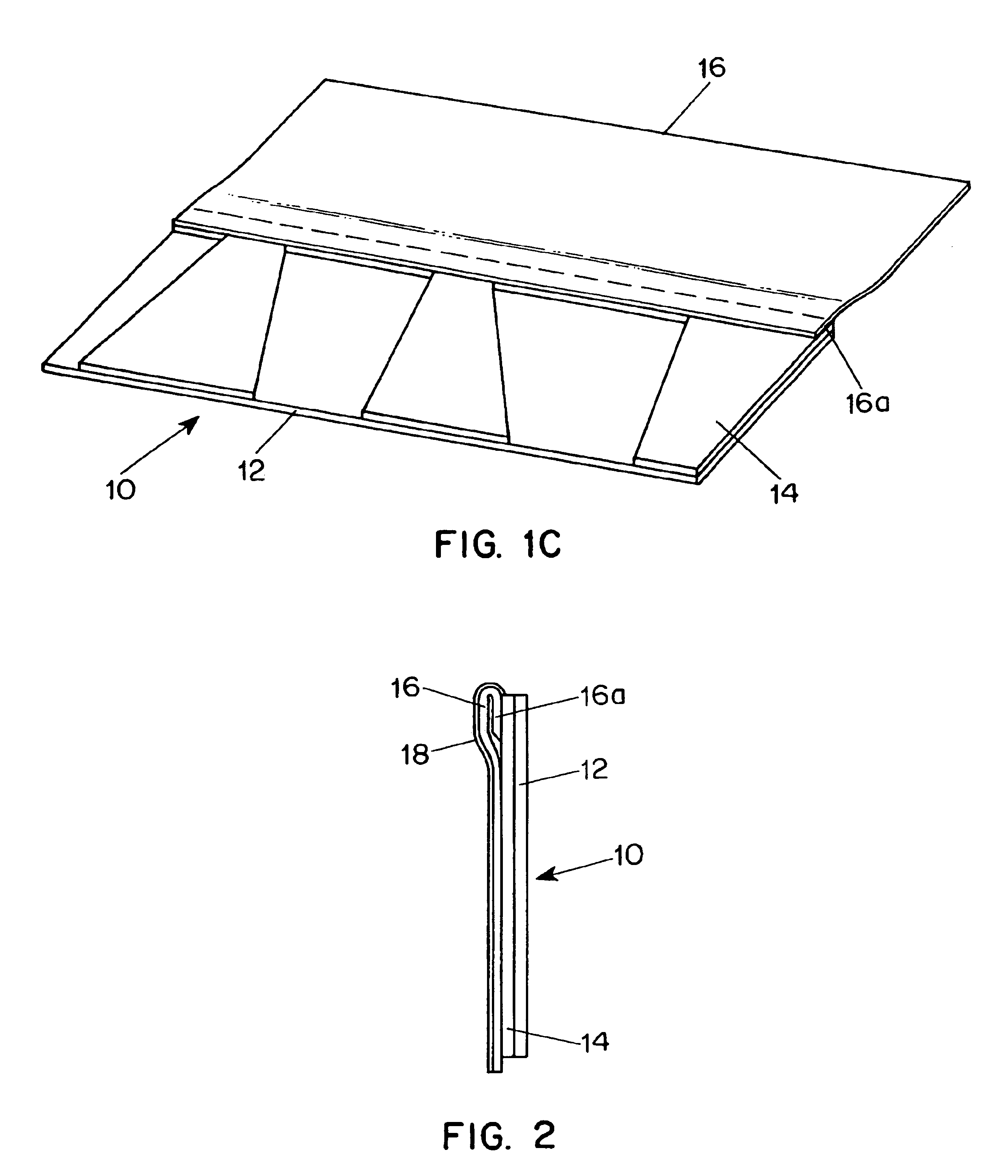

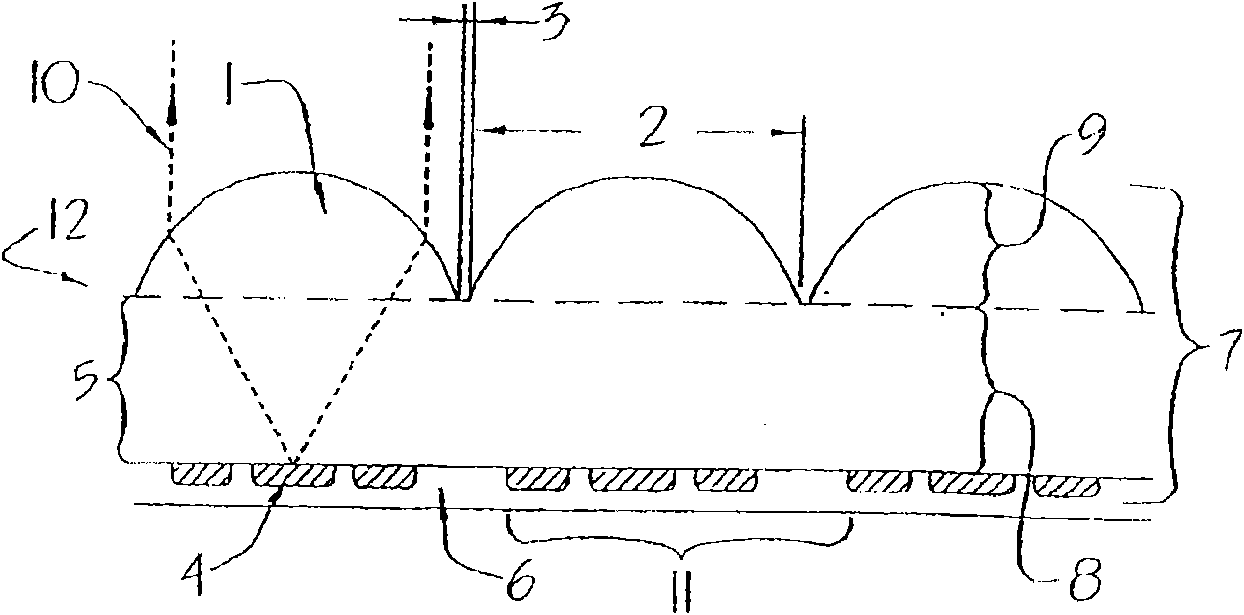

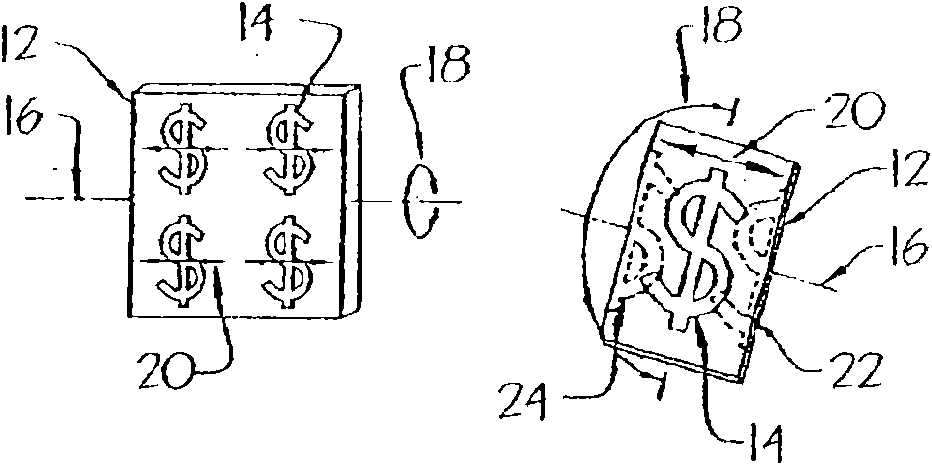

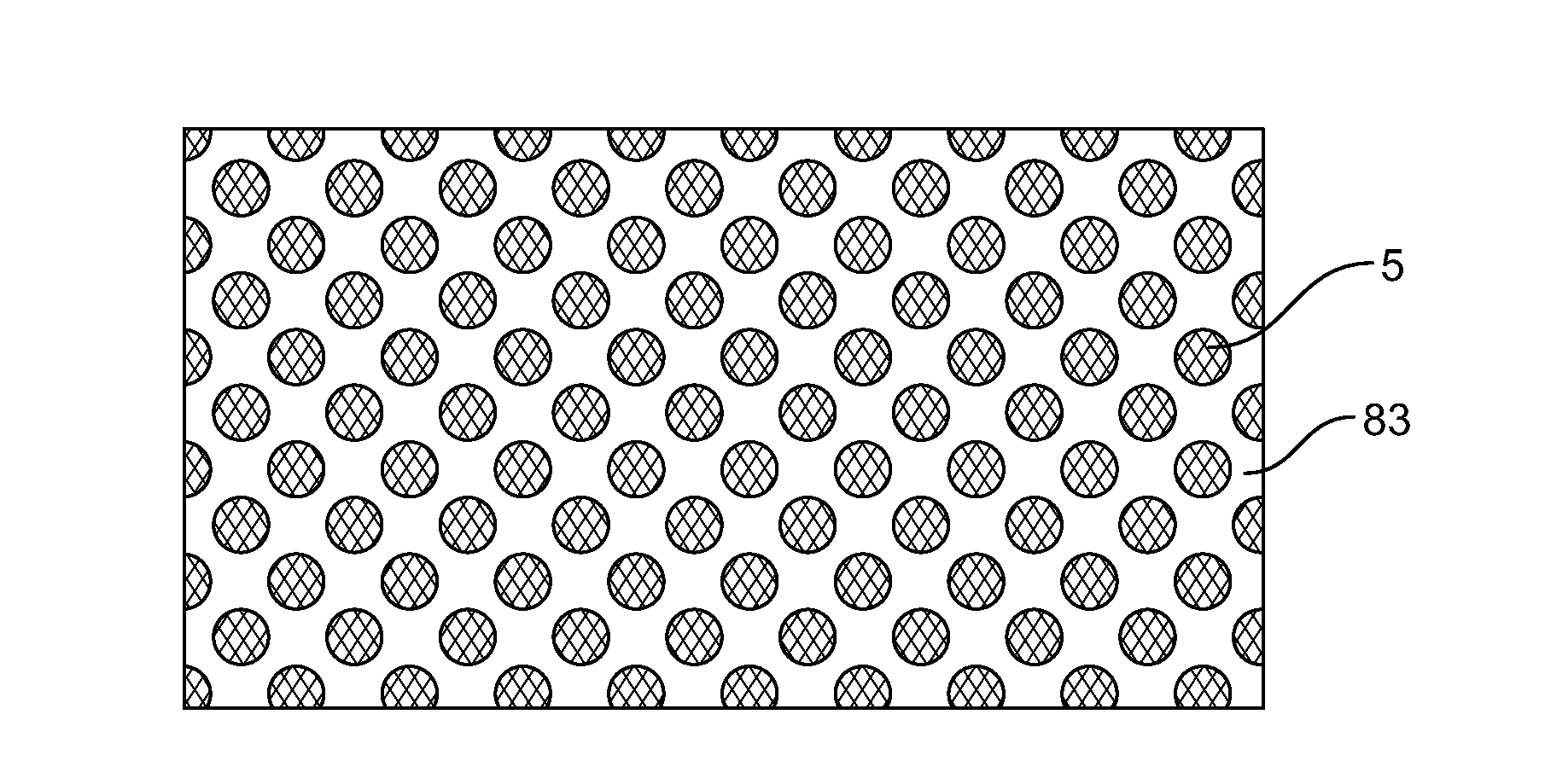

Image presentation and micro-optic security system

A synthetic micro-optic system and security device is disclosed including an in-plane image formed of an array or pattern of image icons and an array of focusing elements, the system producing at least two different synthetic images whereby one synthetic image operates to modulate or control the extent of the appearance of another synthetic image. In an exemplary form, the array of image icons forms an in-plane synthetic image, while the interaction of the array of focusing elements with the array of image icons forms a separate synthetically magnified image that serves to control the field of view of the in-plane image and, thus, serves to modulate or control the extent of appearance of the in-plane image. The appearance of the in-plane image, thus, visually appears and disappears, or turn on and off, depending upon the viewing angle of the system.

Owner:VISUAL PHYSICS LLC (US)

Methods and systems for decorating bevel and other surfaces of laminated floorings

Methods and systems for decorating at least one bevel surface or other surface of a laminated flooring are described. The bevel surface can be decorated by non-transfer printing such as digital printing. The digital printer can be an ink jet printer such as a piezoelectric drop-on-demand (DOD) printer that allows a color and pattern to be placed on the bevel surface that matches the print design (décor pattern or face design) of the laminated flooring. Other devices are provided such as a device that takes a picture of or scans an image of the print design, and modifies the taken picture or the scanned image so that the edge pattern thereof matches with an edge pattern of the print design.

Owner:FLOORING IND LTD

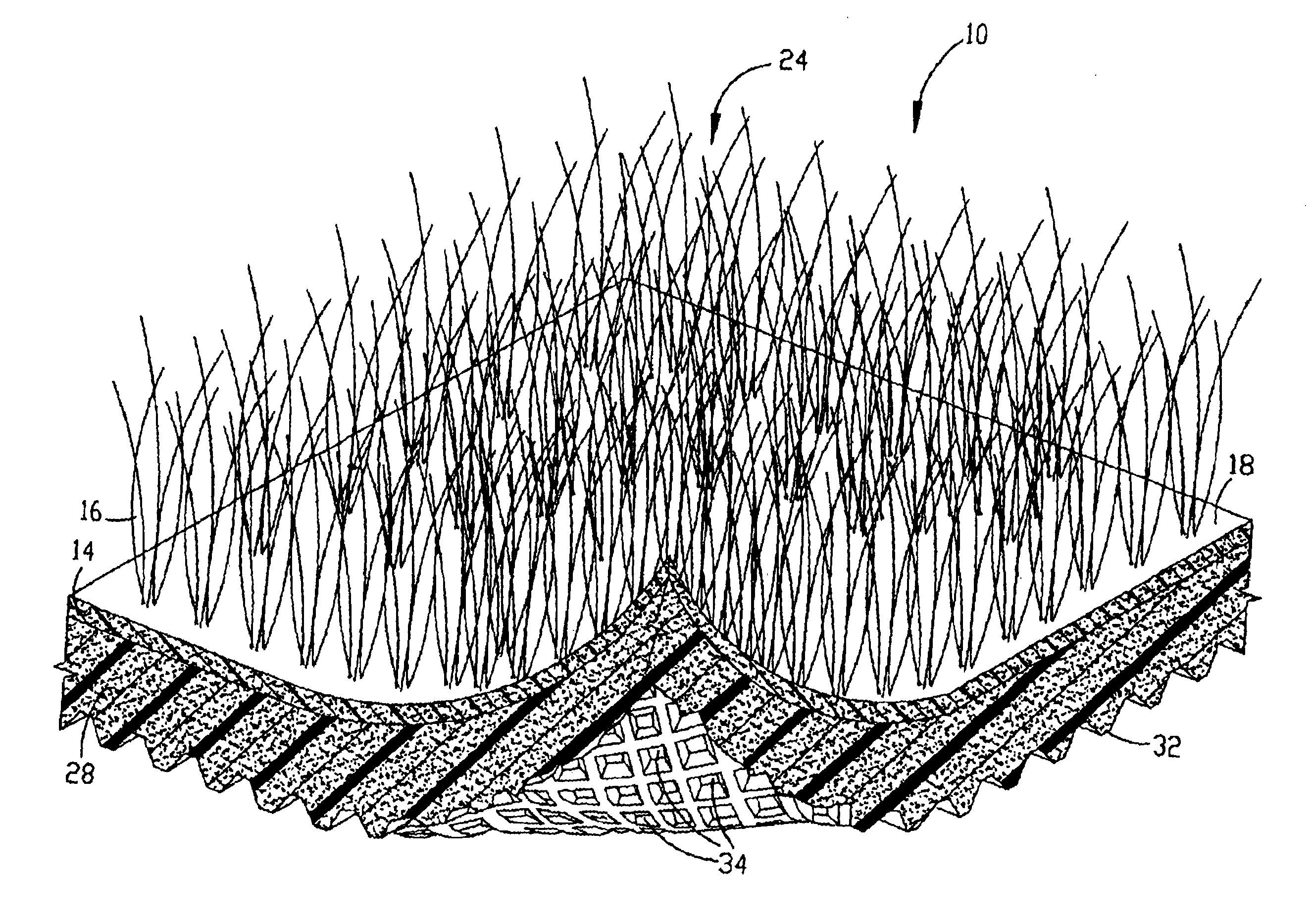

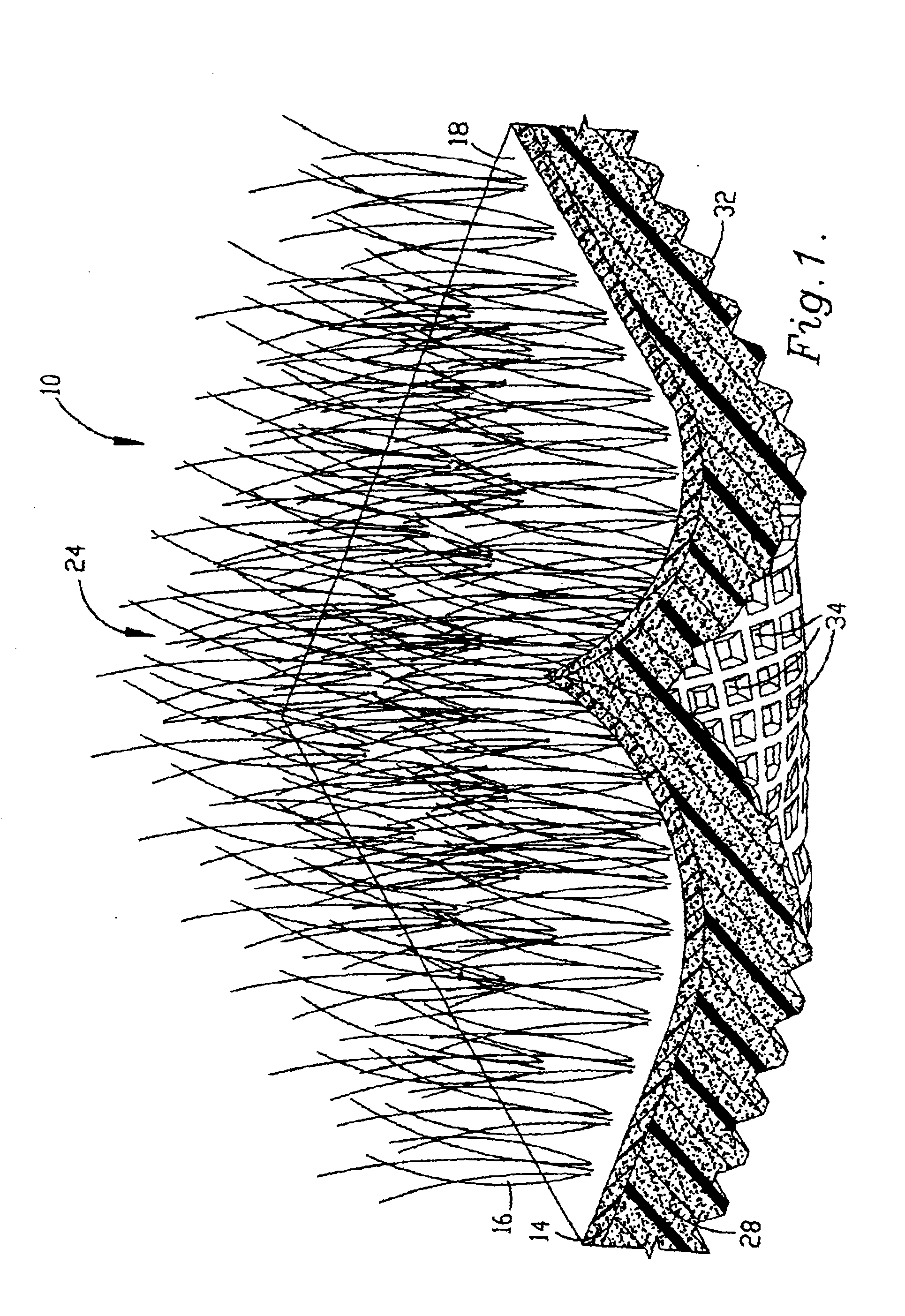

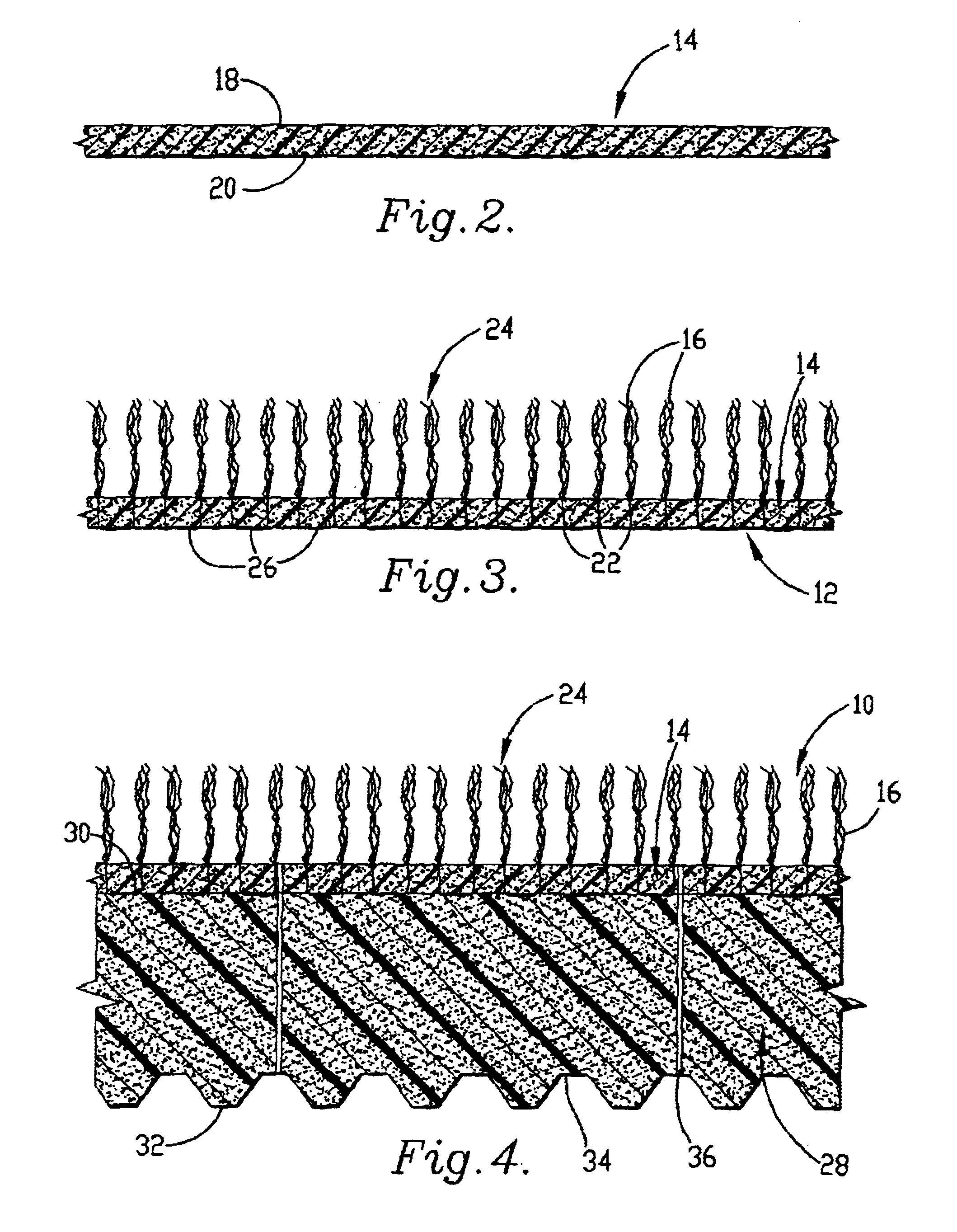

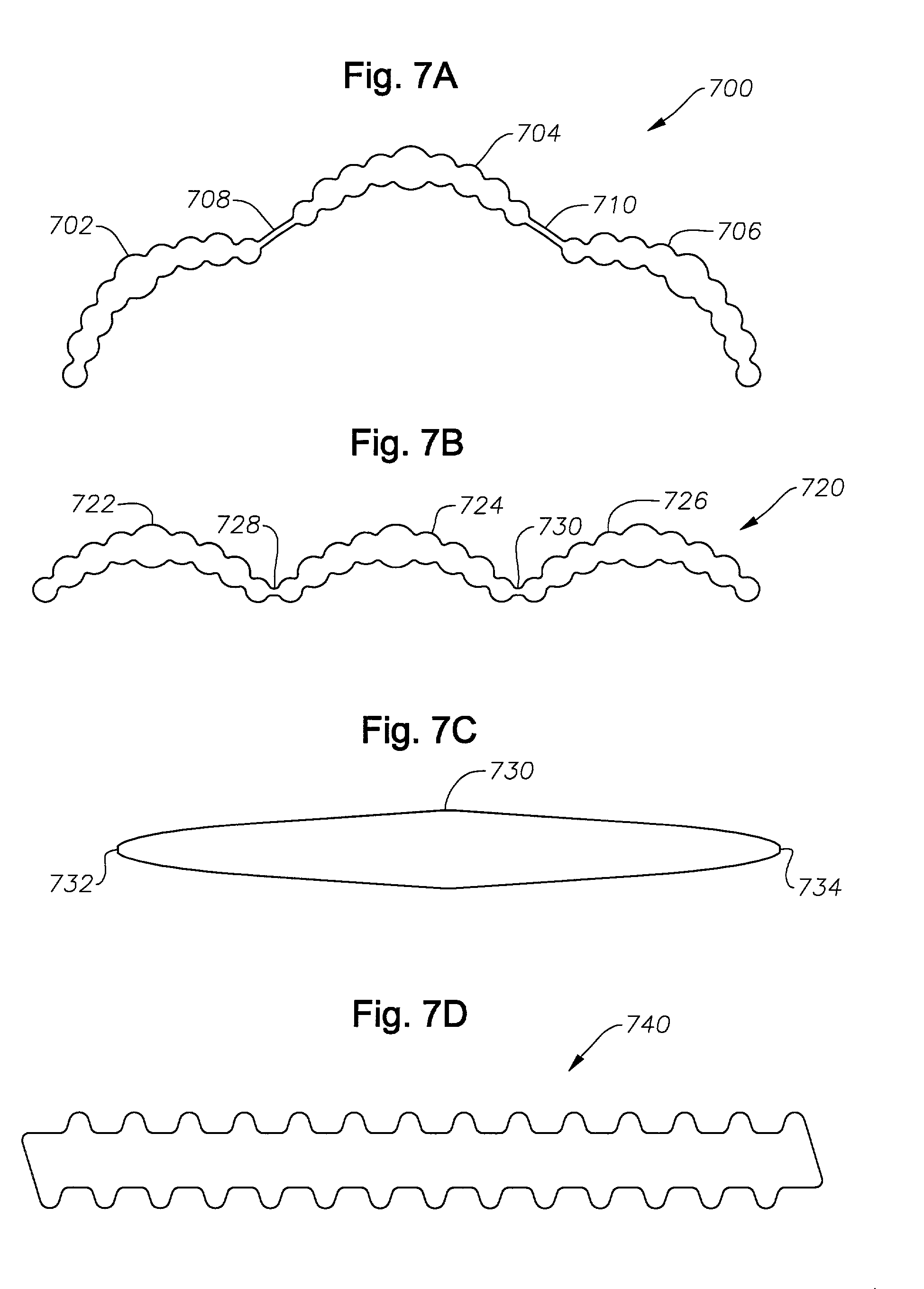

Tufted surface covering and method

The tufted surface covering includes a base formed from particles of a thermosetting polymer compound mixed with a particle binding agent causing a portion of the particles to bind together to form a self supporting web. The base is tufted with a tufting material. Thermosetting vulcanized natural and / or synthetic rubber compounds are employed. The polymer layer is tufted with a tufting material and heated to a temperature of from about 110° C. to about 220° C. at an elevated pressure of up to two tons per square inch, to cause the particles to bind together at elevated temperature and pressure to anchor and seal the tufts in place. Cross-linking agents and polar polymer containing compounds may be employed as particle binding agents. In another aspect of the invention, a second layer of particles of a thermosetting polymer mixed with a particle binding agent may be joined together with the particles of the first layer at elevated temperature and pressure. A series of spaced apertures extends through the first and second layers to enable free draining of the surface covering. The lower surface of the covering includes spaced indentations to reduce the weight of the covering.

Owner:WALTERS IAN D

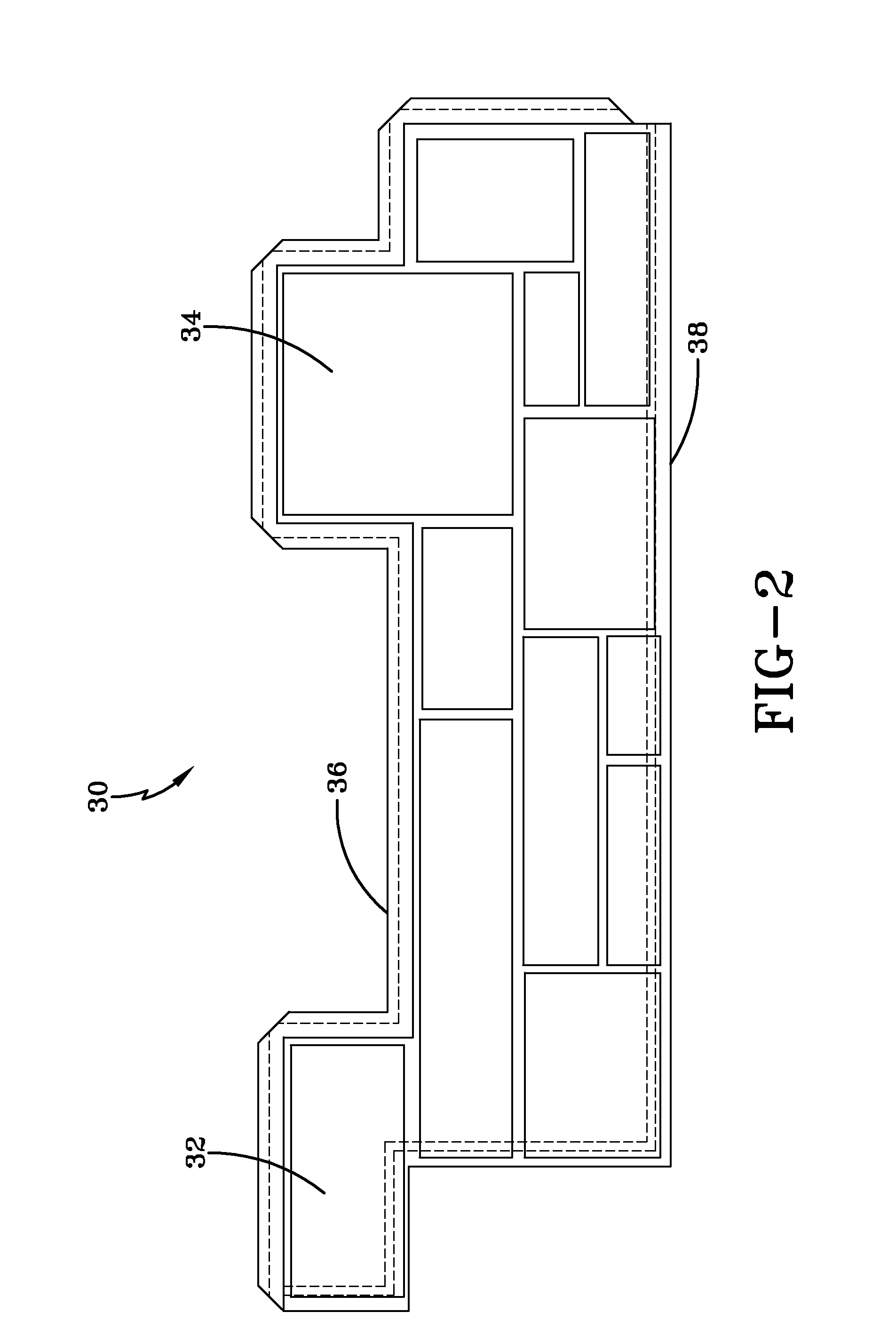

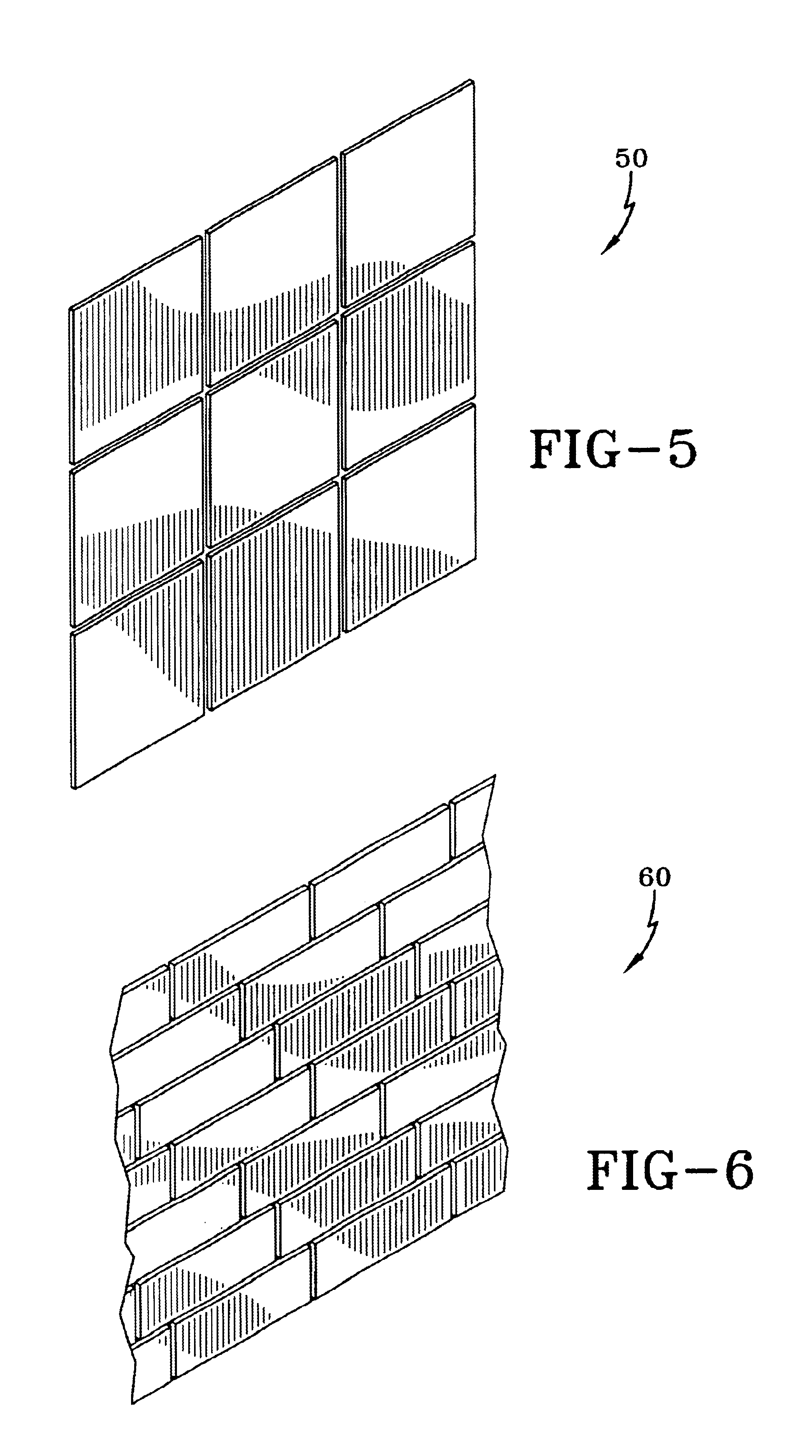

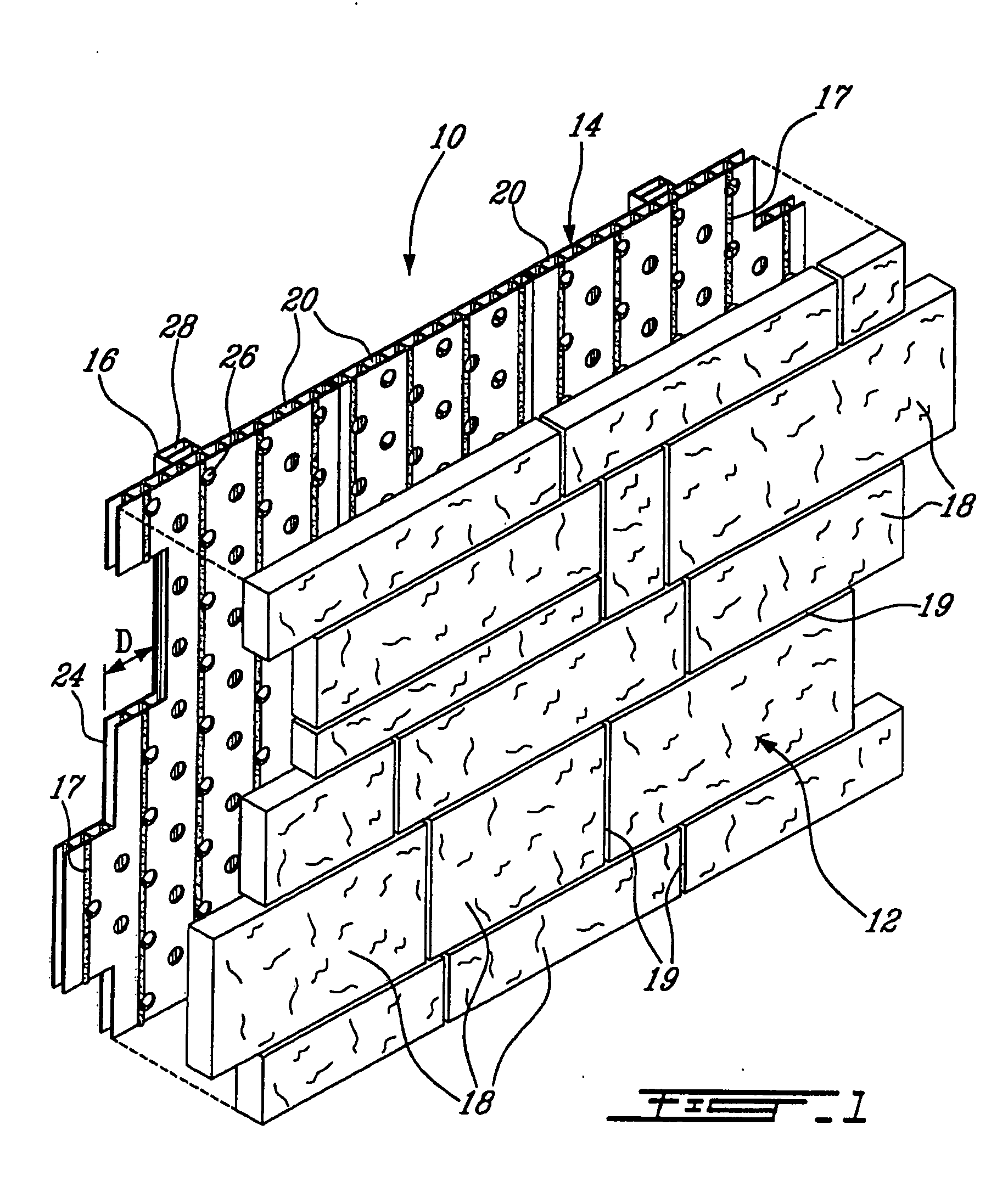

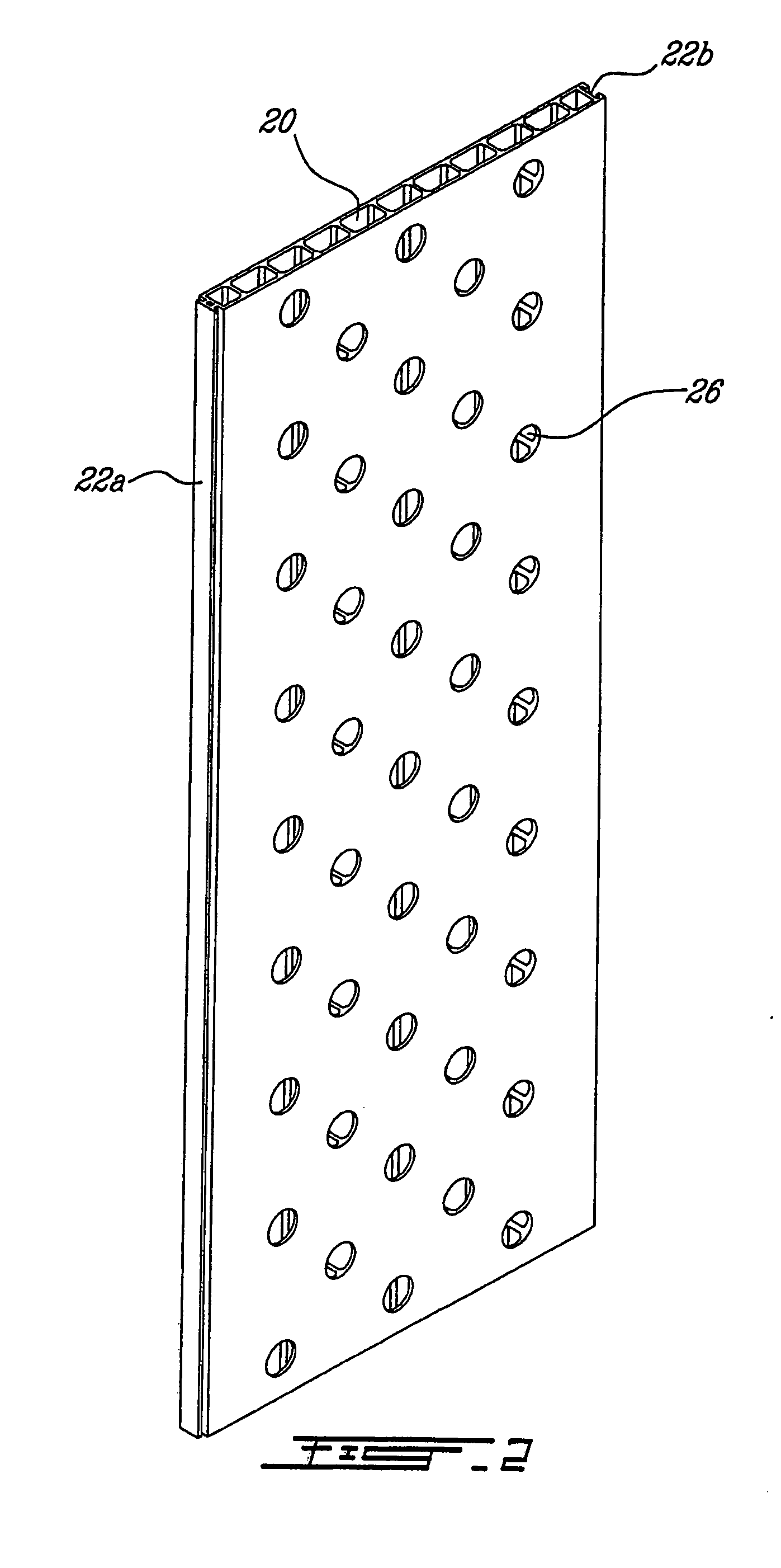

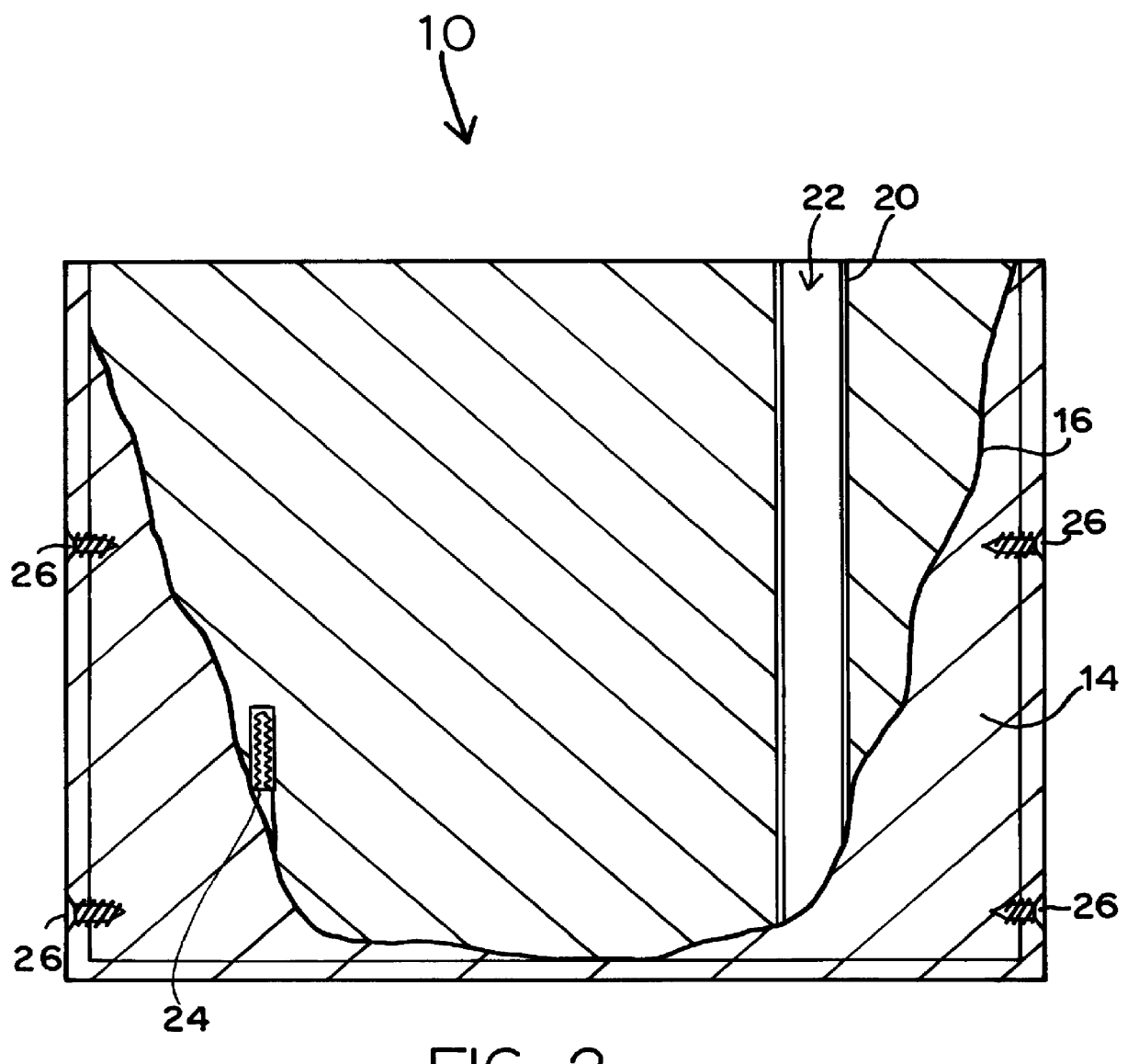

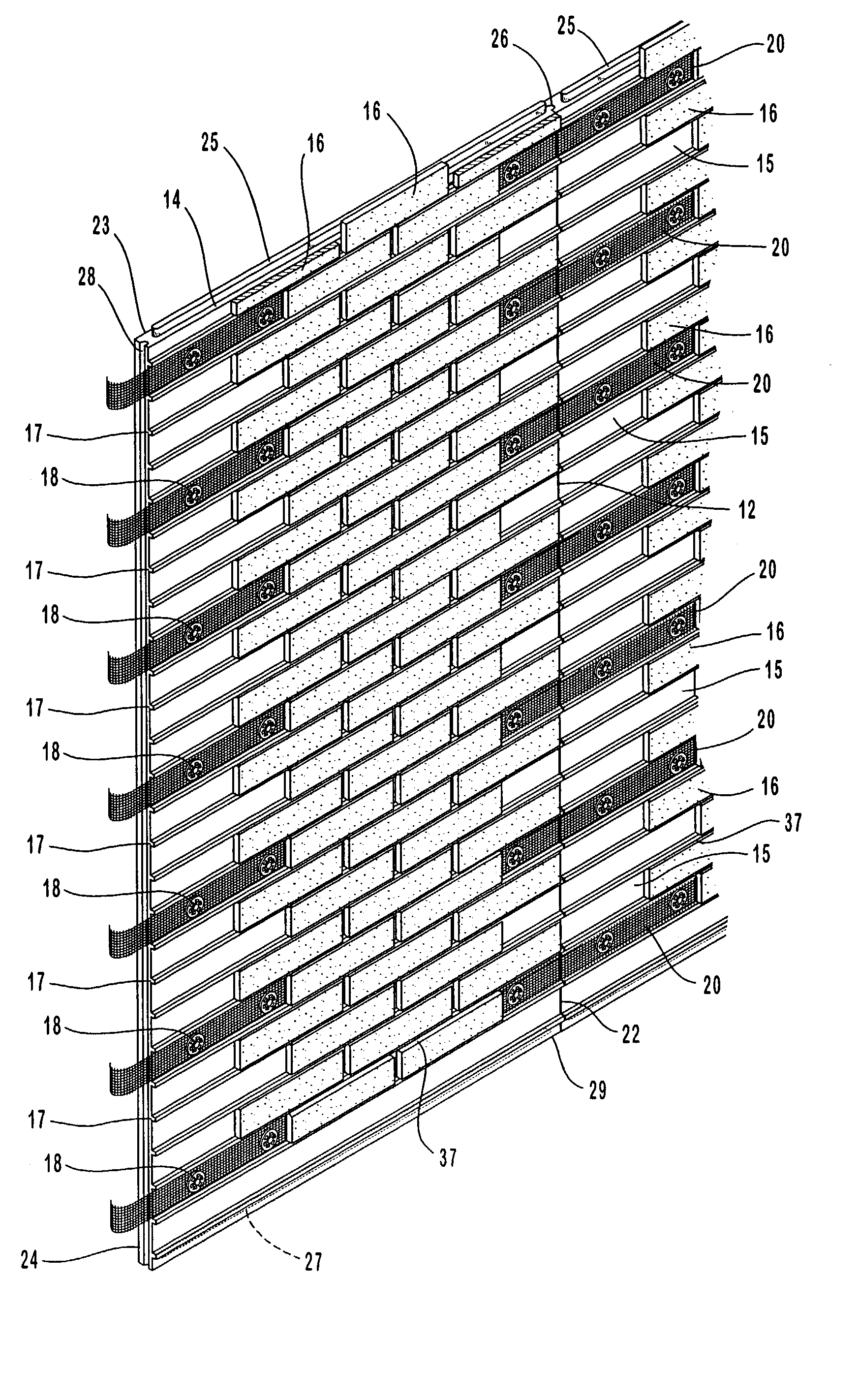

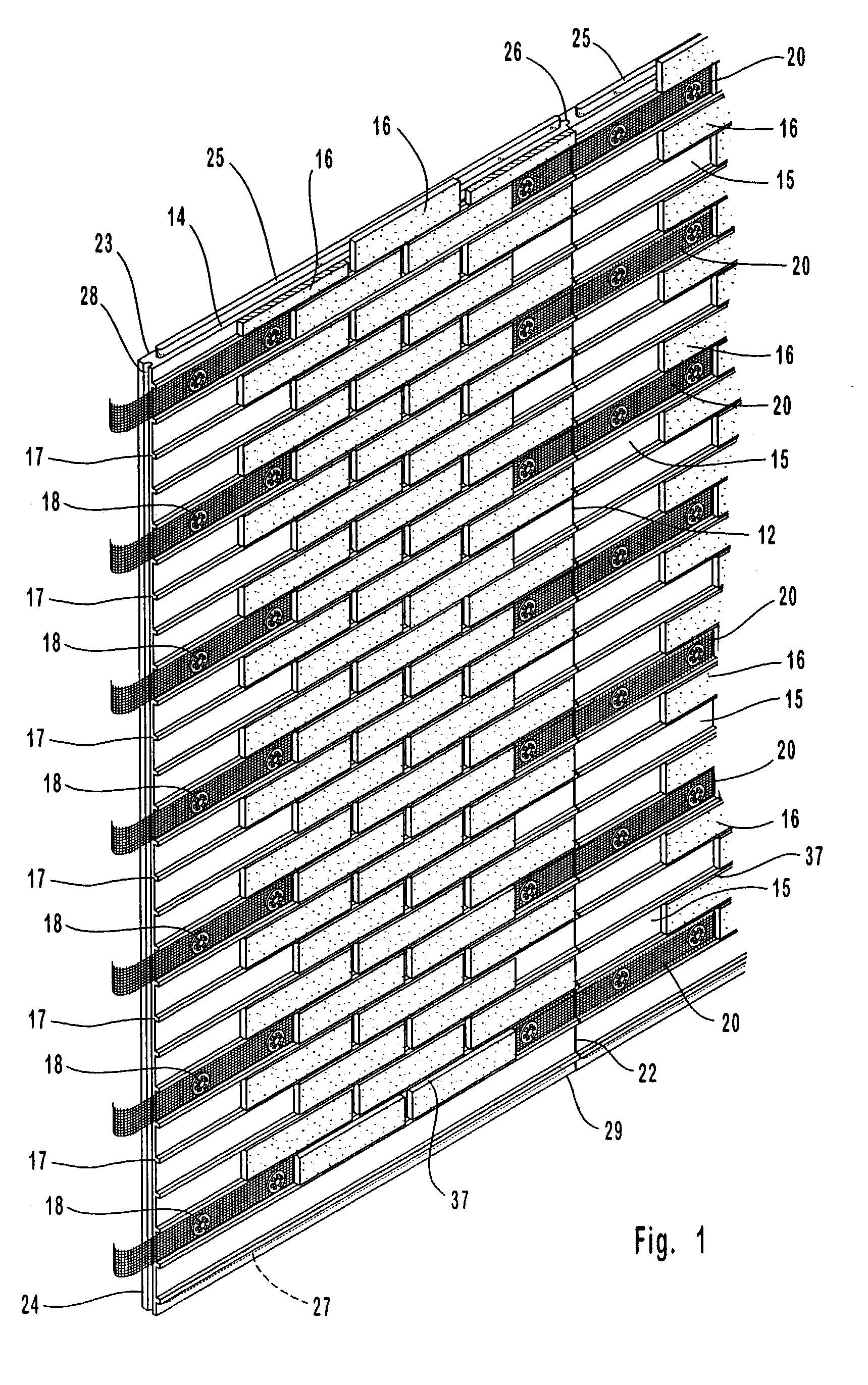

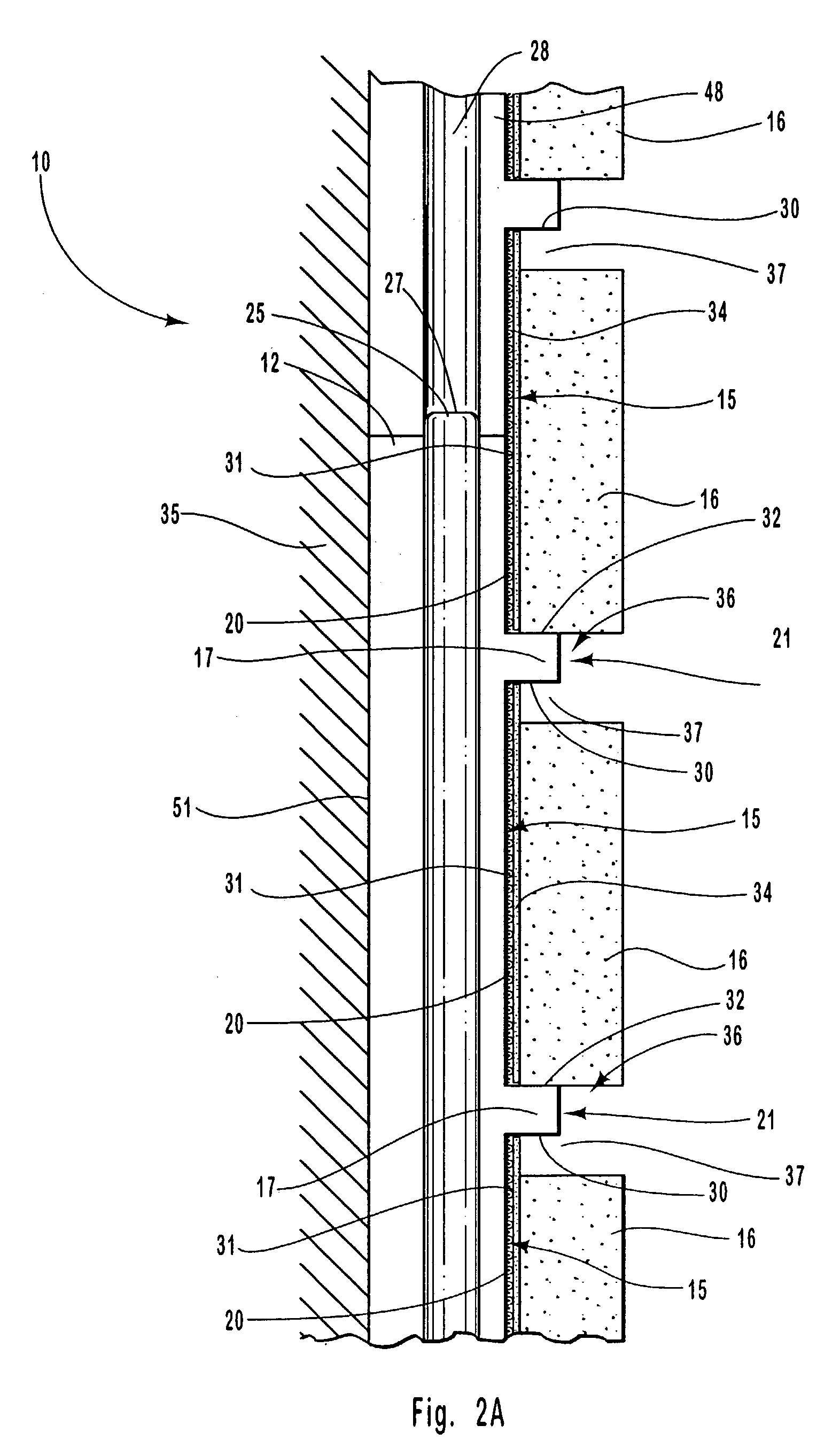

Decorative wall covering with upward movement panel interlock system

InactiveUS6955019B2Easy and reliable panel installationAvoid bowingCeilingsRoof covering using tiles/slatesEngineeringSupport surface

A wall covering comprising a plurality of plastic panels each having a body portion formed with rows of simulated building elements. The panels are mounted on a support surface with a lower marginal edge region of one panel overlying an upper marginal edge region of a previously mounted panel in a lower course and with a side marginal edge region of one panel overlying the side marginal edge region of a previously mounted adjacent panel in the same course. The marginal edge regions are provided with interlocks which engage and secure both the overlapping upper and lower marginal edge regions and the overlapping side marginal edge regions as an incident to upward movement of the panel relative to the underlying previously mounted panels. In the illustrated embodiment, the overlying lower marginal edge region and side marginal edge region of each panel are formed with upwardly directed locking flanges which are respectively engageable with downwardly directed flanges on the upper marginal edge region and apertures in the side marginal edge region of the underlying panels.

Owner:NOVIK INC

Composite roofing panel

InactiveUS20020040557A1Easy to installBetter imitate natural productsRoof covering using tiles/slatesNatural patternsAsphalt shingleNatural fiber

The present invention provides a composite panel for use in construction, and particularly for shingling, which comprises natural fiber and a polymer. Due to its composition and layout the construction panel provides all of the advantages of natural materials and high end roofing materials, particularly an attractive appearance, while at the same time allowing for ease of installation, little or no maintenance requirements, and providing superior impact and fire resistance when compared to other roofing materials. The construction panels can also be installed using conventional equipment and methods similar to the installation of 3-tab asphalt shingles with little or no learning curve.

Owner:COMPOSITECH

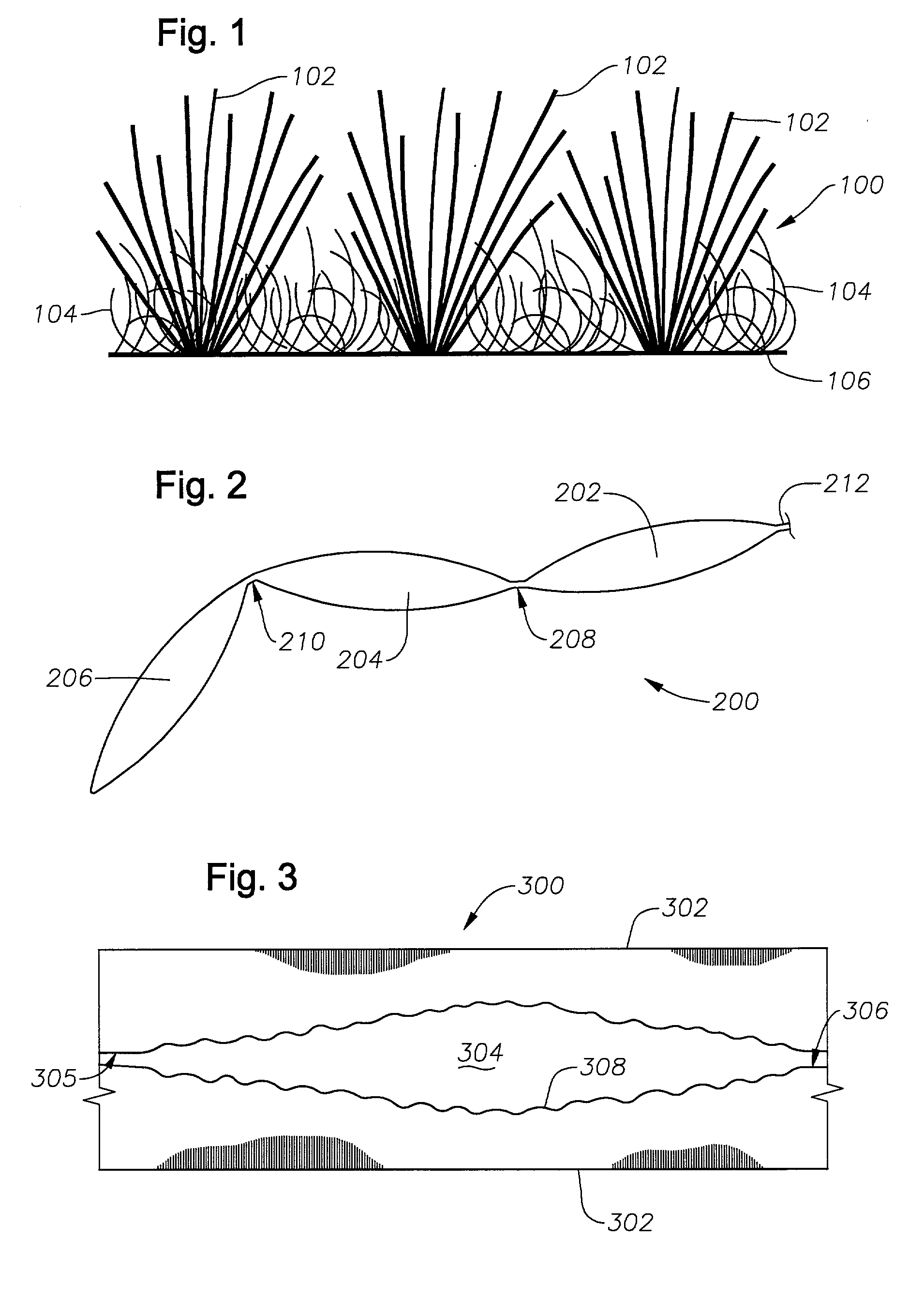

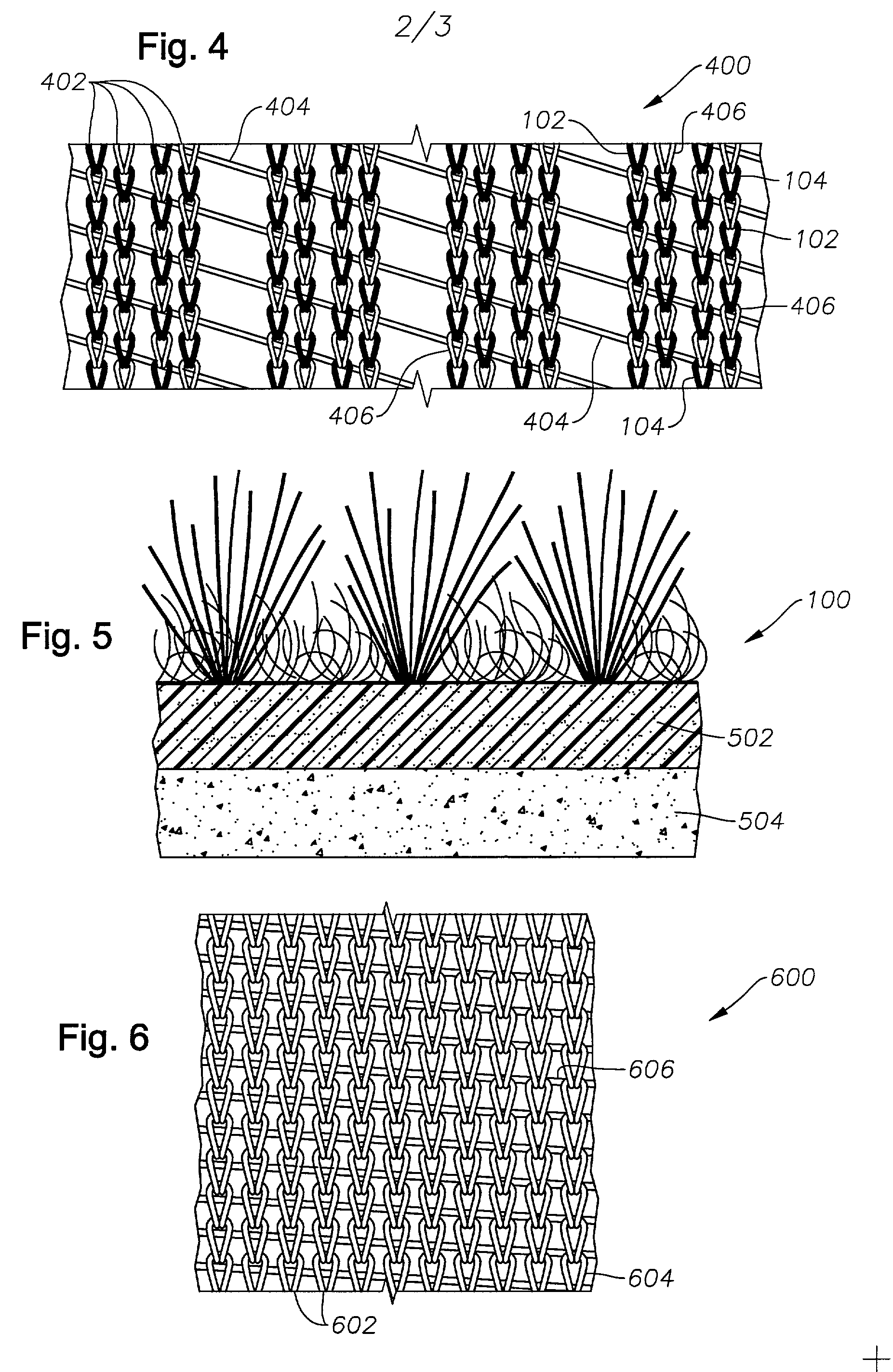

Artificial turf system

An artificial turf that includes a first face yarn, a second face yarn, and a stitch-in yarn. The second face yarn is textured in some embodiments, for at least the reason of creating a zone such as a textured zone. A knot is formed by knitting the first face yarn, the second face yarn, and the stitch-in yarn together. A row of knots is also formed in this manner. A backing is formed when a lay-in yarn is extended between at least two rows of the knots and knitted to hold the at least two rows of knots together. A coating is coupled to the backing to prevent, among other things, detachment of the yarns after extended use of the artificial turf. An underlayment is positioned beneath the backing such that a stable base is provided for the artificial turf.

Owner:APT ADVANCED POLYMER TECH CORP

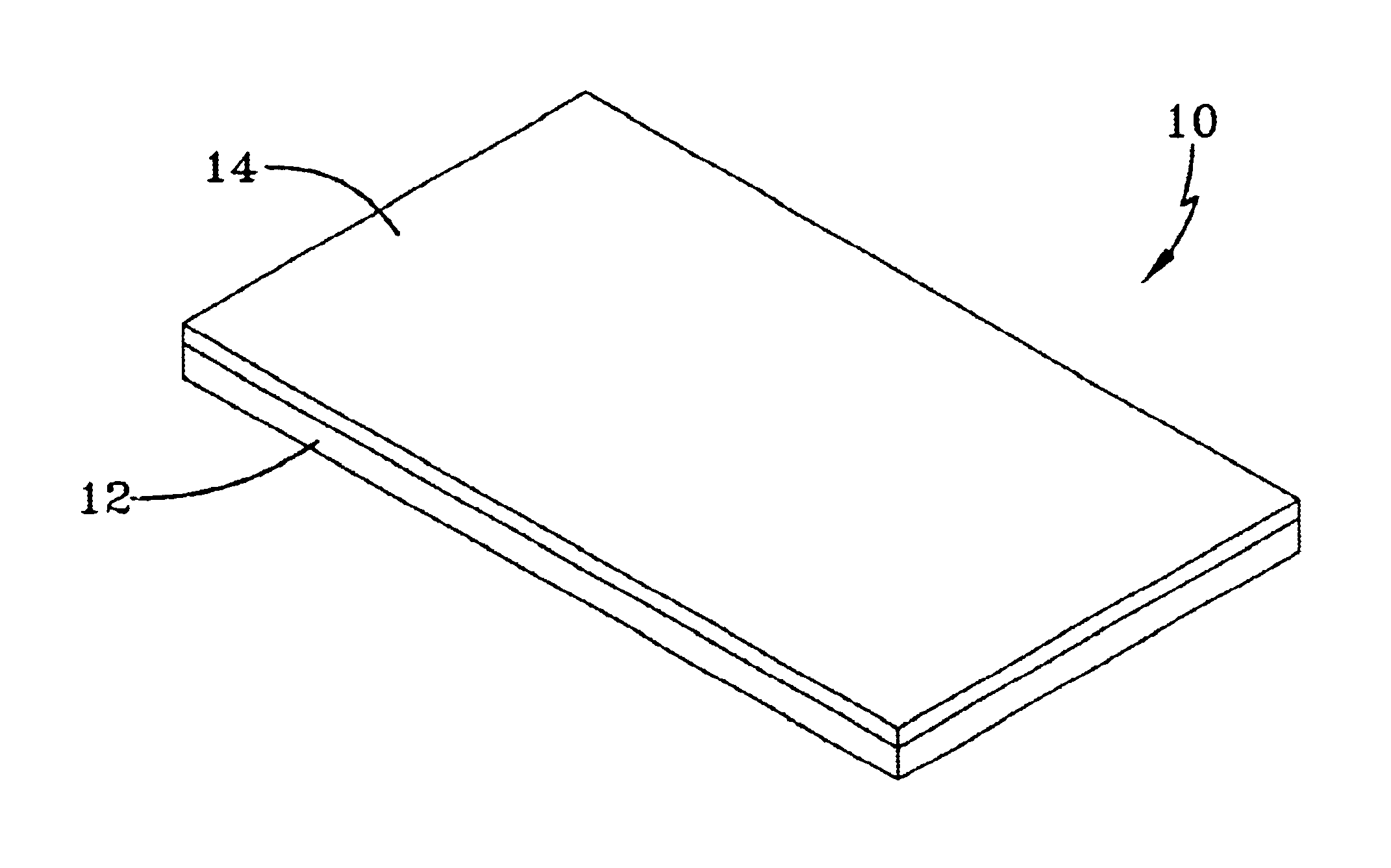

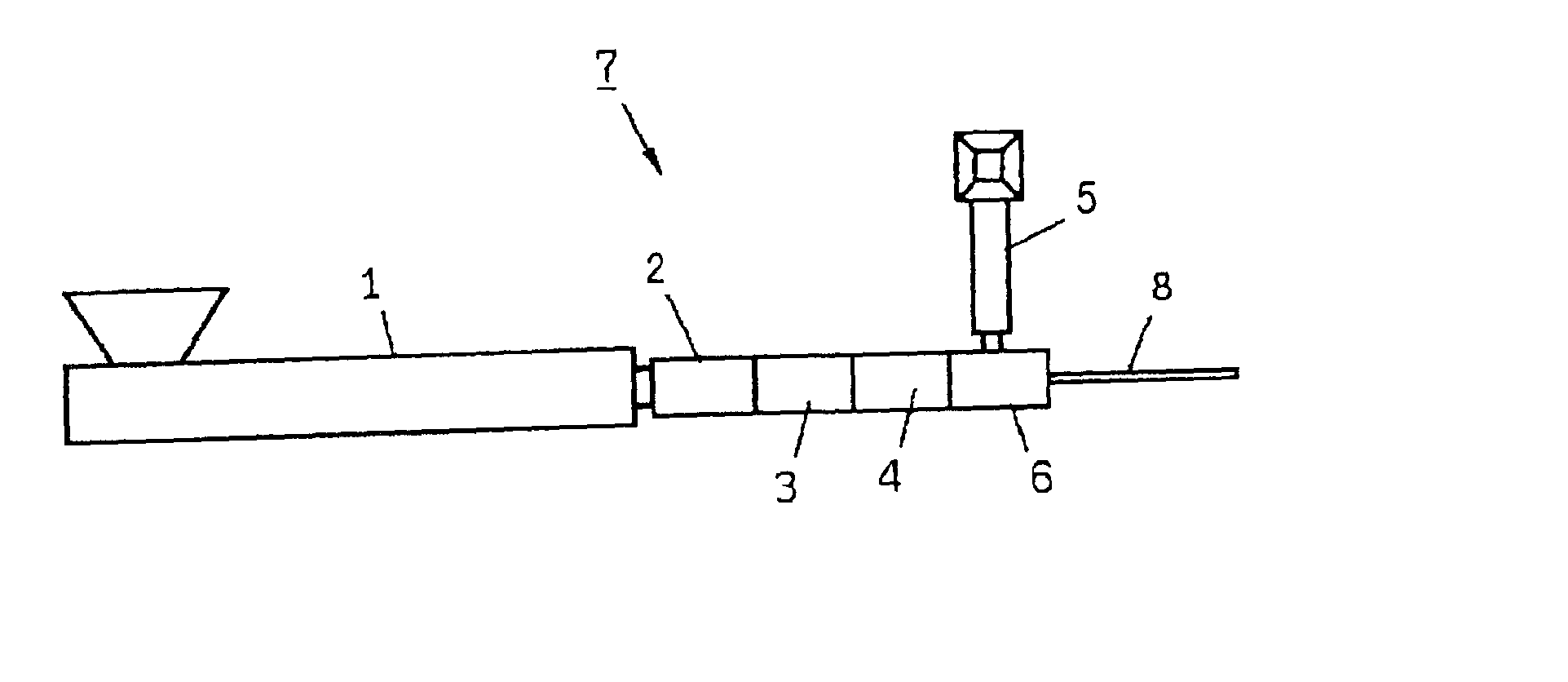

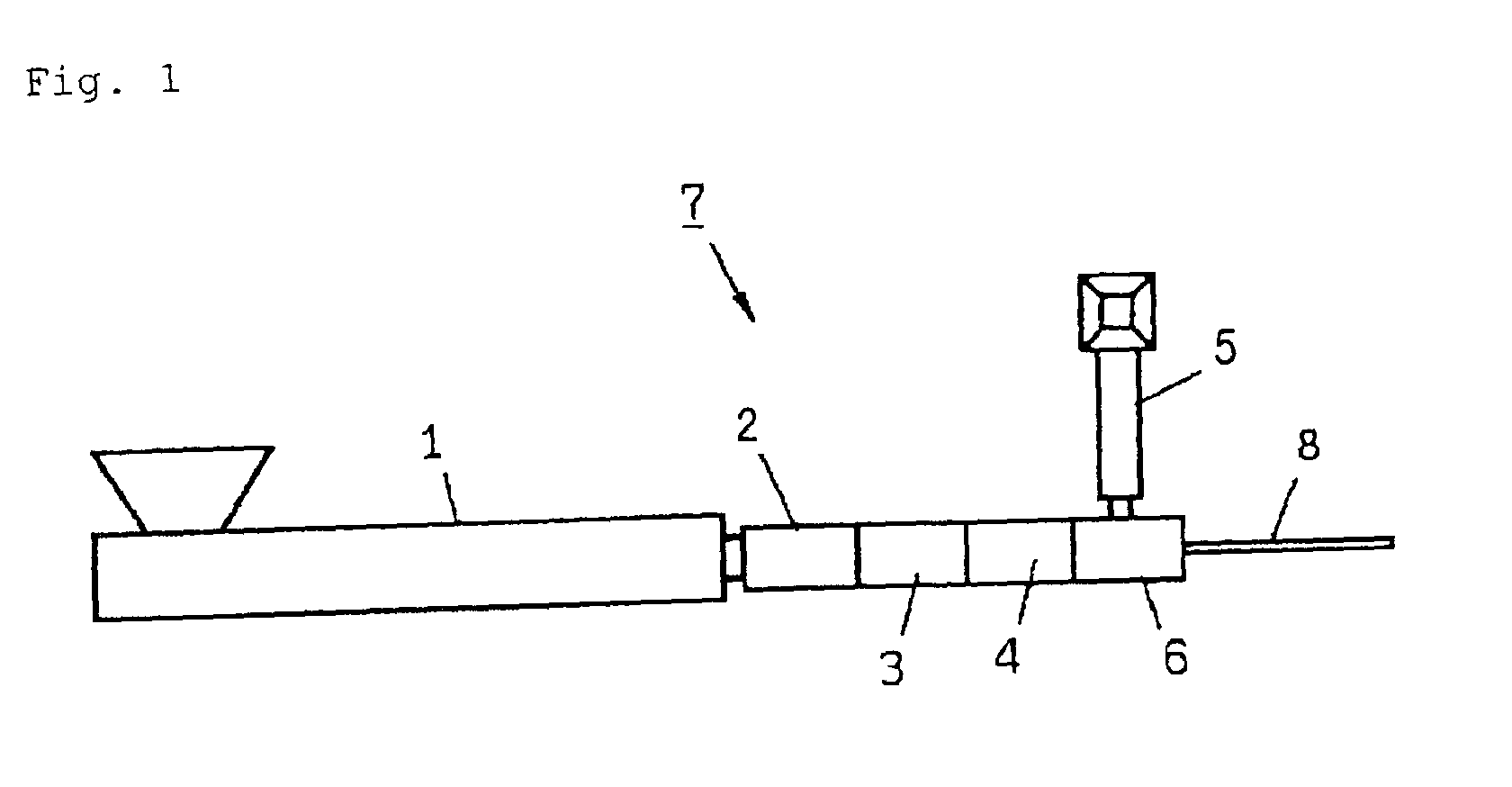

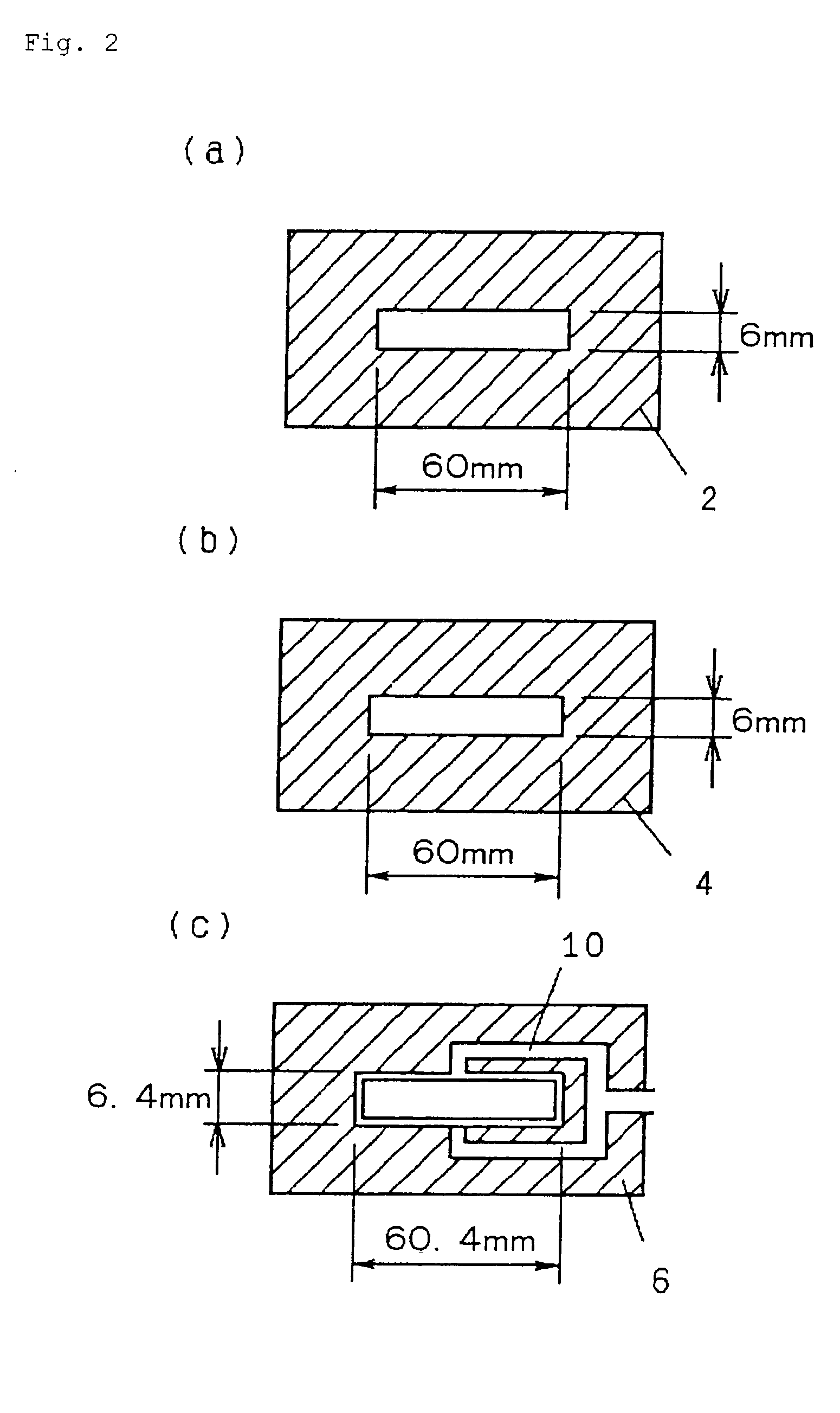

Molded article from thermoplastic composite material and method for producing the same

InactiveUS6716522B2No fading or discolorationIncreased durabilityHair accessoriesToupeesShell moldingThermoplastic composites

The present invention has for its object to provide a molded article of a thermoplastic composite material which is not only durable with little discoloration or fading even on prolonged outdoor exposure and is very satisfactory in physical properties and appearance qualities inclusive of wood-like texture but also has high productivity and good economics.The present invention is a method of producing a molded article of a thermoplastic composite material comprising extruding the thermoplastic composite material containing a thermoplastic resin and a vegetable filler, said vegetable filler content being 50 to 90 weight % of the total weight of said thermoplastic resin and said vegetable filler, wherein extrusion is carried out by means of an extrusion apparatus comprising at least an extruder, a hot shaping die, and a cooling die, said hot shaping die and cooling die being directly coupled.

Owner:SEKISUI CHEM CO LTD

Synthetic wood component having a foamed polymer backing

InactiveUS6863972B2Superior resistance to wear and tearImprove the immunityHair accessoriesDead plant preservationLow-density polyethyleneLinear low-density polyethylene

The present invention is a component having a synthetic wood layer that is secured to a foamed polymer layer. The foamed polymer layer is comprised of a polymer selected from the group consisting of high density polyethylene, polypropylene, polyvinyl chloride, low density polyethylene, chlorinated polyvinyl chloride, acrylonitrile butadiene styrene, ethyl-vinyl acetate, and polystyrene. The component can be used for a variety of different purposes such as fencing, furniture, cabinets, storage devices, lawn edging, flower boxes, flooring, roofing, wall covering, building siding, basement flooring, basement wall covering, interior and exterior decorative house moldings, crown moldings, chair rails, picture frames, porch decks, deck railings, window moldings, window components, door components, door moldings, various other lawn and garden uses, various other below grade uses, and various other indoor and outdoor uses.

Owner:CRANE BUILDING PRODS

One-Way Graphics Materials and Methods

InactiveUS20130330486A1Thin skinStatic indicating devicesDecorative surface effectsGraphicsDisplay device

Included herein are base materials and methods for use in creation of one-way graphics, including a dye-receptive substrate with a pattern of ink-repellent material over the dye-receptive substrate. An image may be printed selectively onto the base material to leave a visual perforation pattern that allows vision through the printed image under appropriate illumination. Also disclosed are printing methods involving the application of variously ordered layers of light-absorbing, light-reflective, and image mediums to printing substrates with physically raised and lowered areas to create one-way graphics. The invention also includes new forms of one-way graphics, including lenticular and holographic one-way displays, and one-way displays having internal lighting sources.

Owner:MINDFLOW

Modular stone panel

A modular stone panel is disclosed. The panel is adapted to be mounted or fastened to a structural wall to provide a stone wall facade therefor. The panel is generally comprised of a shaped backboard and a plurality of stones solidly fastened on a front face thereof. The backboard is adapted to be fastened to the structural wall such that the front face thereof faces away from the wall to provide the stone wall facade. The stones may comprise natural or synthetic molded stones. The backboard may also be ventilated to provide ventilation to the stones fastened thereto. The panels may be fabricated to provide key-cut edges allowing an interlocking of adjacent panels. A method of fabricating such panels is also disclosed.

Owner:STONEADVISE PRODS NORTH AMERICA

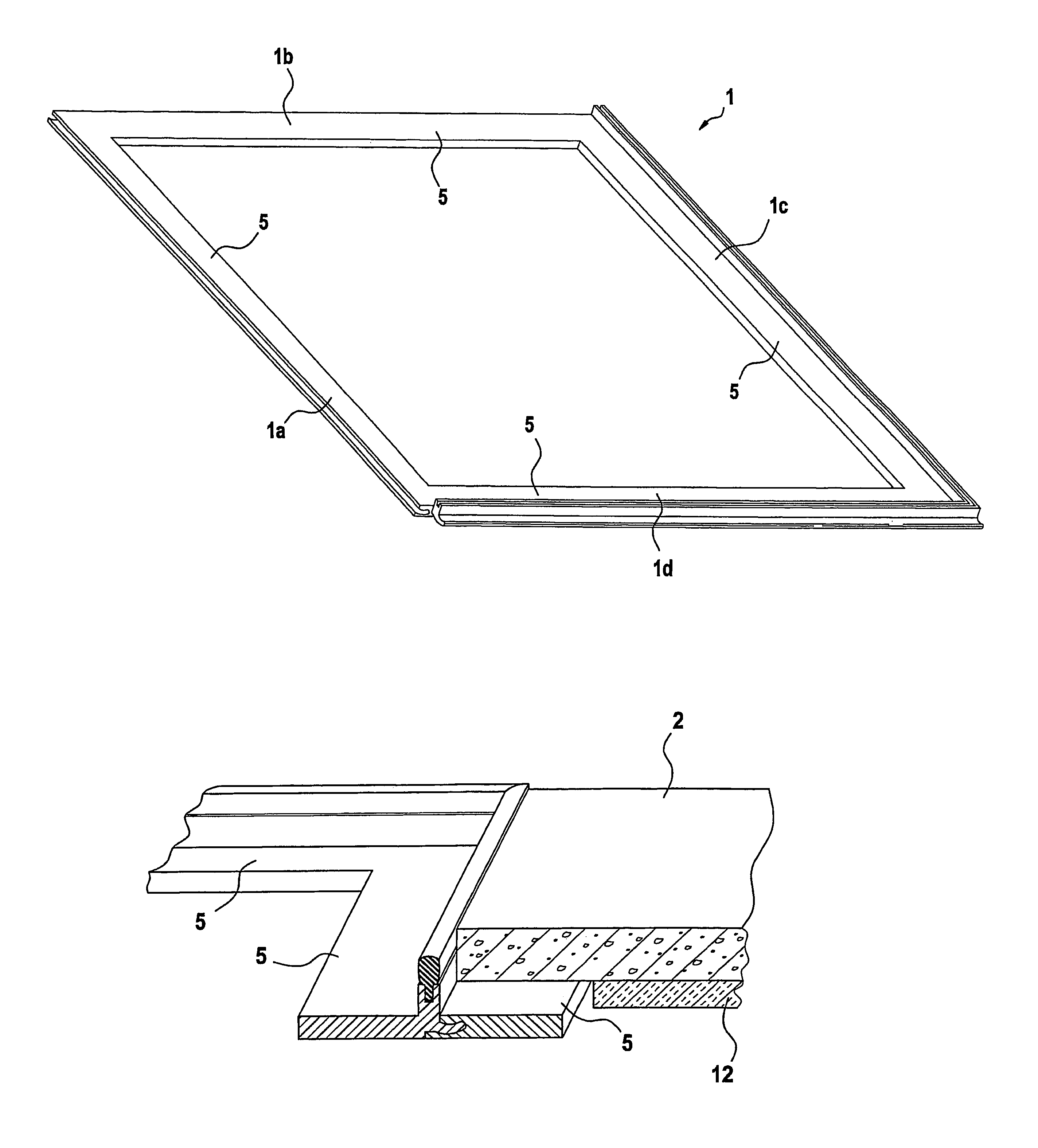

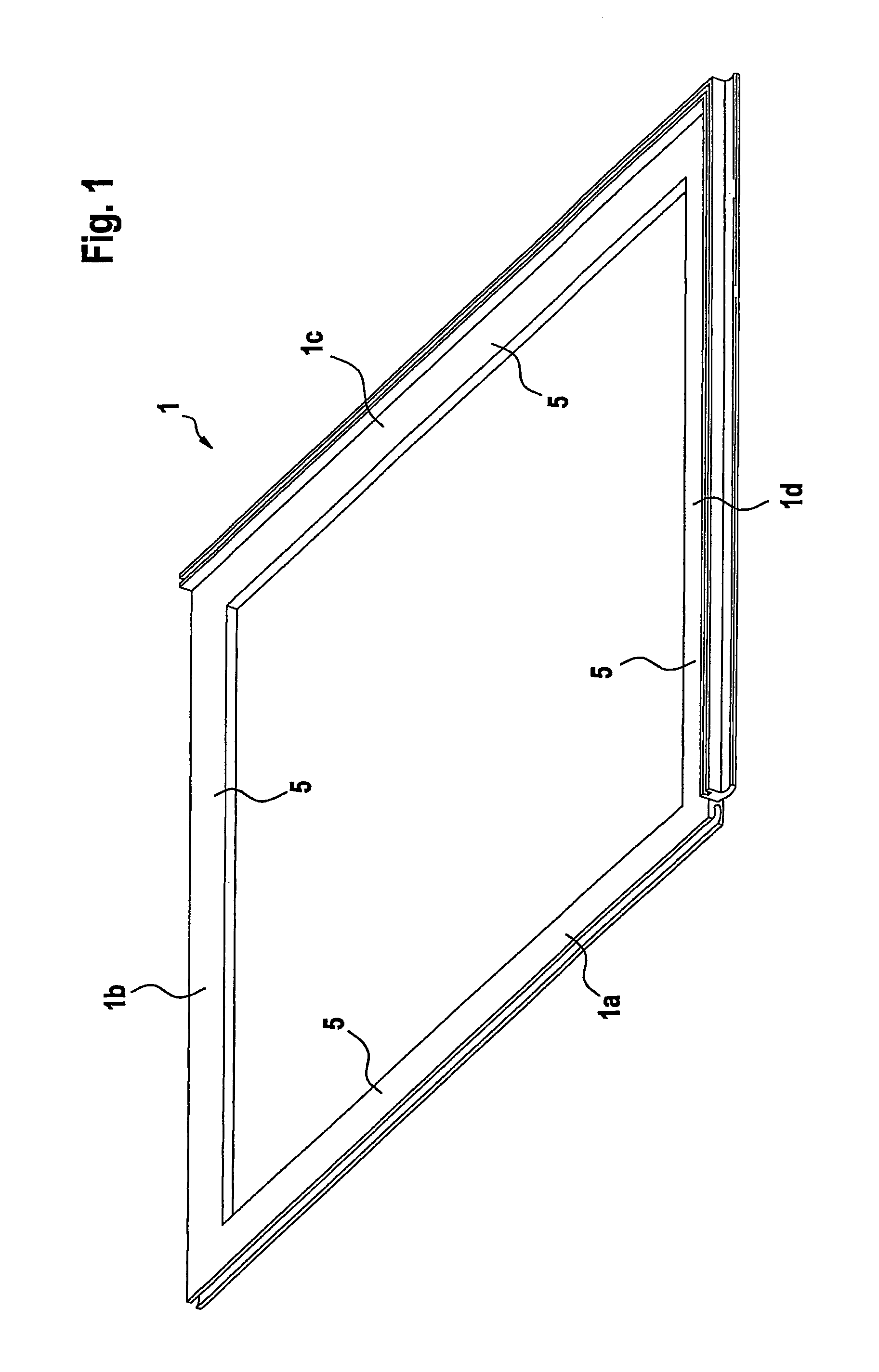

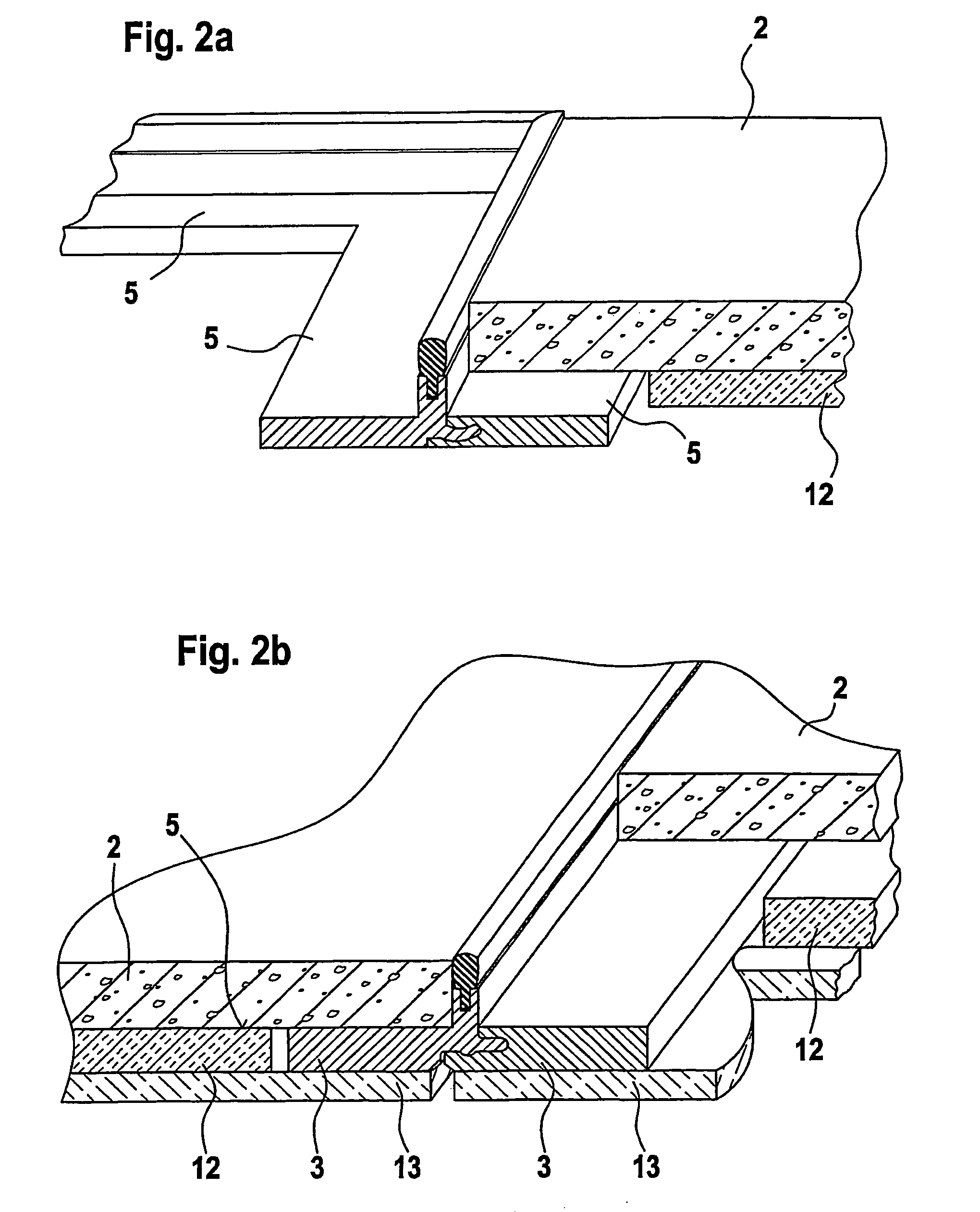

Panel, in particular floor panel

Owner:KRONOTEC

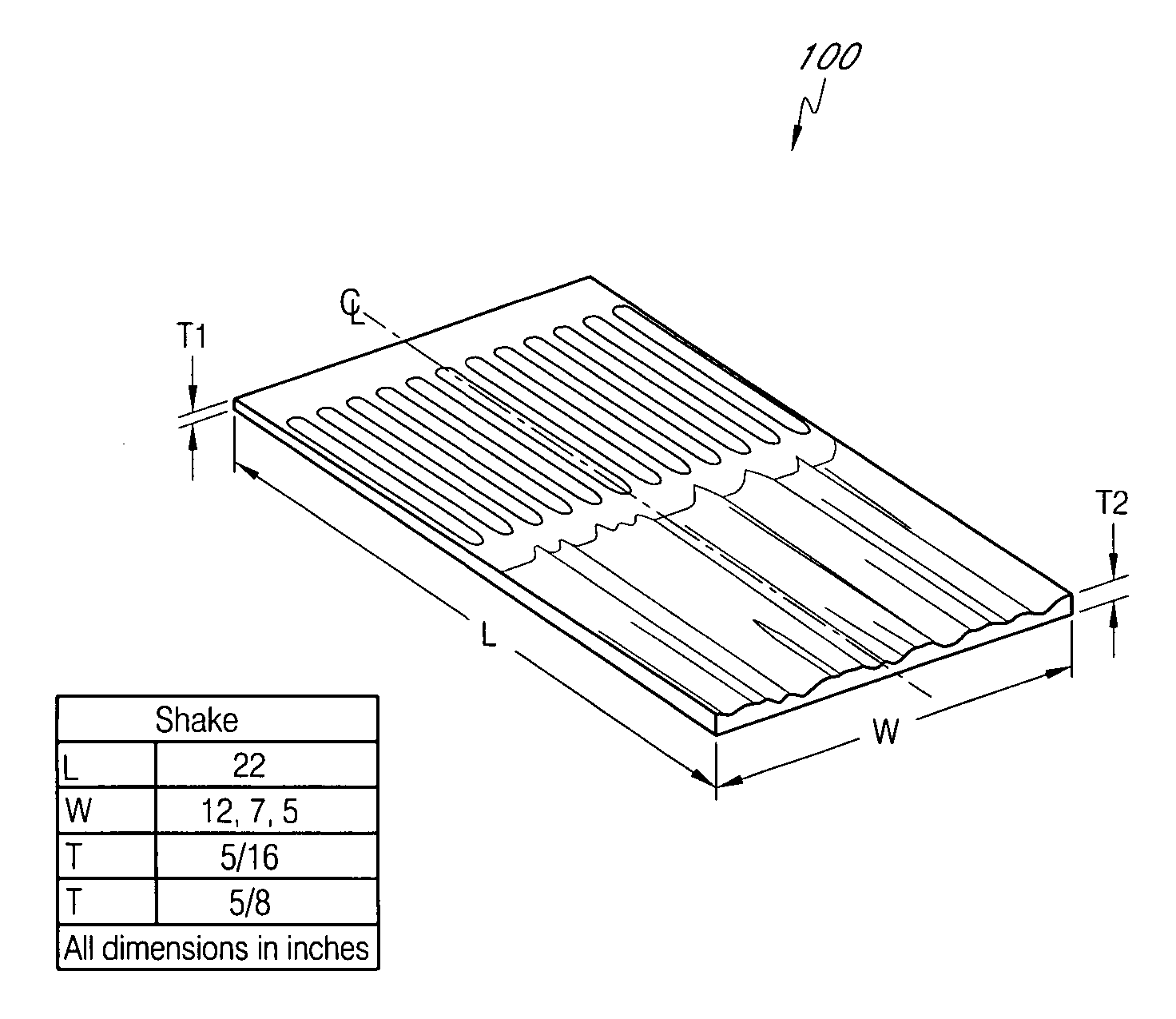

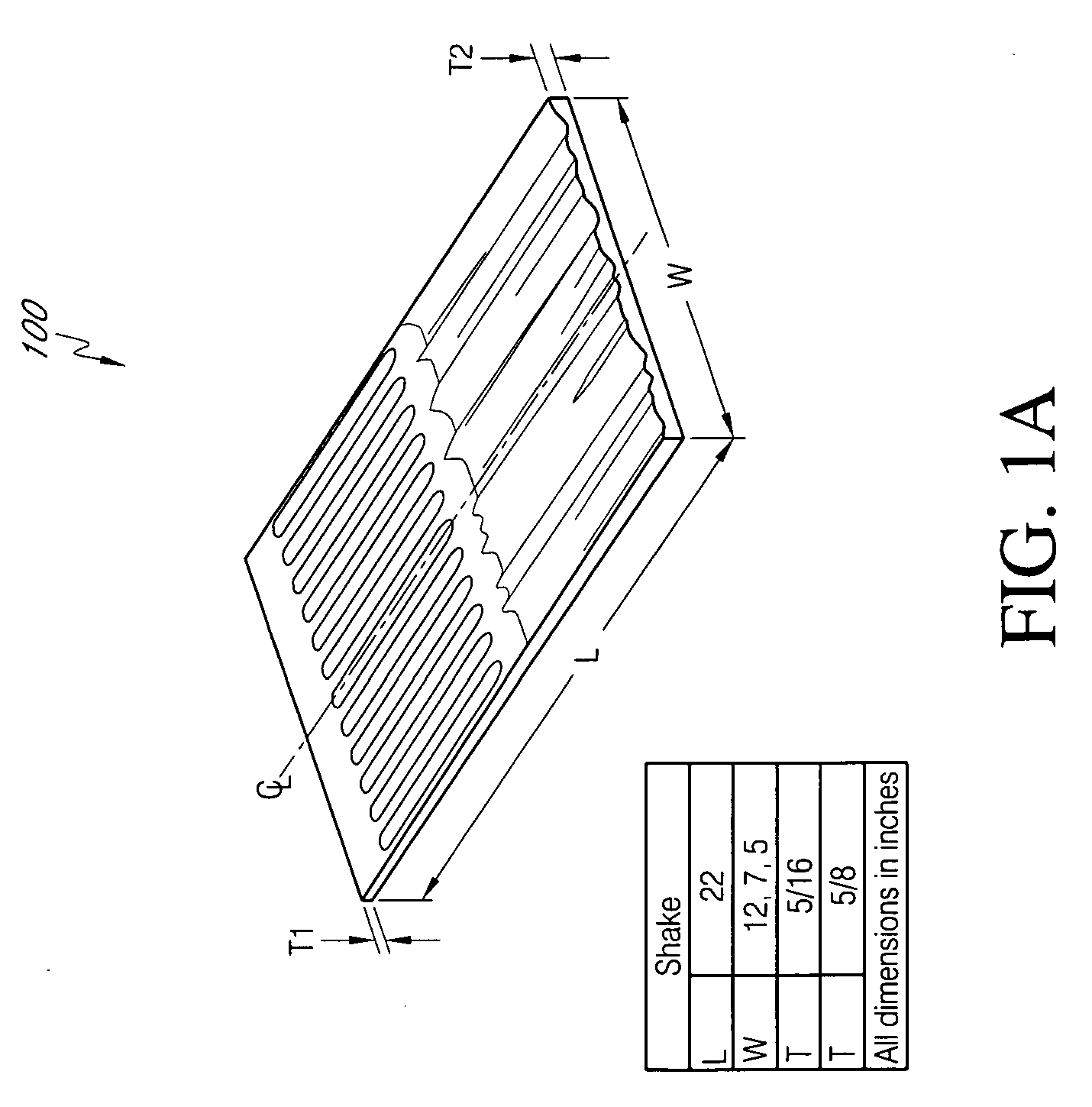

Durable building article and method of making same

InactiveUS20050284339A1Induced crackingRoof covering using tiles/slatesNatural patternsPolymer scienceViscosity

A durable, nailable, lightweight and fire resistant fiber cement article that can be a cost-effective substitute for conventional building materials is provided. The fiber cement article can be profiled to resemble a roofing article such as a wood shake or slate. The fiber cement article incorporates a hydrophobe and a viscosity enhancing agent that are each selected to control the rate of hydration of the binder. The fiber cement article is durable, is walkable and nailable without cracking during installation and maintains walkablilty after exposure in service.

Owner:JAMES HARDIE INT FINANCE BV

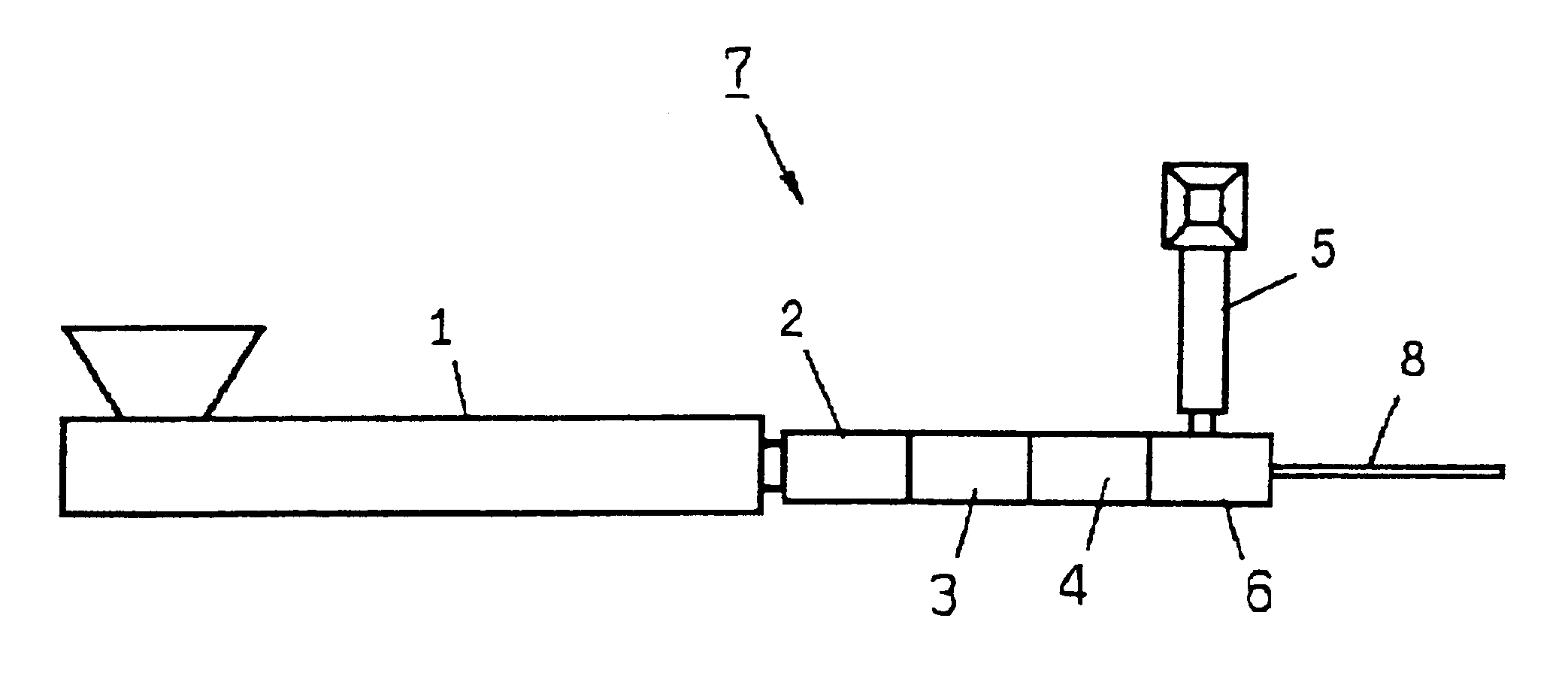

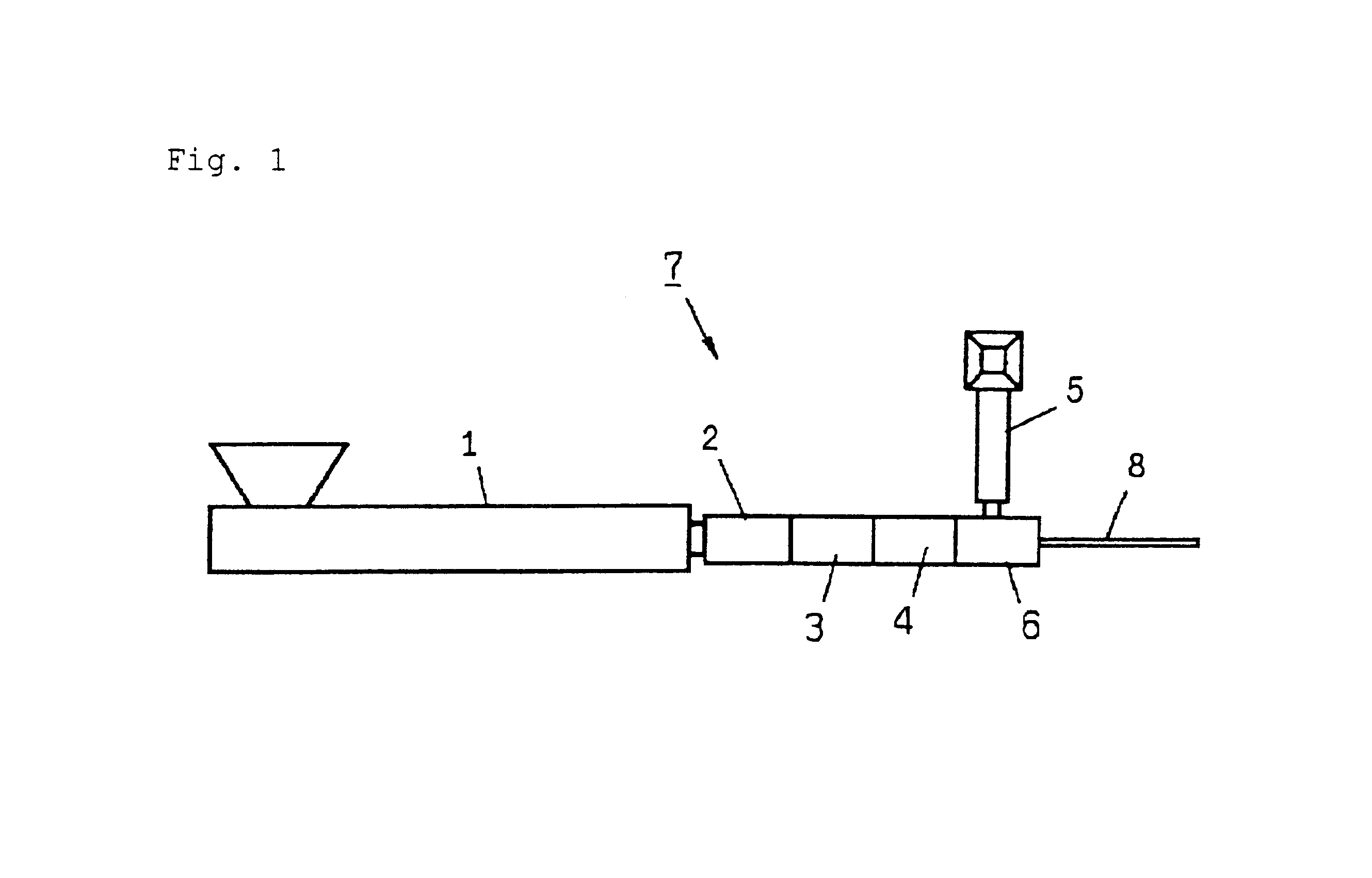

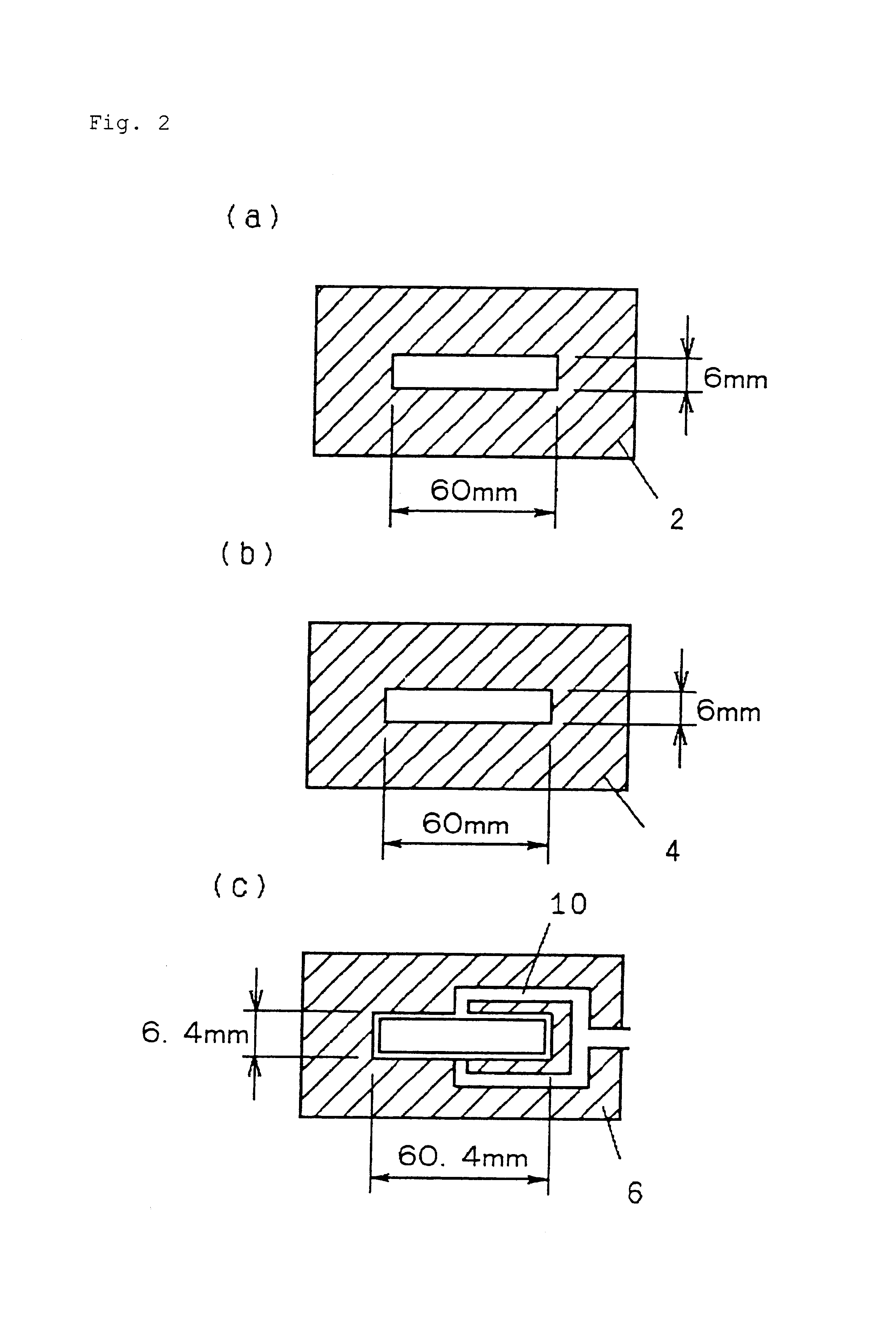

Molded article from thermoplastic composite material and method for producing the same

InactiveUS20020192401A1Uniform temperature distributionSuitable temperatureHair accessoriesWood working apparatusShell moldingThermoplastic composites

The present invention has for its object to provide a molded article of a thermoplastic composite material which is not only durable with little discoloration or fading even on prolonged outdoor exposure and is very satisfactory in physical properties and appearance qualities inclusive of wood-like texture but also has high productivity and good economics. The present invention is a method of producing a molded article of a thermoplastic composite material comprising extruding the thermoplastic composite material containing a thermoplastic resin and a vegetable filler, said vegetable filler content being 50 to 90 weight % of the total weight of said thermoplastic resin and said vegetable filler, wherein extrusion is carried out by means of an extrusion apparatus comprising at least an extruder, a hot shaping die, and a cooling die, said hot shaping die and cooling die being directly coupled.

Owner:SEKISUI CHEM CO LTD

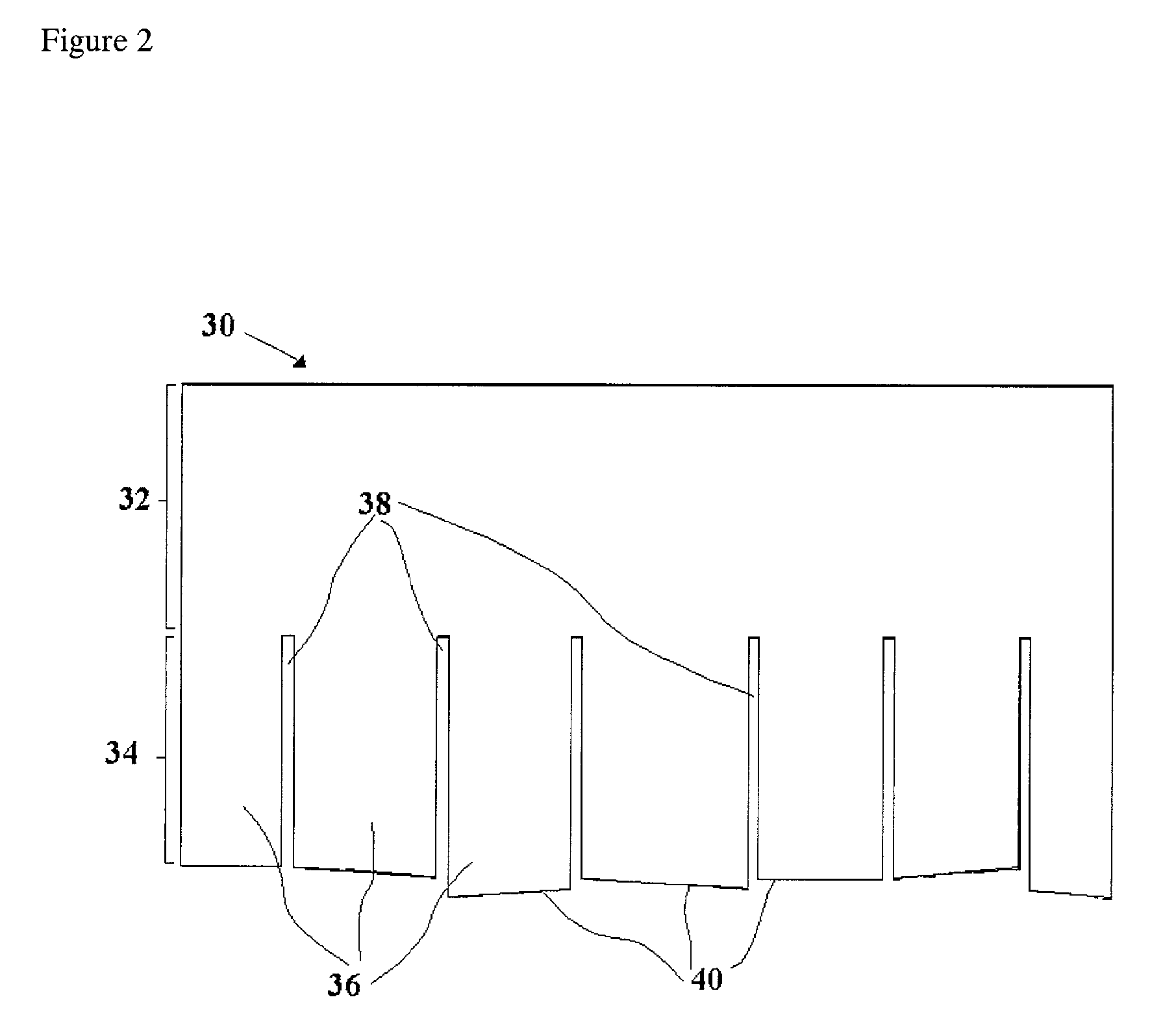

Flooring system having microbevels

Laminated flooring panels include decorative motifs, mechanically embossed-in-registration surface textures, recessed perimeters, and locking mechanisms. The locking mechanisms facilitate the alignment of adjacent flooring panels. Adjacent flooring panels substantially aligned allow embossed-in-registration patterns to be substantially continuous across adjacent flooring panels. The recessed perimeter prevents the edges of the flooring panel from prematurely wearing. Individual flooring panels within the flooring system may comprise at least one partial sub-panel having a decorative motif and / or embossed surface texture that is complementary with a decorative motif and / or embossed surface texture of a neighboring partial sub-panel.

Owner:FAUS GRP INC

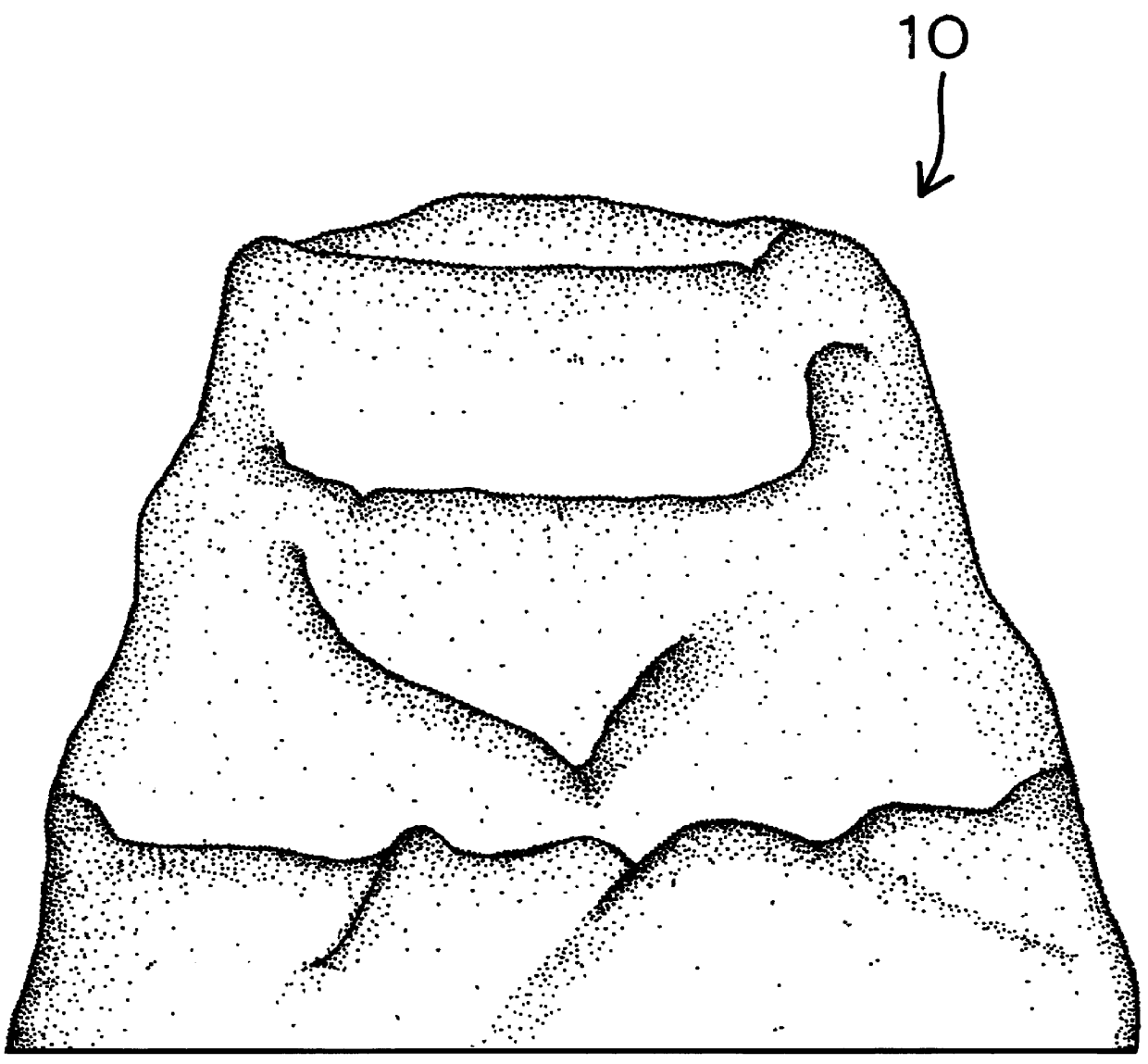

Simulated rock and method of making same

A simulated rock and a method of producing it, using Portland Cement, Bentonite or lime, polystyrene, and water. Ground polystyrene is mixed with cement, Bentonite or lime, and water, to form a settable cement formulation which is poured into removable forms. Reinforcing members are included in the mold, and a lifting hook is provided for later lifting and transporting of the resultant simulated rock. One or more base coats can be applied using a different formula, and a color coat can be applied. The method is use for making landscaping rocks, rock fountains, stone barbecues, light pillars, planters, room dividers, artificial masonry panels, and any structure which uses rocks or masonry.

Owner:CALLAHAN HARVEY J

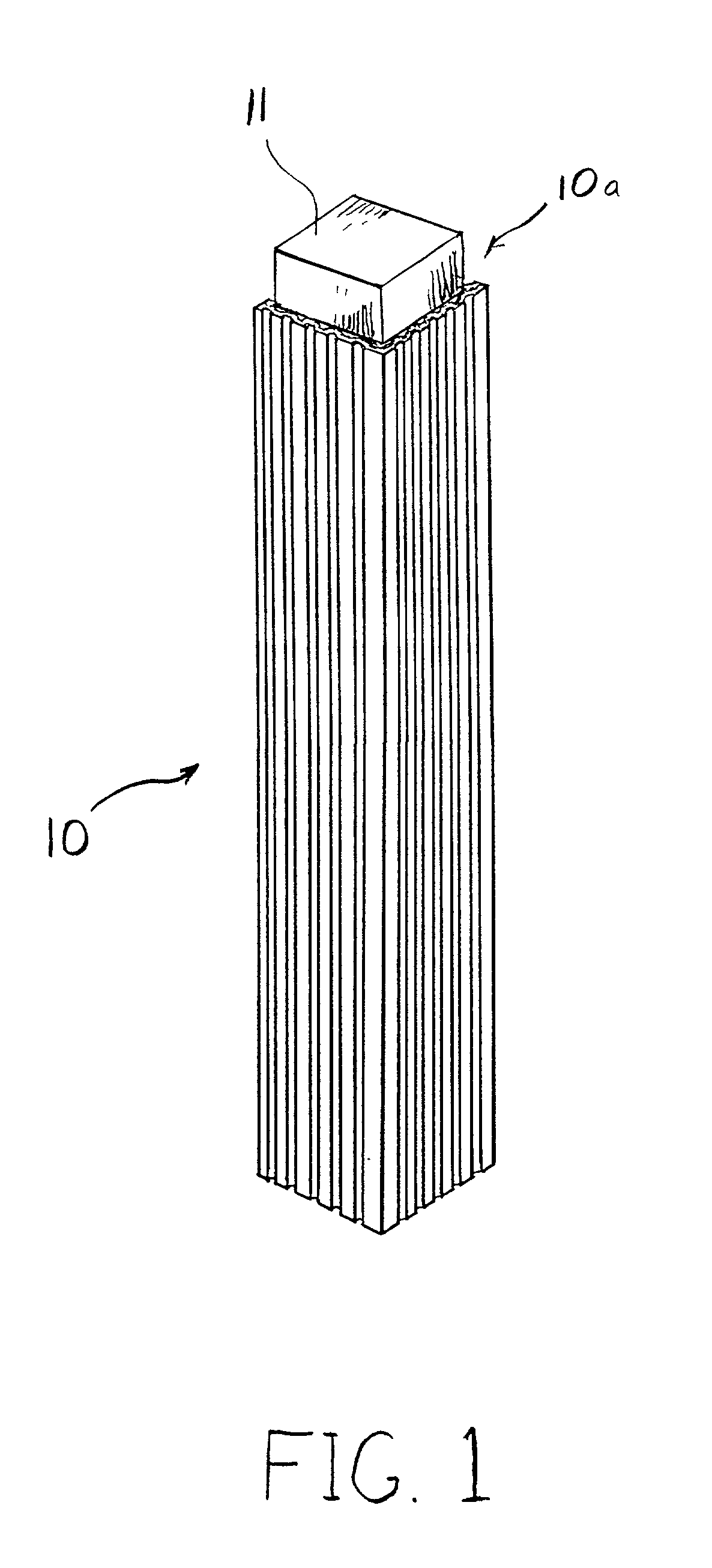

Decorative post cover

Owner:GIFFORD THOMAS

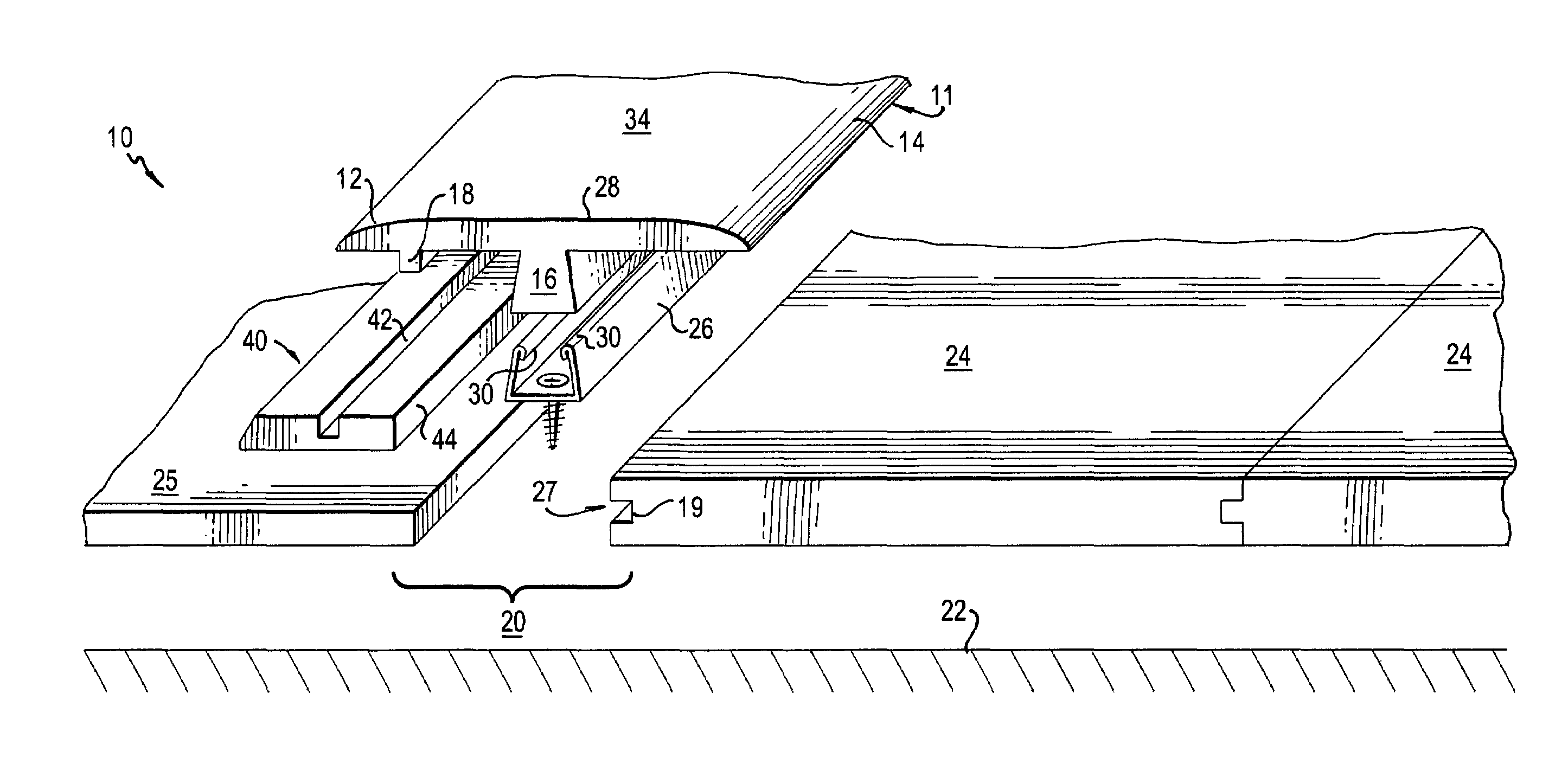

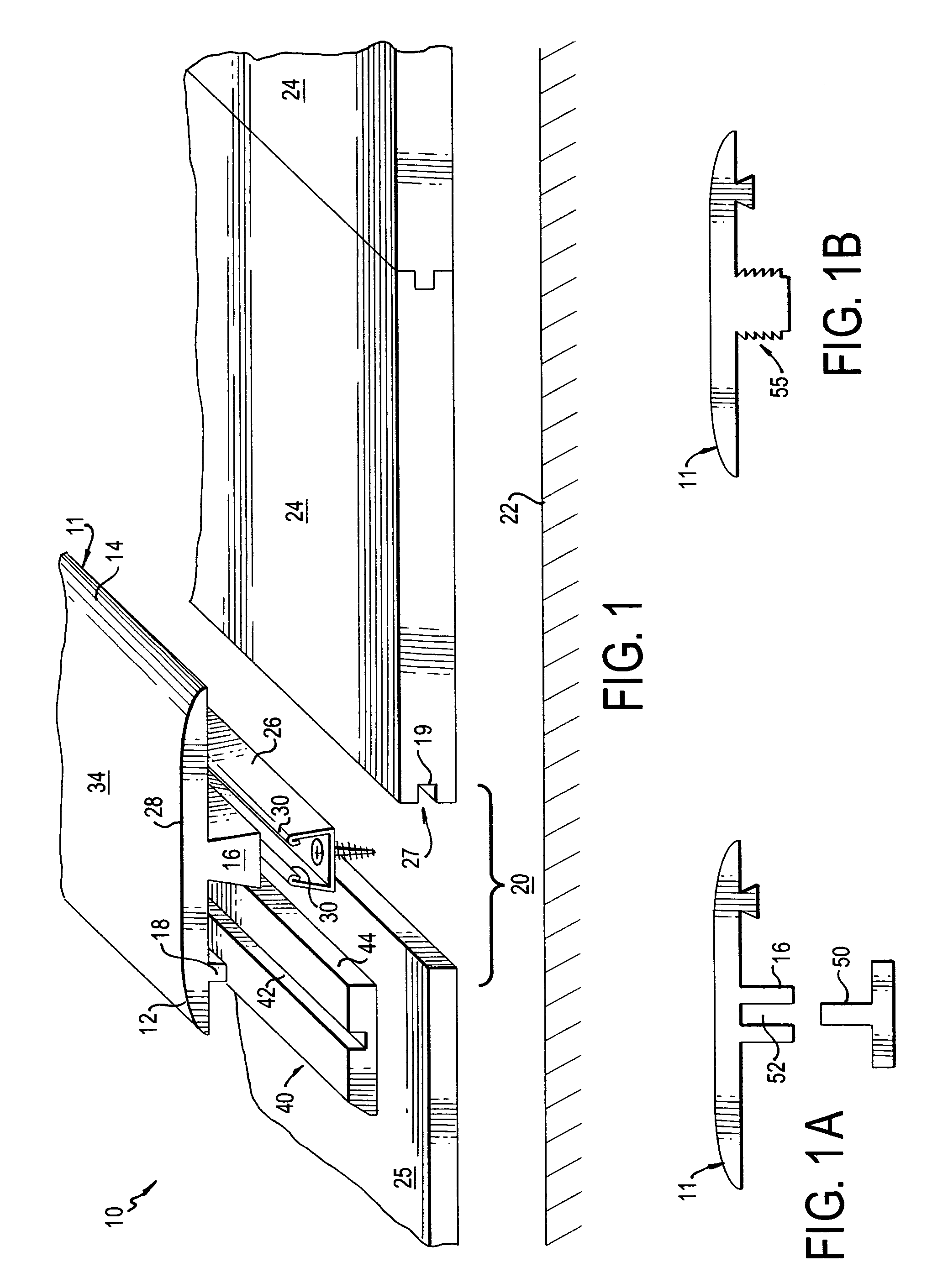

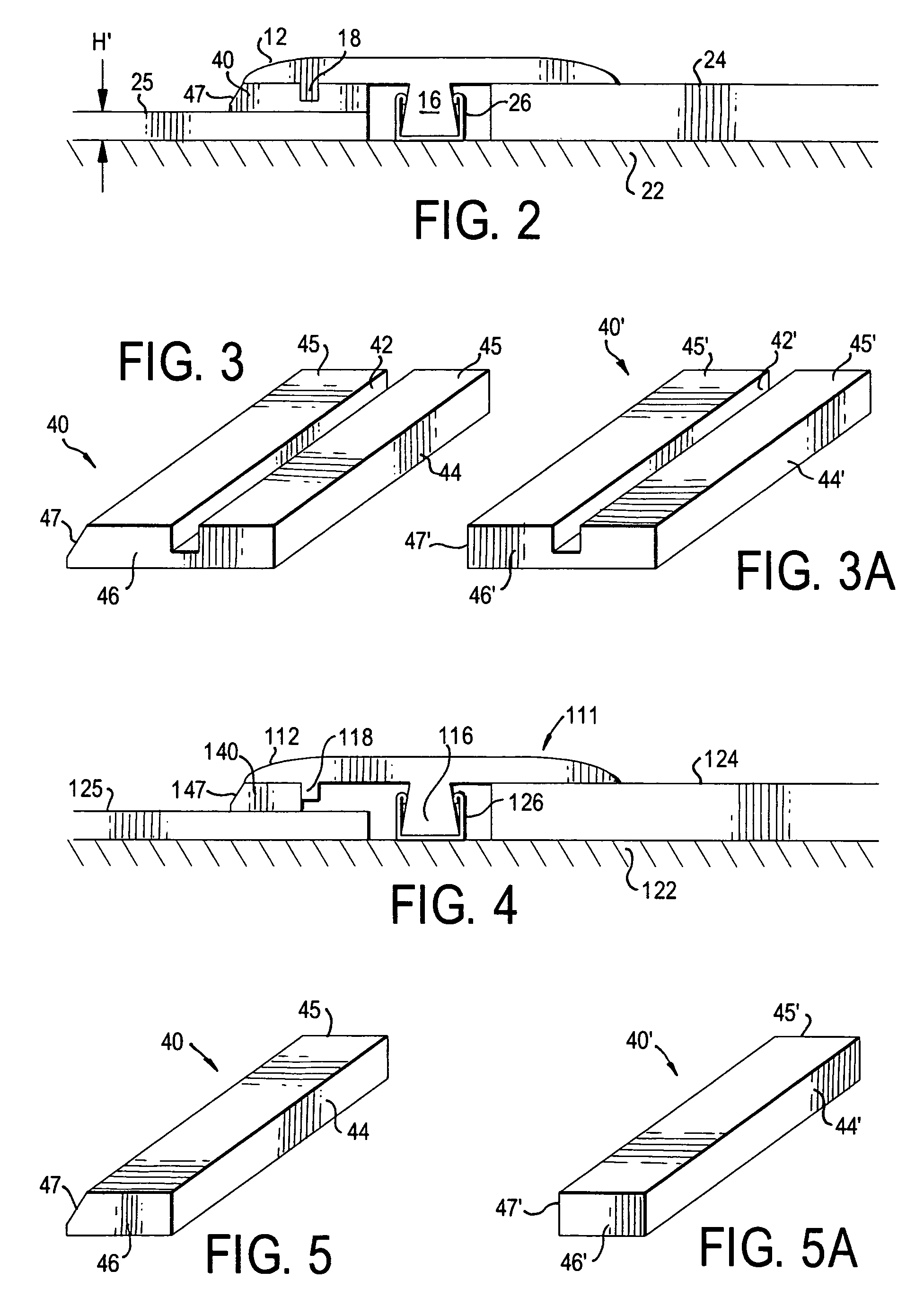

Transition molding and installation methods therefor

InactiveUS7207143B2Easy to useSmooth transitionRoof covering using tiles/slatesNatural patternsEngineeringSurface plate

The invention is a joint cover assembly for covering a gap adjacent an edge of a panel that covers a sub-surface, and a method of covering such a gap. The assembly includes a molding having a foot, a first arm, and a second arm. The foot is positioned along a longitudinal axis of the molding, and the first arm extends generally perpendicularly to the foot. The second arm may also extend generally perpendicularly to the foot. A tab depends from at least one of the first and second arms. At least one of the tab and the foot engage a track in order to position the assembly over the gap. The method includes the steps of placing the foot in the gap, pressing the respective panel engaging surfaces into contact with respective panels, and configuring at least one of the tab and the foot to cooperate to retain the molding in the gap when the assembly is in an installed condition.

Owner:PERGO

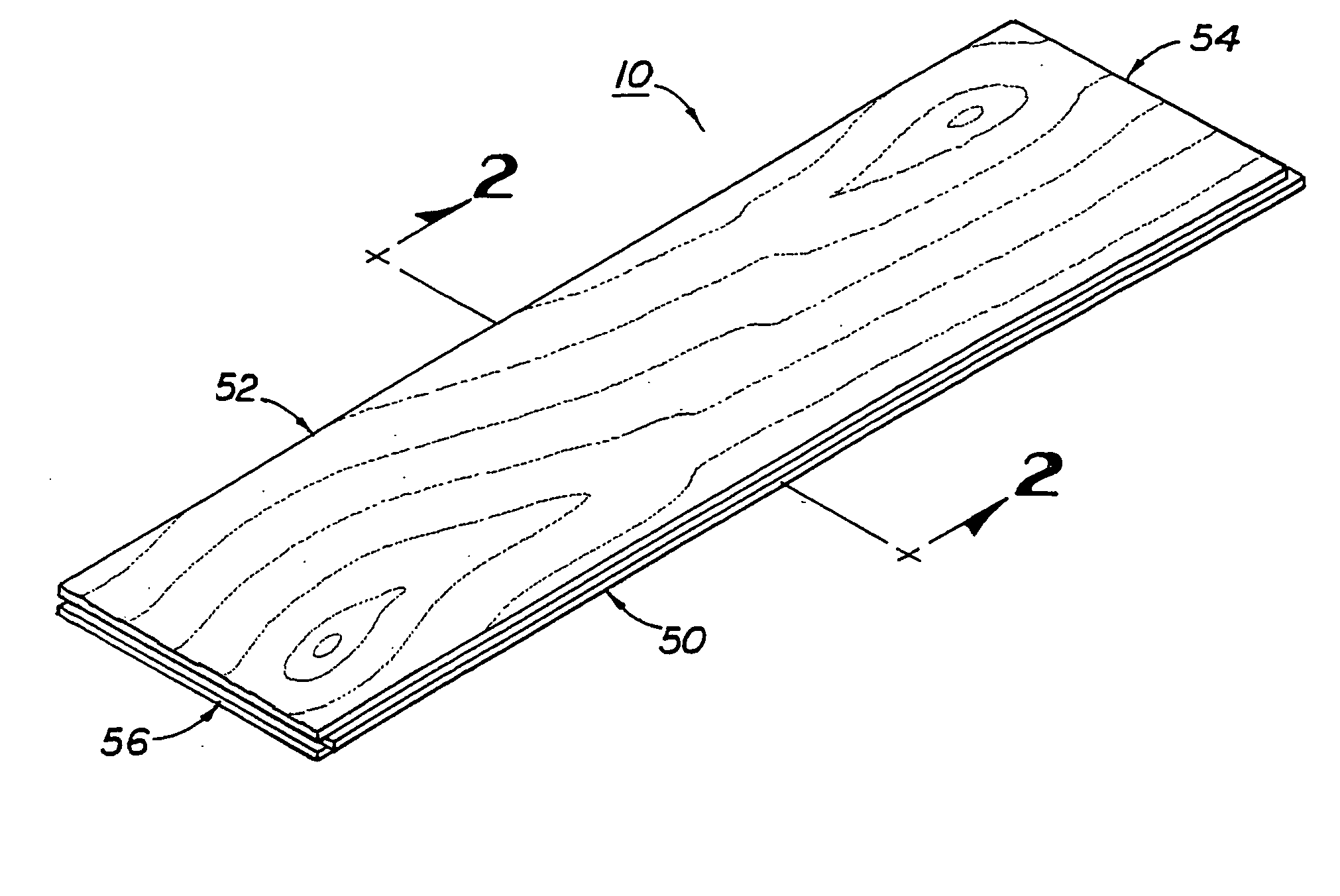

Textured laminate flooring

InactiveUS20050079323A1Provide protectionImprove aestheticsCovering/liningsSpecial paperSubject matterEngineering

A decorated floor panel having a core with a top surface and an opposite bottom surface; a decorative layer coupled to the top surface of the core, the decorative layer having a desired aesthetic appearance; and a wear layer coupled to and substantially covering the decorative layer for protecting the decorative layer. The wear layer has an exposed wear surface with depressions therein of a variable depth below the wear surface, the depressions being arranged to display a desired texture pattern. It is noted that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to ascertain quickly the subject matter of the technical disclosure. The abstract is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims pursuant to 37 C.F.R. § 1.72(b).

Owner:COLUMBIA INSURANCE CO

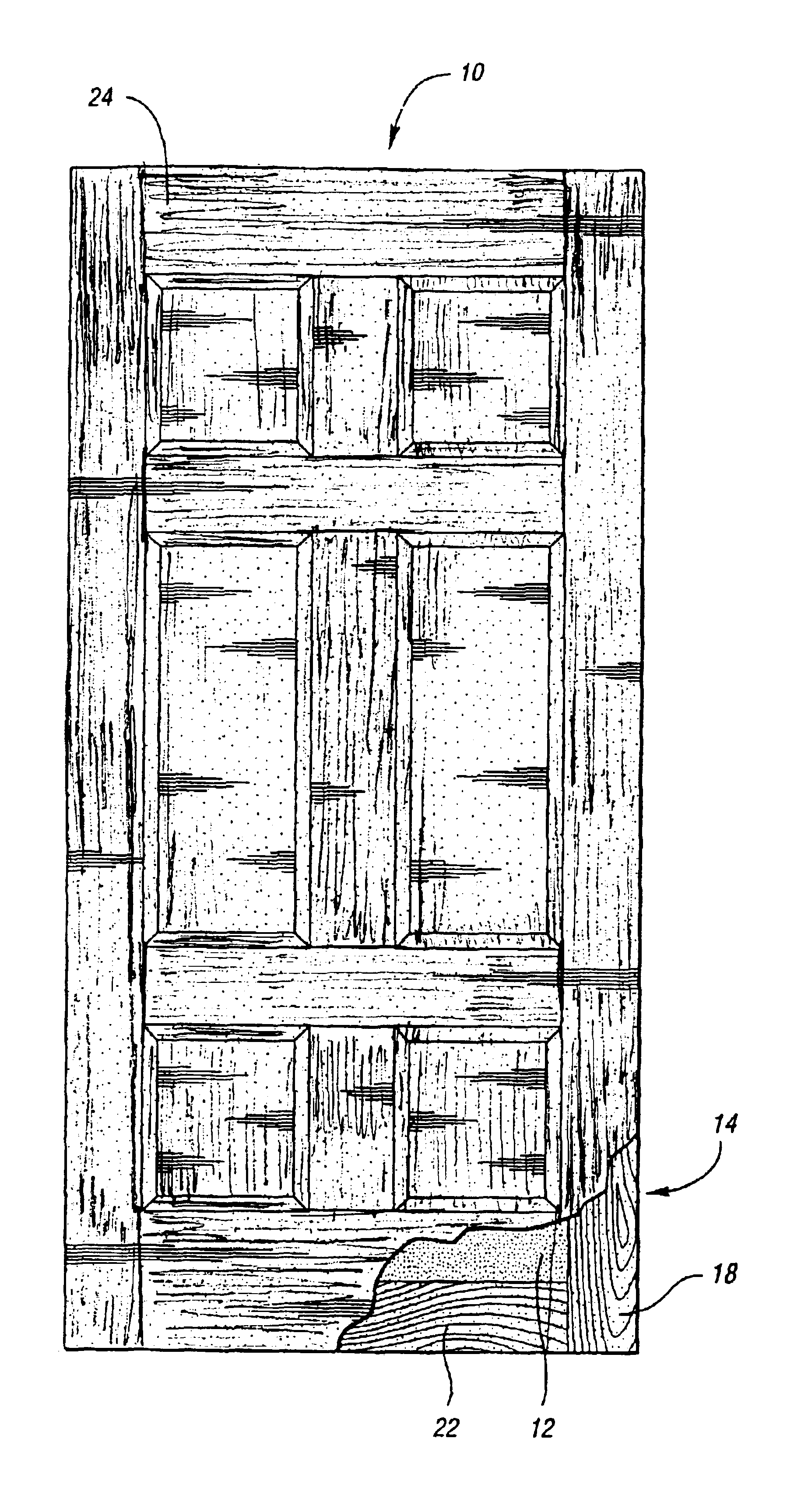

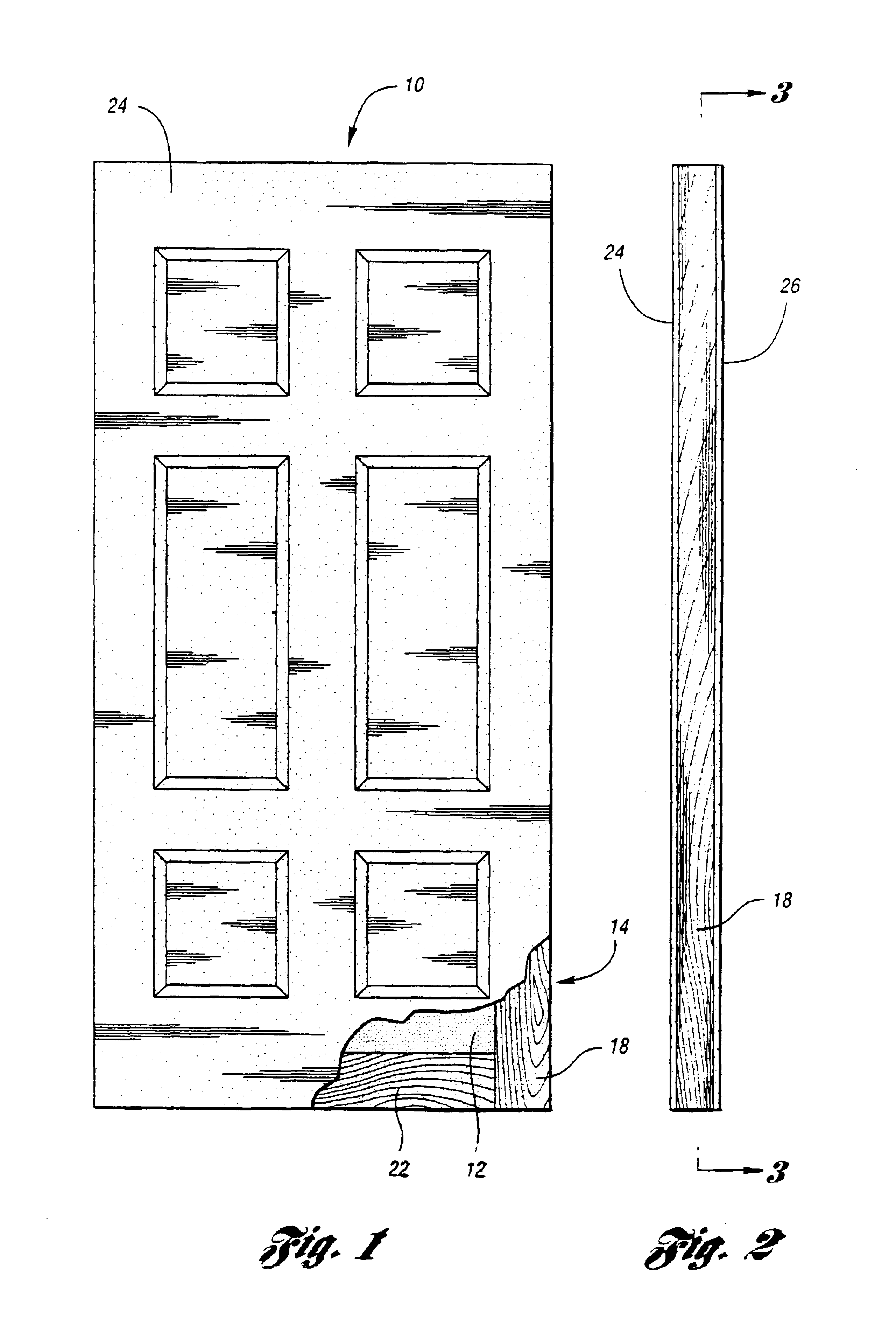

Compression molded door assembly

A door member comprising a frame having a first side and a second side, opposite the first side, a core positioned within the frame, and a molded skin attached to the first side of the frame. The skin is prepared from a molding compound which, when molded, has a shrinkage of between about −0.0003 to about +0.0015. The molding compound comprises a resin system comprising a curable polyester resin, a co-curable unsaturated monomer, and at least two low profile additives. The molding compound also comprises at least about 30 percent by weight, based on the weight of the molding compound, of filler material, and fibrous reinforcement in an amount of less than about 35 weight percent, based on the weight of the molding compound.

Owner:THERMA TRU

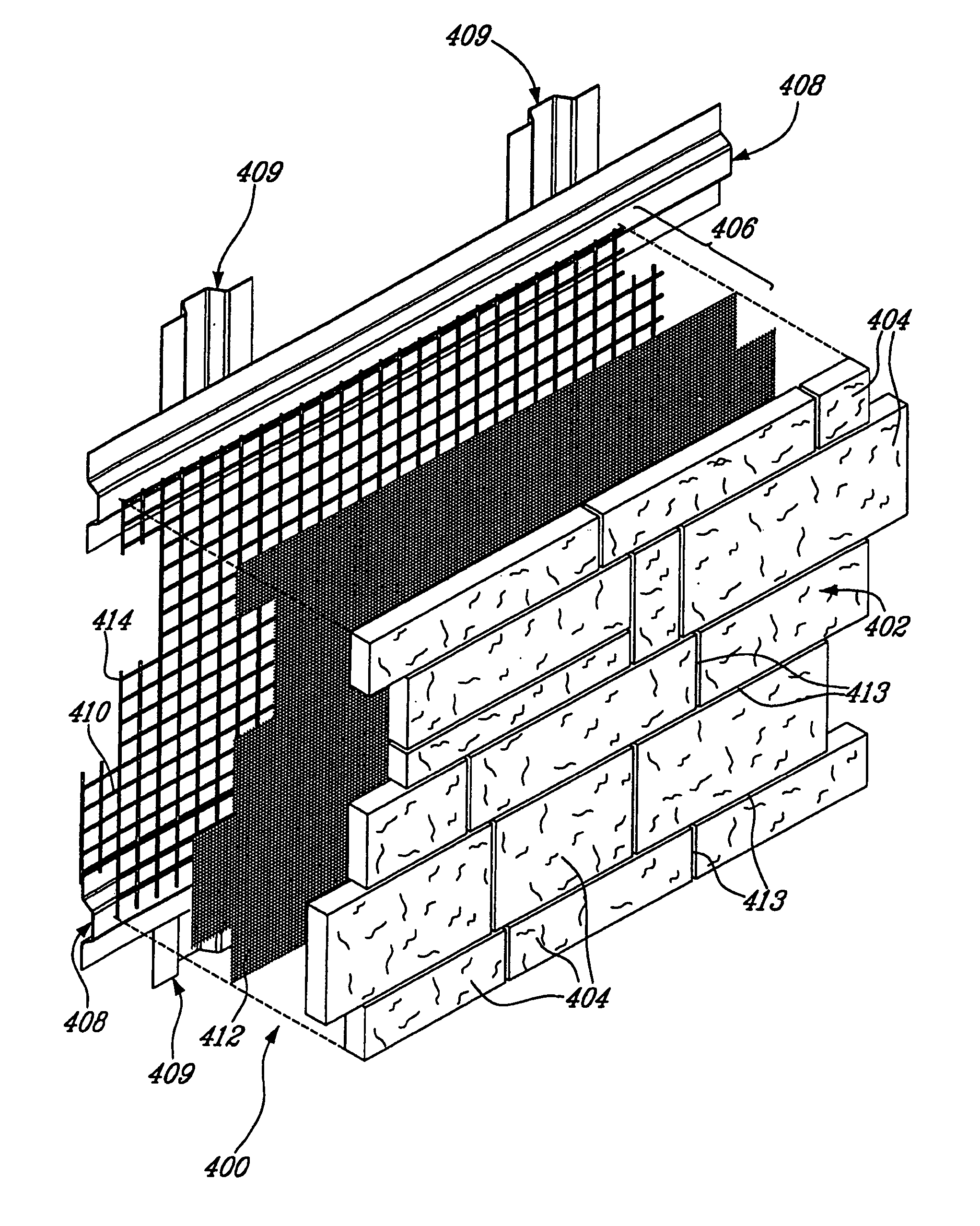

Panel for thin bricks and related systems and methods of use

A thin brick panel system and method of forming a thin brick wall includes an expanded polystyrene foam panel having a plurality of laterally extending channels formed therein for receiving a plurality of thin brick units. The thin brick units are bonded to the channels in the foam panel and the seams between adjacent bricks are filled with a mortar that bonds to the foam panel. The foam panel may be attached to a substrate with an adhesive as well as fasteners. Strips of a mesh fabric may span several panels to bind the panels together to form a structurally sound thin brick wall.

Owner:OLD MILL BRICK LLC

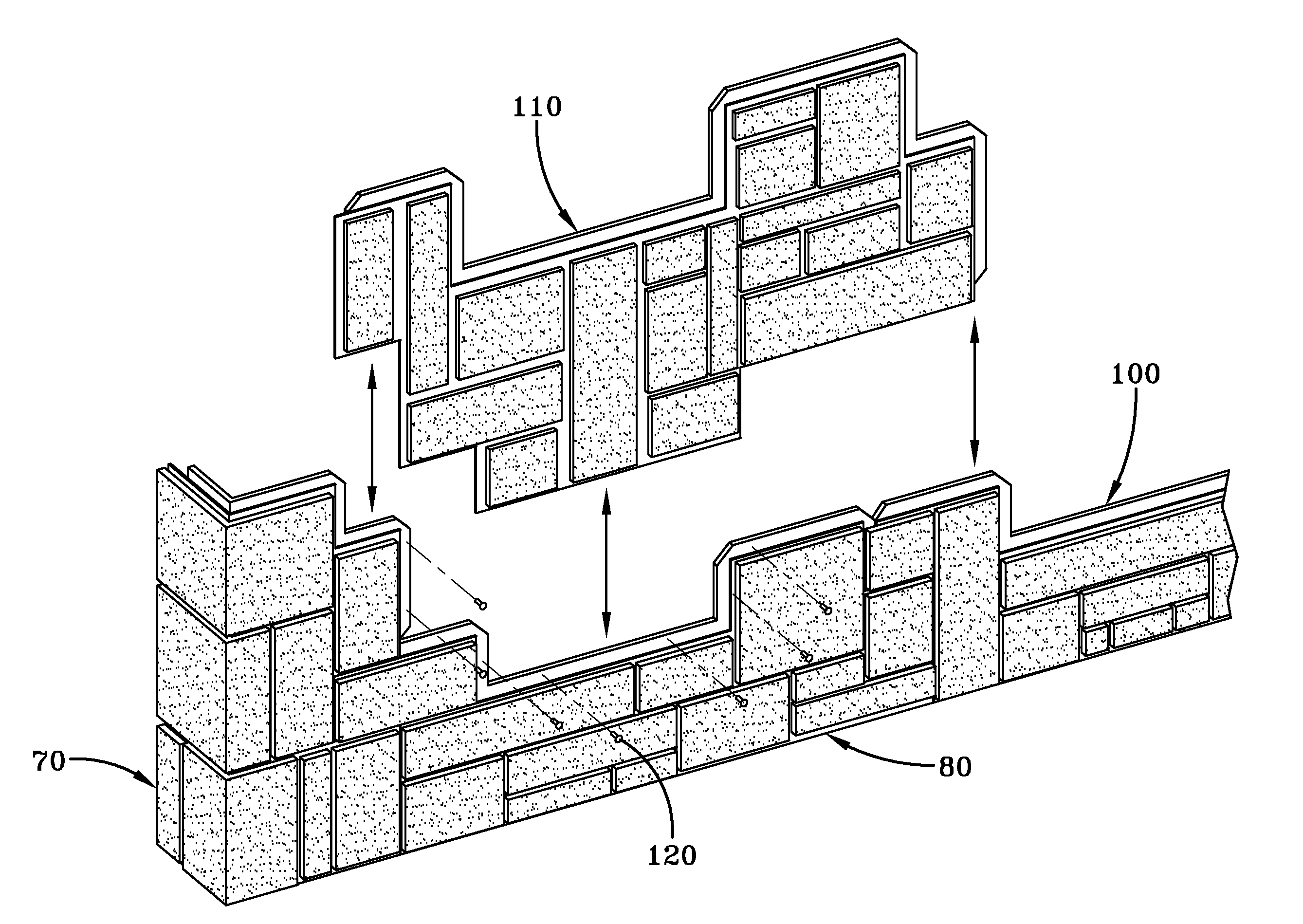

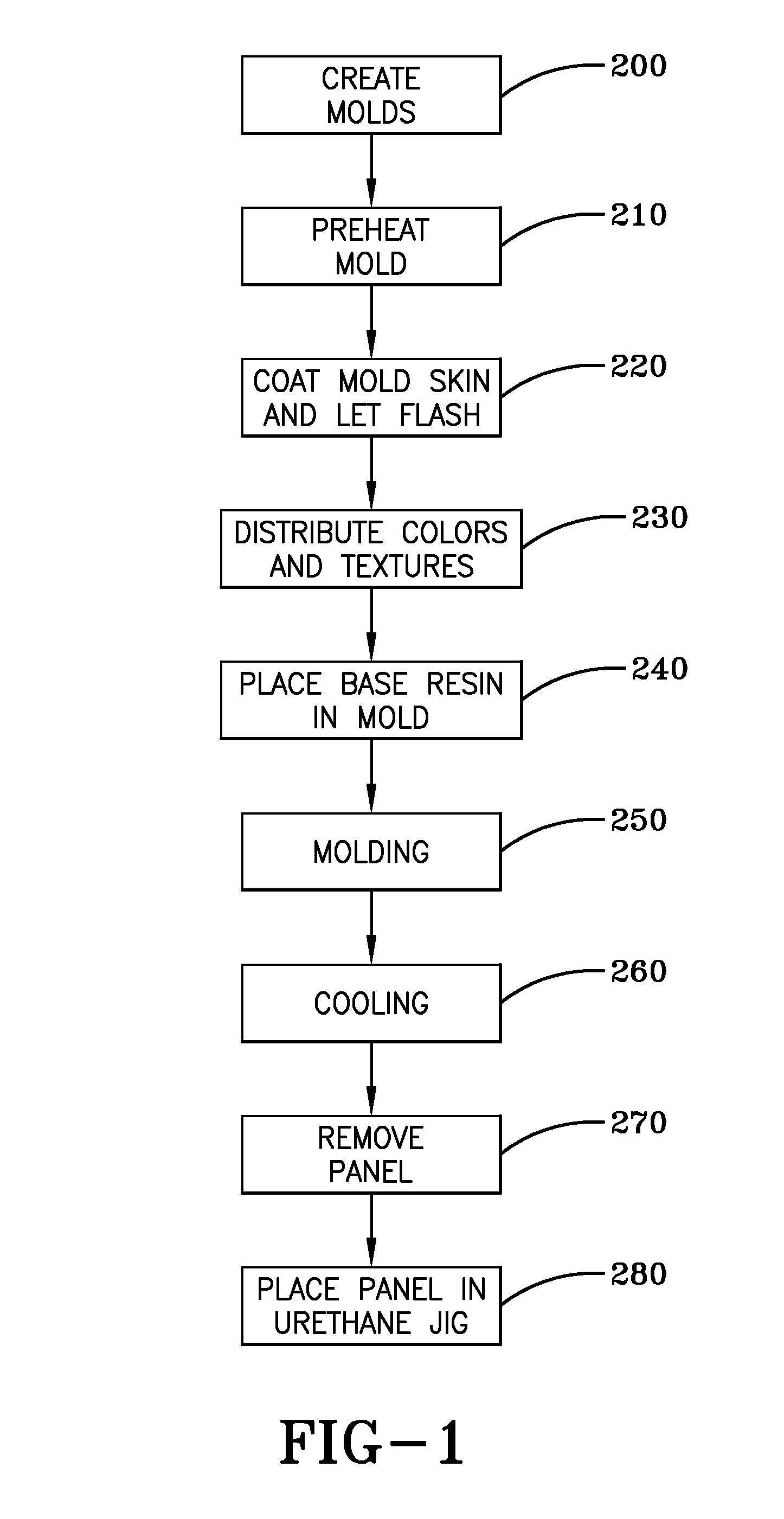

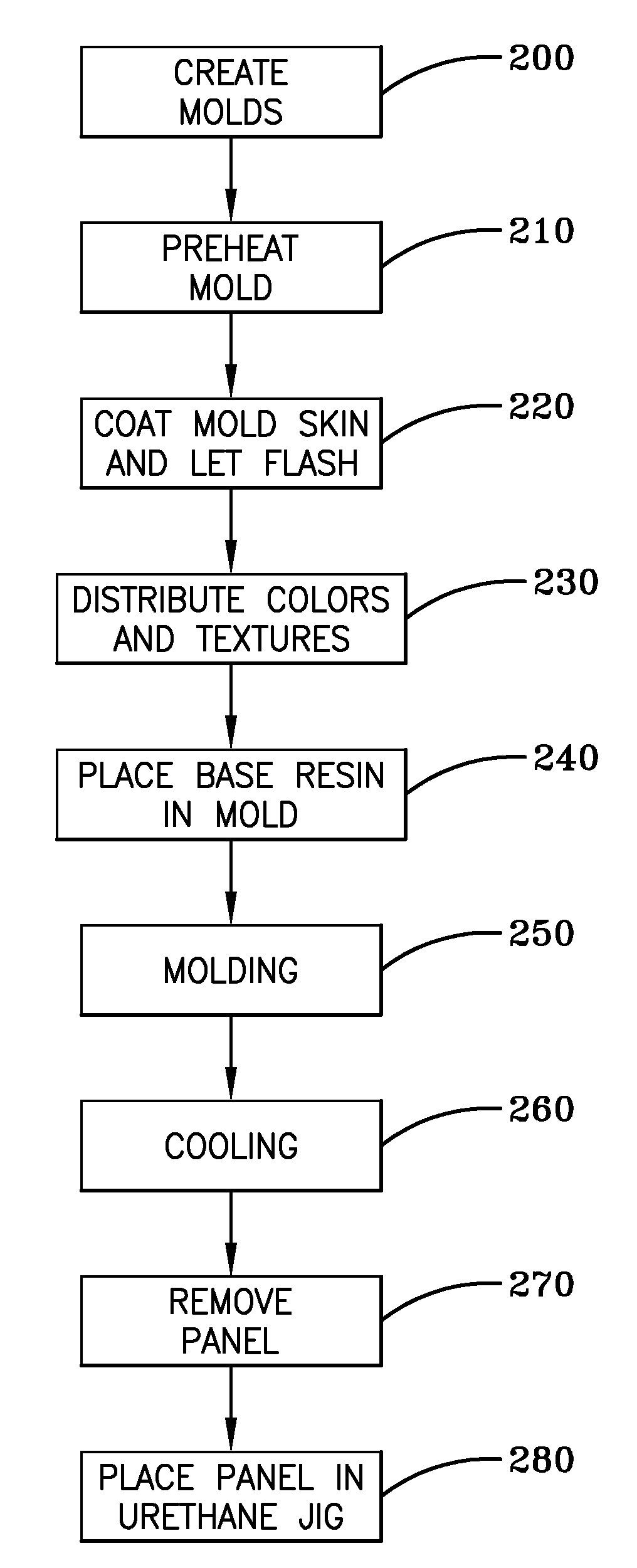

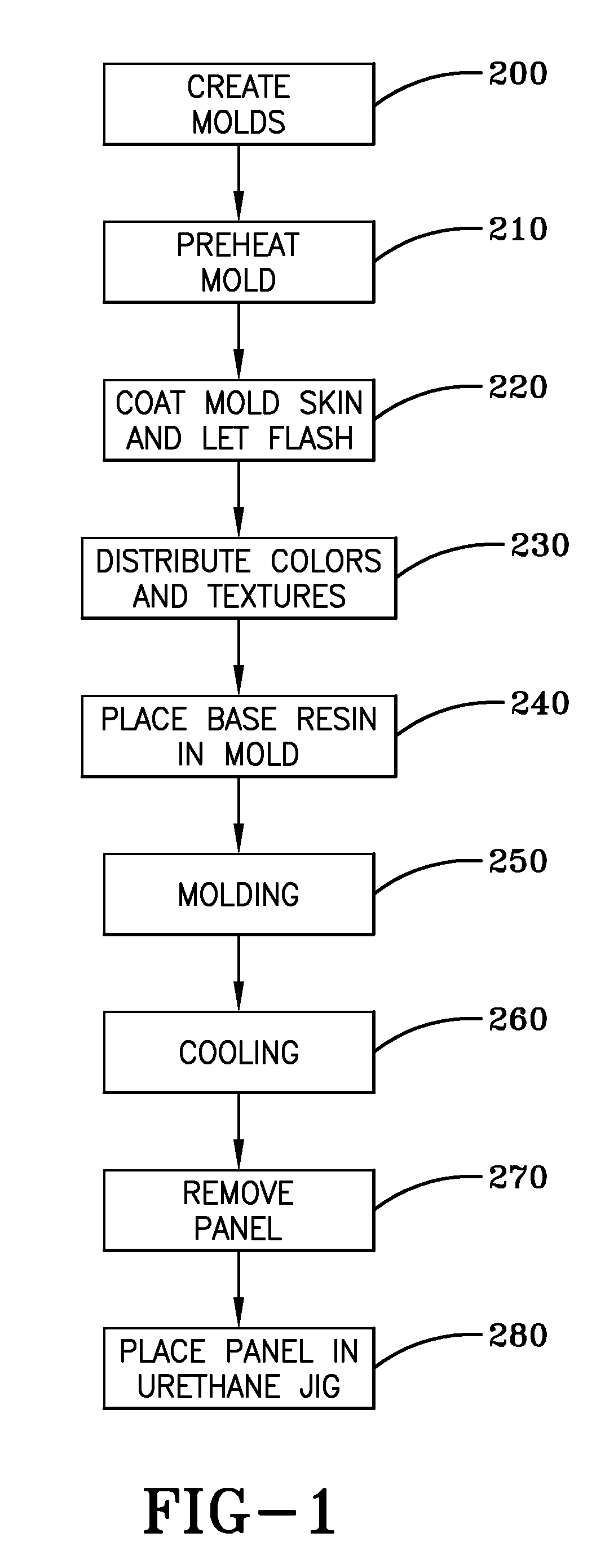

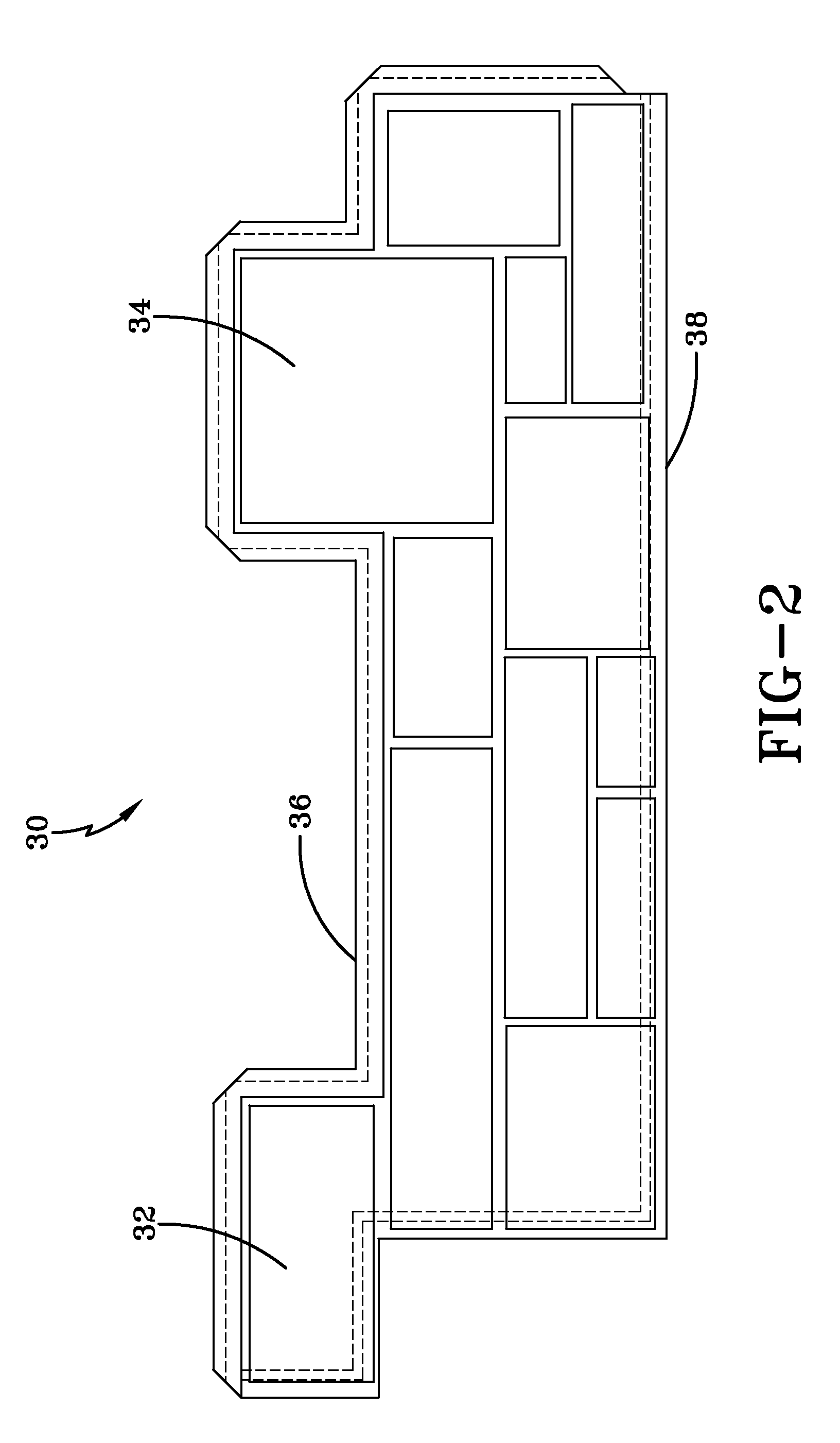

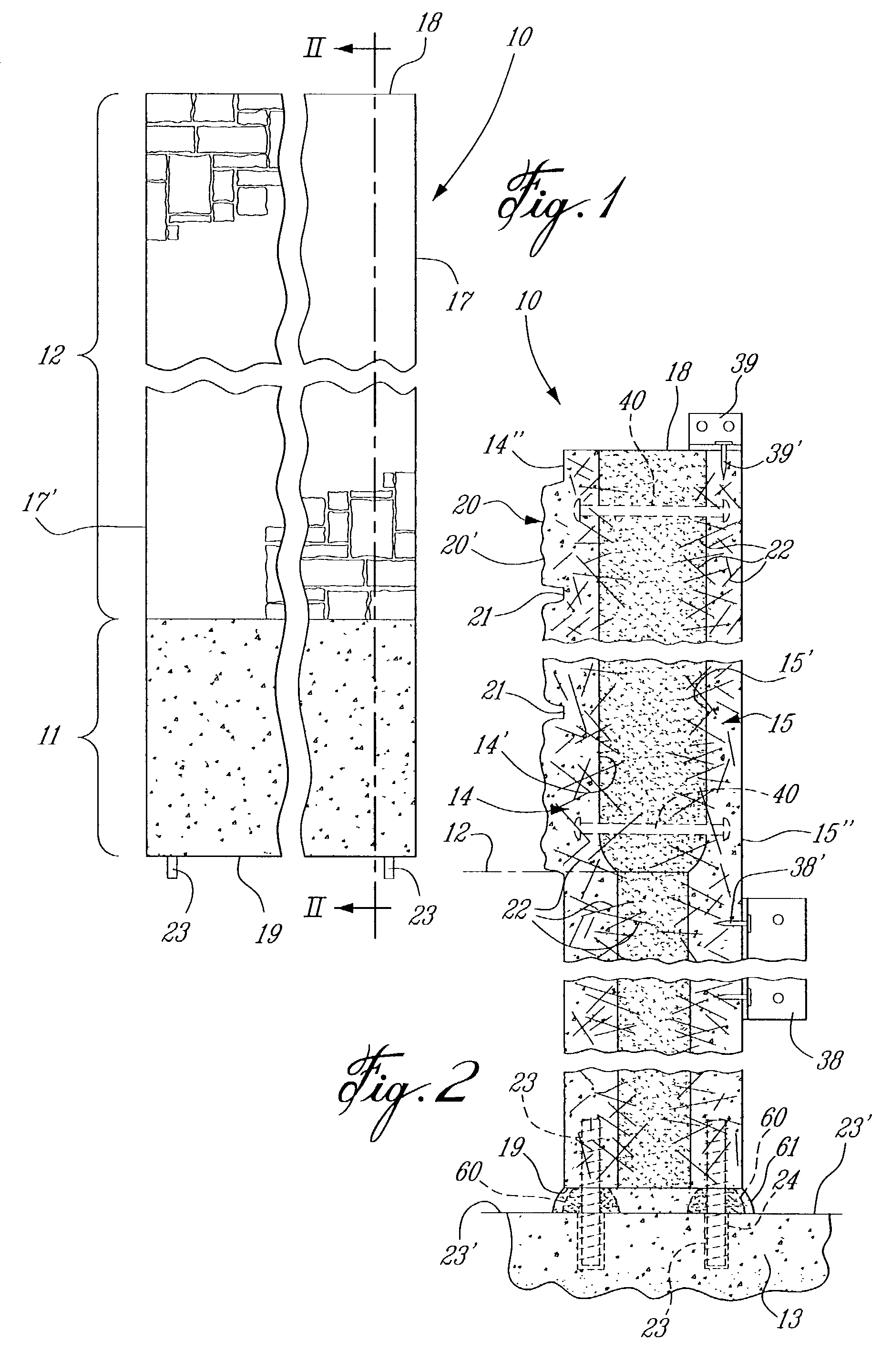

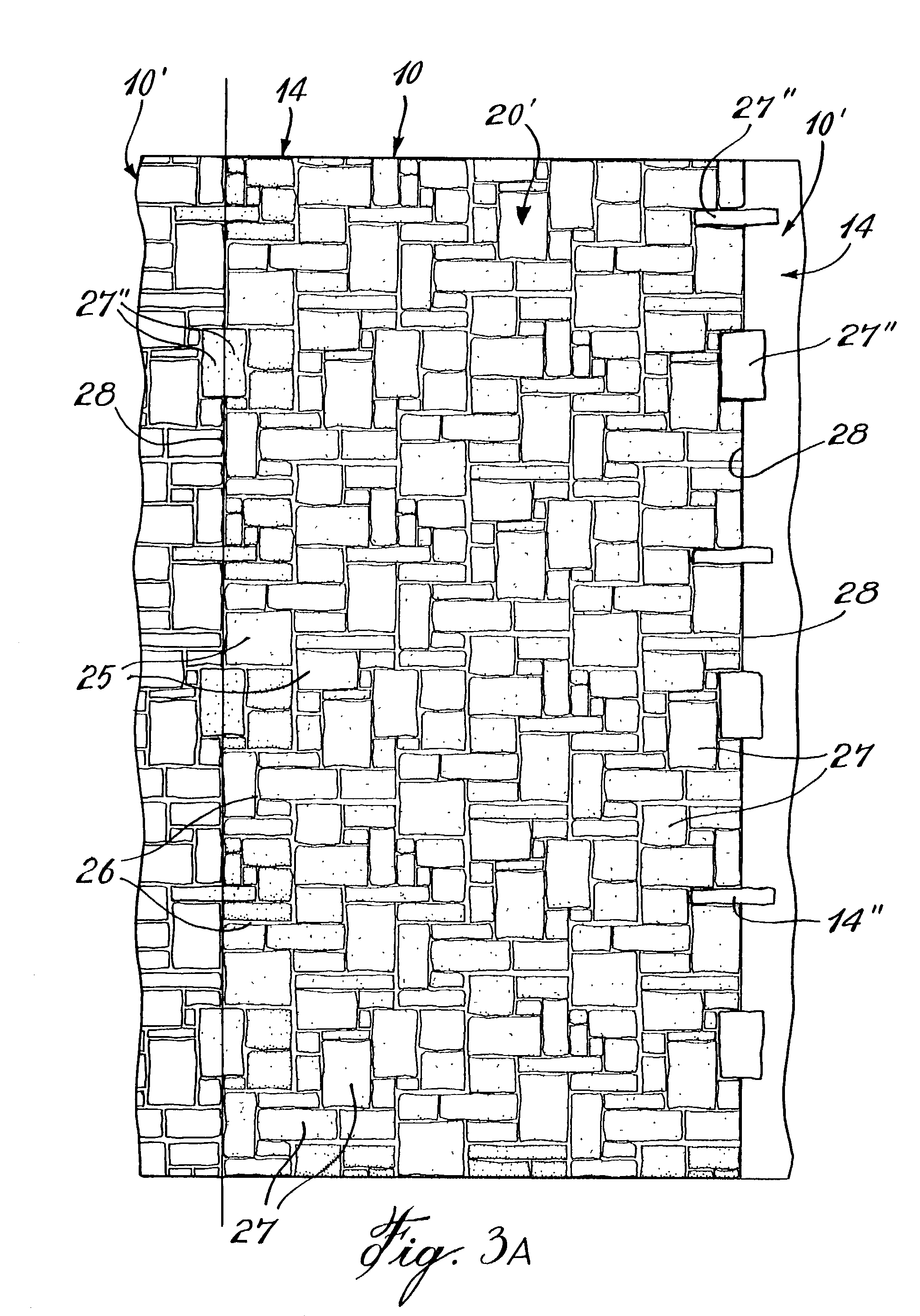

Method of manufacturing simulated stone, brick, and masonry panels and wall structures

InactiveUS20070227087A1Minimize limitationEasy to assembleCovering/liningsNatural patternsBuilding productBrick

Simulated stone, masonry and brick textured products such as siding panels are obtained when specially selected materials are properly admixed and formed via molding techniques. For instance, exemplary methods of manufacturing embodiments of panels, wall structures, and other products that may have contoured and textured surfaces and may simulate the appearances of conventional building or construction materials including, but not limited to, stone, bricks, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials are disclosed. Such products are manufactured from suitable molds according to a prescribed process methodology using synthetic polymeric materials in addition to other materials such as coloring and texturing materials. Prerequisite surface textures may be produced that effectively simulate actual stone, masonry and brick panels. Methods described herein may enhance the manufacturing, structure, appearance, assembly, or installation of synthetic building or construction products. In particular, exemplary embodiments include panels, wall structures, and other panel assemblies that may have contoured or textured surfaces to simulate the appearances of other building or construction products. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:EXTERIOR PORTFOLIO

Prefabricated thin wall concrete panel

Owner:PAUL BAILLARGEON ARCHITECTE

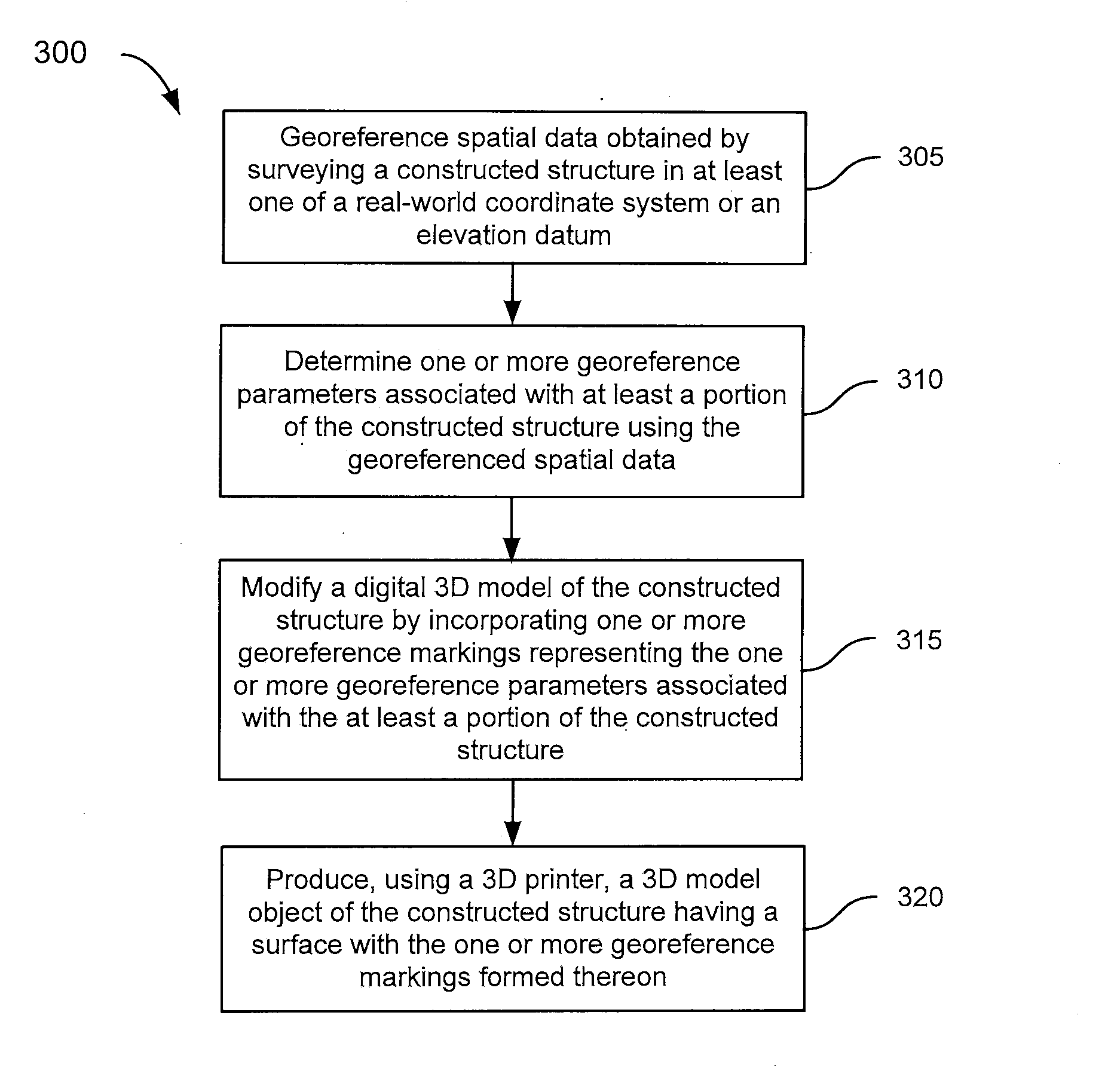

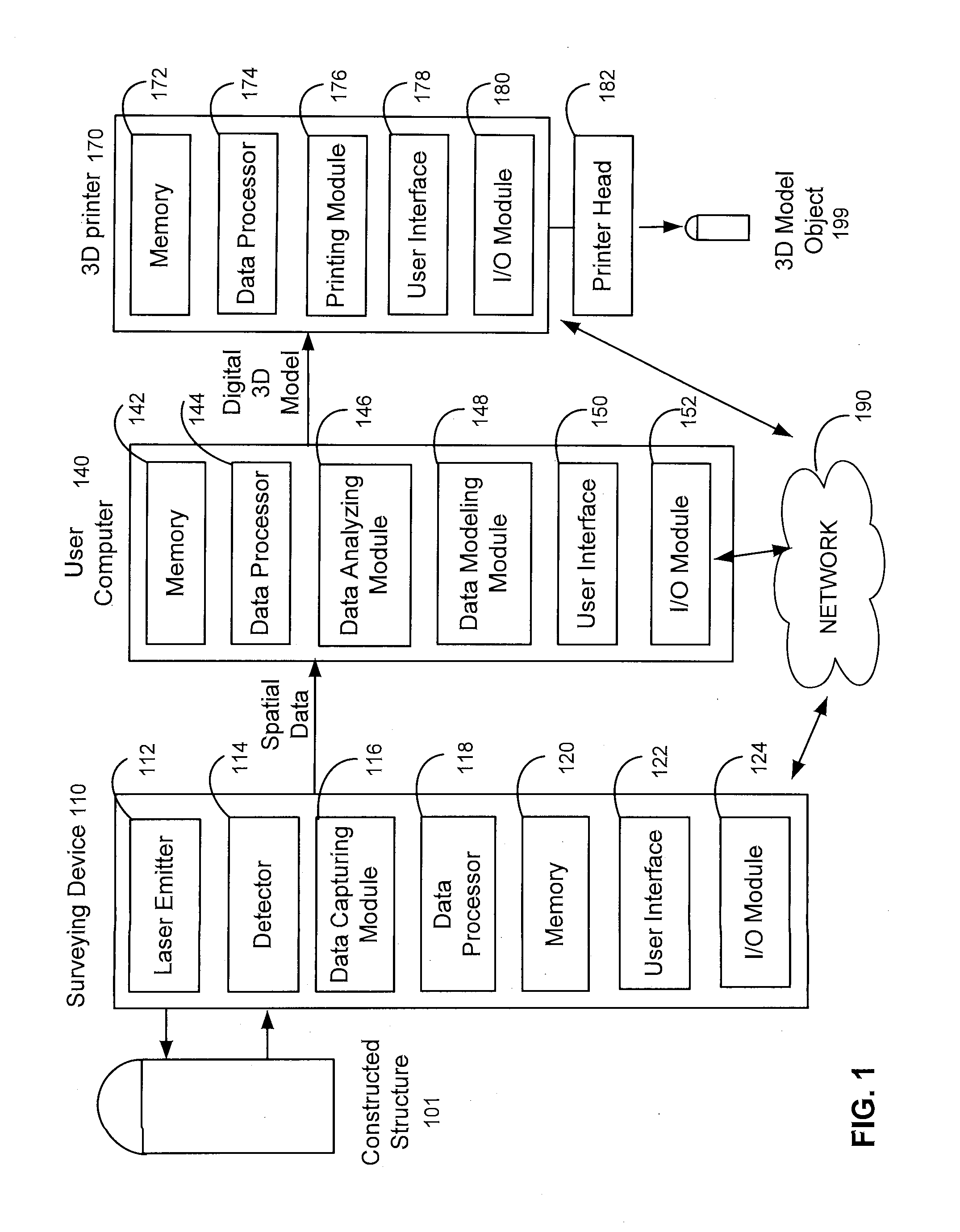

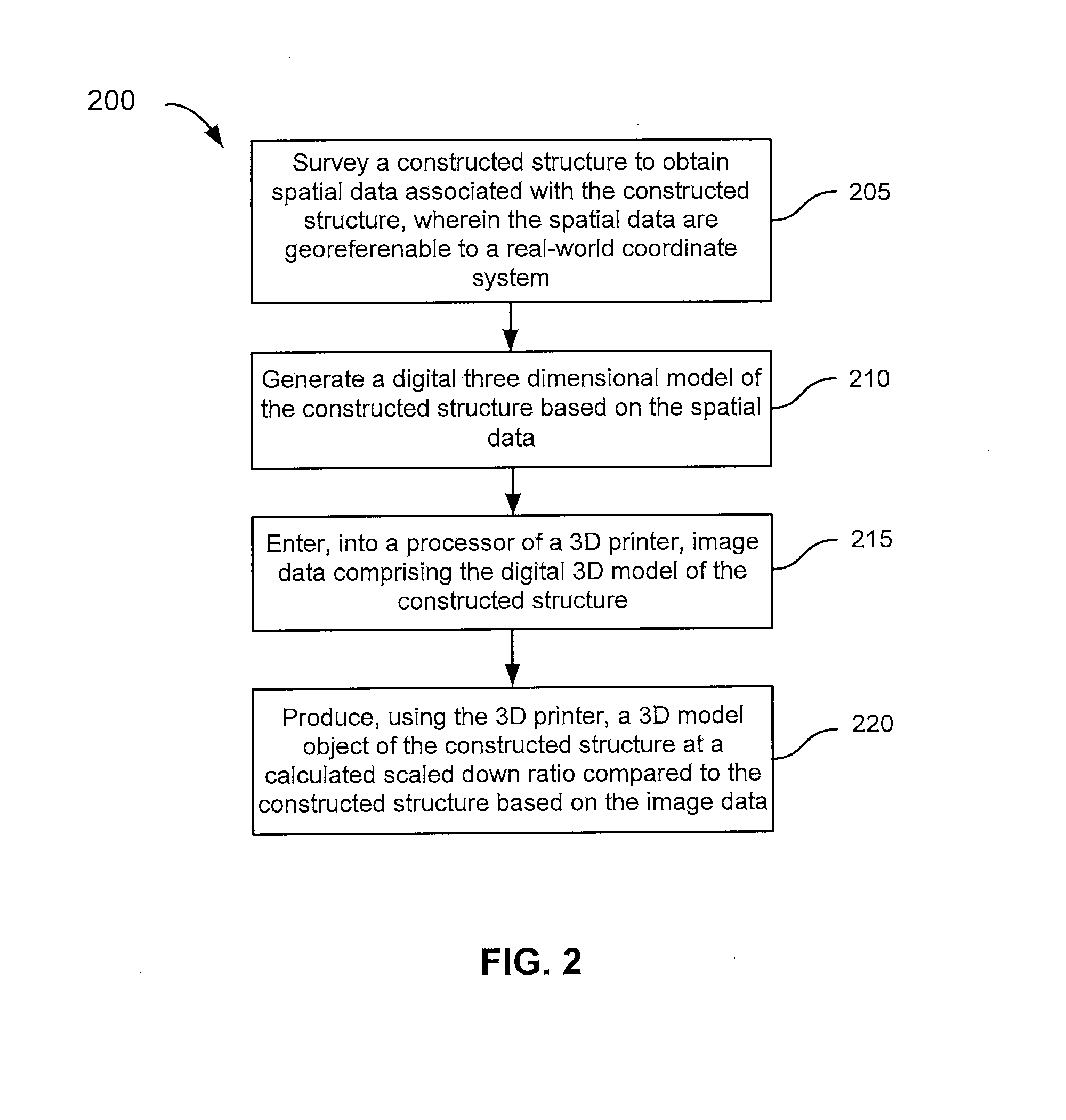

Three Dimensional Model Objects

Embodiments of the present invention provide a three dimensional model object, a method of producing the three dimensional model object, and a kit comprising the three dimensional model object and a scaled measurement device. The method in accordance with the present invention includes surveying a constructed structure which is georeferenceable in the real world, obtaining spatial data associated with the constructed structure, generating a digital three dimensional model of the constructed structure in a computer, and producing a physical model object with accurately surveyed as-built data of the constructed structure. The physical model object of the constructed structure can incorporate, on its surface, surveyed and measured useful real world intelligence, such as dimensions, georeference data, or orientation, associated with the constructed structure.

Owner:F3 & ASSOC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com